Patents

Literature

77results about How to "Reduce recrystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

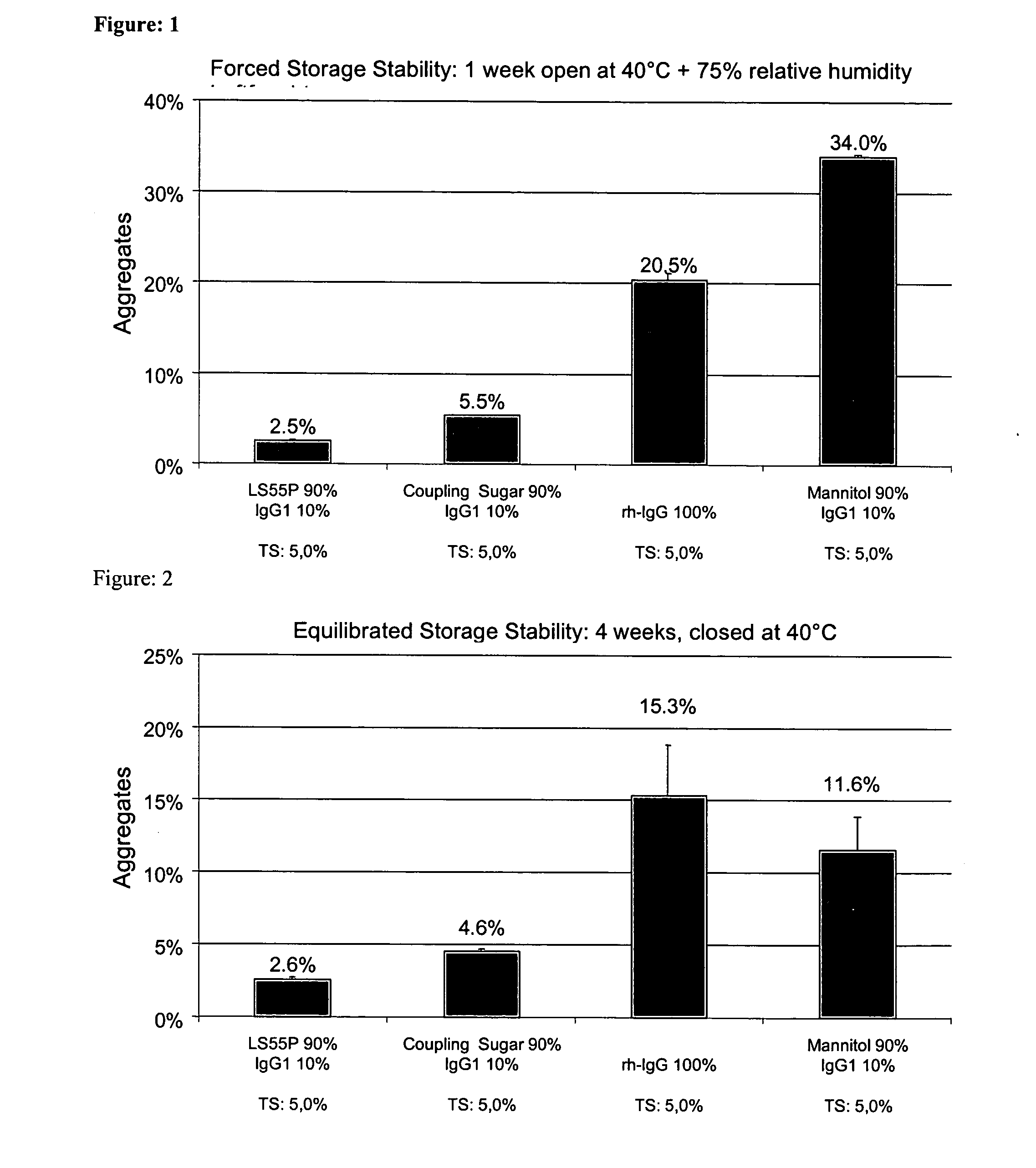

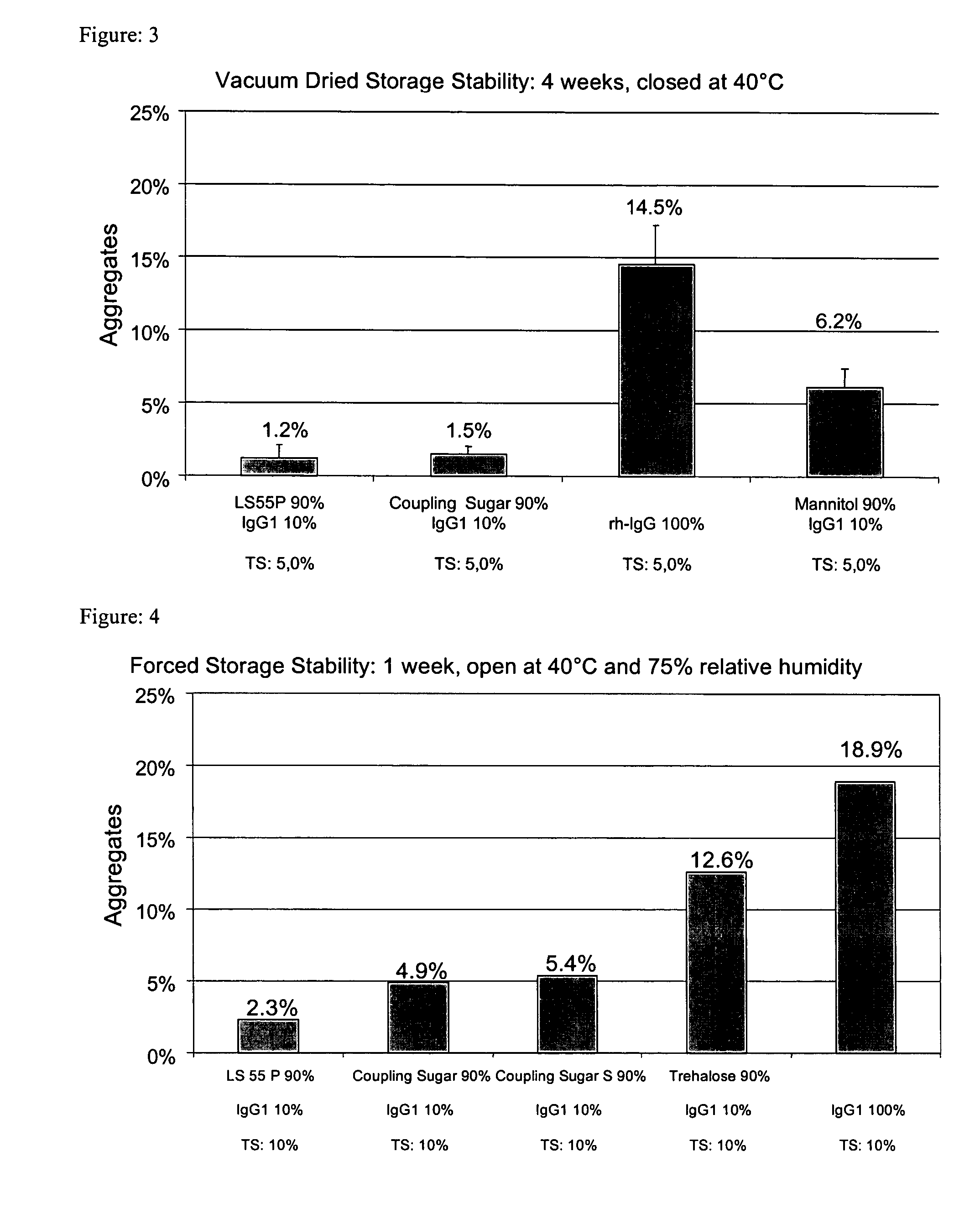

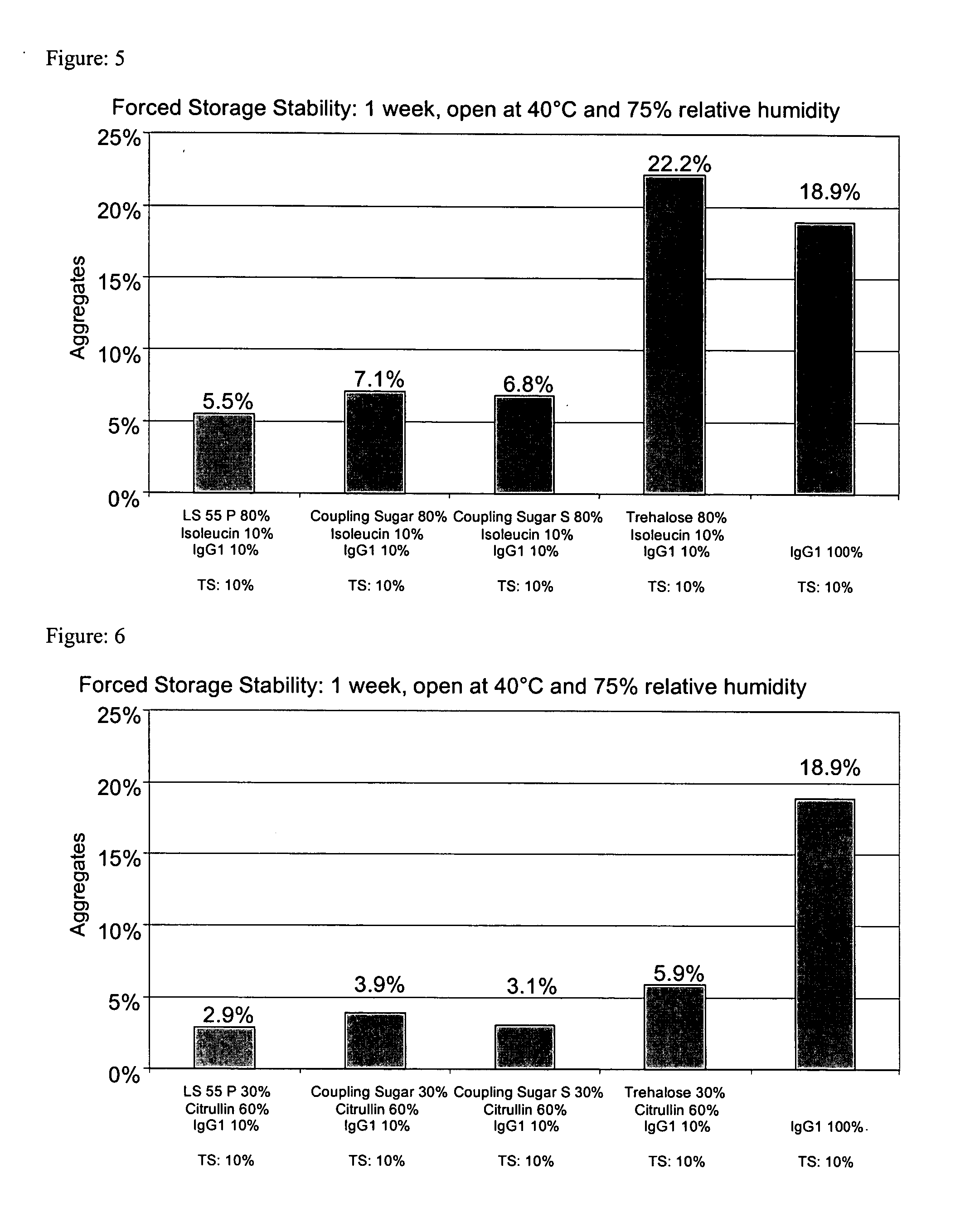

Powder comprising new compositions of oligosaccharides and methods for their preparation

ActiveUS20050250704A1Improve long-term stabilityHigh yieldPowder deliveryBiocideGlucosylsucroseSucrose measurement

The present invention concerns powders containing a pharmaceutical active substance and a combination of excipients comprising at least one 1,4 O-linked saccharose derivative selected from the compounds: 1,4 O-linked D-Gal-saccharose (lactosucrose), 1,4 O-linked D-Glu-saccharose (glucosyl sucrose), or 1,4 O-linked Glu-Glu-saccharose (maltosyl sucrose) in combination with at least one further excipient. The other excipient is preferably an amino acid, a peptide and / or a mono-, di- and / or oligosaccharide, wherein the oligosaccharide may be a second 1,4 O-linked saccharose derivative, provided that this is different from the first.

Owner:BOEHRINGER INGELHEIM PHARM KG

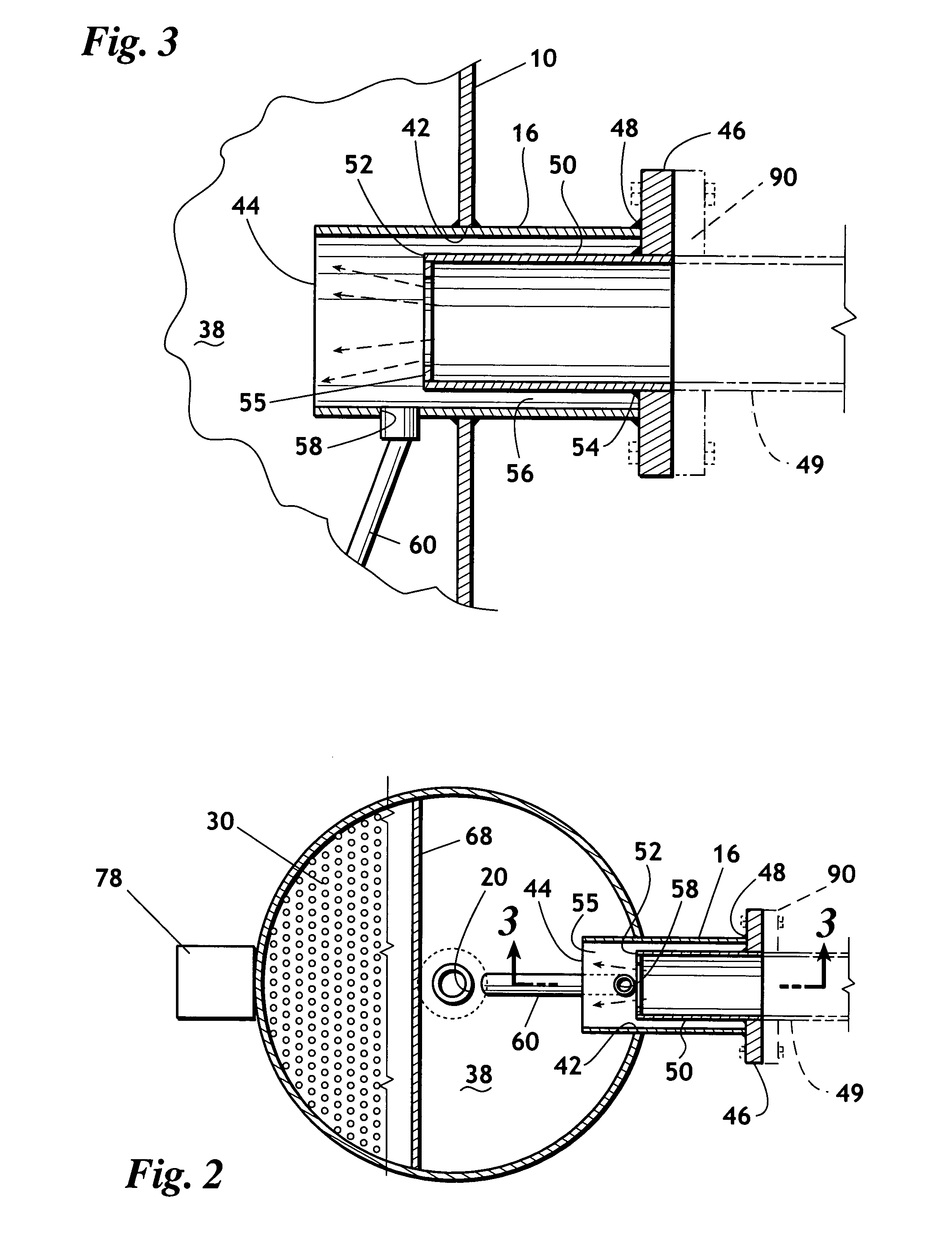

Braze alloy for high-temperature brazing and methods for repairing or producing components using a braze alloy

