Patents

Literature

783results about How to "High matching precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

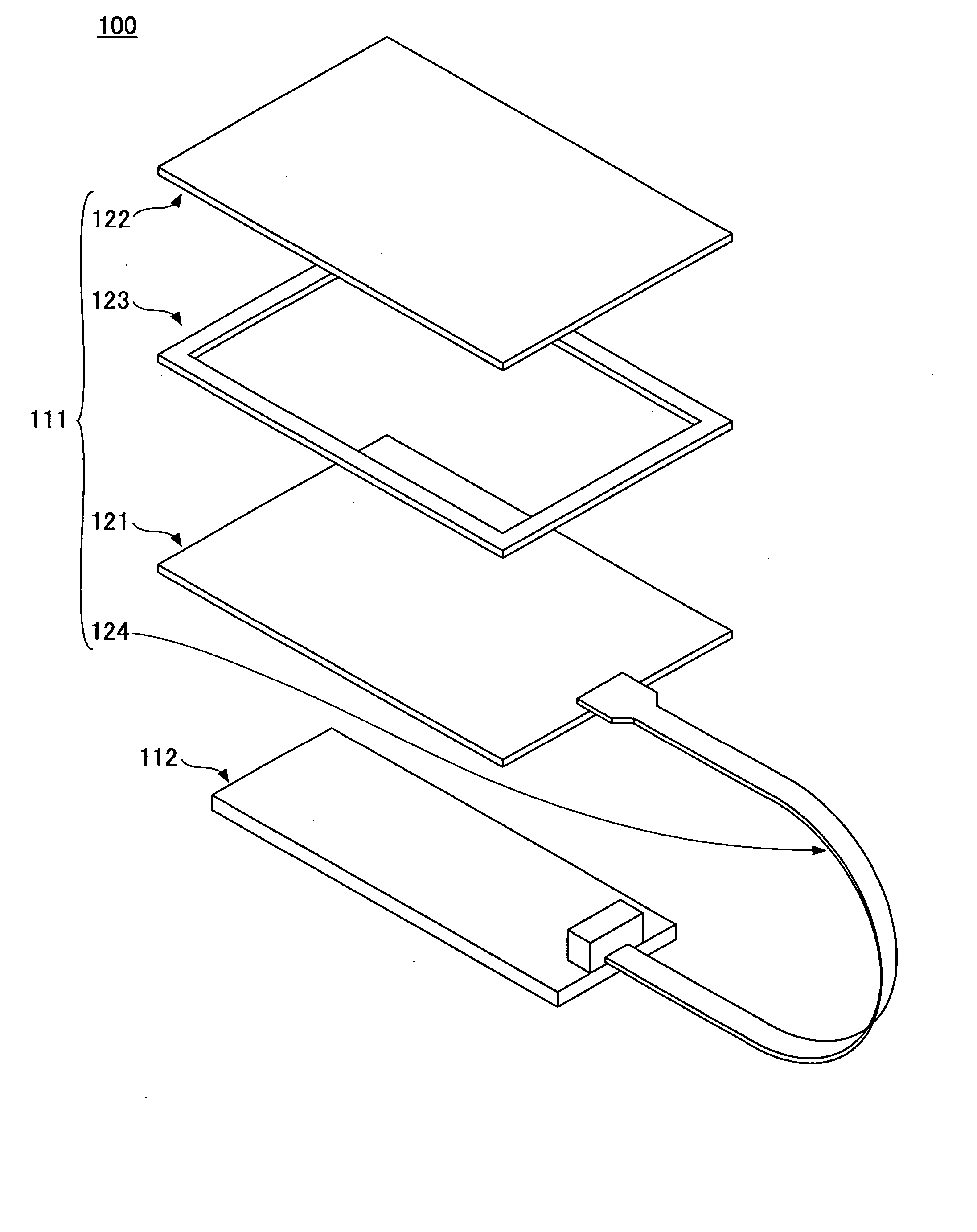

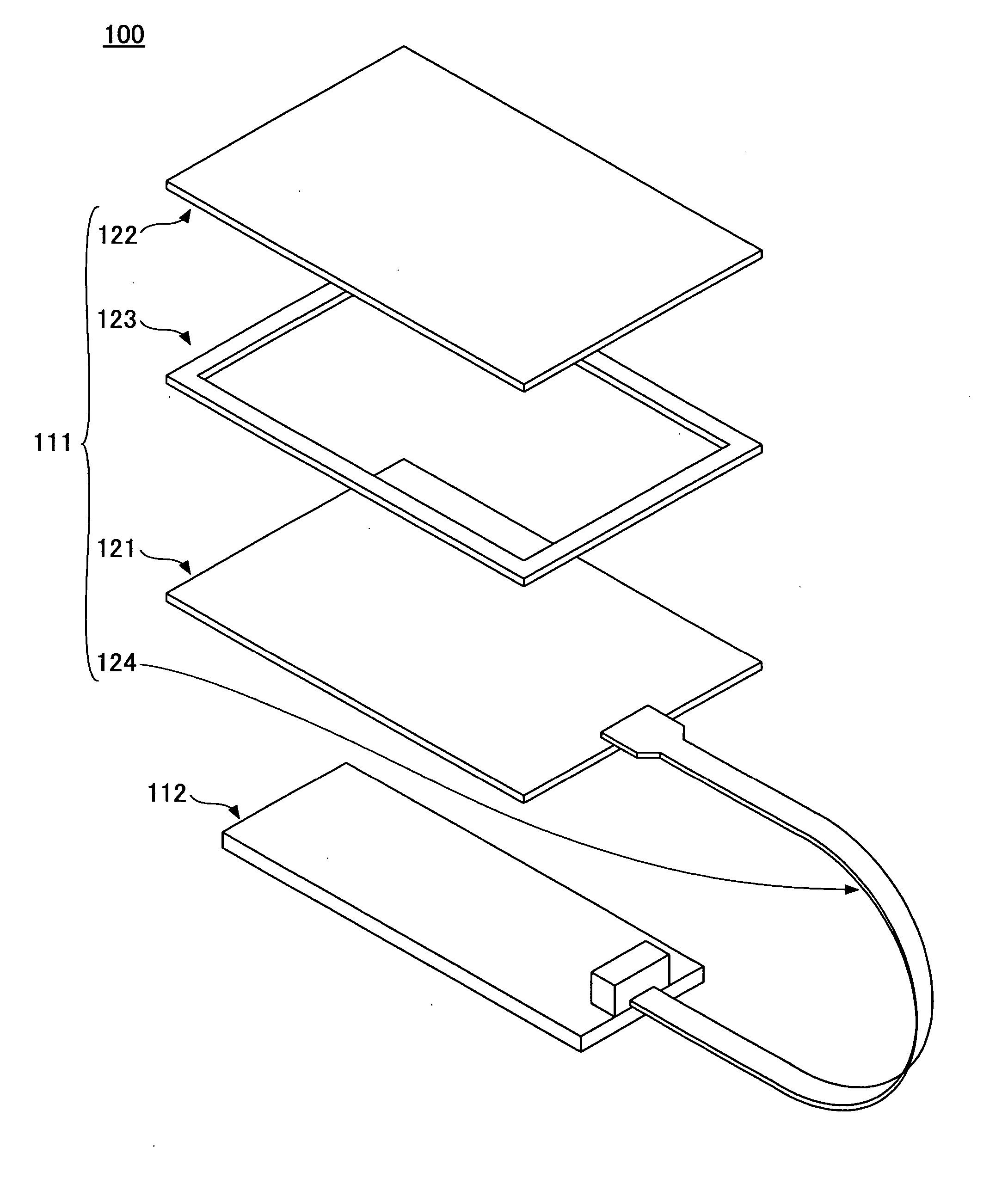

Coordinate detecting device

InactiveUS20070013678A1High matching precisionSmall device sizeCathode-ray tube indicatorsInput/output processes for data processingElectric potentialVoltage

A coordinate detecting device is disclosed. The coordinate detecting device includes a resistance film, a common electrode which applies electric potential to the resistance film, a voltage supplying section which supplies a voltage to the common electrode, wiring which supplies the voltage to the voltage supplying section, an insulation film disposed between the common electrode and the resistance film, and an electric potential supplying section formed in the insulation film for supplying the electric potential from the common electrode to the resistance film. The coordinate detecting device detects a coordinate of a position on a panel when a user touches the position while an electric potential distribution is generated in the resistance film by being applied electric potential from the common electrode.

Owner:FUJITSU COMPONENENT LTD

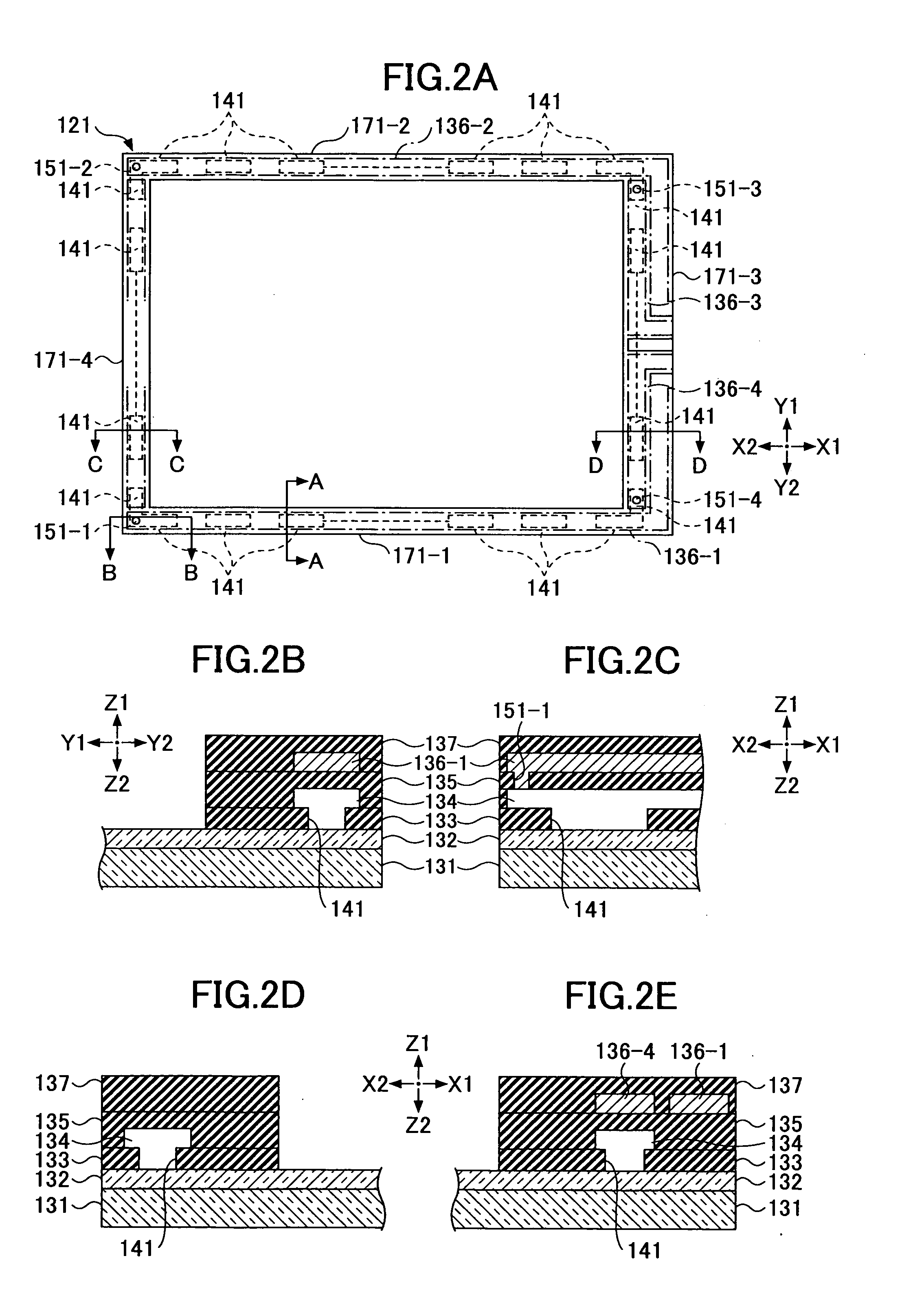

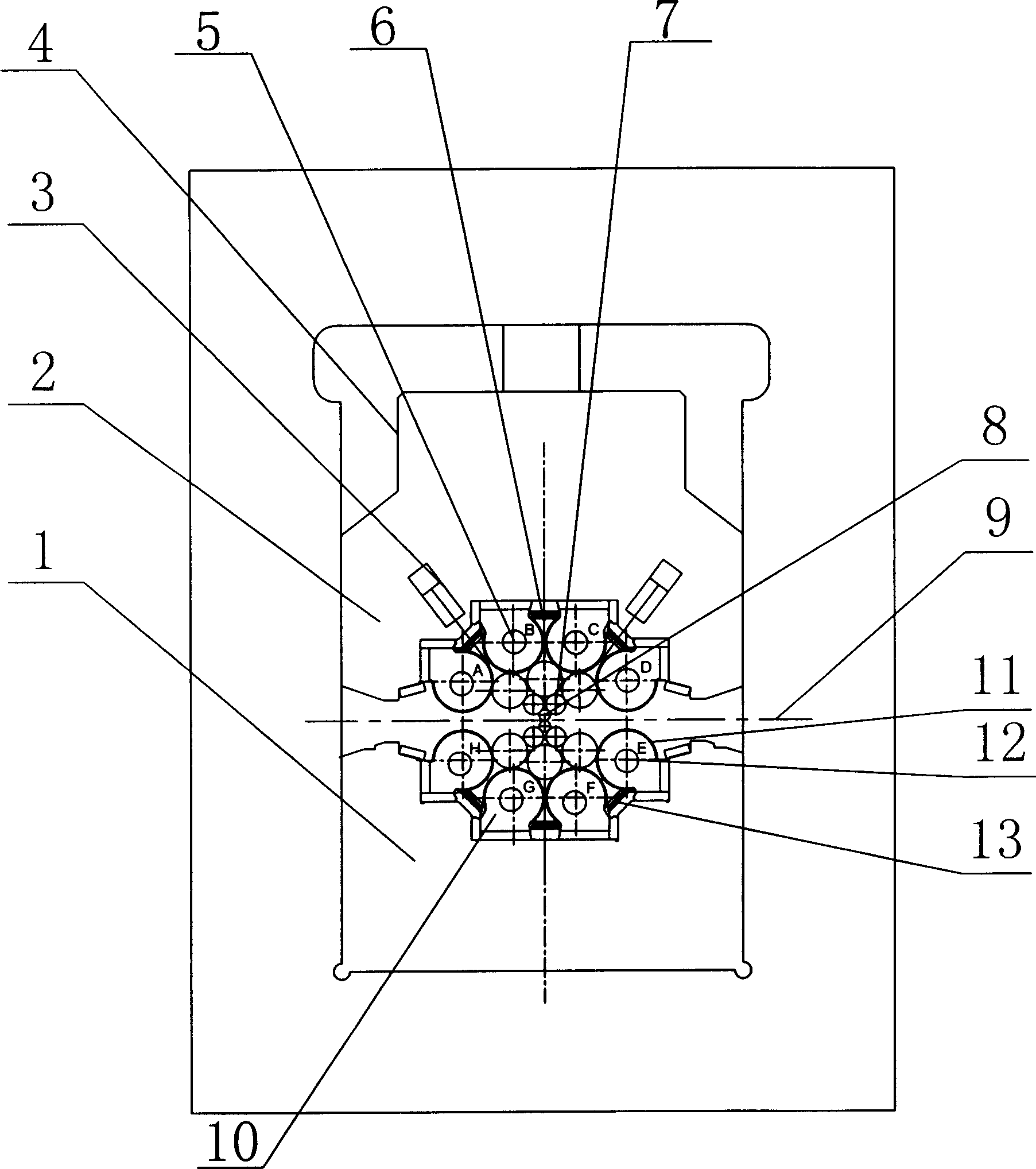

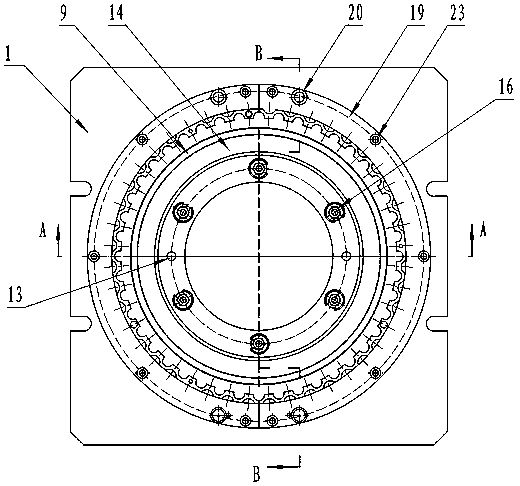

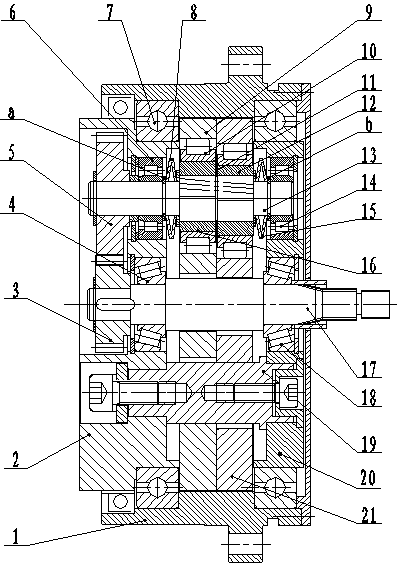

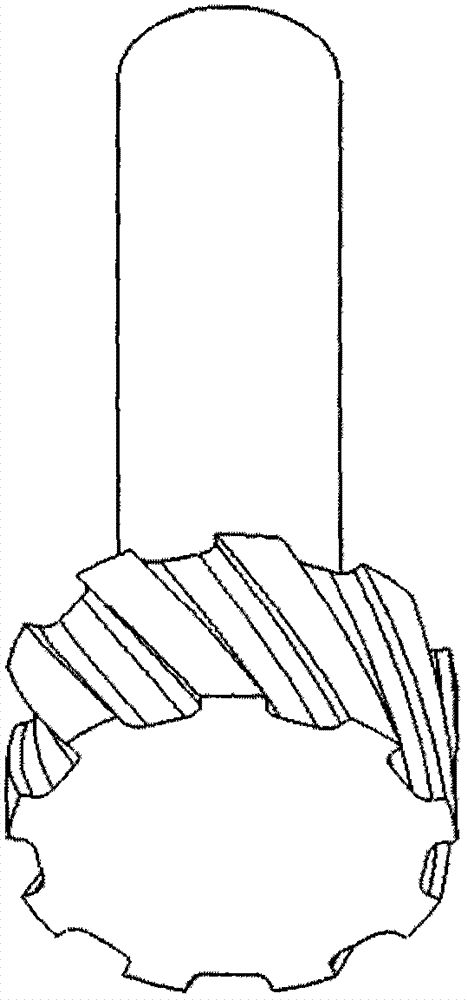

Novel large torque piling machine power head hardened reducer

InactiveCN103016641AReduce loadImprove carrying capacityToothed gearingsFoundation engineeringLow noiseReducer

The invention relates to a novel large torque piling machine power head hardened reducer. The reducer comprises an engine body, a cover body, a central gear, an output shaft and more than two groups of planetary transmission mechanisms, wherein two ends of the output shaft are respectively supported on the engine body and the cover body in a penetrating manner; the output shaft at one side of the engine body is in end connection with a grouting device system; the central gear is connected onto the output shaft in a penetrating manner and is arranged between the engine body and the cover body; the more than two groups of planetary transmission mechanisms are supported on the engine body by taking the output shaft as a symmetric center; the planetary transmission mechanism comprises an input motor, and first-stage and second-stage planetary transmission mechanisms; the input motor is connected to an inclined gear shaft which is arranged in the engine body and the cover body through the first-stage and second-stage planetary transmission mechanisms; and the inclined gear shaft is meshed with the central gear. By adopting the more than two groups of planetary transmission mechanisms, the running power of the reducer is shunted; the reducer can stably and safely run for a long time under the large torque in matched with the meshed inclined gear shaft and the output shaft through the combination supporting of a roller bearing and a plane bearing; and the reducer has the advantages of compact structure, stable running, shunted work load, little equipment abrasion, low noise and long service life.

