Drilling machine with arm type automatic tool changing device

An automatic tool changer and arm technology, applied in the direction of boring/drilling, drilling/drilling equipment, clamping, etc., can solve the problems of low automatic efficiency and complex structure, and achieve high automation efficiency, simple operation, and reduced cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

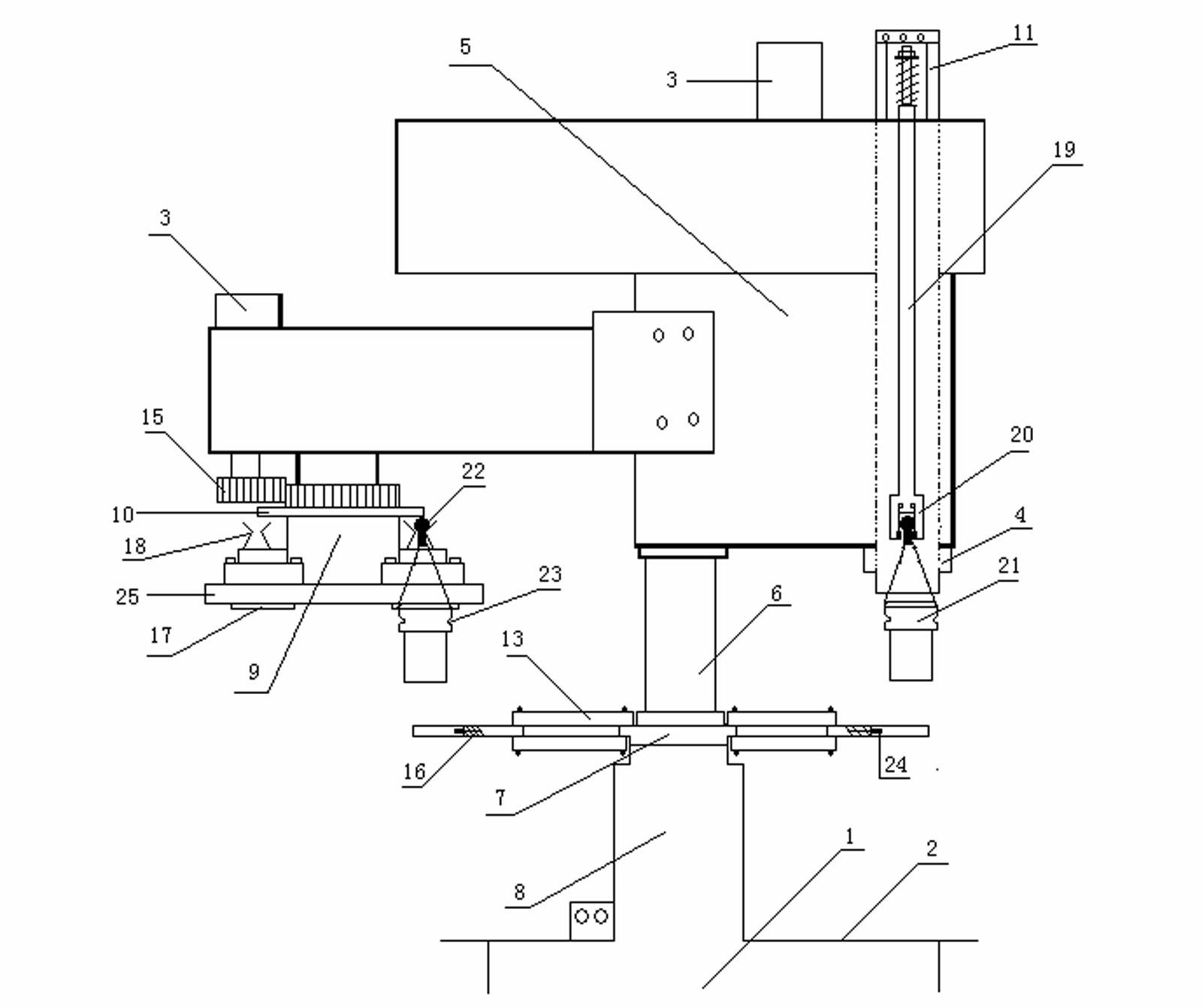

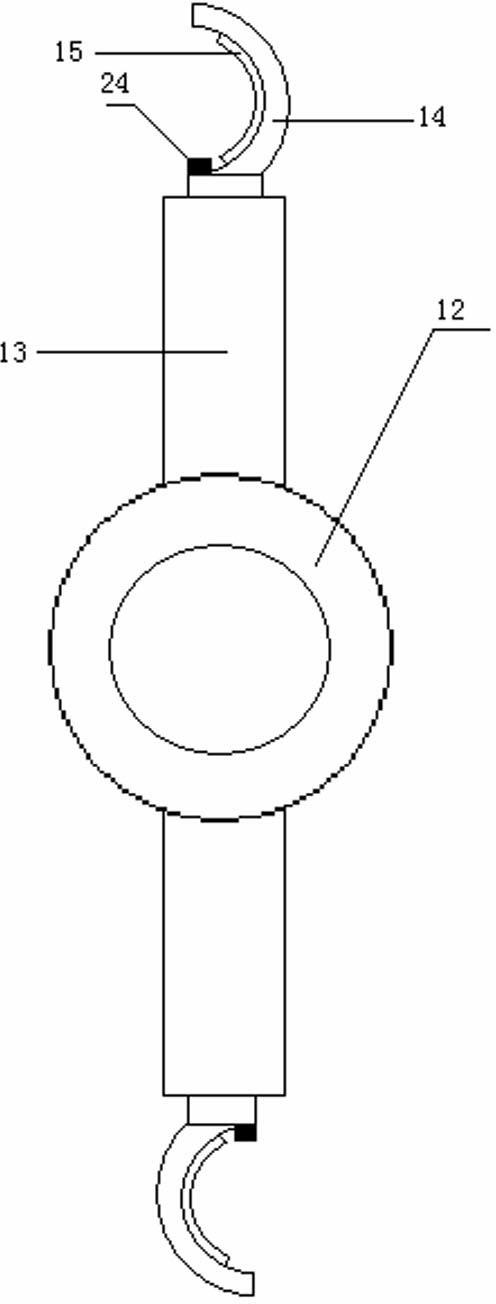

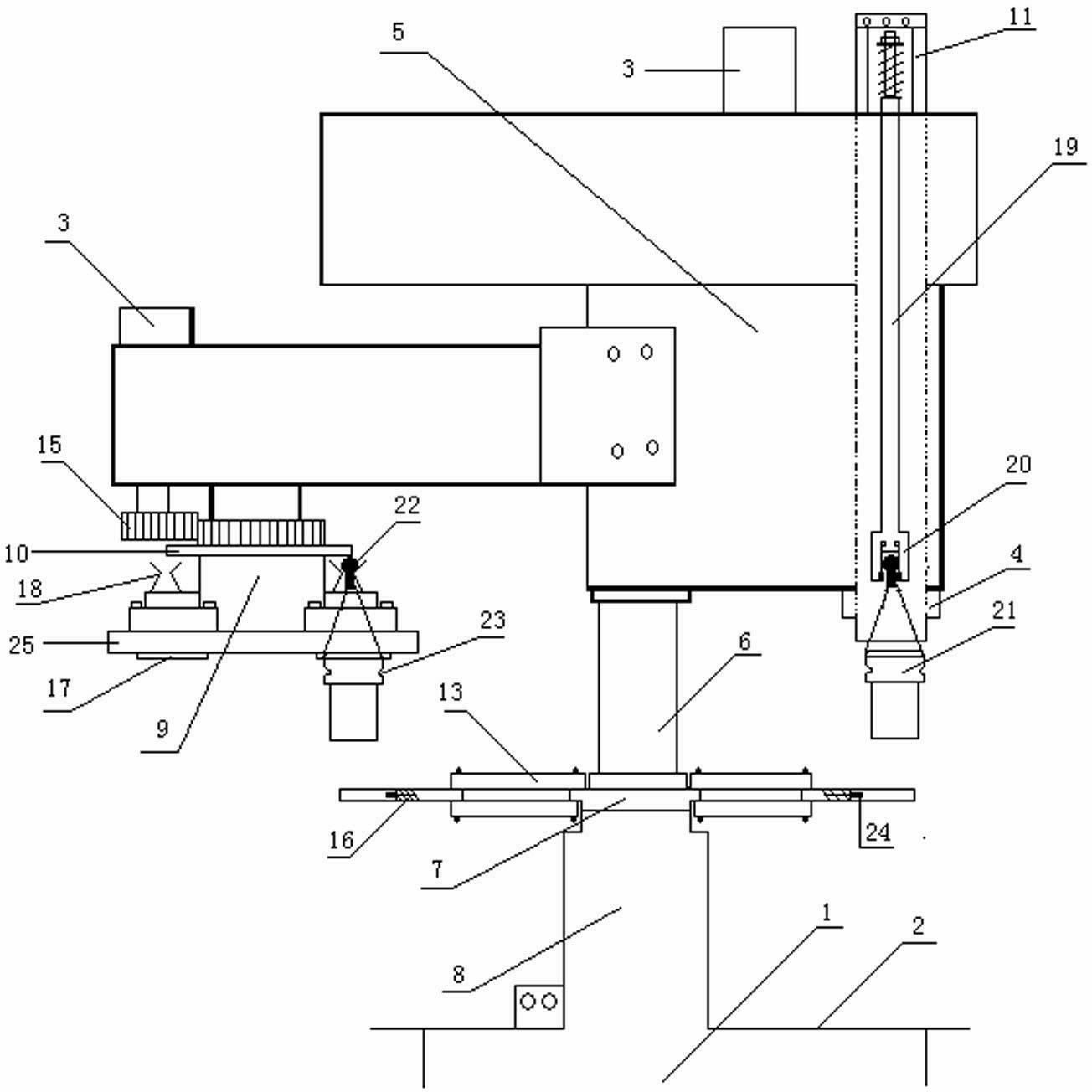

[0011] refer to figure 1 , figure 2 , a drilling machine with an arm-type automatic tool changer, including a machine, 1, a workbench 2, a motor mechanism 3, a rotating spindle 4, a body 5 and a column 6, and the column 6 is also equipped with a rotatable arm-type automatic tool changer Device 7 and column elevating device 8; Multi-station tool magazine device 9 and cylinder device 11 are also provided on the fuselage 5; Rotating main shaft 4 is also provided with clamping and loosening tool linkage device inside. The arm-type automatic tool changer 7 is provided with a steel ring sleeve 12, which can be rotated on the column 6. The two sides of the steel ring sleeve 12 have round-point symmetrical equal moments 13, and the front end of the moment 13 is provided with a semicircular grabbing claw 14. , the front end of the moment 13 is also provided with a spherical convex column 24 of the spring device 16, and an arc-shaped rib 15 is provided on the inner wall of the claw 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com