Patents

Literature

37results about How to "Reduce rotational frictional resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

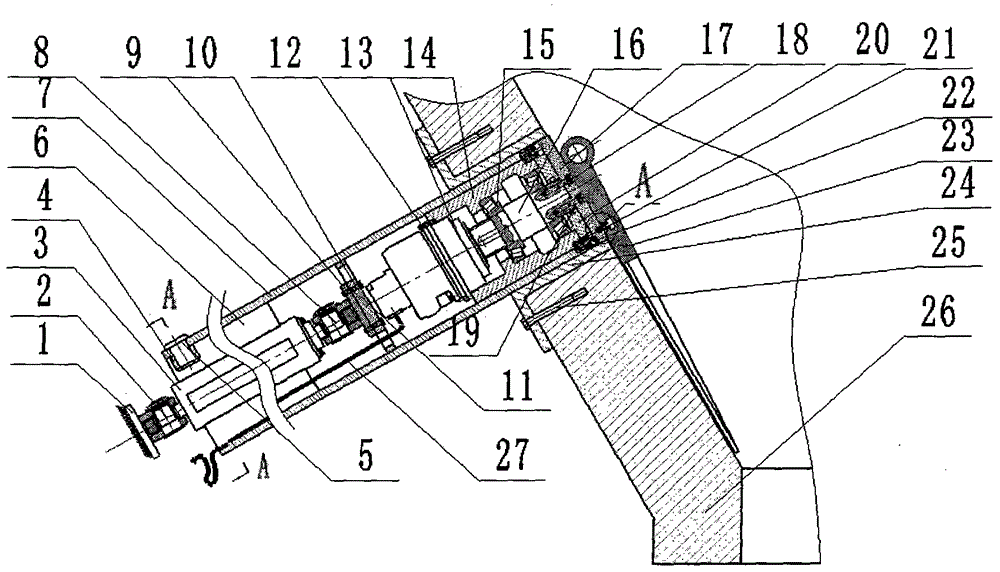

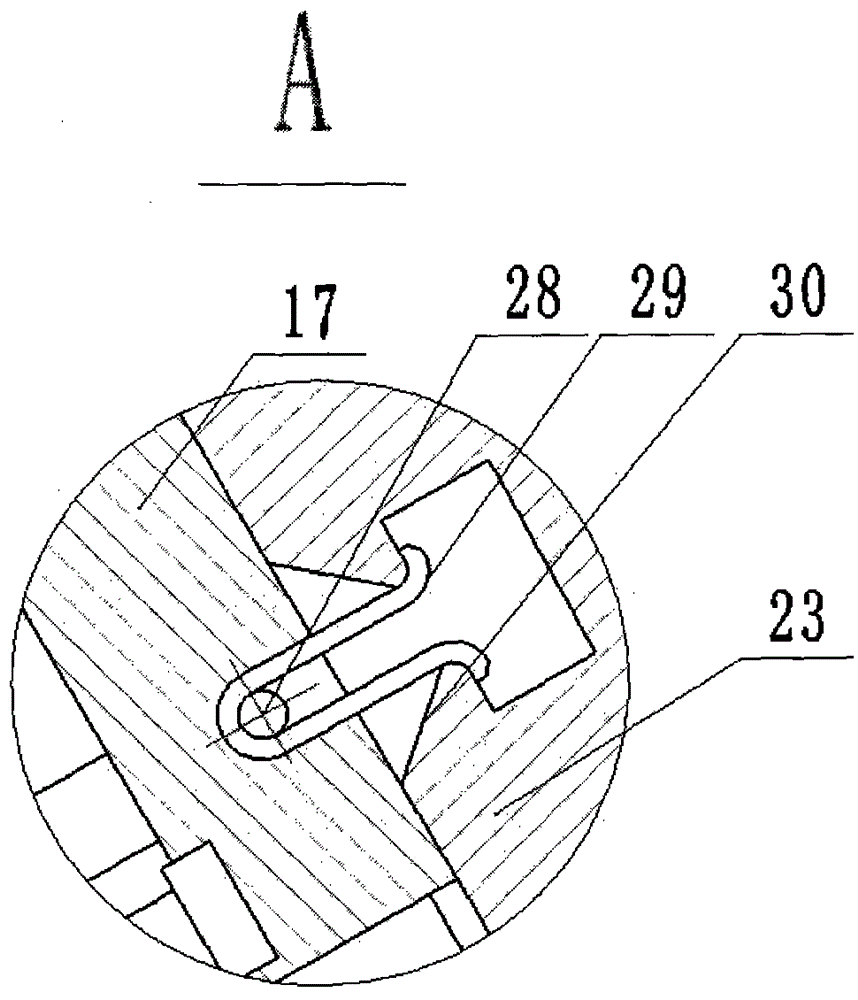

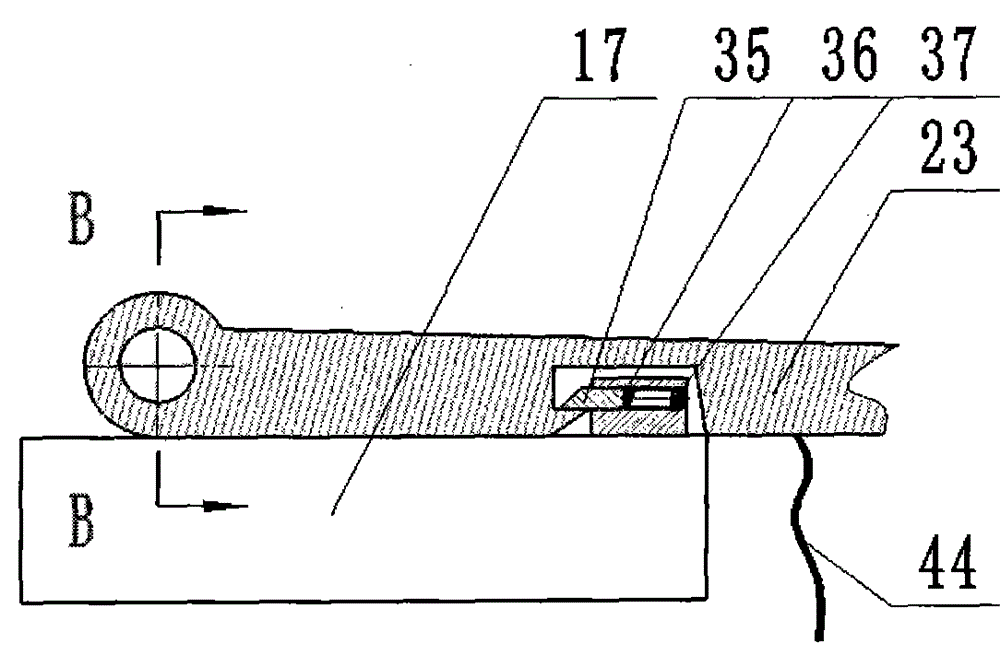

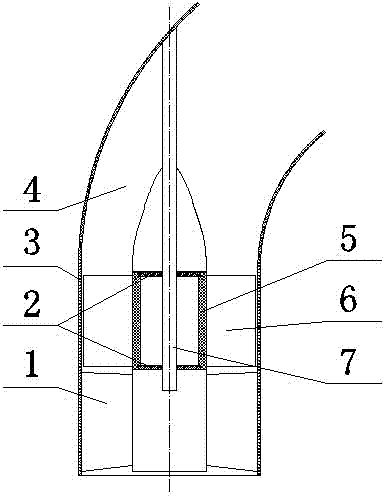

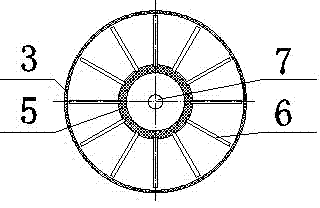

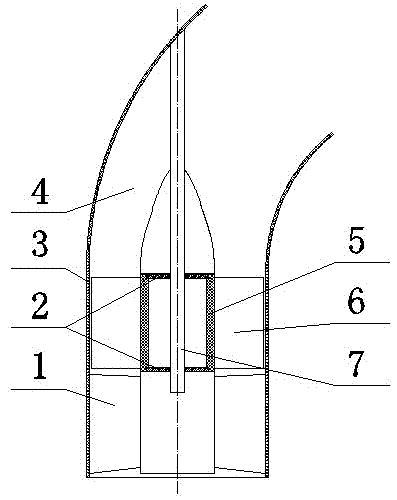

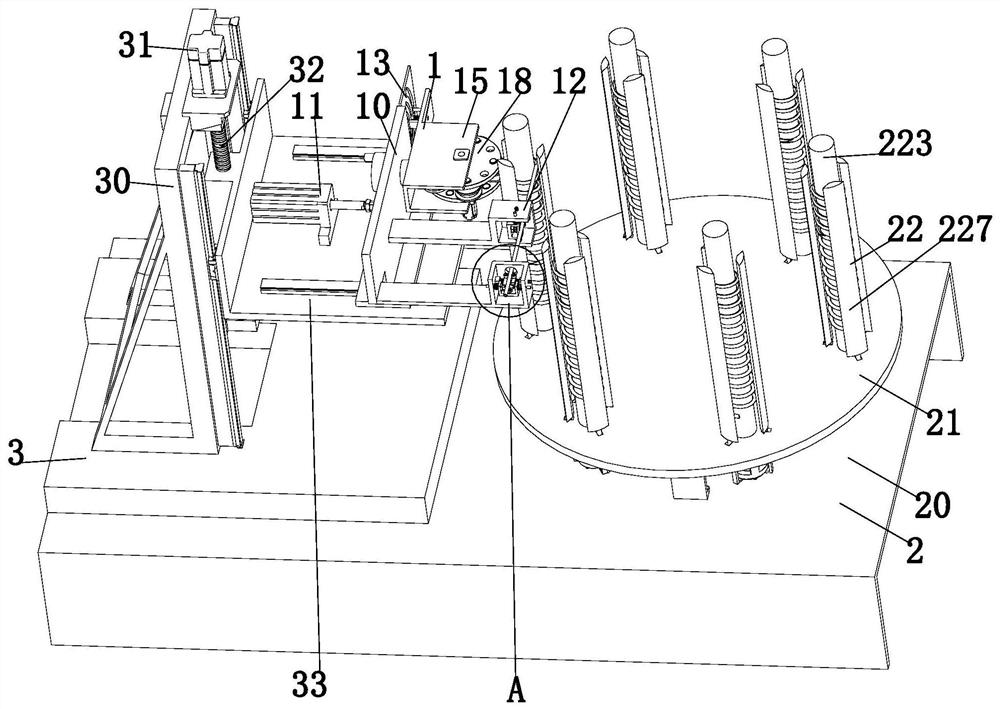

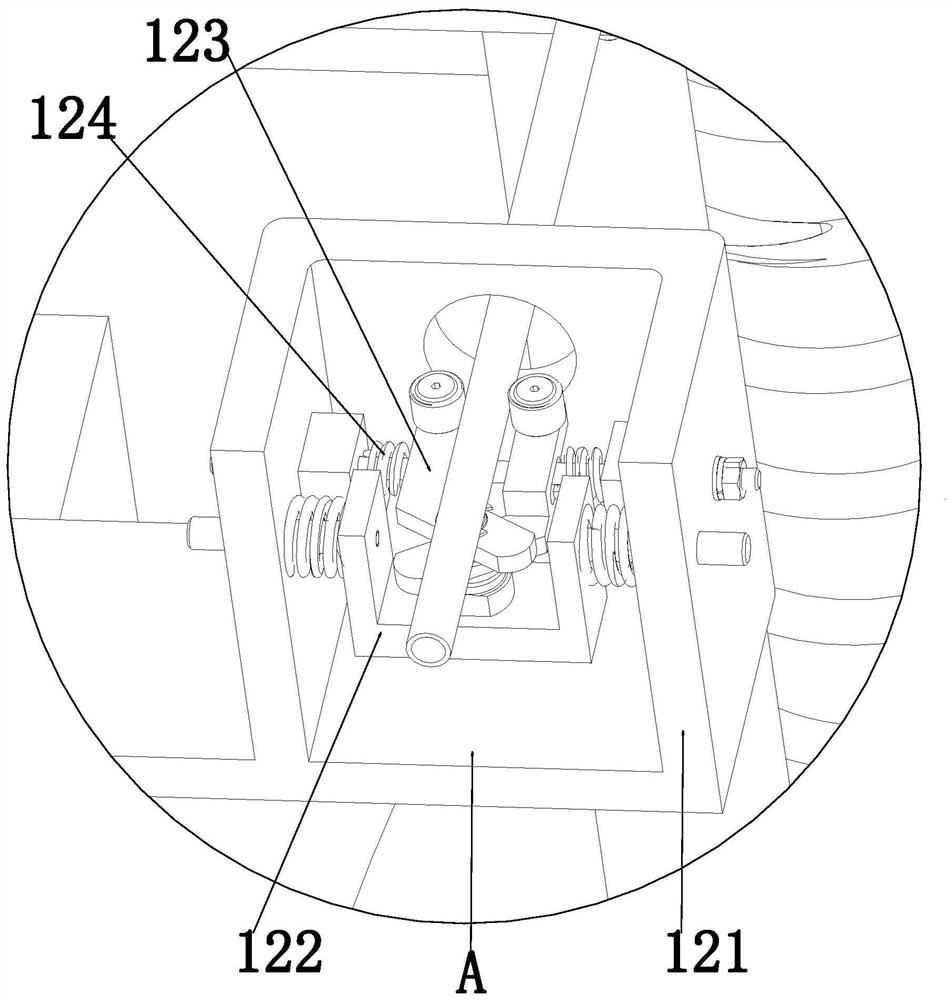

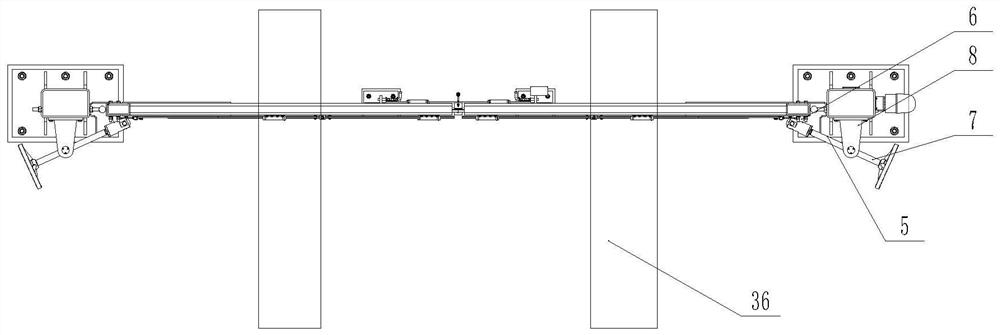

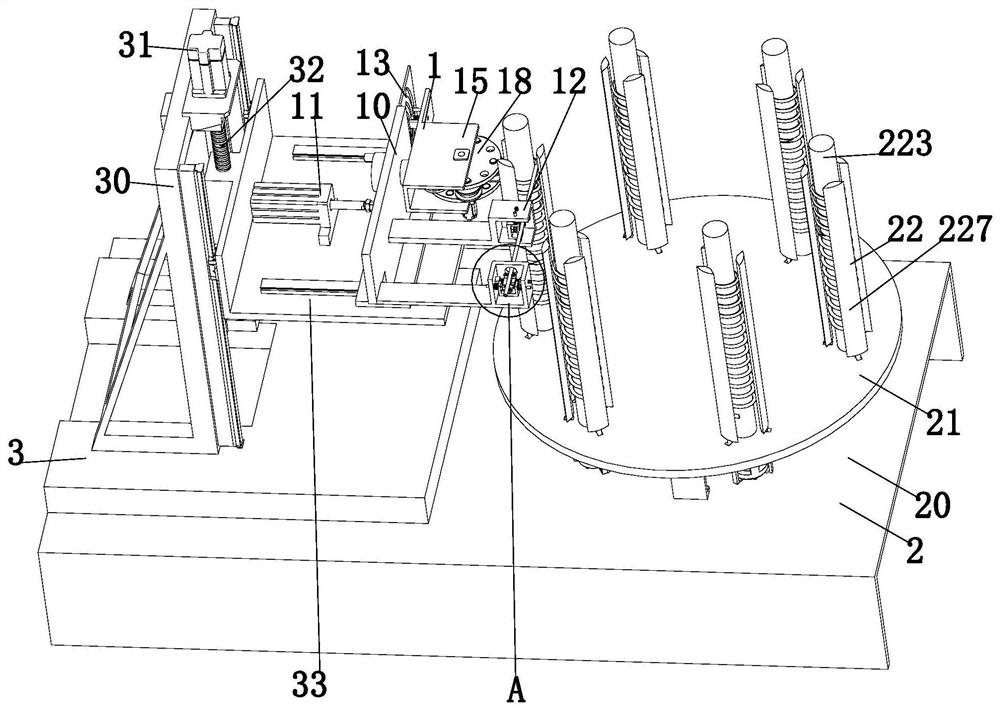

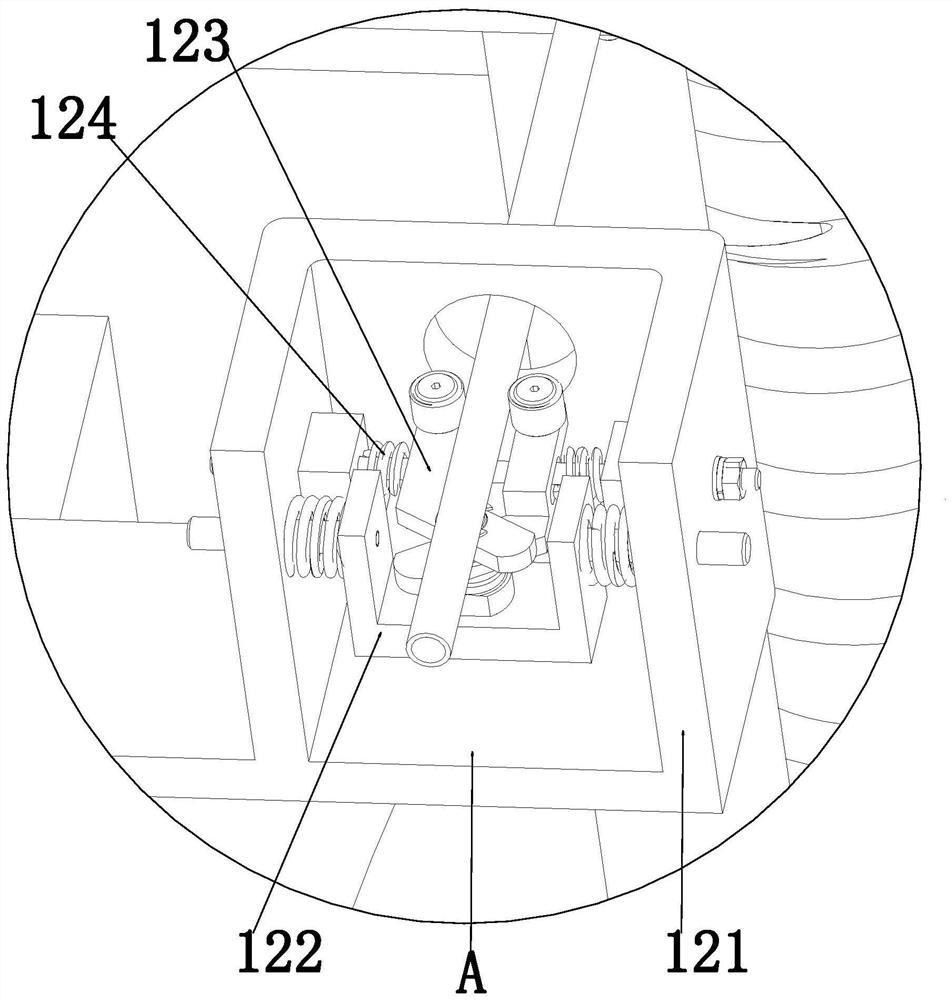

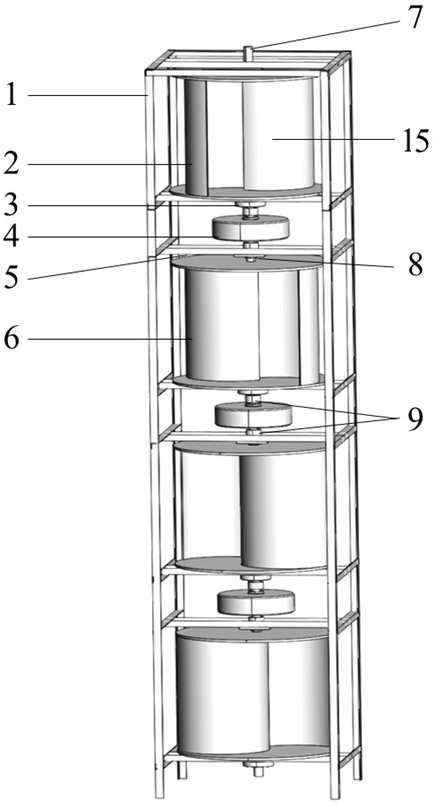

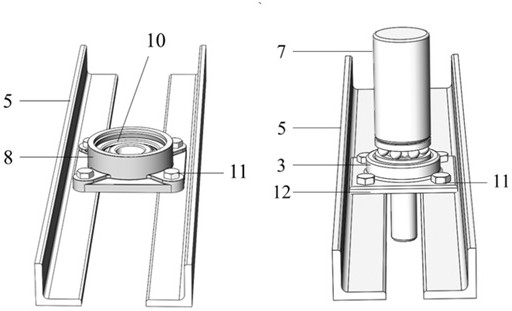

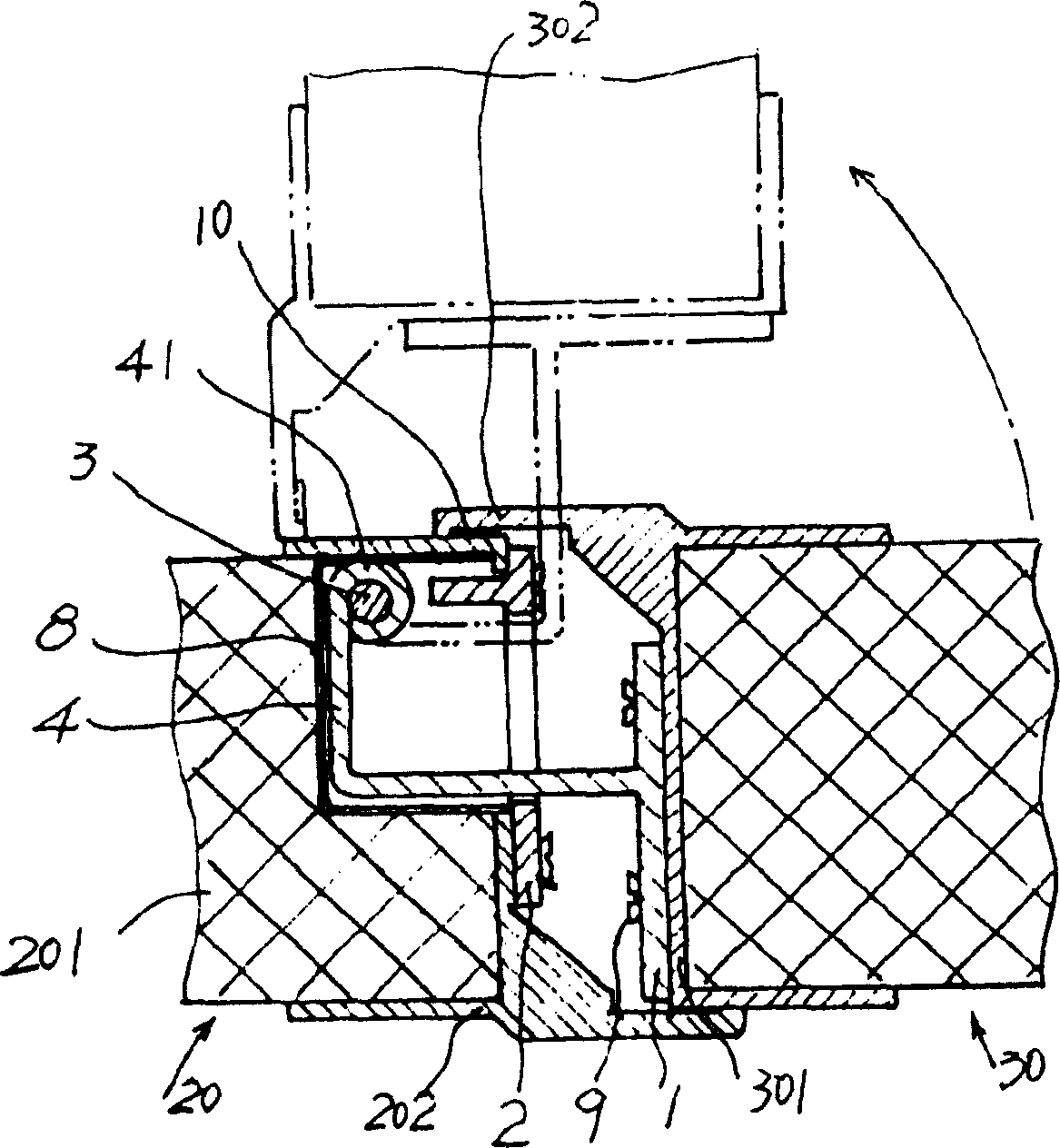

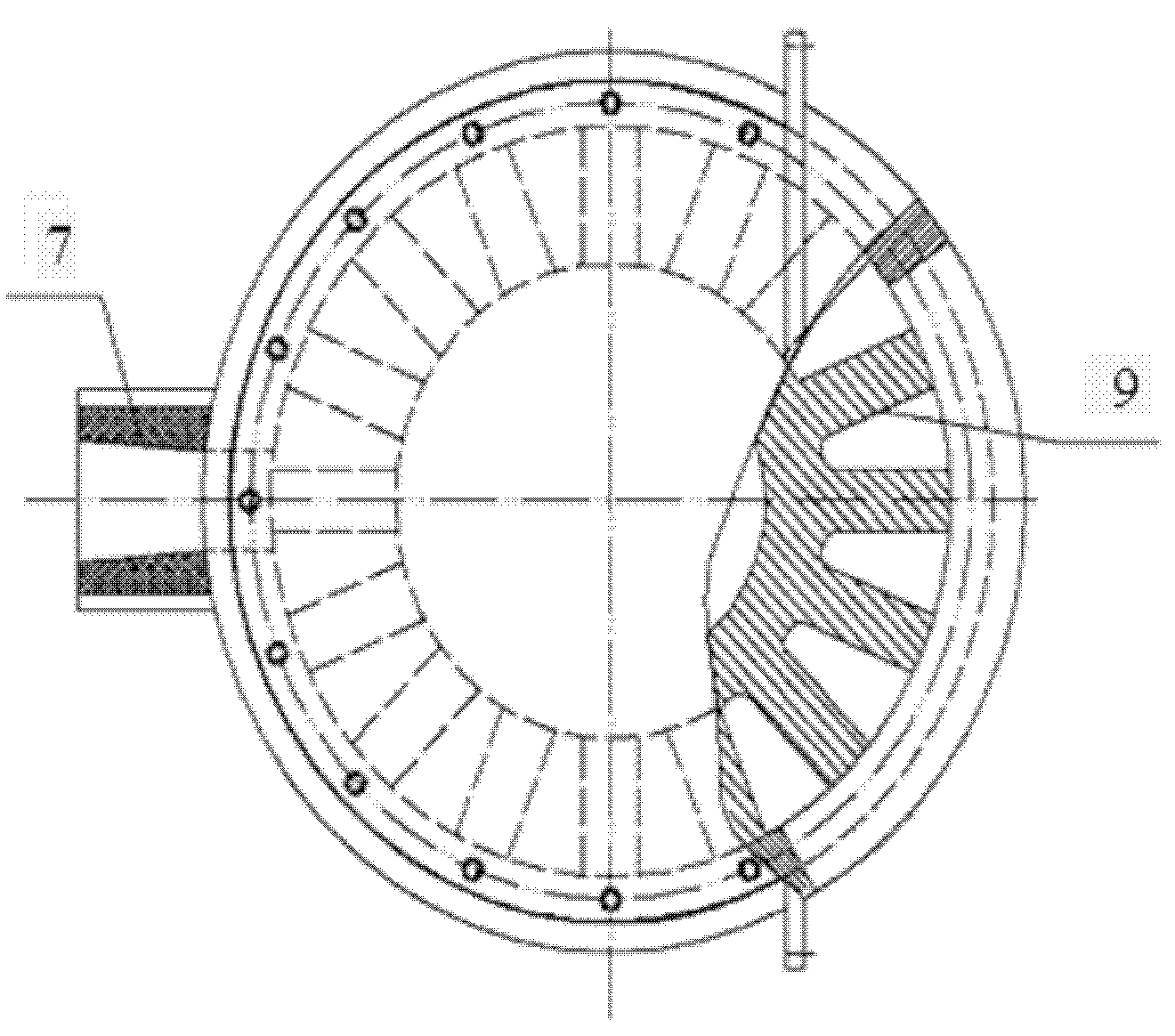

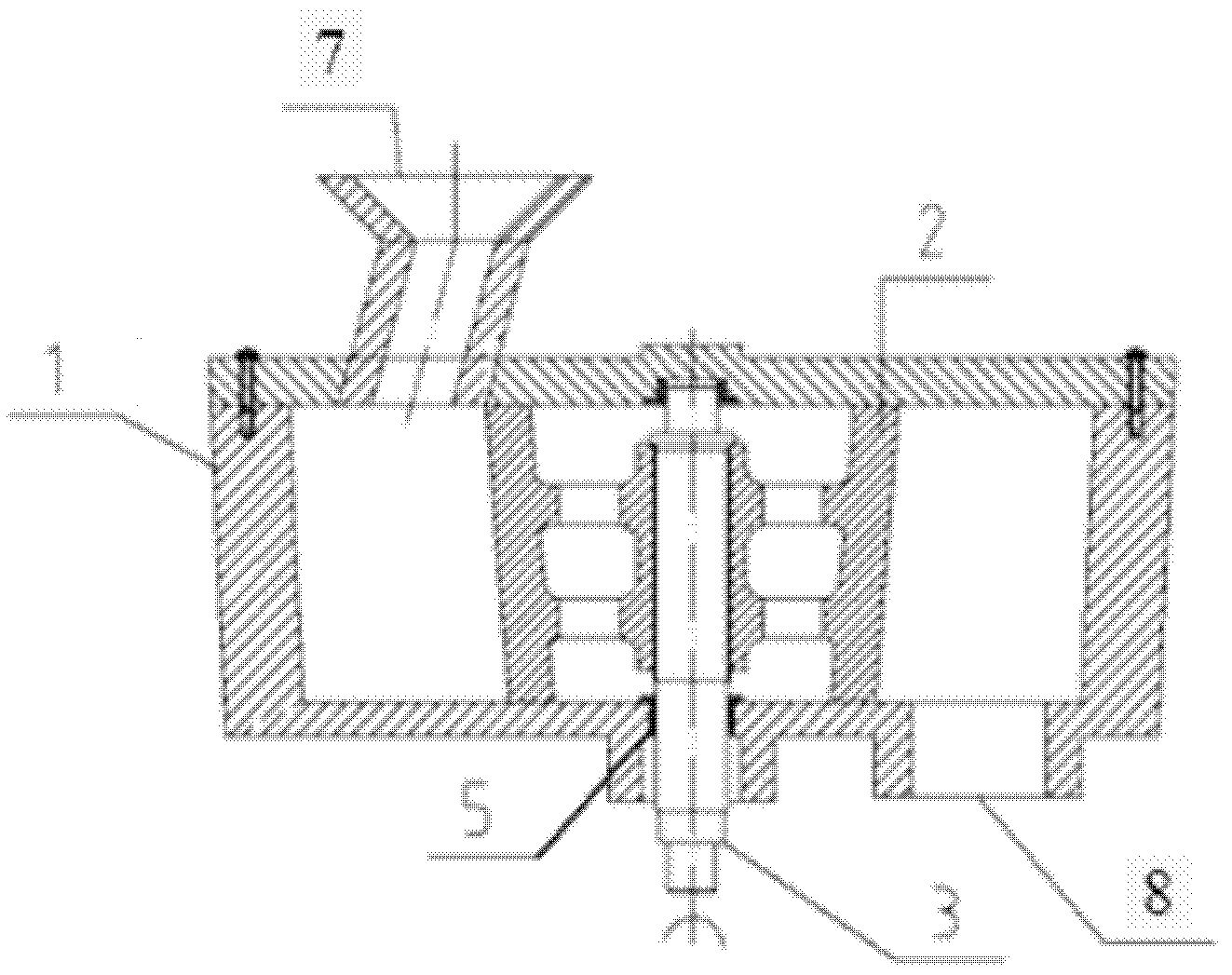

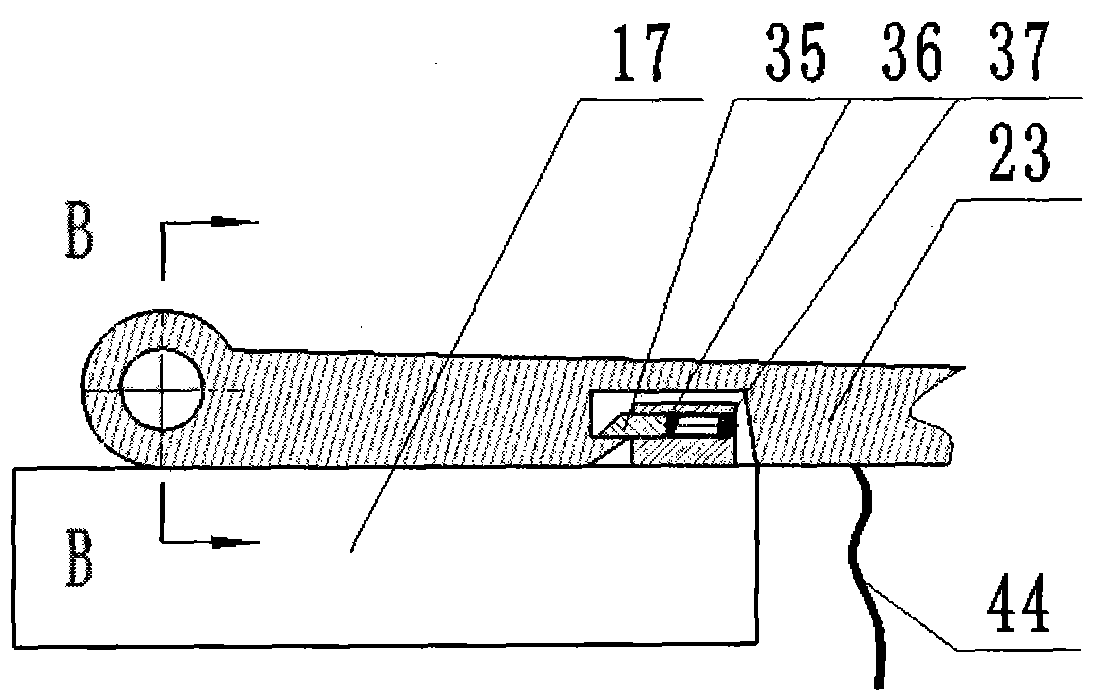

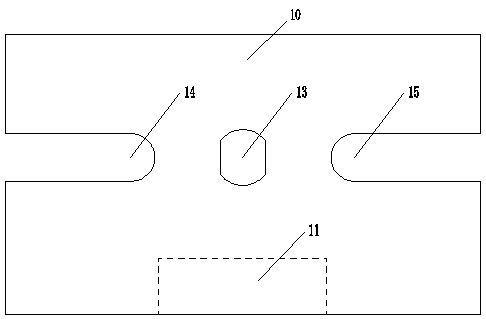

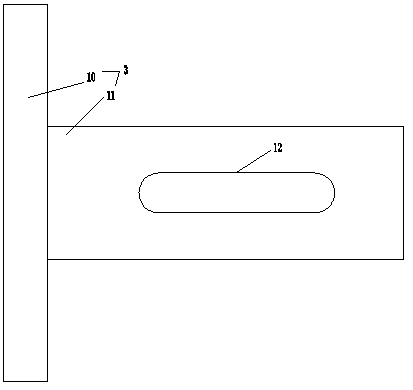

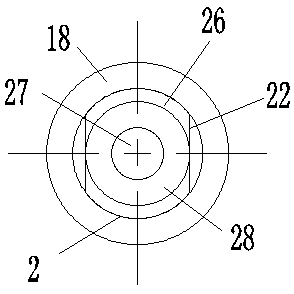

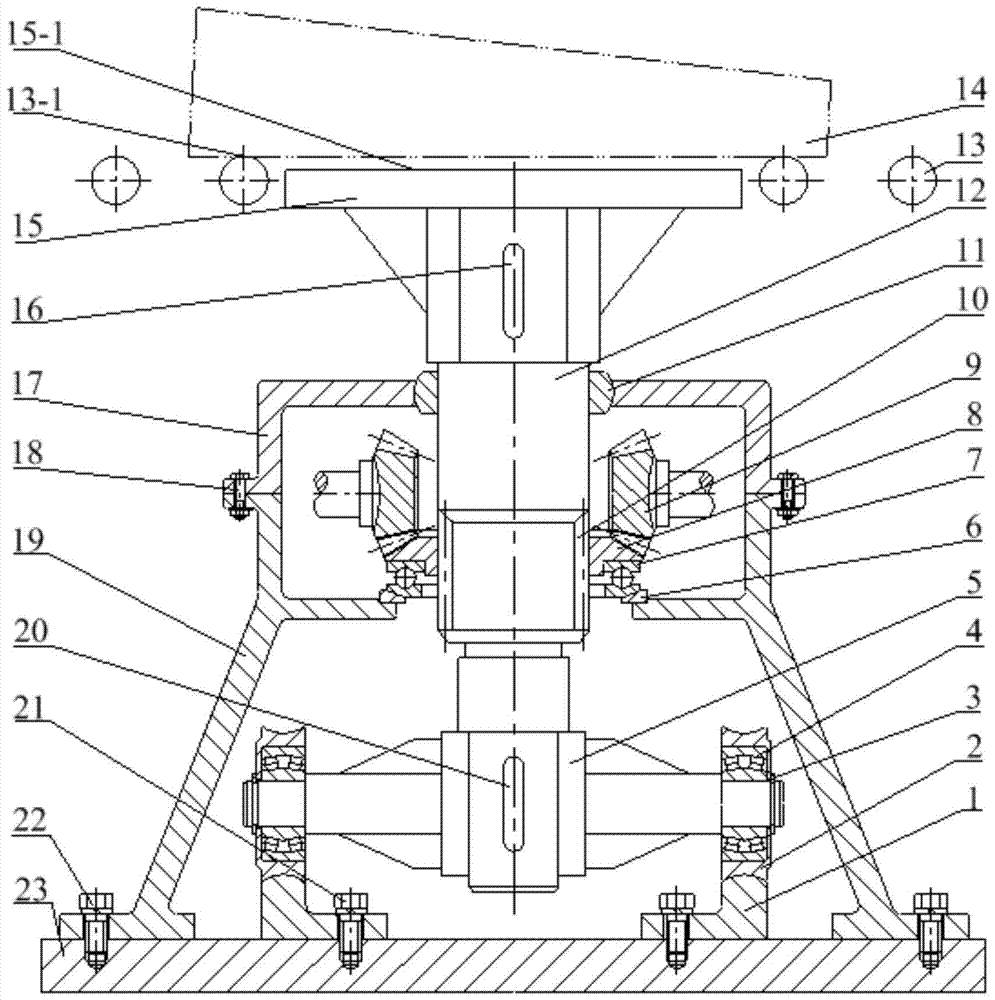

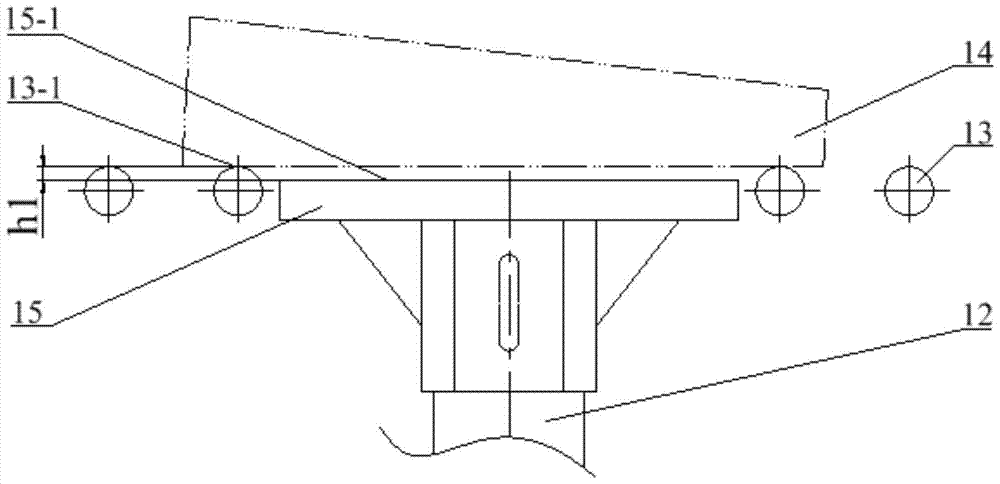

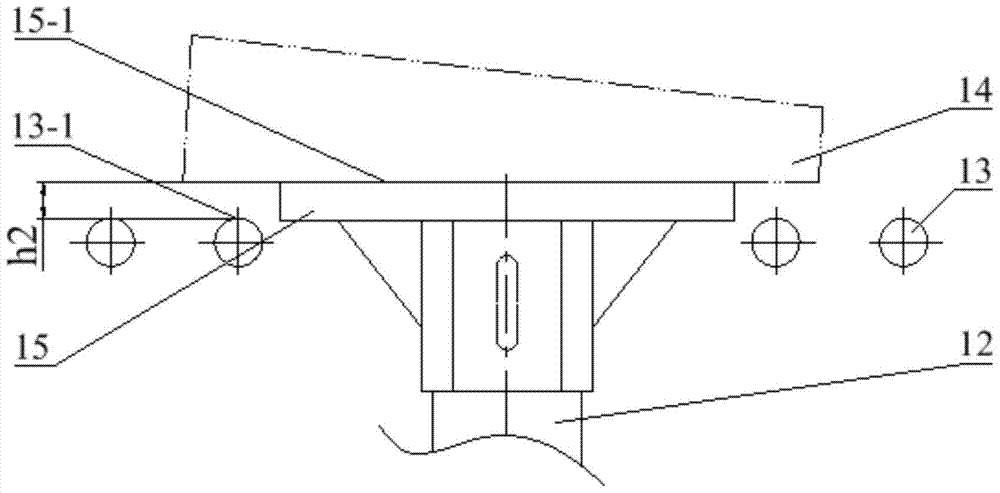

