Patents

Literature

41results about How to "Constant heating temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

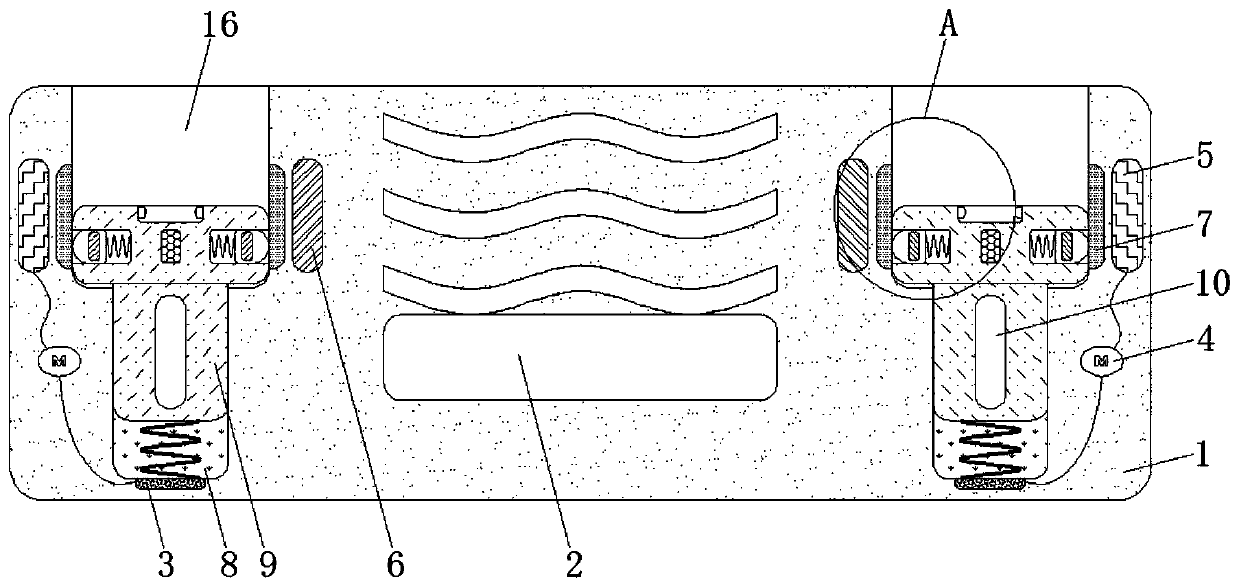

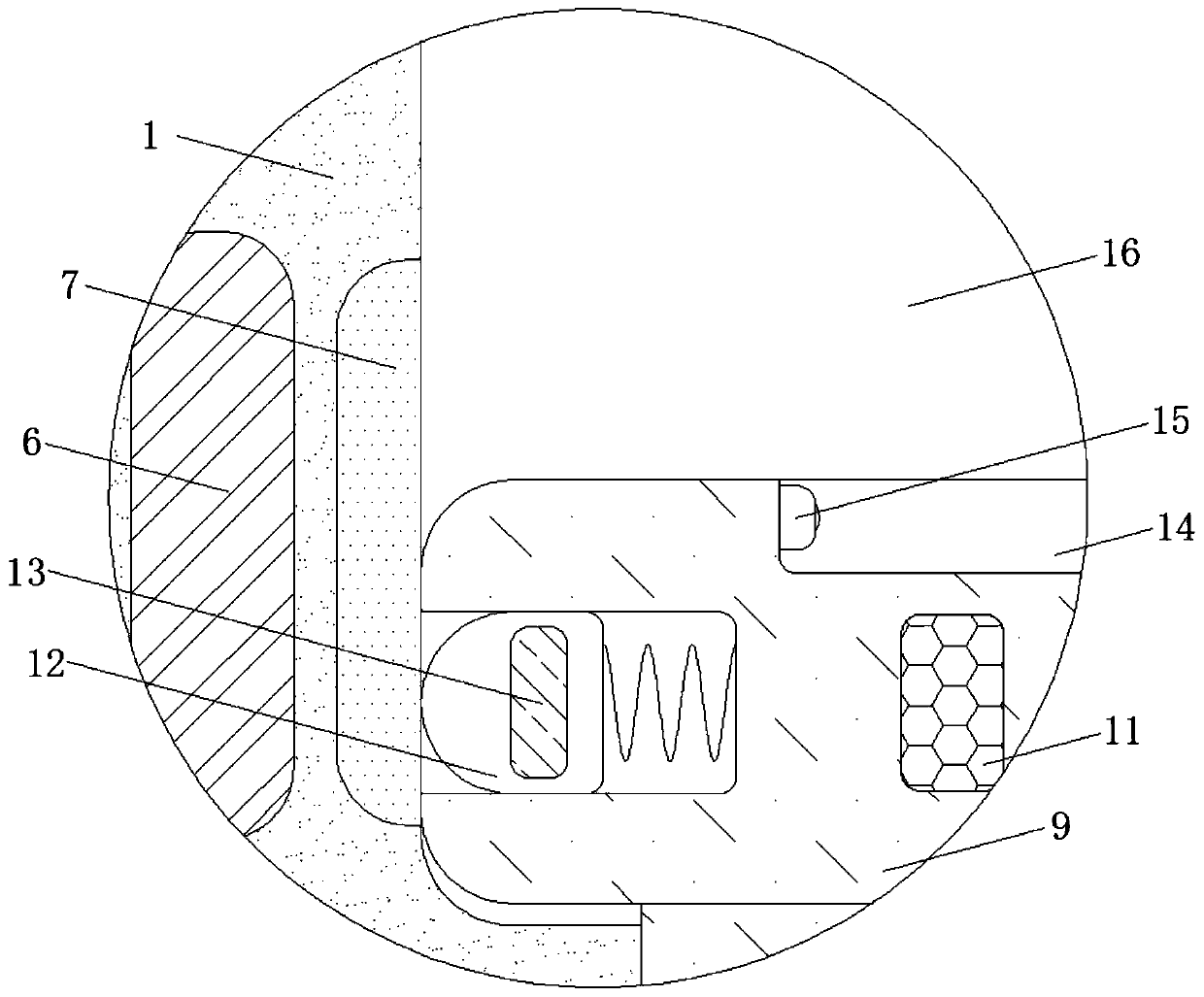

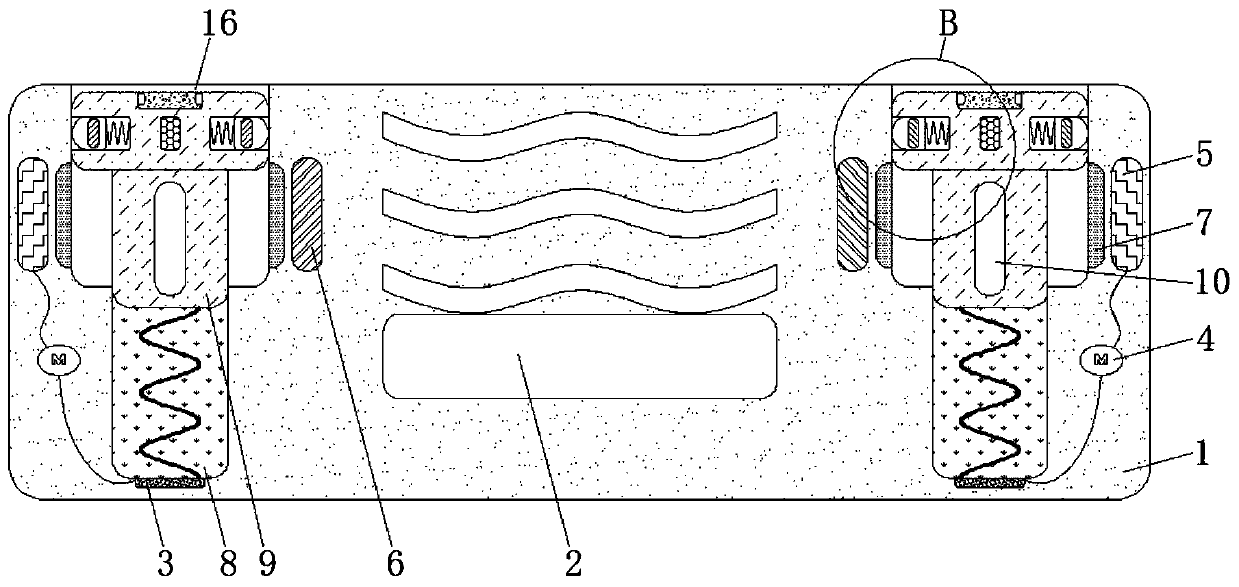

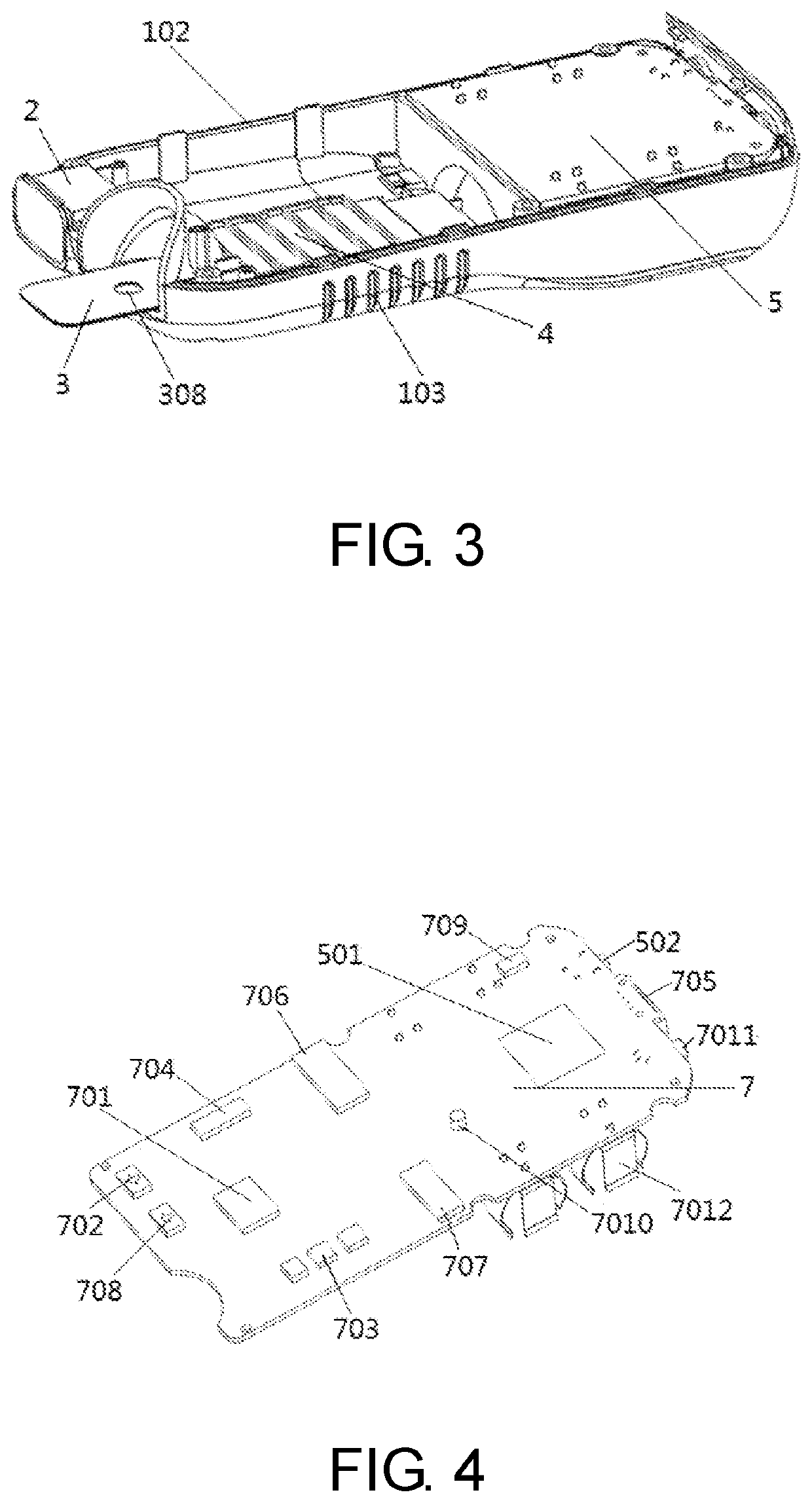

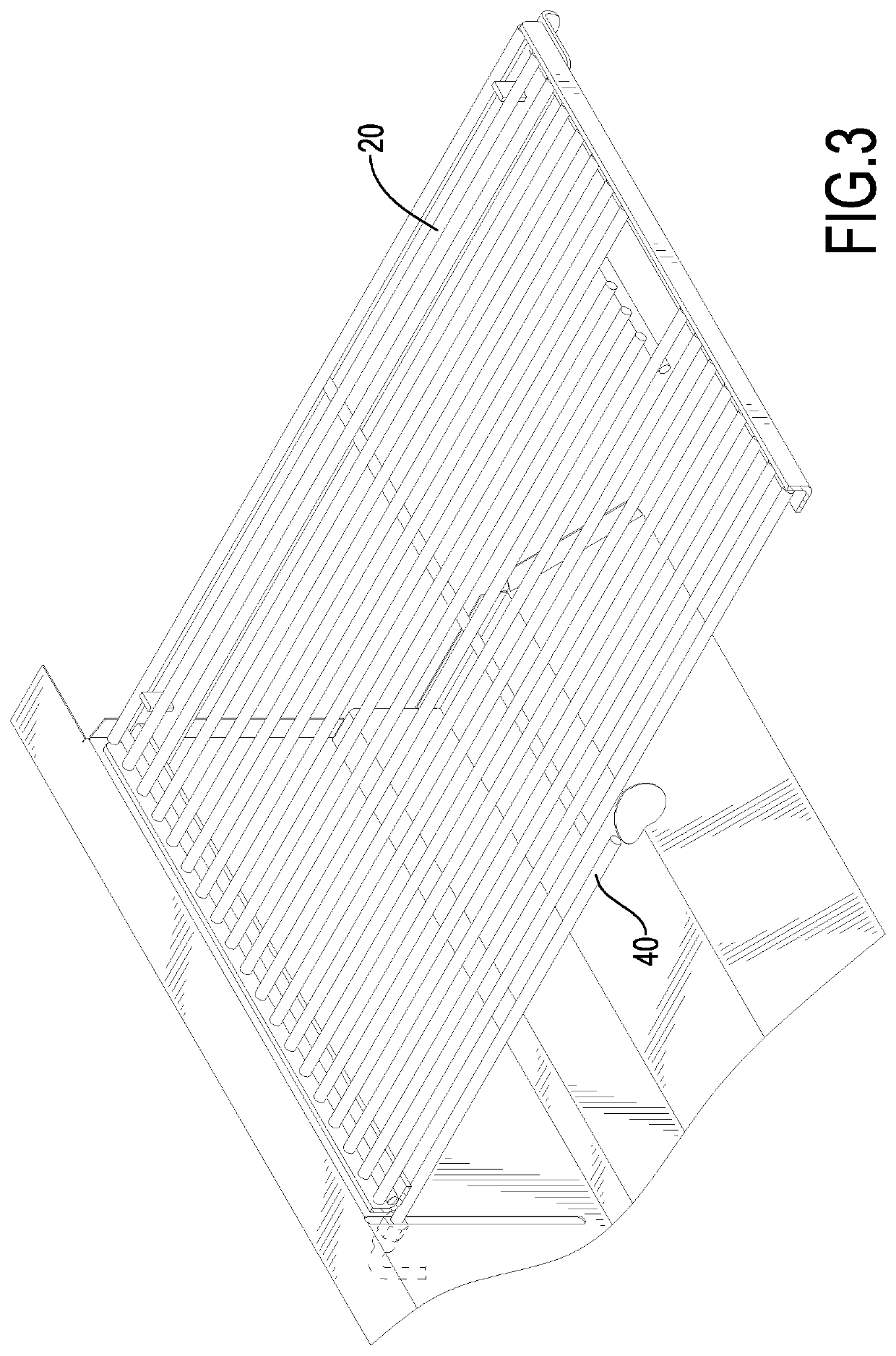

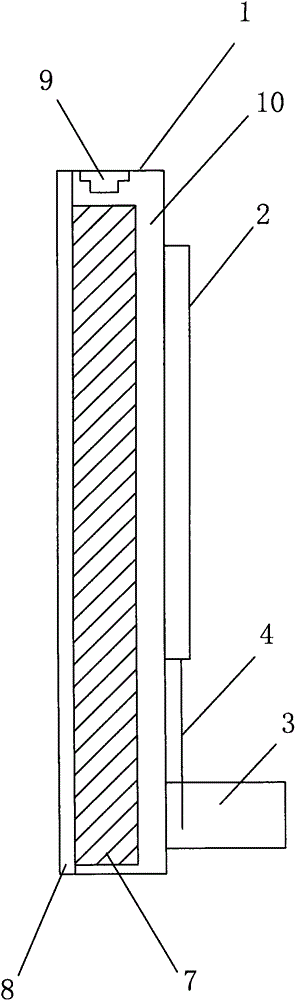

Smoking device with heat storage component and combined type smoking system

InactiveCN104366697AReduce capacity requirementsSmall footprintTobacco pipesTobacco devicesHeat conductingHeat storage material

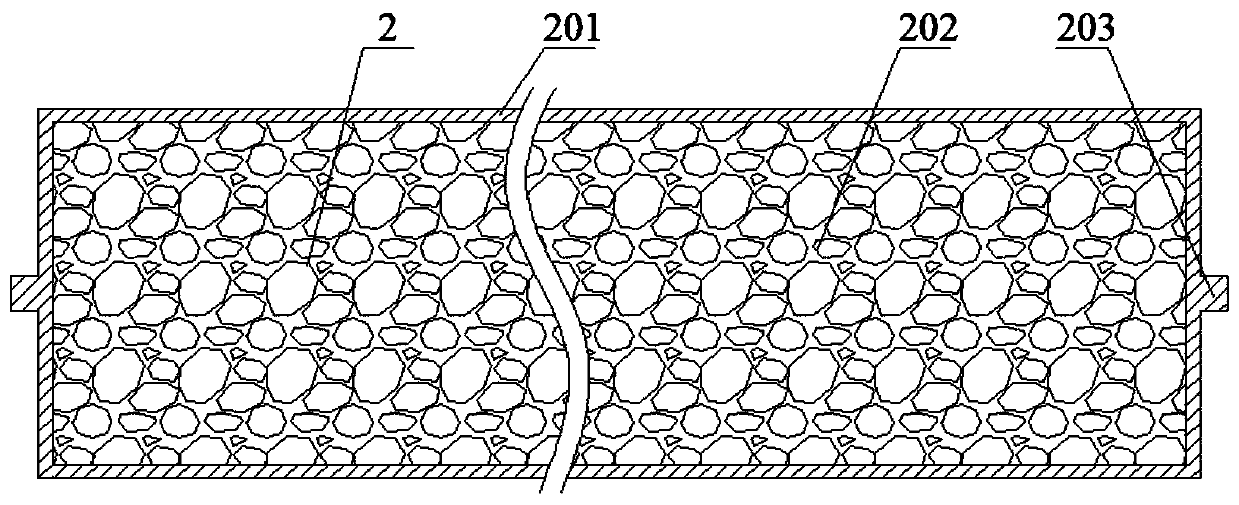

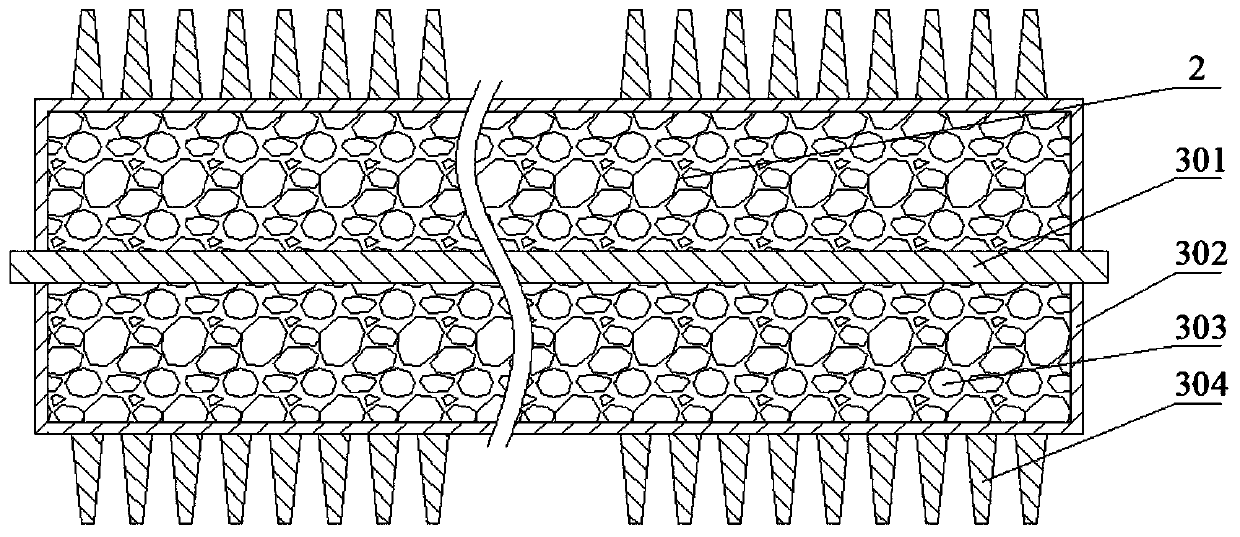

The invention relates to a smoking device with a heat storage component. The smoking device is characterized by comprising a shell (1) and the heat storage component (2) arranged inside the shell (1). The heat storage component (2) comprises a heat storage material container (5) and a heat conducting element (7). One or more tobacco containing cavities (10) are defined by the heat storage material container (5) or defined by the heat storage material container (5) and external components jointly. Heat storage materials are placed into the heat storage material container (5). The heat conducting element (7) comprises a first heat conducting section (7a) and a second heat conducting section (7b), wherein the first heat conducting section (7a) is contained in the heat storage material container (5), and the second heat conducting section (7b) extends out of the heat storage material container (5). The smoking device and an external heat supply device can be connected in a pluggable mode to form a smoking system, heat storage and emission are achieved through phage change materials, and tobaccos are heated in the heat emission process. In this way, the smoking device can be provided with no battery or a small battery, the size of the smoking device is more approximate to a traditional spark ignition type cigarette, and the smoking device is convenient to use.

Owner:CHINA TOBACCO YUNNAN IND

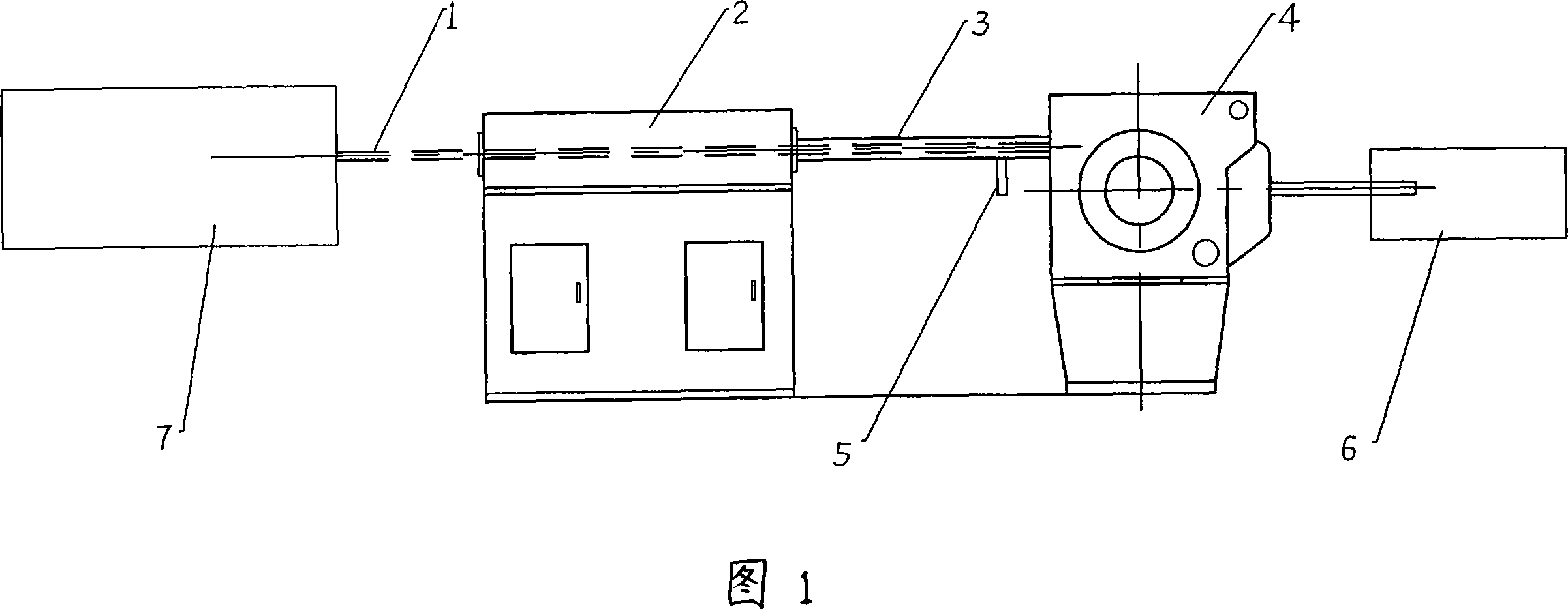

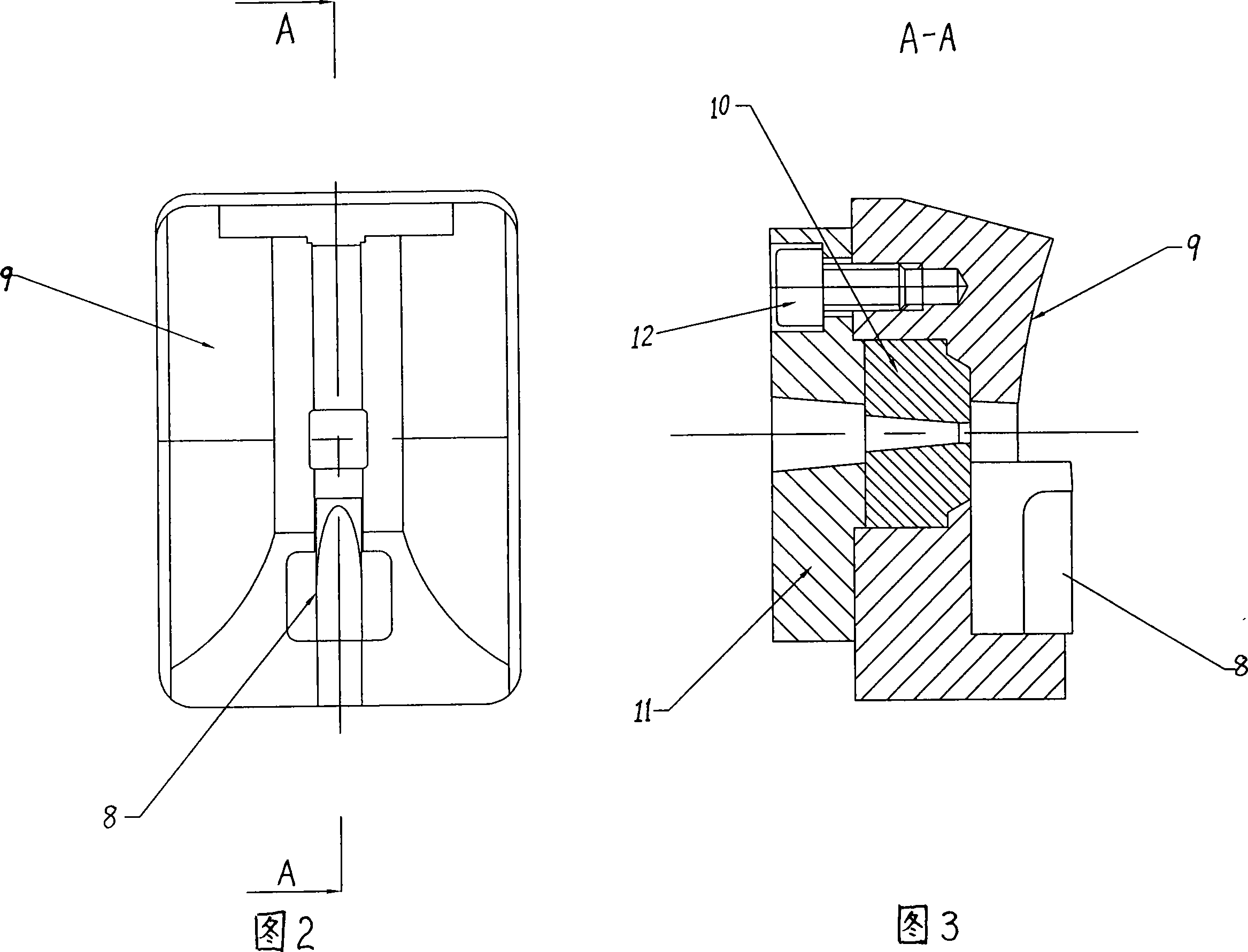

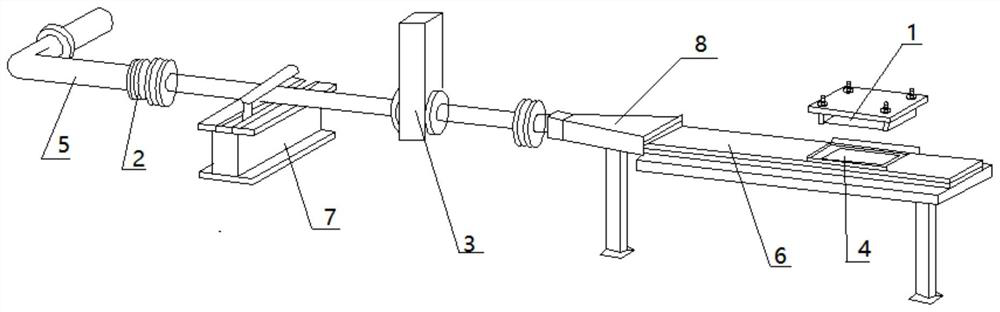

Copper alloy continuous extrusion method and special apparatus

InactiveCN101069901AImprove plasticityReduce deformation resistanceExtrusion control devicesCopper alloyExtrusion

The present invention relates to a continuous extrusion method of rod material and its equipment. In particular, it relates to a rod material preheating continuous extrusion method. Firstly, said blank material is heated, then is fed into a continuous extrusion equipment, extruded and formed. The equipment described by said invention includes rod material pretreatment device, heating device, oxidation proof protection device and continuous extrusion device which are successively dynamically connected together.

