Patents

Literature

72results about How to "Continuous and efficient operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

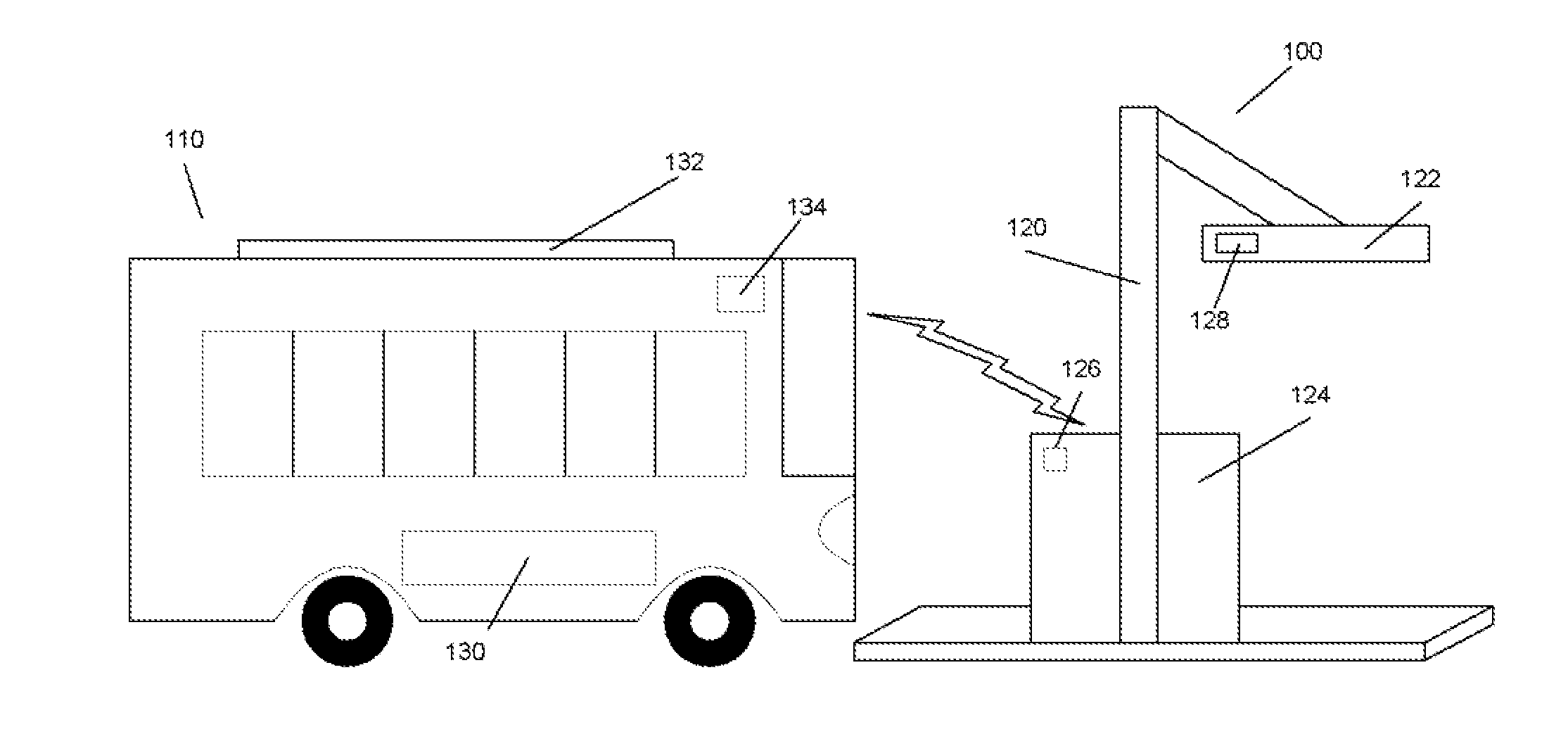

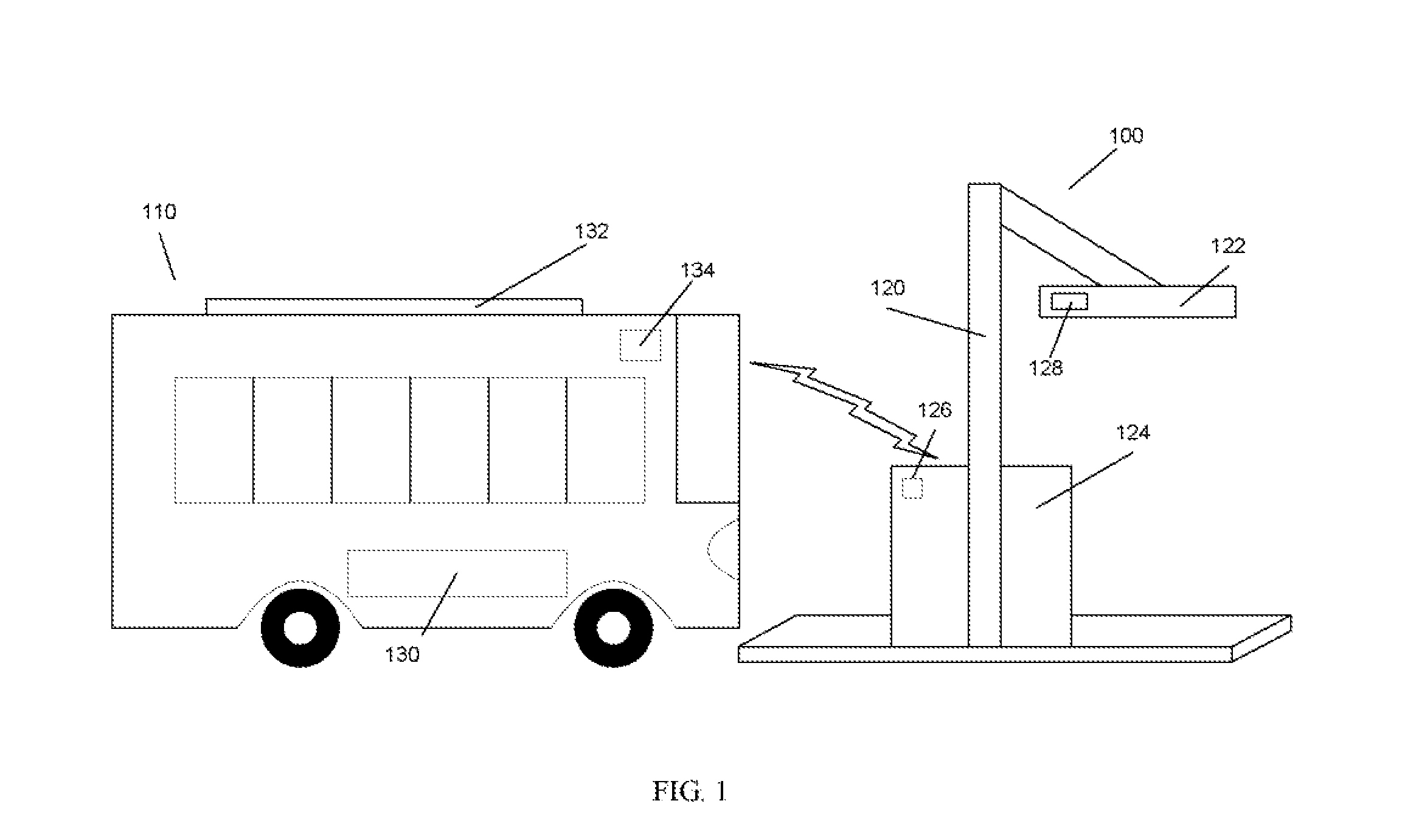

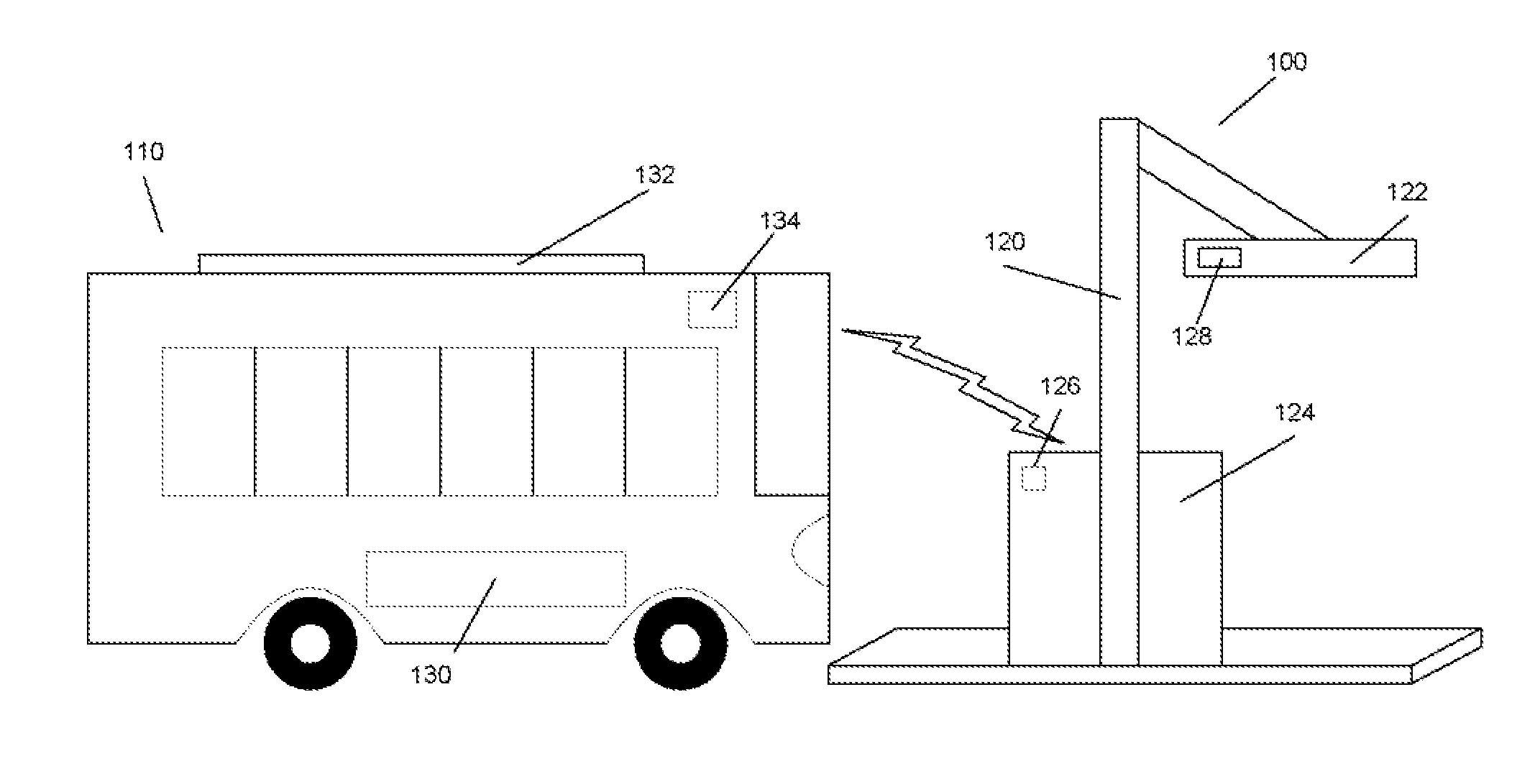

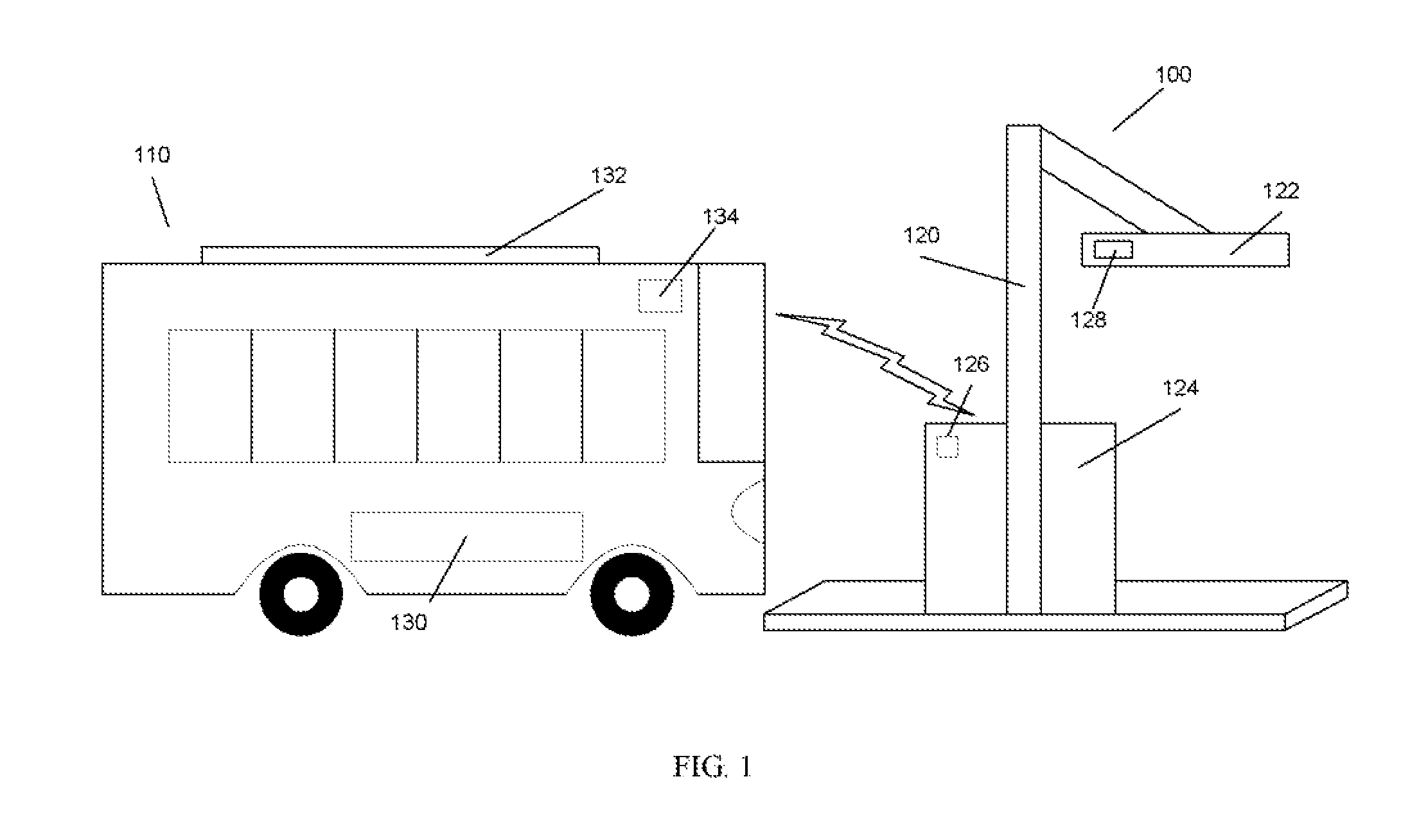

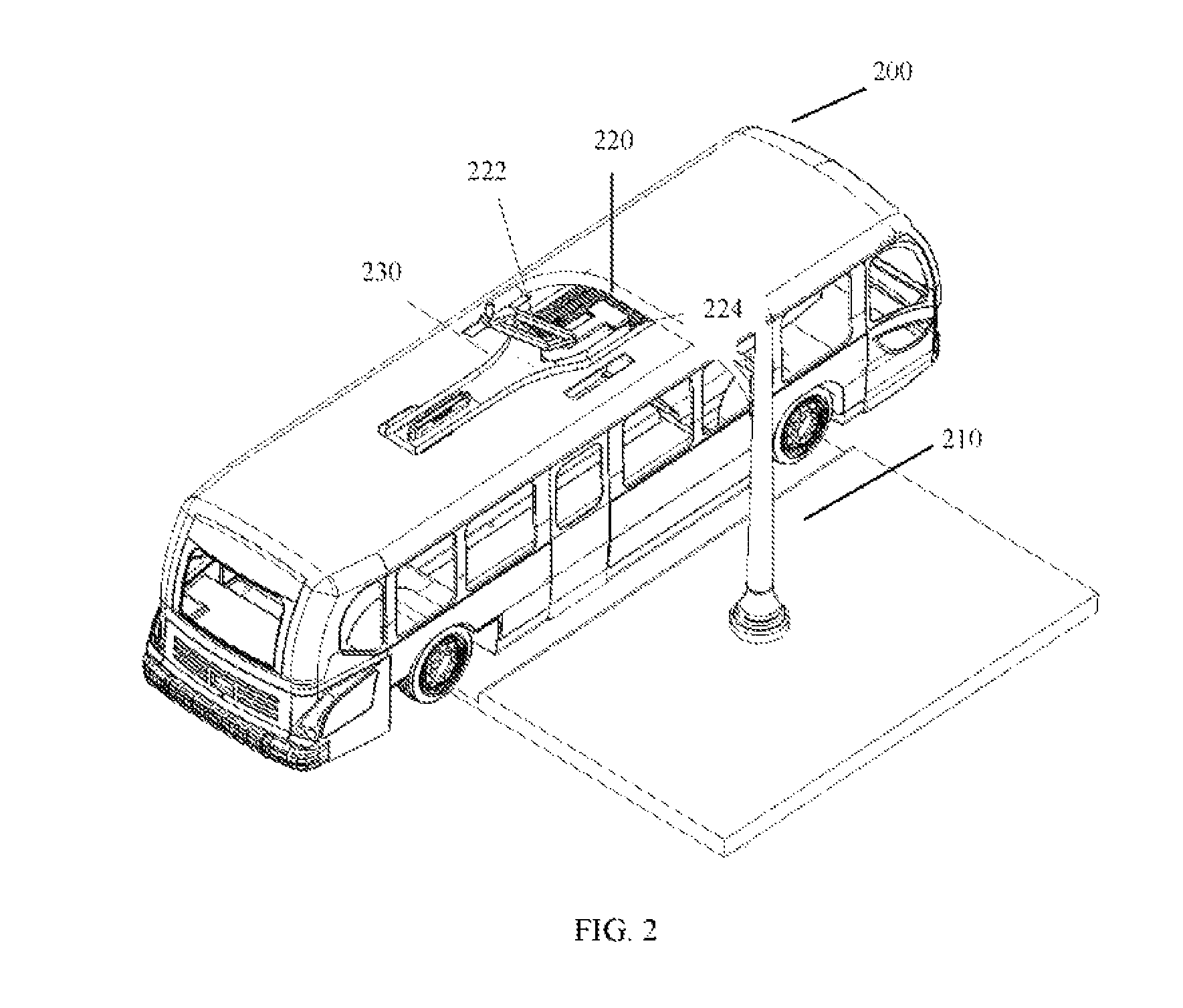

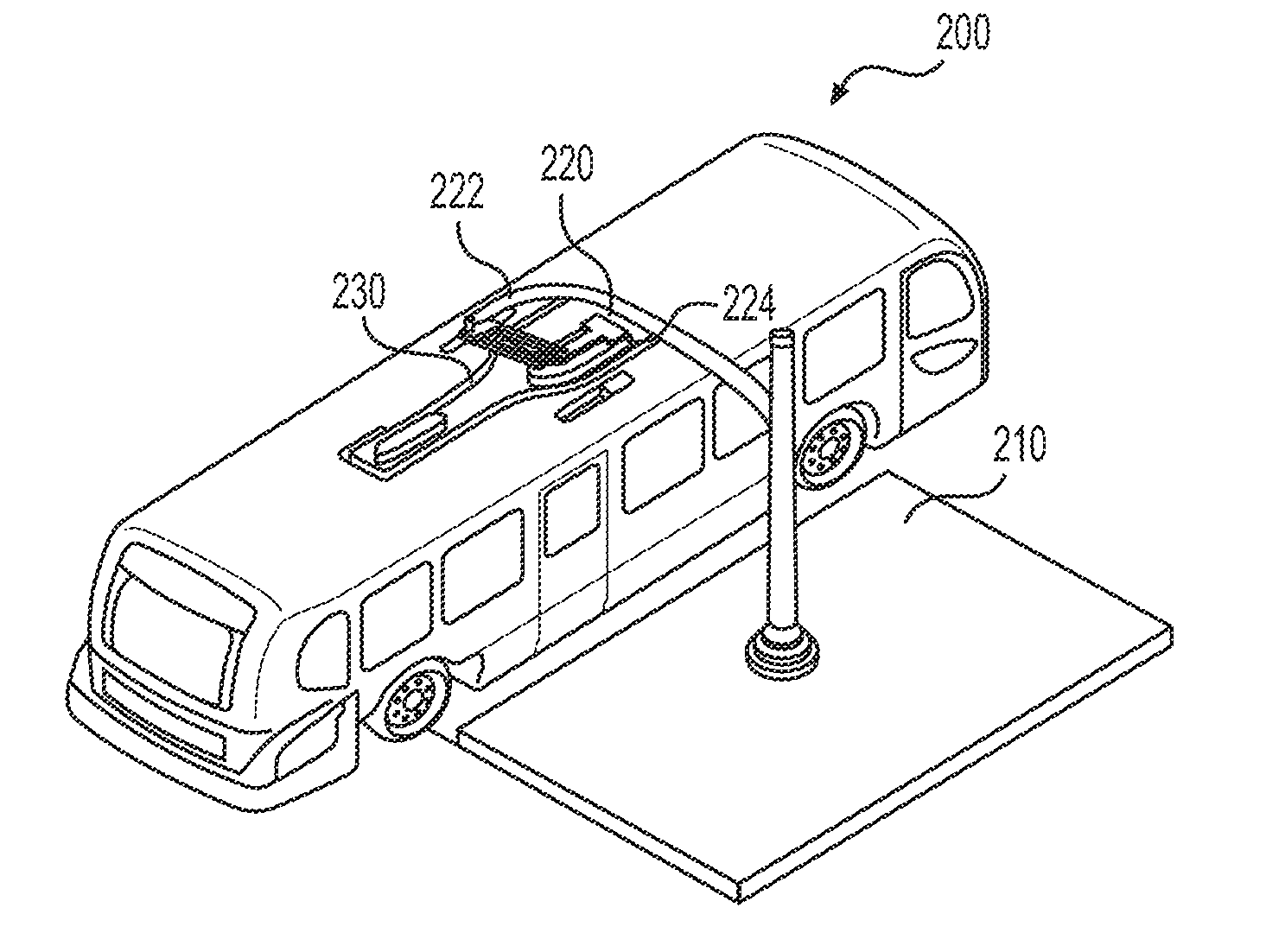

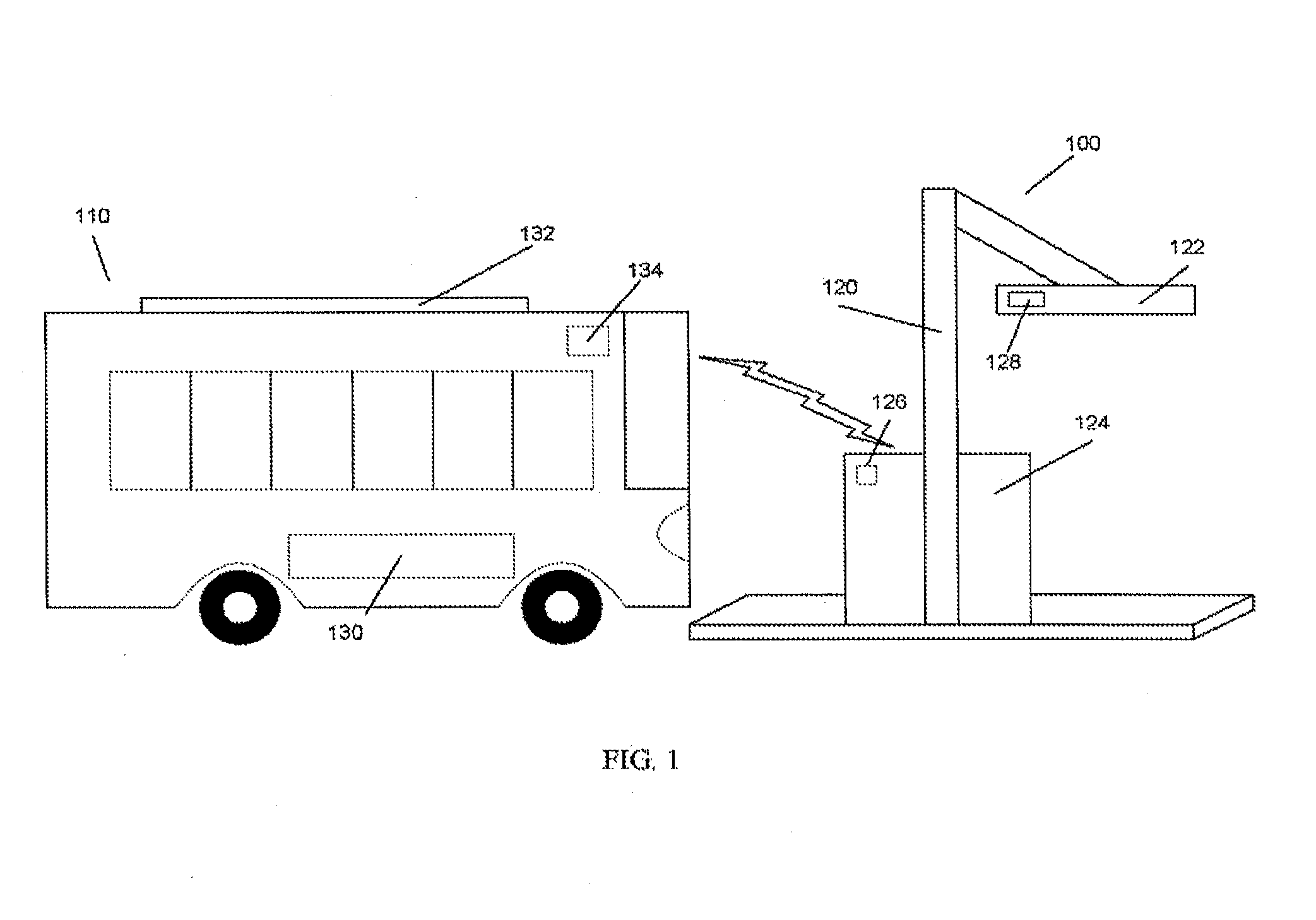

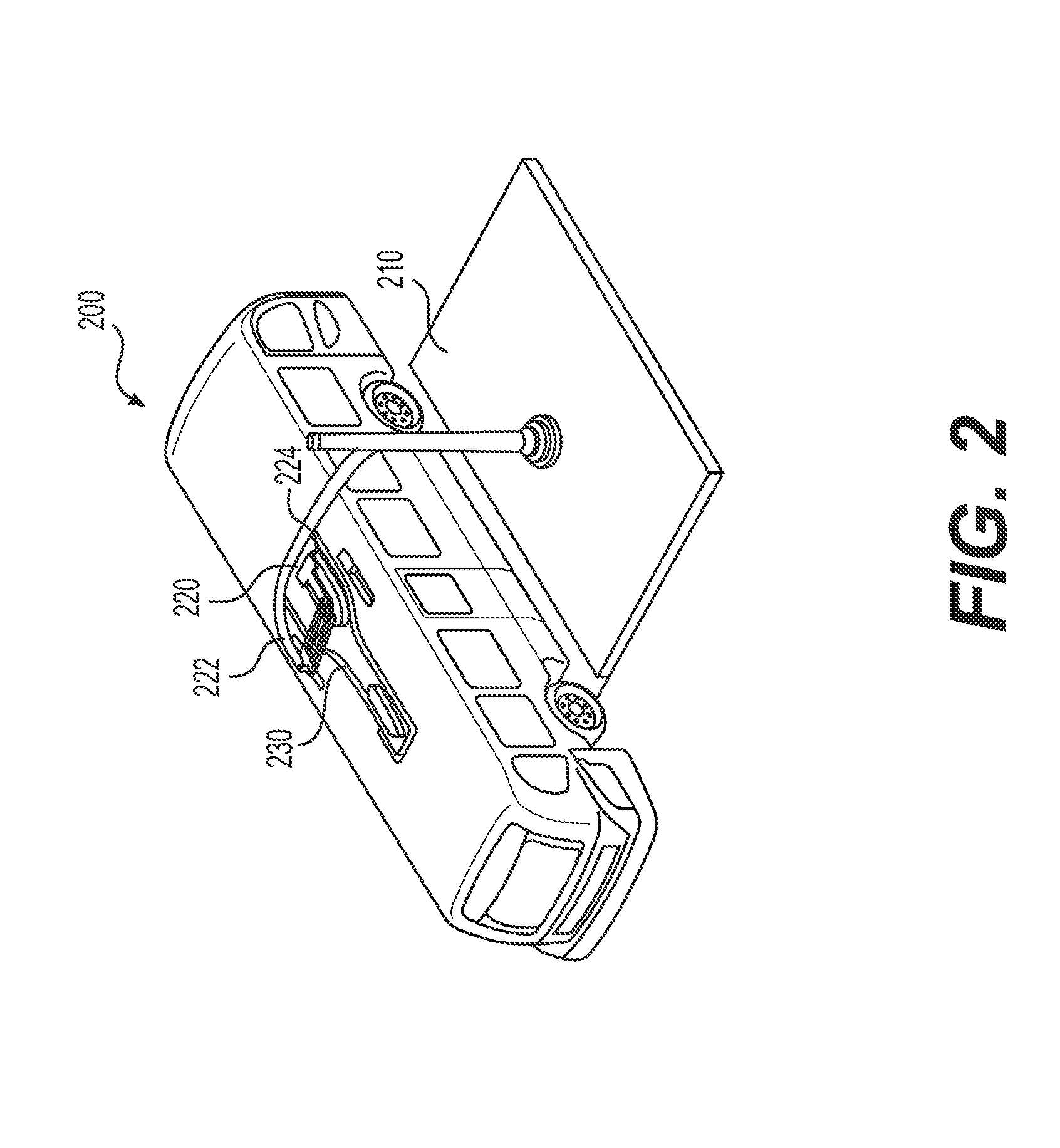

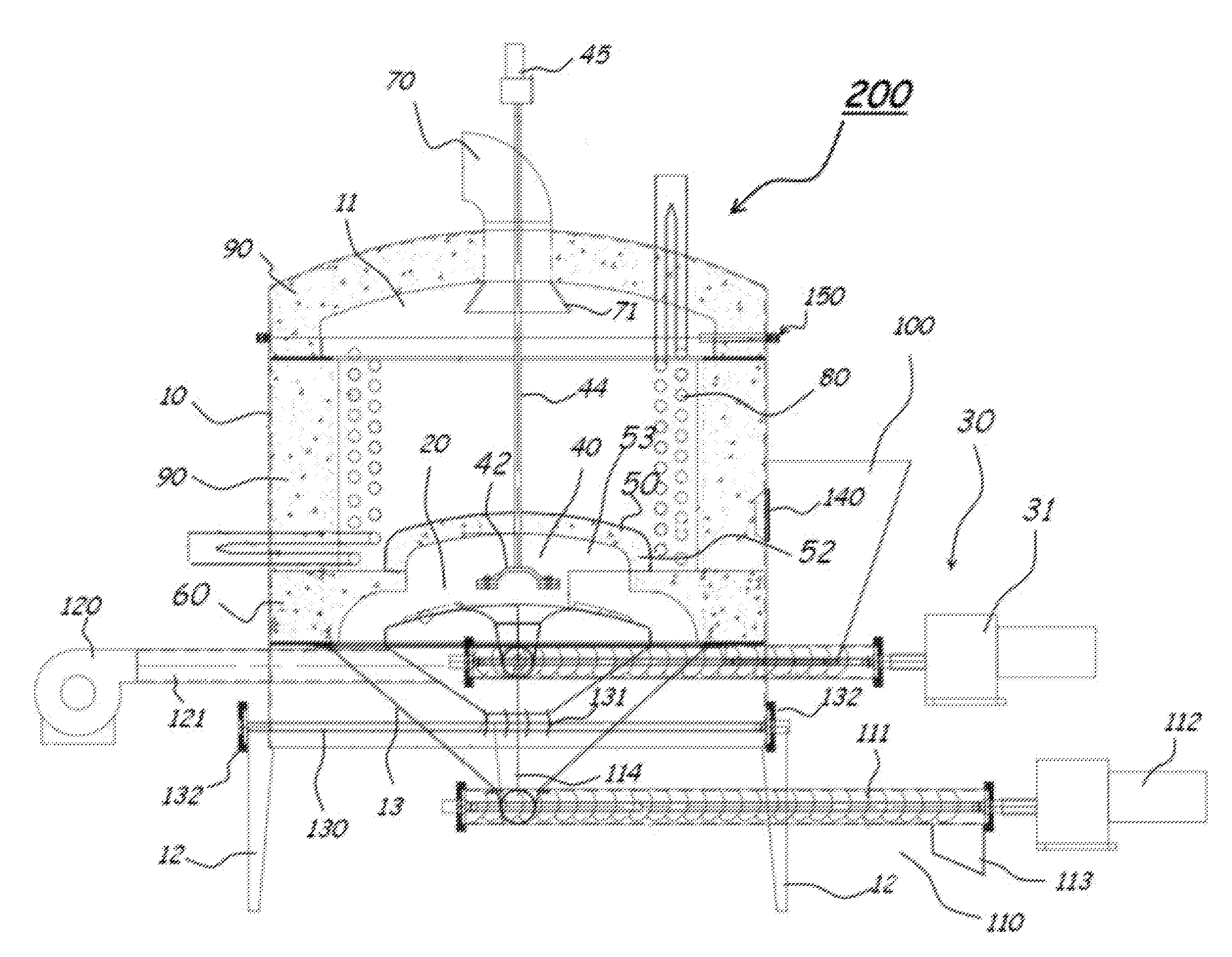

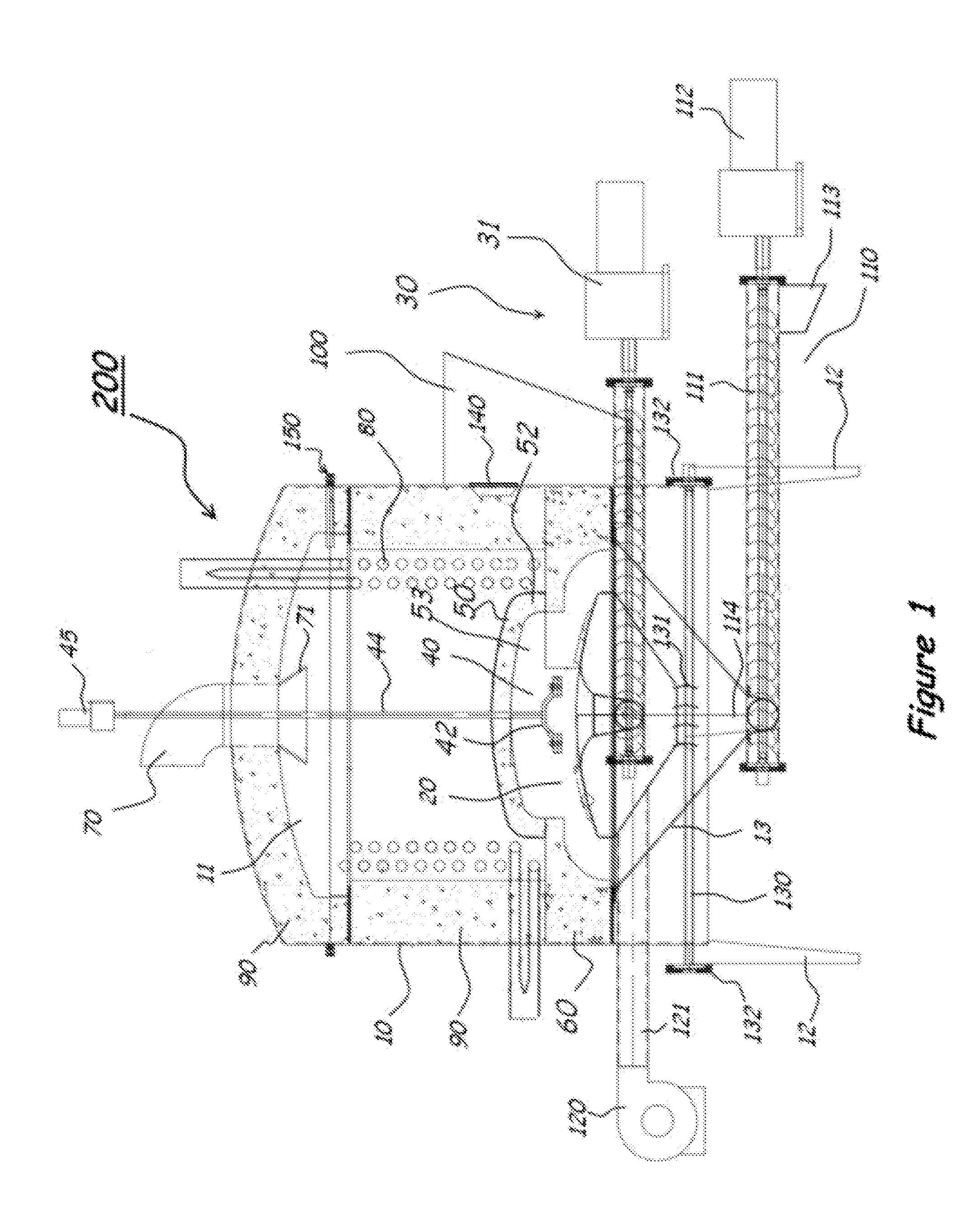

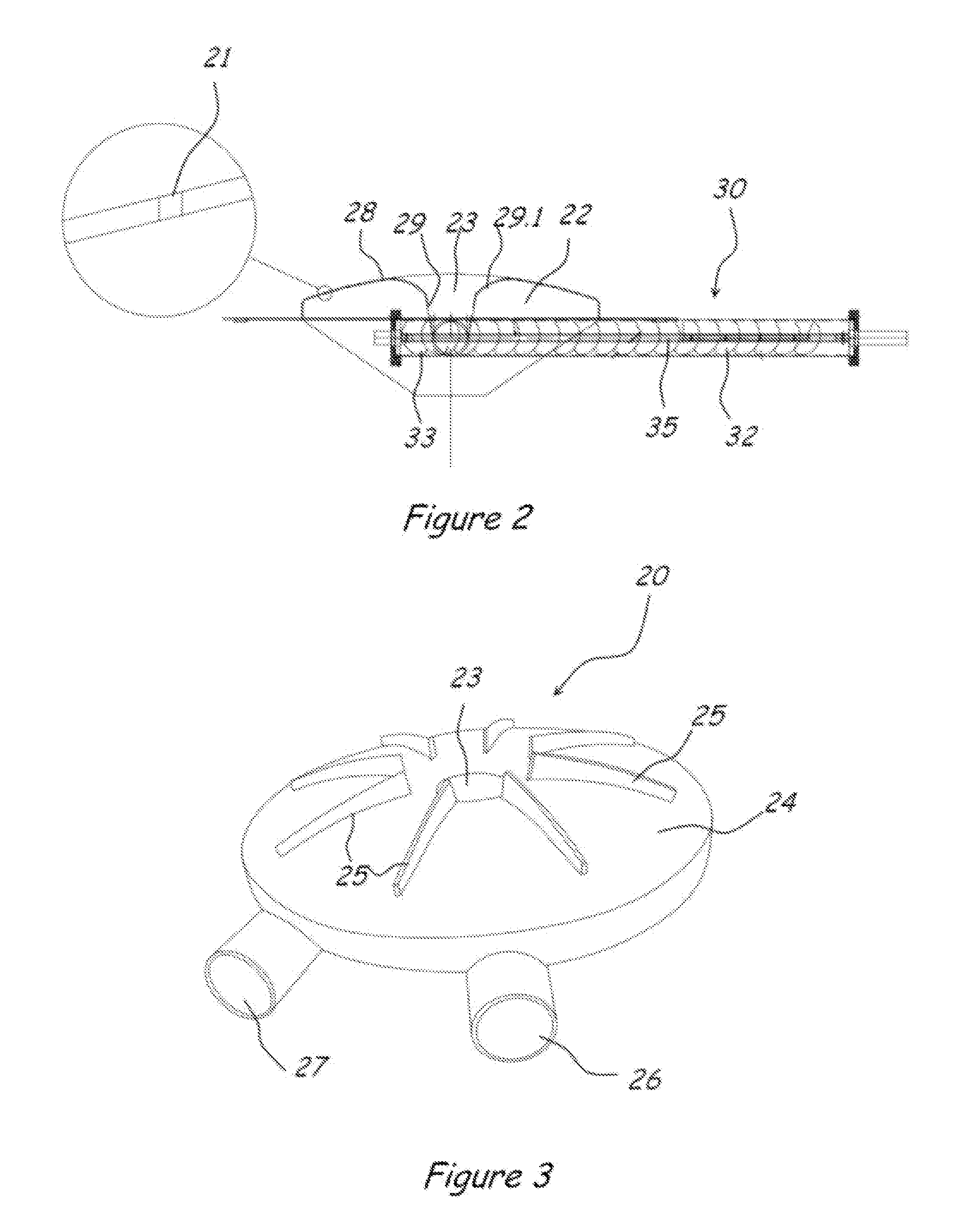

Systems and methods for automatic connection and charging of an electric vehicle at a charging station

ActiveUS20130193918A1Reducing duty cycleResistance changeCircuit monitoring/indicationMobile unit charging stationsEngineeringBattery electric vehicle

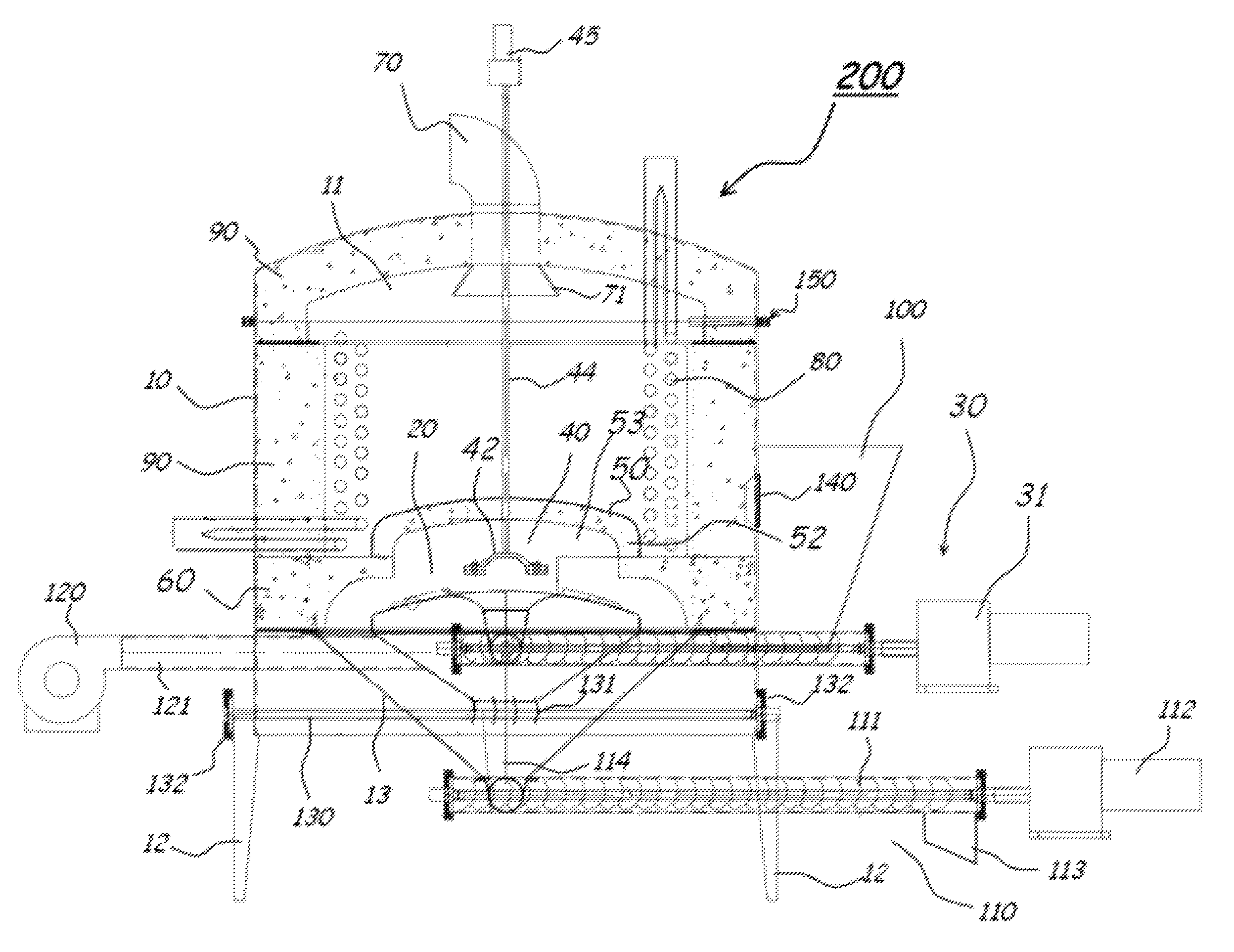

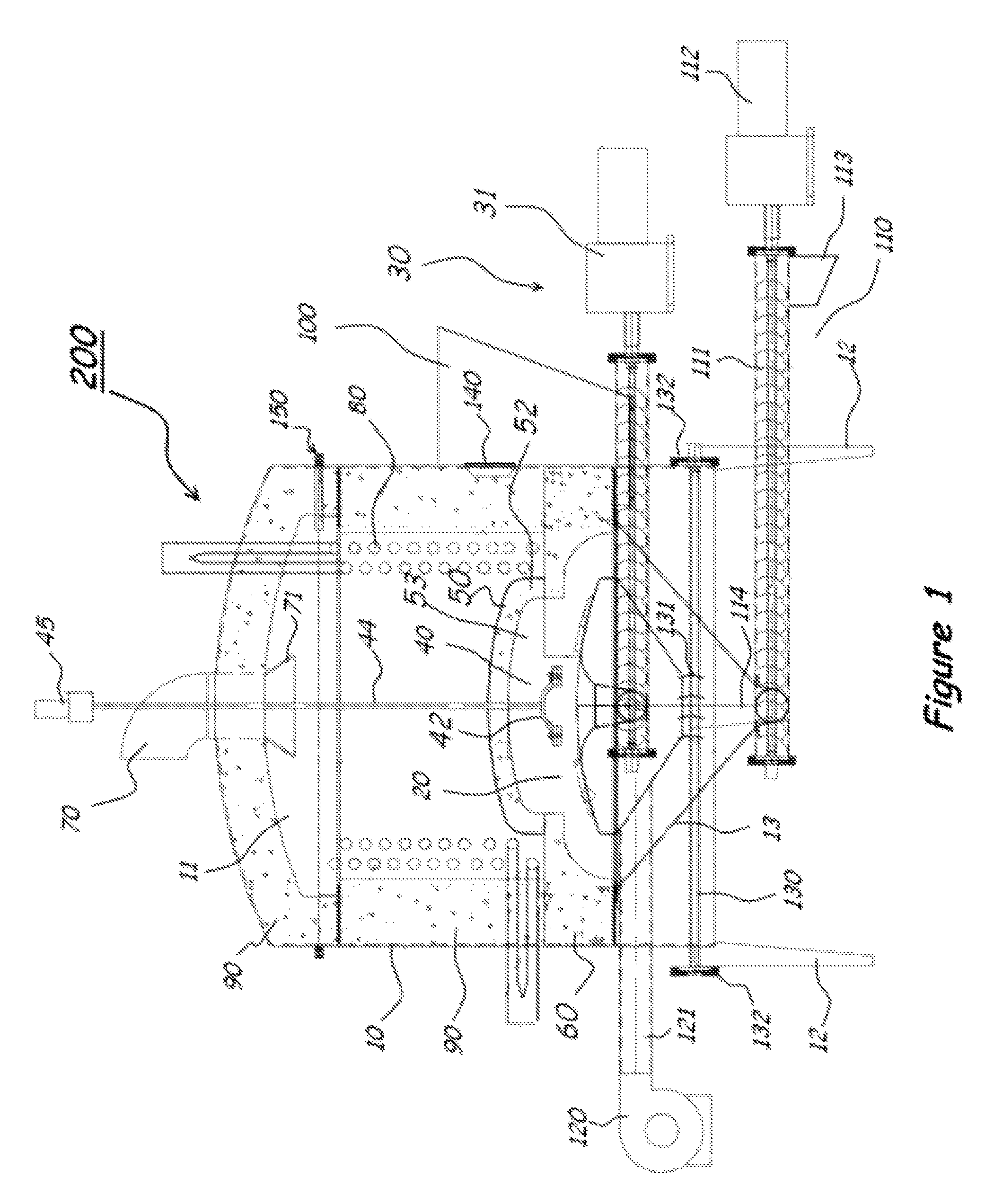

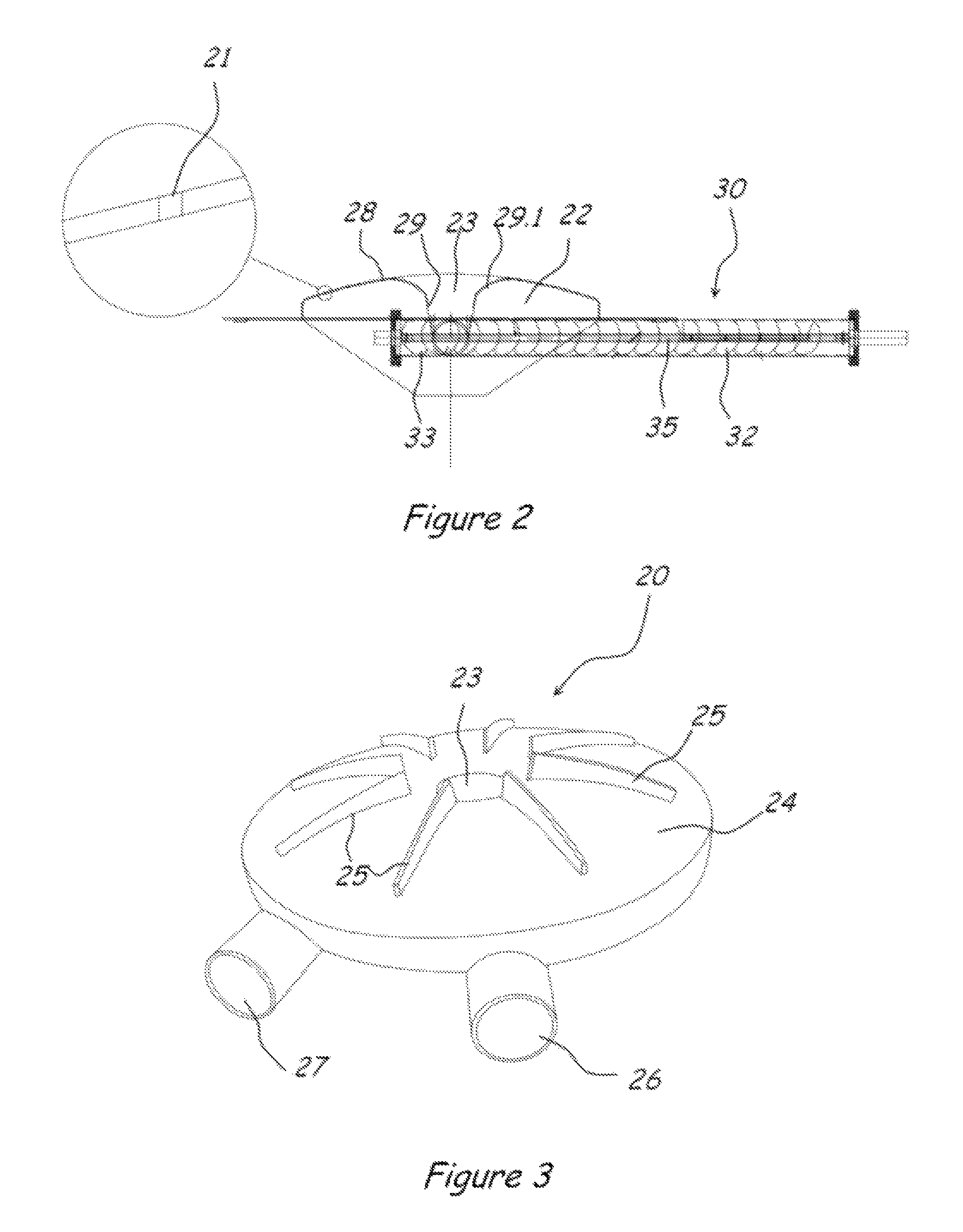

The invention provides systems and methods for connecting an electric or hybrid electric vehicle to a charging station. Automated charging and docking processes may be provided. In some embodiments, a vehicle arrival and position may be detected. The vehicle may be charged with a charging arm and some automated vehicle positioning may occur. The vehicle may be charged and released. Fault detection may occur.

Owner:PROTERRA OPERATING CO INC

Systems and methods for automatic connection and charging of an electric vehicle at a charging station

ActiveUS9365128B2Reducing duty cycleResistance changeCircuit monitoring/indicationMobile unit charging stationsCharging stationAutomatic vehicle location

