Patents

Literature

1639results about "Shearing tools" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

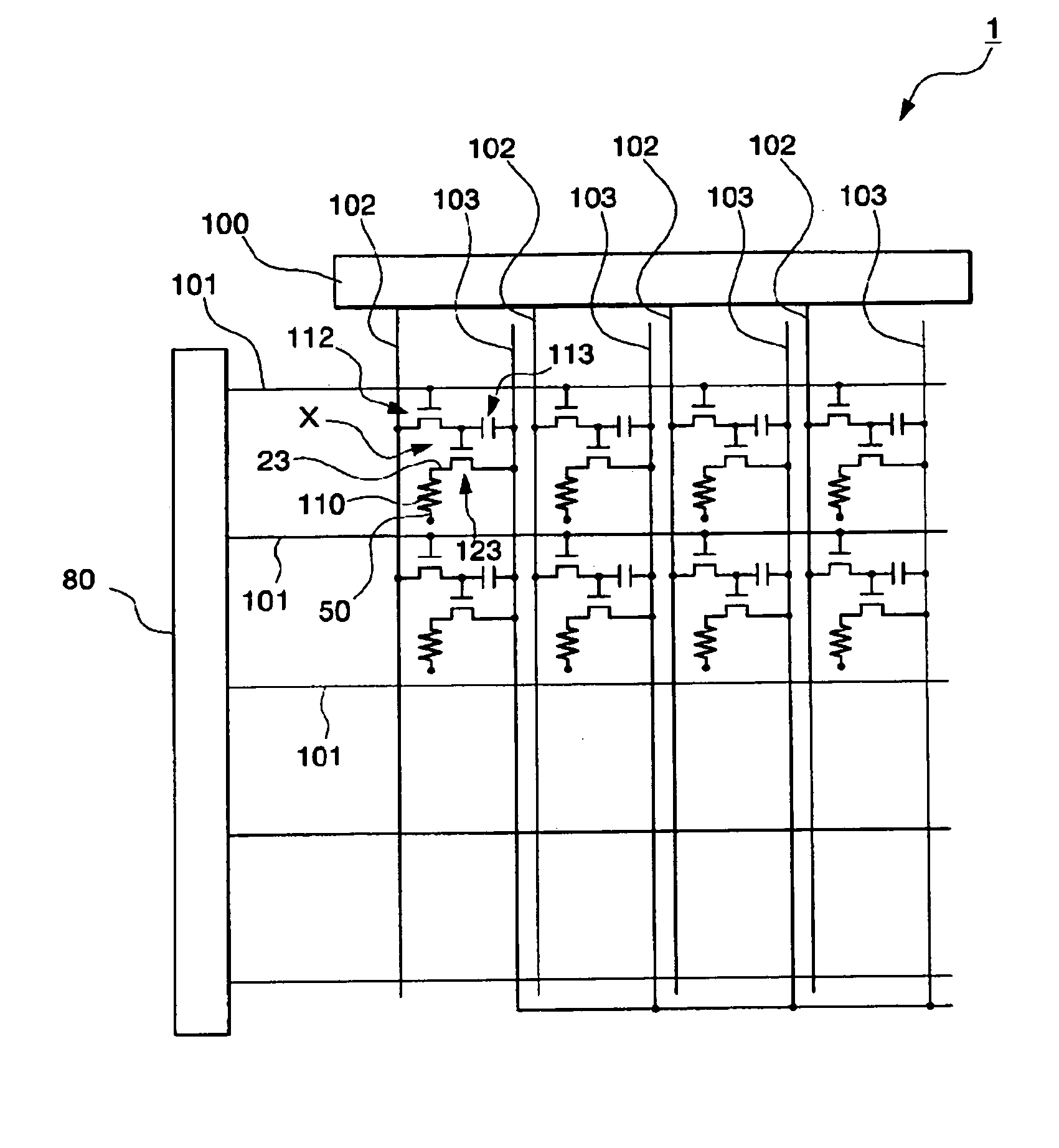

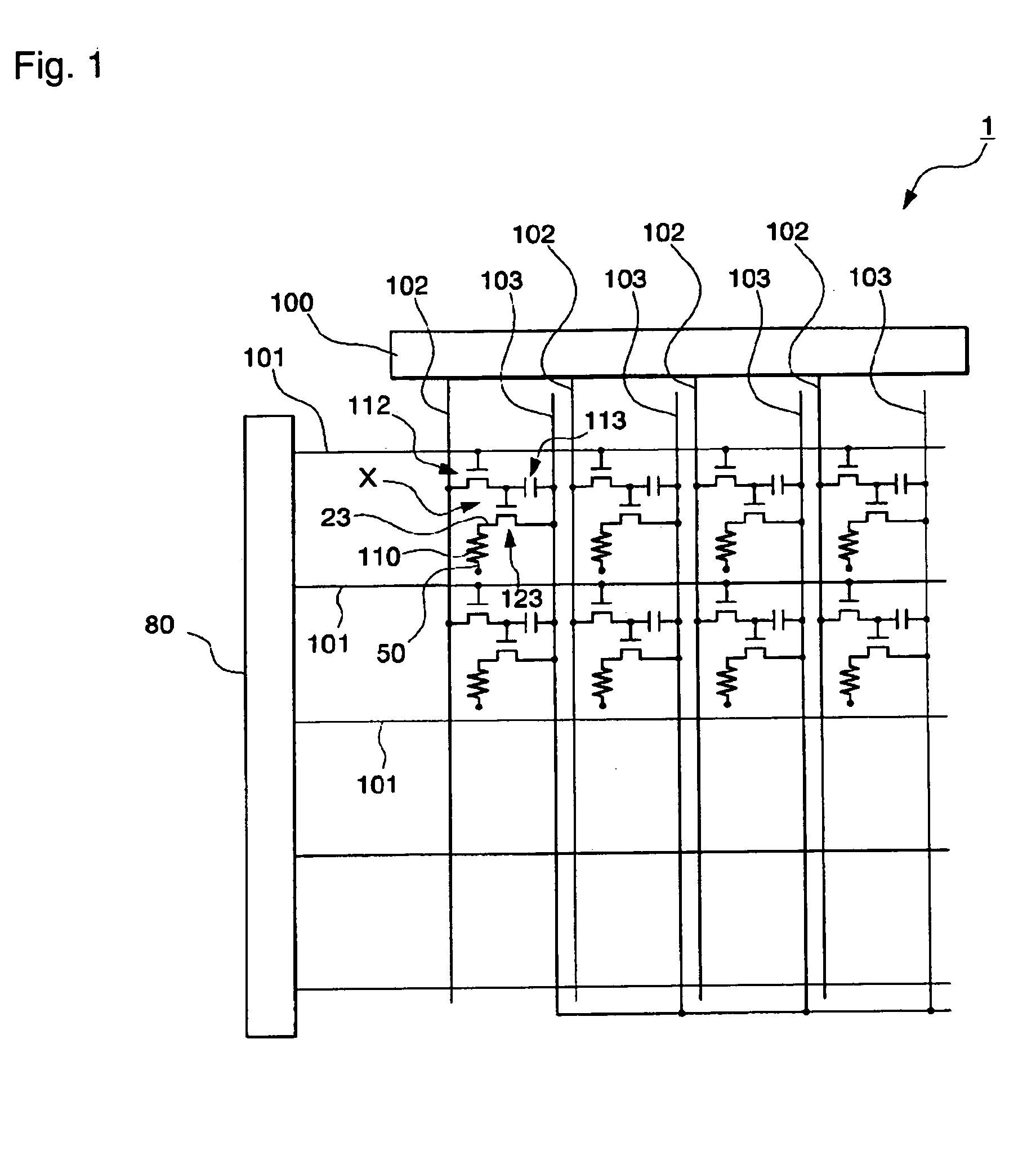

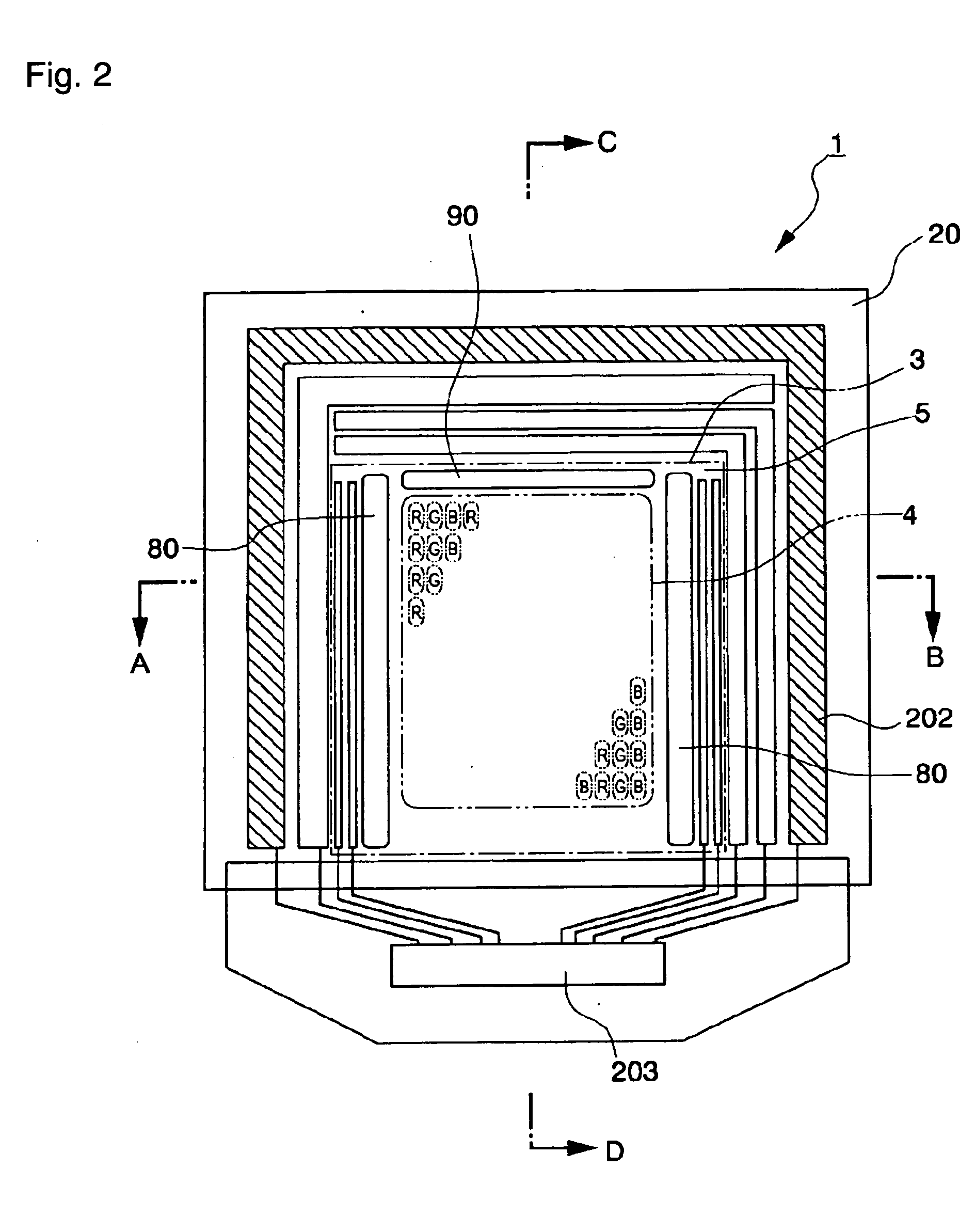

Electro-optical device, method of manufacturing the same, and electronic apparatus

ActiveUS20040212759A1Reduced or prevented from being deterioratedQuality improvementElectroluminescent light sourcesSolid-state devicesUltravioletEngineering

Owner:SEIKO EPSON CORP

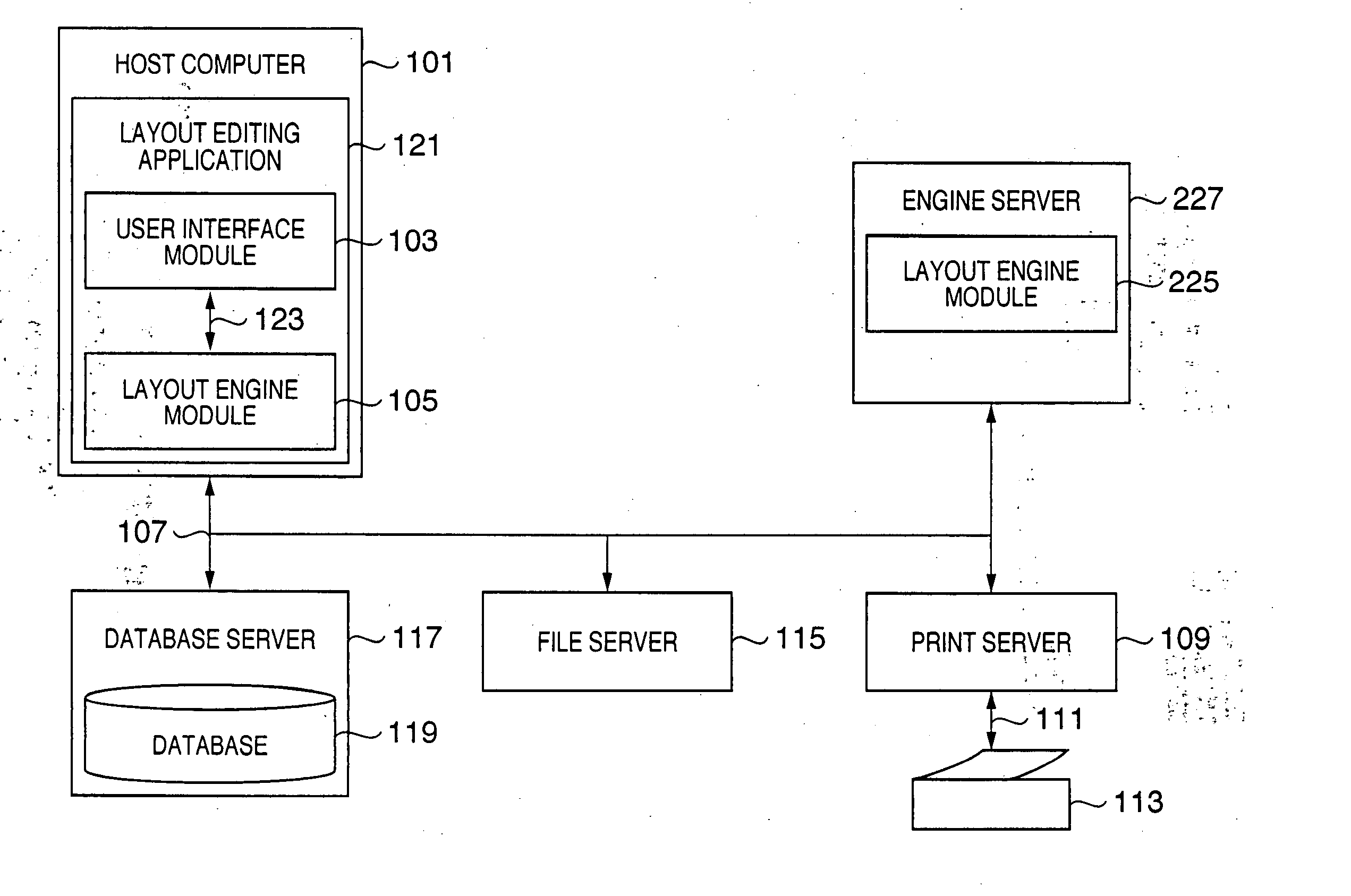

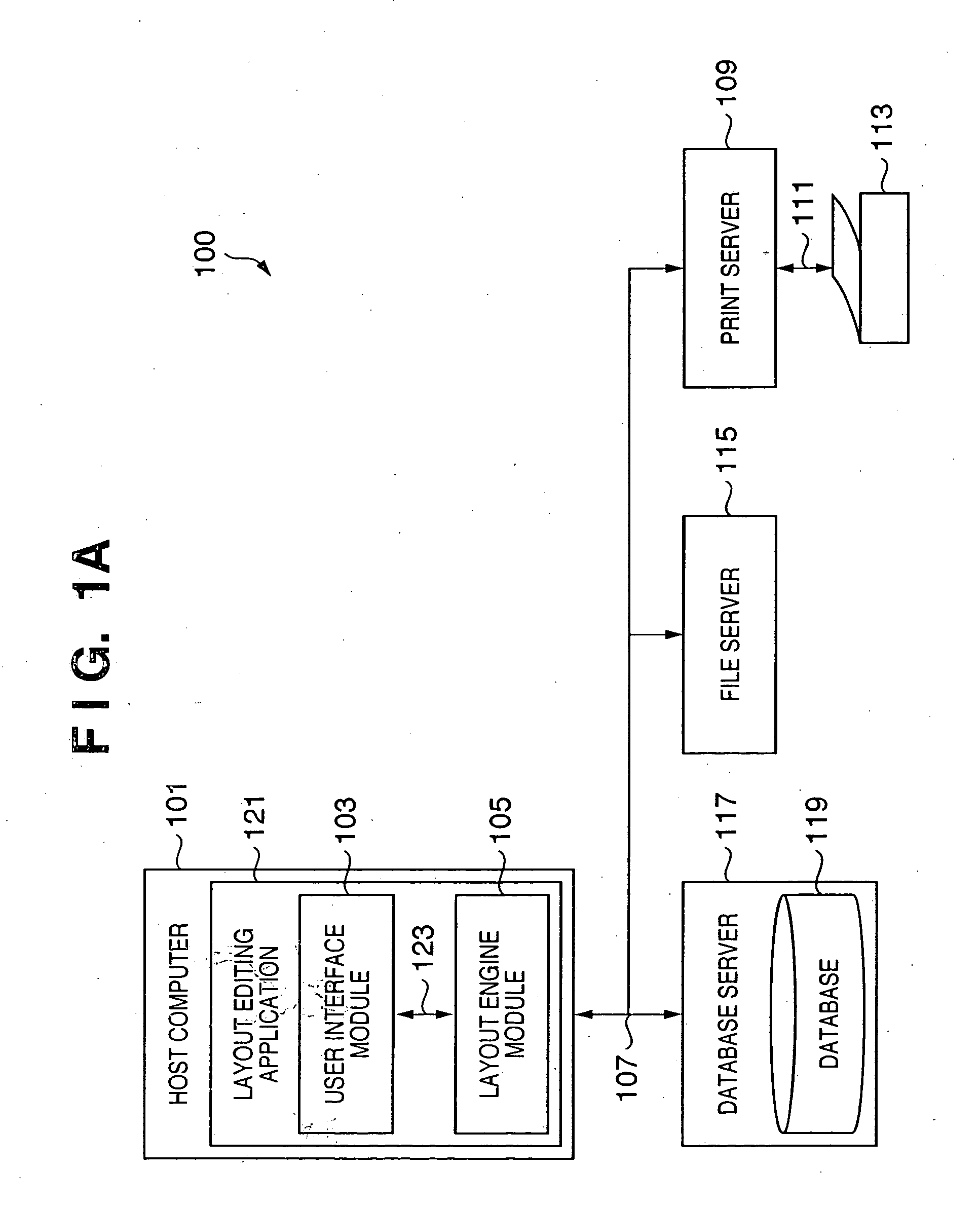

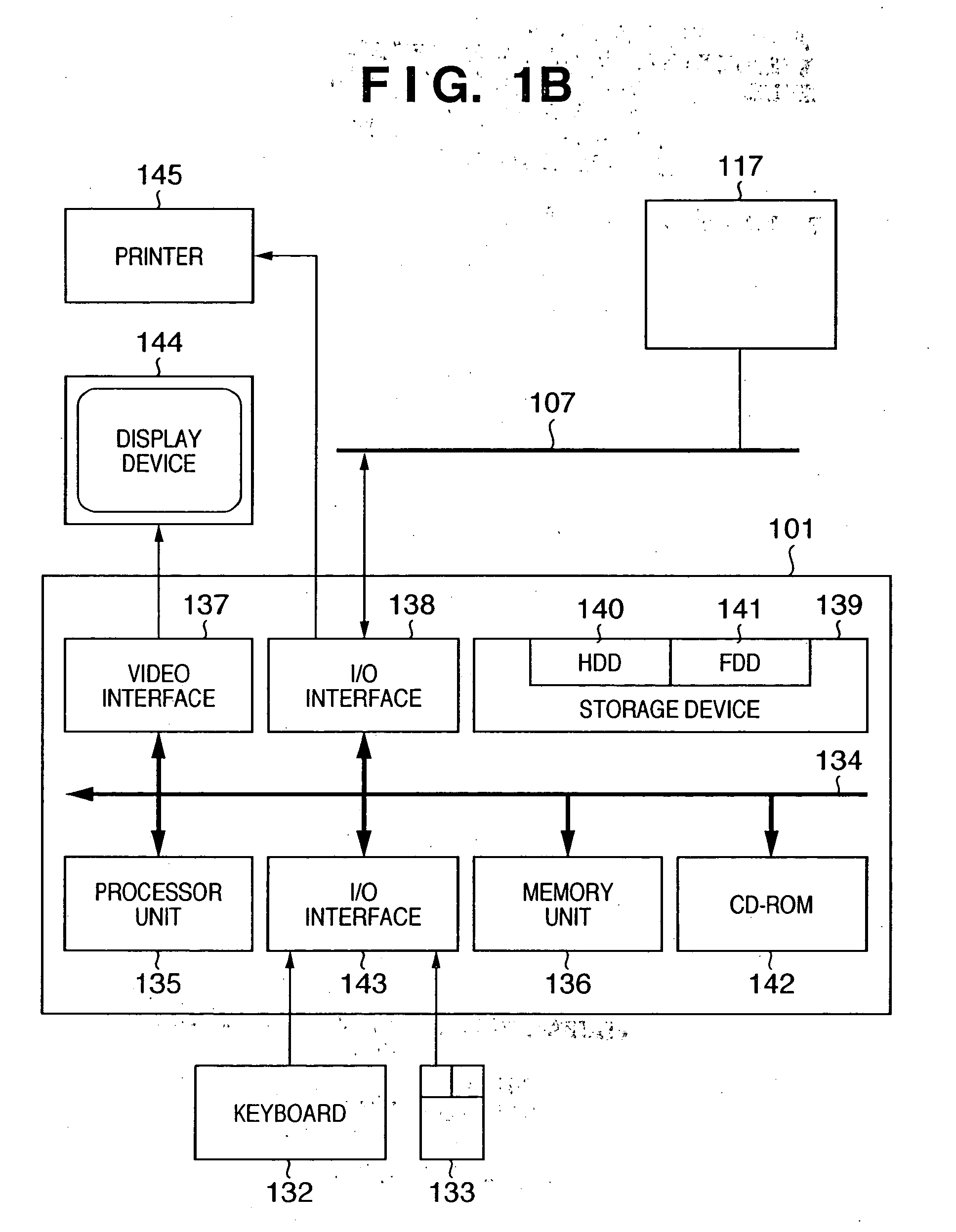

Layout control method, layout control apparatus, and layout control program

InactiveUS20050172226A1Easy to operateShearing machinesNatural language data processingComputer scienceData layout

To implement an efficient user operation by making it possible to set links between a plurality of containers at once by one operation, in a layout control method which sets a link between partial display regions to connect them to each other, the partial display regions receiving assigned data and laying out the data on a page, and adjusts the position of each partial display region on the basis of the data assigned to it, a plurality of links are set for a plurality of partial display regions, the plurality of partial display regions are designated, the position information of each designated partial display region is acquired, and in a case where setting of a plurality of links is instructed, a plurality of links are set for the plurality of designated partial display regions, on the basis of the acquired position information.

