Patents

Literature

264results about How to "Improve preheating efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

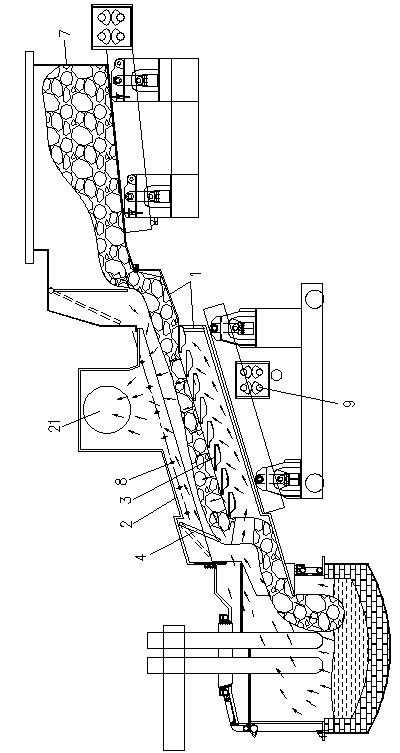

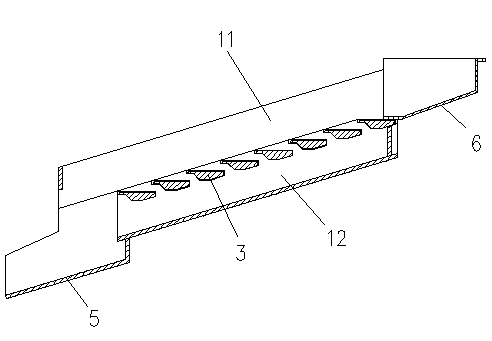

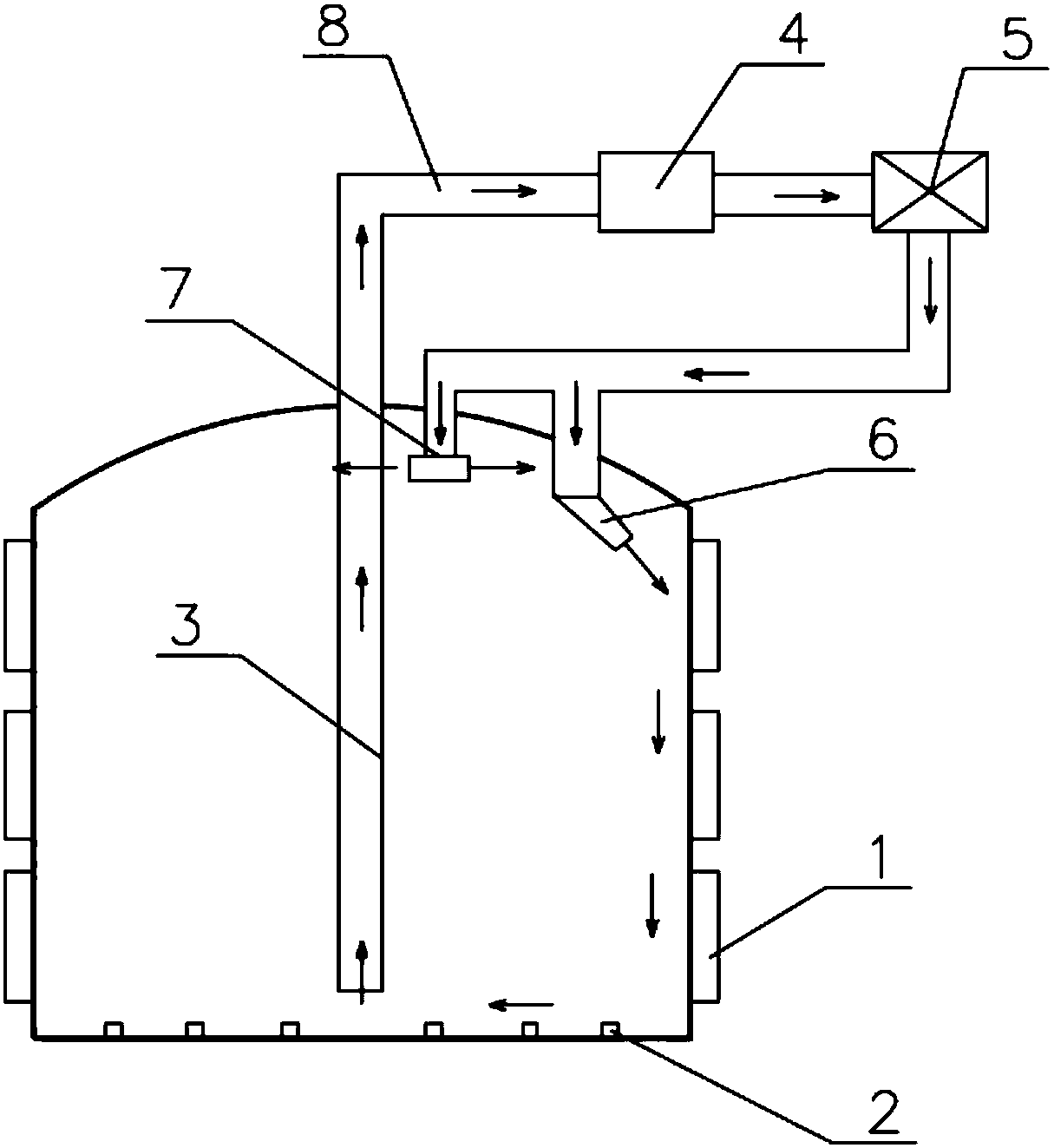

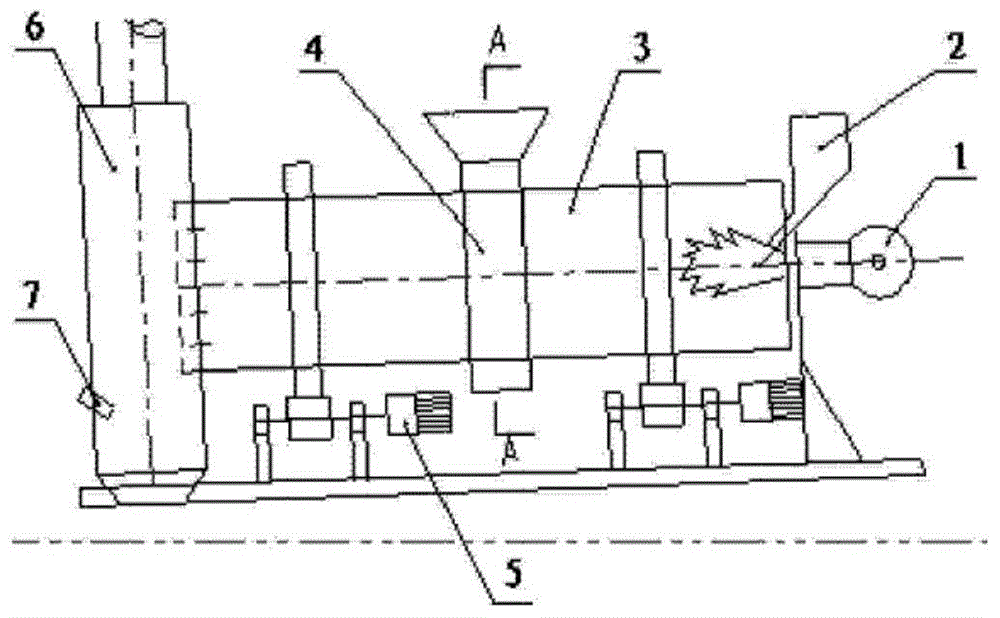

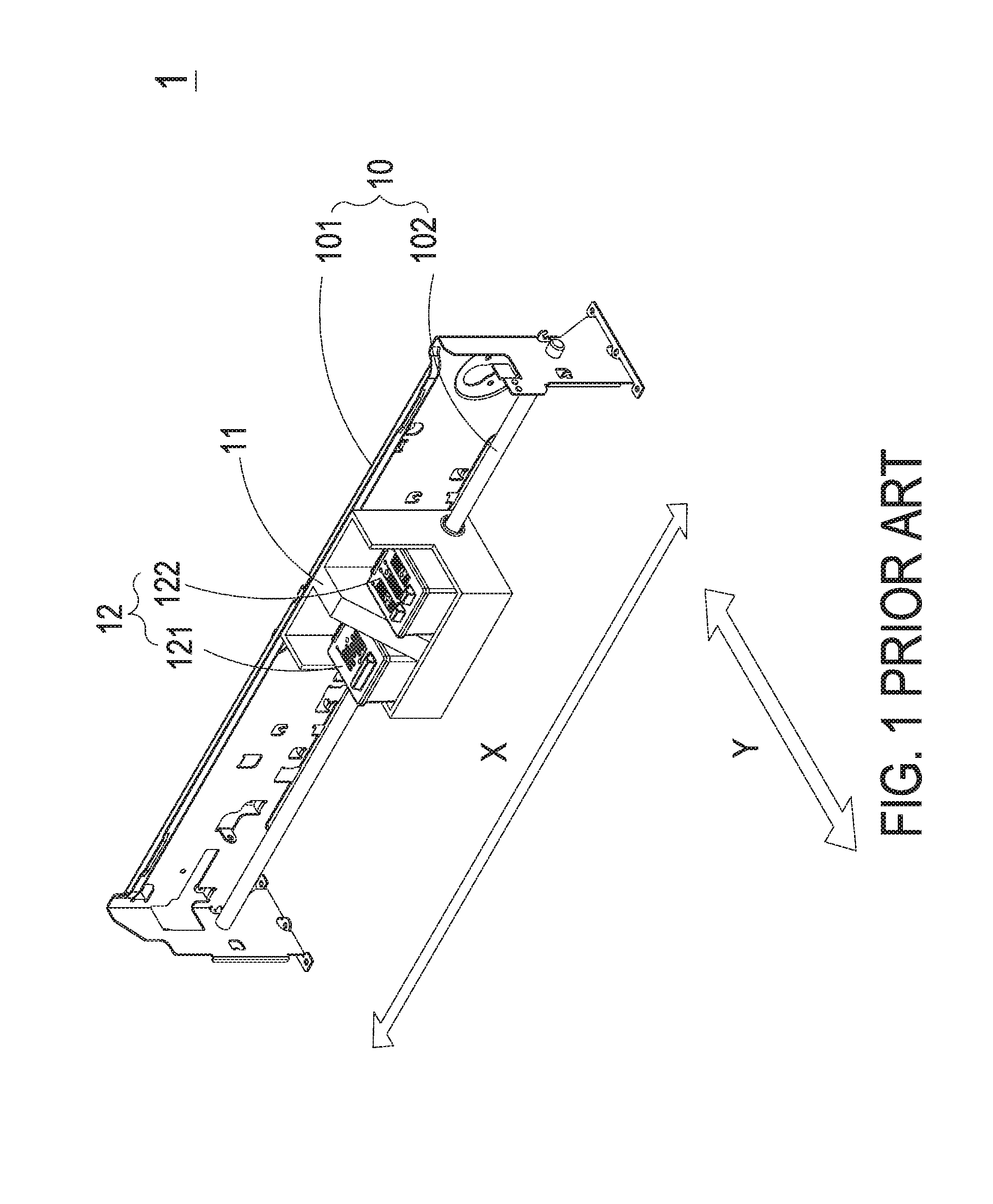

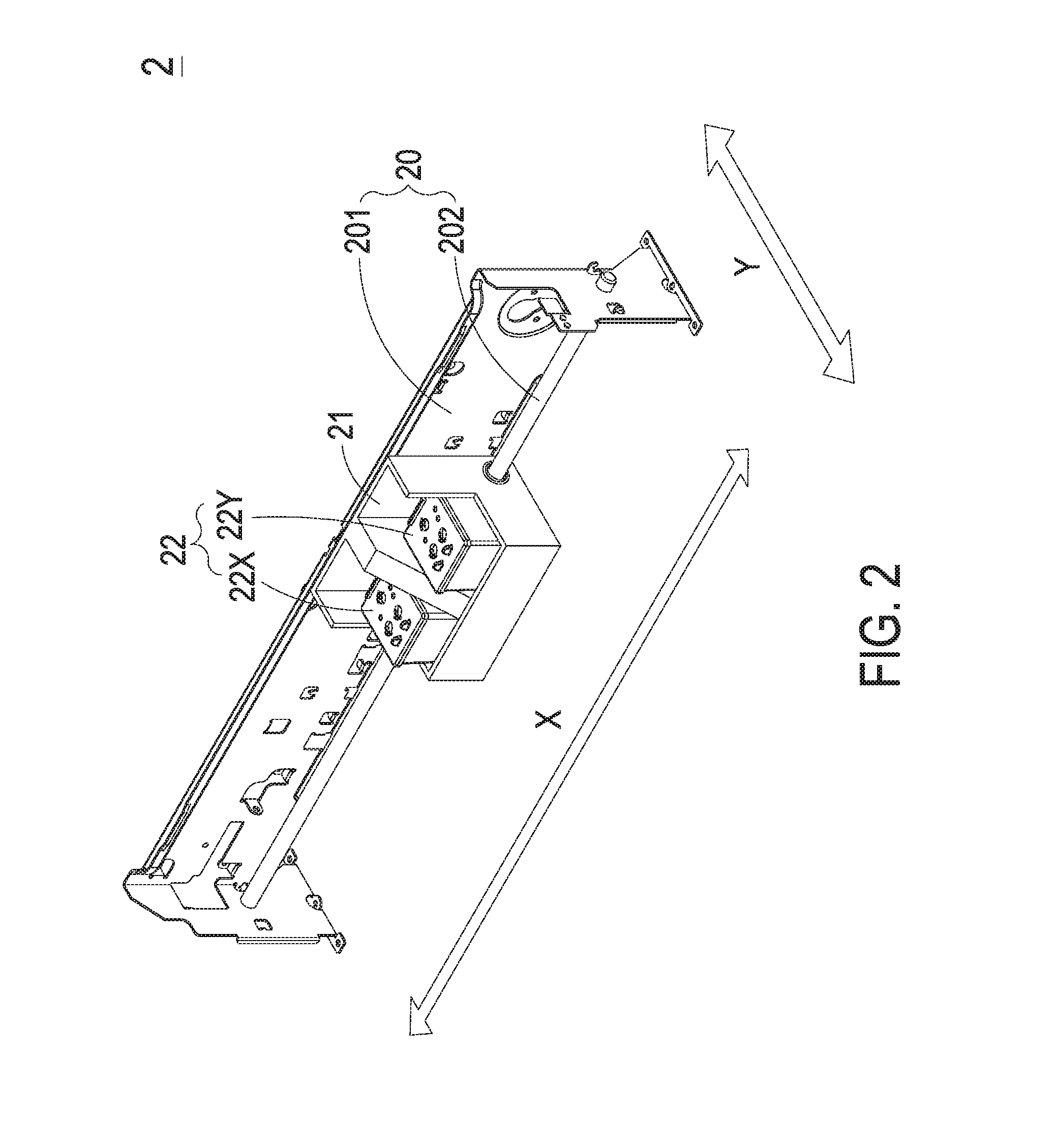

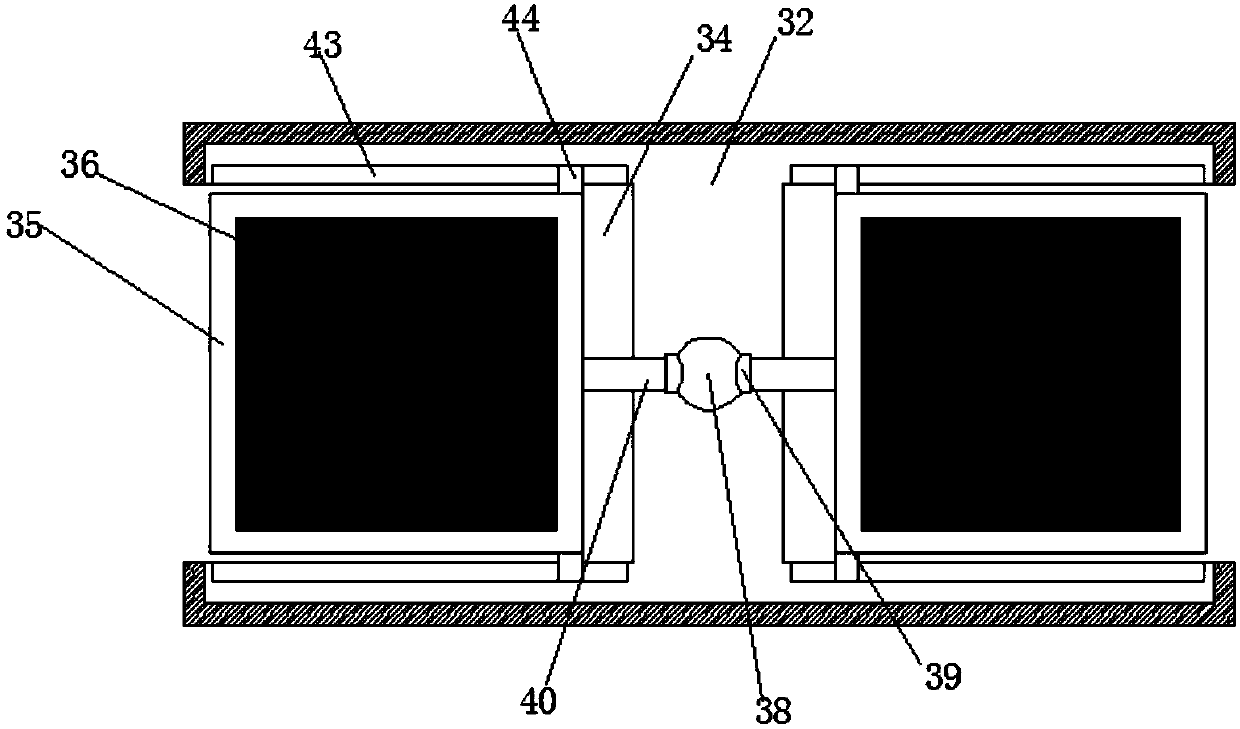

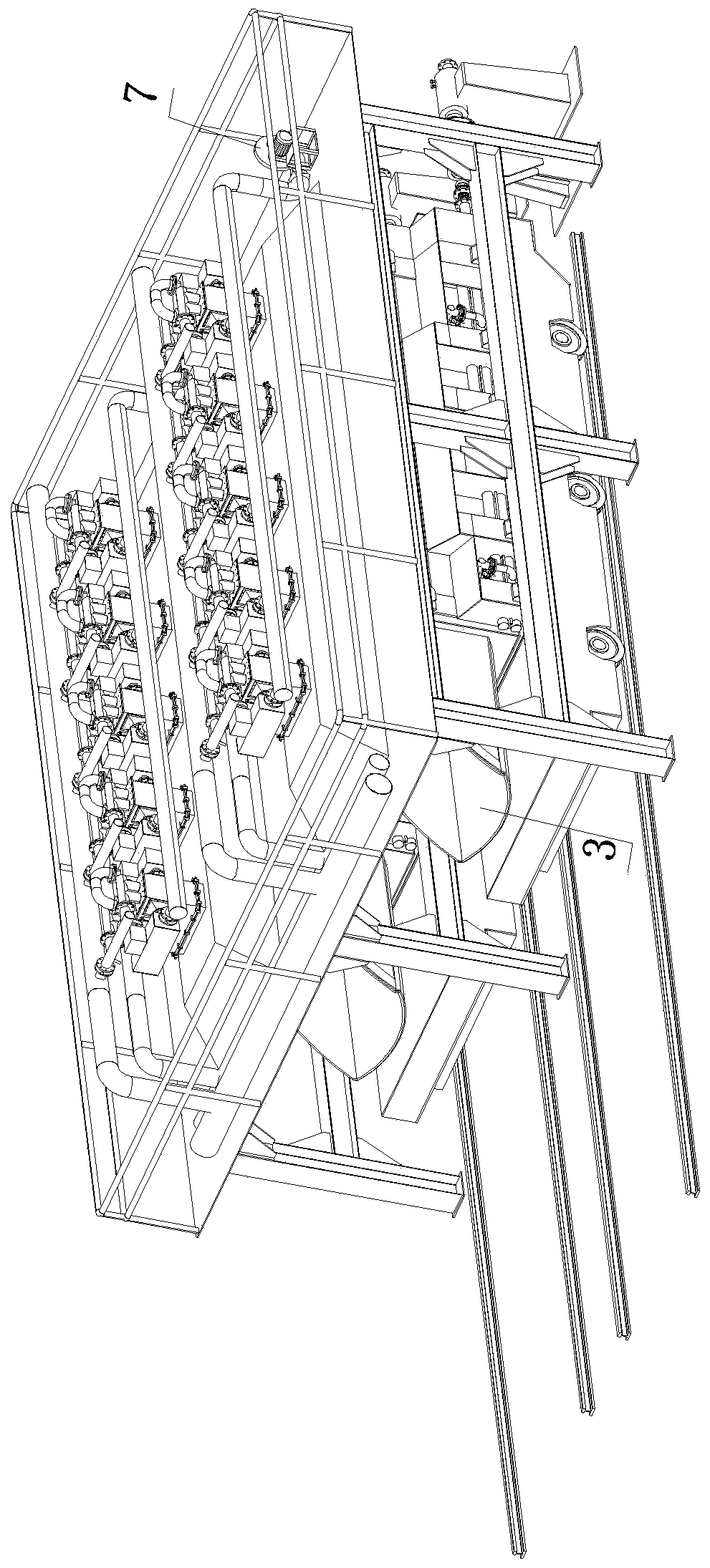

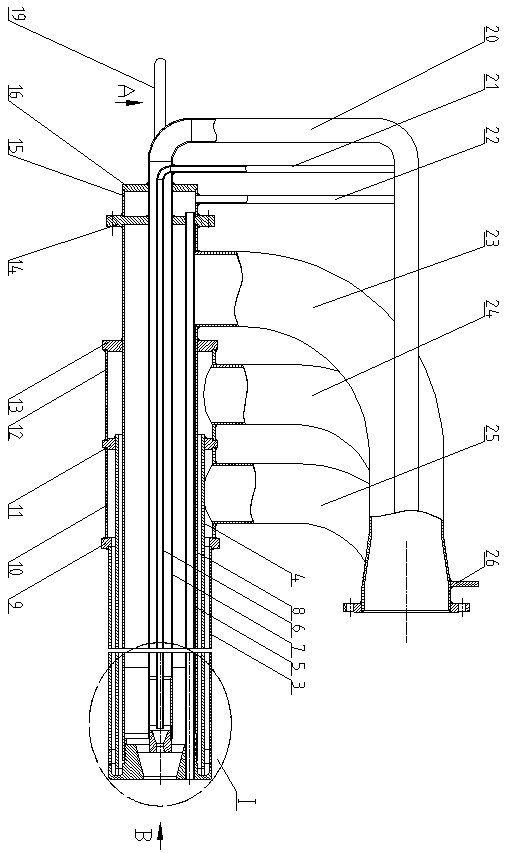

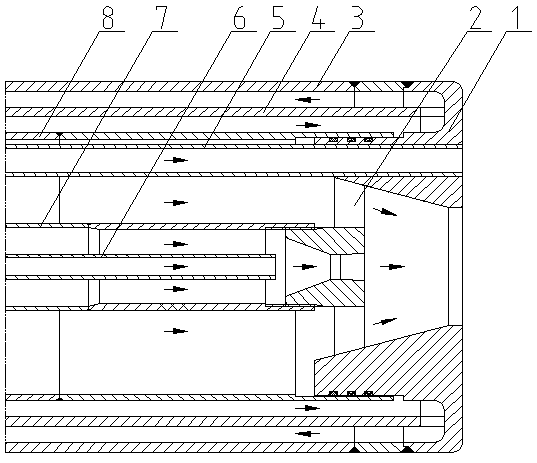

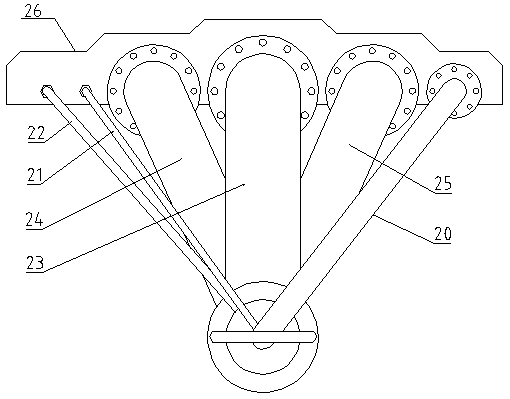

Continuous feeding device for electric arc furnace preheated by flue gases

InactiveCN103075881AImprove mechanical efficiencyIncrease contact areaLighting and heating apparatusFlueCold area

The invention discloses a continuous feeding device for an electric arc furnace preheated by flue gases. The device comprises a double-duct conveying trough and a flue gas guiding hood; a carrier plate with a flue gas channel is arranged in the middle part of the double-duct conveying trough; a material circulating duct is arranged above the carrier plate, and a flue gas circulating duct is arranged below the carrier plate; a seal gate matched with the upper opening of the lower end of the material circulating duct is arranged on the flue gas guiding hood; the double-duct conveying trough forms a flue gas diffusion heat exchanging mechanism from bottom to top, contact area between materials and high temperature flue gas is enlarged, the stay time of the flue gas is long, and the material preheating effect is greatly improved; as the double-duct conveying trough is arranged in an inclined way, the feeding point is raised, the trough bevel is large, the waste steel material blanking point can easily close to the center high temperature area of the furnace, so that the cold area phenomenon is eliminated; as the diffusion and heat exchange designs are realized, the powder dust in the exhausted flue gases is greatly reduced, the flue gas flowing is more in line with the natural rules, and the problems of exhaust pipe blockage and the like are solved.

Owner:CISDI ENG CO LTD

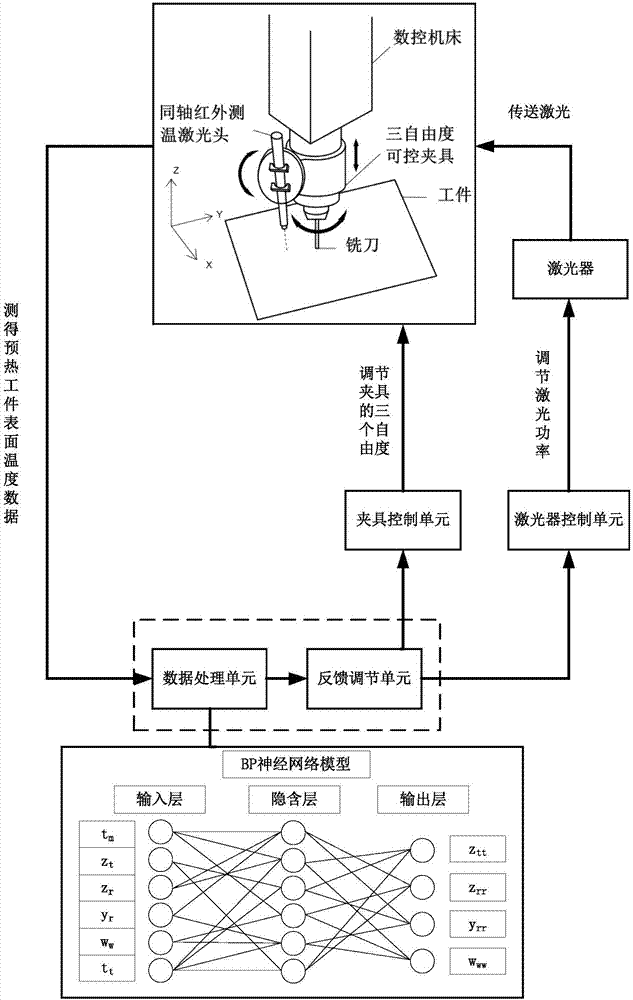

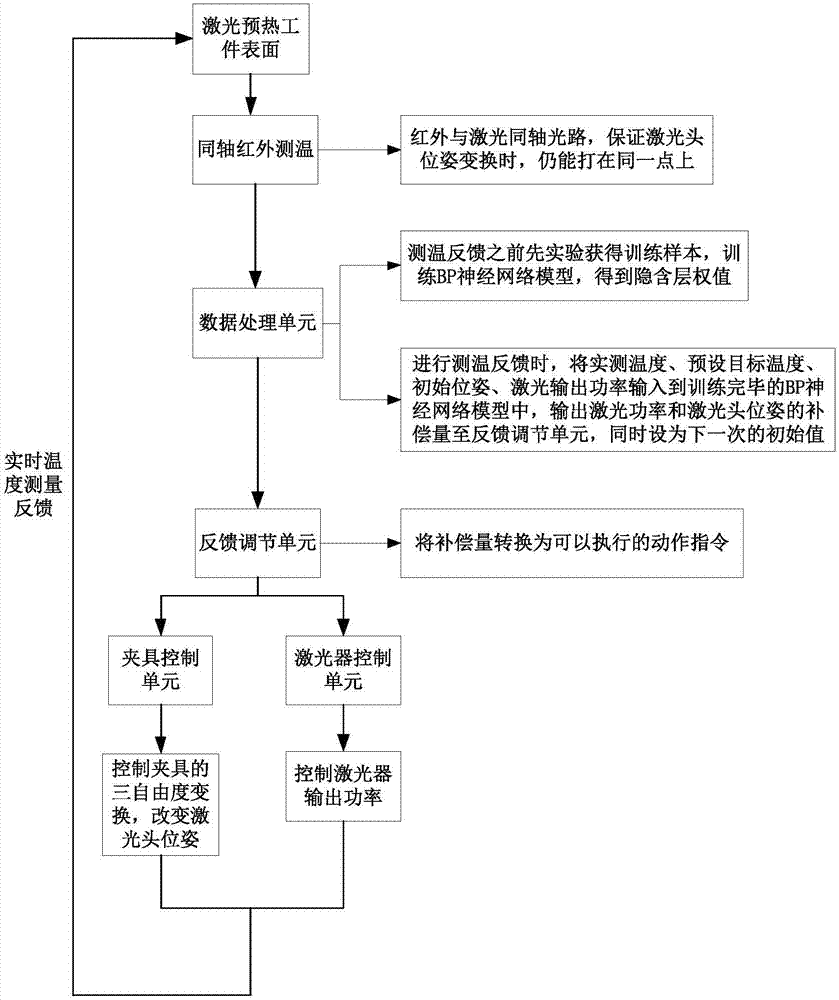

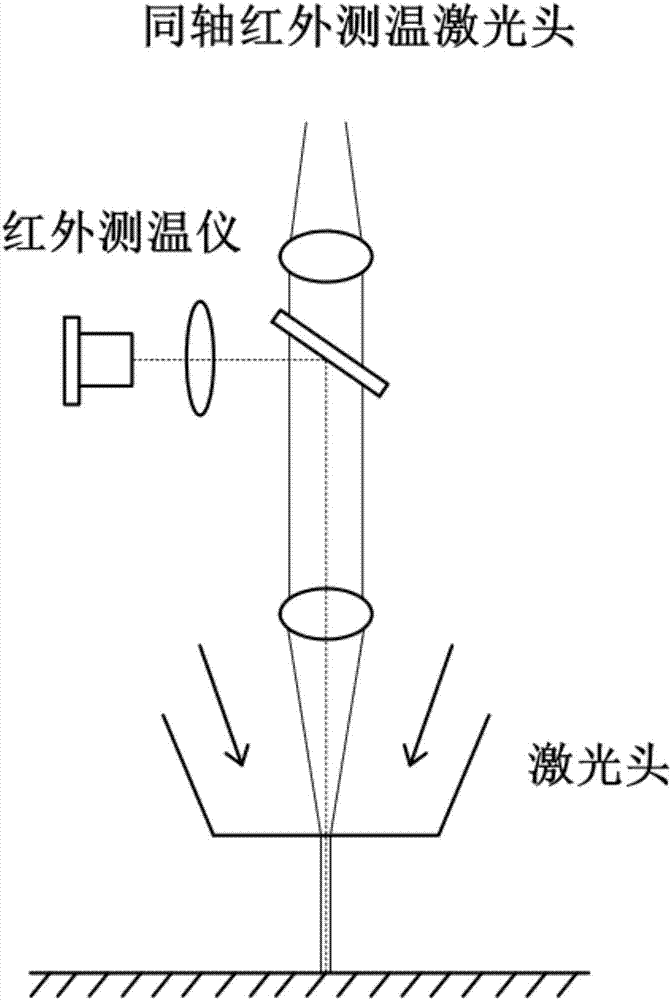

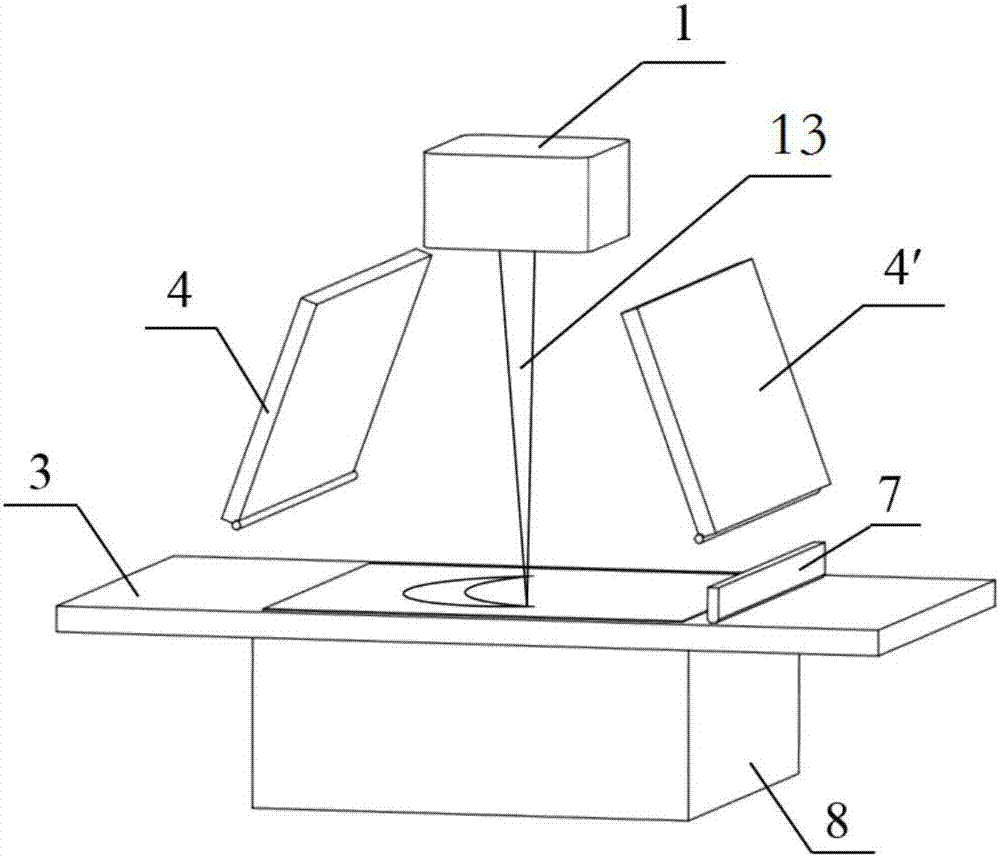

Laser preheating machining system integrated with temperature field real-time measuring and feedback control functions

