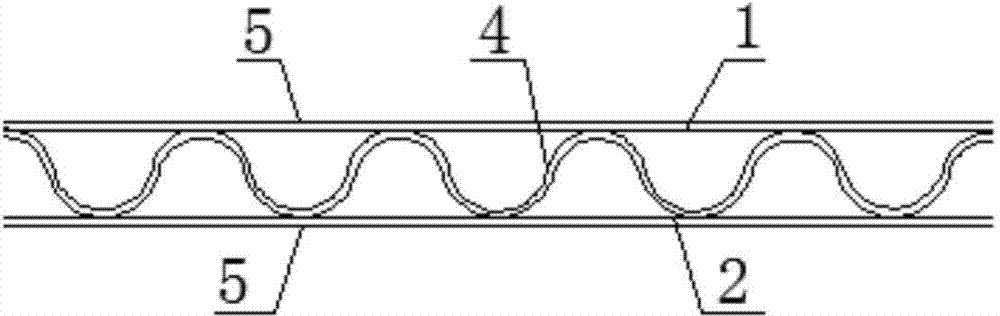

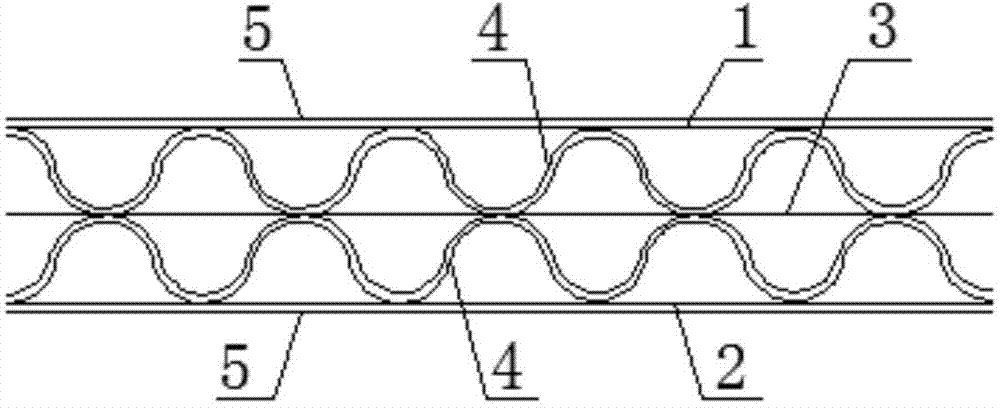

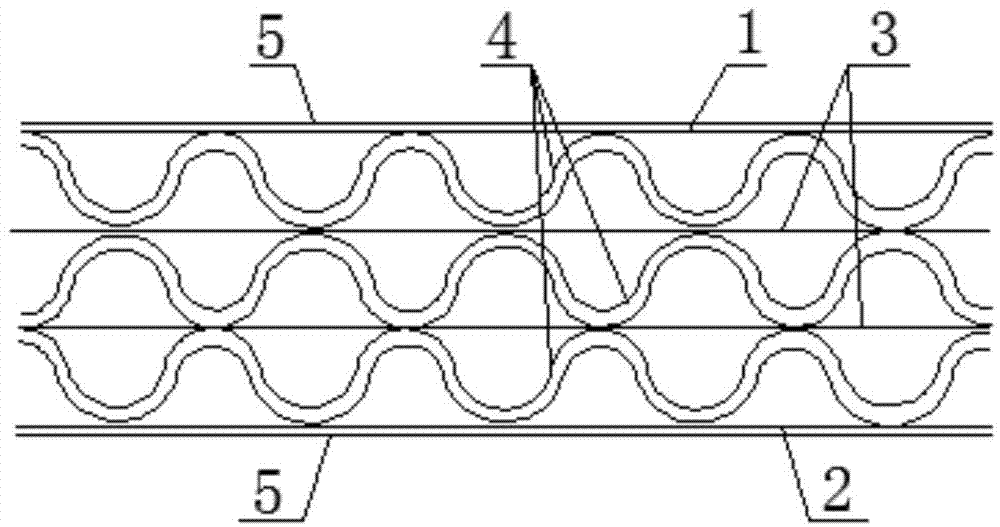

Production technology of corrugated board with two film-coated surfaces

A corrugated cardboard and production process technology, applied in the field of cardboard processing, can solve the problems of surface scratches, damage, moisture resistance, poor abrasion resistance, compression resistance and low breaking strength of printed patterns, and achieve high wear resistance. , Realistic printing effect, good preheating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A production process for double-sided peritoneal corrugated cardboard, comprising the steps of:

[0029] (1) Full-axis pattern printing on the OOP film;

[0030] (2) The OOP film after printing in step (1) is mounted on the whole shaft with the face paper and the bottom paper;

[0031] (3) Preheat the surface paper and bottom paper laminated in step (2) through a preheating machine, the preheating machine includes an upper conveying device and a lower heating device, the upper conveying device includes an upper conveyor belt, and the lower heating device is integrated Formed whole heating plate, steam preheating device is installed under the heating plate, the working surface of the heating plate is coated with polytetrafluoroethylene layer, the laminated surface paper and bottom paper are placed on the upper conveyor belt of the upper conveying device and between the heating plate It is transported between the working surfaces; and then formed into double-sided perito...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com