Patents

Literature

113results about How to "Strong process applicability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

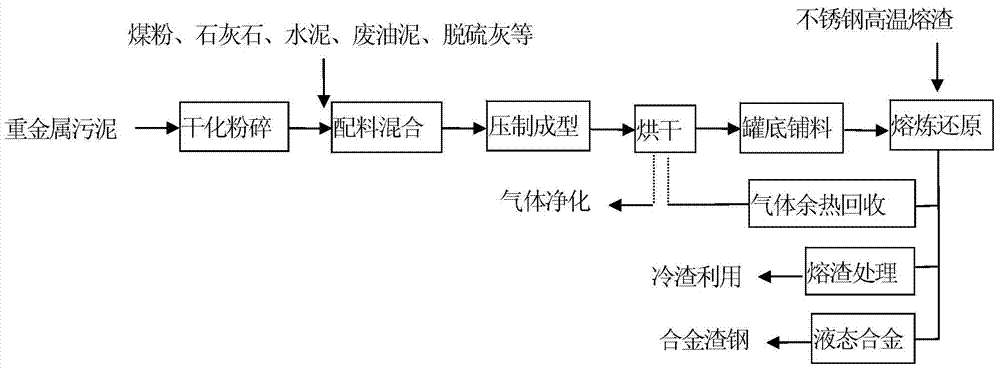

Method for treating heavy metal sludge by using stainless steel molten slag

InactiveCN104512988AIncrease productionIncrease temperatureSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeMetallurgy

The present invention discloses a method for treating heavy metal sludge by using stainless steel molten slag. The method comprises drying crushing, material matching mixing, pressing molding, drying, tank bottom material spreading, smelting reduction, gas purification, molten slag treating, metal recovery and other steps, and specifically comprises that: after heavy metal sludge is subjected to pre-treatment, a certain proportion of ingredients are matched, and the sludge agglomerate is adopted as the bottom spreading material and is placed into a stainless steel molten slag tank to carry out a harmless treatment on the sludge agglomerate. According to the present invention, the characteristics of high production amount, high temperature and rich sensible heat resource of the stainless steel molten slag are adopted, and the stainless steel molten slag is adopted to treat the heavy metal sludge, such that the harmless treatment on the hazardous components and the resource on the valuable material are achieved, the method is the new attempt crossing the industry, and the waste heat resource can be effectively utilized so as to achieve the waste treatment adopting the waste.

Owner:BAOSHAN IRON & STEEL CO LTD +1

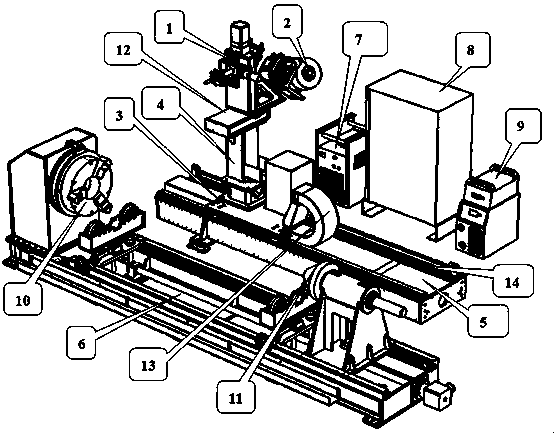

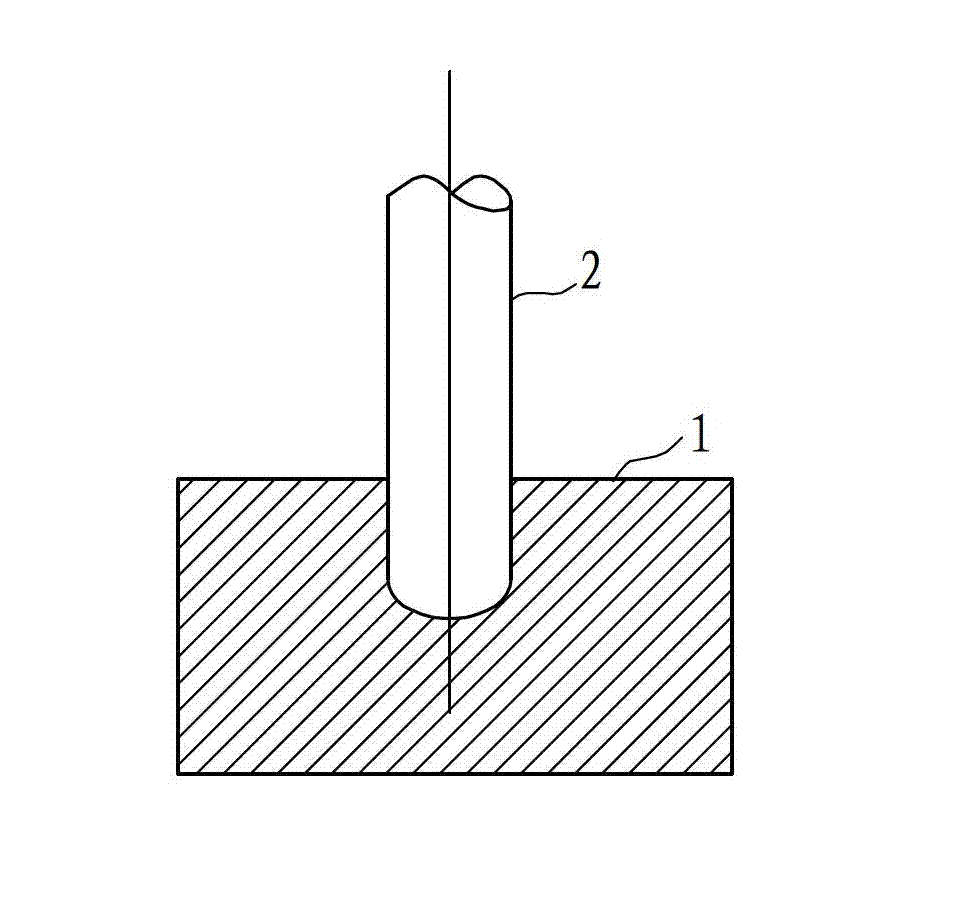

Hydraulic support plunger outer surface laser cladding repairing method

ActiveCN108559996AGuaranteed performanceImprove performanceMetallic material coating processesHardnessOptoelectronics

The invention discloses a hydraulic support plunger outer surface laser cladding repairing method. The hydraulic support plunger outer surface laser cladding repairing method comprises the following steps that firstly, turning is carried out on the outer surface of a hydraulic support plunger to be repaired to remove a fatigue layer and an electroplated layer on the outer surface of the hydraulicsupport plunger, and the outer surface of the hydraulic support plunger is washed; secondly, iron-base alloy powder for laser cladding is put into laser cladding equipment, the laser cladding equipment is used for carrying out laser cladding on the outer surface of the hydraulic support plunger, and a laser cladding layer is formed; thirdly, rough turning is carried out on the hydraulic support plunger which is subjected to laser cladding; fourthly, abrasive machining and polishing treatment are carried out on the hydraulic support plunger which is subjected to rough turning, and the roughnessRa of the outer surface of the polished hydraulic support plunger is smaller than or equal to 0.4; and fifthly, checking and flaw detection are carried out on the outer surface of the polished hydraulic support plunger, and laser cladding repairing of the outer surface of the hydraulic support plunger is completed after it is ensured that no defect exists. The laser cladding layer formed throughthe repairing method is high in hardness, large in thickness and high in corrosion resistance and longer in service life.

Owner:河南省煤科院耐磨技术有限公司

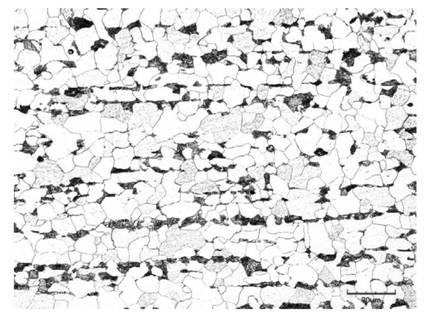

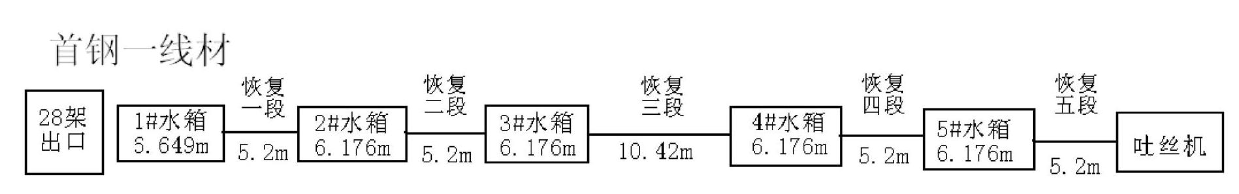

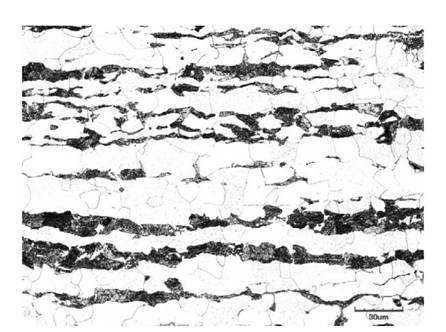

High speed production method for controlling banded structure of low carbon steel wire rod

ActiveCN102671938AImprove uniformityImprove cold heading abilityTemperature control deviceMetal rolling arrangementsWire rodTemperature control

The invention discloses a high speed production method for controlling a banded structure of a low carbon steel wire rod, and belongs to the technical field of steel rolling. The method comprises the following steps: keeping the temperature of 1,080-1,120DEG C of a soaking zone of a heating furnace for 30 to 40 minutes to ensure the homogenous dispersion of alloying elements; performing 6-pass roughing, 6-pass medium rolling, 6-pass pre-finish rolling and 10-pass no twist finish rolling, and reasonably setting the rolling temperature and deformation of each deformation stage; starting and strengthening water cooling guide positions in the finish rolling process, and keeping the finish rolling temperature rise at 100-120DEG C; quickly cooling by using five water cooling tanks, ensuring that the first three water cooling tanks reduce temperature of 100-150DEG C, and keeping the spinning temperature at 850-900DEG C; and after spinning of the wire rod, reasonably setting a roller bed transmission speed and the thickness of the wire rod on a Stelmor air cooling line, and keeping the air cooling speed at 1-3DEG C / s and the phase-transition temperature at 700-780DEG C. The high speed production method has the advantages that the level of the banded structure of the low carbon steel wire rod is effectively controlled to be below level 2, the texture uniformity and cold heading property of the material are greatly improved, and the process applicability is high.

Owner:SHOUGANG CORPORATION

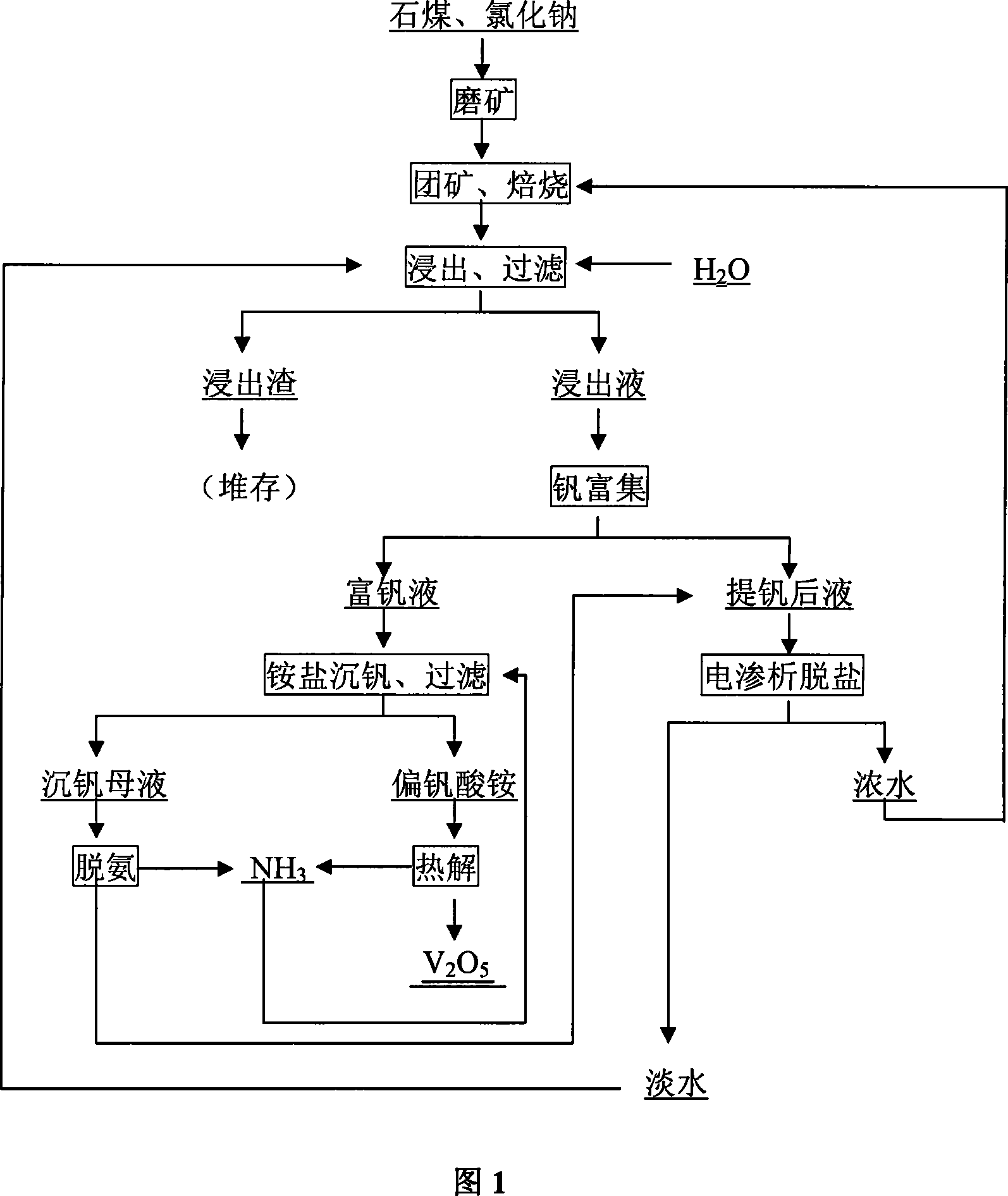

Stone coal sodium roasting vanadium-extracting method

InactiveCN101215636AReduce consumptionHigh recovery rateVanadium oxidesProcess efficiency improvementWater dischargeAmmonium metavanadate

The invention relates to a bone coal sodium roasting vanadium extraction process, which comprises levigating bone coal ore after evenly mixing with common salt, agglomerating ore to roast, calcining to leach through adding water, enriching leaching solution through filter membrane entrapment or anion exchange resin absorption, depositing ammonium metavanadate through adding vanadium-enriching solution, conducting ammonium metavanadate pyrolysis to obtain vanadium pentoxide product, desalting through electrodialysis after vanadium extraction, wherein concentrated water is used to bone coal agglomerate and fresh water is return for roasting and water leaching. The invention has the advantages of simple technology, small water and natrium chloratum agent consumption, high metal recovery, low productive cost and non waste water discharge and the like.

