Controlled directional solidification nickel-base high-temperature alloy recrystallizing method

A nickel-based high-temperature alloy, directional solidification technology, applied in the direction of solid-state diffusion coating, metal material coating process, coating, etc., can solve the problems of inapplicability, and achieve the effects of easy storage, reduced recrystallization, and simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

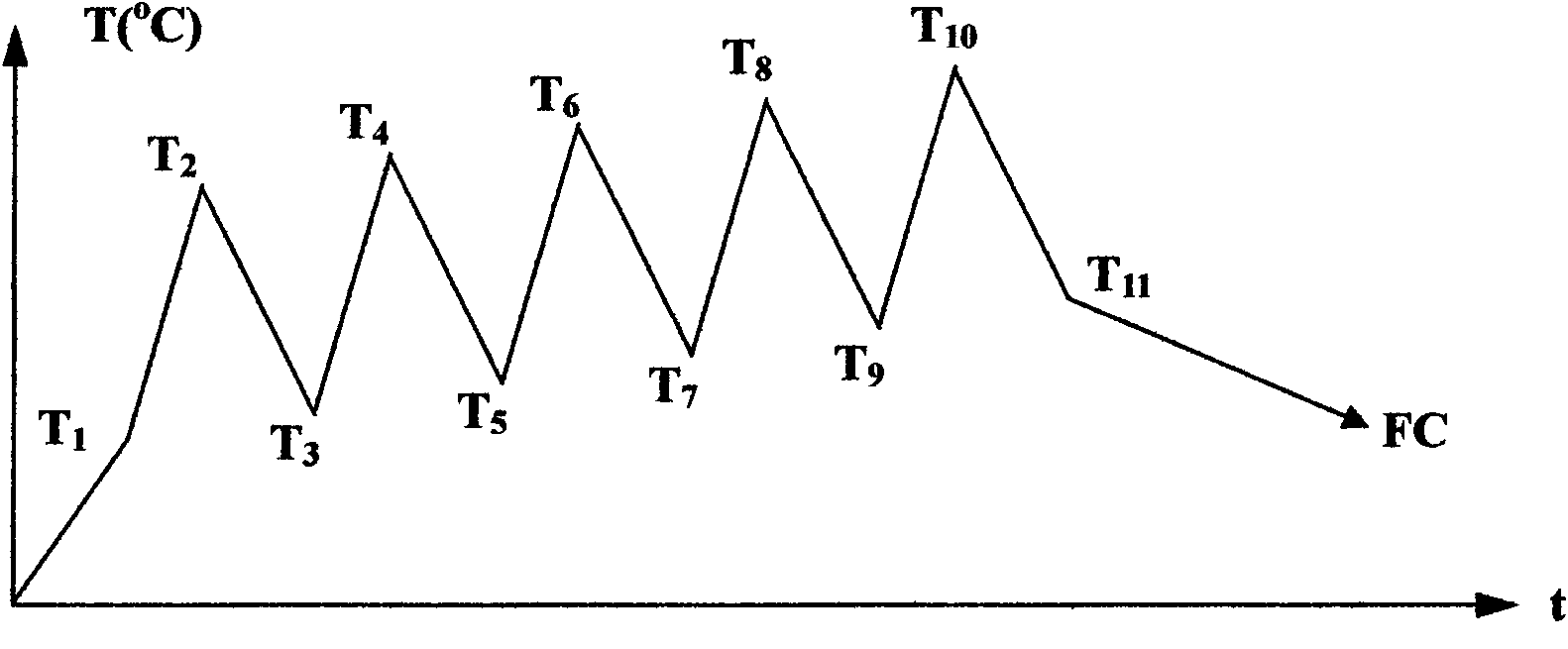

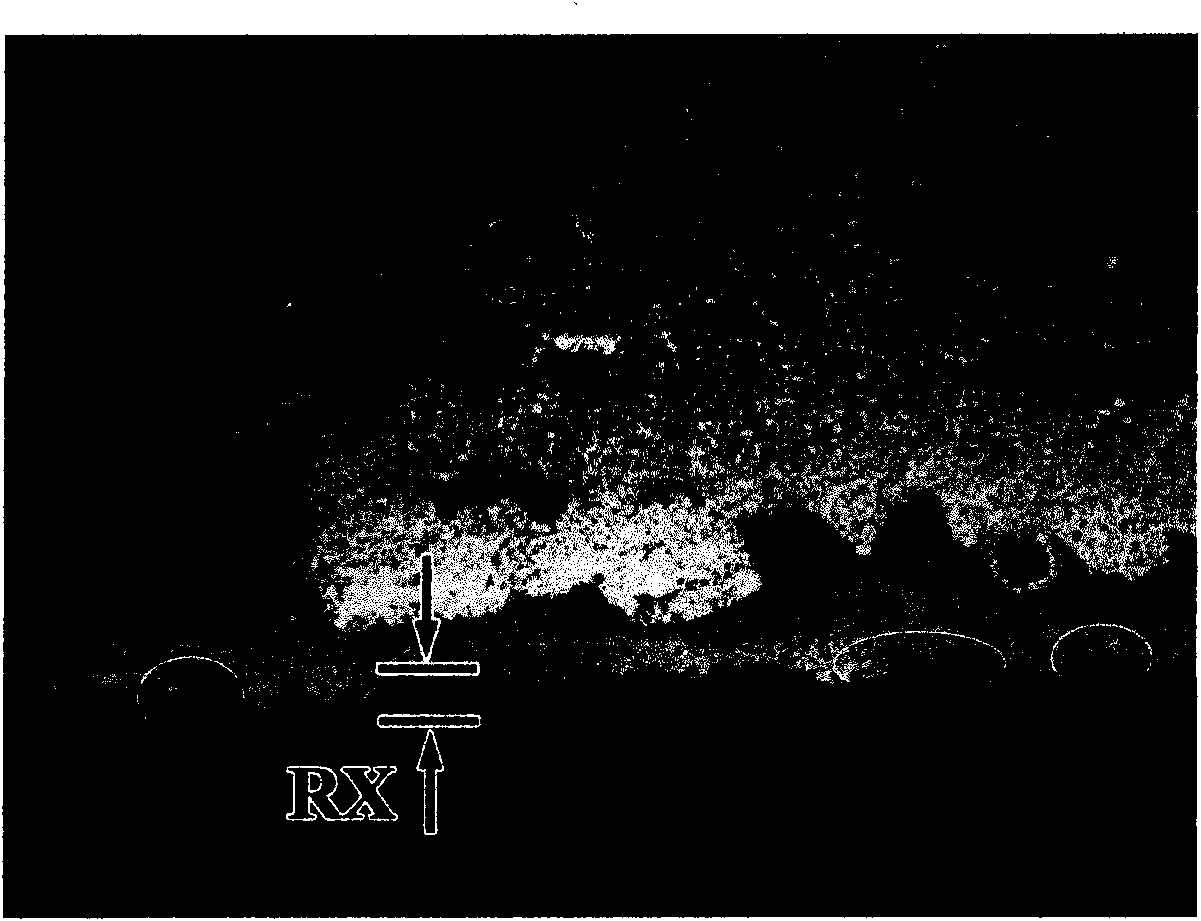

[0028] Example 1 Carburizing combined with cyclic recovery heat treatment controls the recrystallization of DZ125L directionally solidified nickel-based superalloy.

[0029] The directionally solidified nickel-based superalloy plate is prepared by the directional solidification equipment, and a square of 3×12×12 mm is cut from the plate by wire cutting. Polish the surface of 12×12 (the growth direction of oriented columnar crystals), and carry out carburizing treatment with a micro-arc spark machine. The carburizing process equipment is a micro-arc spark processing machine 3H-ES-1500, the frequency of the micro-arc spark processing machine is 1000HZ, the power is 1000W, and the voltage is 50V. The carburizing process should try to keep the surface carburized layer uniform. The samples were then sandblasted with a sandblasting device. Sandblasting parameters are as follows: sandblasting pressure is 0.3MPa, sandblasting time is 1min, and the sand particles are SiO 2 Glass bal...

Embodiment 2

[0031] Example 2 Carburizing combined with cyclic recovery heat treatment controls the recrystallization of DZ17G directionally solidified nickel-based superalloy.