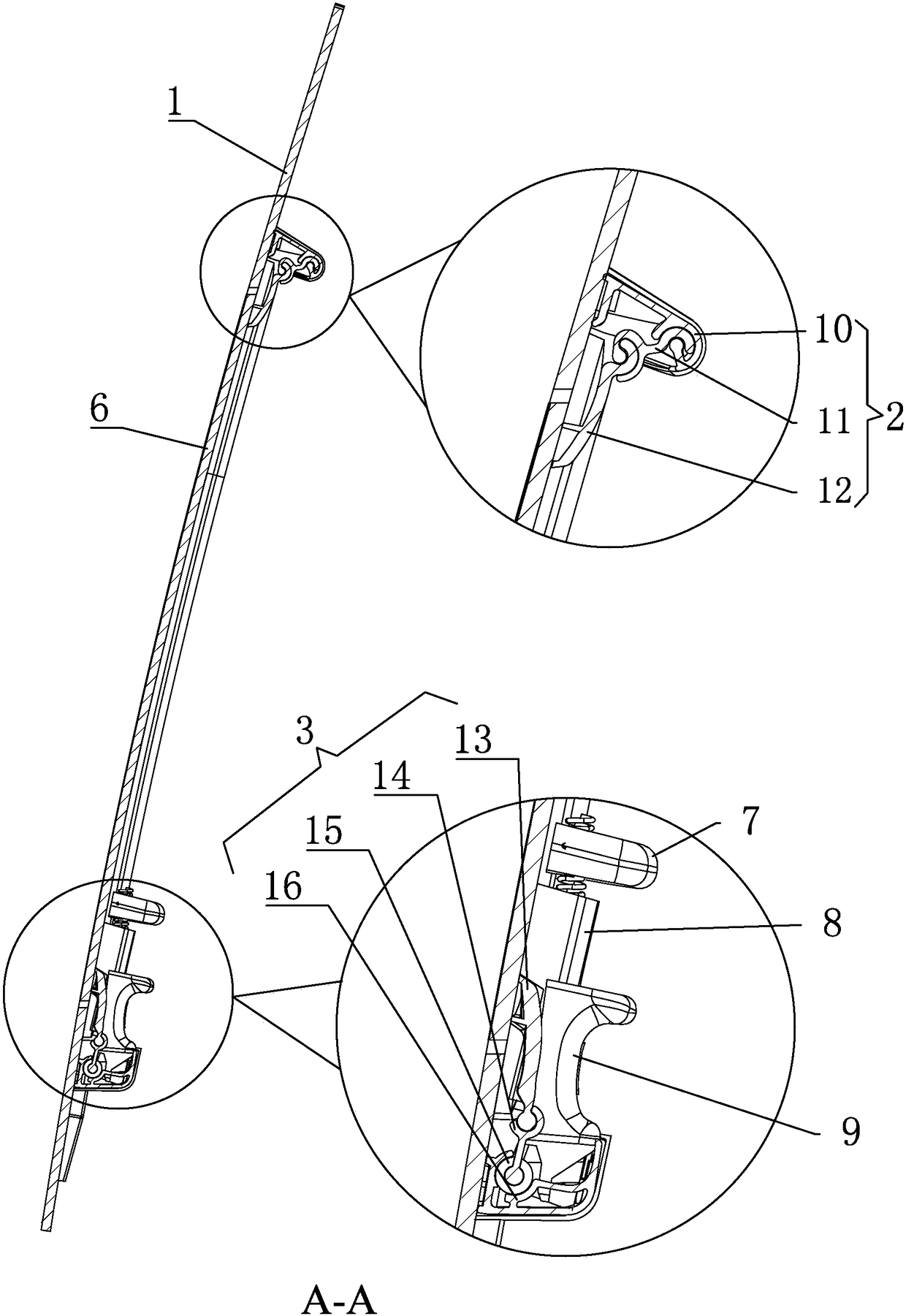

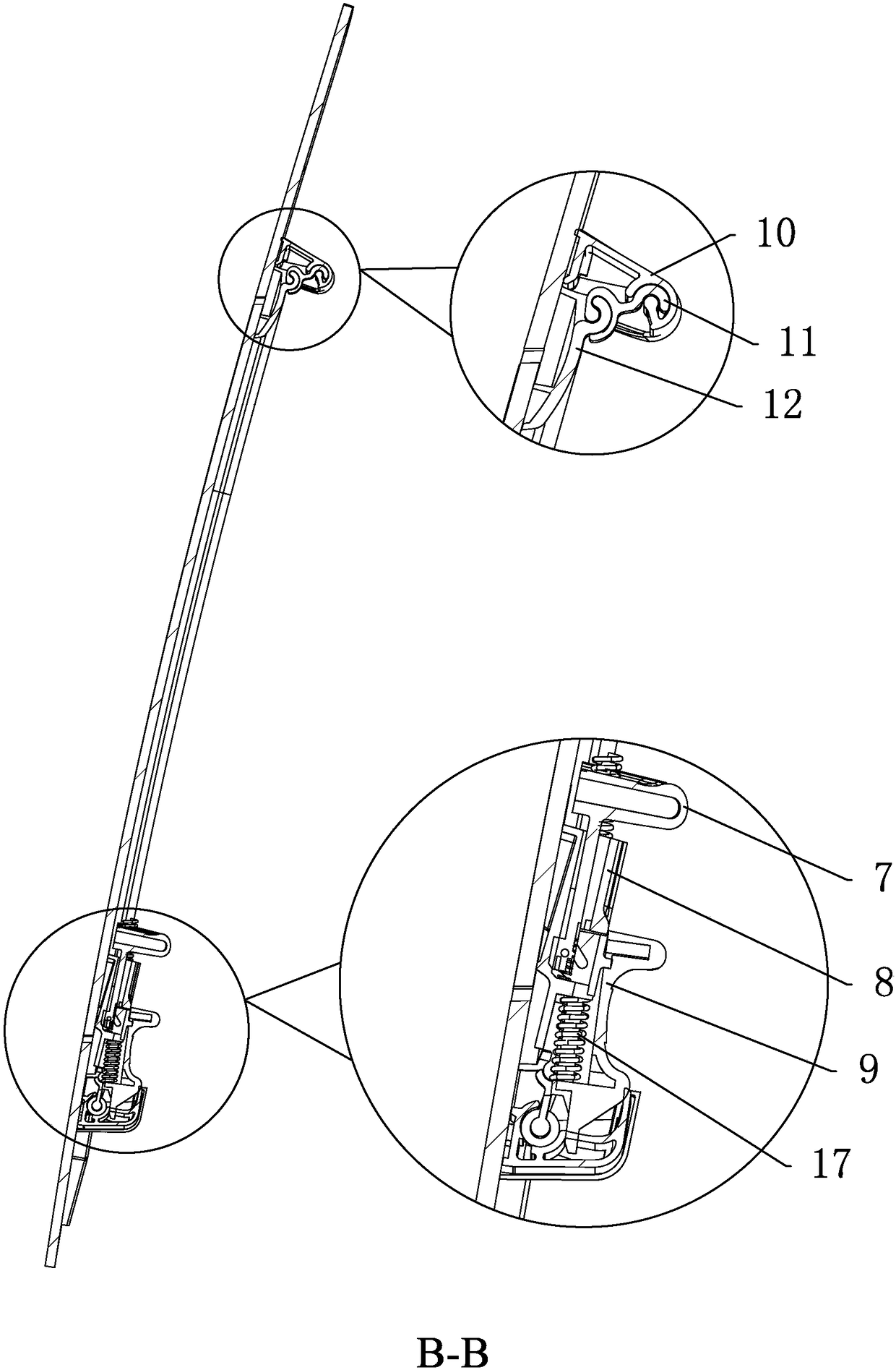

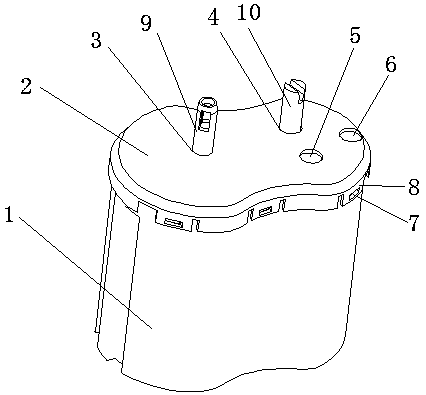

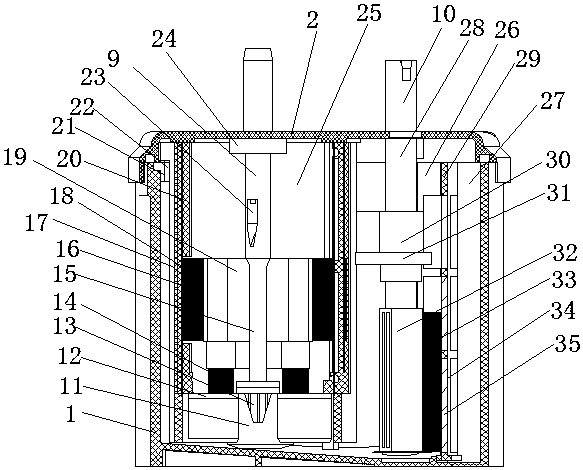

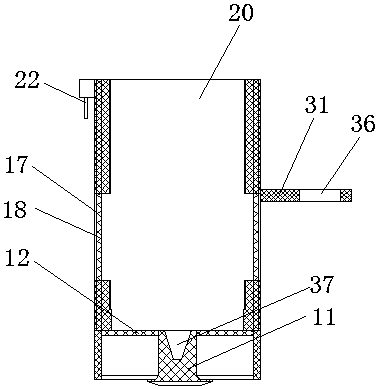

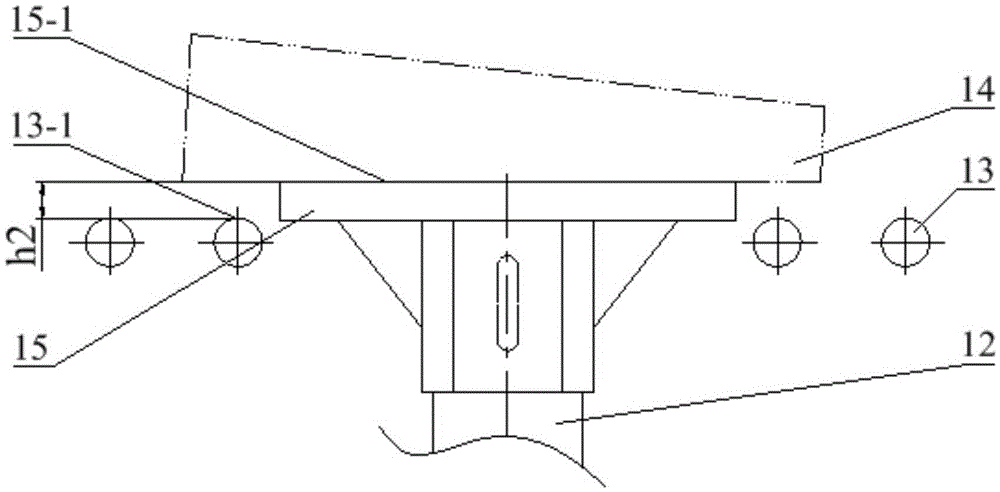

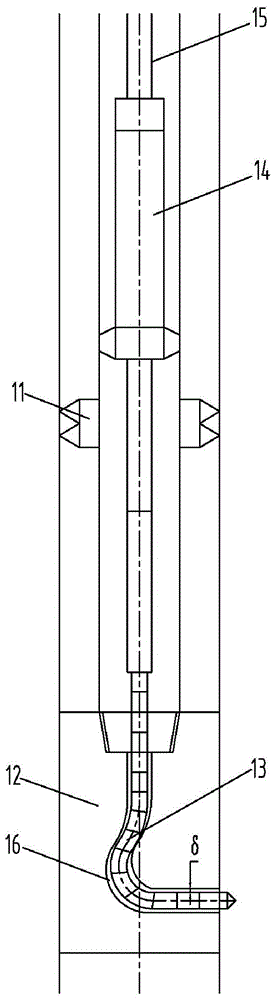

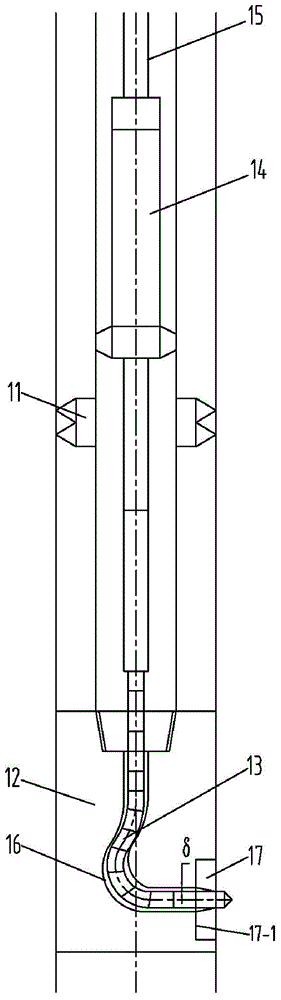

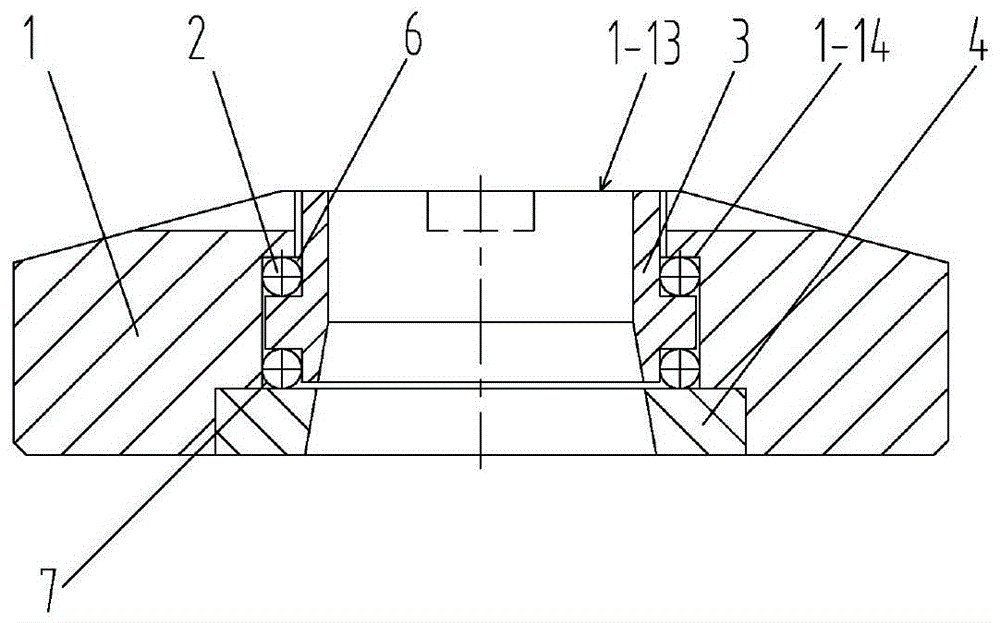

Rotary direct-driving arch breaking device

ActiveCN104555153ACompact structureEasy to install on siteLarge containersOperation safetyOperations security

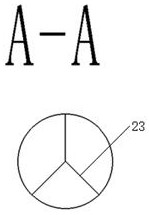

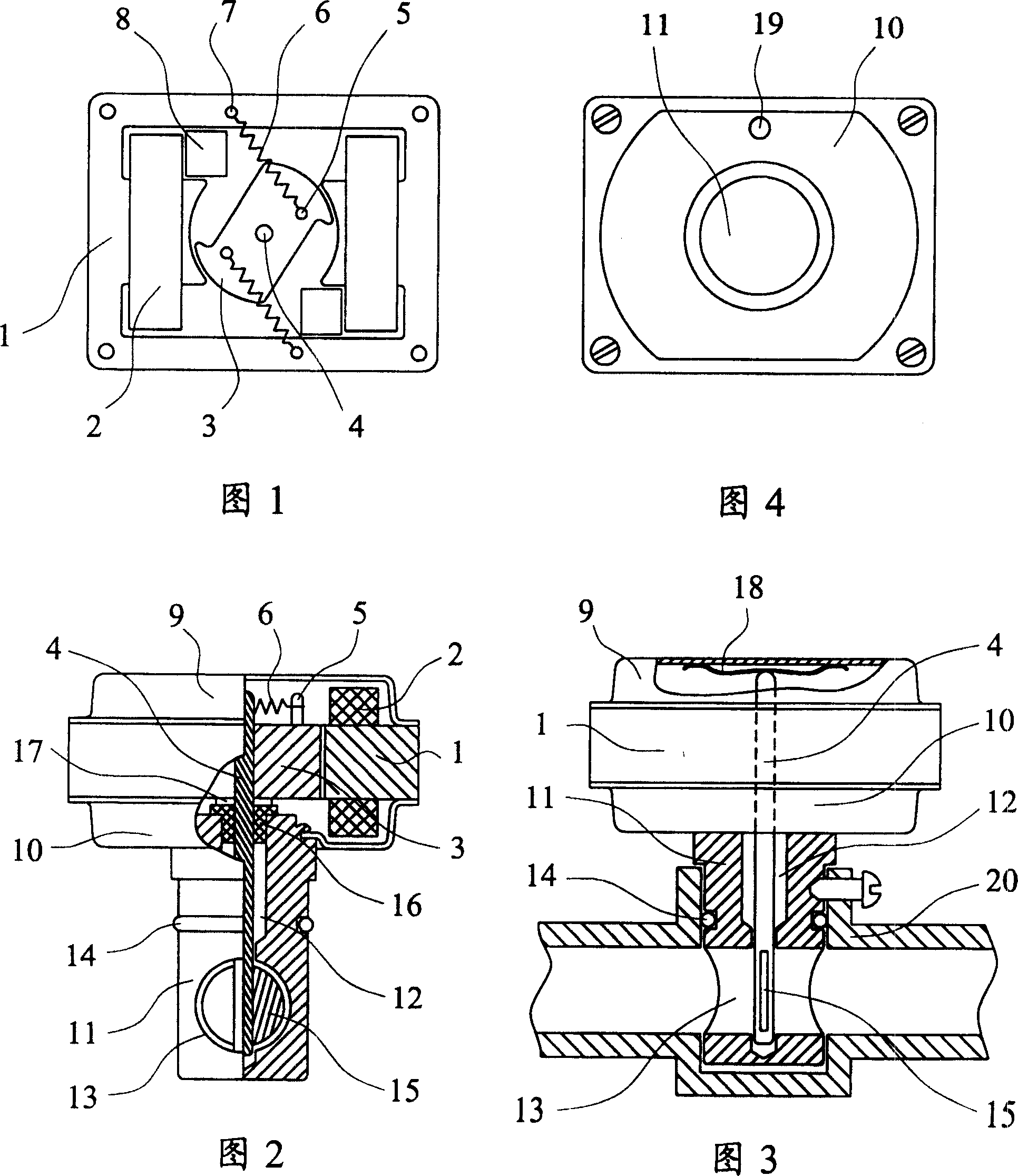

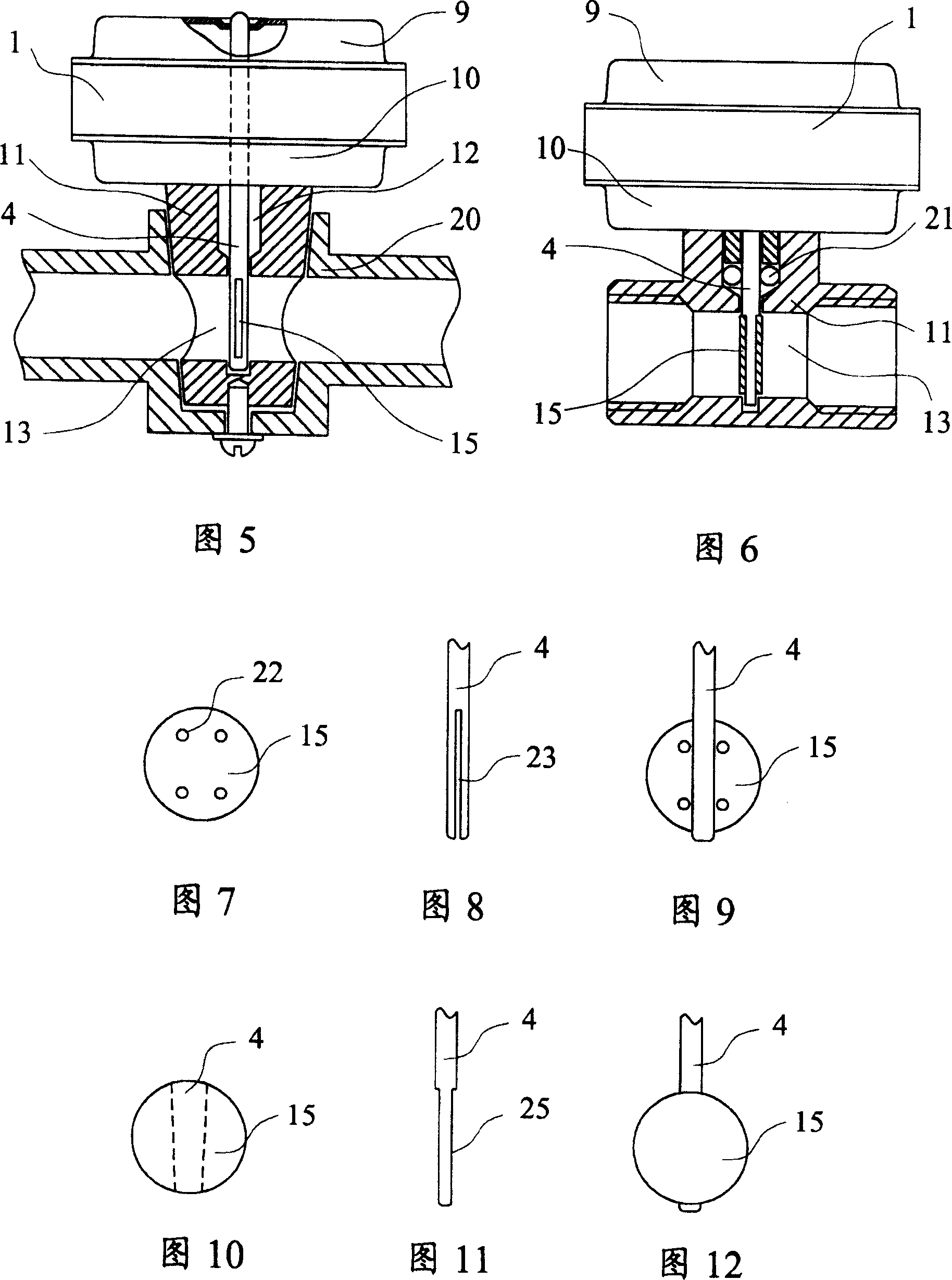

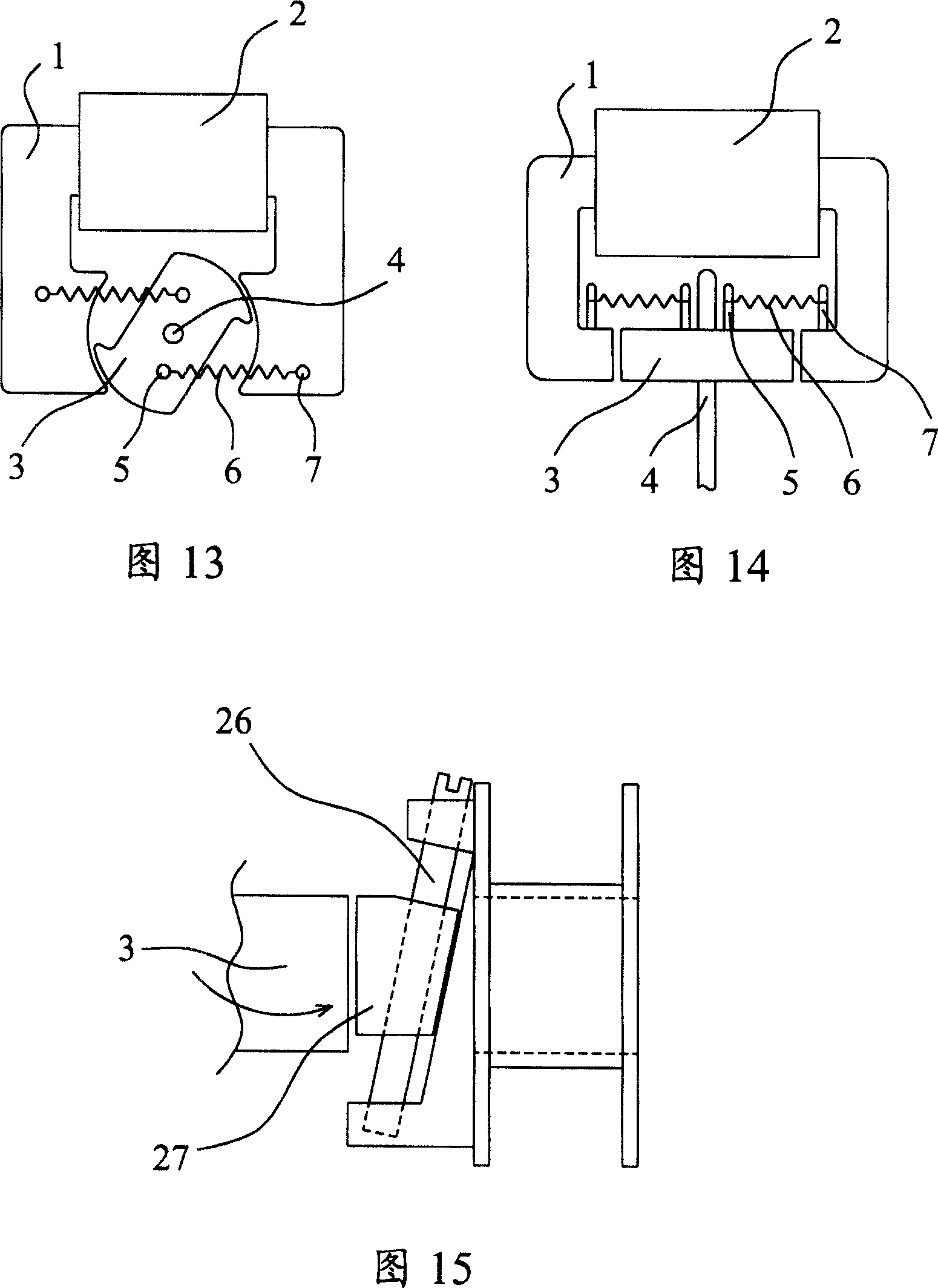

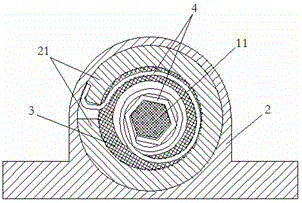

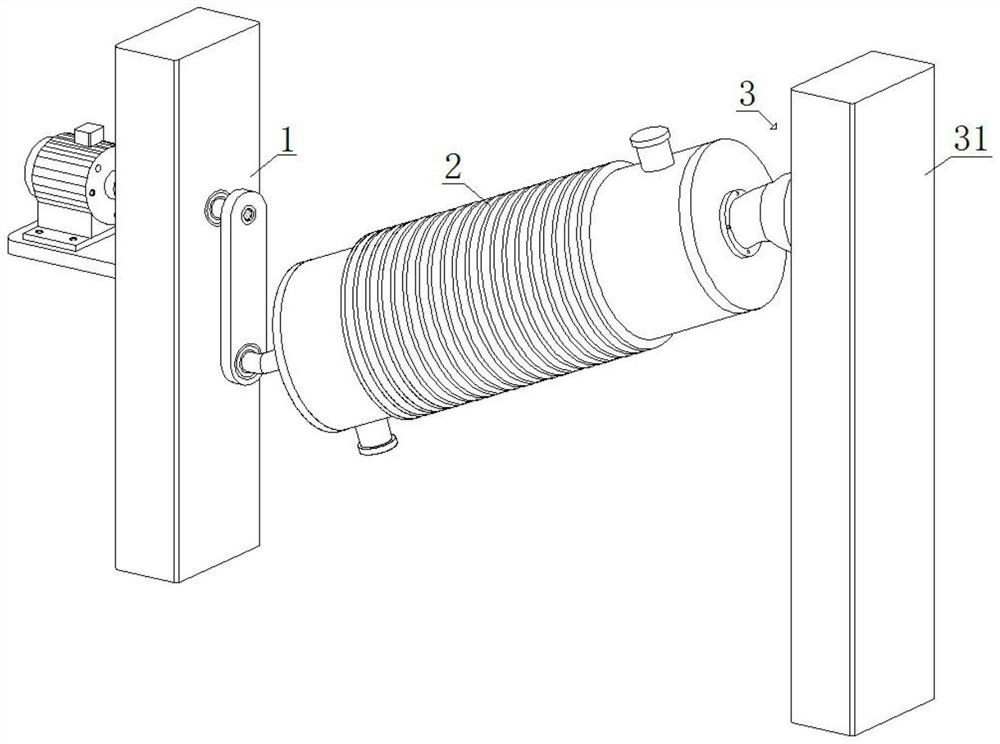

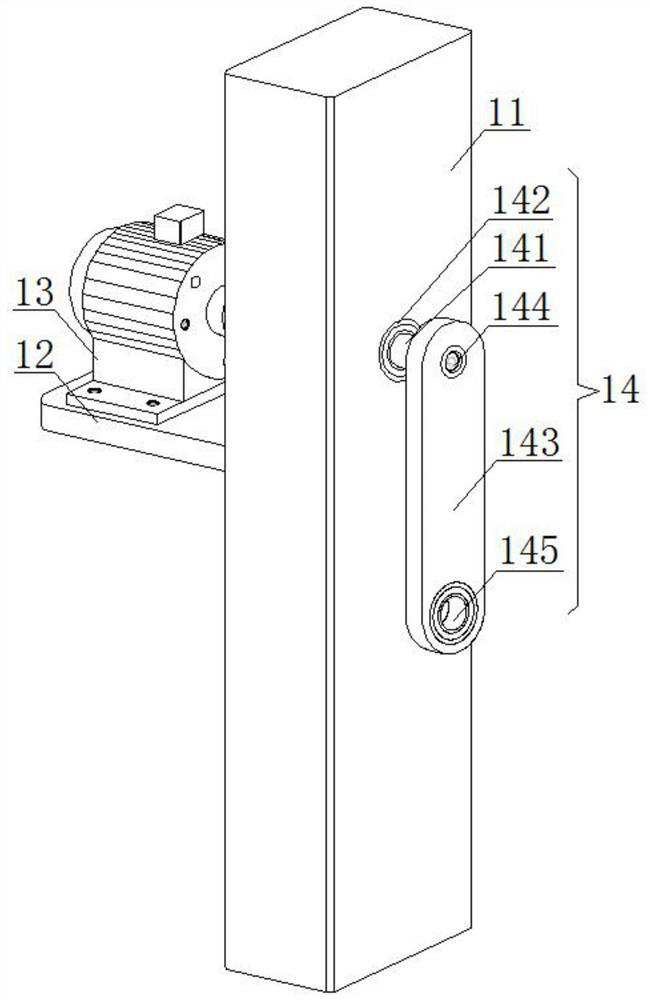

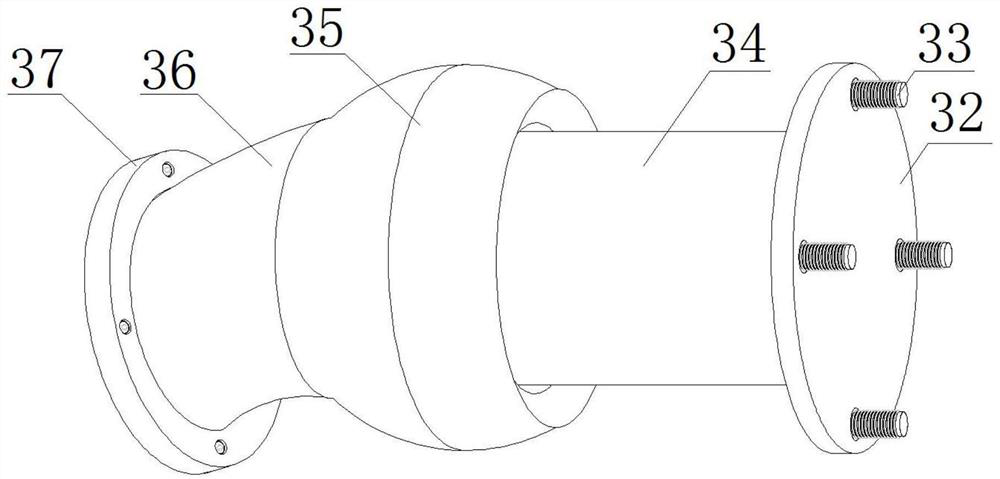

The invention relates to a rotary direct-driving arch breaking device, belonging to the field of material conveying. A lengthening rod is arranged at the end part of the arch breaking device, and meanwhile, the lengthening rod rotates under the driving of a rotary driving device. Compared with an arch breaking range that the diameter of an arch breaking sleeve per se reaches, the arch breaking range of the rotary direct-driving arch breaking device disclosed by the invention is greatly expanded. Moreover, the rotary direct-driving arch breaking device is compact in structure, the quantity of assembling parts in a field installing process is greatly reduced and thus the field installation of the arch breaking device is facilitated. Since the rotary driving device drives a rotary cover and the lengthening rod to rotate through a rotating shaft in a process of rotary arch breaking and fewer rotating components are used, extra rotary friction resistance caused hereby is greatly reduced, the action force of rotary arch breaking can be sufficiently exerted and the arch breaking effect is improved. According to the arch breaking device disclosed by the invention, a stock bin does not need to be cleared in an assembling and disassembling process, operating personnel are unnecessary to enter the stock bin, and thus the operation safety is improved.