Owner:CENT SOUTH UNIV

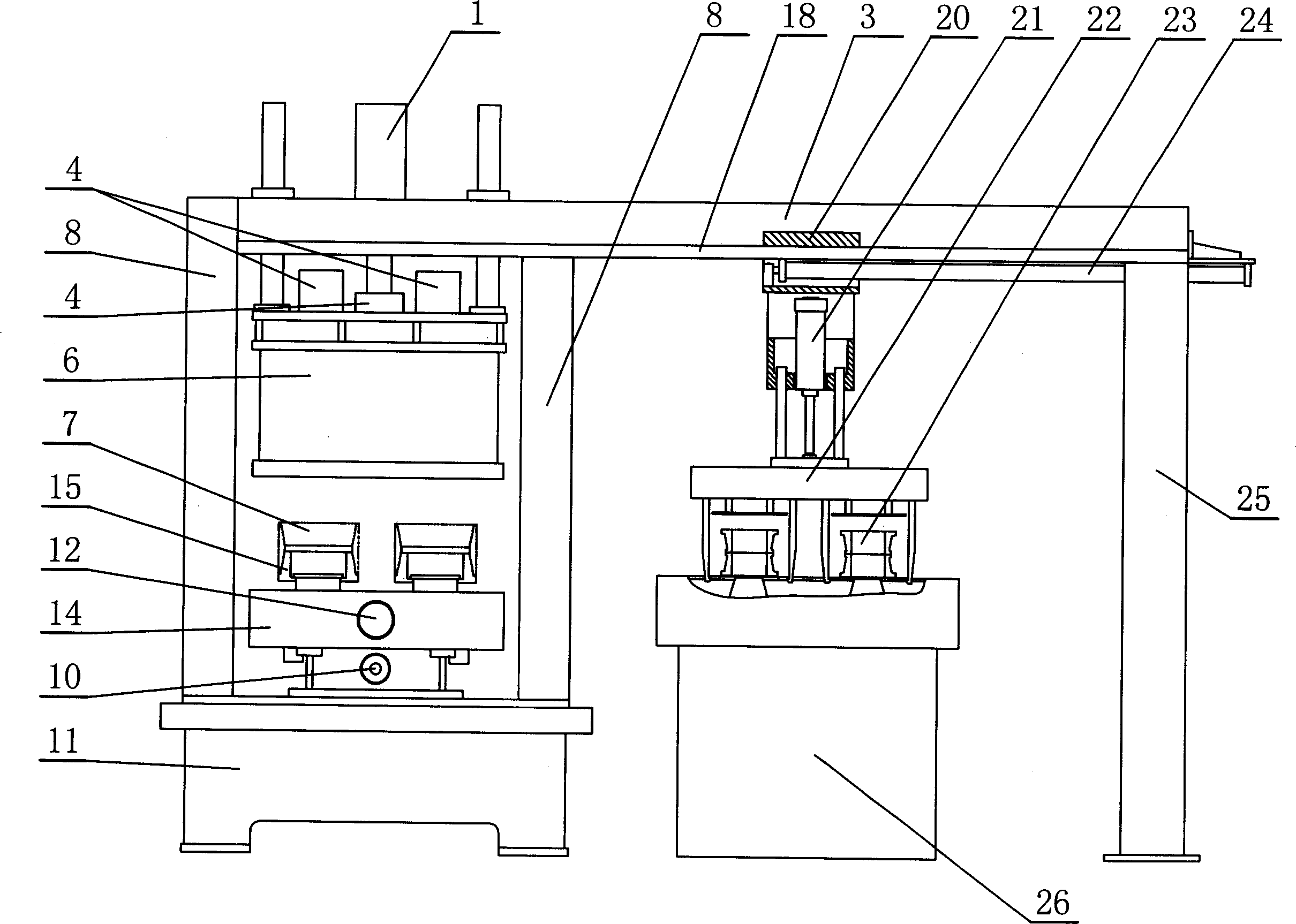

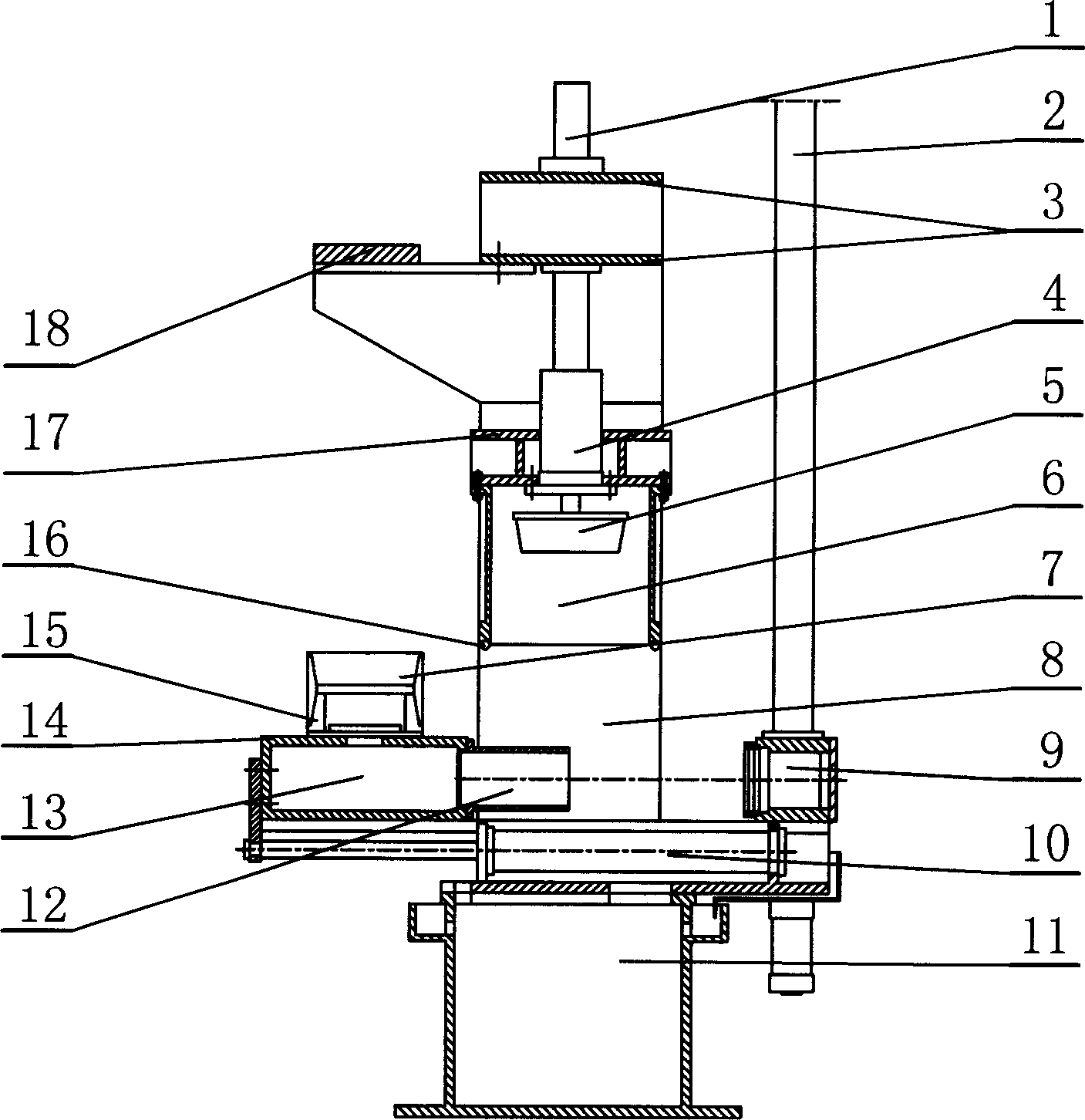

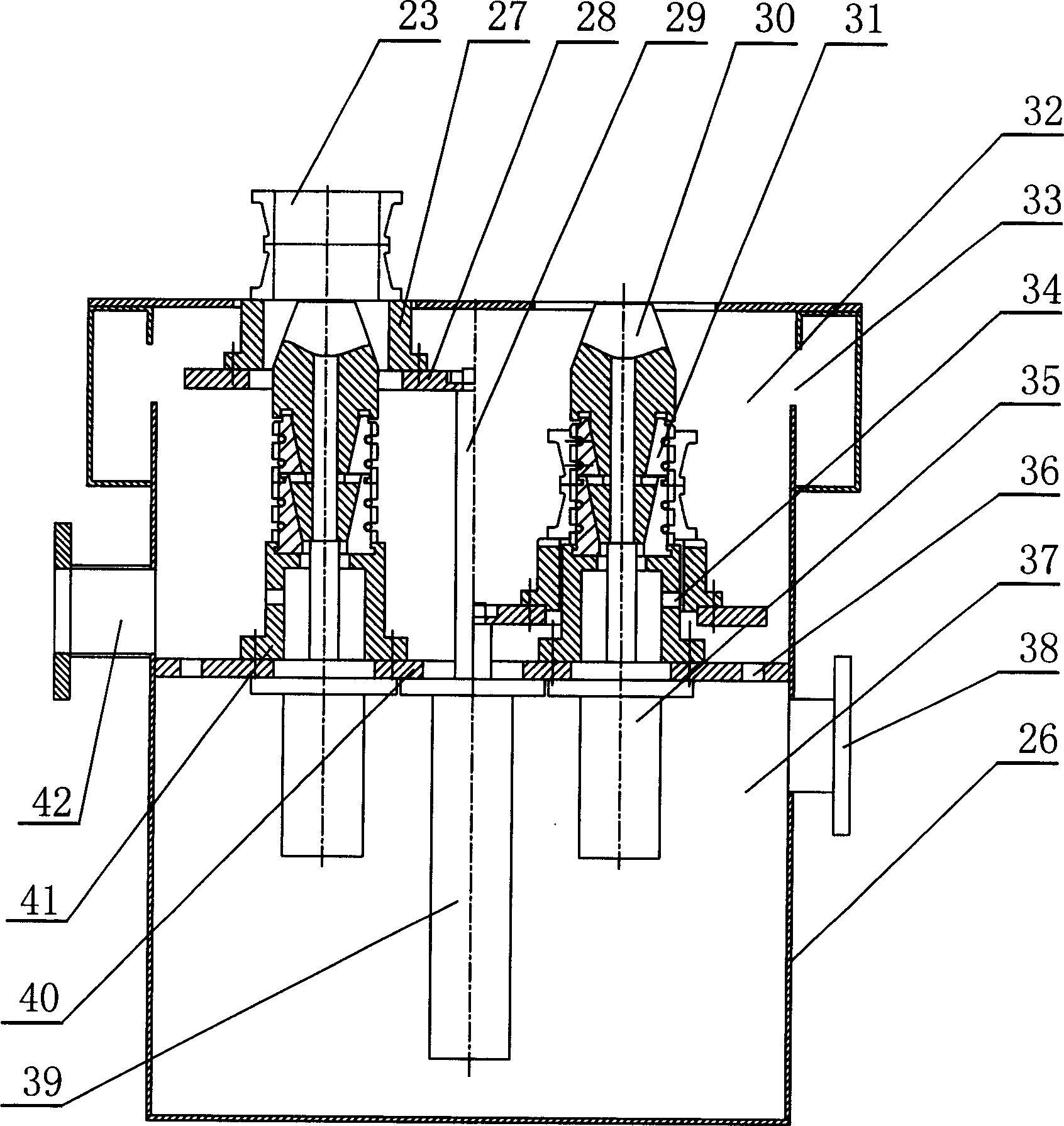

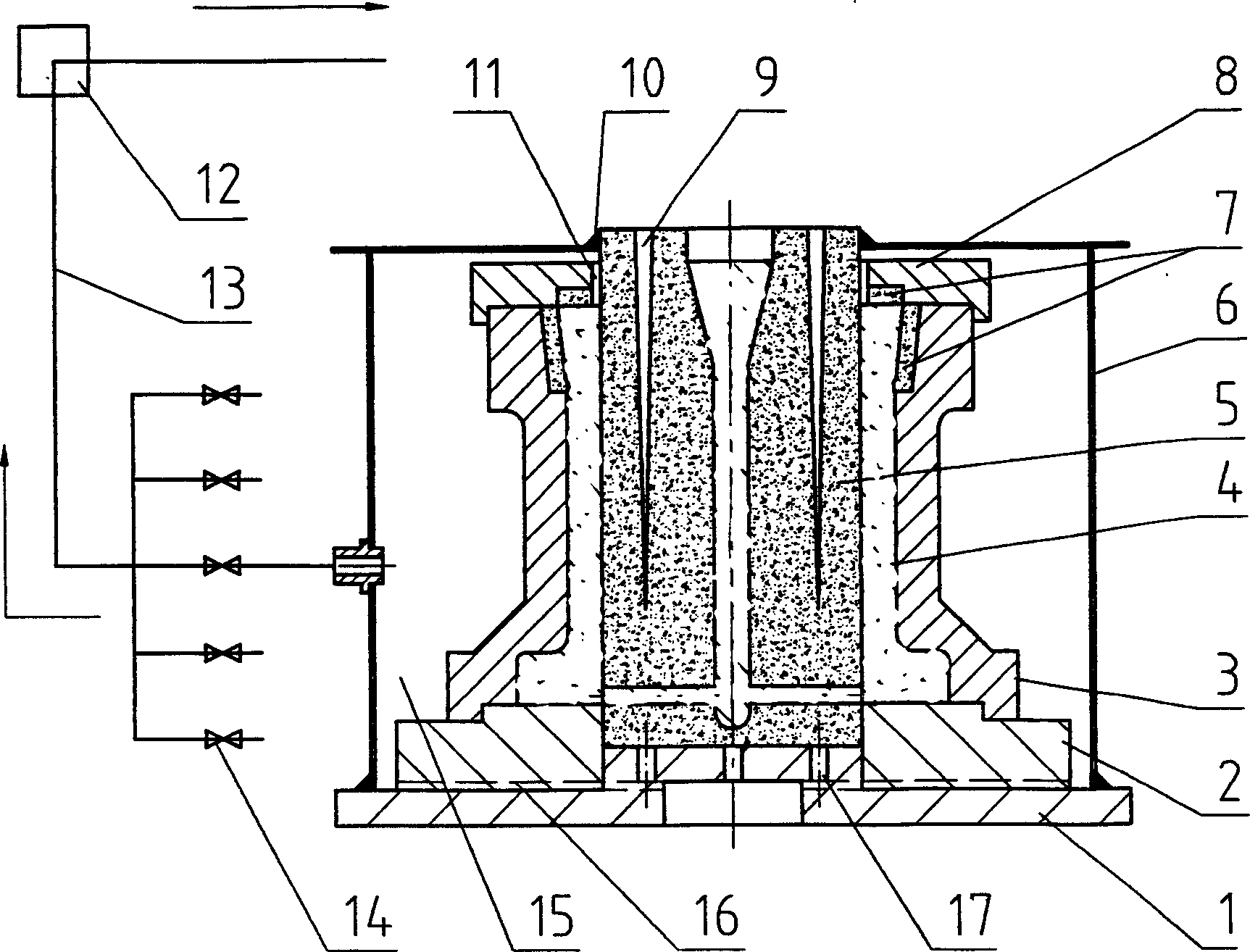

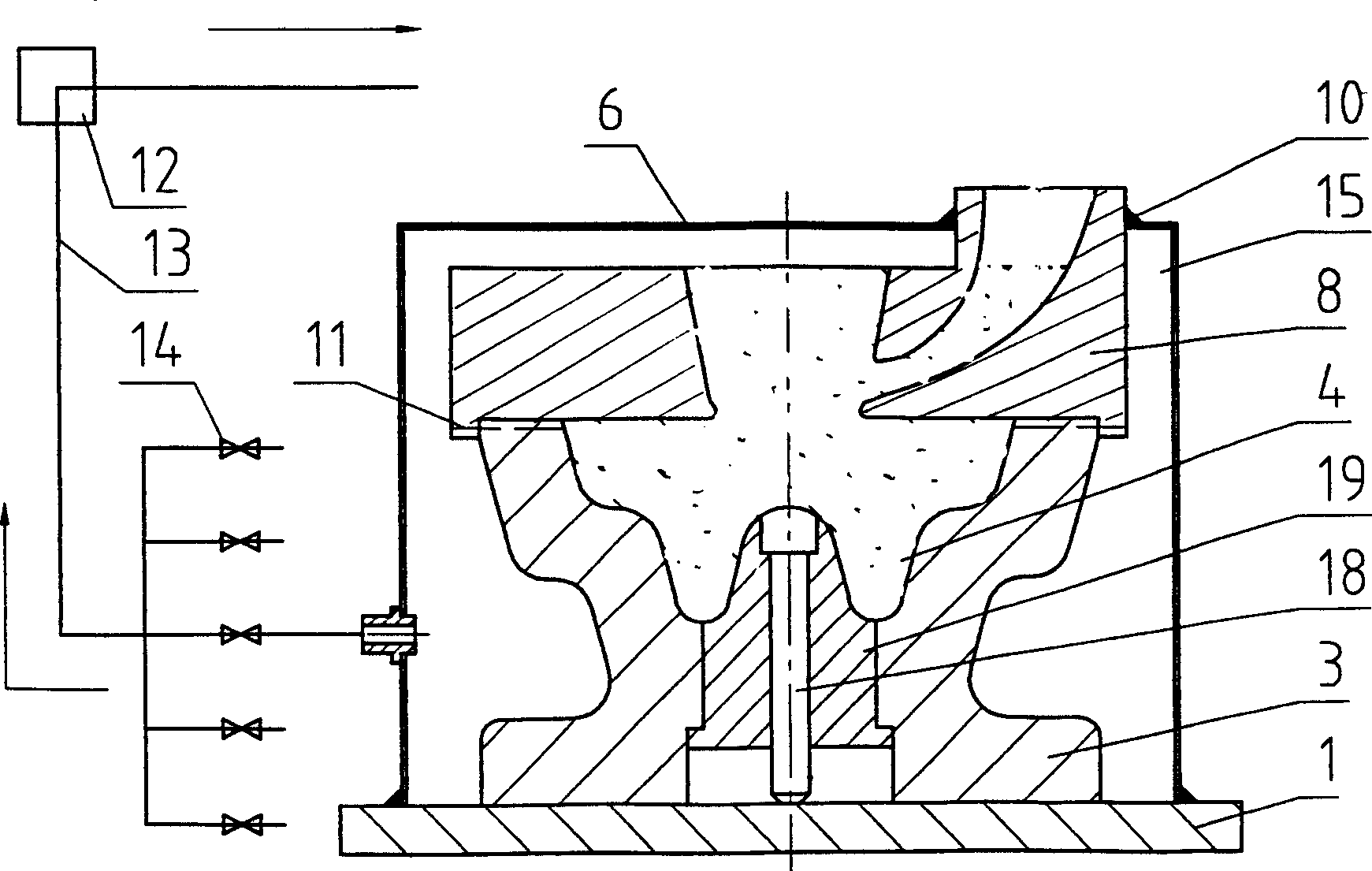

Quenching process and its quenching device for bearing internal and external rings

ActiveCN1858268ASimple structureImprove work efficiencyFurnace typesHeat treatment furnacesSmall footprintManipulator

The present invention relates to heat treatment, and is especially internal and external bearing ring quenching process and quenching press. The quenching process includes the steps of mounting and heating, feeding quenching material, simultaneous quenching of the internal bearing ring and the external bearing ring, and discharging. The special quenching apparatus includes internal bearing ring quenching apparatus, external bearing ring quenching apparatus and manipulator for grabbing the outer bearing ring. The external bearing ring quenching press is provided with fixing mold, the internal bearing ring quenching apparatus is provided with expanding mold, and the quenching process is one closed immersing process. The present invention has homogeneous quenching and is suitable for batch heat treatment.