Owner:JIANGSU TAILAI REDUCER

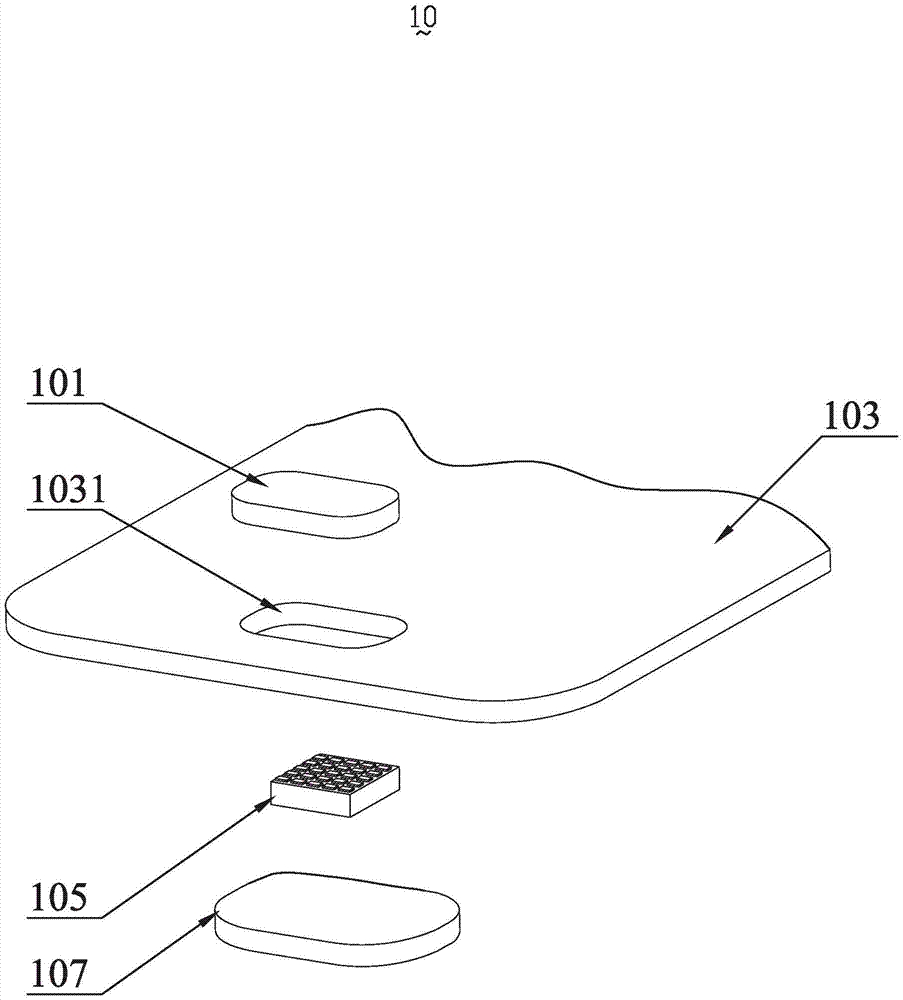

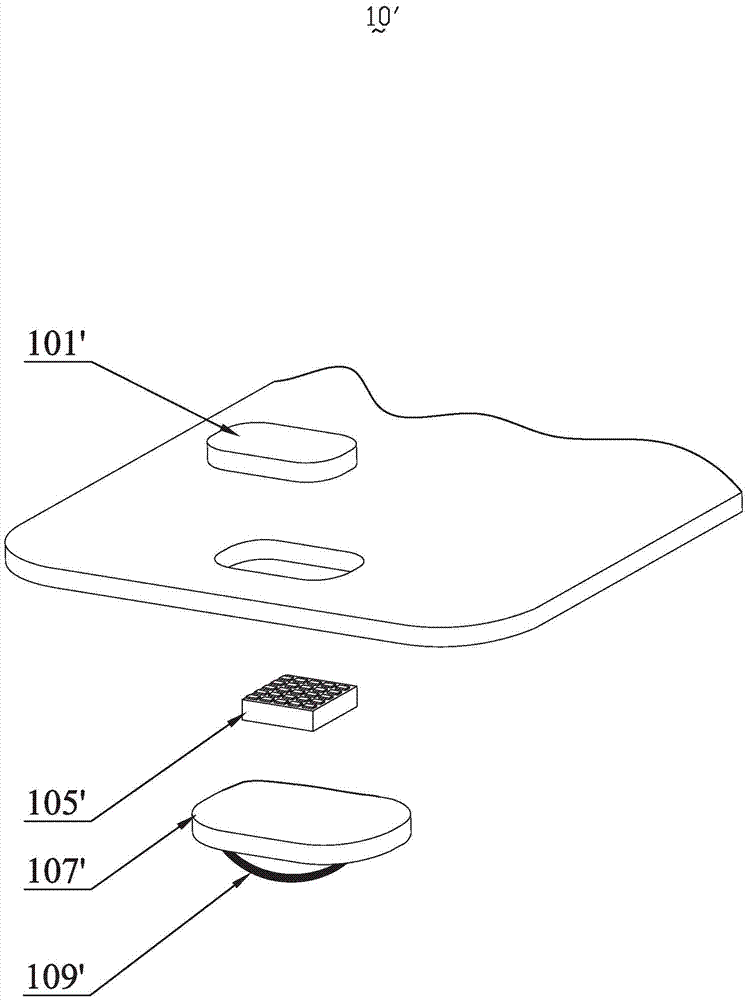

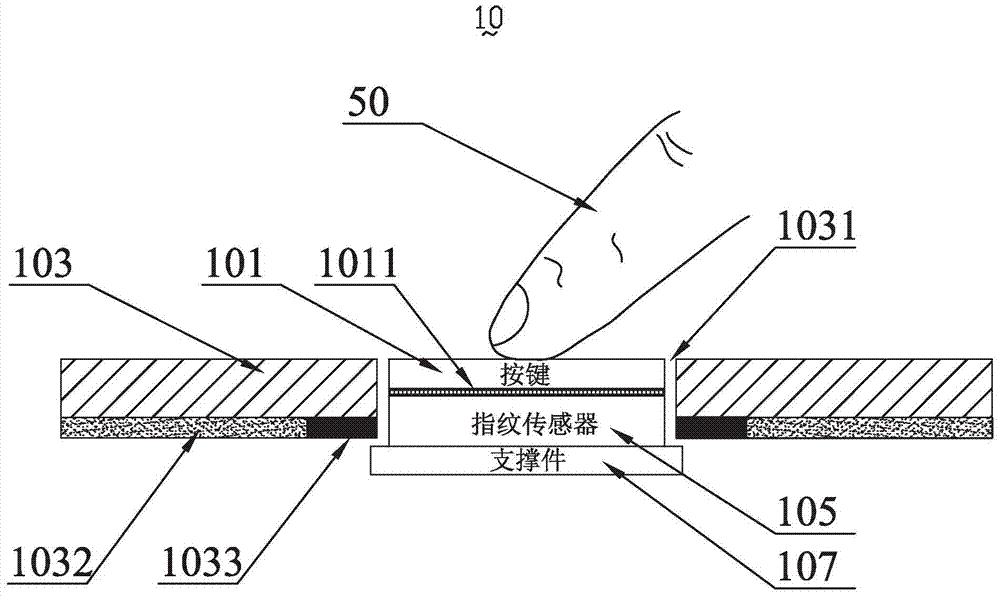

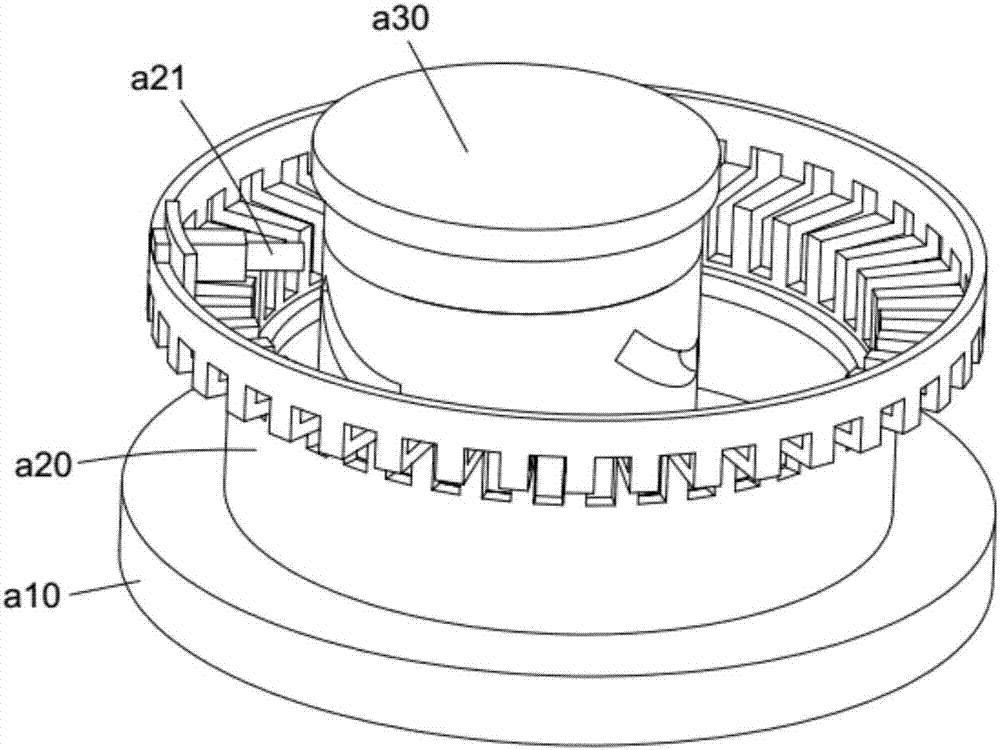

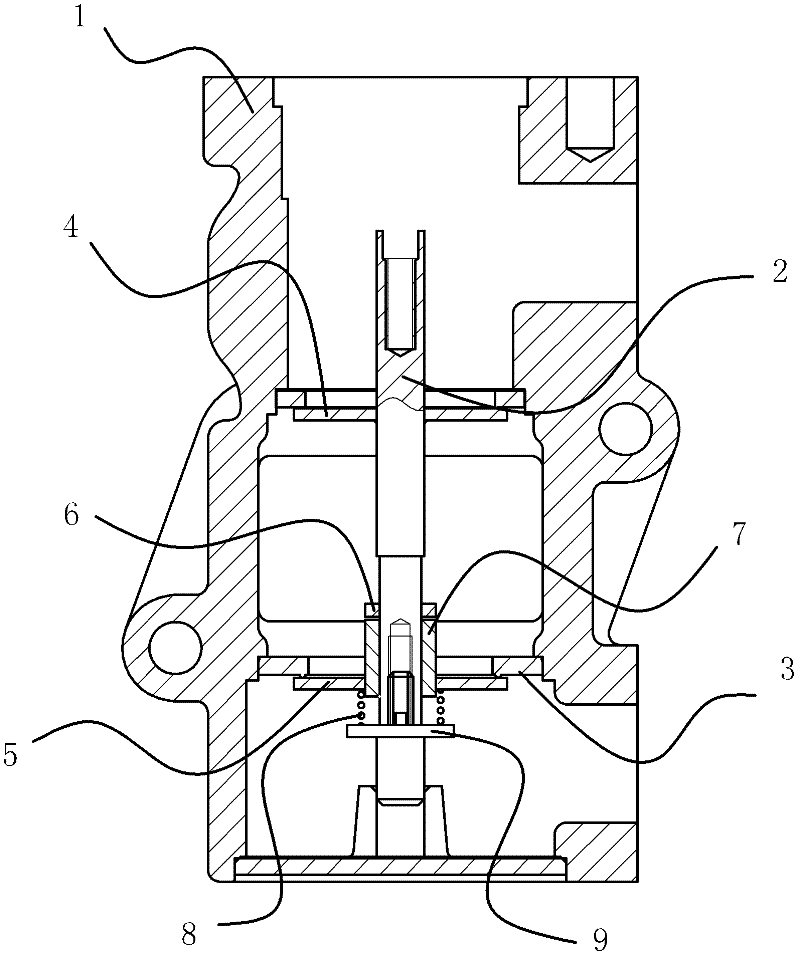

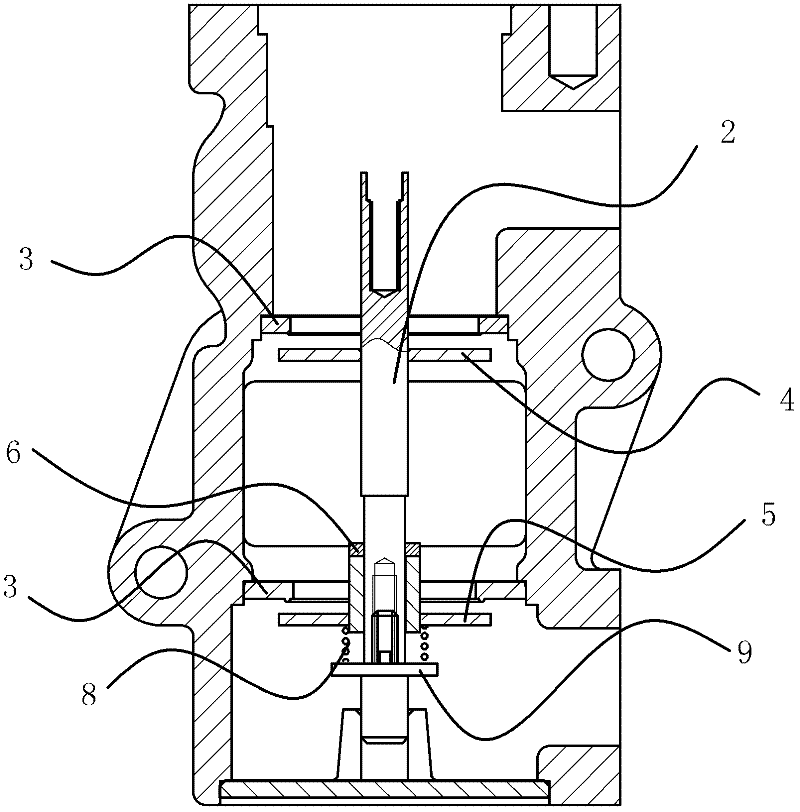

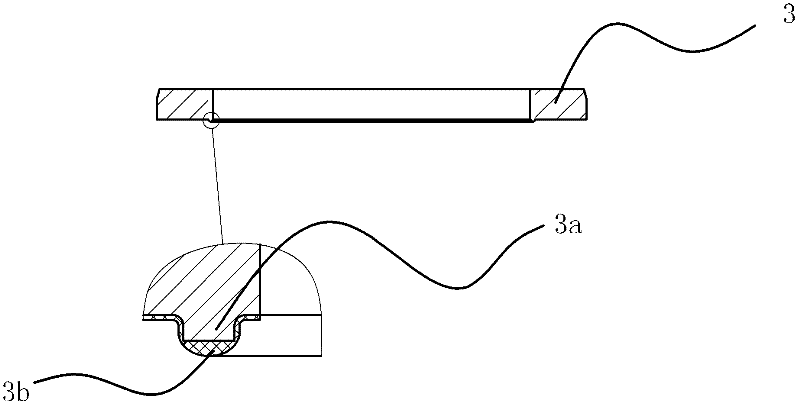

A fingerprint identification apparatus and an electronic apparatus having the fingerprint identification apparatus

ActiveCN105447486AImprove aestheticsFlexible adjustmentCharacter and pattern recognitionEngineeringFingerprint

The invention relates to a fingerprint identification apparatus with a concealed protection member and an electronic apparatus with the fingerprint identification apparatus. The fingerprint identification apparatus comprises a button, a fingerprint sensor which is arranged in a lower portion in the design direction of a button vertical lamination structure, a cover comprising a button hole accommodating the button and a fingerprint sensor positioned below the button and a protection member arranged on below the cover plate or on the side walls of the button hole. The protection member is arranged below the upper surface of the cover plate in a hidden mode. The protection member circes around the surrounding of the fingerprint sensor in order to shield interferences to the fingerprint sensor by outside noise signals. The electronic apparatus with the above fingerprint identification apparatus comprises a housing and a display assembly. The cover plate is embedded in an upper plate of the housing. The display assembly is a display module group or a touch control display module group. The fingerprint sensor is positioned outside of an imaging area of the display assembly.

Owner:TPK UNIVERSAL SOLUTIONS

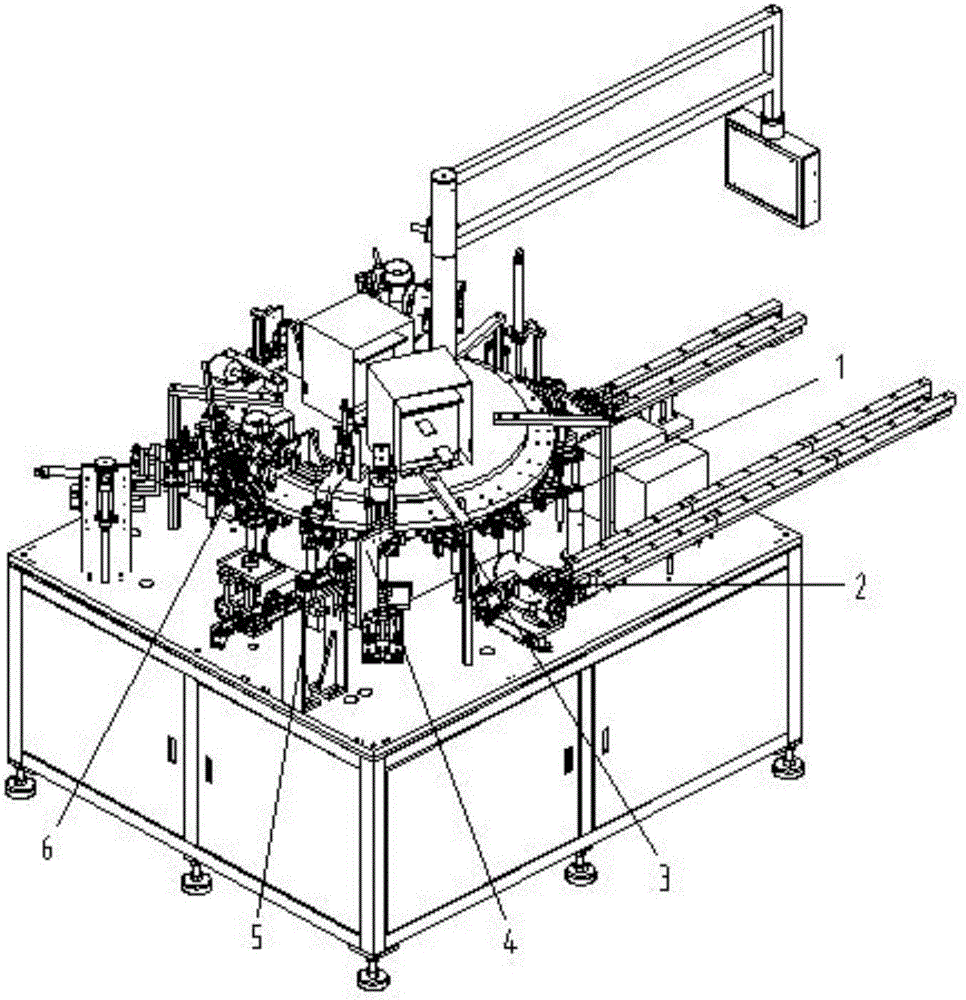

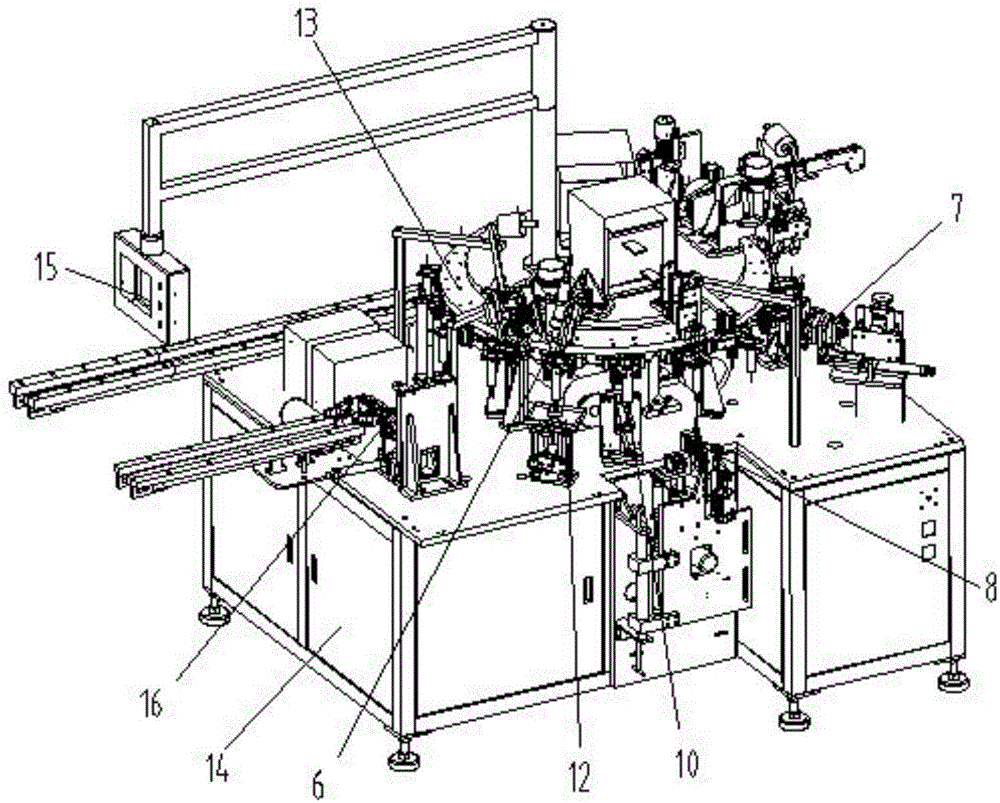

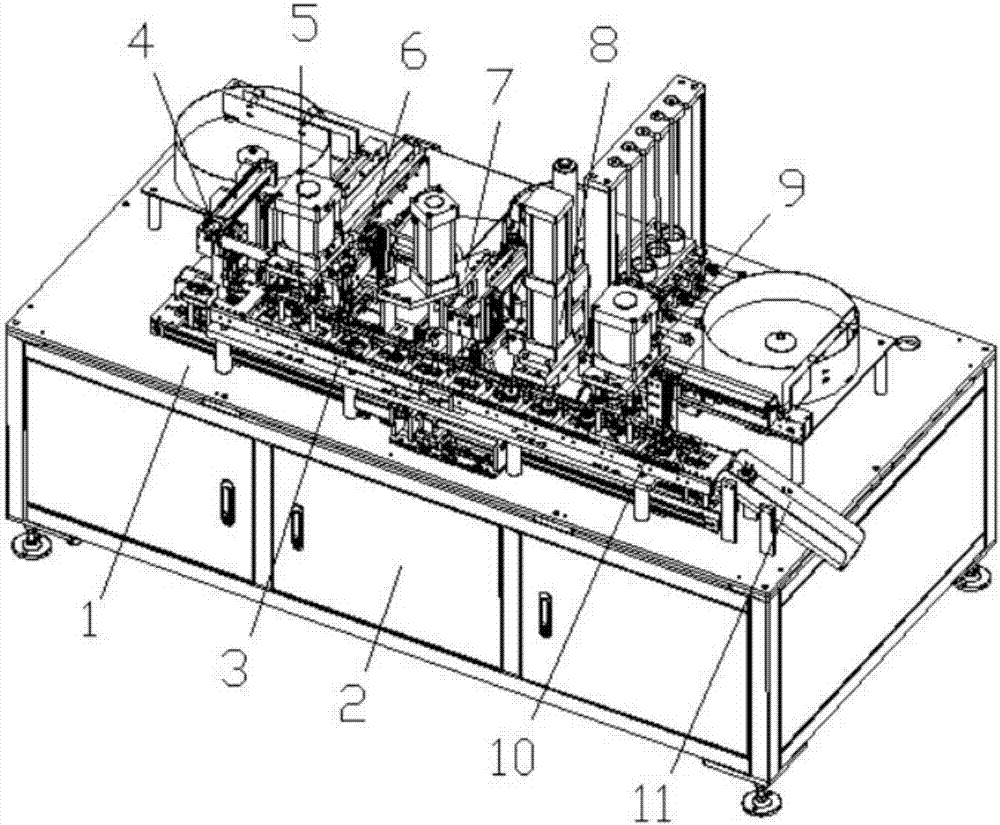

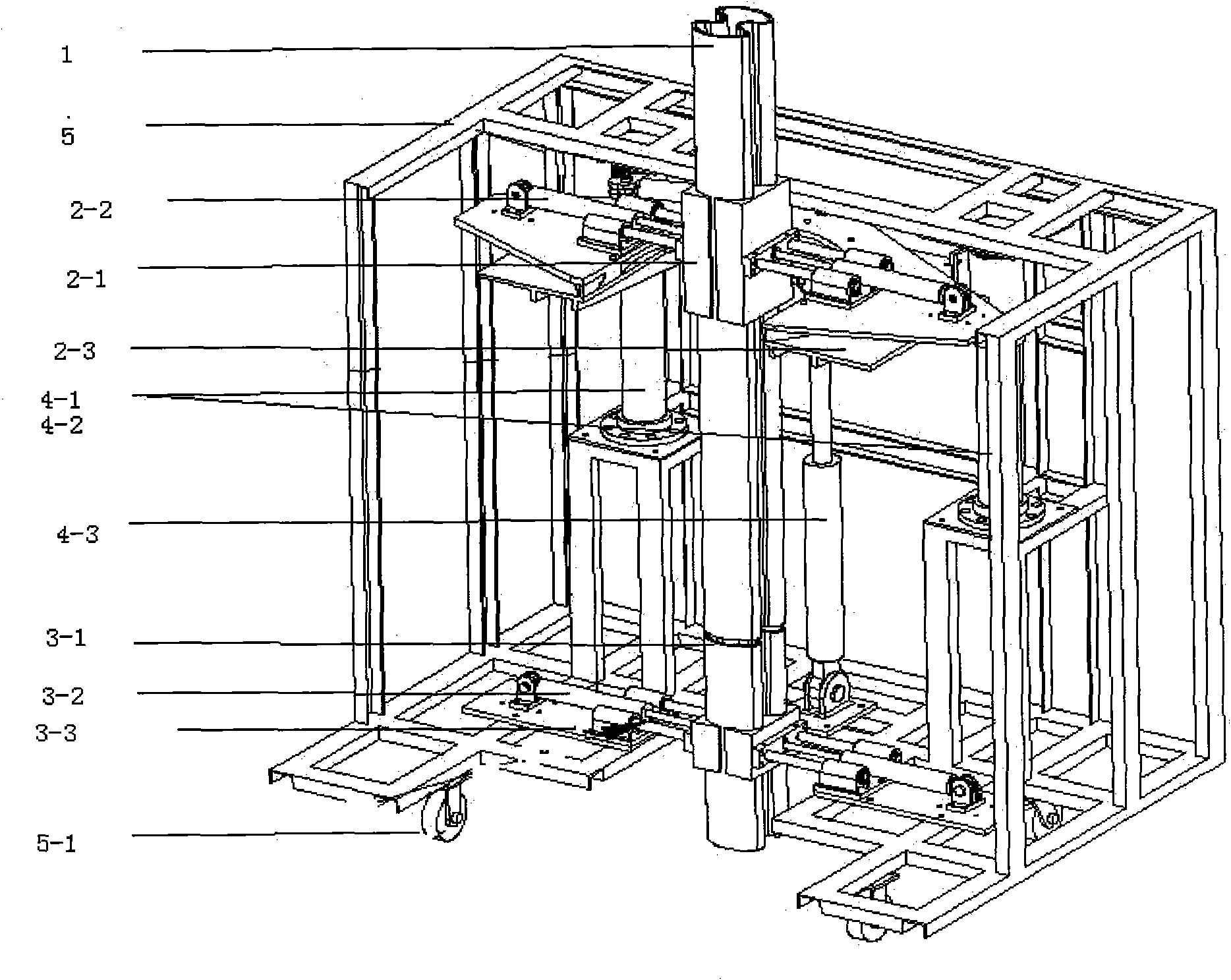

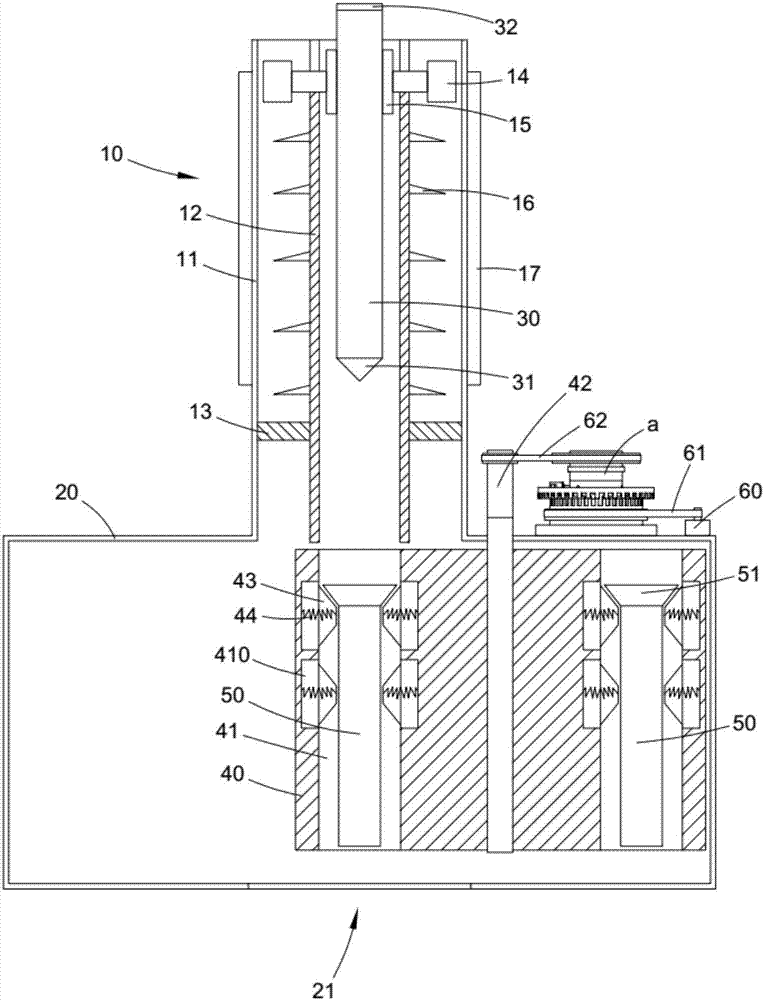

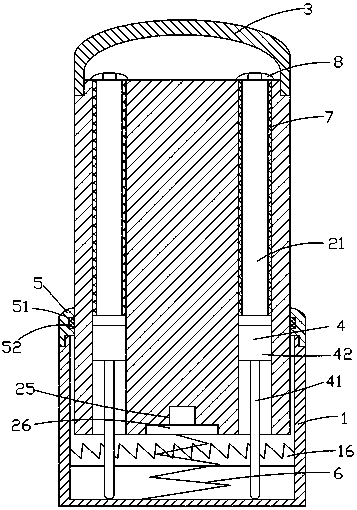

Automatic assembly machine of round capacitor

ActiveCN106847558ARealize automatic flipImprove welding efficiencyTerminal applying apparatusCapacitanceDistribution control

The invention relates to the field of capacitor processing equipment, in particular to an automatic assembly machine of a round capacitor. The machine includes a power distribution control box, a rotary plate and an operation screen, wherein the rotary plate and the operation screen are arranged above the power distribution control box through a bracket and communicated with the power distribution control box; clamps are uniformly arranged along a circle under the rotary plate; a feeding device, a positioning detection device, an upper tin-wire feeding device, a polarity detection device, a first tin-wire welding device, a capacitor turnover device, a lower tin-wire feeding device, a second tin-wire welding device and a discharging device are arranged in sequence on the outer side of the rotary plate in the clockwise direction and connected with the power distribution control box. The automatic assembly machine of the round capacitor has the advantages that automatic operation is adopted from feeding to discharging, the processing accuracy and processing efficiency of the round capacitor are greatly improved, and a large amount of working time is saved.

