Patents

Literature

230results about How to "Warm up evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

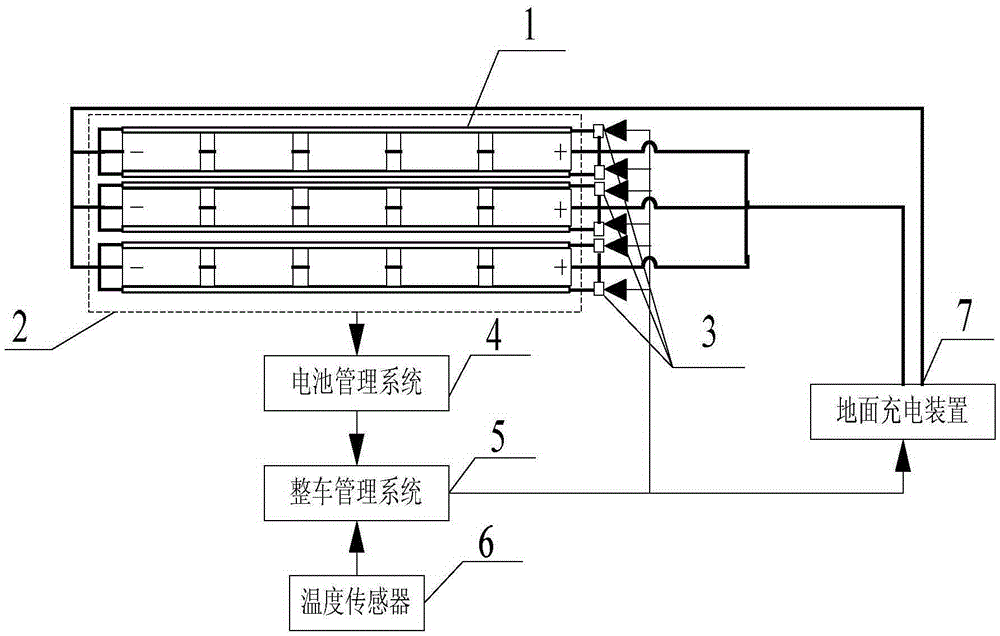

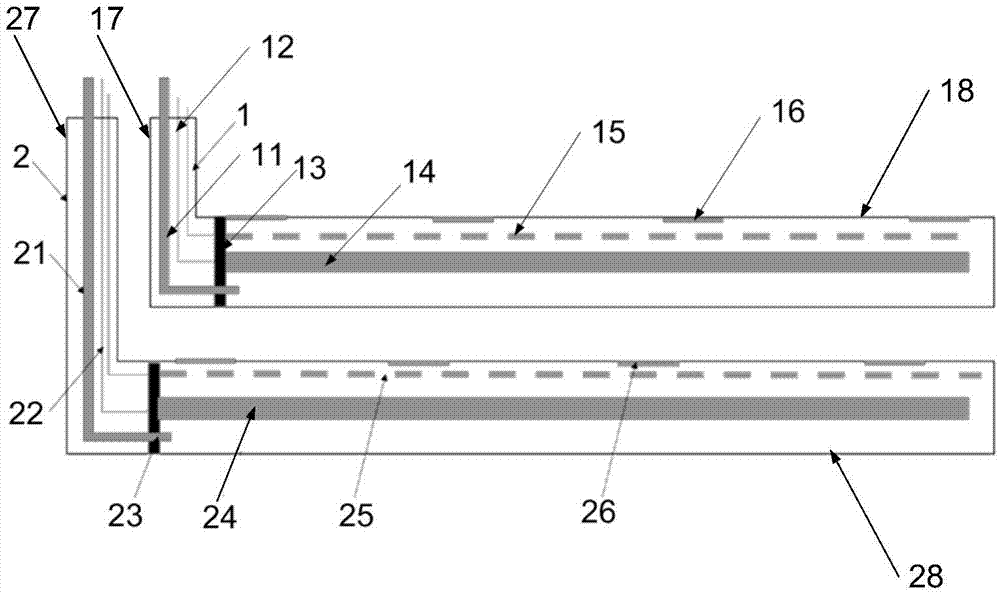

Low-temperature preheating system for battery pack of electric vehicle and control method of low-temperature preheating system

The invention relates to a preheating technology for a battery pack of an electric vehicle, in particular to a low-temperature preheating system for the battery pack of the electric vehicle and a control method of the low-temperature preheating system, and solves the problem of higher cost, complex structure, high control difficulty, high failure rate or poor balance of the battery pack due to failure of even heating of batteries during charge and use of the batteries at the low temperature. Electro-thermal films are attached on outer sides of the outermost row of cells of the battery pack as well as between every two adjacent rows of cells, a battery pack residual capacity signal output end of a battery management system is connected with a battery pack residual capacity signal input end of a whole vehicle management system, a power supply signal input end of a relay set is connected with a power signal output end of the battery pack, and the relay set correspondingly controls power supply switches of the electro-thermal films; a battery charge control signal output end of the whole vehicle management system is connected with a charge control signal input end of a ground charge device, and the ground charge device charges the battery pack. The system is applicable to preheating of batteries of the electric vehicle.

Owner:HARBIN UNIV OF SCI & TECH

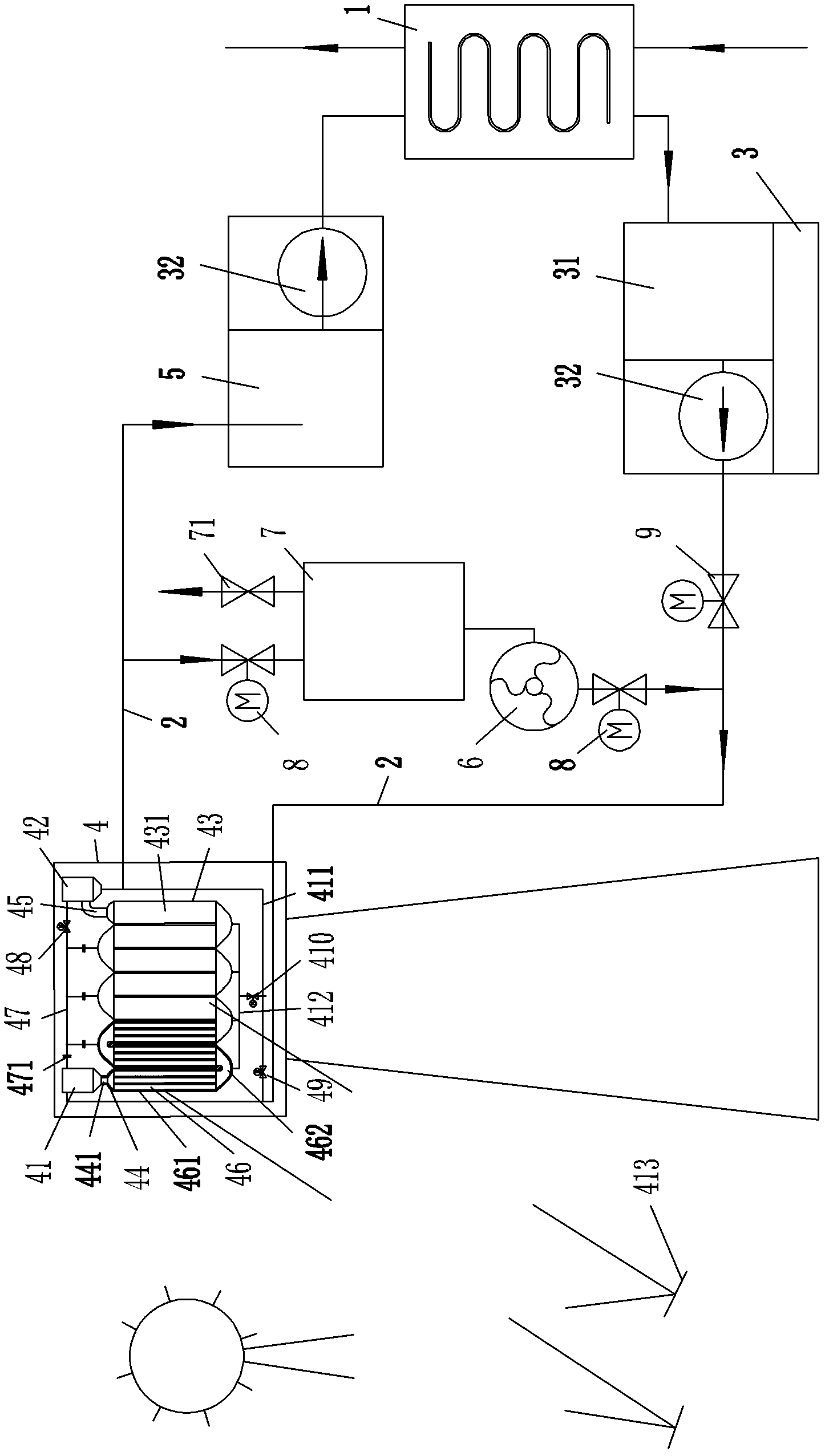

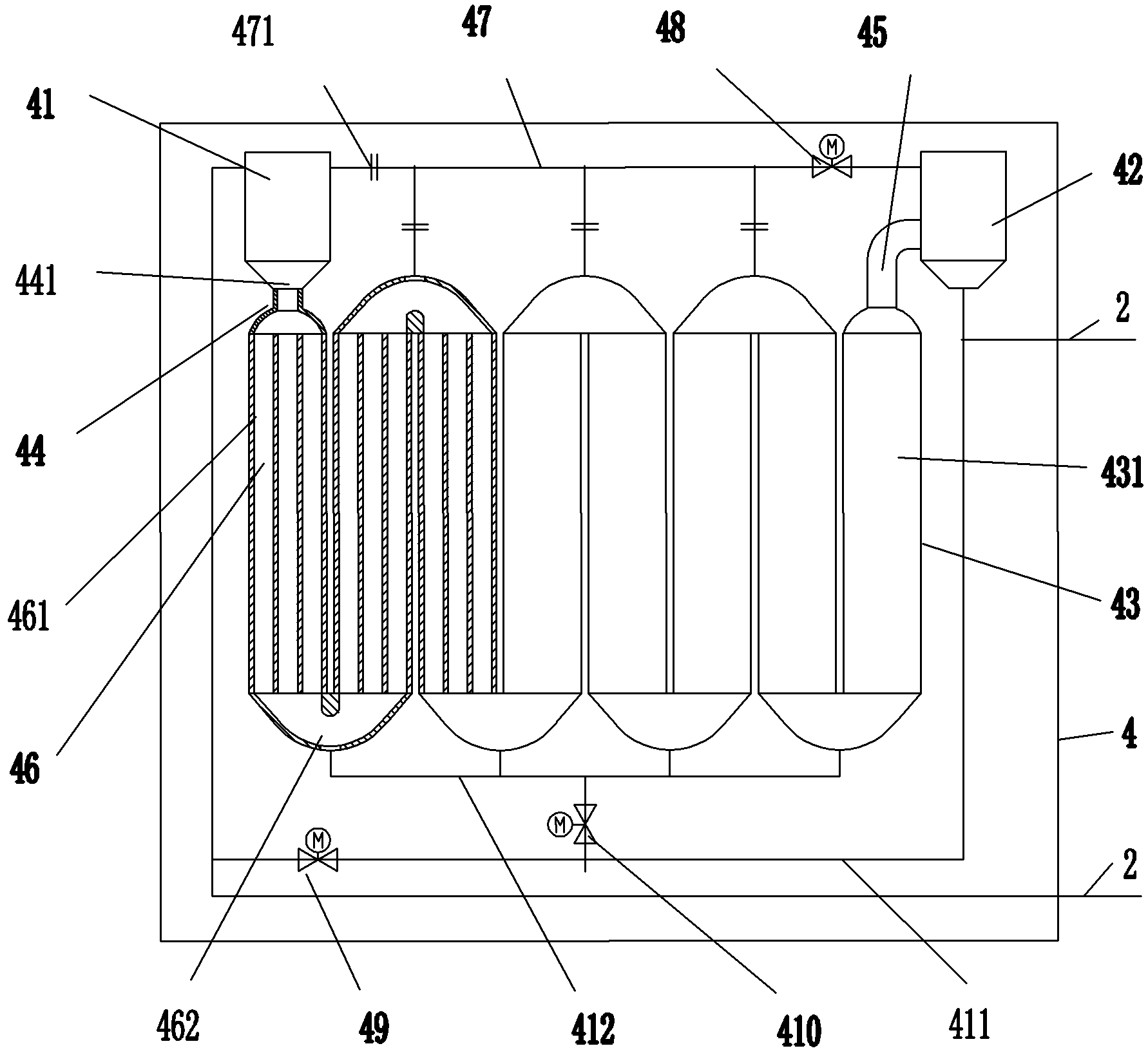

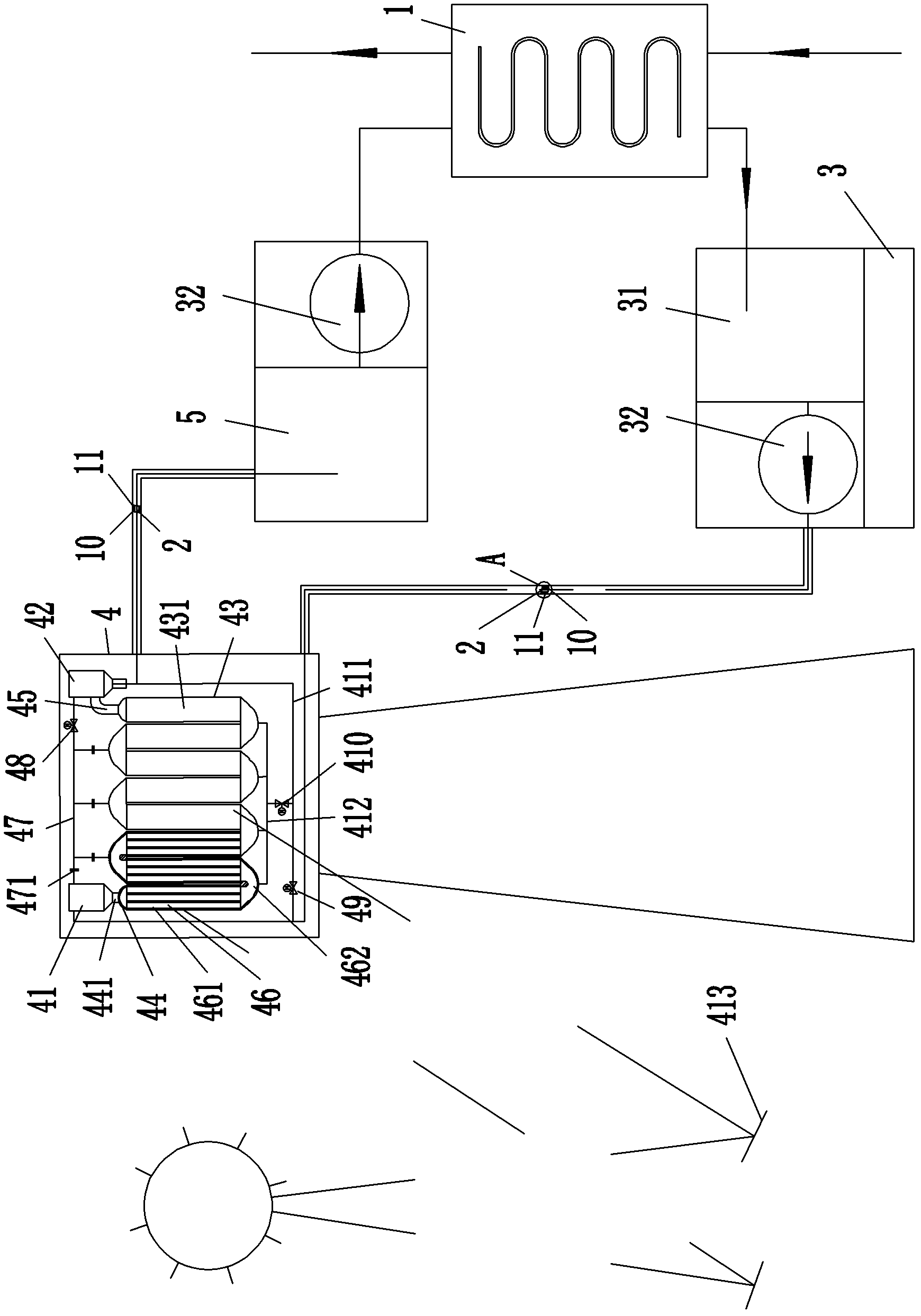

Solar-heating assisted salt melting system

ActiveCN102563867AReduce consumptionReduce flow rateSolar heat devicesStorage heatersMolten saltHot Temperature

The invention belongs to the field of the salt melting equipment and aims to provide a solar-heating assisted salt melting system which consumes less fuel and less affects the environment. The solar-heating assisted salt melting system comprises a salt melting furnace and a heating device, wherein the salt melting furnace is provided with a low-temperature salt storage tank with a salt melting pump; the solar-heating assisted salt melting system further comprises a solar heat absorbing device, two heating pipes and a high-temperature salt storage tank with a salt melting pump; the outlet of the salt melting pump of the low-temperature salt storage tank is communicated with the inlet of the solar heat absorbing device through a first heating pipe; the outlet of the solar heat absorbing device is communicated with the high-temperature salt storage tank through a second heating pipe; the outlet and the inlet of the heating device are communicated with the inlet of the low-temperature salt storage tank and the outlet of the salt melting pump of the high-temperature salt storage tank respectively; and the solar-heating assisted salt melting system is provided with a preheating device used for preheating the heating pipes. The solar-heating assisted salt melting system consumes less fuel and less affects the environment.

Owner:HANGZHOU BOILER GRP CO LTD

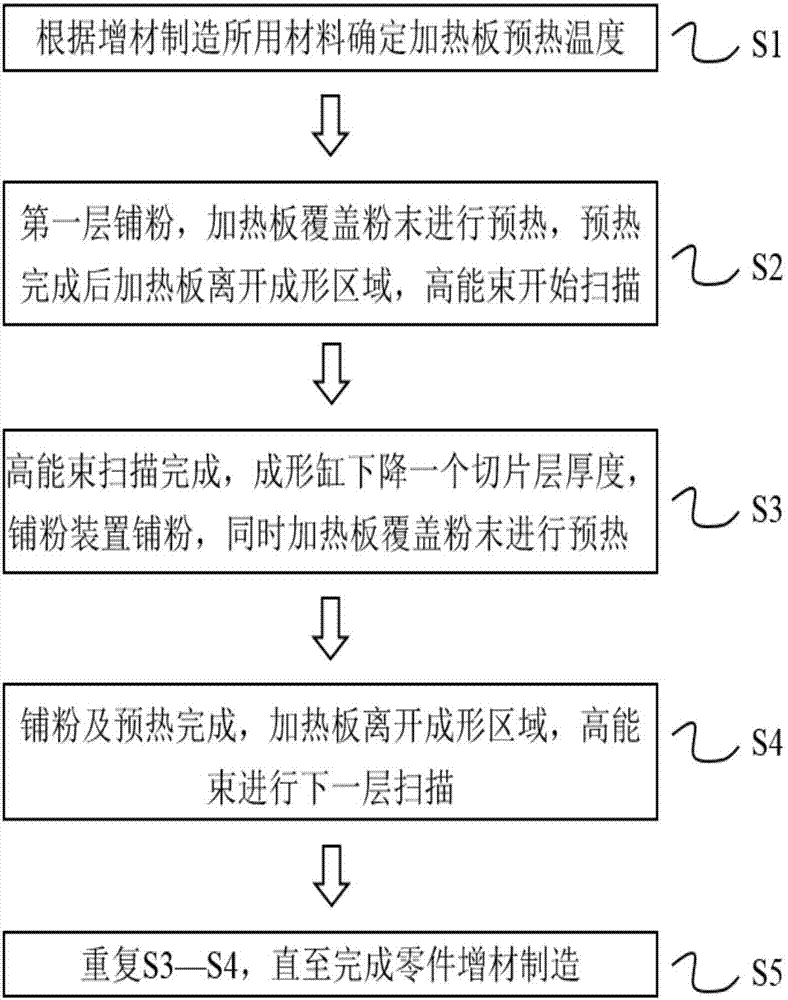

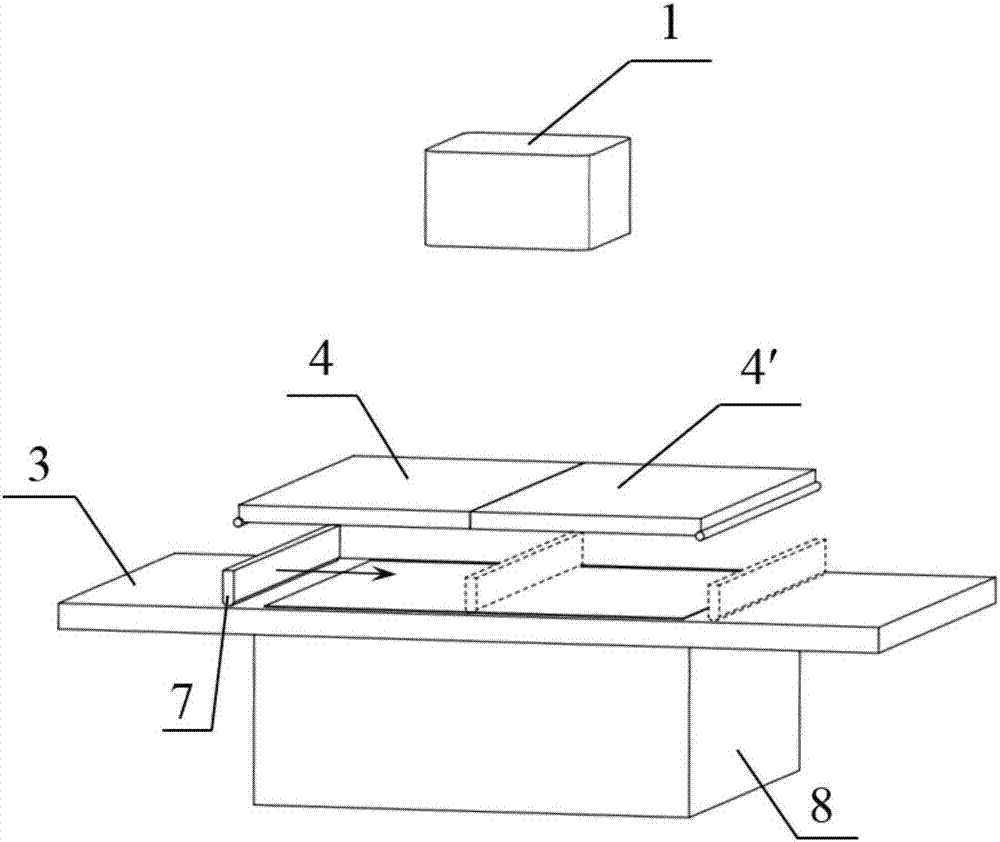

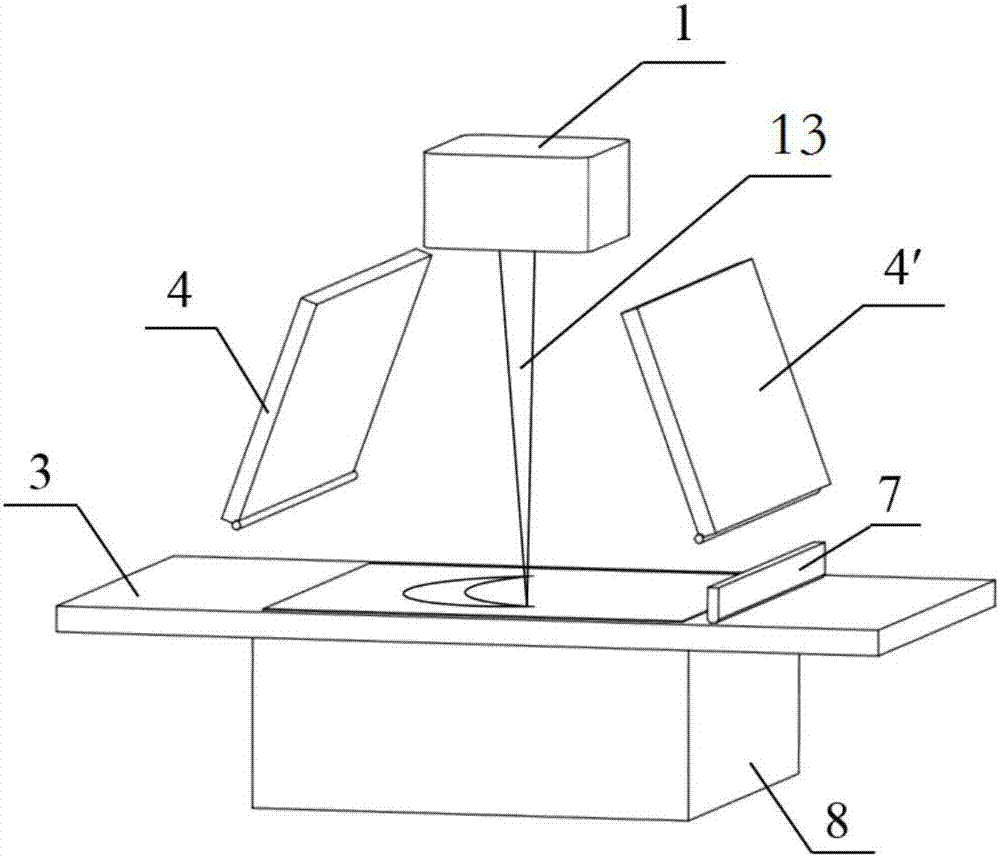

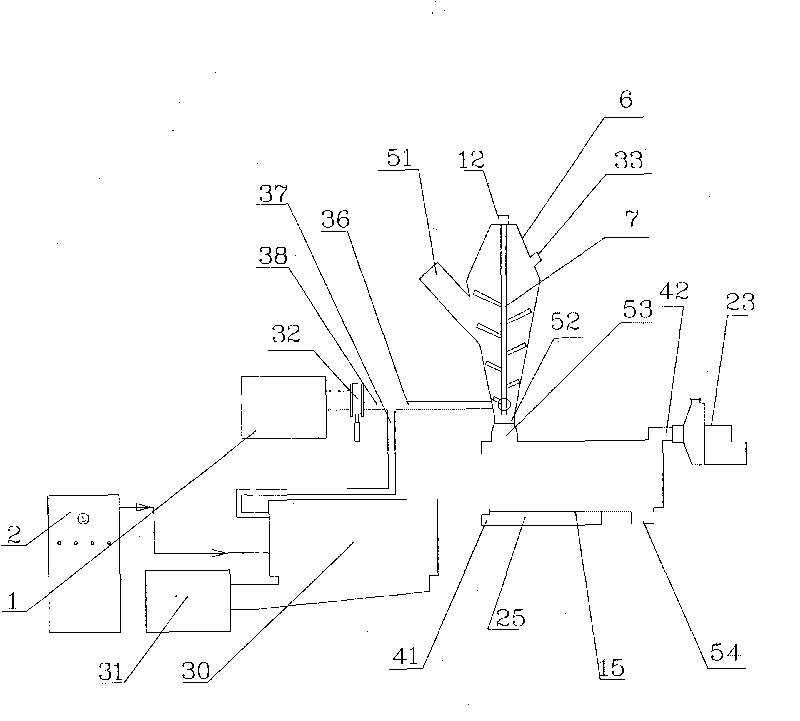

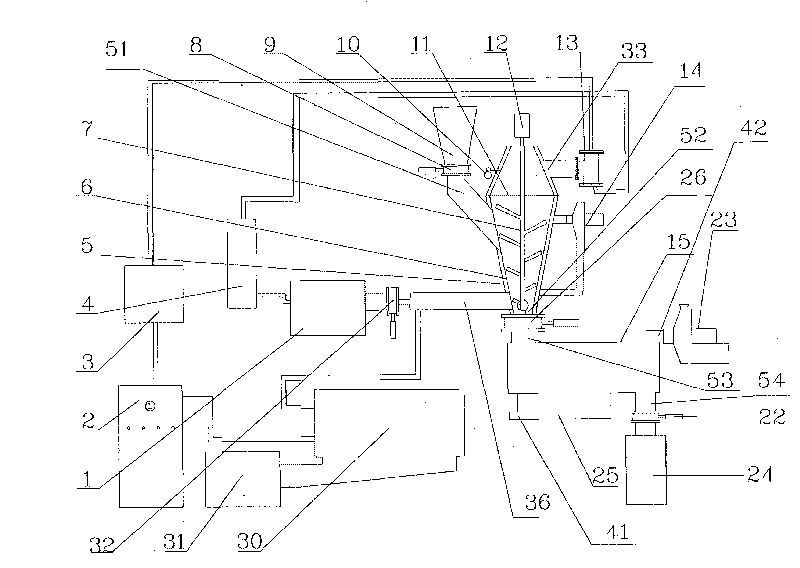

Preheating method and device suitable for powder laying type additive manufacturing

ActiveCN107379527AMonitor temperature in real timeHeating high temperatureManufacturing heating elementsIncreasing energy efficiencyControl systemMetallurgy

The invention provides a preheating method and device suitable for powder laying type additive manufacturing, and belongs to the technical field of additive manufacturing. A movable type plane heating plate capable of covering a whole powder bed is arranged over the powder bed, the mounting height of the plane heating plate is slightly larger than a powder laying device, in the powder laying process, the powder bed and parts are preheated, after powder laying is finished, a plane light source is closed and put away, and the phenomenon that in the machining process, the plane heating plate blocks a high-energy beam is avoided. In the heating process, a temperature measuring sensor is used for monitoring the temperature of the powder bed in real time, a control system is adopted to implement feedback control over preheating of the powder bed according to the temperature monitoring result, full-breadth covering type heating is adopted, and the powder bed and formed parts are subject to high-temperature, efficient and unifier preheating. The invention further provides the device achieving the above method. The method is wide in application material and high in expansibility and is particularly suitable for powder laying type additive manufacturing of multiple large-breadth high-energy beams.