ActiveCN107020520APrecise laser preheating temperature controlImprove preheating efficiencyMeasurement/indication equipmentsMetal working apparatusThree degrees of freedomOptoelectronics

The invention discloses a laser preheating machining system integrated with temperature field real-time measuring and feedback control functions. The system comprises a coaxial infrared temperature measuring laser head, a three-freedom-degree controllable clamp, a laser device, a laser device control unit, a clamp control unit, a data processing unit and a feedback adjusting unit. The system aims at comprehensively considering multiple factors affecting the surface temperature field of a laser preheated workpiece, real measurement temperature and preset target temperature are input to the data processing unit, a trained BP neural network model is optimized to be subject to data processing, laser power and compensation amount of three freedom degrees of the controllable clamp are output to the feedback adjusting unit, the compensation amount is loaded to the laser device and the controllable clamp to properly adjust the laser output power and the spot size and energy density, on the surface of the workpiece, of laser, and the surface of the preheated workpiece accurately reaches the preset target temperature. The system is high in automation degree, high in temperature feedback control precision, good in safety property and convenient to operate.

Owner:HUAZHONG UNIV OF SCI & TECH

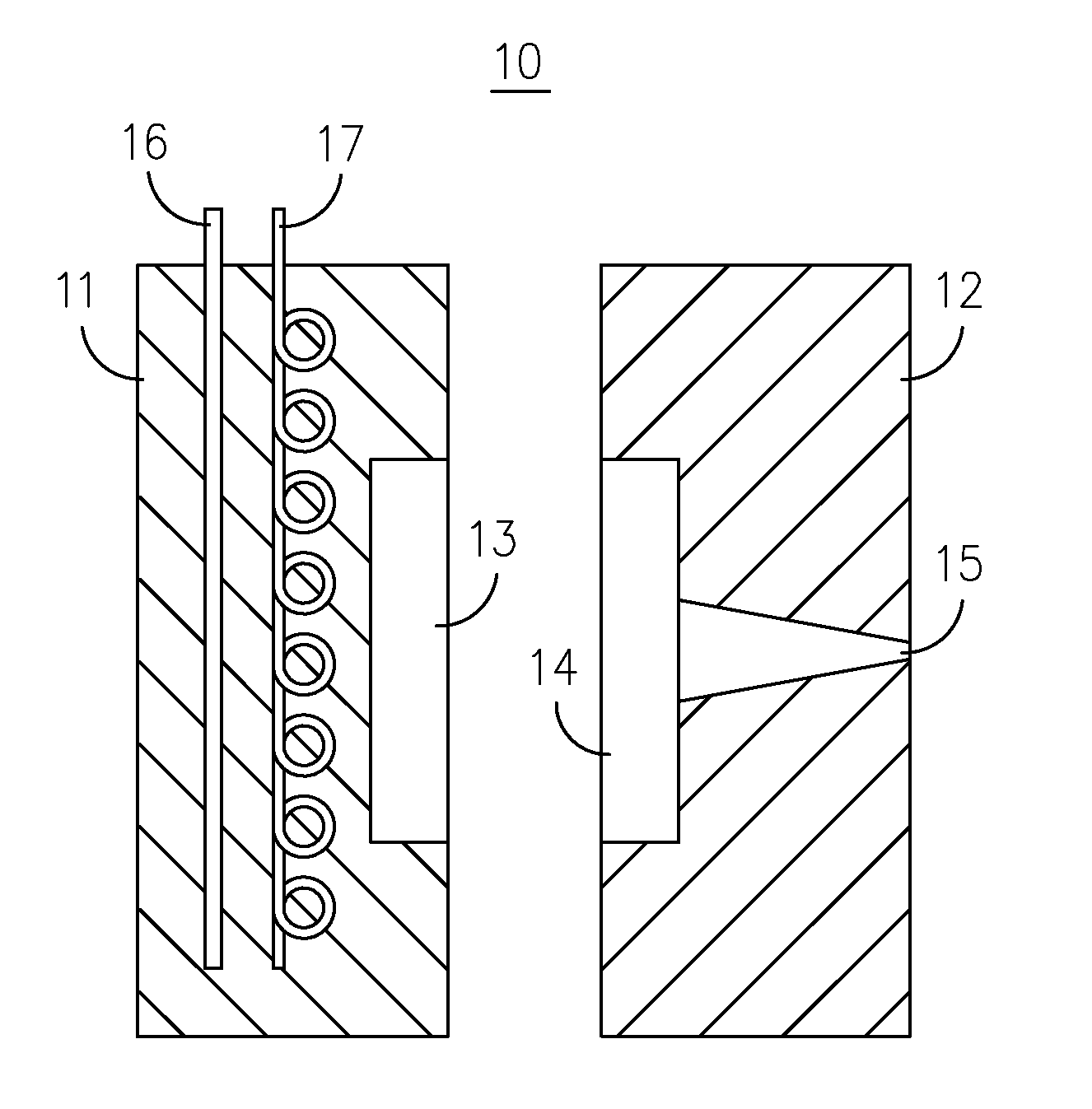

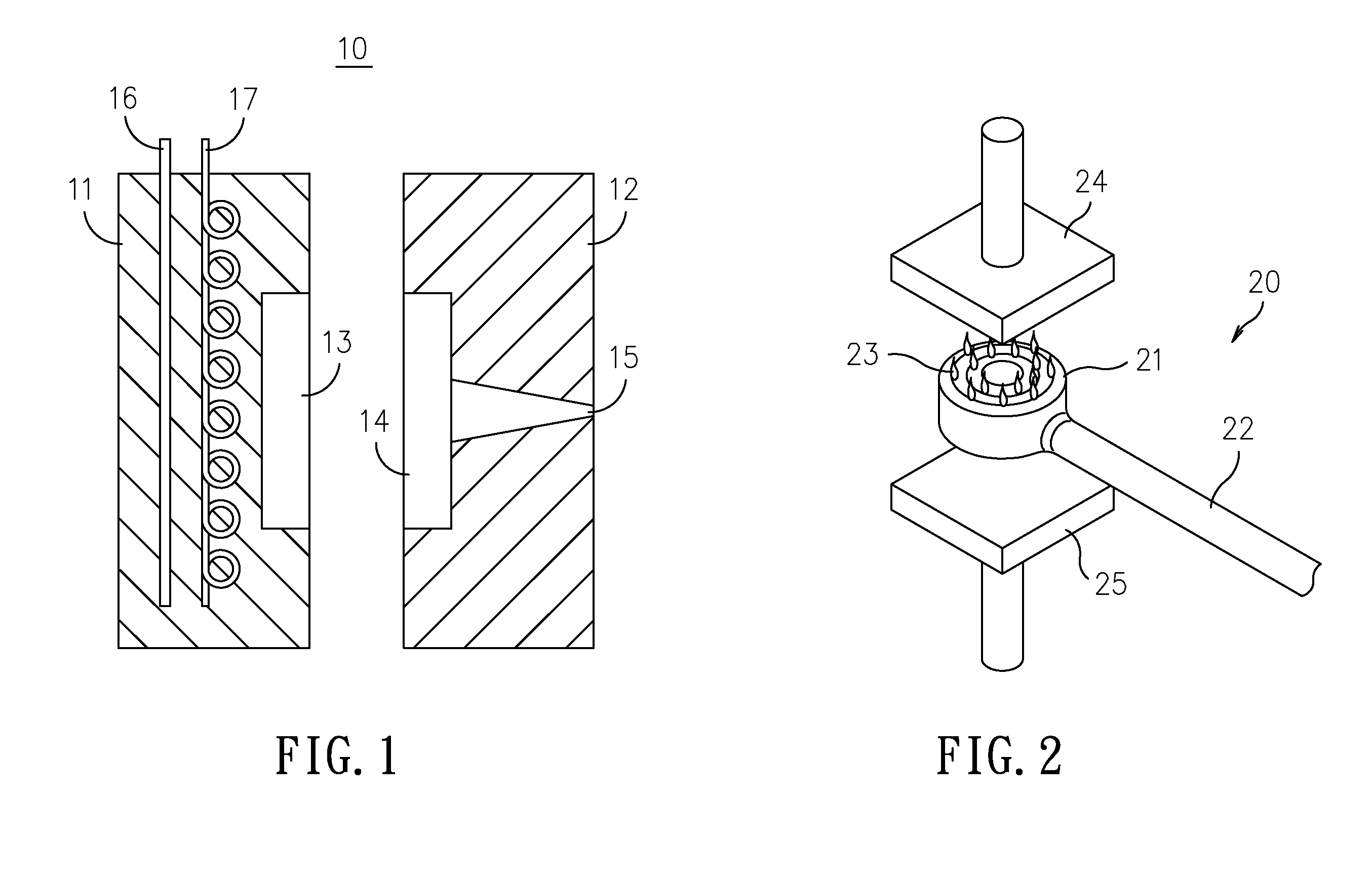

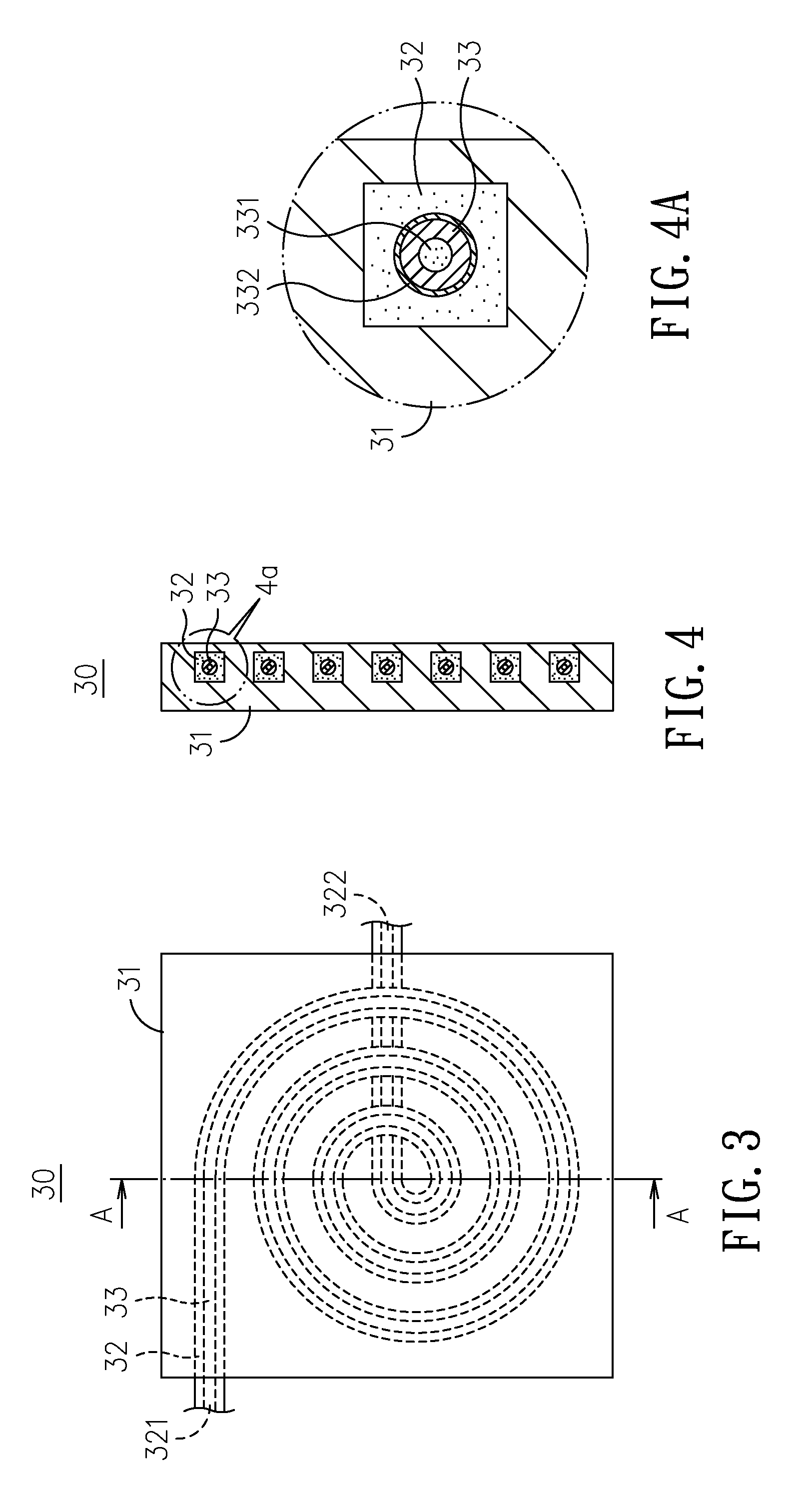

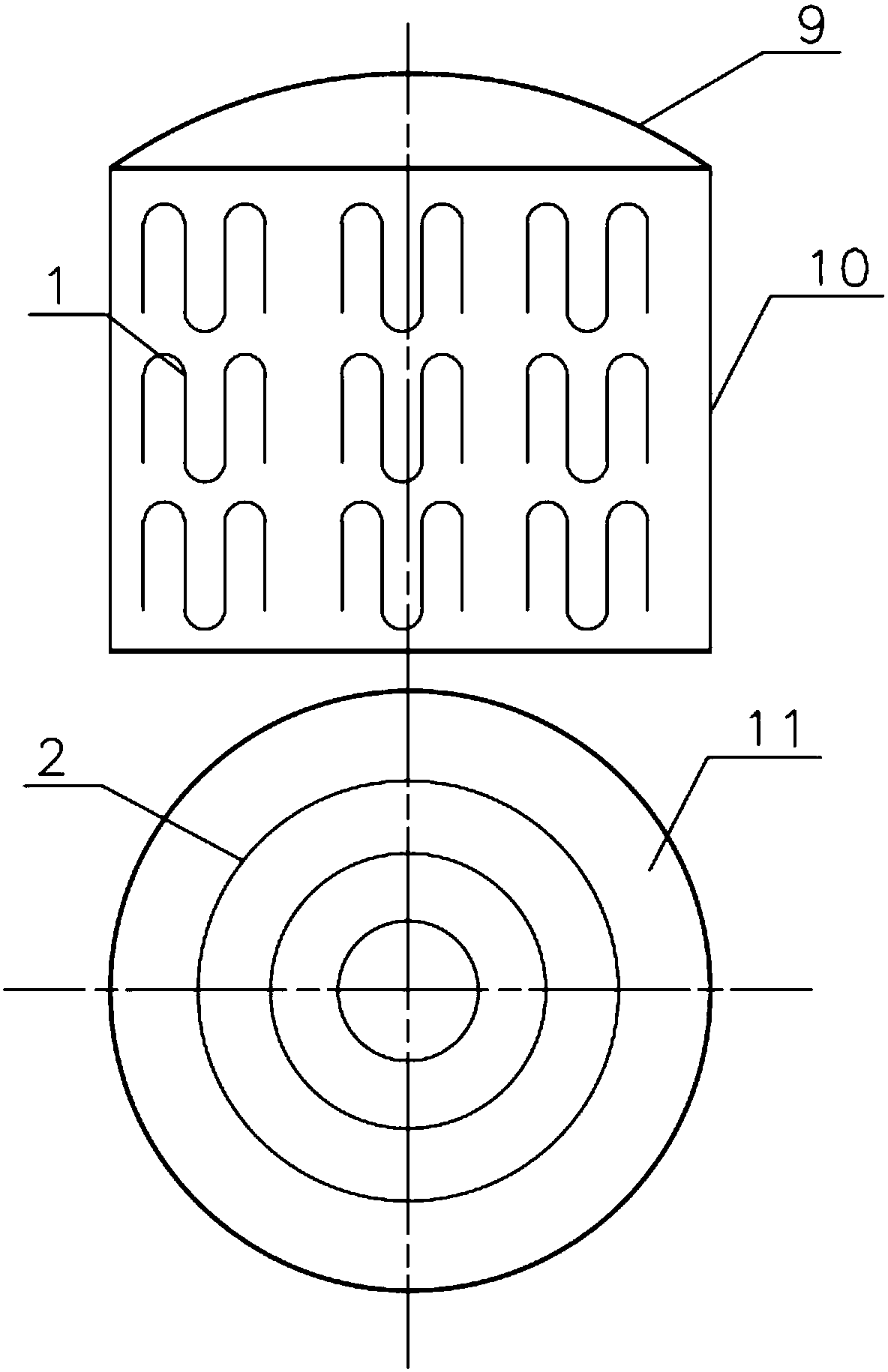

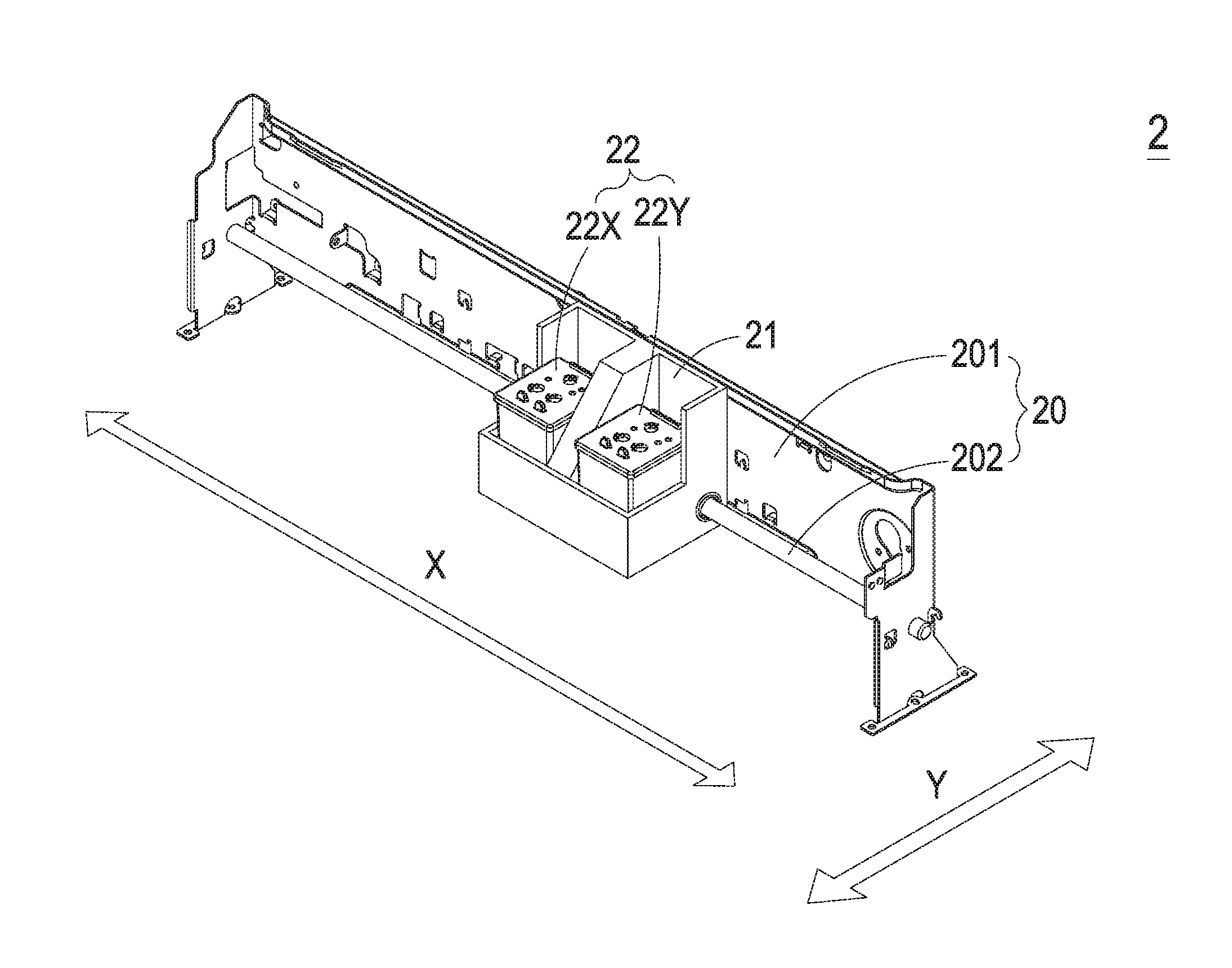

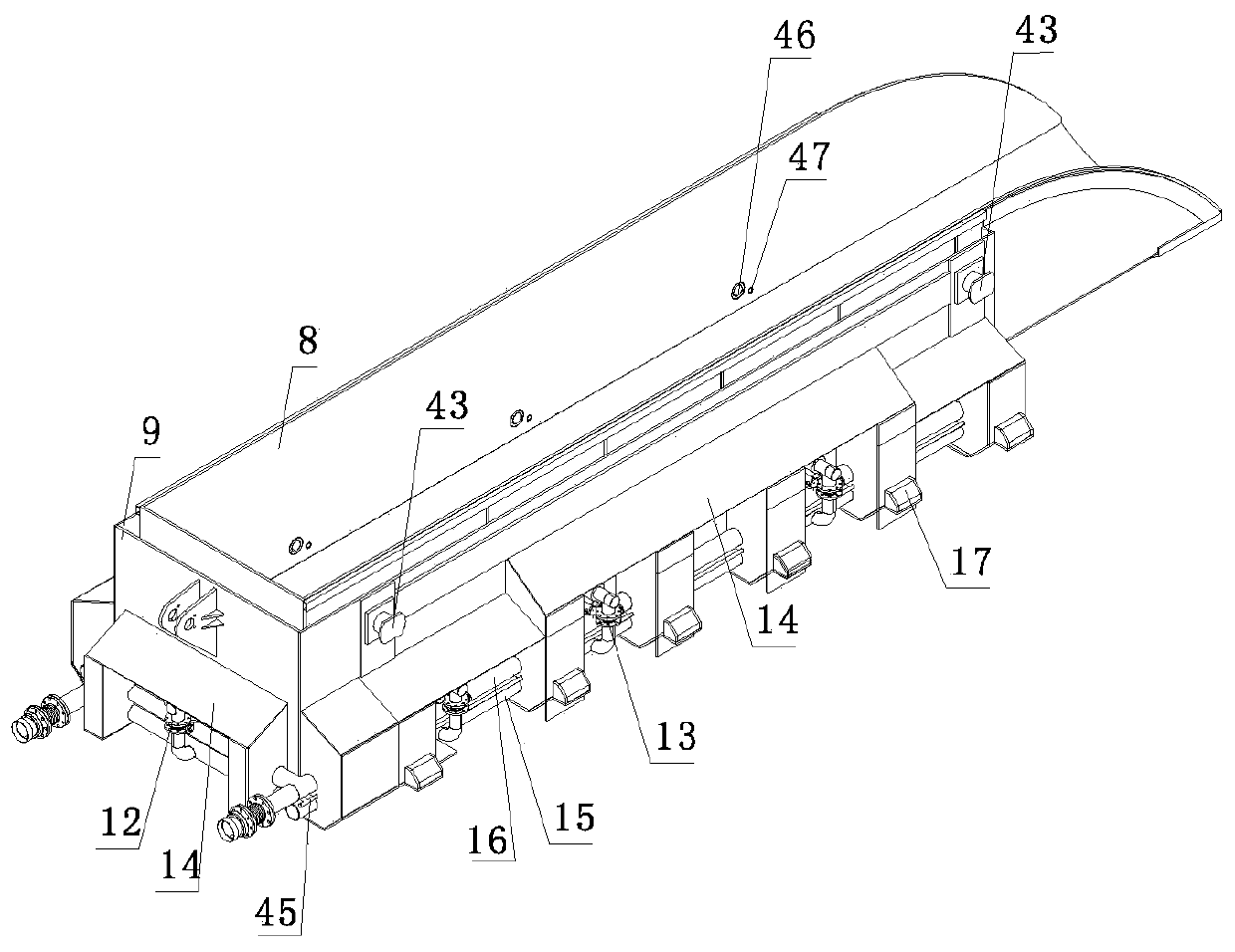

Coaxial cooling/heating coil structure and the mold configured with the same

ActiveUS20100159061A1Improve preheating efficiencyShorten the timeCoil arrangementsIndirect heat exchangersHeat conductingEngineering

The present invention relates to a coaxial cooling / heating coil structure and a mold configured with the same, in which the coaxial cooling / heating coil is comprised of: a frame, configured with a cooling channel having an inlet, provided for a cooling water to flow therein, and an outlet, provided for discharging the cooling water therefrom; and a heat-conducting coil, disposed inside the cooling channel. The coaxial cooling / heating structure is fitted to a mold to be used for enhancing the preheating efficiency of the mold while improving the time required for cooling the mold.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