The invention provides systems and methods for connecting an electric or hybrid electric vehicle to a charging station. Automated charging and docking processes may be provided. In some embodiments, a vehicle arrival and position may be detected. The vehicle may be charged with a charging arm and some automated vehicle positioning may occur. The vehicle may be charged and released. Fault detection may occur.

Owner:PROTERRA OPERATING CO INC

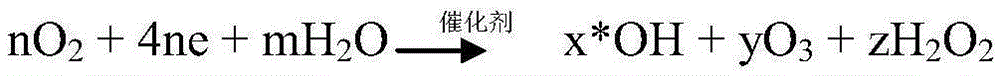

Method and device for degrading organic wastewater by micro active oxygen generated through electrocatalytic reduction of air oxygen

ActiveCN105384224AEfficient reductionAvoid lostWater treatment compoundsWater contaminantsElectrochemical responseElectricity

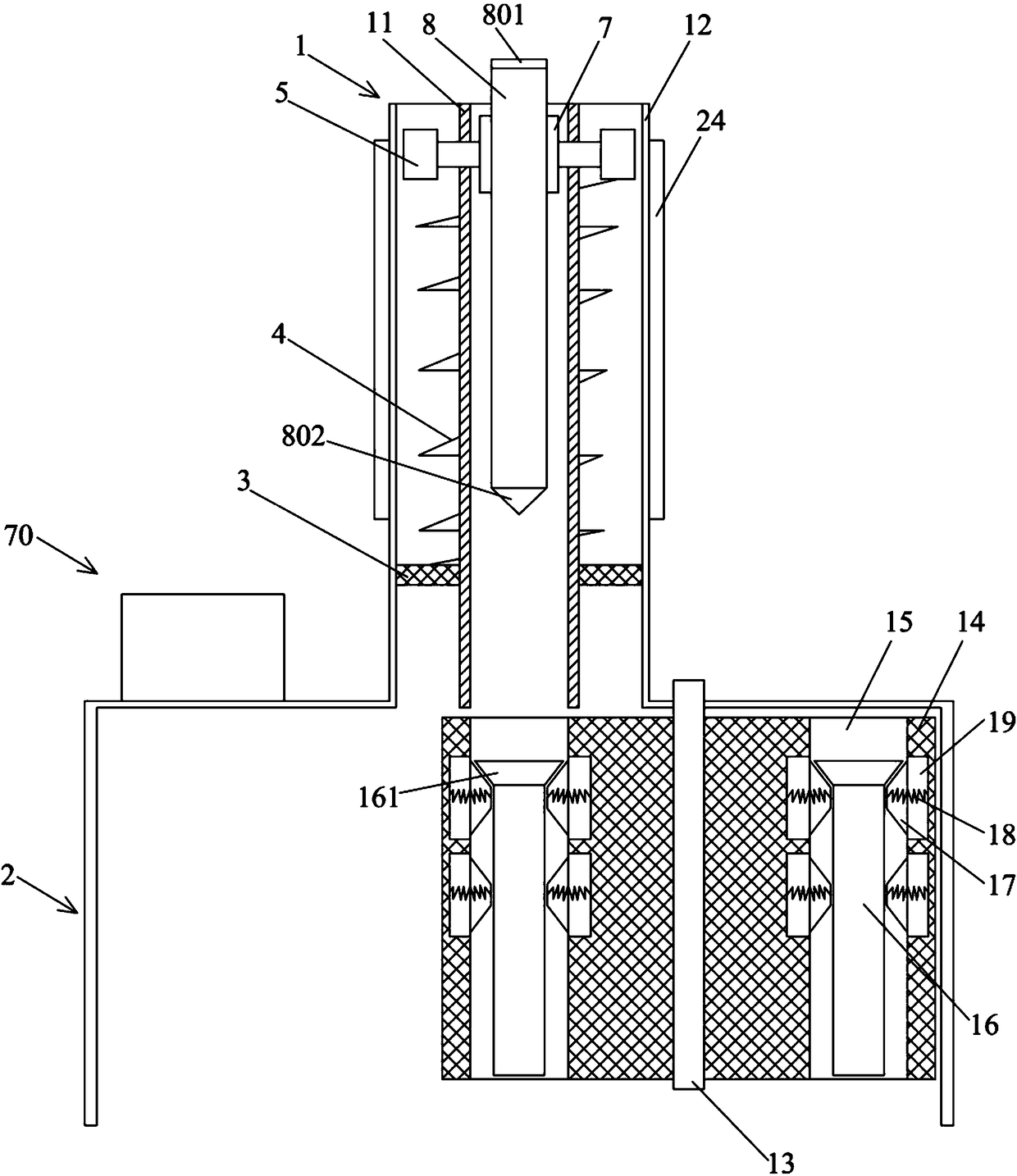

The invention relates to a method and device for degrading organic wastewater by micro active oxygen generated through electrocatalytic reduction of air oxygen, and belongs to the technical field of wastewater treatment. According to the method and device, air (aeration) is continuously connected into the cathode inside an electrochemical reactor, a large amount of micro active oxygen such as O3, free radical *OH and H2O2 is generated through a concerted reaction under the combined action of various catalysts and cathode currents, the micro active oxygen has extremely-high oxidizing capacity, hence, organic matter in the wastewater can be directly oxidized and degraded, and the purpose of deeply removing organic pollutants is achieved. In addition, the adopted method and device are simple, power consumption is small, and the degradation effect is good. Moreover, equipment can continuously and efficiently operate in a circulation mode, and great practical application value is achieved.