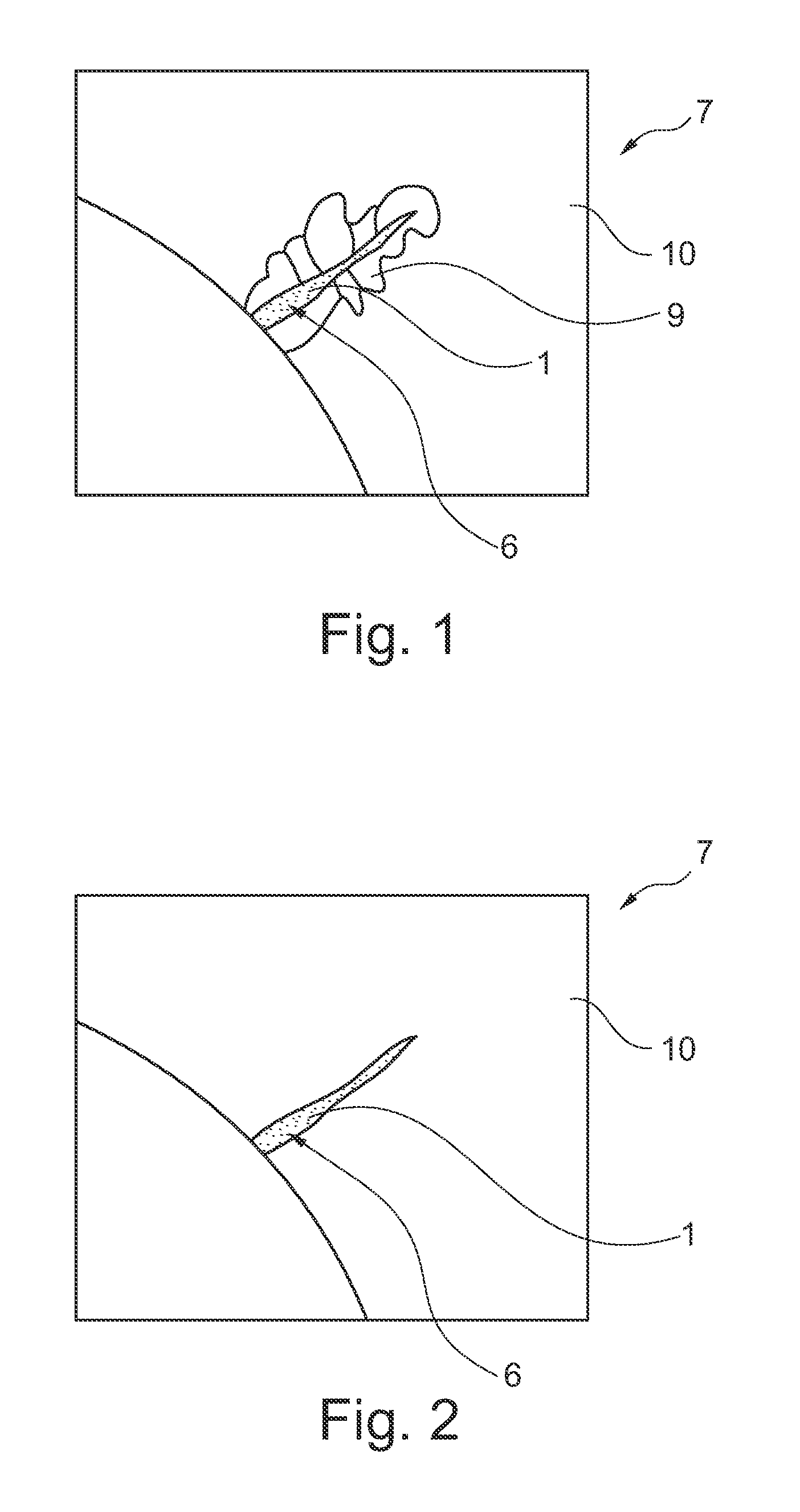

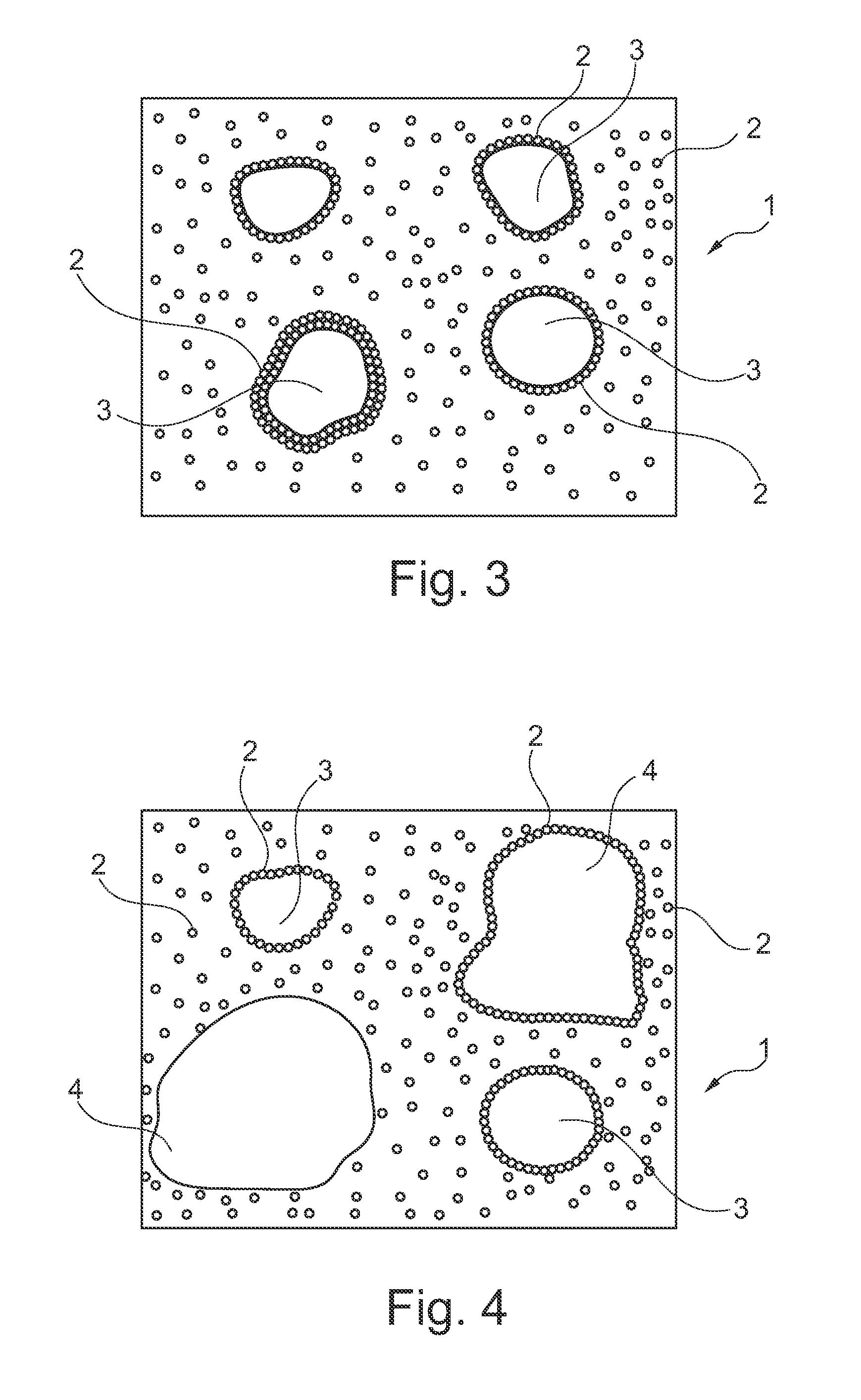

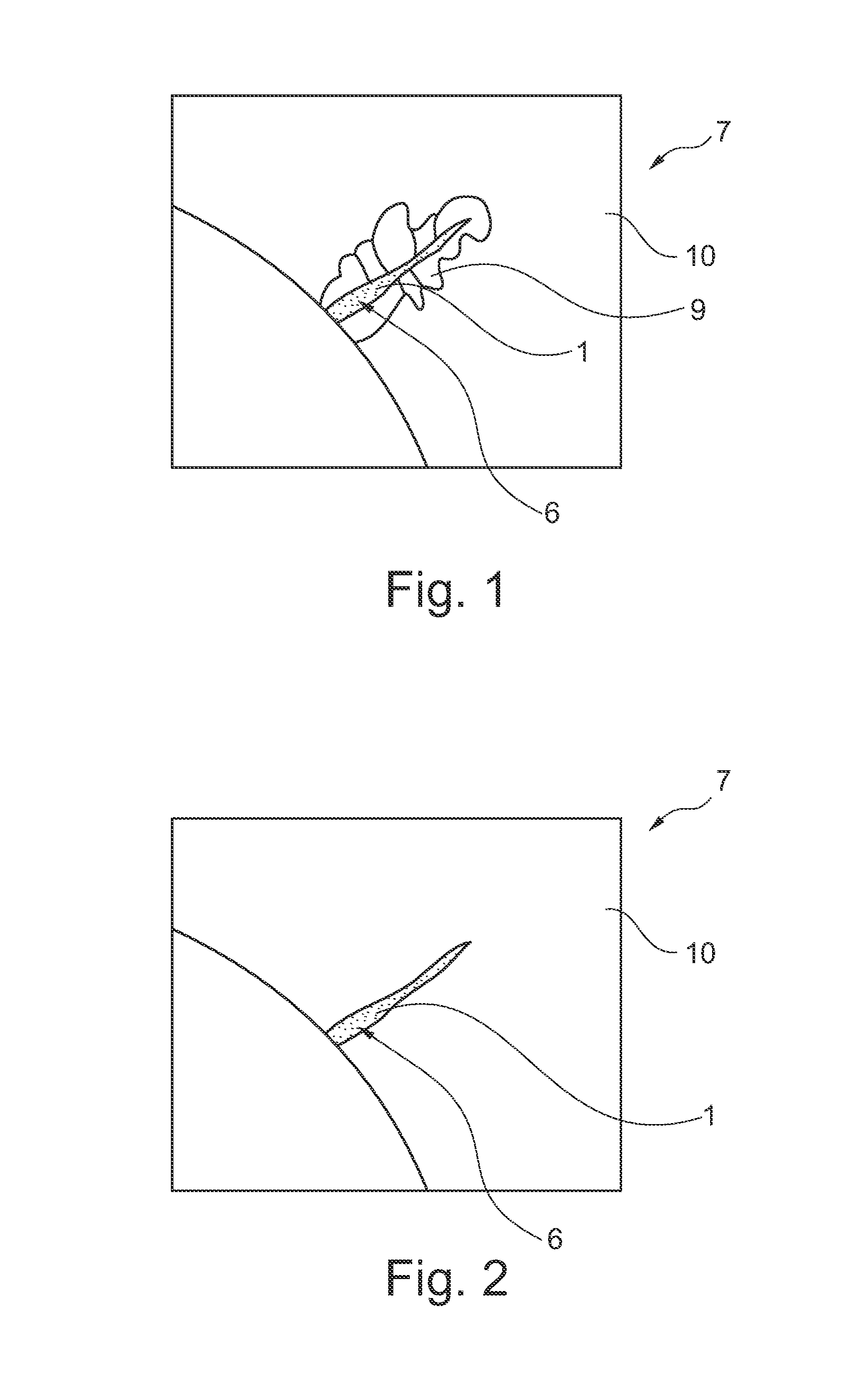

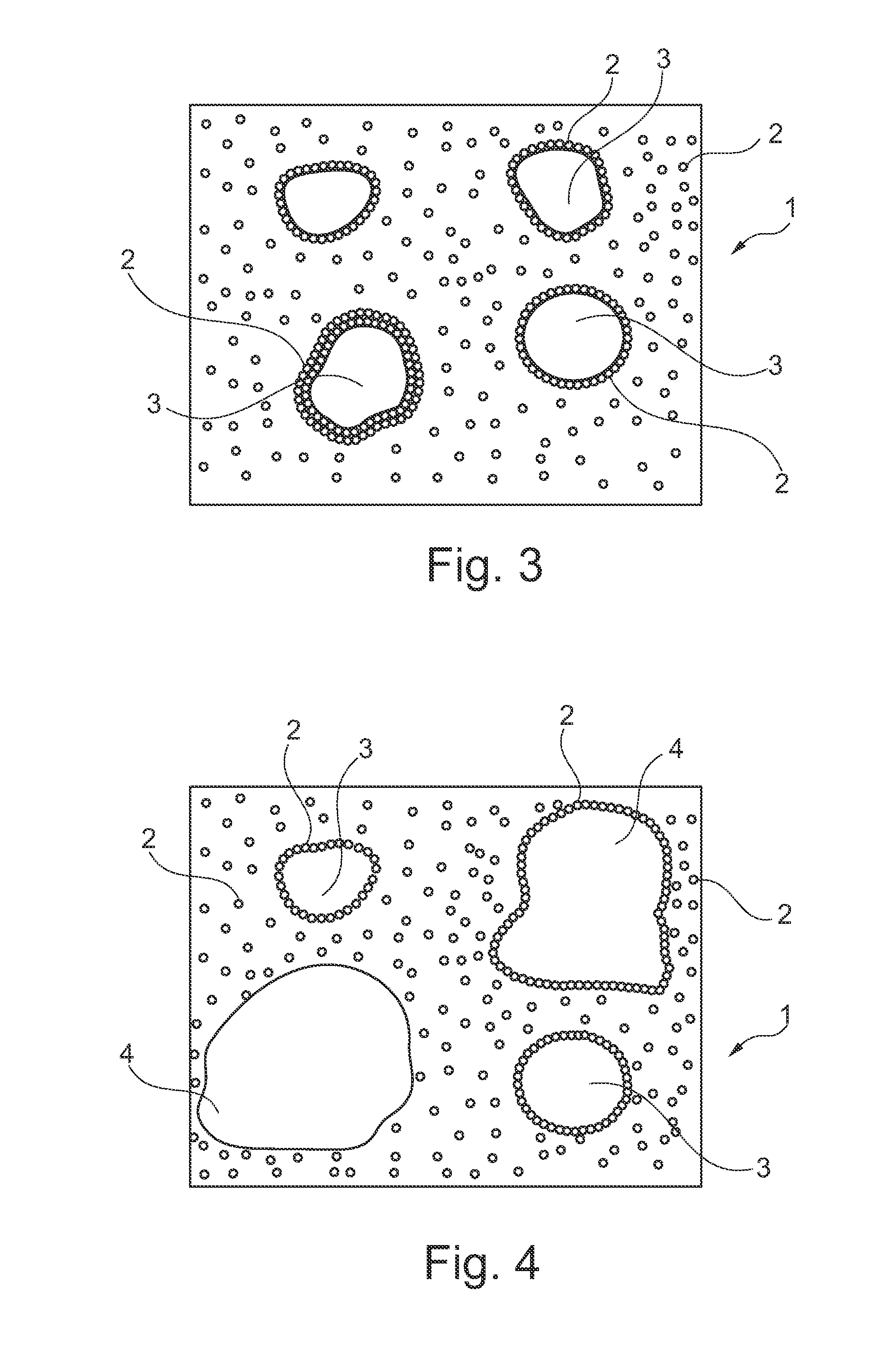

In a Ni-based, Co-based, or Ni—Co-based braze alloy (1) for high-temperature brazing of components (7) of modular structure and for repairing damaged components (7) which are formed of single crystal or directionally solidified superalloys using said braze alloy (1), the braze alloy has a first metallic powder component (2) having particle sizes in the nanometer range and a second metallic powder component (3) having particle sizes in the micrometer range. The surface of the particles of the second powder component (3) is thinly coated with particles of the first powder component (2). The braze alloy (1) additionally includes grain boundary stabilizing elements as alloying elements. In addition, melting point depressants can be present in the braze alloy (1) in a commercially common quantity or with a considerably increased proportion. Both the melting temperature of the braze alloy (1) and the probability of recrystallization are advantageously reduced.

Owner:ANSALDO ENERGIA IP UK LTD

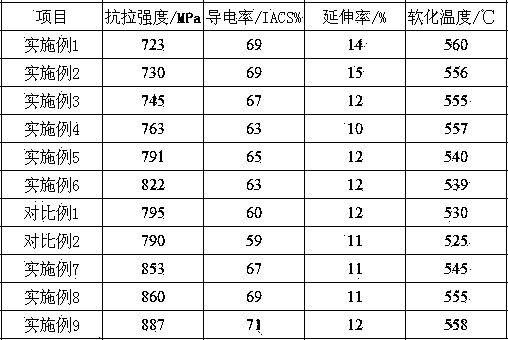

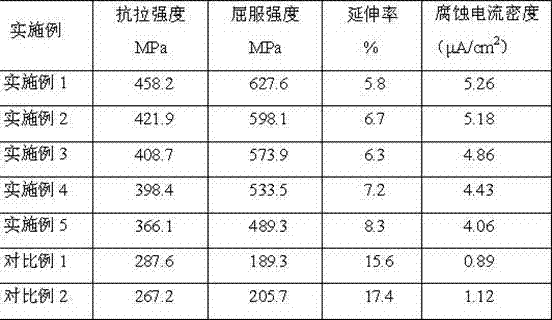

High-strength Cu-Ni-Si alloy and preparation method thereof

The invention relates to a high-strength Cu-Ni-Si alloy and preparation method thereof. The alloy comprises 2.0-6.0% of Ni, 0.5-1.5% Si, 0.5-1.0% of Ti, 0.5-1.0% of Mn, 0.5-1.0% of Ag and the balance of copper and unavoidable impurity elements. The preparation method sequentially comprises the following steps of smelting; casting; homogenization treatment; hot rolling and solution treatment; pre-cold rolling and aging treatment; and cold-rolling deformation. A Ni2Si non-oxide reinforcing phase is generated in the alloy disclosed by the invention; after the rolling is carried out repeatedly, the nucleation positions of precipitated phases can be increased, the more the broken grains, the more grain boundaries, the more nucleation positions of the precipitated phases and the more the precipitated phases; and under the condition that aging treatment is carried out repeatedly, the more precipitated phases are precipitated and thus the comprehensive performance of the alloy is dramatically increased, the strength, the elongation property at a high temperature and the electric conductivity are improved and the bending workability of the alloy is also improved.

Owner:HENAN UNIV OF SCI & TECH

High-strength high-conductivity copper base alloy and preparation method thereof

The invention relates to a high-strength high-conductivity copper base alloy and a preparation method thereof. The copper base alloy is characterized by consisting of the following components in percentage by weight: 0.05-0.15% of Fe, 0.015-0.06% of P, 0.008-0.045% of Zn, 0.005-0.05% of Sn, 0.005-0.04% of Ni, no more than 0.2% of impurity element in total and the balance of Cu. The copper base alloy provided by the invention has high strength and high conductivity as well as high strength and electric conductivity. After being smelted, the elements form a complicated order composite structure in a copper base, and the hardness and conductivity of the C19210 alloy is greatly improved after an aging process.

