Patents

Literature

252results about How to "Good preheating effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

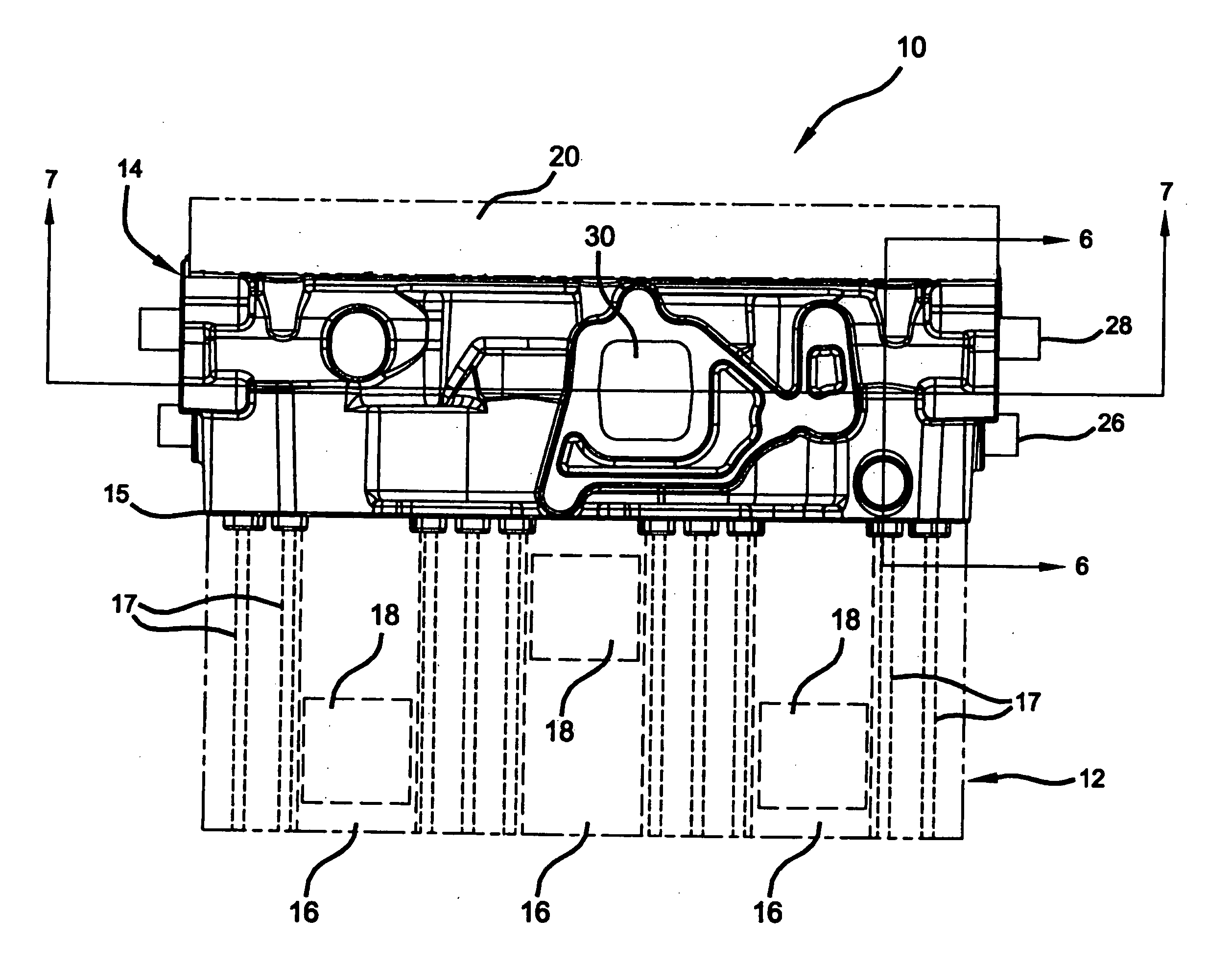

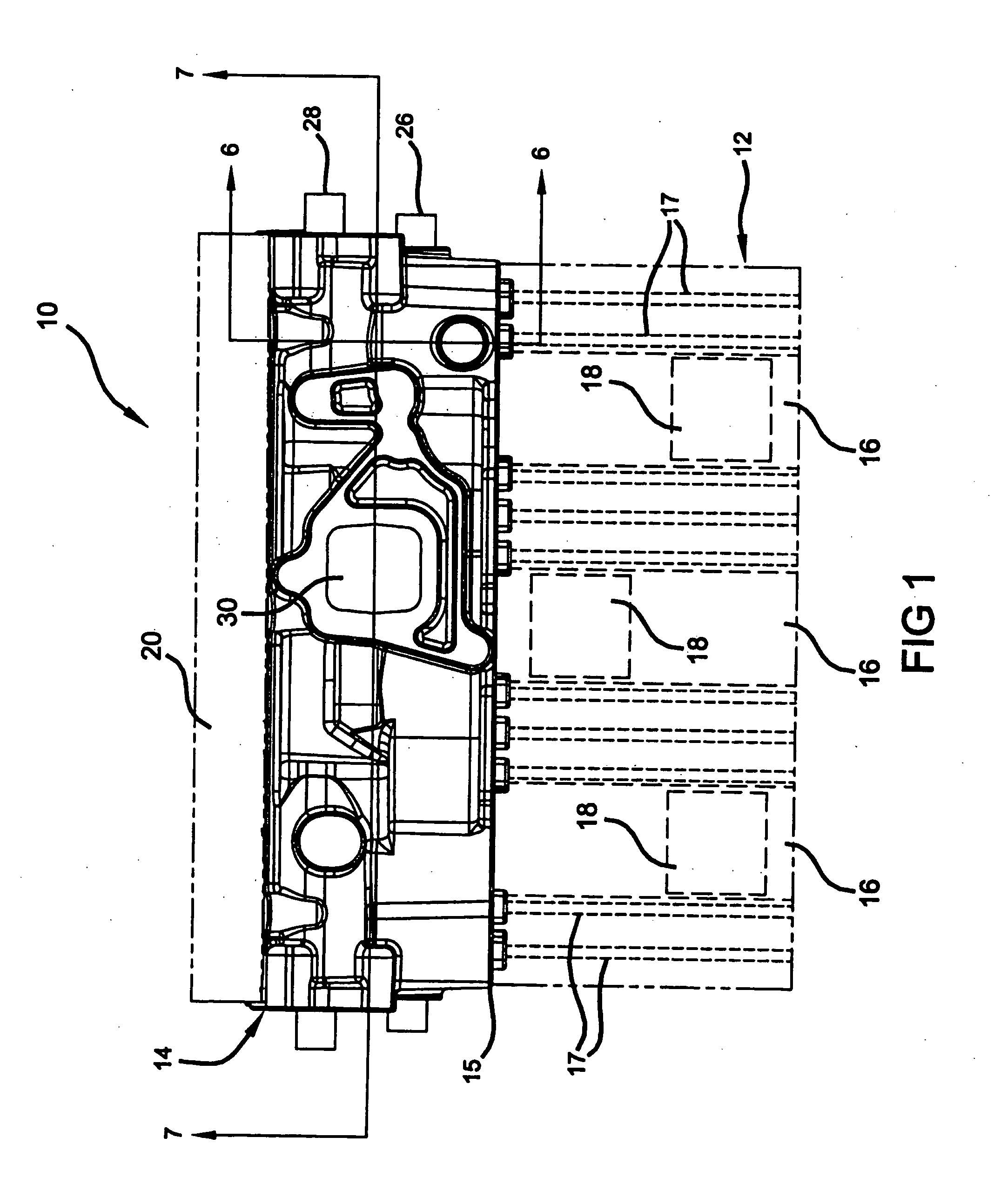

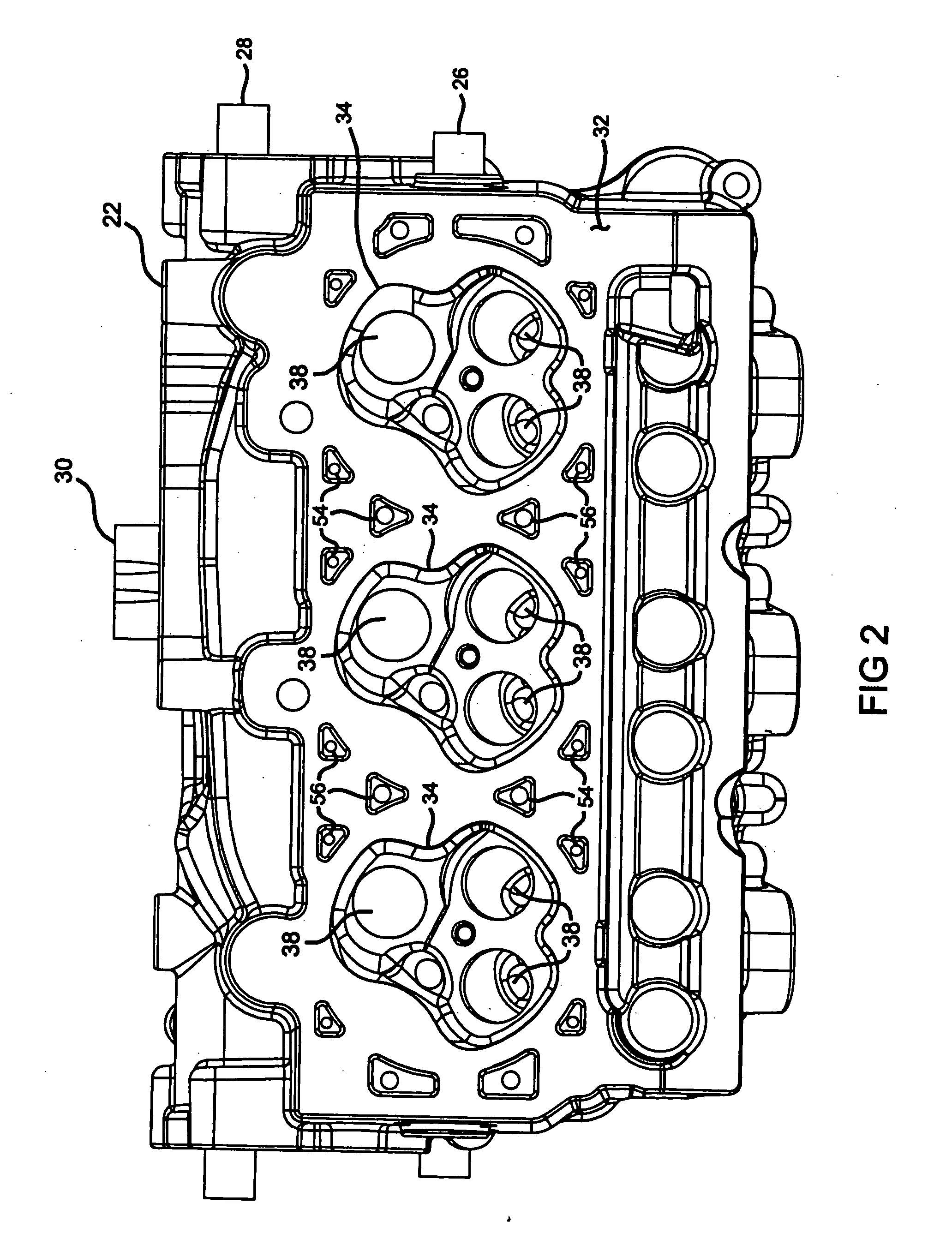

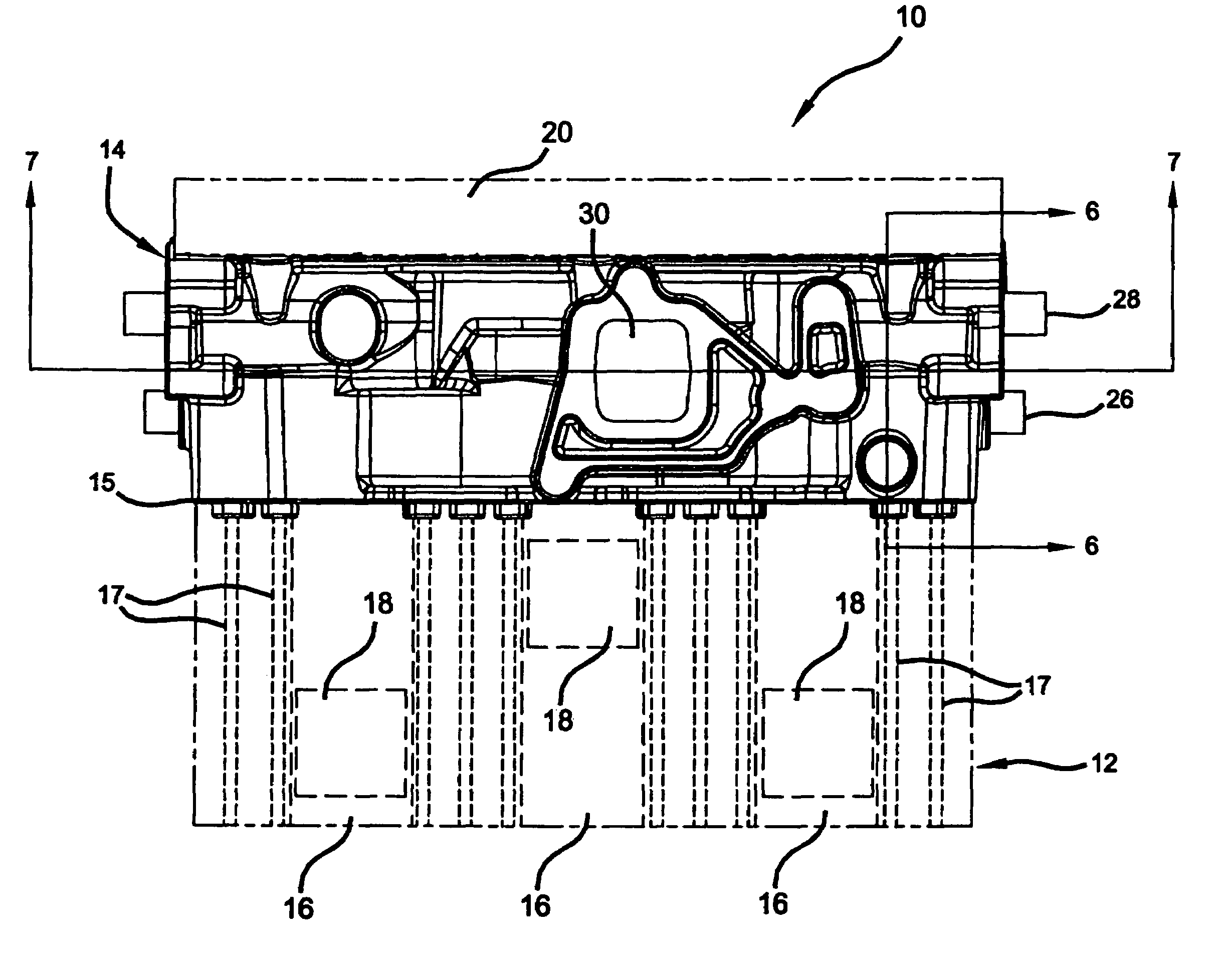

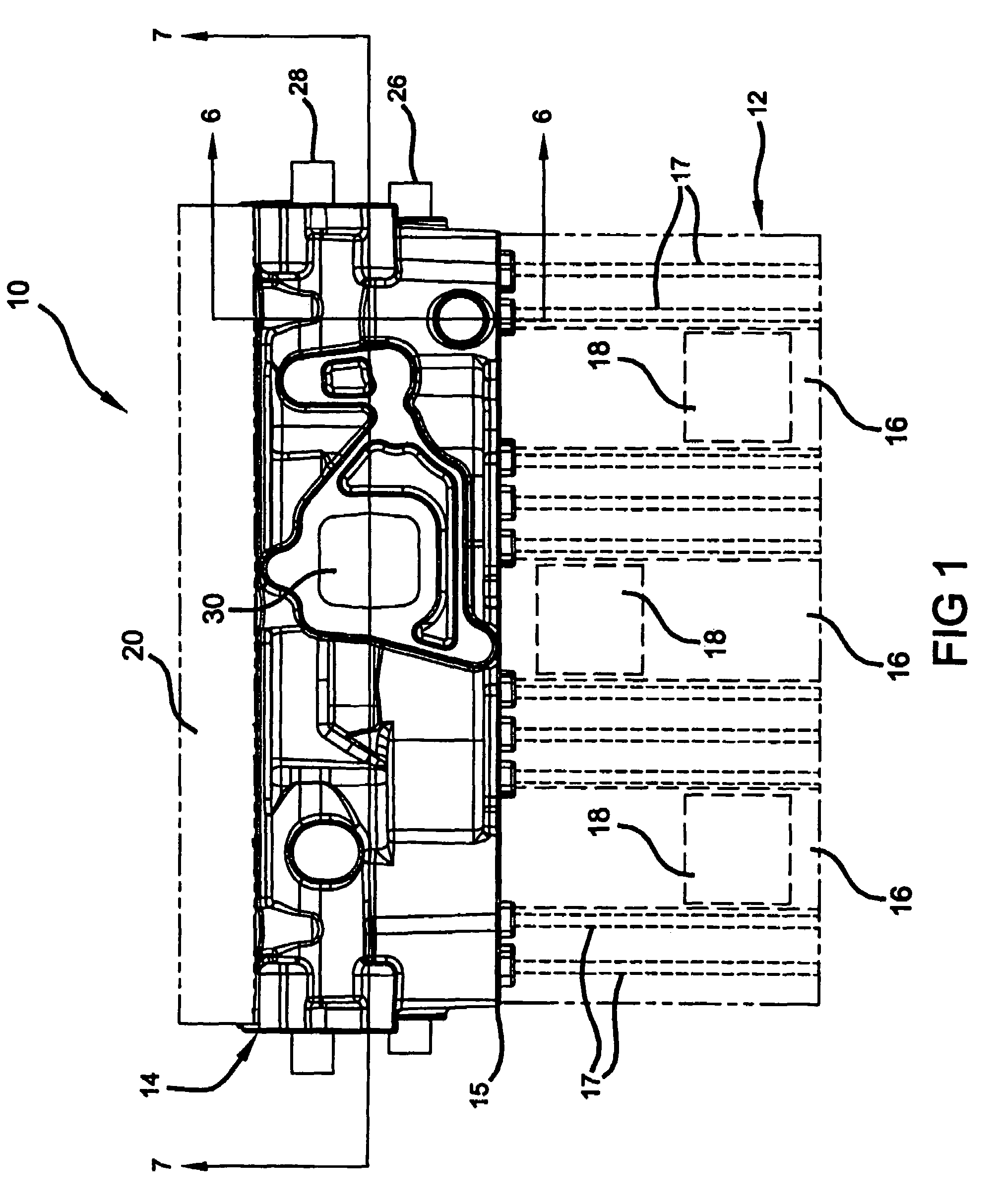

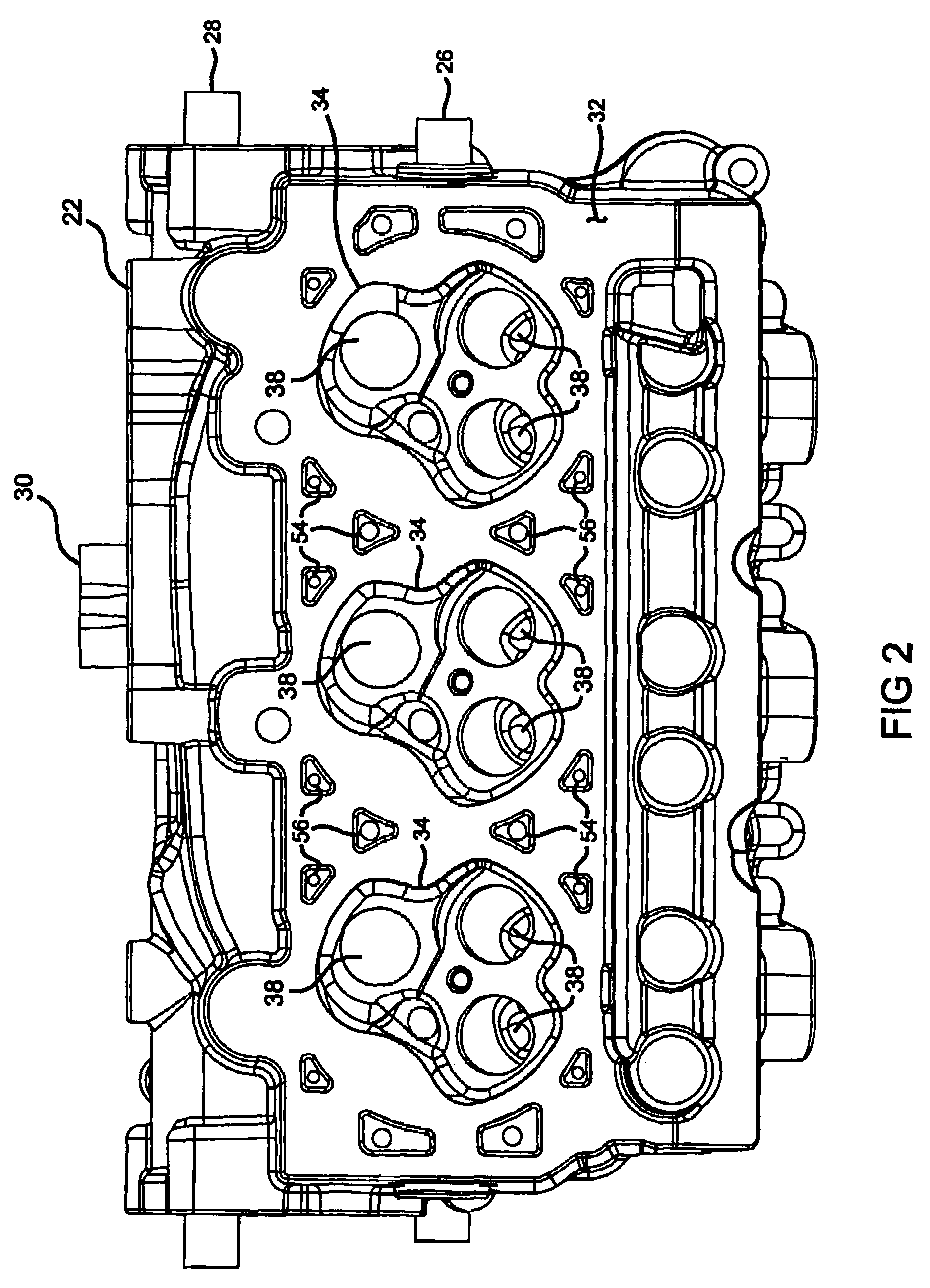

Cylinder head with integrated exhaust manifold

InactiveUS20050087154A1Improved exhaust manifold geometryEasy to assembleInternal combustion piston enginesExhaust apparatusCombustionCylinder head

A cylinder head for an internal combustion engine (ICE) includes a lower cooling jacket, an upper cooling jacket and an exhaust manifold disposed therebetween. The exhaust manifold enables exhaust of combustion gas from cylinders of the ICE. The lower cooling jacket has coolant flow paths in fluid communication with coolant flow paths of a cylinder block of the ICE. Coolant flow paths of the upper cooling jacket are in fluid communication with those of the lower cooling jacket through one of a plurality of passages. The passages can be selectively plugged to define coolant flow direction through the cylinder head. The upper and lower cooling jackets are in heat exchange relationship with surfaces of the exhaust manifold to cool exhaust gas flowing therethrough.

Owner:GM GLOBAL TECH OPERATIONS LLC

Cylinder head with integrated exhaust manifold

InactiveUS7051685B2Improved exhaust manifold geometryEasy to assembleInternal combustion piston enginesExhaust apparatusCombustionCoolant flow

A cylinder head for an internal combustion engine (ICE) includes a lower cooling jacket, an upper cooling jacket and an exhaust manifold disposed therebetween. The exhaust manifold enables exhaust of combustion gas from cylinders of the ICE. The lower cooling jacket has coolant flow paths in fluid communication with coolant flow paths of a cylinder block of the ICE. Coolant flow paths of the upper cooling jacket are in fluid communication with those of the lower cooling jacket through one of a plurality of passages. The passages can be selectively plugged to define coolant flow direction through the cylinder head. The upper and lower cooling jackets are in heat exchange relationship with surfaces of the exhaust manifold to cool exhaust gas flowing therethrough.

Owner:GM GLOBAL TECH OPERATIONS LLC

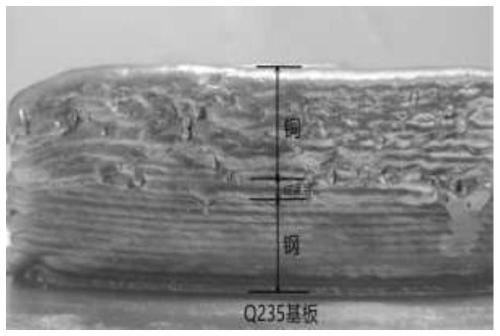

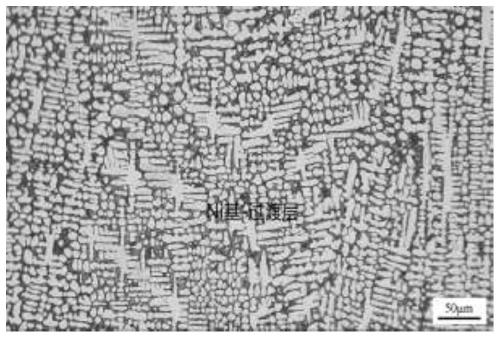

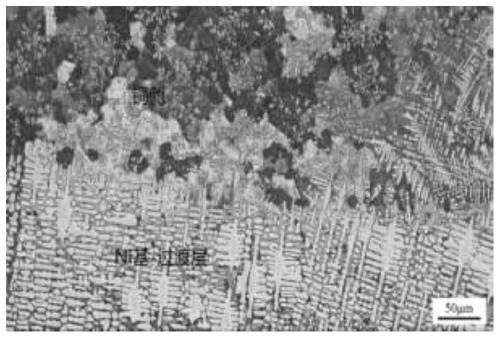

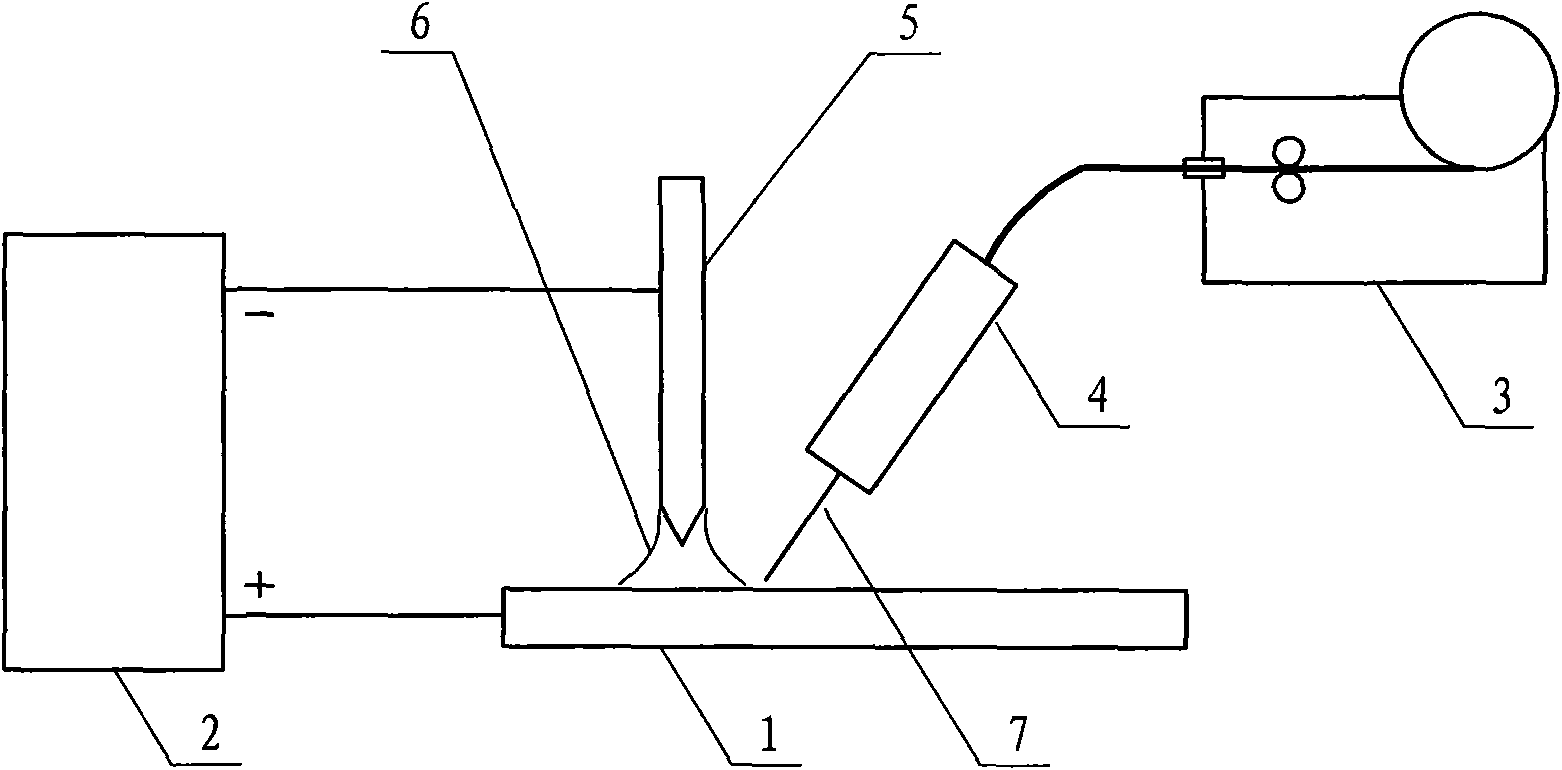

Ni based-flux-cored wire and method for preparing copper-steel base gradient composite

ActiveCN111558793AAvoid Welding DefectsImprove mechanical propertiesArc welding apparatusWelding/cutting media/materialsCopperWelding defect

The invention discloses a Ni based-flux-cored wire. The Ni based-flux-cored wire comprises a flux core and a welding scale, wherein the flux core is prepared from the following components in percentage by mass: 86%-90% of Ni powder, 3%-5% of Mn powder, 6%-7% of Si powder, the balance of Cu powder, and the sum of the mass percentage of the components is 100%. The Ni based-flux-cored wire is used asa transition layer to avoid welding defects caused by thermophysical parameter difference of two types of materials during direction connection of copper-steel. The invention further provides a method for preparing copper-steel base gradient composite based on the Ni based-flux-cored wire used as the transition layer. The problem of the welding defects caused by direct connection in existing copper / steel composite is solved, parts can be combined from the steel side to the copper side to reach a gradient mode, so that the combining capacity of a heterogeneous material interface is enhanced, and the mechanical properties of composite members are improved.