Owner:武汉森宁开源科技有限公司

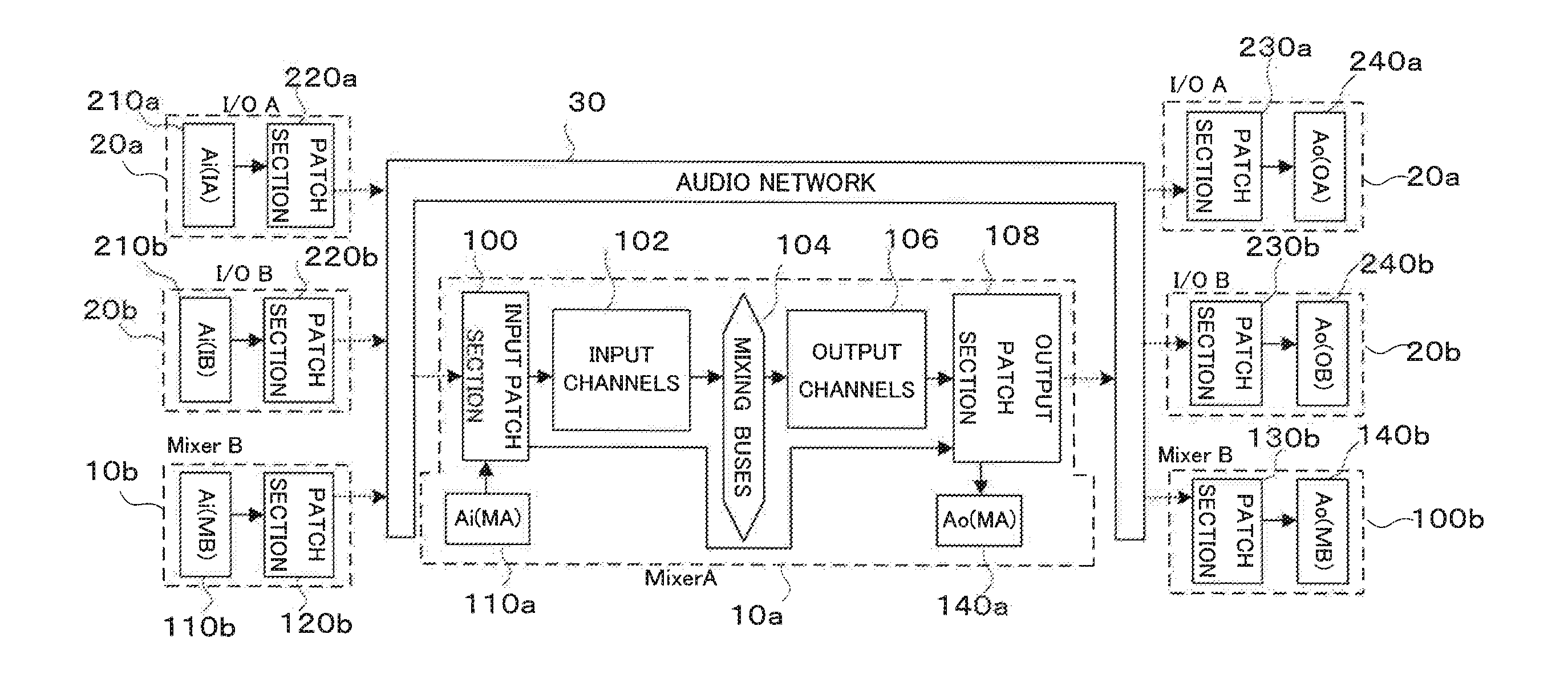

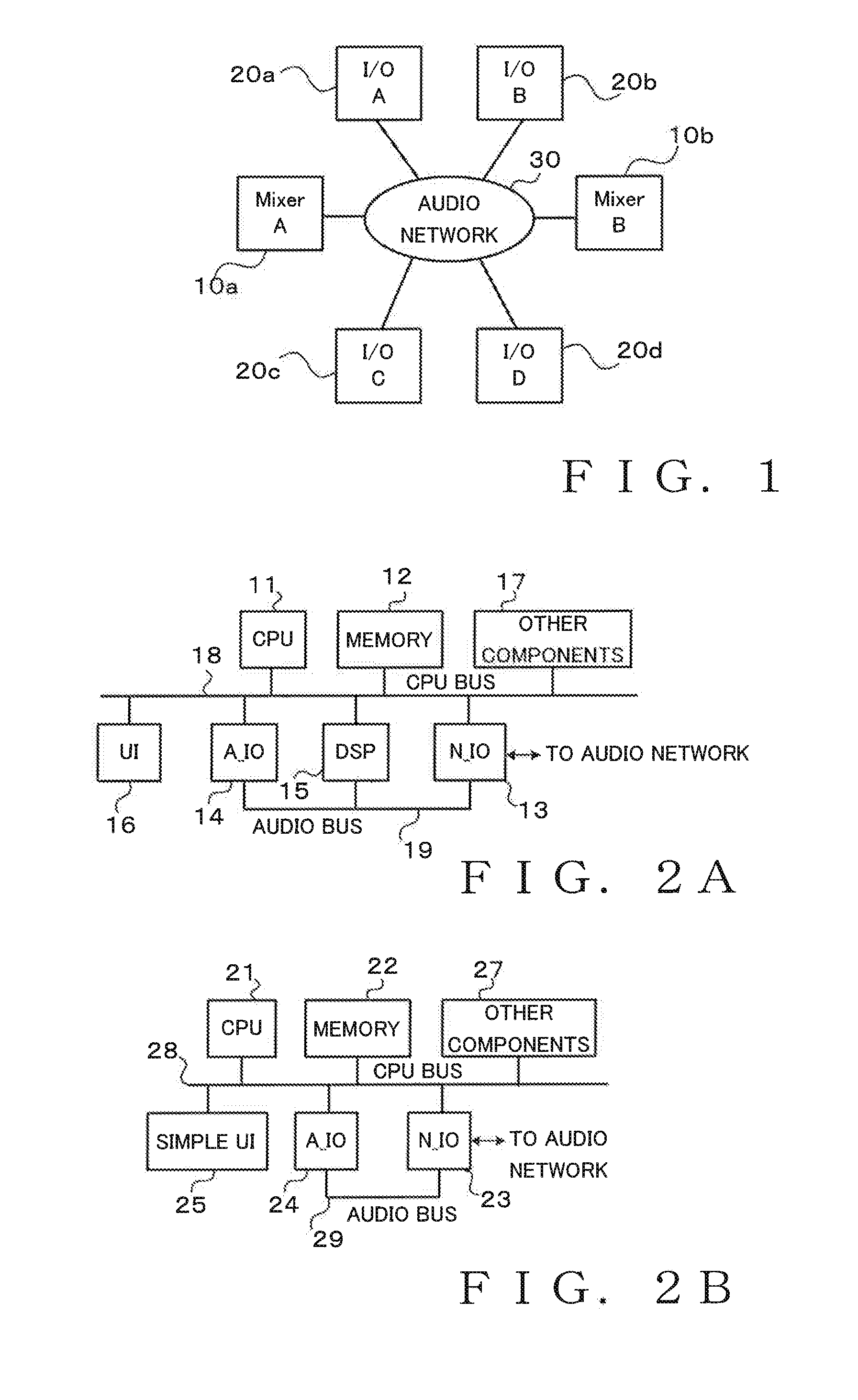

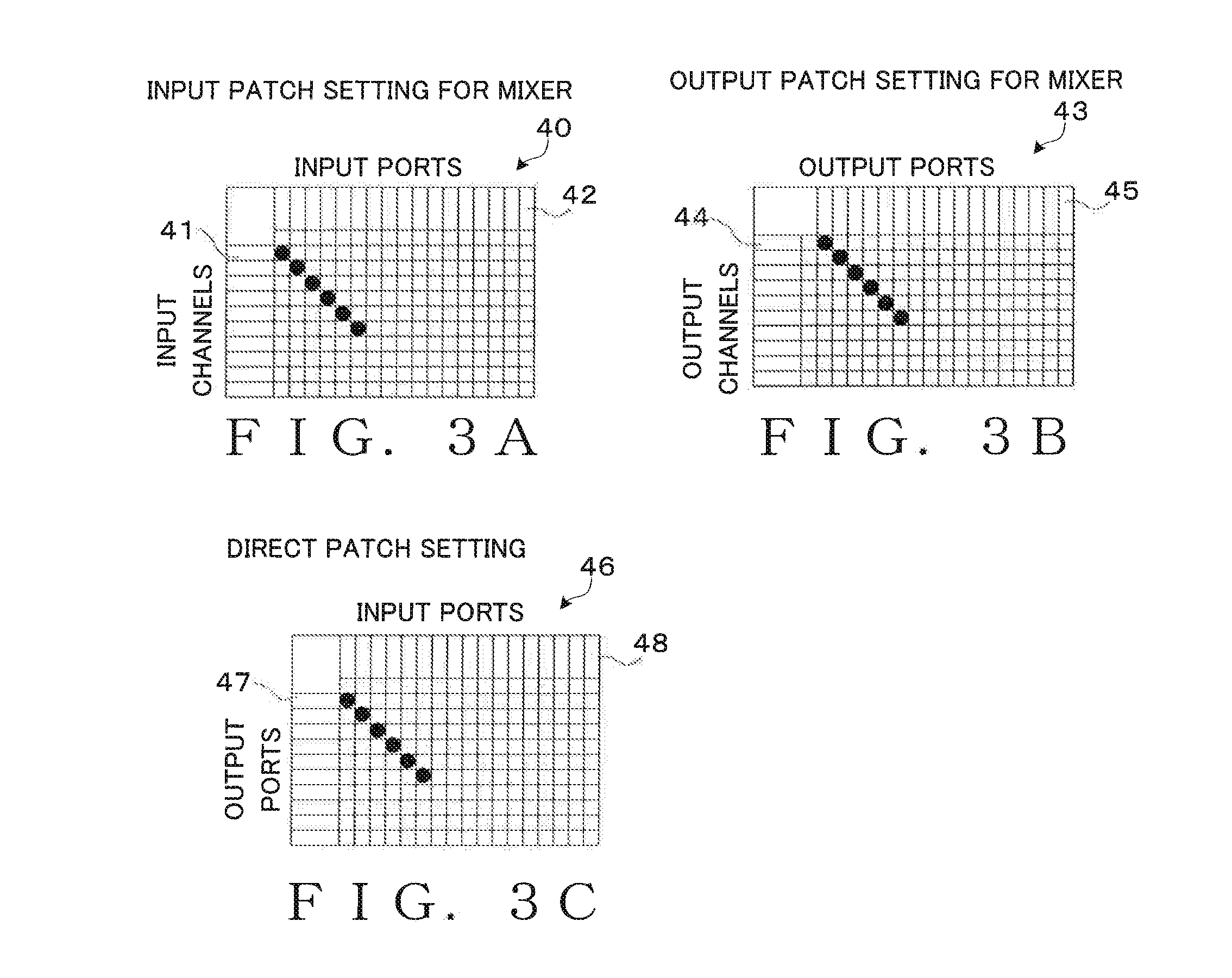

Managing input/output ports in mixer system using virtual port data

ActiveUS20150092960A1Reduce restrictionsImprove usabilityTransmissionBroadcast information generationChannel dataComputer hardware

An I / O unit includes a plurality of ports, a mixer includes processing channels, and the mixer and the I / O unit are interconnected via a network. The mixer stores channel data per processing channel. The channel data includes virtual port data for indirectly controlling signal processing of a port to which the channel is patched. The I / O unit stores real port data for controlling a signal processing in a corresponding port per port. In response to a connection instruction, one port and processing channels are interconnected, and real port data of the one port connected with the processing channels is set to a value of virtual port data being maintained for the processing channels.

Owner:YAMAHA CORP

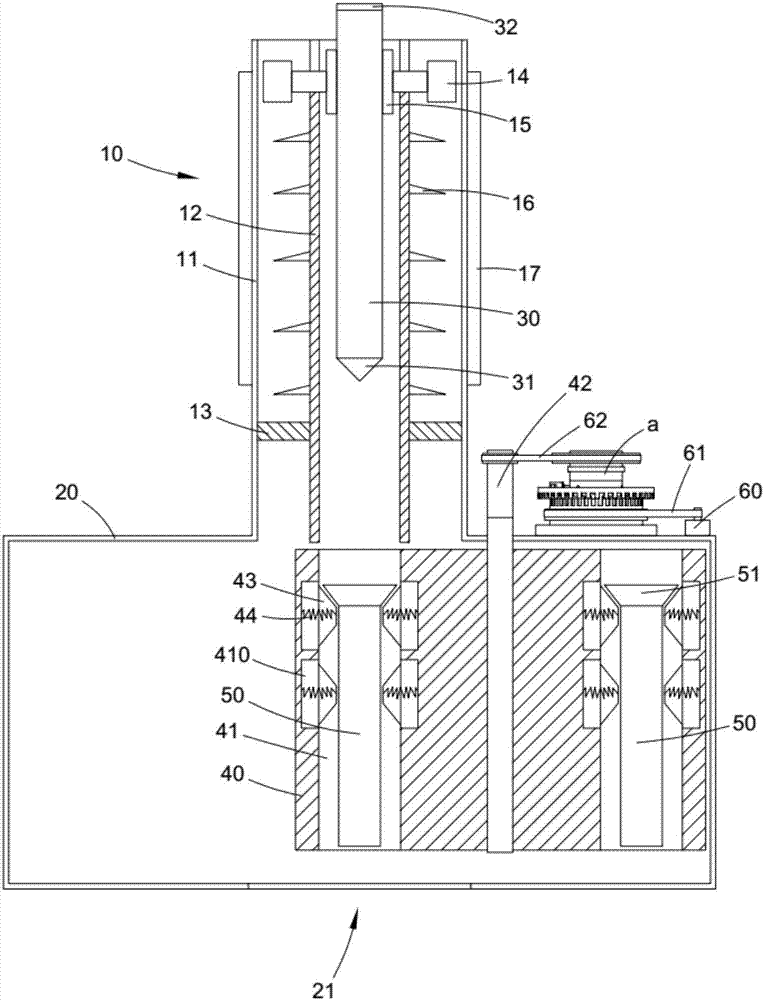

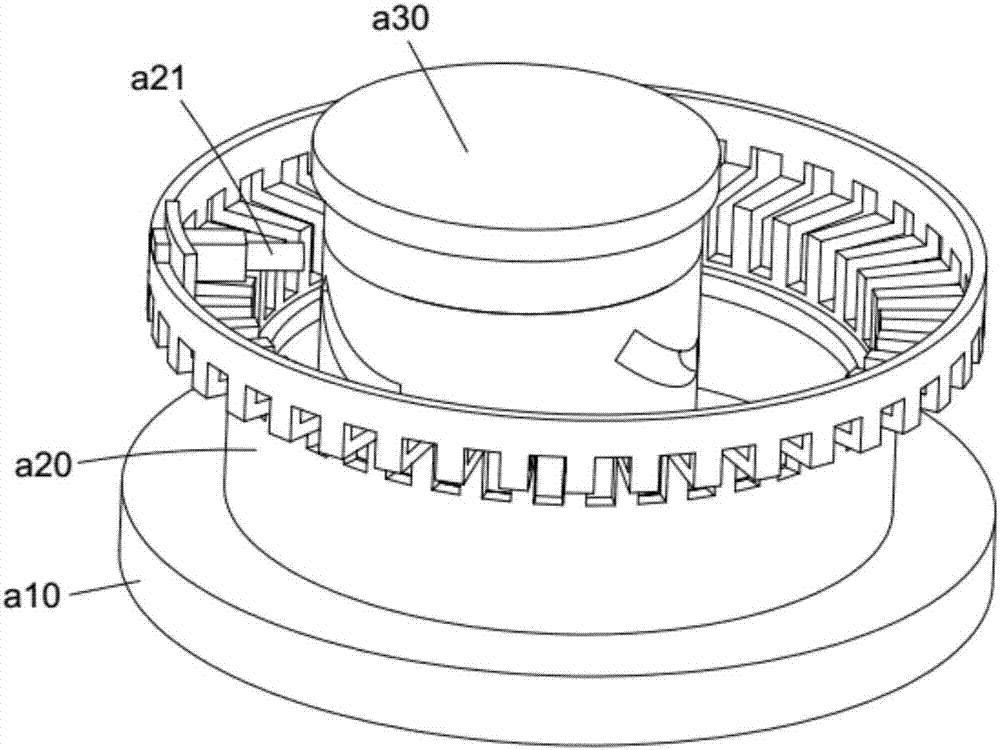

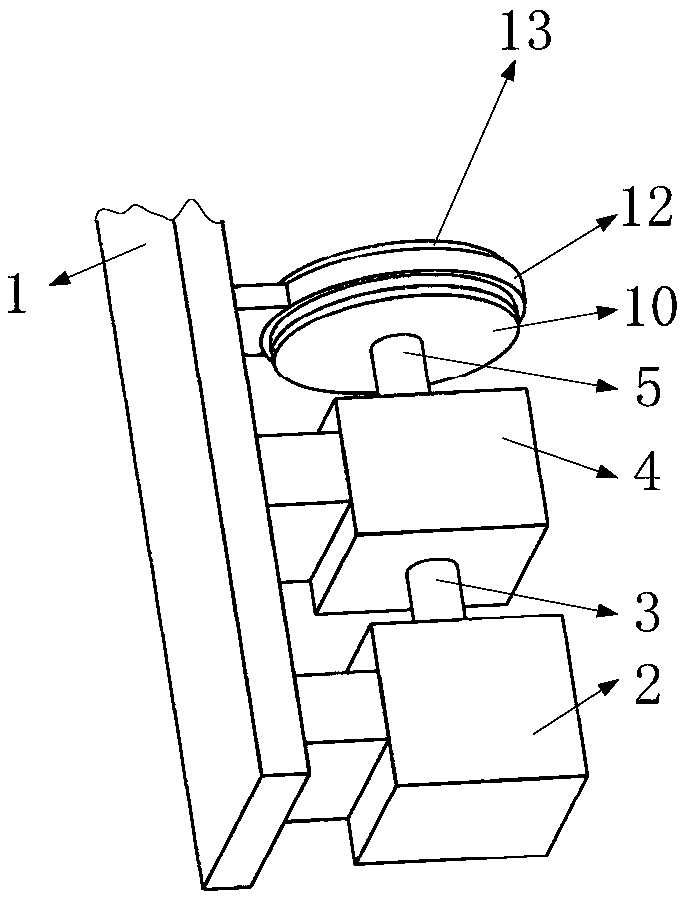

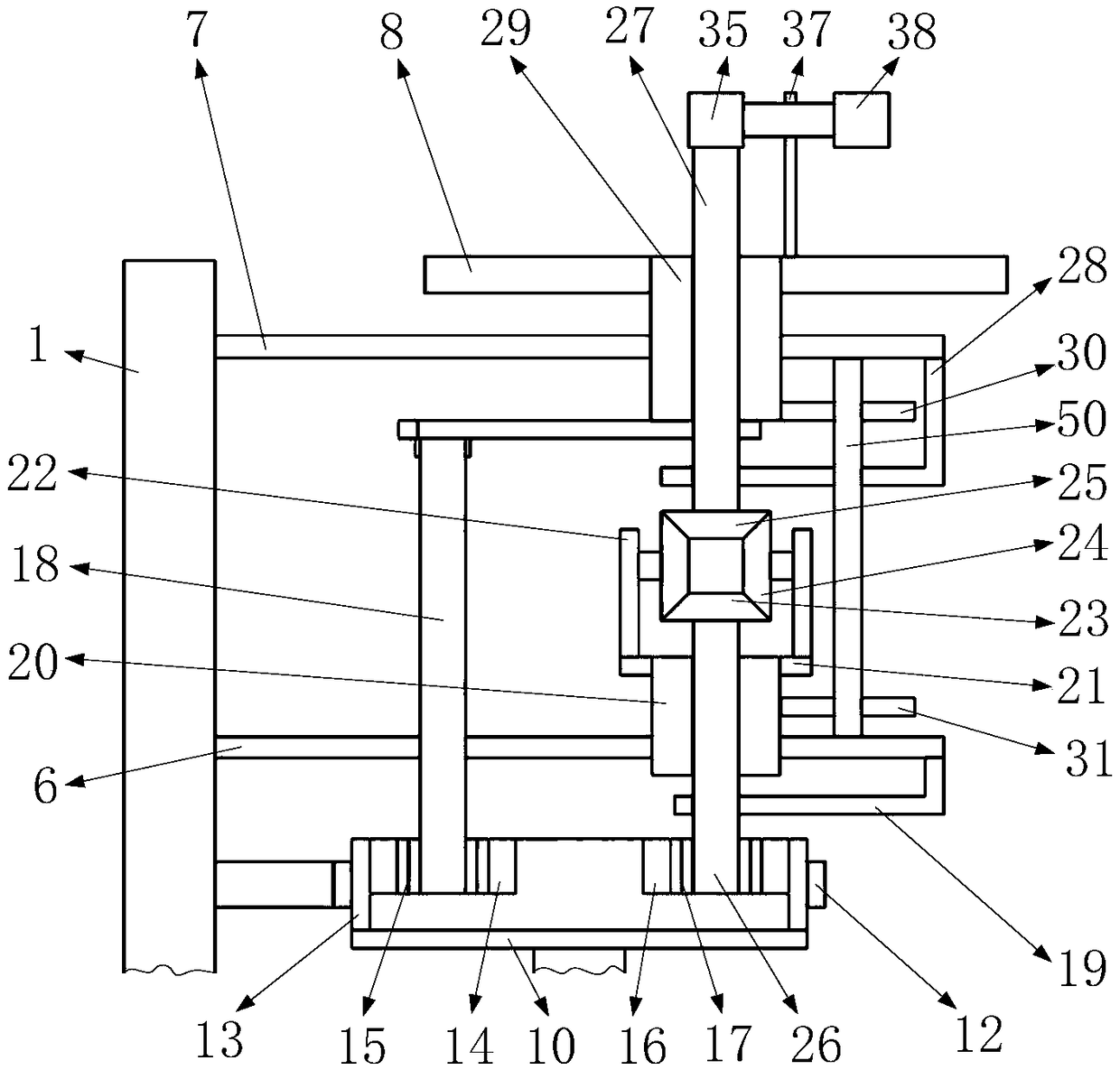

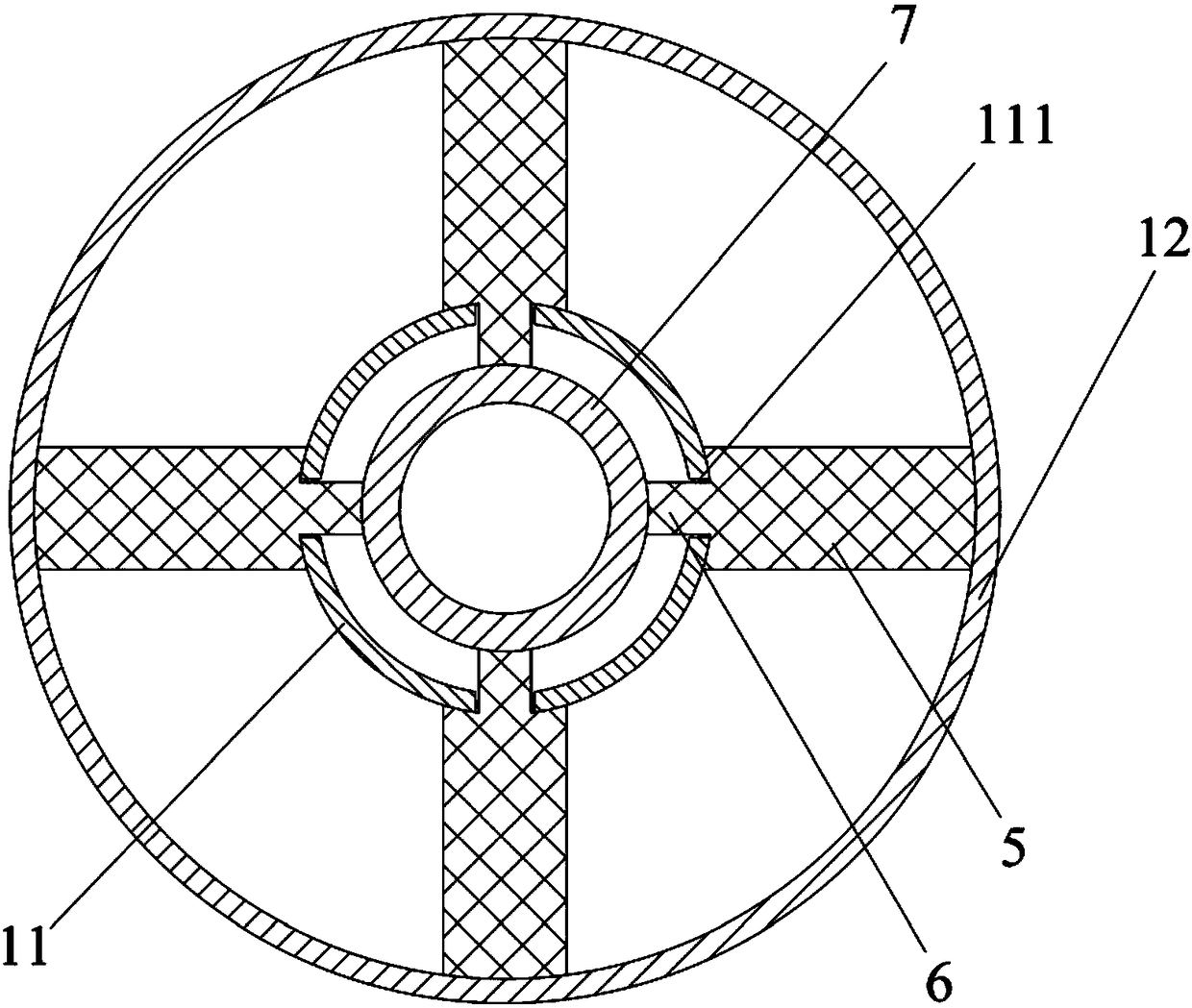

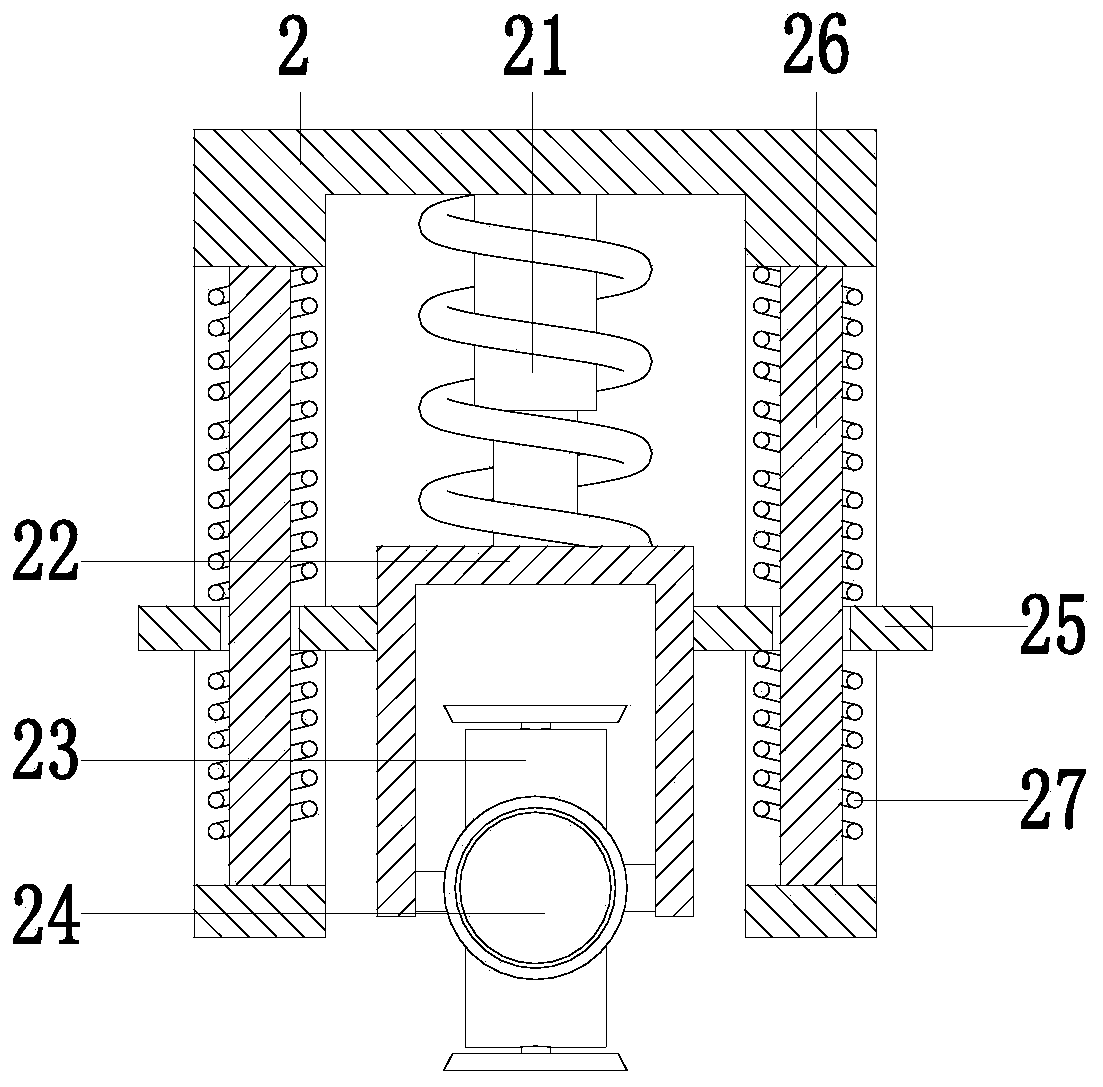

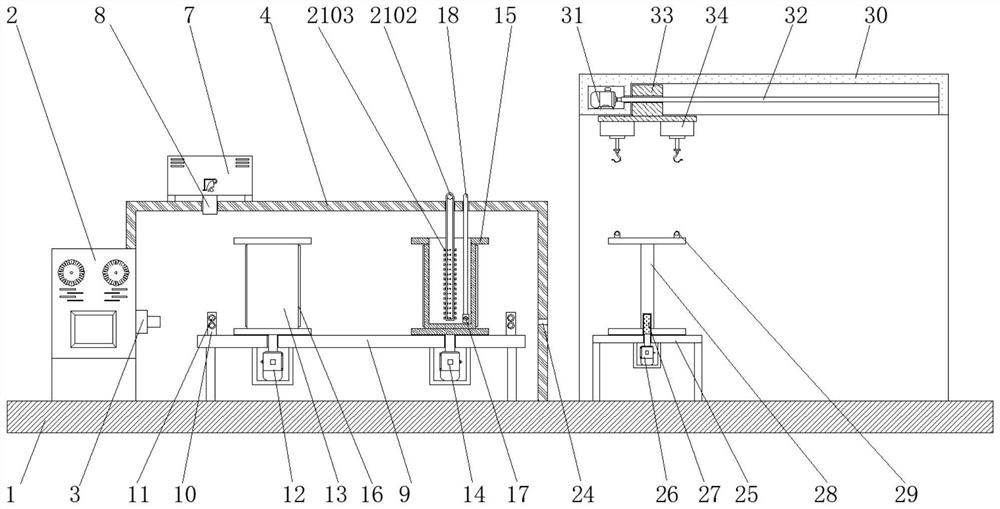

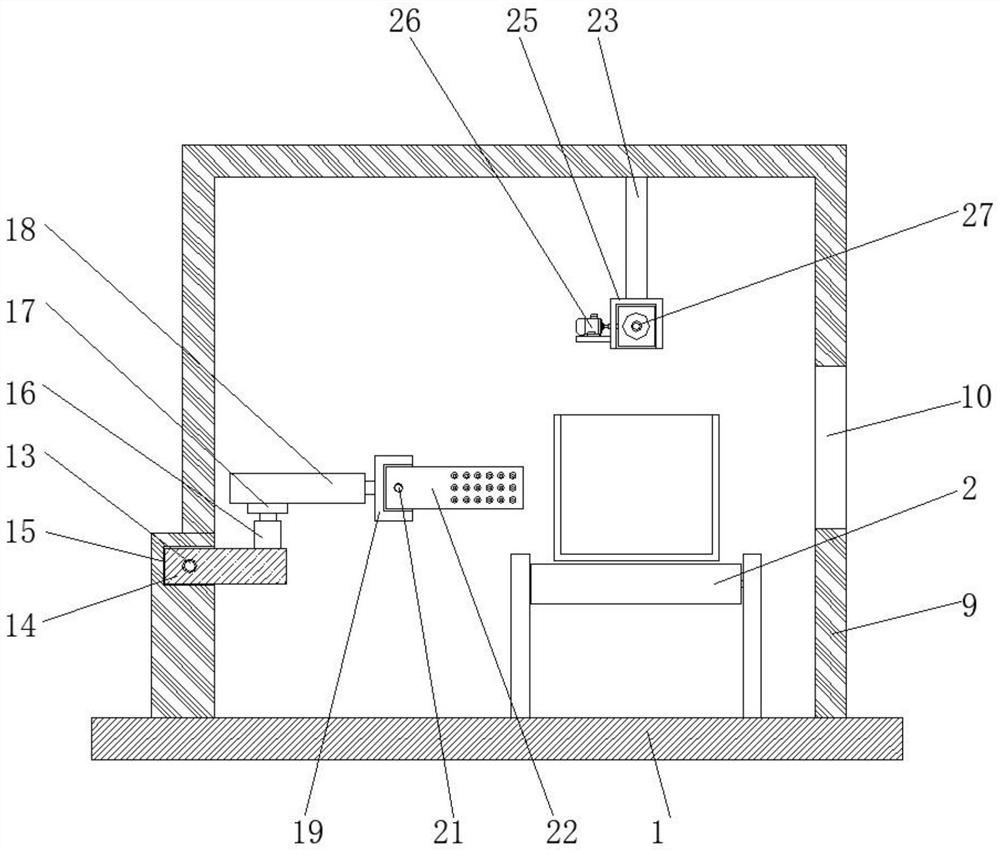

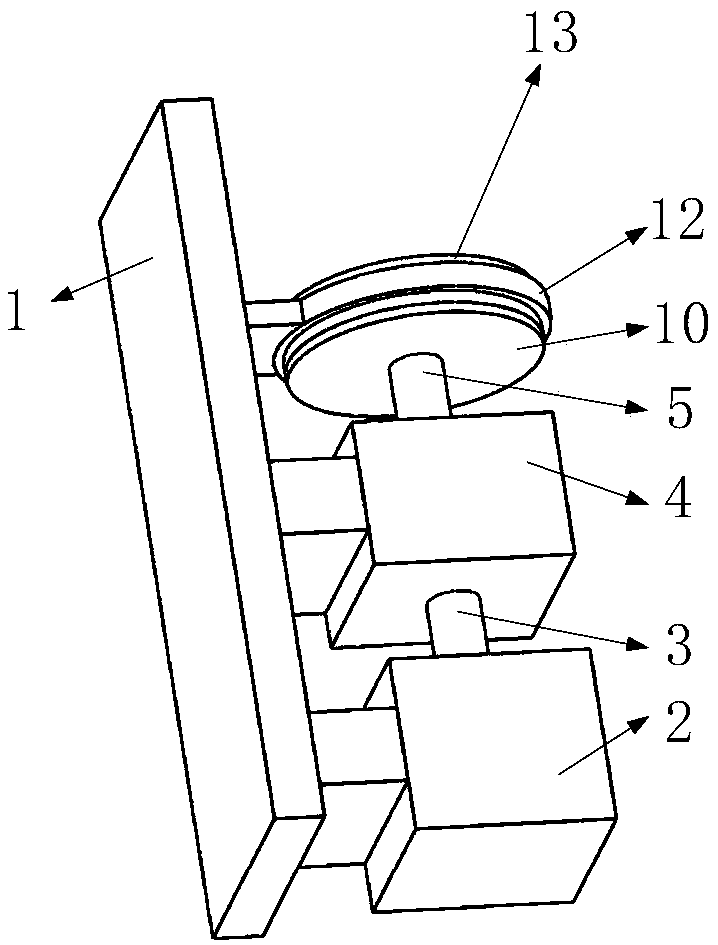

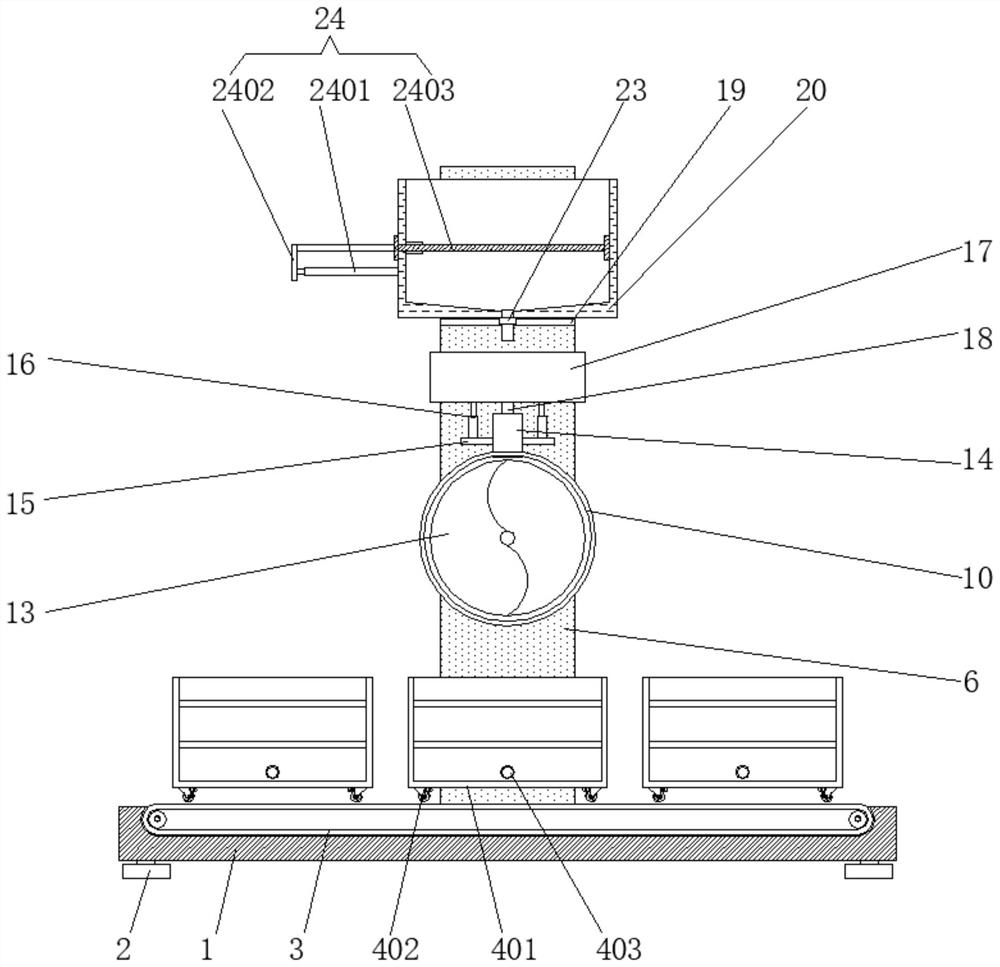

Installation equipment used for civic buildings

PendingCN107336183AImprove fastnessContinuous and efficient operationPower driven toolsPore distributionEquipment use

The invention discloses installation equipment used for civic buildings. The installation equipment comprises an upper barrel and a lower barrel. A guide rod capable of rising, falling and rotating is movably inserted into the upper barrel. A rotating drum is mounted in the lower barrel and provided with a plurality of through holes distributed in the circumferential direction. A rotating shaft of the rotating drum is parallel to the guide rod. The guide rod is aligned with the through hole located under the guide rod in an up-down manner. The through holes are used for accommodating flat head screws. The bottom end of the guide rod is provided with a pointed portion matched with the flat head screws. When the equipment is used, an electric head of an electric tool is in embedded fit with the top of the guide rod, the guide rod is pressed downwards, and the electric head drives the guide rod to rotate to enable the bottom of the guide rod to be in embedded fit with the screw head of one flat head screw; and then the lower end of the lower barrel is placed to a position needing screw fastening, and the electric head is continued to be pressed downwards until the lower end of one flat head screw makes contact with a wood board. After the flat head screw in one through hole is used, the rotating drum enables the next through hole to be aligned with the guide rod in an up-down manner, and thus, efficient and continuous operation is conducted conveniently.