Owner:CNMC NINGXIA ORIENT GRP

Method for removing strained layer on surface of single crystal blade casting through chemical milling

The invention discloses a method for removing a strained layer on the surface of a single crystal blade casting through chemical milling. The method comprises the following steps of: (1) tightly plugging a blade window of the single crystal blade casting by using paraffin; (2) removing degreasing fluid on the surface by washing, and putting into chemical milling fluid for corrosion; (3) after the chemical milling is finished, putting into neutralization solution for neutralization; and (4) removing the neutralization solution on the surface by washing, and removing the paraffin which is used for plugging the blade window. In the invention, the surface of the single crystal blade casting is corroded through chemical milling treatment, so that recrystallization can be effectively prevented, rejection rates are reduced, and the method is easy to operate.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

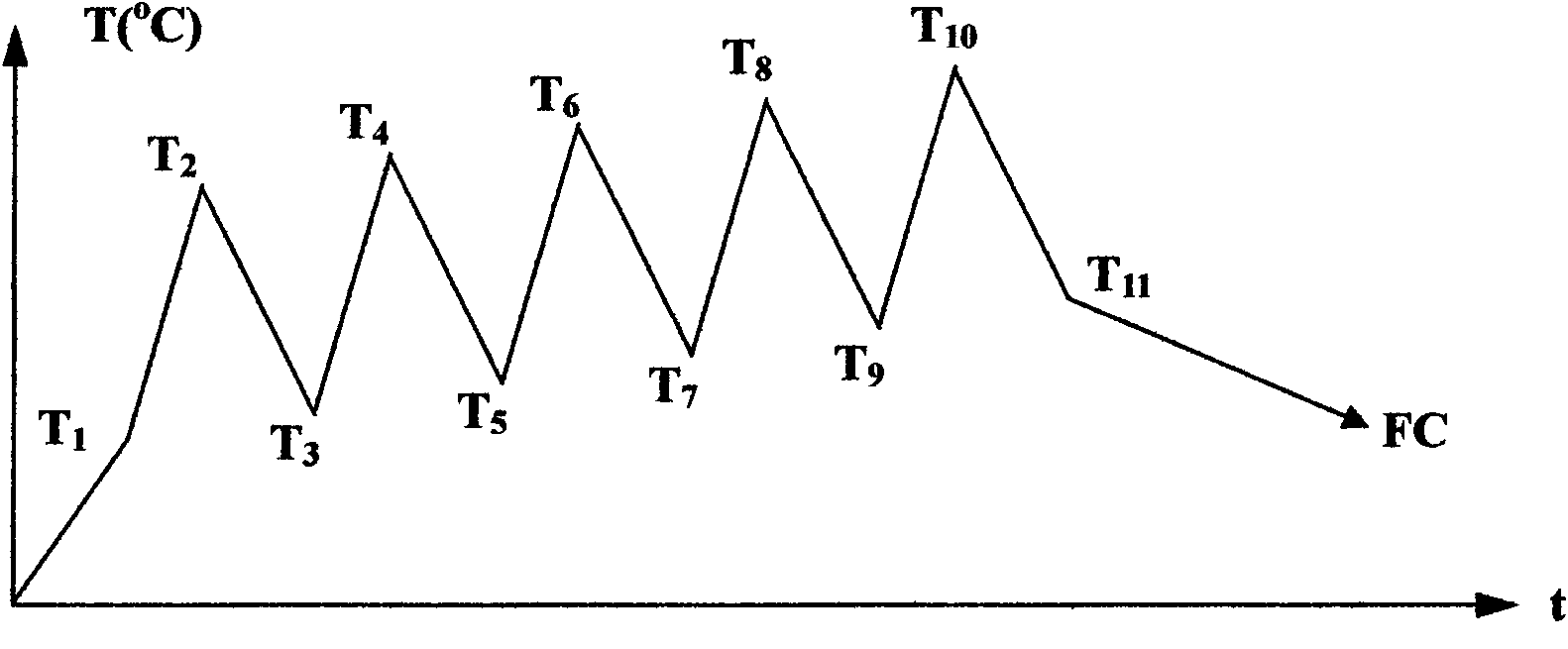

Controlled directional solidification nickel-base high-temperature alloy recrystallizing method

ActiveCN102071385AEasy to get materialsLow priceSolid state diffusion coatingStored energyGraphite electrode

The invention provides a controlled directional solidification nickel-base high-temperature alloy recrystallizing method, which is characterized in that: a carburization and circulating heat treatment combined process is adopted to perform the heat treatment on a deformed directional solidification nickel-base high-temperature alloy, and then the alloy is subjected to standard solution treatment; a carburization is a micro-arc-spark carburization, the carburization material is a graphite electrode, and the carburization process parameters include a frequency of 1,000 to 5,000Hz, a power of 500 to 3,000W and a voltage of 20 to 100V; and the highest heat treatment temperature in each period of a circulating heat treatment process is at least 20 DEG C lower than the solid solution temperature of the alloy, the lowest heat treatment temperature in each period is not lower than the aging heat treatment of the alloy, and 3 to 10 circulation periods are adopted. The method can reduce the recrystallization-nucleation on the surface of the alloy, inhibit the growth of recrystals, reduce the stored energy of the deformed alloy, and thus control the recrystallization and obviously reduce the recrystals generated after the deformation of the nickel-base high-temperature alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Aluminum alloy material for manufacturing power cable link fittings and preparation method of aluminum alloy material

The invention discloses an aluminum alloy material for manufacturing power cable connecting fittings, which belongs to the technical field of electric fittings, and comprises the following raw materials in parts by weight: 1.10-2.15 parts of copper, 0.50-1.20 parts of manganese, 0.20-0.65 parts of silicon, zinc 0.10-1.70 parts, magnesium 0.50-1.05 parts, boron 0.10-0.14 parts, iron 0.10-0.30 parts, chromium 0.12-0.20 parts, nickel 0.08-0.12 parts, titanium 0.10-0.20 parts, zirconium 0.02-0.04 parts, scandium 0.04-parts 0.06 parts, 0.03-0.07 parts of bismuth, and 100 parts of aluminum; the invention also discloses a preparation method of an aluminum alloy material used to manufacture power cable connecting fittings; the invention has better strength and heat resistance, and the preparation process is stable , effective, not easy to crack and deflection.

Owner:HEFEI DAZHUO ELECTRIC POWER CO LTD

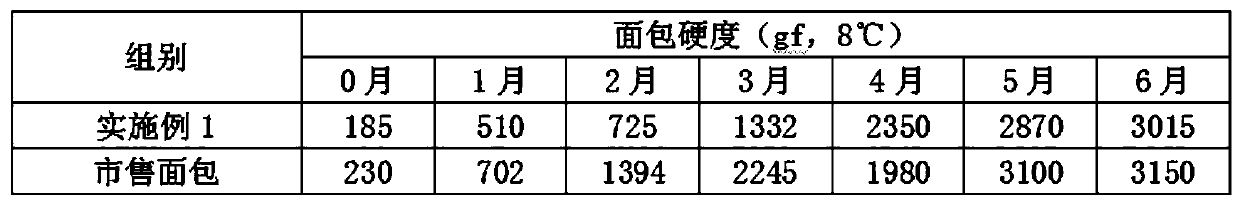

Production method of anti-aging convenient cooked rice

The present invention provides a production method of anti-aging convenient cooked rice and belongs to the technical field of food processing. The anti-aging convenient cooked rice is obtained by thespecific method comprising the steps of rice washing, soaking liquid soaking, sub-packaging, cooking, sterile vacuum sealing, cooling and crystallization, etc. The technologies of soaking by the liquid containing an anti-aging agent and rapid cooling are used to inhibit aging of starch and improve eating quality of starch-based staple food. The aging rate and the aging degree of the obtained convenient cooked rice are low; the aging degree of the convenient cooked rice obtained after storage for 90 days reduces by about 30% compared with that of the traditional convenient cooked rice; and theanti-aging convenient cooked rice has advantages of excellent taste quality, long shelf life, etc.

Owner:JIANGNAN UNIV

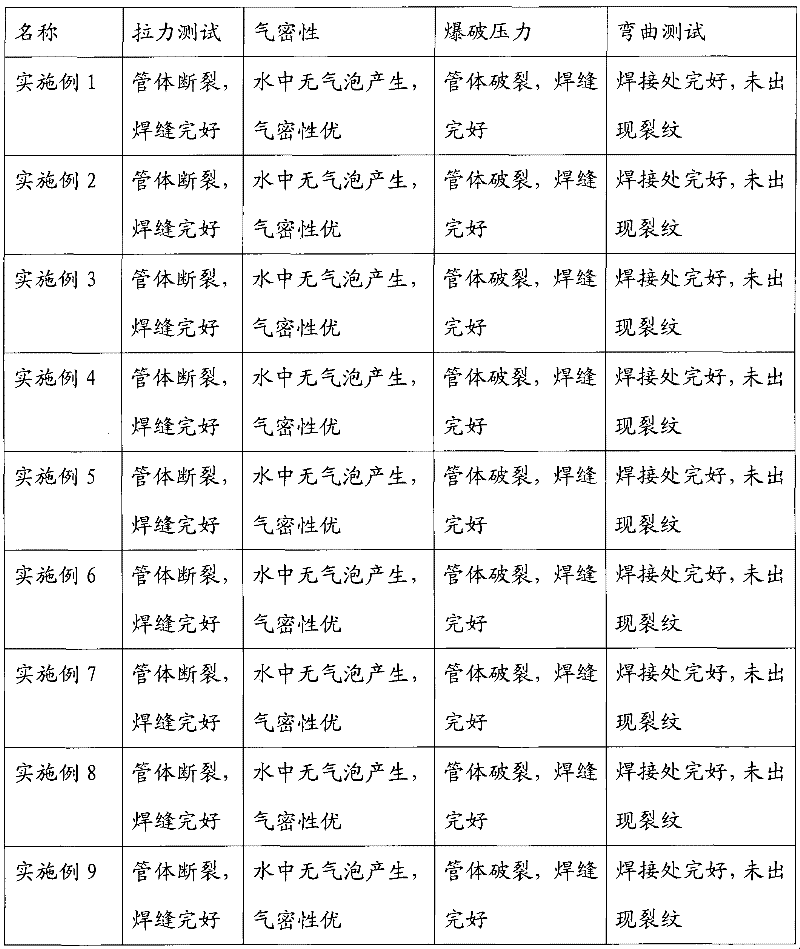

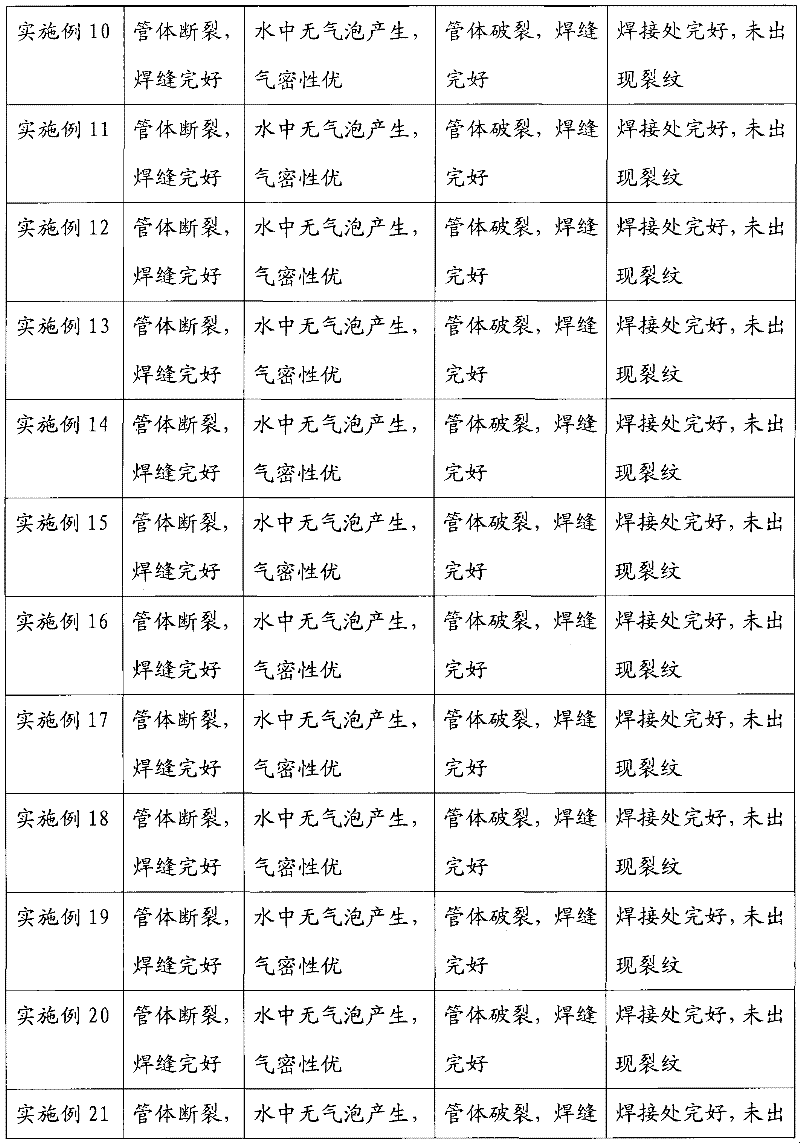

Flux-cored wire for copper and aluminum welding

ActiveCN102441744AImprove air tightnessImprove wettabilityWelding/cutting media/materialsWelding/soldering/cutting articlesCopperUltimate tensile strength

The invention discloses a flux-cored wire for copper and aluminum welding. The wire comprises the following chemical components in percentage by weight: 0-1.0 percent of Ce, 0-1.0 pecent of La, 0-15 percent of Cu, 0-10 percent of Ag, 0-12 percent of Si, 1-15 percent of Al and the balance of Zn and the other inevitable impurities. In the invention, the chemical components of the wire are designed reasonably, so that the wire has the characteristics of high wettability, high penetrating capability, high pulling performance, high fluidity, high welding strength, high air tightness after welding, no corrosion after welding, and the like.

Owner:LICHUANG TAISHAN ELECTRONICS TECH

Aluminum alloy bar with high strength and high tenacity and preparation technology thereof

ActiveCN107201468AReduce heating temperature and extrusion speedDecrease dynamic responsivenessRare-earth elementDislocation

The invention provides an aluminum alloy profile with high strength and high tenacity and a preparation technology thereof, and relates to the technical field of metal material smelting. Setting the total weight of the aluminum alloy profile as the base, an aluminum alloy bar with the high strength and the high tenacity includes, by weight, 3.15-5.21% of Zn, 0.35-1.2% of Mn, 0.56-1.28% of Mg, 0.01-0.08% of Sb, 0.08-0.15% of Cu, 0.05-0.12% of Zr, 0.06-0.16% of V, 0.003-0.012% of rare earth elements, the balance Al and unavoidable impurities. The aluminum alloy profile with the high tenacity forms an aluminide dispersed phase in the system through aluminum and other metal, the synergistic effect is generated, the effects of refining casting grains and strengthening pin dislocation are achieved, so that the recrystallization temperature of the aluminum alloy profile is improved dramatically, recrystallization of the grains is reduced, the problem of quenching sensitivity is solved, and the strength, the fracture tenacity and the stress corrosion resistance of the aluminum alloy profile are improved.