Owner:大连康丰科技有限公司

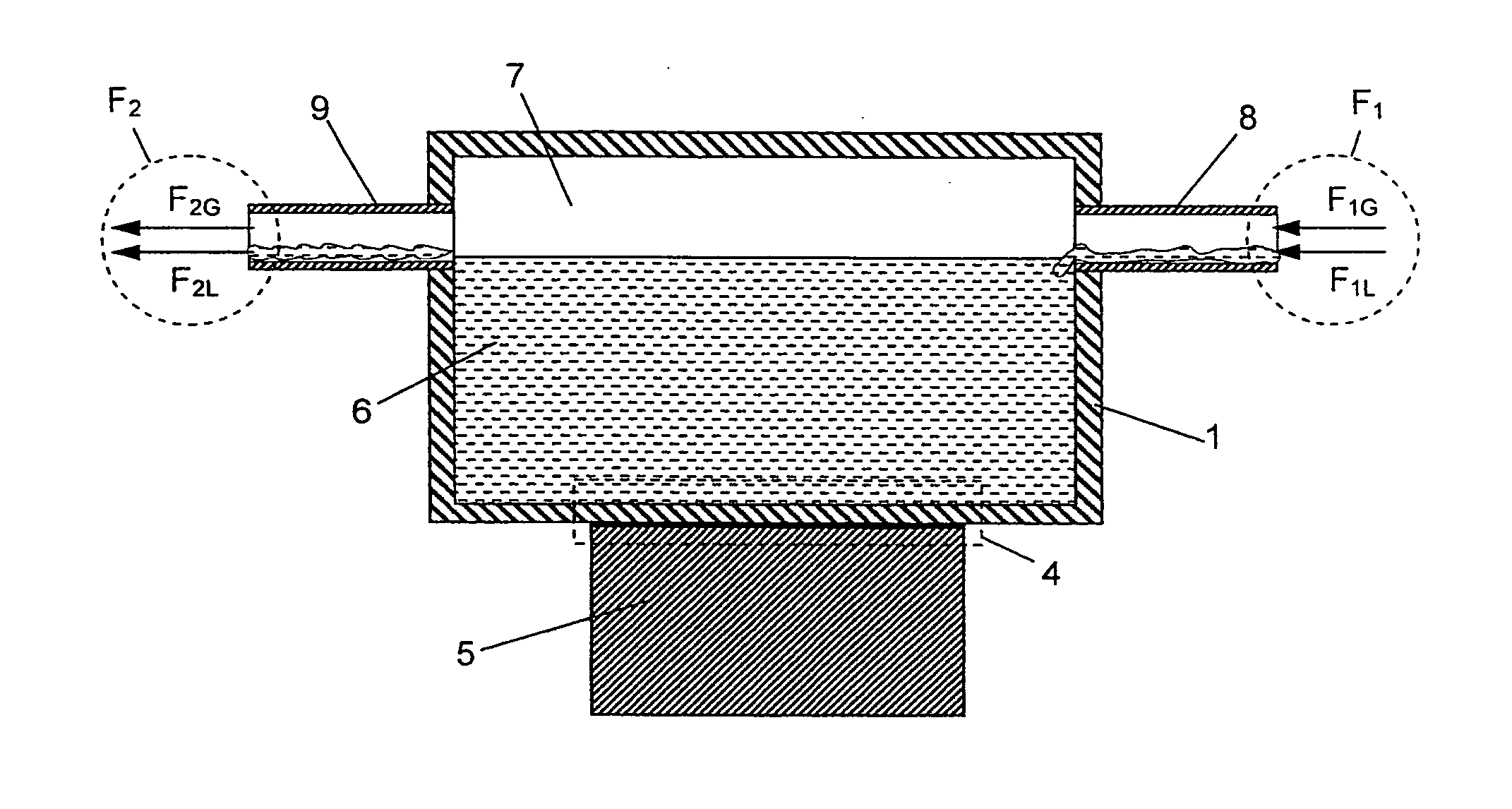

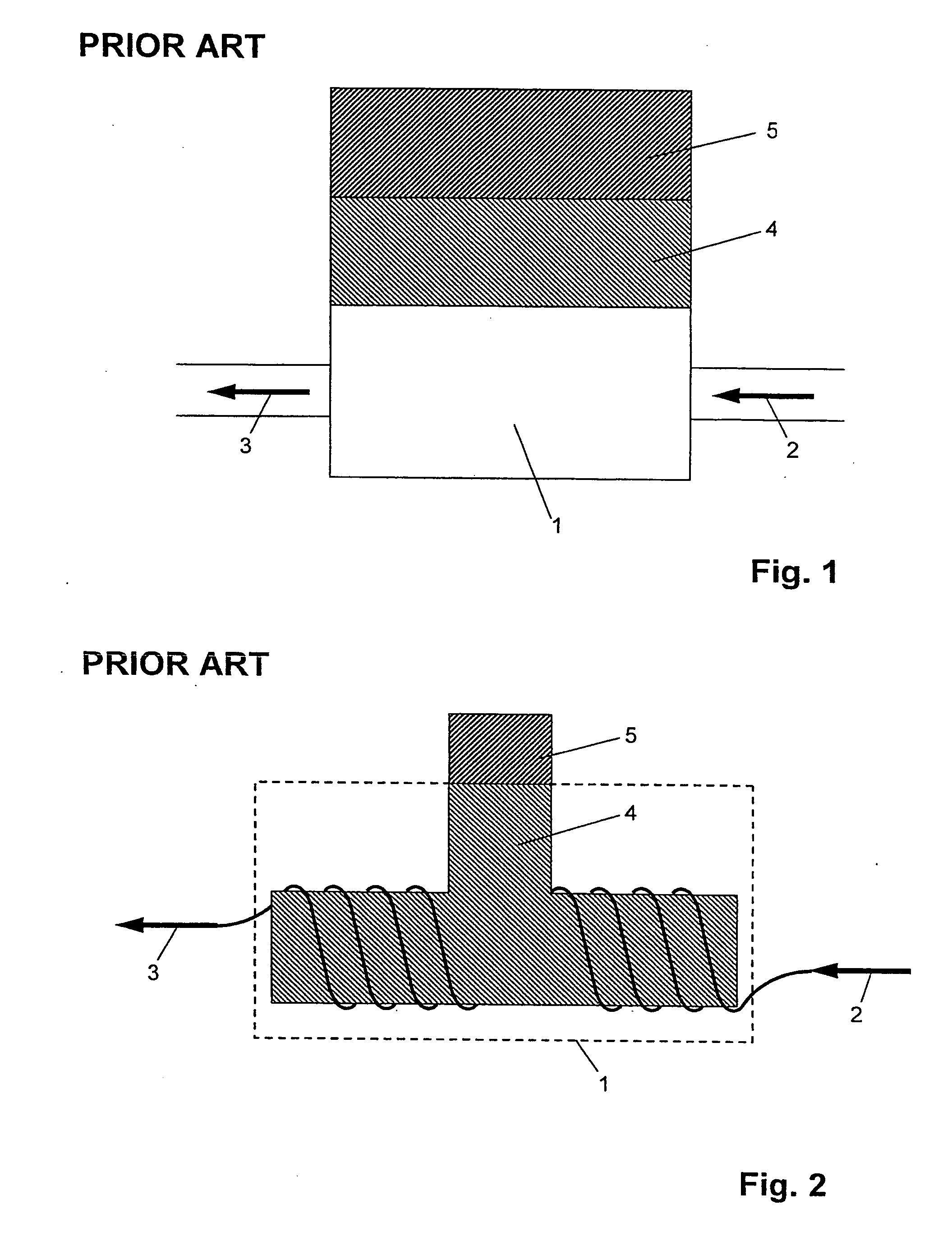

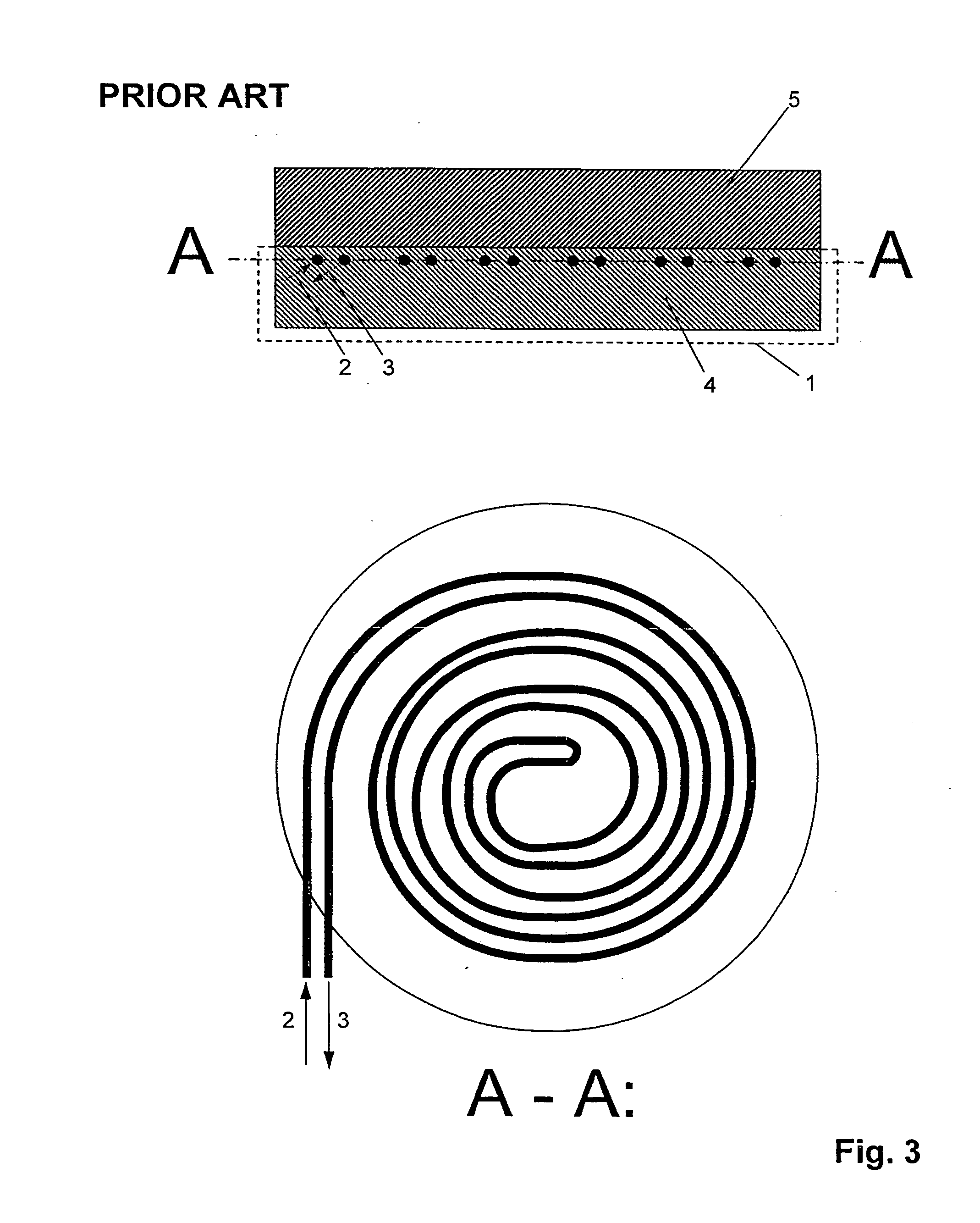

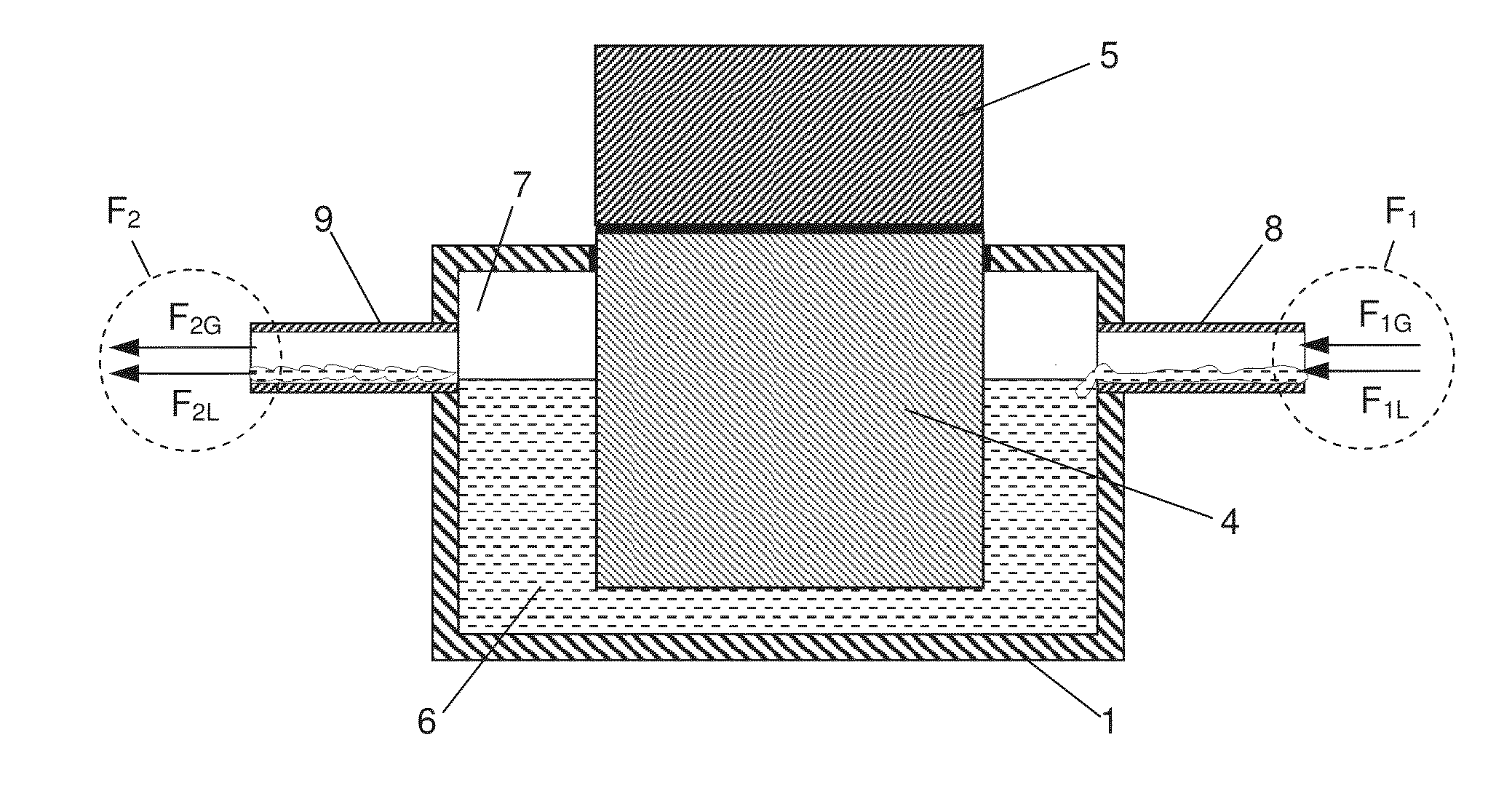

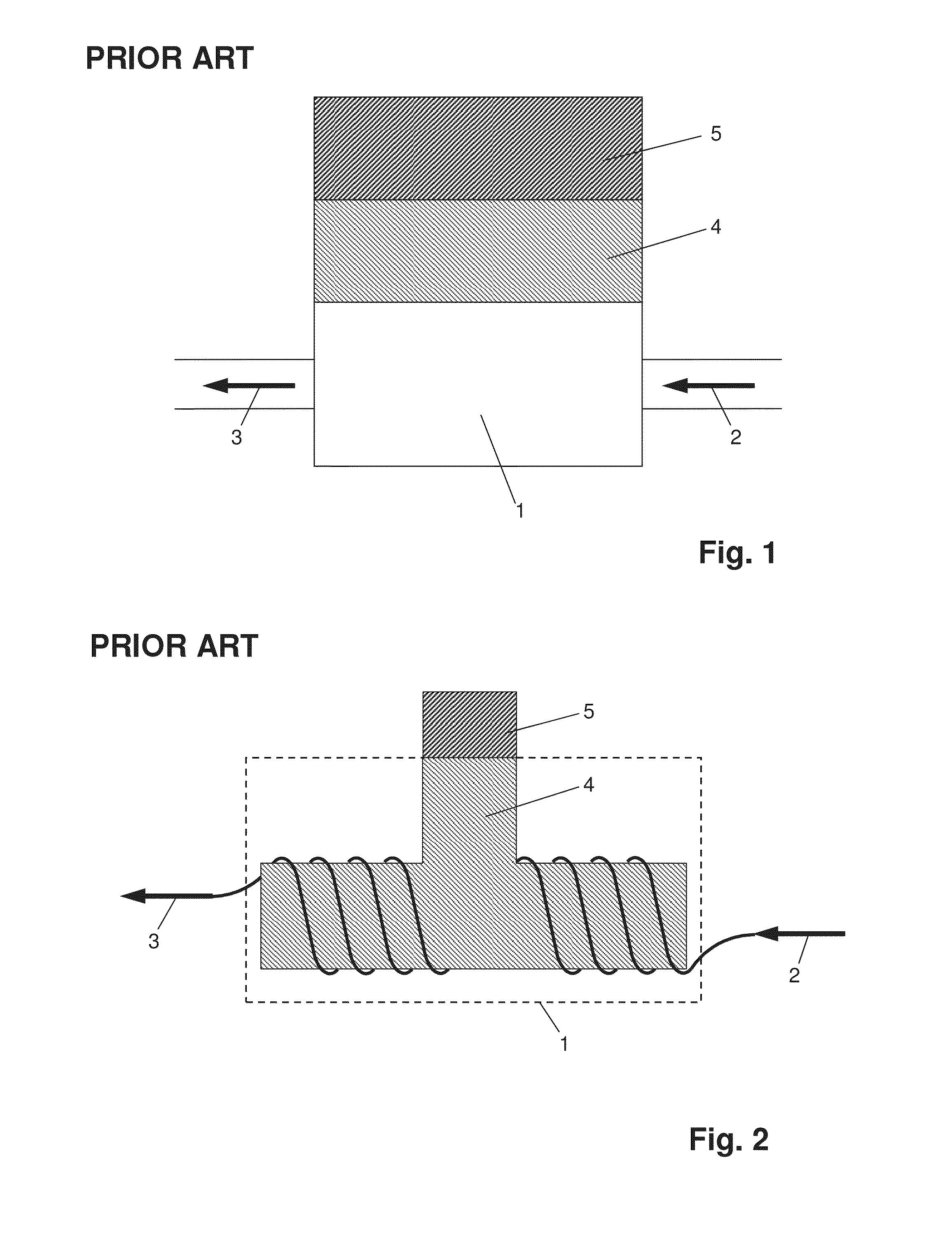

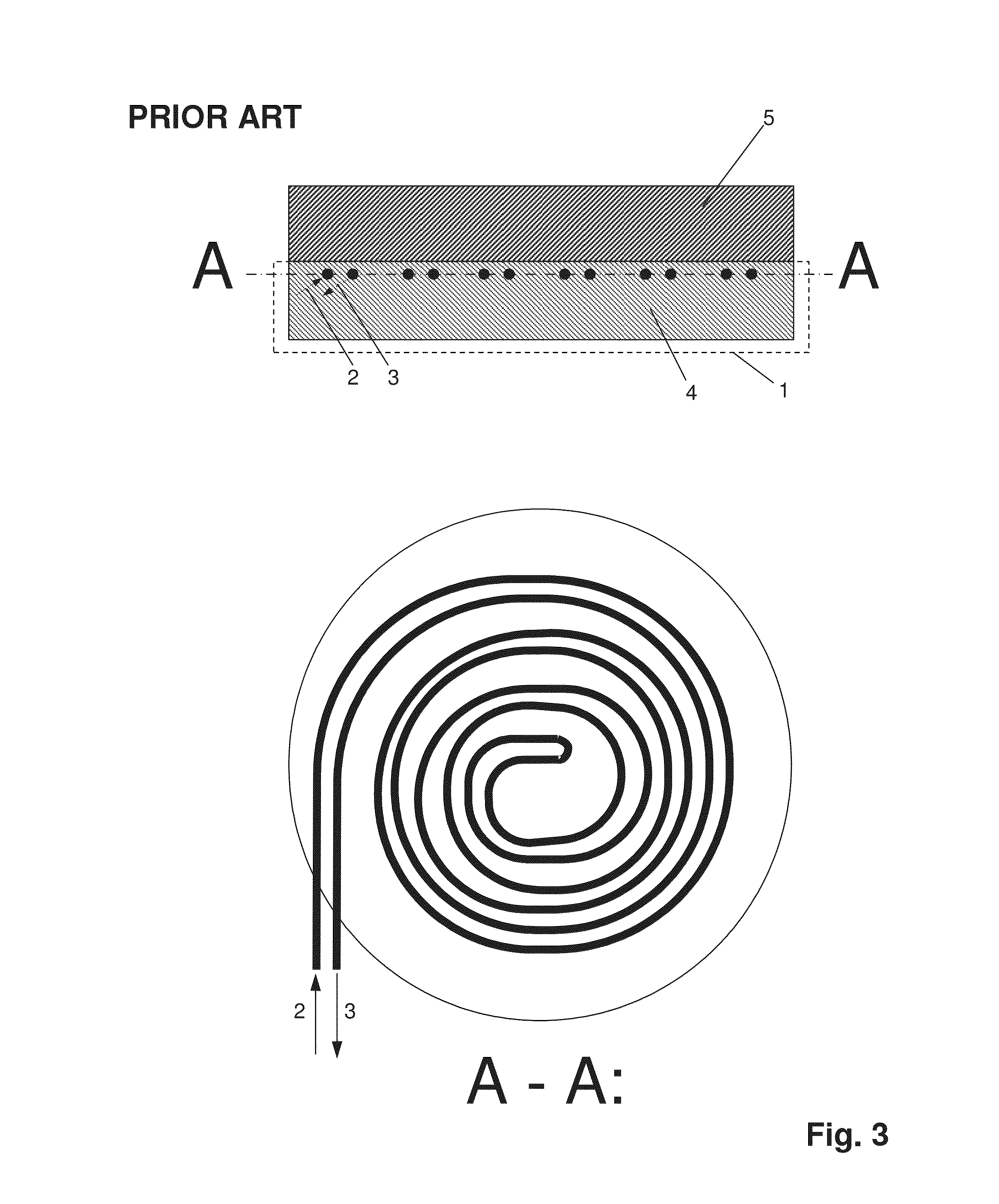

Cooling device for cryogenic cooling of an NMR detection system with the assistance of a container filled with a cryogenic fluid

InactiveUS20110100027A1Undesirable influenceReduce consumptionLevel controlTemperatue controlProcess engineeringThermal contact

A cryo probe head for the transmission / reception of RF signals for NMR measurements with a heat exchanger (1) for cooling heat sources (5), the heat exchanger having a contact element (4.2) for thermal connection between a cryogenic fluid and the heat source, is characterized in that the heat exchanger comprises a container having an interior volume VB into which a first cryogenic fluid F1 that has a liquid component F1L and a gaseous component F1G flows through an inflow conduit (8) and from which a second cryogenic fluid F2 that has liquid component F2L and a gaseous component F2G flows out through an outflow conduit (9). The inflow conduit has a flow cross-section QZ and a circumference UZ from which a characteristic conduit volume VZ=4·Q2Z / UZ results, wherein VB>10·VZ, and the outflow conduit has a flow diameter QA wherein QA≧QZ. The contact element is in close thermal contact with both the liquid volume component VL of the cryogenic fluid and with the heat source. A device for setting the inflow quantity of the first cryogenic fluid F1 into the container is provided that ensures a state F1L / F1G>F2L / F2G during operation. In this way, vibrations due to the cooling process can be largely reduced and the consumption of cryogenic fluid minimized.

Owner:BRUKER BIOSPIN

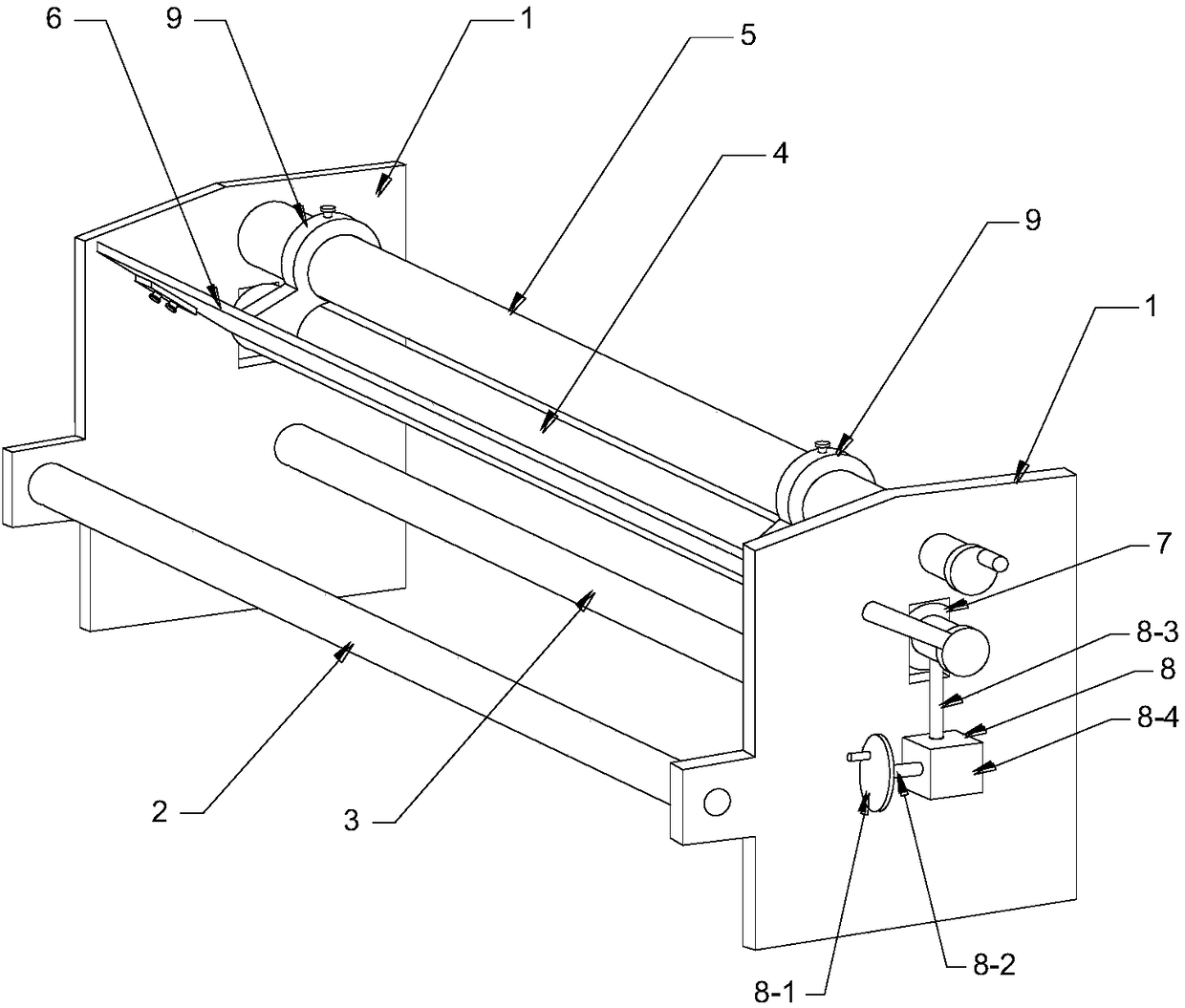

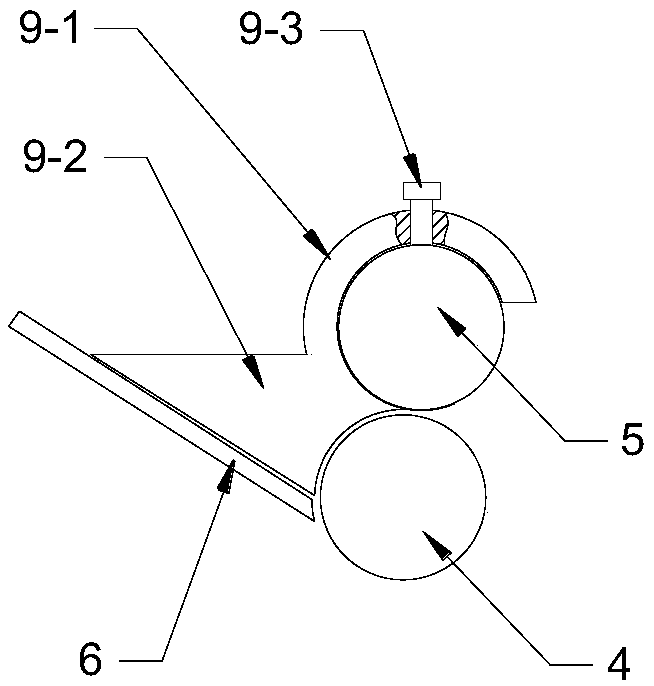

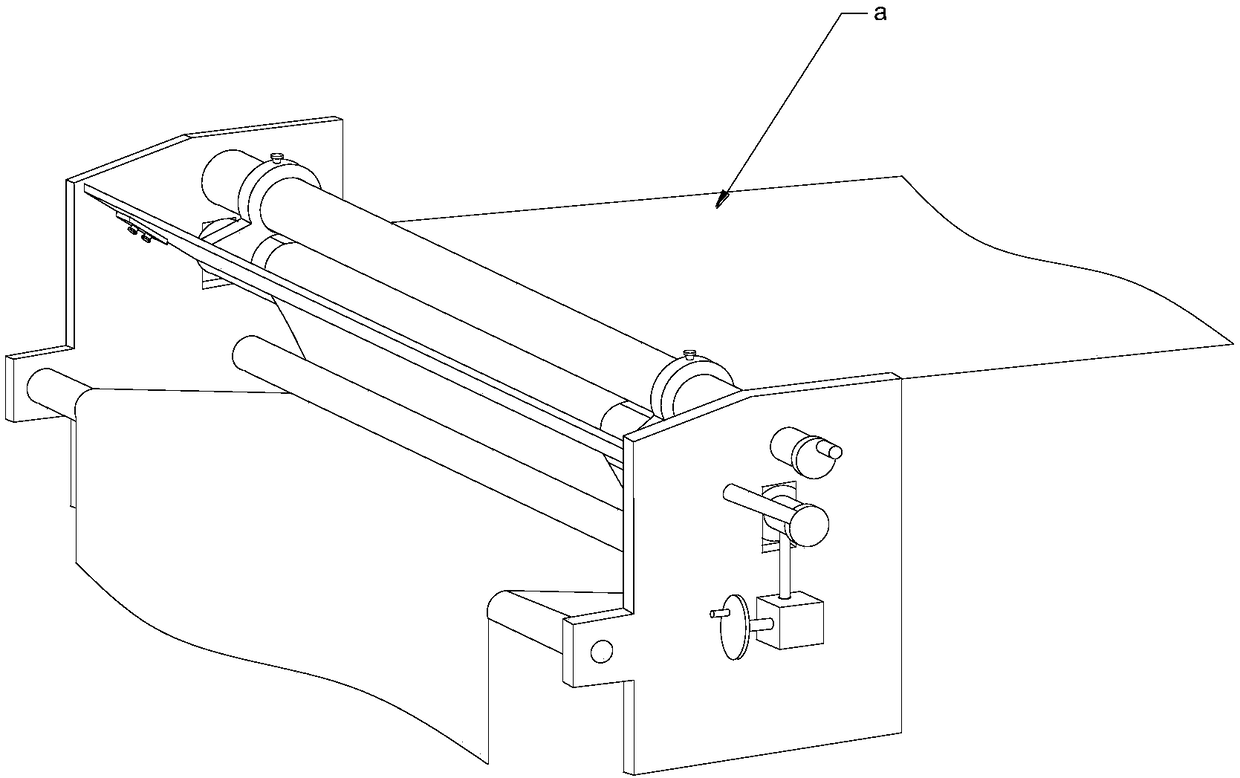

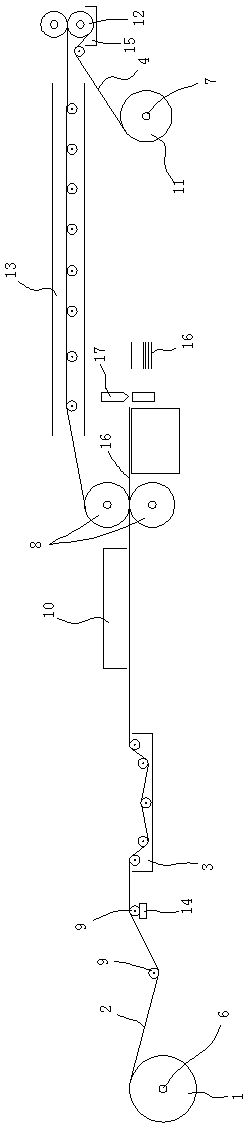

Film coating equipment used in plaster production, and application method thereof