Owner:河南辉强机械设备有限公司

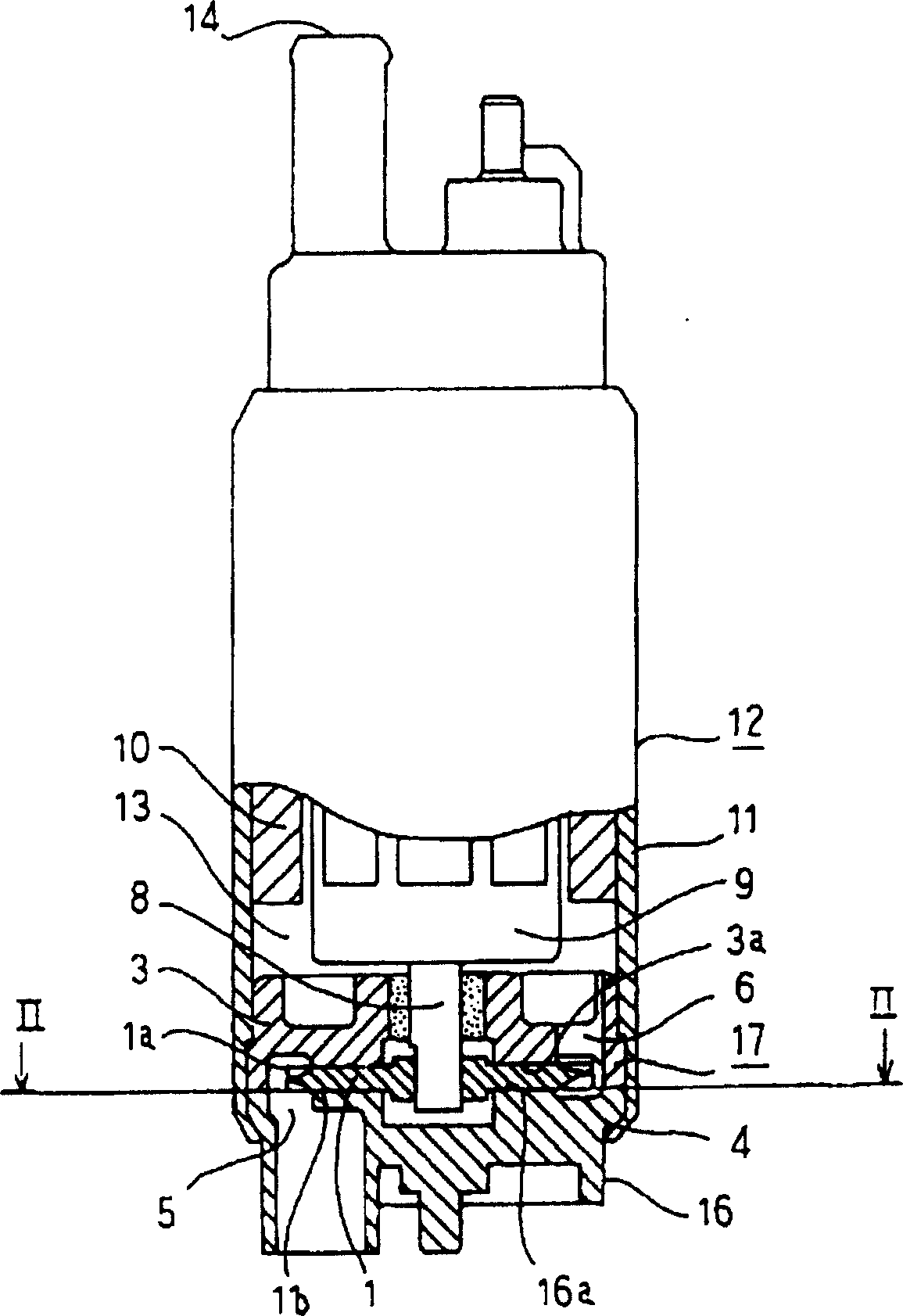

Electric fuel pump

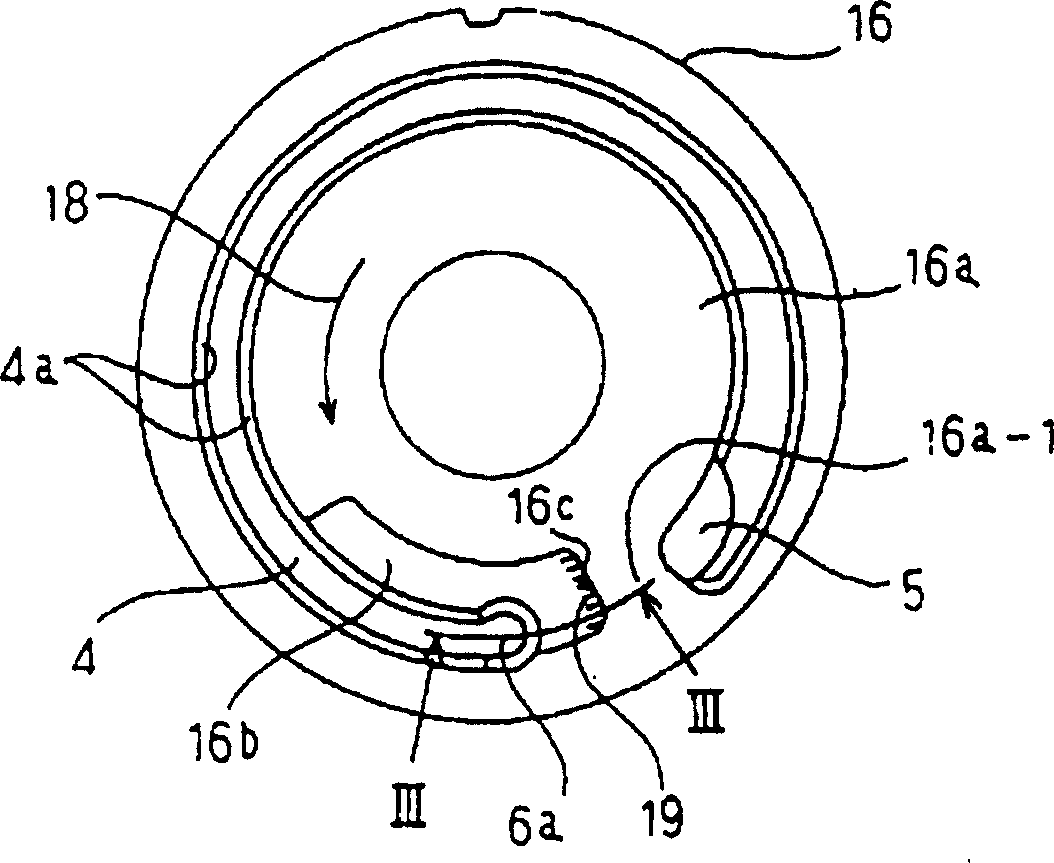

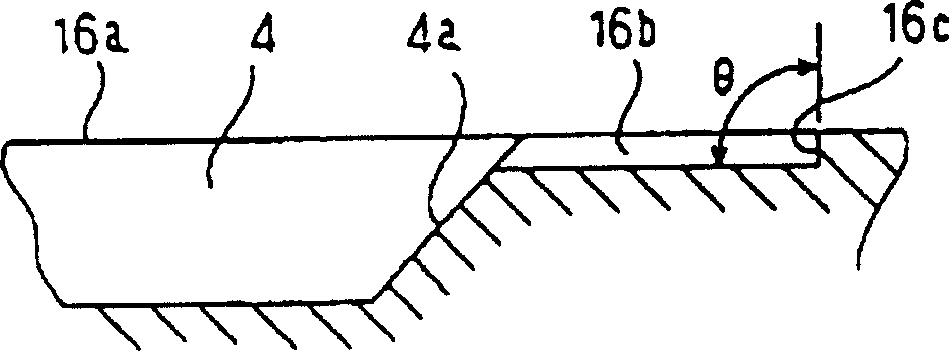

InactiveCN1126872CReduce rotational frictional resistanceCircumferential flow pumpsTransverse flow pumpsImpellerDischarge efficiency

An electric fuel pump provided on a pump casing supporting an impeller by a sliding surface of a pump seat and a sliding surface of a pump cover, and formed on the peripheral side of the pump chamber near the side opposite to the pump chamber outlet of the pump cover sliding surface The contact relief portion with the clearance larger than the small gap between the impeller and the sliding surface, a stepped side wall is formed at the downstream end of the contact relief portion on the side opposite to the pump chamber outlet, and the inclination angle of the stepped side wall is between 90 degrees and 90 degrees. Between 135 degrees, the fuel pump can reduce the frictional resistance between the pump casing and the impeller, prevent the reduction of the motor speed and the increase in power consumption, and improve the discharge efficiency.

Owner:MITSUBISHI ELECTRIC CORP

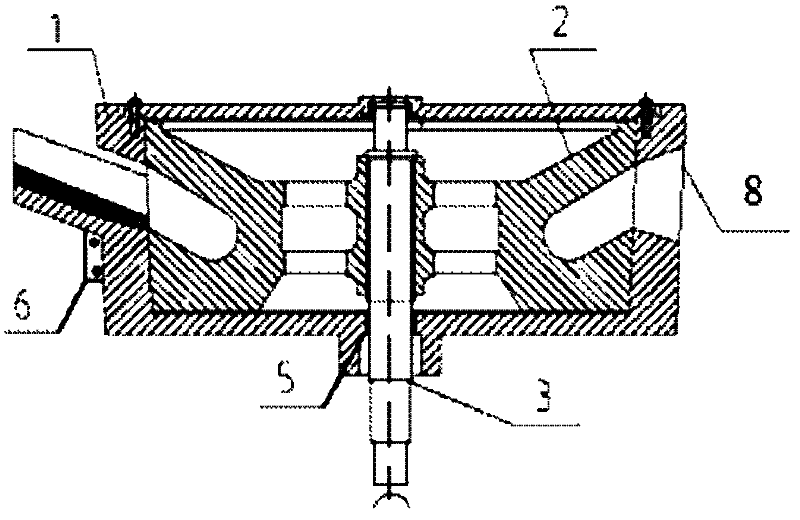

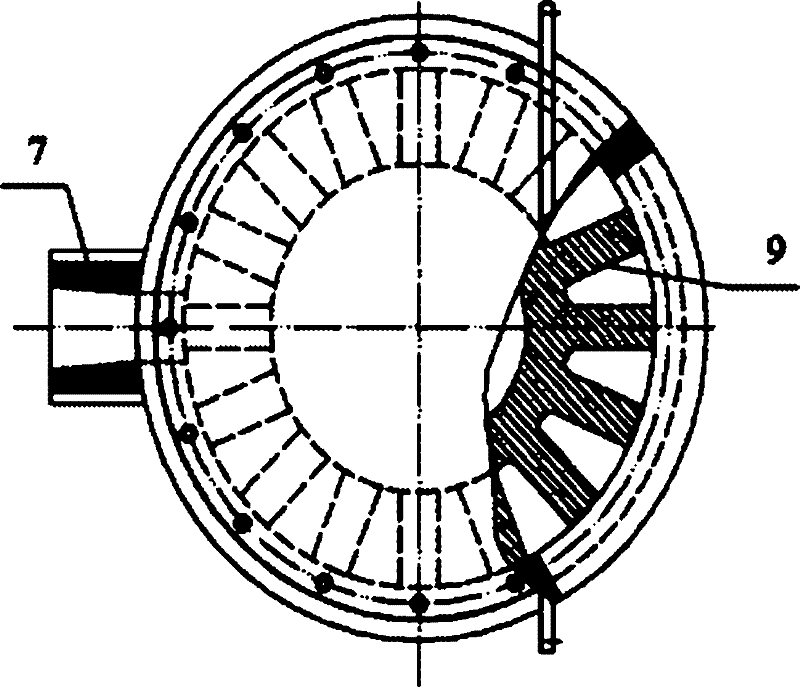

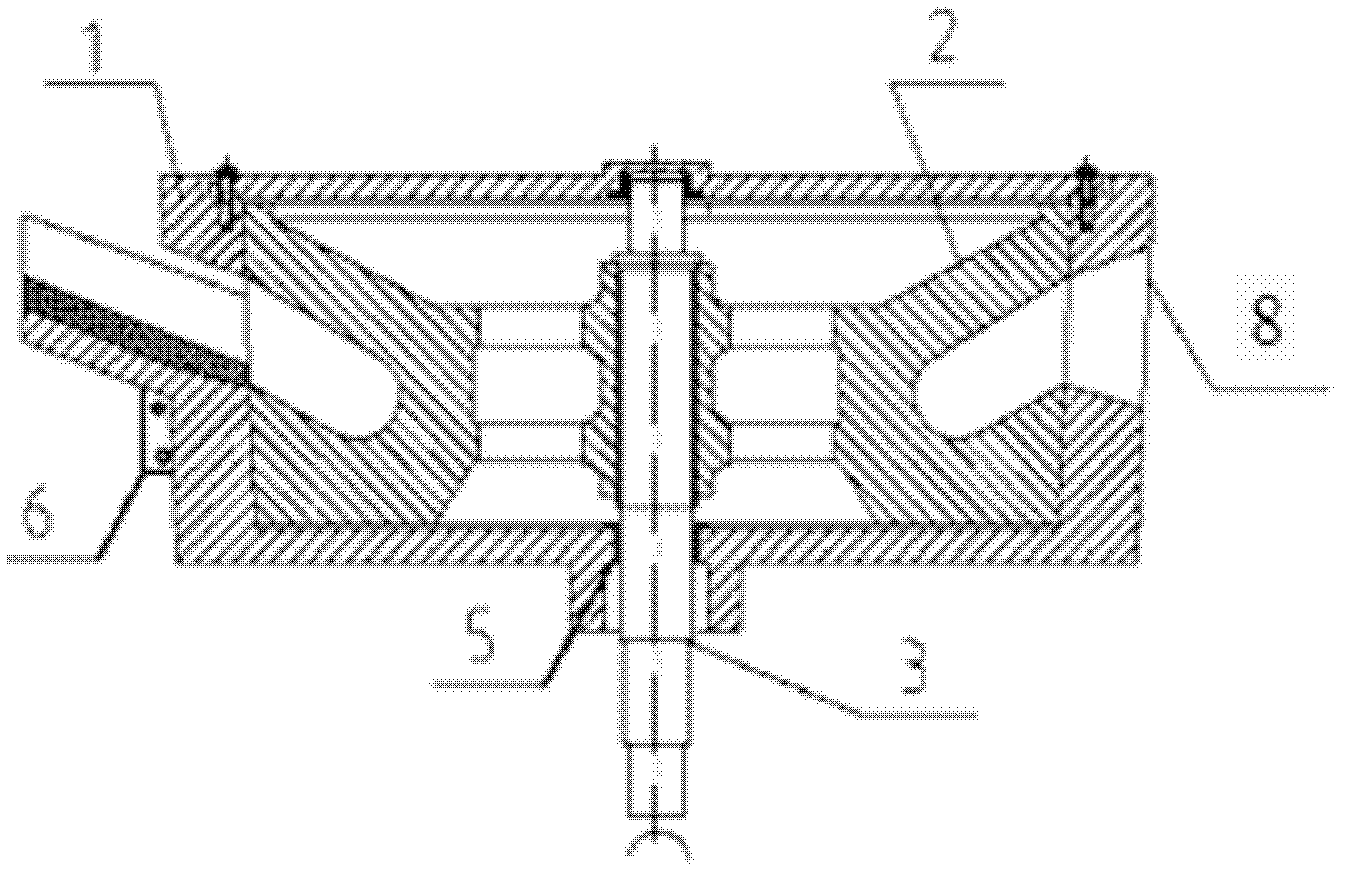

High-temperature liquid furnace slag conveying valve device and method

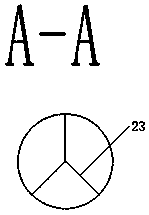

ActiveCN102502196ASolving Rotary Seal Lubrication ProblemsAdjustable pressureRotary conveyorsImpellerSlag

The invention provides a high-temperature liquid furnace slag conveying valve device, which manly consists of a casing, an impeller, a shaft and a support seat and is characterized in that a slag outlet and a slag inlet with cooling walls are arranged on the casing, a bearing is arranged between the casing and the shaft, the impeller comprises a hub and blades and is divided into a plurality of hollow cavities by the blades, the impeller is arranged in the casing in a rotation matching way, the blades and the casing form the rotation sealing, a plurality of longitudinal and transverse lubricating oil hole passages and blowing hole passages are formed on the impeller and the casing, the furnace slag can adopt a side-inlet and side-outlet structure, an upper-inlet and lower-outlet structure and an upper inlet and side-outlet structure, and the sealing structure can be designed into a cylindrical surface sealing structure, a conical surface sealing structure and a plane sealing structure. A high-temperature liquid furnace slag conveying method is characterized in that high-temperature materials enter the device from the slag inlet and are output to the slag outlet by the sealing rotation of the blades to be rotatablely output. The high-temperature liquid furnace slag conveying valve device can be arranged at an inlet and an outlet of a high-temperature furnace slag processing device to be used as a feeding machine and a baiting valve, and the rotation sealing conveying of the high-temperature materials can be realized.

