Patents

Literature

489results about How to "High automation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Detection and identification method oriented to image tablet shot by mobile terminal

InactiveCN106156761AHigh automation efficiencyImprove adaptabilityCharacter and pattern recognitionImage correctionSoftware engineering

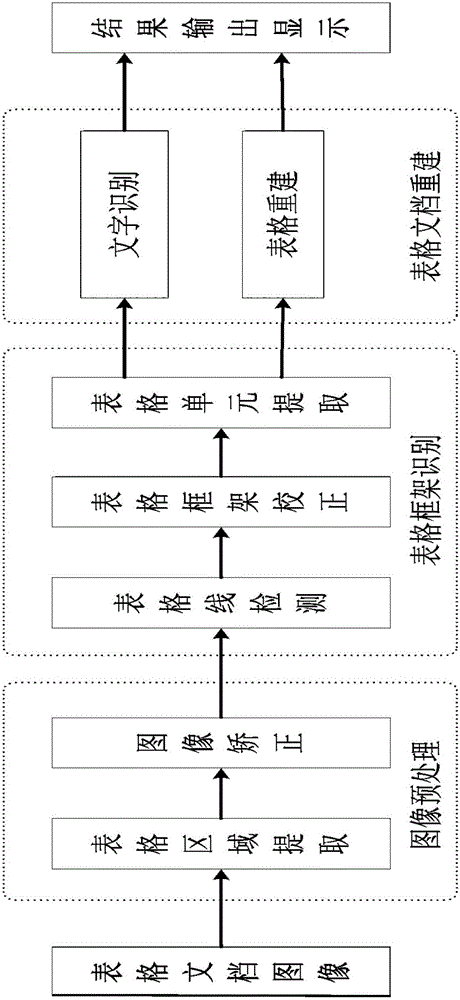

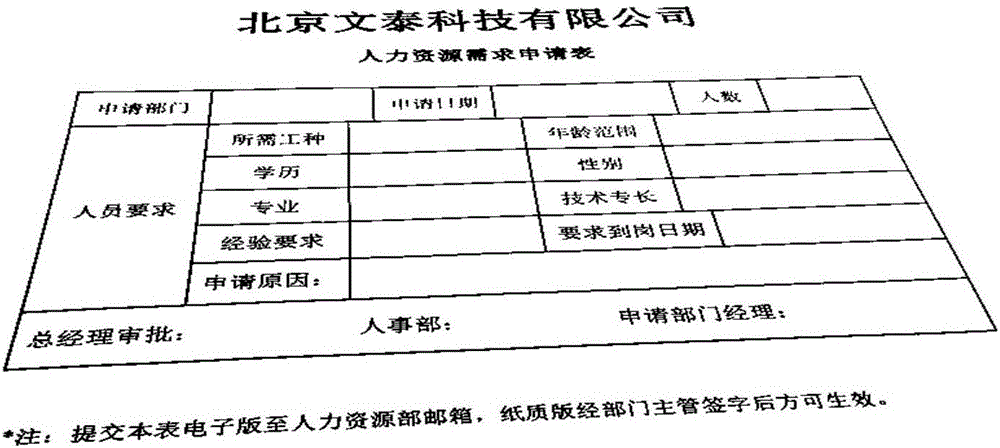

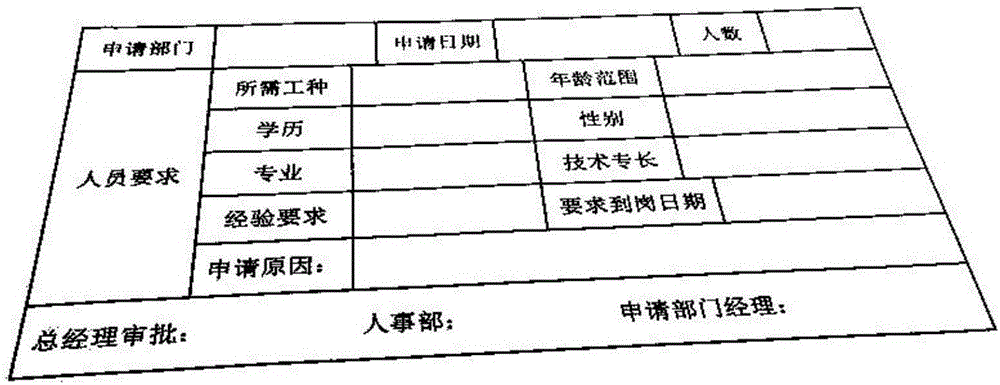

The invention provides a detection and identification method oriented to an image tablet shot by a mobile terminal. The method mainly comprises the following steps: separating a tablet area from a hybrid document image shot by the mobile terminal to obtain a tablet image by virtue of a connected component analysis method, and performing image correction operation on the tablet image; detecting and positioning a straight line in the corrected tablet image by virtue of rough to detailed straight line detection algorithms, performing correction processing on the detected straight line, and extracting information of each tablet cell in the tablet image; performing text identification on the extracted information of the tablet cells, and reconstructing a corresponding tablet in a document by virtue of a cell-combination-based tablet creation algorithm. The method is highly adaptive to regular and irregular tablet creation, and conversion operation from the image tablet to a document file can be finished after simply editing and modifying a created word document, so that the office automation efficiency is improved, and high practicability is achieved.

Owner:BEIJING JIAOTONG UNIV

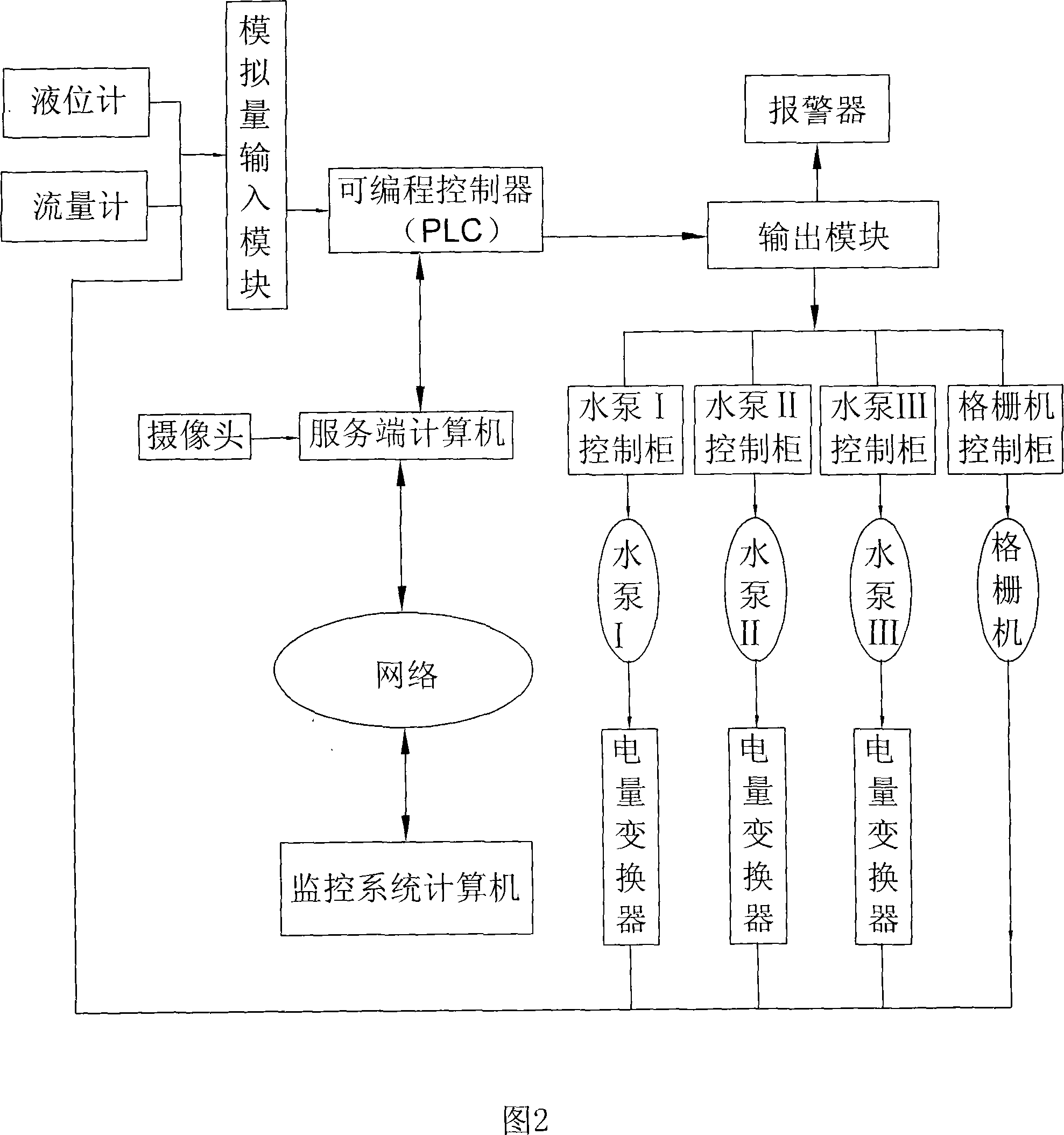

Sewage pump station monitoring system

InactiveCN101021725AHigh automation efficiencyImprove management efficiencyLevel controlComputer controlMonitoring systemComputer module

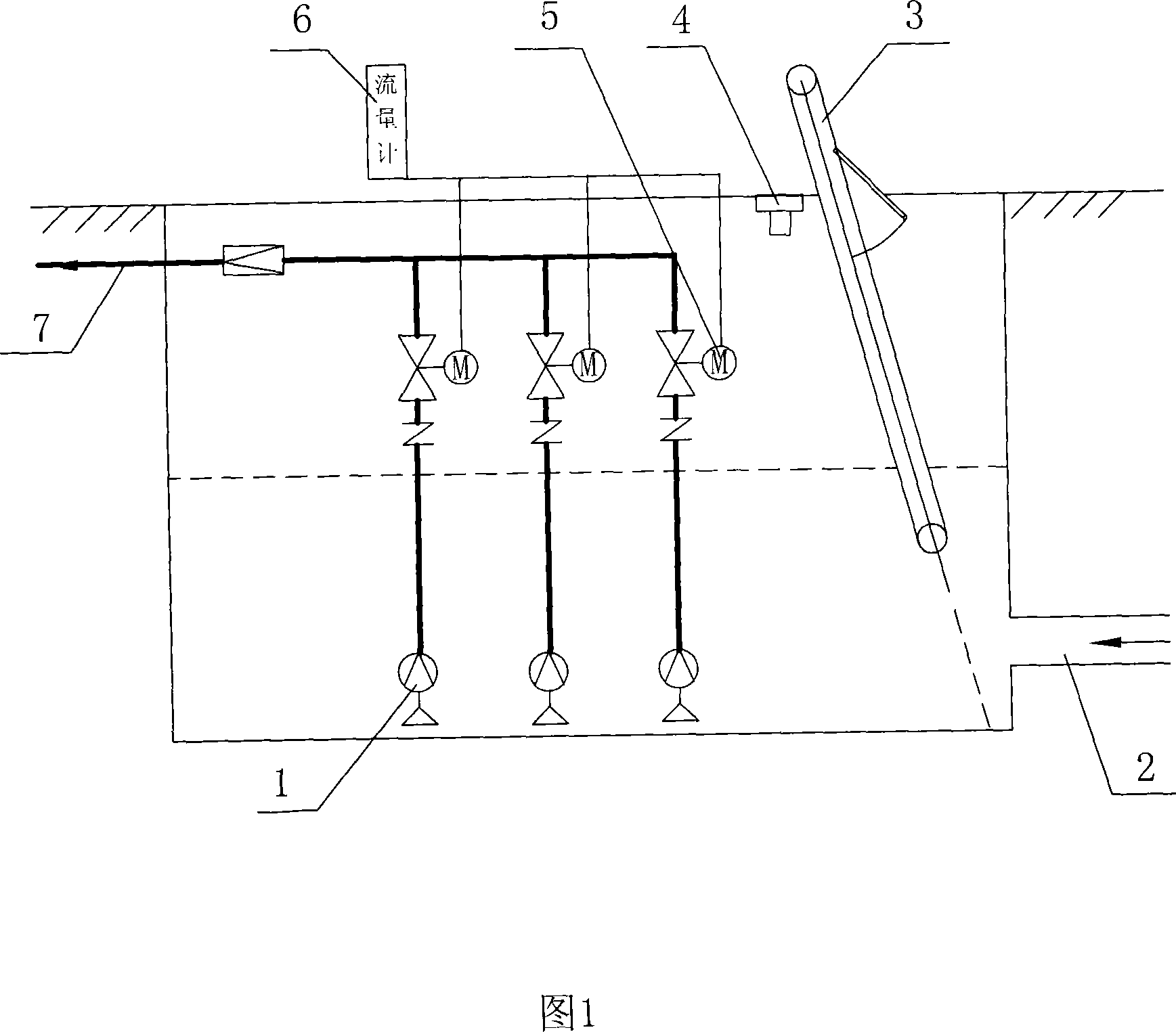

The level meter of this sewage pumping station monitoring system accesses PLC through the simulated volume input module, and PLC links with electric valves of different water pumps and electric switches of grating machines through the output module. The pump outlet is installed with the flow meter linking PLC. PLC reads the level data on real time, and starts or closes one or multiple pumps when reaching the set level, which initiates the pumps on sequence and the sequence regular rotation, and starts up the delay dislocation sequence when starting multiple pumps. According to the set time, PLC starts and stops grating machine regularly. PLC connects the server computer, and transmits the operating data of equipment, which can be started and stop manually without the impact of level. The server computer remotely connects the monitoring system computer, transmitting the operation data and alarming when abnormity happens.