Owner:ZHEJIANG JINGHU CONSTR GRP

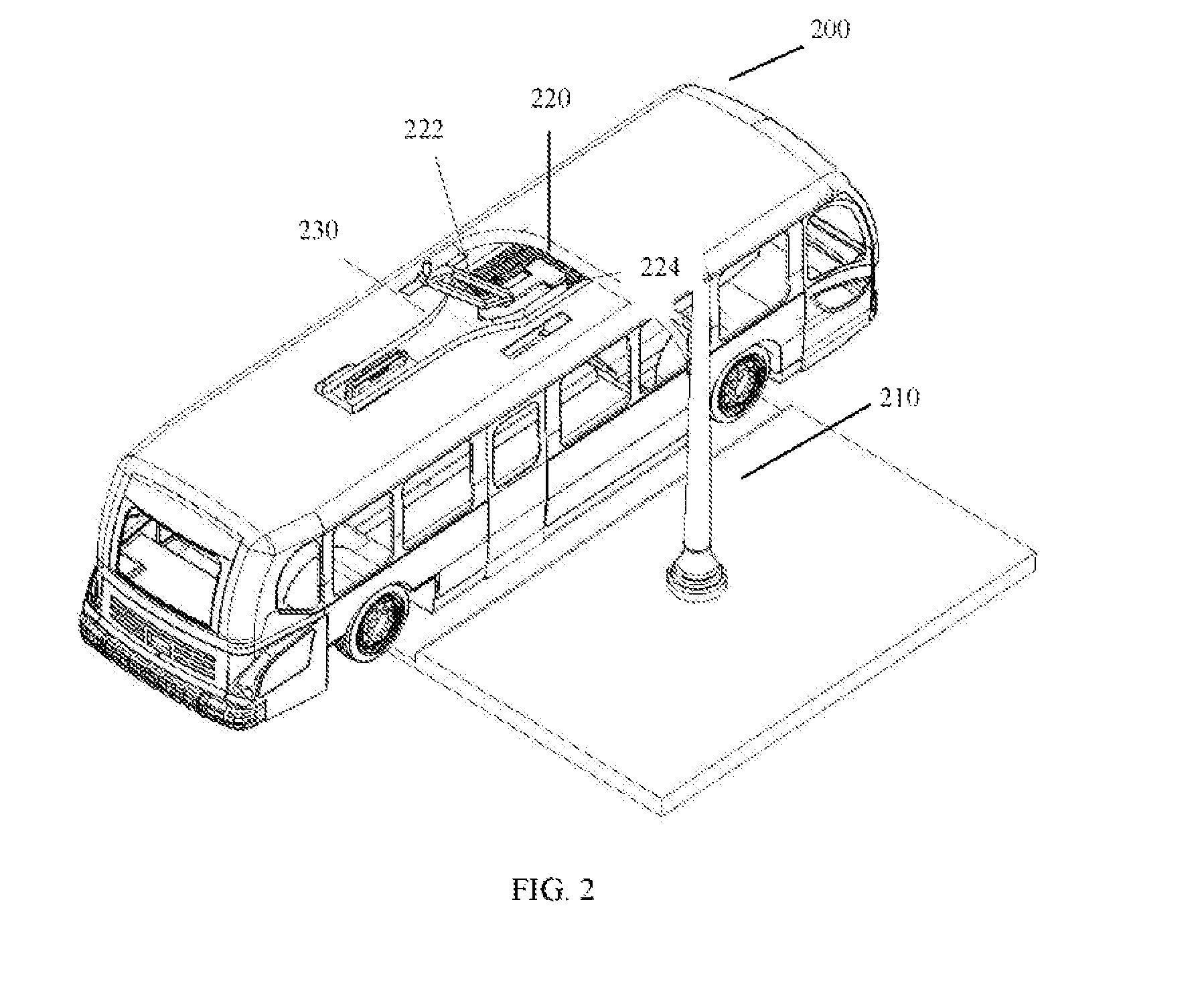

Systems and methods for charging an electric vehicle at a charging station

ActiveUS20160311335A1Reducing duty cycleResistance changeCircuit monitoring/indicationPropulsion by batteries/cellsCharging stationElectric bus

Systems and methods for charging an electric bus having a charging interface on its roof may include determining that an approaching bus is supposed to be charged at the charging station, lowering the charging head of the charging station to land on the roof of the bus, and moving the bus with the charge head on its roof to engage the charging head with the charging interface.

Owner:PROTERRA OPERATING CO INC

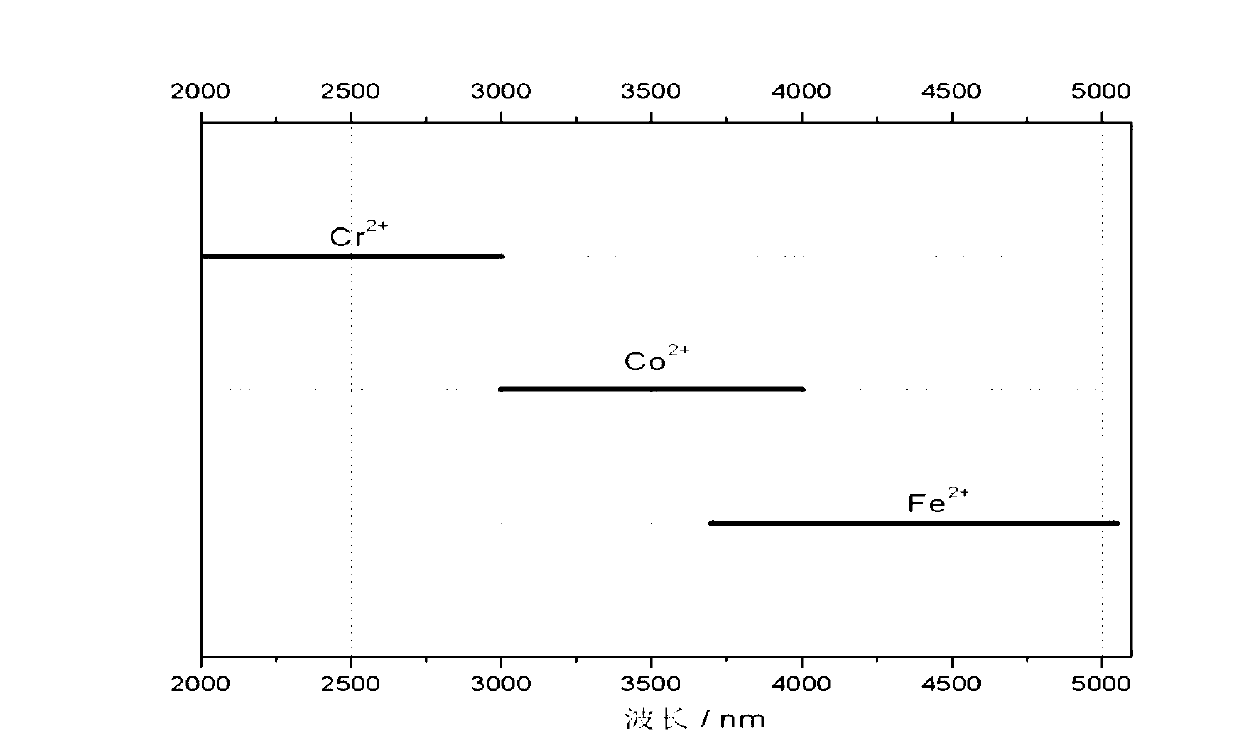

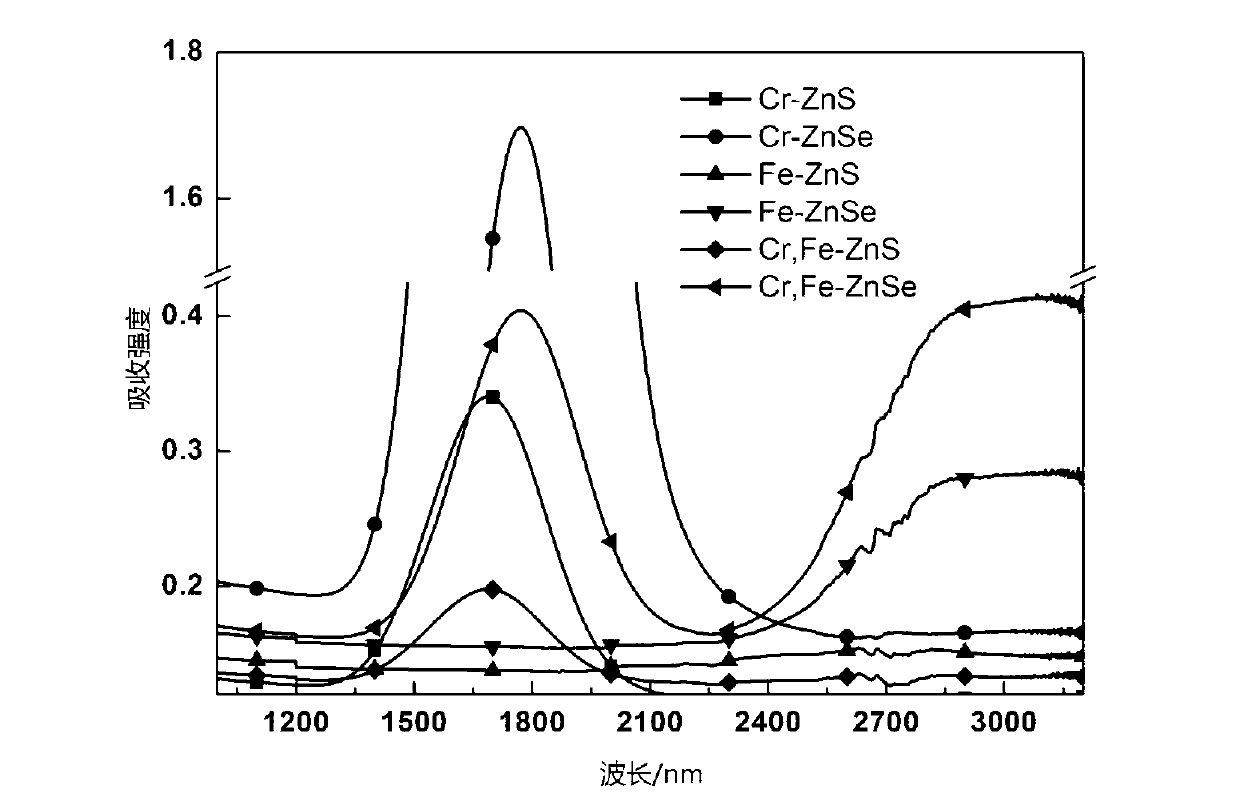

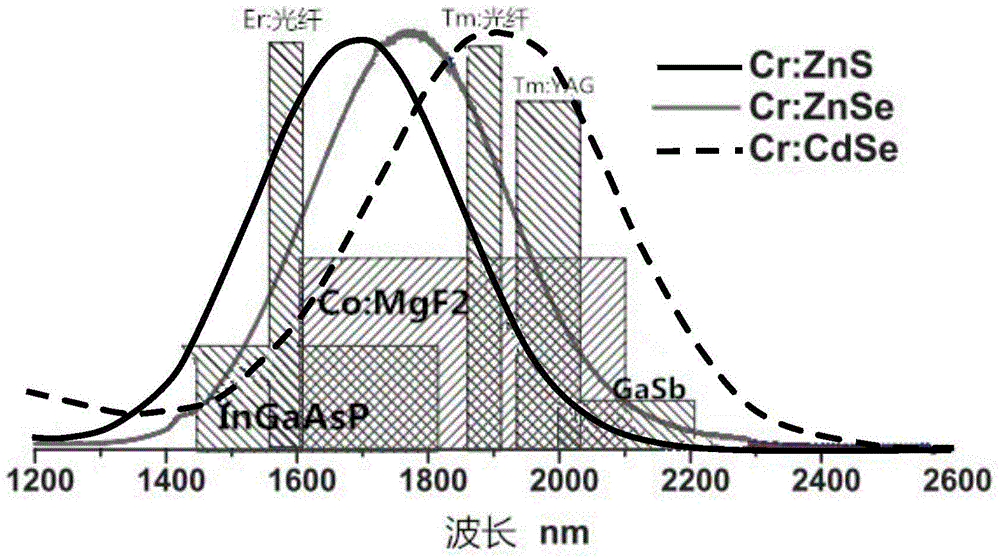

Chrome iron ion double-doped complex selenium zinc sulfide laser material and preparation method thereof

ActiveCN103275723AAchieve deliveryBroad Laser SpectrumLuminescent compositionsMiddle infraredHigh peak

The invention discloses a chrome iron ion double-doped complex selenium zinc sulfide laser material and a preparation method thereof. The molecular formula of the chrome iron ion double-doped complex selenium zinc sulfide laser material is Cr, Fe:ZnSxSe1-x, wherein x is not less than 0 and not more than 1. For the Cr and Fe transition metal ion energy band, the bandwidth is in a middle infrared wavelength range, the absorption and emission bandwidths are wide, the absorption and emission section areas are large, and ultrashort and ultrafast laser output with high peak power can be obtained. The Cr, Fe: ZnSSe laser material with excellent laser optical property can be subjected to LD (Laser Diode) direct pumping to manufacture an ultrafast laser device with low threshold, thus, the laser device is promoted to be more succinct and more miniature.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

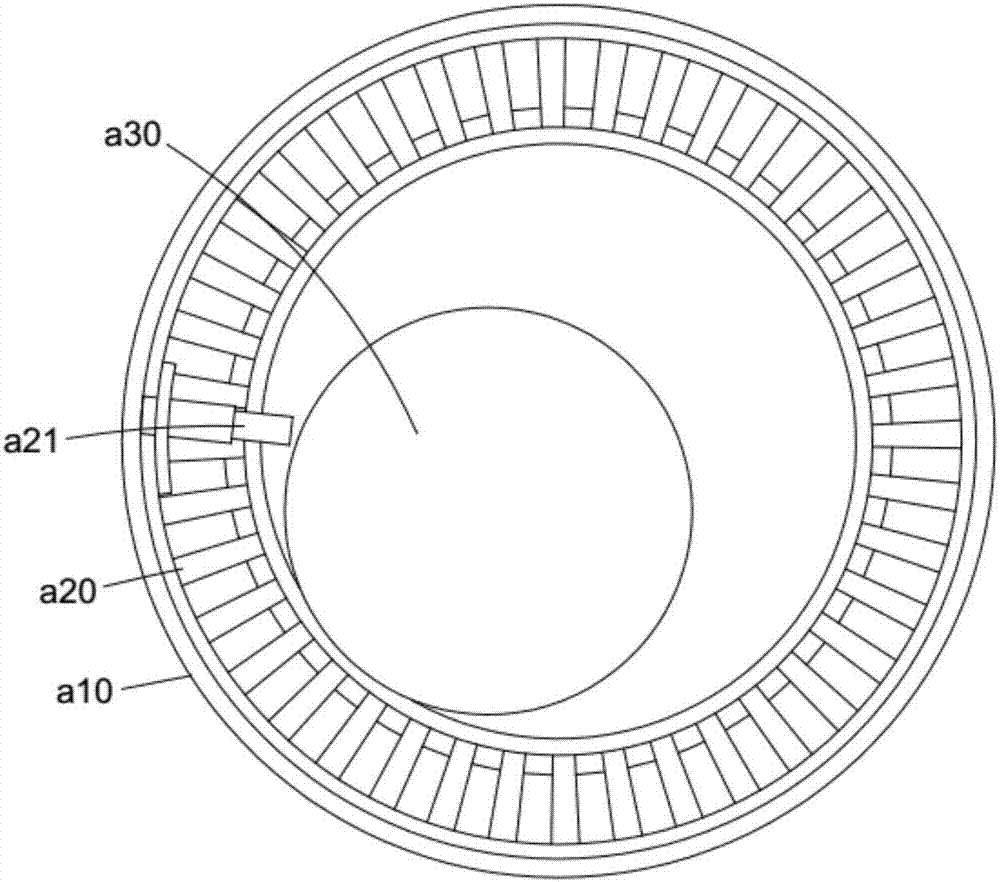

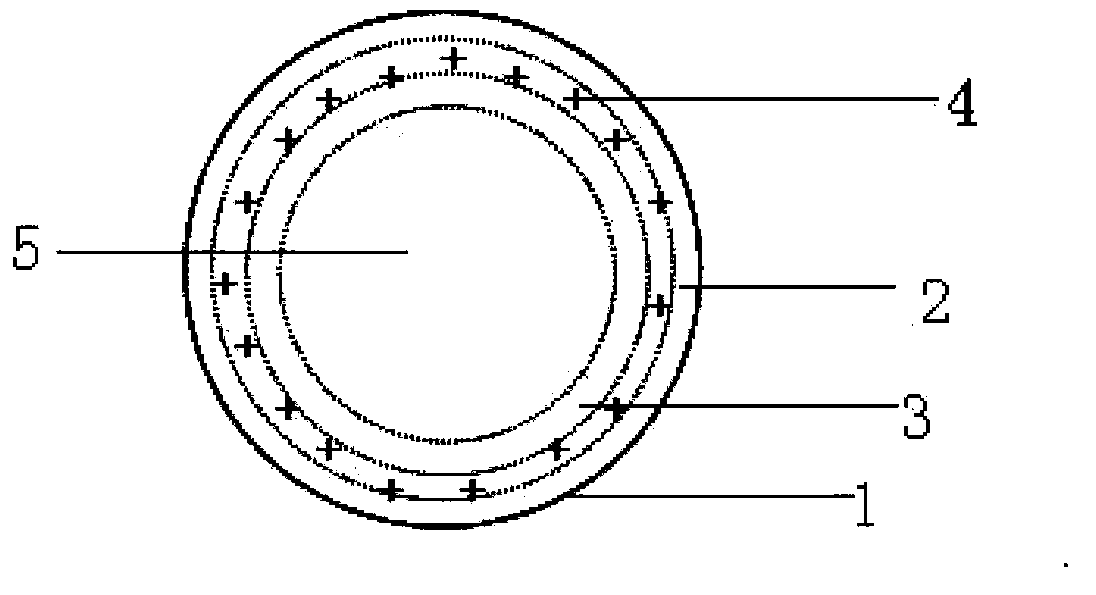

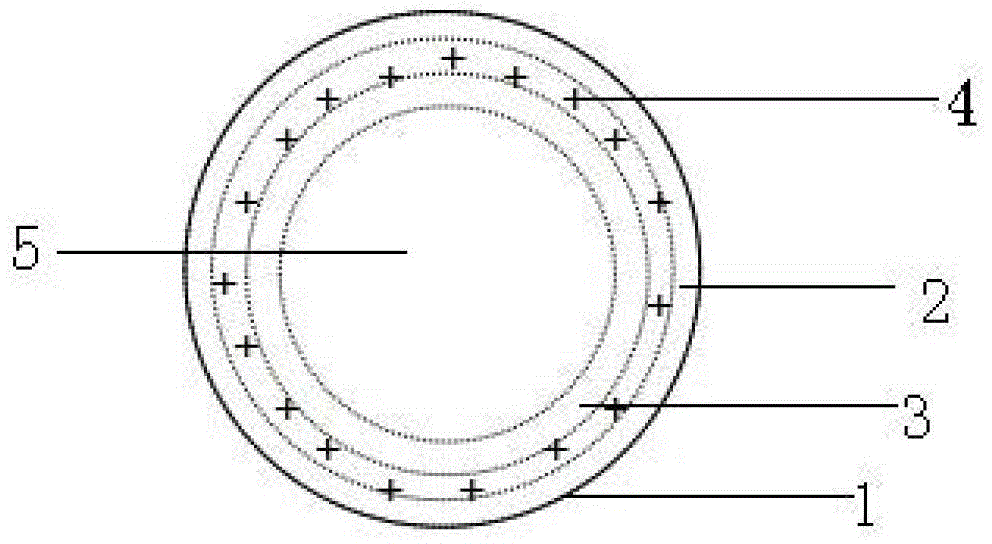

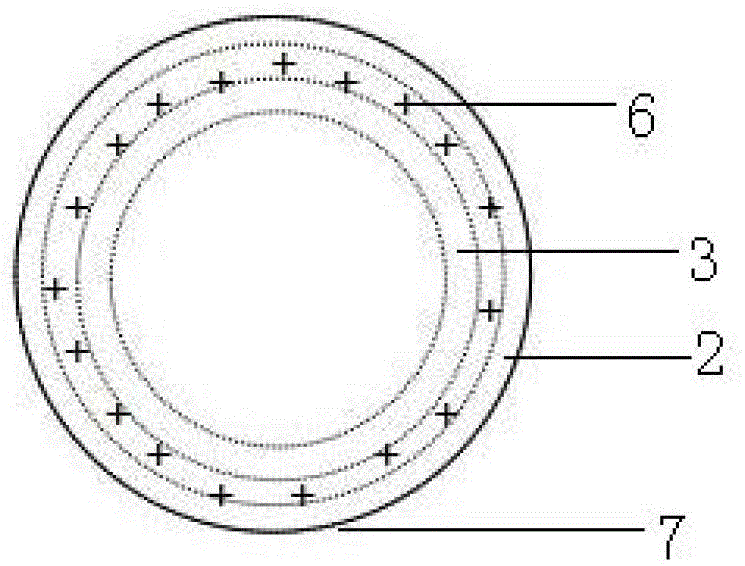

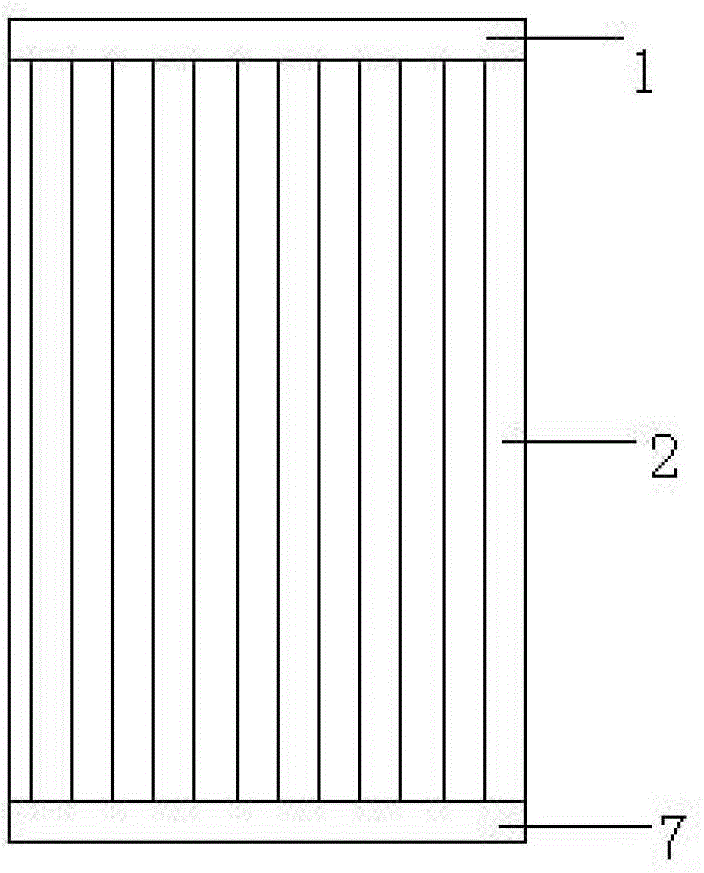

Sleeve type photocatalysis air cleaning device based on dispersion optical fibers

InactiveCN103446879AAvoid safety hazardsAvoid direct importDispersed particle filtrationUltraviolet lightsAir cleaning

The invention discloses a sleeve type photocatalysis air cleaning device based on dispersion optical fibers. The sleeve type photocatalysis air cleaning device comprises a filtering unit, an optical fiber unit and a catalyst unit, wherein the filtering unit is a cylinder-shaped filtering unit; the radial cross section of the filtering unit is annular, and upper and lower ends of the filtering unit are respectively connected with a top end cover and a bottom end cover; the catalyst unit is a cylinder-shaped catalyst unit, the radial cross section of the catalyst unit is annular, the height of the catalyst unit is the same as that of the filtering unit, the diameter of the catalyst unit is smaller than that of the filtering unit, and the catalyst unit and the filtering unit can form a concentric sleeve type structure; the center of the top end cover is provided with an air outlet, and the top end cover is provided with a top end installing hole; bottom installing holes are uniformly formed in the bottom end cover, the optical fiber unit selects the fibrous optical fibers, one end of the optical fiber unit is connected with the top end installing hole, and the other end of the optical fiber unit is connected with the bottom installing holes. The sleeve type photocatalysis air cleaning device provided by the invention has the advantages that 360-degree lateral air incoming is adopted, secondary pollution caused by a by-product of a light-catalyzed reaction is effectively reduced, the ultraviolet light use ratio is improved, meanwhile, the air purification efficiency is improved, and the sleeve type photocatalysis air cleaning device is suitable for sealing, flammable and combustible environment such as airplanes, subways and factories.

Owner:TIANJIN UNIV

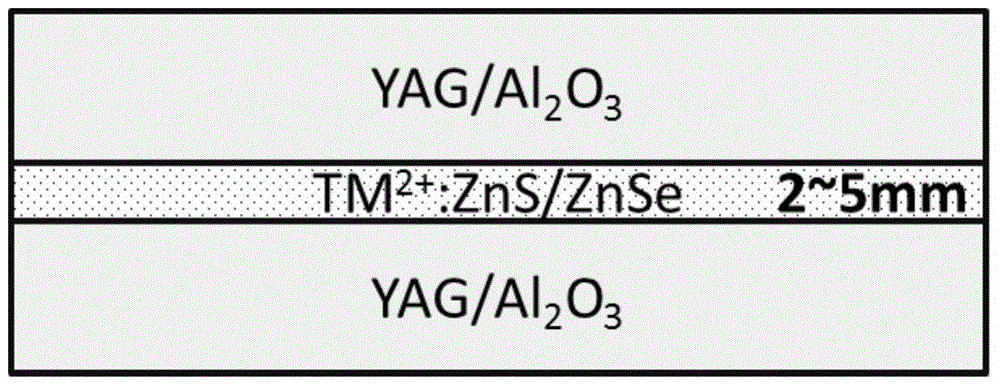

Transition-metal-doped zinc sulfide or zinc selenide planar waveguide material and preparation method

ActiveCN104441849ALower pumping thresholdImprove cooling effectCeramic layered productsZinc selenideHigh power lasers

The invention relates to a transition-metal-doped zinc sulfide or zinc selenide planar waveguide material and a preparation method. The transition-metal-doped zinc sulfide or zinc selenide planar waveguide material is characterized in that a YAG (yttrium aluminum garnet) or Al2O3 lath is respectively combined to two sides of transition-metal-ion-doped zinc sulfide or zinc selenide ceramic to form a sandwich planar waveguide structure, so that a heat-mirror effect of laser can be effectively controlled, and the intermediate infrared waveguide laser output is realized. By adopting the transition-metal-doped zinc sulfide or zinc selenide planar waveguide material, not only can the heat management be effectively realized by virtue of the sandwich composite structure, but also the mass production can be realized, and important significance on the development of a high-power laser technology and integrated optics can be realized.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Solid fuel unit which burns solid fuels together with their volatile gases

InactiveUS20110315056A1Efficient combustionMinimizing ratioSolid fuel combustionLump/pulverulent fuel feeder/distributionAir cellSolid fuel

The invention relates to solid fuel units having a fuel supply chamber wherein the fuel to be sent for combustion to the combustion region found in the body is placed and the feed mechanism carrying the solid fuel found in the chamber forward. It is characterized in that it includes a main burning block having a fuel and air cell connected to the solid fuel supply chamber and air outlet vents formed on the external wall surface. A preventive surface is positioned on the main burning block external wall surface in a way that it would form a closed volume in a certain distance.

