Patents

Literature

371 results about "Bodies oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

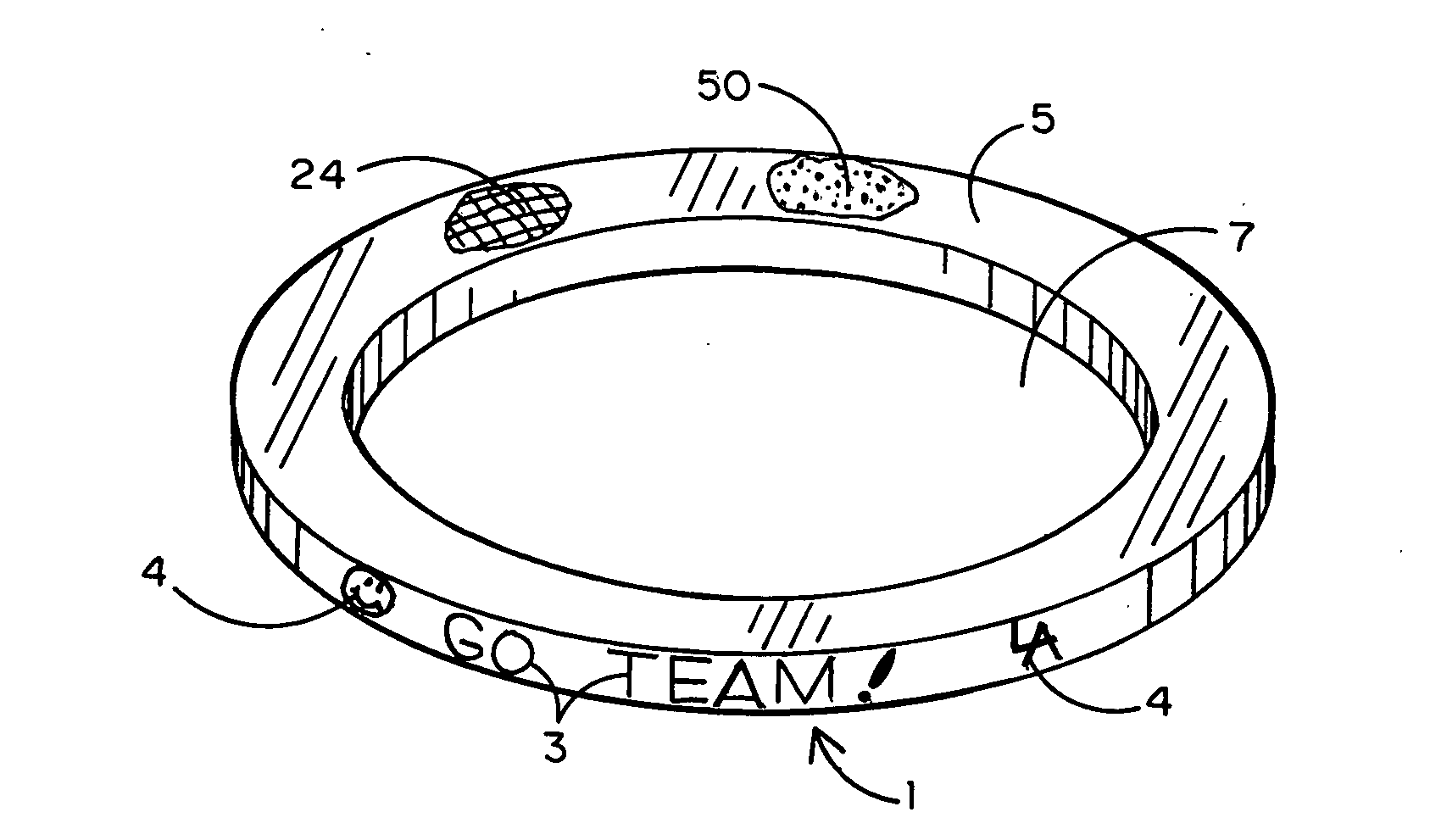

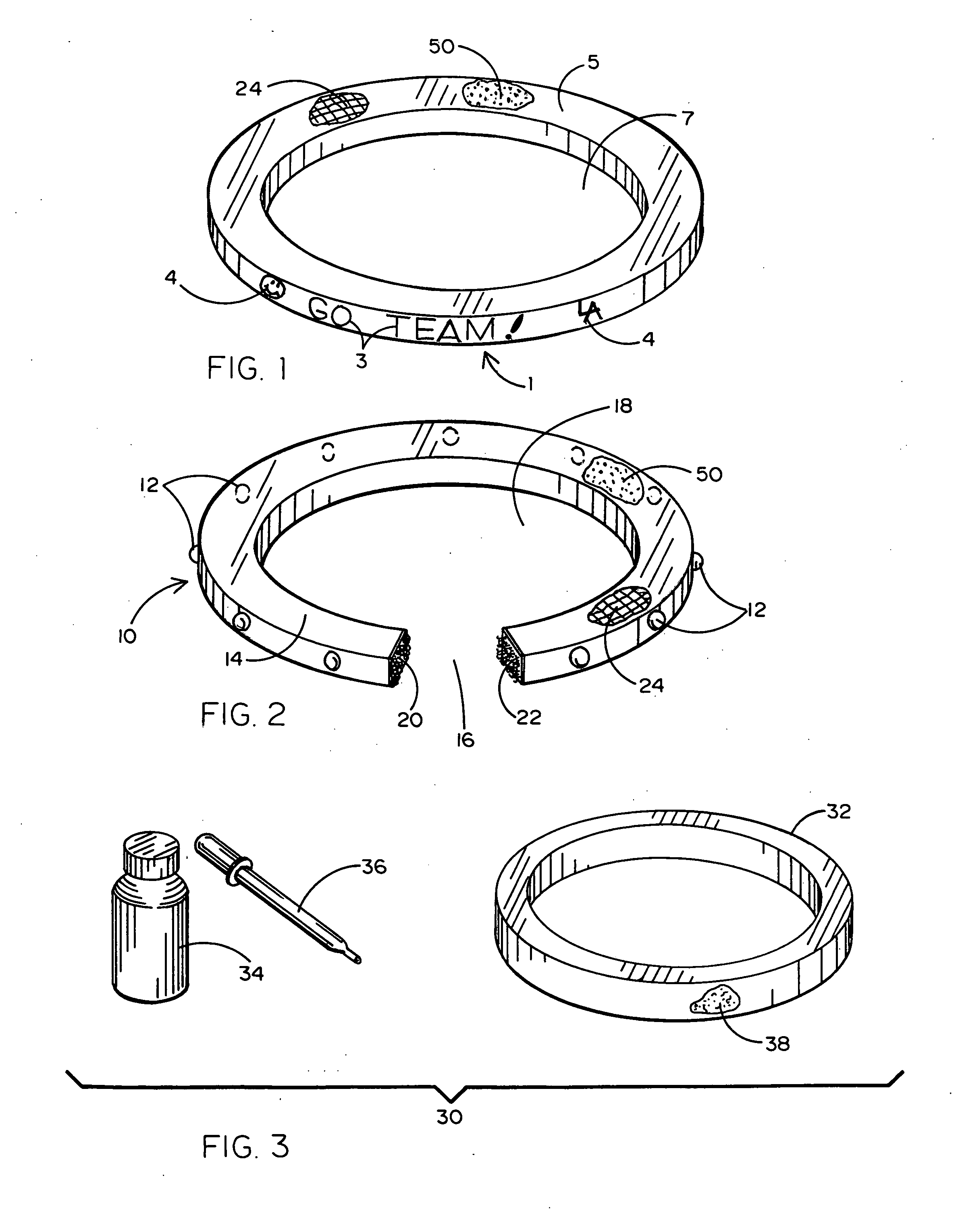

Band, bracelet or strip carrier for an anti-microbial agent to reduce the spread of disease

InactiveUS20130022659A1Reduce transmissionKeep the inherent characteristicsBiocideDead animal preservationDiseaseBodies oil

A band, bracelet, strip or patch to be worn around the wrist or ankle or removably attached to the back of the wearer's hand. Each article is treated with an anti-microbial agent (e.g., tea tree oil) that is capable of killing germs and potentially harmful bacteria. The band, bracelet, strip or patch is impregnated with the anti-microbial agent during manufacture or saturated with the agent by the wearer following manufacture. The agent is delivered to the skin (e.g., the hands) of the wearer by way of either dispersion (exudation) and migration (mixed with the wearer's normal body oil) or by direct touch contact with and transmission to the wearer's fingers so as to reduce the spread of illness and disease.

Owner:ROBERTS ROGER

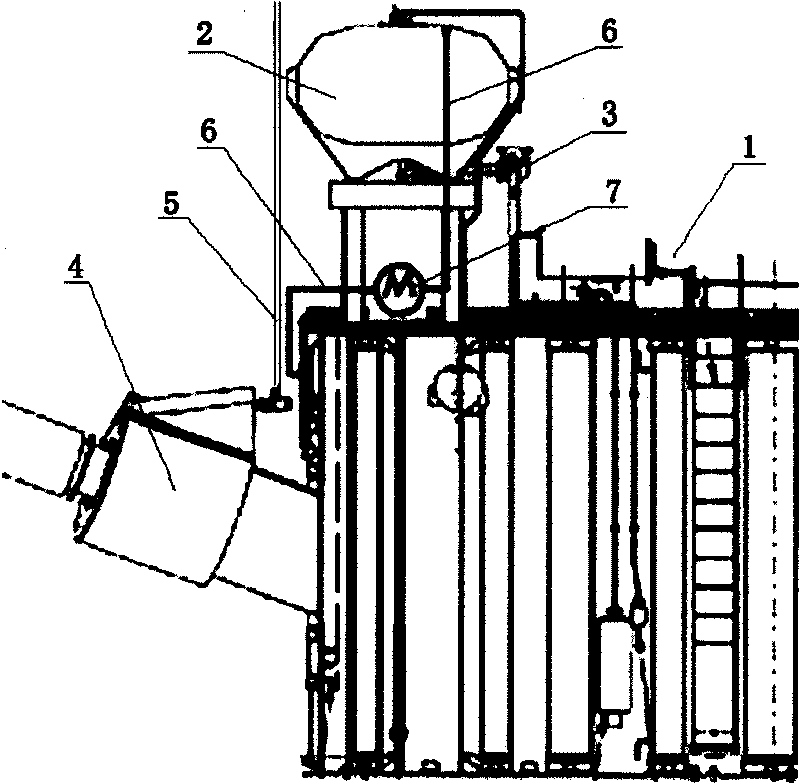

Transformer accessory replacing method

InactiveCN101714449ANo need to wasteReduce cleanupInductances/transformers/magnets manufactureSwitchgearBodies oilExhaust valve

The invention discloses a transformer accessory replacing method comprising the following steps of: (a) connecting a transparent plastic hose on a transformer casing gas relay to serve as an oil level pipe, wherein the length needs to be higher than the height of a body oil conservator so as to observe the actual oil level; (b) connecting a hose on a transformer body to an exhaust valve on the oil conservator and connecting the middle with a vacuum pump; (c) when oil is pumped, closing the valve between the oil conservator and the body; (d) observing the oil level of the oil level pipe when the oil is pumped, and stopping the vacuum pump when the oil level is lower than replaced components; and (e) after the component is replaced, opening the valve between the body and the oil conservator to discharge the oil. The method does not waste insulating oil in the transformer and reduces a series of work of cleaning oil storage equipment, oil stain and the like, thereby increasing the work efficiency.

Owner:国网运行有限公司上海超高压管理处

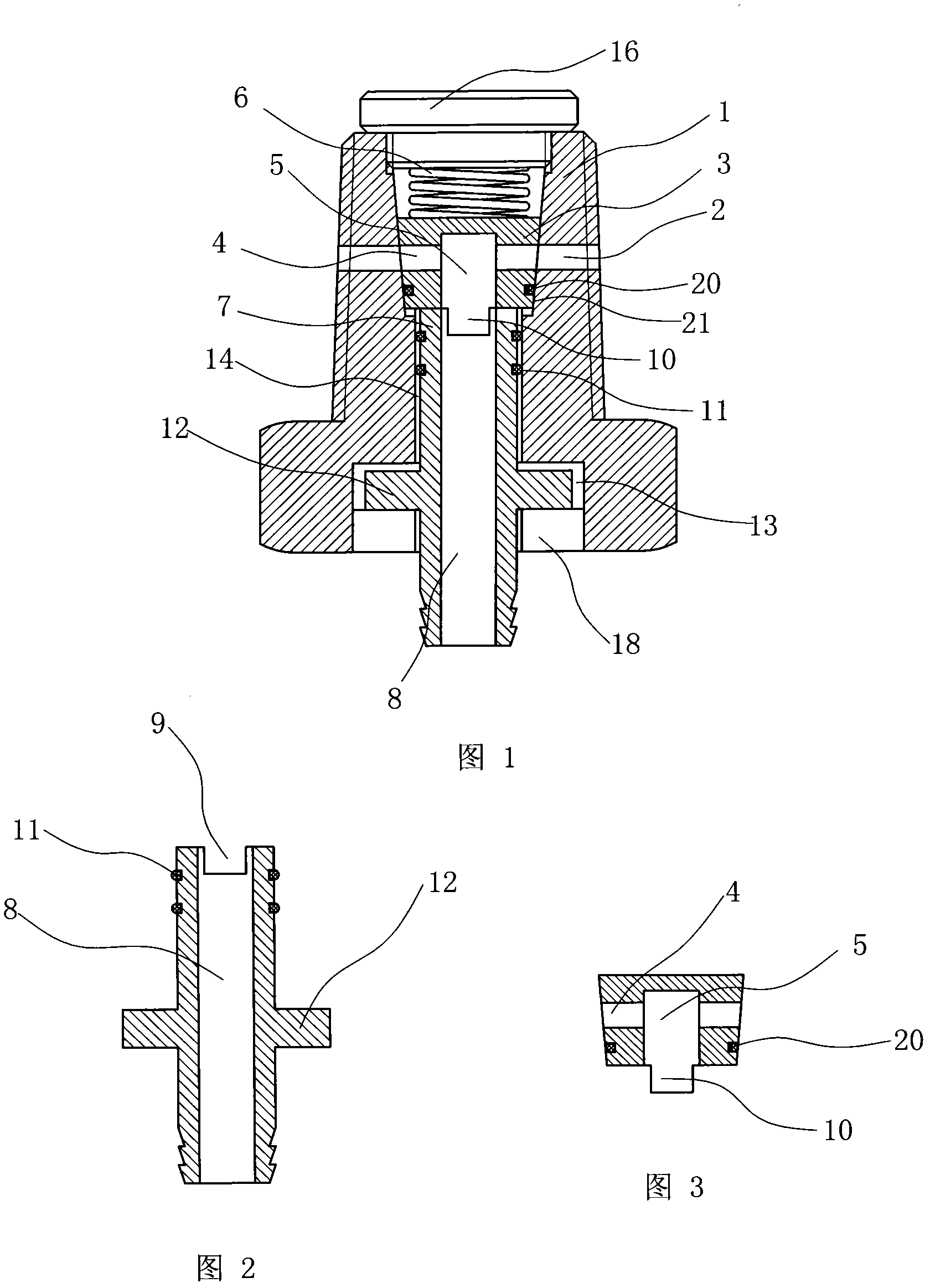

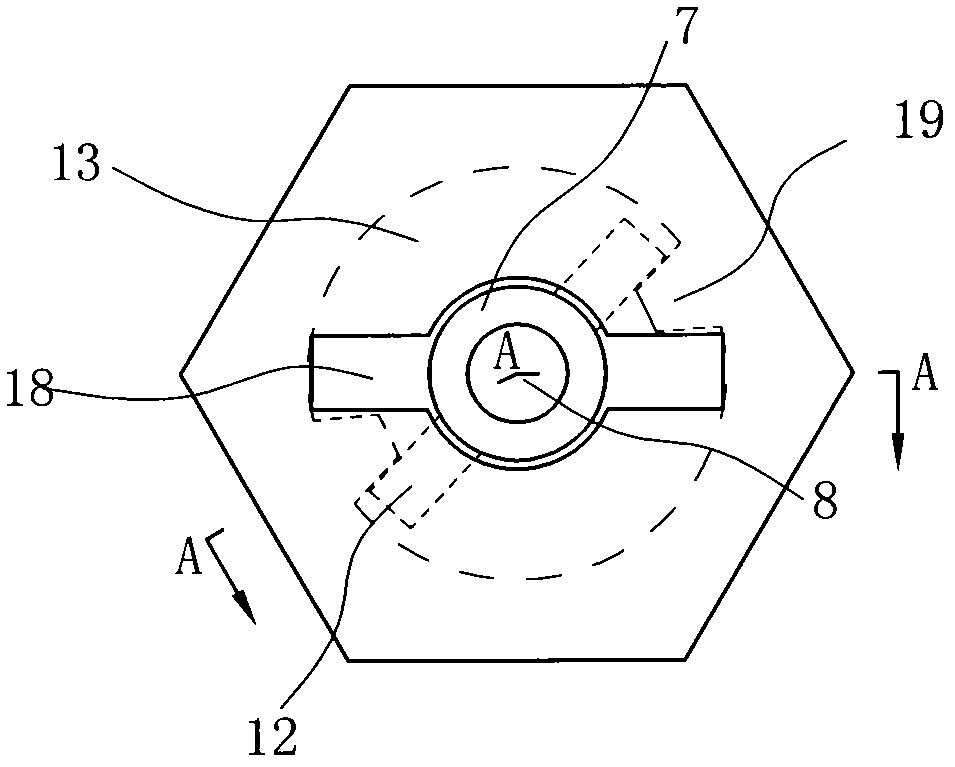

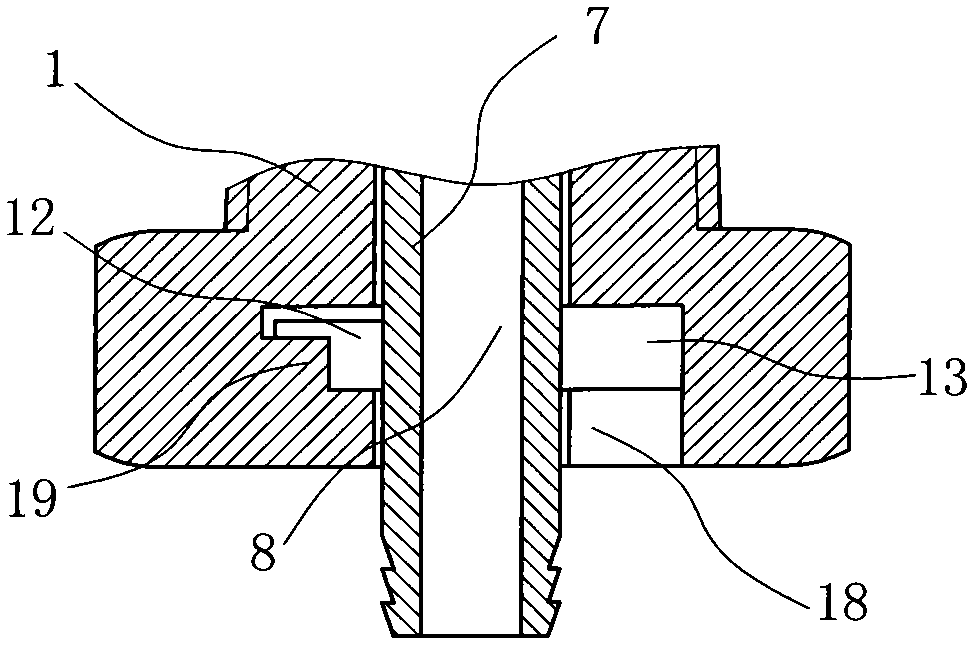

Detachment-free oil drainage bolt

The invention discloses a detachment-free oil drainage bolt, which comprises a valve body, a plug valve core and an oil drainage device. The valve body also serves as an oil drainage bolt and is provided with an external thread, a valve body oil inlet and a valve body oil outlet; the plug valve core is mounted in an inner cavity of the valve body and provided with a valve core oil inlet channel; a valve core oil outlet channel communicated with the valve core oil inlet channel is also arranged in the plug valve core; the valve core oil outlet channel is communicated with the valve body oil outlet; a valve core sealing device is arranged between the plug valve core and the valve body; the oil drainage device comprises an oil drainage pipe inserted into the valve body oil outlet; the oil drainage pipe is provided with an oil drainage channel communicated with the valve core oil outlet channel; a valve core opening device is arranged between the oil drainage pipe and the plug valve core;and an oil drainage pipe inserting / fixing device is also arranged between the oil drainage pipe and the valve body. The oil drainage pipe drives the plug valve core to rotate through the valve core opening device, the valve body oil inlet is opened, and the waste oil enters the valve core oil outlet channel through the valve core oil inlet channel from the valve body oil inlet and then flows out through the oil drainage pipe. Through the invention, the waste oil is prevented from spattering around, and the pollution is reduced.