Owner:XIAN UNIV OF TECH

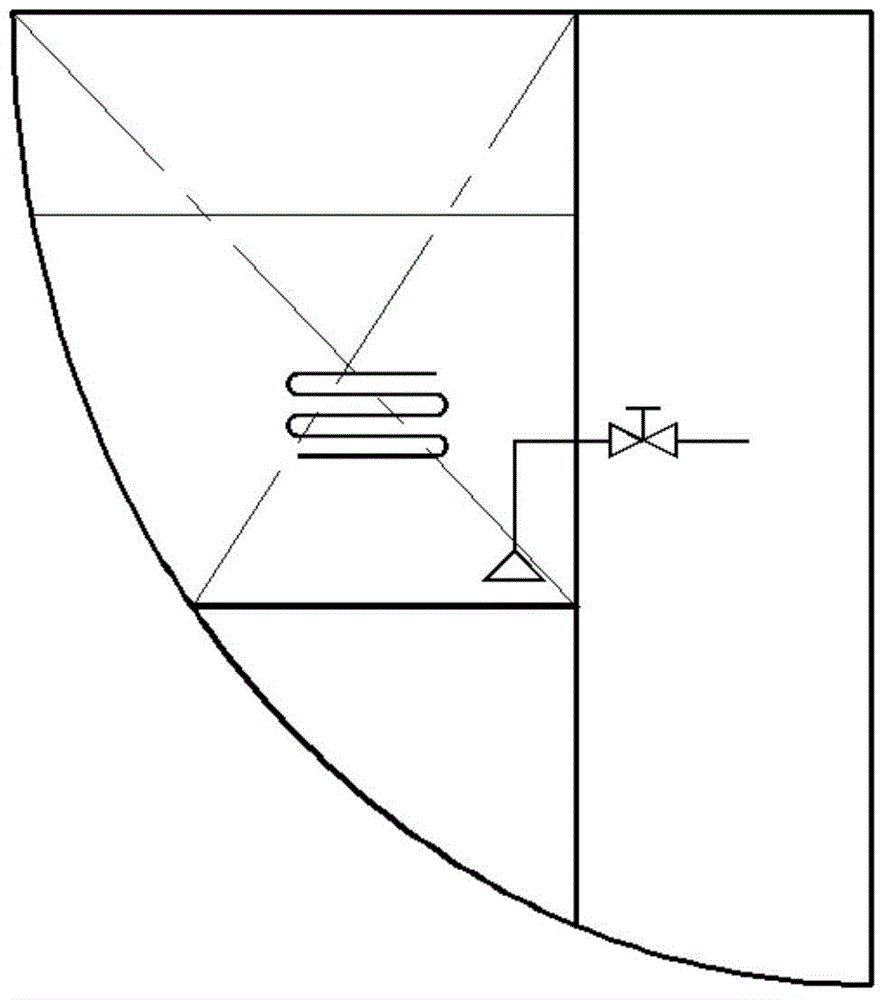

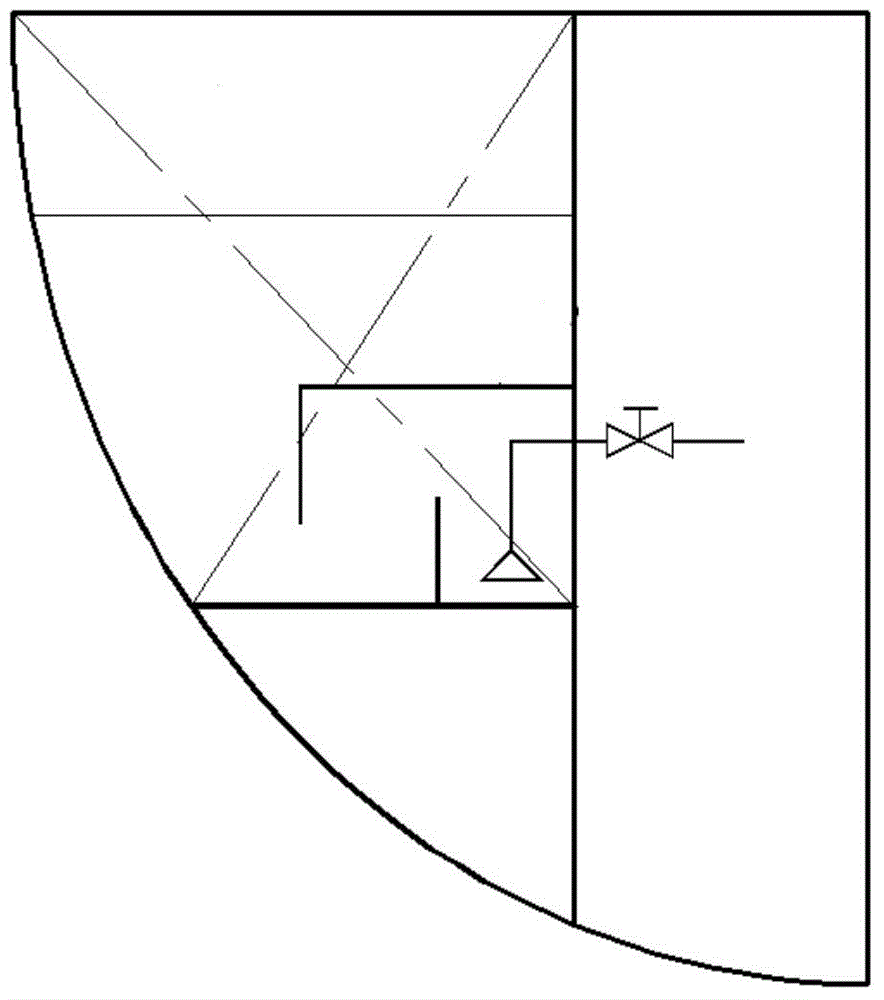

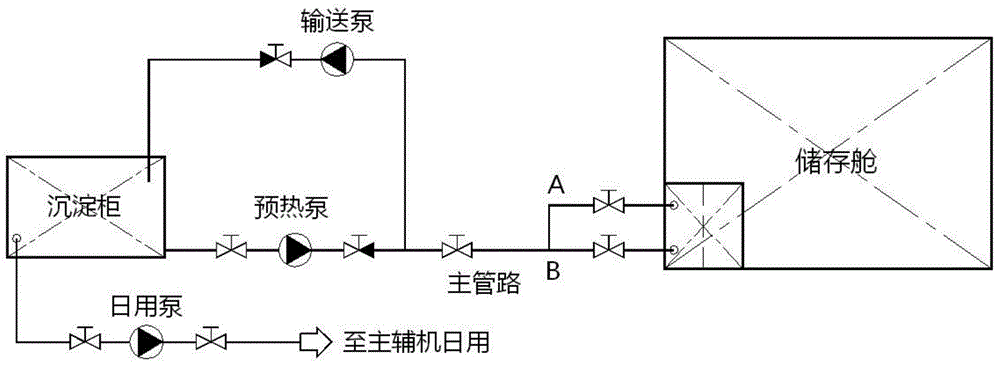

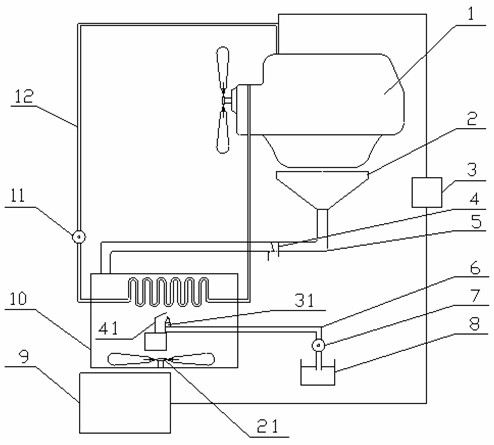

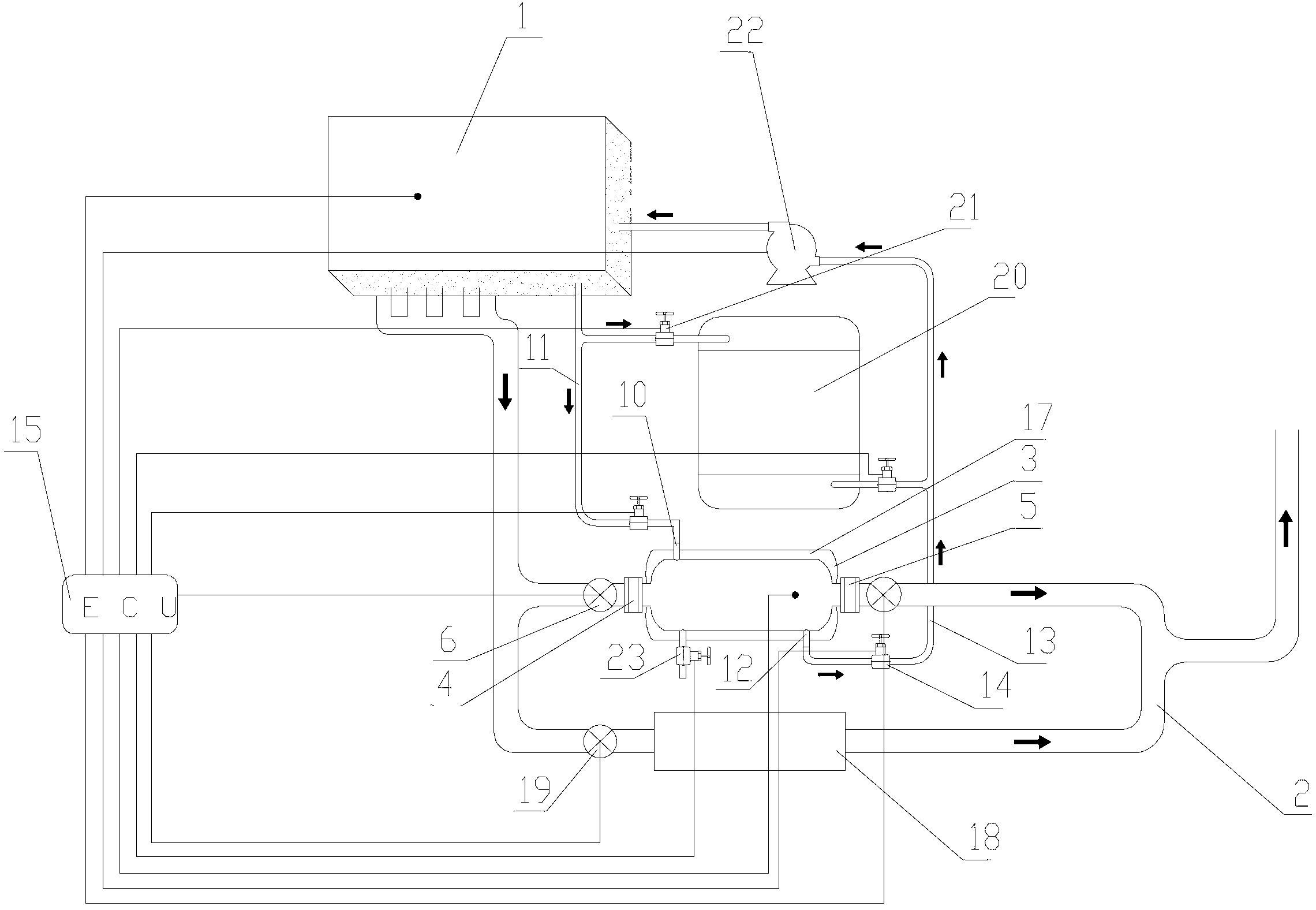

Ship fuel preheating system and preheating method

ActiveCN104819080AReduce operating costsEfficient use ofHull interior subdivisionElectrical controlFuel oilEngineering

The invention relates to a ship fuel preheating system. The ship fuel preheating system is characterized in that a fuel preheating branch pipeline and a fuel conveying branch pipeline are arranged between a storage bin and a sedimentation cabinet. A main pipeline is shared and is divided into two branches near the sedimentation cabinet, a preheating pump is arranged on one branch and provides high temperature fuel for the storage bin, a transfer pump is arranged on the other branch and conveys heated heavy oil to the sedimentation cabinet, and the two branches are provided with stop check valves in the corresponding directions so as to avoid pipeline direction malposition. A small compartment is arranged at one corner of the storage bin, and a first partition plate is arranged in the middle of the small compartment and divides the compartment into two parts in the X direction. A pipe A and a pipe B are arranged in a first sub-compartment, the upper right corner of the first partition plate is provided with a hole, the lower left corner of a second partition plate is provided with a hole, and the two holes are in opposite angle arrangement. Small holes are formed at the bottoms of partition plates to be used for sweeping. An upper plate of the compartment is provided with a plurality of air holes, so as to guarantee timely overflow of generated steam. The pipe A and the pipe B are communicated with the main pipeline and provided with regulating valves respectively.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

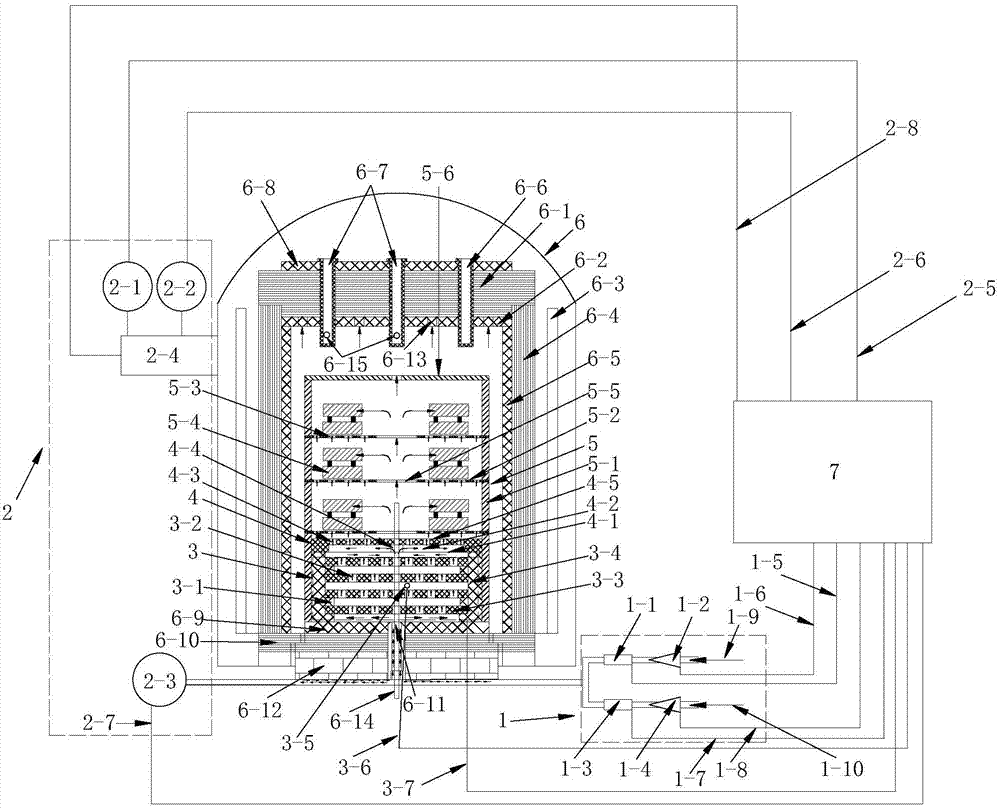

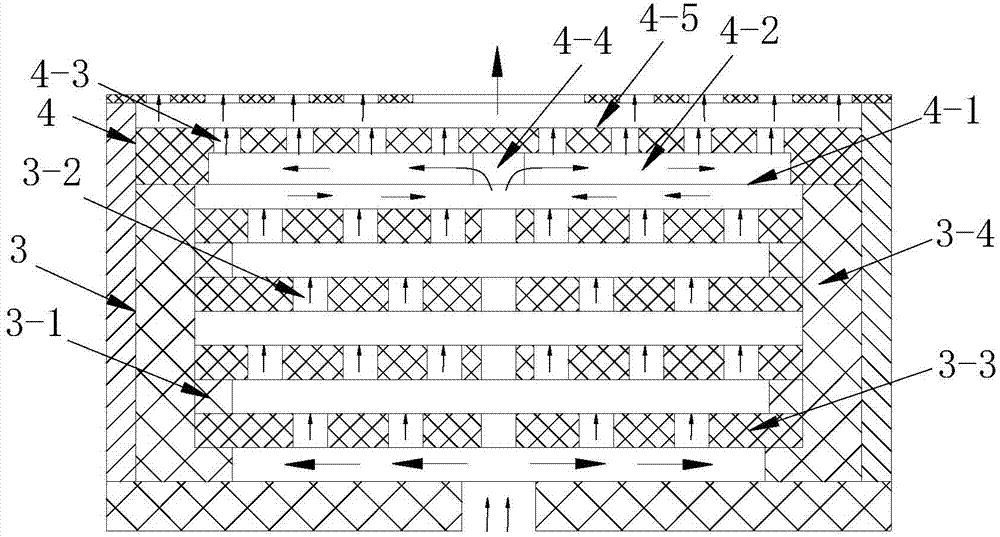

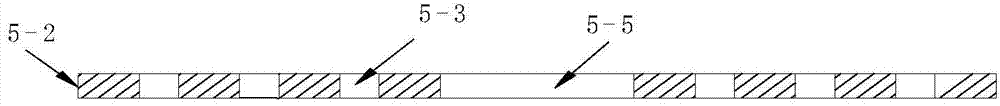

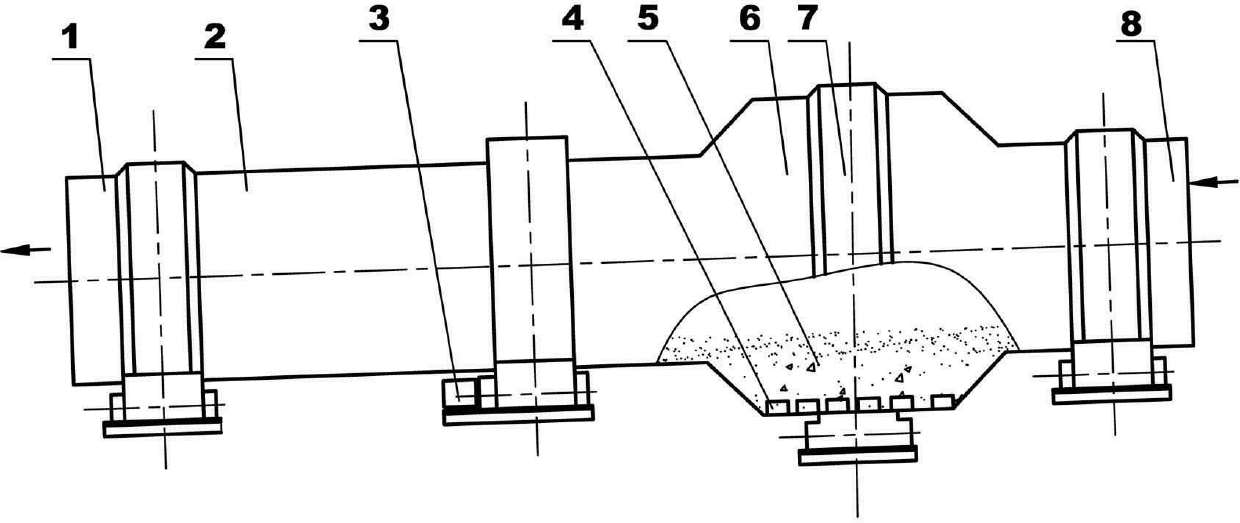

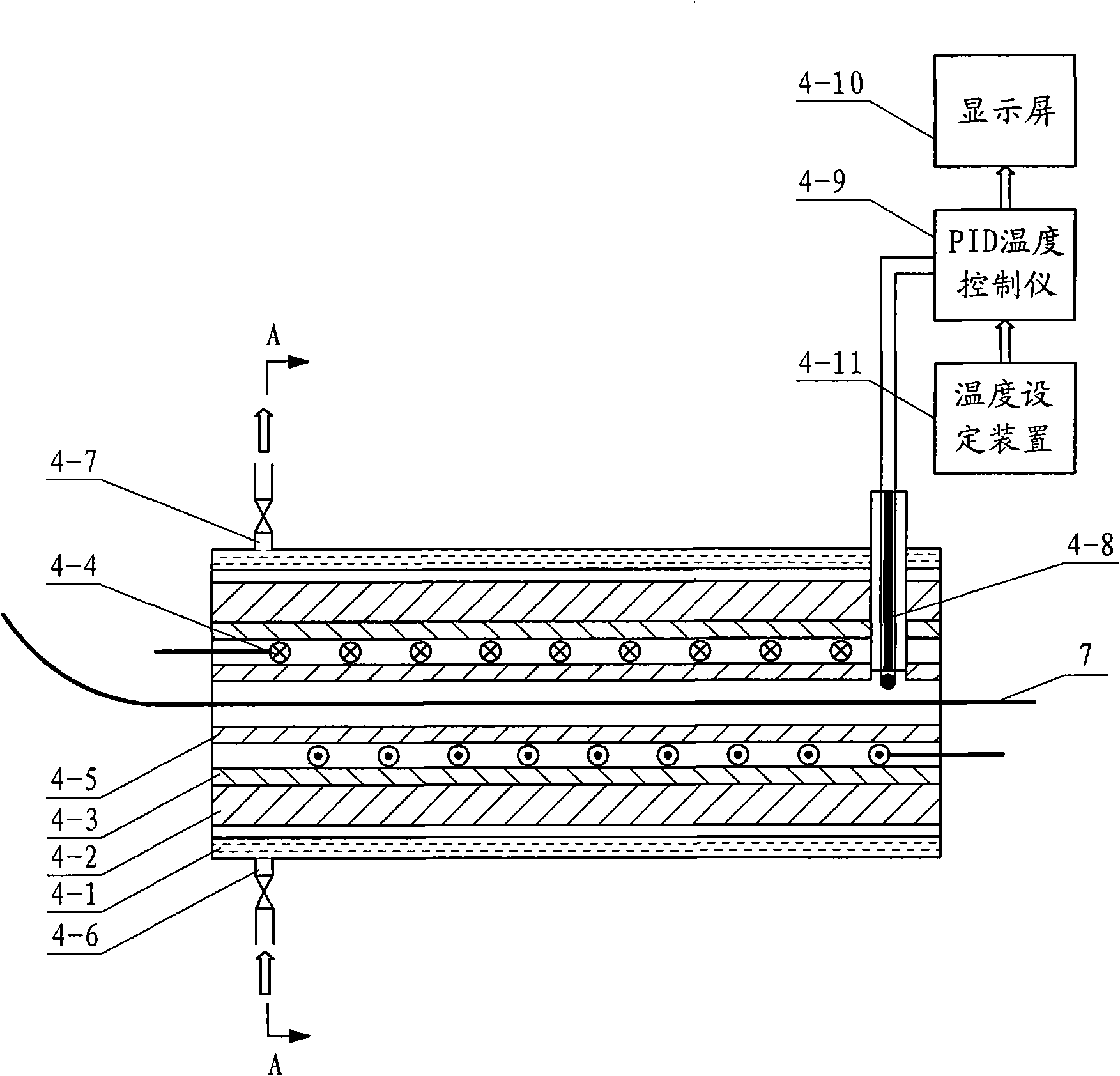

Carbon/carbon composite component chemical vapor infiltration device

ActiveCN104498891AWell mixedIncrease profitChemical vapor deposition coatingPressure controllerCarbon composites

The invention brings forward a carbon / carbon composite component chemical vapor infiltration device and aims to provide a device for solving problems of low reactant gas utilization rate and low infiltration efficiency existing by chemical vapor infiltration in the prior art. The invention is realized by the following technical scheme: a gas mixing and preheating device for primary control of reactant gas diversion direction and a temperature sensor for monitoring preheating temperature of reactant gas are arranged below a deep gas-mixing and outgassing device connected with a sealed infiltration chamber; the regulated and controlled reactant gas enters a gas mixing and preheating device from the bottom of a chemical vapor deposition furnace body through a gas supply device, and a controller automatically regulates electric power on a heater to obtain required preheating temperature; and the preheated reactant gas enters the sealed infiltration chamber and passes through a porous graphite liner plate to infiltrate through a composite preform placed inside the sealed infiltration chamber, and chemical vapor infiltration is performed under constant values by pressure control of a furnace pressure controller and temperature control of a temperature control sensor.