ActiveCN108372076AAdjust the size of the gapAdjustable thicknessLiquid surface applicatorsCoatingsEngineeringFilm-coated tablet

The invention discloses a film coating equipment used in plaster production, and applications thereof. The film coating equipment used in plaster production comprises a machine frame, a gluing lower roller, a gluing upper scraping roller, and a discharge plate; the gluing lower roller, the gluing upper scraping roller, and the discharge plate are transversely arranged on the machine frame; the gluing upper scraping roller is arranged above the gluing lower roller; the discharge plate is arranged on the feed inlet side of the gluing lower roller and the feed inlet side of the gluing upper scraping roller; a gap is arranged between the bottom end of the discharge plate and the gluing lower roller, so that cloth to be coated can be delivered through; a discharge gap is left between the gluinglower roller and the gluing upper scraping roller; slidable mounting is adopted by the end parts of the gluing lower roller; lower gluing roller adjusting devices which are used for acting on the twoends of the gluing lower roller, and adjusting the vertical position of the gluing lower roller are arranged on two side plates respectively; and film width adjusting blocking plates which are used for adjusting film coating width are arranged on the gluing lower roller and the gluing upper scraping roller. The film coating equipment is reasonable in design, excellent in control performance, highin production efficiency, convenient in operation, convenient to clean, and is an ideal plaster film coating equipment.

Owner:JINZHOU ZIJIN PHARMA

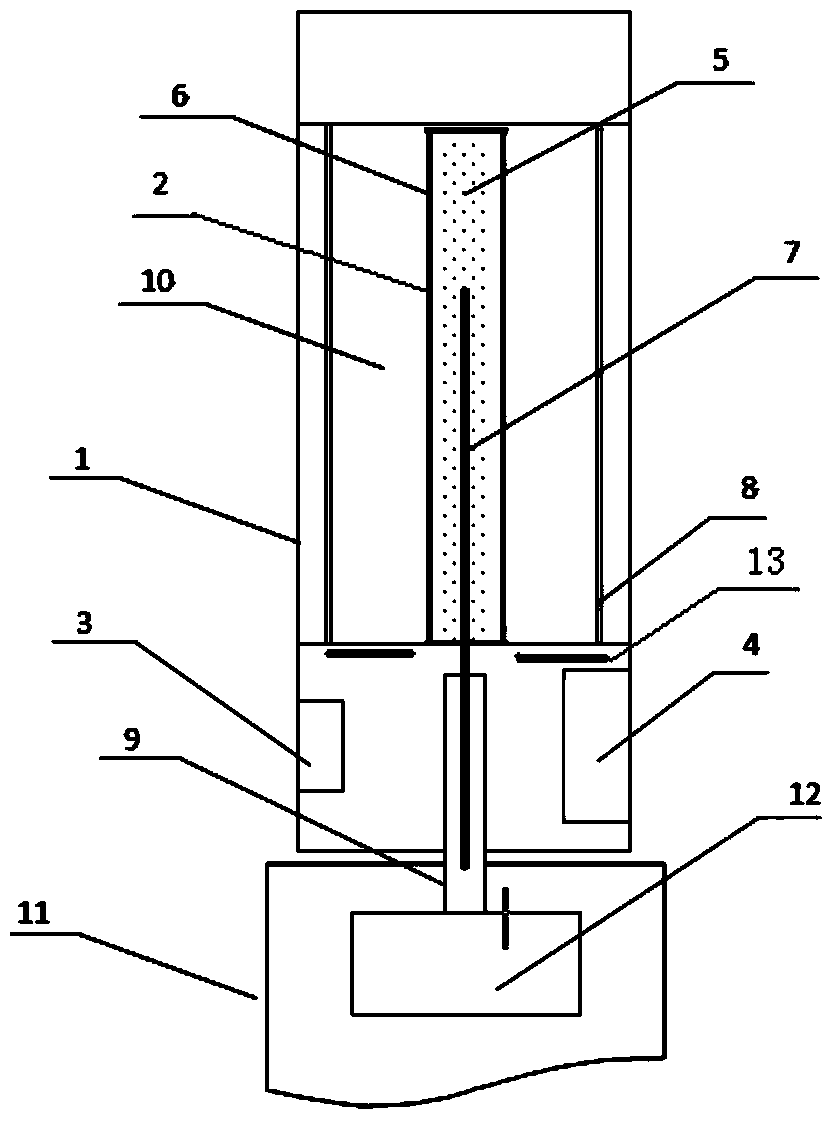

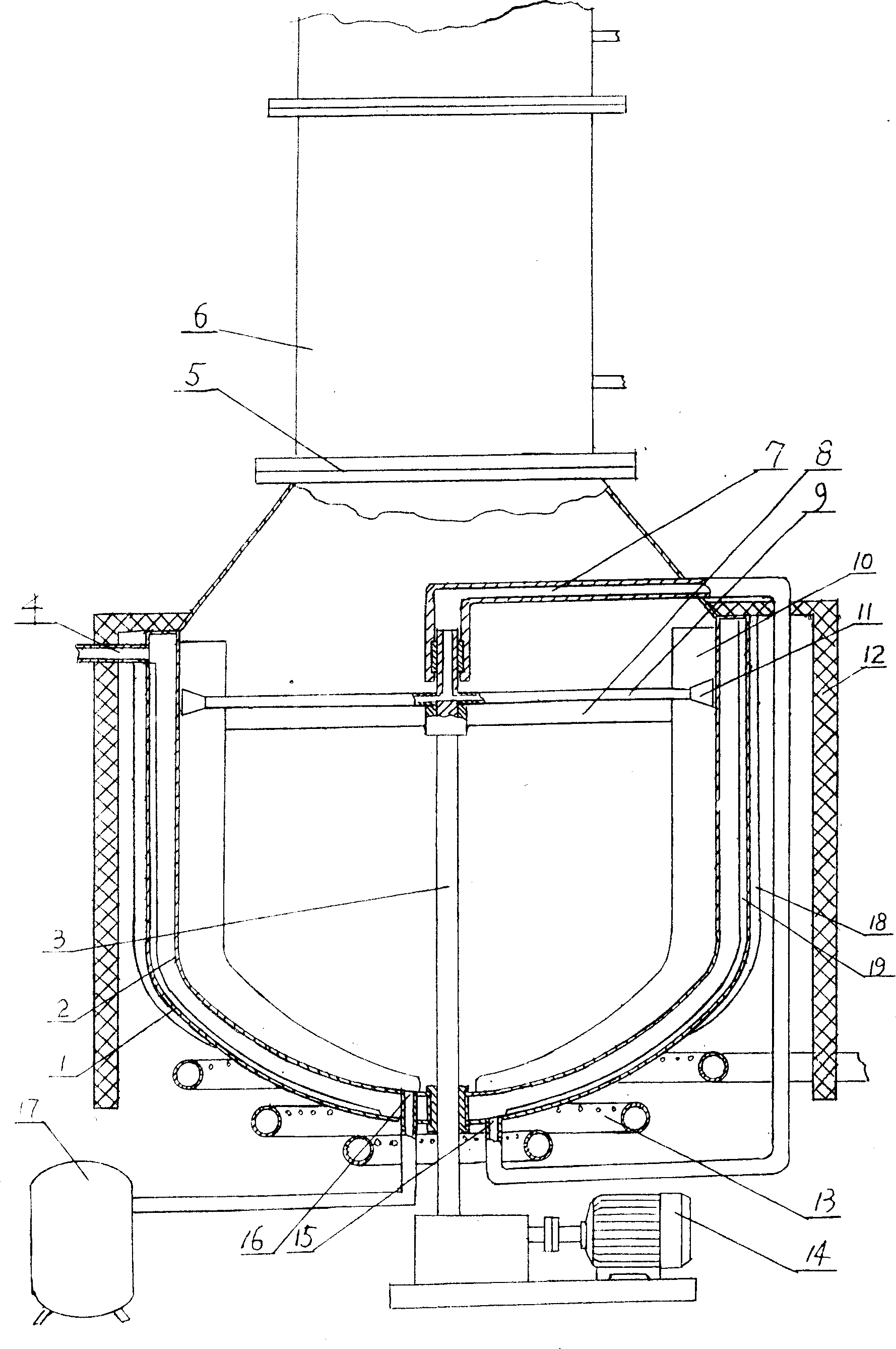

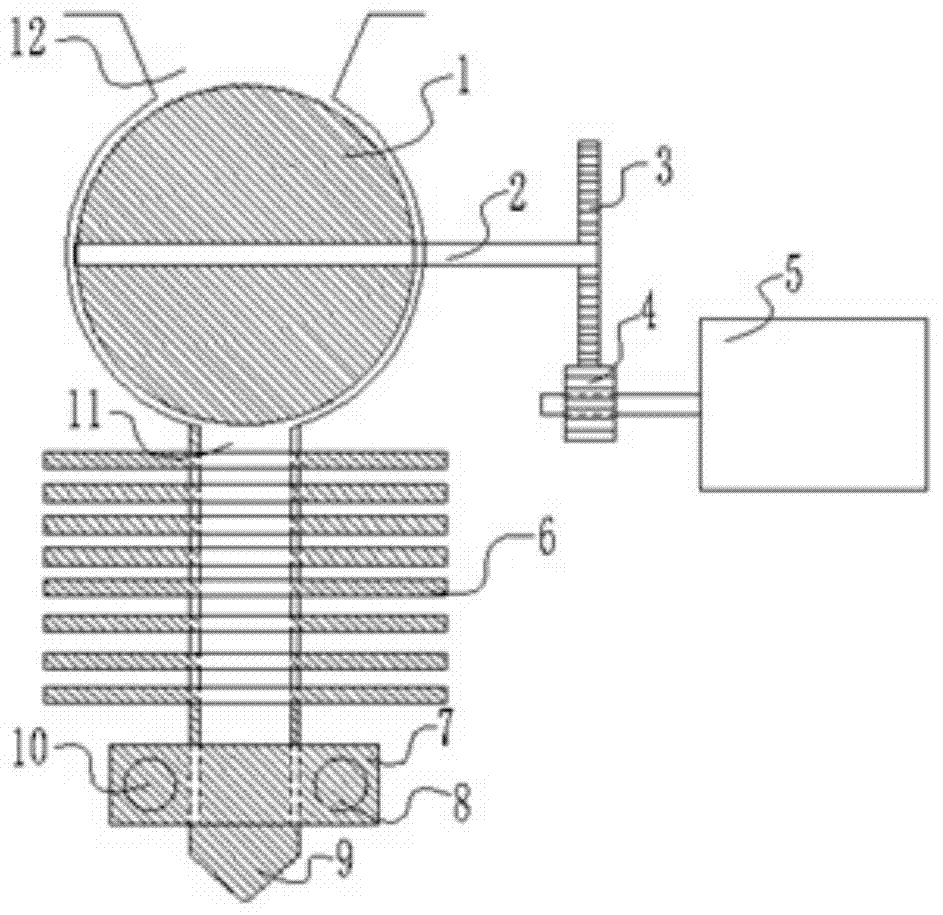

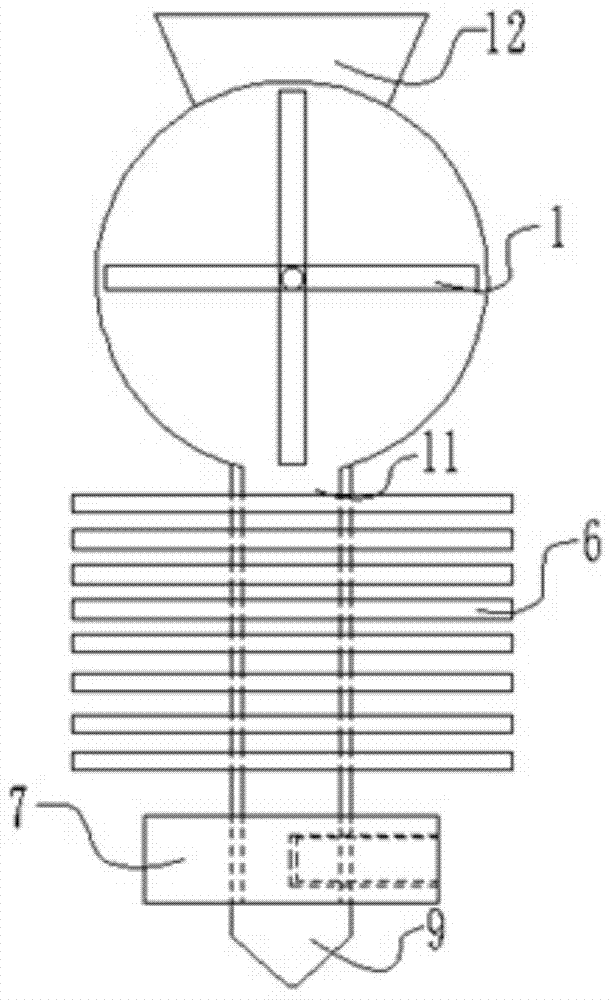

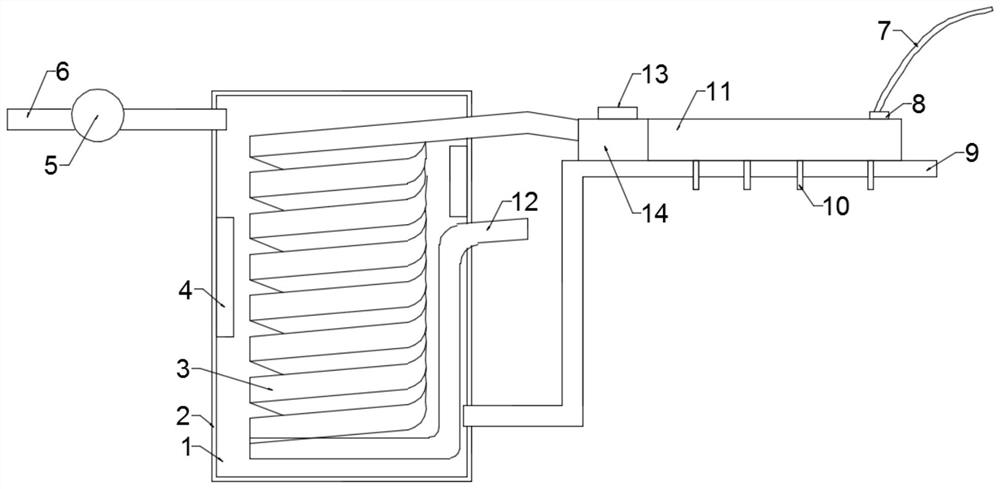

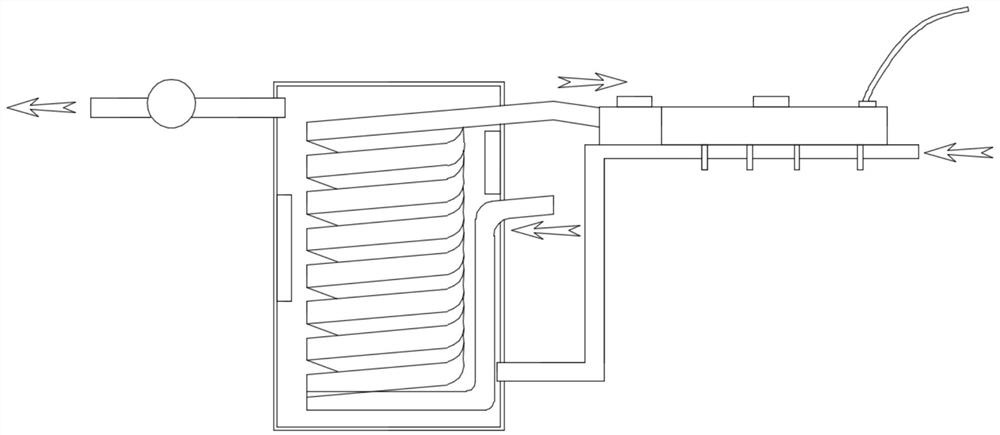

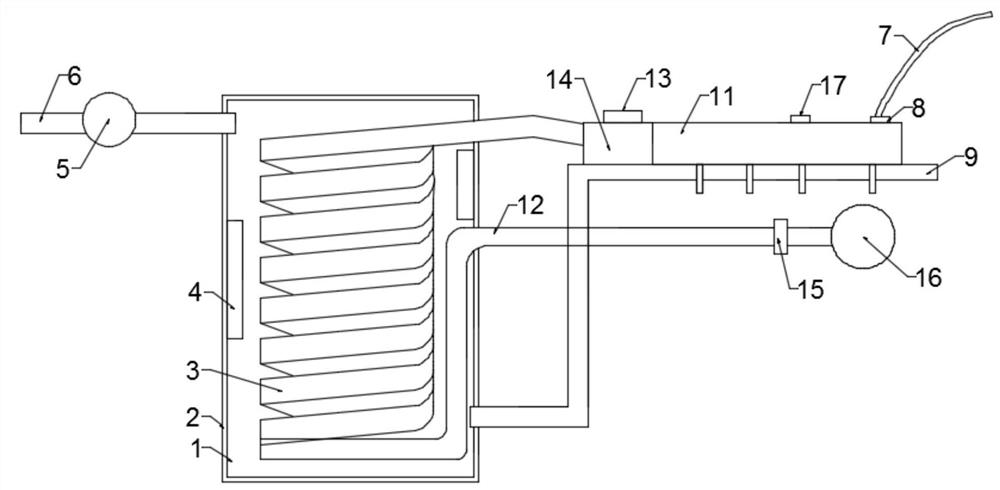

Regeneration processing device for waste lubricant oil

ActiveCN101077459AConstant heating temperatureMaximize evaporation areaDistillation separationLubricant compositionSlagSprayer

The waste lubricating oil regenerating apparatus is one evaporator, which has one outer casing, one inner container with one combined rotating body, one distilling tower, one heating sandwich with oil inlet and oil outlet, one central rotation shaft with oil hole mounted through bearing on the bottom of the inner container, one oil pipe connected to the oil outlet in the bottom of the evaporator, one scraper mounted on the central shaft and fitting the inner wall of the inner container, one sprayer in the upper part of the scraper and communicated with the oil path of the central shaft, one heater in the lower part of the evaporator, one slag draining port in the bottom of the evaporator, and one motor to drive the central shaft. The present invention has constant temperature heating, great evaporating area, less cracking of the lubricating oil and high heat efficiency.