Owner:HUAZHONG UNIV OF SCI & TECH

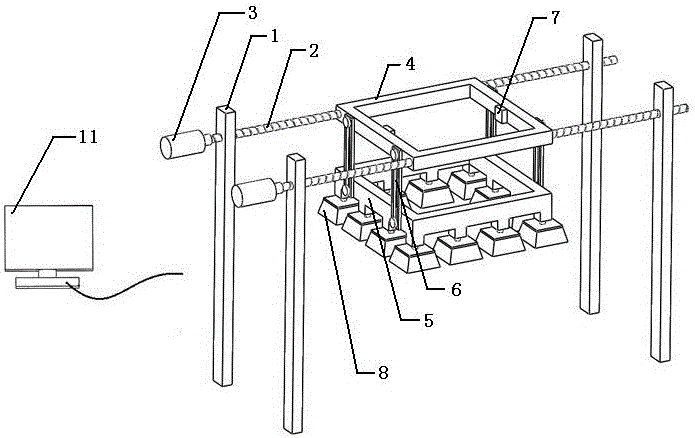

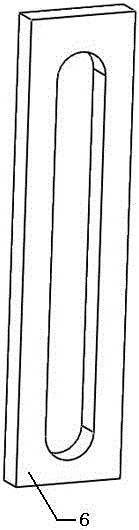

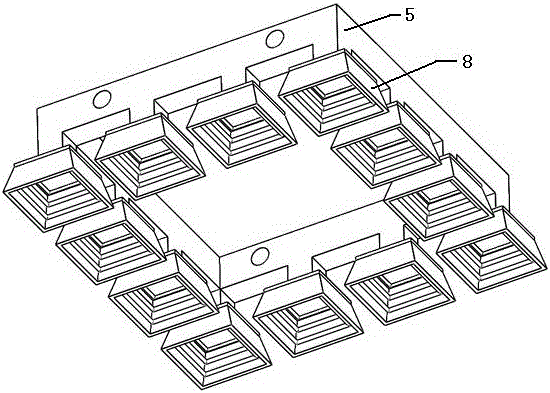

Selective laser sintering SLS laid powder preheating device

InactiveCN106001575AWarm up evenlyHigh precisionAdditive manufacturing apparatusIncreasing energy efficiencyInfraredSelective laser sintering

The invention provides a selective laser sintering SLS laid powder preheating device. The selective laser sintering SLS laid powder preheating device comprises stand columns, lead screws, driving motors, an upper support, a lower support, height adjusting plates, infrared temperature measuring devices, a plurality of rectangular pyramid hollow shells and a control system, wherein each rectangular pyramid hollow shell, a heating rod inside the rectangular pyramid hollow shell and a reflector on the inner wall of the rectangular pyramid hollow shell form a corresponding independent preheating device; and the independent preheating devices divide a forming region into a plurality of small regions capable of preheating independently, are directly controlled by the control system and do not interfere one another. When temperatures of different regions of the laid powder are different, the independent preheating devices can be adjusted to preheat the different regions at different temperatures, so that the laid powder is integrally preheated uniformly; and the direction of each independent preheating device in three-dimensional space is adjustable, the preheating regions can be adjusted according to the size of a formed part, preheating efficiency is improved, and energy is saved. By the selective laser sintering SLS laid powder preheating device, the precision and the structure property of the formed part can be improved effectively; and the selective laser sintering SLS laid powder preheating device has an important significance on development of an SLS forming technology.

Owner:ZHONGBEI UNIV

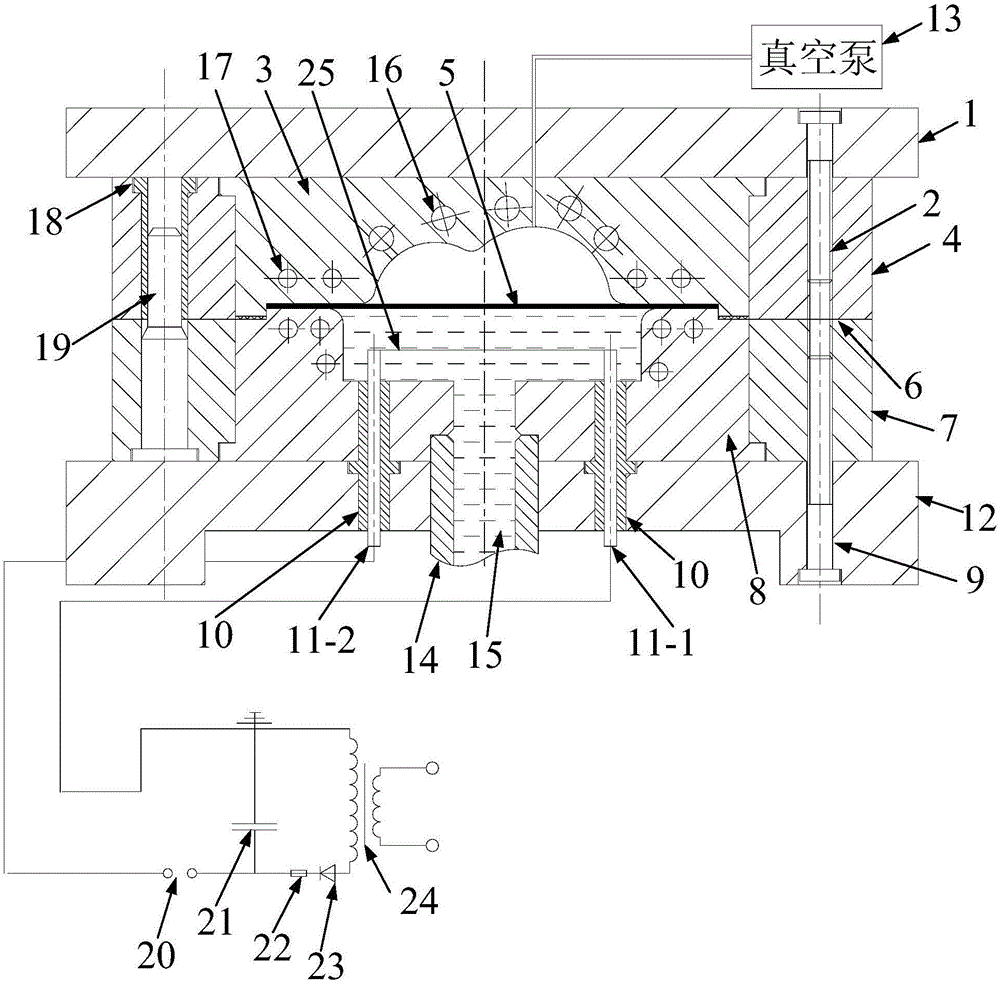

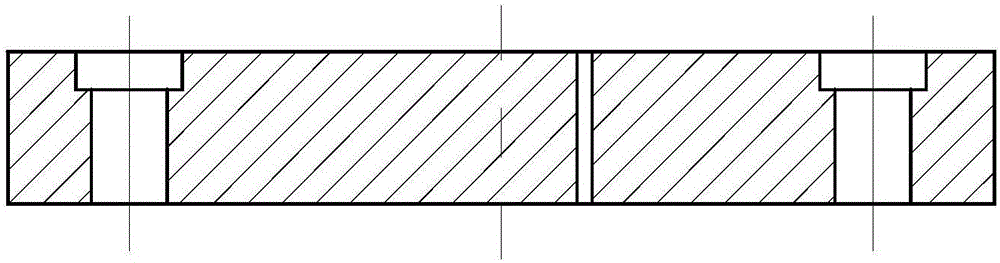

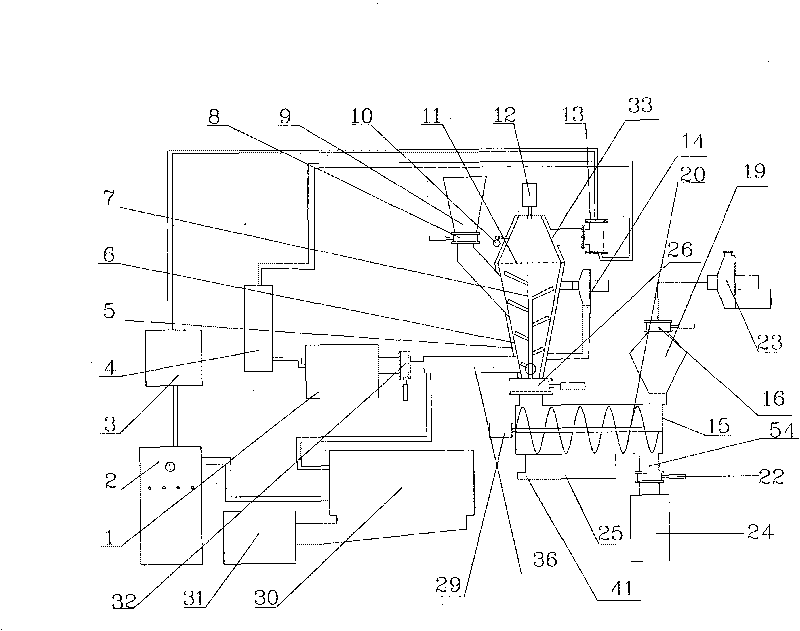

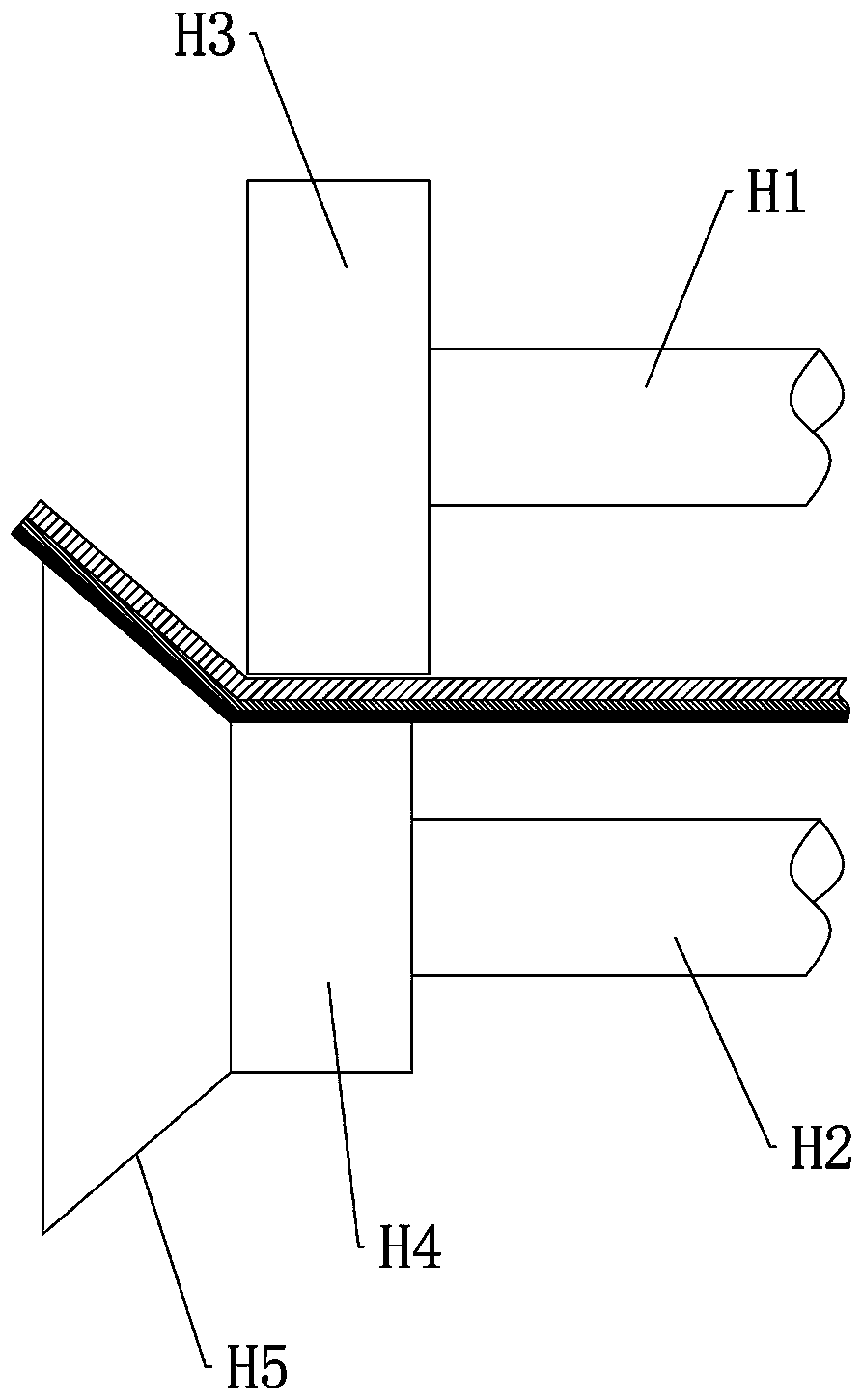

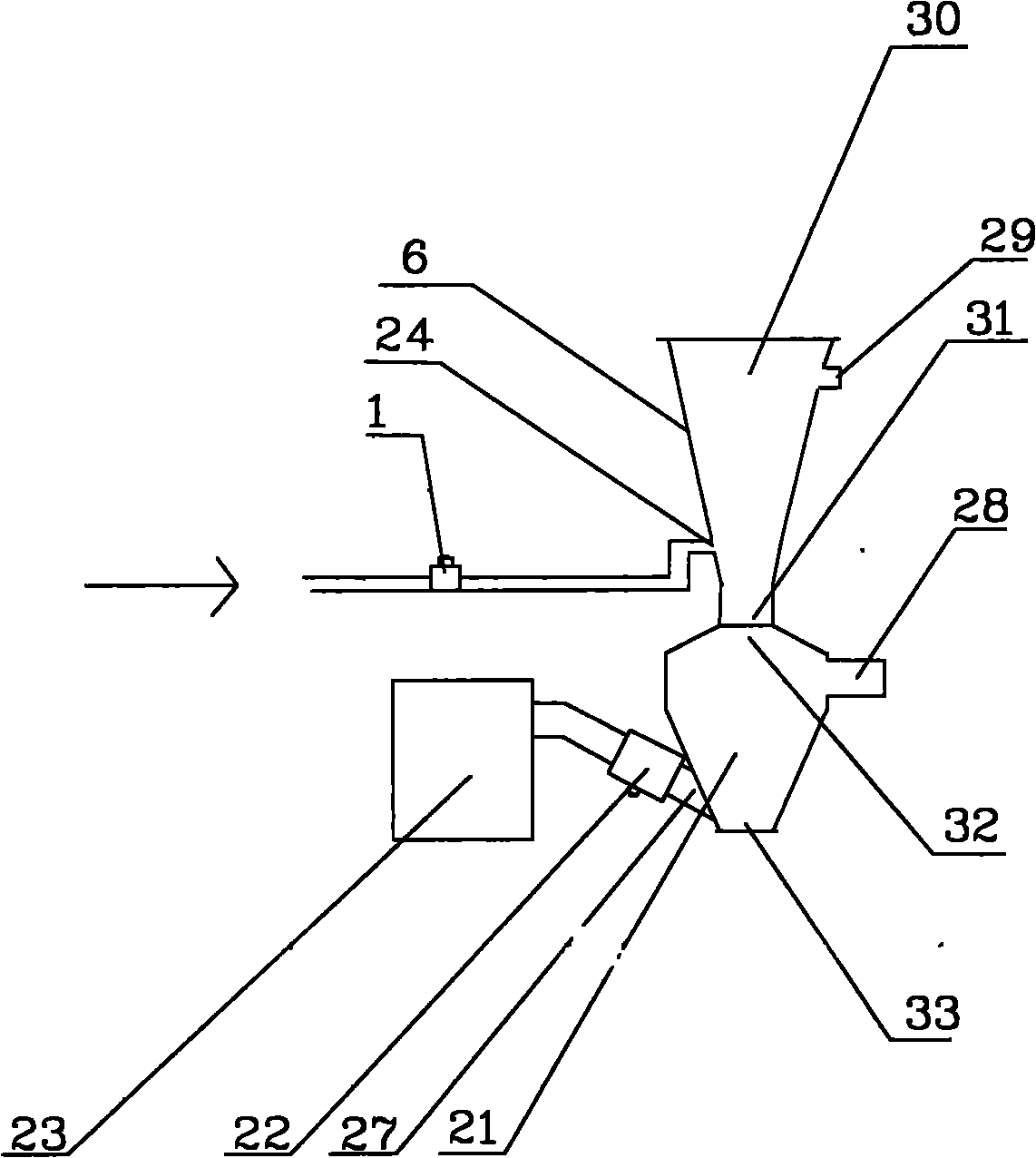

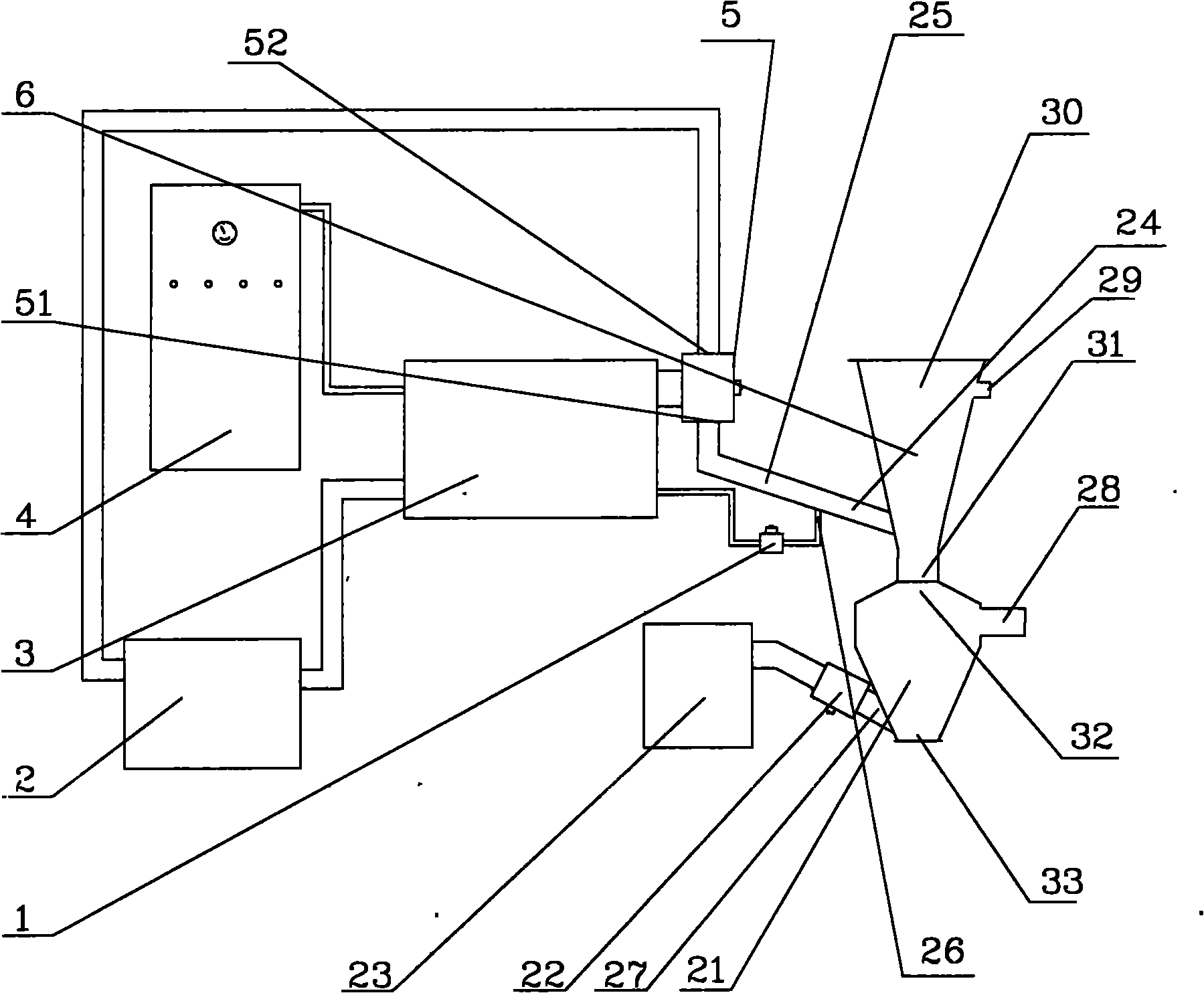

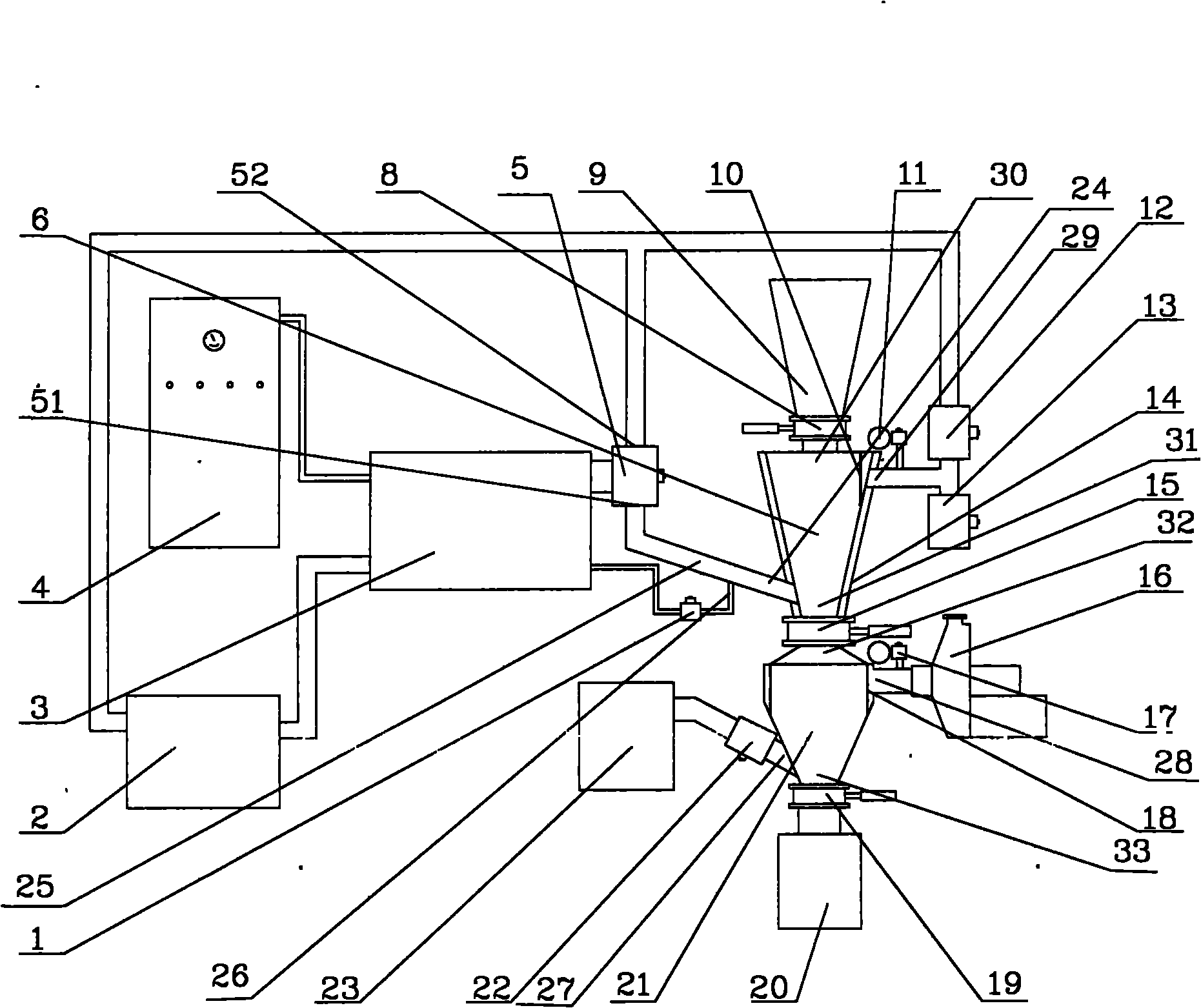

Plate warm electro-hydraulic high-speed impact-quasi static hydraulic composite forming device and plate forming method achieved by adopting device

InactiveCN106734499AGuaranteed forming qualityAvoid crackingShaping toolsElectro hydraulicEngineering

The invention discloses a plate warm electro-hydraulic high-speed impact-quasi static hydraulic composite forming device and a plate forming method achieved by adopting the device and relates to the field of metal material processing forming to solve the problems that forming of plates and complex parts is difficult, film attaching is poor, and deformation is not even. A vacuum pump is used for pumping out gas in a female die cavity; a fluid injection device is adopted for injecting high-temperature-resisting liquid to a liquid chamber; a heating device is used for heating the female die cavity, the high-temperature-resisting liquid in the liquid chamber is heated, preheating on a to-be-processed plate is completed, and heat preservation is conducted on the to-be-processed plate; an electromagnetic forming system is used for conducting discharging forming on the to-be-processed plate; high-pressure warm liquid is slowly injected into the liquid chamber under the quasi static condition, and quasi static hydraulic forming is conducted on the to-be-processed plate; and the high-pressure warm liquid in the liquid chamber is cooled to the room temperature within a period of time, waste liquid is recycled, an electro-hydraulic forming die is opened, and the to-be-processed plate is taken away. The device and the method are used for forming plates.

