Corrosion-resistant zinc alloy for manufacturing zipper and preparation technology for corrosion-resistant zinc alloy

A zinc alloy, corrosion-resistant technology, applied in the field of corrosion-resistant zinc alloy and its preparation technology, can solve the problems of poor occlusal force, broken teeth, lack of comprehensive performance, etc. The effect of as-cast grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

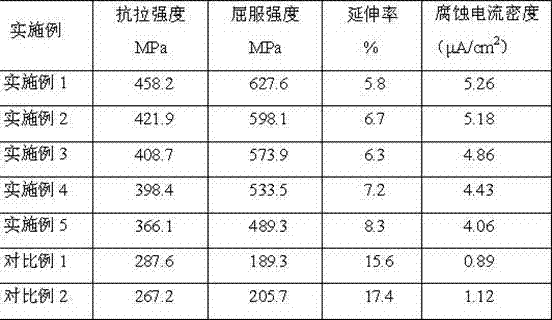

Examples

Embodiment 1

[0028] A corrosion-resistant zinc alloy for making zippers, based on the total amount of zinc alloy, by weight percentage, the zinc alloy contains the following elements: Al 2.16%, Zr 0.034%, B 0.98%, Mg 3.45%, , Cu 0.12%, Ni 1.92%, Ti0.37%, Ta 0.015%, C 0.12%, scandium 0.004%, yttrium 0.003%, niobium 0.002%, lanthanum 0.001%, the rest is Zn and unavoidable impurities;

[0029] The production process of the corrosion-resistant zinc alloy for making slide fasteners comprises the following steps:

[0030] (1) Ingredients and smelting: Add zinc ingots, aluminum ingots, zirconium ingots, boron ingots, magnesium ingots, and nickel ingots into the smelting furnace, raise the temperature until the ore is completely melted, keep it at 750°C for 35 minutes, add NaCl and graphite rods, Raise the temperature to 990°C, then add titanium ingots, tantalum ingots and copper ingots. After the metals are completely melted, remove NaCl on the surface of the molten metal, and ultrasonically trea...

Embodiment 2

[0035]A corrosion-resistant zinc alloy for making zippers, based on the total amount of zinc alloy, by weight percentage, the corrosion-resistant zinc alloy for making zippers contains the following elements: Al 2.06%, Zr 0.056%, B 1.13%, Mg 3.54%, Ni2.34%, Cu 0.14%, Ti 0.49%, Ta 0.042%, C 0.08%, scandium 0.004%, yttrium 0.006%, niobium 0.01%, the rest is Zn and unavoidable impurities;

[0036] The production process of the corrosion-resistant zinc alloy for making slide fasteners comprises the following steps:

[0037] (1) Ingredients and smelting: Add zinc ingots, aluminum ingots, zirconium ingots, boron ingots, magnesium ingots, and nickel ingots into the smelting furnace, heat up until the ore is completely melted, keep it at 755°C for 30 minutes, add Na 3 AlF 6 and graphite rods, heat up to 990°C, then add titanium ingots, tantalum ingots and copper ingots, and remove Na on the surface of the melt after the metals are completely melted 3 AlF 6 , and ultrasonically trea...

Embodiment 3

[0042] A corrosion-resistant zinc alloy for making zippers, based on the total amount of zinc alloy, by weight percentage, the corrosion-resistant zinc alloy for making zippers contains the following elements: Al 2.46%, Zr 0.067%, B 0.96%, Mg 2.45%, Ni2.26%, Cu 0.22%, Ti 0.45%, Ta 0.024%, C 0.15%, Yttrium 0.02%, the rest is Zn and unavoidable impurities;

[0043] The production process of the corrosion-resistant zinc alloy for making slide fasteners comprises the following steps:

[0044] (1) Ingredients and smelting: Add zinc ingots, aluminum ingots, zirconium ingots, boron ingots, magnesium ingots, and nickel ingots into the smelting furnace, raise the temperature until the ore is completely melted, keep it at 760°C for 30 minutes, and then add MgCl 2 and graphite rods, heat up to 990°C, then add titanium ingots, tantalum ingots and copper ingots, and remove MgCl on the surface of the melt after the metals are completely melted 2 , and ultrasonically treat the molten metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com