Owner:天长市中发电子有限公司

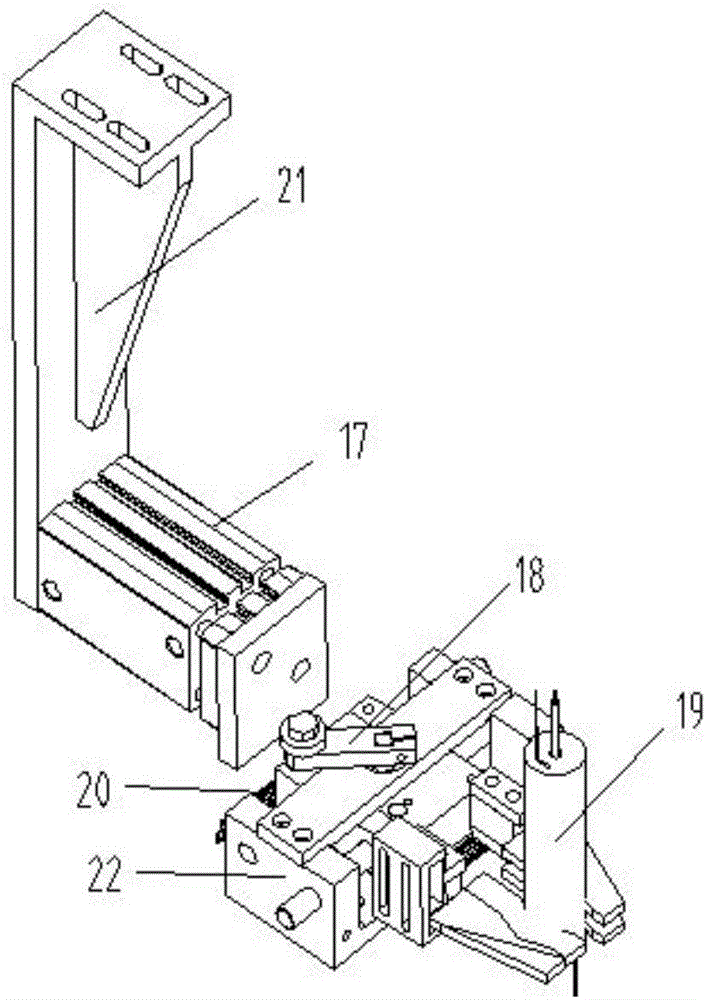

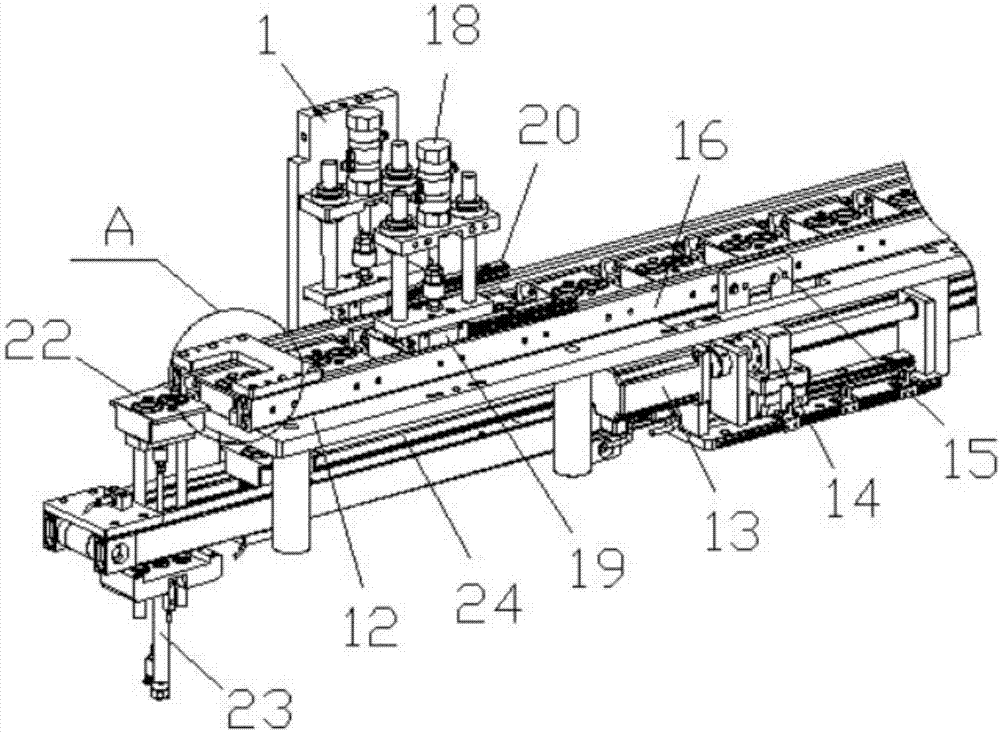

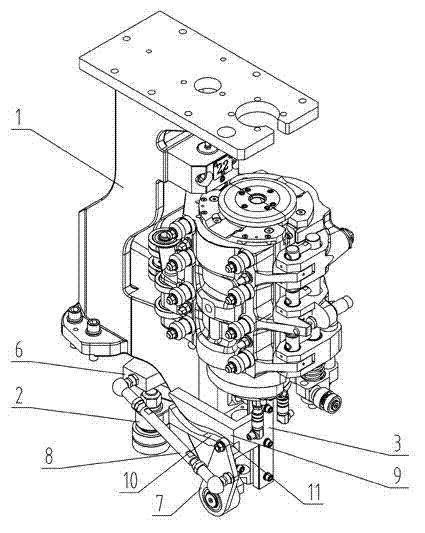

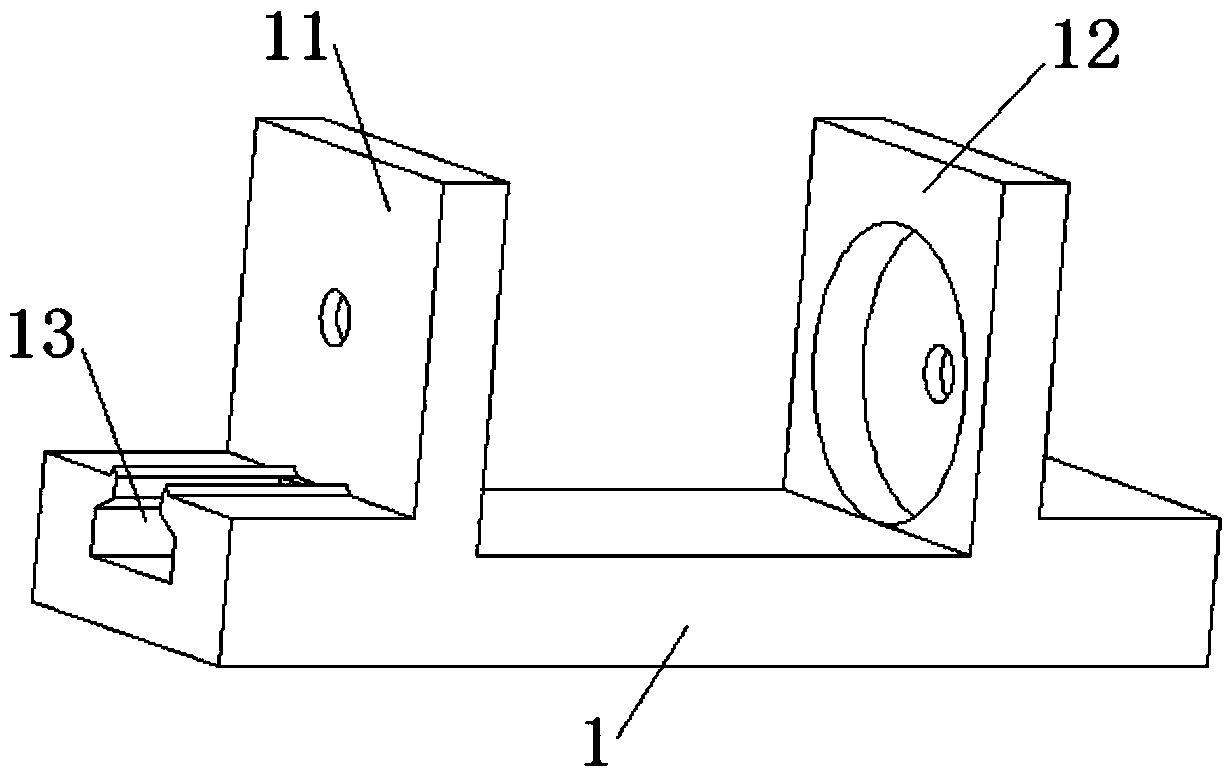

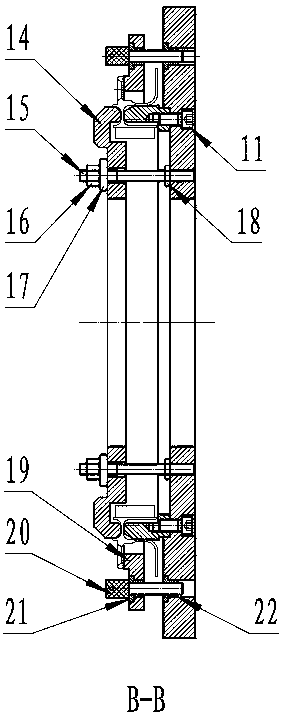

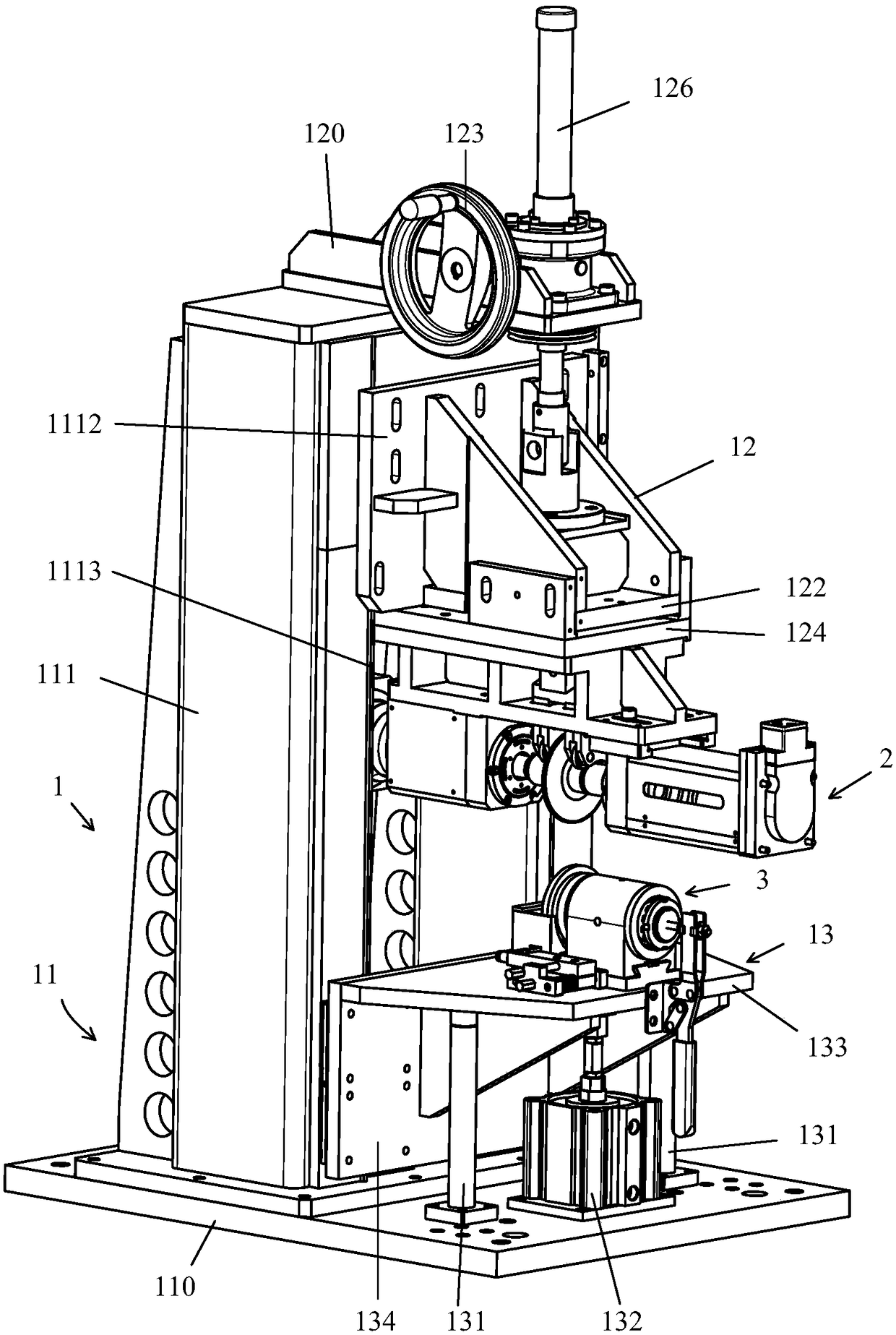

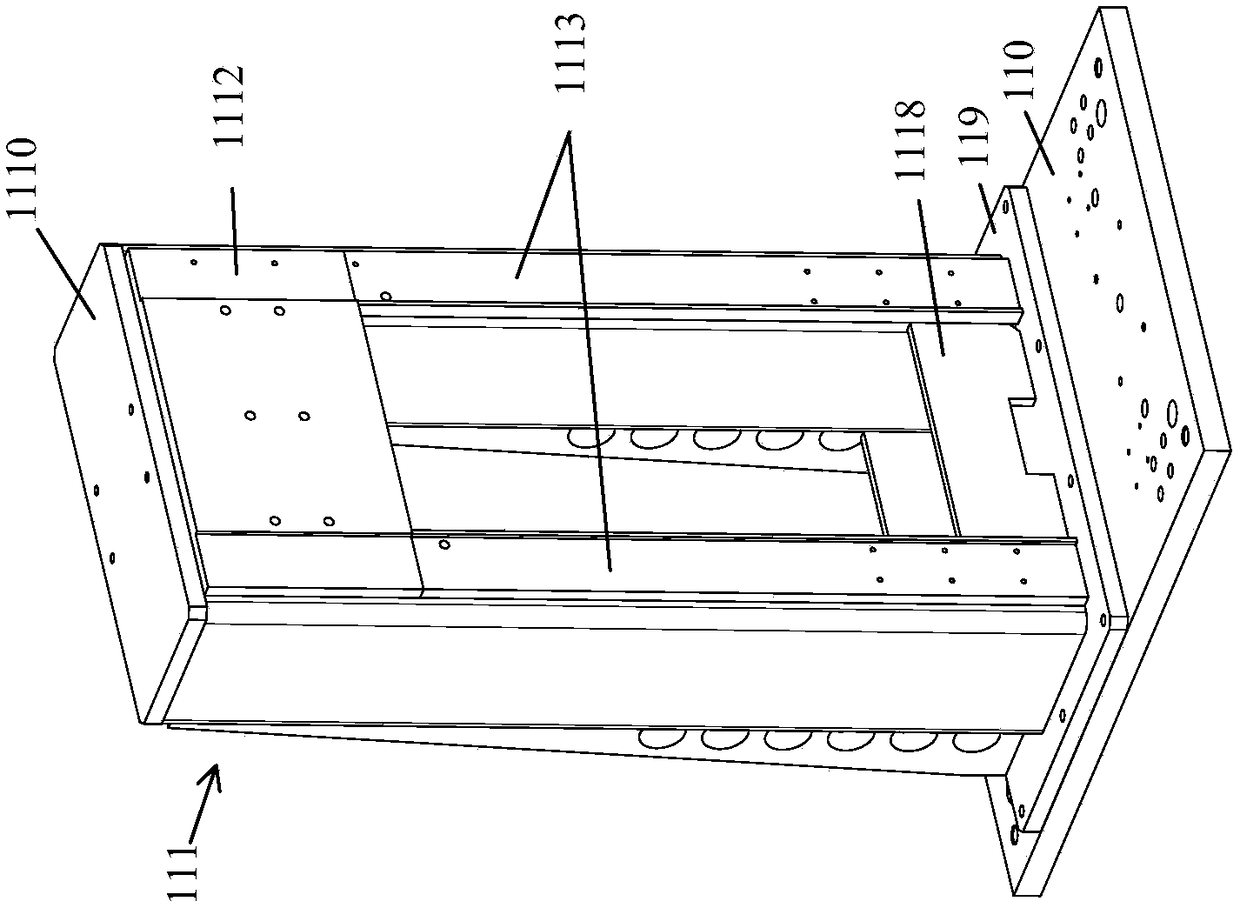

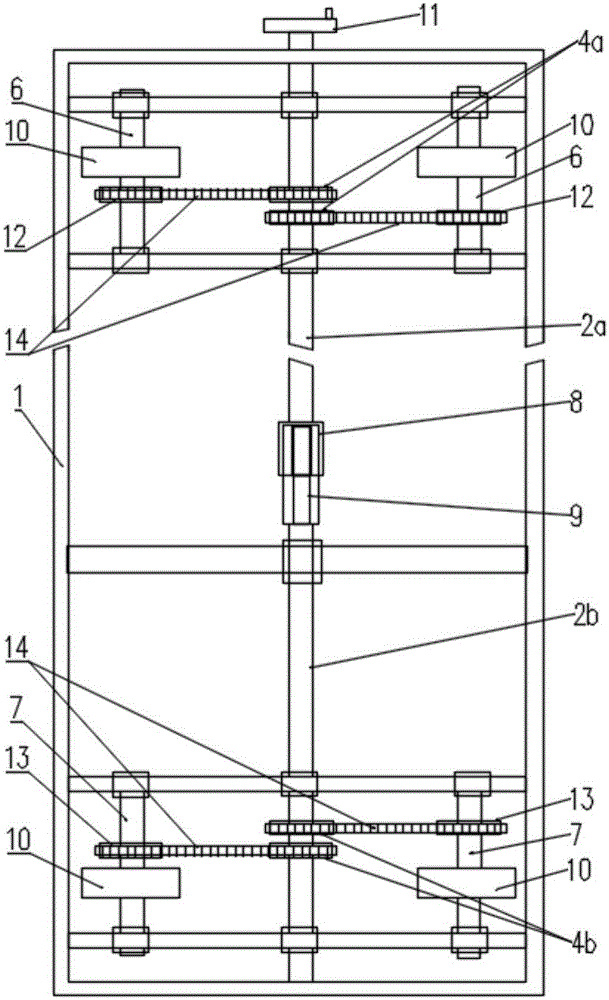

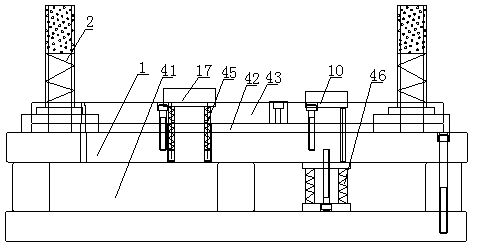

Automatic gear shaft assembling machine

InactiveCN107571008AHigh matching precisionImprove assembly efficiency and yieldAssembly machinesManipulatorBall bearing

The invention relates to an automatic gear shaft assembling machine. The rack is provided with a carrier conveying device. The carrier conveying device comprises a carrier conveying base. Carrier feeding movable air cylinders are arranged on the front side and the rear side of the carrier conveying base and connected with a carrier feeding movable base. The carrier feeding movable base is connected with a carrier feeding movable block. A carrier feeding clamping block matched with a carrier is arranged on the inner side of the carrier feeding movable block. A carrier feeding lifting matched sliding rail is arranged at the upper portion of the carrier feeding movable block and matched with a carrier feeding lifting matched sliding block. The upper portion of the carrier feeding lifting matched sliding block is matched with a carrier feeding lifting air cylinder on the rack. The rack is provided with a ball bearing feeding device, a shaft rod feeding device, an overturning device, a clamping ring feeding device, a gear feeding device, a clamping bearing feeding device and a discharging mechanical arm. According to the automatic gear shaft assembling machine, automatic ball bearing and shaft rod assembling can be achieved, and the assembling efficiency and the yield are greatly improved.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

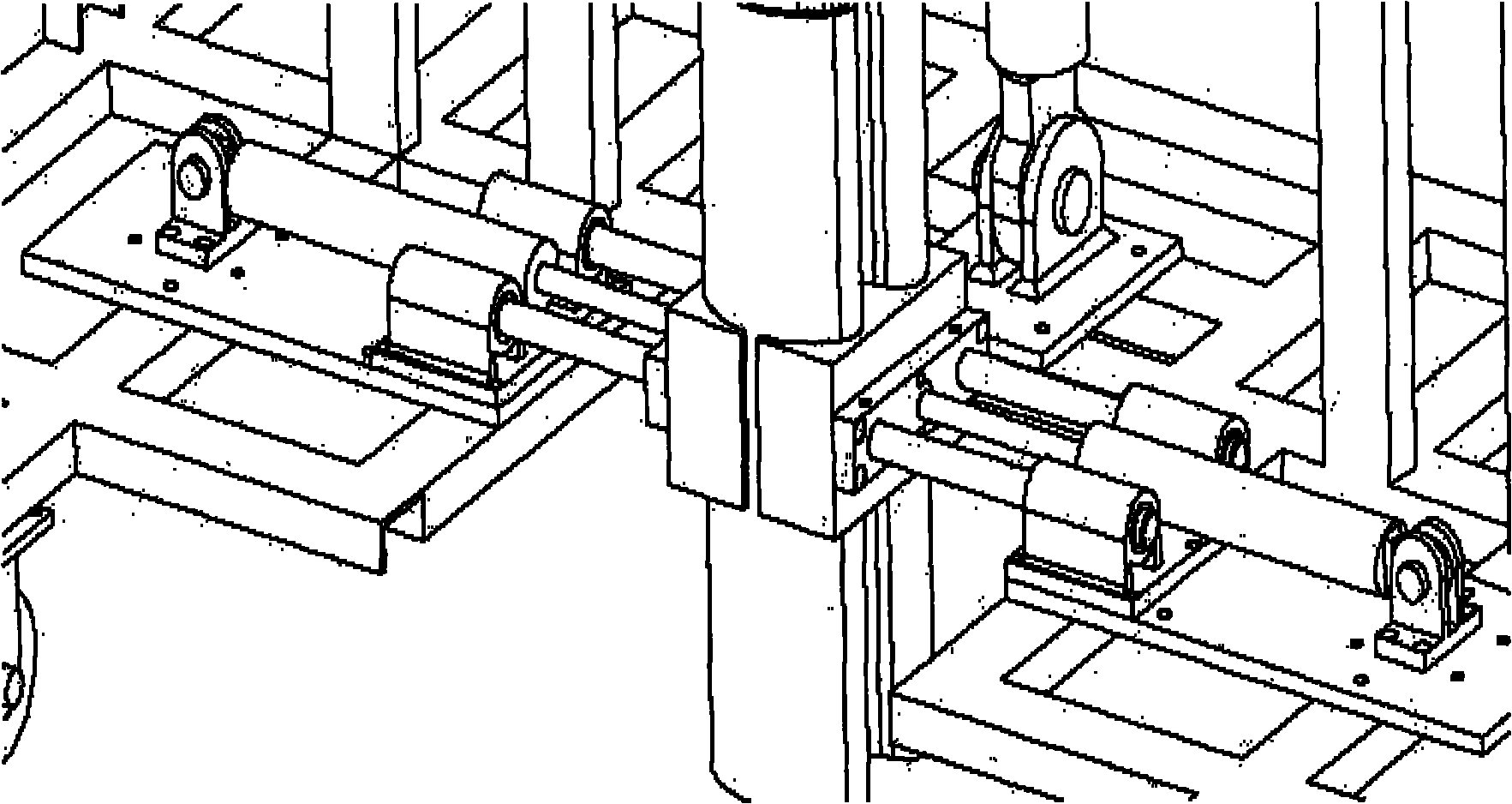

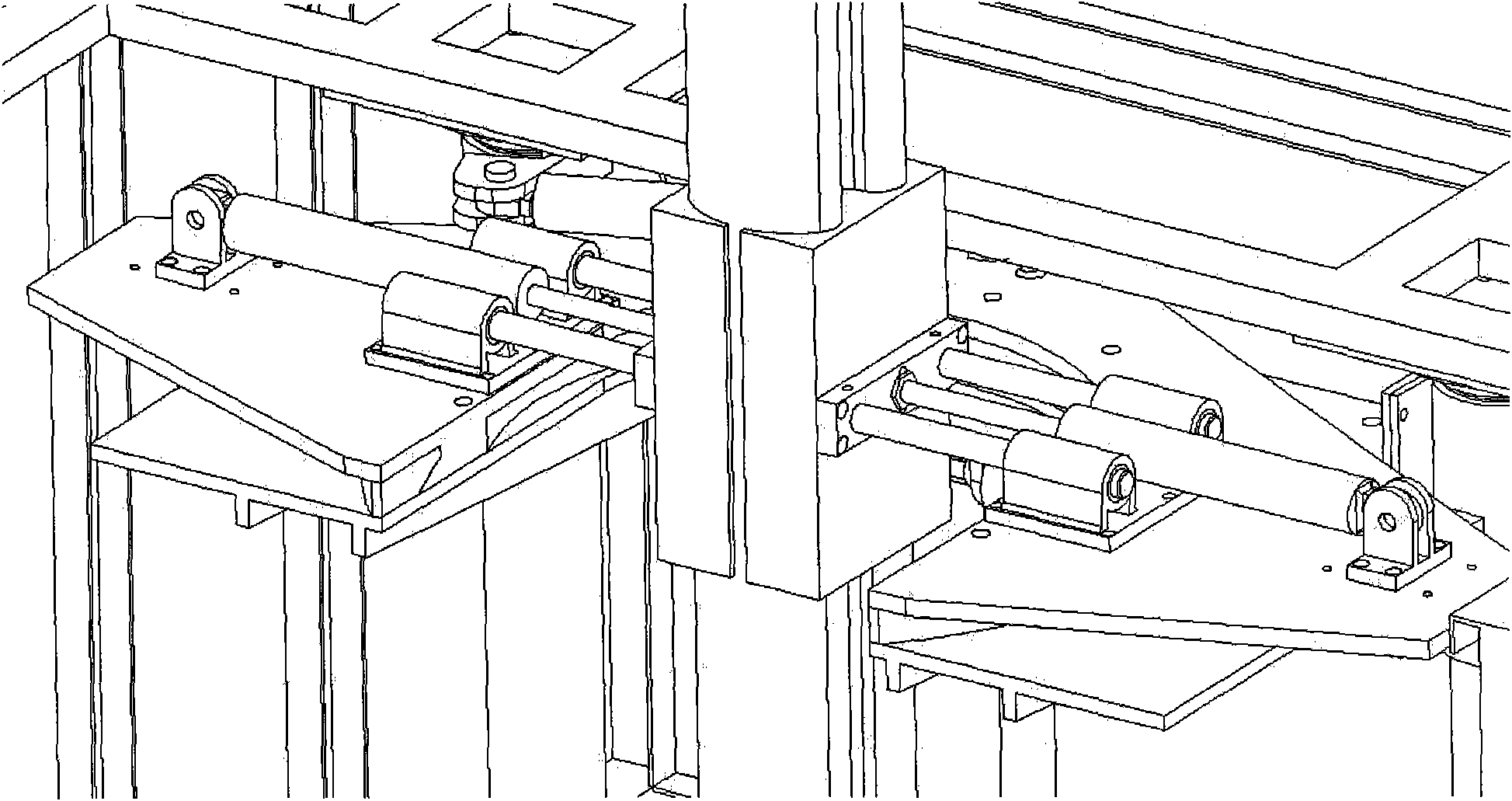

Linkage mechanism of side moulds and bottom mould of bottle blowing machine

The invention discloses a linkage mechanism of side moulds and a bottom mould of a bottle blowing machine. The side moulds and the bottom mould of the bottle blowing machine are connected by a linkage connecting rod device; the linkage of the side moulds and the bottom mould is realized by opening-closing motion of the side moulds and lifting motion of the bottom mould; the bottom mould descends when the side moulds are opened; the bottom mould ascends when the side moulds are closed until the set position is totally closed. The linkage of the side moulds and the bottom mould is realized by opening-closing motion of the side moulds and lifting motion of the bottom mould, and the linkage mechanism has a simple structure, is easy to manufacture and maintain, and reduces the manufacturing cost and the maintenance cost; each component is matched in a hinging or rolling mode and is free of mechanical shock during motion, so that the fault rate of each component is greatly reduced, the stability of the equipment is increased, the operation speed can be safely increased, the production efficiency is improved, and the noise is reduced at the same time.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