Owner:北京中冶设备研究设计总院有限公司

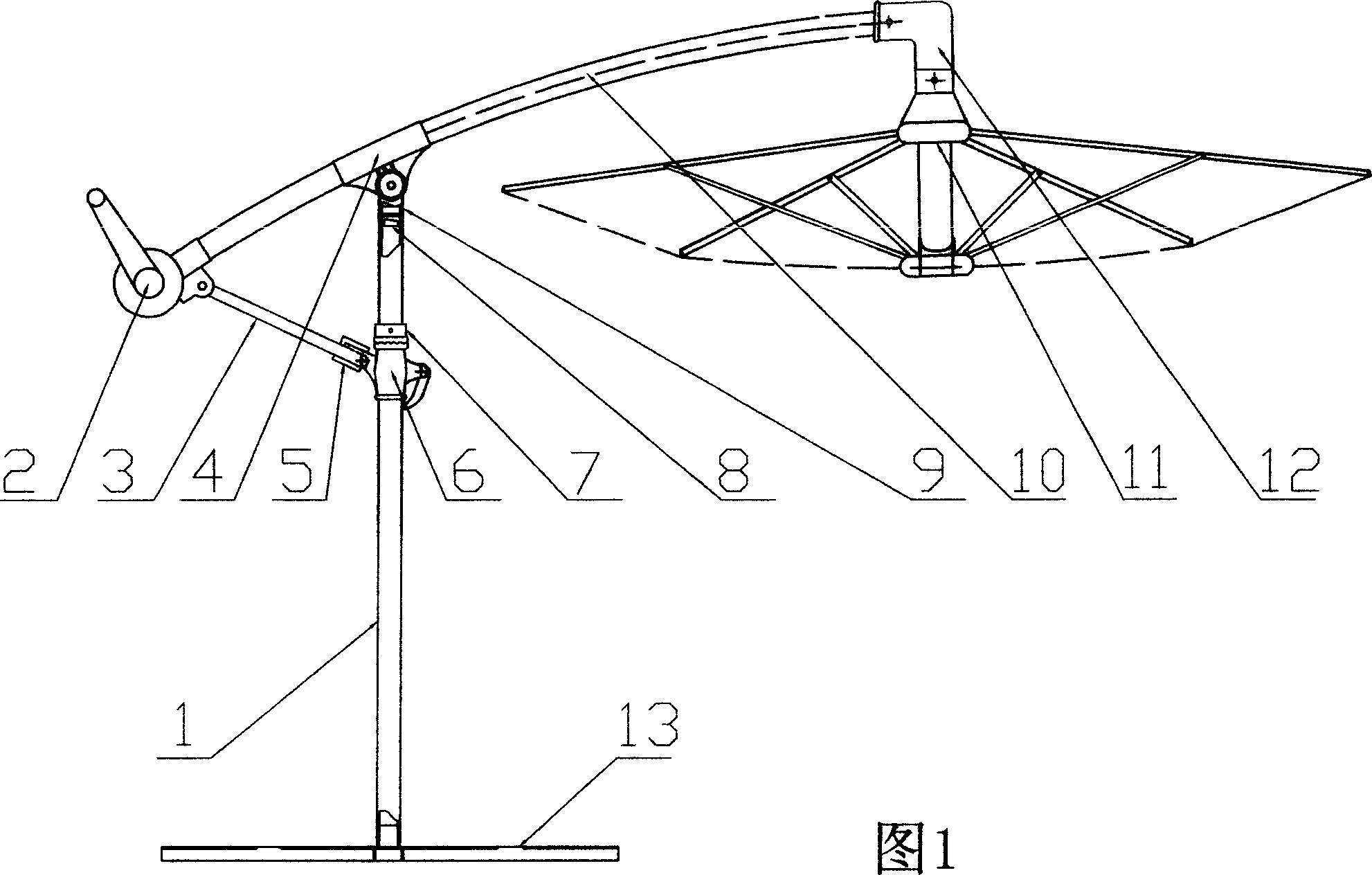

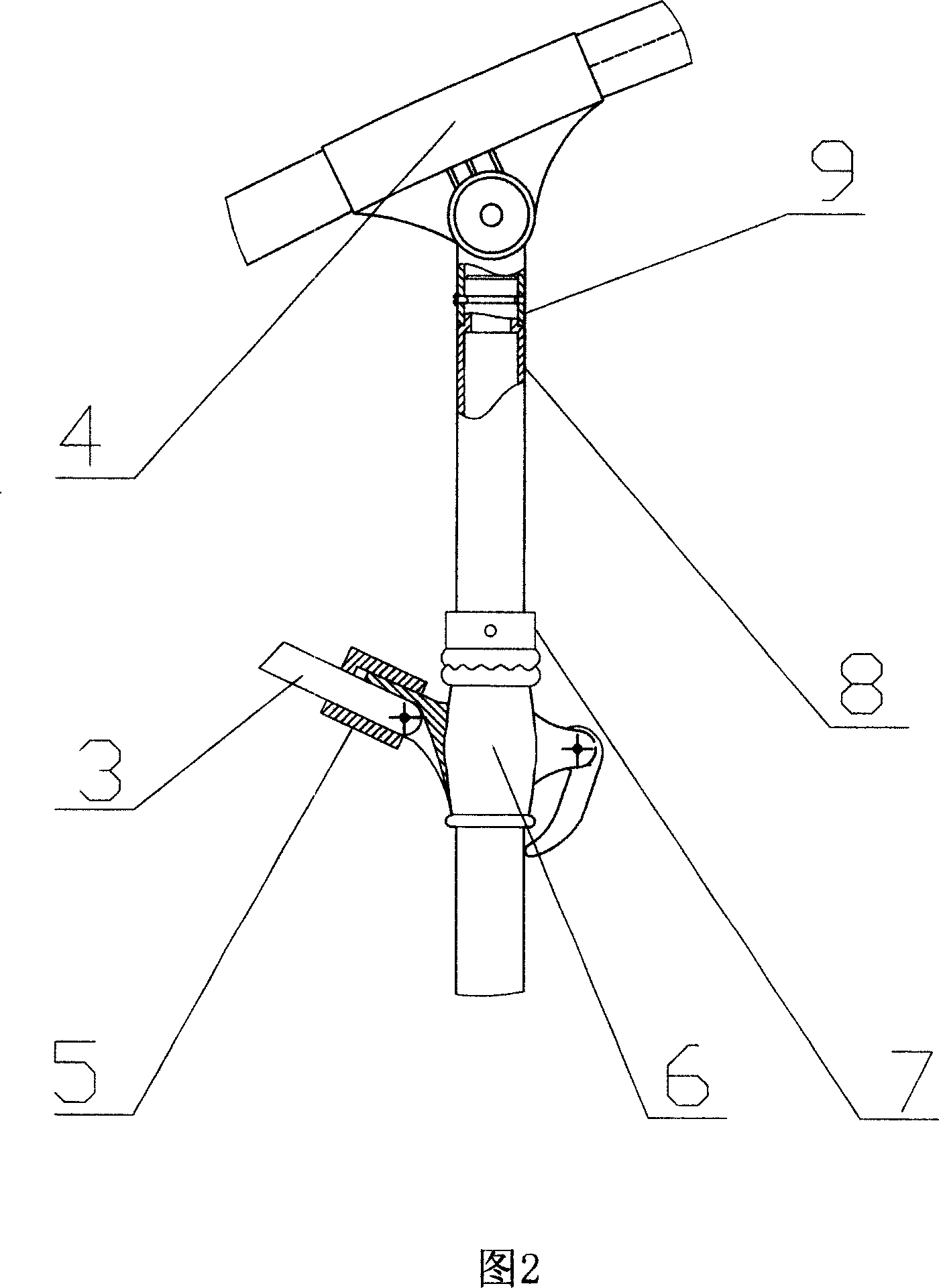

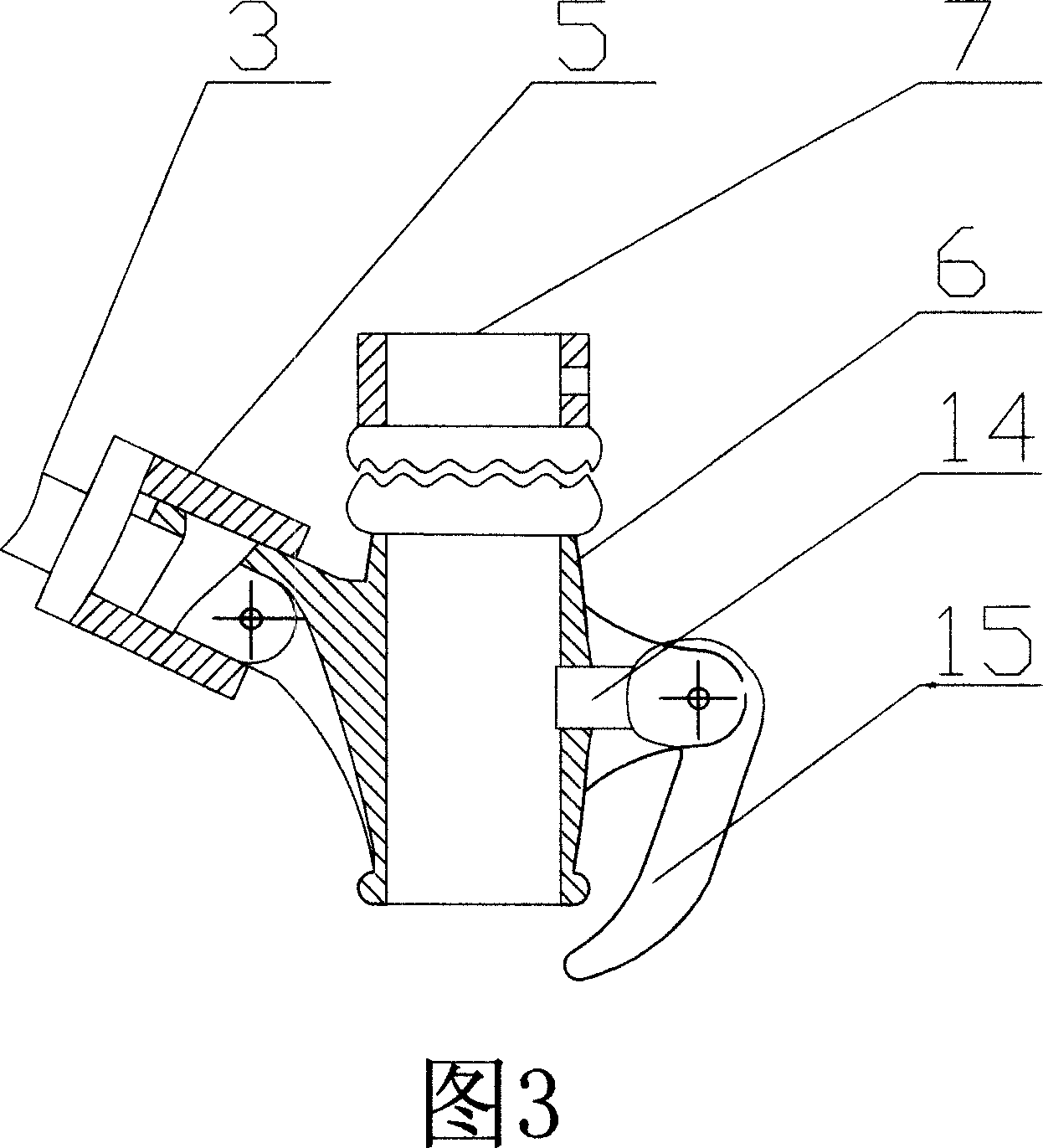

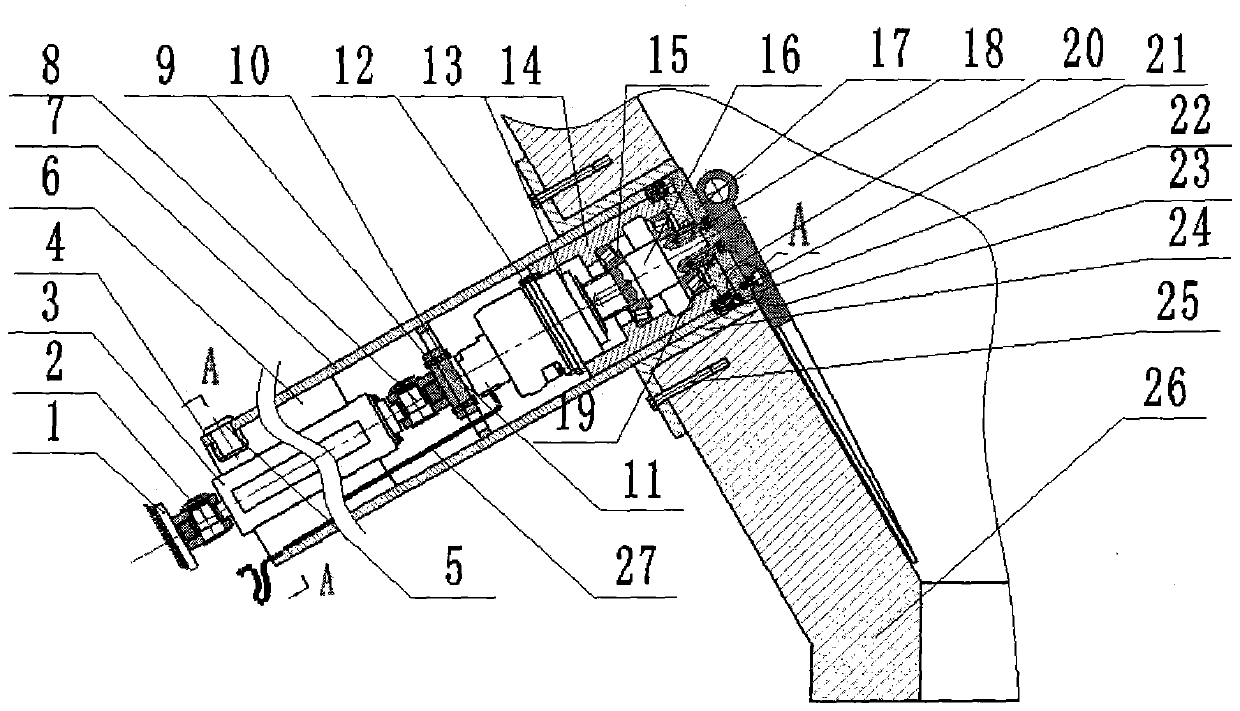

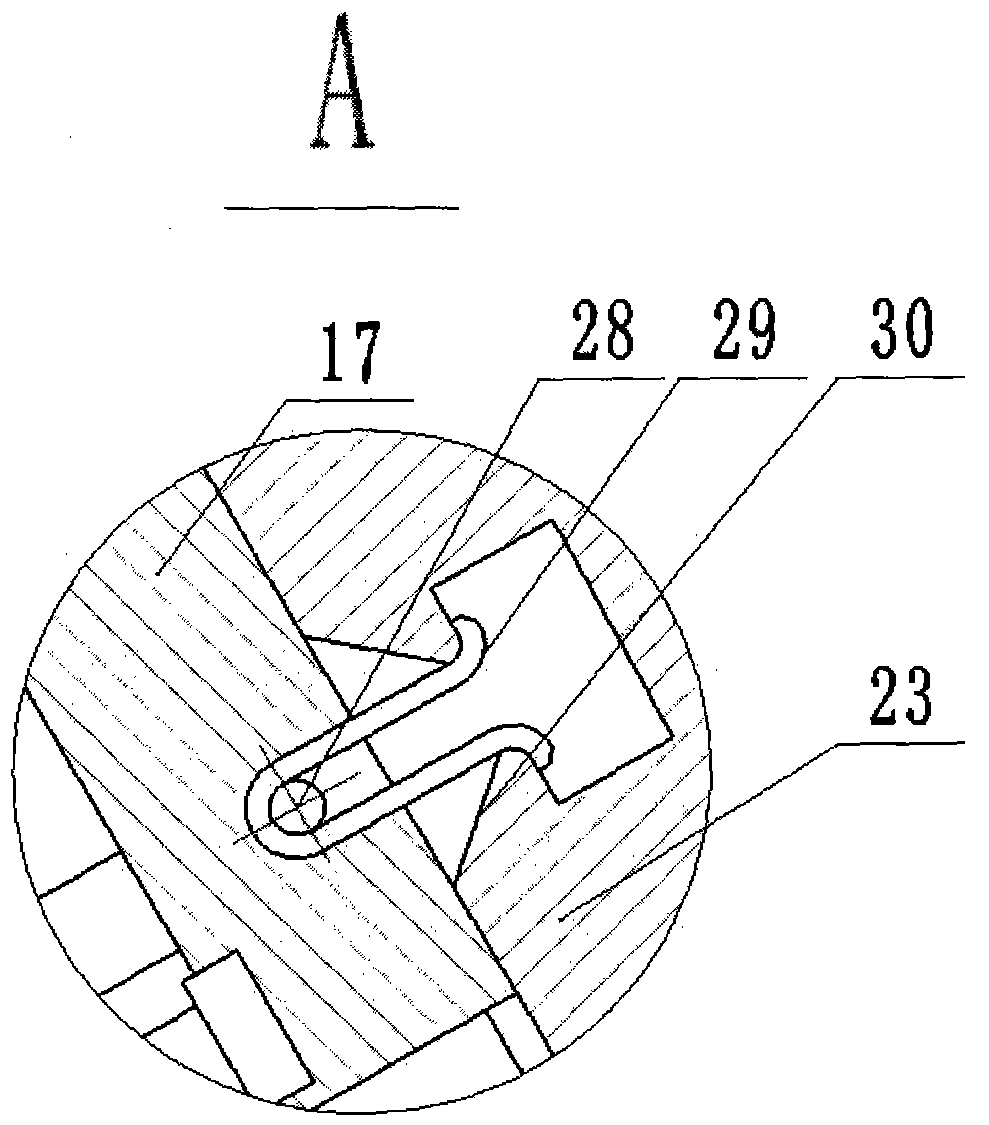

Sunshade banana umbrella

InactiveCN101032355AReduce rotational frictional resistanceReduce lossUmbrellasMachine supportsEngineeringFriction force

The banana-shaped sunshade includes a pedestal, a support rod, a suspending rod and an umbrella fabric bracket, as well as a guide joint connected to the top of the support rod and capable of rotating horizontally, a movable seat connected movably around the support rod, and a locating seat connected to the support rod and the movable seat. The present invention has reduced rotation friction force, less wear of the rotation part, increased rotation regulating stability and lowered material cost.

Owner:何达勤

Guide vane exit circulation homogenizer for axial-flow pump and guide vane type mixed-flow pump model

InactiveCN102330710AEasy production and implementationReduce rotational frictional resistancePump componentsPumpsAxial-flow pumpMixed flow

The invention provides a guide vane exit circulation homogenizer for an axial-flow pump and a guide vane type mixed-flow pump model, belonging to the technical field of water pump model tests. The circulation homogenizer comprises a hub, blades, a fixed axis and supported hole blades, wherein the fixed axis is provided with a shaft concentric with the model pump shaft and the guide vane hub central shaft, the diameter of the hub is the same with that of the guide vane hub, the hub is uniformly provided with 8-12 straight blades along the circumferential direction of the hub, two ends of the hub are provided with the supported hole blades, the hub can be freely sleeved on the fixed shaft through the holes of the supported hole blades on the two ends of the hub; one end of the circulation homogenizer is connected with a guide vane exit, the other end is connected with a water outlet runner; when the swirling current of the guide vane exit and the homogenizer blades in a free state can achieve synchronous rotation by a mutual effect, the water flow circulation flowing through the homogenizer can be homogenized. The homogenizer can homogenize the water flow circulation at the guide vane exit, which can provide an essential condition for studying the waterpower performance of the water outlet runner on the condition that the water flow circulation at the guide vane exit is uniformly distributed.

Owner:YANGZHOU UNIV

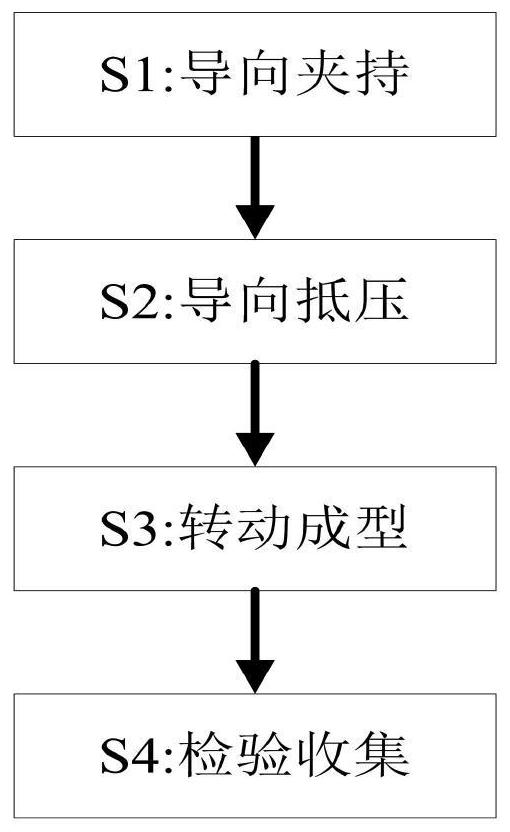

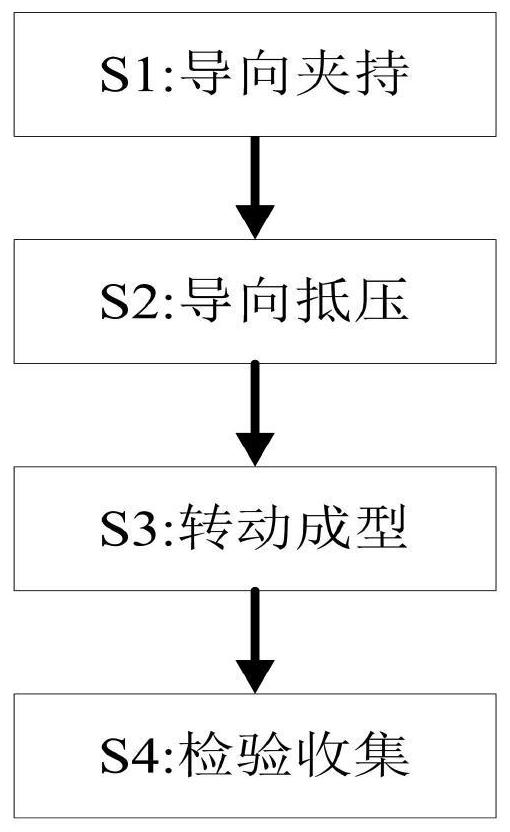

Heat exchanger cooling structure forming manufacturing method

ActiveCN112024669AImprove molding effect and qualityGuaranteed accuracyMetal-working feeding devicesHeat exchange apparatusBatch productionHeat exchanger

The invention provides a heat exchanger cooling structure forming manufacturing method. The heat exchanger cooling structure forming manufacturing method comprises an abutting auxiliary mechanism, anintermittent transposition mechanism and a displacement mechanism, wherein the displacement mechanism is installed on the end face of the left side of the intermittent transposition mechanism, and theabutting auxiliary mechanism is installed on the displacement mechanism and located over the intermittent transposition mechanism. The heat exchanger cooling structure forming manufacturing method solve the problems that an existing copper pipe is bent into a spiral shape and formed through manual winding on a cylinder, but the mode has high requirements for workers, stress is uneven in the winding process, the copper pipe is prone to being flattened, the copper pipe is deformed, meanwhile, wound spiral screw pitches are different, use requirements cannot be met, the service life of the copper pipe is shortened. batch production operation cannot be conducted, certain pressure maintaining operation cannot be conducted on the bent and formed coil pipe, and the situation of bending springback can occur.

Owner:江苏瑞林环保科技有限公司

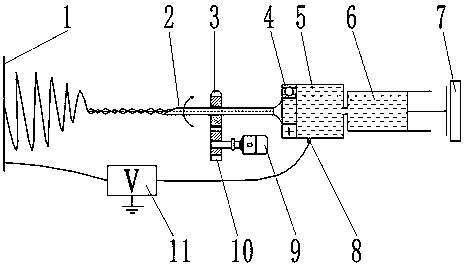

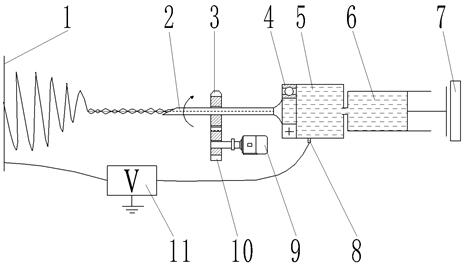

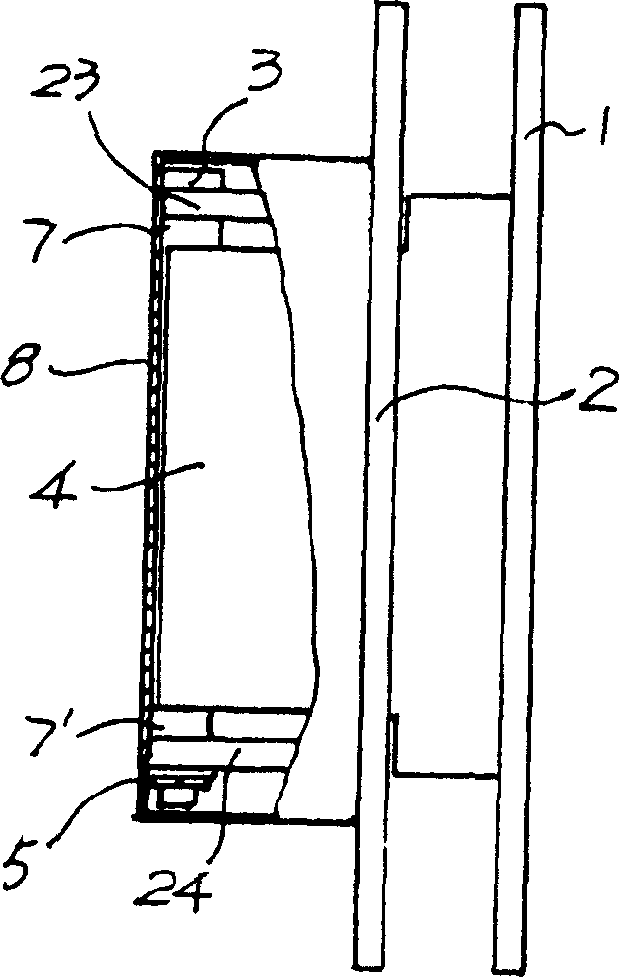

Electrostatic spinning rotation spinneret device and use method thereof

ActiveCN110644063AGuaranteed uniformityReduce rotational frictional resistanceFilament/thread formingElectric machineryEngineering

The invention relates to an electrostatic spinning rotation spinneret device and a use method thereof. The device comprises a micro-injection pump, an injection tube, a bearing sleeve, a bearing, a needle head, a receiving plate and a high voltage power supply. The device has the advantages that according to the electrostatic spinning rotation spinneret device and the use method thereof, the tailof the needle head is connected with the bearing, the rotation friction resistance of the bearing is small, and the bearing is easily replaced after being abraded. According to the device, a needle tube is divided into a plurality of layer according to equal volume, pressure applied onto each layer of spinning solution is same, spinning uniformity is ensured, rotating speed of the needle head is controlled by a motor and can be adjusted according to characteristics of different specific macromolecule polymers, so that the screwing degree of fibers is changed, and product quality is improved.

