Patents

Literature

187results about How to "Short warm-up time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

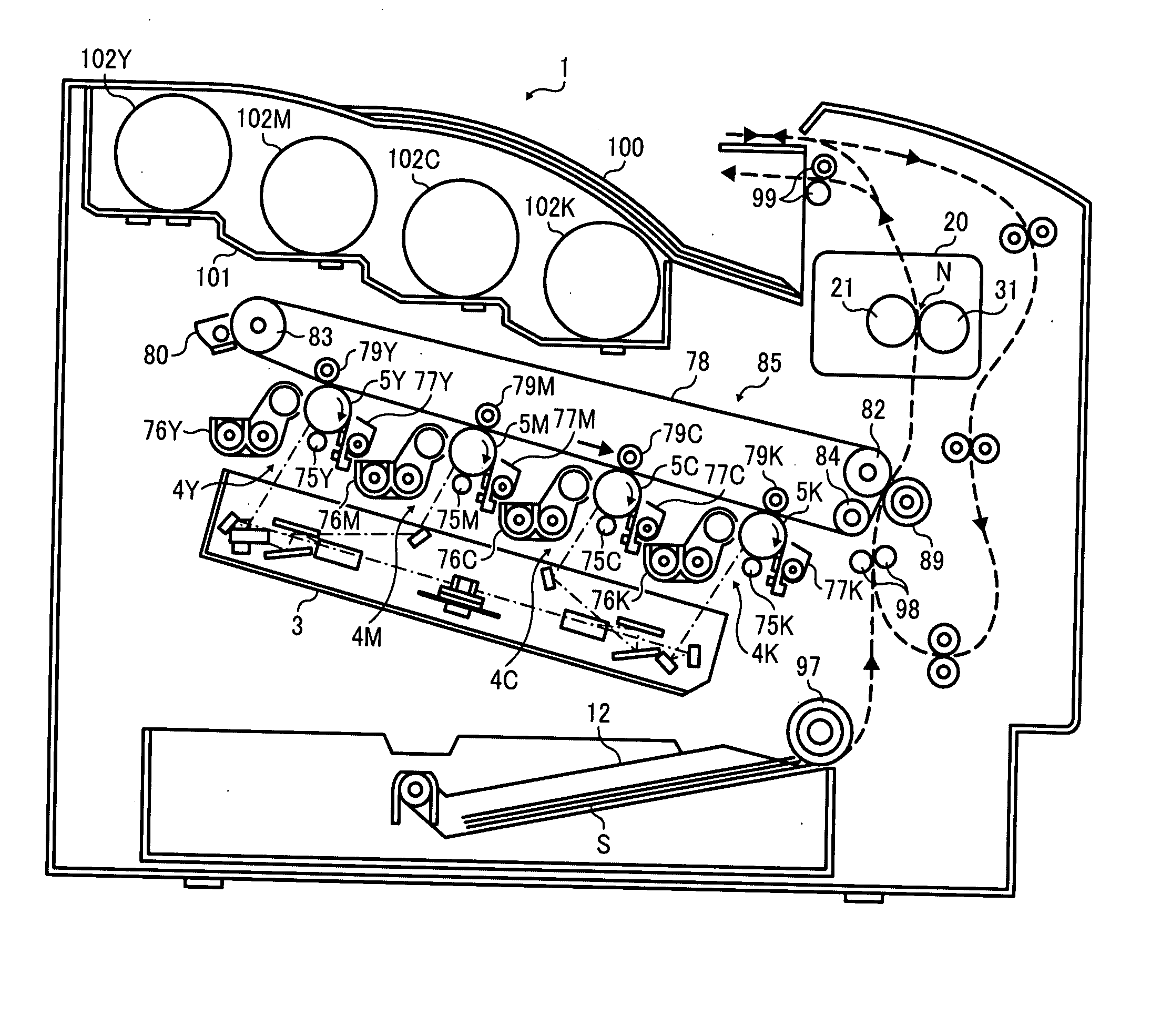

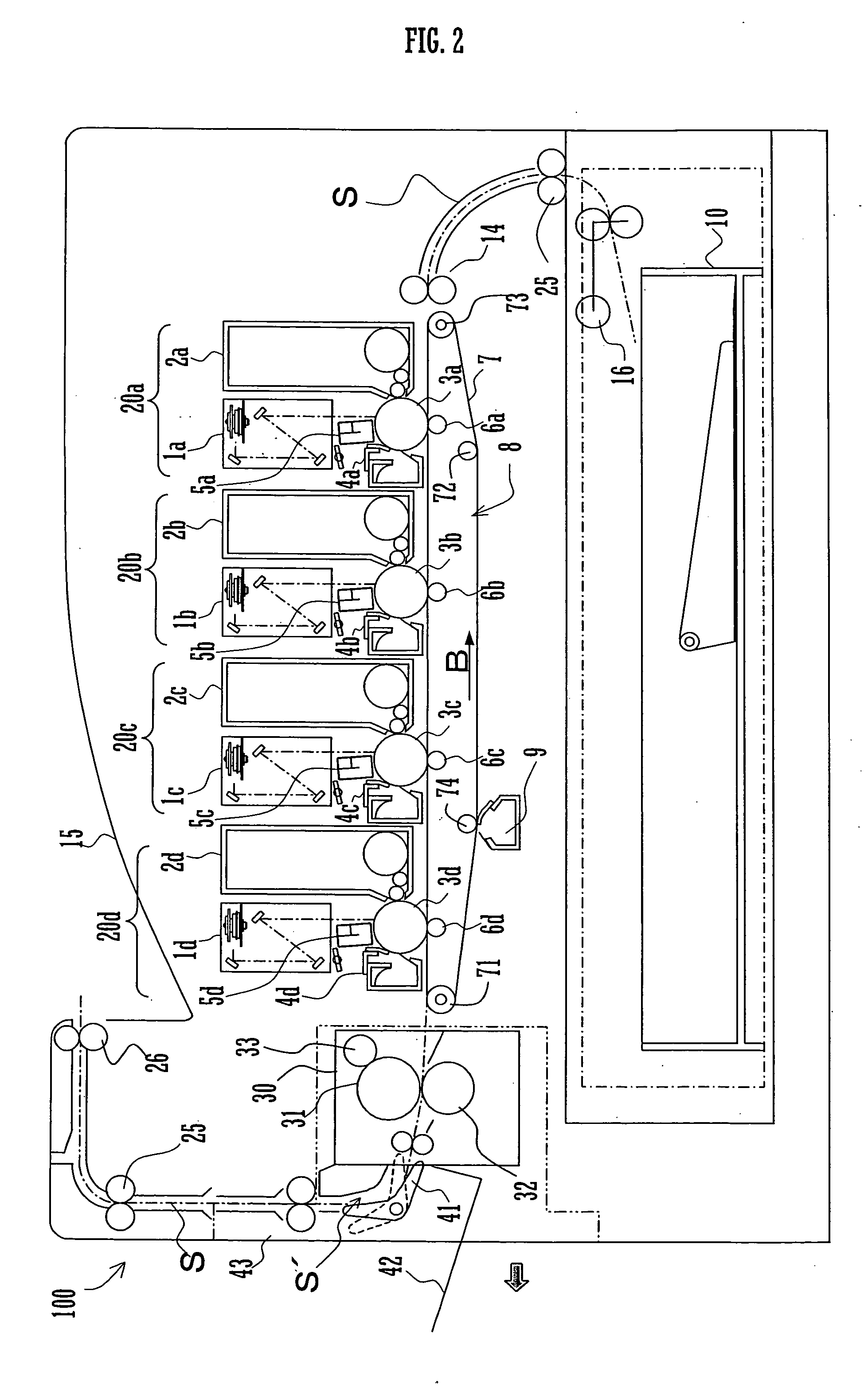

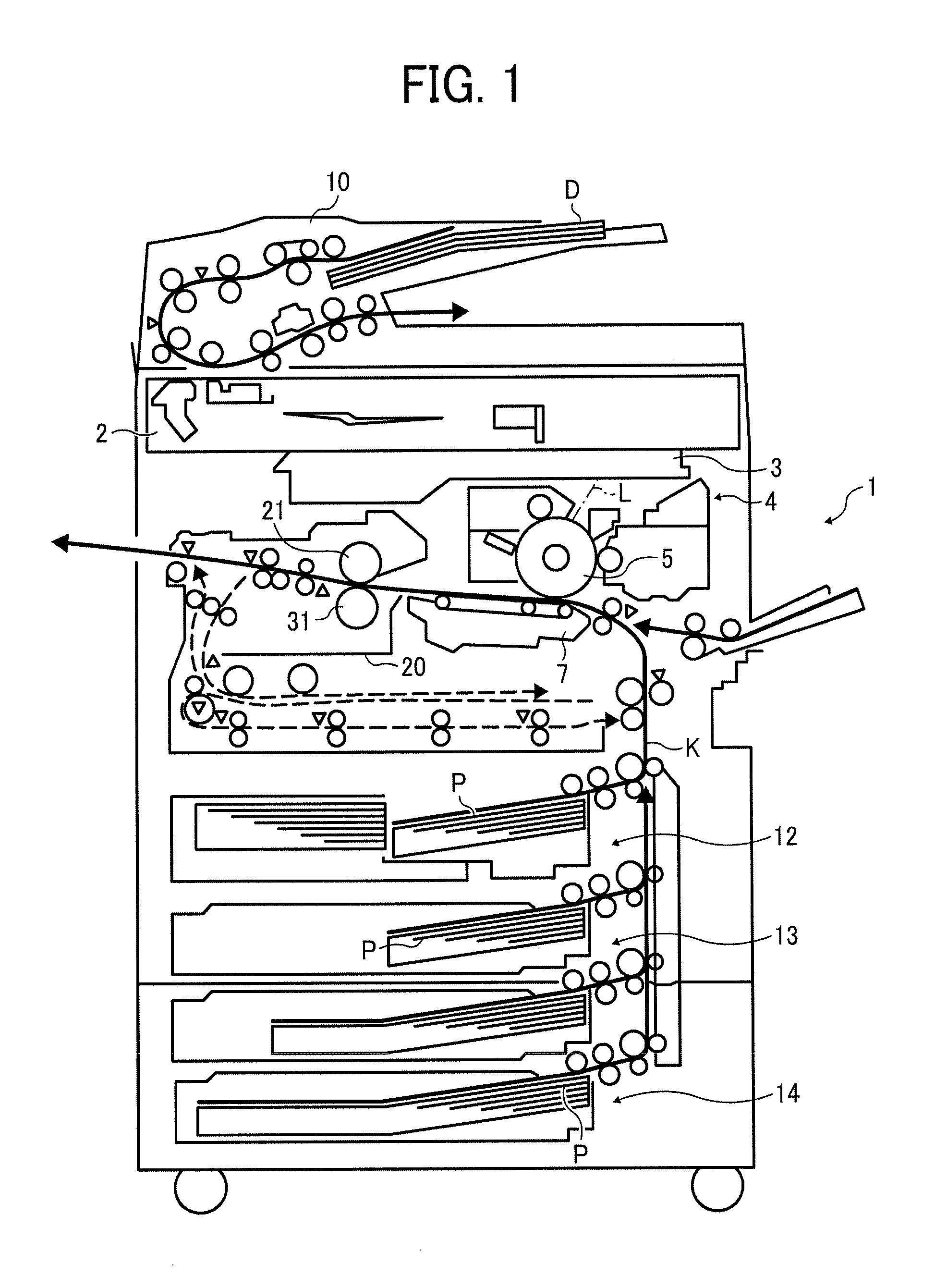

Fixing device and image forming apparatus incorporating same

InactiveUS20110206427A1Short warm-up timeElectrographic process apparatusEngineeringMechanical engineering

Owner:RICOH KK

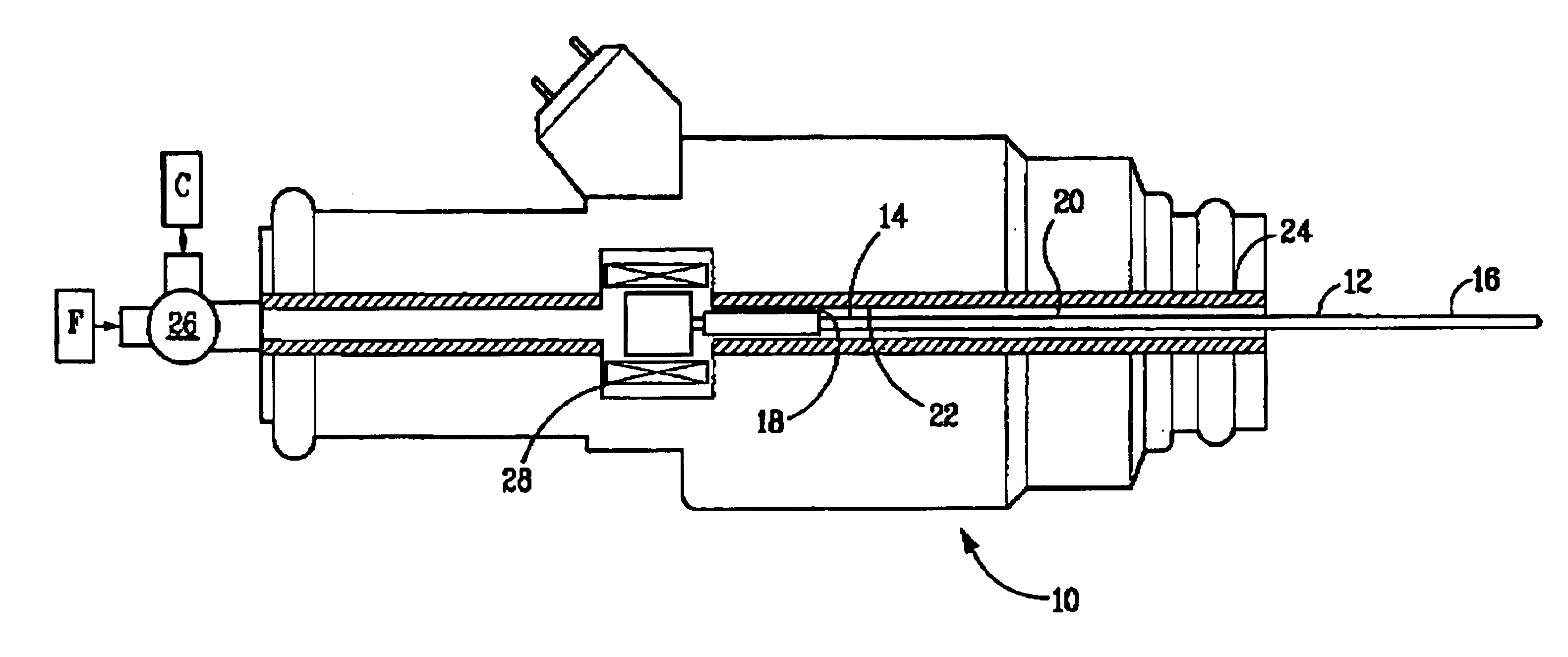

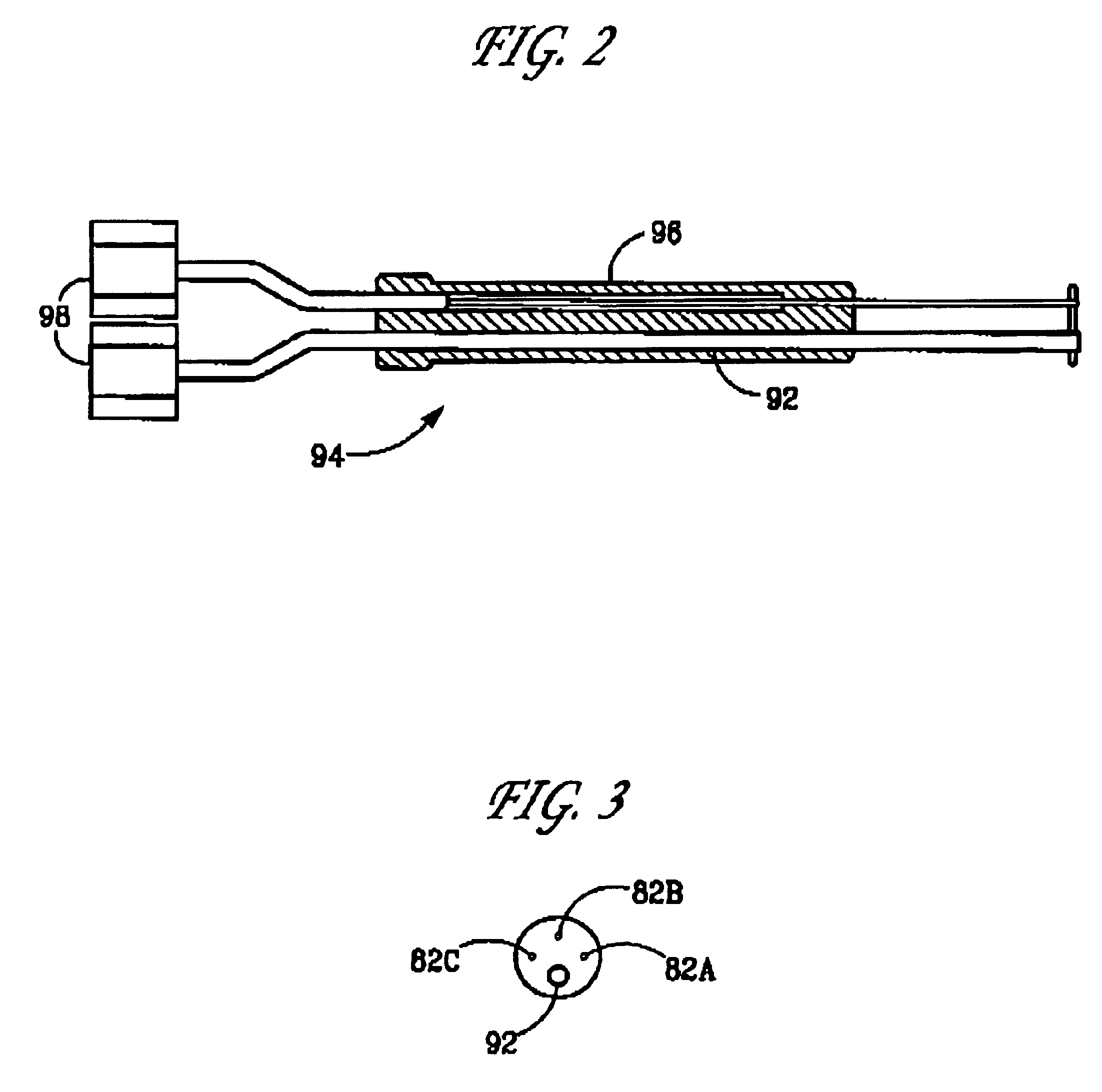

Apparatus and method for preparing and delivering fuel

InactiveUS6871792B2Increase power consumptionOvercome problemsBurnersLiquid surface applicatorsElectrical resistance and conductanceFluid control

A method and apparatus for vaporizing liquid fuel. The apparatus includes at least one capillary flow passage, the at least one capillary flow passage having an inlet end and an outlet end; a fluid control valve for placing the inlet end of the at least one capillary flow passage in fluid communication with the liquid fuel source and introducing the liquid fuel in a substantially liquid state; a heat source arranged along the at least one capillary flow passage, the heat source operable to heat the liquid fuel in the at least one capillary flow passage to a level sufficient to change at least a portion thereof from the liquid state to a vapor state and deliver a stream of substantially vaporized fuel from the outlet end of the at least one capillary flow passage; and means for cleaning deposits formed during operation of the apparatus. The flow passage can be a capillary tube heated by a resistance heater or a section of a tube heated by passing electrical energy therethrough. The liquid fuel can be supplied to the flow passage at any desired pressure depending on the required mass flow rate for the application. The vaporized fuel can be mixed with air to form an aerosol having a mean droplet size of 25 μm or less to minimize ignition energy of the fuel-air mixture, promote fuel flow in an air stream, and combust the liquid fuel efficiently and cleanly.

Owner:PHILIP MORRIS USA INC

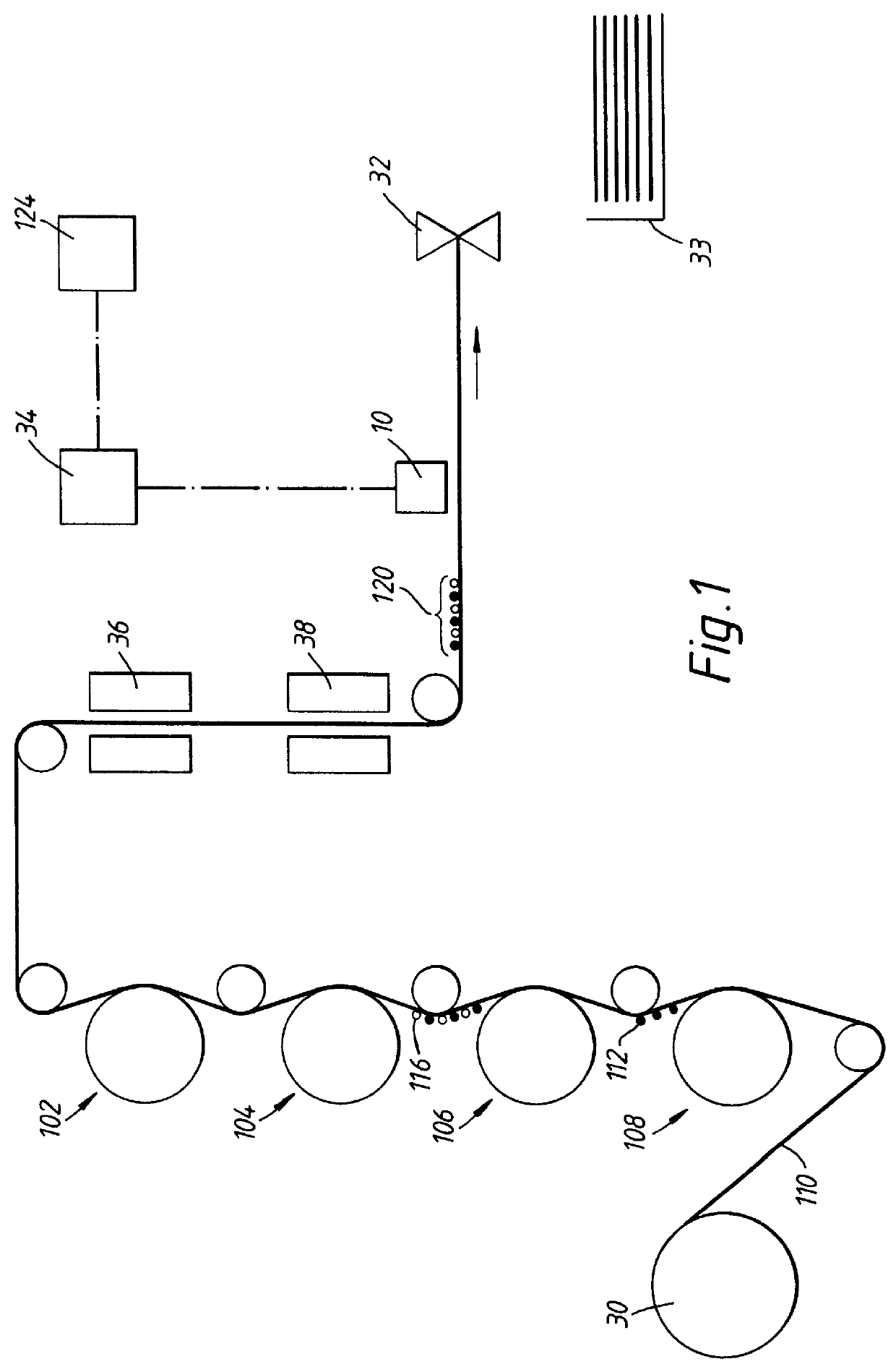

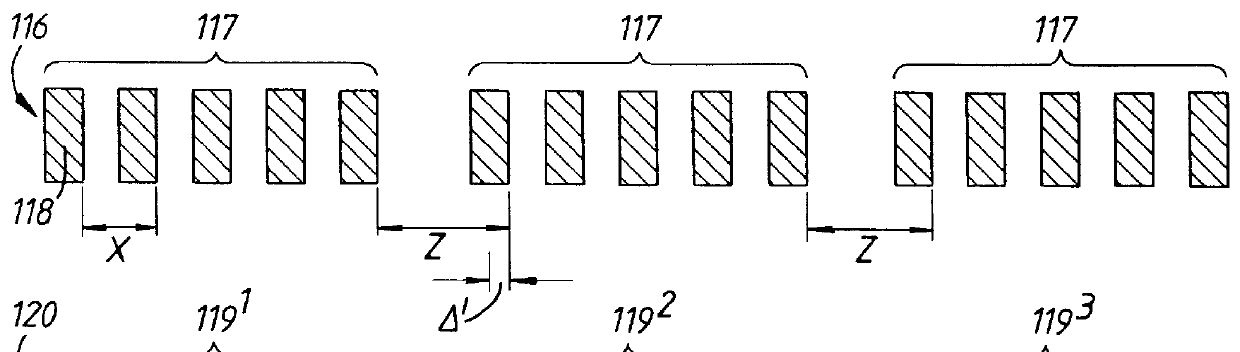

Method for monitoring registration of images printed by a printer

InactiveUS6065400AFacilitate web handlingPrecise positioningPlaten pressesOther printing apparatusComposite patternEngineering

The printer has at least two printing stations which cause images to be printed on a substrate. The printer is capable of registration adjustment. First and second patterns of spaced registration marks are printed onto the substrate by operation of the printing stations. The second pattern partially overlaps the first pattern to form a composite pattern of registration marks. The composite pattern is illuminated and the reflectivity thereof is examined at wavelengths complementary to the colors of the first and second patterns to obtain a reflectivity signature for the composite pattern. The reflectivity signature of the composite pattern (120) is compared with a predetermined signature to determine an adjustment factor for the printer.