Owner:XINJIANG FUKE OIL PROD CO LTD

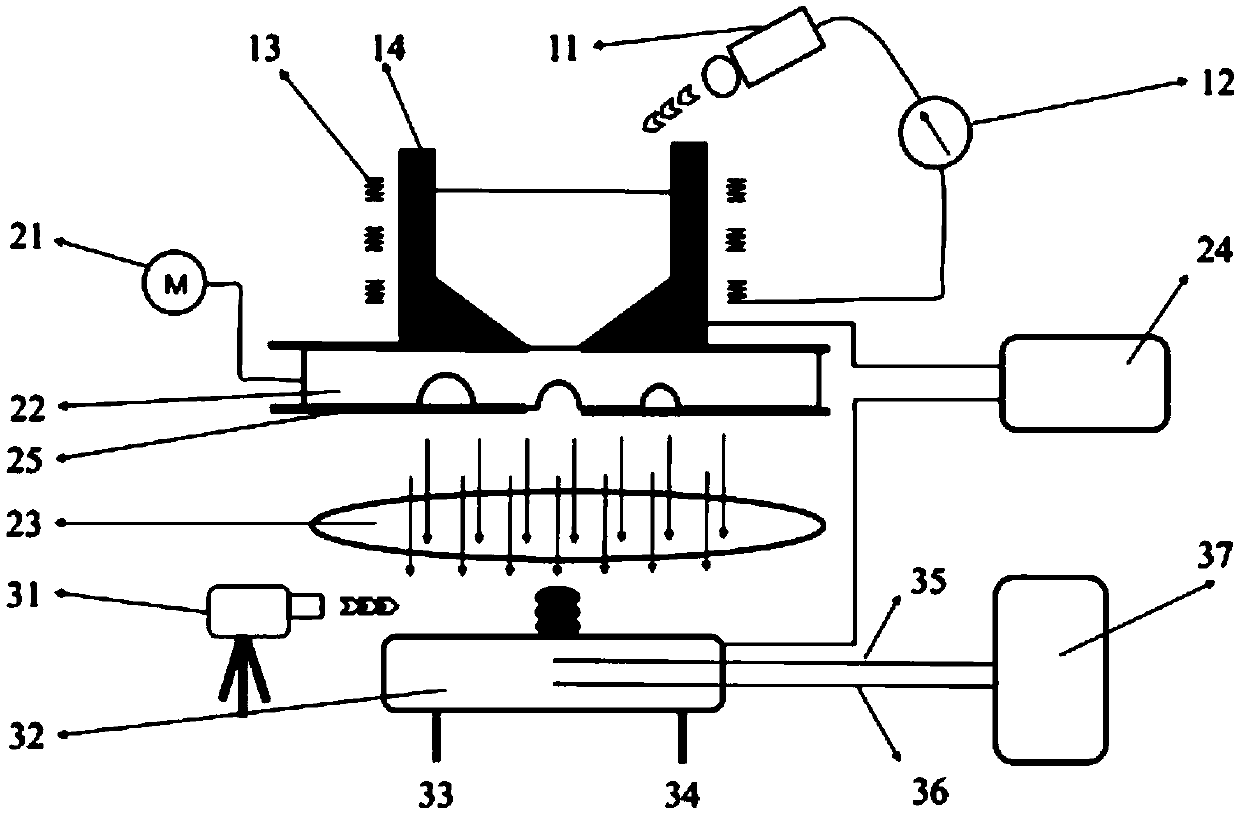

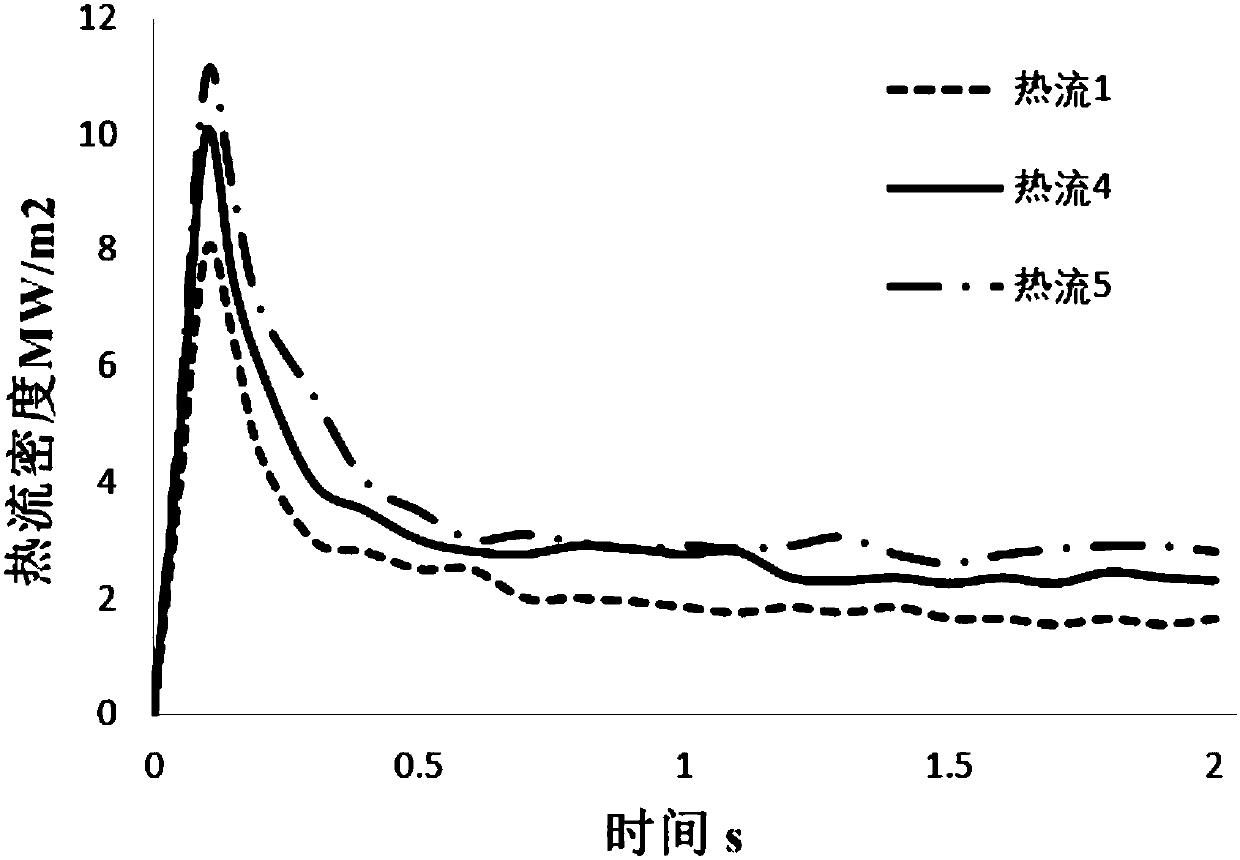

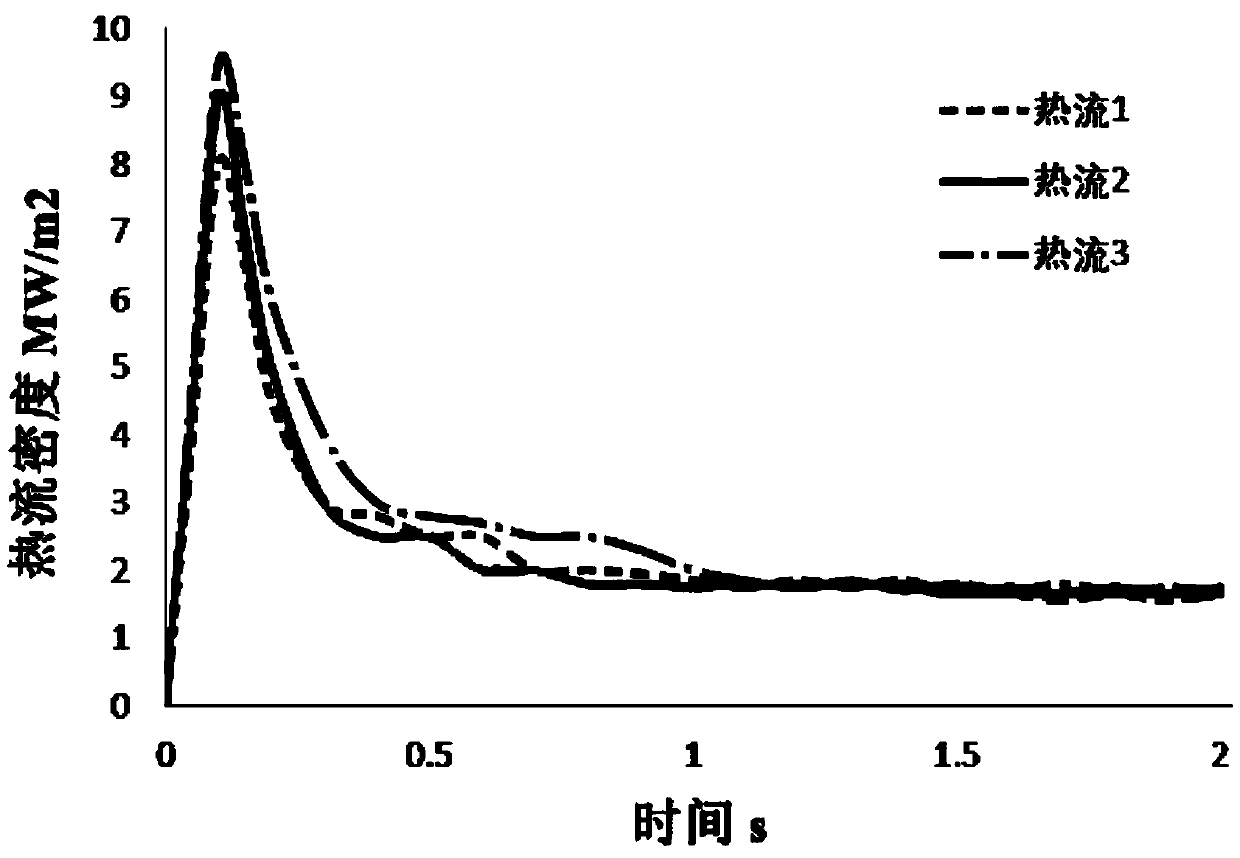

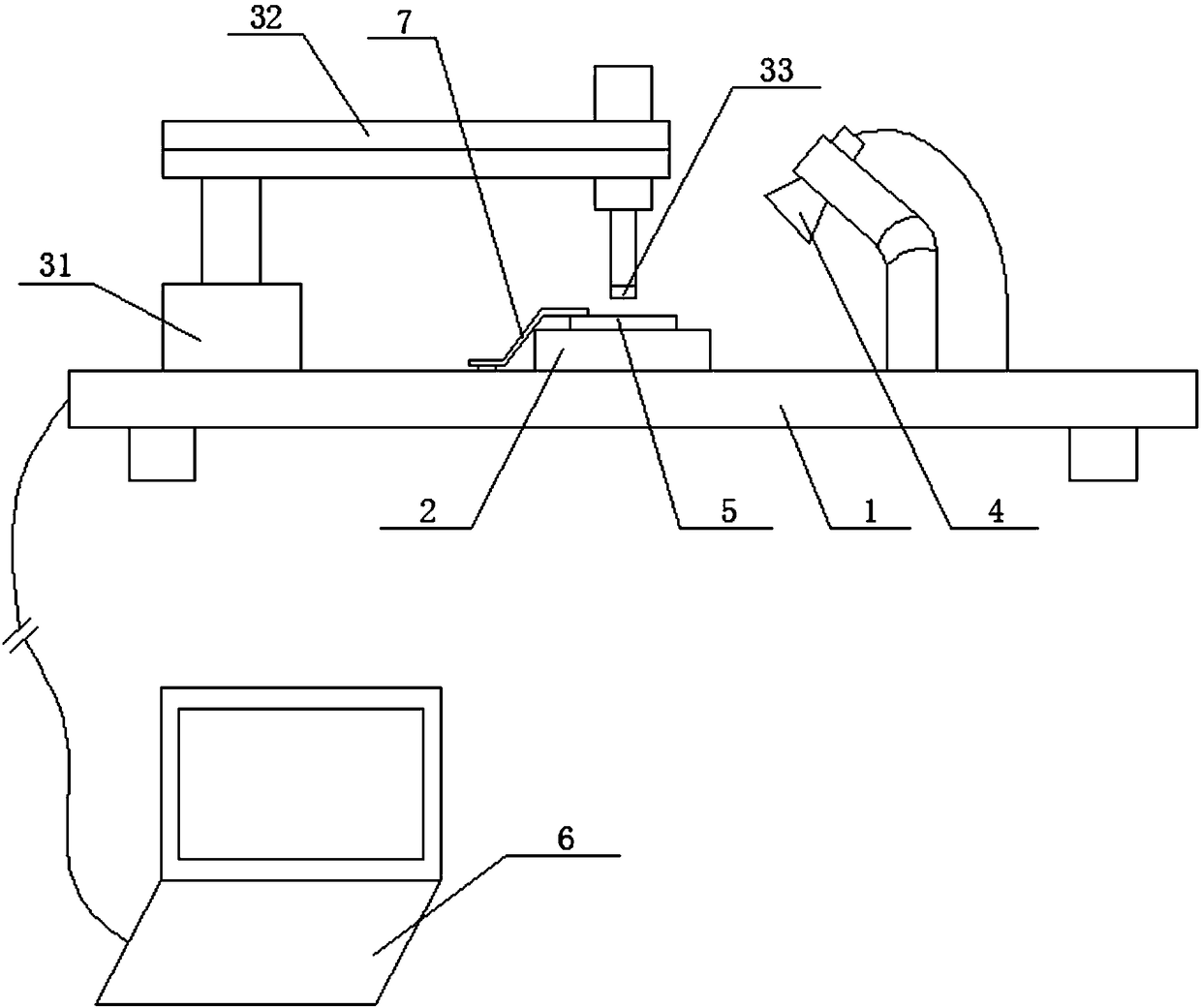

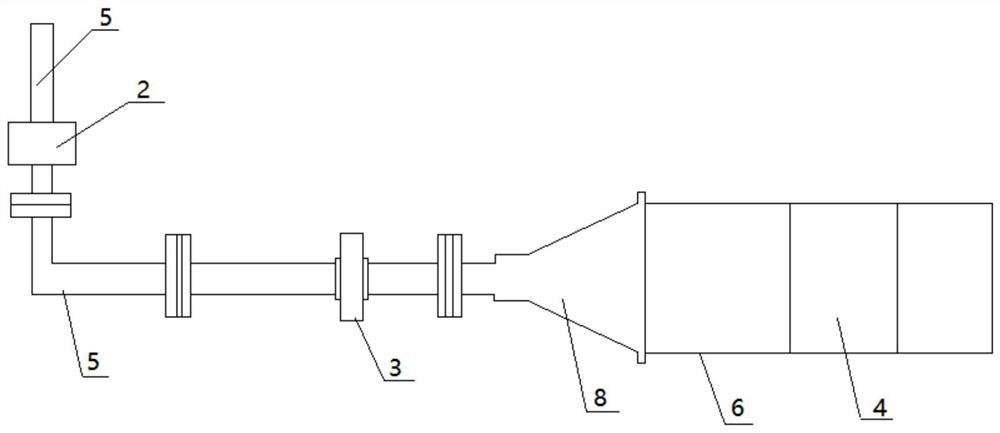

Comprehensive test device and method for rapid solidification heat transfer performance

ActiveCN107643316ADrop speed controlConstant heating temperatureMaterial heat developmentData acquisitionMetal droplets

The invention discloses a comprehensive test device and method for rapid solidification heat transfer performance. The comprehensive test device comprises a metal smelting system, a particle size andspeed control system and a sample collection and measurement system; the metal smelting system comprises a graphite crucible and an infrared thermometer with temperature feedback and is used for heating a metal test sample into liquid; the particle size and speed control system comprises a particle size selector used for controlling dropping size of molten metal droplets and a static electric field used for controlling dropping speed of the molten metal droplets; the sample collection and measurement system comprises a cooling base, a high-speed camera, a thermocouple and a computer and is used for bearing and cooling the metal droplets dropped from the metal smelting system and acquiring data. By the arrangement, low cost and less consumption of materials are achieved, the test method issimple in operation, test results are accurate, initial solidification conditions of the metal droplets in different dropping states (dropping size and dropping speed) can be tested comprehensively, the entire rapid solidification process can be reflected clearly, and high persuasion is achieved.

Owner:CENT SOUTH UNIV

Method for cryogenic cooling of an NMR detection system with the assistance of a container filled with a cryogenic fluid

ActiveUS20140283530A1Constant heating temperatureMinimize signalingFluid transferredMachines using refrigerant evaporationCatheterProcess engineering

A method for the transmission / reception of RF signals for NMR measurements uses a heat exchanger (1) for cooling heat sources (5), the heat exchanger having a contact element (4.2) for thermal connection between a cryogenic fluid and the heat source, is characterized in that the heat exchanger comprises a container having an interior volume V.sub.B into which a first cryogenic fluid F.sub.1 that has a liquid component F.sub.1L and a gaseous component F.sub.1G flows through an inflow conduit (8) and from which a second cryogenic fluid F.sub.2 that has liquid component F.sub.2L and a gaseous component F.sub.2G flows out through an outflow conduit (9). The inflow conduit has a flow cross-section Q.sub.Z and a circumference U.sub.Z from which an associated parameter V.sub.Z=4Q.sup.2.sub.Z / U.sub.Z results, wherein V.sub.B>10V.sub.Z, and the outflow conduit has a flow diameter Q.sub.A wherein Q.sub.A.gtoreq.Q.sub.Z. The contact element is in close thermal contact with both the liquid volume component V.sub.L of the cryogenic fluid and with the heat source. A device for setting the inflow quantity of the first cryogenic fluid F.sub.1 into the container is provided that ensures a state F.sub.1L / F.sub.1G>F.sub.2L / F.sub.2G during operation. In this way, vibrations due to the cooling process can be largely reduced and the consumption of cryogenic fluid minimized.

Owner:BRUKER SWITZERLAND AG

Induction cooker overflow protection device based on thermal expansion and cold contraction of gas

InactiveCN111473370ASensitive to waterControl open and close stateDomestic stoves or rangesLighting and heating apparatusThermodynamicsWater flow

An induction cooker overflow protection device based on thermal expansion and cold contraction of gas relates to the technical field of household appliances. The device comprises a cooker body, wherein a heating device is fixedly connected to the middle of the cooker body, electric heating blocks are fixedly connected to the inner bottom walls of two sides of the cooker body, resistors electrically connected with the electric heating blocks are fixedly connected to the inner walls of two sides of the cooker body, and the inner wall of the cooker body is fixedly connected with negative plates electrically connected with the resistors. According to the induction cooker overflow protection device based on thermal expansion and cold contraction of gas, through cooperative use of the electric heating blocks and electric contacts, when water exists on the upper surface of the induction cooker, the water flows into a water collecting tank, the two electric contacts are electrically connectedat the moment, a circuit of the electric heating blocks is connected, and the electric heating blocks heat compressed gas, so that the compressed gas expands and moves piston blocks upwards, and the electric heating blocks stop heating until conductive blocks are not electrically connected with conductive plates, so that the effect of thermal expansion of gas is achieved, the induction cooker is more sensitive to water, and meanwhile, excessive expansion of compressed gas is prevented.