Owner:NANTONG UNIVERSITY

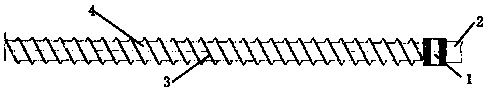

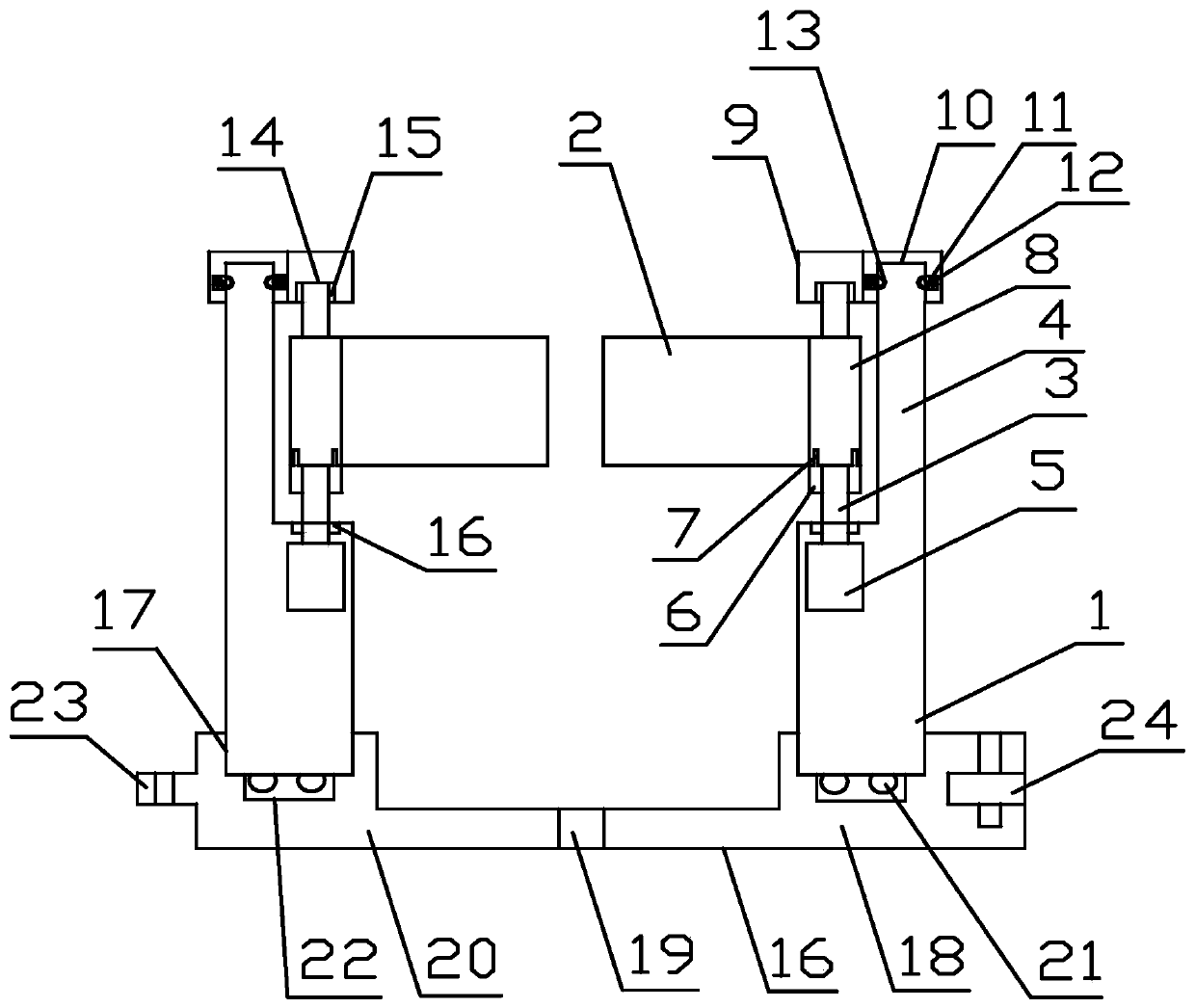

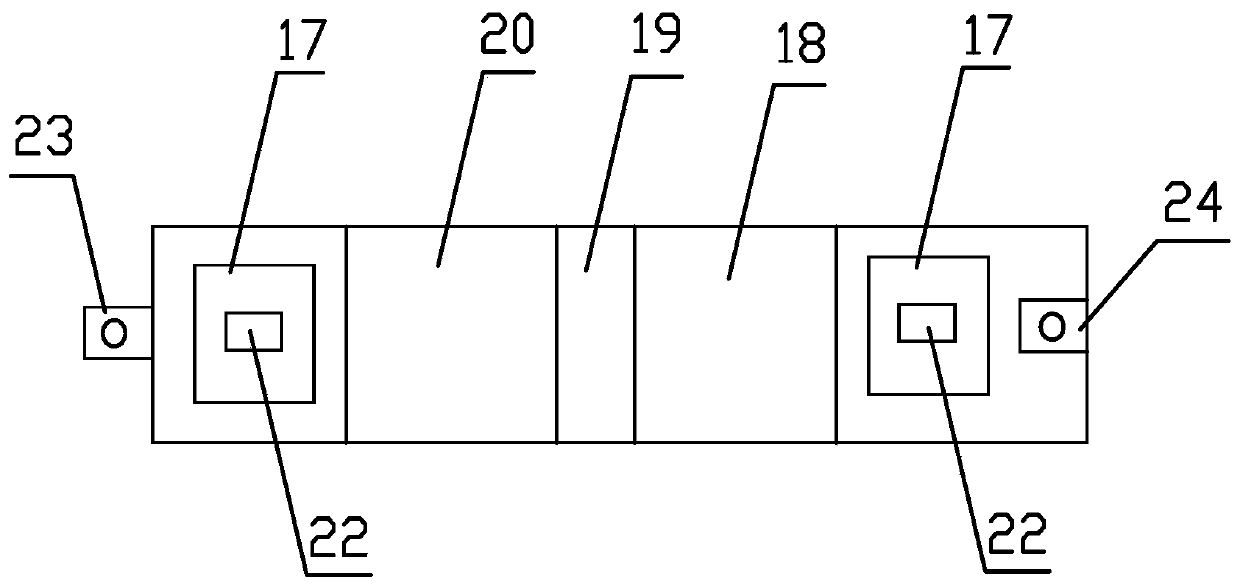

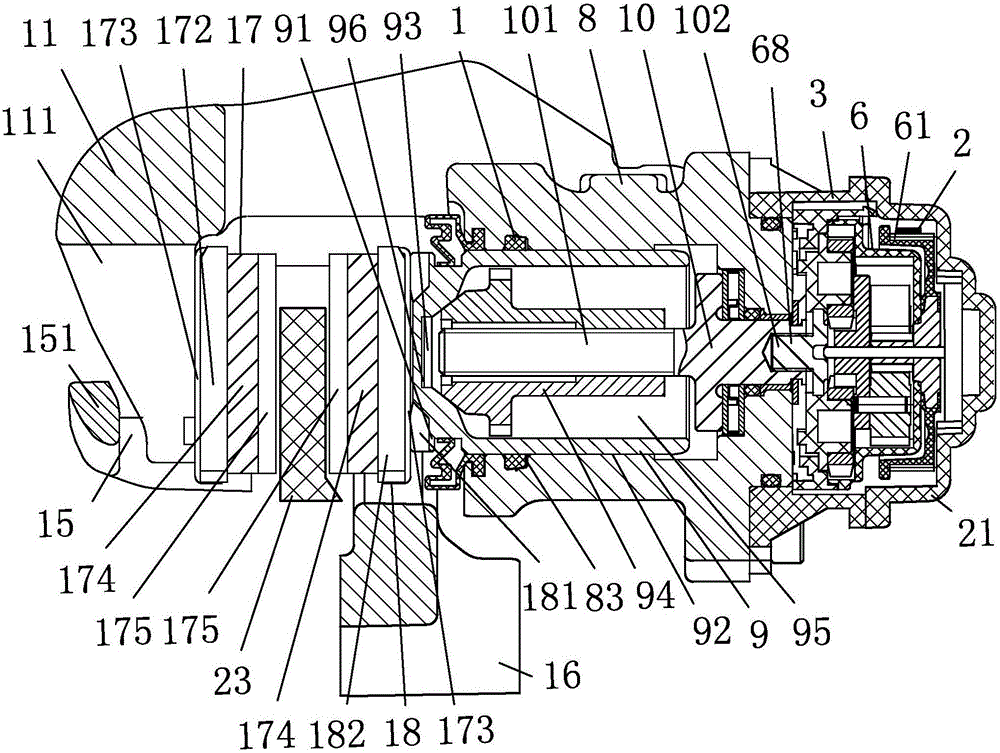

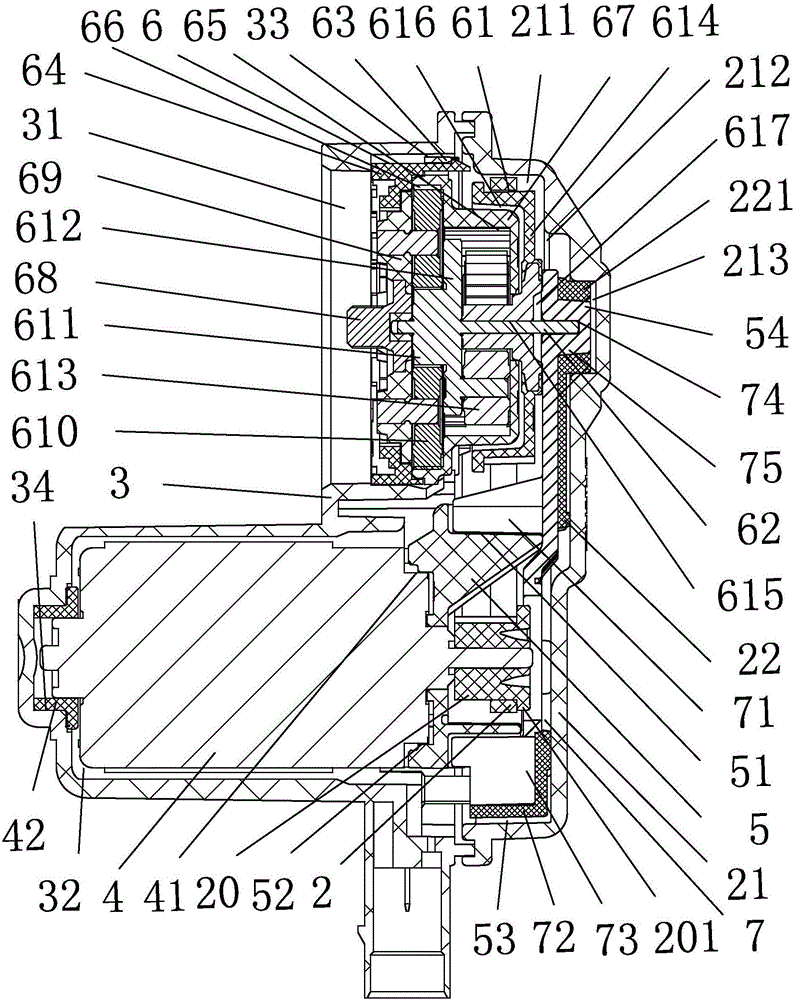

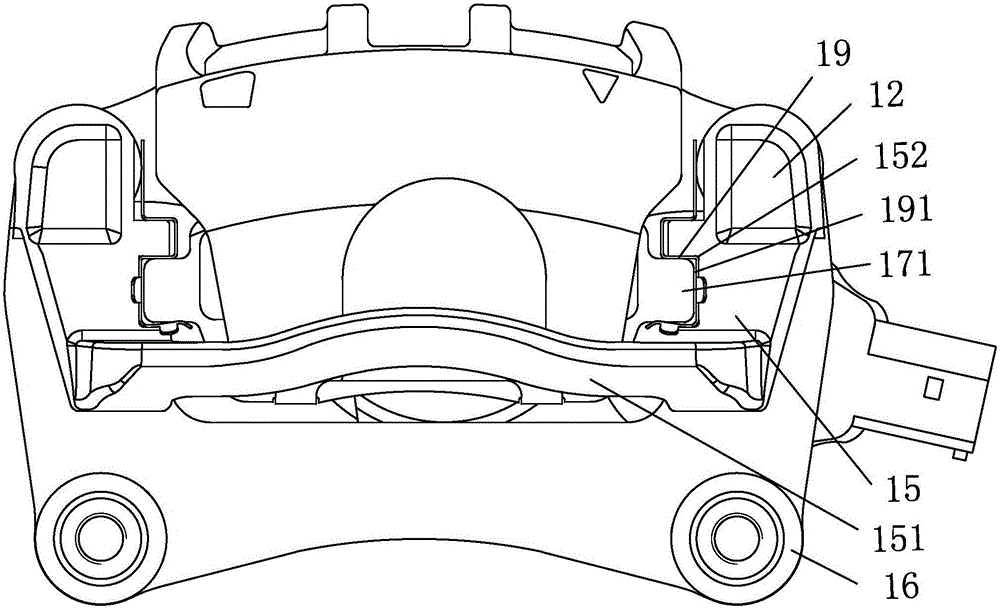

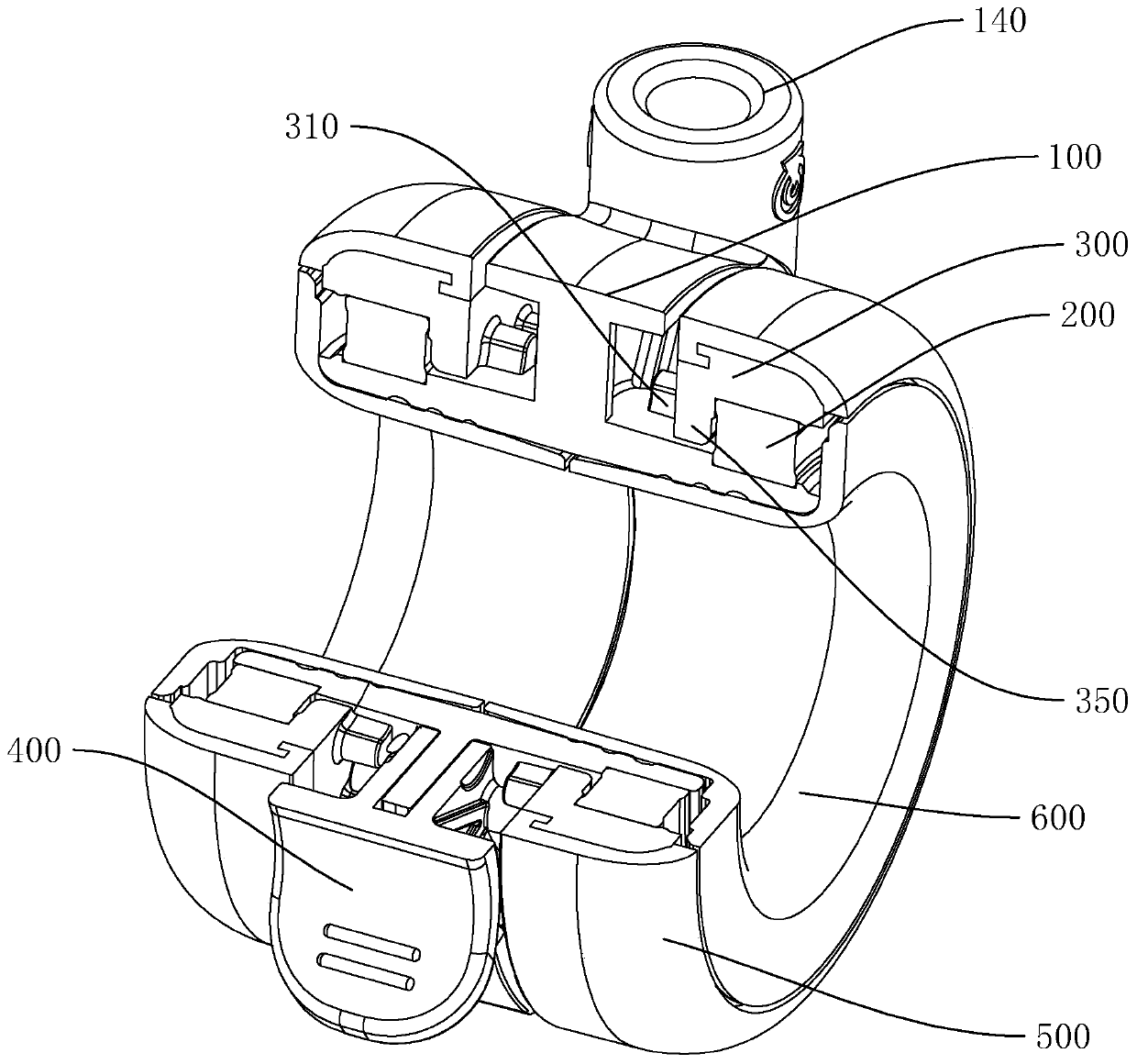

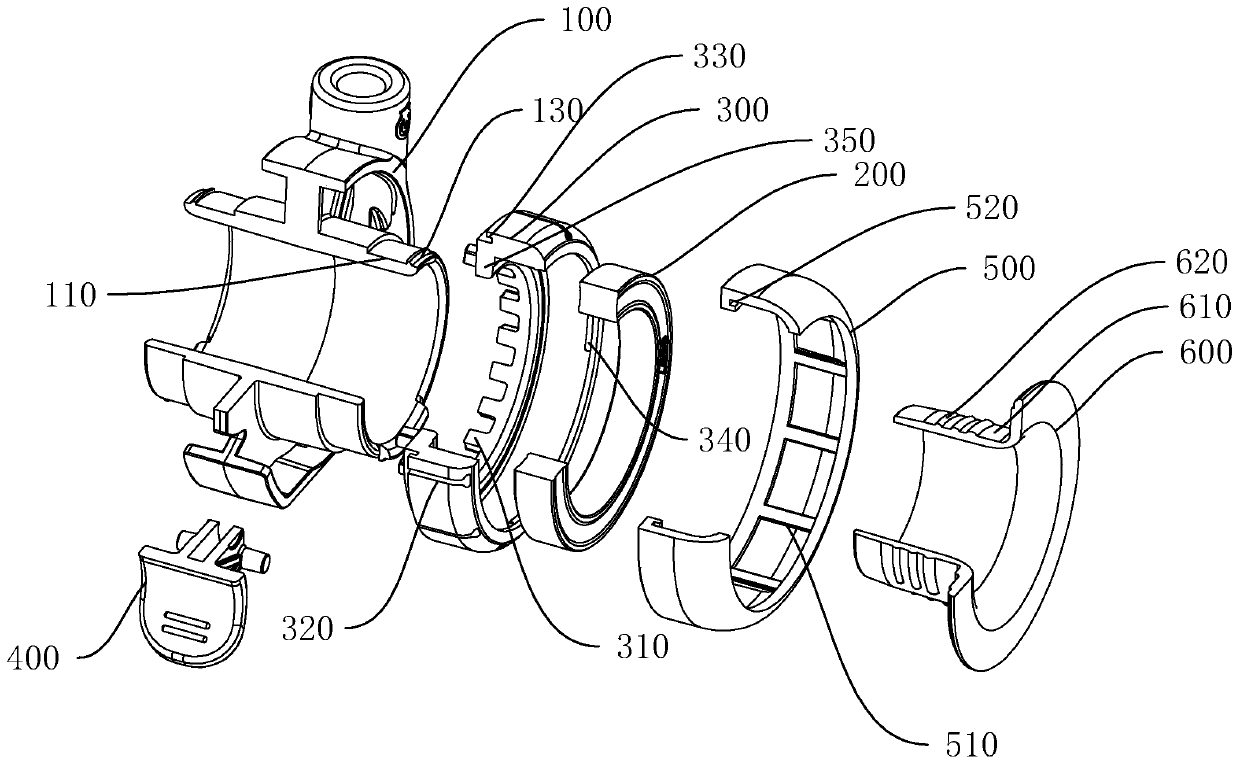

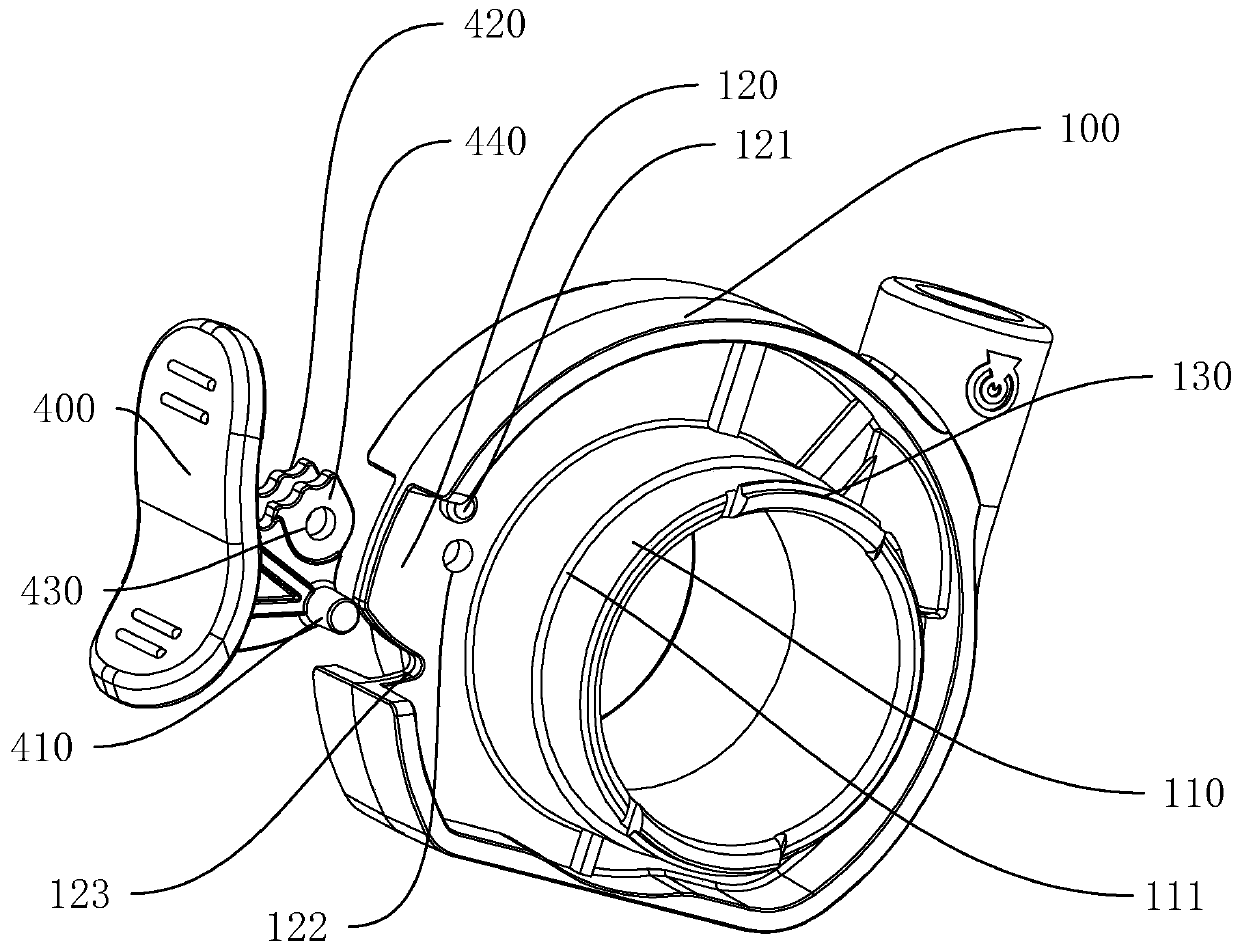

Parking Brake Transmission

ActiveCN104074895BEasy to assembleReduce volumeBrake actuating mechanismsActuatorsElastic vibrationEngineering

The invention relates to the field of automobile braking devices, and aims at providing a parking braking transmission device. The parking braking transmission device comprises a shell provided with an installation through hole and an installation cavity, a planetary reducer located in the installation through hole and provided with a driven synchronous belt wheel and a floating centring shaft, a motor located in the installation cavity and provided with a location convex ring at a front end cover, a lower connection block provided with a location hole which is formed outside the location convex ring in a sleeving manner, and a clamping hole and a buffering hole which are located in the two opposite sides of the location hole respectively, an upper connection block provided with a clamping block which is inserted in the clamping hole, an insertion sheet with a side surrounding which coats a buffering gasket and is inserted in the buffering hole, and a radial limit hole which is in clearance fit with the front end of the floating centring shaft, a shell cover connected with the shell body, an elastic vibration damping block connected with the front end of the lower connection block and the shell cover respectively, a drive synchronous belt wheel which is in transmission connection with the motor output shaft, and a synchronous belt. The parking braking transmission device is low in vibration and noise during working, and easy to assemble.

Owner:ZHEJIANG LIBANG HEXIN INTELLIGENT BRAKING SYST CO LTD

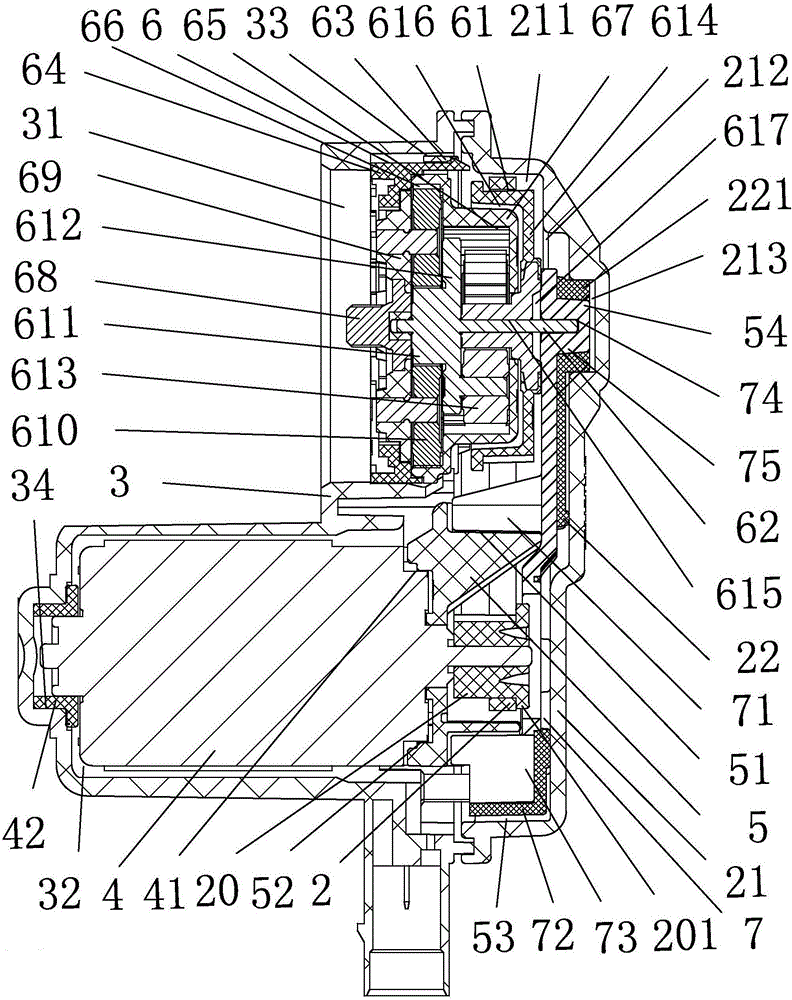

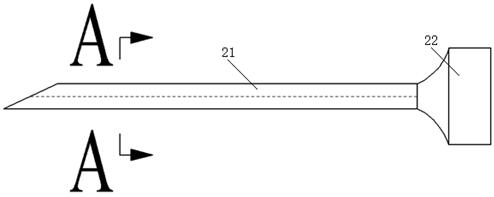

Rubber continuous vulcanization unit extruder screw

PendingCN107672142AEvenly compactedReduce multiple shuntsInsulating conductors/cablesRubber materialVulcanization

The invention discloses a rubber continuous vulcanization unit extruder screw. The screw comprises a screw head and a screw column, and the screw column and the screw head are of an integrated structure; the screw column is provided with an uninterrupted screw edge, and the length-diameter ratio of the screw is 16:1; the whole screw column is provided with a double thread which is equal in interval and unequal in depth, and the depth of the thread is gradually decreased from a feeding inlet to the end of the thread; and the volume ratio of a first thread groove in the feeding section of the screw to a last thread groove of the screw is 1.56. During normal production, the actual outlet speed is improved by 30% compared with a previous mode, on the premise that an applied rubber material isnot changed, that is, on the premise that the formula of the rubber material is not changed, over-vulcanization of the extruded rubber material is avoided, the production requirements are met, and thelabor productivity is improved.