Owner:浙江大侠铝业有限公司

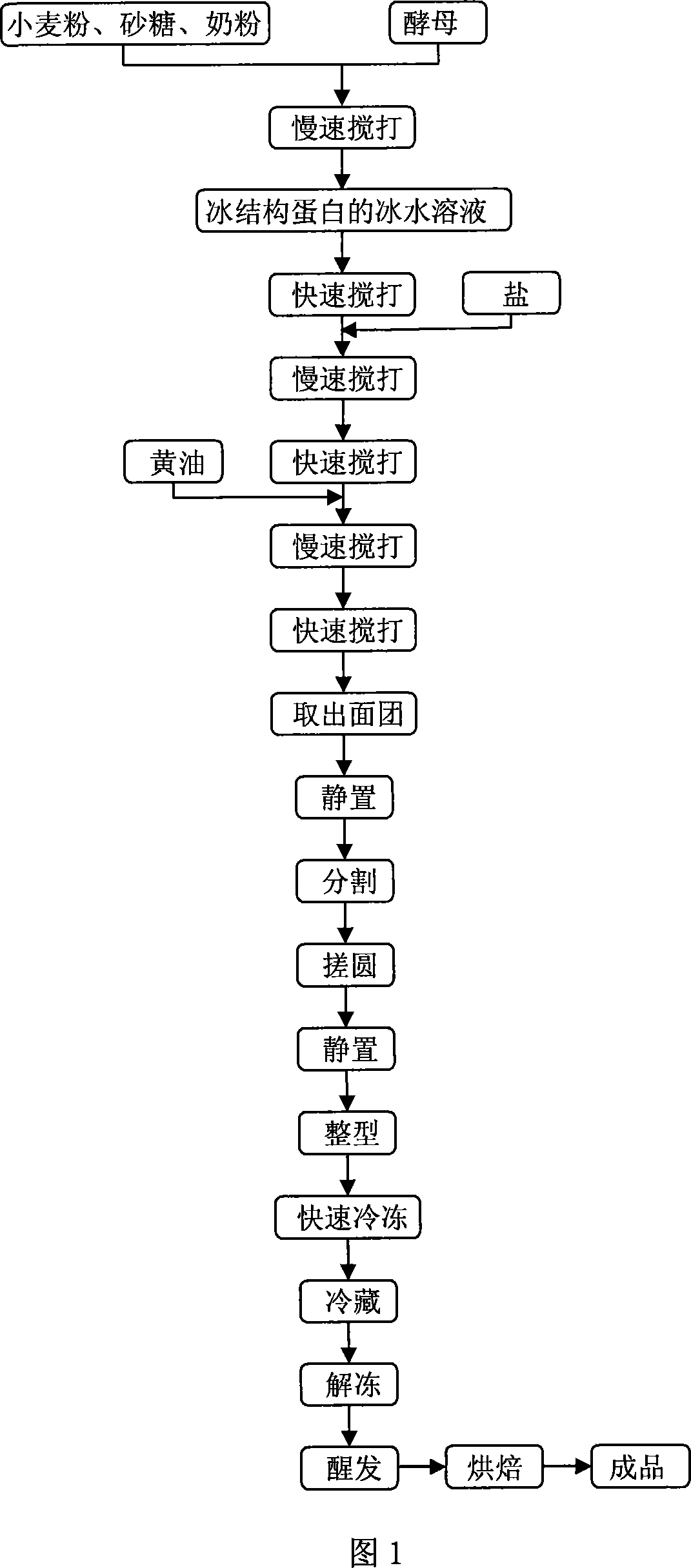

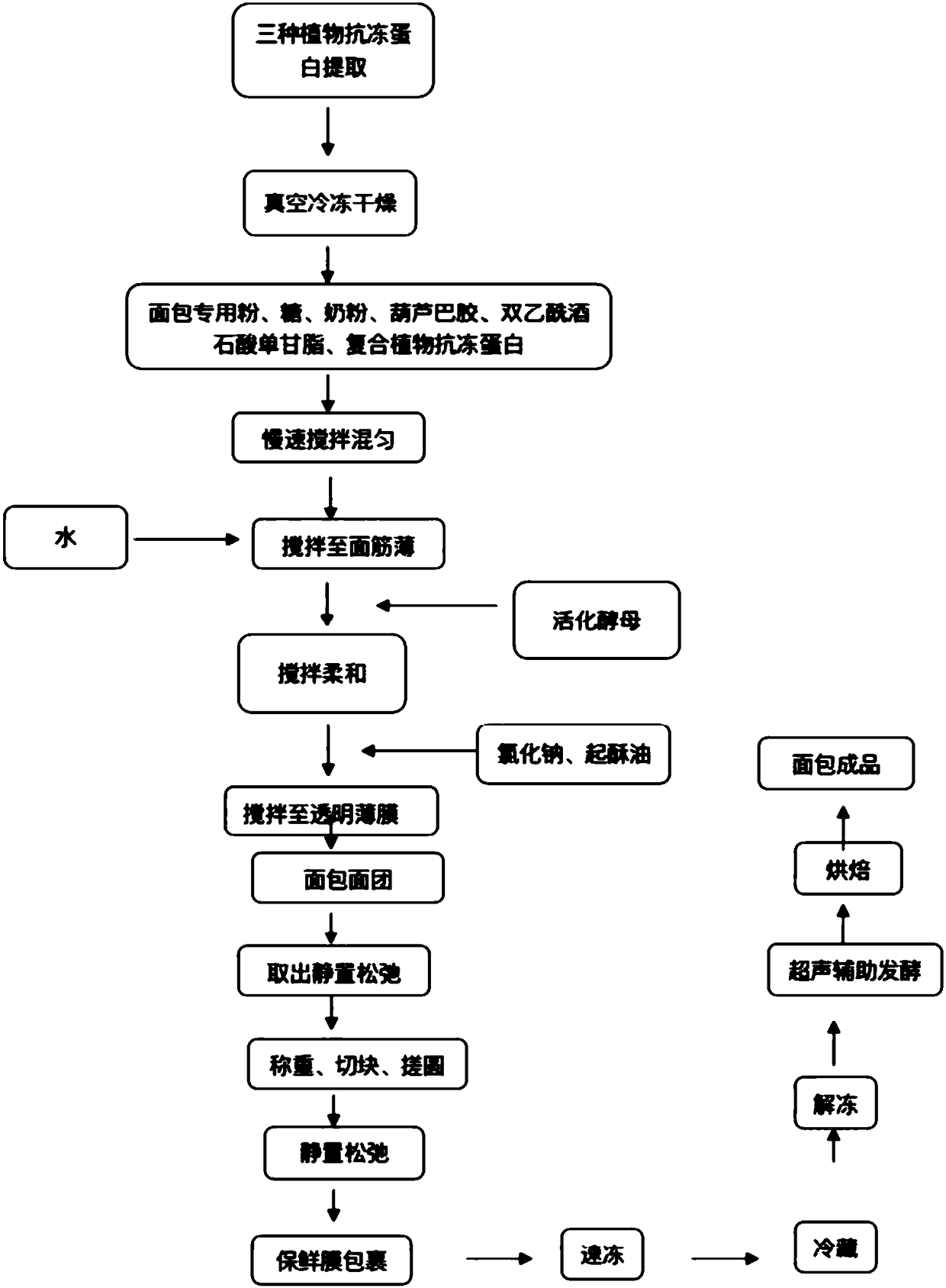

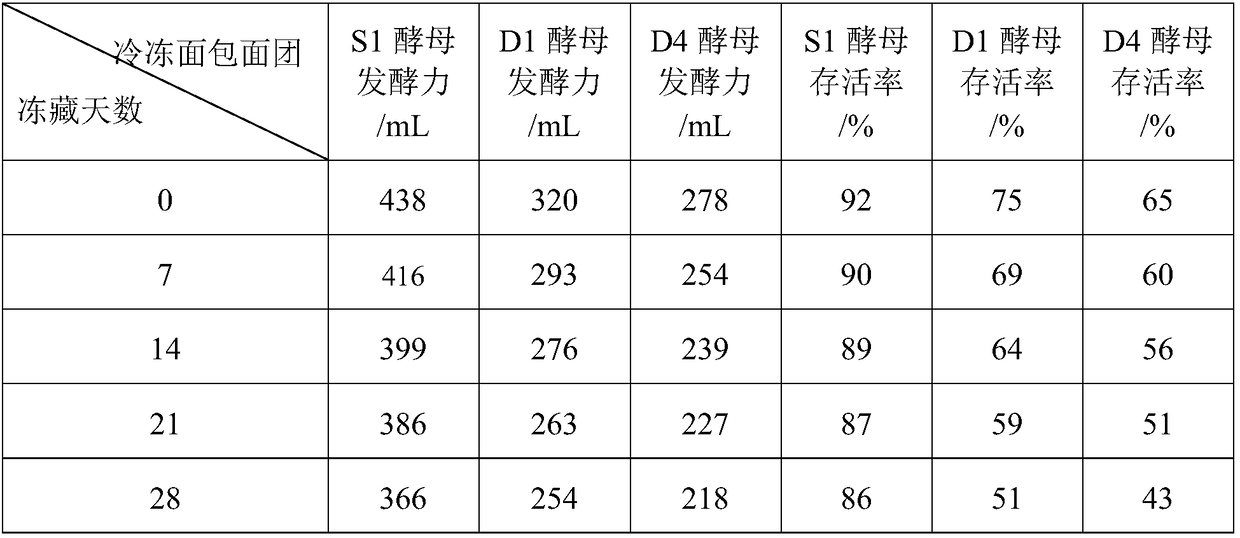

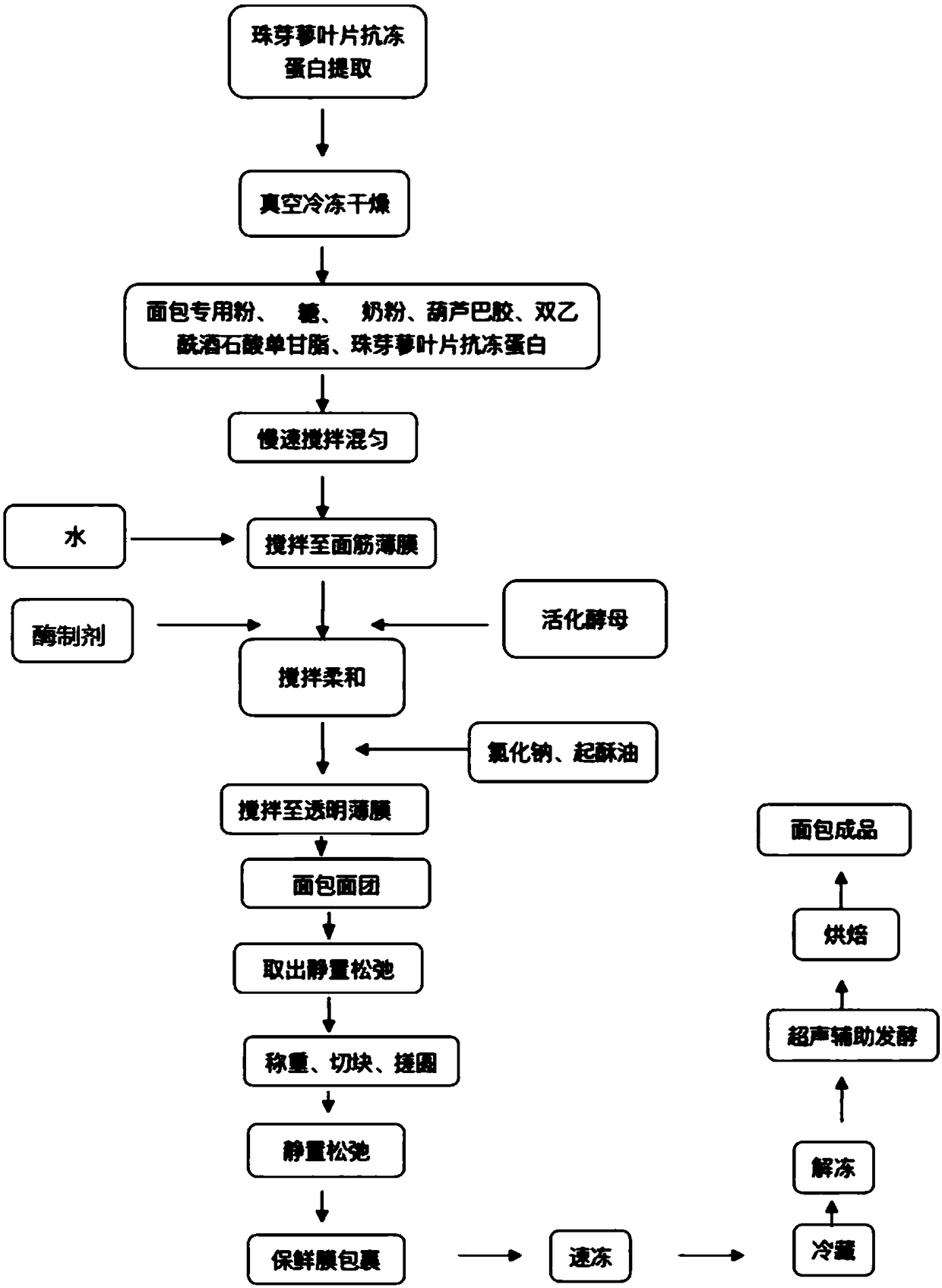

Method for producing freezing dough through the antifreezing zymolysis of ice structure protein

InactiveCN101133751AReduce recrystallizationAvoid growing upDough treatmentPre-baking dough treatmentYeastIce water

The present invention relates to a method for producing frozen dough by using ice-structure protein and utilizing a certain antifreezing fermentation process, belonging to the field of food processing technology. Said production method includes the following steps: adding wheat flour, granulated sugar, milk powder and yeast into a stirring apparatus, slowly beating and uniformly stirring them to obtain their mixture; dissolving ice-structure protein in ice water and adding them into the above-mentioned mixture, beating until the dough is formed into gluten film; adding salt and butter, beating them until the dough is formed into uniform and transparent film, taking out dough, standing still, cutting, rolling, further standing still, shaping and placing the dough into a refrigerator until the dough is completely hardened, sealing and storing; taking out frozen dough and proving so as to obtain the invented finished product.

Owner:JIANGNAN UNIV

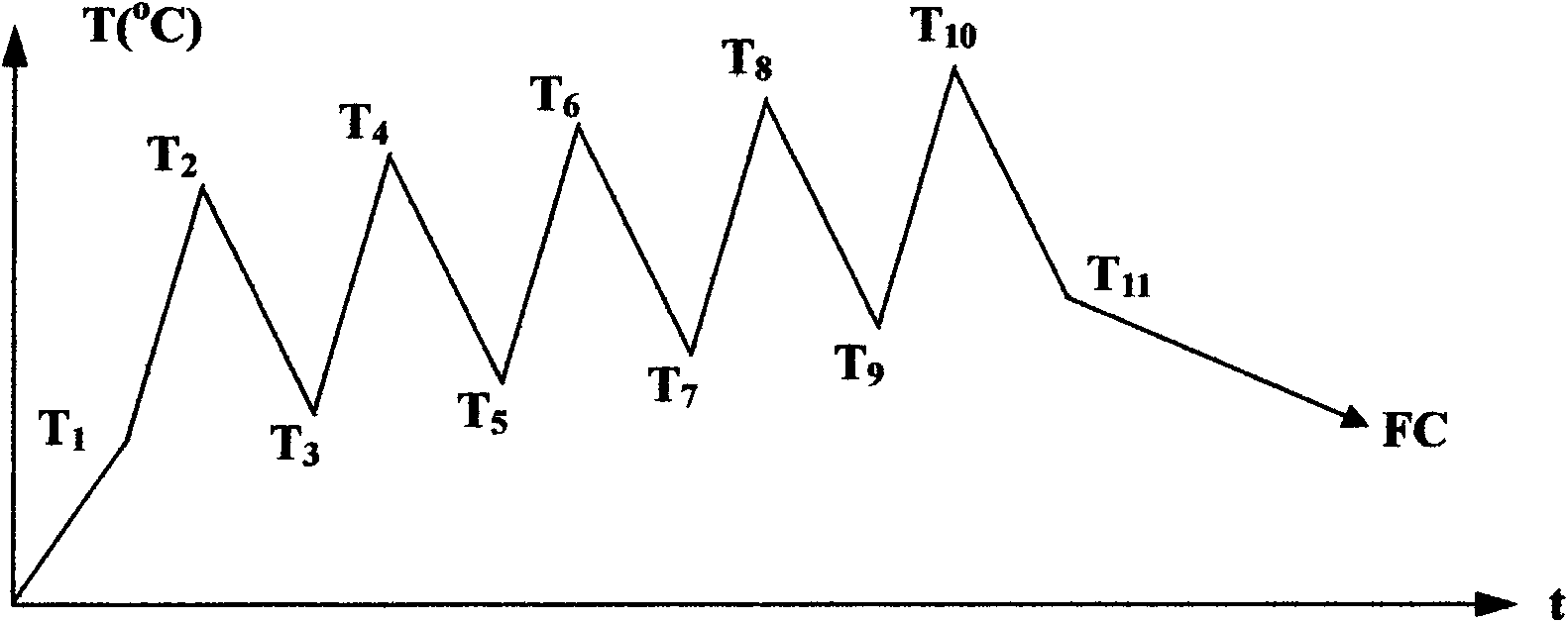

Controlled directional solidification nickel-base high-temperature alloy recrystallizing method

ActiveCN102071384AReduce residual stressConsume stored energyAfter-treatment detailsStored energyNucleation

The invention provides a controlled directional solidification nickel-base high-temperature alloy recrystallizing method, which is characterized in that: a coating and circulating heat treatment combined process is adopted to treat a deformed directional solidification nickel-base high-temperature alloy and then the alloy is subjected to standard solution treatment; a coating is made of Zr / NiCoCrAlYSiB, Zr / ZrO2 / NiCoCrAlYSiB, NiCoCrAlYSiB or C / NiCoCrAlYSiB; and the highest heat treatment temperature in each period of a circulating heat treatment process is at least 20 DEG C lower than the solid solution temperature of the alloy, the lowest heat treatment temperature in each period is not lower than the aging heat treatment of the alloy, and 3 to 10 circulation periods are adopted. The method can reduce recrystallization-nucleation and oxidization on the surface of the alloy, reduce the stored energy of the deformed alloy and thus control the nickel high-temperature alloy to recrystallize.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

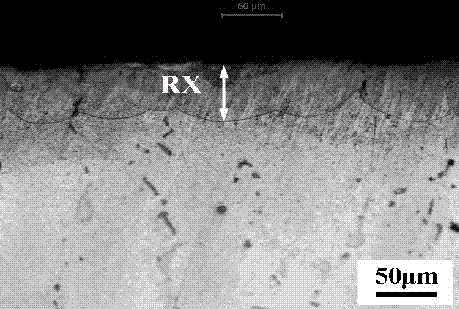

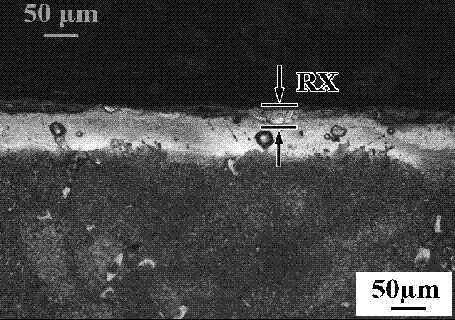

Method for controlling recrystallization of directionally solidified Ni-based superalloy by alumetizing

InactiveCN102899606AInhibition of recrystallizationInhibit the development of recrystallizationAfter-treatment detailsSolid state diffusion coatingSuperalloyMaterials science

The invention provides a method for controlling the recrystallization of directionally solidified Ni-based superalloy by alumetizing, characterized by carrying out alumetizing on the surface of a directionally solidified Ni-based superalloy component that is deformed by alumetizing,; and carrying out standard solution treatment of alloy matrixes on the alumetized directionally solidified Ni-based superalloy component. According to the invention, the depth of the recrystallization of the directionally solidified Ni-based superalloy is controllable, and the control effect on the recrystallization caused by uniform deformation is significant. Compared with recrystals generated by deformed directionally solidified alloy sample without alumetizing, the recrystals are distributed scatteredly and nonuniformly, the maximum recrystallization depth is obviously reduced, the recrystallization area is correspondingly obviously reduced, there is no residual stress in electroplating process, thus the possibility of generating recrystals by residual stress is avoided. The alumetizing method is one of the most efficient methods for inhibiting the development of recrystallization.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Chromium/zirconium/iron/copper alloy electrode material, and preparation and application method thereof

InactiveCN103131886AInhibition of hardness reductionHigh strengthWelding/cutting media/materialsSoldering mediaMechanical propertyImpurity

The invention relates to a chromium / zirconium / iron / copper alloy electrode material, and a preparation and application method thereof. The chromium / zirconium / iron / copper alloy contains the following components in percentage by weight: 0.8-2.0% of chromium, 0.2-0.3% of zirconium, 0.01-0.04% of iron and the balance of copper and impurity. The invention also provides a preparation method of the alloy material. The method comprises the following steps: smelting a copper alloy to form a cast ingot, performing hot rolling, and performing solution treatment at 960-980 DEG C; performing cold rolling deformation pressure processing; and finally, performing aging treatment at 430-630 DEG C. Thus, due to the improved mechanical property and heat resistance, high conductivity, high softening temperature and high yield stress at high temperature, the prepared alloy material can be used as an electrode material in welding and indicates excellent continuous welding capability.

Owner:HUNAN YINLIAN XIANGBEI COPPER IND

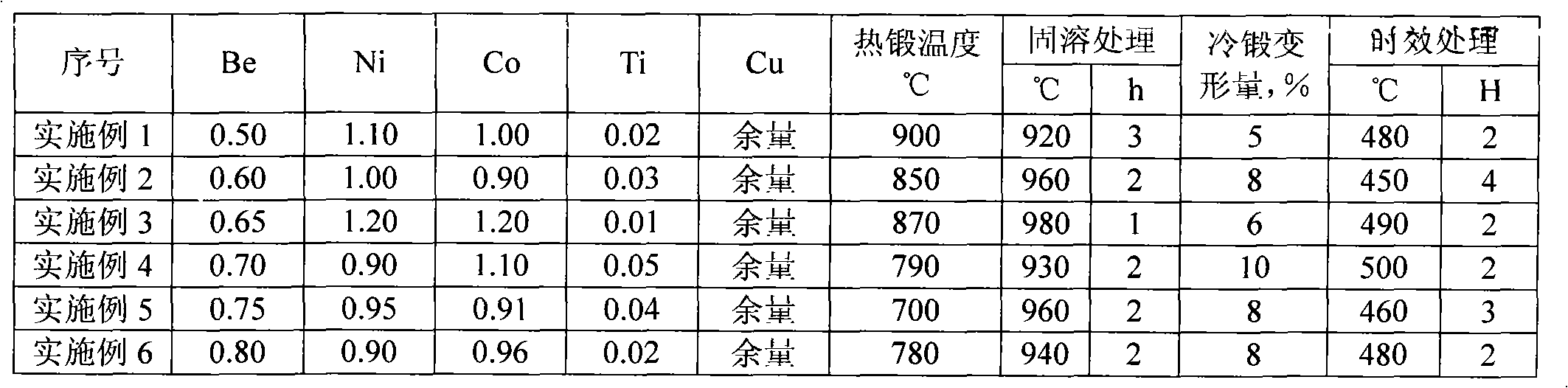

Low copper beryllium mold material for gravitation and low-pressure casting and production process thereof

The invention provides a low beryllium copper alloy mold material used for gravity and low pressure casting as well as a production process, comprising: adding Ni, Co and Ti elements on the basis of a low beryllium copper alloy, giving full play to advantages of the interaction of alloying elements, carrying out processing steps of cold deformation and time effect treatment after the hot forging, solution treatment and water quenching to a cast ingot, and obtaining the special low beryllium copper alloy mold material used in the gravity and low pressure casting industry and having high strength, good toughness and high heat conductivity, and products of the invention are equivalent to ASTM B534 C17500 materials and can fully replace imported goods.