Owner:CANON KK

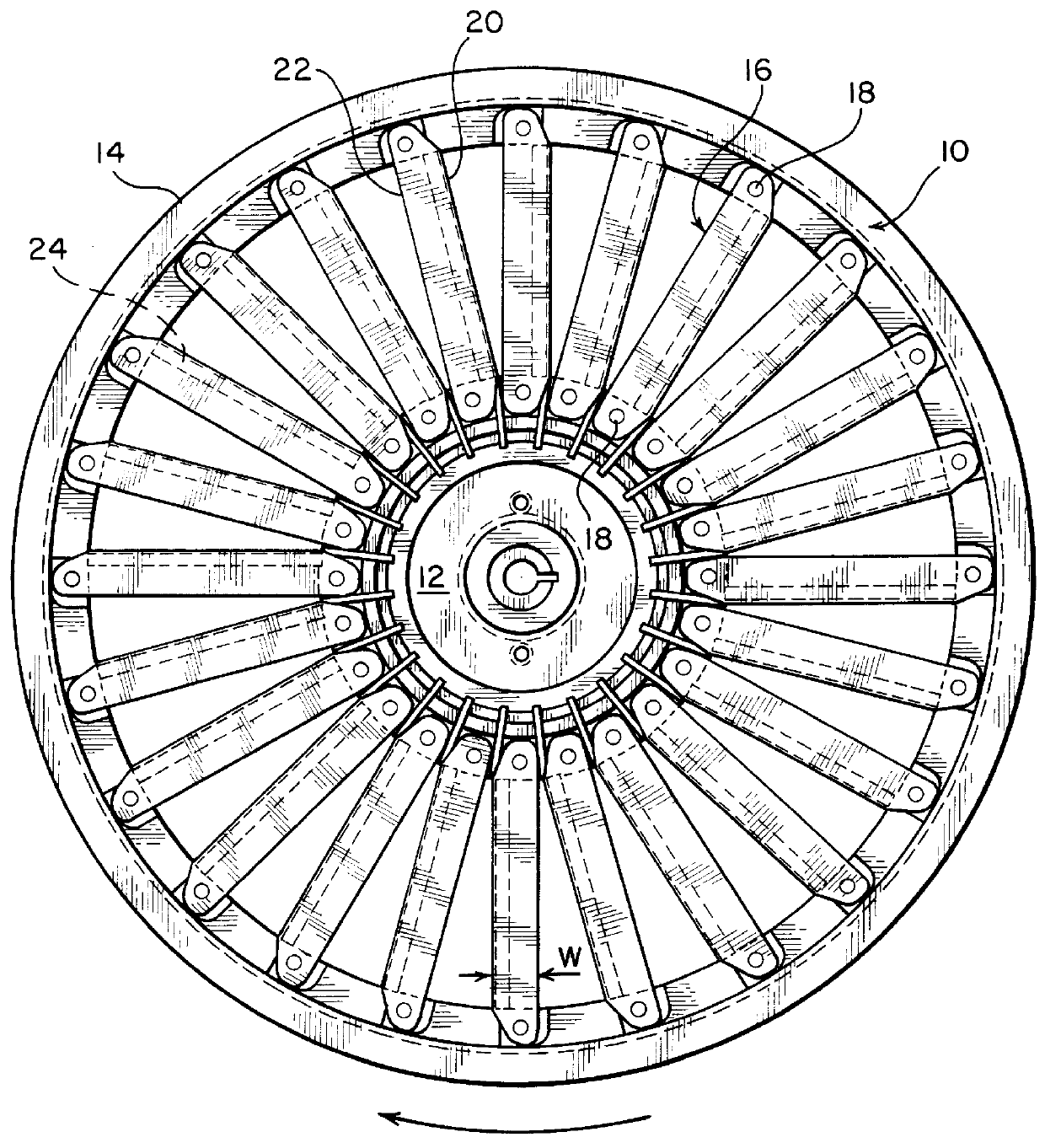

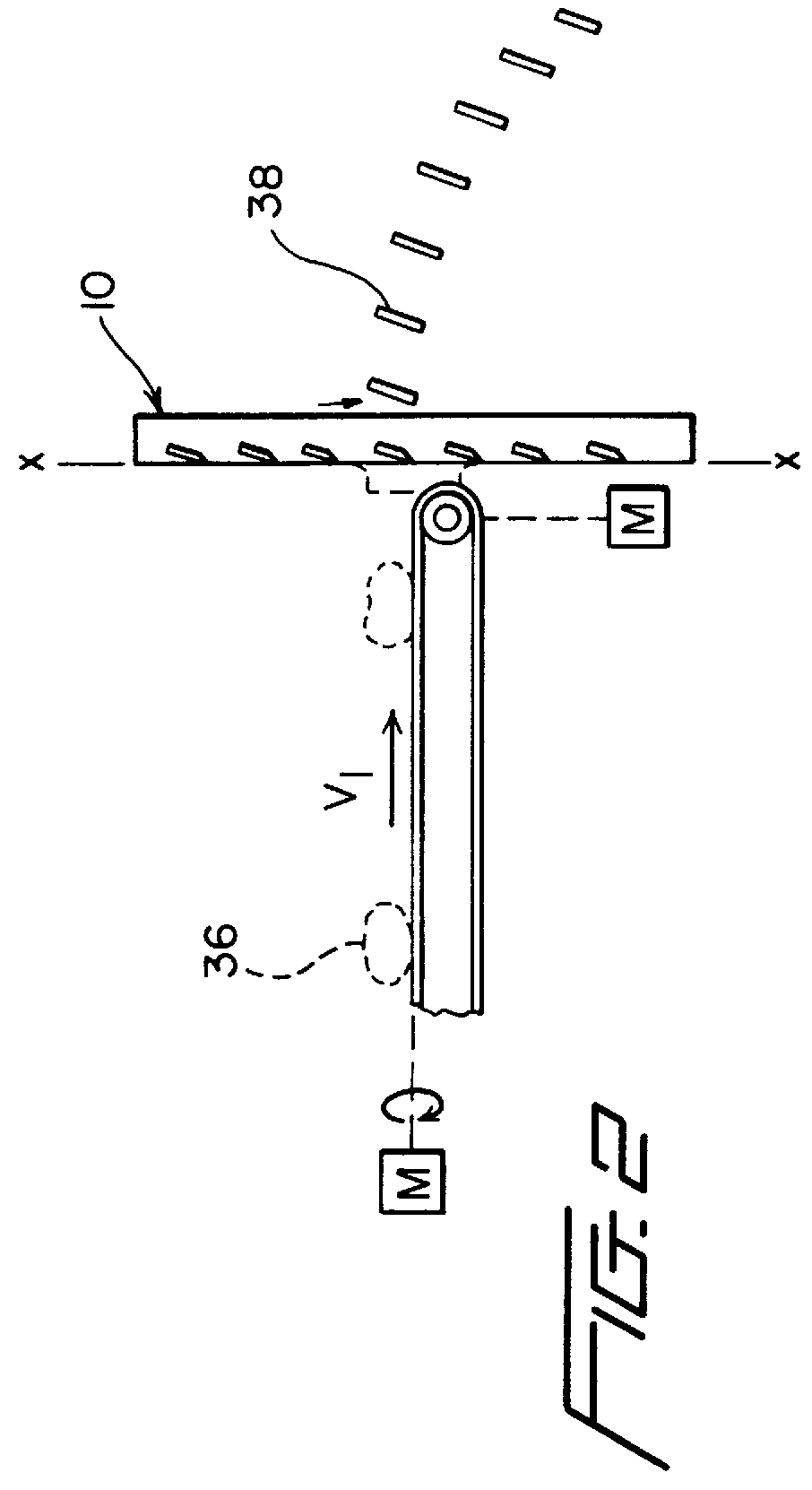

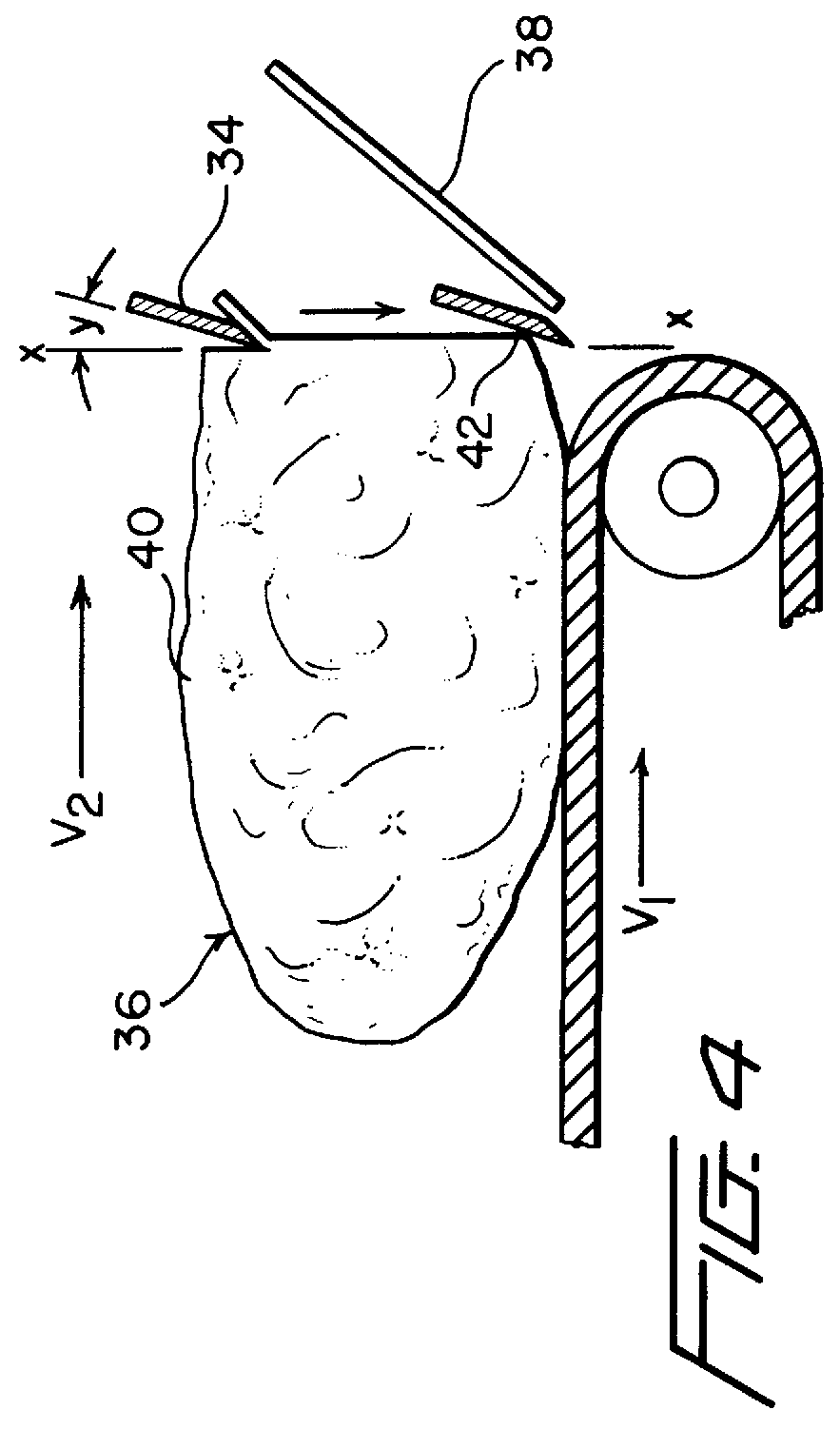

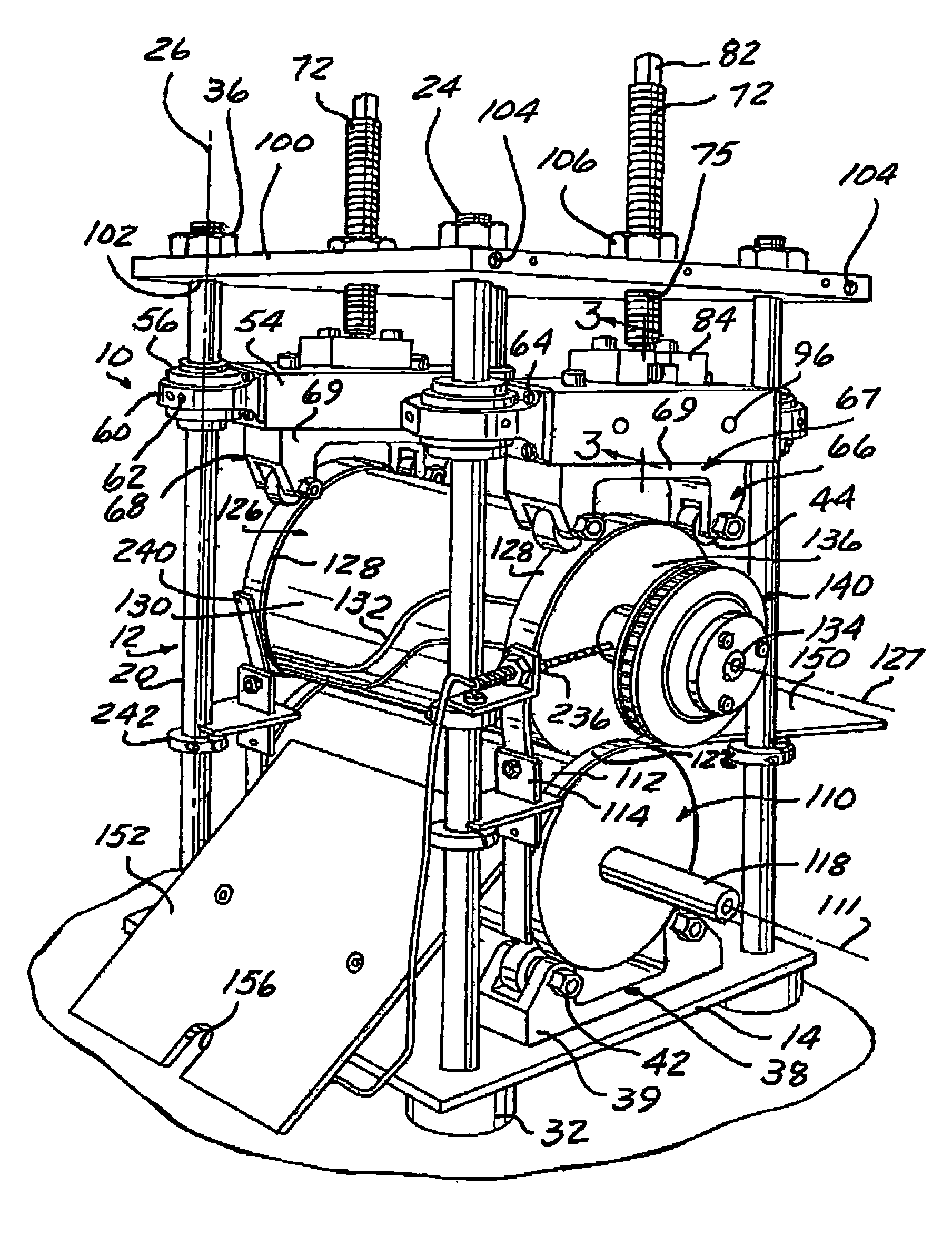

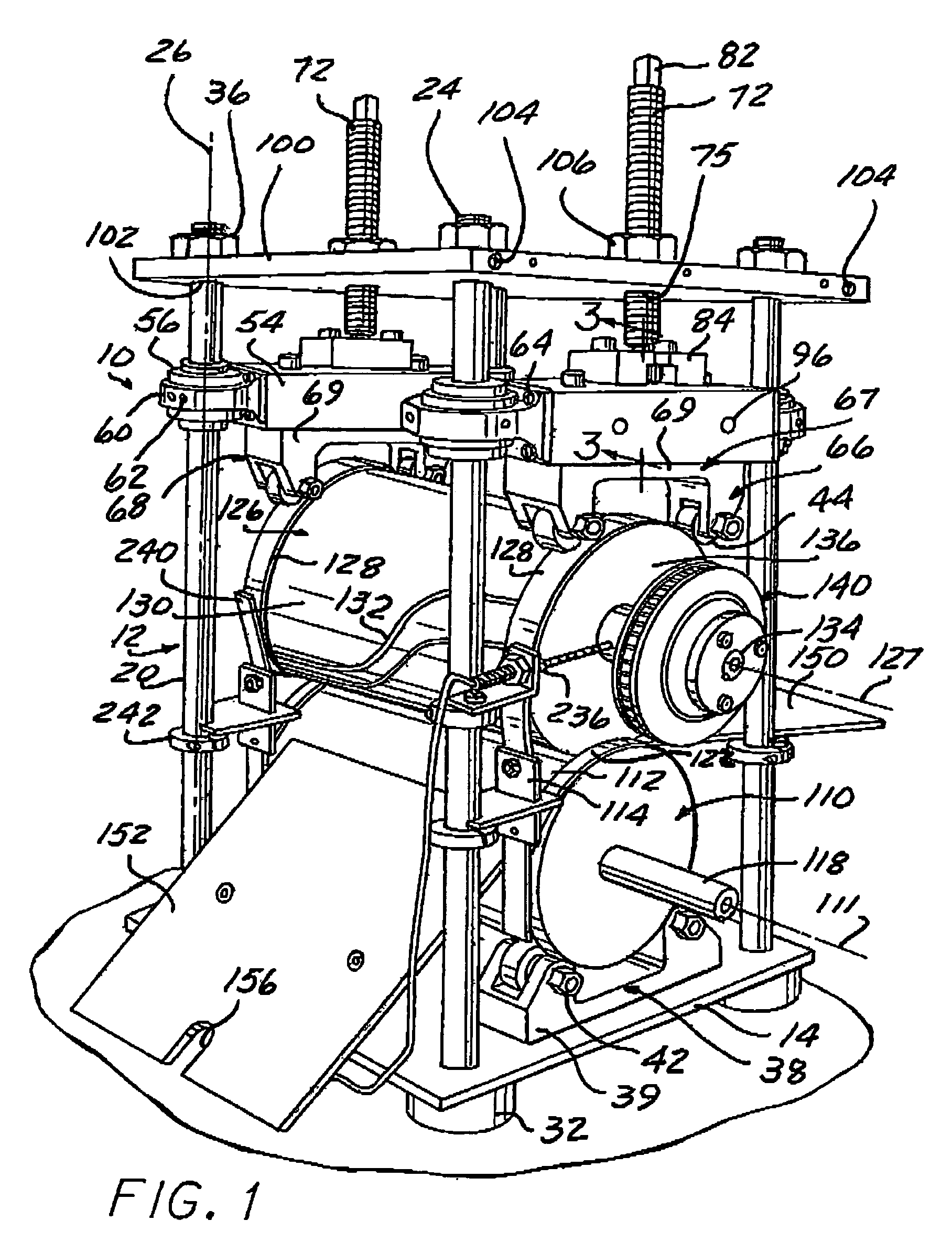

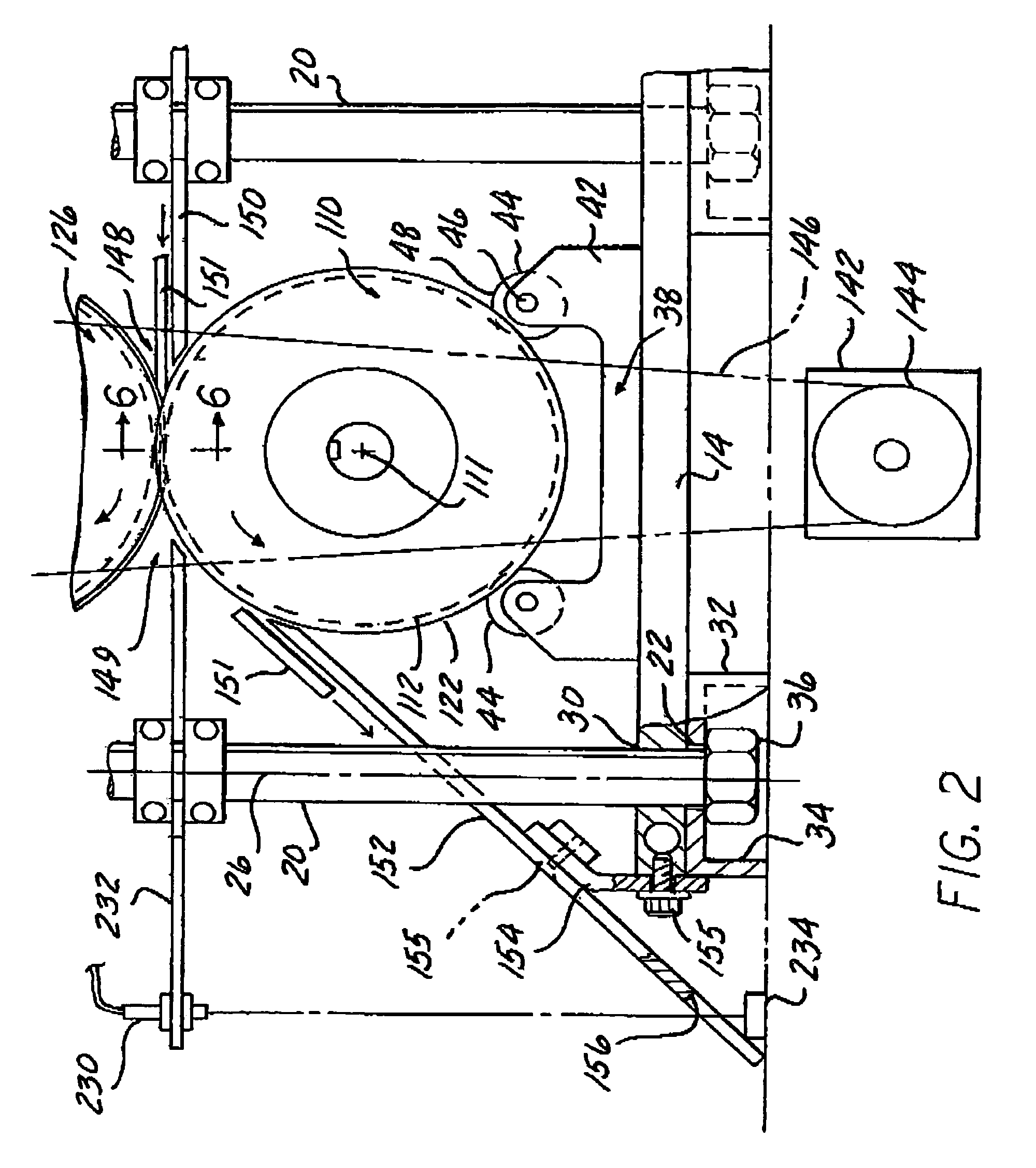

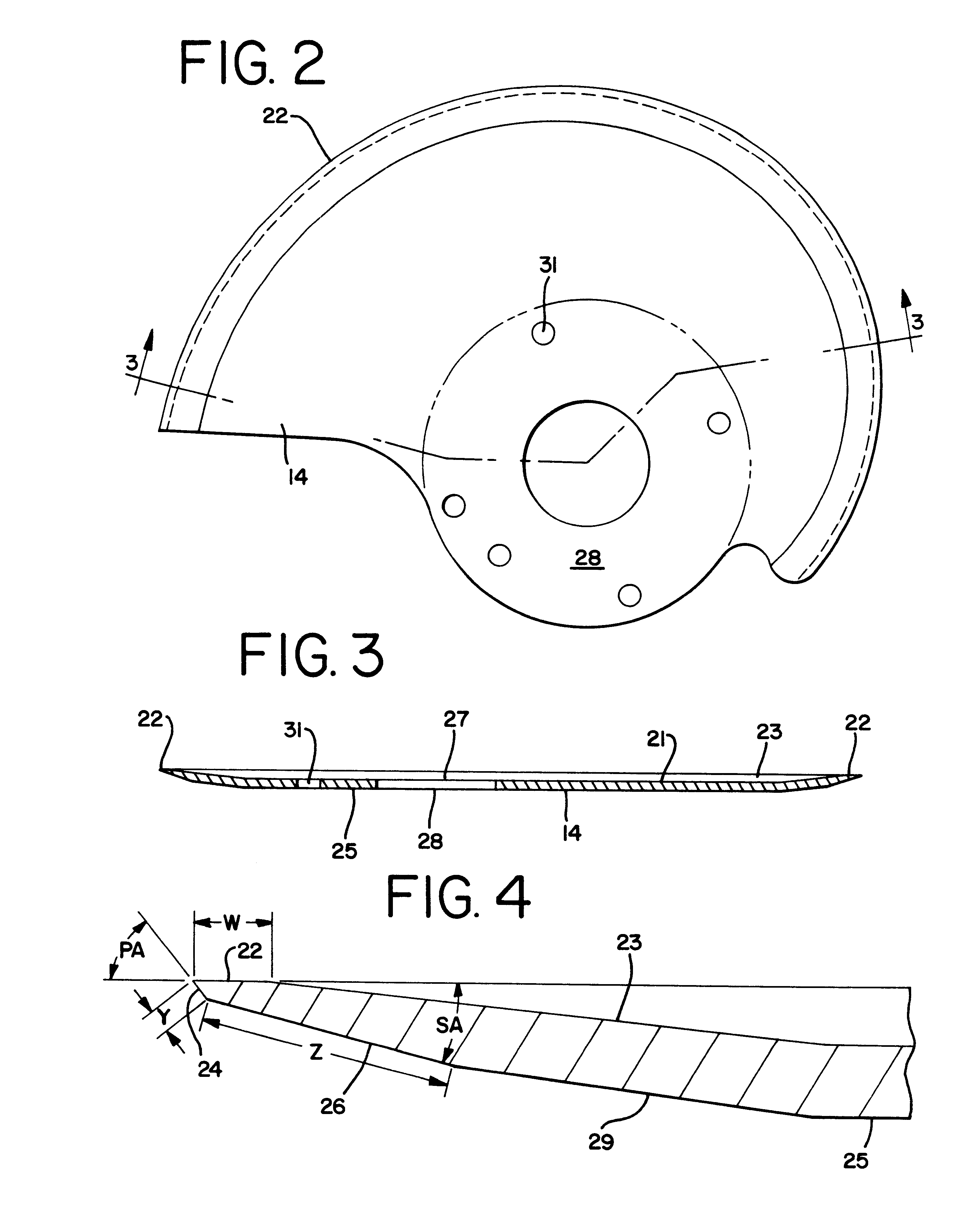

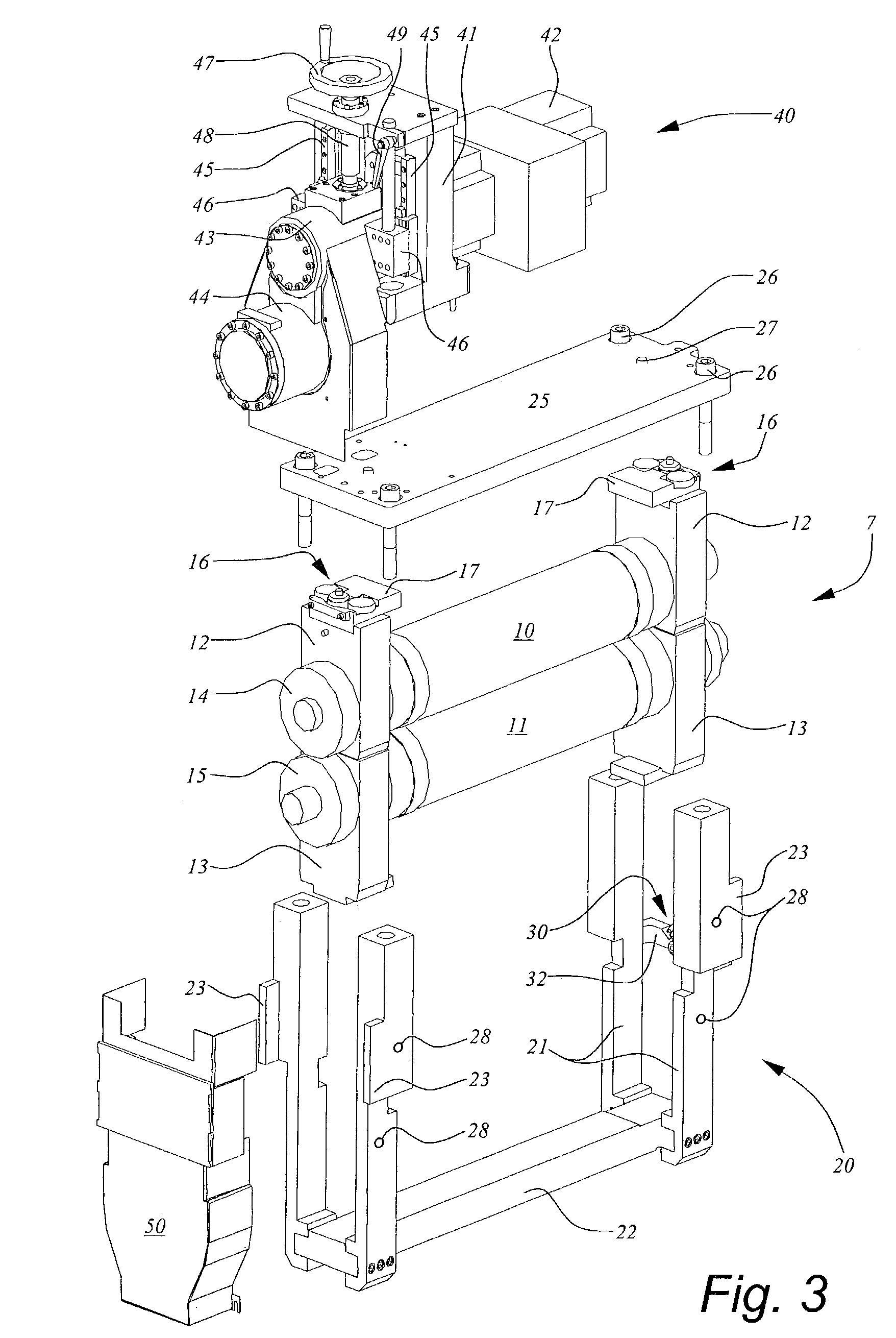

Method and apparatus for uniformly slicing food products

A method of cutting food products into uniform thickness slices using a rotary cutting wheel fitted with radially extending, circumferentially spaced, tensioned and forwardly pitched bevel sharpened cutter blades rotating in a cutter plane and extending between a central hub and an annular rim and wherein the blades produce a first velocity of advancement of unsliced food product across the cutting plane for each revolution of the cutting wheel and a given slice thickness during slicing of food product advanced through the cutting plane. The method includes fitting an appropriate number of blades to the rotary cutting wheel to produce the given slice thickness of food products at the operation rotational velocity of the cutting wheel and rotating the cutting wheel at an operational rotational velocity to produce the first velocity of advancement of unsliced food products through the cutting plane of the cutting wheel. The food products are fed to the cutting plane of the blades of the cutting wheel at a second velocity such that the second velocity corresponds closely to about 101.5% of the first velocity as a result of a selection of configuration and tension of the blades so that they have maximum stiffness and resistance to both longitudinal and transverse flexure during cutting of food products. A cutter blade is disclosed wherein the leading edge portion of the blade member is longer than the maximum distance between fastener apertures at each end area of the blades and wherein the straight trailing edge portion of the blade member is shorter than the minimum distance between aperture diameters.

Owner:URSCHEL LAB

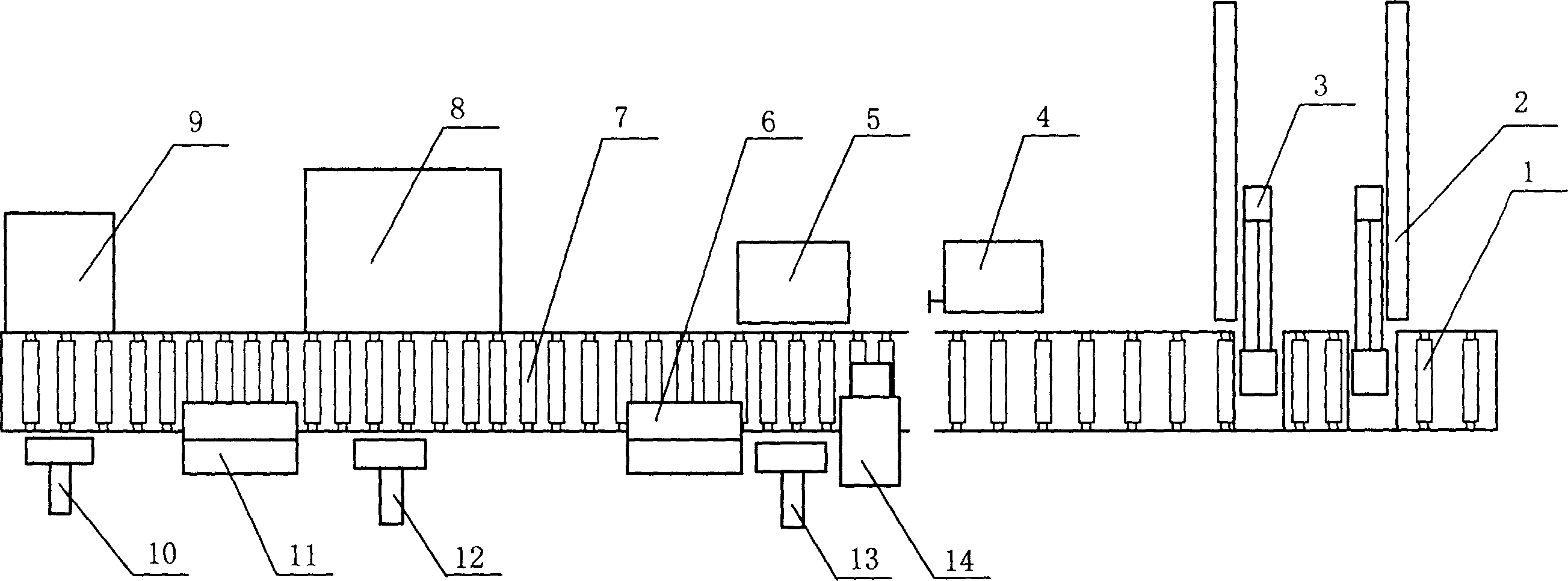

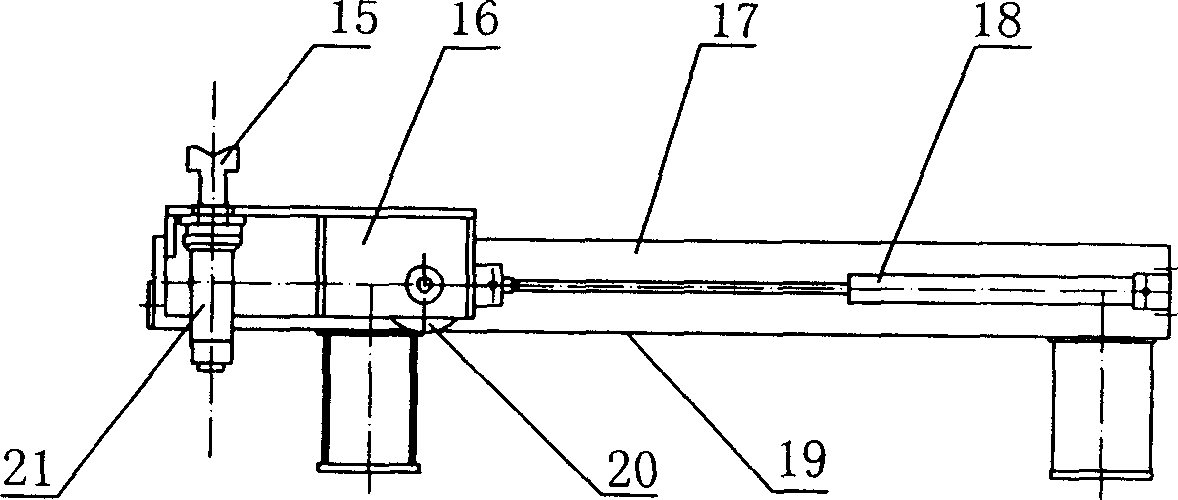

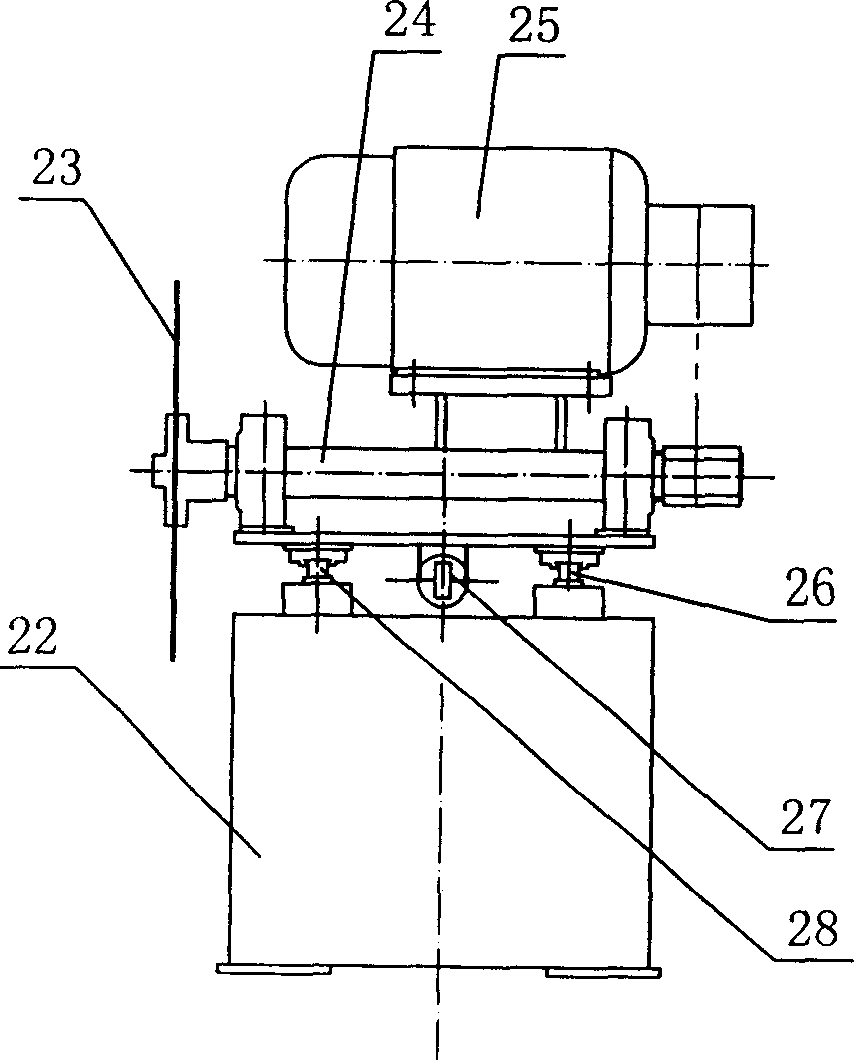

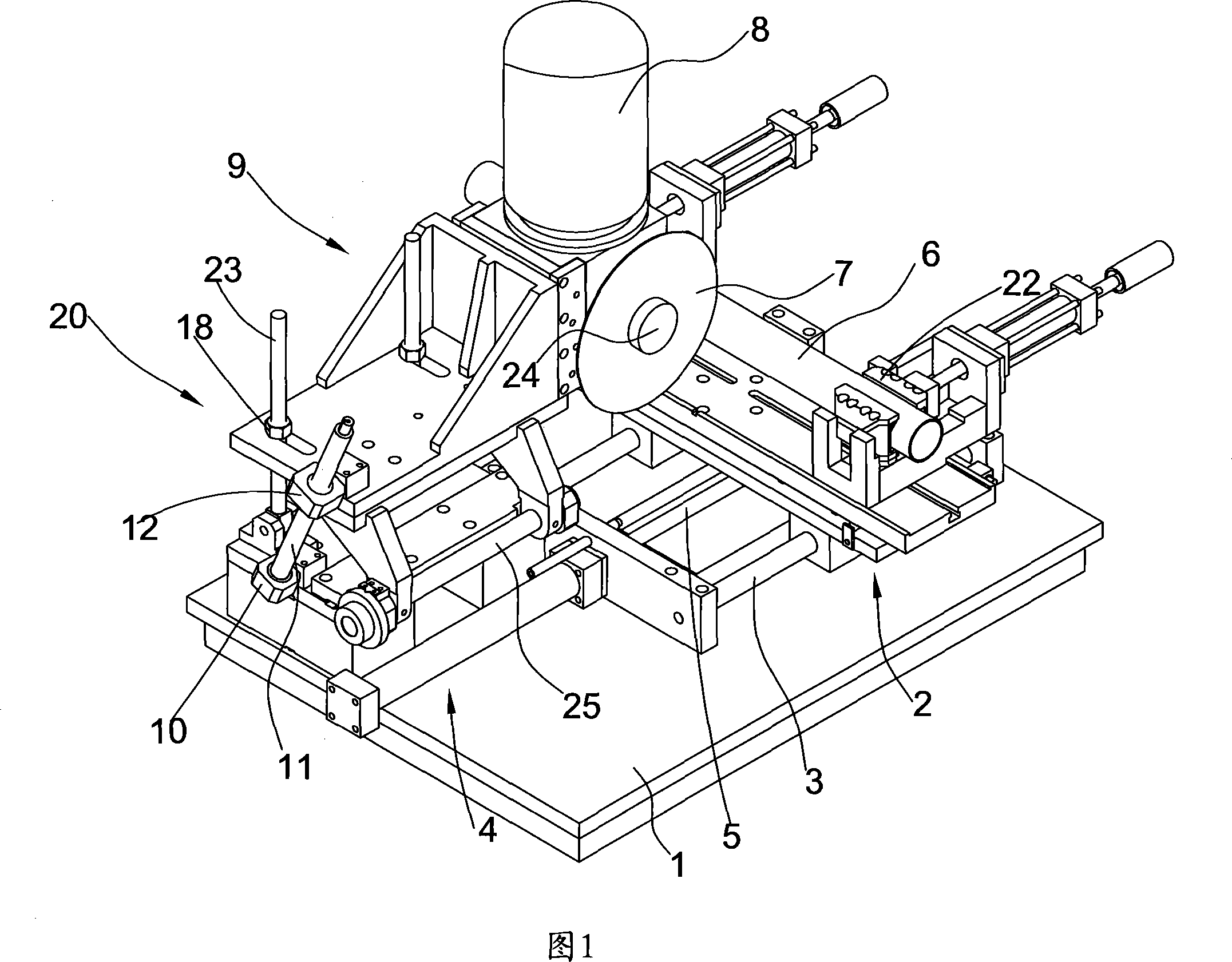

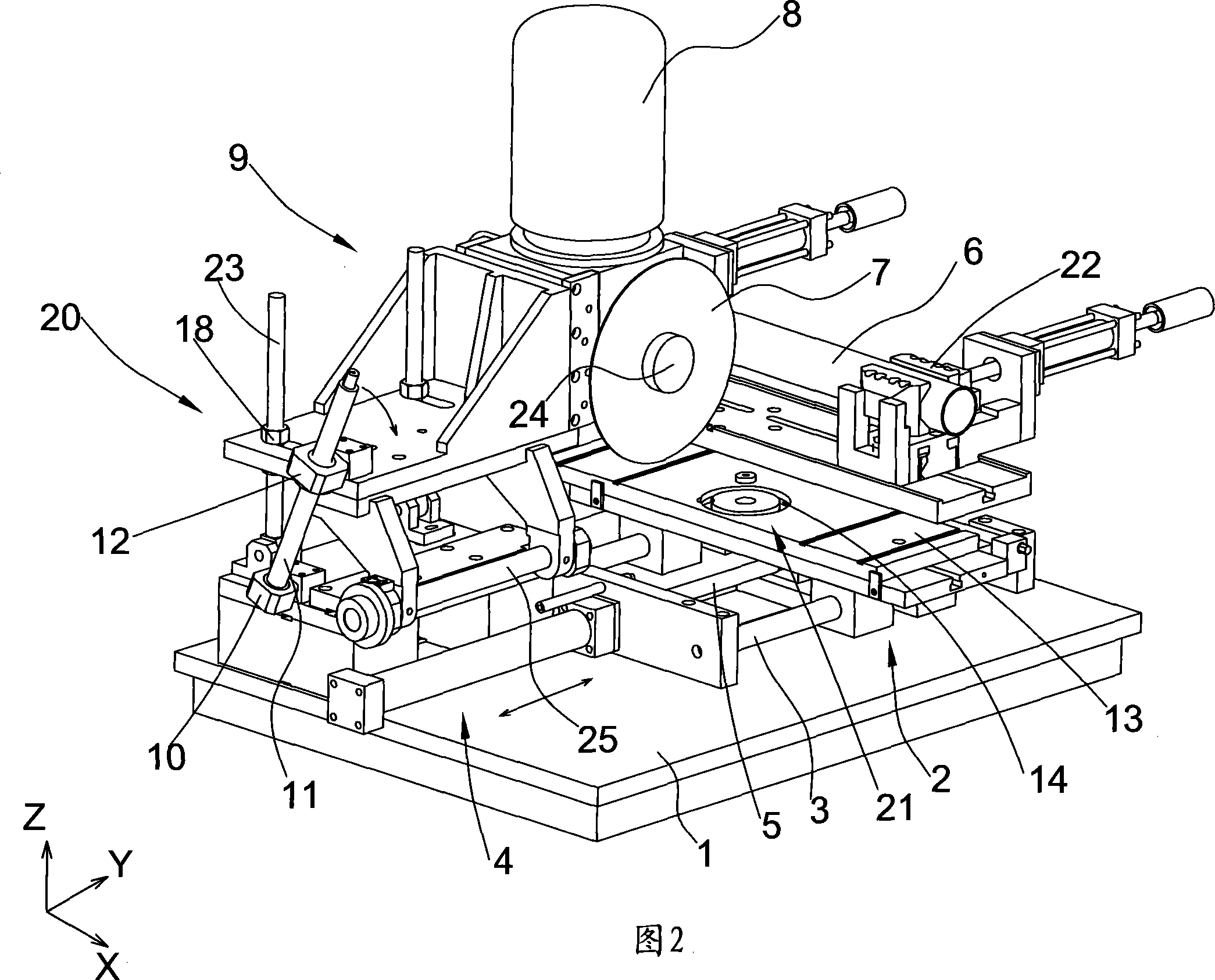

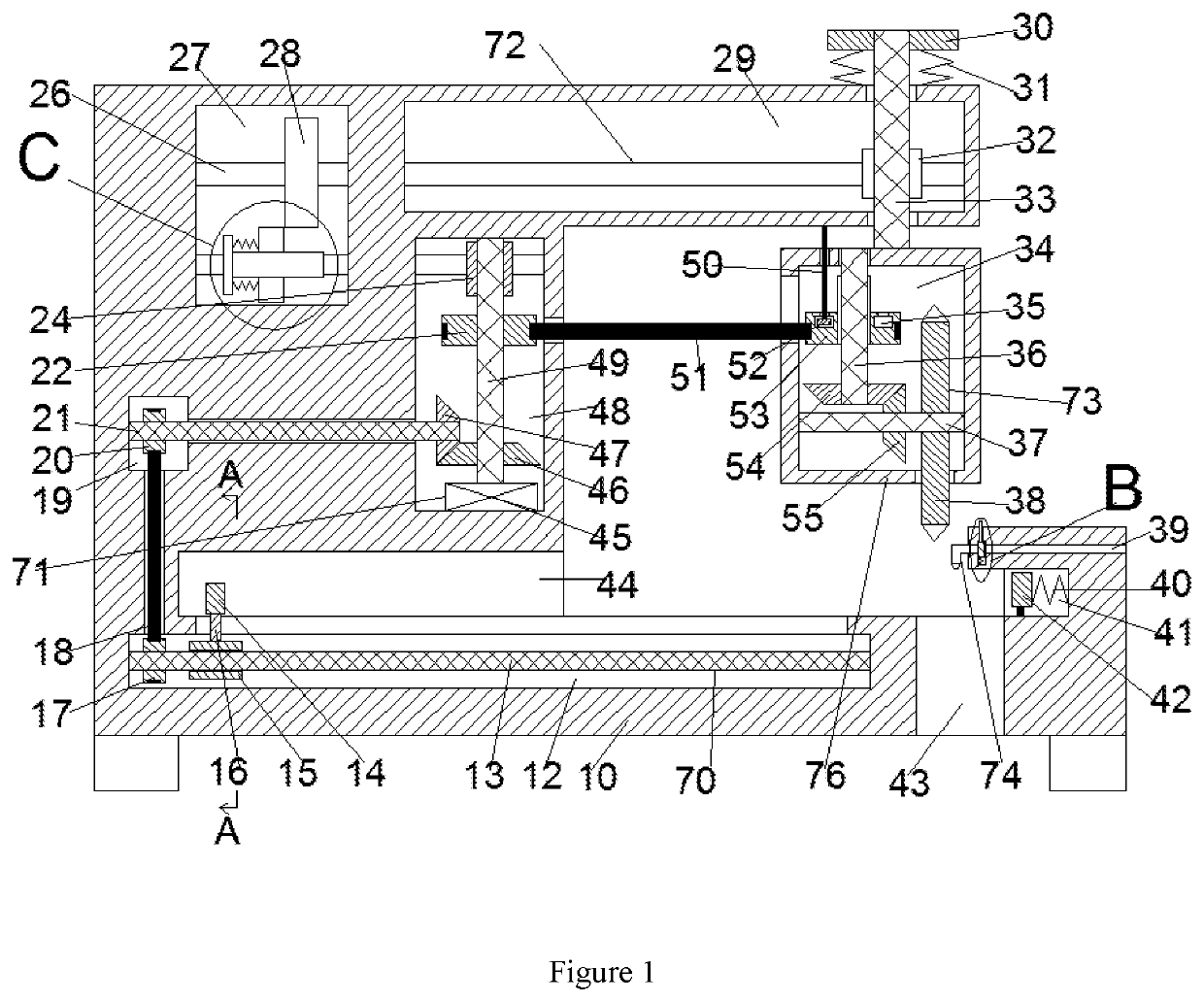

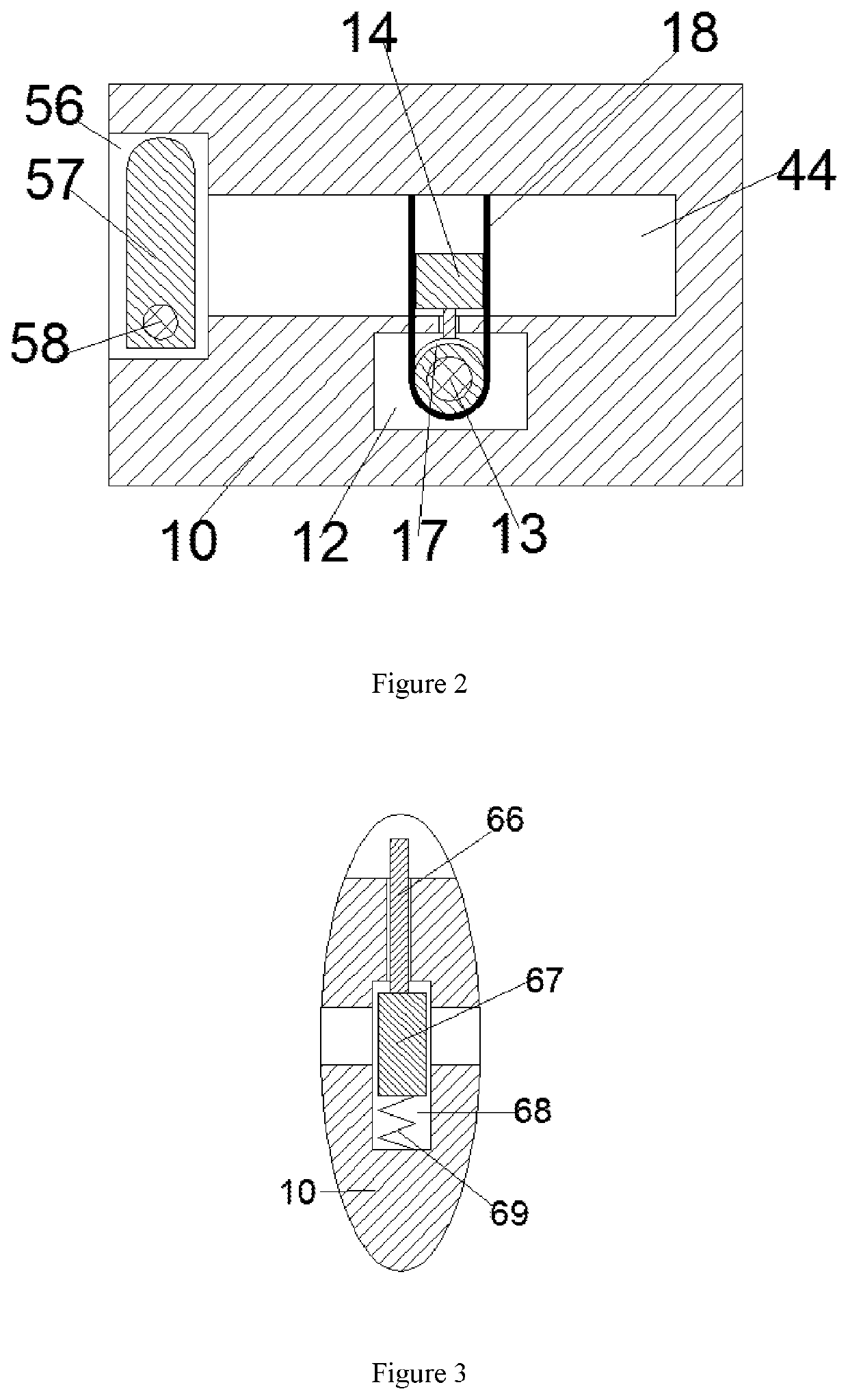

Automatic sawing, cutting and stacking machine for aluminum alloy bar

ActiveCN1899719ARealize automatic controlFree laborMetal-working feeding devicesPositioning devicesAutomatic controlStack machine