Owner:IMANI EMMETT

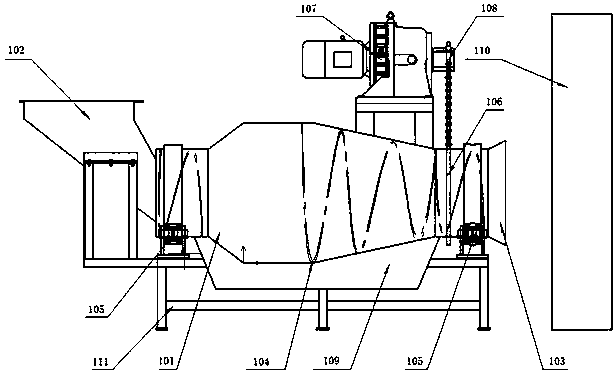

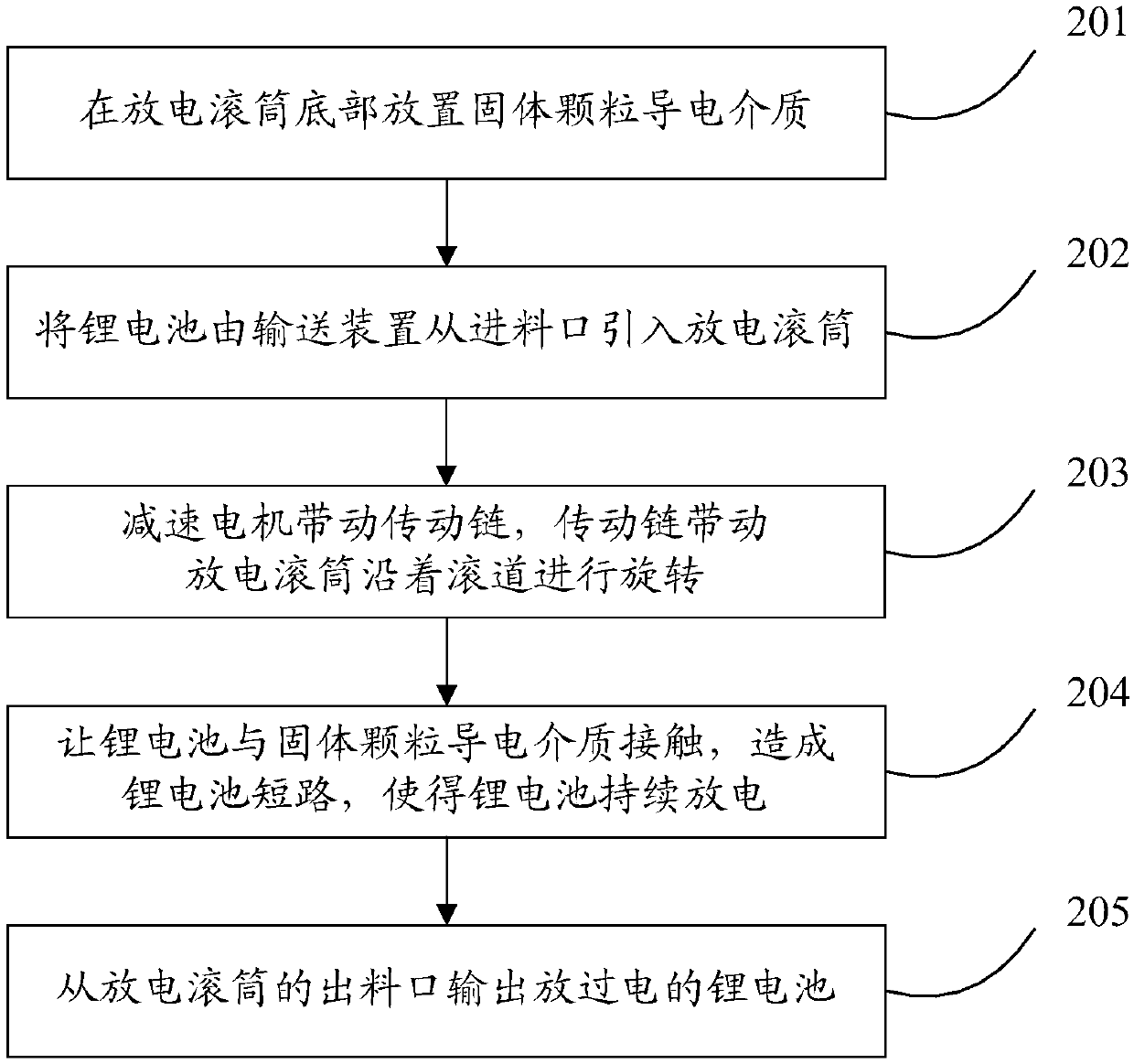

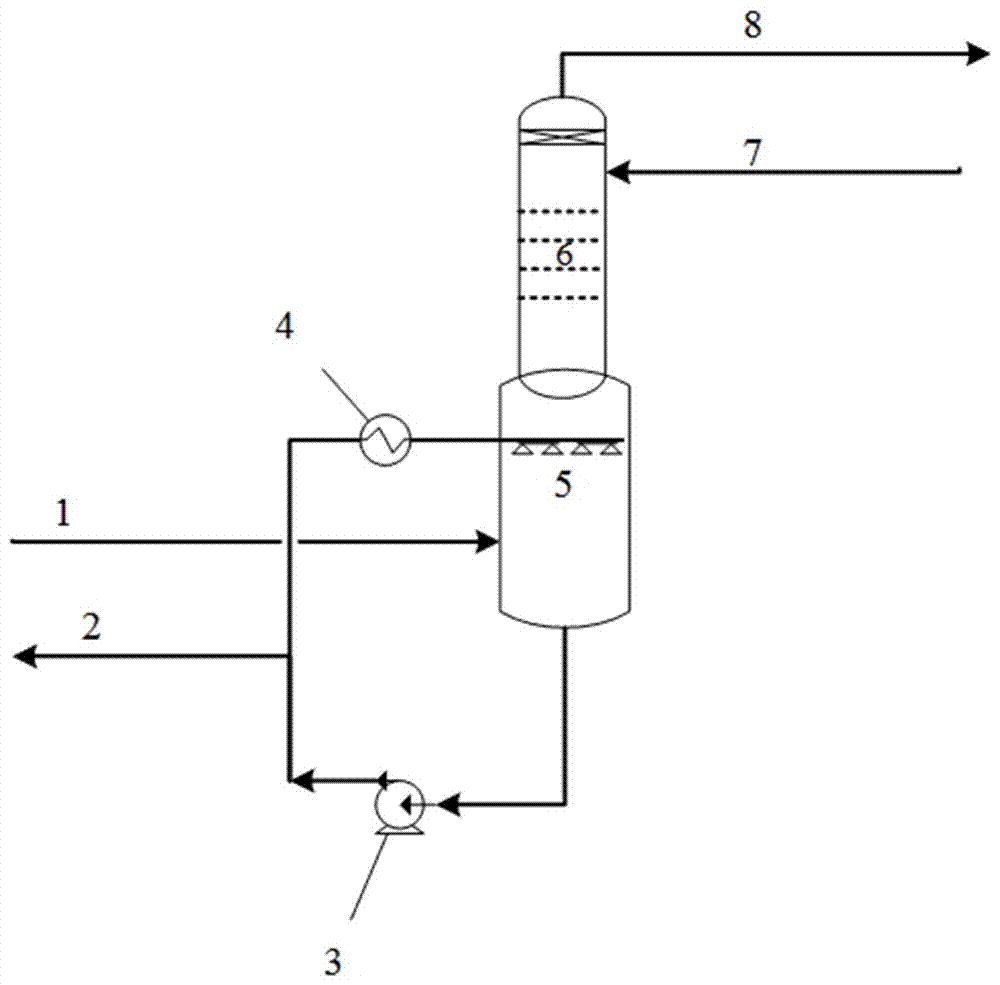

System and method for discharging lithium battery

InactiveCN109585966AQuick releaseContinuous and efficient operationSecondary cells charging/dischargingWaste accumulators reclaimingSolid particleSpiral blade

The present invention discloses a system and a method for discharging a lithium battery. The method comprises the steps of: placing a solid particle conductive medium at a discharge roller introducinga lithium battery from a feed port into the discharge roller; and rotating the discharge roller to allow the lithium battery to be in contact with the solid particle conductive medium to cause the short circuit of the lithium battery for continuous discharge, wherein a spiral blade of the discharge roller pushes the advance of the lithium battery, and the discharged lithium battery is output fromthe discharge port of the discharge roller. According to the technical scheme of the invention, the quick release of the residual electric quantity of the lithium battery can be achieved to naturallyseparate the conductive medium from the lithium battery so as to allow the processing and recovery system of the lithium battery to be continuously and efficiently operated.

Owner:河南小威环境科技有限公司

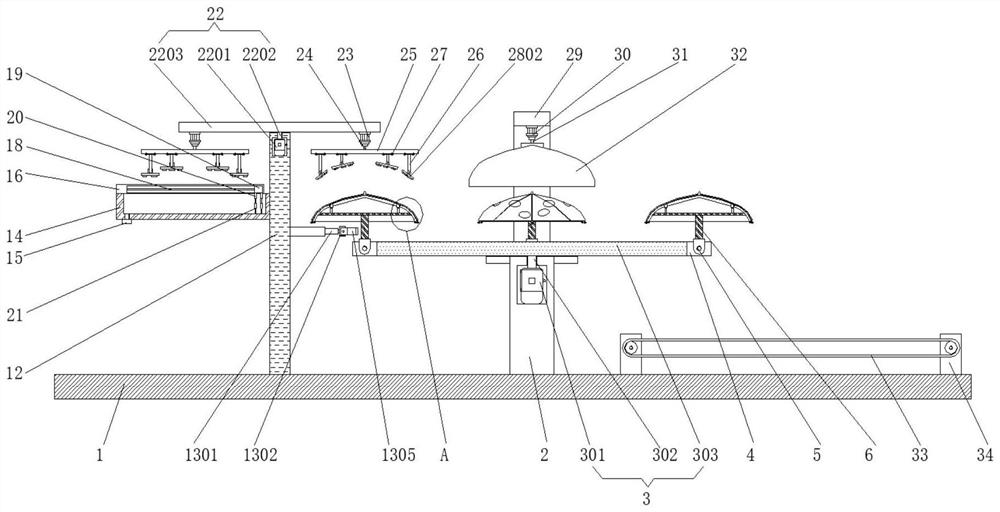

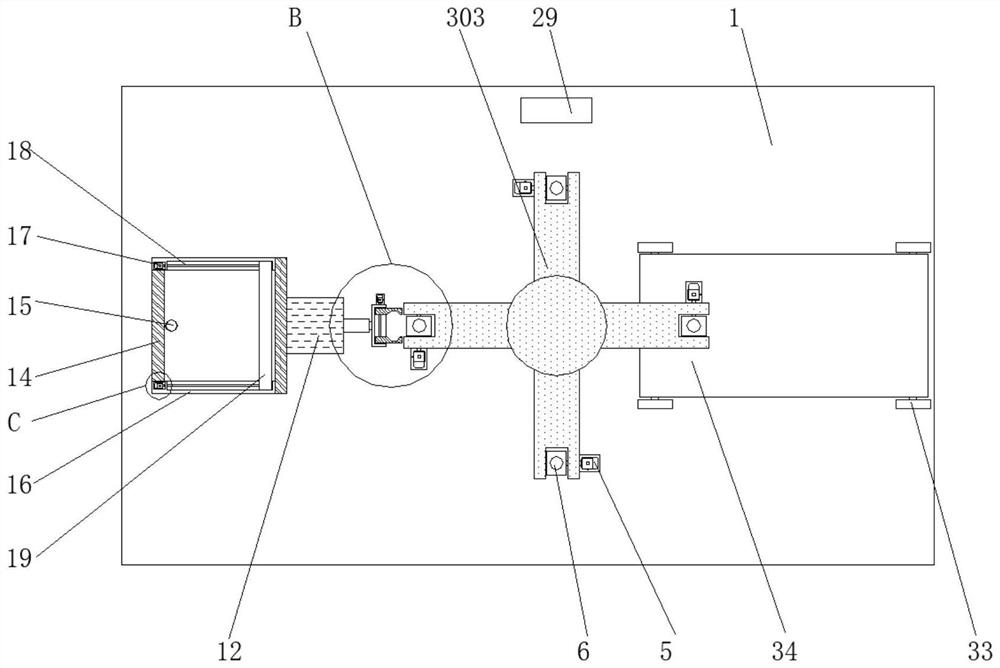

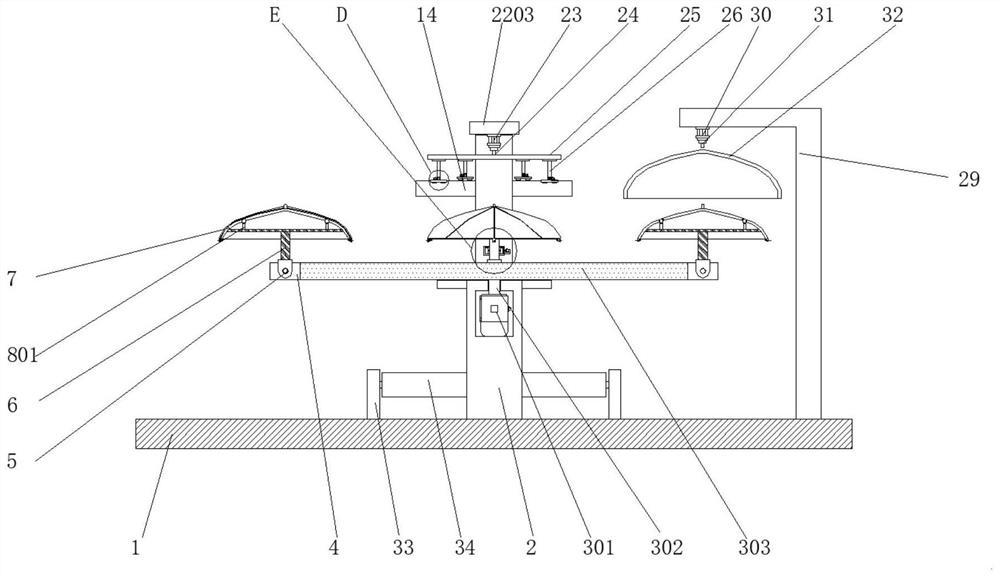

Coating method and coating device applied to umbrella cover colorful coatings

ActiveCN113171949AContinuous and efficient operationGuaranteed uniformityPretreated surfacesCoatingsStructural engineeringDip-coating

The invention discloses a coating method and a coating device applied to umbrella cover colorful coatings. The coating device comprises a rotating mechanism, a jacking mechanism, a locking mechanism, a clamping and fixing mechanism, a switching mechanism, a coating mechanism and a bearing frame, wherein a second sliding channel is fixed on the top of a material storage box; the switching mechanism is arranged at the top of a second support frame; the coating mechanism is arranged at the bottom of a mounting frame; the bottom of the bearing frame is fixed on the rear side of the middle of the upper end surface of a base; and a fixed frame is fixed on the right side of the upper end surface of the base. According to the coating method and the coating device applied to the umbrella cover colorful coatings, a whole piece of spliced and sewn umbrella cloth is placed on a supporting shed on the top of a rotating frame on the front side of the upper end surface of a rotary table, then the umbrella cloth can be locked through the corresponding locking mechanism, and then the rotary table rotates clockwise by 45 degrees; after a coating plate is used for dipping coating in the material storage box, a rotating plate horizontally rotates by 180 degrees; after the angle of the coating plate is adjusted, the coating plate moves downwards, so that the surface of the umbrella cloth is conveniently coated with the coating.

Owner:东阳市好旺伞业有限公司

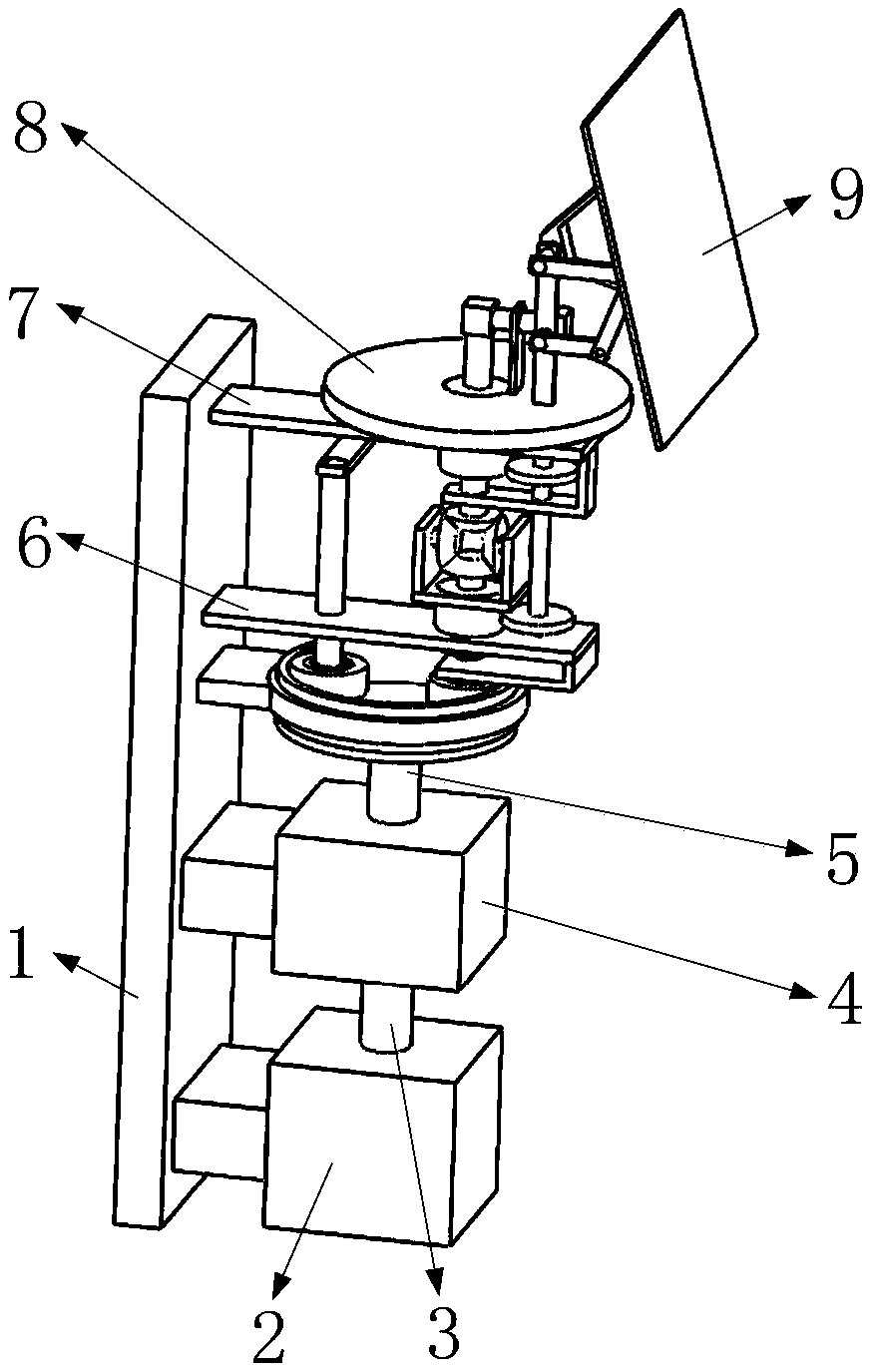

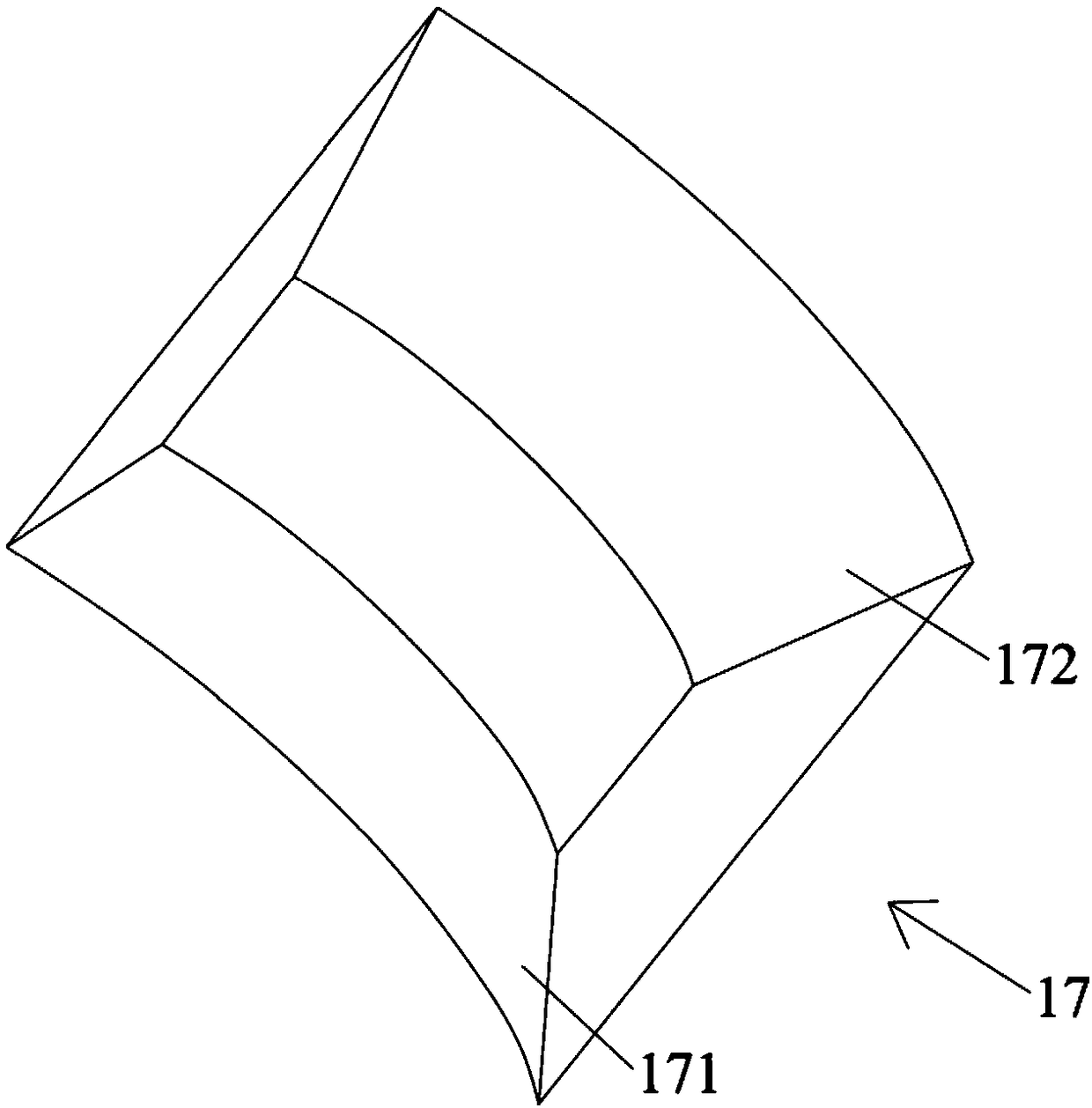

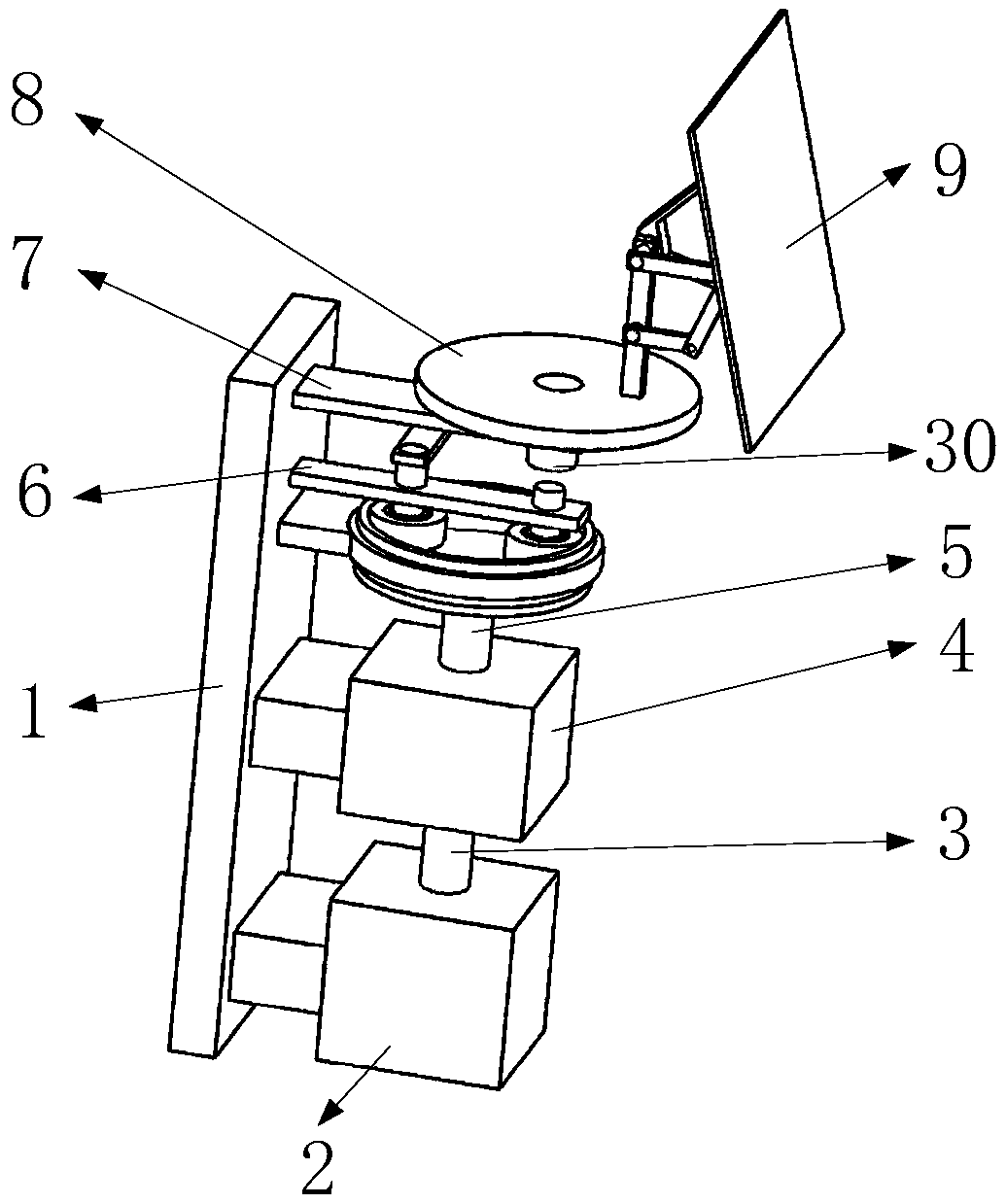

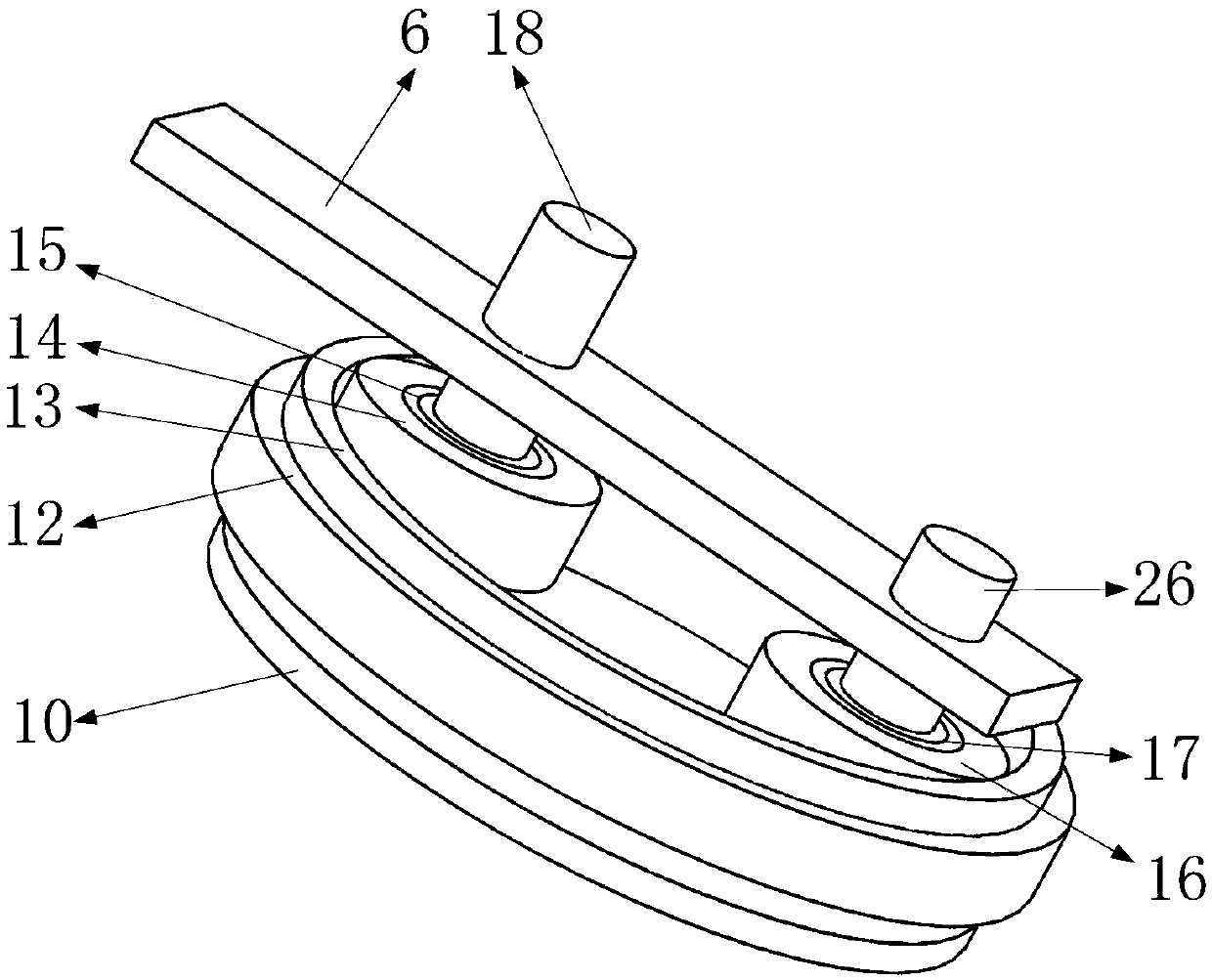

Heliostat used by solar power generating system

InactiveCN108645059ASwing does not produceContinuous and efficient operationSolar heating energySolar heat collector controllersElevation angleHeliostat

The invention belongs to the technical field of heliostats, and particularly relates to a heliostat used by a solar power generating system. The heliostat comprises a drive shaft, a speed reducer, aninput shaft, a first fixing board, a second fixing board, a ring disc, a heliostat body, a round disc, a fixing ring, a gear ring, a first drive gear, a first one-way clutch ring, a second drive gear,a second one-way clutch ring, a first shaft, a first L-type board, a first shaft sleeve and the like. The first one-way clutch ring and the second one-way clutch ring make a first crank rocker mechanism and a second crank rocker mechanism work under different conditions of rotation of a motor, and then the heliostat swings in azimuth angle and elevation angle and keeps the proper angle with the sun all the time. By reducing one motor and one heliostat, the heliostat device achieves the same effect with a traditional heliostat device, so that the economic cost is reduced and resources are saved.

Owner:冯萍

Cutting, edge grinding and chamfering integrated device for tempered glass processing

PendingCN112520993AContinuous and efficient operationHigh degree of automationEdge grinding machinesGlass severing apparatusHydraulic cylinderEngineering

The invention discloses a cutting, edging grinding and chamfering integrated device for tempered glass processing. The device comprises a pushing mechanism and a collecting mechanism, a third supporting plate is fixed to a base, a rotating frame is rotatably connected to the upper end face of a movable table, the collecting mechanism is fixed to the right inner wall of a bearing frame, and a hydraulic cylinder is fixed to the inner top of the bearing frame, and a second electric telescopic column, a sliding rail and a fourth electric telescopic column are fixed to the lower end face of a moving plate, a sliding block is slidably connected into the sliding rail, and the bottom of the fourth electric telescopic column is connected with a second abutting and pressing plate. According to the cutting, edge grinding and chamfering integrated device for tempered glass processing, after positioning, cutting, edge grinding and chamfering operation of one side of tempered glass is completed eachtime, the tempered glass can rotate by 90 degrees along with the supporting plate, then the operation can be repeated, positioning, cutting, edge grinding and chamfering operation of the four sides of the tempered glass can be completed conveniently and orderly, and the whole operation is continuous and efficient, and is high automation degree.