Owner:周水军

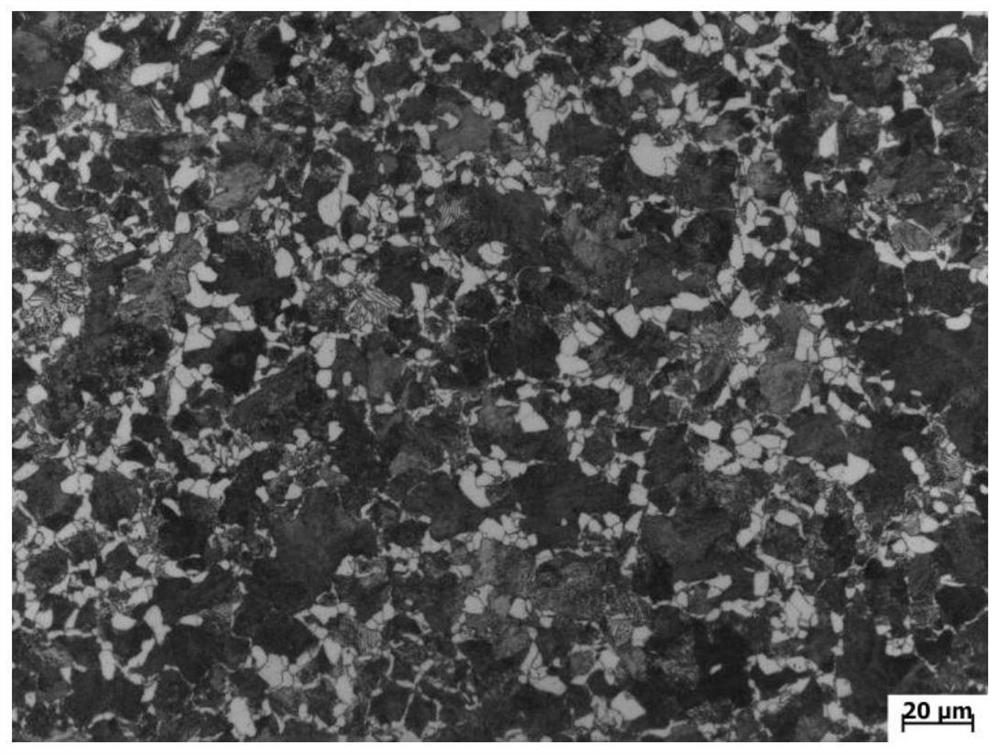

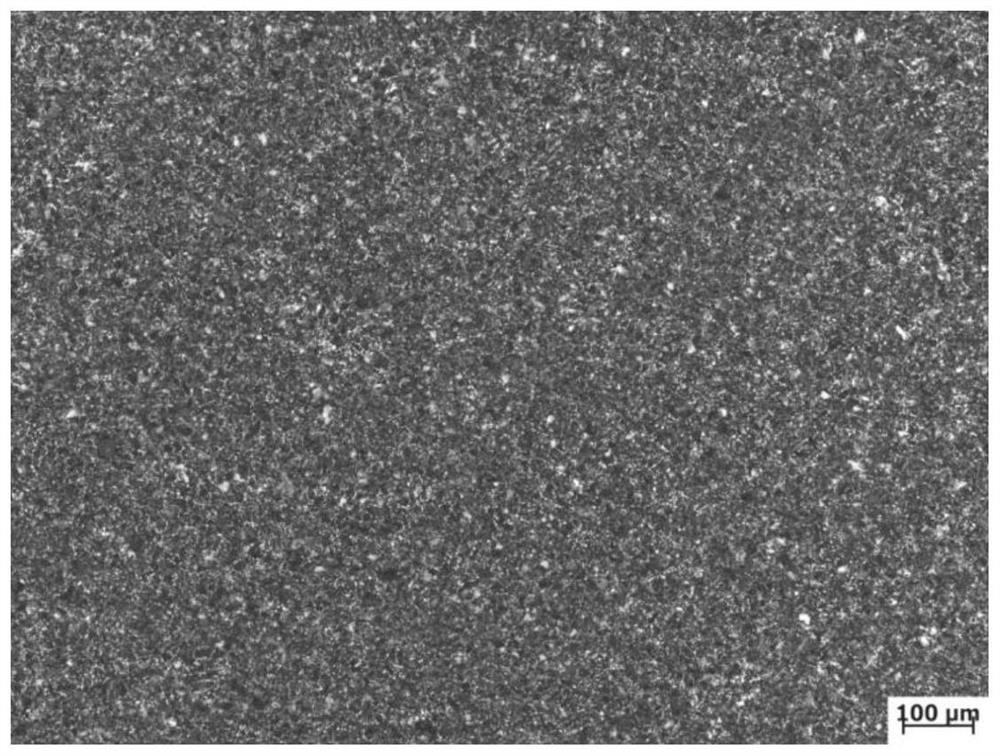

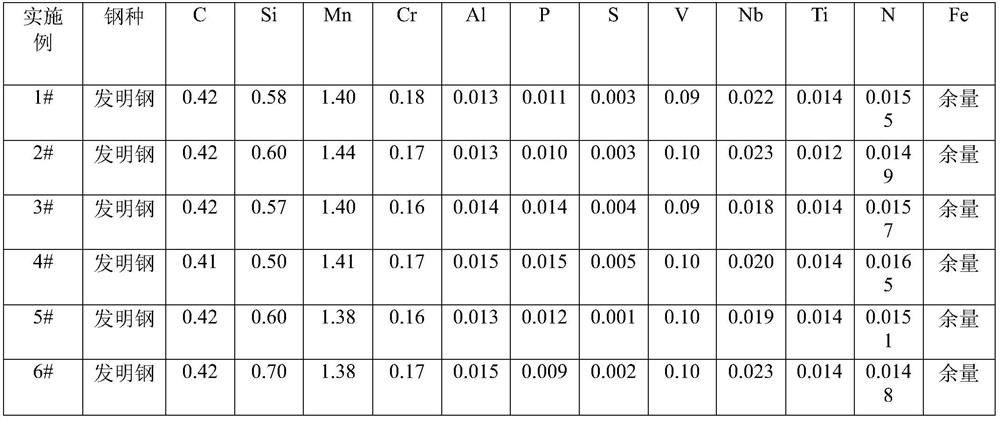

High-strength high-toughness medium and large-diameter non-quenched-and-tempered steel for direct cutting and production process thereof

ActiveCN113122776AIdeal organizationIdeal mechanicsTemperature control deviceWork treatment devicesContinuous rollingToughness

The invention belongs to the technical field of non-quenched-and-tempered steel, and relates to high-strength high-toughness medium and large-diameter non-quenched-and-tempered steel for direct cutting and a production process thereof. The steel comprises the following components of 0.38 to 0.45 % of C, 0.50 to 0.70 % of Si, 1.20 to 1.60 % of Mn, not larger than 0.020 % of P, not larger than 0.035 % of S, 0.10 to 0.20 % of Cr, 0.08 to 0.18 % of V, 0.010 to 0.030 % of Nb, 0.010 to 0.030 % of Ti, not larger than 0.025 % of Ni, not larger than 0.015 % of Mo, not larger than 0.030 % of Al, not larger than 0.2 % of Cu, 130 to 200ppm of N, less than or equal to 2.0 ppm of H, less than or equal to 20ppm of O and the balance Fe and inevitable impurities. By optimizing the components, increasing the silicon content, and combining the semi-continuous rolling technology to achieve a controlled rolling and controlled cooling process, finally the medium and large-diameter non-quenched-and-tempered steel which is excellent in performance and used for direct cutting is obtained.

Owner:JIANGSU YONGGANG GROUP CO LTD

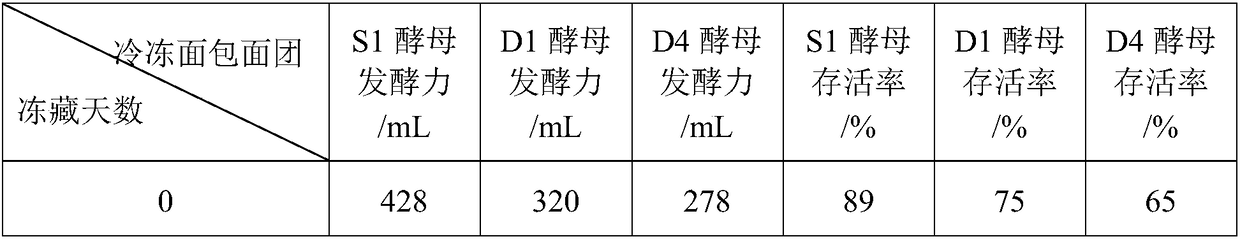

Frozen bread dough containing compound plant antifreeze protein, preparing method thereof and method for preparing bread through optimized process

The invention discloses frozen bread dough containing compound plant antifreeze proteins, a preparing method thereof and a method for preparing bread through an optimized process. The frozen bread dough is prepared from, 40-50 wt% of bread special flour, 9-12 wt% of sugar, 0.5-1.5 wt% of yeast, 0.4-0.8 wt% of sodium chloride, 1.5-3 wt% of milk powder, 5-11 wt% of shortening, 0.05-0.15 wt% of fenugreek gum, 0.05-0.30 wt% of monoglycerides tartartaric acid diacetate, 20-30 wt% of water, 0.25-1.5 wt% of carrot antifreeze protein powder, 0.5-3 wt% of Tangut rhodiola rosea leaf antifreeze protein powder and 0.5-3 wt% of polygonum viviparum leaf antifreeze protein powder. The bread produced after the bread antifreeze dough is unfrozen, leavened and baked has the advantages of being large in specific volume, crispy, soft and delicious, and extremely excellent in sensory quality.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Processing method for inhibiting recrystallization of aluminum alloy sheet

Field of the invention relates to a processing method for inhibiting recrystallization of aluminum alloy sheets. According to the processing method for inhibiting recrystallization of aluminum alloy sheets, after the homogenization, a slab ingot is transferred to a cooling room for strong wind cooling or spray cooling, on order to cool the slab ingot to a temperature below 105 DEG C in 30-50 minutes. At the same time, the preheating process before hot rolling rapidly heats the ingot, in order to reduce the heat preservation time, re-dissolve the fine of precipitated phases and inhibit the re-precipitation or re-coarsening. The invention does not need expensive Sc element for alloying, inhibits the recrystallization of aluminum alloy sheets only through the process, reduces the recrystallization fraction of the aluminum alloy sheets, and has low cost and obvious economic benefits and social benefits.

