Patents

Literature

170results about How to "Easy clearance adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

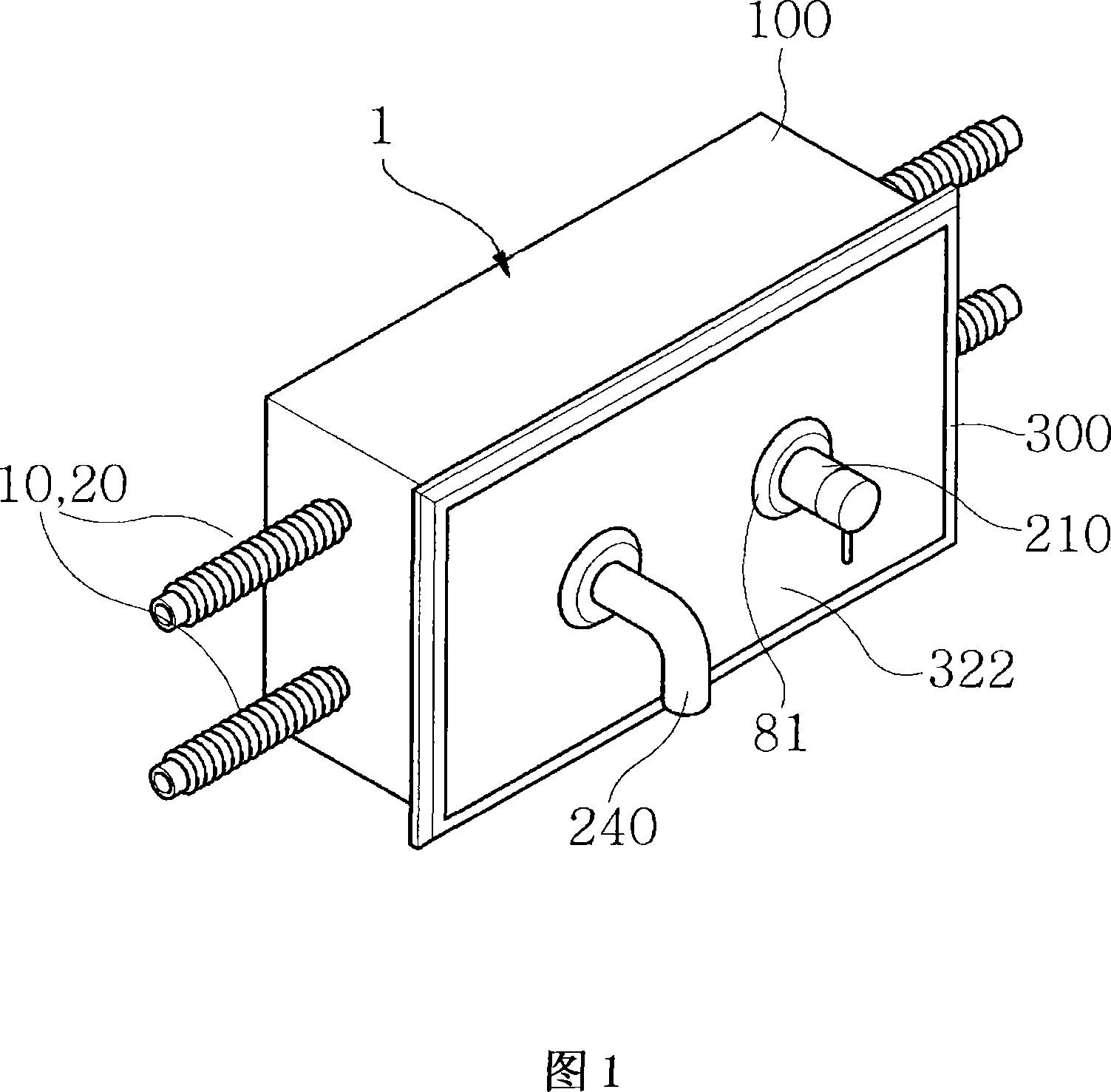

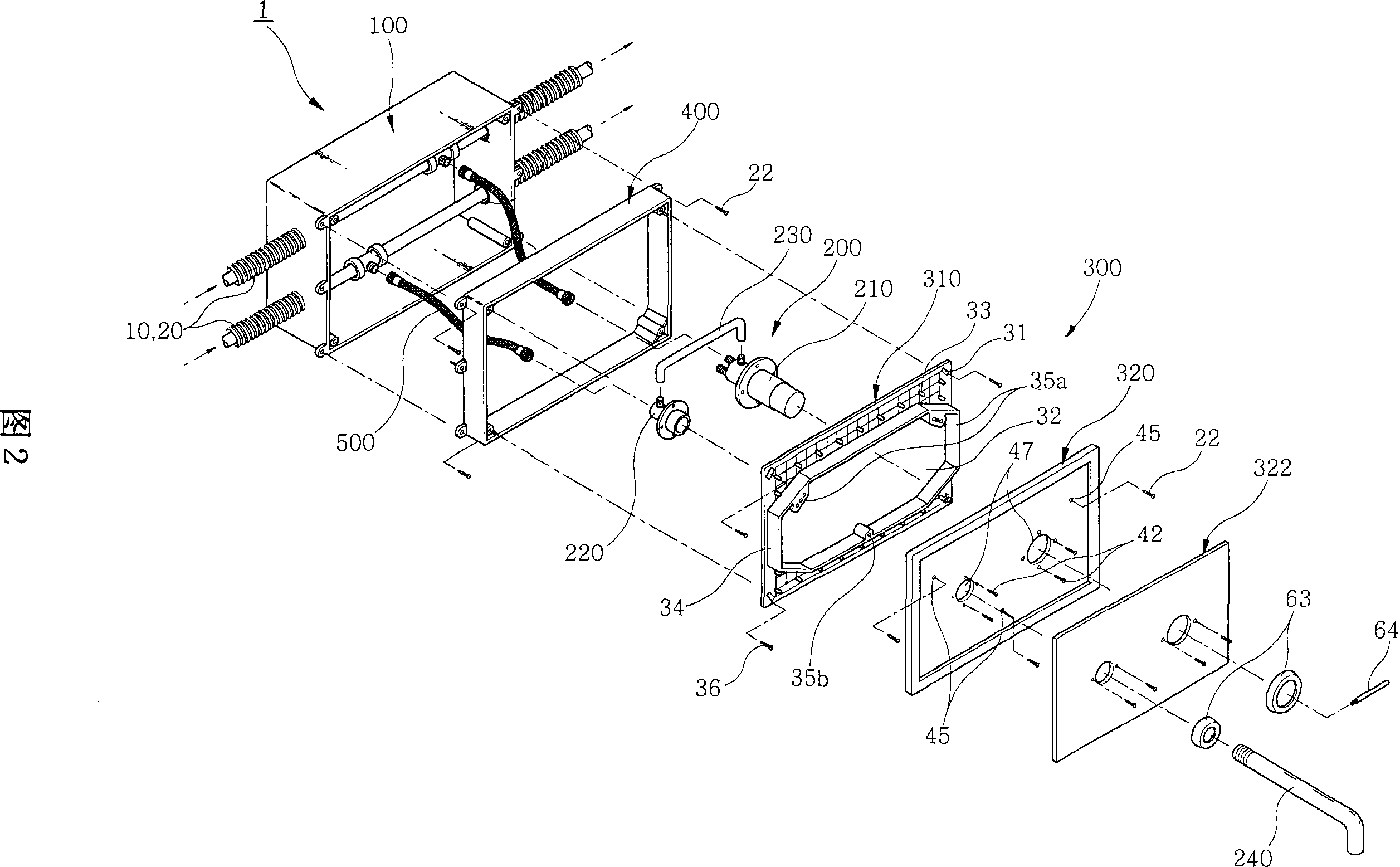

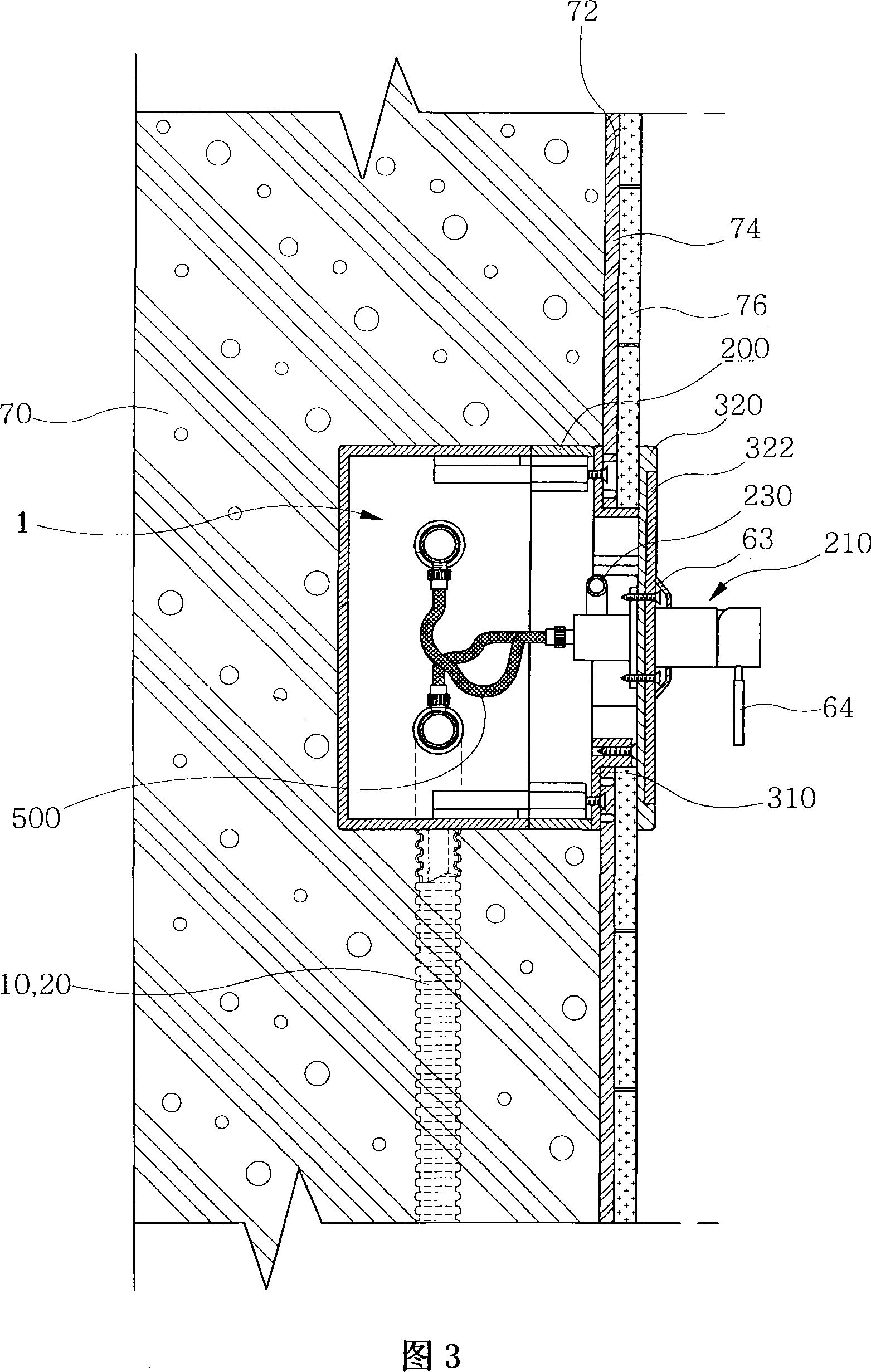

Built-in wall water service box

InactiveCN101065545AEasy to disassembleEasy clearance adjustmentDomestic plumbingDrawing-off water installationsEngineeringWater pipe

Owner:管内管株式会社

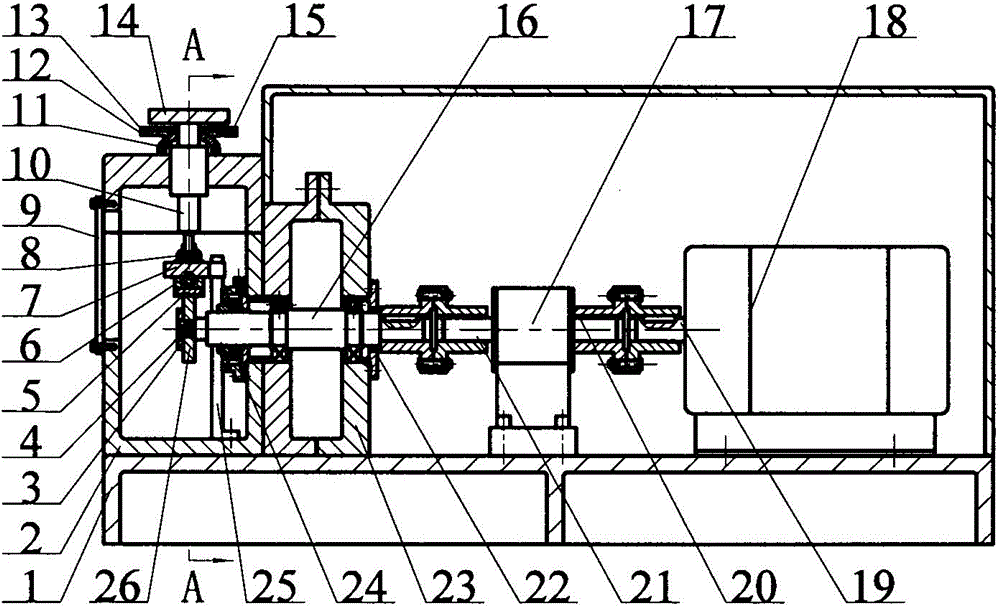

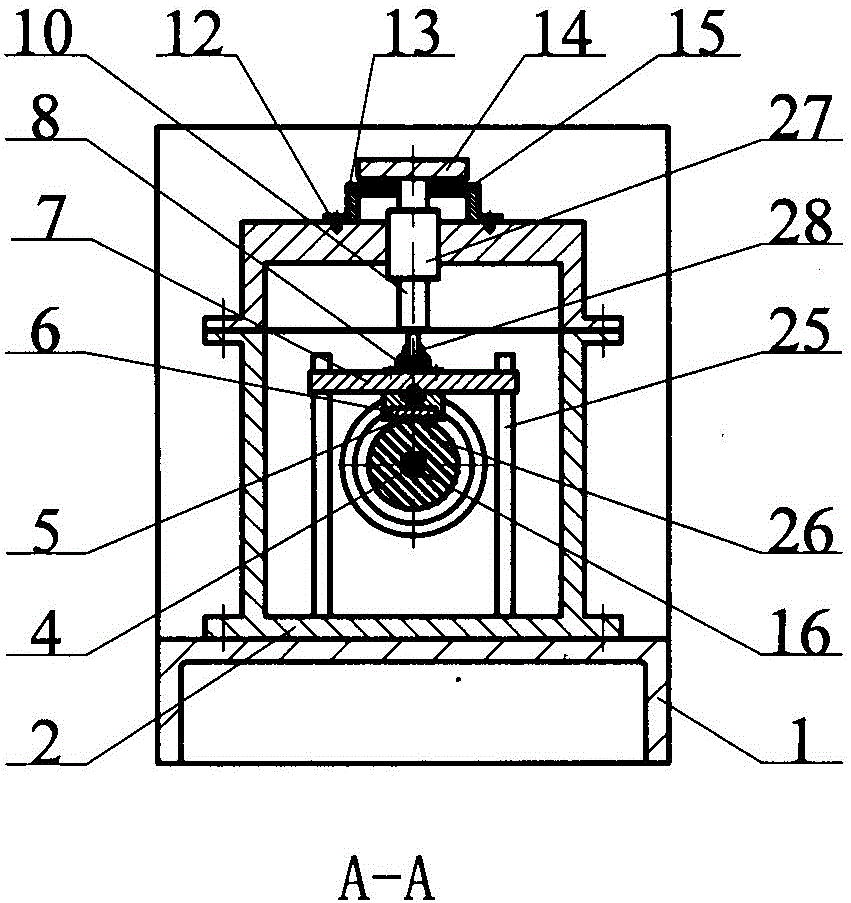

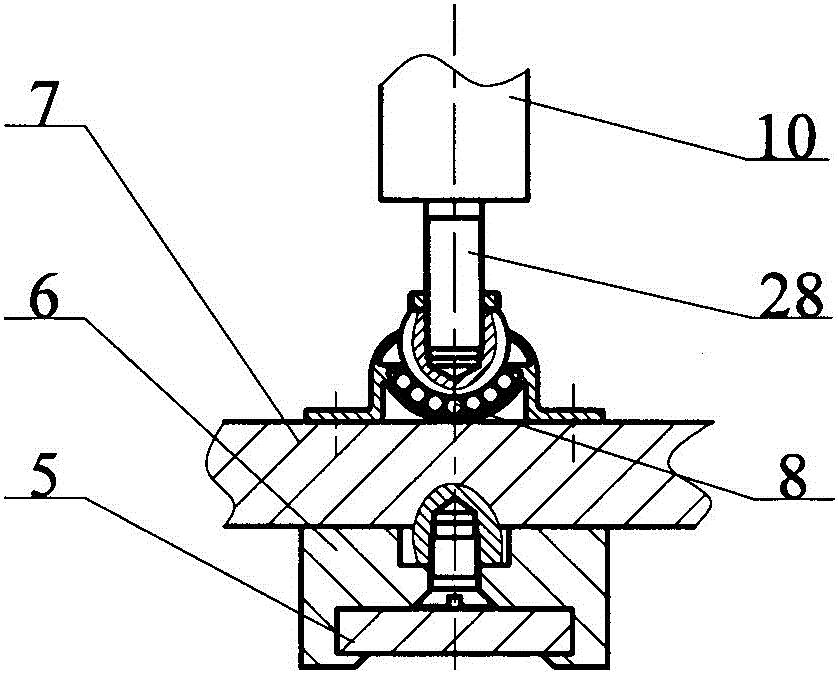

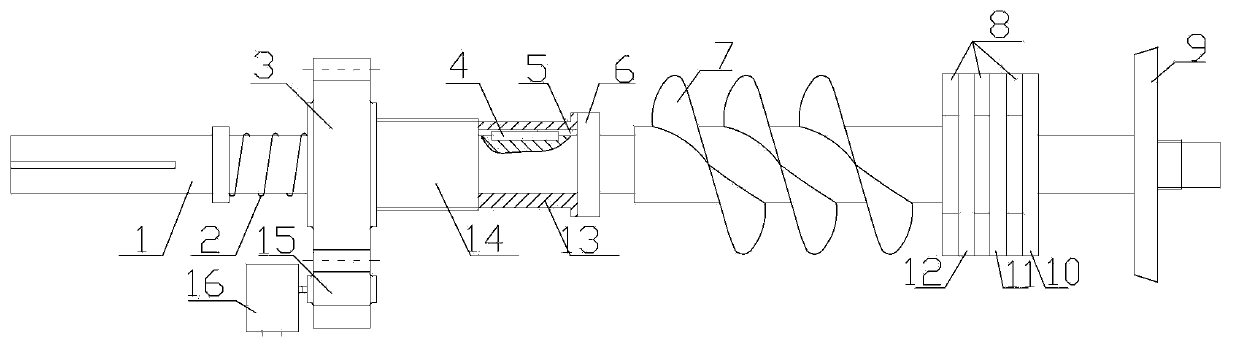

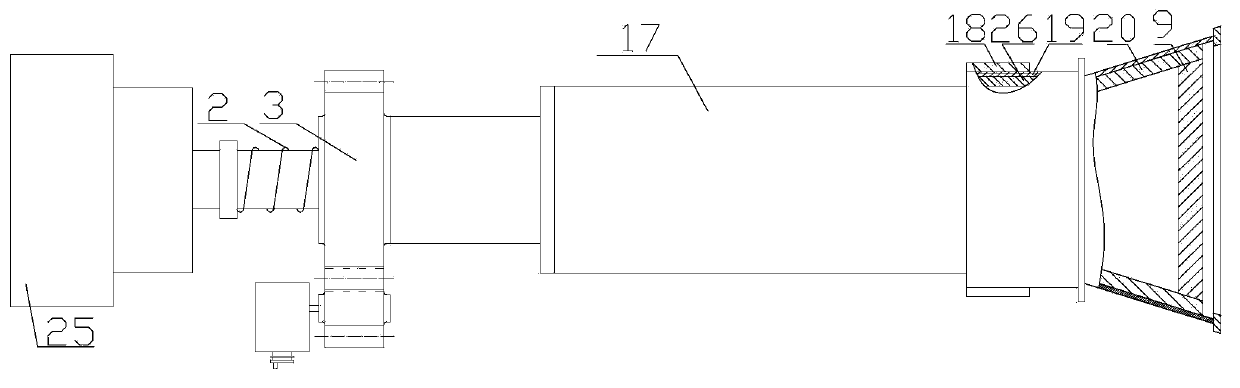

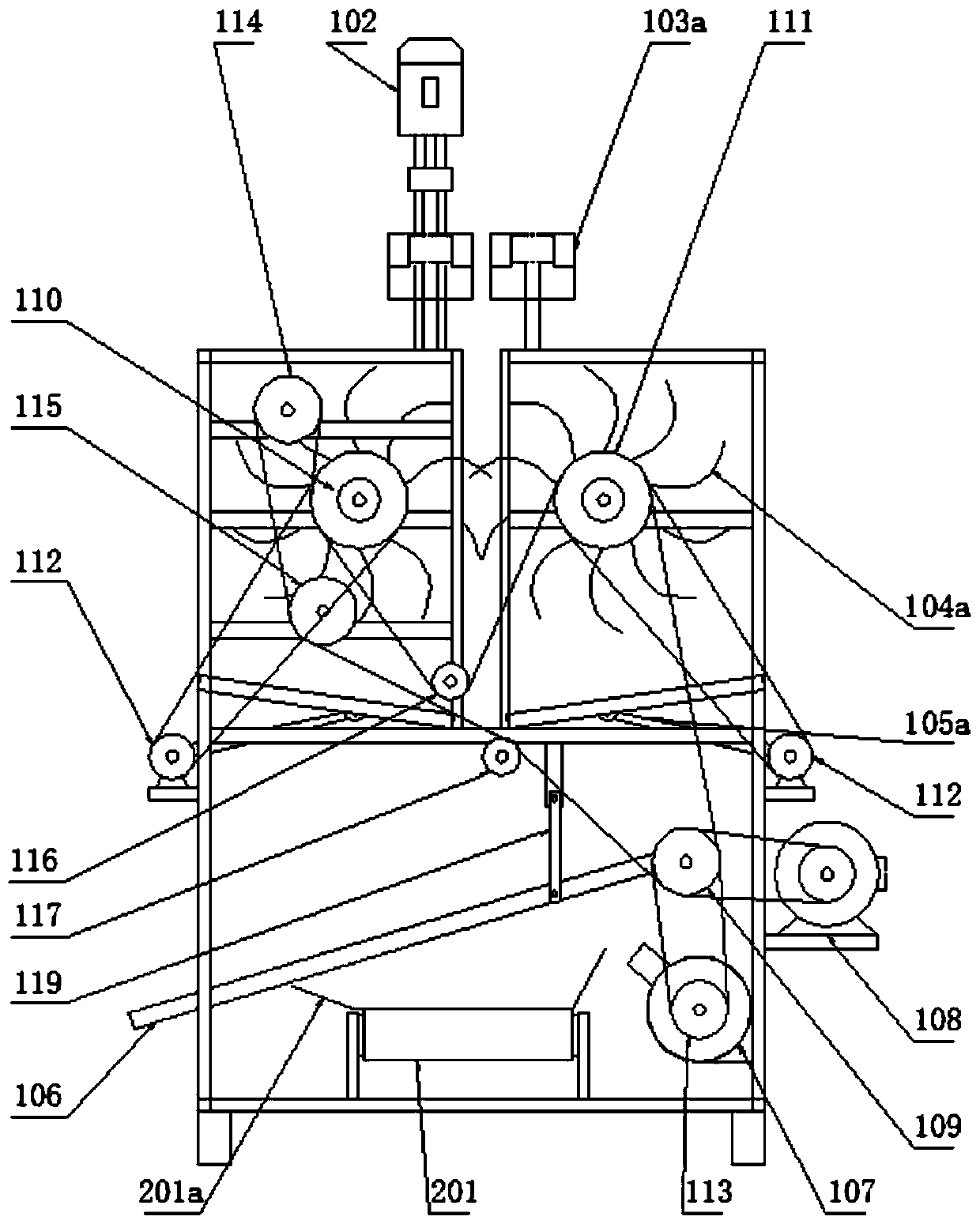

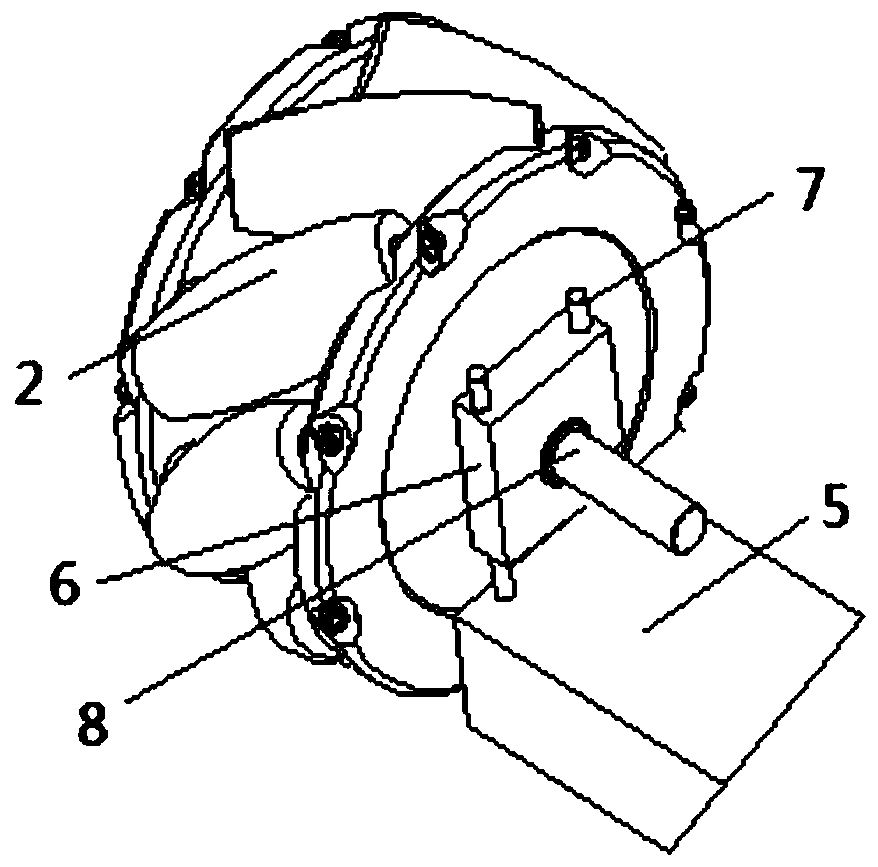

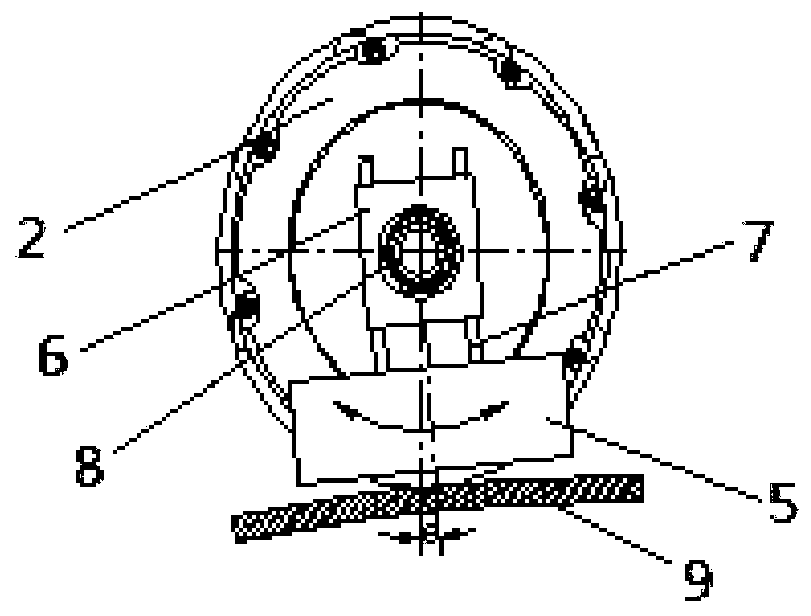

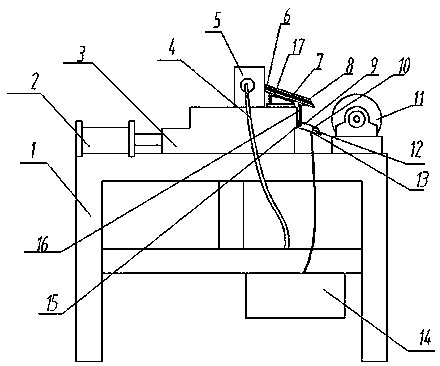

Ring and block friction abrasion testing machine with abrasion gap adjusting function

ActiveCN105158100AEasy loading and unloadingNot easy to damageInvestigating abrasion/wear resistanceMatched pairEngineering

The invention relates to a ring and block friction abrasion testing machine with an abrasion gap adjusting function. The problem that according to an existing friction abrasion machine, test ring and test block loading and gap adjustment cannot be achieved on one testing machine is solved. The ring and block friction abrasion testing machine comprises a machine base, a power and transmission mechanism fixed to the machine base, a material box provided with a loading mechanism and a testing mechanism and a measurement control loop. The ring and block friction abrasion testing machine is characterized in that the loading mechanism comprises an adjusting rod, a handle, a fine adjustment dial, a fixing base, a guide base with a clamp and guide rails, a stud section of the adjusting rod is matched with a threaded hole of the material box to form a spiral matched pair, the handle is fixedly connected to the top end of the adjusting rod, quantitative vertical loading and accurate adjustment of the gap between a test block and a test ring can be realized by rotating the handle, and the adjusting rod is fixed through the fixing device. The ring and block friction abrasion testing machine is reasonable in design, simpler in structure compared with other existing similar products and stable in operation, the test ring and the test block are convenient to load and unload, the gap is easy to adjust, spacing is accurate, and the reliability of test results conforming to actual working conditions is further improved.