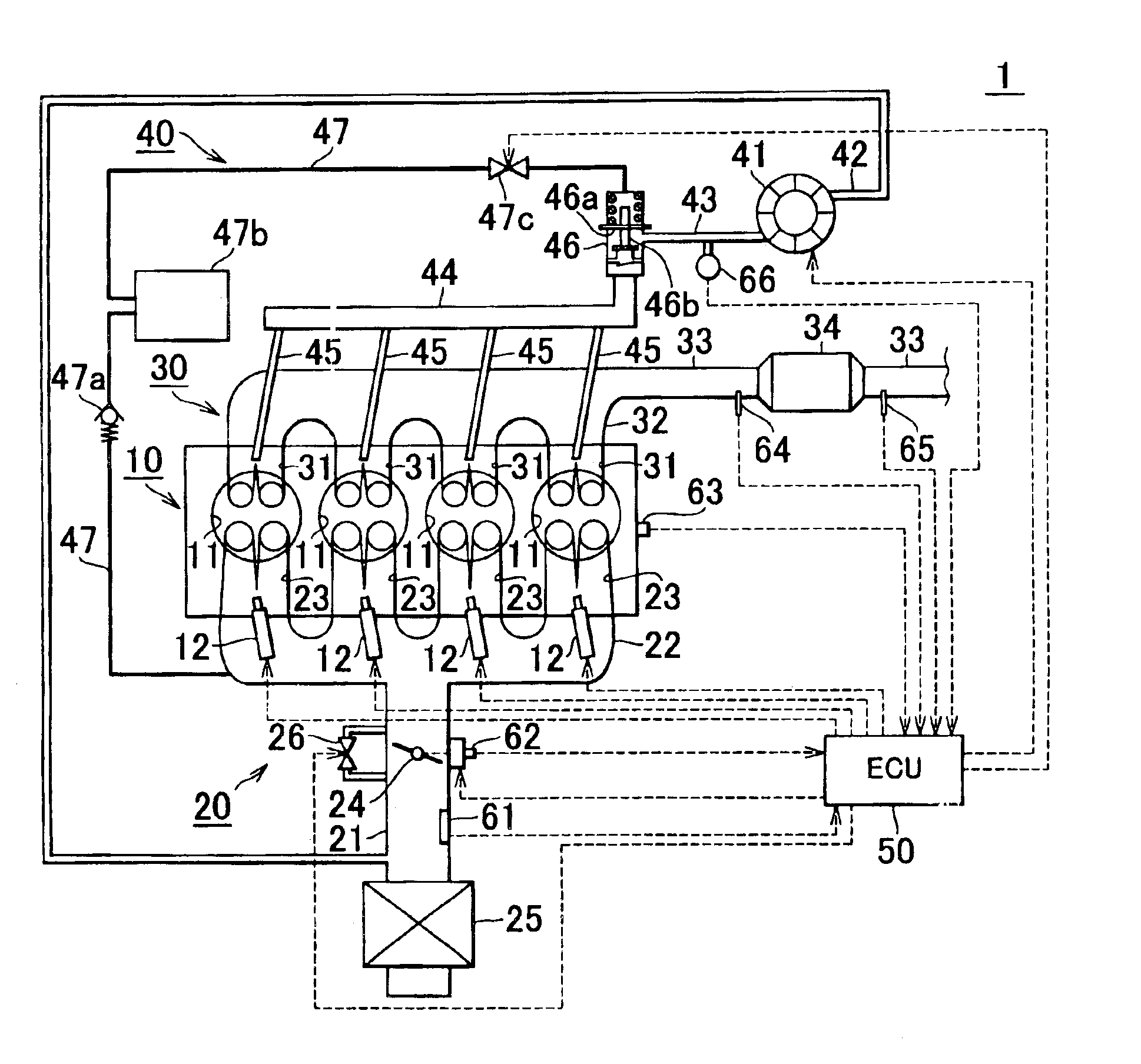

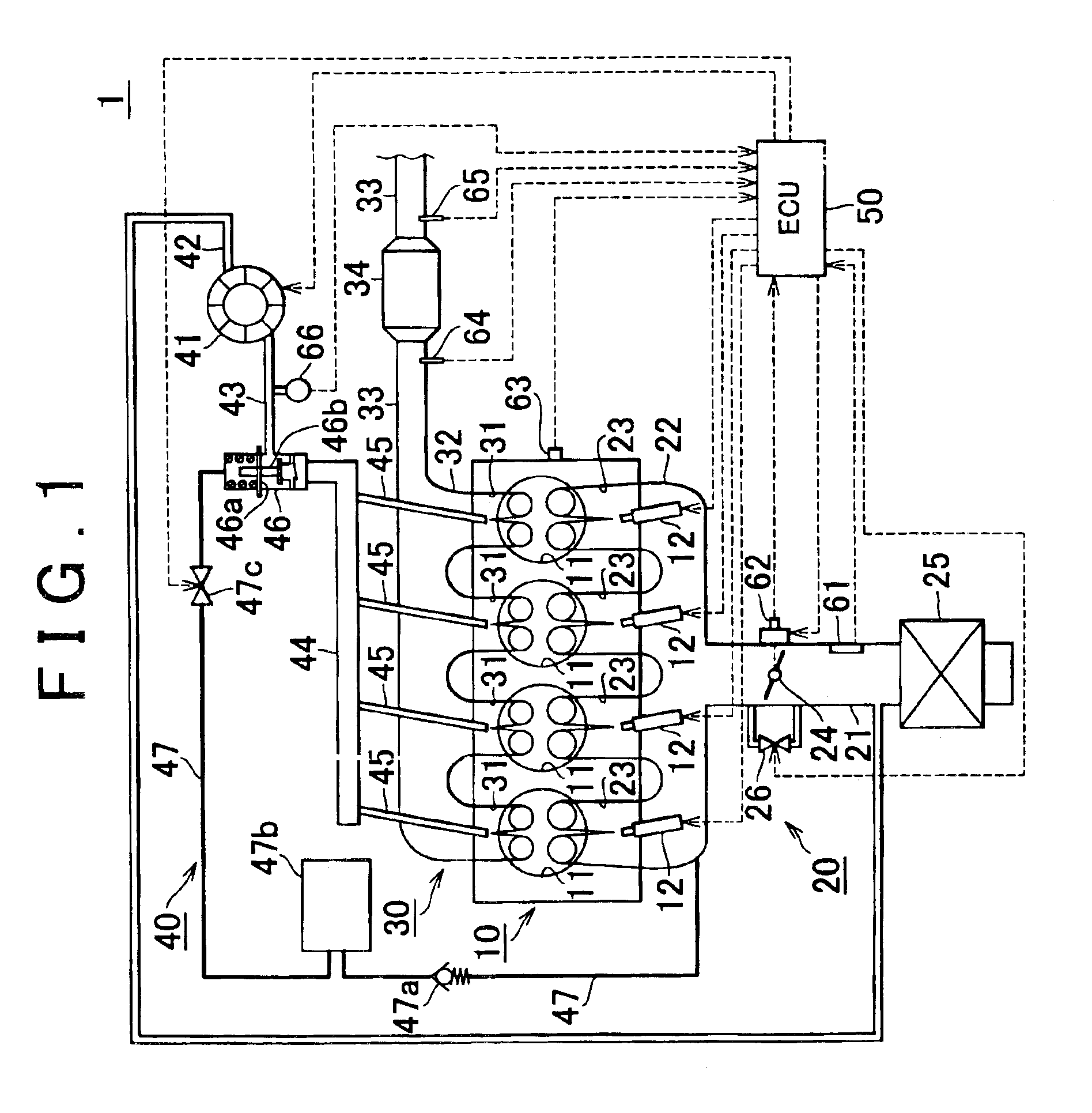

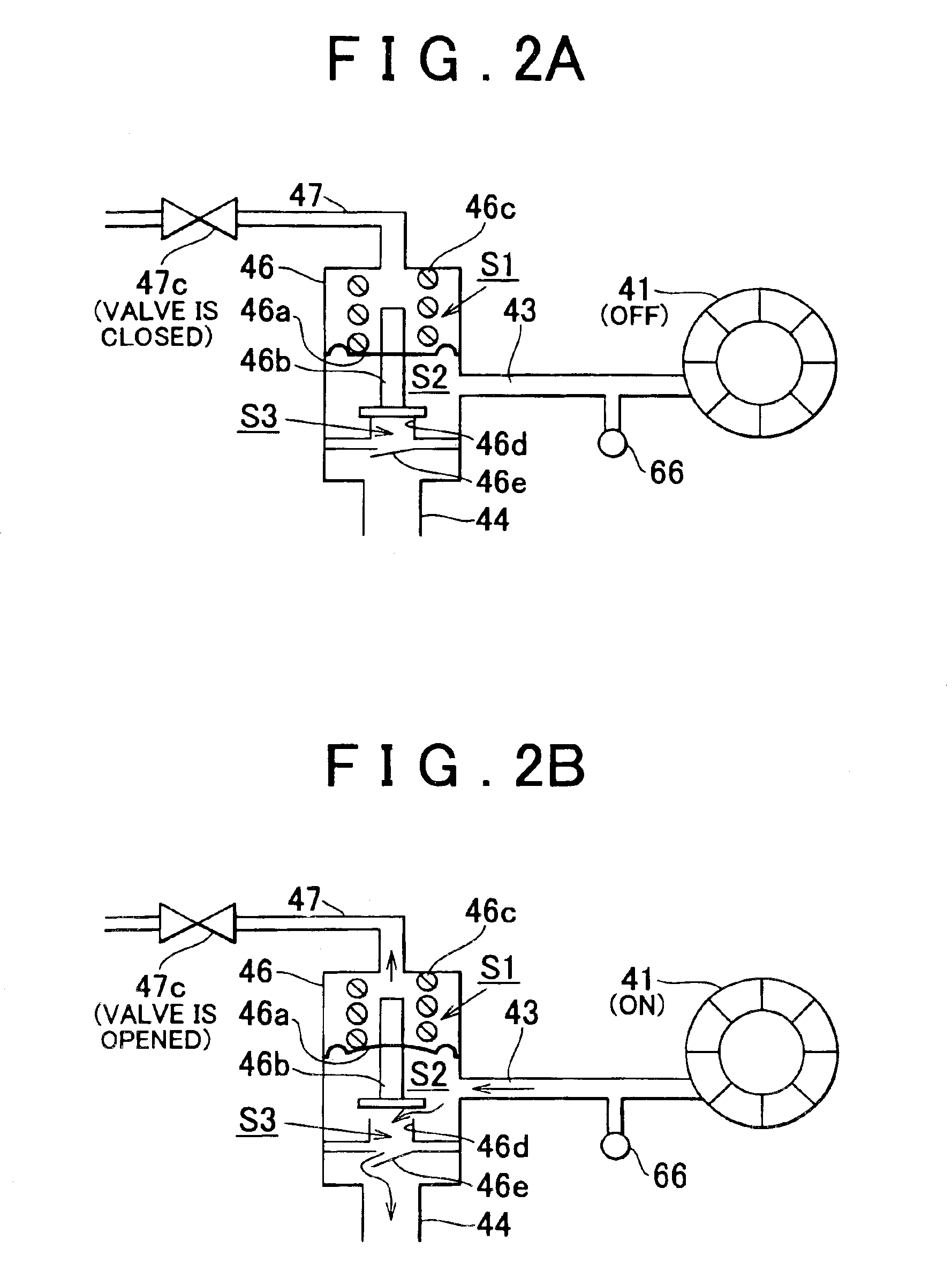

Internal combustion engine, control apparatus for internal combustion engine, and control method for internal combustion engine

InactiveUS6912845B2Engine speed to decreaseIncrease amount of intake airElectrical controlInternal combustion piston enginesExternal combustion engineAir pump

An internal combustion engine includes an air pump that supplies secondary air to an upstream side of an exhaust gas control catalyst in an exhaust pipe via a secondary air supply passage; an adjusting device that adjusts an intake air amount delivered into a combustion chamber from an intake pipe; and a controller that performs control for increase correction of the intake air amount adjusted by the adjusting device when the air pump performs an operation of supplying the secondary air. Thus, it is possible to prevent a problem caused by a reduction in an engine speed due to the secondary air supply.

Owner:TOYOTA JIDOSHA KK

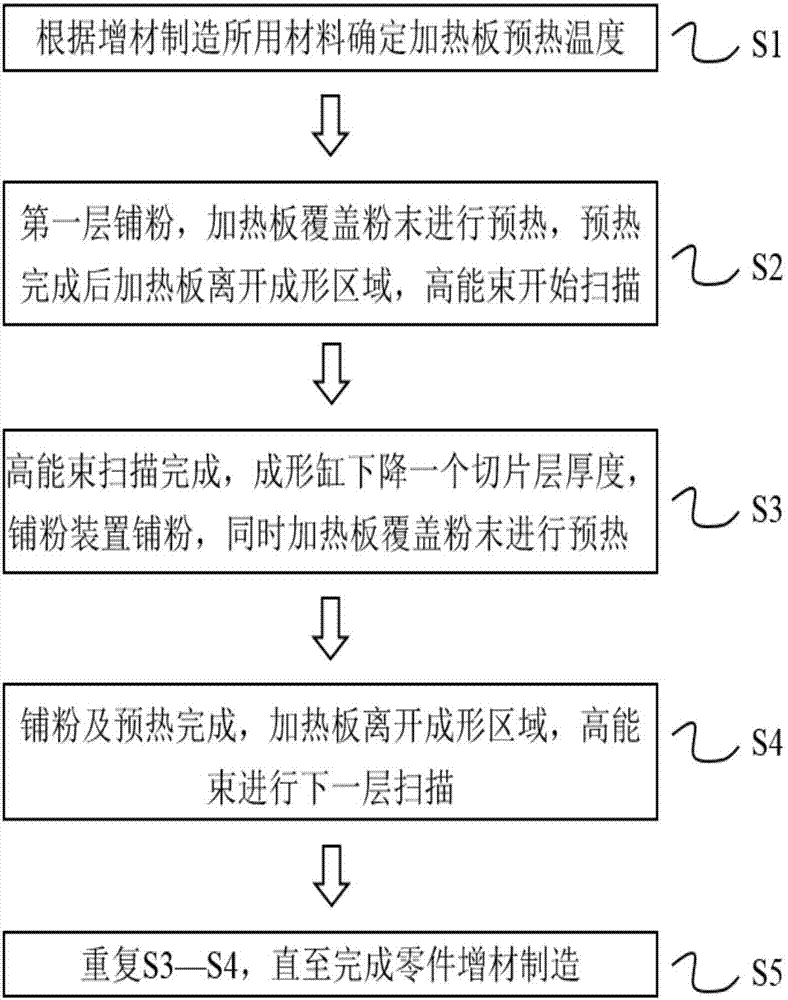

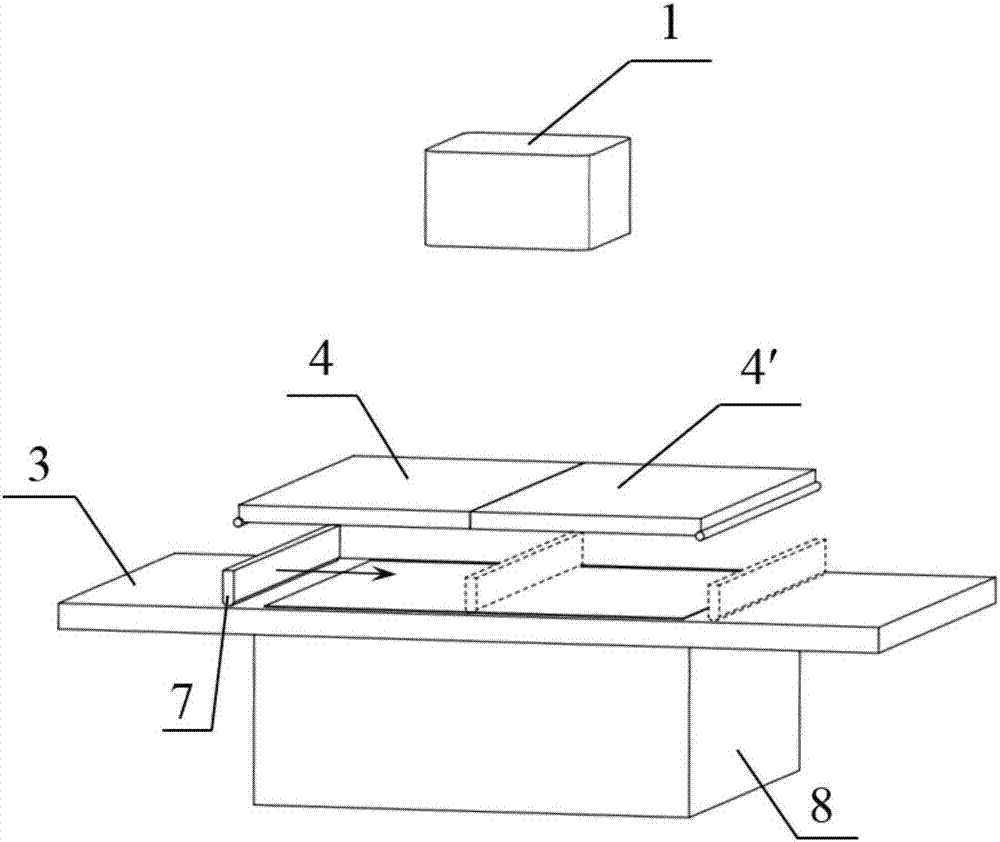

Preheating method and device suitable for powder laying type additive manufacturing

ActiveCN107379527AMonitor temperature in real timeHeating high temperatureManufacturing heating elementsIncreasing energy efficiencyControl systemMetallurgy

The invention provides a preheating method and device suitable for powder laying type additive manufacturing, and belongs to the technical field of additive manufacturing. A movable type plane heating plate capable of covering a whole powder bed is arranged over the powder bed, the mounting height of the plane heating plate is slightly larger than a powder laying device, in the powder laying process, the powder bed and parts are preheated, after powder laying is finished, a plane light source is closed and put away, and the phenomenon that in the machining process, the plane heating plate blocks a high-energy beam is avoided. In the heating process, a temperature measuring sensor is used for monitoring the temperature of the powder bed in real time, a control system is adopted to implement feedback control over preheating of the powder bed according to the temperature monitoring result, full-breadth covering type heating is adopted, and the powder bed and formed parts are subject to high-temperature, efficient and unifier preheating. The invention further provides the device achieving the above method. The method is wide in application material and high in expansibility and is particularly suitable for powder laying type additive manufacturing of multiple large-breadth high-energy beams.

Owner:HUAZHONG UNIV OF SCI & TECH

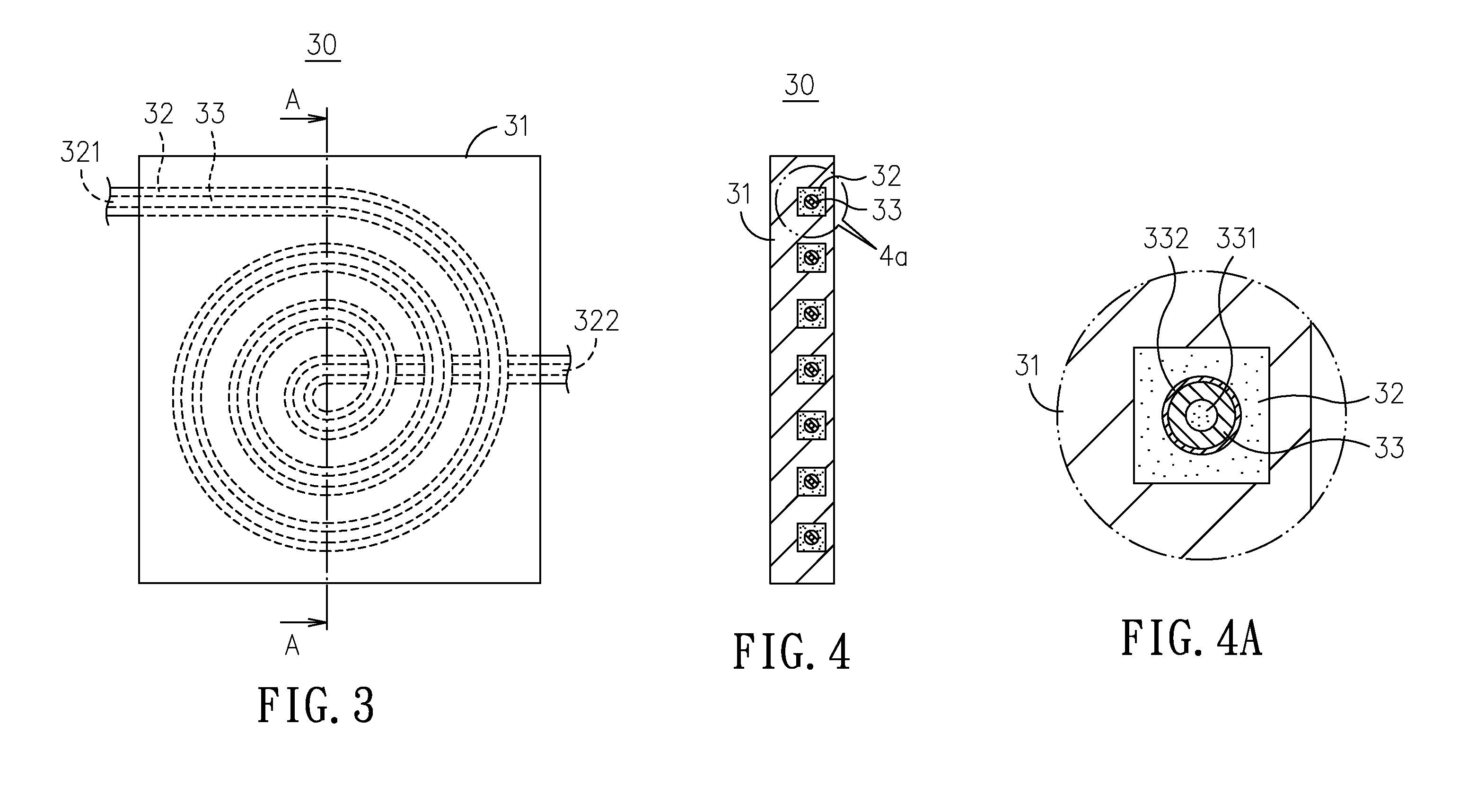

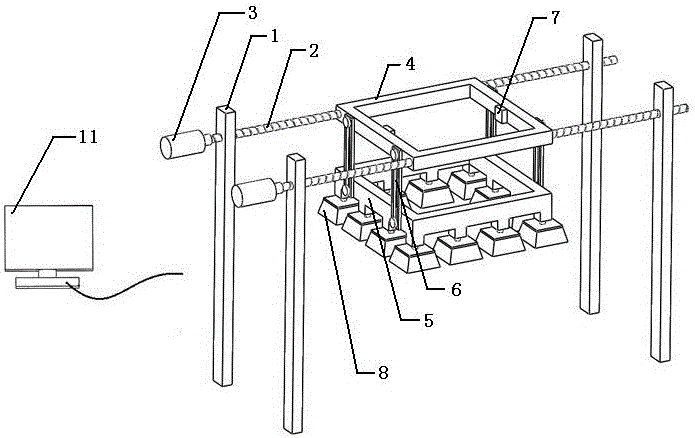

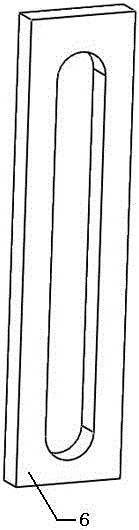

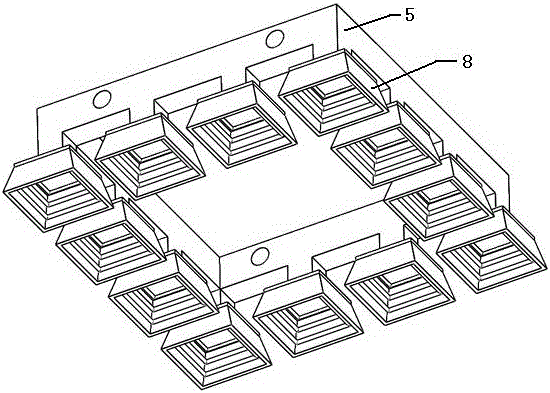

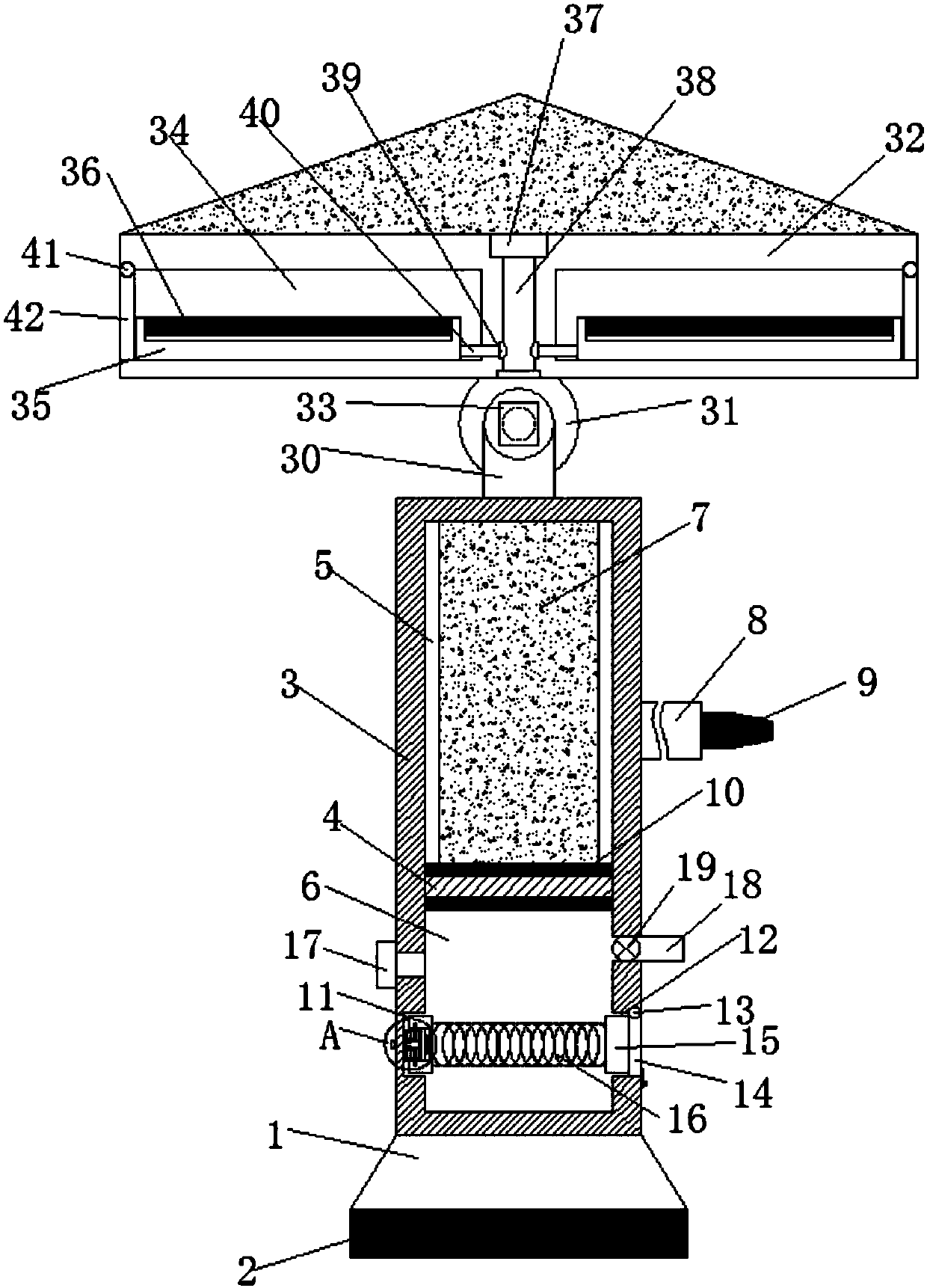

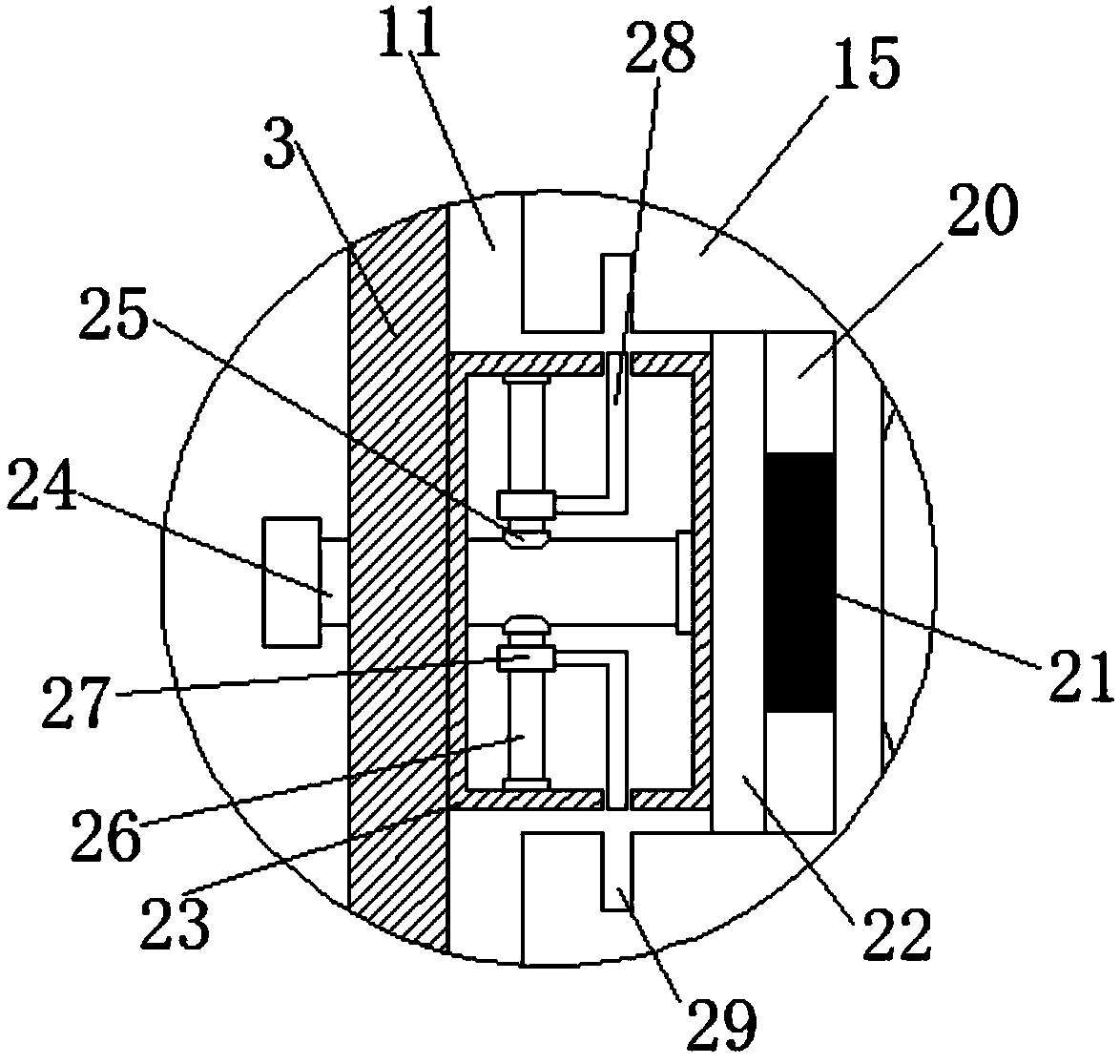

Selective laser sintering SLS laid powder preheating device

InactiveCN106001575AWarm up evenlyHigh precisionAdditive manufacturing apparatusIncreasing energy efficiencyInfraredSelective laser sintering

The invention provides a selective laser sintering SLS laid powder preheating device. The selective laser sintering SLS laid powder preheating device comprises stand columns, lead screws, driving motors, an upper support, a lower support, height adjusting plates, infrared temperature measuring devices, a plurality of rectangular pyramid hollow shells and a control system, wherein each rectangular pyramid hollow shell, a heating rod inside the rectangular pyramid hollow shell and a reflector on the inner wall of the rectangular pyramid hollow shell form a corresponding independent preheating device; and the independent preheating devices divide a forming region into a plurality of small regions capable of preheating independently, are directly controlled by the control system and do not interfere one another. When temperatures of different regions of the laid powder are different, the independent preheating devices can be adjusted to preheat the different regions at different temperatures, so that the laid powder is integrally preheated uniformly; and the direction of each independent preheating device in three-dimensional space is adjustable, the preheating regions can be adjusted according to the size of a formed part, preheating efficiency is improved, and energy is saved. By the selective laser sintering SLS laid powder preheating device, the precision and the structure property of the formed part can be improved effectively; and the selective laser sintering SLS laid powder preheating device has an important significance on development of an SLS forming technology.