Owner:江苏金桥玻璃科技有限公司

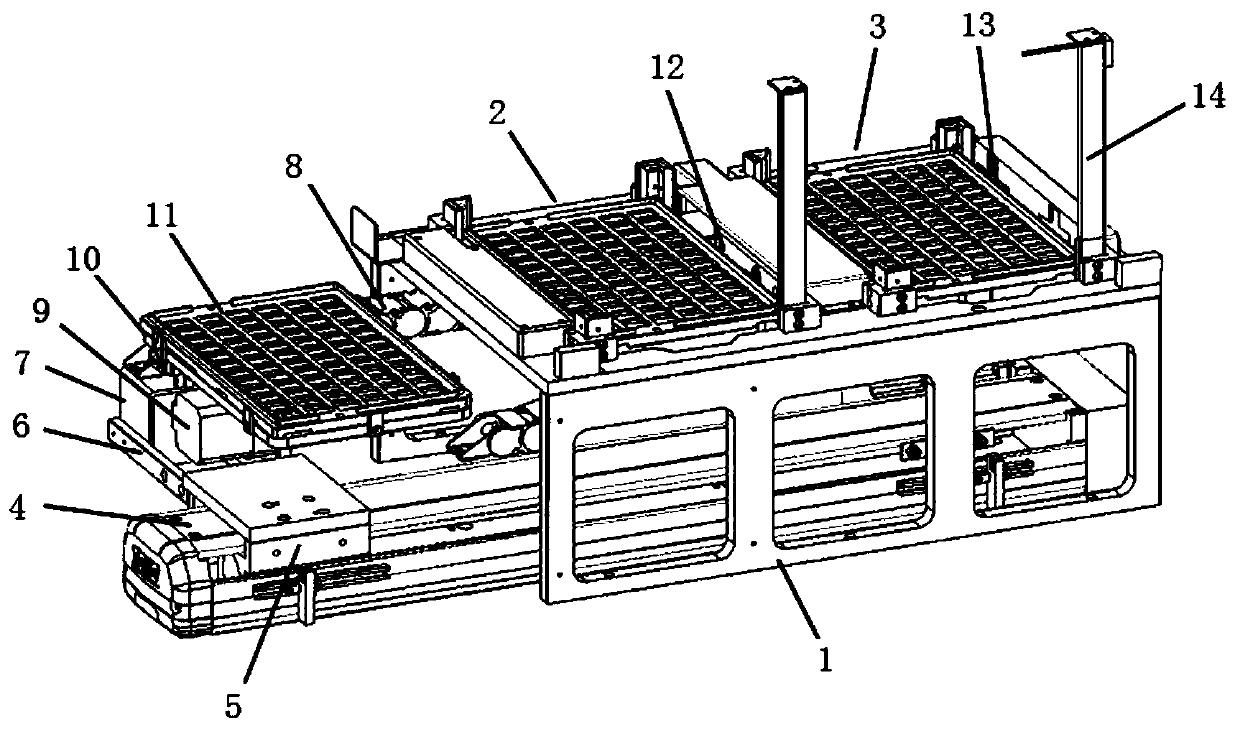

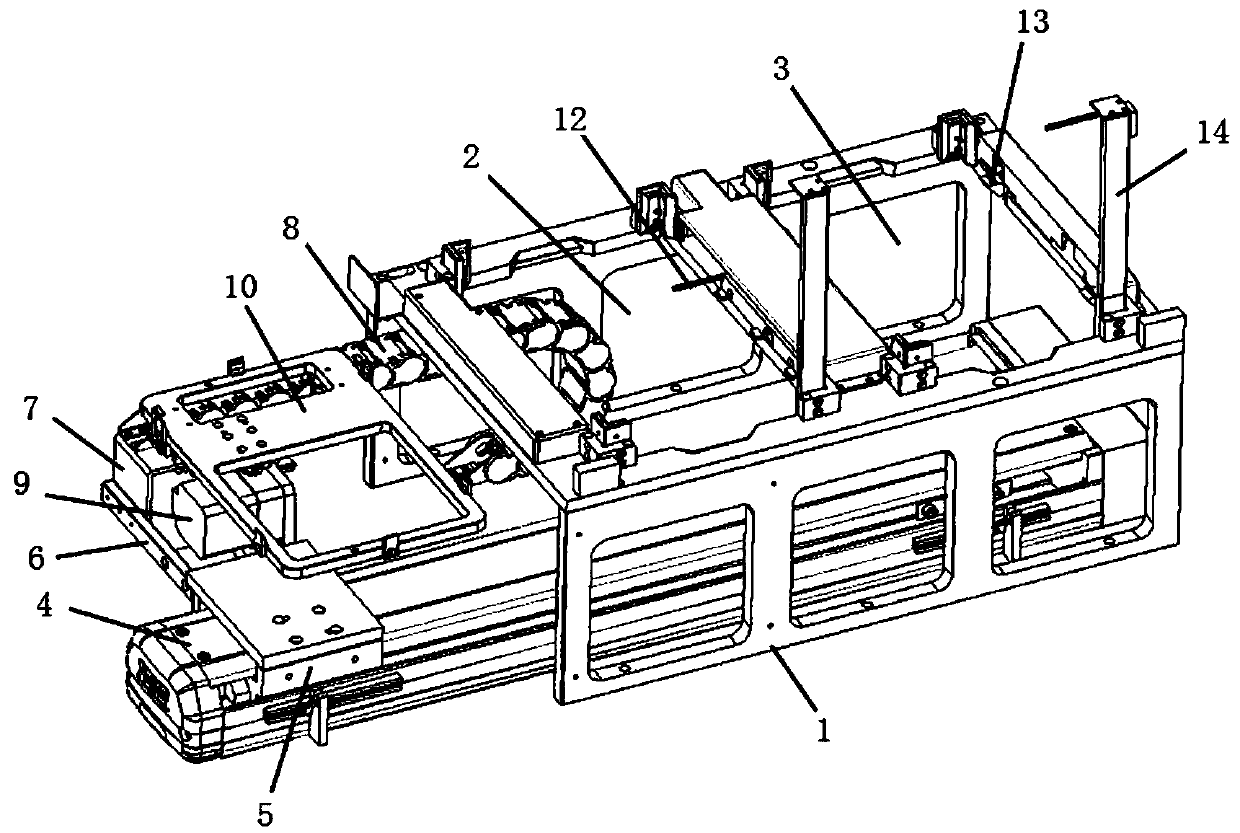

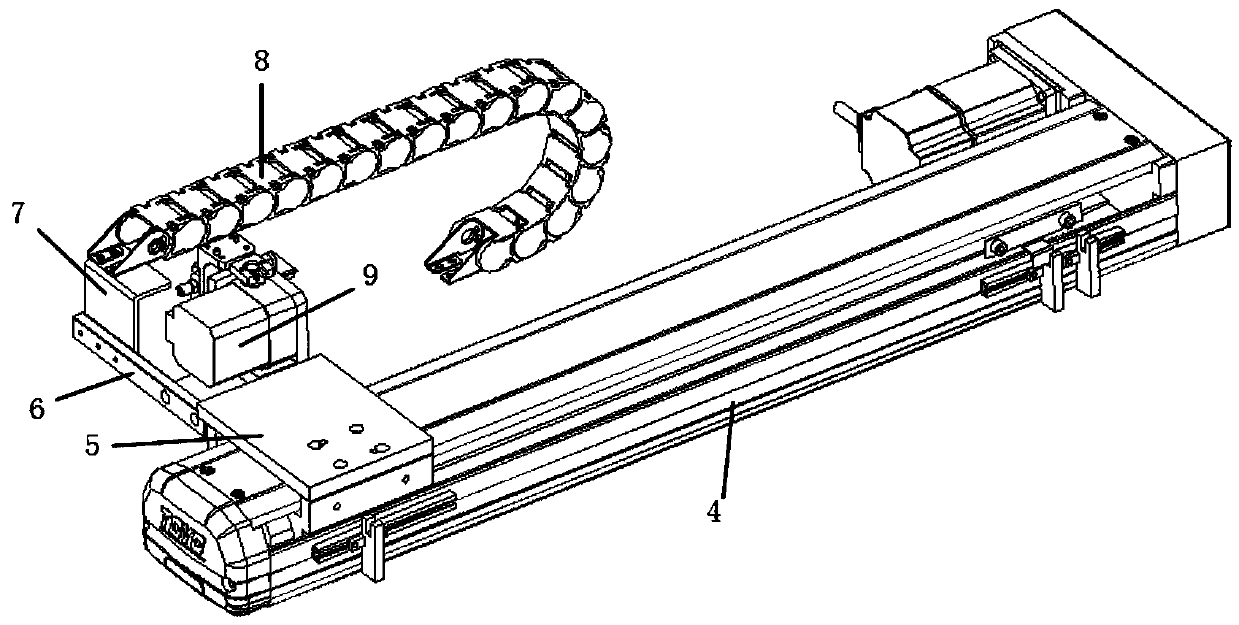

Automatic feeding robot

InactiveCN109250475AEasy to useContinuous and efficient operationStacking articlesConveyor partsEngineeringMachining

The invention discloses an automatic feeding robot which comprises a framework. A second machining station and a stack station are arranged on the framework, a front region is used as a first machining station, a slide rail is fixed to a position below the framework, a driving slider is slidably connected into the slide rail, a connecting seat is fixed to a side of the driving slider, a driven roll section frame is fixed to the left end of the connecting seat by the aid of a support plate, a jacking motor is fixed to the right end of the connecting seat, and a bracket for conveying storage plates is fixedly supported by lifting shafts at the upper end of the jacking motor; horizontal locking devices are arranged in seats on two sides of the second machining station, support movable block mechanisms are arranged in seats on two sides of the stack station, and stacking vertical plates at four corners of the stack station are provided with a plurality of separation movable block mechanisms. The automatic feeding robot has the advantages that the multiple storage plates can be accumulated at the stack station, accordingly, a large amount of waiting time can be saved, use of large quantities of transmission and reversing mechanisms can be simplified, the automation renovation cost can be reduced to a great extent, and the automatic feeding robot is applicable to large-scale technological processes with a plurality of technological links which are obviously long in time consuming.

Owner:CHANGZHOU ZHIDOU INFORMATION TECH CO LTD

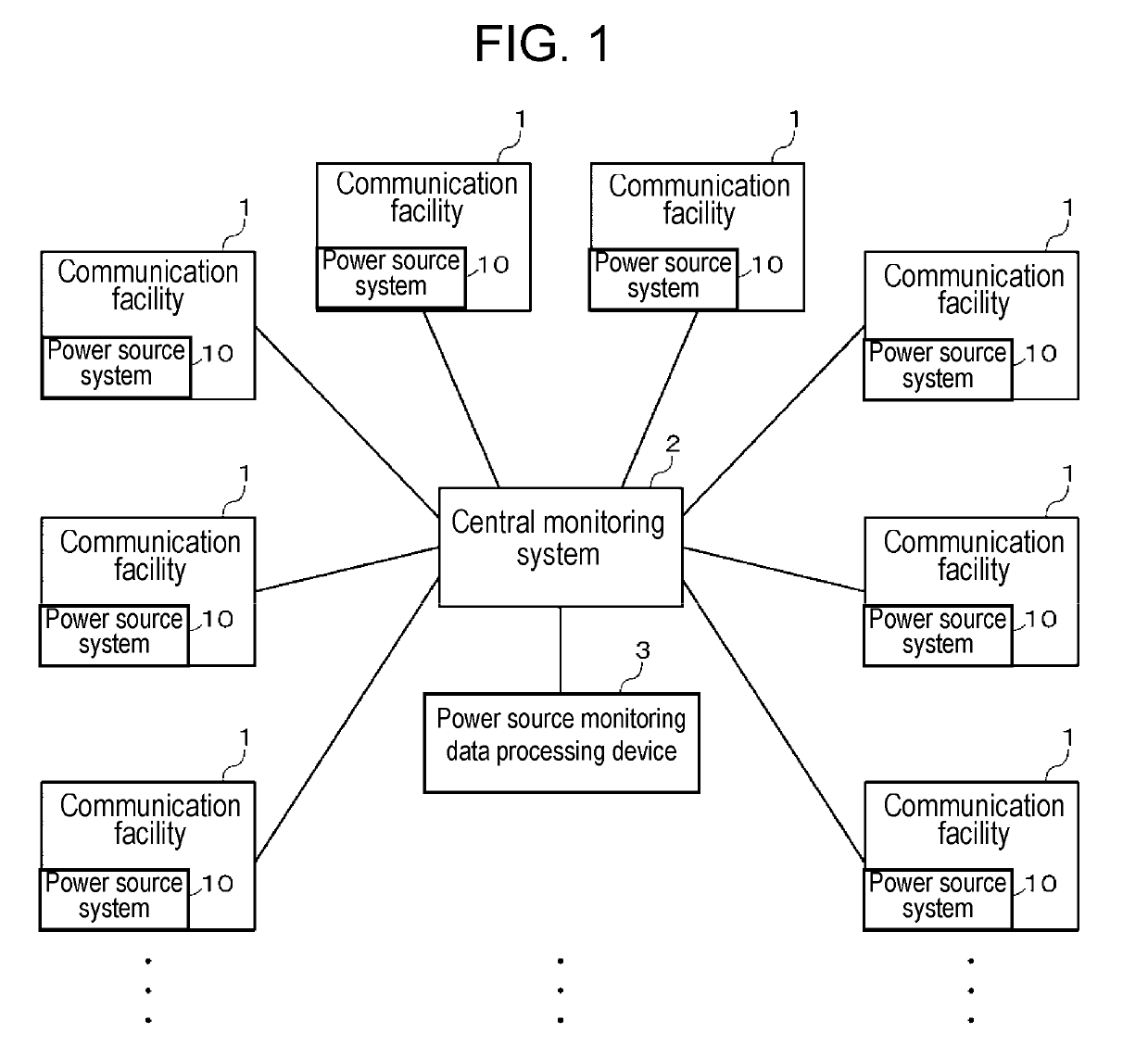

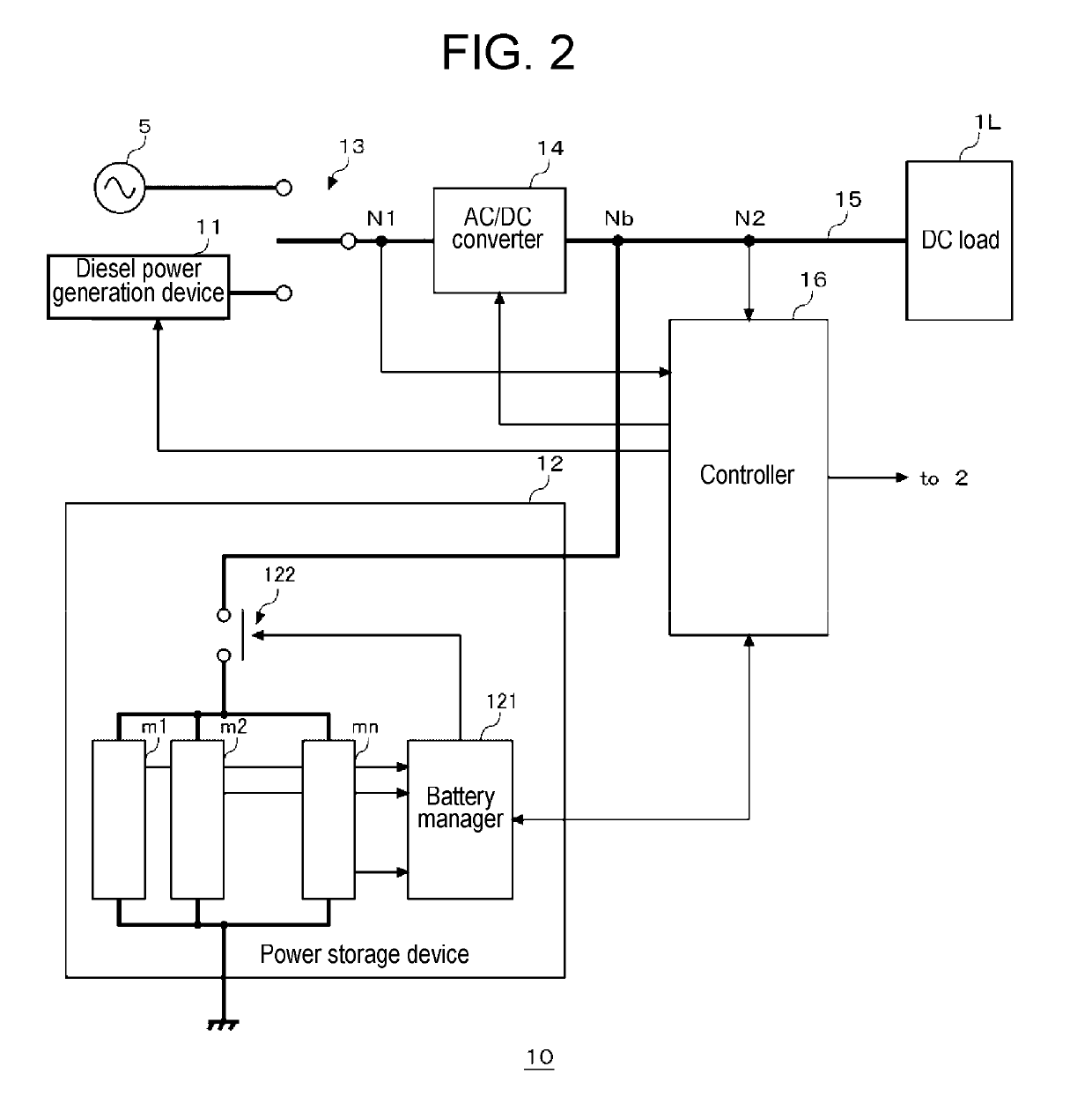

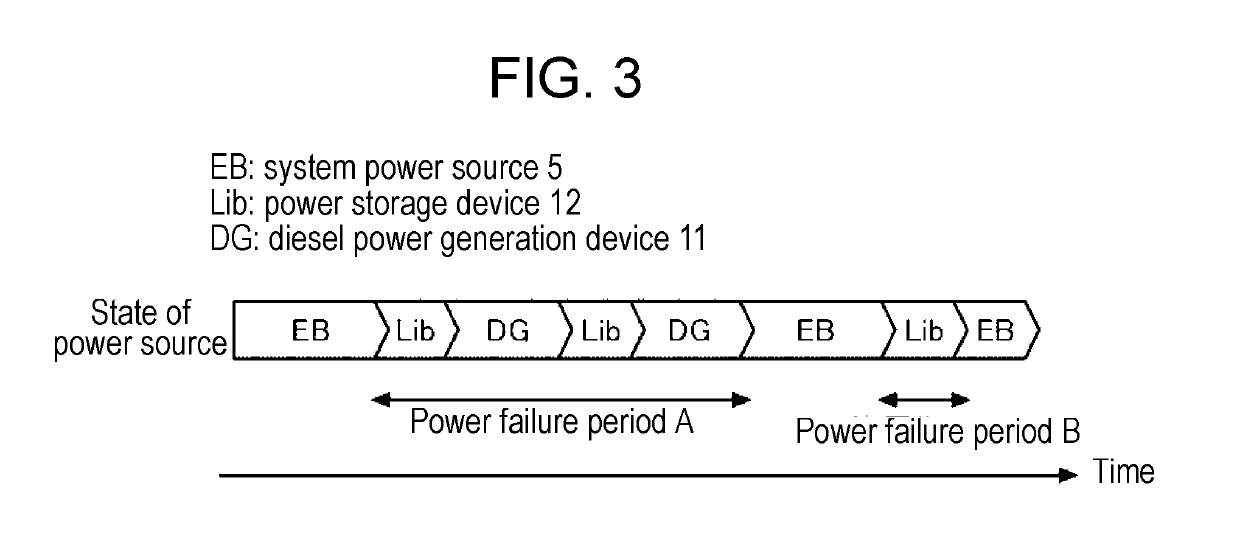

Power supply monitoring data processing device, power supply monitoring data processing method, and power supply monitoring data processing program

InactiveUS20190190268A1Ensure continuous and efficient operationContinuous and efficient operationBatteries circuit arrangementsCurrent/voltage measurementData acquisitionSystem configuration

A data acquisition section acquires first data and second data as monitoring data of a power source system that includes a switching section that selectively outputs AC power supplied from a system power source or an internal combustion power generation device, an AC / DC converter that converts the AC power output from the switching section into DC power and outputs the DC power, and a power storage device connected to a DC bus. The first data contains an output voltage and / or an output current of the switching section; the second data contains an output voltage and / or an output current of the power source system. The data processor estimates an operational state of the internal combustion power generation device, based on the first data and the second data, and generates a modification plan for a system configuration and / or a discharge lower limit of the power storage device to shorten an operational time of the internal combustion power generation device.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

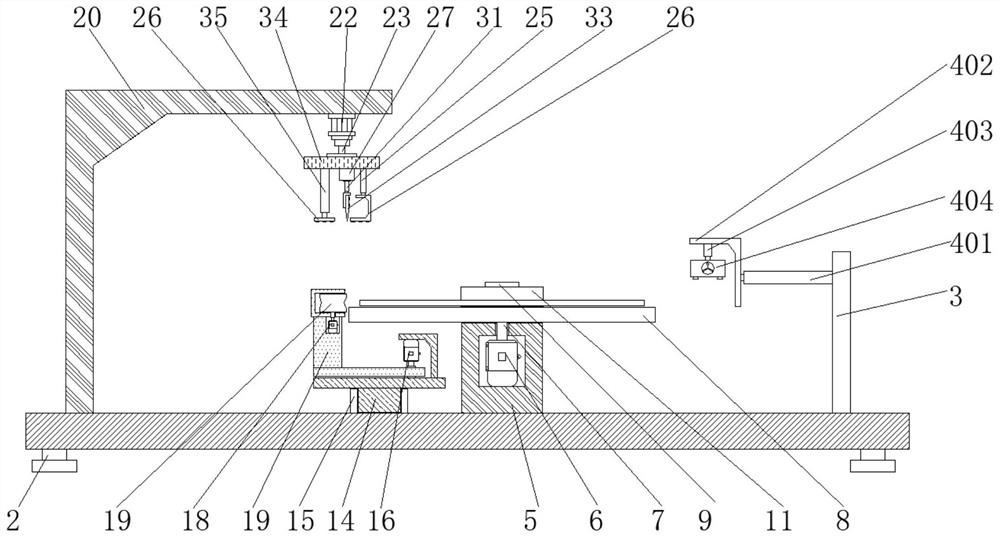

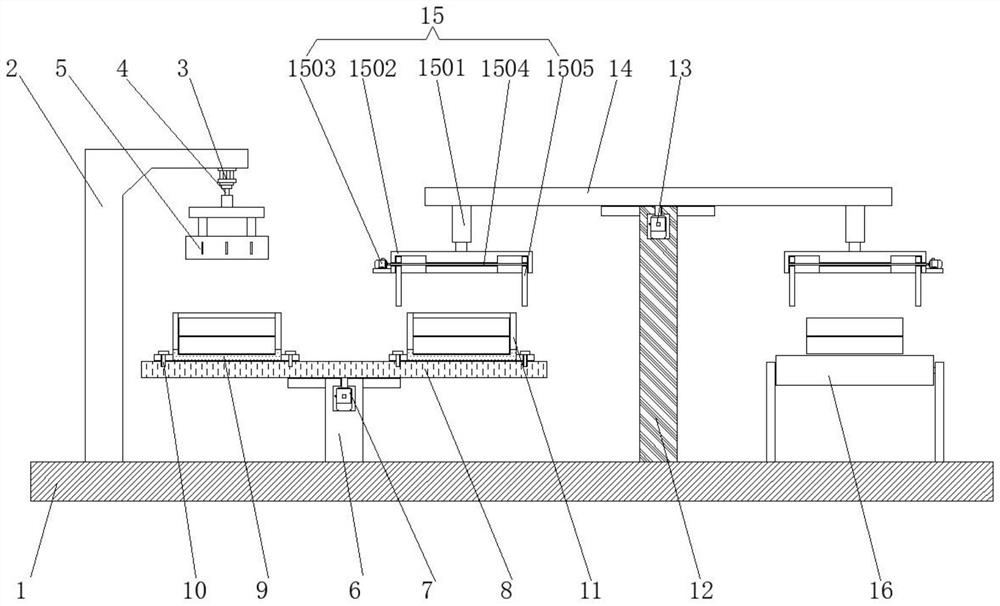

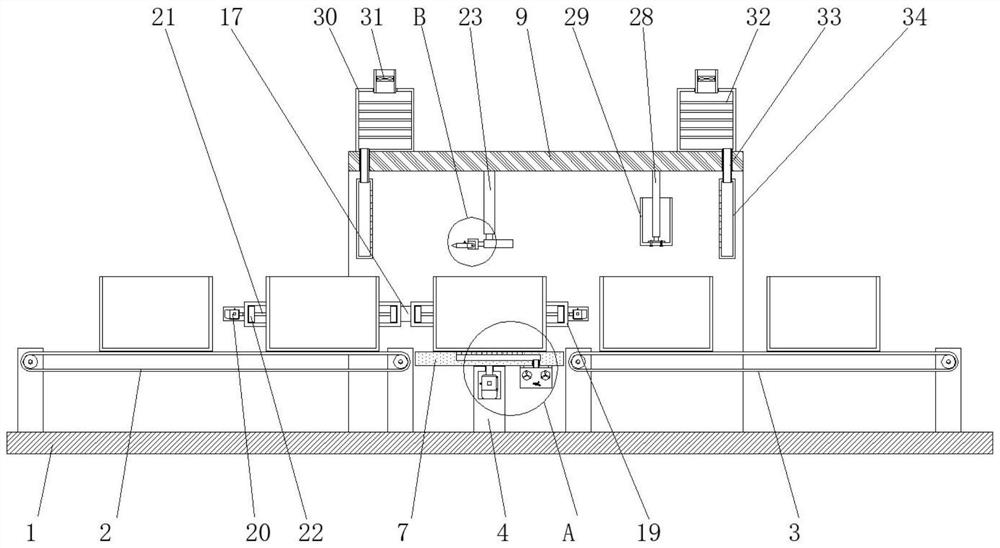

Ultrasonic automatic welding equipment

PendingCN112388146AEasy to transportContinuous and efficient operationNon-electric welding apparatusPhysicsUltrasonic welding

The invention discloses ultrasonic automatic welding equipment. The ultrasonic automatic welding equipment comprises a base, clamping mechanisms and a conveying belt device. A first support is fixed to the left side of the upper end face of the base, a second support is located on the right side of the first support, and molds are fixed to the left side and the right side of the upper end face ofa rotating table through bolts. A third support is arranged on the right side of the rotating table, the third support and the second support are both fixed to the base, the clamping mechanisms are fixed to the left side and the right side of the lower end face of a rotating plate, and the conveying belt device is fixed to the right side of the upper end face of the base. According to the ultrasonic automatic welding equipment, after a material is placed on the conveying belt device, the material can move backwards under the operation effect of the conveying belt device, after the material isclamped by the clamping mechanisms, the rotating plate horizontally rotates by 180 degrees, the material is conveniently transferred, so that the material is placed in the corresponding molds, then the rotating table horizontally rotates by 180 degrees, and finally, an ultrasonic welding machine can be used for completing automatic welding operation.