Owner:铜陵市世纪朝阳数码科技有限责任公司

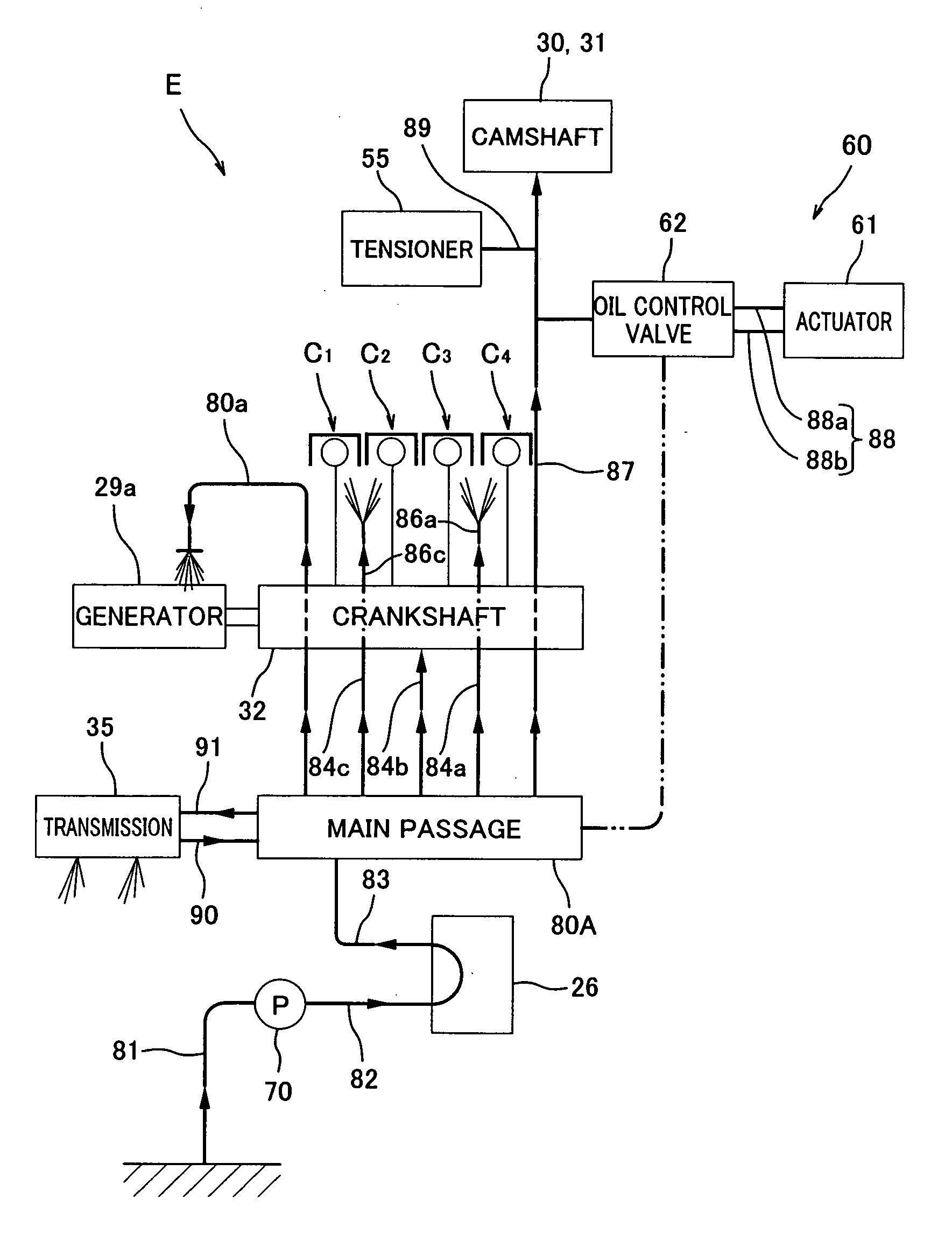

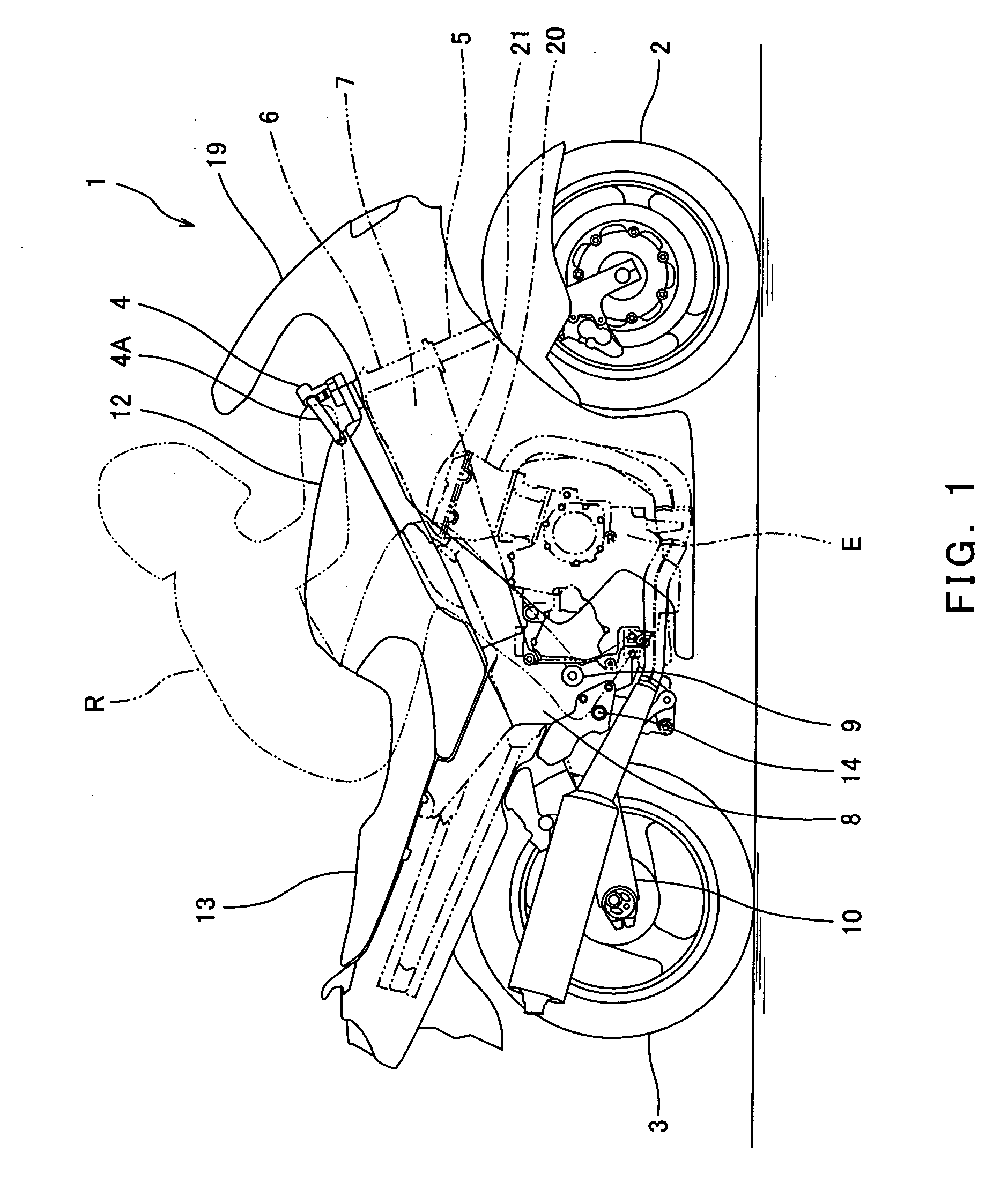

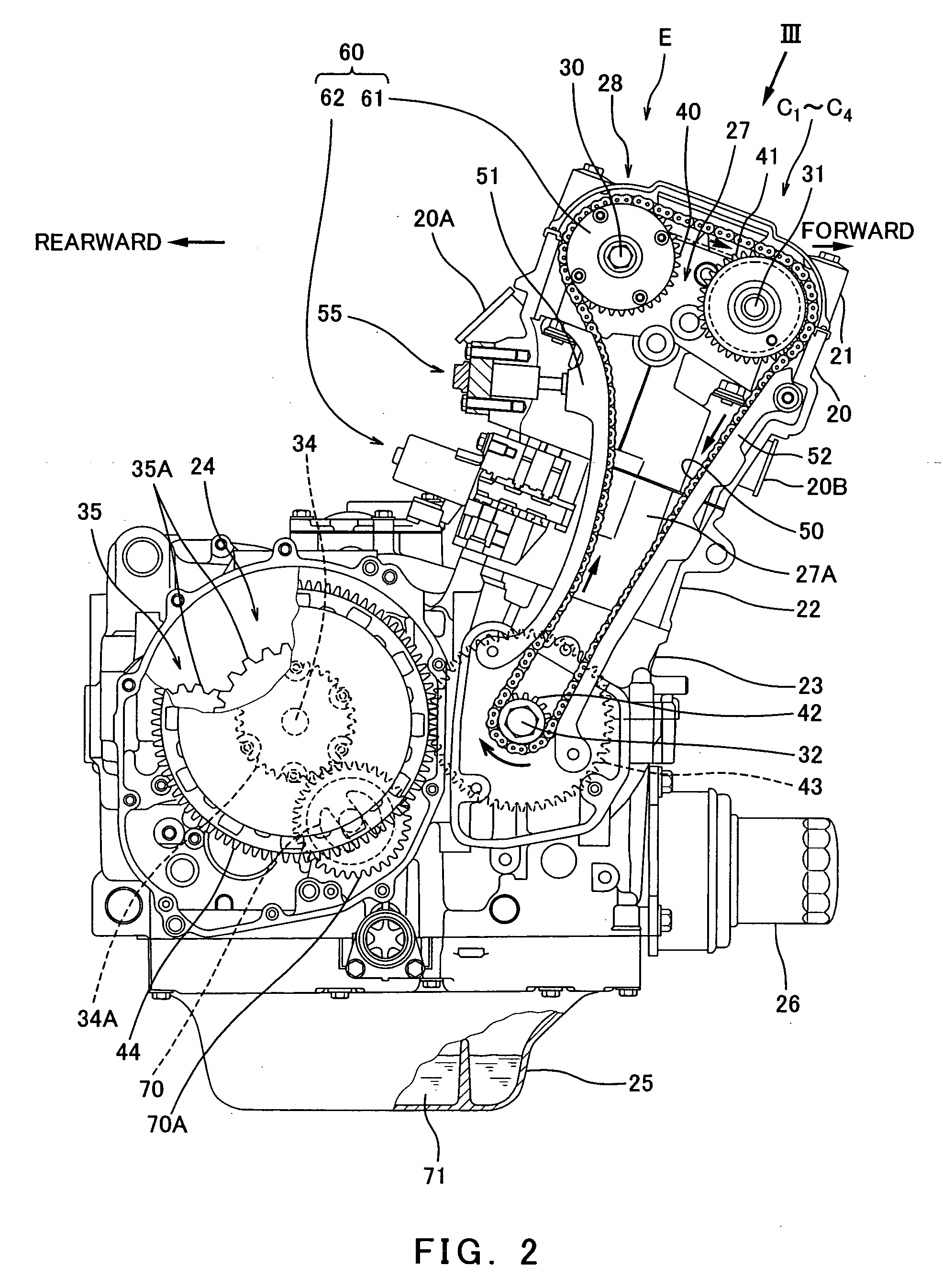

Oil feeding system of engine

InactiveUS20060260873A1Sufficient flow rateReduce flow rateGear lubrication/coolingMachines/enginesBodies oilCrankshaft

An oil feeding system of an engine equipped with a transmission configured to change a rotational speed of rotation of a crankshaft and to output the rotation, including an oil pump configured to be driven in cooperation with the rotation of the crankshaft, an oil passage through which the oil outflowing from the oil pump flows, in which the oil passage includes a transmission oil passage through which the oil outflowing from the oil pump is guided to the transmission, and an engine body oil passage through which the oil outflowing from the oil pump is guided to portions other than the transmission, and an oil control portion configured to change a ratio between a pressure of the oil flowing through the transmission oil passage and a pressure of the oil flowing through the engine body oil passage.

Owner:KAWASAKI HEAVY IND LTD

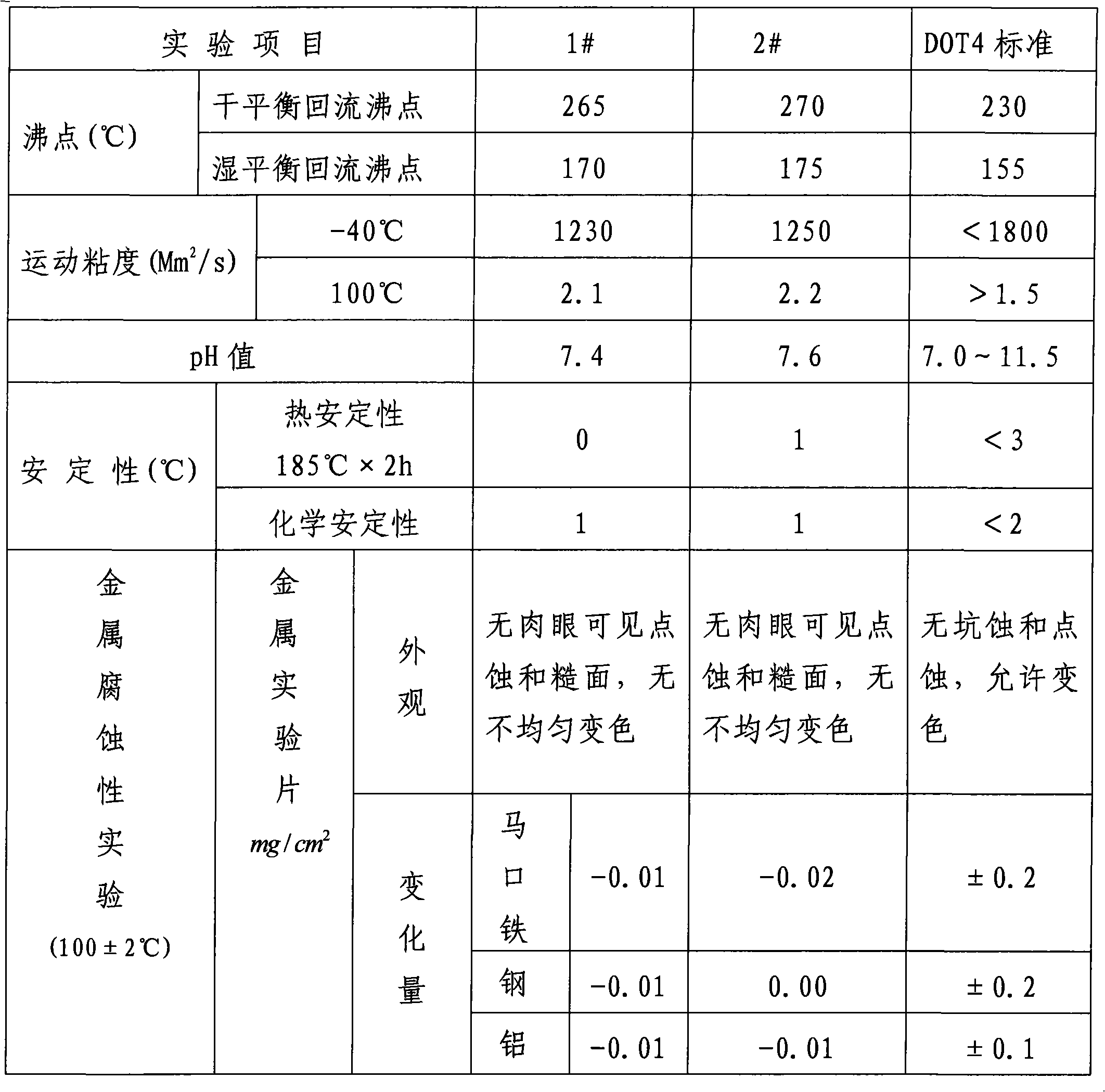

Method for preparing boric acid ester automobile braking fluid with high performance

The invention discloses a method for preparing boric acid ester automobile braking fluid with high performance, which comprises the following three steps: taking propyl alcohol as a raw material to compound polyol ether; compounding esterified fluid; and preparing the braking fluid, wherein the polyol ether compounded by adopting the propyl alcohol as the raw material improves the yield of a main component of braking fluid main body oil; the esterified fluid produced by proper boron content improves the high temperature air resistance and the low temperature mobility of the braking fluid, overcomes the adverse effects brought by low boiling point, incomplete boric acid esterification and unstable hydrolysis of the prior braking fluid and provides the better anticorrosive effect for metal in a brake system.

Owner:XIANGTAN UNIV

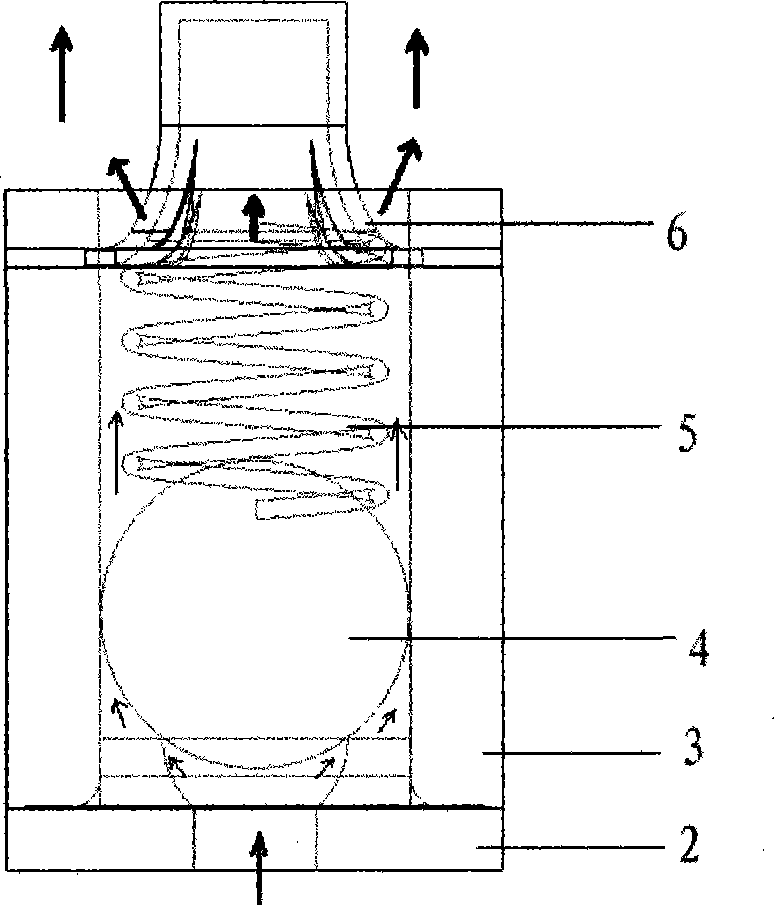

Vacuum oil-gas separator used for transformer on-line monitoring

InactiveCN102371085AAvoid pollutionLow costLiquid degasificationComponent separationBodies oilVacuum pumping

The invention provides a vacuum oil-gas separator used for transformer on-line monitoring. The separator comprises: an oil-gas separation chamber connected with transformer body oil and a gas detection unit, a vacuum-pumping device used for vacuum-pumping of the separation chamber, an ultrasonic generator installed in the oil-gas separation chamber and a cold trap connecting the oil-gas separation chamber and the gas detection unit. The vacuum oil-gas separator of the invention integrates circulating sampling, vacuum ultrasonic degassing and cold trapping, thus thoroughly avoiding oil gas pollution on a chromatographic column and realizing a maintenance-free system really. With the advantages of low cost, long service life and good stability, etc., the vacuum oil-gas separator provided in the invention has obviously higher effect than traditional degassing modes.

Owner:ZHUHAI YUANMING POWER EQUIP

Electronic-magnetic-stirring-based oil-gas separation device

InactiveCN102198340AAvoid pollutionGood effectLiquid degasificationComponent separationBodies oilMagnetic stirrer

The invention provides an electronic-magnetic-stirring-based oil-gas separation device, which can be applied in the field of on-line monitoring of transformer oil. The oil-gas separation device comprises an oil-gas separation chamber connected with transformer body oil and a gas detection unit, and a piston device for vacuumizing the oil-gas separation chamber, wherein the oil-gas separation chamber is connected with the gas detection unit through a cold trap; and an electronic magnetic stirrer is arranged at the bottom of the oil-gas separation chamber. The electronic-magnetic-stirring-based oil-gas separation device integrates oil cycle sampling, electronic magnetic stirring degassing and the cold trap, radically avoids oil-gas pollution on a chromatographic detection unit, realizes a maintenance-free system, has the advantages of low cost, long service life, high stability and the like, and has an obvious effect higher than that of a traditional degassing mode.

Owner:胡志敏

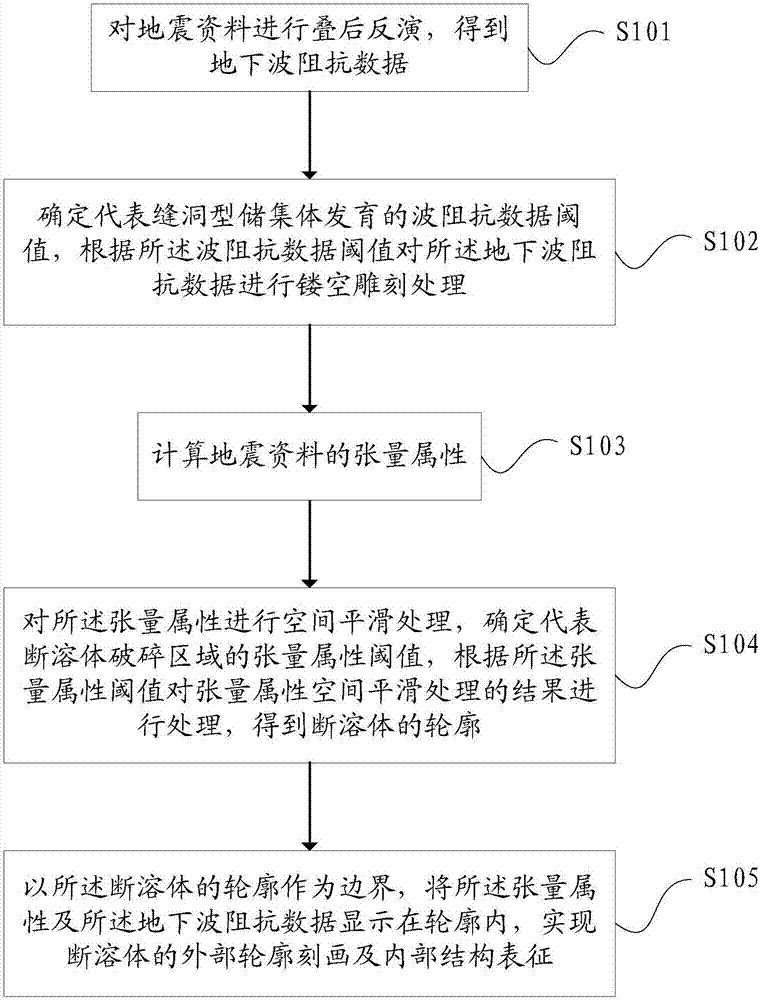

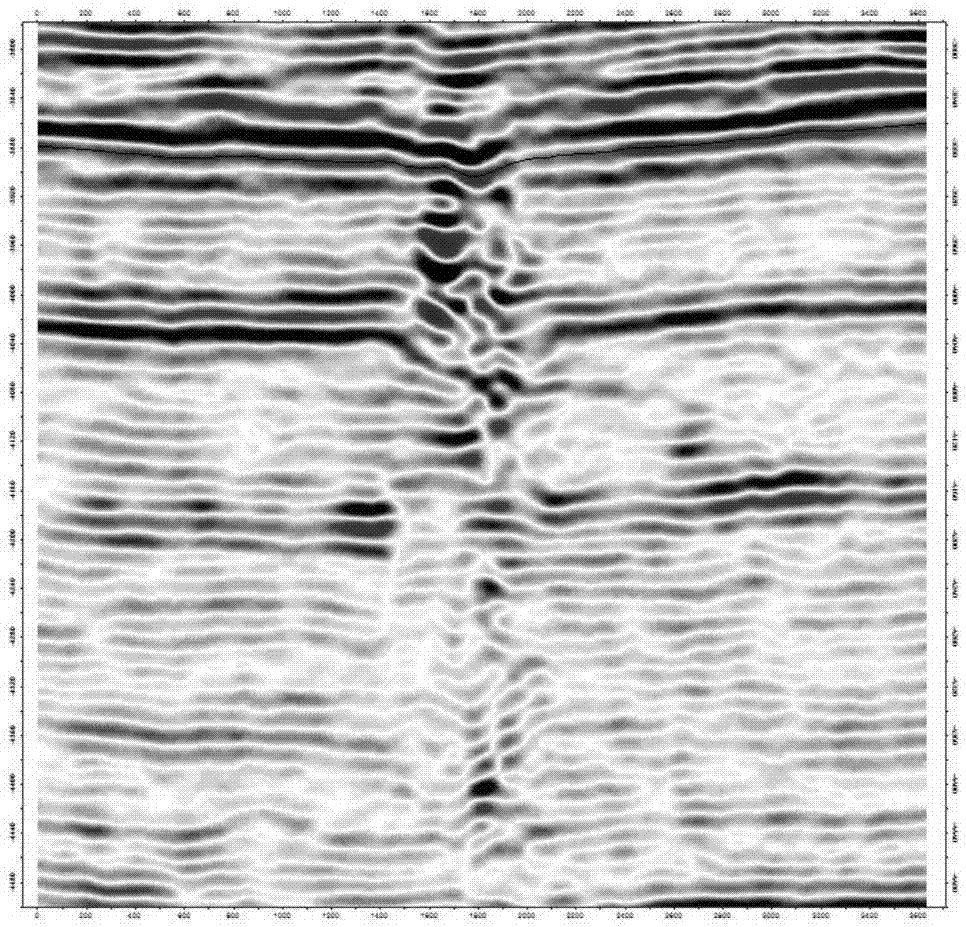

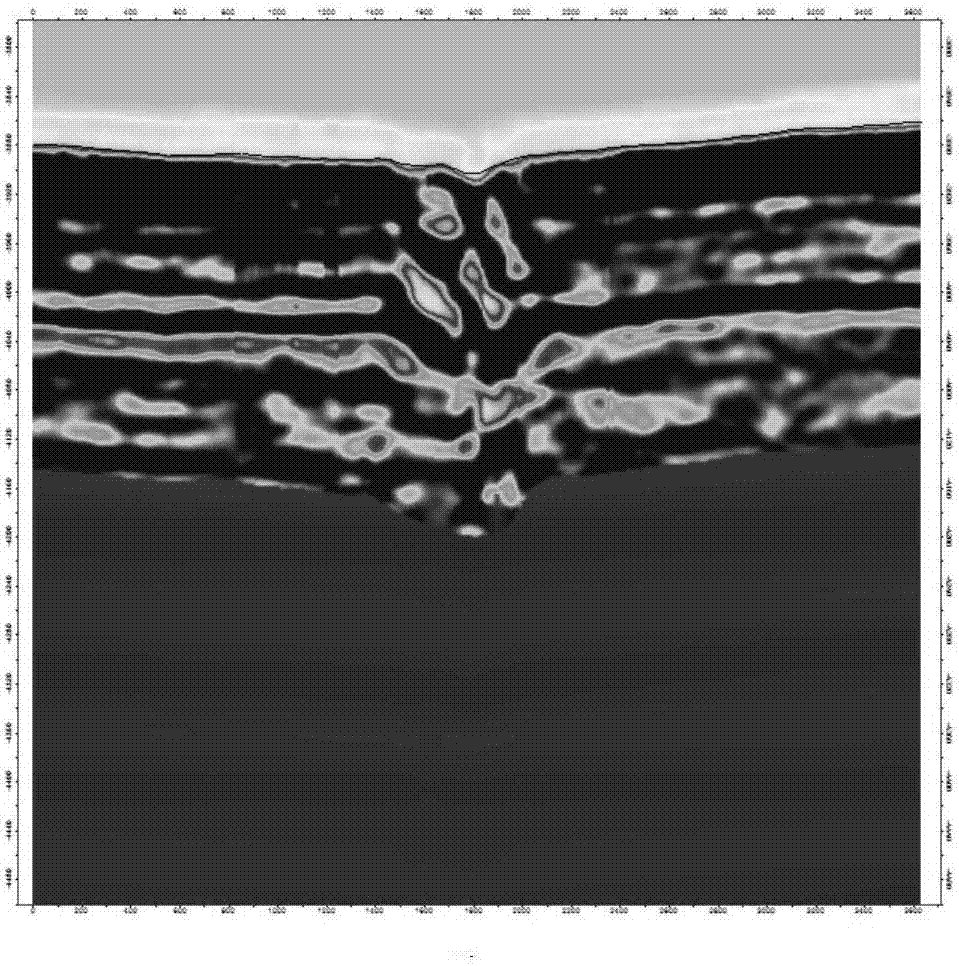

Carbonate rock fault-karst body internal structure characterization method

The invention discloses a carbonate rock fault-karst body internal structure characterization method which comprises the following steps: seismic data is subjected to post-stack inversion, and underground wave impedance data is obtained; a wave impedance data threshold value representing fracture-vug type reservoir body development is determined, and the underground wave impedance data is subjected to hollow-out engraving operation according to the wave impedance data threshold value; tensor attributes of the seismic data are calculated and subjected to spatial smoothing processing, a tensor attribute threshold value representing a broken area of the fault-karst body is determined, a tensor attribute spatial smoothing processing result is processed according to the tensor attribute threshold value, a contour of the fault-karst body can be obtained and used as a boundary, the tensor attributes and the underground wave impedance data are displayed in the contour, and therefore an external contour of the fault-karst body can be carved and an internal structure of the fault-karst body can be represented. According to the carbonate rock fault-karst body internal structure characterization method, comprehensive characterization of the carbonate rock fault-karst body can be realized via graph overlaying technologies, and a boundary of a fault-karst body oil reservoir and spatial distribution of a reservoir body can be carved out.