Owner:PLA NO 5719 FACTORY

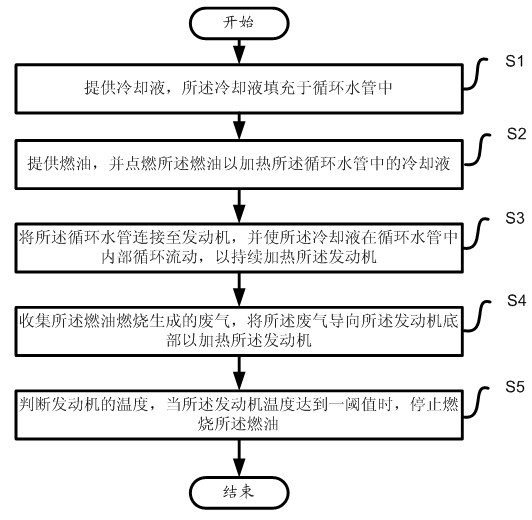

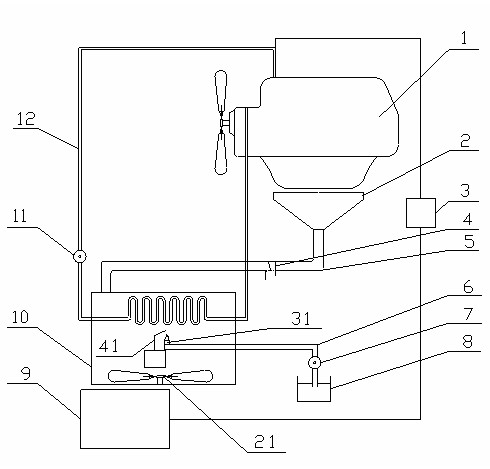

Method for heating cooling fluid so as to realize start-up preheating and heating system

InactiveCN102425523AStable combustionImprove efficiencyBurnersMachines/enginesCombustionExhaust fumes

The invention discloses a method used for heating a cooling fluid so as to realize start-up preheating. The method comprises the following steps: a step 1, providing the cooling fluid, wherein the cooling fluid is filled in a circulating pipe; a step 2, providing fuel oil and igniting the fuel oil so as to heat the cooling fluid in the circulating pipe; a step 3, connecting the circulating pipe to an engine, enabling the cooling fluid to circularly flow in the circulating pip, and continuing to heat the engine; a step 4, collecting the waste gas generated by fuel oil combustion, and introducing the waste gas to the bottom of the engine so as to heat the engine; and a step 5, judging the temperature of the engine, and when the temperature of the engine achieves a threshold, stopping burning the fuel oil. The method provided by the invention has the advantages of low-temperature startup and high-temperature stop functions and high security.

Owner:SANY HEAVY MACHINERY

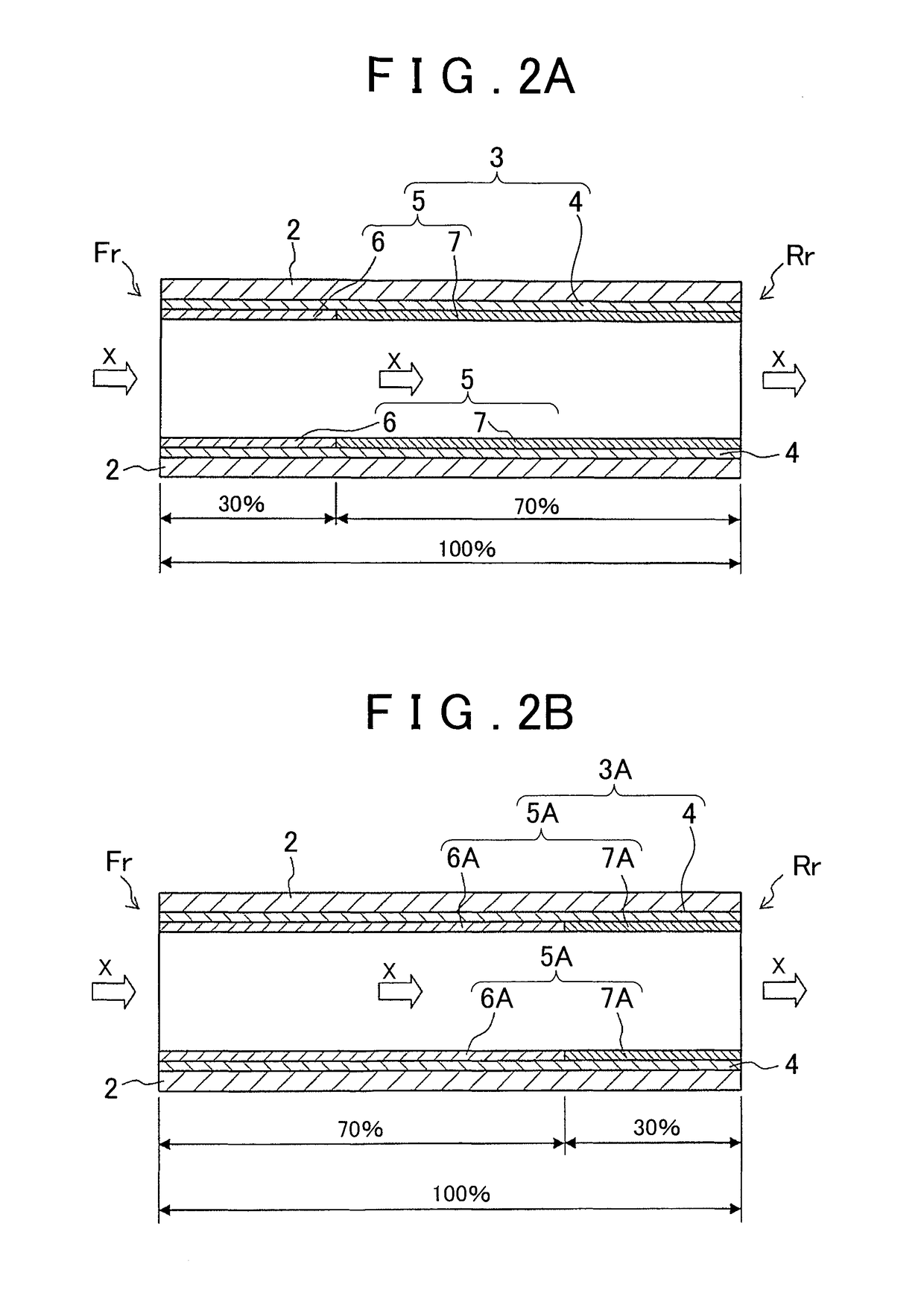

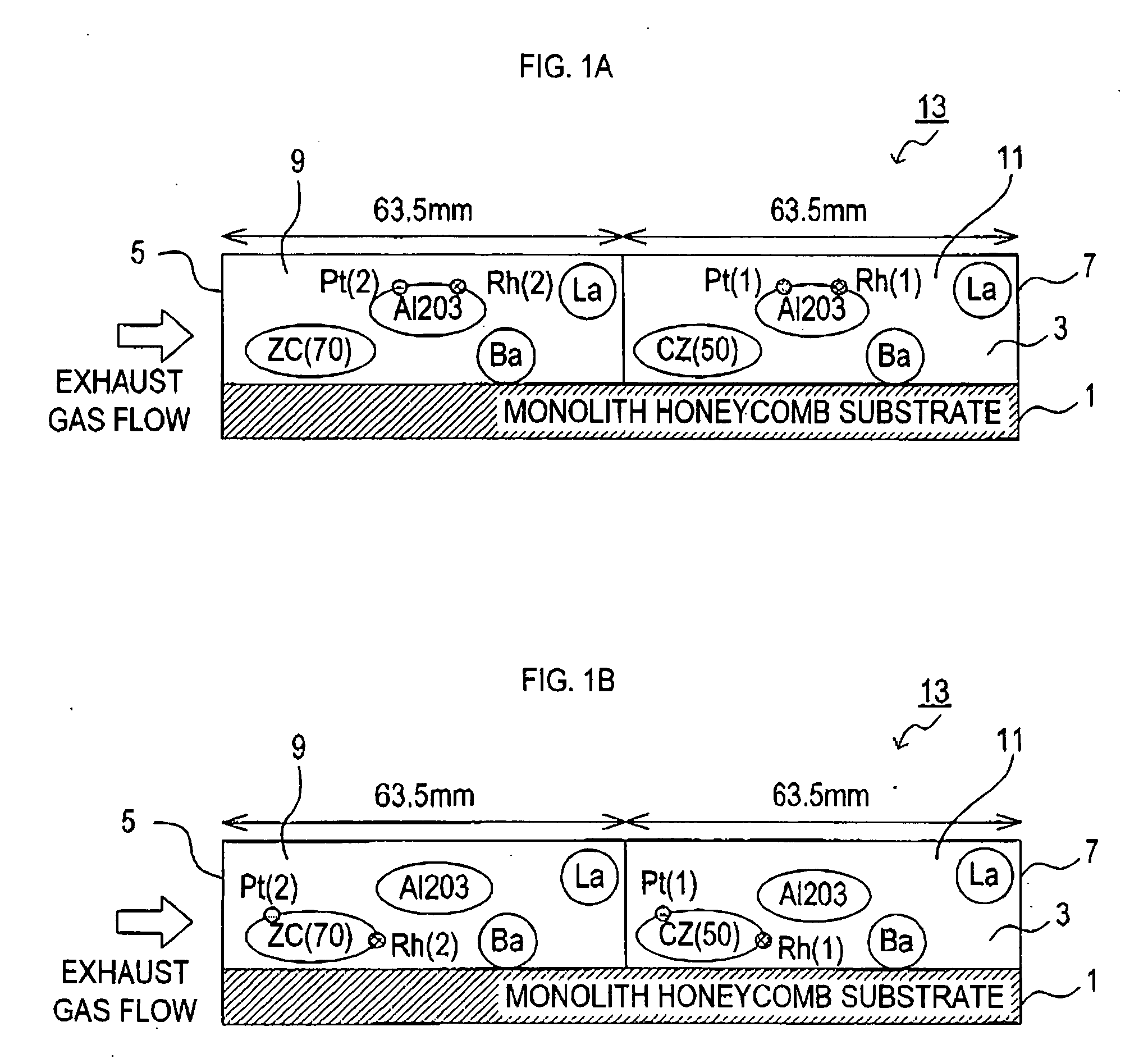

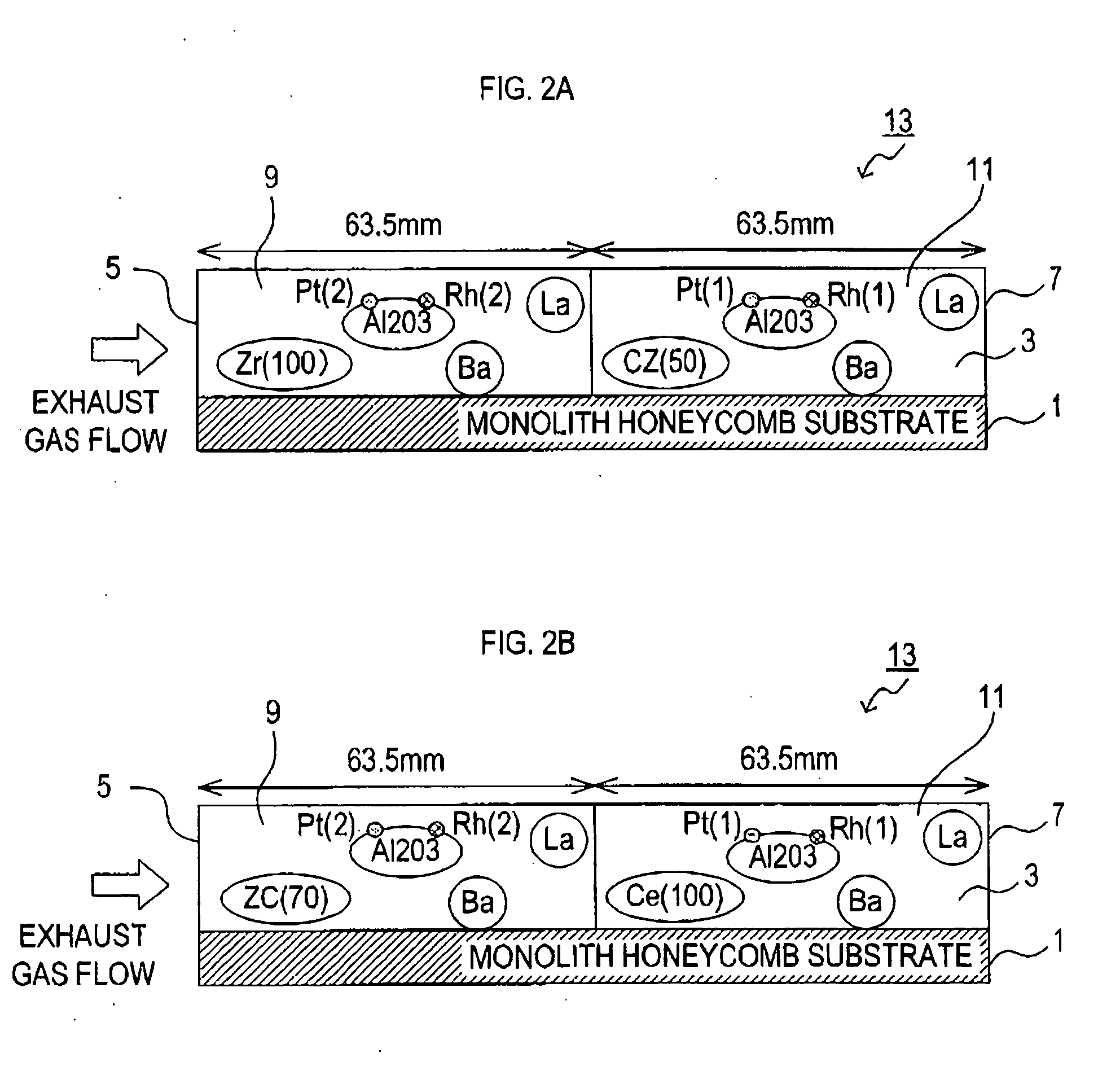

Catalytic converter

ActiveUS9999871B2Excellent OSCPromote conversionGas treatmentInternal combustion piston enginesCatalytic transformationComposite oxide

A catalytic converter includes a substrate (1) and a catalyst layer (3). The catalyst layer includes a bottom catalyst layer (4), a first top catalyst layer (6) and a second top catalyst layer (7). The second top catalyst layer is provided on a downstream side relative to the first top catalyst layer. The first top catalyst layer is made of a ceria-free zirconia composite oxide support and rhodium. The second top catalyst layer is made of a ceria-containing zirconia composite oxide support and rhodium. The first top catalyst layer has a length that is X % of the entire length of the substrate. The second top catalyst layer has a length that is 100−X % of the entire length of the substrate. A ratio of a density of rhodium in the first top catalyst layer to a density of rhodium in the second top catalyst layer is at least 1 and at most 3.

Owner:TOYOTA JIDOSHA KK

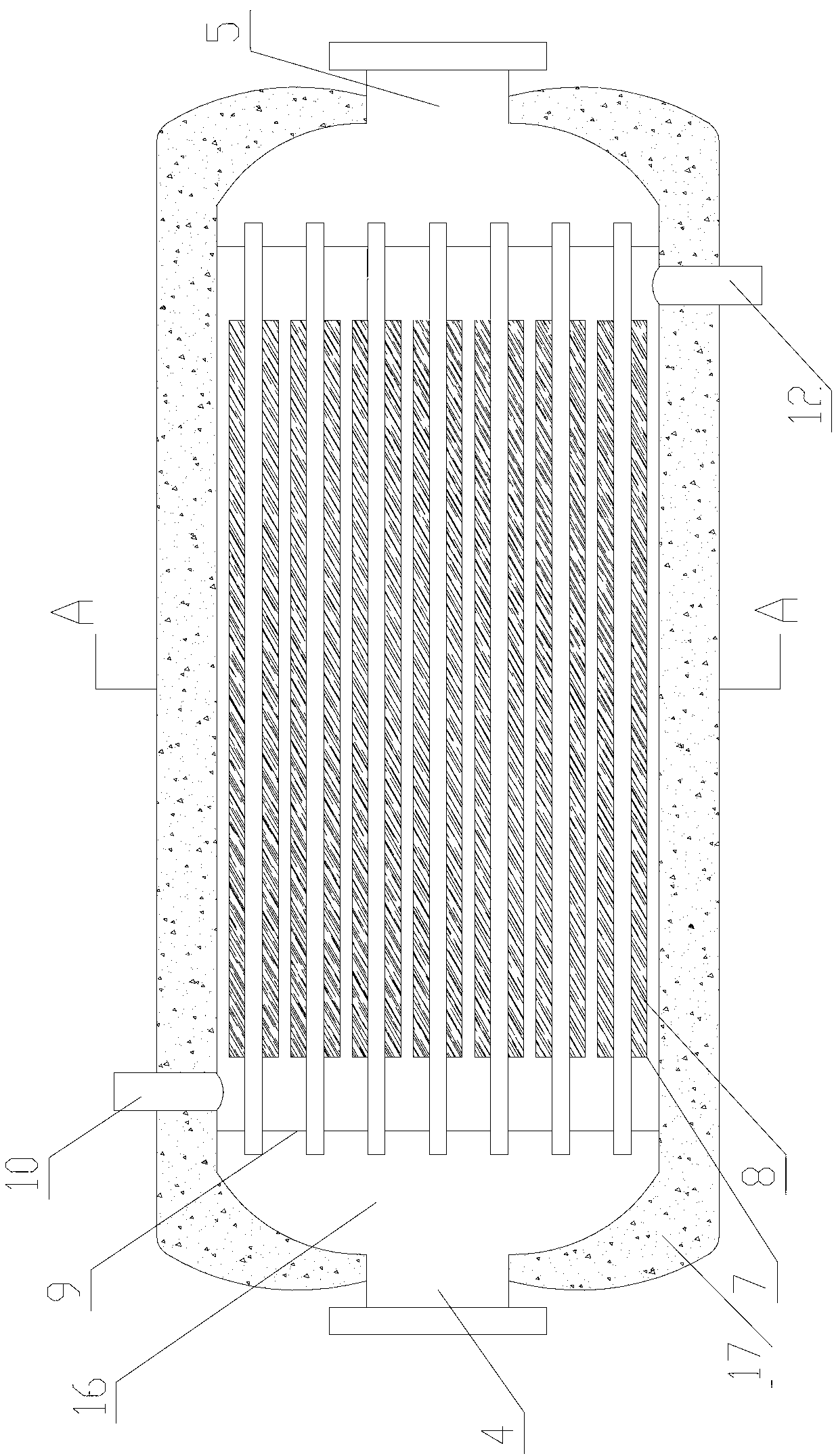

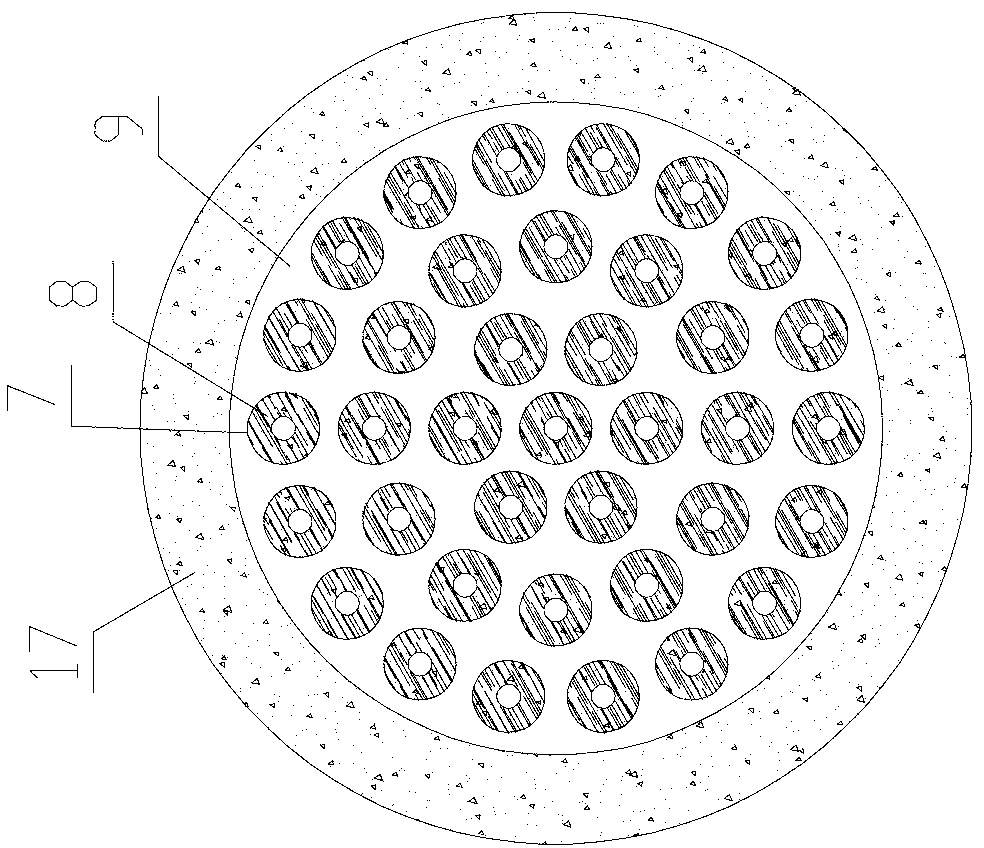

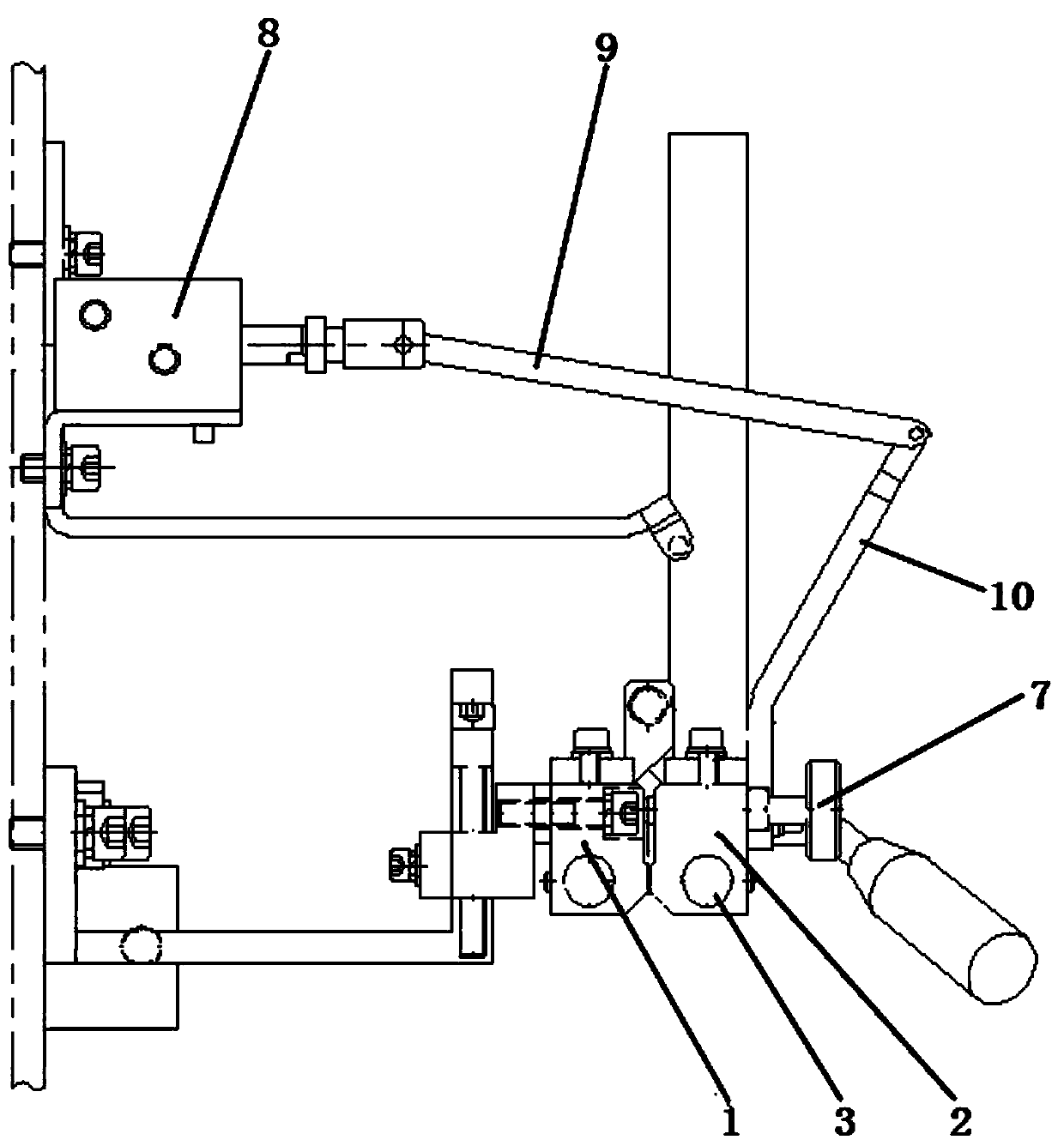

Engine cold-start preheating device

InactiveCN103061947AHigh exhaust gas temperatureStable warm-up performanceInternal combustion piston enginesExhaust apparatusEngineeringPhase change

The invention discloses an engine cold-start preheating device. A heat storing heat exchanger (3) is in a parallel connection with an exhaust pipe (2) of an engine (1), the heat storing heat exchanger (3) is used for storing exhaust air waste heat of the engine (1), the heat storing heat exchanger (3) is in a columnar structure, a plurality of heat storing units are distributed in the heat storing heat exchanger (3), each heat storing unit is a concentric casing pipe (7) which comprises an inner pipe and an outer pipe, a phase change thermal storage material (8) is encapsulated in annular space between the inner pipe and the outer pipe, two ends of the inner pipe are welded on two flow guide plates (9) respectively, a hollow cavity for enabling cooling water of the engine (1) to flow through is formed by the two flow guide plates (9) and inner walls of the heat storing heat exchanger (3), and the inner walls of the heat storing heat exchanger (3) are located between the two flow guide plates (9). The engine cold-start preheating device has the advantages of being low in costs, small in size, efficient, energy-saving and convenient to popularize and use in a wide range.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

