Sleeve-type photocatalytic air purification device based on dispersive optical fiber

An air purification device and dispersive optical fiber technology, applied in the field of air purification, can solve the problems of inapplicability to closed, flammable and explosive environments, unavoidable direct electrical contact, low catalytic efficiency, secondary pollution, etc., to prevent secondary pollution, Avoid direct introduction and solve the effect of saturation failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

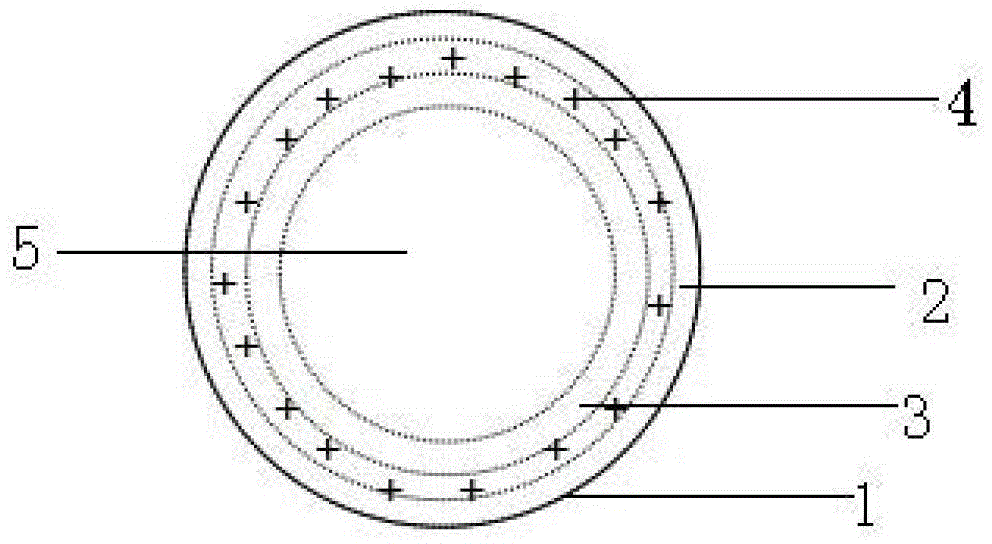

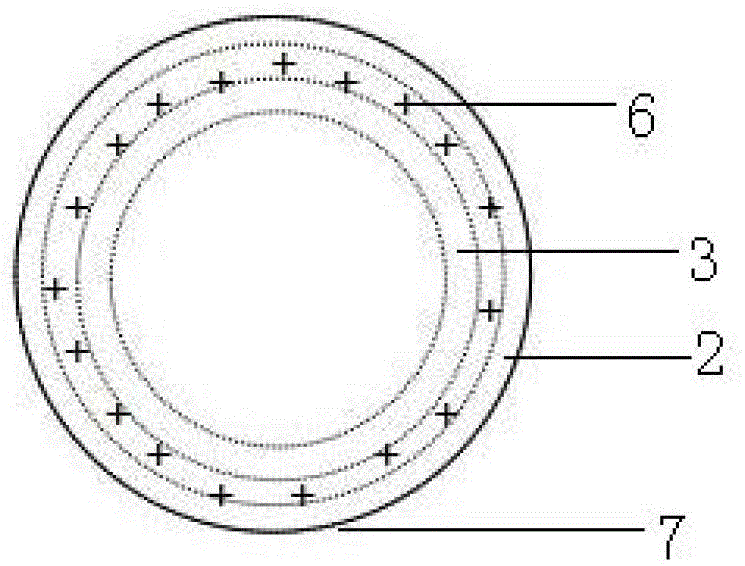

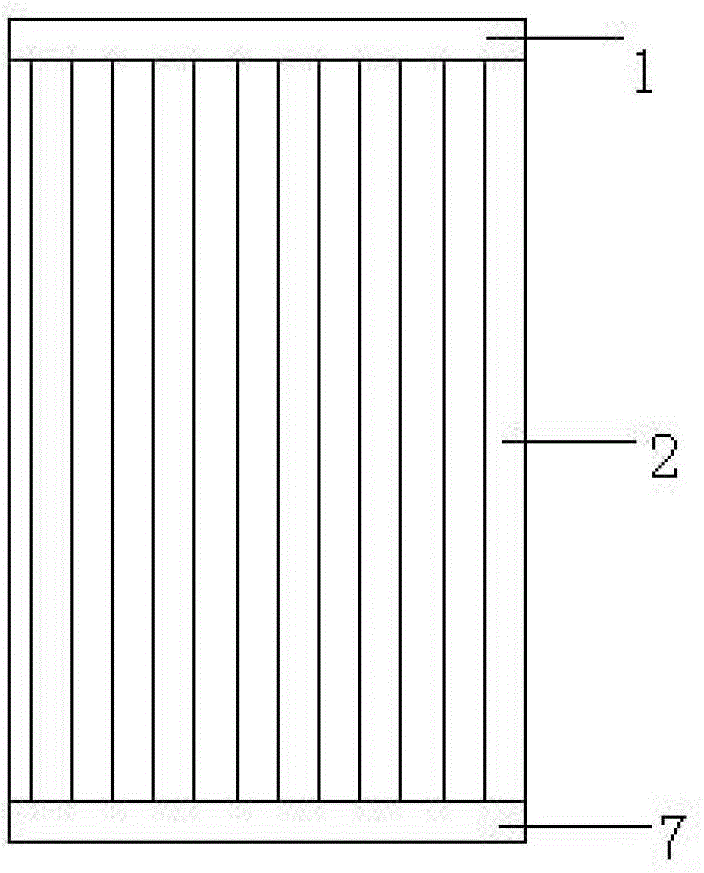

[0044] as attached Figure 1-4 The sleeve-type photocatalytic air purification device based on the dispersion fiber is shown, in which 1 is the top cover, 2 is the filter unit, 3 is the catalytic unit, 4 is the top installation hole, 5 is the air outlet, 6 is the bottom installation hole, 7 Is the bottom end cover, and 8 is the light unit.

[0045] The filter unit is a cylindrical filter unit, and the HEPA filter unit is selected, which can effectively intercept the pollutant particles in the air; The cover is attached.

[0046] The catalytic unit is a cylindrical catalytic unit, its radial cross-section is ring-shaped, its height is consistent with the height of the filter unit, its diameter is smaller than the diameter of the filter unit, and forms a concentric sleeve structure with the filter unit; its upper and lower ends are respectively co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com