Owner:CHINA PETROLEUM & CHEM CORP

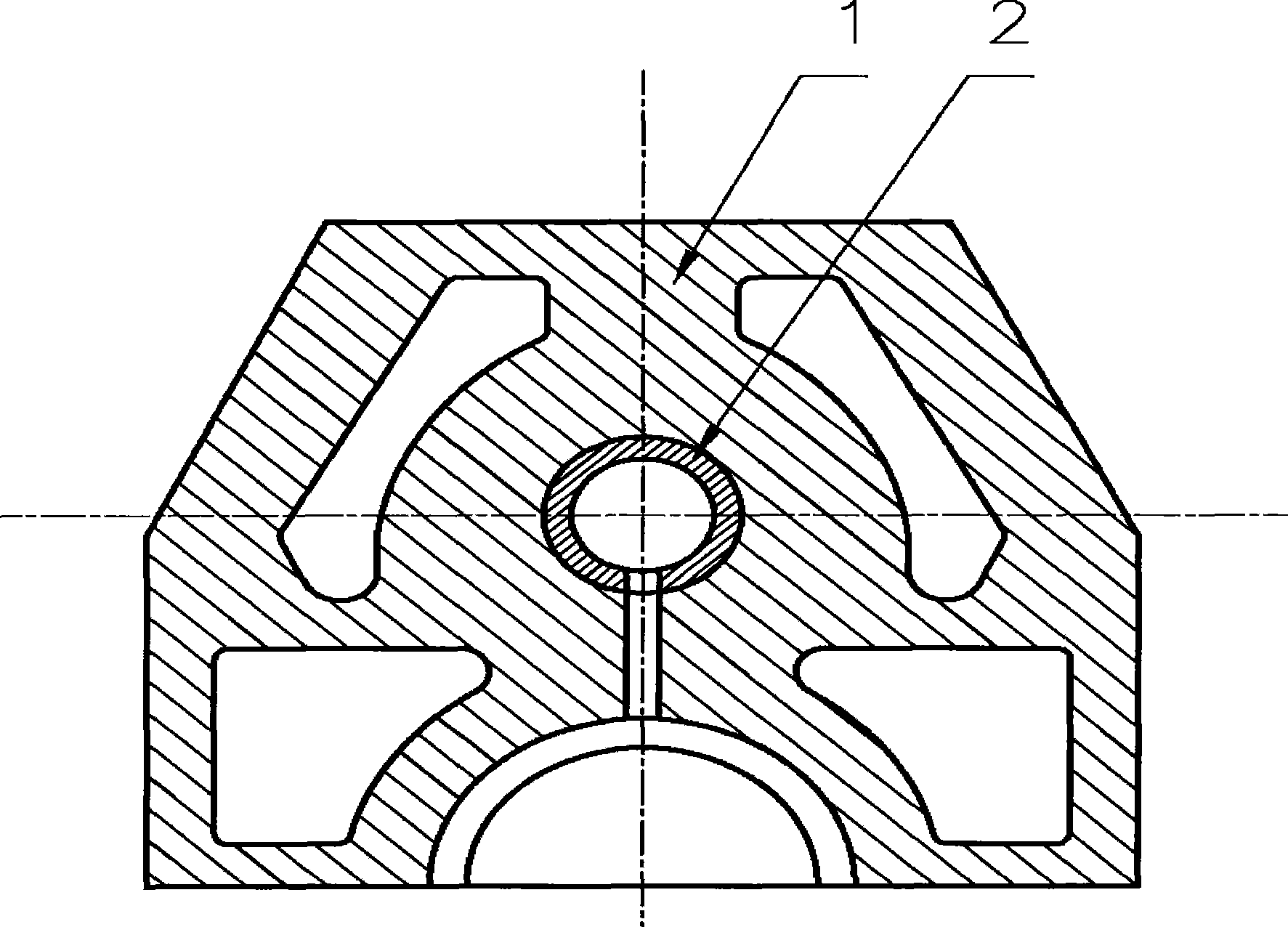

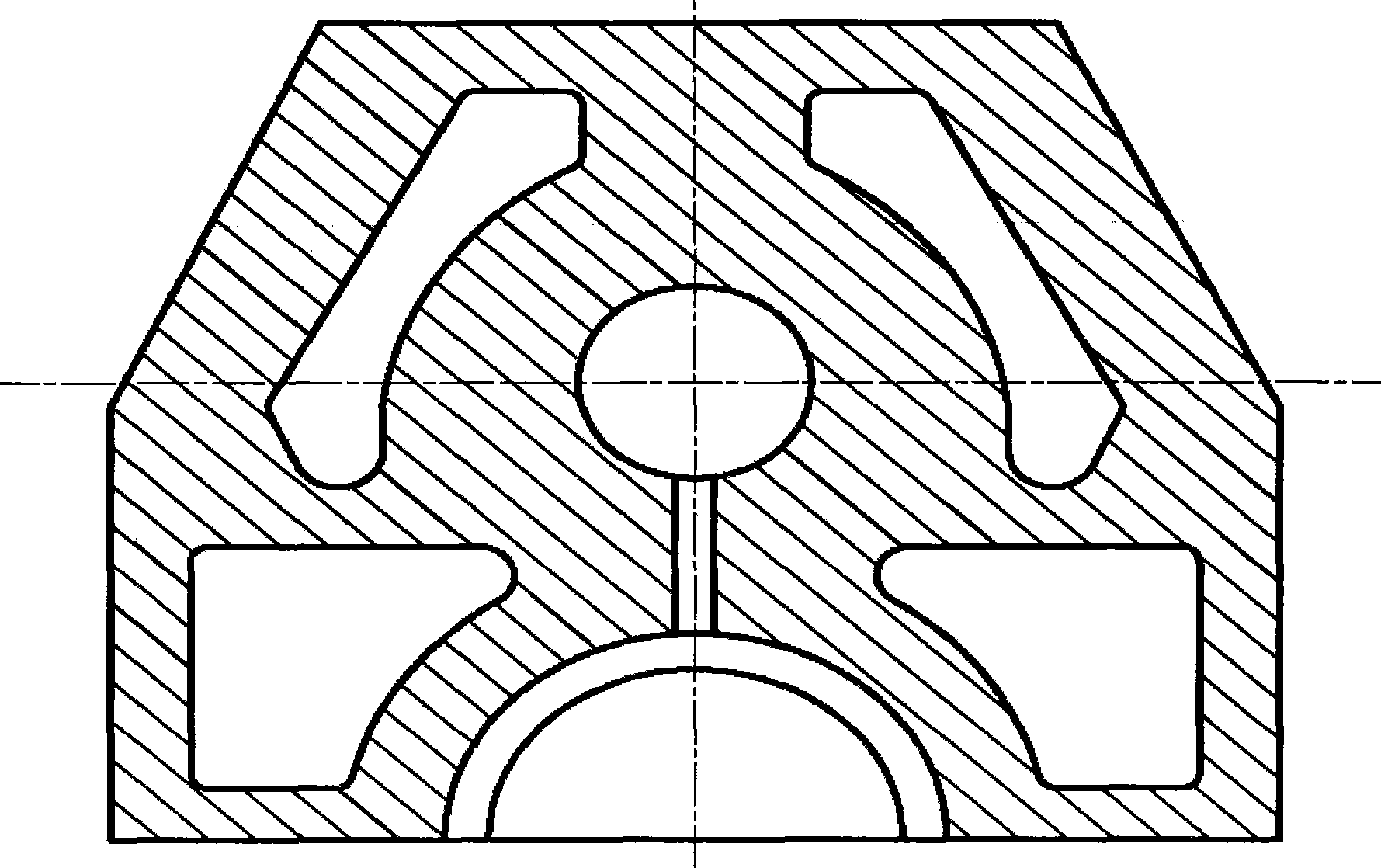

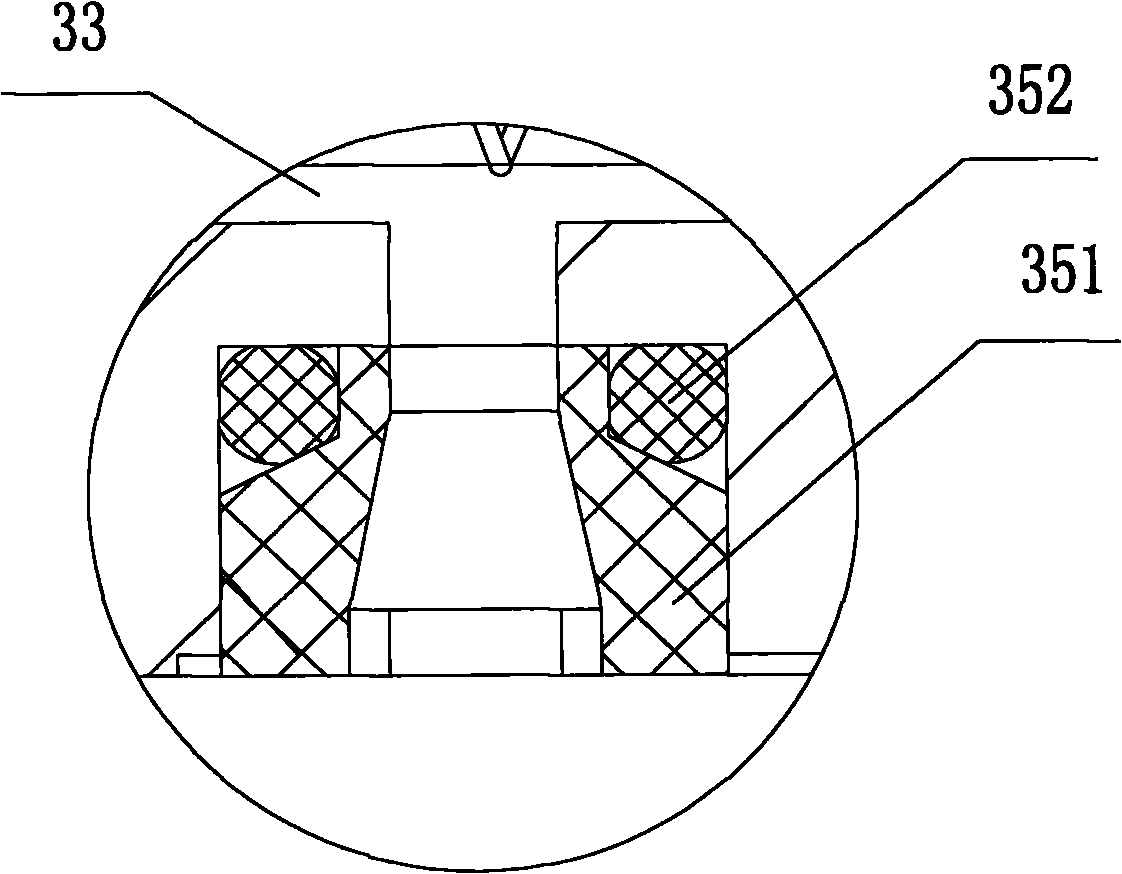

Composite material used for casting aluminum alloy box body oil duct and method thereof

InactiveCN103480794AContinuous adjustment of thermophysical parametersAvoid the hidden danger of entering the oil passageFoundry mouldsFoundry coresBodies oilSurface finish

The invention belongs to the field of casting technologies, and particularly relates to a composite material used for casting an aluminum alloy box body oil duct and a method of the composite material used for casting the aluminum alloy box body oil duct. In order to solve the deep hole casting technical problem which is difficult to solve through an original casting technique, avoid the phenomenon that drilling is performed after hole-forming through an inlaying-cast steel pipe, and thus the oil duct is not homocentric and the aluminum base face is scratched, and solve the problem that a box body oil duct made of a common sand core can not meet the requirement for leakproofness, the composite material comprises metal pills, iron powder, roughing sand and a self-hardening resin sand binding agent, the oil duct core is made from the composite material to take place of an oil duct hole made of a steel pipe, interlayer defects can not be generated between the steel pipe and an aluminum substrate, and the potential hazard that steel scrapes enter the oil duct is avoided. According to the oil duct core made from the composite material, a compact chilling layer can be formed around the oil duct and meet the requirement for the leakproofness of the oil duct and is easy to scatter and low in gas forming, the surface of the oil duct is good in smoothness, and the oil duct can meet use requirements even if the oil duct is not subjected to machining.

Owner:STATE RUN NO 616 FACTORY

Lubricating oil way of automobile engine

InactiveCN101435355ASimple structureLow costSafety devices for pressure lubricationBodies oilCylinder block

The invention relates to a lubrication oil path for an automobile engine. The lubrication oil path can effectively avoid the reflux of lubrication oil in a cylinder body oil duct and a cylinder cap oil duct. The technical proposal comprises that according to the lubrication oil path for the automobile engine, the lubrication oil enters a cylinder cap main oil duct via a cylinder body main oil duct; and the lubrication oil path is characterized in that a one-way valve is arranged at the entrance from the cylinder body main oil duct to the cylinder cap main oil duct.

Owner:CHERY AUTOMOBILE CO LTD

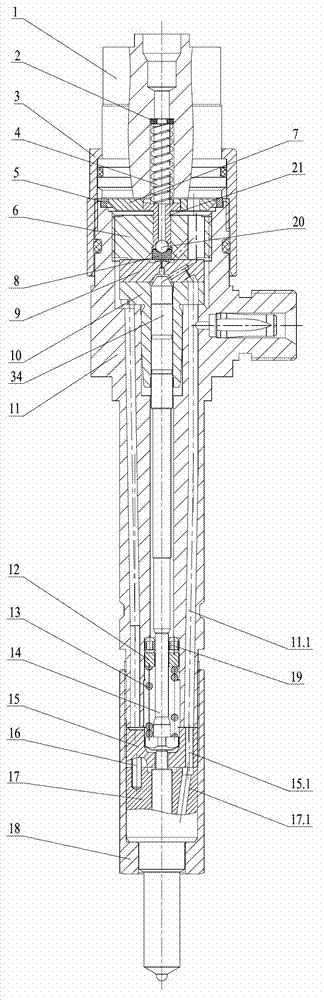

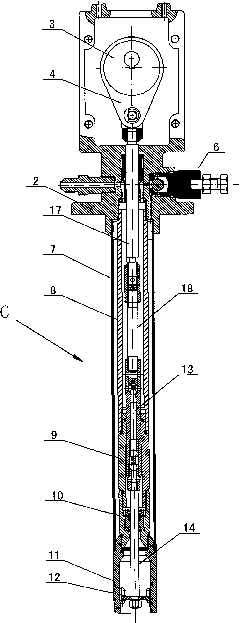

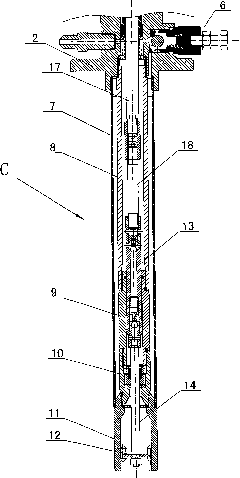

Electronic control oil sprayer for injection valve

InactiveCN103047062AReduce processing difficultyImprove sealingFuel injection apparatusMachines/enginesVena contracta diameterBodies oil

The invention relates to an electronic control oil sprayer for a diesel engine injection valve. An oil sprayer body oil hole is arranged in an oil sprayer body and communicated with an oil inlet port positioned on the oil sprayer body, a bushing ring and a guiding valve seat are arranged in the oil sprayer body, the guiding valve seat is located below the bushing ring and provided with a guiding valve seat oil hole, and a throttling orifice plate is arranged below the guiding valve seat and provided with a control chamber, an oil inlet throttling orifice, a throttling orifice plate oil inlet hole, a connecting oil hole, an oil returning throttling orifice and a throttling orifice plate oil discharging hole. A control piston sleeve is arranged below the throttling orifice plate and provided with a control piston sleeve oil hole, the lower end face of a control flat valve is a plane, and the upper end face of the throttling orifice plate is provided with a pressure relief ring groove, an outer ring groove and a flow guiding groove. The outer ring groove is sleeved outside the pressure relief ring groove, and the pressure relief ring groove is selectively communicated with the oil returning throttling orifice. The electronic control oil sprayer reduces processing difficulty and improves tightness and production rate.

Owner:WUXI KIPOR POWER CO LTD

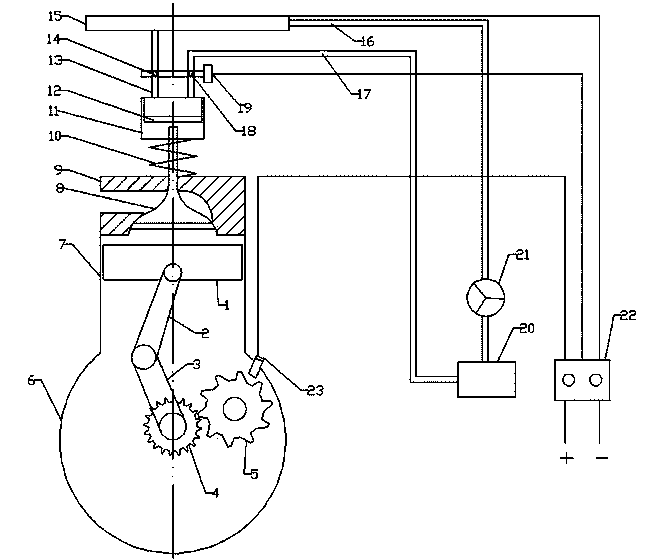

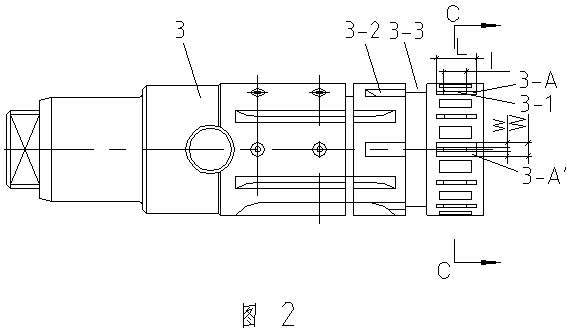

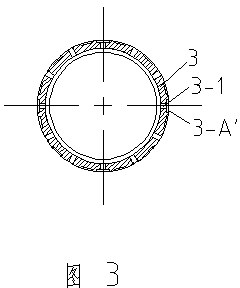

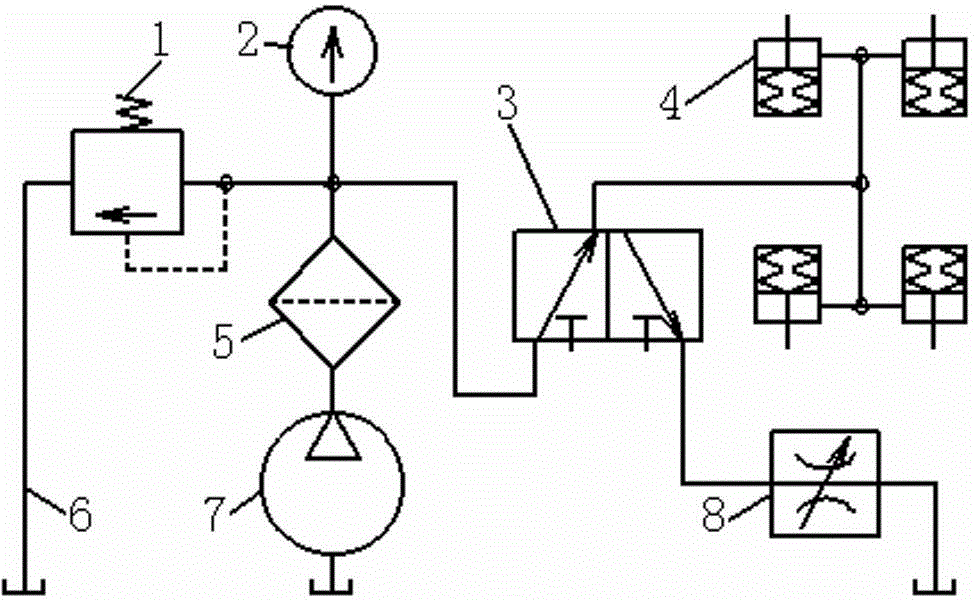

Electric control hydraulic air distribution system for engine

ActiveCN103806973AReduce lossesRapid responseMachines/enginesNon-mechanical valveBodies oilHydraulic cylinder

The invention discloses an electric control hydraulic air distribution system for an engine. The electric control hydraulic air distribution system comprises a cylinder body of a hydraulic air distribution mechanism, a piston execution mechanism, a hydraulic cylinder body oil inlet pipeline, a hydraulic cylinder body oil return pipeline, an ECU and an electromagnetic valve execution mechanism. The hydraulic air distribution mechanism comprises the hydraulic cylinder body and a piston. The piston is arranged inside the hydraulic cylinder body and can vertically move due to the combined action of the hydraulic pressure and a valve spring. One end of the hydraulic cylinder body oil inlet pipeline is communicated with the hydraulic cylinder body, and the other end of the hydraulic cylinder body oil inlet pipeline is communicated with an engine oil bottom shell. The end, close to the hydraulic cylinder body, of the hydraulic cylinder body oil inlet pipeline and the end, close to the hydraulic cylinder body, of the hydraulic cylinder body oil return pipeline are provided with an oil inlet hole and an oil return hole respectively. The ECU is in signal connection with the electromagnetic valve execution mechanism. The ECU controls the electromagnetic valve execution mechanism to open or close the oil inlet hole and the oil return hole by continuously receiving engine working status signals sent by a crankcase signal panel sensor, and therefore the hydraulic pressure inside the hydraulic cylinder body is controlled, and then opening, closing and the lift of an air valve are controlled. According to the electric control hydraulic air distribution system for the engine, the electric control fully variable function of the air valve of the engine can be achieved, and valve timing, the phase of the air valve and the lift of the air valve can be continuously adjusted.

Owner:GUANGXI YUCHAI MASCH CO LTD

Hydraulic pump assembly of turnover device for automobile cab

InactiveCN102556182ASimple structureGood sliding sealLoading-carrying vehicle superstructuresBodies oilCar driving

The invention discloses a hydraulic pump assembly of a turnover device for an automobile cab. According to a technical scheme, a pump body integrates a plunger piston, a reversing valve assembly, a rocker arm, an operating handle, an oil absorption cavity, a pump body oil return opening and a pressure oil channel, wherein the reversing valve assembly comprises a valve body, a longitudinal oil inlet hole, a valve cavity, a valve body oil inlet and a valve body oil return opening. The hydraulic pump assembly has a simple structure, is practical, can control the lowering speed of the cab, and can be stopped at any lowering position according to requirements.

Owner:上海中欧汽车电器有限公司

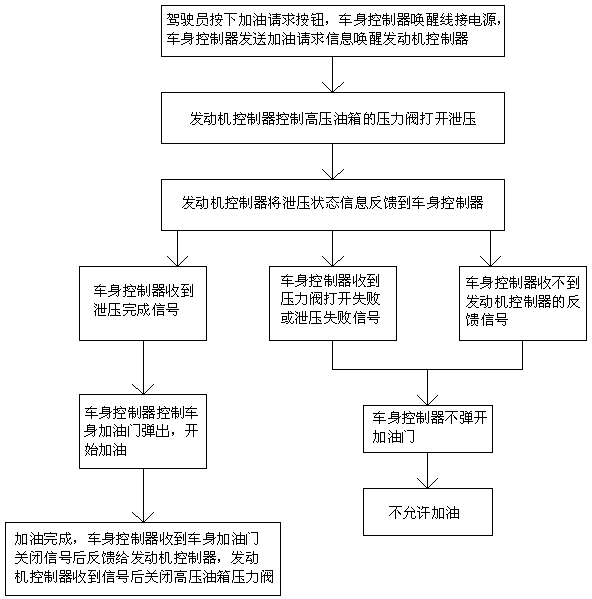

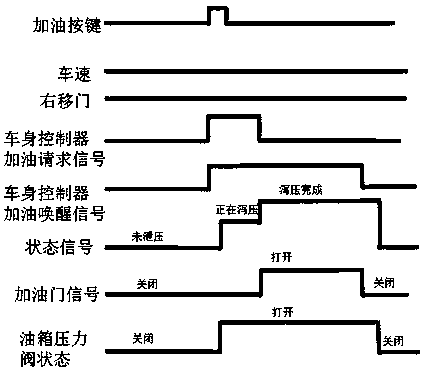

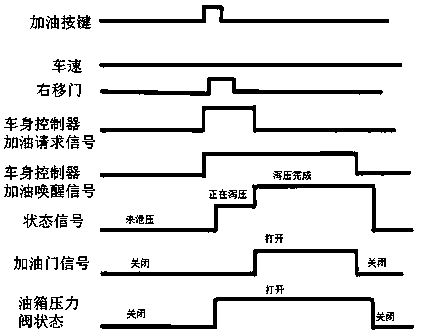

Oil filling control method used for automobile high-pressure oil tank

ActiveCN109553056ASolve the pressure reliefMeet refueling needsLiquid transferring devicesFuel supplyBodies oilFuel tank

The invention discloses an oil filling control method used for an automobile high-pressure oil tank. The oil filling control method comprises the steps that firstly, a driver presses an oil filling request button, and an automobile body controller sends oil filling request information to wake up an engine controller; secondly, the engine controller controls a pressure valve of the oil tank to openand relieve the pressure; thirdly, the engine controller feeds pressure relief status information back to the automobile body controller , if a pressure relief completion signal is received, the fourth step is carried out, if a pressure valve open failure or pressure relief failure signal is received, oil filling is not allowed unless an oil filling door is popped open, and if a feedback signal is not received, oil filling is not allowed unless the oil filling door is popped open by the automobile body controller; fourthly, the automobile body controller controls the automobile body oil filling door to pop open, and oil filling starts; and fifthly, oil filling is completed, the automobile body controller receives an automobile body oil filling door closing signal and then feeds the automobile body oil filling door closing signal back to the engine controller, and the engine controller closes the pressure valve of the high-pressure oil tank. It can be guaranteed that the pressure in the high-pressure oil tank is within a safe range through pressure relief control before the oil filling door is opened.