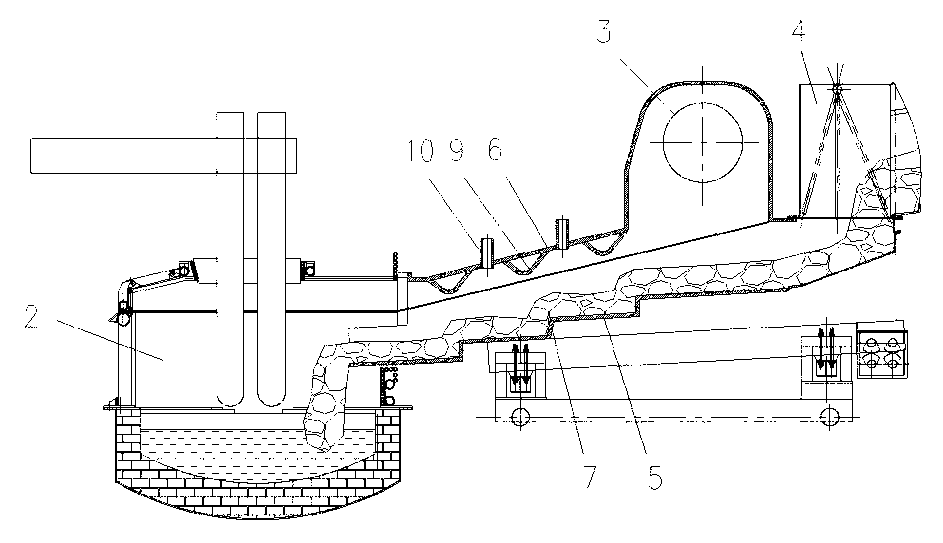

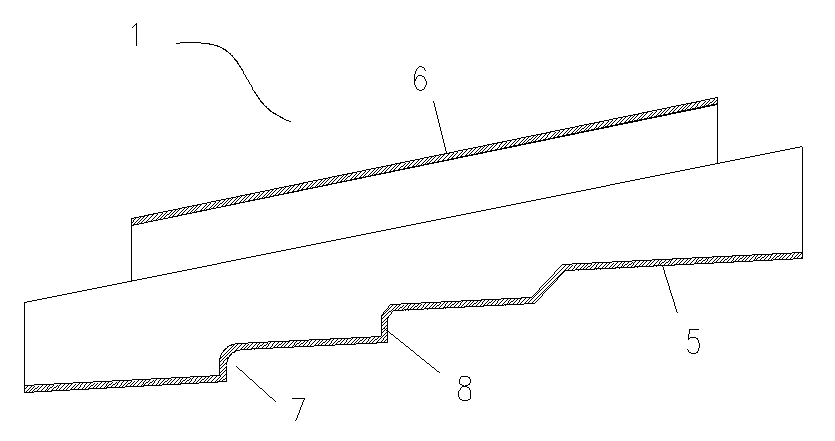

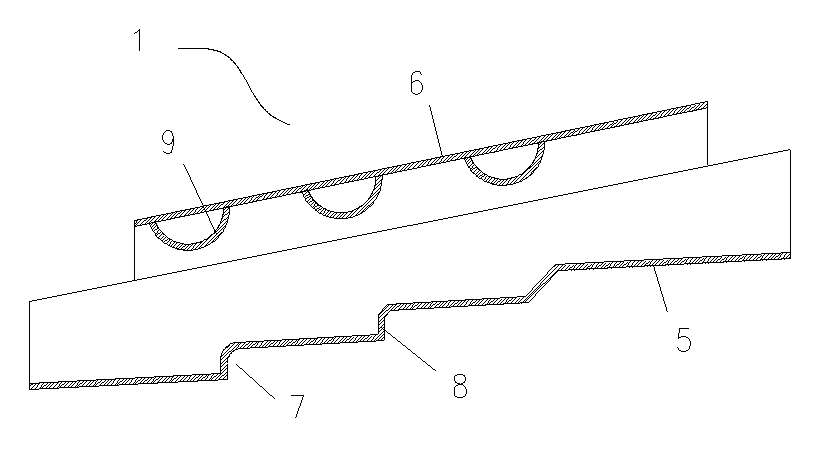

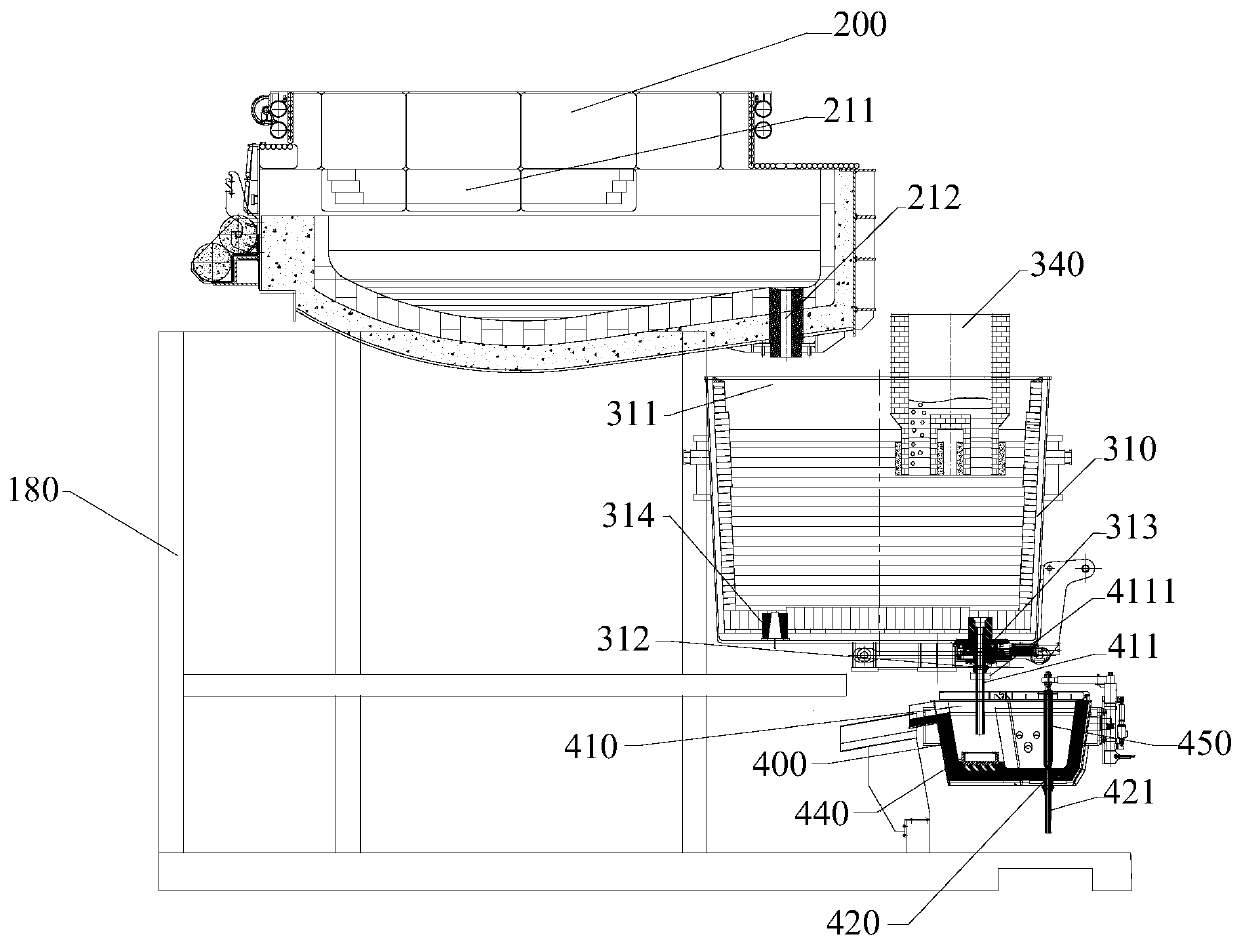

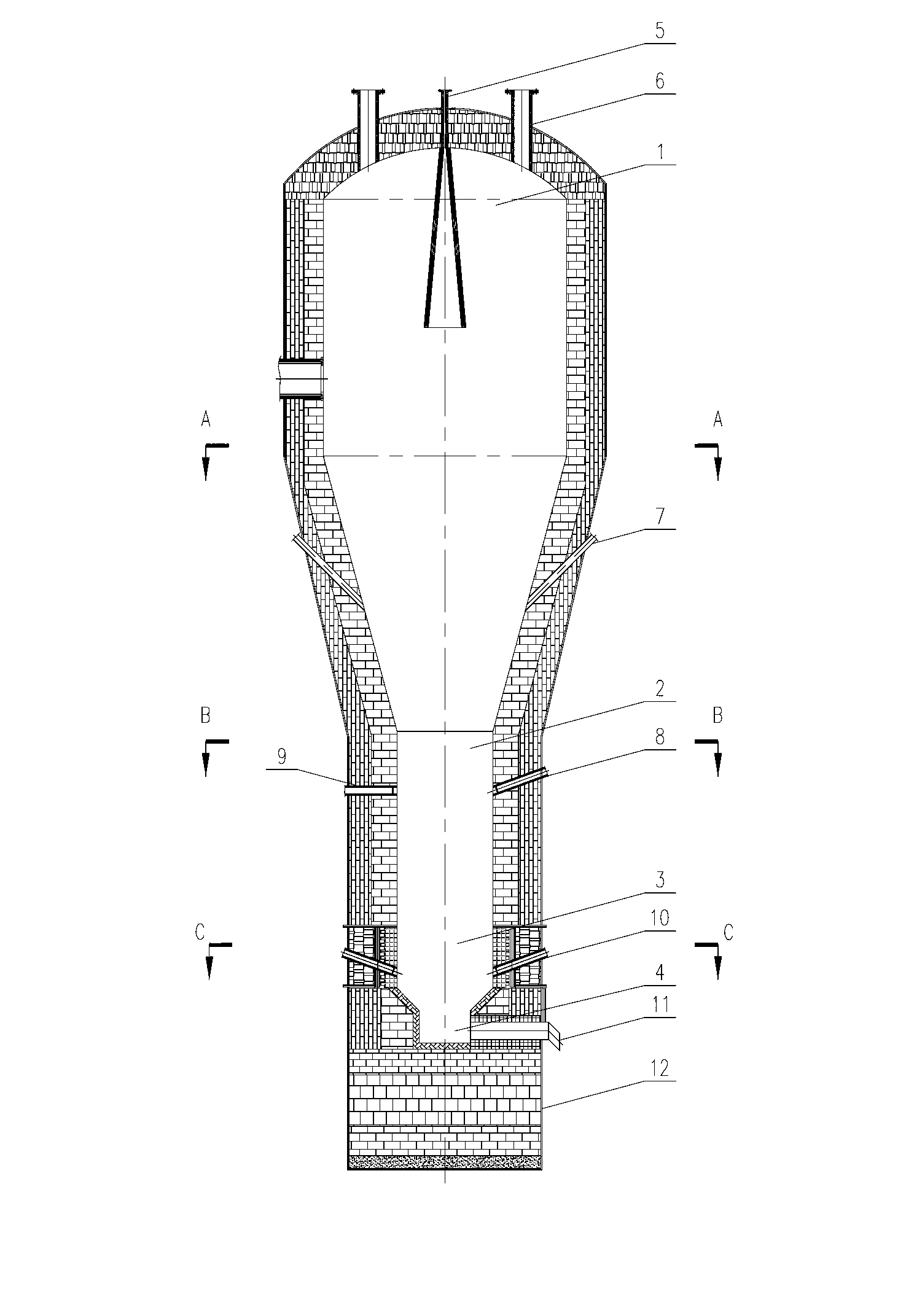

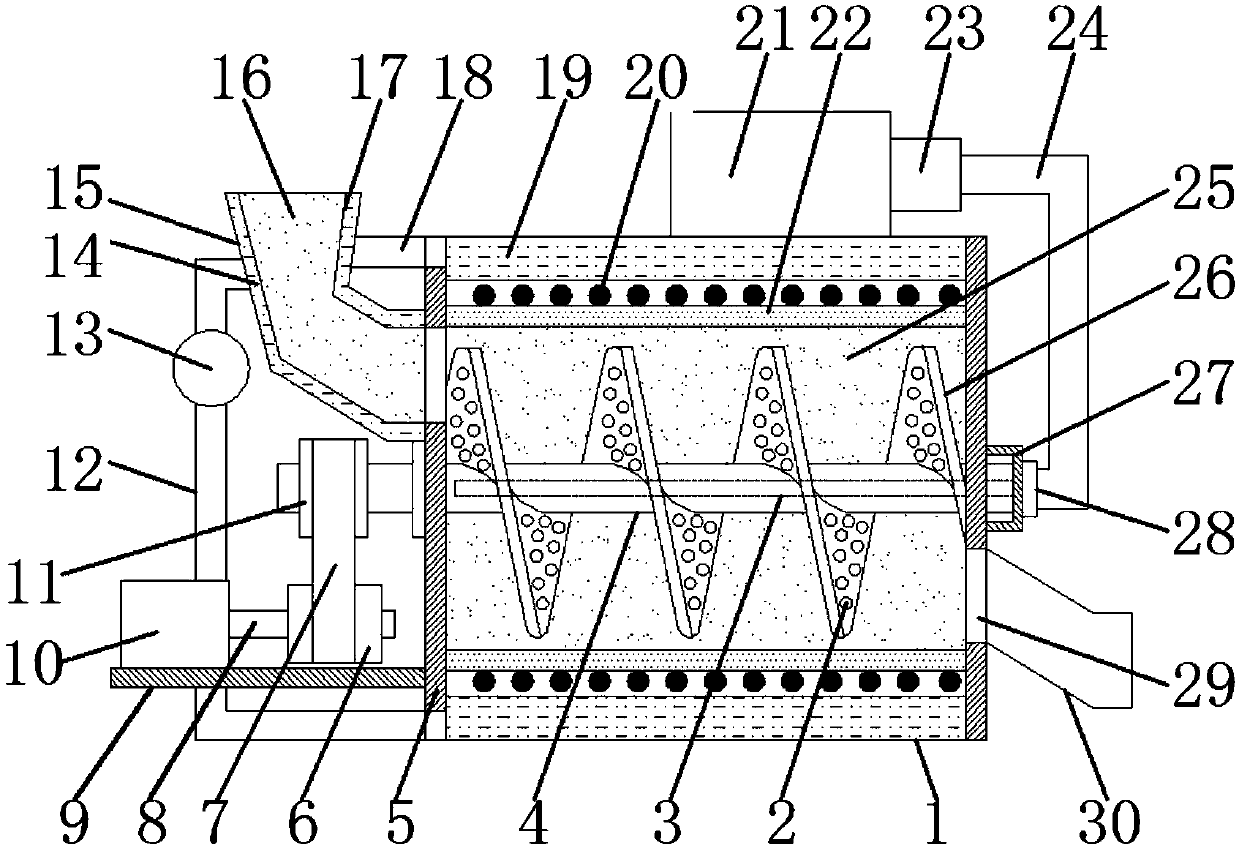

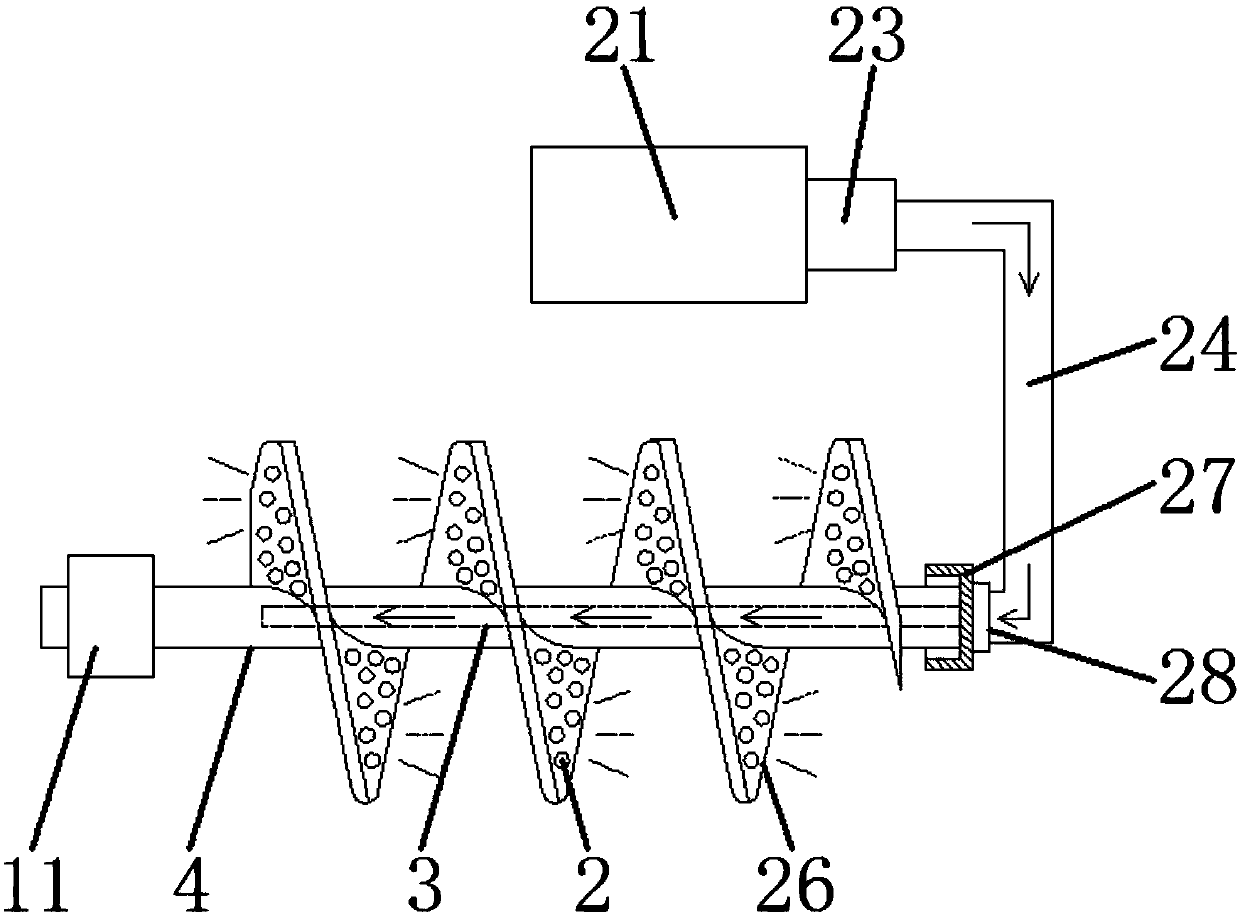

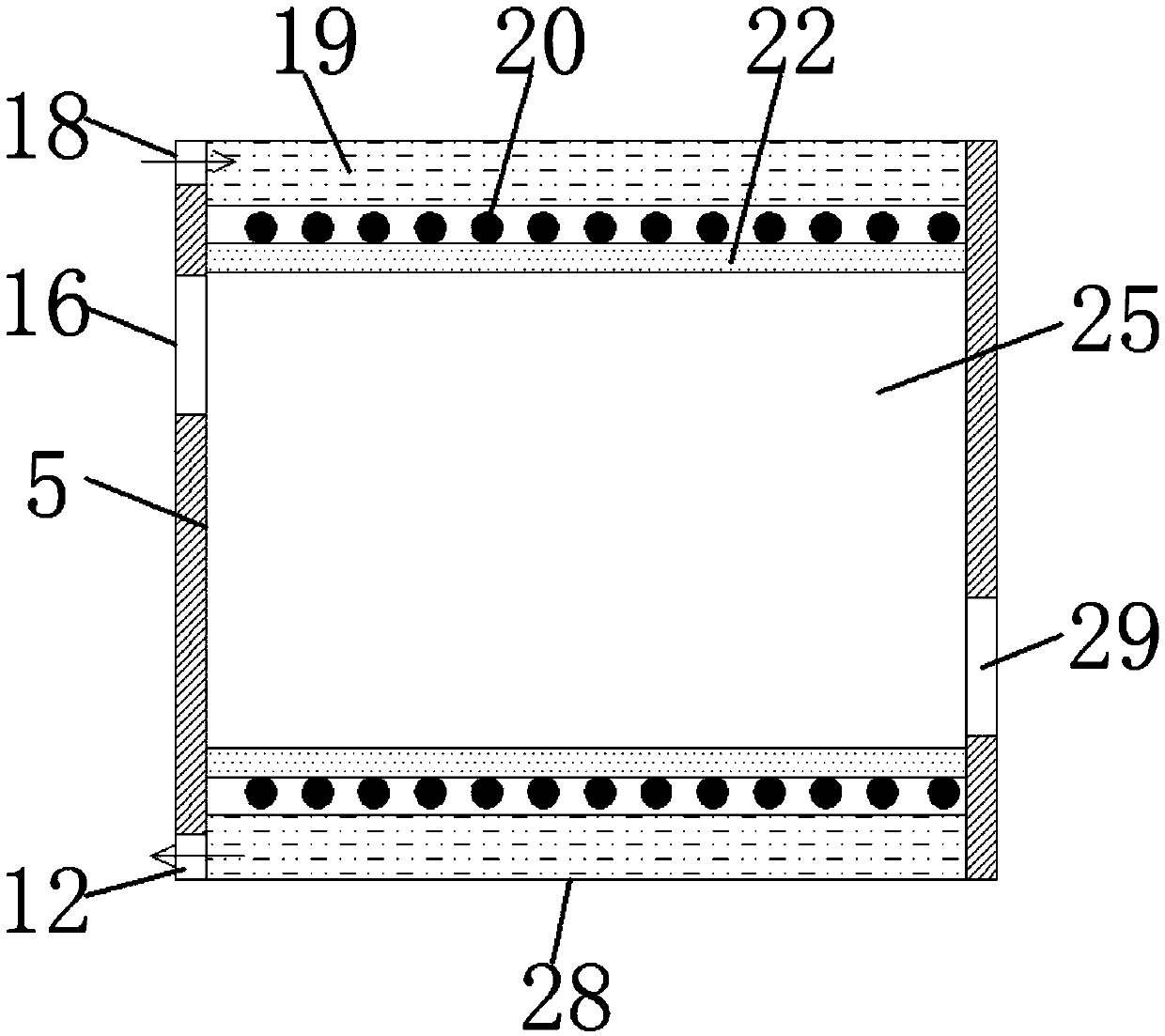

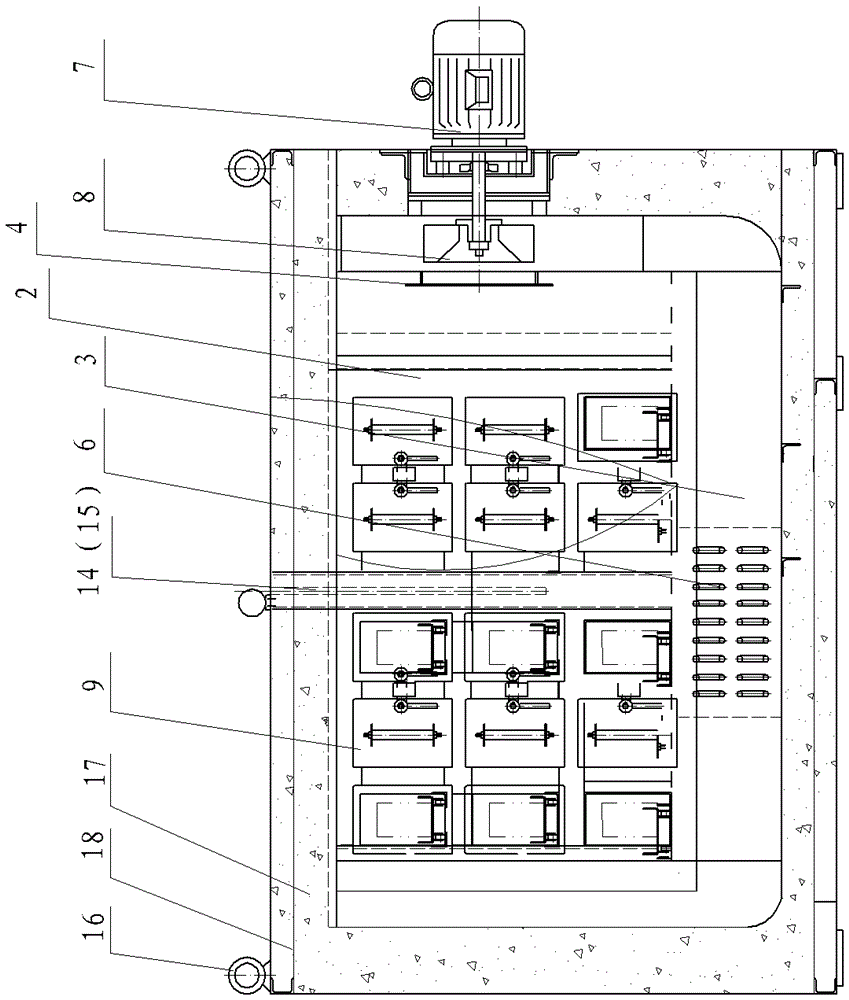

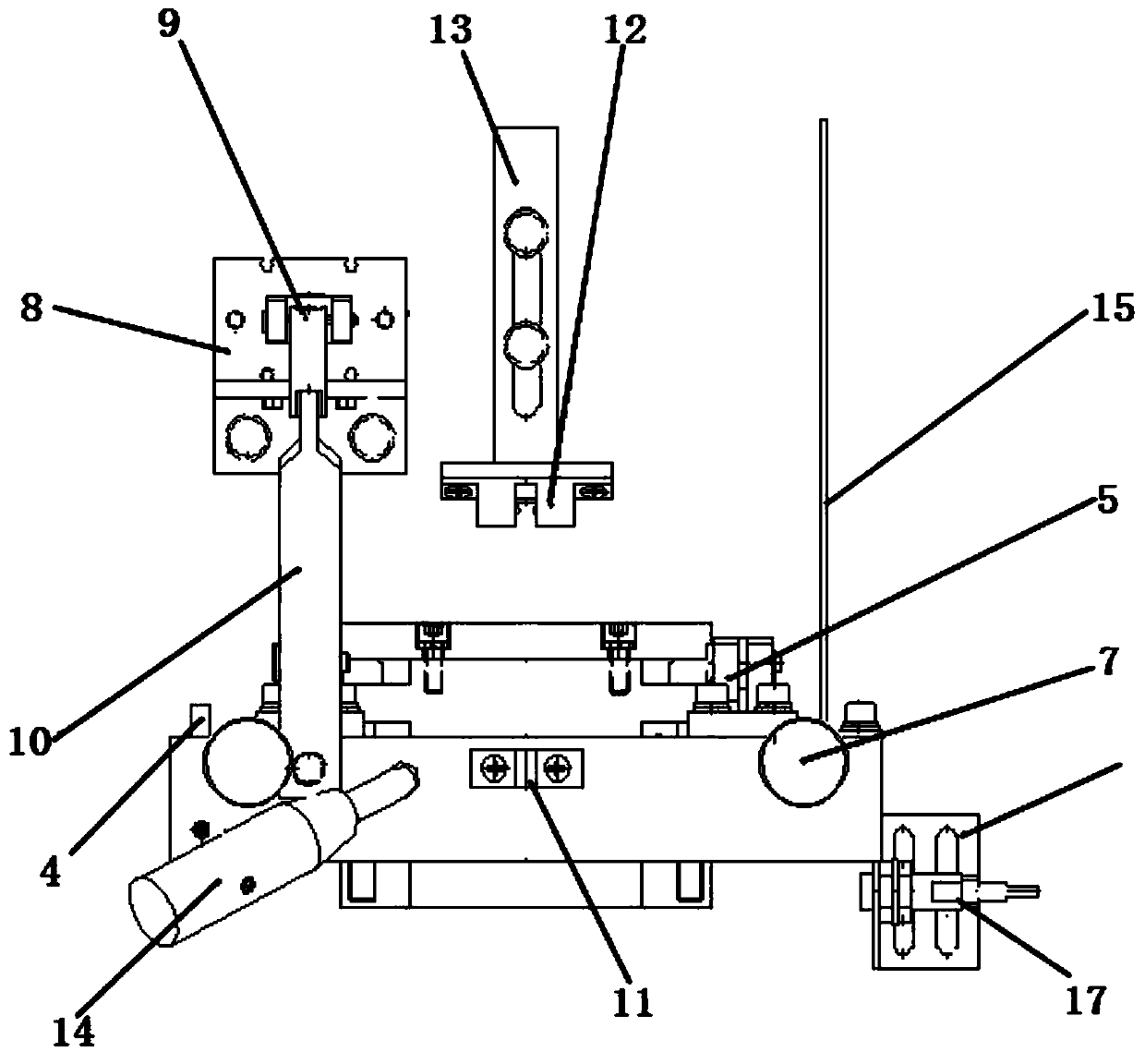

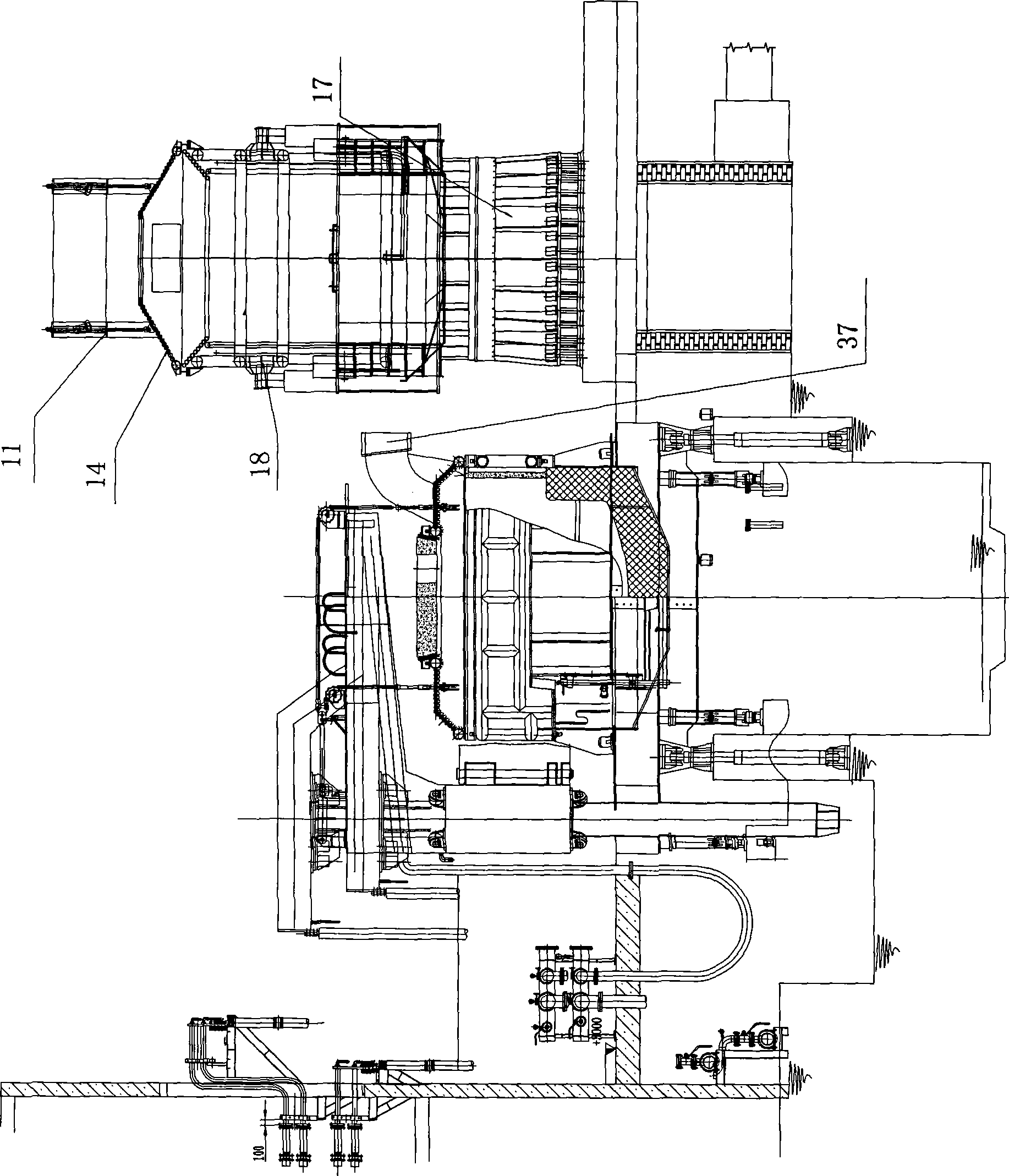

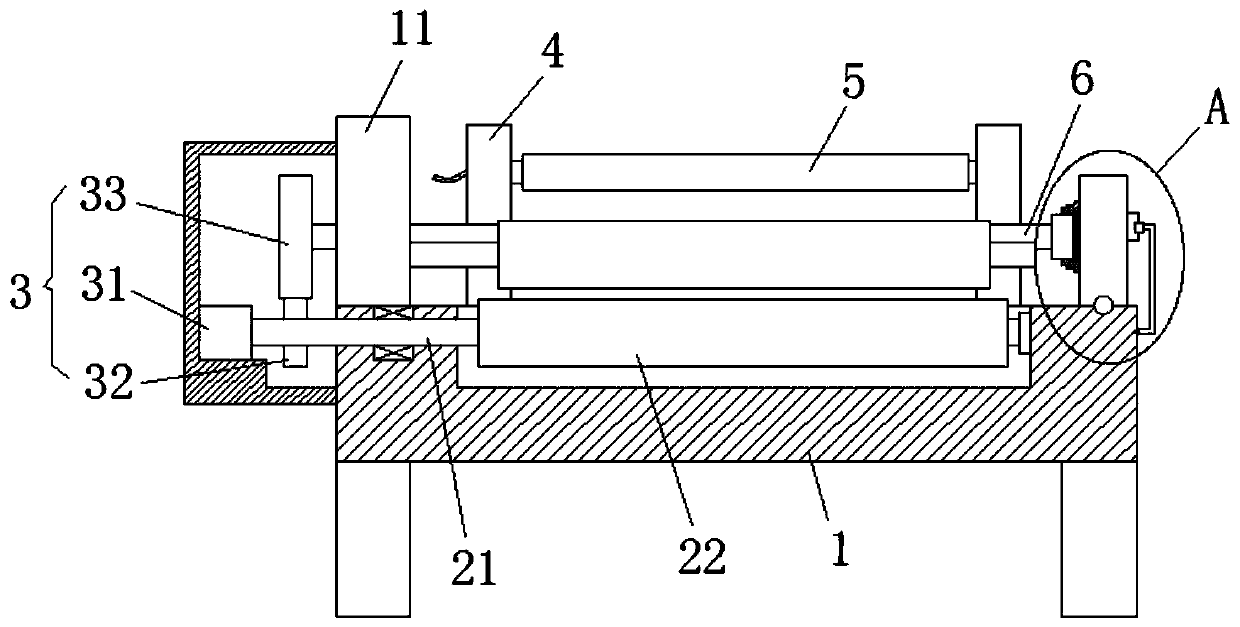

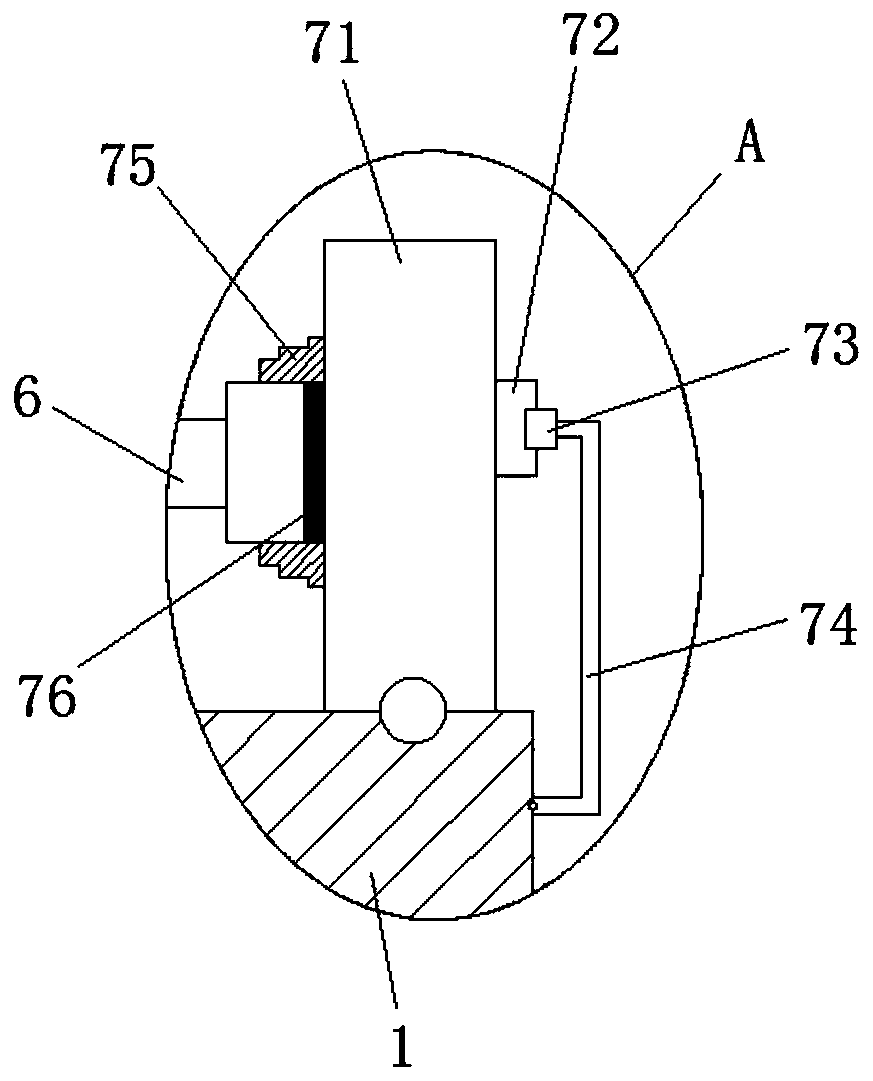

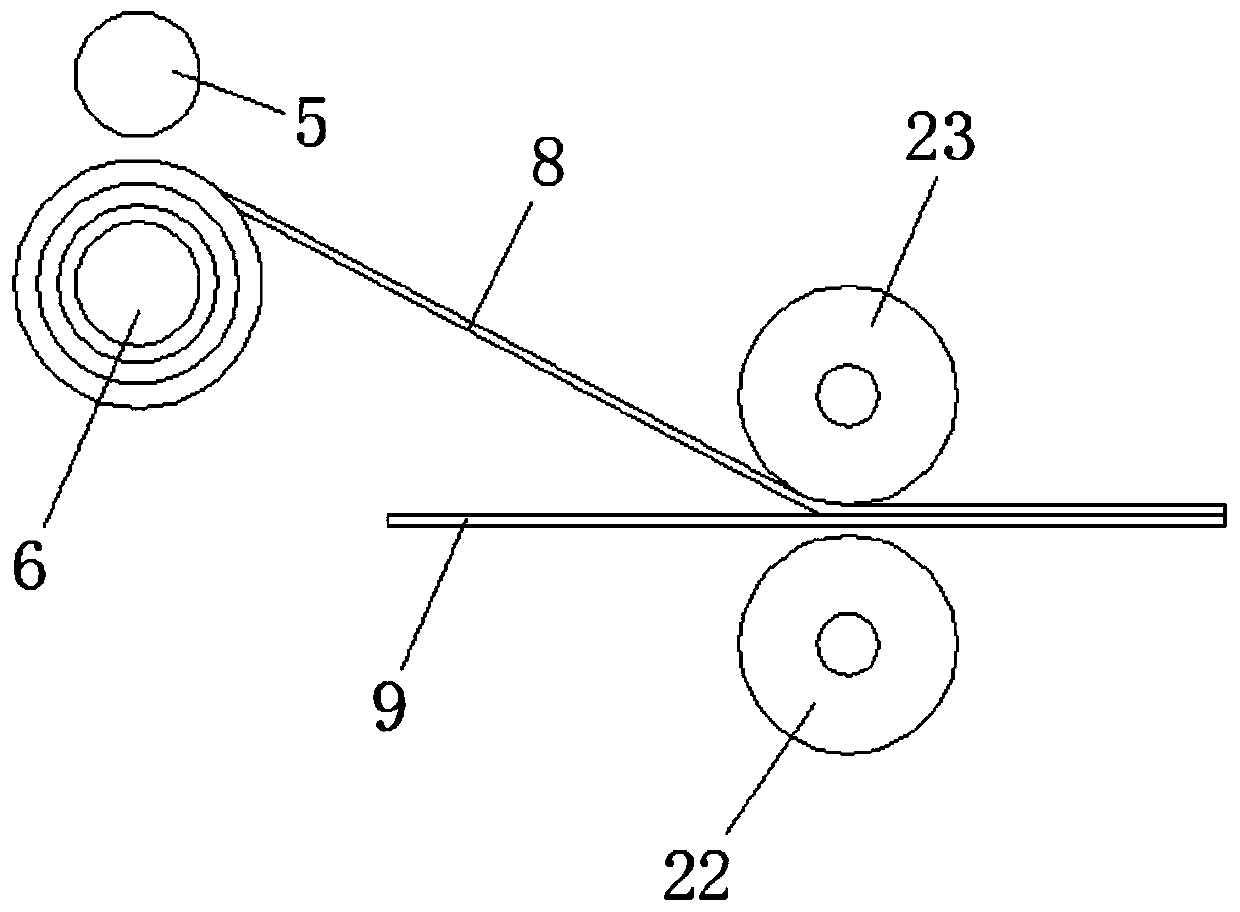

Steel scrap preheater and preheating method of electric-arc furnace step disturbance culvert

The invention discloses a scrap preheater of an electric-arc furnace step disturbance culvert. The scrap preheater comprises a heat-exchanging culvert, the low side of the heat-exchanging culvert is connected with a furnace, the high side of the heat-exchanging culvert is respectively connected with a smoke-collecting and dust-removing pipe and a feed sealing device, the heat-exchanging culvert comprises a material- conveying groove and a smoke guide cover, the material-conveying groove is used for conveying steel scrap materials to the electric-arc furnace, the smoke guide cover is covered on the material- conveying groove and is used for guiding smoke, the heat-exchanging culvert is provided with at least one cross-section abrupt change structure in the height-extending direction, and the cross-section abrupt change structure is used for disturbing the steel scrap material flow state and the smoke flow state. The invention further discloses a preheating method of the electric-arc furnace step disturbance culvert, and the steel scrap materials can be added to the material-conveying groove by the feed sealing device; the steel scrap material flow state is disturbed under the combined action of the cross-section abrupt change structure on the heat-exchanging culvert and horizontal vibration, so that the steel scrap materials have air permeability in a certain area; and the smoke flow state can be disturbed in the smoke guide cover, so that the smoke and the steel scrap materials can be subjected to heat exchanging fully.

Owner:CISDI ENG CO LTD

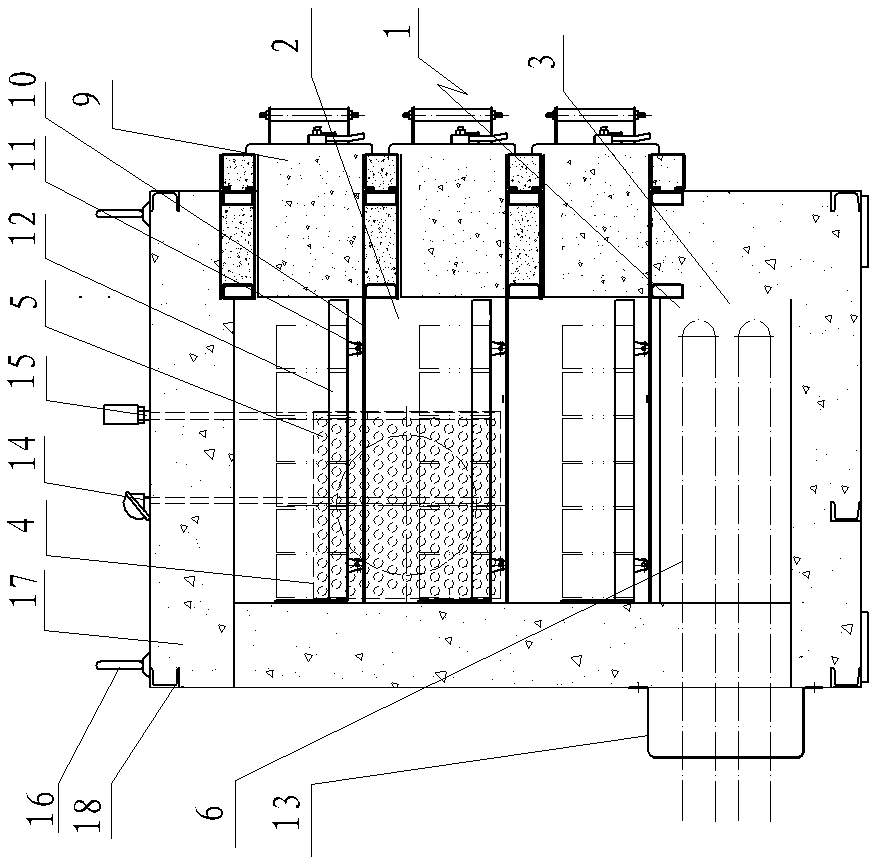

Lime rotary kiln

InactiveCN102564110ASimple structureSave energyRotary drum furnacesEngineeringMechanical engineering

