Three-dimensional pipe cutter

A pipe cutting machine, three-dimensional technology, applied in the direction of pipe shearing device, shearing device, accessories of shearing machine, etc., can solve the problems of affecting assembly, inconvenient adjustment, polluting the environment, etc., and achieve the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

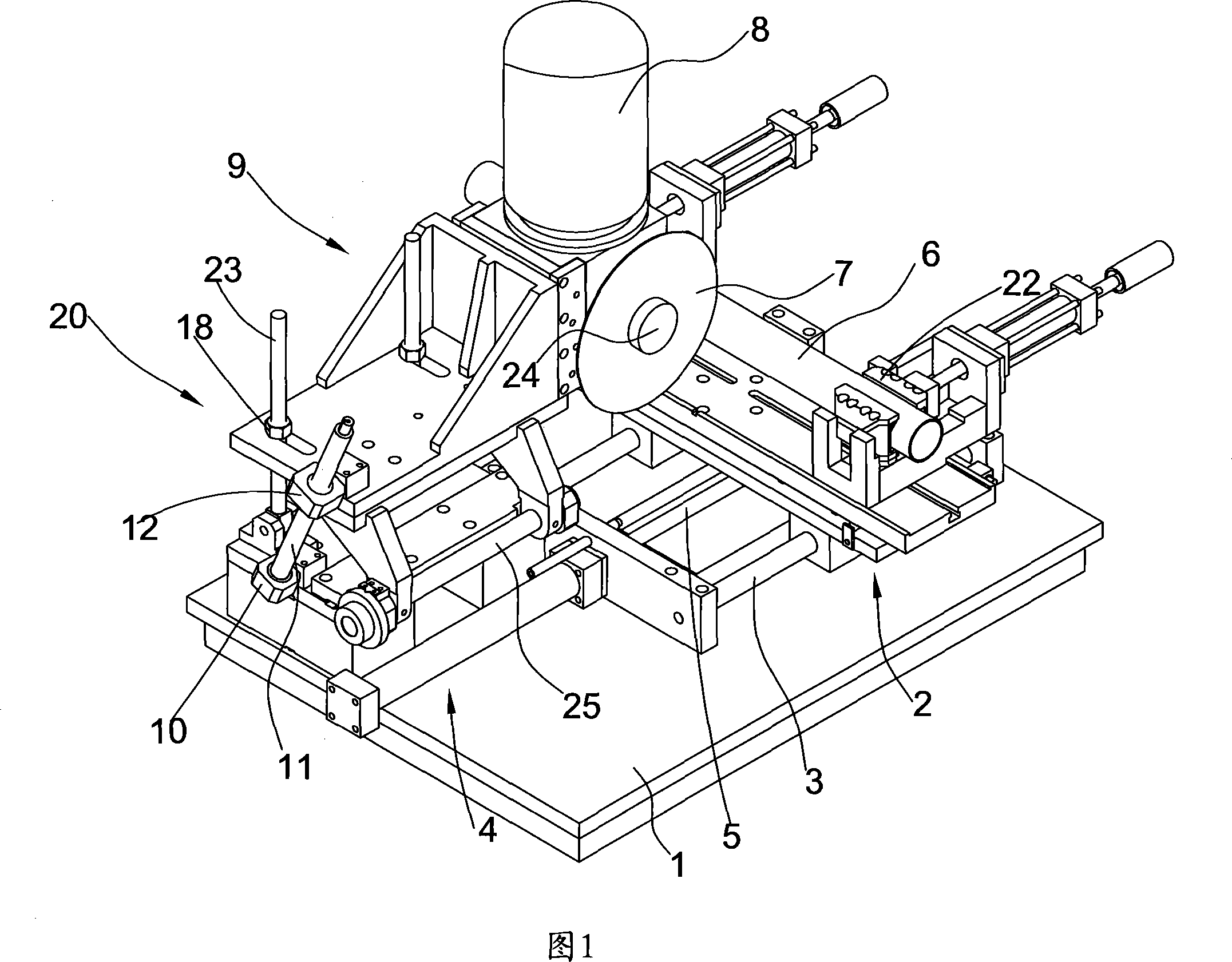

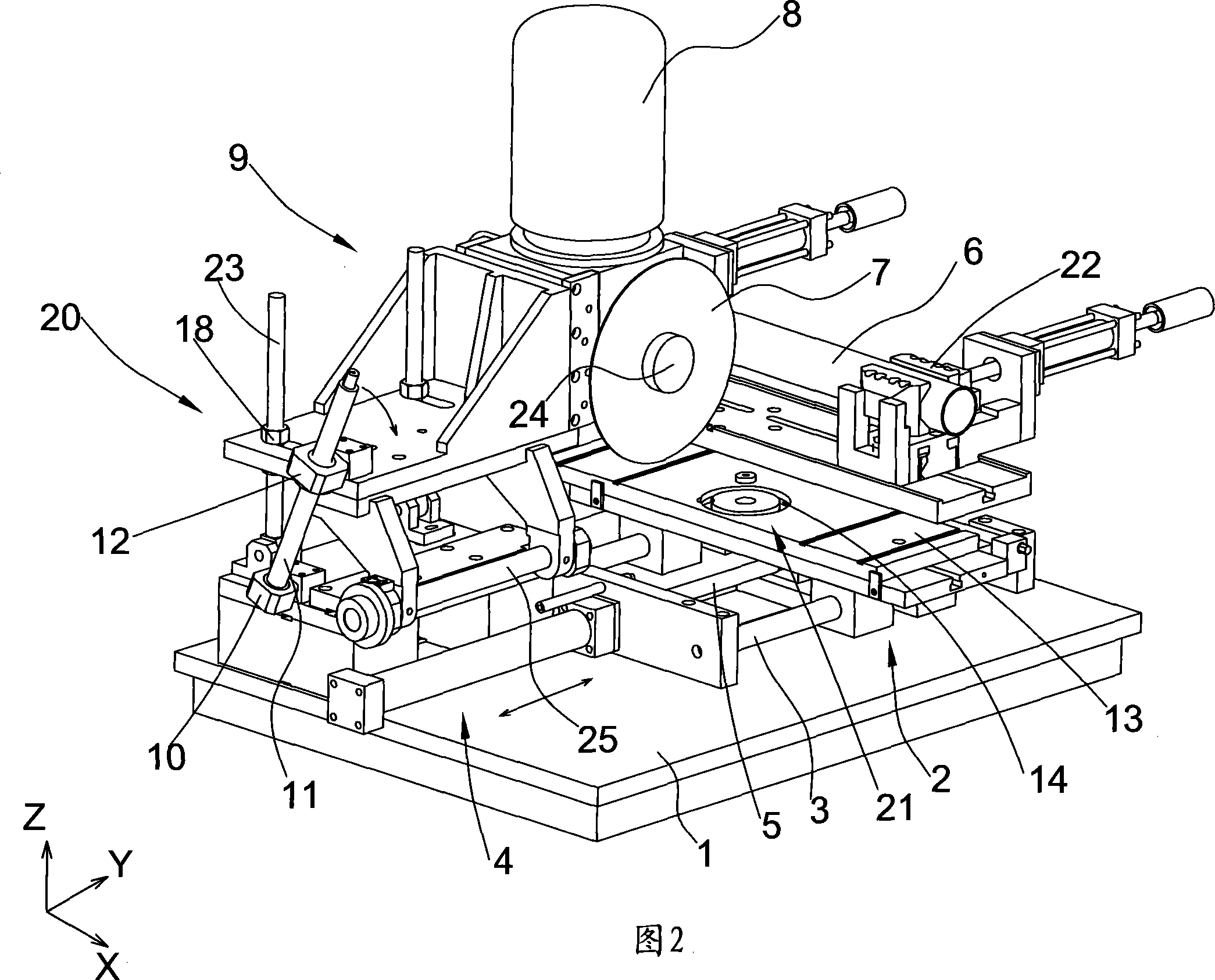

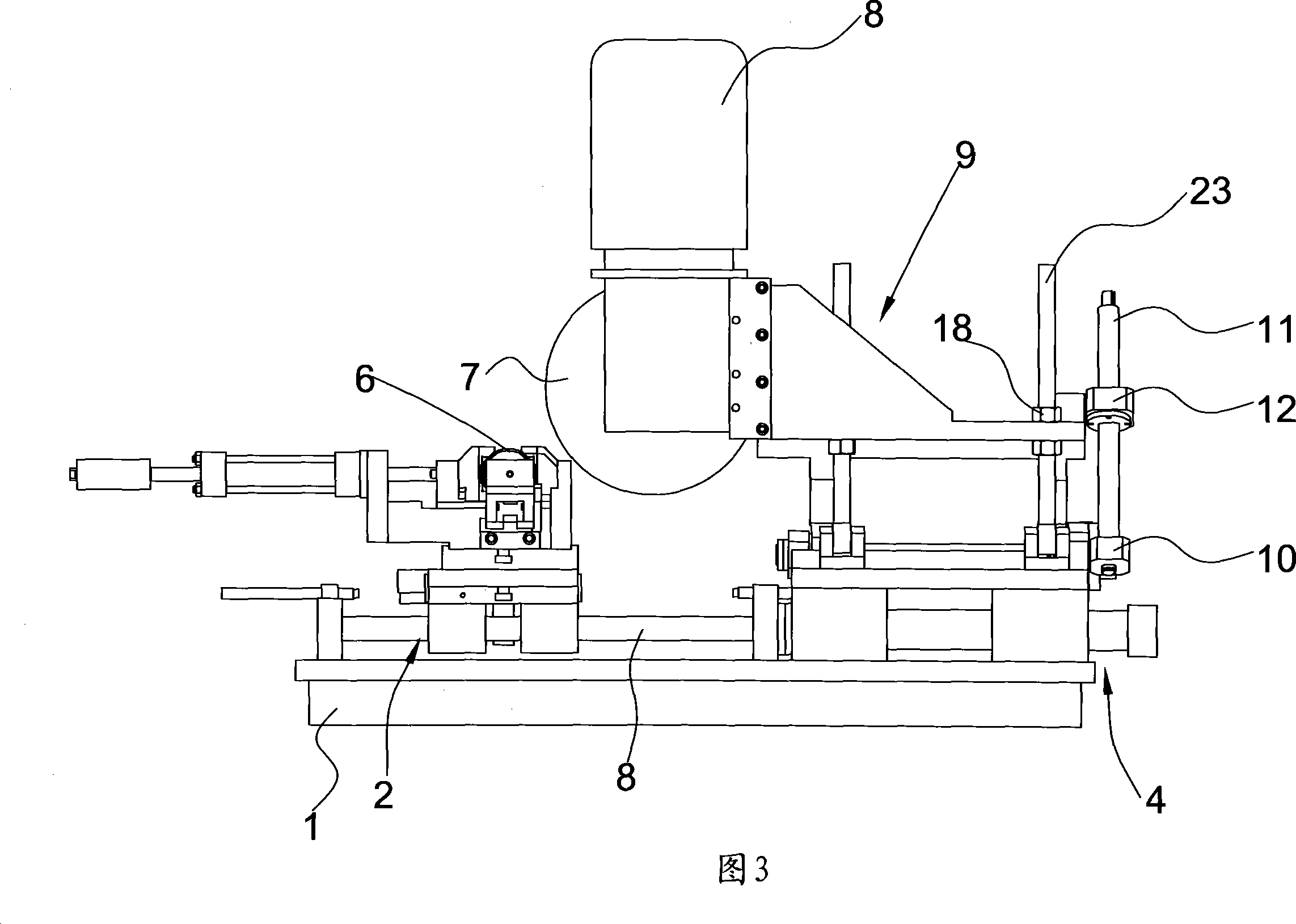

[0018] Referring to accompanying drawings 1 to 5, a three-dimensional pipe cutting machine includes a frame 1, a clamping device 2 for fixing a pipe 6 to be processed, a tool set on the frame 1 and a tool 7 is installed The fixed seat 9 is rotatably provided with a first rotating shaft 24 extending along the X-axis direction on the tool fixing seat 9, and the tool 7 is fixedly connected to the first rotating shaft 24; the frame 1 has a guide rail 3 extending in the horizontal direction, and the clip The holding device 2 is slidably arranged on the guide rail 3. The frame 1 has a second rotating shaft 25 extending along the direction of the Y axis perpendicular to the X axis. The tool holder 9 is rotatably connected to the second rotating shaft 25, and the tool is fixed A first locking device 20 is also provided between the seat 9 and the frame 1 so that the tool fixing seat 9 and the frame 1 are relatively fixed. When the first locking device 20 is in a locked state, the tool f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com