[0032]The directionally solidified nickel-based superalloy plate is prepared by the directional solidification equipment, and a square of 3×12×12 mm is cut from the plate by wire cutting. Polish the surface of 12×12 (the growth direction of oriented columnar crystals), and carry out carburizing treatment with a micro-arc spark machine. The carburizing process equipment is a micro-arc spark processing machine 3H-ES-1500, the frequency of the micro-arc spark processing machine is 1000HZ, the power is 1000W, and the voltage is 50V. The carburizing process should try to keep the surface carburized layer uniform. The samples were then sandblasted with a sandblasting device. Sandblasting parameters are as follows: sandblasting pressure is 0.3MPa, sandblasting time is 1min, and the sand particles are SiO 2 Glass ball....

Embodiment 3

[0034] Example 3 Carburizing combined with cyclic recovery heat treatment controls the recrystallization of DZ125L directionally solidified nickel-based superalloy.

[0035] The directionally solidified nickel-based superalloy plate is prepared by the directional solidification equipment, and a square of 3×12×12 mm is cut from the plate by wire cutting. Polish the surface of 12×12 (the growth direction of oriented columnar crystals), and carry out carburizing treatment with a micro-arc spark machine. The carburizing process equipment is a micro-arc spark machine 3H-ES-1500, the frequency of the micro-arc spark machine is 1000HZ, the power is 2000W, and the voltage is 50V. The carburizing process should try to keep the surface carburized layer uniform. The samples were then sandblasted with a sandblasting device. Sandblasting parameters are as follows: sandblasting pressure is 0.3MPa, sandblasting time is 1min, and the sand particles are SiO 2 Glass ball.

[0036] Next, tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com