Owner:ZHONGBEI UNIV

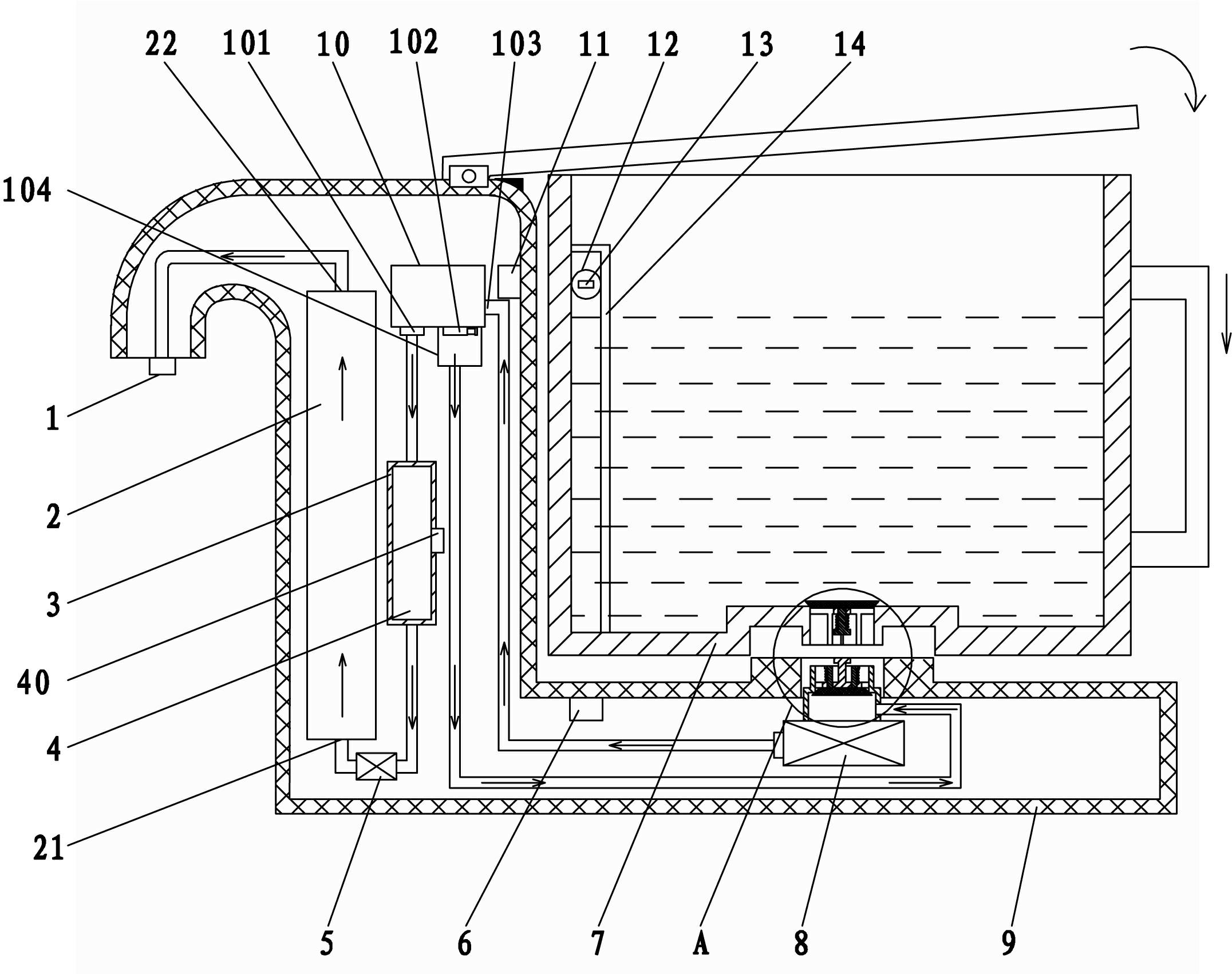

Drinking water heating device with pre-heating function

The invention relates to a drinking water heating device, in particular to a drinking water heating device with a pre-heating function, which comprises a seat body, a water outlet nozzle and an instant-heating heater, wherein the instant-heating heater is provided with an inlet and an outlet; the inlet is connected with a water inlet pipeline; the outlet is communicated with the water outlet nozzle. The drinking water heating device is characterized in that: the drinking water heating device also comprises a pre-heater; the pre-heater is arranged on the water inlet pipeline; the drinking water heating device pre-heats the water entering the instant-heating heater so as to primarily increase the water temperature; and the primarily heated water can be quickly heated to a boiling point or a temperature close to the boiling point after being heated by the instant-heating heater so that the heating time is saved and large water outlet flow can be ensured for drinking without increasing power of the instant-heating heater. The drinking water heating device is simple and rational in structure, simple and safe in use, low-carbon and energy-saving, and long in service life, and can satisfy various different drinking requirements of people, for example, making tea, making coffee and the like.

Owner:冯海涛

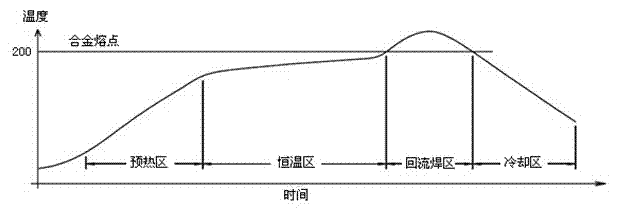

Reflow soldering method of SMD (Surface Mounted Device) components

InactiveCN104325205AReduce shockEfficient use ofPrinted circuit assemblingPrinted circuit aspectsLower limitSurface mounting

The invention discloses a reflow soldering method of SMD (Surface Mounted Device) components. The method comprises the following steps: stopping heat when the temperature is increased for 80-90 DEG C during a heating process of a preheating region, keeping for 8-10 seconds, and continuously heating to 150-200 DEG C at a slope rate of 4 DEG C / S; and controlling the temperature of the heating region to increase at a slope rate less than or equal to 4 DEG C / S until the temperature increases to 150-200 DEG C; fully preheating a workpiece at 150-200 DEG C, so that impact of heat in the heating process is decelerated, residual heat is effectively utilized, the preheating efficiency is improved and energy sources are saved; and keeping the temperature within a range of a peak temperature+ / -5 DEG C for not more than 10 seconds during a reflow soldering process of a reflow soldering region, reducing the temperature to the lower limit of a peak temperature range of 25-35 DEG C, and keeping for 10-20 seconds, so that workpiece damage caused by long-time continuous high temperature can be avoided and effective welding is achieved.

Owner:佛山市德艾光电科技有限公司

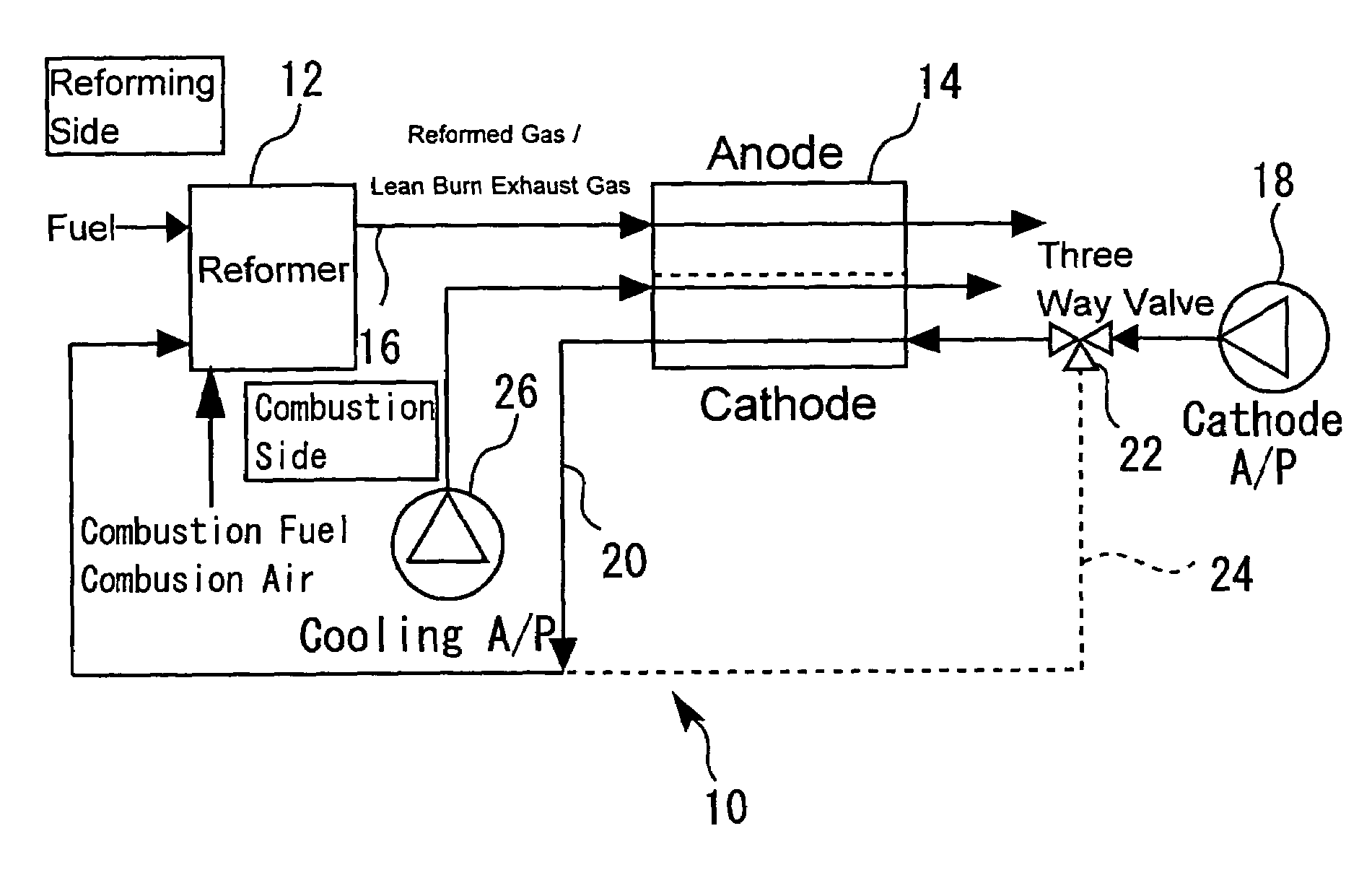

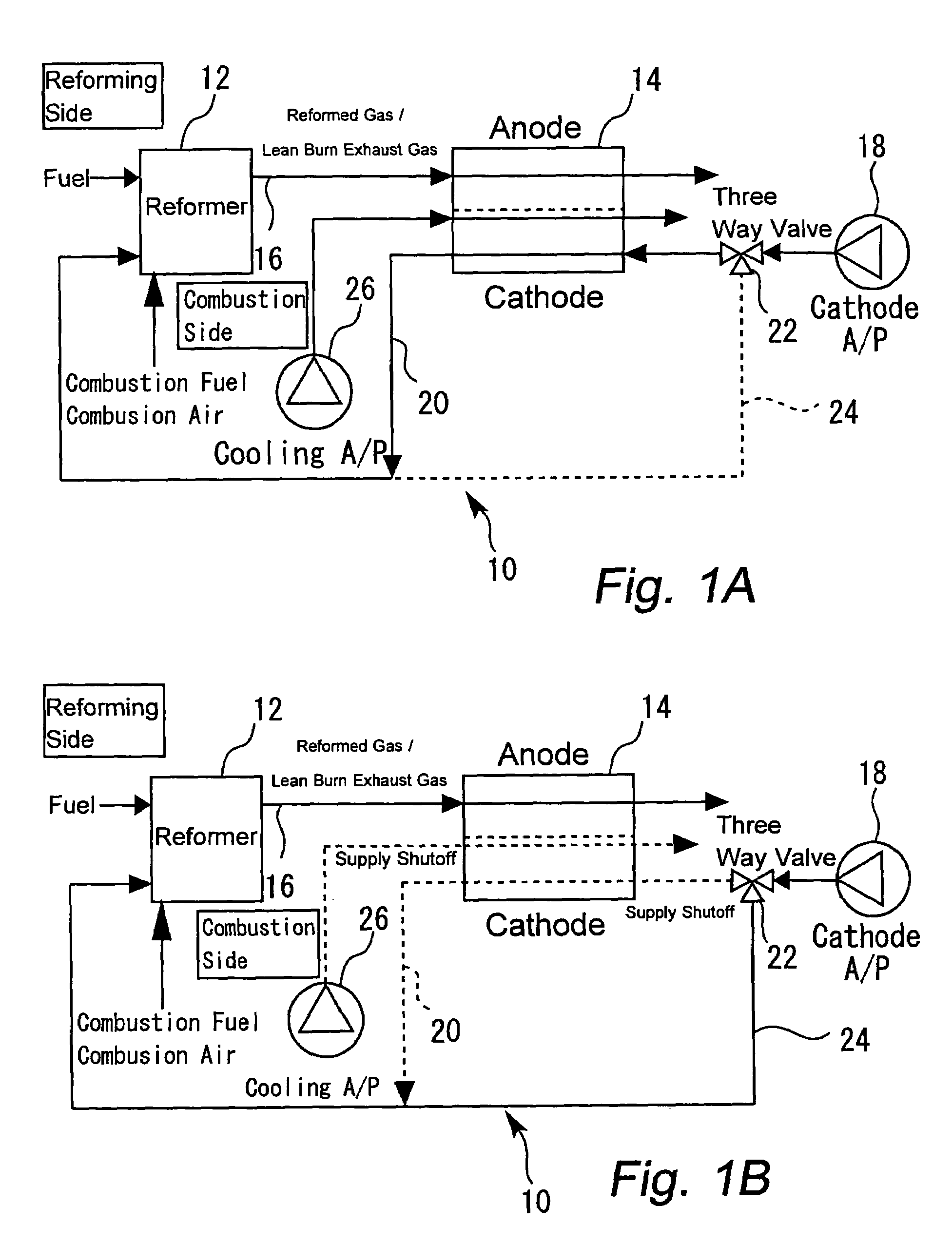

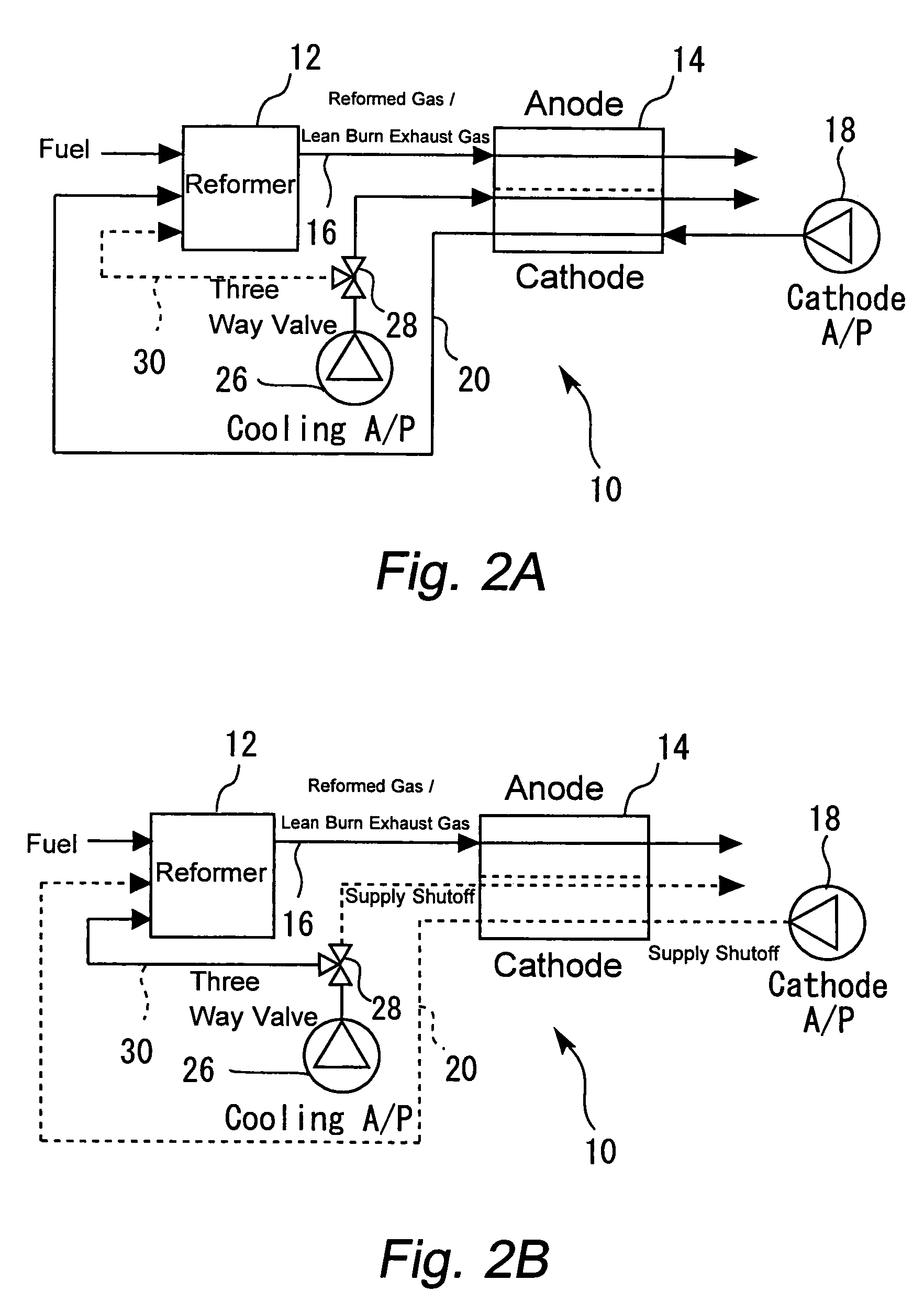

Fuel cell system

InactiveUS7132184B2Improve preheating efficiencyAvoid assemblyFuel cell heat exchangeCell temperature controlFuel cellsHydrogen