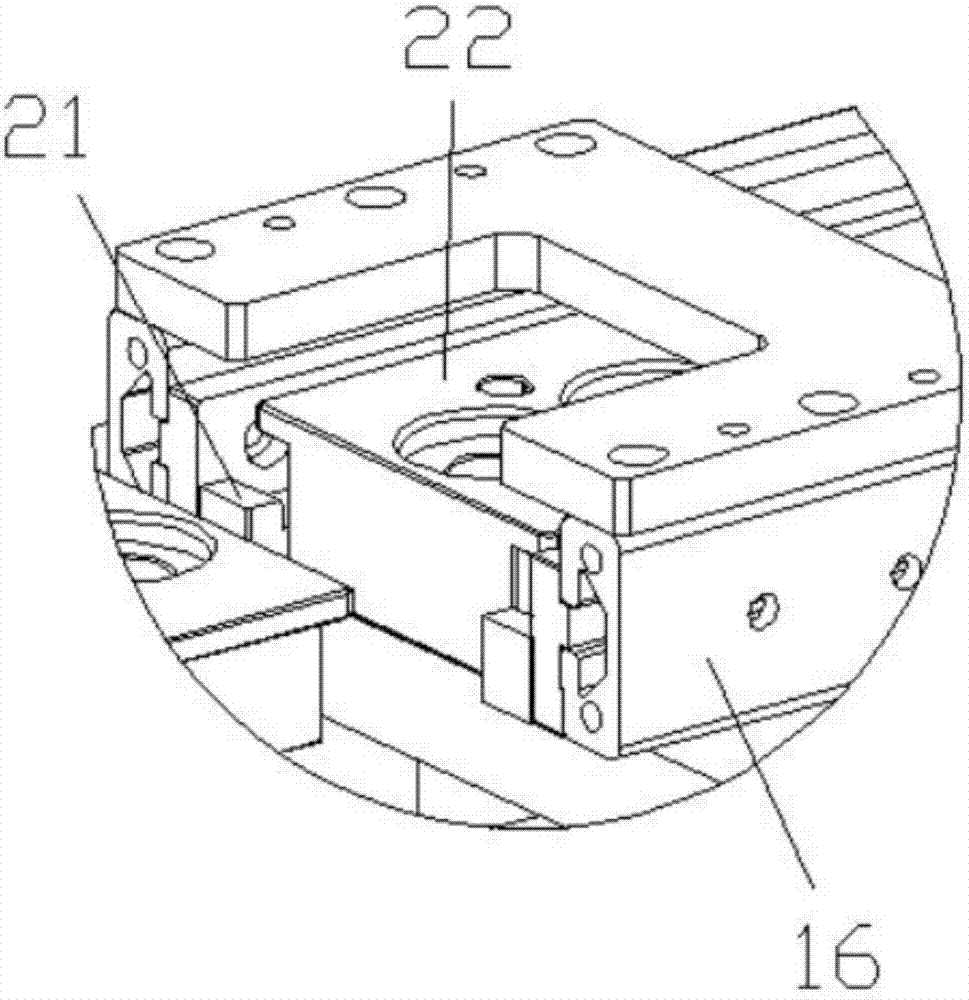

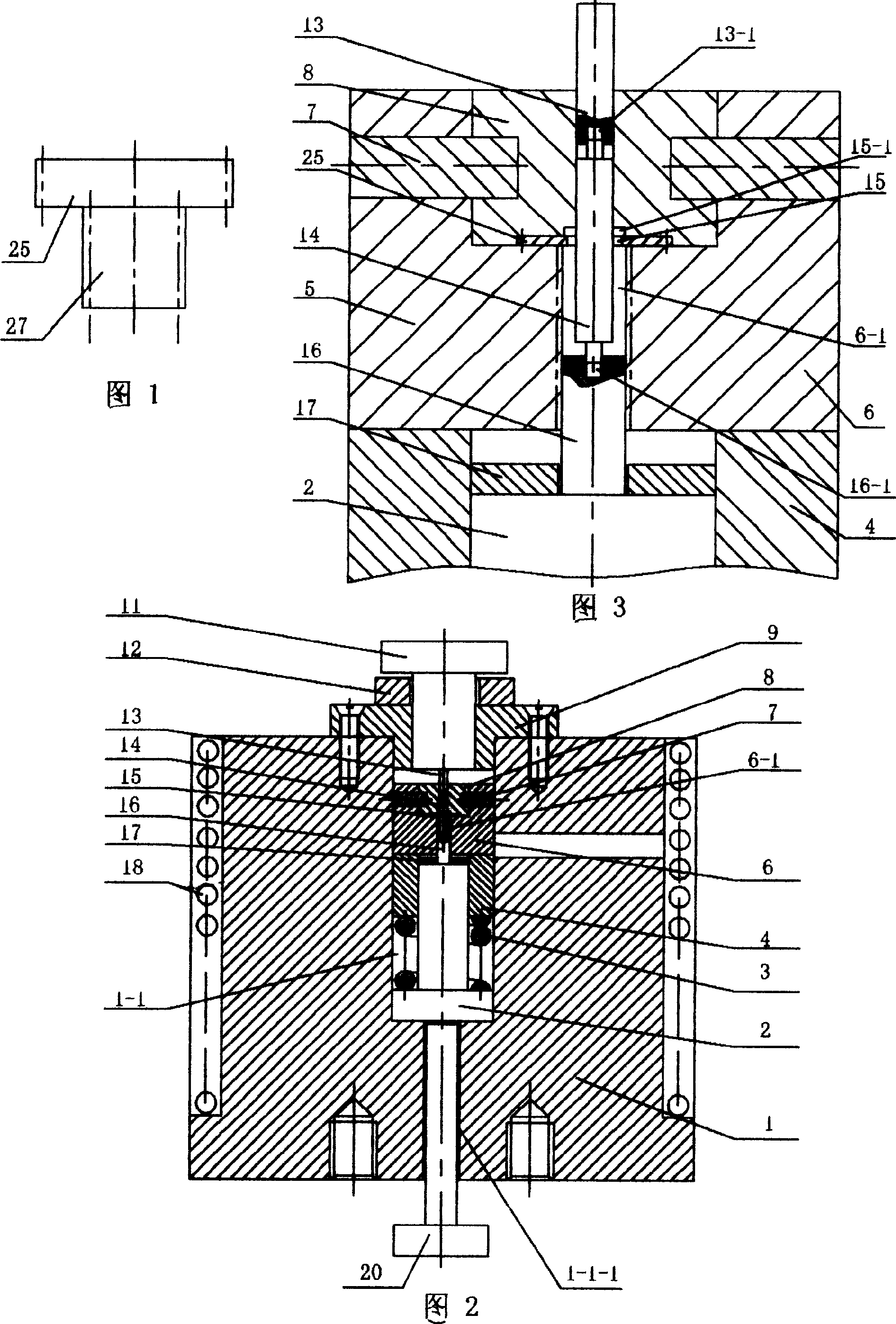

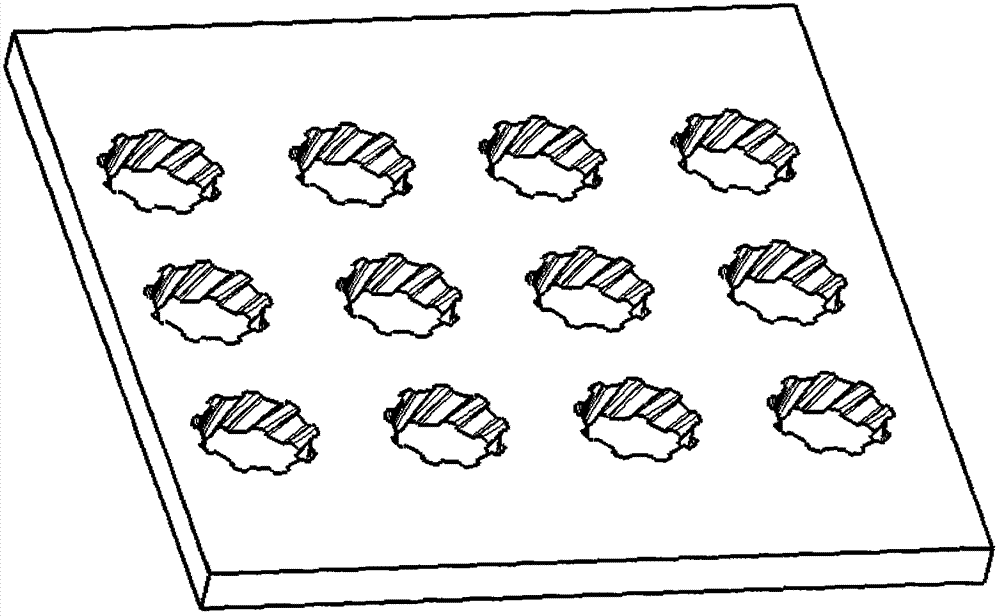

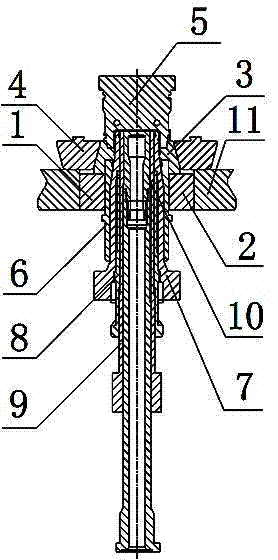

Minisize mould device for precise compound forming of minisize double gears

InactiveCN1698994AOvercome the disadvantages of relatively high processing costsHigh matching precisionShaping toolsForging/hammering/pressing machinesEngineeringMechanical engineering

This invention discloses a mini die device used for precision forming mini double gears, which comprises die backer, top column, spring, slide block, cavity die 6, terrace die 16, drift guiding-sheathing, drift pin 11, spacing ring, electrical heating coil, ejector rod, up inlaid 8, up drift pin 13 and pin 7, wherein the cavity die 6 has gear shape cavity, the 8 is inserted on the upside of the 6 and has a same axial center with 6, at least two pins are set inside 6 and 8 horizontally to fix the position; 13 inserts to the center hole of 8, and its upside connects the lower surface of 11, on the lower surface of 8 has cavity 15 which has a same axial center with 6. The device can finish the gear shaping and double-gears assemblage at the same time.

Owner:HARBIN INST OF TECH

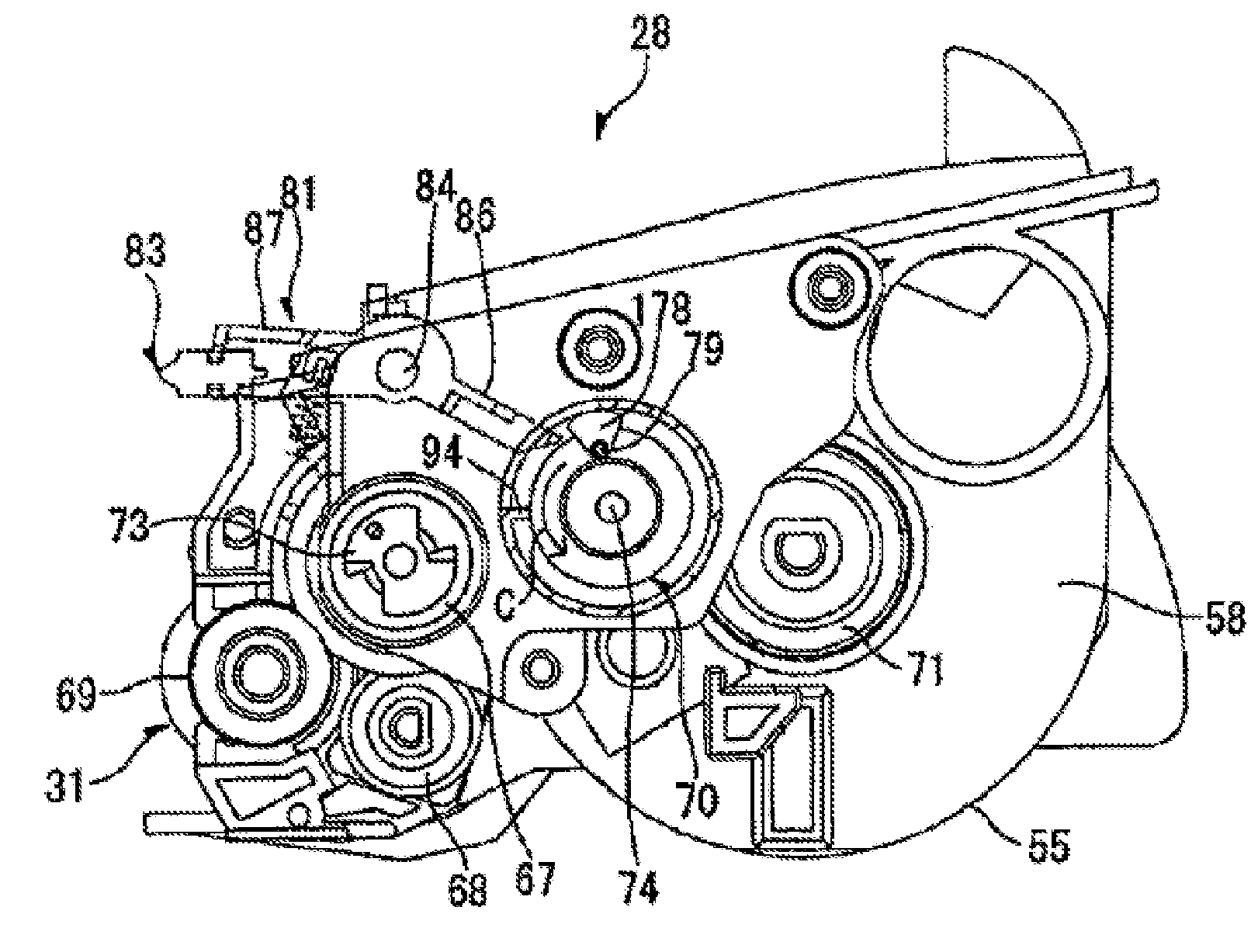

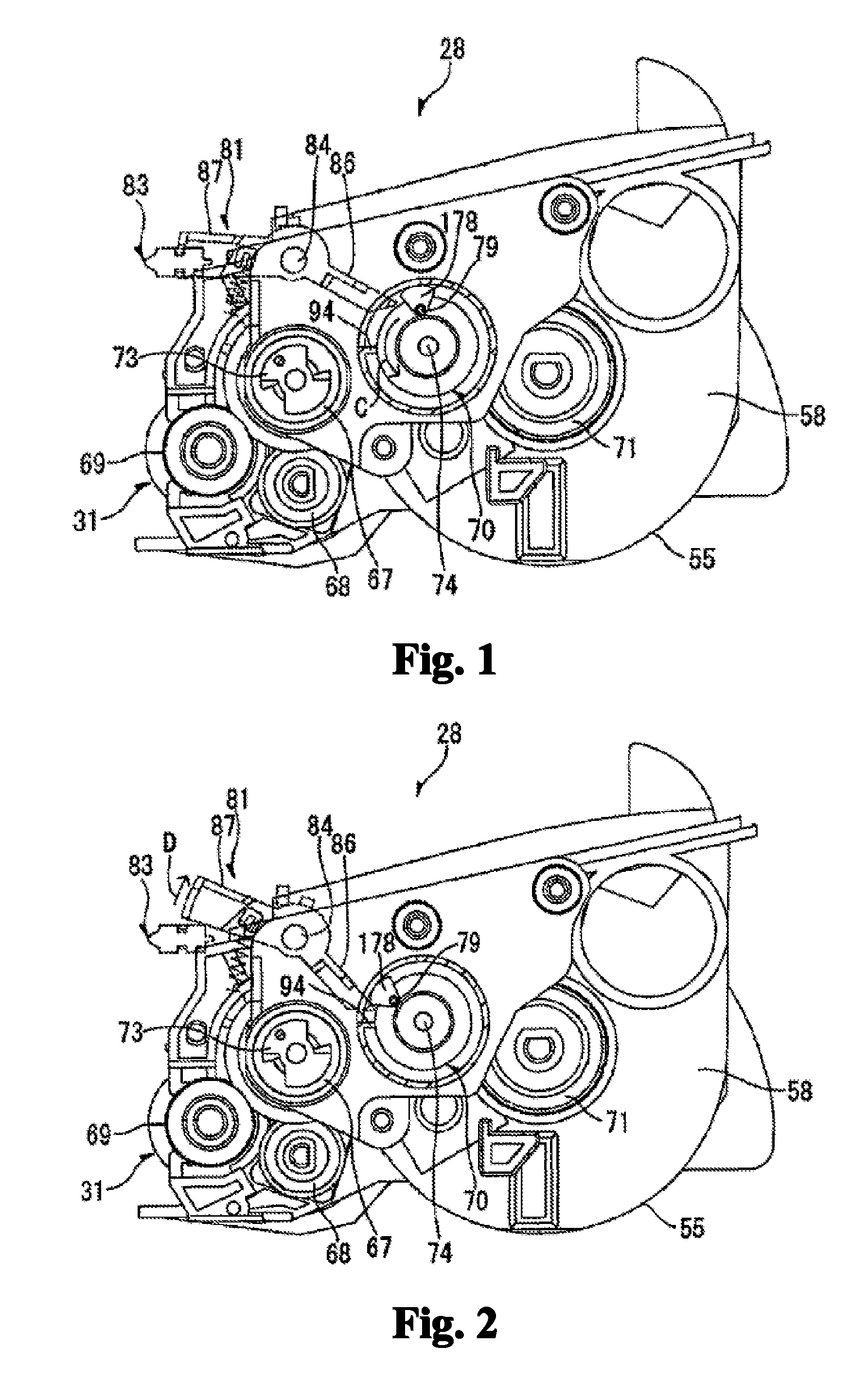

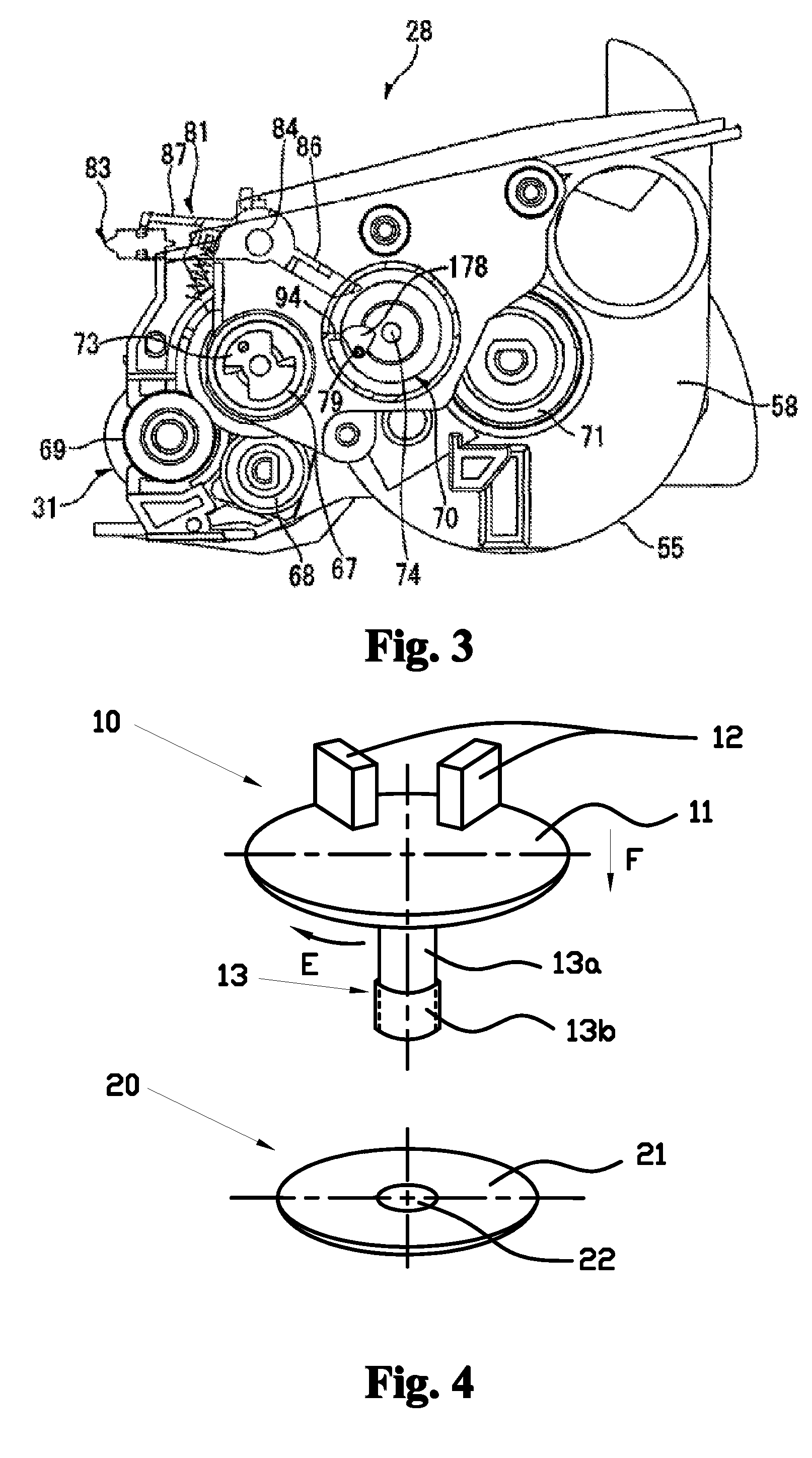

Developer cartridge with counting mechanism

ActiveUS20120148297A1High matching precisionReducing precision costElectrographic process apparatusEngineeringMechanical engineering

The invention provides a developer cartridge with a counting mechanism. The developer cartridge comprises a developer and the counting mechanism, wherein the counting mechanism is provided with protrusions which come in contact with a contact lever on an electronic photographing device so as to count the developer cartridge; and each protrusion has a first position and a second position in the direction perpendicular to a side wall of the developer cartridge, and is, in the first position, in contact with the contact lever, but is not, in the second position, in contact with the contact lever. The working principle of the developer cartridge adopting the counting mechanism is greatly different from the prior art. Therefore, the structure of the counting mechanism of the developer cartridge is simpler and more convenient and reliable; the production precision and the production cost are reduced; and the market competitiveness of the developer cartridge is improved.