Owner:广西南南铝加工有限公司

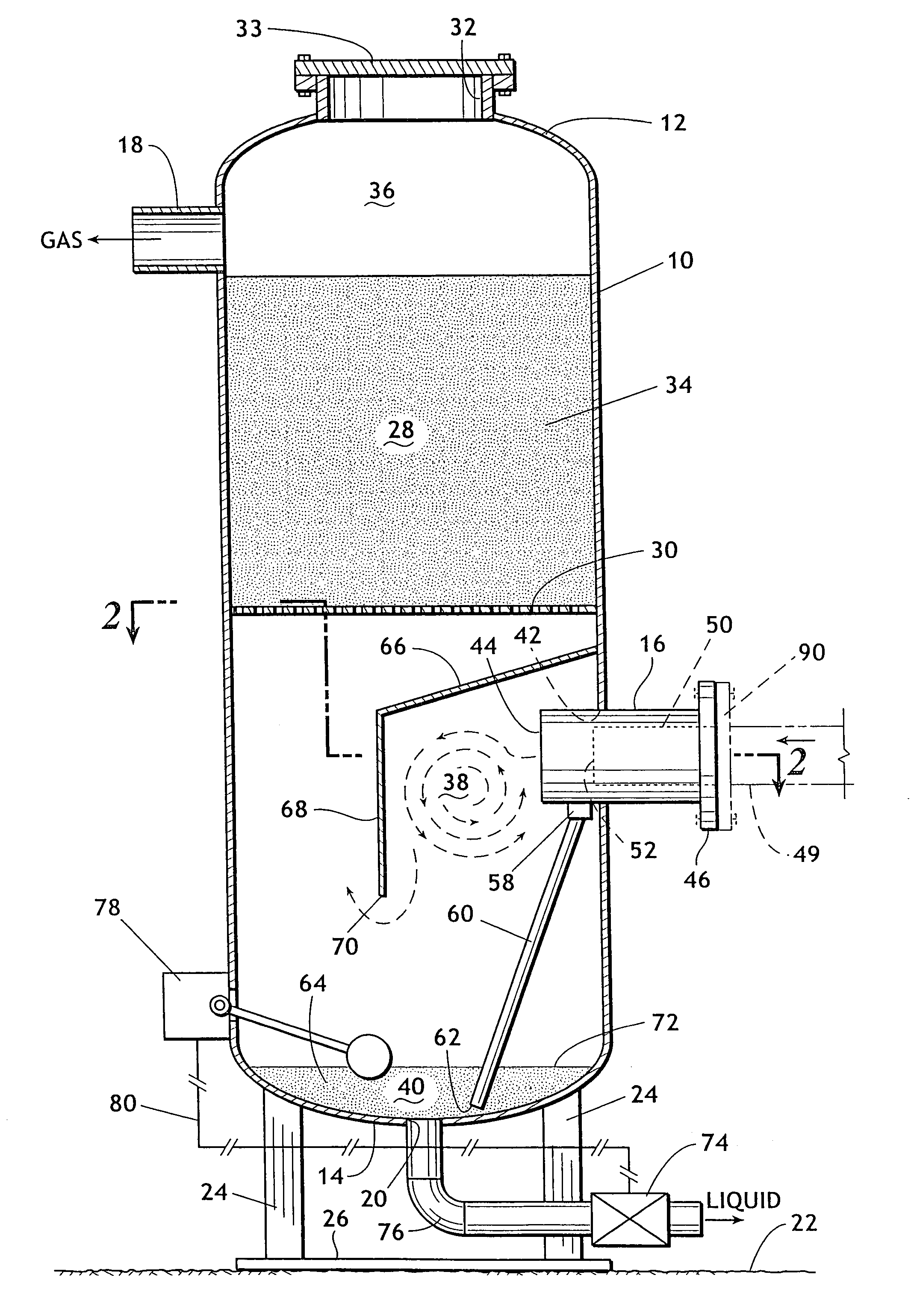

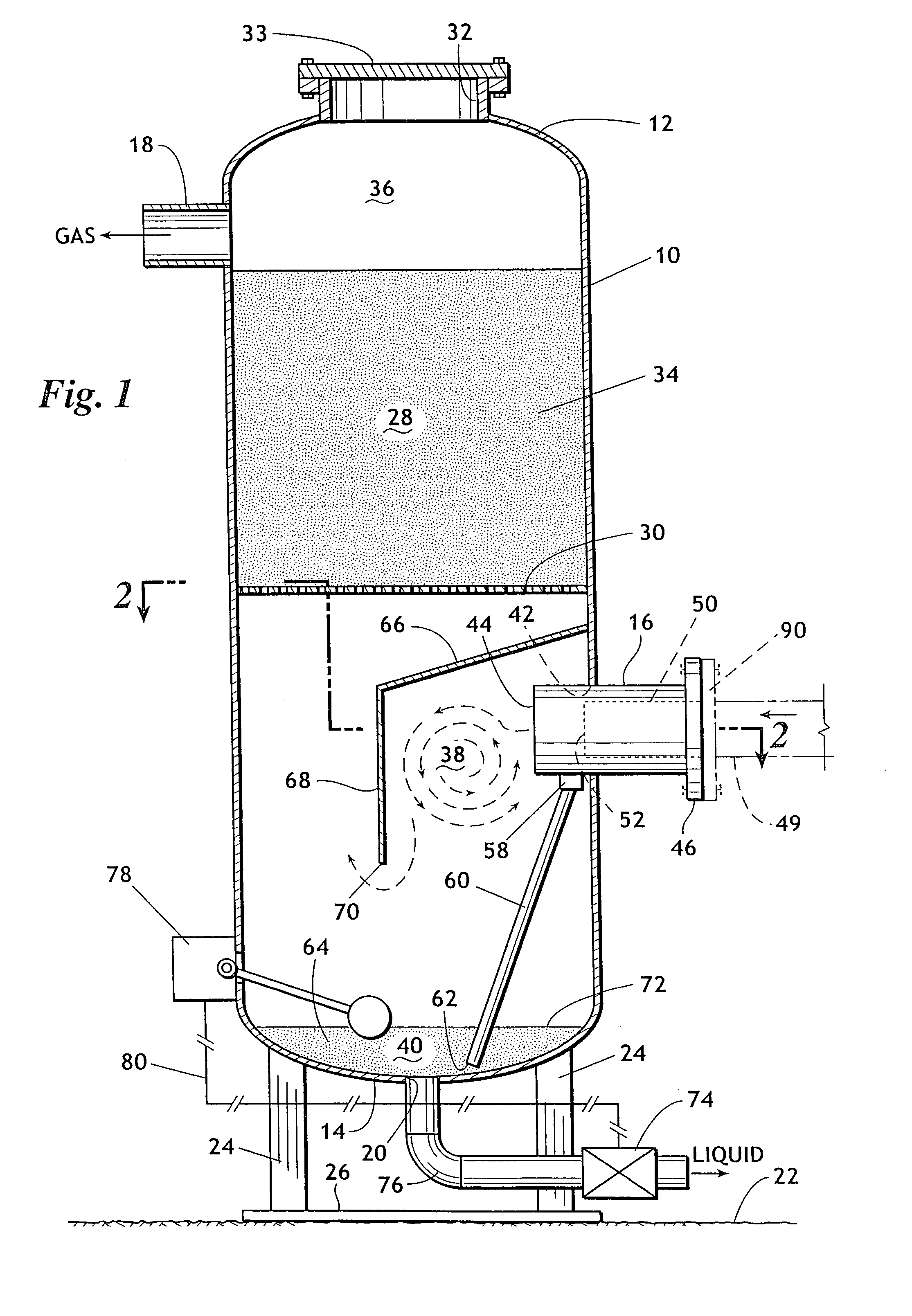

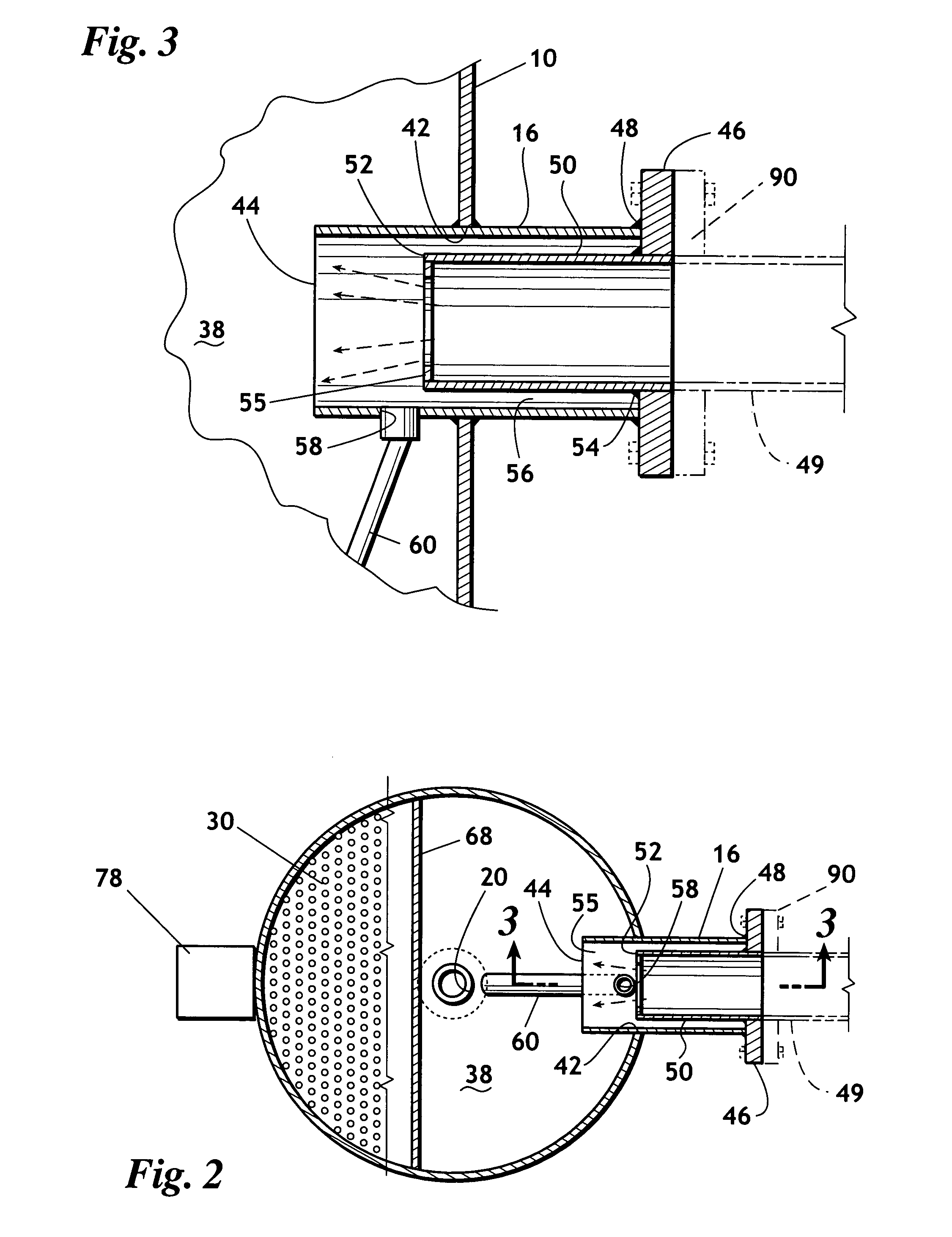

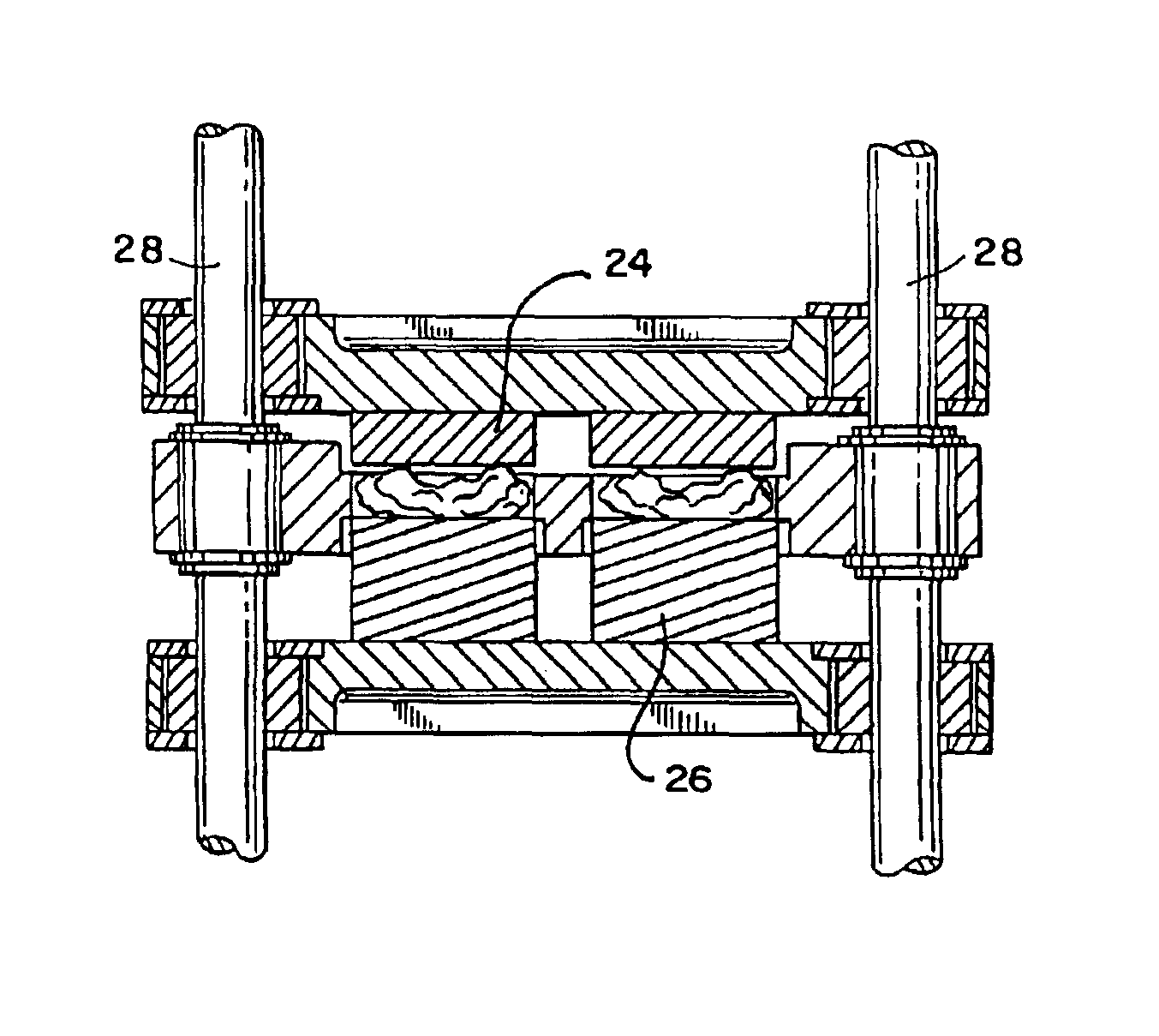

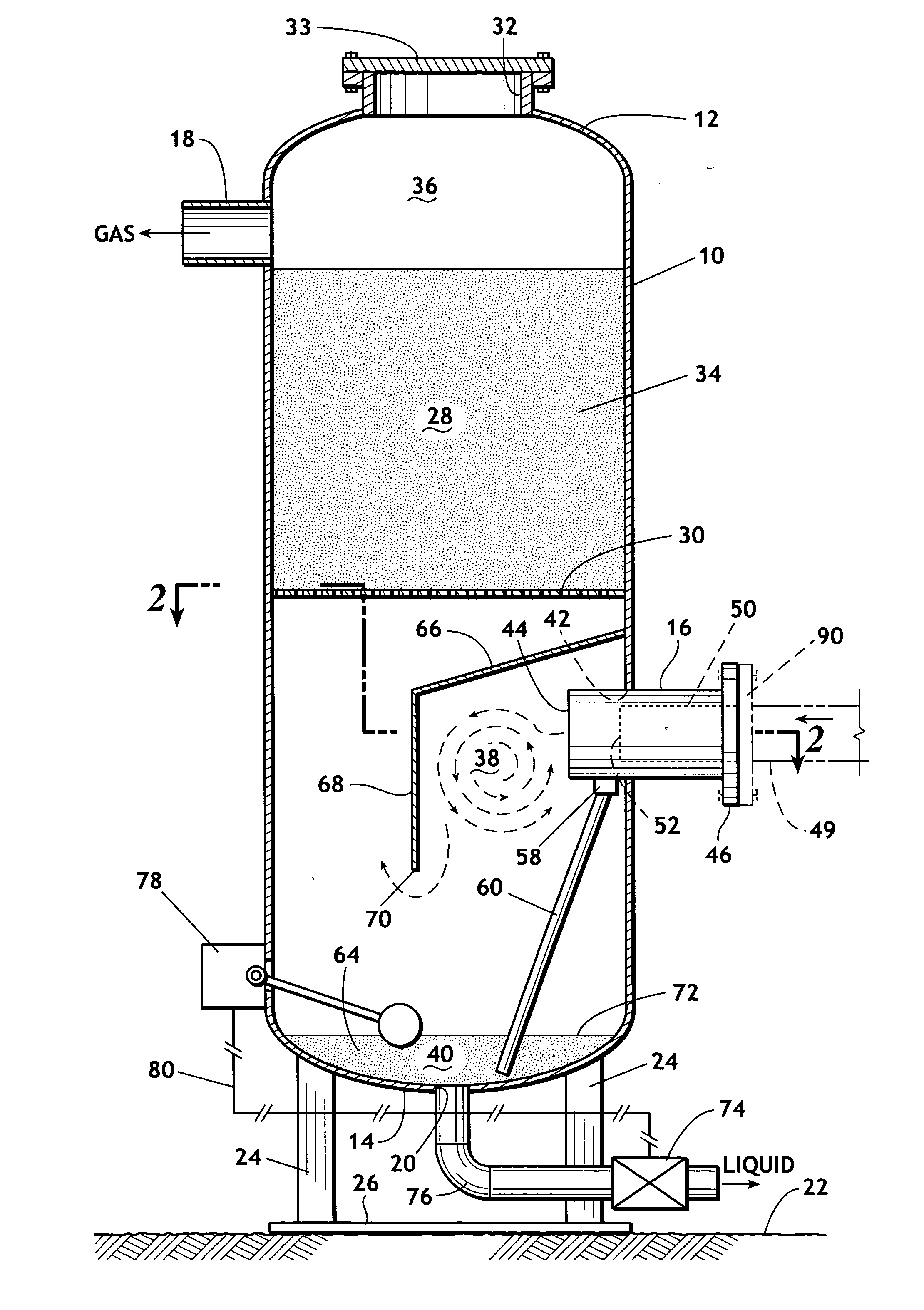

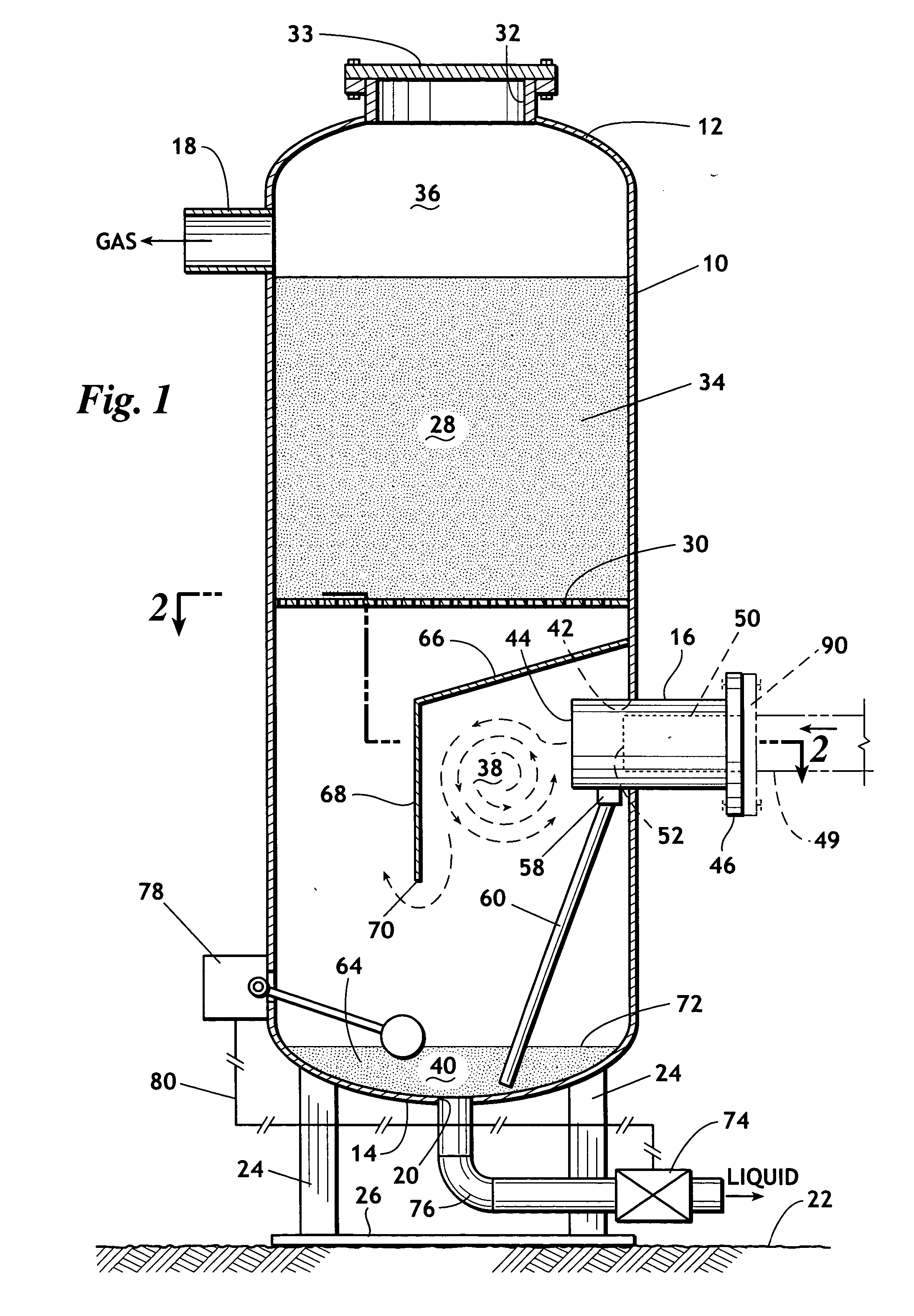

Dehydration of wet gas utilizing intimate contact with a recirculating deliquescent brine

InactiveUS7008464B2Improve efficiencyReduce recrystallizationCombination devicesAuxillary pretreatmentEngineeringEnvironmental engineering

A system for removing moisture from a wet gas stream including a vessel having a contact area containing deliquescing salts that produces brine as water is absorbed, the brine flowing to a collection area in the bottom of the vessel. A venturi positioned in a wet gas inlet stream produces an area of reduced pressure that is applied to a brine flow path connected to the brine collection area. In this way, the brine is recirculated into intimate contact with the wet gas inlet stream causing the brine to be diluted with water extracted from the wet gas stream.

Owner:NAT TANK

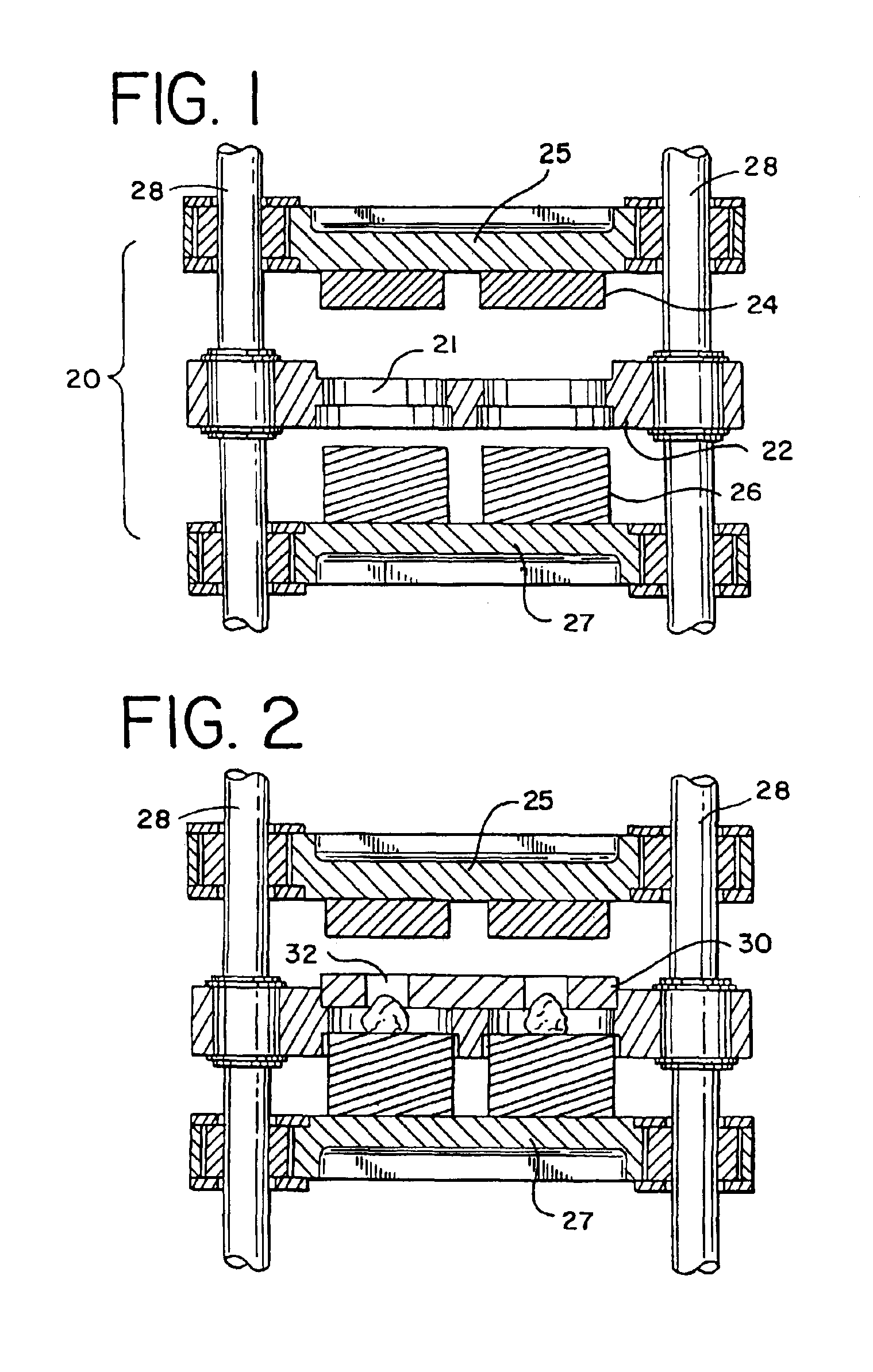

Method for making a puffed food starch product

InactiveUS6929813B2Reduce pressurePromote puffingBakery productsFood shapingFood productsFOOD STARCH

The present invention provides a method of making a puffed food starch material product. A food starch material capable of volumetric expansion in three dimensions is placed into a puffing chamber. Expansion of the food starch material includes constraining expansion of the food starch material in at least a first dimension while permitting unconstrained expansion of the food starch material in a second dimension to produce a unitary, puffed food starch material product with at least one surface having a wavy contour.In a method of making a puffed food starch material product of the present invention, a puffing chamber is provided having inner surfaces and a chamber volume. A bulk amount of the food starch material is placed into the puffing chamber. The bulk amount of food starch material is caused to volumetrically expand. The expanding food starch material is constrained in its expansion in at least a first dimension, while permitting expansion of the bulk amount in at least a second dimension.

