Wood columnar activated carbon production equipment

A technology of activated carbon production, columnar, applied in the field of wooden columnar activated carbon production equipment, can solve the problems of uneven drying and carbonization, affecting the use of columnar activated carbon, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

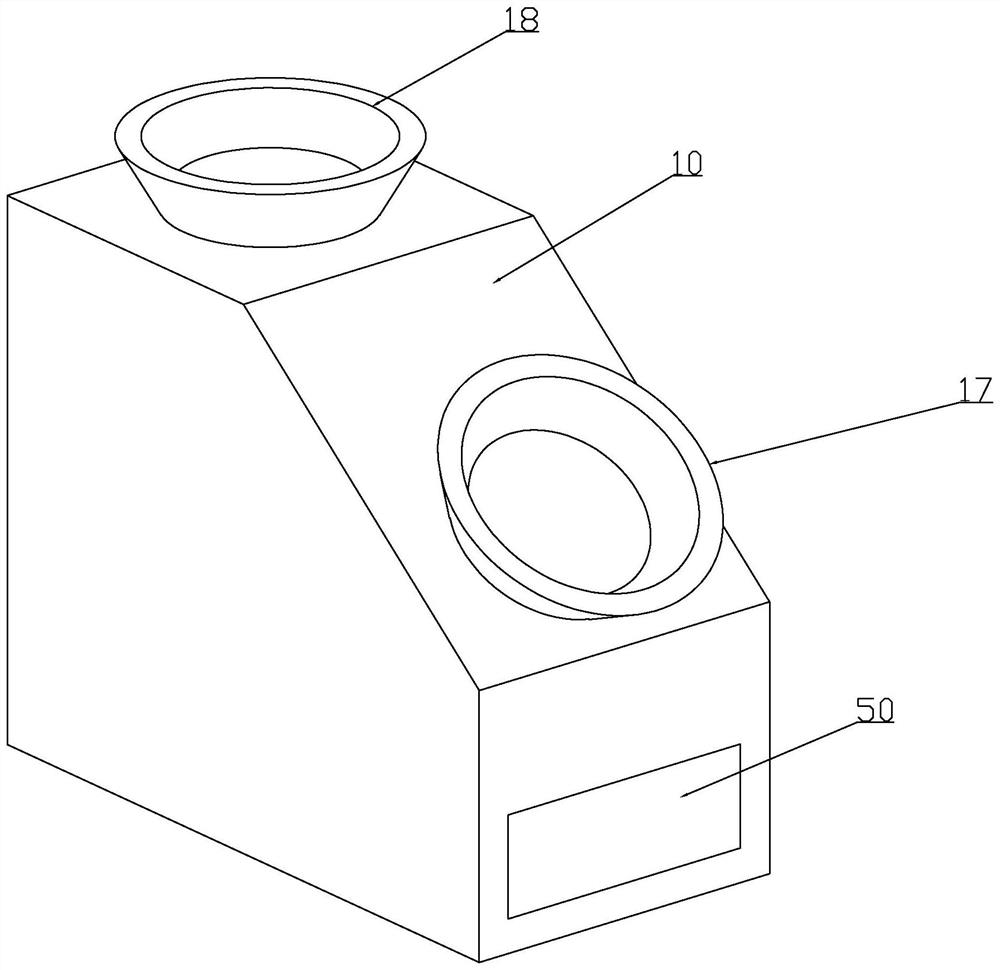

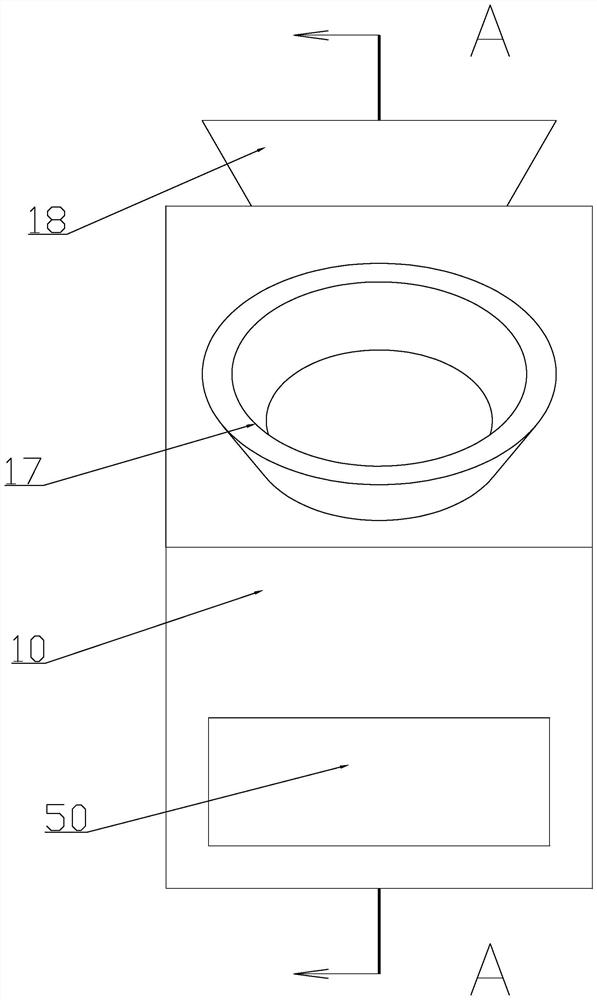

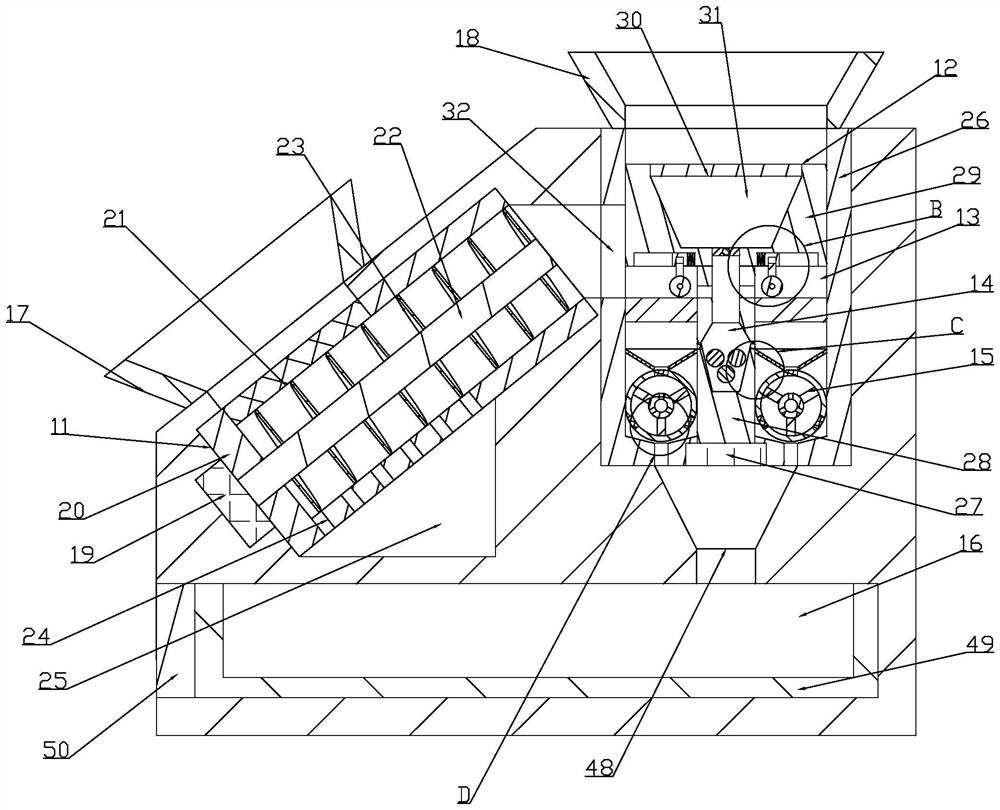

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0025] combine Figure 1-6 ,

[0026] Further, combine Figure 1-6 , a kind of wooden columnar activated carbon production equipment, comprises processing case 10, and carbonization part 15 is positioned at the inner middle of processing case 10, and carbonization part 15 comprises and is provided with treatment cylinder 26, and treatment cylinder 26 is fixed in processing case 10, and the inside of treatment cylinder 26 Two carbonization rotating shafts 43 are arranged on both sides below, and three rotating rods 44 are fixedly arranged in the circumferential direction of the carbonizing rotating shaft 43. The cylinder 42 is connected with three rotating rods 44 in a rotating and sealed manner. A heating chamber 45 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com