Owner:SHENYANG POLYTECHNIC UNIV

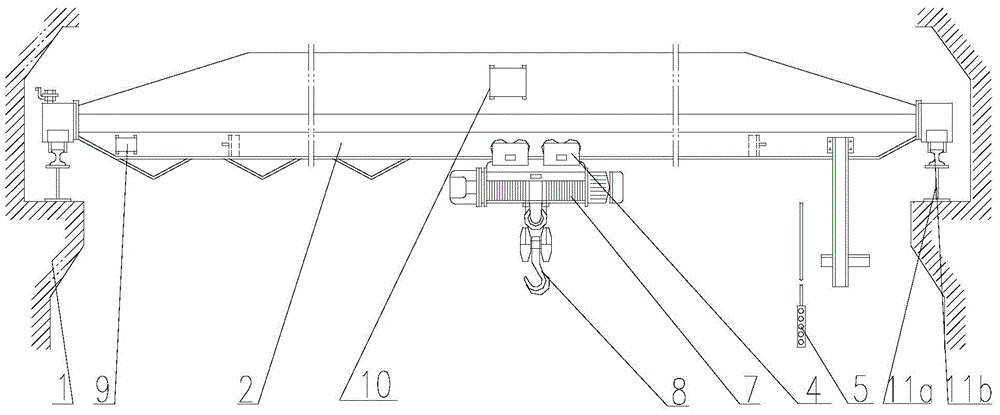

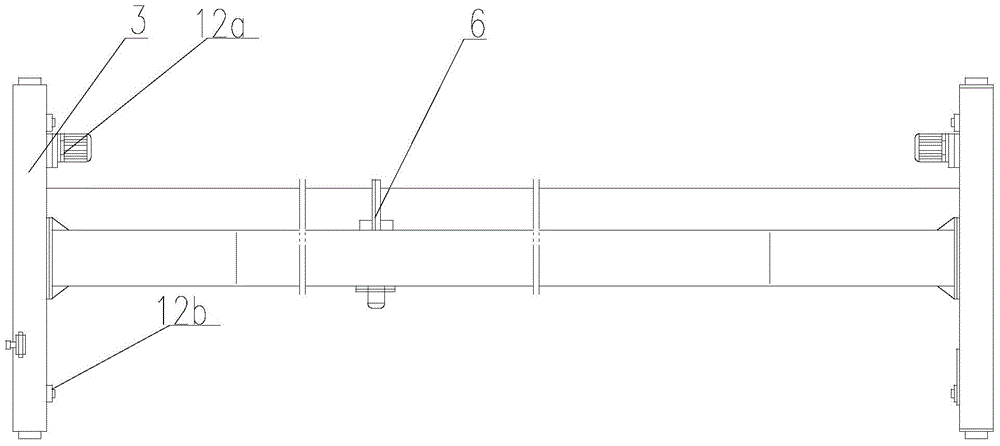

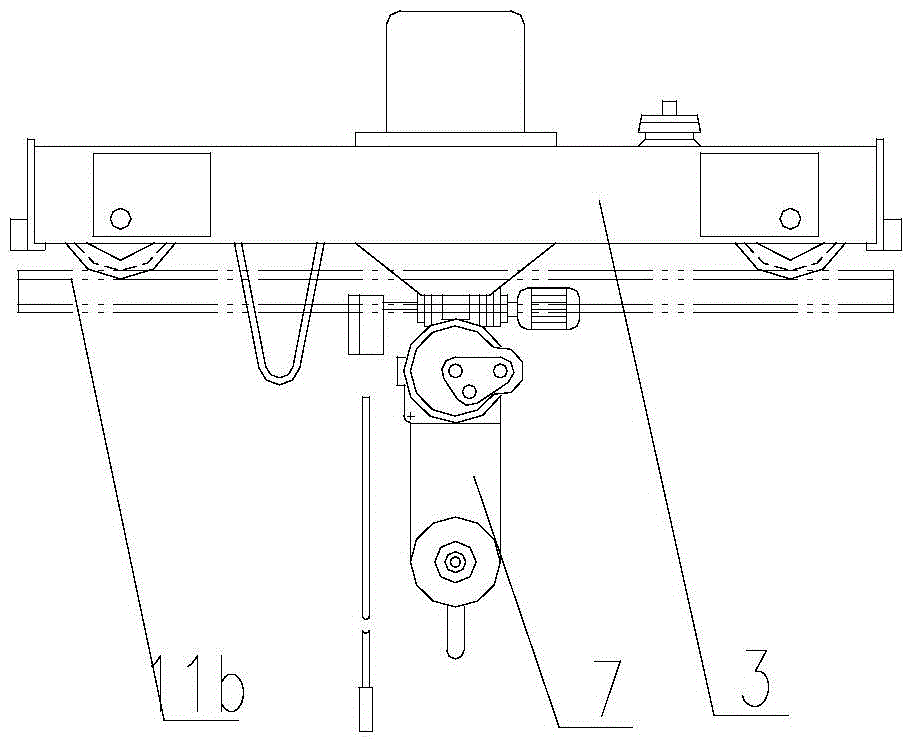

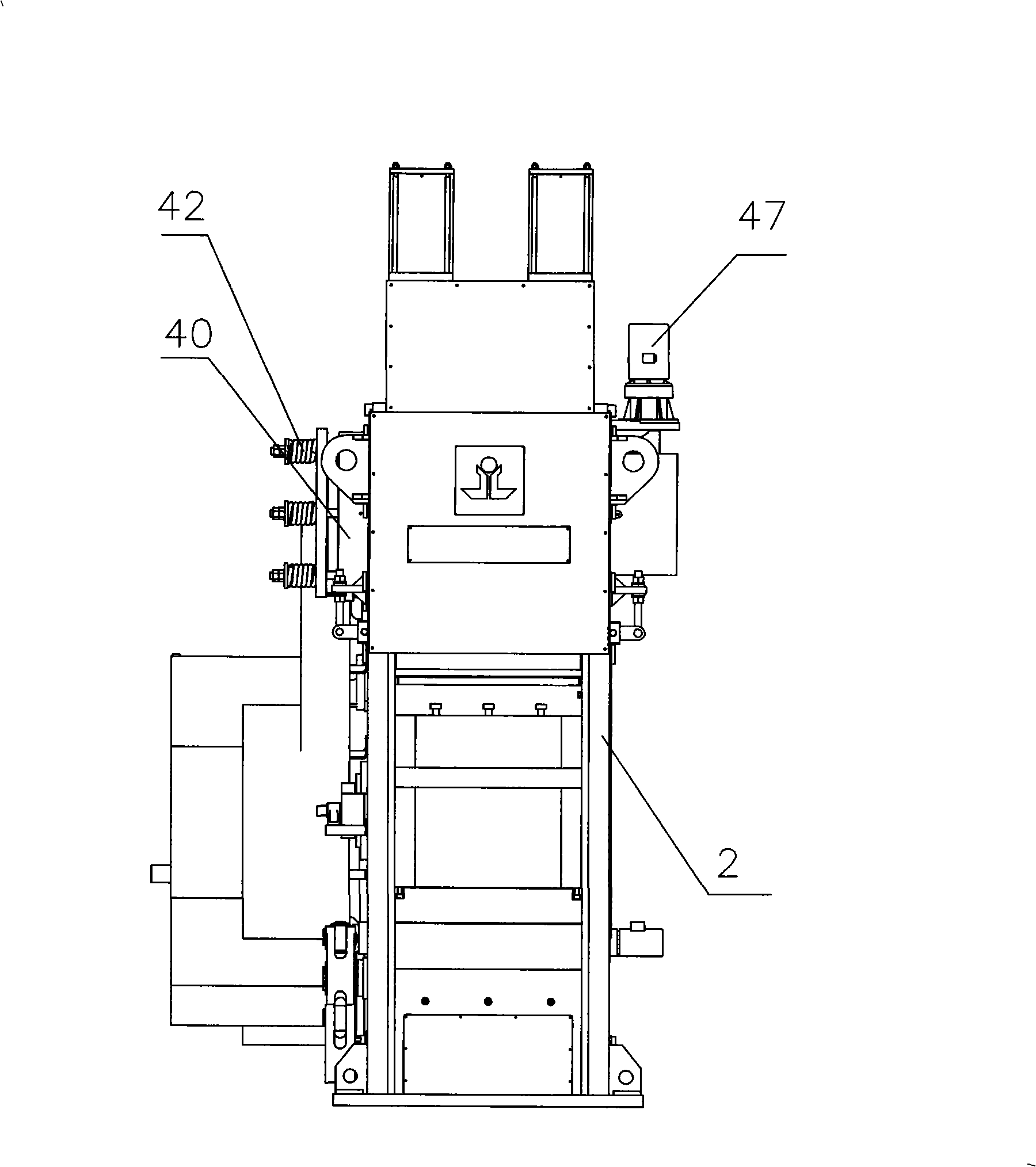

Single-beam overhead crane

InactiveCN104692257AGuaranteed uptimeRun quick stopLoad-engaging girdersTravelling cranesManufacturing cost reductionVehicle frame

The invention discloses a single-beam overhead crane in one embodiment. The single-beam overhead crane comprises a beam frame, a cart, a trolley, an electric block and a control mechanism; an end beam is composed of end beams on the two sides and a main beam connected with the end beams; the end beams are driven by the cart to travel on an end beam track; the electric block runs on a main beam track along with the trolley; a guide wheel device is mounted on the frame of the cart or the trolley or on both the frames of the cart and the trolley to keep the cart and / or the trolley run stably; the control mechanism is provided with an anti-crossing system to shut down a motor in case of a crossing fault. According to the single-beam overhead crane, the overall single-beam overhead crane and the auxiliary system thereof are improved, and therefore, the performance of the product can be improved in the aspects of manufacturing cost reduction, steady operation guarantee, safety performance improvement and the like.

Owner:周磊

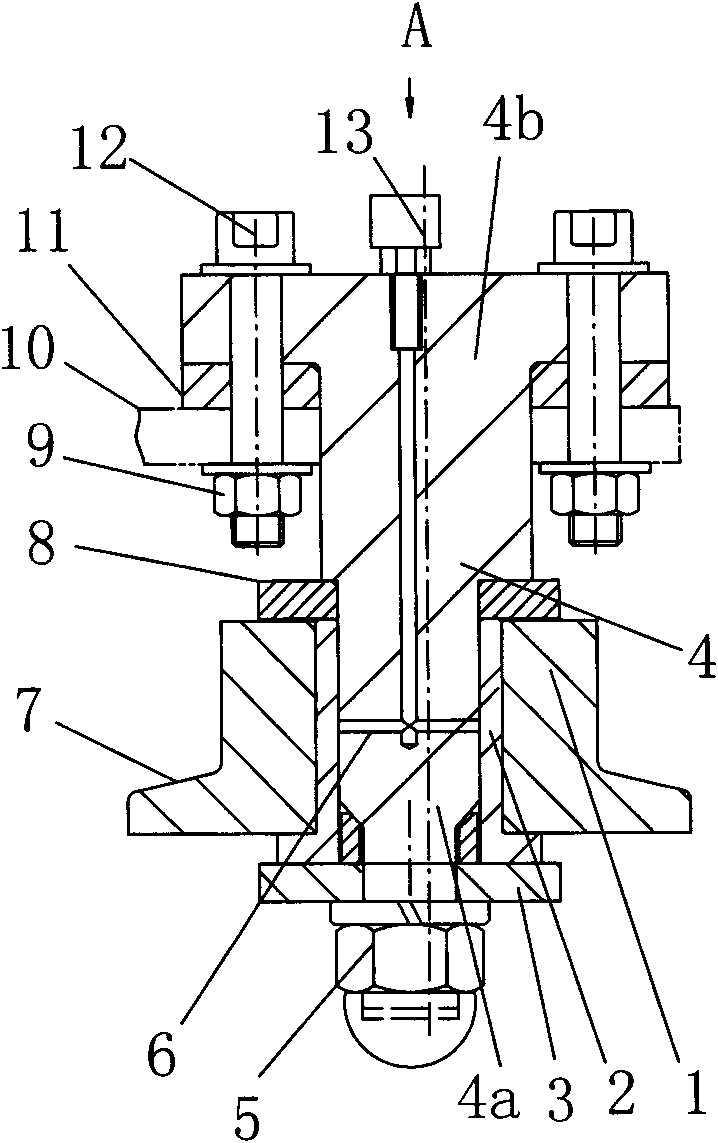

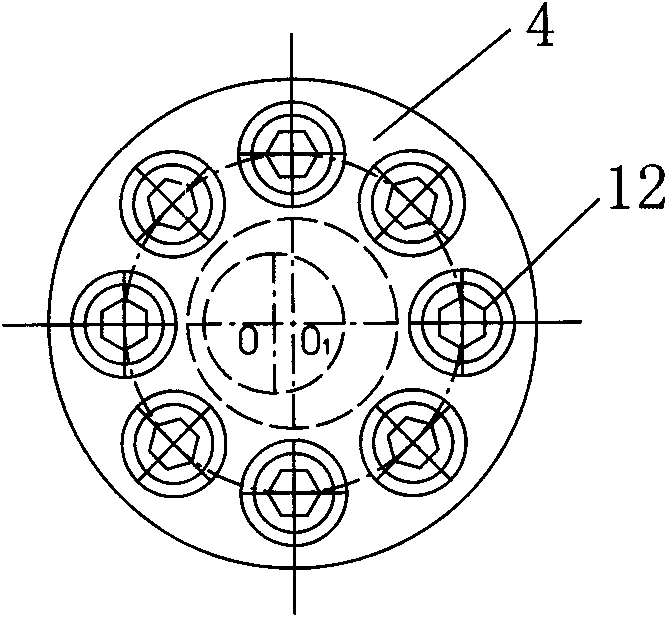

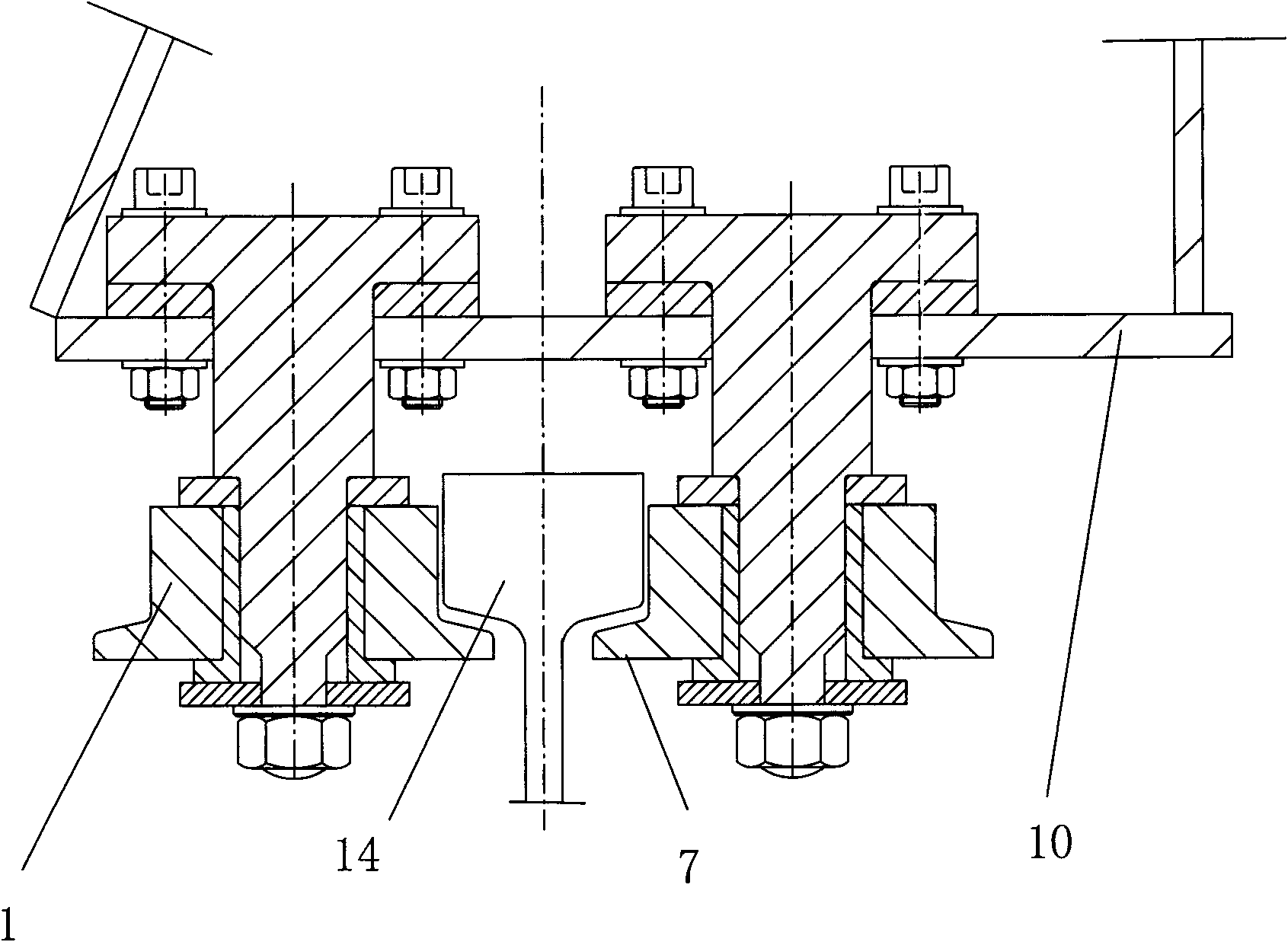

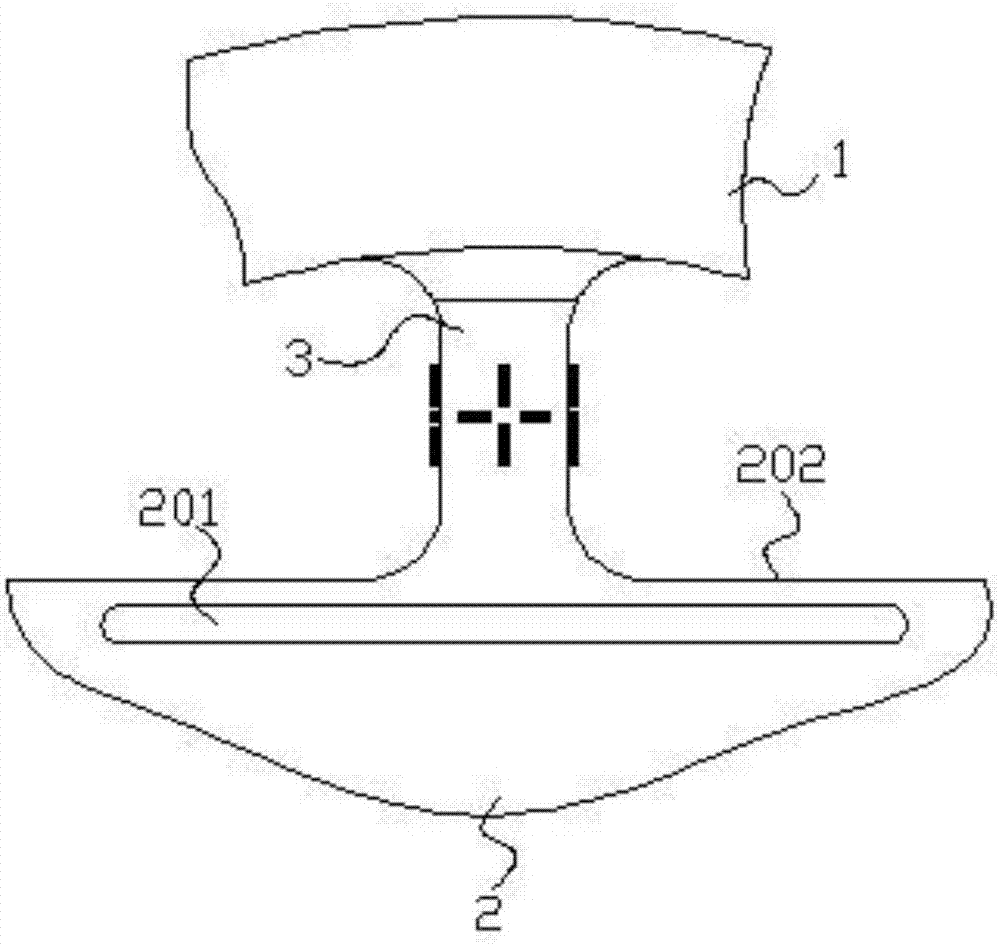

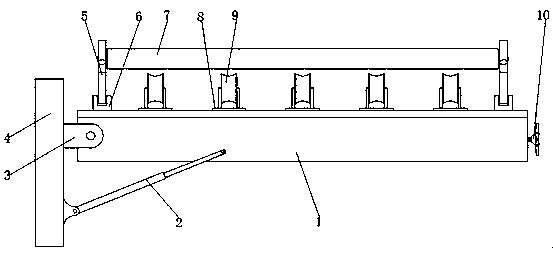

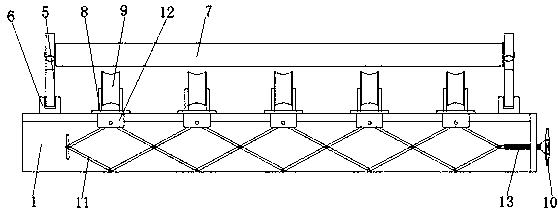

Anti-turnover device for track running vehicle

InactiveCN101966916APrevent dumpingEasy clearance adjustmentConveyorsConveyor partsVehicle frameEngineering

The invention relates to an anti-turnover device for a track running vehicle. The device at least comprises two guide devices which are fixed on the two sides of a track or inside or outside the two parallel tracks, wherein each guide device consists of a guide wheel and a wheel shaft; the guide wheel is vertically fixed on a chassis at the bottom of the vehicle body through the wheel shaft; a cylindrical surface of the guide wheel is contacted with a lateral wing of the track; and the bottom of the cylindrical surface of the guide wheel is provided with a bump which is extended to a wheel rim at the lower edge of the track. By matching the guide device with the lateral wing and the lower edge of the track, the device has good guidance effect and a simple structure, and can prevent a vehicle from turning over, and a clearance between the guide wheel and the lateral wing of the track can be conveniently adjusted.