Owner:NINGXIA MACHINERY RES INST

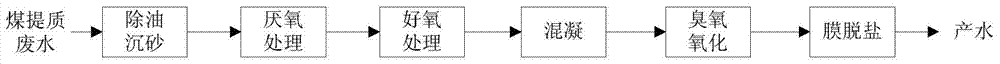

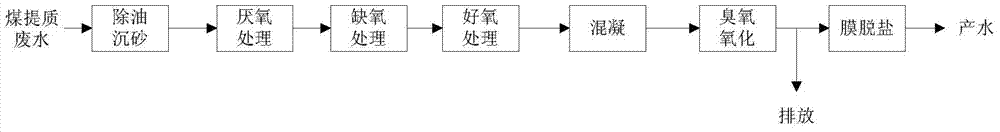

Coal upgrading wastewater treatment process

ActiveCN103613253AStrong process applicabilityStrong impact resistanceMultistage water/sewage treatmentHazardous substanceEmission standard

The invention relates to a coal upgrading wastewater treatment process and belongs to the technical field of wastewater treatment. Aiming at the characteristics that the coal upgrading wastewater is high in content of suspended solids, difficult in settling, rich in degradation-resistant organic matters even toxic and harmful materials, high in chromaticity, and the like, the wastewater is firstly subjected to oil-removing and sand-conditioning treatment to remove most of suspended solids and oil in the wastewater, so that the impact to a subsequent biochemical system is reduced; the biochemical system comprises an anaerobic tank and an aerobiotic tank, and can further comprises an oxygen-deficient tank, wherein most of pollutants are removed in a biochemical treatment phase, and then the wastewater is disinfected through ozone oxidation, decolored, and subjected to removal of the degradation-resistant pollutants so as to reach the emission standard, and can also be recycled through a film desalting system. The coal upgrading wastewater treatment process provided by the invention has the characteristics of high process applicability, good removing effect special for pollutants, easiness for operation and great impaction resistance capacity.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

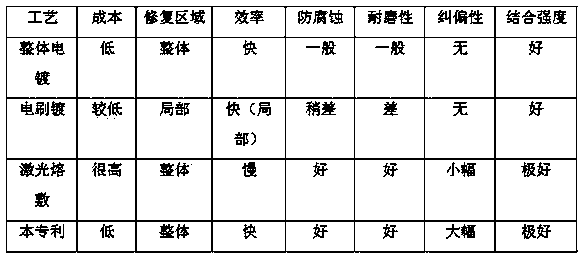

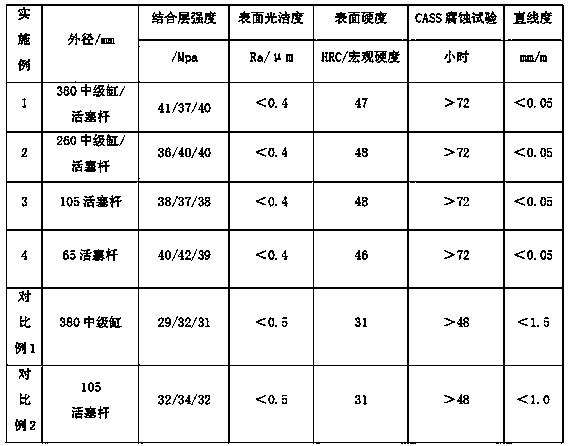

Method for repairing and remanufacturing outer surface of piston rod of hydraulic cylinder or outer surface of intermediate cylinder

ActiveCN104191152AHigh surface macrohardnessImprove wear resistanceArc welding apparatusHydraulic cylinderMetal filament

The invention provides a method for repairing and remanufacturing the surface of a piston rod of a hydraulic cylinder or the outer surface of an intermediate cylinder for coal mines. Aiming at remanufacturing after the surface of the piston rod of the hydraulic cylinder or the outer surface of the intermediate cylinder for the coal mines is damaged and fails, the long-term practice is combined, a metal wire adopting the specific metal powder proportion is creatively designed to serve as a powder core wire, and namely the metal wire is formed by wrapping the metal powder with Cr, Ni and Fe as the main ingredients through a stainless steel foil layer; based on the arc thermal spraying process method, the surface is repaired and remanufactured creatively, and on the premise that the corrosion resistance and the hardness of the repaired layer of the surface are equal to those of the surface treated through the surface laser cladding technology, consideration is given to the good economic applicability and the good practical production efficiency; an existing electroplating technology can be completely replaced, and the method has the wide application and popularization prospects in repairing of the piston rod of the hydraulic support oil cylinder and the intermediate cylinder for the coal mines.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

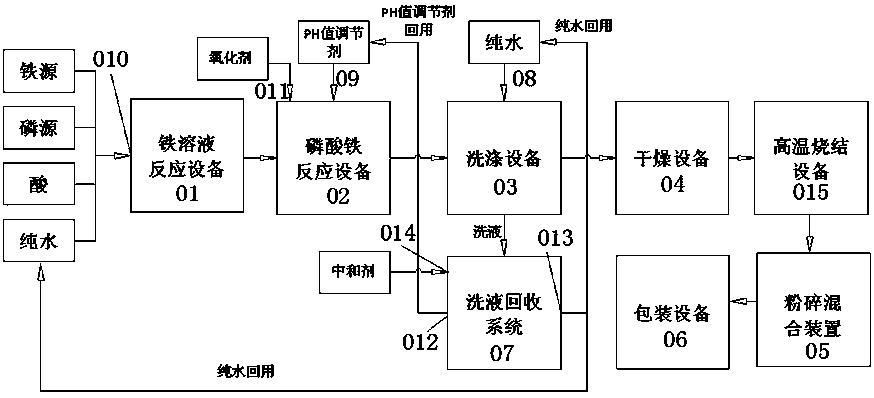

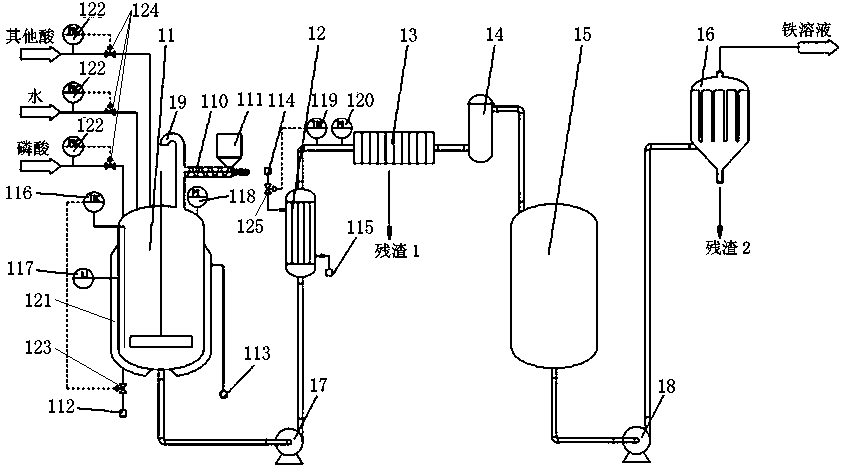

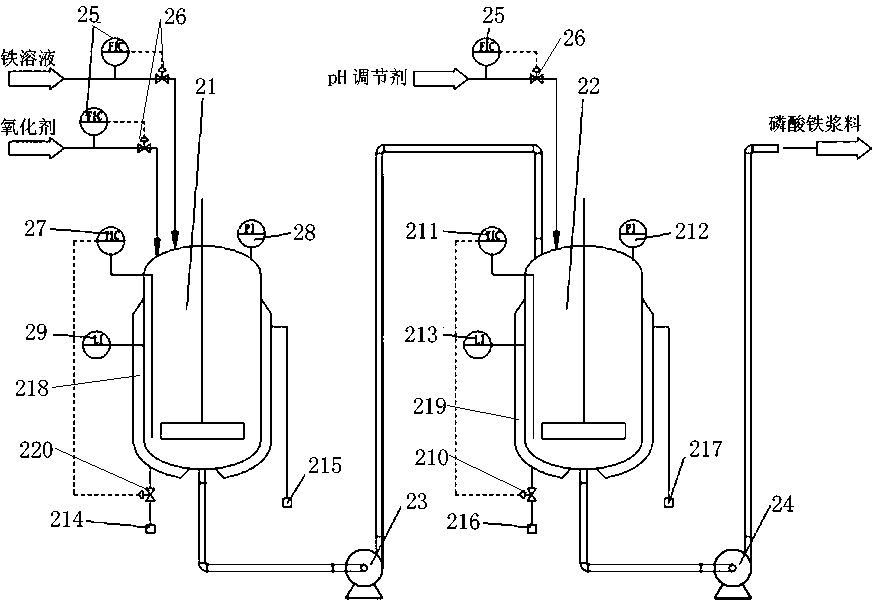

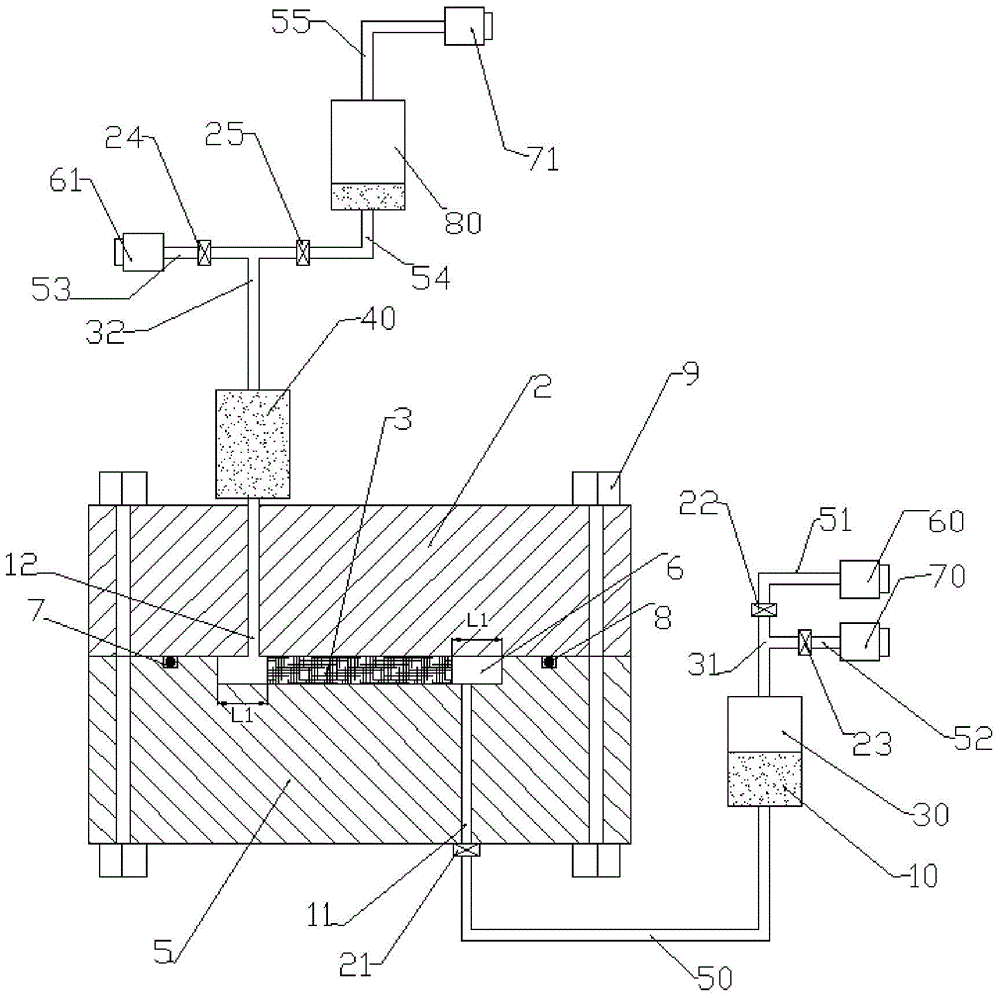

Production technology for iron phosphate and production device thereof

PendingCN109761209AWide variety of sourcesLow costPhosphorus compoundsPhosphoric acidWater resources

The invention discloses a production technology for iron phosphate and a production device thereof. The production technology for iron phosphate comprises the following steps: 1) synthesizing an ironsolution; 2) synthesizing iron phosphate; 3) washing; 4) recycling washing liquor; 5) drying and sintering; 6) smashing, mixing and packaging. The device used in the invention has a simple structure and convenience in operation; raw materials are extensive in source, easy to get and low in cost; a great convenience is brought to industrial production. The technology defined in the invention is high in applicability and is capable of adapting to various raw materials, such as iron source, phosphorus source and oxidizing agent; wastewater generated by the production technology of the invention can be conventionally treated and then recycled; recycling of water resource can be realized; salts in recycled wastewater are used as raw materials; the risk in polluting environment of discharging can be reduced; cost of raw materials is lowered.

Owner:博创宏远新材料有限公司

Liquid pressure forming method of composite material

The invention belongs to a resin based composite material liquid forming technique, and relates to a composite material liquid pressure forming method. The periphery of a predetermined mold body is filled with resin, and the predetermined mold body is continuously pressurized and cured successively by resin via a first pressure source and a second pressure source. According to the invention, the predetermined mold body is pressurized and cured continuously by resin; a molded composite material product not only has high fiber volume content equivalent to a composite material molded by a prepreg / autoclave technique, but also has the high precision equal to the composite material molded by an RTM technique; the applicable range of the composite material molded by a liquid forming technique is expanded; the molding efficiency is improved obviously; the manufacturing cost is reduced.

Owner:AVIC COMPOSITES

Anisotropic conductive rubber film comprising oxidation-reduction initiating system microcapsule and its preparation

InactiveCN1775884AImprove performanceShort hot pressing timeFilm/foil adhesivesElectrically-conducting adhesivesLacquerAnisotropic conductive adhesive

The invention discloses an anisotropy conductive lacquer containing oxidation reduction primosome system microcapsule. The feature is making the oxidation reduction primosome system to microcapsule and shielding its activity to achieve the effect of storing anisotropy conductive film in room temperature. The invention has advantages of high cementing reliability, good conductivity, and convenience using.

Owner:湖北省化学研究院

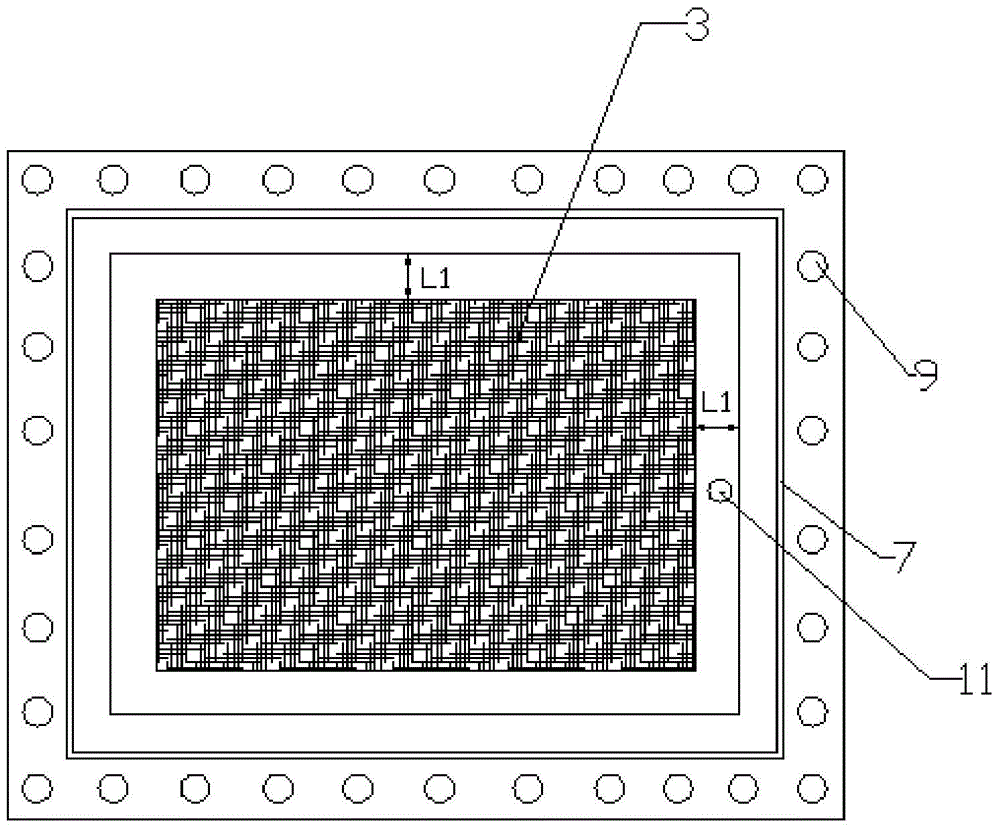

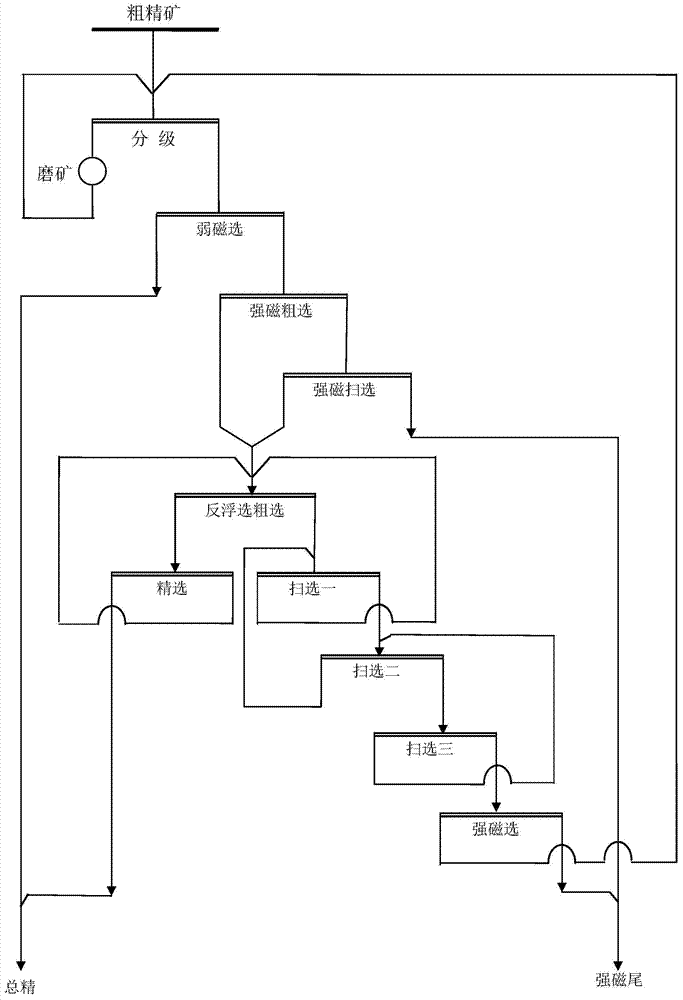

Beneficiation method for improving micro-fine particle refractory iron ore flotation ore-concentrate production rate and recovery rate