The automatic sawing, cutting and stacking machine for aluminum alloy bars includes conveying roller bed comprising conveying rollers and chain wheel driving mechanism, operating stations set along the conveying roller bed, material feeding mechanism, material setting mechanism, cutting mechanism, sizing mechanism, stacking mechanism, side aluminum bar pushing mechanism, power mechanism and control mechanism. The present invention has power mechanism and control mechanism, and can realize PLC automatic control and automatic operation of feeding, sizing, cutting and stacking aluminum alloy bars, and possesses high production efficiency.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Adjustable length punch assembly

Owner:WILSON TOOL INT

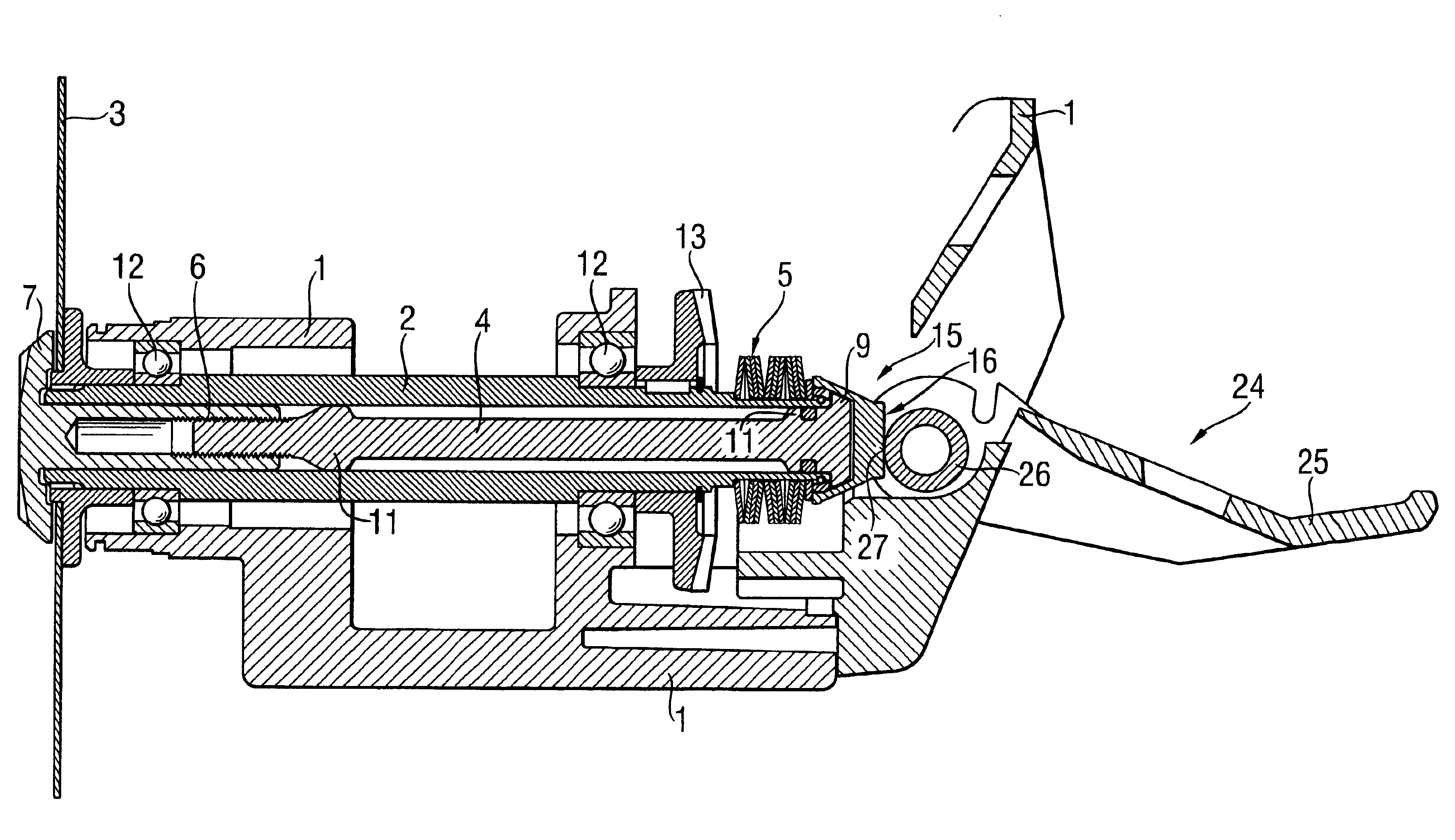

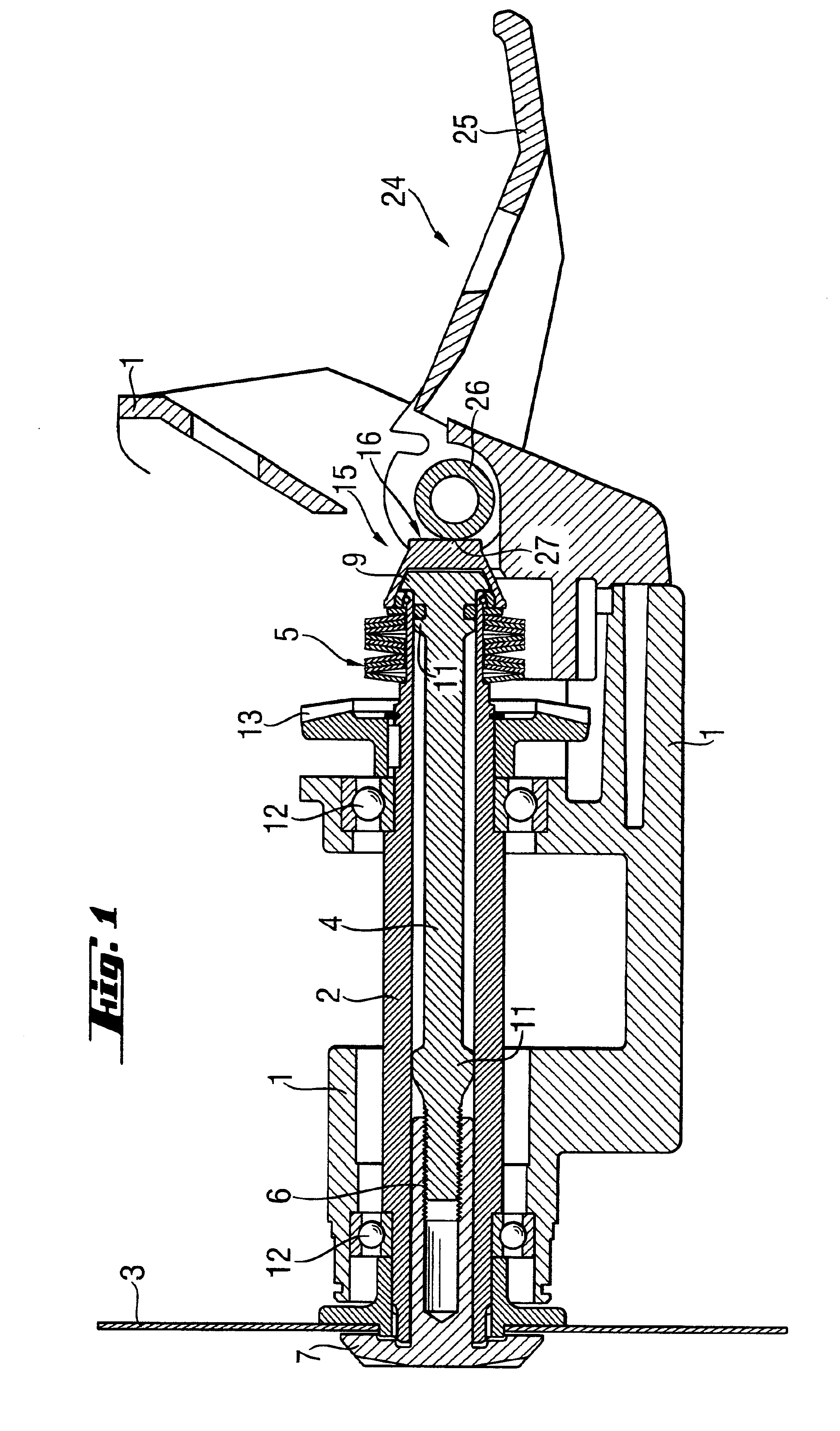

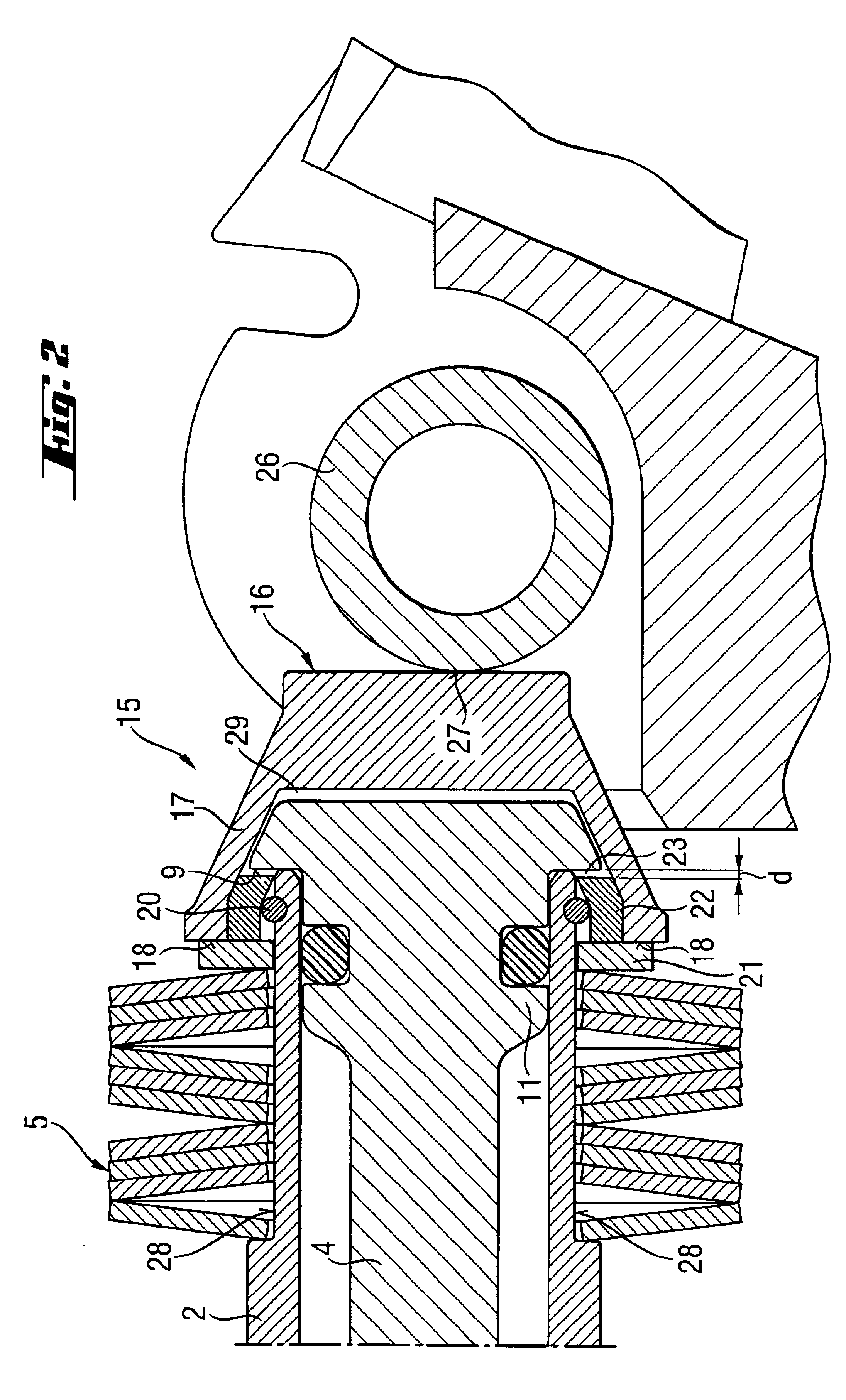

Electrical tool with a quick-action clamping device

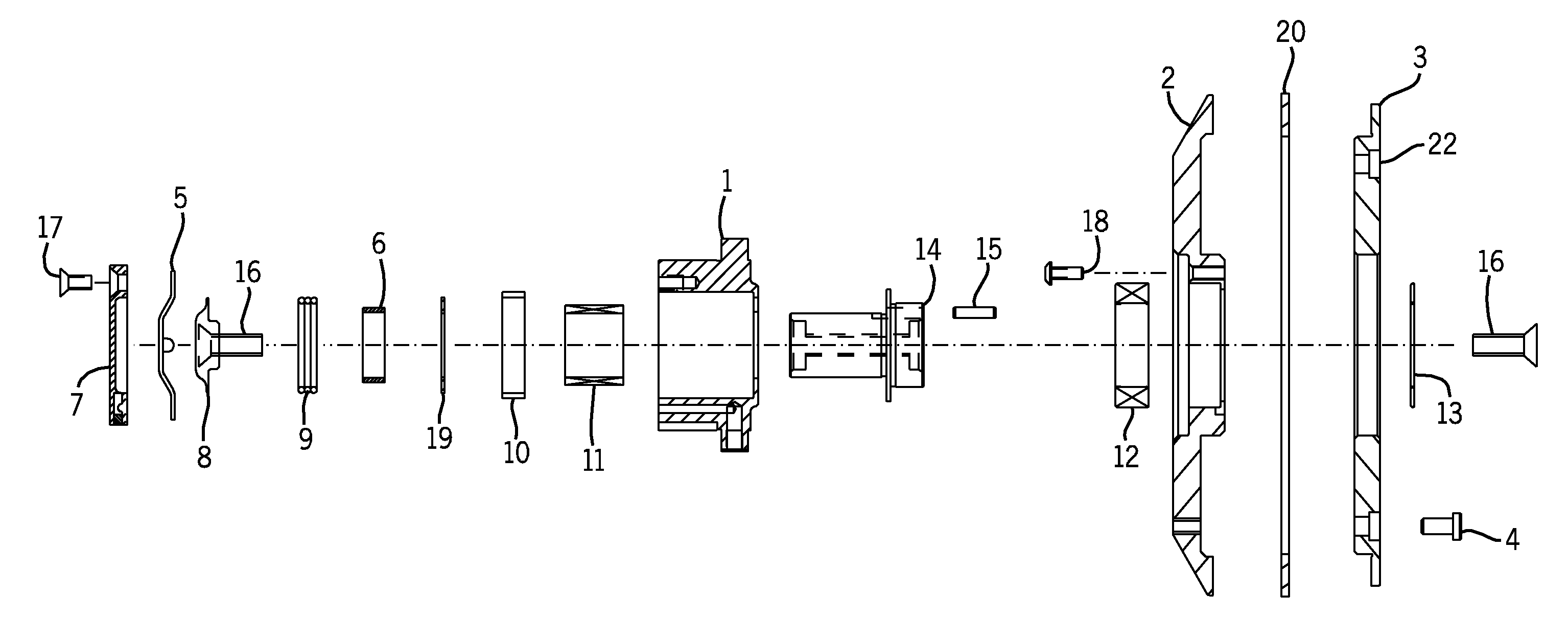

InactiveUS6910694B2Action be interruptEasy constructionGrinding wheel securing apparatusCircular sawsEngineeringPower tool

A quick-action clamping device for a power tool includes a clamping spindle (4) arranged in the hollow spindle (2) of the power tool, an elastic member (5) for biasing the clamping spindle (4) into its clamping poition, in which the working tool is claming between a claming flange (7) provided on a working tool-side end of the claming spindle (4) and the hollow spindle (2), an actuation element (24) for displacing the claming spindle (4) against the biasing force of the elastic member and into its exchange position in which the working tool (3) is released, and a compansator (15) for interrupting action of the elastic member (5) on the clamping spindle (4) in the exchange position of the clamping spindle (4).

Owner:HILTI AG

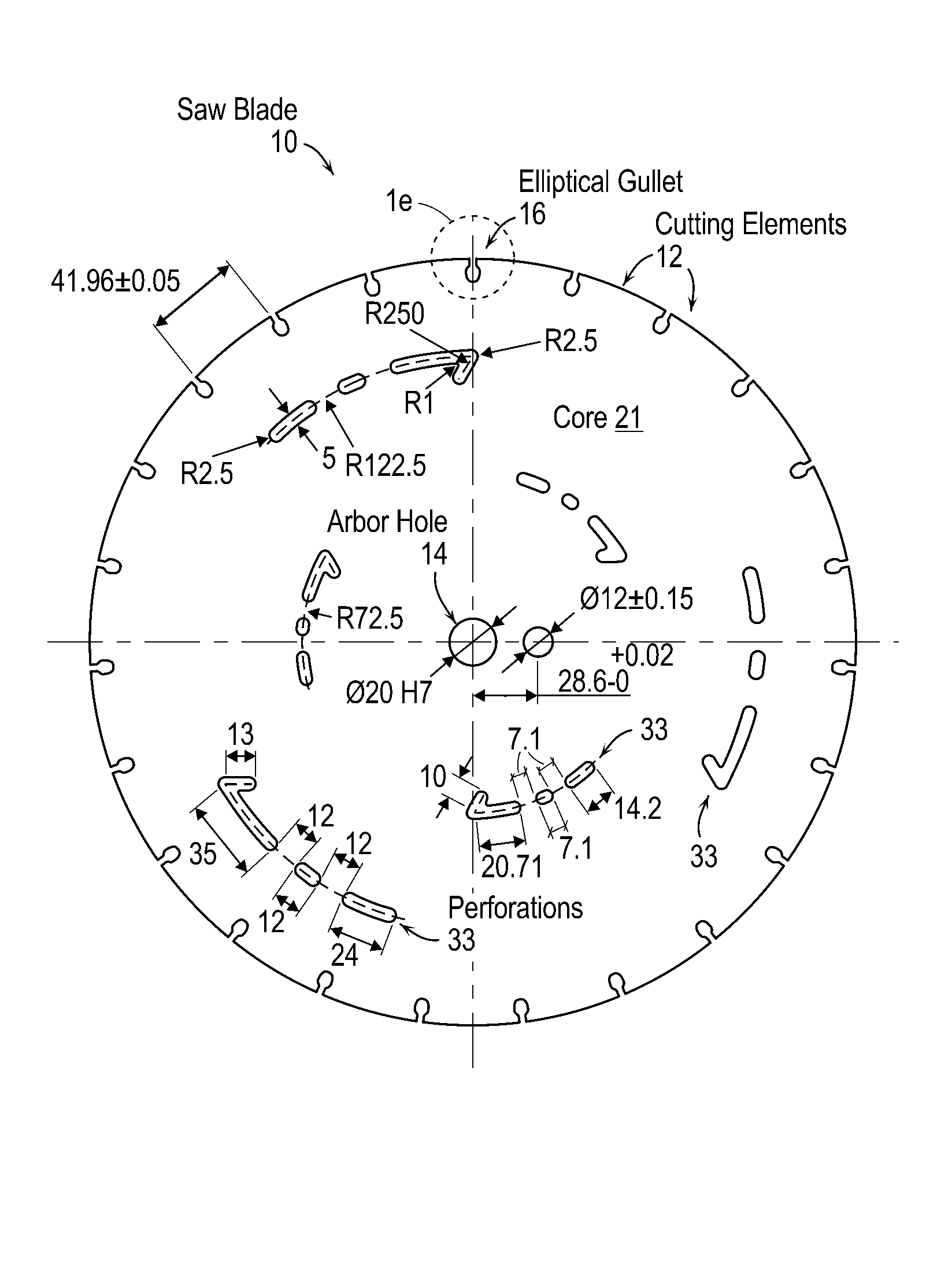

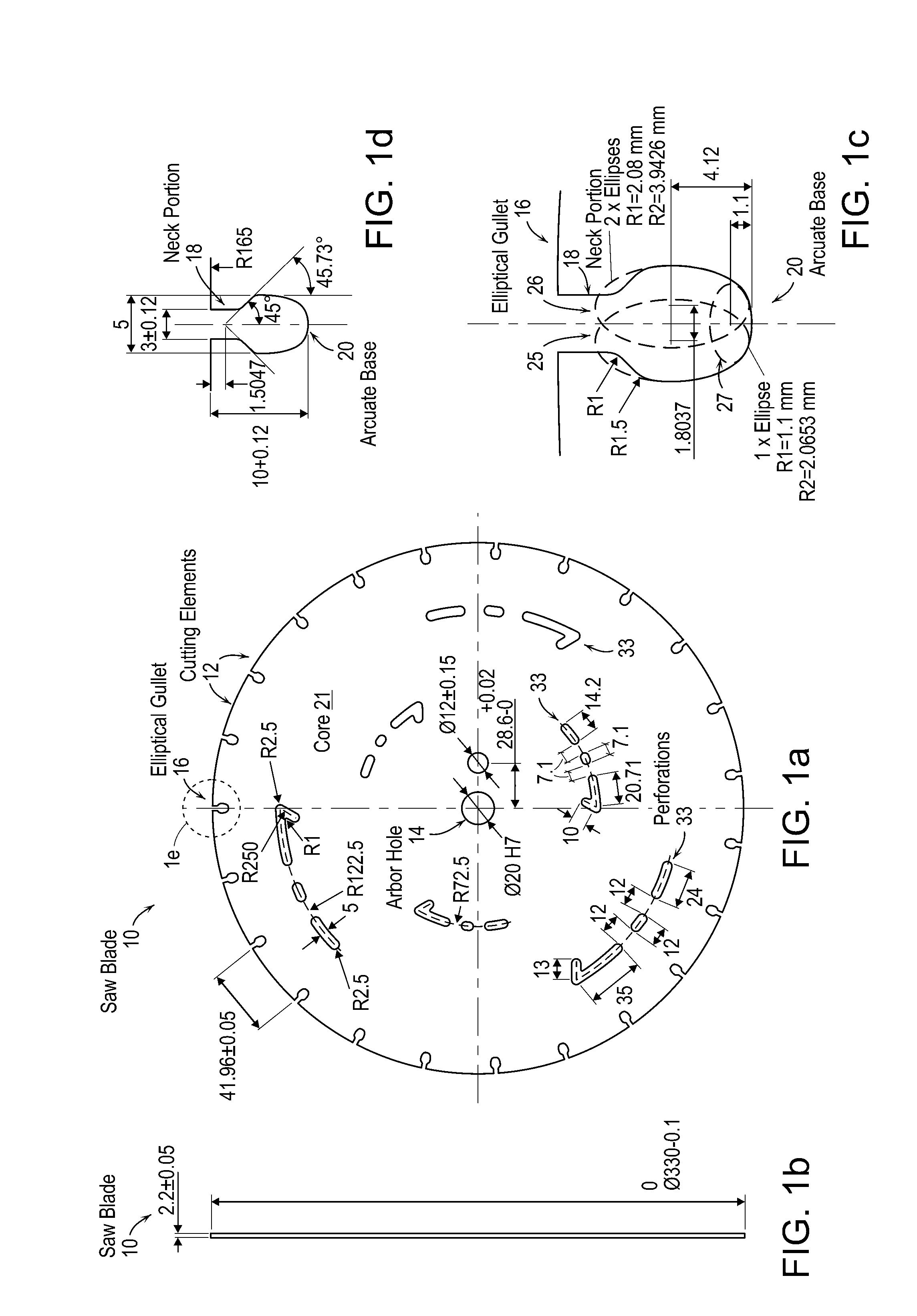

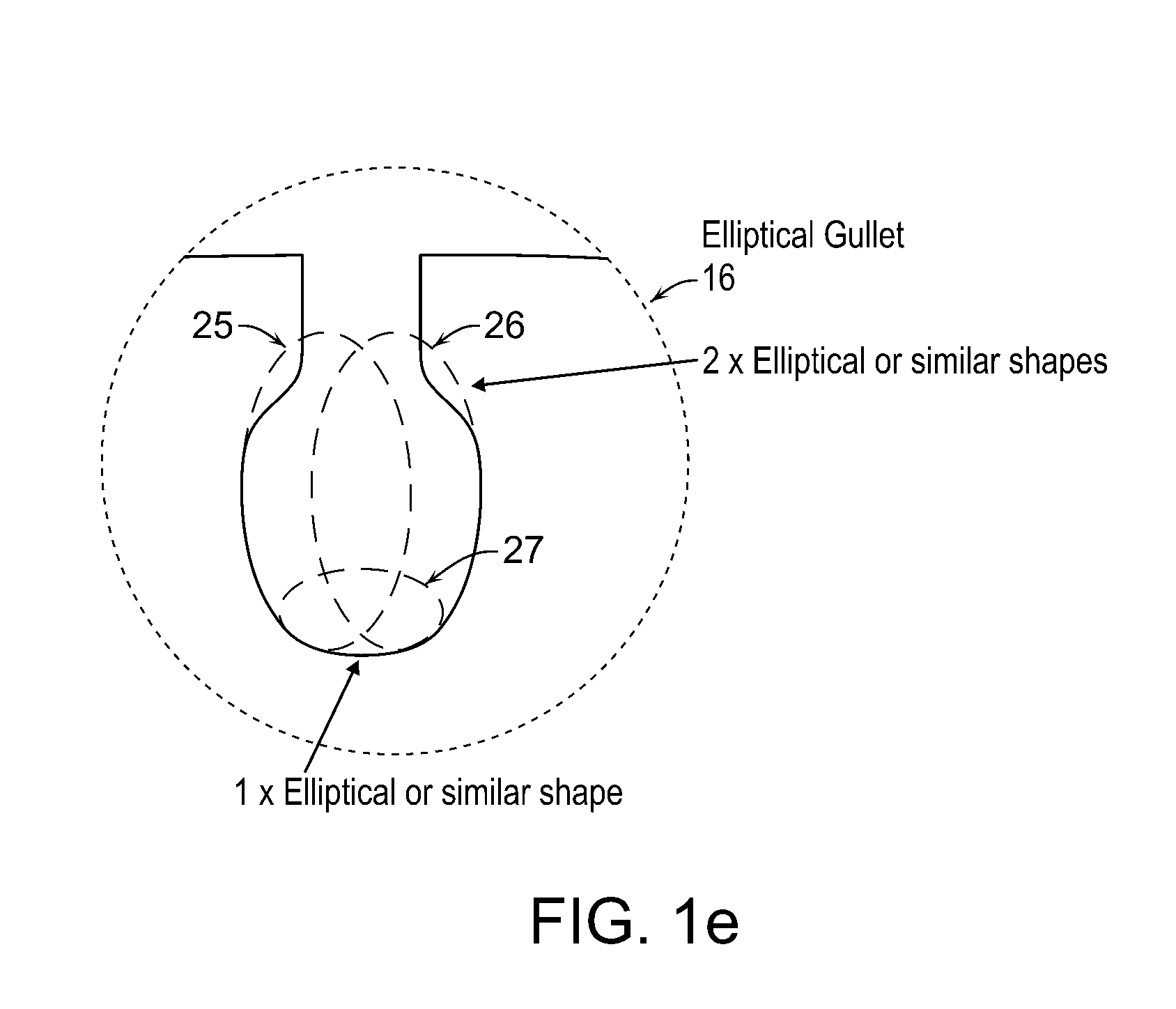

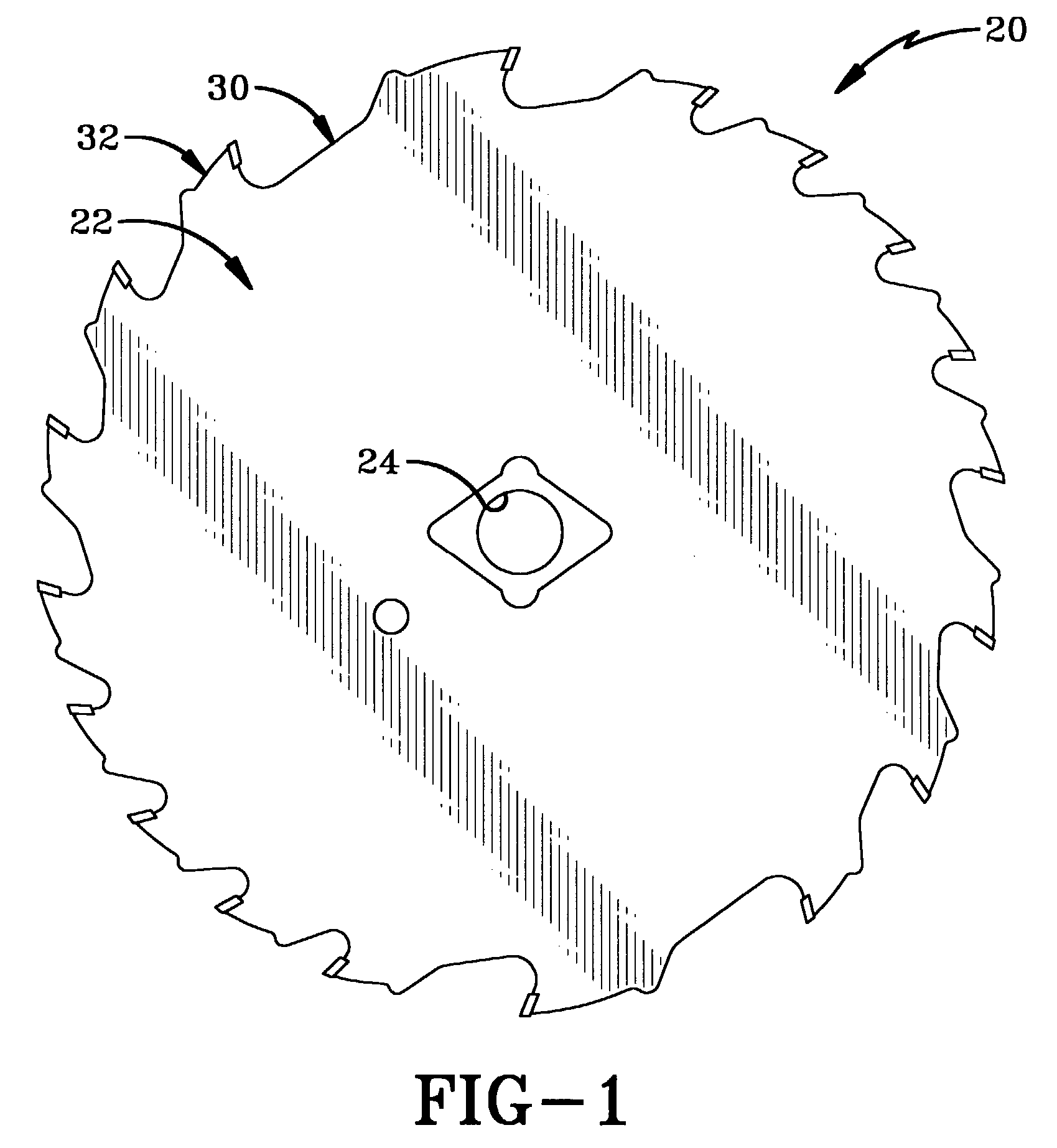

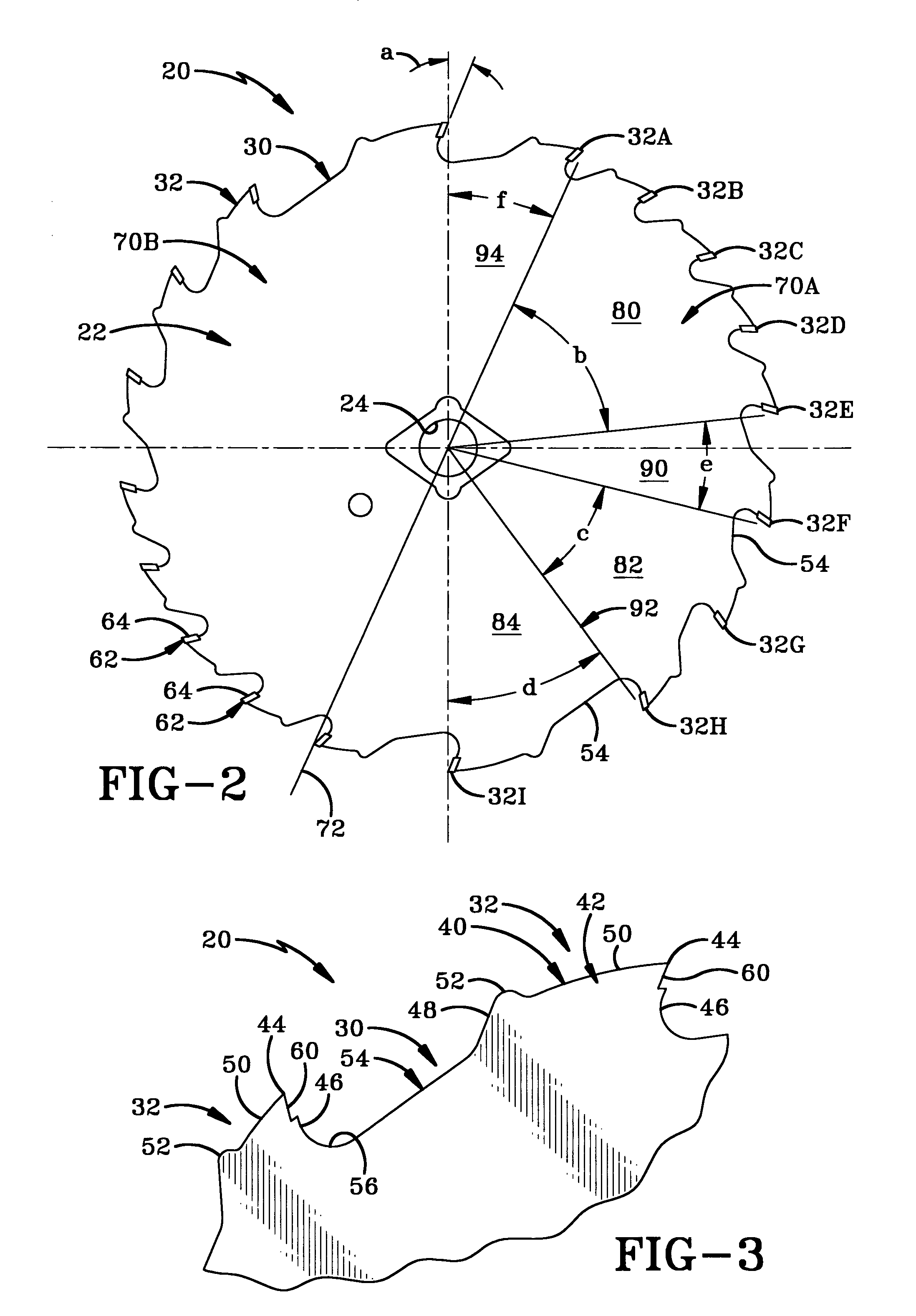

Circular Saw Blade With Elliptical Gullets

A saw blade includes a circular core having a plurality of cutting elements along its periphery, and a central arbor hole. One or more gullets extend radially inward from the perimeter of the core. Each gullet includes a shape that includes at least one elongated curve that enlarges radii in gullet areas prone to cracking, relative to other gullet areas.

Owner:SAINT GOBAIN ABRASIVES INC +1

Flying shear blade and preparation method thereof

InactiveCN101144140AImprove wear resistanceImprove hardenabilityHeat treatment process controlShearing toolsQuenchingImpurity

The present invention discloses a flying shear blade. The component has the weight percentage that C is 0.40-0.70, Si is 0.50-1.20, Mn is 0.20-0.50, Cr is 4.00-6.00, Mo is 0.50-2.00, V is 0.30-1.50, P is less than or equal to 0.02, S is less than or equal to 0.02, and Fe and inevitable impurity are the residual. The present invention provides a manufacture method of electric furnace smelting, and ingot casting; hydrogen removing and annealing treatment, and forging; preliminary heat treatment, rough machining, quenching and tempering heat treatment (primary quenching and high temperature tempering), semi finishing, ultimate heat treatment (secondary quenching, primary low temperature tempering, and secondary low temperature tempering), and fine finishing. By effectively controlling the material texture and the morphology, the quantity, the size and the distribution of carbonide, the quenching temperature and the tempering temperature of the quenching and tempering heat treatment, and the quenching temperature and the tempering temperature of the ultimate heat treatment are controlled, the texture crystal grains are more refined, the carbonide is distributed in a dispersed way, and simultaneously, the thermal stability and the retentivity are remarkably enhanced, thereby being advantageous for improving the operational performance of the blade.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Device for lengthwise slitting a web and method relating thereto

InactiveUS6092452ALittle maintenanceSimple and inexpensiveShearing machinesGang saw millsEngineeringMechanical engineering

A method is described for changing between jobs in a device for slitting a web (N) into a plurality of lengthwise strips (L1, L3, L5, L1', L3', L5') with two series of slitting tools (25, 25B). At the moment of the job changeover, the tools of a first series are moved from a slitting position to an inactive position and the tools of the second series are moved from an inactive position to a slitting position. The passage from one position to the other is delayed for one of the tools of each series in order to generate two slit lines (L3', L5) extending into the job changeover zone (CA), and these lines are subsequently joined up by a transverse slit (L9). (FIG. 6)

Owner:FOSBER

Shear with replaceable shearing tip

Owner:CATERPILLAR WORK TOOLS

Disk shearing blade and method for manufacturing the same

ActiveCN101177765AImprove wear resistanceHigh strengthShearing machinesFurnace typesHigh intensityWear resistance

A disc scissors blade and its manufacturing method, the composition weight percentage of the material of the disc scissors blade is: C: 0.40-0.70%, Si: 0.50-1.2%, Mn: 0.20-0.50%, Ni: 1.00-1.50% %, Cr: 4.00-6.00%, Mo: 0.50-2.00%, V: 0.30-1.50%, Nb: 0.10-0.80%, P≤0.02%, S≤0.02%. The method introduces an electroslag remelting process into a common manufacturing method of disc shears, and increases the temperature of quenching and tempering heat treatment and final heat treatment. The disc scissors have good wear resistance and deformation resistance, and are suitable for slitting or trimming hot-rolled high-strength thick steel plates. In addition, the disc shear blade of the present invention also has a good use effect on disc shears in other similar working conditions, and can also be applied to disc shears for stripping or edge trimming of cold-rolled strip steel, and also has a promotional effect on non-ferrous metal disc shears. value and application prospects.