Owner:PUNCH GRAPHIX INT

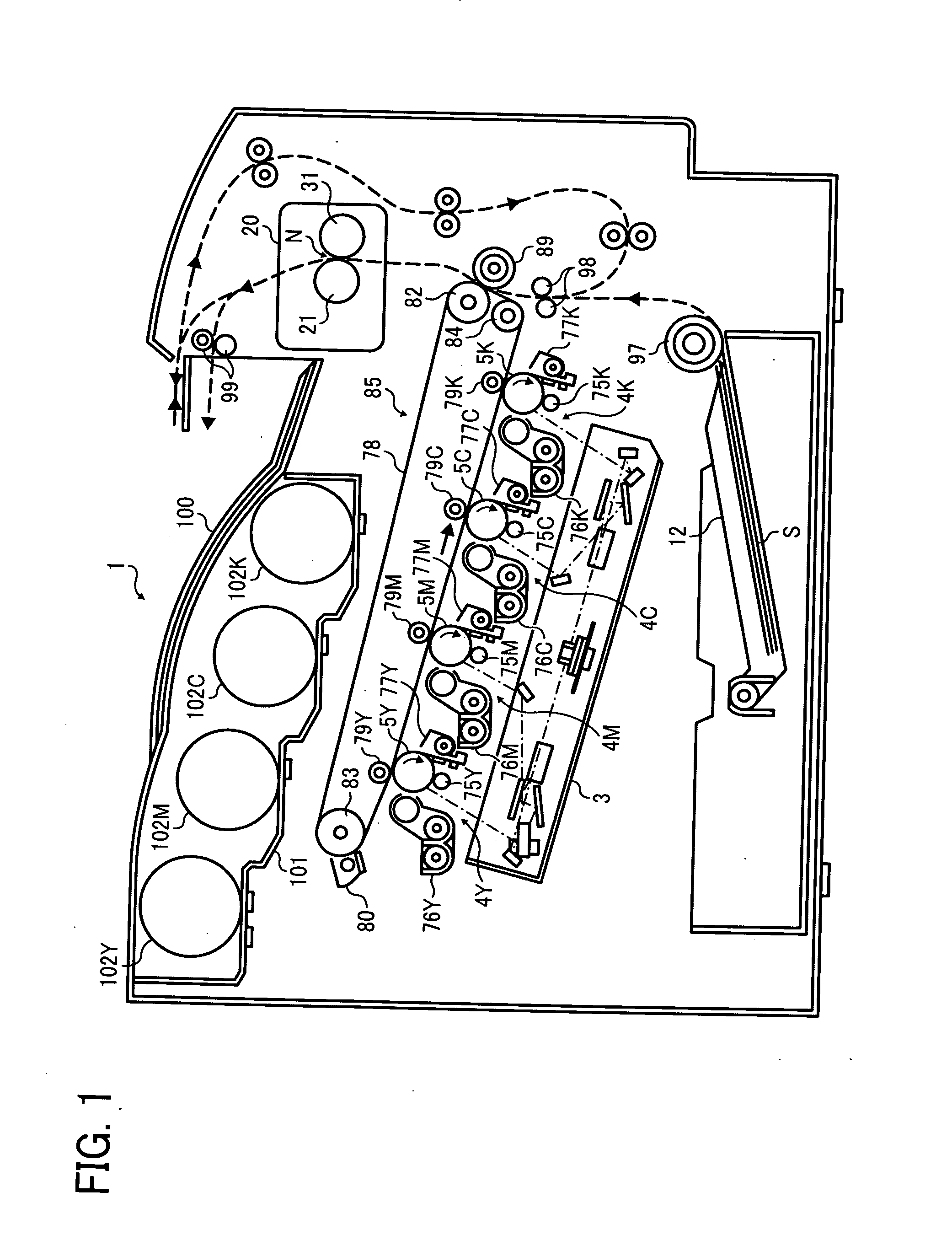

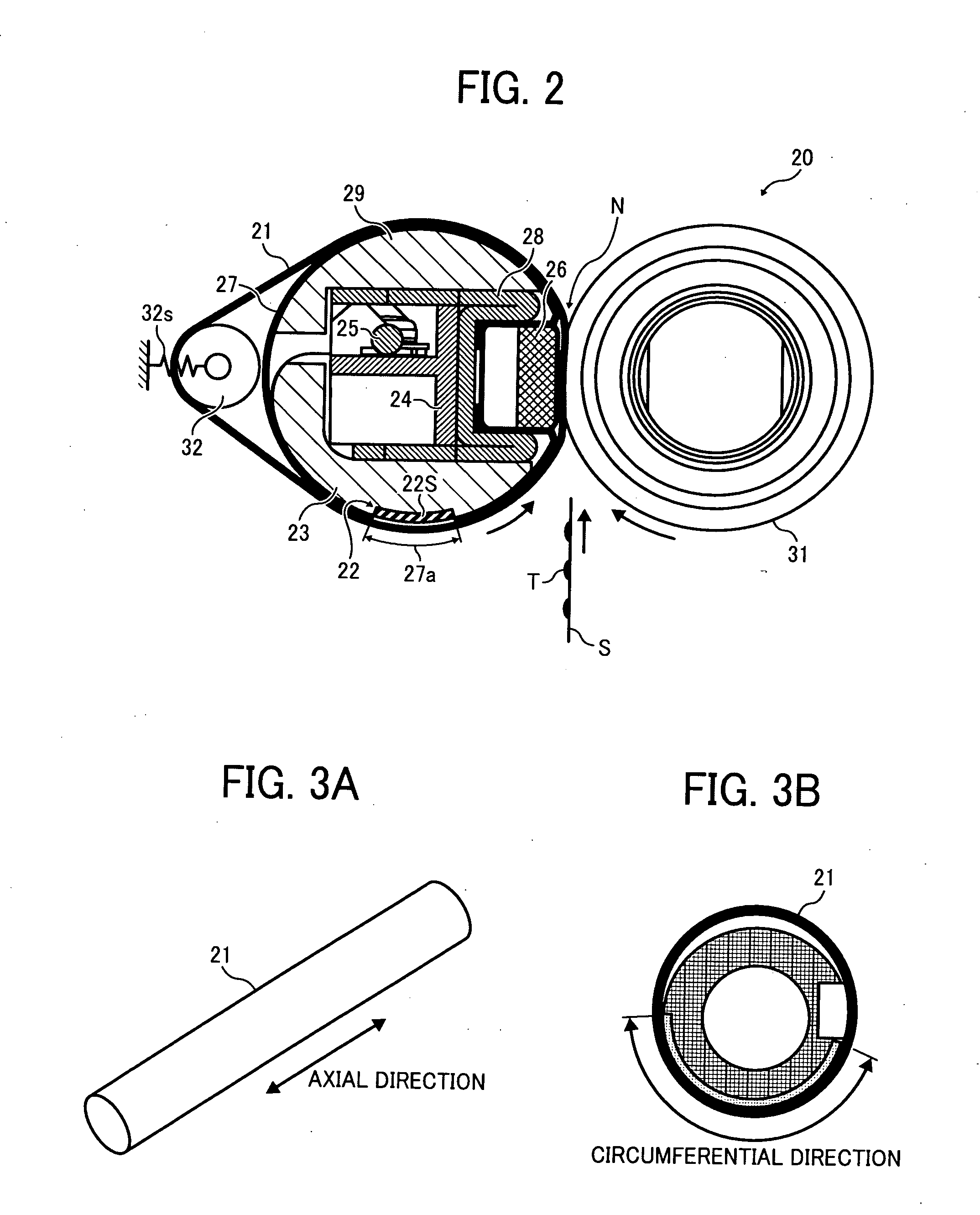

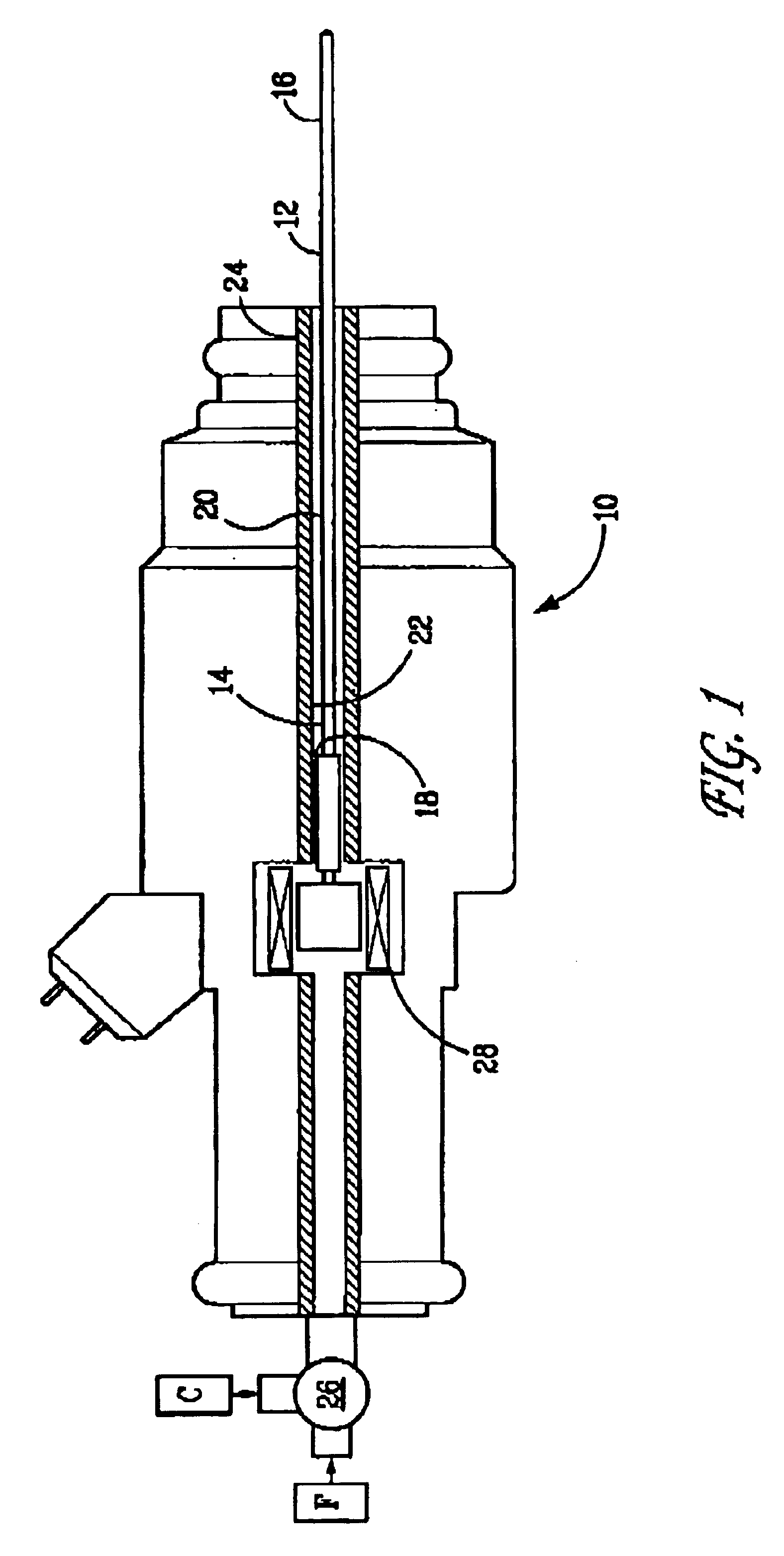

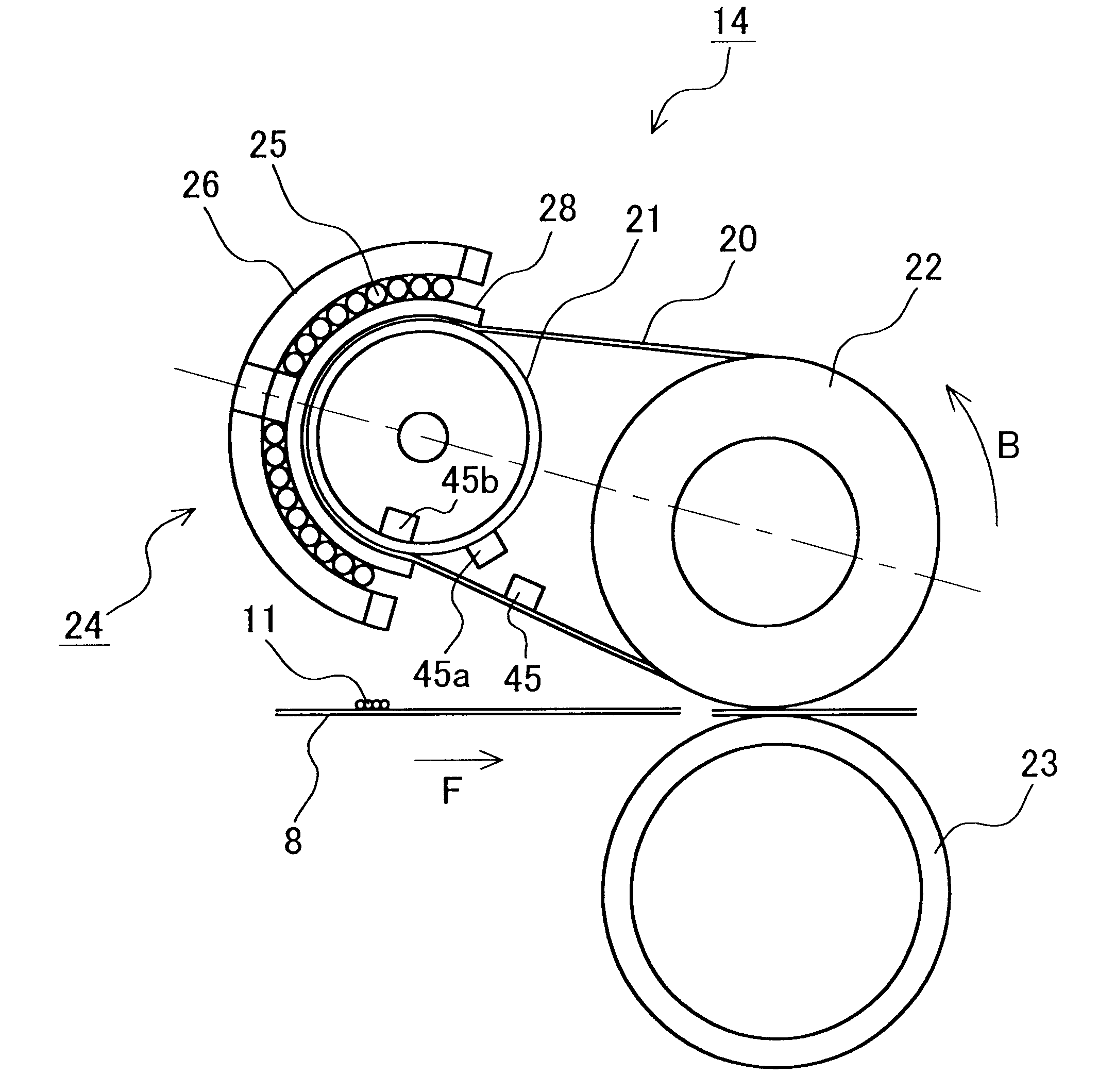

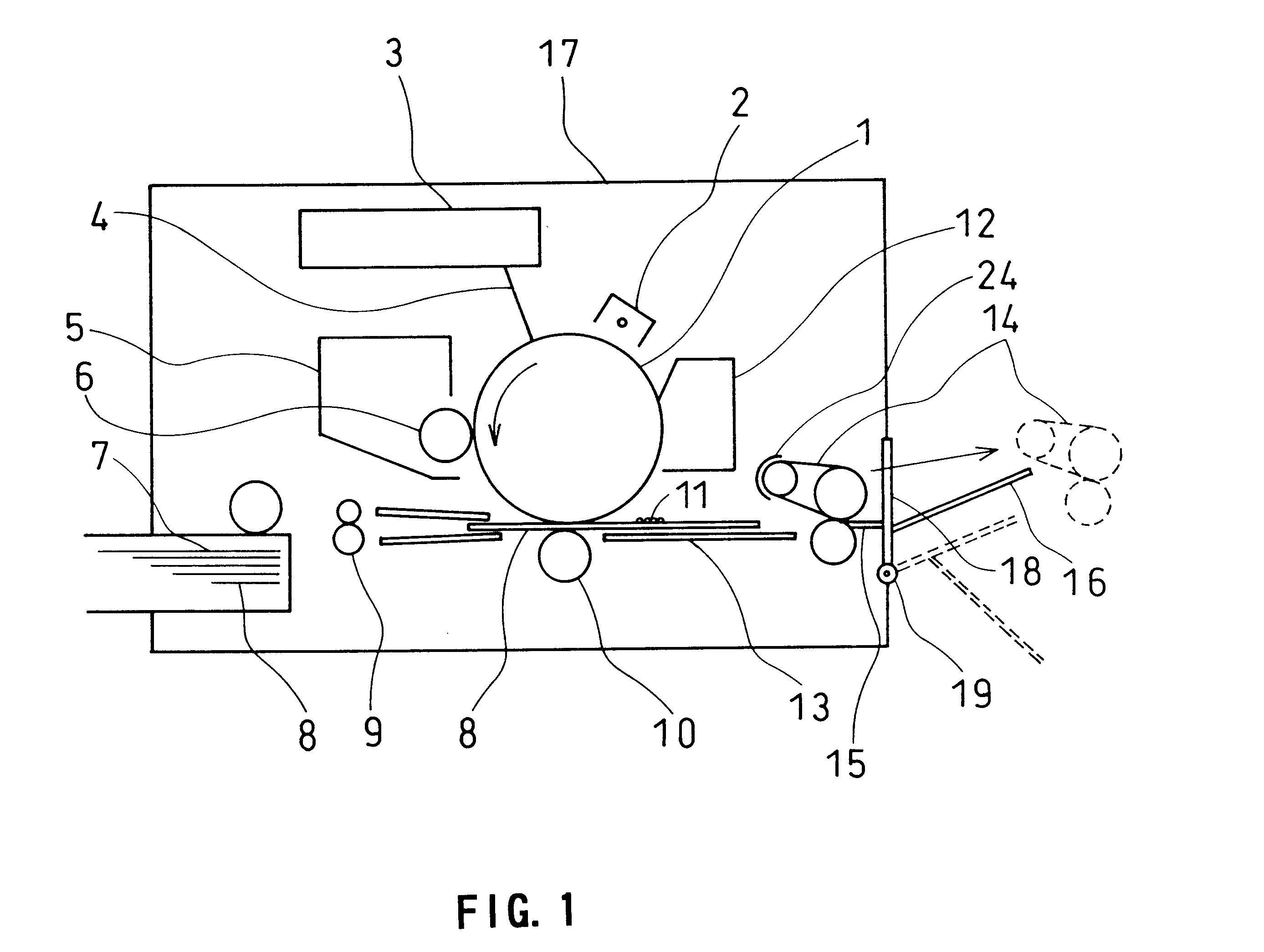

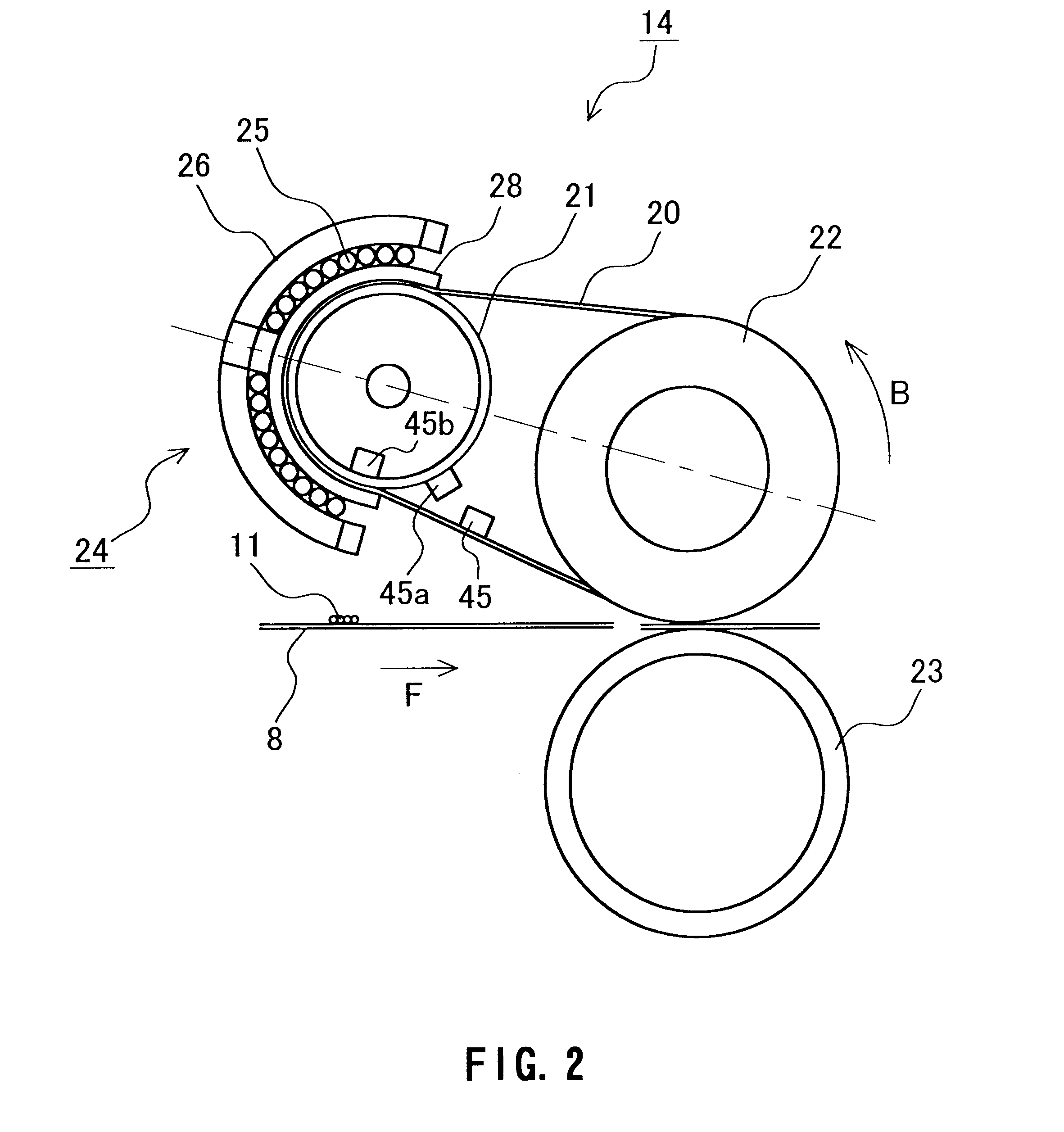

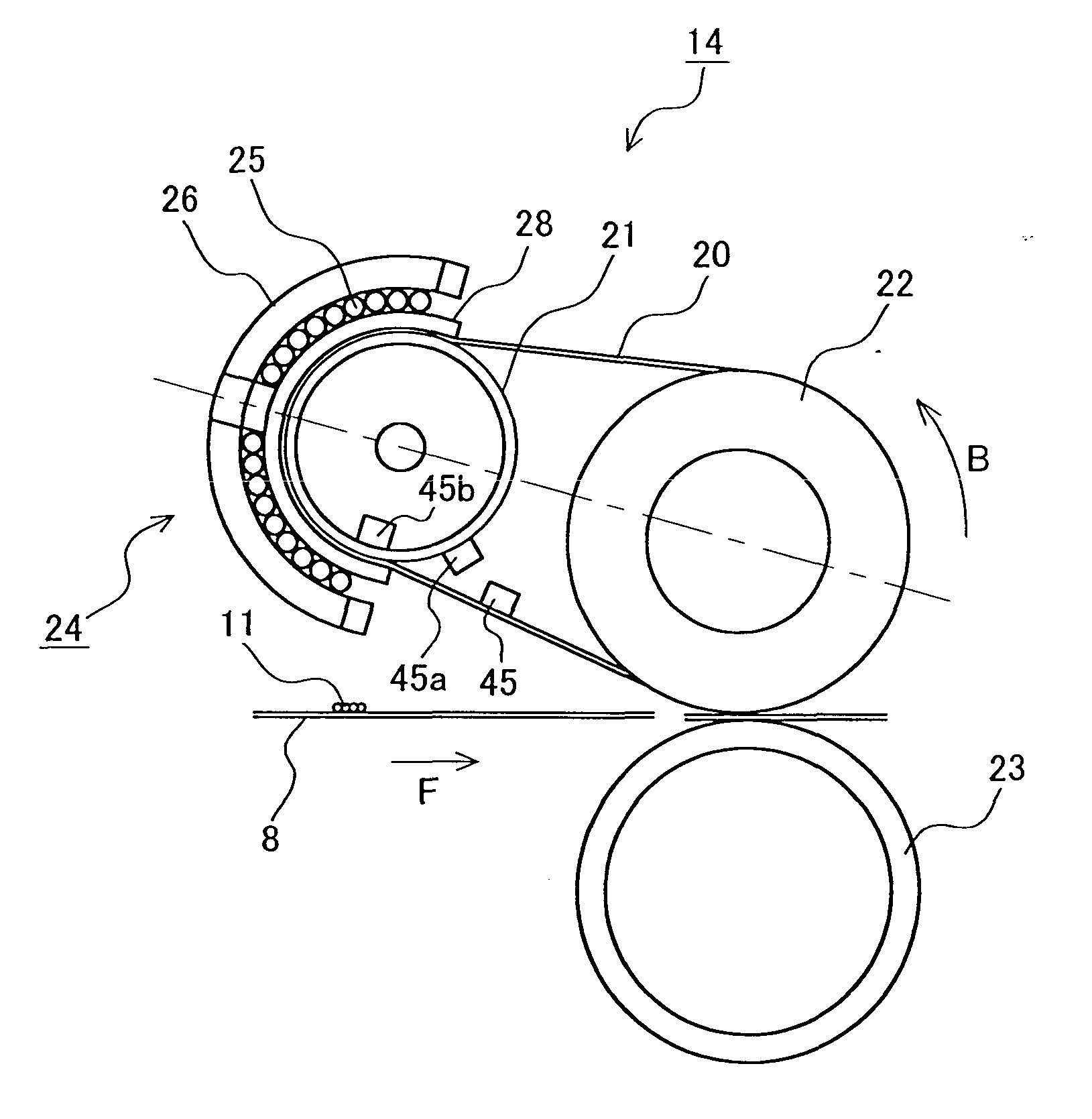

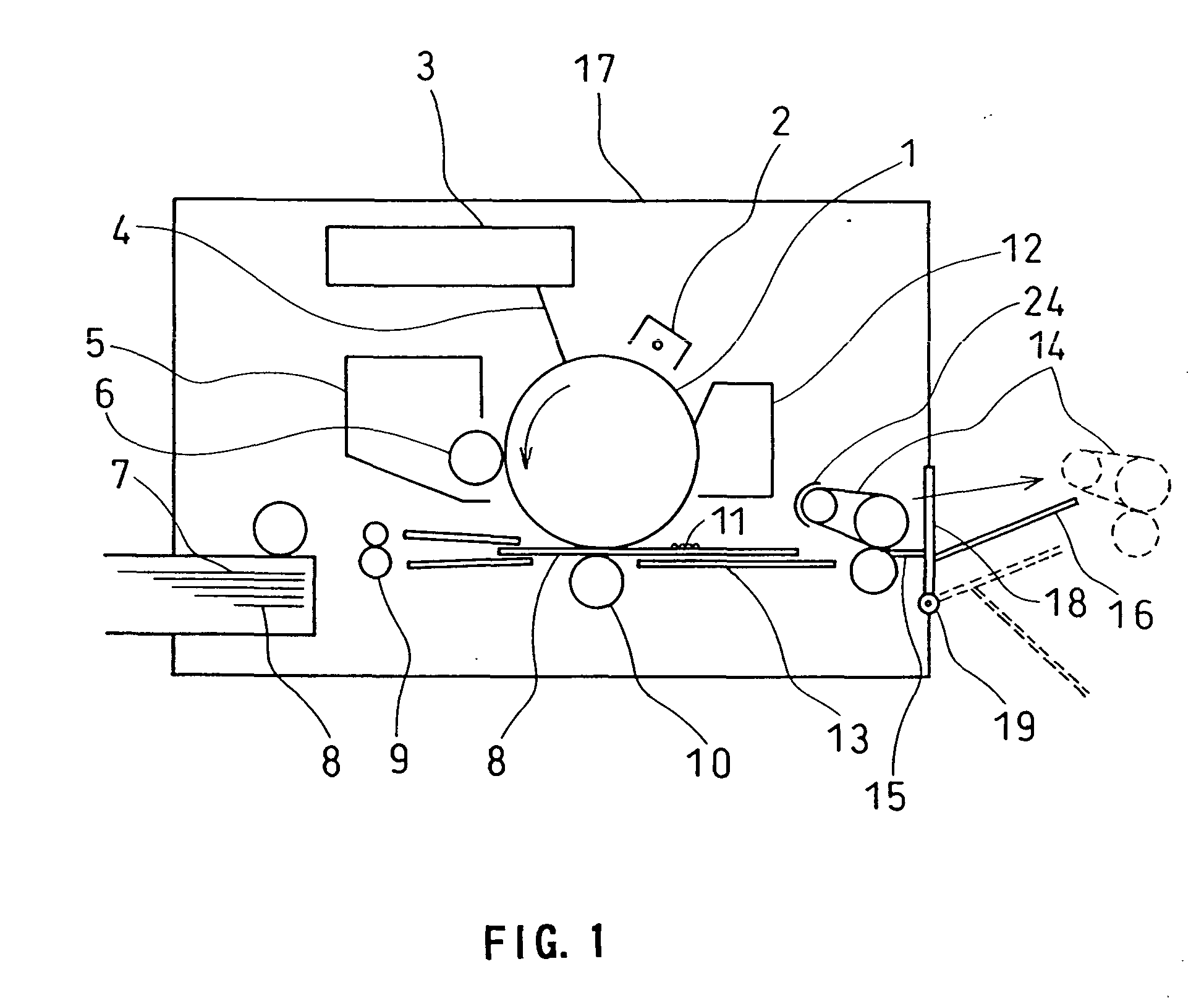

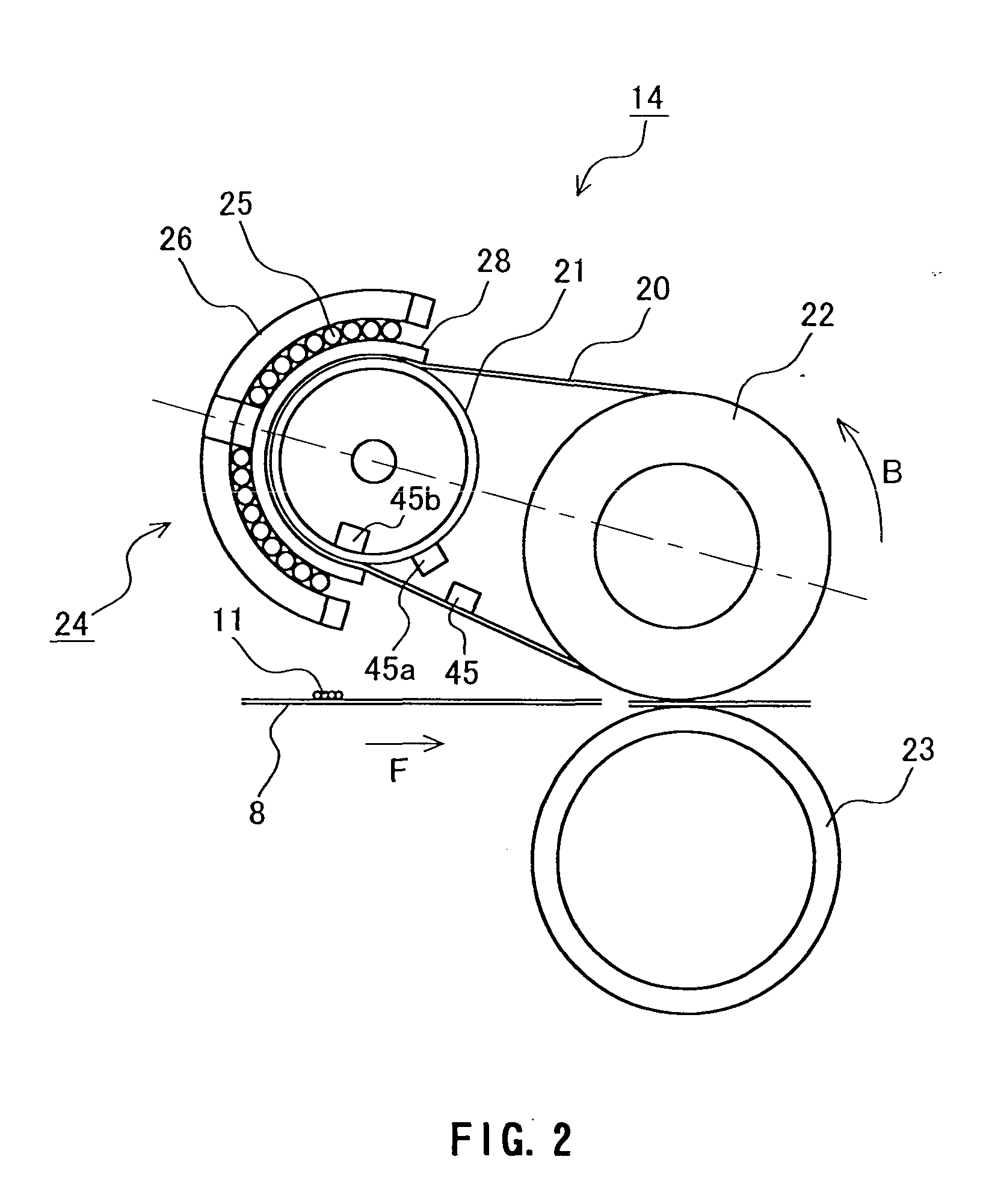

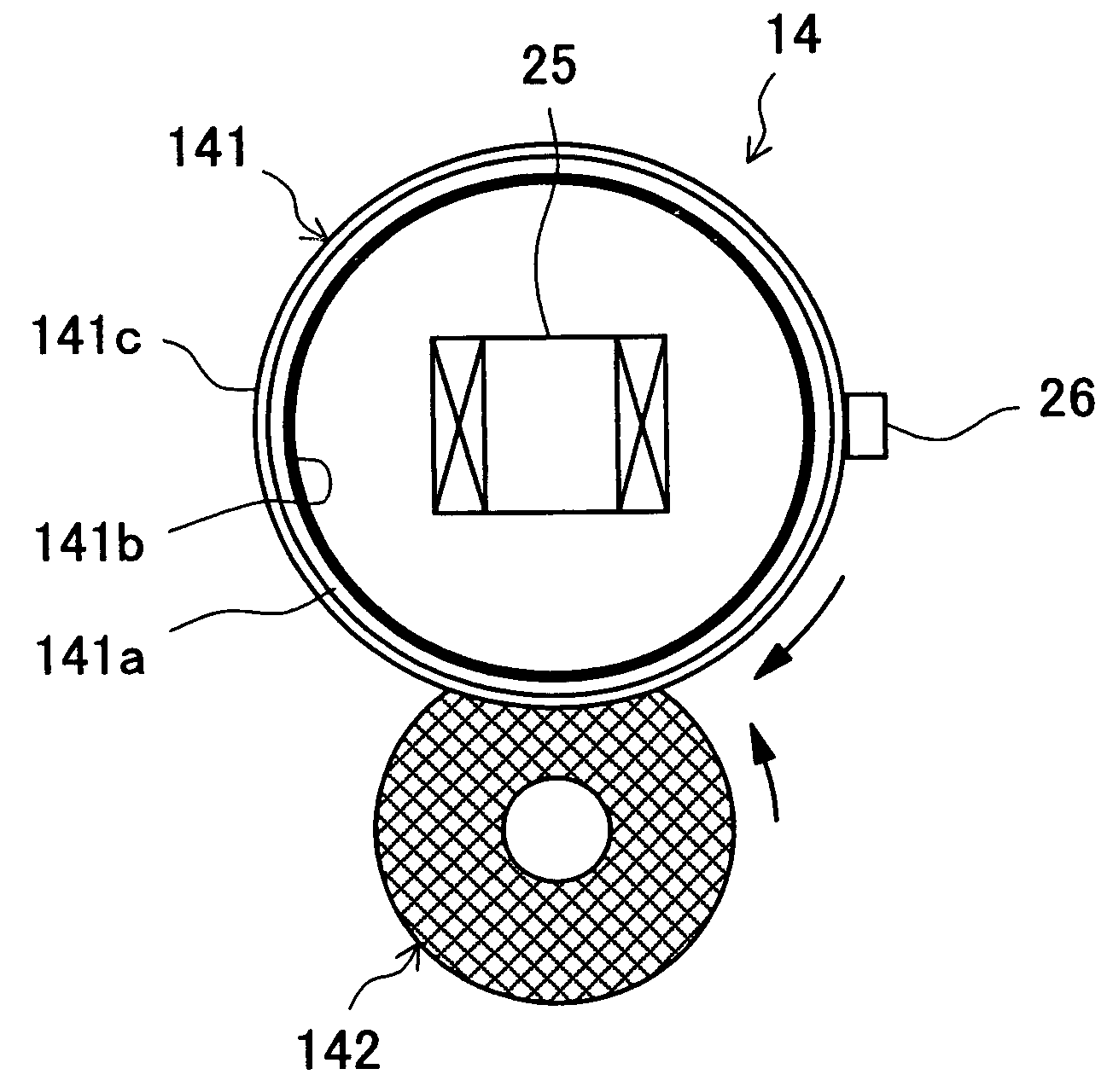

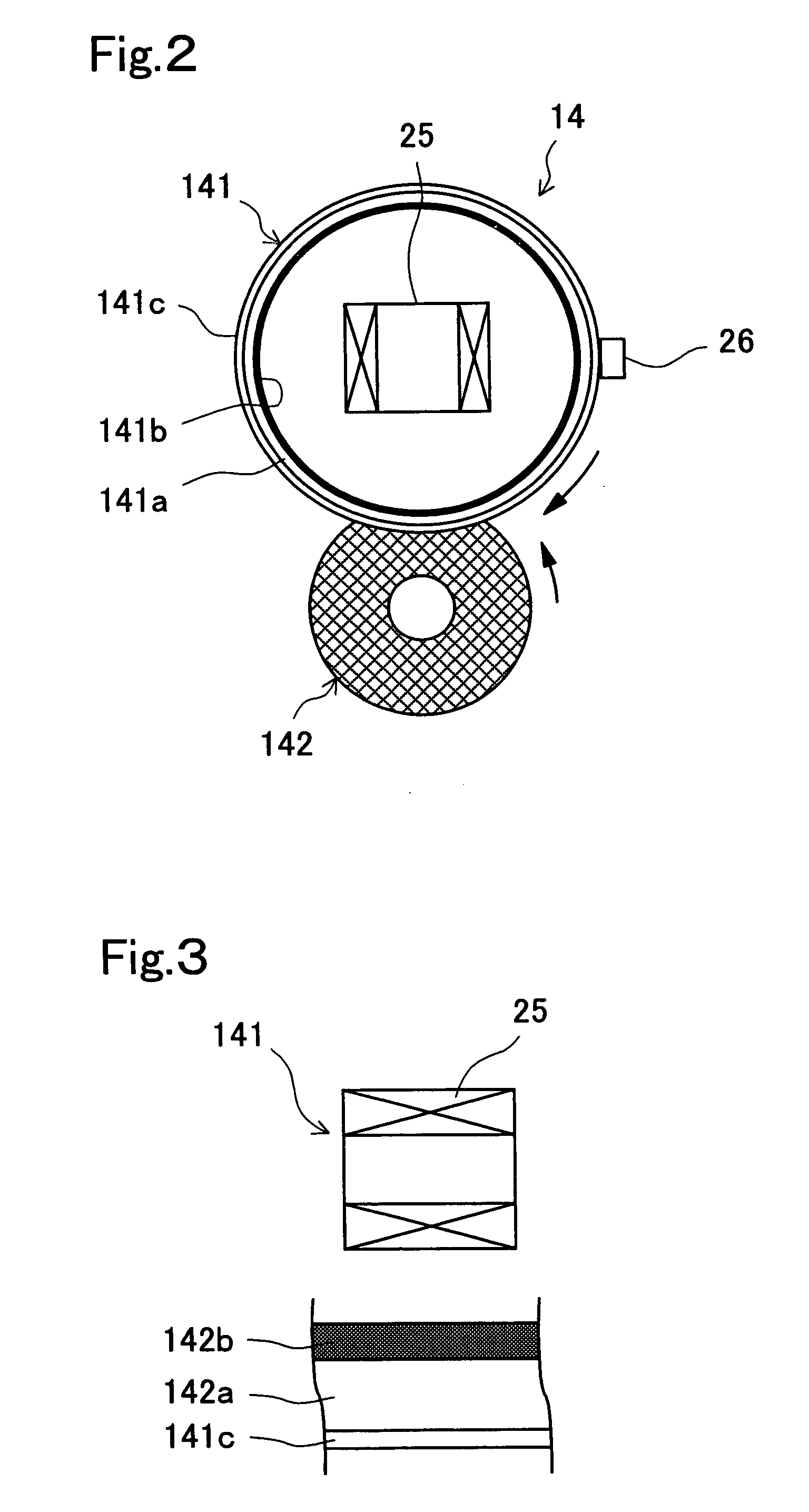

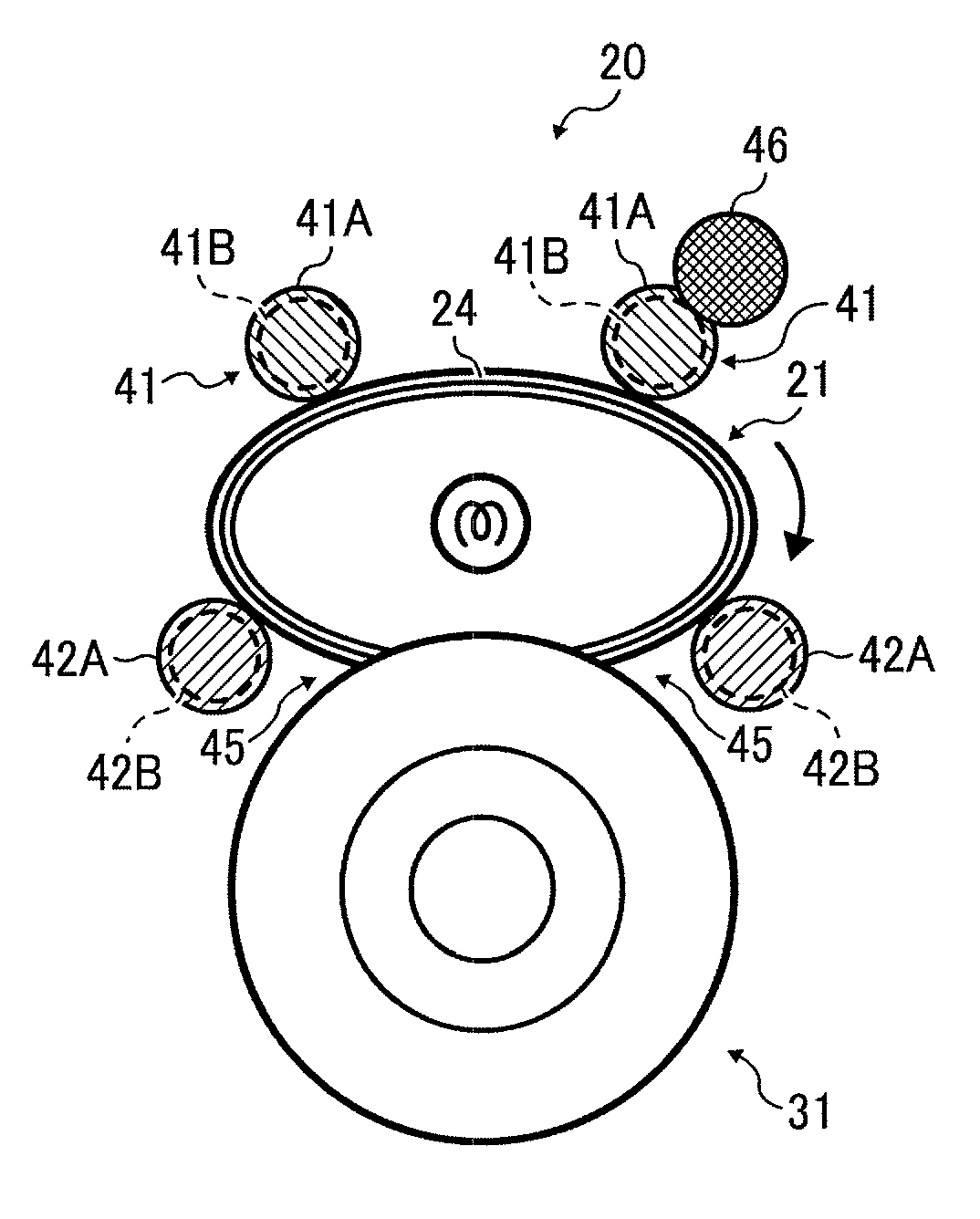

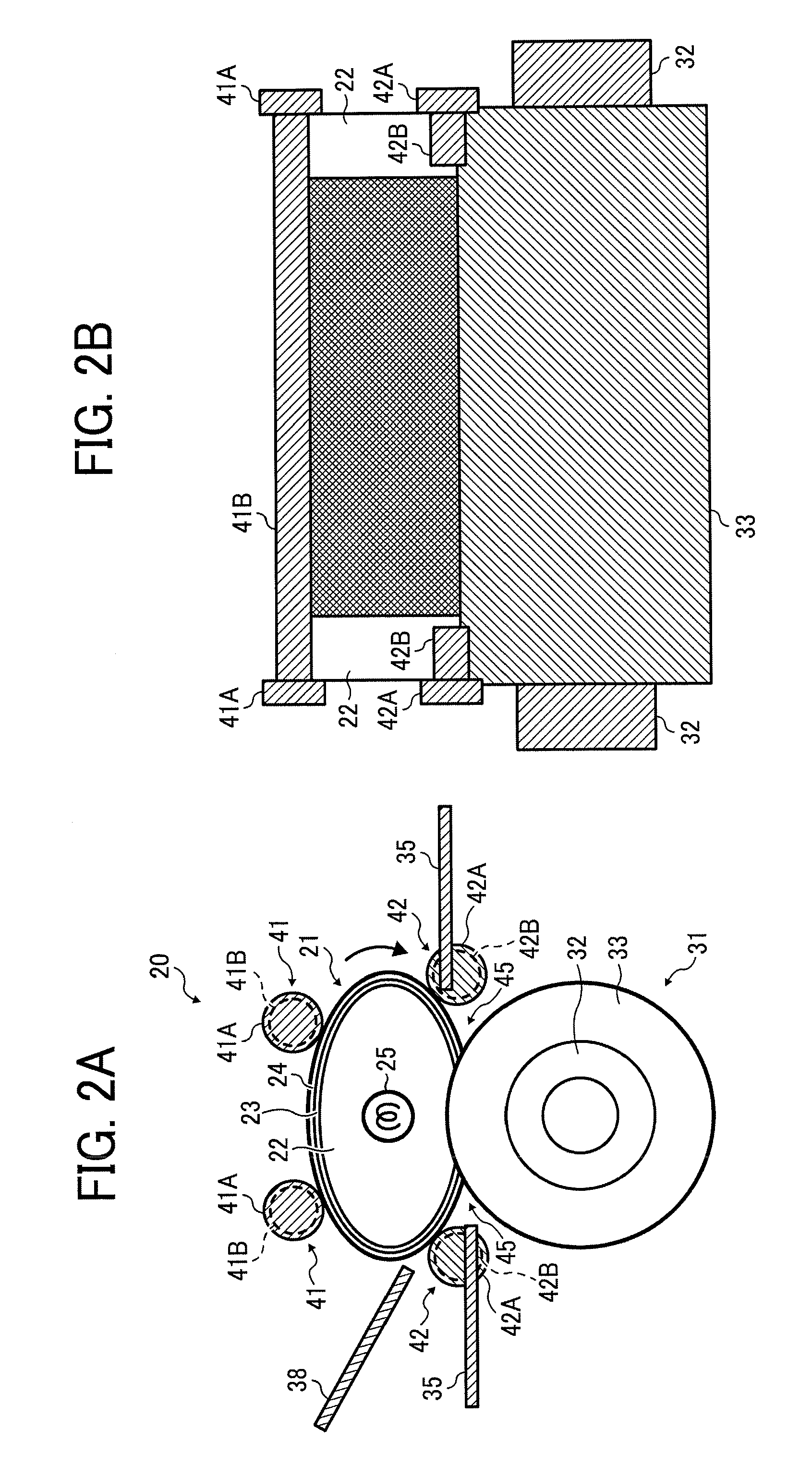

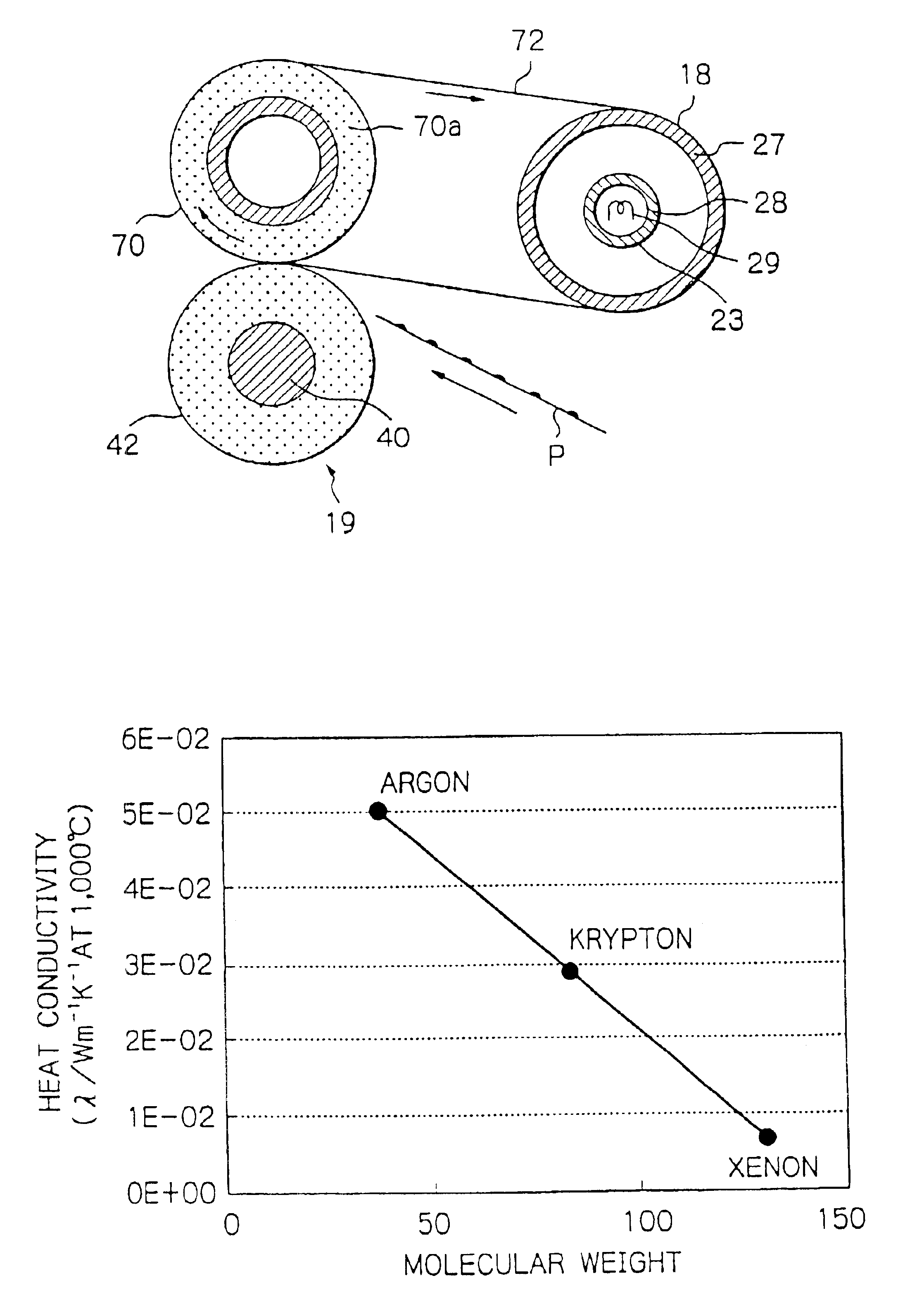

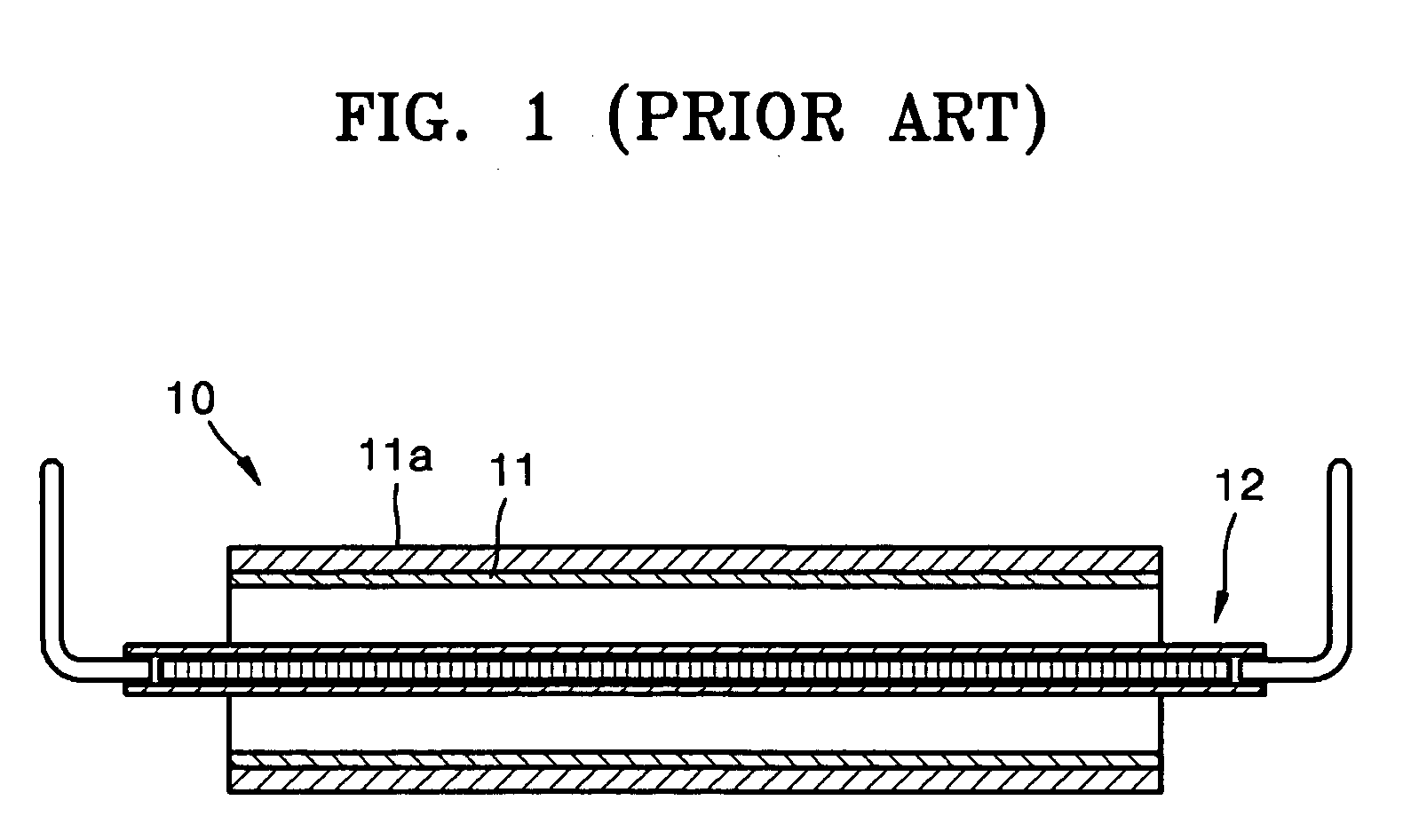

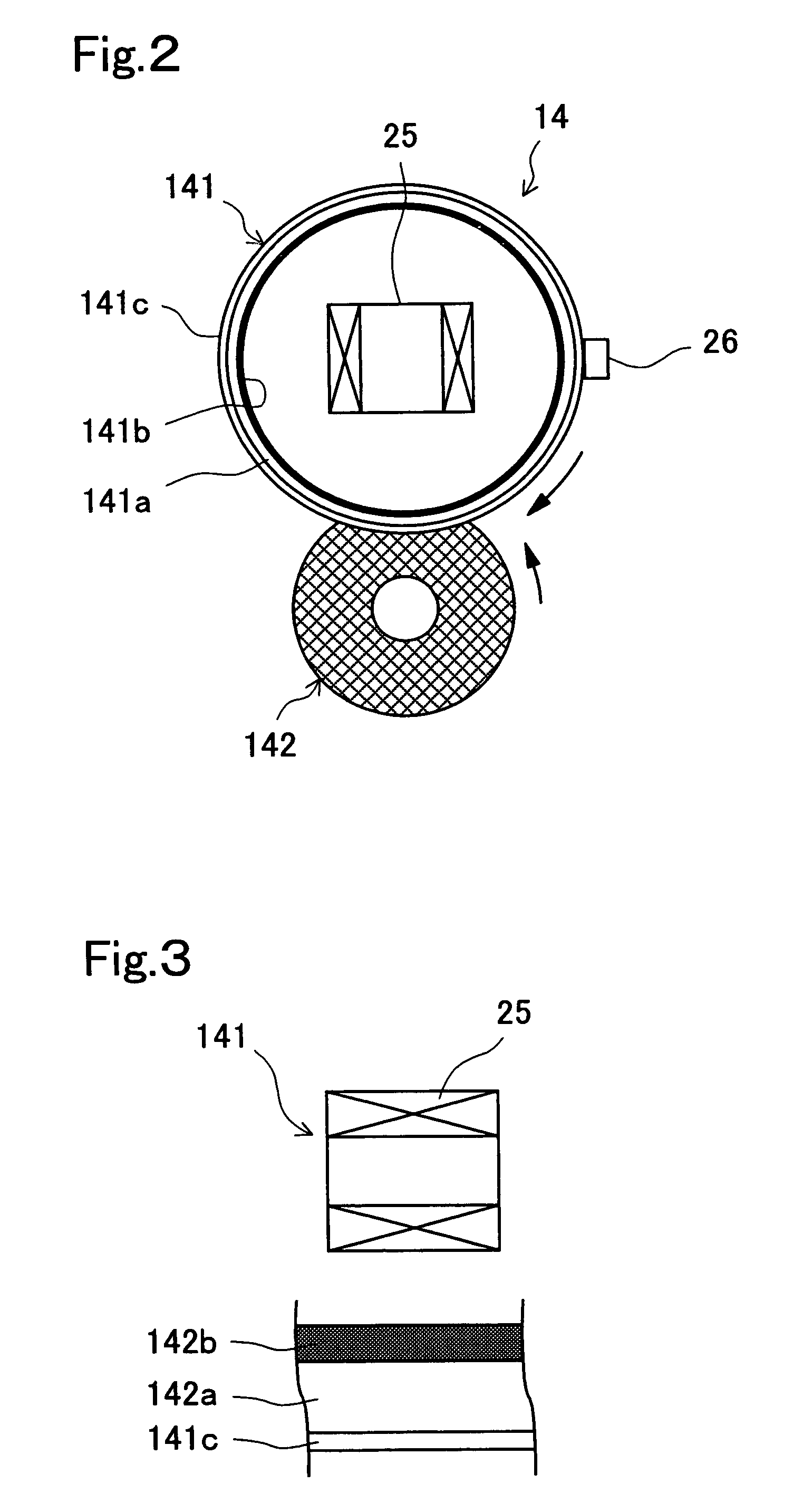

Image heating device and image forming apparatus using the same

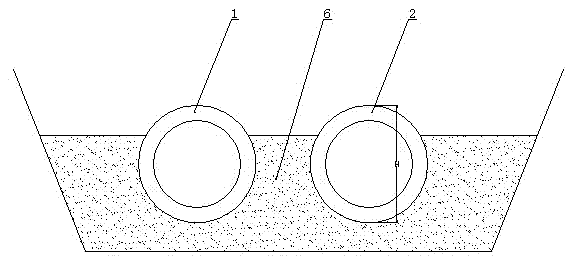

InactiveUS6725009B1Solve large capacityShort warm-up timeOhmic-resistance heatingElectrographic process apparatusHeat resistanceMagnetization

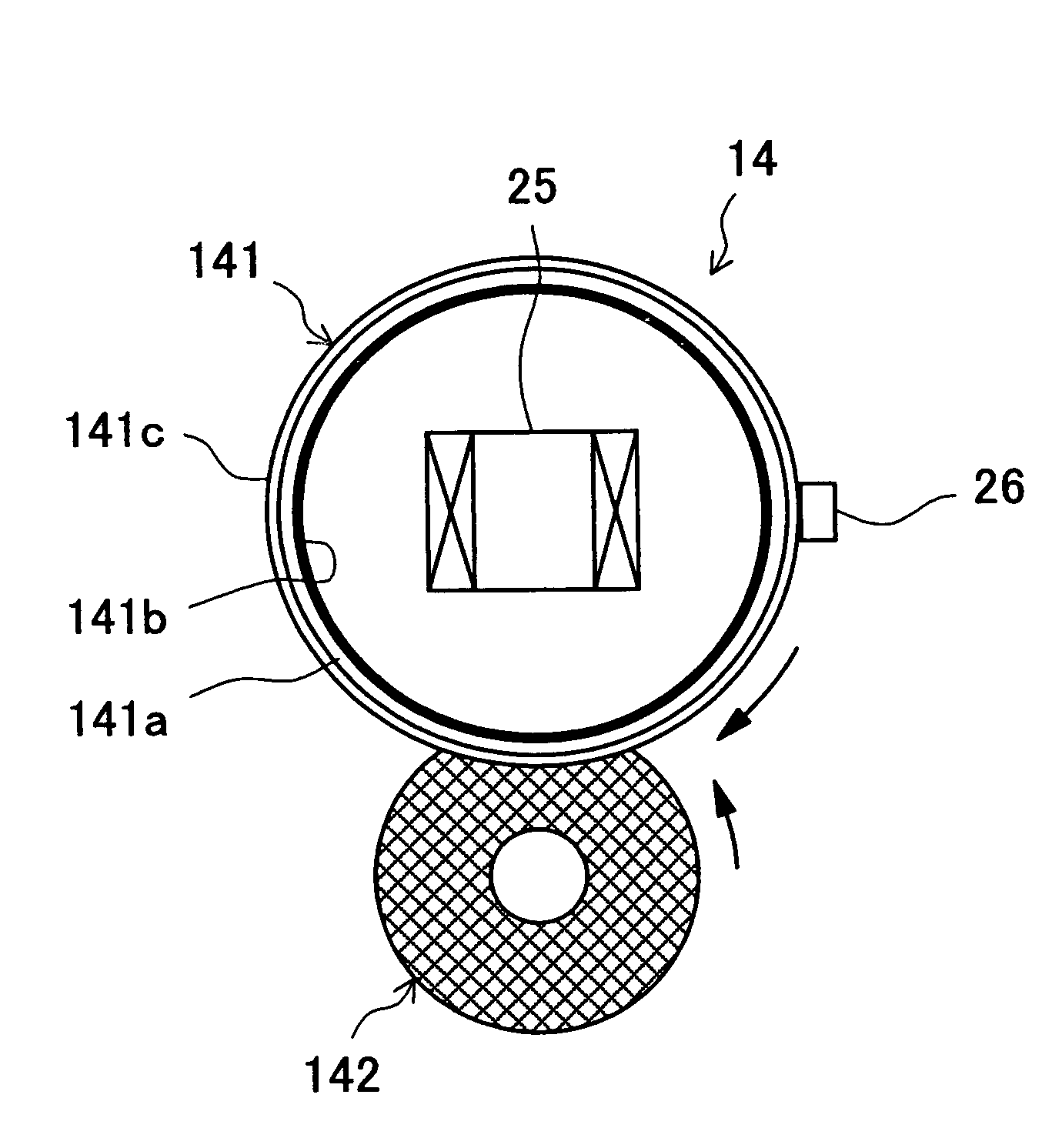

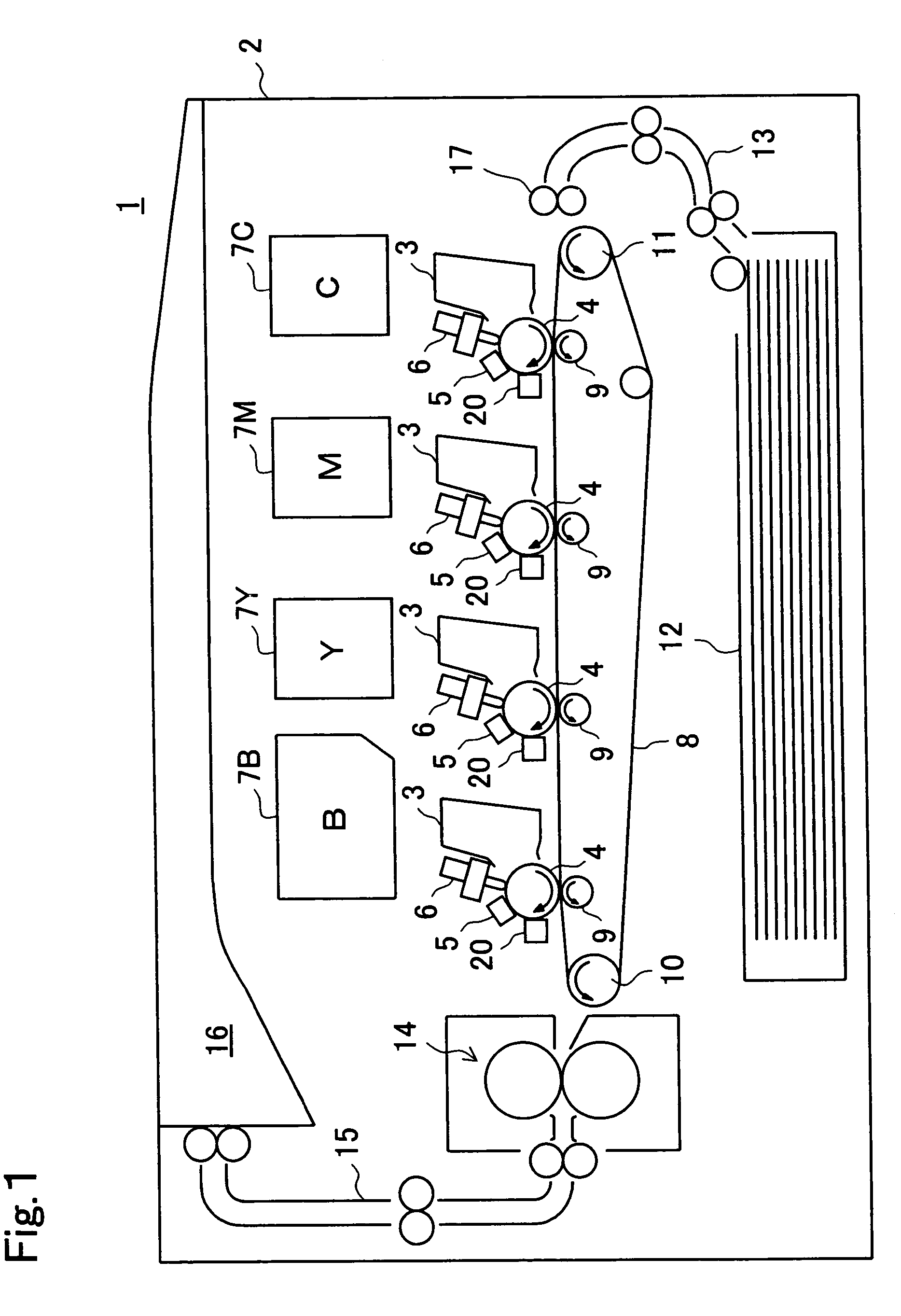

An image heating device with a small thermal capacity that can be heated rapidly. The image heating device includes a fixing belt (20) having a heat resistance; a rotatable heat-generating roller (21), which is at least partially conductive and arranged in contact with an inner peripheral surface of the fixing belt (20); a fixing roller (22), the fixing roller and the heat-generating roller (21) movably suspending the fixing belt (20) therebetween; and a magnetization means (24) for heating the heat-generating roller (21) through magnetization, which is arranged outside the heat-generating roller (21). In this image heating device, the magnetization means (24) heats the heat-generating roller (21) through magnetization after a rotating operation of the heat-generating roller (21) is started.