The invention discloses a beneficiation method for improving the micro-fine particle refractory iron ore flotation ore-concentrate production rate and the recovery rate. The method includes the following steps that pre-treated micro-fine particle rough concentrate is sent to a closed circuit grinding grading system, so that most of the rough concentrate undergoes monomer separation; obtained ground ore products which undergo monomer separation sequentially undergo low-intensity magnetic separation, high-intensity magnetic rough flotation and high-intensity magnetic scavenging carried out at least once, and ultimately, low-intensity magnetic ore-concentrate and high-intensity magnetic rough ore-concentrate are obtained, the obtained high-intensity magnetic rough ore-concentrate is concentrated, concentration bottom currents are involved in a reverse flotation operation, and accordingly reverse flotation ore-concentrate is obtained; the low-intensity ore-concentrate and the reverse flotation ore-concentrate are combined to form a finished ore-concentrate product, foam after reverse flotation enters a high-intensity magnetic floatation procedure for re-flotation, the ore-concentrate after high-intensity magnetic flotation treatment returns to the closed circuit grinding grading system, and the preceding steps are repeated. The method has the advantages that procedure operations are easy and controllable, the iron grade of flotation tailings is low, and the recovery rate of the ore-concentrate is high.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

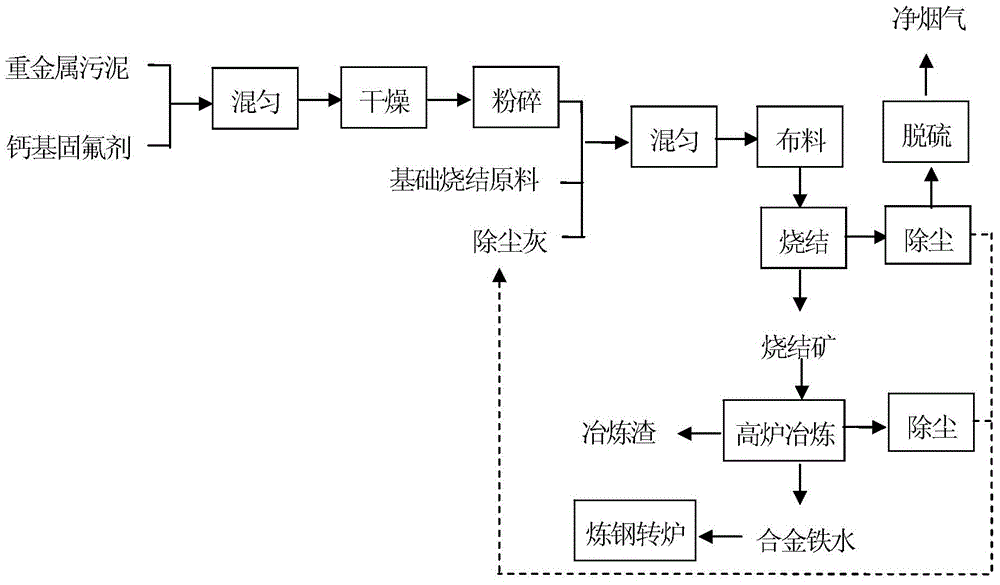

Method for synergistically treating heavy metal sludge

ActiveCN105271624AEfficient recyclingNo slag effectSludge treatmentWaste water treatment from metallurgical processSteelmakingSludge

The present invention provides a method for synergistically treating heavy metal sludge. The method comprises: uniformly mixing heavy metal sludge with a water content of 20-50% and a calcium-based fluorine fixing agent, drying, crushing to obtain calcium-based sludge, uniformly mixing with a base sintering raw material and dust removing ash, granulating, and distributing the material, wherein a mass ratio of the base sintering raw material to the heavy metal sludge to the calcium-based fluorine fixing agent to the dust removing ash is 50-120:0.3-20:0.1-2:0.5-5; sintering the granulated mixing material to obtain sintered ore, wherein the flue gas produced during the sintering process passes through a dust removing and desulfurization device, and the purified flue gas is externally discharged through a chimney; and conveying the sintered ore into a blast furnace, and smelting, wherein the flue gas is externally discharged after the dust removing, the smelting residue is comprehensively utilized, and the alloy hot metal enters the steelmaking converter of the stainless steel enterprise. According to the present invention, dust, gas and wastewater can be discharged into the existing facilities so as to be treated; and with the synergetic treatment of the sintering process and the blast furnace smelting, most of the metal elements can be effectively recovered so as to achieve harmlessness and resources.