Owner:NINESTAR CORP

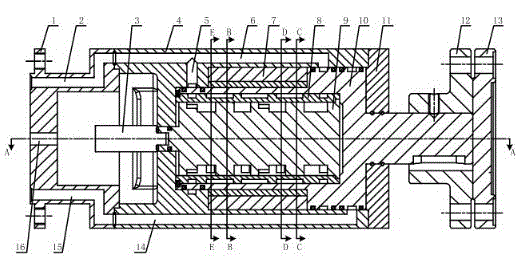

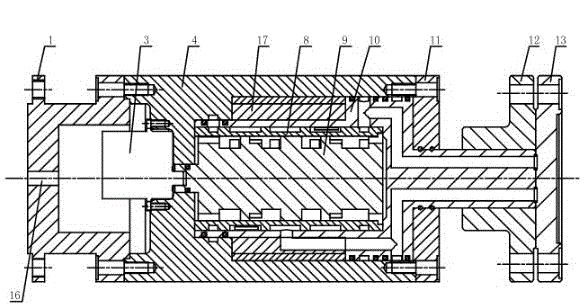

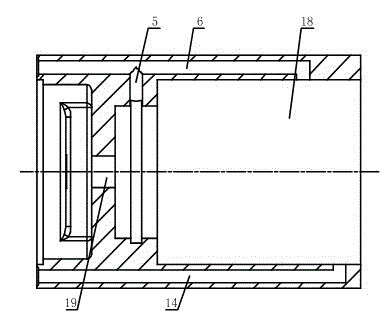

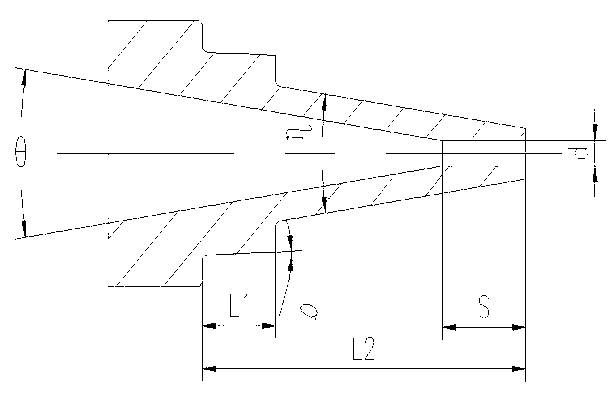

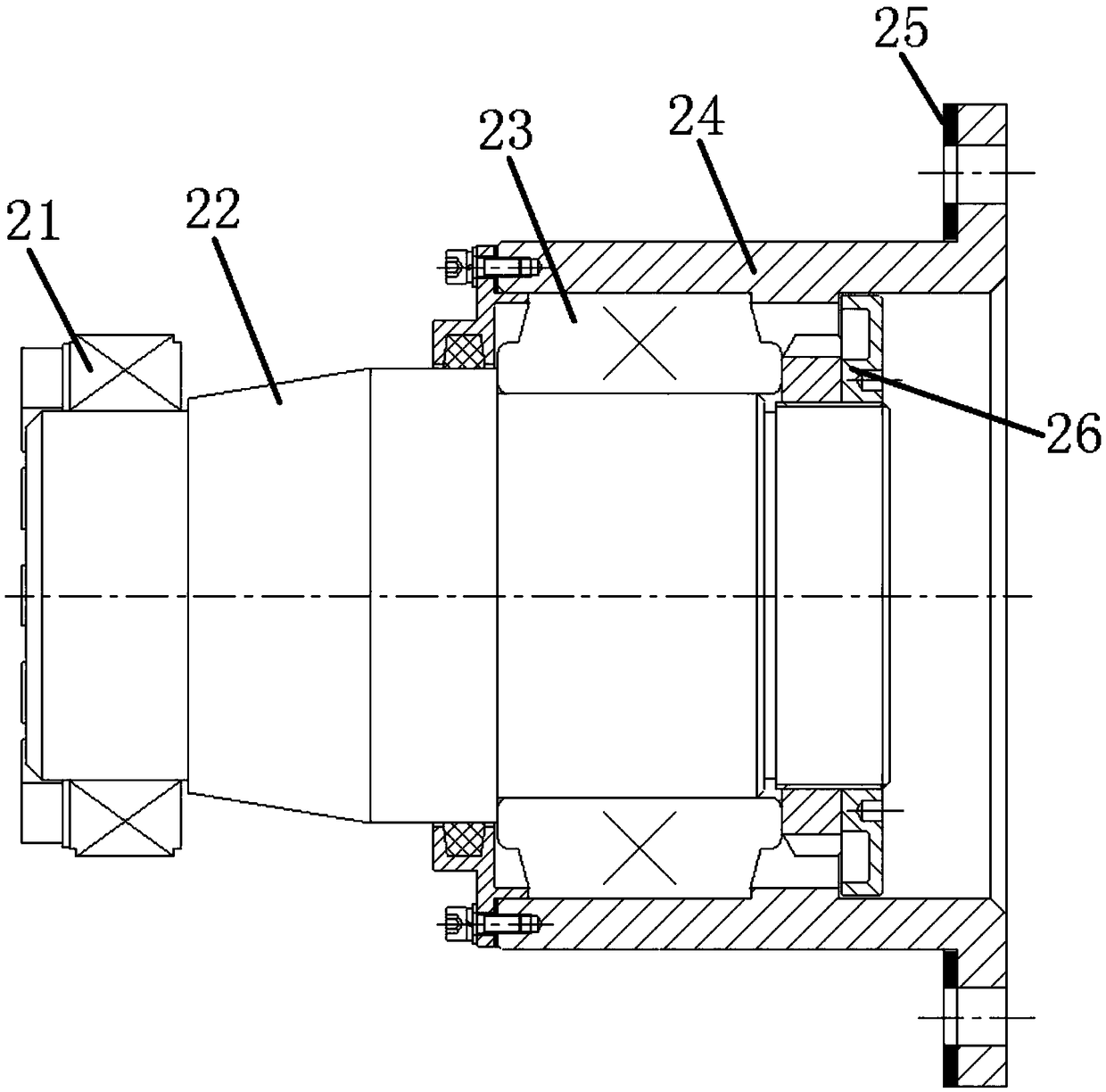

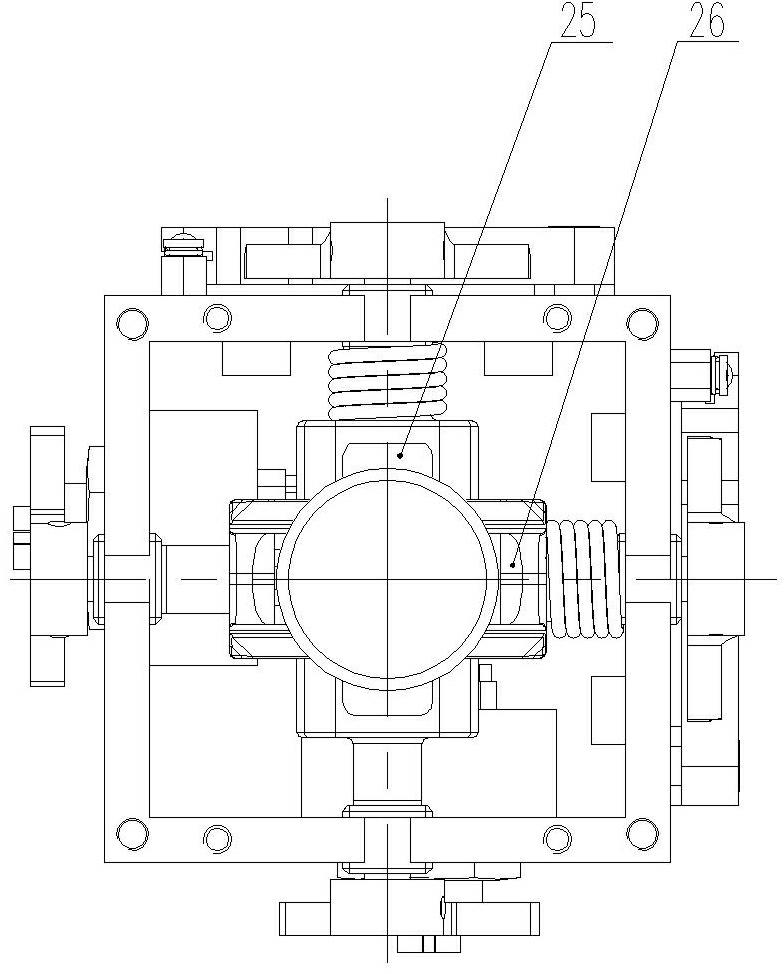

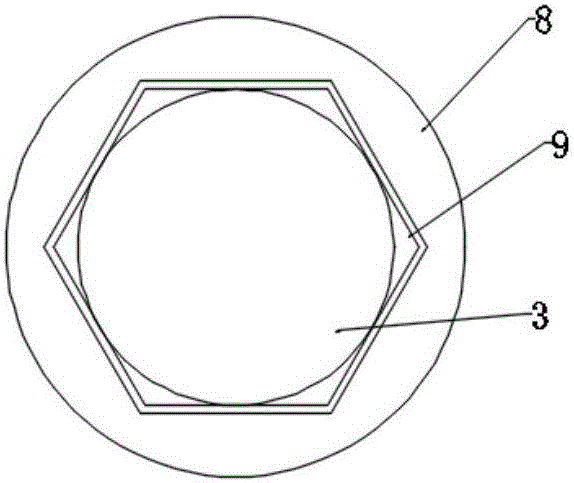

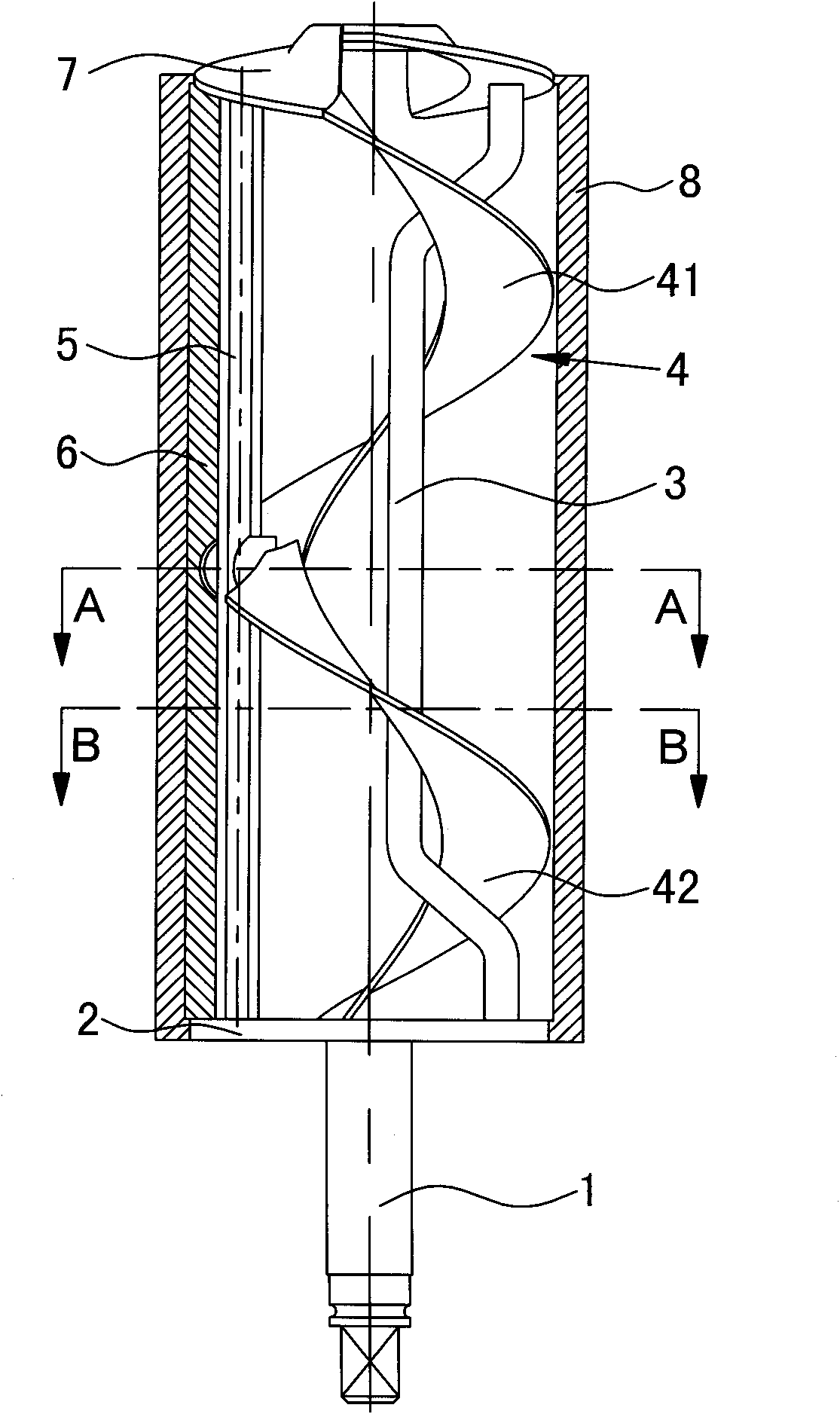

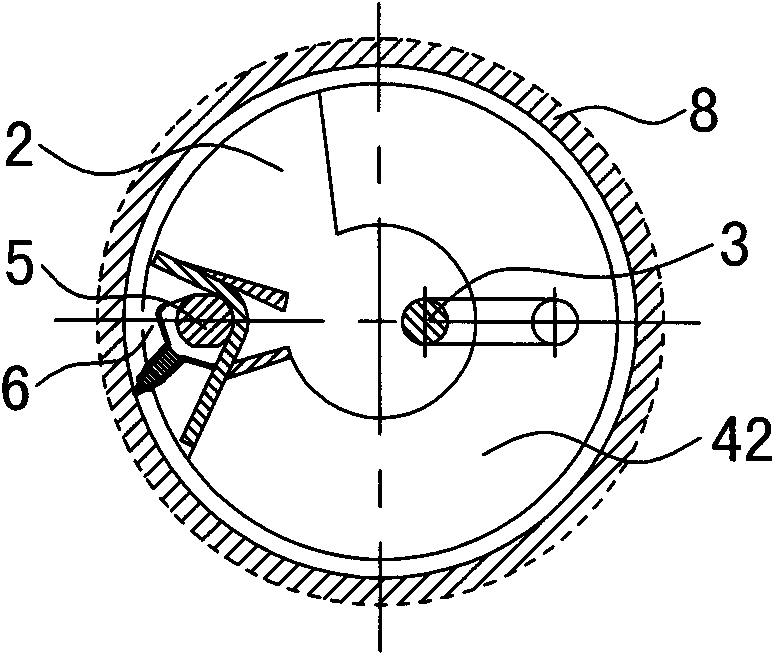

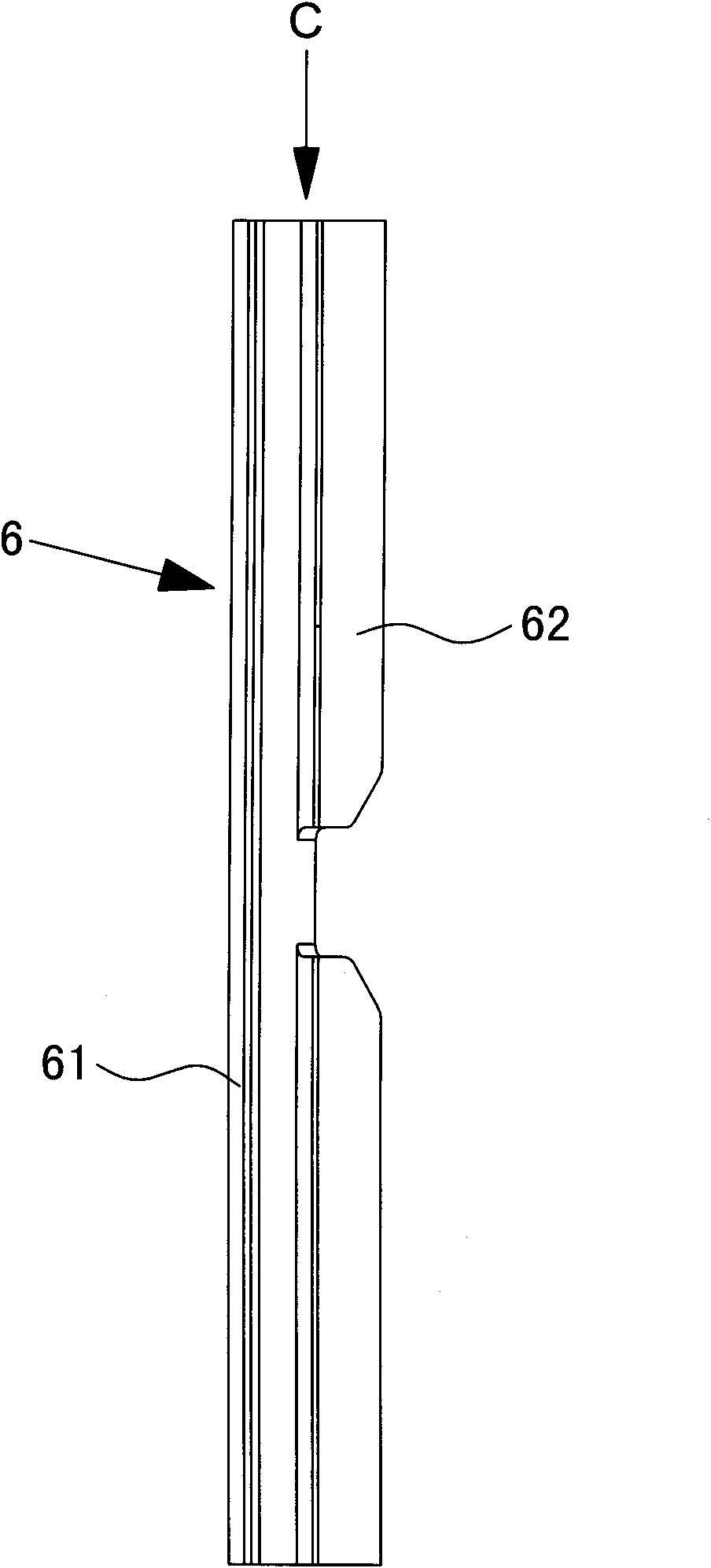

Rotary valve type large torque hydraulic corner self-servo valve

The invention relates to a rotary valve type large torque hydraulic corner self-servo valve, which has the technical scheme that: a valve body (10) is concentrically arranged in a cylinder body cylindrical cavity (18); a valve sleeve (8) is concentrically arranged in a valve body cylindrical cavity (27); a right end of a valve plug (9) penetrates through the valve sleeve (8) so as to be concentrically arranged in the valve body cylindrical cavity (27); and an output shaft of a motor (3) is in key joint with an inner hole (46) on a left end of the valve plug (9) concentrically. Fixed stops (7) are respectively arranged on an upper part and a lower part of an inner wall of a cylinder body (4), and are in movable fit with the valve body (10); two blades (17) are fixed on an outer wall of the valve body cylindrical cavity (27), are arranged at an angle of 180 degrees, and are in movable fit with the cylinder body (4); and the fixed stops (7) and the blades (17) are in staggered arrangement with the blades (17). The rotary valve type large torque hydraulic corner self-servo valve has the characteristics of simple structure, easiness in processing, balance in stressing of the valve plug, large output torque, good dynamic property, flow gain linear, quick respond speed, and high control accuracy.

Owner:武汉科技大学资产经营有限公司

New type 20 roller mill

InactiveCN1872439AMachining accuracy is easy to guaranteeHigh precision of product sizeMetal rolling stand detailsRollsRoller millRolling mill

A novel 20-roller rolling mill is composed of integral rectangular machine frame, a roller box unit consisting of upper and lower roller boxes with rectangular saddle and lock unit, a dual-wedge regulator for said lower roller box and comprising swinging cylinder, swinging arm, connecting rod and wedge blocks, and the convexity controller consisting of hydraulic cylinder, rack bar and sectorial gear.

Owner:曹全有

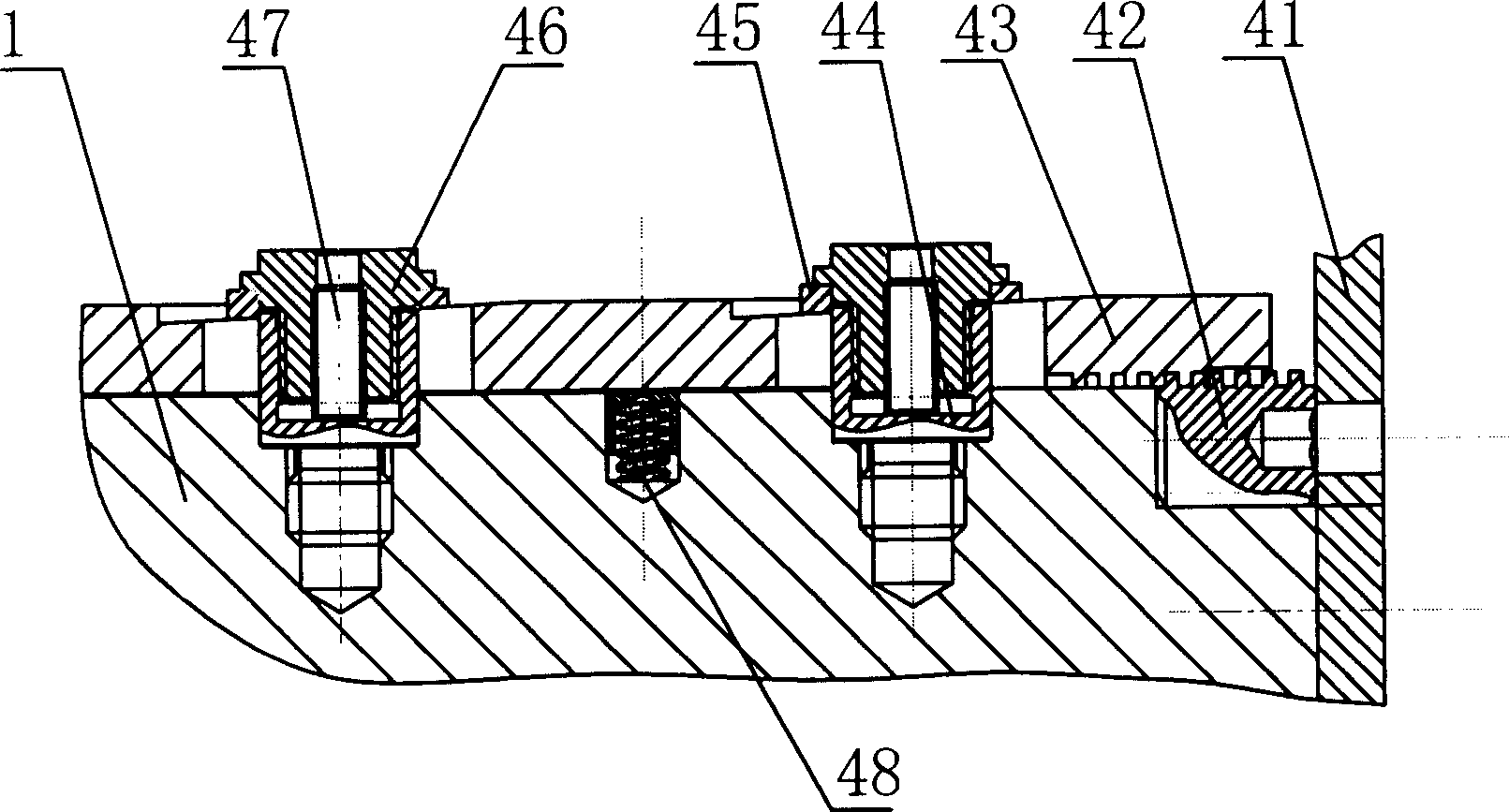

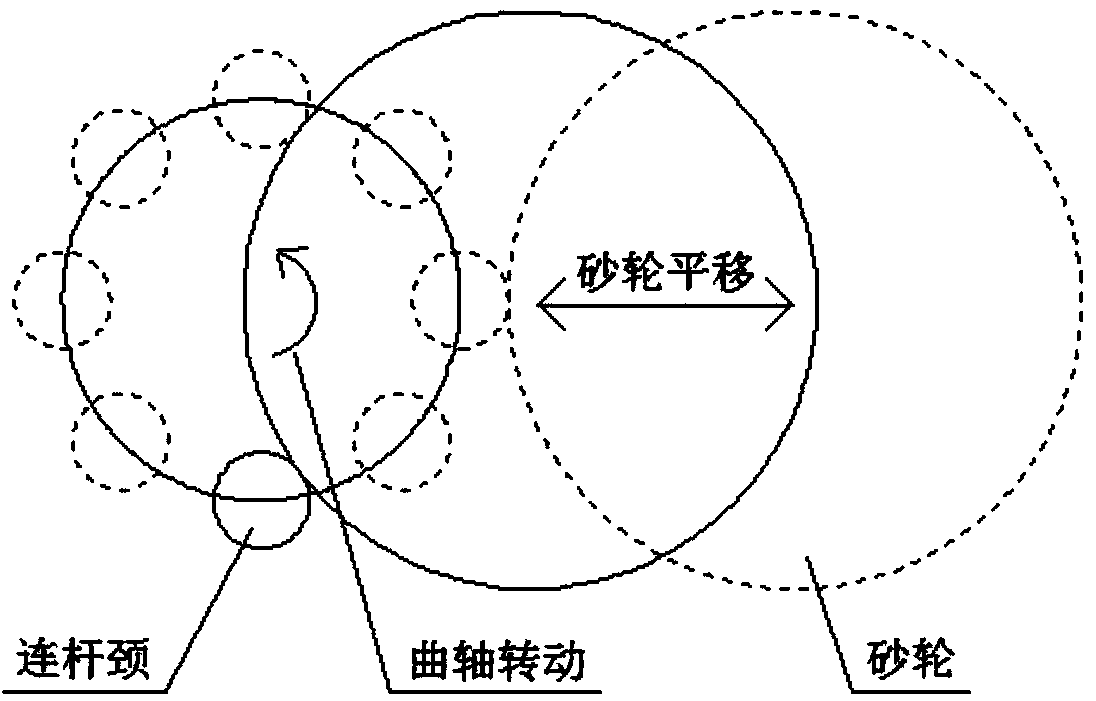

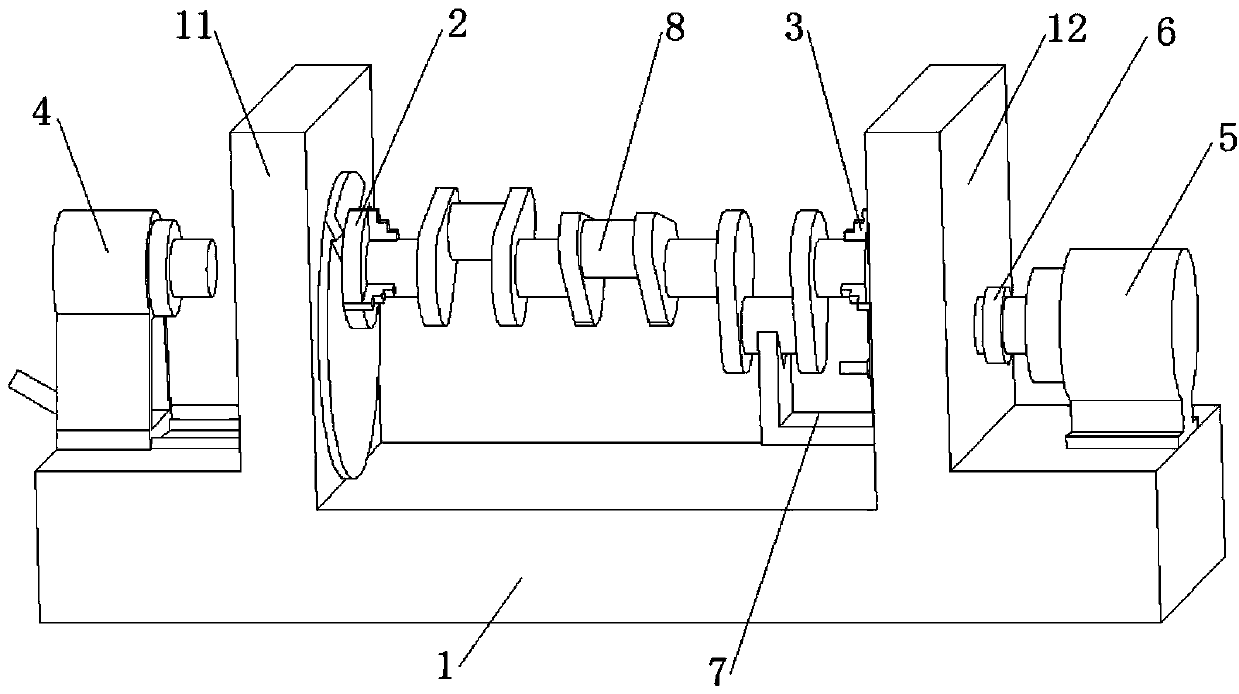

Grinding device and method of crankshaft by one clamping

ActiveCN103949948AImprove processing efficiencyReduce processing costsRevolution surface grinding machinesGrinding work supportsDrive motorEngineering

The invention discloses a grinding device of a crankshaft by one clamping, and belongs to the field of crankshaft grinding. Left and right supporting plates are vertically arranged on a rack, and left and right double rotating shaft positioning discs are respectively and coaxially arranged on the left and right supporting plates and are in a cylindrical shape; crankshaft clamping chucks and V-shaped block mounting grooves are arranged on the left and right double rotating shaft positioning discs, and the crankshaft clamping chucks and the double rotating shaft positioning discs are eccentrically arranged; the eccentric distance is equal to the radius of a crank of the crankshaft, and V-shaped blocks are arranged in the V-shaped block mounting grooves; an output shaft of a driving motor is coaxially connected with the right double rotating shaft positioning disc, and an output shaft of a movable indexing mechanism and the crankshaft clamping chuck on the left double rotating shaft positioning disc are coaxial. The invention also discloses a grinding method of the crankshaft by one clamping. The main journal and the rod journal of the crankshaft can be ground only by one clamping without a complicated numerical control system, and the operation is simple; the main journal and the rod journal of the crankshaft are theoretical cylinders, so that the principle error is avoided, and the machining accuracy is improved.