Owner:陈金龙 +2

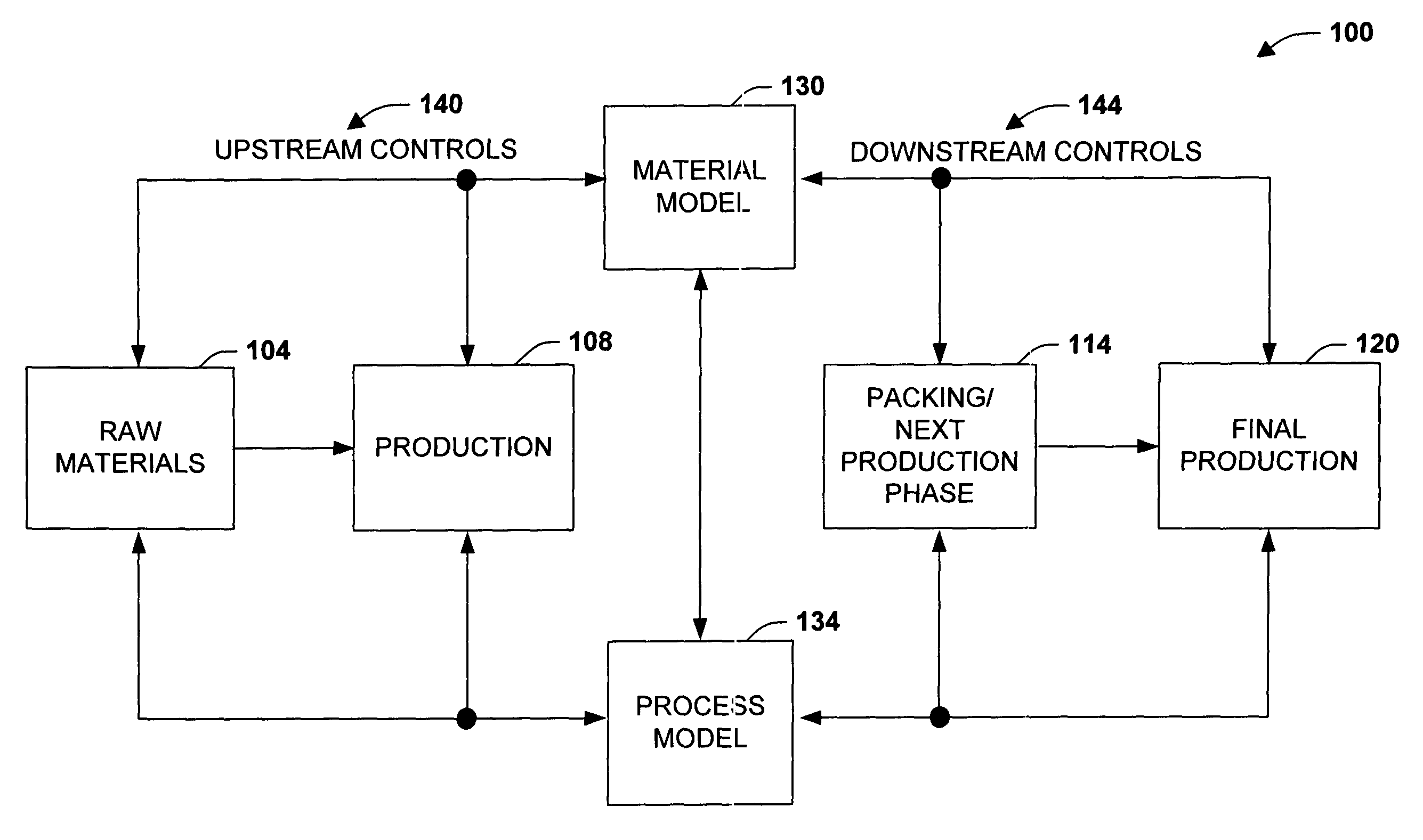

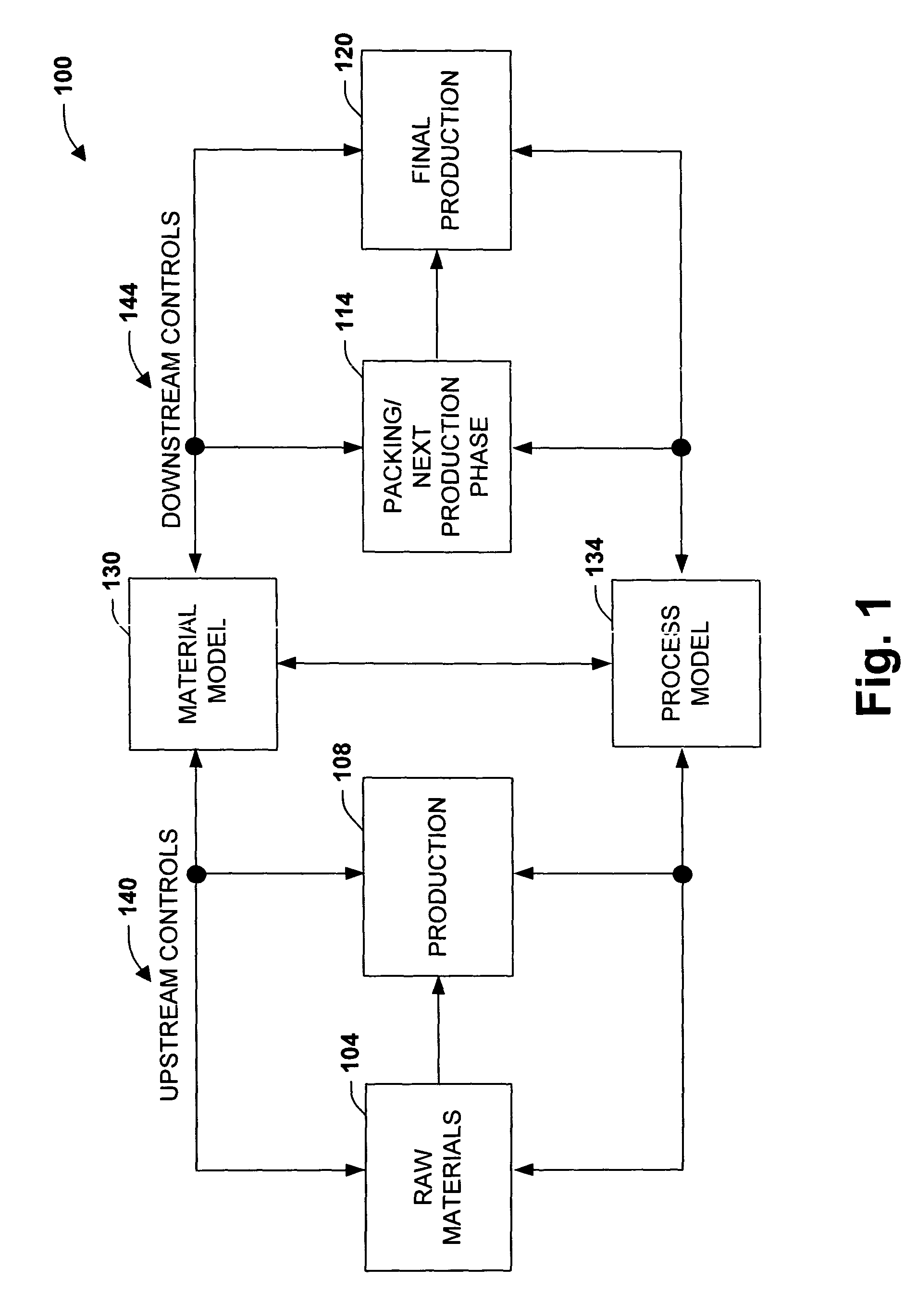

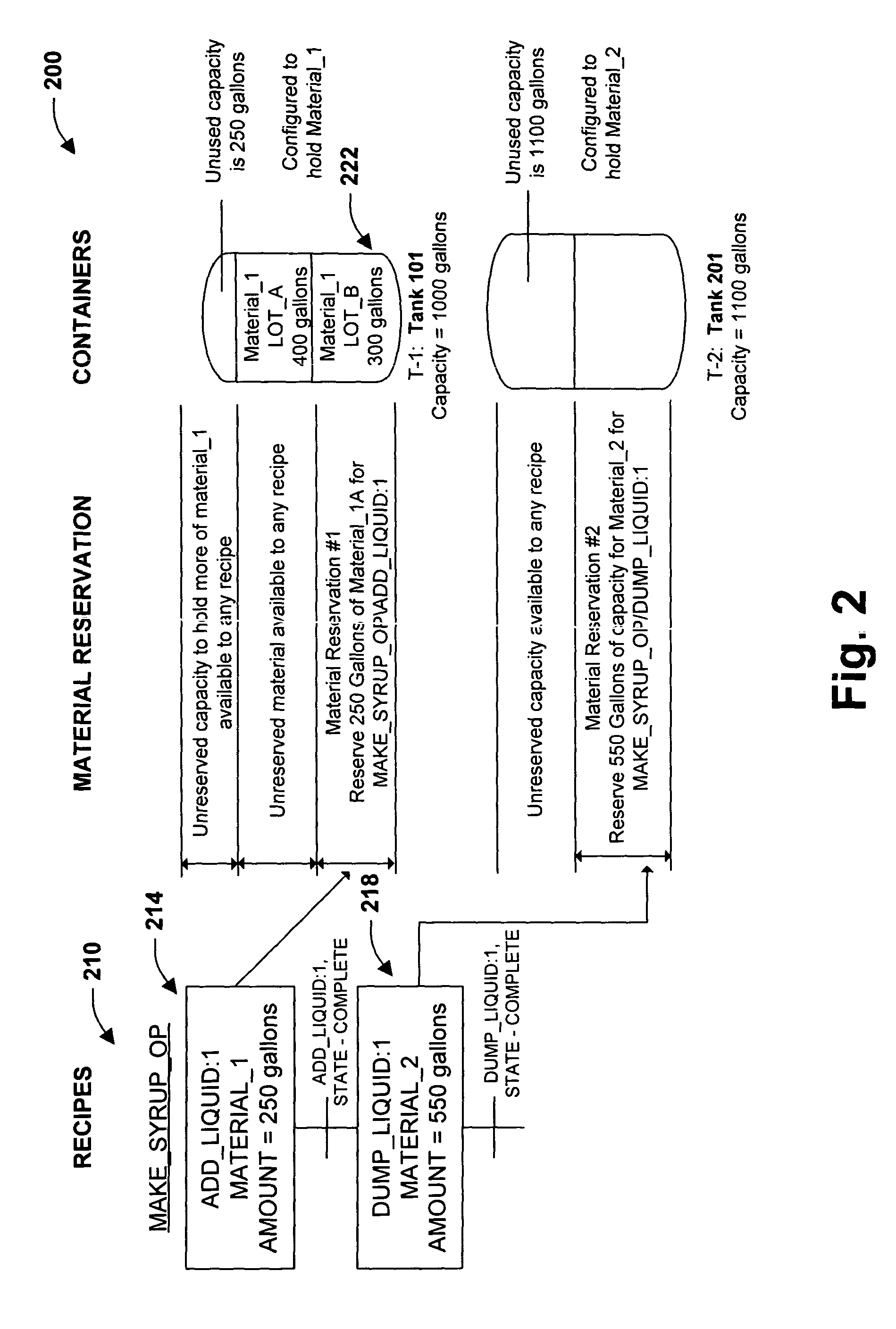

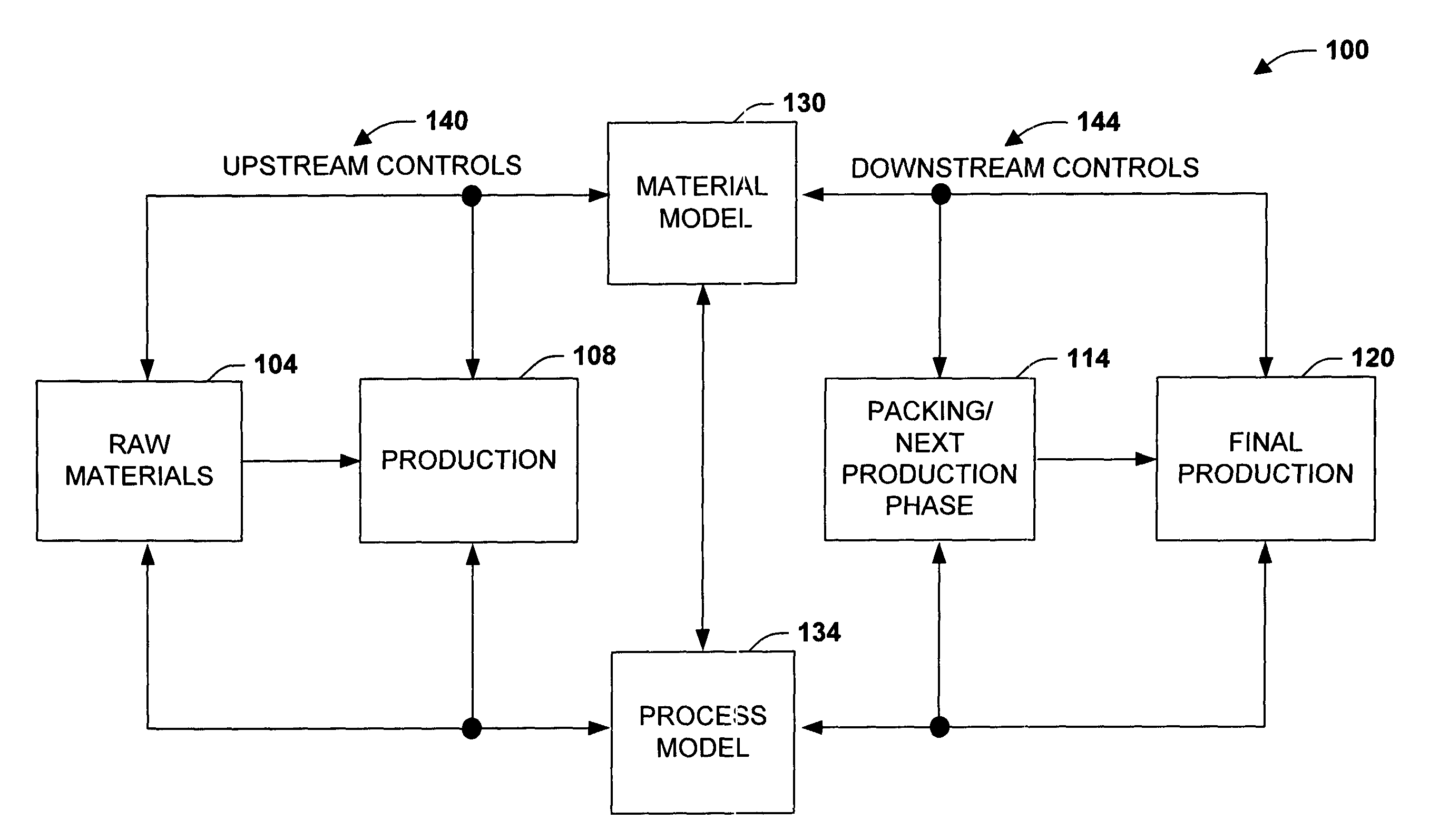

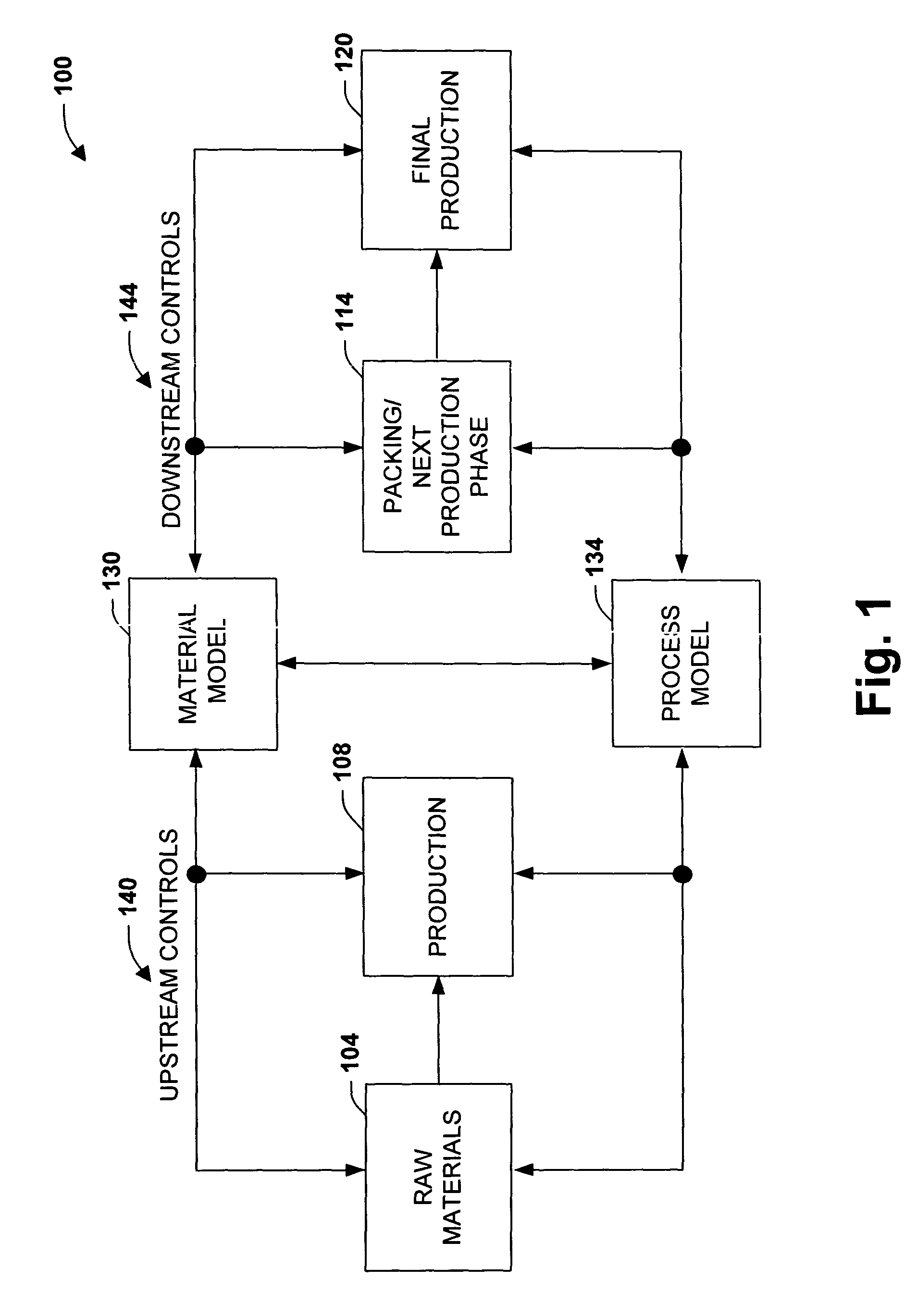

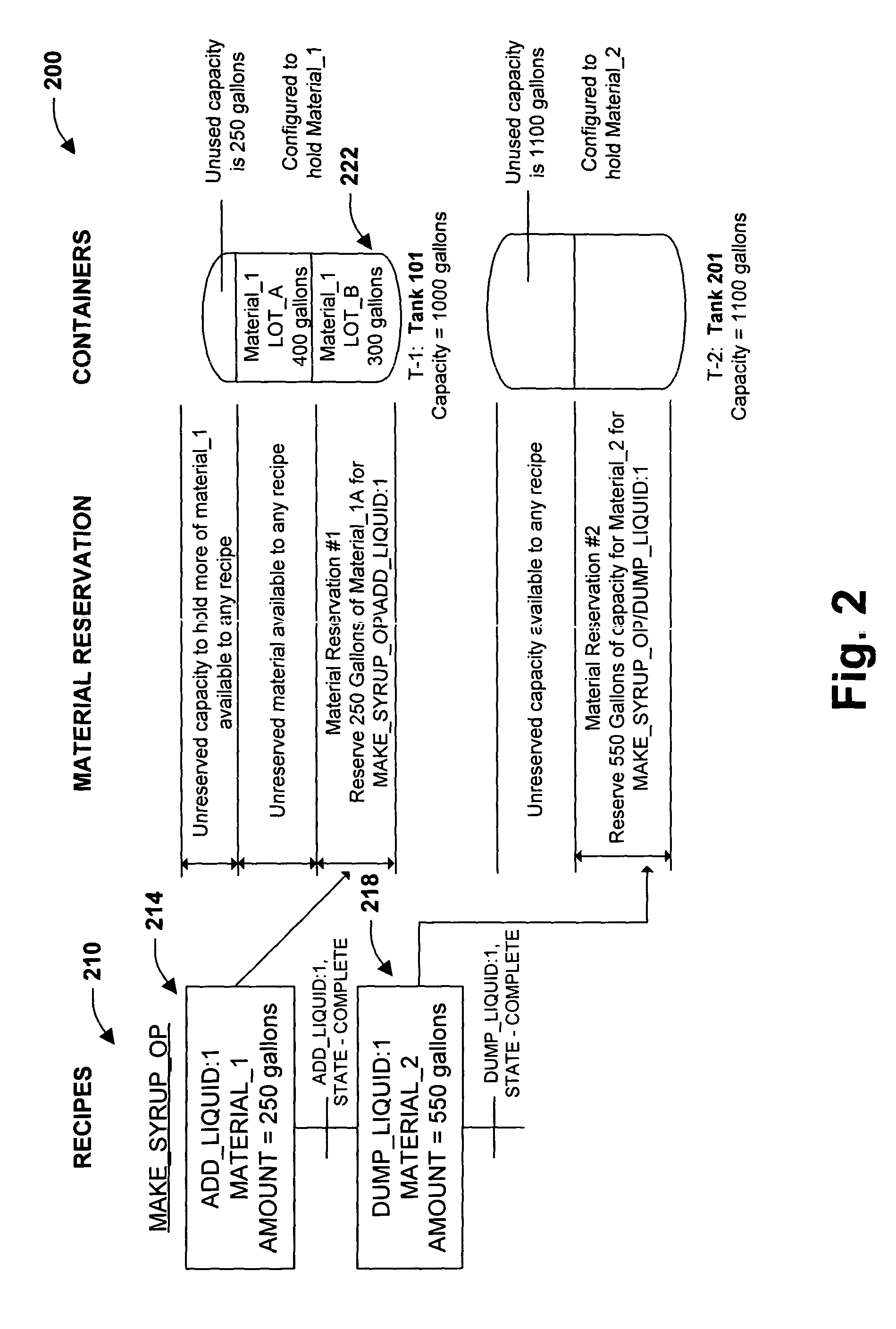

Material reservation distribution system and method

InactiveUS20050065626A1Easy to optimizeEfficient managementProgramme controlHand manipulated computer devicesBatch processingManufacturing operations

The present invention relates to a system and methodology facilitating material-driven processing in an industrial controller environment. Various models supported by database objects are provided to automatically and dynamically map inventory systems / processes to control systems / process such as in batch or recipe operations. A material model is provided that tracks to an inventory database and includes such aspects as defining material types and containers to house such materials. An area model maps the material model to possible units and equipment modules to process the materials. These models include phased-based parameters that define amounts of material that flow into and out of a determined area for processing the materials. Before, during and / or after automated manufacturing operations, object binding operations occur between material-based servers associated with an inventory system and batch servers associated with a process-control system. Such binding includes Just-In-Time or on-demand binding at run time, and relates material requirements of a recipe (or batch) to the units and equipment that are available to produce the recipe.

Owner:ROCKWELL AUTOMATION TECH

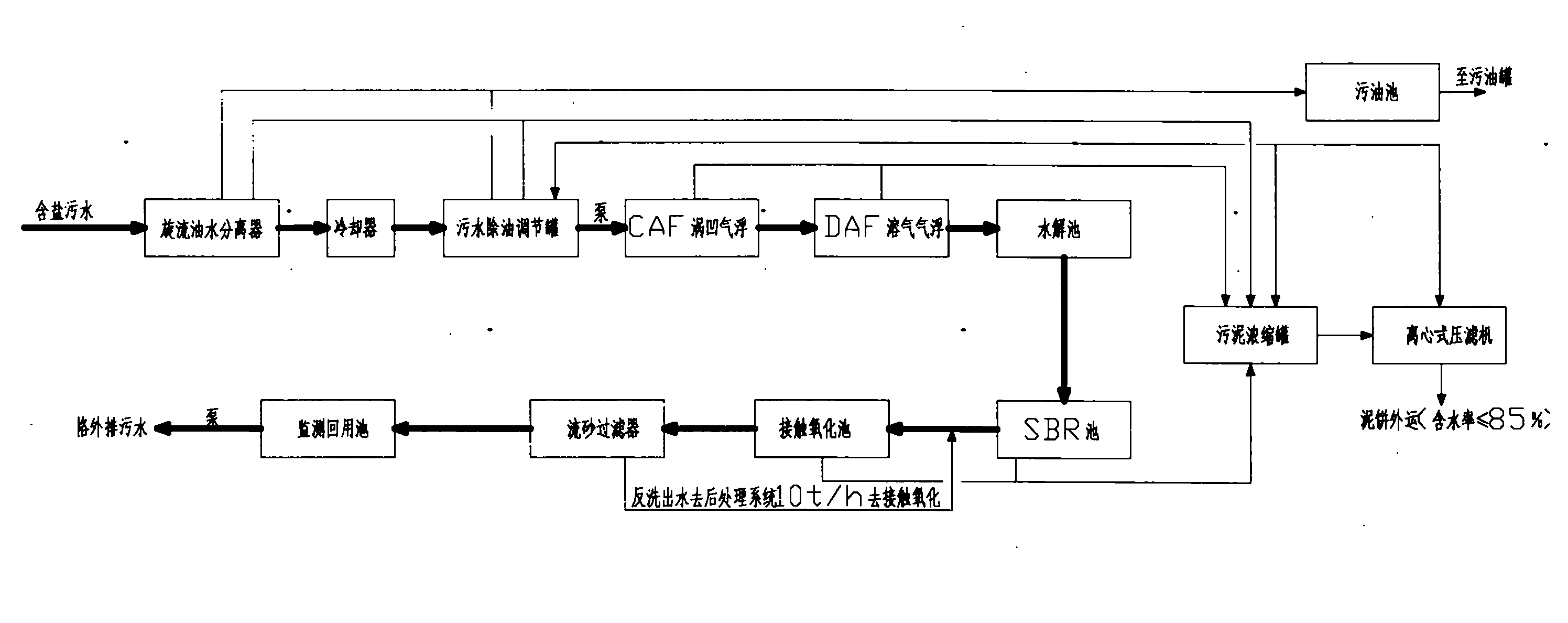

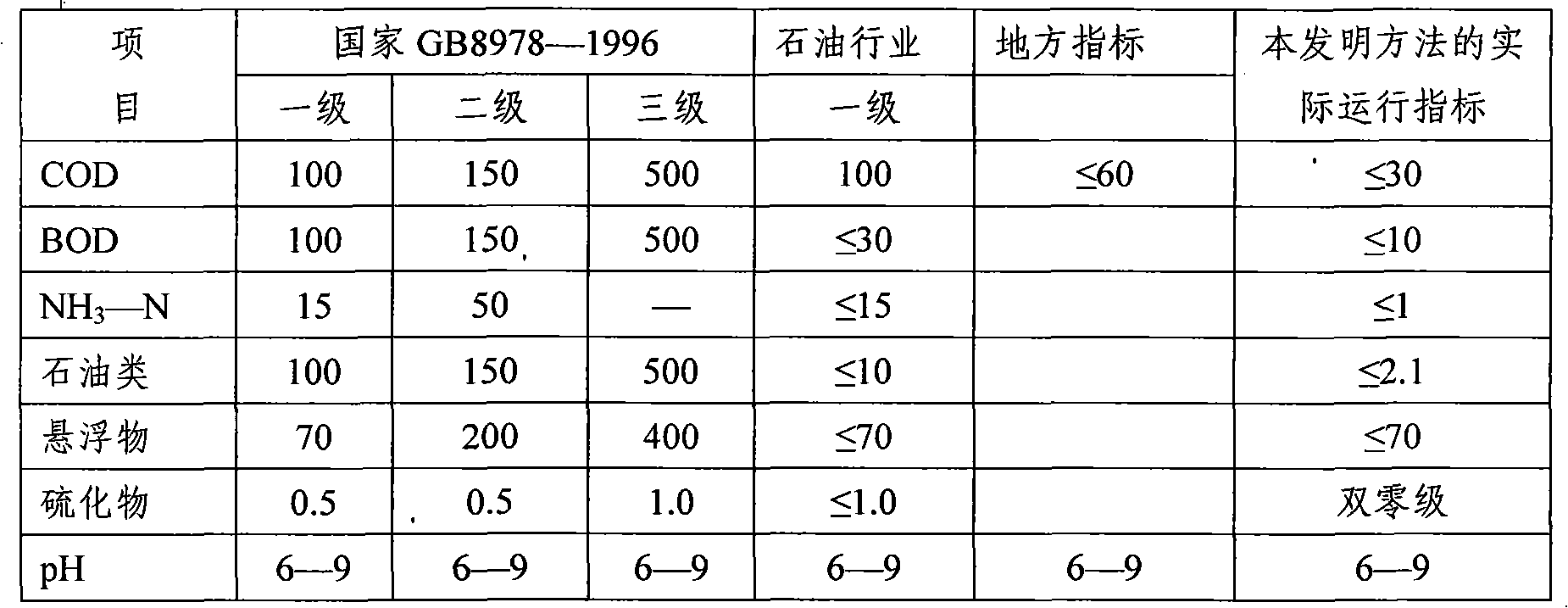

Method for treating petroleum refining waste water

InactiveCN101870544AEasy to handleHigh implementabilityTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentTechnical standardEmission standard

The invention relates to a method for treating petroleum refining waste water. The method for treating petroleum refining waste water comprises the steps of a gravity oil-separating unit, a two-stage air floatation treatment unit, an anaerobic and aerobic two-stage biochemical treatment unit, a biochemical posttreatment unit and the like. Through the analysis of the specific implementation effect, the technical implementation effect of the method is much more excellent than the conventional technical standards. Compared with the prior art, the treatment effect of the method is obviously more excellent than the traditional process method; qualitative improvement on the quality of the treated water is achieved; the current newest national and local emission standard is completely met; and therefore, the method has a very wide application prospect.

Owner:大庆市新中瑞环保有限公司

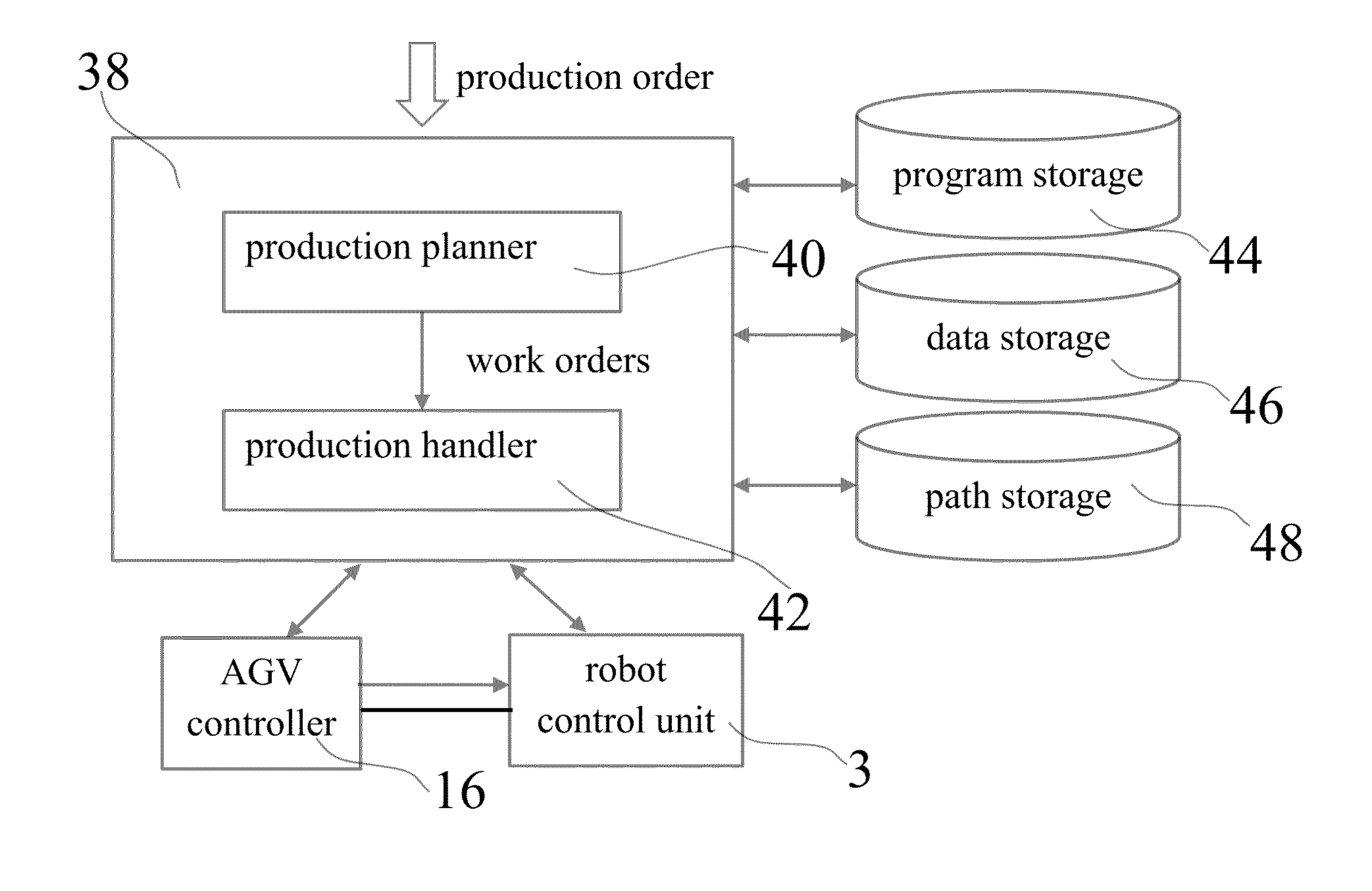

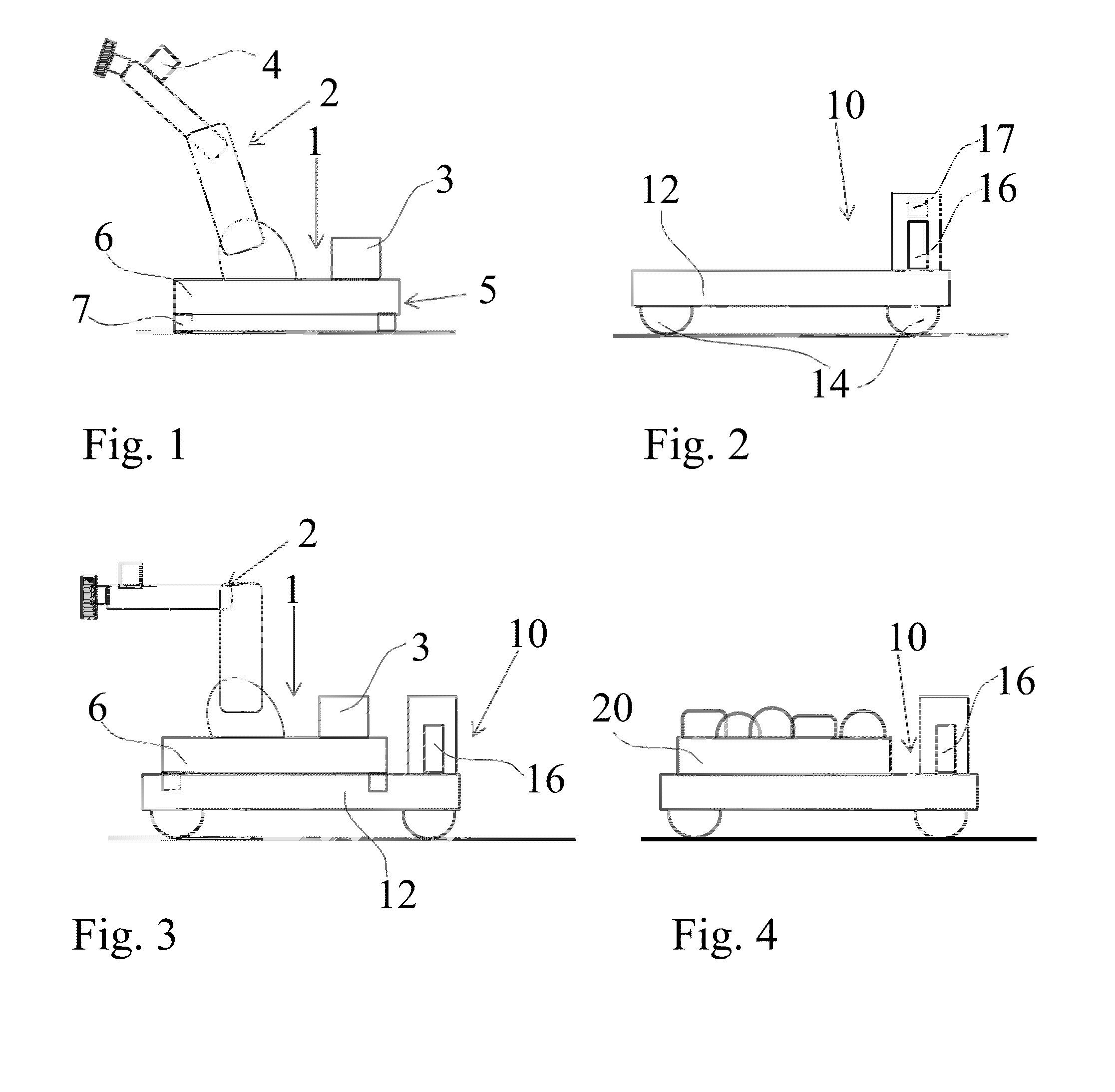

Automation system and a method for tending a production system

InactiveUS20150316925A1Improve efficiencyIncrease profitProgramme-controlled manipulatorElectric/hybrid propulsionWorkstationMobile manipulator

The present invention relates to an automation system for tending a production system comprising a plurality of workstations for producing products. The automation system comprises a mobile manipulator (2) adapted to perform work at the workstations, and an automatic guided vehicle (10), in the following named an AGV, arranged to move the manipulator between the workstations. The AGV and the manipulator are designed as two separate units, which can be positioned and moved independently of each other, and the AGV is arranged to supply the workstations with material needed for producing the products while the manipulator is carrying out work at one of the workstations.