Owner:BAOSHAN IRON & STEEL CO LTD +1

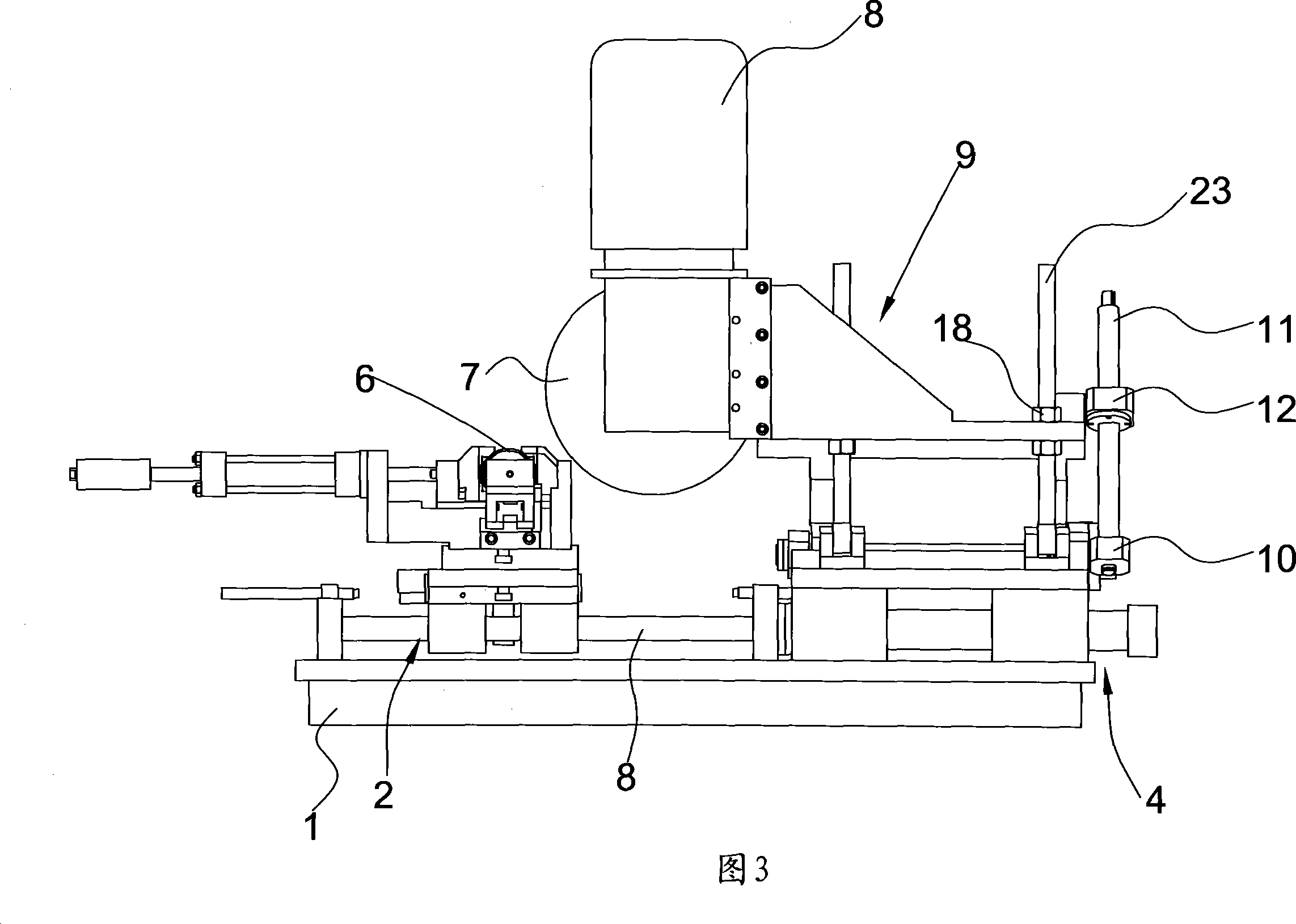

Three-dimensional pipe cutter

The invention is concerned with a kind of three-dimensional machine to cut pipe, relating to machine rack, holding equipment, fixing seat for drill. The drill connects with the fixing seat in moving, and the holding equipment sets on the machine rack in sliding. The drill connects on the first running axis extending to the axis of X and the machine rack has guiding rail extending along the level direction and the holding equipment set on this guiding rail in sliding. The machine rack has the second running axis extending along the axis of Y that being upright to axis of X and the drill seat connects with the second running axis in sliding. There is the first lock equipment between the drill fixing equipment and machine rack, and the holding equipment relates to the sliding seat connecting with guiding rail and worktable on the sliding seat moving around the axis of Z, and the sliding seat and worktable can match and slide with each other and there is the second lock equipment between the sliding seat and worktable. The three-dimensional relationship between the drill and pipe piece to cut the pipe piece from multi-angle, and the adjustment is easy to cut the strange shape of pipe piece or cut for many times.

Owner:庄添财

Replaceable demolition shear piercing tip

Owner:ANTARES CAPITAL AS AGENT

Saw blade with cutting depth gauge

ActiveUS7210474B2Non-rotary toothed toolsPower driven reciprocating sawsPower toolMaterial Perforation

Cutting tools are provided that include a circular core with a cutting means located on its periphery, a central bore to receive an arbor of a rotating power tool and one or more perforations extending through the central core. The perforations are disposed along a circumference disposed concentrically with, and between, the central bore and the periphery. The perforations are arranged to form an annular window through the core which corresponds to a predetermined cutting depth during rotational operation of the tool.

Owner:SAINT GOBAIN ABRASIVES INC

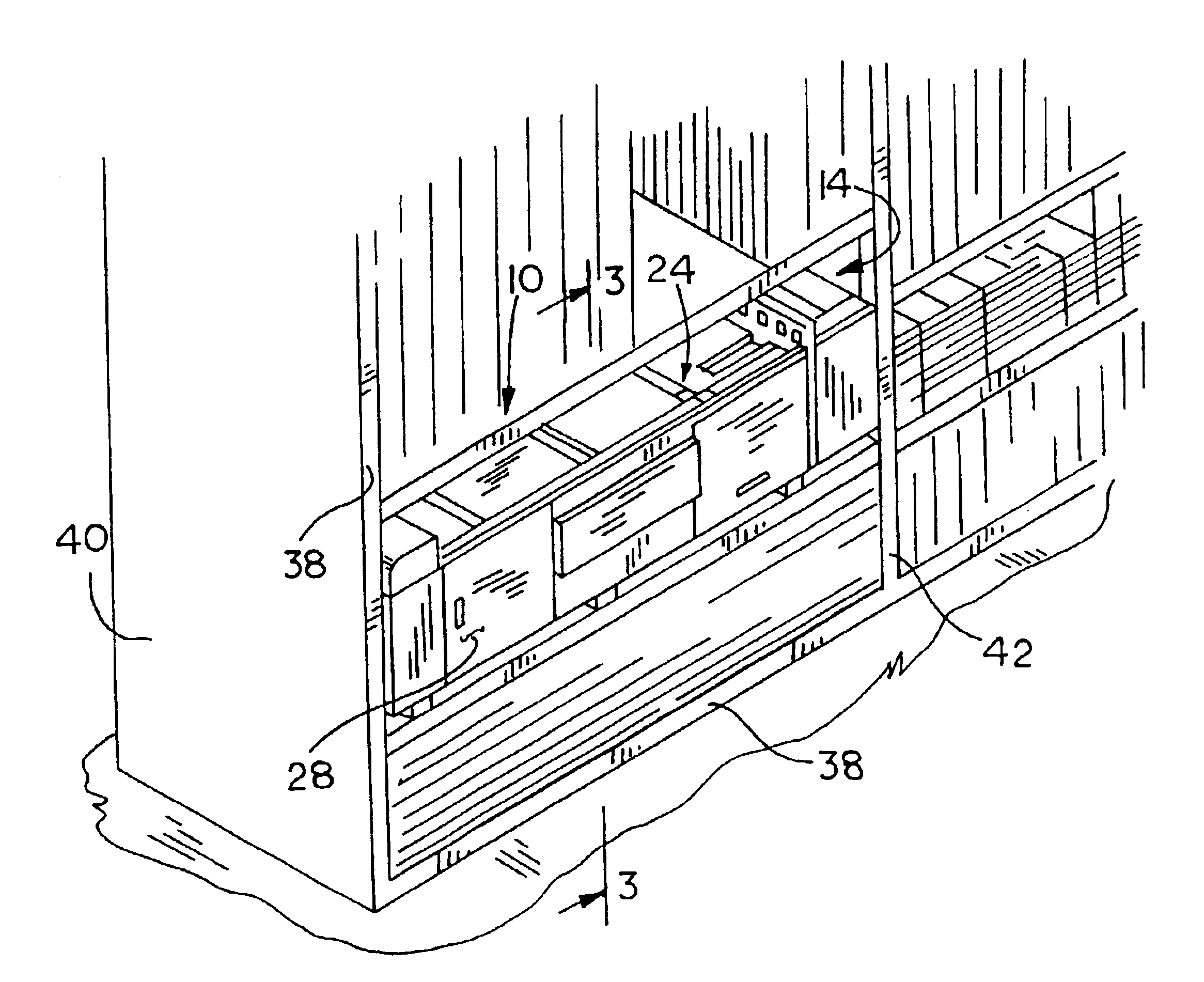

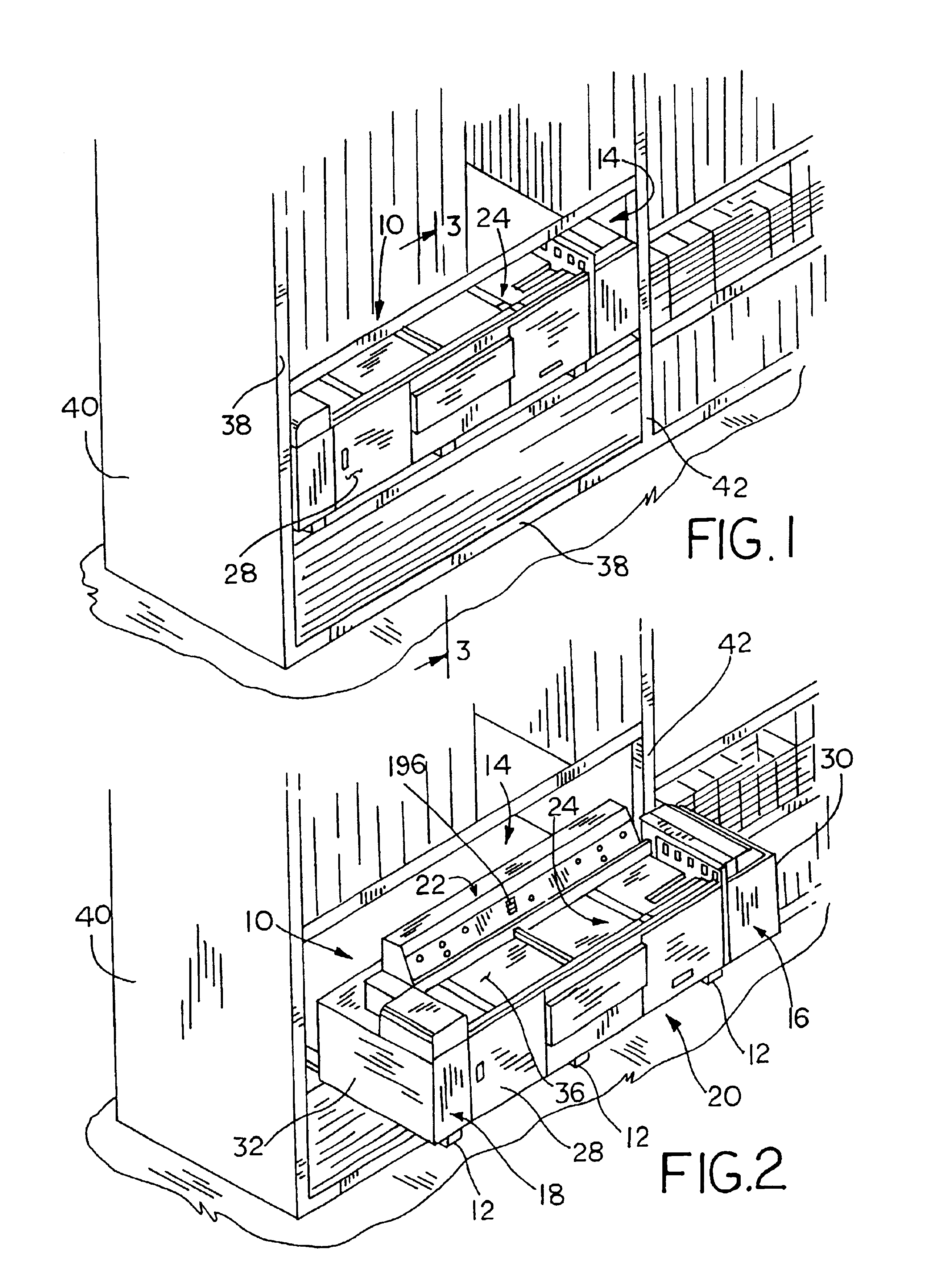

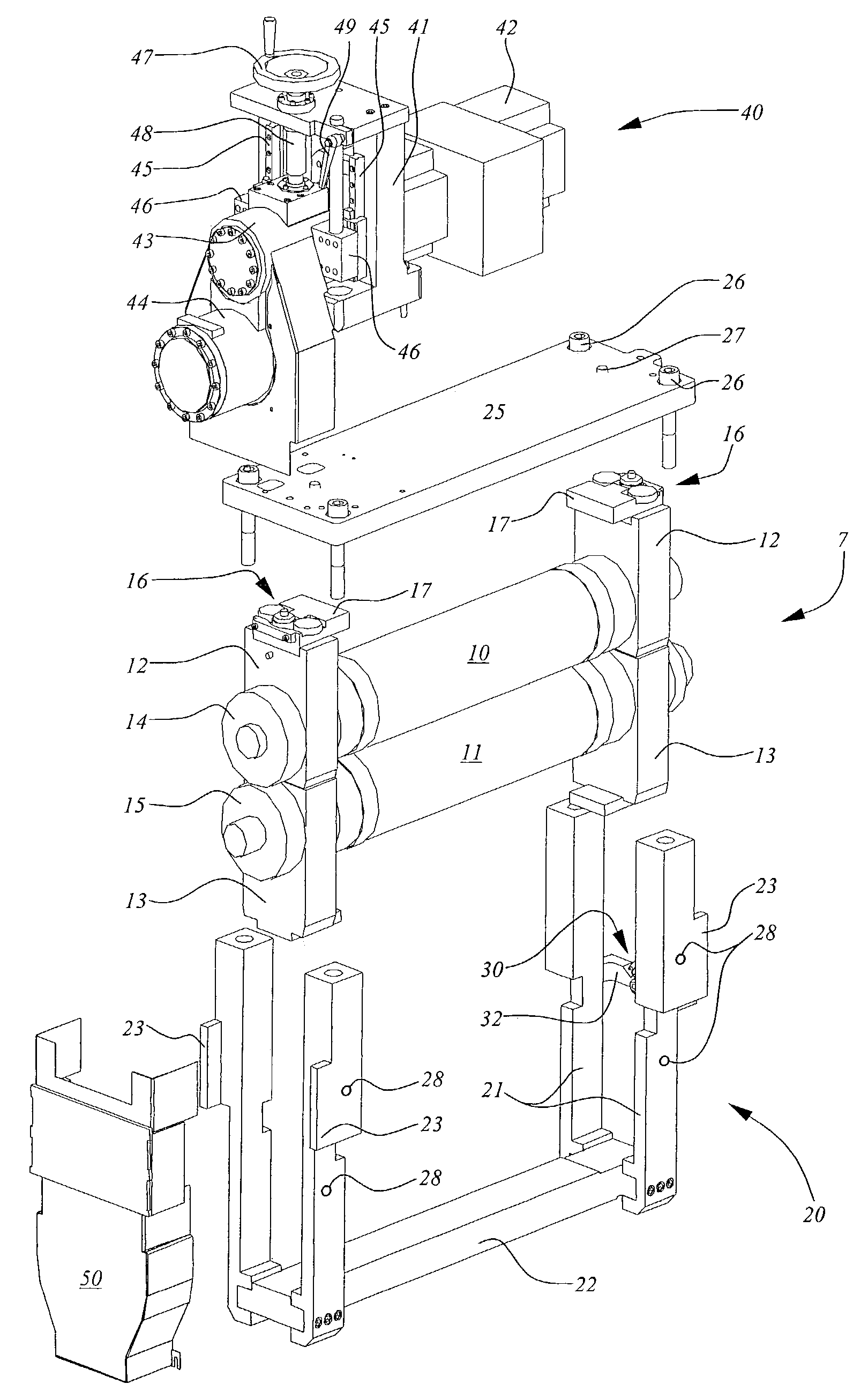

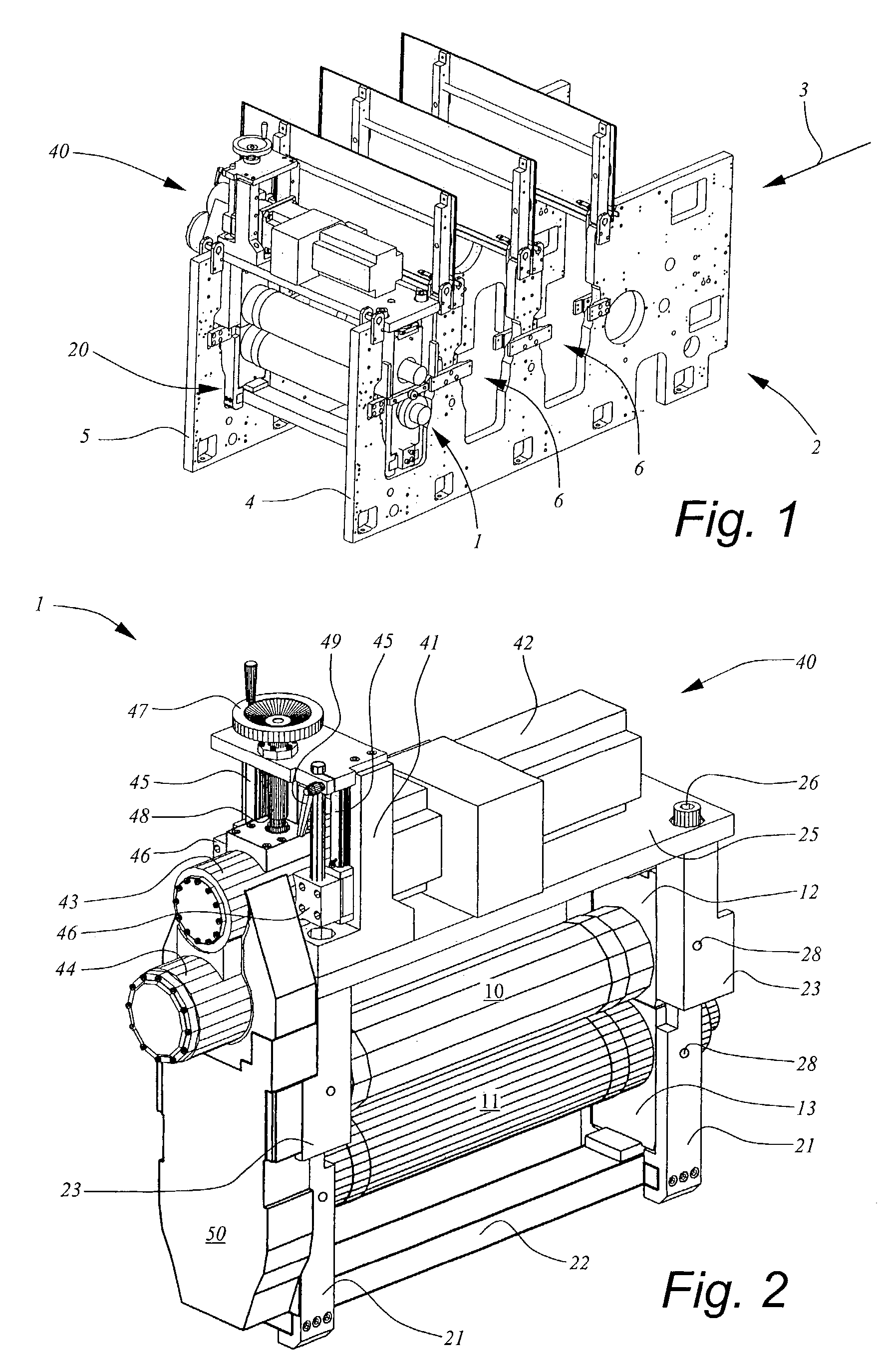

Method of positioning a window covering in a sizing mechanism

InactiveUS7007576B2Metal sawing devicesDoor/window protective devicesEngineeringMechanical engineering

A method of and apparatus for positioning a stock window covering in a sizing mechanism for sizing the window covering in a retail outlet includes obtaining a width specification for a finished window covering, which includes a bottom rail, a window covering material and a head rail, the method comprising. The stock window covering is disposed in a sizing mechanism adjacent a scale. The scale is calibrated from a cutting plane of the sizing mechanism, and has indicia that are twice the actual distance from the cutting plane. The center of the stock window covering is located on an indicia in the scale having a value equal to the width specification.

Owner:HUNTER DOUGLAS INDS SWITZERLAND

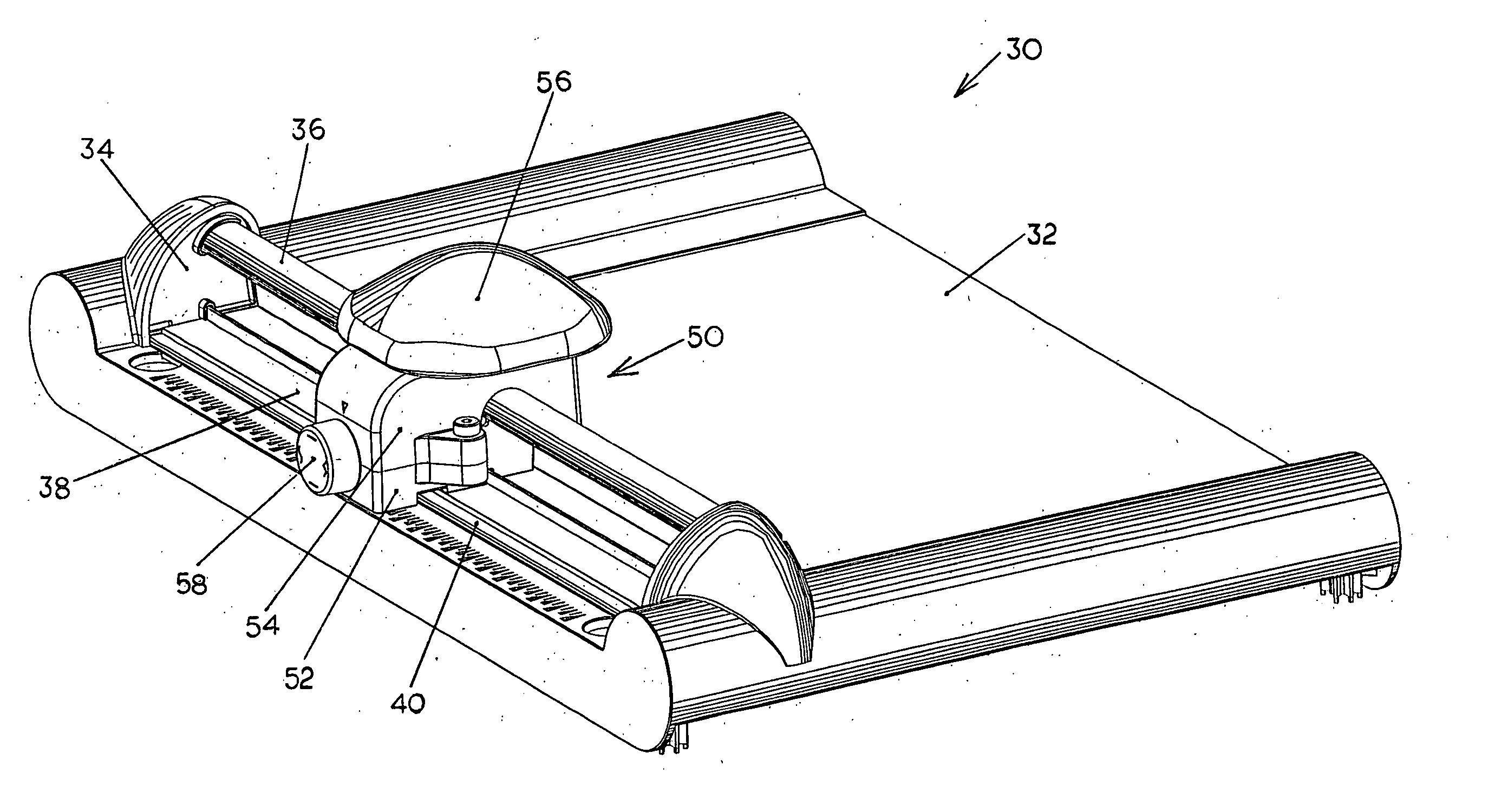

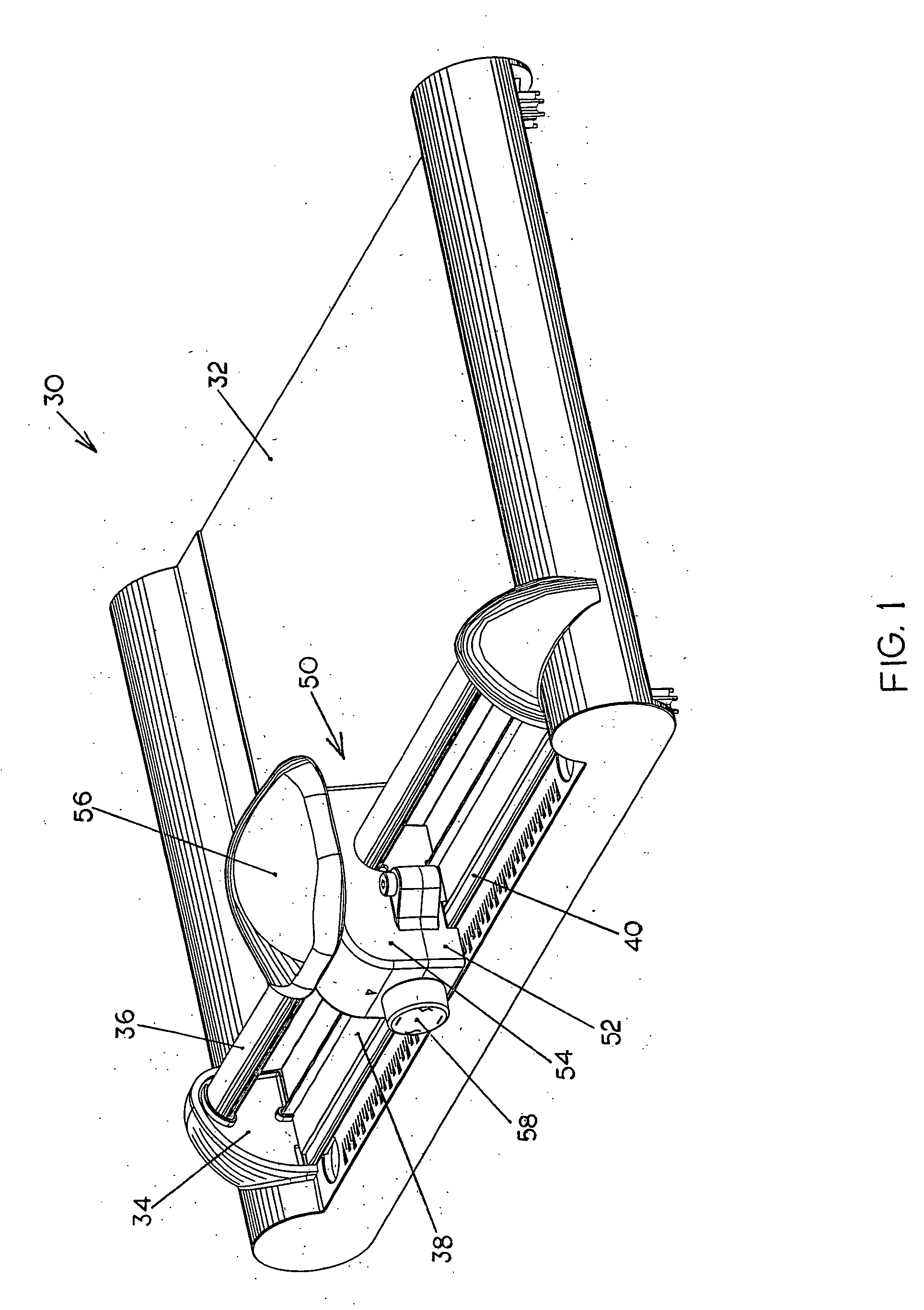

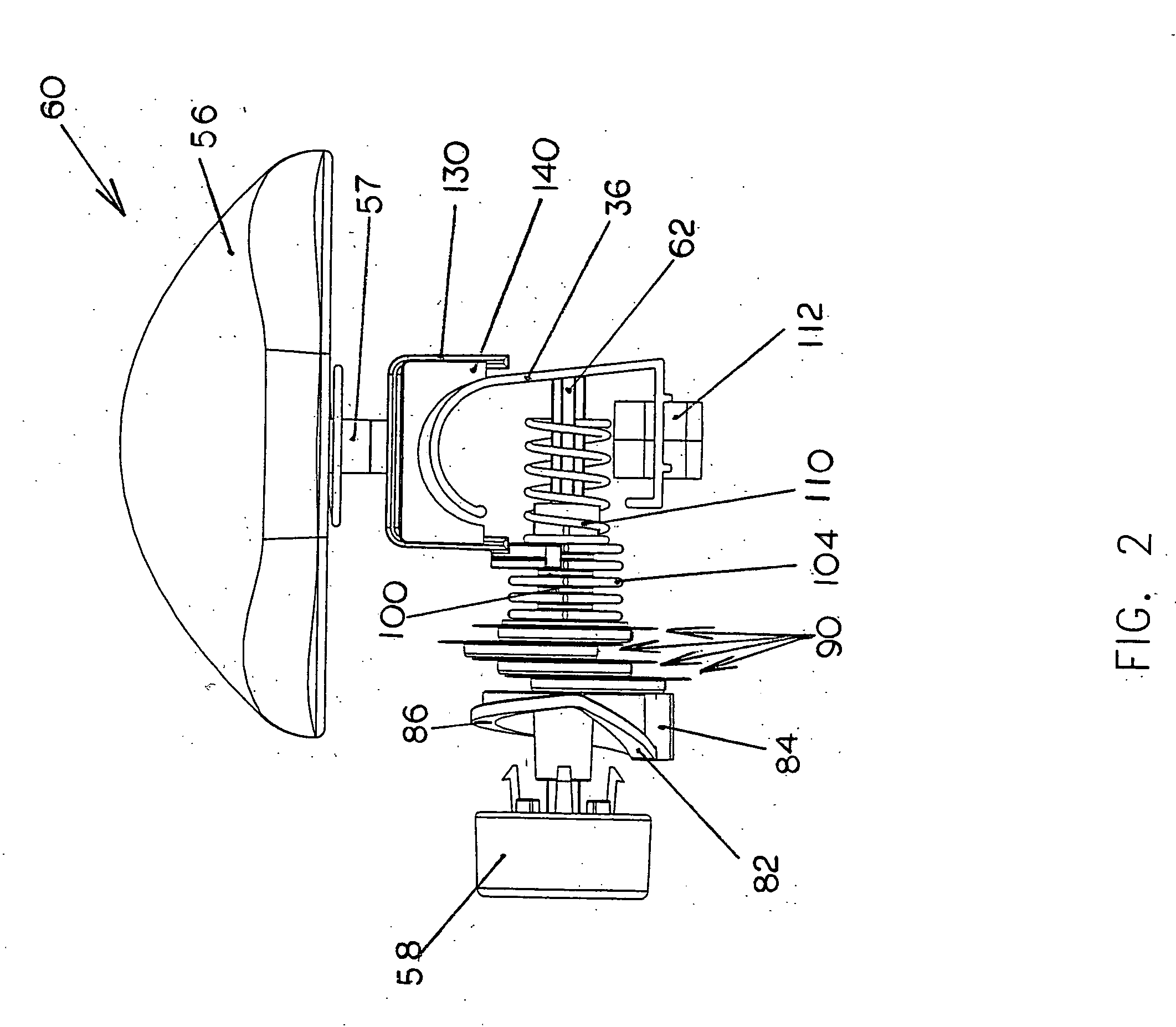

Rotary trimmer with switchable blades

The rotary trimmer with switchable blades of the present invention comprises a base with end retainers moveably supporting a rail, and a cutting assembly disposed on the rail. The cutting assembly includes a switching mechanism to switch between different blades by turning a switch knob accessible outside the housing containing the switching mechanism and the blades. The different blades can have different cutting edges such as a straight, patterned, scalloped, pinking, wave, perforating, or zig-zag edge. Turning the switch knob rotates the desired blade into radial position and locates the desired blade axially over a cutting strip. A clutch engages the switching mechanism during cutting to prevent rotation or axial movement of the switching mechanism.

