Automatic turret-type nozzle replacing device of laser cutting machine

A laser cutting machine, automatic replacement technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of relatively long time and affect processing efficiency, so as to improve work efficiency, save costs, and shorten non-production time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

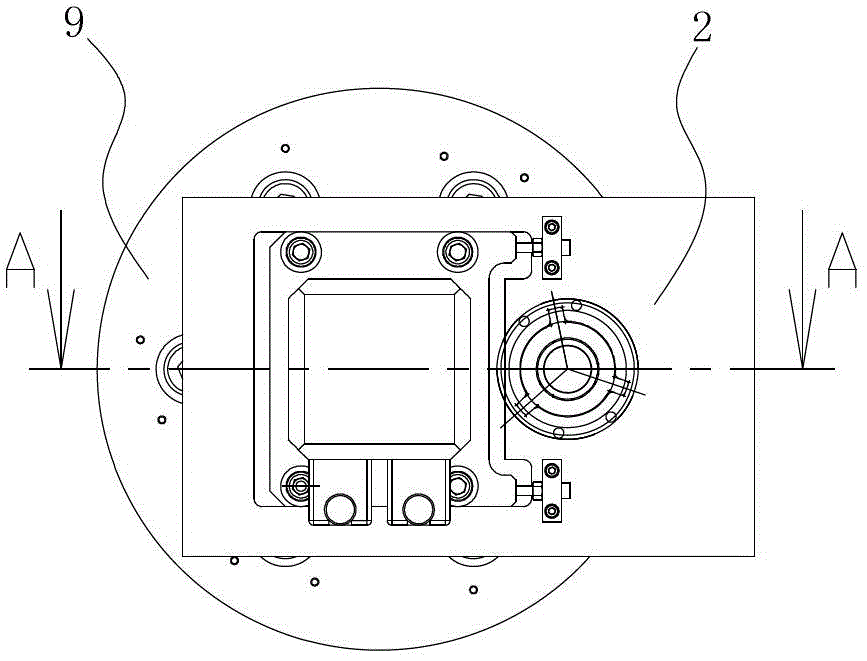

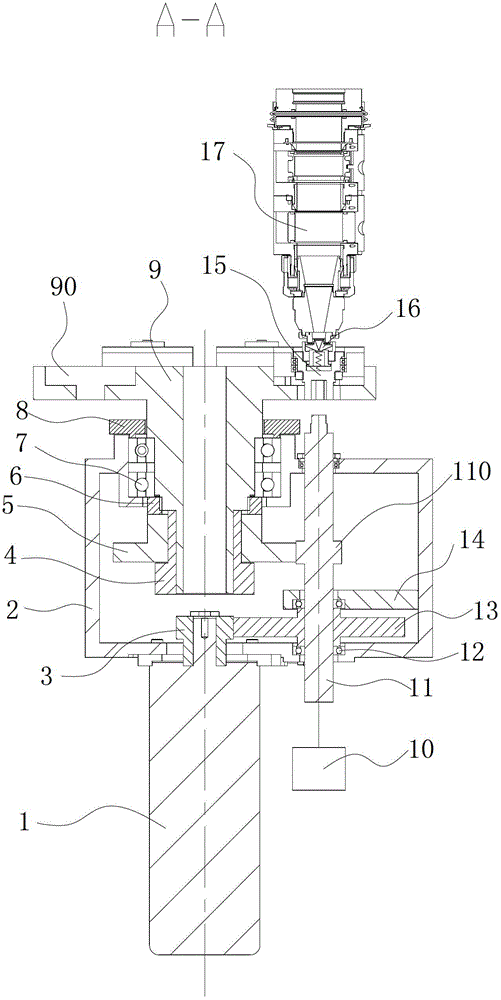

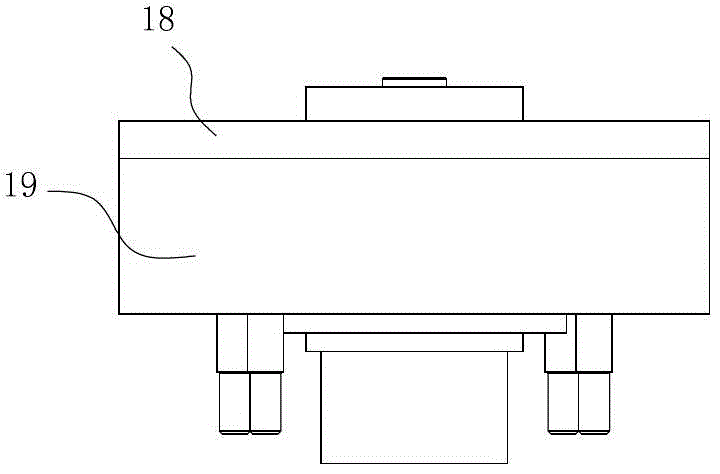

[0033] The invention as Figure 1-16 As shown, the laser cutting machine includes a workbench, a cutting head 17 and a nozzle 16, and the nozzle 16 is detachably connected to the cutting head 17; A replacement device, the automatic nozzle replacement device includes a turntable 9, a nozzle receiving member 15, a box body 2, a transmission shaft 11, a lifting cylinder 10 and a gear transmission mechanism;

[0034] The top surface of the turntable 9 has several holes 90 evenly distributed on the same circumference, and the nozzle receiving member 15 is arranged in the holes 90;

[0035] The top surface of the box body 2 is provided with a turntable placement hole and a drive shaft placement hole 1, and the bottom surface of the box body 2 is provided with a transmission shaft placement hole 2, and the gear transmission mechanism is arranged in the box body 2; The transmission shaft placement hole 1 and the transmission shaft placement hole 2 are respectively provided with d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com