Owner:TONGLING MIRACLE MECHANICAL EQUIP

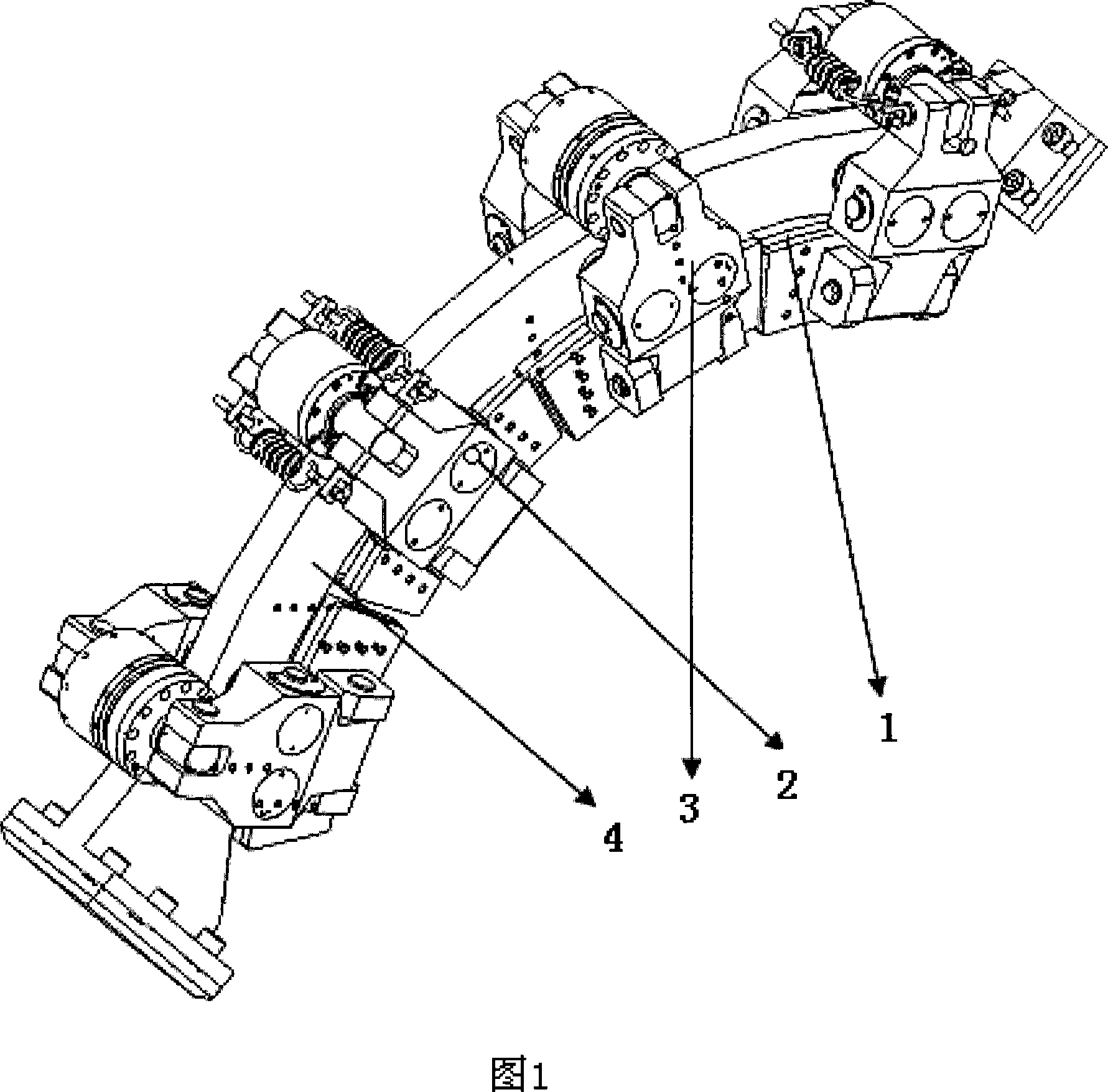

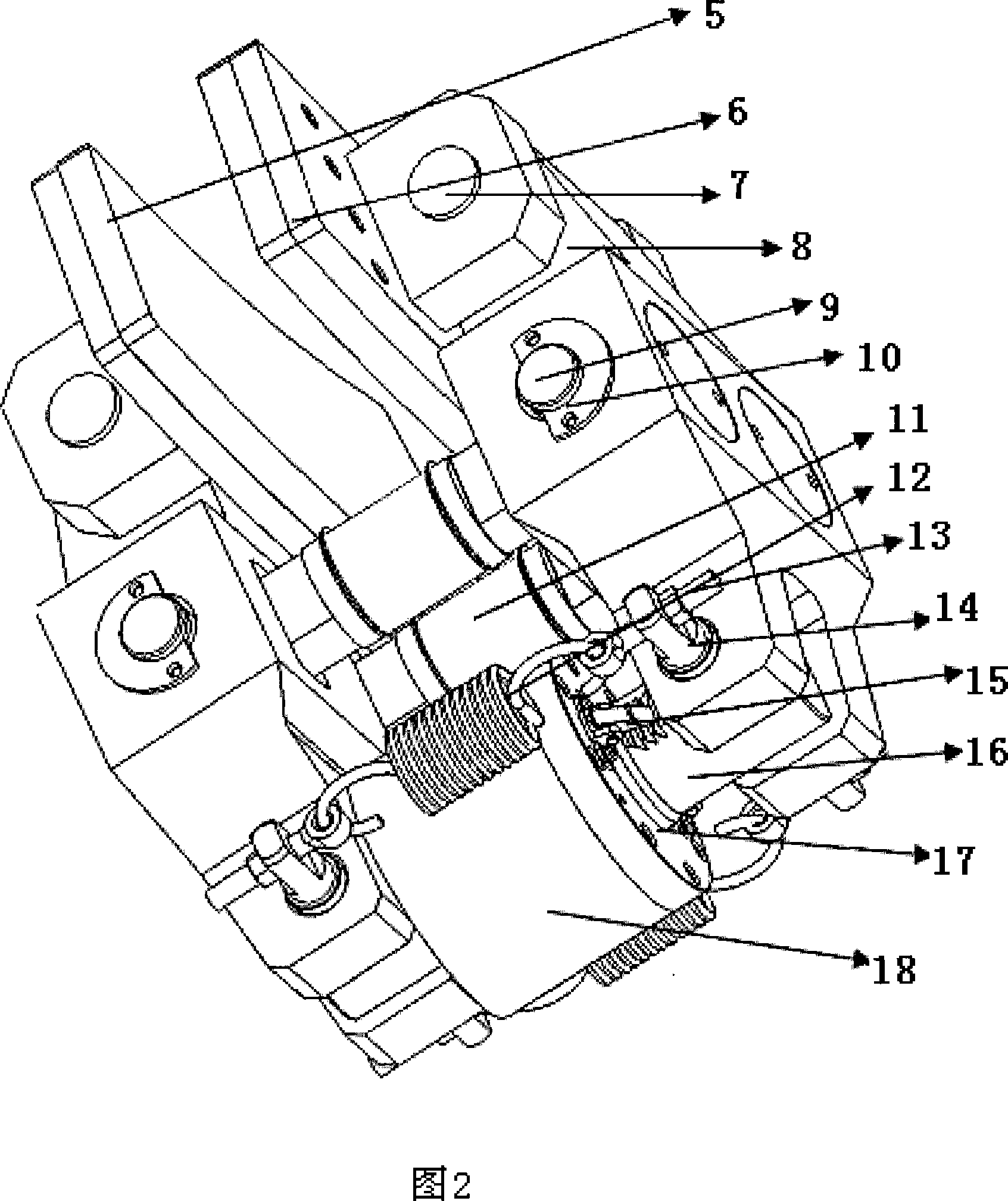

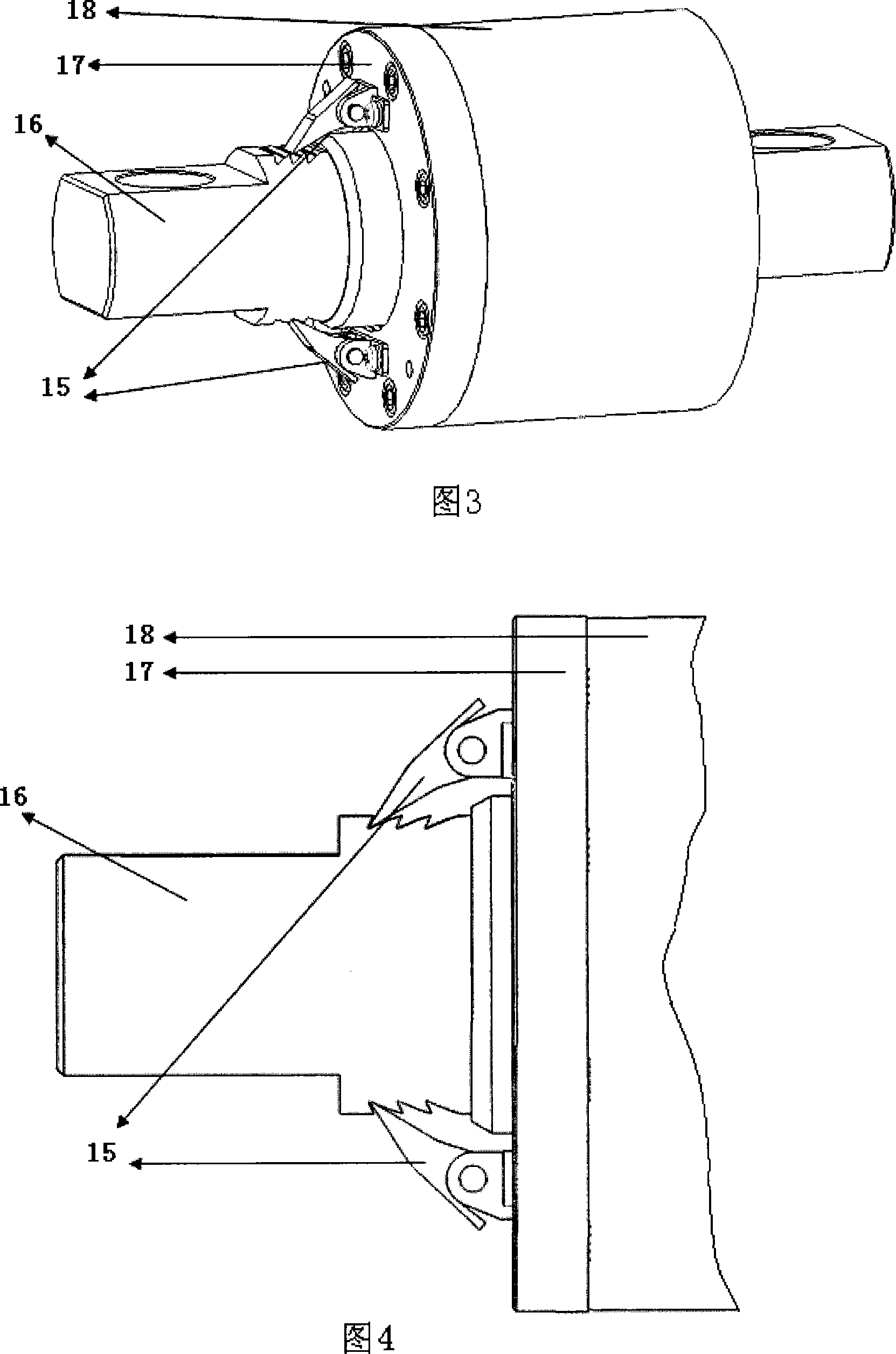

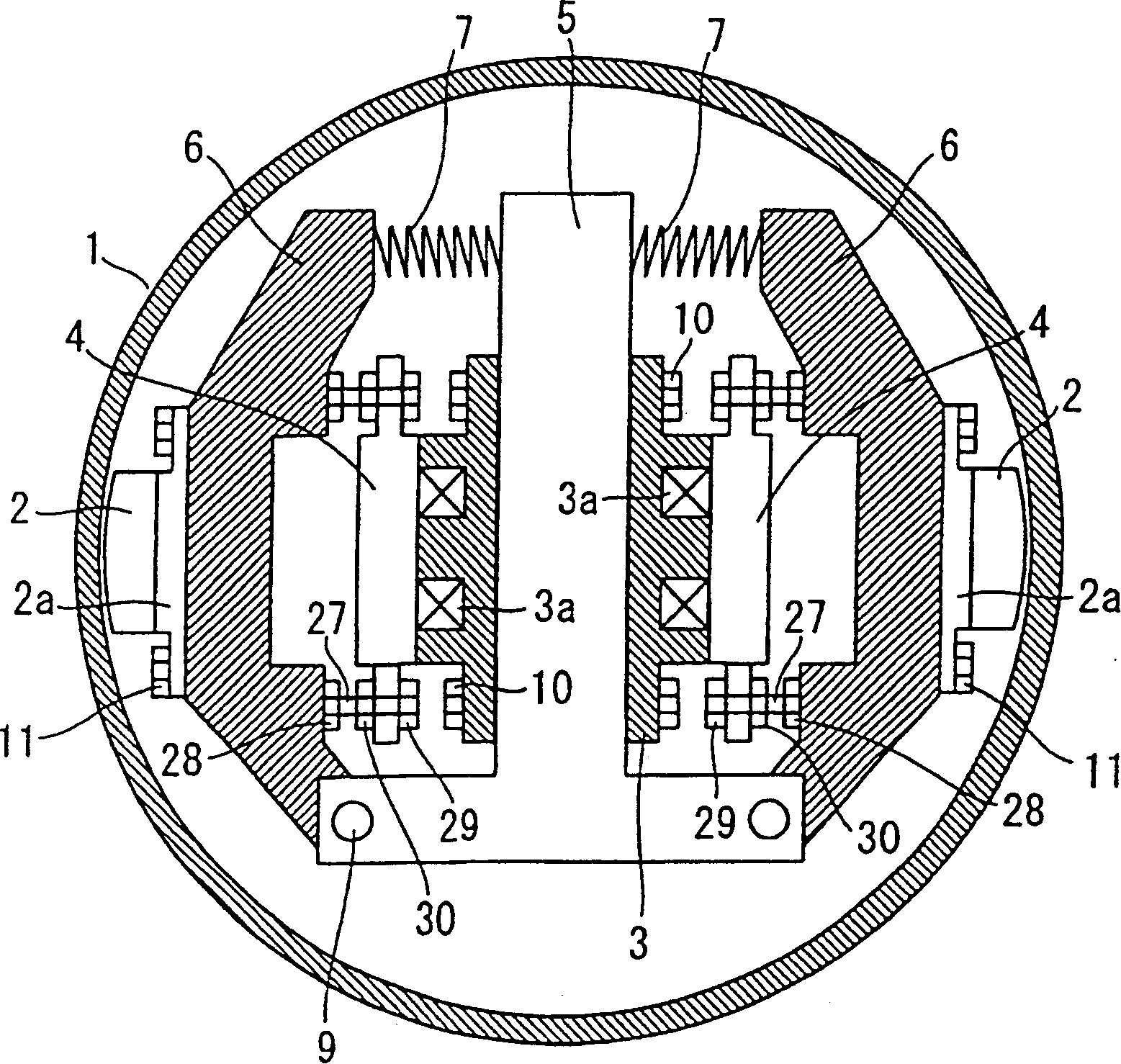

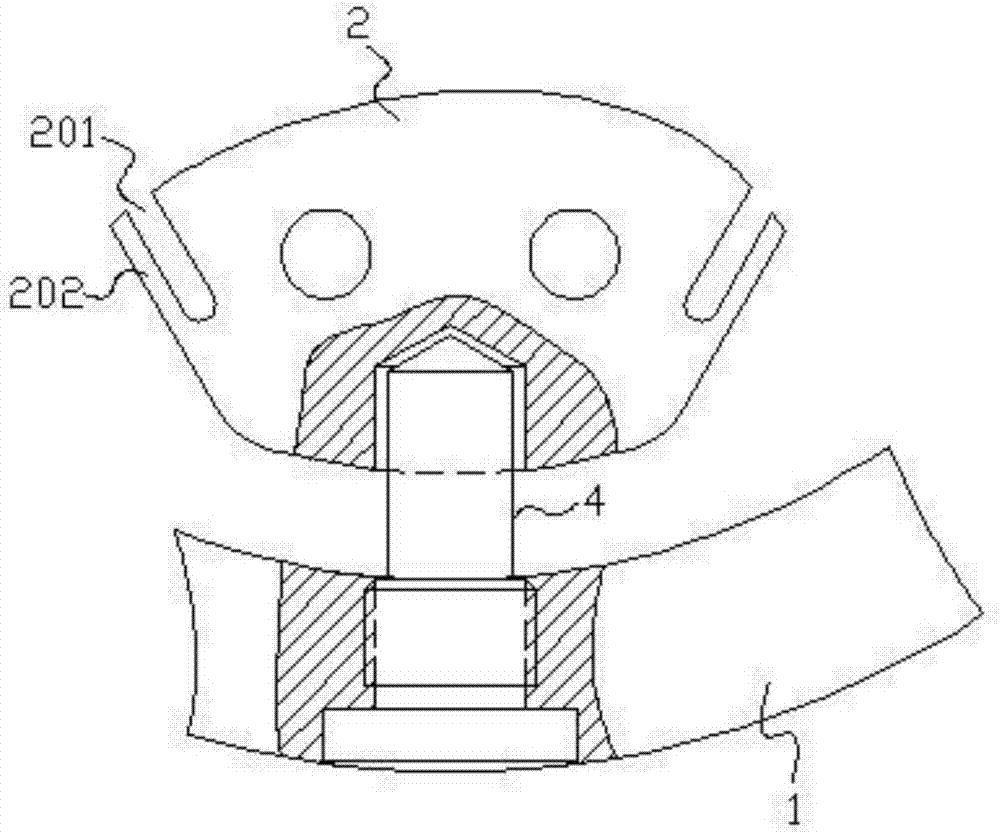

Disc type brake automatic compensation gap braking clamp

ActiveCN101169164ASafe and convenient adjustmentTroubleshoot gap adjustment issuesAxially engaging brakesBrake actuating mechanismsCoil springEngineering

A caliper with automatic gap compensation for a disk brake applies to a brake device of an oil drilling rig. The invention is characterized in that the caliper comprises essentially a working cylinder, a piston rod, working levers, caliper bodies, spiral springs, a support axle and brake blocks, wherein, the brake blocks are respectively fixed at the inner sides of the two caliper bodies; the two caliper bodies connect respectively with ends of the two working levers via pin rolls; the other ends of the two working levers are respectively provided with a fixed clip-cylinder pin roll; the working cylinder is connected between the two clip-cylinder pin rolls; two ends of the two clip-cylinder pin rolls respectively have a spring tensioning screw; the spiral springs are connected between two opposite spring tensioning screws; the working cylinder comprises essentially a cylinder body, the piston rod and a cylinder cover; a pawl mechanism is arranged between the piston rod and the cylinder cover. The invention has the advantages that the caliper can compensate the gap between a brake block and a brake disc; the gas compensation can be safely and quickly carried out after the brake block is worn, thereby guaranteeing the safety and the reliability of the brake system; the gap compensation can be done automatically, conveniently and quickly.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

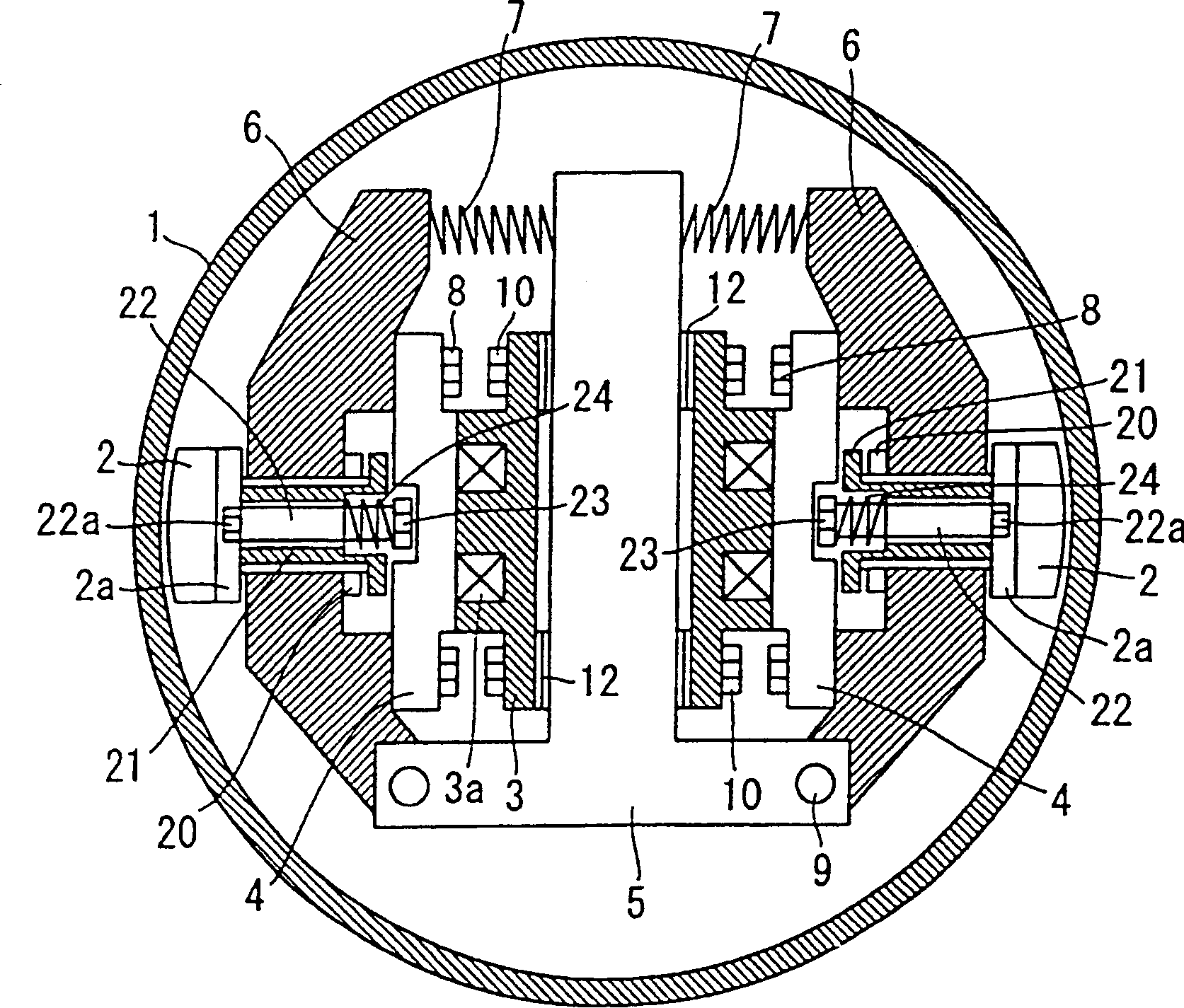

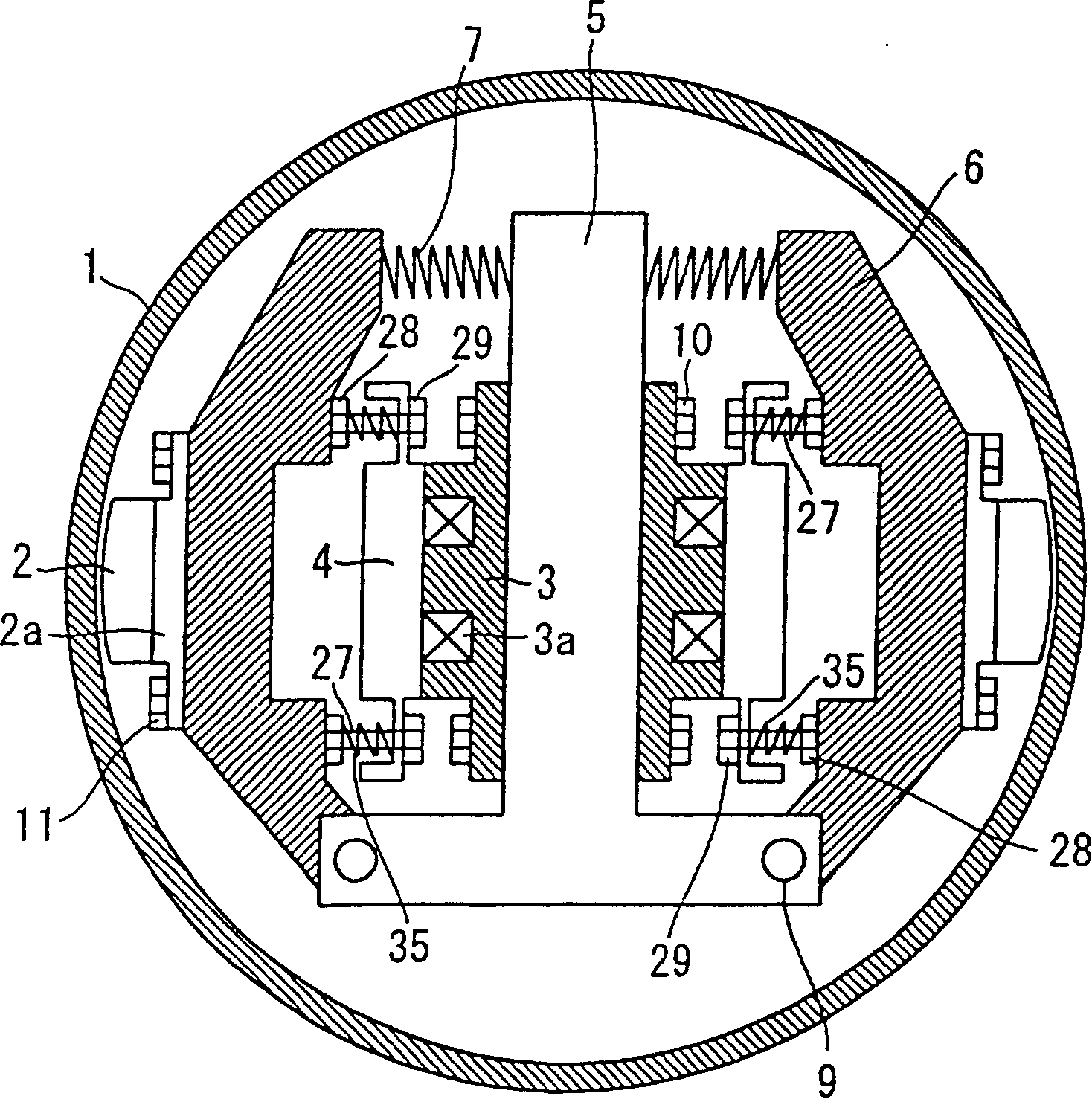

Elevator hoist and elevator device

InactiveCN1450974AAdjust the clearanceEasy to adjustBuilding liftsHoisting equipmentsEngineeringMechanical engineering

An elevator hoist, wherein mechanisms for adjusting a gap between linings formed so as to come into contact with and separate from a brake drum and the brake drum when the linings are separated from the brake drum are installed in an arms for supporting the linings, whereby the adjustment of the gap between the linings and the brake drum can be performed easily in a short time.

Owner:MITSUBISHI ELECTRIC CORP

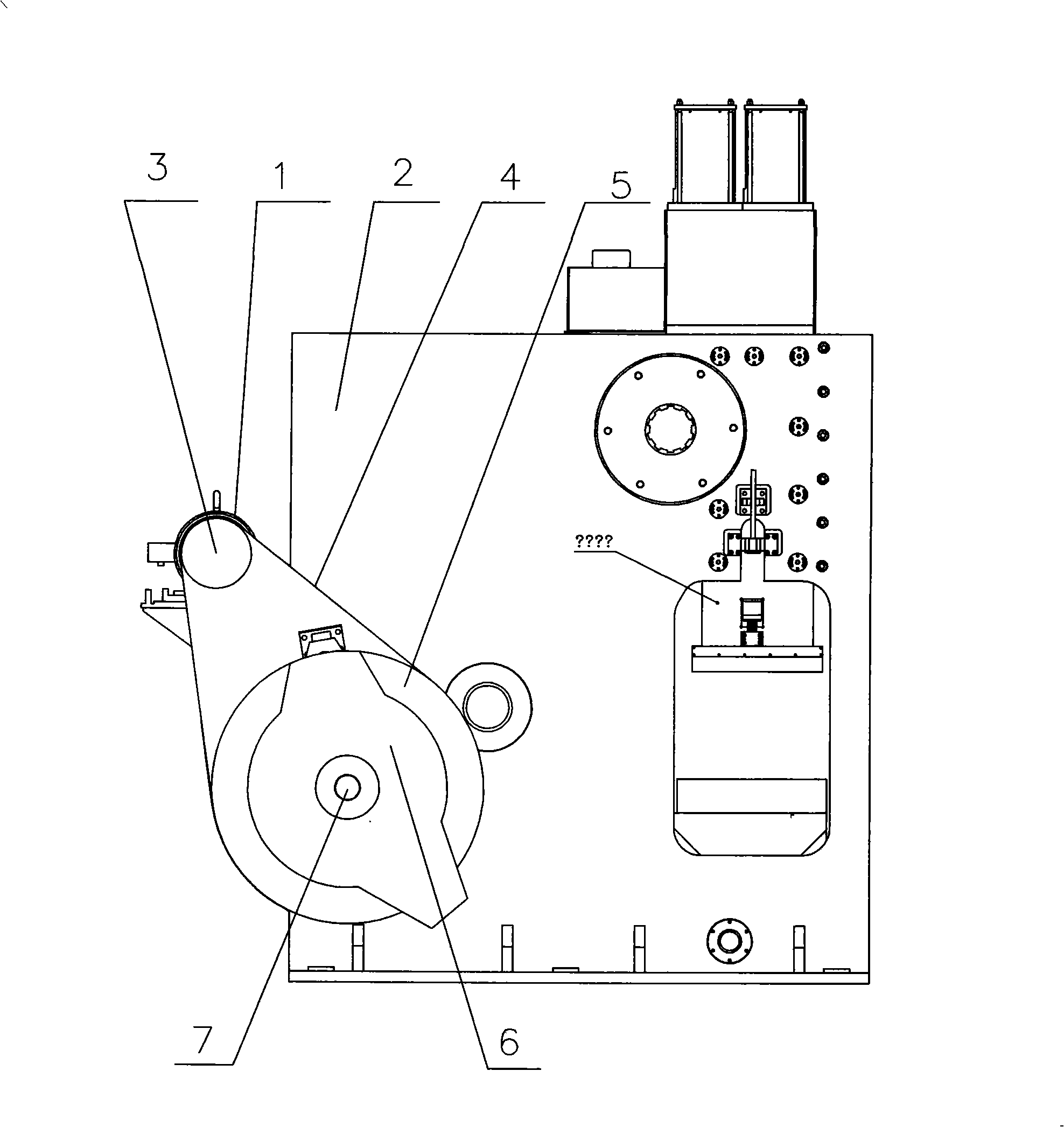

Stepless regulation device for gap between compression roller and ring die

The invention discloses a stepless regulation device for a gap between a compression roller and a ring die, comprising an elastic clamping tumbler fixedly connected to a main shaft, wherein the elastic clamping tumbler is symmetrically provided with two compression roller assemblies; the front ends of the two compression roller assemblies are provided with junction plates fixed by levorotatory round nuts; the middle of each junction plate is provided with a tension stud connected with the elastic clamping tumbler; the middle of the elastic clamping tumbler is rectangular; two sides of the elastic clamping tumbler are in reverse symmetric arc shape; the middle of the elastic clamping tumbler is provided with a center hole matched with a main shaft key; two sides of the center hole are symmetrically provided with two side holes respectively matched with the two compression roller assemblies; one side of the two side holes, which is near the direction of the arc shape, is respectively provided with a gap; and a plane vertical to the gap is provided with an inner hexagon screw. The stepless regulation device has simple structure, can realize the purpose of the stepless regulation of the gap, is convenient to regulate the gap between the compression roller and the ring die and is practical and reliable.

