Engine cold-start preheating device

A technology of preheating device and engine, which is applied in the direction of engine starting, engine components, combustion engine, etc., can solve the problem of uneven heat storage and heat release process, low sensible heat storage and heat storage density, limited engine preheating function, etc. problems, to enhance the defrosting effect and heating effect, fast warm-up, improve emissions and cold start performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

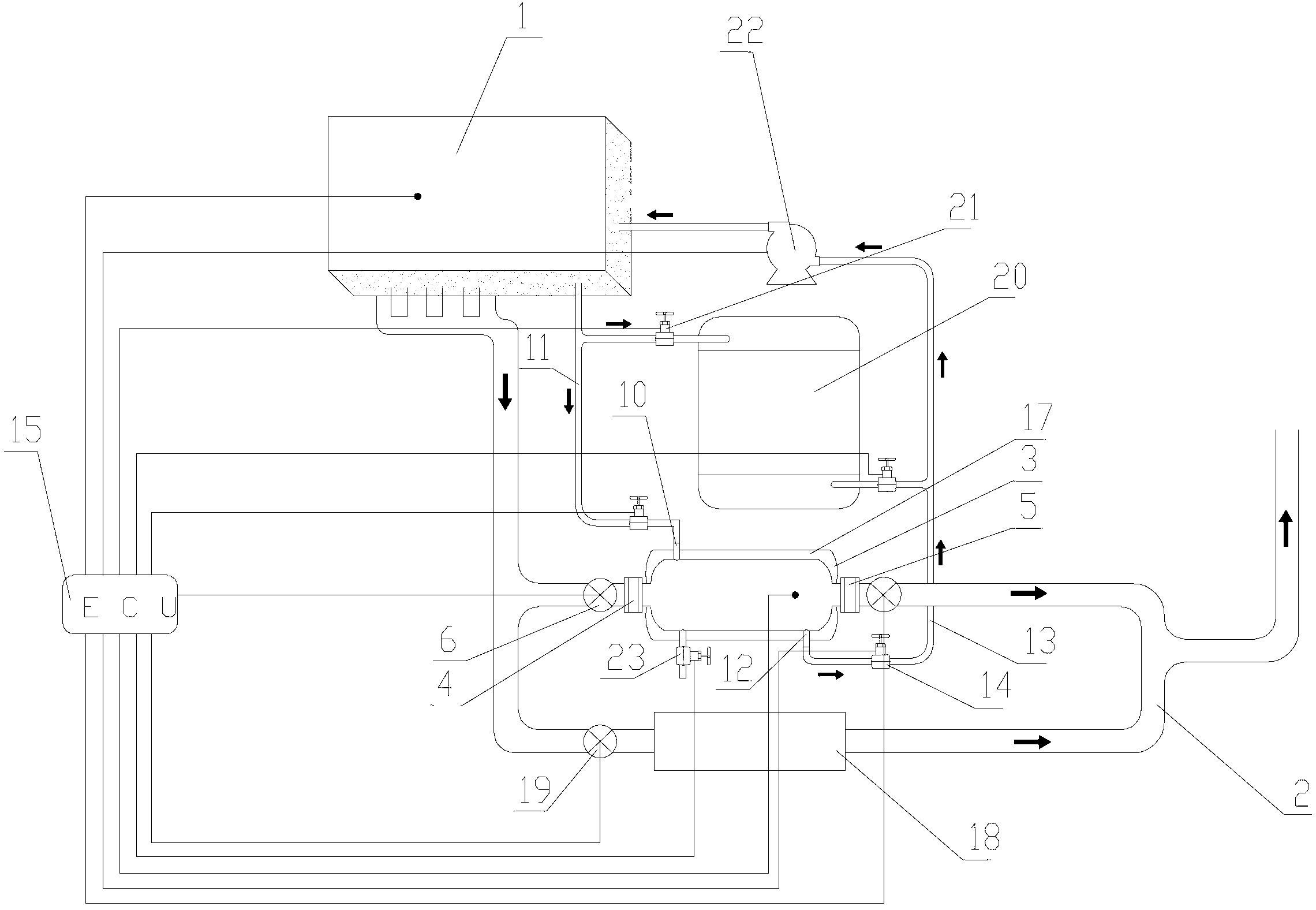

[0021] The present invention will be further described below in conjunction with accompanying drawing.