Owner:TOYOTA JIDOSHA KK

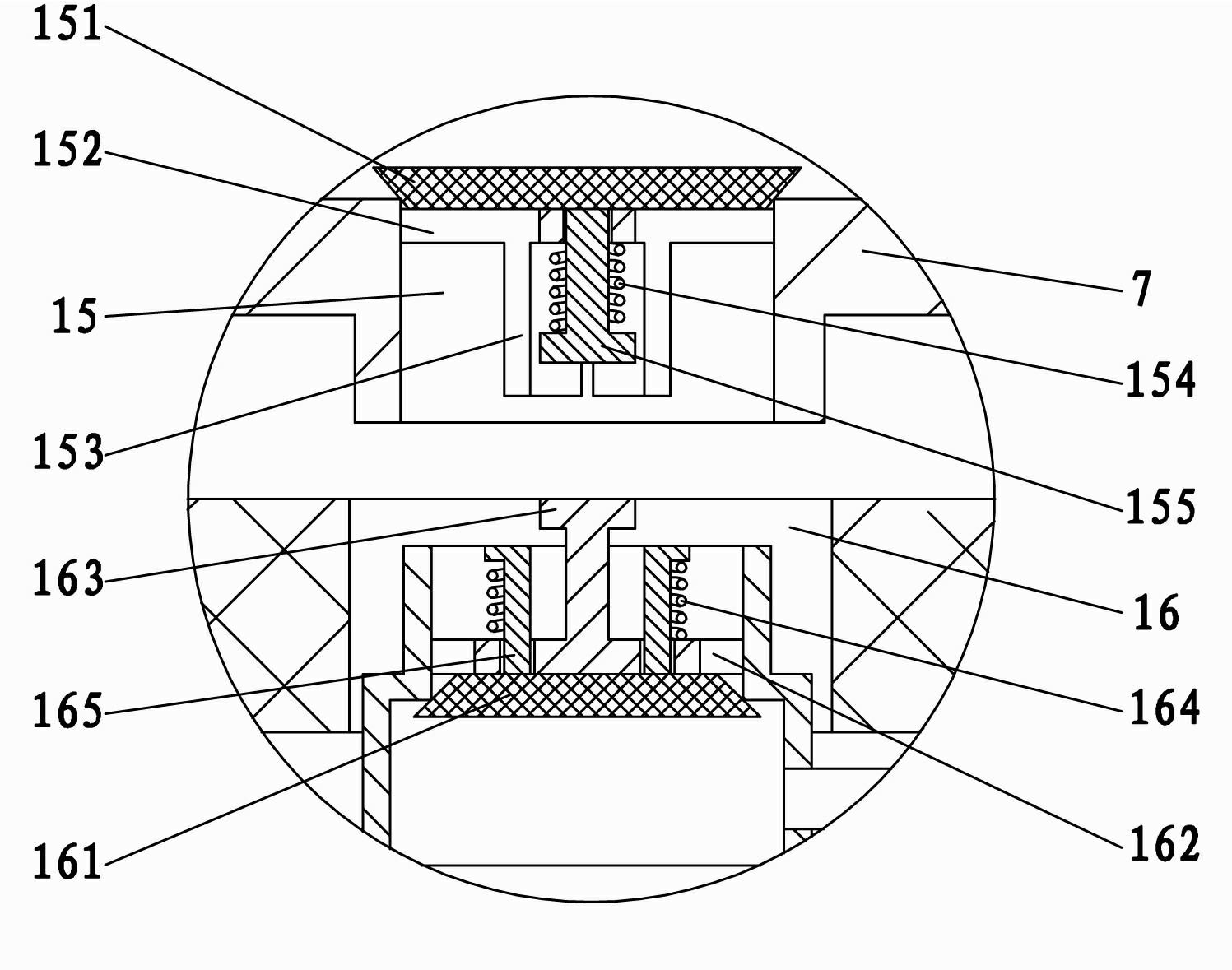

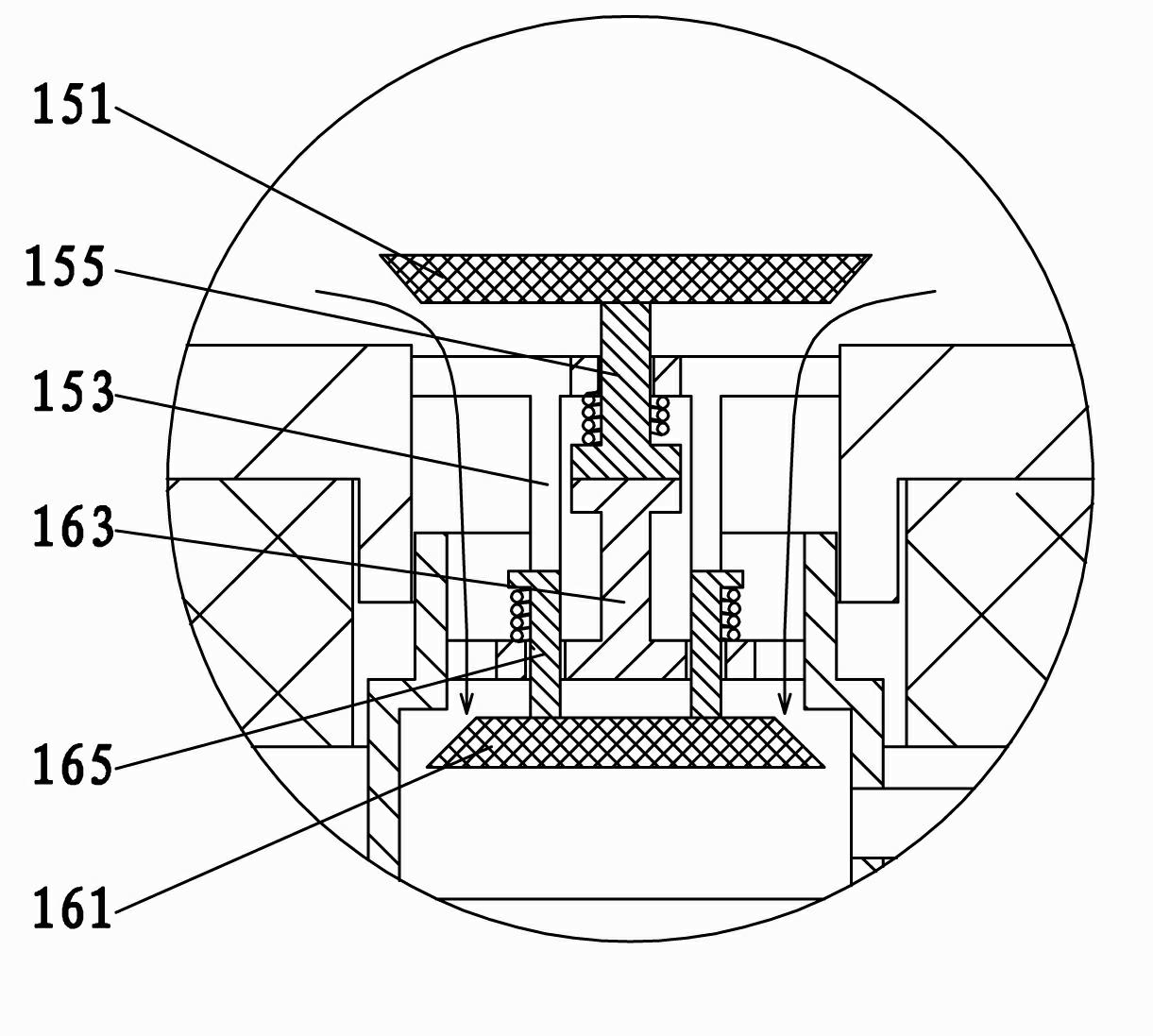

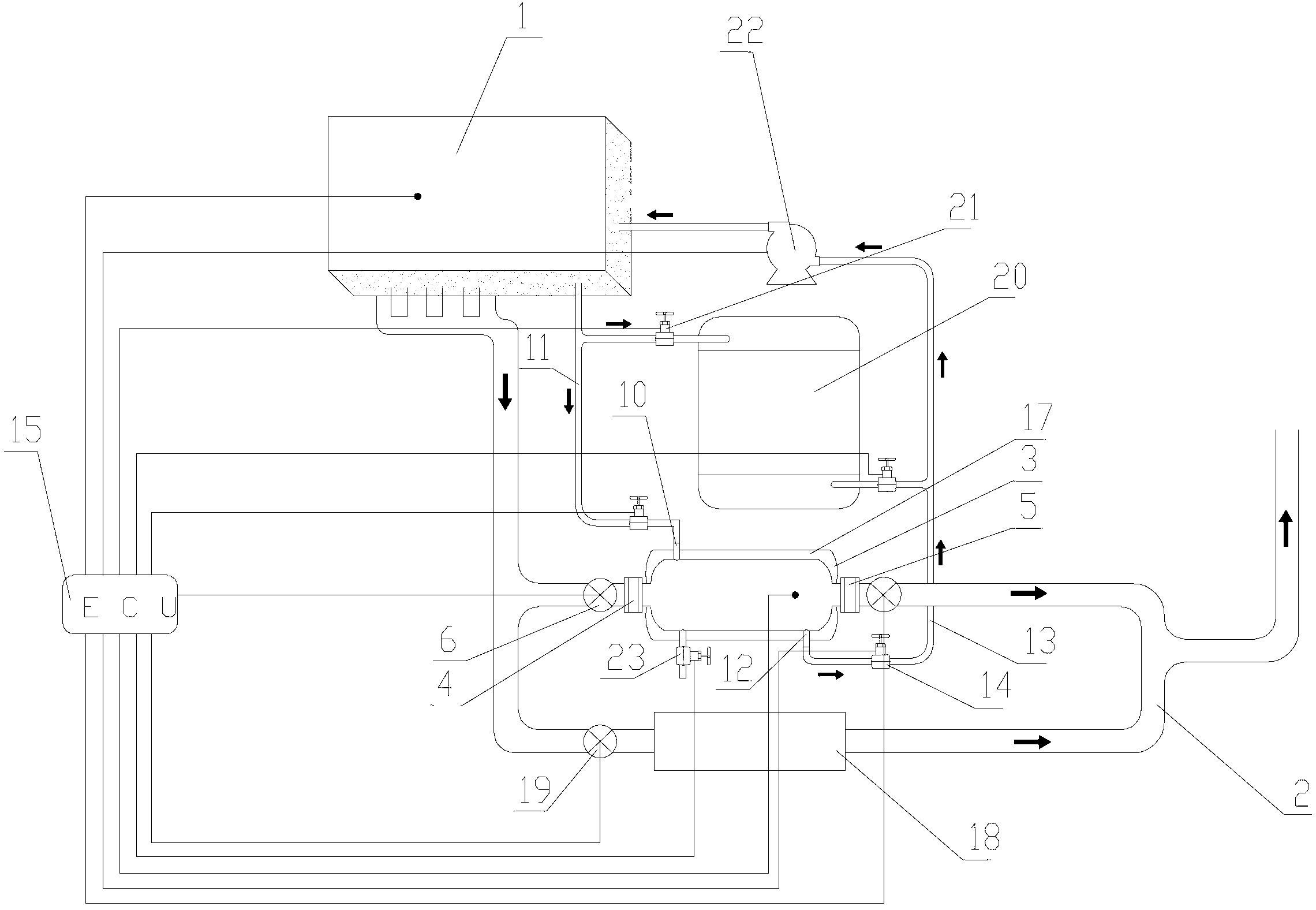

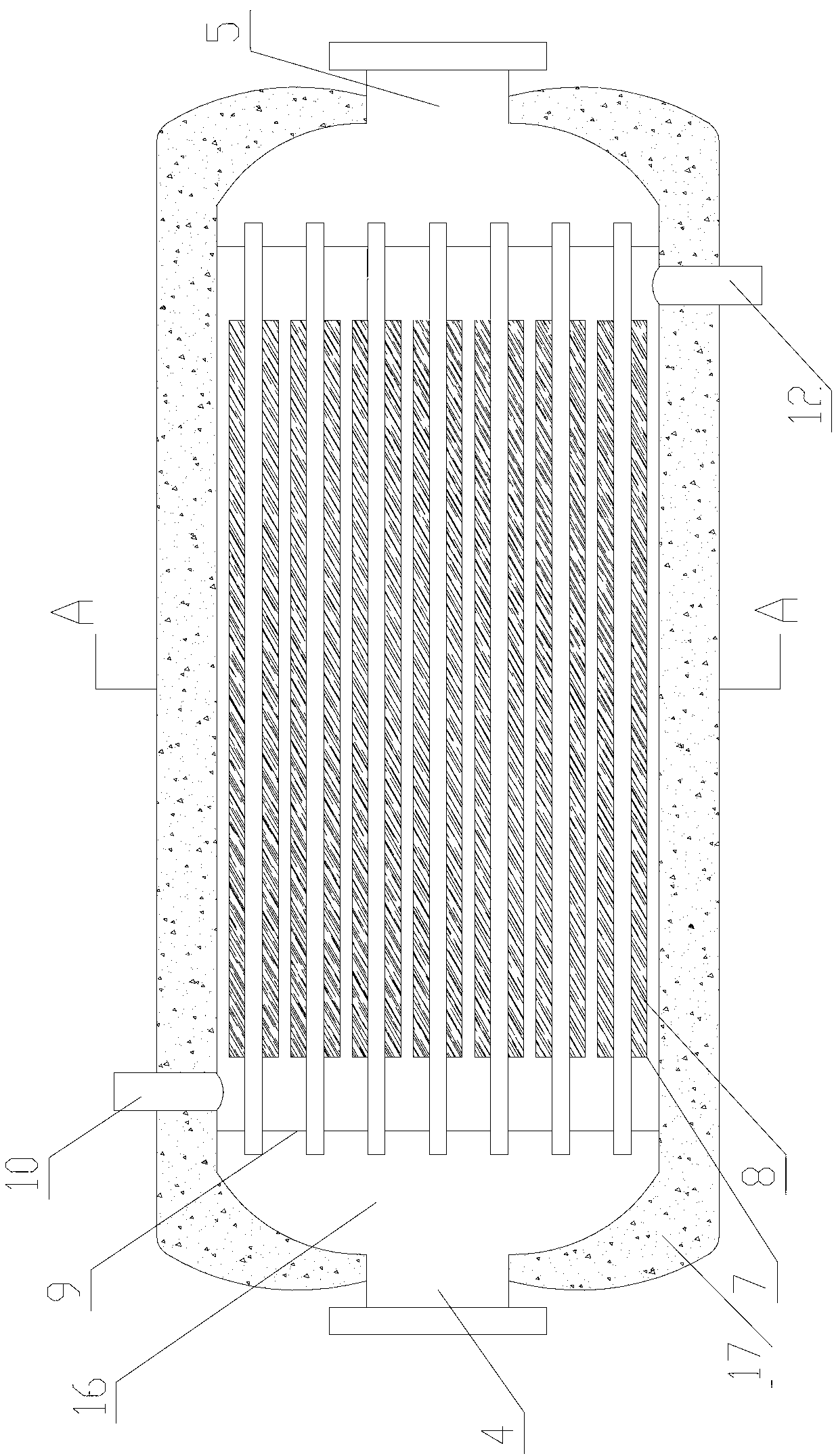

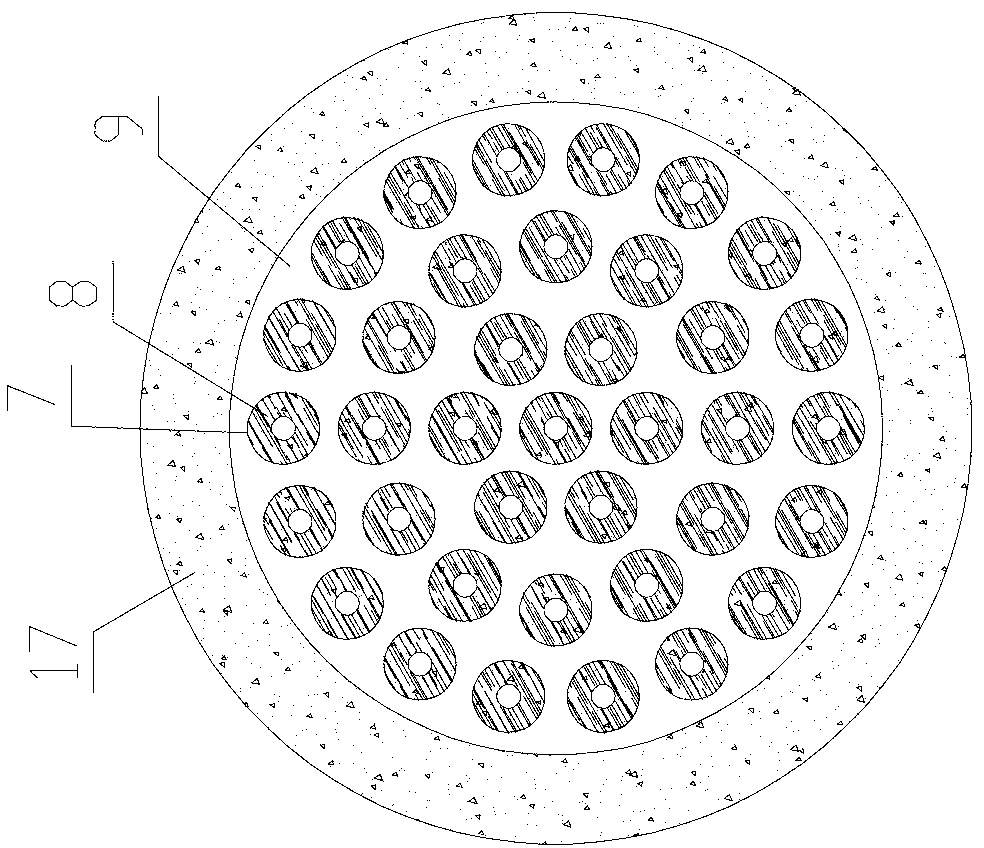

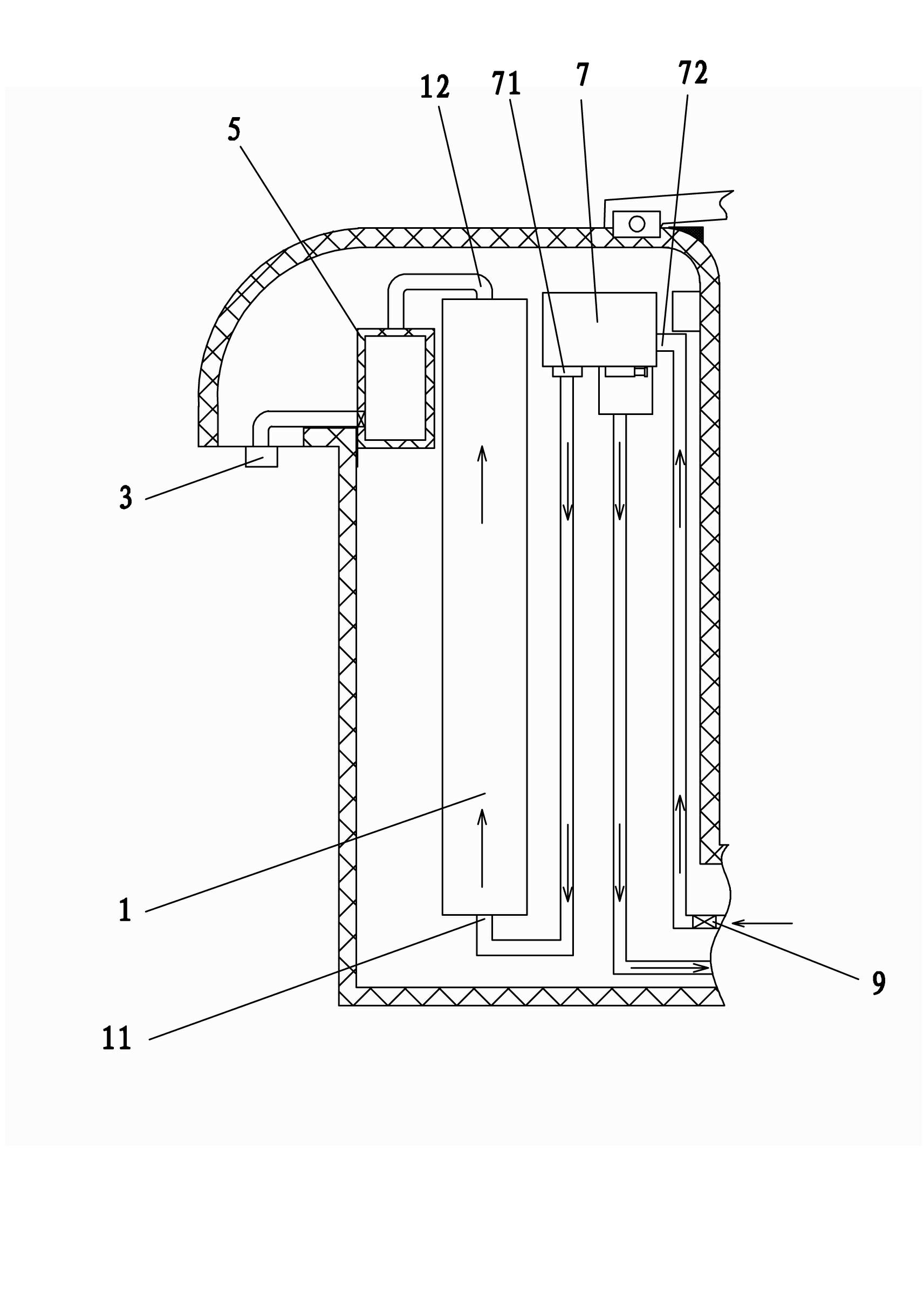

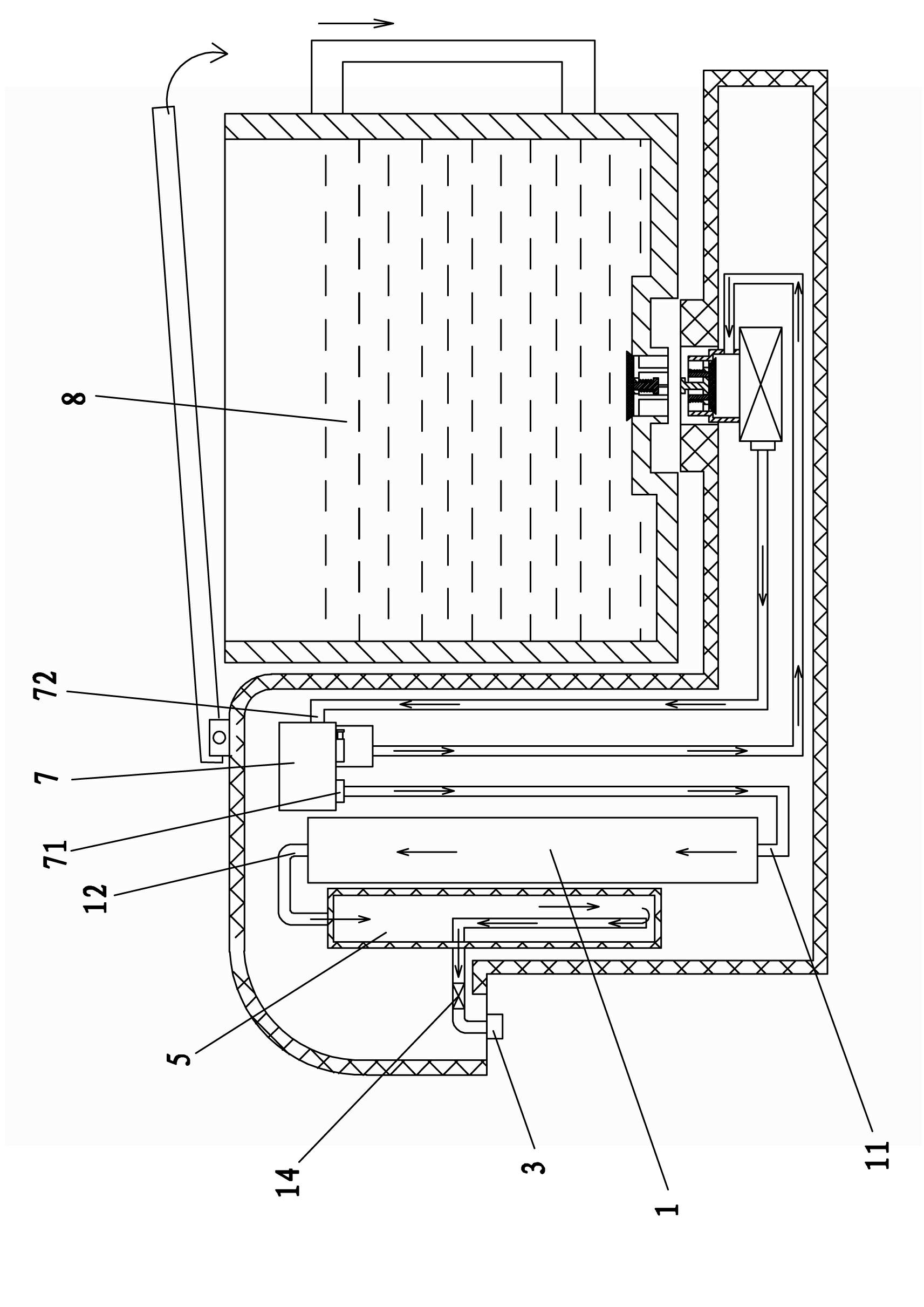

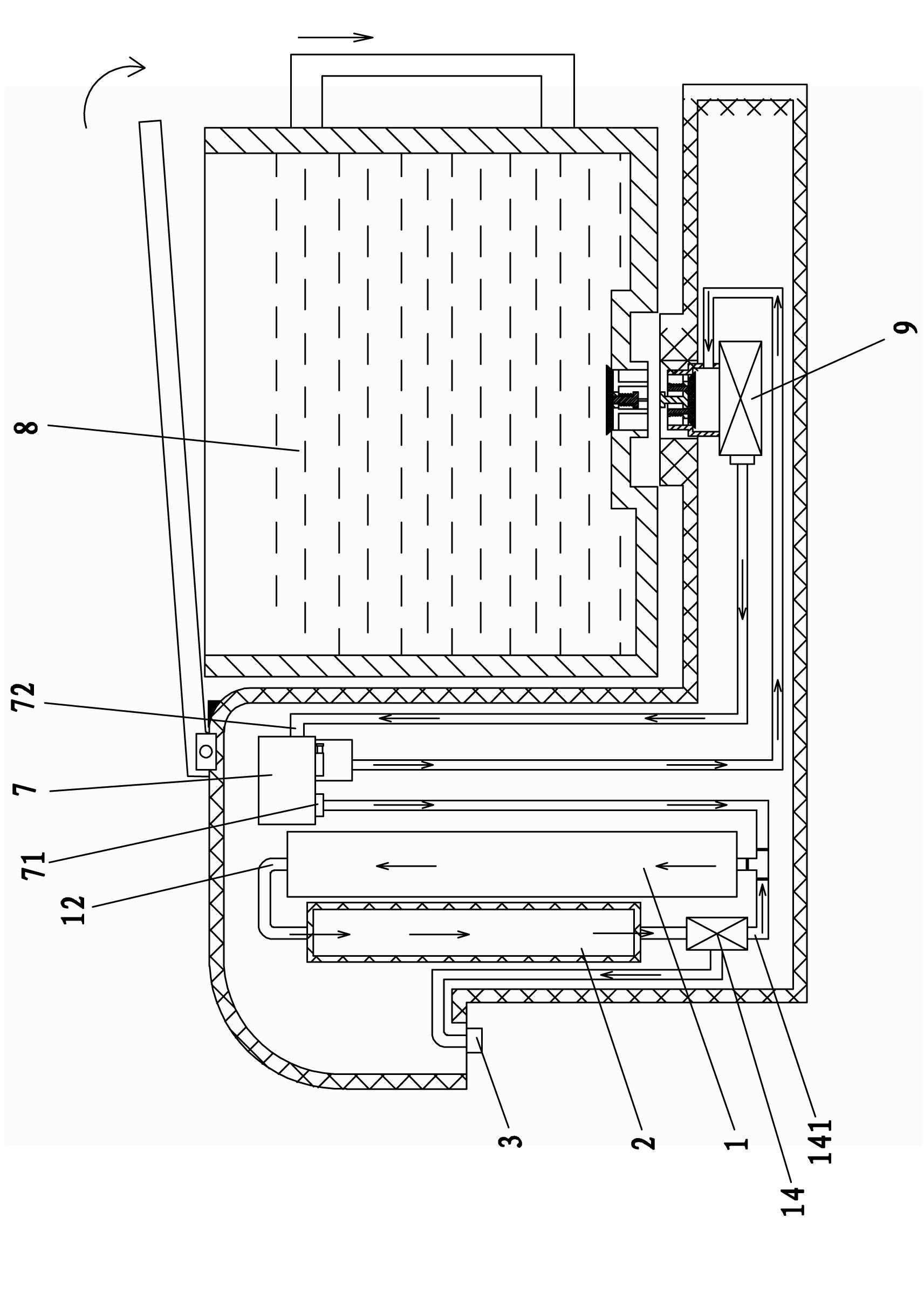

Engine cold-start preheating device

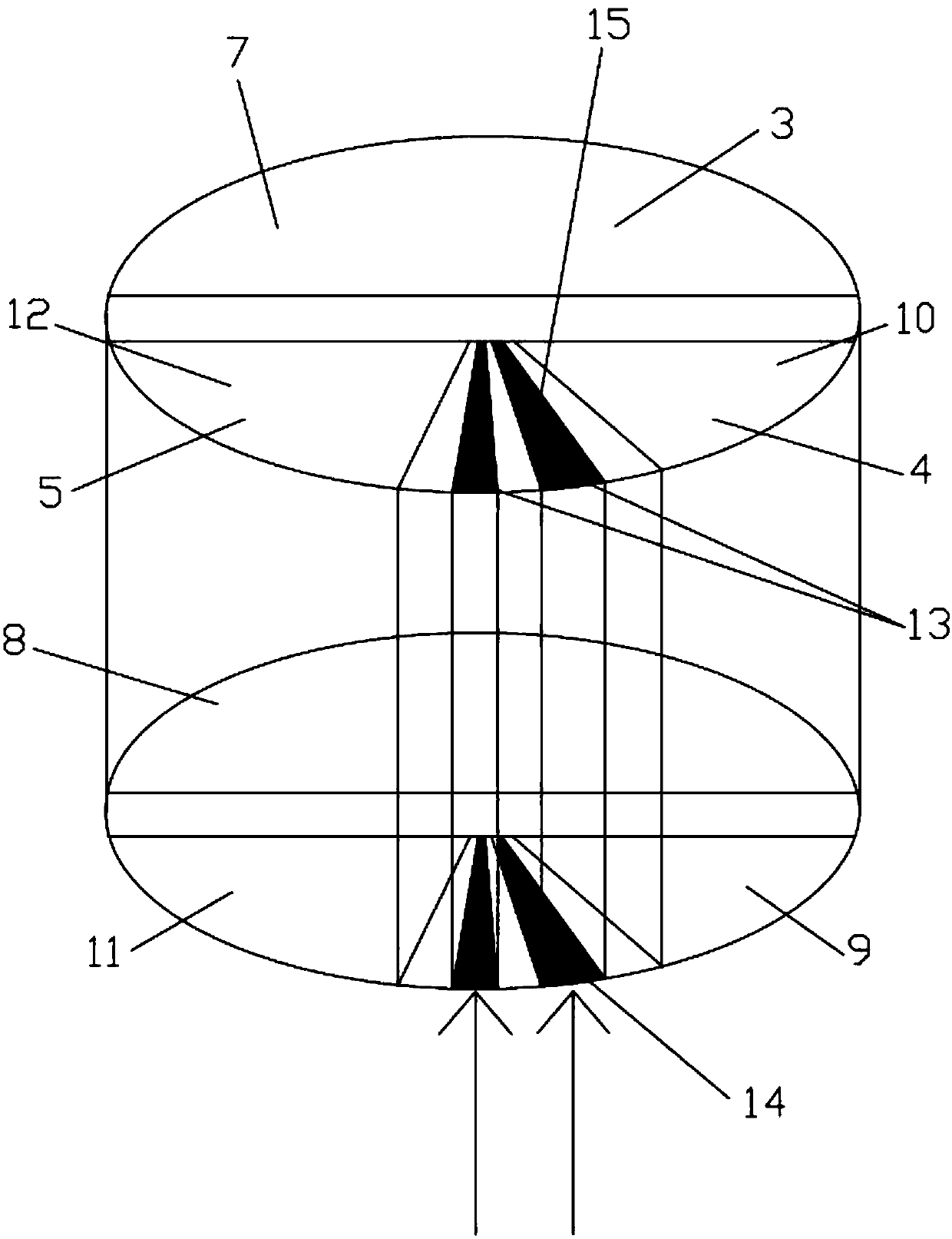

InactiveCN103061947AHigh exhaust gas temperatureStable warm-up performanceInternal combustion piston enginesExhaust apparatusEngineeringPhase change

The invention discloses an engine cold-start preheating device. A heat storing heat exchanger (3) is in a parallel connection with an exhaust pipe (2) of an engine (1), the heat storing heat exchanger (3) is used for storing exhaust air waste heat of the engine (1), the heat storing heat exchanger (3) is in a columnar structure, a plurality of heat storing units are distributed in the heat storing heat exchanger (3), each heat storing unit is a concentric casing pipe (7) which comprises an inner pipe and an outer pipe, a phase change thermal storage material (8) is encapsulated in annular space between the inner pipe and the outer pipe, two ends of the inner pipe are welded on two flow guide plates (9) respectively, a hollow cavity for enabling cooling water of the engine (1) to flow through is formed by the two flow guide plates (9) and inner walls of the heat storing heat exchanger (3), and the inner walls of the heat storing heat exchanger (3) are located between the two flow guide plates (9). The engine cold-start preheating device has the advantages of being low in costs, small in size, efficient, energy-saving and convenient to popularize and use in a wide range.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

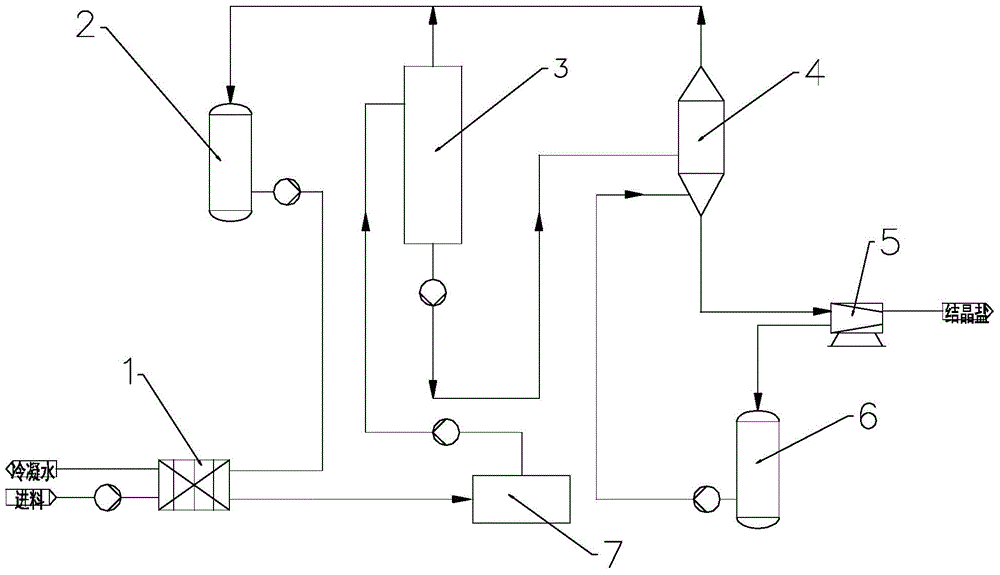

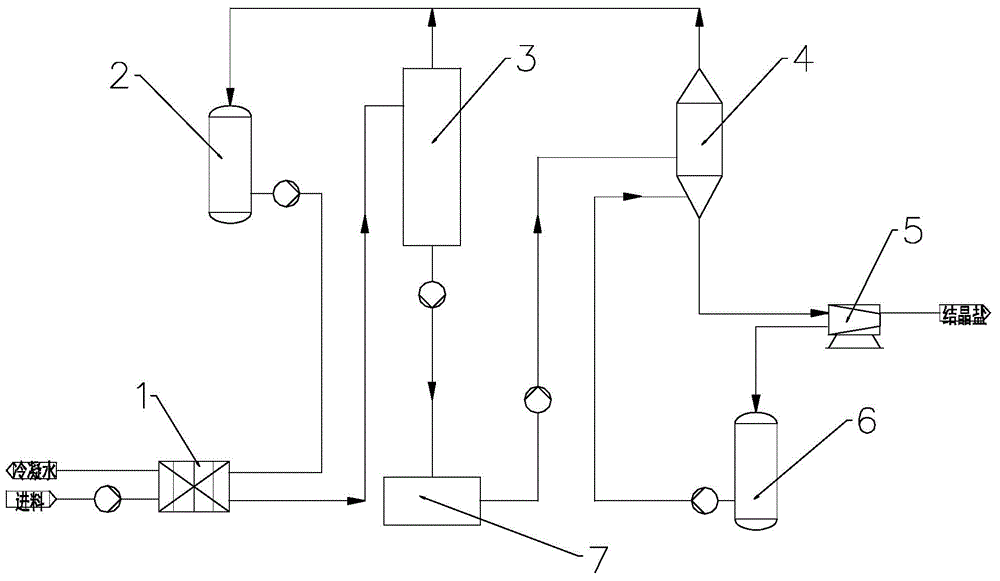

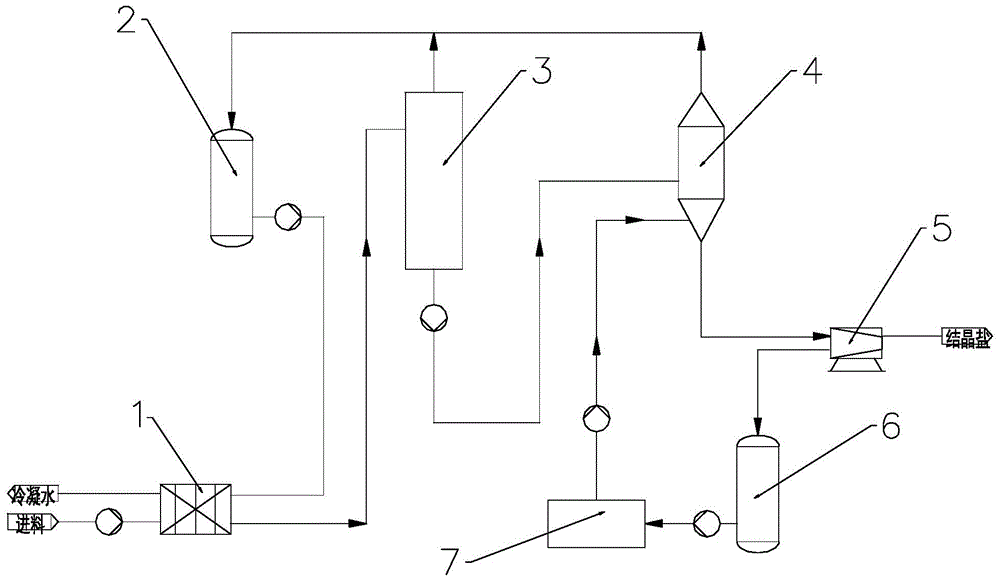

Evaporating and crystallizing zero-discharge treatment system and method for high-COD waste water

The invention discloses an evaporating and crystallizing zero-discharge treatment system and method for high-COD waste water. The system comprises a preheater, an evaporator, a crystallizer, a centrifugal separator, a mother liquor tank and a quality adjusting unit, a water inlet and a water outlet of the preheater are connected with raw waste water and a water inlet of the evaporator respectively, concentrated liquor generated by evaporation of the evaporator enters the crystallizer, crystal slurry generated by the crystallizer enters the centrifugal separator, mother liquor generated by centrifugal separation of the centrifugal separator returns to the crystallizer, crystallized salt generated by separation is discharged or recycled, and the quality adjusting unit removes COD in the waste water through electrocatalytic oxidation and is arranged between the water outlet of the preheater and the water inlet of the evaporator, or between a concentrated liquor water outlet of the evaporator and a water inlet of the crystallizer or between a water outlet of the mother liquor tank and the water inlet of the crystallizer. The system can realize zero discharge truly under the premise of running stably for a long time.

Owner:BEIJING BIOTECHINA ENVIRONMENT CORP

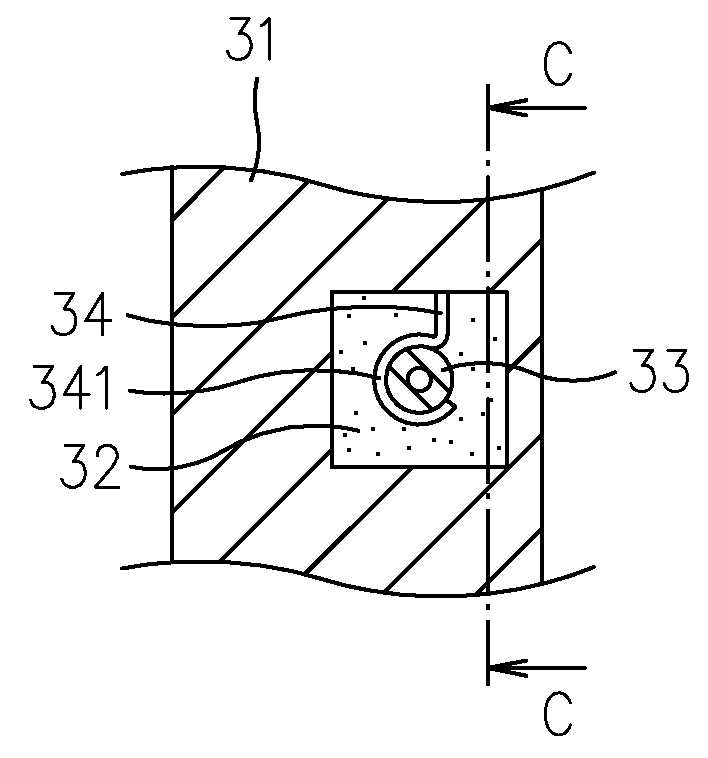

Mold having a coaxial cooling and heating coil structure

ActiveUS8052415B2Improve preheating efficiencyShorten the timeCoil arrangementsIndirect heat exchangersHeat conductingEngineering

The present invention relates to a coaxial cooling / heating coil structure and a mold configured with the same, in which the coaxial cooling / heating coil is comprised of: a frame, configured with a cooling channel having an inlet, provided for a cooling water to flow therein, and an outlet, provided for discharging the cooling water therefrom; and a heat-conducting coil, disposed inside the cooling channel. The coaxial cooling / heating structure is fitted to a mold to be used for enhancing the preheating efficiency of the mold while improving the time required for cooling the mold.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

Drinking water heating device with water collecting tank

The invention relates to a drinking water heating device with a water collecting tank, which comprises a water outlet mouth, an instant heater, a balance water tank and a first water pump. The balance water tank is provided with a water inlet and a water outlet, the water inlet is connected with the first water pump, and the water outlet is communicated with an inlet of the instant heater. The drinking water heating device is characterized by further comprising the water collecting tank, wherein the water collecting tank is disposed between an outlet of the instant heater and the water outlet mouth. The water collecting tank is communicated with the outlet of the instant heater and the water outlet mouth and temporarily stores a certain amount of high-temperature hot water for drinking, accordingly, power of the instant heater does not need to be increased, sufficiency and stability of outlet water can be guaranteed, the drinking water heating device is simple and reasonable in structure, simple and safe in use and long in service life, is low-carbon and energy-saving, and can meet different drinking needs (particularly the requirement on high-temperature water quantity) for making tea, brewing coffee and the like of people.

Owner:FOSHAN FOUR SEASONS TEA SET CO LTD

Pre-heating and heating device of high-temperature molten salt storage tank

ActiveCN107555003AImprove preheating efficiencyControl temperature rise rateOhmic-resistance heatingTank wagonsElectricityMolten salt

The invention discloses a pre-heating and heating device of a high-temperature molten salt storage tank. The pre-heating and heating device comprises a tank wall electric heat tracing, a tank bottom electric heat tracing, an air gathering pipe, a circulating fan, an air door regulator, a fixed type spiral nozzle, a rotation type nozzle and an air channel, and the pre-heating and heating device combines tank body pre-heating and a storage medium together. The electric heat tracings are arranged at the tank bottom and the tank wall, the electric heat tracings heat the tank body metal and conducts heat preservation in the pre-heating process of the tank body, the temperature of the tank wall is cooled and balanced through a closed type circulating air system, meanwhile, the circulating air isheated, and the circulating hot air reheats the tank top and the tank bottom. The electric heat tracings heat molten salt to maintain the temperature of the medium in the long-time break down. The pre-heating and heating device avoids that a conventional electric heating bar sleeve pipe conducts trepanning at the bottom of the tank wall, so that the risk that the storage tank leaks is reduced. Meanwhile, a high-power air heater does not need to be configured. The pre-heating efficiency and the operation reliability of the storage tank are improved.