Owner:MARTIN YALE INDS

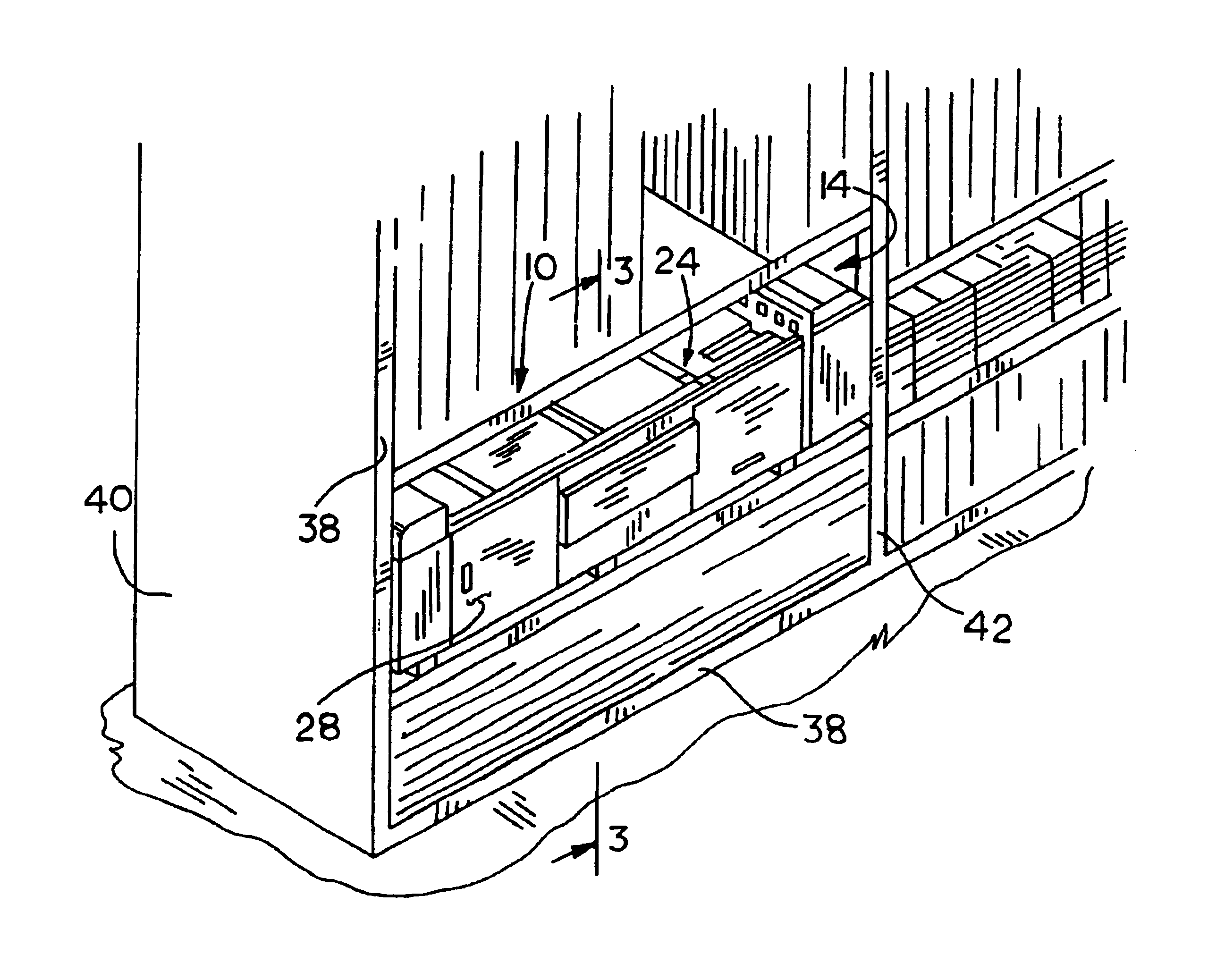

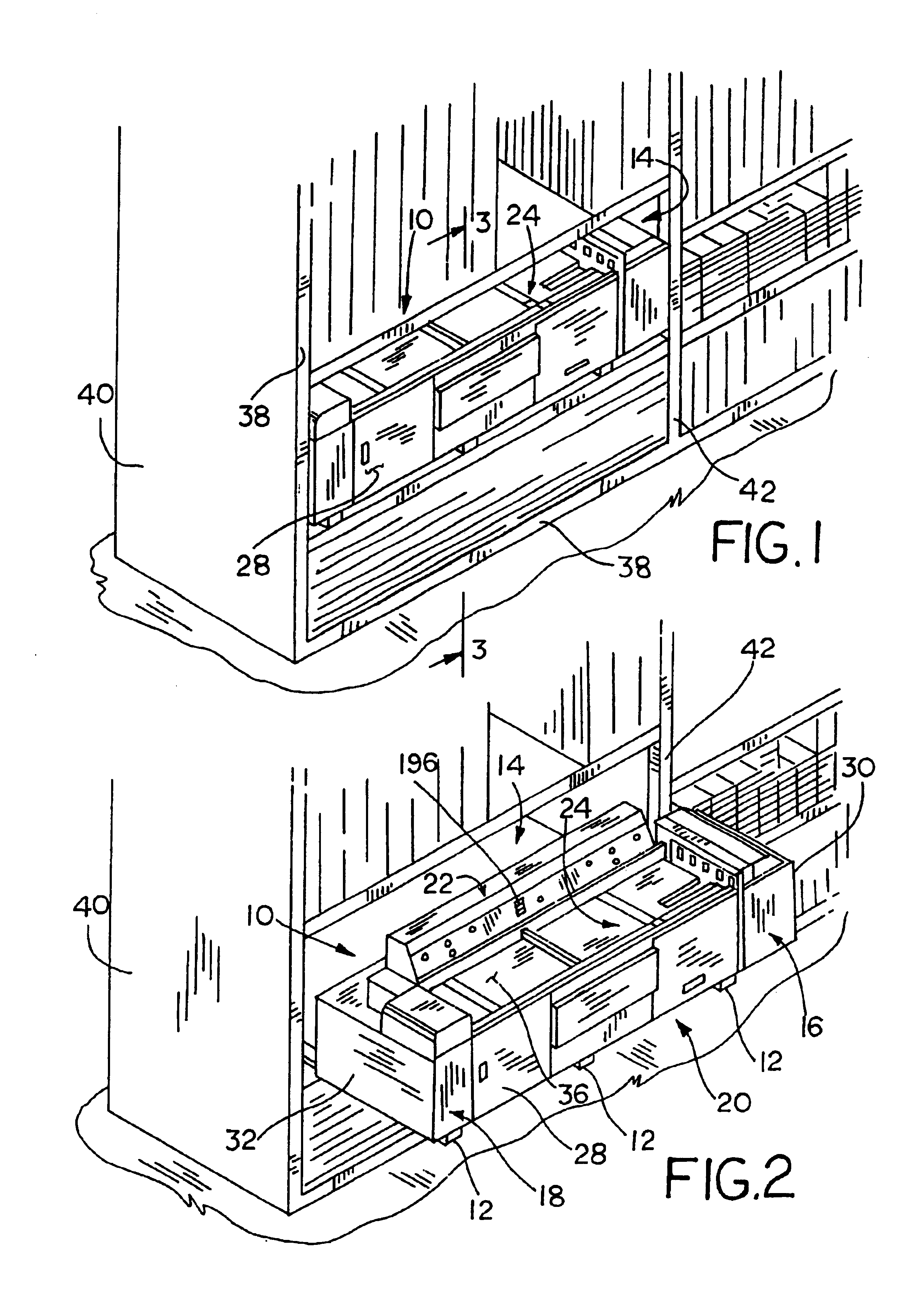

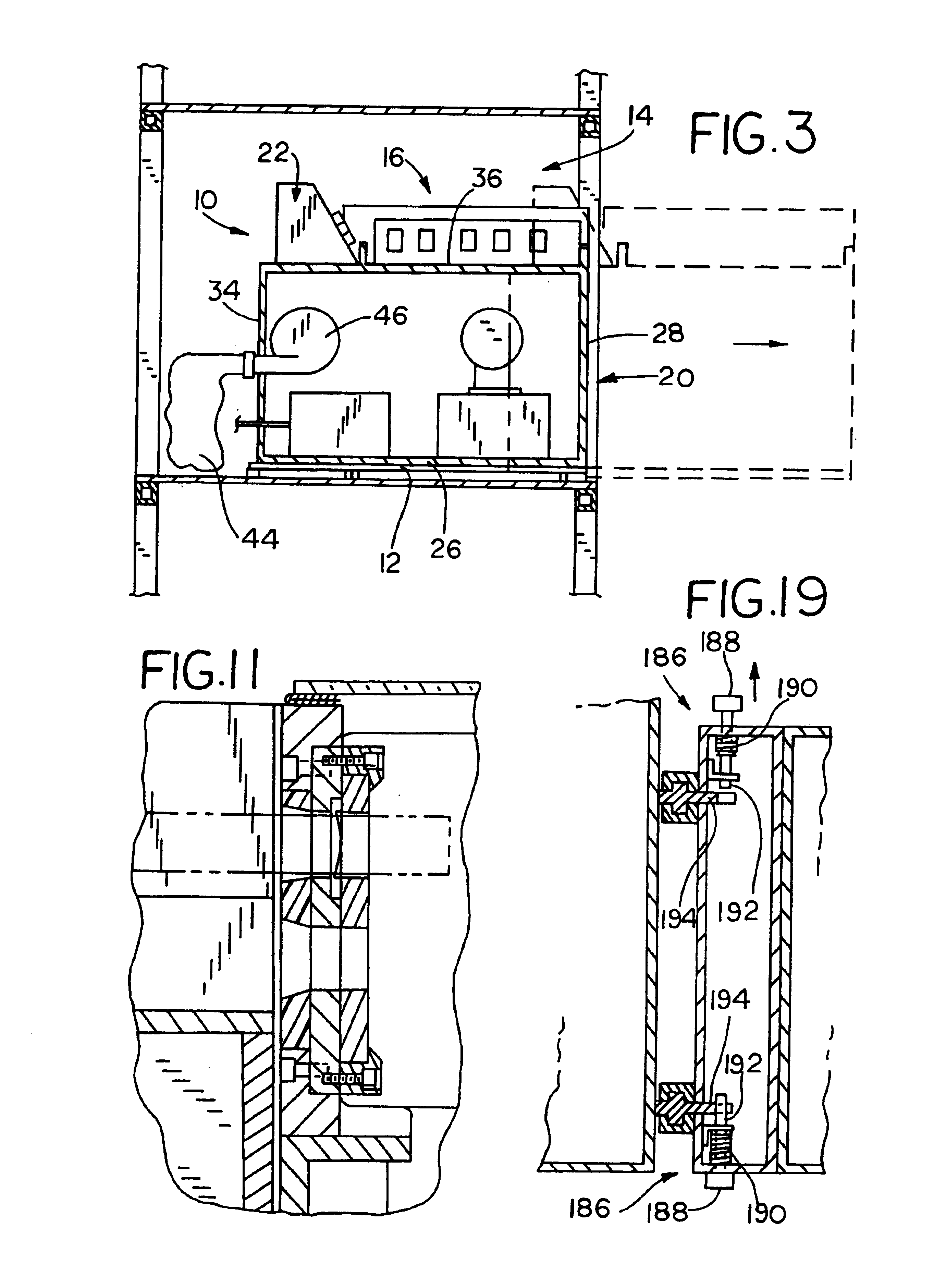

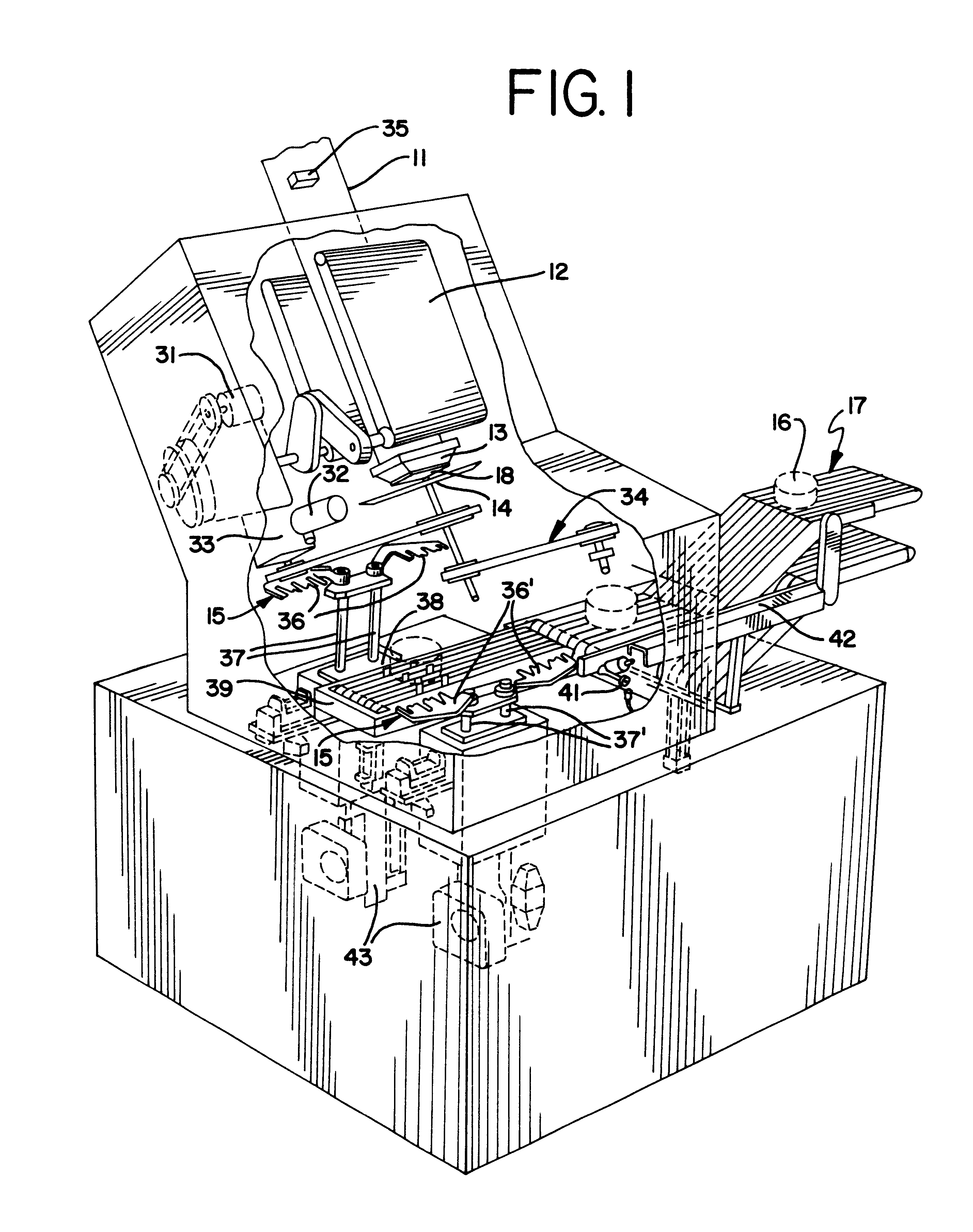

Moveable blind and shade cutting center

InactiveUS7069833B2Metal sawing devicesDoor/window protective devicesMechanical engineeringWindow covering

An apparatus for and a method of sizing a window covering in a sizing mechanism in a retail outlet includes a slide secured to a bay of a retail outlet. A housing configured to support a sizing mechanism for sizing a window covering is slidably coupled to the slide and is movable from a retracted position located substantially within the bay to a extended position in which at least a portion of the housing extends out of the bay. A sizing mechanism for sizing a window covering is disposed on the housing.

Owner:HUNTER DOUGLAS INDS SWITZERLAND

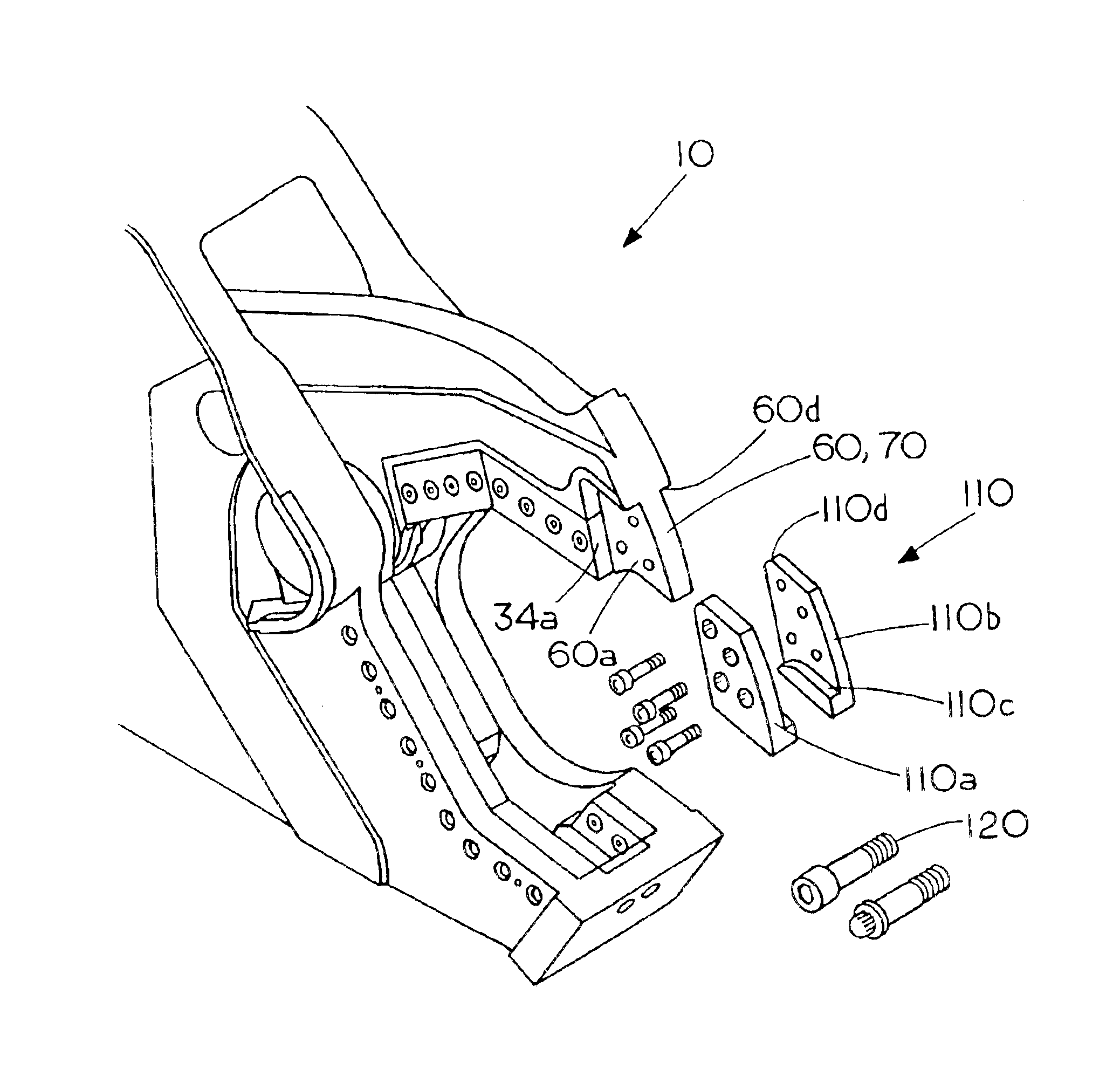

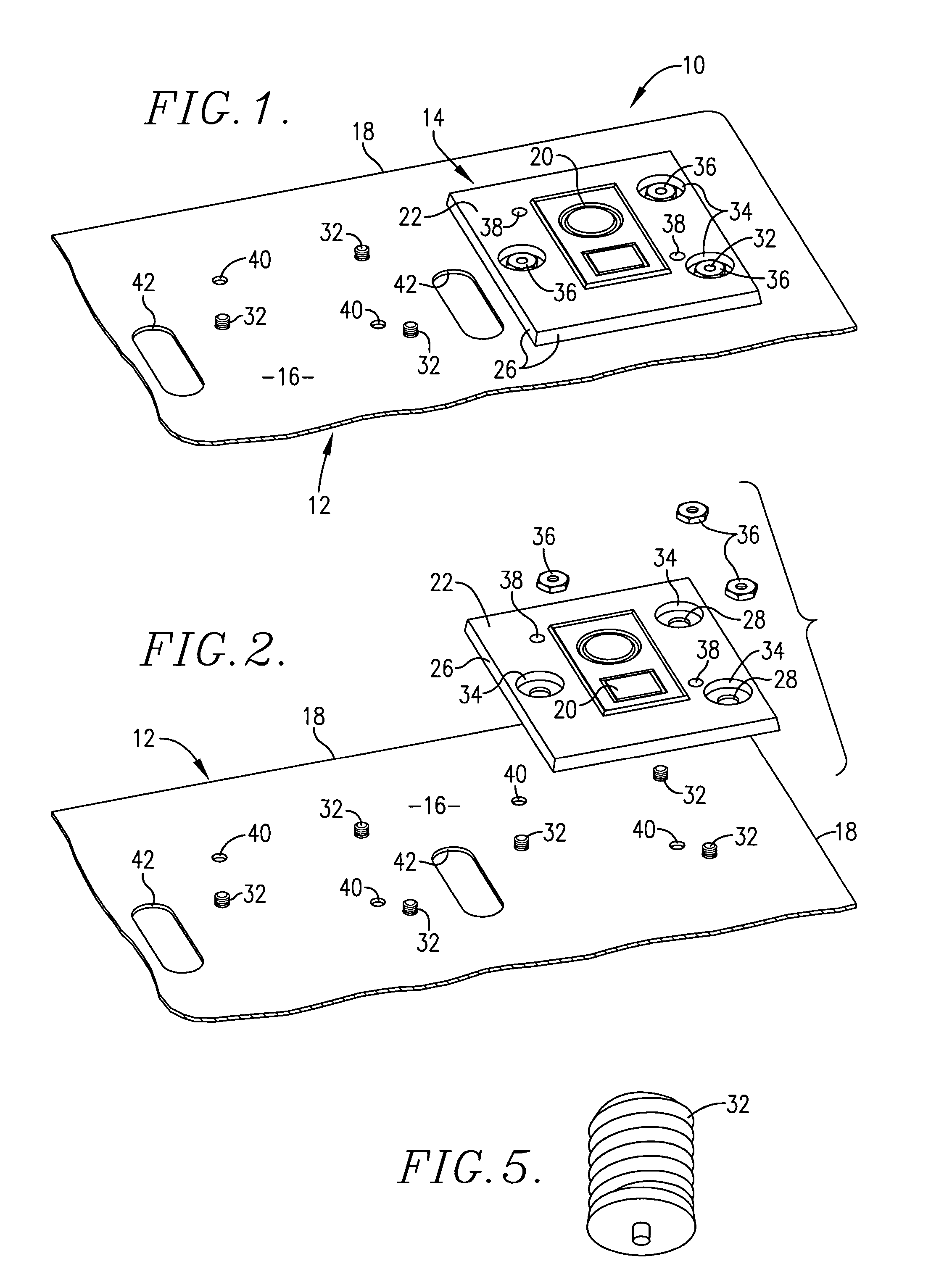

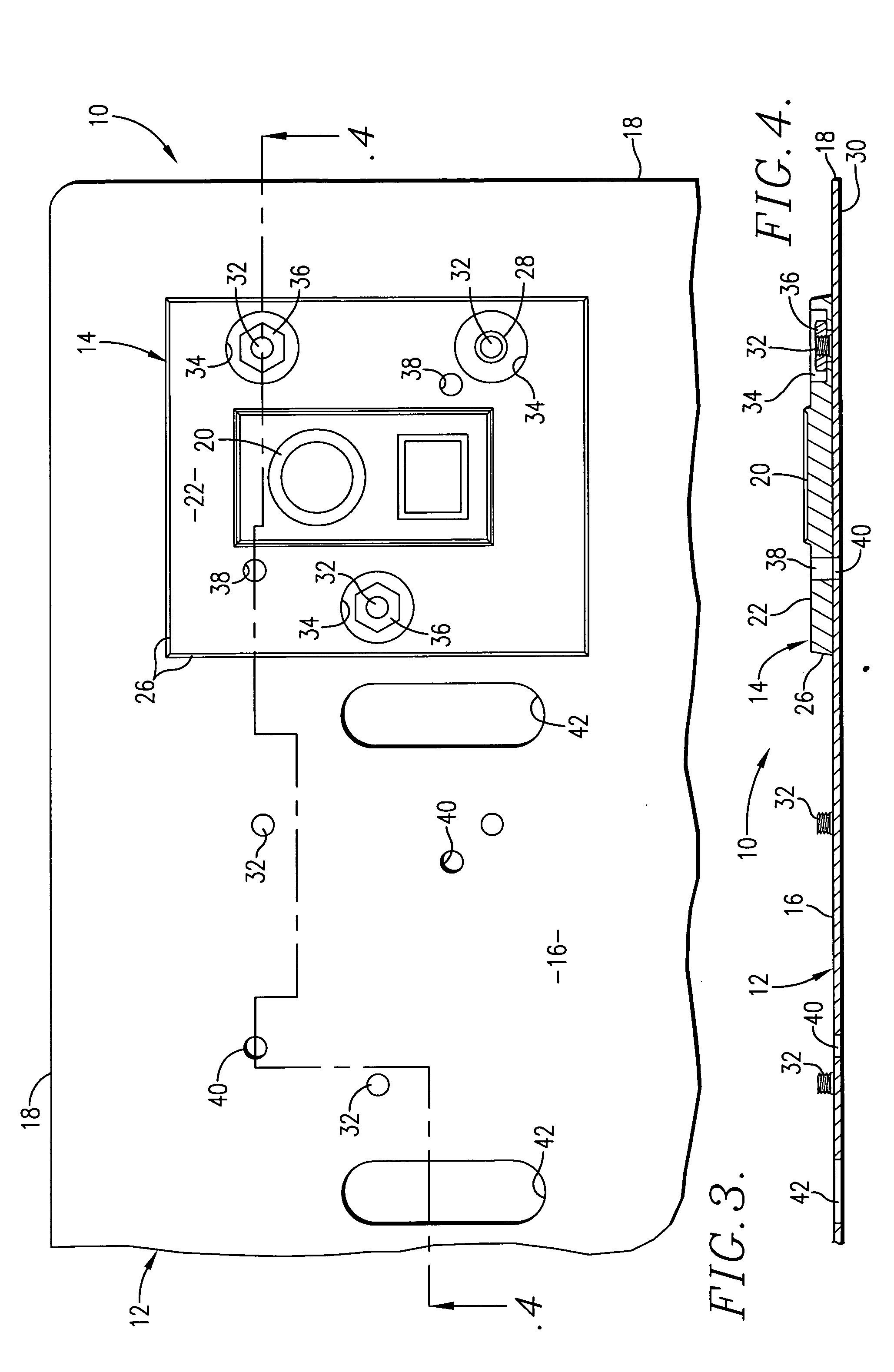

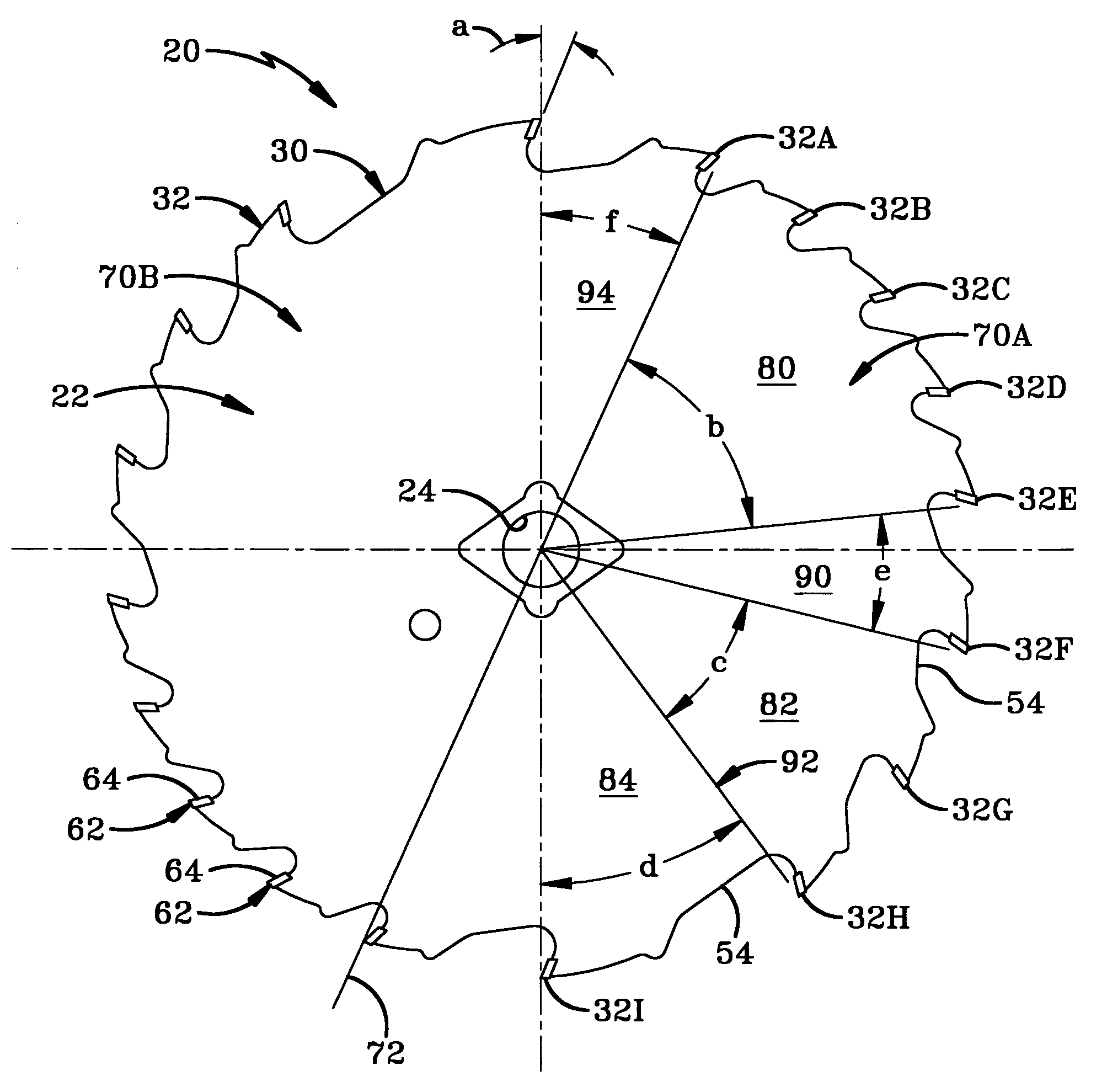

Graphic arts die and support plate assembly

ActiveUS20050257594A1Convenient registrationLess preparationShaping toolsMechanical working/deformationGraphicsEngineering

A graphic arts die and support plate assembly is provided that is adapted to be mounted as a unit on the chase of a flat bed or rotary graphic arts press. The assembly includes a plurality of spaced individual dies fixedly mounted in predetermined relative relationship on a support plate member of the unit. Alignment holes in each die that register with orifices in the support plate member are adapted to receive temporary alignment pins thereby assuring correct positioning of the dies with respect to one another on the support plate member until the dies are affixed to the support plate member. Makeready and die lock-up time of the press is significantly decreased because all dies of the assembly may be preregistered with a design artwork before mounting of the die and support assembly on the press. A series of graphic arts die units are also provided that are adapted to be mounted as an assembly encompassing more than 180° of the circumference of a rotary press chase. The graphic arts die units have die support plate members that may be aligned with indicia on the press chase, and that have notch structure receiving a tool for facilitating alignment and spacing between adjacent die support plate members. Cutouts in the die support plate members permit manual selective shifting of a die relative to the die support plate member therefor using a tool received in a cutout and engageable with the die.

Owner:UNIVERSAL ENGRAVING

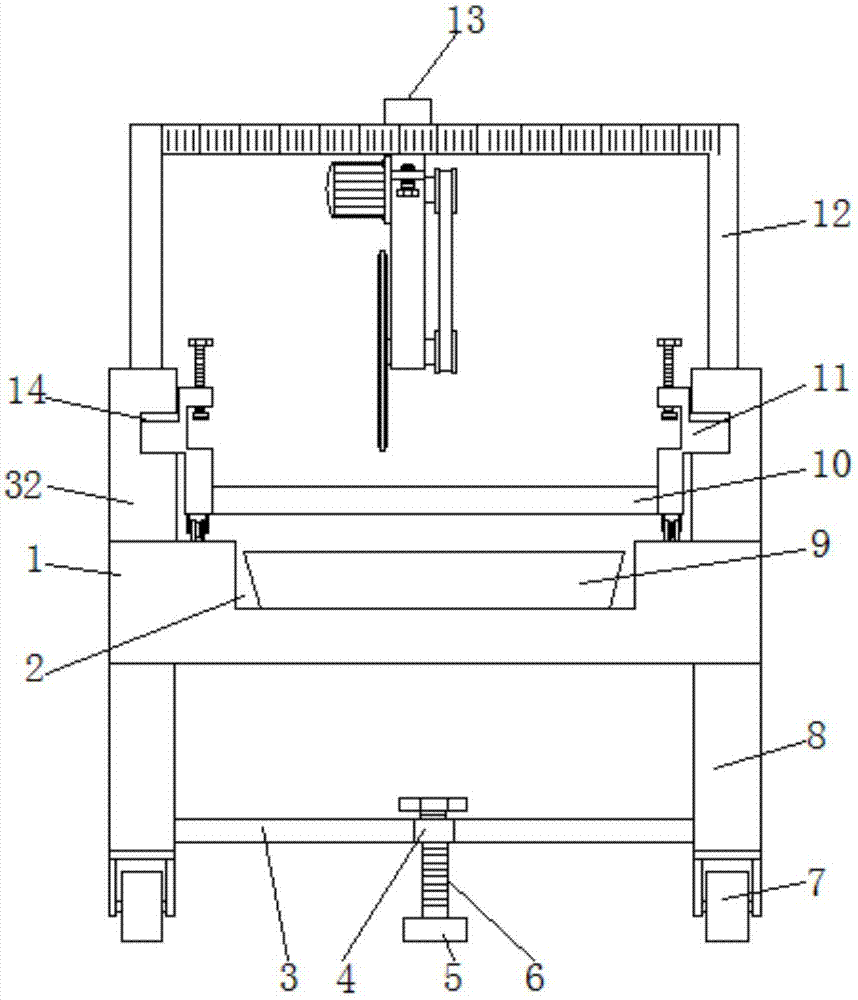

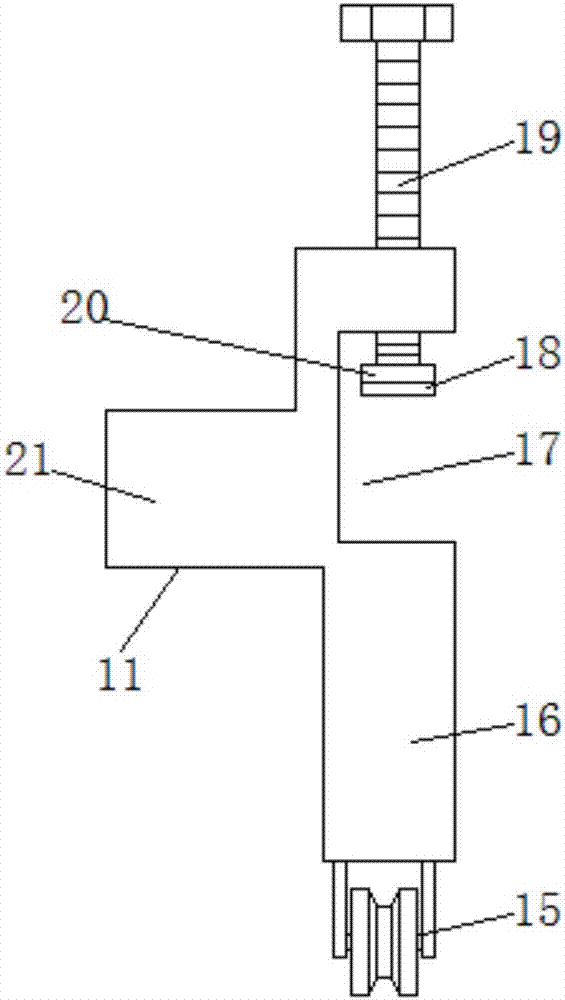

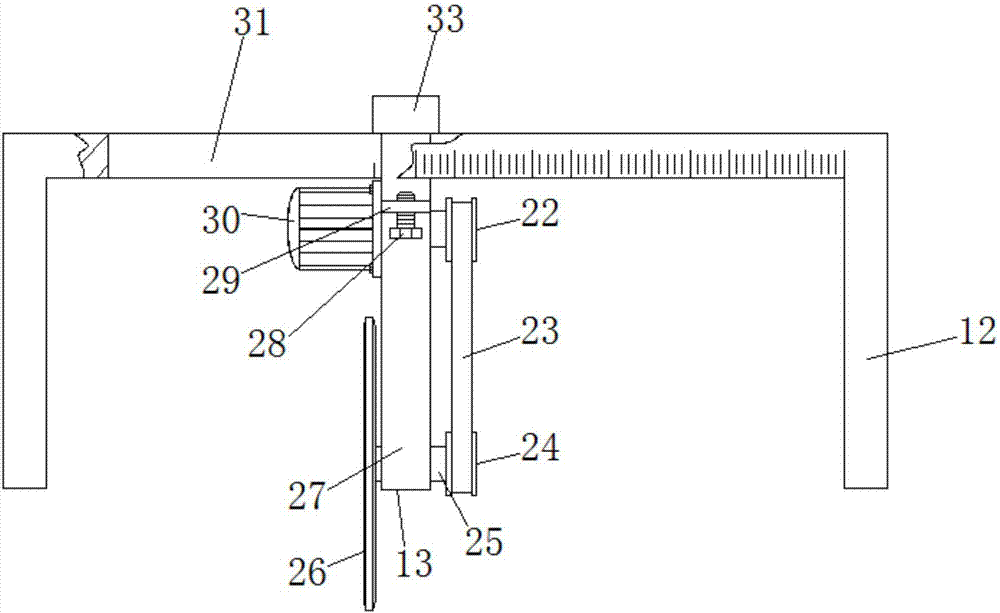

Plate cutting machine easy to adjust

InactiveCN107214374AEasy to adjustEasy to fixShearing machinesMaintainance and safety accessoriesThreaded pipeEngineering

The invention discloses an easy-to-adjust plate cutting machine, which includes a workbench, the four corners of the bottom surface of the workbench are welded with supporting legs, and the bottom end of each supporting leg is equipped with rollers. Beams are welded, the middle of each beam is welded with a threaded pipe, the threaded pipe is threaded with a first screw, the bottom of the first screw is welded with a pad, and the upper surface of the workbench is provided with a groove. This easy-to-adjust board cutting machine uses the cooperation of two fixing mechanisms to fix the board, so that the board is fixed more firmly, and the walking wheel is installed on the bottom of the vertical board, and the rolling of the walking wheel on the workbench is convenient for the board. For placement and removal, since the fixing mechanism uses the slider to slide and connect with the first chute, the slider can be used to limit the position of the vertical plate, and the setting of the pole can strengthen the space between the two fixing mechanisms, improving the fixing institutional stability.

Owner:金陈敏

Saw blade gullet configuration

ActiveUS7946907B2Protective switch detailsCircuit-breaking switches for excess currentsEngineeringMechanical engineering

A saw blade includes a circular core having a plurality of cutters disposed along a periphery thereof, and a central bore configured to receive an arbor of a rotating power tool. A plurality of gullets is located in spaced relation between the cutters, extending radially inward from the periphery. Each of the gullets includes a neck portion defined by side walls extending radially inward and extending divergently from one another into an arcuate base. The arcuate base extends along concave arcs to a linear base portion disposed at a radially innermost portion thereof, and which intersects a radius of the saw blade.

Owner:SAINT GOBAIN ABRASIVES INC

Variable tooth saw blade

An apparatus for cutting materials and more specifically an improved saw blade includes a plurality of variable teeth thereon. The variable tooth saw blade cuts faster and smoother while reducing harmonic vibrations. Specifically, the teeth on the saw blade are grouped into sections with differing circumferential widths and differing spacing between the sections.

Owner:BLACK & DECKER INC

Automatic cooling and steel cutting equipment

InactiveUS20200055155A1Simple structureEasy to operateMetal sawing devicesMetal sawing accessoriesStructural engineeringMechanical engineering

The invention discloses an automatic cooling and steel cutting device, which includes a casing, wherein the right end of the casing is provided with a conveying cavity, a connecting cavity and a driving cavity, the conveying cavity is provided with a conveying mechanism for pushing steel for cutting and the opening is upward, the connecting cavity is provided with a lifting mechanism for lifting the cutting part, the lower side of the connecting cavity is provided with a cutting mechanism for cutting steel. The device can cut off the steel evenly by itself when it is in use. During the cutting process, it will automatically spray water to cool down the steel and the cutter, so as to reduce the damage. After each section is cut, the cutter will automatically lift up to prepare the next section of steel cutting of wood.