Owner:PANASONIC CORP

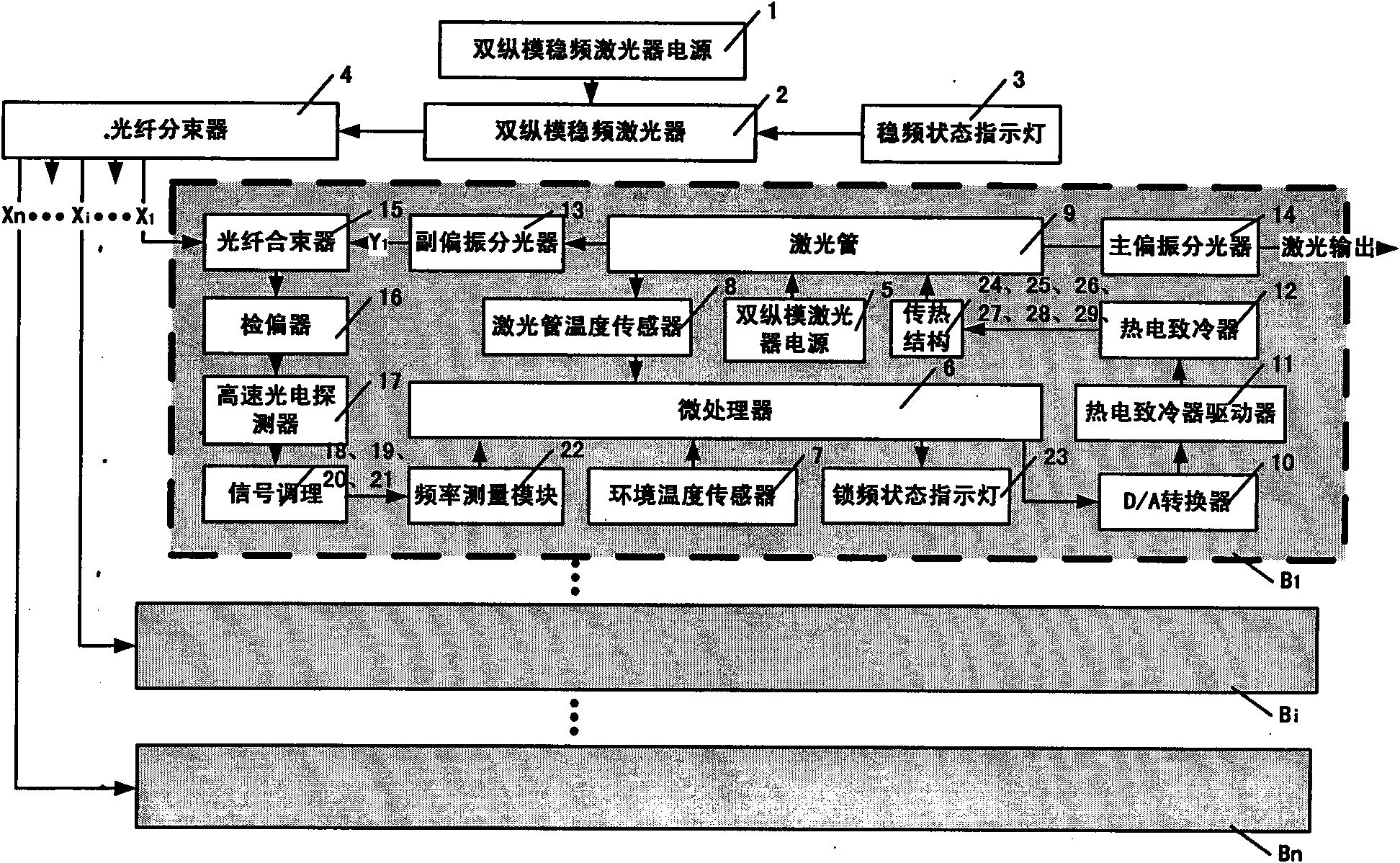

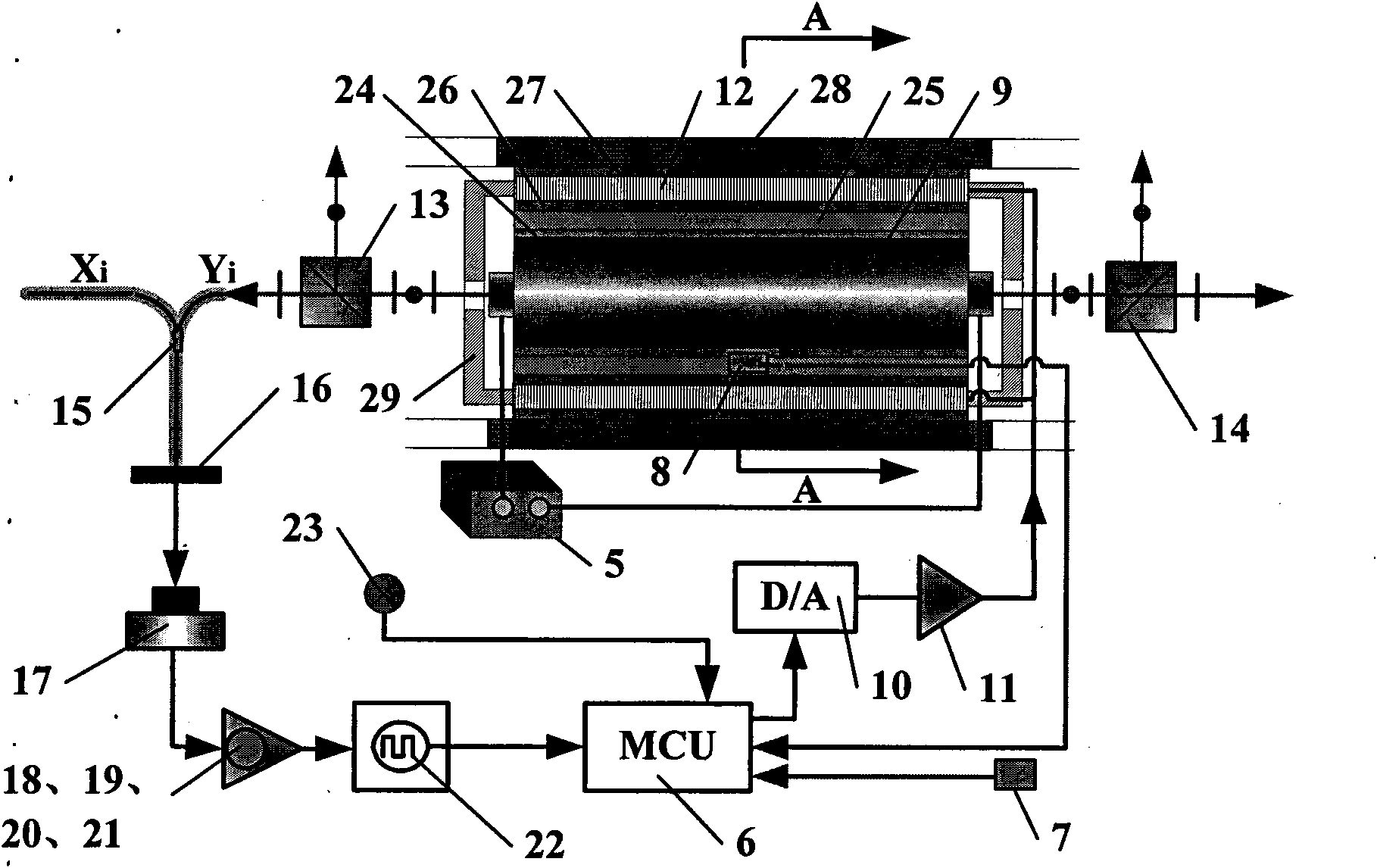

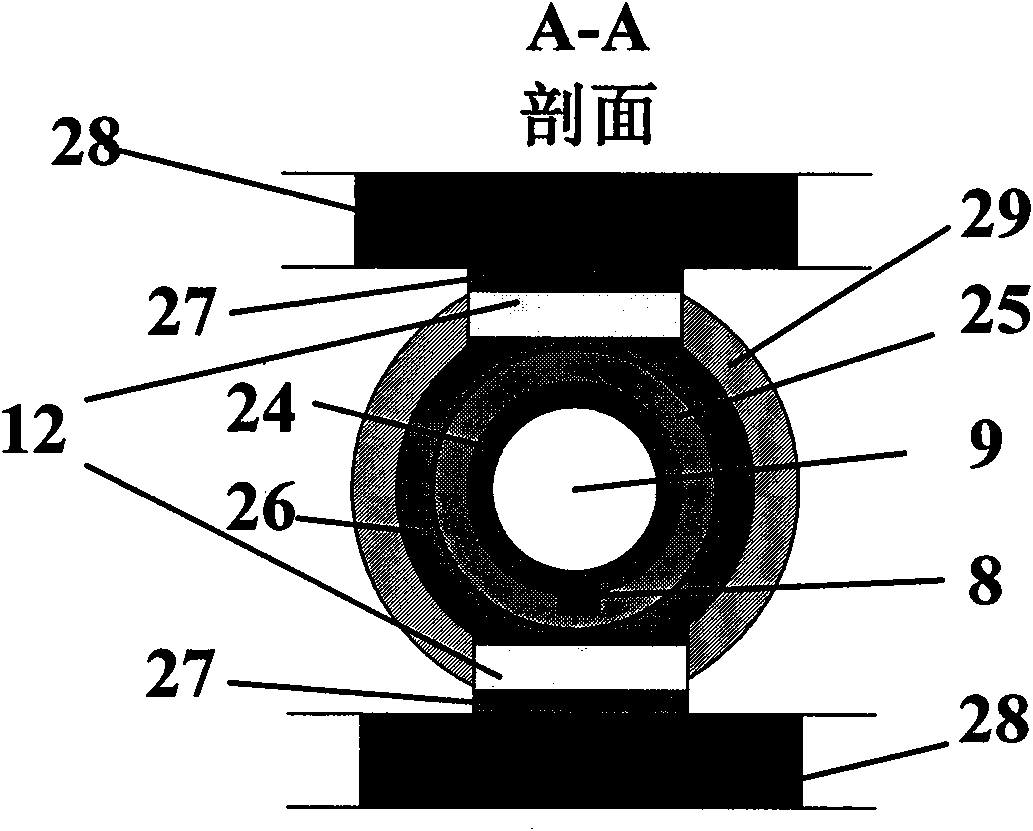

Double longitudinal mode laser offset frequency locking method and device based on thermoelectric cooler

InactiveCN101609958AShort warm-up timeStrong shock resistanceLaser detailsProgramme control in sequence/logic controllersPower balancingFrequency stabilization

A double longitudinal mode laser offset frequency locking method and a device based on a thermoelectric cooler belong to the technical field of laser application. In the invention, the frequency of the output laser of a power balance type double longitudinal mode frequency stabilized laser A is taken as the reference frequency, and simultaneously the thermoelectric cooler is used for controlling the temperature to adjust the cavity length so that a fixed difference value is maintained between the frequency of the output laser of n>=1 double longitudinal mode lasers B1, B2, ..., Bn and the reference frequency, thus ensuring the output laser of the double longitudinal mode lasers B1, B2, ..., Bn to have uniform frequency value and the relative frequency stability and the frequency invariance to reach 10 and overcoming the shortcoming that the frequency invariance between the frequency stabilized lasers only reaches 10-10 because of inconsistency of the reference frequency in the traditional frequency stabilized lasers.