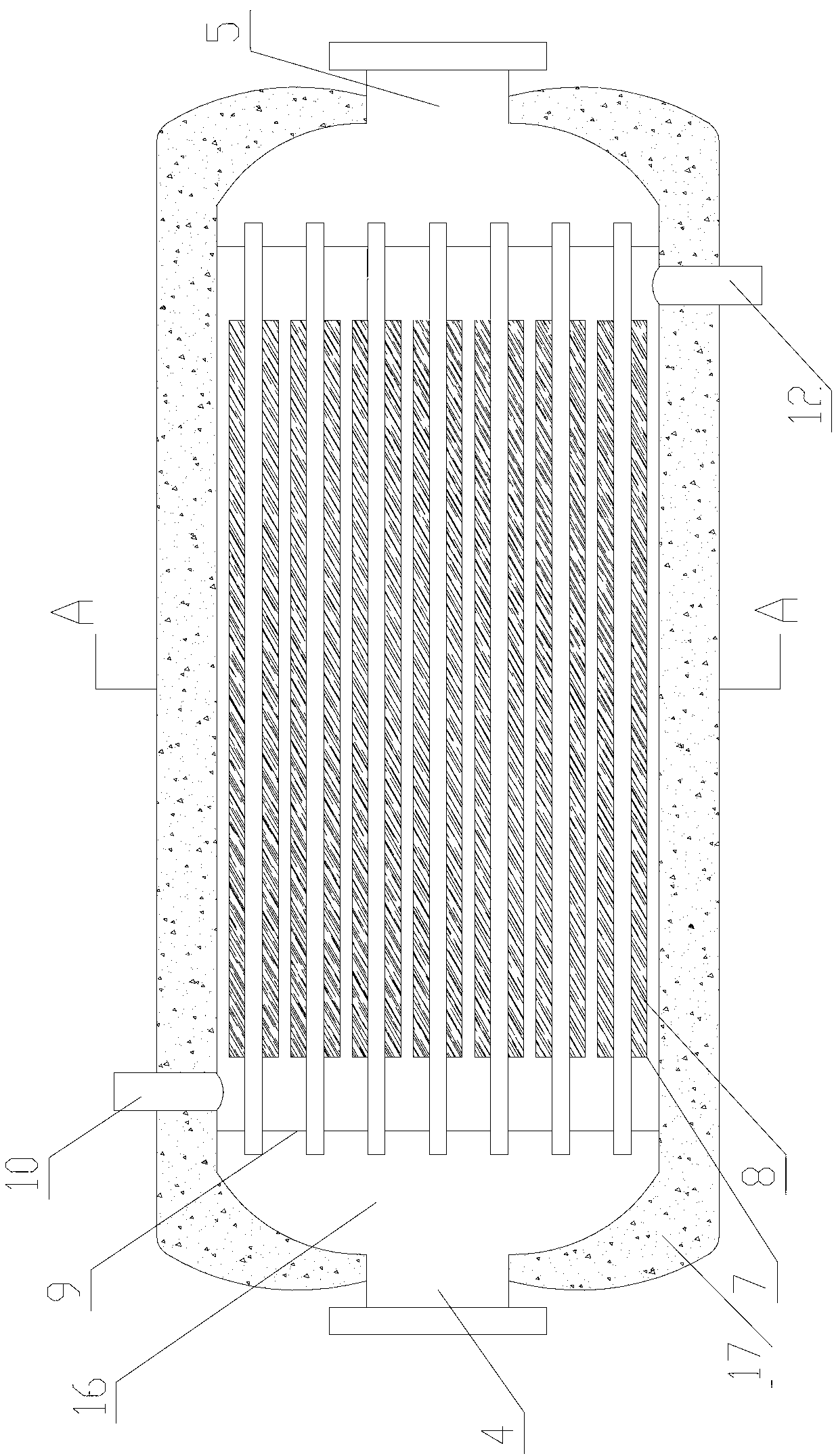

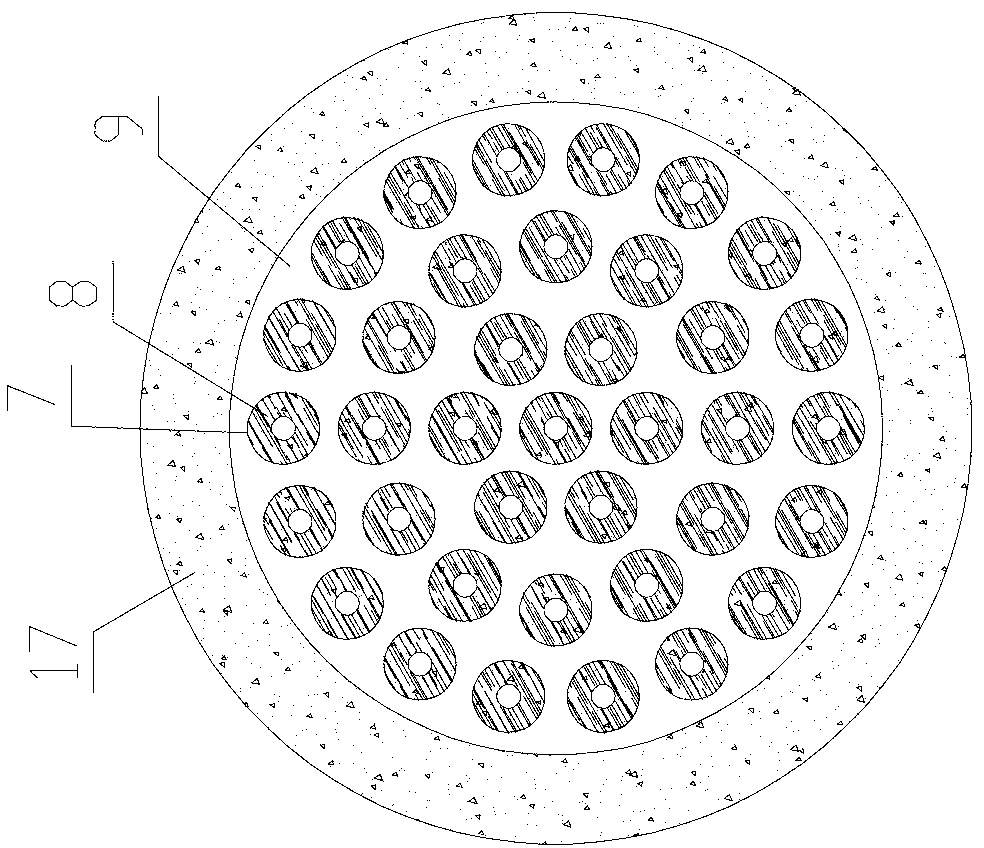

[0022] In the engine cold start preheating device of the present invention, a heat storage heat exchanger 3 is connected in parallel on the exhaust pipe 2 of the engine 1, and the inlet end 4 and the air outlet end 5 of the heat storage heat exchanger 3 are provided with first electronically controlled valves 6 To control whether the exhaust gas of the engine 1 passes through the heat storage heat exchanger 3; the heat storage heat exchanger 3 is used to store the exhaust heat of the engine 1. unit, each heat storage unit is a concentric casing 7 including two inner and outer tubes, and the phase change heat storage material 8 is packaged in the annular space between the inner and outer two tubes, and the packaging volume of the phase change heat storage material 8 should be less than that The volume of the space is such that there is an appropriate margin for the melting a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com