The invention discloses a rotary kiln, in particular to a lime rotary kiln used in production of aluminum oxide or cement. The lime rotary kiln is structurally characterized in that a kiln head is connected with an inclined rotary kiln body, a transmission device driving the kiln body to rotate counterclockwise is arranged outside the rotary kiln body, a kiln tail is connected to the rear end of the rotary kiln body, a variable-diameter section is arranged at the kiln tail close to the rotary kiln body, and a raising plate is arranged on the inner wall of the variable-diameter section. The lime rotary kiln has the advantages that the lime rotary kiln is simple in structure, energy-saving, cost-saving and effective in preheating, and productivity is improved.

Owner:中铝国际技术发展有限公司

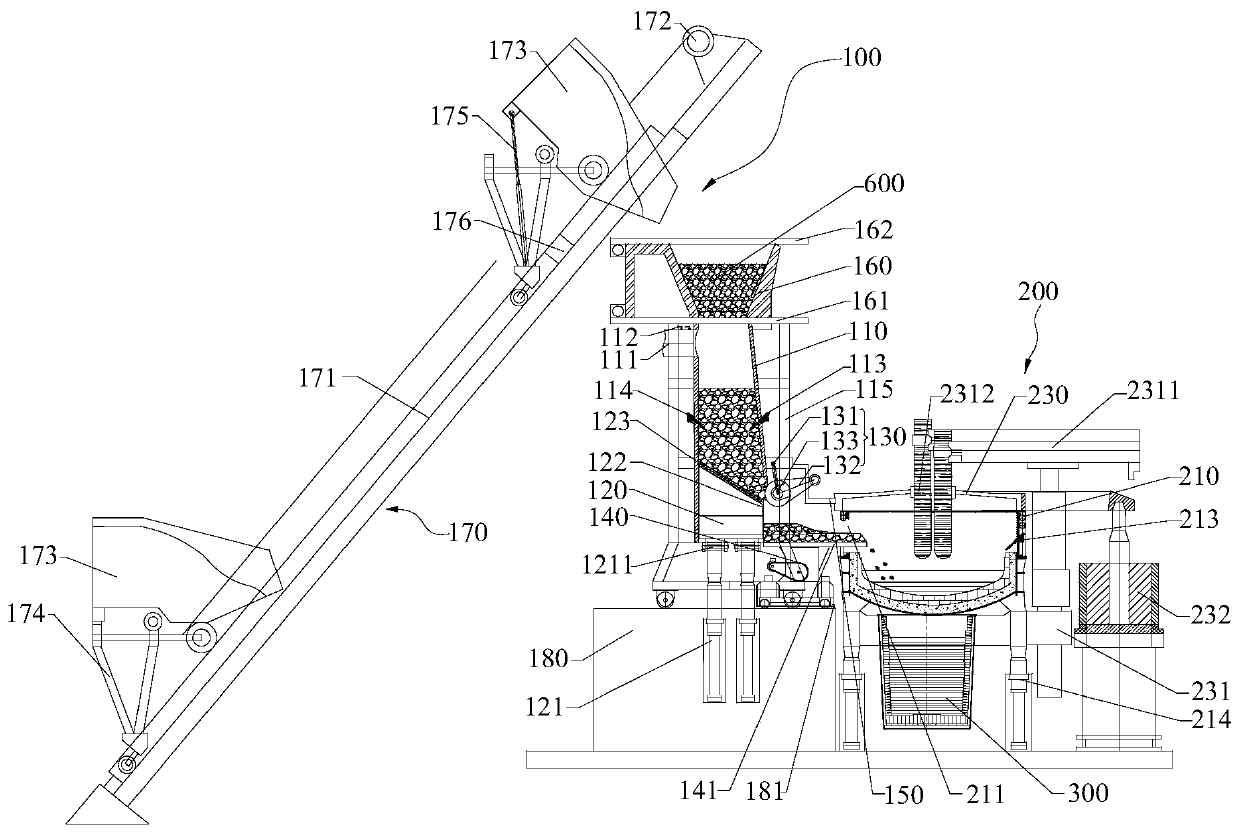

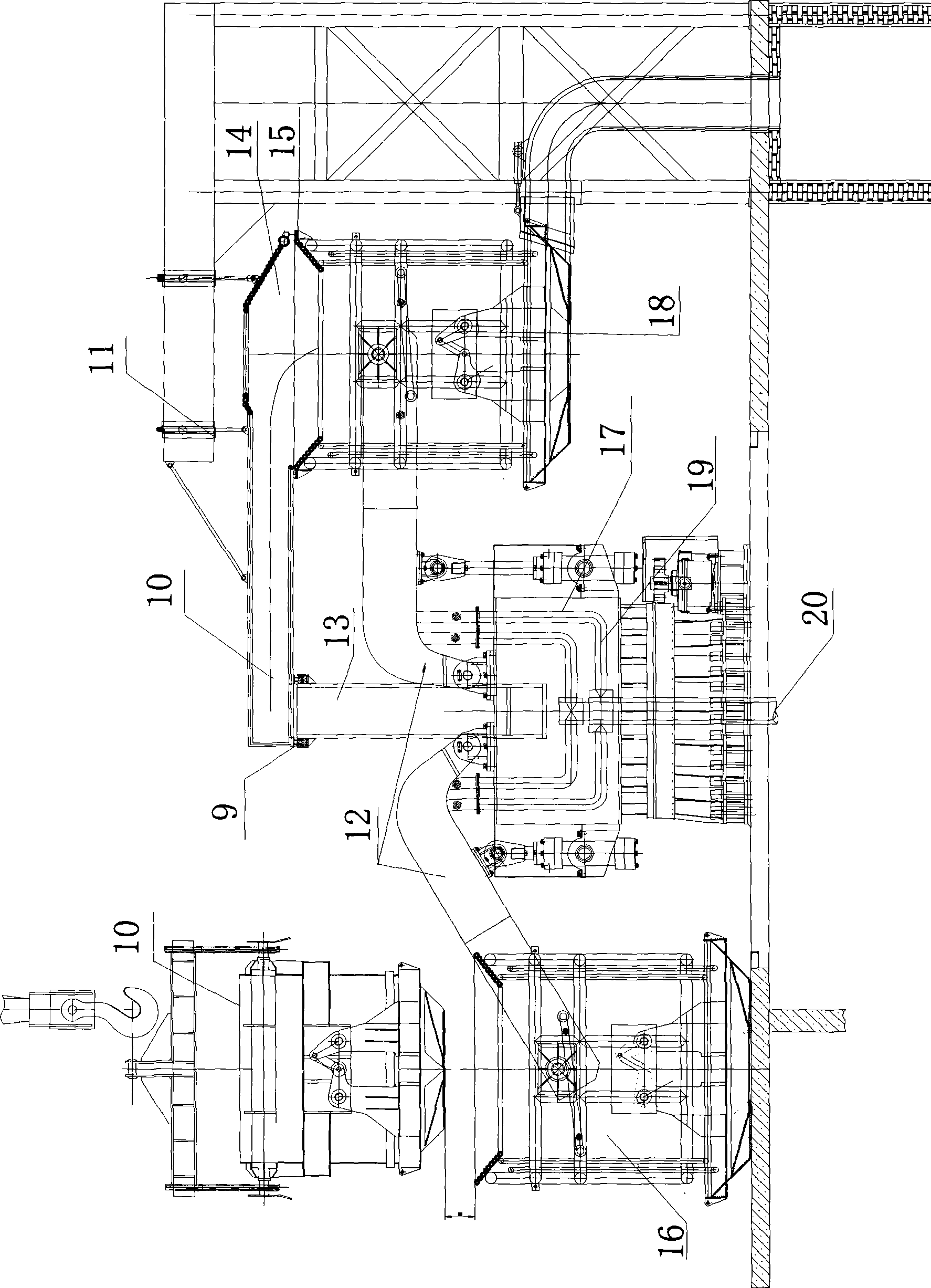

Steel-making device and steel-making method

PendingCN110923394ARealize continuous warm-upShorten the production cycleProcess efficiency improvementElectric furnaceSteelmakingElectric arc furnace

The invention provides a steel-making device and a steel-making method. The steel-making device comprises a pre-heating device, an electric-arc furnace, a refining device, a middle smelting device anda continuous casting machine, wherein the pre-heating device is provided with a feeding inlet and a discharging outlet; the electric-arc furnace comprises a furnace housing, the furnace housing is provided with a feed inlet and a steel outlet, the feed inlet is communicated with the discharging outlet, and the bottom of the furnace housing is provided with a first stirring device for stirring molten steel. The refining device is provided with a liquid inlet and a liquid outlet, and the liquid inlet is communicated with the steel outlet; the middle smelting device is provided with an inlet andan outlet, the inlet is communicated with the liquid outlet, and the middle smelting device is internally provided with a filter assembly; the continuous casting machine is provided with a feed inletand a steel outlet, and the feed inlet is communicated with the outlet. In the steel-making device, it is not required that steel ladles are transferred, in the steel-making process, dynamic continuous running can be achieved, the production period is shortened, and the yield is increased.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