Owner:SAIC MOTOR

Pressure stabilization compensation device and energy accumulator detection system with same

ActiveCN104533879ALarge energy storage powerMitigate hydraulic shockFluid-pressure actuator testingBodies oilPressure stabilization

The invention discloses a pressure stabilization compensation device. The bottom of a nitrogen cylinder body is installed on the top of a master cylinder, the piston rod extension end of a nitrogen cylinder piston extends into the master cylinder and is fixed to a master cylinder piston body through a screw, the master cylinder piston body is in clearance fit with an inner cavity of the master cylinder and is sealed with master cylinder piston body oil seals, the bottom end of a hand is fixed to the master cylinder piston body, the top end of the hand penetrates out of a rod end chamber of the master cylinder, and the bottom of the master cylinder is in threaded connection with a master cylinder end cover and is sealed with end cover oil seals. When used as an energy accumulator, the pressure stabilization compensation device serves as an auxiliary power source, is used for system pressure maintaining or serves as an emergency power source, absorbs system pulses, alleviates hydraulic shock, is long in service life and low in cost and saves energy resources; when overpressure or insufficient pressure occurs, the hand or a warning device is observed, and safety is guaranteed.

Owner:YUN DONG LI INTELLIGENT MFG EQUIP CO LTD

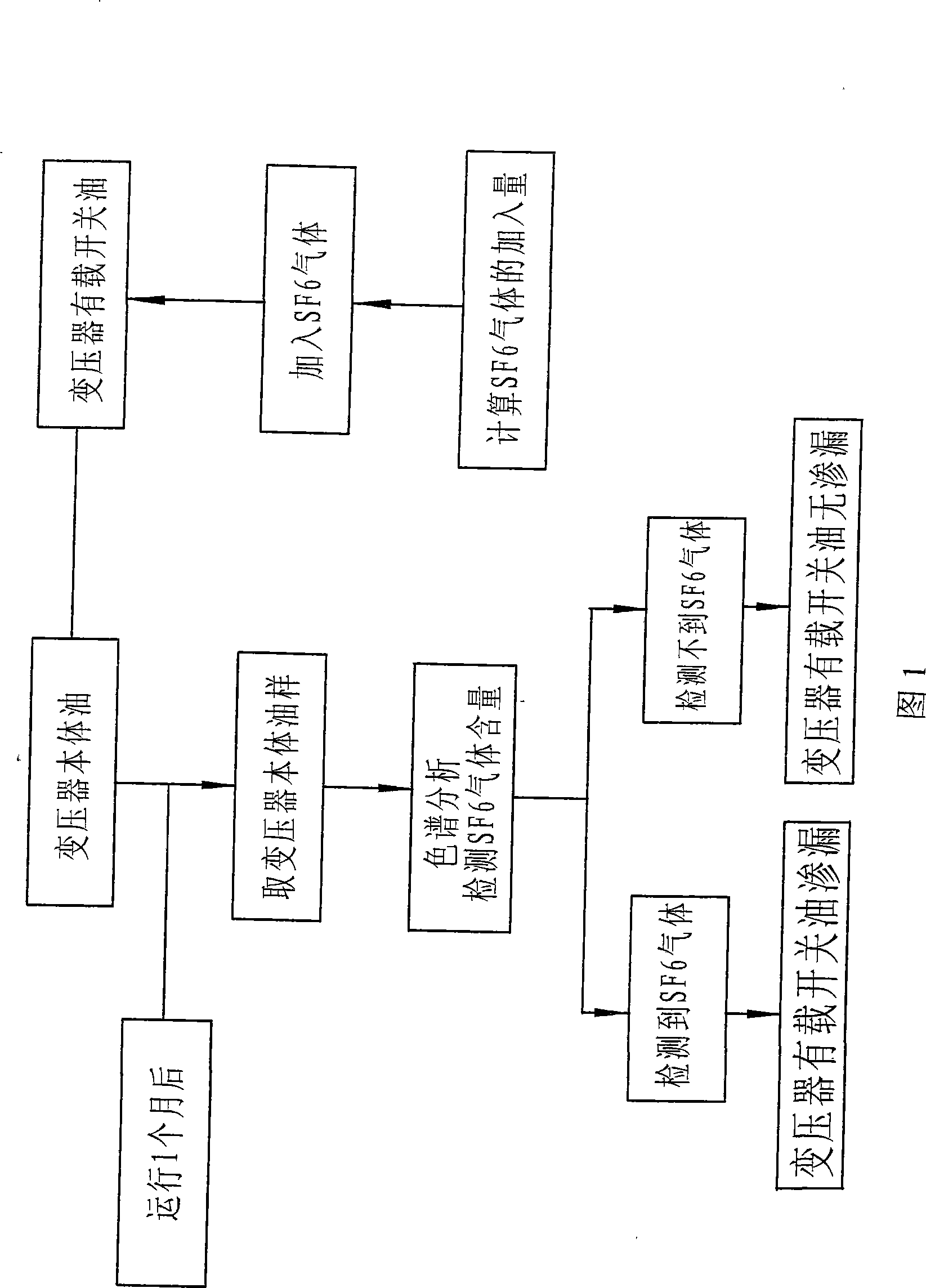

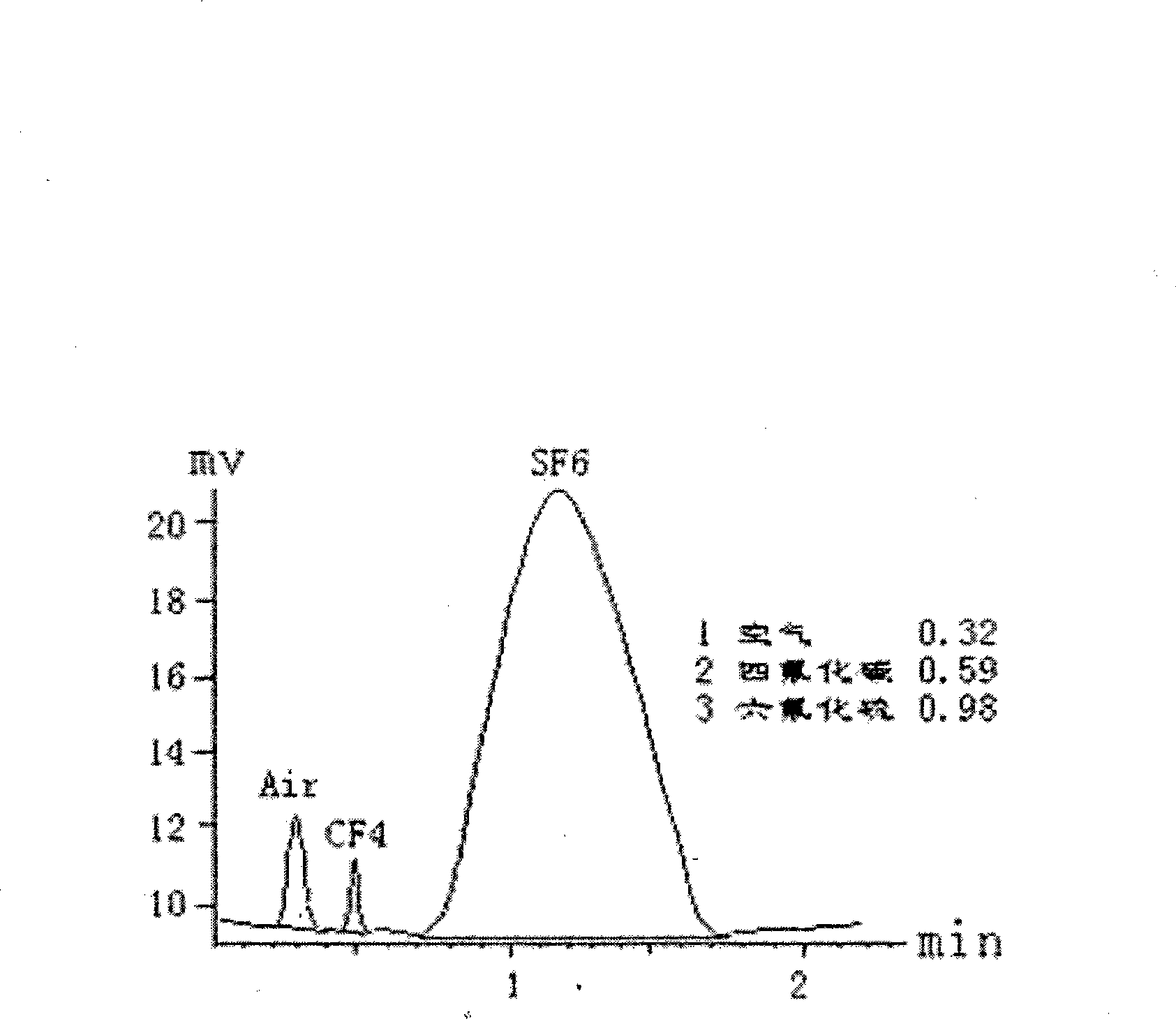

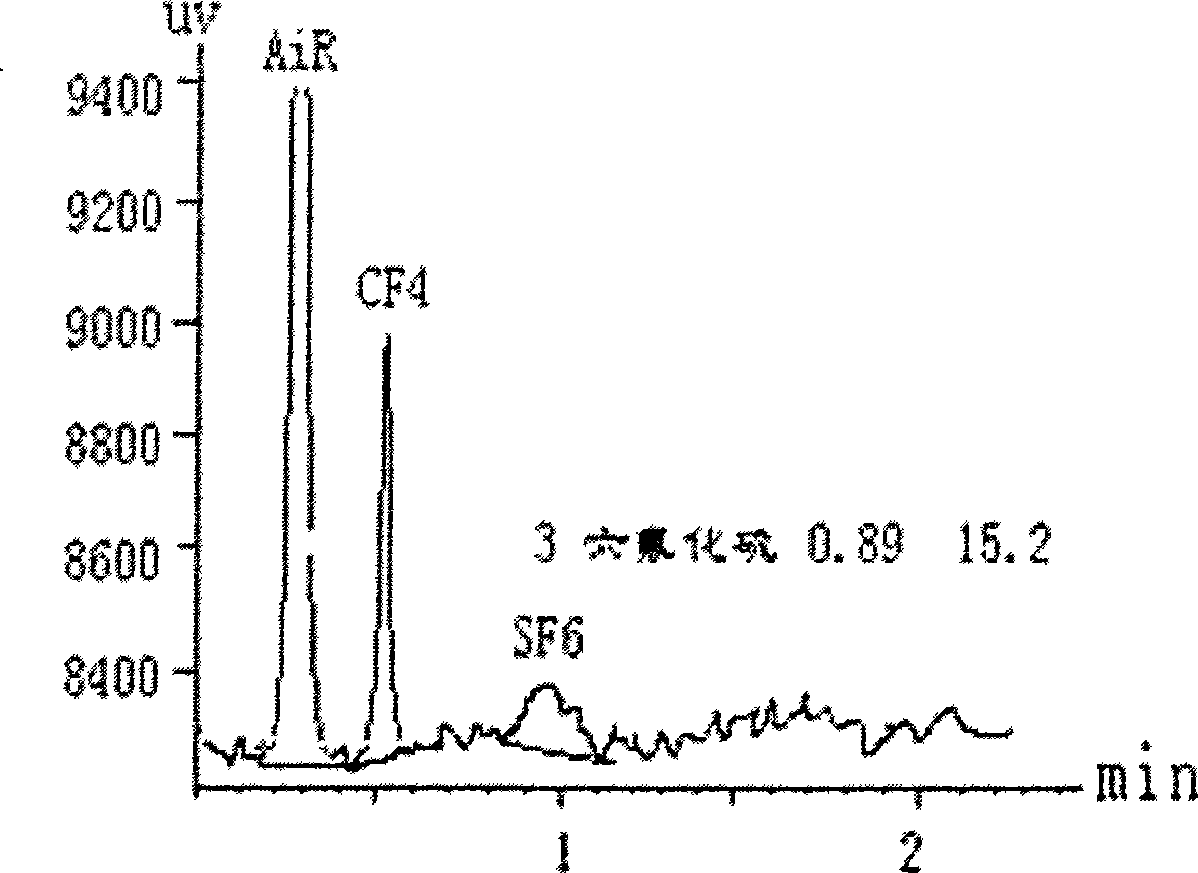

Method for detecting transformer on-load tap changer insulating oil leakage by SF6 gas

InactiveCN101435734AAvoid Misjudgment AccidentsReduce unplanned outagesFluid speed measurementFluid-tightness measurement using fluid/vacuumBodies oilTap changer

The invention relates to a method for detecting leakage of insulating oil in an on-load tapping switch of a transformer by using SF6 gas, which comprises the following steps: firstly, calculating volume of the SF6 gas in the insulating oil added to the on-load tapping switch; adding the SF6 gas to the insulating oil for the on-load tapping switch according to a calculated value; selecting an oil sample of transformer body oil; and using a gas chromatograph to carry out chromatographic analysis for the selected oil sample of the transformer body oil. If the SF6 gas is detected out, which proves that the on-load tapping switch leaks the insulating oil; and if no SF6 gas is detected out, which proves that the on-load tapping switch does not leak the insulating oil. The method determines the problem of oil leakage of the on-load tapping switch by using an indirect method to avoid occurrence of misjudgment accidents, can judge failure property and approximate position inside equipment to provide reliable scientific basis for maintenance work, reduce unplanned power failure and limited loading time of a transformer, greatly reduce economic expenditure on manpower, physical resources and materials, and reduce labor intensity, insecurity factors and the like.

Owner:PINGDINGSHAN POWER SUPPLY ELECTRIC POWER OF HENAN

Chromatographic diagnosis method of oil-immersed type transformer on-load switch leakage

InactiveCN107314860AOvercoming the Defects of Oil Seepage JudgmentAvoid misjudgmentComponent separationFluid-tightness measurement using fluid/vacuumBodies oilTransformer

The invention discloses a chromatographic diagnosis method of an oil-immersed type transformer on-load switch leakage. According to the invention, a chromatographic analyzer detects gas components and concentration contents in a transformer body oil tank, each phase of sleeve oil chamber and on-load switch oil conservator insulation oil for at least three times; according to the detection time, a trend graph where time is taken as the transverse coordinate and the gas components and the concentration contents are taken as the horizontal coordinate is drawn; according to the trend graph, the gas components and the concentration contents in each part of insulation oil of each transformer are judged according to a certain rule, and if the judgment condition is met, the oil-immersed type transformer on-load switch leakage is determined. According to the invention, disadvantages in traditional judgment of the on-load switch oil leakage are overcome; the existence of oil leakage faults of the on-load switch is effectively diagnosed; mis-judgment is avoided; diagnosis efficiency is improved; fault power outage and diagnosis cost of the transformer is reduced; normal production orders are ensured.

Owner:SHANGHAI JINYI INSPECTION TECH

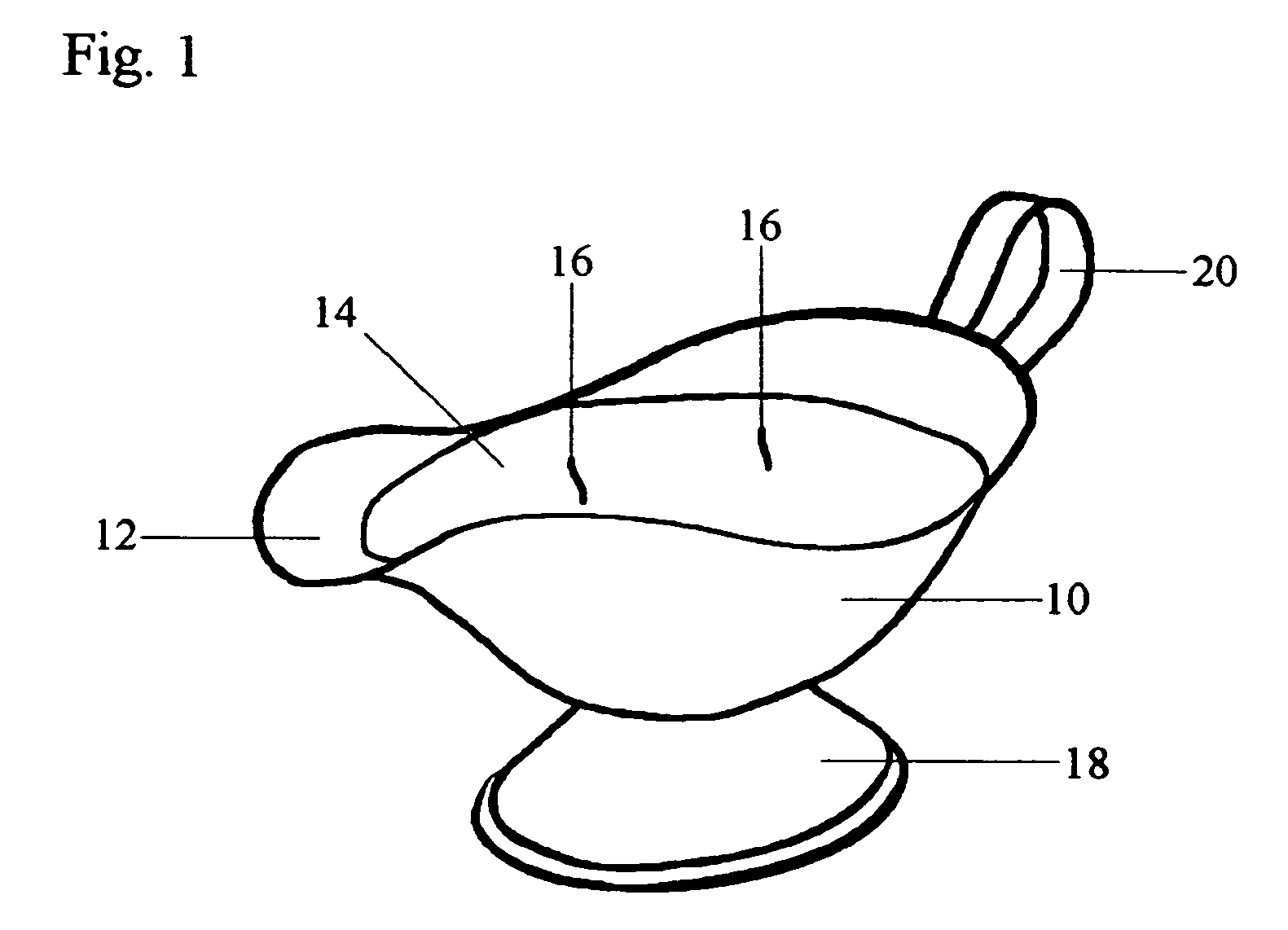

Candle for creating and pouring a body oil composition

A candle for pouring includes a container including a bowl having a continuous wall surface, wherein the continuous wall surface includes a pour spout, a soy-based candle composition formed inside the container, and at least one wick extending from the soy-based candle composition. A candle for pouring may also include an attached base section and at least one attached handle.