Owner:OPIFLEX AUTOMATION

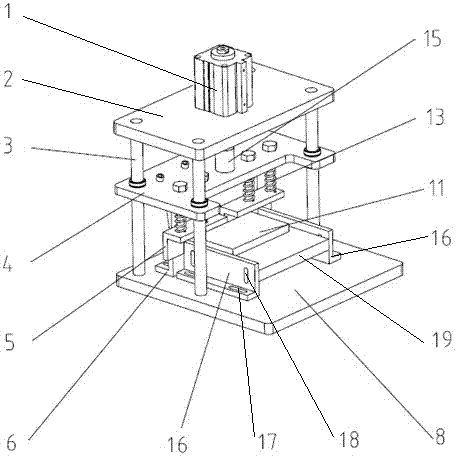

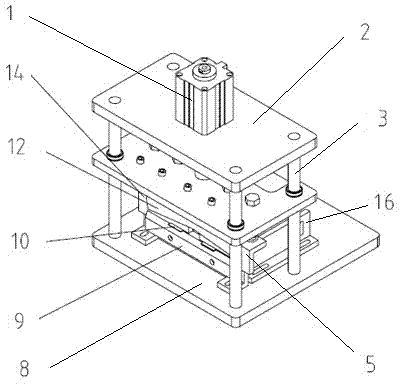

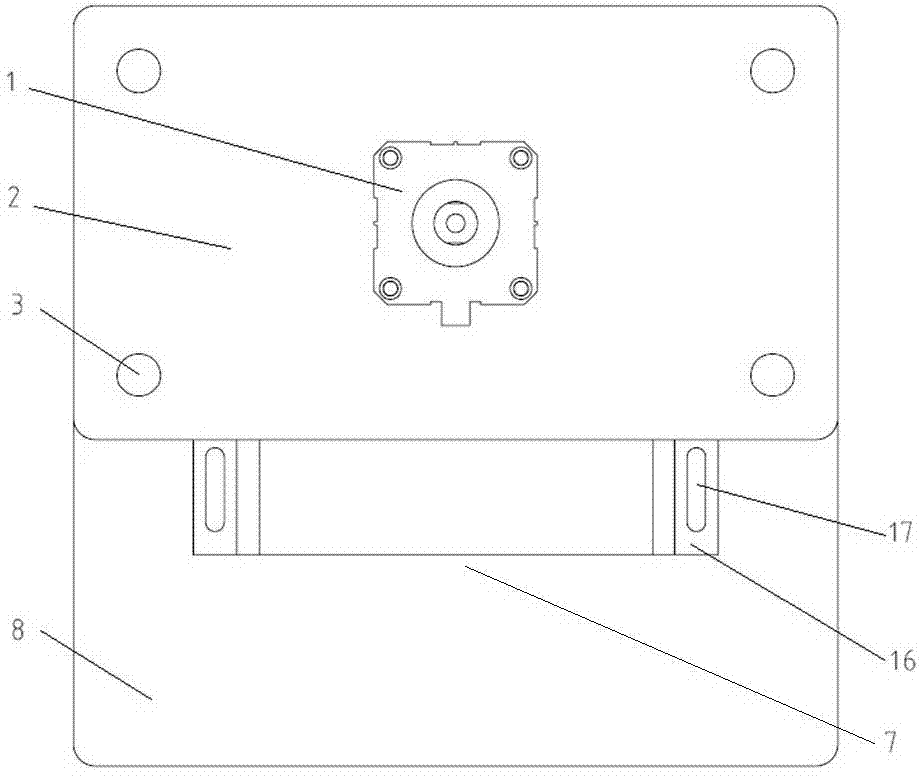

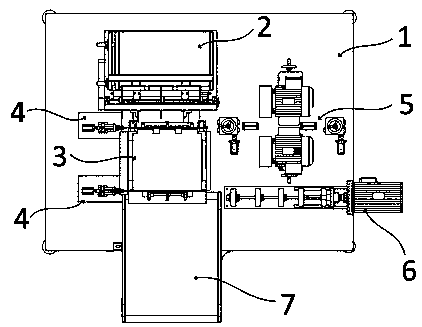

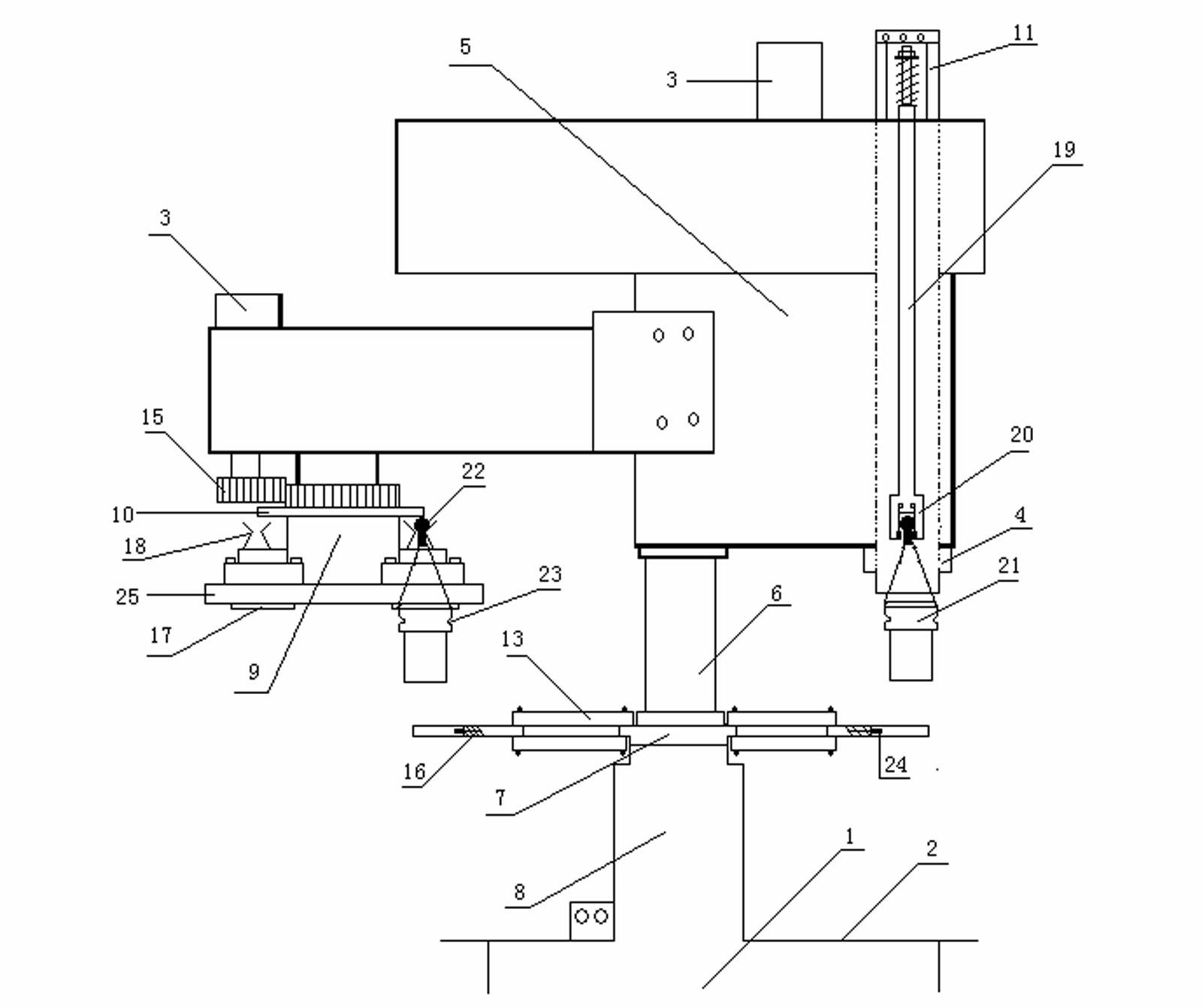

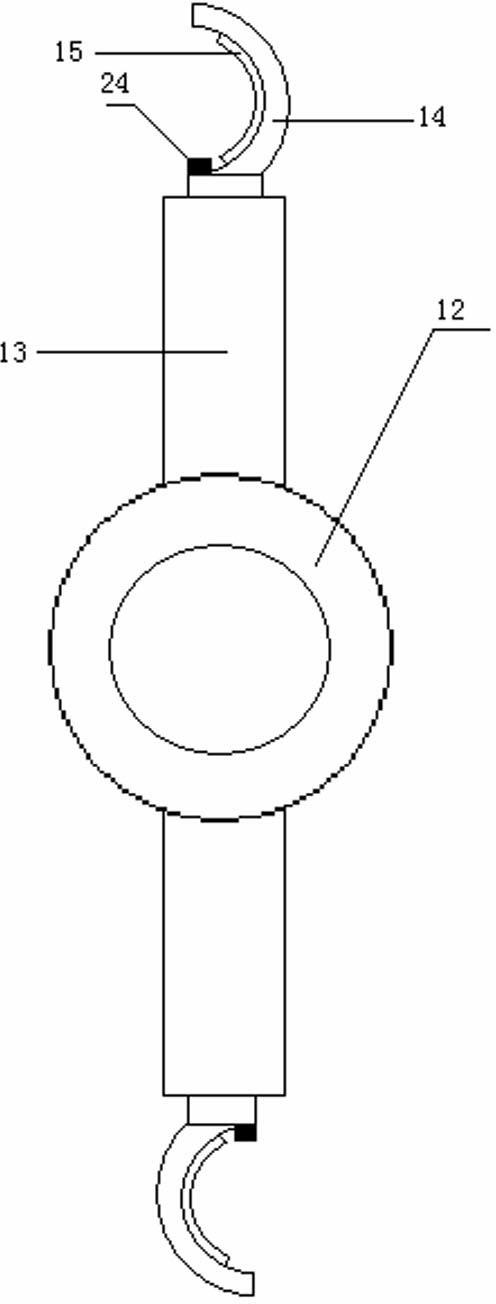

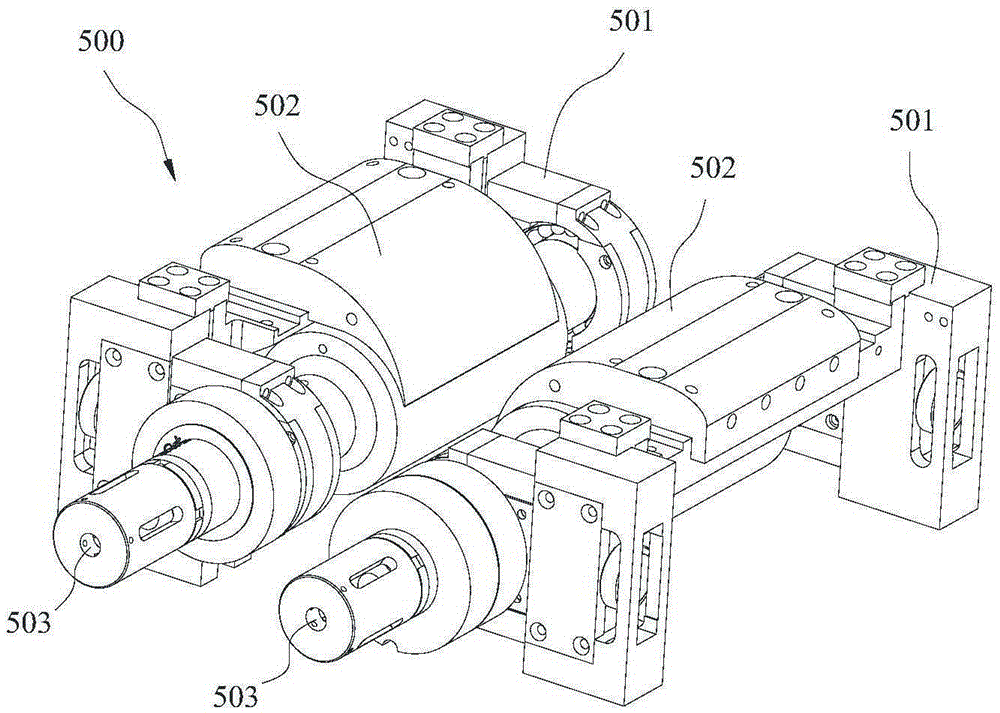

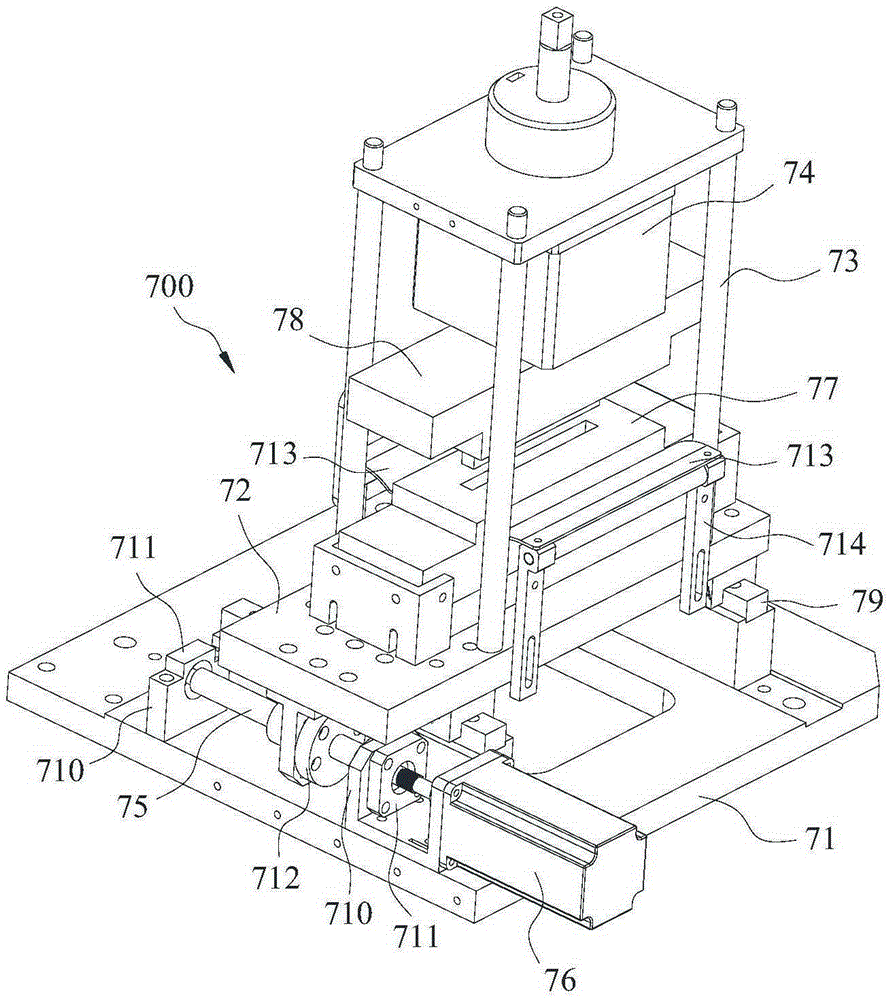

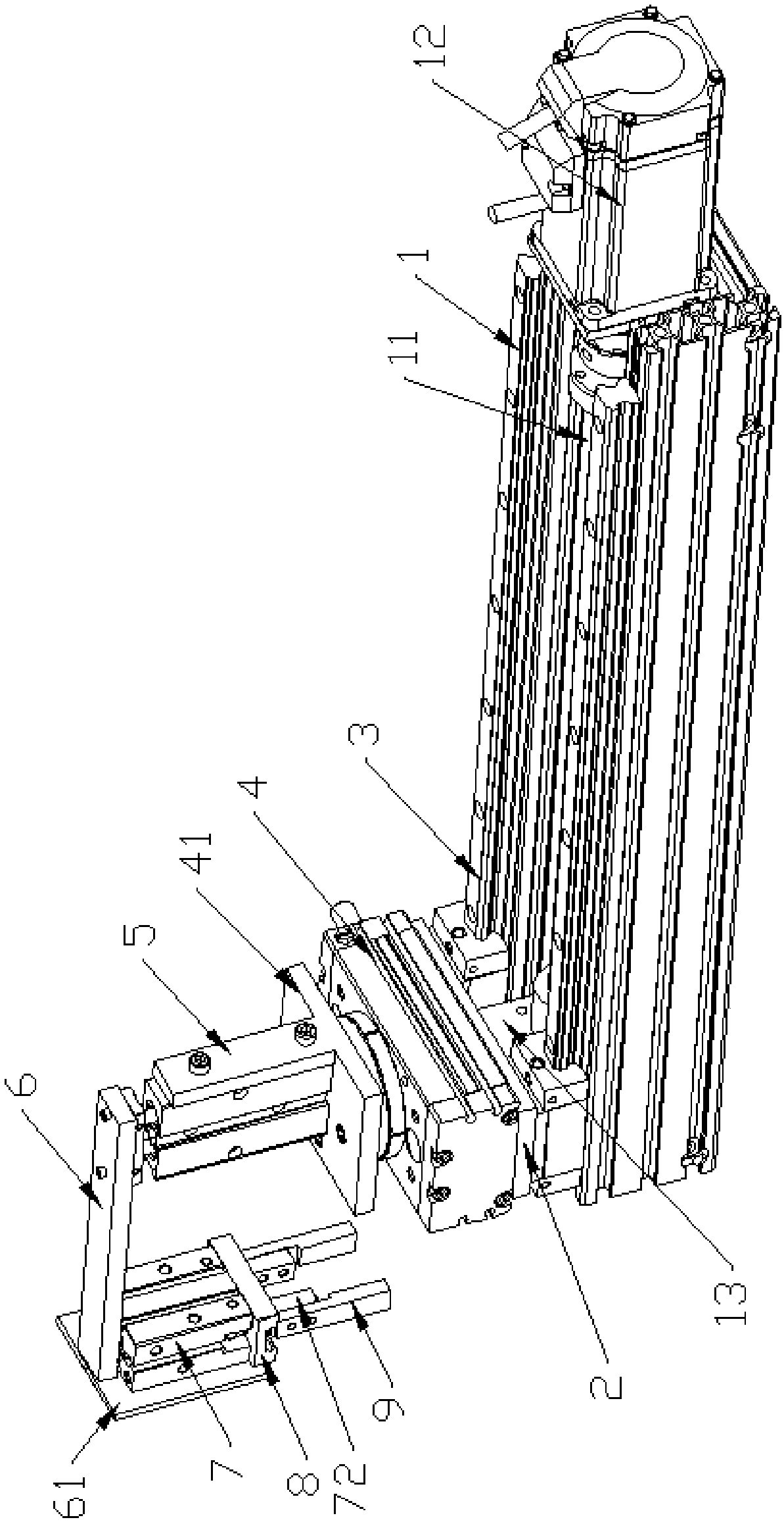

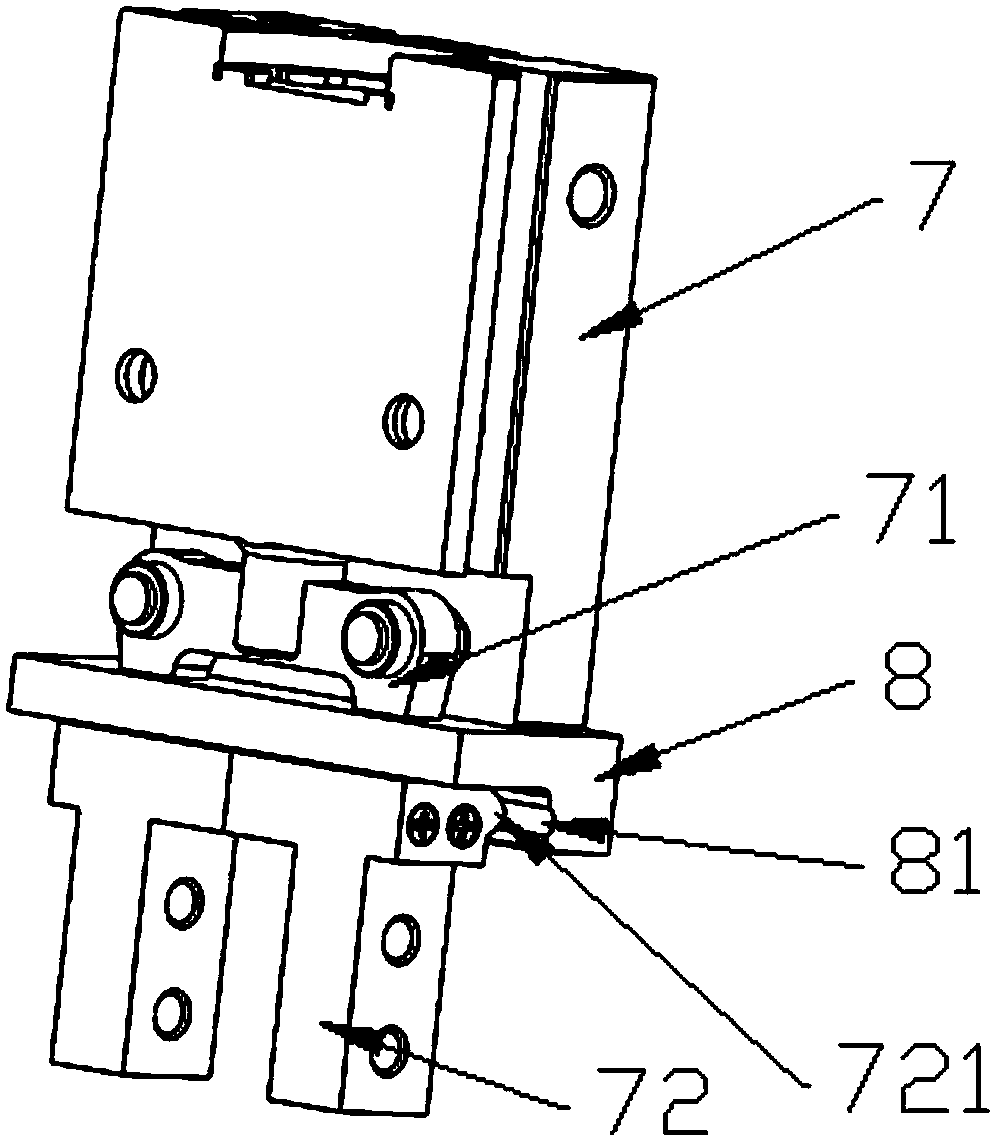

Tab cutting device of lithium battery core and tab cutting equipment using tab cutting device

ActiveCN102873390AIncrease profitHigh automation efficiencyShearing machinesShearing machine accessoriesPower batteryElectrical battery

The invention relates to the field of manufacturing of lithium ion power batteries, in particular to a tab cutting device of a lithium battery core and tab cutting equipment using the tab cutting device. The tab cutting device of the lithium battery core comprises a driving mechanism and a tab compressing component, wherein the driving mechanism is used for driving an upper cutter to move up and down; the tab compressing component compressing component comprises a lower cushion block and an upper compressing block; the upper compressing block vertically corresponding to the lower cushion block is arranged on the driving mechanism; the upper compressing block and the upper cutter can move together up and down; a compressible elastic supporting device is arranged between the upper compressing block and the driving mechanism; or the tab cutting device of the lithium battery core is provided with a guide device, an elastic reset device, a jacking mechanism and an elastic supporting device; the guide device is used for guiding the upper compressing block to move up and down; the elastic reset device is used for providing upward elastic support for the upper compressing block; the jacking mechanism is arranged on the driving mechanism in a guide motion manner and can downwards jack the upper compressing block; and the elastic supporting device is arranged between the jacking mechanism and the driving mechanism. By adoption of the scheme, a tab can be automatically compressed in the downcutting process of the cutter.

Owner:中创新航科技(江苏)有限公司

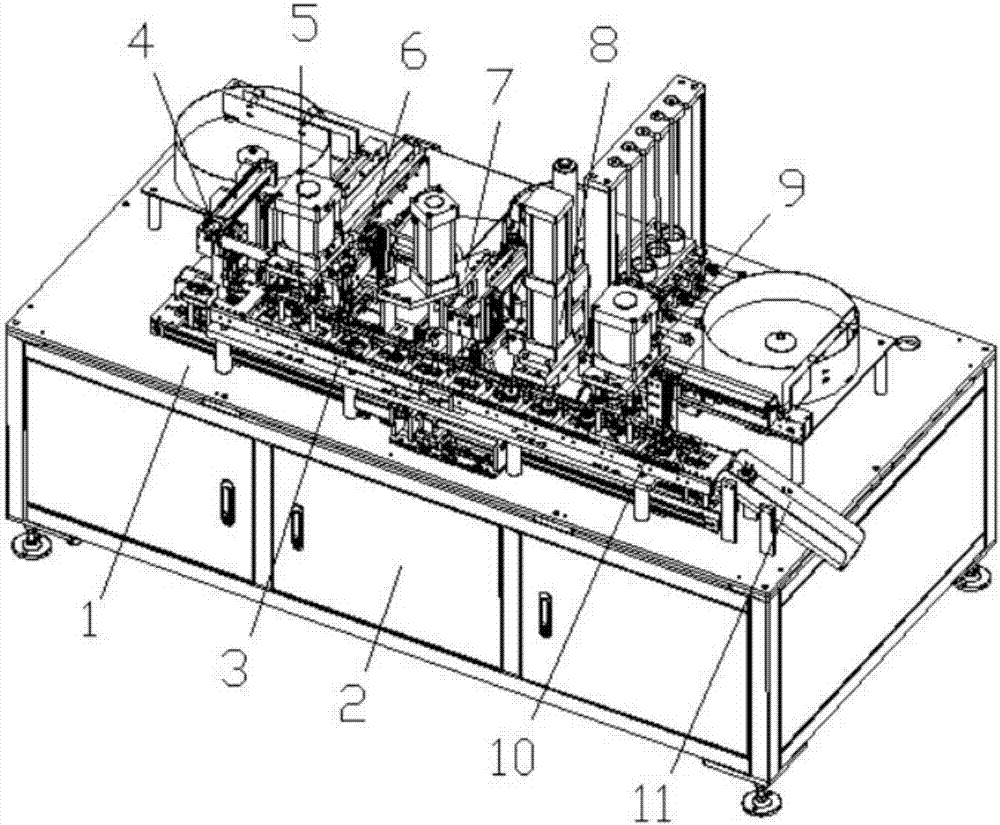

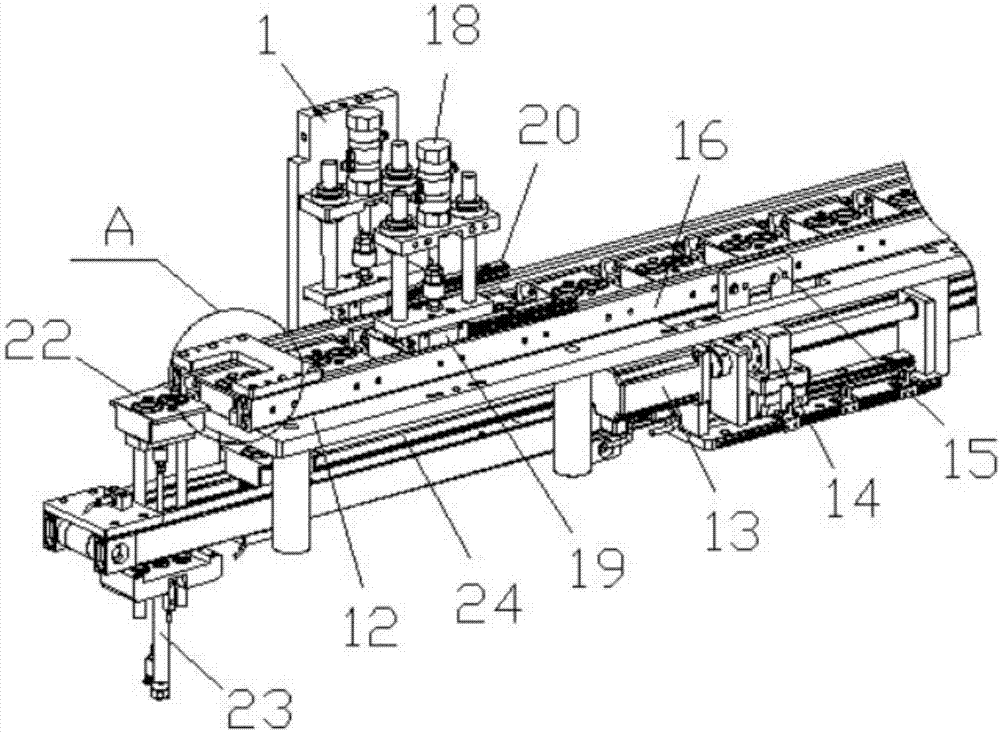

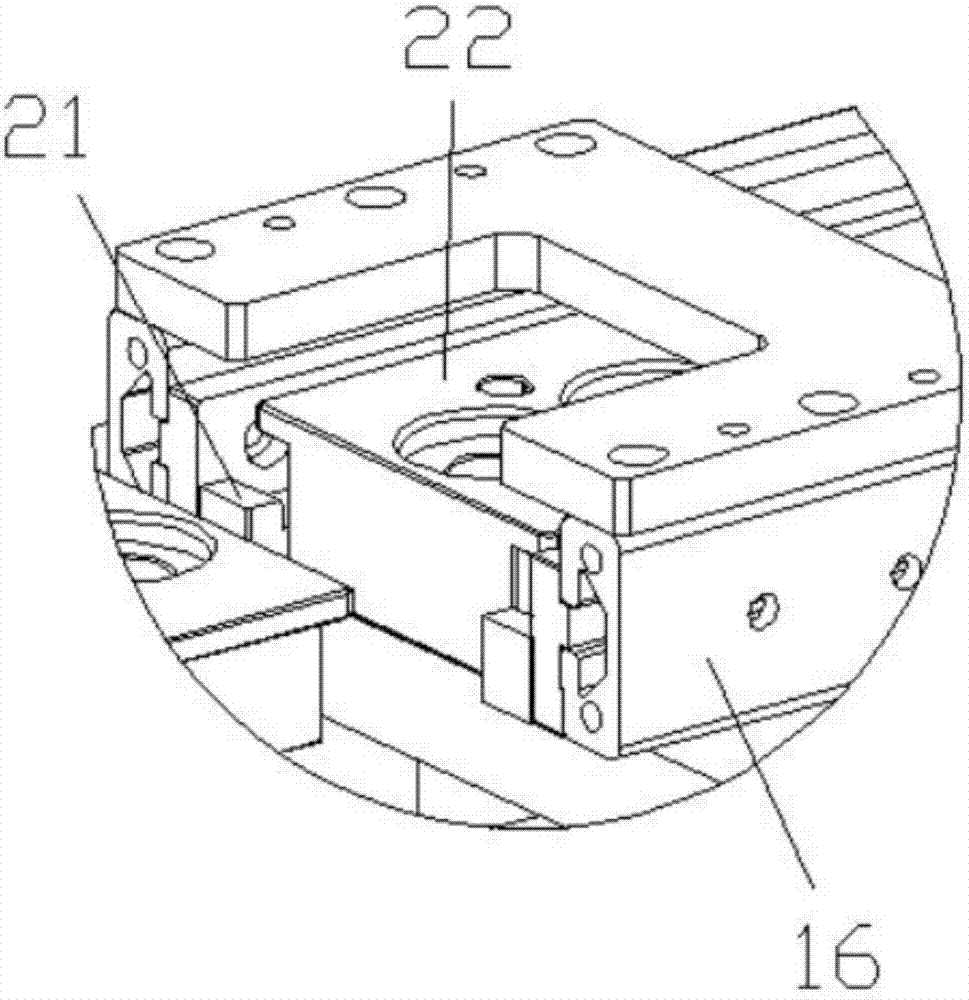

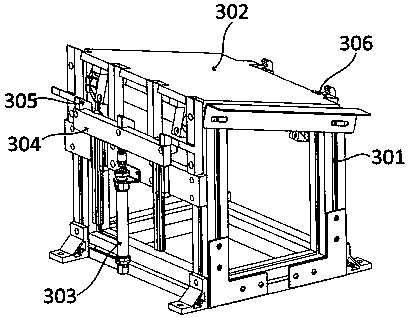

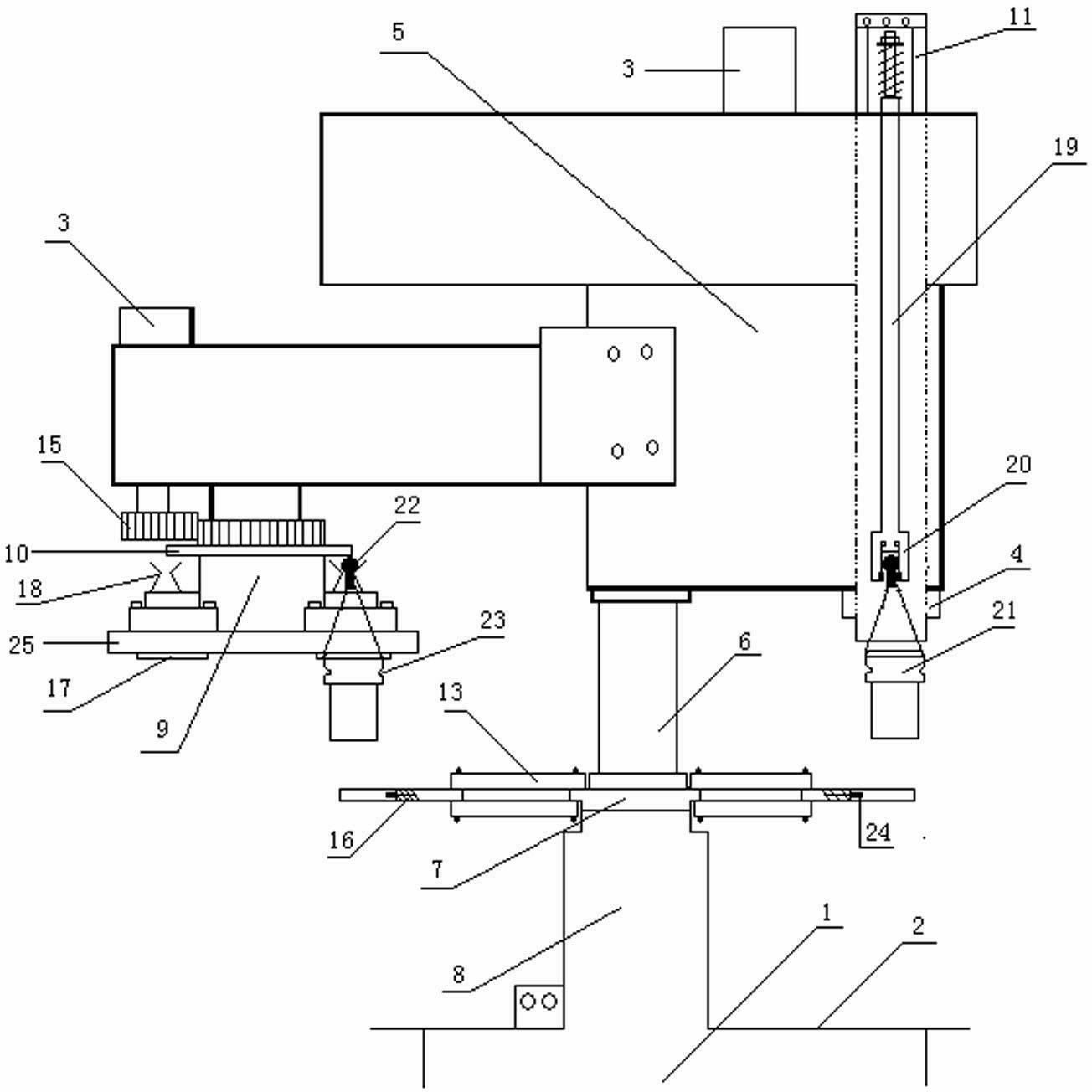

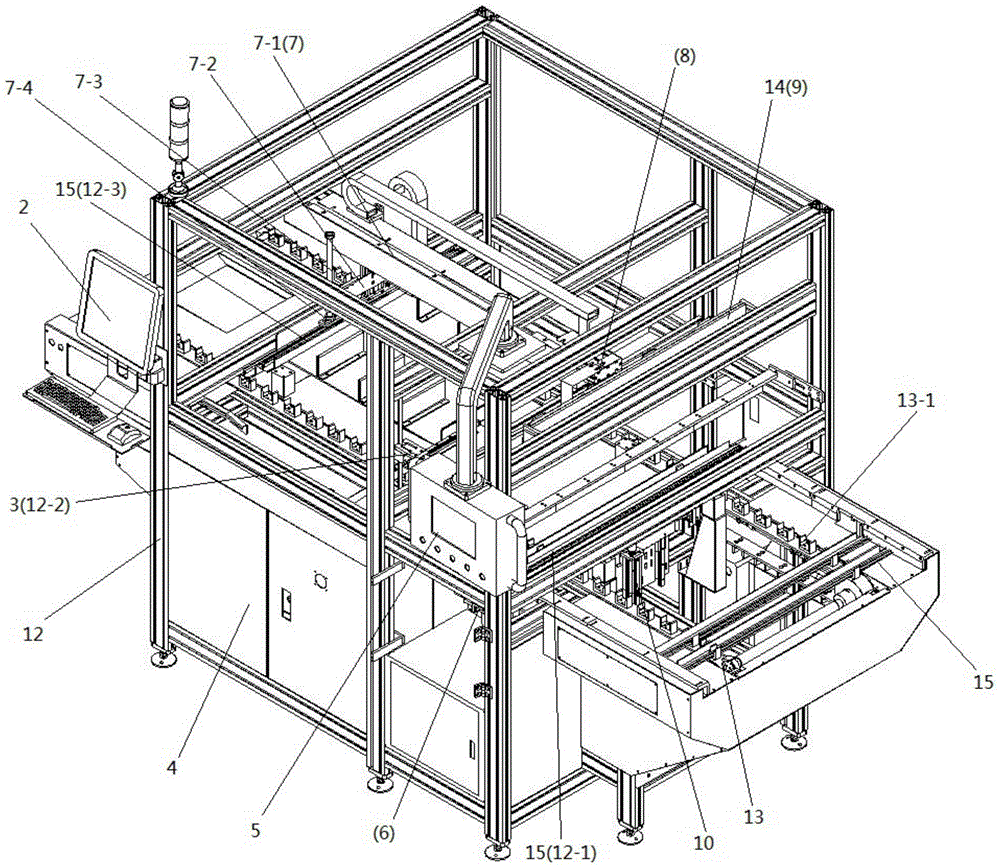

Automatic gear shaft assembling machine

InactiveCN107571008AHigh matching precisionImprove assembly efficiency and yieldAssembly machinesManipulatorBall bearing

