Butt clamp heat exchanger for preheating air by using waste heat of flue gas

A technology for preheating air and waste heat of flue gas, which is applied in the types of heat exchangers, indirect heat exchangers, lighting and heating equipment, etc., and can solve the problem of complex structure of double-helix heat exchangers, affecting heat exchange effect, and large gap between outer walls and other problems, to achieve the effect of good preheating effect, simple assembly, and small airflow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

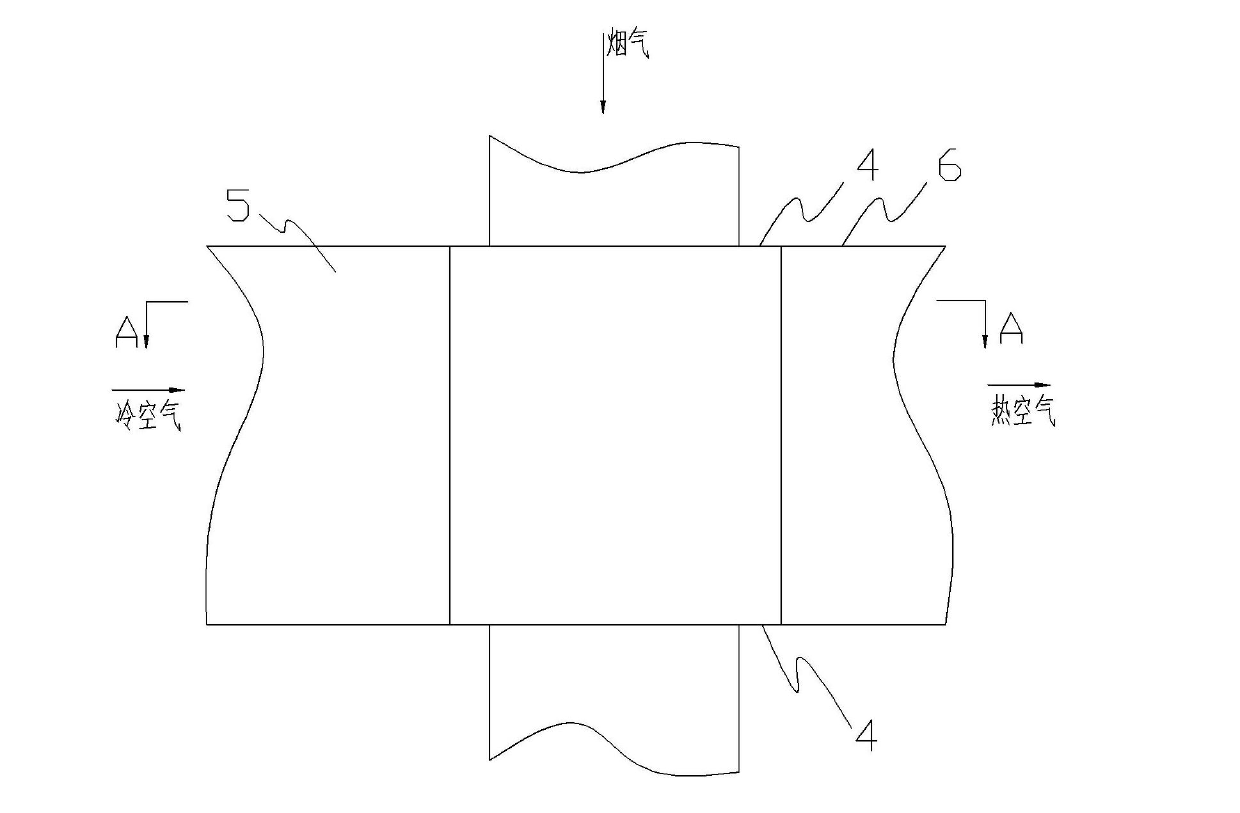

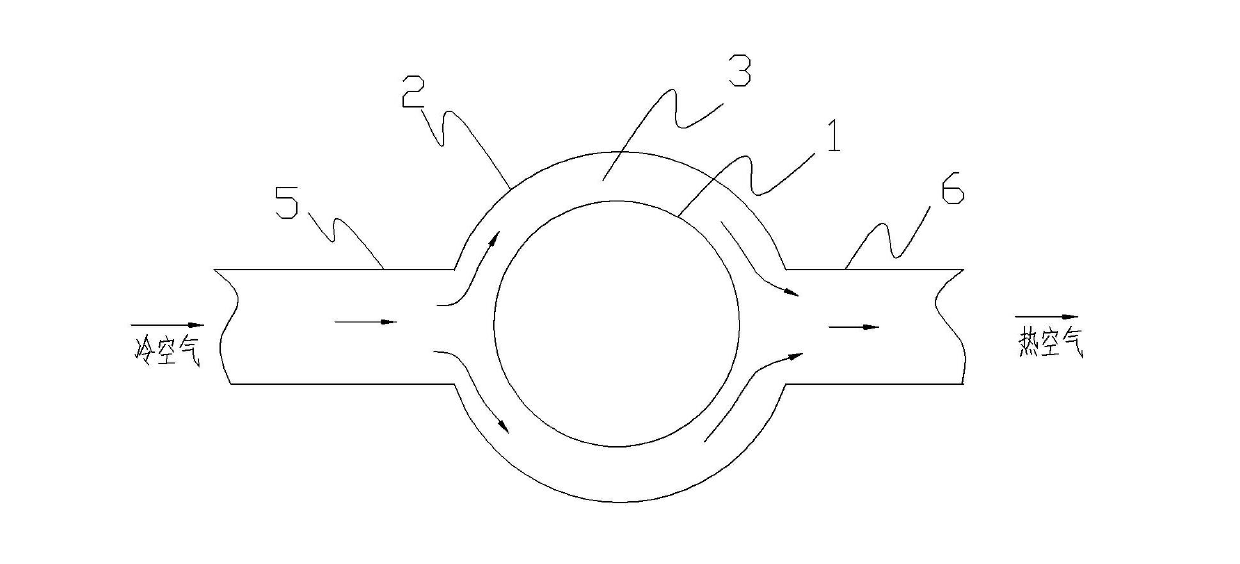

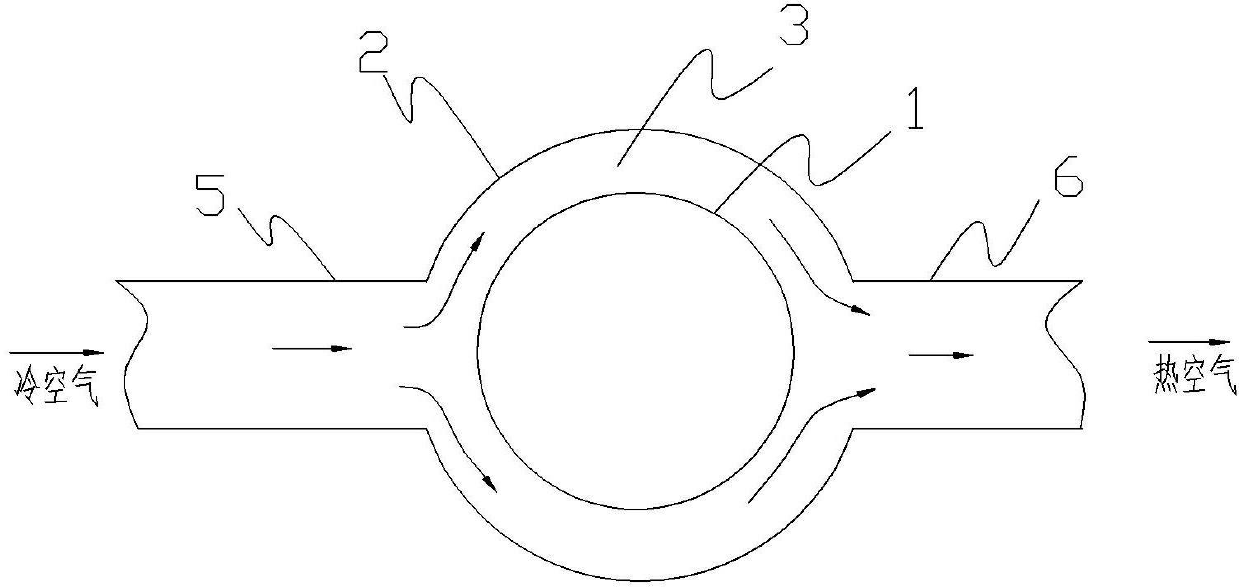

[0010] from figure 1 with figure 2 It can be seen that the heat exchanger of the present invention has an inner cylinder 1, an outer cylinder 2, and an annular plate 4. The outer cylinder 2 is covered outside the inner cylinder 1, and the upper and lower sides are respectively closed by an annular plate to form a heat exchange jacket chamber 3. The outer cylinder The two sides of 2 respectively have a rectangular cold air inlet 5 and hot air outlet 6, the cold air inlet 5 and hot air outlet 6 are arranged symmetrically to the outer cylinder and directly opposite to each other, the cold air inlet 5 and the hot air outlet 6 The height is the same as that of the outer cylinder 2, the width is between 10cm and the width of the outer cylinder (including the width), and the optimal width is between 50 and 300mm. When the width of the cold air inlet 5 and the hot air outlet 6 is smaller than that of the outer cylinder 2 When the width of urceolus 2 is round, when the width of cold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com