Owner:HARRIS DENISE M

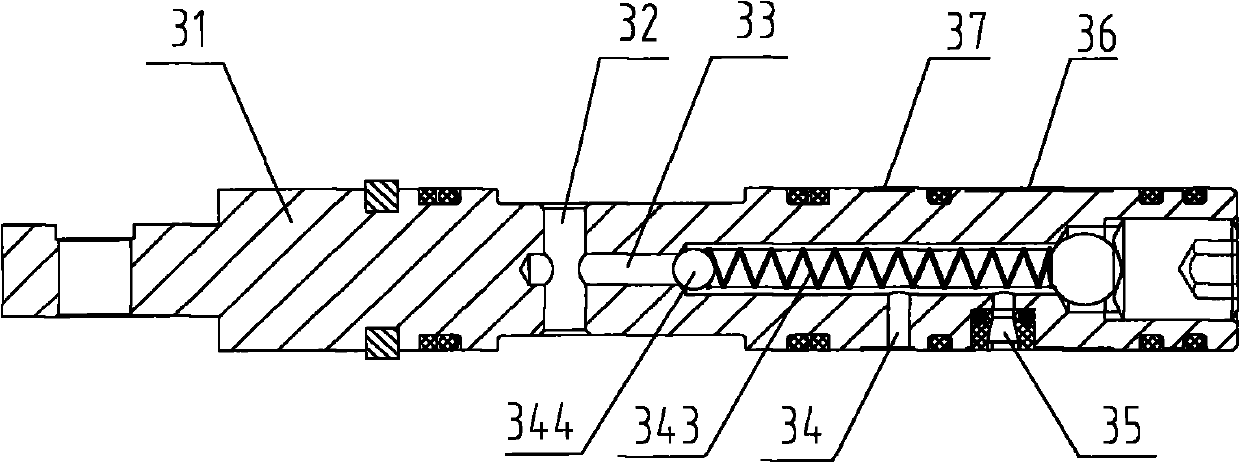

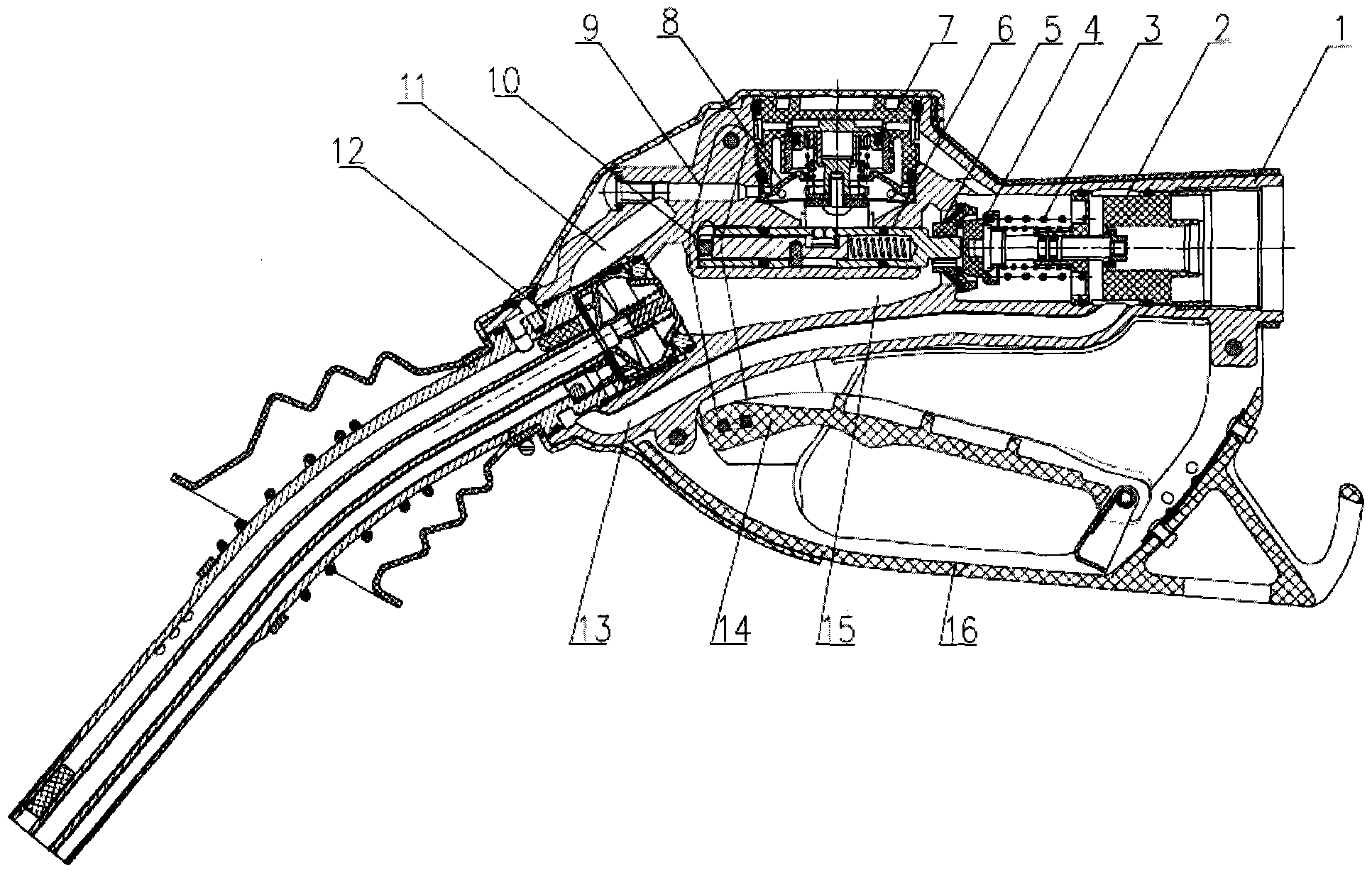

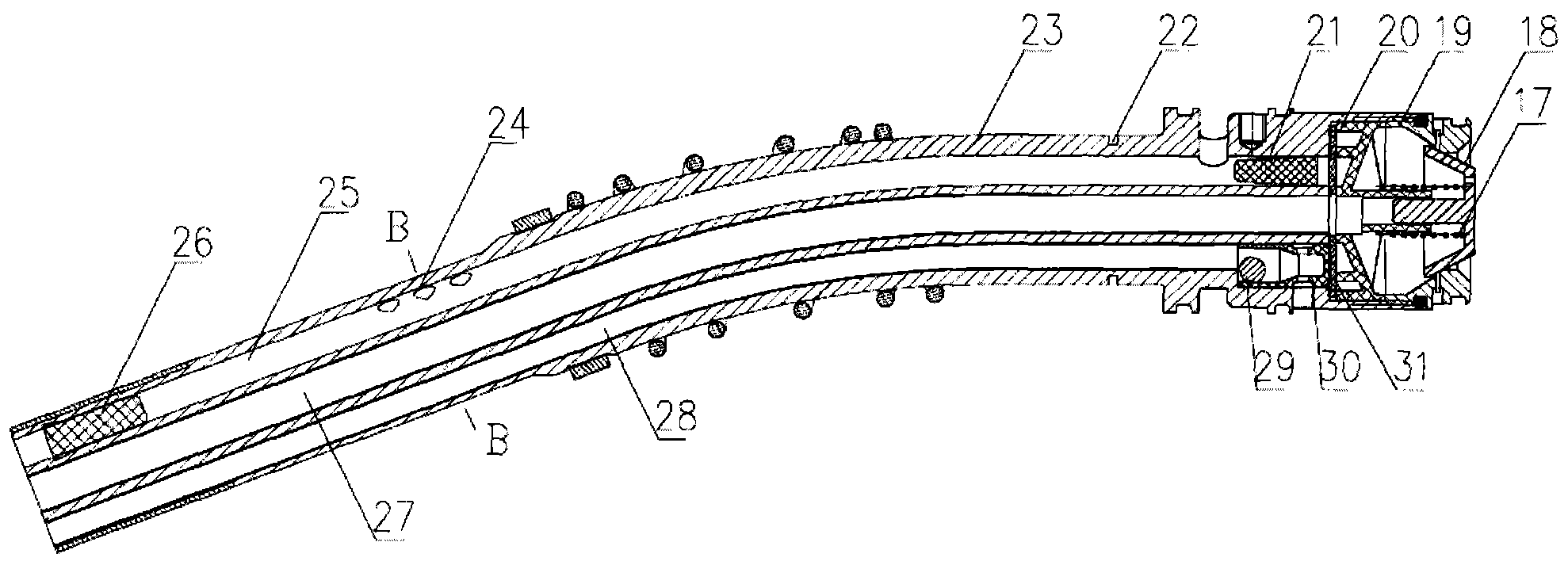

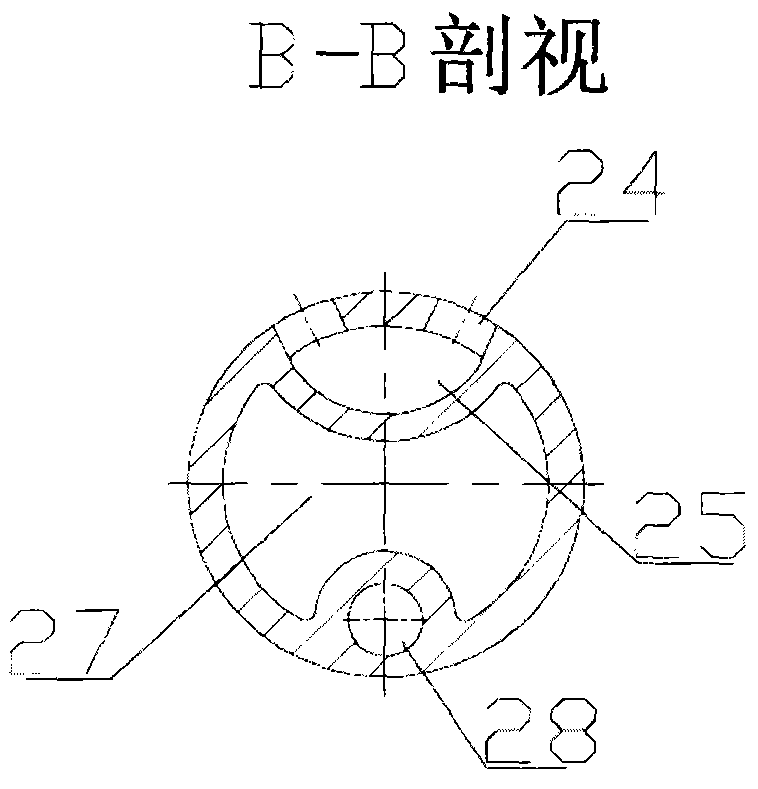

Self-sealing oil gun for oil gas recovery

InactiveCN103663335AFaster assembly processImprove maintainabilityLiquid transferring devicesBodies oilGas supply

The invention discloses a self-sealing oil gun in the oil gas recovery field. An oil gas recovery channel is integrated in the self-sealing oil gun. The self-sealing oil gun comprises an oil gun body, a gun barrel assembly, a non-pressure self-sealing assembly, a vacuum self-sealing assembly, a push rod assembly, an oil gas separating assembly and a wrench assembly. An oil gas recovery cavity is integrated in the lower portion of a gun body oil way channel cavity. As the gun barrel structure integrally formed by the oil gas recovery channel, a gas supply channel and an oil liquid output channel, and a special oil gas separating assembly structure are adopted, the low flow resistance and the high flow rate are achieved, the efficiency of recovering oil gas when the oil gun works is improved, and the probability of oil-gas leakage is reduced. By the application of a novel non-pressure self-sealing and gun-jumping mechanism, the safety reliability and the stability of oil gun work are improved, atmosphere pollution is further reduced, and the self-sealing oil gun plays an important role in saving resources.

Owner:ZHEJIANG CHUNHUI INTELLIGENT CONTROL

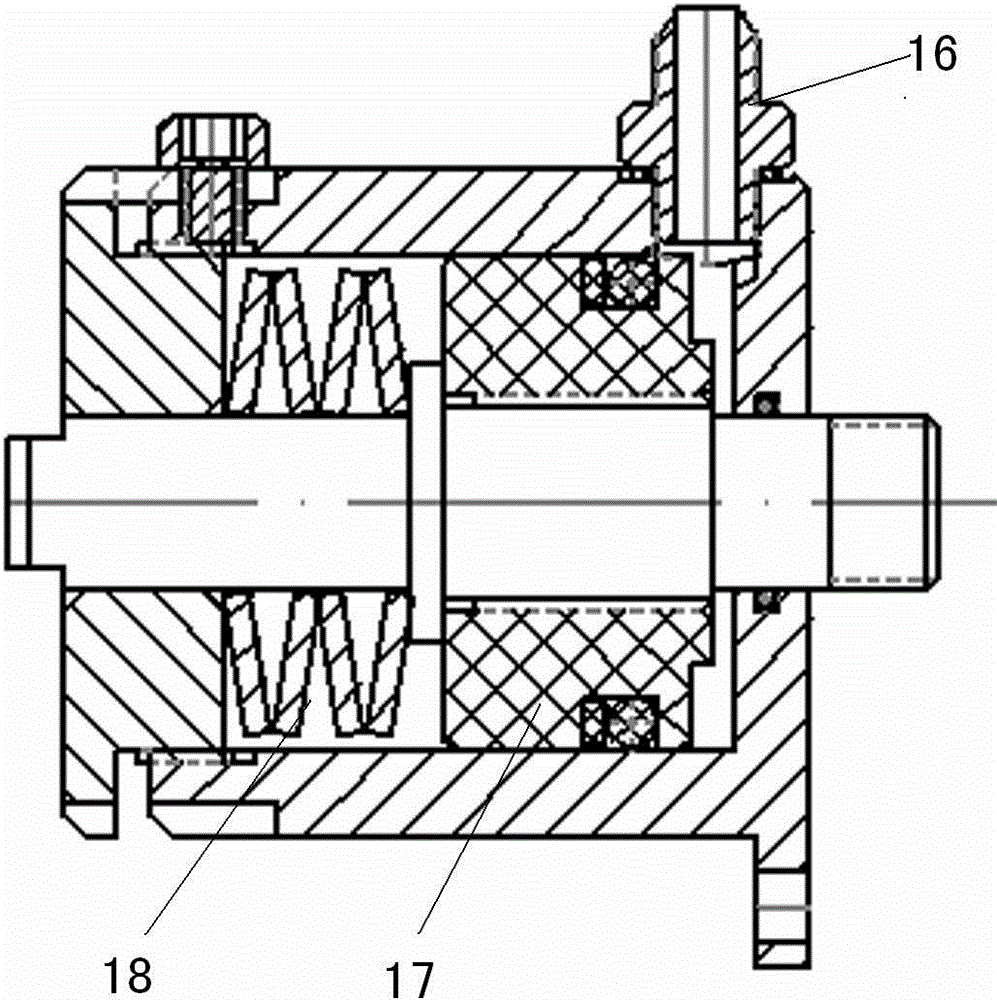

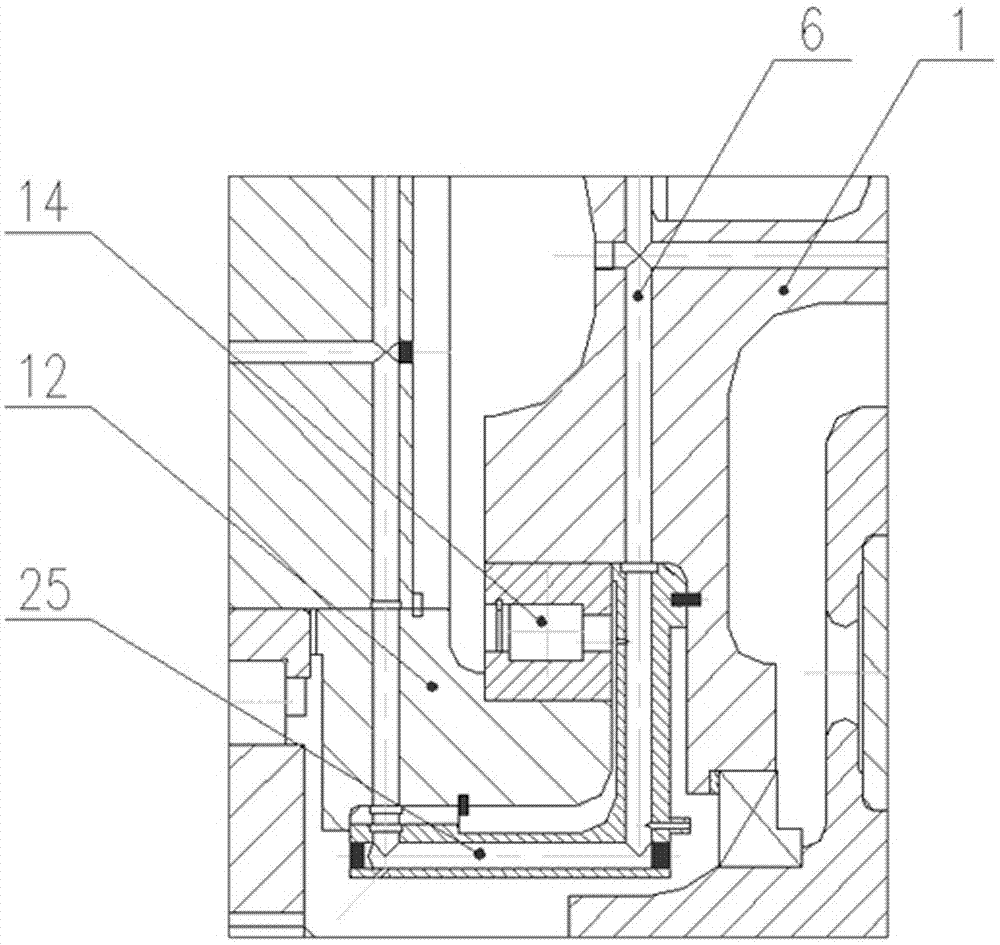

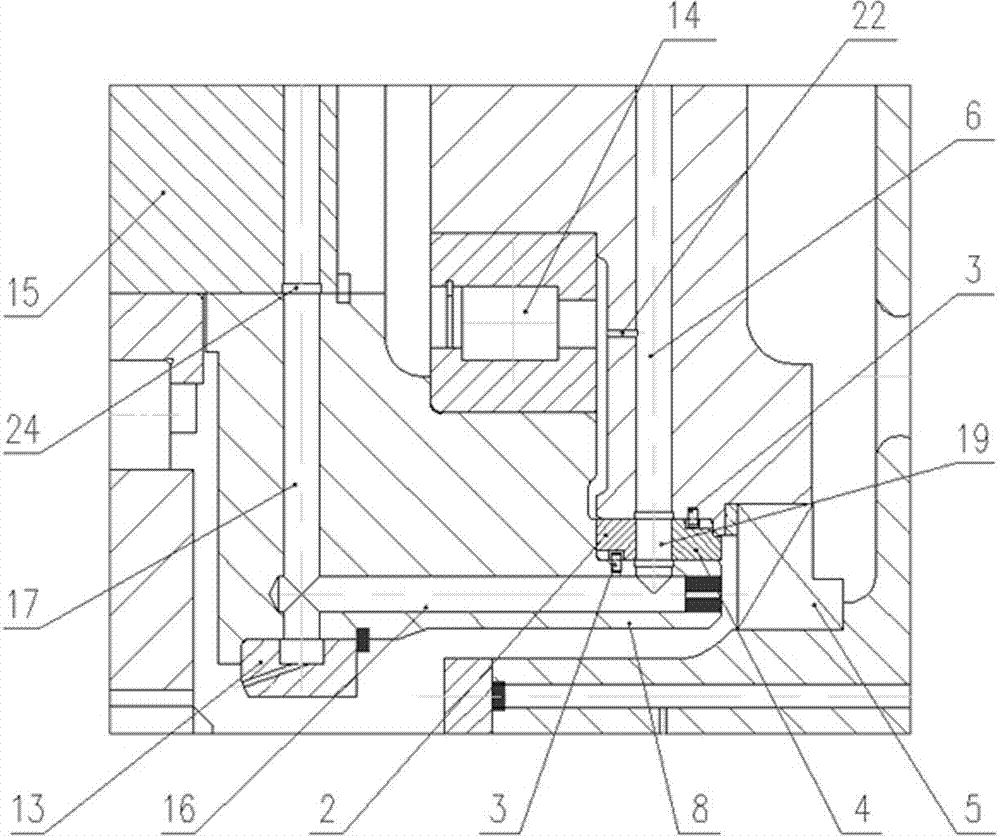

Normally-closed fixed belleville spring caliper disc brake

InactiveCN104930081AEasy to replaceEasy clearance adjustmentAxially engaging brakesBraking elementsBodies oilBrake torque

The invention discloses a normally-closed fixed belleville spring caliper disc brake. The brake comprises a brake disc, friction sheets, push plates and machine body oil cylinders, wherein the friction sheets, the push plates and the machine body oil cylinders are symmetrically arranged on the two sides of the brake disc. The friction sheets are arranged on a friction plate, and the friction plate, the push plates and pistons are fixedly connected. The pistons are arranged in the machine body oil cylinders, and the tail ends of the pistons are sleeved with belleville springs. The friction sheets are arranged on the side face of the brake disc, the friction sheets can be tightly attached to the brake disc and act on the brake disc under the acting force of the belleville springs, and the brake is made in a closely-closed state; oil is supplied to the machine body oil cylinders through an oil supply port, so that opening brake is realized. According to the normally-closed fixed belleville spring caliper disc brake, the positions between the friction sheets and the brake disc are fixed, gaps can be adjusted conveniently, the friction sheets can be replaced conveniently, the size is small, the braking torque is large and the braking effect is good.

Owner:杨崇庆

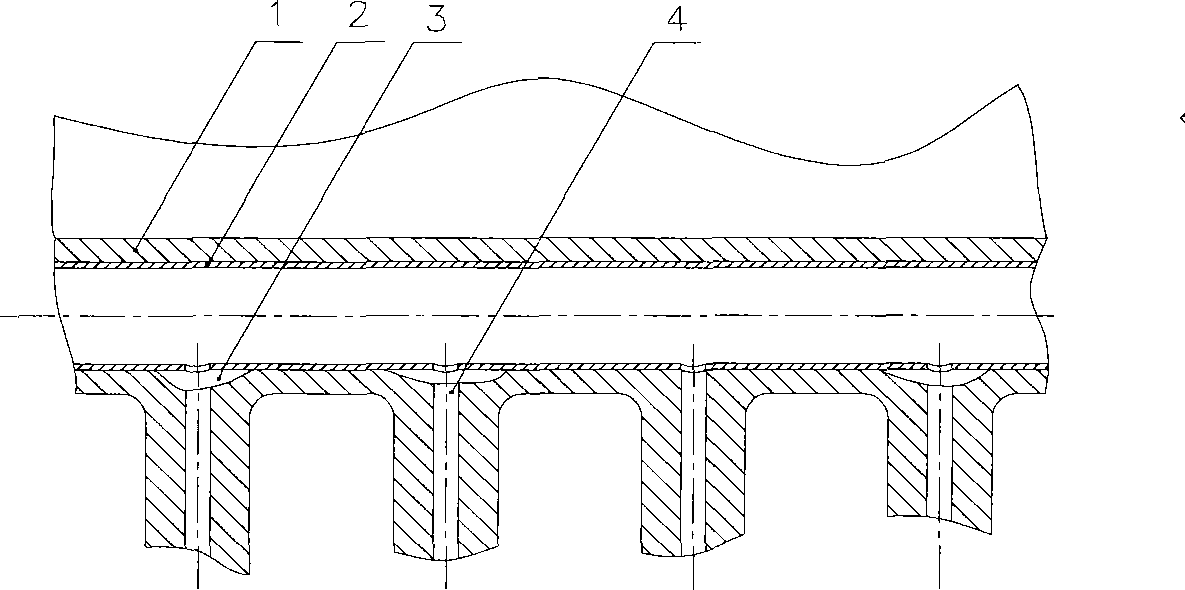

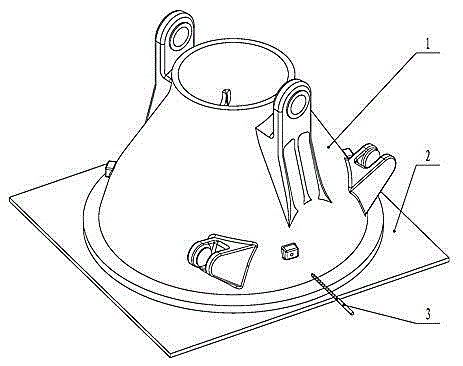

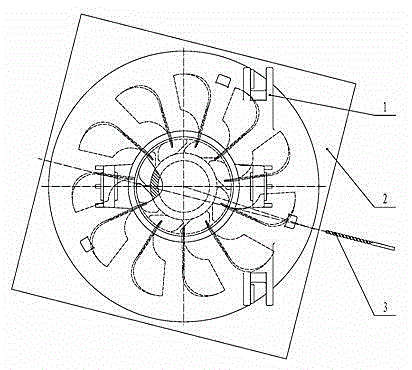

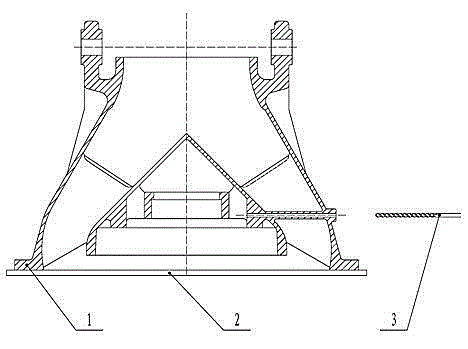

Guide vane body oil hole machining method

The invention provides a guide vane body oil hole machining method, which is characterized by comprising the following steps: firstly placing and fixing a flat plate with a proper size on a boring lathe guide rail and scribing a straight line which is collinear with a main shaft of a boring lathe on the flat plate; then placing a guide vane body on the flat plate by overlapping an oil hole central line mark marked on the outer circular edge of a guide vane body flange with the straight line previously scribed on the flat plate; and finally, vertically moving the center of the main shaft of the boring lathe clamped with a drilling bit to the boss direction for a corresponding distance from the plane of the flat plate according to the vertical distance from the central line of an oil hole in a boss to the flange plane in a design drawing, wherein a short drilling bit is firstly used and then changed into a long drilling bit after a certain depth is reached during machining. The method is simple, easy and efficient, a special tool clamp is not required to be designed additionally, and the production cost is reduced.

Owner:湖北省天门泵业有限公司

Low-noise hydraulic steering gear

The invention relates to a low-noise hydraulic steering gear, and belongs to the field of hydraulic technologies. The steering gear is provided with a valve body oil inlet ring groove, a valve sleeve and a valve core, valve sleeve oil return holes are formed in one end of the valve sleeve, valve sleeve oil distributing holes are formed in the middle section of the valve sleeve, and valve sleeve oil inlet holes are formed between the valve sleeve oil return holes and the valve sleeve oil distributing holes; a set of valve core oil return holes which correspond to the valve sleeve oil return holes in position and are distributed at intervals in the circumferential direction is formed in one end of the valve core, an oil distributing ring groove is formed in the position, corresponding to the valve sleeve oil inlet holes, of the valve core, and the oil distributing groove extends at intervals in the circumferential direction to form a set of communicating grooves corresponding to the valve sleeve oil distributing holes in position; buffering grooves are manufactured in the positions corresponding to at least one set of the valve sleeve oil return holes and the valve core oil return holes, and the axial extending length of the buffering grooves is larger than the circulating length of the oil return holes. Closure or communication of the oil return holes will become gentle due to the gradual transition of the intermediate state, the flow rate and the pressure of hydraulic oil change gently, and consequently noise is reduced effectively.

Owner:ZHENJIANG HYDRAULICS

Automobile hydraulic braking device

InactiveCN103144622ANo accidentPrecise distribution of braking forceFluid braking transmissionBrake actuating mechanismsBodies oilDriving risk

The invention discloses an automobile hydraulic braking device, which comprises an oil pump, a filter, a pressure gauge, a control valve, a braking oil cylinder, an adjustable flow valve, an overflow valve and an oil return pipe, wherein an oil inlet and an oil return port are formed in one side of the valve body of the control valve, and an oil outlet is formed in the other side of the valve body of the control valve; a spring is arranged between the tail end of the valve core and the valve body; the valve core is provided with a valve hole; when the valve core moves, the oil outlet is communicated with the oil inlet or the oil return port through a valve hole; a cylinder body oil inlet of a braking oil cylinder is provided with an oil pipe joint; a belleville spring is arranged between the tail end of a piston and the cylinder body; a brake block is fixed to the cylinder body through a stop screw; the tail end of a piston rod is then connected with the brake block through a connecting screw; the oil pump is connected with the filter; the filter is communicated with the oil inlets of the overflow valve and the control valve through an oil path provided with the pressure gauge respectively; the oil outlet of the control valve is communicated with an oil pipe joint of the braking oil cylinder; the oil return port is communicated with the adjustable flow valve; and the overflow valve is connected with the oil return pipe. The automobile hydraulic braking device has extremely high safety and reliability, and the driving risk can be effectively reduced.