Owner:XIANGTAN UNIV

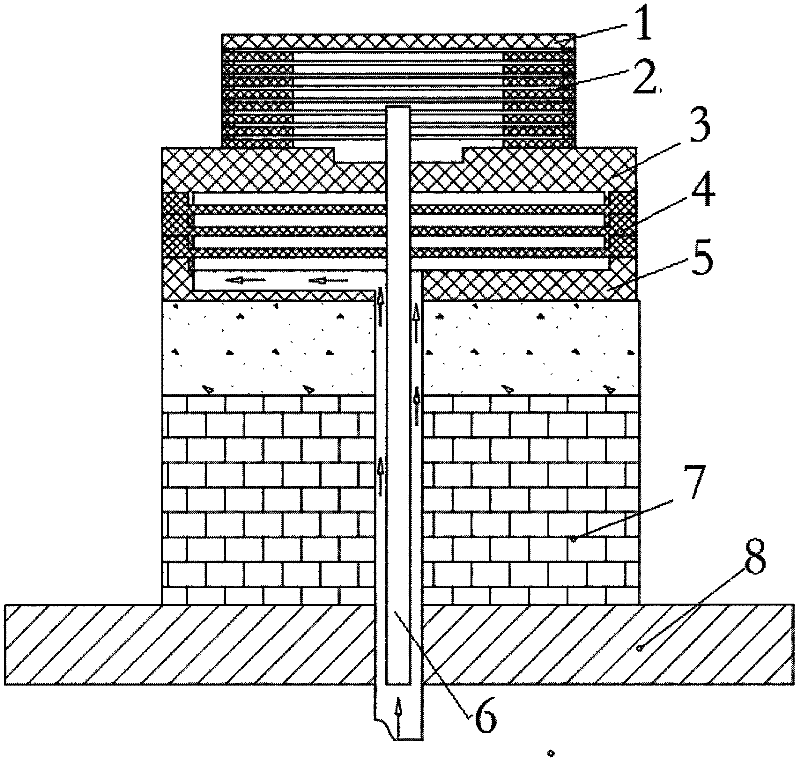

Preheating device for chemical vapor deposition furnace

ActiveCN102363878ASimple processExtend heating timeChemical vapor deposition coatingEngineeringChemical vapor deposition

The invention discloses a preheating device for a chemical vapor deposition furnace. Air flow plates which are arranged in parallel so as to increase air processes and prolong heating time, and beams are arranged simultaneously so as to improve heat radiation capacity; therefore, the aims of fully and uniformly preheating organic air can be fulfilled. An outlet is provided with disturbance holes which are positioned on the same circumference; and a certain included angle is formed between the axial direction of the disturbance holes and a horizontal plane; after preheated air enters the disturbance holes, the preheated air is forced to be sprayed along the axial direction of the disturbance holes to form strong rotation air flow under the collision action of disturbance walls, and organic air which is decomposed in advance forms macromolecules under the actions of centrifugal force and polymerization along with the rising of the rotation air flow; and the macromolecules preferentially enter the bottom of a stock column under the double actions of inertia force and centrifugal force, so axial back mixing probability is reduced, the macromolecules are diffused and deposited in a prefabrication body to achieve the effect of densifying the bottom, the air which is not decomposed rises continuously to ensure that top pressure and air pressure are reduced, and finally the aims of densifying the whole carbon disc stock column can be fulfilled.

Owner:XIAN AVIATION BRAKE TECH

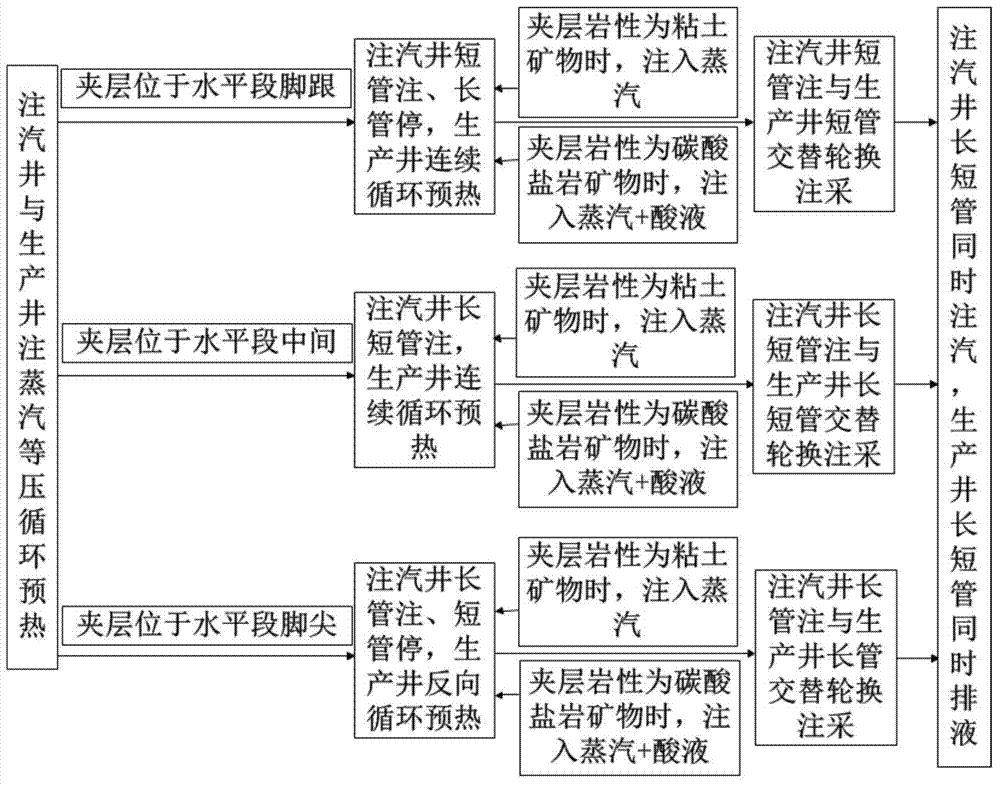

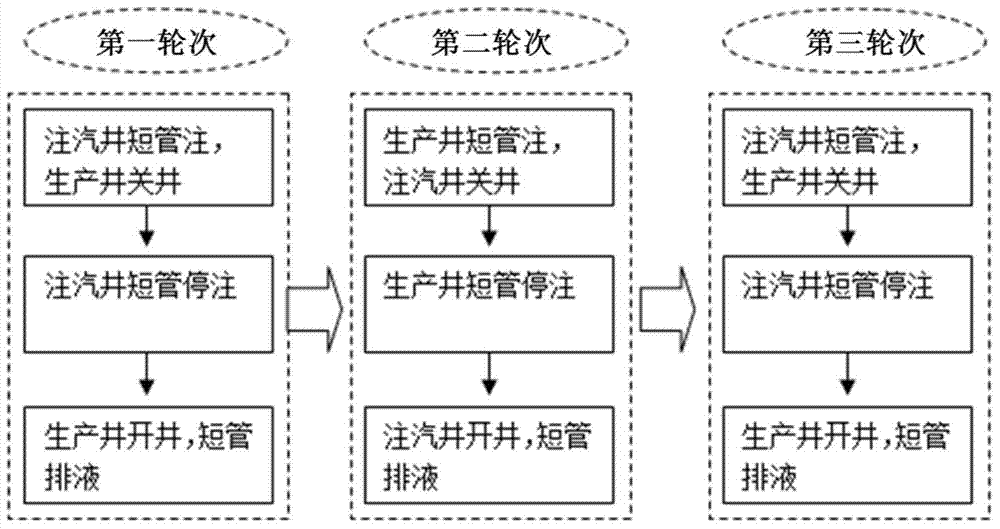

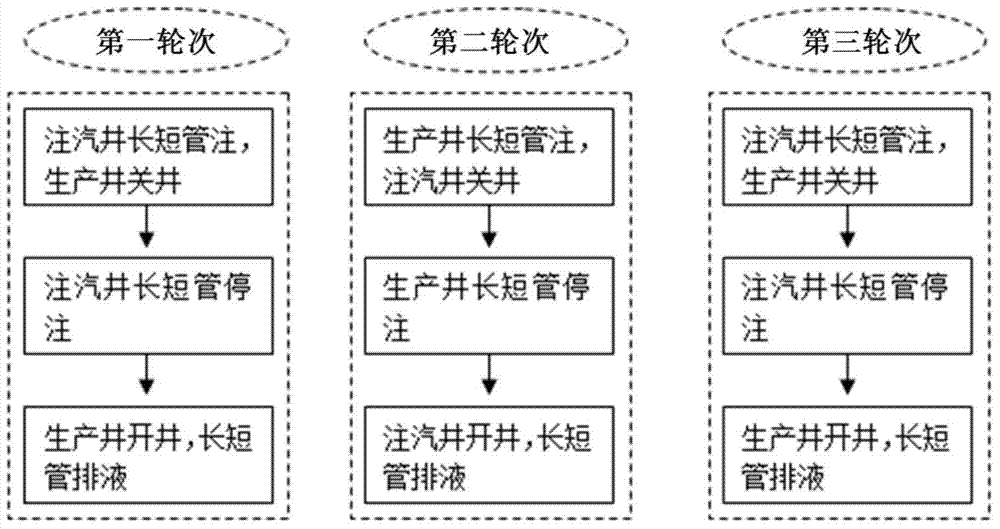

SAGD starting method for interlayer heterogeneous thickened oil pool

InactiveCN104500012AAvoid the problem of creeping inHeating evenlyFluid removalOil productionInjection well

The invention provides an SAGD starting method for an interlayer heterogeneous thickened oil pool. According to the interlayer heterogeneous thickened oil pool in the method, an interlayer exists between horizontal segments of an injection well and a production well, the spreading range of the interlayer along the horizontal segments does not exceed half length of the horizontal segments, and the thickness of the interlayer ranges from 0.3 m to 3 m. The method specifically comprises the steps that steam injection equipressure cycle preheating is carried out on the steam injection well and the production well; according to the different positions of the interlayer between the injection well and the production well, the different modes are adopted to carry out steam injection of the steam injection well and cycle preheating of the production well; according to the different positions of the interlayer between the injection well and the production well, the different modes are adopted to carry out alternative injection and production; a long pipe and a short pipe of the steam injection well carry out pure steam injection at the same time, a long pipe and a short pipe of the production well drain liquid at the same time, then, the step is converted into the SAGD production stage, and the SAGD starting method for the interlayer heterogeneous thickened oil pool is completed. According to the method, uniform development of a steam cavity of the SAGD horizontal segments can be achieved, and the oil production and the recovery efficiency are effectively improved.

Owner:PETROCHINA CO LTD

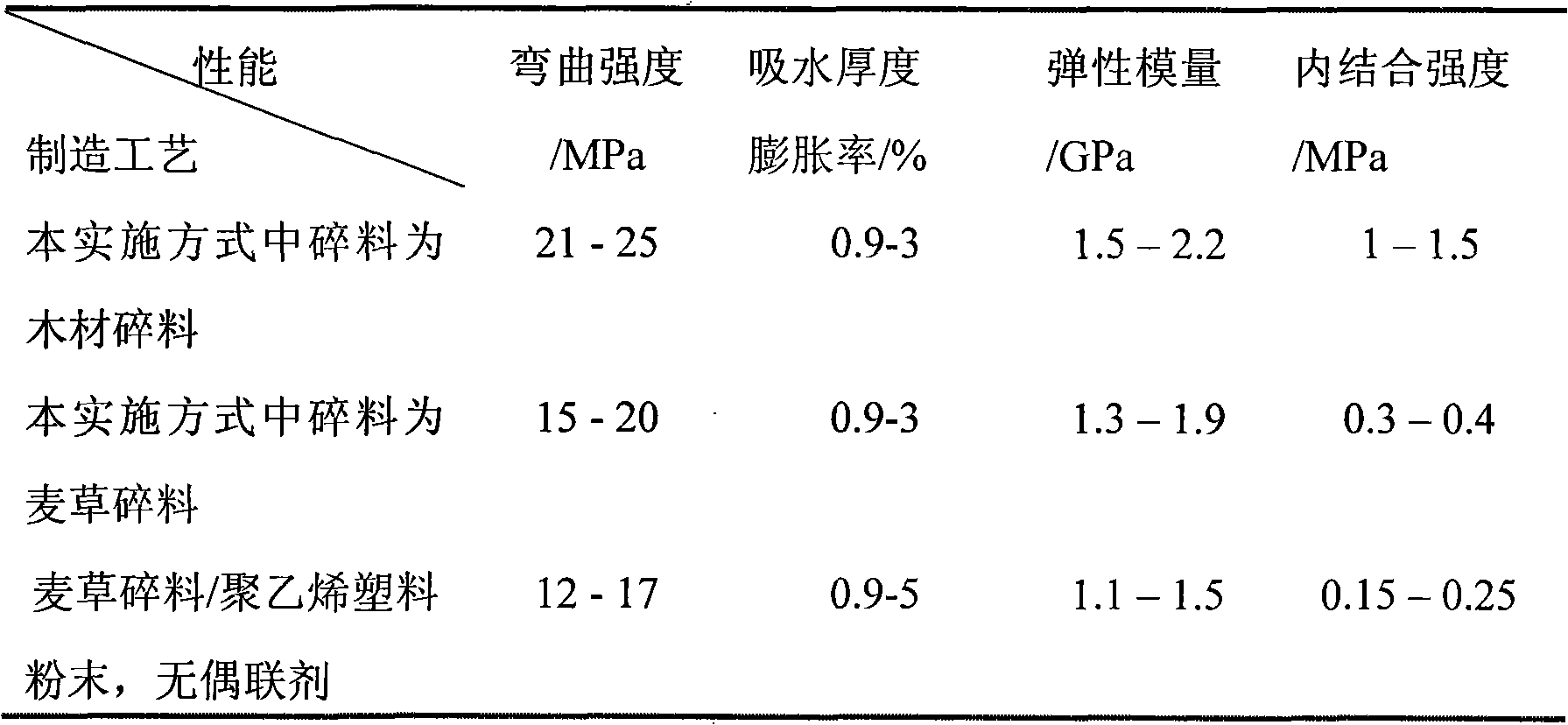

Heat pressing production method of polyethylene fiber-plant fibre compound material

InactiveCN101323130AShorten heating timeEasy to melt and transfer heatFlat articlesDomestic articlesFlexural strengthPlastic compounding

A heat pressing method for polyethylene plant fiber composite material relates to a method for manufacturing plant fiber material. The invention solves the problems that only fibril can be applied, plant format is narrower, straw is liable to thermolysis and charring and the mechanical properties of plant manufactured by pre-heat pressing are poor in the production of WPC in the manner of extraction. The method of the invention has the steps that: PE plastic fiber is mixed with crushed plant aggregates to obtain mixture that is paved into a plate base; the plate base is pre heated under a pressure of 1 to 3 MPa and at a temperature of 170 to 190 CEG D; the plate base is kept under a pressure of 4 to 6 MPa for 8 to 15mins; and at last, the plate base is cooled to 70 to 80 CEG D under a pressure of 3 to 6 MPa; and after pressure relief, the plank is obtained. The flexural strength of the plank manufactured in the method of the invention is 20 MPa. The invention adopts the polyethylene in fiber configuration and the crushed aggregates of the plant and the fiber is evenly mixed and has high productivity. In addition, the crushed aggregates of the plant and the fiber can be prevented from being deteriorated and darkened due to high temperature.