Owner:THYSSENKRUPP ENGINE COMPONENTS (CHINA) CO LTD

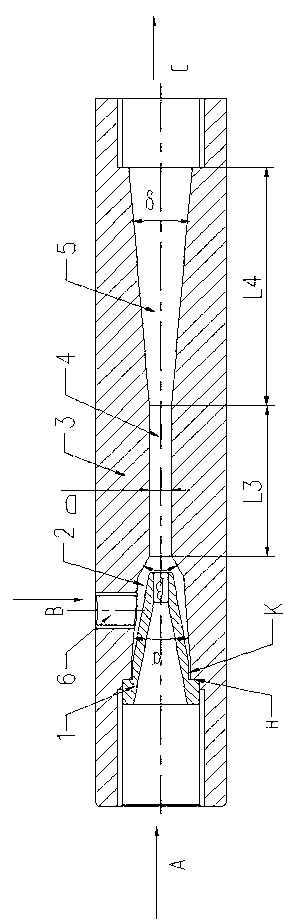

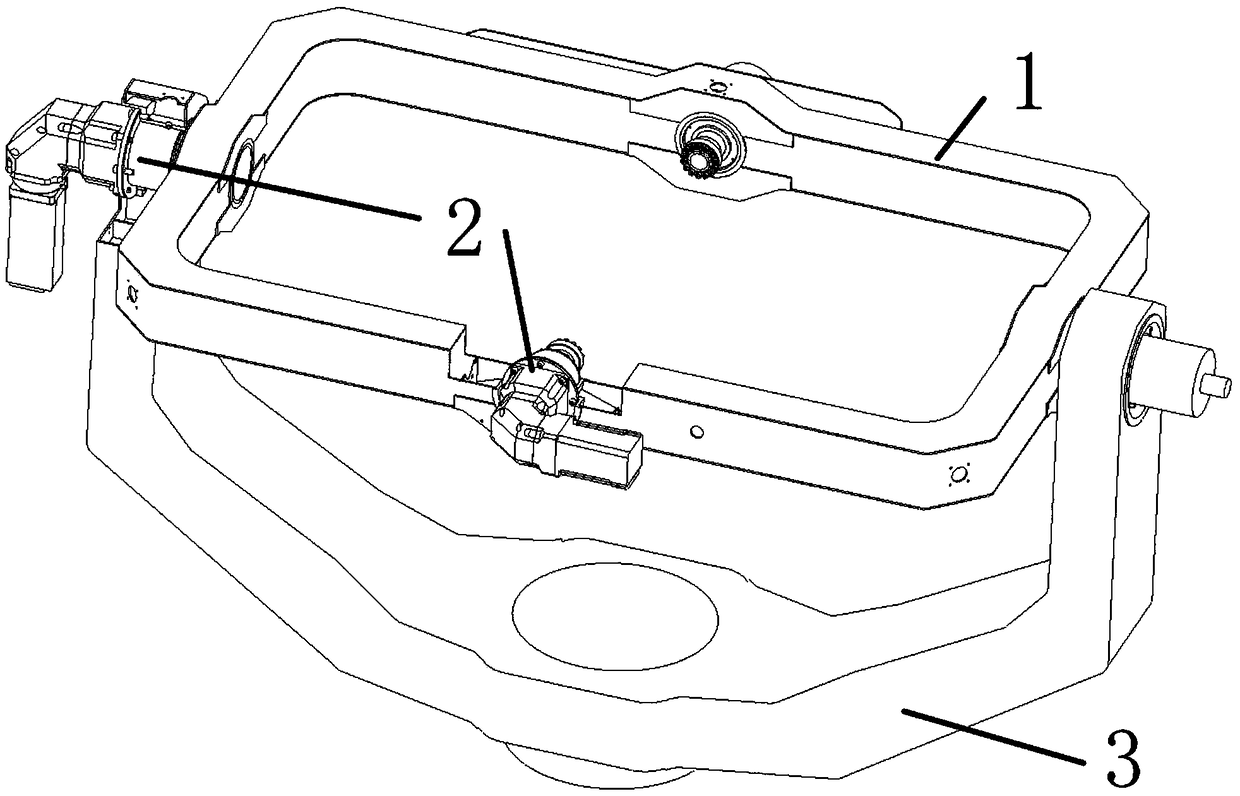

Vehicle-mounted pesticide mixing device

The invention relates to a vehicle-mounted pesticide mixing device, in particular to an online pesticide mixing device for a large and medium sprayer with a large spray volume. The device can automatically suck pesticide liquid and uniformly mix the pesticide liquid and water online. The vehicle-mounted pesticide mixing device comprises a jet nozzle 1 and a pesticide mixing device shell 3, wherein the pesticide mixing device shell comprises a suction chamber, a tube, a diffusion tube and a pesticide suction port. The requirements of spraying of pesticide liquids of different concentrations are met, the structure is simple, and the nozzle and the shell are convenient to change. According to the vehicle-mounted pesticide mixing device, pesticide and water in the large and medium sprayer are stored separately, and the operations of mixing and spraying are conducted online, so that the degree of automation is high, and environment friendliness and high efficiency are achieved.

Owner:JIANGSU UNIV

Auxiliary supporting clamp for thin-walled part edge and hole machining and working method of auxiliary supporting lamp

ActiveCN108466083AEliminate or weaken positioning gapsHigh matching precisionPositioning apparatusMetal-working holdersEngineeringMachining

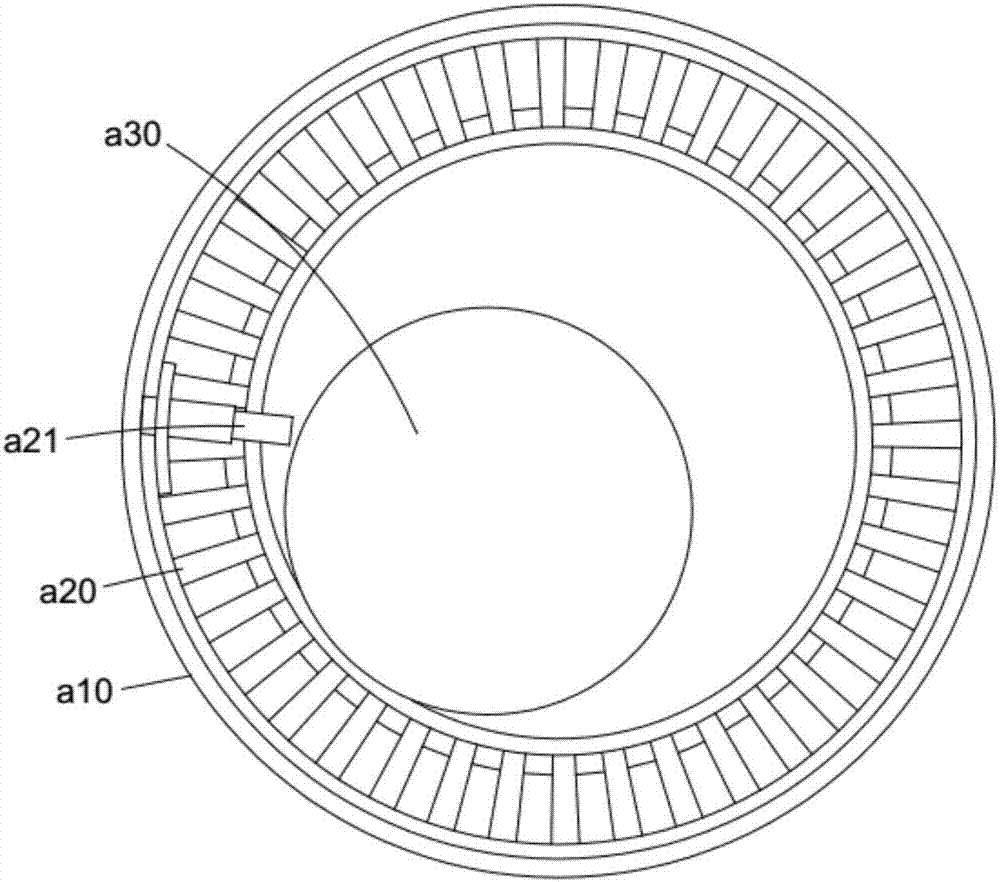

The invention relates to the technical field of aeronautical part machining, in particular to an auxiliary supporting clamp for thin-walled part edge and hole machining and a working method of the auxiliary supporting lamp. Supporting semi-rings are arranged on the edge part of a part, the rigidity of the thin-walled part is effectively improved, the fit clearance between the thin-walled part andthe auxiliary support is controlled, the problem that the stress of the auxiliary support and the stress of the thin-walled part are unbalanced is solved, and deformation generated after part edge and hole machining is controlled. According to the adopted technical scheme, the auxiliary supporting clamp comprises a clamp base, the two ends of the rectangular clamp base are provided with opened U-shaped grooves, the clamp base is provided with a circular ring-shaped chassis, an inner ring of the circular ring-shaped chassis is provided with a concaved platform, the concaved platform is provided with a positioning ring, the height of the positioning ring is larger than that of the circular ring-shaped chassis, the clamp base is further provided with the two symmetric semi-rings, and the semi-rings are arranged on the outer side of the circular ring-shaped chassis. The certain method is adopted to machine the thin-walled part.

Owner:西安西航集团莱特航空制造技术有限公司

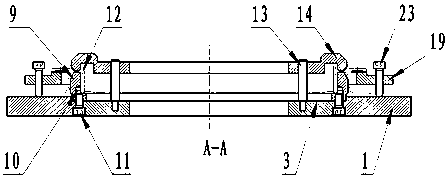

Ultrasonic rolling welding machine

PendingCN108393573AOvercoming Position Accuracy IssuesHigh matching precisionNon-electric welding apparatusUltrasonic weldingEngineering

The invention discloses an ultrasonic rolling welding machine which facilitates installing and adjusting between a spindle system and an anvil block device of a welding machine. One side of a verticalframe is provided with a linear guiding rail extending in the vertical direction; an ultrasonic welding head of an upper frame body and an anvil block ring of a lower frame body are arranged in a centering mode; the upper frame body is used for mounting the first part of the spindle system of the upper frame body and the anvil block device of the lower frame body, and the upper frame body is connected to the linear guiding rail of the vertical frame in a coupled mode and can be adjusted up and down along the linear guiding rail; the lower frame body is used for mounting the second part of thespindle system of the upper frame body and the anvil block device of the lower frame body, and the lower frame body is connected to the linear guiding rail of the vertical frame in a coupled mode andcan move up and down along the linear guiding rail; a driving device is mounted on a main frame bottom plate and used for driving the lower frame body to move up and down.

Owner:SBT ULTRASONIC TECH CO LTD

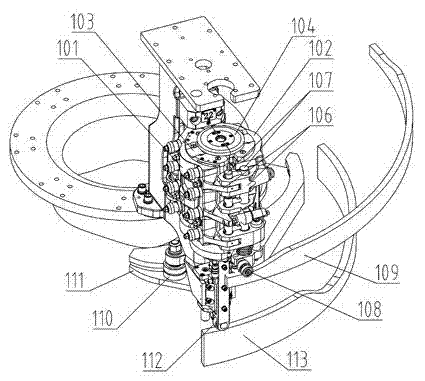

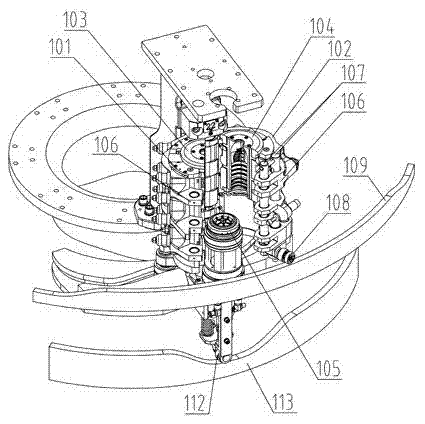

Double-cycloid speed reducer of RV-E type substituted industrial robot

InactiveCN103234007ALow mechanical manufacturing process difficultyReduce manufacturing costToothed gearingsGearing detailsProduction linePhase difference

The invention relates to a double-cycloid speed reducer of an RV-E type substituted industrial robot. The double-cycloid speed reducer of the RV-E type substituted industrial robot comprises a planetary transmission part and a double-cycloid transmission part, wherein the planetary transmission part comprises a central shaft, a sun wheel, a planet wheel and an input shaft, and the double-cycloid transmission part comprises a first cycloid wheel, a second cycloid wheel, a first eccentric bearing, a second eccentric bearing, an inner cycloid gear ring, a left machine frame and a right machine frame. The cycloid wheels are connected through a roller bearing in a penetrating mode, eccentric sleeves are installed in inner holes of the roller bearing, and an inner hole of the eccentric sleeve is an involute oblique inner tooth, and the involute oblique inner tooth is matched with an involute oblique outer tooth in a sliding mode on the input shaft. The oblique inner teeth and the oblique outer teeth are processed by a cutting machine tool with medium-slow production lines, a processing technology is simple, the production efficiency is high, the cost is low, and the matching accuracy of the oblique inner teeth and the oblique outer teeth is high. Elastic retainer rings are respectively arranged on outer sides of disc springs on two sides of the input shaft. The double-cycloid speed reducer aims at enabling phase difference of the two single eccentric sleeves to be 180 degrees-delta psi, wherein a small deflection angle delta psi is that wheel teeth of the first cycloid wheel 9 lean against one anticlockwise side of wheel teeth of an upper half region of the inner cycloid gear ring, and wheel teeth of the second cycloid wheel 21 lean against one clockwise side of wheel teeth of a lower half region of the inner cycloid gear ring. The shortcoming of repeated dismantling in the former invention is improved.

Owner:JIANGSU TAILAI REDUCER

Three-degree-of-freedom turning frame system applied to dynamic flight simulator of helicopter

ActiveCN108766101ARealize pitching motionRealize three degrees of freedom rotationCosmonautic condition simulationsSimulatorsRound tableThree degrees of freedom

The invention discloses a three-degree-of-freedom turning frame system applied to a dynamic flight simulator of a helicopter. A rolling and turning frame is connected with a manned cabin in a rotatable manner to realize pitching motion of the manned cabin; a yawing frame is connected with the rolling and turning frame in a rotatable manner to realize rolling and turning motion of the manned cabin;the yawing frame is connected with the tail end of a turning arm of a centrifugal machine through a bearing to realize yawing motion of the manned cabin, so that the manned cabin rotates in three degrees of freedom in a centrifugal field; the rolling and turning frame and the manned cabin as well as the rolling and turning frame and the yawing frame are respectively connected through expansion sleeves; furthermore, a power system is mounted on a shaft sleeve; the shaft sleeve is mounted in a shaft hole. The structural cooperation is relatively easy to mount and dismount; due to the design ofa round table structure on a pin shaft and a conical surface in the shaft hole, the pin shaft can be automatically guided and located during mounting, and the cooperation precision is high.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

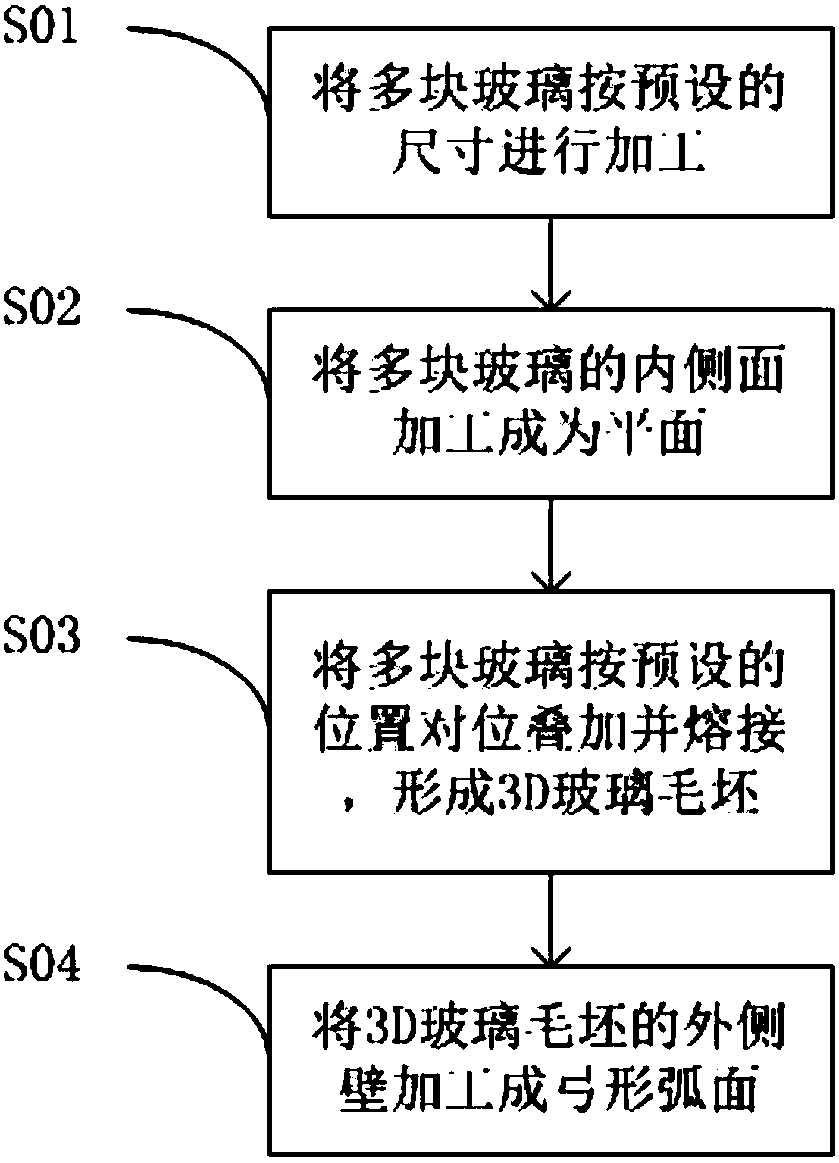

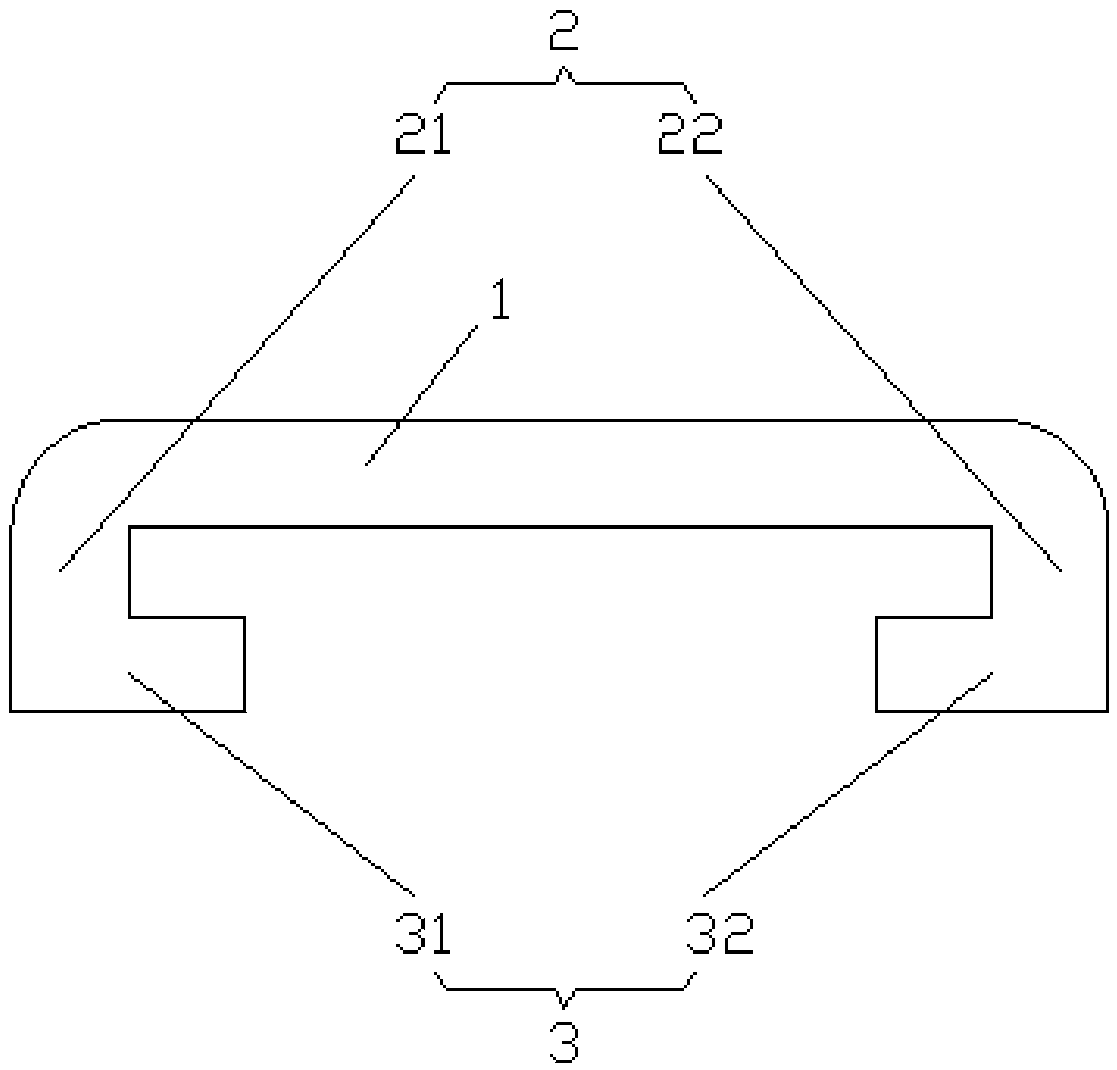

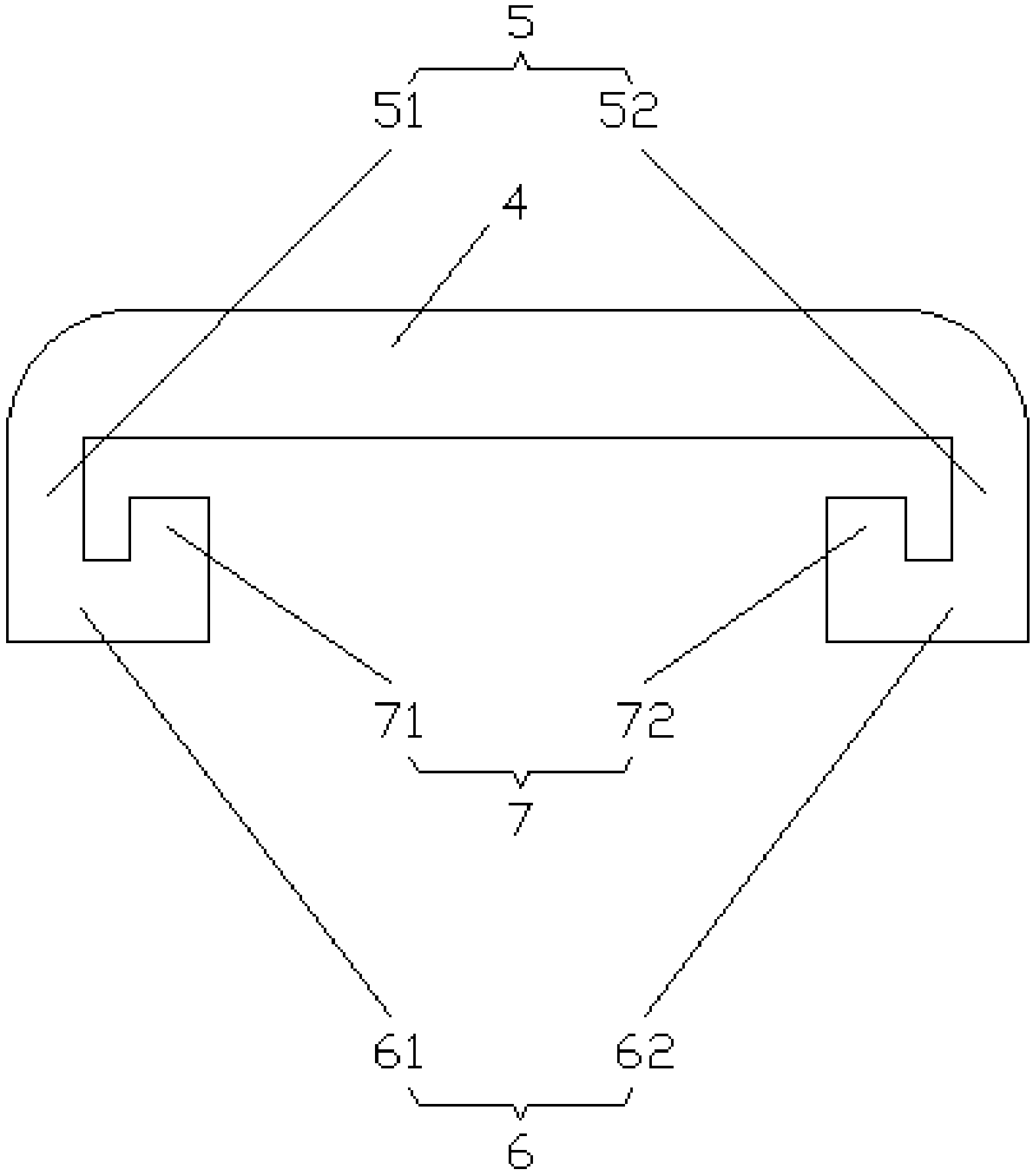

3D glass cover plate, processing method and electronic device

InactiveCN107902878AEasy to assembleHigh matching precisionGlass reforming apparatusGlass coverWhole body

The invention discloses a processing method of a 3D glass cover plate. The processing method comprises the following steps: processing a plurality of pieces of glass according to a preset size; processing an inner side surface of each glass into a plane; superimposing a plurality of pieces of glass according to a preset position, and welding the glass to form a 3D glass blank; and processing the outer side wall of the 3D glass blank into a bow-shaped arc surface. By adopting the method, the 3D glass cover plate with a complicated structure can be processed, the process is simple, and the yieldis high. The invention also provides a 3D glass cover plate. The 3D glass cover plate comprises at least three glass assemblies of different sizes, the glass assemblies of different sizes are weldedinto a whole body, other glass assemblies of other sizes except for the glass assembly of the largest size form a fastener group for installation, the upper surface of a cross section of the glass assembly of the largest size is in a bow shape, and the lower surface is a plane. The 3D glass cover plate has a fastener structure design, thereby being convenient in assembling. The invention also provides an electronic device, which comprises the 3D glass cover plate. The use experience is better.

