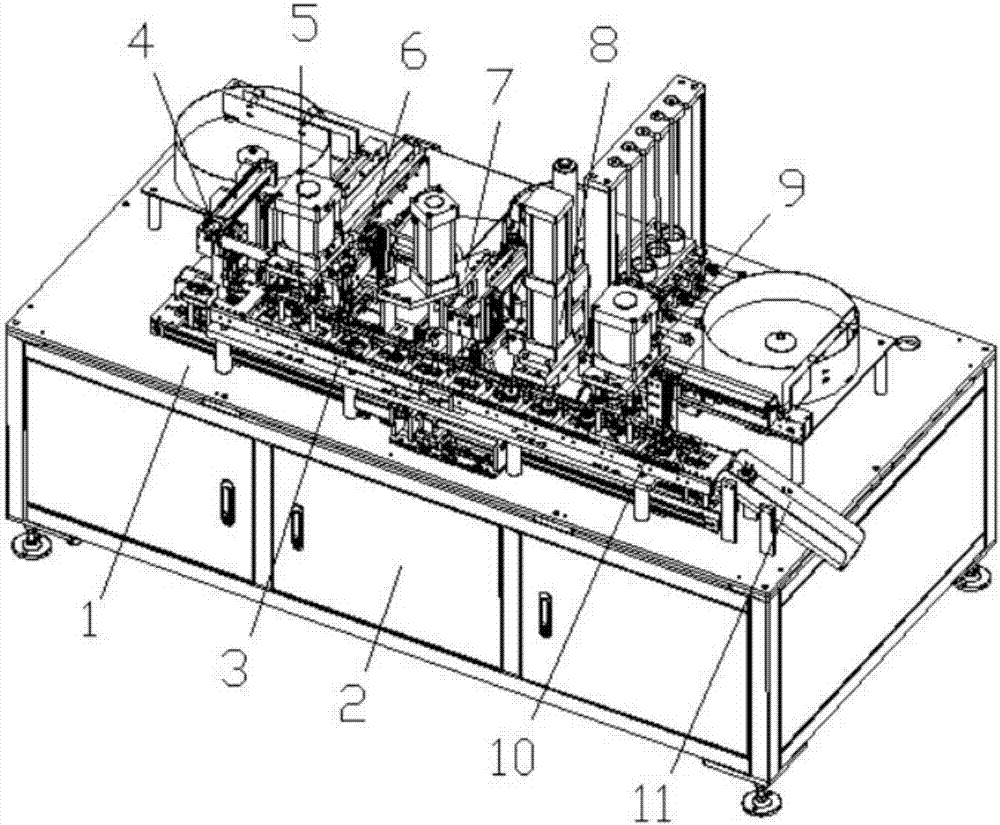

Automatic gear shaft assembling machine

A gear shaft and assembly machine technology, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of inaccurate gear shaft assembly, inaccurate shaft clamping position, and high defective product rate, and achieve continuous automatic assembly , easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