The invention relates to an automatic gear shaft assembling machine. The rack is provided with a carrier conveying device. The carrier conveying device comprises a carrier conveying base. Carrier feeding movable air cylinders are arranged on the front side and the rear side of the carrier conveying base and connected with a carrier feeding movable base. The carrier feeding movable base is connected with a carrier feeding movable block. A carrier feeding clamping block matched with a carrier is arranged on the inner side of the carrier feeding movable block. A carrier feeding lifting matched sliding rail is arranged at the upper portion of the carrier feeding movable block and matched with a carrier feeding lifting matched sliding block. The upper portion of the carrier feeding lifting matched sliding block is matched with a carrier feeding lifting air cylinder on the rack. The rack is provided with a ball bearing feeding device, a shaft rod feeding device, an overturning device, a clamping ring feeding device, a gear feeding device, a clamping bearing feeding device and a discharging mechanical arm. According to the automatic gear shaft assembling machine, automatic ball bearing and shaft rod assembling can be achieved, and the assembling efficiency and the yield are greatly improved.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

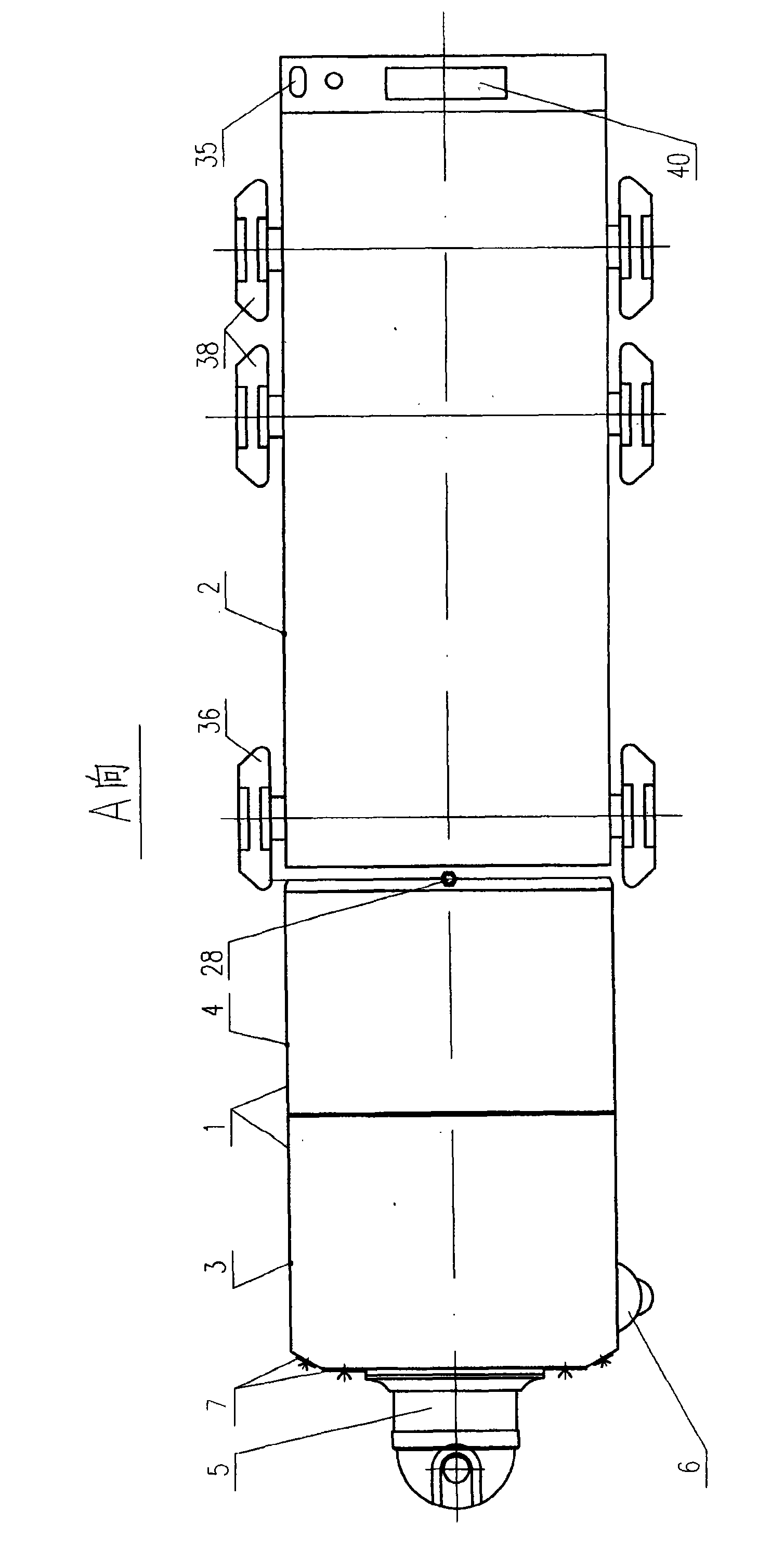

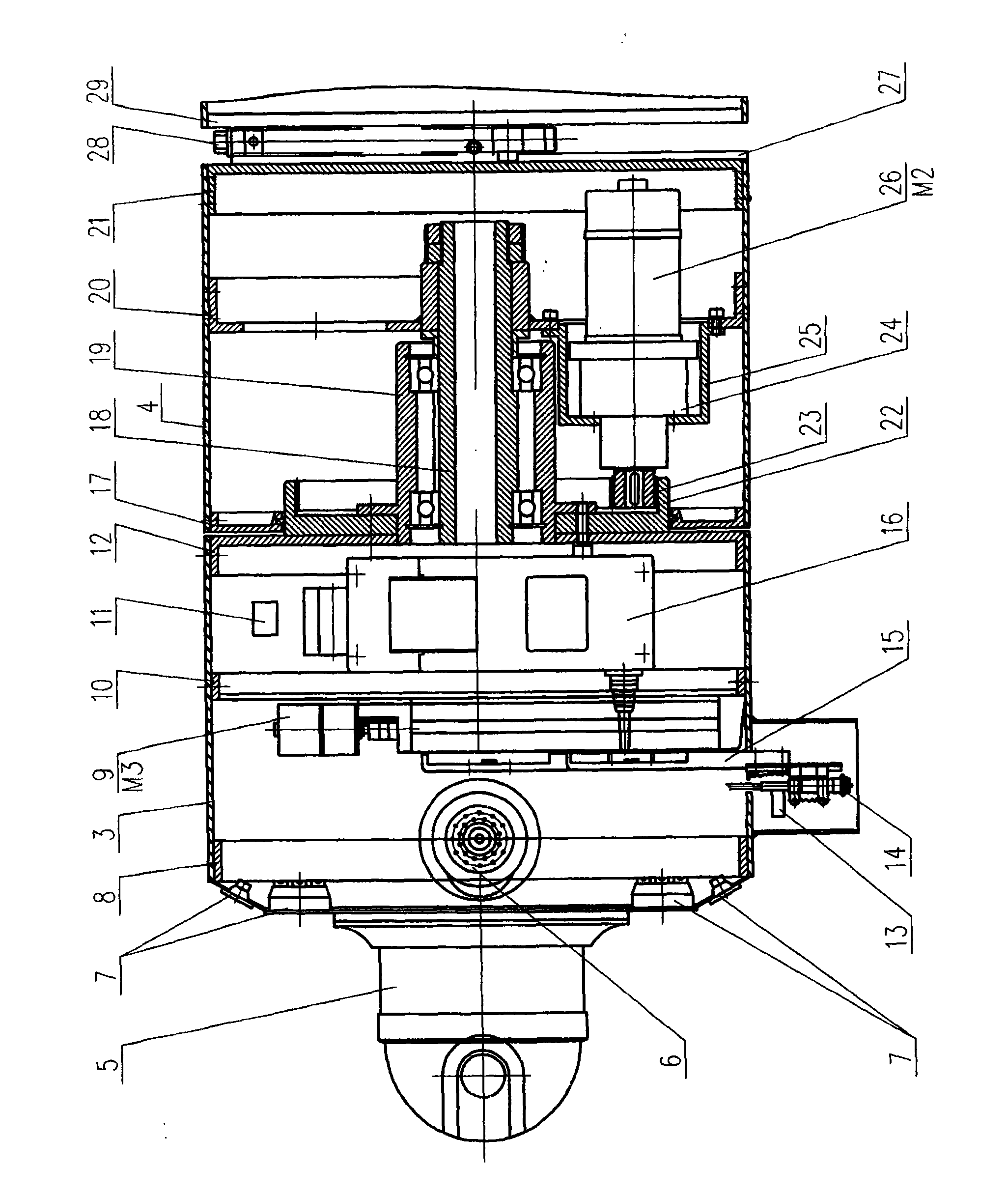

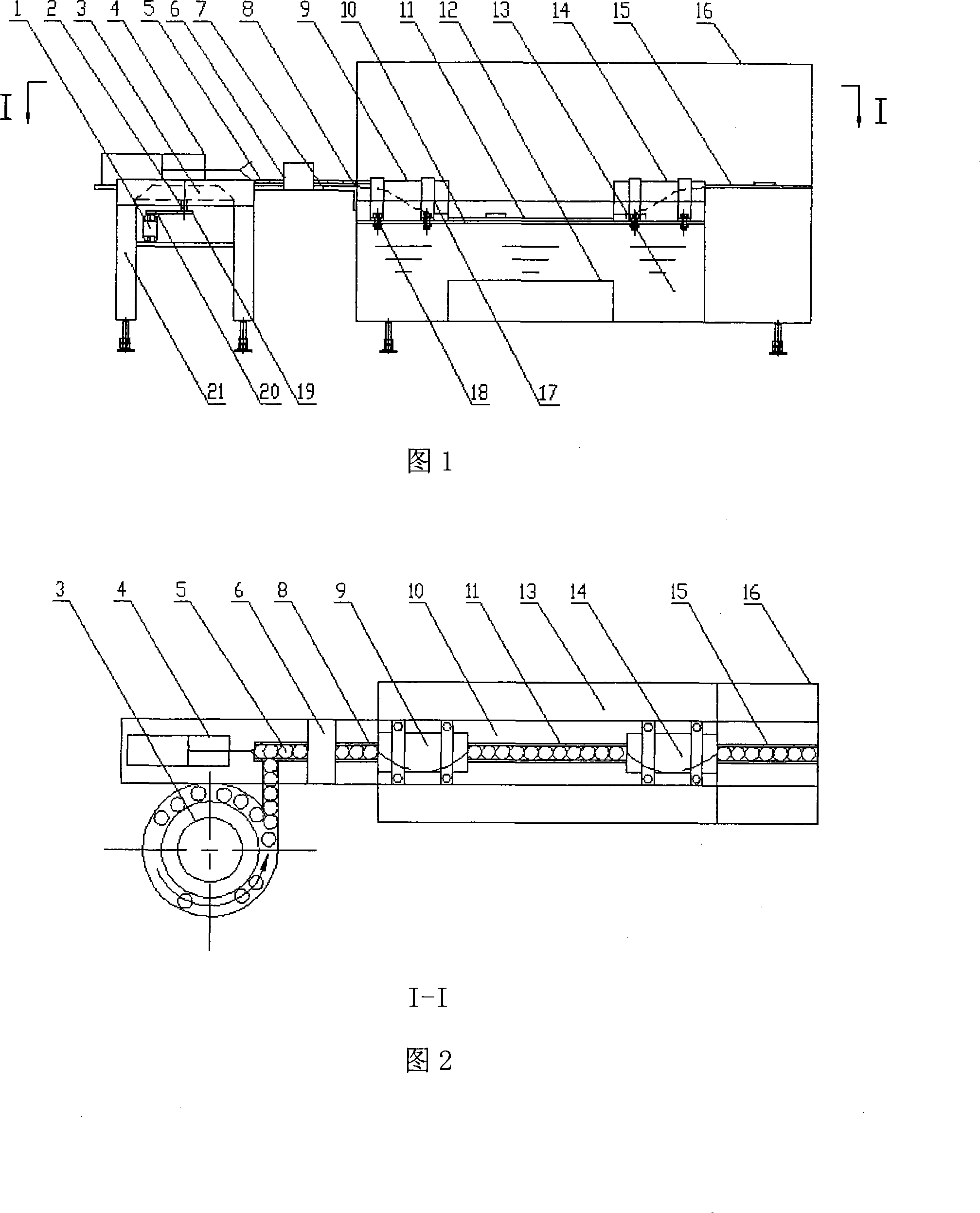

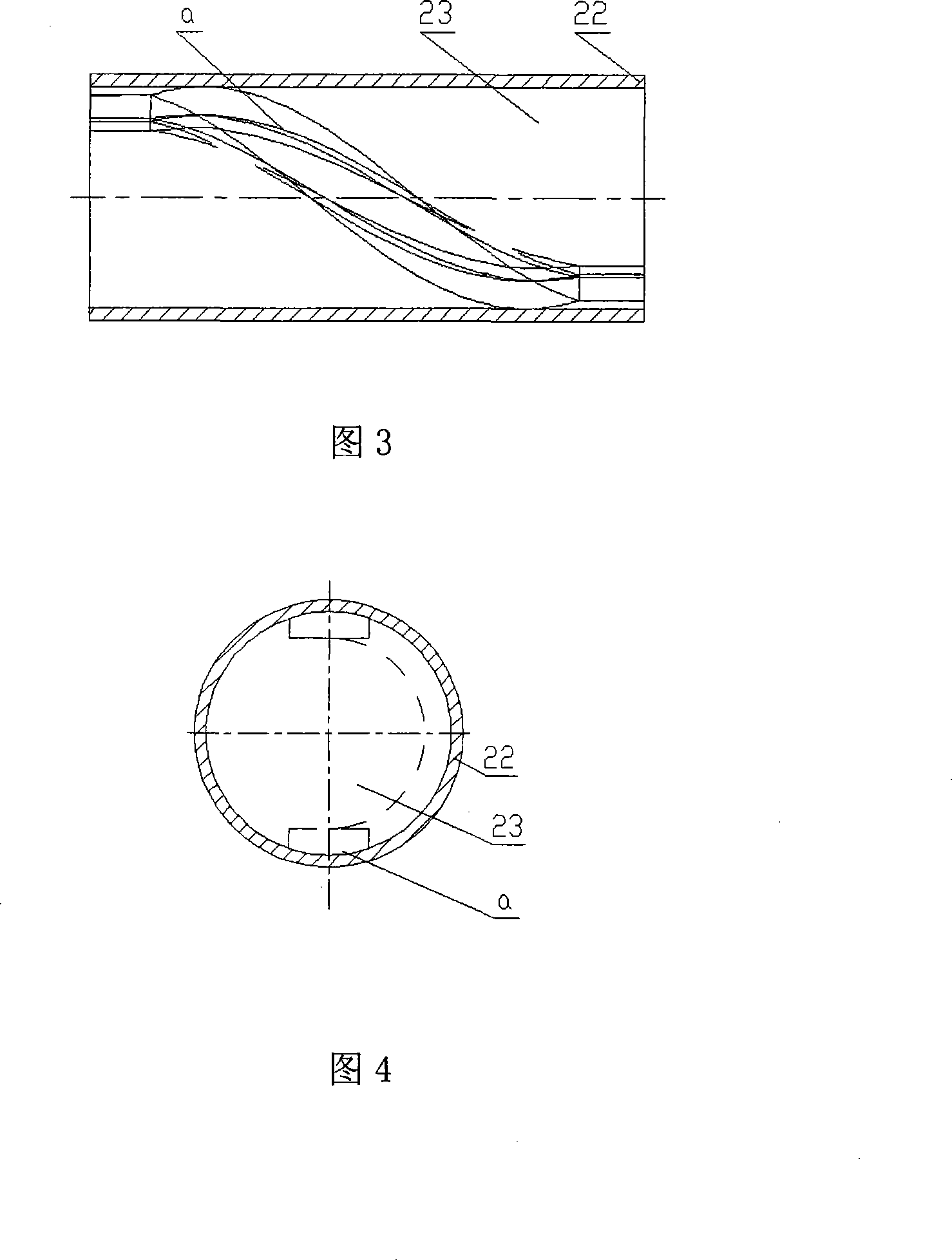

Automatically detecting machine for antirust coating in pipeline

ActiveCN101539415AFully functional wireless remote controlCompact structureNon-electrical signal transmission systemsMaterial analysis by optical meansDrive wheelOn board

The invention relates to an automatically detecting machine for an antirust coating in a pipeline, which belongs to the field of thickness measurement and detection for a metal surface coating. The automatically detecting machine comprises a detecting machine head, a drive machine body and a wireless remote controller, wherein the detecting machine head consists of a rotating part of a front half part and a fixed part of a rear half part; the rotating part of the machine head consists of a front camera, a lateral camera, an illuminating lamp and a thickness gauge; the fixed part of the machine head consists of a motor, a speed reducer, a hollow shaft, a shaft bush, a gear and an inner toothed ring; and a walking motor, a contracting brake, a speed reducer, a gear box and a driving wheel of the machine body part are arranged on the rear half part, and an on-board remote control box, a battery set and a driven wheel are arranged on the front half part. The automatically detecting machine is wirelessly and remotely controlled to walk in a pipe so as to detect coating defects and measure the coating thickness, and wirelessly transmits real-time images to a display outside the pipe, thereby achieving the man-machine conversation. The whole automatically detecting machine has compact structure, reasonable arrangement, smooth operation, reliable working and high automation efficacy. The automatically detecting machine is integrated pipeline construction innovative equipment of machinery, electron, communication and optics and has popularization and application prospects.

Owner:QINGDAO BEIHAI PETROLEUM EQUIP TECH

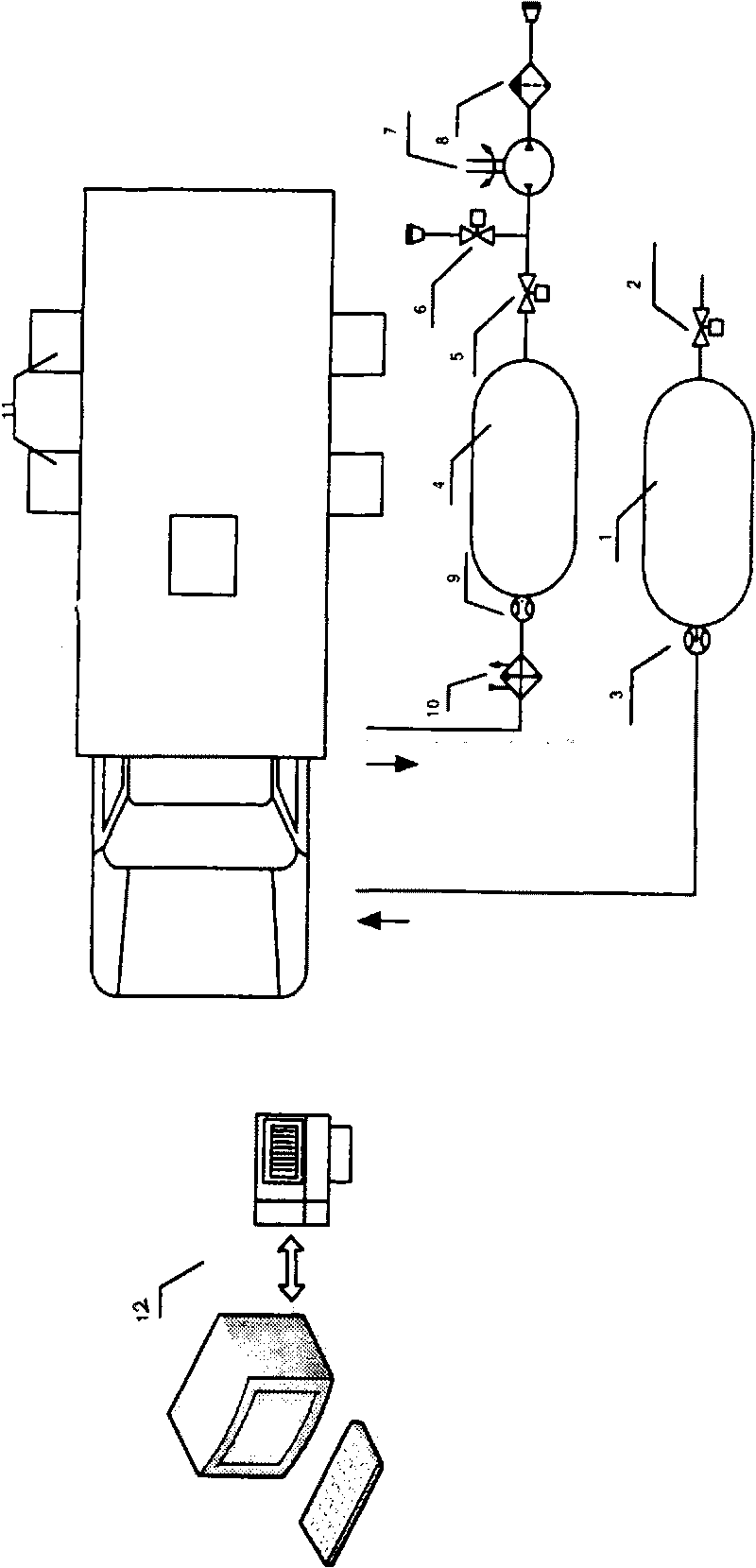

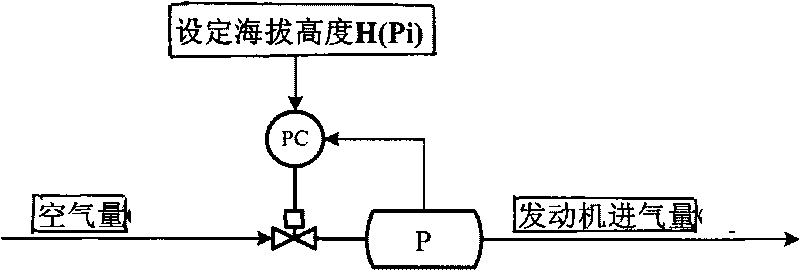

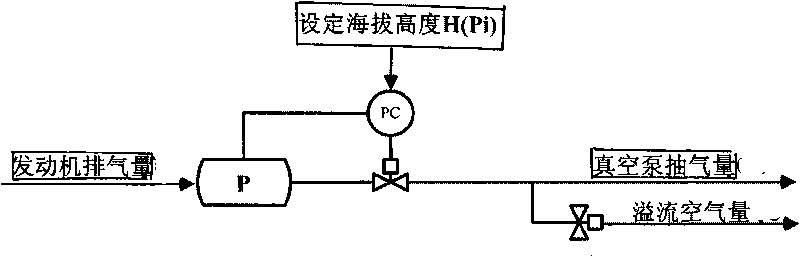

Vehicle high altitude performance simulation test system

InactiveCN101738322AEasy to adjustHigh automation efficiencyVehicle testingControl systemNational standard

The invention relates to a vehicle high altitude performance simulation test system which comprises an air inlet pressure simulation system, an exhaust pressure simulation system and a control system; the air inlet pressure simulation system comprises an air inlet electric regulating valve, an air inlet pressure stabilizing box and an air flowmeter which are sequentially connected; the exhaust pressure simulation system comprises an air flowmeter, an exhaust pressure stabilizing box, an exhaust electric regulating valve and a vacuum pump which are sequentially connected; and the output end of the control system is respectively connected with the input ends of the air inlet electric regulating valve and the exhaust electric regulating valve. The invention has the advantages that the system can realize that a vehicle simulates a low air pressure environment with the altitude exceeding 5000m in a laboratory, and the simulation precision thereof completely meets a national standard requirement; and the automation efficiency and the quality are high.

Owner:MILITARY TRANSPORTATION UNIV PLA

Material reservation distribution system and method

InactiveUS7031782B2Efficient managementEasy to processProgramme controlHand manipulated computer devicesMaterial typeControl system

The present invention relates to a system and methodology facilitating material-driven processing in an industrial controller environment. Various models supported by database objects are provided to automatically and dynamically map inventory systems / processes to control systems / process such as in batch or recipe operations. A material model is provided that tracks to an inventory database and includes such aspects as defining material types and containers to house such materials. An area model maps the material model to possible units and equipment modules to process the materials. These models include phased-based parameters that define amounts of material that flow into and out of a determined area for processing the materials. Before, during and / or after automated manufacturing operations, object binding operations occur between material-based servers associated with an inventory system and batch servers associated with a process-control system. Such binding includes Just-In-Time or on-demand binding at run time, and relates material requirements of a recipe (or batch) to the units and equipment that are available to produce the recipe.

Owner:ROCKWELL AUTOMATION TECH

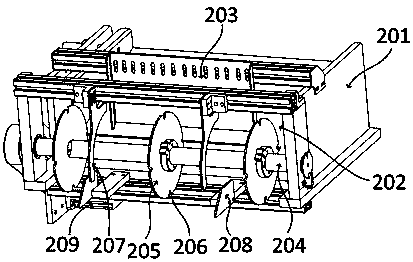

Pipe polishing machine and polishing method thereof

ActiveCN110253412AReduce work intensityHigh automation efficiencyPolishing machinesFlexible-parts wheelsEngineeringUltimate tensile strength

The invention discloses a pipe polishing machine and a polishing method thereof, and belongs to the field of surface polishing. The polishing machine comprises a base mechanism, a feeding mechanism, a polishing mechanism and a discharging mechanism, wherein the base mechanism comprises a machine frame and a machining table top arranged above the machine frame; the feeding mechanism comprises a disc feeding device arranged on the machining platform top, a pipe sliding platform and two linear propelling mechanisms arranged at the starting end and the tail end of the pipe sliding platform; the polishing mechanism comprises an outer surface polishing device and an inner surface polishing device; the outer surface polishing device and the inner surface polishing device are respectively aligned with the two propelling mechanisms. According to the polishing machine, a conveying belt, the disc feeding device and the pipe sliding platform are matched to replace manual feeding and discharging, the working intensity of workers is reduced, and the automation efficiency is improved; and a polishing head of the inner surface polishing device is made of sand cloth and is designed in a cross shape, so that the polishing acting force is more uniform, and the quality of polished products is improved.