Owner:厦门祐尼三的新材料科技有限公司

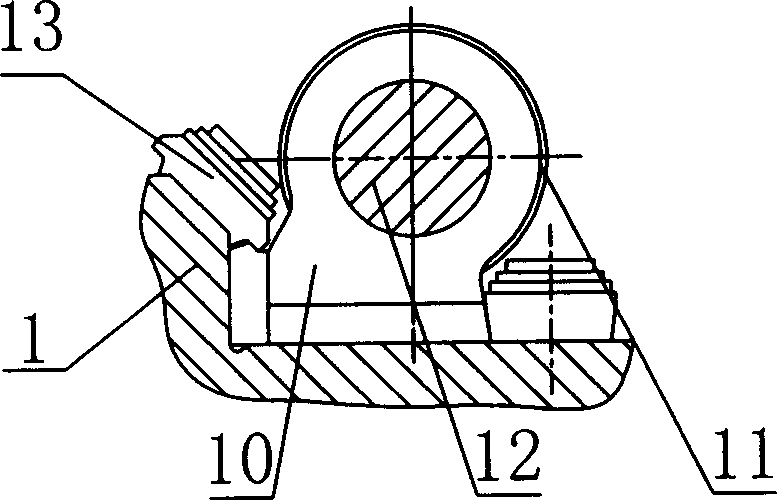

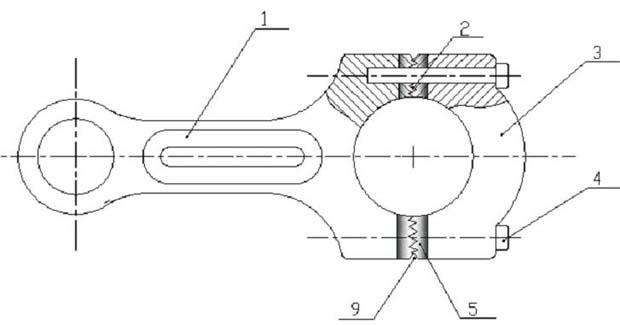

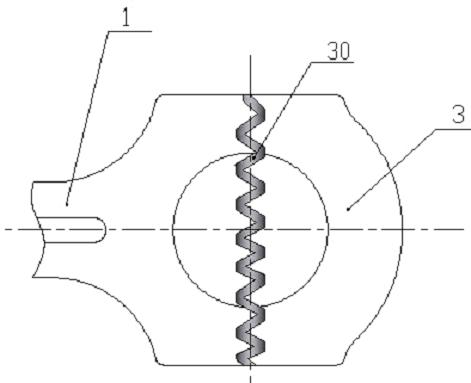

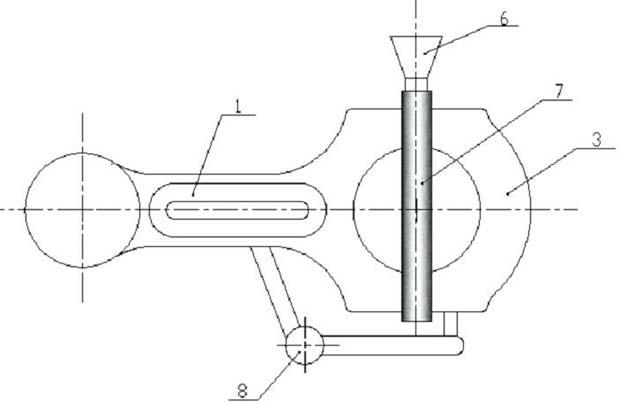

Manufacturing method of composite double-metal cracking connecting rod

InactiveCN102626777ABroaden your optionsGuarantee the performance of the main bodyConnecting rodsShaftsHigh loadMechanical engineering

The invention relates to a manufacturing method of a composite double-metal cracking connecting rod. The method disclosed by the embodiment of the invention comprises the following steps of: arranging a movable isolating plate at a big head part of a connecting rod cavity; dividing the mold cavity into two independent parts; firstly casting a connecting rod body and a connecting rod cover by adopting materials of a connecting rod main body; when large parts of the connecting rod body and the connecting rod cover are solidified, pulling out the isolating plate from the mold cavity, then injecting materials for cracking areas into the cavity formed after the isolating plate is pulled, and forming a composite double-metal casting piece by combining two materials in a metallurgical manner; and then finishing cracking separation for the connecting rod body and the connecting rod cover along preset cracking surfaces by adopting cracking equipment, and carrying out positioning and accurate assembly by utilizing a meshed intertongue structure on the two cracking surfaces. The manufacturing method of the composite double-metal cracking connecting rod has the advantages that the material selection range of the cracking connecting rod is expanded, the process is simple and feasible, the cost is low, and the assembling accuracy of the connecting rod is high; the technology is also suitable for manufacture of high-power engine connecting rods so as to meet the requirement for bearing high-load and large-torque connecting rods; and the process method has a wide application prospect.

Owner:JIANGSU UNIV

Vertical pipe jointing device for expansion corrugated pipes and pipe jointing welding method

ActiveCN102398131AEffective clampingAdapt to clamping needsWelding/cutting auxillary devicesAuxillary welding devicesSymmetrical componentsUltimate tensile strength

The invention discloses a vertical pipe jointing device for expansion corrugated pipes and a pipe jointing welding method. The vertical pipe jointing device comprises an upper and a lower expansion corrugated pipe hydraulic servo clamping mechanisms, a gap hydraulic servo adjusting mechanism and a device bracket, wherein the upper and the lower expansion corrugated pipe hydraulic servo clamping mechanisms are arranged by taking vertically and coaxially-jointed expansion corrugated pipes as centers, and consist of upper and lower corrugated pipe clamps and upper and lower clamp hydraulic servo transmission mechanisms; the upper and the lower corrugated pipe clamps are two symmetrical components which are connected to the upper and the lower expansion corrugated pipe hydraulic servo clamping mechanisms and of which the inner side cross sections have semi-8-shaped structures matched with the standard shape of a clamped corrugated pipe; and the upper and the lower corrugated pipe clamps are connected with pistons of the hydraulic servo transmission mechanisms respectively. By adopting the vertical pipe jointing device for performing horizontal pipe jointing operation on expansion corrugated pipes, high pipe jointing accuracy, high efficiency, high automatic degree and low labor intensity are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

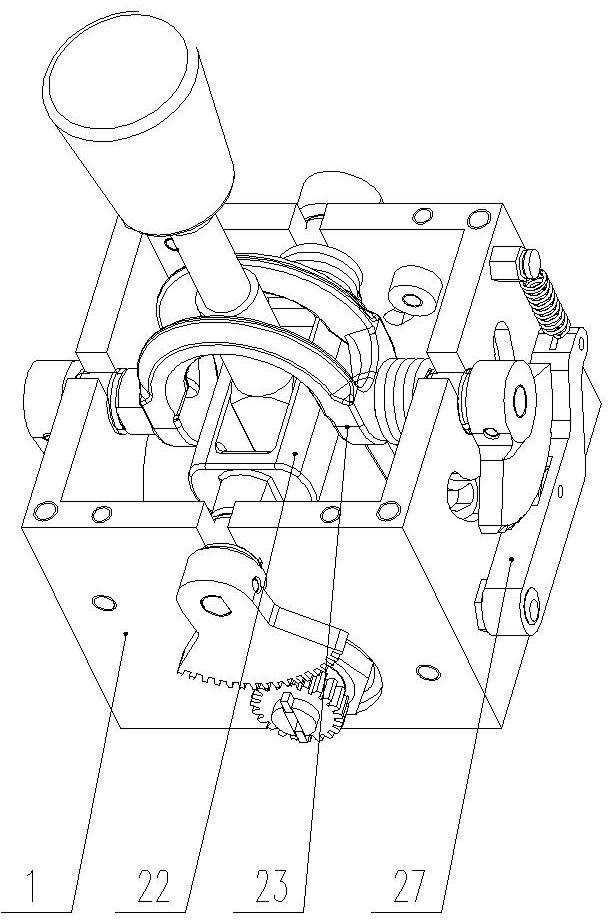

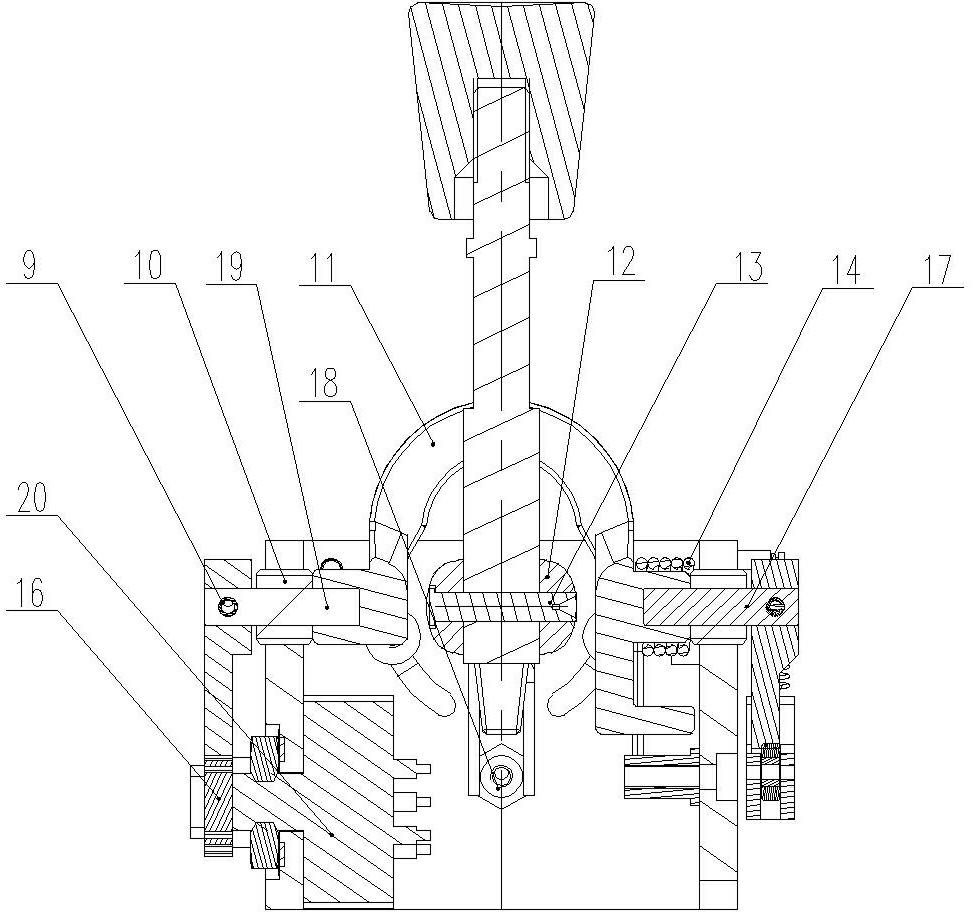

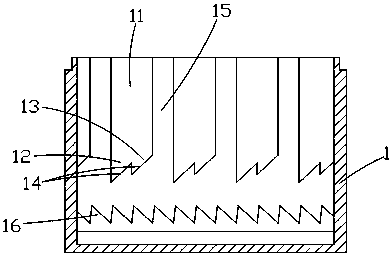

Control stick apparatus

InactiveCN102591402AImprove installation accuracyHigh matching precisionControlling membersLimiting/preventing/returning movement of partsGear driveGear wheel

The invention discloses a control stick apparatus which mainly comprises a fixed seat, a straight shaft assembly and an arc shaft assembly. The fixed seat is a box shaped body with an upper opening and a lower opening. The straight shaft assembly and the arc shaft assembly are in vertical crossed symmetrical arrangement and are installed on the fixed seat through a shaft sleeve with an outside thread. A center of the straight shaft assembly is superposed with that of the arc shaft assembly. A rocking bar is installed at the superposition center. Two ends of the straight shaft assembly and the arc shaft assembly are provided with a shift balance wheel and a potentiometer balance wheel respectively. On the fixed seat, a position corresponding to the shift balance wheel is provided with a swing rod assembly, and a position corresponding to the potentiometer balance wheel is provided with a gear which is engaged with the potentiometer balance wheel. The gear drive an antenna of a potentiometer installed with the gear to move, and a signal of each level of shift is sent out through the enclosed potentiometer. The shift balance wheel is engaged with a bearing on the swing rod assembly, and a clear shift sense is brought to an operator. The control stick apparatus has the advantages of the clear shift sense, a good sealing effect and convenience in use.

Owner:湖南锦润智能科技有限公司

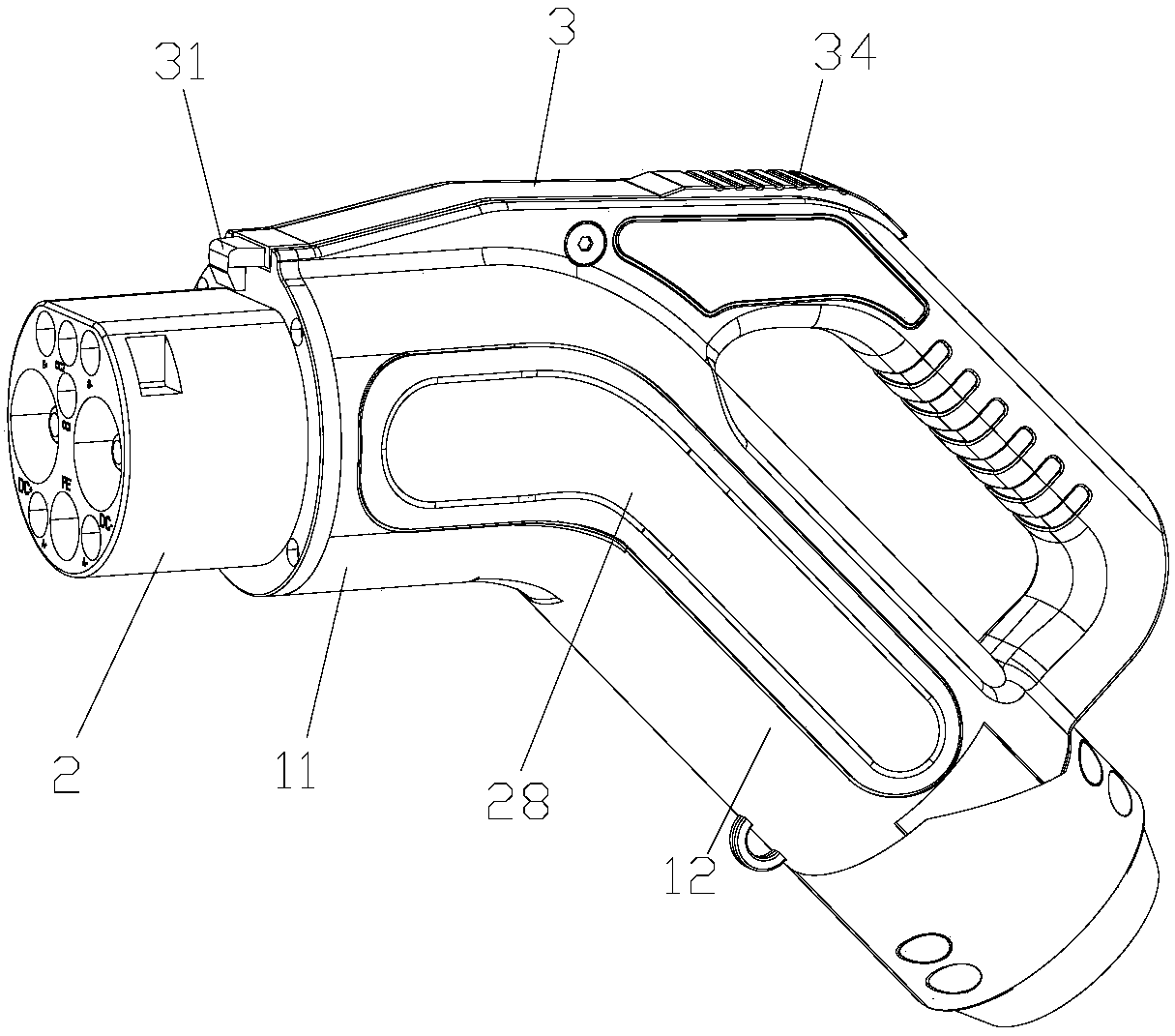

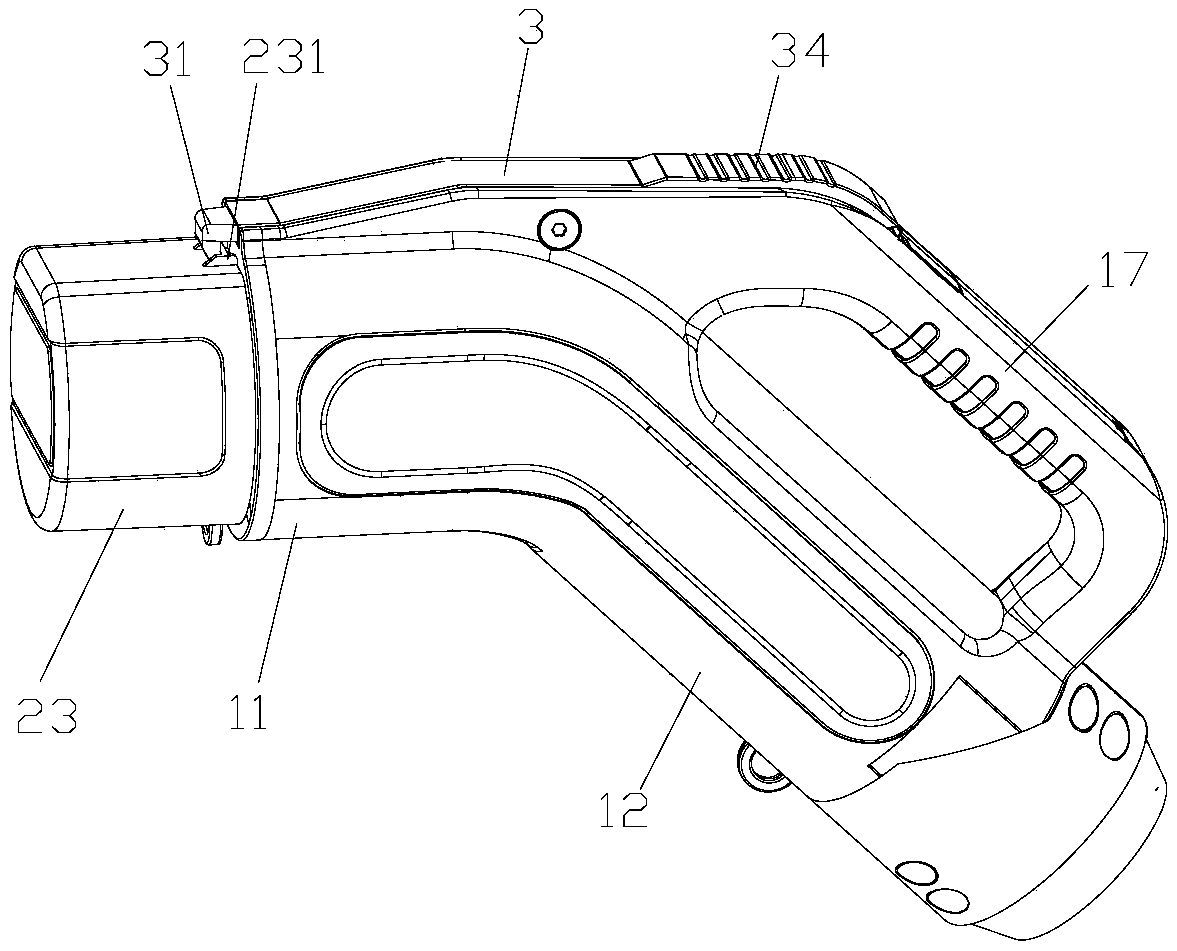

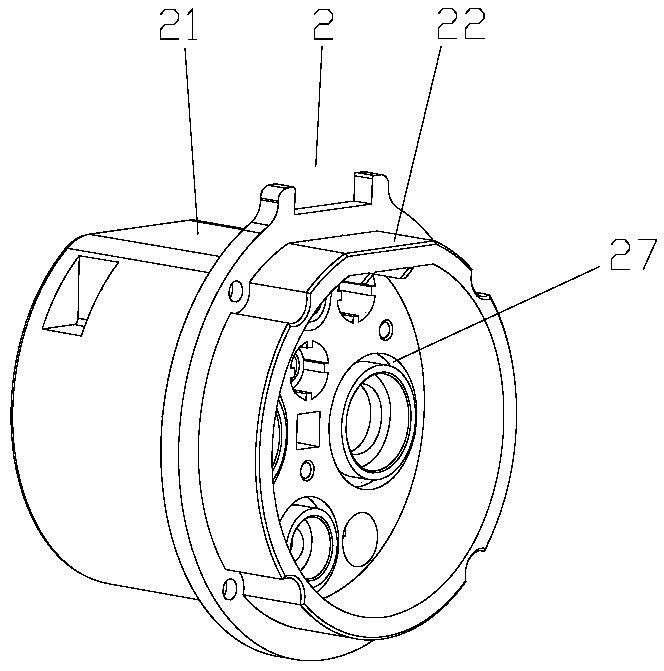

Direct-current charging gun of new energy electric automobile

PendingCN109346878APrevent intrusionStrong impact resistanceVehicle connectorsRelieving strain on wire connectionNew energyTemperature monitoring

The invention relates to the technical field of electric vehicle charging guns, and particularly relates to a direct-current charging gun of a new energy electric automobile; the direct-current charging gun comprises a gun body, a charging plug and a locking plate, wherein a charging contact pin is arranged in the charging plug; the gun body is of an integrated forming structure, and an inner cavity is formed in the gun body; an assembling cavity which is independent from the inner cavity and is not communicated with the inner cavity is formed in the upper part of the gun body; the locking plate is movably arranged at the opening of the assembling cavity; a detection assembly is arranged at the bottom of the locking plate in the assembling cavity; a sealing shell is arranged outside the detection assembly; a contact pin fixing base for fixing the contact pin is arranged in the charging plug, and a contact pin fixing hole is formed in the contact pin fixing base; a temperature monitoring hole is formed in the edge side of the contact pin fixing hole; a temperature monitoring device for monitoring the temperature in the position of the charging contact pin is arranged in the temperature monitoring hole; the temperature monitoring hole is poured and sealed with glue; the structure strength, the protection level and the safety performance of the charging gun are high, so that electrified operation of a user can be avoided; and the structure of the gun body conforms to the human engineering design, the grabbing is convenient and labor-saving, and the charging operation is facilitated.

Owner:常州中电新能电器科技有限公司

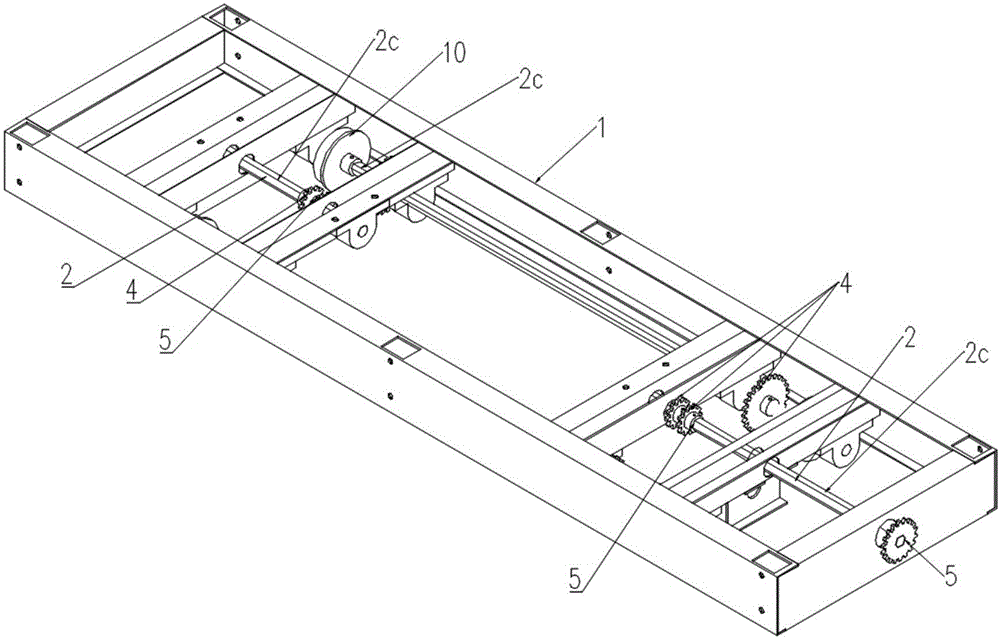

Compact shelving

InactiveCN106763578ASimple structureIt is reasonable to cooperate with the transmission modeBook cabinetsGearingReliable transmissionDrive shaft

The invention discloses a compact shelving. The compact shelving comprises chain wheels, ground wheels, or comprises chain wheels, ground wheels, driving wheels and transmission shafts connected with the chain wheels and the ground wheels, or connected with the chain wheels, the ground wheels and the driving wheels. The chain wheels and the ground wheels, or the chain wheels, the ground wheels and the driving wheels are provided with polygon shaft holes connected with the corresponding transmission shafts. The chain wheels and the ground wheels, or the chain wheels, the ground wheels and the driving wheels are connected with the corresponding transmission shafts through the polygon shaft holes. The compact shelving transmission device has the advantages of simple assembling structure, rational and cooperative transmission structure, smooth and steady and reliable transmission movement and high transmission efficiency.

