Ship fuel preheating system and preheating method

A technology for fuel oil and ships, which is applied in the direction of charging system, fuel heat treatment device, hull, etc. It can solve the problems of uneven distribution of fuel oil temperature in compartments, accumulation of hot oil above compartments, insufficient heat exchange between hot and cold oil, etc. problem, to achieve the effect of prolonging the heat exchange time, free from installation, and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

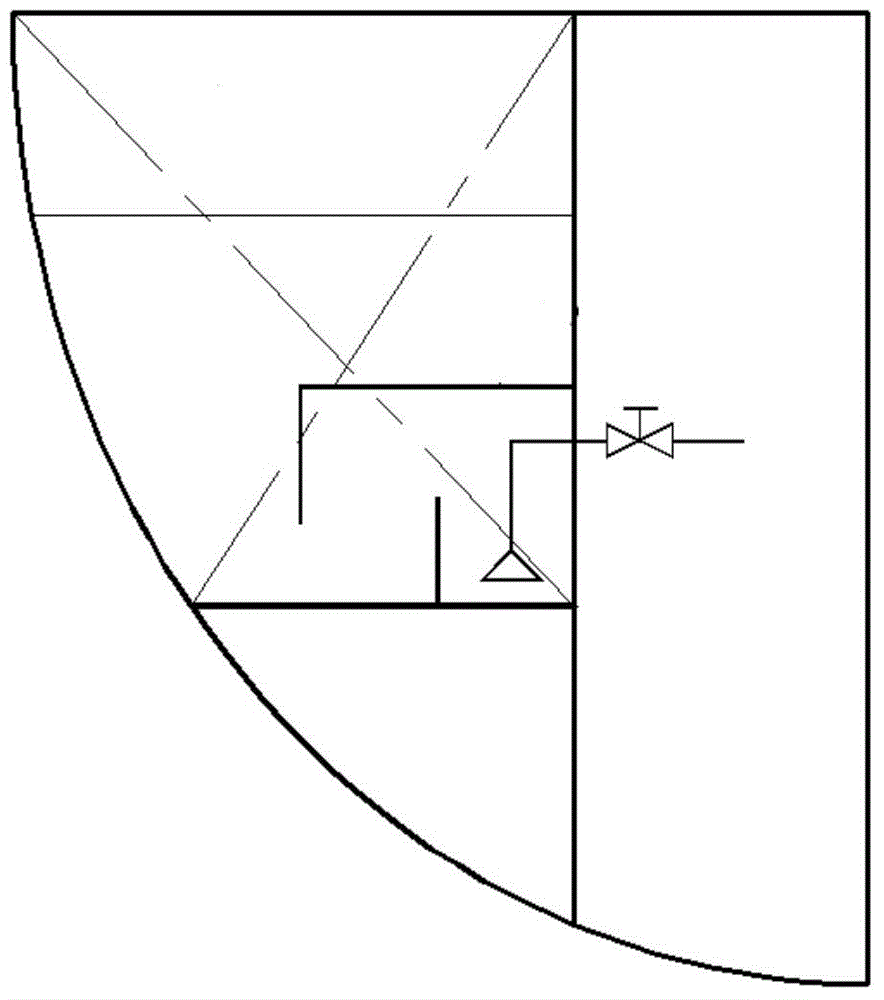

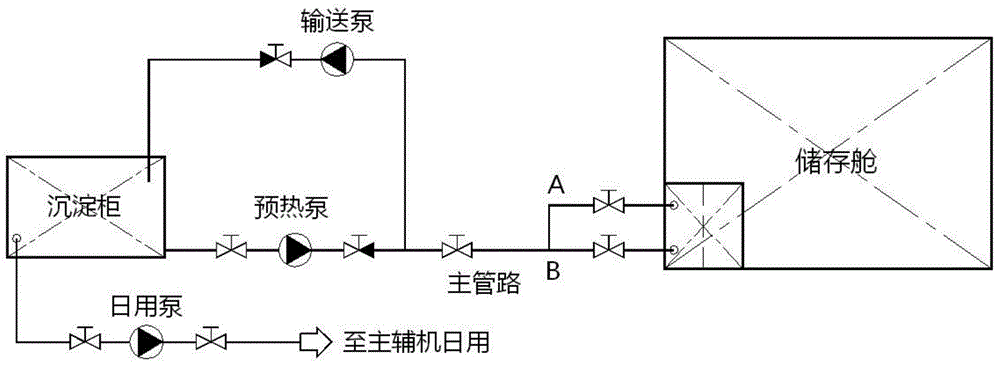

[0037] The specific design scheme of the present invention is as image 3 Shown: Two pipelines for fuel preheating and transportation are set between the fuel storage tank