Owner:黄冈艾格尔五金制造有限公司

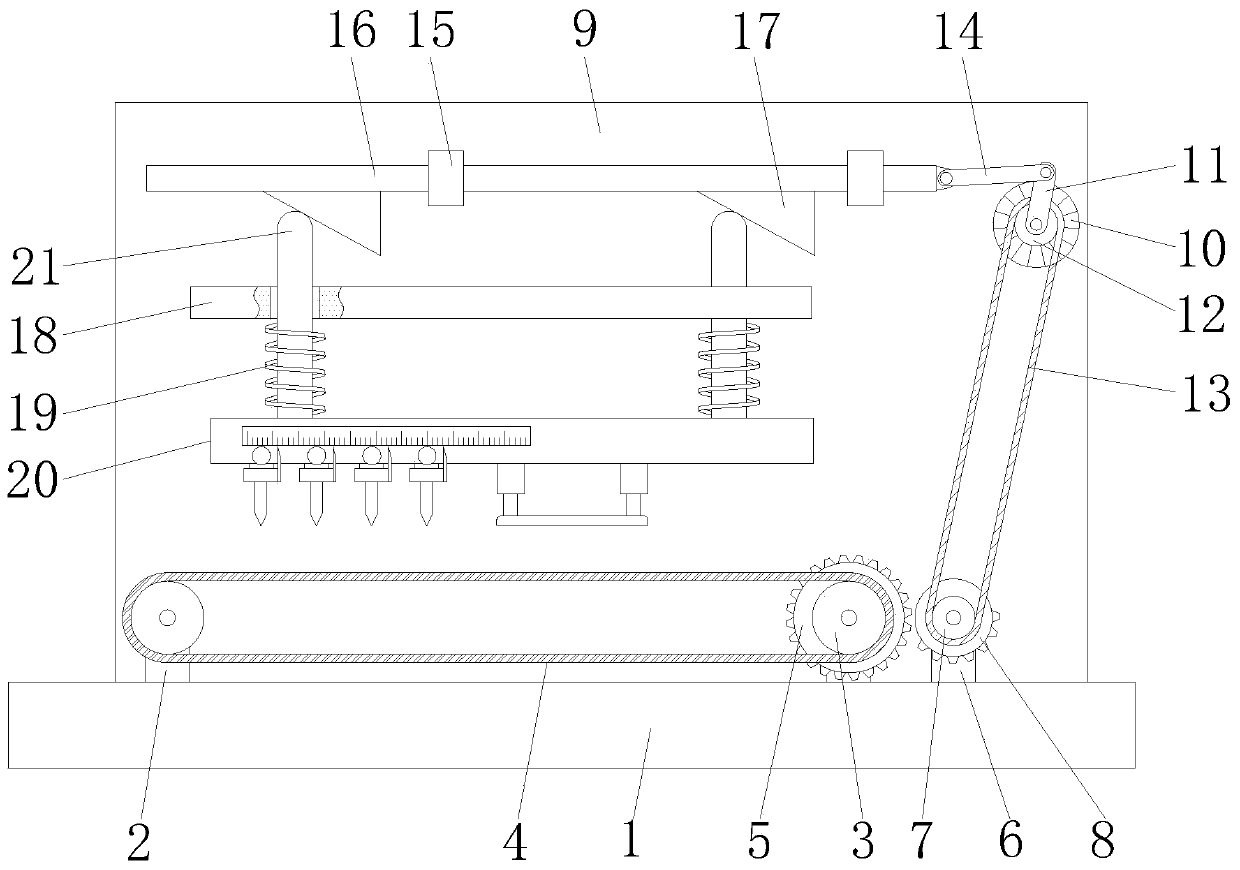

Automaticcake slicing devicewithhigh efficiency

InactiveCN109794973AHigh degree of automationReduce work intensityMetal working apparatusEngineeringCircular surface

The invention relates to the technical field of slicing devices for slicing cakes, and discloses an automatic cake slicing devicewith the high efficiency. Theautomatic cake slicing device with the high efficiency comprises a base, two first brackets are fixedly connected to the top of the base, roller wheels are rotatably connected to the upper ends of the first brackets, a conveyor belt sleeves between the outer circular surfaces of the two roller wheels, the position, on the right side, of the first bracket is rotatably connected with a circular gear, the circular gear and the roller wheel on the right side are coaxial, a second bracket is fixedly installed at the top of the base, the upper end of the second bracket is rotatably connected with a first belt pulley and a missing gear, andthe first belt pulley and the missing gear are coaxial, a fixing plate is fixedly installed at the top of the base, and the front face of the fixing plate is fixedly connected with a motor. Accordingto theautomatic cake slicing devicewith the high efficiency, the problems that according to existing slicing devices for the slicing cakes, the working efficiency is low, the yield is not high, operation of workers is tedious, the labor intensity is high, and during slicing, the condition of deviation can appear sometimes, and the quality of the sliced cakes is affected are solved.

Owner:安徽皖源食品有限公司

Drilling machine with arm type automatic tool changing device

InactiveCN102528116AClear structureClear operationPositioning apparatusMetal-working holdersElectric machineryMaterial resources

The invention discloses a drilling machine with an arm type automatic tool changing device, wherein the drilling machine comprises a machine base, a work table, a motor mechanism, a rotating spindle, a machine body and an upright and further comprises the rotatable arm type automatic tool changing device, an upright lifting device, a multi-station tool changer device and an air cylinder, meanwhile, the rotating spindle is internally provided with a clamping and loosening tool linkage device, and a feed drill connected to the rotating spindle can be subjected to tool changing by the rotatable arm type automatic tool changing device and the multi-station tool changer device. The drilling machine is clear and simple in structure, is simple to operate and has high efficiency of automation, meanwhile, precision finishing is carried out by incorporating a numerical control system, so that the precision and the efficiency can be improved, in addition, the cost is greatly lowered, material resources, financial resources and labor force are saved, and the working benefit is greatly increased.

Owner:NANJING YONGYI MACHINERY

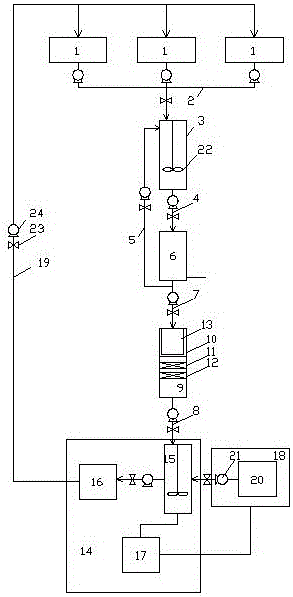

Diamond wire slicing cooling liquid integrated treatment method for sapphire and silicon wafers

ActiveCN106378876AReduce pollutionLow costWater treatment parameter controlTreatment involving filtrationDevice failureSwitching time

The invention relates to a diamond wire slicing cooling liquid integrated treatment method for sapphire and silicon wafers. The treatment method comprises following steps that firstly, a first pipeline conveys waste cooling liquid drained by slicing machines to a storage tank; secondly, a plate frame pressure filter carries out pressure filtering to remove solid wastes in the cooling liquid; thirdly, a precise filter tank is used for carrying out precise filtering to remove fine particles and metal ions in the cooling liquid; fourthly, a fourth pipeline conveys the cooling liquid treated by the precise filter tank to a preparation tank, a PLC is controlled to enable a cooling liquid supplementing system to supplement cooling liquid to the preparation tank, and a finished product tank conveys the cooling liquid to a plurality of slicing machines through a fifth pipeline. The cooling liquid can be circularly used, the machining quality is improved, the equipment failure and switching time can be shortened, the product manufacturing cost is reduced, and the water treatment environment pollution is reduced.

Owner:江苏美科太阳能科技股份有限公司

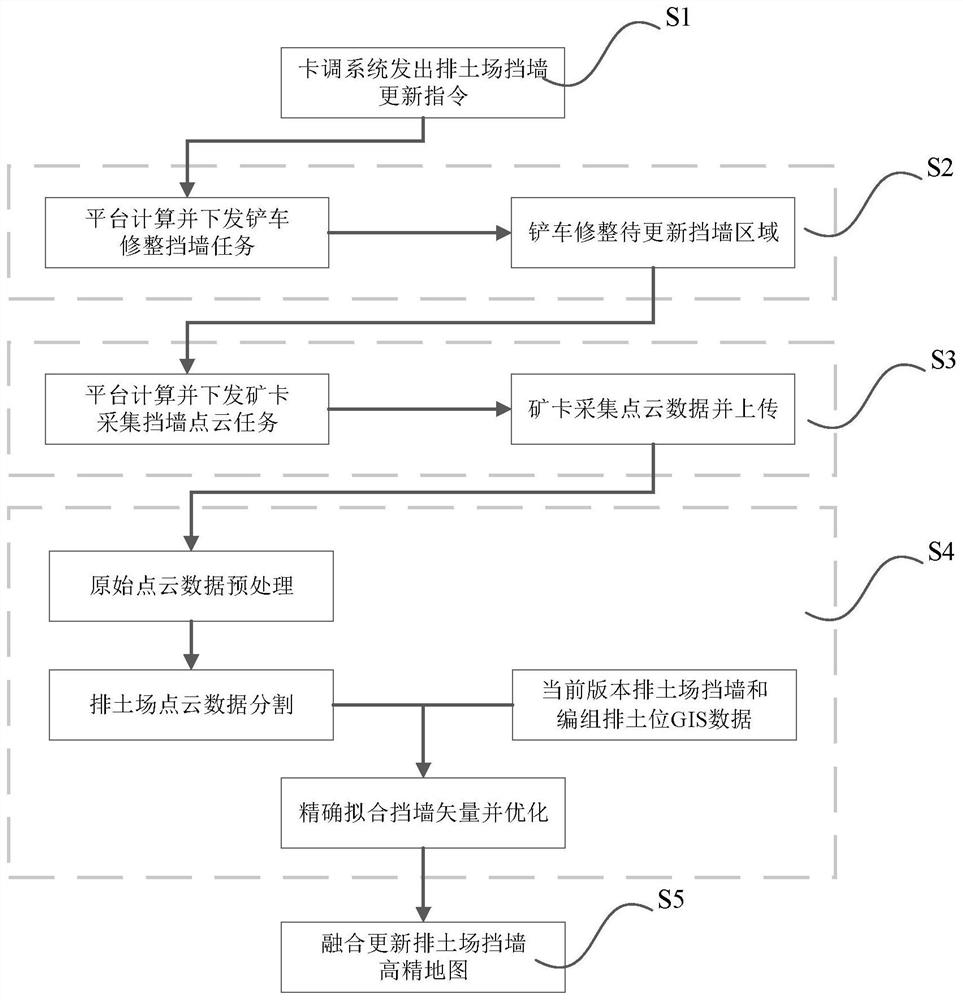

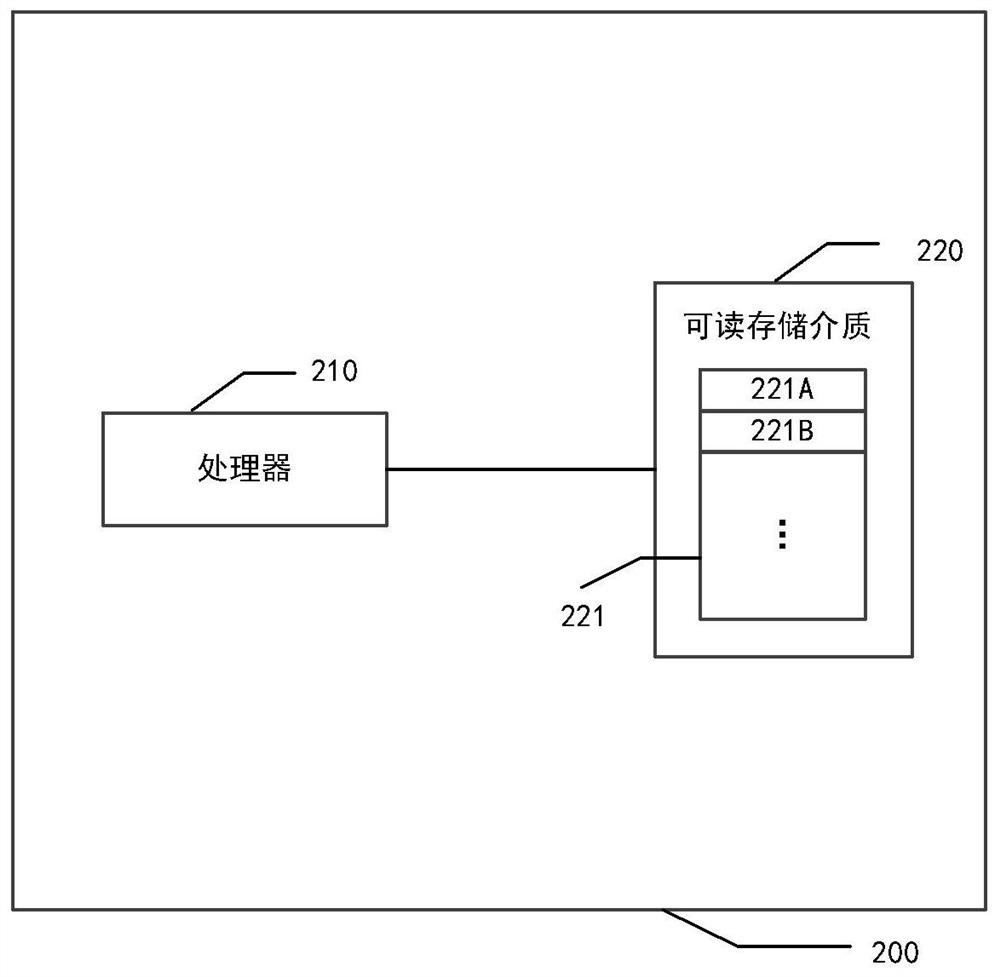

Dump retaining wall map updating method applied to open pit mine automatic driving

ActiveCN111829507AImprove securityImprove efficiencyNavigation instrumentsProfile tracingPoint cloudCloud data

The invention provides a dump retaining wall map updating method applied to open pit mine automatic driving. The dump retaining wall map updating method comprises the steps that a dump retaining wallupdating instruction sent by a truck dispatching system is waited to be received; if the dump retaining wall updating instruction is received, a forklift is dispatched to trim the terrain of a to-be-updated dump retaining wall area; when a retaining wall finishing signal is received, a mine truckis dispatched to collect point cloud data of a retaining wall area of the dump after finishing; after receiving the laser point cloud data uploaded by the mine truck, a dump retaining wall updating vector is calculated; and after a dump retaining wall updating vector updating completion message is obtained, the dump retaining wall high-precision map is fused and updated by adopting the dump retaining wall updating vector. High-precision automatic extraction of the updatingvector of the updatingareaof the dump retaining wall is realized, and the safety and the efficiency of automatic driving in an open pit mine scene are greatly improved.

Owner:SHANGHAI YIAO TECH CO LTD

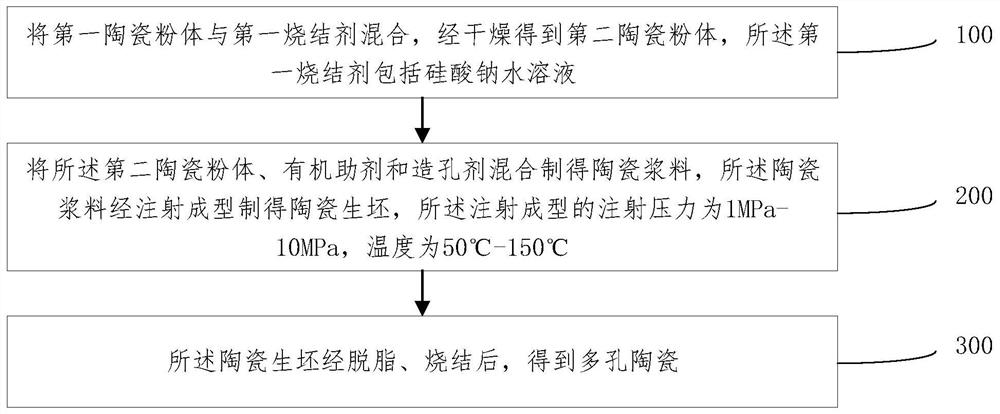

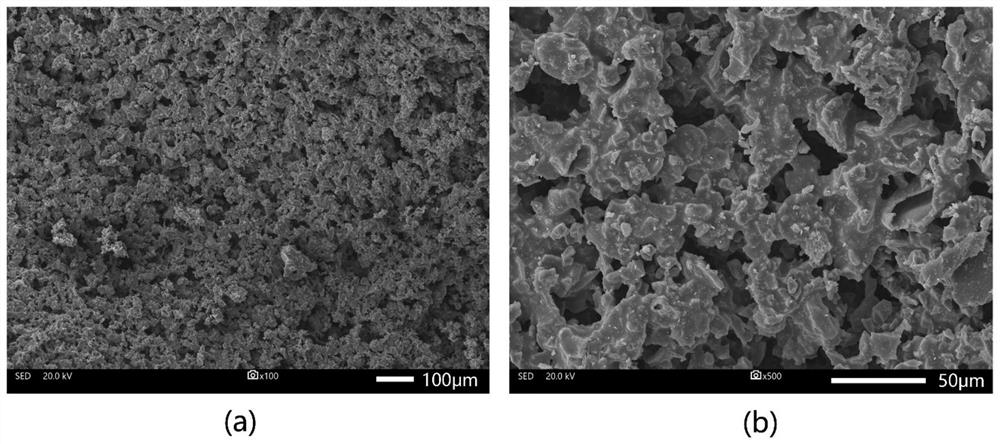

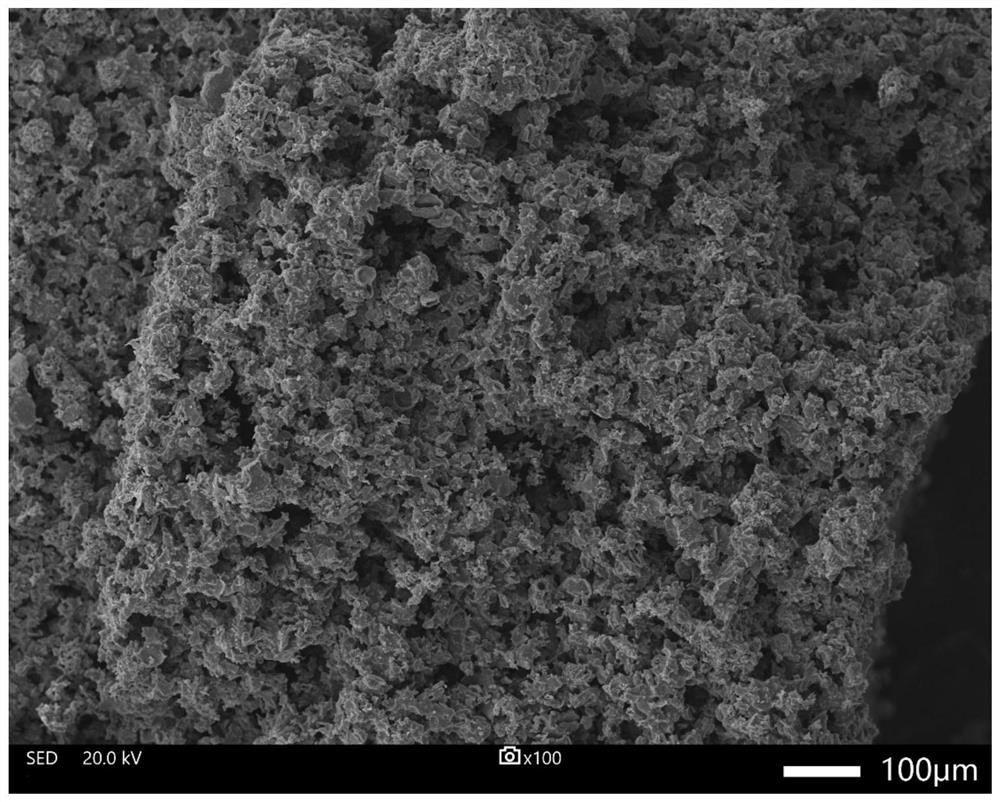

Porous ceramic and preparation method and application thereof

ActiveCN112047753AHigh bulk densityHigh compressive strengthTobaccoCeramicwareInjection pressureElectronic cigarette

The invention provides a porous ceramic preparation method, which comprises: mixing first ceramic powder and a first sintering agent, and performing drying to obtain second ceramic powder, the first sintering agent comprising a sodium silicate aqueous solution; mixing the second ceramic powder, an organic auxiliary agent and a pore forming agent to obtain ceramic slurry, performing injection molding on the ceramic slurry to obtain a ceramic green body, the injection pressure of the injection molding being 1MPa to 10MPa, and the temperature being 50 DEG C to 150 DEG C; and degreasing and sintering the ceramic green body to obtain the porous ceramic. According to the preparation method, the yield of porous ceramic production is effectively improved, the steps are simple, the process is simple, multiple ceramic green bodies can be produced at a time, the automation efficiency is high, and the porous ceramic is suitable for large-scale industrial production. The invention further providesporous ceramic and application thereof in an electronic cigarette atomizer. The porous ceramic has good compression resistance and porosity.

Owner:SHENZHEN TRANSPRING ENTERPRISE LTD

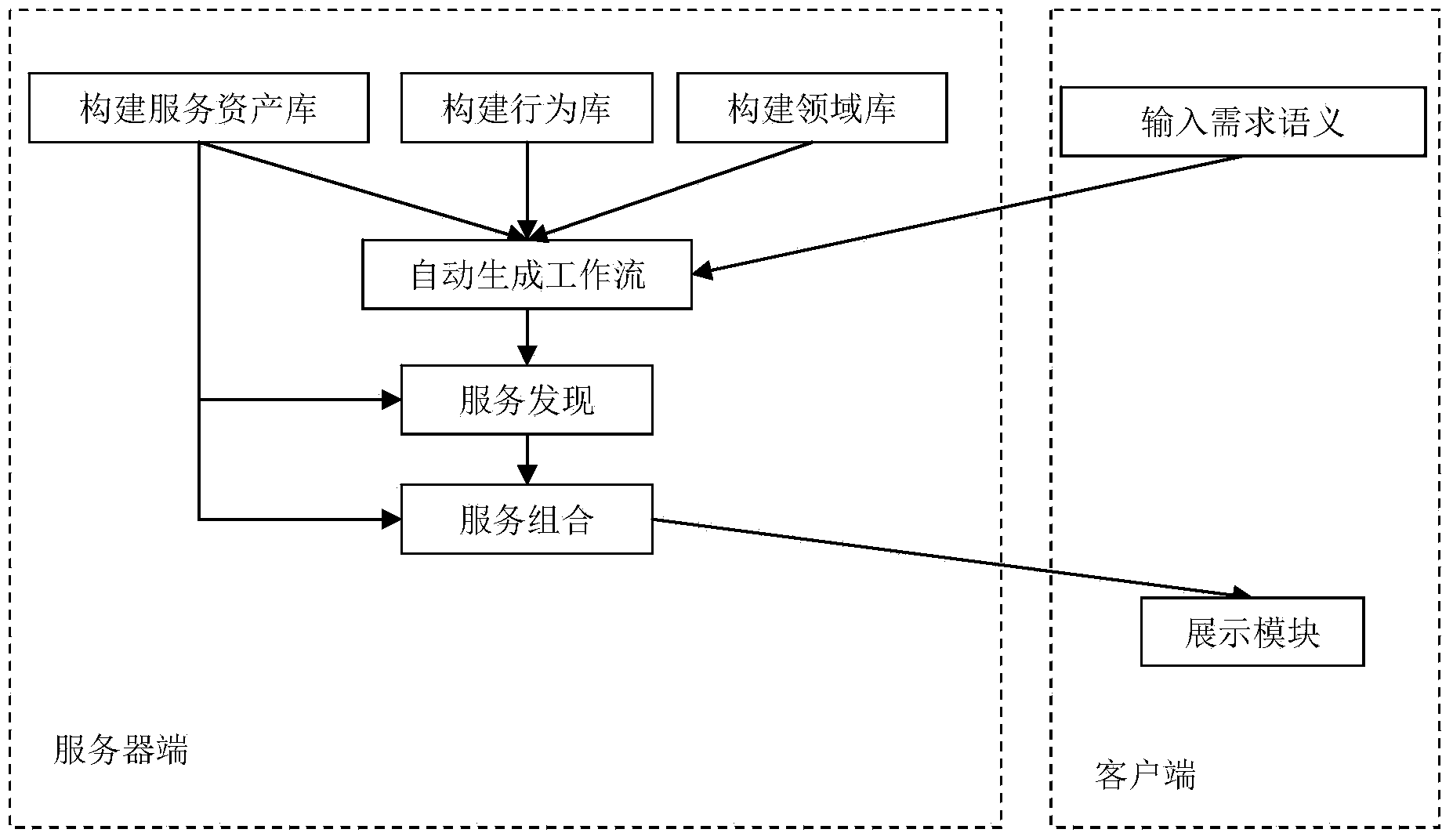

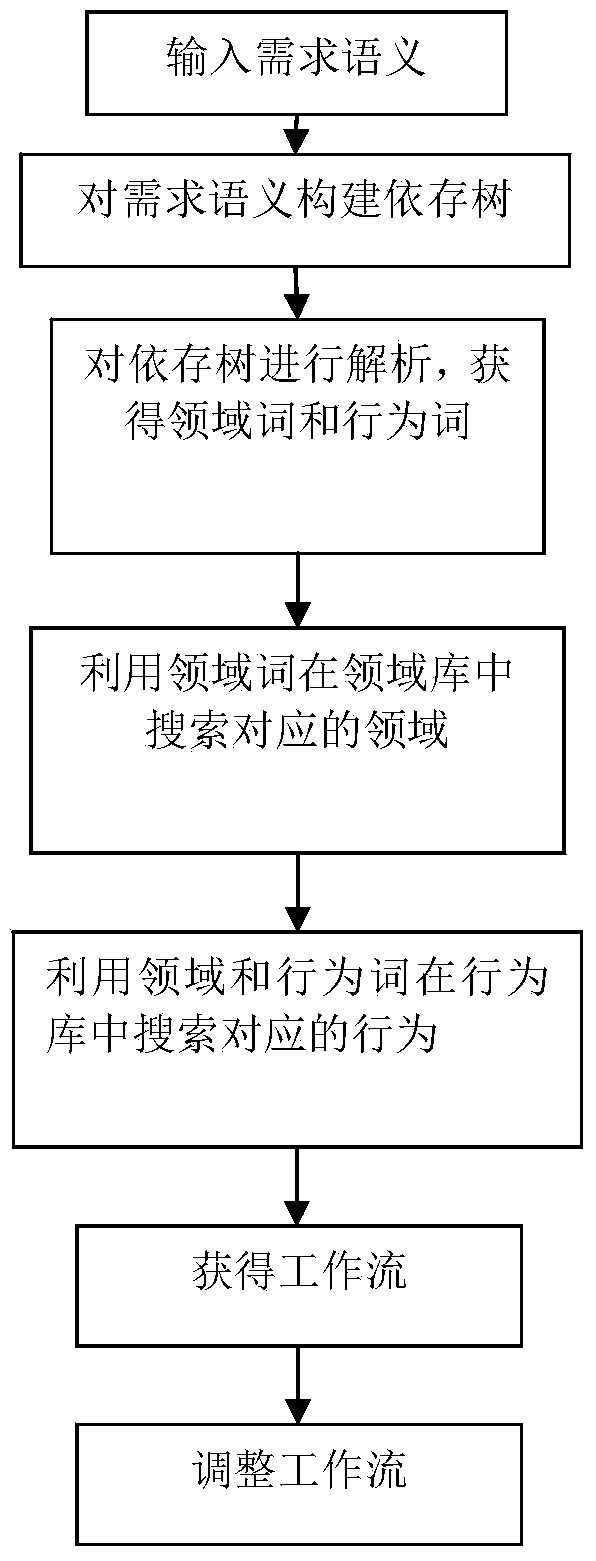

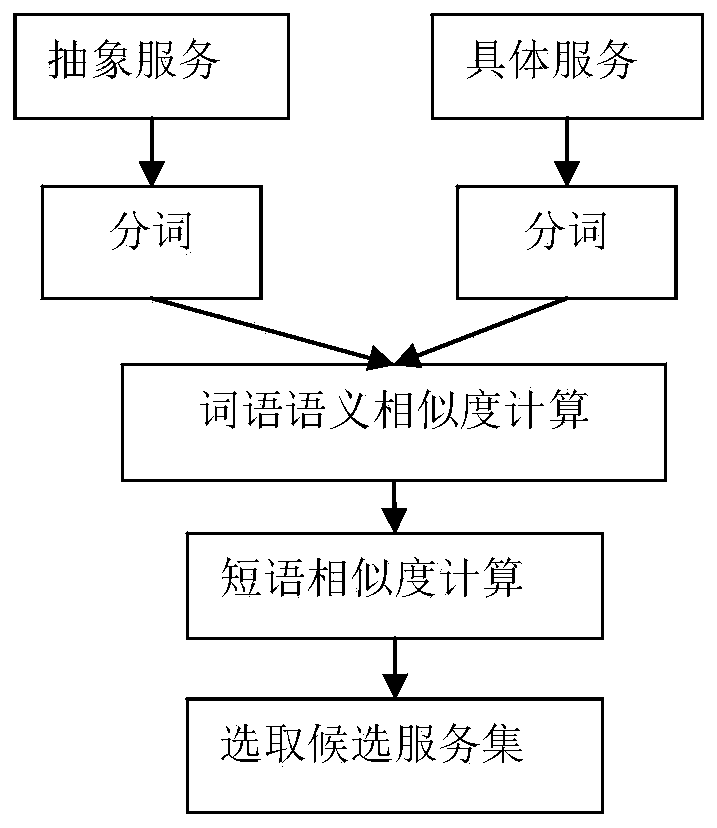

Automatic service combination system and method based on semantics

InactiveCN103838857AHigh automation efficiencySolve the problem of automatic generationSpecial data processing applicationsSemantic tool creationService compositionSemantics

The invention relates to an automatic service combination system and method based on semantics. The system comprises a server terminal and a client terminal. The server terminal comprises a database constructing module, an automatic workflow generating module, a service discovering module and a service combination module. The client terminal comprises a requirement semantics inputting module and a display module. The method includes the following steps that according to input requirement semantics, a domain library and a behavior library; workflow is automatically generated; fine adjusting is carried out on the generated workflow; according to the workflow and the semantic information of a service, a candidate service set is obtained through calculation of semantics similarity; according to QoS information of the service, an executing path which can meet the QoS constraint of a user and has the optimal QoS property is chosen. Authentic automatic evolution growth of complicated software is achieved in a large scale, the workflow is provided without need of manual intervention and the service combination efficiency is extremely improved.