Owner:HANGZHOU BOILER GRP CO LTD

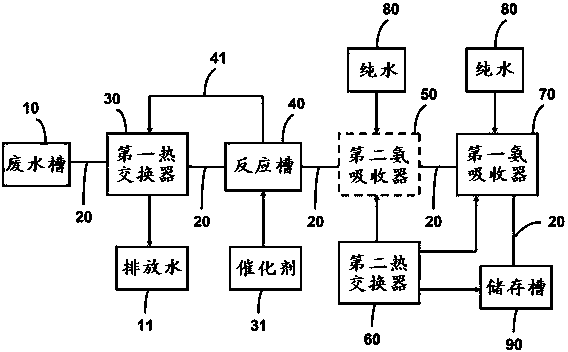

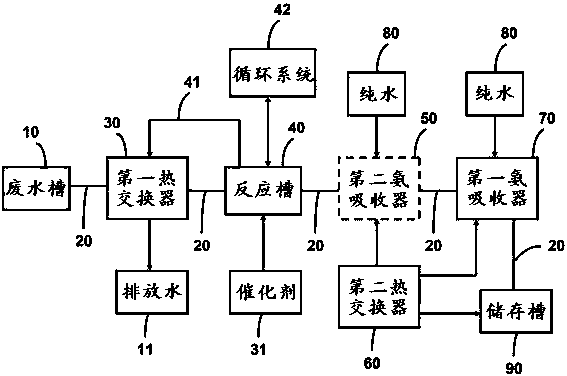

High-performance ammonia recovery system

InactiveCN103964623AEfficient conversionImprove preheating efficiencyWater contaminantsChemical industryAmmonia gasEffluent

The invention discloses a high-performance ammonia recovery system. The high-performance ammonia recovery system at least comprises a first heat exchanger, a reaction tank and a first ammonia absorber. The first heat exchanger is used for preheating wastewater, and the reaction tank is communicated to the first heat exchanger. The reaction tank heats the preheated wastewater to a first temperature, and also comprises a catalyst for allowing ammonia in the wastewater to be divorced from the wastewater and then be converted into ammonia gas. The first ammonia absorber is connected with a second heat exchanger and is communicated to the reaction tank; a second absorber allows the ammonia gas to be dissolved in pure water so as to be converted into ammonia water by spraying pure water, and the ammonia water is cooled to a second temperature through the second heat exchanger.

Owner:I ZHAN SYST TECH

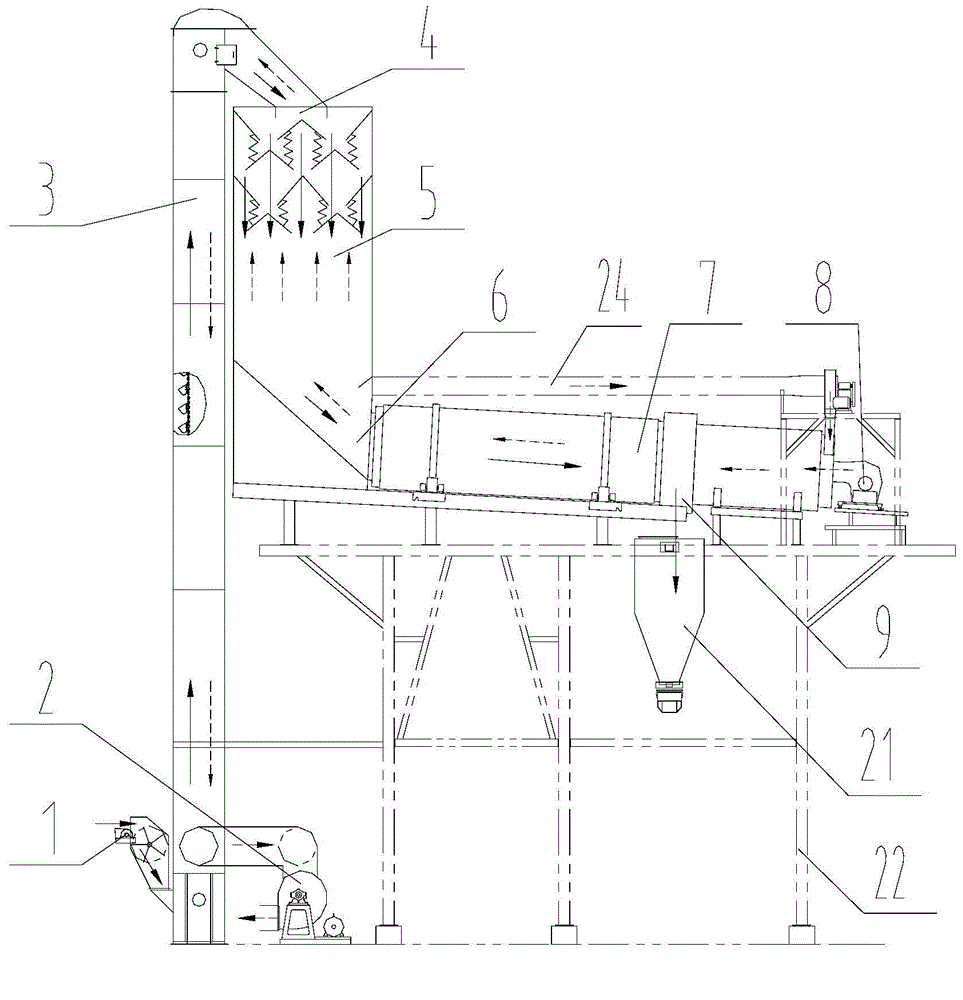

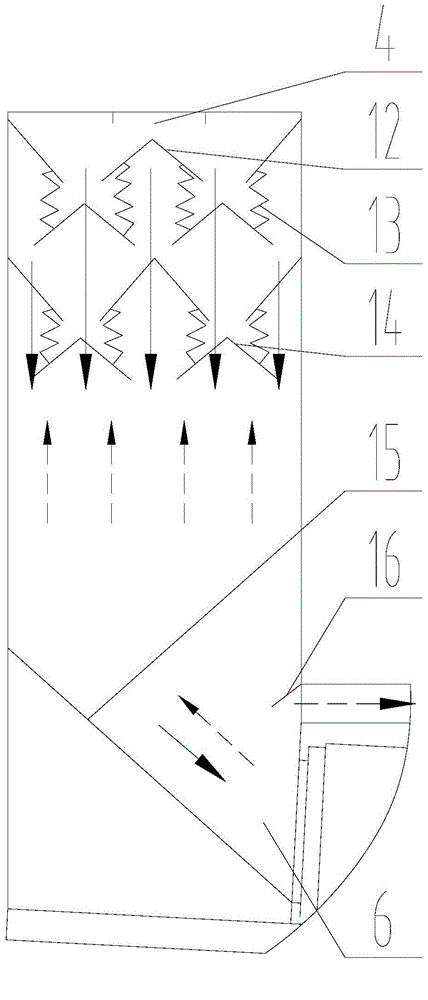

Heat regeneration device

ActiveCN104131506ALow process pollutionImprove preheating efficiencyRoads maintainenceHeat regenerationThermal efficiency

The invention provides a heat regeneration device, comprising an elevator for conveying materials. One side of the elevator is provided with a feeding tower; one end of the elevator is communicated to one end of the feeding tower; the other end of the elevator is provided with an induced draft fan communicated with the elevator; the other end of the feeding tower is provided with a roller; the roller is provided with a combustor for heating the materials and a material-discharging tank. With the structure, a moving direction of high temperature smoke is opposite to a flowing direction of the material under the effect of the induced draft fan during a working process, so that the heat regeneration device can absorb and recover smoke dust in the smoke while preheating the feeding tower, thereby having relatively small energy consumption and pollution and high thermal efficiency.

Owner:HUNAN SANY ROAD MACHINERY

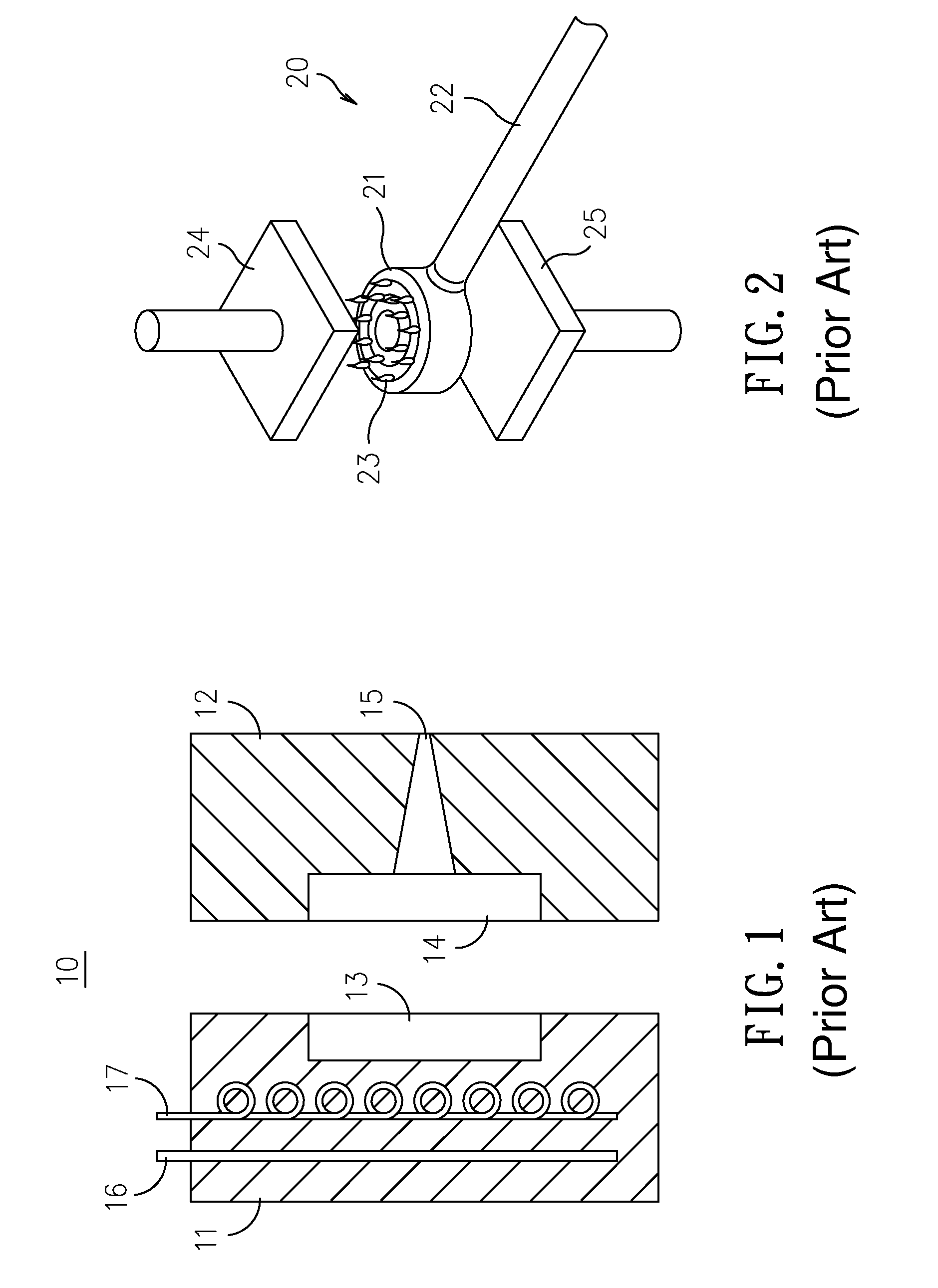

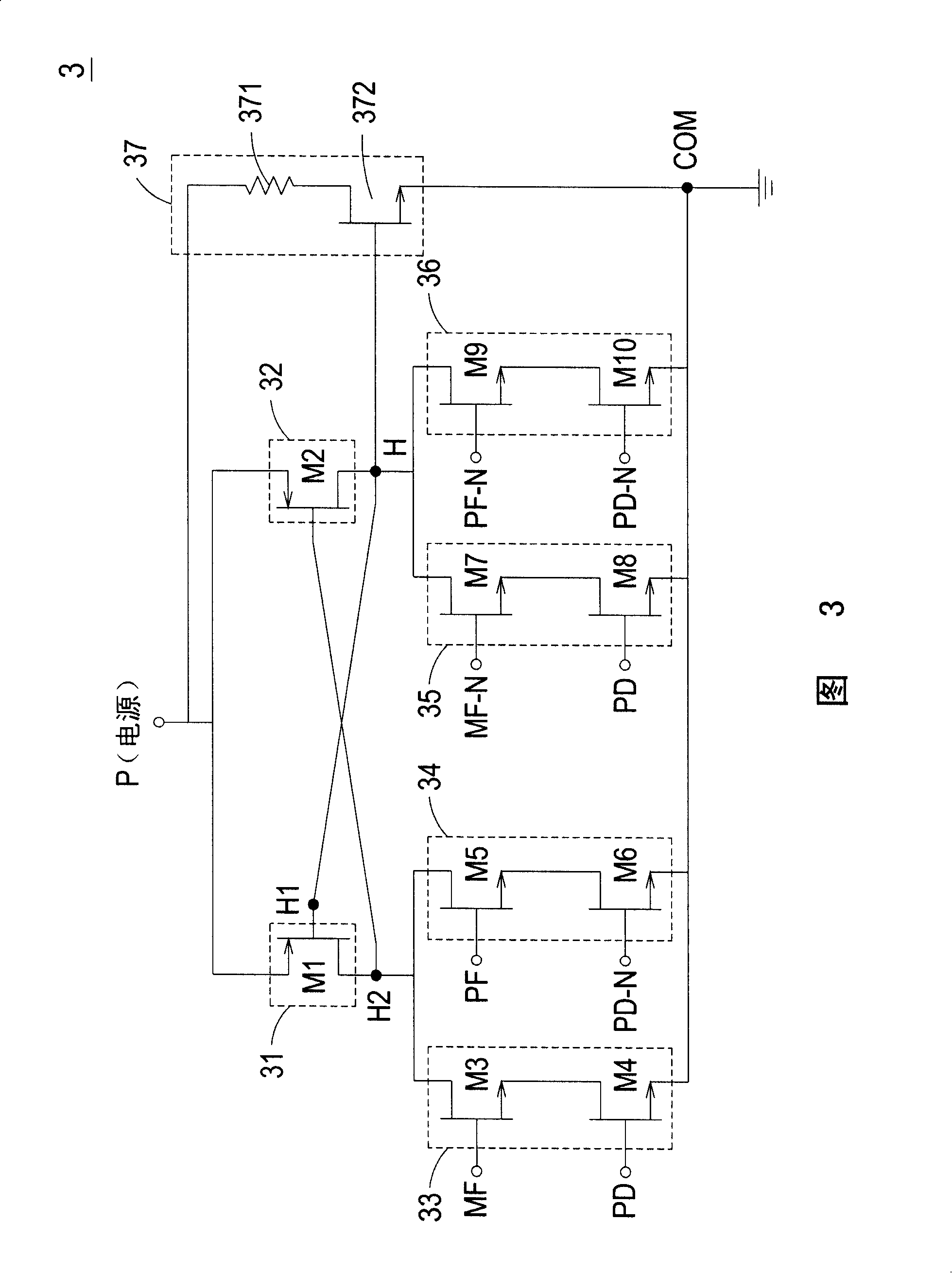

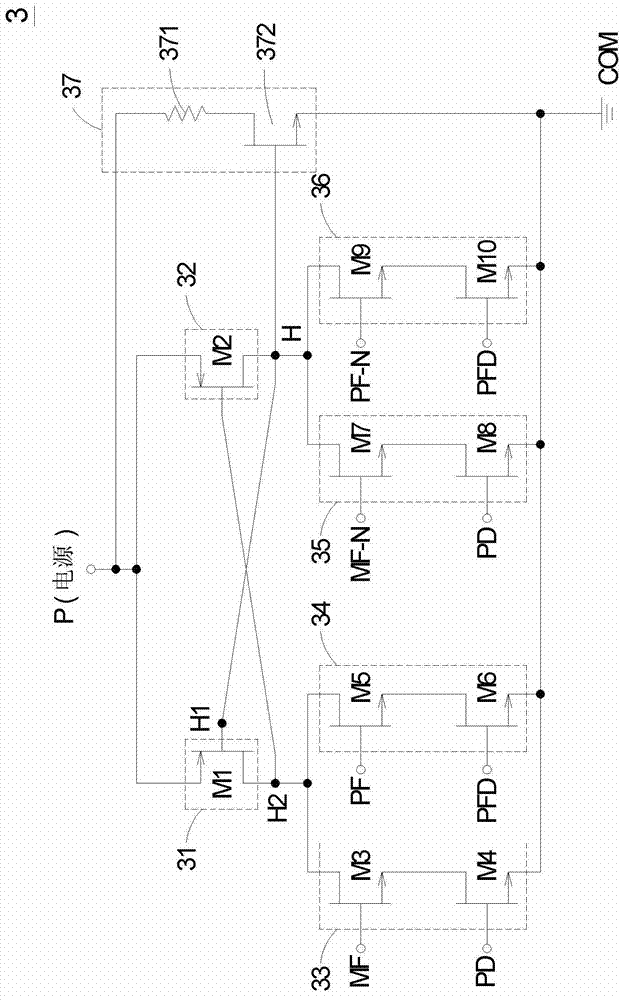

Inkjet chip and contro circuit of printing module of rapid prototyping apparatus

ActiveUS20160207264A1Facilitate heating circuitEasy to operateConfectioneryCouplings bases/casesLiquid jetControl signal

An inkjet chip of printing module of a rapid prototyping apparatus and a control circuit thereof are disclosed. The inkjet chip has a length and a width to define a total area including an unwiring area and a wiring area. The unwiring area has at least three liquid supply slots in parallel with each other and respectively connected to one of the ink chambers of the modular ink cartridge. The wiring area has a control circuit. The control circuit includes a plurality of liquid ejectors. Each liquid ejector has a heating resistor, a driving transistor, and a nozzle. The control circuit is connected to receive a power signal, a printing data signal, a preheating data signal, a preheating control signal, a reverse preheating control signal, a heating control signal, and a reverse heating control signal and connected with the common connection node for controlling the liquid ejector.

Owner:MICROJET TECH

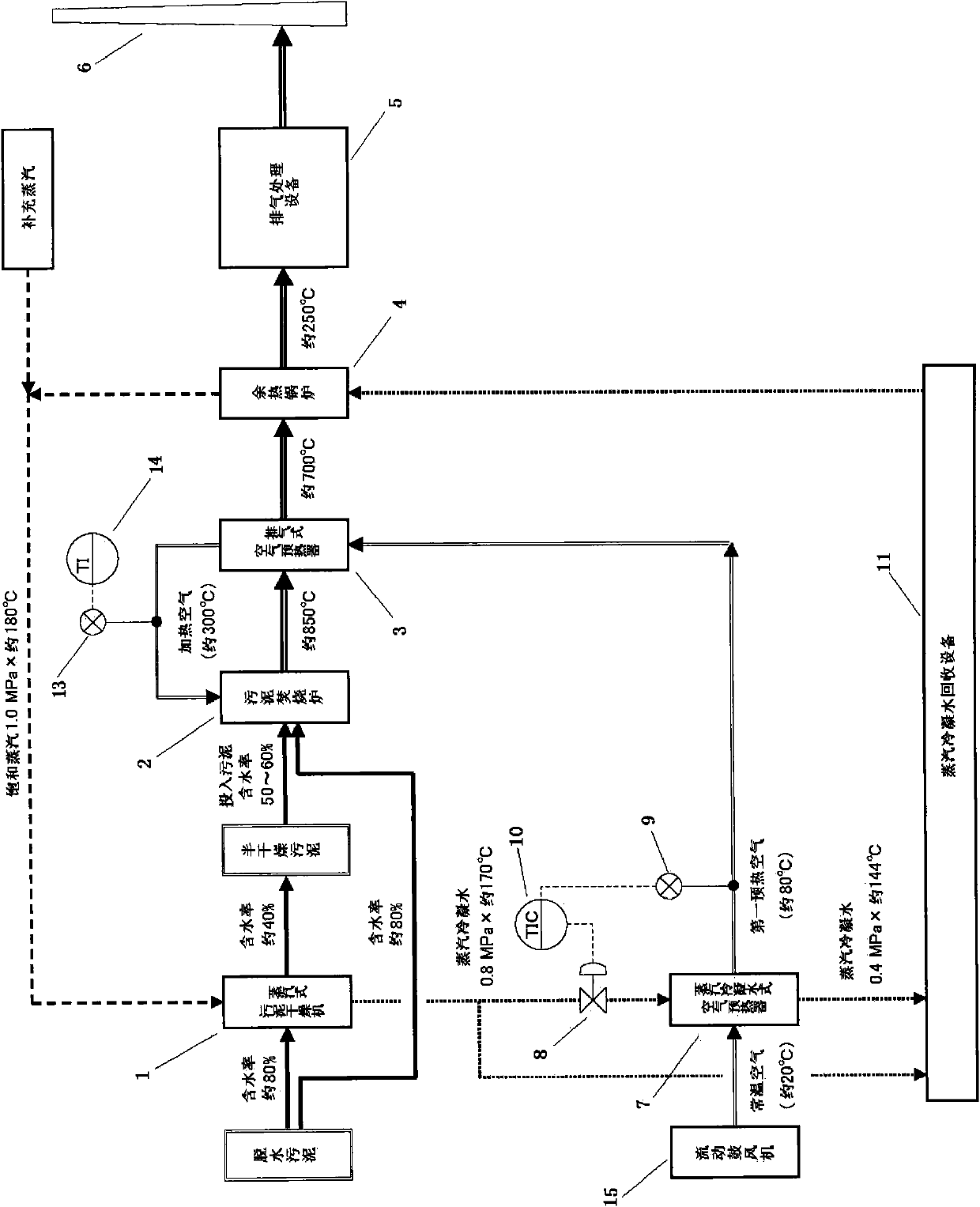

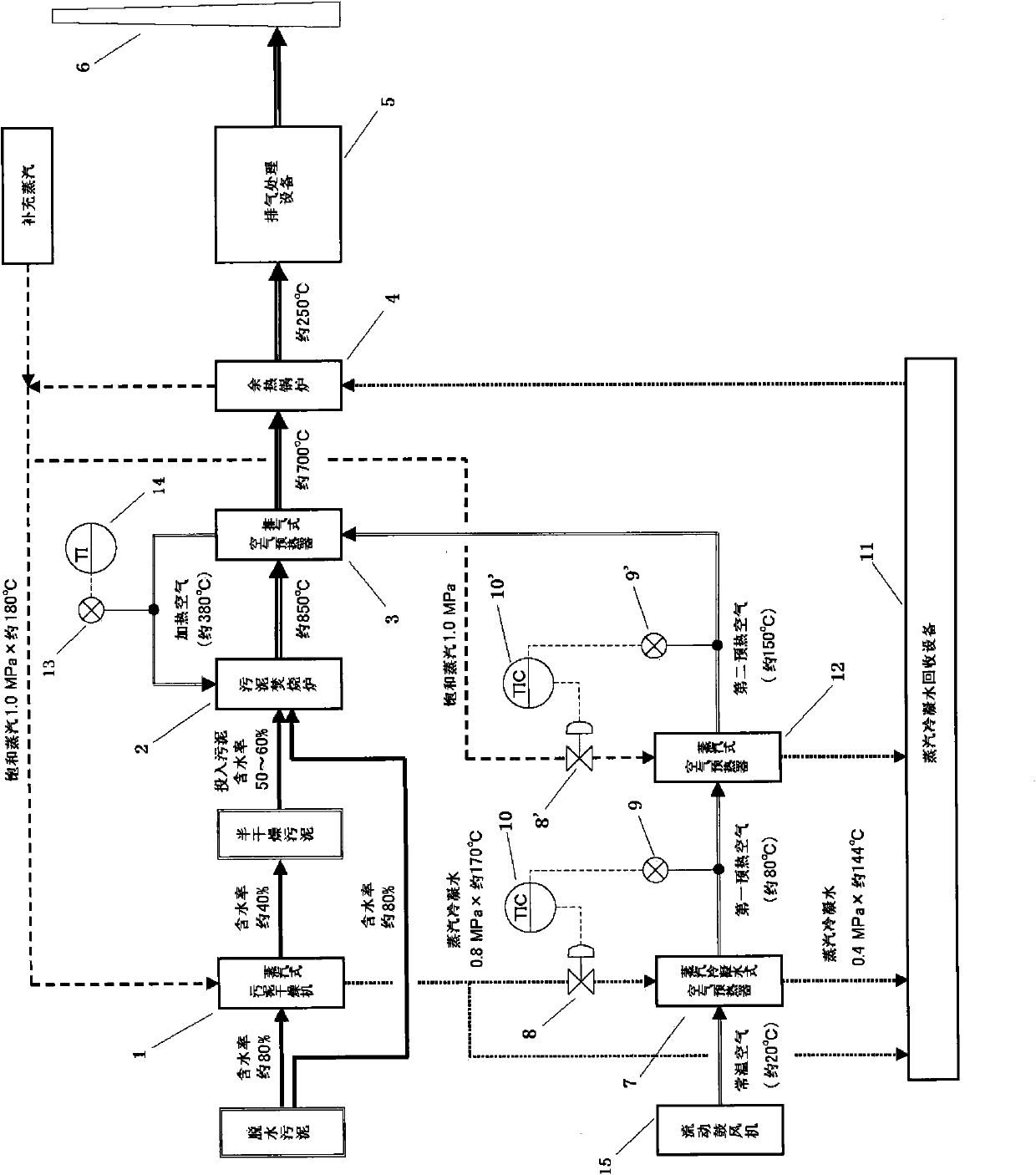

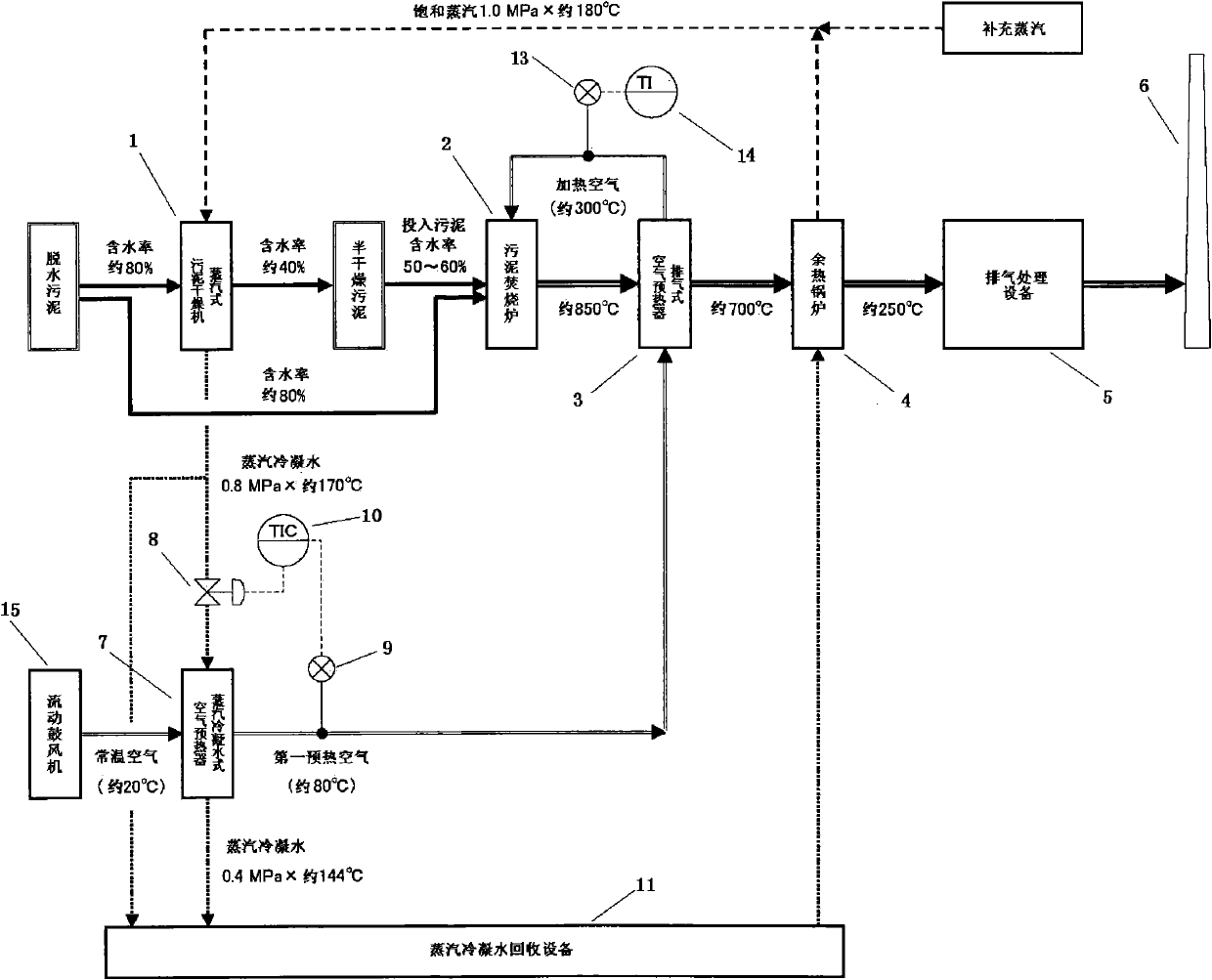

Sludge incineration method and sludge incineration facility

InactiveCN102563666AFlexible response to incineration needsIncrease temperatureIndirect carbon-dioxide mitigationIncinerator apparatusCombustionEngineering

The invention provides a sludge incineration method and a sludge incineration facility adopting the same. The sludge incineration method includes the following steps: a sludge incinerator is utilized to incinerate half-dried sludge dried by a steam type sludge drier, the heat of the steam condensate of the steam type sludge drier is recovered, the recovered heat is utilized to preheat the normal-temperature air, so that the first preheated air is obtained, the heat of the exhausted gas of the sludge incinerator is recovered, the recovered heat is utilized to heat the first preheated air which is already preheated, so that the heated air is obtained, the heated air is used as the combustion air and supplied to the sludge incinerator, and moreover, according to the character of the half-dried sludge, the temperature of the combination air is regulated by increasing and decreasing the amount of the steam condensate. When the sludge incineration method is adopted, the temperature of the heated air not only can be regulated but also can reach a higher level, and the sludge incineration method can meet the incineration requirement of various types of sludge with shapes varying in a wide range.