Owner:HARBIN INST OF TECH

Image heating device and image forming apparatus using the same

InactiveUS20040101334A1Solve large capacityShort warm-up timeOhmic-resistance heatingElectrographic process apparatusHeat resistanceMagnetization

An image heating device with a small thermal capacity that can be heated rapidly. The image heating device includes a fixing belt (20) having a heat resistance; a rotatable heat-generating roller (21), which is at least partially conductive and arranged in contact with an inner peripheral surface of the fixing belt (20); a fixing roller (22), the fixing roller and the heat-generating roller (21) movably suspending the fixing belt (20) therebetween; and a magnetization means (24) for heating the heat-generating roller (21) through magnetization, which is arranged outside the heat-generating roller (21). In this image heating device, the magnetization means (24) heats the heat-generating roller (21) through magnetization after a rotating operation of the heat-generating roller (21) is started.

Owner:PANASONIC CORP

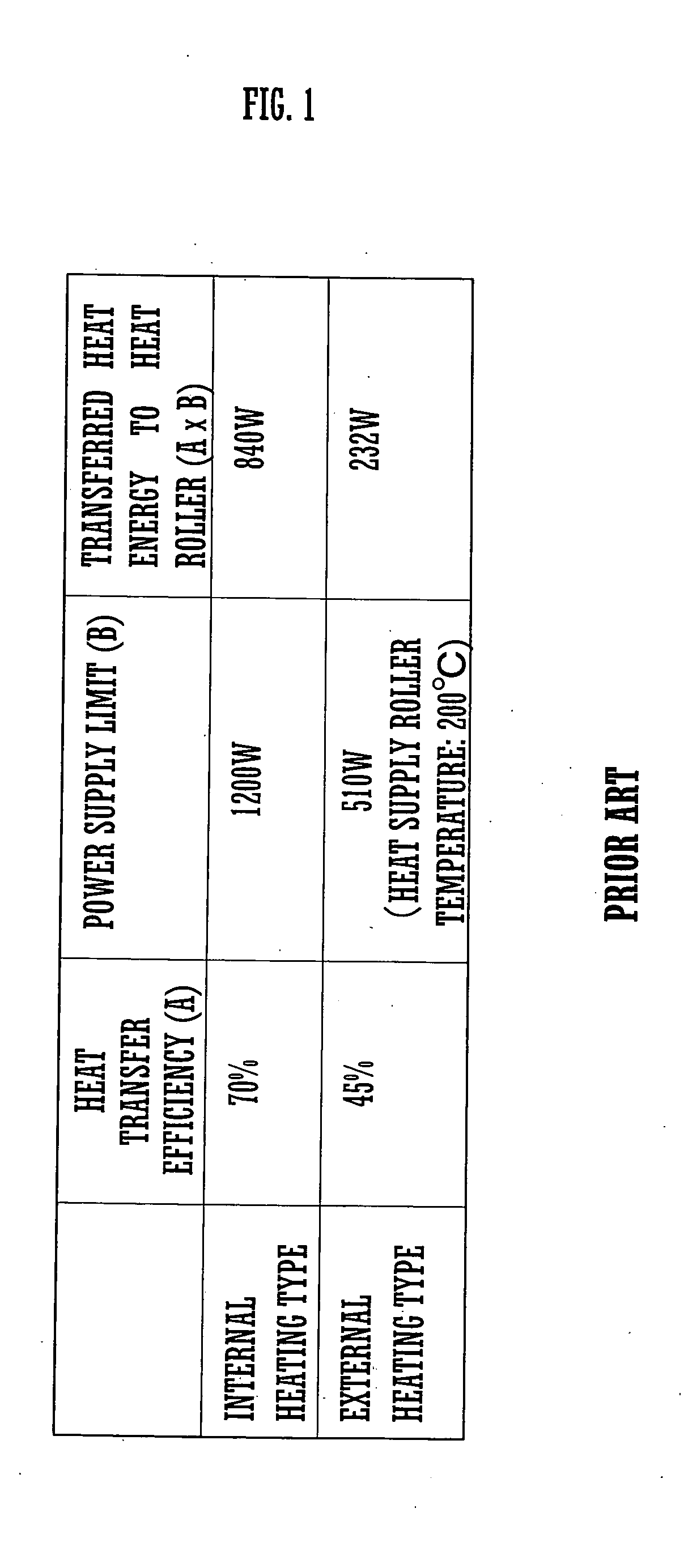

Heating device and heating method

InactiveUS20050061792A1Short warm-up timeReduce standby power consumptionWave amplification devicesOhmic-resistance heating detailsEngineeringPaper sheet

An upper heat roller with an external heat source and a lower heat roller with an internal heat source are arranged with a paper transport path therebetween, in such a manner as to be pressed against each other. The lower heat roller is heated sufficiently, thereby supplying a paper sheet with sufficient heat when the paper sheet is transported through a contact region between the upper and lower heat rollers to be heated.

Owner:SHARP KK

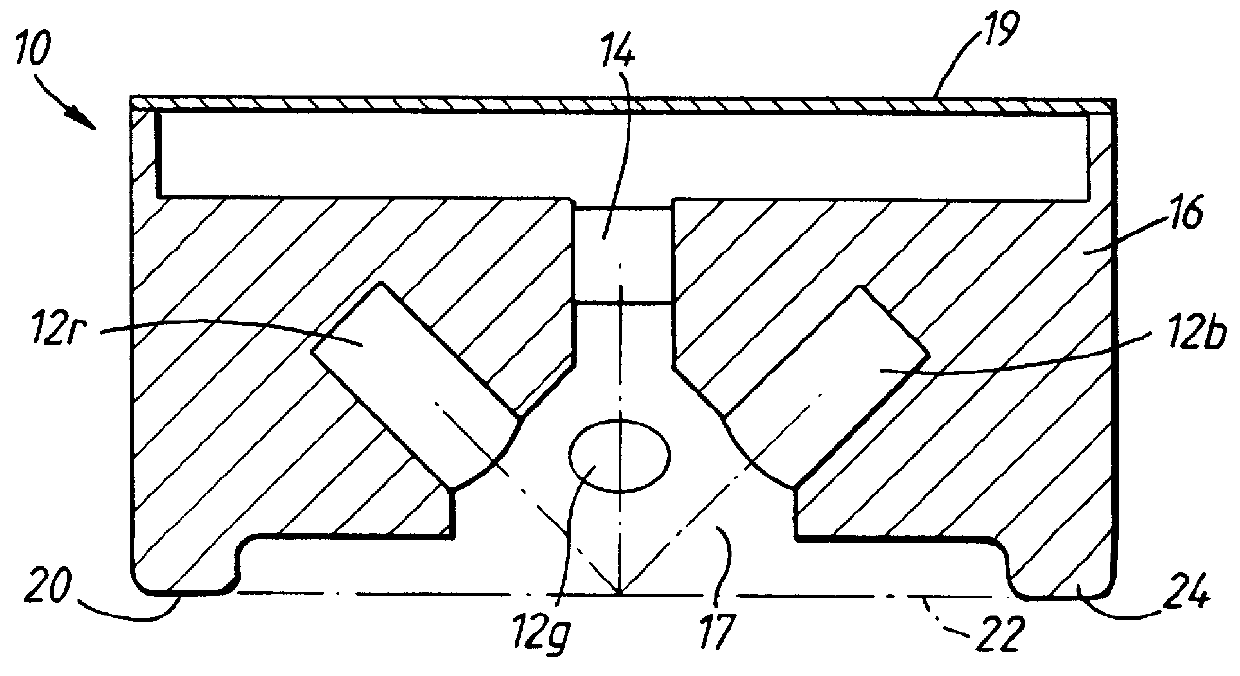

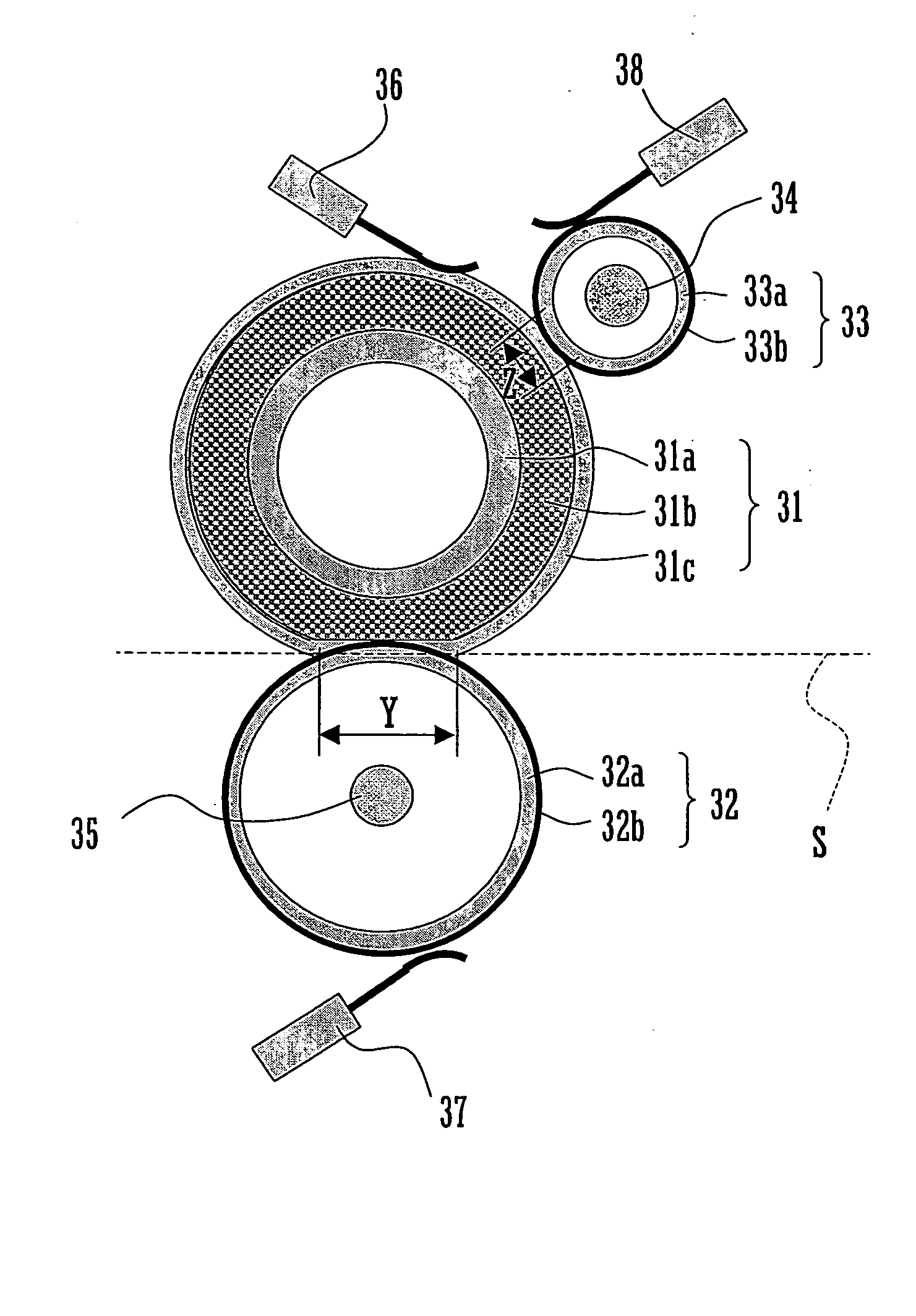

Fixing apparatus

ActiveUS20060165444A1Improve heating efficiencyAvoid Flux LeakageElectrographic process apparatusInduction heating apparatusThin layerEddy current

A fixing apparatus used in an image forming apparatus has a fixing member for fixing toner on paper and a pressure member making contact therewith to form in between a nip through which paper is passed. The fixing member has a support member formed of a ferromagnetic material and a heating layer formed adjacent thereto in the form of a thin layer of a non-magnetic, electrically conductive material. When a high-frequency electric current is passed through an exciting coil that is combined with the fixing member, the fixing member produces a high-frequency magnetic field, thereby produces induced eddy currents in the heating layer of the fixing member, thereby produces Joule's heat in the heating layer, and thereby heats the fixing member. A leaking magnetic flux is absorbed by the support member of the ferromagnetic member, and thus has reduced influence on metal parts located around the fixing apparatus.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

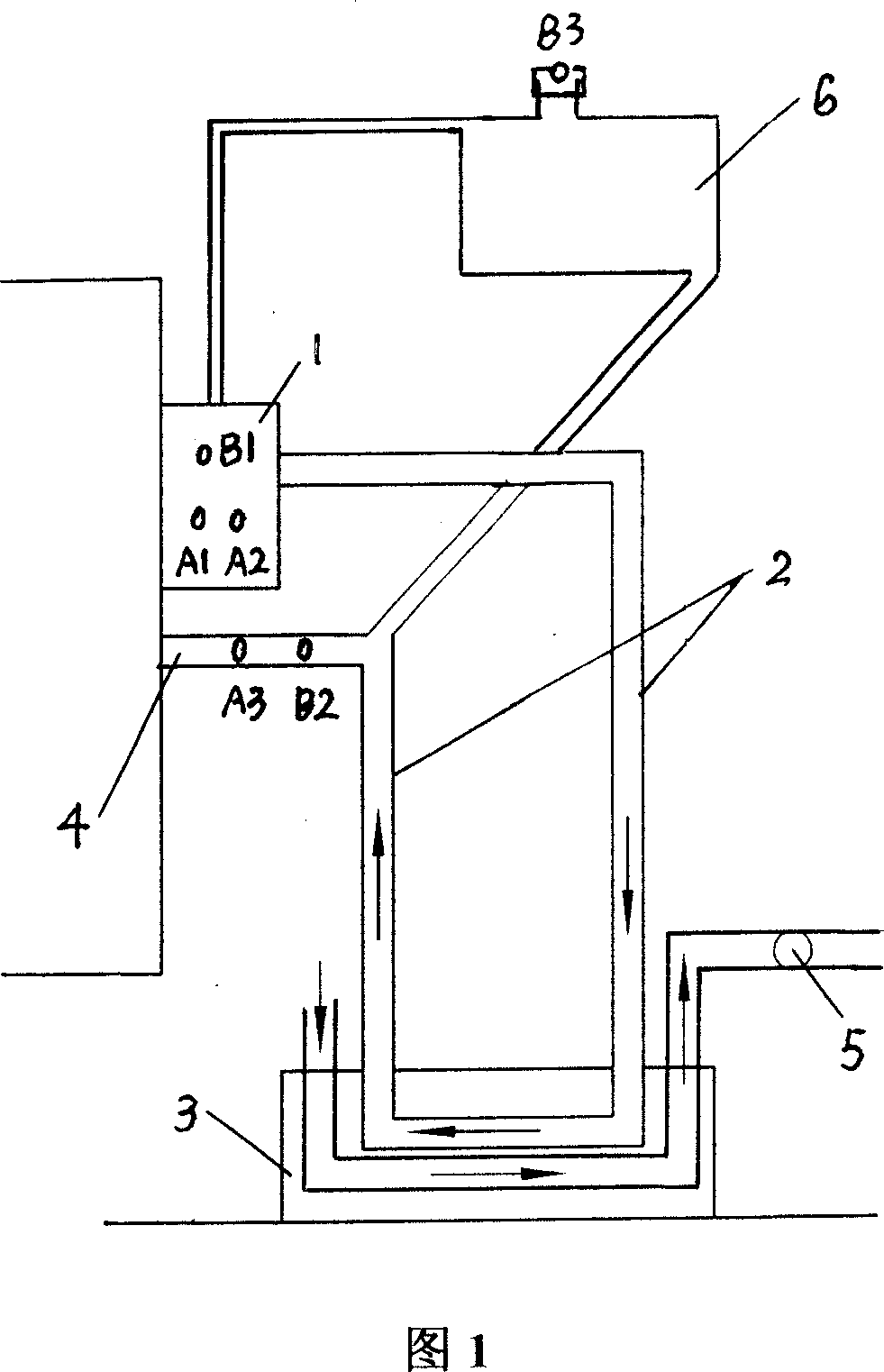

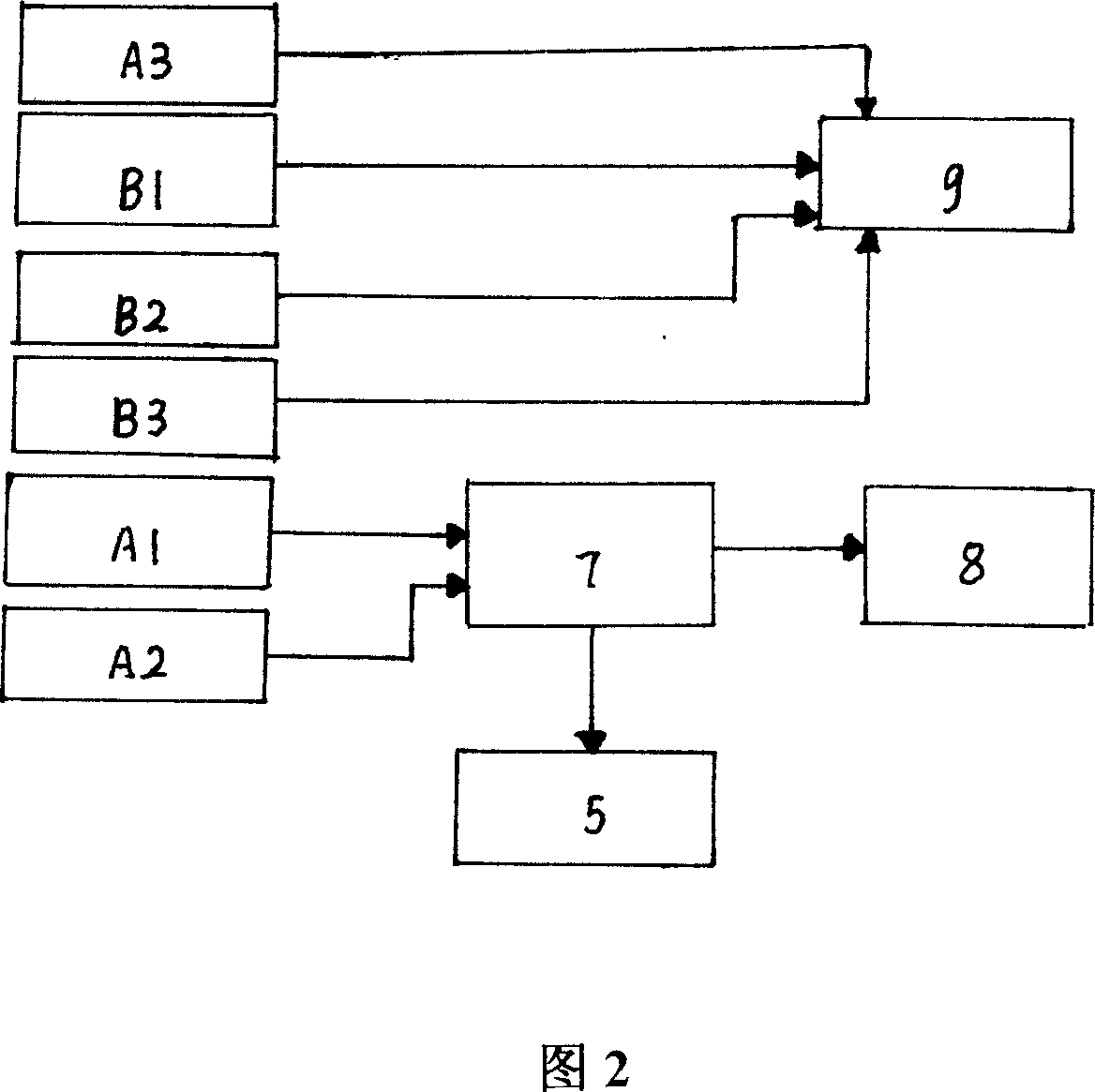

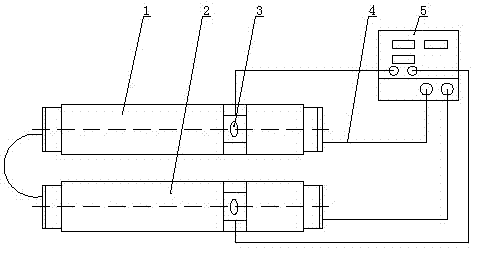

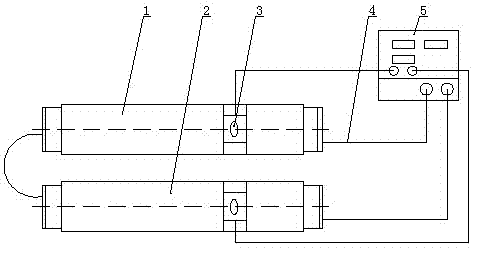

Coolant liquid external circulating system for engine bench test

The invention is to protect the coolant extrinsic cycle system of the engine bench test. The engine water-yielding is educed the cooling liquid pipe which returns to the engine infall after passing a heat exchanger to form a closed circle. The cool end pipe of the heat exchanger is installed with the valve which is closed. The temperature sensor is set in the engine water-yielding and the signal line is connected to the controlling unit which the controlling line is connected with the valve and the alarming device. The controlling unit is set with two temperature value, one is the highest cooling liquid temperature endured by the engine and the other is the proper cooling liquid temperature of the engine. The invention can shorten the warming time of the engine and improve the quality and reliability of the engine bench test.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

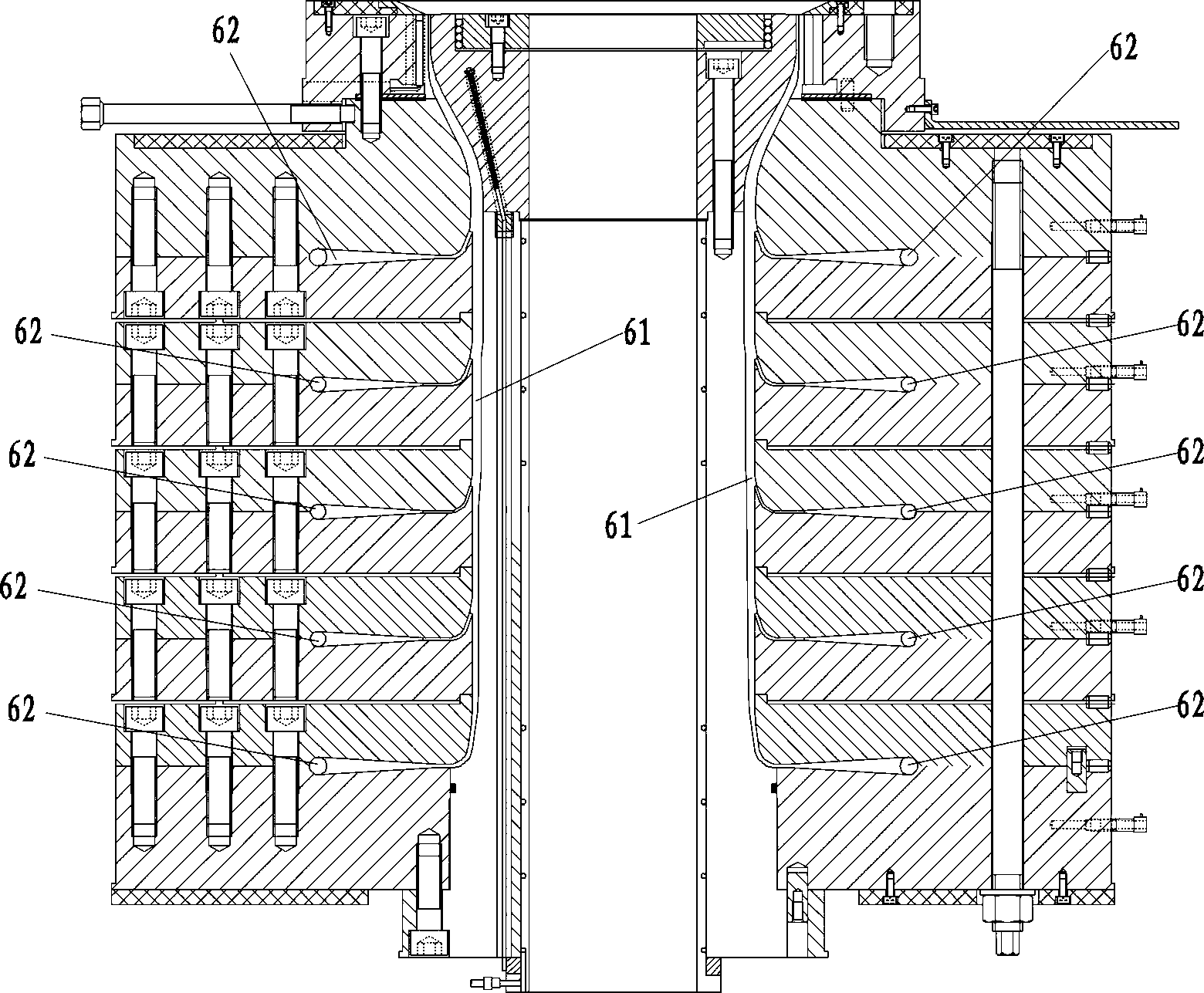

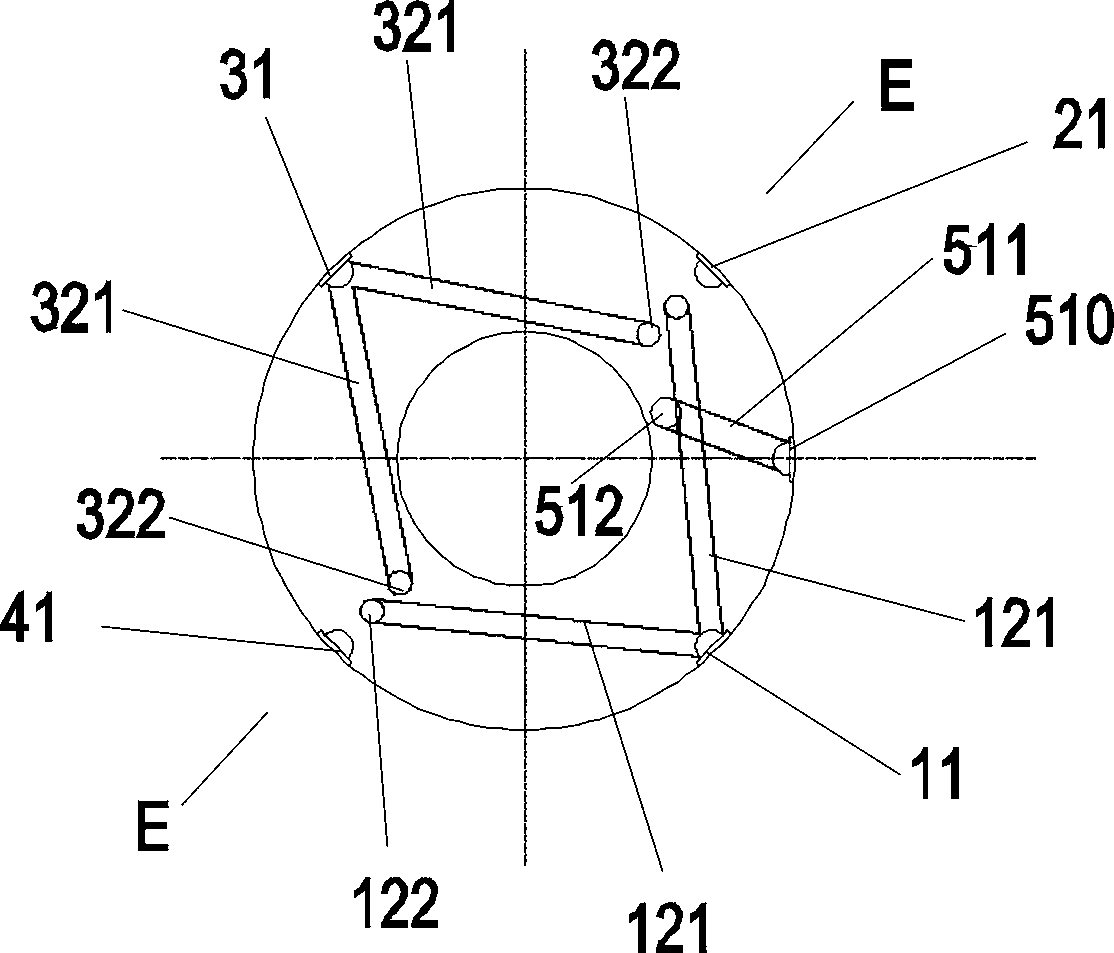

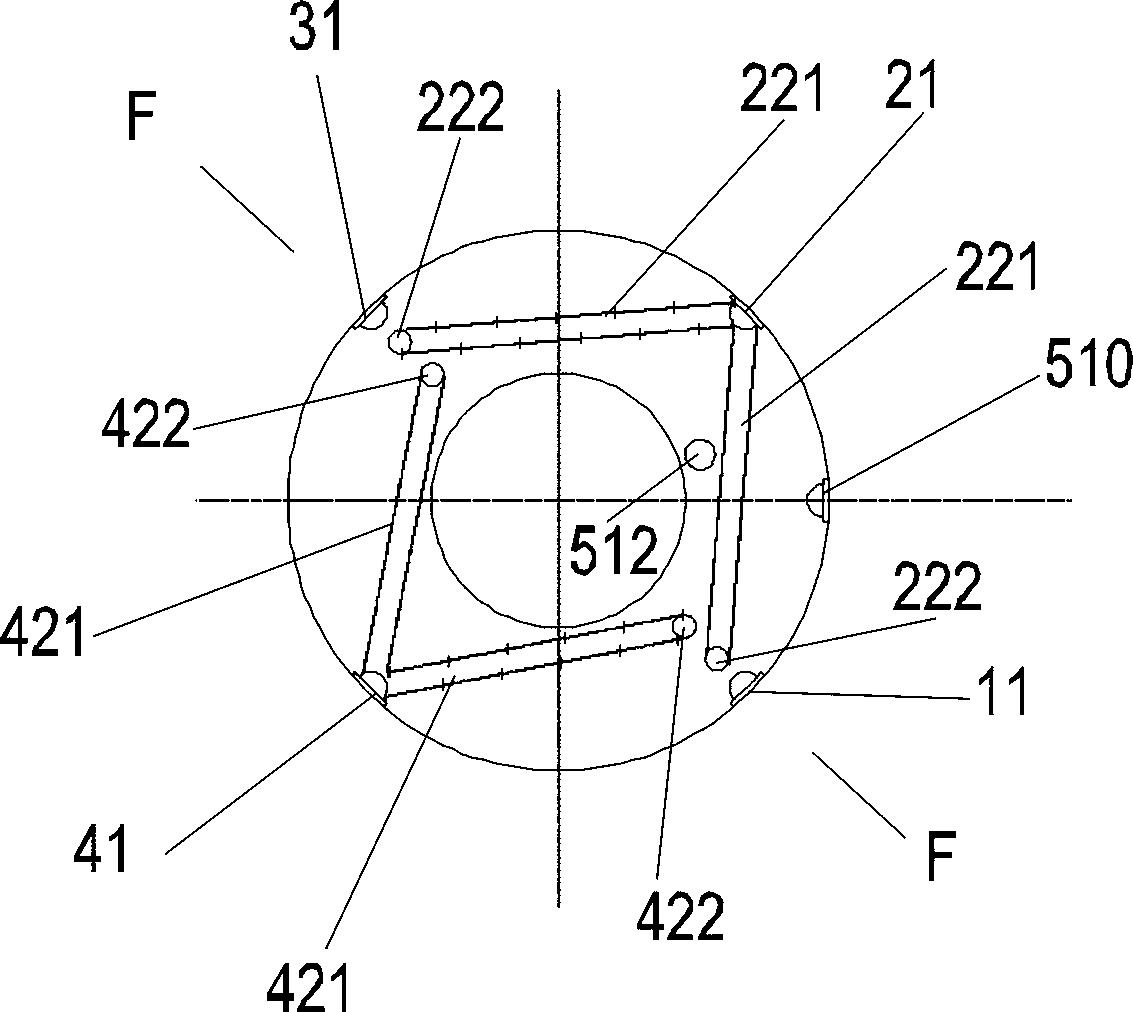

Concentric sleeve type five-layer coextrusion film blower handpiece

A concentric sleeve type five-layer coextrusion film blower handpiece comprises five sets of runner systems, wherein each set of runner system correspondingly guides one layer of fused material to flow, and comprises one layer of spiral runner at the upper part of the handpiece and a total feeding port at the lower part of the handpiece; four layers of distribution discs are arranged at the lower part of the handpiece, and consist of a bottom-layer distribution disc, a second-layer distribution disc, a third-layer distribution disc and a fourth-layer distribution disc; the tail end points of all forty horizontal arrangement branch runners in the five sets of runner systems are positioned on one circle of a third interface; the eccentric distances of the tail end points of the forty horizontal arrangement branch runners are all the same, and are more than those of vertical branch runners of the first set of runner system; the tail end points of eight horizontal arrangement branch runners in each set of runner system are evenly distributed in the peripheral direction; and the tail end points of two adjacent horizontal arrangement branch runners in one set of runner system are staggered from each other at a directional angle of 45 degrees. The handpiece can produce five-layer coextrusion plastic films with large breadths, and is small in size and convenient for processing.