Owner:高平市泫氏铸管有限公司

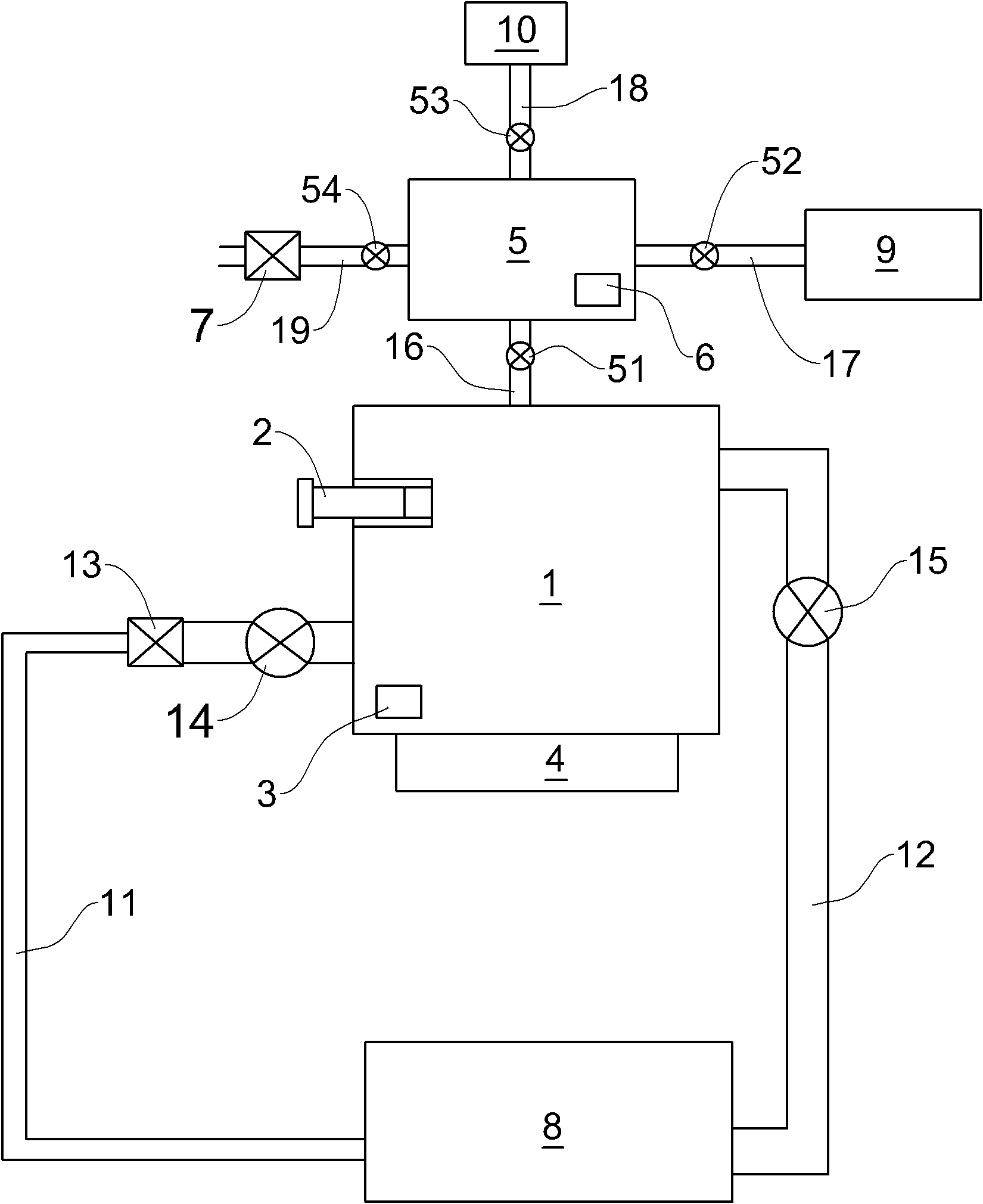

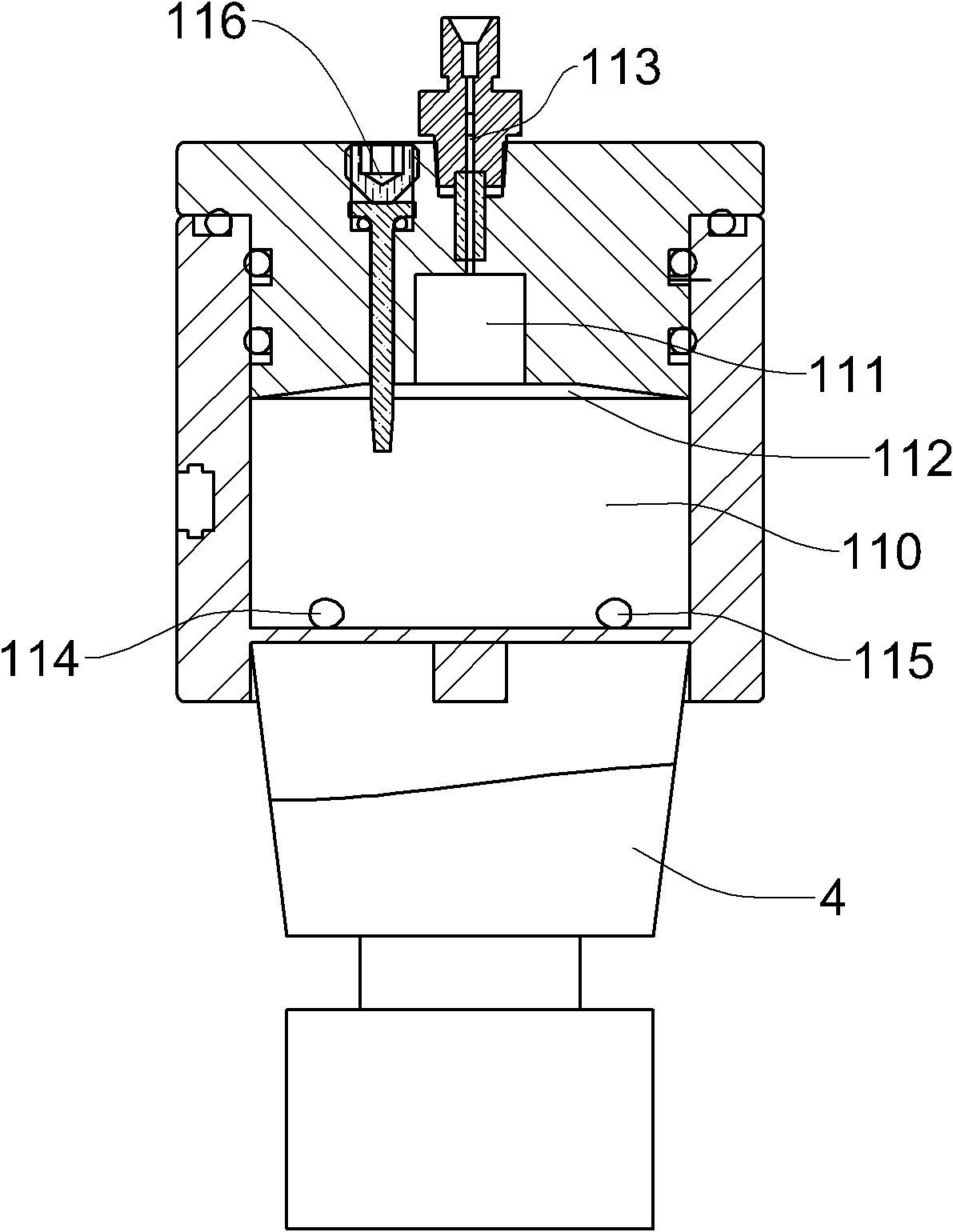

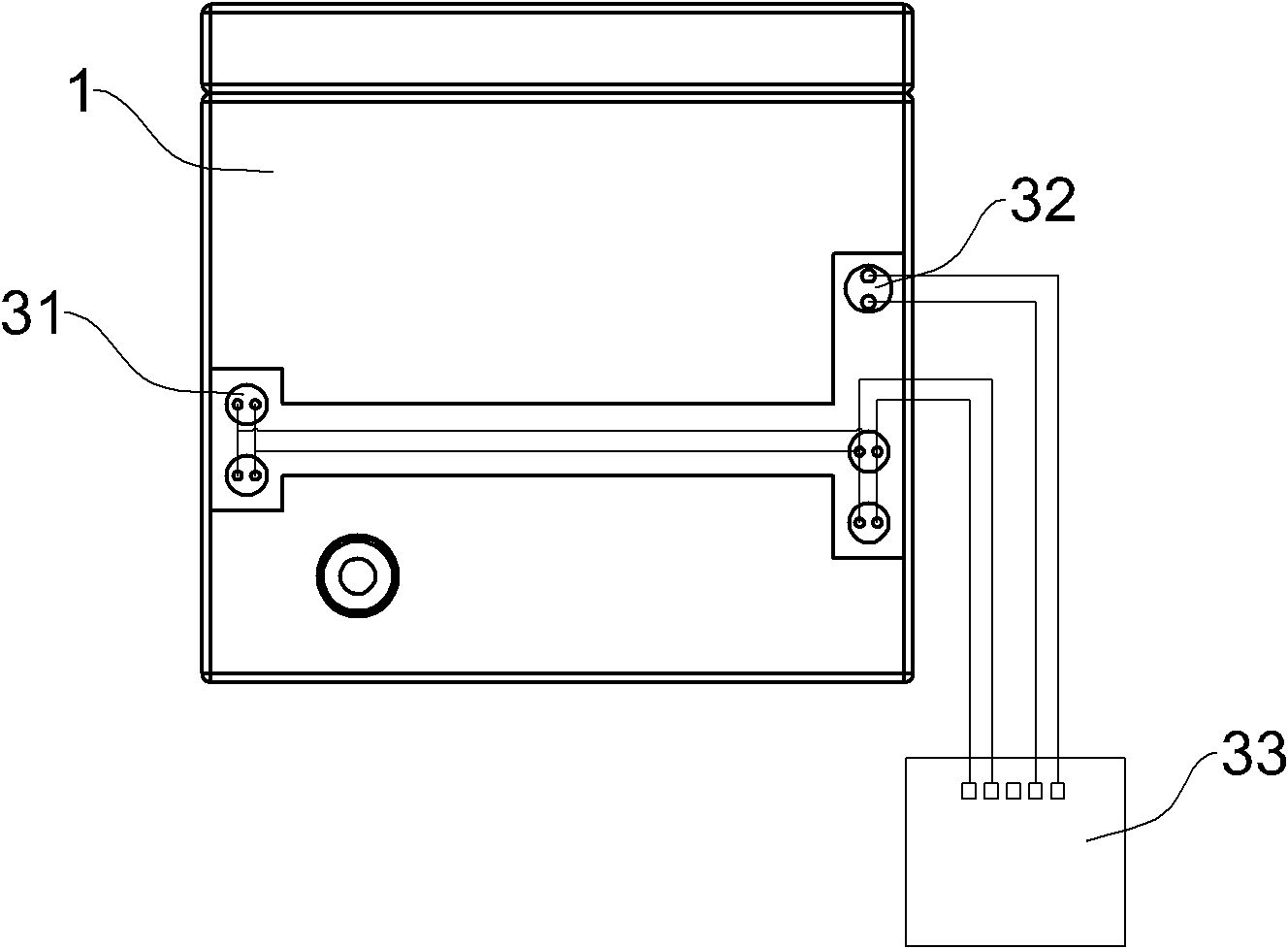

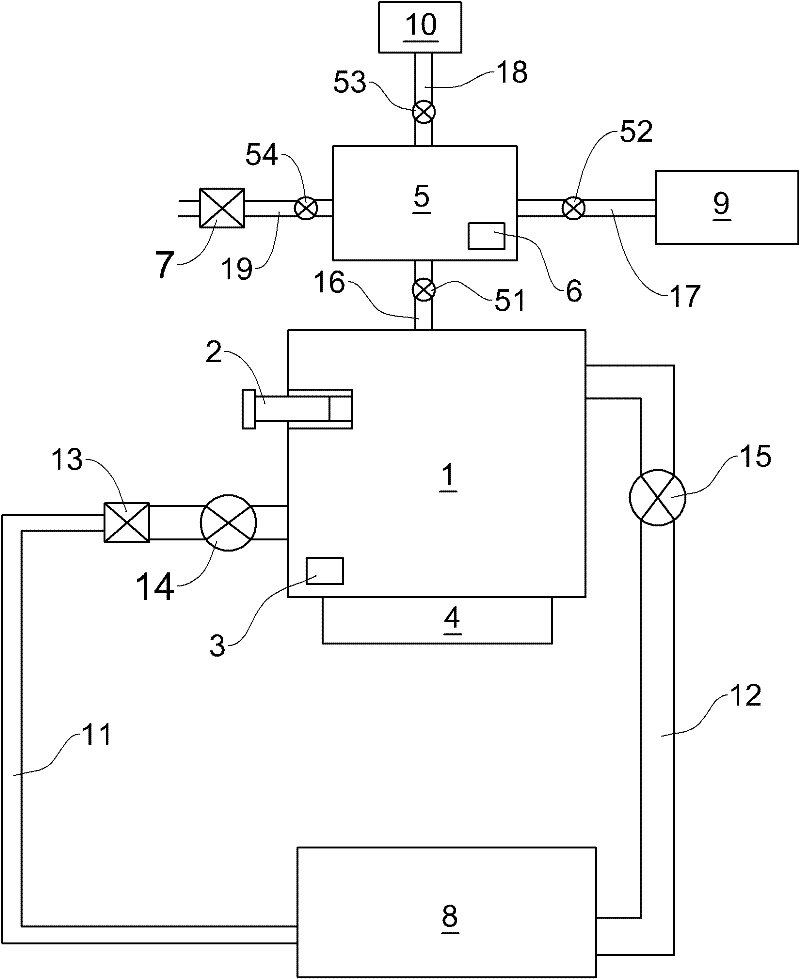

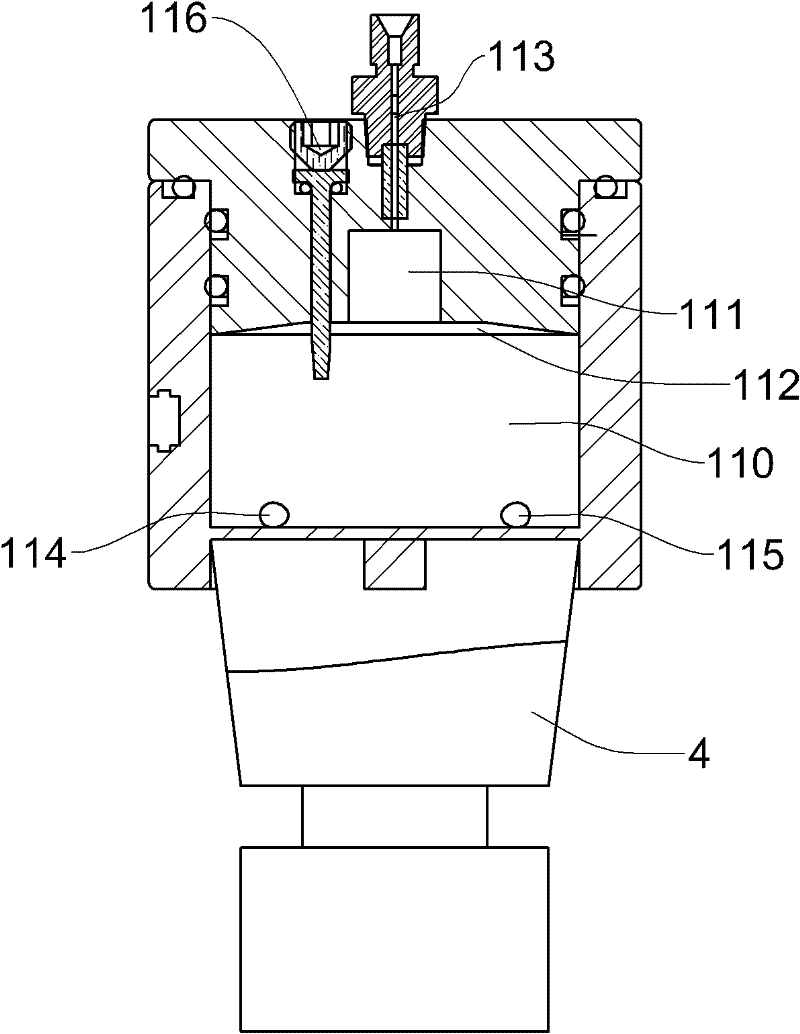

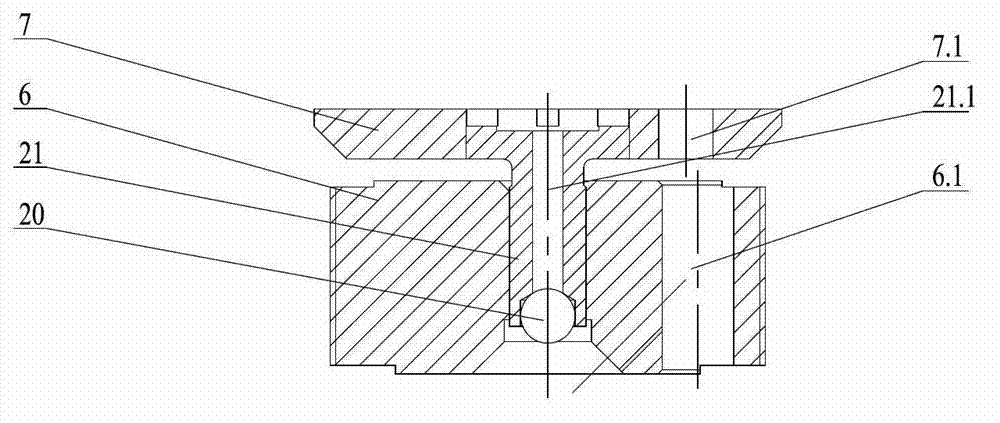

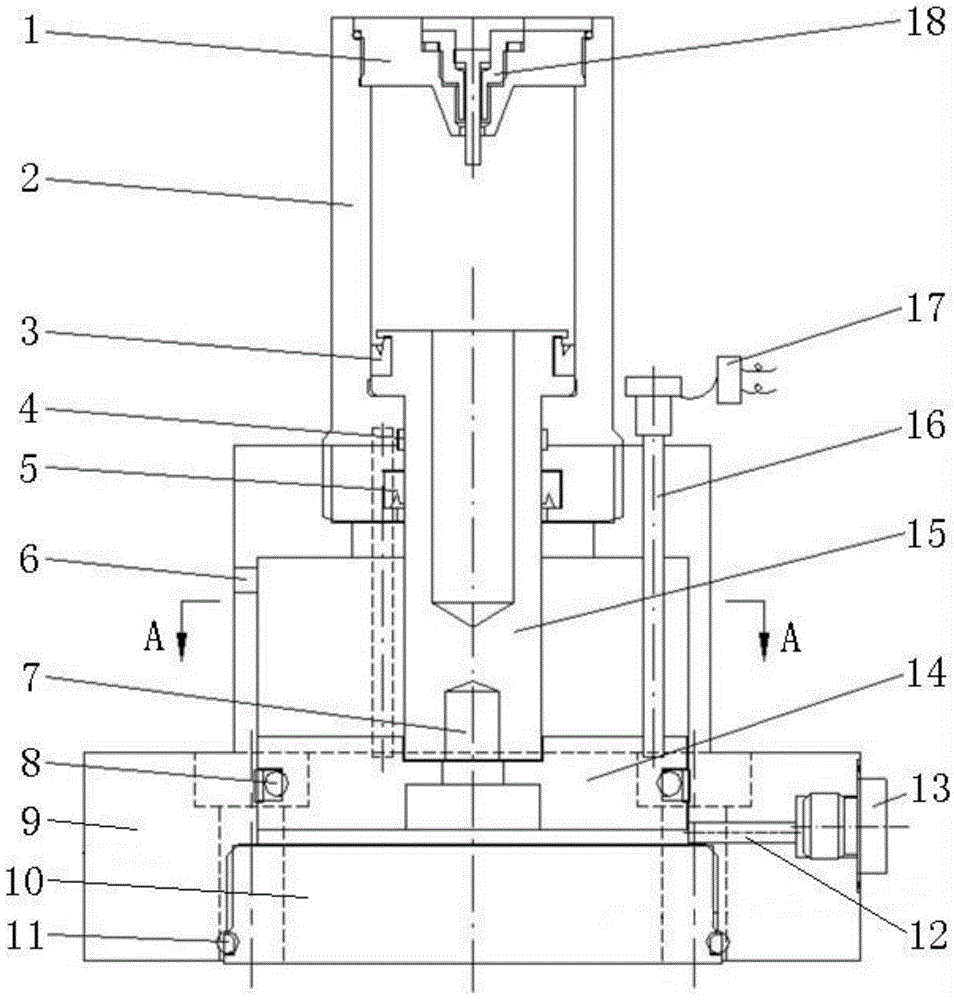

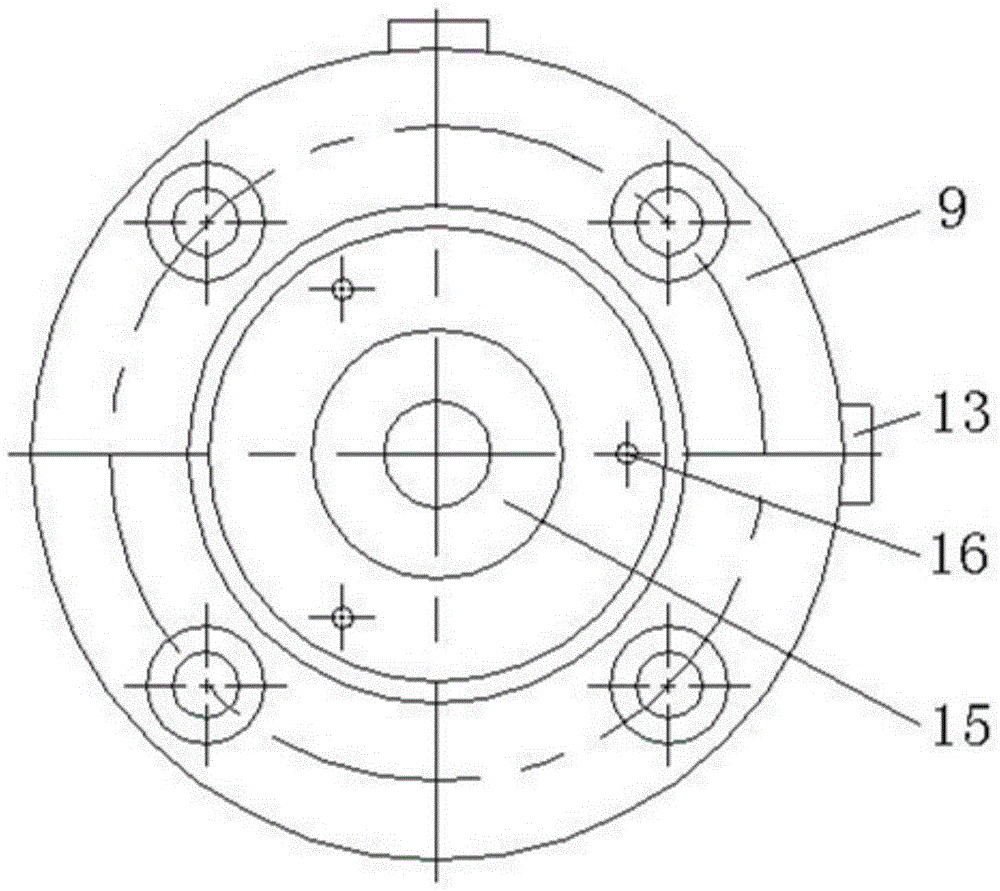

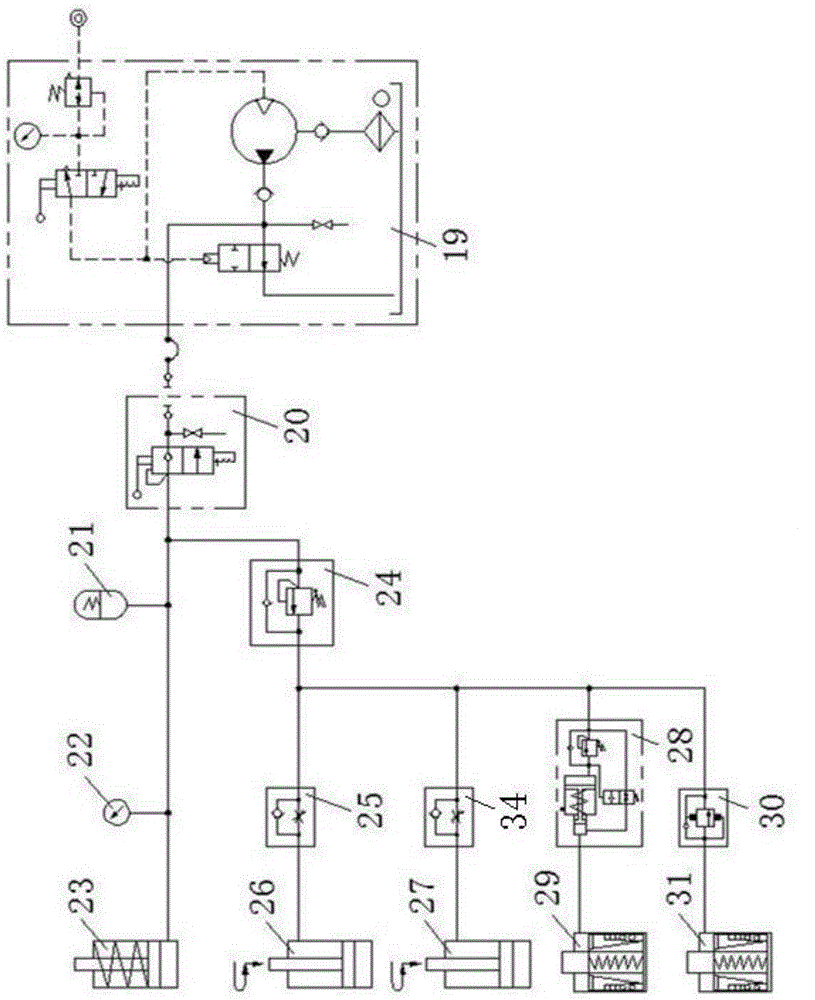

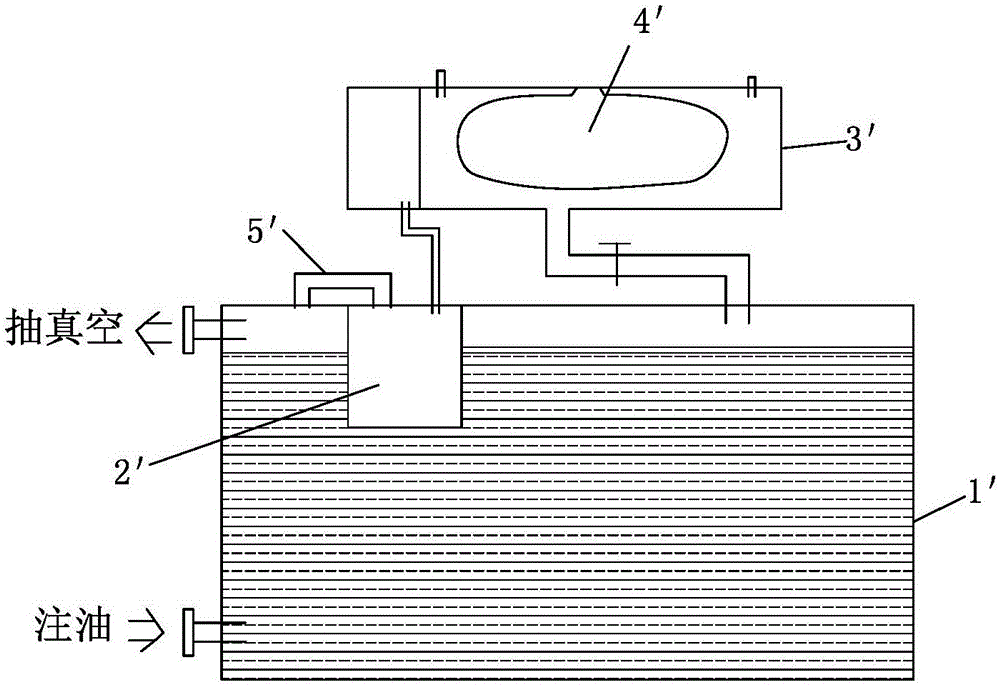

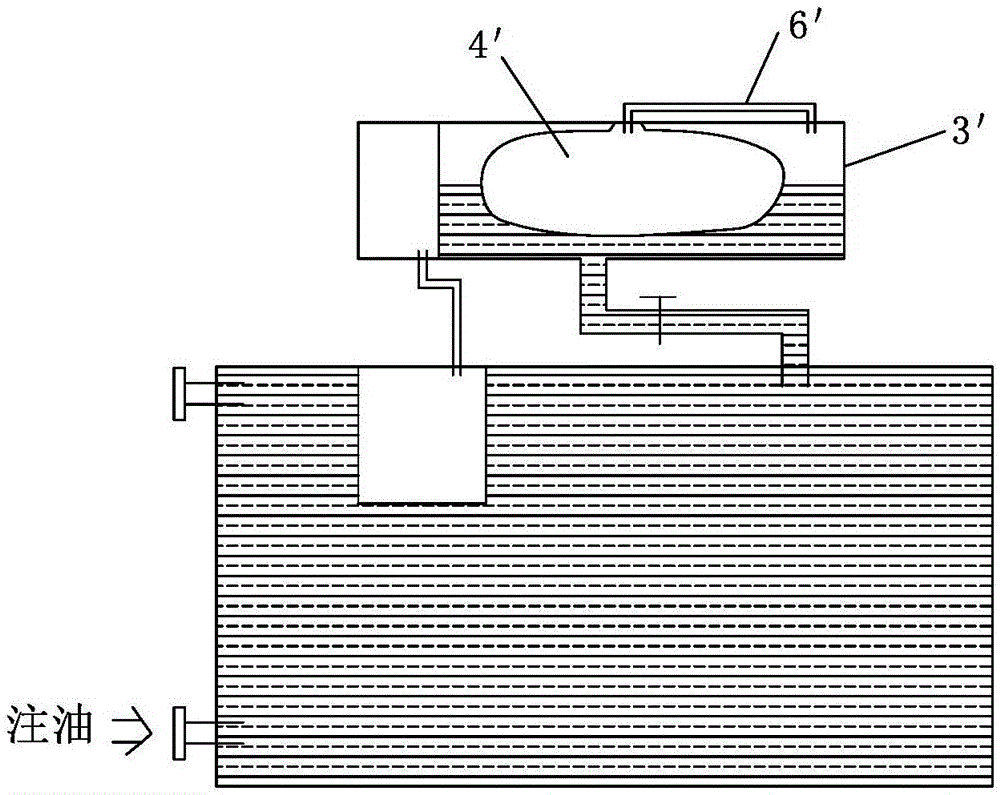

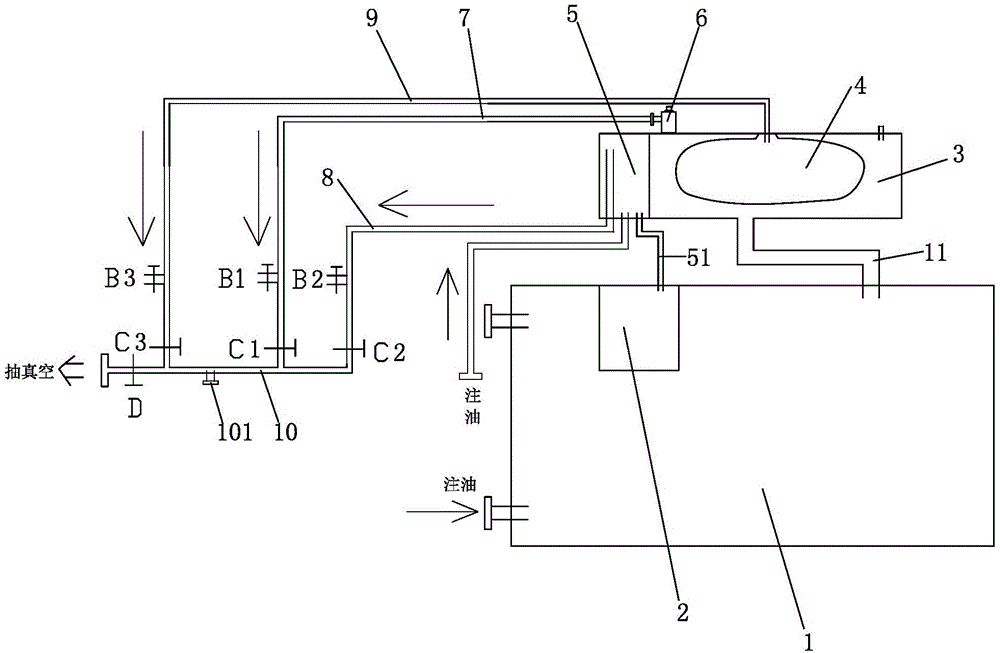

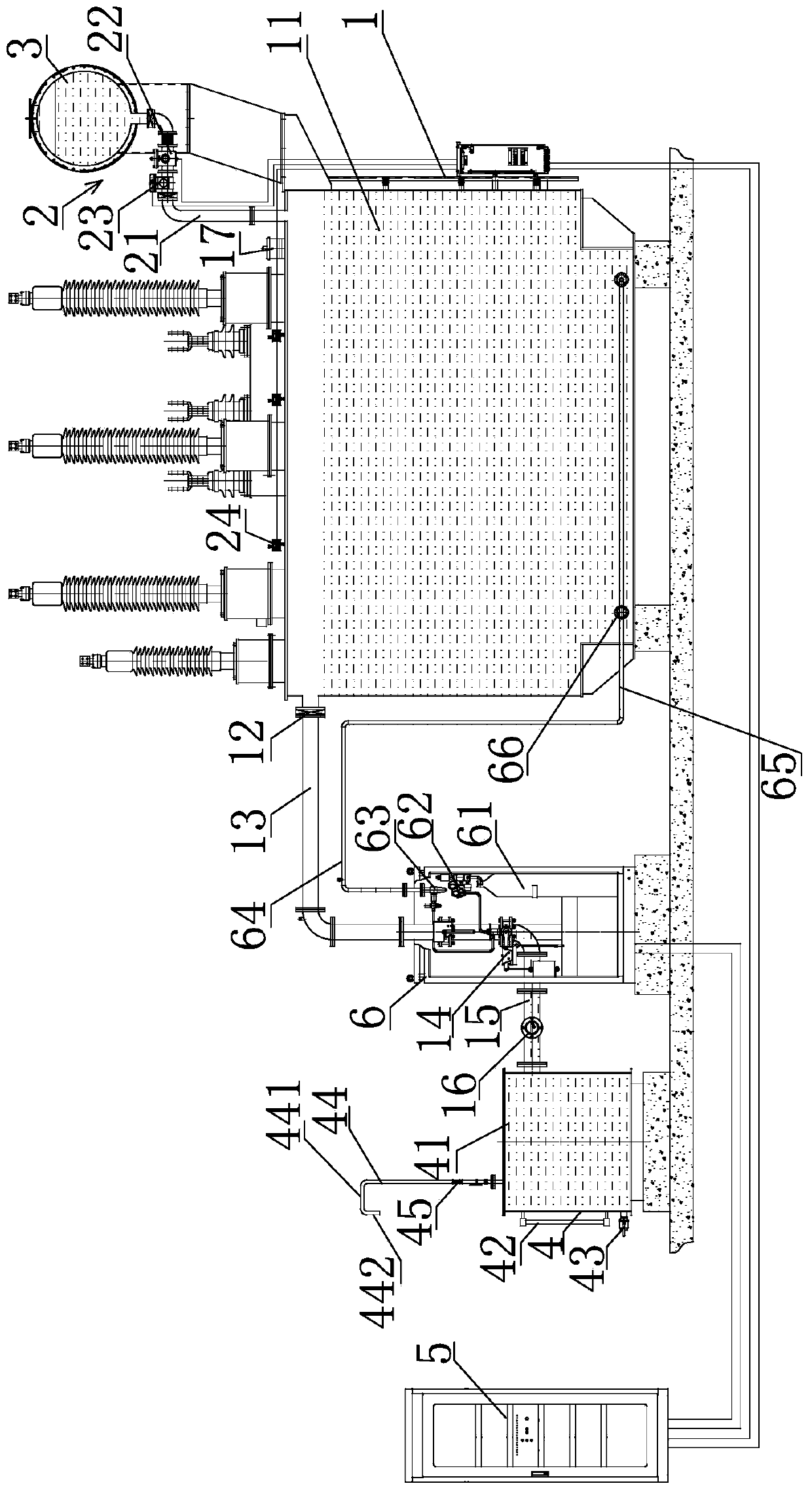

Power-transformer overall vacuumizing device

ActiveCN105047377AReduce gas contentImprove insulation performanceTransformers/inductances coolingSwitchgearBodies oilTap changer

The invention discloses a power-transformer overall vacuumizing device. The power-transformer overall vacuumizing device comprises a transformer body, a body oil conservator, a capsule and an on-load oil conservator. The transformer body is communicated with the body oil conservator. The capsule is arranged in the body oil conservator. The on-load oil conservator is communicated with an on-load tap-changer oil chamber in the transformer body. A control assembly used for installing a relief plug back in the vacuum state is installed at an exhausting opening of the body oil conservator and comprises a cavity communicated with the body oil conservator before the relief plug is placed down. The cavity is communicated with a first vacuumizing pipe. The power-transformer overall vacuumizing device further comprises a pipe assembly used for vacuumizing the on-load oil conservator, the on-load tap-changer oil chamber and the capsule. According to the power-transformer overall vacuumizing device, recovering in the vacuum undamaged state is achieved through the exhausting opening of the body oil conservator in cooperation with the control assembly, oil injection can be carried out in the state of being not in contact with air completely, insulating oil is not in contact with the air completely, the content of the air in transformer oil is greatly reduced, and the insulation effect inside a transformer is improved.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +2

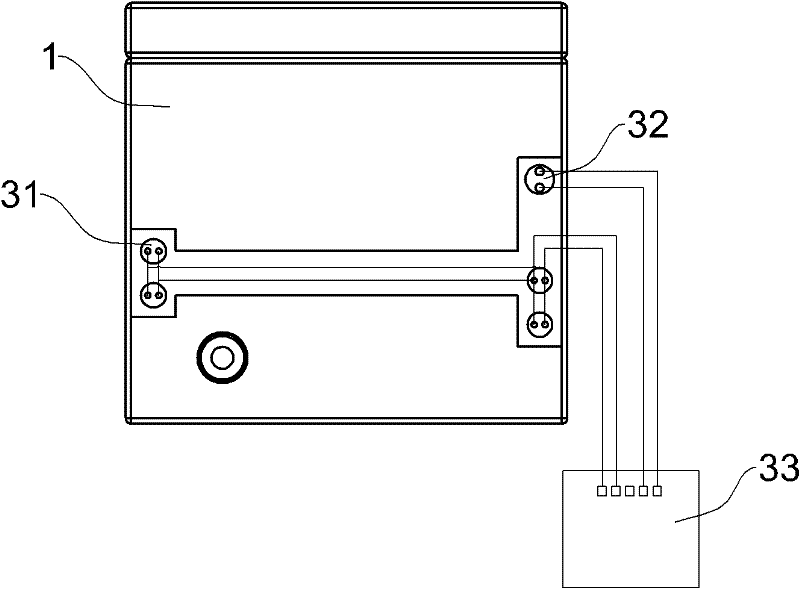

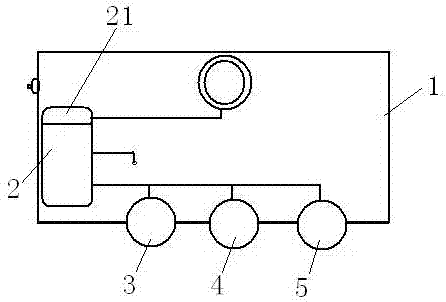

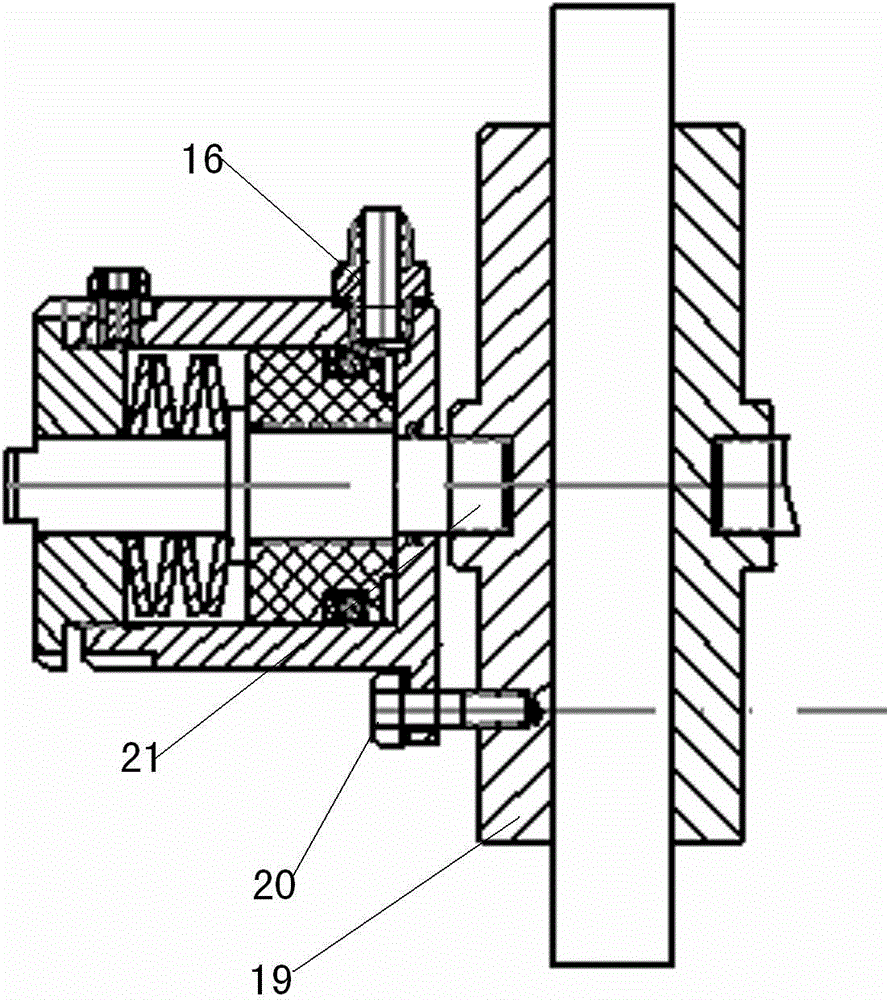

Electric grease injecting machine