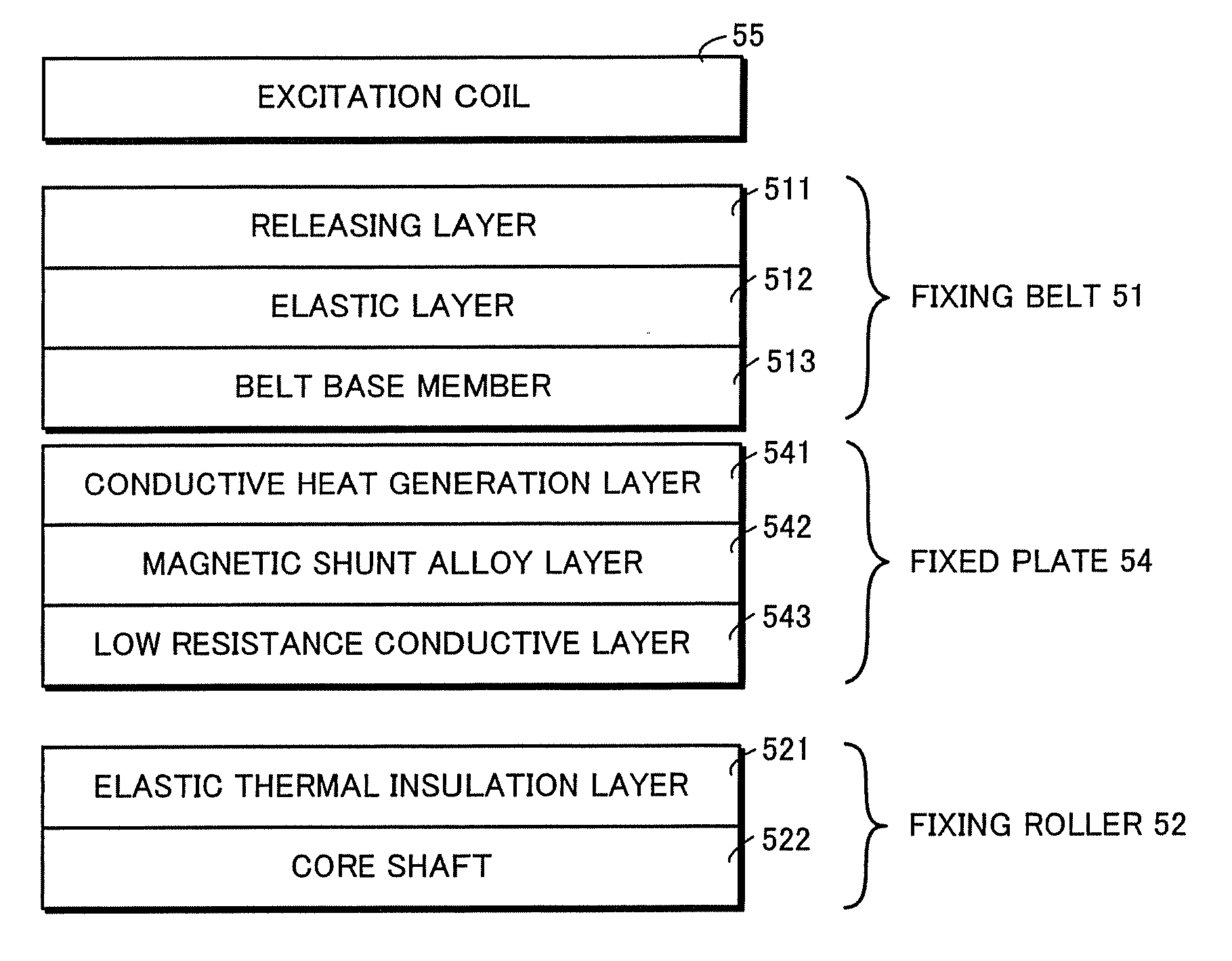

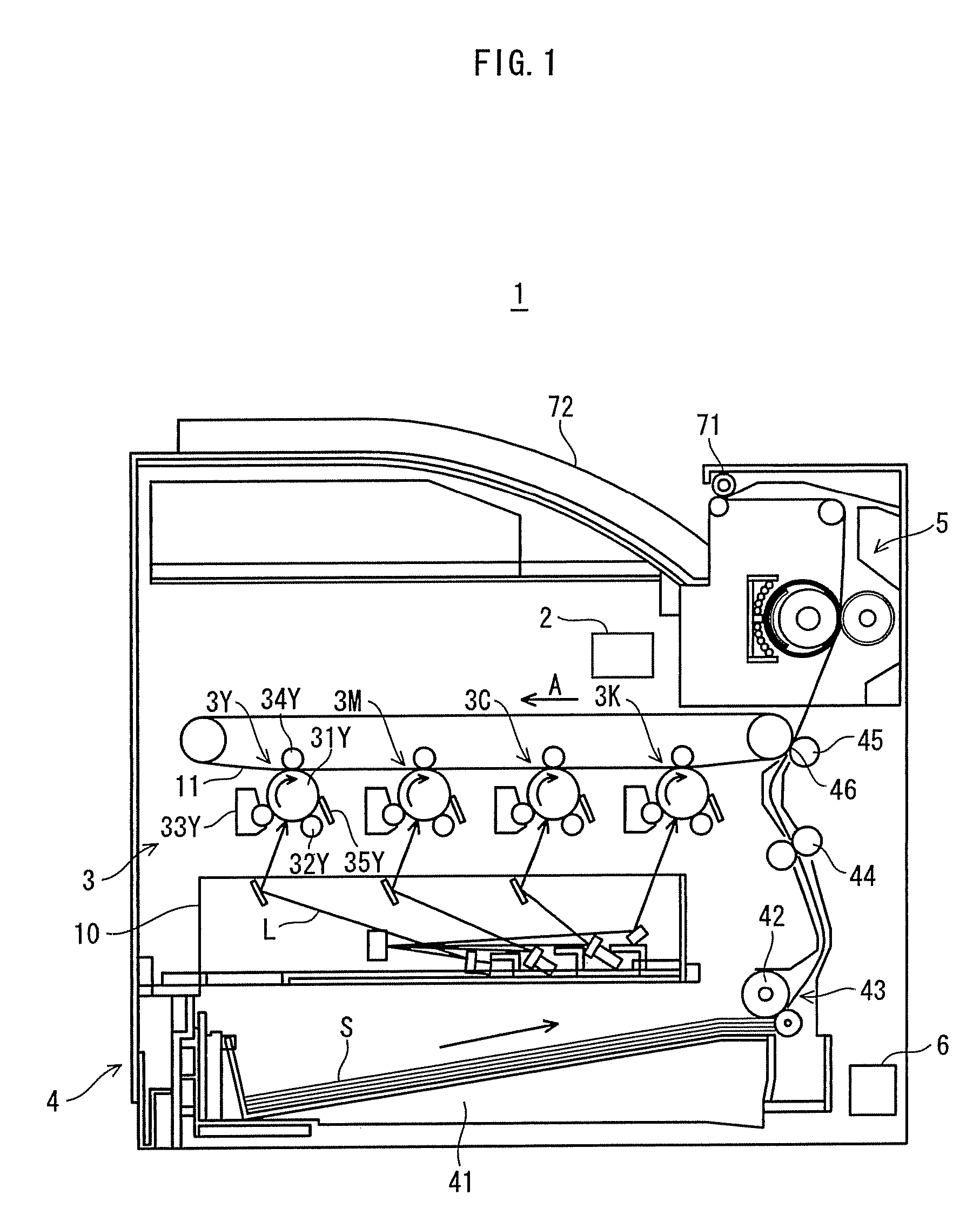

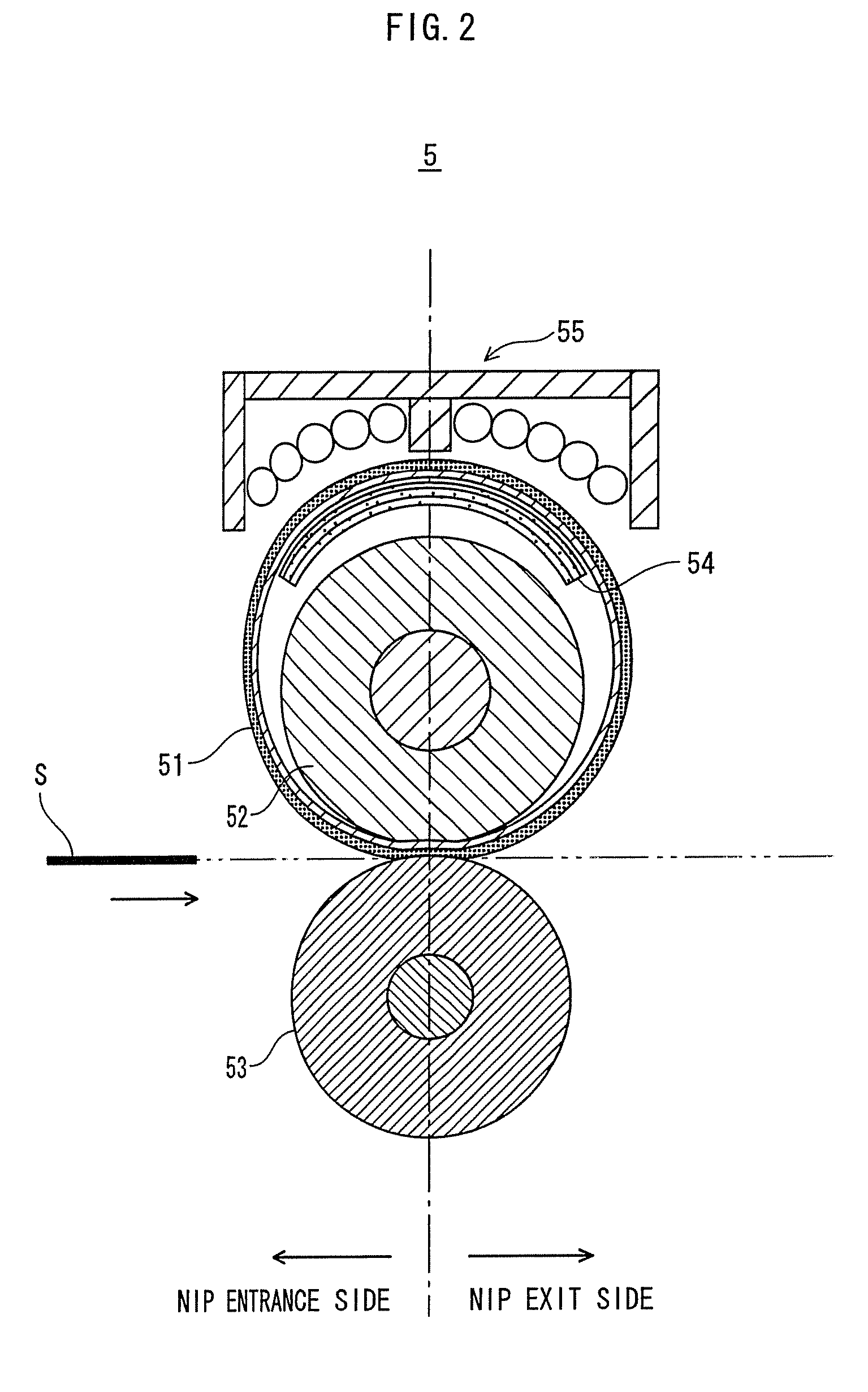

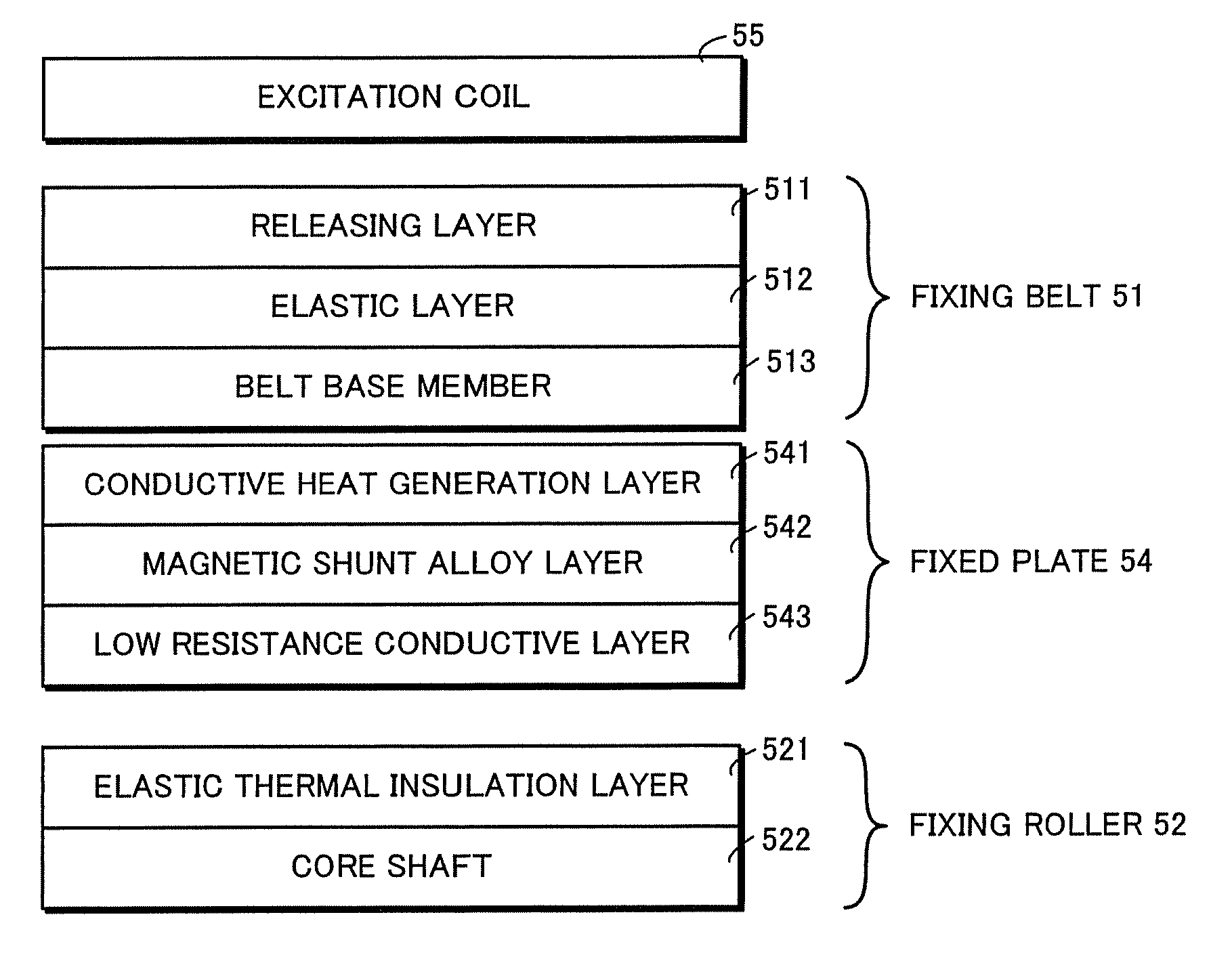

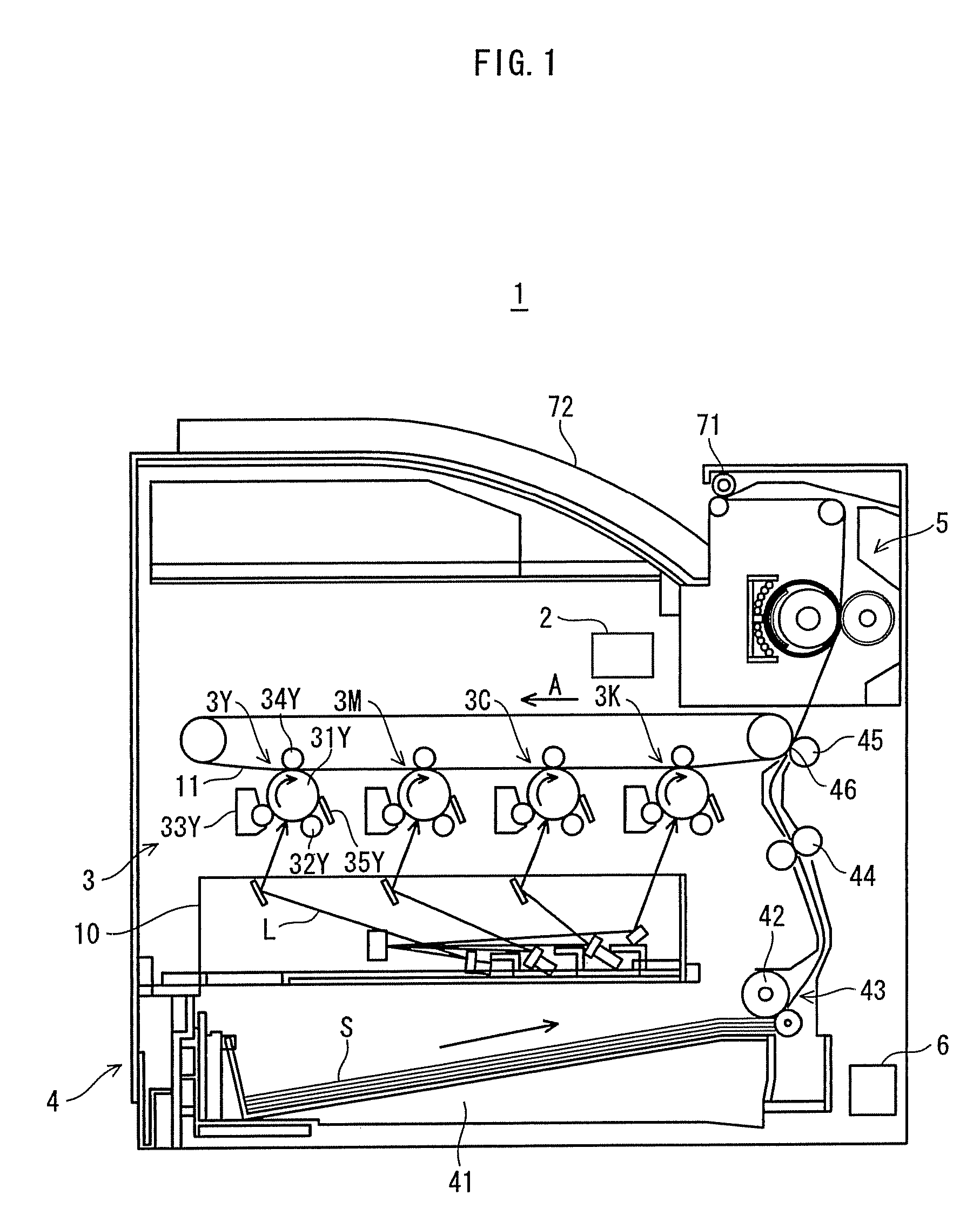

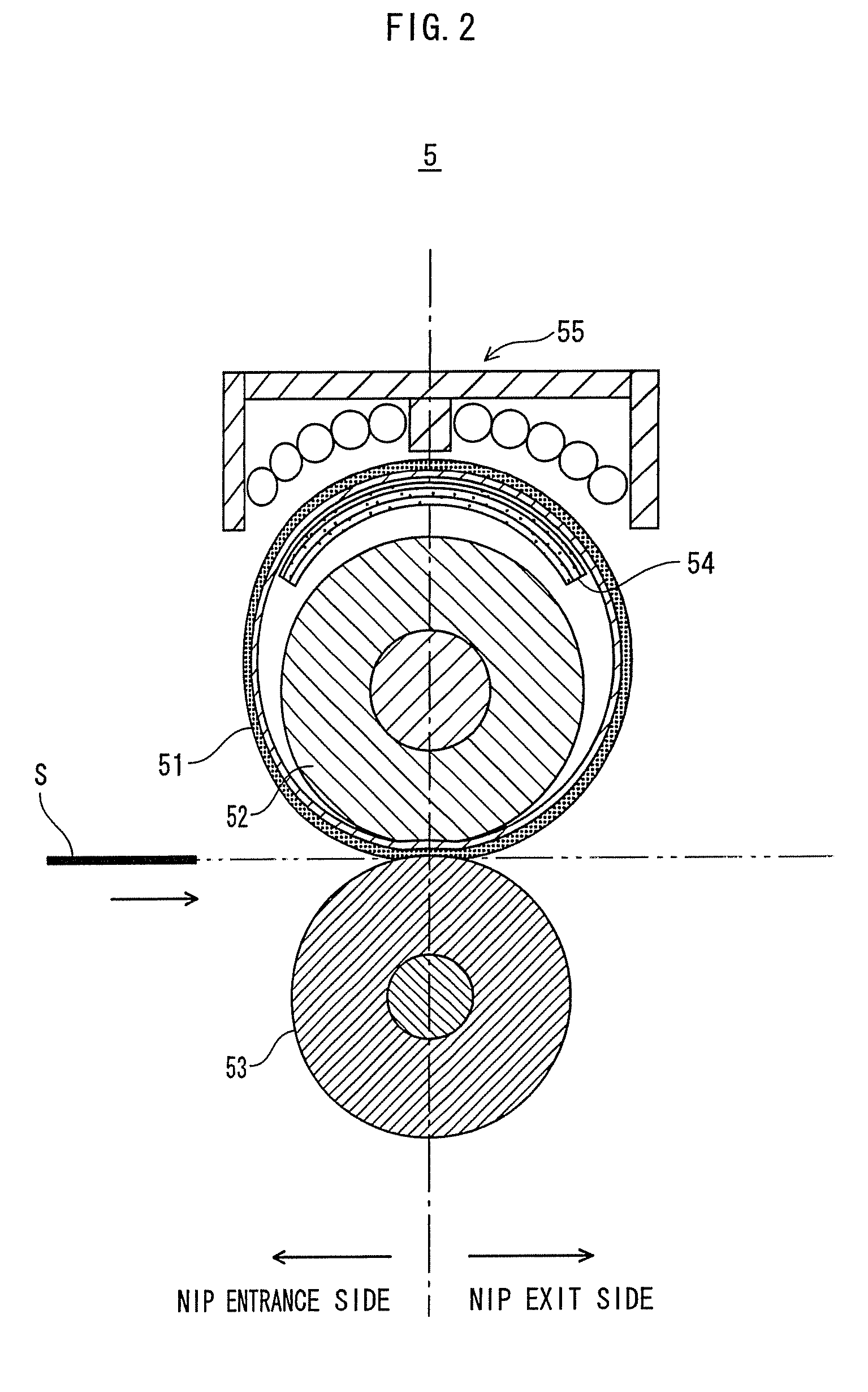

Fixing device having good warm-up property and image formation apparatus

ActiveUS20090317157A1Save energyGood preheating effectElectrographic process apparatusInduction heating apparatusTemperature controlElectrical resistance and conductance

Disclosed is a fixing device having a self-temperature control function, and reducing a heat capacity of a heat generation member for saving energy and achieving good warm-up property. The fixing device includes a fixed plate inside a closed rotation path of a belt, contacting an inner circumferential surface of the belt, substantially opposed to an excitation coil with the belt therebetween, keeping the belt on the rotation path. The fixed plate includes: a magnetic shunt alloy layer made of a magnetic shunt alloy; a conductive heat generation layer being disposed toward a main surface of the magnetic shunt alloy layer facing the belt, being made of a conductor other than the alloy, and being thinner than the alloy layer; and a low resistance conductive layer being disposed toward another main surface, having a lower electric resistance value than the heat generation layer, and being thicker than the heat generation layer.

Owner:KONICA MINOLTA BUSINESS TECH INC

Sulfureous resistant four-effect catalyst for purifying tail gas of vehicle

InactiveCN101269335AImprove sulfur resistanceEffect of catalytic efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsEmission standardAutomotive emissions

The invention relates to an anti-sulfur four-way catalyst which is provided with optimal performance and used for purifying automobile exhaust. First, a glass coating solution is prepared, then a metal alloy carrier is repeatedly immerged into the glass coating solution for coating, drying, calcinating so as to get the glass coating on the carrier, then the glass coating is repeatedly immerged into a mixed solution composed of titanium and zirconium salts and into a precious metal catalyst solution; after being baked and calcinatied, the anti-sulfur four-way catalyst which is provided with optimal performance and used for purifying automobile exhaust and takes the alloy metal as a carrier is obtained. The four-way catalyst of the invention has the following advantages that: (1) PM and NOx are catalyzed on the same catalytic bed; (2) the catalytic efficiency is not affected if the concentration of SO2ranges from 500 to 800ppm; (3) compared with other catalysts, the catalyst has high anti-sulfur performance and takes metal as the carrier. Besides, the catalyst can ensure an engine meeting the emission of European III in a laboratory, a bench experimental testing and application to meet the requirements for emission standards above European IV.

Owner:JILIN UNIV

Method for preparing calcium carbide and synthetic gas via flameless oxidation heating method, and calcium carbide reactor

ActiveCN103011164AExtended service lifeIncrease reaction rateCalcium carbideFixed-bed gasificationMixed gasInternal heating

The invention discloses a method for preparing calcium carbide and a synthetic gas via a flameless oxidation heating method, and a calcium carbide reactor, and solves problems of influencing time and effect of calcium carbide reaction caused by uneven heat distribution of the calcium carbide and the synthetic gas prepared by a conventional method and non-uniform particle size of materials entering a reaction chamber. In the method, flameless combustion in the reaction chamber is realized by controlling oxygen content in a mixed gas passing into the reaction chamber; and problems of non-uniform particle size of materials in the reaction chamber is solved by designing feeding particle size at two feeding ports. The reactor enables heat distribution in the chamber to be more uniform through the improvement of oxygen burners of the reaction chamber and a vaporizing chamber. The method is simple in process, is safe and reliable, has more uniform heat distribution, high calcium carbide reaction efficiency and high calcium carbide purity, low loss to furnace walls, the content of the generated synthetic gas is over 7 times that a conventional electrothermal method, and at the same time, consumption rate of raw materials and fuels is low.

Owner:WUHUAN ENG

An efficient energy-saving pyrolysis tank device for soil restoration

InactiveCN107552556AIncreased efficiency of pyrolytic remediationReduce repair costsContaminated soil reclamationSpiral bladeSoil remediation

An efficient energy-saving pyrolysis tank device for soil restoration is disclosed. The device includes a superconducting magnetic annular water jacket, a soil pyrolysis restoration tank body, a preheating water jacket, a high-frequency coil, a ceramic inner cylinder and a spiral blade. The ceramic inner cylinder is mounted inside the soil pyrolysis restoration tank body. The inside of the ceramicinner cylinder is a pyrolysis restoration cavity. A rotating shaft is mounted in the middle of the pyrolysis restoration cavity. The rotating shaft in the pyrolysis restoration cavity is welded to the spiral blade. The surface of the spiral blade is provided with a plurality of liquid spraying holes. The liquid spraying holes are communicated with a flow guide passage in the rotating shaft. The external wall of the ceramic inner cylinder is wound with the high-frequency coil. The superconducting magnetic annular water jacket is disposed outside the high-frequency coil. The inside of the superconducting magnetic annular water jacket is a hot-water cavity. Energy-saving effects of the device are good. The soil restoration cost is reduced. Agent spraying uniformity and sufficiency during soil restoration are improved. Heating and restoration effects on soil in the pyrolysis restoration cavity are improved, and the heating efficiency is high. The superconducting magnetic annular water jacket completely shields electromagnetic drifts.

Owner:郑州晨昱硕电子科技有限公司

Metal carrier triple-effect catalytic unit and method for making same

InactiveCN1995713AHigh mechanical strength against thermal shockGood preheating effectCatalyst carriersInternal combustion piston enginesChemical reactionActive component

The invention relates to a metal carrier three-way catalyst with high performance and the manufacturing method. The method comprises metal carrier treatment, overlaying coating method and active component inducting so on. Technological characteristics are that 1, large surface area of coat can be maintained at the largest extent so as to provide good conditions for chemical reaction; 2, active components of expensive metal is distributed in uniformity so that it is favor of bringing into play the catalytic performance of expensive metal and the dosage of expensive metal is decreased and under the precondition of ensuring tail gas purified ratio the producing and using cost is decreased; 3, the process flow is short so as to arrange production in convenience; 4, there is few quality control points so as to operate and control easily.

Owner:北京英泰世纪环境科技有限公司

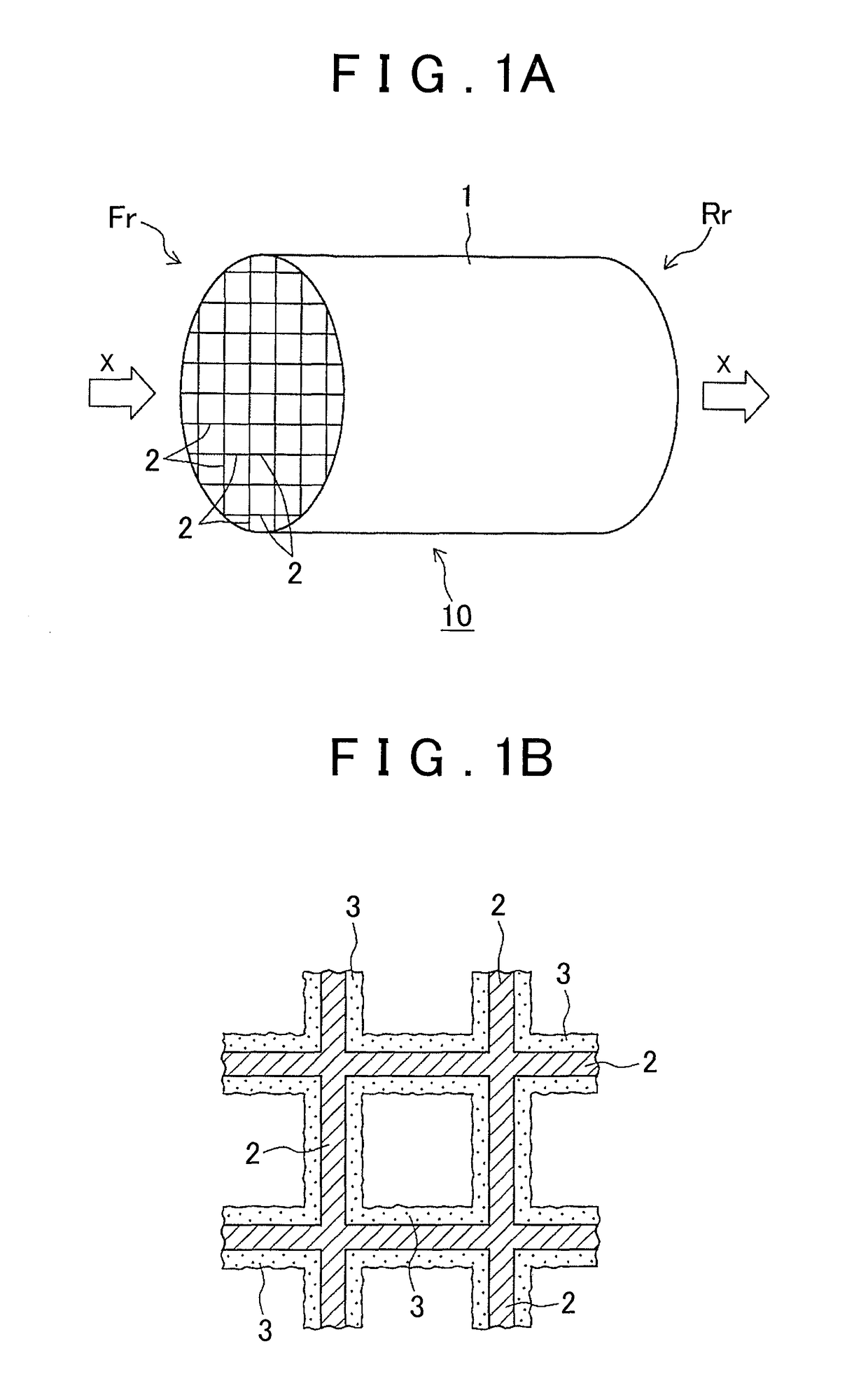

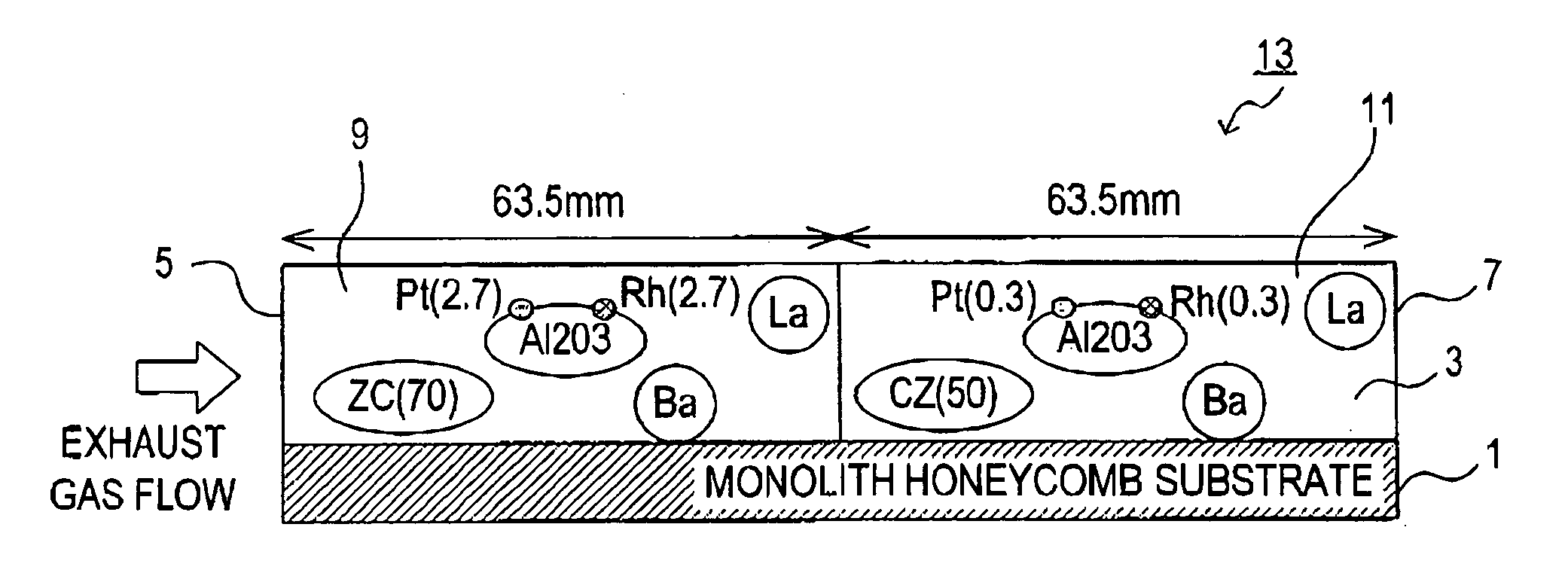

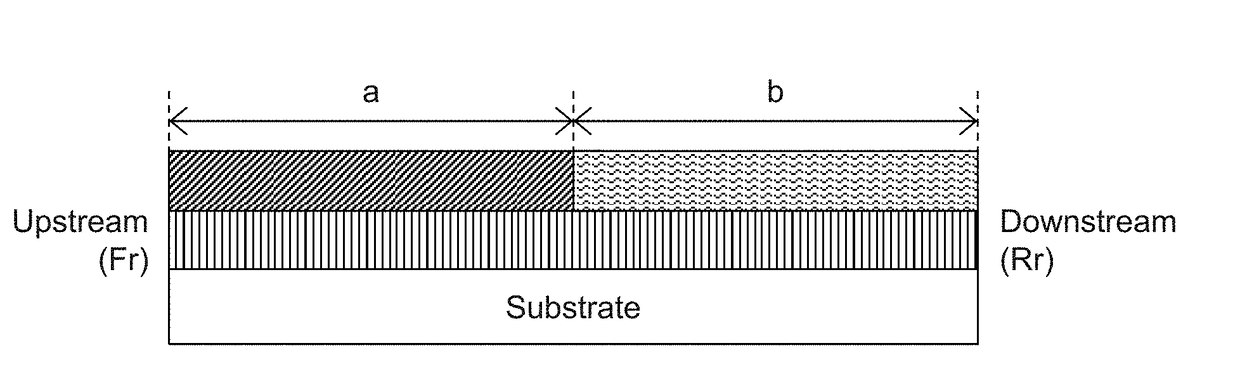

Exhaust gas purifying catalyst

ActiveUS20060142151A1Increased durabilityImproved warm-up performanceInternal combustion piston enginesDispersed particle separationMixed oxideEquivalent weight