and the fuel sedimentation tank. The main pipeline is shared, and it is divided into two branches near the sedimentation tank. For fuel oil, a fuel delivery pump is installed along the way to transport the heated heavy oil to the settling tank. Both branches are equipped with cut-off check valves in the corresponding direction to prevent the direction of the pipeline from being misaligned. In order to cooperate with the compartment scheme and make the compartment have a better fuel preheating effect, this design sets two pipelines of the same height in the small compartment, and each is equipped with a regulating valve.

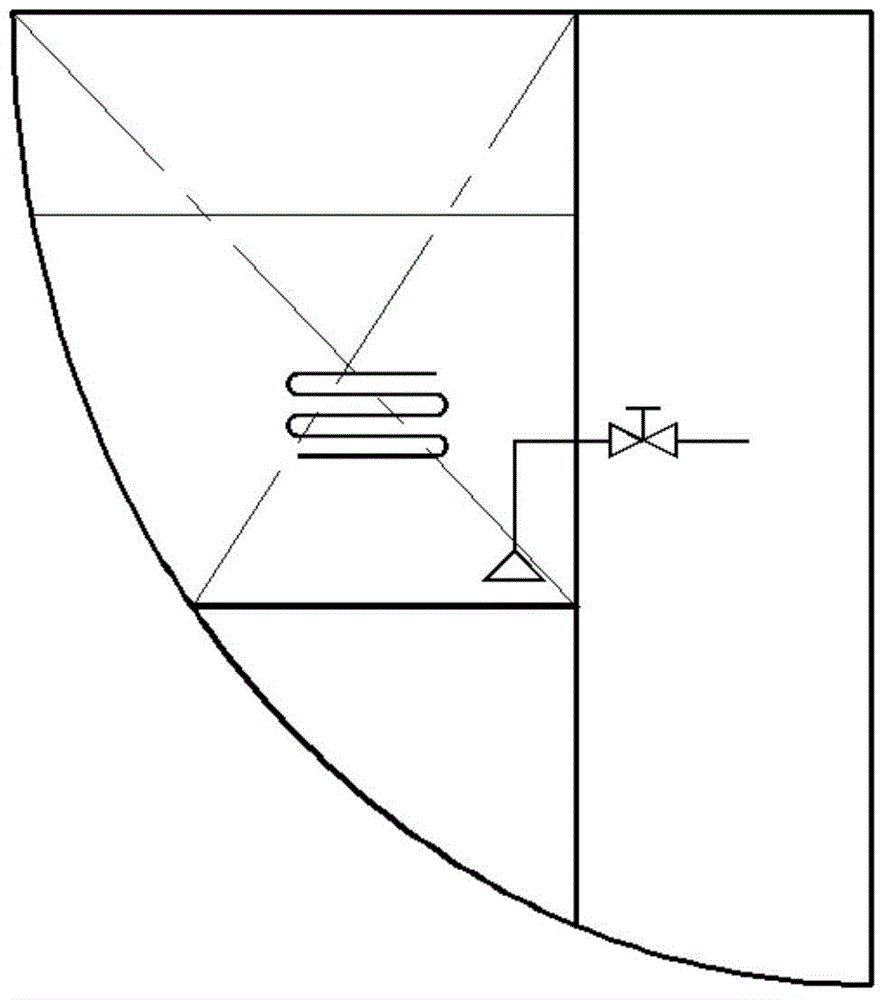

[0038] Compartment scheme design such as Figure 4 S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com