Tungsten powder carbonization device in tungsten carbide production and implementation method of device

A carbonization device, tungsten carbide technology, applied in the direction of carbide, tungsten/molybdenum carbide, etc., can solve the problems of tungsten carbide quality influence, reduced carbonization effect, uneven mixing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

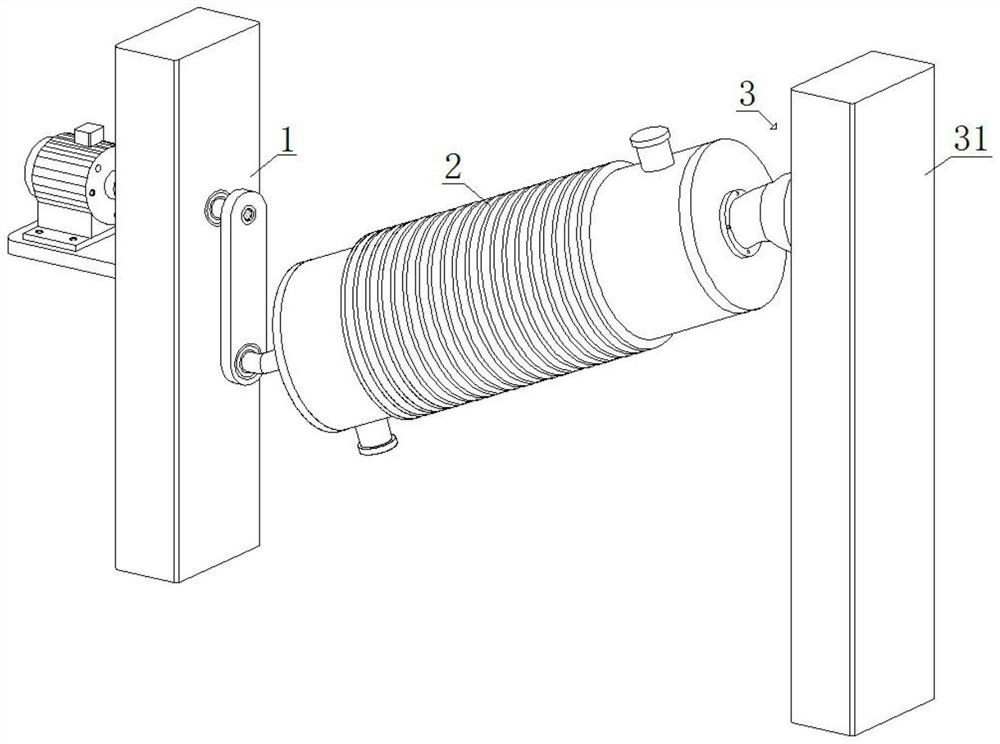

[0038] refer to figure 1 , a tungsten powder carbonization device for tungsten carbide production, comprising a rotary mechanism 1, a carbonization furnace 2 and an auxiliary rotary mechanism 3, one end of the carbonization furnace 2 is movably connected to the lower end of one side of the rotary mechanism 1, and the other end of the carbonization furnace 2 is connected to the auxiliary One end of the rotating mechanism 3 is connected.