Owner:BAOSHAN IRON & STEEL CO LTD +1

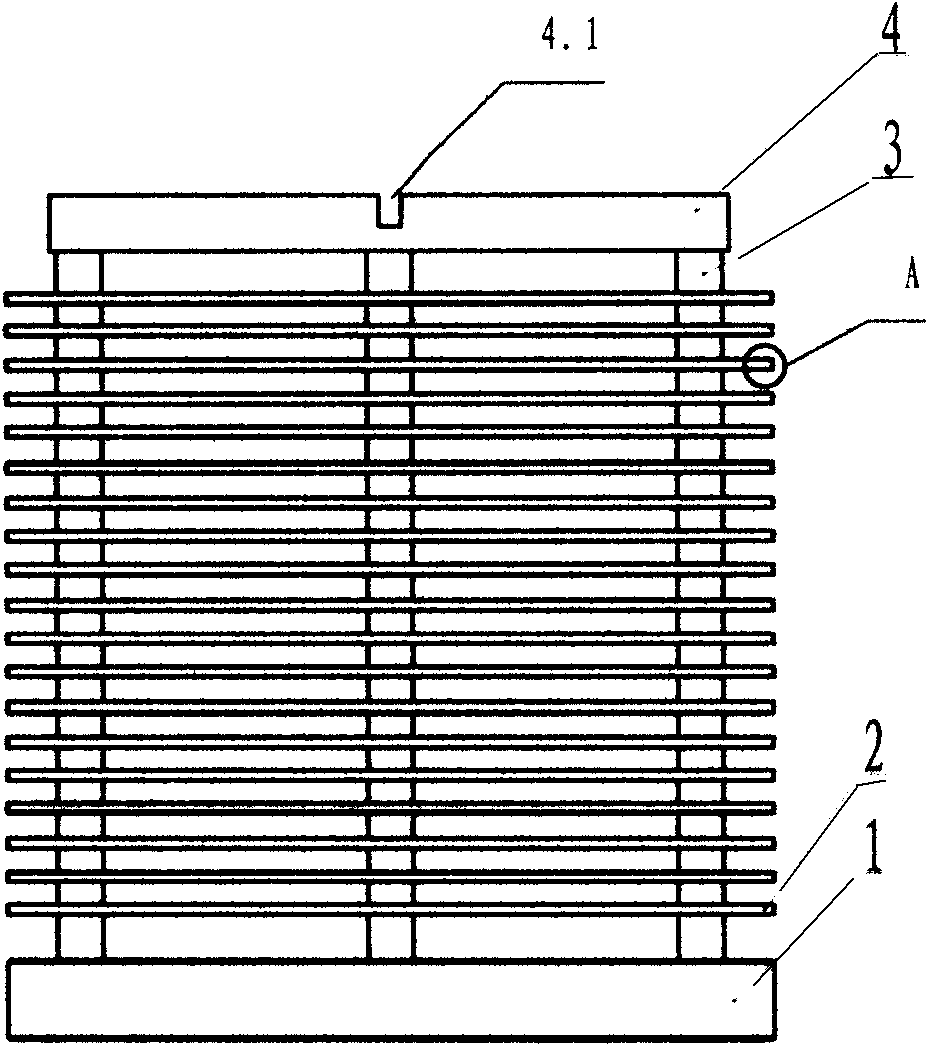

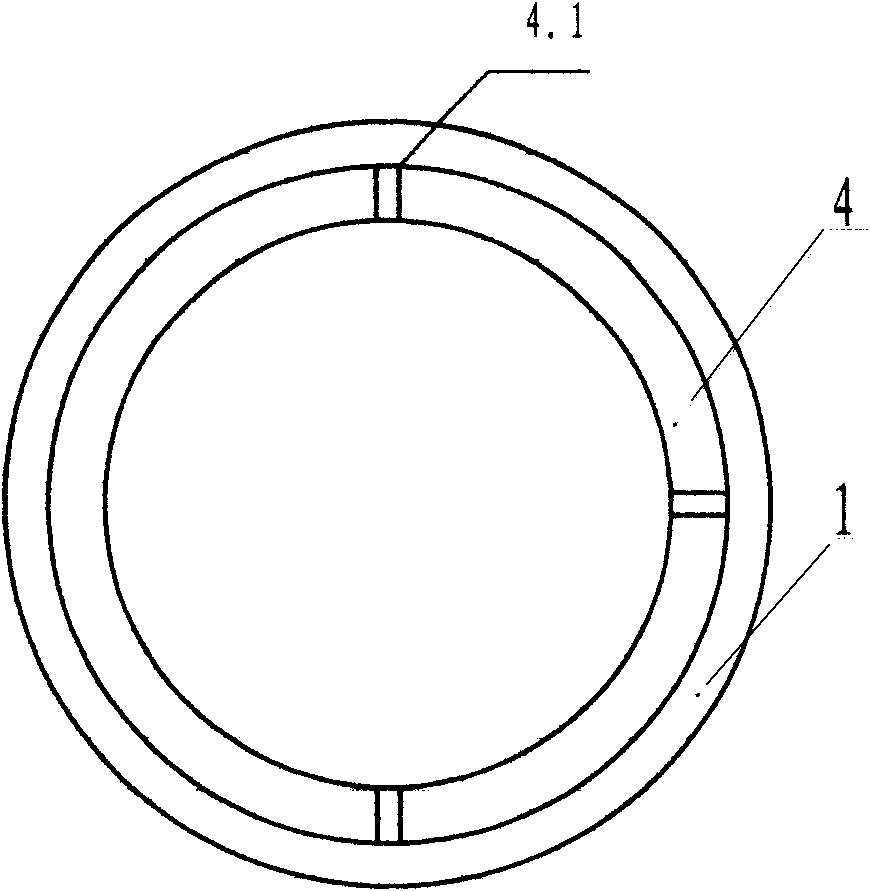

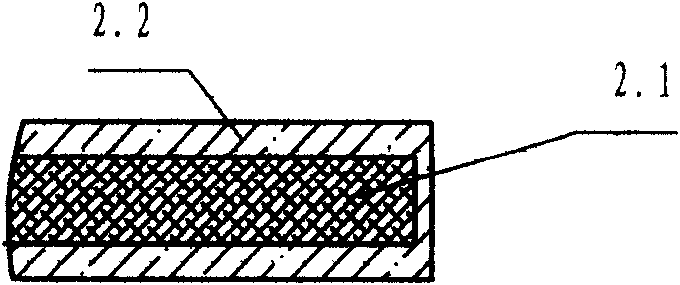

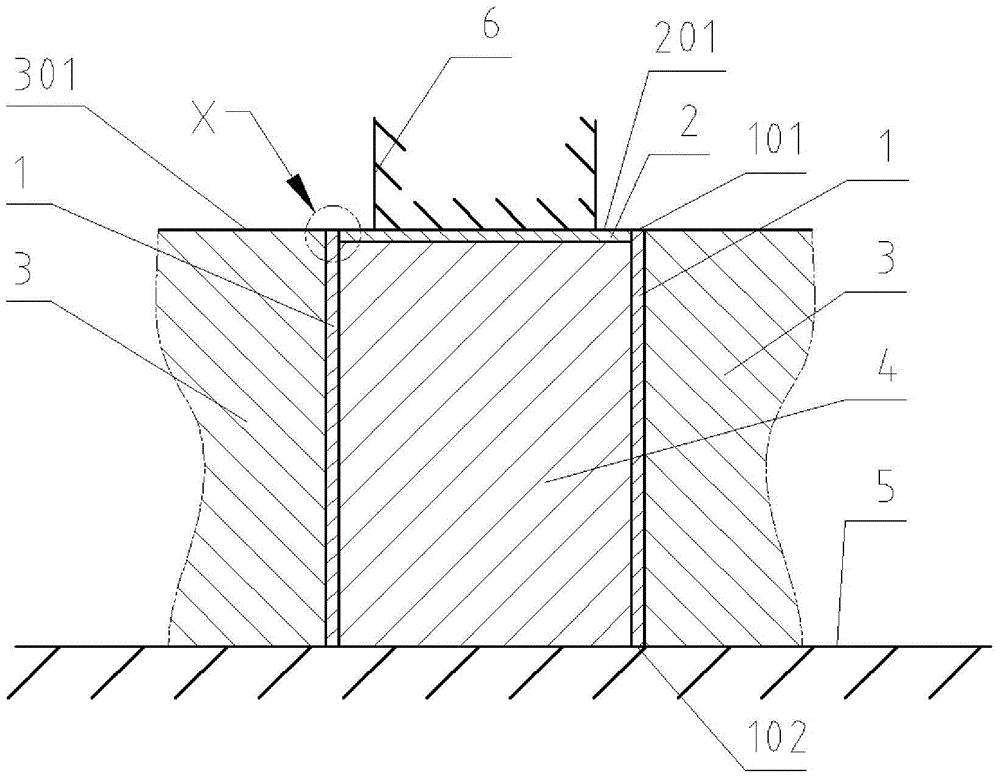

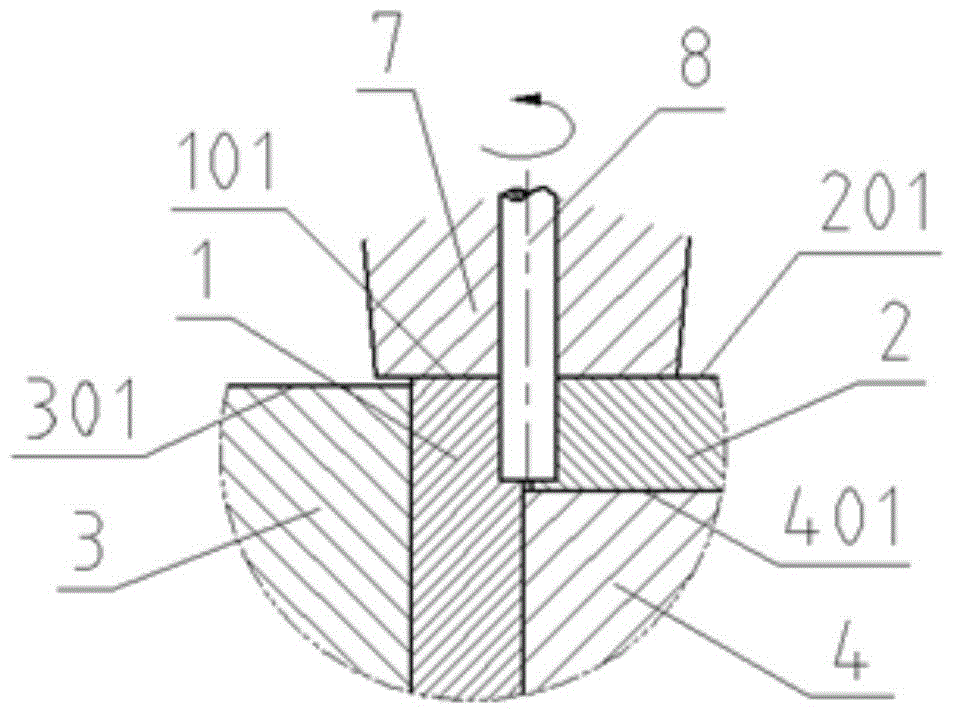

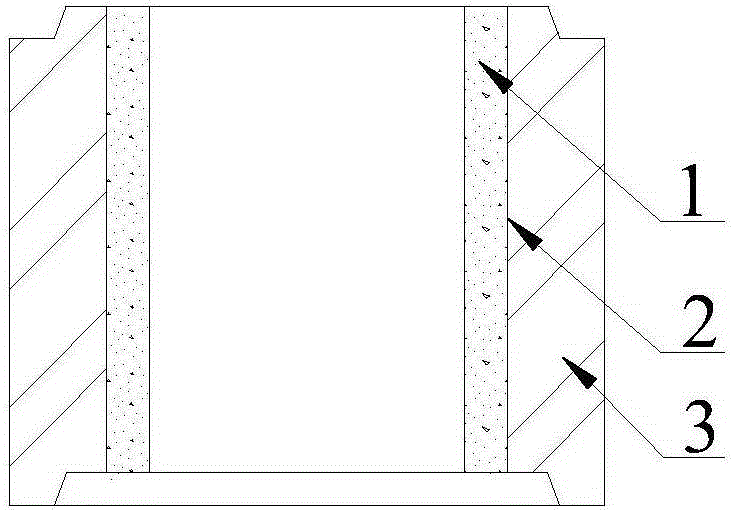

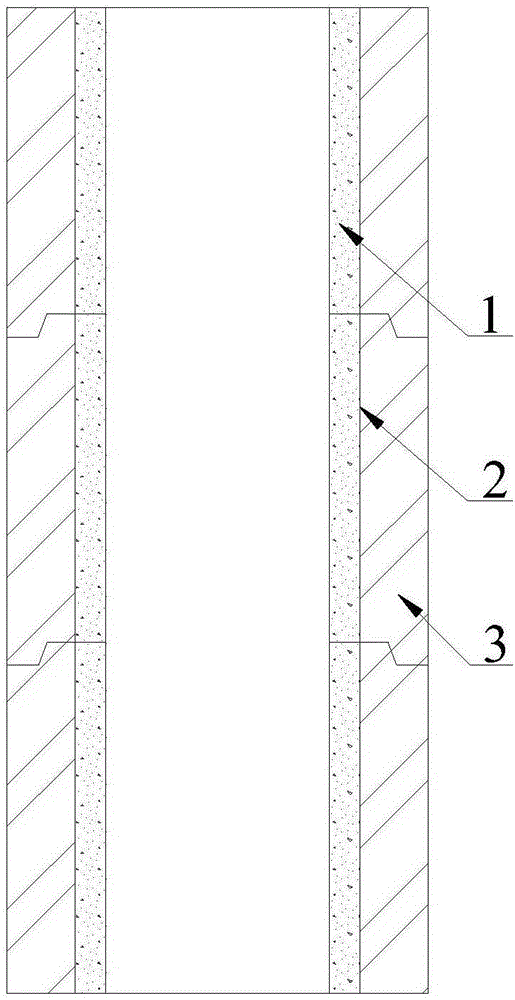

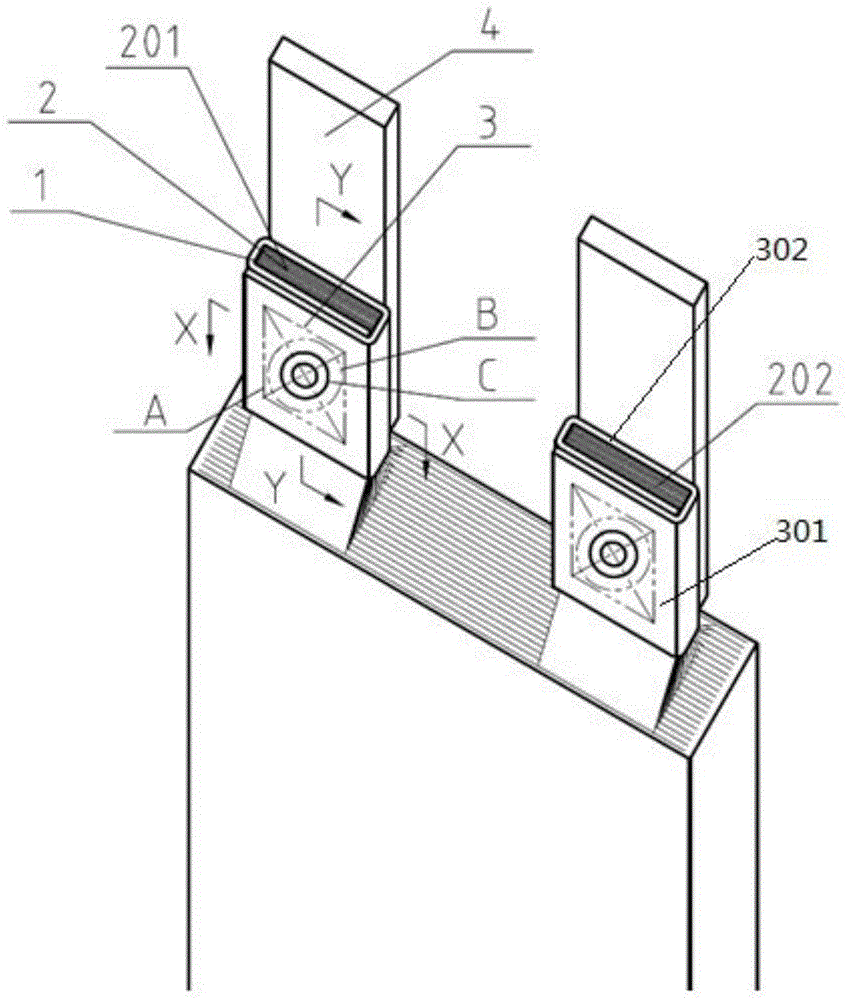

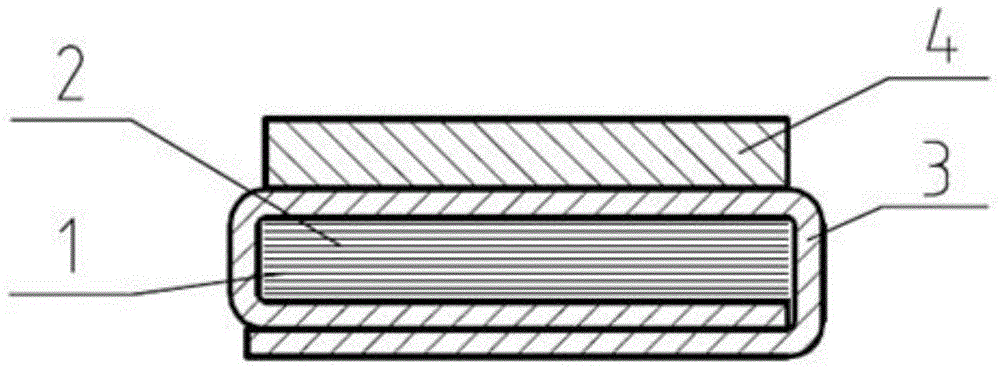

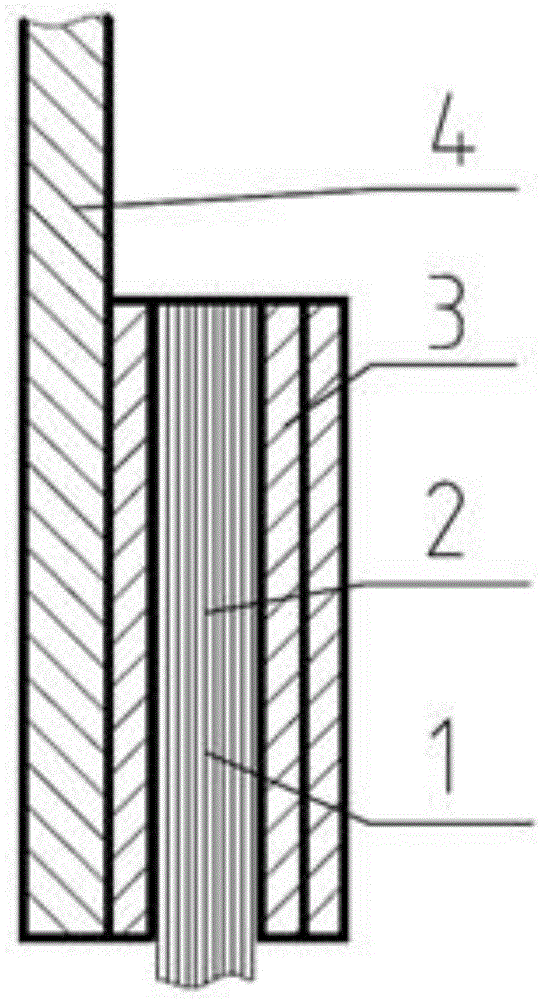

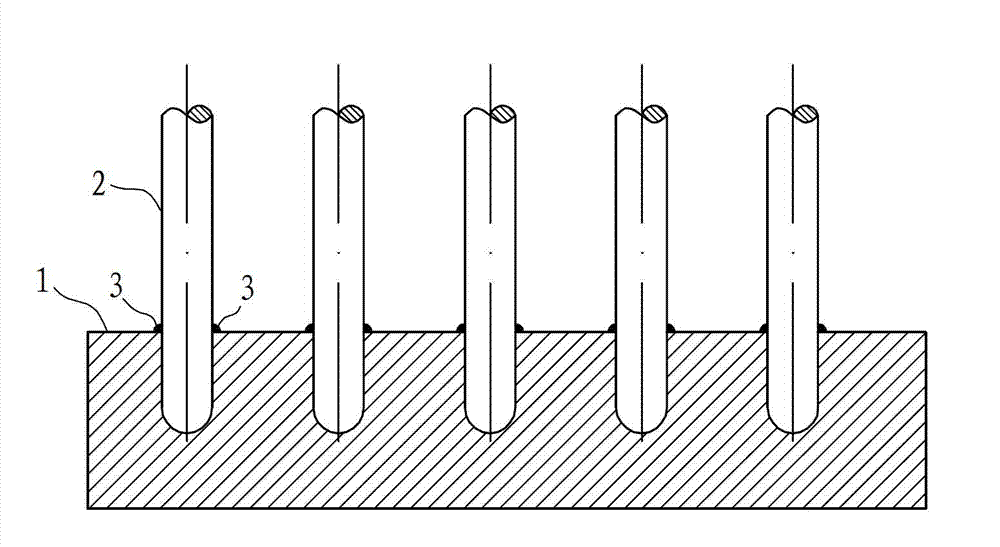

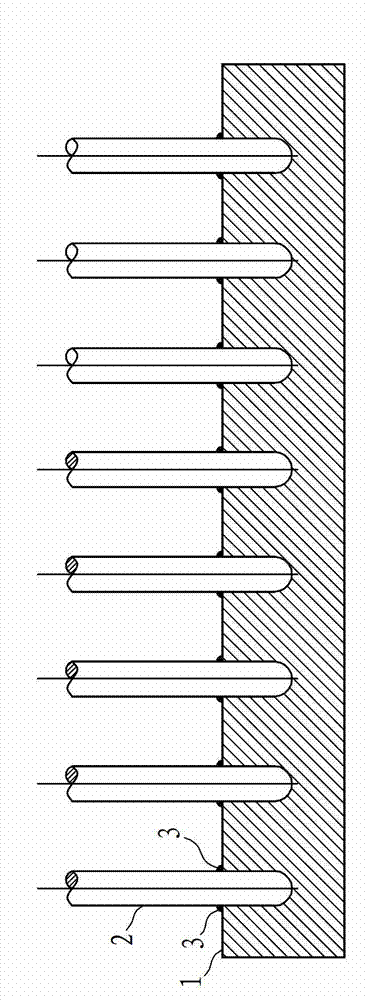

300mm vertical oxidation furnace heat preservation barrel

InactiveCN101552198AReduce churnReduce lossSemiconductor/solid-state device manufacturingEngineeringQuartz

The invention discloses a 300mm vertical oxidation furnace heat preservation barrel, which is characterized by being provided with a bottom quartz plate (1), intermediate quartz sheets (2), supporting rods (3) and a top quartz plate (4); a plurality of supporting rods are vertically and fixedly installed between the bottom quartz plate and the top quartz plates; a plurality of quartz sheets are transversely, uniformly and fixedly installed on the supporting rods at intervals; and the upper surface of the top quartz plate is provided with a fixing groove (4.1) which is used for fixing a quartz boat. The bottom quartz plate and the top quartz plate are in the shape of circular ring; the intermediate quartz sheets are in the shape of circular sheet, and the structure of the intermediate quartz sheets is an OP material layer (2.1) in the middle and a high-purity transparent quartz plate material coating layer (2.2) on the upper layer, lower layer and the periphery. The invention is applicable to the support and heat preservation of the quartz boat of a vertical oxidation furnace, has complete structure, good heat preservation effect and high cleanness, and can ensure the processing quality.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

Vacuum, gravity and precision casting method with metallic mould

A vacuum-gravitational precise casting technology with metallic mould includes such steps as preparing metallic mould, putting it in a cover, sealing the cover, vacuumizing, pouring molten metal while vacuumizing, immediately taking the cast workpiece out and cooling.

Owner:王一诚

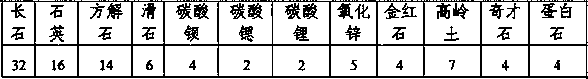

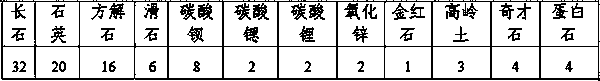

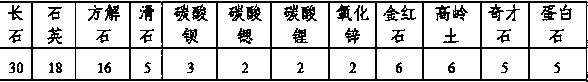

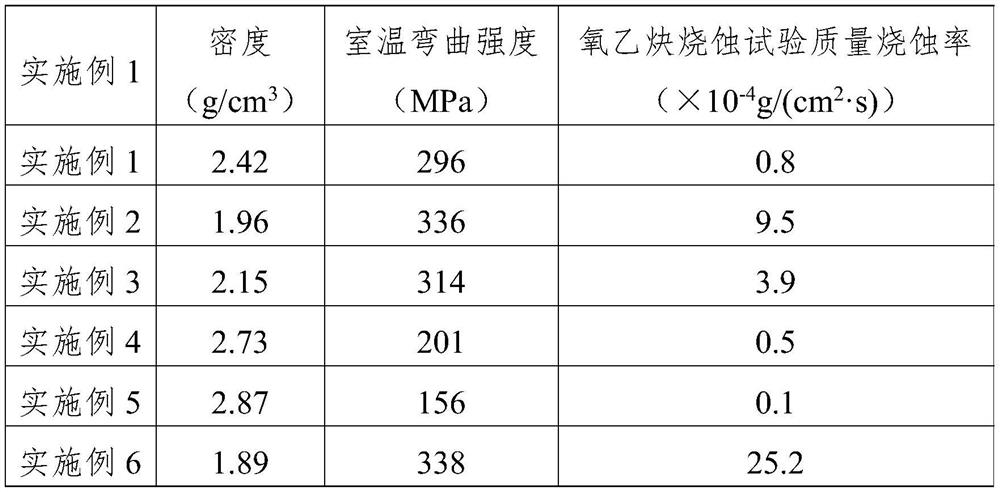

Ceramic basic glaze with health maintenance function and environment-friendly function and use method thereof

InactiveCN103864464ARaise the firing temperatureSolve technical problems with narrow useStrontium carbonateKaolin clay

The invention relates to a ceramic basic glaze with a health maintenance function and an environment-friendly function and a use method thereof. The ceramic basic glaze is prepared from natural mineral raw materials and industrial pure raw materials by weight percent: 30-55% of feldspar, 15-30% of quartz, 10-25% of calcite, 1-8% of talc, 3-8% of barium carbonate, 1-3% of strontium carbonate, 1-3% of lithium carbonate, 1-8% of zinc oxide, 1-8% of rutile, 3-8% of kaolin and 3-10% of negative ion generating agent; the glaze is prepared by mixing, ball-milling and screening the raw materials. The glaze manufacture process is basically same as the normal ceramic glaze process, the cost is low, the monochrome glaze, fancy glaze or transmutation glaze can be manufactured by adding different ceramic pigment, the manufactured ceramic product is integrated with functionality and beauty, and is stronger in practicability, higher in technique content and better in process applicability in comparison with the similar technique principle product on the market at present, and the manufactured ceramic product has wide application prospect.

Owner:朱仙炳

C/ZrC-SiC ultrahigh-temperature ceramic-based composite material and preparation method thereof

The invention relates to a C / ZrC-SiC ultrahigh-temperature ceramic-based composite material and a preparation method thereof. The method comprises the following steps: preparing a powder-added carbonfiber preform by alternately superposing and laying carbon cloth layers and ZrC powder layers; preparing a C interface layer on the surface of the powder-added carbon fiber preform to obtain a low-density C / C composite material; carrying out SiC matrix densification on the low-density C / C composite material through a PIP process with a polycarbosilane precursor solution as impregnation liquid; andrepeating the PIP process multiple times to prepare the C / ZrC-SiC ultrahigh-temperature ceramic-based composite material. The method is high in process applicability, simple in preparation process and easy to operate, the addition amount of ZrC powder in the prepared C / ZrC-SiC ultrahigh-temperature ceramic-based composite material is adjustable and controllable, and the C / ZrC-SiC ultrahigh-temperature ceramic-based composite material has excellent mechanical properties and oxidation resistance and ablation resistance and shows wide application prospects in the field of aerospace and aviation.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