Owner:MAO LIYING

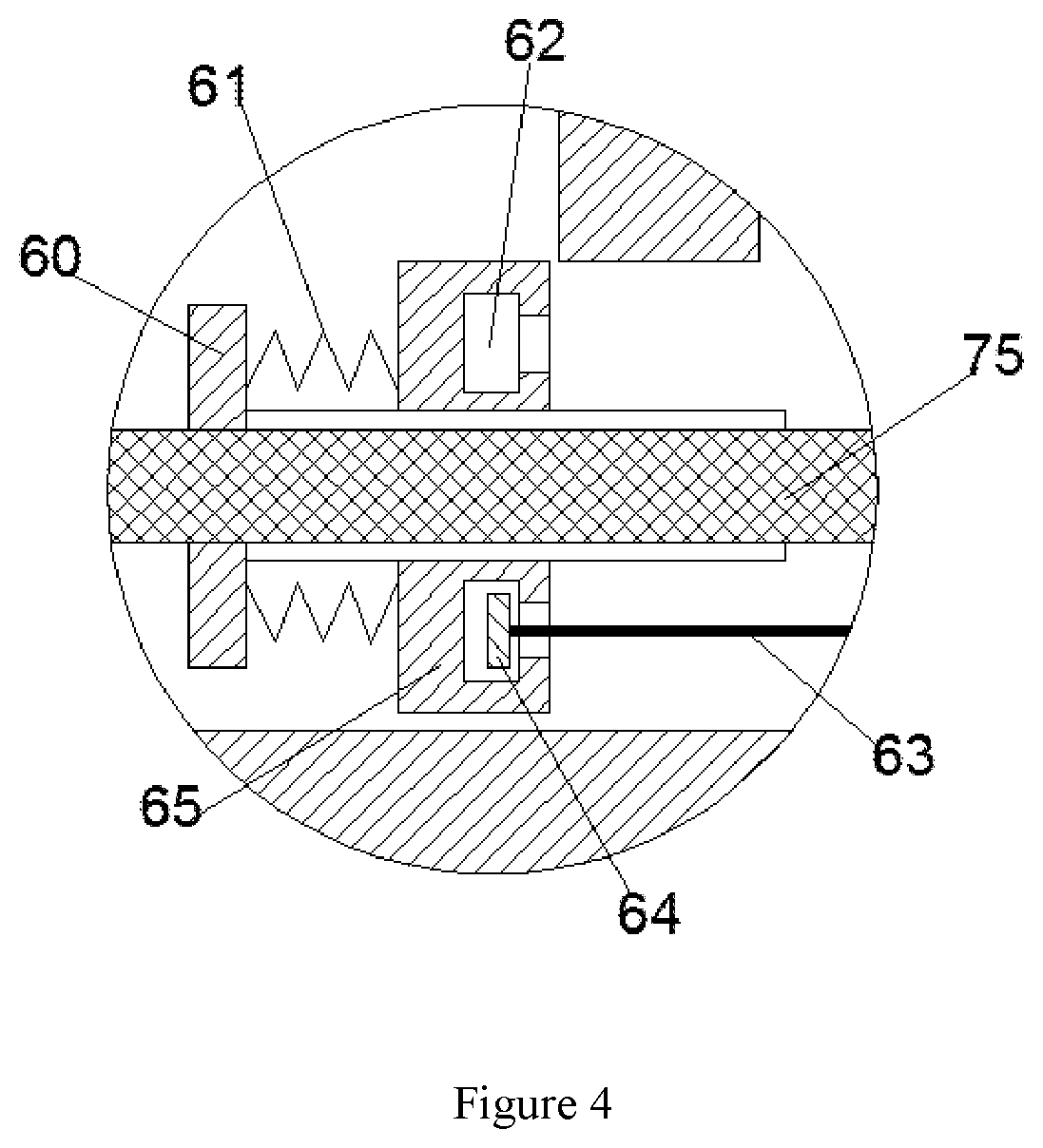

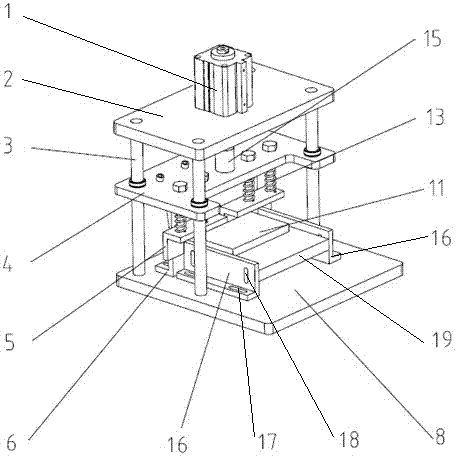

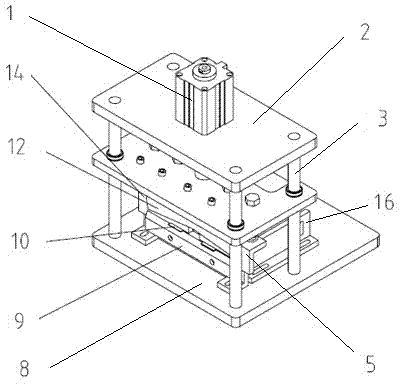

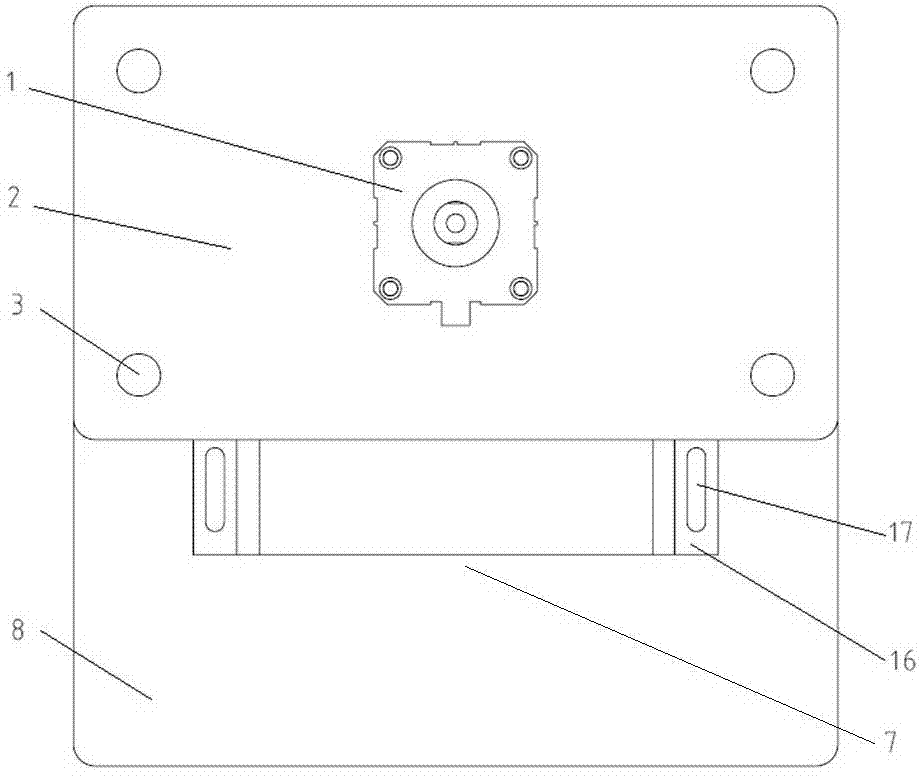

Tab cutting device of lithium battery core and tab cutting equipment using tab cutting device

ActiveCN102873390AIncrease profitHigh automation efficiencyShearing machinesShearing machine accessoriesPower batteryElectrical battery

The invention relates to the field of manufacturing of lithium ion power batteries, in particular to a tab cutting device of a lithium battery core and tab cutting equipment using the tab cutting device. The tab cutting device of the lithium battery core comprises a driving mechanism and a tab compressing component, wherein the driving mechanism is used for driving an upper cutter to move up and down; the tab compressing component compressing component comprises a lower cushion block and an upper compressing block; the upper compressing block vertically corresponding to the lower cushion block is arranged on the driving mechanism; the upper compressing block and the upper cutter can move together up and down; a compressible elastic supporting device is arranged between the upper compressing block and the driving mechanism; or the tab cutting device of the lithium battery core is provided with a guide device, an elastic reset device, a jacking mechanism and an elastic supporting device; the guide device is used for guiding the upper compressing block to move up and down; the elastic reset device is used for providing upward elastic support for the upper compressing block; the jacking mechanism is arranged on the driving mechanism in a guide motion manner and can downwards jack the upper compressing block; and the elastic supporting device is arranged between the jacking mechanism and the driving mechanism. By adoption of the scheme, a tab can be automatically compressed in the downcutting process of the cutter.

Owner:中创新航科技(江苏)有限公司

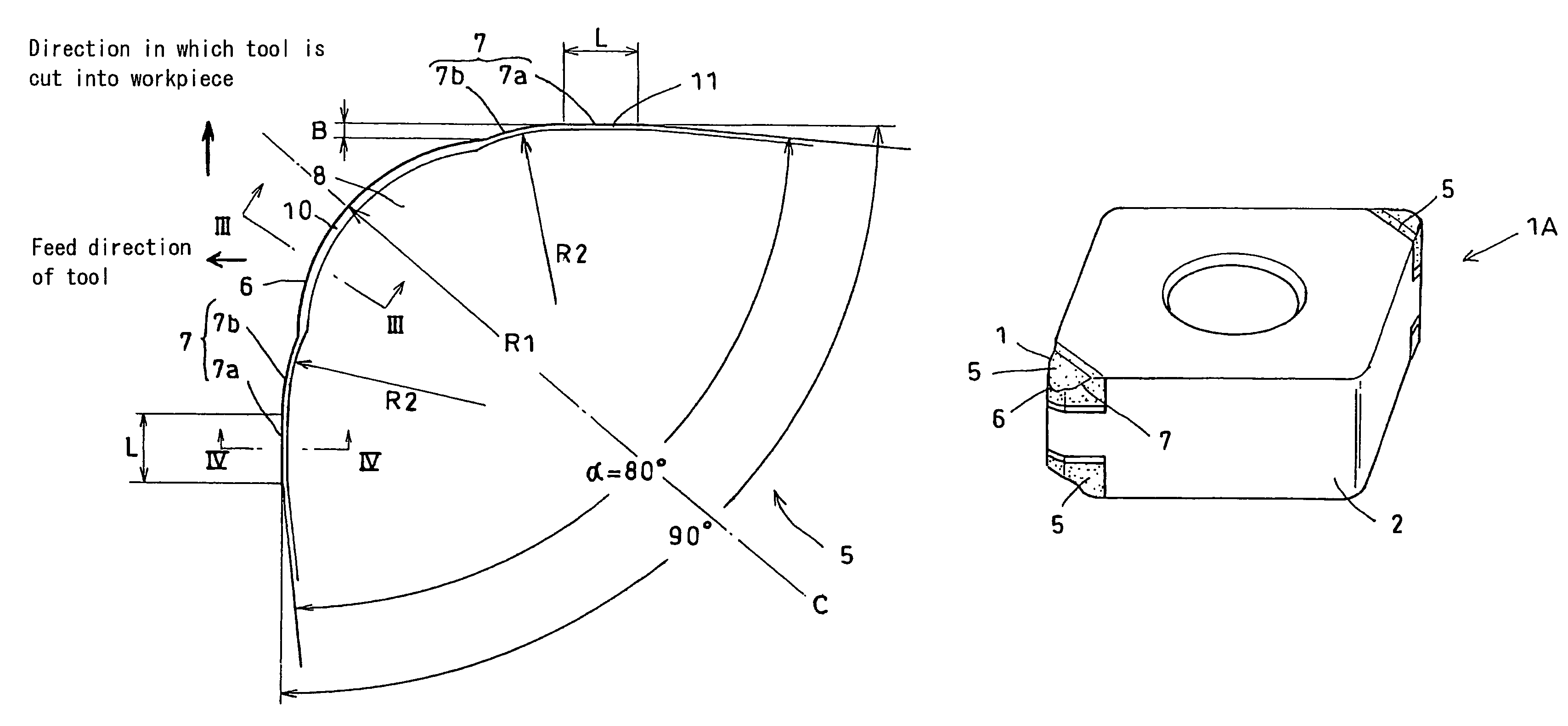

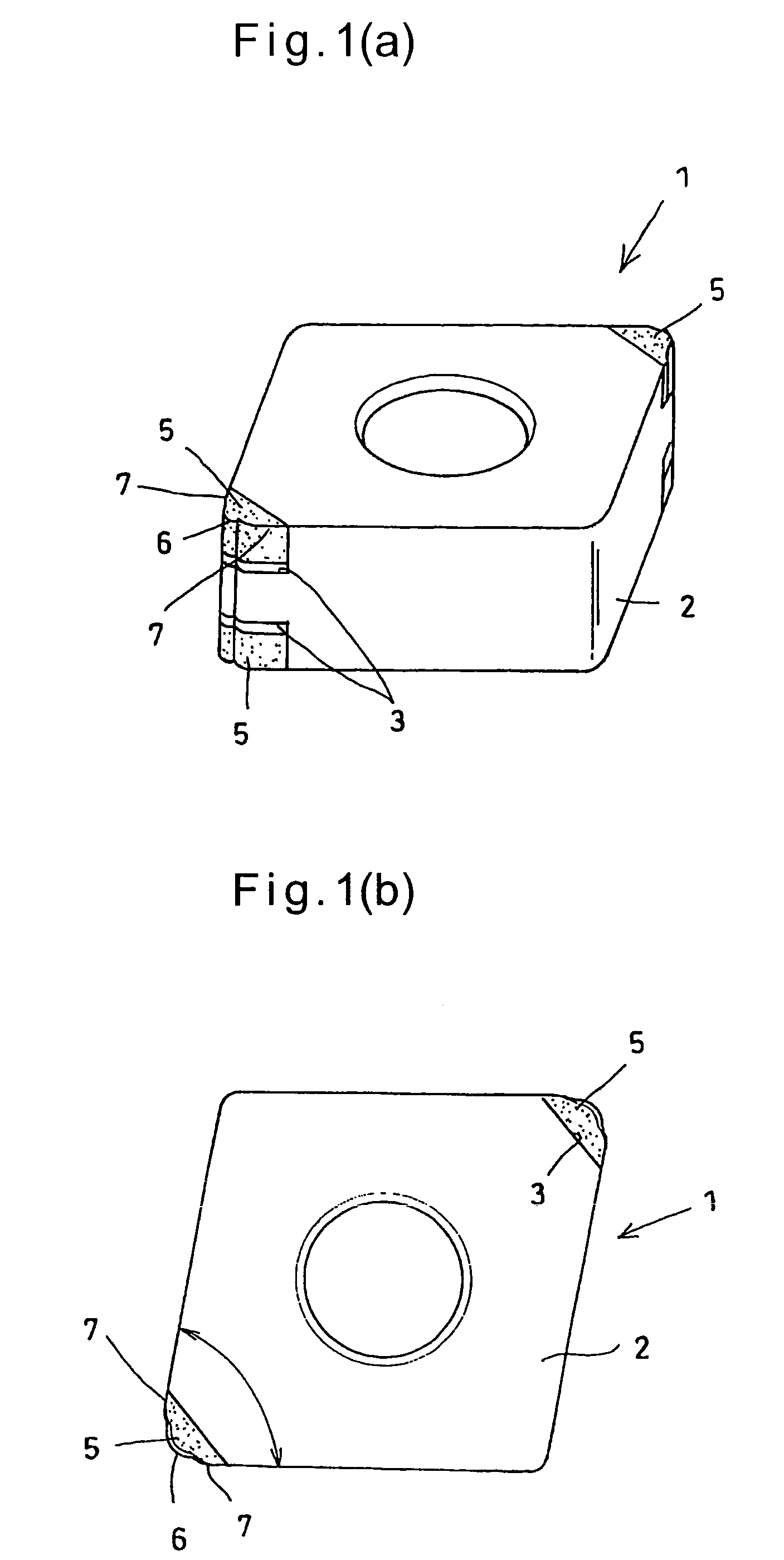

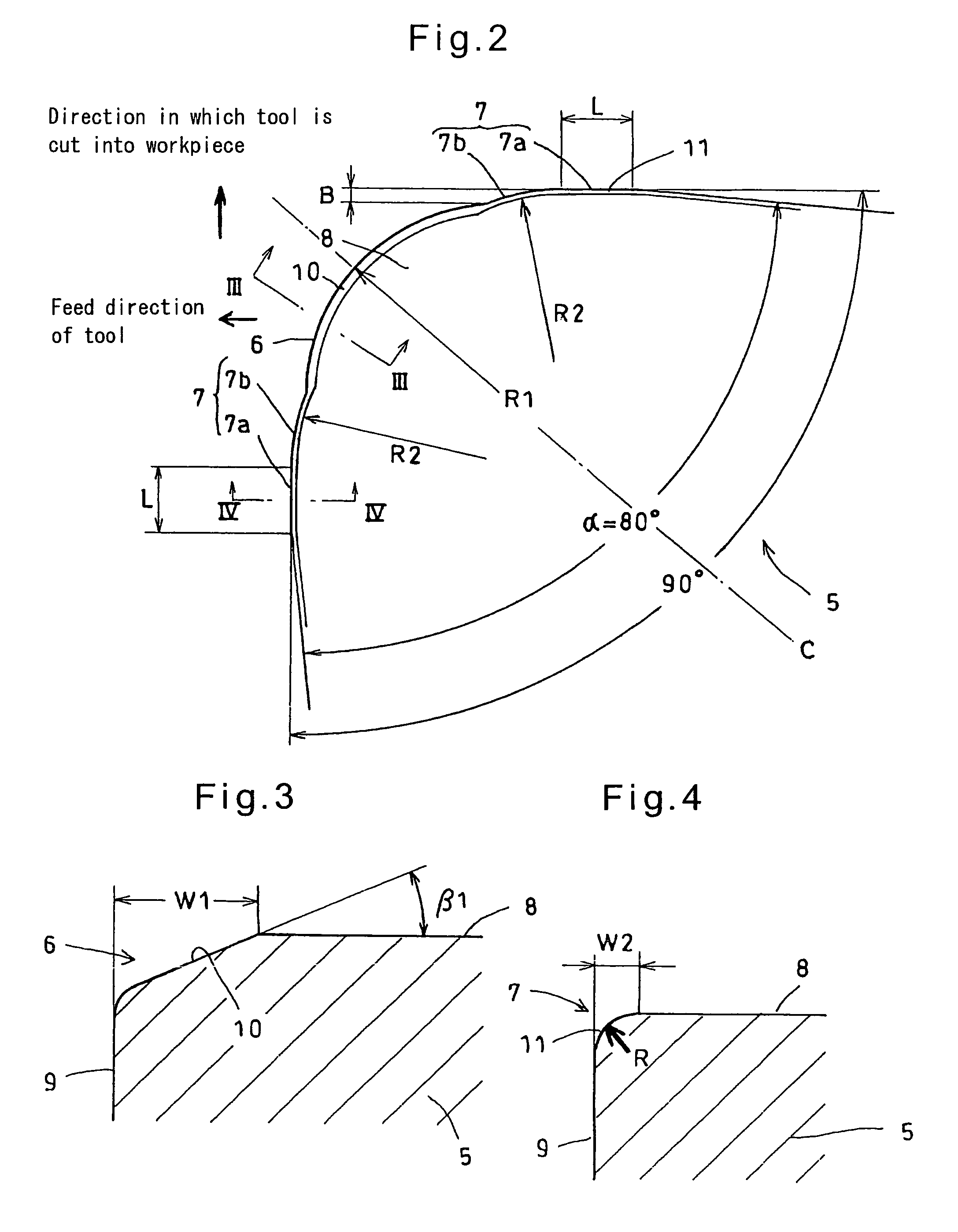

Cutting tool for high-quality high-efficiency machining and cutting method using the same

It is an object to provide a cutting tool which can perform high-quality, high-efficiency machining of a workpiece such as hardened steel.The cutting tool includes a finishing cutting edge 6 which initially cuts into the workpiece, and superfinishing cutting edges 7 for finishing the workpiece cut by the finishing cutting edge. The superfinishing cutting edges 7 project from the finishing cutting edge by a predetermined amount B in such a direction that the depth of cut of the superfinishing cutting edges increases. Each superfinishing cutting edge includes a burnishing portion 7a having a predetermined width L in the feed direction of the tool, and a wiper portion 7b. The superfinishing cutting edges 7 burnish the finished surface formed by the finishing cutting edge, while removing a affected layer formed by the finishing cutting edge.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