Owner:KUBOTA LTD

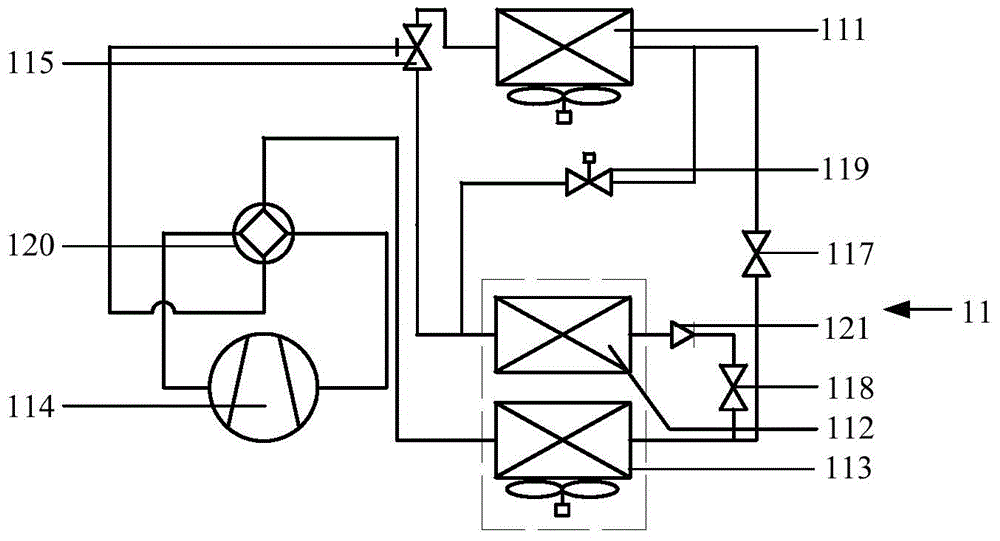

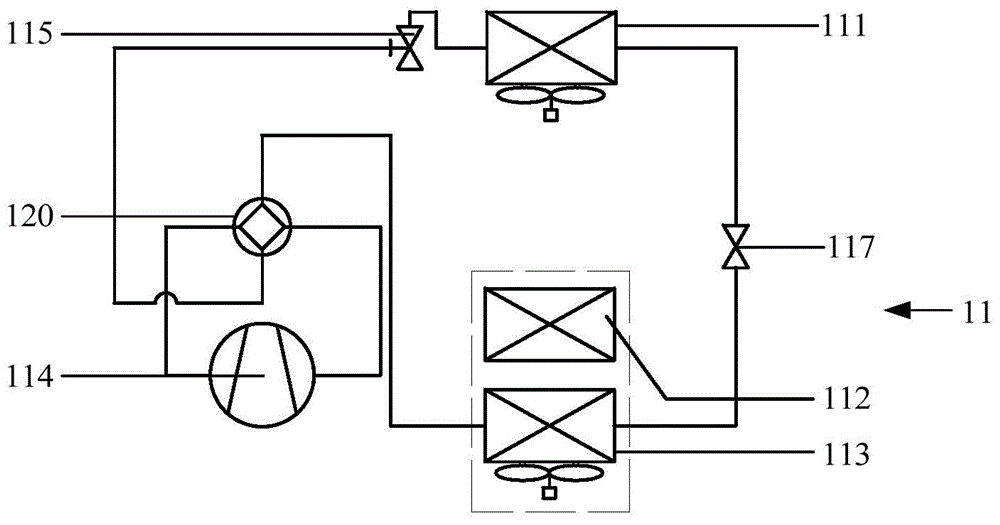

Drying system, air conditioner and work mode switch method

ActiveCN105066656AImprove experienceRealize automatic controlMechanical apparatusDrying gas arrangementsAutomatic controlFour-way valve

The invention provides a drying system, an air conditioner and a work mode switch method. The drying system comprises an outdoor heat exchanger, a first indoor heat exchanger, a second indoor heat exchanger, a compressor, a three-way electromagnetic valve and a controller. The three-way electromagnetic valve is provided with three ports at the first end, second end and third end, wherein the first end is connected to the compressor through a four-way valve, the second end is connected to the outdoor heat exchanger, and the third end is connected to the first indoor heat exchanger. The controller is connected to the three-way electromagnetic valve and used for switching the three ports according to a received mode adjustment instruction to adjust the work modes of the air conditioner, and the work modes include a pre-heating mode, a temperature-control mode and a drying and dehumidification mode. The technical scheme replaces the scheme in the correlation technique that air is pre-heated in an electric heating mode, so that energy consumption is reduced, automatic control over drying of a heat pump is realized, energy is saved greatly, and emission is reduced greatly.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

Multi-sector self-cleaning anti-corrosion and anti-blocking rotary air preheater

PendingCN107726356ASimple structureStrong targetingCombustion processIndirect carbon-dioxide mitigationAir preheaterSmoke

The invention discloses a multi-sector self-cleaning anti-corrosion and anti-blocking rotary air preheater comprising a shell, a center rotor installed in the shell and capable of rotating, a smoke sector, a primary air sector, a secondary air sector and a self-cleaning sector. The center rotor is a chamber segmented by multiple partition plates in the circumferential direction. A heat storage element is arranged in the chamber. The smoke sector, the primary air sector, the secondary air sector and the self-cleaning sector are all installed on the shell. Air penetrates a sector of the heat storage element of the center rotor. The self-cleaning sector is arranged between the primary air sector and the secondary air sector. Self-cleaning hot air enters the lower portion of the self-cleaningsector and is discharged from the upper portion. The air preheater is simple in structure, scientific, convenient, high in pertinence and novel in design, the self-cleaning sector is quite scientifically arranged, the self-cleaning hot air is injected, and the problems of corrosion and ash clogging of the air preheater are thoroughly solved.

Owner:HANGZHOU XINJI ENERGY TECH

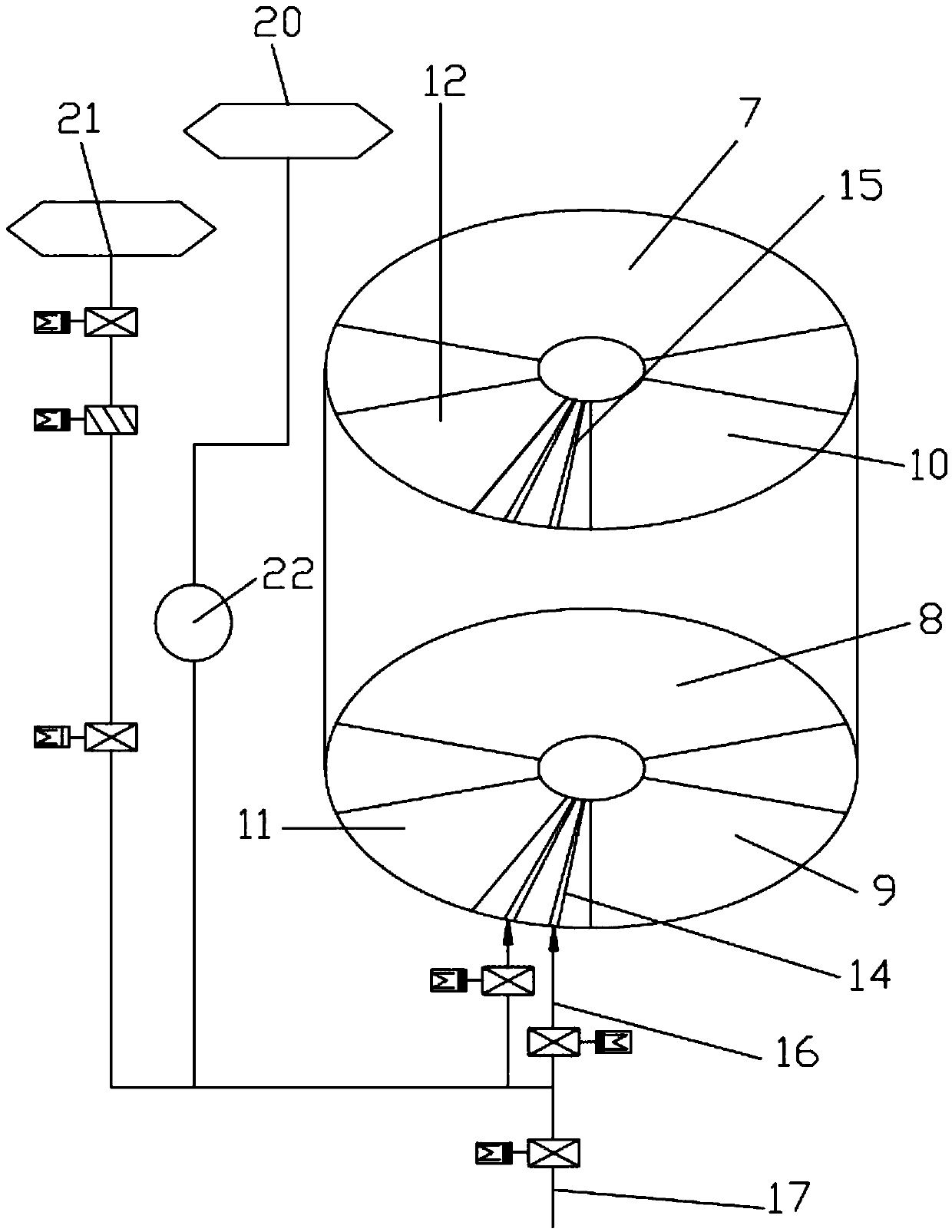

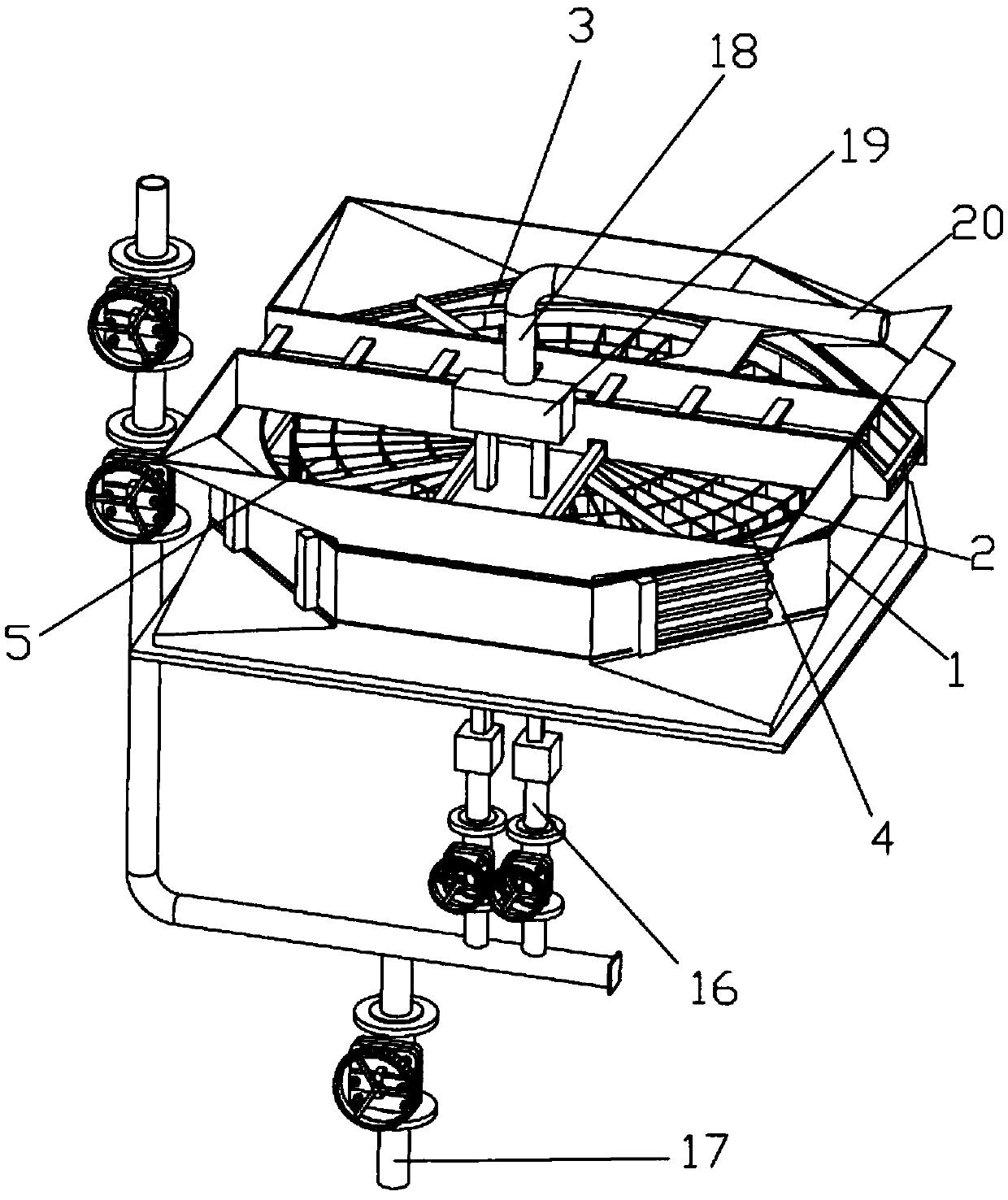

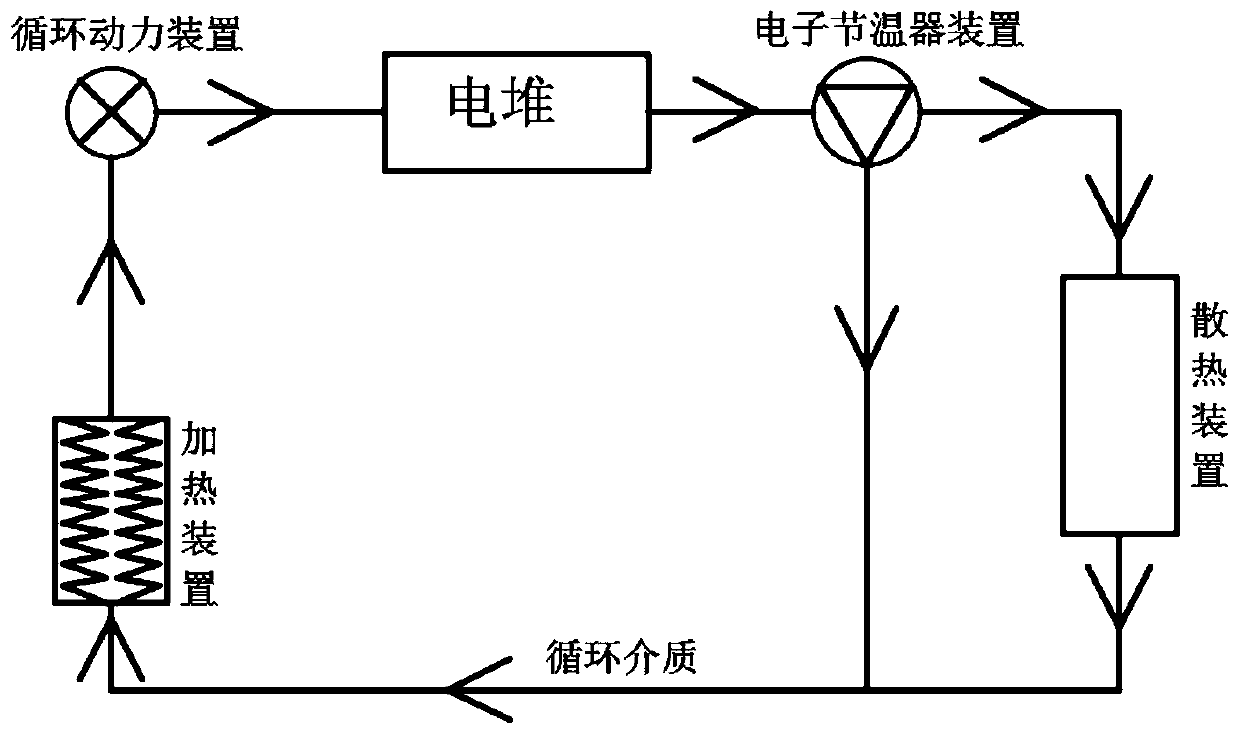

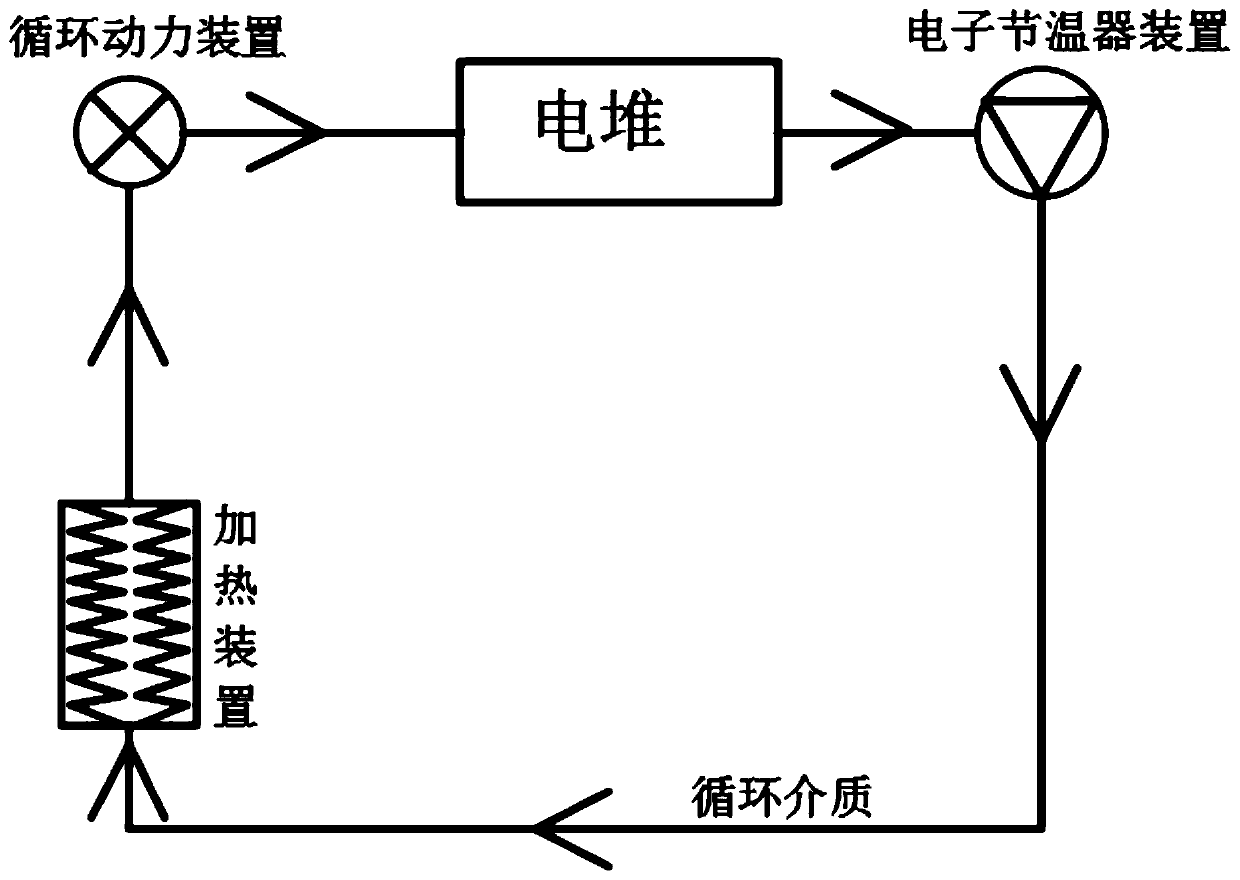

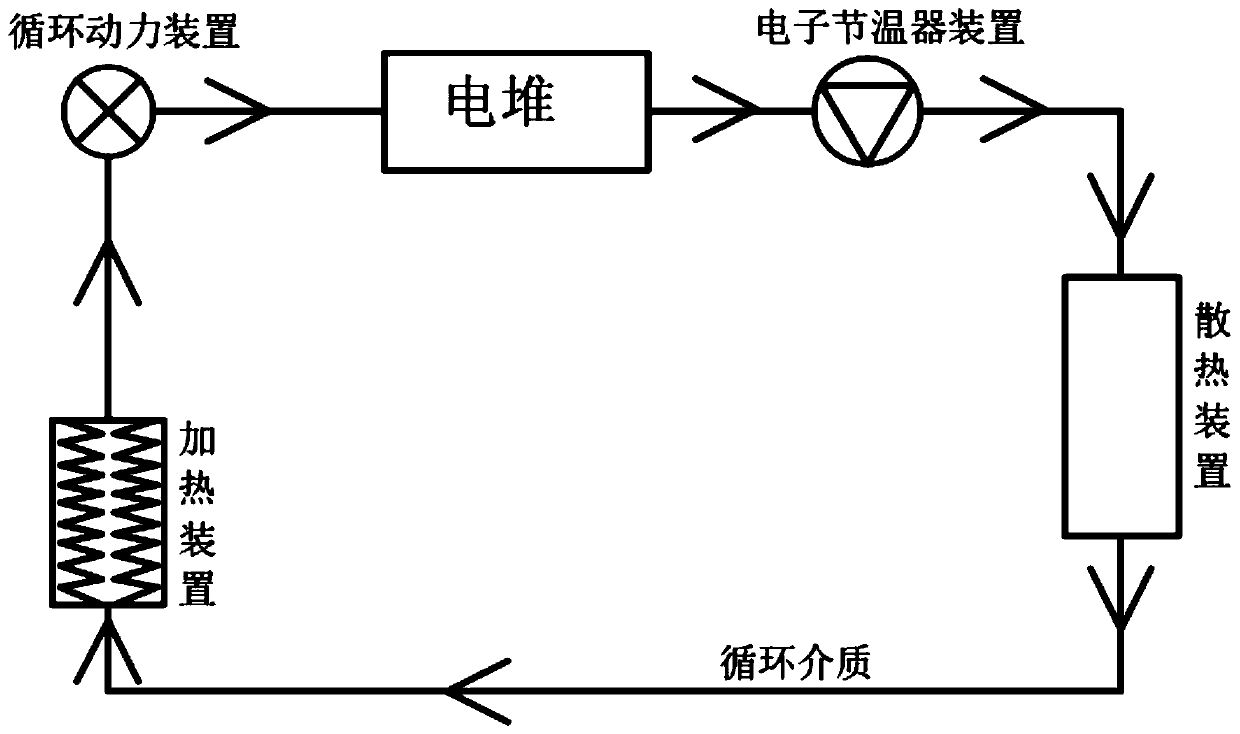

Methanol reforming fuel cell heat utilization method based on major cycle and minor cycle

PendingCN109742424AImprove electrochemical reaction efficiencyIncrease power generationFuel cellsFuel cellsHeat losses

The invention discloses a methanol reforming fuel cell heat utilization method based on major cycle and minor cycle. A cycle system corresponding to the methanol reforming fuel cell heat utilization method is composed of a cycle power device, a heating device, an electric pile runner, an electronic thermostat device, a radiating device and a cycle medium. And the method is relates to the technicalfield of the fuel cell. The methanol reforming fuel cell heat utilization method based on major cycle and minor cycle can add the electronic thermostat device in the cycle system, so that the entirecycle system is divided into two cycle systems, the path and time of each cycle period can be shortened, the heating speed is improved, the path and the time of the period cycle are reduced, and the unnecessary heat loss is avoided at the same time; the preheating efficiency is improved when the power consumption is reduced, the electric pile is faster in temperature rise rate and shorter in generation waiting time, and the waiting time of a user is reduced.

Owner:CHINA HYDROGEN NEW ENERGY TECH CO

Charging pile device of electric automobile

ActiveCN107825971AImprove preheating efficiencyAvoid damageBatteries circuit arrangementsCharging stationsEngineeringPower load

The invention discloses a charging pile device of an electric automobile. The charging pile device comprises a base and a shell arranged on the upper side of the base. The shell is of a hollow structure. The inner portion of the shell is divided into a first cavity and a second cavity through a transversely-arranged separation board. The first cavity is located above the second cavity. A storage battery is arranged in the first cavity. The side wall of the shell is connected with a charging head through a connecting wire. The end, away from the charging head, of the connecting wire is connected with the output end of the storage battery. A heating device is arranged in the second cavity. An air compressor is further arranged on the side wall of the shell. The output end of the air compressor communicates with the second cavity. By the adoption of the charging pile device, the battery in the electric automobile can be preheated, the battery preheating efficiency is improved, and a quickcharging effect is achieved; meanwhile, the situation that the battery is charged at a low temperature and thus damaged is avoided, arrangement of the heating device for each automobile is avoided aswell, and waste of resources is reduced; and furthermore, the power load is reduced.

Owner:DANGTU COUNTY KEHUI TRADING

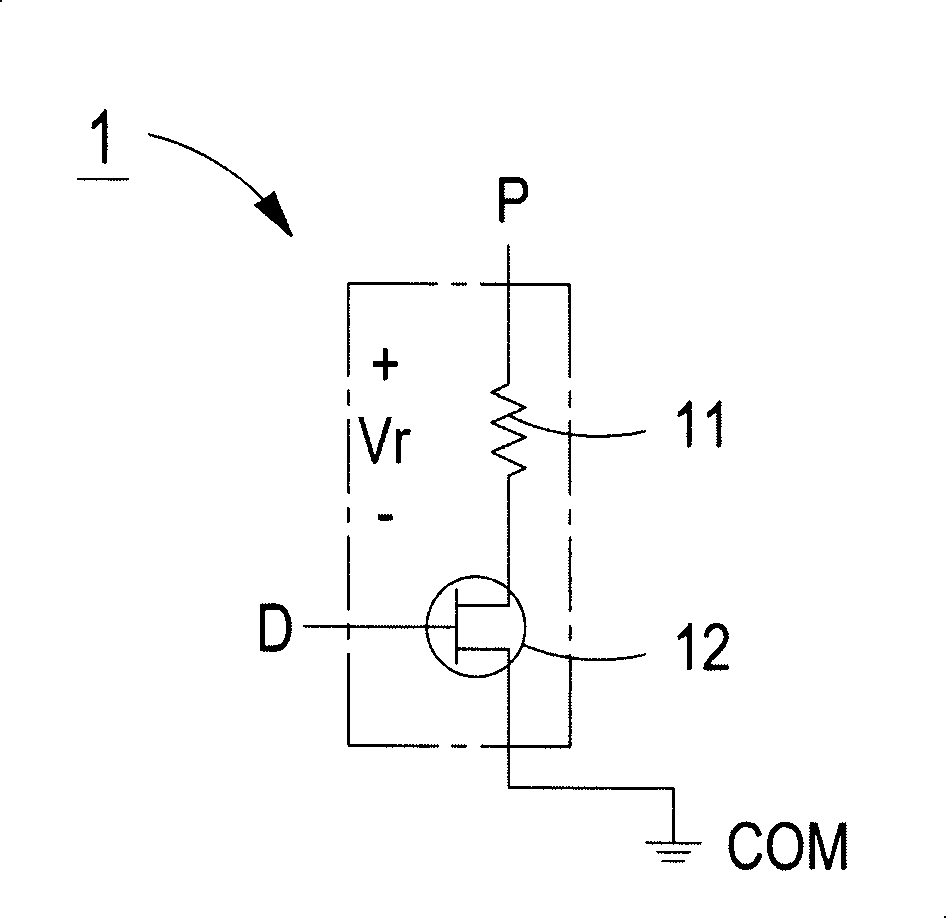

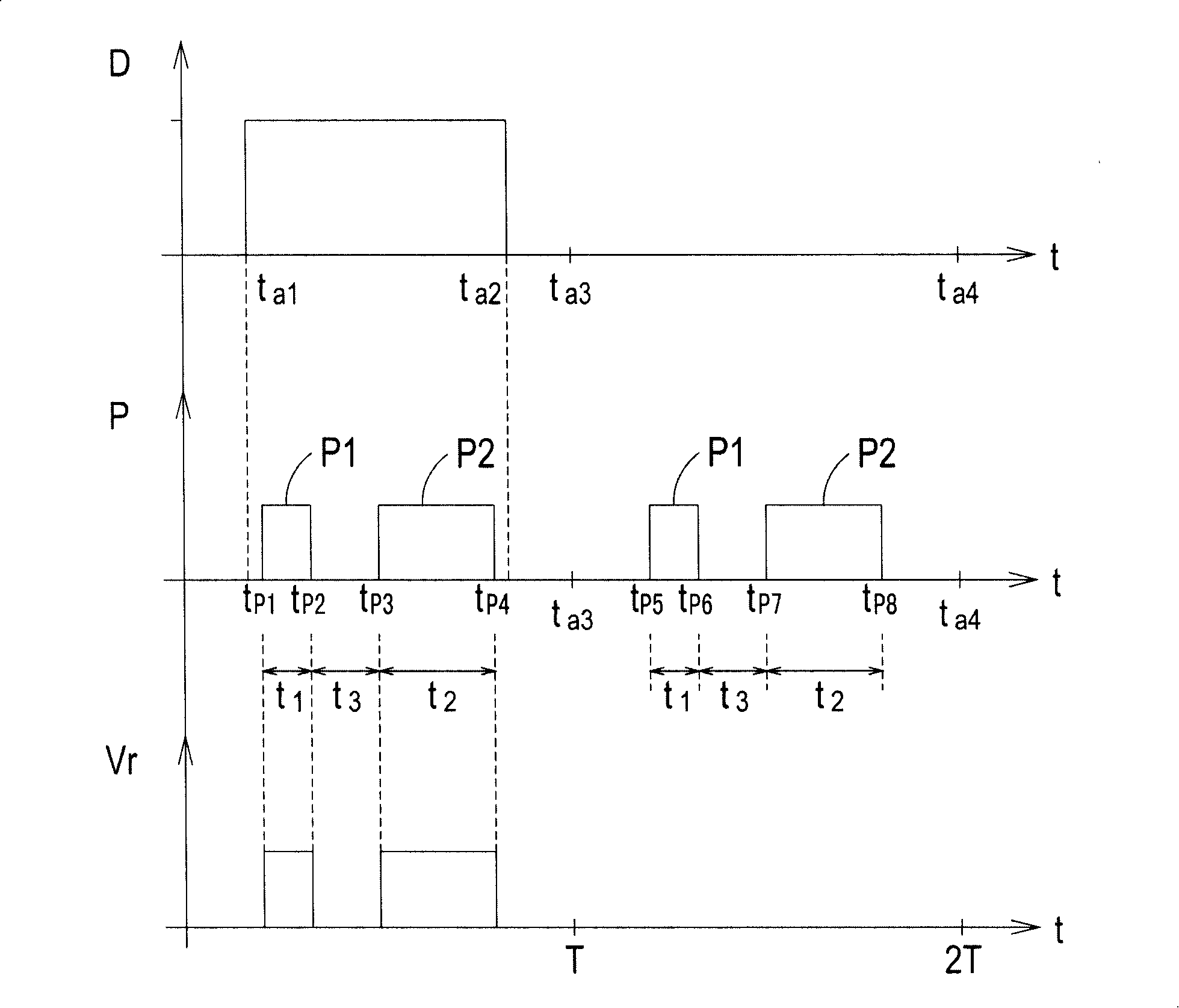

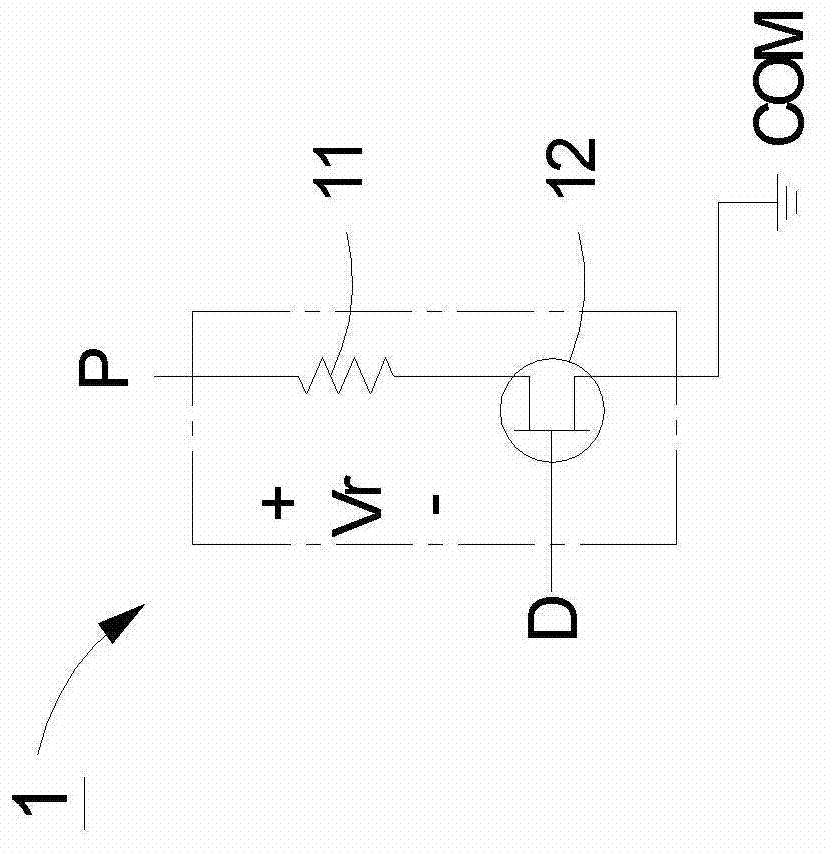

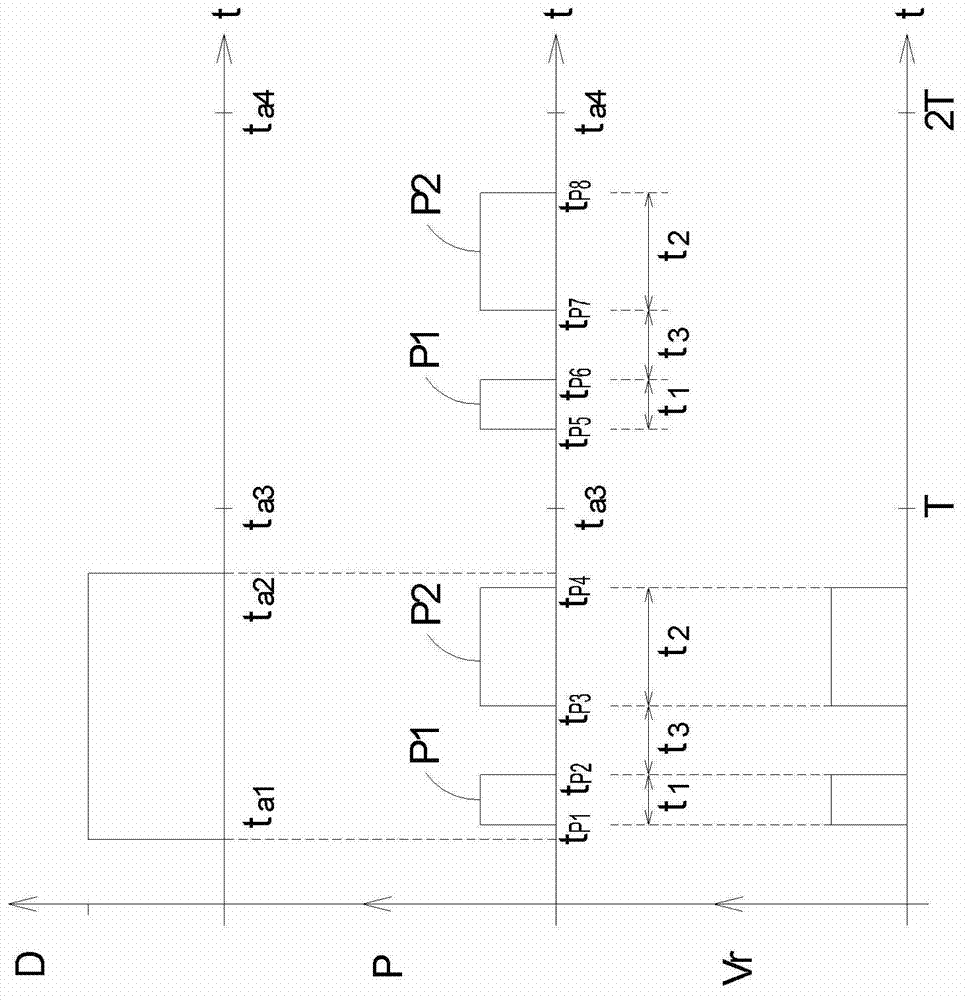

Ink-jet driving circuit with preheat function

ActiveCN101219597APreheat temperature controllableImprove preheating efficiencyElectronic switchingPrintingHigh potentialEngineering