Owner:杭州勤语机械租赁有限公司

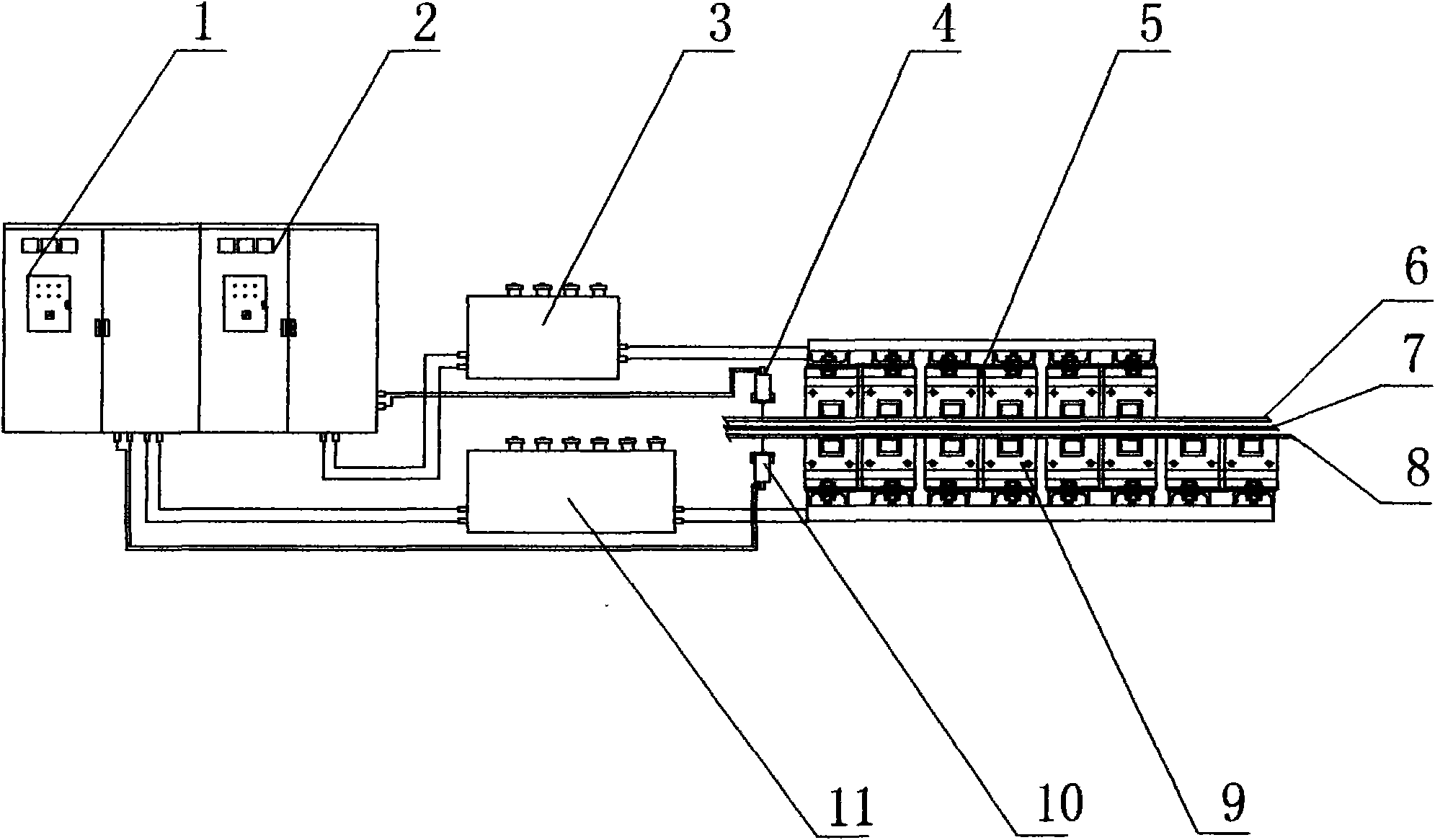

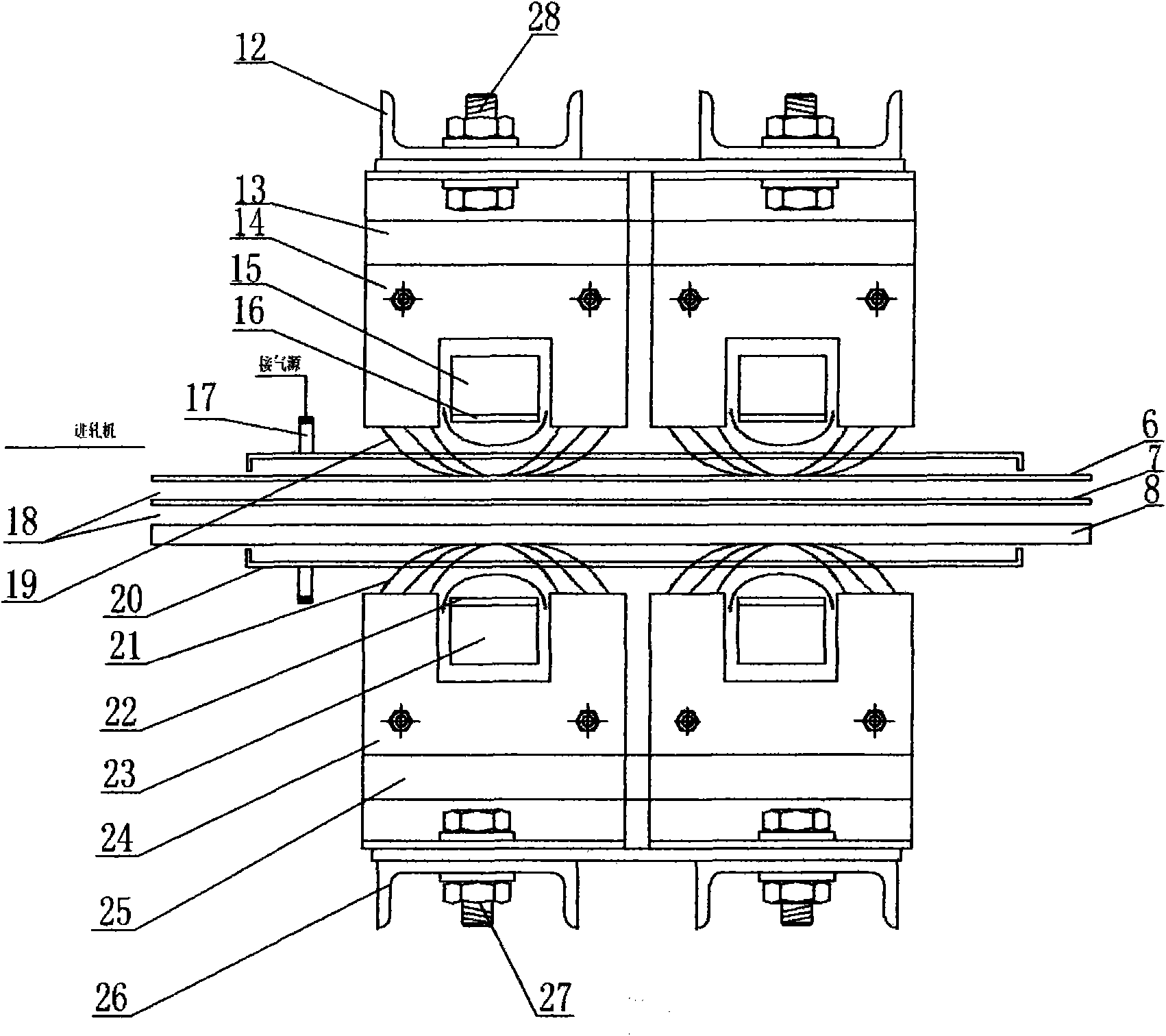

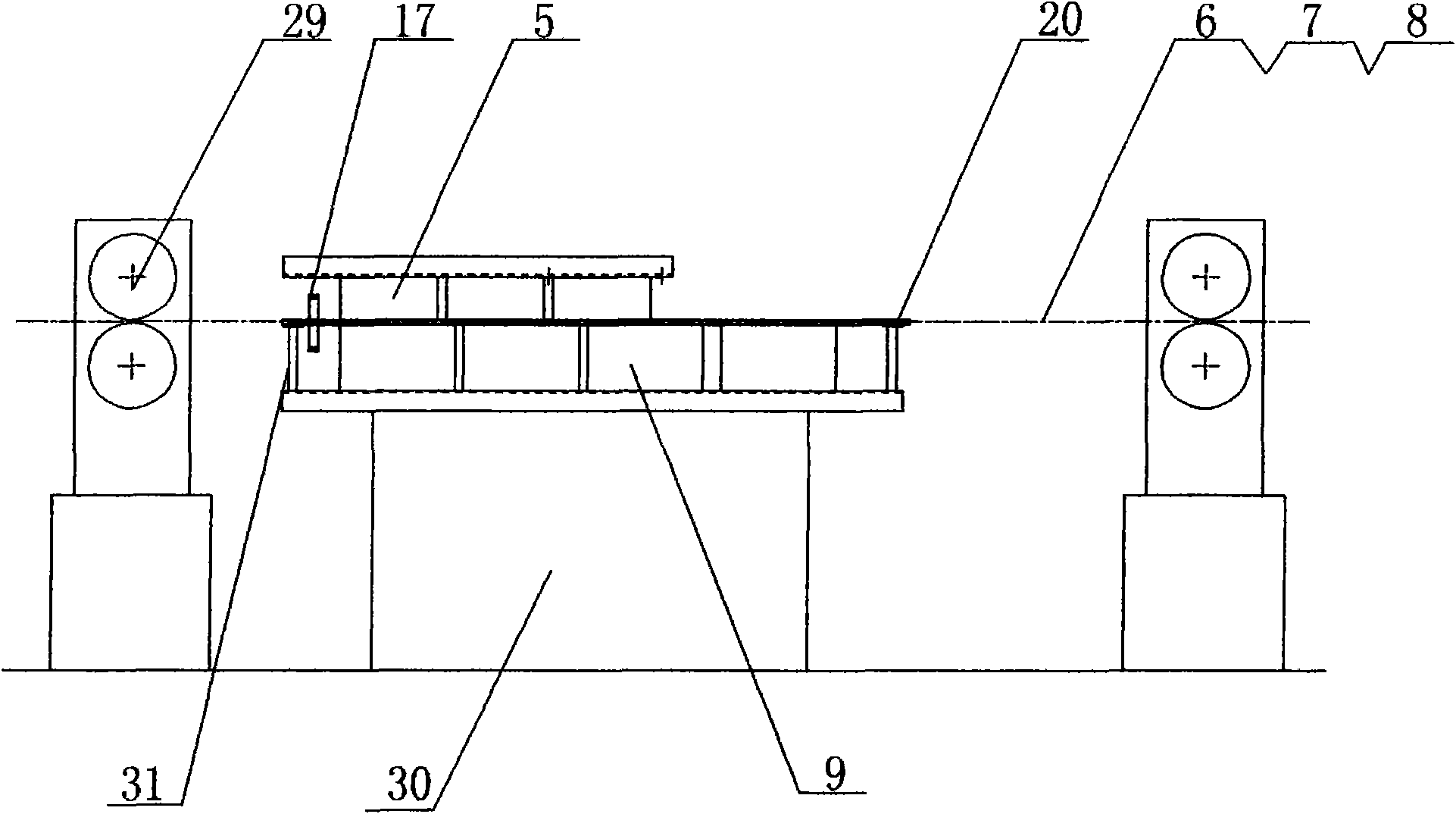

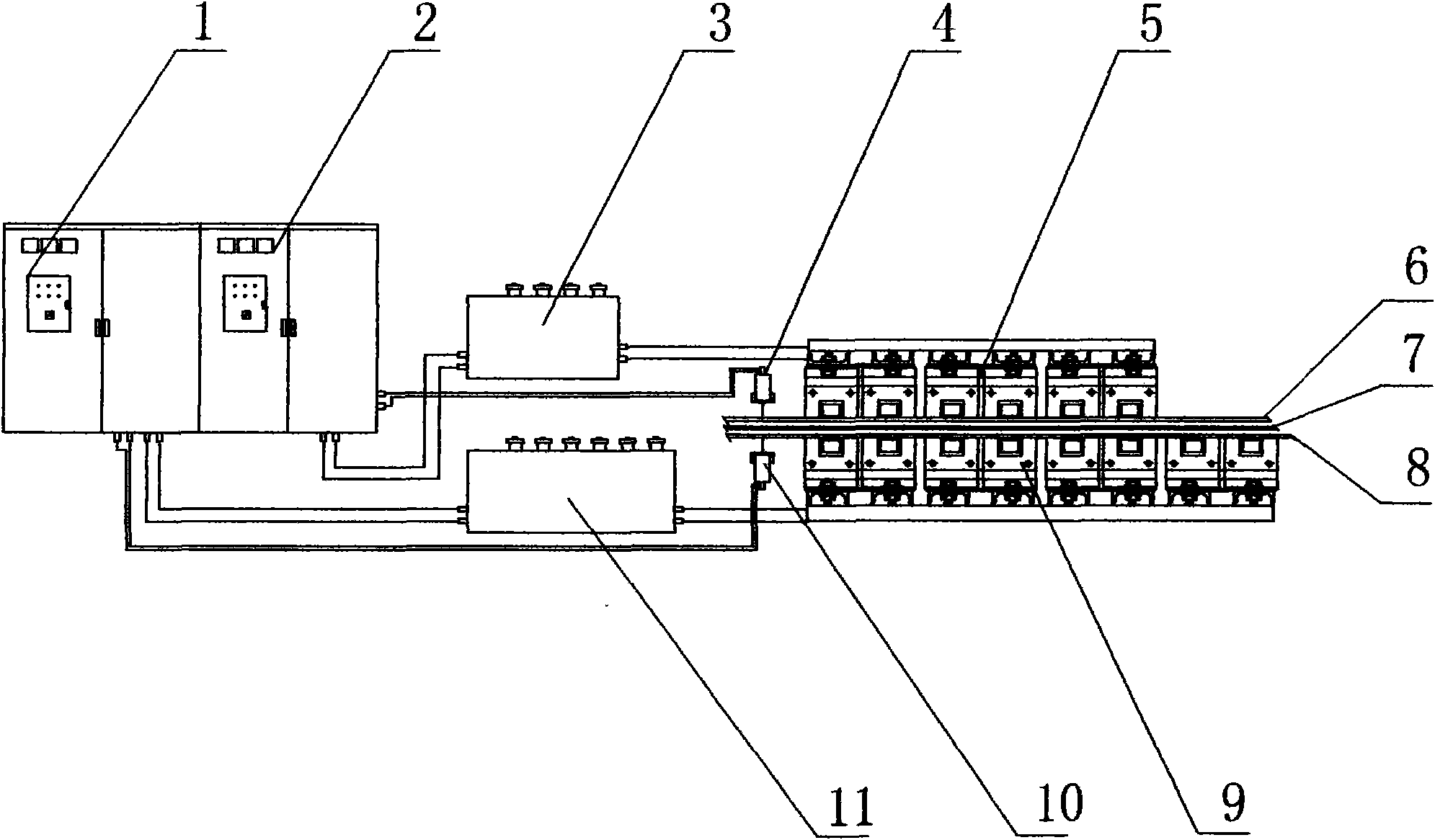

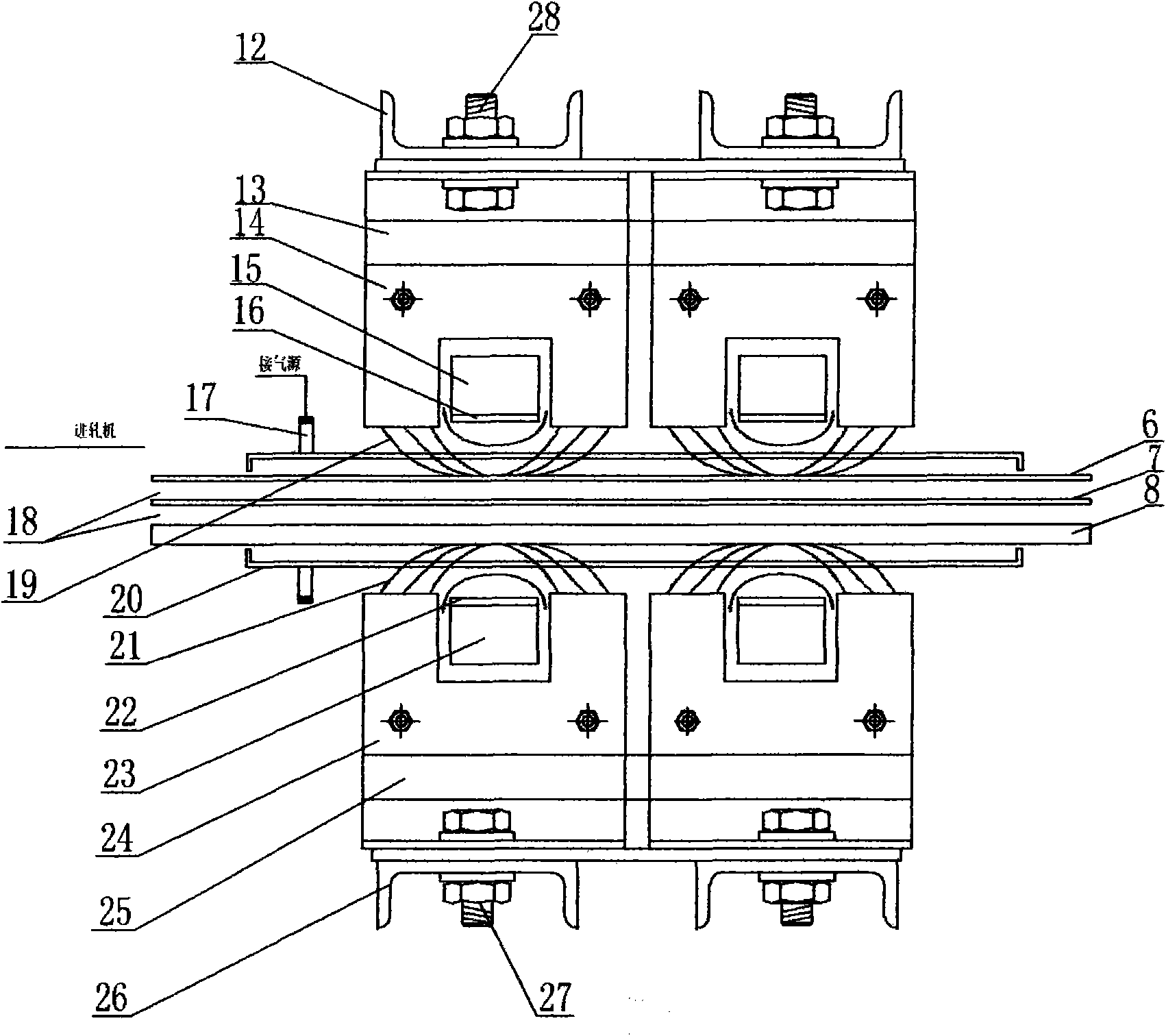

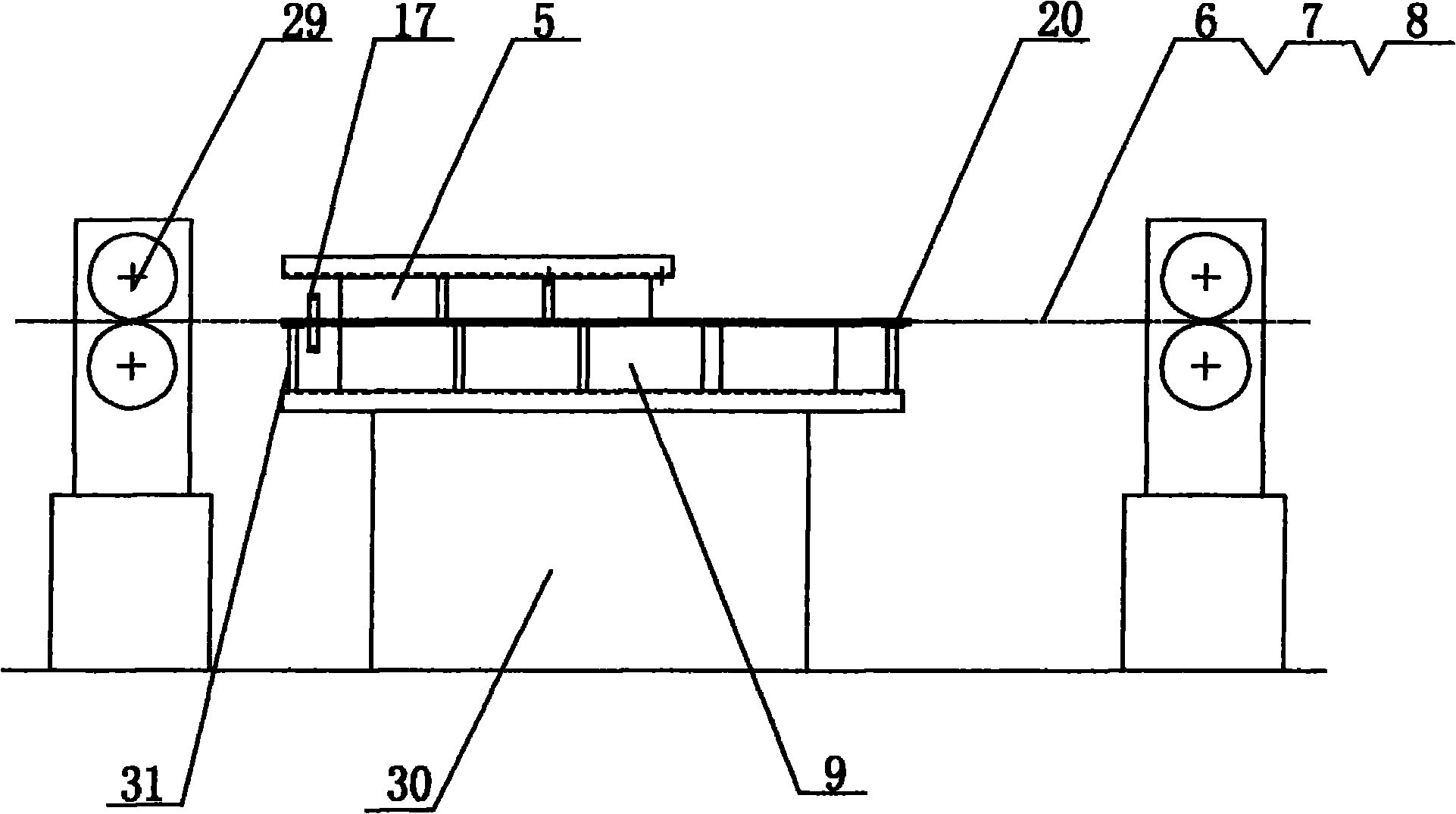

Equipment for manufacturing stainless steel clad plates by low temperature induction heating

InactiveCN101983001AHigh temperature control accuracyLower working temperatureInduction heating controlInduction heating apparatusCapacitanceWorking temperature

Equipment for manufacturing stainless steel clad plates by low temperature induction heating is used for carrying out medium frequency induction heating and welding on the composite materials before continuous rolling and forming. The equipment is characterized in that a medium frequency power supply heating control system is connected with induction heaters by a medium frequency capacitance compensator and the medium frequency alternating current power generated by the medium frequency power supply heating control system is input to the medium frequency capacitance compensator and the induction heaters to form resonance; heavy alternating current is generated on the induction heaters; a surface layer and base metal are heated through eddy effect; and a bonding layer receives the heat from the surface layer and the base metal and is melted; and then the surface layer, the base metal and the bonding layer are fit under inert atmosphere and enter into a rolling mill to be rolled into the clad plates. The equipment has the following advantages: the equipment utilizes the induction heating technology to carry out continuous contactless heating on large format metal, thus ensuring hightemperature control precision, low working temperature and low unit energy consumption and effectively saving energy; the thermodetector and the medium frequency power supply heating control system ensure the heating temperature of the metal layer to be constant, thus ensuring the surface of the metal layer to be uniformly heated; and the inert gas protection cavity structure can avoid surface oxidation of the metal layer in the heating process, thus greatly lowering the production cost.

Owner:湖北一新世科电气有限公司

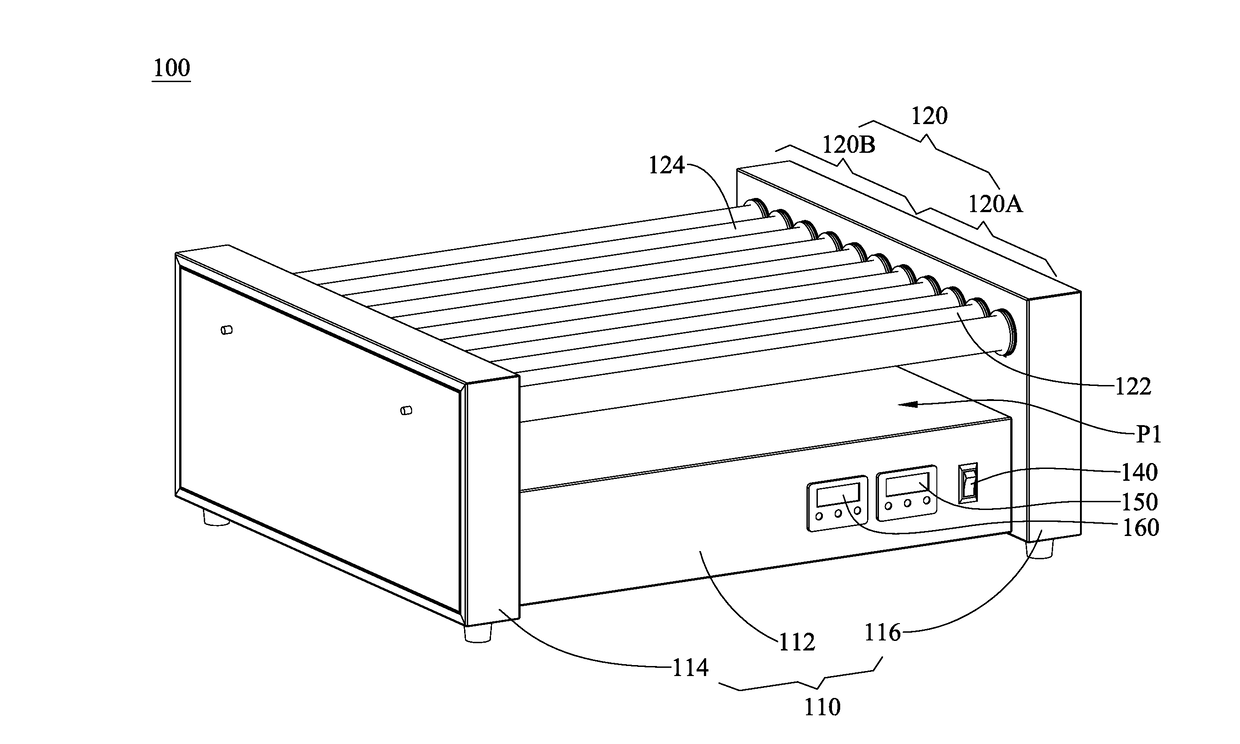

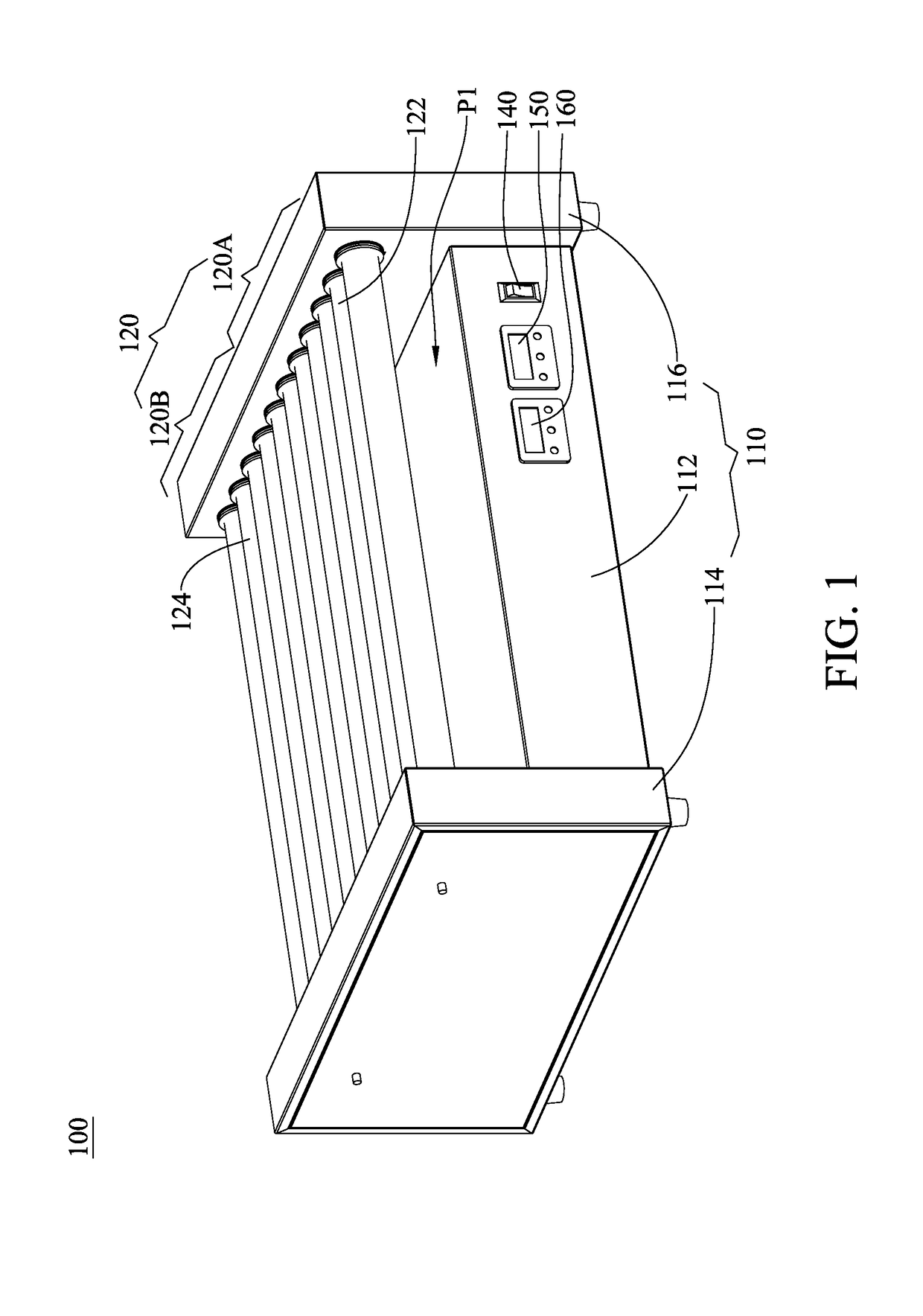

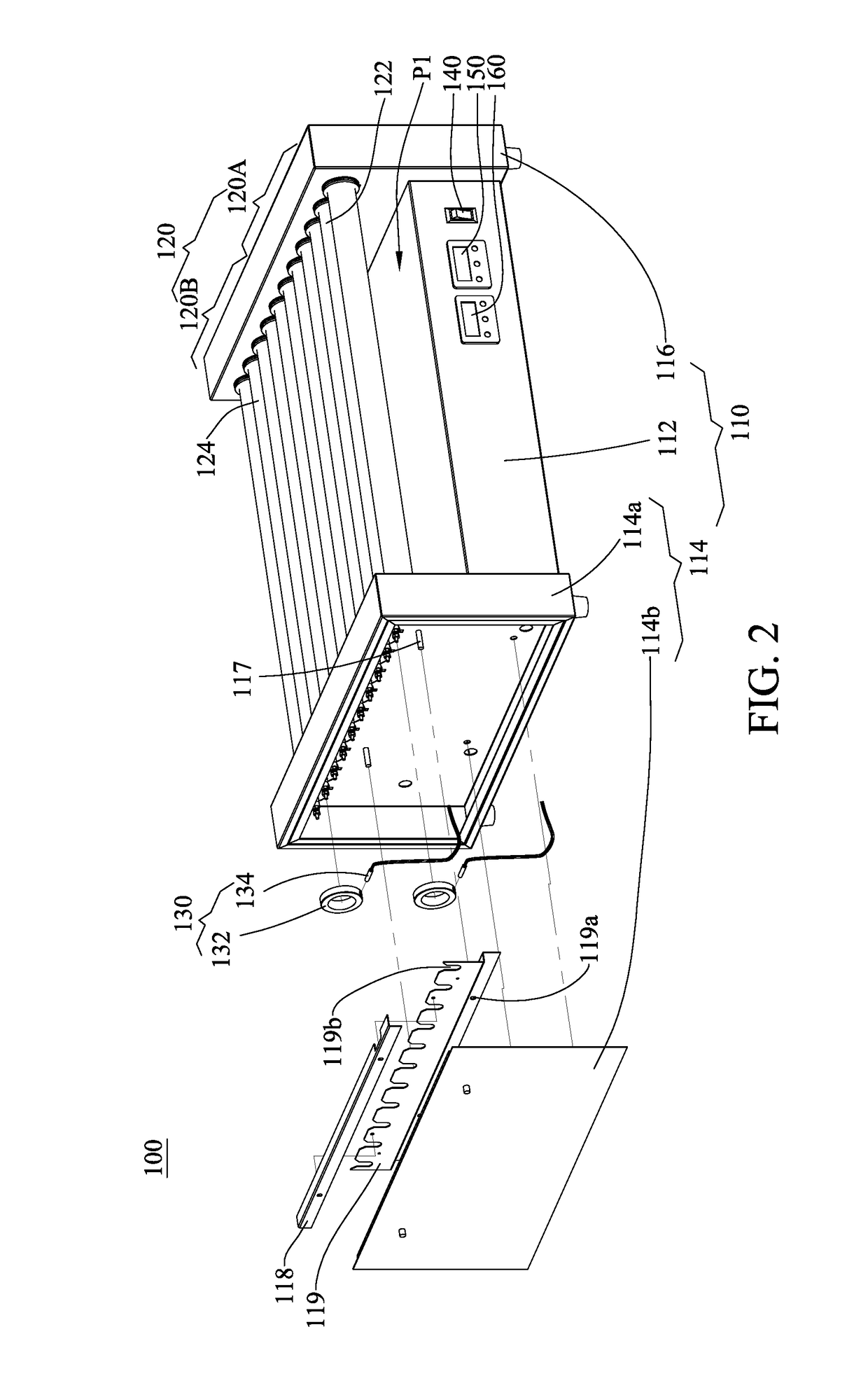

Hot dog roller grill

InactiveUS20170265681A1Constant heating temperaturePreventing situationRoasting apparatusEngineeringMechanical engineering

A hot dog roller grill includes a machine body, a plurality of heating rollers and a plurality of temperature-sensing assemblies. The heating rollers are rotationally pivotally mounted to the machine body. Each of the temperature-sensing assemblies is mounted to one end of a specific heating roller.

Owner:ROUND SHINE INDUSTRAIL

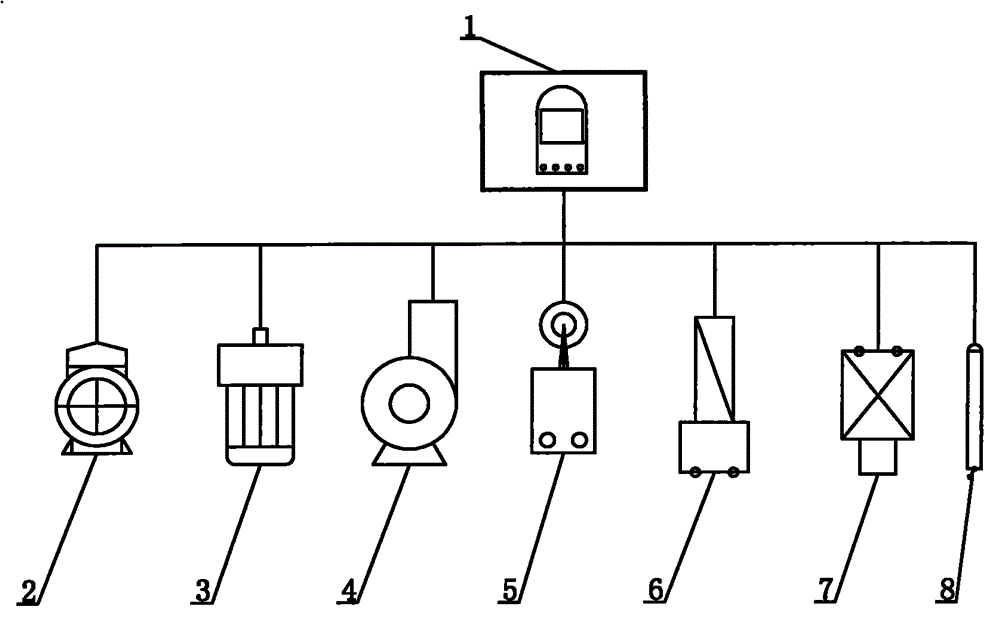

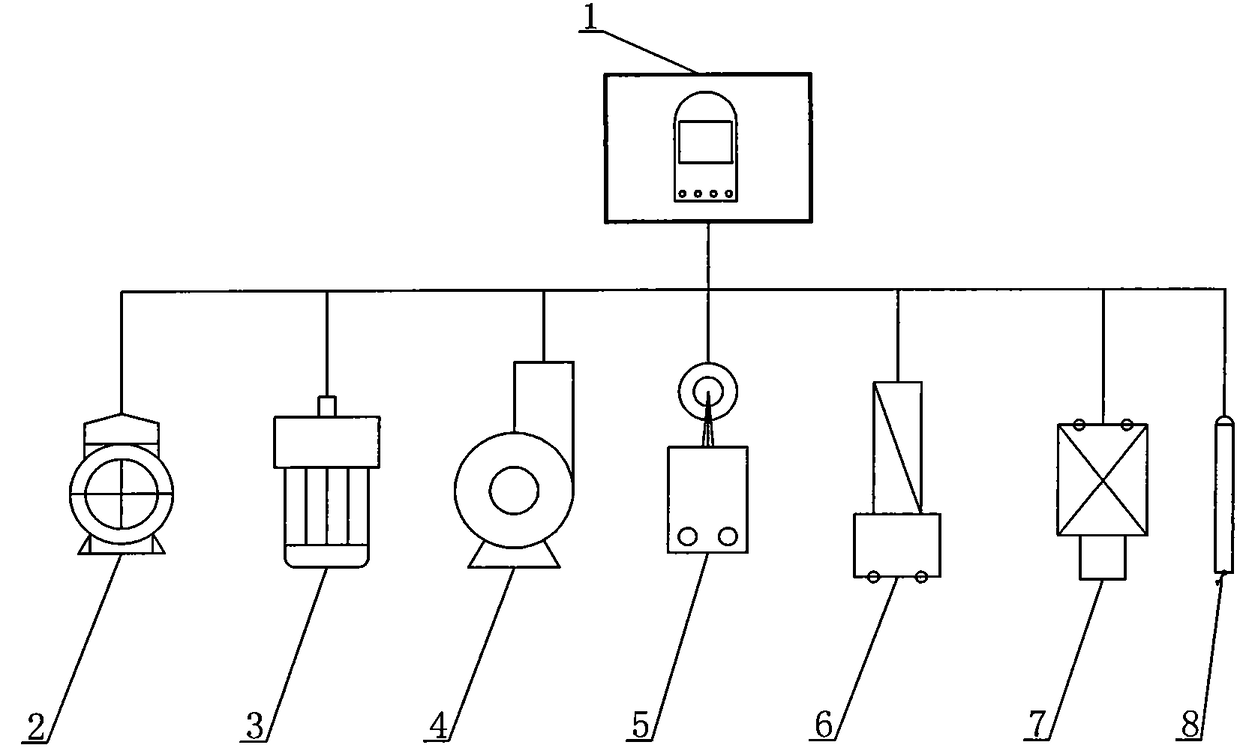

Intelligent control system for biomass particle heating water heater

InactiveCN104913507AEasy to operateConstant heating temperatureFluid heatersEngineeringHeating temperature

An intelligent control system for a biomass particle heating water heater comprises an electric controller, and further comprises a stepping motor, a limiting switch, a direct current fan, an ignition needle, a water pump, a temperature sensor and a pressure switch. The stepping motor is used for conveying biomass particle fuel, the limiting switch is used for detecting the remaining amount of the biomass particle fuel, the direct current fan is used for providing air needed when biomass particles are combusted, the ignition needle is used for igniting the biomass particle fuel, the water pump is used for providing kinetic energy for a heat exchange circulating water way so that the heating water heater can supply heat outwards, the temperature sensor is used for detecting the water temperature of the heat circulating water way, the pressure switch is used for detecting the water pressure inside a heat circulating water way pipeline, and the electric controller is connected with the stepping motor, the limiting switch, the direct current fan, the ignition needle, the water pump, the temperature sensor and the pressure switch and controls working of the stepping motor, the limiting switch, the direct current fan, the ignition needle, the water pump, the temperature sensor and the pressure switch. The intelligent control system can keep the heating temperature constant by automatically adjusting the combustion heat power, meets the requirement for the comfortable heating environment, and has the intelligent functions of automatically giving an alarm when fuel is used up, achieving excessively-high water pressure protection, achieving startup and shutdown intelligently and the like, and the water heater is easy and convenient to operate, safe and comfortable.

Owner:佛山市顺德区旭政实业有限公司

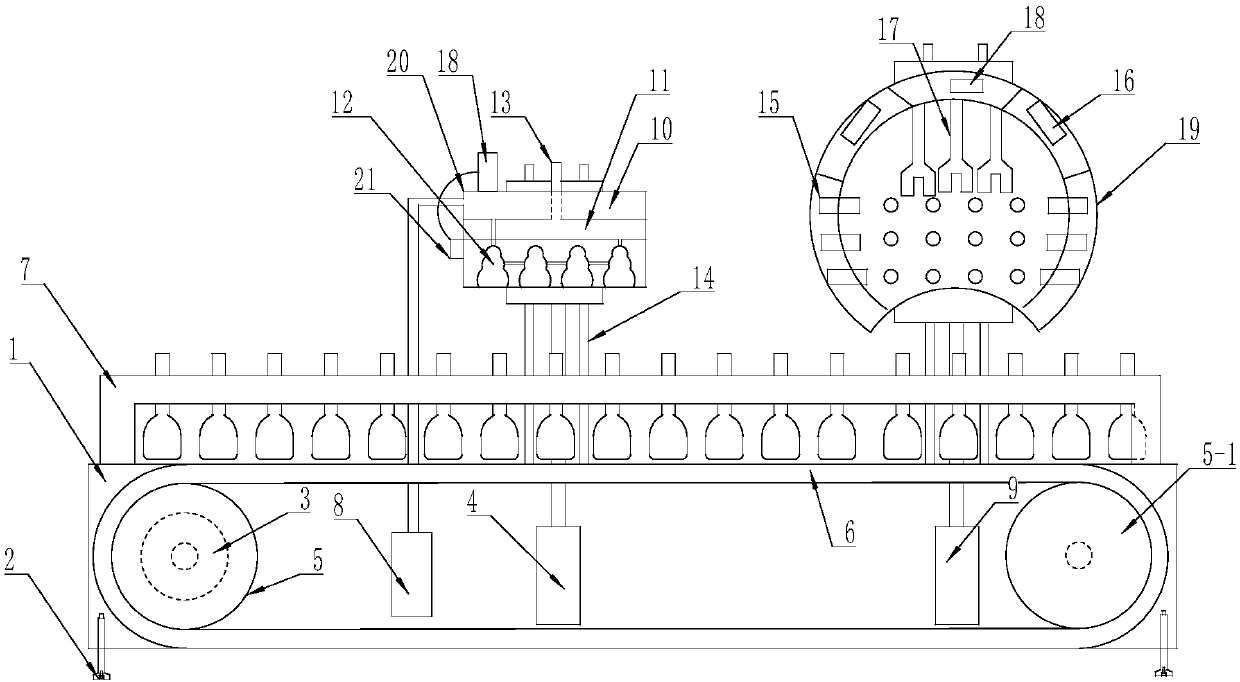

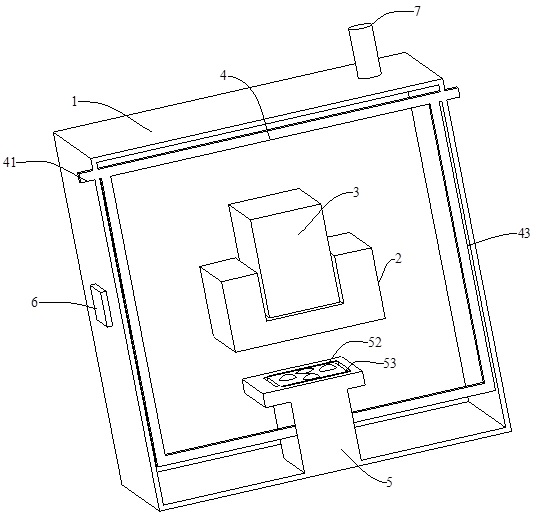

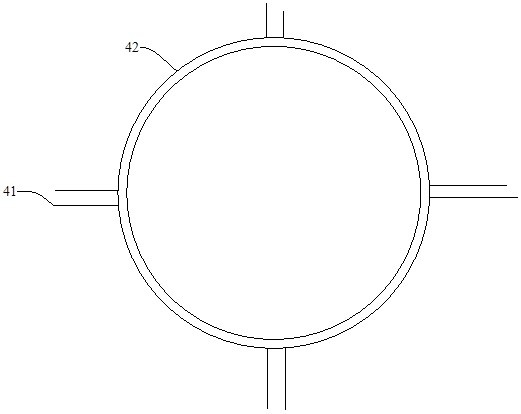

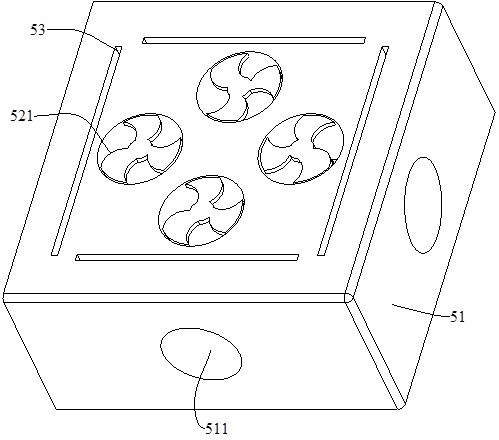

Operation method of ampoule laser wire drawing filling and sealing machine

PendingCN107804496AConstant heating temperatureAvoid poor seal qualityLiquid materialGlass productionElectric machineryAmpoule

The invention discloses an operation method of an ampoule laser wire drawing filling and sealing machine. A medicine bottle is placed in a rectangular hole on the top surface of a box; after a motor is started, a piston rod of a first cylinder is shortened to drive a medicine filling mechanism on a left side fixed block to descend; the inner wall of a medicine filling nozzle is correspondingly matched with the outer wall of a bottle mouth of the medicine bottle; a vacuum machine vacuumizes a vacuum cavity and the medicine bottle; the piston rod of the first cylinder of an operation module at the top of the medicine filling mechanism is elongated to drive the medicine filling mechanism on the left side fixed block to ascend to an origin; a piston rod of a second cylinder is shortened to drive a sealing mechanism on a right side fixed block to descend; and an operation module of the sealing mechanism starts a laser head to emit laser to heat the bottle mouth, controls an extension rod ofa clamp to elongate, and controls the piston rod of the second cylinder to elongate to drive the sealing mechanism on the right side fixed block to ascend to the origin, so that the adverse factors of potential safety hazards, environmental pollution, mounting troubles and the like caused by use of flammable and combustible substances in the prior art are prevented.