Owner:长春英纳维特自动化设备有限公司

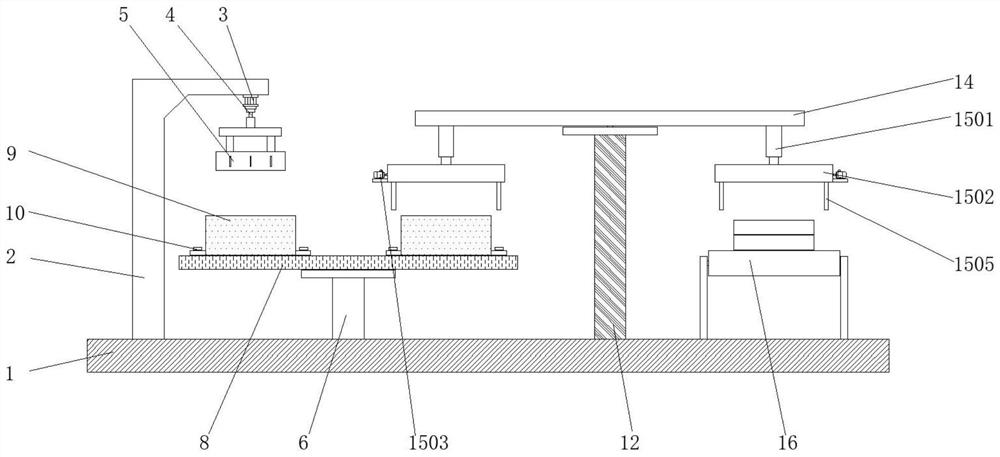

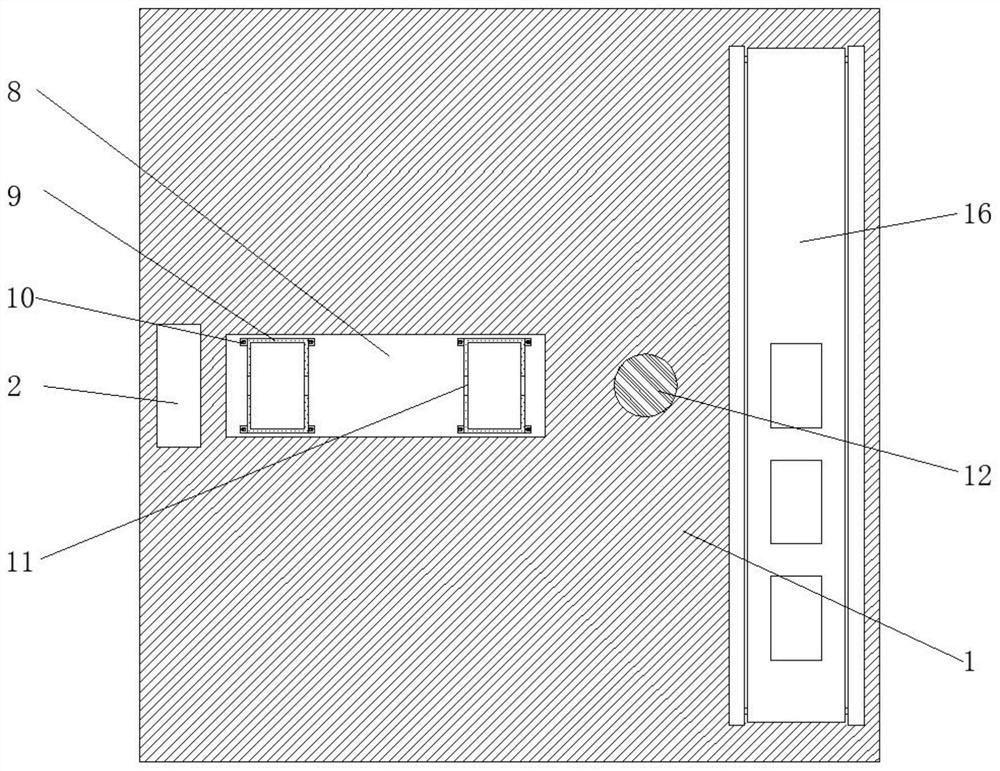

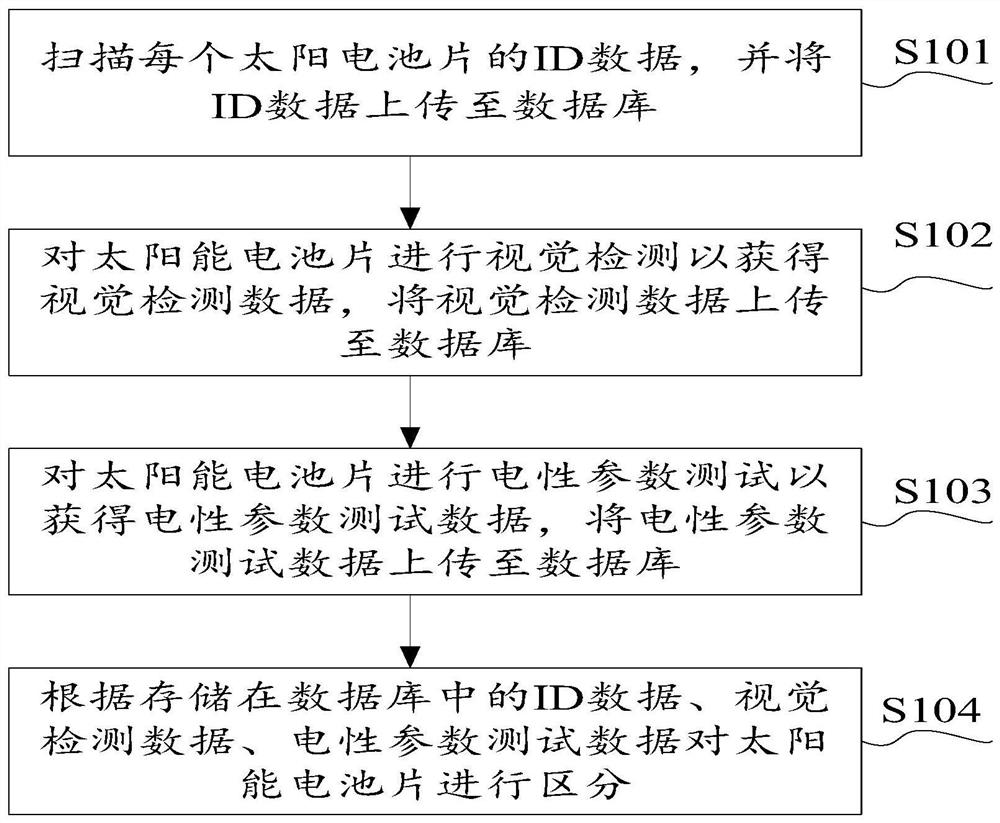

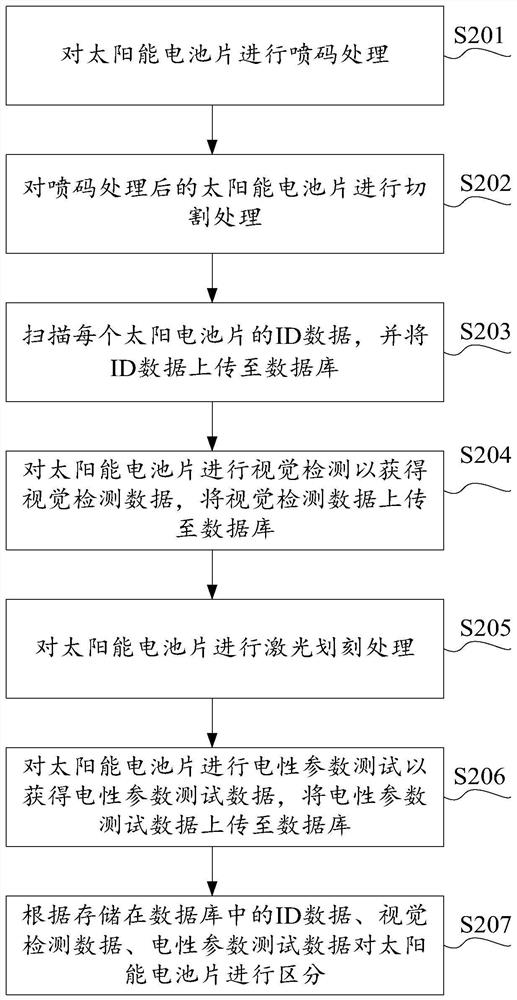

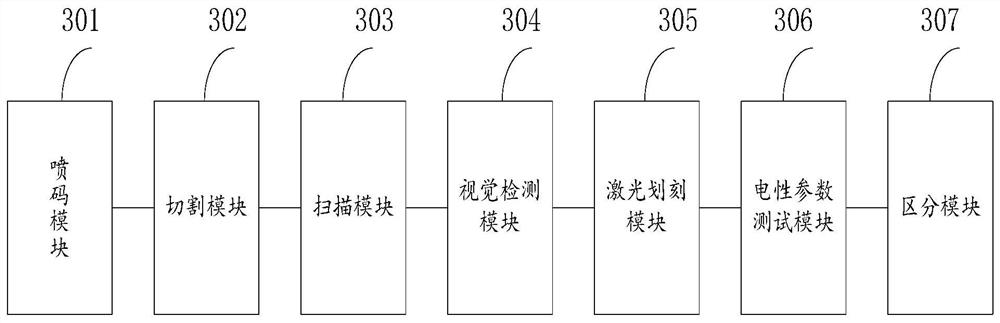

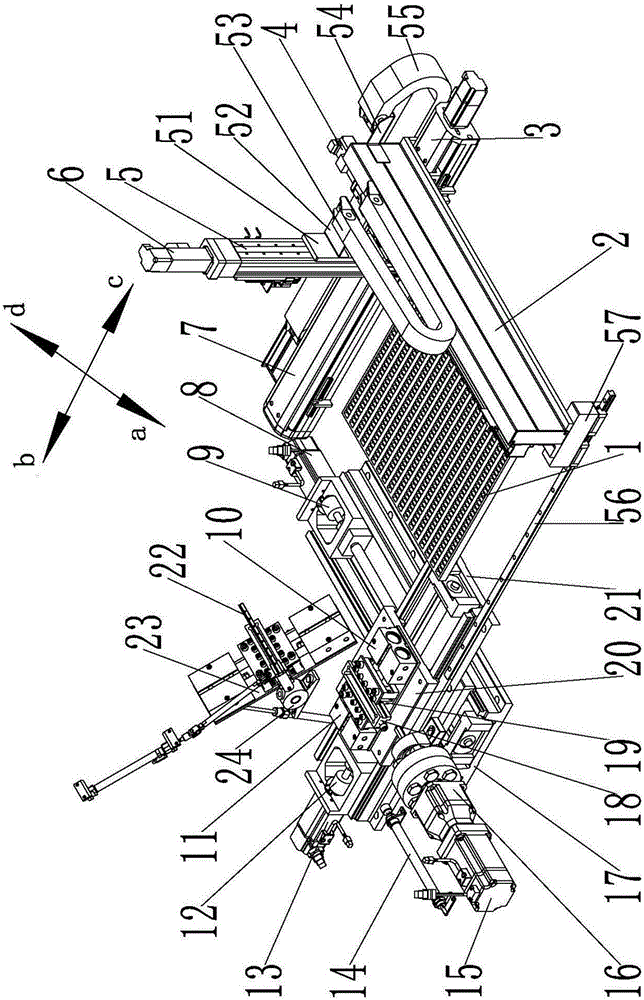

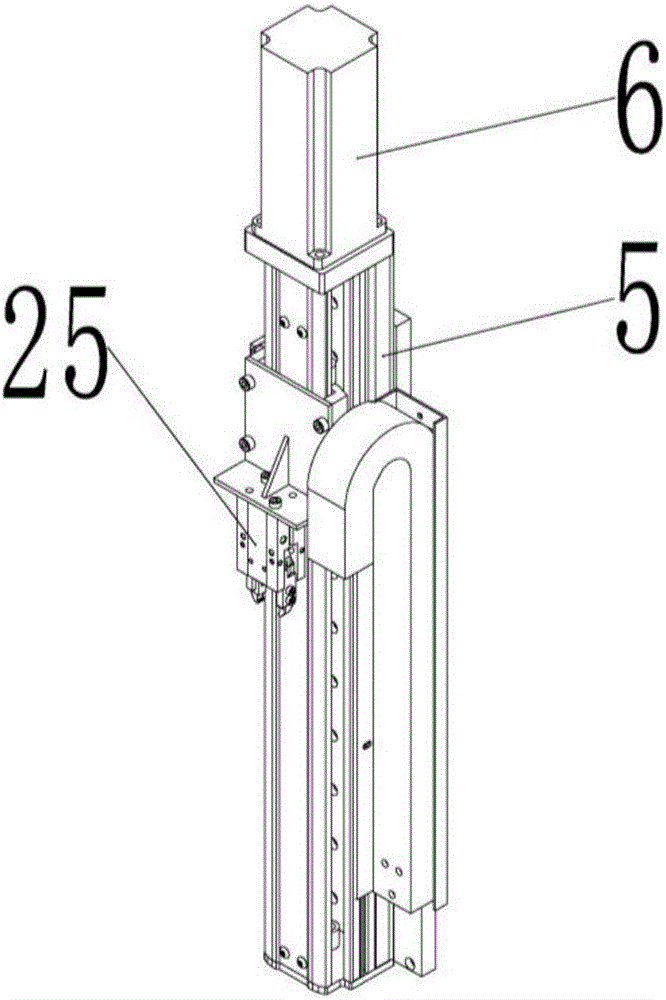

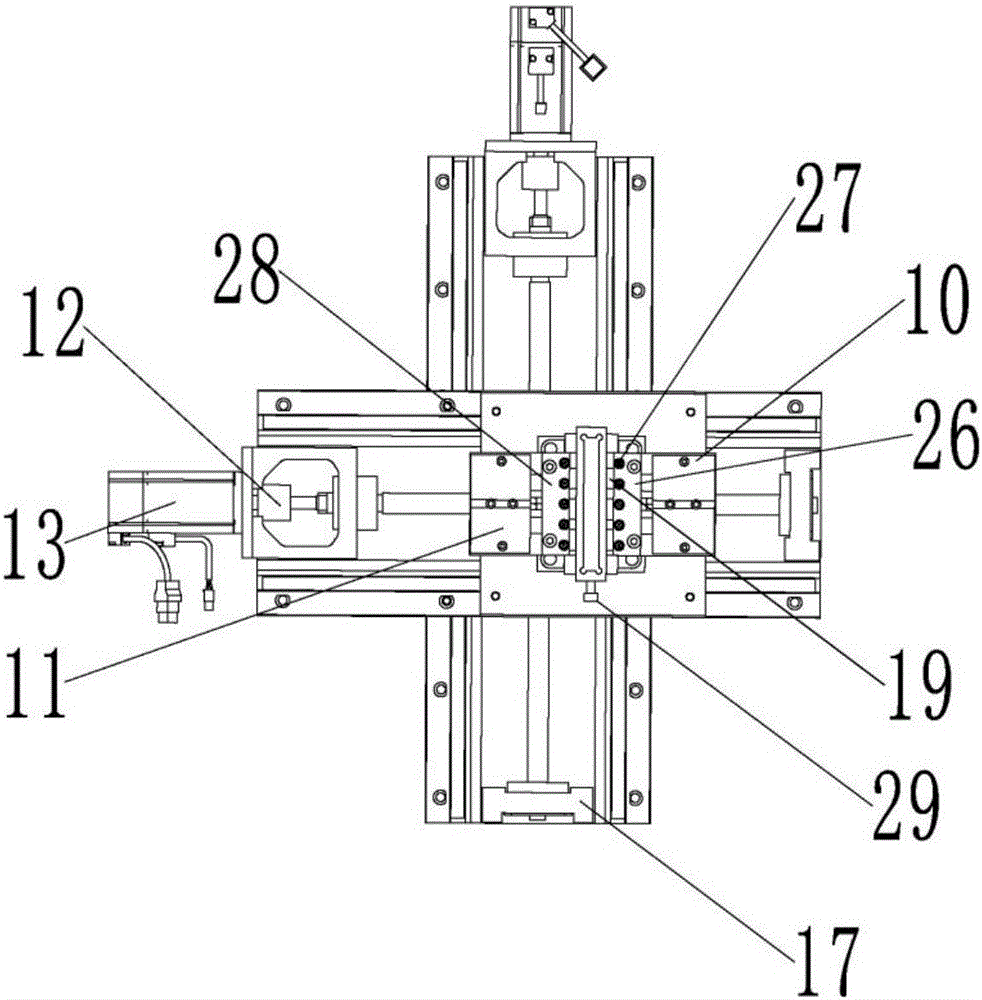

Solar cell detection method and system

PendingCN111860705AContinuous and efficient operationNo human intervention requiredDatabase management systemsCo-operative working arrangementsElectrical batteryEngineering

The invention relates to a solar cell detection method and system. The method comprises the steps: scanning the ID data of each solar cell, and uploading the ID data to a database; performing visual inspection on the solar cell to obtain visual inspection data, and uploading the visual inspection data to a database; performing an electrical parameter test on the solar cell to obtain electrical parameter test data, and uploading the electrical parameter test data to a database; and distinguishing the solar cells according to the ID data, the visual detection data and the electrical parameter test data stored in the database. According to the detection method of the solar cell part, the solar cell part can be continuously and efficiently detected, unqualified products can be selected out, nomanual interference exists in detection, and the accuracy is improved.

Owner:鸿翌科技有限公司

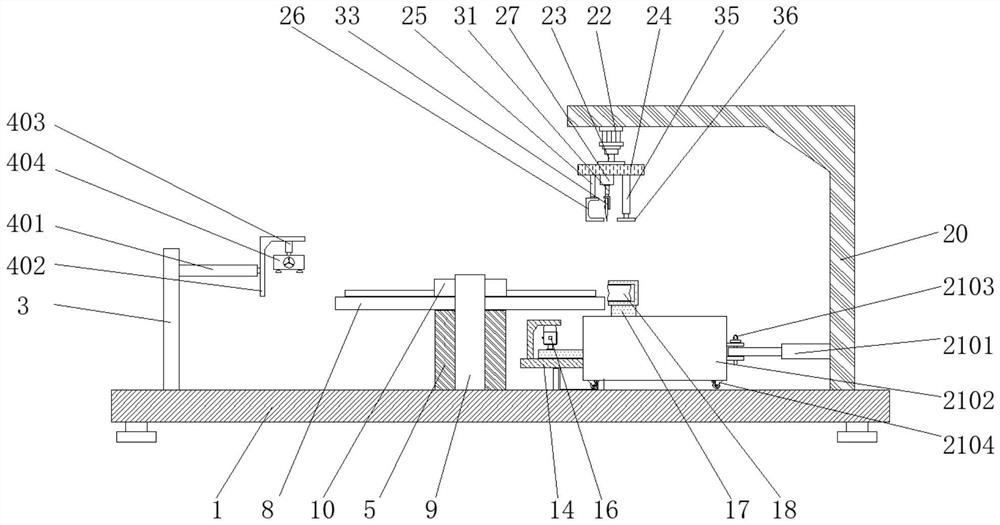

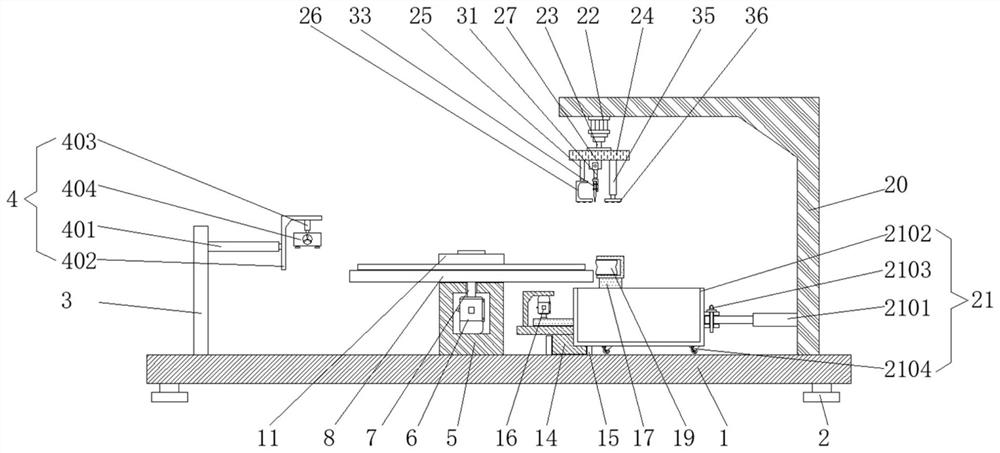

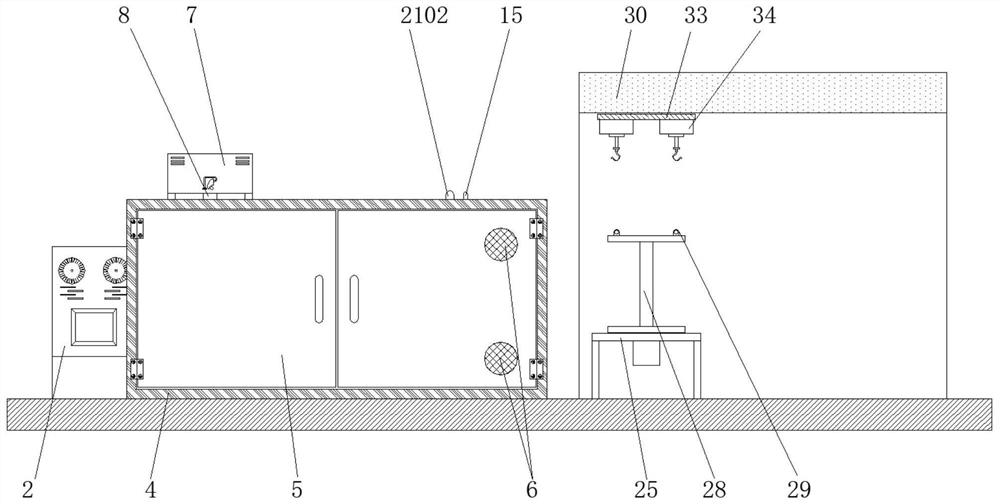

Automatic adjusting and allocating coding system for stamping steel character die

ActiveCN106739578ACompact structureHigh degree of automationStampingManufacturing technologyAutomatic testing

The invention discloses an automatic adjusting and allocating coding system for a stamping steel character die and relates to the technical field of equipment manufacturing. According to the automatic adjusting and allocating coding system for the stamping steel character die, through steel character head automatic adjusting and allocating coding equipment, a steel character head is automatically arranged in a character head clamp, and the position of the steel character head is adjusted to be matched with a stamping type marking machine for making a piece of angle steel. Adjusting and allocating equipment comprises a character head library, a right-angle coordinate robot, a character head arrangement workbench, a character head clamp fastening and conveying device and a character head clamp adjusting and allocating device. The character head arrangement workbench comprises a cross-shaped sliding table and a character head clamp clamping device, the character head clamp fastening and conveying device comprises a bolt tightening device and an air cylinder, and the character head clamp adjusting and allocating device comprises an oblique assembly table and an electromagnet taking and conveying mechanism. The automatic adjusting and allocating coding system for the stamping steel character die is compact in structure and high in automation degree, automatic adjusting and allocating coding of the character head is achieved, and the requirement that the stamping type marking machine conducts continuous efficient operation can be met.

Owner:河北省机电一体化中试基地有限公司

Solid fuel unit which burns solid fuels together with their volatile gases

InactiveUS9016215B2Same efficiencyContinuous and efficient operationSolid fuel combustionLump/pulverulent fuel feeder/distributionSolid fuelProduct gas

The invention relates to solid fuel units having a fuel supply chamber wherein the fuel to be sent for combustion to the combustion region found in the body is placed and the feed mechanism carrying the solid fuel found in the chamber forward. It is characterized in that it includes a main burning block having a fuel and air cell connected to the solid fuel supply chamber and air outlet vents formed on the external wall surface. A preventive surface is positioned on the main burning block external wall surface in a way that it would form a closed volume in a certain distance.

Owner:IMANI EMMETT

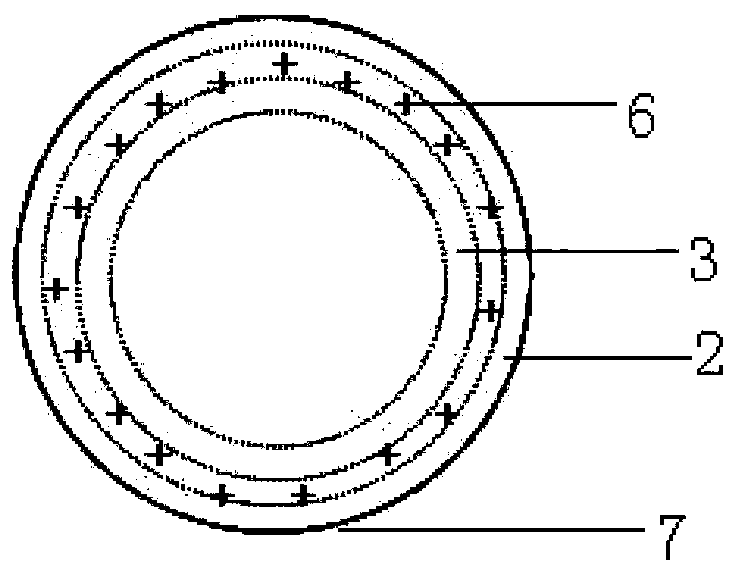

Installation equipment for environmentally-friendly building decoration

InactiveCN108343215AQuick switch installation stationUniform outputAnti-corrosive paintsBuilding constructionsEnvironmentally friendlyEngineering

The invention discloses installation equipment for environmentally-friendly building decoration. The installation equipment comprises an upper cylinder body and a lower cylinder body which are arranged coaxially, wherein the upper cylinder body and the lower cylinder body are fixedly connected. The upper cylinder body comprises an inner cylinder body and an outer cylinder body which are disposed in a double-layer mode, and the inner cylinder body and the outer cylinder body are connected through a closure plate. The closure plate is located at the lower position of the middle portion of the upper cylinder body, and a first spring is disposed in an interlayer between the inner cylinder body and the outer cylinder body. The lower end of the first spring is connected to the closure plate, andthe upper end of the first spring is connected with four guiding sliding blocks. Guiding sliding grooves formed in the axial direction are evenly formed in the side wall of the inner cylinder body. The installation equipment for the environmentally-friendly building decoration can enable flat-head screws to be screwed into a working surface in a vertical state to achieve the ideal fastening effect, and since a rotating drum is provided, the operation can be conveniently and efficiently performed continuously. A rotating shaft motor outputs at a constant speed. The rotating drum is driven by atension spring to rotate, so that the quick switching of the installation positions of the screws can be realized, efficiency and convenience are achieved, and practicability is achieved.

Owner:许根娣

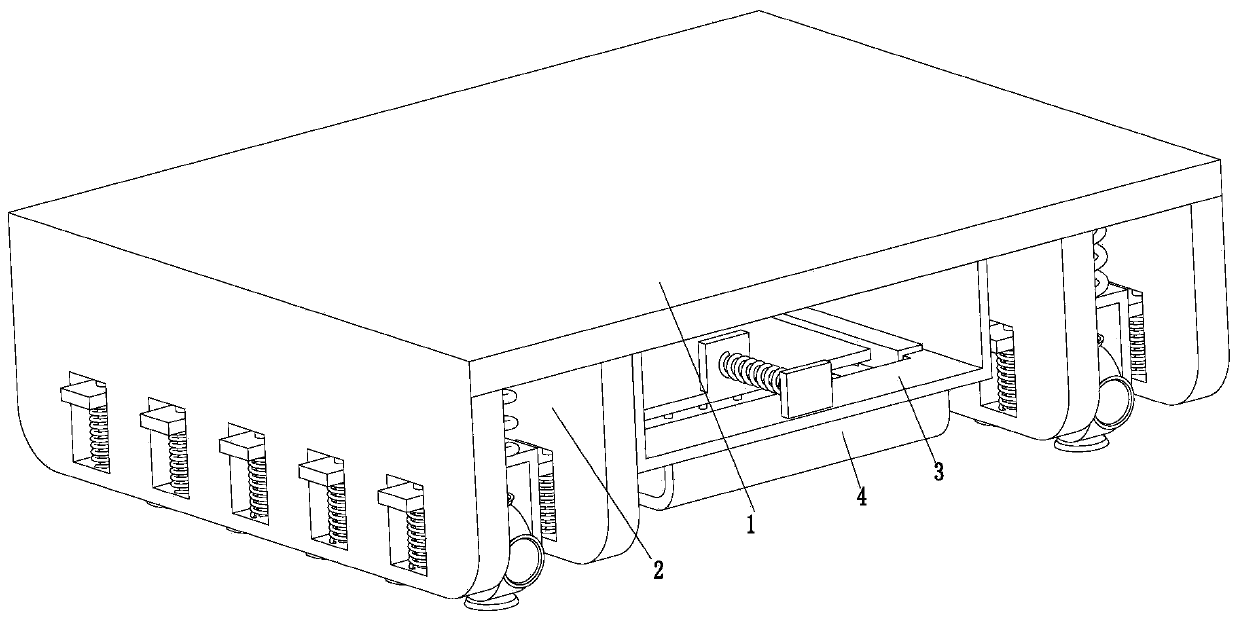

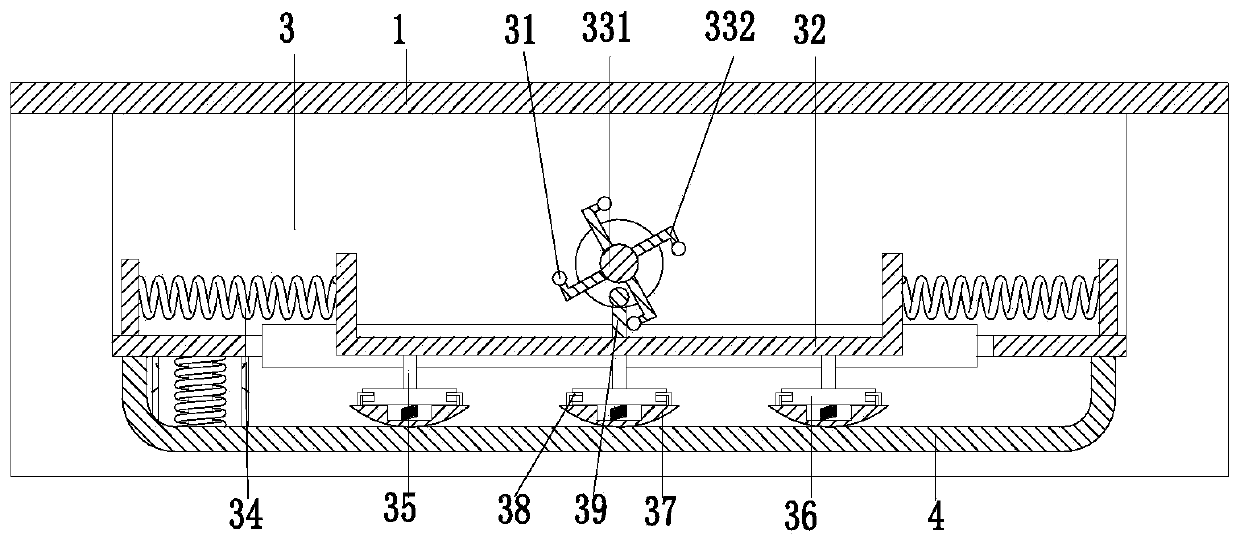

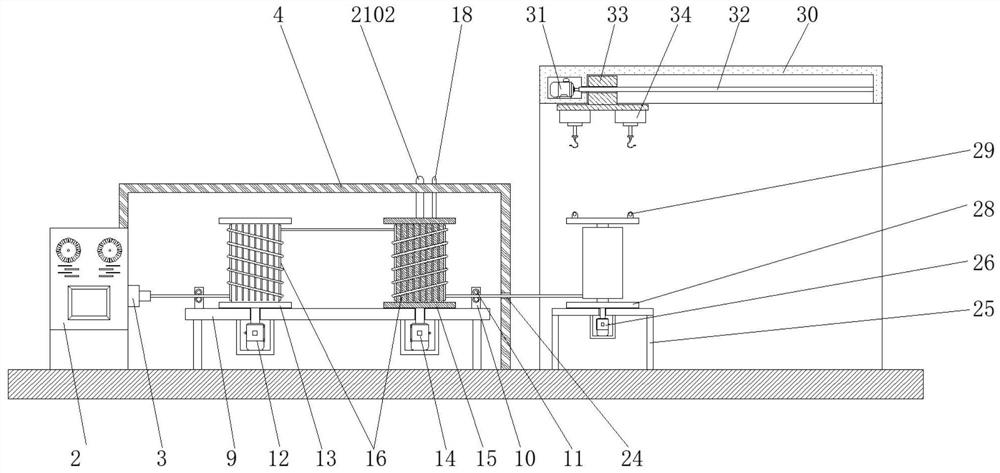

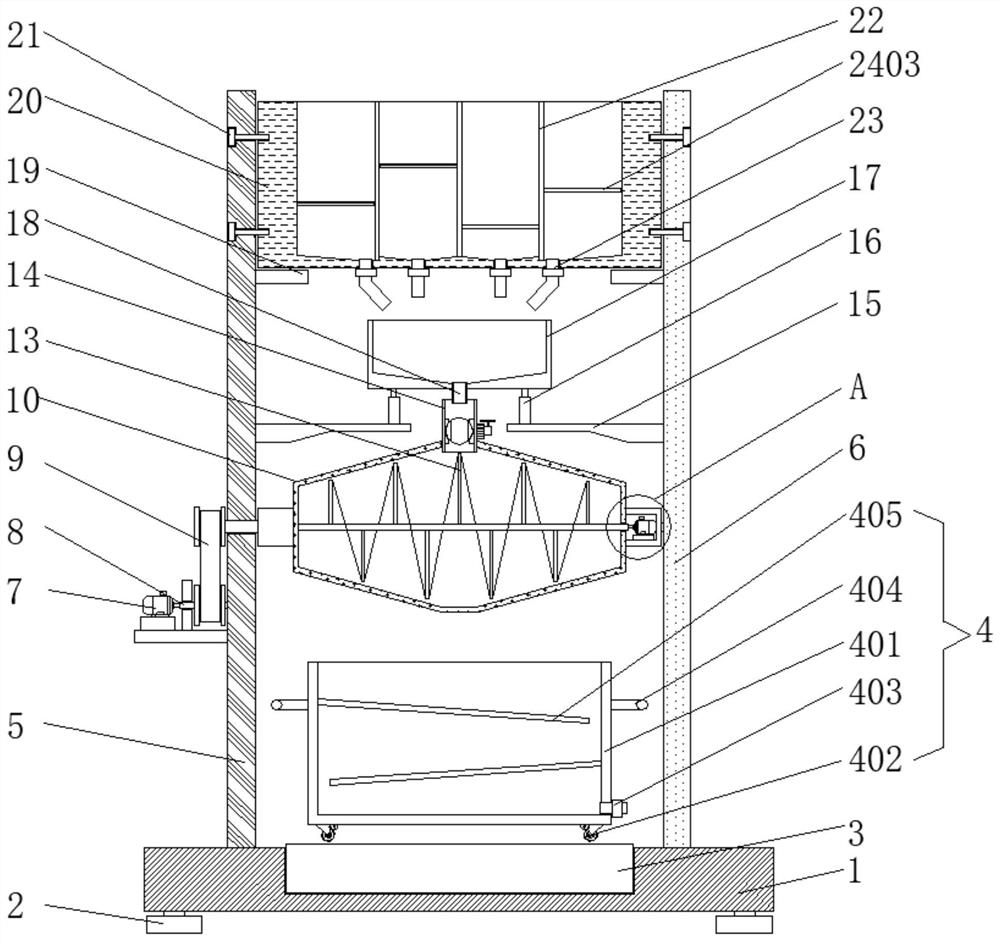

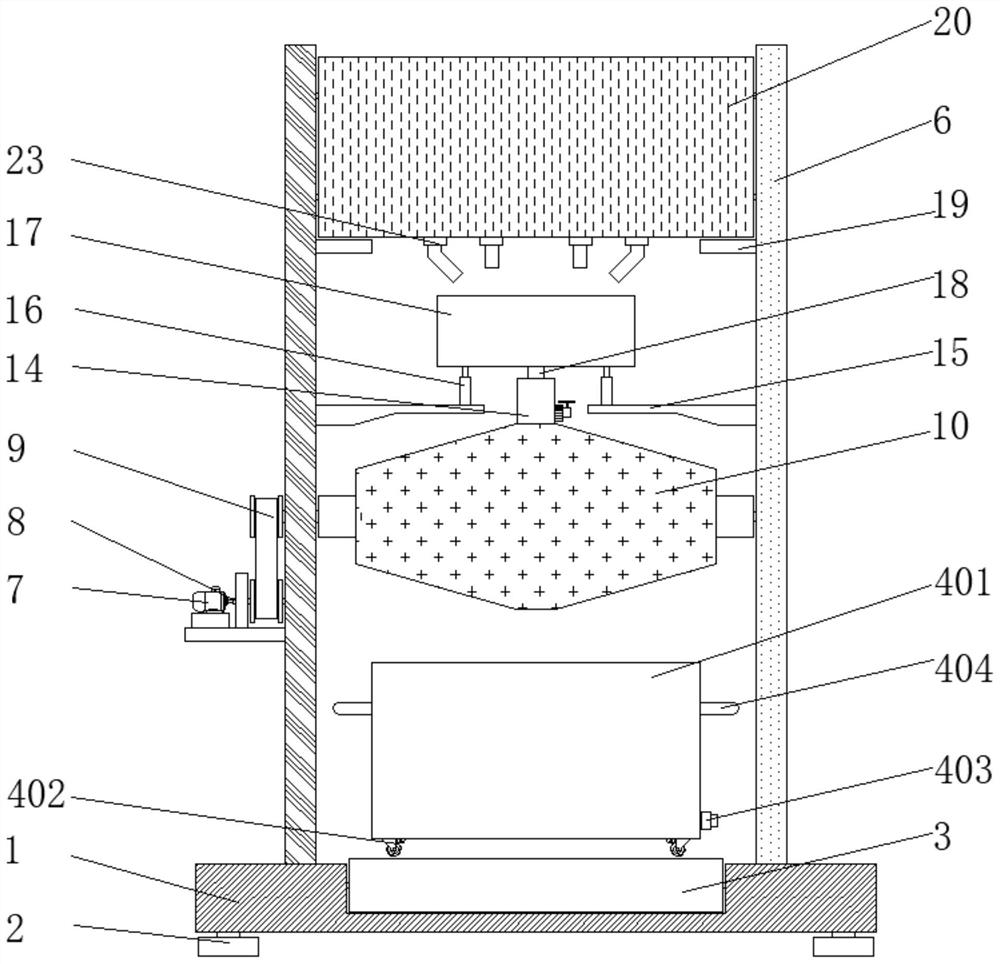

Carbon fiber cloth wall surface continuous compaction treatment system for reinforcing buildings

ActiveCN110080553ARealize the function of continuous pressing and smoothingContinuous and efficient operationBuilding repairsFiberCarbon fibers

The invention relates to a carbon fiber cloth wall surface continuous compaction treatment system for reinforcing buildings. The system comprises a repair support plate, repair brackets are symmetrically arranged on the left side and the right side of the repair support plate, a repair operation frame is mounted in the middle of the repair support plate, a repair operation groove is formed in themiddle of the repair operation frame, and a repair rubber pad is arranged at the lower end of the repair operation frame. According to the invention, the following problems in the process of repairingand reinforcing the building wall surface by using the carbon fiber cloth in the prior art can be solved: a, manual and simple attaching of carbon fiber cloth to a building wall surface and manual pressing and smoothing cannot ensure the carbon fiber cloth being tightly attached to the building wall surface, the repairing and reinforcing effect is poor, and the ideal reinforcing effect cannot beachieved; b, the surface of the building wall body needed to be repaired is uneven, the carbon fiber cloth attached to the wall surface cannot be continuously pressed and smoothened manually, and theeffect of reinforcing the building wall surface through the carbon fibers is influenced.

