Silicon wafer line cutter winding displacement mechanism

A cutting machine and silicon wafer technology, applied in grinding machines, fine working devices, working accessories, etc., can solve the problems of unreasonable air seal design, high maintenance frequency, easy damage of bearings, etc., to reduce maintenance costs and disconnection rate , Improve the running stability, improve the effect of fastening rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

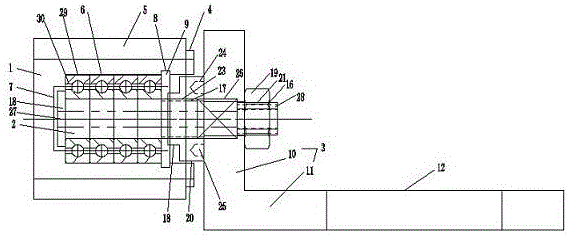

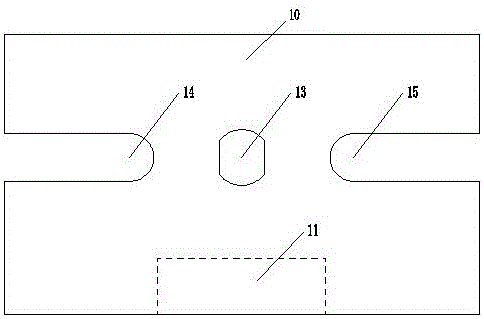

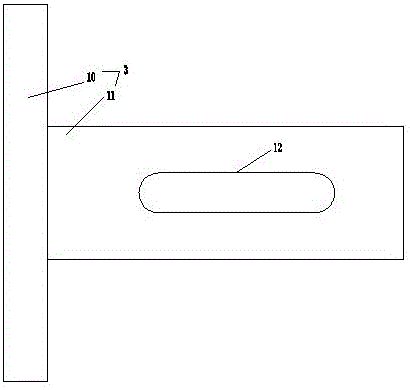

[0027] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0028] A wire arranging mechanism for a silicon wafer wire cutting machine, including a wire arranging roller, a roller shaft and a roller bracket, wherein the wire arranging roller is located on one side of the roller bracket, and a gasket is arranged between the roller bracket and the roller bracket. The gasket is arranged on the outside of the wire arranging drum, and the outside of the wire arranging roller is provided with a polyurethane bushing, and one side of the polyurethane bush is arranged adjacent to the gasket;

[0029] A cavity is provided in the cable arrangement drum, a mounting groove is provided on one side of the cavity, and a circlip groove is provided on the other side, and a circlip is provided in the circlip groove, and the width of the circlip groove is d1 , the distance from the circlip groove to one side of the cabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com