Owner:洛阳市兽药厂

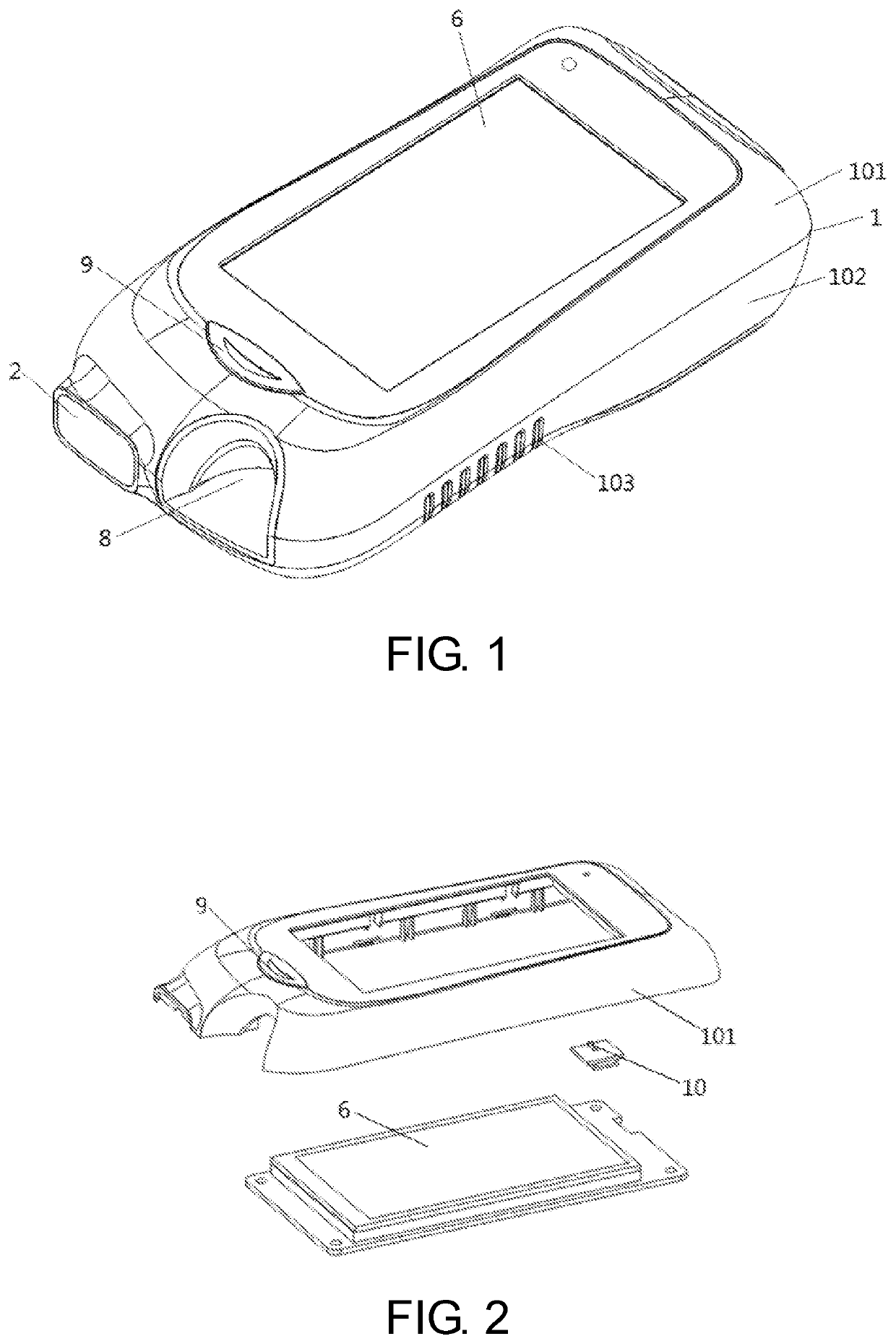

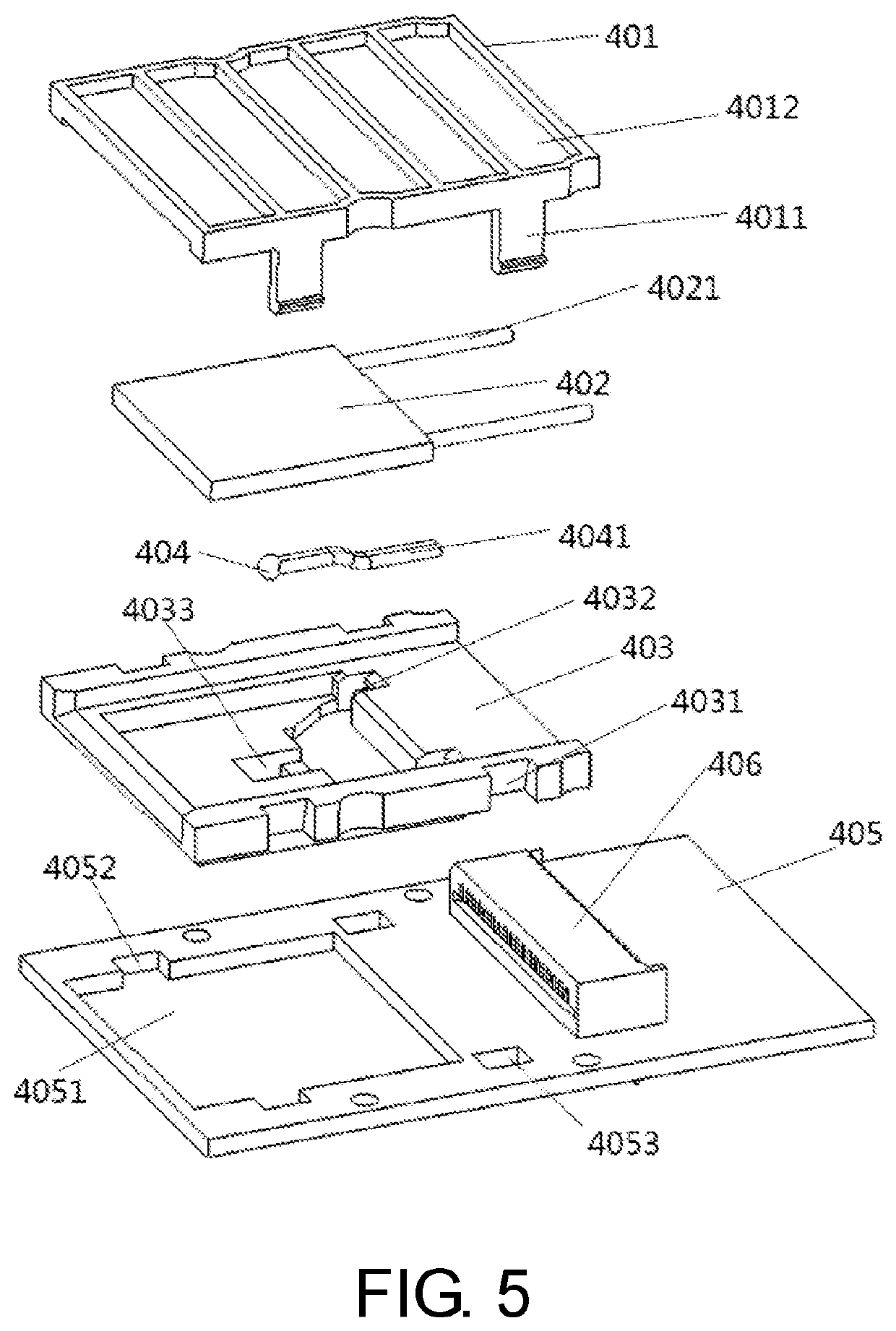

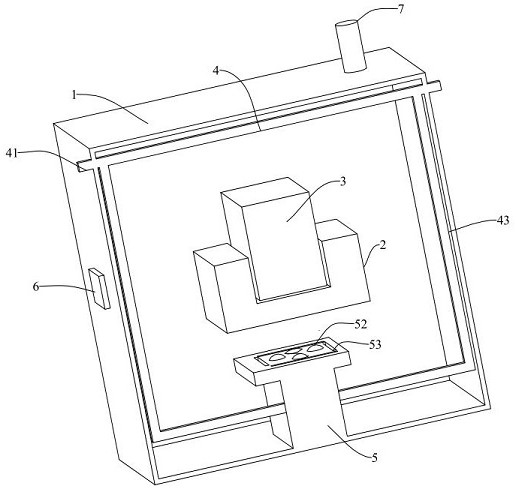

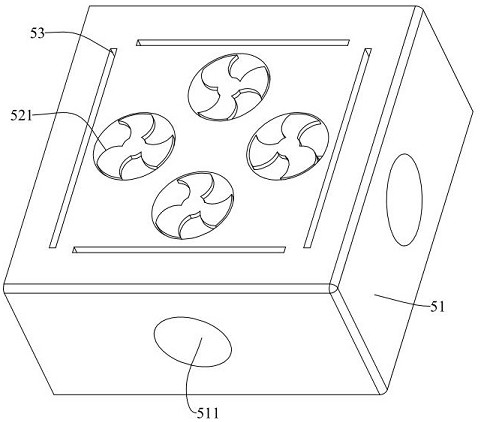

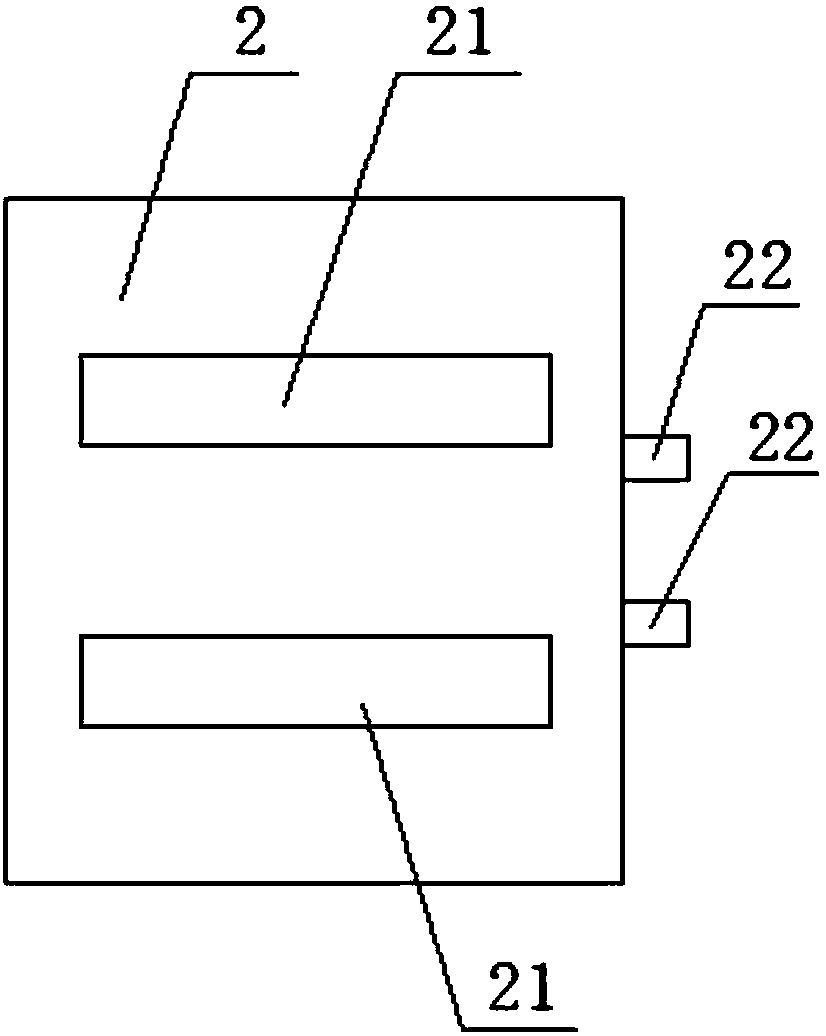

Detection system of multi-index coagulation items

PendingUS20210387183A1Easy injectionSimple structureHeating or cooling apparatusLaboratory glasswaresEngineeringBattery cell

A detection system for multi-index coagulation items, including a housing, a detection and heating module, a battery module, a touch display screen and a mainboard. The housing includes an upper housing and a lower housing, and is an enclosed space formed by the upper housing abutting the lower housing; the mainboard is disposed between the upper and the lower housing, and is arranged in the enclosed space; the touch display screen is disposed at the upper surface of upper housing, and is connected with the mainboard; the detection and heating module is disposed in the enclosed space, and is arranged at the front end of lower housing for connecting with the mainboard; the battery module is arranged at the bottom of terminal of lower housing, and is connected with the mainboard; and a detection inlet for inserting and placing a detection card is disposed at the front end of housing.

Owner:NANJING LANSION BIOTECH CO LTD

A sintering furnace for sintering silicon nitride ceramics and its working method

ActiveCN112393583BContinuous and even heatingReduce recrystallizationMuffle furnacesCharge treatment typeCeramic sinteringCrucible

Owner:宁波银瓷新材料有限公司

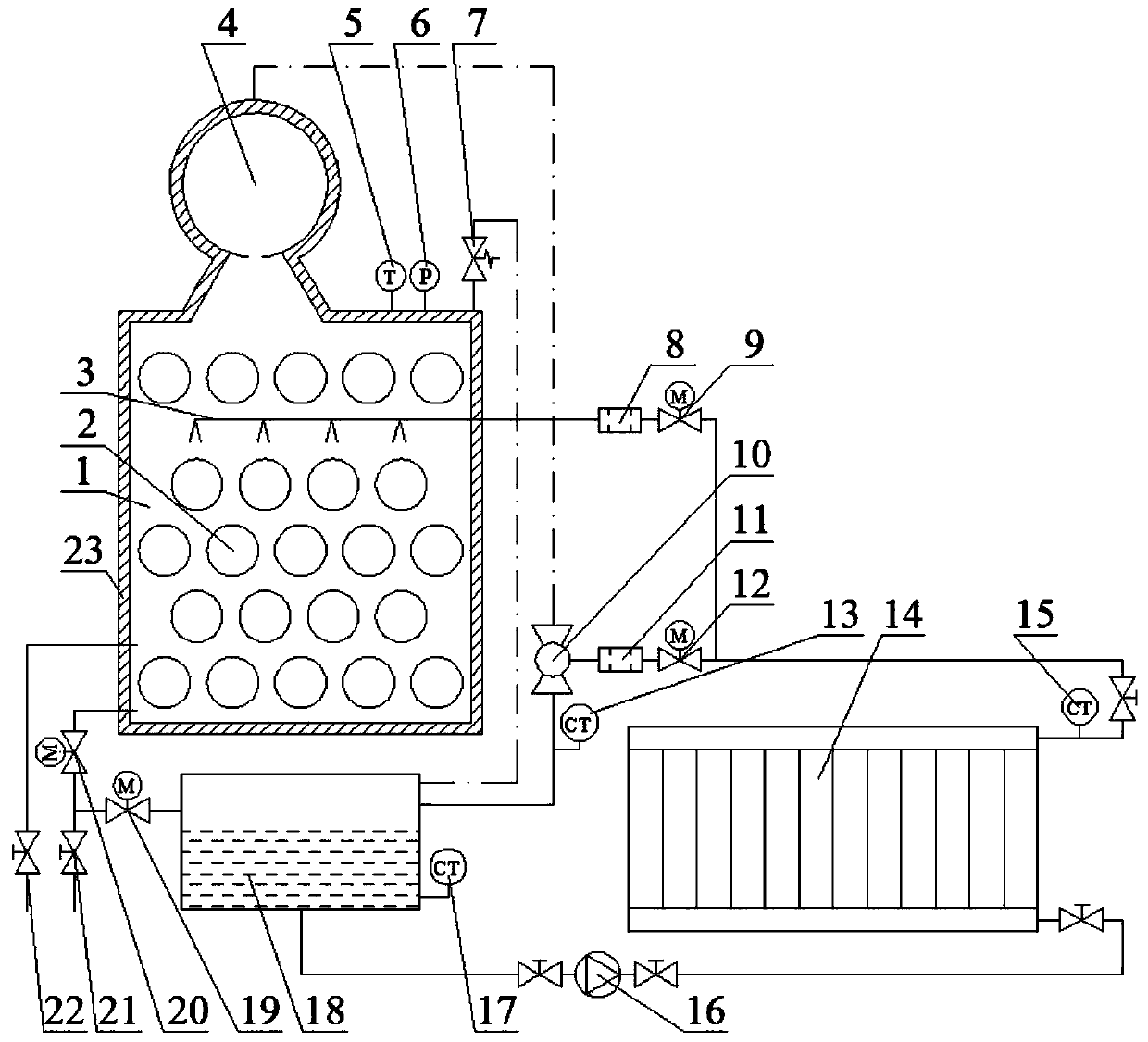

Off-peak electricity heat storage house type heating system

ActiveCN110173749AConstant heating temperatureHeating fuelElectric heating systemElectricityHeat storage material

The invention discloses an off-peak electricity heat storage house type heating system. A heat storage and release unit and a water spray device are installed inside a heat exchange water tank. A steam header is installed on the top of the heat exchange water tank. An outlet of the steam header is connected with a steam and water mixer, a constant-temperature water tank, a variable-frequency watersupply pump and a radiator in sequence. An outlet of the radiator is divided into two paths. One path of the outlet of the radiator is connected with a first electric control valve, and the other path of the outlet of the radiator is connected with a second electric control valve. The first electric control valve is connected with a first flow sensor and the water spray device in sequence. The second electric control valve is connected with a second flow sensor and an inlet on the water side of the steam and water mixer. A water supplement pipe and a drain pipe are further arranged at the bottom of the heat exchange water tank. According to the off-peak electricity heat storage house type heating system, off-peak electricity of low price at night is utilized for heating heat storage materials in the heat storage and release unit, steam and hot water generated due to control over the surface temperature of the heat storage and release unit are mixed with heating return water to form hot water with a certain temperature, the mixed hot water enters the constant-temperature water tank, and a continuous constant-temperature heat source is provided for a user.

Owner:BEIJING UNIV OF TECH

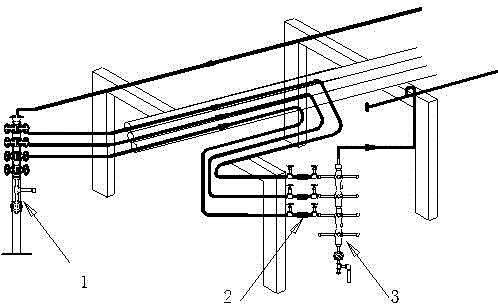

Hot-water tracing solving system

InactiveCN104595613AEasy to installExtended service lifeOperating means/releasing devices for valvesPipe heating/coolingPipingTemperature sense

The invention relates to a hot-water tracing solving system. The hot-water tracing solving system comprises a complete-set component of overall design, overall assembling and overall testing. A core component comprises a water supply pipe bundle, a water returning pipe bundle and a temperature sensing automatic water draining valve. According to the system, all components are designed together, design and mounting cost is reduced, and a centralized positioning component which is compact and easy to dismount, mount and operate is provided.

