EGR (Exhaust Gas Recirculation) valve

An EGR valve and valve plate technology, applied in the mechanical field, can solve the problems of high emission standards, large leakage, difficult control of processing and installation and assembly, and achieve the effect of high matching accuracy and improving sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

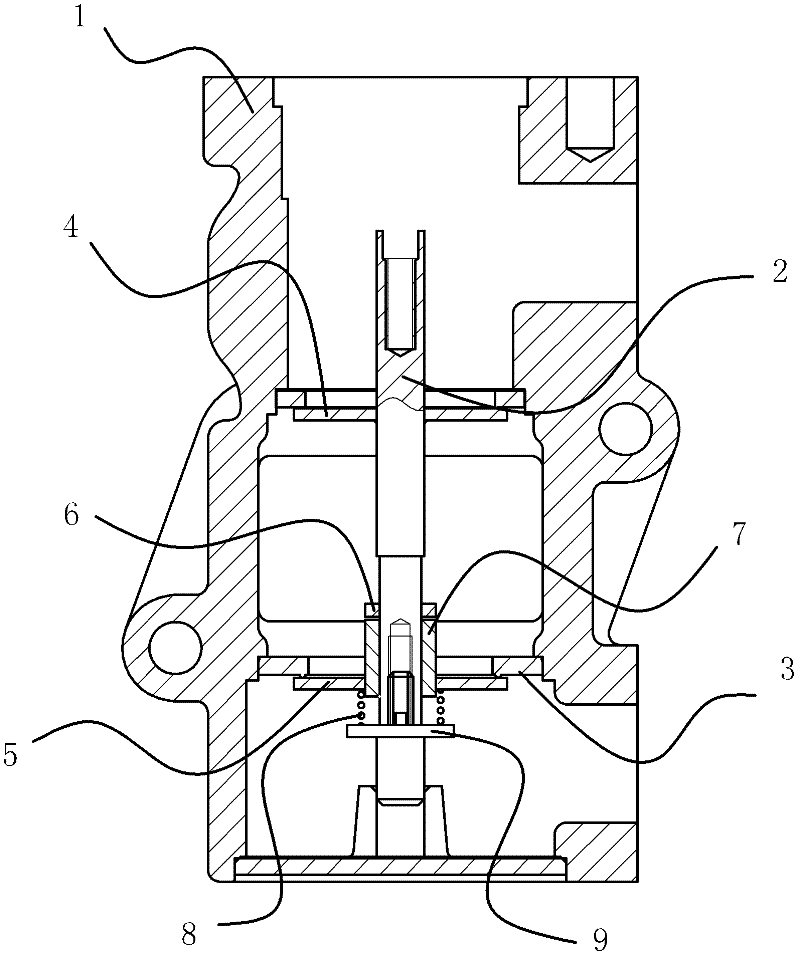

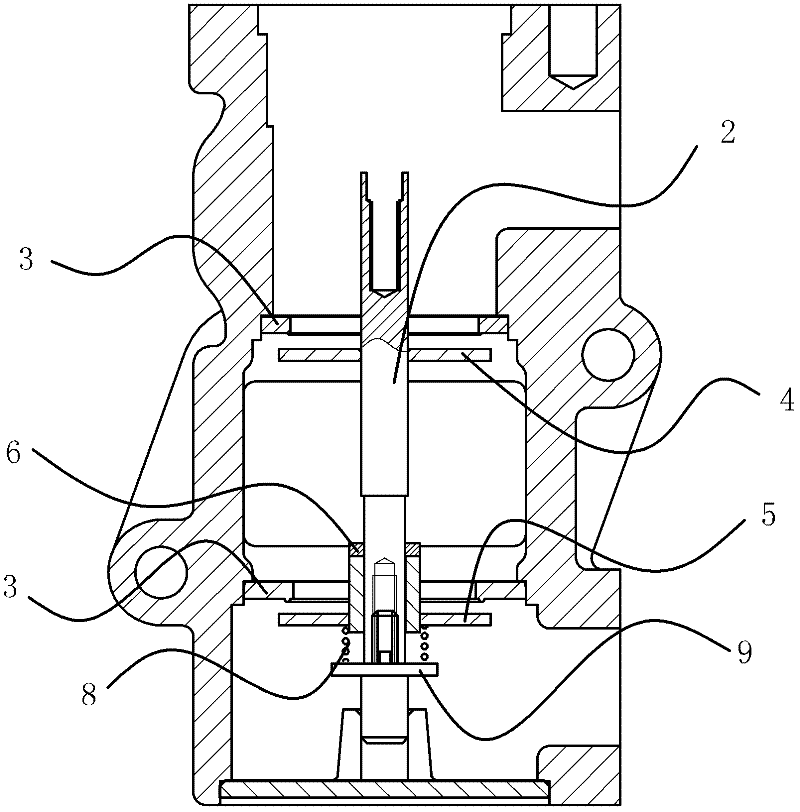

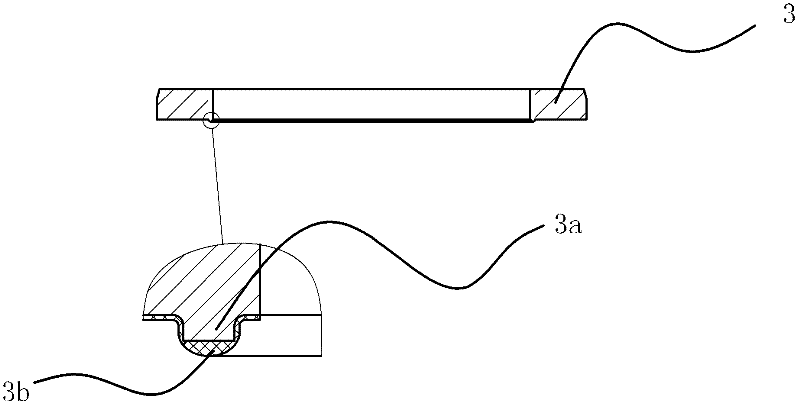

[0020] Such as figure 1 , figure 2 As shown, what this embodiment adopts is the EGR valve of double valve structure. The EGR valve includes a valve body 1 with a cavity inside. The valve body 1 has an inlet and an outlet communicating with the inner cavity. The valve body 1 has a valve stem 2 connected with the power part. The inside of the valve body 1 has two The protruding sealing seat 3 has two valve plates on the valve stem 2 along its axial direction, and a sealing structure is formed between the valve plates and the sealing seat 3 .

[0021] Specifically, the valve plate includes a valve plate one 4 and a valve plate two 5 , and the valve plate one 4 is fixedly connected to the valve stem 2 . The valve stem 2 is provided with a positioning piece 6, the lower end of the valve stem 2 is fixedly connected with a base 9, the sleeve 7 is located between the base 9 and the positioning piece 6, and the sleeve 7 can move axially along the valve stem 2. The second valve plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com