Owner:GUANGDONG JINMING MACHINERY

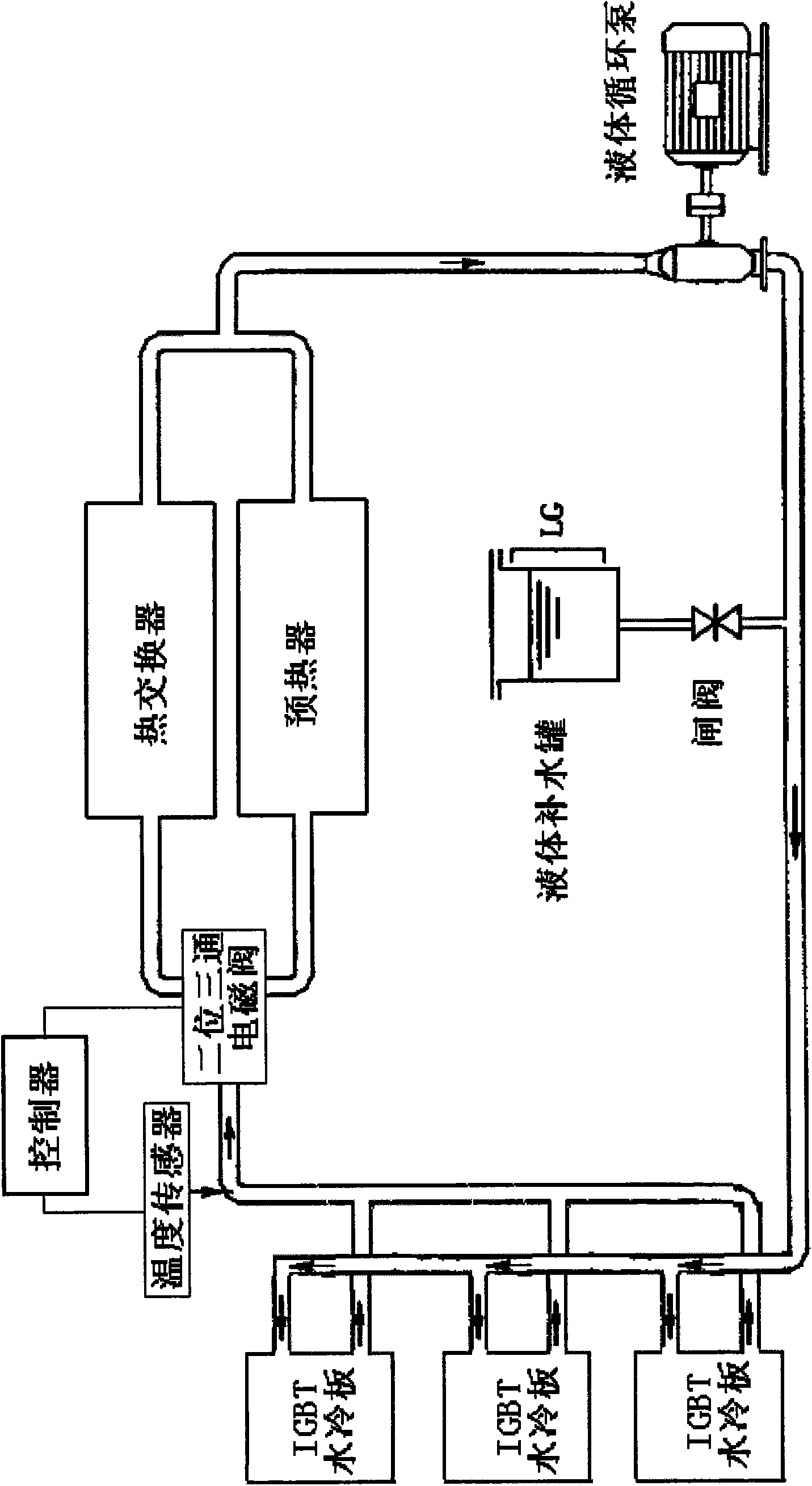

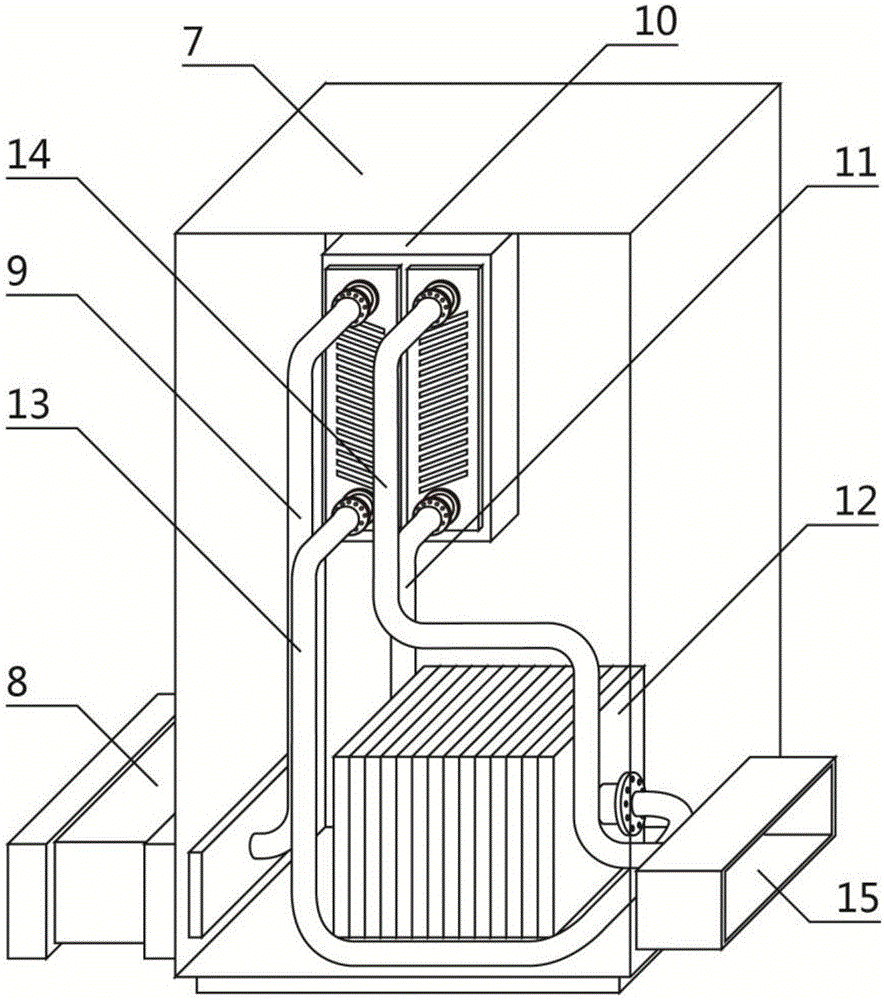

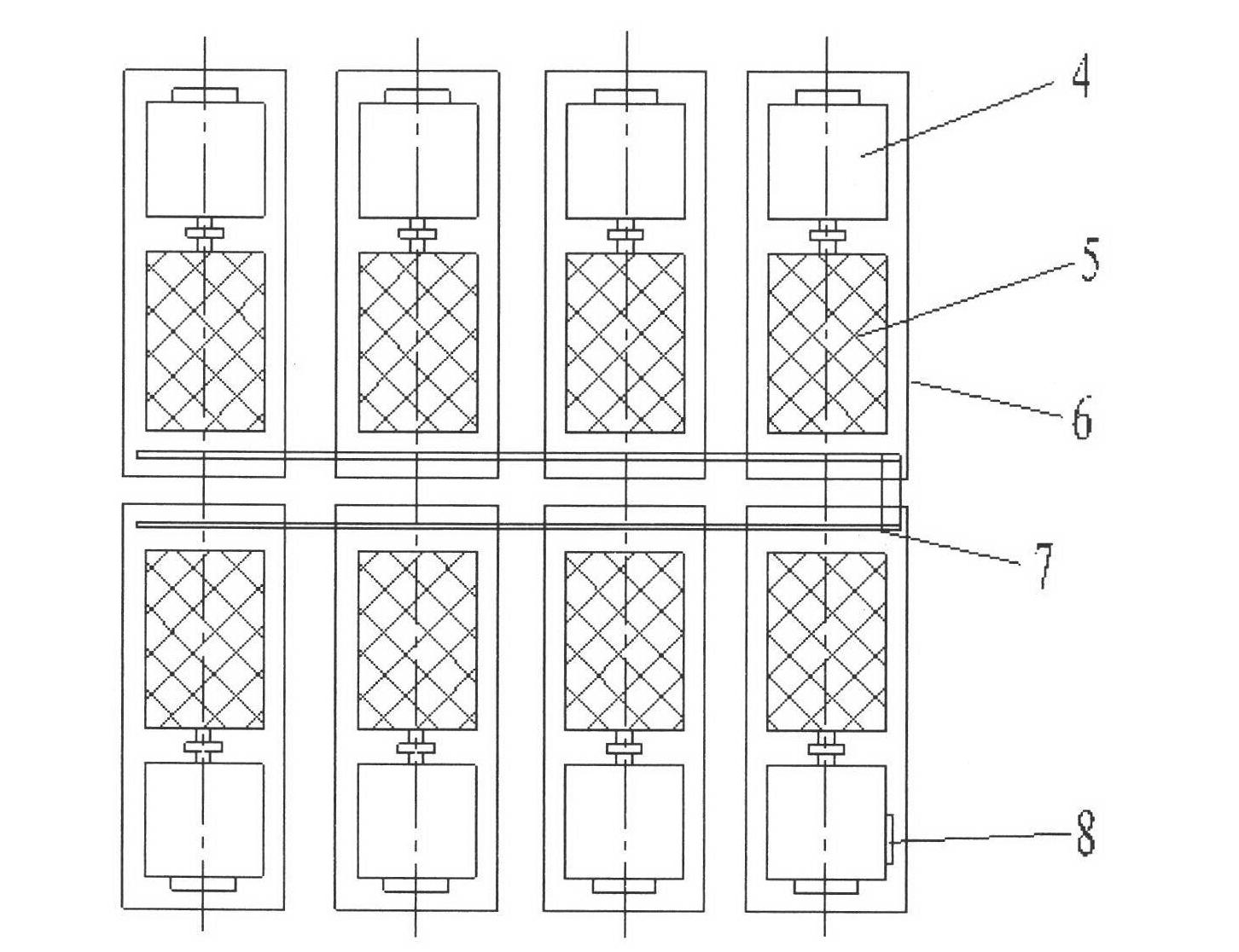

Working temperature control device for high-power power electronic device

InactiveCN101667044AImprove heat transfer efficiencyImprove efficiencyTemperatue controlHeating timeEngineering

The invention relates to a working temperature control device for a high-power power electronic device, consisting of a circulated water cooling device. A heater is arranged in the circulation loop, a2-position 3-way electromagnetic valve controls the switching between the heater and the radiator, a temperature sensor of the controller is arranged at a water outlet of the water cooling plate of the power electronic device, and the output end of the controller is connected with the 2-position 3-way electromagnetic valve. The working temperature control device has the advantages of high heat transfer efficiency, even pre-heating, short pre-heating time, high efficiency and reduced energy consumption.

Owner:CRRC DALIAN CO LTD

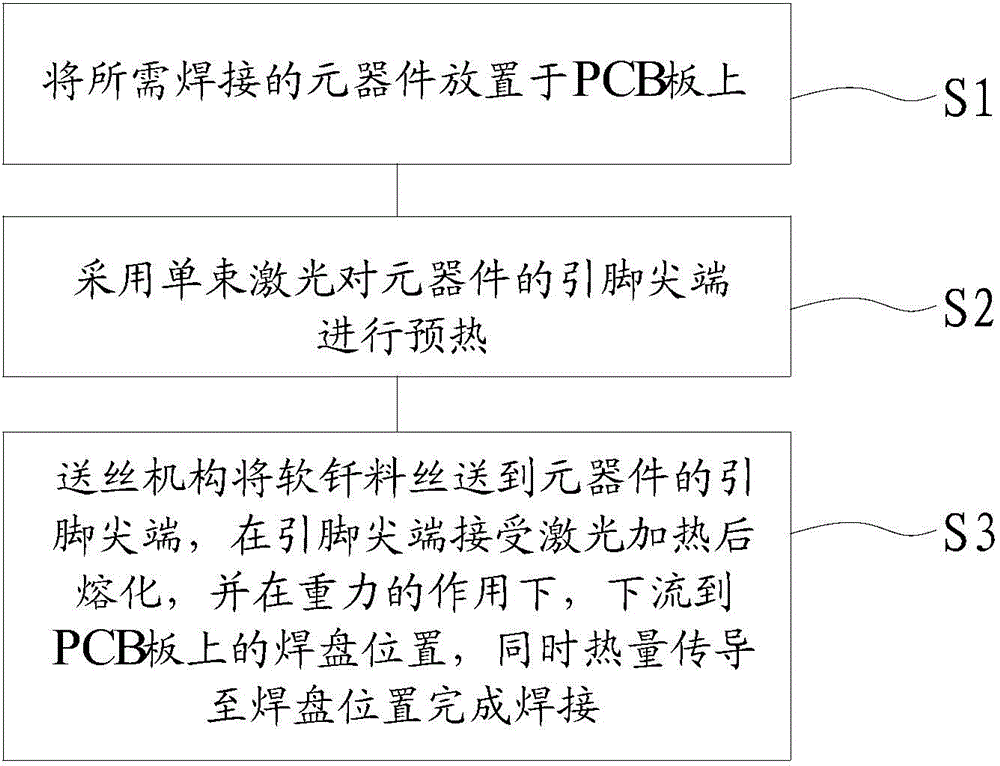

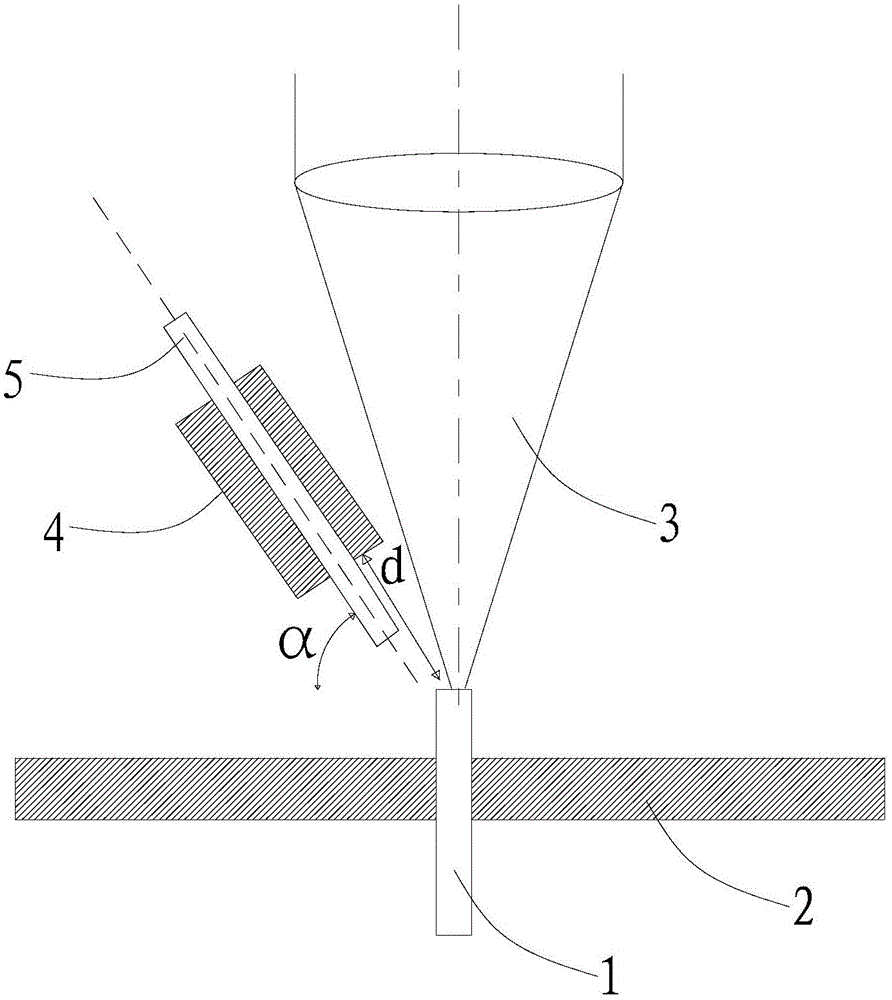

Method for welding component pin and apparatus thereof

ActiveCN104923914AShort warm-up timeEasy to debugPrinted circuit assemblingMetal working apparatusHeating timeEngineering

The invention relates to the field of welding technology, and discloses a method for welding a pin of a component and an apparatus thereof. The method herein comprises welding the component pin to a PCB board by using laser and a wire feeder, wherein the laser refers to a single beam laser. During welding, the laser supplies heat to the tip end of the component pin, and the wire feeder delivers the wire to the tip end of the component pin. According to the invention, the laser supplies heat to the tip end of the component pin instead of a coated copper layer on the PCB board, and the wire feeder delivers the wire to the tip end of the component pin instead of the coated copper layer on the PCB board. Thus, the method herein is applicable to welding pins of all plug-in types of components with no concerns of the morphology of the cross section or the size of the cross section area, or factors like heat radiation property of the coated copper layer. The method herein has the advantages of short pre-heating time, simple modulation, and a wide range of application.

Owner:HANS LASER TECH IND GRP CO LTD

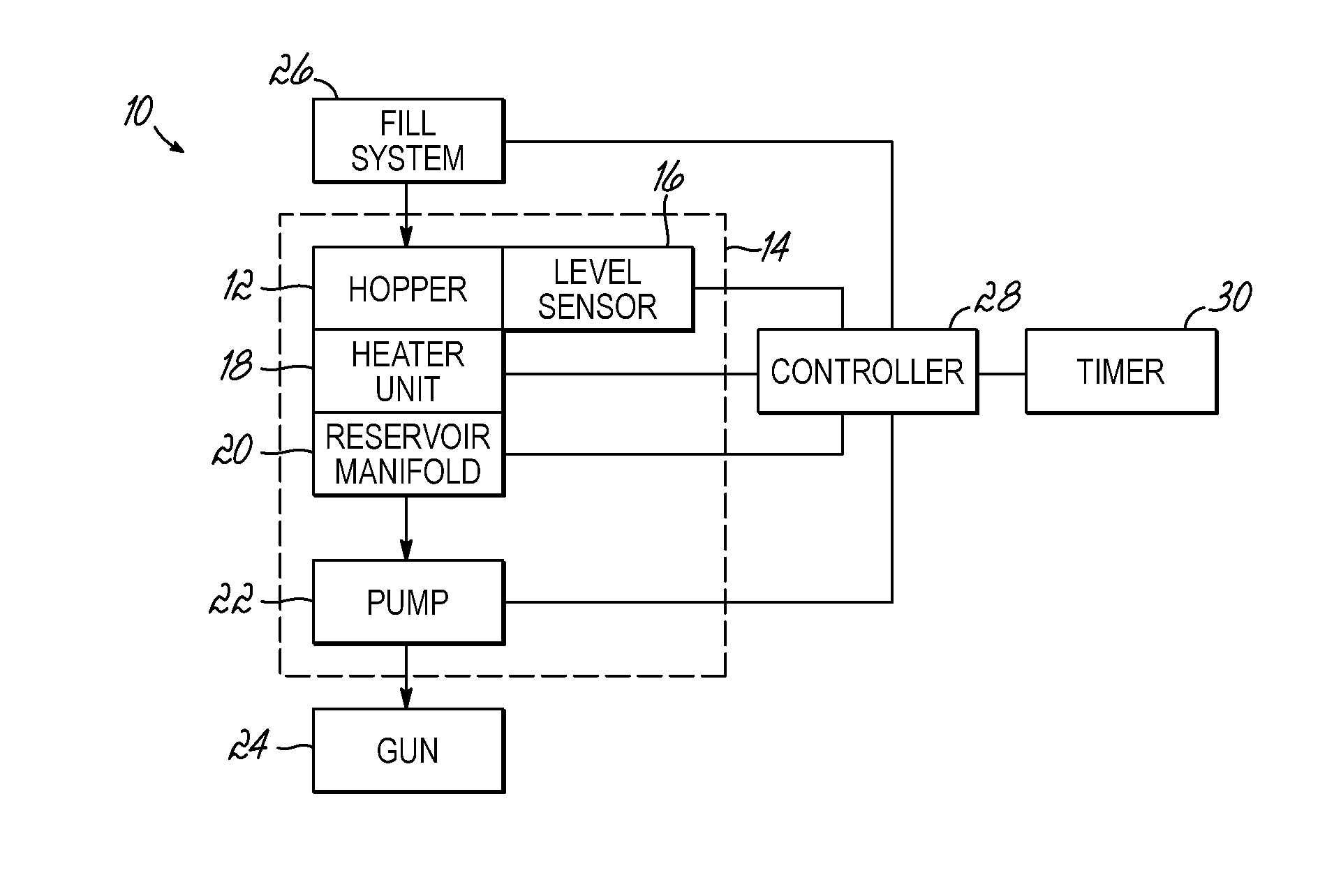

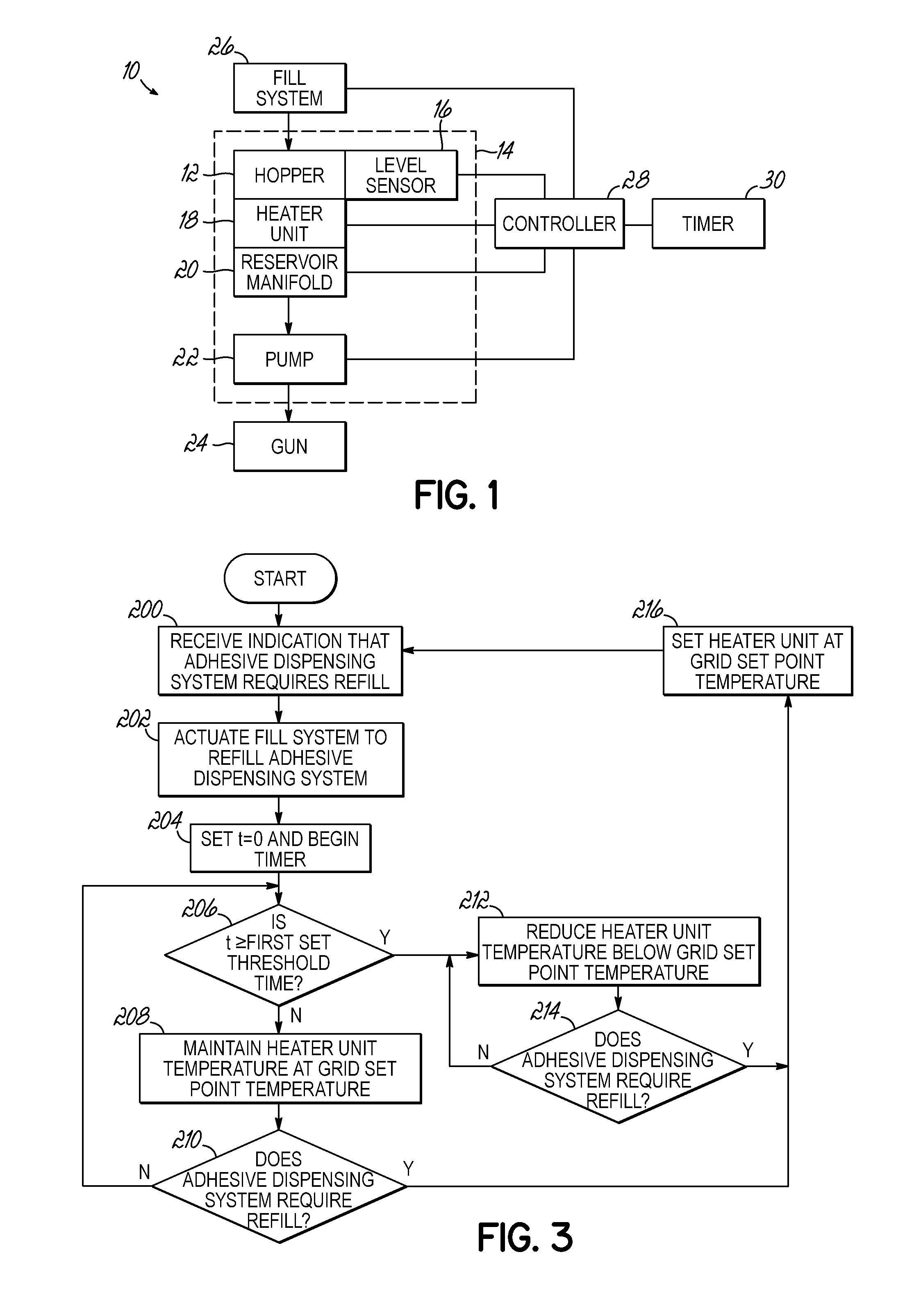

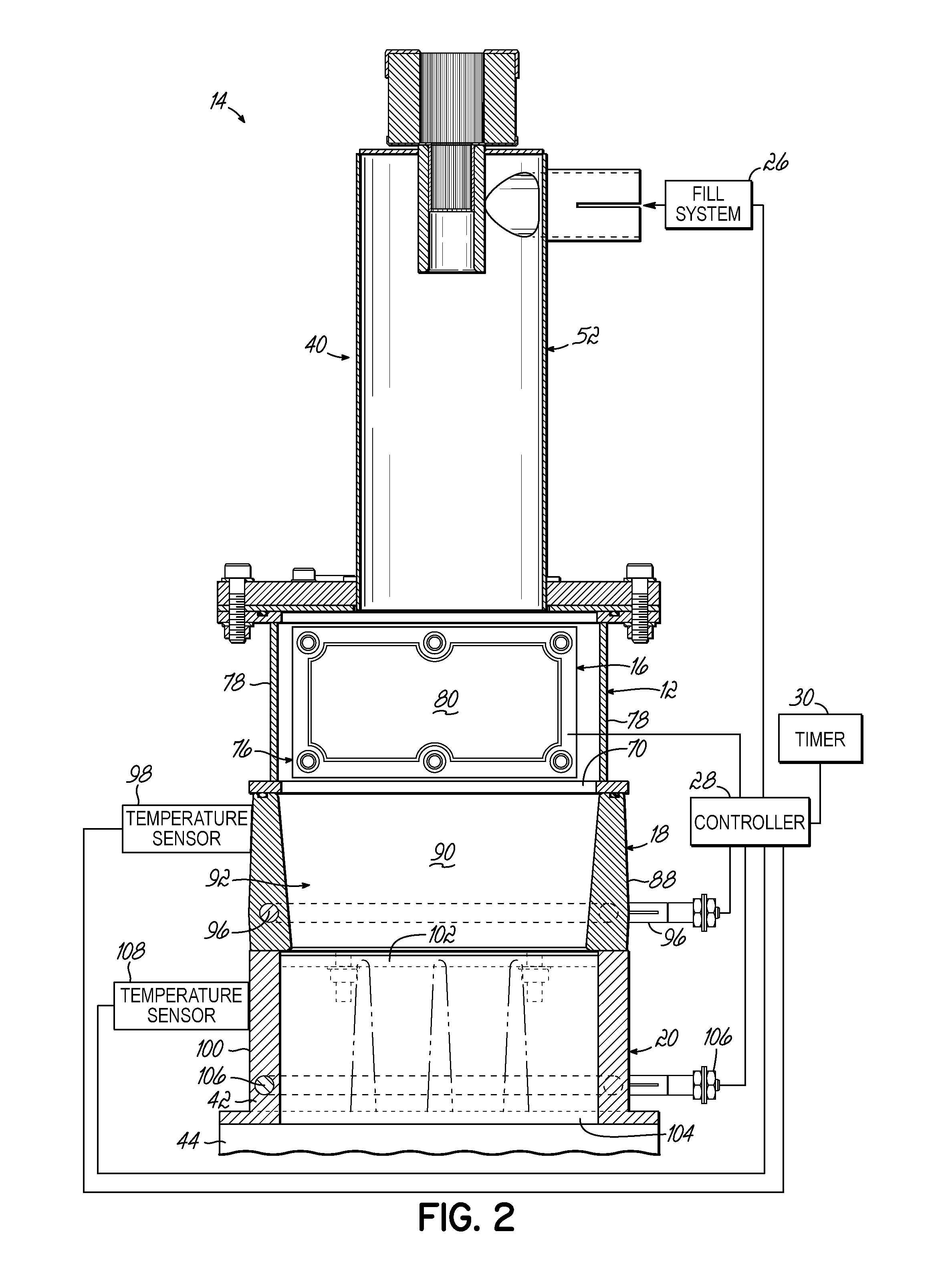

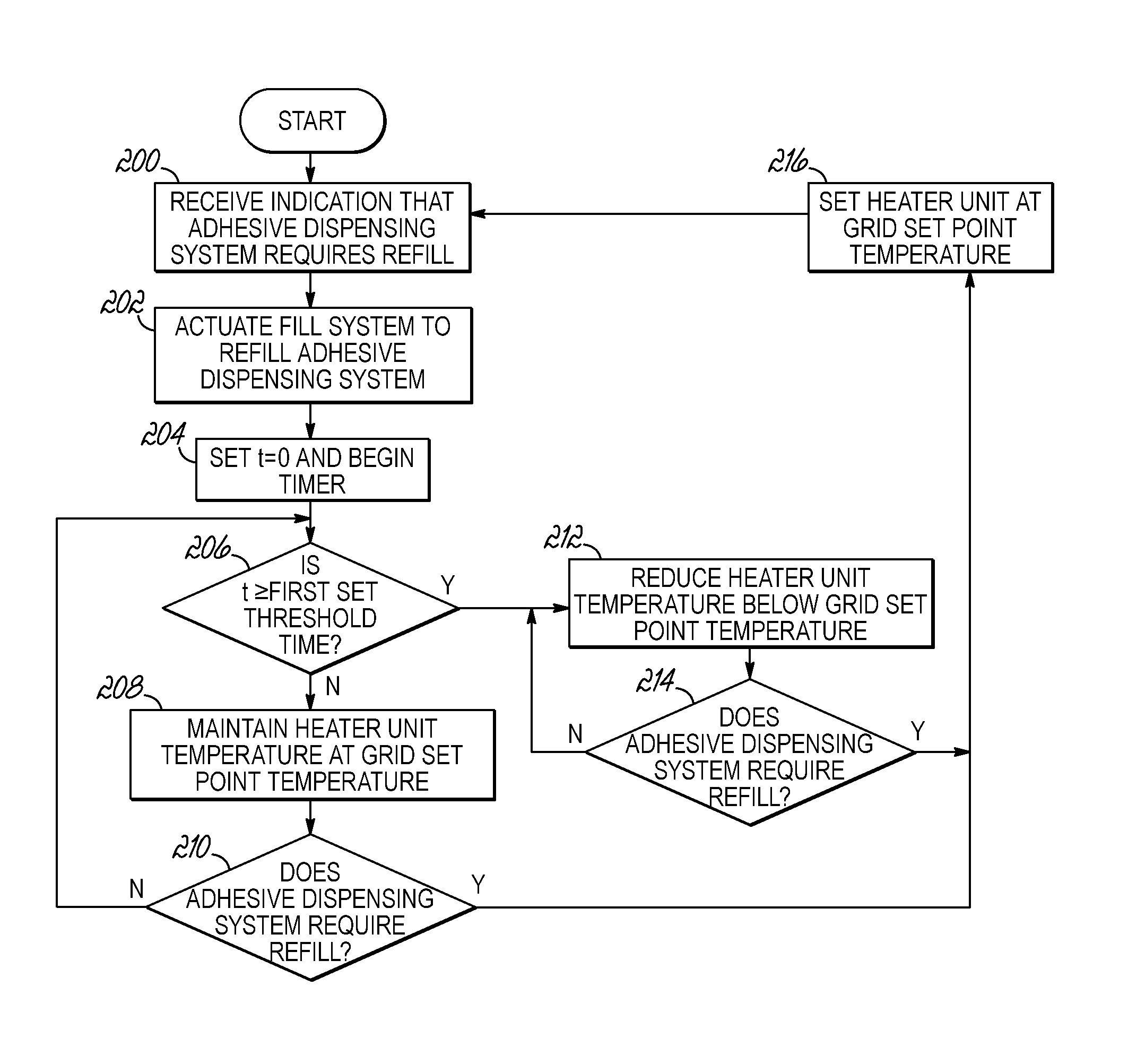

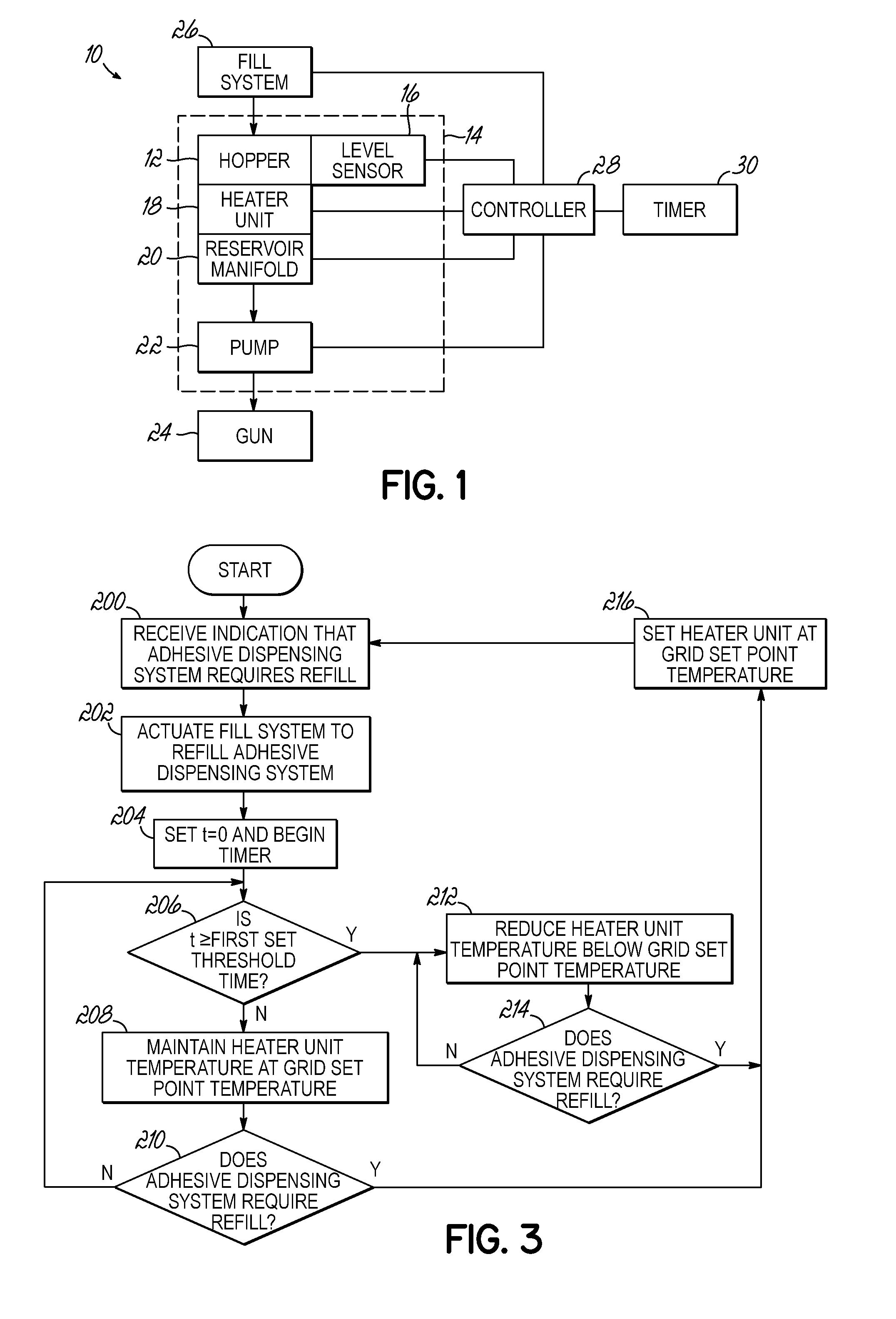

Adhesive dispensing system and method using smart melt heater control

ActiveUS20140116525A1Reduce the degradation rateMinimizing outgassingLiquid surface applicatorsValve members for heating/coolingOutgassingEngineering

An adhesive dispensing system is configured to automatically reduce the temperature of adhesive material to reduce degradation of the adhesive caused by holding the adhesive at an application temperature during periods of low throughput. To this end, a controller of the system operates a heater unit to maintain a unit set point temperature to heat and melt adhesive until a set threshold time has elapsed since the most recent supply of adhesive to the system by a fill system. Once the time elapsed since the most recent supply of adhesive exceeds the set threshold time, the heater unit is reduced in temperature to reduce the temperature of adhesive. This reduction is temperature is large enough to minimize degradation and outgassing but small enough to enable rapid warm-up times after a new supply of adhesive occurs.