The invention discloses an electric grease injecting machine comprising a grease pumping device. The upper end of the grease pumping device is coaxially connected with a fixed seat which is vertically connected with a drive motor; a reversing mechanism is arranged in the fixed seat and comprises a bearing block, a pair of ball bearings and an eccentric wheel in sequence from the outside to the inside; the eccentric wheel is provided with a key slot; a motor driving shaft is provided with a key which is in interference fit with the key slot, is connected with the eccentric wheel by a key, and drives the eccentric wheel to do 360-degree rotating motion; the eccentric wheel is connected with the bearing block through a pair of ball bearings and drives the bearing block to do up-down reciprocating motion; the bearing block is movably connected with a driving rod through a driving rod joint; the fixed seat is connected with a pump body through an inner connecting pipe; and the fixed seat is provided with a pressure adjusting mechanism communicated with a pump body oil path. The invention carries out grease injecting operation under the condition of having no air source by only taking a common single-phase 220V power supply as the power; in addition, the invention has the advantages of widening the application range, prolonging the service life of the reversing mechanism, and reducing the wear degree of oil seal.

Owner:上海科球机电有限公司

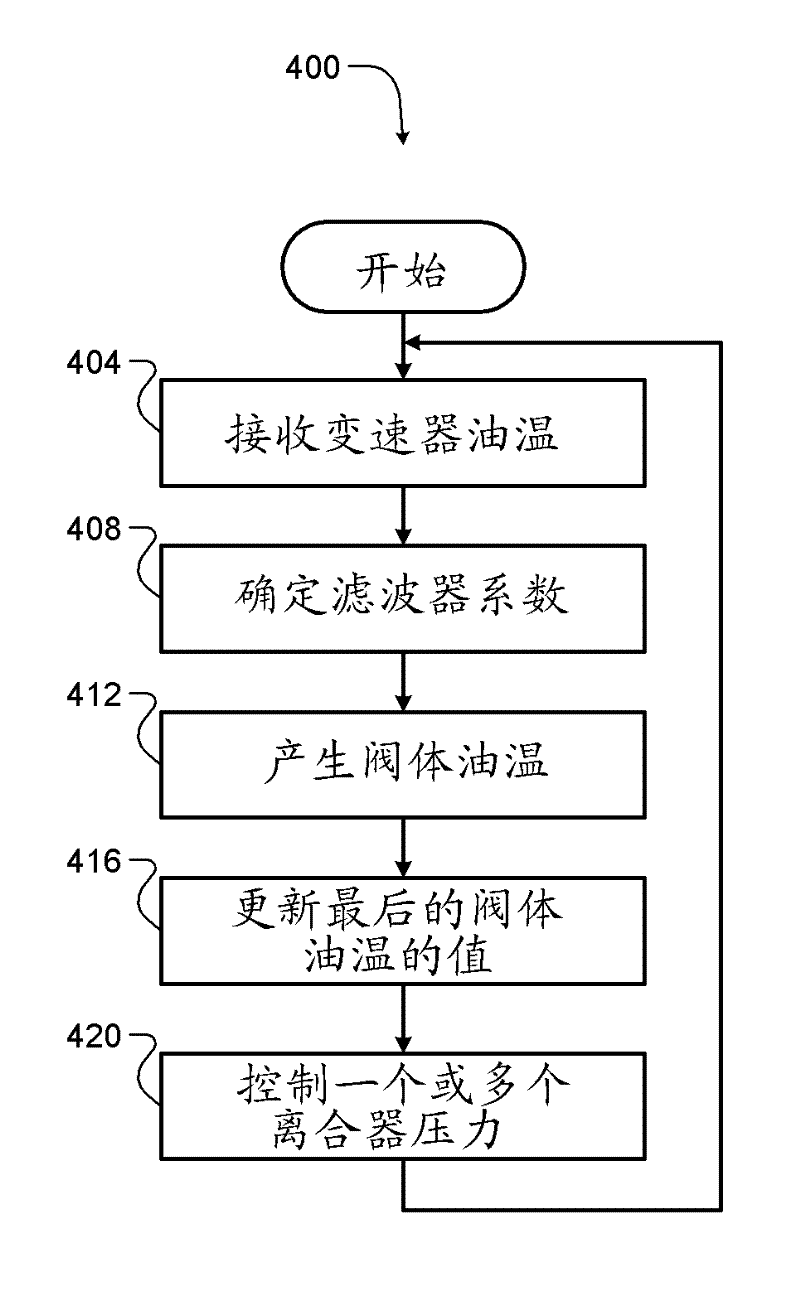

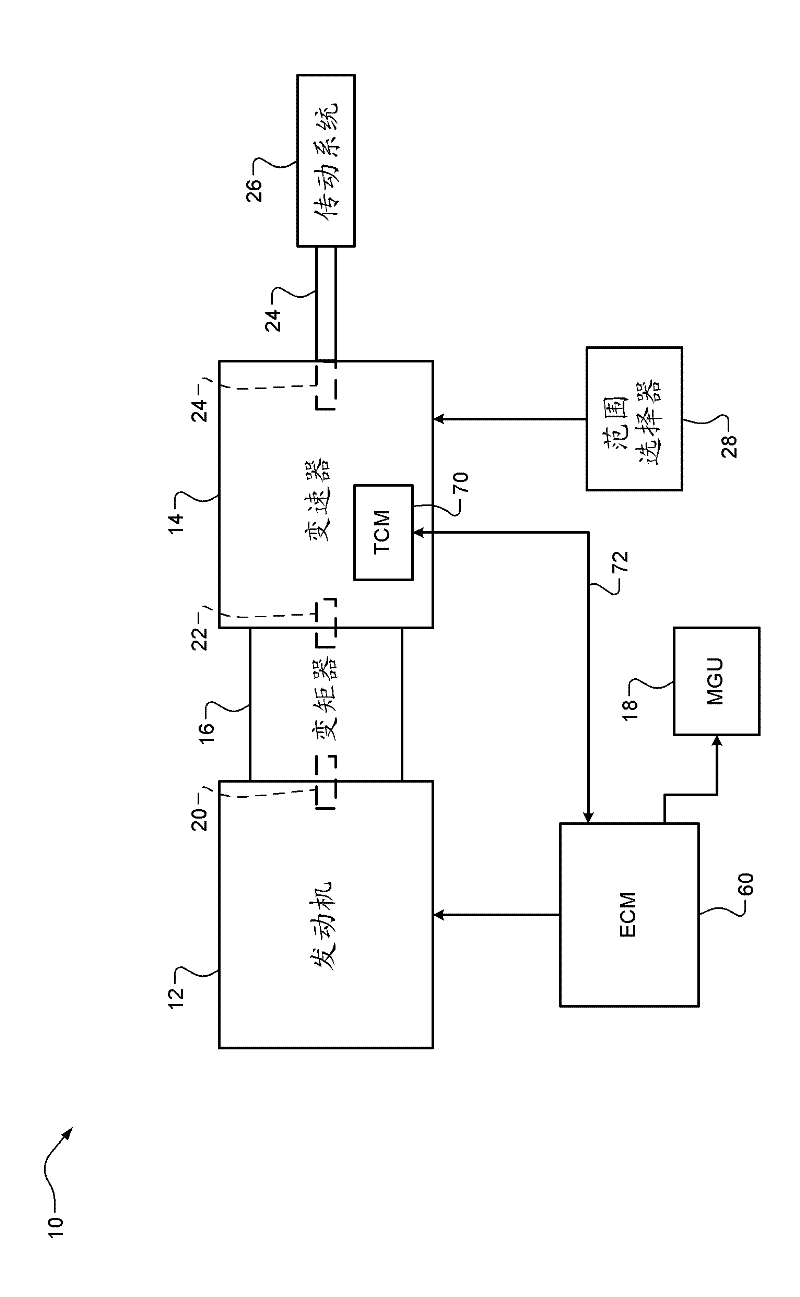

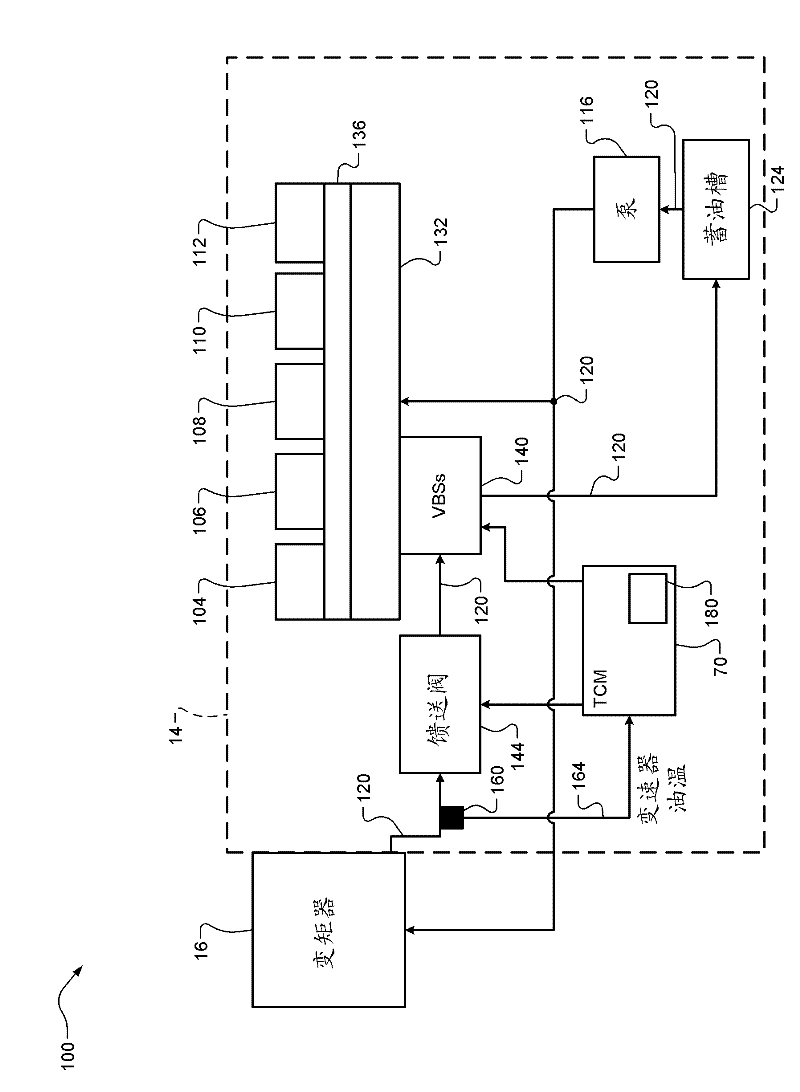

Transmission oil temperature estimation systems and methods

The invention relates to transmission oil temperature estimation systems and methods, and concretely provides a system for a vehicle. The system for a vehicle includes a filter module and a coefficient determination module. The filter module generates a valve body oil temperature signal as a function of a transmission oil temperature signal, the valve body oil temperature signal, and a filter coefficient. The coefficient determination module varies the filter coefficient based on the valve body oil temperature signal. The transmission oil temperature signal corresponds to a first temperature of transmission oil measured at a location between a torque converter and a variable bleed solenoid (VBS). The valve body oil temperature signal corresponds to a second temperature of transmission oil provided to a clutch of a transmission from a valve body.

