Automatic feeding robot

一种机器人、给料的技术,应用在机器人领域,能够解决降低生产效率、工控系统控制压力、结构复杂等问题,达到节约等待的时间、检修维护方便、操作连续高效的效果

Inactive Publication Date: 2019-01-22

CHANGZHOU ZHIDOU INFORMATION TECH CO LTD

View PDF10 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the traditional automatic production, the plane conveying method is generally adopted, and different stations are arranged on the conveying route to perform different operations, and the time difference between each process is used to achieve the purpose of continuous production, but sometimes it cannot be completely Grasp the time difference. The process on a certain station takes a long time. For example, it takes 2s to process at the current station, and the next station takes much more than 2s, such as 30s. It takes about 2s, and multiple processes are required to complete the entire processing process. Generally, when this kind of working condition is encountered, the traditional planar conveying method needs to install a shunt device in front of the time-consuming station, which not only requires a complex structure The reversing mechanism will also bring great pressure to the control of the industrial control system, and will also increase the cost of automation transformation. If the entire process of manufacturing products requires multiple time-consuming processes set at intervals, it will be extremely difficult. The efficiency of production will be greatly reduced, and the whole set of automation equipment will become more and more complicated

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

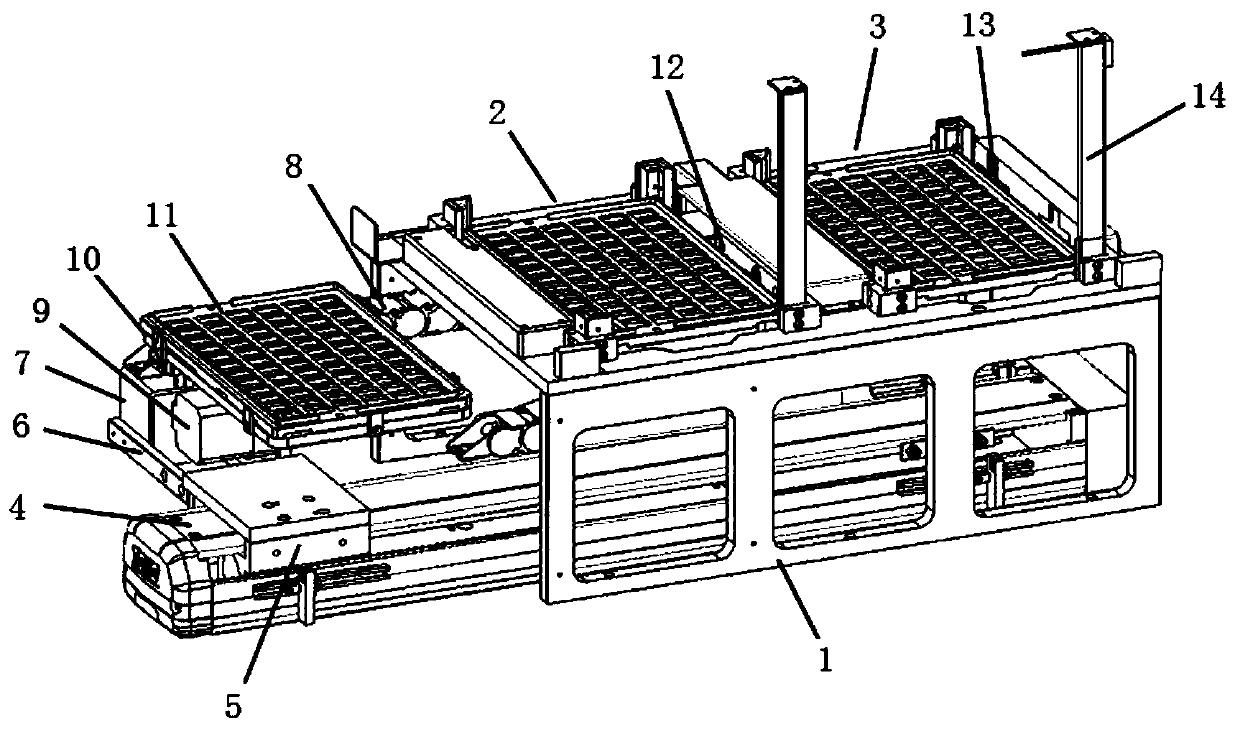

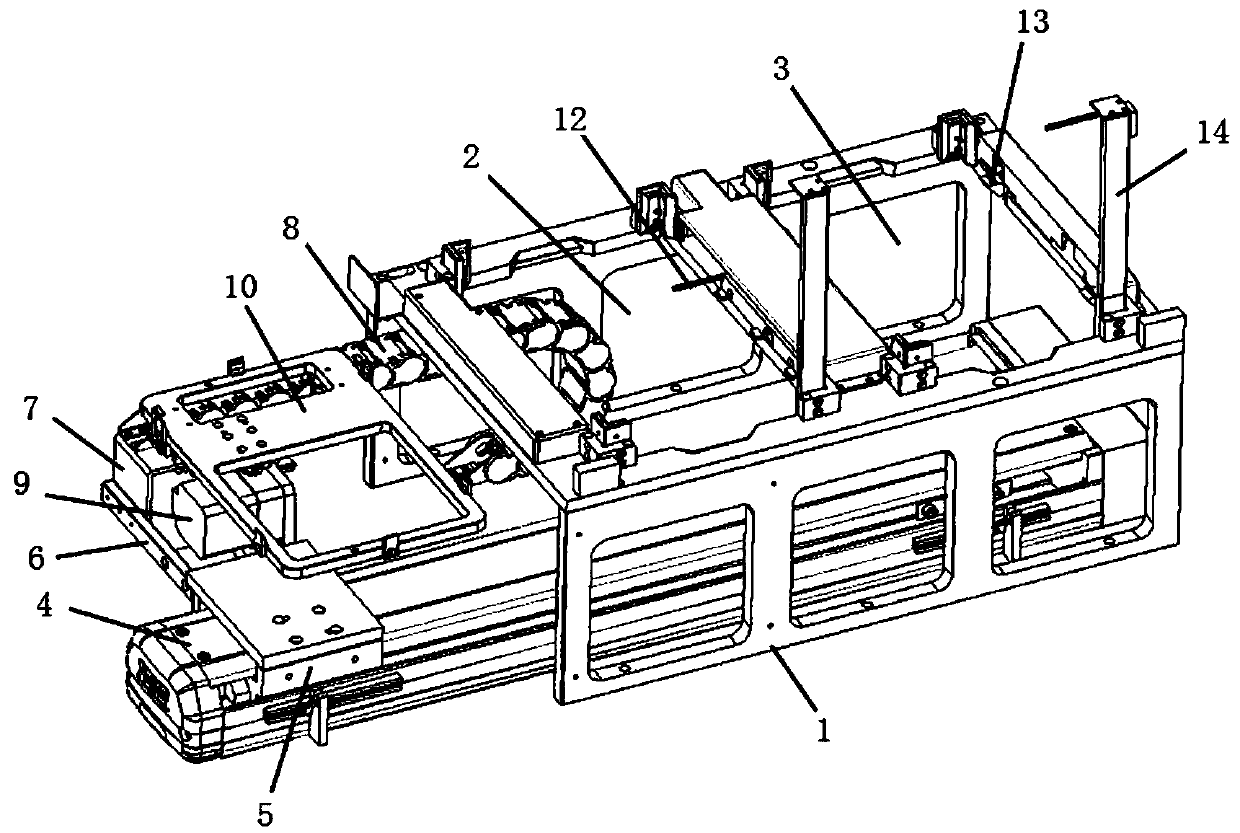

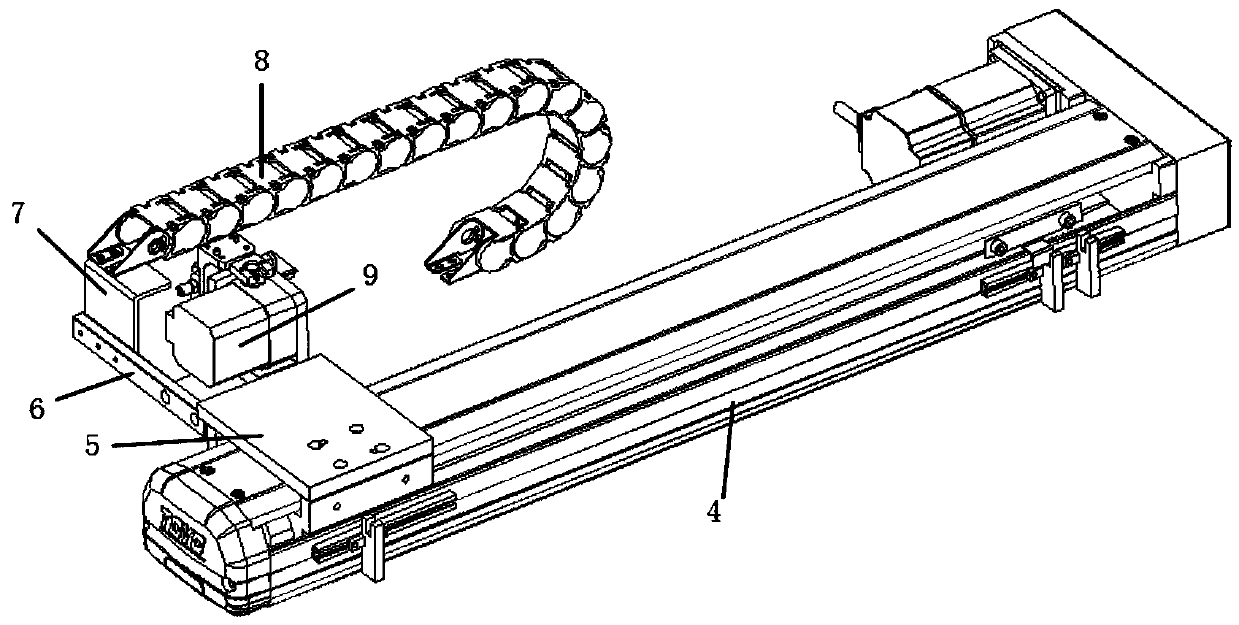

The invention discloses an automatic feeding robot which comprises a framework. A second machining station and a stack station are arranged on the framework, a front region is used as a first machining station, a slide rail is fixed to a position below the framework, a driving slider is slidably connected into the slide rail, a connecting seat is fixed to a side of the driving slider, a driven roll section frame is fixed to the left end of the connecting seat by the aid of a support plate, a jacking motor is fixed to the right end of the connecting seat, and a bracket for conveying storage plates is fixedly supported by lifting shafts at the upper end of the jacking motor; horizontal locking devices are arranged in seats on two sides of the second machining station, support movable block mechanisms are arranged in seats on two sides of the stack station, and stacking vertical plates at four corners of the stack station are provided with a plurality of separation movable block mechanisms. The automatic feeding robot has the advantages that the multiple storage plates can be accumulated at the stack station, accordingly, a large amount of waiting time can be saved, use of large quantities of transmission and reversing mechanisms can be simplified, the automation renovation cost can be reduced to a great extent, and the automatic feeding robot is applicable to large-scale technological processes with a plurality of technological links which are obviously long in time consuming.

Description

technical field The invention relates to the technical field of robots, in particular to an automatic feeding robot. Background technique In the traditional automatic production, the plane conveying method is generally adopted, and different stations are arranged on the conveying route to perform different operations, and the time difference between each process is used to achieve the purpose of continuous production, but sometimes it cannot be completely Grasp the time difference. The process on a certain station takes a long time. For example, it takes 2s to process at the current station, and the next station takes much more than 2s, such as 30s. It takes about 2s, and multiple processes are required to complete the entire processing process. Generally, when this kind of working condition is encountered, the traditional planar conveying method needs to install a shunt device in front of the time-consuming station, which not only requires a complex structure The reversing...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65G47/82B65G47/90B65G57/26

CPCB65G47/74B65G47/82B65G47/901B65G57/02B65G57/26

Inventor 曹云娟

Owner CHANGZHOU ZHIDOU INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com