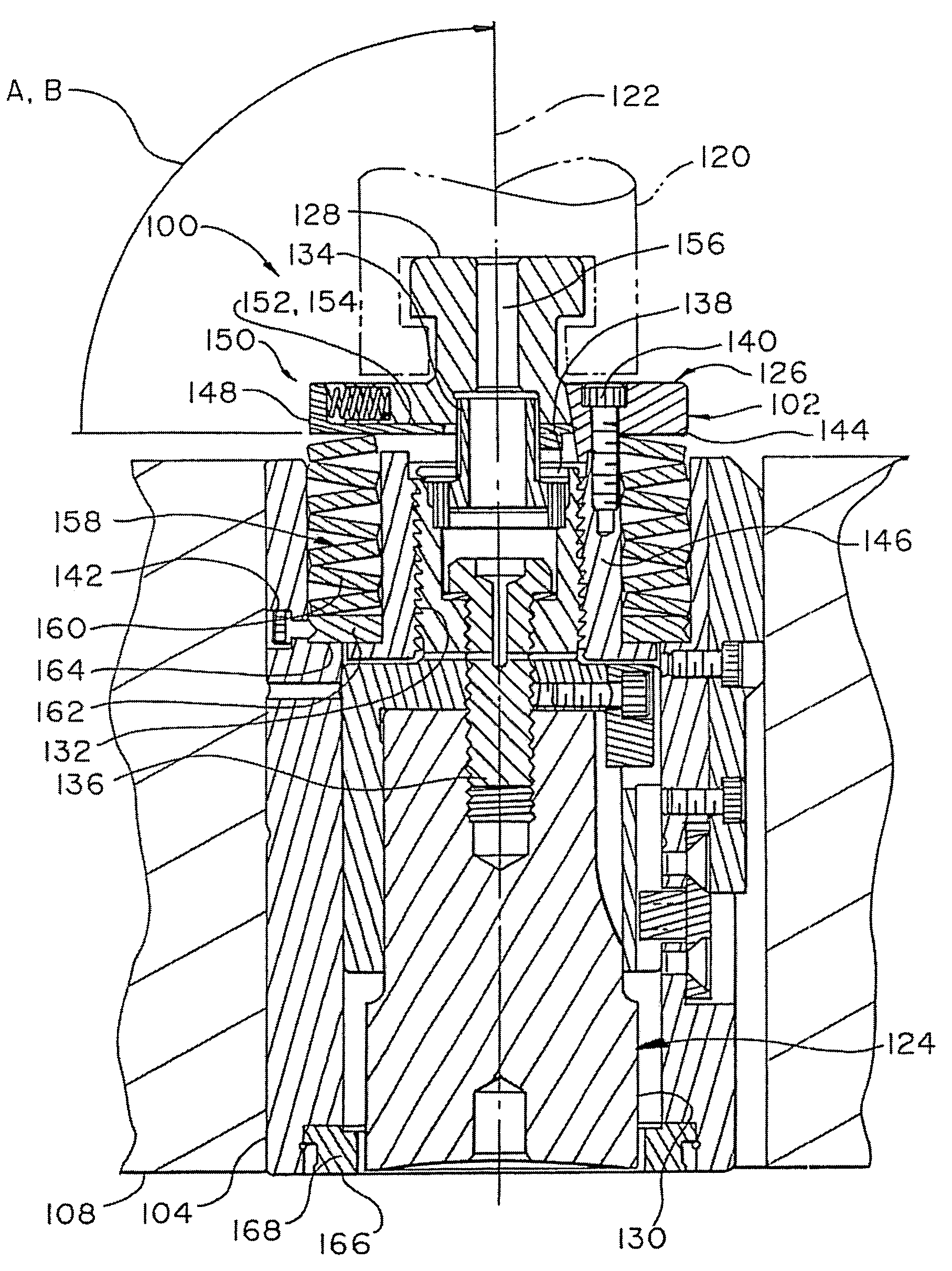

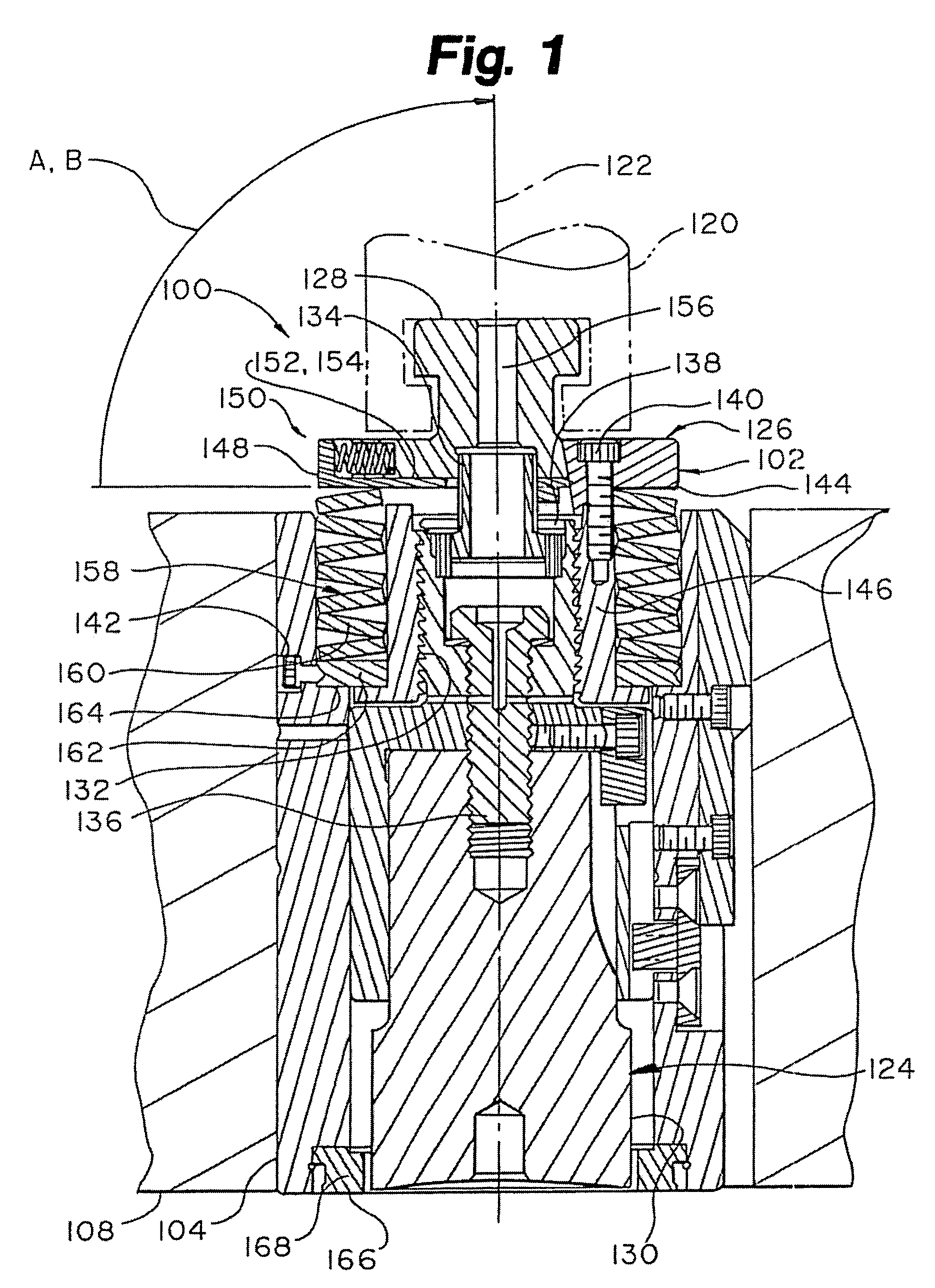

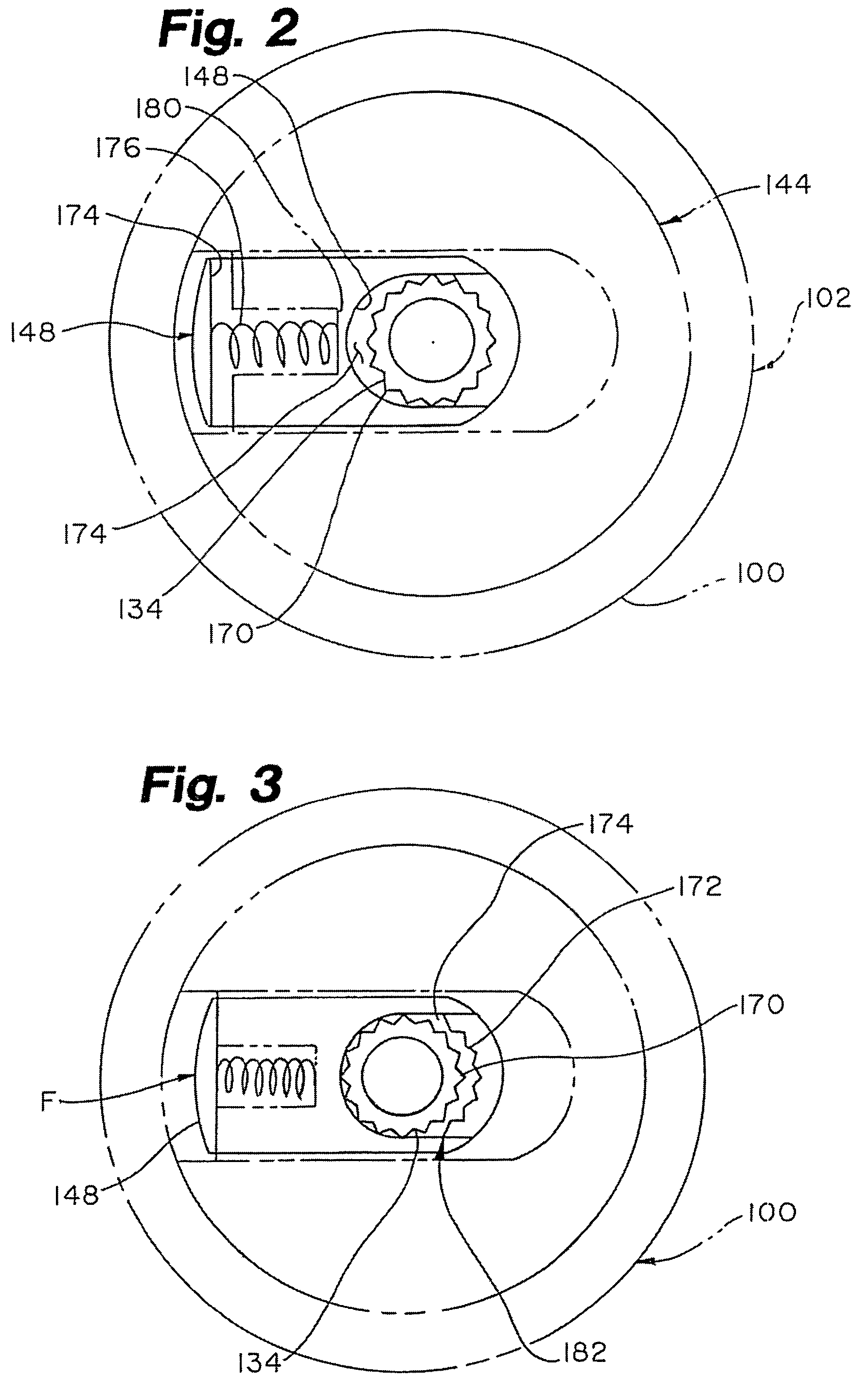

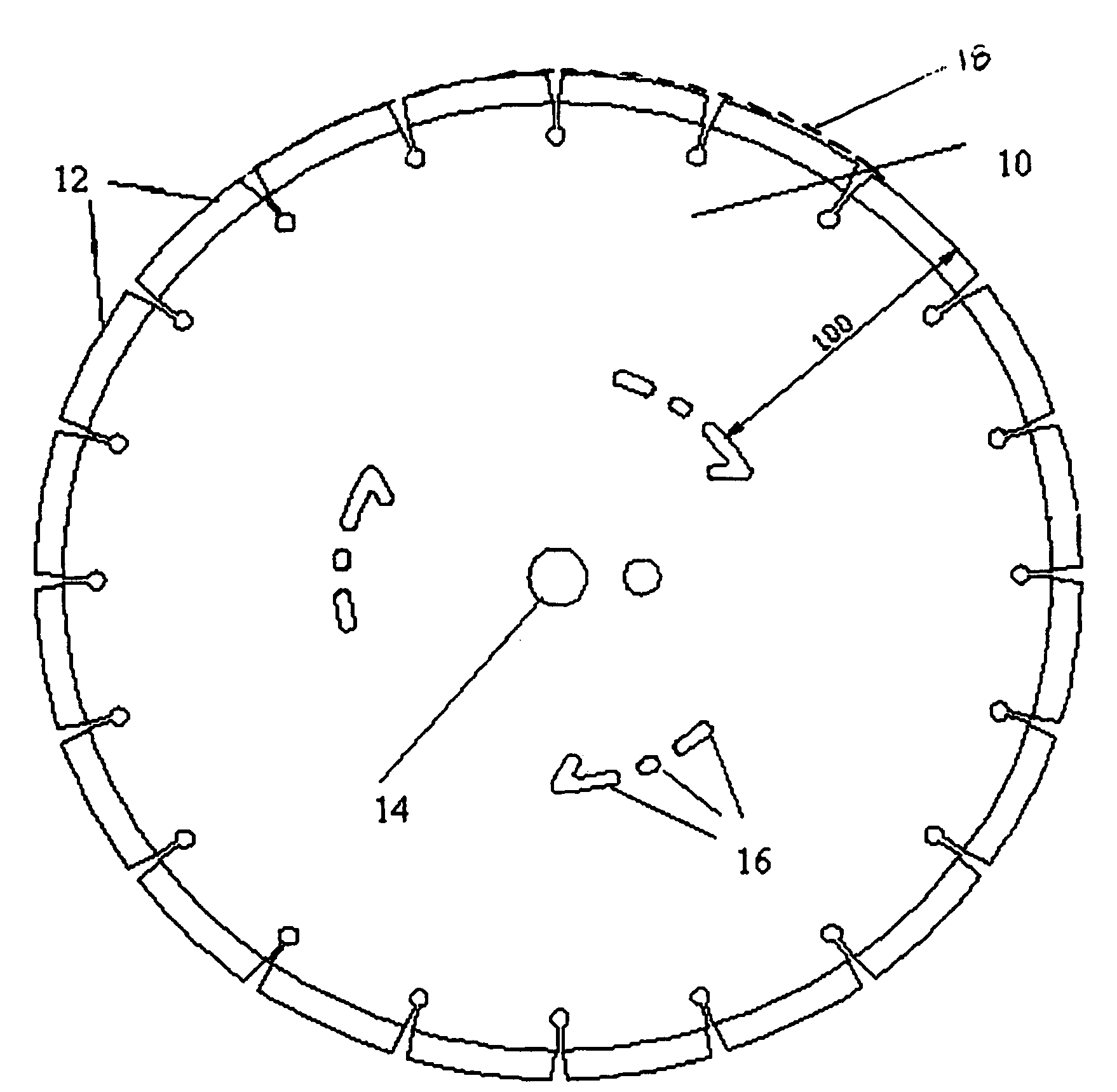

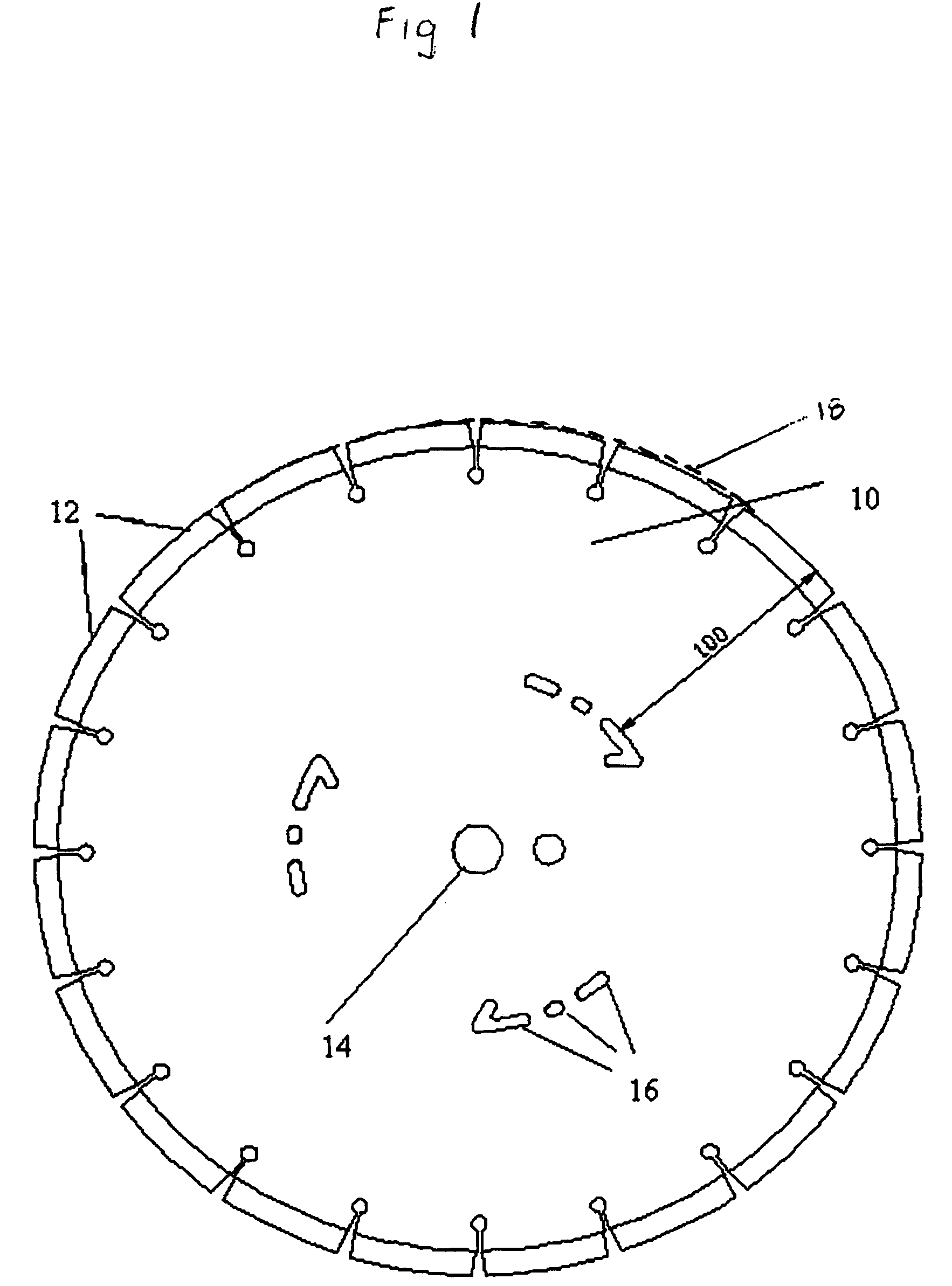

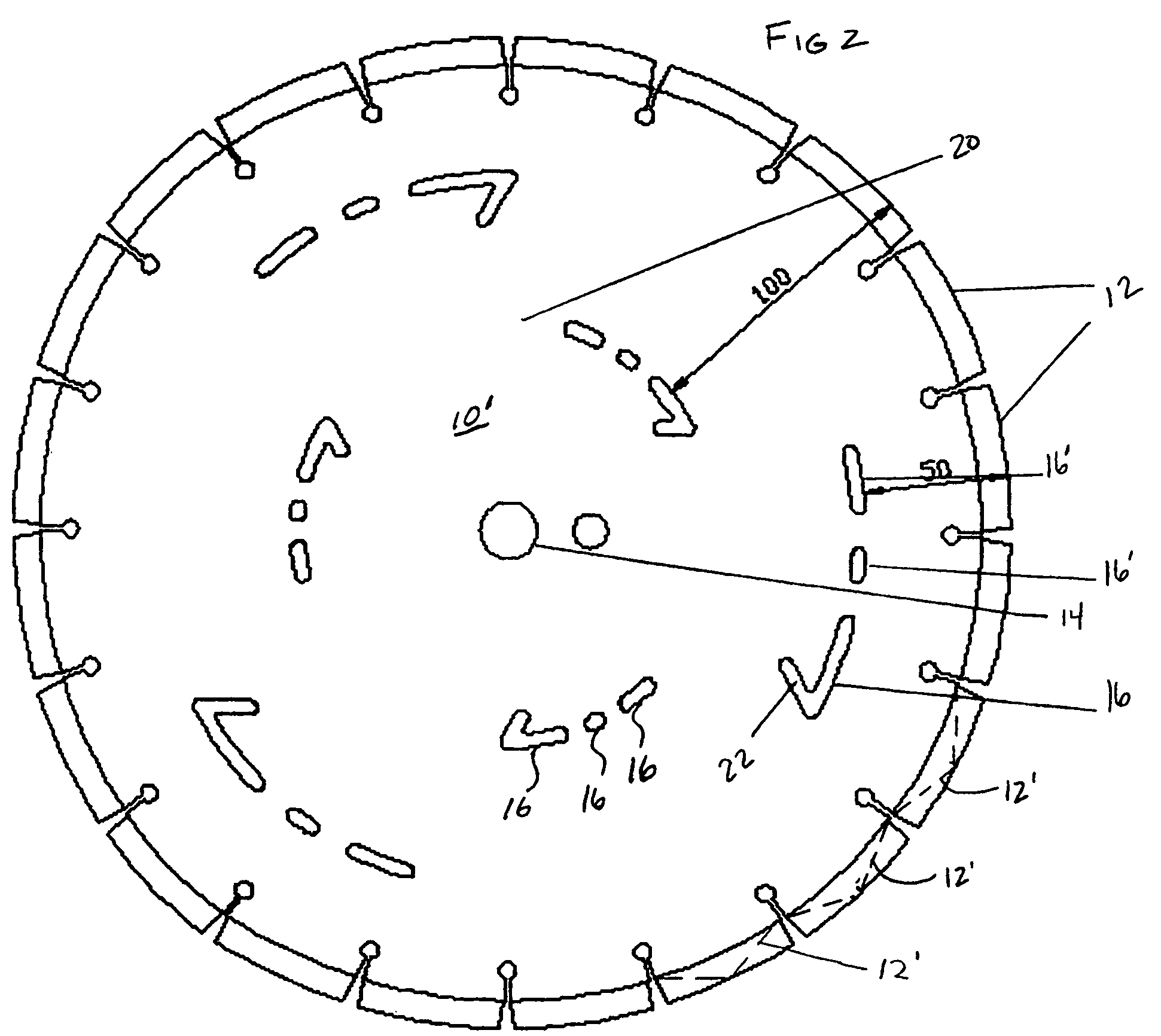

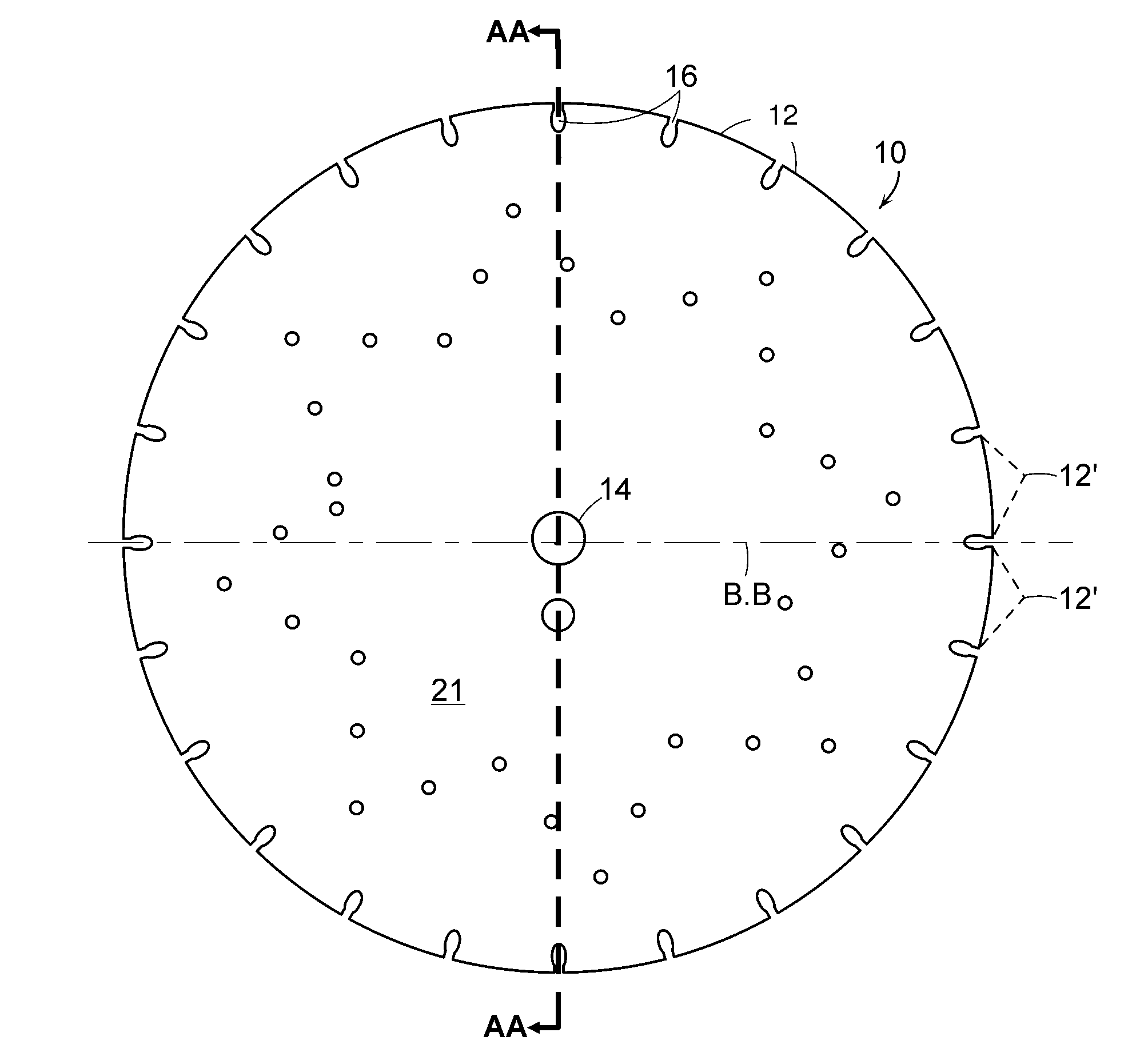

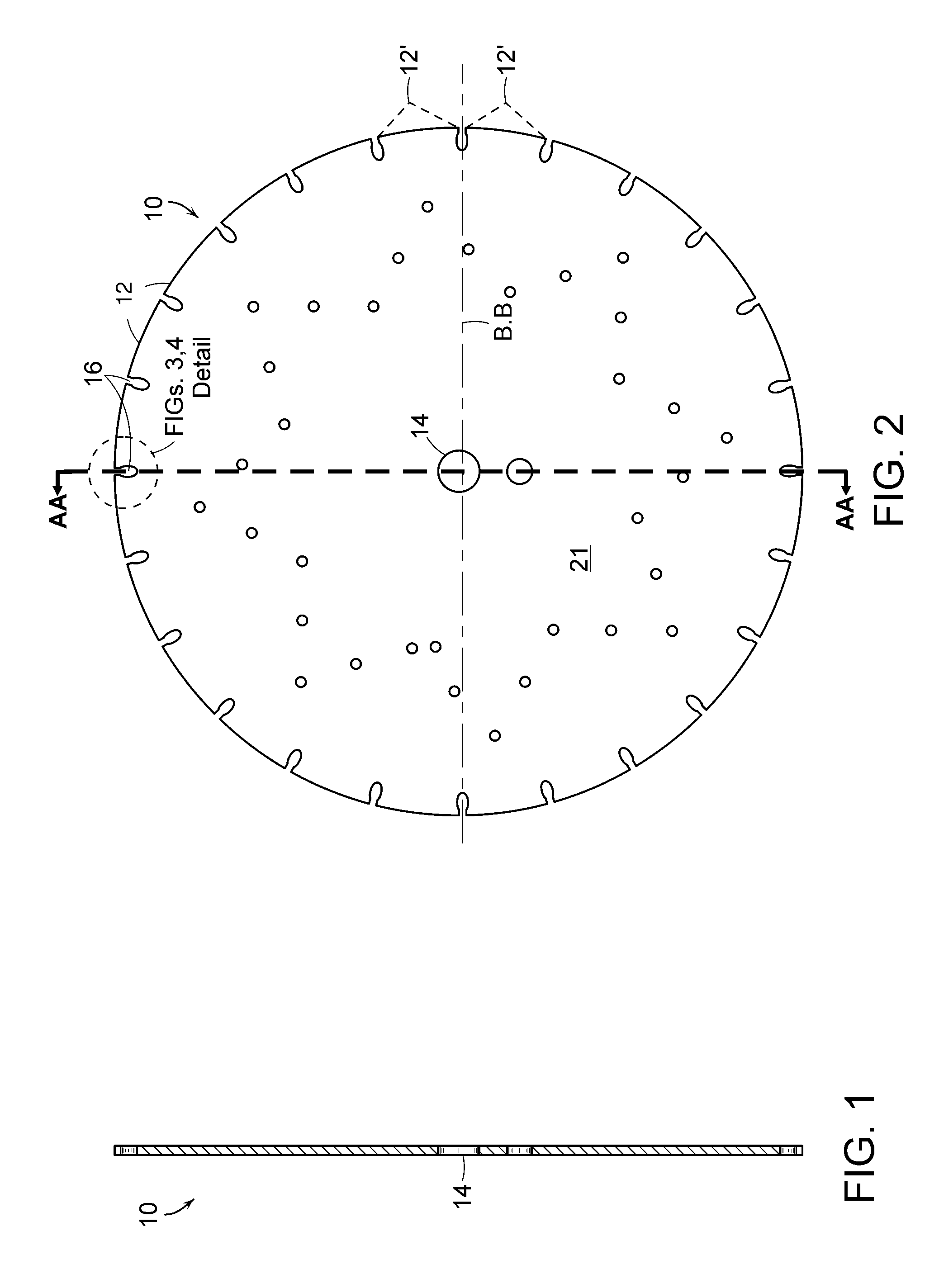

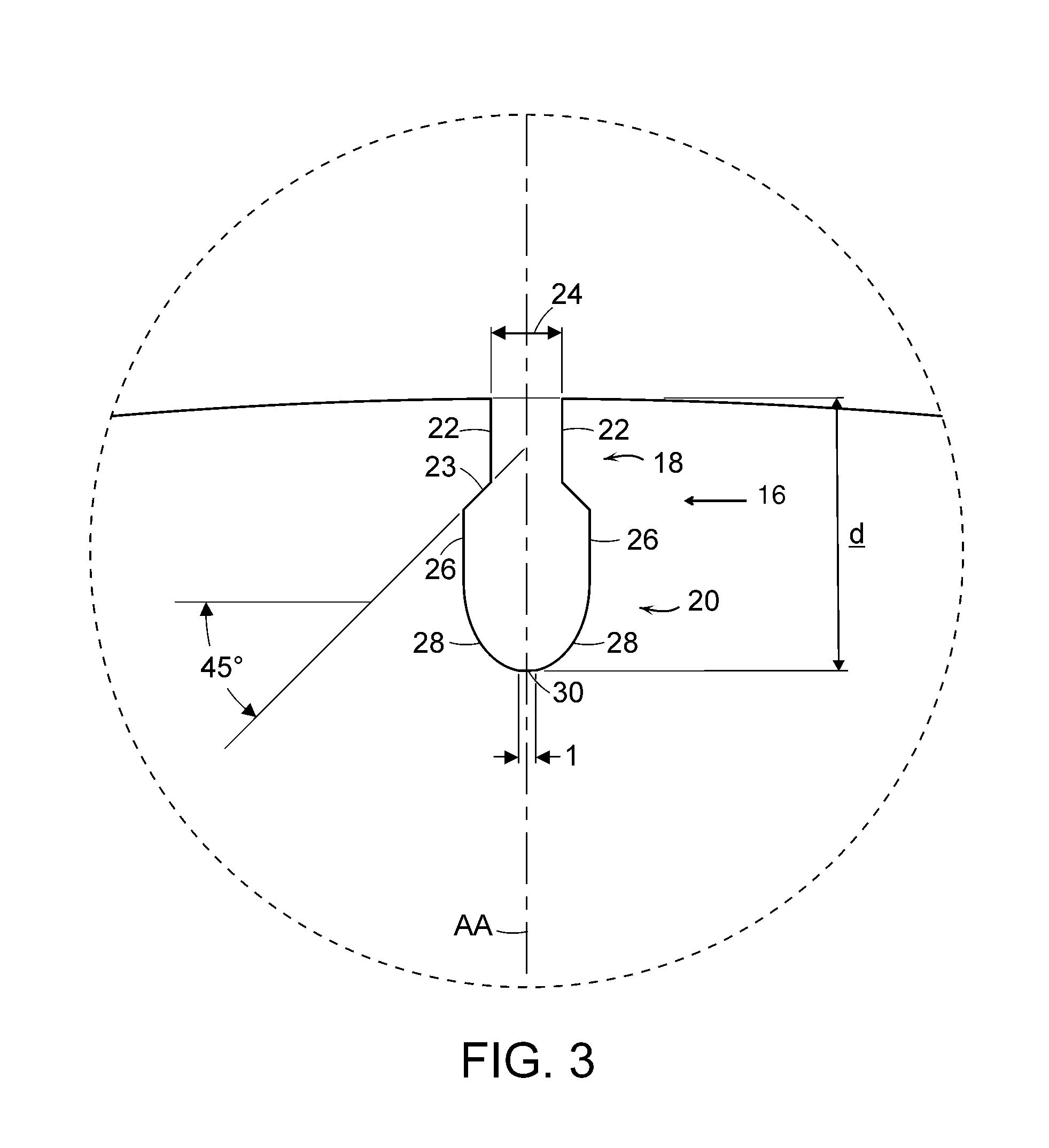

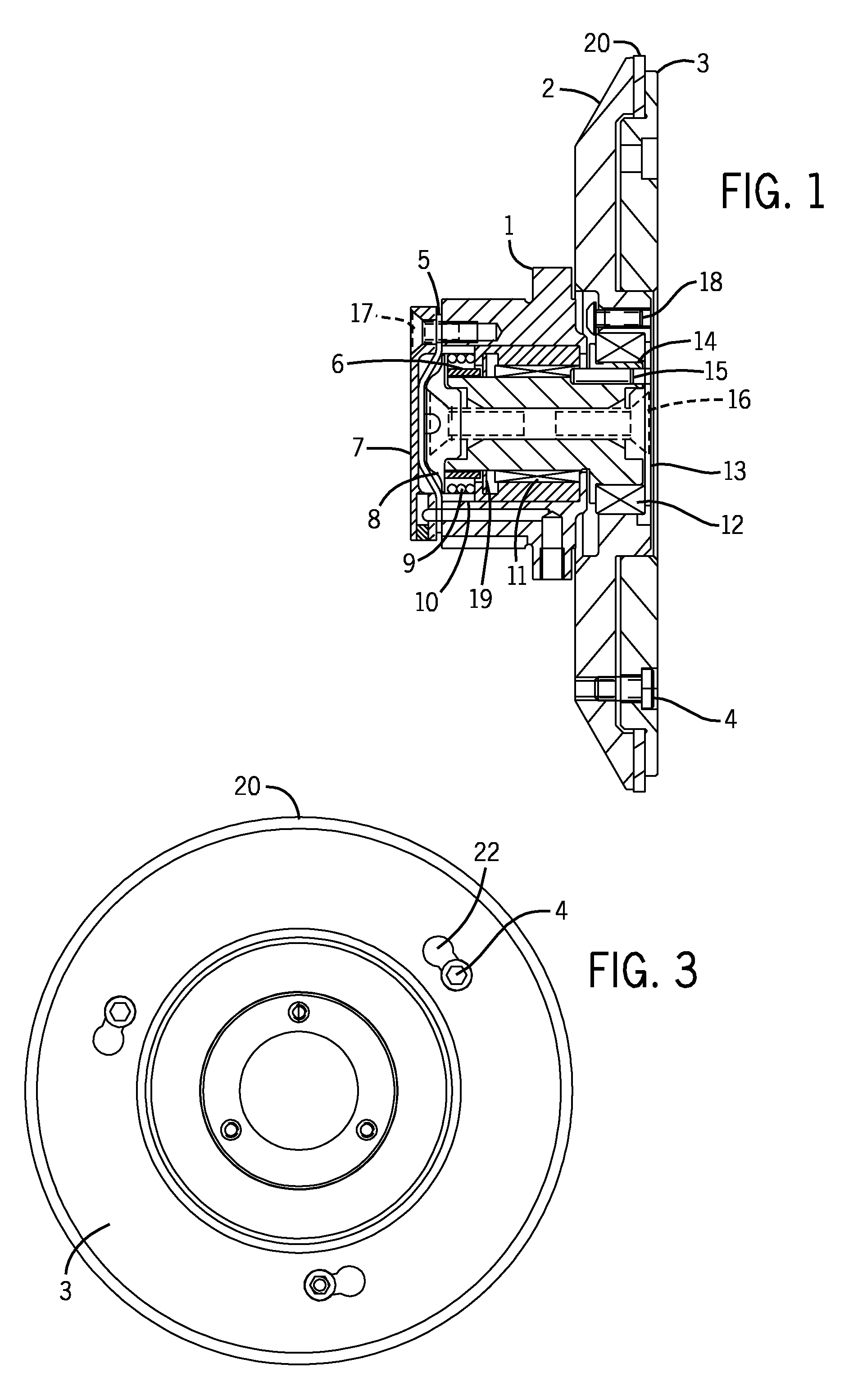

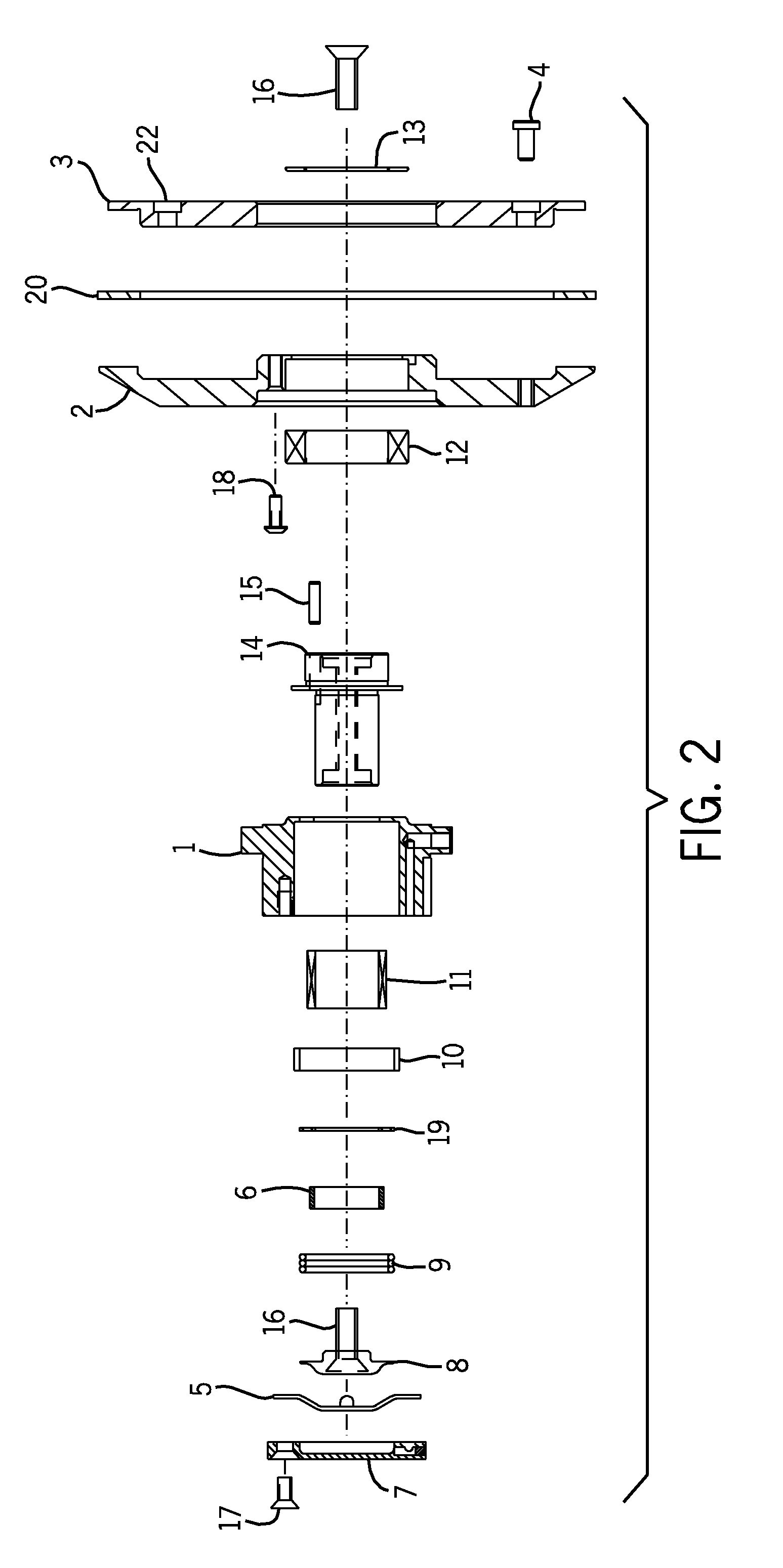

Cutting Wheel with Disposable Blade

InactiveUS20090293696A1Cheap manufacturingCheap replacementMetal working apparatusShearing toolsImpellerAlloy

A cutting wheel having a disposable blade is a constructed of a disposable blade wheel, an inner support wheel and an outer support wheel to define a three part cutting assembly. An interior hub adapted to be mounted to the three part cutting assembly to provide a cutting wheel assembly. The disposable blade wheel is adapted to be connected to the inner support wheel and the outer support wheel, and may be located between the inner support wheel and outer support wheel. In the three part cutting assembly, an outer periphery of the blade wheel extends radially outwardly of an outer periphery of the inner support wheel and of an outer periphery of the outer support wheel to provide a cutting surface having a cutting edge. The cutting edge comprises a cutting material such as hardened tool steel, high carbon steel, non-ferrous alloys or the like. The cutting wheel assembly is adapted to be mounted onto a conventional rotatable shaft of a conventional web processing machine of the types well known in the art to process a web of material.

Owner:EMT INT CO LTD

Rotary die module

InactiveUS7299729B2Easy to disassembleStock shearing machinesMetal working apparatusMechanical engineering