Owner:NORDSON CORP

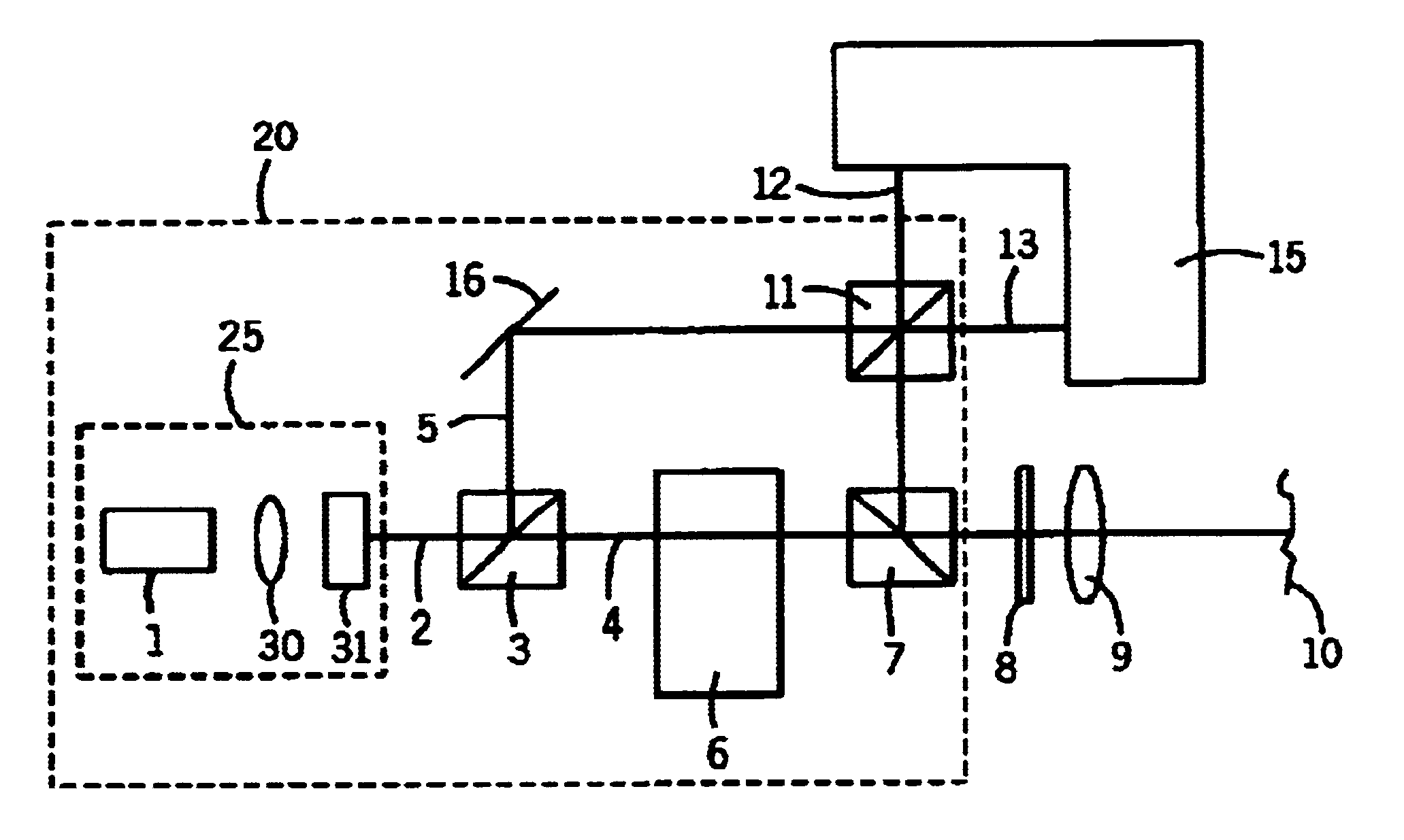

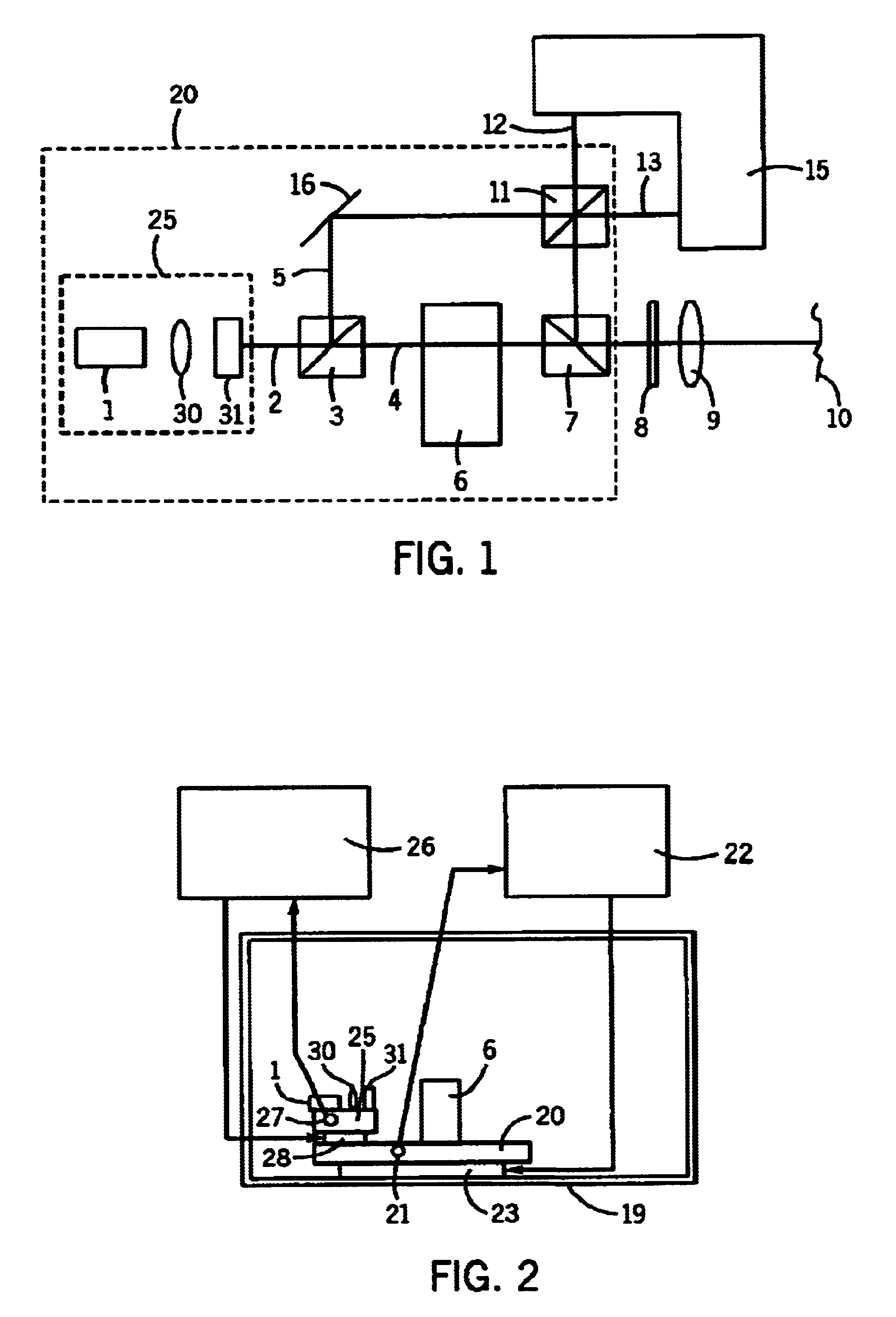

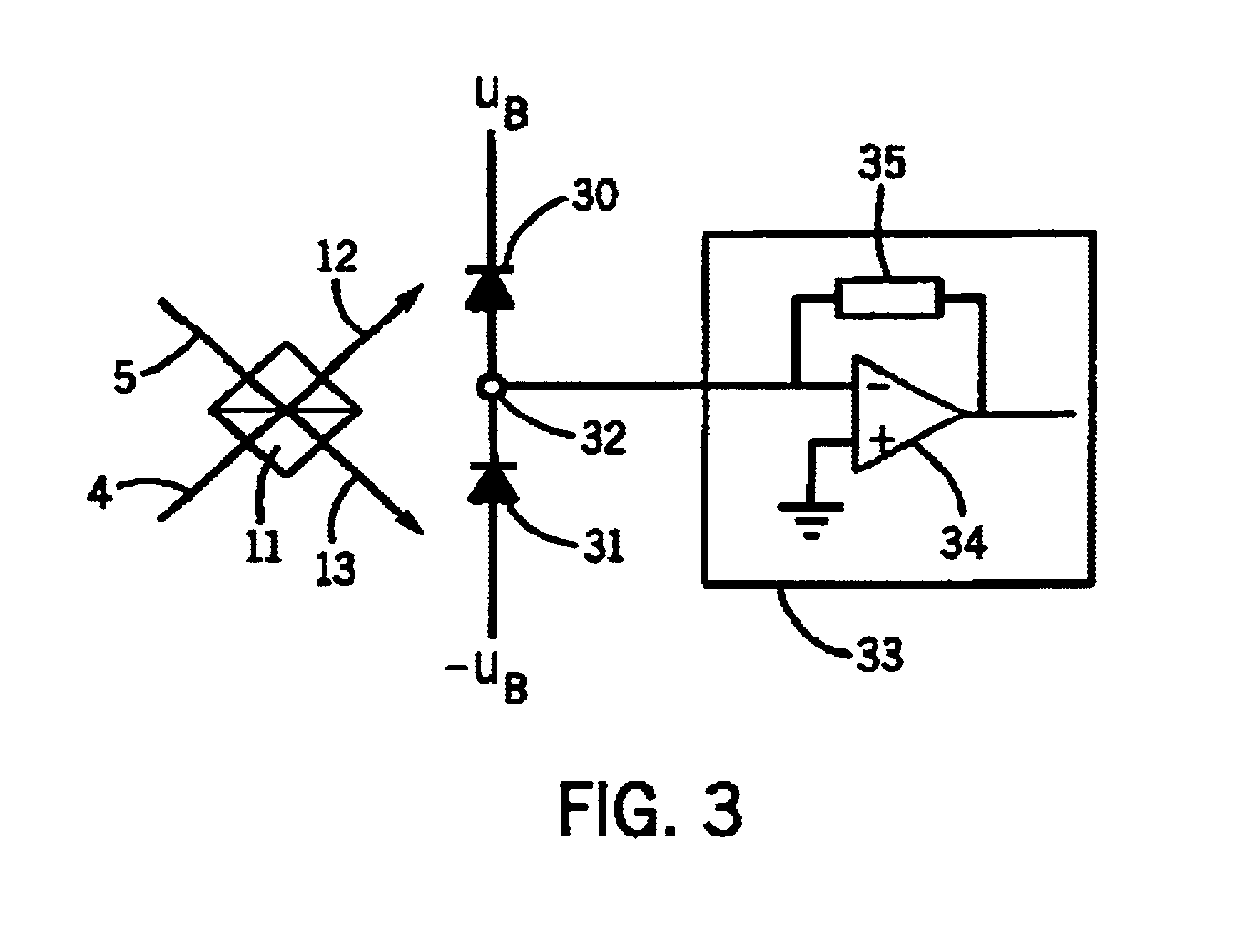

Device for the non-contacting measurement of an object to be measured, particularly for distance and/or vibration measurement

InactiveUS6844936B2High measurement accuracyStructural economyInterferometersUsing optical meansVibration measurementAudio power amplifier

A device for the non-contacting measurement of an object to be measured, particularly for distance and / or vibration measurement, has at least one laser light source, optical devices for splitting the light into object light (4) and reference light (5) for interacting with the object to be measured and for superimposing object light and reference light following the interaction of the object light with the object to be measured, preferably a frequency shift device in the form of a Bragg cell for producing a frequency shift between the object light and the reference light and a detecting device (15) for converting reference light and object light into electrical signals suitable for further processing. The detecting device has at least two series-connected optoelectronic transducers in the form of photodiodes (30, 31). Between the transducers is located a tap (32) for tapping a difference signal which, for further processing, is supplied to a transimpedance circuit (33) associated with one of the transducers. Thus, there is a subtraction of photodiode currents prior to processing in an amplifier circuit in a balanced detection arrangement. This inexpensively permits measurements at high reference light power with resolutions in the quantum noise limit range.

Owner:ZENNER HANS PETER

Construction method for prefabricating directly-buried uncompensated centralized heat supply pipeline by electrically preheating

InactiveCN102444750AImprove running stabilityGuaranteed elongationPipe laying and repairElectricityEngineering

The invention relates to a construction method for prefabricating a directly-buried uncompensated centralized heat supply pipeline by electrically preheating. The method comprises the following steps of: (1) grooving, adjusting the coordinate and scale height of the heat supply pipeline, and computing the preheating temperature and the designed elongation of the heat supply pipeline; (2) controlling the sand refilling height at a half to three quarters of the pipeline height H; (3) connecting the same-side end of the heat supply pipeline with preheating equipment through a cable respectively, and short-circuiting the other side of the heat supply pipeline through a cable; (4) arranging temperature sensors on the heat supply pipeline respectively; (5) recording the initial temperature of the heat supply pipeline and the initial position of a measuring point, starting temperature raising, controlling the temperature raising gradient within 1 DEG C per hour, and preserving heat after a preheating temperature is reached; (6) refilling sand into both sides of the heat supply pipeline, tamping, and controlling the preheating temperature within the range of + / -2 DEG C; (7) after the designed elongation is reached, shutting down the preheating equipment; and (8) performing subsequent construction according to the steps (1)-(7). The construction method disclosed by the invention is safe, reliable, easy and practical, is easy for accurately controlling construction equipment, and is consistent with the national policy of energy saving and emission reduction.

Owner:MCC TIANGONG GROUP

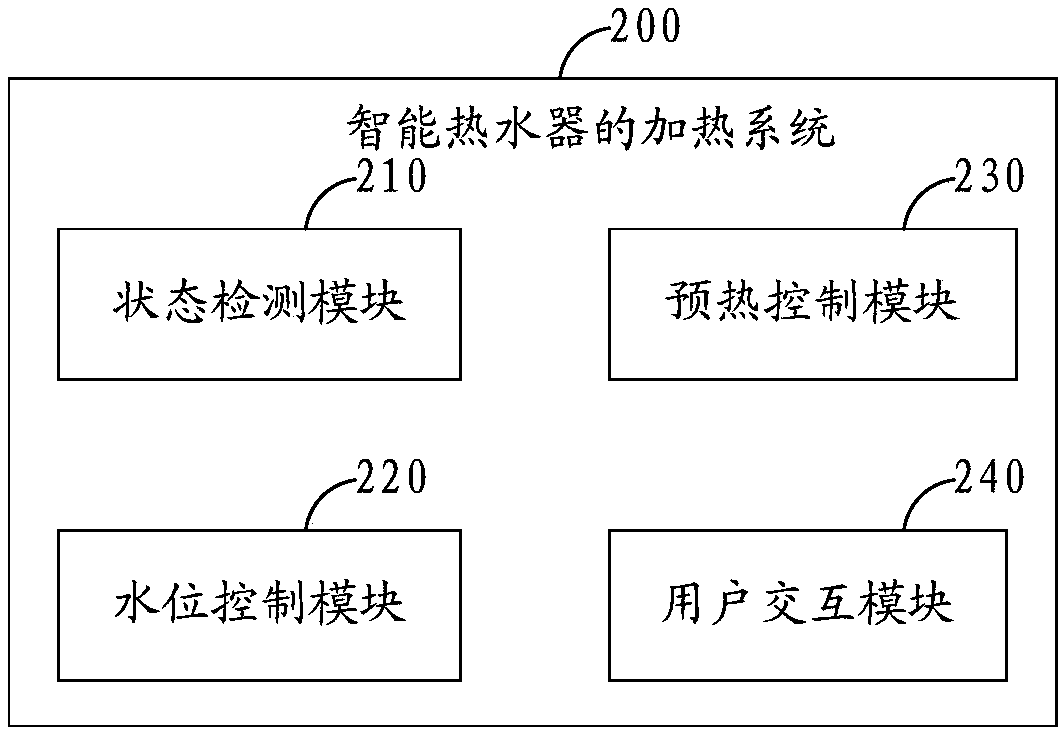

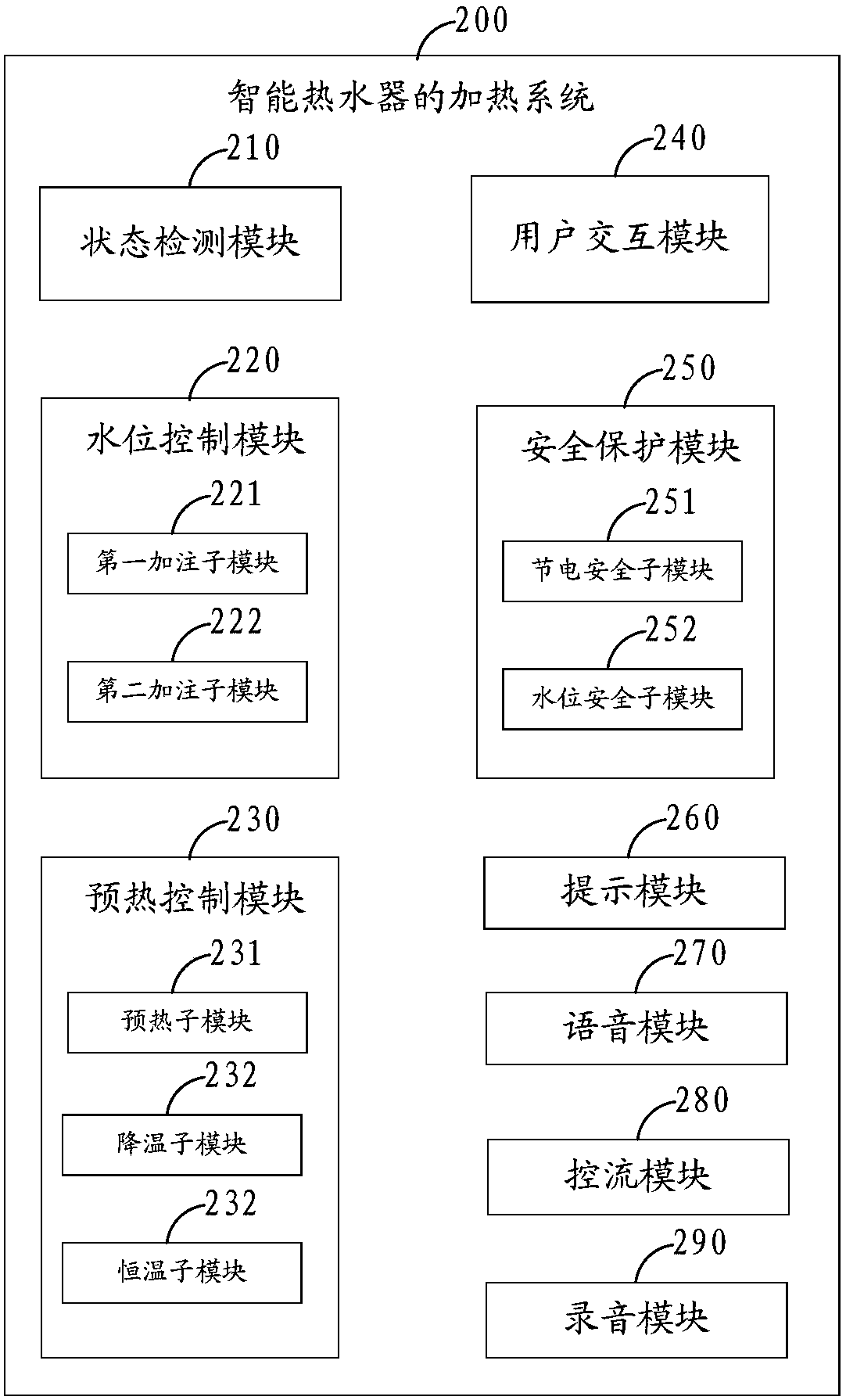

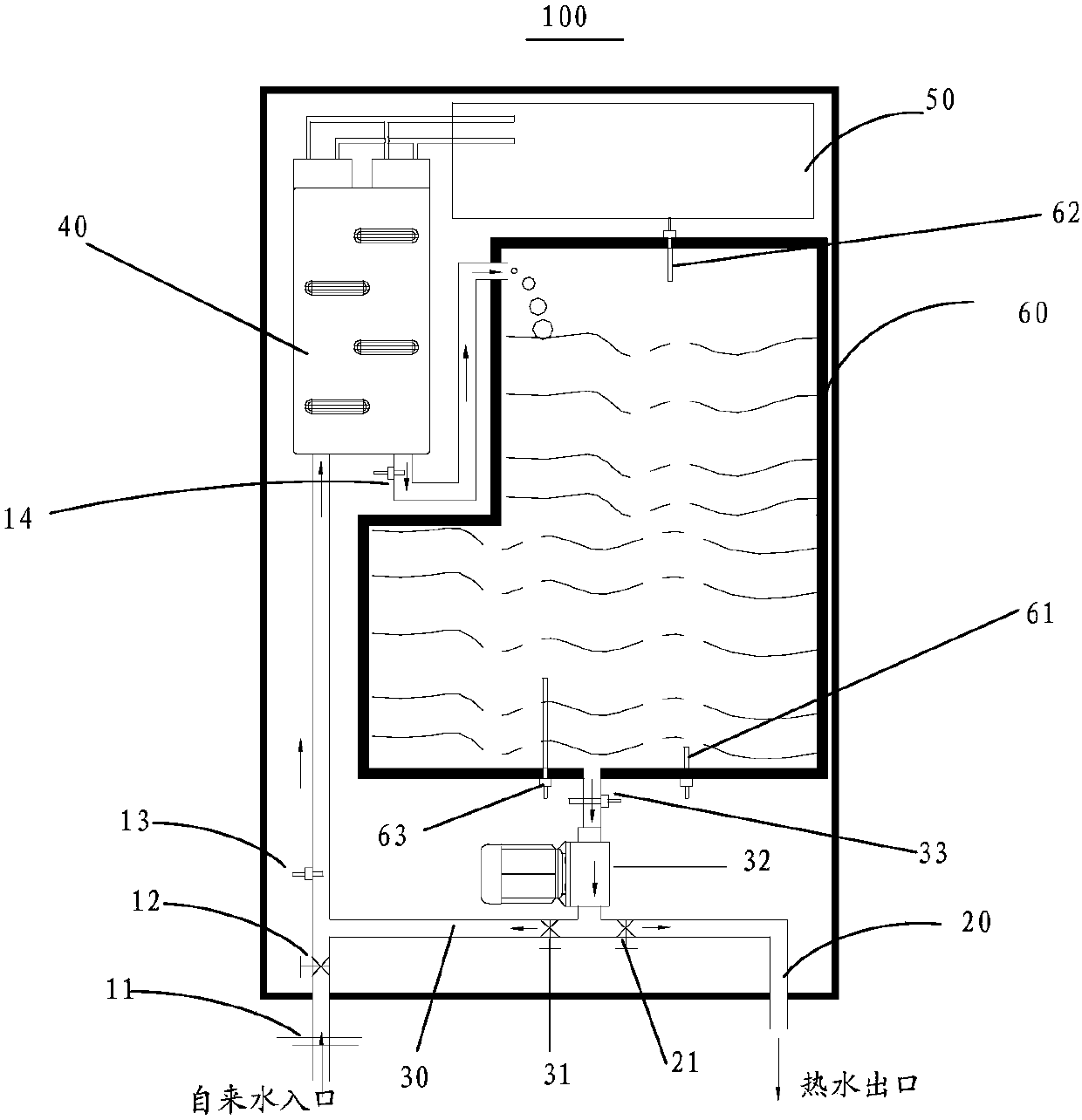

Intelligent water heater and heating system thereof

PendingCN107816796ALarge amount of waterShort warm-up timeMechanical apparatusWater heatersHeating systemWater storage tank

The invention provides an intelligent water heater and a heating system thereof and belongs to the technical field of water heaters. The intelligent water heater comprises a water inlet pipeline, a heating device, a water outlet pipeline, a circulating pipeline, a water storage tank and a control panel. An inlet of the water inlet pipeline is connected with a tap water pipeline, and then the waterinlet pipeline enters the heating device; the water inlet pipeline comes out of the heating device and then is connected with the water storage tank in an extending mode; the water storage tank is connected with the bottom end of the water inlet pipeline through the circulating pipeline, and the circulating pipeline is provided with at least one water pump; the water storage tank is connected with the water outlet pipeline, and the water inlet pipeline, the circulating pipeline and the water outlet pipeline are each provided with at least one electric control switch device and at least one temperature probe; and the water storage tank is provided with at least one temperature probe and at least one liquid level meter. Thus, the water heater which is large in water outlet quantity, short is preheating time, safe and reliable is achieved.

Owner:东莞市芯翼科技有限公司

Fixing device and image forming apparatus

InactiveUS20110311283A1Short warm-up timeGood fixabilityElectrographic process apparatusLongest DiameterEngineering

A fixing device to fix a toner image on a recording medium, including a pressure roller to press the toner image on the recording medium; an elastically-deformable cylindrical fixing roller to contact the pressure roller to form a nip and transfer the recording medium to the nip to fix the toner image; and a holder to rotatably hold both ends of the fixing roller, wherein the holder is located at least two positions at both sides on an outer circumference of the fixing roller across the longest diameter thereof, and the nip is formed between the two holders at the side of the pressure roller.

Owner:RICOH KK

Manufacturing method of commercial high-magnesium aluminum alloy wheel hubs

The invention discloses a manufacturing method of commercial high-magnesium aluminum alloy wheel hubs. The manufacturing method includes the following steps that 1 raw materials of high-magnesium aluminum alloy hot rolled plates are made into annular blank; 2 a spinning machine or a punching machine is used for drawing the annular blank into the shape of a disc, and disc-shaped blank is obtained; 3 the disc-shaped blank which is cooled to the temperature below the re-crystallization temperature is placed into a forging and pressing mould, a forging and pressing machine is used for forging and pressing spoke portions, and forged and pressed aluminum alloy wheel hub blank is obtained; 4 on the spinning machine, the forged and pressed aluminum alloy wheel hub blank is spun into hollow rotating body wheel hub blank; 5 the hollow rotating body wheel hub blank formed through spinning is placed in the environment at the temperature of 100 DEG C-250 DEG C for 0.5-6 hours, and low-temperature stabilizing treatment is achieved; 6 machining and surface treatment are conducted. According to the manufacturing method, the problems that an existing technology is complicated, low in production efficiency and high in energy consumption are solved, and the purposes that energy consumption is reduced, the production efficiency is increased and products have good mechanical properties are achieved.

Owner:ZHEJIANG GKO IND CO LTD

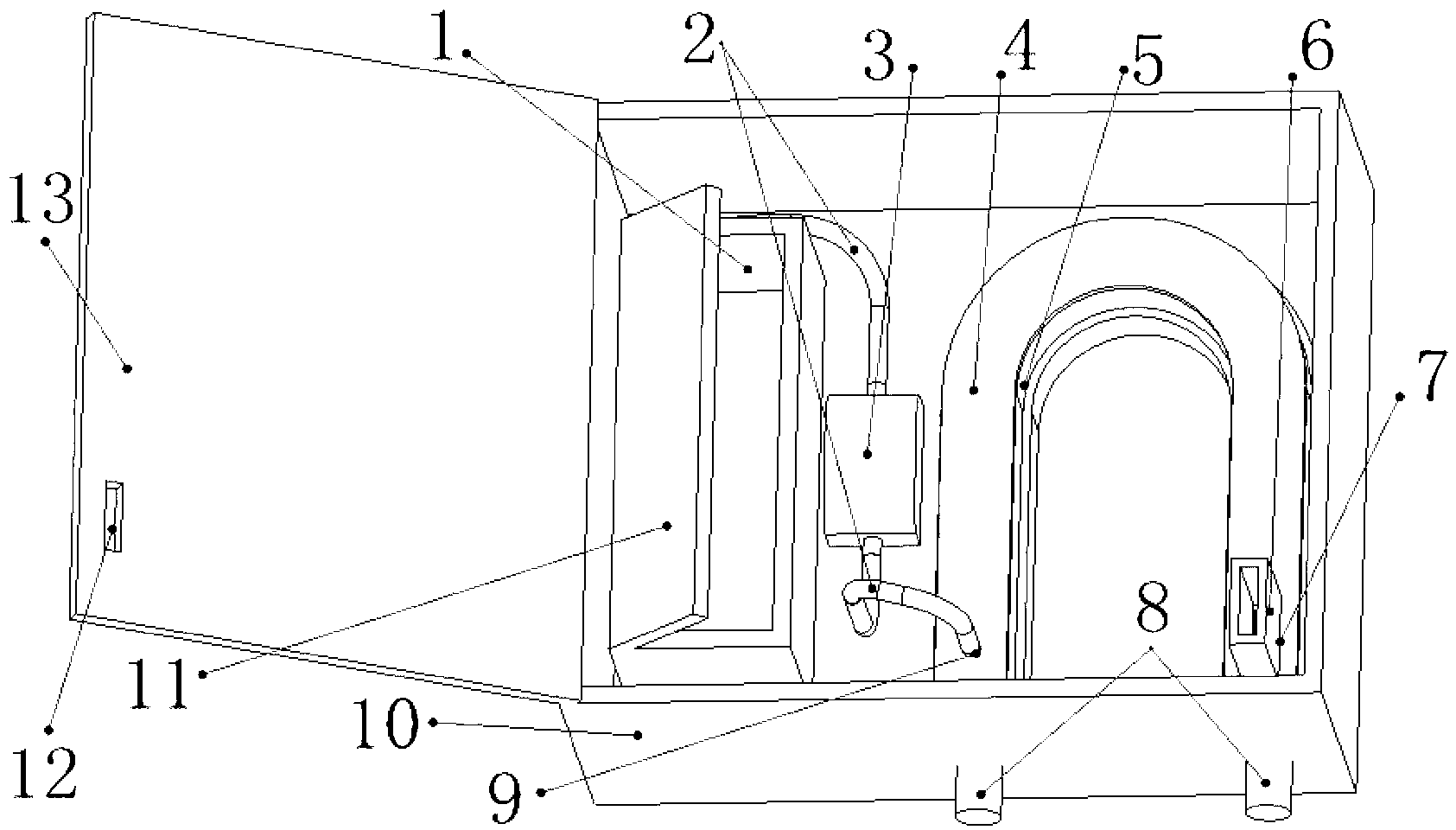

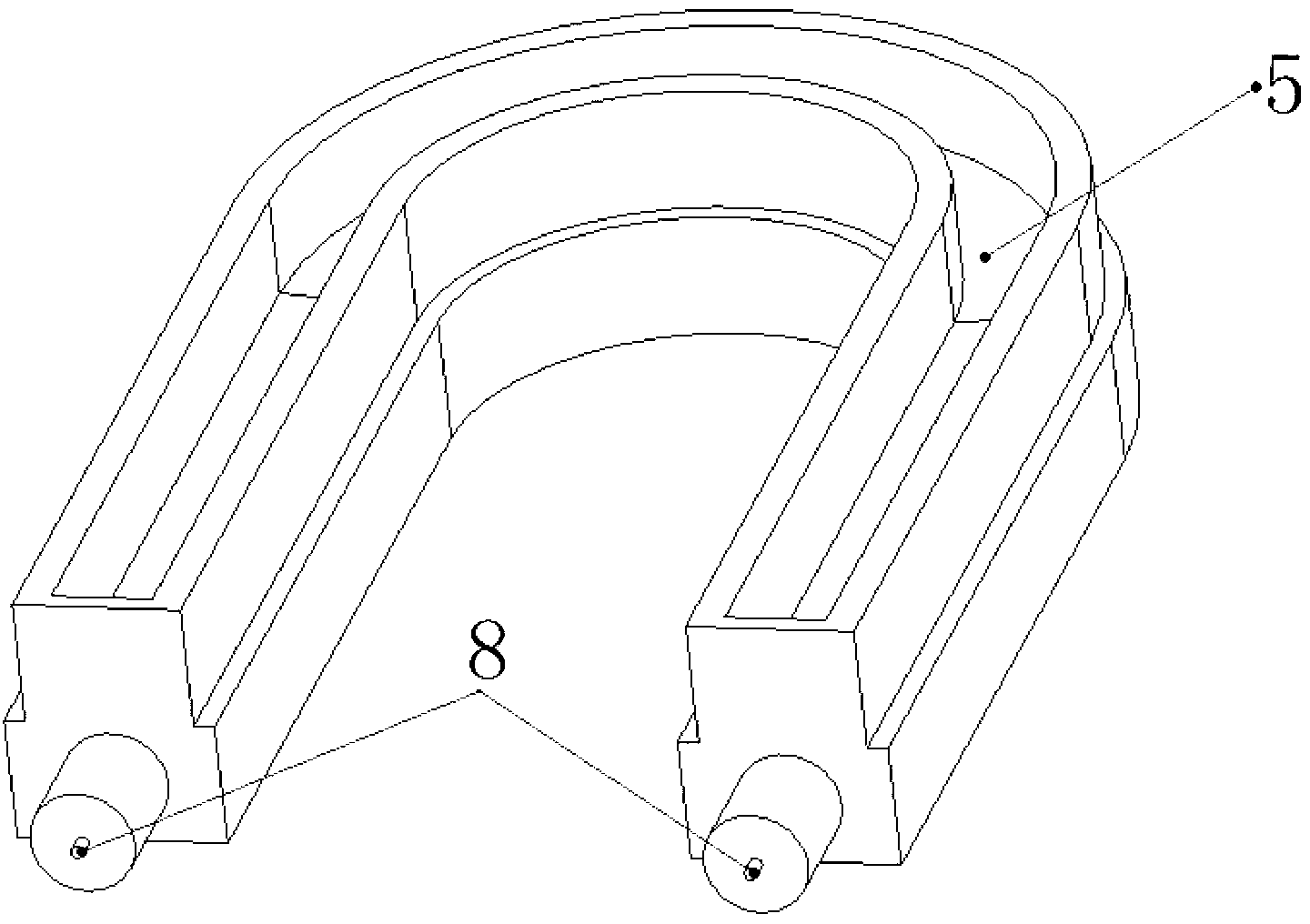

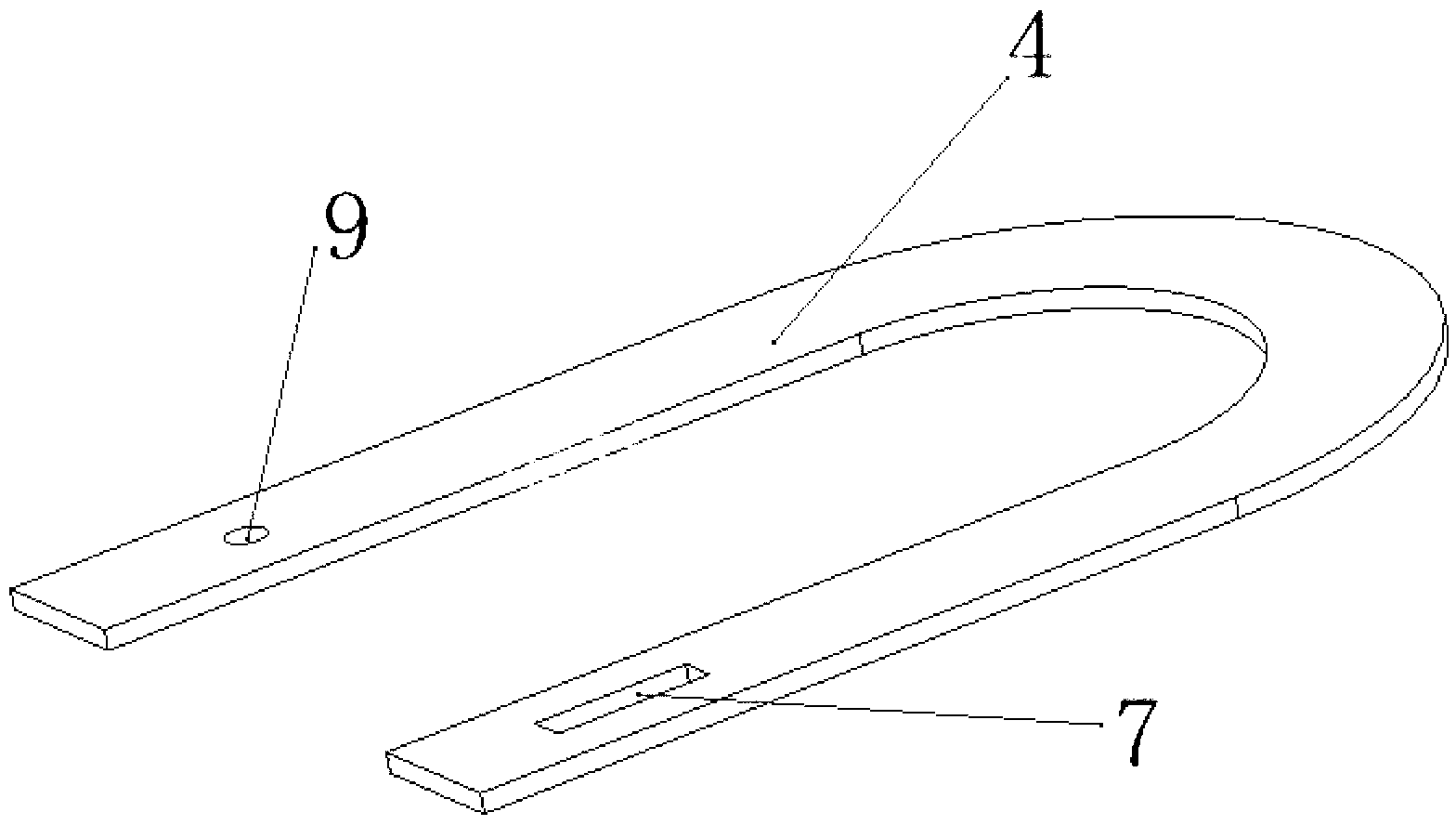

Electrical heating humidification method and electrical heating humidifier based on slanting U-shaped rail

ActiveCN103307687AIncrease contact areaImprove purityLighting and heating apparatusAir humidification systemsEvaporationEngineering

The invention discloses an electrical heating humidification method and an electrical heating humidifier based on a slanting U-shaped rail. The electrical heating humidification method is characterized in that flow of supplied water is controlled by a pump, supplied water enters the slanting U-shaped rail, the contact area of water and a heating surface supplied by a heater is increased and the heating mode is changed to convection boiling heating by aid of the slanting U-shaped rail, and therefore the purpose of high evaporation speed, supplied water instant evaporation and scaling reducing are achieved. The electrical heating humidifier comprises a box body and a box cover, wherein a water tank, the pump and the slanting U-shaped rail which are sequentially connected are arranged in the box body, the heater is arranged in the slanting U-shaped rail, a rail water way inlet is arranged at one end of the slanting U-shaped rail, a rail steam outlet is arranged at the other end of the slanting U-shaped rail, and an extending pipe is arranged on the rail steam outlet and is connected with a box body steam outlet arranged on the box cover. The electrical heating humidification method and the electrical heating humidifier can reduce scaling, improve the humidification effect and shorten the preheating time.