Owner:和或科技(天津)有限公司

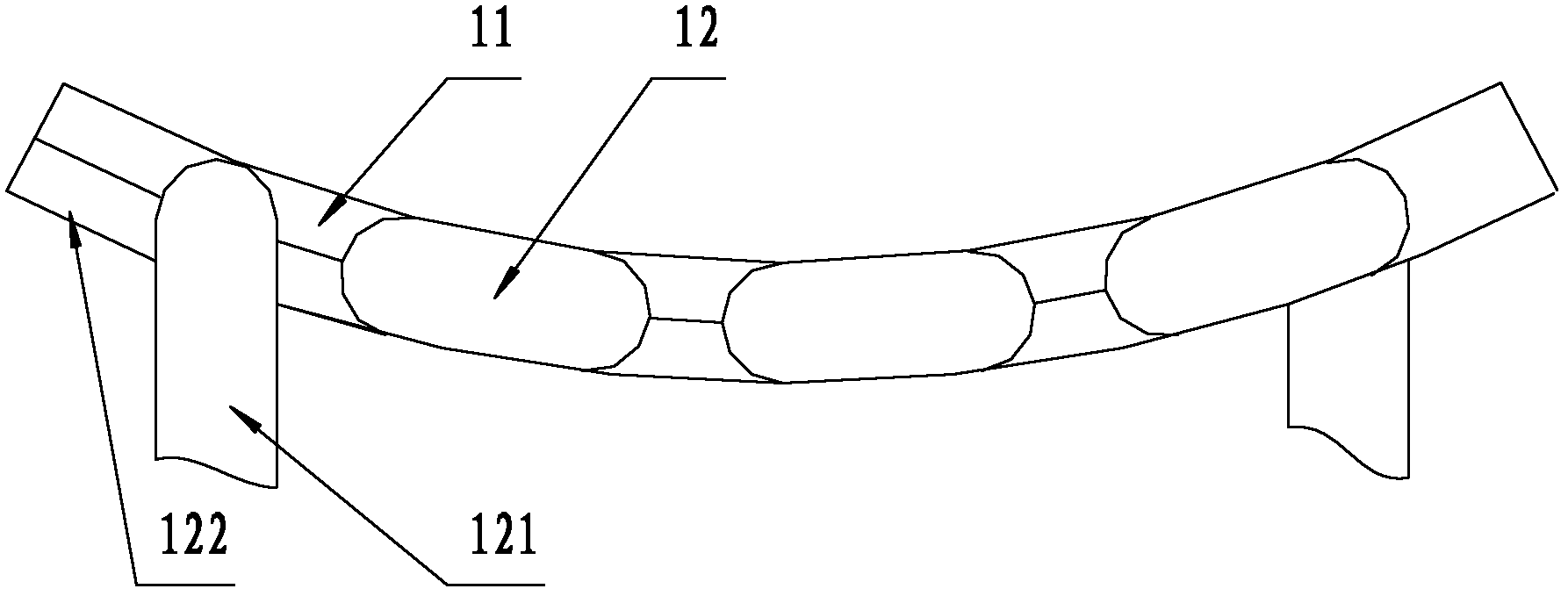

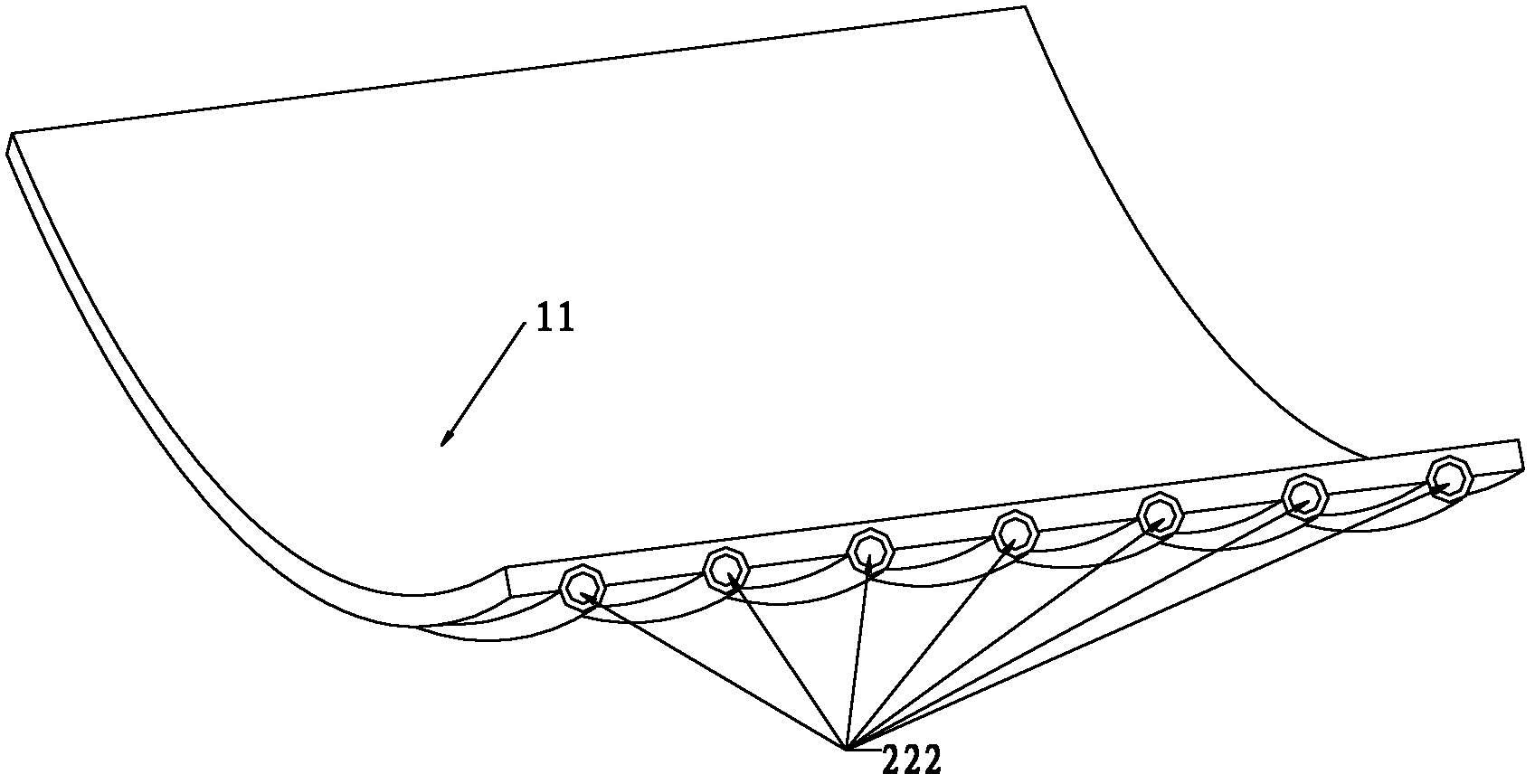

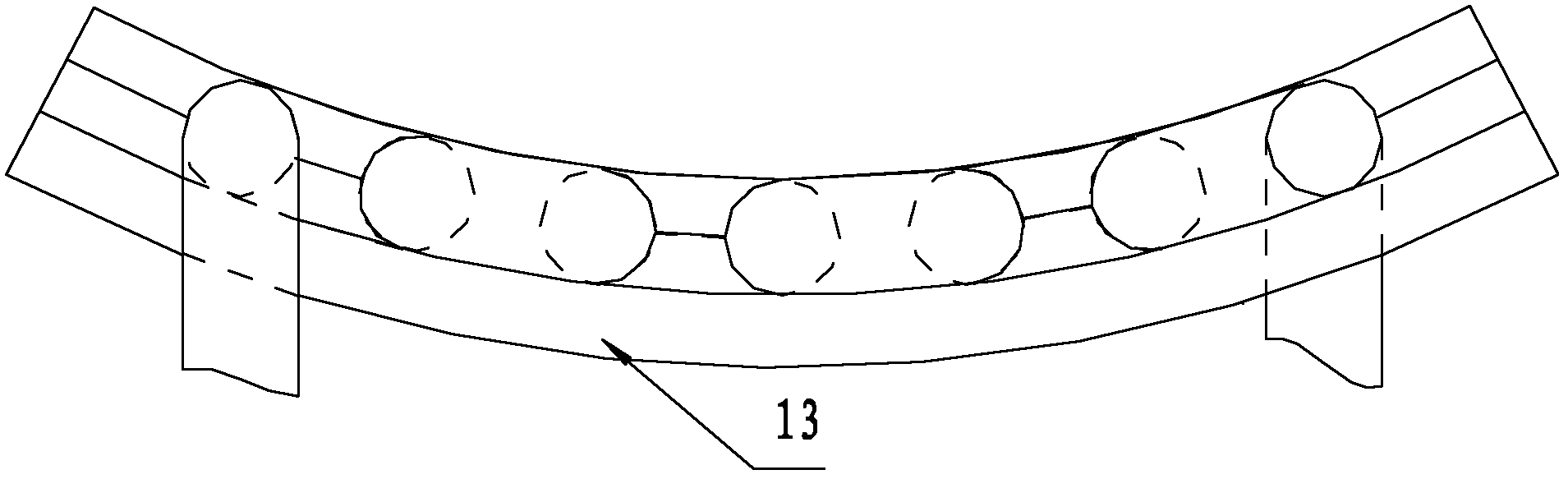

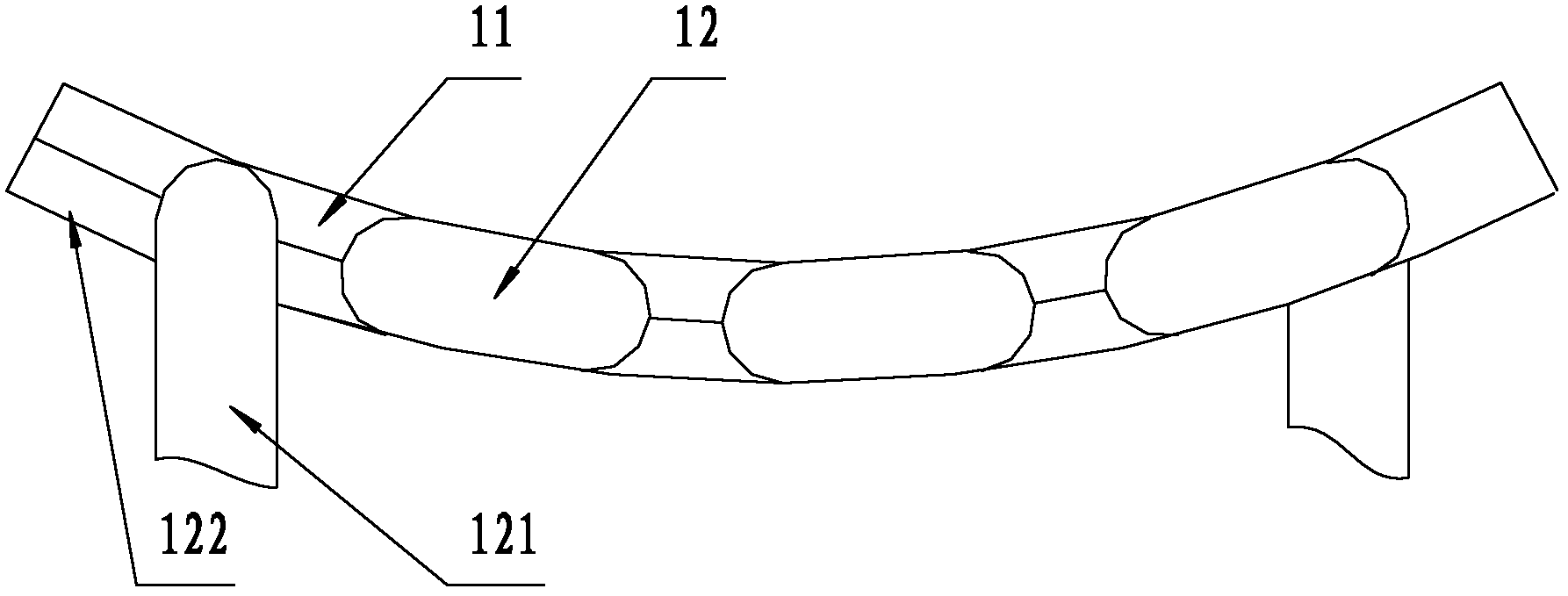

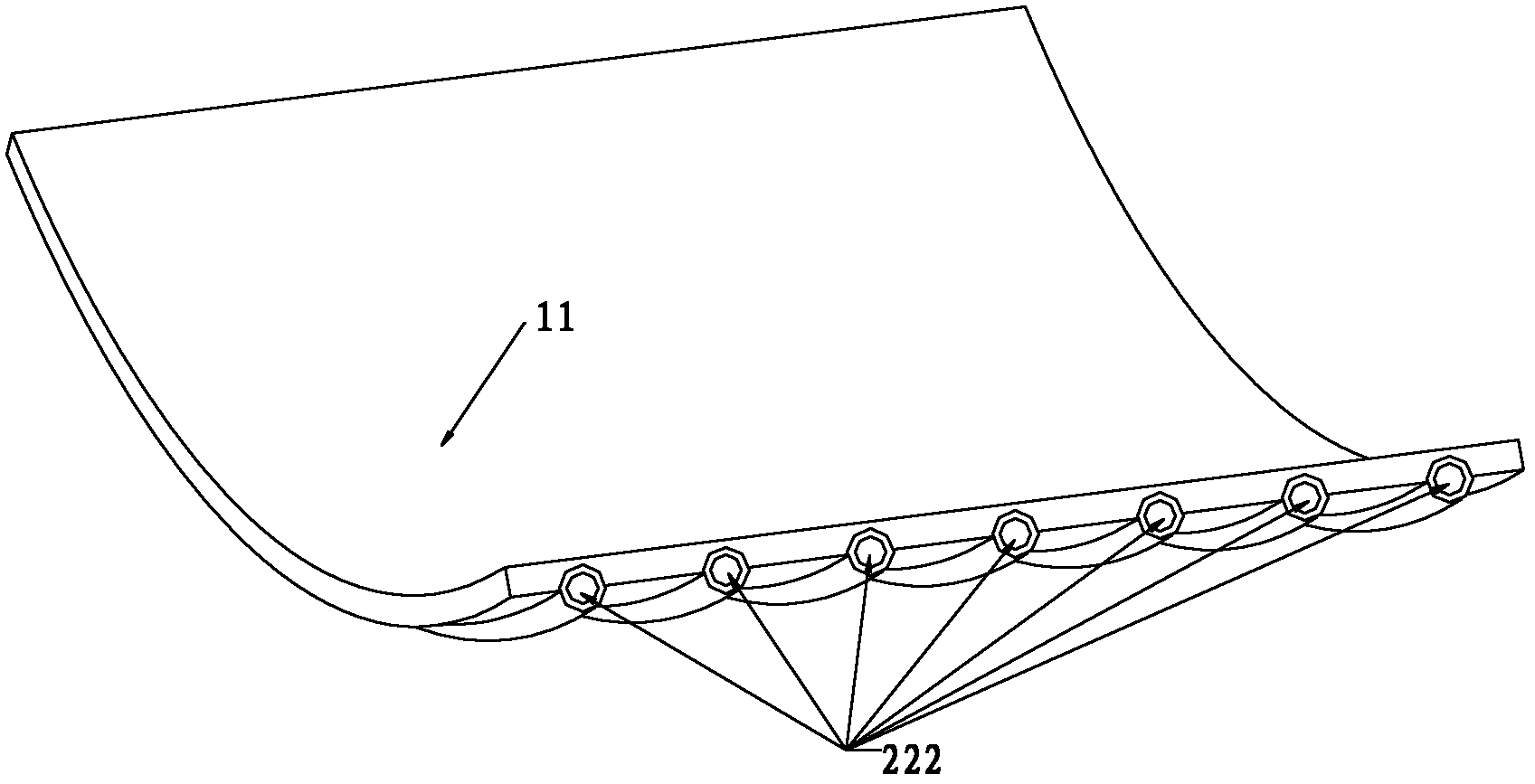

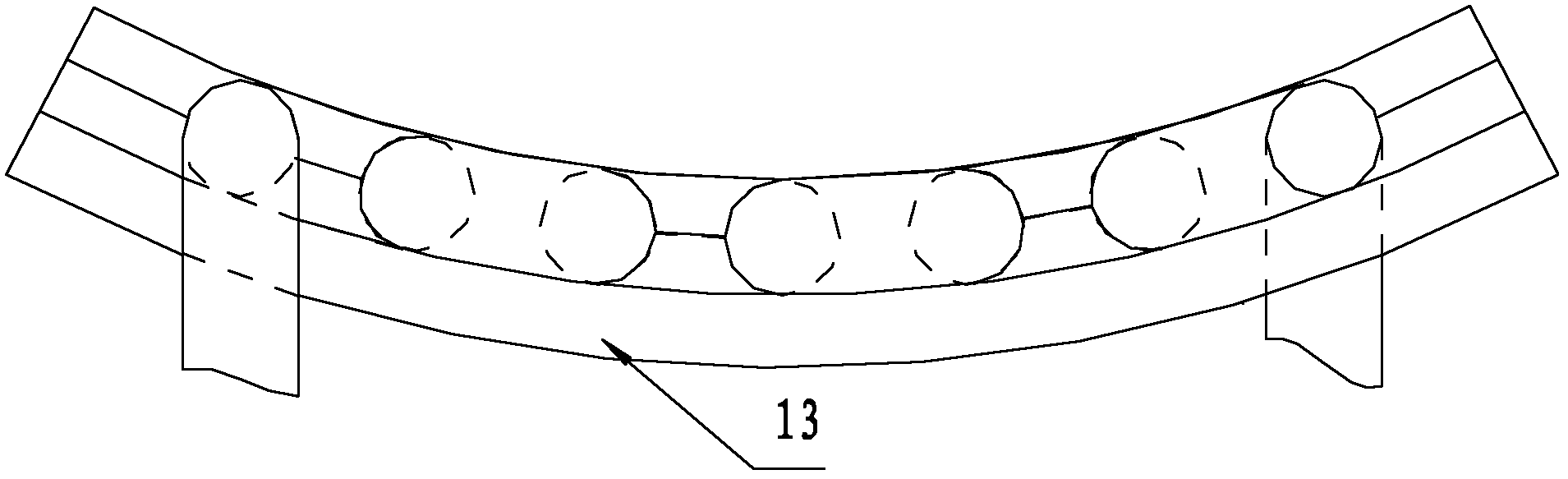

Constant temperature heating device

InactiveCN102517866AReliable test resultsConstant heating temperatureInspecting textilesAluminiumTurbine blade

The invention discloses a constant temperature heating device, which is used for detecting multi-axial fabrics for wind turbine blades. The constant temperature heating device comprises a fiber reinforced plastic mold, a constant temperature water tank and a heating layer, wherein the fiber reinforced plastic mold has an arc surface matched with an appearance of the wind turbine blade; the constant temperature water tank comprises a water tank, a heating device and a water pump; the heating layer comprises a heating conductive medium and a heating pipe; the heating conductive medium is formed by mixing aluminum powder and a resin, and is coated at the bottom of the fiber reinforced plastic mold; and the heating pipe is laid in the heating conductive medium and is connected with the constant temperature water tank. Compared with a heating device in the prior art, the constant temperature heating device has the advantages that: the fiber reinforced plastic mold has the arc surface, the arc of the arc surface is the same as that of the blade, and when the multi-axial fabrics are laid on the fiber reinforced plastic mold with the arc surface and detected, the condition is similar to a condition in the actual application process, and the detection result is more reliable.

Owner:CHONGQING POLYCOMP INT

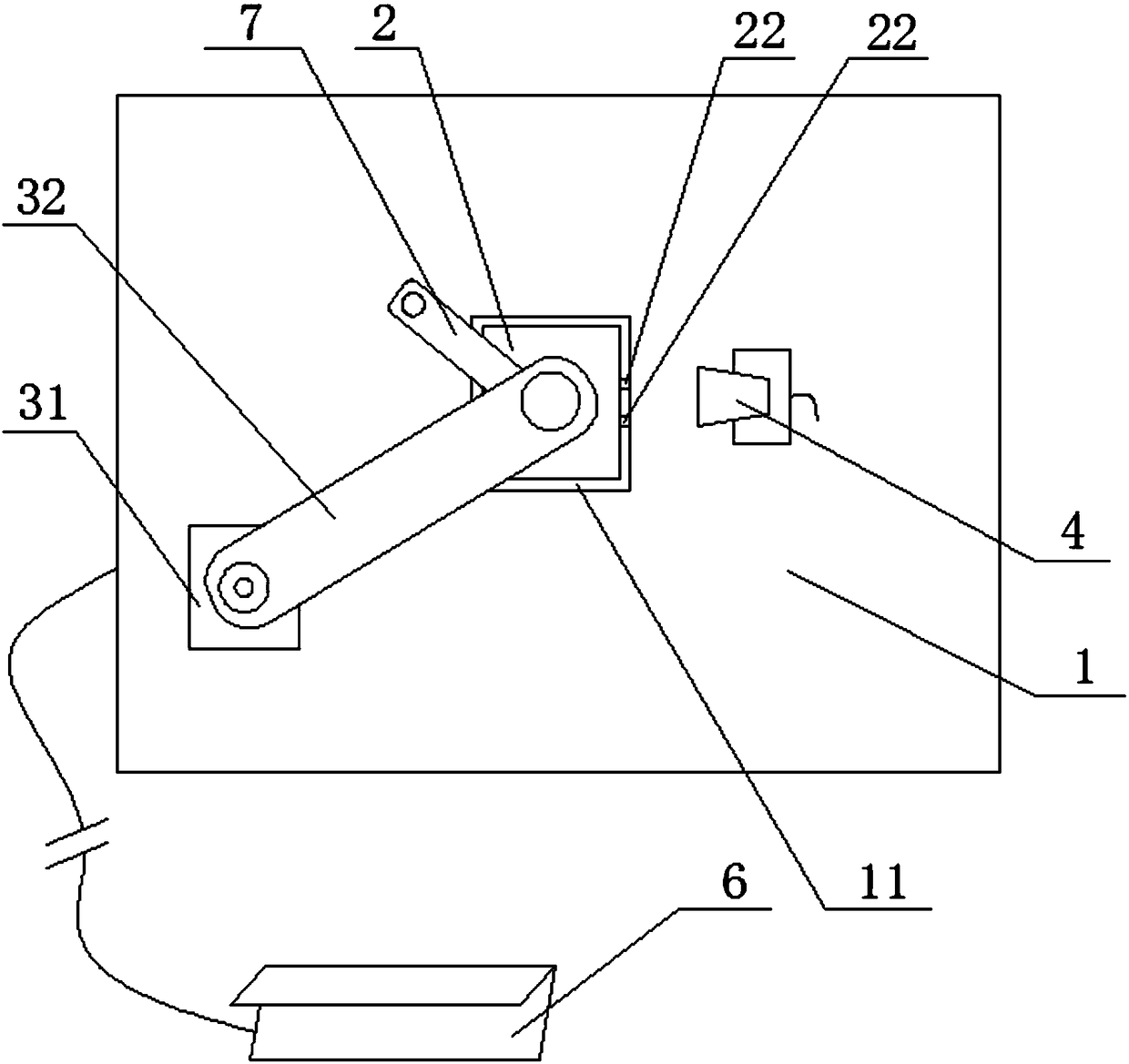

Device and process for picking sensor light window

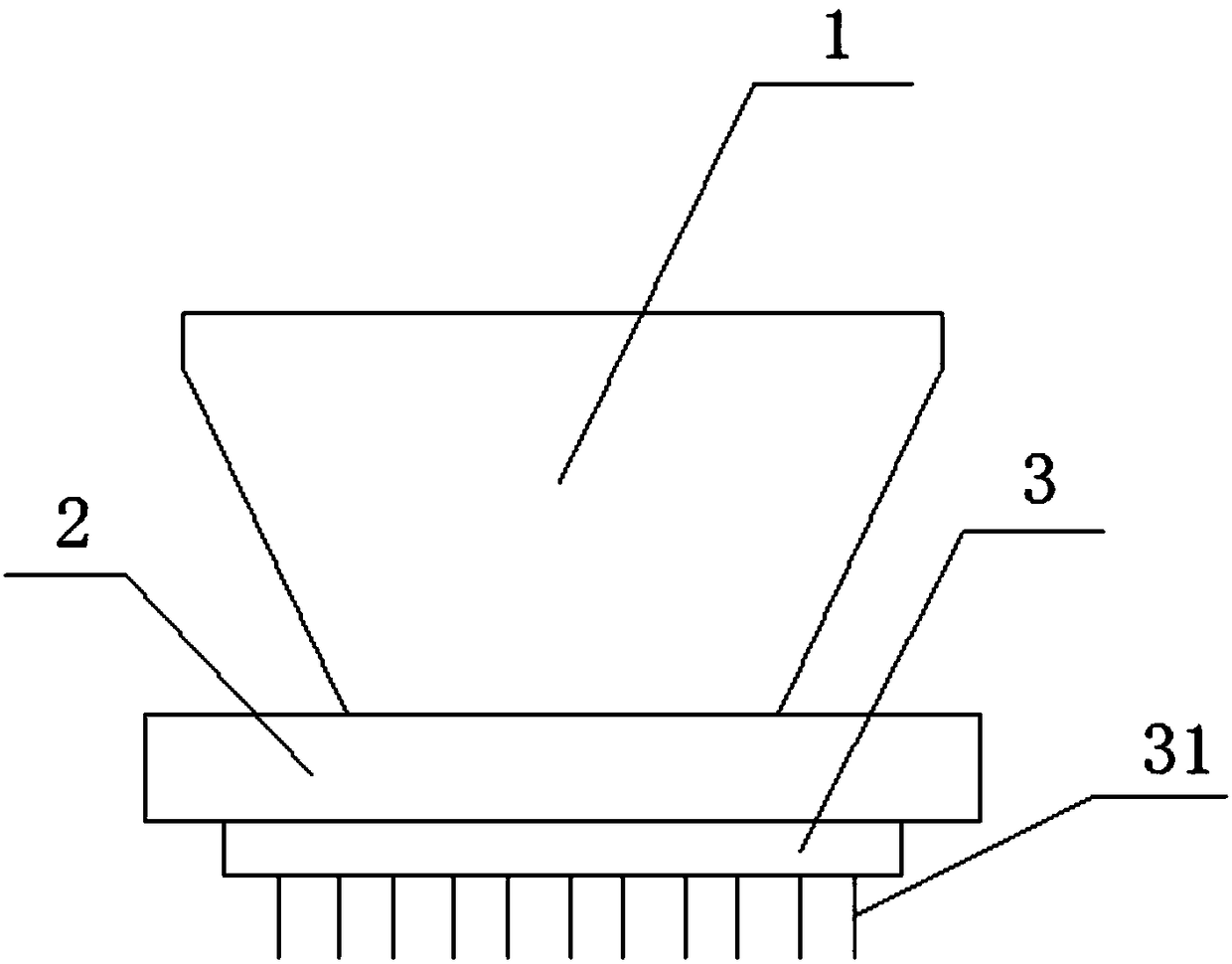

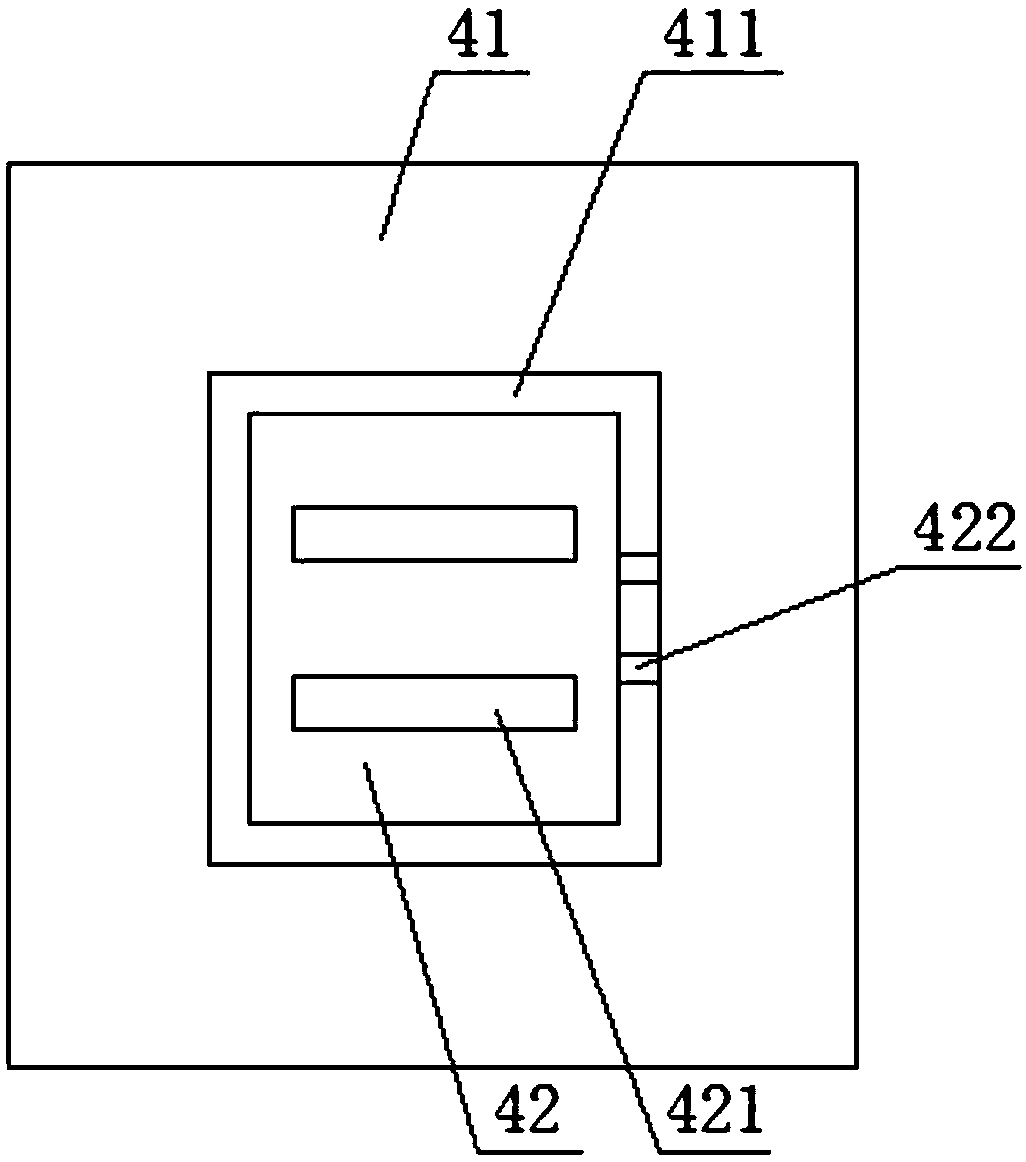

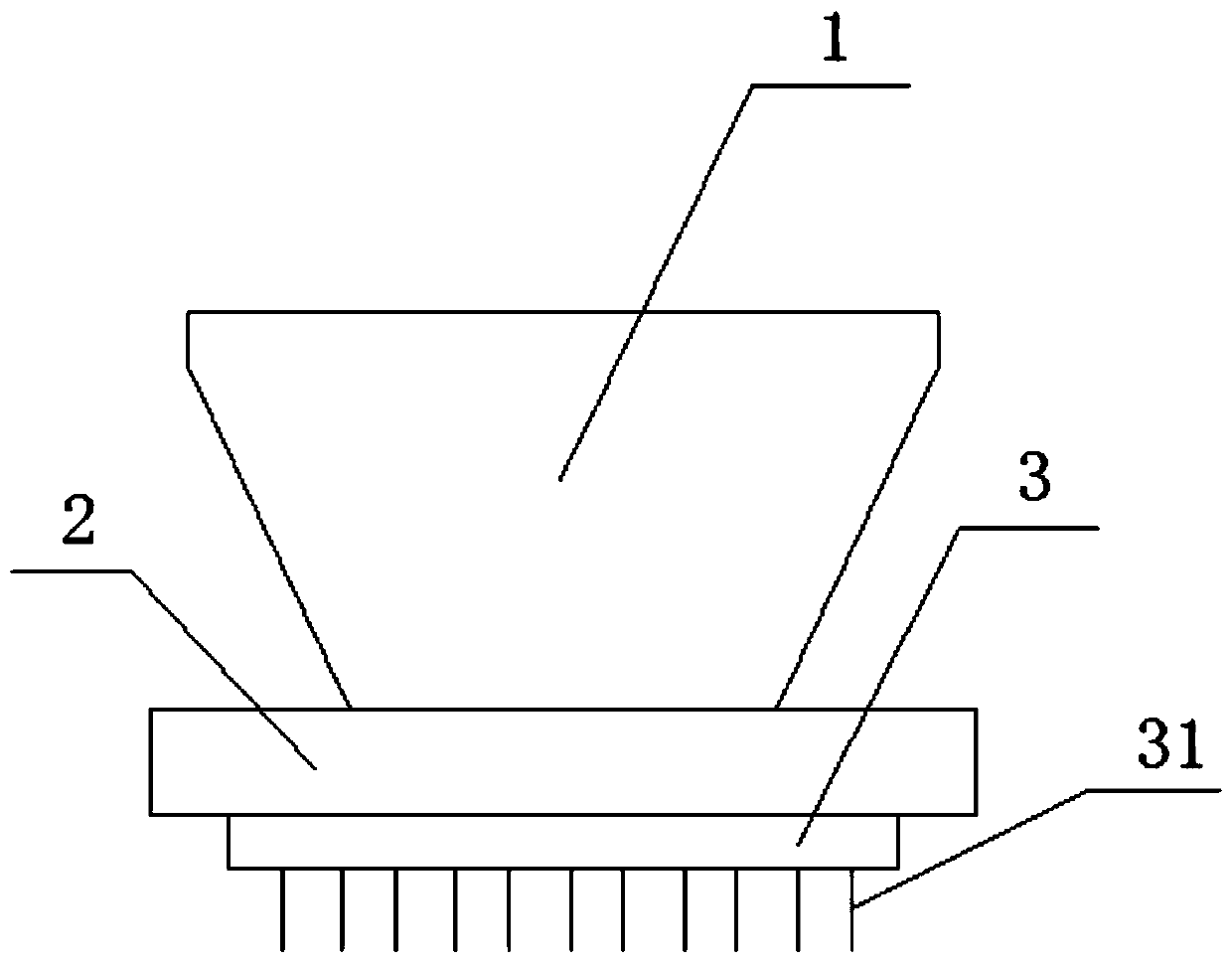

PendingCN108417596AAvoid damageImprove the efficiency of extracting the light windowSolid-state devicesRadiation controlled devicesEngineering

The invention relates to the technical field of photosensitive elements, in particular to a device and a process for picking a sensor light window. The device includes a base on which a heating station for fixing and heating a sensor is mounted. The base is further equipped with a picking mechanism for picking a sensor light window. The device and process of the invention have the beneficial effects that heating and melting the optical resin for fixing the light window through the heating station is beneficial to avoid damage to the sensor, improve the efficiency of picking the light window and the yield of the product, and reduce the cost.

Owner:重庆港宇高科技开发有限公司

A fiber manufacturing device for weaving

ActiveCN105332064BStir wellInto the uniformSpinning head liquid feederTextile fiberTextile manufacturing

Owner:SUZHOU BUWU JIAXIANG TEXTILE TECH CO LTD

Sintering furnace for silicon nitride ceramic sintering and working method of sintering furnace

ActiveCN112393583AConstant heating temperatureReduce the impactMuffle furnacesCharge treatment typeSilicon nitrideCrucible

The invention relates to a sintering furnace for silicon nitride ceramic sintering and a working method of the sintering furnace. The sintering furnace for silicon nitride ceramic sintering comprisesa furnace body, a heating body arranged in the furnace body, a crucible borne on the heating body and a pipeline device for transmitting high-pressure gas, wherein the pipeline device is suitable forconveying the high-pressure gas to the position below the heating body. The continuous and uniform heating temperature is ensured, and the recrystallization phenomenon of a sintered alloy material isreduced; when the high-pressure gas is added into the furnace body through the pipeline device, the influence of the high-pressure gas on the crucible is reduced in cooperation with an air control device, meanwhile, the crucible is heated continuously and evenly, and materials in the crucible react sufficiently; and the temperature inside the furnace body is detected through a temperature sensor arranged on the furnace wall, so that the high-pressure gas with the proper temperature is selected to be introduced into the furnace body, and an air control system is further matched.

Owner:宁波银瓷新材料有限公司

Oil temperature control fuel economizer of fuel vehicle

PendingCN111734564AThe heating temperature is basically constantConstant heating temperatureInternal combustion piston enginesCombustion-air/fuel-air treatmentEngineeringFuel oil

The invention discloses an oil temperature control fuel economizer for a fuel vehicle. The oil temperature control fuel economizer comprises a heater, a heater shell is arranged outside the heater, ahot water outlet is formed in one side of the shell, a hot water inlet is formed in the other side of the shell, and a water pump is additionally arranged at the hot water outlet; a pressure fuel pipeis installed on one side of the heater, one end of the pressure fuel pipe is connected with an oil pump, and the other end of the pressure fuel pipe is connected with a heating copper pipe; and one end of the heating copper pipe is connected with an electronic injection rail, the upper portion of the electronic injection rail is connected with an air inlet pipe through an oil rail oil return valve, and the lower portion of the electronic injection rail is provided with a plurality of electric nozzles. Compared with the prior art, the oil temperature control fuel economizer has the following advantages that the fuel oil is heated, enters the nozzles under the conditions of proper temperature and pressure and then is vaporized into oil molecules, the oil molecules are in full contact with oxygen to generate deflagration, the fuel oil is fully combusted, carbon deposition is eliminated, the pollutant discharge amount is reduced, the atmospheric environment is protected, and the fuel oilamount per hundred kilometers is reduced; due to the design of a preheating container, the fuel heating temperature is basically constant, and the stability is improved; and stable hot water supply isachieved through a water pump.

