Constant-axial-force self-balanced loading device for different column section joints

A loading device and self-balancing technology, applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., can solve the problems that the vertical force cannot be kept constant, the loading frequency and continuity cannot be effectively controlled, and large test errors, etc. , to achieve the effect of effective clamping, avoiding progress delay, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] For the convenience of description, the "left", "right", "upper" and "lower" referred to below are consistent with the left, right, up and down directions of the drawings themselves, but do not limit the structure of the present invention.

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

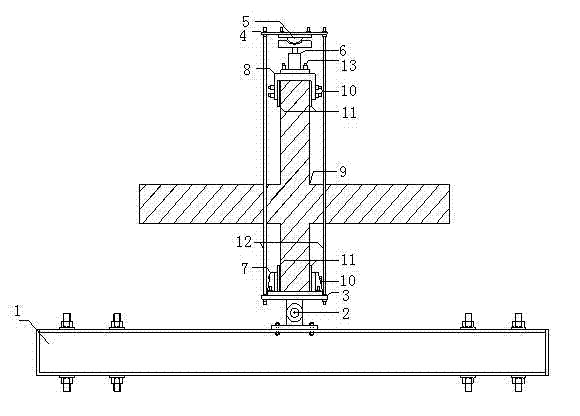

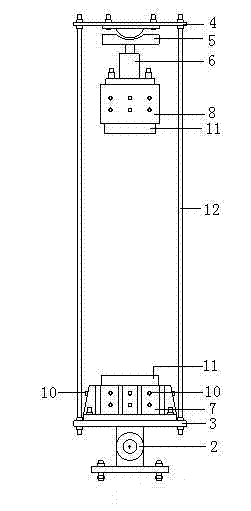

[0016] like figure 1 , 2 Shown: a constant axial force self-balancing loading device for nodes with different column sections. The two sides of the bottom beam 1 are fixedly connected to the ground through ground anchor bolts. The bottom spherical hinge 2 is placed on the bottom beam after adjusting the angle and fixed with high-strength bolts. The lower reaction force plate 3 is fixedly connected with the bottom spherical hinge 2 with high-strength bolts. The lower clamping structure 7 is fixedly installed on the lower reaction plate 3 by bolts. The lower clamping structure 7 and the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com