The invention relates to an inkjet drive circuit with a preheating function. A heating chip arranged in an inkjet head structure comprises a heater and six switch circuits, which can receive power signals, printing data signals, heating control signals and preheating control signals. When the printing data signals and the heating control signals are high potential signals, part of the ink is heated by the heater to produce bubble so as to push the ink out of an inkjet hole of the heating chip; when the printing data signals are low potential signals and the preheating control signals are the high potential signals, part of ink and the inkjet hole are preheated by the heater to ensure that the preheating temperature of the inkjet head are easy to control and the preheating efficiency is enhanced.

Owner:MICROJET TECH

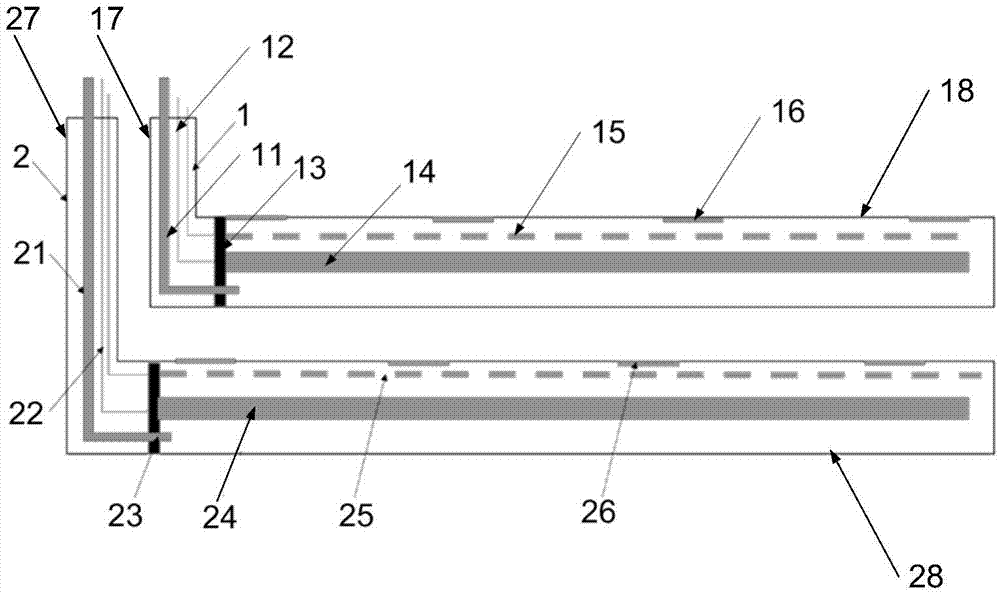

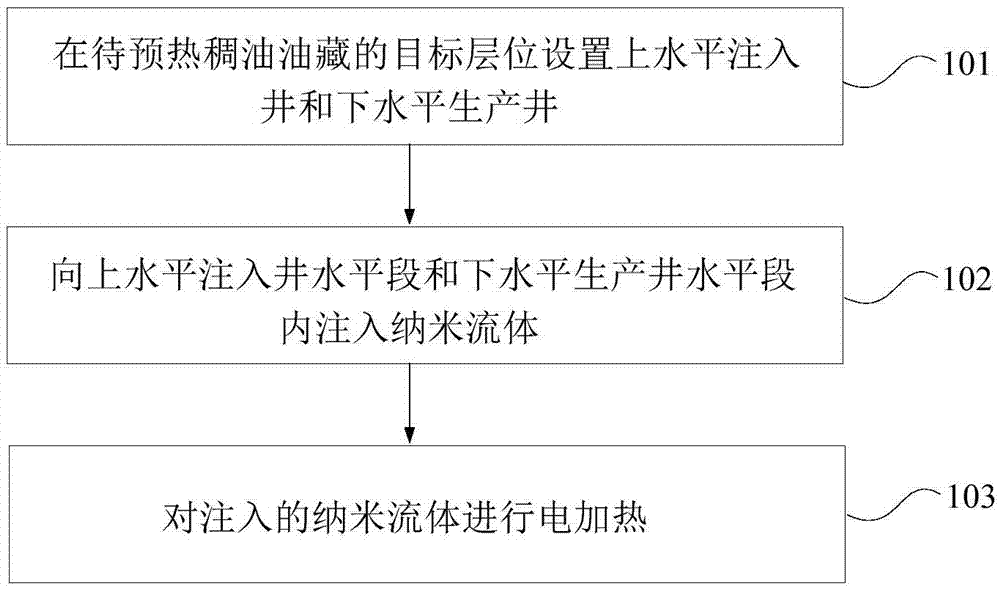

Preheating device and method for heavy oil reservoir

The invention discloses a preheating device and method for a heavy oil reservoir. The preheating device includes an upper horizontal injection well and a lower horizontal production well which are arranged on a target position of a heavy oil reservoir to be preheated; an injection pipe of the upper horizontal injection well which is arranged in a vertical section of the upper horizontal injection well and is used for injecting a nanofluid into a horizontal section of the upper horizontal injection well; an electrical heating column of the upper horizontal injection well which is arranged in a horizontal section of the upper horizontal injection well and is used for electrically heating the injected nanofluid; an injection pipe of a lower horizontal production well which is arranged in a vertical section of the lower horizontal production well and is used for injecting a nanofluid into a horizontal section of the lower horizontal production well; an electrical heating column of a lower horizontal production well which is arranged in the horizontal section of the lower horizontal production well and is used for electrically heating the injected nanofluid. The technical scheme can improve the preheating efficiency and evenness of the heavy oil reservoir, can improve the use degree of the horizontal section, can reduce the operation cost and complexity of preheating, and can enlarge the application range of preheating.

Owner:PETROCHINA CO LTD

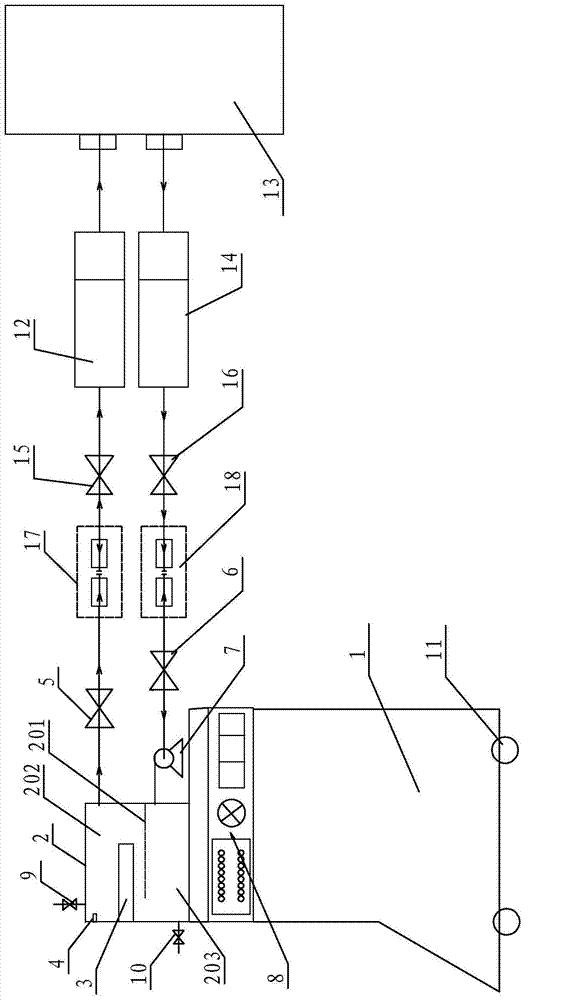

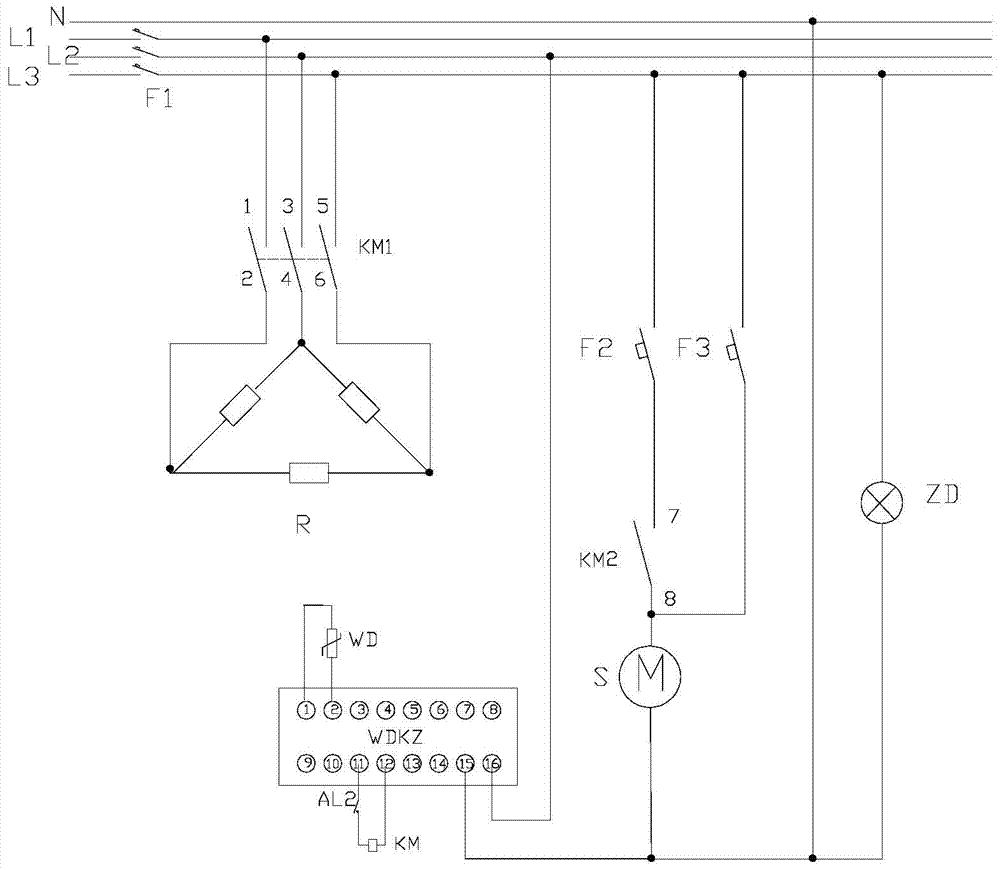

Movable internal combustion locomotive preheating device with automatic constant-temperature control function

InactiveCN104747342AImprove preheating efficiencyEnsure optimum efficiencyMachines/enginesEngine startersElectricityTemperature control

The invention discloses a movable internal combustion locomotive preheating device with an automatic constant-temperature control function. The internal combustion locomotive preheating device comprises a preheating device structure, a heating box, a heating bar, a temperature sensor, a water supply valve, a water return valve, a circulating water pump and a preheating control device. The heating box is arranged at the top of the preheating device structure and divided into a water outlet area and a water return area through a horizontal partition plate internally arranged, wherein the water outlet area and the water return area are communicated. The heating bar and the temperature sensor are arranged in the water outlet area. The water outlet area is communicated with a water inlet of an internal combustion locomotive water circulating system through a water outlet pipe. The water return area is communicated with a water drain opening of the internal combustion locomotive water circulating system through a water return pipe. The circulating water pump is arranged in a pipeline of the water return pipe. The preheating control device is arranged below the heating box, electrically connected with the heating bar, the temperature sensor and the circulating water pump and used for achieving automatic control over the preheating device. The preheating device can reduce preheating energy consumption of a north internal combustion locomotive in winter, and improve the preheating efficiency of the locomotive in winter.

Owner:SHANDONG IRON & STEEL CO LTD

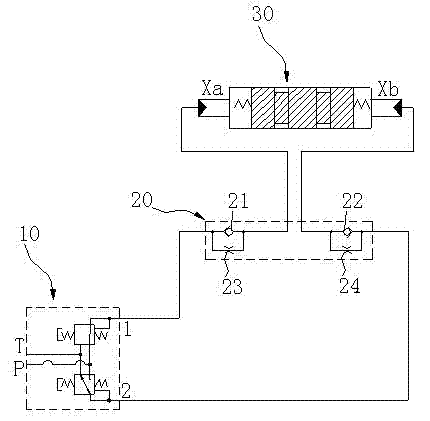

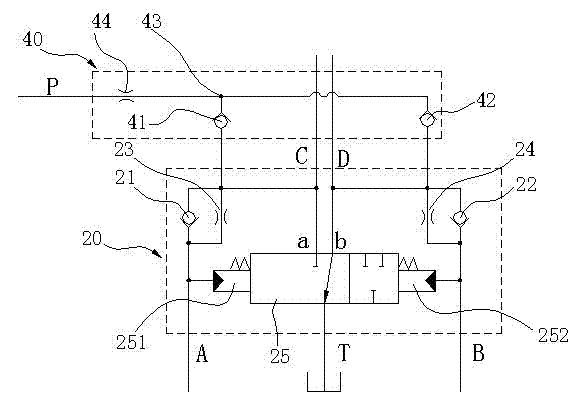

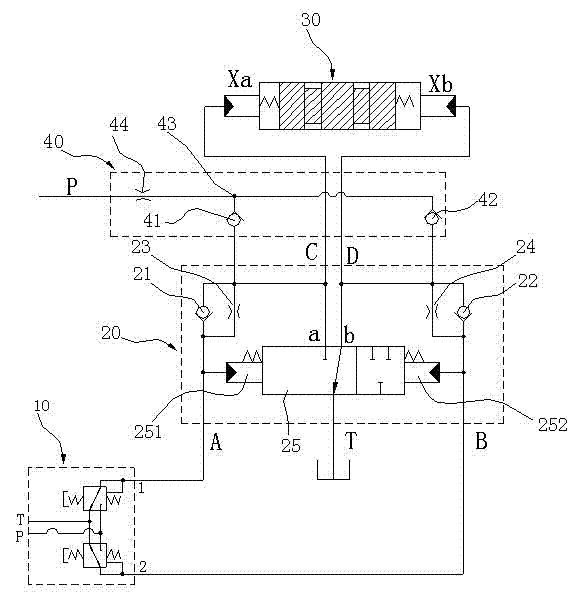

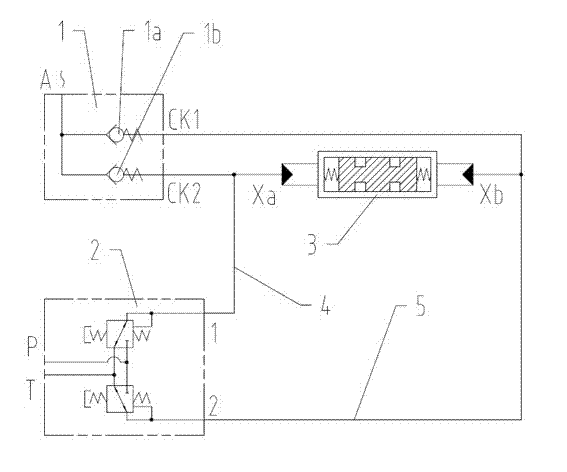

Oil changing and buffering device and pilot hydraulic control system with same

InactiveCN102788052AImprove preheating efficiencyDoes not cause sluggishnessServomotor componentsControl systemPetroleum engineering

The invention relates to an oil changing and buffering device used in a pilot hydraulic control system, which solves the problems that the existing oil circuit requires a long preheating time and is slow to start, wherein two throttlers are connected in parallel between the oil inlet and oil outlet of a first one-way valve and the oil inlet and oil outlet of a second one-way valve respectively; the left control oil port of a three-position three-way reversing valve is communicated with the oil inlet A of the first one-way valve, the right control oil port is communicated with the oil inlet B of the second one-way valve, a left oil inlet a is communicated with the oil outlet C of the first one-way valve, the right oil inlet b is communicated with the oil outlet D of the second one-way valve, the oil outlets of the third one-way valve and the fourth one-way valve of an oil-changing oil circuit are correspondingly connected with the oil outlets of the first one-way valve and the second one-way valve, and the oil inlets thereof are oil-changing and intake port. The oil changing and buffering device used in the pilot hydraulic control system avoids the delay and stagnation of the starting action, causes no impact when stops, and at the same time can shorten the hydraulic oil preheating time in the pilot pipeline.

Owner:LIUGONG CHANGZHOU MACHINERY +3

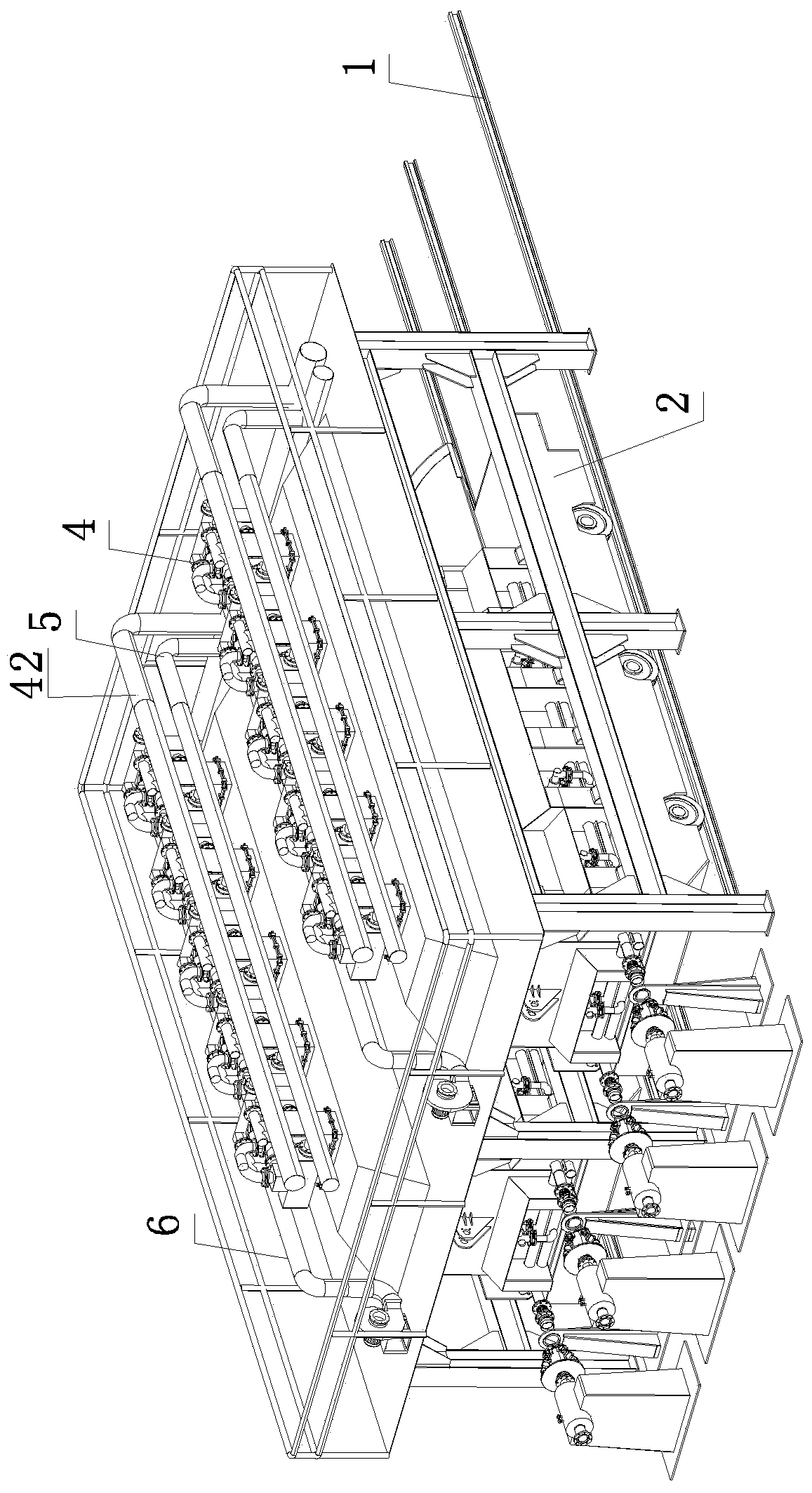

Steel scrap baking system

PendingCN109913617AAdaptableSimplify trace designProcess efficiency improvementCooking & bakingCombustor

The invention relates to a steel scrap baking system. The system comprises one or multiple steel scrap preheating units arranged in parallel side by side. Each steel scrap preheating unit comprises arail, a moving trolley sliding along the rail, a dual-layer composite heating ship bucket arranged on the moving trolley, and multiple top layer combustors arranged on a rack platform; each heating ship bucket comprises an inner layer steel plate, an outer layer steel plate and refractory matter cast between the inner layer steel plate and the outer layer steel plate, one end of each ship bucket is opened and used for discharging, the other end of each ship bucket is closed, a tail combustor is arranged on each outer layer steel plate, the two side faces of each ship bucket are each provided with multiple side face combustors, three side faces surrounding the outer layer steel plate of each ship bucket are provided with U gas pipelines and U air pipelines, and the U gas pipelines and the Uair pipelines communicate with the outer air source through quick-change connectors. The system is reasonable in structural arranging, novel in type, high in adaptation, and high in work efficiency,cost is reduced, use needs are met, and the system is efficient and practical.

Owner:LUOYANG WODA MACHINERY TECH DEV

An ink jet control circuit

InactiveCN103587244APreheat temperature controllableImprove preheating efficiencyPrintingControl signalData signal

The invention relates to an ink jet control circuit. A heating chip disposed inside an ink-jetting head structure comprises a heater and six switch circuits and receives a power signal, a printing data signal, a preheating data signal, a heating control signal, and a preheating control signal. When the printing data signal and the heating control signal are maintained at high potential, the heater heats a part of ink and generates bubbles such that the ink is pushed out of the ink-jetting holes on the heating chip. When the preheating control signal and the preheating data signal are maintained at high potential, the heater preheats a part of the ink and the ink-jetting head. Therefore, the ink-jetting head has easily-controlled preheating temperature and high preheating efficiency.

Owner:MICROJET TECH

Refining furnace oxygen burning gun with anti-temper and anti-explosion functions and application method thereof

PendingCN110207122AImprove preheating efficiencyPrevent flashback and explosionManufacturing convertersGaseous fuel burnerCombustionEngineering

The invention discloses an efficient refining furnace oxygen burning gun with anti-temper and anti-explosion functions and an application method thereof. The efficient refining furnace oxygen burninggun includes a gun barrel body and a nozzle at the end of the gun barrel body, wherein the gun barrel body is composed of a multi-layer central line collinear sleeving; the sleeving comprises a compressed air pipe, an oxygen pipe, a converter gas pipe, a water pipe and an external pipe in sequence from inside to outside; and three long open fire pipes with triangular distribution are arranged in aclamping chamber between the oxygen pipe and the converter gas pipe. Compared with the prior art, the efficient refining furnace oxygen burning gun with anti-temper and anti-explosion functions and the application method thereof can avoid the phenomenons of tempering and explosion of the oxygen burning gun at the moment of extinguishing; the situation that the gas emitted by the oxygen burning gun can be ignited in time is ensured, so that the explosion at the moment of ignition is avoided; and double combustion of the gas is carried out by oxygen and compressed air, so that the preheating efficiency is improved.

Owner:山东崇盛冶金氧枪有限公司

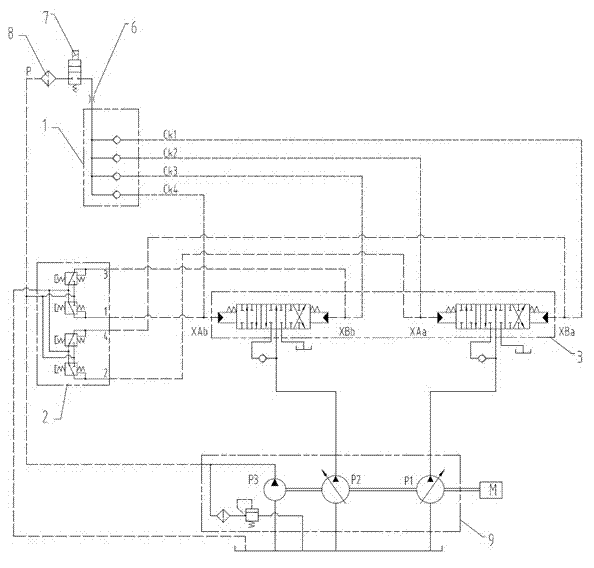

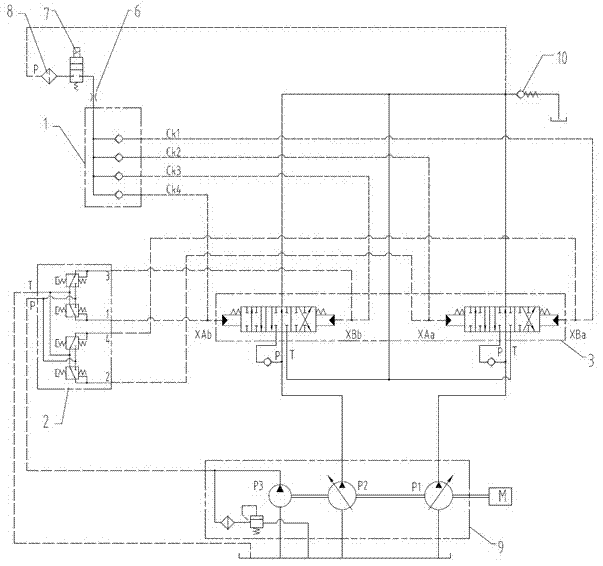

Guide hydraulic control system with oil changing function

InactiveCN102777437AImprove preheating efficiencyShorten warm-up timeServomotor componentsControl systemEngineering

The invention relates to a guide hydraulic control system with oil changing function, which is aimed at solving the problem of long preheating time in the existing guide hydraulic control oil line. The guide hydraulic control system comprises a guide control valve, a change valve and an oil-changing oil line; an opening 1 of the guide control valve is connected with an Xa oil chamber of the change valve through a left pipeline; an opening 2 of the guide control valve is connected with an Xb oil chamber through a right pipeline; the oil-changing oil line comprises a one-way valve unit and an oil-changing inlet; the one-way valve unit comprises two one-way valves; oil inlets of the one-way valves are communicated with each other and then is communicated with the oil-changing inlet; an oil outlet of one one-way valve in the one-way valve unit is communicated with the left pipeline; and an oil outlet of the other one-way valve is communicated with a right pipeline. According to the guide hydraulic control system, preheated hydraulic oil for hydraulic oil in the guide control pipeline can be replaced through the oil-changing oil line during preheating a machine, so that preheating efficiency can be improved, and preheating time can be shortened.

Owner:LIUZHOU LIUGONG EXCAVATORS +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com