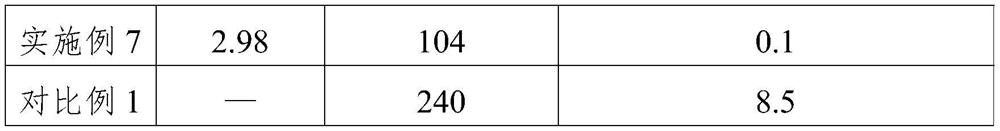

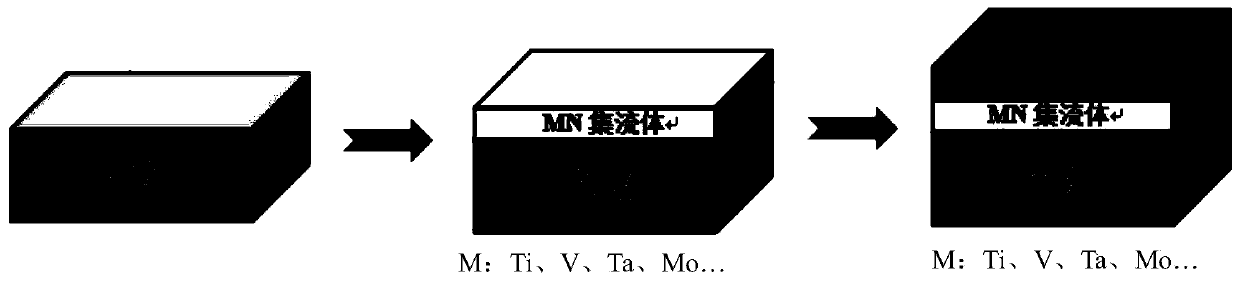

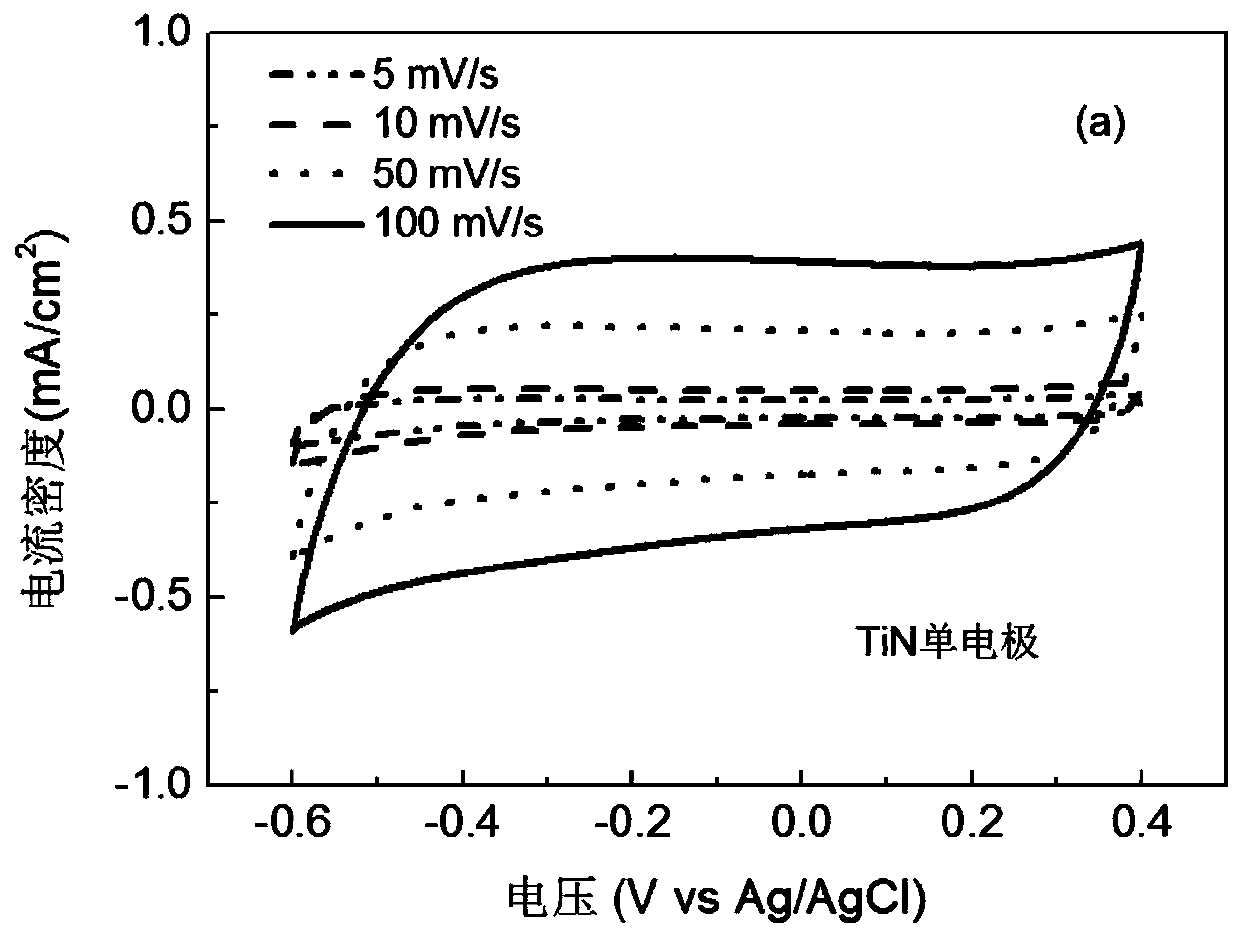

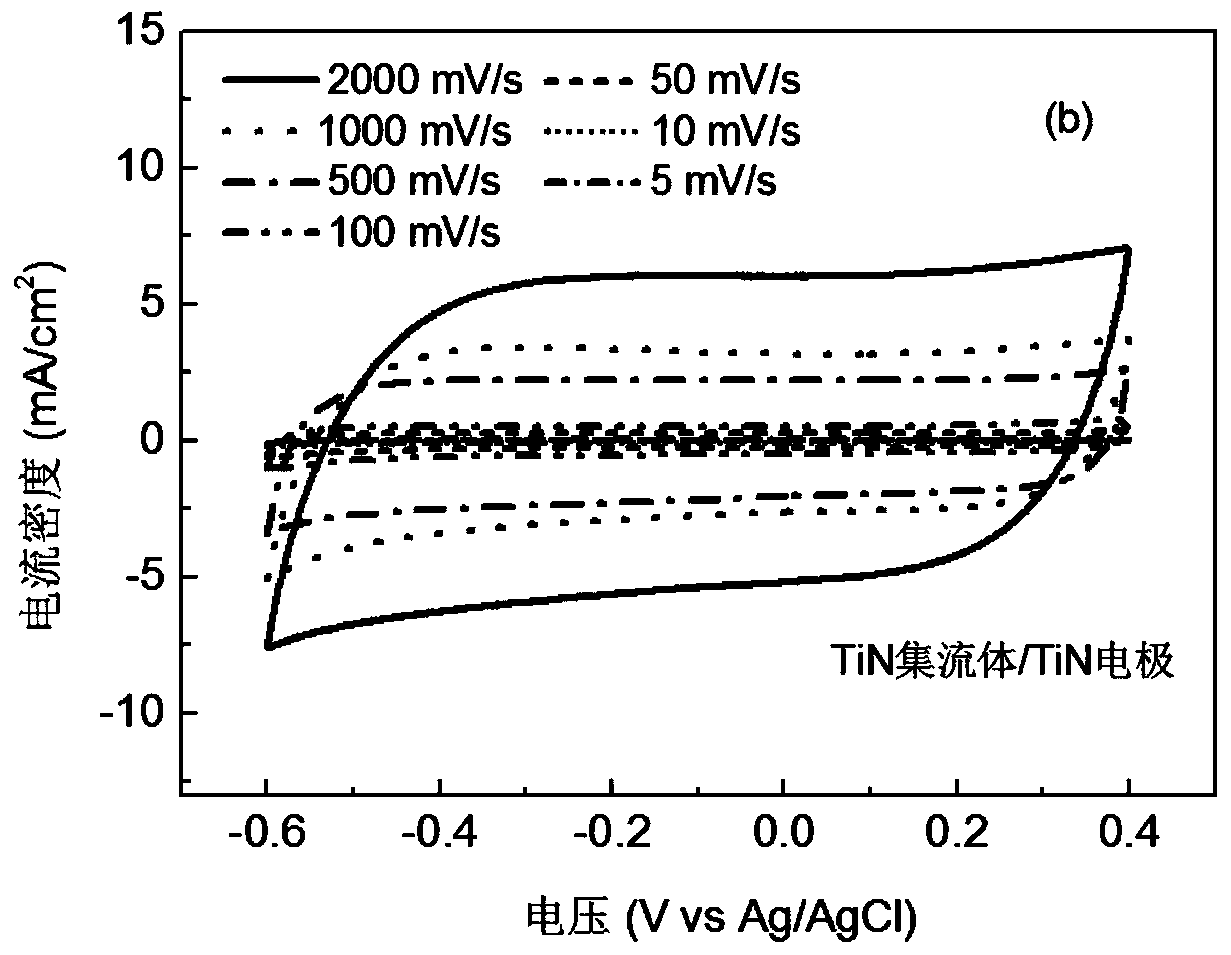

Full-transition metal nitride current collector/electrode supercapacitor and preparation method thereof

ActiveCN109712820AMany choicesStrong process applicabilityHybrid capacitor electrodesHybrid/EDL manufactureNew energyLattice mismatch

The invention discloses a full-transition metal nitride current collector / electrode supercapacitor and a preparation method thereof, and belongs to the technical field of new energy materials and devices. Firstly, impurities on the surface of a substrate material are removed through cleaning. Secondly, a layer of high-density and high-conductivity transition metal nitride film is deposited on thesurface of the substrate to serve as an electron transport current collector material. Thirdly, a layer of loose, porous and low-conductivity transition metal nitride film is directly and continuouslygrown on the current collector by regulating and controlling deposition process parameters to serve as an electrode material. According to the invention, the current collector and the electrode are both transition metal nitrides which grow continuously. The performance of the material is cut by simply changing film deposition process parameters. The preparation method is simple, convenient and feasible in process, low in cost, multiple in thin film deposition technology selection types and high in process applicability. The problems of layered cracking and large contact resistance caused by poor adhesion force, lattice mismatch and thermal expansion coefficient difference between a heterogeneous current collector and an electrode material are solved. The power density, the thermal stability and the long-term service reliability of the super capacitor are greatly improved.

Owner:DALIAN UNIV OF TECH

Dyeing defect positioning and stripping method for real silk fabric

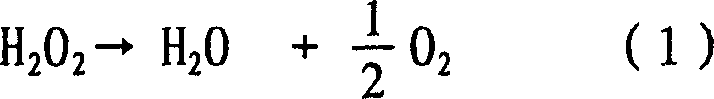

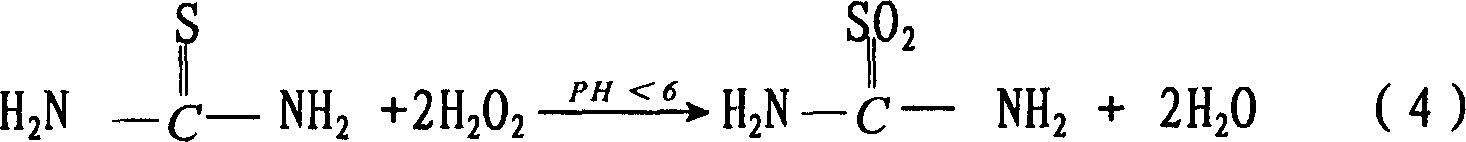

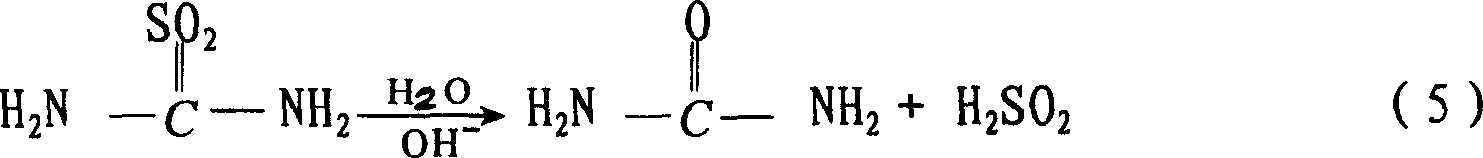

InactiveCN1730800ADecompose thoroughlySevere oxidizingBleaching apparatusDyeing processThioureaDye molecule

The present invention discloses method of locating and eliminating dyeing defect for silk fabric and solves the technological problem of eliminating dyeing defect from silk fabric without obvious damage on the strength of the silk fiber. The method includes the following steps: treating the silk fabric with dyeing defect with catalyst metal salt to make the dye adsorb the catalyst metal salt; rinsing to eliminate the catalyst metal salt adsorbed onto the silk protein while maintaining the catalyst metal salt adsorbed onto the dye molecules; oxidizing and stripping with hydrogen peroxide solution; reducing and eliminating color with thiourea to eliminate dyeing defect; and water washing. Thus treated silk fabric has whiteness over 68 and silk strength maintaining rate over 71 %.

Owner:ZHEJIANG SCI-TECH UNIV +1

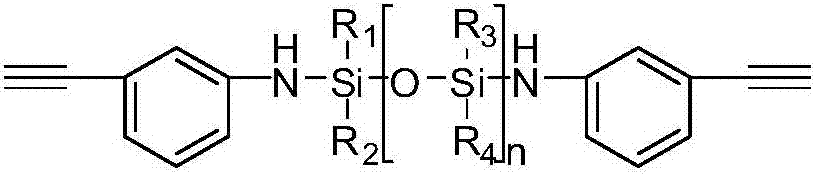

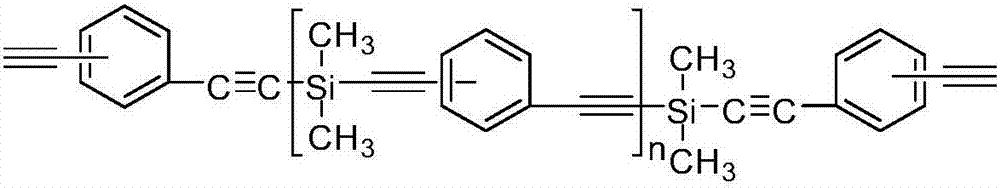

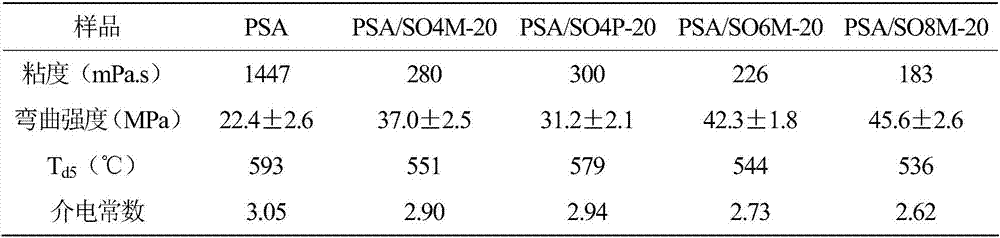

Preparation method of polysiloxane modified silicon-containing arylacetylene resin

The invention discloses polysiloxane modified silicon-containing arylacetylene resin and a preparation method thereof. The preparation method comprises the following steps: under inert gas shielding, stirring 5-30 parts of ethynyl aniline terminated polysiloxane (SO) and 70-95 parts of silicon-containing arylacetylene resin (PSA) by weight part at 100-140 DEG C to carry out reaction for 0.5-3h to obtain redish brown modified silicon-containing arylacetylene resin. As for the obtained ethynyl aniline terminated polysiloxane modified silicon-containing arylacetylene resin, while excellent heat resistance of the silicon-containing arylacetylene resin is kept, the viscosity of the resin is remarkably lowered, the processing properties and the dielectric properties are improved, the mechanical properties are further improved, and the application range of the silicon-containing arylacetylene resin as an ablation resistant material, a high-temperature resistant wave-transparent material, a ceramic precursor, a structure and function integrated material and the like in the aerospace field, the military field, the electronic field and the like is expanded.