Owner:THE QUAKER OATS CO

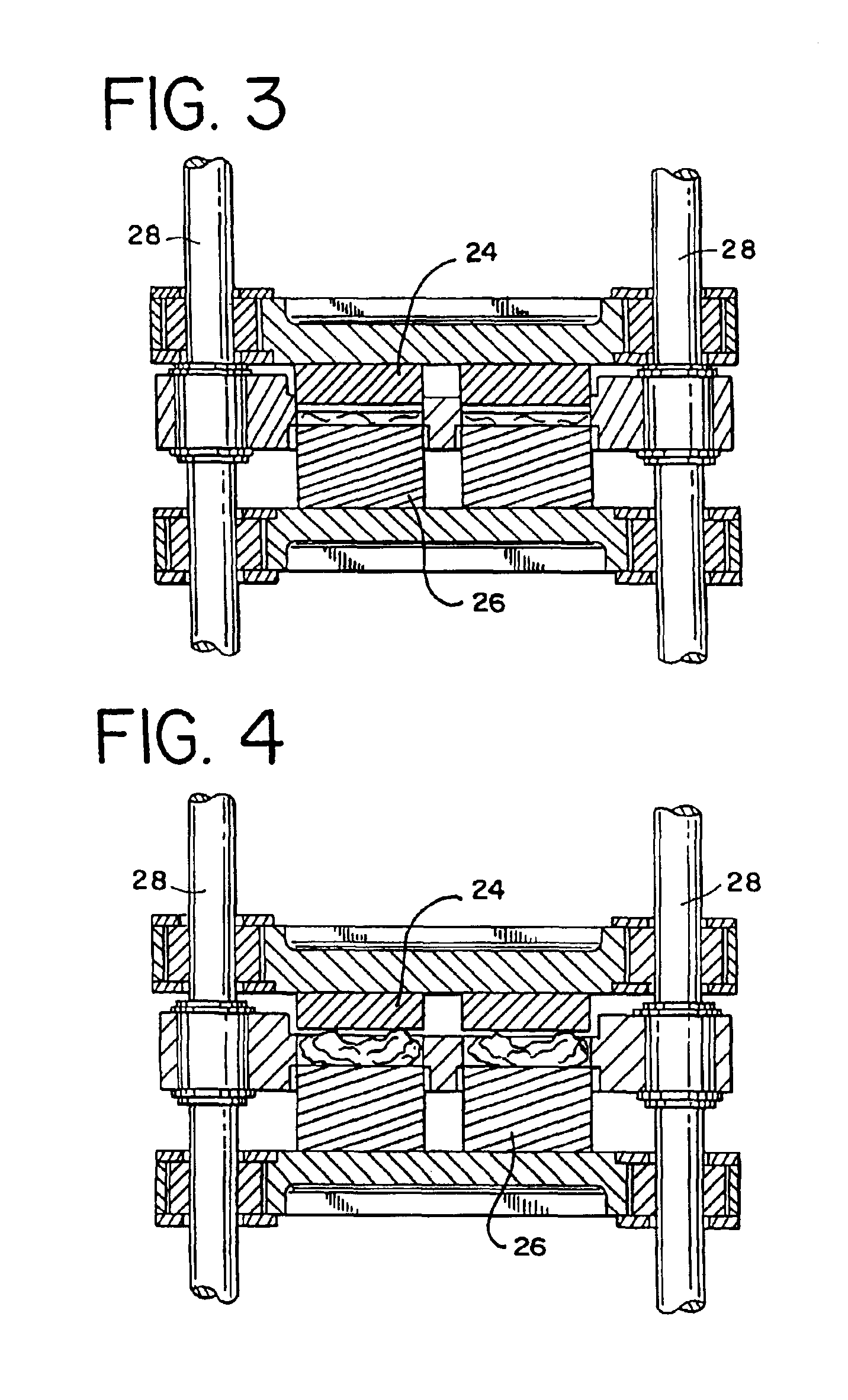

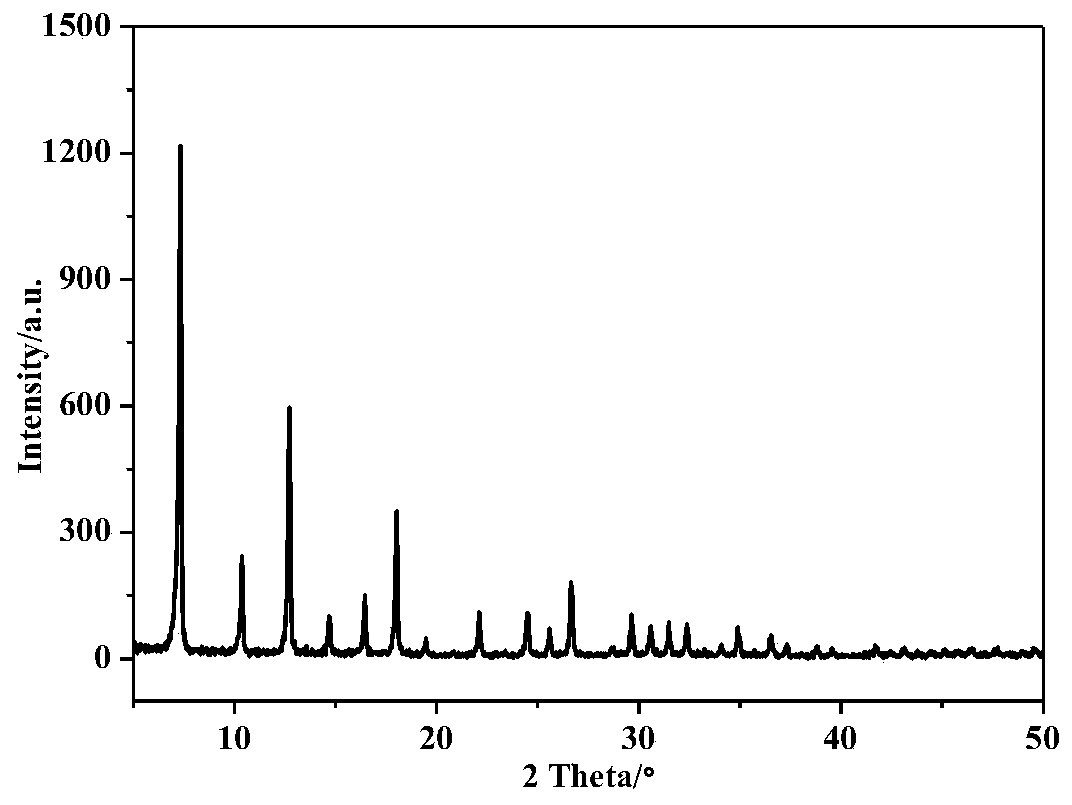

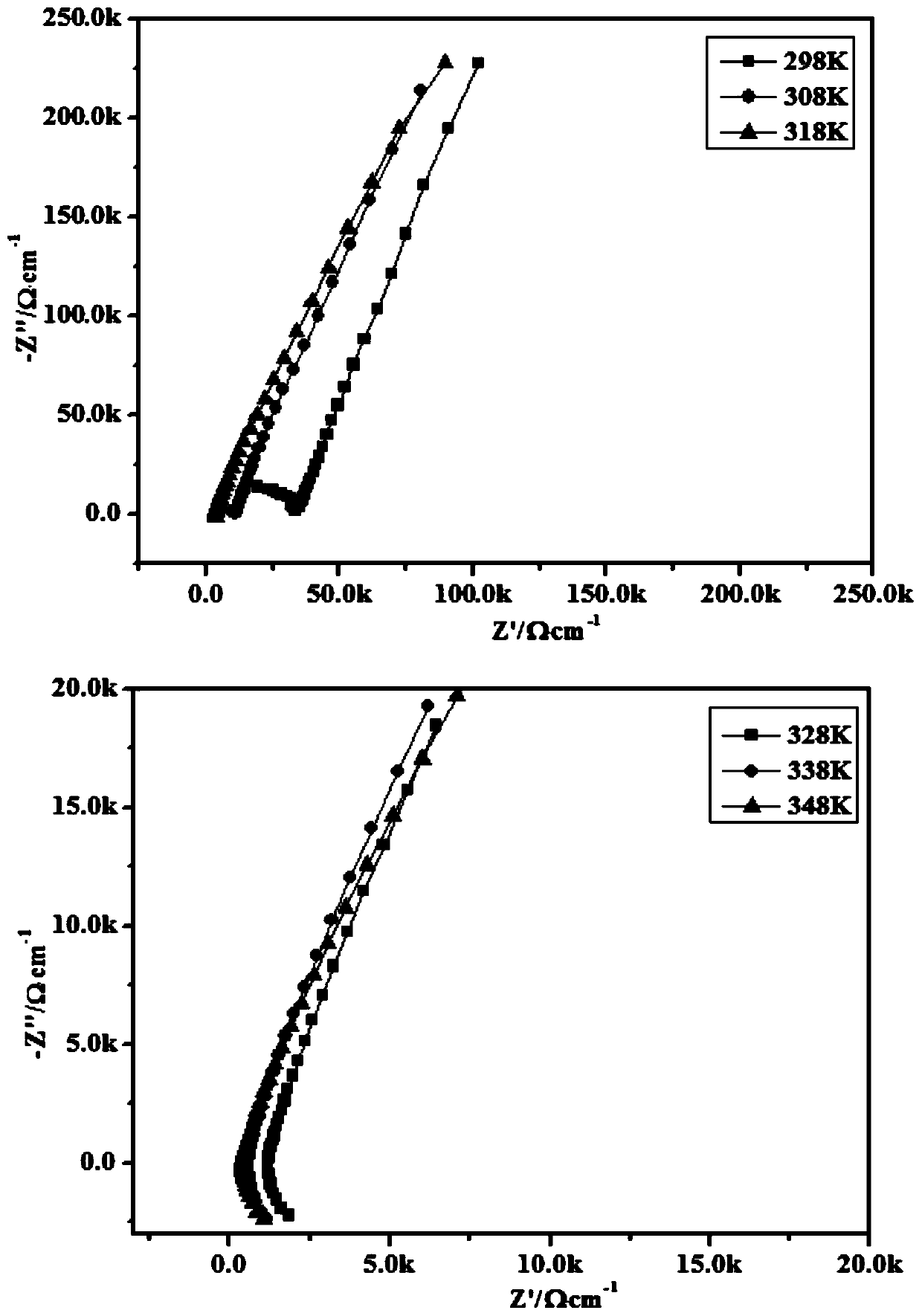

Solid-state lithium ion composite electrolyte membrane and preparation method thereof

PendingCN111048829AHigh porosityControllable channel sizeSolid electrolytesSecondary cellsAll solid stateComposite electrolyte

The invention relates to a solid-state lithium ion composite electrolyte membrane and a preparation method thereof, in particular to the field of all-solid-state lithium ion batteries. A volatilization method is adopted, methanol is used as a solvent, an organic metal framework ZIF-67 material with high crystallinity and uniform morphology is synthesized and the material is used as a filling material to be mixed with PEO and LITFSI to form composite electrolyte membrane slurry. ZIF-67 / PEO / LITFSI composite electrolyte membranes with different components are prepared by using a casting method. When the mass percentage of ZIF-67 in (ZIF-67 + PEO) is 3wt%, the composite electrolyte membrane has the optimal room-temperature conductivity, and the numerical value of the optimal room-temperature conductivity is 1.51 * 10 <-5 > S / cm and is about 5 times of the conductivity of a PEO / LITFSI electrolyte.

Owner:HENAN INST OF SCI & TECH

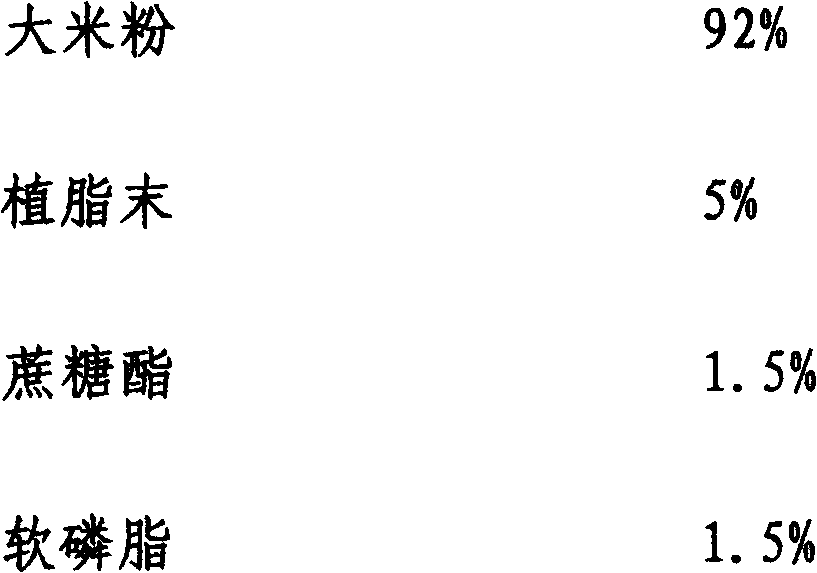

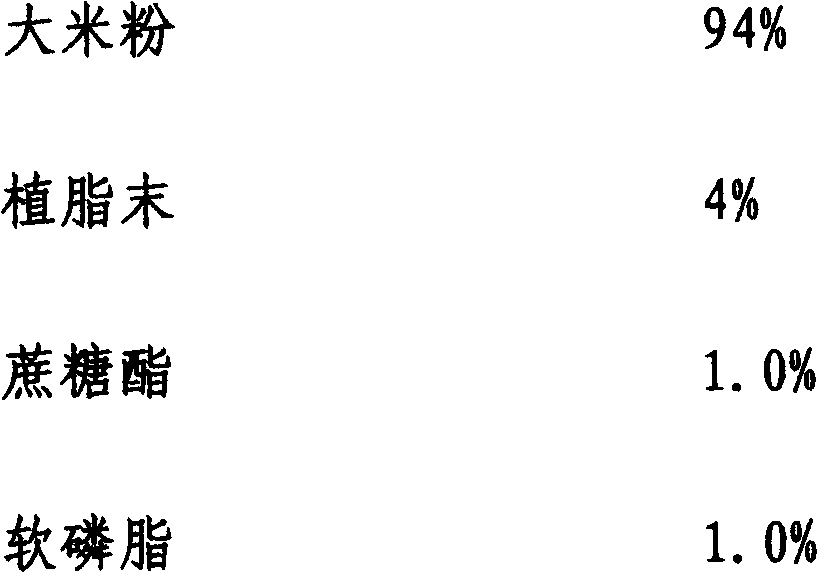

Ingredient for slowing down retrogradation of starch in grain-based nutritious rice flour and production process thereof

InactiveCN102429156ADelay aging and rejuvenationReduce recrystallizationFood preparationSucroseHydrogen

The invention provides an ingredient for slowing down retrogradation of starch in grain-based nutritious rice flour and a production process thereof, relating to the ingredient of infant foods and a preparation process thereof. The ingredient comprises the following components in percentage by weight: 90-95% of rice flour, 3-5% of vegetable fat power, 1-3% of sucrose ester and 1-3% of lecithin. The production process comprises the following steps of: soaking rice with water for more than 3 hours so that rice absorbs water as much as possible to expand; carrying out primary grinding and fine grinding; mixing slurry; homogenizing; pregelatinizing; drum-drying; crashing and screening to finally obtain the finished product. According to the invention, emulsifiers for resisting aging and retrogradation of starch are added in the production process of rice flour, and hydrogen bonds in the molecular helical structure of starch are destroyed under the interaction of the emulsifiers and starch in the gelatinization production process of starch, and thus the recrystallization process of starch is slowed down and the aging and retrogradation process of starch is delayed.

Owner:SHENZHEN WEICKY BIOLOGICAL TECH

Bread anti-aging baking oil and preparing method thereof

InactiveCN110447678AGood flexibilityImprove qualityDough treatmentEdible oils/fatsFood additiveRapeseed

The invention belongs to the technical field of food additives, and particularly relates to a bread anti-aging baking oil and a preparing method thereof. The bread anti-aging baking oil is prepared from an oil base, an emulsifier, an amylase, food spices, pigments and tertiary butylhydroquinone. The oil base comprises palm oil liquid oil, palm oil stearin, soybean oil, rapeseed oil, beef tallow, cream, coconut oil and palm kernel oil. The emulsifier comprises monoglycerol fatty acid ester, diglycerol fatty acid ester, phospholipid, sodium stearyl lactate, polyglycerol fatty acid ester, propylene glycol fatty acid ester and diacetyl tartaric acid ester of mono(di)glycerides. The amylase comprises alpha-amylase, xylanase and maltogenic amylase. By means of the bread anti-aging baking oil, the ageing speed of bread can be effectively delayed, the softness and humidity of the bread are kept, and the mouthfeel of the bread is improved.