An exhaust gas purifying catalyst comprises a substrate having a through hole serving as a passage for exhaust gas; and a catalyst coating layer formed on an internal surface of the through hole. The catalyst coating layer contains: a component (i): a precious metal; and a component (ii): at least one of a Zr oxide, a Ce oxide and a ZrCe mixed oxide. On an upstream portion of the passage, an oxide equivalent weight of Zr is within a range of 51-100 wt % of an oxide equivalent weight of Zr and Ce contained in the component (ii). On a downstream portion of the passage, the component (ii) includes at least one of a Ce oxide and a ZrCe mixed oxide in which an oxide equivalent weight of Ce is within a range of 58-100 wt % of an oxide equivalent weight of Zr and Ce contained in the ZrCe mixed oxide.

Owner:CATALER CORP

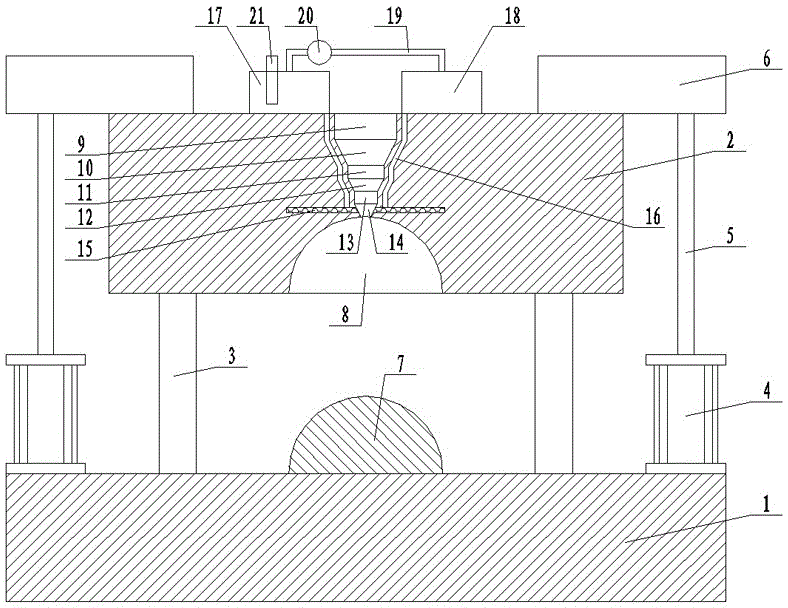

Vehicle lamp machining mold

InactiveCN106217714AAvoid condensationCompact structureDomestic articlesInjection molding machinePiston rod

The invention discloses a vehicle lamp machining mold. The vehicle lamp machining mold comprises a fixed template and a movable template; the fixed template is provided with a guide column; the movable template is slidingly arranged on the guide column; jacking cylinders are arranged on the fixed template at the lower ends of two sides of the movable template; piston rods of the jacking cylinders are connected with the upper ends of the movable template through connecting blocks; a vehicle lamp convex mold is arranged at the middle part of the upper end of the fixed template; a vehicle lamp concave mold matched with the vehicle lamp convex mold is arranged at the middle part of the lower end of the movable template; a first-grade vertical injection molding channel, a first-grade conical injection molding channel, a second-grade vertical injection molding channel, a second-grade conical injection molding channel, a third-grade vertical injection molding channel and a third-grade conical injection molding channel communicated with each other are arranged in the movable template at the upper end of the vehicle lamp concave mold in sequence from top to bottom; and the diameters of the first-grade vertical injection molding channel, the second-grade vertical injection molding channel and the third-grade vertical injection molding machine are gradually reduced.

Owner:JIANGSU YUYAN MOLD IND

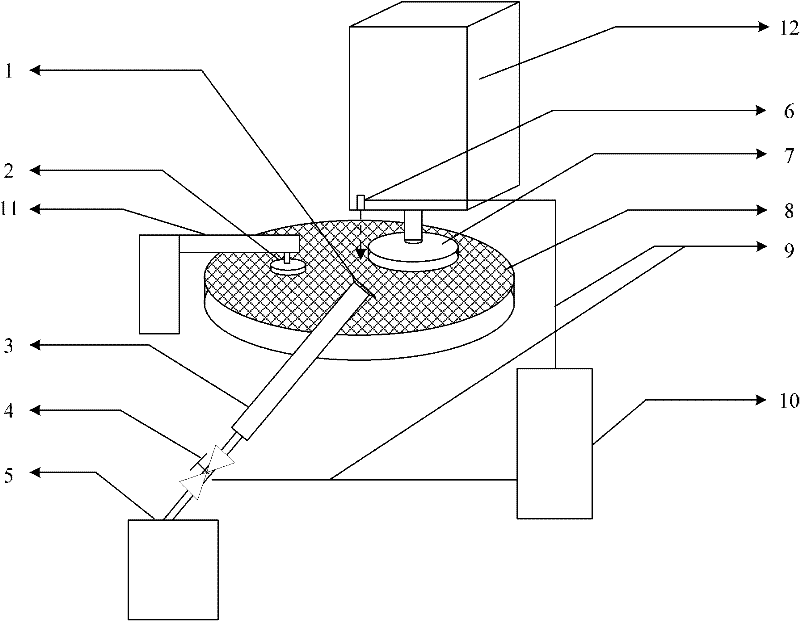

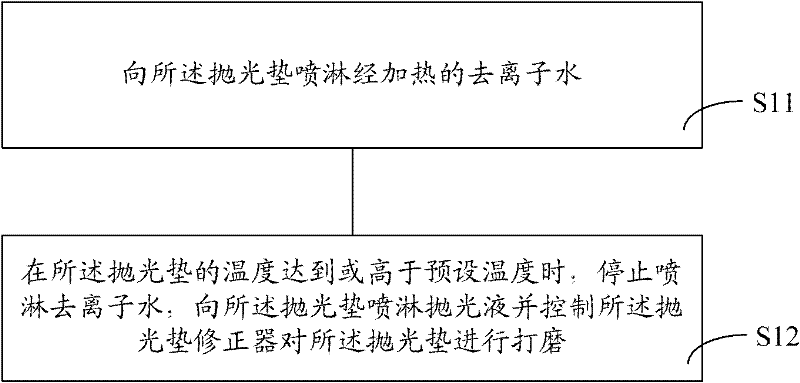

Chemical mechanical polishing equipment and preheating method for same

ActiveCN102528651AReduce lossReduce manufacturing costSemiconductor/solid-state device manufacturingLapping machinesControl systemWater flow

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Fixing device having good warm-up property and image formation apparatus

ActiveUS7912413B2Save energyGood preheating effectElectrographic process apparatusInduction heating apparatusTemperature controlElectrical resistance and conductance

Disclosed is a fixing device having a self-temperature control function, and reducing a heat capacity of a heat generation member for saving energy and achieving good warm-up property. The fixing device includes a fixed plate inside a closed rotation path of a belt, contacting an inner circumferential surface of the belt, substantially opposed to an excitation coil with the belt therebetween, keeping the belt on the rotation path. The fixed plate includes: a magnetic shunt alloy layer made of a magnetic shunt alloy; a conductive heat generation layer being disposed toward a main surface of the magnetic shunt alloy layer facing the belt, being made of a conductor other than the alloy, and being thinner than the alloy layer; and a low resistance conductive layer being disposed toward another main surface, having a lower electric resistance value than the heat generation layer, and being thicker than the heat generation layer.

Owner:KONICA MINOLTA BUSINESS TECH INC

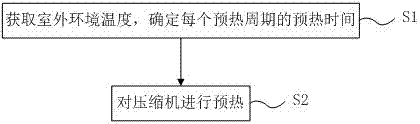

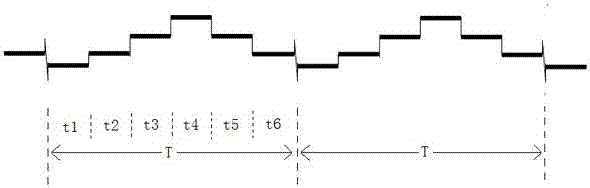

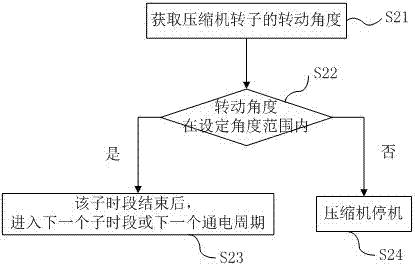

Control method for lowering preheating noise of compressor

ActiveCN107246392AReduced warm-up noiseEffective warm-upRotary/oscillating piston pump componentsLiquid fuel engine componentsPower flowTime-sharing

The invention discloses a control method for lowering preheating noise of a compressor. When the compressor is preheated, a compressor winding U, a compressor winding V and a compressor winding W are electrified in a time sharing manner; two-phase windings are electrified at the same time within each electrification period, current during compressor preheating is reduced, accordingly, noise generated during compressor preheating is lowered, influences on normal life of users are avoided, user complaints due to the noise problem are avoided, and the using experience of the users is improved. Meanwhile, effective preheating of the compressor is guaranteed, and a good preheating effect is achieved. Meanwhile, in each electrification period, electrification current is fluctuated and is not constant, compressor damage due to continuous too high constant current is avoided, and the poor preheating effect caused by continuous too low constant current is avoided; and a good preheating effect is guaranteed, and compressor damage is avoided as well.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

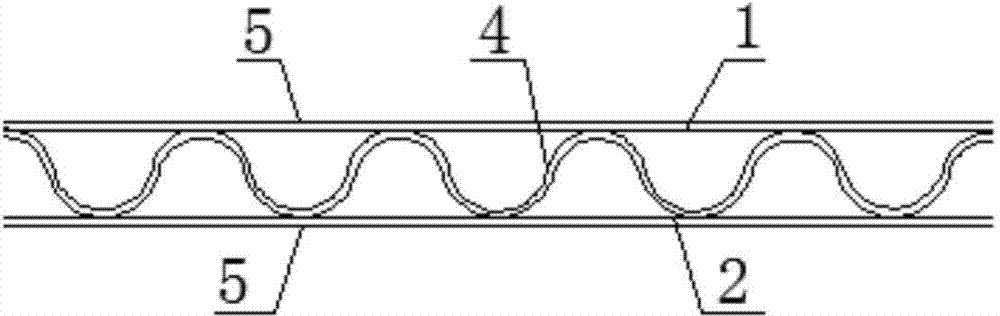

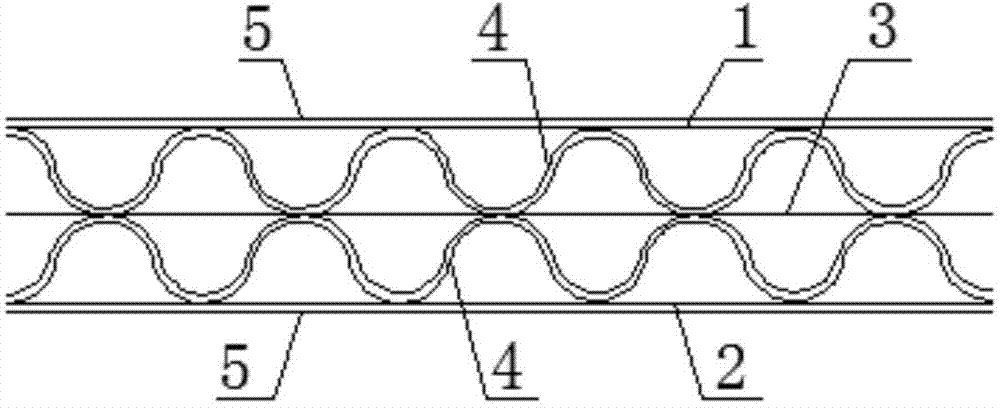

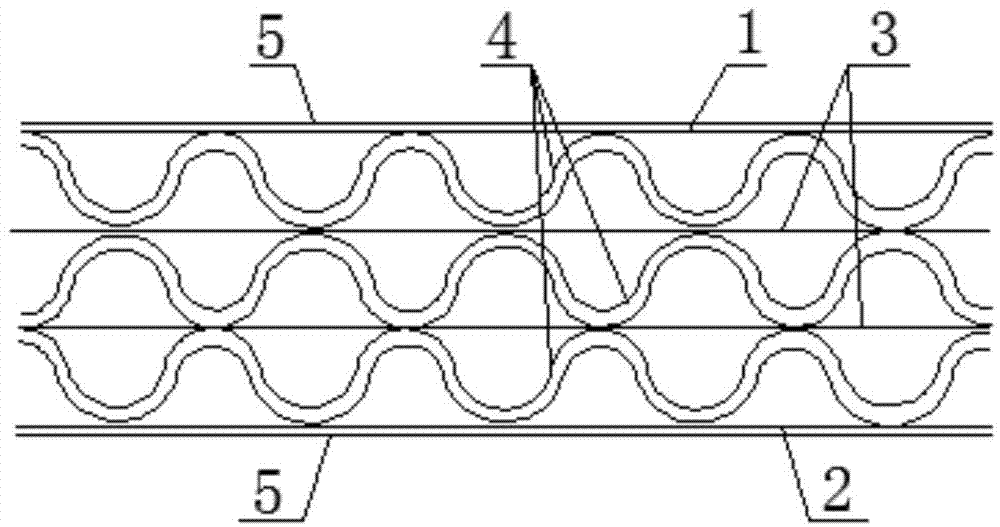

Production technology of corrugated board with two film-coated surfaces

InactiveCN104772970AIncrease productivityReduce manufacturing costLamination ancillary operationsLaminationCold chainCardboard

The invention provides a production technology of a corrugated board with two film-coated surfaces, and belongs to the technical field of cardboard processing. The technology comprises the following steps: (1) printing patterns on OPP films; (2) laminating the printed OPP films on the top surface and bottom surface of a corrugated board; (3) pre-heating the corrugated board with laminated OPP films, and finally moulding the corrugated board in a moulding machine to obtain the corrugated board with two film-coated surfaces. The invention further provides a corrugated board with two film-coated surfaces, which is produced by the provided production technology. The production technology has the advantages of high production efficiency, low production cost, and simple technology, and can achieve film-coating and printing on two surfaces of a corrugated board. The surface of the printed patterns cannot be easily scratch or damaged, and the pre-heating effect is good. The produced corrugated board with two film-coated surfaces has a good dampproof and wear-resistant performance, and can be applied to refrigeration of high-end seafood and dairy products. The corrugated board will not absorb water and become soft in the refrigeration house, so the corrugated board is suitable for being used in the cold-chain transportation or storage.

Owner:天津市三元泰纸业有限公司

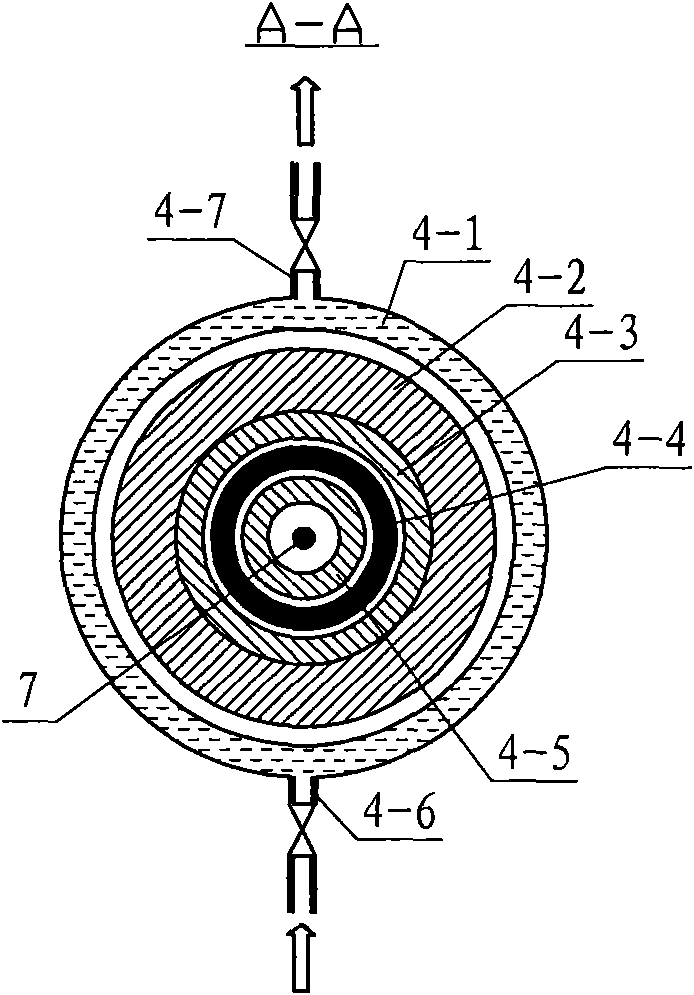

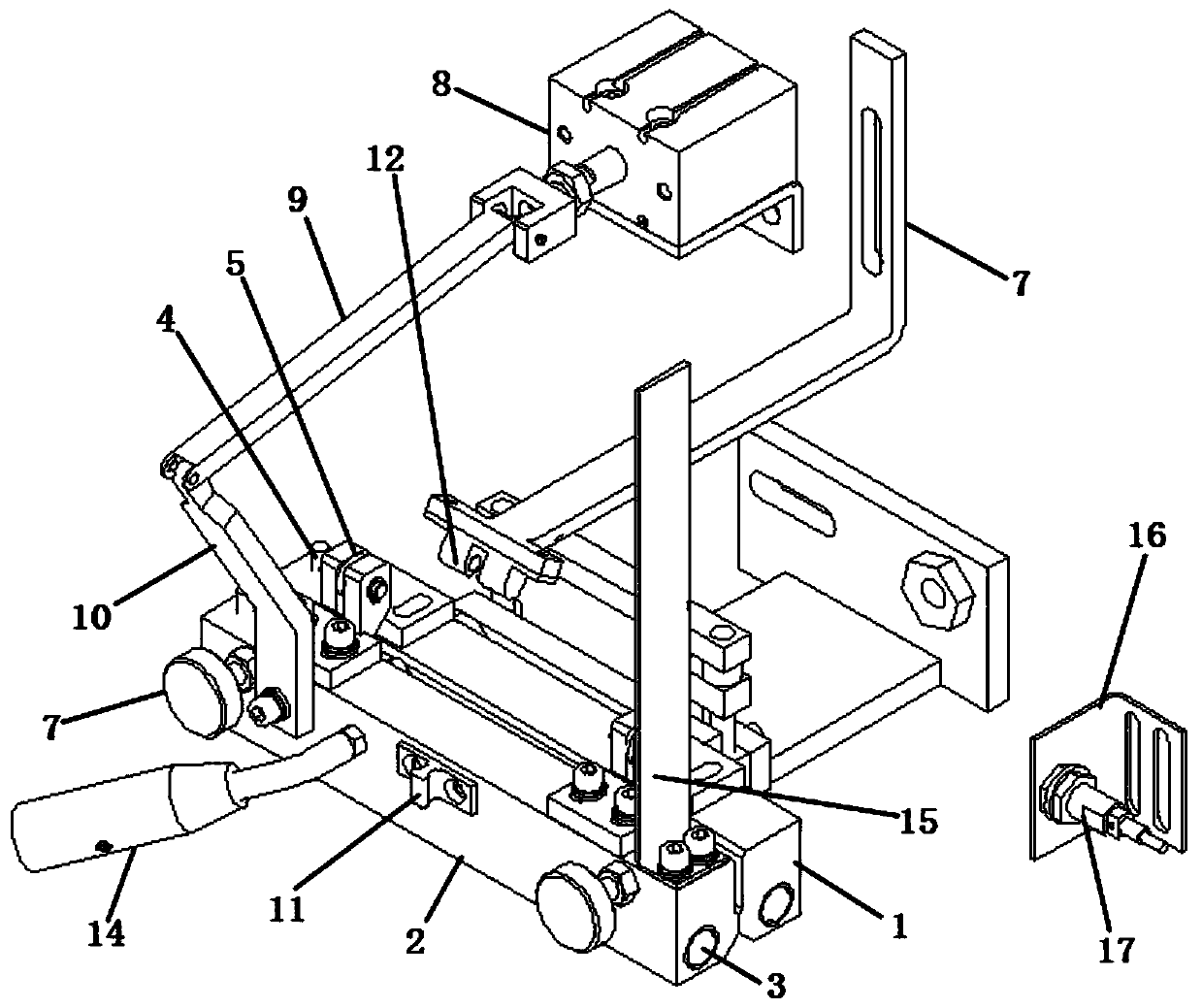

Temperature-controlled resistor housing of preheating welding wire

A temperature-controlled resistor housing of preheating welding wire belongs to welding field. The aim of the invention is to settle the problems of low efficiency when the resistor heating and high-frequency induction method is adopted for preheating the low-resistivity and non-magnetic material welding stick and complicated technique for directly preheating the welding wire with an auxiliary TIG electrical arc. The temperature-controlled resistor housing of preheating welding wire according to the invention comprises a cooling water jacket, a specular stone layer, an outer ceramic pipe, an electric heating wire, an inner ceramic pipe, a water inlet pipe and a water outlet pipe. The welding wire is positioned in the inner ceramic pipe. The electric heating wire is positioned between the inner ceramic pipe and the outer ceramic pipe. The electric heating wire is winded at the outer surface of inner ceramic pipe. The outer surface of outer ceramic pipe is installed with the specular stone layer. The outer surface of specular stone layer is installed with a cylindrical cooling water jacket. The outer wall of cooling water jacket is installed with a water inlet pipe and a water outlet pipe for circulating the cooling water. The temperature-controlled resistor housing of preheating welding wire according to the invention is used for preheating the welding wire.

