Chrome iron ion double-doped complex selenium zinc sulfide laser material and preparation method thereof

A technology of laser material and zinc selenium sulfide, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of complex pump source system, and achieve the effect of simplifying system structure, narrow and ultra-short pulse, and realizing simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] According to the molecular formula, the raw material ratio is prepared, and Cr, Fe: ZnSe ceramics are prepared by the hot pressing method, and x=0 is taken as the raw material ratio. First, the high-purity ZnSe powder is weighed according to the above-mentioned ratio, and after the mechanical mixing is uniform, it is put into a hot-press furnace for vacuum hot-press sintering, sintered at 900 degrees Celsius and 400 MPa for 2-5 hours, and then slowly reduced to room temperature. Take out the ZnSe ceramic, polish the surface of the prepared ZnSe ceramic, plate a mixed film of metal Cr and Fe, and perform high-temperature diffusion annealing at 850 degrees Celsius for 2 weeks under vacuum conditions to obtain high-quality Cr, Fe: ZnSe ceramics. Using the prepared Cr, Fe: ZnSe ceramics, processing the coating, and designing the laser cavity, using a 1.7 micron LD pump, an ultra-fast laser output of 70 fs can be obtained.

Embodiment 2

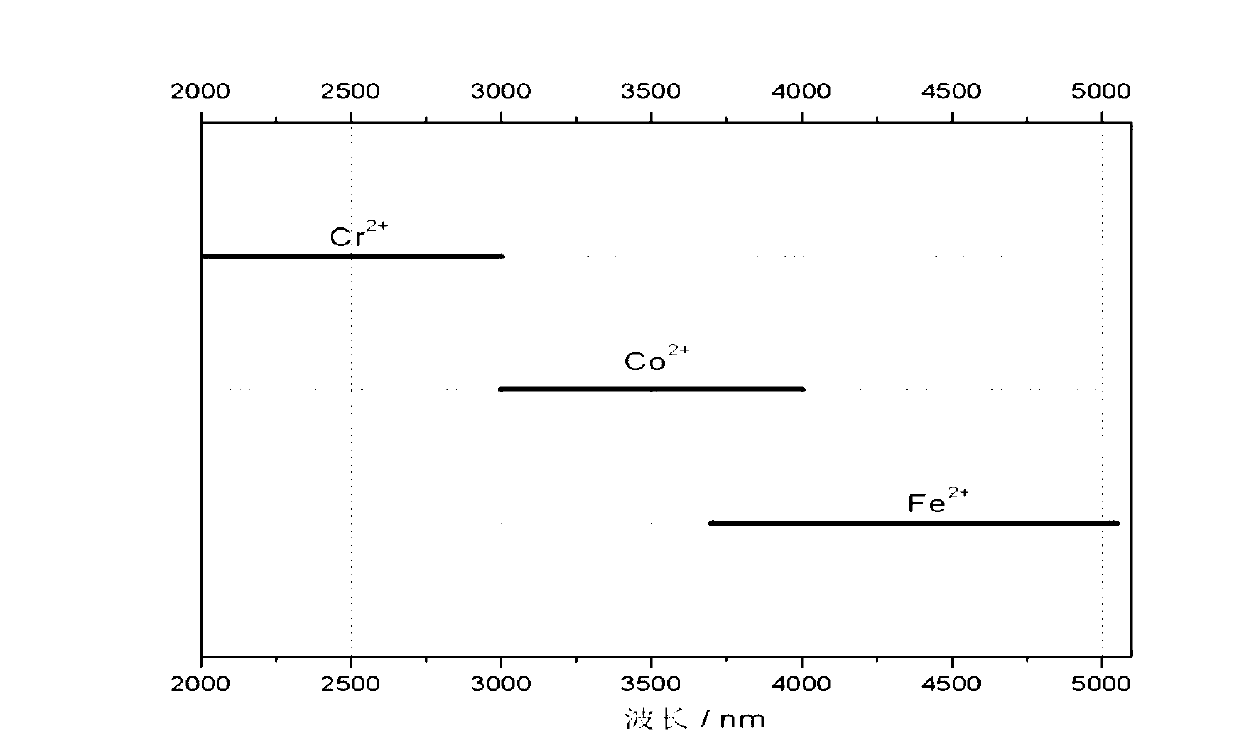

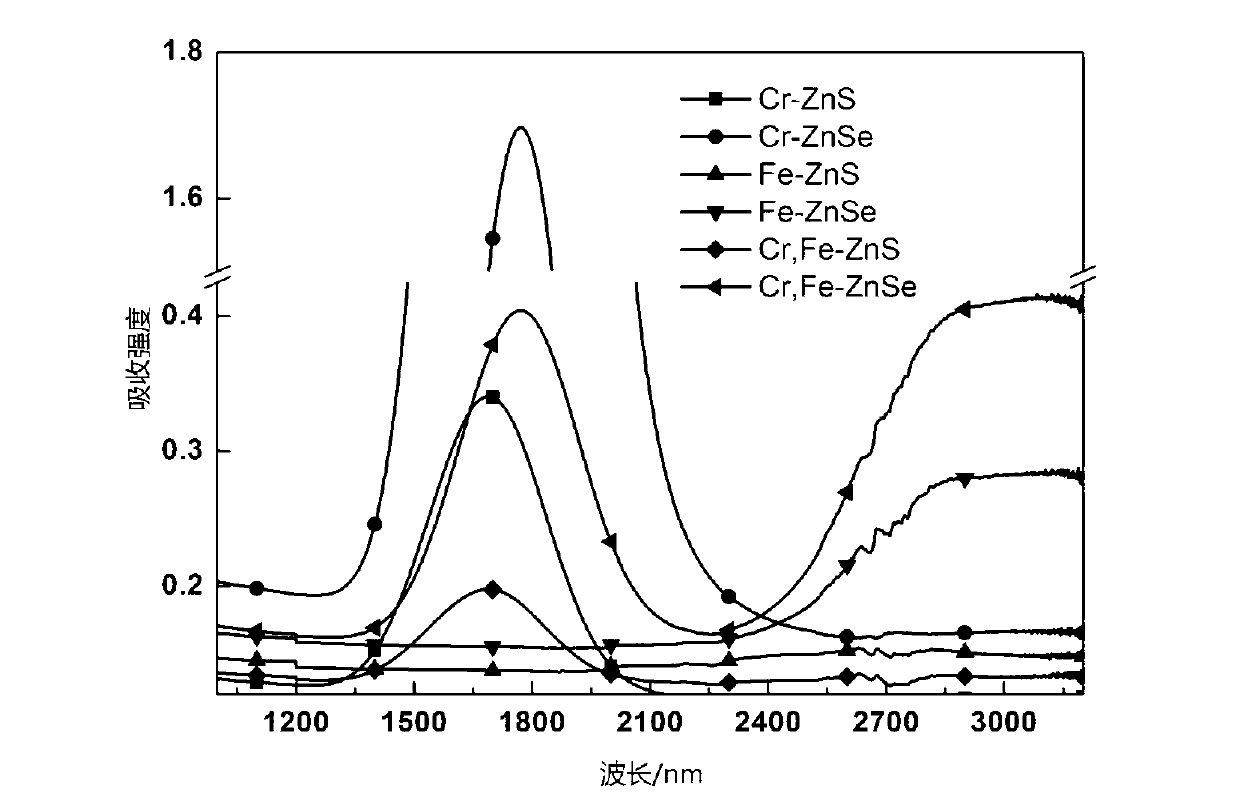