Owner:佛山市深茂科技有限公司

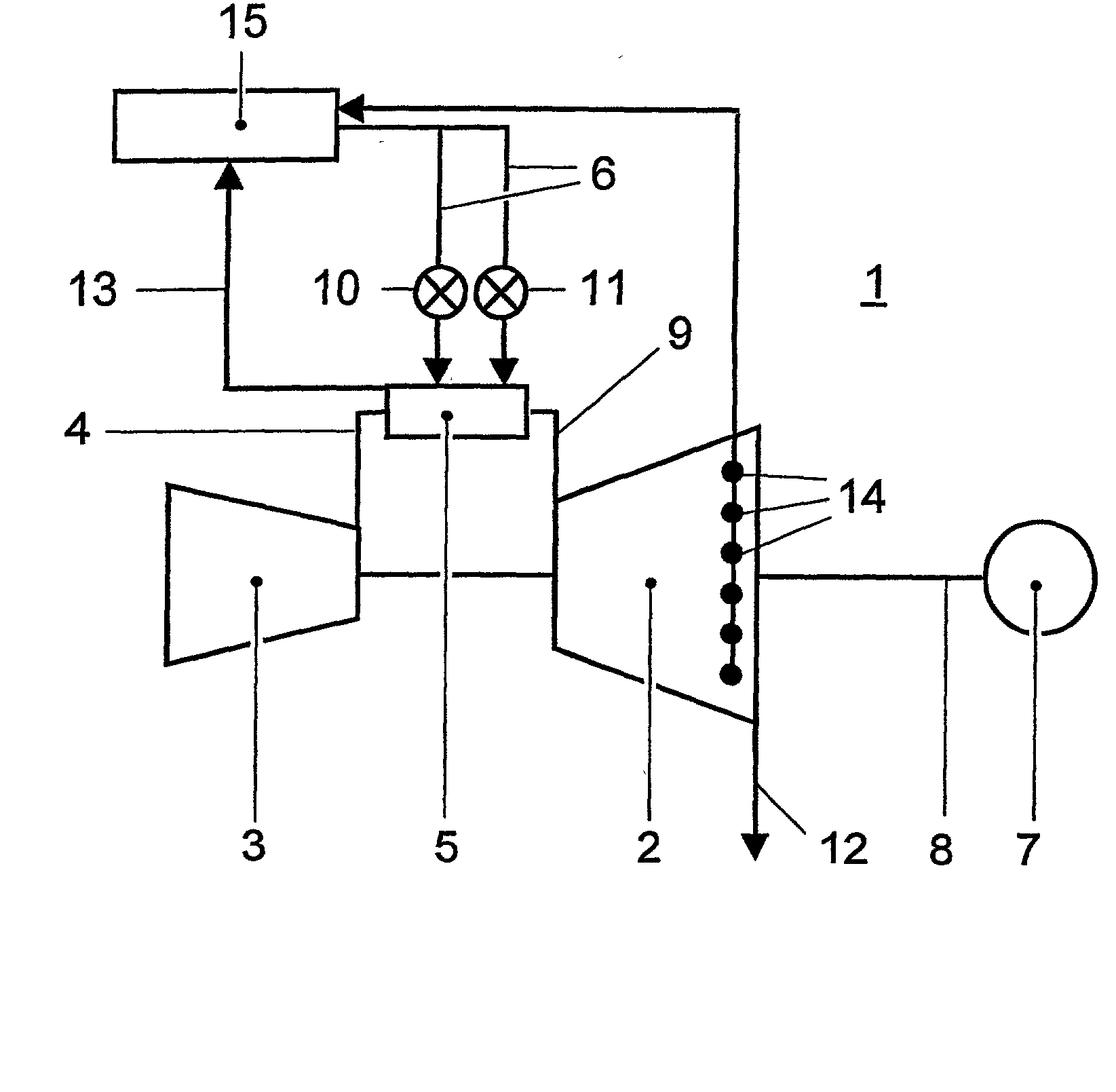

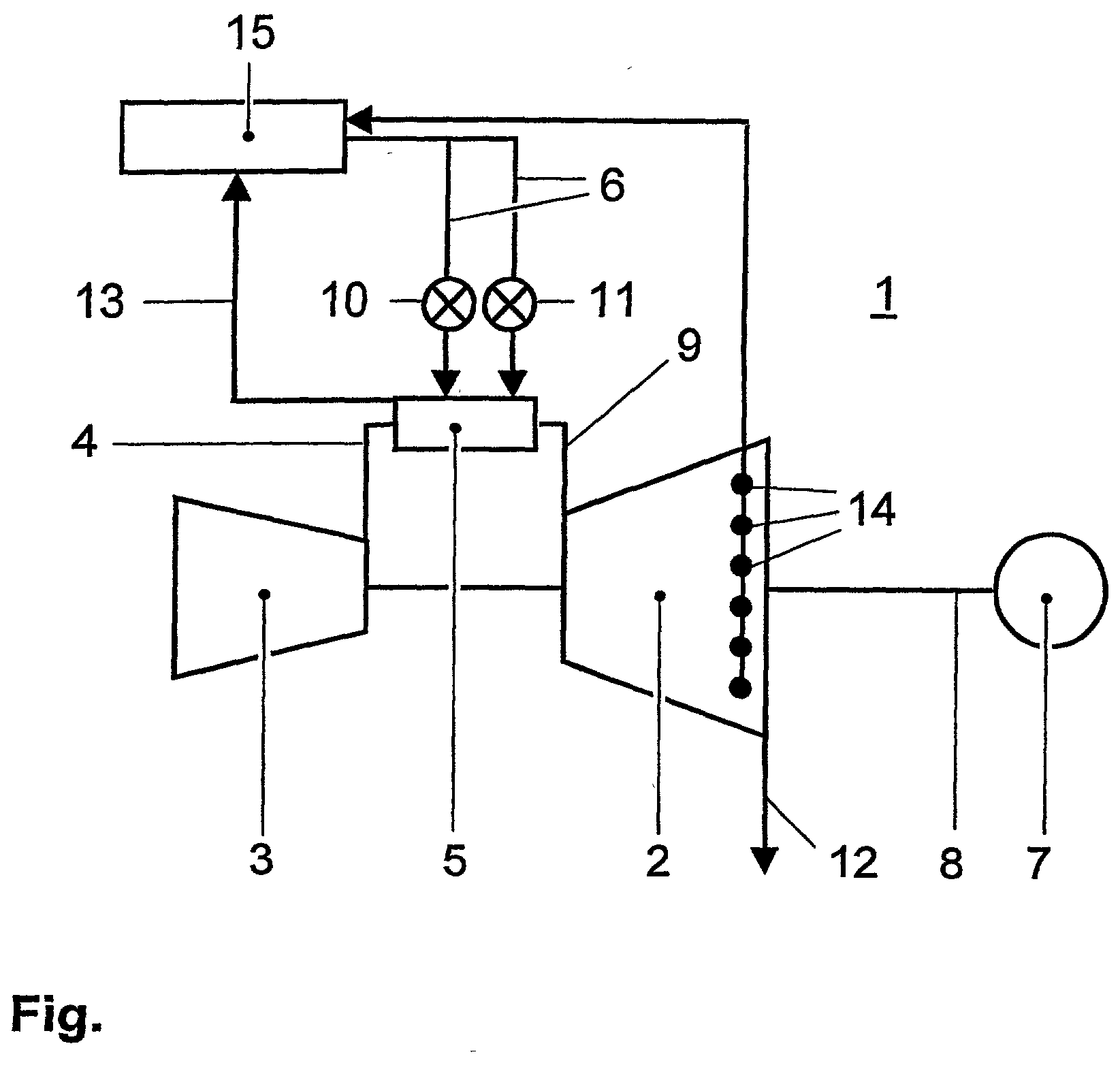

Method for running up a gas turbine plant

InactiveUS20020194851A1Short warm-up timeSignificant positive effectContinuous combustion chamberTurbine/propulsion engine ignitionCombustion chamberLow load

A method for running up a gas turbine plant (1) is disclosed. In the method, a fuel (6) is injected into the combustion chamber (5) via a plurality of pilot burners (10) and premix burners (11). During the start-up and in a lower load range, the combustion chamber (5) is operated in the pilot mode, and, at a specific time point, the combustion chamber (5) is changed over from the pilot mode to the premix mode. The changeover time point from the pilot mode to the premix mode depends on a variable changeover temperature (TSWO), and this changeover temperature (T-SWO) is determined from pulsations occurring in the flame of the combustion chamber (5).

Owner:ANSALDO ENERGIA IP UK LTD

Organic waste gas catalytic purification device

ActiveCN106122986AReduce safety concernsEffectively extinguishedIncinerator apparatusFlame arresterChemical industry

The invention aims to provide an organic waste gas catalytic purification device. According to the technical scheme, the organic waste gas catalytic purification device is composed of a front processing device, a preprocessing output pipeline, an accident emptying valve, a flame arrester, a catalytic purification unit, a purified gas delivery pipeline, a volume adjusting valve, a draught fan and a purified gas exhaust pipeline. The front processing device is further provided with a preprocessed gas inlet. The accident emptying valve is further provided with an emptying pipe. The catalytic purification unit is further provided with a waste gas inlet, a waste gas delivery pipe, a heat exchanger, a heat exchange gas output pipe, a catalyst chamber, a catalytic gas output pipe, a purified gas output pipe and a purified gas output port. The device is an output mechanism, the low-temperature oxidation technology is adopted, organic waste gas is converted into carbon dioxide and water at low temperature under the action of a precious metal catalyst, the gas is purified, and power consumption is low; safety performance is improved; and the organic waste gas catalytic purification device is small in occupied area, high in purification efficiency and applicable to purification treatment of common pollutants discharged by various chemical industries.

Owner:溧阳迈微环保科技有限公司

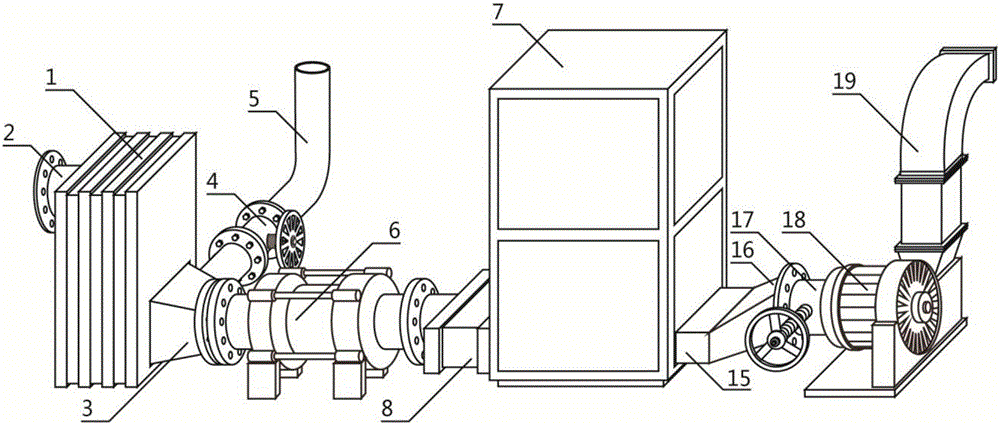

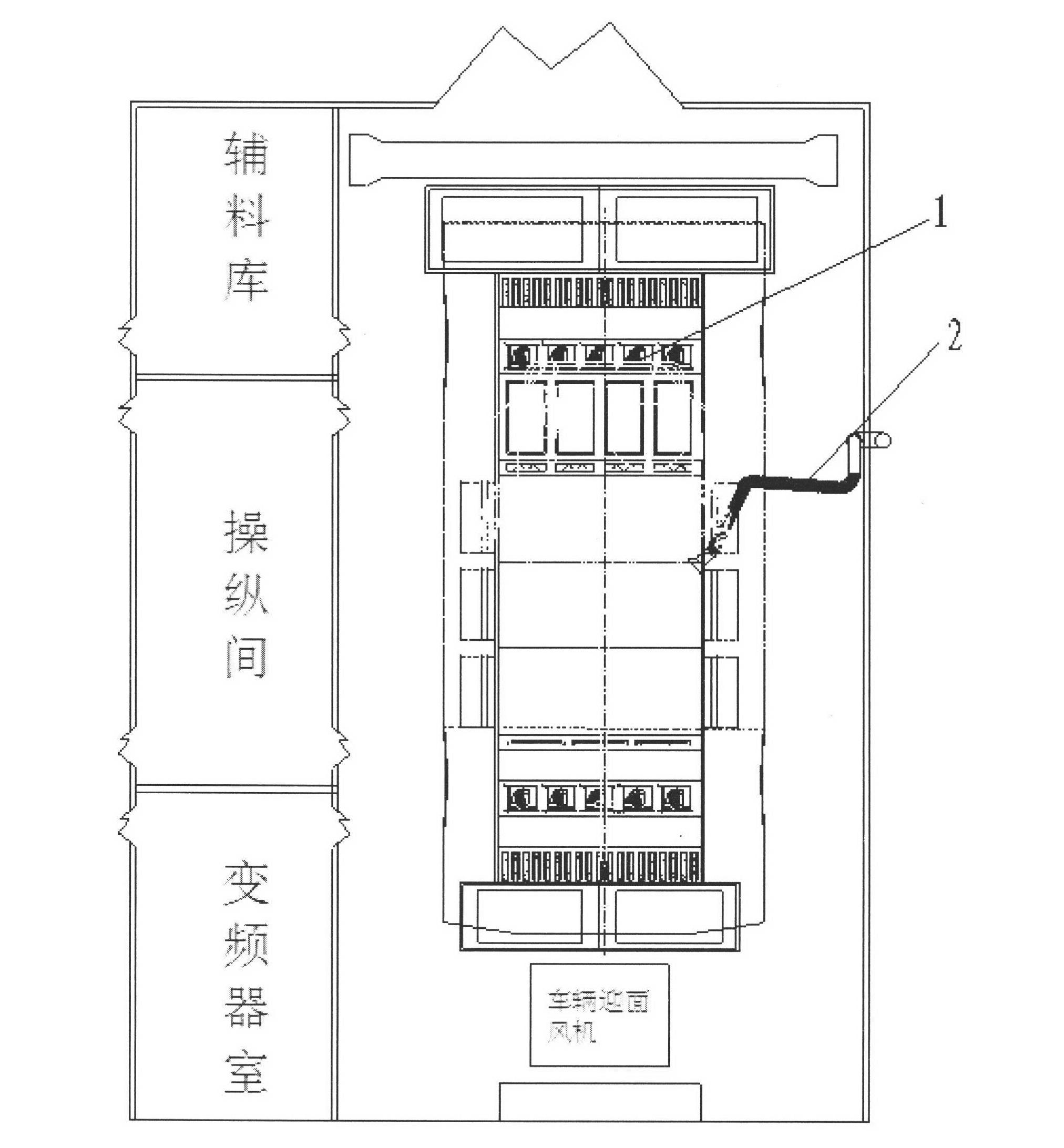

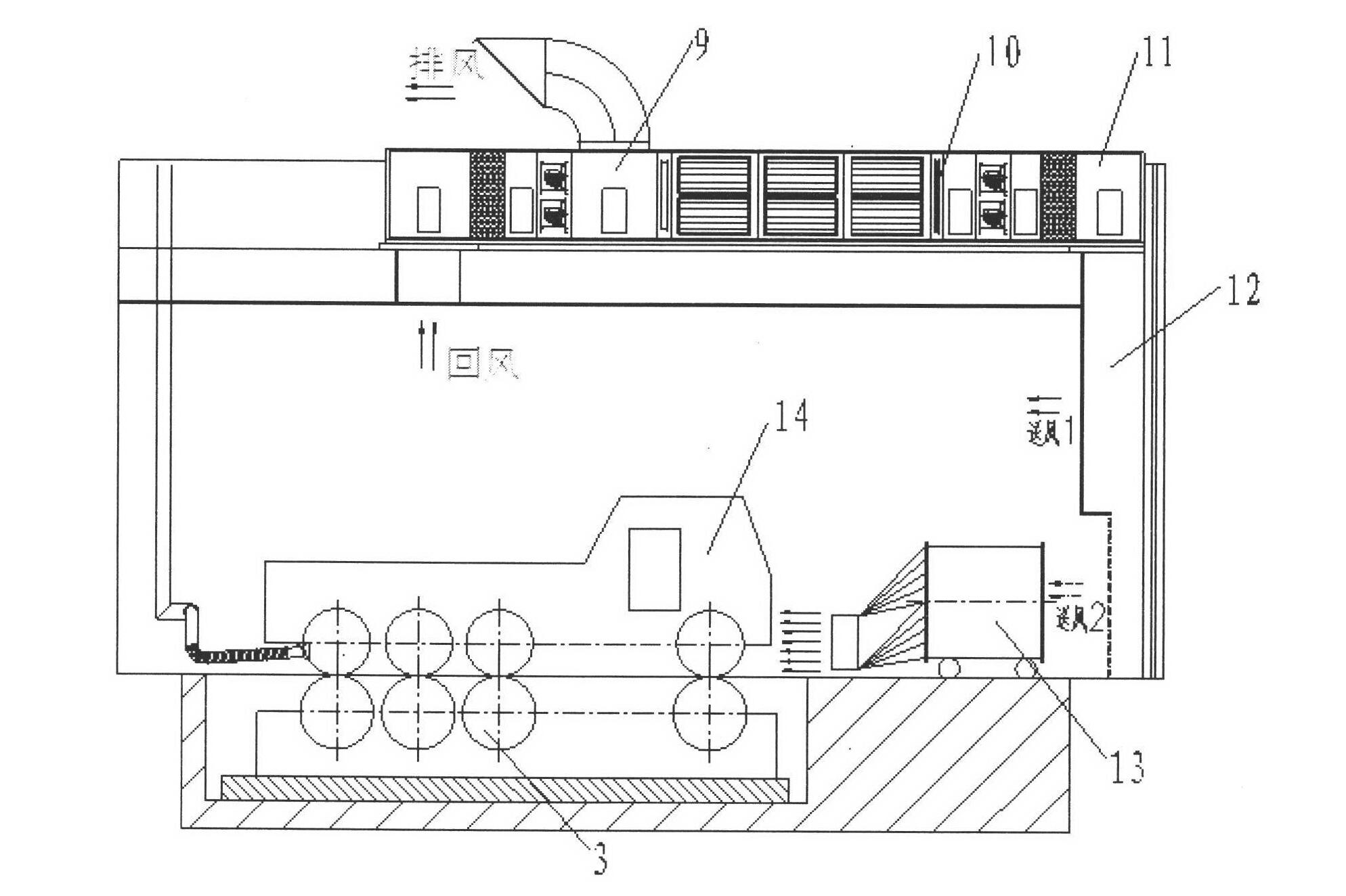

High-temperature environment simulation test system of commercial vehicle

InactiveCN102426103AMeet testing needsImprove the design levelVehicle testingEngineeringEnvironmental simulation

The invention provides a high-temperature environment simulation test system of a commercial vehicle. The test system comprises a high-temperature environment simulation system, an engine tail gas exhausting system and drum test equipment, wherein the high-temperature environment simulation system leads high-temperature air into the test system through an air supply unit with an electric heating function so as to perform high-temperature environment simulation of the test system. Through the high-temperature environment simulation test system of the commercial vehicle provided by the invention, the test cost of the commercial vehicle is reduced, and the test period is shortened.

Owner:CHINA NORTH VEHICLE RES INST

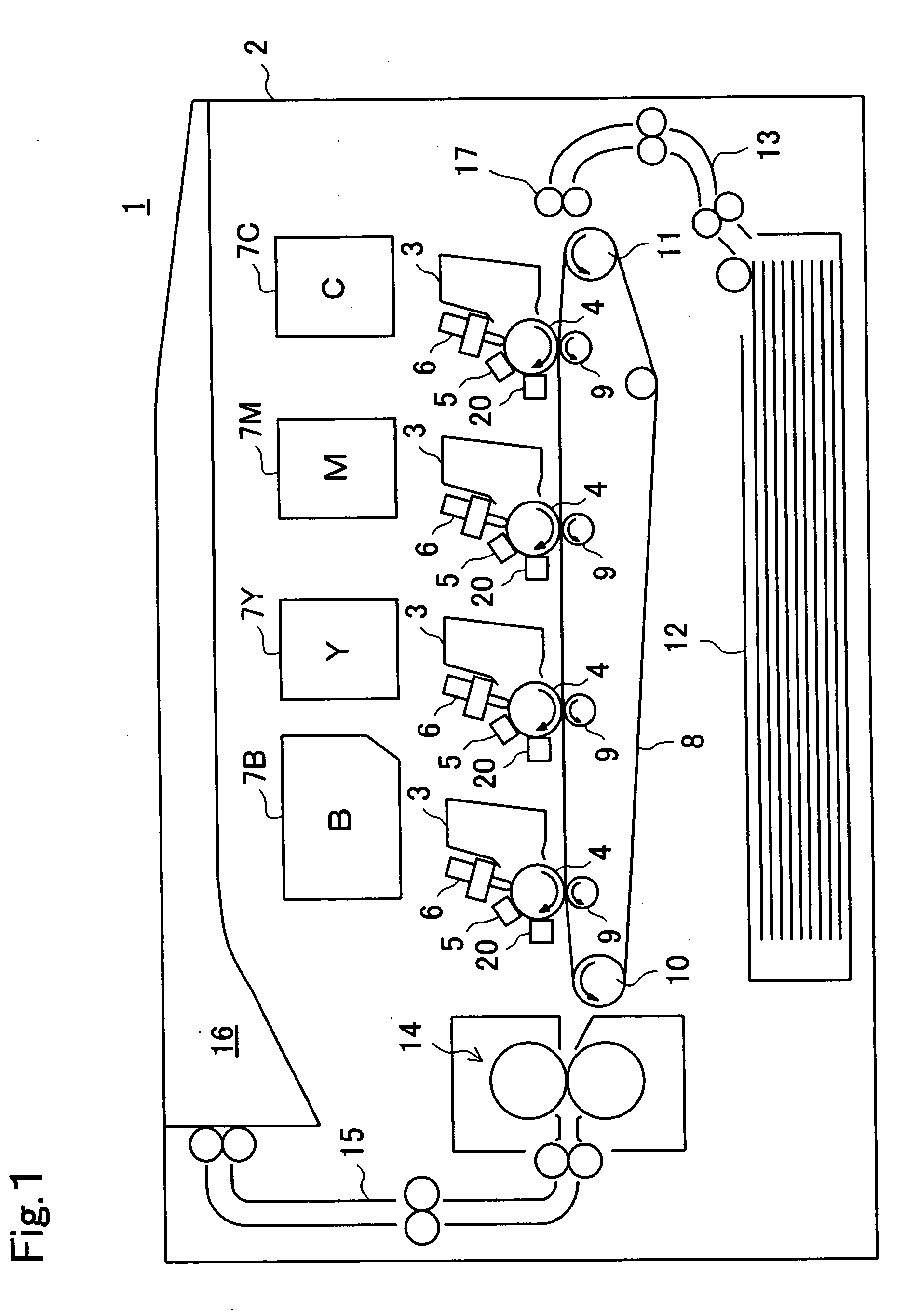

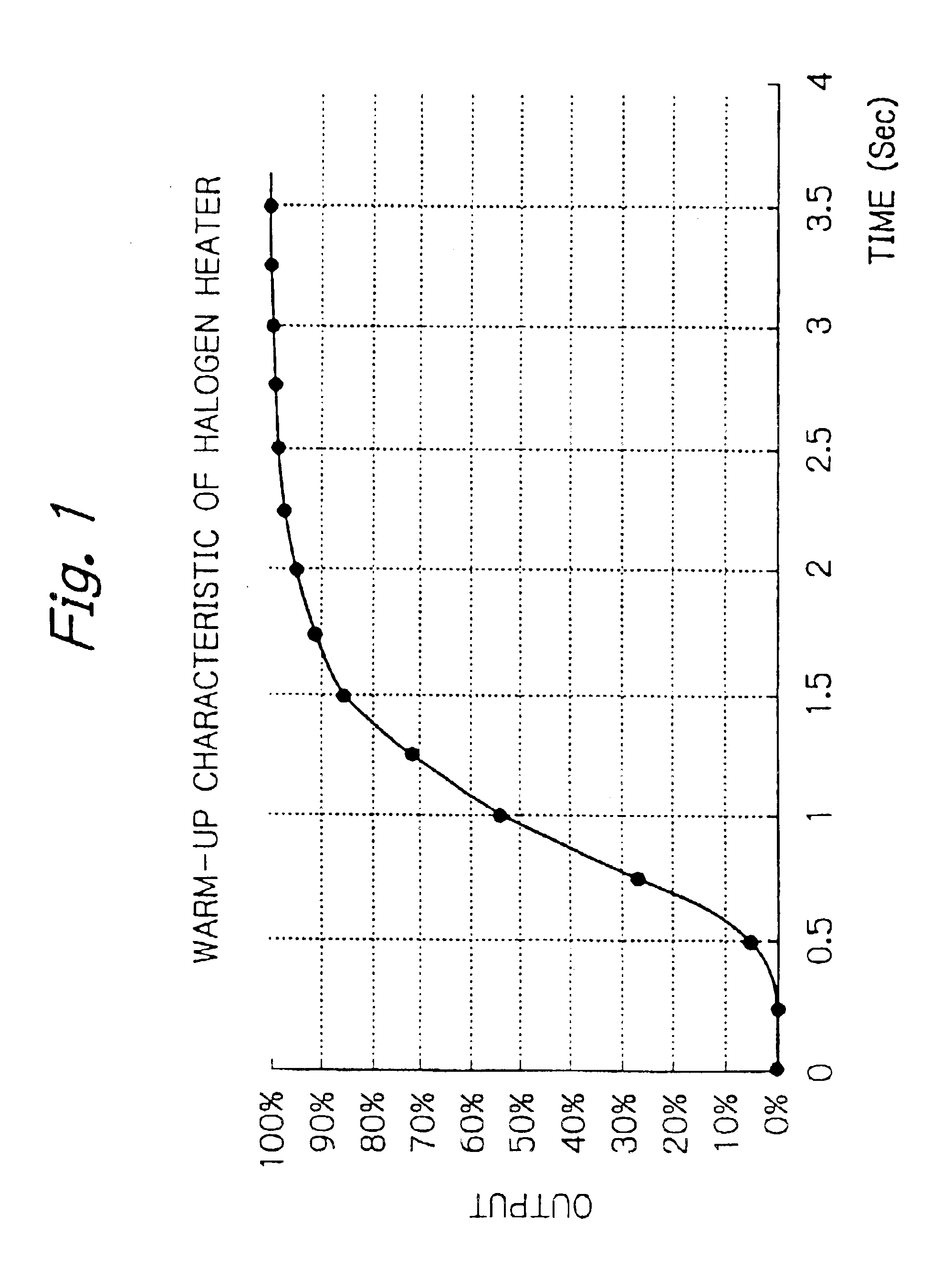

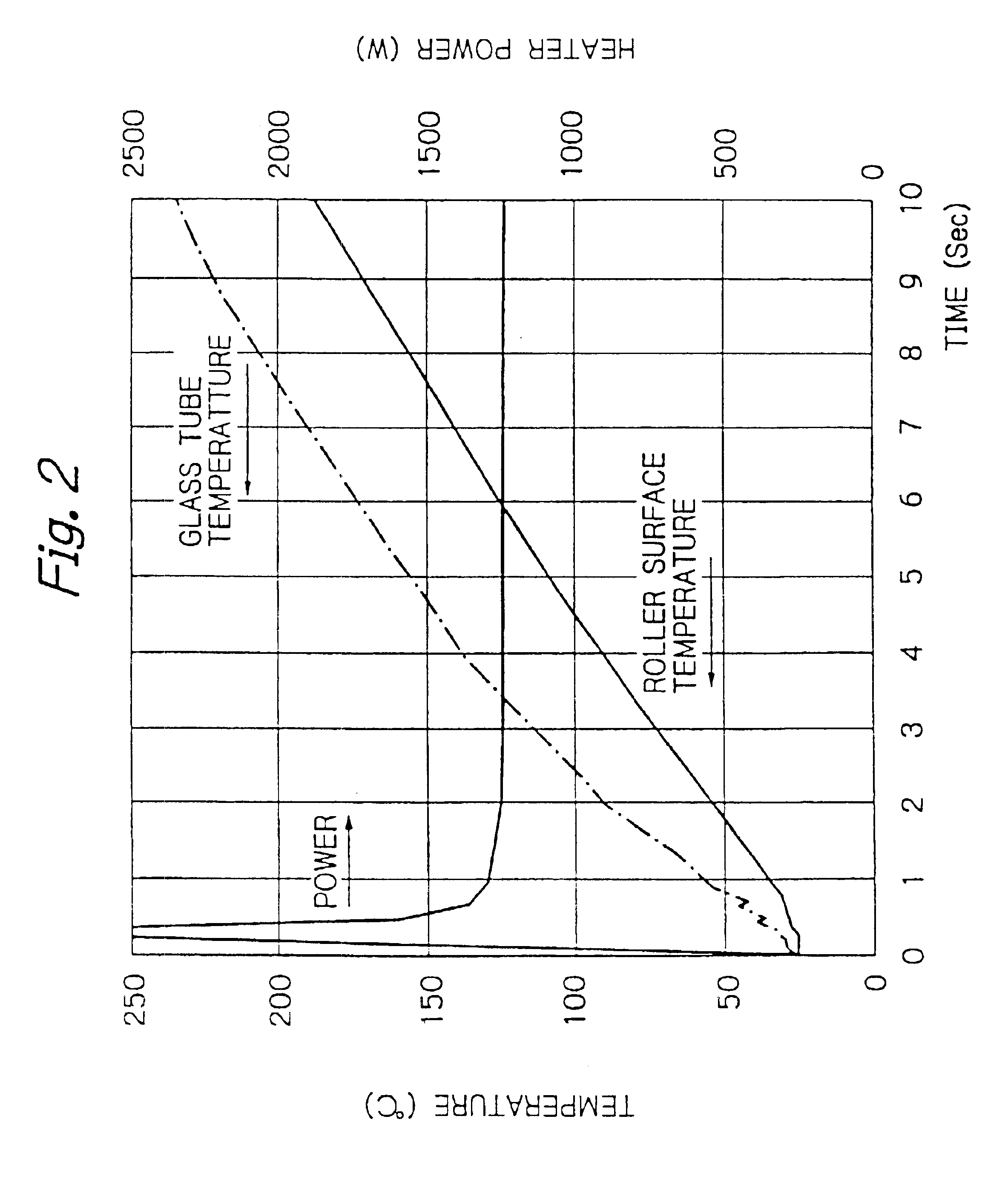

Image forming apparatus and fixing device therefor

InactiveUS6897409B2Short warm-up timeSave energyOhmic-resistance heatingElectrographic process apparatusKryptonImage formation

A fixing device for forming a toner image formed on a recording medium includes a heat roller accommodating a halogen heater. The halogen heater includes a glass tube formed of transparent quartz and provided with a wall thickness of 0.8 mm or below to increase transmission thereof. The increased transmission reduces a heat loss ascribable to the glass tube at the time of warm-up of the fixing device. The heat roller has such a thermal capacity that it can be warmed up in 10 seconds or less. The glass tube is filled with inactive gas whose major component is krypton or xenon. A tungsten filament accommodated in the glass tube has its diameter reduced in order to implement a color temperature of 2,500 K or above. An image forming apparatus using the fixing device is also disclosed.