Owner:COX WILLIAM A

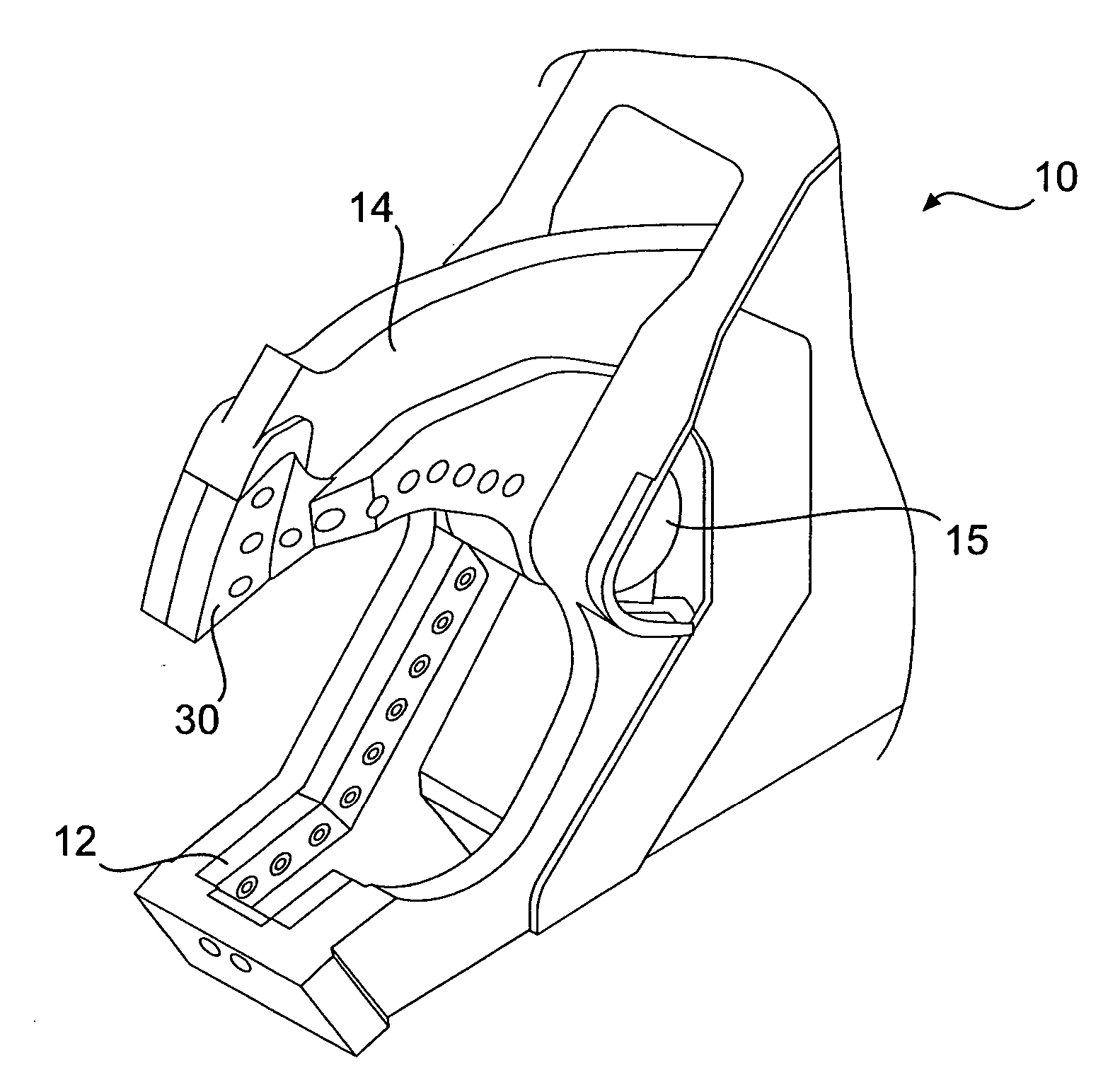

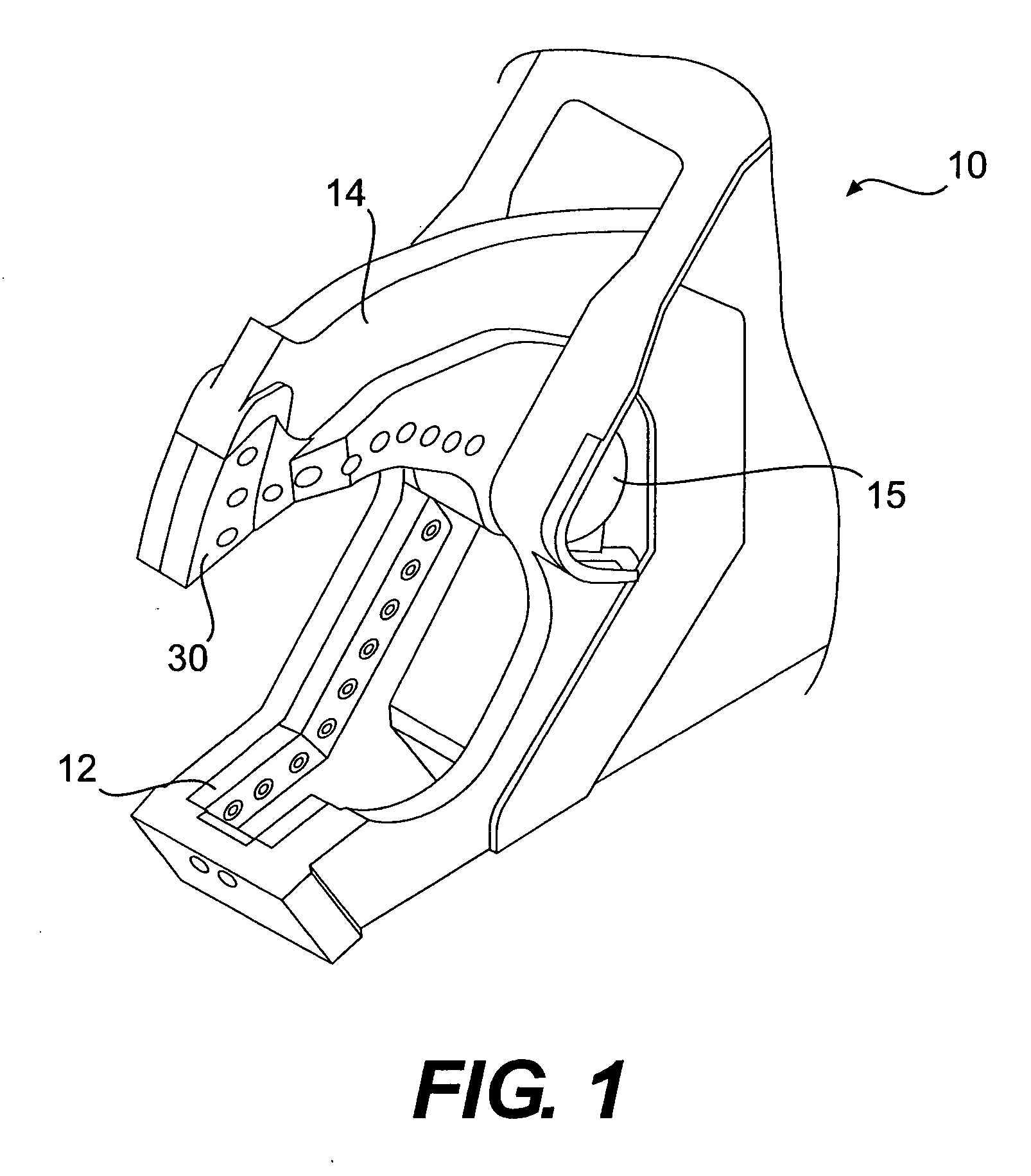

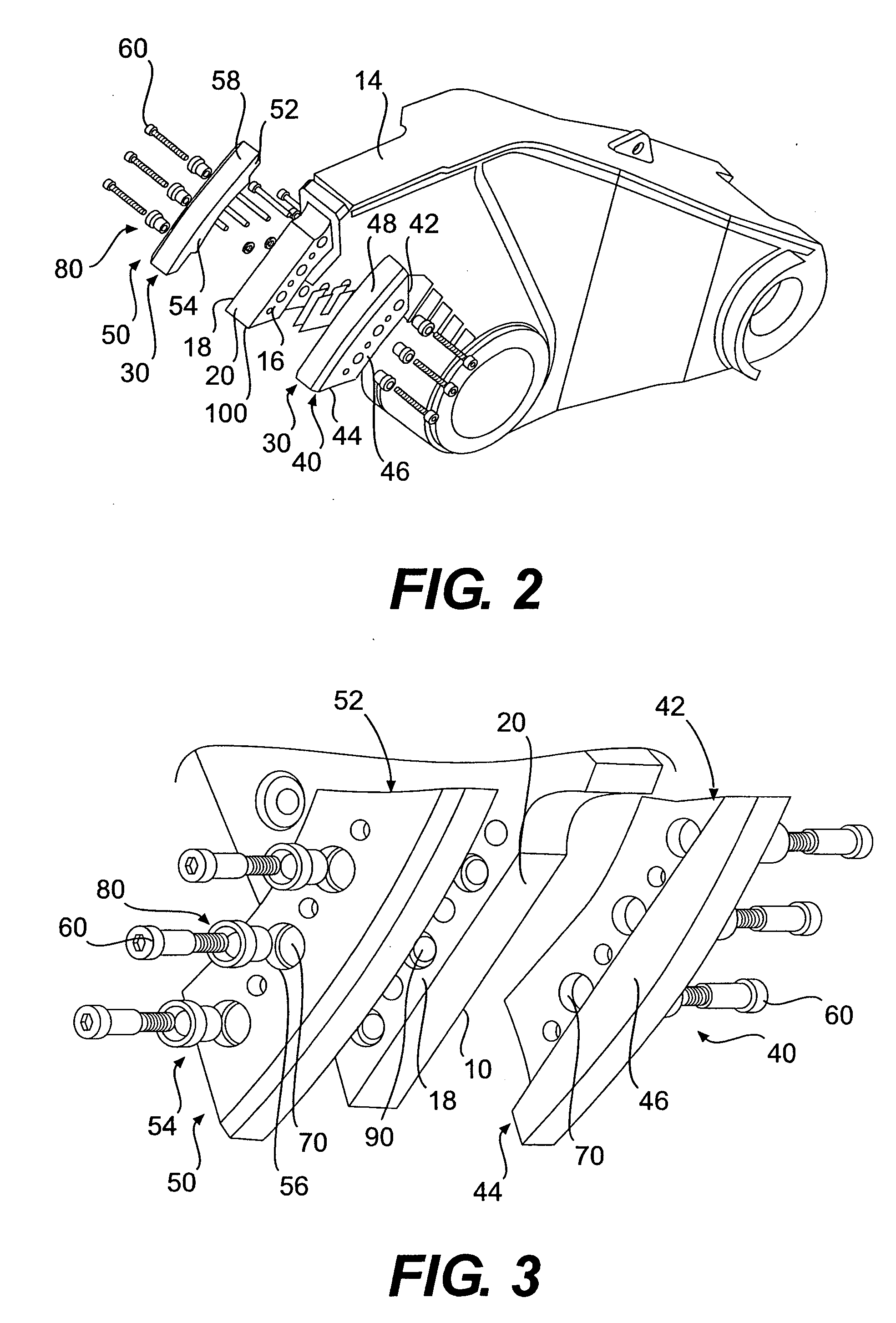

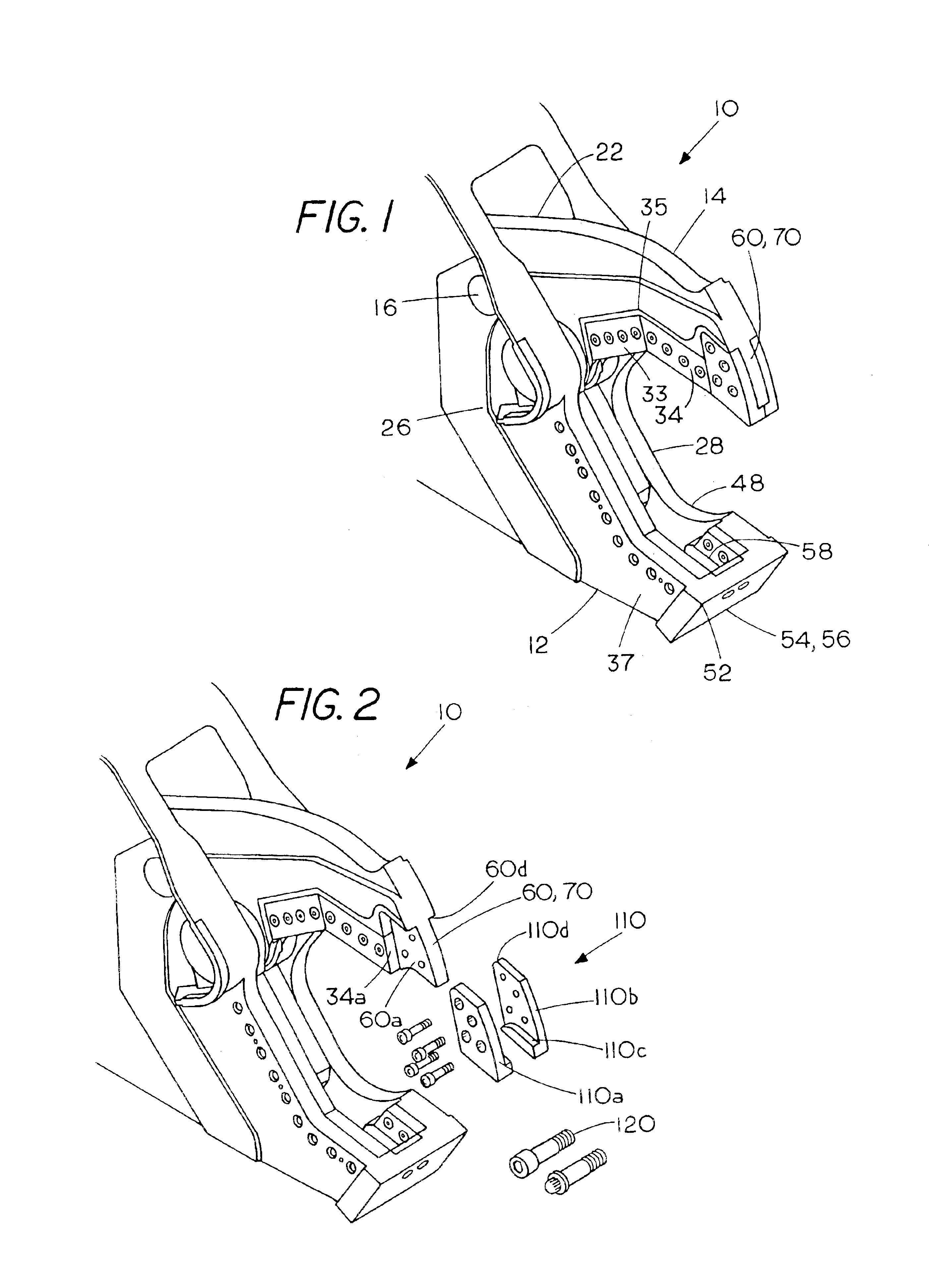

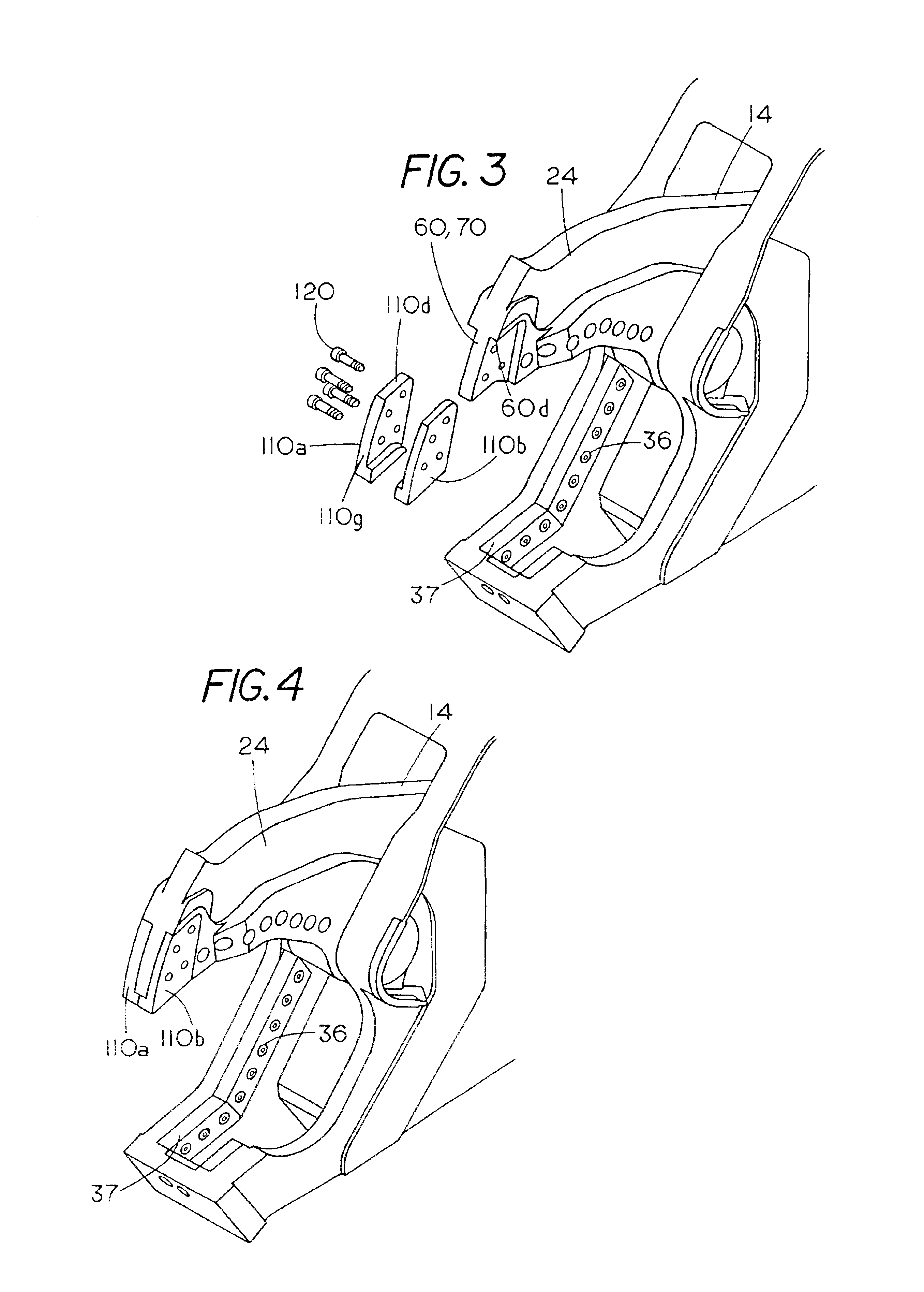

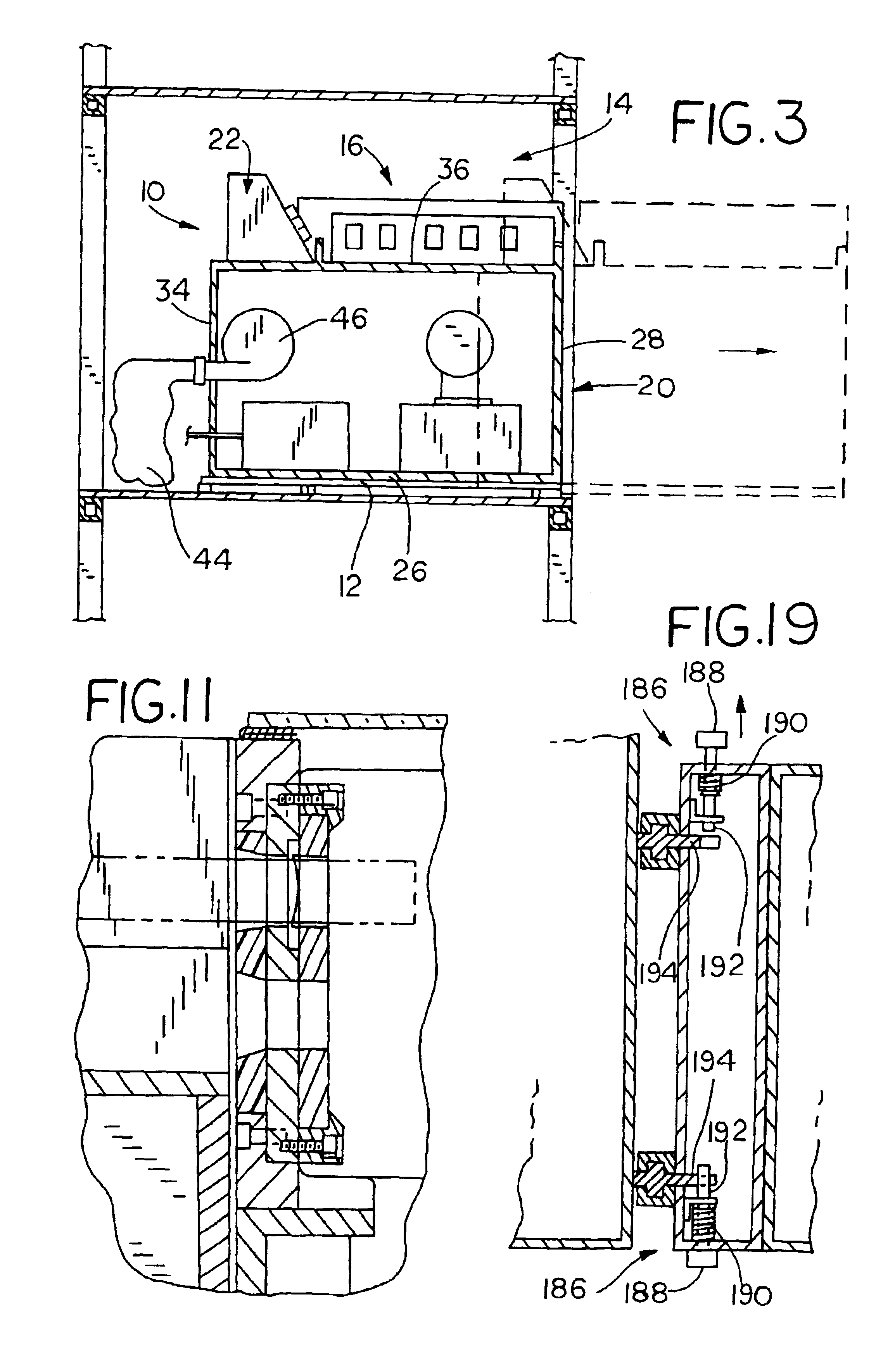

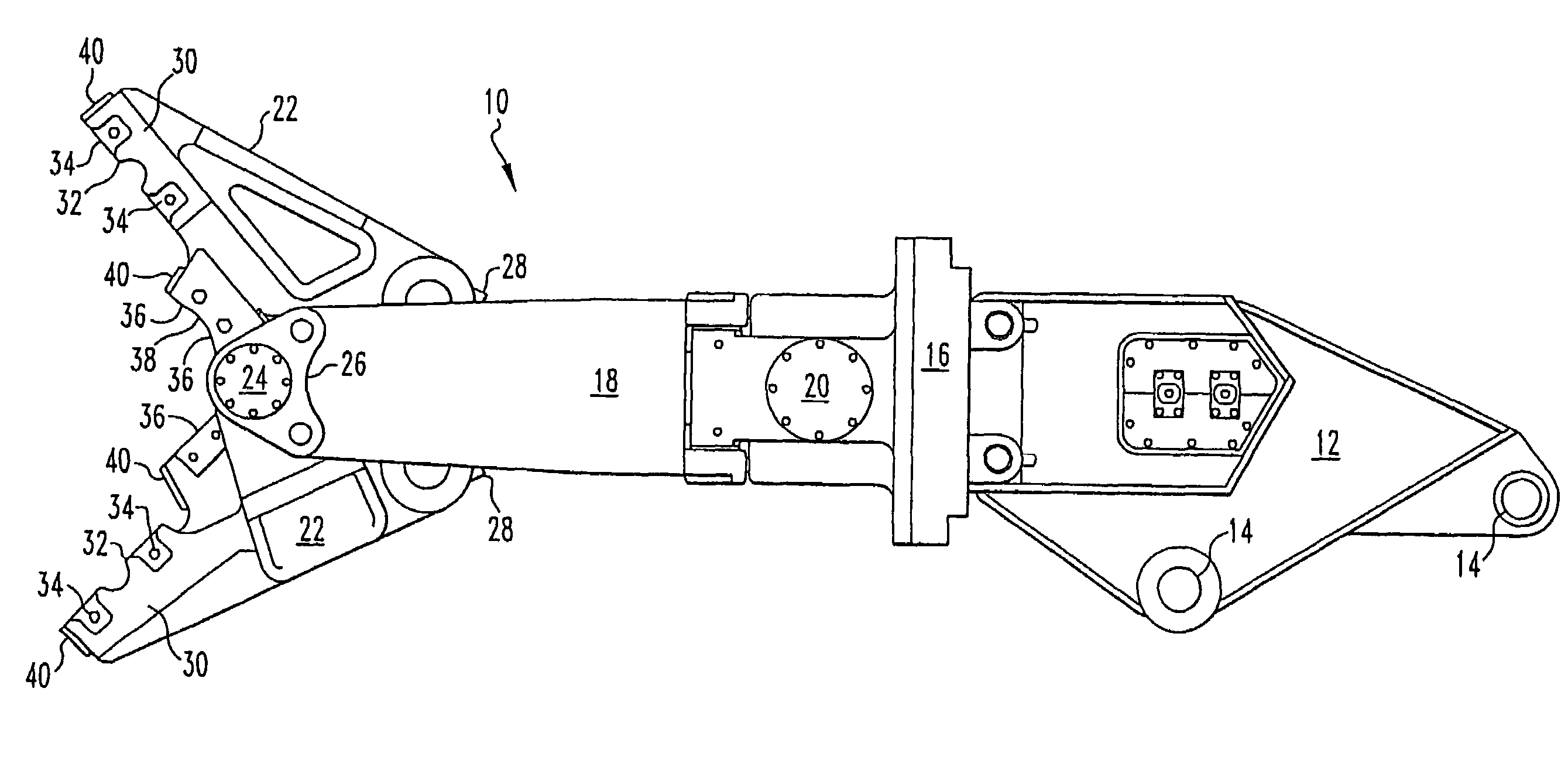

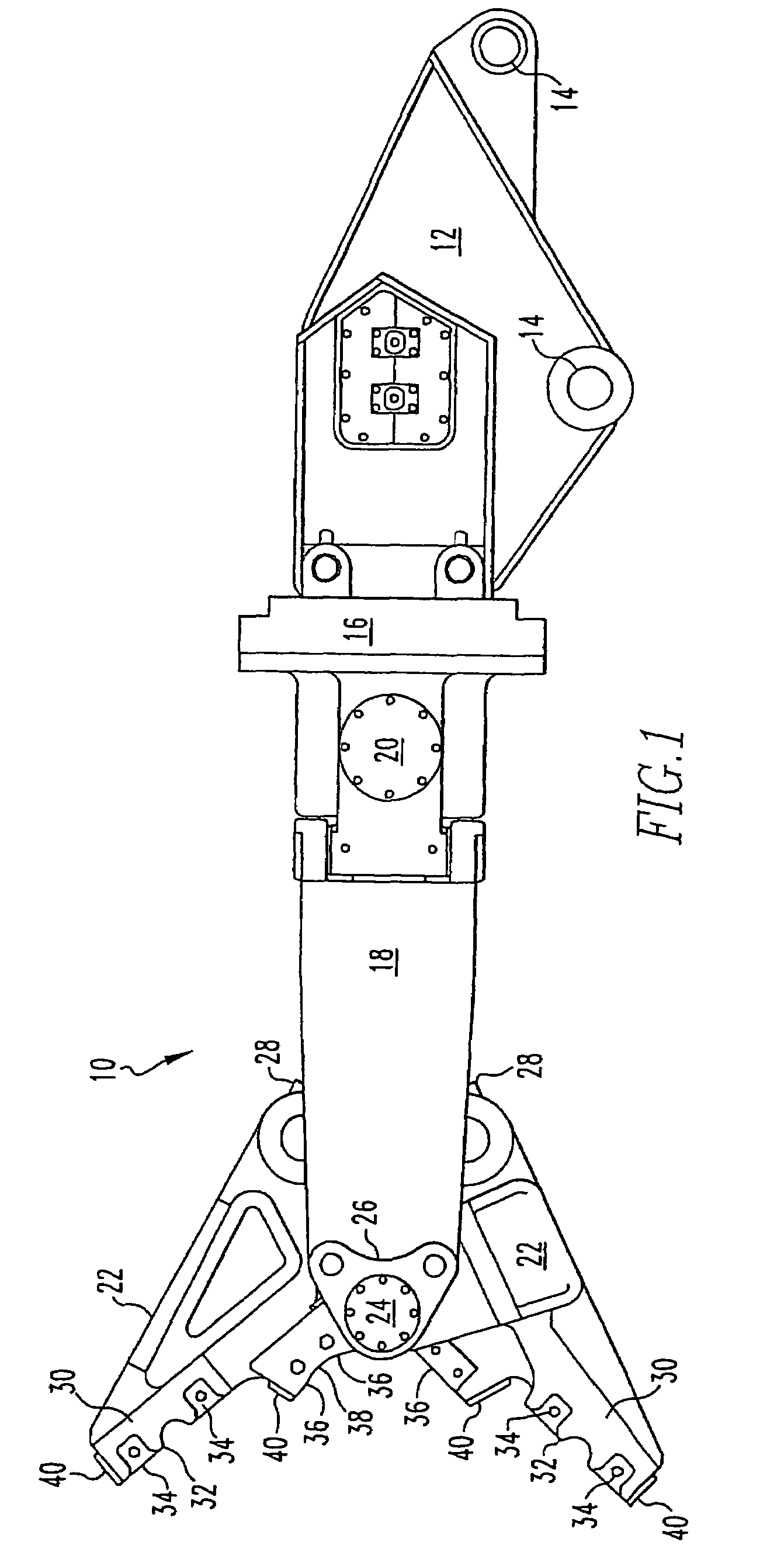

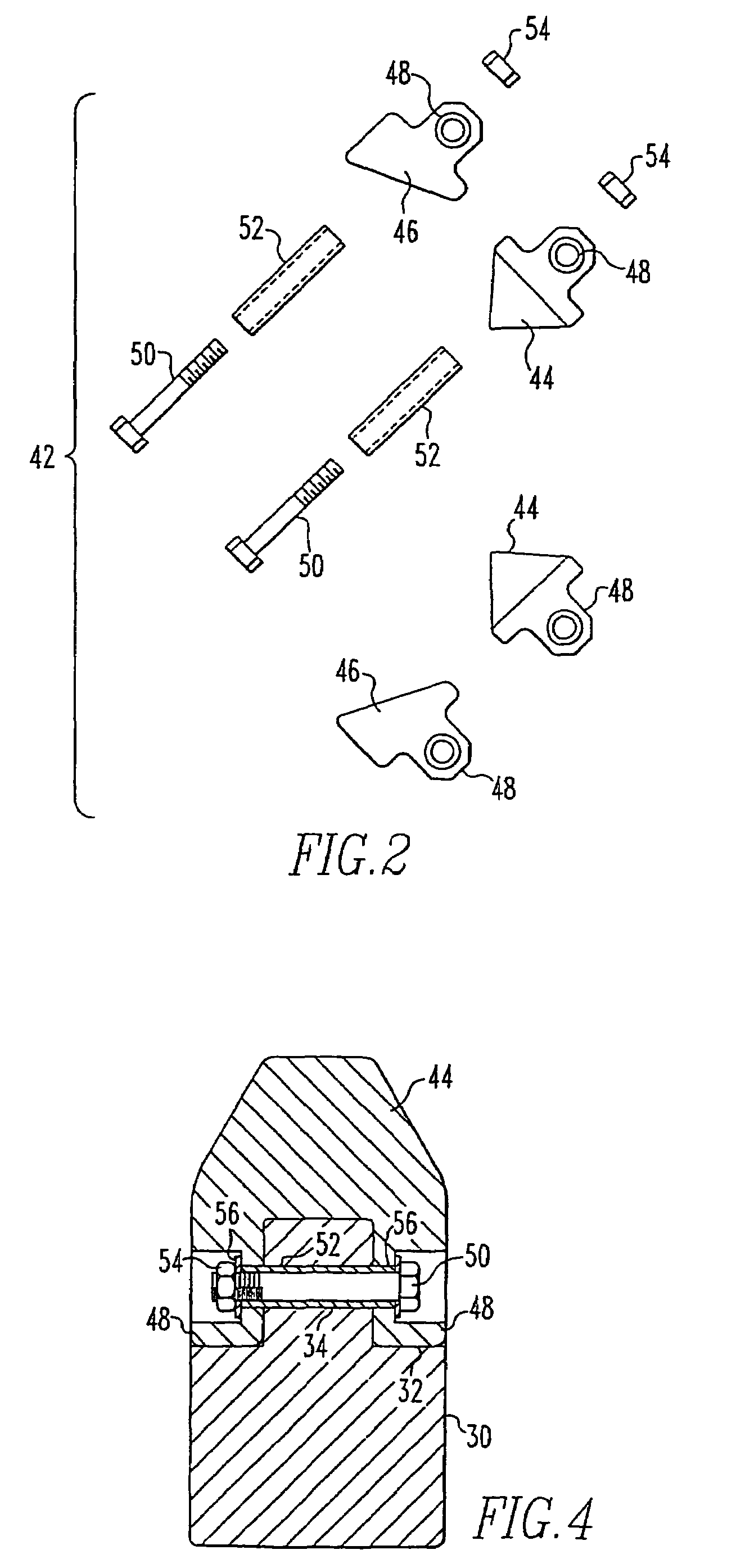

Single jaw set multiple tool attachment system

ActiveUS7354010B2Easy to convertSimple structureMechanical machines/dredgersMowersEngineeringPulverizer

A multiple tool attachment system (10) for demolition equipment includes an adapter (12) and a universal body (18) coupled to the adapter with a pair of pivotable jaws (22) pivotally attached to the universal body. Each of the jaws includes a tool carrier for mounting one of a selective set of tool attachments. Each tool attachment forms a distinct tool for the system. The tools can include, but are not limited to a cracker, a pulverizer, a wood shear, an iron / rail cracker and a grapple.

Owner:RAMUN JOHN R +1

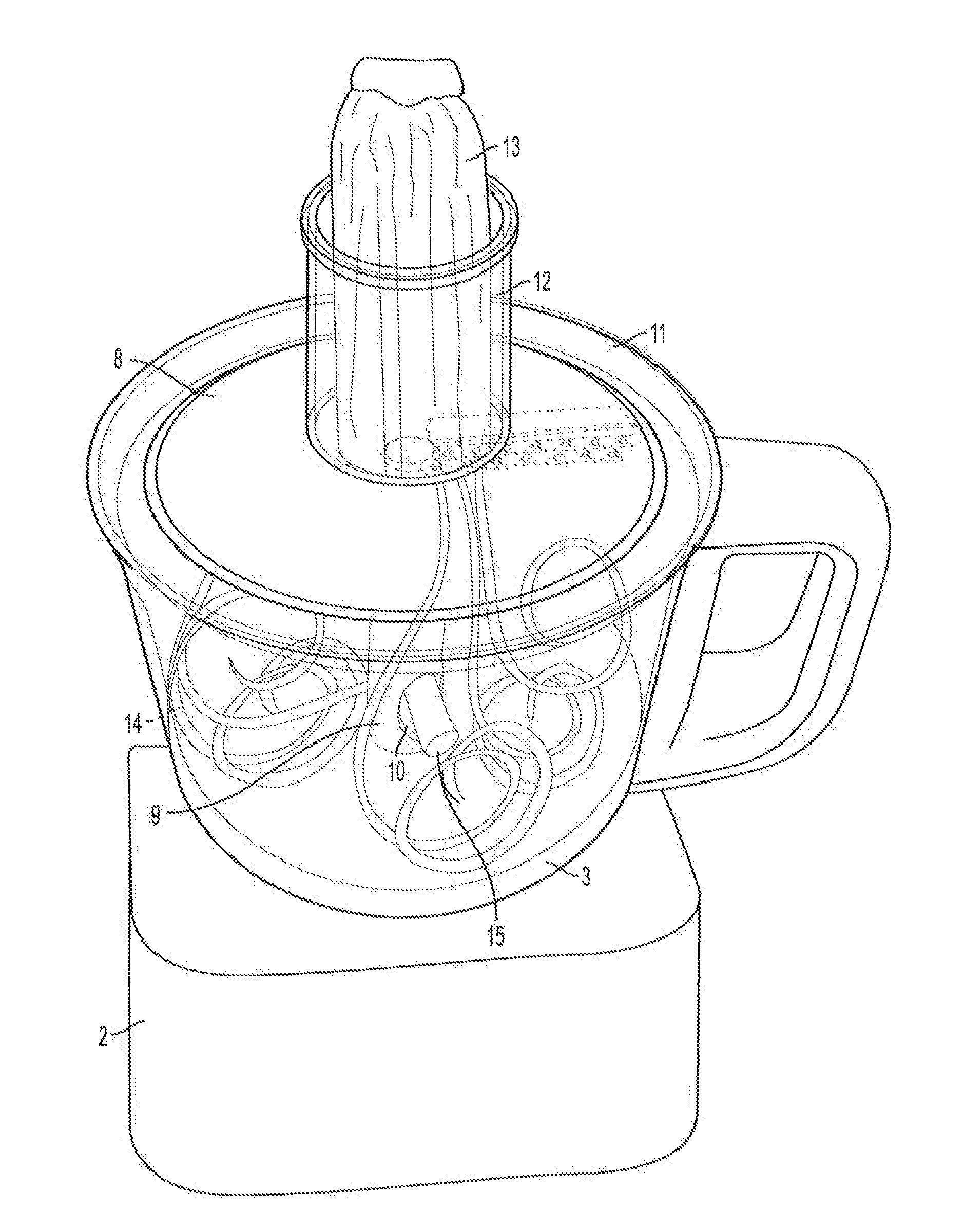

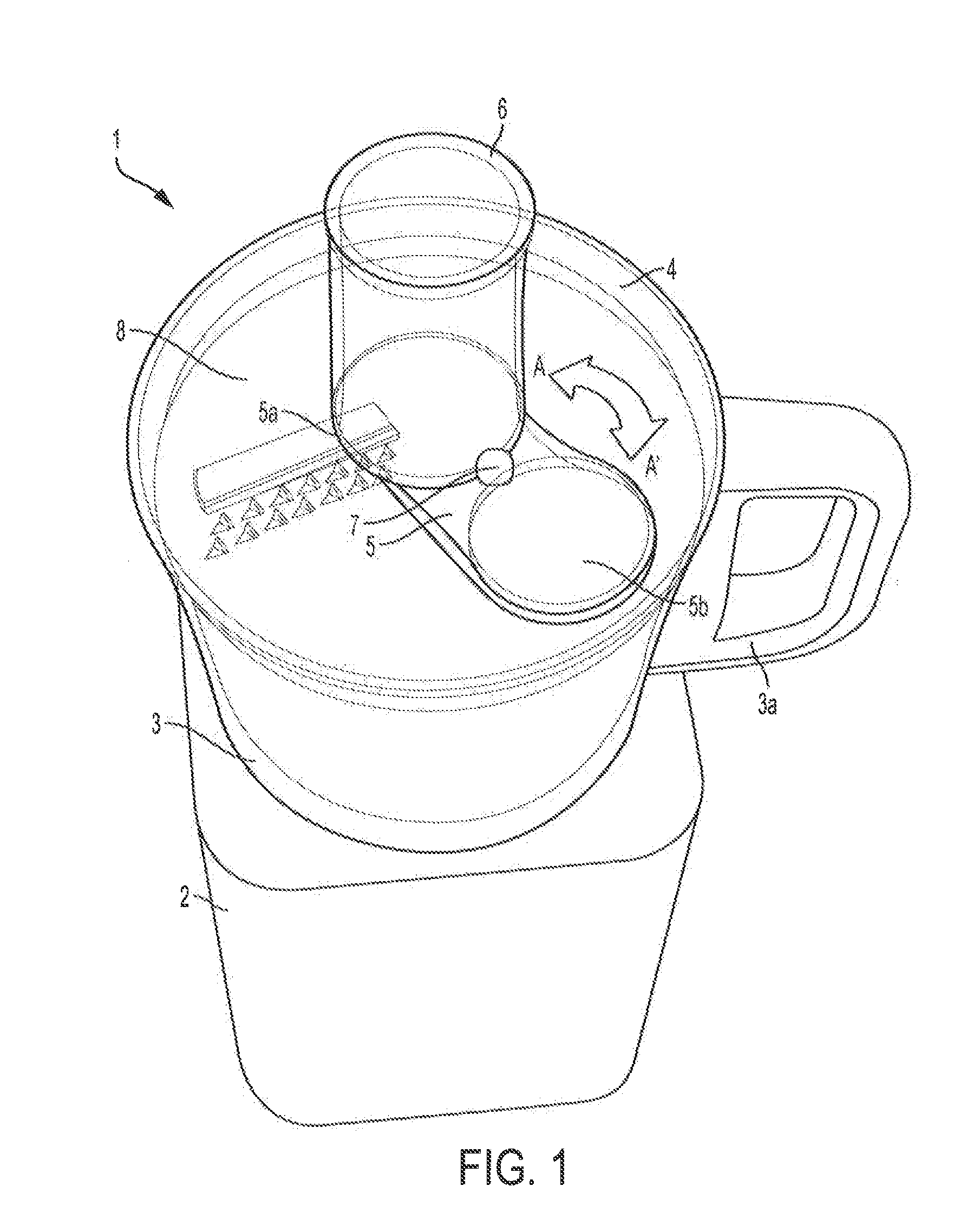

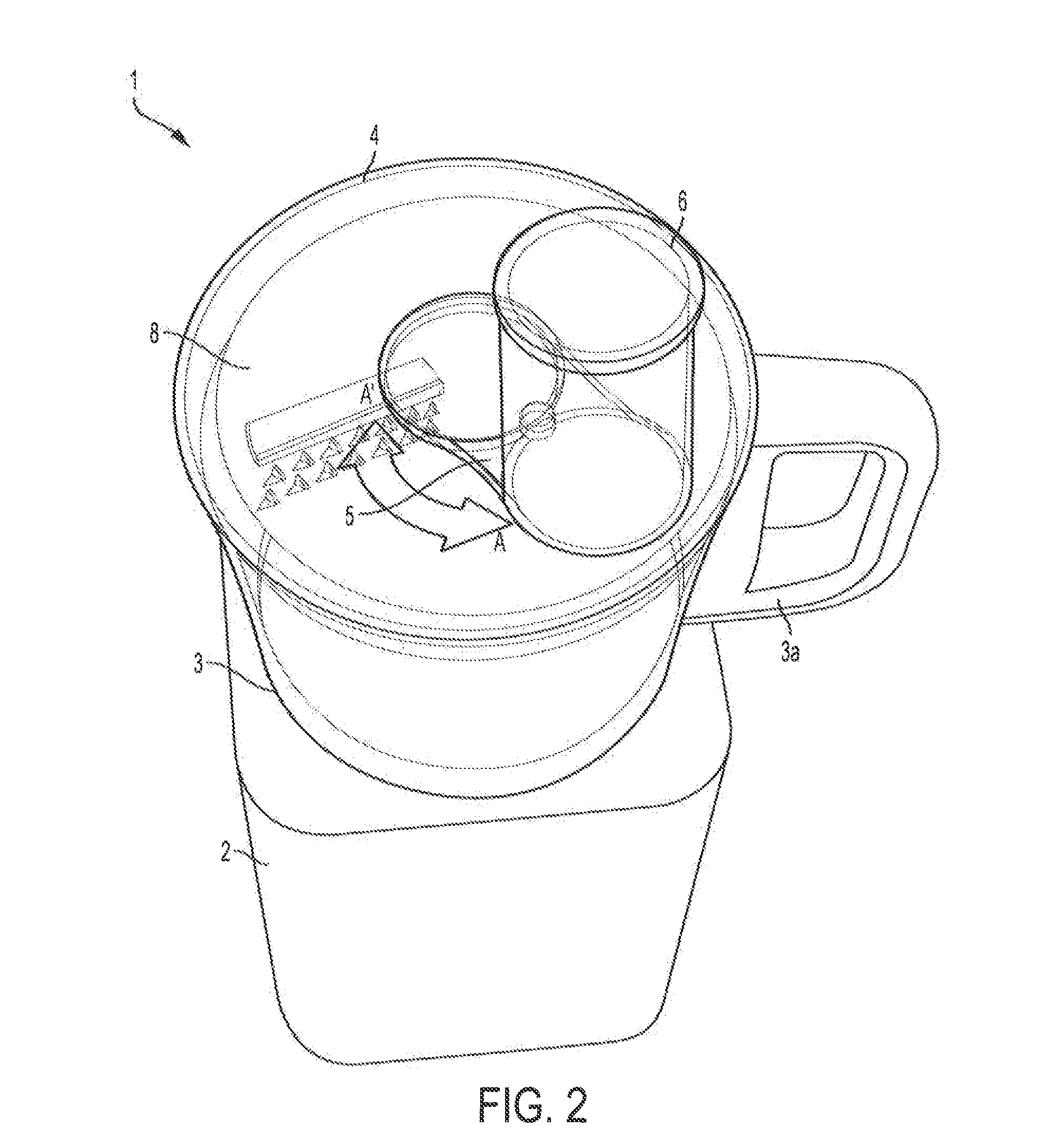

Food Processor with Spiralizer Feature

A food processor for cutting a food ingredient includes: a motorized base for generating a rotational force; a processor bowl removably attached to the motorized base; a spindle within the processor bowl in which the spindle can be rotated by the rotational force from the motorized base; a spiralizer cutter attached to the spindle within the processor bowl, the spiralizer cutter having a blade along a radius of the spiralizer cutter; a lid for the processor bowl, the lid having a center position corresponding to the spindle and a radial position between the center position and an edge of the lid; and a feed tube for positioning at one of the center position and the radial position, wherein the feed tube can be repositioned between the center and radial positions.

Owner:SUNBEAN PROD INC

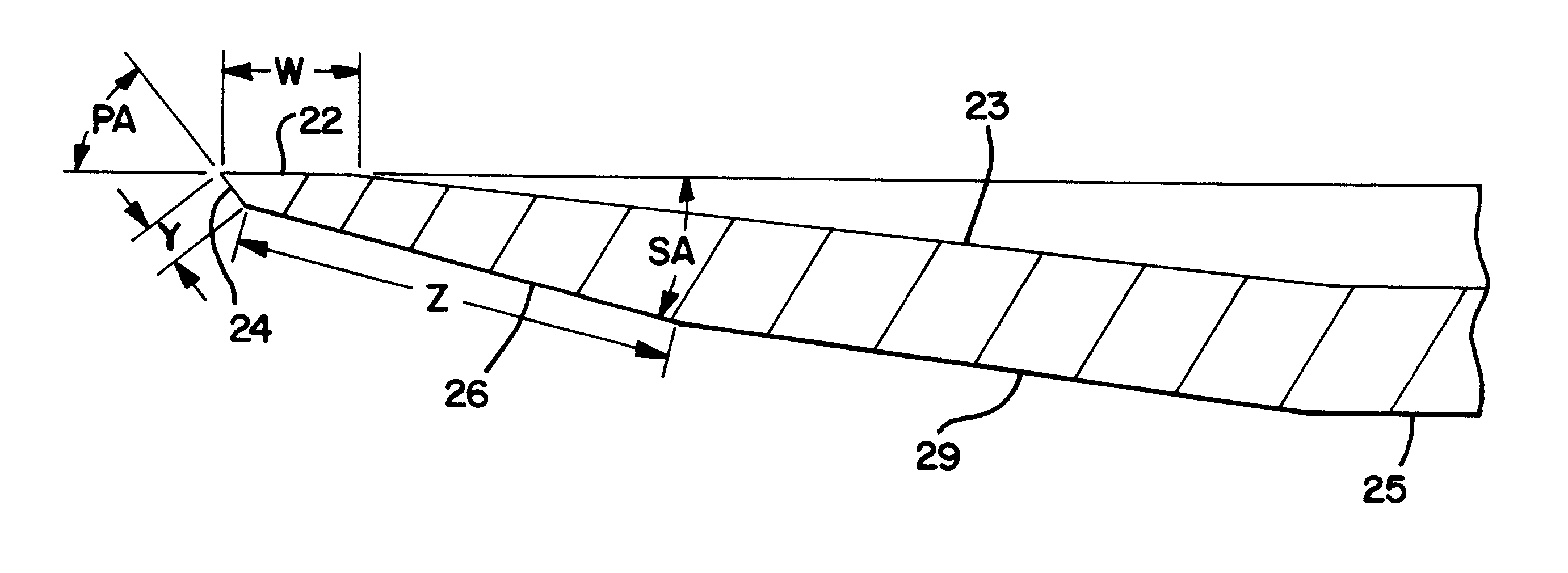

Close tolerance food slicing apparatus, blade and method

InactiveUS6267033B1Improve quality consistencyGood repeatabilityMetal working apparatusShearing toolsHigh water contentMechanical engineering

Apparatus device and method improved slicing of large food sticks, loaves and the like are provided. A slicing blade which may have a top flat surface or top flat land width along its cutting edge provides generally longitudinal forces on the food product being sliced, which forces are in a direction generally opposite to the direction through which the food products are fed through a slicing apparatus. The slicing blade includes a bottom primary bevel surface and typically steep primary angle for imparting angularly directed forces on the food products being sliced so as to throw the slices at a generally corresponding deposit angle. The invention is particularly important in improving handling of large luncheon meat sticks including non-frozen, high water content and reduced fat content luncheon meat sticks. Fast feed rates can be practiced without experiencing jamming, yields are increased, slice quality is made more consistent and repeatable, slicing line utilization is enhanced, and sanitary conditions are more easily maintained.

Owner:KRAFT FOODS GRP BRANDS LLC

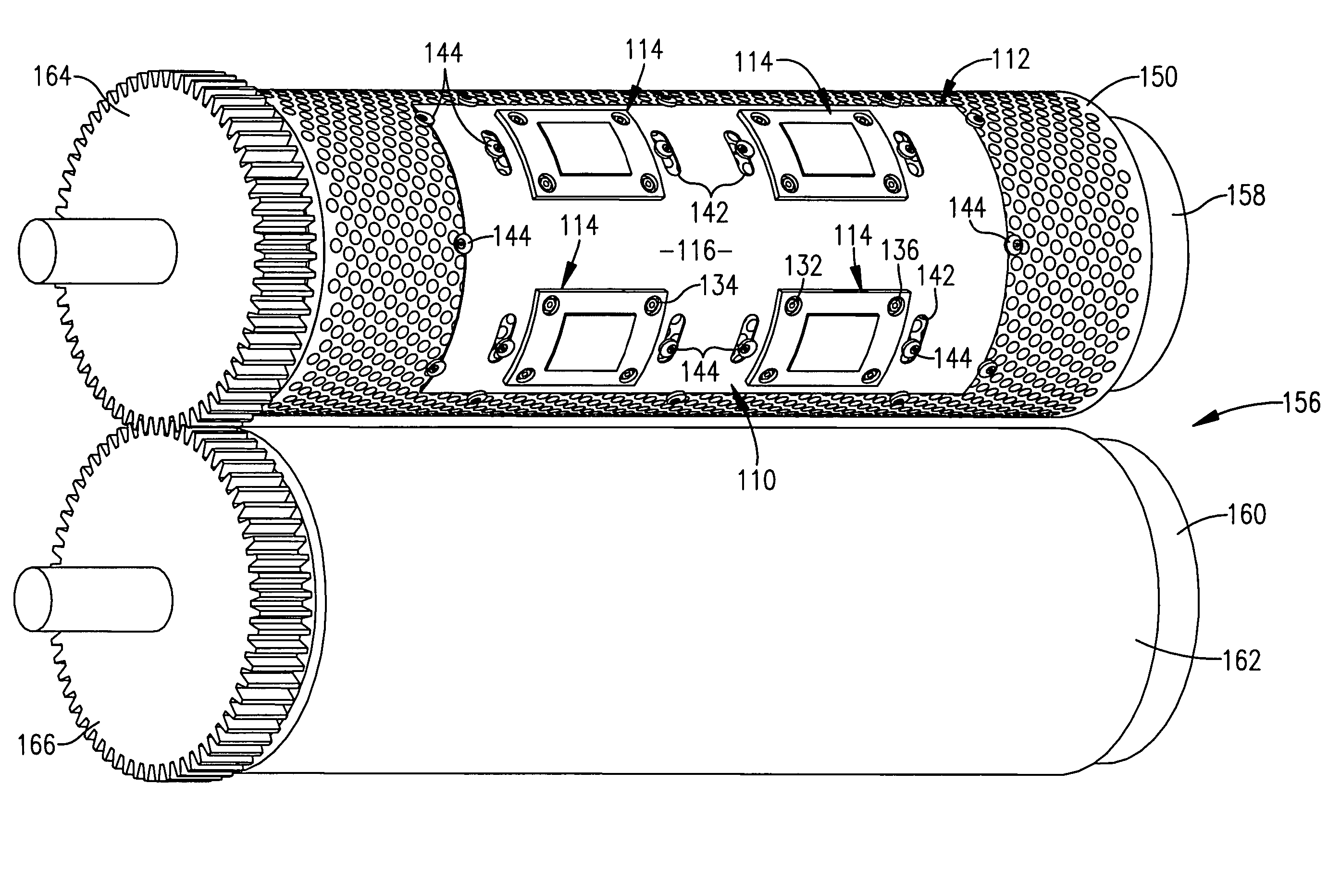

Device for rotary converting a web or sheet matter

InactiveUS7060016B2Improve reasonableLower cost of capitalEnvelopes/bags making machineryMechanical working/deformationEngineeringSheet material

A device for rotary conversion of a web or sheet material by cooperating cylindrical tools. The tools are arranged in a cassette. A driving device connects with the tools for rotating them. The cassette with the tools is placed in an adaptive cassette receiver. The driving device includes a motor and is supported on the lid of the cassette receiver. The cassette is placeable in and removable from the cassette receiver and is secured there and the driving device is connected to the tools.

Owner:BOBST SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com