Owner:徐州科融科技园发展有限公司

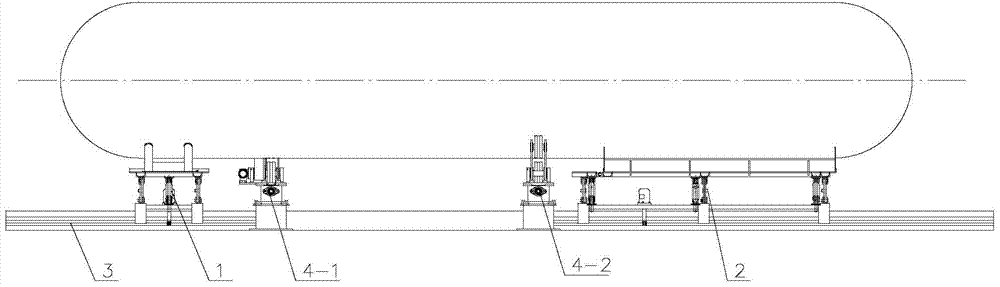

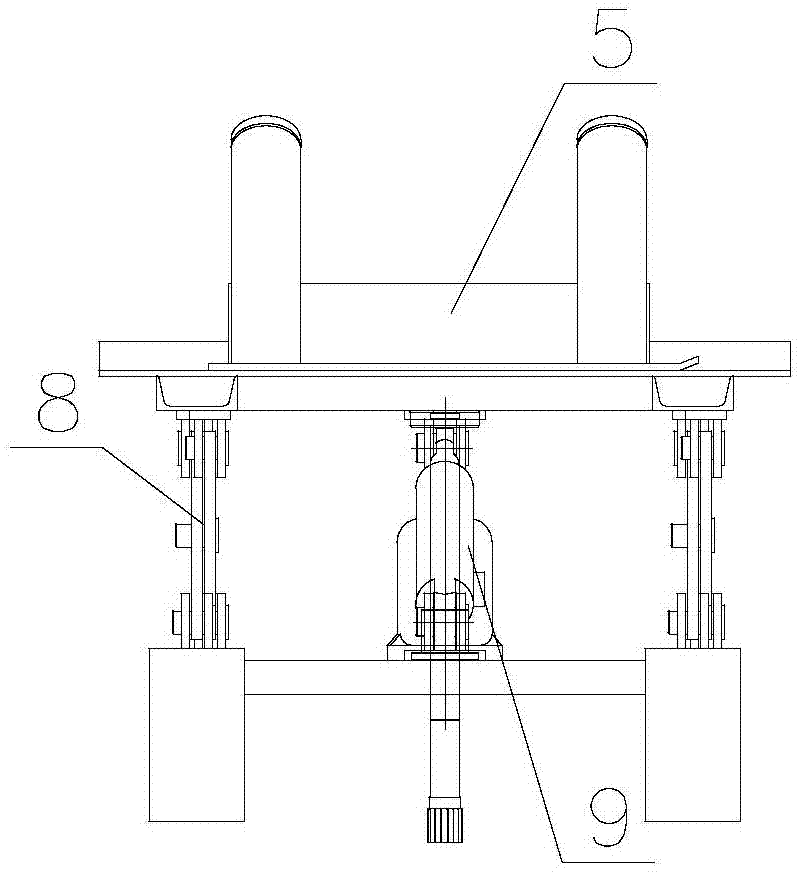

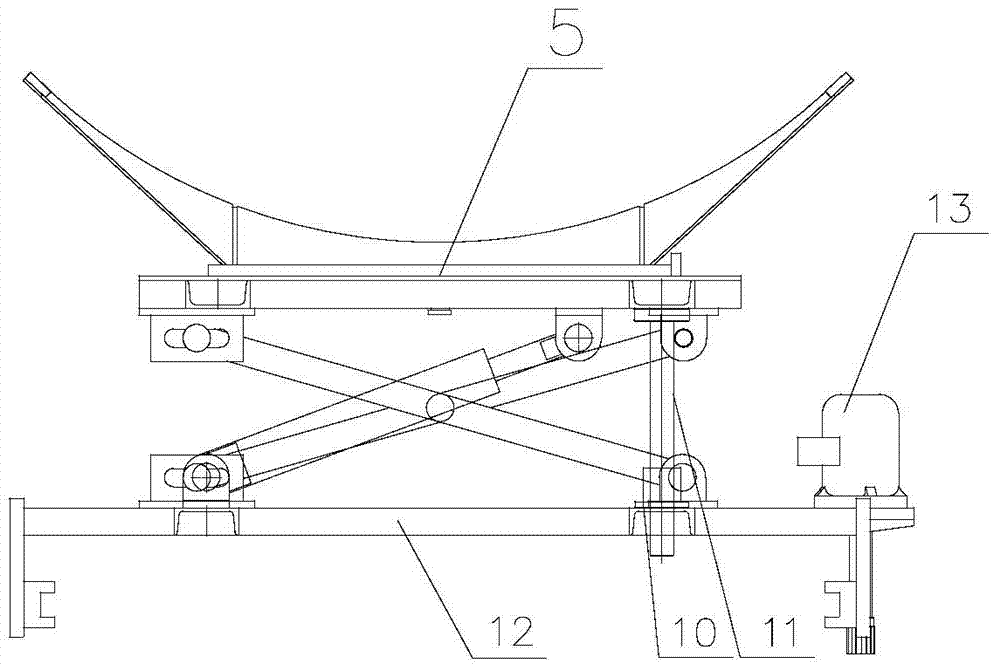

Assembly tool for accurately locating large-size storage tank

ActiveCN103567690AEasy to adjust the gapRealize standardized productionWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderStructural engineering

The invention relates to an assembly tool for accurately locating a large-size storage tank and belongs to the technical field of equipment manufacturing. The assembly tool for accurately locating the large-size storage tank is mainly composed of a pin base lifter arranged on a base assembly, a V base lifter and a supporting idler wheel frame. A V base, a pin base and a walking mechanism move on a base after being reasonably combined so that accurate rapid assembly of a tank body, the V base and the pin base can be achieved. According to the assembly tool for accurately locating the large-size storage tank, standardized production is achieved, the V base, the pin base and the walking mechanism are combined and assembled respectively, so that the V base lifter and the pin base lifter are formed, hydraulic lifting control is adopted, and therefore lifting is stable and reliable. Meanwhile, due to the fact that the V base is long, a front hydraulic cylinder and a rear hydraulic cylinder are adopted by the V base lifter, lifting is conducted independently, a gap between the V base and the tank body can be adjusted conveniently, and accurate locating is achieved.

Owner:NANJING AUTO ELECTRIC

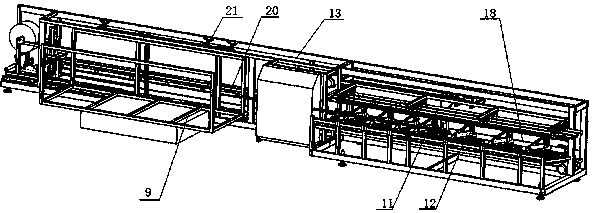

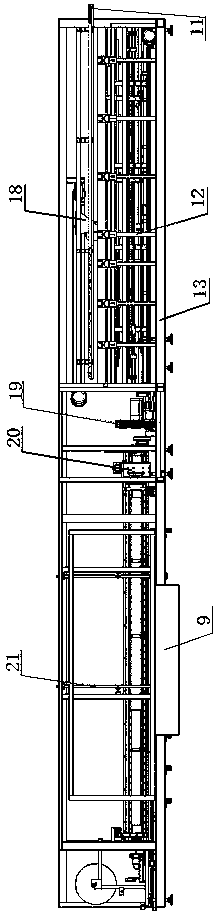

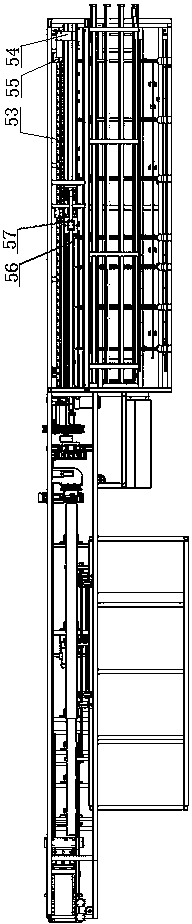

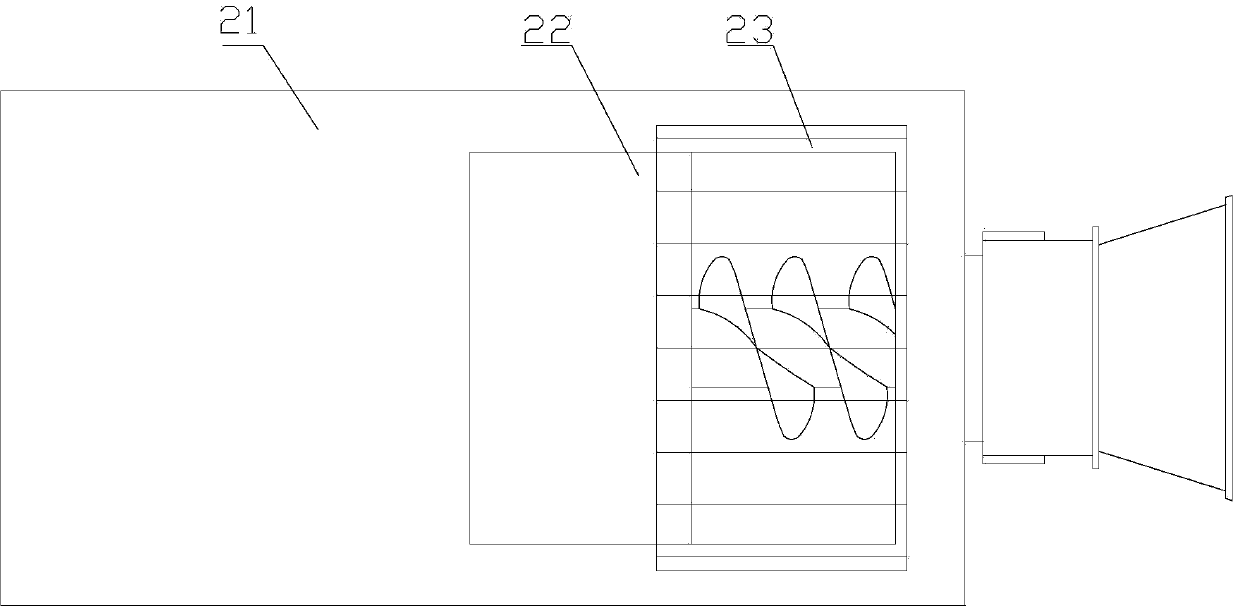

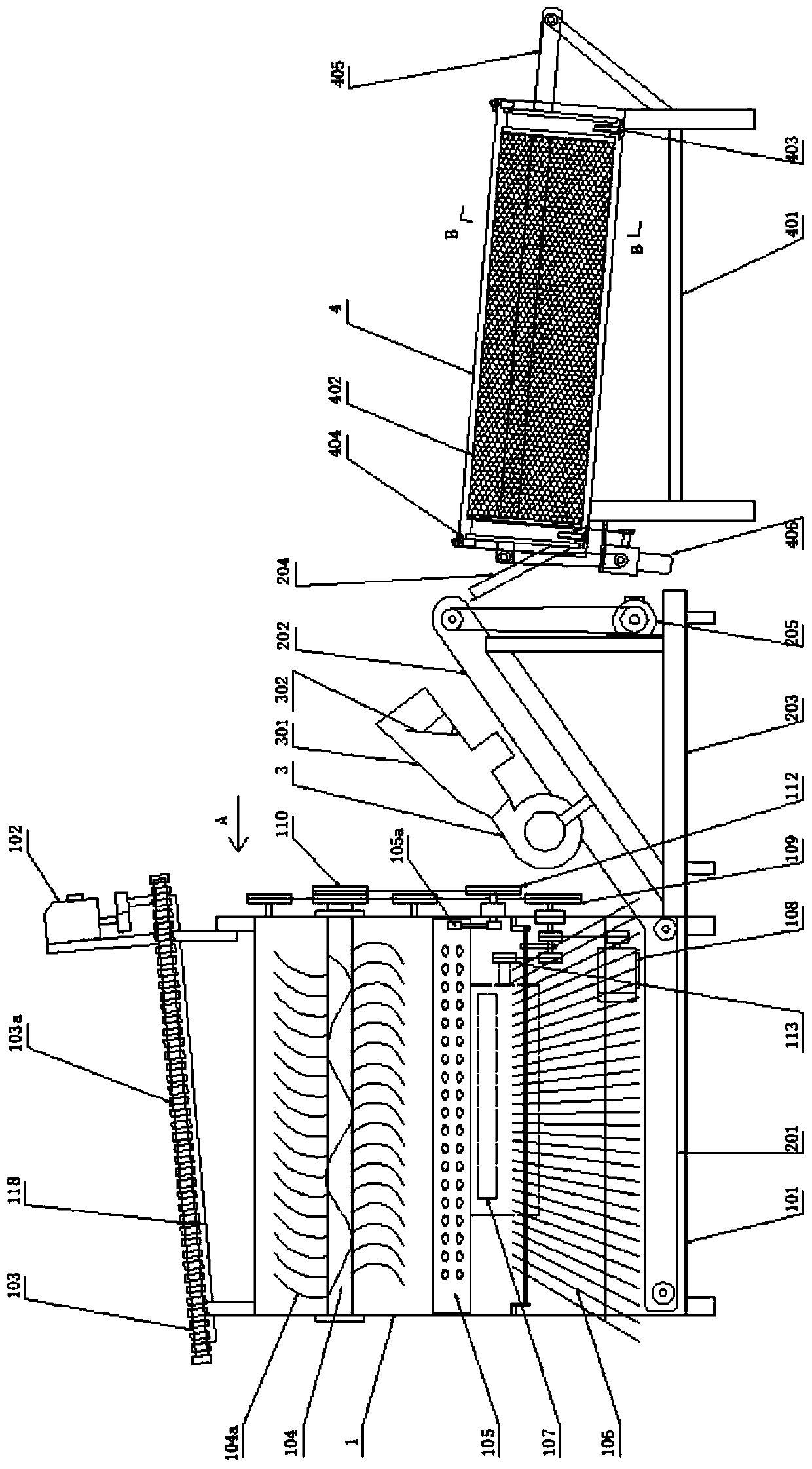

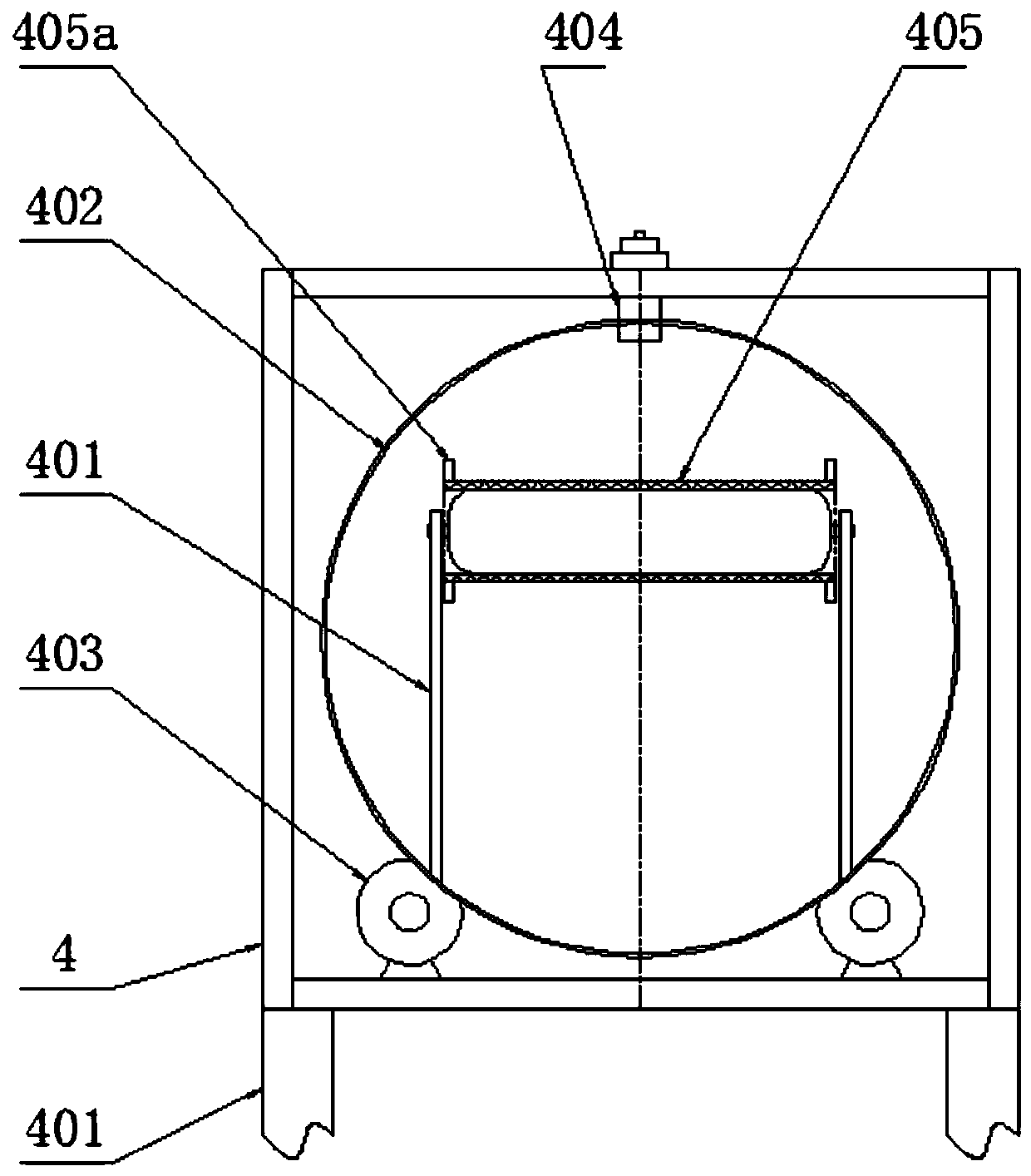

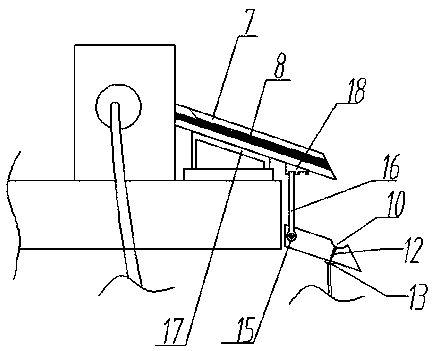

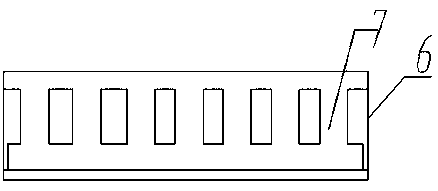

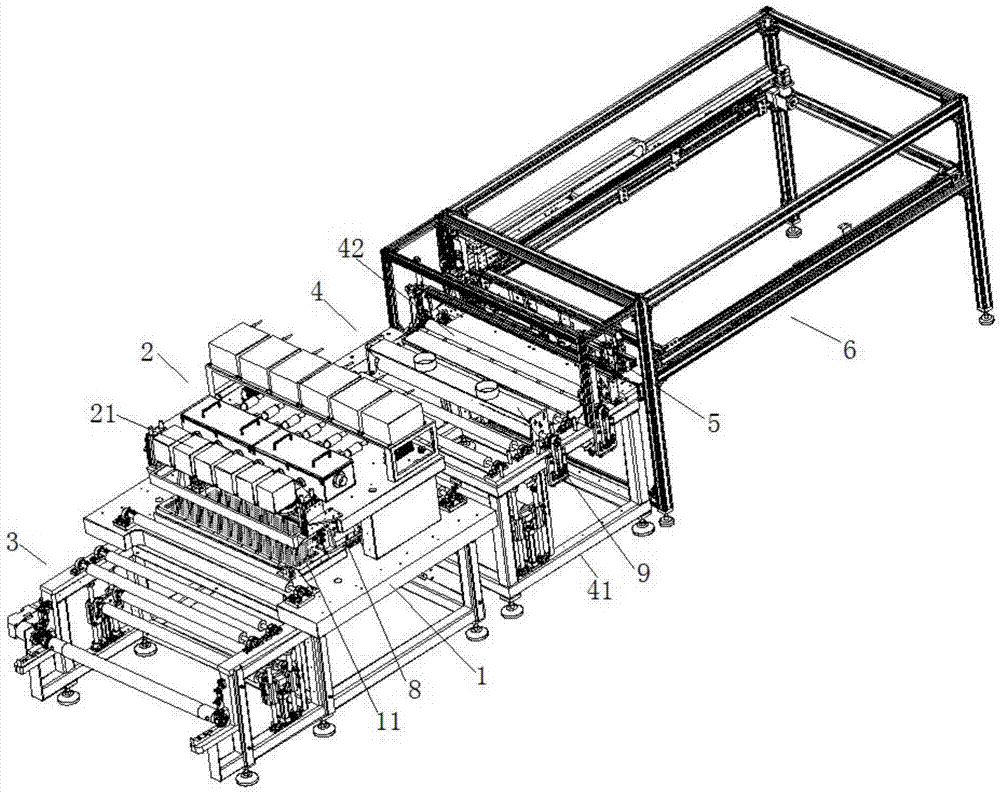

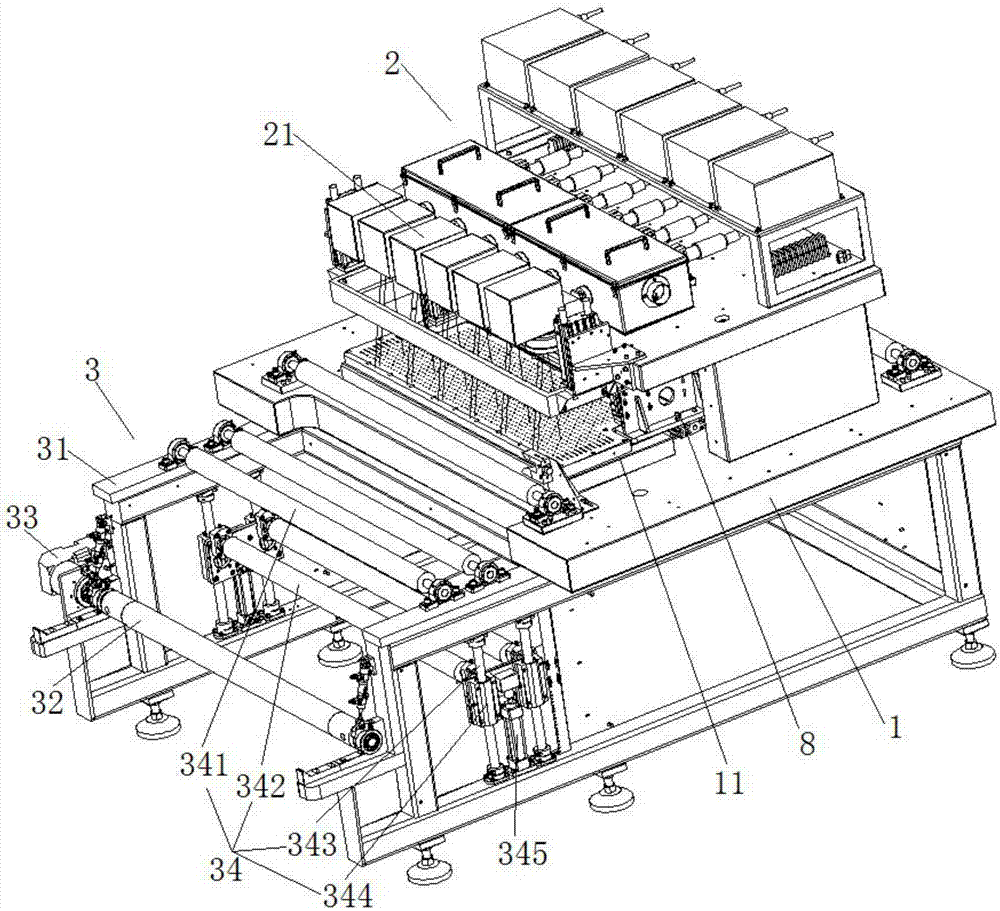

Automatic Bundling Pipe Bagging Machine

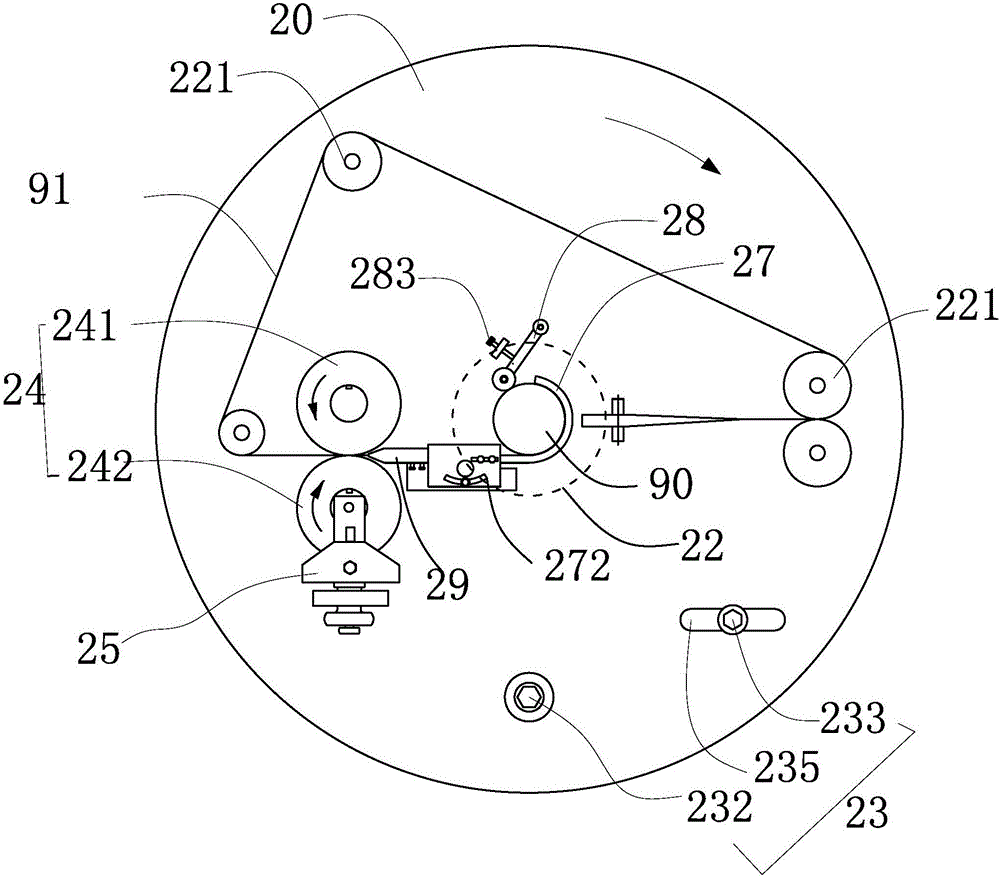

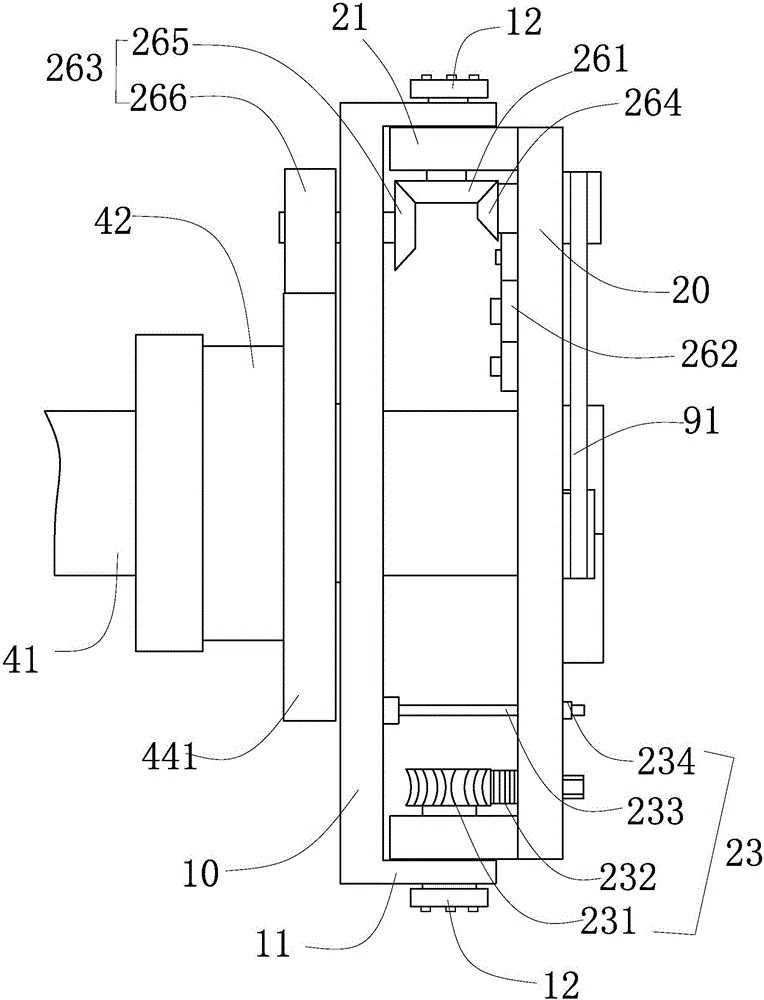

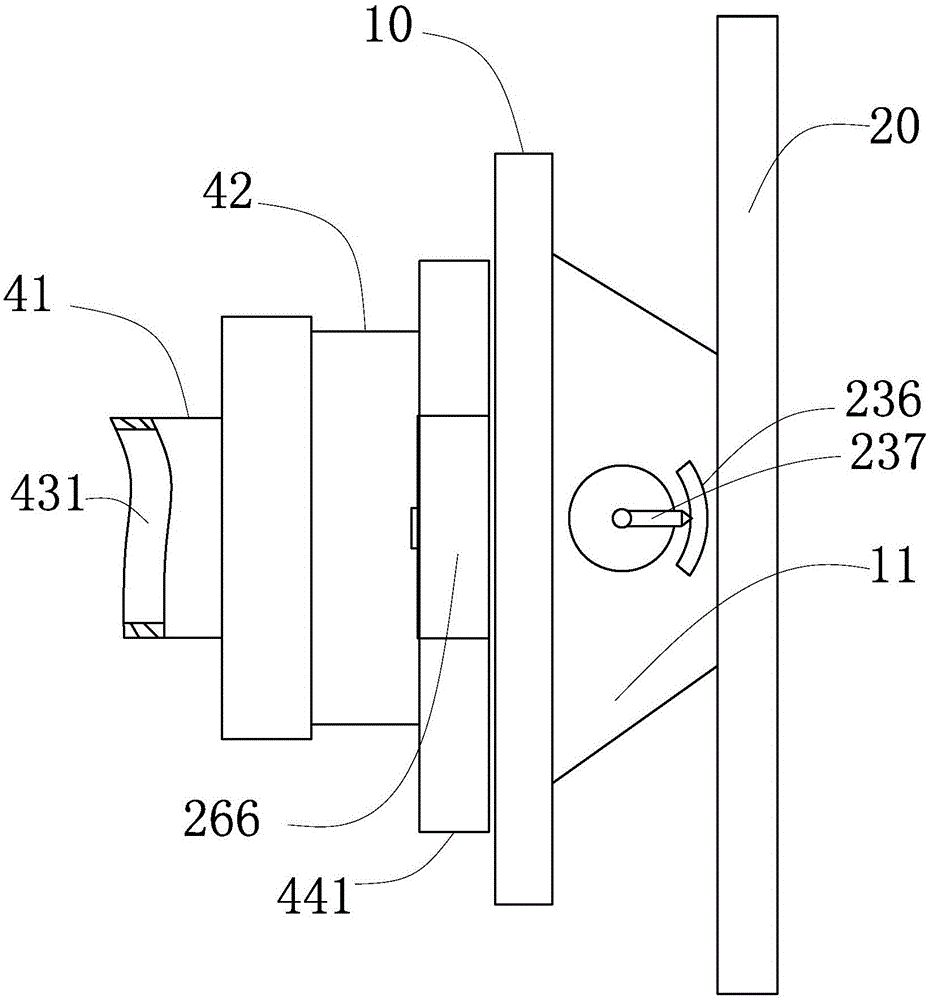

ActiveCN105292584BFully automatedSmall footprintWrapper twisting/gatheringBinding material applicationHorizontal axisEngineering

