Working temperature control device for high-power power electronic device

A technology of power electronic devices and working temperature, applied in temperature control, non-electric variable control, control/regulation system, etc., can solve the problems of large energy consumption, long warm-up time, uneven warm-up, etc., and achieve heat transfer efficiency High temperature, short warm-up time and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

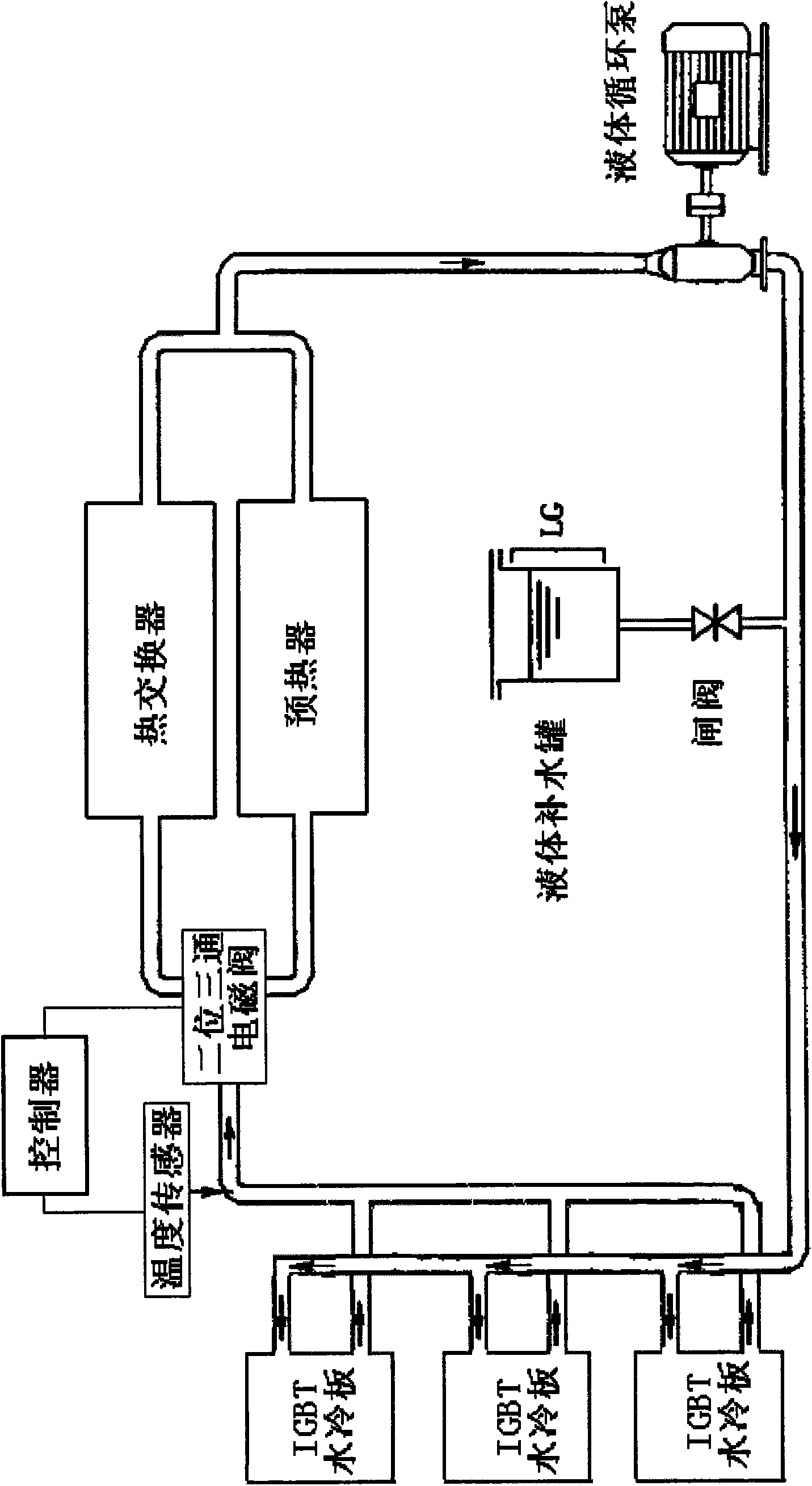

[0009] Referring to the accompanying drawings, the embodiments of the present invention will be described in detail. The operating temperature control device for high-power power electronic devices in the embodiment of the present invention mainly includes a device cooling plate, a water circulation pump, a radiator, a water supply tank, various valves, instruments and detection elements, external piping, etc., and is heated through a two-position three-way solenoid valve. Enter the loop. The temperature sensor of the controller is set at the cooling liquid outlet of the cooling plate of the IGBT device, and the output end is connected to the two-position three-way solenoid valve. When the device is working, the temperature sensor detects the temperature of the coolant at the outlet of the cooling plate of the device. If it is lower than the minimum working environment temperature limit value, the controller will control the circulation circuit to switch to the heater through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com