Drawer type preheating oven

A kind of preheating furnace and drawer-type technology, which is applied in the field of drawer-type preheating furnace, can solve the problems of too simple structure, unsatisfactory preheating effect, and the internal temperature of the equipment cannot be kept stable and uniform, so as to achieve a good preheating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

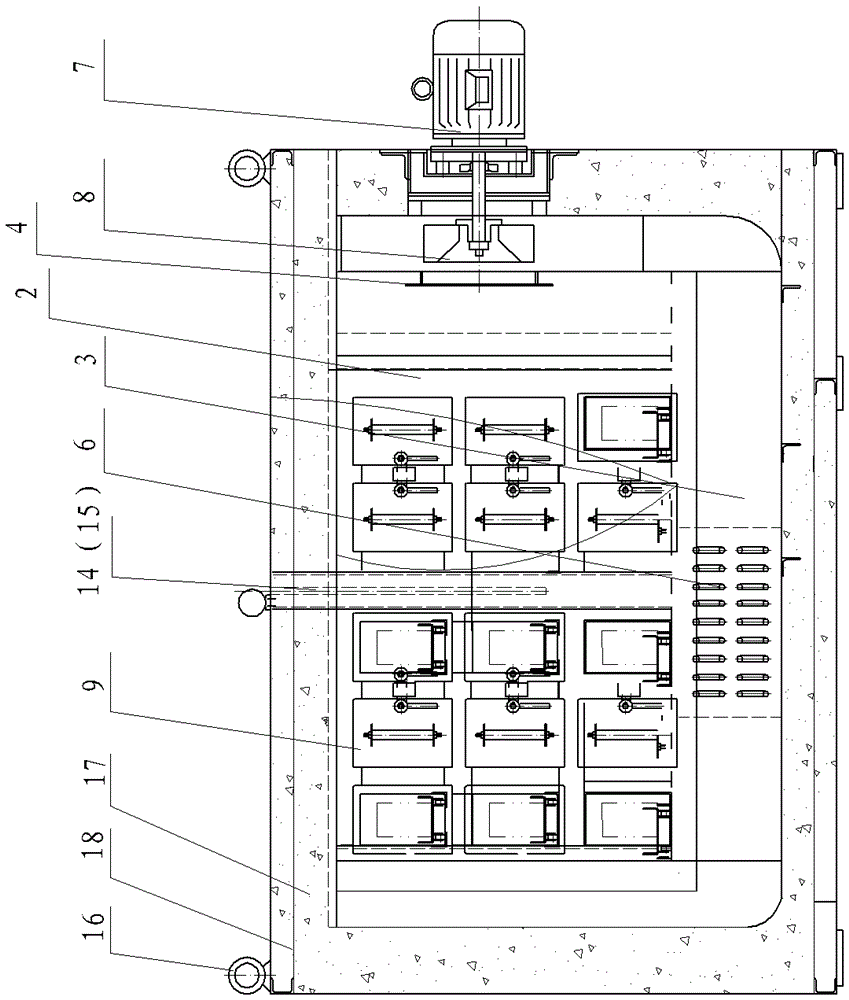

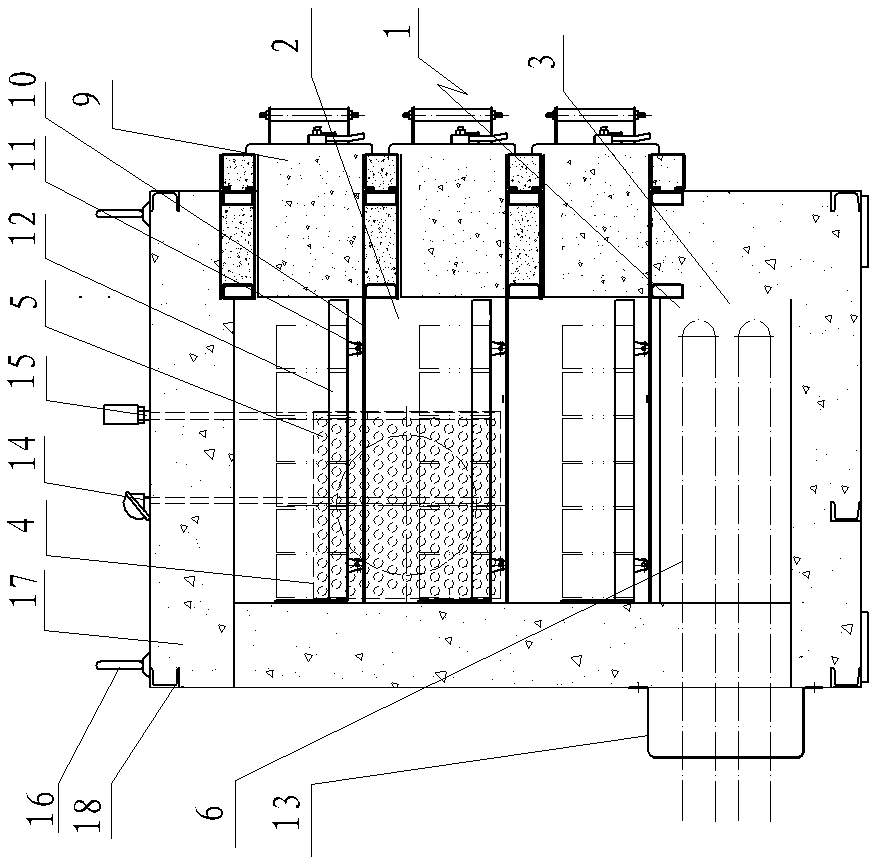

[0012] See figure 1 , figure 2 As shown, a drawer-type preheating furnace includes a furnace 1, and a connected preheating chamber 2 and an air duct 3 are arranged in the furnace 1, and an air equalizing plate 4 is arranged at the connection between the air duct 3 and the preheating chamber 2, and the air uniformity is uniform. There are evenly arranged ventilation holes 5 on the air plate 4, electric heating pipes 6 are installed in the air duct 3, blowing blades 8 connected to the motor 7 are arranged on the outside of the air equalizing plate 4, and a material inlet and outlet are opened on the front side of the preheating chamber 2 A furnace door 9 is installed on the inlet and outlet, corresponding to the inlet and outlet, a guide rail 10 is arranged in the furnace 1, and a component support plate 12 is installed on the guide rail 10 through a guide wheel 11 . A protective cover 13 is installed outside the electric heating tube 6 to play a protective role; a bimetallic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com