Owner:GUANGDONG LIANSU MACHINERY MFG

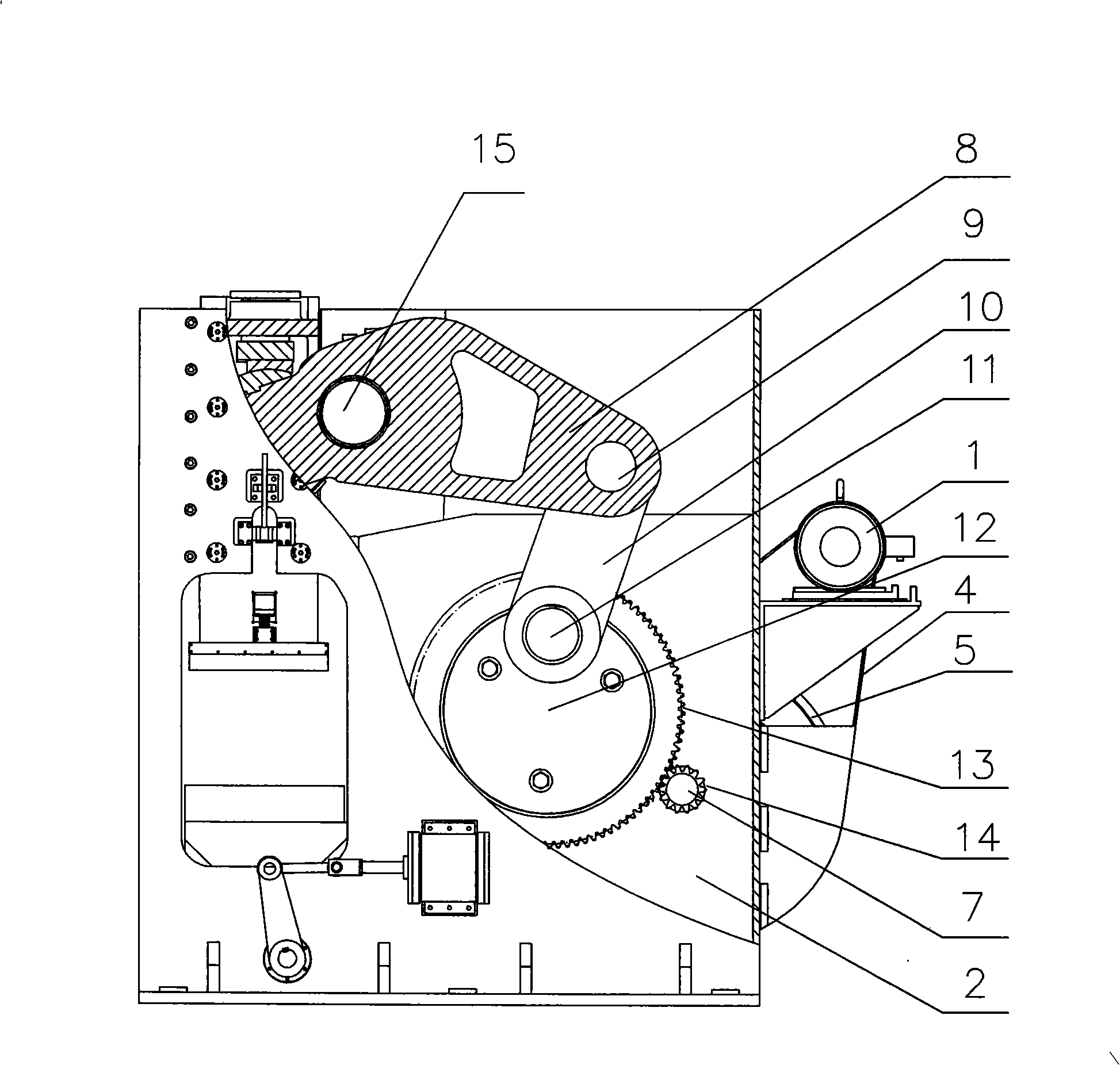

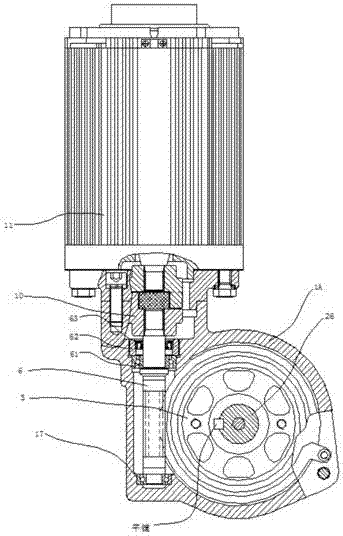

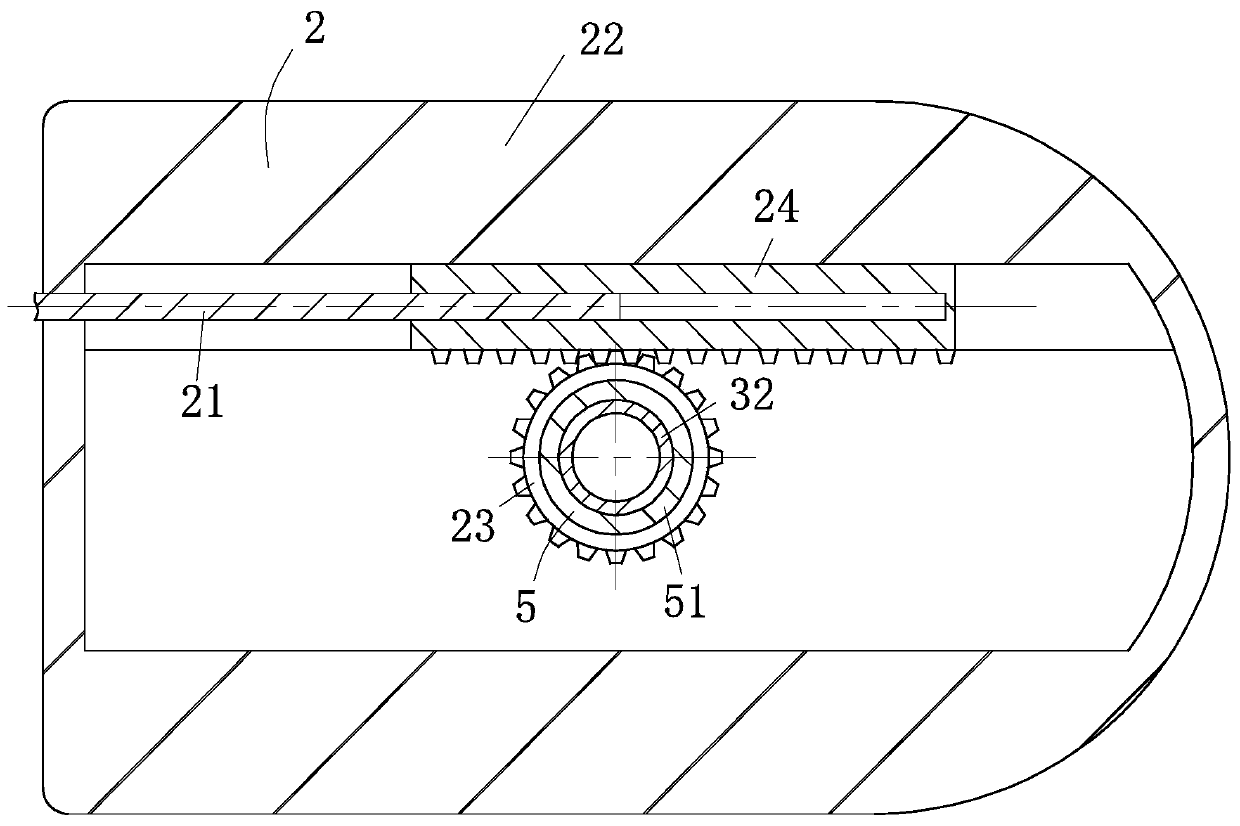

Speed changing type straw briquetting machine and application thereof

InactiveCN103317749AReduce energy consumptionReduce production energy consumptionShaping pressGear wheelLubrication

The invention provides a speed changing type straw briquetting machine and application of the speed changing type straw briquetting machine. According to the scheme, an original high-power motor is changed into two low-power motors. The motors are in transmission connection with a main shaft through a speed changing box. A briquetting wheel is locked and fixed through a briquetting wheel support gear sleeve and an adjusting pulling block. A second module is additionally arranged on the basis that a first module outwards extends. A machine oil lubrication channel is formed in a machine body of the briquetting machine, the machine oil lubrication channel passes through the main shaft and each bearing base in the machine body of the briquetting machine, and an oil pump provides power to form the lubrication circulation. The speed changing type straw briquetting machine has the advantages of being low in energy consumption, low in labor strength, even in extrusion, free of machine blocking, high in yield, high in efficiency, convenient to maintain and the like. The speed changing type straw briquetting machine is suitable for briquetting maize straws, cotton stalks, peanut shells, saw dust, soybean straws and the like, the fuel density of rod-shaped compact maize straw briquetted fuel obtained by the speed changing type straw briquetting machine after the rod-shaped compact maize straw briquetted fuel is briquetted is 1.1-1.3g / cm<3>, and the briquetting effect is good.