Owner:SHENZHEN EXCELSIOR LIPIDS TECH

Frozen bread dough containing composite antifreeze agent made from plant antifreeze proteins, preparation method of dough and method for preparing bread with optimized process

InactiveCN108157428AAvoid harmIncrease specific volumeDough/pre-mixesPre-baking dough treatmentMonoglycerideAntifreeze protein

The invention discloses frozen bread dough containing a composite antifreeze agent made from plant antifreeze proteins, a preparation method of the dough, and a method for preparing bread with an optimized process. The frozen bread dough comprises the following components in parts by weight: 40-55% by weight of bread specialized bread powder, 10-12.5% by weight of sugar, 0.5-1.5% by weight of yeast, 0.4-0.8% by weight of sodium chloride, 1.5-3% by weight of milk powder, 5-10.5% by weight of shortening, 0.05-0.15% by weight of bottle gourd Pakistan rubber, 0.05-0.30% by weight of diacetytartaric esters of monoglycerides, 20-30% by weight of water, 0.05-0.1% by weight of glutamine transaminase, 0.05-0.1% by weight of xylanase, and 0.5-3% by weight of antifreeze protein powder made of polygonum viviparum leaves. The produced frozen bread dough is subjected to thawing, curing and baking so as to form bread which has the characteristics of large specific volume, a soft and tasty mouth feeland excellent organoleptic quality.

Owner:WUHAN POLYTECHNIC UNIVERSITY

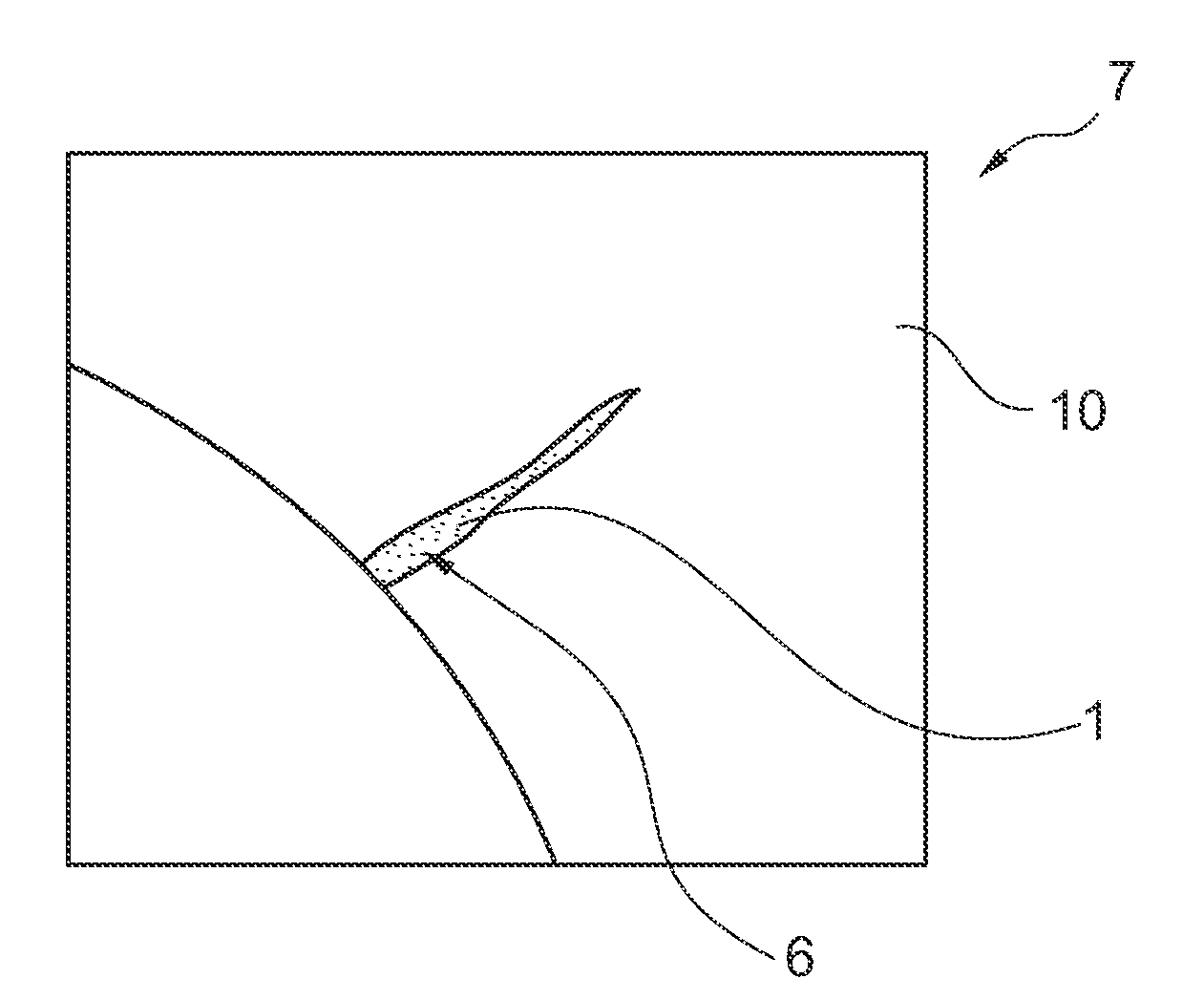

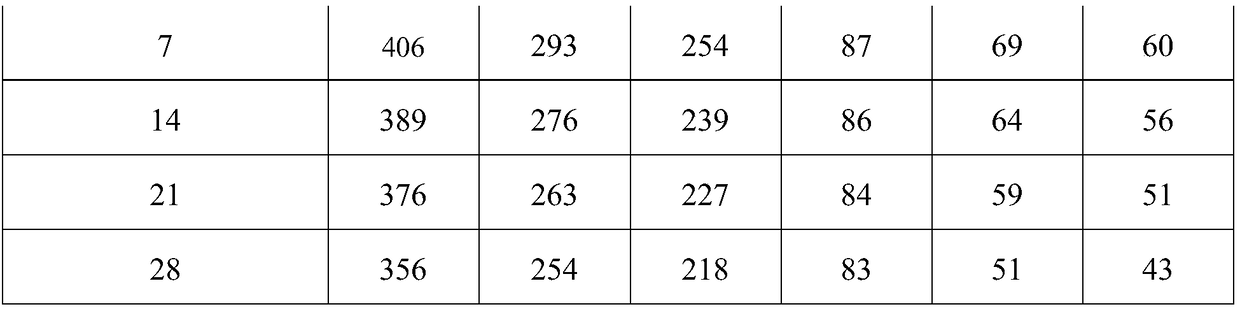

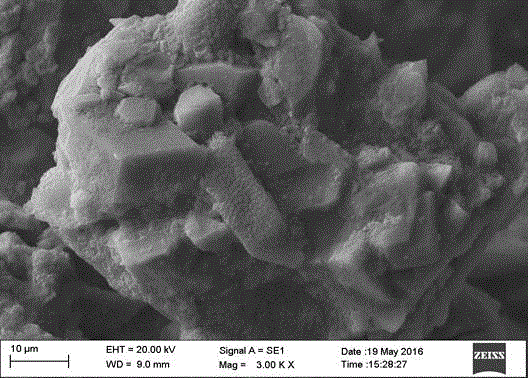

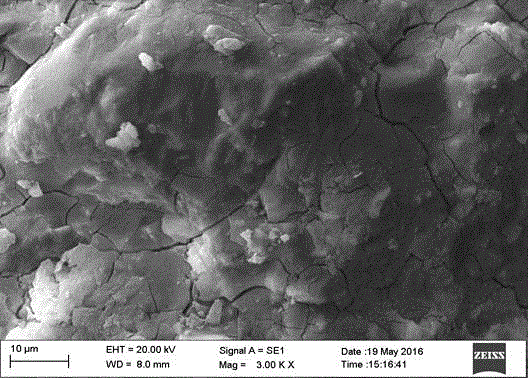

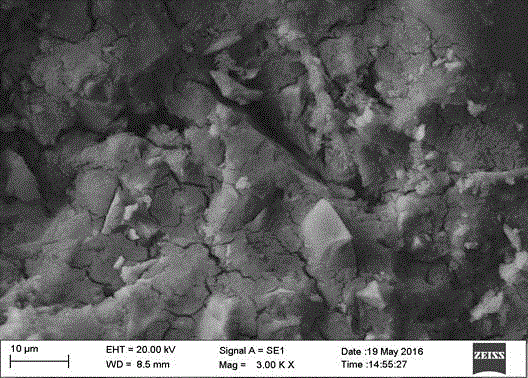

Braze alloy for high-temperature brazing and methods for repairing or producing components using a braze alloy

InactiveUS8881965B2Inhibition of recrystallizationSimple methodTurbinesBlade accessoriesSingle crystalBraze alloy

In a Ni-based, Co-based, or Ni—Co-based braze alloy (1) for high-temperature brazing of components (7) of modular structure and for repairing damaged components (7) which are formed of single crystal or directionally solidified superalloys using said braze alloy (1), the braze alloy has a first metallic powder component (2) having particle sizes in the nanometer range and a second metallic powder component (3) having particle sizes in the micrometer range. The surface of the particles of the second powder component (3) is thinly coated with particles of the first powder component (2). The braze alloy (1) additionally includes grain boundary stabilizing elements as alloying elements. In addition, melting point depressants can be present in the braze alloy (1) in a commercially common quantity or with a considerably increased proportion. Both the melting temperature of the braze alloy (1) and the probability of recrystallization are advantageously reduced.

Owner:ANSALDO ENERGIA IP UK LTD

Corrosion-resistant zinc alloy for manufacturing zipper and preparation technology for corrosion-resistant zinc alloy

The invention relates to the technical field of metal material smelting, in particular to a corrosion-resistant zinc alloy used for making zippers and a preparation process thereof. In percentage terms, the corrosion-resistant zinc alloy used to make zippers contains the following elements: Al 1.17-3.48%, Zr 0.008-0.21%, B 0.89-1.75%, Mg 1.25-3.71%, Ni 1.21-3.81%, Cu 0.08 ~0.36%, Ti 0.26~0.84%, Ta 0.005~0.12%, C 0.05~0.26%, rare earth elements 0.01~0.03%, and the rest are Zn and unavoidable impurities. In the present invention, various metals are formed in the zinc alloy system Alloy dispersed phase, and produce a synergistic effect, refine the as-cast grains, strengthen the role of pinning dislocations, thereby significantly increasing the recrystallization temperature of zinc alloy profiles, reducing the recrystallization of grains, and improving the zinc alloy strength, fracture toughness and stress corrosion resistance.

Owner:浙江华冠拉链有限公司

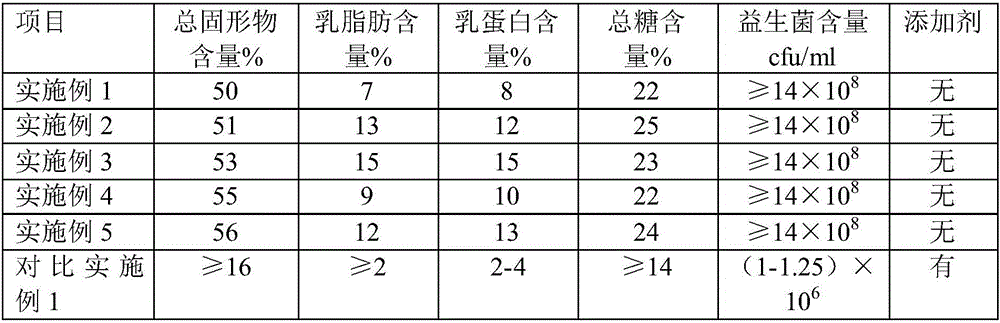

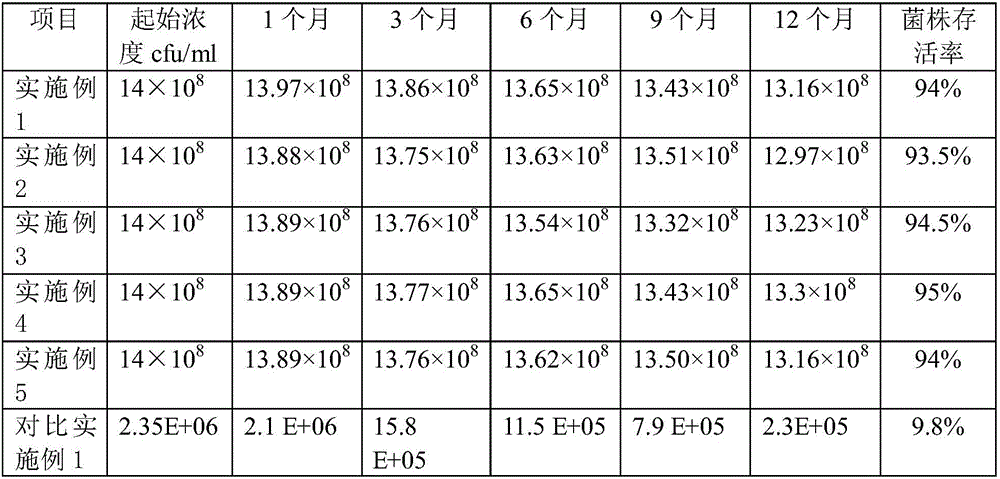

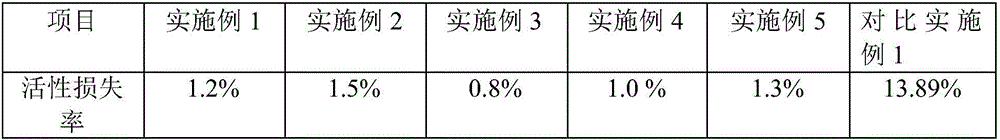

Probiotic ice cream and production process thereof

The invention discloses a probiotic ice cream and a production process thereof. The probiotic ice cream comprises, by weight, more than 20% of full-cream milk powder, more than 15% of sugar, more than or equal to 14*108cfu / ml of probiotics and the balance water. The invention further discloses a production process of the probiotic ice cream. The production process is simple to operate, and the prepared probiotic ice cream tastes smooth, sour, sweet and delicious and has high structure stability and melting resistance.

Owner:内蒙古利尔健奶制品分解科技有限公司

Dehydration of wet gas utilizing intimate contact with a recirculating deliquescent brine

ActiveUS20050028673A1Improve efficiencyReduce recrystallizationCombination devicesAuxillary pretreatmentEnvironmental engineeringMoisture

A system for removing moisture from a wet gas stream including a vessel having a contact area containing deliquescing salts that produces brine as water is absorbed, the brine flowing to a collection area in the bottom of the vessel. A venturi positioned in a wet gas inlet stream produces an area of reduced pressure that is applied to a brine flow path connected to the brine collection area. In this way, the brine is recirculated into intimate contact with the wet gas inlet stream causing the brine to be diluted with water extracted from the wet gas stream.

Owner:NAT TANK

Retarder-free waterproof magnesium ammonium phosphate cement and preparation method thereof

ActiveCN106746811AReduce dissolution rateGood flexibilityIsolation effectMagnesium ammonium phosphate

The invention discloses retarder-free waterproof magnesium ammonium phosphate cement and a preparation method thereof. The cement comprises dead burned magnesia coated with graphene oxide, ammonium dihydrogen phosphate and mineral admixtures, wherein the mass ratio of dead burned magnesia coated with graphene oxide and ammonium dihydrogen phosphate is (62-78):(22-38), and the mineral admixtures are 5-15% of the total mass of dead burned magnesia and ammonium dihydrogen phosphate. According to the cement, dead burned magnesia powder is pretreated by graphene oxide, so that a comparatively obvious isolation effect is formed between magnesia and an external environment, therefore, the dissolution rate of magnesia is greatly decreased, a forming process of a hydration product is delayed, and the heat release of a whole reaction system is reduced; macroscopically, the time of coagulation is greatly prolonged, and any retarders do not need to be added. Moreover, a dissolution process of the hydration product and phosphate is inhibited, a large amount of pores are prevented from being formed in the cement, and the strength of hardened cement paste is ensured.

Owner:UNIV OF JINAN

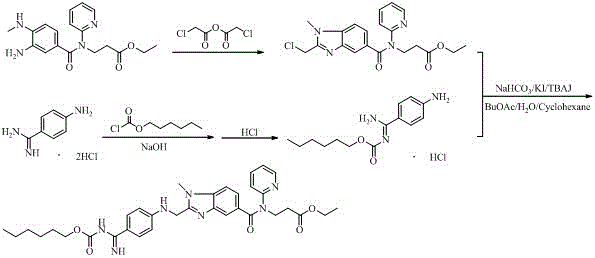

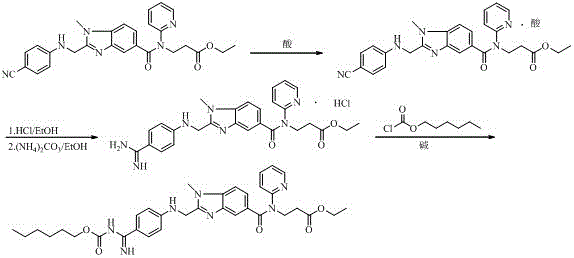

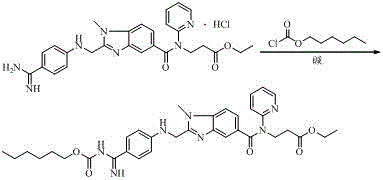

Industrial preparation method of dabigatran

ActiveCN106543144AReduce recrystallizationSimple processOrganic chemistryPurification methodsDistillation

The invention discloses an industrial preparation method of dabigatran, and belongs to the field of medicinal chemistry, wherein the preparation method sequentially comprises a condensation reaction, a closed cyclization reaction, a Pinner reaction, and other steps. According to the present invention, the hydrogen chloride / alcohol / ester solution is prepared by using acyl chloride and alcohol as raw materials, such that the problems of corrosion on equipment, high hidden safety danger, environmental pollution and the like caused by the use of hydrogen chloride gas in the prior art are solved; and the reactions in various steps are subjected to the industrial-scale-based optimization, the unnecessary distillation, extraction and re-crystallization process is reduced, the process is simplified, the purification method of the final product dabigatran is improved, the purification efficiency is increased in the case of the ensuring of the process yield and the product quality, the process reproducibility is good, the preparation cost is low, and the method is the ideal industrial preparation method of the dabigatran.

Owner:CHENGDU LIKAI CHIRAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com