Owner:GM GLOBAL TECH OPERATIONS LLC

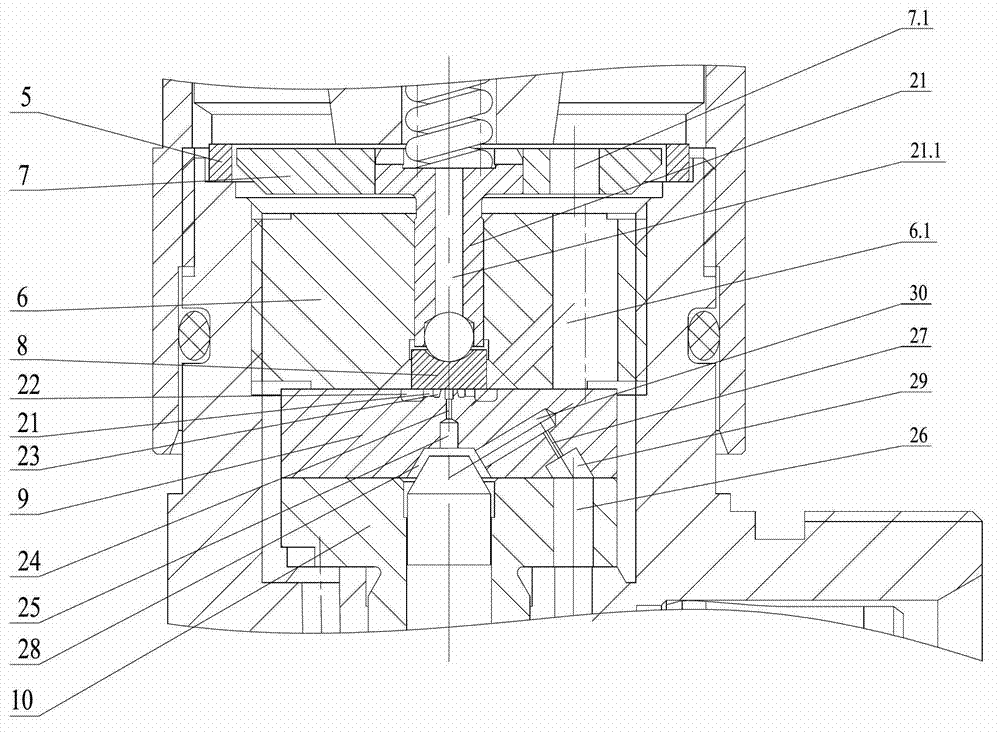

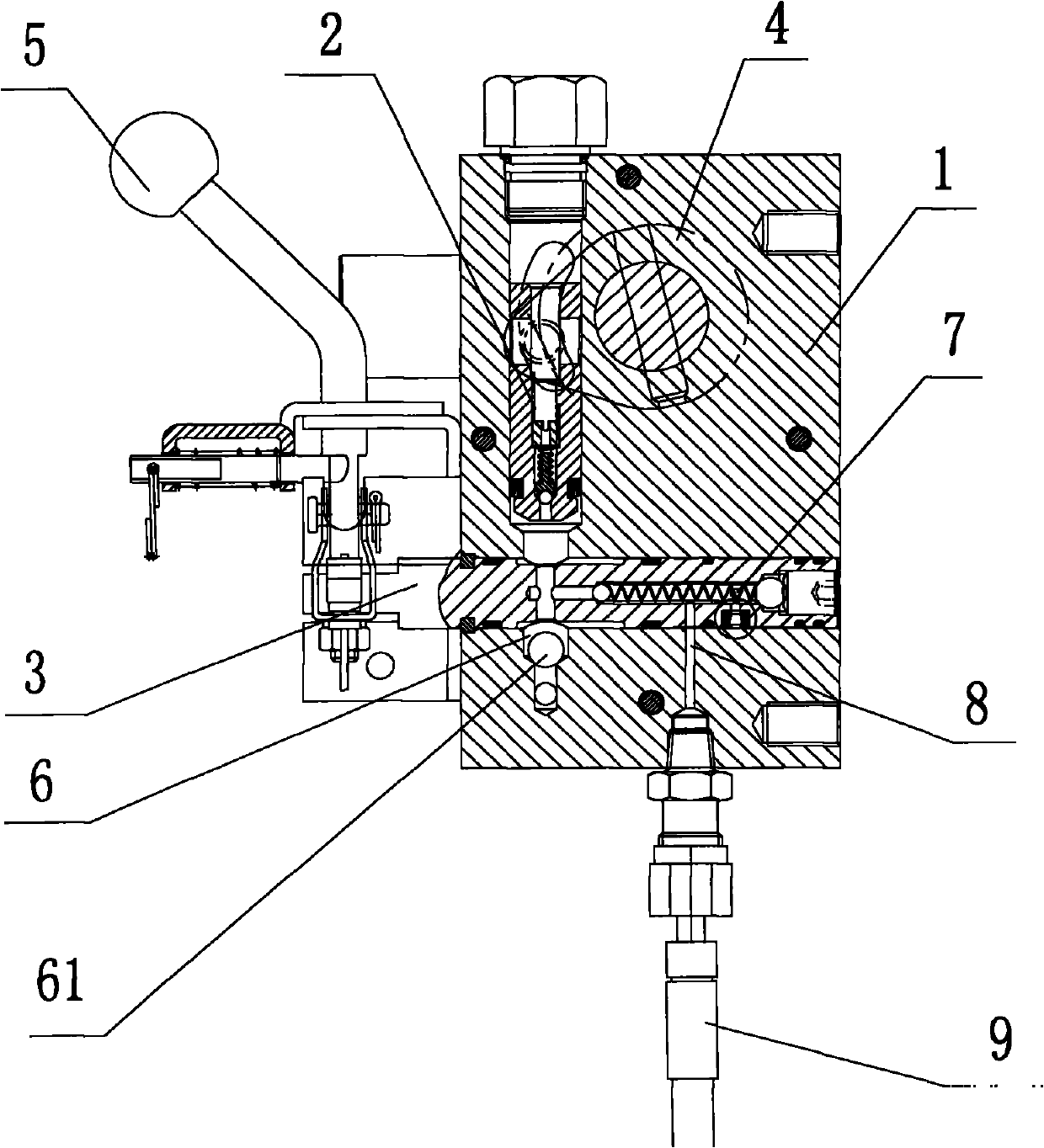

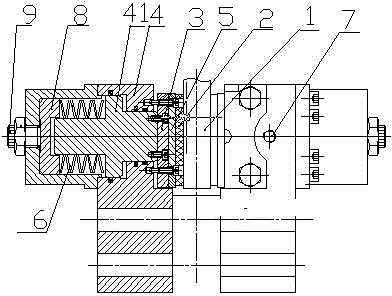

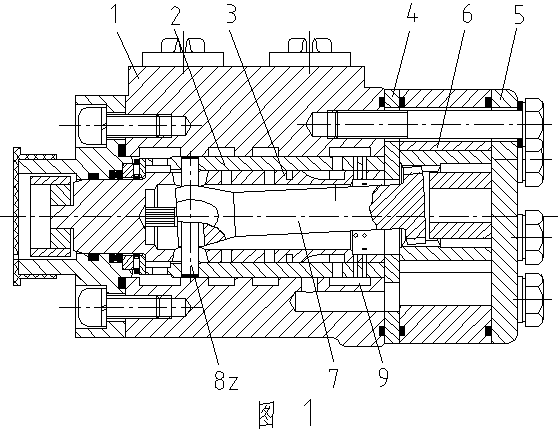

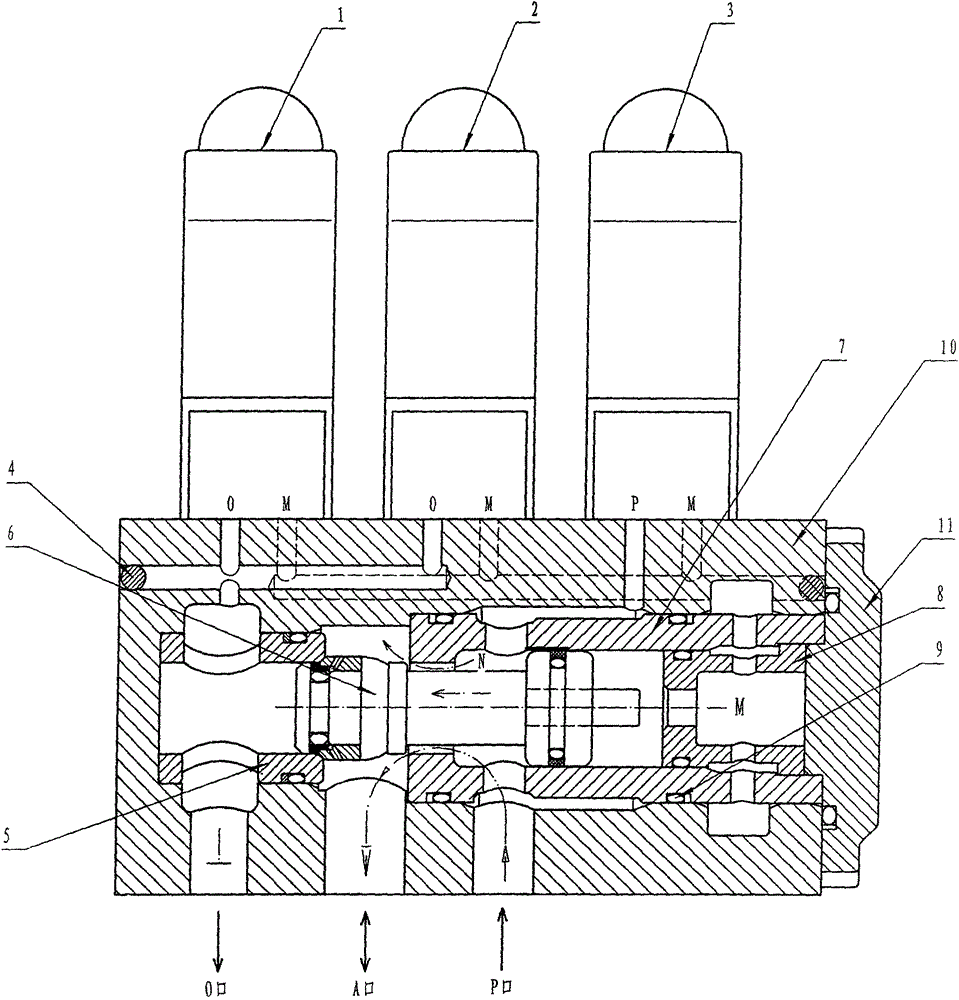

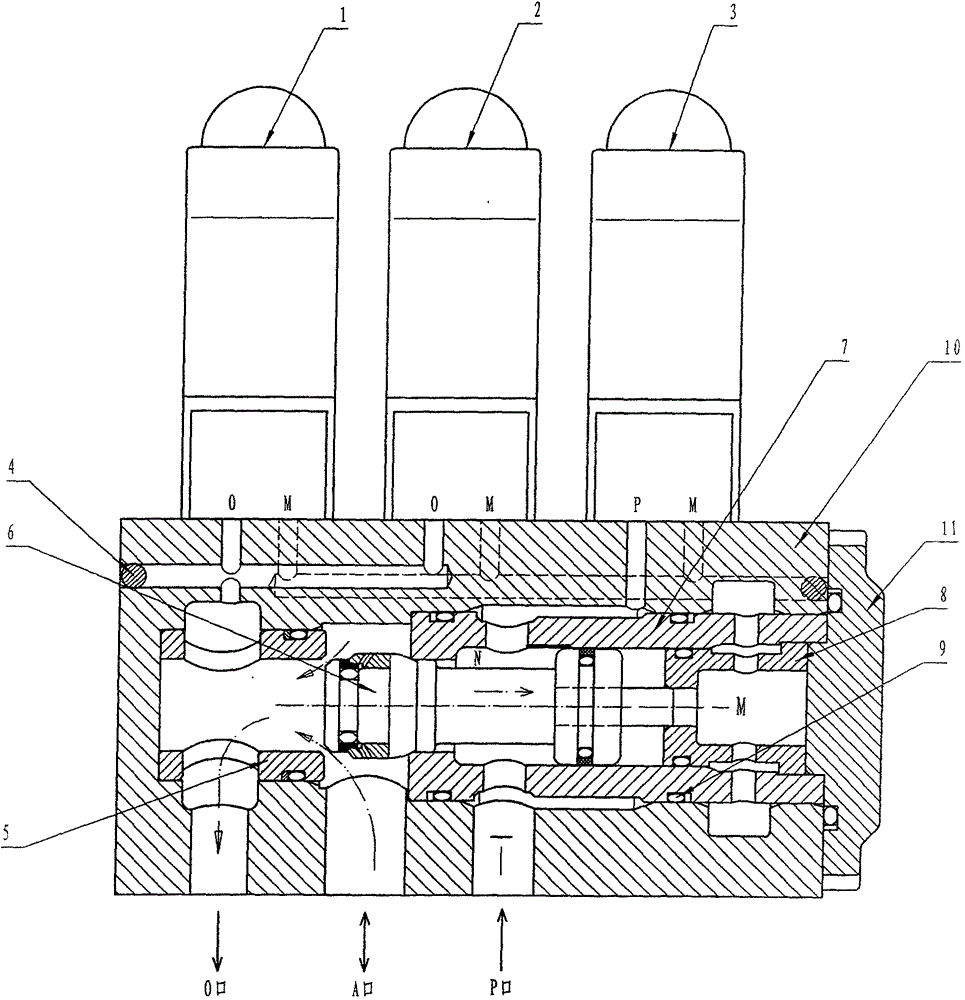

High-oil-pressure and large-drift-diameter combined reversing valve for electric high-voltage switch hydraulic mechanism

ActiveCN104896141AOperating means/releasing devices for valvesServomotor componentsBodies oilEngineering

The invention relates to a reversing valve, in particular to a high-oil-pressure and large-drift-diameter combined reversing valve for an electric high-voltage switch hydraulic mechanism. The reversing valve comprises a valve body 10, an end cover 11, a valve core 6, a valve body oil way channel and a valve body auxiliary mechanism, and is characterized in that the valve body auxiliary mechanism is an electromagnetic pilot valve, which is mounted on the valve body 10, is respectively communicated with a port O, a port P and a cavity M on the valve body 10 through oil ways, and outwards stops an oil ways on the valve body 10 through a ball plug 4; a short valve sleeve 5, a valve core 6 and a long valve sleeve 7 are arranged in an inner cavity of the valve body 10, and are sealed in the inner cavity of the valve body 10 through the end cover 11; the fit between all the valve sleeves and the valve body 10 is inlaid fit and sealing through a sealing piece 9; and the valve core 6 horizontally moves in inner cavities of the long and short valve sleeves (5, 7). The reversing valve has the following advantages: because of the innovated design of the internal structure of the valve body, the reversing valve becomes the combined reversing valve capable of adapting to high oil pressure of 60 Mpa, changing a conversion port to high drift diameter and enabling the conversion speed to reach the millisecond level.

Owner:WENZHOU YIKUN ELECTRIC

Fire extinguishing and oil recovery device for oil-immersed transformer or oil storage tank

InactiveCN109859926ASimple structureRealize the discharge oil recovery functionTransformers/inductances coolingFire rescueBodies oilFuel tank

The invention relates to a fire extinguishing and oil recovery device for an oil-immersed transformer or an oil storage tank. The problems are solved that the design is not reasonable enough and the like in the prior art. The device comprises a transformer body oil tank, one side of the upper end of the transformer body oil tank is provided with a transformer oil conservator through an oil supplementary on-off structure, the other side of the upper end of the transformer body oil tank is provided with a transformer oil discharge port, the transformer oil discharge port is connected with an oildischarge pipeline which is connected with a connection pipe through an oil discharge mechanism, the connection pipe is provided with an observation window and an oil leakage feedback device, the connection pipe is connected with an oil collection box, the oil collection box is internally provided with an oil collection cavity, the outer side of the oil collection box is provided with an oil level meter, the connection pipe communicates with the oil collection cavity, the lower end of the oil collection box is provided with an oil discharge valve, the upper end of the oil collection box is provided with an air exhaust pipe, and the air exhaust pipe is provided with a check valve. The special oil collection box is additionally arranged to achieve a discharged oil recovery function, is convenient to construct, protects the environment and greatly reduce the recovery and cleaning cost after fire extinguishing.

Owner:ZHEJIANG RIXIN ELECTRIC CO LTD

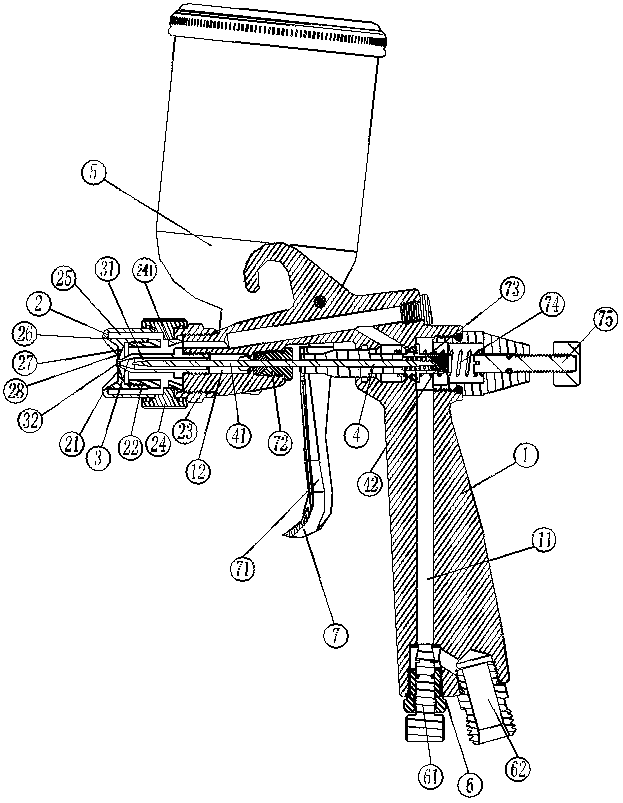

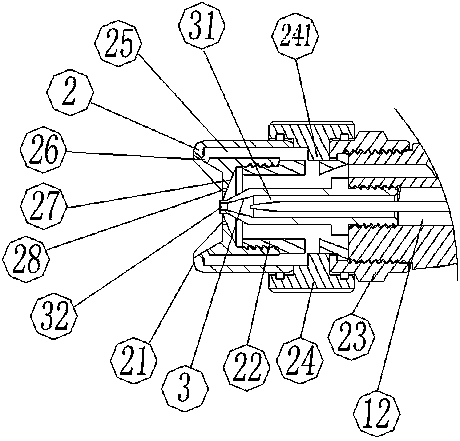

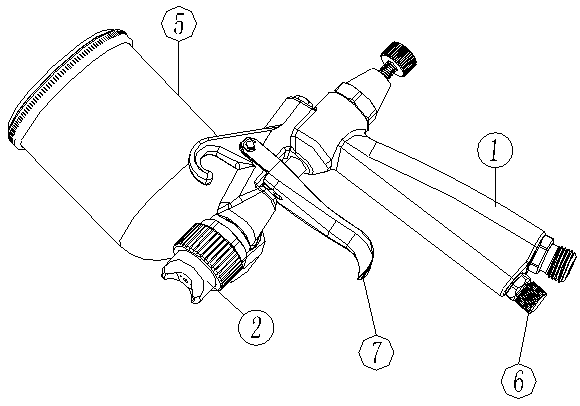

Spray gun capable of adjusting mist-spray surface

InactiveCN105499002AScientific and reasonable structureScientific and reasonable structure designLiquid spraying apparatusBodies oilNozzle

The invention discloses a spray gun capable of adjusting a mist-spray surface. The spray gun comprises a gun body, a gun head outer nozzle, a gun head inner nozzle, a gas needle adjustment device and an oil pot, wherein the gun head outer nozzle comprises an outer nozzle outer spray head, an outer nozzle inner ring, an outer nozzle connection ring and a mist-spray rotary adjustment ring, two gas paths are formed in the outer nozzle outer spray head, a tangential spray port is formed in the tail end of each gas path, the outer nozzle inner ring is of a hollow structure, an inclined stop wall and a positive spray port are installed at the front end of the outer nozzle inner ring, and two communication holes are formed in the tail part of the outer nozzle inner ring; the gas paths on the gun head outer nozzle are connected with the outer nozzle inner ring through the communication holes; the gun head inner nozzle is of a hollow conical structure, an oil path is arranged in the gun head inner nozzle, and an oil outlet port is formed in the front end of the gun head inner nozzle; and the gun body comprises a gun body gas path and a gun body oil path, the gun body gas path is communicated to the outer nozzle inner ring, and the gun body oil path is communicated with the oil path of the gun head inner nozzle. The spray gun disclosed by the invention has the advantages of being wide in application range, convenient to operate, low in cost and high in efficiency.

Owner:广西凯纵机械制造有限公司

Lubrication branch of planetary gear train

InactiveCN104500715ACompact structureCompact installation accuracy requirementsGear lubrication/coolingBodies oilGear train

The invention relates to a lubrication branch of a planetary gear train. The branch comprises a box body oil path, planet carrier oil paths and a planet wheel hinge pin oil path, wherein a mounting hole of a planet carrier shaft neck is formed in a box body; the oil outlet hole of the box body oil path is formed in the mounting hole of the planet carrier shaft neck; the planet carrier oil paths comprise an axial oil path and a radial oil path which are communicated with each other; the oil outlet hole of the box body oil path is communicated with the oil inlet hole of the axial oil path of the planet carrier oil paths through a combined annular oil path; the combined annular oil path comprises a fixed sliding ring and a moving sliding ring; the fixed sliding ring is positioned in the box body on the inner side of the oil outlet hole of the box body oil path; the moving sliding ring is positioned on the planet carrier shaft neck of the planet carrier shaft neck; after being assembled, the moving sliding ring is positioned on the outer side of the oil outlet hole of the box body oil path; the distance between the inner walls of the fixed sliding ring and the moving sliding ring is larger than the diameter of the oil outlet hole of the box body oil path; the inner wall of the mounting hole of the planet carrier shaft neck of the box body, the outer wall of the planet carrier shaft neck and the inner walls of the fixed sliding ring and the moving sliding ring are arranged in a surrounding manner to form an annular oil path.

Owner:NANJING HIGH SPEED GEAR MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com