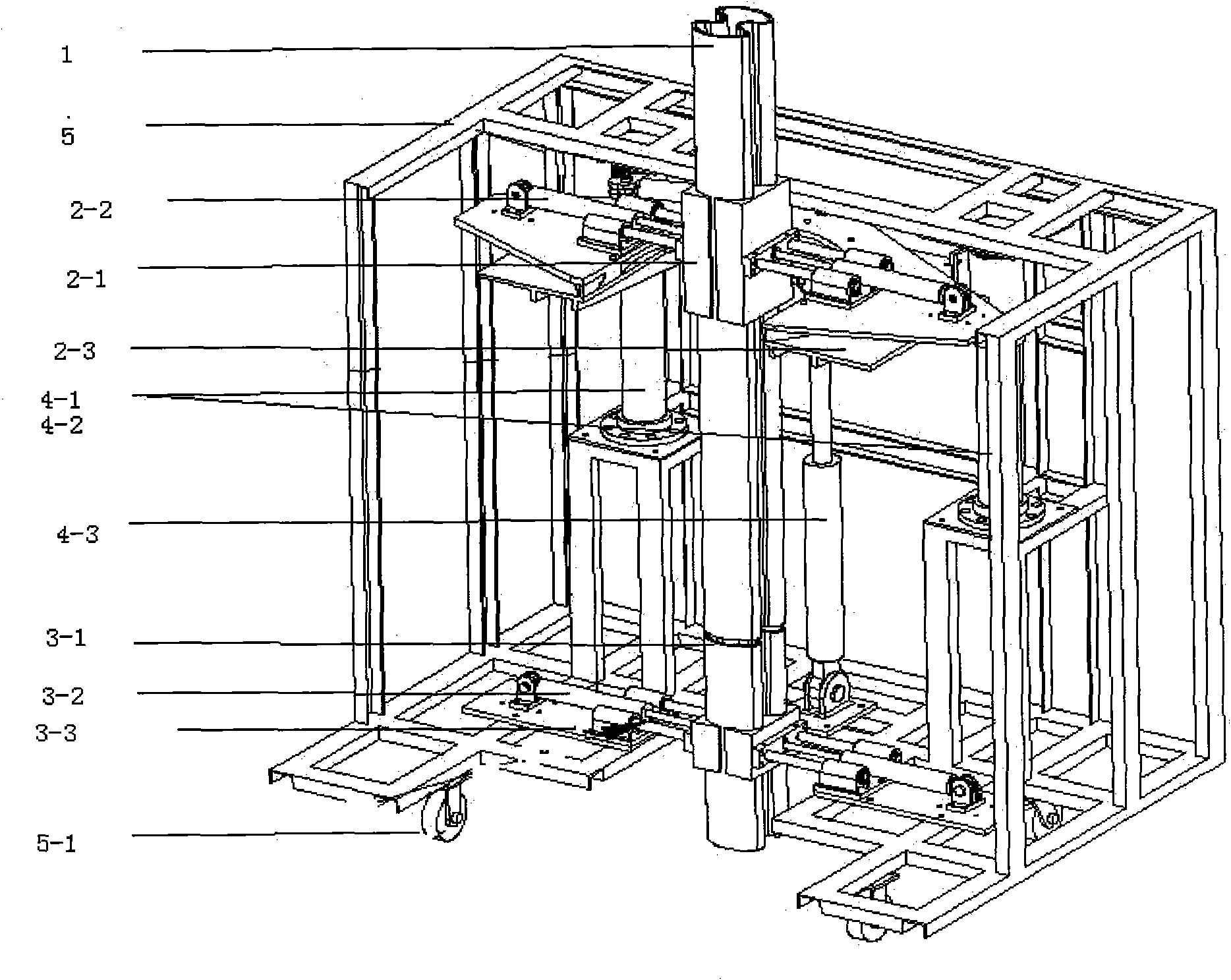

Vertical pipe jointing device for expansion corrugated pipes and pipe jointing welding method

The technology of corrugated pipes and opposite pipes is applied in the field of end-to-face connection devices in the welding process of corrugated pipes. , The size of the gap is continuously adjustable, and the effect of increasing the clamping friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with specific embodiments.

[0045] Embodiments of the invention:

[0046] (1) Hang the vertical pipe fitting device on the drill floor.