Owner:蒋朝勇

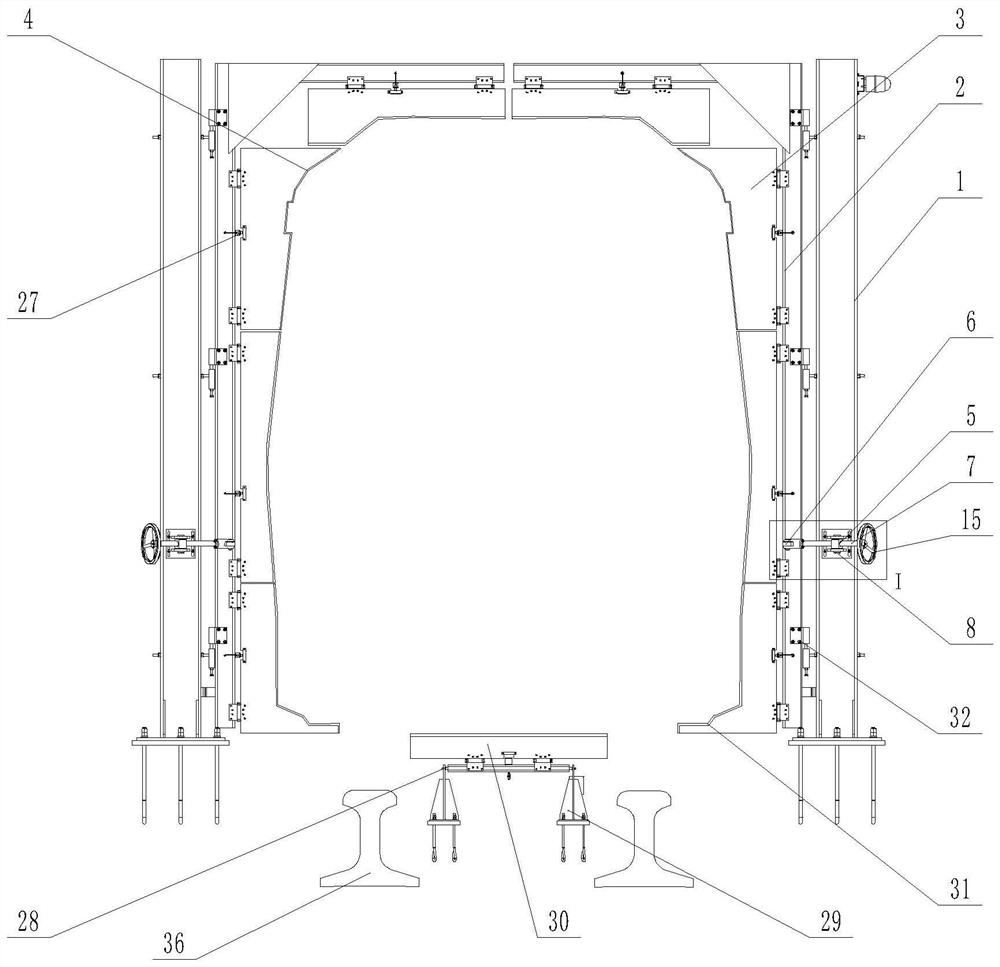

Locomotive limit detection device

ActiveCN112319539AEasy accessEasy to operateRailway auxillary equipmentRailway profile gaugesBlade plateElectrical and Electronics engineering

Owner:XIANGYANG GOTOO MASCH&ELECTRONICS APPLIANCE CO LTD

A kind of electrospinning rotary spinneret and using method thereof

ActiveCN110644063BGuaranteed uniformityReduce rotational frictional resistanceFilament/thread formingFiberPolymer science

The invention relates to an electrospinning rotary spinning device and a method of using the same, comprising a micro-injection pump, an injection tube, a bearing sleeve, a bearing, a needle, a receiving plate and a high-voltage power supply. The advantages of the present invention lie in: the electrospinning rotary spinneret device and its using method of the present invention, the tail of the needle head is connected with a bearing, the bearing rotational frictional resistance is small, and the bearing is easy to be replaced after wear; the needle tube in the device is divided into equal volumes. Several layers, each layer of spinning solution is under the same pressure to ensure the uniformity of spinning; the speed of the needle is controlled by the motor, and the speed can be adjusted according to the characteristics of different polymers, so as to change the degree of spinning of the fibers and improve the product quality. quality.

Owner:NANTONG UNIVERSITY

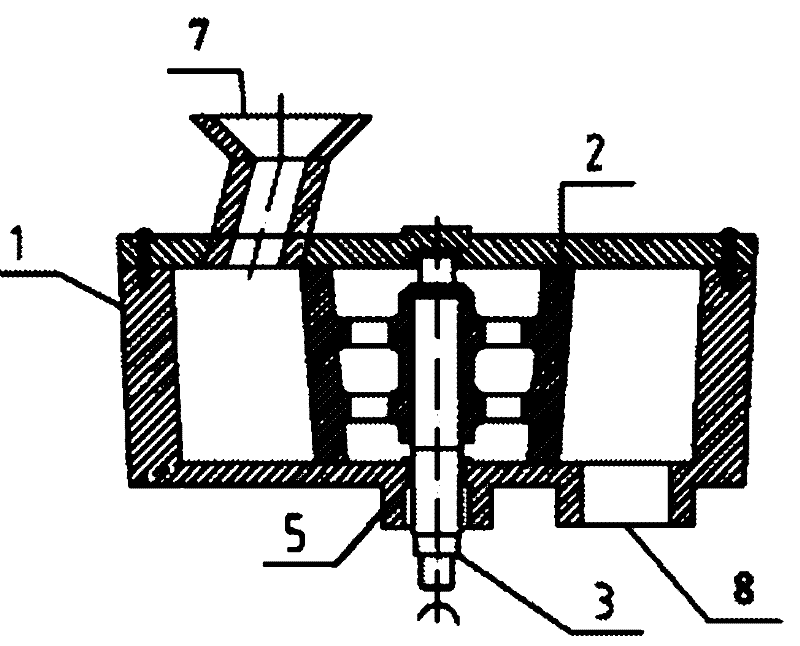

Small-sized rotor type electromagnetic regulating valve and method of use thereof

InactiveCN1328526CReduce volumeSimple structureOperating means/releasing devices for valvesLift valveAuto regulationEngineering

A small-sized rotor type electromagnetic regulating valve and method of use thereof, comprising rotor type electromagnetic driving mechanism and butterfly type valve regulating mechanism in coaxial connection, wherein the electromagnetic driving mechanism includes a stator, a rotor arranged in the stator and a rotor return spring, the valve regulating mechanism includes a valve body and a valve plate. The invention realizes simple structure, sensitive opening and closing, high resolution factor, small return difference, accurate valve position and good linearity.

Owner:黎阳胜 +2

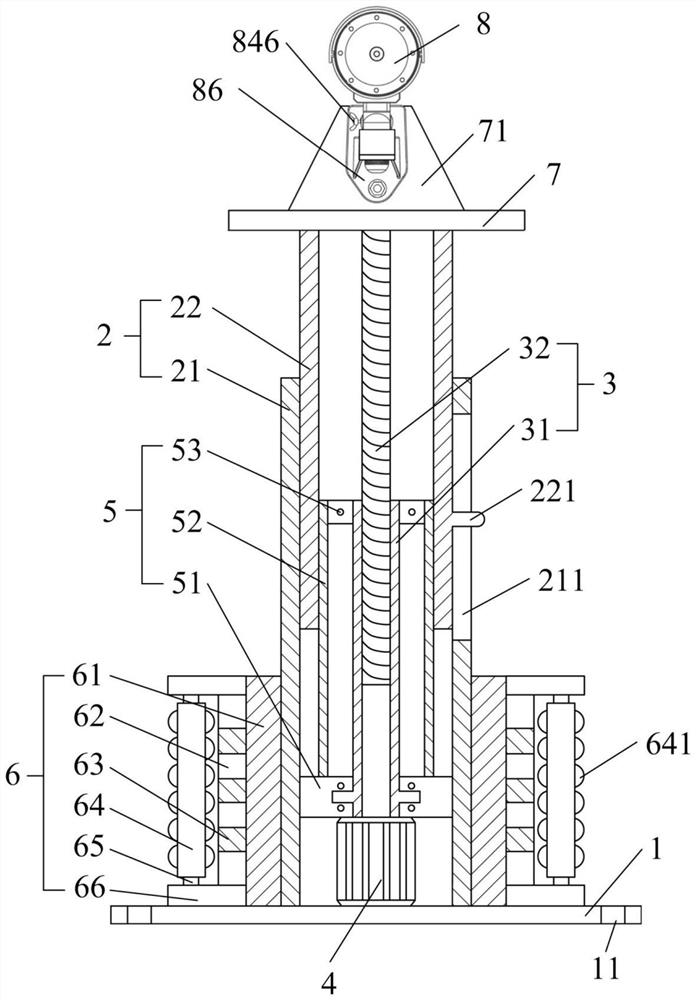

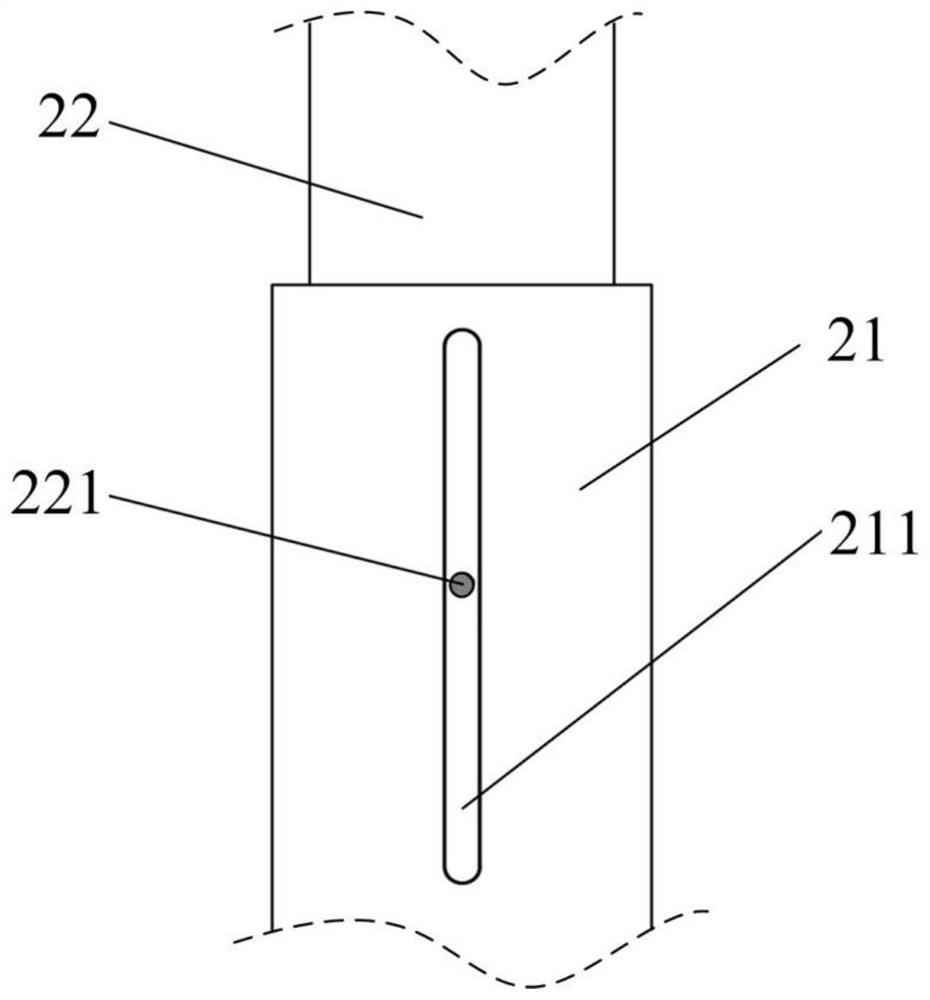

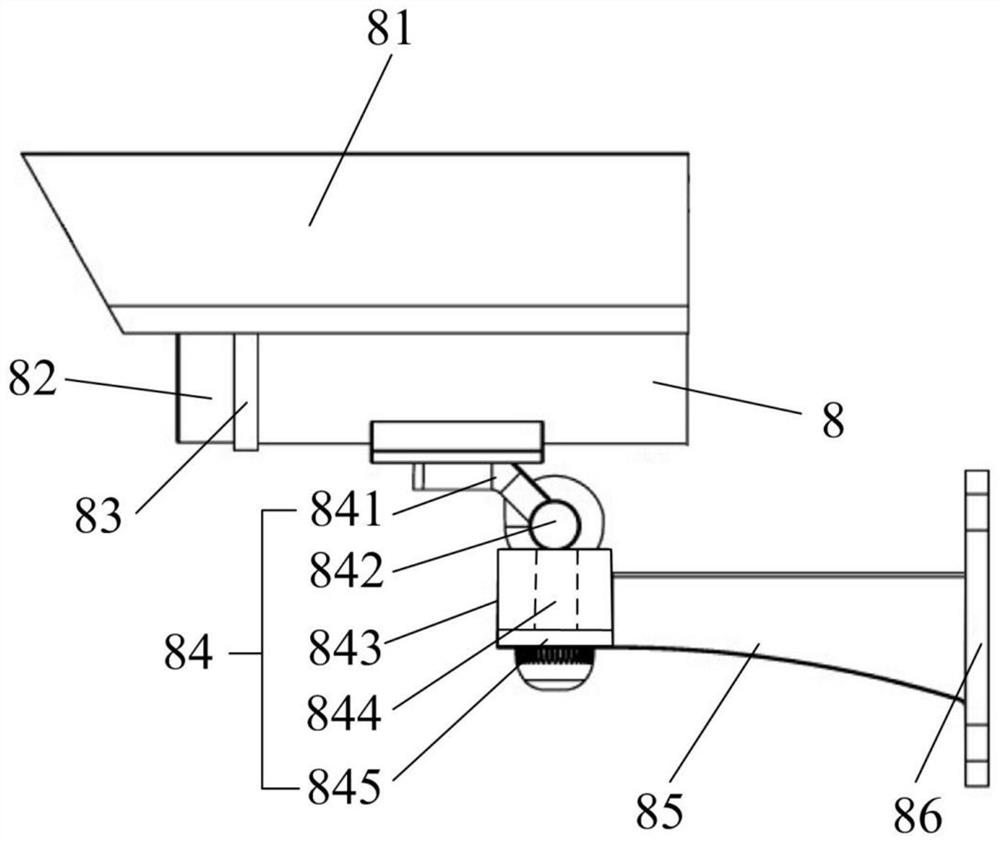

Anti-collision monitoring equipment

InactiveCN112780885AGuaranteed reliabilityEnsure safetyTelevision system detailsNon-rotating vibration suppressionEngineeringStructural engineering

The invention belongs to the technical field of security and protection monitoring, and particularly relates to anti-collision monitoring equipment which comprises a bottom plate, and a sleeve telescopic structure is arranged at the upper end of the bottom plate; the sleeve telescopic structure comprises an outer sleeve and an inner pipe, the outer sleeve is vertically fixed at the upper end of the bottom plate, the telescopic inner pipe is sleeved with the outer sleeve, a supporting plate is fixedly arranged at the top end of the inner pipe, and a camera body is installed on the supporting plate; an anti-collision structure is arranged on the bottom plate and comprises a pressure-bearing barrel arranged on the periphery of the outer sleeve, annular check rings are arranged at the upper end and the lower end of the pressure-bearing barrel, an elastic barrel is arranged between the two annular check rings and located on the outer side of the pressure-bearing barrel, a plurality of damping springs are evenly arranged in the elastic barrel, and a plurality of rotating shafts are arranged between the two annular check rings and located on the outer side of the elastic barrel; and a roller is arranged on each rotating shaft, and a plurality of elastic protrusions are evenly arranged on the outer surface of each roller. According to the anti-collision monitoring equipment, by arranging a height adjusting structure and the anti-collision structure, safety monitoring can be achieved while the monitoring range is adjusted according to needs.

Owner:西安发威电子科技有限公司

A kind of heat exchanger cooling structure forming method

ActiveCN112024669BGuaranteed accuracyEliminate loosenessMetal-working feeding devicesHeat exchange apparatusMechanical engineeringPhysics

The invention provides a method for forming and manufacturing a cooling structure of a heat exchanger, which includes a pressing auxiliary mechanism, an intermittent indexing mechanism and a displacement mechanism. The displacement mechanism is installed on the left end surface of the intermittent indexing mechanism. The pressure auxiliary mechanism is installed on the displacement mechanism, and the pressure auxiliary mechanism is located directly above the intermittent indexing mechanism; the present invention solves the problem that the existing copper tube is bent into a spiral shape by manually turning and forming on a cylinder, However, this method has high requirements on the staff, and the force is uneven during the rotation process, which easily crushes the copper tube, resulting in deformation of the copper tube. Large-scale production operations, and certain pressure-holding operations cannot be performed on the bent and formed coils, resulting in the occurrence of bending and springback.

Owner:江苏瑞林环保科技有限公司

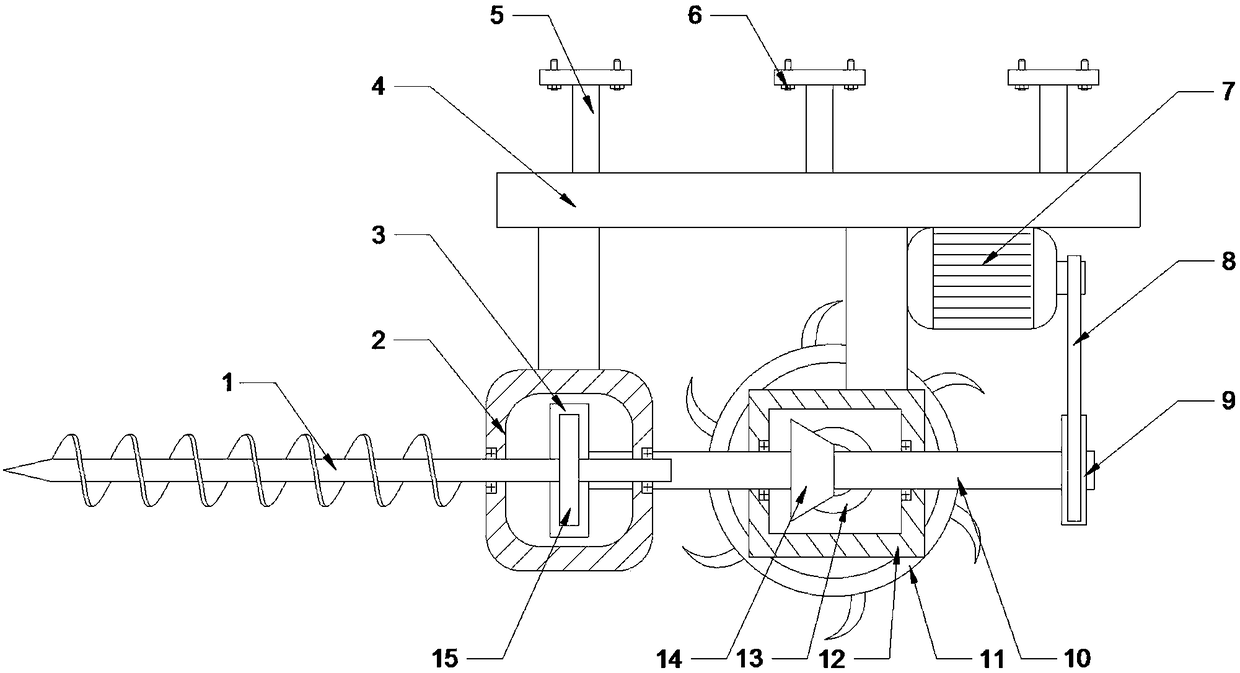

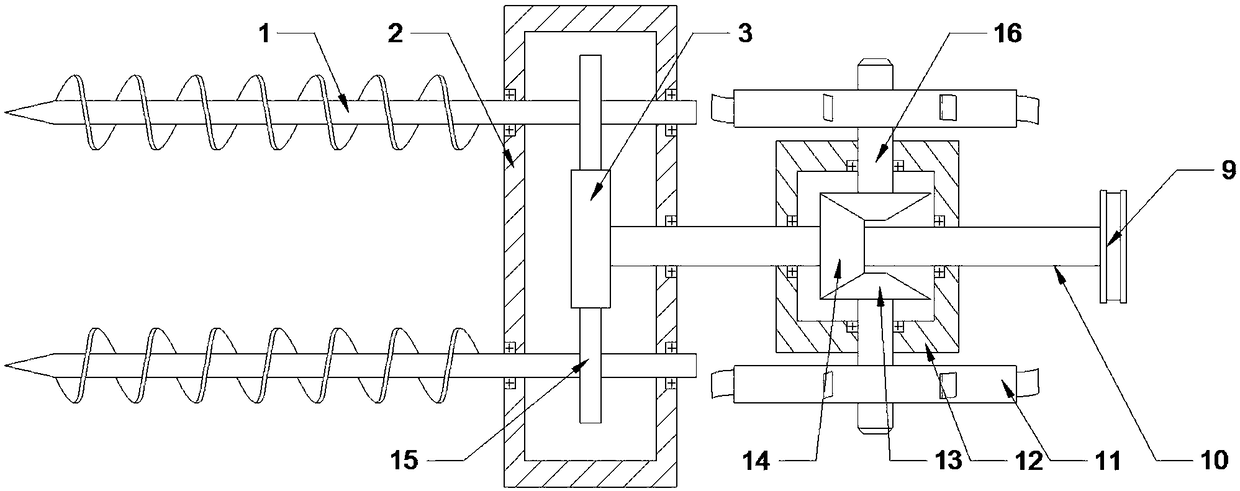

Soil turning mechanism for hard soil

InactiveCN108551779AImprove the quality of cultivated landIncrease productionSpadesPloughsDrive shaftEngineering

The invention relates to the field of agricultural operation equipment, in particular to a soil turning mechanism for hard soil. The agricultural operation equipment comprises a driving shaft, a soilturning cutterhead and a soil turning rotating shaft, wherein the driving shaft is arranged on a soil drilling positioning box and a soil loosening positioning box; one end of the driving shaft extends into the soil drilling positioning box; the extending-end end of the driving shaft is provided with a driving gear; the other end of the driving shaft transversely passes through the soil looseningpositioning box; a second bevel gear is arranged on the shaft section positioned inside the soil loosening positioning box; the driving gear and a driven gear are engaged; the driven gear is arrangedon the rotating shaft part of a soil loosening drill; the soil loosening drill extends out of the soil drilling positioning box; the second bevel wheel is engaged with the first bevel wheel; the firstbevel wheel is arranged on the soil turning rotating shaft; the soil turning rotating shaft passes out of the soil drilling positioning box; the soil turning cutterhead is arranged on the extending-out end of the soil turning rotating shaft. The soil with the high hardness or serious hardening conditions can be loosened; the soil loosening effect is good; the soil cultivation quality is improved;the crop yield is favorably improved.

Owner:HENAN LINQUAN ENVIRONMENTAL PROTECTION TECH CO LTD

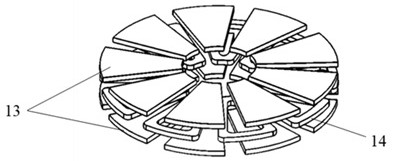

Vertical bidirectional wind generating set and application thereof

PendingCN113107762ACompact structureImprove efficiencyRenewable energy generationMachines/enginesImpellerEngineering

The invention provides a vertical bidirectional wind generating set and application thereof. The vertical type bidirectional wind generating set comprises a fixing frame, 2-10 groups of impellers and 1-9 groups of disc type bidirectional permanent magnet generators. Each impeller is provided with a rotating shaft, and is rotationally connected with the fixing frame in the same direction through the rotating shafts; and every two adjacent groups of impellers rotate in opposite directions and are connected through the disc type bidirectional permanent magnet generators. Through bidirectional rotation of the upper-layer impeller and the lower-layer impeller, wind energy in a three-dimensional space can be collected, and the internal stress of a wheel shaft can be reduced to improve the stability and strength of the generators; and the vertical bidirectional wind generating set has the advantages of high power generation efficiency, good stability, low cost and the like, and has a wide application prospect in large wind field environments such as power supply for deep and far sea floating devices and roofs.

Owner:青岛亿恩方能源环保科技有限公司

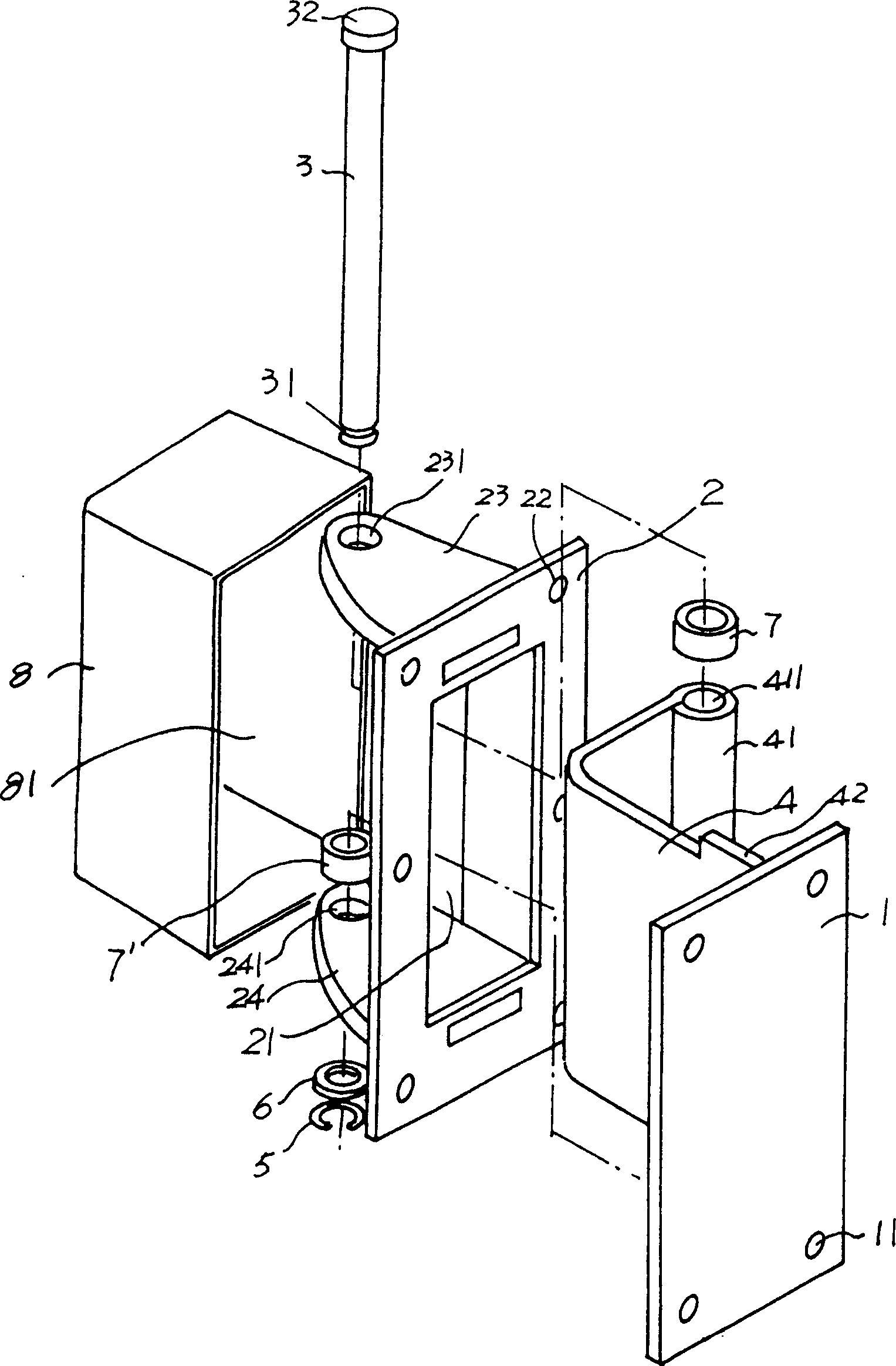

Structure improved hinge

InactiveCN1223749CReduce rotational frictional resistanceFlexible and stable rotationPin hingesEngineeringMechanical engineering

A hinge with improved structure is composed of a hinge plate for door sash, a hinge plate for door frame, and a mandrel. Said hinge plate for door sash has an extended and curved plate whose end is curled for passing the mandrel through it. Said hinge plate for door frame has a central rectangular hole for recepting said curved plate, and upper and lower connecting plates with mandrel hole on them. The lower end of mandrel has a fastening part. When the door is closed, the hinge is hidden. Its other advantages are low friction and noise, and flexible rotation.