Owner:RICOH KK

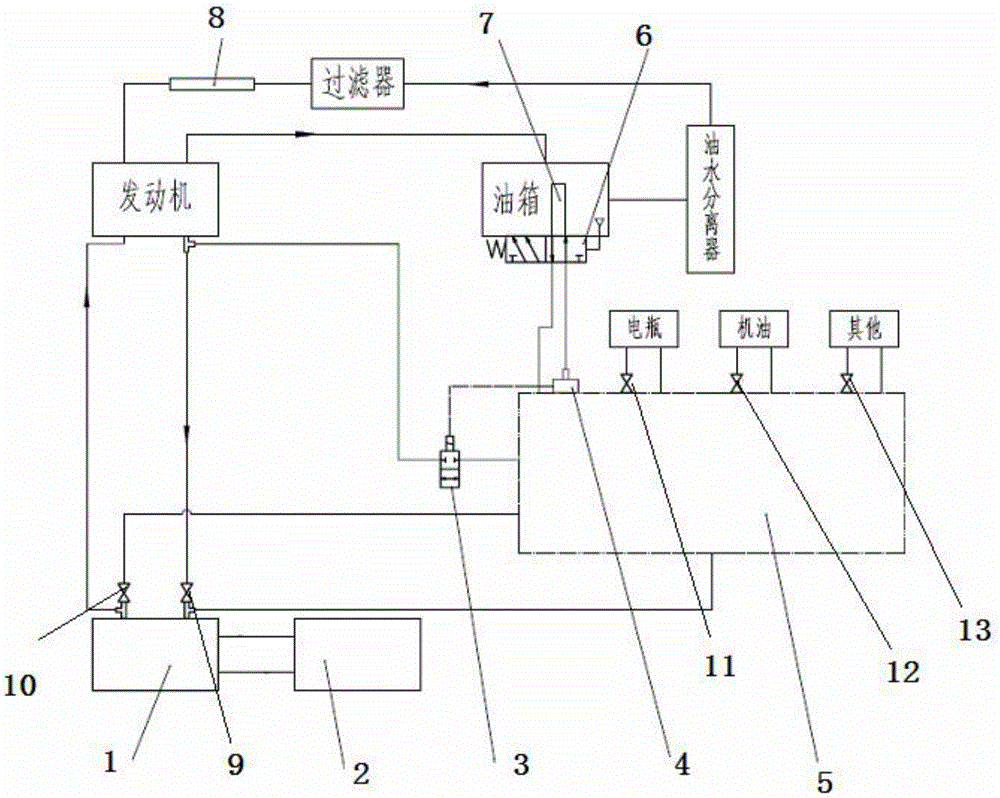

Low-temperature heating system for diesel engine

ActiveCN106401834AShort warm-up timeGood heating effectMachines/enginesThermal treatment of fuelHeating systemFuel tank

The present invention discloses a low-temperature heating system for a diesel engine. The system comprises an engine, a fuel heater, an electromagnetic valve, a coolant leakage alarm, a distribution control valve block, a temperature sensing directional valve, an oil tank heating device, and a pipe heating device. A first stop valve and a second stop valve are disposed on the fuel heater. A water outlet of the engine is divided into two passages with one being connected to the first stop valve and the other one being connected to a first water inlet of the distribution control valve block by means of the electromagnetic valve. The oil tank heating device is provided with the temperature sensing directional valve that has a control end connected with a temperature sensor. A first water outlet of the distribution control valve is connected to a temperature sensing directional valve of the oil tank heating device by means of the coolant leakage alarm. The pipe heating device is connected to an engine filter and an oil pump. The low-temperature heating system for a diesel engine effectively improves the viscosity and flowability of diesel oil at a low temperature to allow for sufficient combustion of the diesel oil, thereby ensuring that the diesel engine is started successfully and operates normally with achieved cost reduction and environmental protection.

Owner:席瑾

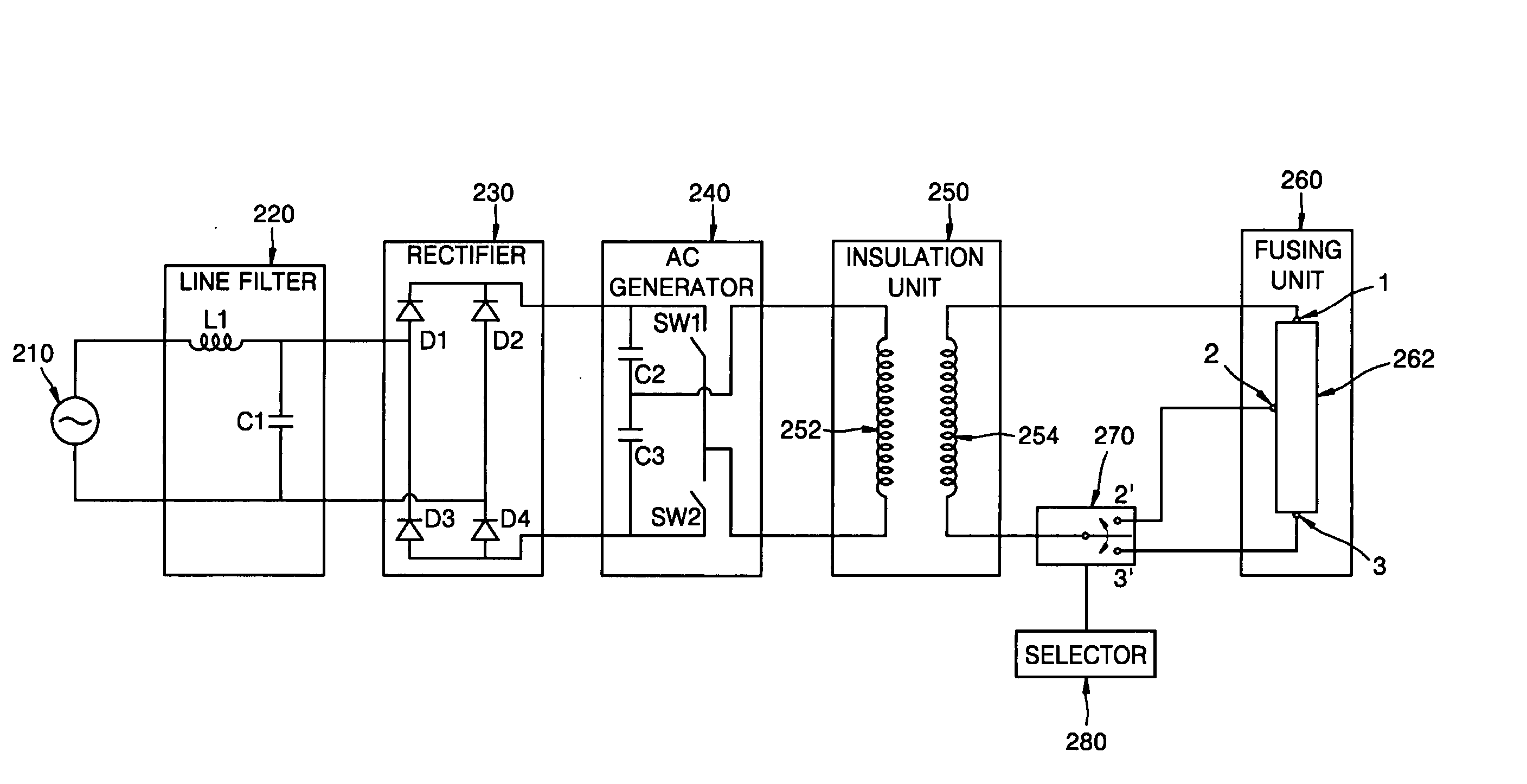

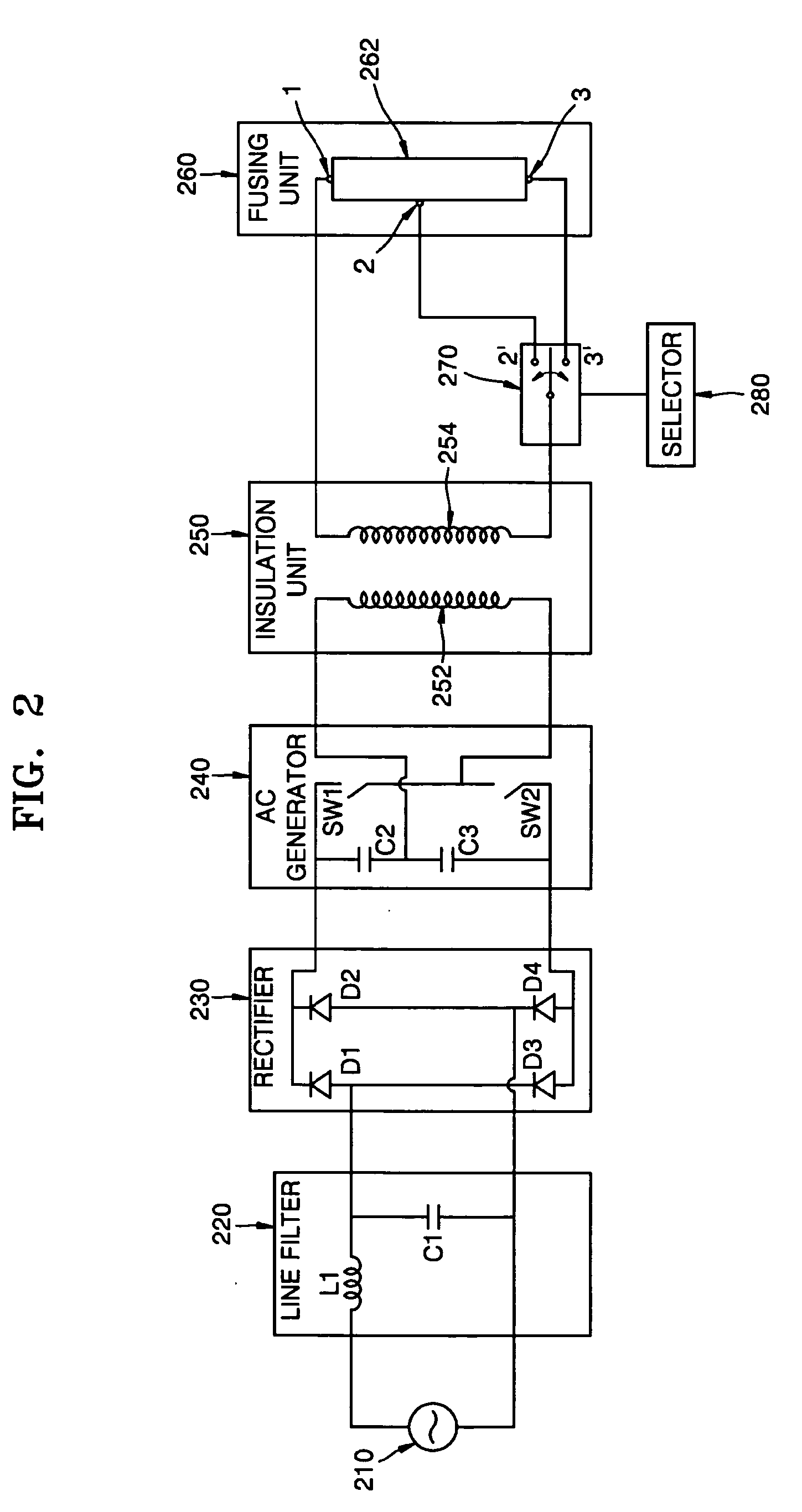

Device for fusing toner on print medium

InactiveUS20060045591A1Short warm-up timeElectrographic process apparatusElectrical resistance and conductanceAC - Alternating current

A fusing device for fusing a predetermined toner image on paper, and which controls the heating range of a fusing unit by inputting an eddy current generated by a transformer to a terminal corresponding to the size of paper selected from a plurality of terminals of the fusing unit. The fusing device includes a power supply unit to which a predetermined alternating current is input and which generates an induced current in response to the input alternating current, a fusing unit being resistance-heated and induction-heated by the induced current and fusing the toner image on the paper using the generated heat, and a controller for controlling the induced current supplied to the fusing unit according to the size of the paper.

Owner:S PRINTING SOLUTION CO LTD

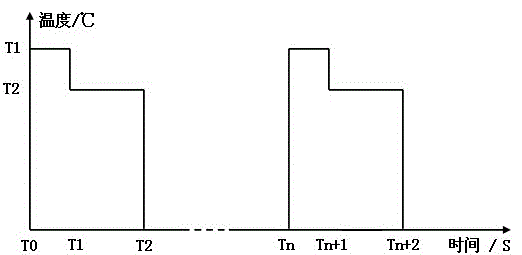

Low-power working method of MEMS (micro-electromechanical system) metal oxide semiconductor gas sensor

InactiveCN106770500AMeet application needsReduce power consumptionMaterial resistanceElectrical batteryEngineering

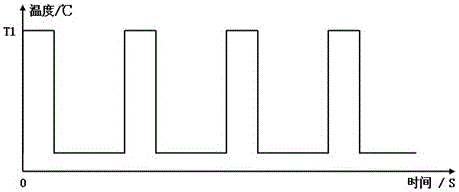

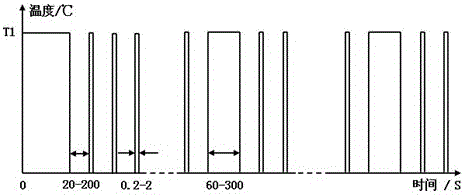

The invention discloses a low-power working method of an MEMS (micro-electromechanical system) metal oxide semiconductor gas sensor, and relates to the technical field of application circuits of metal oxide semiconductor gas sensors. The low-power working method is characterized in that under the clean air state, the primary preheating is performed, so that a sensitive resistor of the sensor can reach the stable state, and the base line automatic calibration test is performed; the low-frequency and low-duty cycle heating standby is adopted between two times of harmful gas concentration test (including base line calibration test); before testing, the short-time preheating is performed and then the testing is executed according to requirements; after the short-time preheating is periodically performed, the base line automatic calibration test is performed. The MEMS metal oxide semiconductor gas sensor adopting the working method has the advantages that the problems of high power consumption and complicated calibration in the prior art are overcome, the required preheating time before sensor testing is short, and the base line is automatically calibrated without correction; the optimum property of the gas sensor can be fully realized, the low-concentration harmful gas can be measured, and the superlow power consumption meets the long-time application requirement of low-capacity batteries.

Owner:武汉微纳传感技术有限公司

Fixing apparatus

ActiveUS7239836B2Efficient heatingShort warm-up timeElectrographic process apparatusInduction heating apparatusThin layerEngineering

A fixing apparatus used in an image forming apparatus has a fixing member for fixing toner on paper and a pressure member making contact therewith to form in between a nip through which paper is passed. The fixing member has a support member formed of a ferromagnetic material and a heating layer formed adjacent thereto in the form of a thin layer of a non-magnetic, electrically conductive material. When a high-frequency electric current is passed through an exciting coil that is combined with the fixing member, the fixing member produces a high-frequency magnetic field, thereby produces induced eddy currents in the heating layer of the fixing member, thereby produces Joule's heat in the heating layer, and thereby heats the fixing member. A leaking magnetic flux is absorbed by the support member of the ferromagnetic member, and thus has reduced influence on metal parts located around the fixing apparatus.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Adhesive dispensing system and method using smart melt heater control

ActiveUS9200741B2Reduce the temperatureDegradation rate of will decreaseLiquid surface applicatorsPipe heating/coolingOutgassingEngineering

An adhesive dispensing system is configured to automatically reduce the temperature of adhesive material to reduce degradation of the adhesive caused by holding the adhesive at an application temperature during periods of low throughput. To this end, a controller of the system operates a heater unit to maintain a unit set point temperature to heat and melt adhesive until a set threshold time has elapsed since the most recent supply of adhesive to the system by a fill system. Once the time elapsed since the most recent supply of adhesive exceeds the set threshold time, the heater unit is reduced in temperature to reduce the temperature of adhesive. This reduction is temperature is large enough to minimize degradation and outgassing but small enough to enable rapid warm-up times after a new supply of adhesive occurs.

Owner:NORDSON CORP

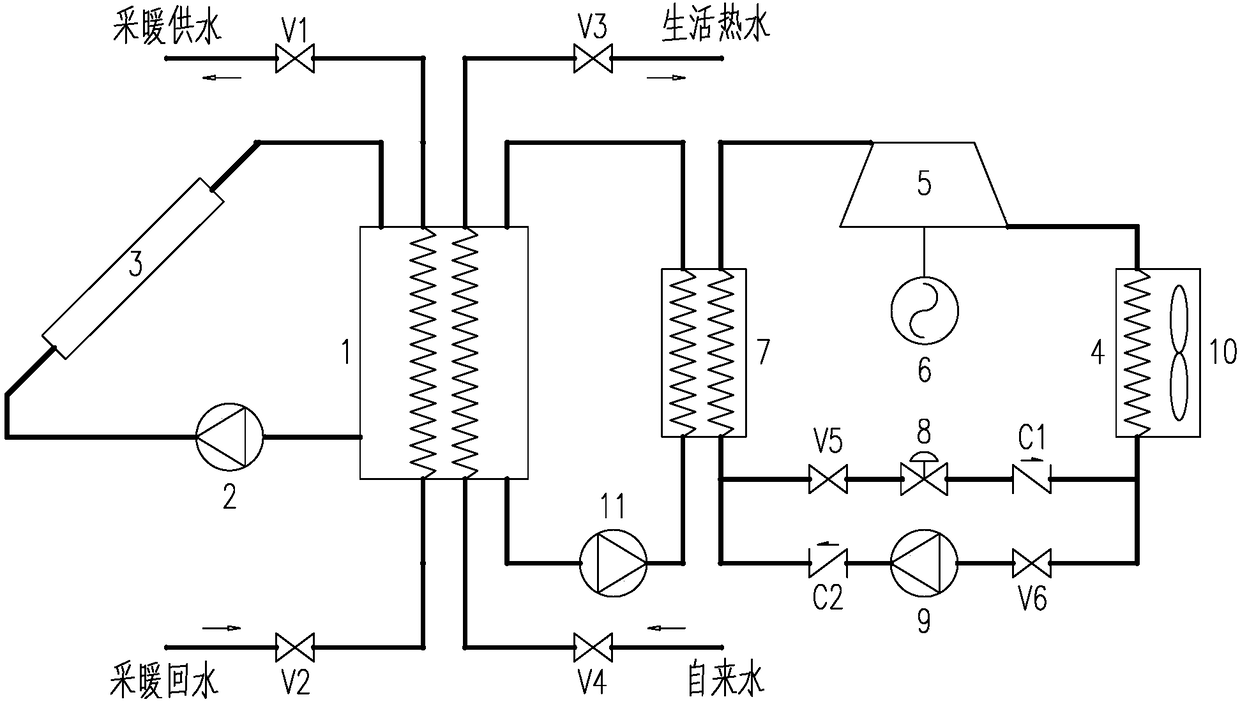

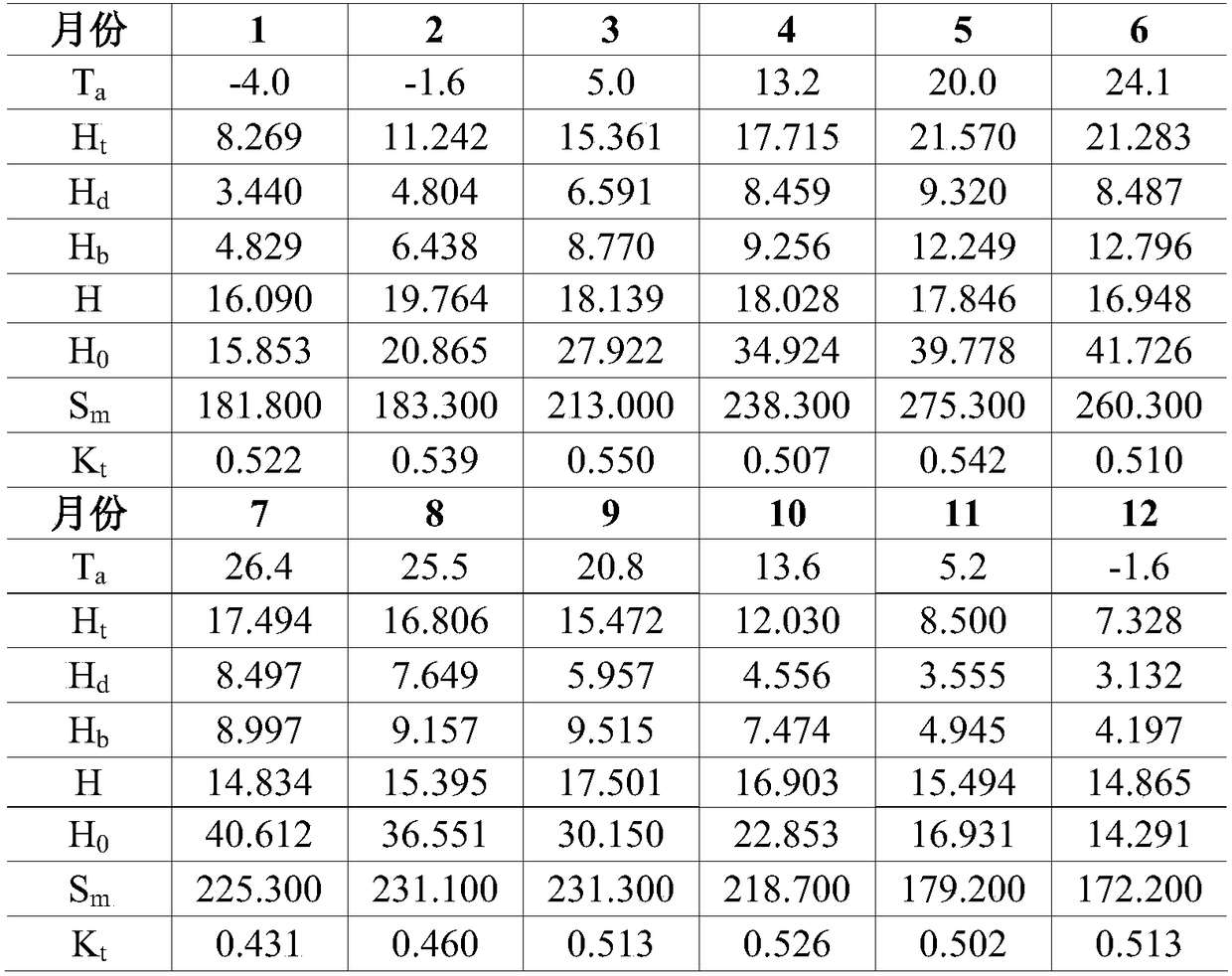

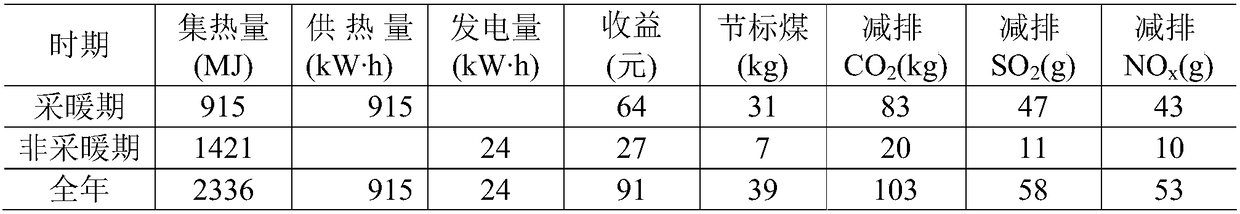

Hot water type solar energy and air energy combined heat and power generation integrated system and running method

PendingCN108375101ALow costEasy to installSolar heating energyFrom solar energyEnvironmental resistanceWater storage

The invention discloses a hot water type solar energy and air energy combined heat and power generation integrated system which comprises a water storage box, a first water pump, a solar heat collector, a low-position side heat exchanger, a compression and expansion difunctional machine head, a permanent magnet electric power generation integrated motor, a high-position side heat exchanger, an expansion valve, a working medium pump and a second water pump. Air cooling is adopted by the low-position side heat exchanger, one port of a low-position side heat exchanger working medium side passes through the compression and expansion difunctional machine head to be connected to one port of a high-position side heat exchanger working medium side, two bypasses are connected to the other port of the high-position side heat exchanger working medium side and the other port of the low-position side heat exchanger working medium side in parallel, opening or closing of the valve is adjusted, solarenergy and air energy can achieve heating in the heating period and power generation in the non-heating period, and the building requirement for hot water supplying all year around is met; the air source heat pump cost is low, installation is simple, the energy efficiency is high, environmental protection is achieved, the preheating time is short, the indoor temperature requirement can be quicklymet, and the hot water type solar energy and air energy combined heat and power generation integrated system is suitable for supplementary heat sources of a solar heating system.

Owner:TIANJIN UNIV

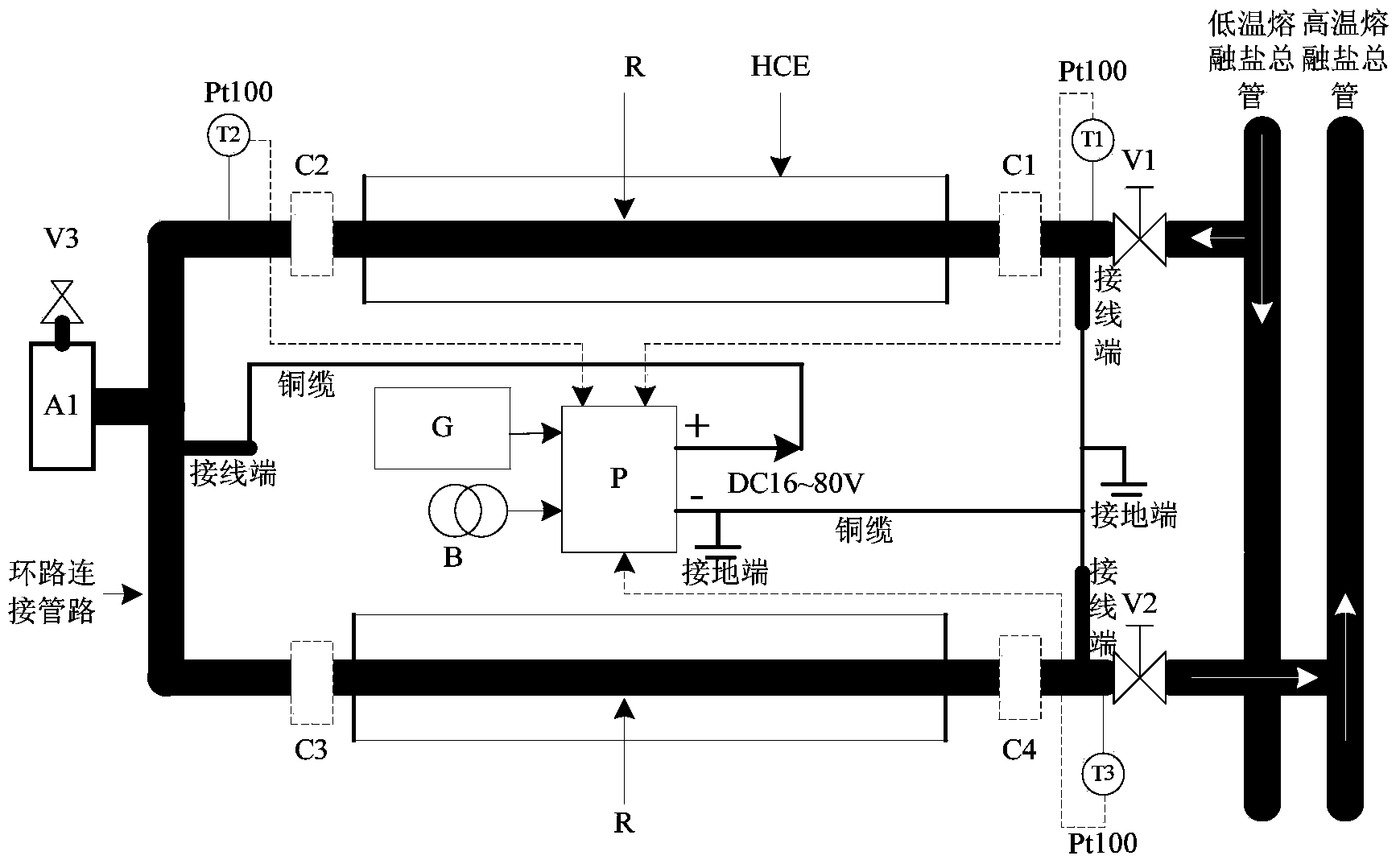

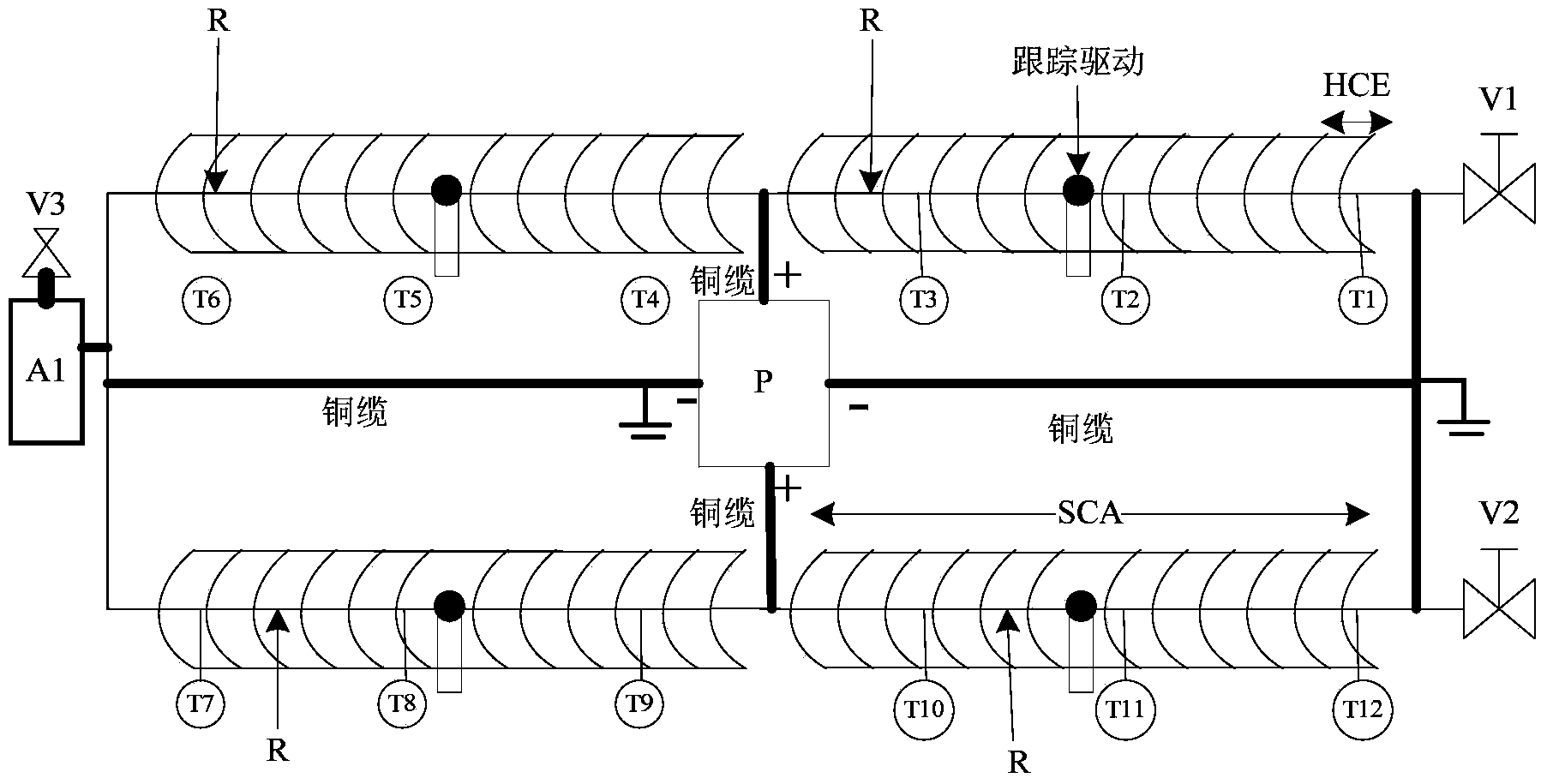

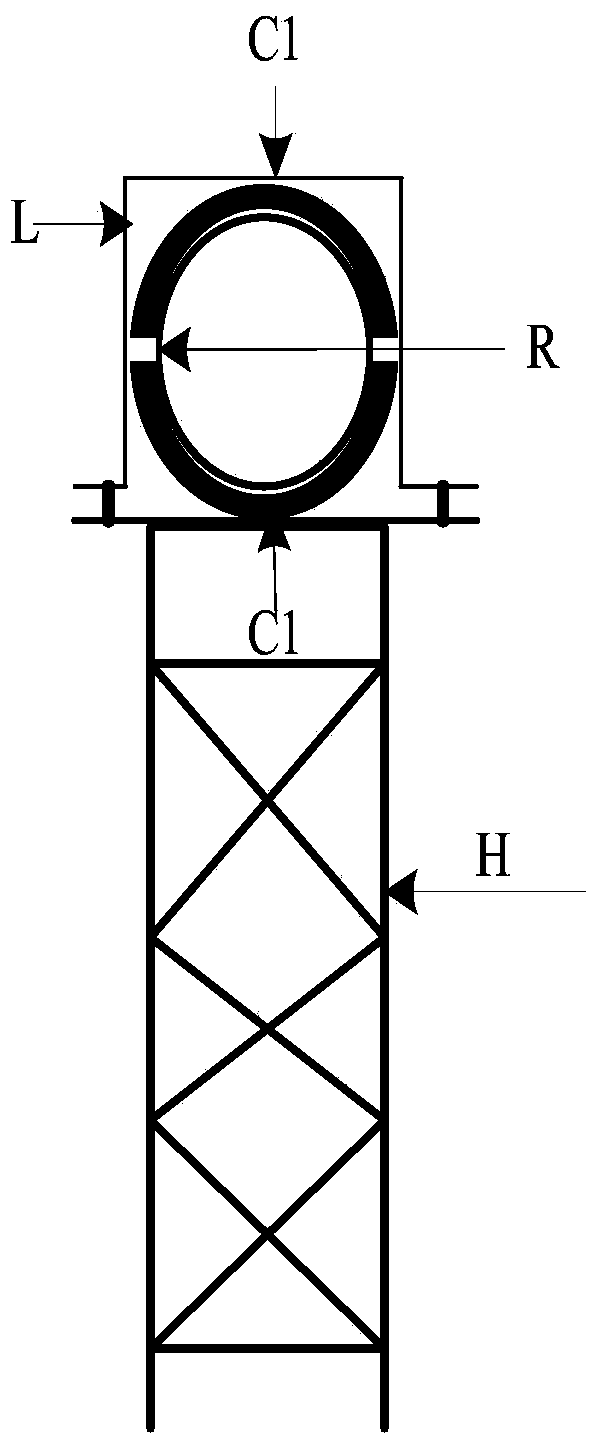

Direct-current large-current fused salt defreezing and preheating device of groove type vacuum heat collecting pipe

ActiveCN103712358ASave spaceEasy to implementSolar heat devicesPipe heating/coolingExpansion tankTransformer

The invention discloses a direct-current large-current fused salt defreezing and preheating device of a groove type vacuum heat collecting pipe and belongs to the technical field of thermal equipment. The direct-current large-current fused salt defreezing and preheating device is composed of a pipeline system and a direct electric heating system. The pipeline system comprises a voltage limiting valve V1, a voltage limiting valve V2, a ceramic electric insulating structure used for being connected with a heat absorber supporting mechanism, an expansion tank and a voltage limiting valve V3. The direct electric heating system comprises a field transformer, a standby alternator, an AC / DC module used for AC-DC conversion, a connection copper cable, a terminal block, a Pt100 temperature sensor T1, a Pt100 temperature sensor T2 and a Pt100 temperature sensor T3, wherein the Pt100 temperature sensor T1, the Pt100 temperature sensor T2 and the Pt100 temperature sensor T3 are used for controlling. According to the direct-current large-current fused salt defrosting and preheating device of the groove type vacuum heat collecting pipe, a body resistor in a stainless steel inner pipe of the vacuum heat collecting pipe is used as an electric-heating heating element, the problems of freezing and blocking of fused salt and preheating starting in the groove type system vacuum heat collecting pipe are solved, and the direct-current large-current fused salt defrosting and preheating device has the advantages of being convenient to carry out, capable of saving space in the vacuum heat collecting pipe, even in peripheral heating, little in heat transfer resistance and short in defreezing and preheating time.

Owner:河北井矿新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com