Owner:HARBIN INST OF TECH

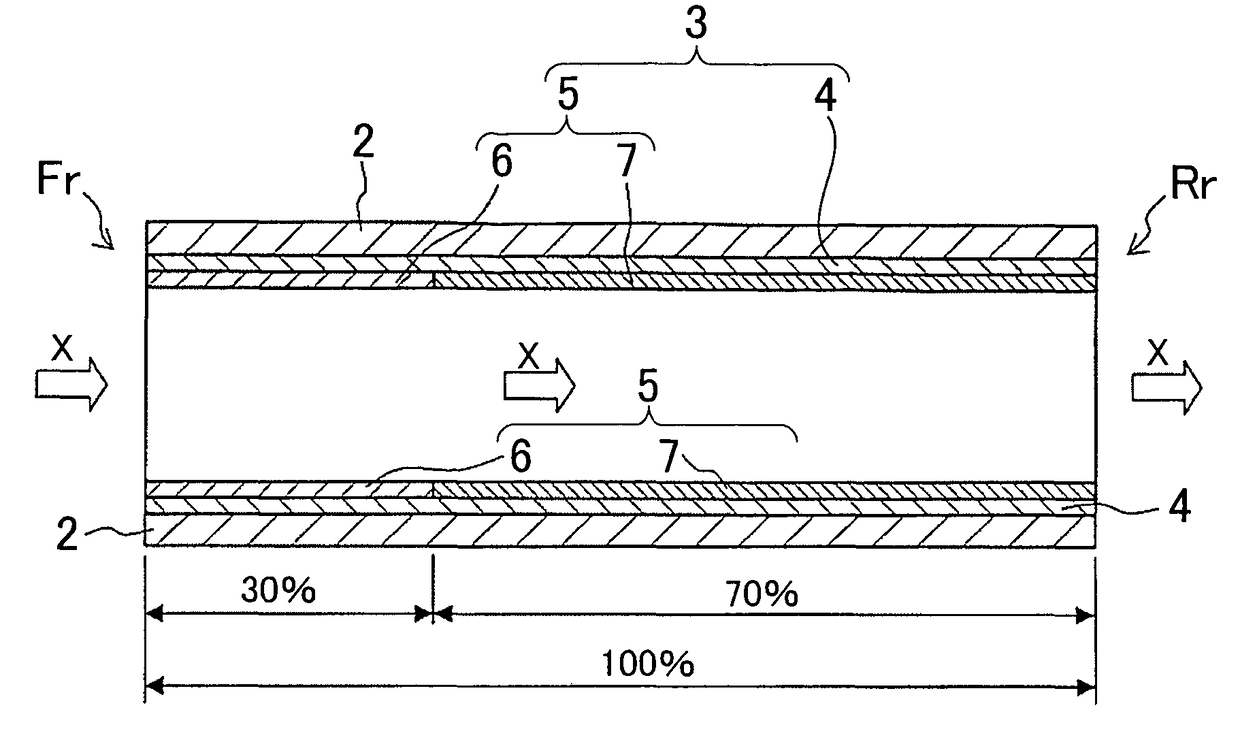

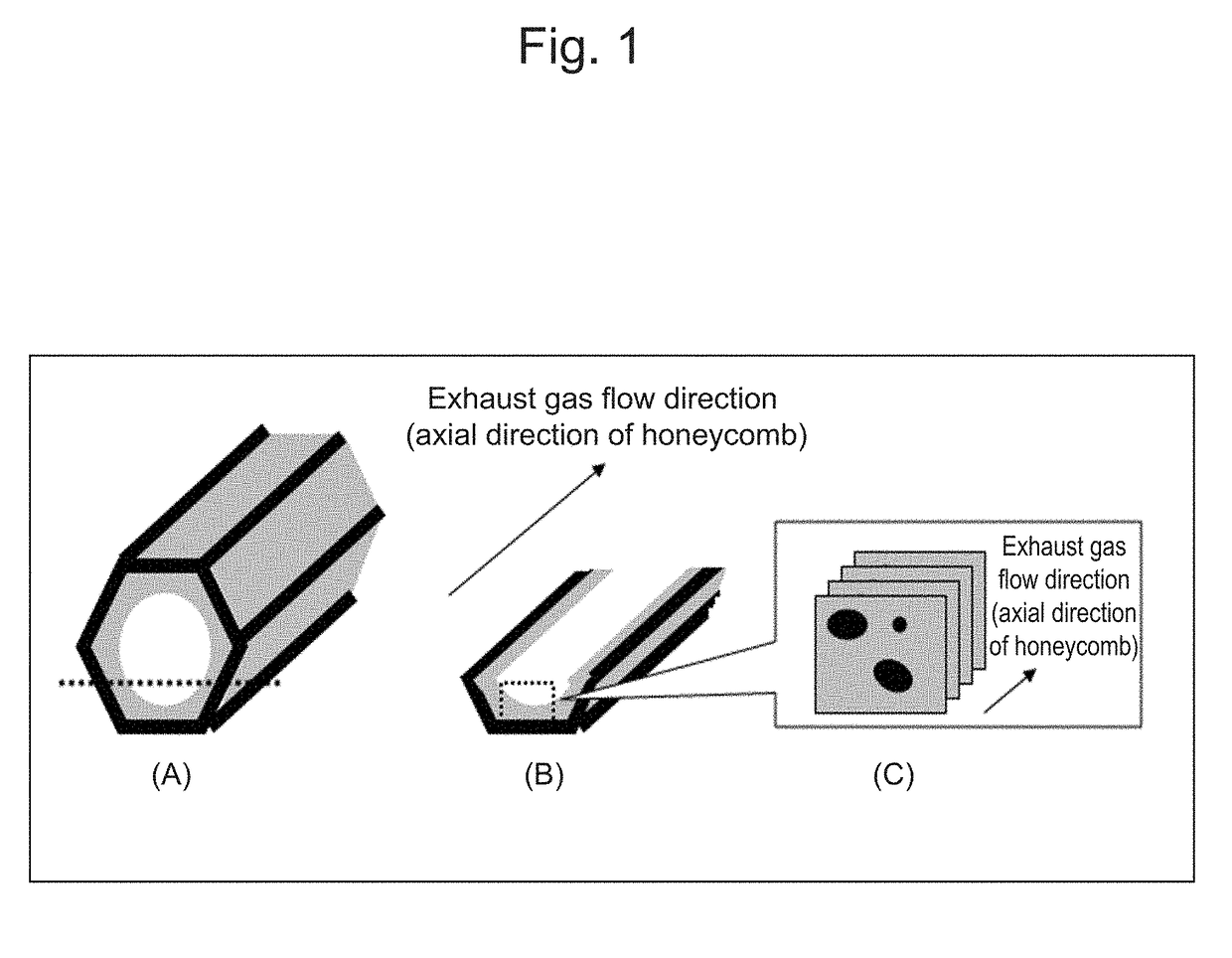

Exhaust gas purification catalyst

ActiveUS20180252132A1Improve diffusivityGood preheating effectInternal combustion piston enginesExhaust apparatusExhaust gasCoating

An object of the present invention is to provide an exhaust gas purification catalyst which can exhibit high durability and warm-up performance. The present invention relates to an exhaust gas purification catalyst comprising a substrate and a catalyst coating layer formed on the substrate, wherein the catalyst coating layer comprises catalyst particles, the catalyst coating layer having an upstream region extending by 40 to 60% of the entire length of the substrate from an upstream end of the catalyst in the direction of an exhaust gas flow and a downstream region corresponding to the remainder portion of the catalyst coating layer, the composition of the catalyst particle of the upstream region being different from that of the downstream region. The upstream region in the direction of an exhaust gas flow has a structure where a void is included in a large number, and furthermore high-aspect-ratio pores having an aspect ratio of 5 or more account for a certain percentage or more of the whole volume of voids. Thus, the exhaust gas purification catalyst exhibits enhanced purification performance.

Owner:TOYOTA JIDOSHA KK +1

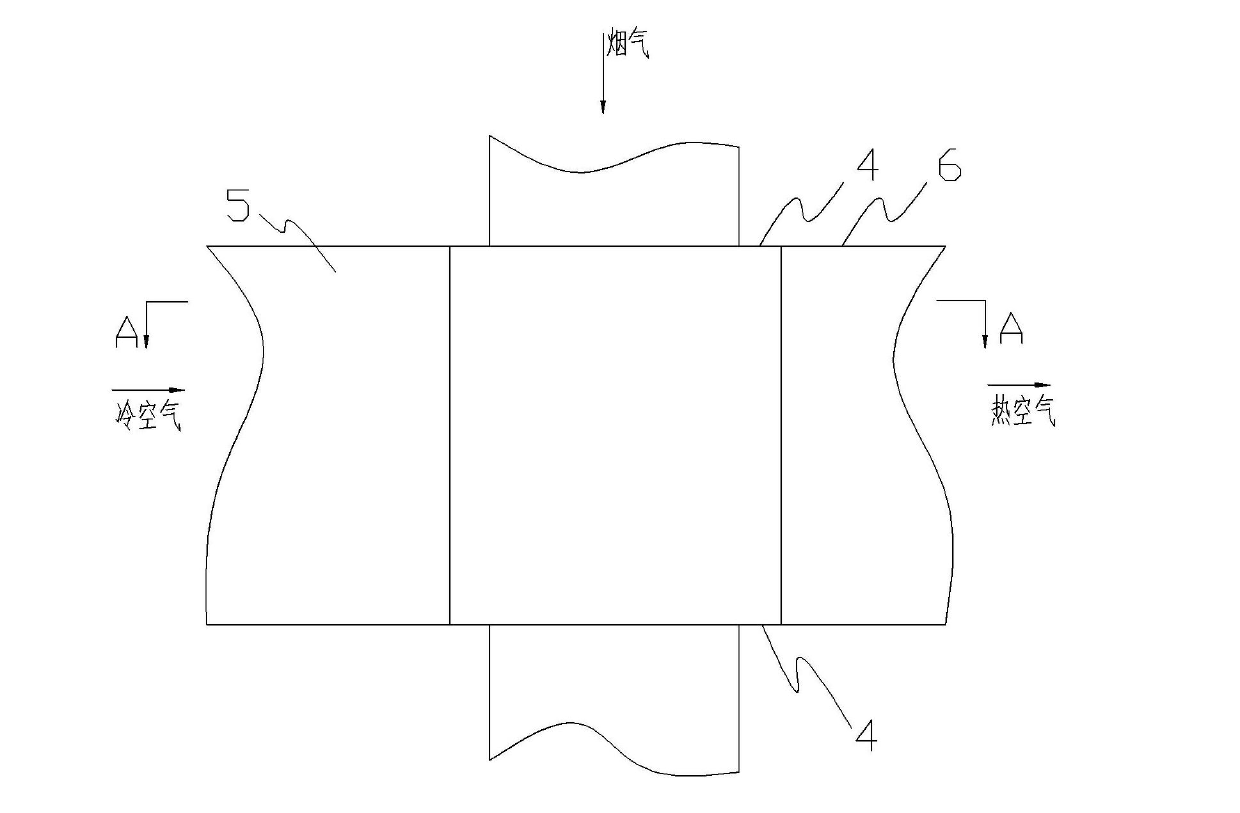

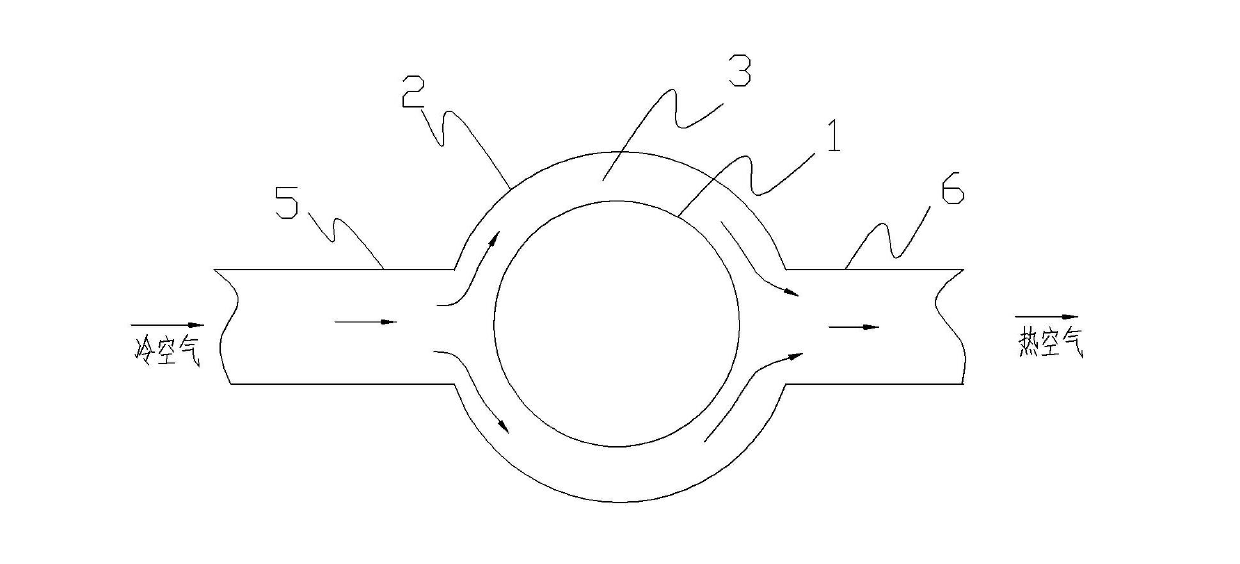

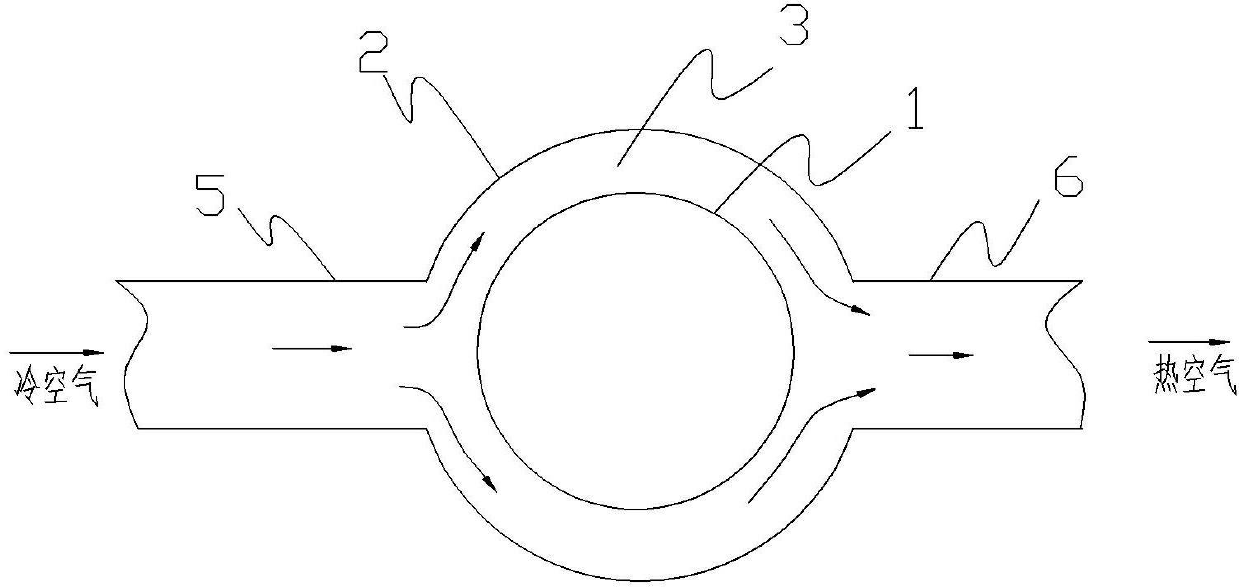

Butt clamp heat exchanger for preheating air by using waste heat of flue gas

InactiveCN102168928ASimple structureExtend the lifespanStationary tubular conduit assembliesCold airFlue gas

The invention discloses a butt clamp heat exchanger for preheating air by using waste heat of flue gas, which comprises a heat exchange clamp jacket cavity formed by an inner cylinder and an outer cylinder, wherein openings at both ends of the inner cylinder are used for allowing the waste heat flue gas to flow through; both ends of the outer cylinder and the inner cylinder are sealed by an annular plate; a cold air inlet is connected to one edge of the lateral surface of the outer cylinder, and a hot air outlet is connected to the other edge of the lateral surface of the outer cylinder; and the cold air inlet and the hot air outlet are opposite mutually. The butt clamp heat exchanger has a simple structure, small airflow resistance and good heat exchange effect, and is convenient to manufacture.

Owner:娄底市兴华有色金属有限公司

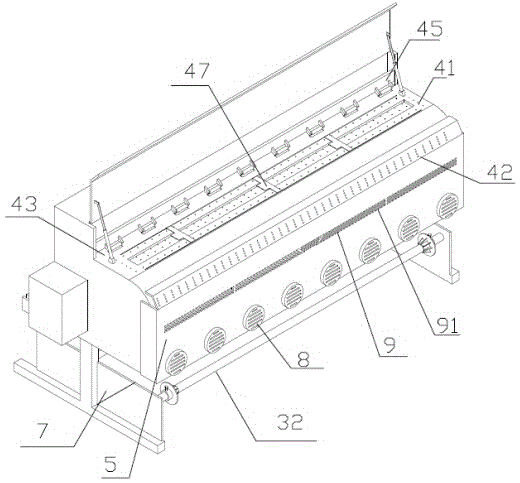

Drawer type preheating oven

InactiveCN106705670AContinuous and even heatingGood preheating effectArtificial thread manufacturing machinesFurnace typesEngineeringHeating furnace

The invention relates to the technical field of heating oven equipment, in particular to a drawer type preheating oven through which the continuous uniform heating can be conveniently realized, and of which the preheating effect is good. The drawer type preheating oven comprises an oven chamber, wherein a preheating compartment and a wind channel which communicate are formed in the oven chamber; a wind distributing plate is arranged at a connecting position of the wind channel and the preheating compartment; ventilation holes which are uniformly formed are formed in the wind distributing plate; an electric heating pipe is mounted in the wind channel; blowing blades connected with a motor are arranged on the outer side of the wind distributing plate; a material inlet and outlet is formed in the front side of the preheating compartment; an oven door is mounted on the material inlet and outlet; a guide rail is arranged in the oven compartment corresponding to the material inlet and outlet; and an assembly retainer is mounted on the guide rail through a guide wheel.

Owner:无锡南方声学工程有限公司

A digital printing machine for wide-width polyester wall covering

ActiveCN104228341BAdapt to the needs of multiple processesHigh thermal efficiencyTypewritersOther printing apparatusPolyesterPolymer science

The invention relates to the field of printing equipment, in particular to a digital printing machine for wide-width polyester wall coverings. The above technical purpose of the present invention is achieved through the following technical solutions: a digital printing machine for wide-width polyester wall coverings, including a frame, a printing device on the frame, a transmission device and a The heating device on the frame, the heating device includes a fixed area and a low-temperature preheating area connected to the frame in sequence according to the conveying direction of the polyester wall covering and located between the unwinding drum and the winding drum And medium temperature fixing area. The purpose of the present invention is to provide a digital printing machine for wide-width polyester wall covering, which has a simple structure and is convenient for implementation. Wide-width polyester wall coverings require low-temperature color development, medium-temperature color fixation, and drying and heat dissipation.

Owner:南京裂潭科技有限公司

Preheating structure

PendingCN111114912AAvoid Defects That Are Difficult to CleanEasy maintenance spaceWrapper twisting/gatheringThermodynamicsEngineering

Owner:北京新龙立自动化技术有限公司

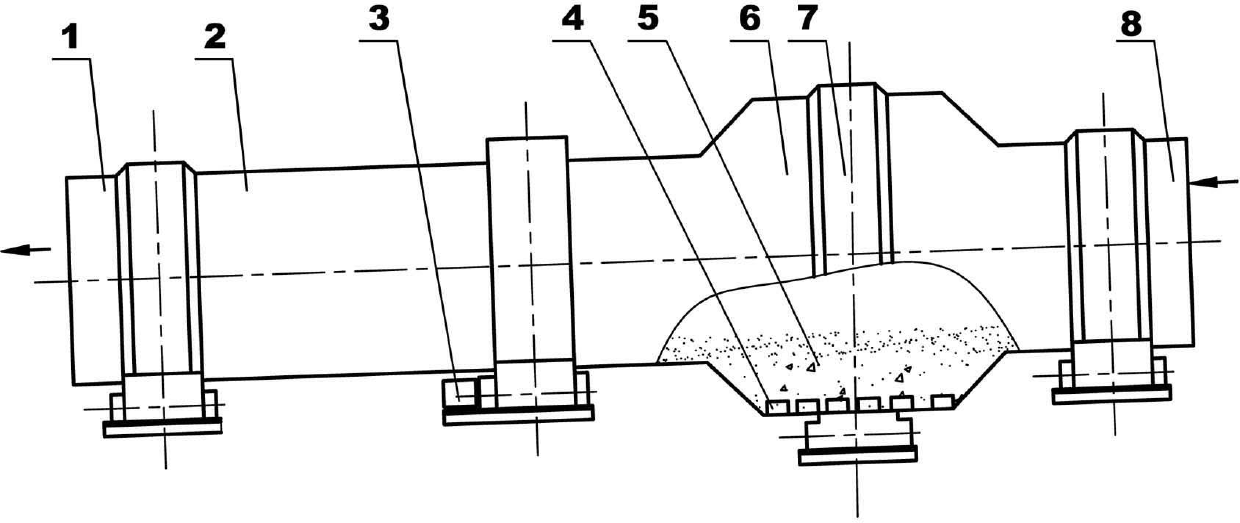

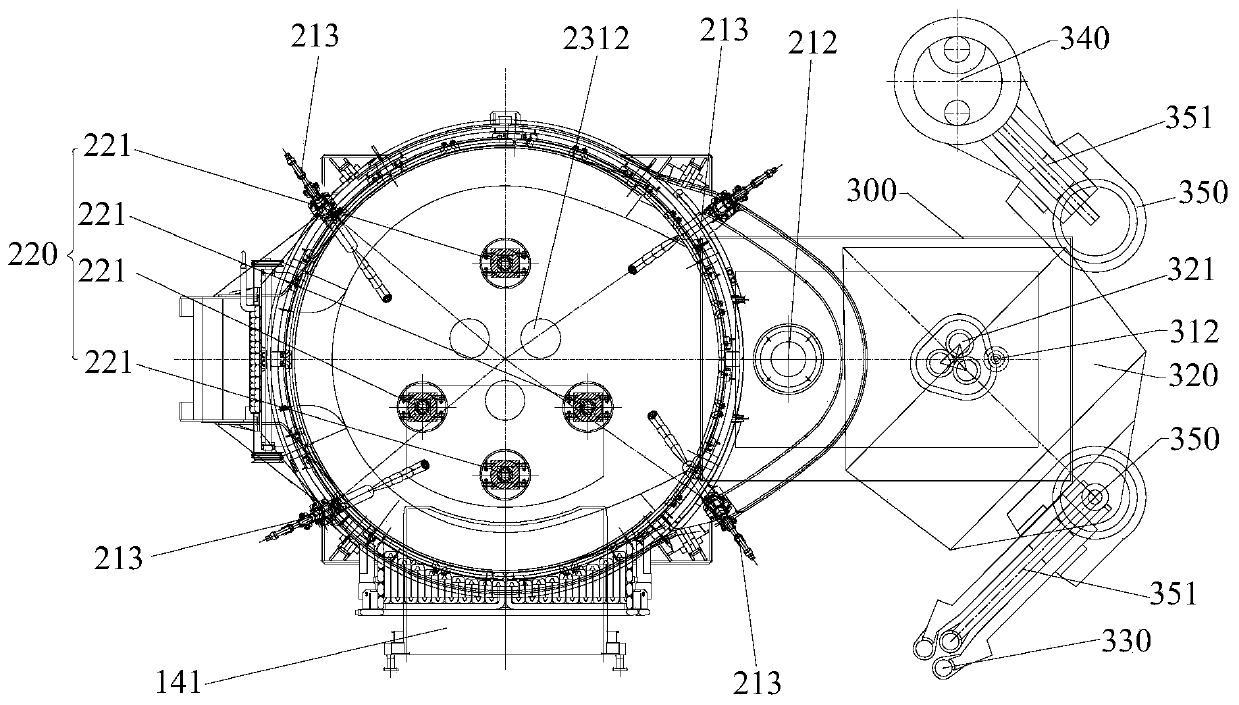

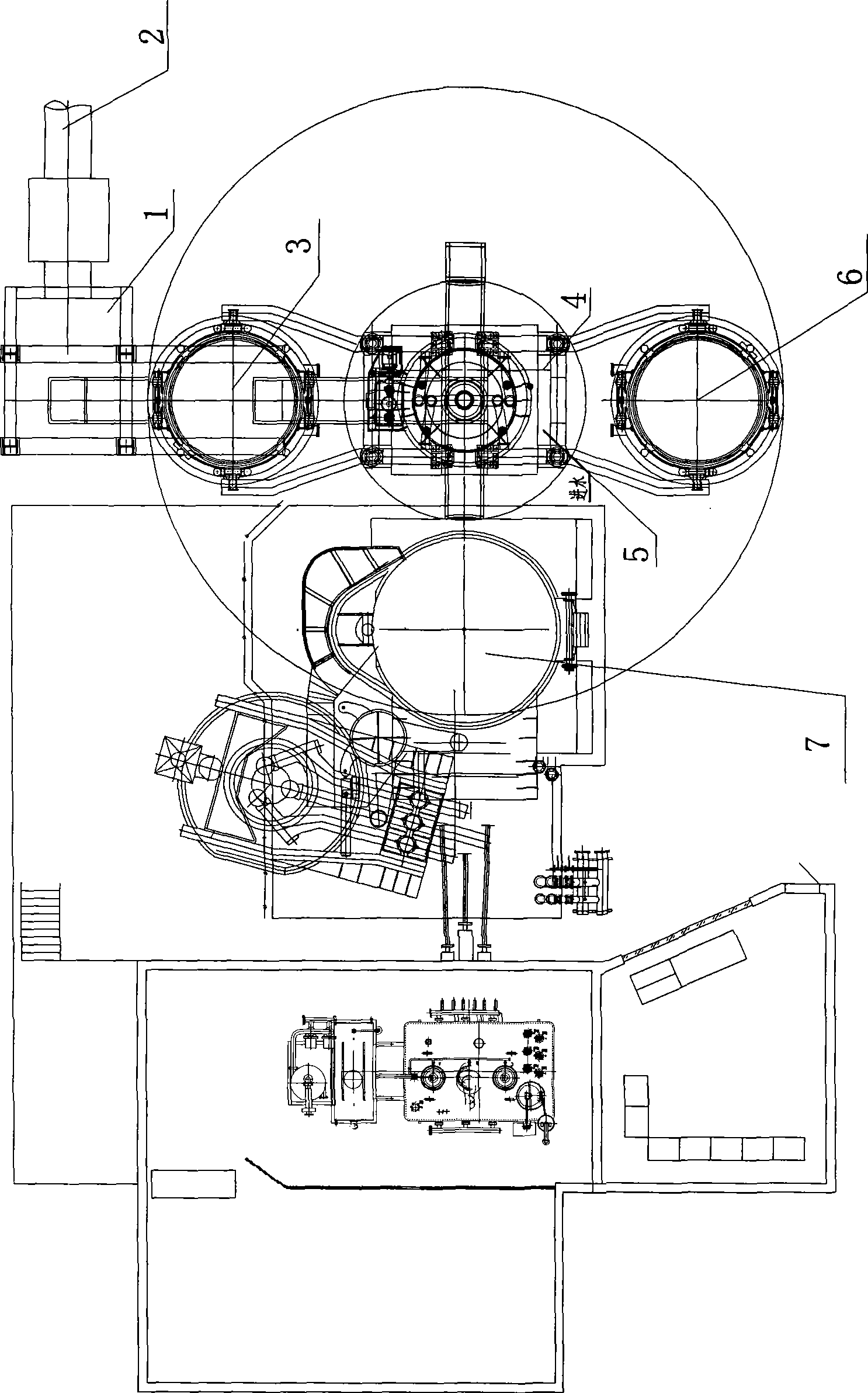

Scrap steel preheating system for electric arc furnace

ActiveCN101545724AAchieve energy savingAchieve environmental protectionPreheating chargesSteelmakingElectric arc furnace

The invention relates to a scrap steel preheating system for an electric arc furnace, which realizes the preheating for steelmaking raw materials for the electric arc furnace by fully utilizing the physical and chemical waste heat of high-temperature flue gas of the electric arc furnace and enables a dust removal system to filter and cool the high-temperature flue gas to achieve the purposes of energy saving, reduction of consumption, emission reduction and environment protection as well as improve the steelmaking production ratio of the electric arc furnace and to realize the investment and alteration of preheating scrap steel by high-temperature flue gas in a current old factory workshop. The scrap steel preheating system for an electric arc furnace comprises scrap steel preheating basket mechanisms and a basket rotation swing mechanism; the basket rotation swing mechanism is respectively connected with the scrap steel preheating basket mechanisms positioned at a scrap steel receiving position and a scrap steel preheating position through swing supporting frames; and a high-temperature flue gag water-cooling flue and a scrap steel preheating cap are arranged between the basket rotation swing mechanism and the upper end of the scrap steel preheating basket mechanism at the scrap steel preheating position.

Owner:XIAN TAOYUAN METALLURGY EQUIP ENG CO LTD

Anti-counterfeiting label outer surface laminating machine

ActiveCN110126431AWarm up evenlyProtect the internal structureLamination ancillary operationsLaminationTectorial membraneCoupling

The invention relates to an anti-counterfeiting label outer surface laminating machine. The laminating machine comprises a base, wherein the left end of the base is provided with a power mechanism, the top surface of the base is provided with an upper pressing roller and a lower pressing roller through a driving shaft, a gap is left between the upper pressing roller and the lower pressing roller to ensure the passage of an anti-counterfeiting label and a membrane, the driving shaft is connected with the power mechanism by a coupling, a driven shaft is arranged above the base by a left side plate and a right side plate, the driven shaft is connected with the power mechanism, a membrane roll is arranged on the periphery of the driven shaft, and the top surface of the base is provided with apre-heating mechanism through two mounting mechanisms. According to the provided anti-counterfeiting label outer surface laminating machine, a gap is left between pre-heating rollers and the membraneroll, the membrane roll temperature is reduced, the inner structure of the membrane is protected, the service life of the membrane is prolonged, the membrane roll is uniformly pre-heated, the pre-heating effect is good, the laminating quality is improved, the membrane is prevented from falling off, the pre-heating hot air flow impact force is small, and the risk of breaking the membrane is reduced.

Owner:湖北强大包装实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com