Paper feed mechanism of sticky box machine

A paper feeding mechanism and gluer technology, applied in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve problems such as inconvenient use, reducing the contact area between cardboard and belt, and reducing transmission stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

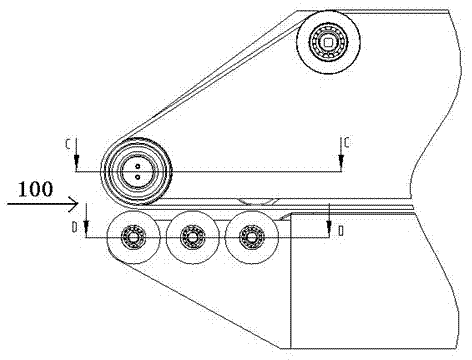

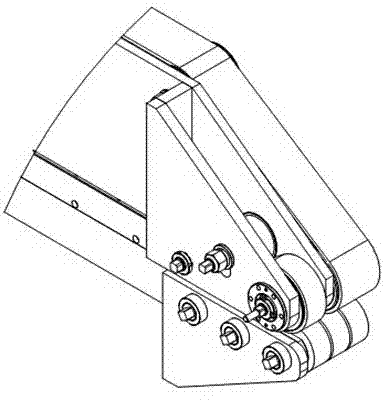

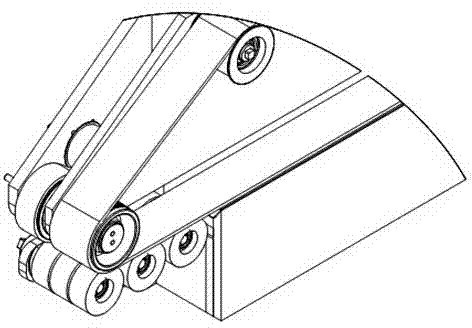

[0023] Such as Figure 1-5 Shown: a paper feeding mechanism for a folder gluer, including an upper beam 104 and a lower beam 111, a pulley mechanism is installed on the upper beam 104; three sets of roller mechanisms are installed on the lower beam 111, and the roller mechanism is located at the The pulley mechanism is arranged below the pulley mechanism and along the paper feed direction 100, and there is a gap between the pulley mechanism and the roller mechanism. Such as Figure 5 As shown: each set of the roller mechanism includes three elastic rollers 114, bearings 115 and eccentric shafts 113, the rollers 114 are rotatably mounted on the eccentric shafts 113 through the bearings 115, and the eccentric shafts 113 pass through the flange 112 Installed on the lower beam 111. Such as Figure 4 As shown: the upper beam 104 is fixed with a small side plate 105, the support shaft 102 is rotatably installed on the upper beam 104 through the bearing 115, the main pulley 101 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com