Owner:INST OF SOFTWARE - CHINESE ACAD OF SCI

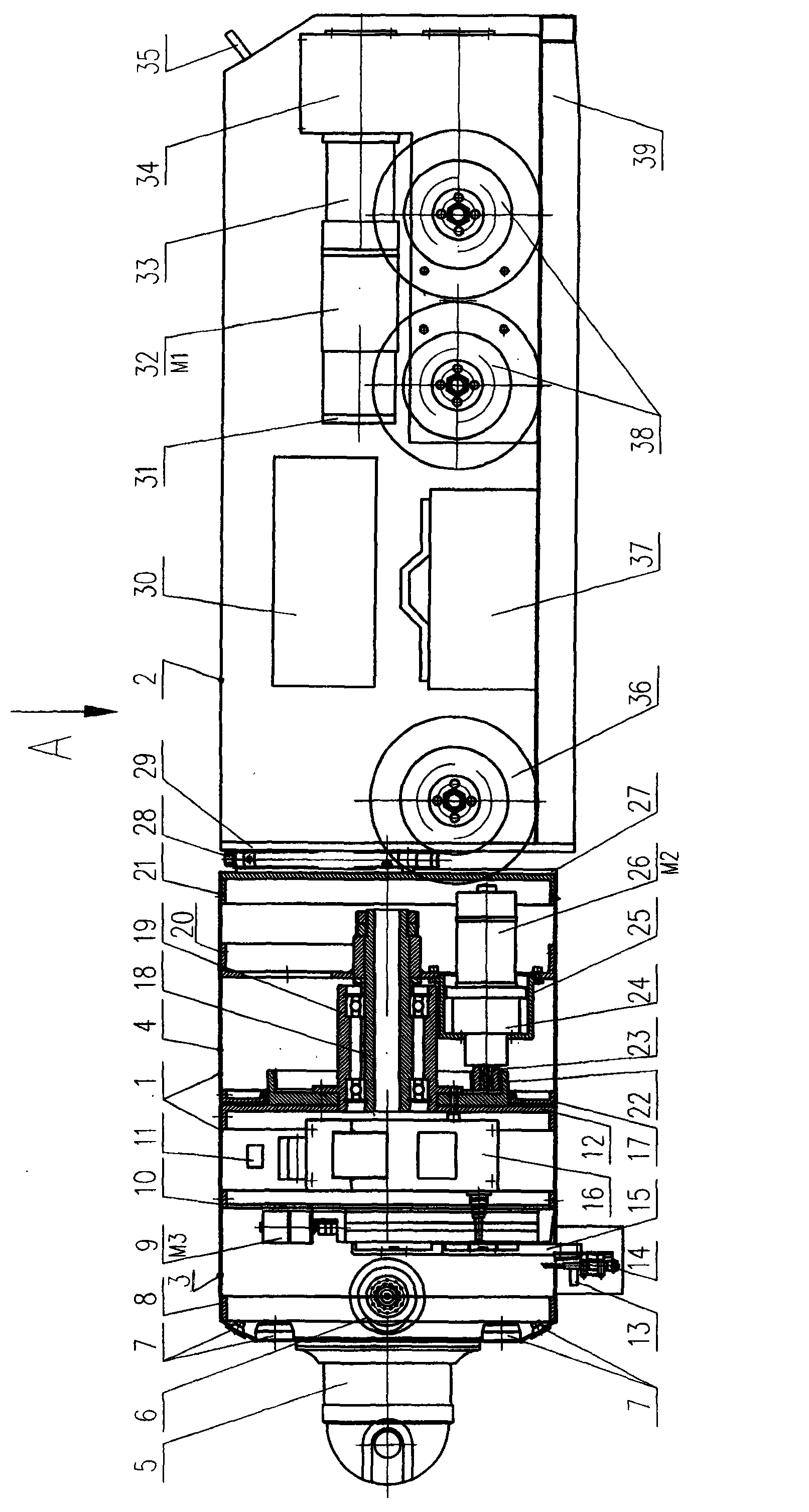

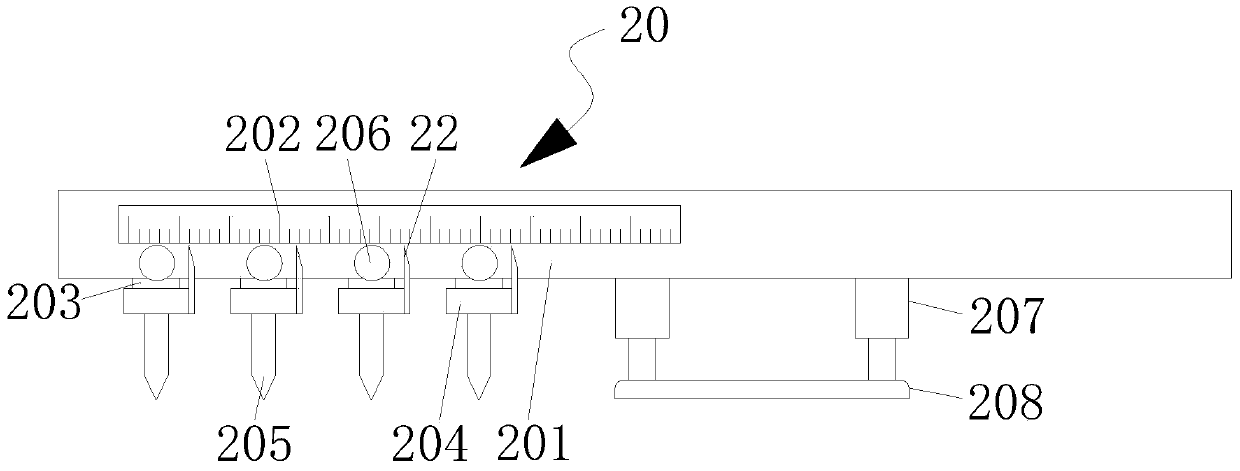

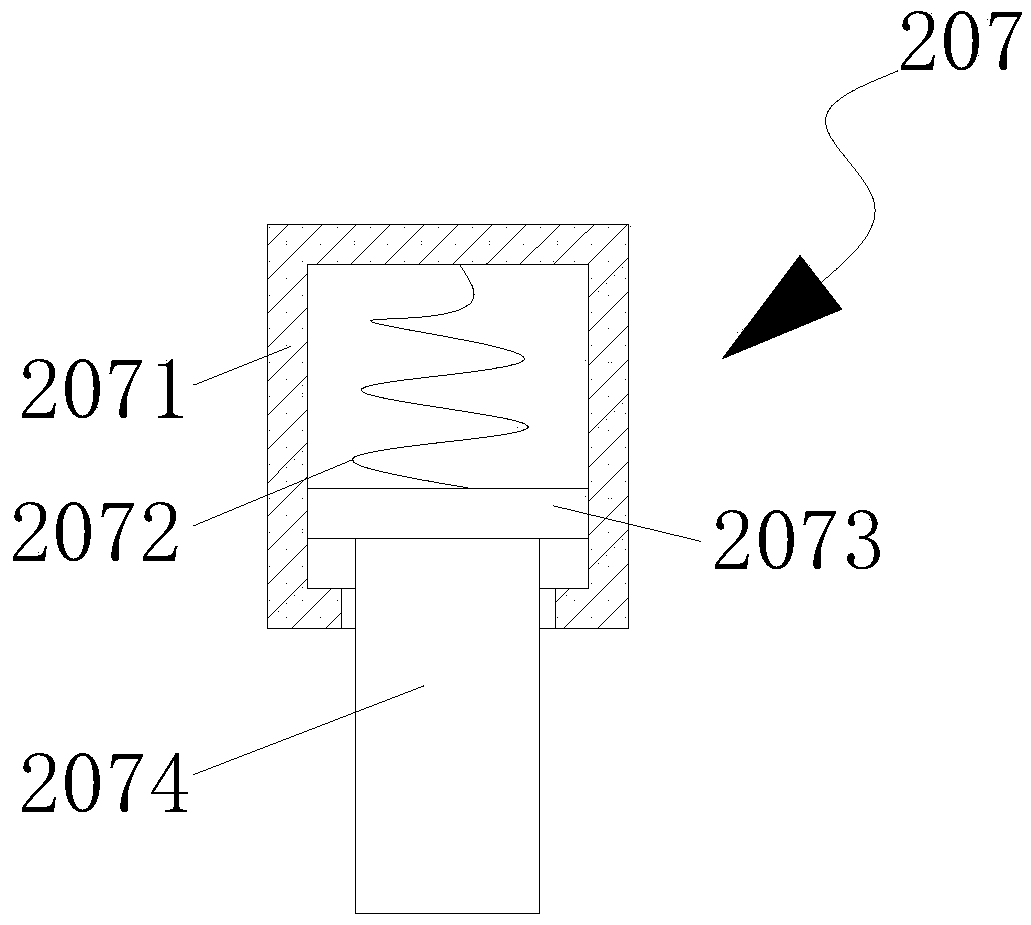

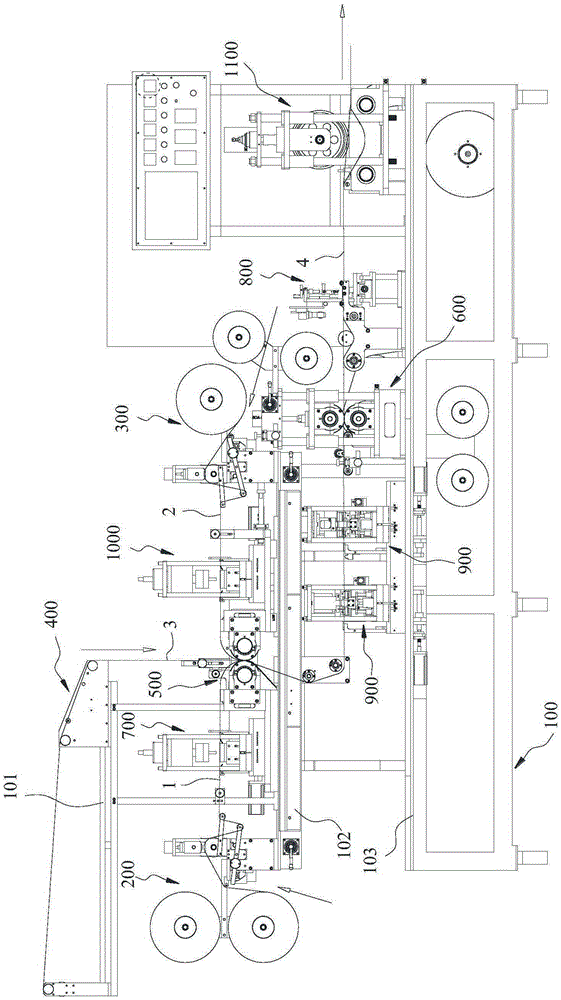

Automatic FFC pressure connecting forming machine

The invention discloses an automatic FFC pressure connecting forming machine. The automatic FFC pressure connecting forming machine comprises a machine frame, a first film feeding mechanism, a second film feeding mechanism, a conductor feeding mechanism, a first hot press device, a second hot press device, a first punching device, a second punching device, a reinforcing plate attaching device and a striping device. The machine frame comprises a top layer frame, a middle layer frame and a bottom layer frame. The conductor feeding mechanism is installed on the top layer frame. The first film feeding mechanism and the second film feeding mechanism are arranged at the two ends of the middle layer frame respectively. The first hot press device is installed on the middle layer frame and located between the first film feeding mechanism and the second film feeding mechanism. The reinforcing plate attaching device, the second hot press device and the striping device are sequentially installed on the bottom layer frame in the conveying direction of semi-finished FFC products. An outlet of the first film feeding mechanism and an outlet of the second film feeding mechanism are right opposite to the first hot press device horizontally. An outlet of the conductor feeding mechanism is right opposite to the first hot press device vertically. By means of the automatic FFC pressure connecting forming machine, the semi-finished FFC products can be attached firmly, reinforcing plates are attached precisely and firmly, the product quality is improved, and the rate of finished products is increased.

Owner:佛山市顺德区禾惠电子有限公司

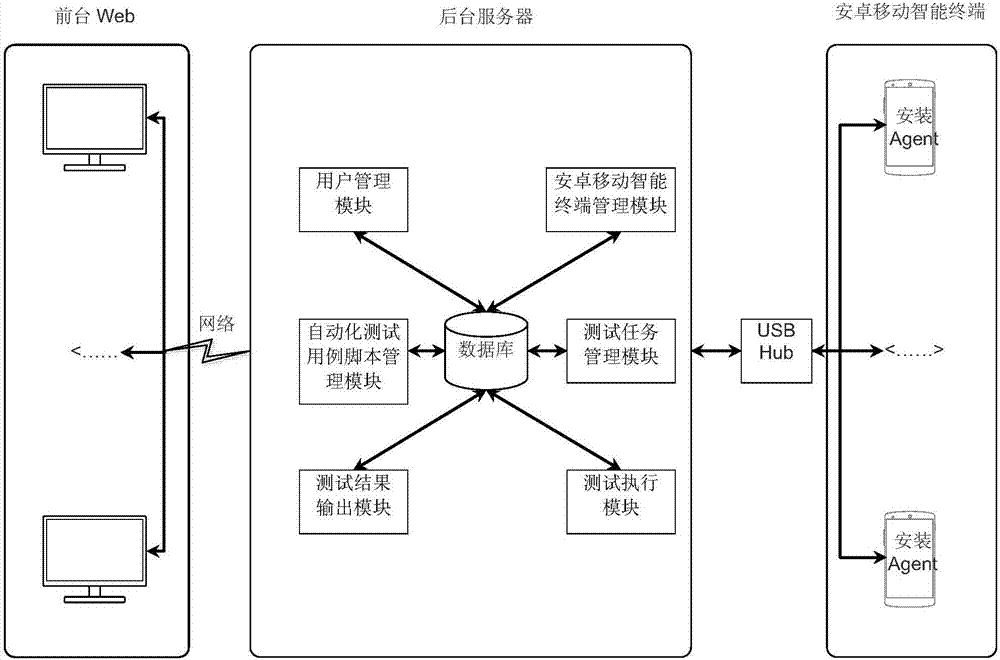

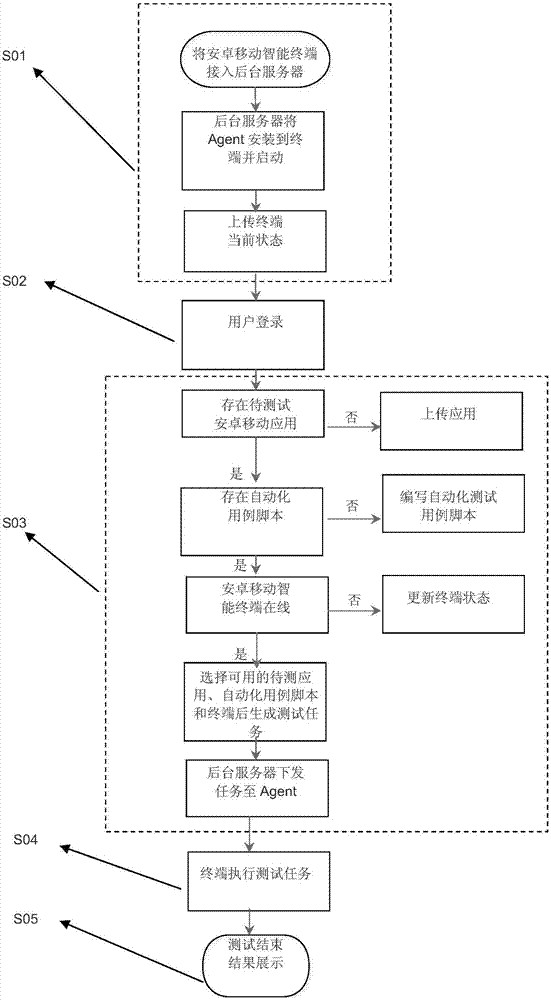

Automated testing platform and testing method of Android mobile-applications

InactiveCN107315683AHigh automation efficiencyShorten test timeSoftware testing/debuggingTest efficiencyManual testing

The invention relates to testing technology of Android mobile-applications, and discloses an automated testing platform of the Android mobile-applications. The platform solves the problems of low testing efficiency, high costs and long testing periods existing in traditional manual testing solutions. The automated testing platform includes: a foreground web client, which is used for providing an interaction function between a user and a background server on the basis of a network; the background server, which is used for providing user management, Android mobile-intelligent-terminal management, Android mobile-application management, automated test case script management, test task management, mobile intelligent terminal driving for completing test work according to configured automated test cases, and analysis and processing of test results; and an Android mobile-intelligent-terminal, which is equipped with Android mobile-intelligent-terminal agent modules used for communication between the background server and the Android mobile-intelligent-terminal. The invention also discloses a corresponding automated testing method, which is suitable for use in high-efficient testing of the Android mobile-applications.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Automatic detection equipment

InactiveCN105598043AHigh automation efficiencyReduce worker workloadSortingEngineeringAutomatic test equipment

The invention discloses automatic detection equipment. The technical problems that in the prior art, in the process of detecting the length, hole site, cut side, counter bore, groove width and planes of a workpiece, manual detection is adopted, so that labor intensity of staff is high, and detection errors are large are solved. By the adoption of the technical scheme, the automatic detection equipment comprises an equipment rack, a working table is arranged on the equipment rack, and a detection station, a code spraying station and an unqualified product moving-out station are arranged on the working table; a collector and a jacking cylinder are arranged at the detection station, wherein the collector is used for collecting detection data of the workpiece to be detected; a code spraying machine is arranged at the code spraying station; an unqualified product moving-out mechanism is arranged at the unqualified product moving-out station. The automatic detection equipment has the advantages of being low in labor intensity and small in detection error.

Owner:SUZHOU AMITY ELECTRONICS & PLASTICS

Small-sized bearing drop height type continuous ultrasonic cleaning method and device

InactiveCN101168158AReduce equipment costsImprove continuous deliveryCharge manipulationCleaning using liquidsMegasonic cleaningEngineering

The invention relates to a drop style continuous ultrasonic cleaning method and device for small sized bearings, in particular to a method and device conducting continuous transition and drop style ultrasonic cleaning to small sized precise bearings, which belongs to the field of precise bearing cleaning. With usage of ultrasonic cleaning method, utilization of an air cylinder, a track, a cleaning fluid basin, a left drop device, a right drop device, and usage of altitude difference of an inlet and an outlet of a screwed basin equipped on the left drop device and the right drop device, bearings outside the cleaning basin for cleaning are continuously inputted into the cleaning basin to clean, the cleaned bearings are continuously outputted, and automatic transition and ultrasonic cleaning of bearing are accomplished. The cleaning device is composed of a feeding apparatus and an ultrasonic cleaning device. The feeding device is composed of an electric motor, a feeding rotation disk, a rotating shaft, and an air cylinder, a supporting plate of air cylinder, a demagnetizer, a left track, a belt pulley, a belt and a feeding support. Ultrasonic cleaning of the drop devices has the advantages of simple structure, convenient operation, low cost, and high efficiency, which is capable of increasing the usage performance and market competitive strength of medium and small sized finish products of precise bearing.

Owner:DALIAN UNIV OF TECH

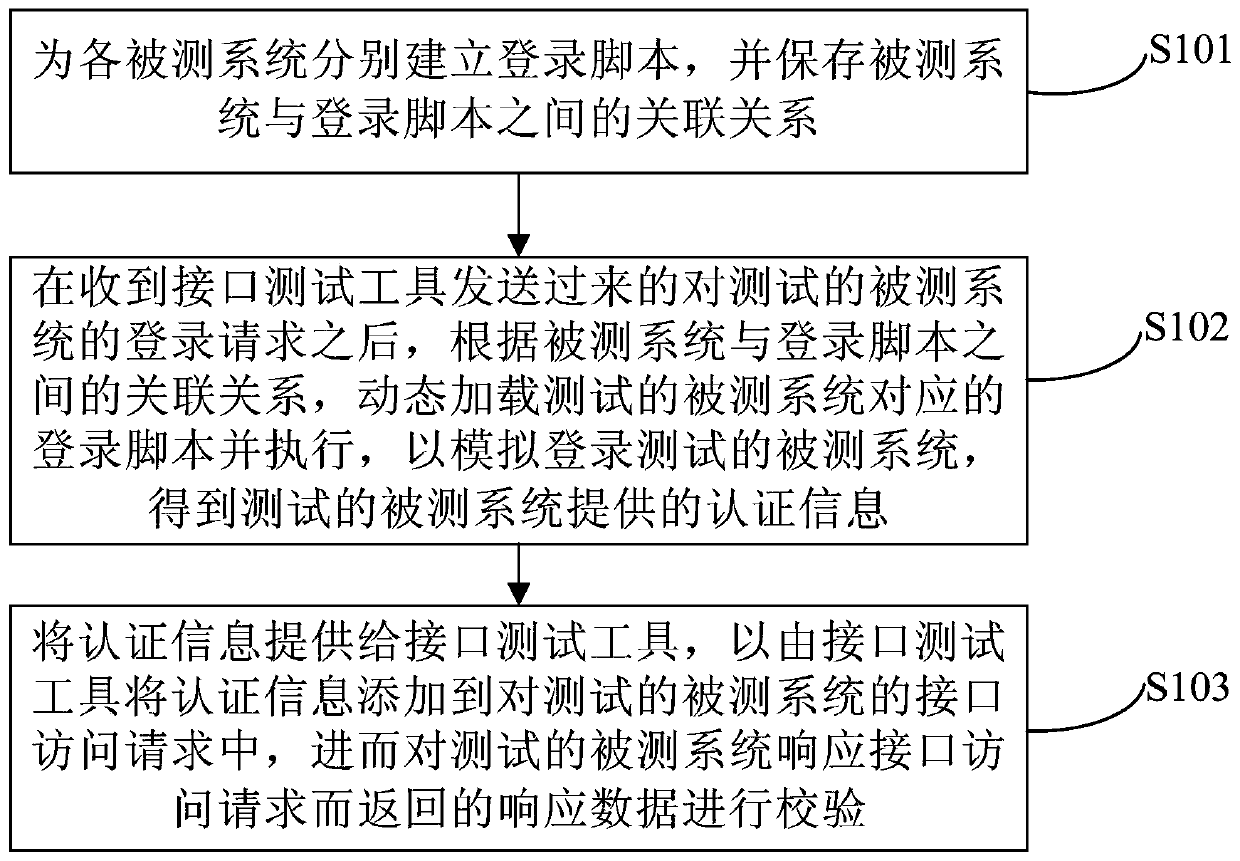

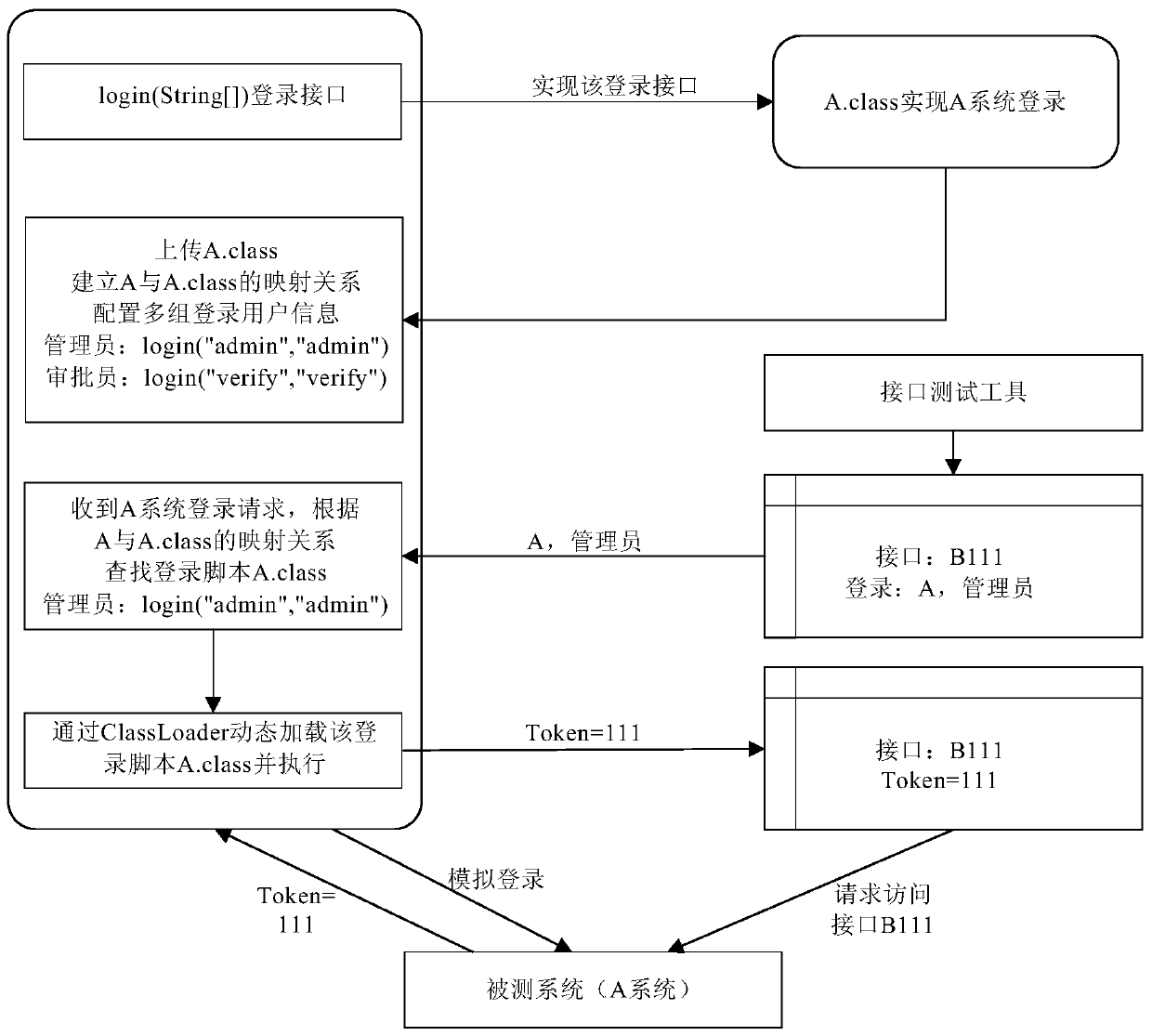

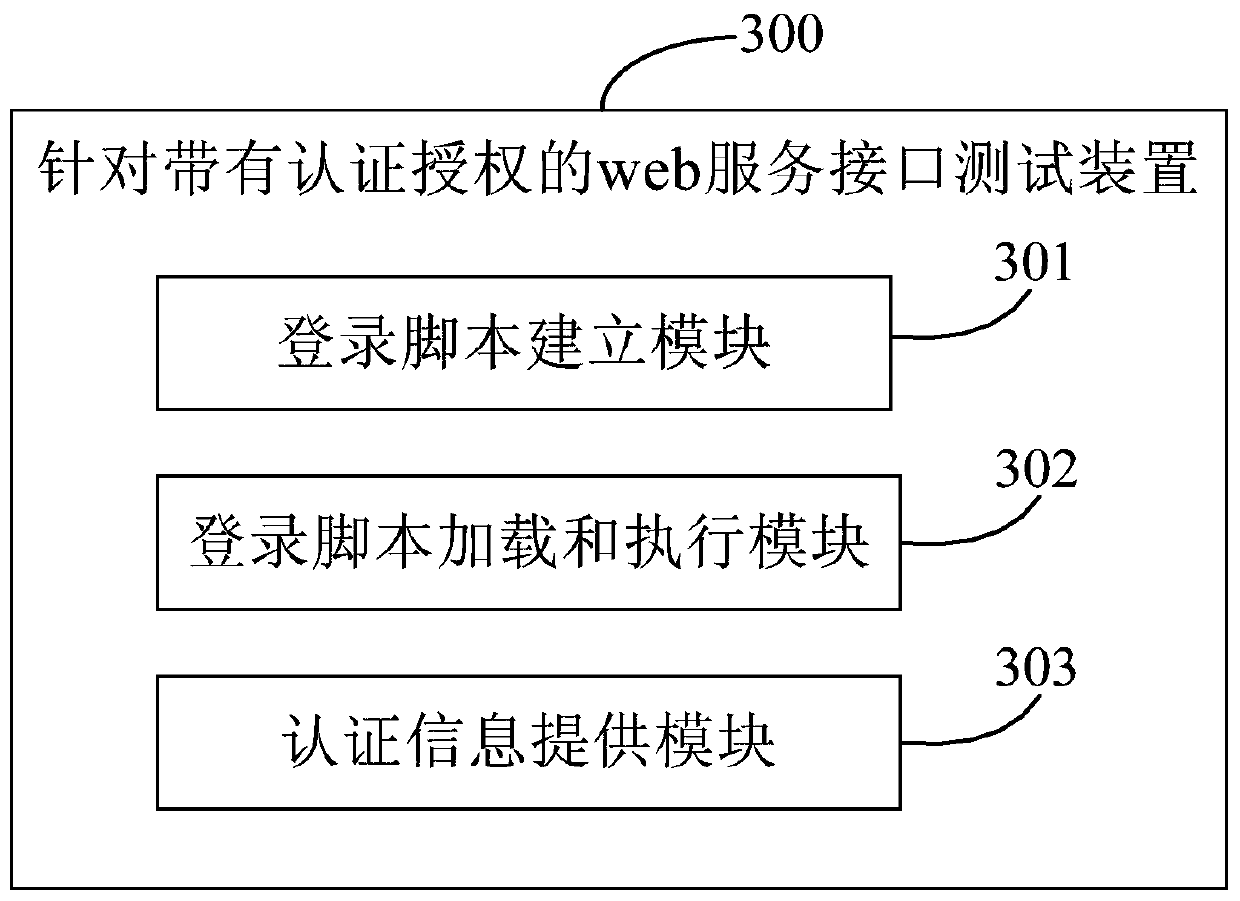

Test method and device for web service interface with authentication authorization

ActiveCN110442524AOvercome too invasive flawsReduce errorsSoftware testing/debuggingExtensibilityWeb service

The invention discloses a test method and device for a web service interface with authentication authorization, and relates to the technical field of computers. One specific embodiment of the method comprises the following steps: respectively establishing a login script for each tested system; dynamically loading and executing a login script corresponding to the tested system according to the incidence relation between the tested system and the login script so as to simulate the tested system for login testing and obtain authentication information; and providing the authentication informationto an interface test tool so as to add the authentication information to an interface access request of the tested system, and verifying response data returned by the tested system. The implementationmode is suitable for automatically testing the web service interface of the tested system with authority control. The method avoids too large invasiveness to the system, reduces errors, does not needto manually configure authentication authorization information, improves automation efficiency, is high in expandability, can achieve multi-user multi-role login, guarantees interface test sufficiency, does not need to be restarted, and improves system availability.