Owner:EAST CHINA UNIV OF SCI & TECH

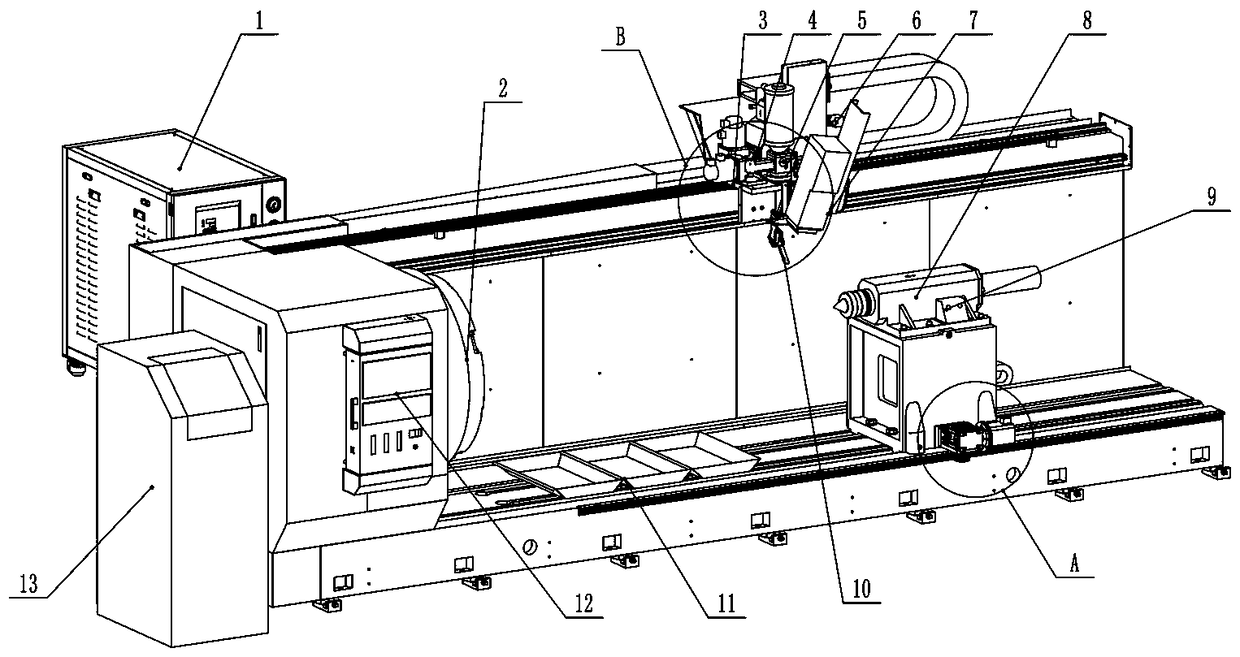

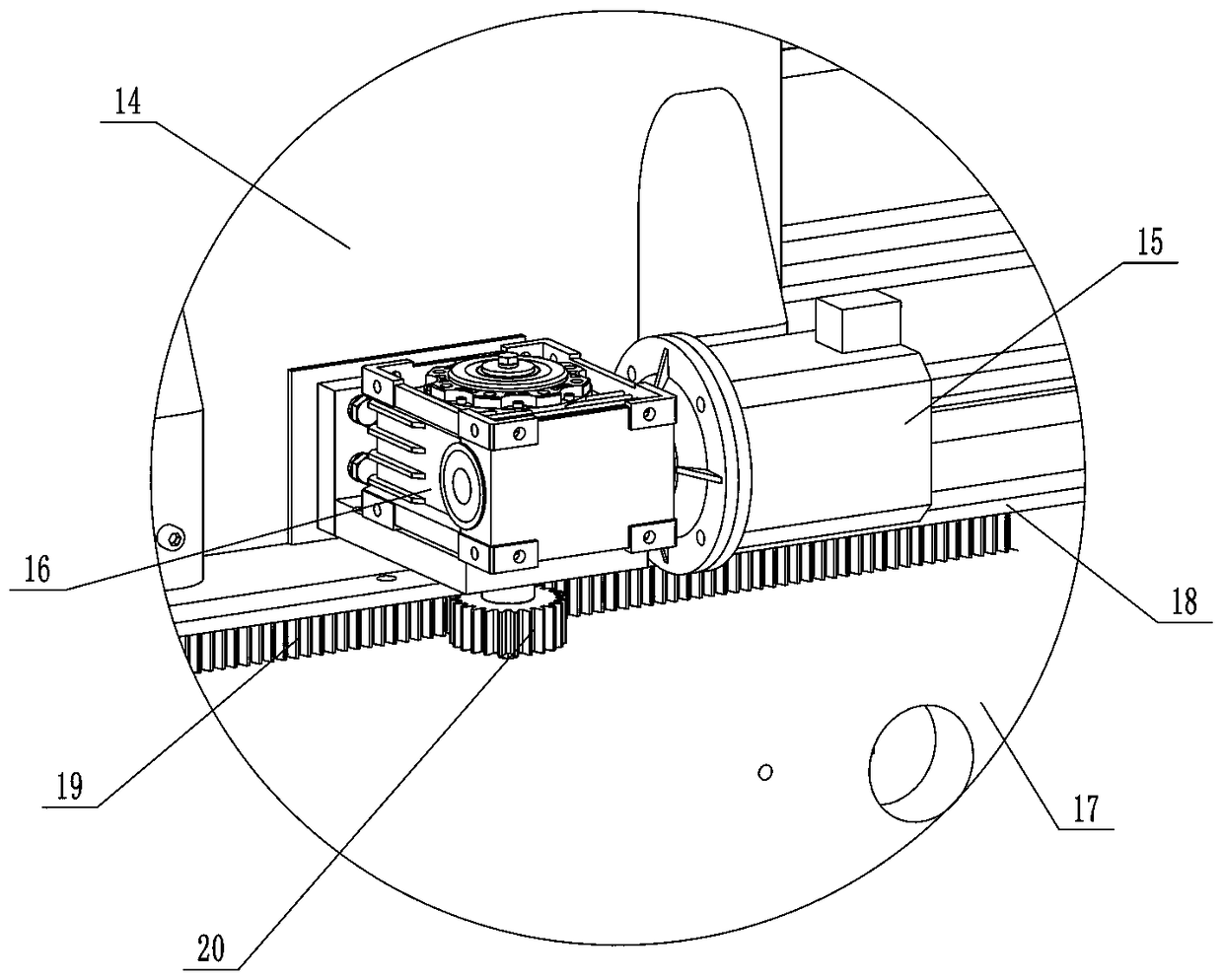

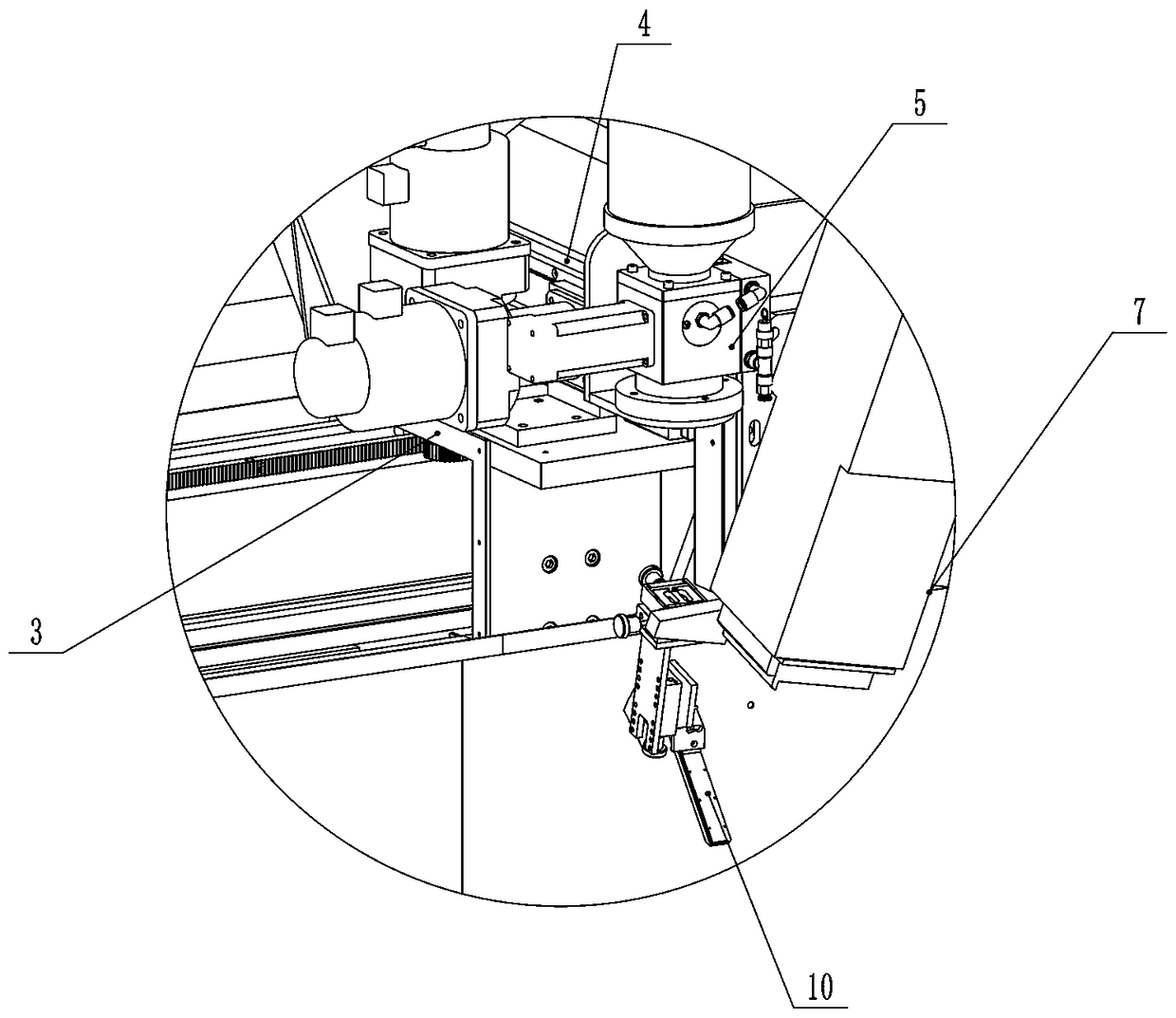

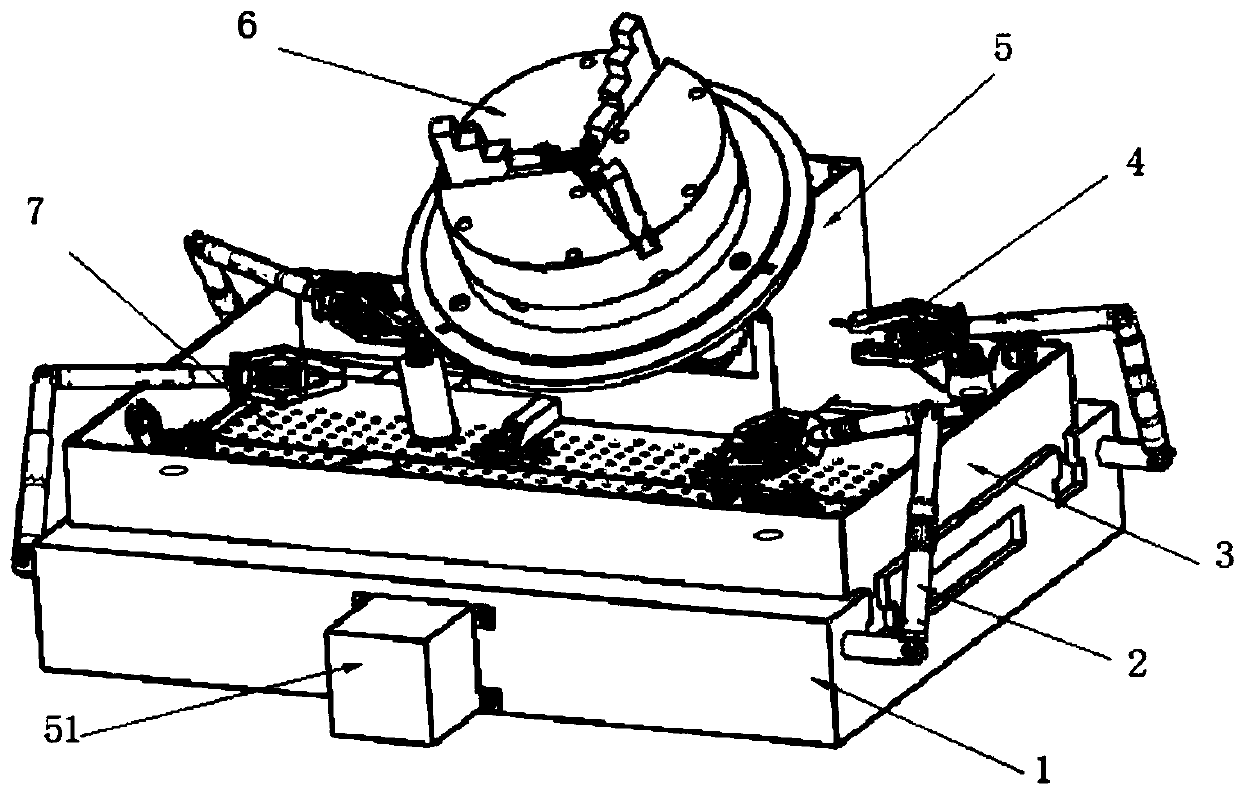

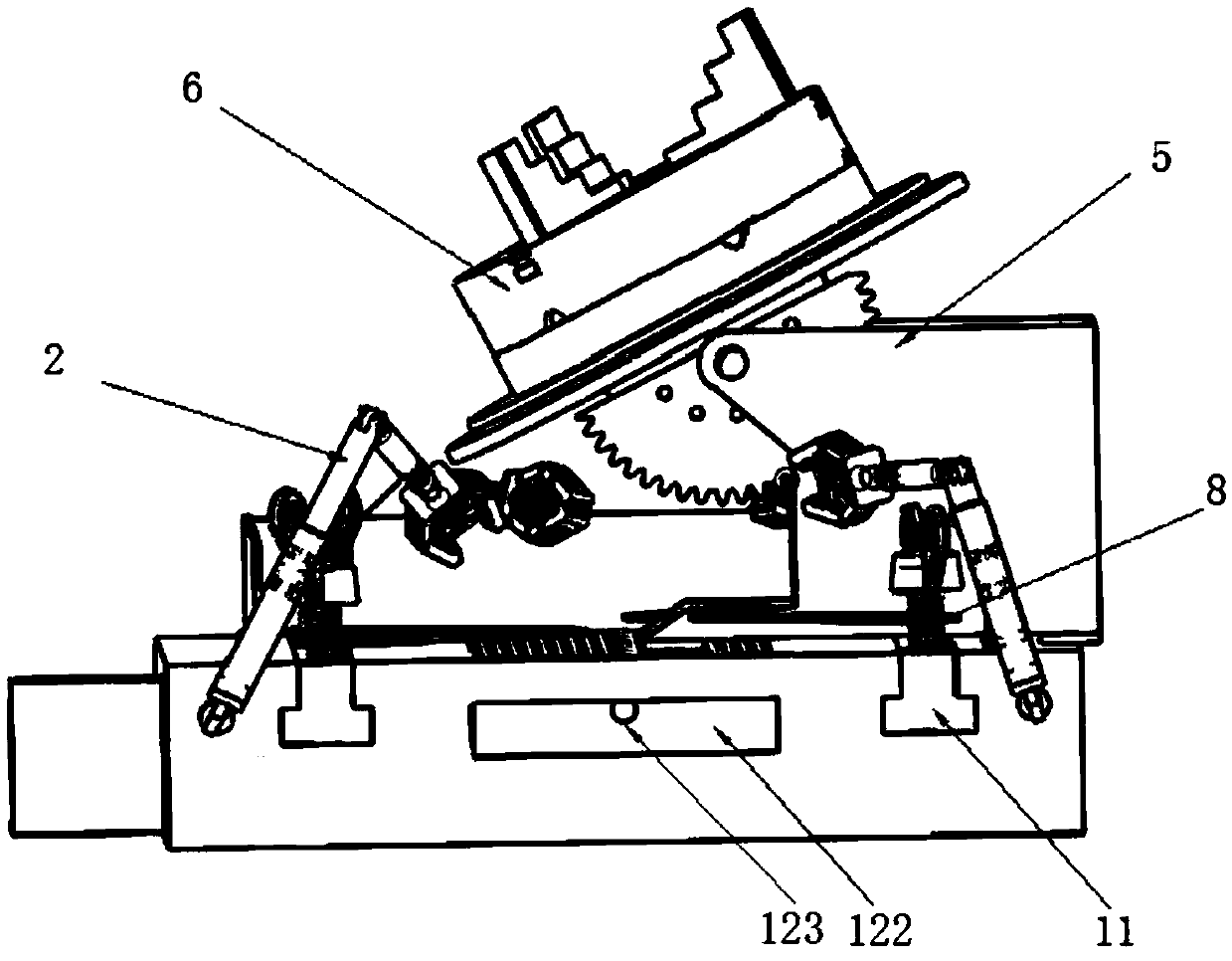

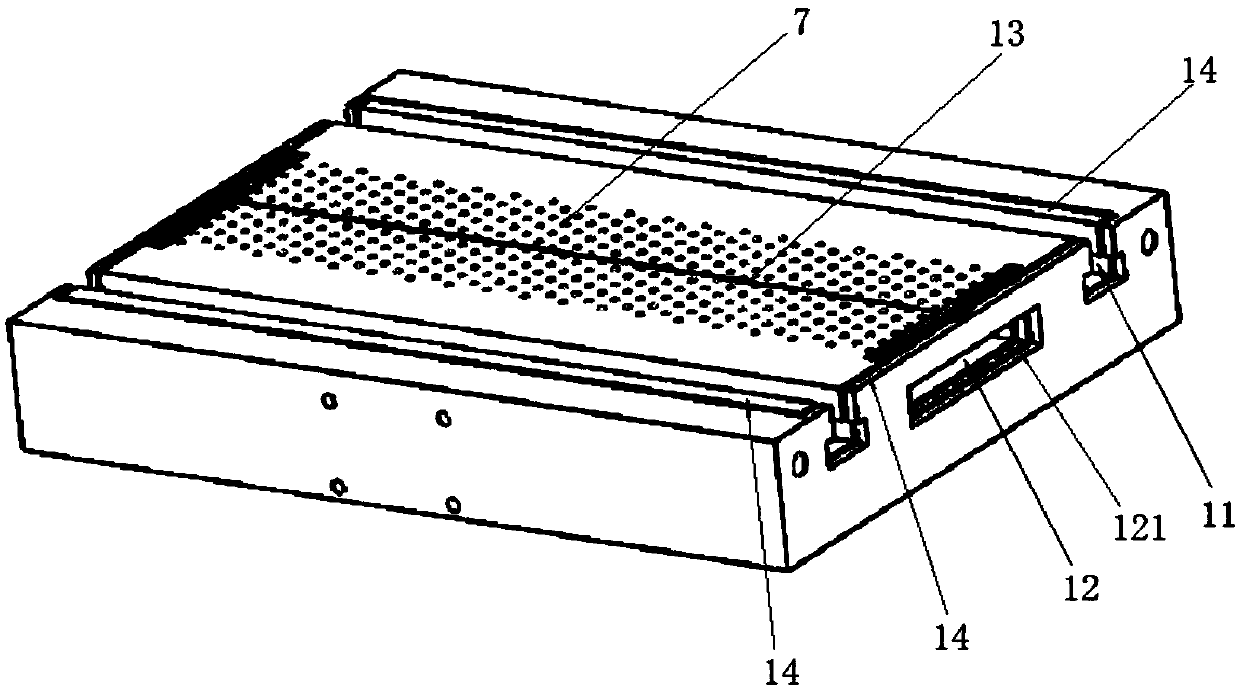

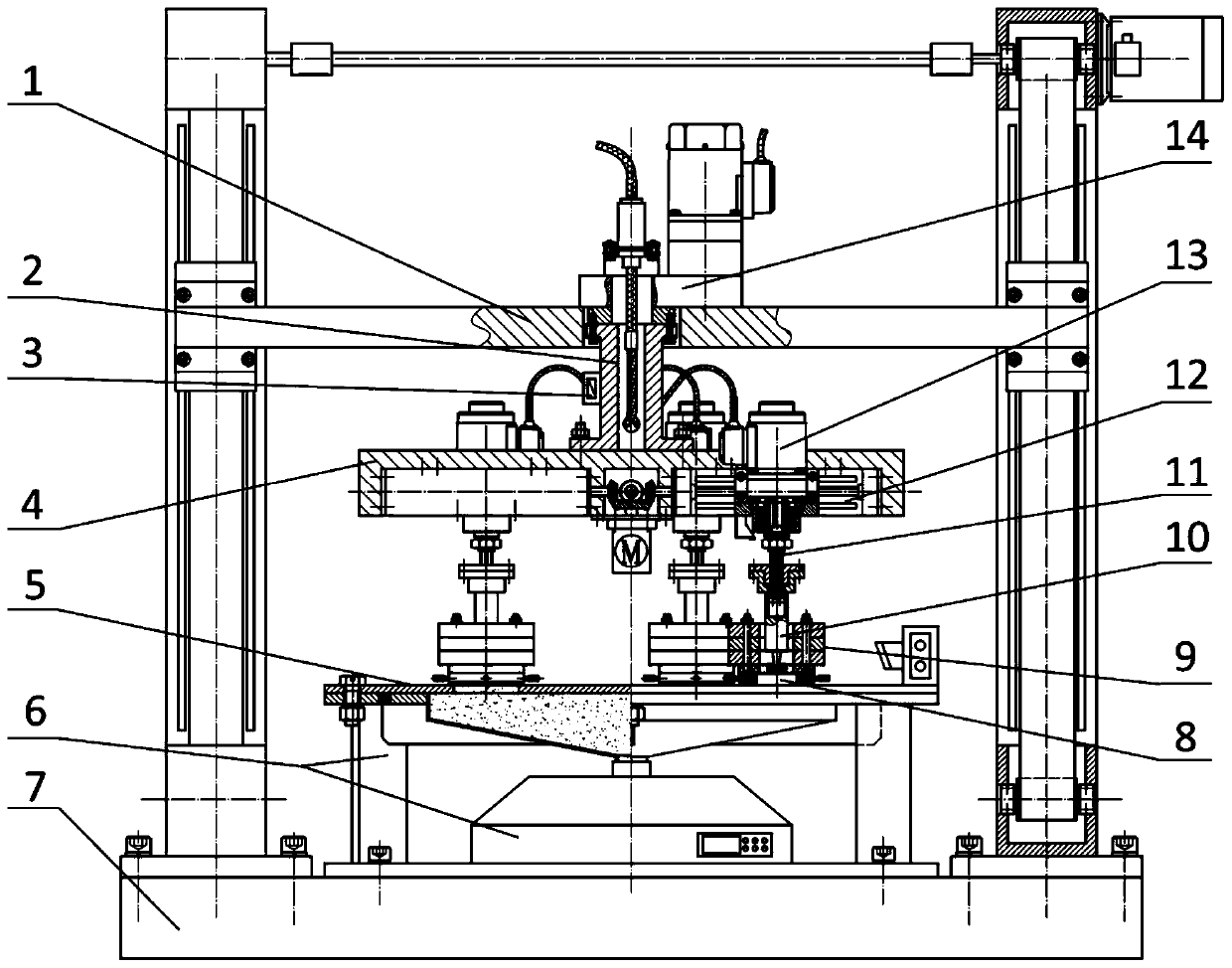

Blade type irregular hook face thin-walled workpiece laser remanufacturing multifunctional tool clamp

ActiveCN108672961AImprove cladding qualityImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesMachine controlEngineering

The invention discloses a blade type irregular hook face thin-walled workpiece laser remanufacturing multifunctional tool clamp, and relates to the field of laser remanufacturing tool clamps. The blade type irregular hook face thin-walled workpiece laser remanufacturing multifunctional tool clamp comprises a base, mechanical clamping mechanisms, a position changing machine, a three jaw chuck and apressing device. An air storage groove is transversely formed in the base. A through hole array is distributed in the part between the air storage groove and the upper surface of the base. The uppersurface of the base is provided with a penetration type T-shaped guiding groove in the transverse direction. A sliding block is arranged in the guiding groove and connected with the pressing device. The base is provided with the two-freedom-degree position changing machine. A position changing machine control box matched with the position changing machine is arranged in front of the base. The position changing machine is provided with the three jaw chuck. The mechanical clamping mechanisms are arranged at the left end and the right end of the base. The blade type irregular hook face thin-walled workpiece laser remanufacturing multifunctional tool clamp achieves high-precision forming shape and deformation control, and meanwhile the defect eliminating effect is good.