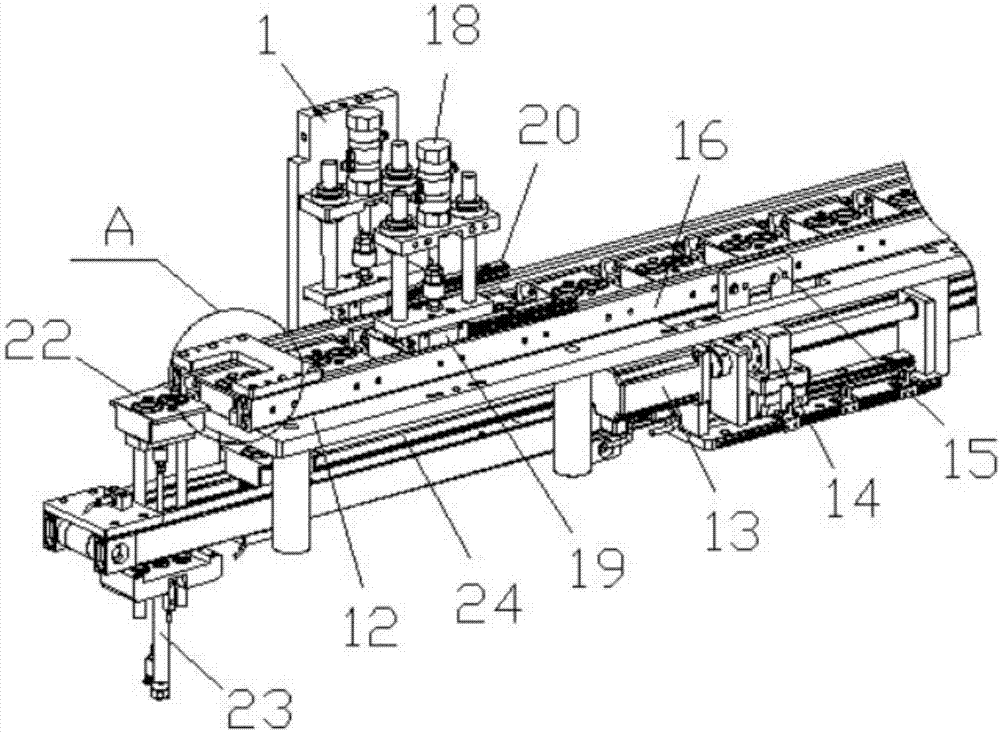

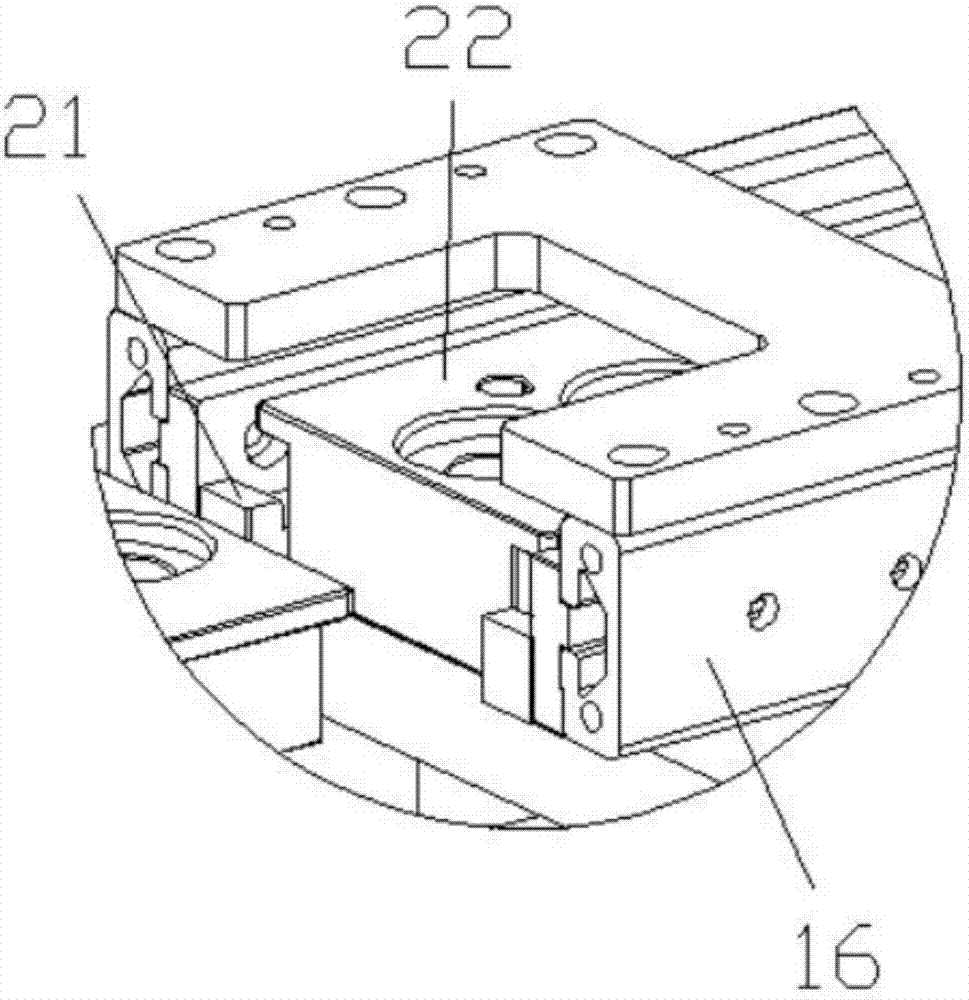

[0038] Such as Figure 1-Figure 12 As shown, the specific structure of the present invention is: a gear shaft automatic assembly machine, which includes a frame 1 and a power distribution control box 2, the frame 1 is provided with a carrier conveying device 3, and the carrier The conveying device 3 includes a carrier conveying seat 12, the front and rear sides of the carrier conveying seat 3 are provided with a carrier feeding movable cylinder 13, and the carrier feeding movable cylinder 13 is connected with a carrier feeding movable seat 14 , the carrier feed movable block 16 is connected with a lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com