Owner:DASHIQIAO CHENGTIAN NEW ENERGY DEV

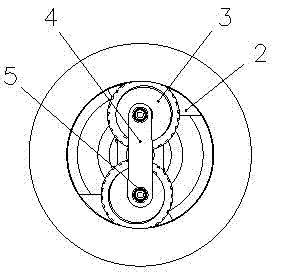

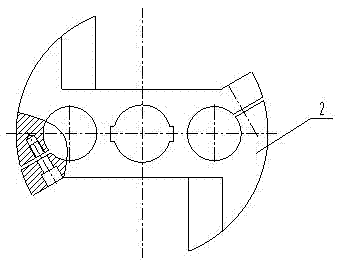

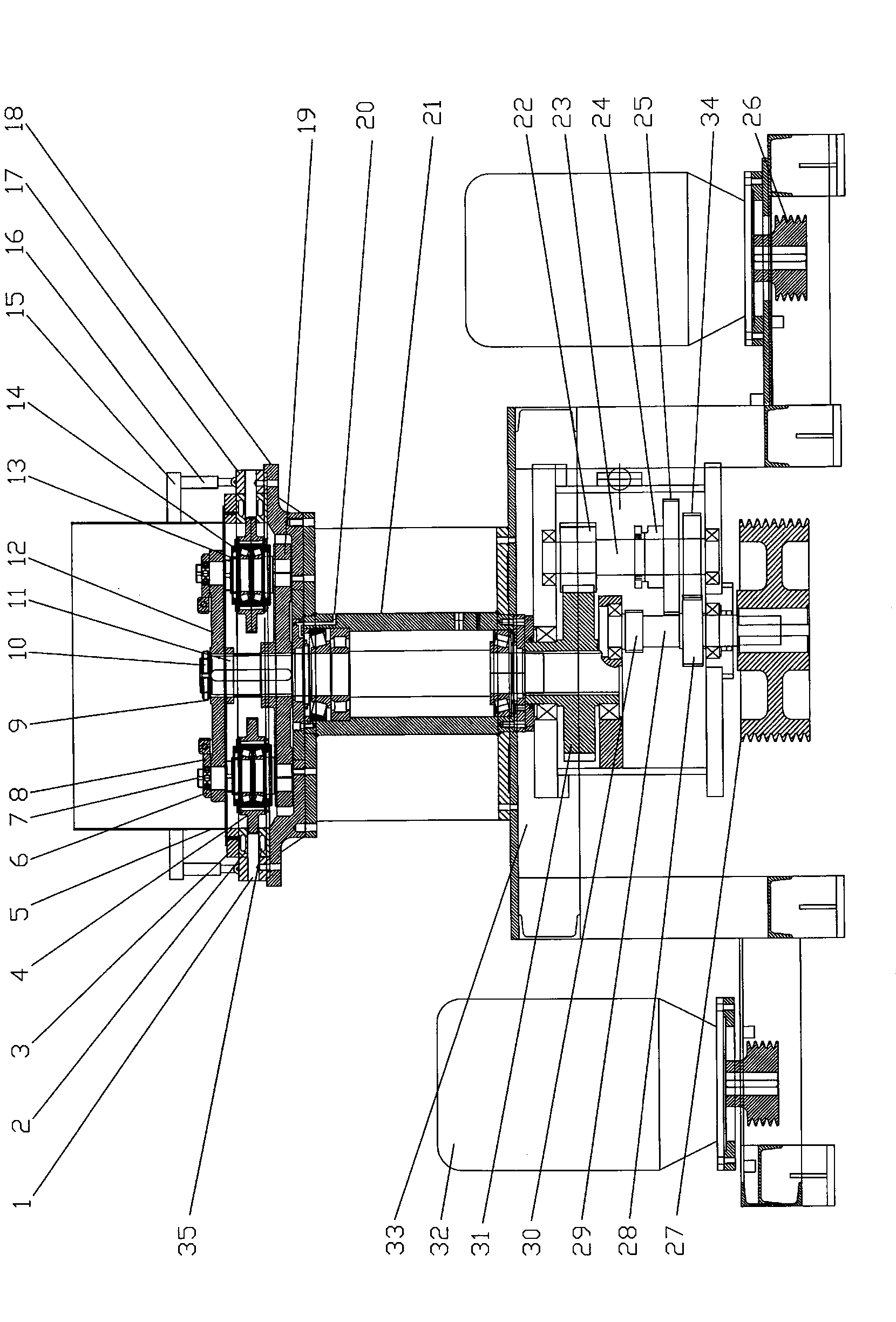

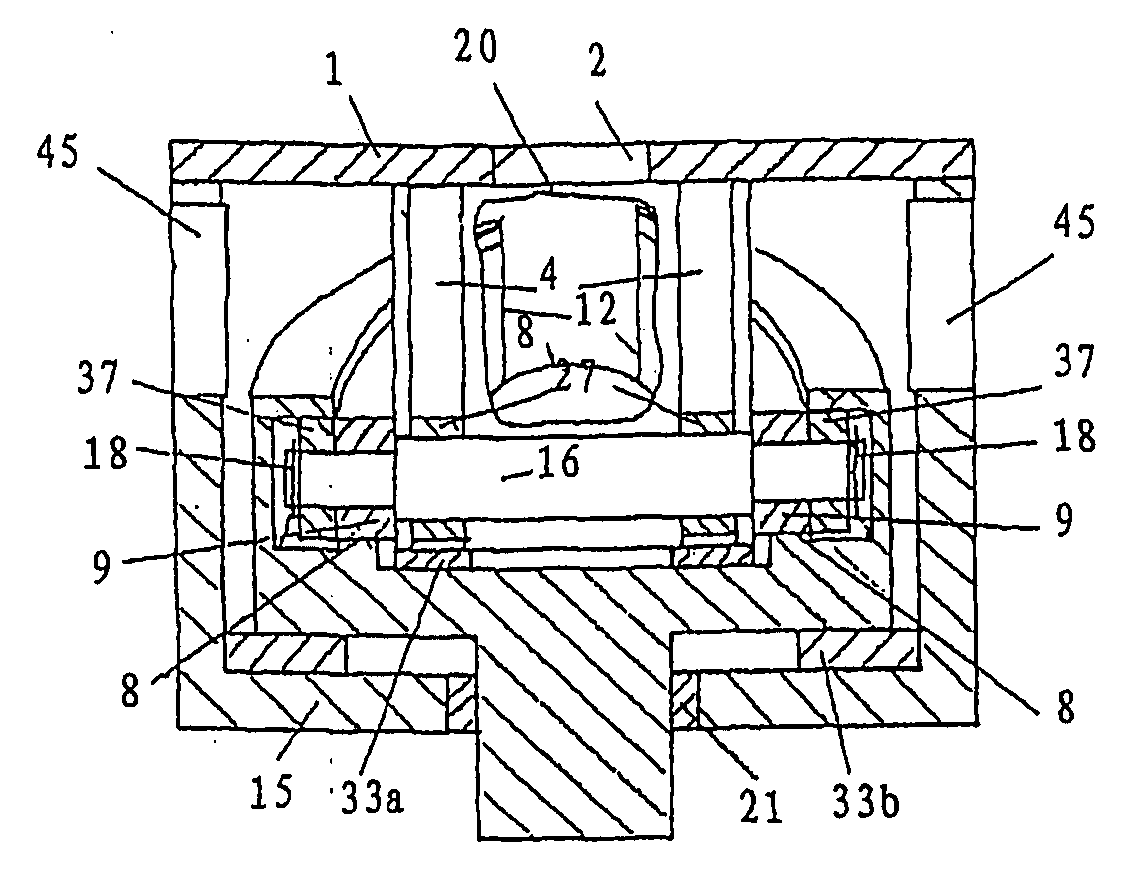

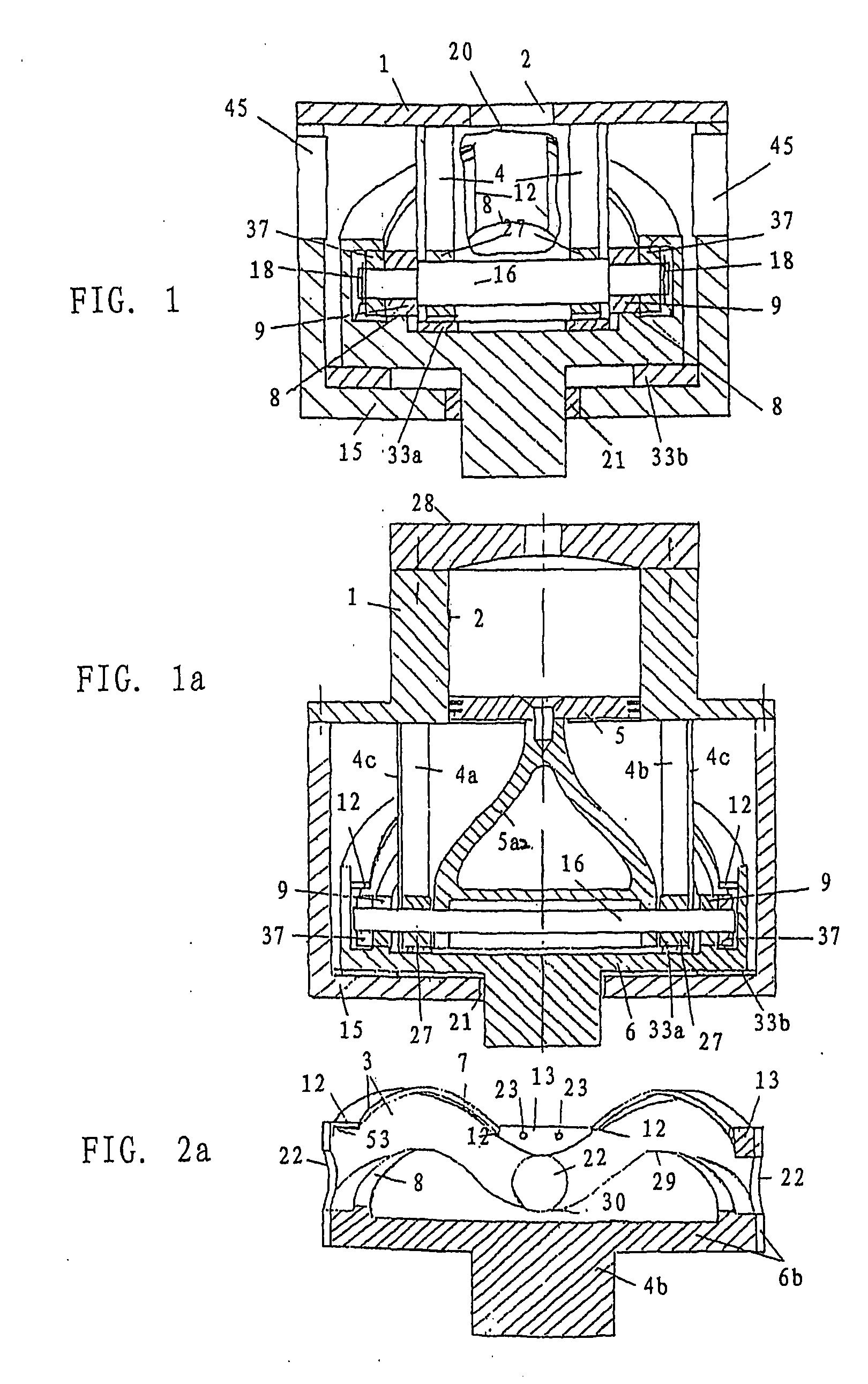

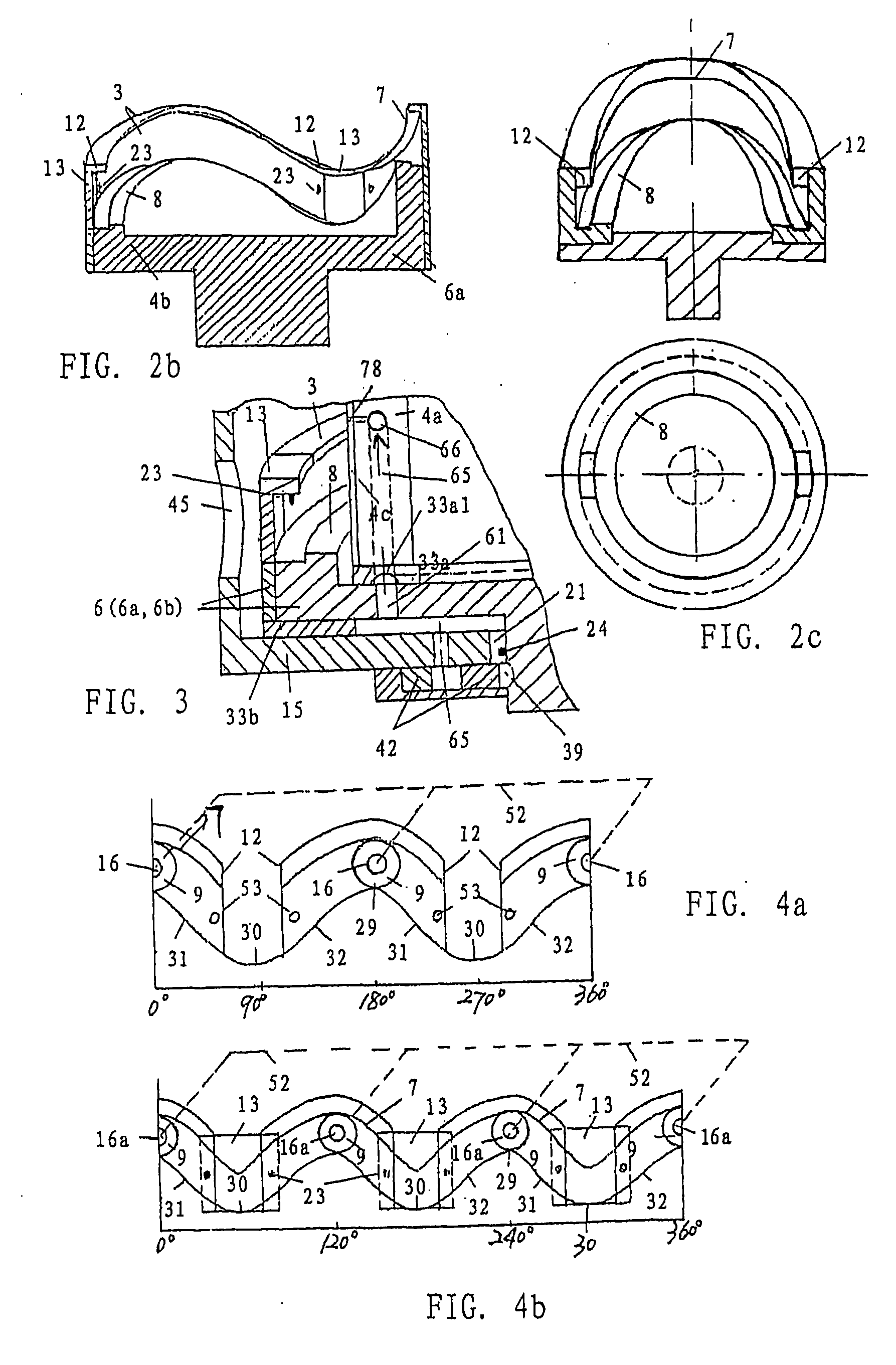

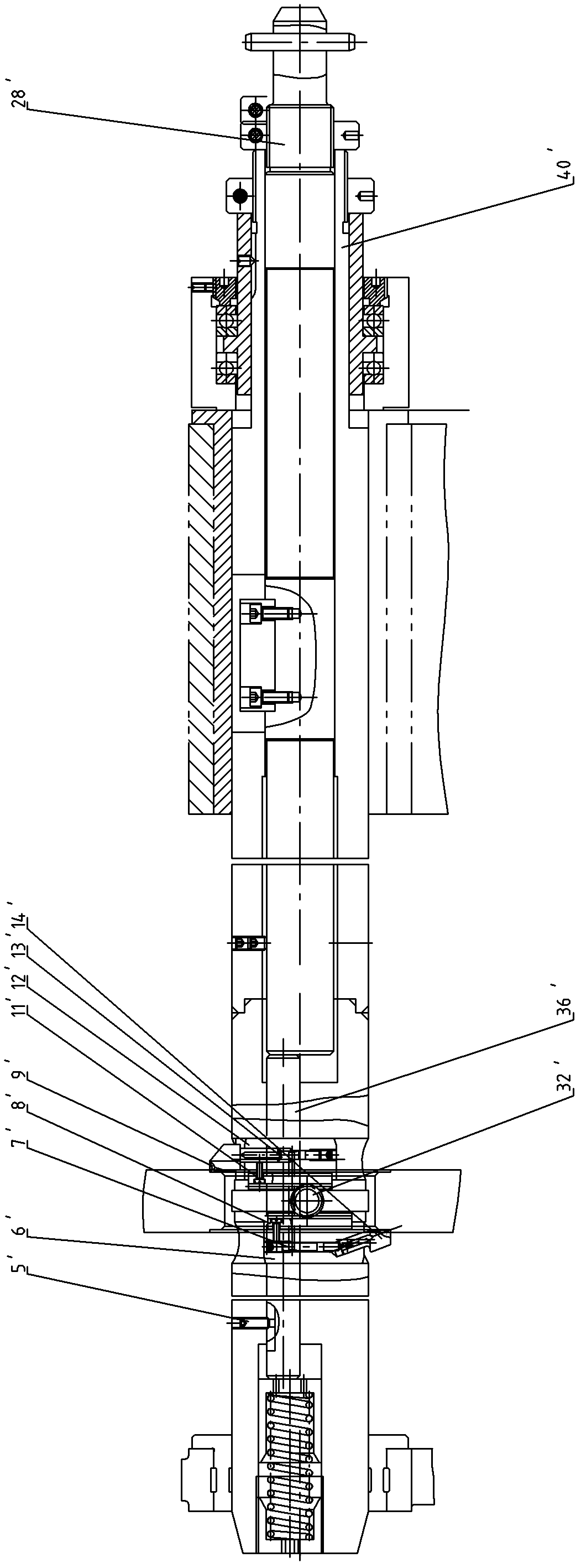

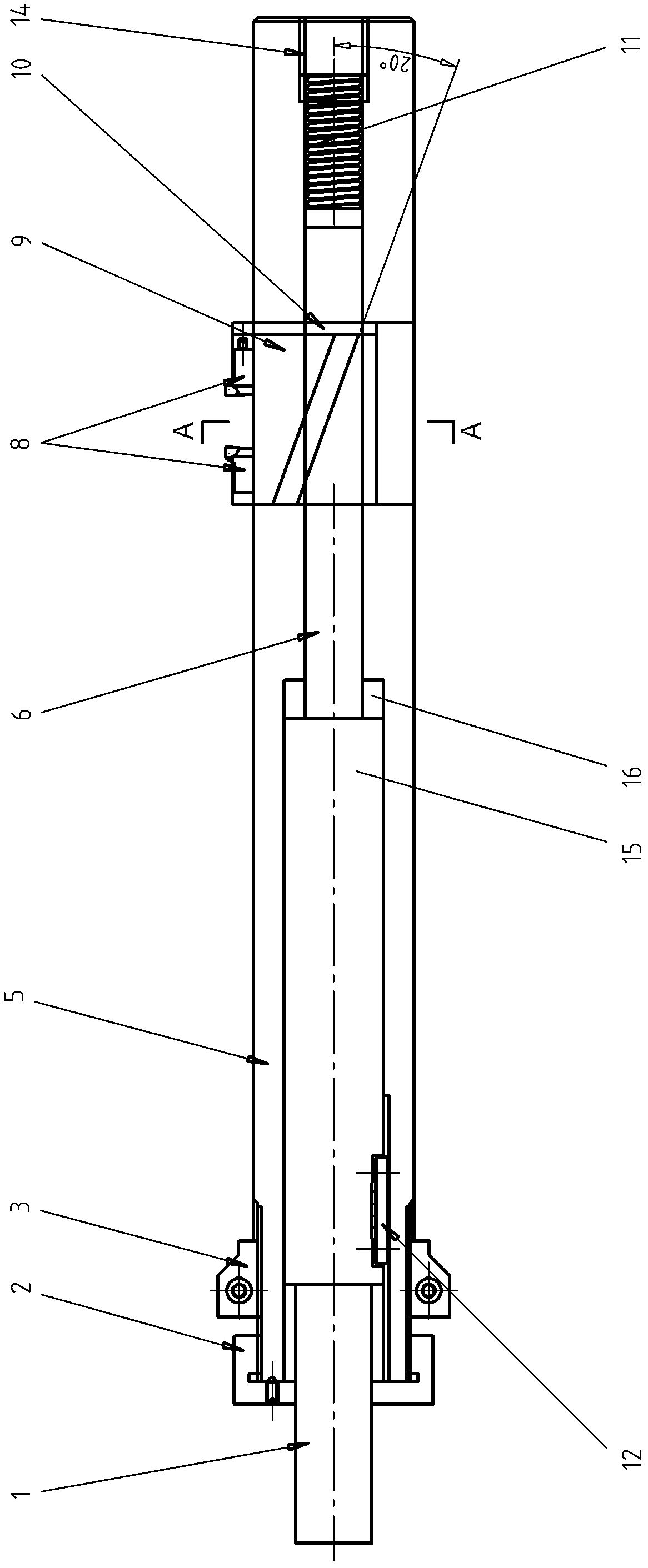

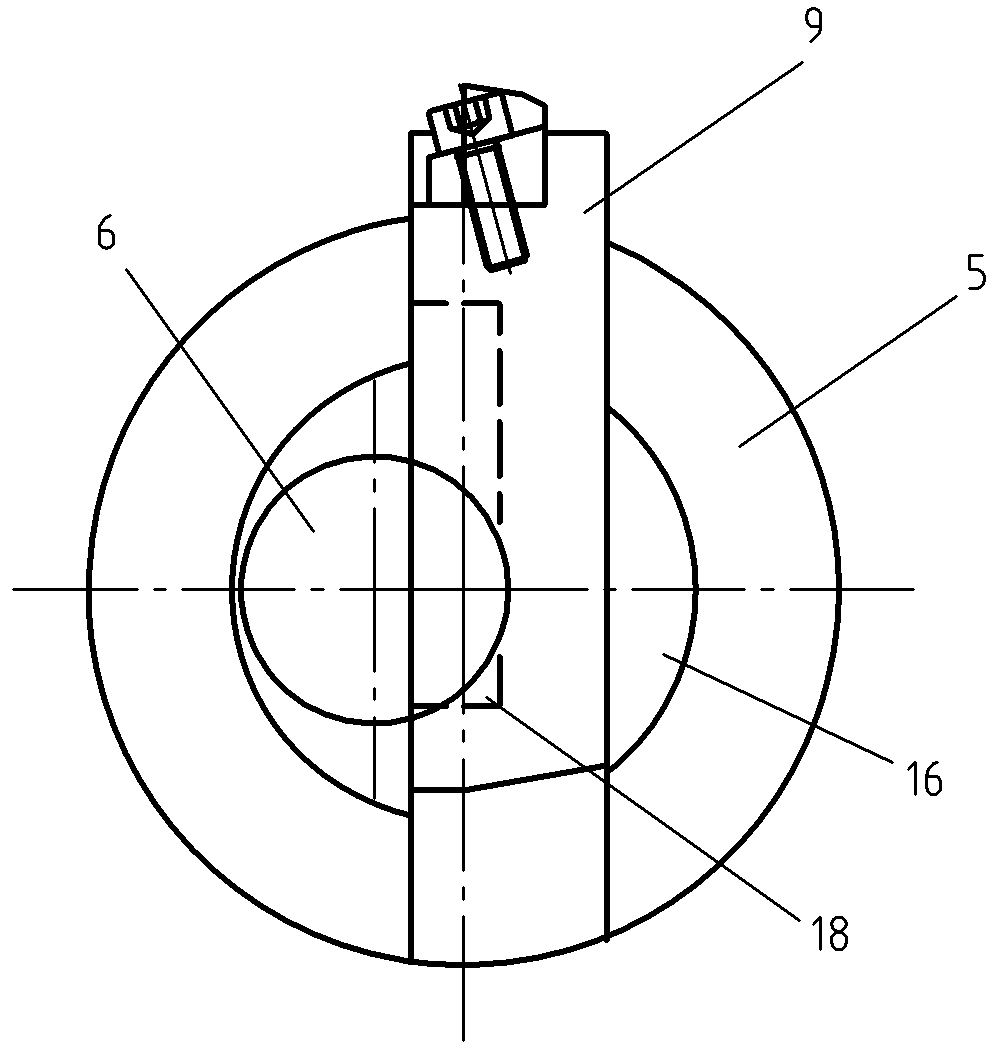

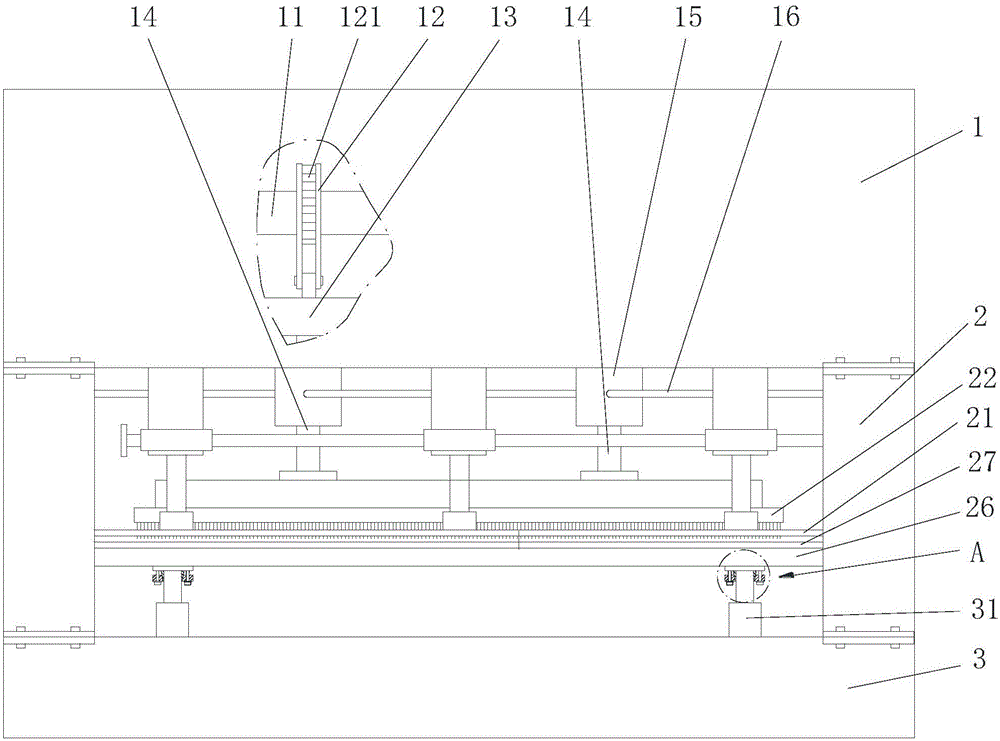

Power Transmission Mechanism for Conversion Between Linear Movement and Rotary Motion

The present invention relates to a spatial cam power transmitting mechanism for the conversion between linear movement and rotary motion. Several transmitting mechanisms for the conversion between reciprocating motion of a roller shaft and rotary motion of an internal groove cam are provided, which do not have a piston and a piston bore. A roller shaft 16 is provided on a upper portion of internal groove cam 6 in a cam casing 15, and rollers are mounted to the outer end of the roller shaft. The rollers roll in a circumferential direction on the contour line of the groove of the internal groove cam 6. At the position of fixed rails 4 opposing to the roller shaft 16, guiding rollers or slide blocks 27 are provided, wherein the fixed rails 4 are provided axially in a lower portion of a cover 1 of the cam casing. The guiding rollers or slide blocks 27 can move up and down respectively in the fixed rails. The power transmitting mechanism is used in an internal combustion engines burning petrol, diesel oil or gas, a stirling engine, a motive engine, such as air or liquid motor, a pump transmitting gas and liquid, a compressor, or other fields which need movement translation.

Owner:XIAMEN TUXIAN ENERGETIC SCI & TECH

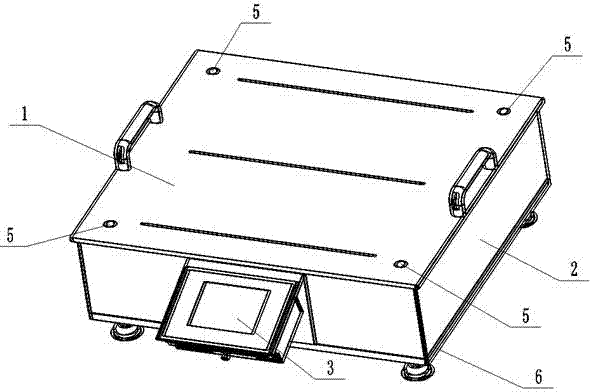

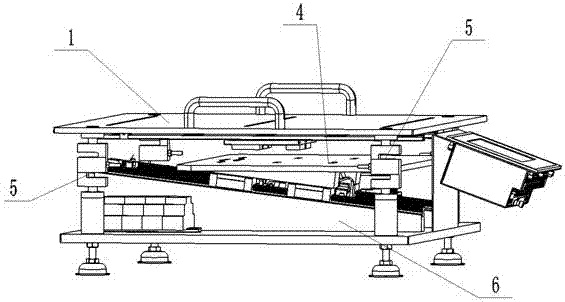

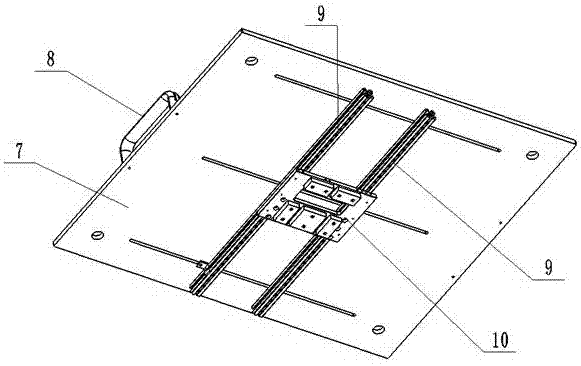

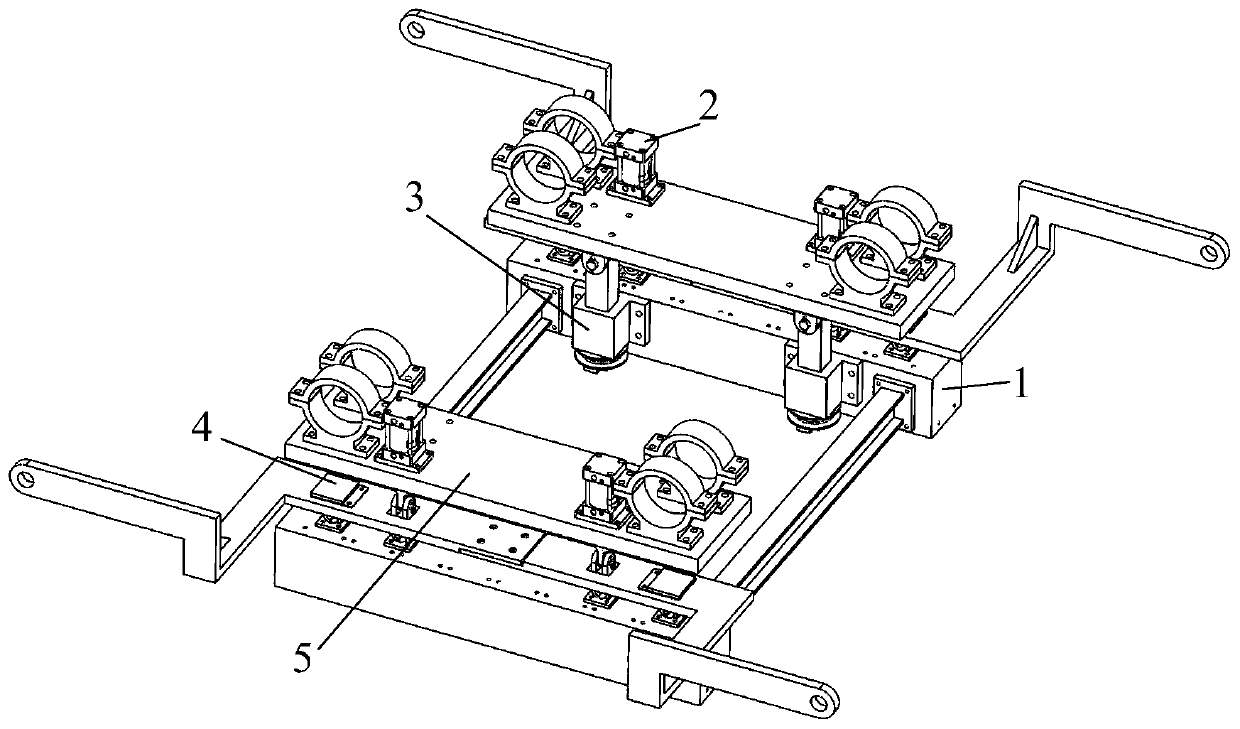

Gap-adjustable magnetic force testing device

PendingCN106990371AQuick measurementAccurate measurementMagnetic property measurementsMagnetic tension forceControl system

The invention relates to a magnetic force testing device and particularly relates to a device for testing the gap adsorption magnetic force, including a housing, a support mechanism, pull-pressure sensors, a magnet installation system, a gap adjusting mechanism, a magnetic conductive plate and a measurement and control system. The support mechanism is fixedly connected with the plurality of pull-pressure sensors. The magnet installation system is horizontally arranged on the probes of the plurality of pull-pressure sensors. The magnetic conductive plate is arranged under the magnet installation system. The magnetic conductive plate is fixedly connected on the gap adjusting mechanism. The gap adjusting mechanism is fixedly connected on the support mechanism. The support mechanism is provided with the measurement and control system. The gap-adjustable magnetic force testing device achieves rapid and precise measurement of the magnetic force of the magnetic material, provides magnetic force testing data for the magnetic absorption robot and other magnetic absorption devices, and provides the reliable basis for the design.

Owner:东方电气集团科学技术研究院有限公司

Bone paste machine

ActiveCN103962213AImprove cut qualityIncrease productivityGrain treatmentsFood preparationEngineeringReamer

The invention relates to a grinder, in particular to a bone paste machine for processing animal bone. The bone paste machine comprises a housing, a rotation shaft, a drive device, a gap adjustment device and a grinding head, wherein the bone paste machine also comprises a mincing device, the mincing device is arranged on a rotation sleeve and comprises three reamers, a precutting plate, a coarse pore plate and a fine pore plate, the precutting plate, the coarse pore plate and the fine pore plate are sequentially arranged at intervals along the rotation sleeve, one reamer is arranged close to a spiral feeder, the other reamers are respectively arranged between the precutting plate and the coarse pore plate and between the coarse pore plate and the fine pore plate, holes are arranged in the precutting plate, the coarse pore plate and fine pore plate at intervals, the diameter of the holes in the precutting plate is larger than the diameter of the holes in the coarse pore plate, and the diameter of the holes in the coarse pore plate is larger than the diameter of the holes in the fine pore plate. The bone paste machine is simple in structure and is convenient to install, the device can be used for directly mincing large materials and grinding the materials into bone paste, a gap between a movable grinding head and a fine grinding head can be adjusted, and the production efficiency of the bone paste machine is improved.

Owner:QINGDAO HAIYUNTIAN MACHINERY EQUIP

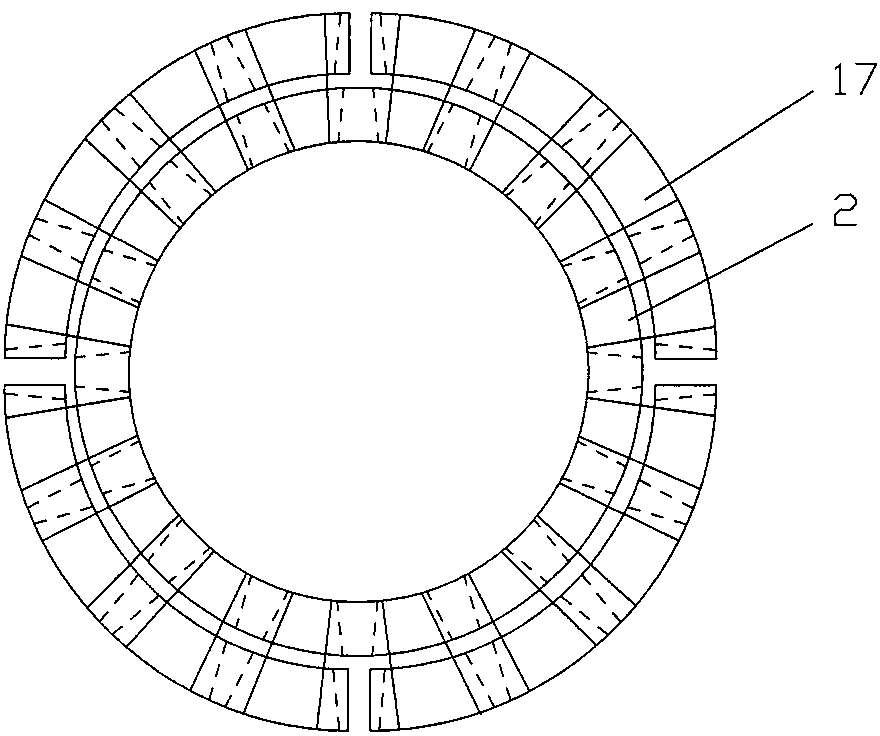

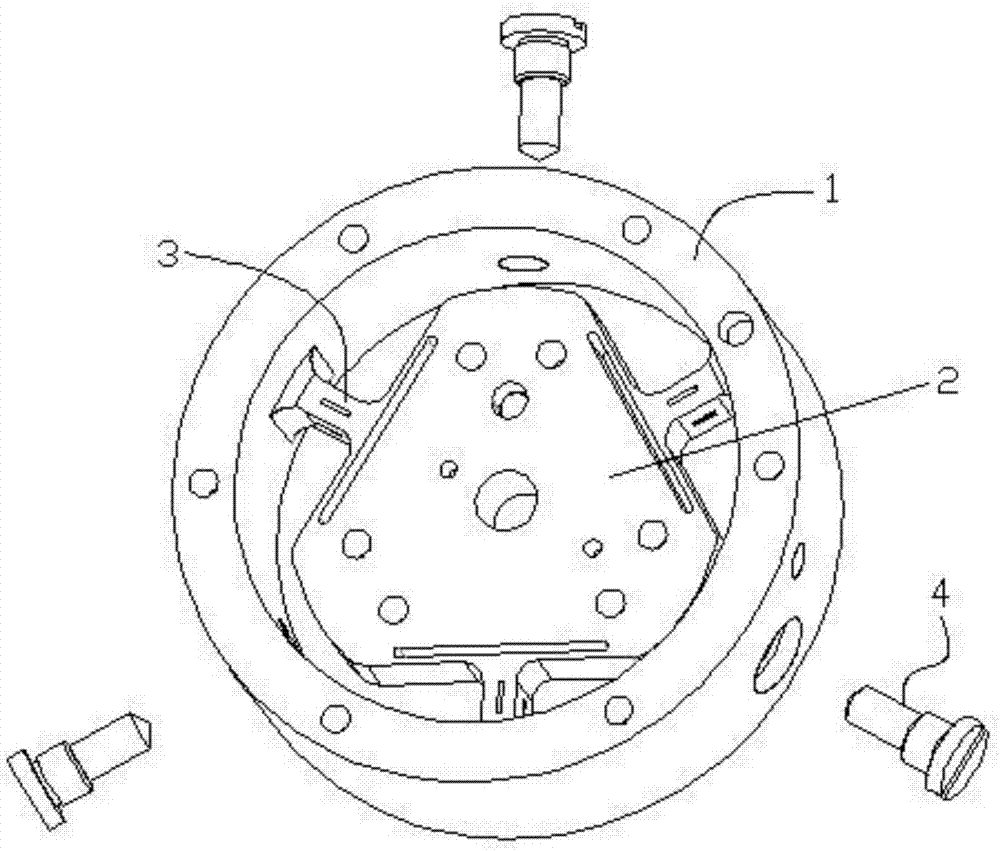

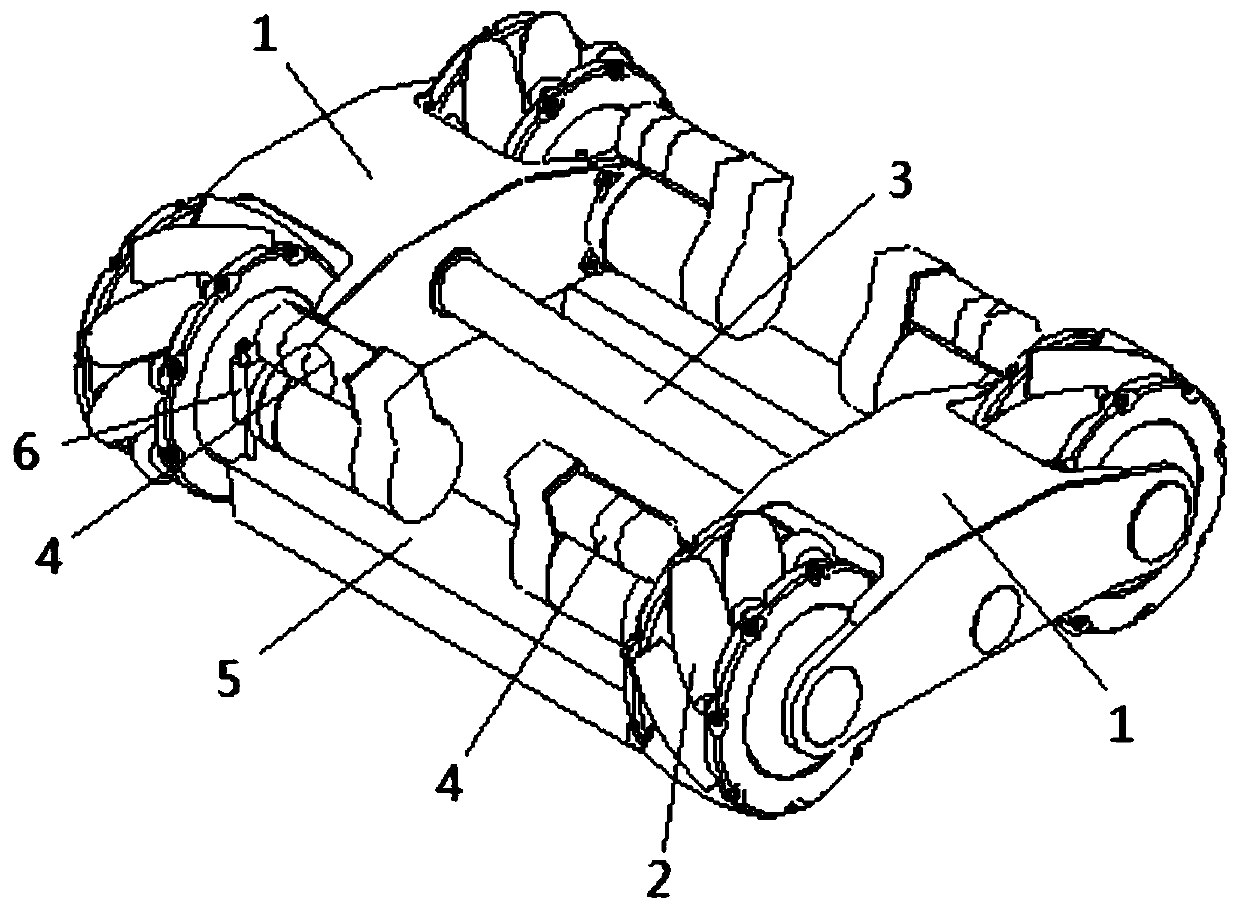

Multidimensional force sensor and calibration method thereof

ActiveCN107167267AEasy to adjust the gapAchieve calibrationForce measurement by permanent gauge deformationForce/torque/work measurement apparatus calibration/testingEngineeringStrain gauge

The invention discloses a multidimensional force sensor comprising an external circle structure, an internal circle structure, elastic columns, strain gauges and protectors. The external circle structure is circular-ring-shaped. The internal circle structure and the external circle structure are connected through at least three elastic columns. The two ends of each elastic column are respectively connected with the external circle structure and the internal circle structure. The area, which is contacted with the elastic columns, of the internal circle structure is provided with long slots. Each long slot forms an edge supported overhead flat plate on the surface of the internal circle structure. The elastic columns are connected on the overhead flat plate. The protectors are installed on the external circle structure, and gaps are reserved between the protectors and the internal circle structure. The side surface of each elastic column is provided with the strain gauge in an adhesive way. The thickness of the overhead flat plate is reasonably designed and the proper material is adopted so that the overhead flat plate is enabled to generate reasonable deformation in case of bearing load, the internal circle structure is contacted with the protectors when the load is excessively high, and the excessive load is directly borne by the protectors without being conducted to the elastic columns so as to realize the protection effect.

Owner:HEBERSON TECH (SHENZHEN) CO LTD

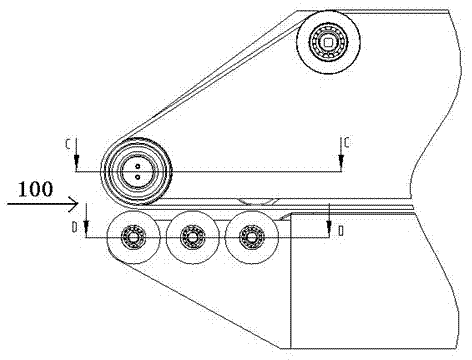

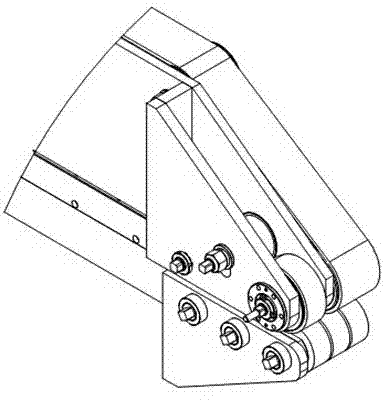

Pepper sorting production line and sorting method thereof

PendingCN110369287AEfficient extractionHigh quality extractionSievingGas current separationProduction lineDrivetrain

The invention discloses a pepper sorting production line and a sorting method thereof, and belongs to the technical field of agricultural machines. The production line comprises a separator, a conveying belt and a fruit sorting machine which are sequentially connected from front to back. The separator comprises a separator rack, a hanging conveying device for conveying pepper seedlings, a screening device and a power transmission system; the hanging conveying device is arranged on the top of the separator rack, a pair of claw rollers are arranged below the hanging conveying device, multiple claw teeth used for taking the pepper fruits are arranged on the claw rollers, the claw rollers are driven by the power transmission system to rotate, the screening device is arranged below the claw rollers, a horizontal conveying belt of the conveying belt is arranged below the screening device, a lifting conveying belt of the conveying belt is arranged behind the separator in an inclined manner, the output end of the lifting conveying belt is connected to a rolling screen cylinder of the fruit sorting machine through an inclined hopper, and the outlet end of the rolling screen cylinder is provided with a pepper fruit collection container. According to the pepper sorting production line, pepper fruits can be efficiently picked from the pepper seedlings in a high-quality manner, and impurities are separated.

Owner:河北牛博士机械设备有限公司

Sliding block driving mechanism of multiple slide rod press machine

The invention relates to a slide block driving device for multi-connecting-rod press machine. The slide block driving device comprises a frame, a motor, a fly wheel, a drive shaft, a transmission member, a slide block and a slide block lead rail. One end of the drive knuckle-lever of the transmission member is connected with and drives a connecting rod by a connection shaft and the other end of which is arranged on the side leg of a crank shaft. The coaxial deceleration gear of the crank shaft gears into a transmission gear arranged on the drive shaft. The slide block driving device is characterized in that the drive shaft is supported below one side of the frame by a bearing; the drive knuckle-lever is supported against the frame by the bearing in the manner of mismatched length; a drive tee is arranged at the other end; an upper fixed block and a lower fixed block are arranged in the drive chamber of the slide block; an upper rubbing block and a lower rubbing block are arranged between the drive tee and two fixed blocks respectively; the sphere of the drive tee is matched with two rubbing blocks and the drive tee can relatively slide between the running-in surfaces of two rubbing blocks; the upper fixed block is assembled by an adjustment bolt that is against the upper fixed block; and the lower fixed block is supported by a strut member that is against the lower fixed block. The slide block driving device has the advantages of stable running, small eccentric load and quick clearance adjustment, and thus is suitable for the such technologies as precise cold forging, cold warm forging, etc.