Owner:安徽富煌建筑科技有限公司

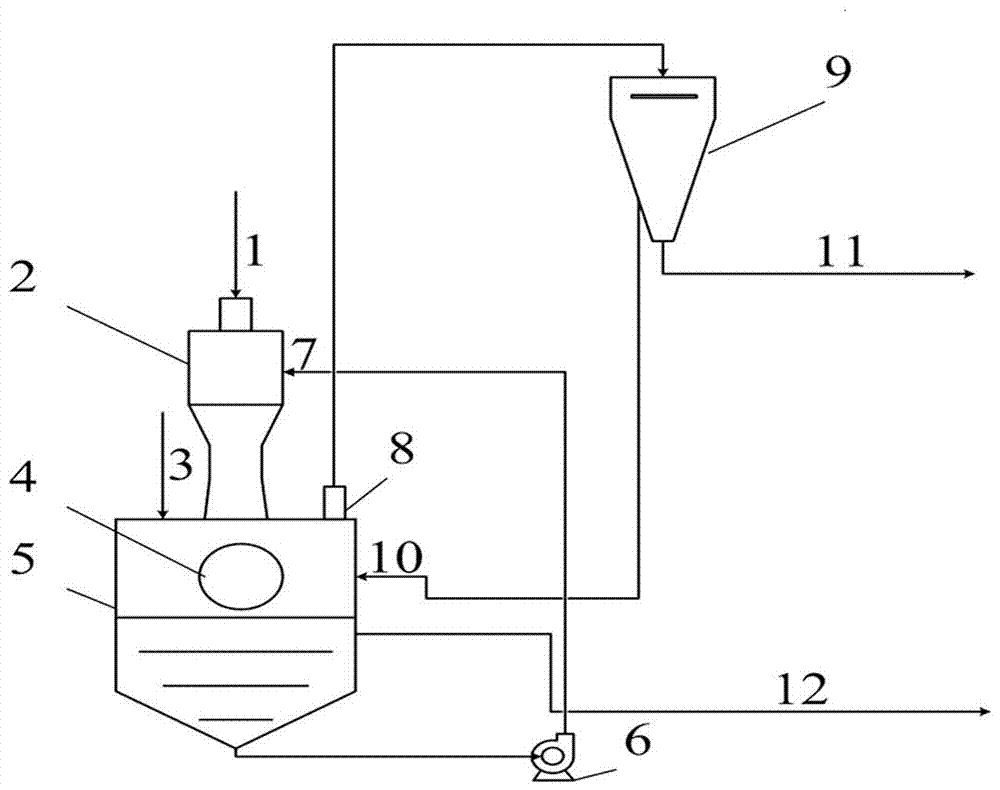

Method for removing tar from biomass thermal conversion gas-phase product

InactiveCN107338077ASimple structureStrong process applicabilityCombination devicesGas purification by liquid washingGas phaseSpray nozzle

The invention discloses a method for removing tar from a biomass thermal conversion gas-phase product. The method mainly comprises the two steps of fogging and separating. The technical scheme is characterized in that a circulation liquid is sprayed through a Venturi tube or a nozzle, and is in full contact with pyrolysis gas mingled with the tar, so that tar particles are enlarged and then separate gas and liquid in a cyclone separator, and the tar is prevented from coking in a subsequent pipeline and equipment. By means of the method, the risk of explosive gas explosion caused by static electricity tar removal is avoided, the whole process is simple in equipment and low in operation cost, and continuous and efficient operation can be achieved.

Owner:BEIJING FORESTRY UNIVERSITY

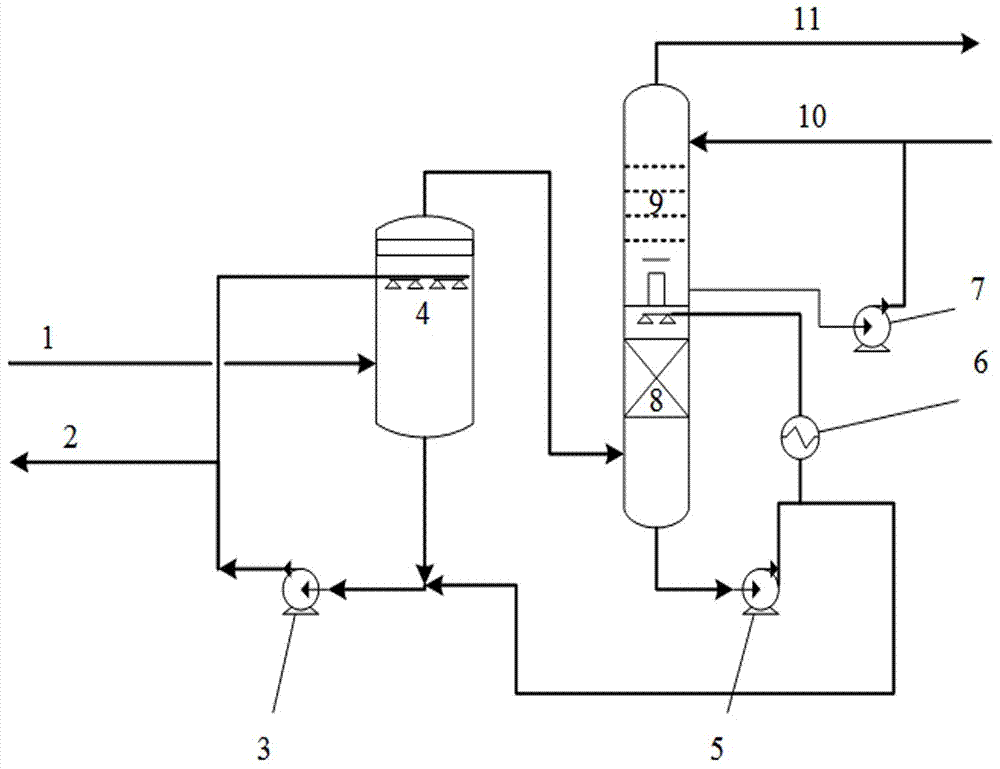

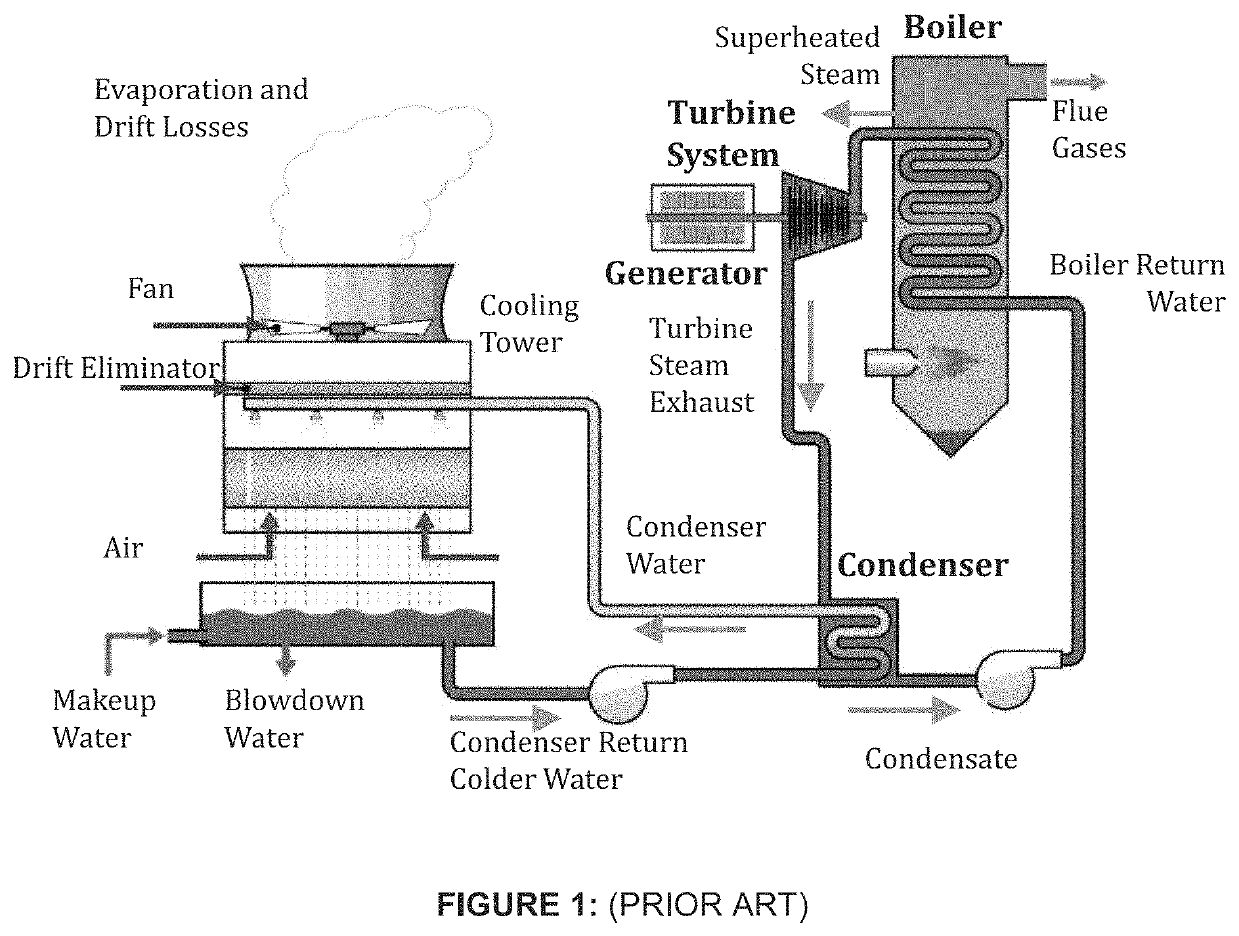

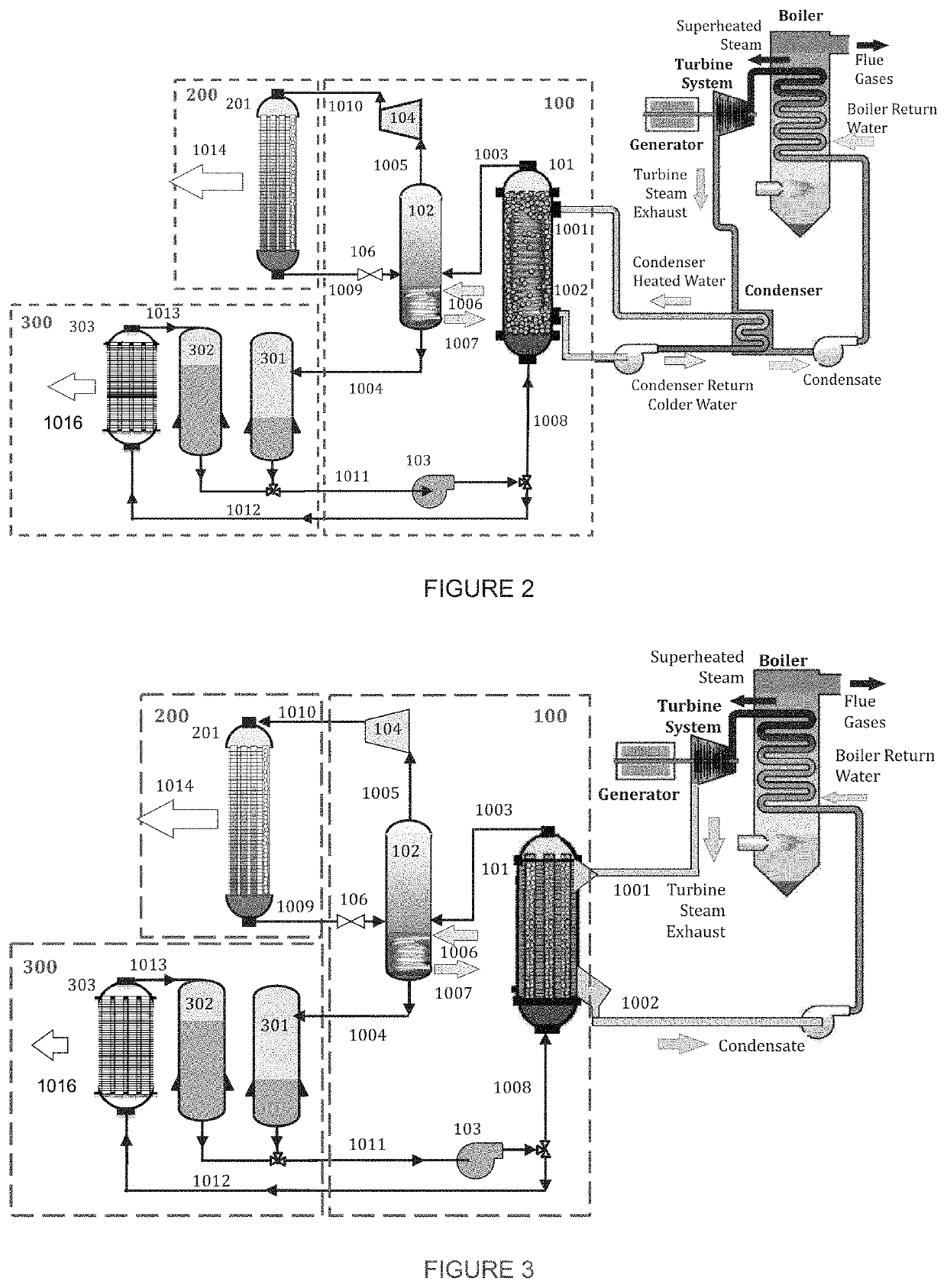

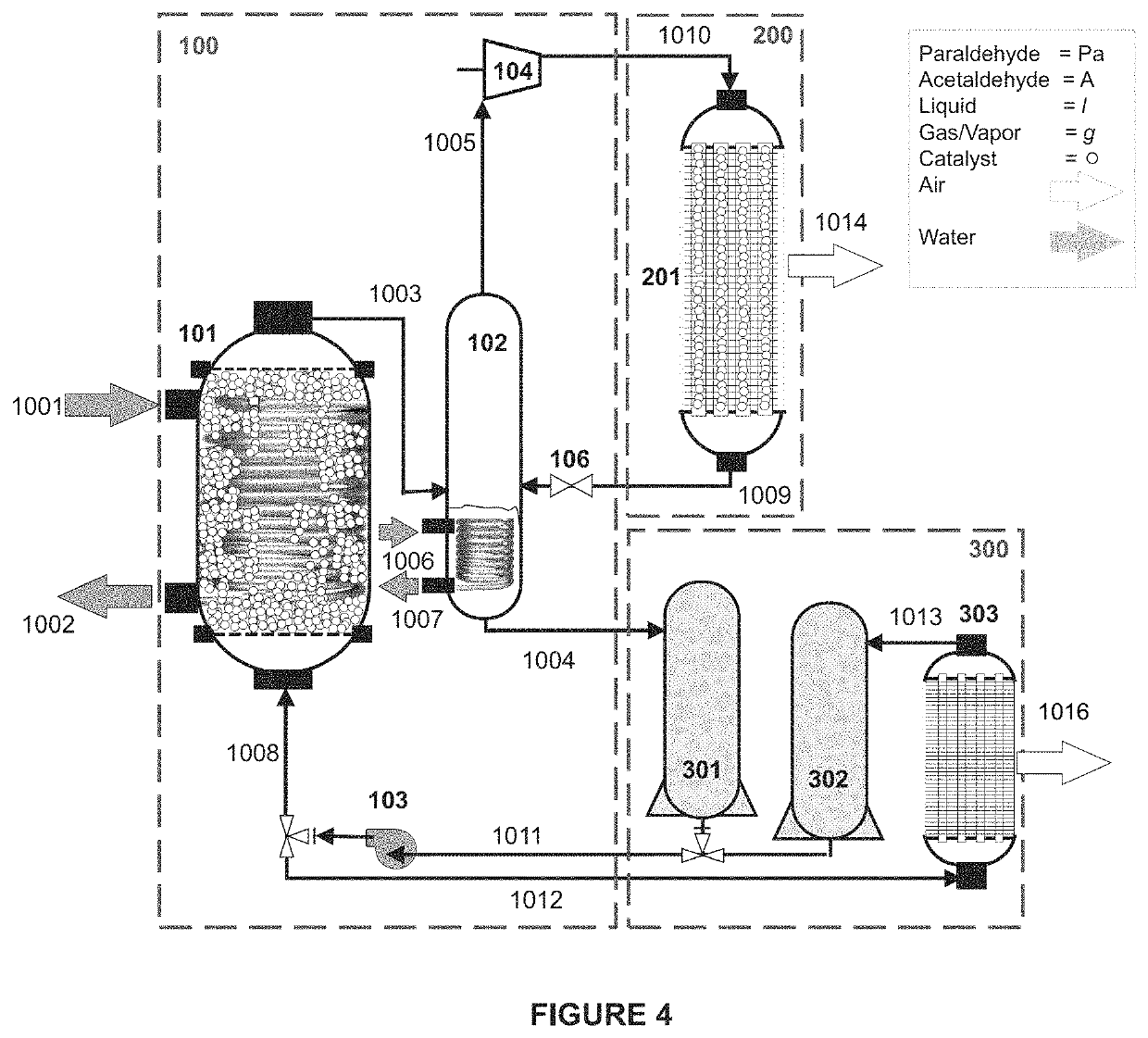

Dry cooling systems using thermally induced polymerization

ActiveUS10752821B2Continuous and efficient operationHeat pumpsHeat storage plantsPolymer scienceDepolymerization

A dry-cooling system useful in absorbing heat from a heat source and related dry cooling methods including a depolymerization cooling unit (DCU) in fluid communication with a polymerization heating unit (PHU). The DCU includes a DCU heat exchanger which receives a polymer and a catalyst, wherein contact of the polymer and the catalyst within the DCU heat exchanger causes an endothermic reaction, converting the polymer to a monomer and drawing heat from a first heat source. The monomer is then withdrawn from the DCU. The PHU includes a PHU heat exchanger, which receives the monomer, wherein contact of the monomer with the catalyst causes an exothermic reaction within the PHU heat exchanger, converting the monomer to the polymer. The polymer is then withdrawn from the PHU for conveyance back to the DCU, and the cycle is repeated.

Owner:APPLIED RES ASSOCS INC

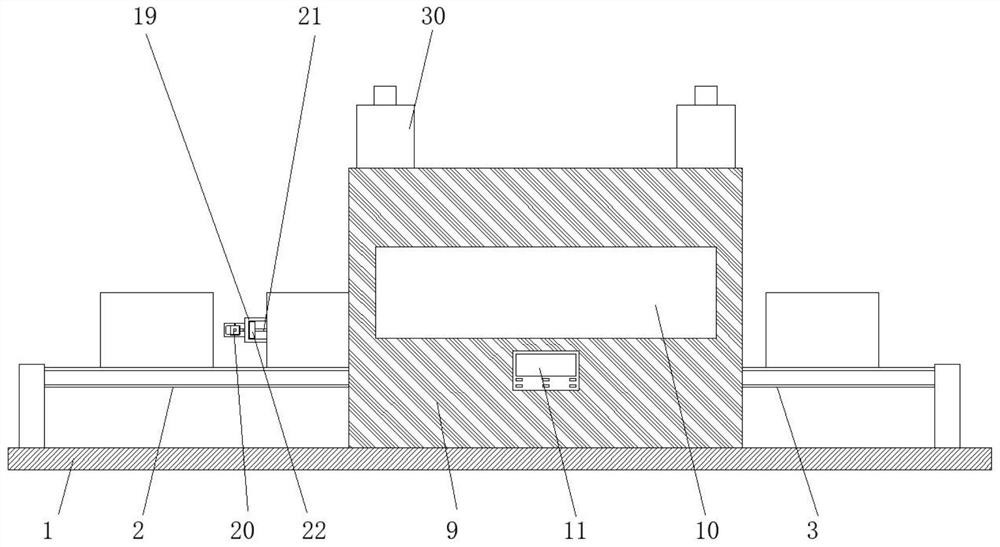

Fast cooling large-rotation wire drawing machine capable of rapidly cooling

The invention discloses a fast cooling large-rotation wire drawing machine. The fast cooling large-rotation wire drawing machine comprises a base, a dust collection pipeline, a first motor, a first rotary drum, a second motor, a second rotary drum, a fast cooling mechanism and a second bearing table, a first water pump is arranged at the inner bottom of the second rotary drum, a water storage tank is fixed on the base, the fast cooling mechanism is arranged in the water storage tank; and the second bearing table and a bearing frame are both fixed to the other side of the upper end face of the base, a square column is rotationally connected to the top of the second bearing table, and a supporting plate is slidably connected to the inner top of the bearing frame. According to the fast cooling large-rotation wire drawing machine, before the device is used, dust in a bearing box can be pumped away through a dust collector and the dust collection pipeline, it is guaranteed that the interior of the bearing box is clean and tidy, and after water is introduced into the water storage box, the water in the water storage box can be sprayed to the inner wall of the second rotary drum through a water conveying pipeline and a spray head in sequence through a second water pump; and a material wound on the surface of the second rotary drum can be fast cooled.

Owner:江苏弘亚钨钼科技有限公司

Gluing device capable of adjusting direction of carton

PendingCN113442507AAdjustable orientationEasy to transportBox making operationsPaper-makingCartonAdhesive glue

The invention discloses a gluing device capable of adjusting the direction of a carton. The gluing device comprises a base, an auxiliary stabilizing mechanism, a first motor, a second electric telescopic column, a third motor and bearing boxes, wherein the left end of the second electric telescopic column is connected with a bearing frame, and a third electric telescopic column is fixed to the right side of the top in the bearing frame; and the bearing boxes are fixed to the left side and the right side of the top of the bearing frame, and connecting pipelines are fixed to the bottoms of the bearing boxes. According to the gluing device capable of adjusting the direction of the carton, a second electric telescopic rod, the bearing frame and a glue spraying head integrally move downwards and enter the carton, then the glue spraying head moves leftwards along with the bearing frame, the carton can rotate along with a rotary table, the direction of the carton can be adjusted conveniently, meanwhile, the glue spraying head can rotate under the action of the third motor, the angle of the glue spraying head is convenient to adjust, after the glue spraying head is aligned to the joint of the carton, the glue spraying head sprays glue outwards, meanwhile, the glue spraying head moves downwards, and gluing and bonding operation of one joint can be completed conveniently.

Owner:宿迁海宇包装有限公司

Sleeve-type photocatalytic air purification device based on dispersive optical fiber

InactiveCN103446879BAvoid safety hazardsAvoid direct importDispersed particle filtrationUltraviolet lightsAir cleaning

The invention discloses a sleeve type photocatalysis air cleaning device based on dispersion optical fibers. The sleeve type photocatalysis air cleaning device comprises a filtering unit, an optical fiber unit and a catalyst unit, wherein the filtering unit is a cylinder-shaped filtering unit; the radial cross section of the filtering unit is annular, and upper and lower ends of the filtering unit are respectively connected with a top end cover and a bottom end cover; the catalyst unit is a cylinder-shaped catalyst unit, the radial cross section of the catalyst unit is annular, the height of the catalyst unit is the same as that of the filtering unit, the diameter of the catalyst unit is smaller than that of the filtering unit, and the catalyst unit and the filtering unit can form a concentric sleeve type structure; the center of the top end cover is provided with an air outlet, and the top end cover is provided with a top end installing hole; bottom installing holes are uniformly formed in the bottom end cover, the optical fiber unit selects the fibrous optical fibers, one end of the optical fiber unit is connected with the top end installing hole, and the other end of the optical fiber unit is connected with the bottom installing holes. The sleeve type photocatalysis air cleaning device provided by the invention has the advantages that 360-degree lateral air incoming is adopted, secondary pollution caused by a by-product of a light-catalyzed reaction is effectively reduced, the ultraviolet light use ratio is improved, meanwhile, the air purification efficiency is improved, and the sleeve type photocatalysis air cleaning device is suitable for sealing, flammable and combustible environment such as airplanes, subways and factories.

Owner:TIANJIN UNIV

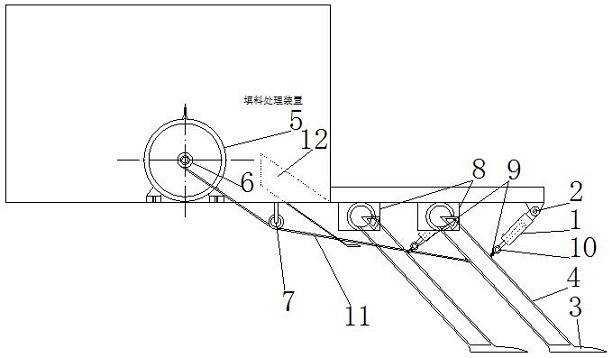

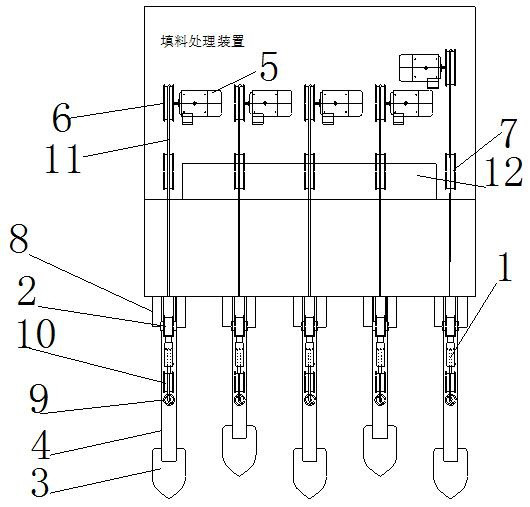

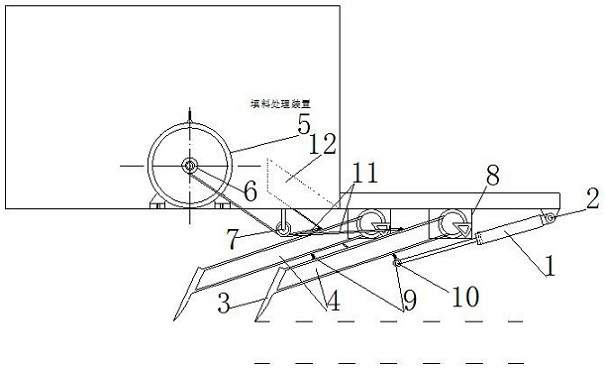

Intelligent stone avoiding device and method for over-wet embankment filler scarifying through plough

ActiveCN112359907ASave human effortReduce labor intensitySoil-shifting machines/dredgersAgriculture gas emission reductionArchitectural engineeringEngineering

The invention discloses an intelligent stone avoiding device and method for over-wet embankment filler scarifying through a plough. The intelligent stone avoiding device comprises a filler treatment device, a plurality of plough arms parallel to one another are arranged at the front lower portion of the filler treatment device through a horizontal fixing frame, plough shares arranged horizontallyare fixedly arranged on the lower portion of the front end of each plough arm, the plough arms are obliquely arranged, so that the plough shares extend forwards below a soil inlet of the filler treatment device, the plough arms are rotatably connected with the horizontal fixing frame, the plough arms can rotate forwards or backwards under the action of external force to drive the plough shares atthe bottoms of the plough arms to ascend and descend, intelligent stone avoiding device bodies corresponding to the plough arms one to one are fixedly arranged on the plough arms, and the intelligentstone avoiding device bodies can drive the plough arms corresponding to the intelligent stone avoiding device bodies to rotate forwards or backwards, and the the plough shares are driven to ascend anddescend for stone avoiding. The problem that an existing roadbed scarifying construction instrument is prone to damage when encountering large stones in the scarifying process is solved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Heliostat used in solar power generation system based on flexible shaft connection

InactiveCN108679861AContinuous and efficient operationReduce economic costsPhotovoltaic supportsSolar heating energyHeliostatDrive shaft

The invention belongs to the technical field of heliostats, in particular to a heliostat used in a solar power generation system based on a flexible shaft connection. The heliostat comprises a total fixed plate, a motor, a drive shaft, a reducer, an input shaft, a first fixed plate, a second fixed plate, a ring plate, a heliostat, a disk, a fixing ring, a ring gear, etc.. Wherein the first one-wayclutch ring and the second one-way clutch ring perform different rotations of the motor, so that the first crank rocker mechanism and the second crank rocker mechanism work under different conditions. Then the heliostat swings at azimuth and elevation to maintain a proper angle with the sun. The heliostat used in a solar power generation system based on a flexible shaft connection makes the heliostat device of the invention have the same effect as the conventional heliostat device by reducing one motor and one heliostat, which can reduce economic cost and save resources.

Owner:朱敏

Mixing device for environmental sanitation cleaning liquid

InactiveCN112473478AContinuous and efficient operationHigh degree of automationRotating receptacle mixersTransportation and packagingEngineeringProcess engineering

The invention discloses a mixing device for environmental sanitation cleaning liquid. The mixing device comprises a collecting mechanism and a material blocking mechanism, first supporting plates arefixed to the right end face of a first support and the left end face of a second support correspondingly, and a connecting pipeline is fixed to the bottom of a material guiding box; and second supporting plates are fixed to the right end face of the first support and the left end face of the second support correspondingly, a partition plate is fixed to the inner bottom of the batching box, and thematerial blocking mechanism penetrates through the rear side of the batching box. According to the mixing device for the environmental sanitation cleaning fluid, before the device is used, a proper batching box needs to be selected according to the proportioning requirement, the batching box is placed and fixed, then the batching box, a partition plate and a baffle can be used in cooperation to complete automatic proportioning work of different raw materials, and after a third electric valve is opened, raw materials can fall into the material guiding box and flow into the material mixing barrel in a centralized mode under the guiding effect of the material guiding box, then the material mixing barrel and the screw rod can be used in cooperation to conduct thorough mixing treatment on theraw materials, the whole operation is continuous and efficient, and the automation degree is high.

Owner:XUZHOU YIER ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com