Owner:NORTHEAST FORESTRY UNIVERSITY

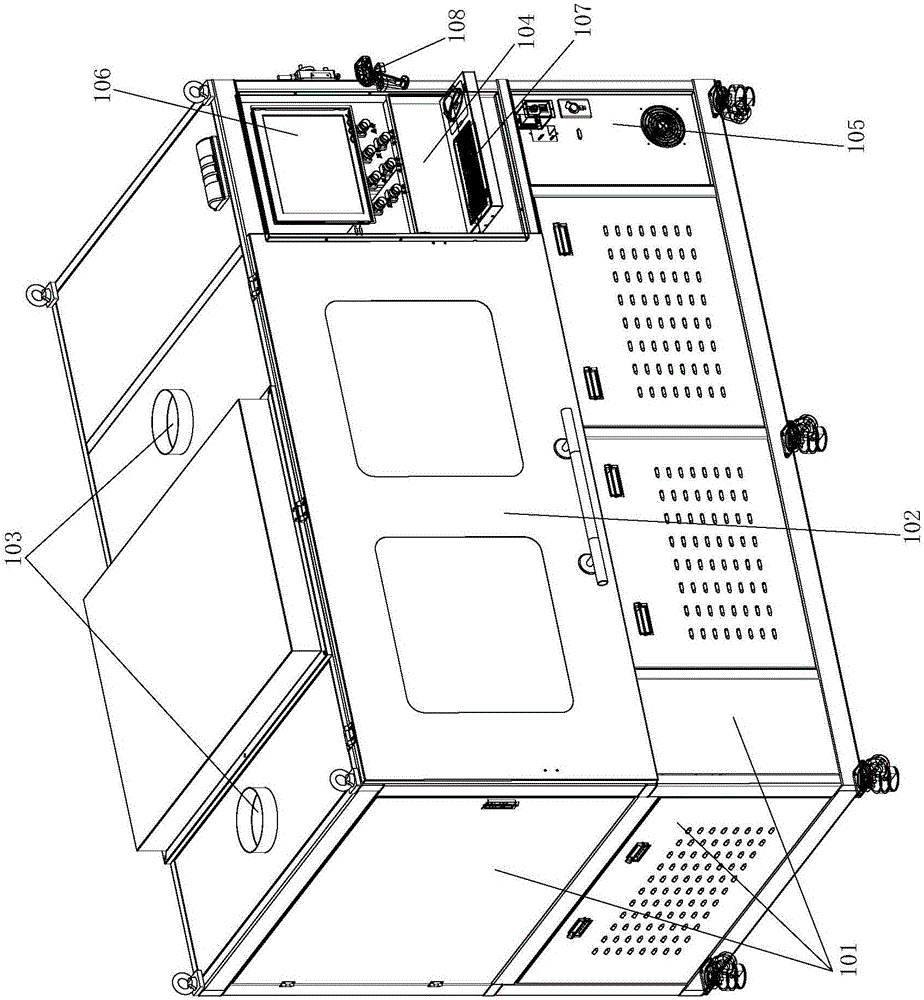

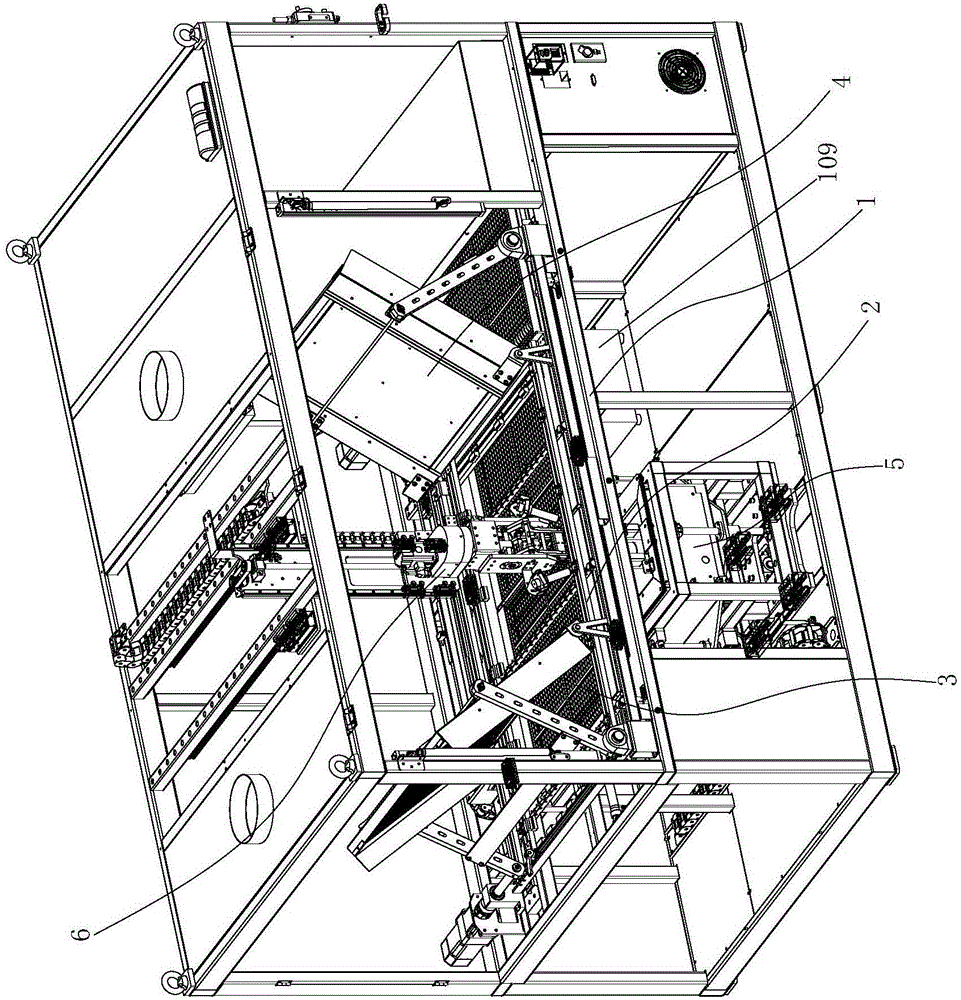

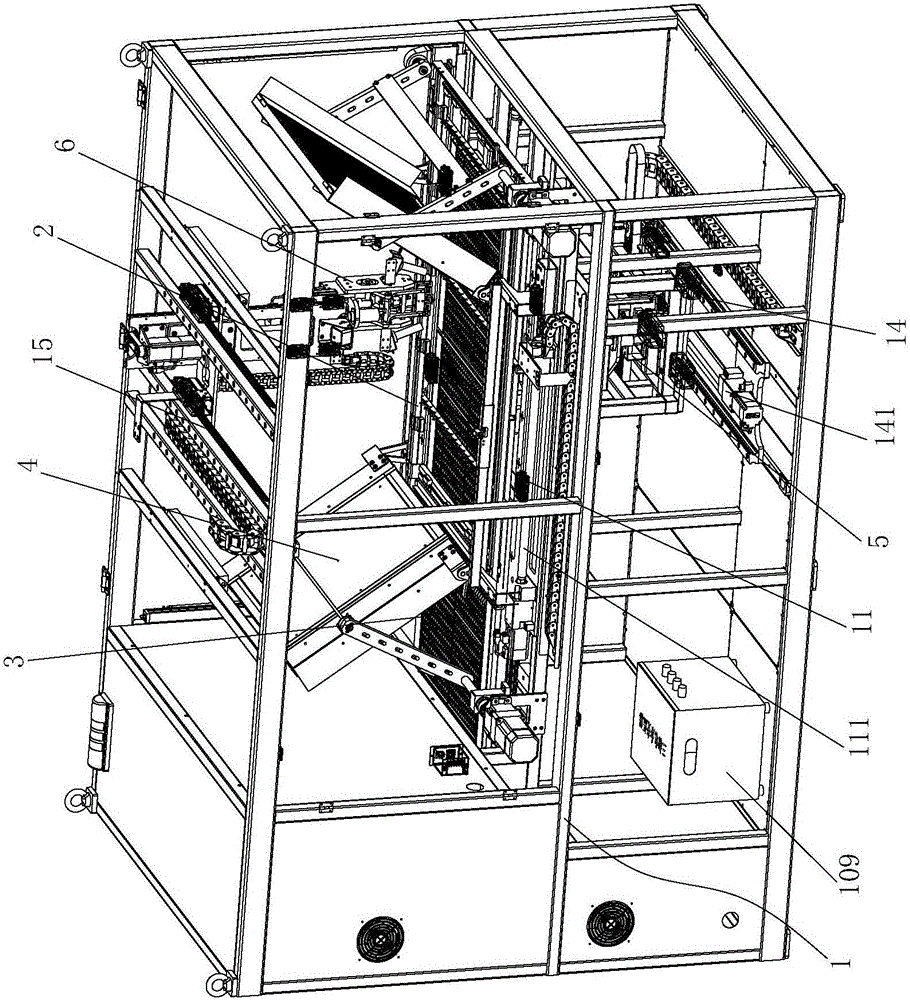

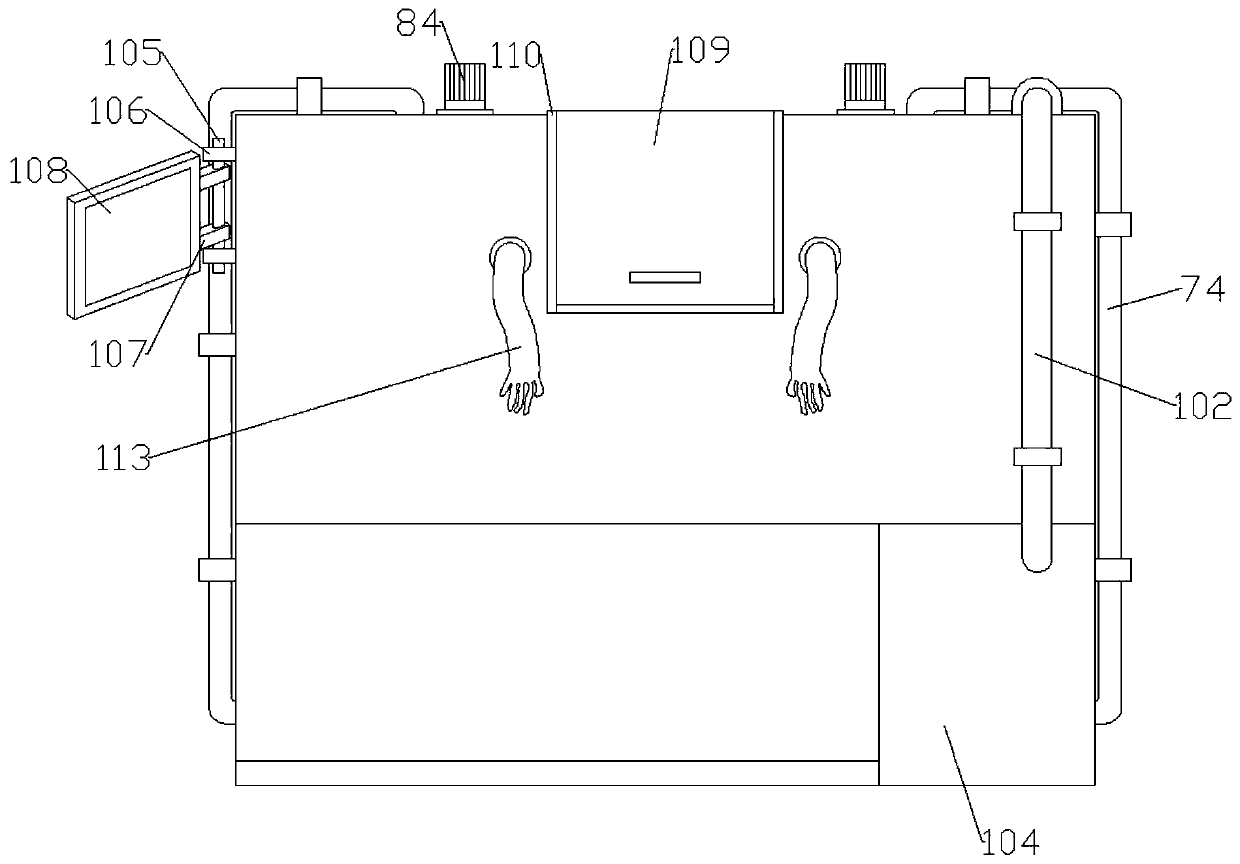

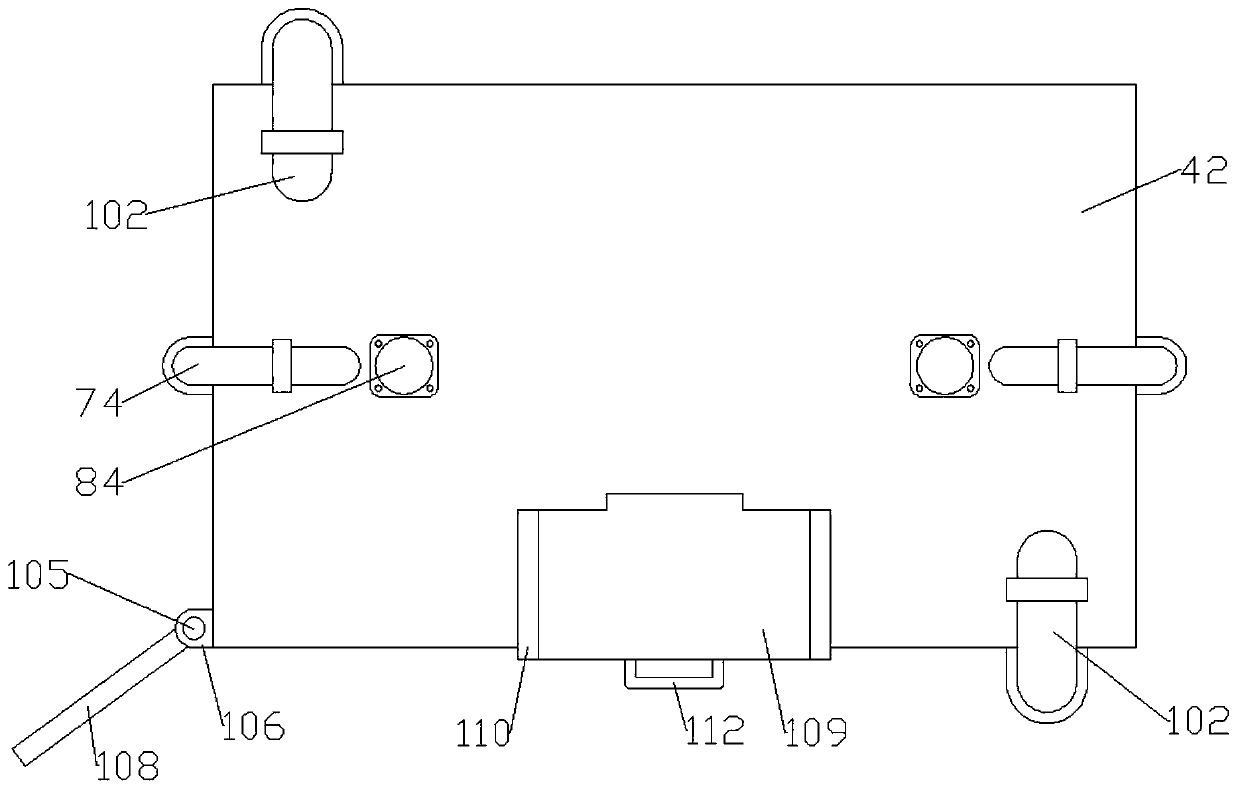

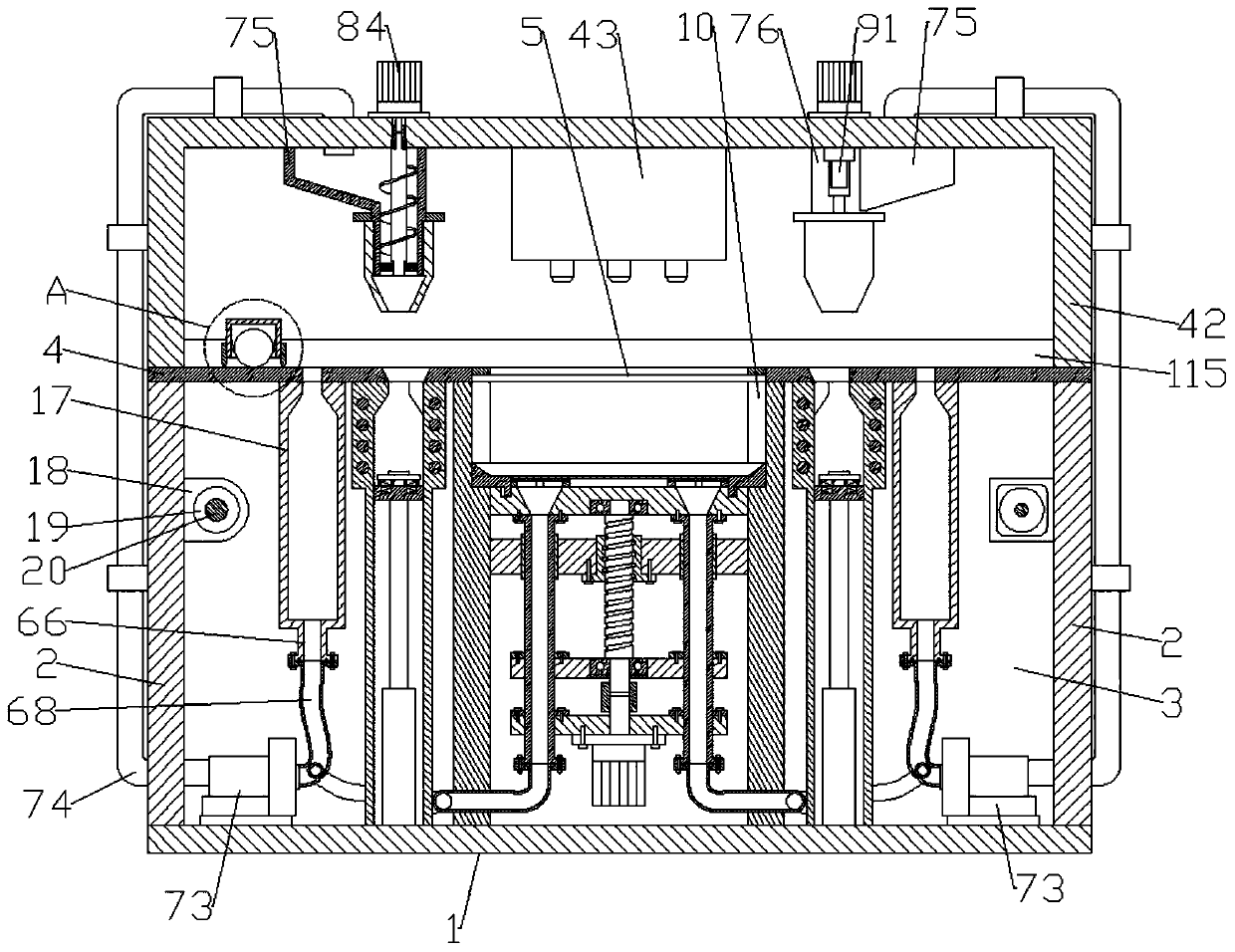

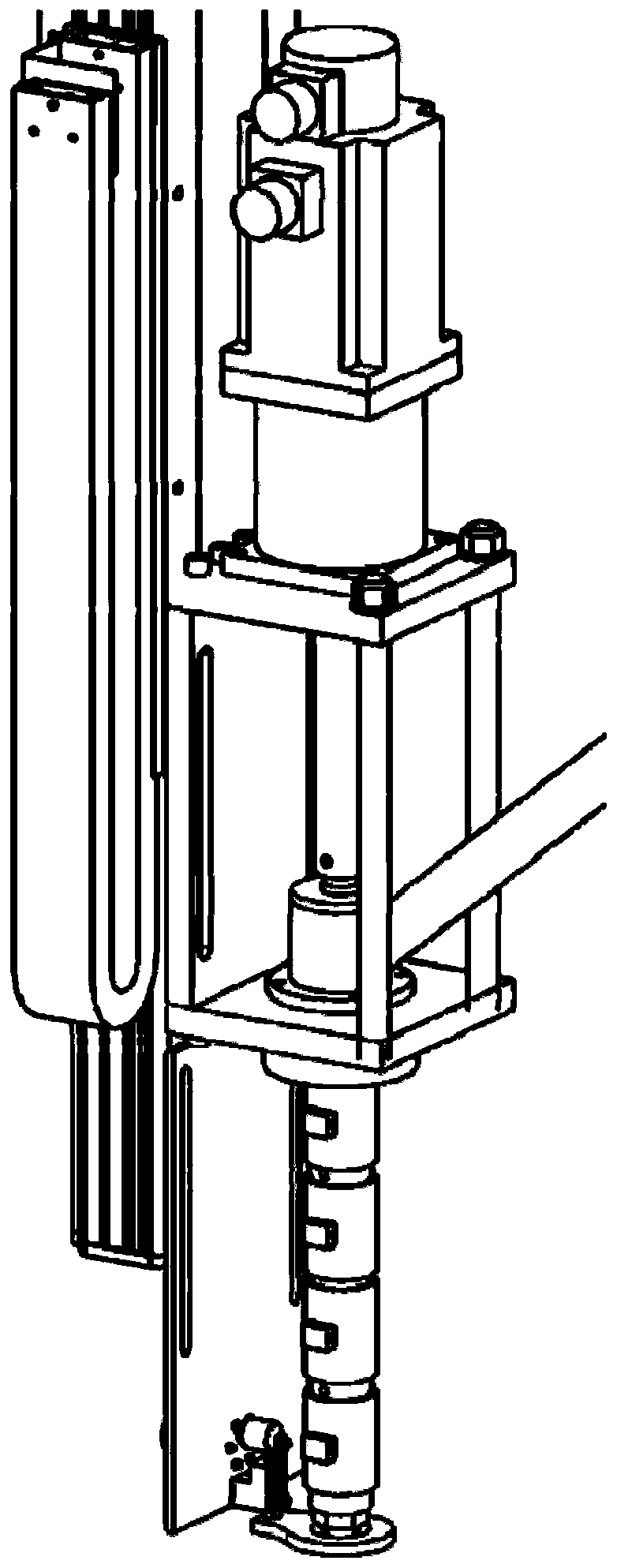

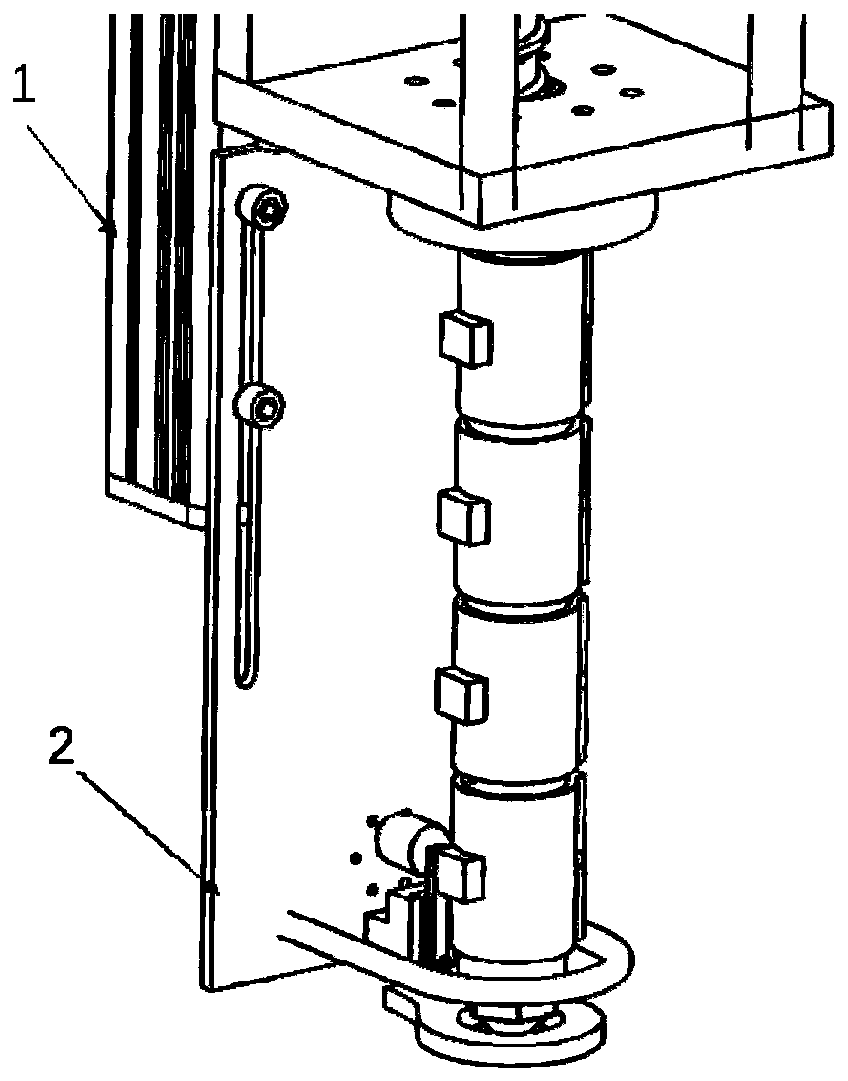

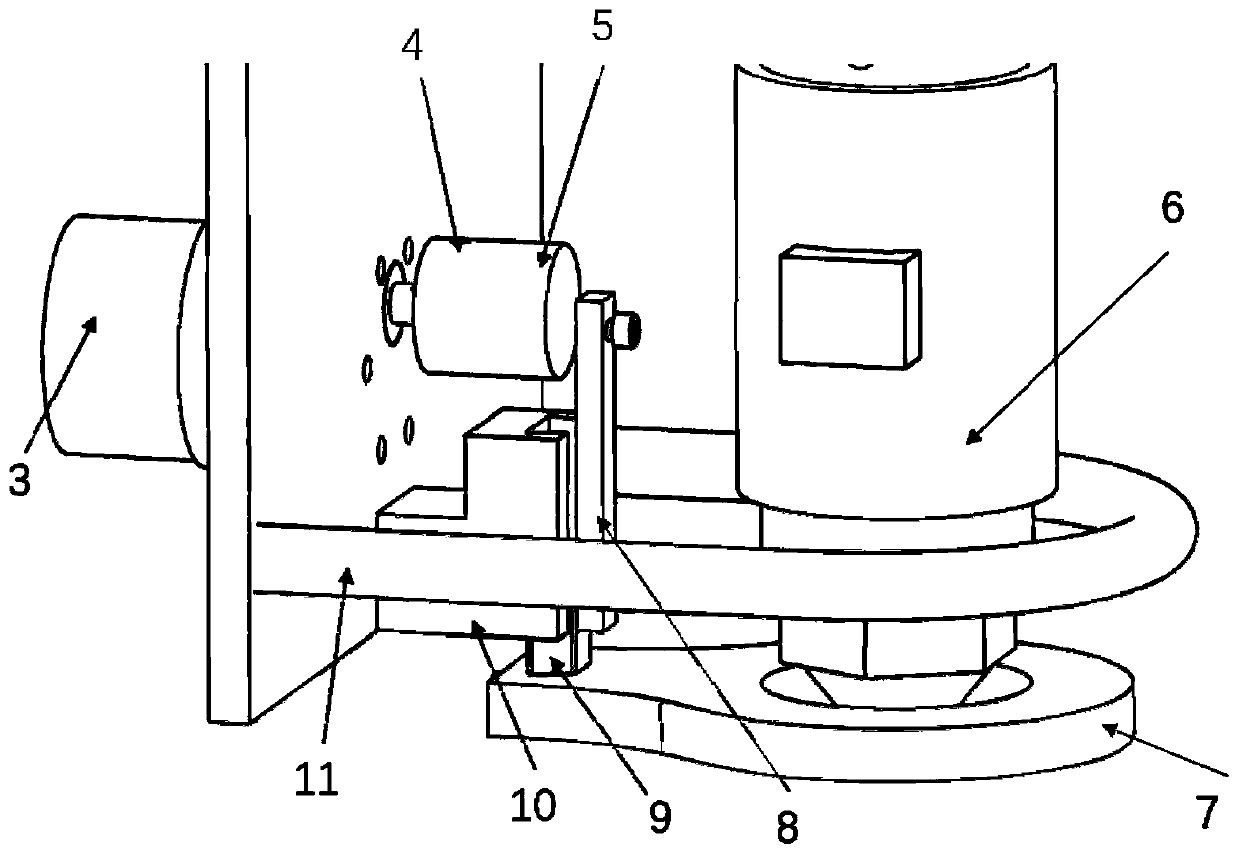

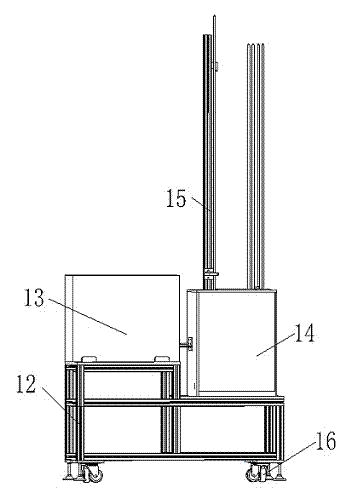

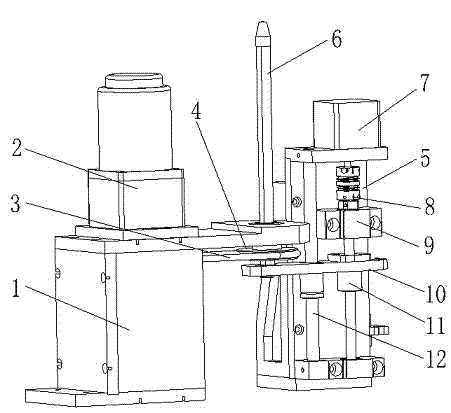

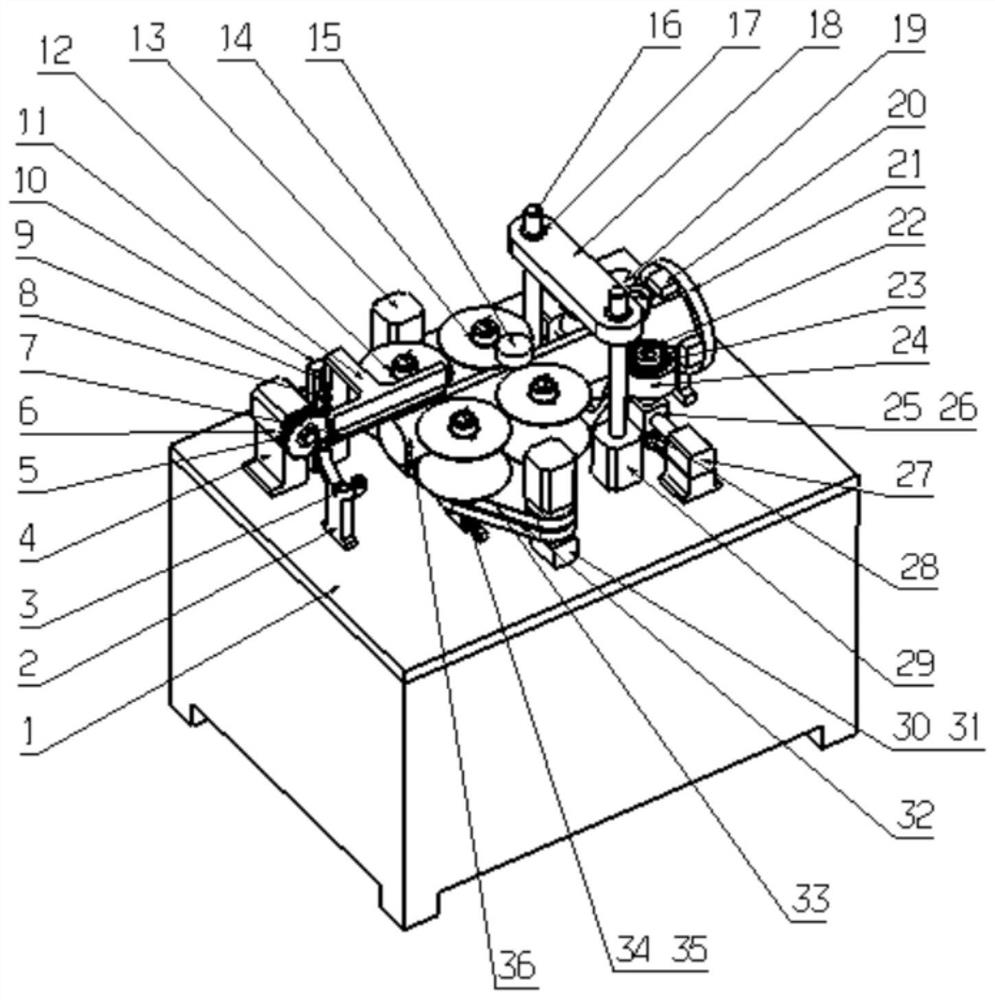

Improved automatic repair machine for PCBA through hole direct insertion device

PendingCN106793546AFully warmed upWarm up evenlyPrinted circuits repair/correctingEngineeringHeat losses

The invention relates to an improved automatic repair machine for a PCBA through hole direct insertion device. The automatic repair machine is provided with a main rack, and a PCBA fixing fixture is installed in the middle of the main rack; two lower heating assemblies and lower heating assembly driving cylinders are installed below the PCBA fixing fixture; two upper heating assemblies are erected above the PCBA fixing fixture, each connected with a swing frame and driven by a first y-direction servo motor; a flow jet tin furnace assembly is installed below the PCBA fixing fixture, and a manipulator device is installed in the area above the PCBA fixing fixture. According to the automatic repair machine, a preheating device of the repair machine is formed by the two movable lower heating assemblies and the two movable upper heating assemblies to fully and uniformly preheat a PCBA, a preheating area and disassembling, soldering and workpiece taking and inserting areas are located at the same position, therefore, a circuit board does not need to leave from the preheating area during working, heat losses are reduced, energy is saved, the tin immersion time is shortened, and the repair quality is improved; automatic workpiece extraction operation is conducted through the manipulator device, and therefore the workpiece insertion operation precision is improved.