Owner:张国云

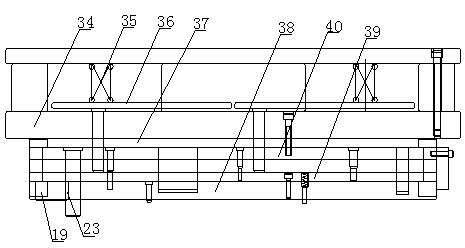

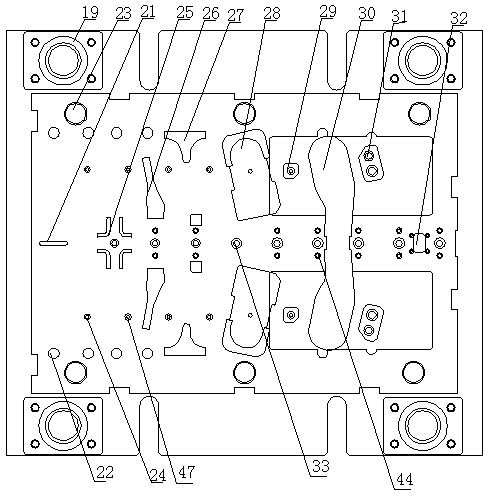

Automatic continuous forming mold of automobile armrest framework

ActiveCN104384350AGuaranteed accuracyIncrease stiffnessShaping toolsVehicle componentsPunchingMaterials science

The invention discloses an automatic continuous forming mold of an automobile armrest framework. The automatic continuous forming mold comprises an upper mold assembly with a guide mechanism and a lower mold assembly, wherein the lower mold assembly is provided with a lower necking mold (18), a primary punching mold (4), a primary blanking mold (5), a secondary blanking mold (6), a thrice blanking mold (7), a lower bending mold (8), a lower correction mold (9), a lower forming mold (10), a secondary punching mold (11), a cutting mold (12), a material outlet (13), material supporting blocks (16 and 17) and a positioning block (20); the upper mold assembly is provided with an upper necking mold (21), a primary punching head (24), a primary blanking punching mold (25), a secondary blanking punching mold (26), a thrice blanking punching mold (27), an upper bending mold (28), an upper correction mold (29), an upper forming mold (30), a secondary punching head (31), a cutting punching head (32), a precise guide column (23), a guide hole (22), a first guide pin (33), a material pressing pin (44) and a second guide pin (47).

Owner:CHANGSHA JINBAILI AUTO PARTS CO LTD

Installation equipment used for civic buildings

PendingCN107336183AImprove fastnessContinuous and efficient operationPower driven toolsPore distributionEquipment use

The invention discloses installation equipment used for civic buildings. The installation equipment comprises an upper barrel and a lower barrel. A guide rod capable of rising, falling and rotating is movably inserted into the upper barrel. A rotating drum is mounted in the lower barrel and provided with a plurality of through holes distributed in the circumferential direction. A rotating shaft of the rotating drum is parallel to the guide rod. The guide rod is aligned with the through hole located under the guide rod in an up-down manner. The through holes are used for accommodating flat head screws. The bottom end of the guide rod is provided with a pointed portion matched with the flat head screws. When the equipment is used, an electric head of an electric tool is in embedded fit with the top of the guide rod, the guide rod is pressed downwards, and the electric head drives the guide rod to rotate to enable the bottom of the guide rod to be in embedded fit with the screw head of one flat head screw; and then the lower end of the lower barrel is placed to a position needing screw fastening, and the electric head is continued to be pressed downwards until the lower end of one flat head screw makes contact with a wood board. After the flat head screw in one through hole is used, the rotating drum enables the next through hole to be aligned with the guide rod in an up-down manner, and thus, efficient and continuous operation is conducted conveniently.

Owner:ZHEJIANG JINGHU CONSTR GRP

Stainless steel auger of ice cream machine

The invention provides a stainless steel auger of an ice cream machine, which comprises a stainless steel mixing barrel, wherein an auger shaft and an auger blade are installed in the stainless steel barrel; the auger shaft comprises a positioning shaft and an auger fixing shaft; a bottom plate is connected between the positioning shaft and one end of the auger fixing shaft; a material pushing impeller is connected at the other end of the auger fixing shaft; the auger blade is a spiral blade made of stainless steel; a fixing shaft of the material pushing impeller is installed at a side of an edge between the bottom plate and the material pushing impeller; a plastic scrapper which can swing freely is arranged at the outer part of the fixing shaft of the material pushing impeller; and the plastic scrapper is matched with the inner wall of the stainless steel mixing barrel. In operation, the positioning shaft is driven to rotate through a driving force, and drives the bottom plate, and the fixing shaft of the stainless steel auger connected on the bottom plate; the spiral blade made of stainless steel is installed on the fixing shaft of the auger; particularly the plastic scrapper which can swing freely is arranged at the outer part of the fixing shaft of the material pushing impeller, therefore, the plastic scrapper always adheres to the inner wall of the mixing barrel, and materials on the inner wall of the mixing barrel can be scraped cleanly in time.

Owner:王日君

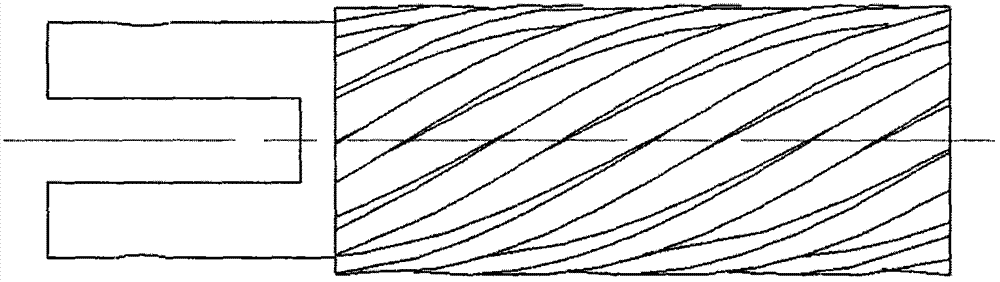

Electrical discharge machining (EDM) shaping method for external spiral structure

ActiveCN103302367AHigh precisionLower requirementElectrical-based machining electrodesAgricultural engineeringHardness

The invention discloses an electrical discharge machining (EDM) shaping method for an external spiral structure. The EDM shaping method for the external spiral structure is charaterized by comprising the following steps: I, machining a tool electrode according to outer contour parameters of the external spiral structure by adopting a tractable electrode material; II, machining out a plate-shaped material spiral hole electrode on a plate-shaped material by using the tool electrode; III, machining out the external spiral structure by adopting an EDM shaping mode according to the plate-shaped material spiral hole electrode. According to the EDM shaping method for the external spiral structure disclosed by the invention, firstly, the tool electrode is machined out by adopting the conventional tractable electrode material, then, a spiral hole is machined out according to the tool electrode, and finally, the external spiral structure made of the high-hardness material is machined out by adopting the EDM shaping technology according to the spiral hole. The external spiral structure processed by the EDM shaping method disclosed by the invention has the advantages that the precision is high, the requirement on tools is not high, and the processing cost is lower.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

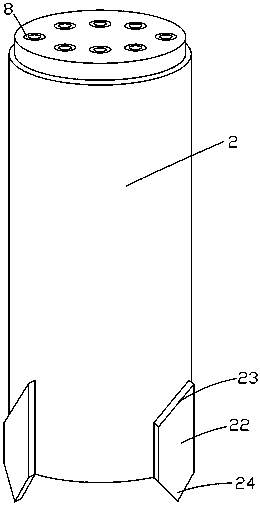

A thermometer storage container with disinfection function

InactiveCN108482821BHigh matching precisionAvoid cross infectionPackaging under vacuum/special atmosphereContainers preventing decayDisinfectantEngineering

The invention discloses a thermometer storing barrel with a disinfecting function. The thermometer storing barrel comprises a base, a barrel body and a barrel cover, the barrel body can slide up and down along the base, the barrel body is provided with containing cavities used for containing thermometers, each containing cavity is provided with a push plug, each push plug comprises a guide rod andan insertion hole head, thermometer hydrargyrum bubbles can be fixed into insertion holes in the insertion hole heads so that the thermometers keep in the upright state all the time, the lower ends of the guide rods abut against the bottom of the base, disinfectants are contained into the base, guide sleeves in sliding fit with the barrel body are installed at the upper end of the base in a sleeving manner, the multiple thermometers can be stored, structure layout is reasonable, the matching accuracy of all mechanisms is high, meanwhile, the thermometers can be disinfected, and cross infection between patients is avoided.

Owner:漯河市第一人民医院

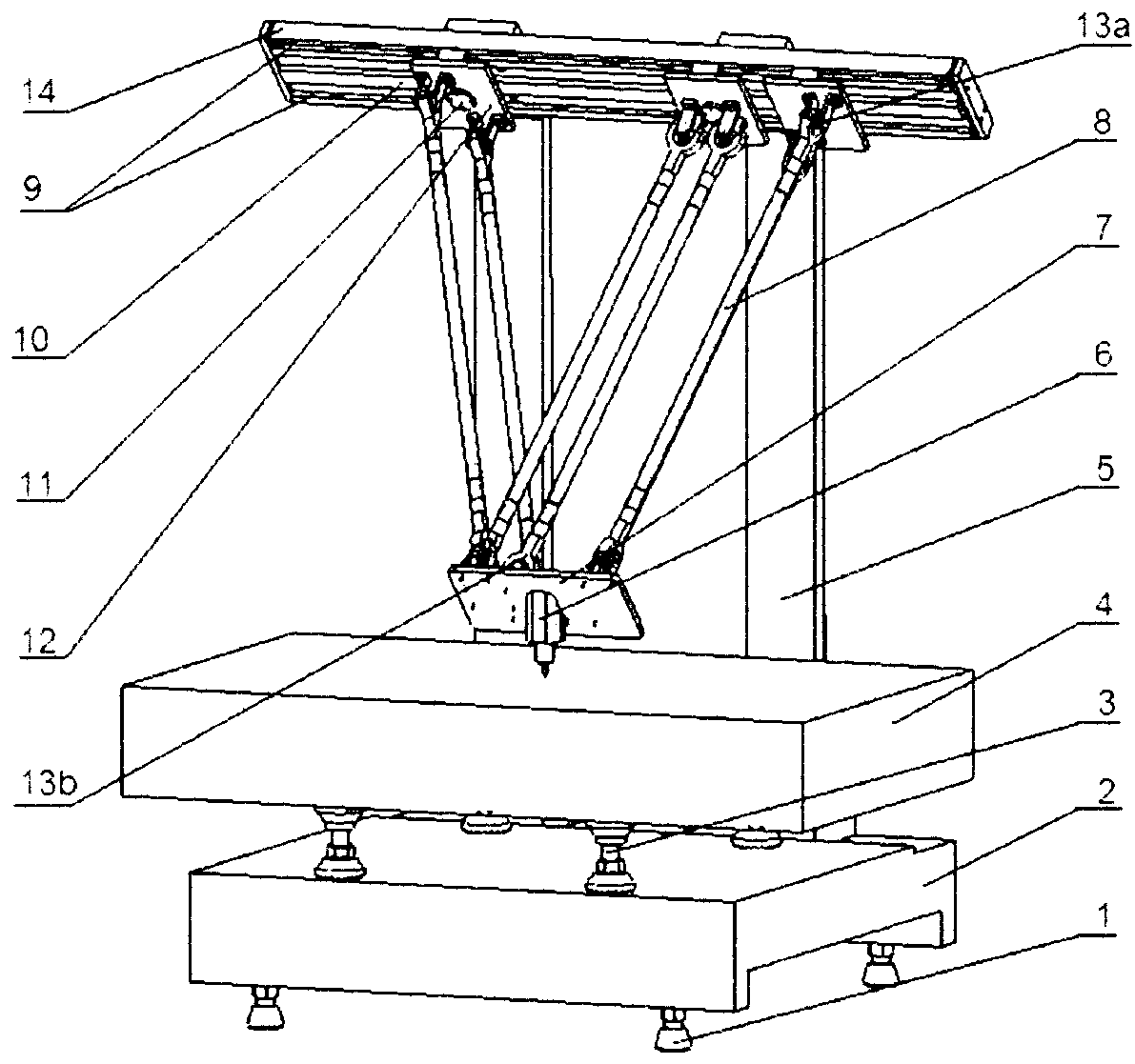

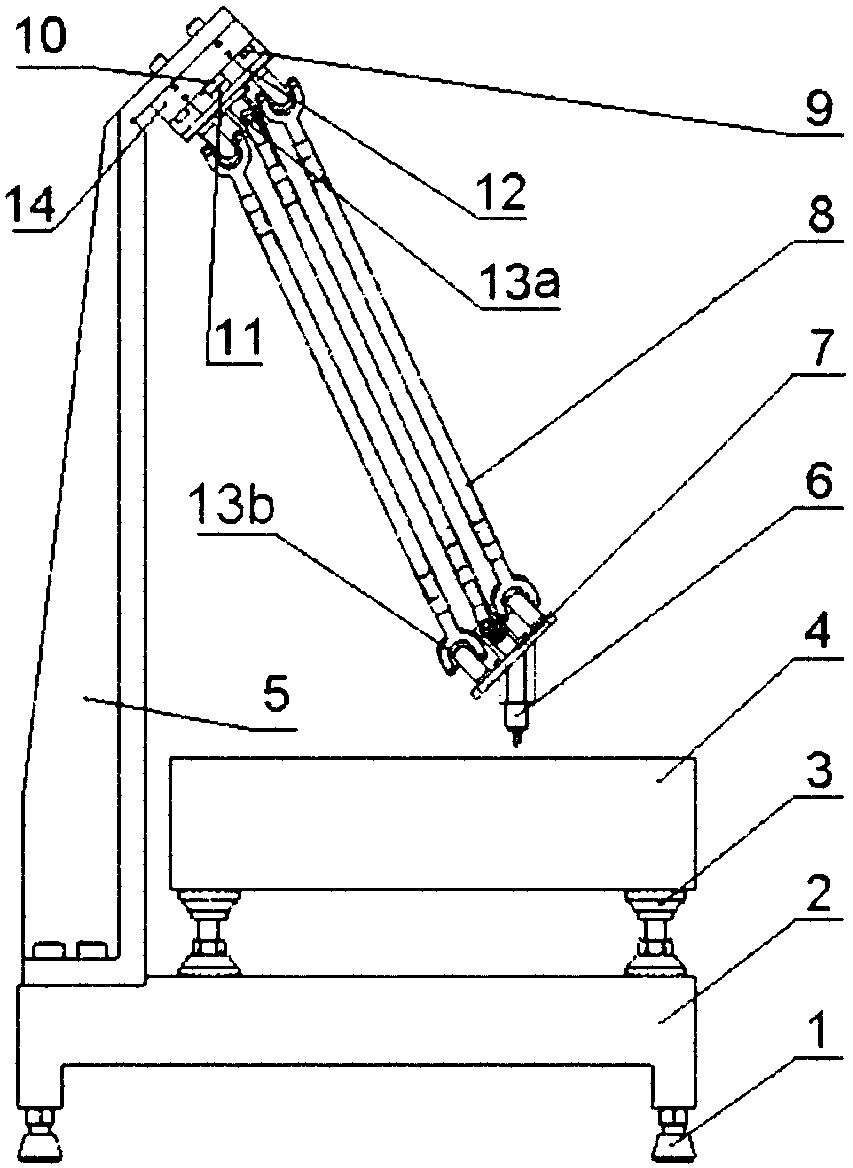

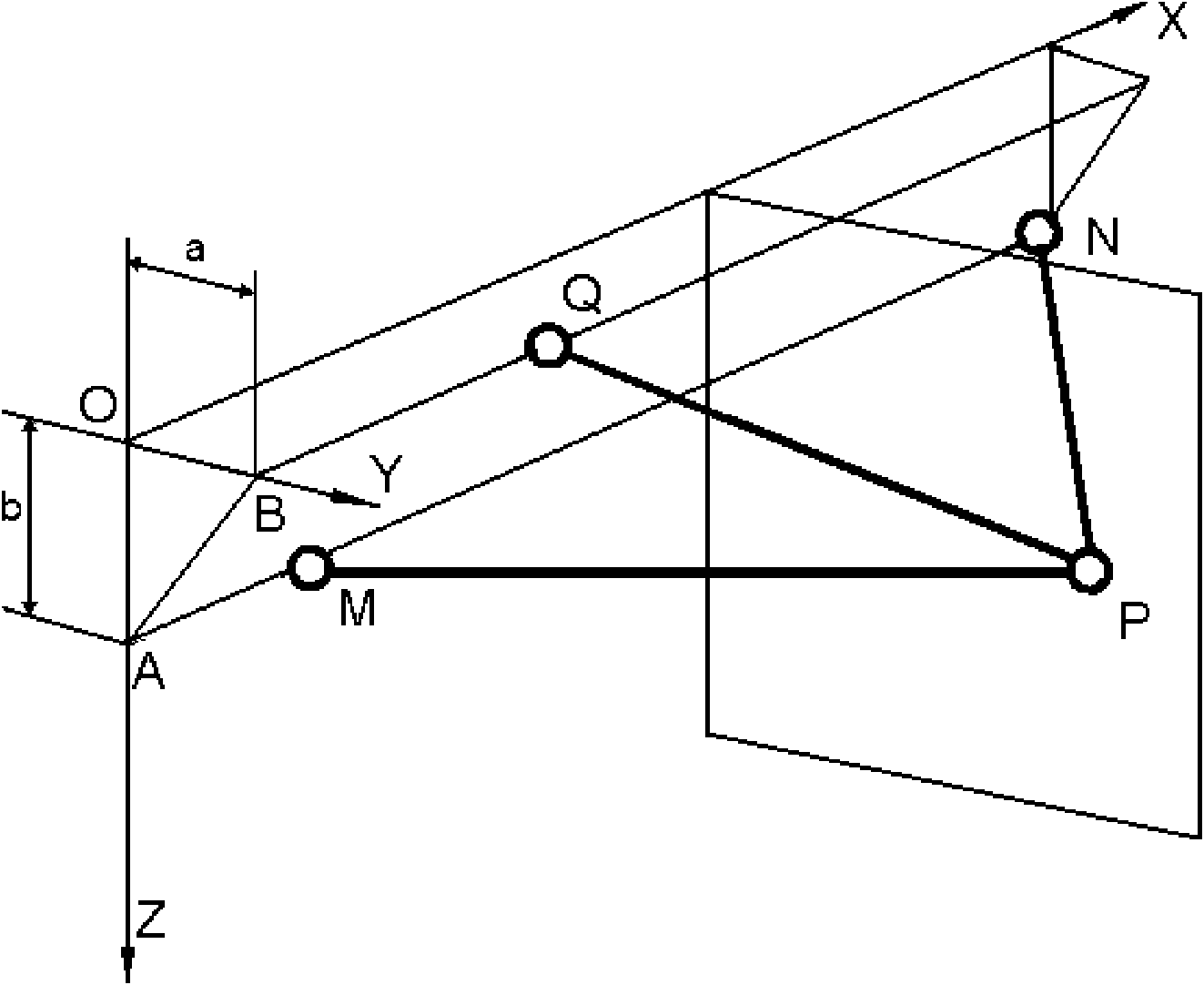

Three pairs of sliding pair-spherical hinge-spherical hinge (3-PSS) mechanism-based coordinate measuring machine

InactiveCN102012211AReduce the error factorHigh measurement accuracyUsing optical meansGratingSpherical bearing

The invention discloses a three pairs of sliding pair-spherical hinge-spherical hinge (3-PSS) mechanism-based coordinate measuring machine. The 3-PSS mechanism-based coordinate measuring machine is characterized in that: a three pairs of sliding pair-spherical hinge-spherical hinge parallel mechanism is provided; three motion sliding blocks are independently arranged on a pair of ball guide rails which are arranged in parallel and can slide freely along the ball guide rails respectively; the three motion sliding blocks are connected with one end of each of three pairs of link rods through one end of a universal joint respectively; the other end of each of three pairs of link rods are connected with a measuring moveable platform through the other end of the universal joint respectively; a measuring head is arranged on the lower plane of the measuring moveable platform; three indication gratings are fixedly connected to the three motion sliding blocks respectively; a scale grating and the pair of ball guide rails are arranged in parallel and are arranged on the guide rail mounting surfaces of guide rail cross beams; and the guide rail cross beams are suspended and fixedly connected to a pair of brackets. The 3-PSS mechanism-based coordinate measuring machine has high rigidity, a simple structure, high processing assembly property and low cost and can measure the three-dimensional space sizes, the shapes and the mutual positions of parts quickly and precisely.

Owner:合肥工大科教开发部

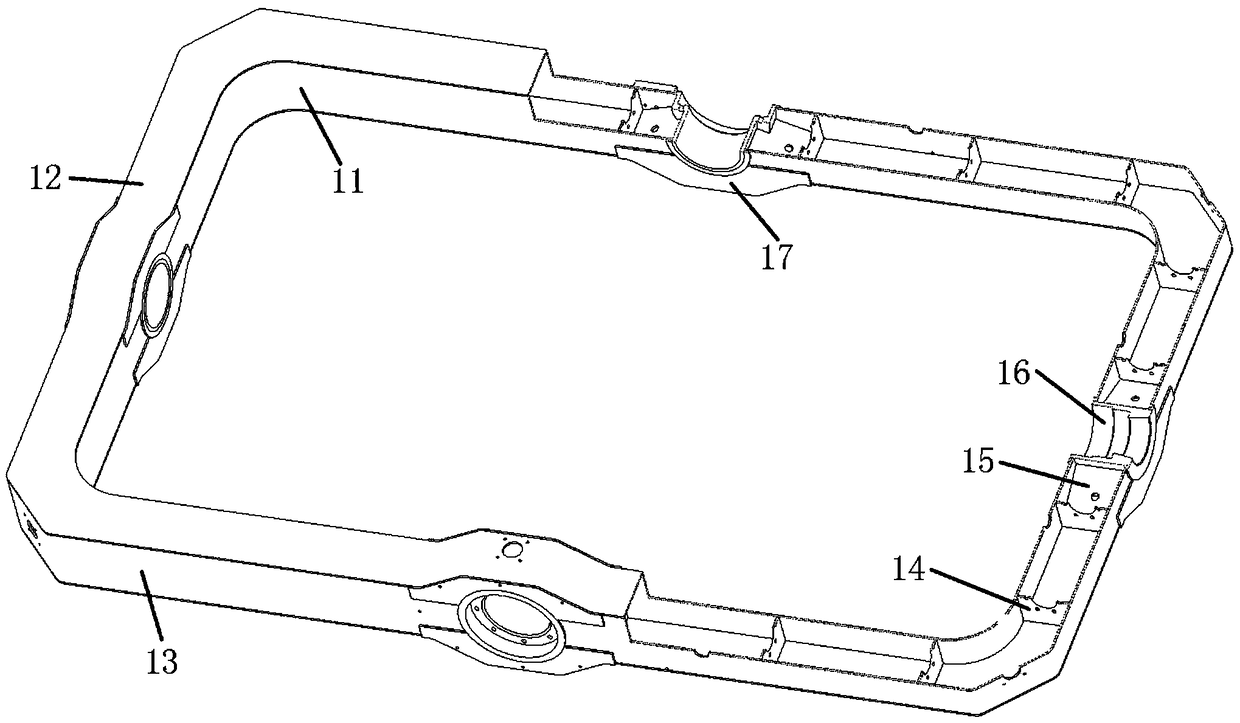

EGR (Exhaust Gas Recirculation) valve

ActiveCN102230430AImprove sealingHigh matching precisionInternal combustion piston enginesNon-fuel substance addition to fuelMulti-valveEmission standard

The invention provides an EGR (Exhaust Gas Recirculation) valve, belonging to the technical field of machines. The EGR valve solves the problem that the existing EGR valve of the double-valve structure can not satisfy the higher emission standard. The EGR valve comprises a valve body of which the inner part is a cavity, wherein the valve body is provided with an inlet and an outlet, and the inletand the outlet are communicated with the inner cavity of the valve body; a valve rod partially connected with a power part is arranged in the valve body; the inner side of the valve body is provided with at least two extruded sealing sockets; the valve rod is provided with valve blocks which are of the same amount with the sealing sockets and correspond to the position with the sealing sockets along the axial direction of the valve rod; and a sealing structure is arranged between the valve blocks and the sealing sockets. The EGR valve is provided with a multi-valve structure composed of multiple valves and sealing sockets, so that the valve rod has high control precision to each valve, and thus the tightness of the EGR valve can be greatly improved.

Owner:ZHEJIANG JIULONG MACHINERY

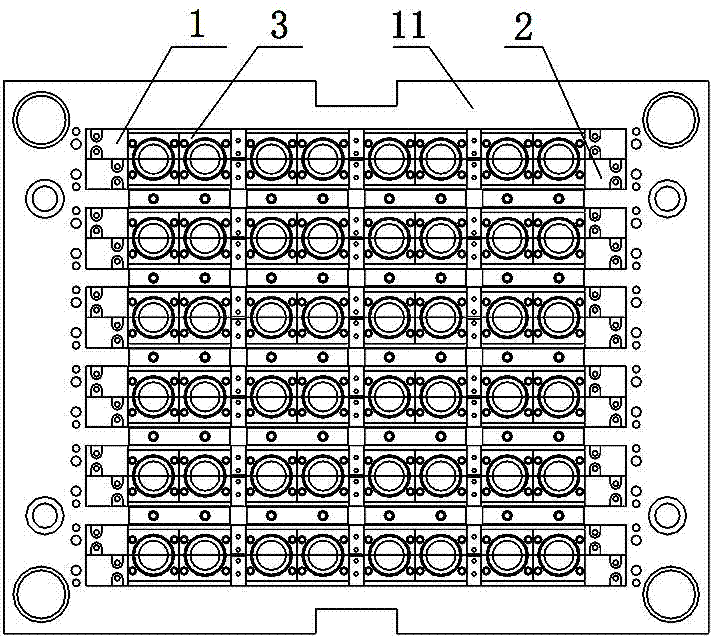

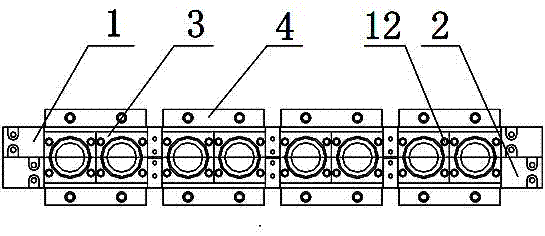

High-cavity precision bottle cap die of novel HALF block structure

The invention relates to a high-cavity precision bottle cap die of a novel HALF block structure. The high-cavity precision bottle cap die comprises an HALF block (3), a cavity (5), a large slider A (1), a large slider B (2) and a wedge block (4), wherein a positioning taper hole and a positioning straight hole are formed on the upper and lower end faces of the HALF block (3), respectively; inclined surfaces are formed on the two sides of the HALF block (3); the cavity (5) is fitted and mounted inside the positioning taper hole; the wedge block (4) is in close fit with the inclined surfaces; a push ring (6) is fitted and mounted inside the positioning straight hole; the large slider A (1) and the large slider B (2) are arranged under the HALF block (3); a cooling water core (8) is in fit connection with a threaded core (7); a push pipe (9) is sleeved inside the cooling water core (8); and an inner core (10) is mounted inside the push pipe (9). The high-cavity precision bottle cap die is small in boundary dimension, low in manufacture cost, high in die fit precision and stable in operation, easily guaranteed in processing precision and long in service life.

Owner:CHENGDU LIANYU PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com