Owner:常熟开关制造有限公司

Swing gates for emergency barriers

The invention discloses a pendulum brake suitable for an emergency barrier. The pendulum brake suitable for the emergency barrier comprises columns and baffles, wherein a rotary shaft and a fixing rodare arranged on the axial end face of each column, and the rotary shafts are driven by motors in the columns to rotate; a limiting plate is circularly arranged on the side wall of the axial bottom end of each rotary shaft in the circumferential direction, and limiting strips are arranged on the limiting plate in a protruding mode; a connecting sleeve is arranged on one side edge of each baffle, the axial bottom end faces of the connecting sleeves are provided with limiting grooves matched in a concave mode, and the limiting grooves are matched with the limiting strips; the rotary shafts are sleeved with the connecting sleeves; and the limiting strips are embedded in the limiting grooves and fixed in a transition fit mode. The pendulum brake suitable for the emergency barrier further comprises cover plates which are detachably connected with the axial tops of the fixing rods and rotationally connected with the axial tops of the rotary shafts. The pendulum brake suitable for the emergency barrier further comprises a base, the two ends of the base in the long axis direction are each provided with a mounting groove, and the axial bottom ends of the columns are embedded in the mountinggrooves in a transition fit mode. According to the pendulum brake suitable for the emergency barrier, the structure is simple, the main components are detachably connected, assembly and disassembly are convenient, and thus workers can conveniently carry the pendulum brake for storage at any time or move the pendulum brake to a place needing traffic limitation and arrange the pendulum brake quickly.

Owner:CHENGDU ZHIRONG ZHICHUANG INTPROP MANAGEMENT CO LTD

Parking brake device and parking brake system

ActiveCN104071136BImprove vibrationImprove noiseBraking element arrangementsMechanical braking transmissionDrive wheelGear wheel

A parking brake device, comprising a transmission mechanism and a brake caliper that is transmission-connected to the transmission mechanism; the transmission mechanism includes a housing provided with an installation through hole and an installation cavity, located in the installation through hole and provided with a driven A planetary reducer with a synchronous pulley and a floating centering shaft, a motor located in the installation cavity and with a positioning bead on the front cover, a positioning hole sleeved outside the positioning bead, and snaps on opposite sides of the positioning hole. The lower connection block of the hole and the buffer hole is equipped with a block inserted into the hole, an insert piece wrapped around the buffer pad and inserted into the buffer hole, and an upper part of the radial limit hole that is matched with the front end of the floating centering shaft. The connecting block, the shell cover connected with the housing, the elastic damping block connected with the front end of the lower connecting block and the shell cover respectively, the active synchronous pulley and the synchronous belt connected with the output shaft of the motor. When the parking brake device works, the vibration and noise are small and the assembly is easy.

Owner:ZHEJIANG LIBANG HEXIN INTELLIGENT BRAKING SYST CO LTD

High-temperature liquid furnace slag conveying method using valve conveying device

ActiveCN102502196BSolving Rotary Seal Lubrication ProblemsAdjustable pressureRotary conveyorsImpellerSlag

Owner:北京中冶设备研究设计总院有限公司

Rotary direct motion arch breaking device

ActiveCN104555153BCompact structureEasy to install on siteLarge containersEngineeringOperation safety

The invention relates to a rotary direct-driving arch breaking device, belonging to the field of material conveying. A lengthening rod is arranged at the end part of the arch breaking device, and meanwhile, the lengthening rod rotates under the driving of a rotary driving device. Compared with an arch breaking range that the diameter of an arch breaking sleeve per se reaches, the arch breaking range of the rotary direct-driving arch breaking device disclosed by the invention is greatly expanded. Moreover, the rotary direct-driving arch breaking device is compact in structure, the quantity of assembling parts in a field installing process is greatly reduced and thus the field installation of the arch breaking device is facilitated. Since the rotary driving device drives a rotary cover and the lengthening rod to rotate through a rotating shaft in a process of rotary arch breaking and fewer rotating components are used, extra rotary friction resistance caused hereby is greatly reduced, the action force of rotary arch breaking can be sufficiently exerted and the arch breaking effect is improved. According to the arch breaking device disclosed by the invention, a stock bin does not need to be cleared in an assembling and disassembling process, operating personnel are unnecessary to enter the stock bin, and thus the operation safety is improved.

Owner:河南辉强机械设备有限公司

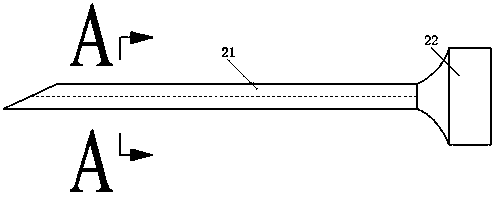

A wiring mechanism for a silicon wafer line cutting machine

ActiveCN106426584BAvoid cutsAvoid enteringWorking accessoriesGrinding machinesScrew threadConductor Coil

Owner:江苏美科太阳能科技股份有限公司

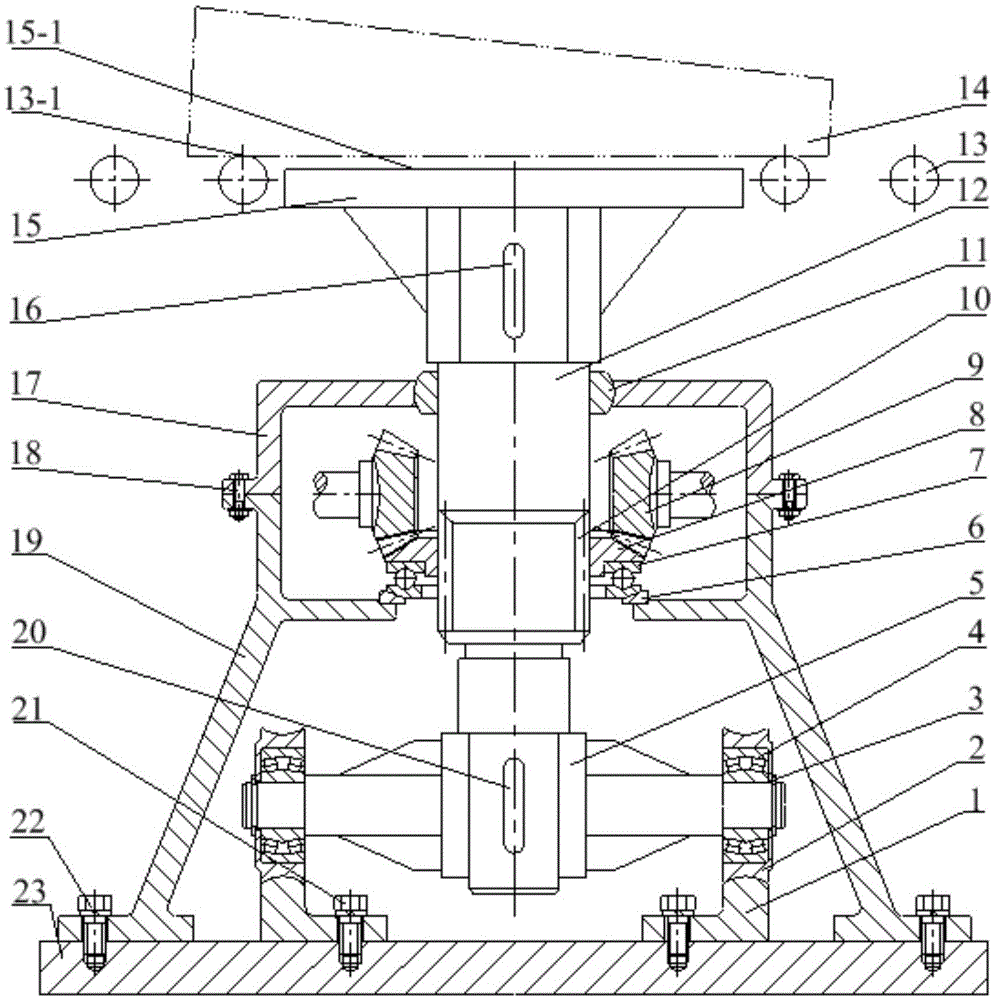

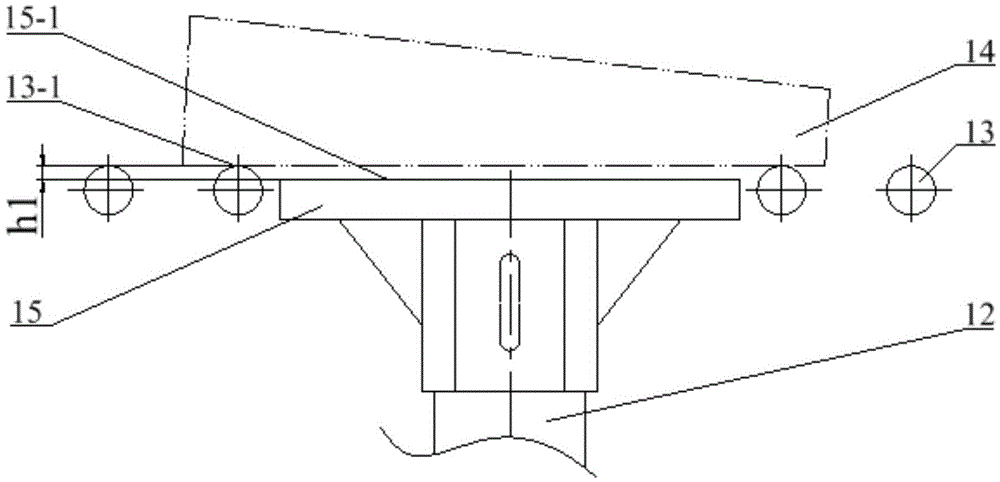

A steel ingot turning machine

The invention discloses a steel ingot reversing machine. The steel ingot reversing machine comprises a base, a rail body, groove wheels, aligning roller bearings, a connecting frame, a main shaft, driving bevel gears, driven bevel gears, transmitting shafts, spherical bases, thrust ball bearings, motors, self-aligning sliding bearings, a tray, roller ways, a supporting cover and a cover cap. The rail body is formed by a cylinder body and installing convex lugs arranged at the lower end of the inner wall of the cylinder body, the upper end face of the cylinder body is a convex arc face, a convex-arc-shaped annular rail is formed on the upper end face of the cylinder body, and the convex-arc-shaped annular rail is composed of two same-shape lower concave sections which are symmetric with respect to the axis of the cylinder body and two same-shape standard sections which are symmetric with respect to the axis of the cylinder body in an alternate manner; and the groove wheels are in circular ring shapes, the outer ring faces of the groove wheels are concave arc faces, and the concave arc faces are matched with the convex arc face on the upper end face of the cylinder body in the rail body. When the steel ingot reversing machine operates, stress of a transmitting system is balanced, the driven bevel gears can not shift vertically along with rotation of the main shaft, and jamming and off tracking of the groove wheels can be avoided.

Owner:SICHUAN UNIV

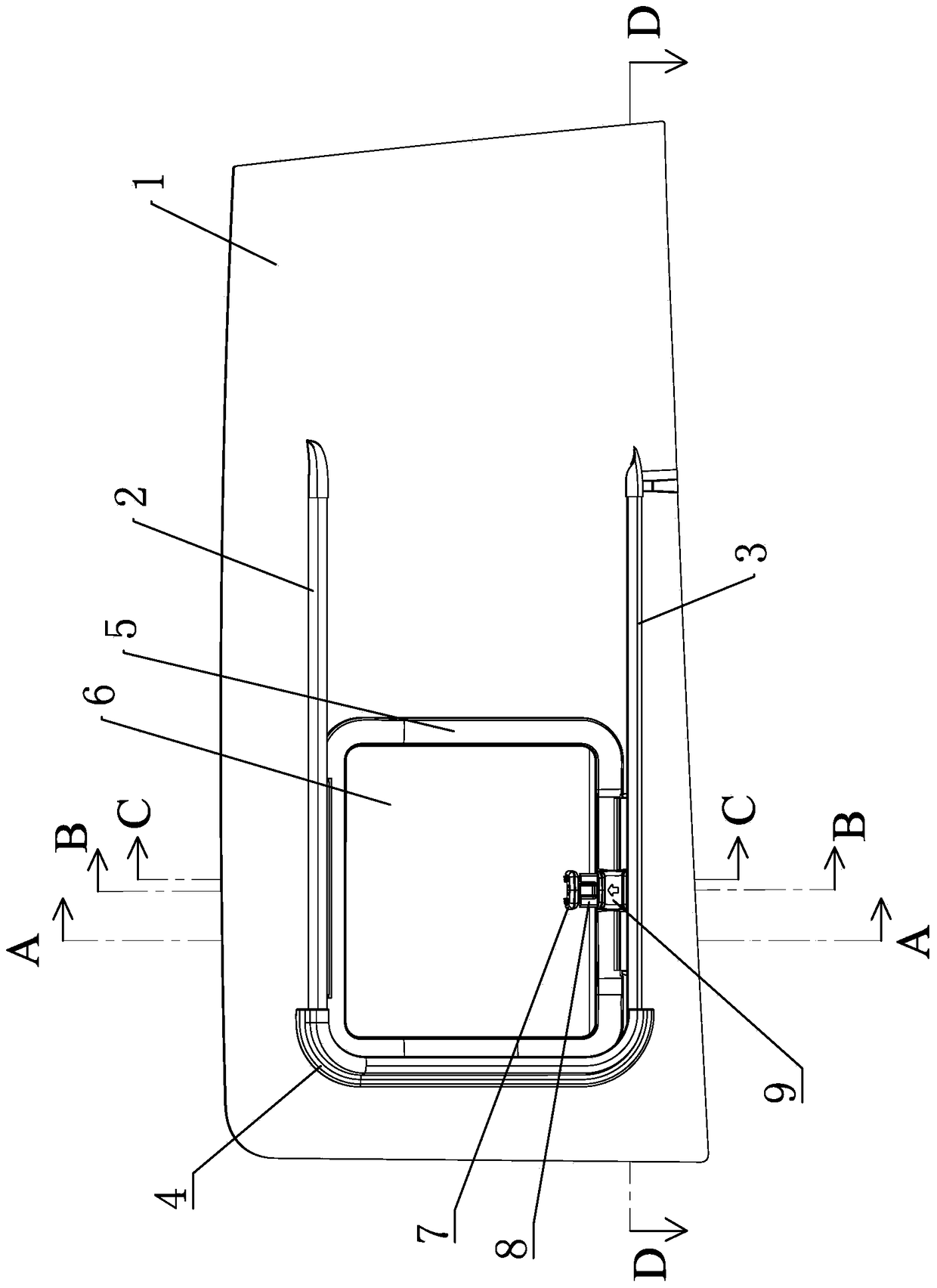

Sliding windows and how they work

ActiveCN105863446BLarge opening angleReduce occupancySealing arrangementsWing arrangementsSlide windowEngineering

Owner:JIANGSU CHANG NING ET LTD

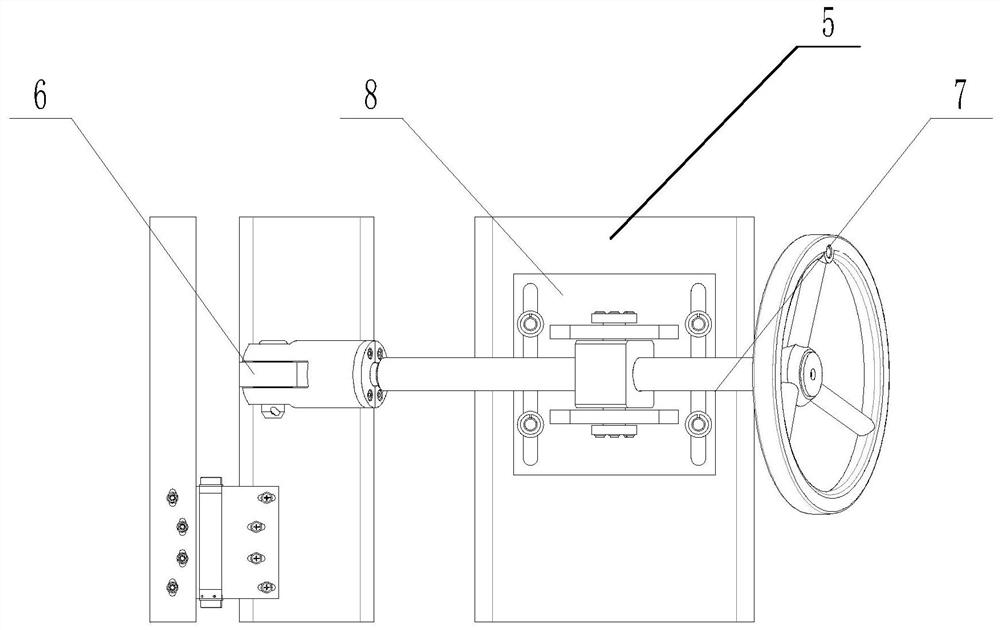

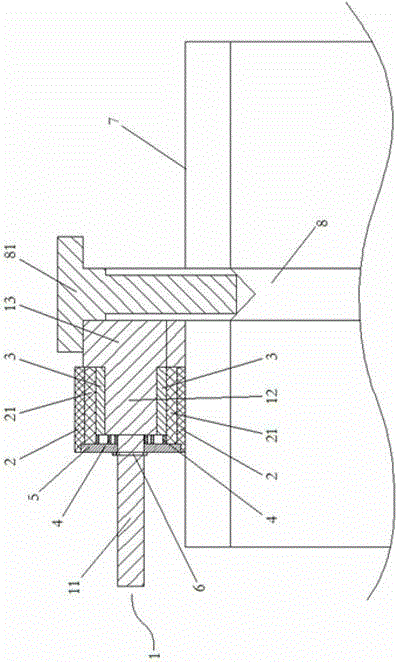

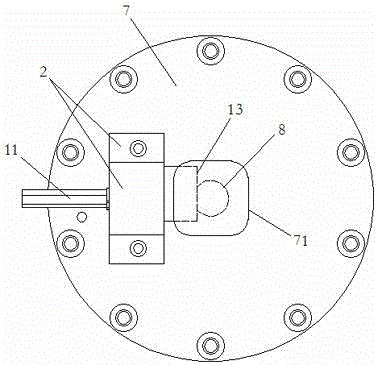

An external mechanical manual opening device and a permanent magnet drive mechanism

ActiveCN103413719BPrevent automatic rotation phenomenonReduce rotational frictional resistanceHigh-tension/heavy-dress switchesAir-break switchesEngineeringSliding contact

The invention relates to an external mechanical manual opening device and a permanent magnet driving mechanism. The opening device comprises a manual opening shaft, a fixing base, a bearing and an elastic rolling spring. The bearing is fixedly arranged in the fixing base. The manual opening shaft is horizontally arranged in the fixing base and is arranged on the bearing in a penetrating mode. The front end and the back end of the manual opening shaft both extend out of the fixing base. An eccentric circular column is arranged at the back end of the manual opening shaft. The elastic rolling spring is arranged in the fixing base. The outer end portion and the inner end portion of the elastic rolling spring are fixedly connected with the fixing base and the manual opening shaft respectively. When the opening device is arranged on the permanent magnet driving mechanism, the end face of the eccentric circular column is in face contact with an opening guiding rod of the permanent magnet driving mechanism, and the periphery side face of the eccentric circular column is in sliding contact connection with an opening head of the opening guiding rod. Accordingly, manual opening and automatic closing of the permanent magnet driving mechanism can be achieved, the number of component parts is small, structure is simple and reasonable, stability and reliability of performance are high, self rotating of the opening guiding rod can be avoided, manual rotating is easy and smooth, performance is stable, and service life is long.

Owner:ZHUHAI WANLIDA ELECTRICAL AUTOMATION

Tungsten powder carbonization device in tungsten carbide production and implementation method of device

InactiveCN112811425AUniform heating and carbonizationImprove the carbonization effectTungsten/molybdenum carbideCarbonizationTungsten

The invention discloses a tungsten powder carbonization device in tungsten carbide production and an implementation method of the tungsten powder carbonization device in tungsten carbide production. The tungsten powder carbonization device in tungsten carbide production comprises a rotating mechanism, a carbonization furnace and an auxiliary rotating mechanism, one end of the carbonization furnace is movably connected with the lower end of one side of the rotating mechanism, and the other end of the carbonization furnace is connected with one end of the auxiliary rotating mechanism. The tungsten powder carbonization furnace has the beneficial effects that a mixed tungsten powder raw material can move left and right back and forth while rotating in a carbonization furnace main body, so that the mixed tungsten powder raw material cannot aggregate, the heating and carbonization effects of the mixed tungsten powder raw material are more uniform, the carbonization effect of tungsten powder is improved, a sleeve ball is smoother in the rotating process, the rotating friction resistance is reduced, the service life of the device is prolonged, and tungsten powder and carbon powder are uniformly mixed in the tungsten powder carbonization process, so that the tungsten powder is carbonized and heated more uniformly, and the carbonization effect of the mixed tungsten powder raw material is further improved.

Owner:李福生

A three-chamber connected sample detection cup

ActiveCN108362722BMicroscopic observation is clearUndisturbedMaterial analysis using wave/particle radiationFiltrationEngineering

Owner:HUNAN OUJIE BIOTECH DEV

Rubber wheel

The invention discloses a rubber wheel. The rubber wheel comprises a bracket, a bearing, an inner rim and a brake piece; the bracket is provided with a shaft barrel; the bearing inner ring sleeves theshaft barrel; the inner rim sleeves on the bearing outer ring and is provided with brake convex teeth which are arranged around the rotation center of the inner rim at intervals; the brake piece canbe movably mounted on the bracket in a locking mode, and is provided with a brake structure capable of moving along with the brake piece to be inserted into or separated from the gap of the brake convex teeth. According to the rubber wheel, the bearing inner ring sleeves the shaft barrel, and the bearing outer ring sleeves the inner rim, so that the relative rotation of the inner rim and the bracket is realized, the rotation friction resistance is reduced through the bearing, and the rubber wheel rotates smoothly; the inner rim is provided with a circle of brake convex teeth, the brake piece is inserted into the brake convex teeth through the brake structure to realize braking of the rubber wheel, braking of the rubber wheel can be realized through matching of the inner rim and the brake piece, braking is realized without adding additional accessories, the structure and the size of the rubber wheel are simplified, the rubber wheel is lighter, and meanwhile, the cost of the rubber wheelis reduced.

Owner:ZHONGSHAN ROBBY HARDWARE PROD CO LTD

Steel ingot reversing machine

The invention discloses a steel ingot reversing machine. The steel ingot reversing machine comprises a base, a rail body, groove wheels, aligning roller bearings, a connecting frame, a main shaft, driving bevel gears, driven bevel gears, transmitting shafts, spherical bases, thrust ball bearings, motors, self-aligning sliding bearings, a tray, roller ways, a supporting cover and a cover cap. The rail body is formed by a cylinder body and installing convex lugs arranged at the lower end of the inner wall of the cylinder body, the upper end face of the cylinder body is a convex arc face, a convex-arc-shaped annular rail is formed on the upper end face of the cylinder body, and the convex-arc-shaped annular rail is composed of two same-shape lower concave sections which are symmetric with respect to the axis of the cylinder body and two same-shape standard sections which are symmetric with respect to the axis of the cylinder body in an alternate manner; and the groove wheels are in circular ring shapes, the outer ring faces of the groove wheels are concave arc faces, and the concave arc faces are matched with the convex arc face on the upper end face of the cylinder body in the rail body. When the steel ingot reversing machine operates, stress of a transmitting system is balanced, the driven bevel gears can not shift vertically along with rotation of the main shaft, and jamming and off tracking of the groove wheels can be avoided.

Owner:SICHUAN UNIV

Rotary exit device with guide for drilling radial and horizontal holes

ActiveCN105525874BReduce eccentric wear resistanceRotational resistance torque increasesDrilling rodsDirectional drillingEngineeringSteel ball

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com