Owner:CCB FINTECH CO LTD

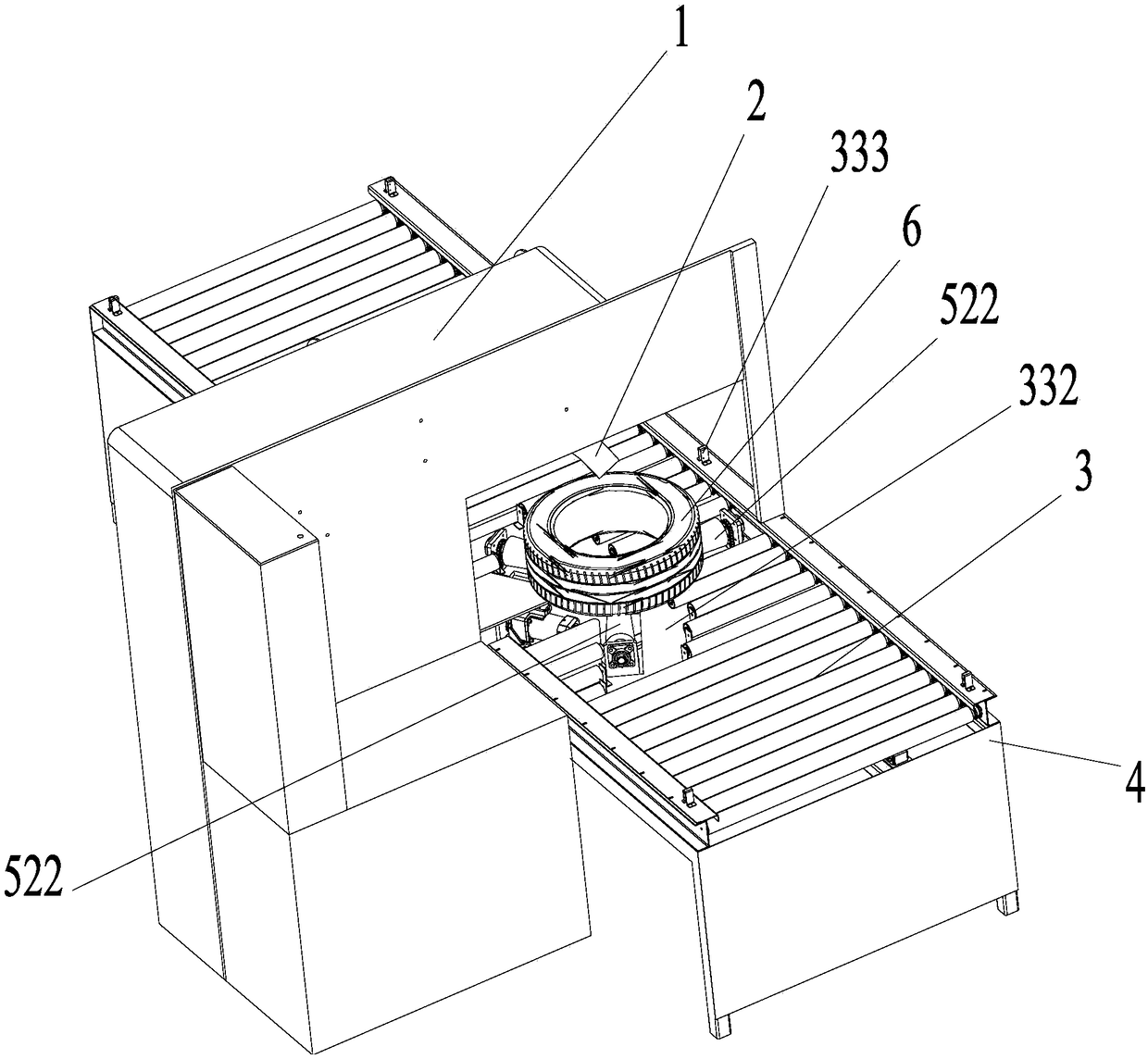

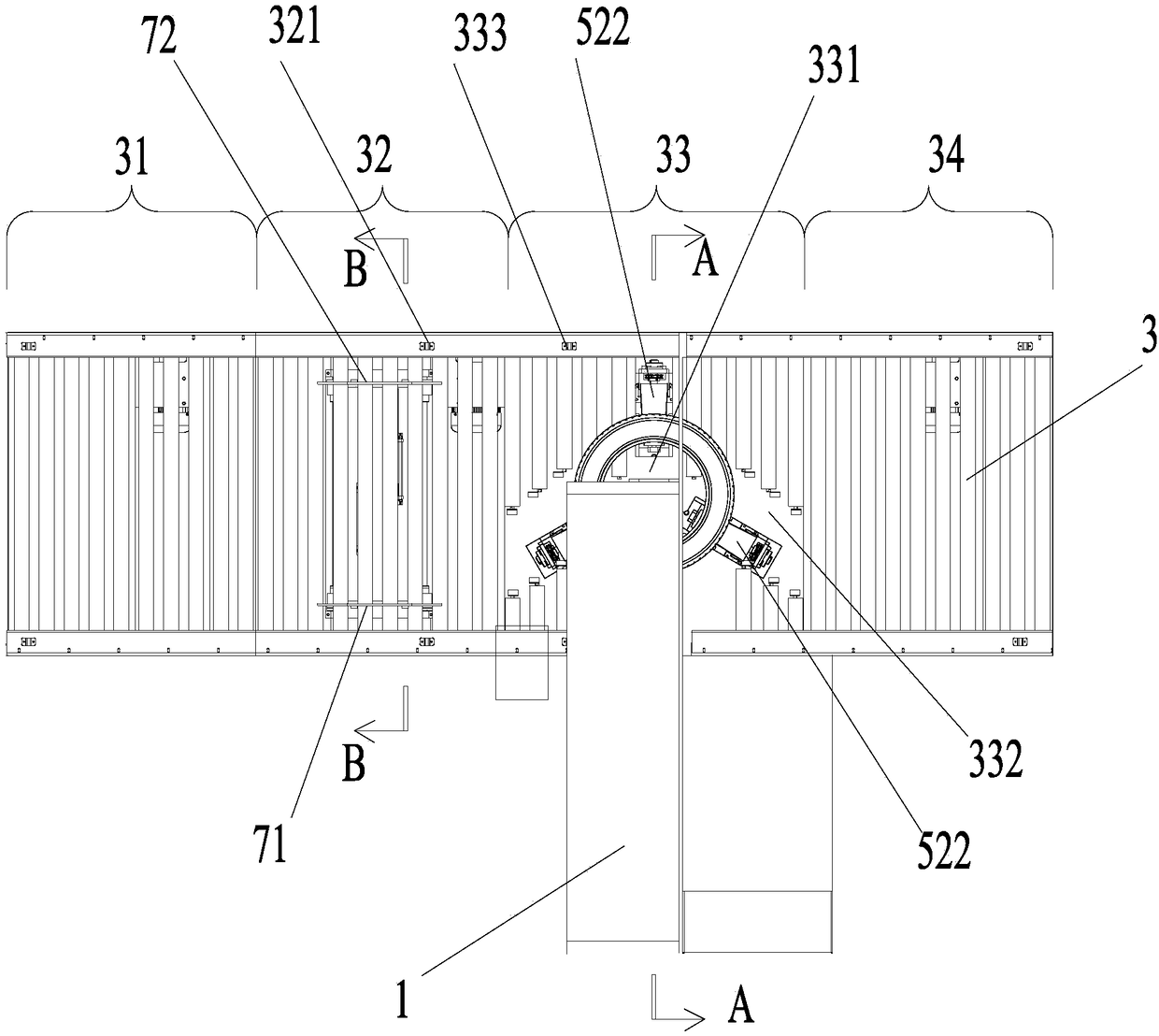

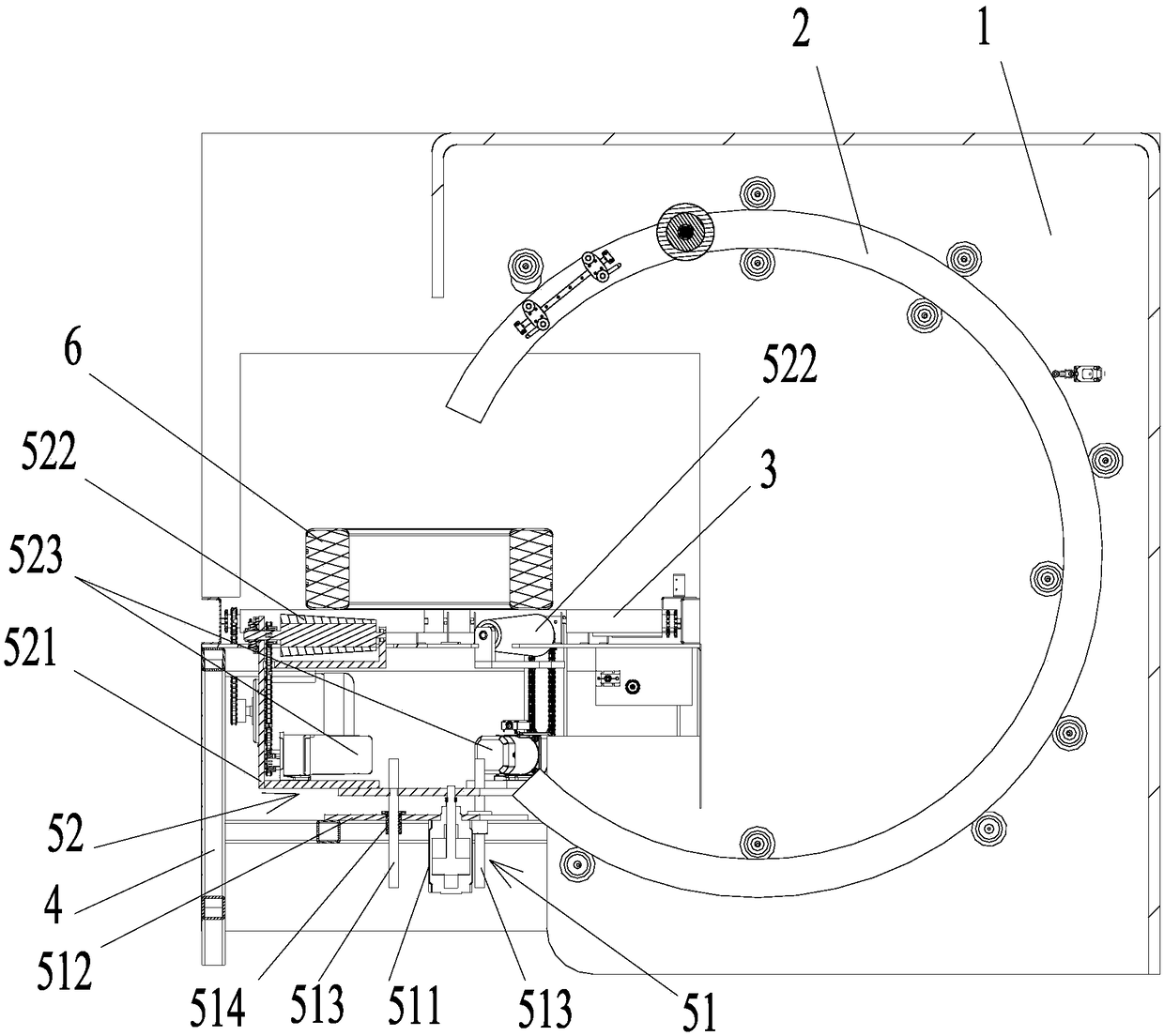

Tire baler and production line

PendingCN108394594AIncrease productivityImprove production safetyPackaging automatic controlWrapping with article rotationElectric machineryEngineering

The invention discloses a tire baler and a production line. The tire baler comprises a machine frame and a C-shaped winding ring, and further comprises a roller conveyor belt provided with a feeding area, a baling area and a discharging area. A winding ring notch and a rotating roller notch are formed in a baling station of the conveyor belt. A tire lifting and rotating mechanism is arranged belowthe roller conveyor belt and comprises a lifting mechanism and a tire rotating mechanism. The tire rotating mechanism comprises a rack and a plurality of conical rotating rollers. When the tire rotating mechanism is lifted, the conical rotating rollers are matched to jack a tire and drive the tire to rotate on spot under driving of a motor. When the tire rotating mechanism descends, the conical rotating rollers are lowered to be lower than the roller conveying face. The production line comprises a main conveyor belt and a plurality of tire balers, and tires are conveyed from the main conveyorbelt to the tire balers in a matched mode. According to the tire baler and the production line, the automation degree of tire baling equipment is greatly improved, so that work efficiency is greatlyimproved, and automatic winding and baling production of a large amount of tires can be achieved.

Owner:SHANGHAI LANTU INFORMATION TECH CO LTD

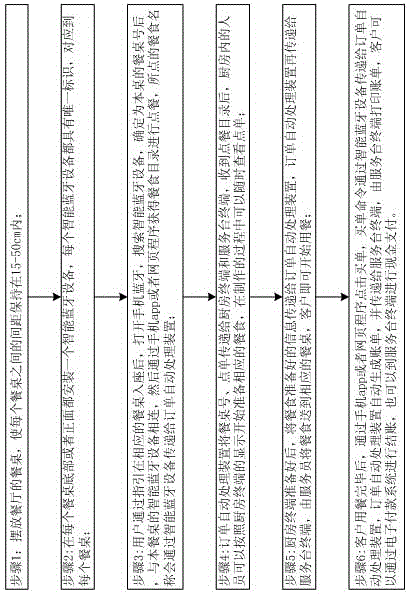

Mobile phone self-service ordering system based on iBeacon

InactiveCN104881824AReduce in quantityReduce operating costsData processing applicationsWaiters/waitressesOperational costs

The invention belongs to the catering technology field, and provides a mobile phone self-service ordering system based on iBeacon. The system includes an intelligent Bluetooth device that is arranged under each table or on the front side of each table. When a user takes a seat, the user turns on the Bluetooth on a mobile phone, connects the Bluetooth with the intelligent Bluetooth device of the table, and obtains a menu directory and orders food by the mobile phone. An order automatic processing device transmits the dining table number and an order to a kitchen and a reception desk terminal, and people in the kitchen start to prepare corresponding food. A waiter brings the food to the corresponding table, and the user can enjoy the food. After finishing eating, the user clicks and pays for the meal through a mobile phone app or a webpage program. A paying command is transmitted to the order automatic processing device through the intelligent Bluetooth device, and the user can pay the bill through an electronic payment system and also pay the bill with cashes through the reception desk terminal. Through adoption of the system, intelligent ordering, paying and printing can be achieved, the operation costs of a restaurant are reduced, the restaurant can be more ordered, and people can enjoy eating more comfortably.

Owner:SHANGHAI SUIYUN INFORMATION TECH

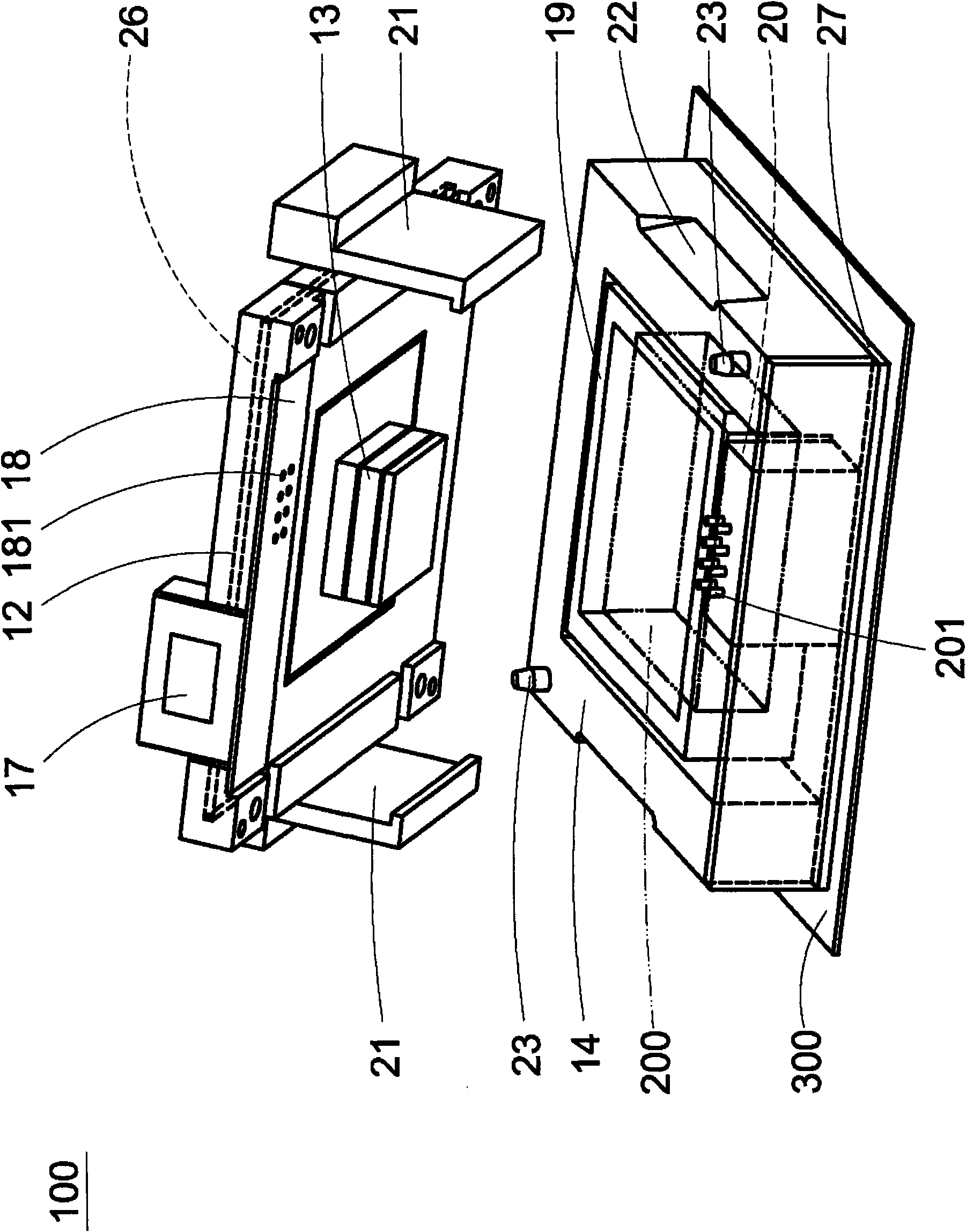

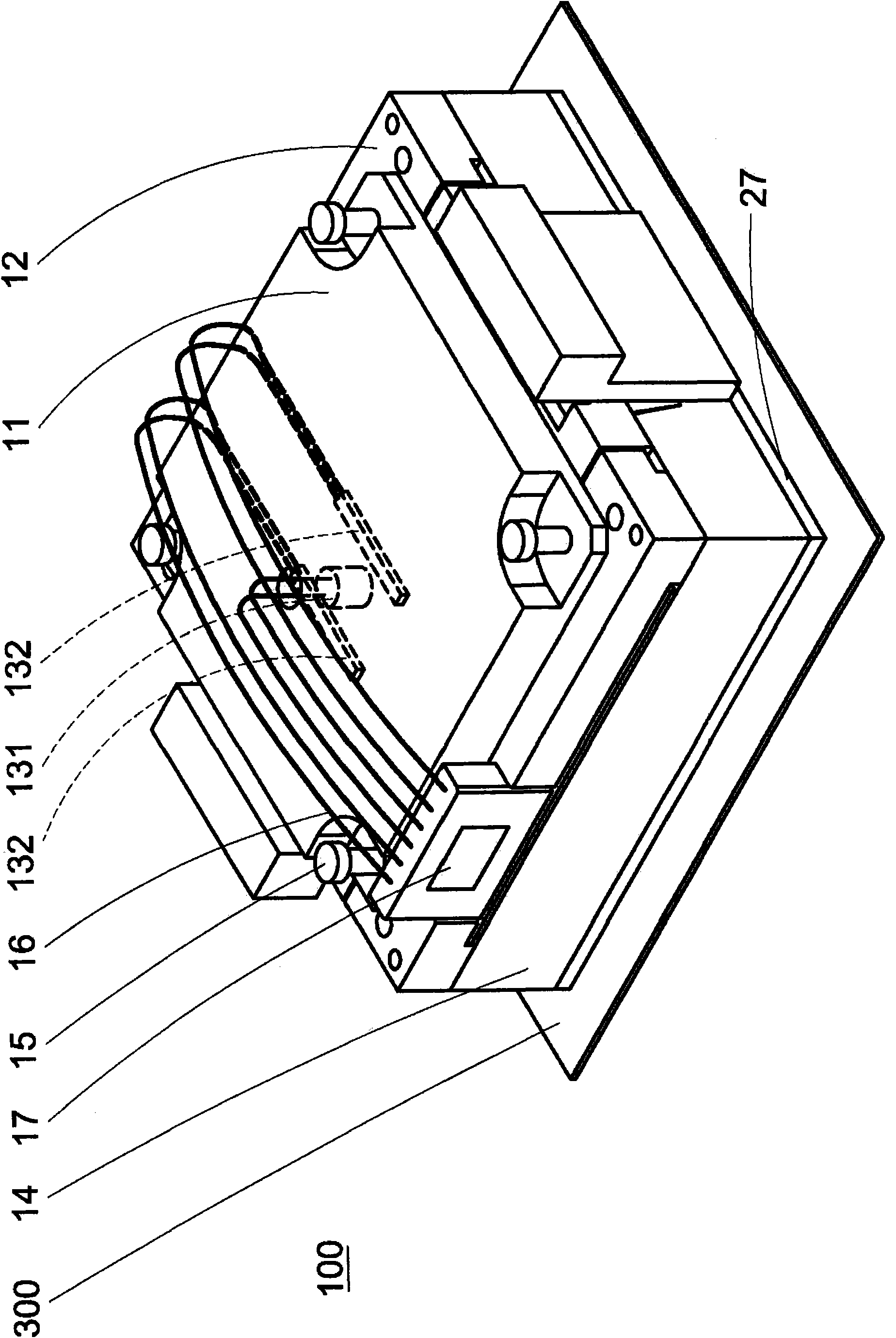

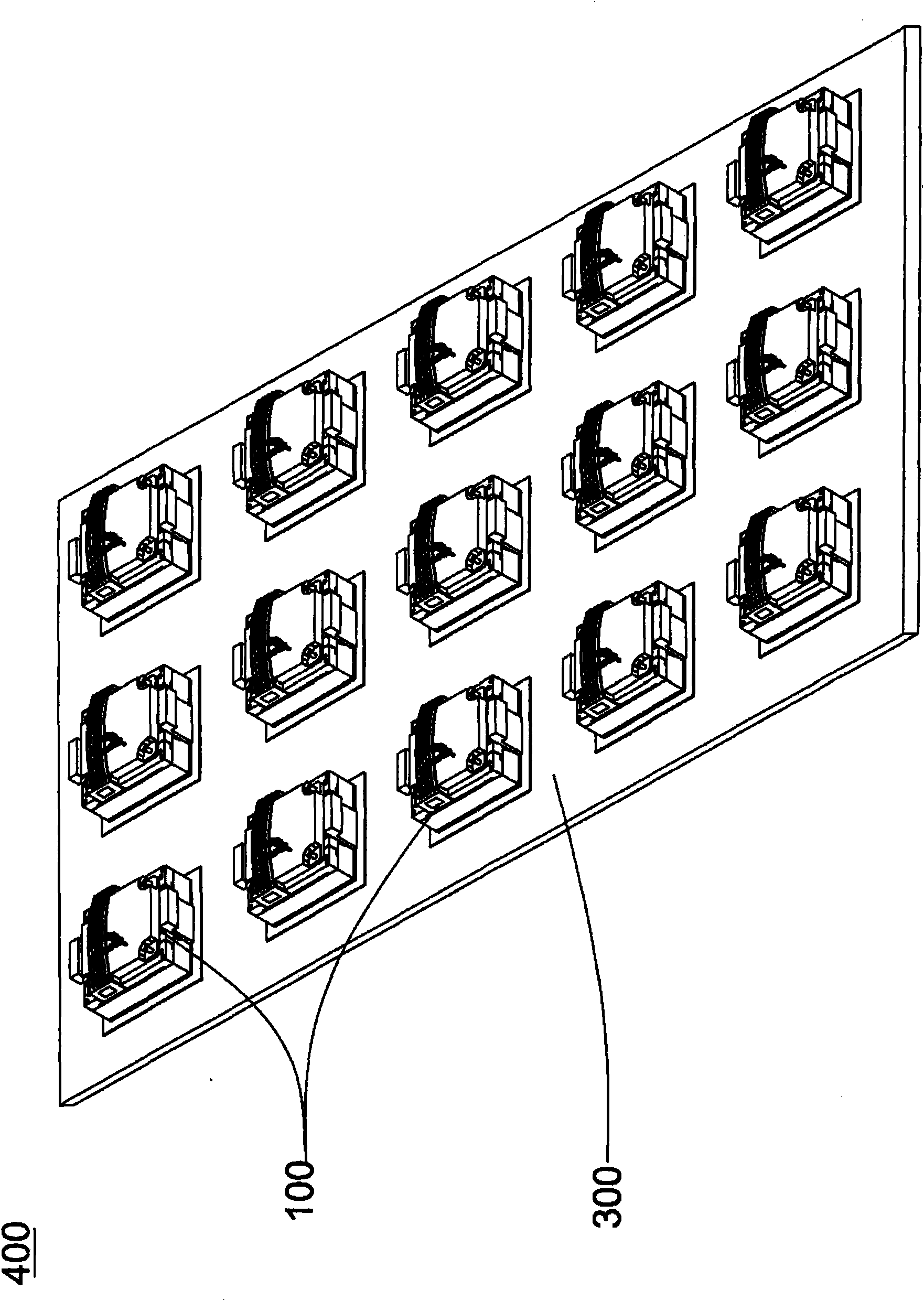

IC (integrated circuit) assembly burn-in equipment and IC heating device used by same

The invention provides IC (integrated circuit) assembly burn-in equipment and an IC heating device used by the same, wherein the IC heating device mainly comprises an upper cover plate, a fixing seat, a heating block and a base; the heating block is used for providing a heating surface close to uniformity so as to contact a measured IC; a heater and temperature inductor are accommodated in the heating block and electrically connected to a connector by utilizing a plurality of leads; the bottom of the connector is provided with a circuit board and a plurality of first connection points; an accommodating seat is arranged below the heating block for placing the measured IC; a part near the accommodating seat and corresponding to the circuit board is provided with a connecting seat; and the connecting seat is provided with a plurality of second connection points for correspondingly contacting and being conducted to the plurality of first connection points of the circuit board.