Owner:东莞市崴泰电子有限公司

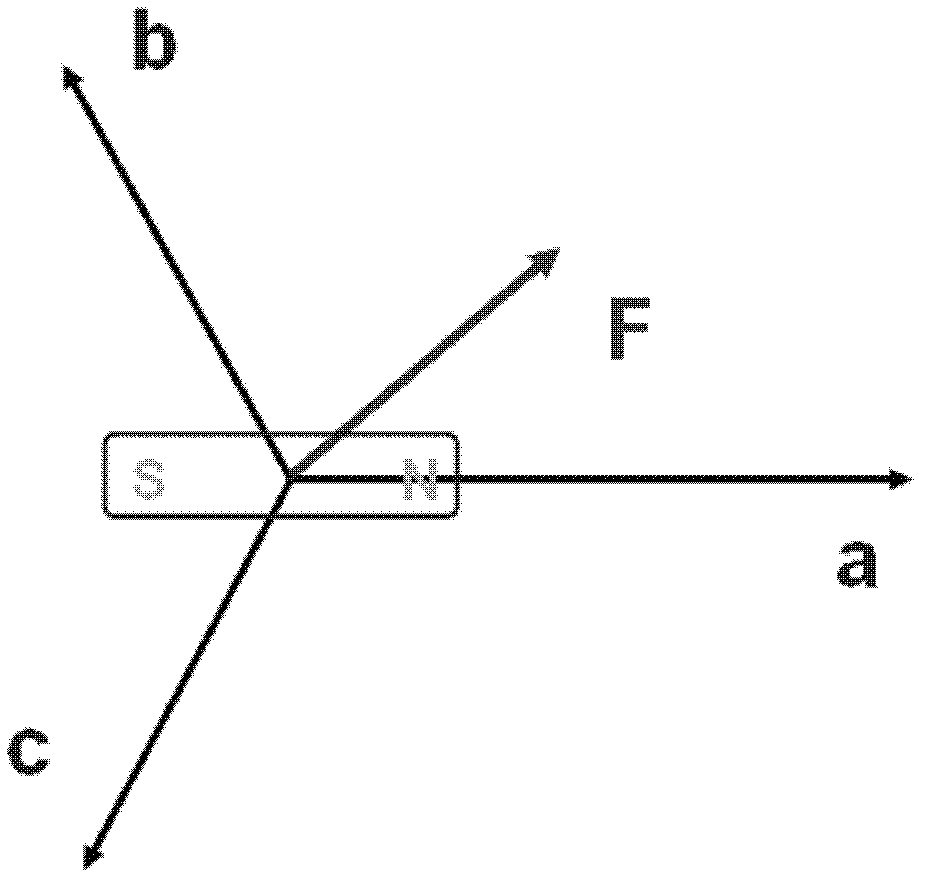

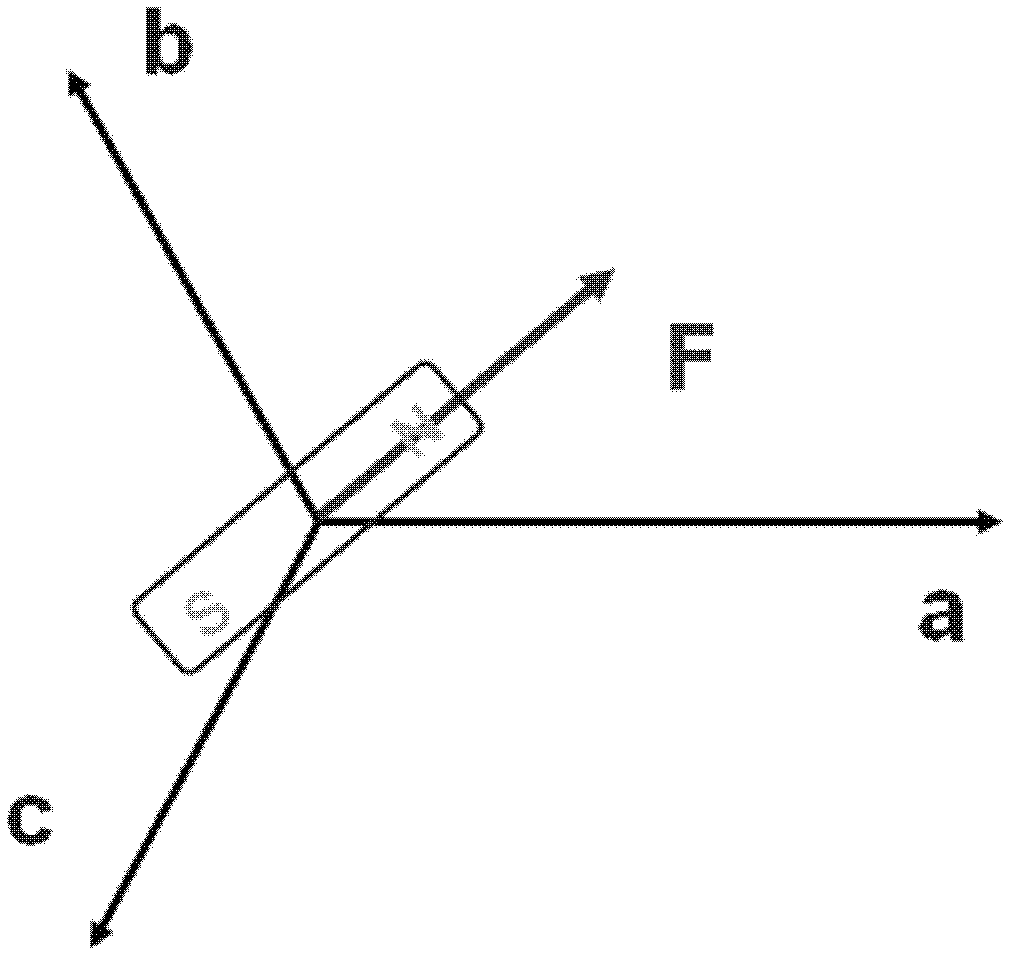

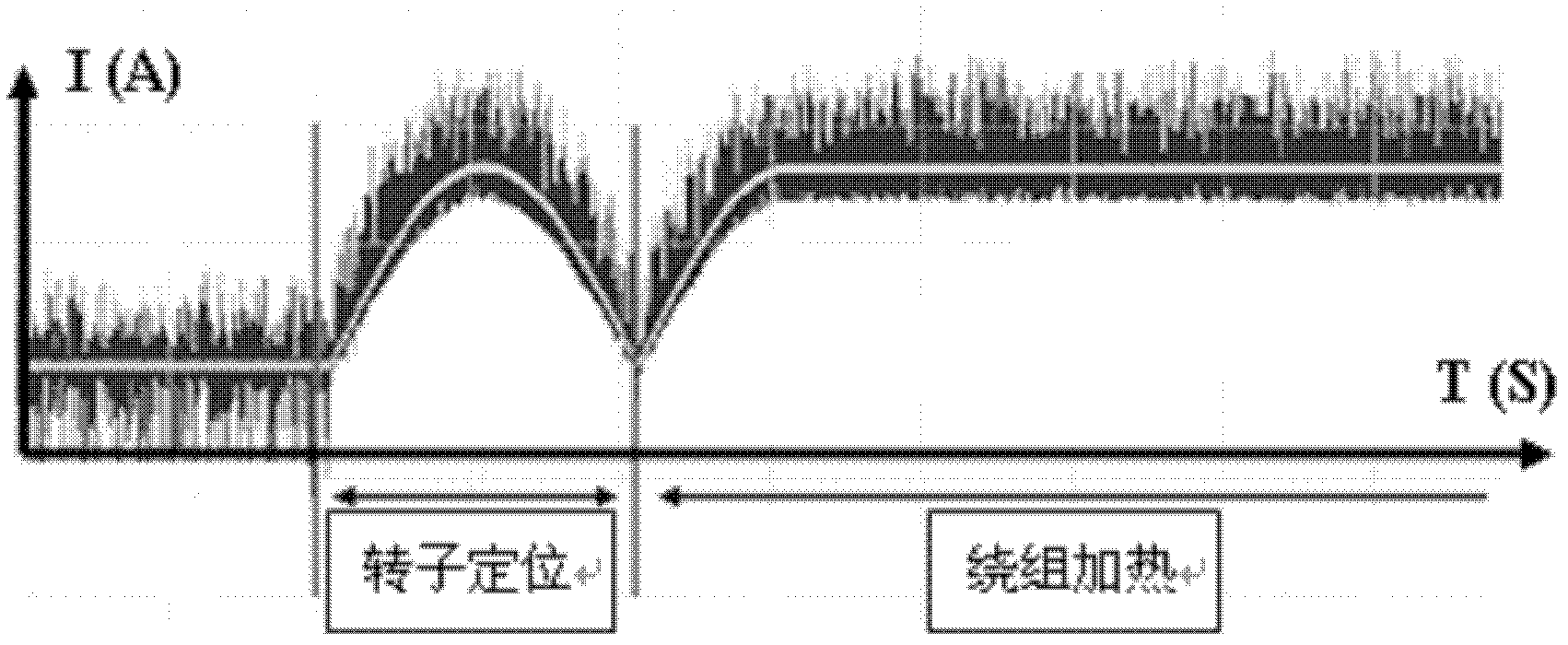

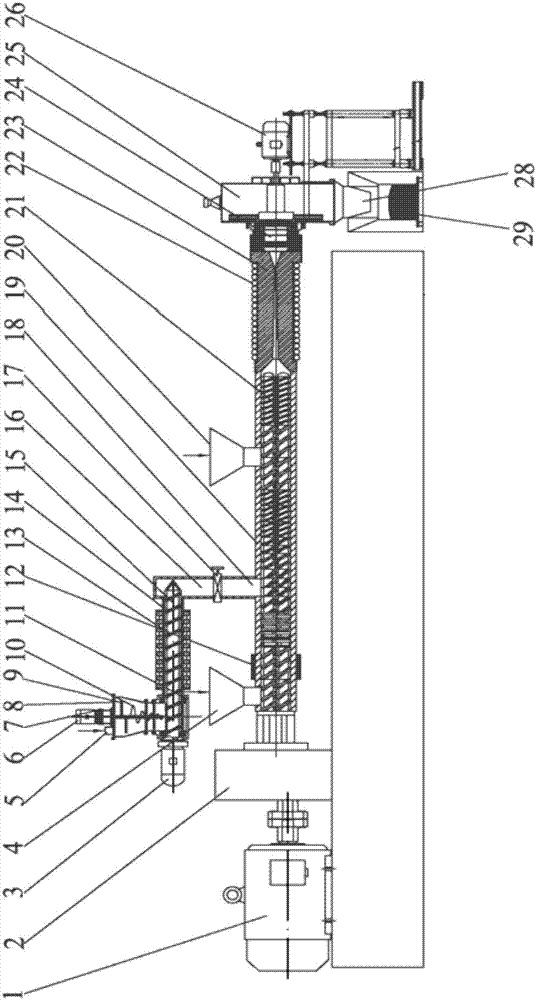

Winding preheating and start-up method of permanent magnetic synchronous motor

ActiveCN102761300AMake sure to startReduce the probability of startup failureStarter arrangementsFrequency changerSynchronous motor

The invention discloses a winding preheating and start-up method of a permanent magnetic synchronous motor. The motor comprises a stator three-phase winding, a rotor and a frequency converter. The winding preheating method comprises the following steps of: (1) maintaining the F direction of the resultant magnetic field of the stator three-phase winding unchanged by the frequency converter, and outputting torque by the frequency converter to draw the rotor to rotate so as to make the magnetic field direction of the rotor parallel to the F direction of the resultant magnetic field of the statorthree-phase winding, so that the rotor is positioned; and (2) after the rotor is positioned, outputting current by the frequency converter to preheat the stator three-phase winding. According to the permanent magnetic synchronous motor winding preheating method disclosed by the invention, on the premise of not increasing an external auxiliary preheating device, the positioned preheating of the motor winding at a low-temperature environment is realized, so that the motor is ensured to be started-up at appropriate winding temperature, the probability of start-up failure of the motor is reduced,overshoot current at the time of start-up is eliminated, the motor is well protected, the reliability of the motor is improved and the service life of the motor is prolonged.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION +1

Tungsten inert gas welding (TIG) welding torch and welding device for manufacturing multi-wire common molten pool electric wire additives, and additive manufacturing method

PendingCN106994546ASimple structural designWarm up evenlyArc welding apparatusEngineeringElectric wire

The invention relates to a tungsten inert gas welding (TIG) welding torch and welding device for manufacturing multi-wire common molten pool electric wire additives, and an additive manufacturing method. The TIG welding torch for manufacturing the multi-wire common molten pool electric wire additives comprises a torch body, and a ceramic nozzle is arranged at the front end of the torch body. The TIG welding torch is characterized in that a cavity is formed inside the torch body, a hollow tungsten electrode is inserted in the cavity in a penetrating mode, the front end of the hollow tungsten electrode extends out from the port of the ceramic nozzle, and a shielding gas cavity is formed between the inner wall of the torch body and the hollow tungsten electrode; one or more wire feeding channels are arranged in the hollow tungsten electrode in the axial direction; and the end, away from the ceramic nozzle, of the torch body is provided with an air intake hole communicating with a shielding gas supply, and the shielding gas supply further communicates with the wire feeding channels. Due to the fact that the number of the wire feeding channels is one or more, one or more welding wires participate in the welding operation, the deposition capacity is increased on the basis of high deposition efficiency, and as for additive manufacturing and forming, the machining efficiency is improved.

Owner:JIANGSU ASWEMET PRECISION TECH CO LTD

Low-fire-consumption pure-titanium forging heating technology

The invention relates to the field of metal forging, in particular to a low-fire-consumption pure-titanium forging heating technology. The technology comprises the steps of pretreatment, preheating for 60 minutes to 100 minutes at the temperature ranging from 500 DEG C to 700 DEG C, heat preservation for 50 minutes to 70 minutes at the temperature ranging from 850 DEG C to 880 DEG C at a second heating stage, heat preservation for 20 minutes to 30 minutes at the temperature ranging from 920 DEG C to 9600 DEG C and the like. According to the technology, by means of a three-stage heating mode, defects of cracks produced in a traditional one-step heating mode and oxide skin and hard and brittle phases which are produced on the surface can be effectively overcome, the heating cycle can be shortened, the energy consumption can be reduced, the production cost is saved, and energy-saving and emission reduction purposes are achieved.

Owner:CHANGZHOU UNIV

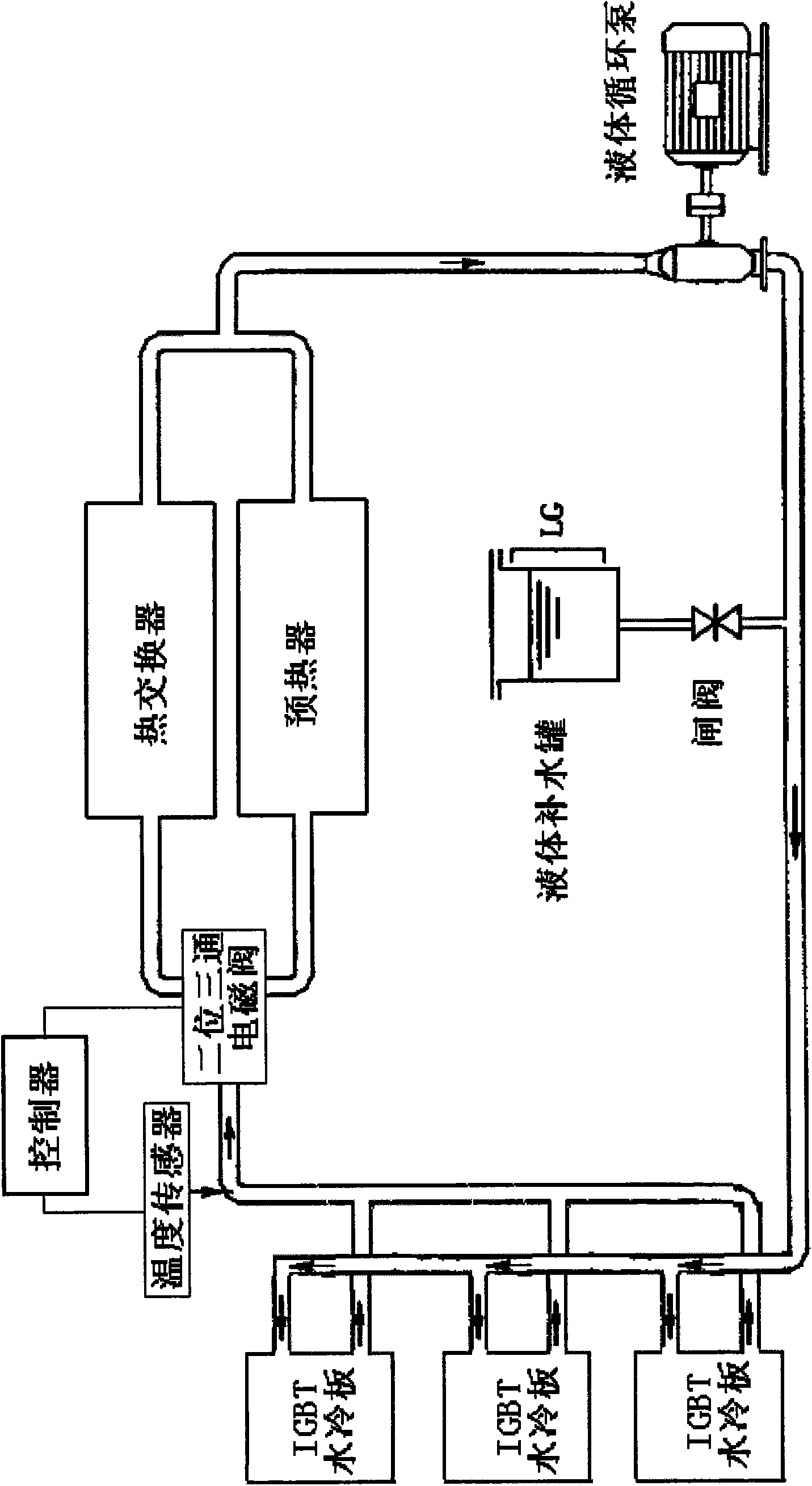

Working temperature control device for high-power power electronic device

InactiveCN101667044AImprove heat transfer efficiencyImprove efficiencyTemperatue controlHeating timeEngineering

The invention relates to a working temperature control device for a high-power power electronic device, consisting of a circulated water cooling device. A heater is arranged in the circulation loop, a2-position 3-way electromagnetic valve controls the switching between the heater and the radiator, a temperature sensor of the controller is arranged at a water outlet of the water cooling plate of the power electronic device, and the output end of the controller is connected with the 2-position 3-way electromagnetic valve. The working temperature control device has the advantages of high heat transfer efficiency, even pre-heating, short pre-heating time, high efficiency and reduced energy consumption.

Owner:CRRC DALIAN CO LTD

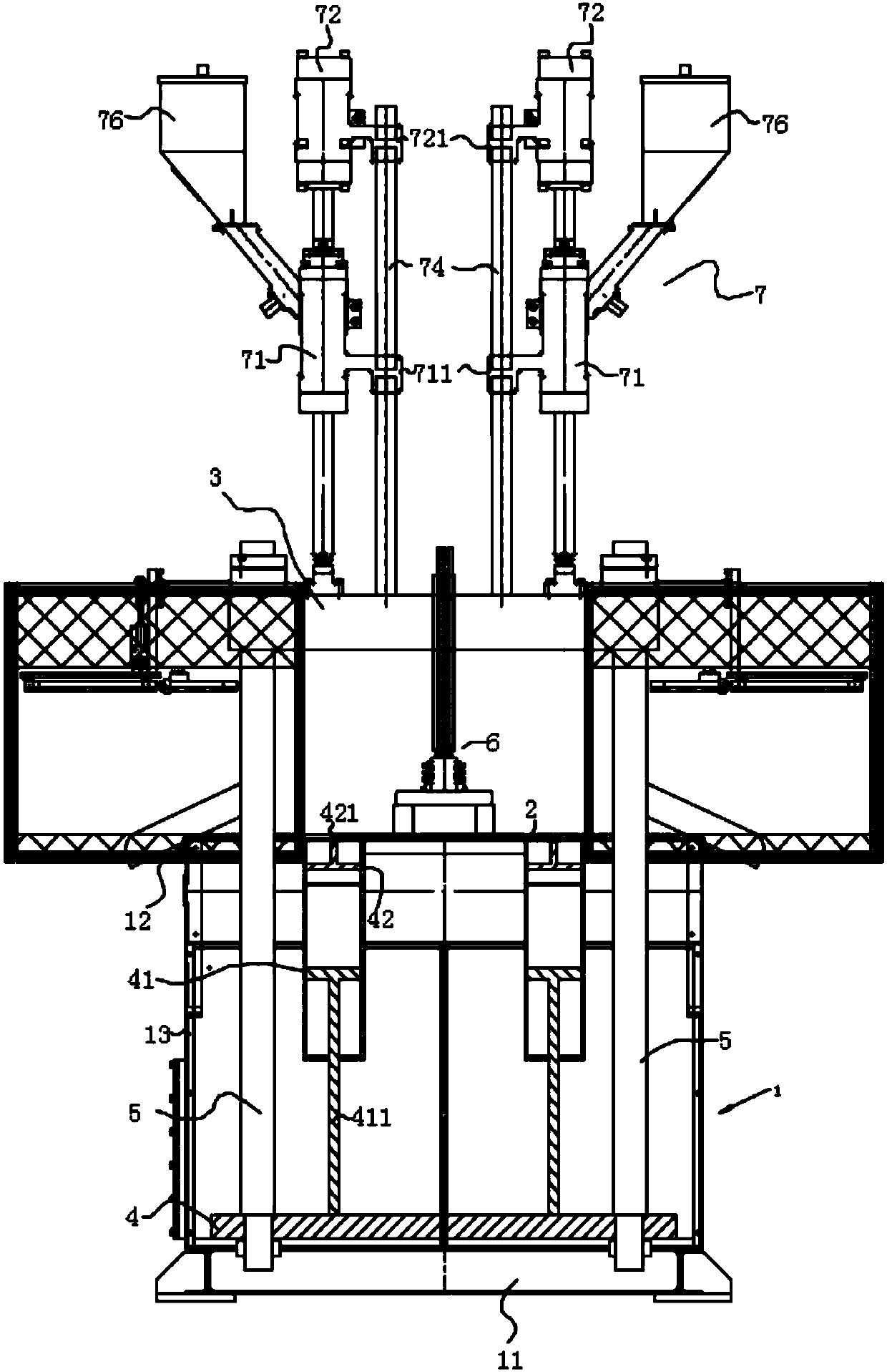

3D printer for metal powder

ActiveCN109877322AEasy to paveImprove compactionAdditive manufacturing apparatusMaterial resources3d printer

The invention relates to a 3D printer for metal powder and belongs to the field of 3D printing equipment. According to the 3D printer for the metal powder, the structural design is reasonable, operation is convenient, the powder laying quality is good, the powder is preheated uniformly, the part machining time is greatly shortened, formed parts are taken easily and conveniently, automatic powder adding operation can be achieved, a large quantity of manpower and material resources are saved, and an operator is prevented from inhaling a large amount of the powder. According to the adopted technical scheme, a first electric push rod is mounted on the inner side of a powder outlet sleeve, a lifting device is mounted on the inner sides of a connecting plate and a positioning plate, a conical hole, a shielding plate, a jacking rod and a guiding pipe connected with the conical hole are arranged on a lifting plate to suck the powder around the parts, an electric heating pipe is arranged on theinner side of the upper end of the powder outlet sleeve to preheat the powder, an anti-sticking part is arranged on a powder laying roller, a sealing cover is mounted on an operating panel, and a feeding sleeve, a telescopic sleeve and a feeding screw are arranged at the upper end of a sealing cover to achieve material-adding operation.