[0047] (2) Hang a column of expansion bellows about 20m into the well, and place it on the drill floor plane with the elevator.

[0048] (3) Lift the other column of expansion bellows, about 20m, and start the vertical pipe-aligning device to clamp the suspended expansion bellows, and at the same time, clamp the expansion bellows column seated on the drilling platform.

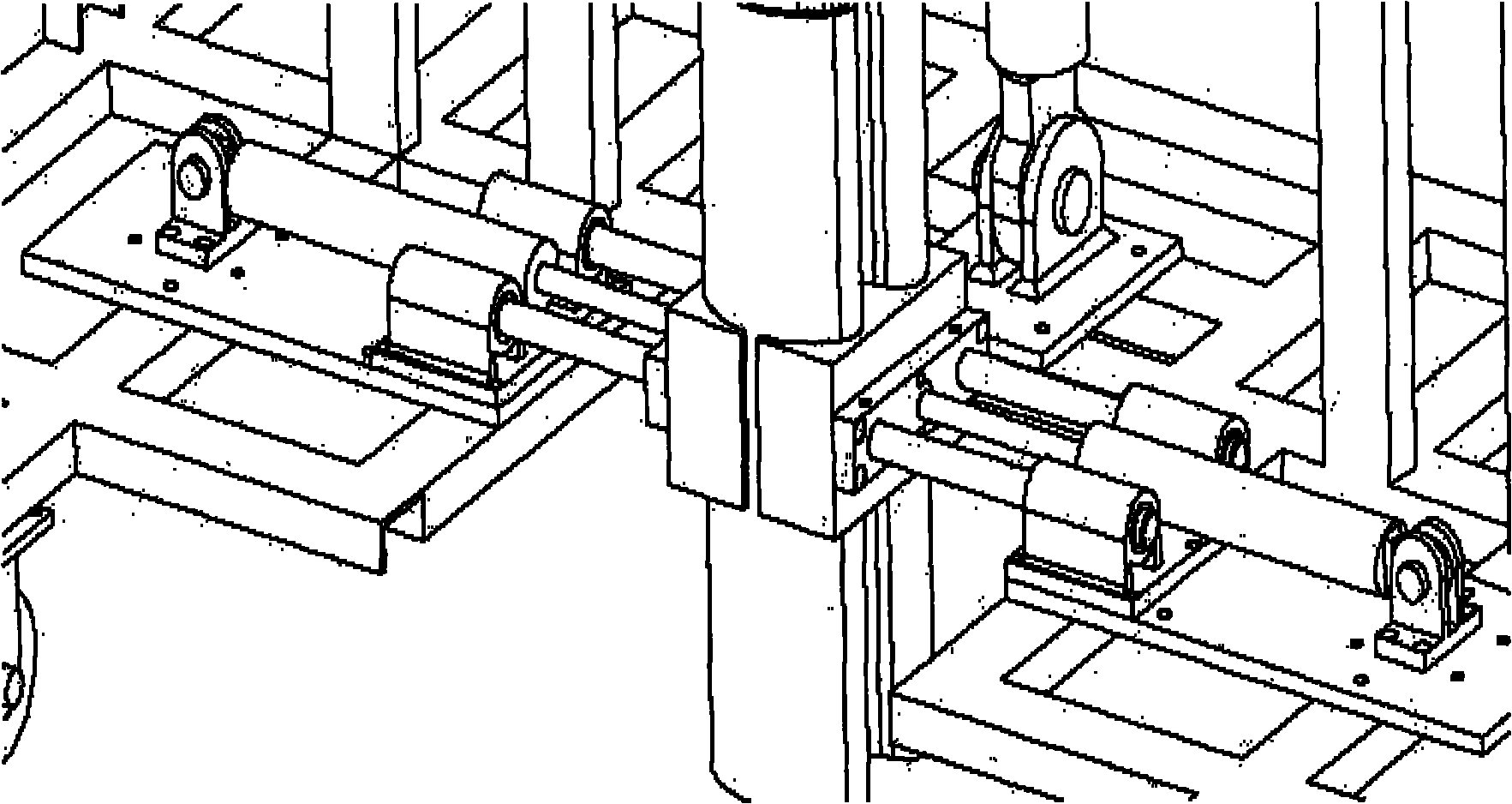

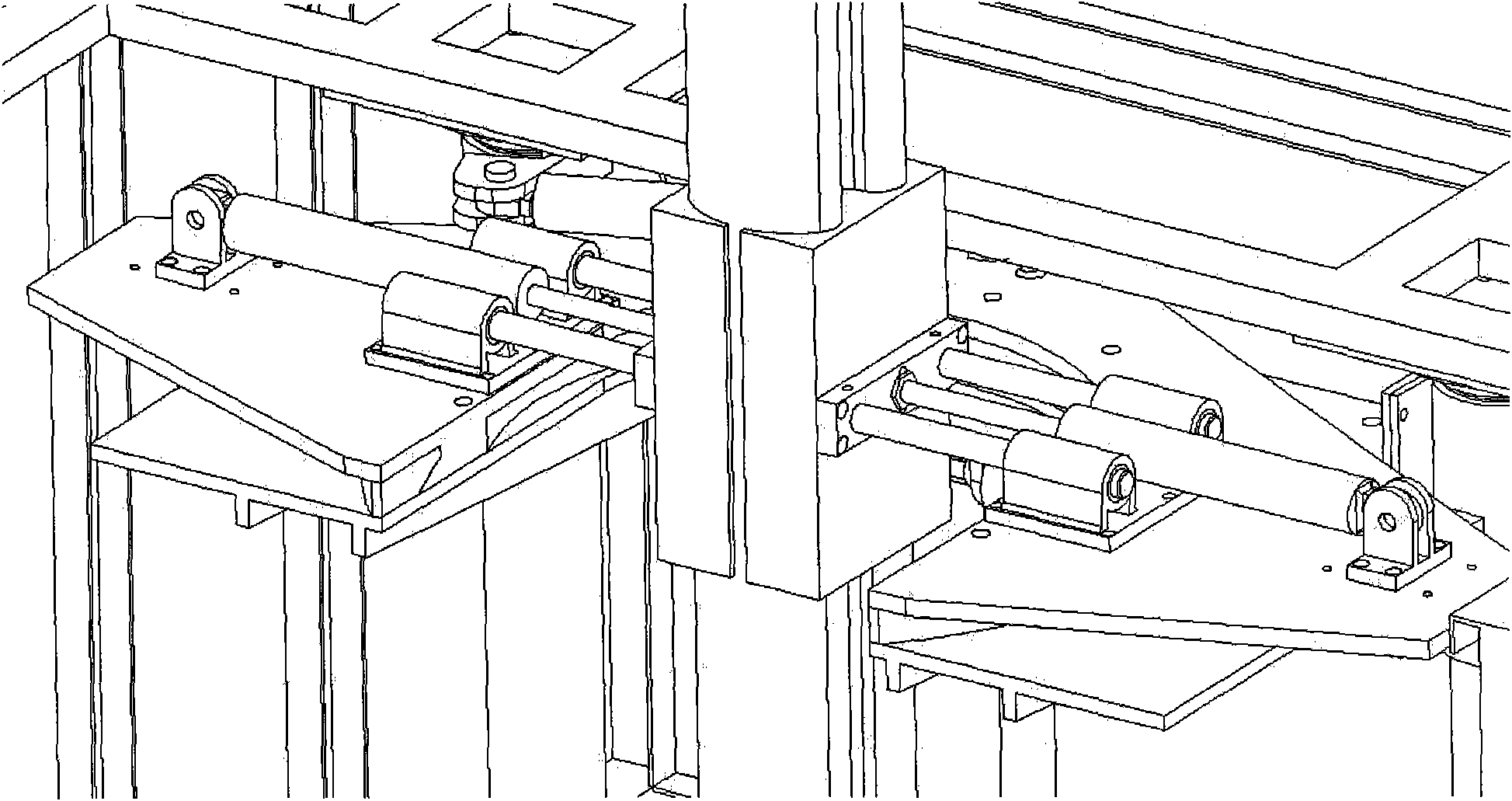

[0049] (4) Adjust the horizontal angle of the expansion bellows clamping mechanism so that the end faces of the expansion bellows are aligned and keep coaxial; start the gap adjustment mechanism, adjust the vertical height of the expansion bellows clamping mechanism, until the end faces of the expansion bellows are aligned, and the gap meets the welding process Require.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com