Lime rotary kiln

A lime rotary kiln and rotary kiln technology, applied in the field of rotary kiln, can solve the problems of expensive hydraulic system and hydraulic push rod, falling off of refractory bricks of preheater, falling off of refractory bricks, etc., to achieve good preheating effect, improve productivity and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

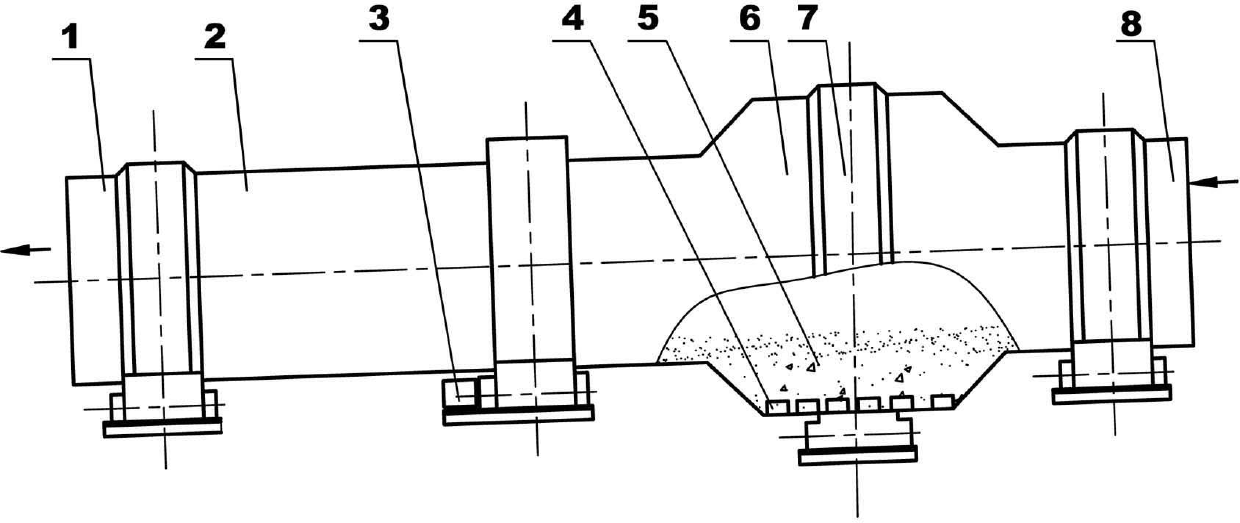

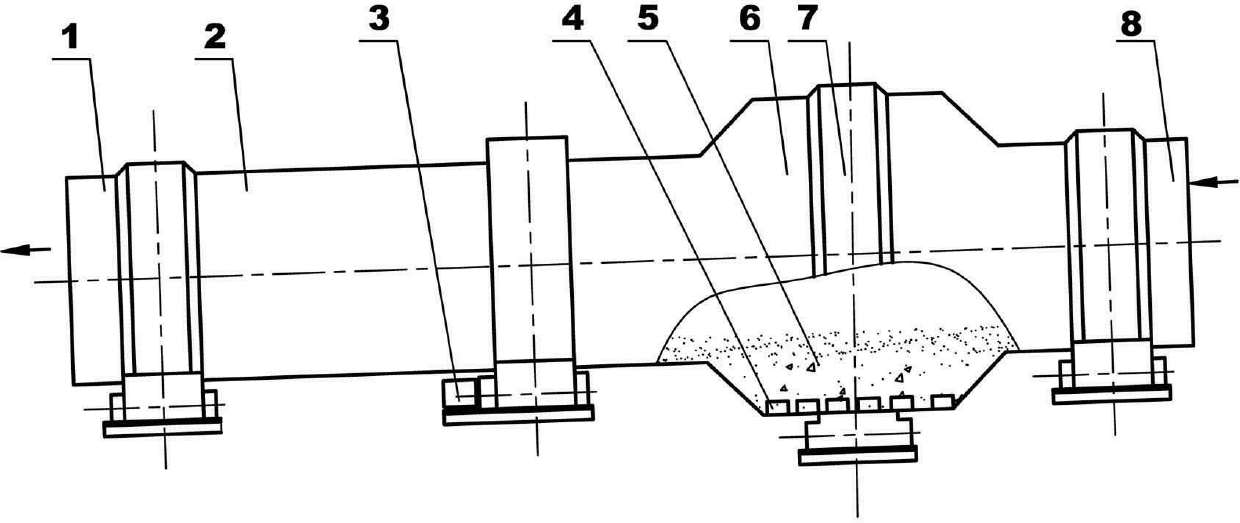

[0016] Below the embodiments of the present invention are combined with the attached figure 1 Described in detail, but the protection scope of the present invention is not limited by the examples.

[0017] Such as figure 1 As shown, a lime rotary kiln of the present invention has the following structure: the kiln head 1 is connected with the inclined rotary kiln body 2, and the rotary kiln body 2 is provided with a transmission device 3 that drives the kiln body to rotate counterclockwise. The rear end of the body 2 is connected to the kiln tail 8, and the kiln body 2 of the rotary kiln is provided with a variable diameter section 6 near the kiln tail 8, and the lifting plate 4 is arranged on the inner wall of the variable diameter section 6. The distance between the variable diameter section 6 and the kiln tail is 0.5-3 meters. A plurality of support frames 7 are arranged on the kiln body 2 of the rotary kiln. Support frame 7 is 2-8. The support frame 7 is used to support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com