Owner:HANGZHOU HIMALAYA INFORMATION TECH

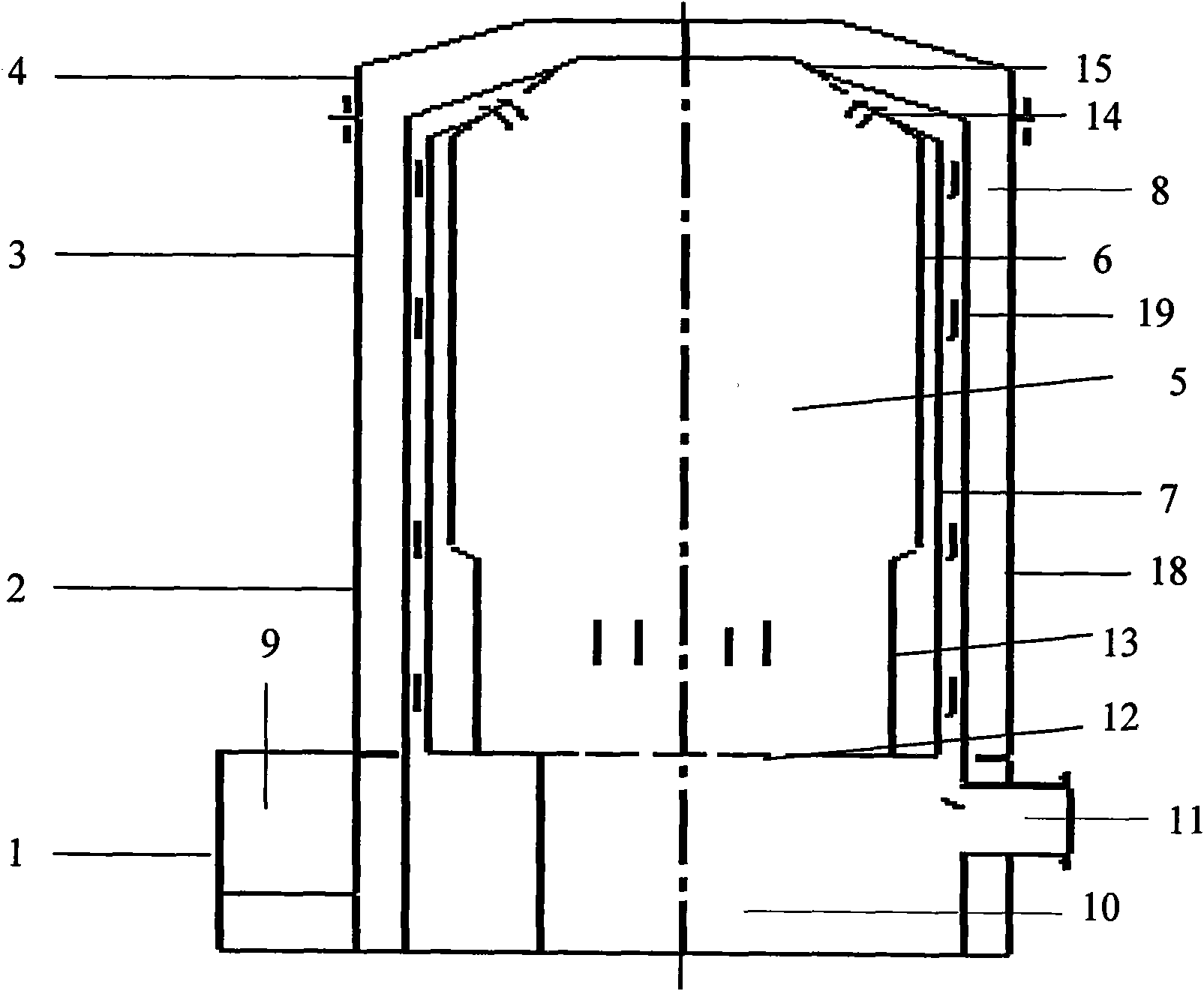

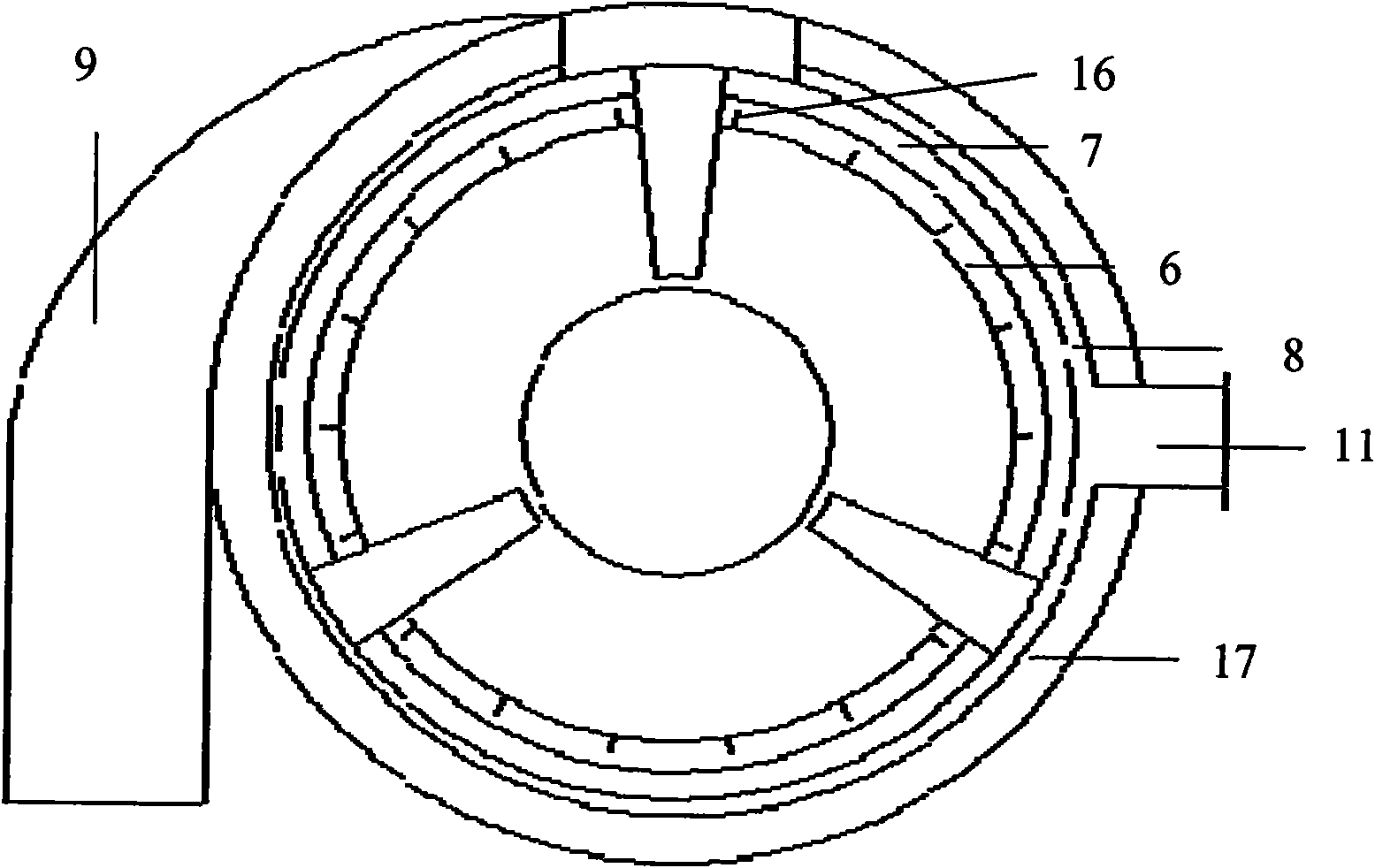

Eccentric air heating furnace

The invention discloses an eccentric air heating furnace for heating foods, tea, medicines, and the like. The air heating furnace structurally comprises a furnace body lower part (1), a furnace body middle part (2), a furnace body upper part (3) and a furnace body top part (4) and comprises four layers from inside to outside, i.e. a combustion chamber (5), a warm air space layer (6), an exhaust space layer (7) and a cold air space layer (8), wherein the furnace body lower part (1) comprises an air inlet (9), a coal cinder chamber (10) and an exhaust port (11), a fire grate (12) is arranged between the furnace body middle part (2) and the furnace body lower part (1), the innermost face of the furnace body middle part (2) is provided with a fireproof wall (13), the furnace body middle part (2) and the furnace body upper part (3) are totally called as the combustion chamber (5), the combustion chamber (5) and the exhaust space layer (7) at the top of the furnace body are mutually communicated through a flue (14), and the warm air space layer and the cold air space layer are sealed and communicated through an upper cover (15). The air heating furnace is mainly characterized in that the cold air space layer of the furnace body lower part (1) is provided with an eccentric air uniform plate, and air entering the furnace is uniformly preheated in an improved mode to absorb heat emitted by the exhaust space layer (7) to the maximum limit so that the heat efficiency is effectively improved.

Owner:CHANGSHA XIANGFENG TEA MACHINERY MFG

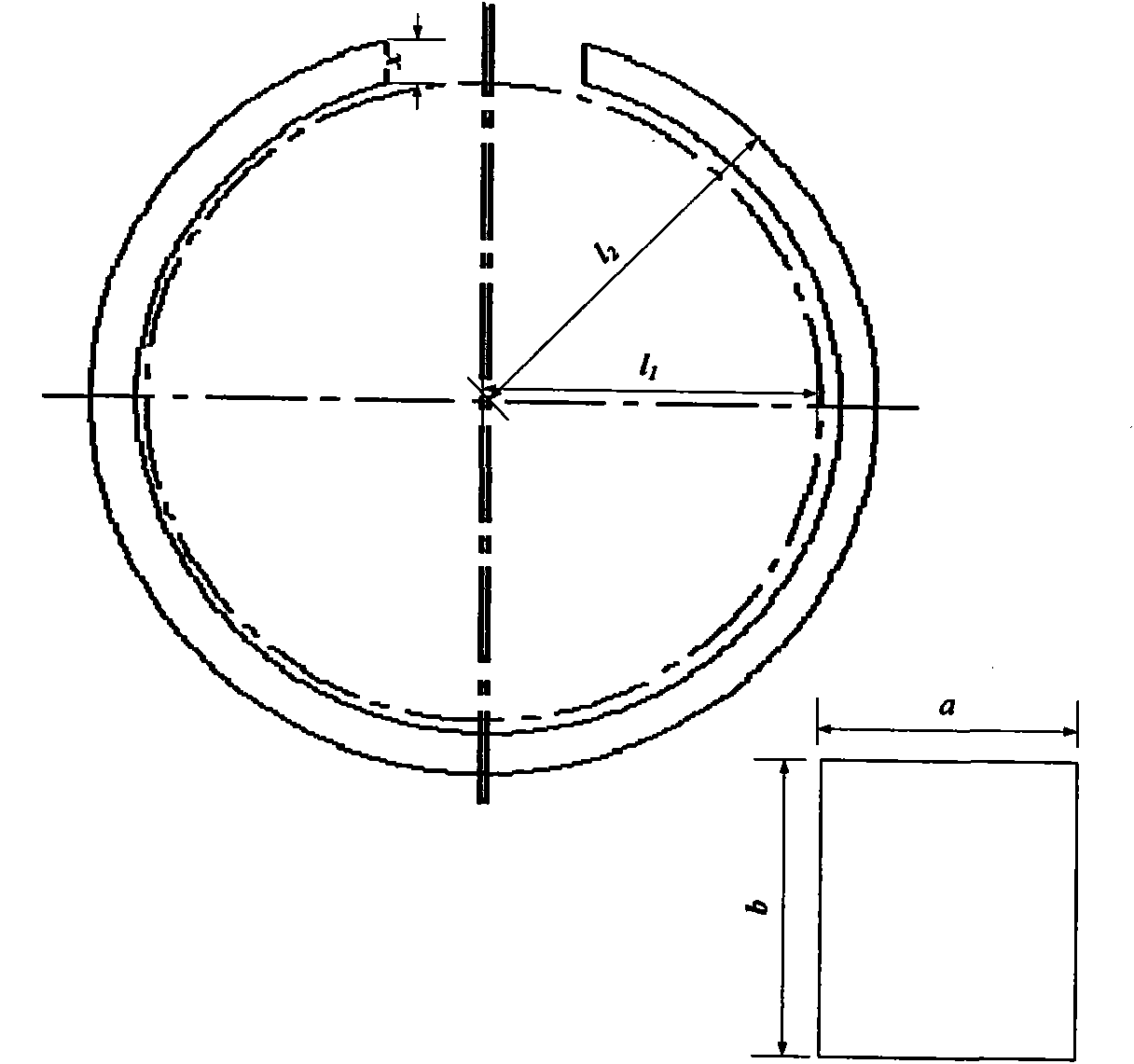

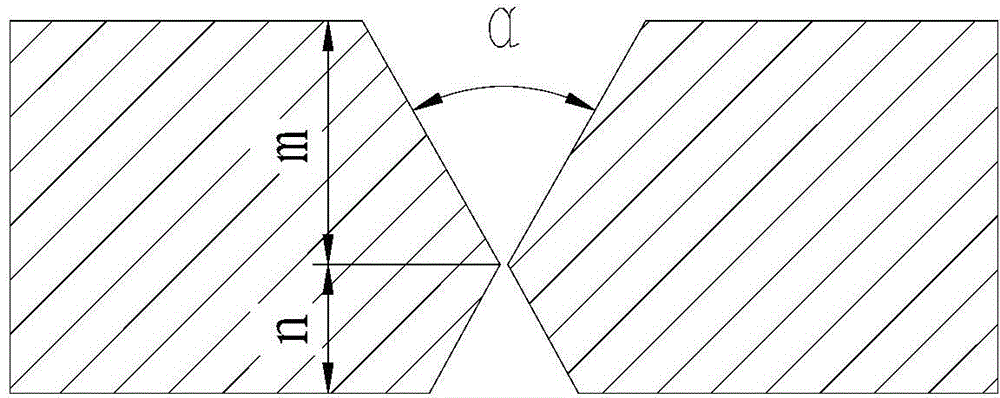

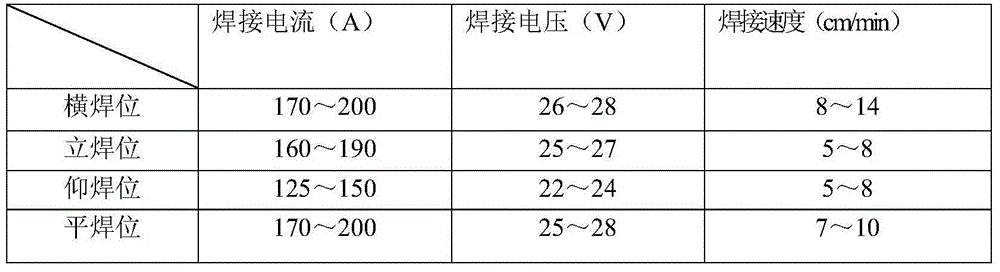

Large non-standard device thick-plate all-position welding method

The invention discloses a large non-standard device thick-plate all-position welding method. The large non-standard device thick-plate all-position welding method comprises the following steps of machining an asymmetric X-shaped groove at the welded position of a weld part and then vertically assembling the weld part, adopting a far infrared electric heating method to preheat the weld part on two sides of a weld joint and using an infrared digital temperature measuring instrument to perform detection, firstly conducting tack welding in the smaller groove of the asymmetric X-shaped groove during part welding and then adopting a multi-layer multi-channel mode to perform multi-point simultaneous welding, sequentially perform heating, heat preservation and air cooling to eliminate hydrogen after welding is completed, and finally performing appearance inspection and whole annealing. According to the large non-standard device thick-plate all-position welding method, angle deformation after welding is small and symmetry is good by forming the reasonable asymmetric X-shaped groove, the multi-point simultaneous welding and the multi-layer multi-channel mode are adopted to enable all positions of the whole weld part to be stressed evenly and enable overall deformation to be small, and finally the whole annealing is adopted to eliminate internal stress and enable the whole weld part to be more stable in structure and better in plasticity.

Owner:温江

Steam sterilizing device of crude drug of Tibetan medicine

The invention relates to a steam sterilizing device of a crude drug of a Tibetan medicine, comprising a sterilizing bin and a cooling bin, wherein the sterilizing bin is provided with a sterilizing bin feeding hole and a sterilizing bin discharging hole, and the cooling bin is provided with a cooling bin feeding hole and a cooling bin discharging hole; the cooling bin feeding hole is connected with the sterilizing bin discharging hole; a gas exhaust port is arranged on the upper part of the sterilizing bin; a rotary agitator is arranged in the sterilizing bin which is provided with a hot air inlet; the hot air inlet is provided with a first branch air inlet and a second branch air inlet; the first branch air inlet is connected with a first hot air induced draft fan through a pneumatic valve; and the second branch air inlet is respectively connected with a second hot air induced draft and a steam generator through an energy-accumulated steam heat exchanger. The invention solves the problems that the steam sterilizing device in the prior art does not preheat or thoroughly preheat and is easy to generate condensed water, is especially suitable for sterilizing devices of crude medicinal materials of the Tibetan medicine, traditional Chinese medicinal materials, Chinese patent drugs, food, seasonings and other raw materials.

Owner:TIBET QIZHENG TIBETAN MEDICINE

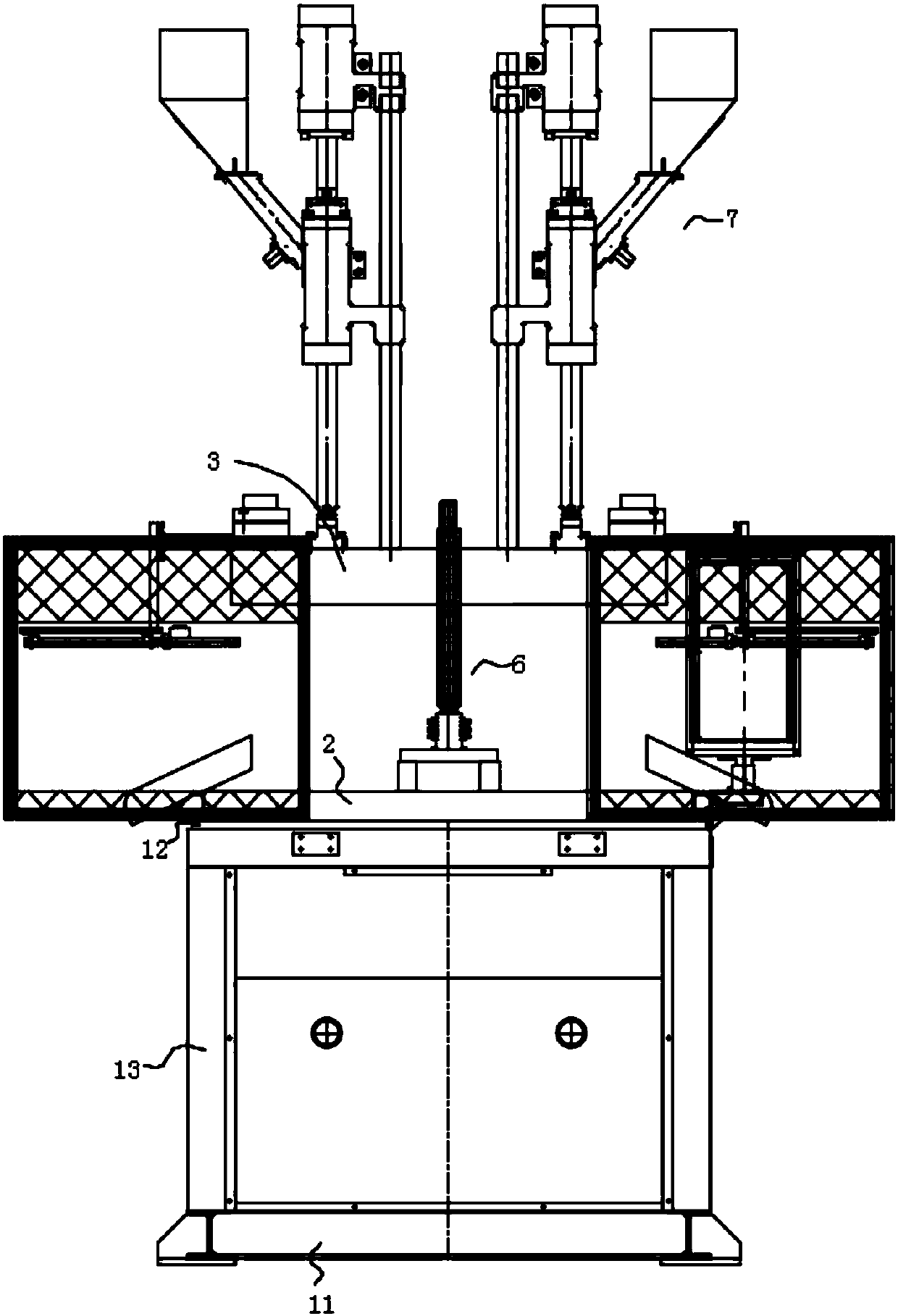

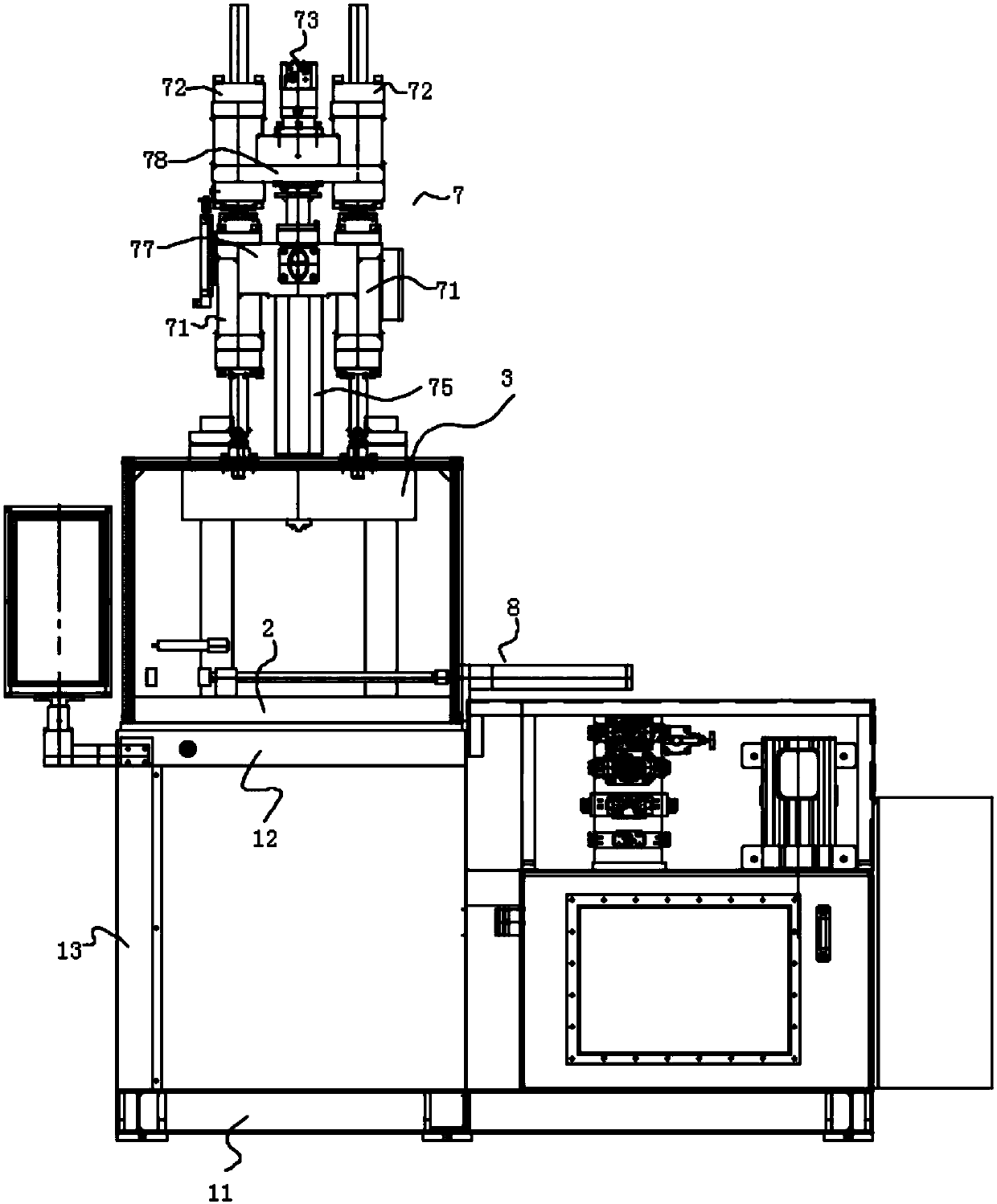

Multicolor vertical injection molding machine for center rotating tower and injection molding method

The invention discloses a multicolor vertical injection molding machine for a center rotating tower and an injection molding method. The injection molding machine comprises a rack, a lower die plate,an upper die plate, a die locking plate, guide pillars, the center rotating tower, a material injection device and a center rotating tower stripping device. The center rotating tower is internally provided with positioning grooves used for positioning insert seats so that the insert seats can be installed conveniently. A hopper basket in the material injection device is provided with heating plates which are intersected longitudinally and transversely so that materials can be evenly heated. The material injection effect can be better by controlling the temperature of a material cylinder. The material cylinder is provided with a material nozzle. A needle valve and pneumatic control are adopted so that material control can be more reliable. Reliable stripping of finished products can be achieved through the stripping device. By means of the injection molding method, die locking is adopted for achieving die opening and die assembling; the center rotating tower is used for achieving multicolor material injection forming; and the center rotating tower stripping device is used for achieving stripping.