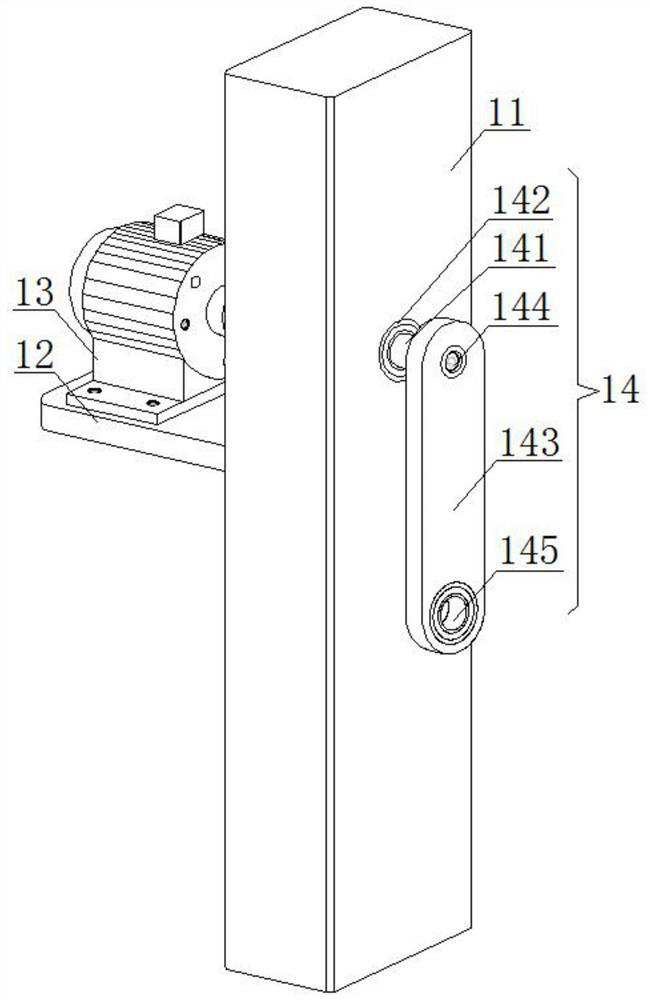

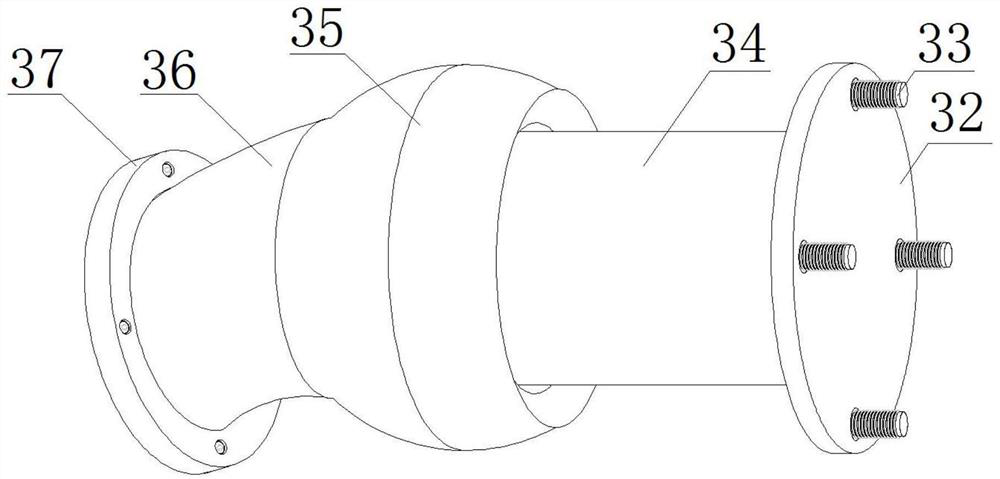

[0039] refer to figure 2 and 5 , a tungsten carbide production medium tungsten powder carbonization device, the rotating mechanism 1 includes a first supporting column 11, a supporting plate 12, a servo motor 13 and a rotating assembly 14, the supporting plate 12 is arranged on the upper end of one side of the first supporting column 11, and the servo The motor 13 is installed on the upper end of the supporting plate 12, one end of the rotating assembly 14 is connected to the driving end of the servo motor 13, and the other end of the rotat...

Embodiment approach

[0042] In order to better the carbonization process of tungsten powder, this embodiment now proposes an implementation method of a tungsten powder carbonization device in tungsten carbide production, including the following steps:

[0043] Step 1: After starting the carbonization furnace 2 and heating it for a period of time, pour the mixed tungsten powder raw material from the feed port 22, and close the feed port 22;

[0044] Step 2: start the servo motor 13, and under the transmission action of the rotating assembly 14, the mixed tungsten powder raw material is turned up and down while turning inside the carbonization furnace main body 21;

[0045] Step 3: After the carbonization time is up, tilt the main body 21 of the carbonization furnace obliquely downward, and discharge the tungsten carbide powder from the discharge port 25 to complete the carbonization of the tungsten powder.

Embodiment 2

[0047] refer to figure 1 , a tungsten powder carbonization device for tungsten carbide production, comprising a rotary mechanism 1, a carbonization furnace 2 and an auxiliary rotary mechanism 3, one end of the carbonization furnace 2 is movably connected to the lower end of one side of the rotary mechanism 1, and the other end of the carbonization furnace 2 is connected to the auxiliary One end of the rotating mechanism 3 is connected.

[0048] refer to figure 2 , a tungsten carbide production medium tungsten powder carbonization device, the rotating mechanism 1 includes a first supporting column 11, a supporting plate 12, a servo motor 13 and a rotating assembly 14, the supporting plate 12 is arranged on the upper end of one side of the first supporting column 11, and the servo The motor 13 is installed on the upper end of the supporting plate 12 , one end of the rotating assembly 14 is connected to the driving end of the servo motor 13 , and the other end of the rotating a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com