Owner:SHANDONG JINCHEN MACHINERY CORP LTD LTD

Magnetic robot

ActiveCN110371210AImprove adsorption capacityImprove stabilityWheelsVehiclesMagnetic tension forceMagnet

The invention relates to the technical field of robots, in particular to a magnetic robot. The magnetic robot comprises a vehicle body assembly, a plurality of swinging structures and a plurality of magnet bodies, wherein the swinging structures are connected to the vehicle body assembly and are suitable for swinging relative to the vehicle body assembly; and the magnet bodies are connected to theswinging structures, so that the resultant force of the magnet bodies is perpendicular to a crawling adsorption surface all the way in a crawling process of the magnetic robot. The magnetic robot canbe suitable for reducing crawling well and can keep a relatively large adsorption force in the reducing crawling process, so that the adsorption stability is improved.

Owner:上海酷酷机器人有限公司

Draw frame for cotton yarn production and processing

The invention discloses a draw frame for cotton yarn production and processing. The frame comprises a support base, the top end of an outer wall of one side of the support base is fixed to a hinge block by a bolt, a side wall of the hinge block is hinged to a groove seat, one side of an inner wall of the groove seat is in threaded connection with a threaded rod, one end, penetrating through the groove seat, of the threaded rod is fixed to a rotating disc through a bolt, a universal joint is hinged to one end of the threaded rod, a scissor telescopic frame is movably connected to one end, awayfrom the threaded rod, of the universal joint, a vertical slot is formed in the inner wall of one side of the groove seat, one end of the scissor telescopic frame is slidably connected to the verticalslot, the top end of the scissor telescopic frame is movably connected with sliding blocks arranged equidistantly, and the sliding blocks are slidably connected with the inner wall of the groove seat. The frame is convenient to fold, reduces the storage volume, is convenient to carry, can press a cotton yarn limit position, and conveniently adjusts the length of the scissor telescopic adjustmentframe, thereby adjusting the gap between adjacent two guiding rollers, the adjustment is convenient, and the operation is simple.

Owner:盐城得力复合材料有限公司

Armored forming device and equipment, and cable armoring technology

ActiveCN106205889AHigh strengthEasy to adjust the gapCable/conductor manufactureEngineeringUltimate tensile strength

The invention discloses an armored forming device and equipment, and a cable armoring technology. The armored forming device comprises a rotating seat, wherein two sides of the rotating seat are fixedly connected with fixed shafts; a rotating disc, wherein two sides of the rotating disc are rotatingly connected with the fixed shafts, and the rotating disc is provided with an angle adjustment mechanism which takes the fixed shafts as the center; a plurality of groups of compression wheels which are disposed at the front end of the rotating disc, wherein each group of compression wheels comprises a movable compression wheel and a fixed compression wheel. A bulged die cavity and a recessed die cavity are formed between the movable compression wheels and fixed compression wheels. The rotating disc is provided with the angle adjusting mechanism, thereby facilitating the adjustment of the winding angle of a metal tape on a cable. The strength of an armored layer can be improved through the selection of a proper winding angle. The compression wheels comprise the fixed compression wheels and the movable compression wheels, thereby facilitating the adjustment of the gap between two compression wheels, and adapting to the metal stapes with different thicknesses. The metal tapes are formed through extruding of the compression wheels are wound around the cable, thereby forming an interlocking armored layer. The device is compact in structure, is high in efficiency, and is low in cost. The produced interlocking armored layer is firm and reliable.

Owner:深圳市金环宇电线电缆有限公司

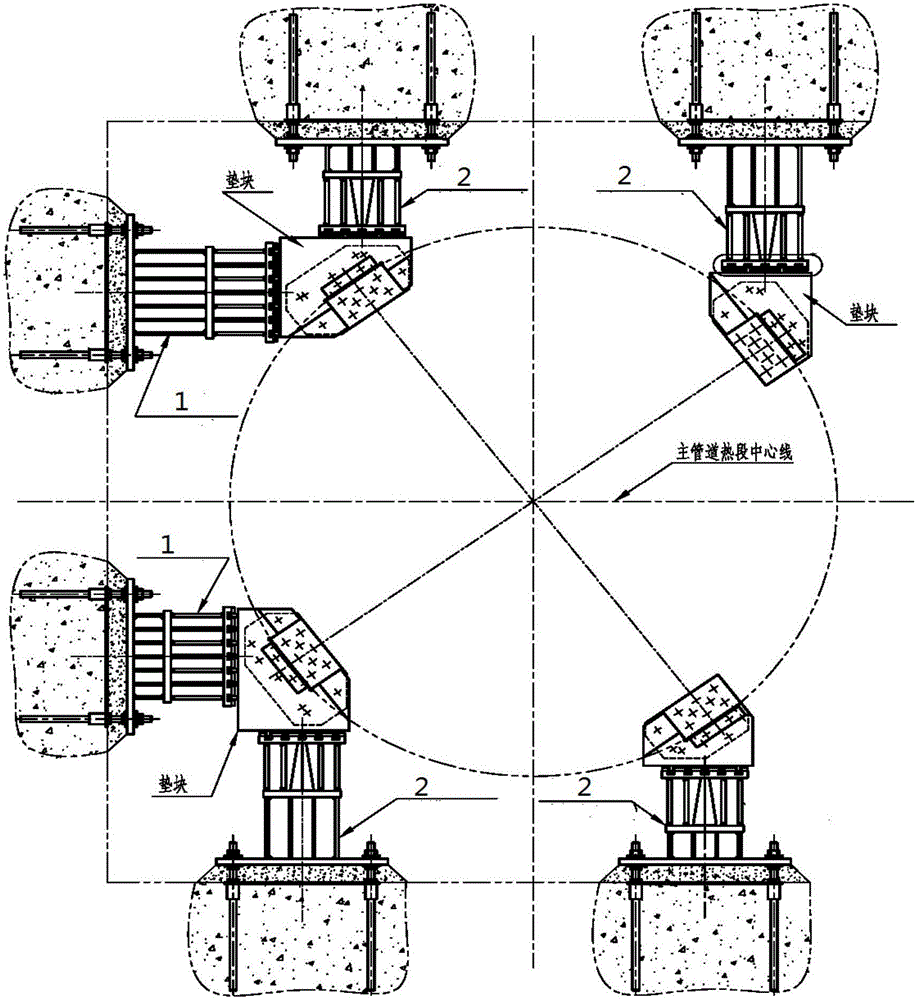

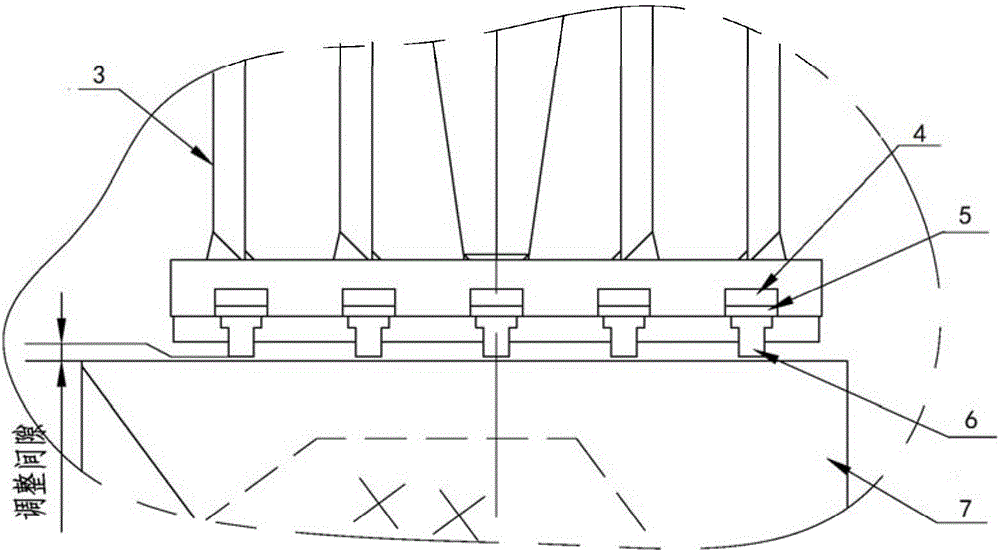

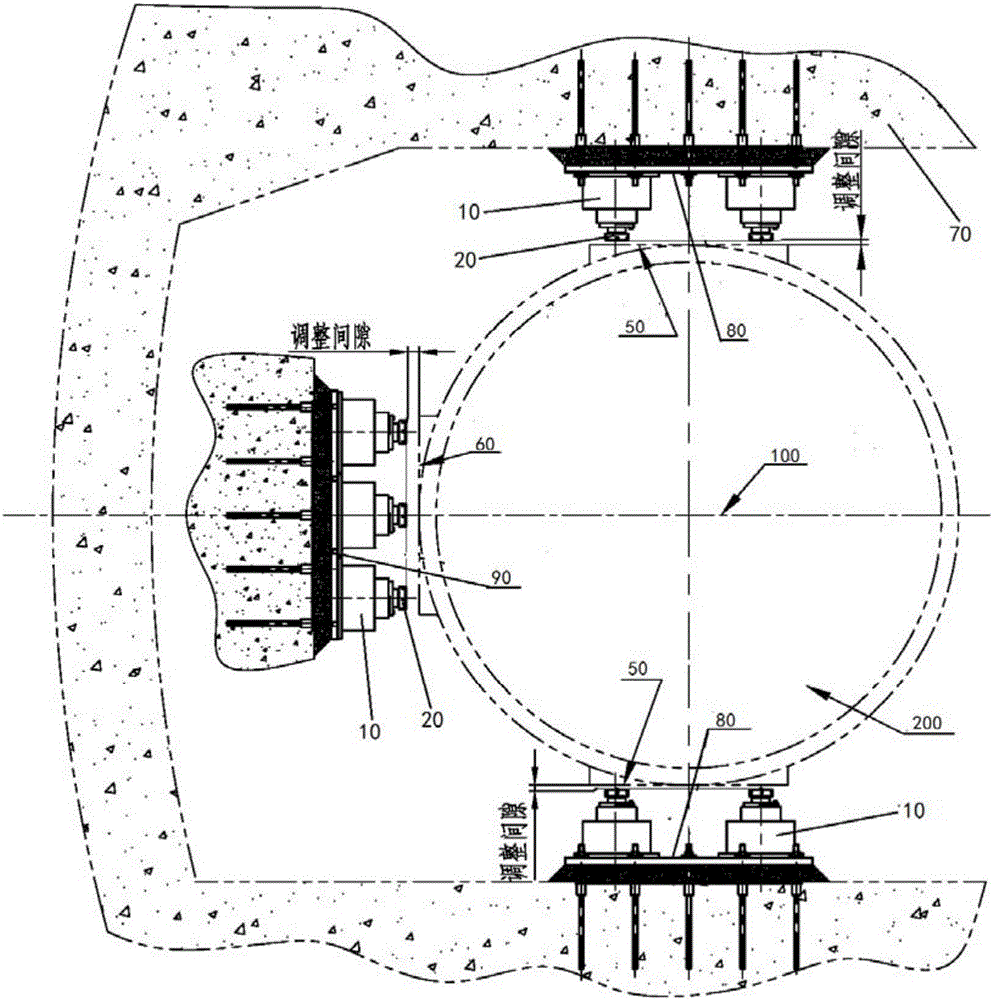

Lower horizontal supporting structure of nuclear power plant vapor generator

ActiveCN106051722ASimple structureImprove buffering effectSteam boilersSteam boilers componentsStructural engineeringTime cost

The invention discloses a lower horizontal supporting structure of a nuclear power plant vapor generator. The lower horizontal supporting structure of the nuclear power plant vapor generator comprises a supporting device for preventing the vapor generator from generating instant displacement. The supporting device comprises a base and an axial clearance adjustment device arranged on the base. The base is shaped like a stepped shaft in outline, and the outer diameter of the base is gradually decreased from back to front to form a base large end and a base secondarily large end. The front section of the base large end is of a hollow structure, the inner diameter of the front section of the base large end is larger than the outer diameter of the base secondarily large end, and therefore a radius difference delta[r] is formed between the inner wall of the front section of the base large end and the outer wall of the base secondarily large end. Compared with the prior art, the lower horizontal supporting structure of the nuclear power plant vapor generator has the following effects that (1) the base with a buffering function is simple in structure, excellent in buffering performance and convenient to install and maintain, and the manufacturing and installation cost is effectively lowered; (2) clearance measurement operation is convenient and rapid, and the measurement result is small in error; and (3) clearance adjustment is more convenient, the time of clearance measurement and adjustment is effectively shortened through the structure, and the time cost and labor cost are reduced.

Owner:中广核工程有限公司 +1

Electromagnetic eddy current braking device

PendingCN110271426ANovel structureWorking principle is clearElectrodynamic brake systemsRailway vehiclesBogieHorizontal force

The invention discloses an electromagnetic eddy current braking device, and belongs to the technical field of high speed train braking. The electromagnetic eddy current braking device is composed of a magnet exciting coil unit, lifting devices, braking force transferring devices, gap adjusting devices and supporting plate devices. According to the electromagnetic eddy current braking device, the structure of the device is novel, the operating principle is clear, the magnet exciting unit is utilized to provide stable and reliable braking force, and iron cores and magnet yokes adopt integrated modeling; the lifting devices are utilized to bear the resultant force of brake gravity and electromagnetic attraction, air cylinders have high impact resistance, and dual hinges enable pistons of the air cylinders to only bear the force in the direction perpendicular to a rail; the braking force transferring devices are utilized to transfer the braking force horizontally on the rail surface to a bogie, lifting and lowering of the brake are not affected, and supporting rod structures only bear the horizontal force and can move in the vertical direction freely; the gap adjusting devices are utilized to adjust the size of gaps, the space occupied by the gap adjusting devices is small, and the gap adjusting operation is easy; and the supporting plate devices are utilized to provide support for the lifting devices and the braking force transferring devices, and the whole device is safe and reliable.

Owner:YANGZHOU UNIV

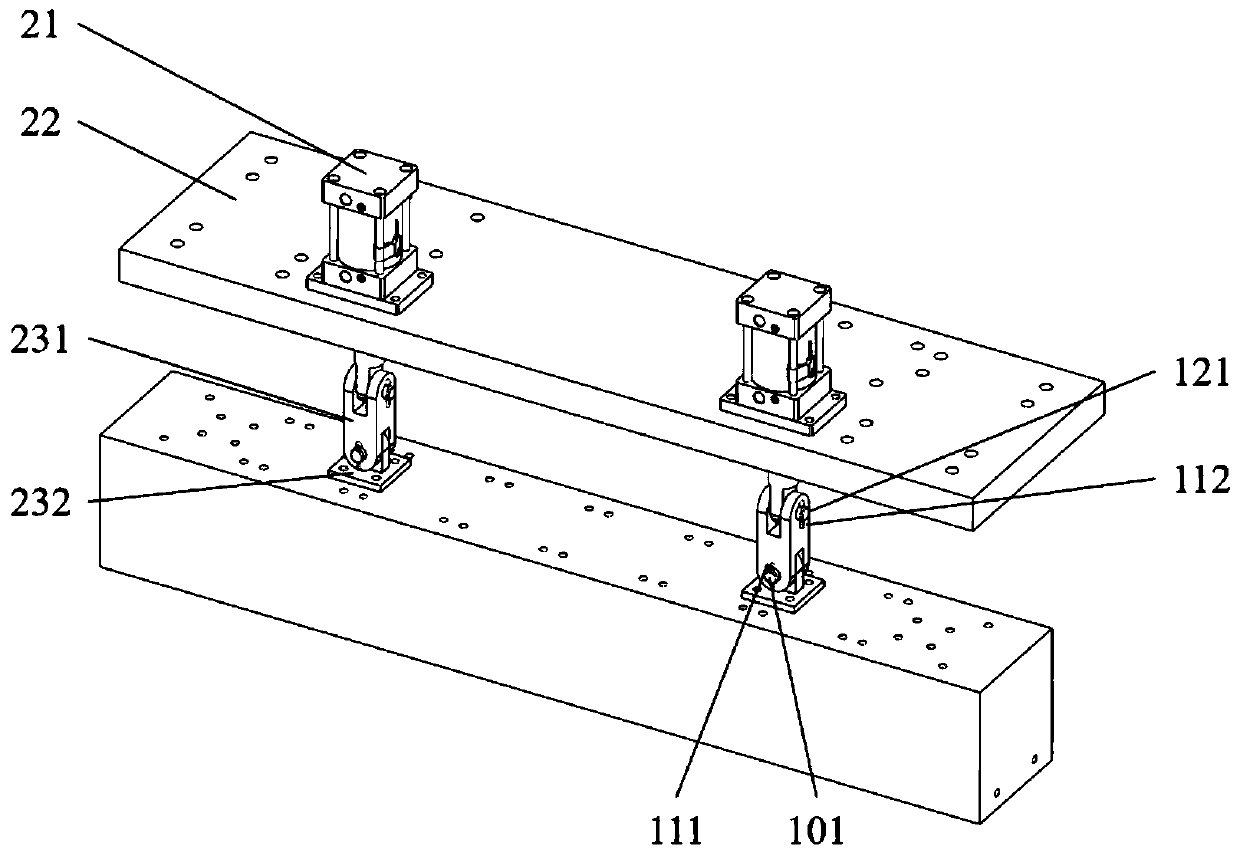

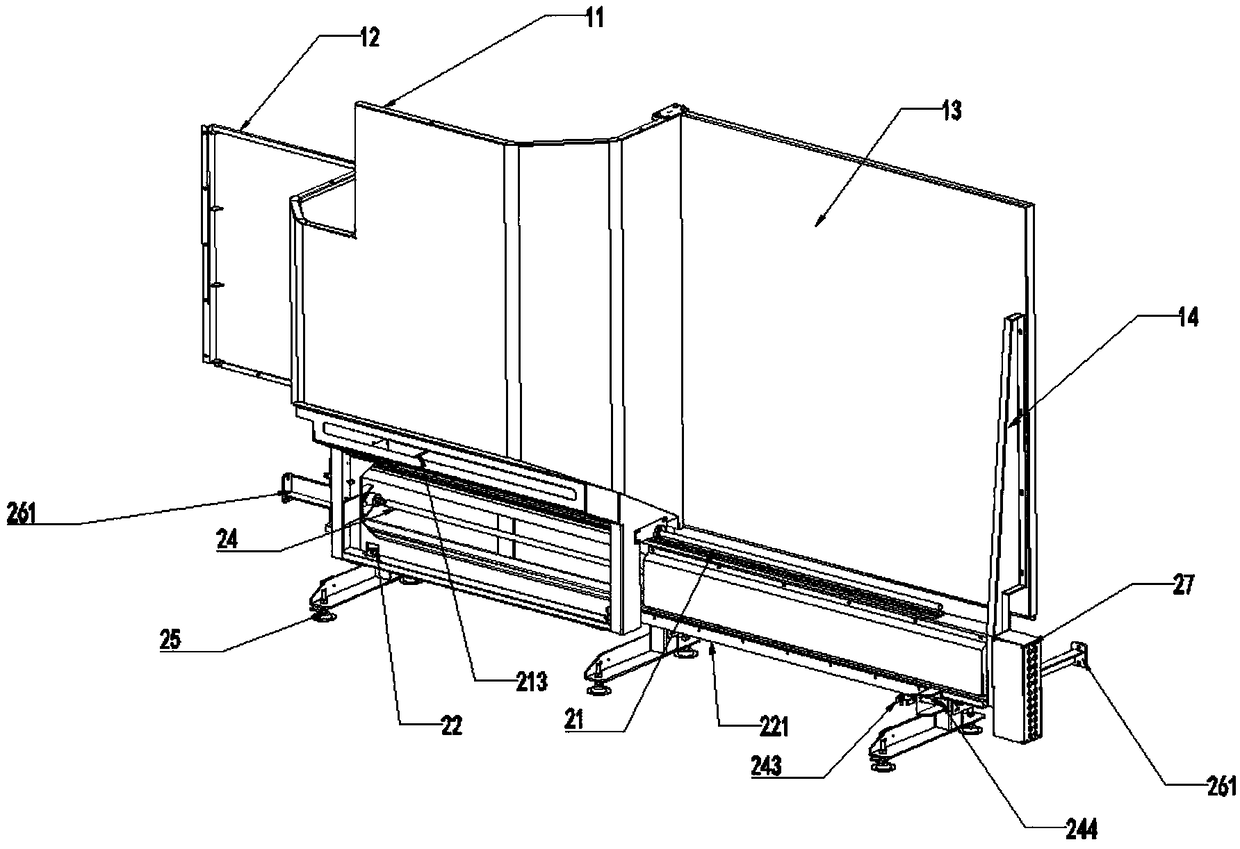

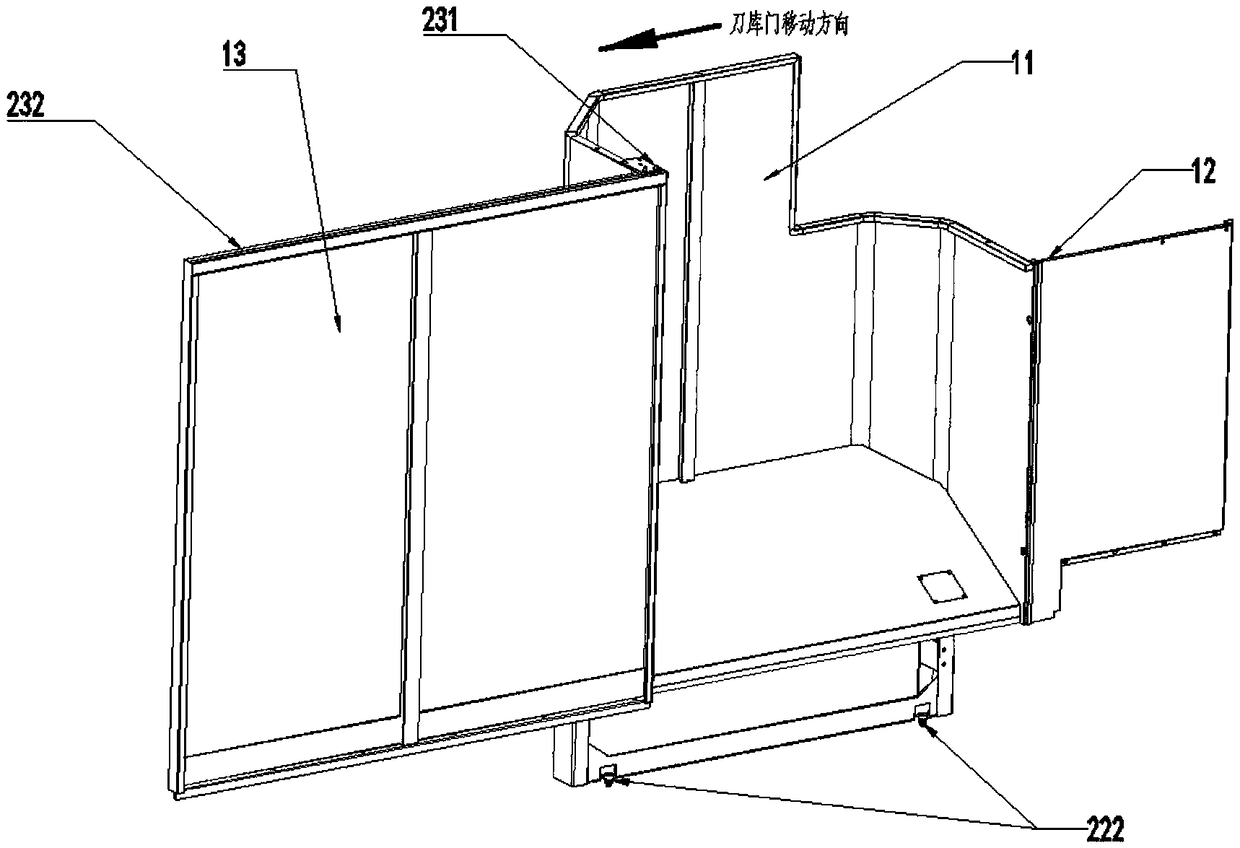

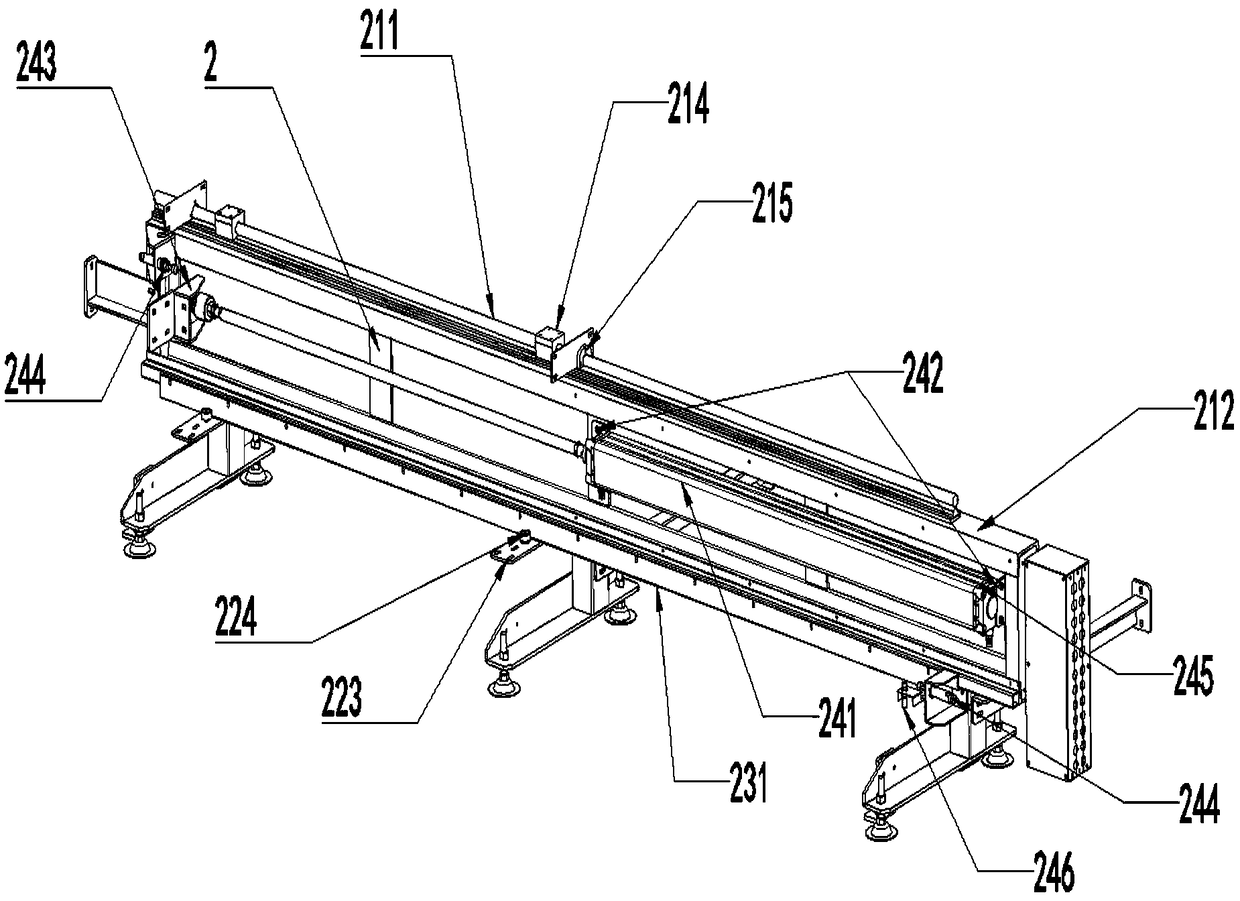

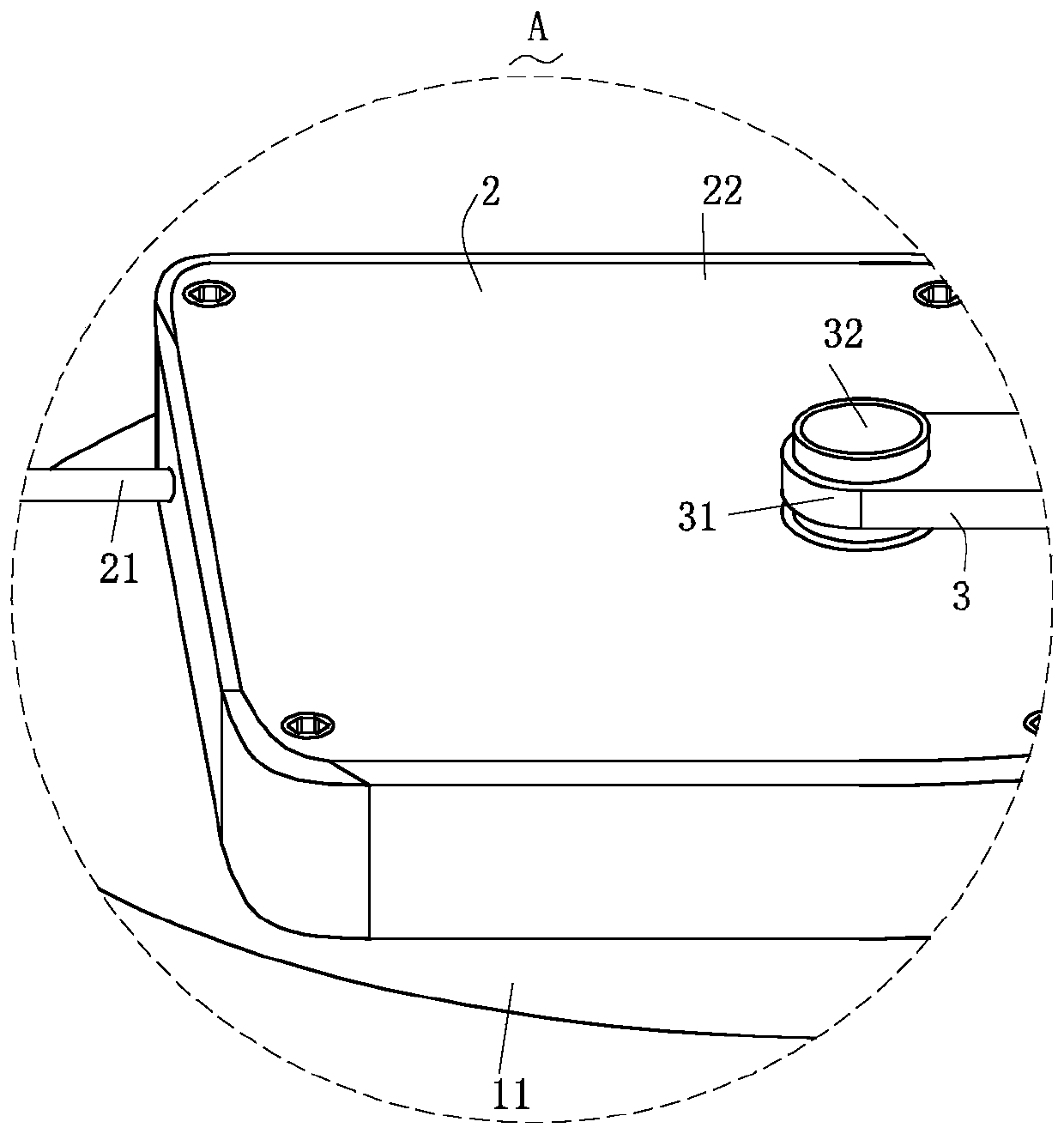

Separation type knife library protection device for moving beam gantry machining center

ActiveCN108637762AAvoid deformationEasy clearance adjustmentPositioning apparatusMaintainance and safety accessoriesExtreme positionMachine tool

The invention discloses a separation type knife library protection device for a moving beam gantry machining center. A protection door base structure adopts a welding piece framework to guarantee thewhole rigidity, and a first sliding unit arranged in the middle of a knife library door and used for load bearing and guiding, a second sliding unit arranged at the bottom for guiding, and a third sliding unit arranged on the top for guiding are included. A driving unit of the separation type knife library protection device is fixed to the middle portion of a base and certain protection is added,and the driving unit is connected with the knife library door through a middle connection piece so that the reciprocating motion of the knife library door can be manipulated; and noise generated due to waggling when the knife library door fast moves and deformation generated after use for a period of time are avoided. The extreme positions of a knife library protection door switch are each additionally provided with a buffering device, and impacting and deforming generated due to impacting of the knife library door switch are avoided. The bottom of a knife library protection base is supportedon the ground by using foot cups so that a gap between the mechanism and a machine tool body protection chamber can be conveniently adjusted and interference can be avoided.