Owner:丰铁塑机(广州)有限公司

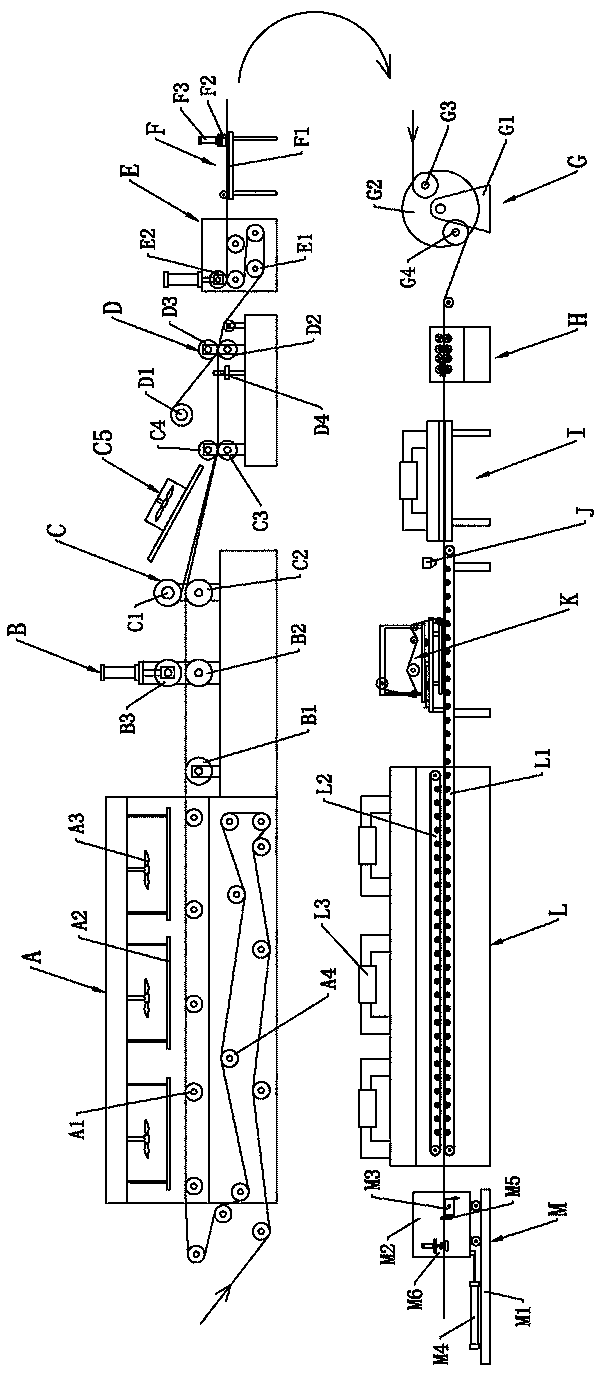

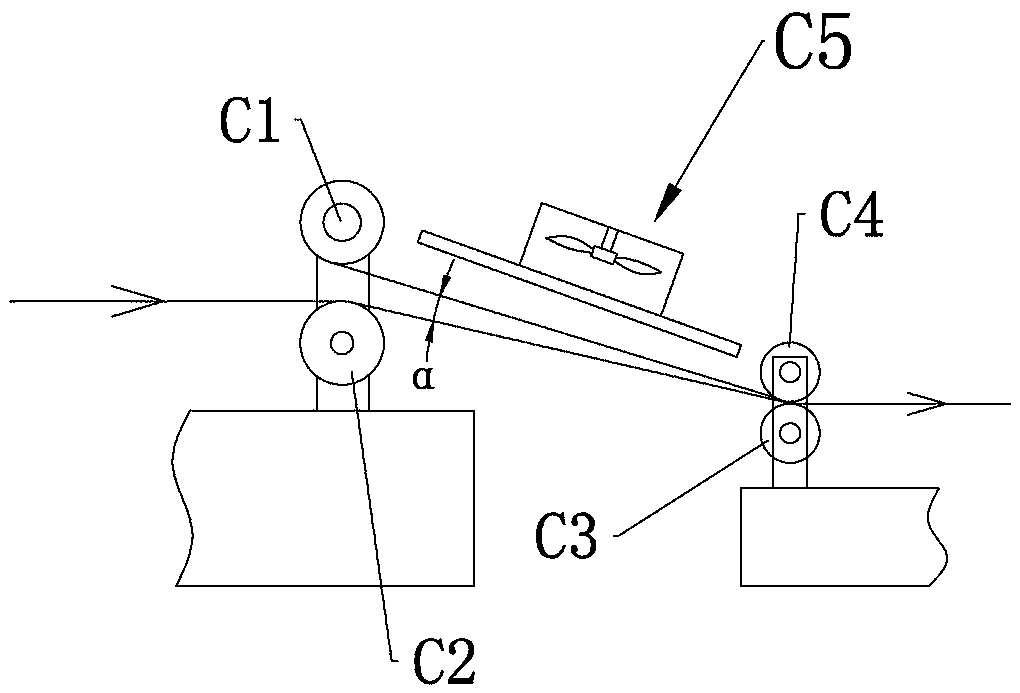

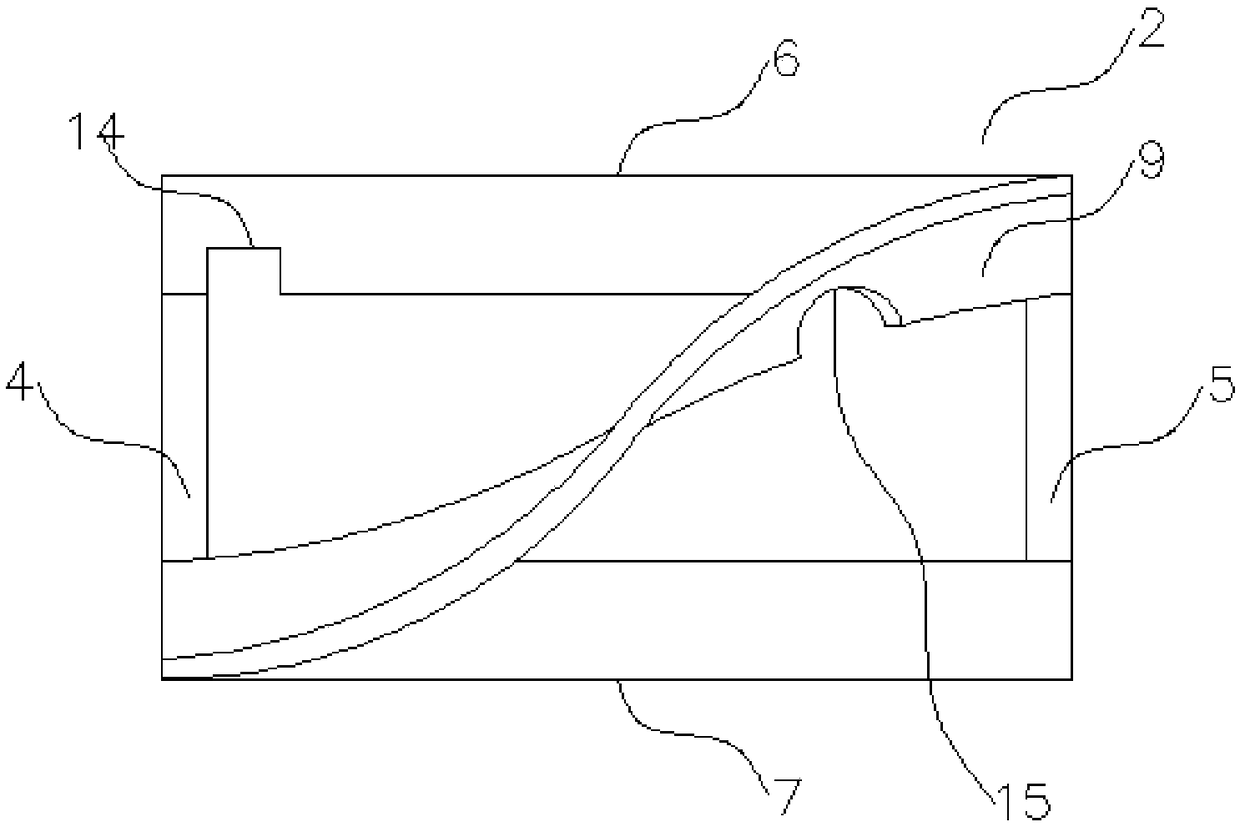

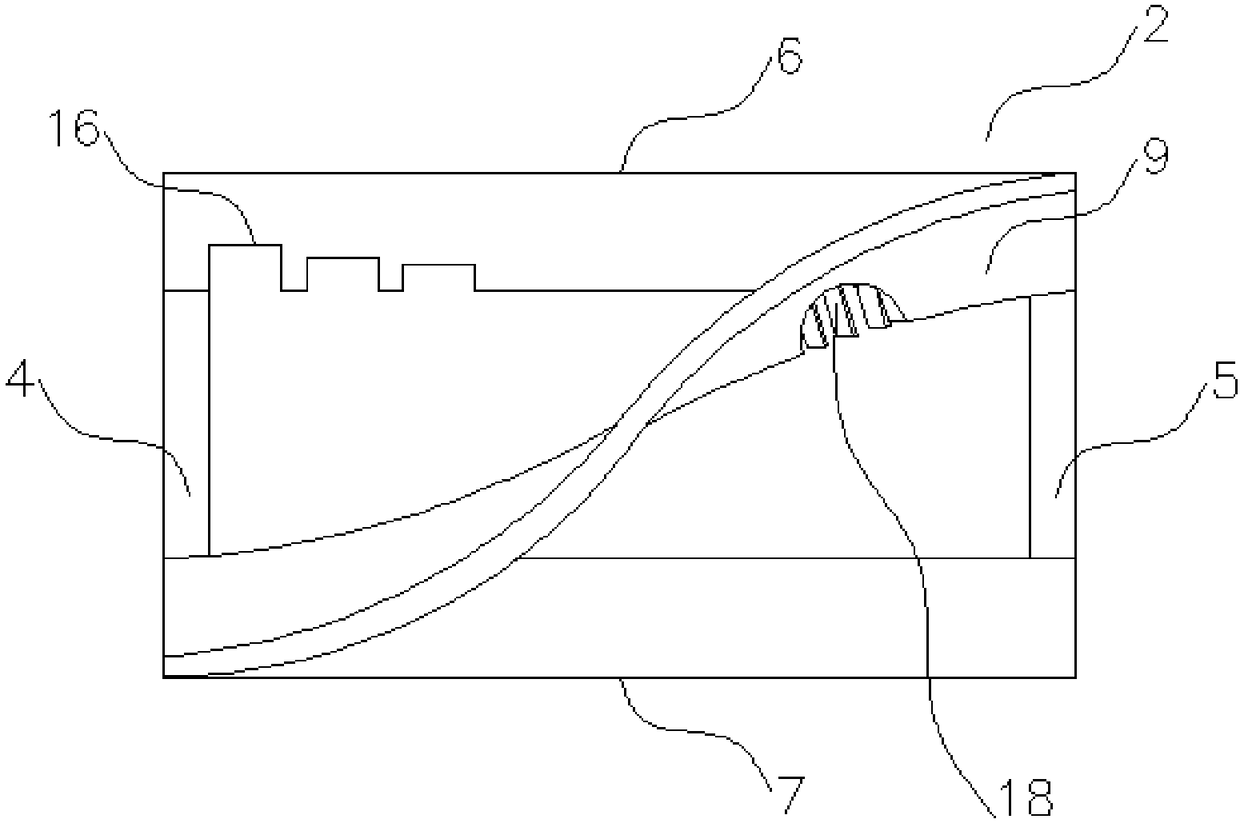

Integrated production system for integrated wall panel

InactiveCN109648898AWarm up evenlySmall surface temperature differenceBuilding componentsFlat articlesTectorial membraneFoaming agent

The invention relates to an integrated production system for an integrated wall panel. The integrated production system comprises a drying oven, a PVC coating mechanism, a protective film coating mechanism, a composite pressing mechanism, a clamping mechanism, a temporary storage mechanism, a mortise forming mechanism, a foaming agent filling mechanism, an aluminum foil overlying mechanism and a tunnel foaming box. The integrated production system provided by the invention can realize continuous automatic production of coating, mortise formation and foaming, and realizes good quality of the panel. Before a coating process, a base belt is heated by virtue of the drying oven so as to be uniformly preheated, the temperature difference of the surface of the base belt is reduced, and the coating quality if improved; the base belt in a hot state can realize proper heat transfer to a film so that the overall film can be slightly softened, therefore the film firmly coats the surface of the metal base belt; a conveying belt and a shaping conveying belt which are arranged inside the funnel foaming box can be used for clamping and conveying a base material continuously and also provide pressure application and pressure bearing effects, and thus a closed space is formed after the base material is fed, and foaming can be conveniently implemented.

Owner:RONGDE ANJIA NEW MATERIALS FUZHOU CO LTD

Steam sterilizing device of rare precious medicinal material

The invention discloses a steam sterilizing device of rare precious medicinal materials such as cordyceps, comprising a sterilizing bin and a cooling bin which are respectively provided with a sterilizing bin feeding opening, a sterilizing bin discharge opening, a cooling bin feeding opening and a cooling bin discharge opening; the cooling bin feeding opening is connected with the sterilizing bin discharge opening; a gas exhaust opening is arranged at the upper part of the sterilizing bin; a hot blast air inlet is arranged at the lower part of the sterilizing bin; high-temperature or overheat sterilizing steam enters the sterilizing bin through a pulse control valve via the hot blast air inlet; and the cooling bin is provided with the cooling bin air inlet and the cooling bin air outlet. The invention solves the problems that the steam sterilizing device in the prior art uniformly and thoroughly sterilizes by rotating a stirrer during sterilization but influences the medicinal value of a material to be sterilized caused by being damaged and provides a steam sterilizing device of the rare precious medicinal material, which can effectively ensure that the material is not damaged and the medicinal value of the material cannot be reduced.

Owner:TIBET QIZHENG TIBETAN MEDICINE

3D printing head with follow-up pressurization and heating

PendingCN109719935AHigh bonding strengthPromote mutual integrationManufacturing heating elements3D object support structuresReciprocating motionUltimate tensile strength

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

Automatic brazing device of connection between copper and stainless steel

InactiveCN103111697AGood welding effectImprove welding qualitySoldering apparatusInduction weldingTemperature sense

The invention discloses an automatic brazing device of connection between copper and stainless steel. The automatic brazing device of the connection between the copper and the stainless steel comprises an operating platform and is characterized by further comprising a high-frequency induction welding machine, a sealing box and a brazing clamp. The high-frequency induction welding machine and the sealing box are arranged on the operating platform, argon is aerated into the sealing box, the brazing clamp is arranged in the sealing box, and a welding joint of the high-frequency induction welding machine stretches to a welding post on the brazing clamp inside the sealing box. The problems that in the prior art, when the copper and the stainless steel are welded, the stainless steel is relatively fast in temperature rising and the copper is relatively slow in temperature rising due to the fact that temperature sensing coefficients have a big difference, therefore, in the process of welding, the copper and the stainless steel are heated for same time, but the reached temperature is different so that the welding effect is relatively poor, and the product quality is influenced are solved. The automatic brazing device of the copper and the stainless steel is simple in structure, convenient to use and has relatively good welding quality.

Owner:KUNSHAN FOR EASIER AUTOMATION TECH

Waste rubber regenerated rubber compound production system

The invention discloses a waste rubber regenerated rubber compound production system. The production system consists of three parts of a rubber powder single spiral plasticizing device, a multi-feed-port multi-section double-screw extruder and a pelletizing and packing device; the multi-feed-port multi-section double-screw extruder comprises a multi-feed-port multi-section double-screw main body part and a cooling extrusion device, wherein a first discharge port of the rubber powder single spiral plasticizing device is connected with a second feed port of the multi-feed-port multi-section double-screw extruder through a connecting valve; and the pelletizing and packing device is mounted at the tail end part of the multi-feed-port multi-section double-screw extruder. The production system realizes continuous production of per-desulfurized rubber particles obtained by rubber particle microwave heating / double-screw shearing, semi-desulfurized rubber powder obtained by rubber powder electromagnetic heating / single-spiral plasticizing and waste rubber regenerated rubber compound obtained by rubber powder mixing; products are green, environment-friendly and excellent in performances, and the performances can be adjusted according to actual demands; and the products can be widely applied to such fields as such rubber products as tires and rubber plates, waterproof coiled materials and road asphalt.

Owner:ANHUI GVG NEW MATERIAL CO LTD

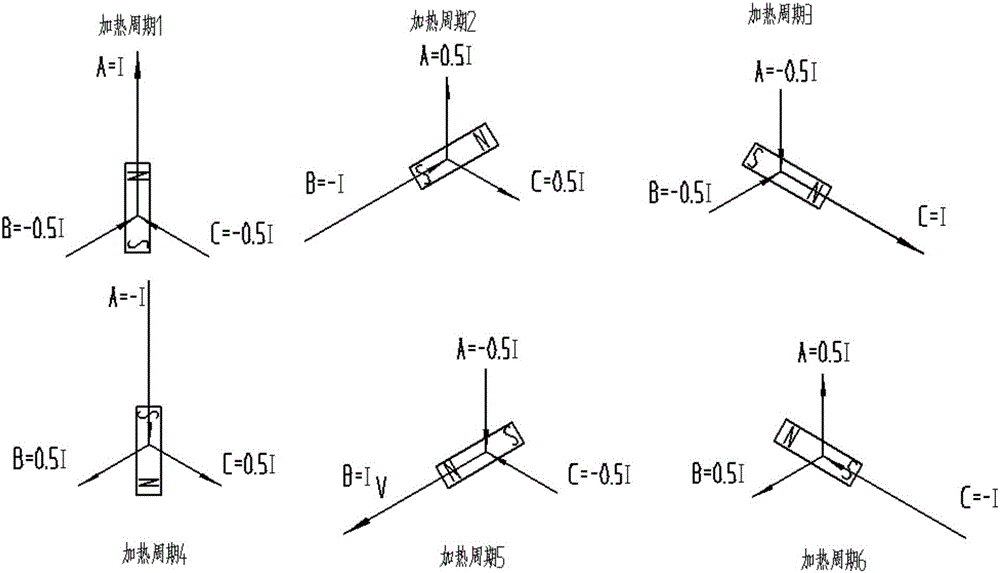

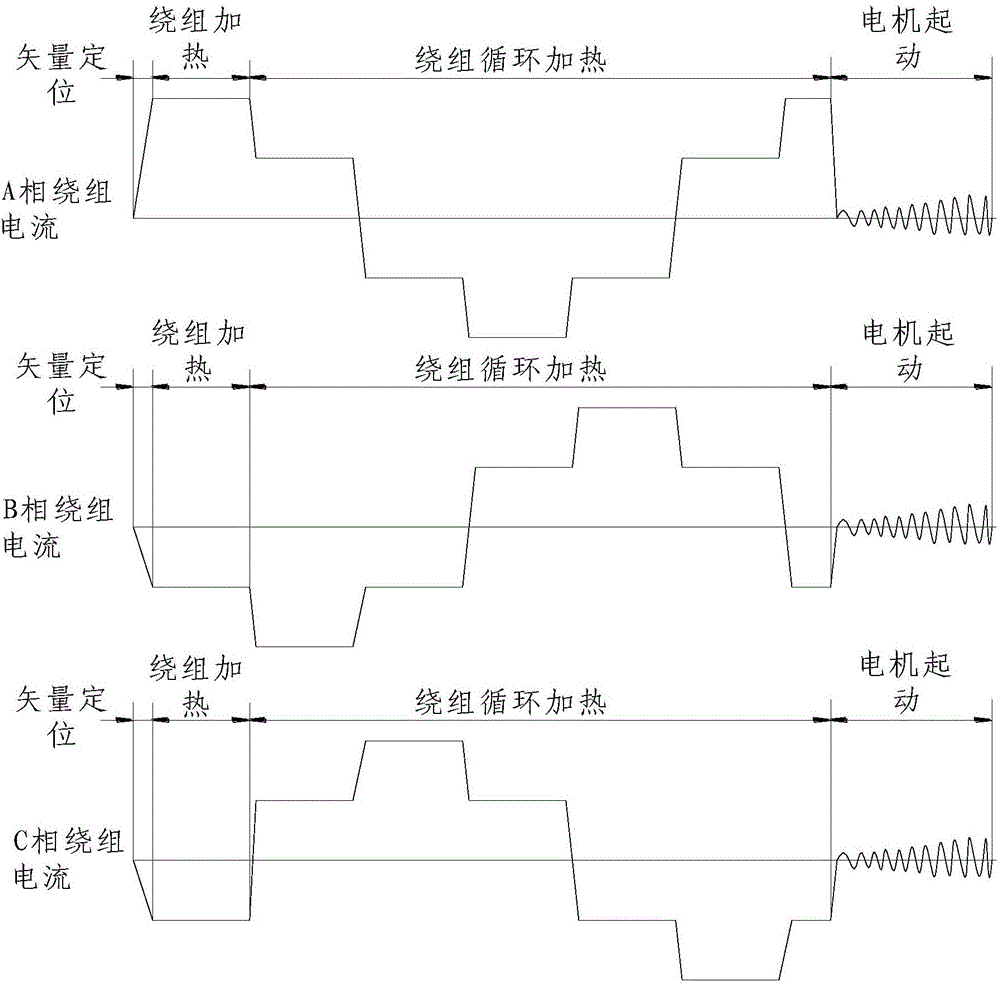

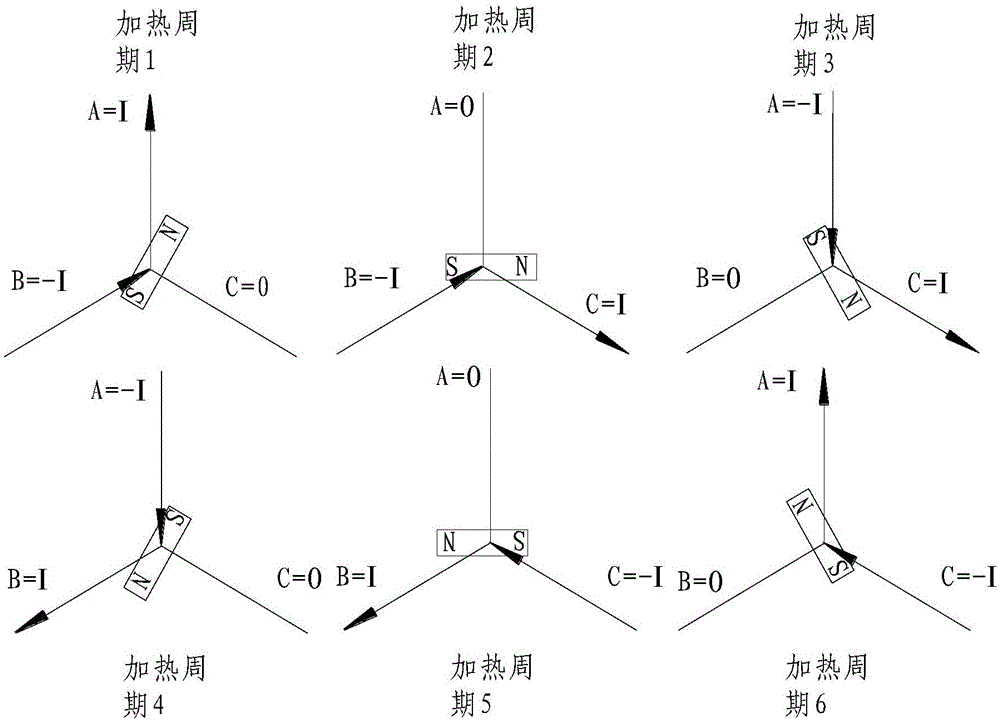

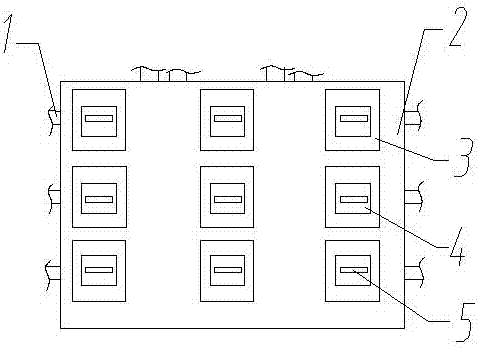

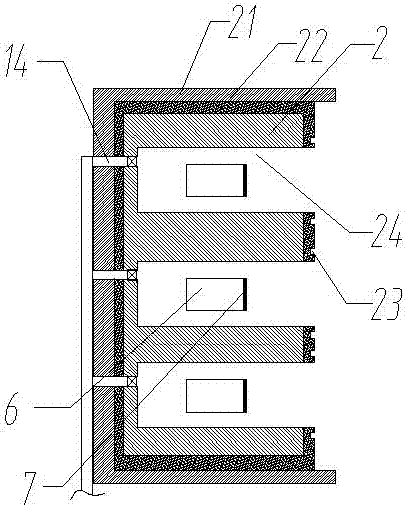

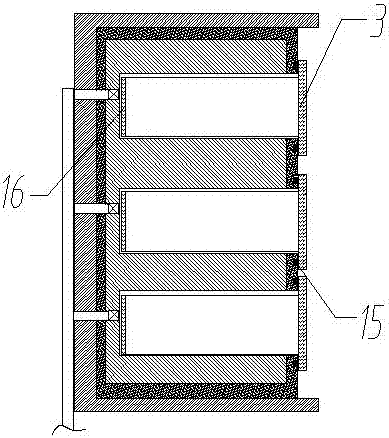

Motor control system, compressor and motor heating starting method

InactiveCN106160615AWarm up evenlyAvoid demagnetizationElectronic commutation motor controlVector control systemsDC - Direct currentElectric machine

The invention discloses a motor control system, a compressor and a method for heating and starting the motor. The motor control system includes a stator winding and a rotor. The stator winding includes an A-phase winding, a B-phase winding, and a C-phase winding. The rotor includes a permanent magnet , further comprising a drive controller for controlling the energization current of the stator windings, the drive controller can control the direct currents of different directions and sizes to be fed into the A-phase windings, B-phase windings and C-phase windings respectively, so as to Make the rotor rotate at a preset angle and perform positioning heating. After positioning and heating, the drive controller can control the direction and magnitude of the direct current fed into the A-phase winding, B-phase winding, and C-phase winding, so that After the rotor continues to rotate the preset angle in the same direction, positioning heating is performed. With such arrangement, the motor control system provided by the present invention can solve the problem that the permanent magnet of the motor is easy to demagnetize.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

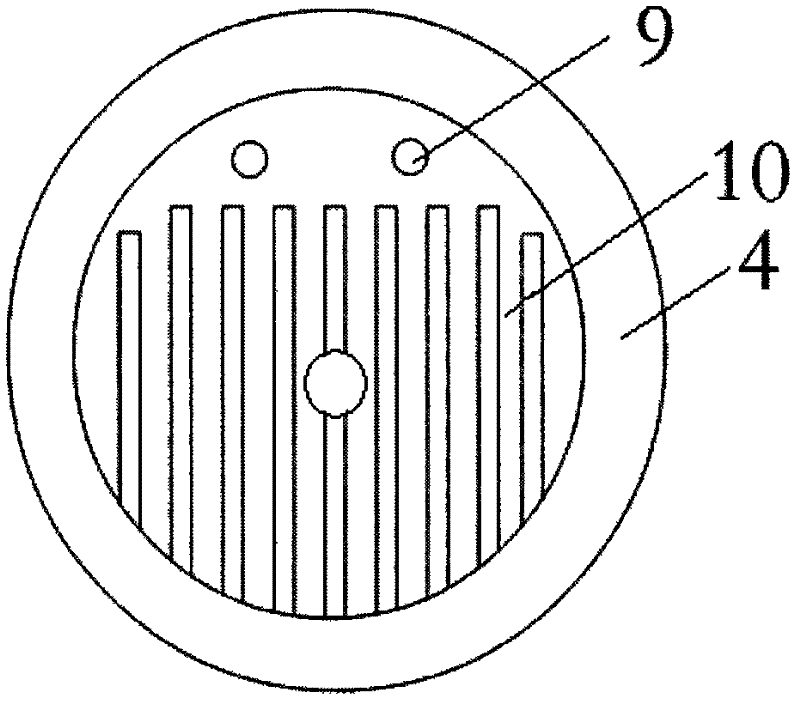

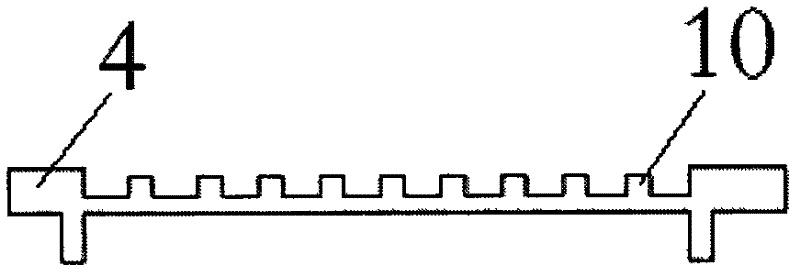

Furnace body structure of energy-saving type preheating furnace

ActiveCN107449280AAvoid heatingReduce energy consumptionMaintainance of heating chambersPreheating chargesThermal insulationSurface plate

The invention discloses a furnace body structure of an energy-saving type preheating furnace. The furnace body structure comprises a preheating furnace body. A plurality of preheating cavities are formed in the preheating furnace body, and the side walls of each preheating cavity are provided with air inlets. An air return opening is formed in the rear wall of the preheating furnace body. The air inlets are provided with wind shields, and the wind shields can move left and right in guide grooves of the upper inner walls and the lower inner walls of the air inlets. Each preheating cavity is provided with a drawer-type storage box, and each storage box body is further internally provided with a roller. Through holes are evenly distributed in the side walls of the rollers. The two ends of each roller are connected with rotating shafts. One ends of the rotating shafts are connected with inner side bearing pedestals, and each inner side bearing pedestal is coated with a thermal insulation layer. The other ends of the rotating shafts penetrate through drawer panels and are connected with outer bearing pedestals and motors arranged outside the drawer panels. The front face of each drawer panel is provided with a mounting box body. Each mounting box body is further internally provided with a fan. Each drawer panel is made of a thermal insulation material. The furnace body structure is uniform in preheating and long in service life.

