Method for producing freezing dough through the antifreezing zymolysis of ice structure protein

A technology of ice-structural protein and frozen dough, which is applied in the field of food processing, and can solve problems such as the decrease of dough gas retention, the destruction of gluten protein network structure, and poor bread quality, so as to improve quality, prevent ice nuclei from growing, and improve storage The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

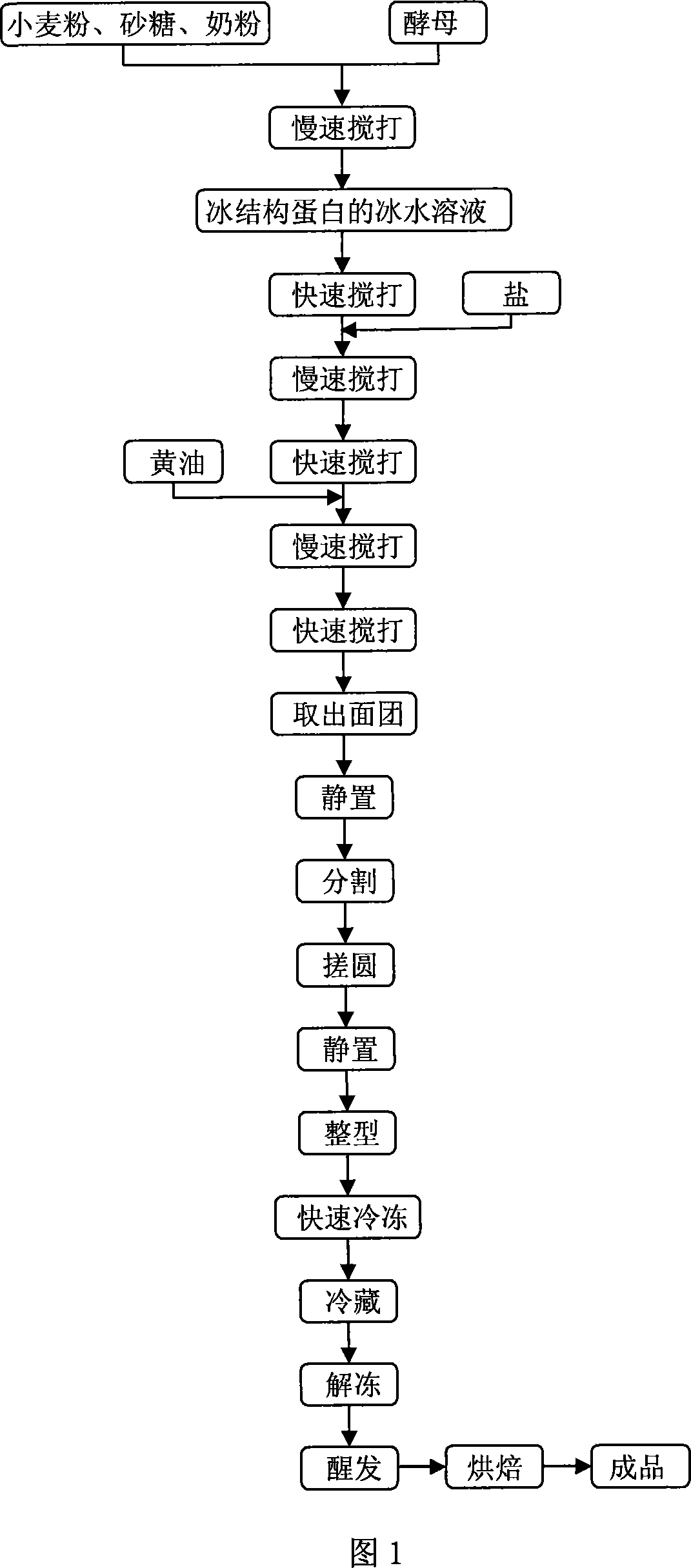

[0018] Embodiment one: a kind of ice structure protein antifreeze fermentation method of the present invention produces frozen dough adopts following process step:

[0019] In the embodiment of the present invention, wheat flour is 55% by weight; granulated sugar is 3.3% by weight; milk powder is 1.0% by weight; yeast is 0.9% by weight; water is 36% by weight; butter is 2.4% by weight; : 0.9% by weight; ice structure protein: 0.5% by weight.

[0020] In the present invention, firstly take wheat flour, granulated sugar, milk powder and yeast and add them into the noodle mixer and stir at a slow speed; dissolve the ice-structured protein in ice water, add it to the mixture, and continue to whip for 3 minutes at a slow speed until there is no dry powder in the mixing tank , switch to fast whipping, the whipping time is: 8 minutes, beat until the dough forms a fascia; add salt, continue to beat for 3 minutes at a slow speed, beat until there is no salt in the tank, then switch to ...

Embodiment 2

[0022] Embodiment two: a kind of ice structure protein antifreeze fermentation method of the present invention produces frozen dough adopts following process step:

[0023] The present invention takes wheat flour: 57% by weight; sugar: 3.5% by weight; milk powder: 0.9% by weight; yeast: 1.0% by weight; water: 34% by weight; butter: 2.3% by weight; salt: 0.7% by weight %; ice structural protein: 0.6% by weight.

[0024] In the present invention, firstly take wheat flour, granulated sugar, milk powder and yeast and add them to the noodle mixer and stir them at a slow speed; dissolve the ice-structured protein in ice water, add them to the mixture, and continue to whip for 4 minutes at a slow speed until there is no dry powder in the mixing tank , change to fast whipping, the whipping time is 7 minutes, beat until the dough forms a fascia; add salt, continue to beat for 2 minutes at a slow speed, beat until there is no salt in the tank, then switch to fast whipping for 4 minutes;...

Embodiment 3

[0025] Embodiment three: a kind of ice structural protein antifreeze fermentation method of the present invention produces frozen dough adopts the following process steps:

[0026] The present invention takes wheat flour: 59% by weight; sugar: 3.7% by weight; milk powder: 1.0% by weight; yeast: 1.2% by weight; water: 32% by weight; butter: 2.1% by weight; salt: 0.5% by weight %; ice structural protein: 0.5% by weight.

[0027] In the present invention, firstly, wheat flour, granulated sugar, milk powder and yeast are added to a noodle mixer and stirred at a slow speed; the ice-structured protein is dissolved in ice water, added to the mixture, and whipped at a slow speed for 5 minutes until there is no dry powder in the mixing tank , turn to fast whipping, the whipping time is 8 minutes, beat until the dough forms a fascia; add salt, continue to beat for 3 minutes at a slow speed, beat until there is no salt in the tank, turn to fast whipping for 3 minutes; take Add butter, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com