Owner:KING YUAN ELECTRONICS

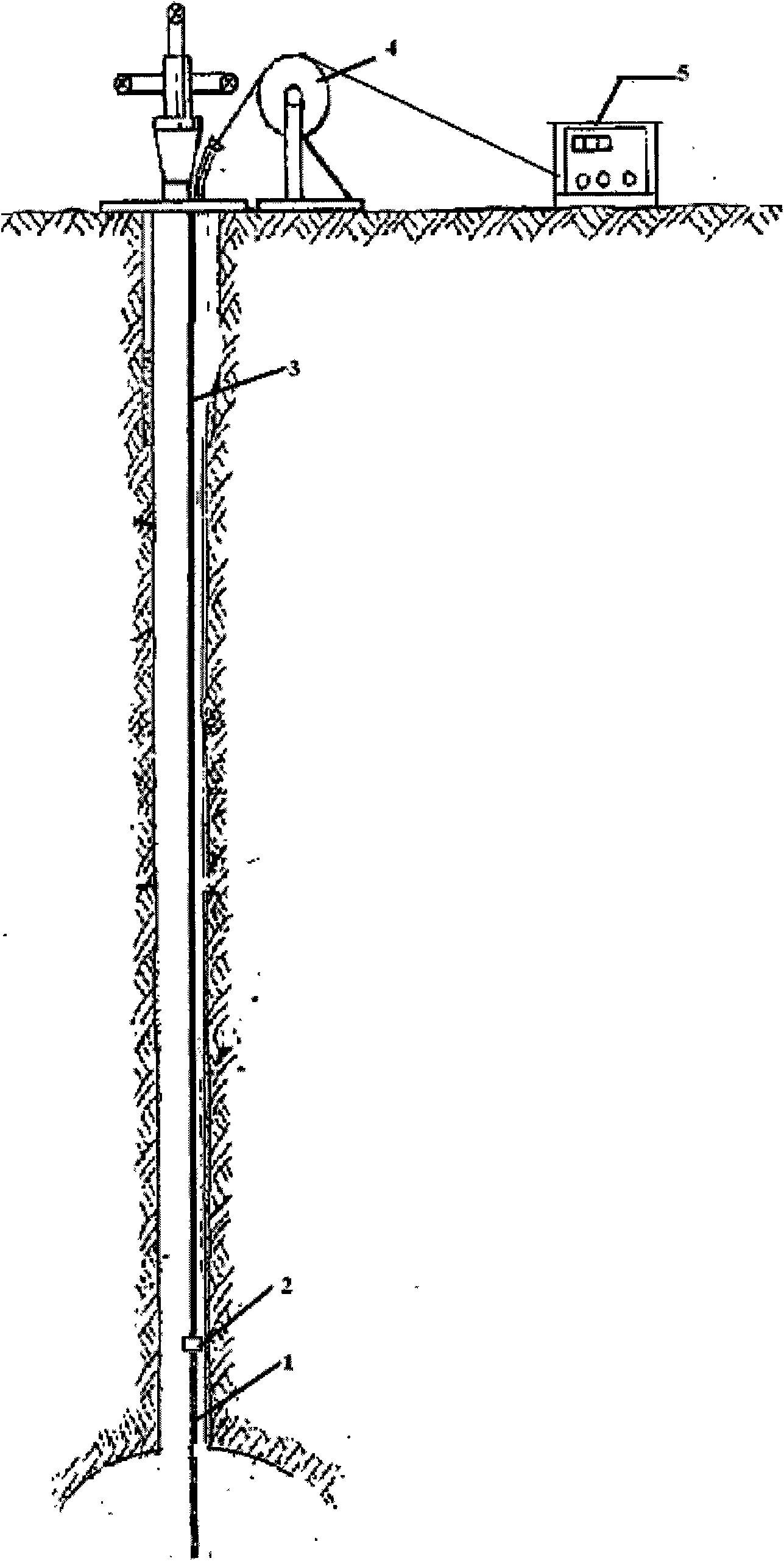

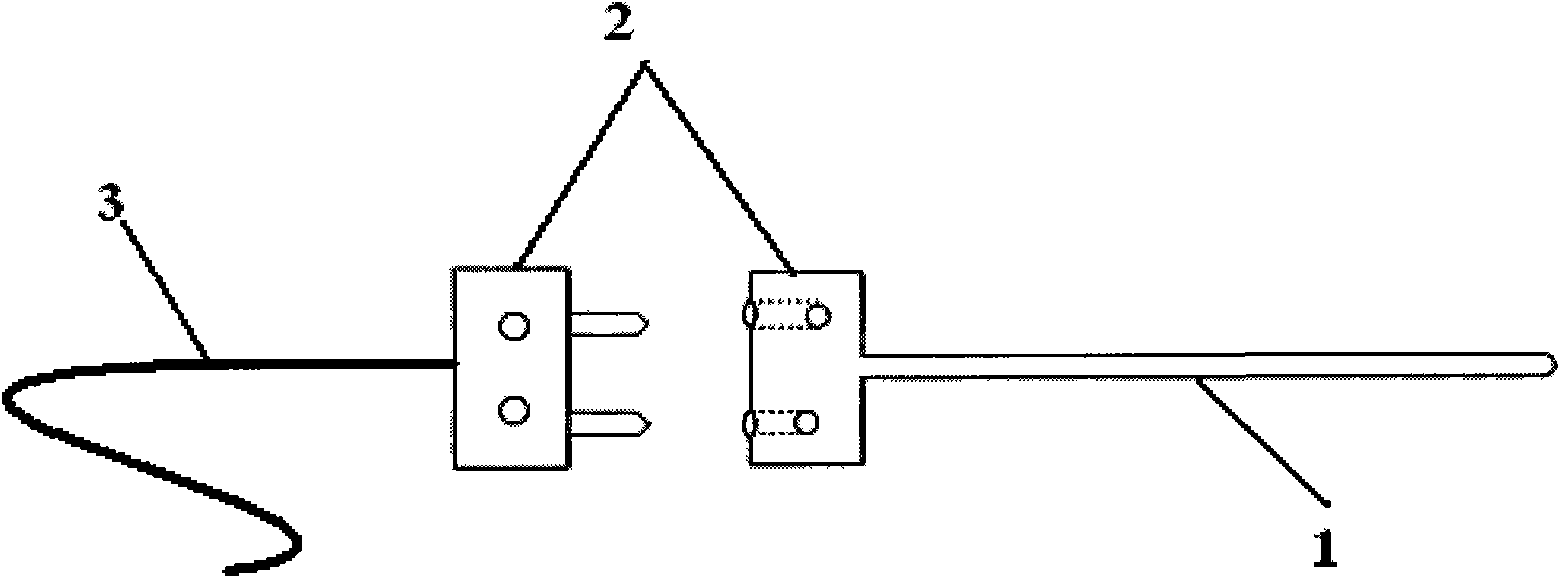

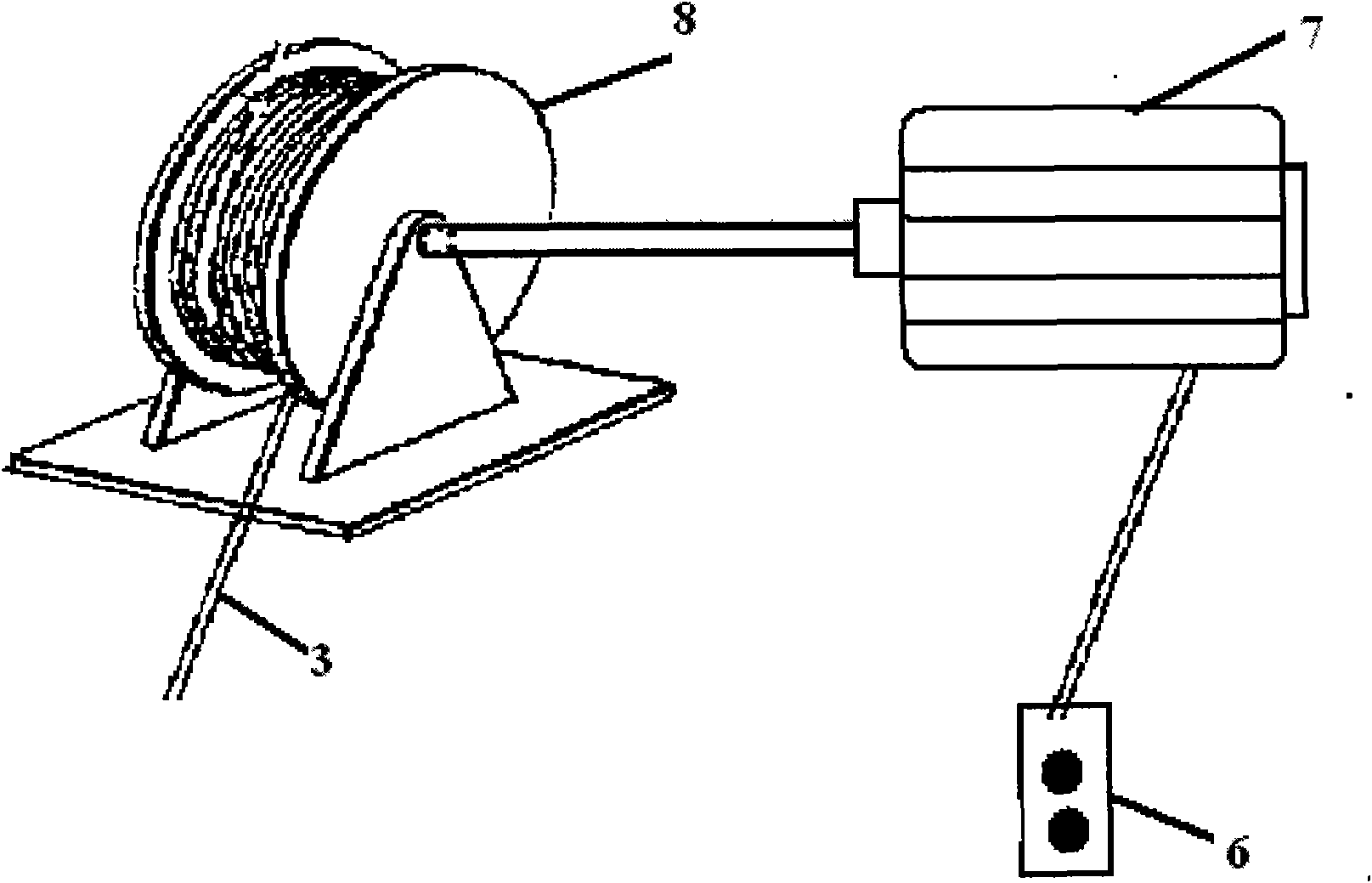

Thermocouple device used for measuring underground gasification temperature

ActiveCN101614598AImprove temperature measurement accuracyExtended service lifeThermometer detailsThermometers using electric/magnetic elementsMeasurement precisionMaterials science

The invention provides a thermocouple device used for measuring underground gasification temperature, which comprises a metal clad thermocouple, a ceramic joint, a compensation lead, a telpher, a temperature detector, and the like. The thermocouple device has the advantages of high measurement precision, long service life, good mechanical strength, strong corrosion resistance, simple structure, high automation degree, low cost and the like, and can solve various problems that the prior thermocouple used by underground gasification is easy to damage under high-temperature strong reducing atmosphere, has poor environment adaptability, low working efficiency, high cost, and the like.

Owner:ENN SCI & TECH DEV

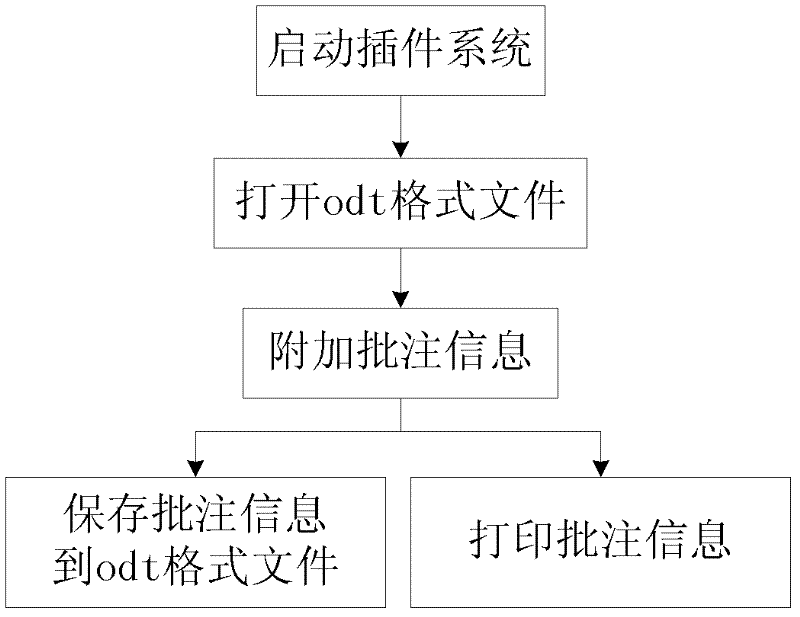

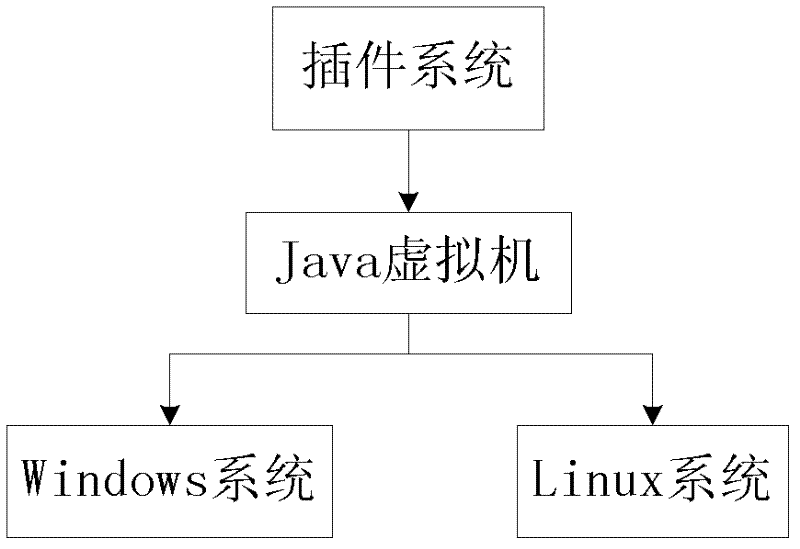

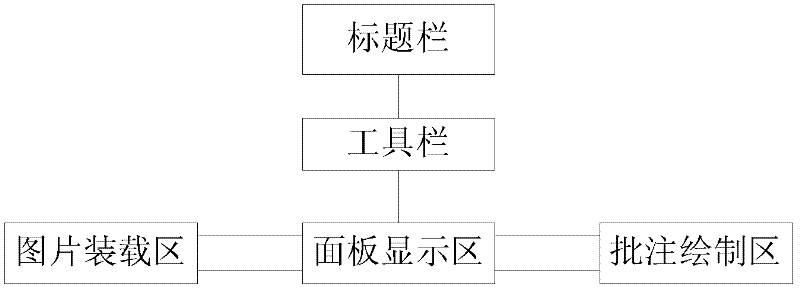

Method for handwriting comment for odt format file

InactiveCN102467495AHigh automation efficiencyAvoid time costSpecial data processing applicationsHandwritingUnit system

The invention relates to a method for a handwriting comment for an odt format file, comprising the following steps: reading a source odt format file into an internal storage and calling for a picture output function, and converting the file into an internal storage structure which is in a picture data format capable of being identified by a plug-in unit system, and achieving the handwriting comment operations for odt format files on different systems with characteristics of the Java cross-platform, wherein document reading and any handwriting comments are supported while crossing the platform. The method for handwriting the comment for the odt format file solves the problem that the handwriting comment method for the odt format file is deficient, and achieves handwriting comments on the different systems, and reduces time and production cost caused by repeated developments on the cross-platform or comment tools.

Owner:CHINA STANDARD SOFTWARE

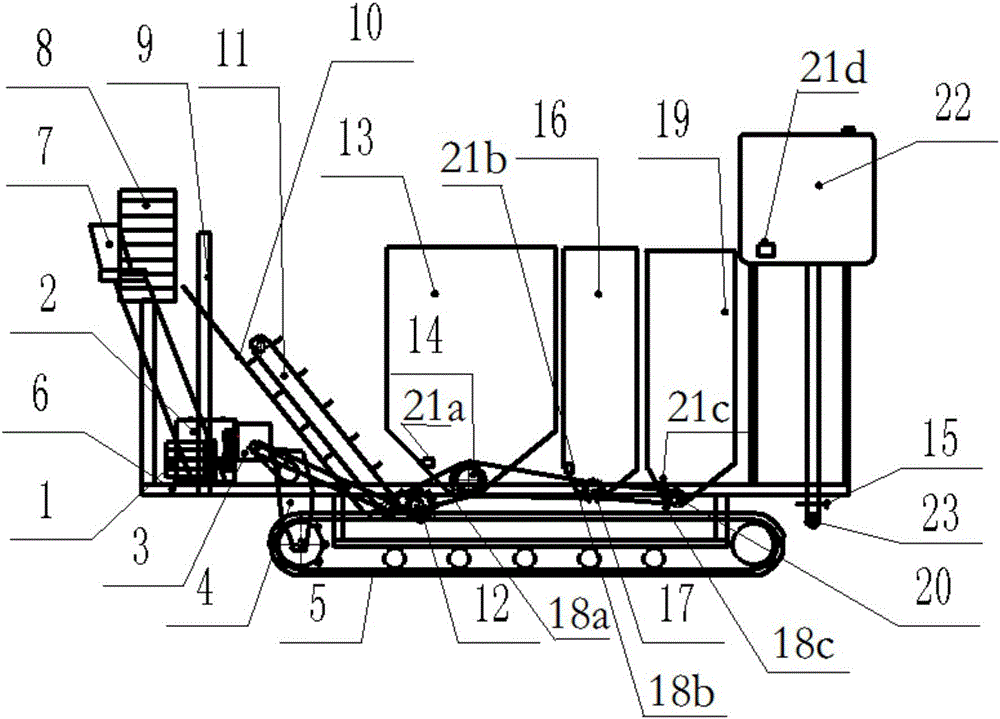

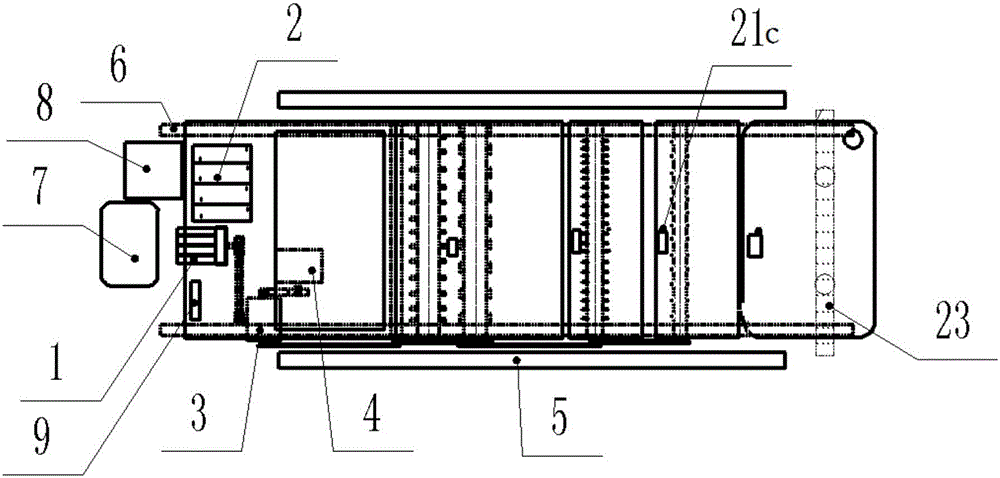

Tray arranging and sowing machine for seedling raising

ActiveCN106134831AAutomated program highSeedling effect guaranteeGrowth substratesCulture mediaSeederWater volume

The invention discloses a tray arranging and sowing machine for seedling raising and relates to the technical field of agricultural machinery. The tray arranging and sowing machine comprises a nutrient soil box, a seed box, a soil covering box and a water box, and is characterized by further comprising a nutrient soil amount sensor, a seed amount sensor, a soil covering amount sensor and a water volume sensor which are arranged in the nutrient soil box, the seed box, the soil covering box and the water box respectively and used for monitoring the quantity of remaining materials in the corresponding boxes, and the tray arranging and sowing machine further comprises a control device and an alarm device; each sensor sends a signal to the control device when monitoring that the quantity of remaining materials in the corresponding box is lower than a corresponding preset value, and the control device controls the alarm device to perform alarming to remind a worker to add the corresponding material timely.

Owner:JIANGXI ACAD OF AGRI SCI INST OF AGRI ENG

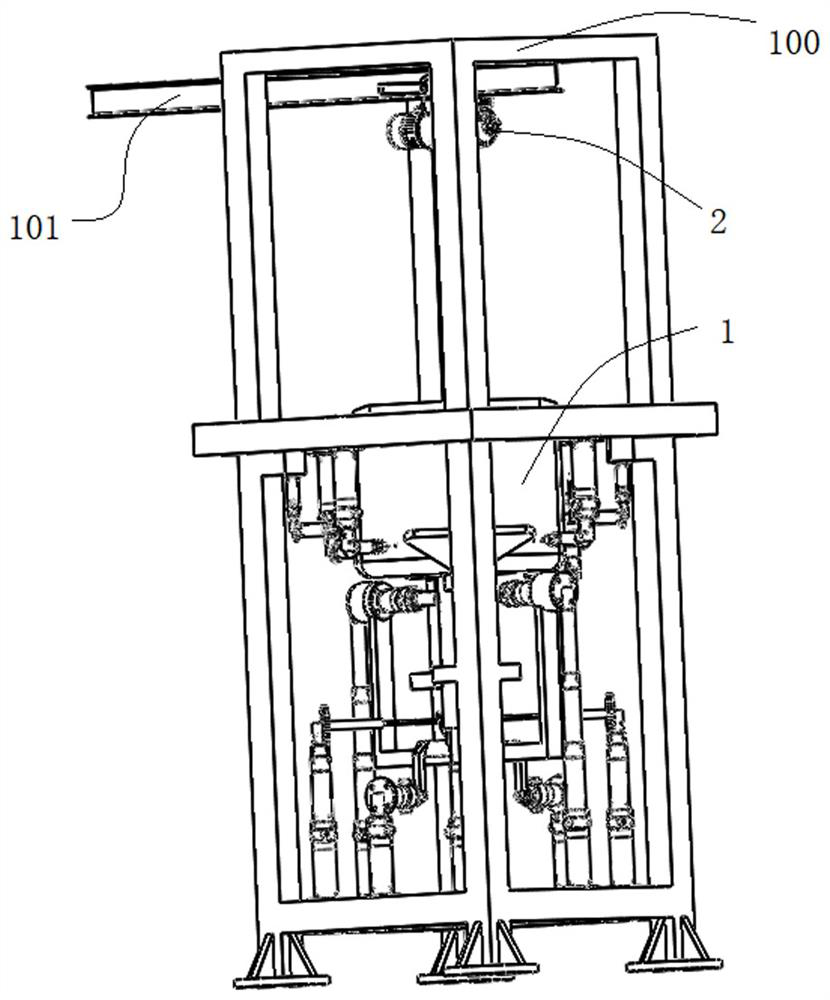

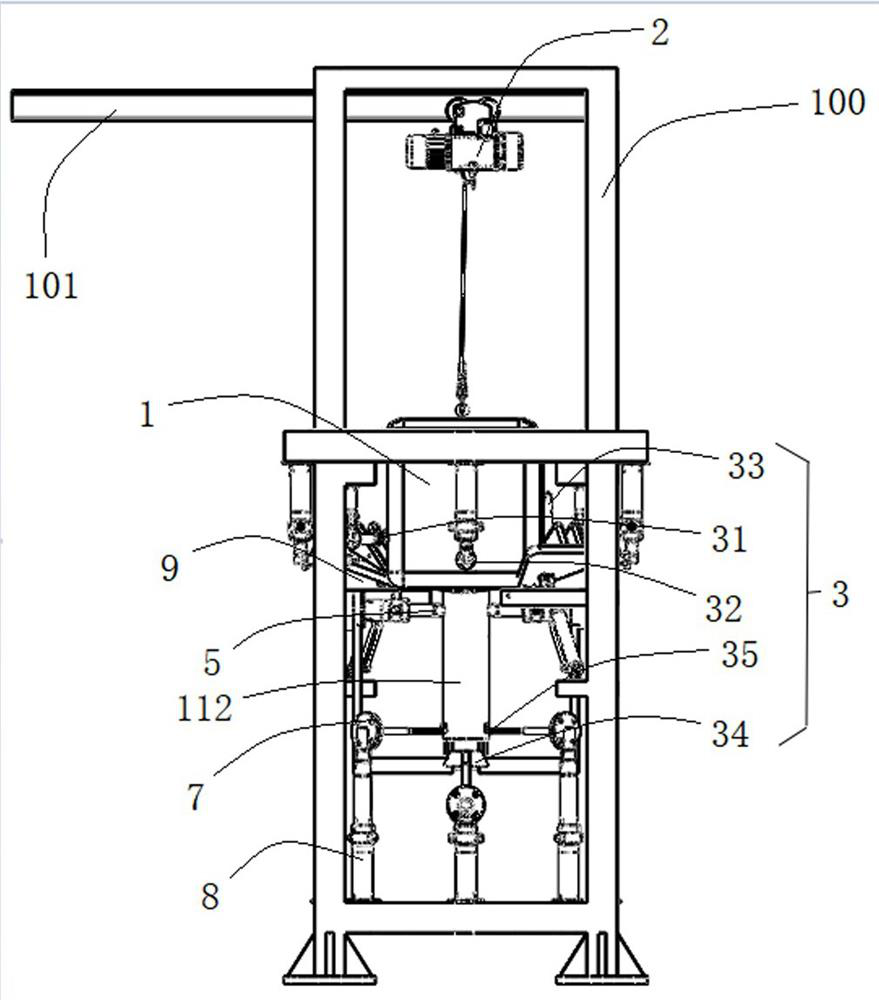

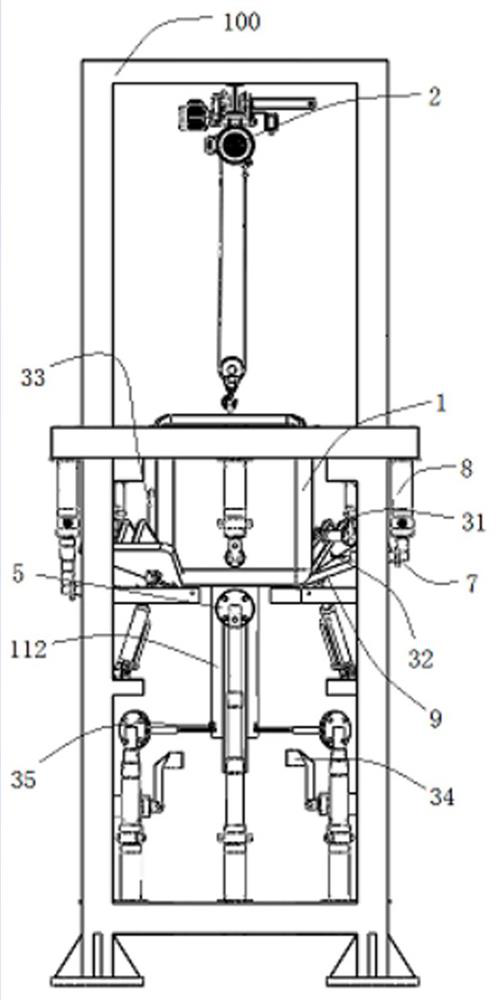

Automatic ton bag unpacking device and method

ActiveCN112429353ARealize automatic bag unpackingNo human assistance requiredFlexible bulk container emptying systemsBinding material removalHydraulic cylinderElectric machinery

The invention discloses an automatic ton bag unpacking device. The automatic ton bag unpacking device comprises a ton bag with an outer layer and inner tongue double-layer structure, a supporting frame made of an aluminum alloy material and used for mounting components, a rail arranged at the top of the supporting frame and a power device for driving the ton bag to transversely move and longitudinally move along the rail. The automatic ton bag unpacking device is characterized in that disassembling devices, a discharging barrel arranged at the bottom end of the supporting frame, ascending anddescending in the longitudinal direction and connected with an inner tongue in a sleeved mode, an inner bag knife arranged in the discharging barrel, and a barrel hoop arranged at the outer end of thejoint of the inner tongue and the discharging barrel and used for sealing and fixing are further included; and the disassembling devices are connected with three-level hydraulic cylinders through transition pieces separately and are driven by a control unit, the three-level hydraulic cylinders are all fixedly arranged on the supporting frame, the rail for lifting of the inner bag knife is arranged in the discharging barrel, and the inner bag knife drives a rope to ascend and descend in the rail through a motor. By means of the automatic ton bag unpacking device, automatic bag unpacking operation is achieved, and accidental leakage of powder in the bag unpacking process is avoided.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Component transfer tool

PendingCN108032279ARealize automatic transferImprove positionProgramme-controlled manipulatorGripping headsDrive motorForce output

The invention provides a component transfer tool, and belongs to the field of component processing equipment. The component transfer tool comprises a base, a movable seat, a rotary cylinder and a lifting cylinder. A mounting groove is formed in the middle of the base, a lead screw is erected in the mounting groove, the axis of the lead screw is parallel to the longitudinal center line of the base,a driving motor is arranged at an end of the base, a force output shaft of the driving motor is fixedly connected with an end of the lead screw, and a nut is fittingly arranged on the lead screw andis fixedly connected with the movable seat by a connecting plate which is vertically arranged. The component transfer tool has the advantages that components at different locations can be quickly transferred by the component transfer tool, and the component transfer tool is high in precision and efficiency.

Owner:TIANJIN KAIDA HEAVY HYDROPOWER EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com