Owner:骆雅雅

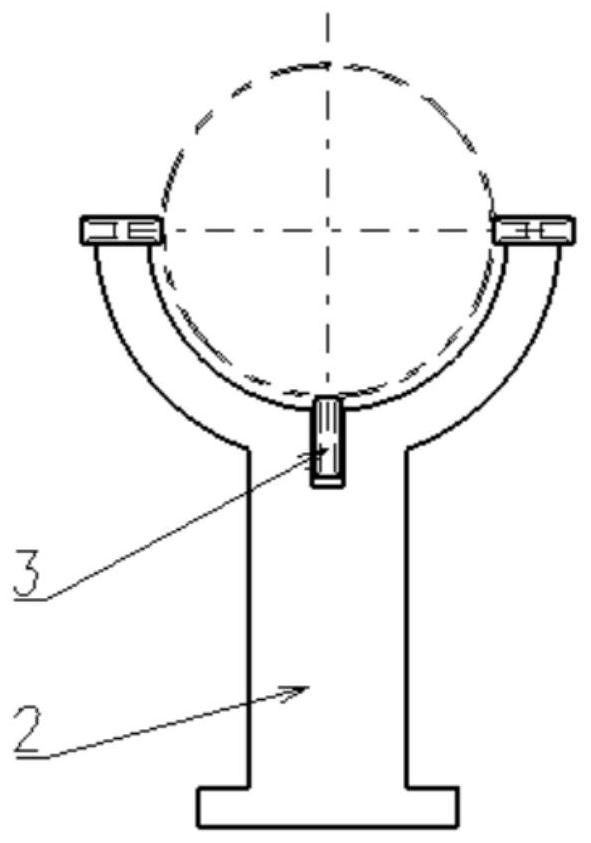

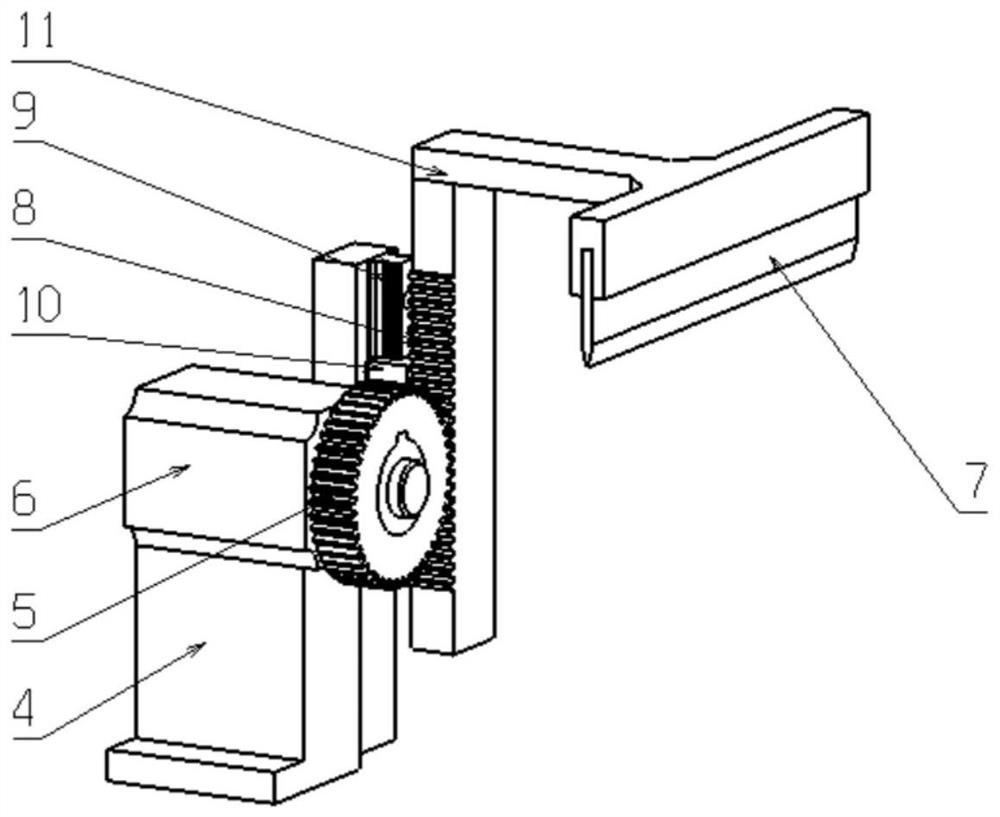

Laser welding longitudinal seam joint guiding, preheating and distressing dynamic correction device for thin-walled cylinder

ActiveCN112247381AMeet relative position accuracy requirementsWarm up evenlyFurnace typesMetal working apparatusWelding residual stressEngineering

The invention discloses a laser welding longitudinal seam joint guiding, preheating and distressing dynamic correction device and method for a thin-walled cylinder, and belongs to the technical fieldof laser welding. The device comprises a supporting mechanism, a longitudinal joint centering and guiding mechanism, double-side self-preheating feeding mechanisms, destressing correction mechanisms and a size detection structure. A blade-shaped guiding body of the device is embedded into the open cylinder, a longitudinal connector is automatically centered and guided, the guiding body is gradually separated from the connector along with opposite movement and enclasping of heating and enclasping wheels on the two sides, centering and guiding of the longitudinal connector are completed, weldingdefects are effectively avoided, the welding quality is improved, and the equipment configuration and investment cost is reduced. Uniform preheating and longitudinal feeding of the cylinder are completed through self-rotation of the heating and enclasping wheels on the two sides; the cylinder is subjected to rolling correction through circumferential high-temperature correction wheels, and meanwhile, the welding residual stress is eliminated; and laser sensors are used for detecting the size of the cylinder in real time, a circumferential shape correcting die is synchronously adjusted, and the problem of welding deformation of the thin-walled cylinder is solved.

Owner:CHANGCHUN UNIV OF SCI & TECH

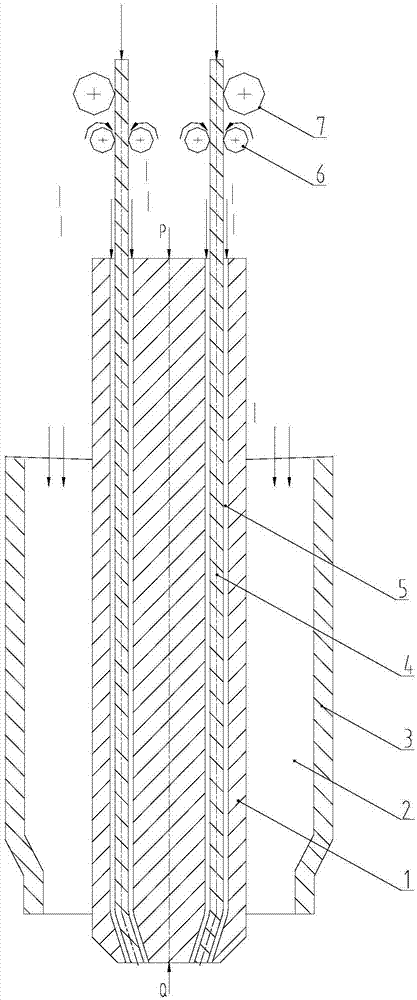

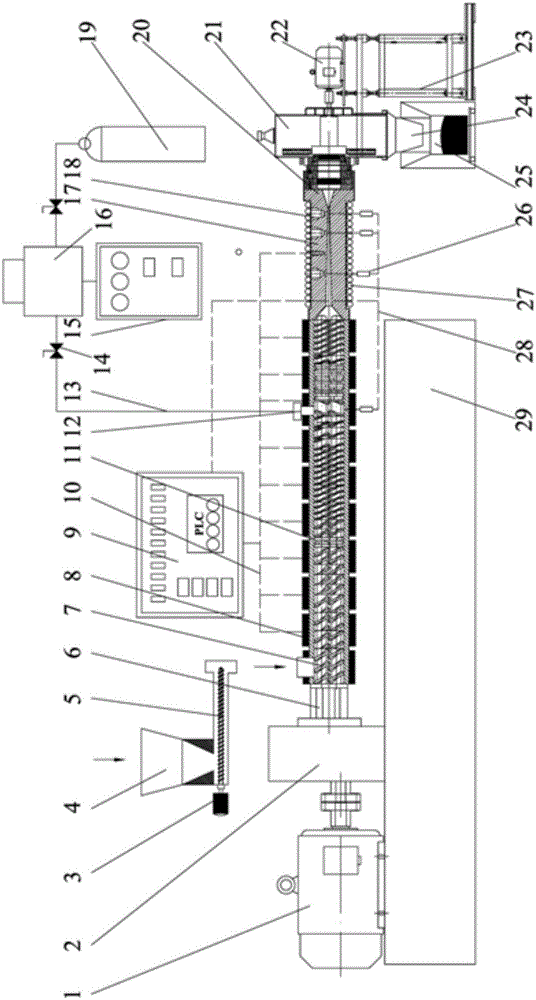

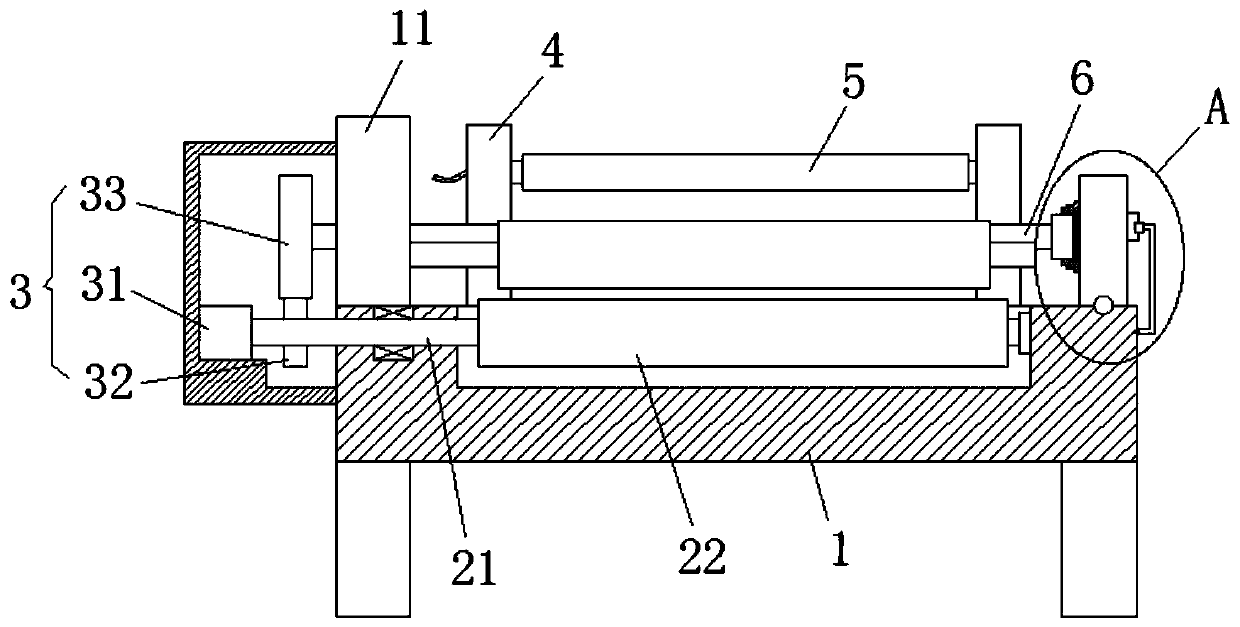

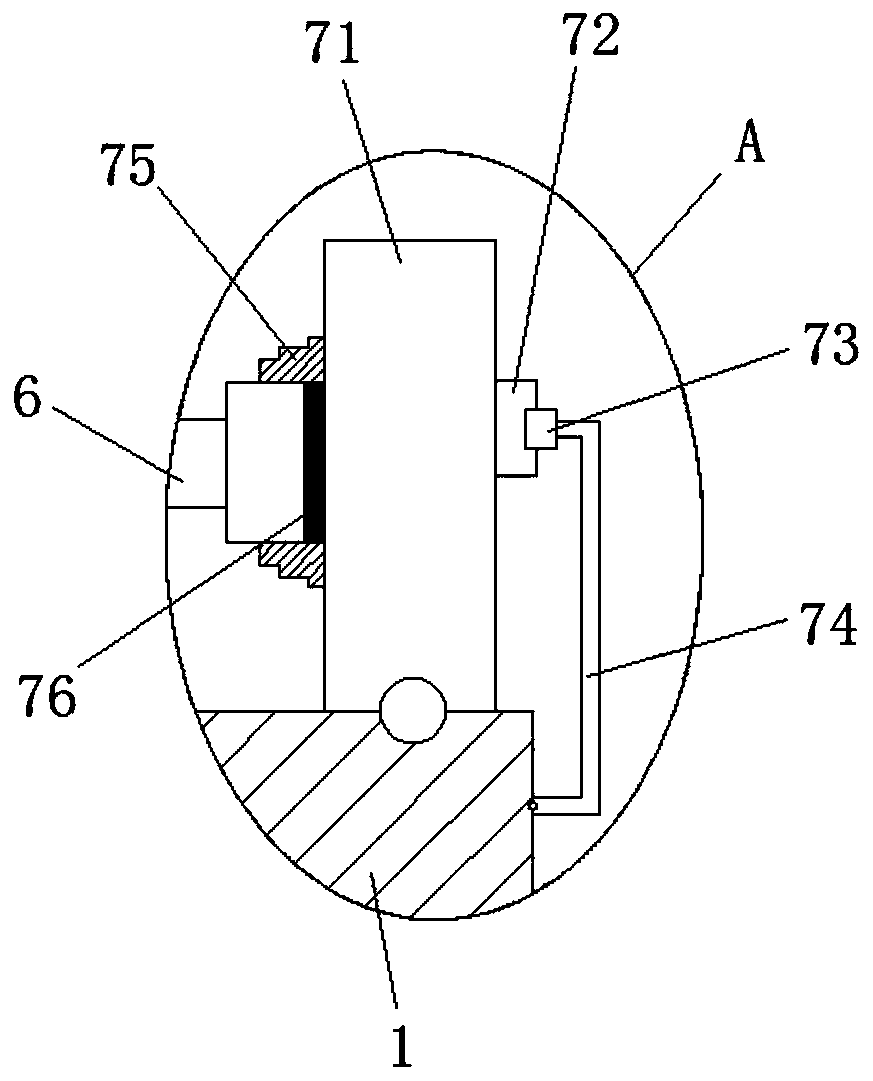

Preheating device and method for heavy oil reservoir

The invention discloses a preheating device and method for a heavy oil reservoir. The preheating device includes an upper horizontal injection well and a lower horizontal production well which are arranged on a target position of a heavy oil reservoir to be preheated; an injection pipe of the upper horizontal injection well which is arranged in a vertical section of the upper horizontal injection well and is used for injecting a nanofluid into a horizontal section of the upper horizontal injection well; an electrical heating column of the upper horizontal injection well which is arranged in a horizontal section of the upper horizontal injection well and is used for electrically heating the injected nanofluid; an injection pipe of a lower horizontal production well which is arranged in a vertical section of the lower horizontal production well and is used for injecting a nanofluid into a horizontal section of the lower horizontal production well; an electrical heating column of a lower horizontal production well which is arranged in the horizontal section of the lower horizontal production well and is used for electrically heating the injected nanofluid. The technical scheme can improve the preheating efficiency and evenness of the heavy oil reservoir, can improve the use degree of the horizontal section, can reduce the operation cost and complexity of preheating, and can enlarge the application range of preheating.

Owner:PETROCHINA CO LTD

Green devulcanizing and reclaiming apparatus with supercritical CO2 and microwave assisted multi-segment twin-screw extrusion

The invention discloses a green devulcanizing and reclaiming apparatus with supercritical CO2 and microwave assisted multi-segment twin-screw extrusion, comprising a horizontal barrel; a twin-screw is rotationally mounted in the barrel; the barrel is provided with a feed port at the left upper end of the twin-screw, and the upper end of the barrel is fitted ith a microwave heating device; the middle of the barrel is provided with a gas injection end for supplying supercritical CO2; the rear end of the barrel is provided with a cooling extruder, the tail end of the cooling extruder is fitted with a dicing device, and a discharge port of the dicing device is provided with a product packaging device. The apparatus of the invention has simple structure, uses small floor area, is full-automatically controllable, low in production process energy consumption and green, and the defect that traditional reclaimed rubber production process has high contamination, high energy consumption, intermittence, high labor intensity and unstable product properties is effectively solved.

Owner:ANHUI GVG NEW MATERIAL CO LTD

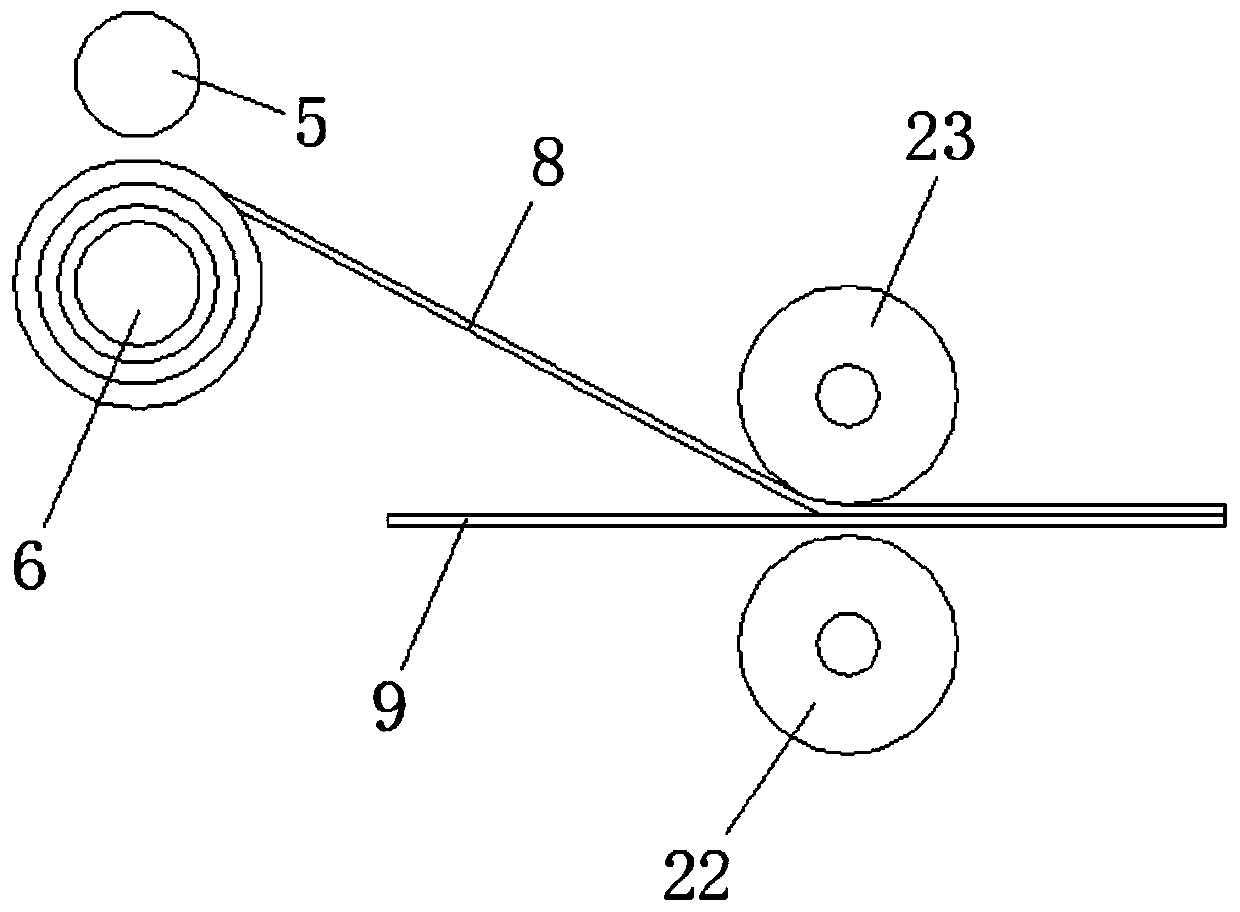

Anti-counterfeiting label outer surface laminating machine

ActiveCN110126431AWarm up evenlyProtect the internal structureLamination ancillary operationsLaminationTectorial membraneCoupling

The invention relates to an anti-counterfeiting label outer surface laminating machine. The laminating machine comprises a base, wherein the left end of the base is provided with a power mechanism, the top surface of the base is provided with an upper pressing roller and a lower pressing roller through a driving shaft, a gap is left between the upper pressing roller and the lower pressing roller to ensure the passage of an anti-counterfeiting label and a membrane, the driving shaft is connected with the power mechanism by a coupling, a driven shaft is arranged above the base by a left side plate and a right side plate, the driven shaft is connected with the power mechanism, a membrane roll is arranged on the periphery of the driven shaft, and the top surface of the base is provided with apre-heating mechanism through two mounting mechanisms. According to the provided anti-counterfeiting label outer surface laminating machine, a gap is left between pre-heating rollers and the membraneroll, the membrane roll temperature is reduced, the inner structure of the membrane is protected, the service life of the membrane is prolonged, the membrane roll is uniformly pre-heated, the pre-heating effect is good, the laminating quality is improved, the membrane is prevented from falling off, the pre-heating hot air flow impact force is small, and the risk of breaking the membrane is reduced.

Owner:湖北强大包装实业有限公司

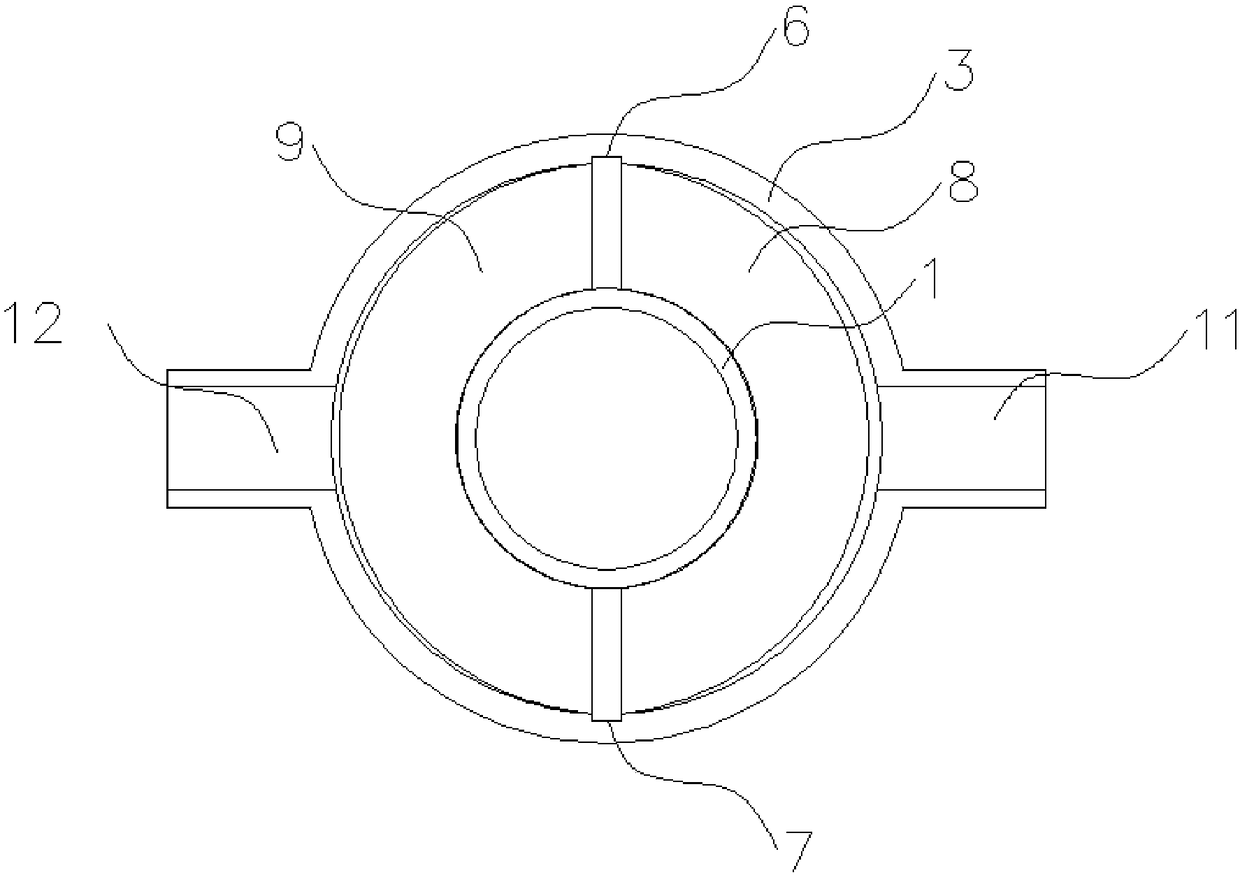

Feed pipe spiral preheating device for molecular distillation equipment

ActiveCN108159727AWarm up evenlyEvenly distributedLiquid distribution in distillationMolecular distillationHeat conductingDistillation

The invention provides a specific structure of a feed pipe spiral preheating device for molecular distillation equipment. According to the technical scheme, through the structural setting of an internal isolation frame and an external protection pipe, and optimized improvement of the internal isolation frame structure, the route of a heat-conducting medium flowing through the spiral preheating device is optimized, so that the heat-conducting medium can flow through the outer side wall of the feed pipe regularly, and uniform preheating of the whole outer side wall of the feed pipe can be ensured.

Owner:天津君歌化工设备集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com