Chemical mechanical polishing equipment and preheating method for same

A chemical machinery and equipment technology, applied in the field of chemical mechanical polishing equipment and its preheating, can solve problems such as high consumption of consumables and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The chemical mechanical polishing equipment in the prior art completes preheating by polishing multiple wafers, which consumes a lot of wafers, polishing fluid, etc., and reduces the use of polishing pads and polishing pad modifiers. life, resulting in increased production costs.

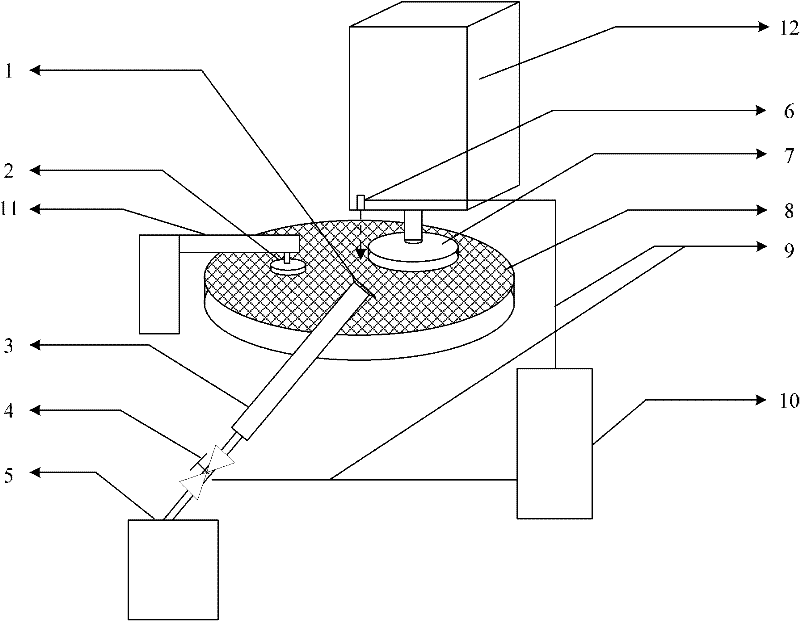

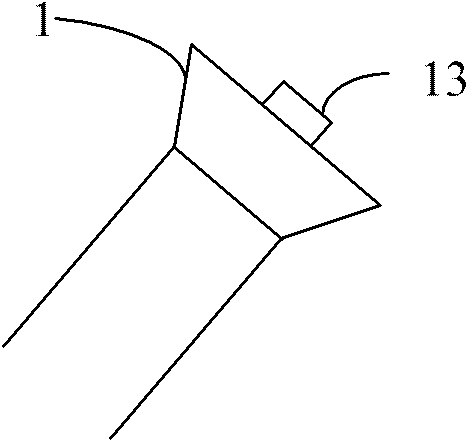

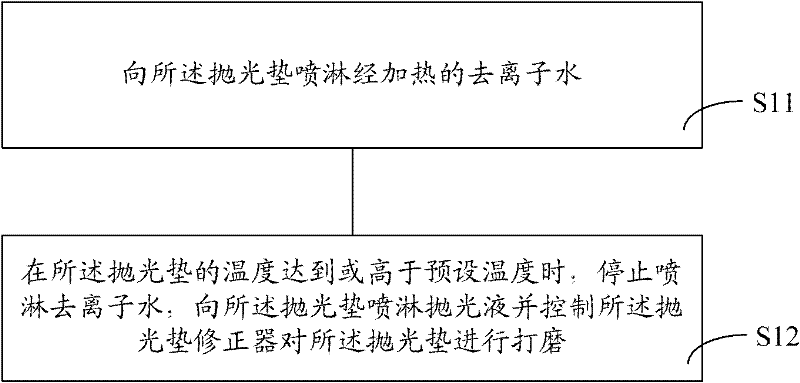

[0035] The chemical mechanical polishing equipment of this technical solution includes a polishing pad, a deionized water supply pipeline, a polishing liquid supply pipeline, and a polishing pad modifier, and also includes: a heating device for controlling the flow into the deionized water supply pipeline The deionized water in the heating pad is heated; the temperature sensor is close to the polishing pad to detect the temperature of the polishing pad; the preheating control system is connected with the temperature sensor and is used to control the deionized water supply pipeline to the The polishing pad is sprayed with heated deionized water, and when the temperature detected by the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com