[0029] Preparation of Cr, Fe: ZnS by Chemical Vapor Deposition χ Se 1-χ For ceramics, take x=0.7% in the ratio of raw materials. First, the high-purity ZnS and ZnSe targets are made according to the above ratio, and at the same time, 0.1at% of Fe ions and 0.2at% of Cr ions are mixed into the target, and Cr,Fe:ZnS is prepared by CVD method 0.7 Se 0.3 For polycrystalline ceramics, the prepared Cr, Fe: ZnSSe ceramics are subjected to hot isostatic pressing, and then subjected to high-temperature diffusion annealing at 1000 degrees Celsius under vacuum for 1 week to obtain high-quality Cr, Fe: ZnSSe ceramics. The prepared Cr, Fe: ZnSSe ceramics are processed according to Brewster's angle, and the laser cavity is designed. 1.7 micron LD pump is used to obtain 3-5 micron mid-infrared laser output. figure 2 Is Cr 2+ And Fe 2+ Absorption spectrum in ZnSSe composite laser material doped with ZnS, ZnSe, Cr and Fe ions.

Embodiment 3

[0031] The Cr, Fe: ZnS ceramics are prepared by chemical vapor deposition method, and x=1 in the raw material ratio. The experiment was carried out in a horizontal quartz tube reactor. The reaction furnace is divided into a zinc evaporation zone and a deposition zone, which are heated by three-temperature zone resistance heating. The raw material used is H 2 S gas and analytical pure Zn, the substrate is graphite. H 2 The flow of S gas is controlled by a rotameter, and the flow of Zn is controlled by adjusting the evaporation temperature of Zn. The prepared ZnS material is subjected to hot isostatic pressing, and the surface is polished and then coated with Fe and Cr metal films, and then the sample is subjected to high temperature diffusion annealing at 950 degrees Celsius under vacuum conditions for 2 weeks to obtain high-quality Cr, Fe:ZnS ceramics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com