Owner:张哲

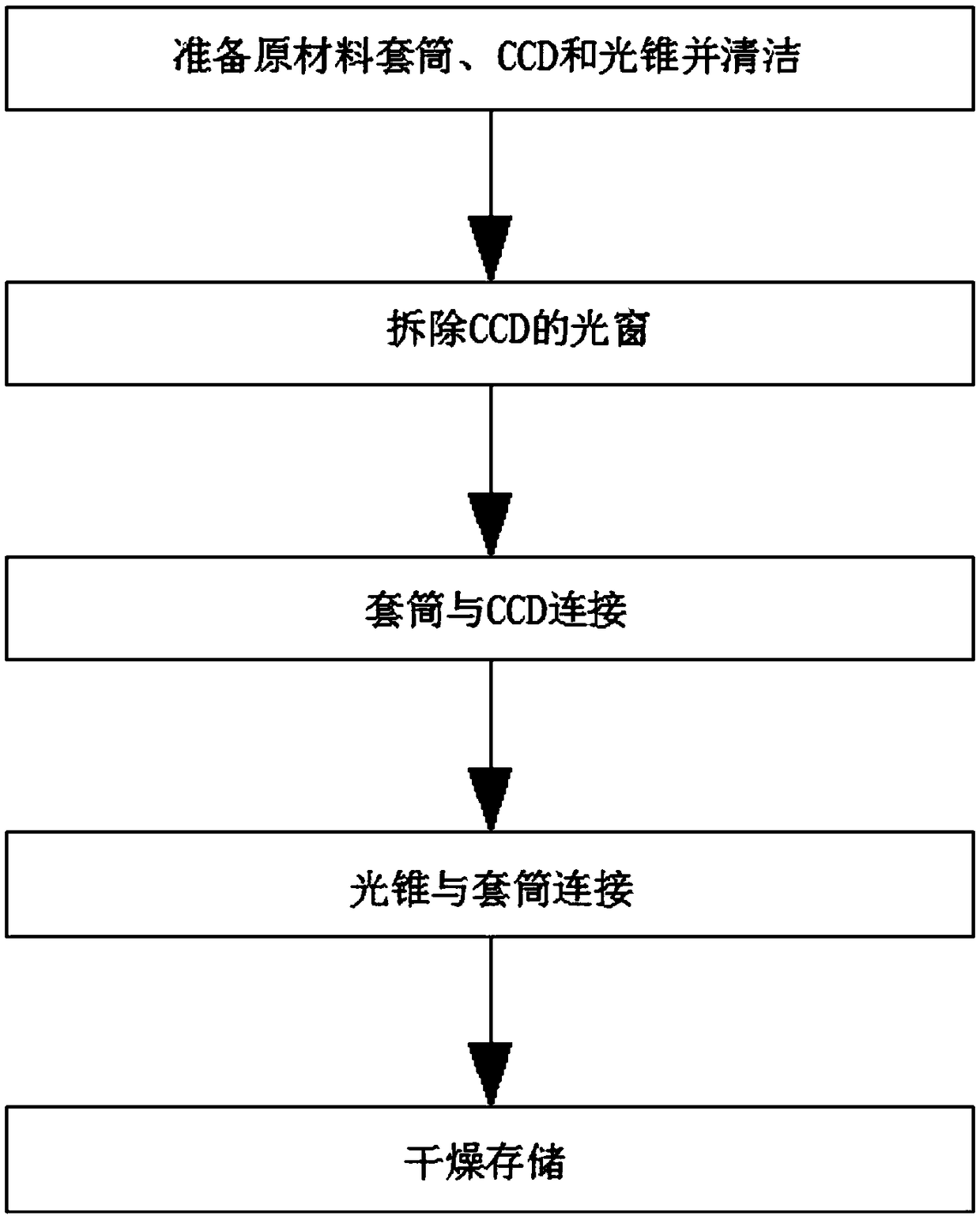

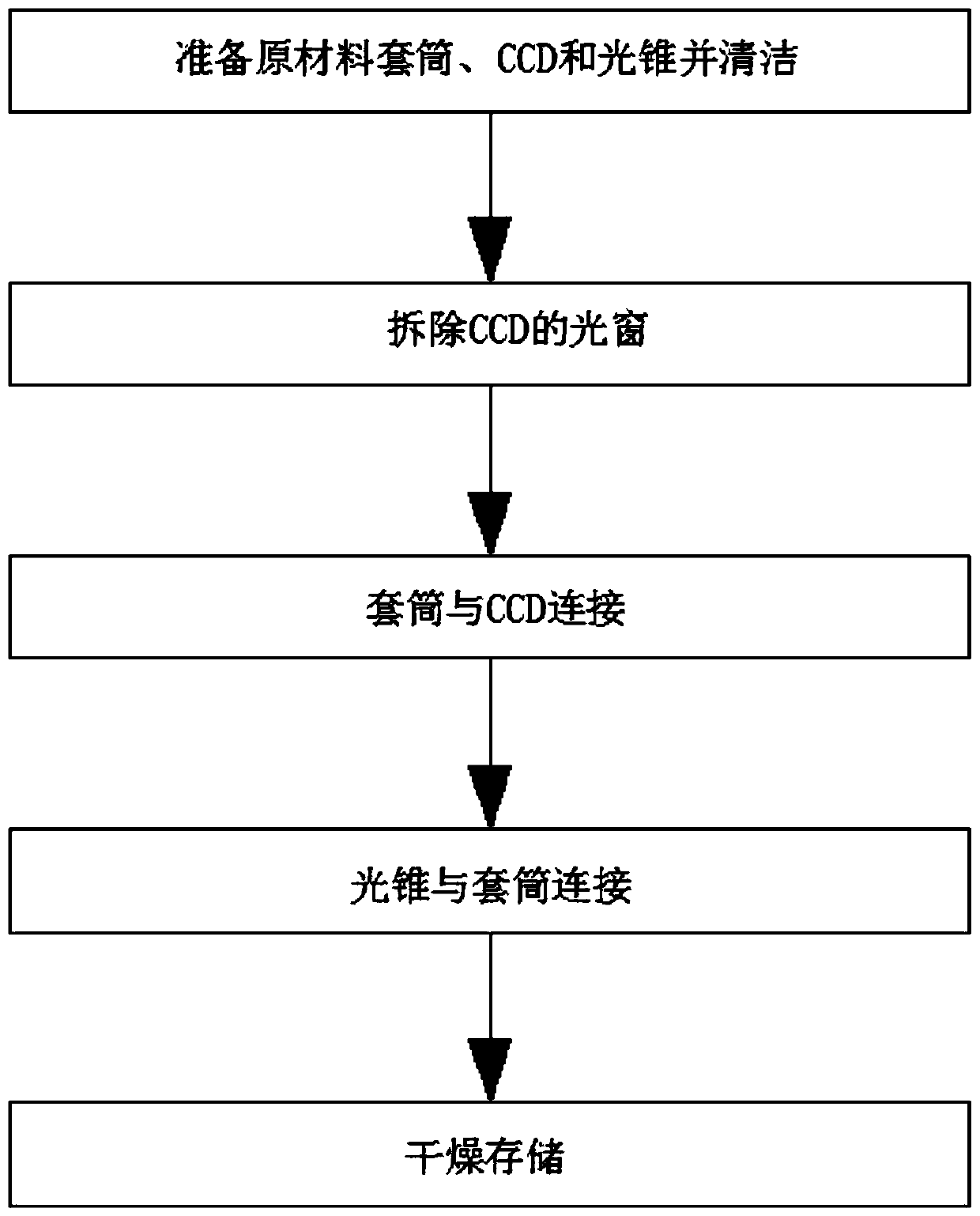

Light cone coupling process

The invention relates to the technical field of photosensitive elements, particularly to a light cone coupling process, comprising the following steps: preparing a raw material sleeve, a CCD and a light cone and cleaning; dismantling a light window of the CCD; fixedly connecting the bottom of the sleeve with the CCD, and performing imaging detection on the CCD; positioning and installing a small diameter end of the light cone on the sleeve, adjusting the light cone till CCD detection imaging is clear, and fixing the light cone and the sleeve; and performing drying storage. The beneficial effects of the light cone coupling process are that the coupling operation is simple, the process is simple, the light window of the CCD is dismantled, and the imaging quality is improved.

Owner:重庆港宇高科技开发有限公司

Light Cone Coupling Process

The invention relates to the technical field of photosensitive elements, particularly to a light cone coupling process, comprising the following steps: preparing a raw material sleeve, a CCD and a light cone and cleaning; dismantling a light window of the CCD; fixedly connecting the bottom of the sleeve with the CCD, and performing imaging detection on the CCD; positioning and installing a small diameter end of the light cone on the sleeve, adjusting the light cone till CCD detection imaging is clear, and fixing the light cone and the sleeve; and performing drying storage. The beneficial effects of the light cone coupling process are that the coupling operation is simple, the process is simple, the light window of the CCD is dismantled, and the imaging quality is improved.

Owner:重庆港宇高科技开发有限公司

Equipment for manufacturing stainless steel clad plates by low temperature induction heating

InactiveCN101983001BHigh temperature control accuracyLower working temperatureInduction heating controlInduction heating apparatusCapacitanceWorking temperature

Equipment for manufacturing stainless steel clad plates by low temperature induction heating is used for carrying out medium frequency induction heating and welding on the composite materials before continuous rolling and forming. The equipment is characterized in that a medium frequency power supply heating control system is connected with induction heaters by a medium frequency capacitance compensator and the medium frequency alternating current power generated by the medium frequency power supply heating control system is input to the medium frequency capacitance compensator and the induction heaters to form resonance; heavy alternating current is generated on the induction heaters; a surface layer and base metal are heated through eddy effect; and a bonding layer receives the heat from the surface layer and the base metal and is melted; and then the surface layer, the base metal and the bonding layer are fit under inert atmosphere and enter into a rolling mill to be rolled into the clad plates. The equipment has the following advantages: the equipment utilizes the induction heating technology to carry out continuous contactless heating on large format metal, thus ensuring high temperature control precision, low working temperature and low unit energy consumption and effectively saving energy; the thermodetector and the medium frequency power supply heating control system ensure the heating temperature of the metal layer to be constant, thus ensuring the surface of the metal layer to be uniformly heated; and the inert gas protection cavity structure can avoid surface oxidation of the metal layer in the heating process, thus greatly lowering the production cost.

Owner:湖北一新世科电气有限公司

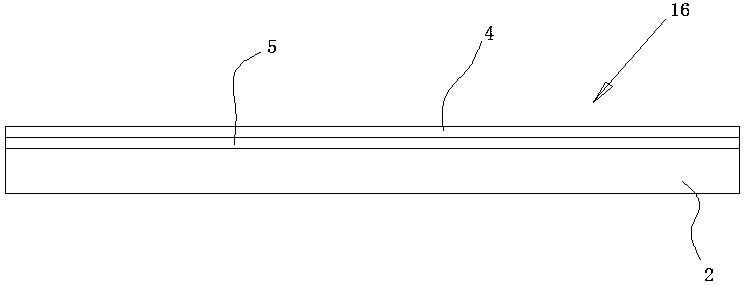

Single-glue-layer plastic card applied to rapid diagnosis, and preparation method and equipment thereof

ActiveCN107718818ASolve leveling problemsReduce exposure timeNon-macromolecular adhesive additivesLamination ancillary operationsWarm waterBiomedical engineering

The present invention discloses a single-glue-layer plastic card applied to rapid diagnosis, and a preparation method and equipment thereof. The method comprises the following steps: step one, flattening a plastic sheet; step two, simultaneously applying a non-drying glue onto release paper; and step 3: enabling the glue face of the release paper to face to the flattened plastic sheet, and performing rolling press to bond the non-drying glue layer of the release paper to the plastic sheet. The single-glue-layer plastic card includes the plastic sheet and the release paper which are adhered bythe non-drying glue layer. The equipment comprises a plastic-sheet reeling and unreeling roller, a release-paper reeling and unreeling roller, a constant-tension stretching device playing a role in both plastic-sheet reeling and rolling combination, a warm water tank, a cooling device and a non-drying glue applying roller and a drying tunnel. According to the invention, the flattening problem of the plastic sheet during a continuous feeding process is solved, the heating temperature is constant, the flattening effect is good, the detection card only need one layer of non-drying glue, a film isomitted, the cost is greatly reduced, the processing steps are fewer and adverse effects such as dust pollution is greatly improved.

Owner:杭州瑞健科技有限公司

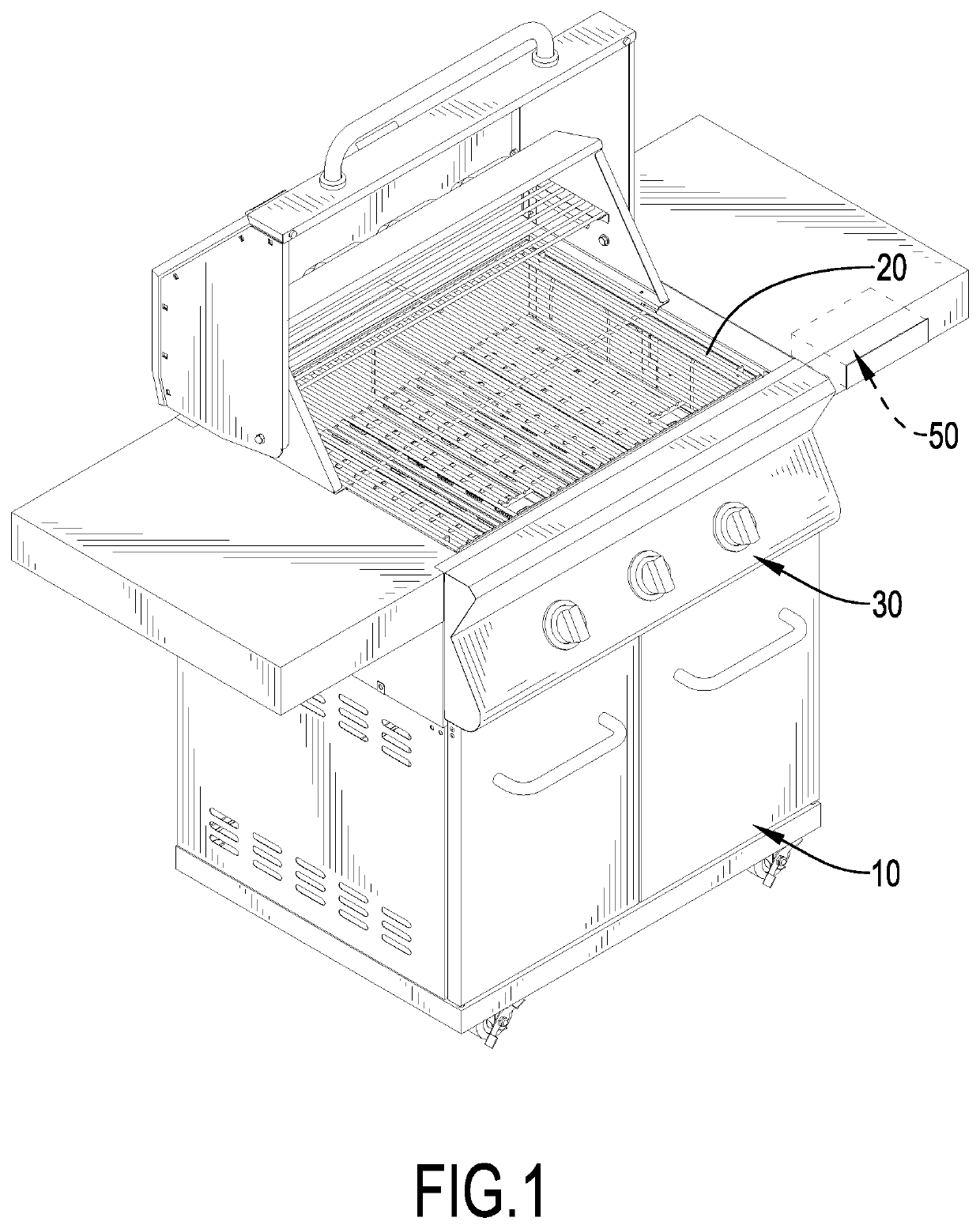

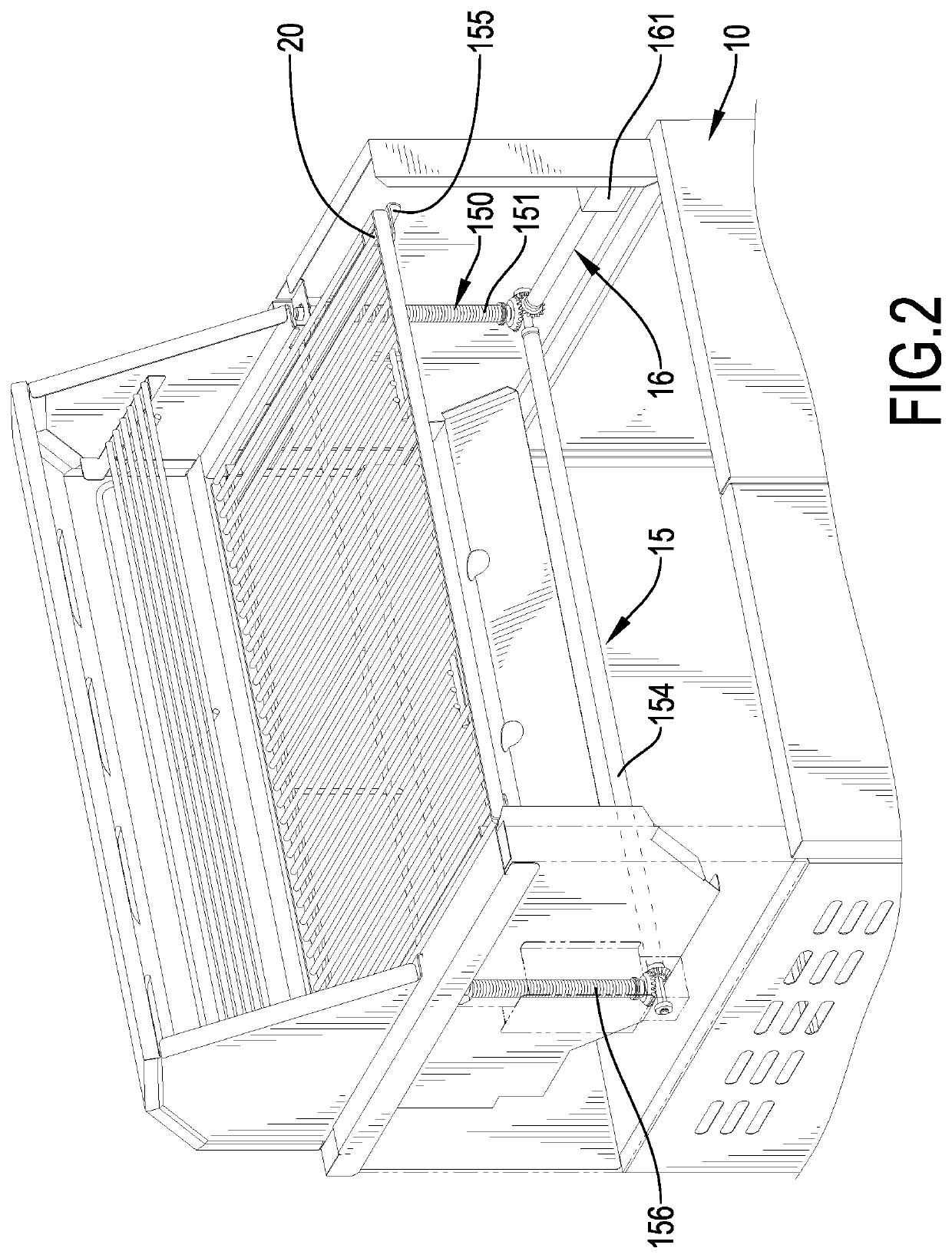

Barbecue grill

PendingUS20220279968A1Constant heating temperatureFuel supply regulationDomestic stoves or rangesTemperature controlEngineering

A barbecue grill has a body, a barbecue grid, a heating device, a heating adjustment unit, a thermal sensor, and a control device. The heating adjustment unit is connected with the heating device. The thermal sensor is mounted in the body and detects an actual temperature. The control device has a constant temperature control module electrically connected to the heating adjustment unit and the thermal sensor. The constant temperature control module controls the heating adjustment unit to adjust heat output of the heating device according to a difference value between a target temperature and the actual temperature. The heat output of the heating device is increased or decreased according to the difference value to keep the temperature constant at the position of the thermal sensor.

Owner:LIU CHIA MING

A convection cooling heat transfer test device

ActiveCN111169656BHeating evenlyUniform and unstable heatingCosmonautic condition simulationsAircraft components testingCold airEngineering

The invention discloses a convection cooling heat exchange test device. The heating system adopts a quartz lamp heater. The measuring system includes a gas proportional valve, a gas flow meter, a heating controller, a temperature measuring instrument and a test piece. The cooling system includes a gas Source, air path hose, air flow rectification device and air flow transition device, its support system includes air path fixing device and test piece heat insulation device, the test piece and test piece heat insulation device are arranged in the air flow transition device, and the test piece heat insulation device It is arranged on the left and right sides of the lower bottom surface of the test piece, and the quartz lamp heater is installed on the upper top surface of the airflow transition device at the position corresponding to the test piece to realize the heating of the heating surface of the test piece. The proportional valve, gas flow meter, and airflow rectification device enter the interior of the test piece located in the airflow transition device to realize convection cooling of the test piece. The invention has simple components, simple operation, low cost, little external interference and reliable test results.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

An intelligent control system for a biomass pellet heating water heater

InactiveCN104913507BEasy to operateConstant heating temperatureFluid heatersPore water pressureEngineering

An intelligent control system for a biomass pellet heating water heater, including an electric controller, and also includes: a stepper motor, used to transport biomass pellet fuel; a limit switch, used to detect the remaining amount of biomass pellet fuel; a direct current The fan is used to provide the air required for the combustion of biomass particles; the ignition needle is used to ignite the biomass particle fuel; the water pump is used to provide kinetic energy for the heat exchange circulation waterway to make the heating water heater externally heated; the temperature sensor is used to detect The water temperature of the thermal circulation waterway; the pressure switch is used to detect the water pressure in the thermal circulation waterway pipeline; control their work. The invention can make the heating temperature relatively constant by automatically adjusting the combustion firepower, meeting the requirements of a comfortable heating environment, and has intelligent functions such as automatic alarm for no fuel, high water pressure protection, intelligent switch machine, etc. The operation of the heating furnace is simple, convenient and safe comfortable.

Owner:佛山市顺德区旭政实业有限公司

Constant temperature heating device

InactiveCN102517866BReliable test resultsGuaranteed uniformityInspecting textilesOhmic-resistance heatingFiberTurbine blade

The invention discloses a constant temperature heating device, which is used for detecting multi-axial fabrics for wind turbine blades. The constant temperature heating device comprises a fiber reinforced plastic mold, a constant temperature water tank and a heating layer, wherein the fiber reinforced plastic mold has an arc surface matched with an appearance of the wind turbine blade; the constant temperature water tank comprises a water tank, a heating device and a water pump; the heating layer comprises a heating conductive medium and a heating pipe; the heating conductive medium is formed by mixing aluminum powder and a resin, and is coated at the bottom of the fiber reinforced plastic mold; and the heating pipe is laid in the heating conductive medium and is connected with the constant temperature water tank. Compared with a heating device in the prior art, the constant temperature heating device has the advantages that: the fiber reinforced plastic mold has the arc surface, the arc of the arc surface is the same as that of the blade, and when the multi-axial fabrics are laid on the fiber reinforced plastic mold with the arc surface and detected, the condition is similar to a condition in the actual application process, and the detection result is more reliable.

Owner:CHONGQING POLYCOMP INT

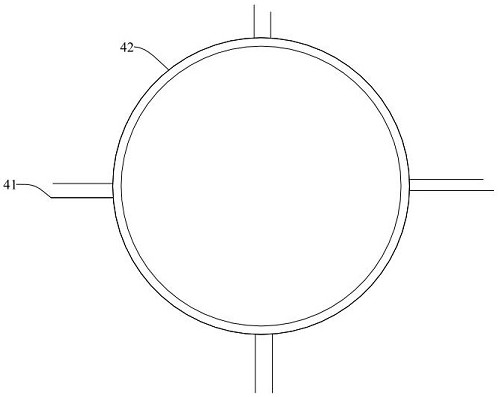

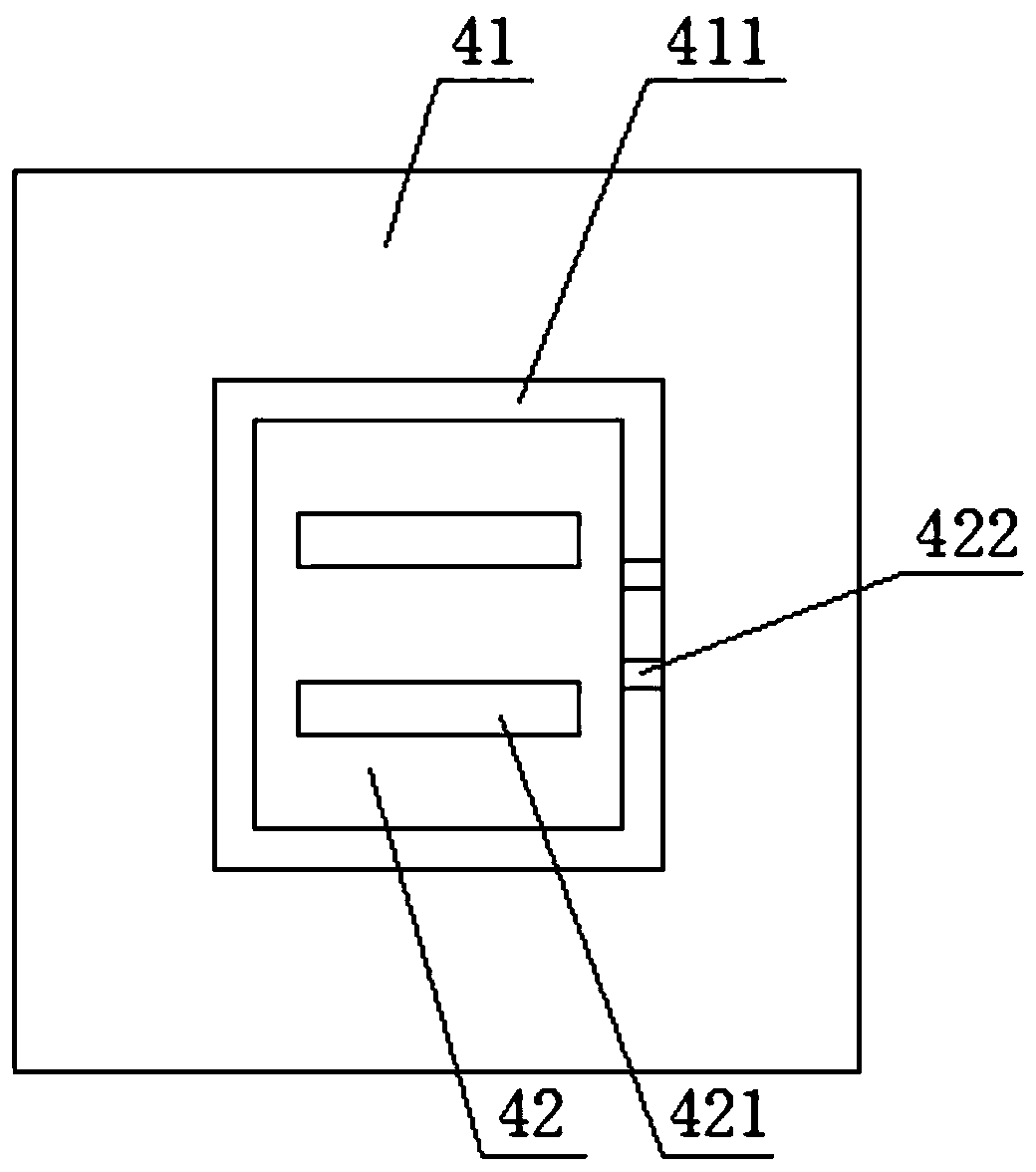

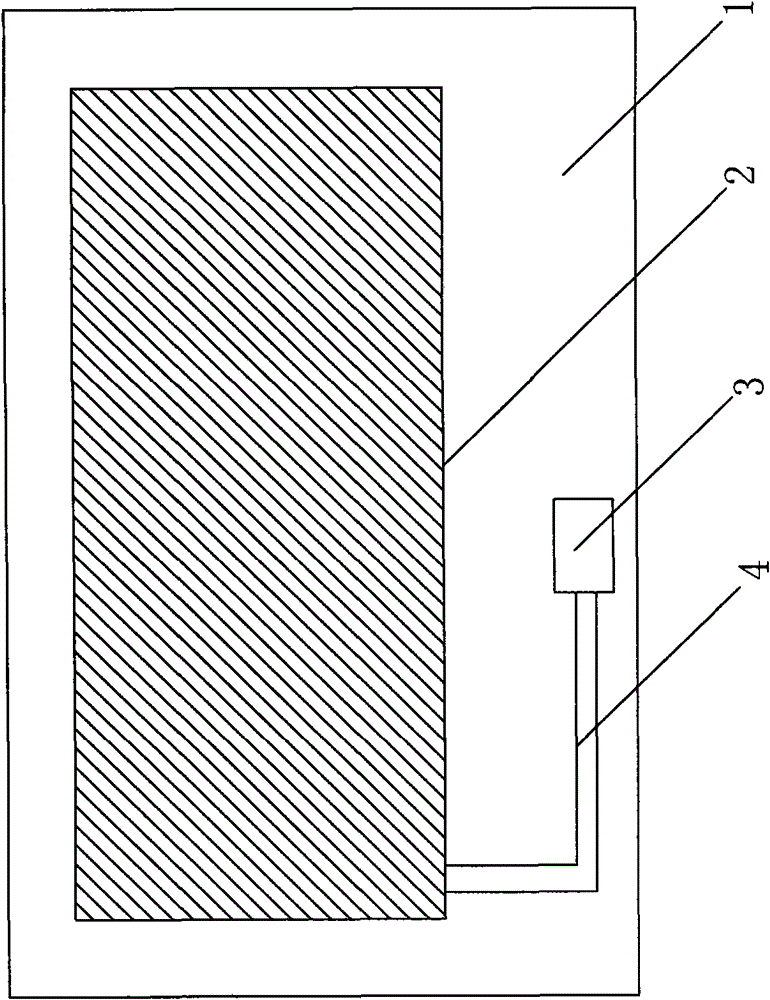

Device, method and liquid crystal module for adjusting temperature gradient of liquid crystal module

ActiveCN102749742BImprove "smearing" phenomenonReduce temperature distribution gradientStatic indicating devicesEquipment temperatureWorking temperature

The invention relates to a device and a method for controlling and regulating a temperature of display equipment, in particular to a device for regulating a temperature gradient of a liquid crystal module and a method for adjusting the temperature by utilizing the device, as well as the liquid crystal module utilizing the device. According to the device provided by the invention, the temperature of an overall machine can be increased to a normal working temperature as soon as possible, and the delay phenomenon when a liquid crystal television is turned on is improved; the temperature in the overall machine can be balanced during working, a gradient of temperature distribution of a whole backlight system is reduced, and phenomena of heated light leakage and the like are avoided; the heating temperature of the device is constant, a resistor can be automatically adjusted according to the temperature, addition of a control unit is not needed, and the structure is simple; and meanwhile by the adoption of low-pressure direct-current electricity, the device has remarkable protective functions aiming to current overload, voltage overload and temperature overheat, and has excellent safety.

Owner:HISENSE VISUAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com