Owner:NANTONG GUOSHENG INTELLIGENCE TECH GRP CO LTD

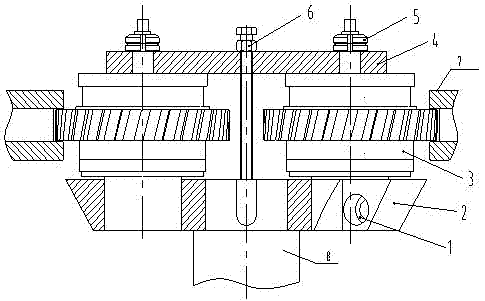

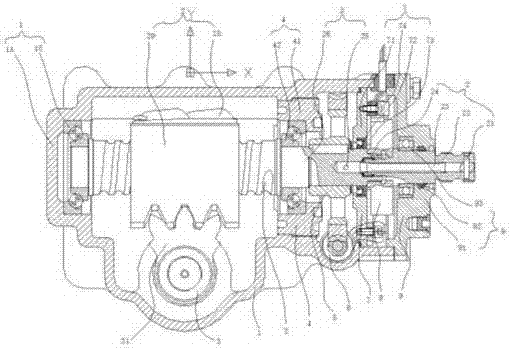

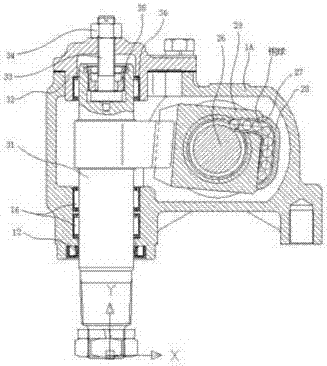

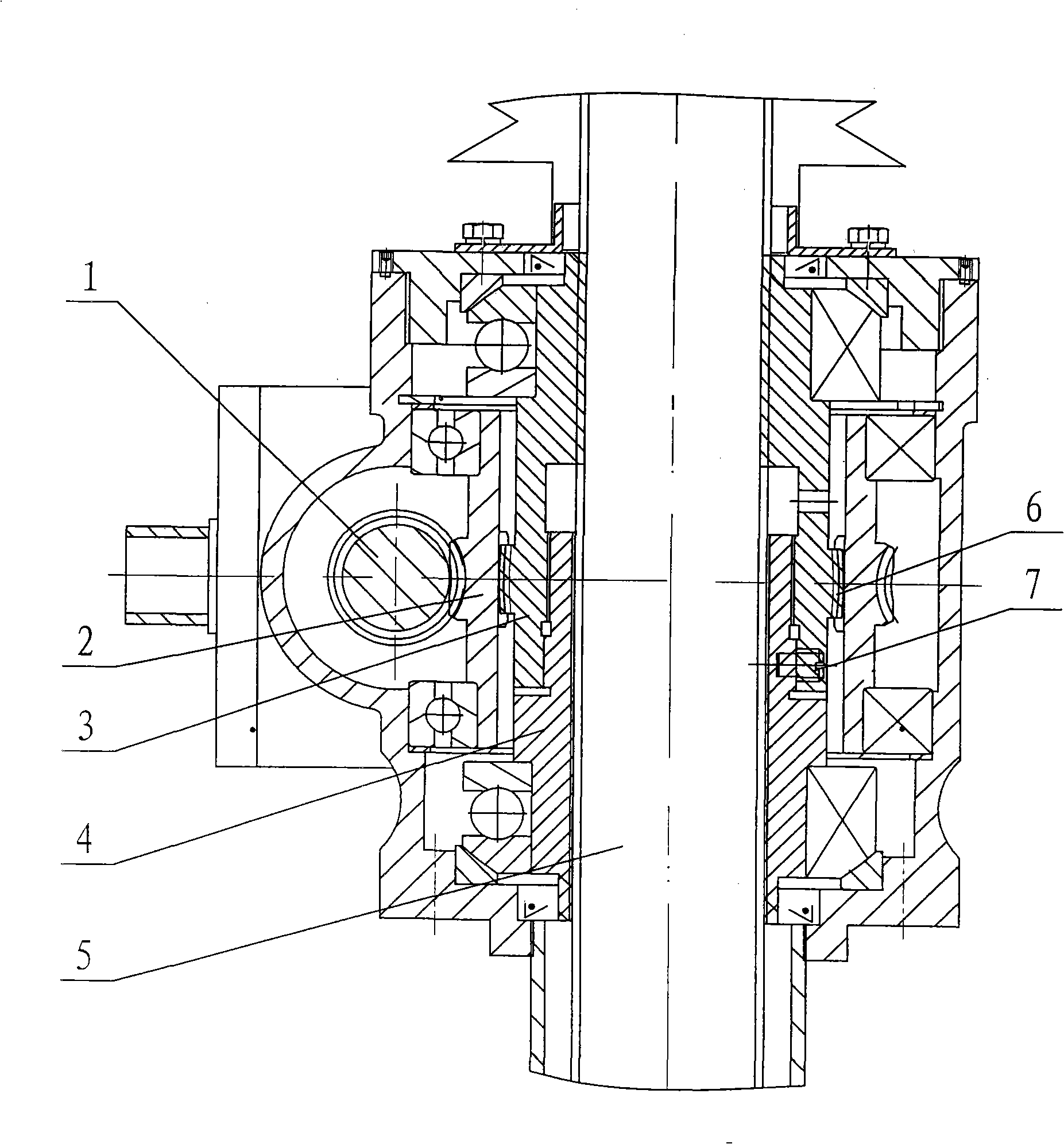

Gear sector shaft assembly of electric power steering device and device of same

The invention provides a gear sector shaft assembly (3) of an electric power steering device. The gear sector shaft assembly comprises a gear sector shaft (31), a gear sector shaft side cover plate (32), a gear sector shaft adjusting pin (33), a gear sector shaft adjusting nut (34), a gear sector shaft screw plug (35) and a roller pin bearing (36). The invention provides a heavy circulating ball type dual-mode electric power steering device. A large deceleration ratio mechanism and a corner torque sensor replace a rotary valve structure of the circulating ball type dual-mode electric power steering device; conversion from hydraulic transmission to intelligent electric transmission is achieved when extra space is not increased; and compared with a circulating ball type hydraulic power steering device of the same volume, power demand can be reduced by 30% and output maximum torque can be improved by 5%. Compared with the prior art, the excellent effects of the gear sector shaft are that overall strength is improved and strong impact vibration bearing capacity is achieved; reliable use is provided; a gap can be conveniently adjusted; vehicle linear driving stability can be improved and great driving feeling can be guaranteed; the design of the gear sector side cover plate (7) enables convenient link with the an electric circulating ball steering machine total housing; and the gear sector side cover plate can be easily processed, requires low cost and is suitable for batch production.

Owner:CHINA NORTH VEHICLE RES INST

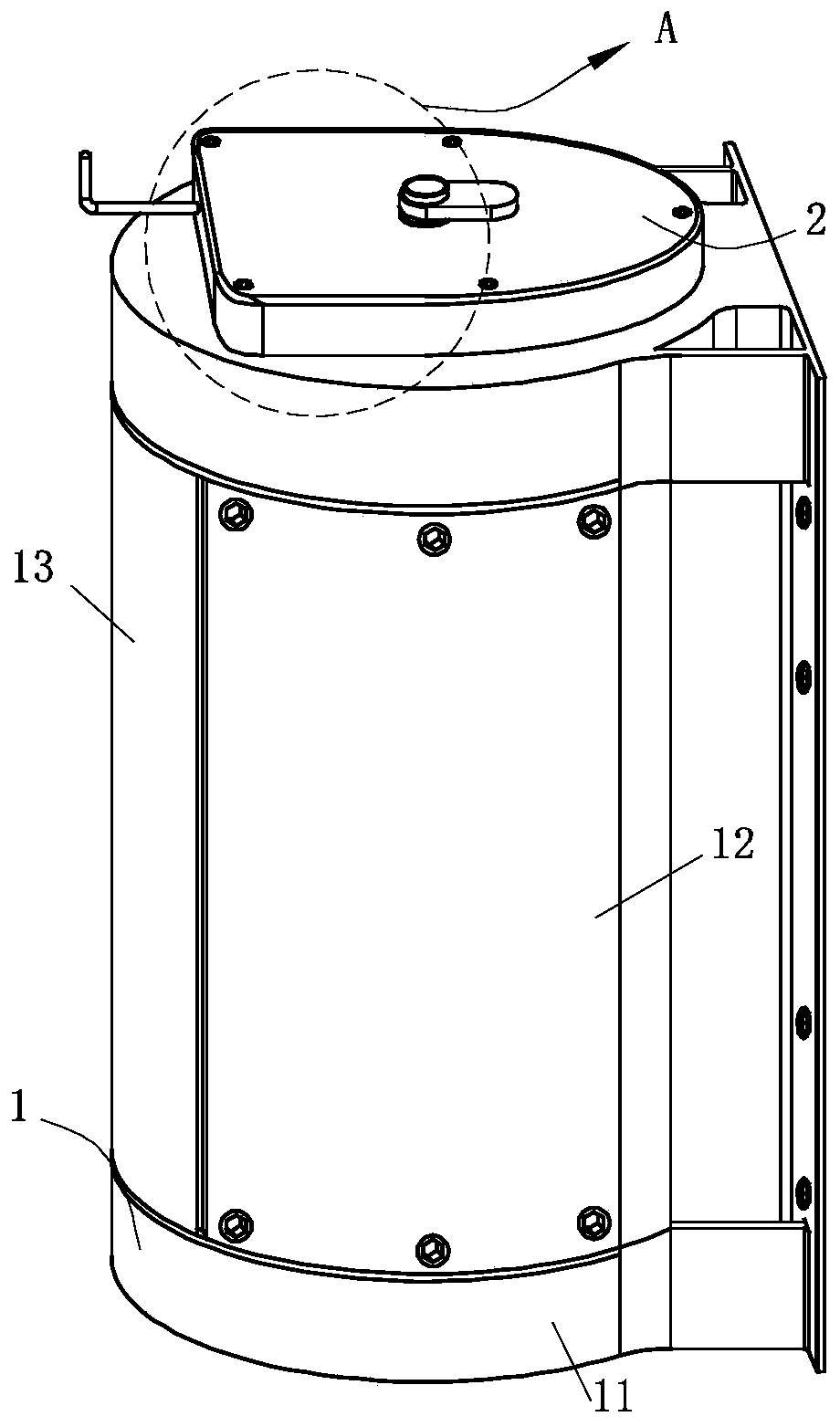

Filter element replacement visual water purification equipment

ActiveCN111484103AEasy maintenanceInstalled and disassembledMembranesReverse osmosisStructural engineeringProcess engineering

The invention relates to the technical field of water purification equipment, in particular to filter element replacement visual water purification equipment which comprises a storage structure, driving structures, a water inlet structure, RO filter elements, transmission structures, fixing structures and sealing structures. The transmission structures can be conveniently driven to rotate throughthe driving structures, so that any RO filter element can be rotated to one side of an operator, the space utilization efficiency is greatly improved, and the RO filter elements are more convenient and faster to overhaul and maintain; the plurality of RO filter elements which are arranged in a circumferential array are respectively arranged between every two sealing structures which are symmetrical in pairs on the two transmission structures; when the transmission structures rotate, one RO filter element facing the operator is automatically controlled to be separated from the sealing structure, so that the sealing of a plurality of other RO filter elements is convenient to realize, and meanwhile, the end part of the sealing structure separated from the RO filter elements is sealed, so thatoverhaul and maintenance of the RO filter elements one by one are not influenced while purification is carried out, overhaul and maintenance are more convenient and faster, and the water purificationefficiency and quality are greatly improved.

Owner:氧生康(山东)生物科技有限公司

Self locking type worm gear-worm screw-threaded shaft elevator

InactiveCN101337648AGuaranteed integrityLarge number of envelope teethLifting devicesProduct processingSmooth surface

The invention provides a self-locking type worm gear screw rod lifter which comprises a worm, a worm wheel, a nut, a screw rod and crowned teeth. The nut adopts an integrated structure of a concave nut piece and a convex nut piece which are screwed mutually; the clearance between the nut and the screw rod is small; the screwing of the concave nut piece and the convex nut piece combines smooth surface positioning connection with threaded connection, thereby ensuring the screwing precision of double nut; the concave depth of the concave nut piece is larger than the convex height of the convex nut piece, thereby reserving adjustment space, and being favorable for adjusting the clearance between the nut and the screw rod; a worm gear pair adopts the double enveloping teeth shape, the number of enveloping teeth is large, the contact surface is large, the bearing capacity is high and the self-locking property is better. The self-locking type worm gear screw rod lifter has the advantages of reasonable structure, stable work, high load capacity, good self-locking effect under the condition of bearing vibration load, less possibility of axial excursion of the screw rod, reduced error and improved product processing precision.

Owner:JIANGSU TAILONG MACHINERY GRP CO CO LTD

Scraper blade mechanism capable of feeding glue quantitatively

PendingCN109225748AQuality assuranceEasy clearance adjustmentLiquid surface applicatorsCoatingsThermal insulationEngineering

The invention discloses a scraper blade mechanism capable of feeding glue quantitatively. The scraper blade mechanism comprises a movable seat and a cutter installation seat, wherein the movable seatis arranged on a machine frame, the cutter installation seat is arranged on the movable seat, a glue discharging box and an upper scraper blade are arranged on the movable seat, the tail of the upperscraper blade is connected with the head of the glue discharging box, a plurality of glue spraying pipes which are evenly distributed are arranged on the glue discharging box, the glue discharging boxis connected with a glue feeding tank, the glue feeding tank is a sealed box body, a thermal insulation layer and a heating mechanism are arranged in the glue feeding tank, a glue discharging pipe isarranged on the glue discharging box, a flow meter is arranged on the glue discharging pipe, and the glue discharging box can be set to quantitatively discharge glue at regular intervals; the head ofthe upper scraper blade extends out of the movable seat, a lower scraper blade is connected to a lower end face of the part extending out of the movable seat of the upper scraper blade through a connection block, and an angle between the lower scraper blade and the connection block can be adjusted. According to the scraper blade mechanism disclosed by the invention, the upper scraper blade and the lower scraper blade are utilized, the upper scraper blade is utilized to feed glue, the lower scraper blade is used for scraping the glue evenly, and the sealed thermal-insulation glue tank is utilized to feed glue; furthermore, the glue can be feed evenly and quantitatively, and the glue feeding quality is ensured.

Owner:JIANGSU YUANHUA LIGHT CHEM EQUIP

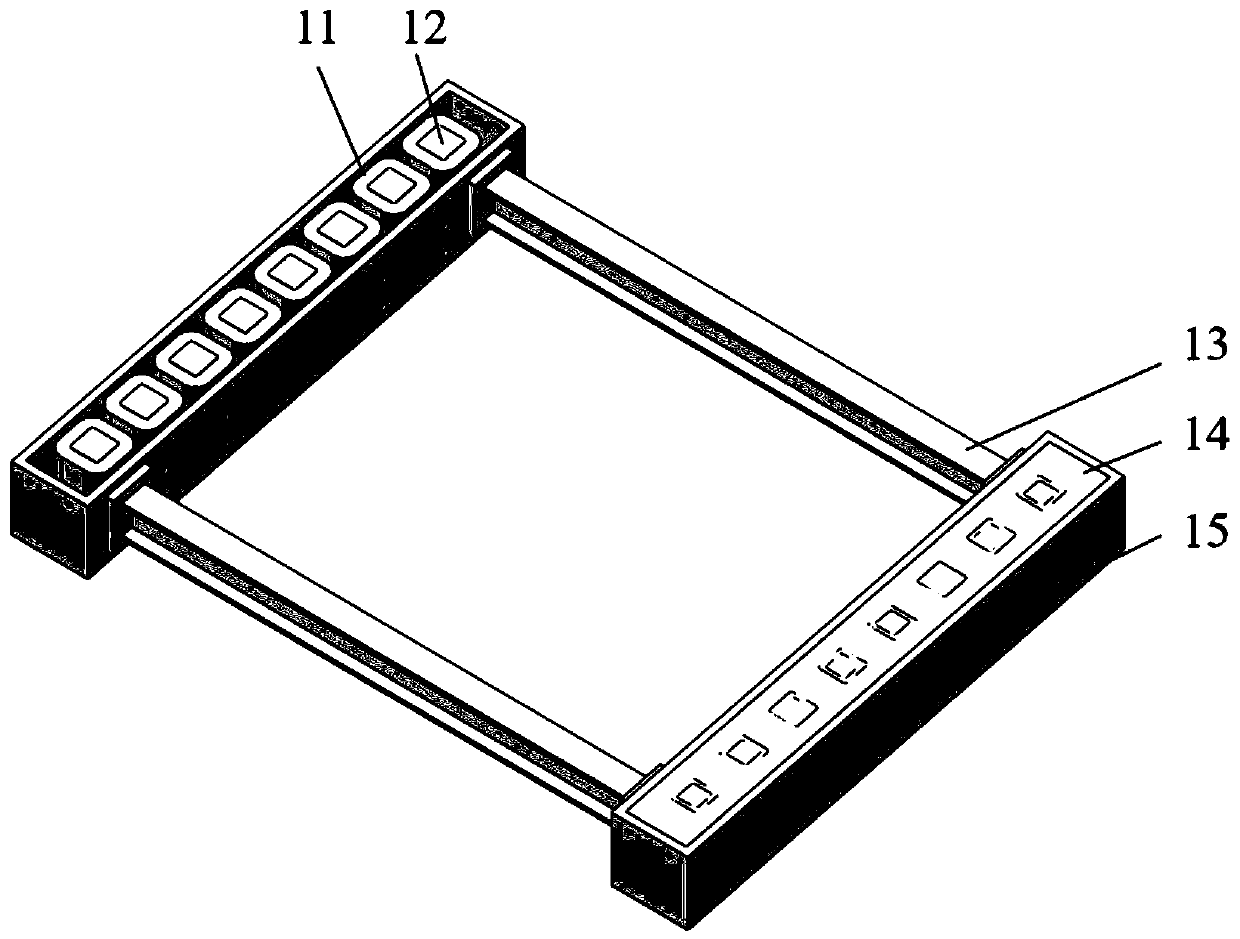

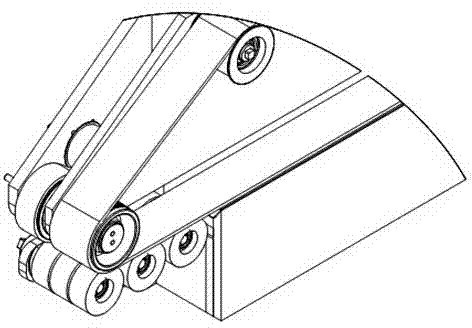

Paper feed mechanism of sticky box machine

ActiveCN104494203AEasy to adjust the gapAdaptableBox making operationsPaper-makingCardboardPulp and paper industry

The invention relates to the technical field of sticky box machines, in particular to a paper feed mechanism of a sticky box machine. The paper feed mechanism comprises an upper beam (104) and a lower beam (111), and is characterized in that a belt pulley mechanism is mounted on the upper beam (104); a roller mechanism is mounted on the lower beam (111); the roller mechanism is positioned below the belt pulley mechanism; a gap is reserved between the belt pulley mechanism and the roller mechanism. The paper feed mechanism adopts a paper feed manner that the roller is cooperated with the belt, due to the strong adaptability of the roller, the paper feed realized by cooperating of the roller and the belt can effectively guarantee the stability of cardboard transmission.

Owner:GUANGDONG DONGFANG PRECISION SCI & TECH CO LTD

Boring rod component for machining thrust surface of diesel body

InactiveCN102581321AImprove machining accuracyElimination of tool pillows (i.e. sliders)Boring barsTurning toolsTorque transmissionMechanical engineering

The invention discloses a boring rod component for machining a thrust surface of a diesel body, which comprises a driving rod, a push rod, a slider and a return spring. A boring rod is in a hollow structure, a backing positioning nut and a thrust surface axial positioning nut are arranged at the rear end of the boring rod, the driving rod, the push rod and the return spring are sequentially arranged in a hollow cavity of the boring rod, the driving rod is connected with the boring rod through a feather key, and the driving rod is kept in contact with the push rod under the action of the return spring. The slider is arranged on the boring rod and corresponds to an oblique protruding strip on the push rod through an oblique groove, and radial turning tools in pair are arranged at the top of the boring rod. The boring rod component has the advantages that the feather key is used for the driving structure to simply combine torque transmission with feeding, the tool is withdrawn first and then the boring rod is pulled out when the spring is returned, and the push rod is combined with the radial slider through the oblique groove, so that the boring rod component is high in rigidity and machining manufacturability.

Owner:CHINA NAT HEAVY DUTY TRUCK GRP HANGZHOU ENGINE

High-speed needling machine

InactiveCN106757797AEasy to useExtended service lifeNeedling machinesEngineeringMechanical engineering

The invention provides a high-speed needling machine. The high-speed needling machine comprises a spindle box, a supporting machine body and a base, wherein the supporting machine body is used for supporting a fixed shaft box; the base is used for fixing the supporting machine body; a driving crank shaft is rotatably arranged in the spindle box; a connecting rod is slidably hinged to the driving crank shaft; a push plate is hinged to the lower end of the connecting rod; a push rod is fixedly arranged on the lower side of the push plate; the upper end of the push rod is fixedly connected with the push plate; the push rod is slidably connected with the spindle box; a sliding sleeve which is in sliding fit with the push rod is fixedly arranged on the spindle box; an oil accommodating cavity for containing cooling oil sleeves the outer side of the sliding sleeve and is provided with an oil delivering tube for delivering the cooling oil; and the oil delivering tube communicates with an oil delivering pump. The high-speed needling machine is simple in structure; the service life of the needling machine is prolonged, the repair times are reduced, and the working efficiency is improved.

Owner:QINGDAO KAISHUO MACHINERY TECH CO LTD

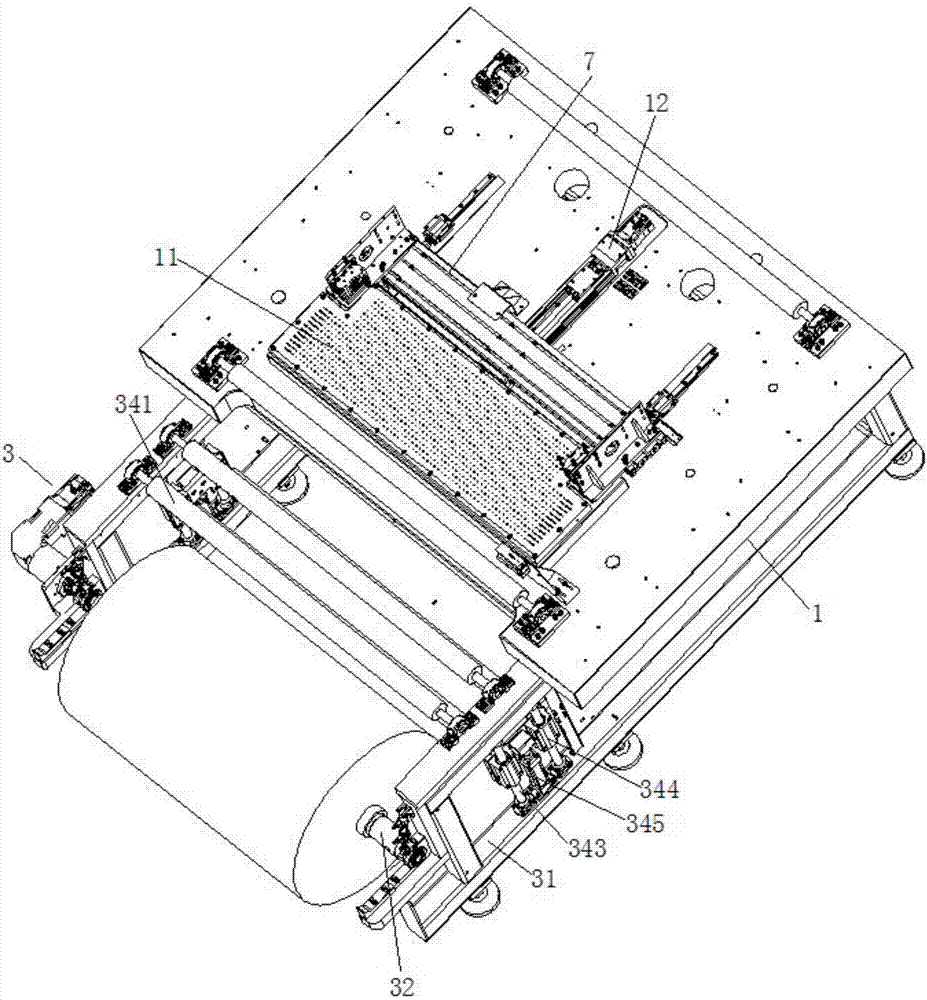

Thin film laser engraving processing equipment

ActiveCN107442945ASimple structureEasy to operateLaser beam welding apparatusLaser processingLaser engraving

The invention relates to thin film laser engraving processing equipment which comprises a machine base, a laser engraving processing module, a feeding mechanism and a discharging mechanism. The front end of the machine base serves as a feeding end, and the rear end of the machine base serves as a discharging end. The feeding mechanism is arranged at the front end of the machine base. The discharging mechanism is arranged at the rear end of the machine base. A processing table face is arranged at the upper end of the machine base. The laser engraving processing module is erected at the upper end of the machine base and provided with a laser engraver set, and the laser engraver set is transversely distributed towards the two sides of the machine base and is located above the processing table face. A feeding charging mechanism used for clamping a thin film on the processing table face is arranged below the laser engraving processing module, and the feeding charging mechanism is mounted on the machine base in a sliding manner and can linearly move towards the discharging end or the feeding end of the machine base. The thin film laser engraving processing equipment has the beneficial effects that the structure is simple; operation is convenient; the laser engraving processing module does not move in the use process; thin film conveying and moving are achieved through the feeding charging mechanism; it is ensured that a laser processing light path is stable; the processing efficiency is higher; the processing quality is better; and feeding and discharging are convenient.

Owner:WUHAN DR LASER TECH CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com