Owner:JIANGSU UNIV OF TECH

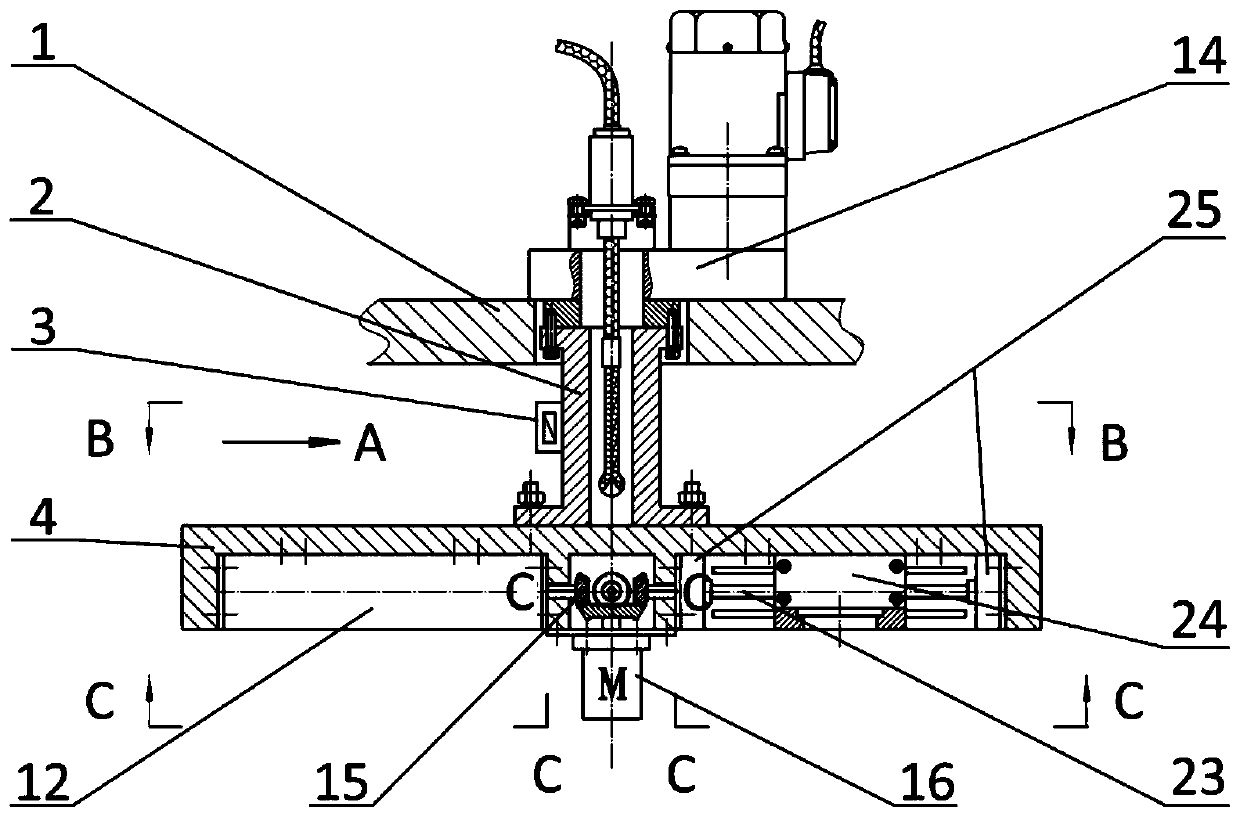

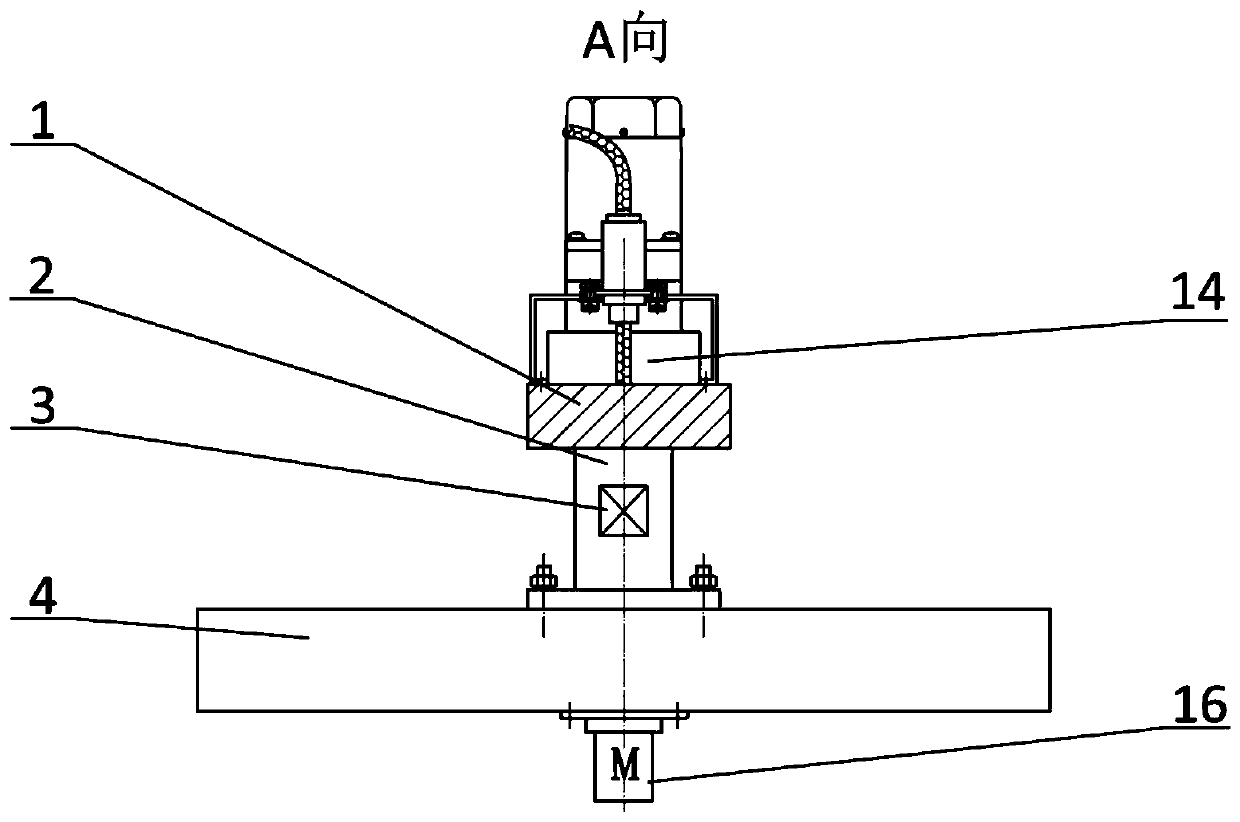

Multi-station self-adaption actuator for micro water mist polishing

ActiveCN110026903AStrong process applicabilityImprove consistencyGrinding work supportsGrinding/polishing safety devicesActuatorFace shape

The invention discloses a multi-station self-adaption actuator for micro water mist polishing. The multi-station self-adaption actuator for micro water mist polishing comprises a multi-station revolution unit, self-adaption auto-rotation units, a pressurizing and clamping unit and a mist supplying unit, wherein the multi-station revolution unit is arranged on a movable cross beam of a gantry device; and the self-adaption auto-rotation units, the pressurizing and clamping unit and the mist supplying unit are arranged under the multi-station revolution unit from top to bottom. According to the multi-station self-adaption actuator for micro water mist polishing provided by the invention, an auto-rotation motor and a precise rotary table are adopted for controlling auto-rotation and revolutionmotion, so that the independent wide-range stepless regulation of auto-rotation and revolution speeds is realized. According to the multi-station self-adaption actuator for micro water mist polishingprovided by the invention, a gravity type loading scheme based on a balance weight ring is adopted, the polishing pressure is uniformly applied to the polished surface of a crystal workpiece, so thatthe degradation of the surface figure accuracy is effectively suppressed. According to the multi-station self-adaption actuator for micro water mist polishing provided by the invention, a ball splinesliding pair is adopted for realizing the self-adaption of the axial direction of an auto-rotation axis, so that the influence of a self-flatness error of a grinding and polishing plate on the polishing movement and the pressure smoothness is avoided. According to the multi-station self-adaption actuator for micro water mist polishing provided by the invention, the multiple self-adaption auto-rotation units are adopted, so that the number of polishing stations is increased, and the polishing efficiency is remarkably improved.

Owner:DALIAN UNIV OF TECH

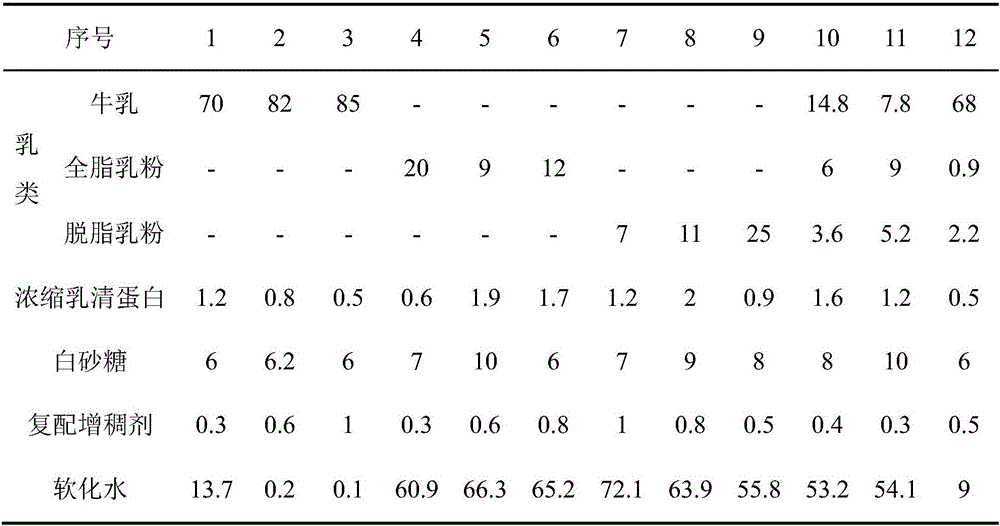

High-protein low-fat milk and production method thereof

The invention relates to high-protein low-fat milk and a production method thereof and belongs to the technical field of milk products. The high-protein low-fat milk and the production method thereof have the advantages that by formula and production method optimization, the protein content of the produced high-protein milk is increased from 2.3-3.5% to 6.0-8.0%, NRV% is increased from 4-6% to 10-13%, the milk is rich in nutrition, and a box of 250mL milk can provide 25-30% of required protein quantity for a consumer; high process adaptability is achieved, and milk material or water material can be satisfied; the production method is wide in raw material applicability and applicable to fresh milk, whole milk powder, skim milk powder or MPC whole-milk protein; meanwhile, the high-protein low-fat milk can adapt to UHT (137-140 DEG C, 3-30 seconds) sterilization and can be sold under normal temperature, the tetra pack sterilizing and filling technology allows the shelf life to reach six months, distribution channels and range are expanded, large-area popularization can be achieved, and more consumers can obtain high-quality enjoyment.

Owner:HEBEI BROS ILONG FOOD TECH LLC

Laminated lithium battery aluminum shell structure and manufacturing method thereof

ActiveCN105140429AImprove sealingImprove connection reliabilitySmall-sized cells cases/jacketsLarge-sized cells cases/jacketsEngineeringSpot welding

The invention discloses a laminated lithium battery aluminum shell structure and a manufacturing method thereof. The structure comprises a shell bottom and a shell wall, wherein the shell bottom is completely located in the shell wall, the peripheral outline of the shell bottom is attached to the shell wall with a 0-0.2 mm gap reserved on each side, and the shell bottom and the shell wall are connected through friction stir spot welding. The laminated lithium battery aluminum shell structure manufactured with the method is high in strength reliability and sealing performance, neat and attractive in appearance, and capable of improving the shape consistency of batteries.

Owner:昆山斯格威电子科技有限公司

High-accuracy-control-molded composite tap hole tubular brick and manufacturing method thereof

ActiveCN105219916AThe post-processing trimming amount is smallSave raw materialsMelt-holding vesselsManufacturing convertersBrickAntioxidant

The invention discloses a high-accuracy-control-molded composite tap hole tubular brick and a manufacturing method thereof. The composite tap hole tubular brick comprises an inner wall, an outer wall and a thin-wall barrel between the inner wall and the outer wall. Main raw materials of the composite tap hole tubular brick include high-purity magnesia, fused magnesia, graphite, antioxidants and binding agents. The manufacturing process includes the following steps of preparing, mixing grinding, green body molding, heat treating and assembling. In the mixing grinding step, the raw materials of the inner wall and the raw materials of the outer wall are independently mixed and ground. According to the high-accuracy-control-molded composite tap hole tubular brick, the length can be designed according to the requirements of steel mills, and the high-accuracy-control-molded composite tap hole tubular brick further has the beneficial effects that the amount of later-period machining finishing is small, the raw materials are saved, appearance is attractive, assembling and transporting are convenient, and integrality is high; and as the composite tap hole tubular brick is made of two kinds of fireproof materials in the diameter direction, and the ratio of the two kinds of materials is adjusted according to practical conditions of the steel mills, the beneficial effects that in the whole use process of the tubular brick, the tapping speed is relatively stable, and the quality of molten steel is relatively stable can be achieved on the premise of guaranteeing the whole service life of the tubular brick.

Owner:WUGANG REFRACTORY CO LTD

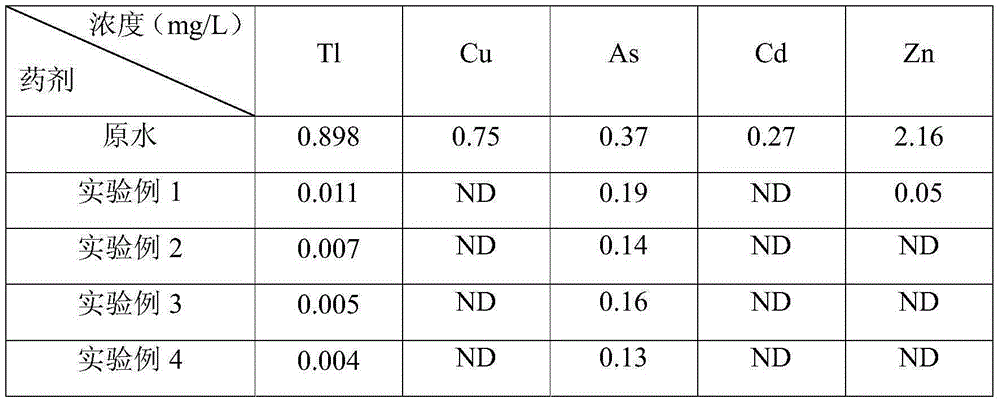

Heavy metal collecting agent and thallium-removal method used for sintering desulfurization waste water

ActiveCN105254075AAchieve simultaneous removalReduce dosageWater contaminantsMultistage water/sewage treatmentEpoxyWater treatment

The invention relates to a heavy metal collecting agent and a thallium-removal method used for sintering desulfurization waste water. The method is divided into two stages, wherein the first-stage treatment comprises the steps of adjusting the thallium-containing waste water to be alkaline, and adding coagulant; the second-stage treatment comprises the steps of adding agentia and coagulant to supernatant obtained after solid-liquid separation of the first-stage treatment, and effluent is drained outward directly after being subjected to press filtering. The agentia is prepared from, by weight, 20-30% of urea, 1-3% of linear chain small molecule amine substances, 4-9% of carbon disulfide, 0.4-0.7% of epoxy chloropropane, 0.5-0.8% of surfactant and the balance water. A preparation method comprises the steps of adding water for being mixed with urea, amine substances and epoxy chloropropane, stirring the mixture for a certain time at the room temperature, then dropwise adding carbon disulfide, continuing with the reaction, after a period of time passes, raising the temperature, continuing stirring, after the reaction is completed, lowering the temperature to the room temperature, adding surfactant, stirring the mixture uniformly, and obtaining the product. According to the heavy metal collecting agent and the thallium-removal method used for sintering the desulfurization waste water, the agentia is added to the thallium-containing waste water to be treated, and metal complex is formed after the mixture is stirred sufficiently. By means of the process, thallium and other heavy metal ions in the sintering desulfurization waste water can be effectively removed, environmental pollution is avoided, and waste water treatment cost is effectively lowered.

Owner:GUANGDONG PROVINCIAL ACADEMY OF ENVIRONMENTAL SCI

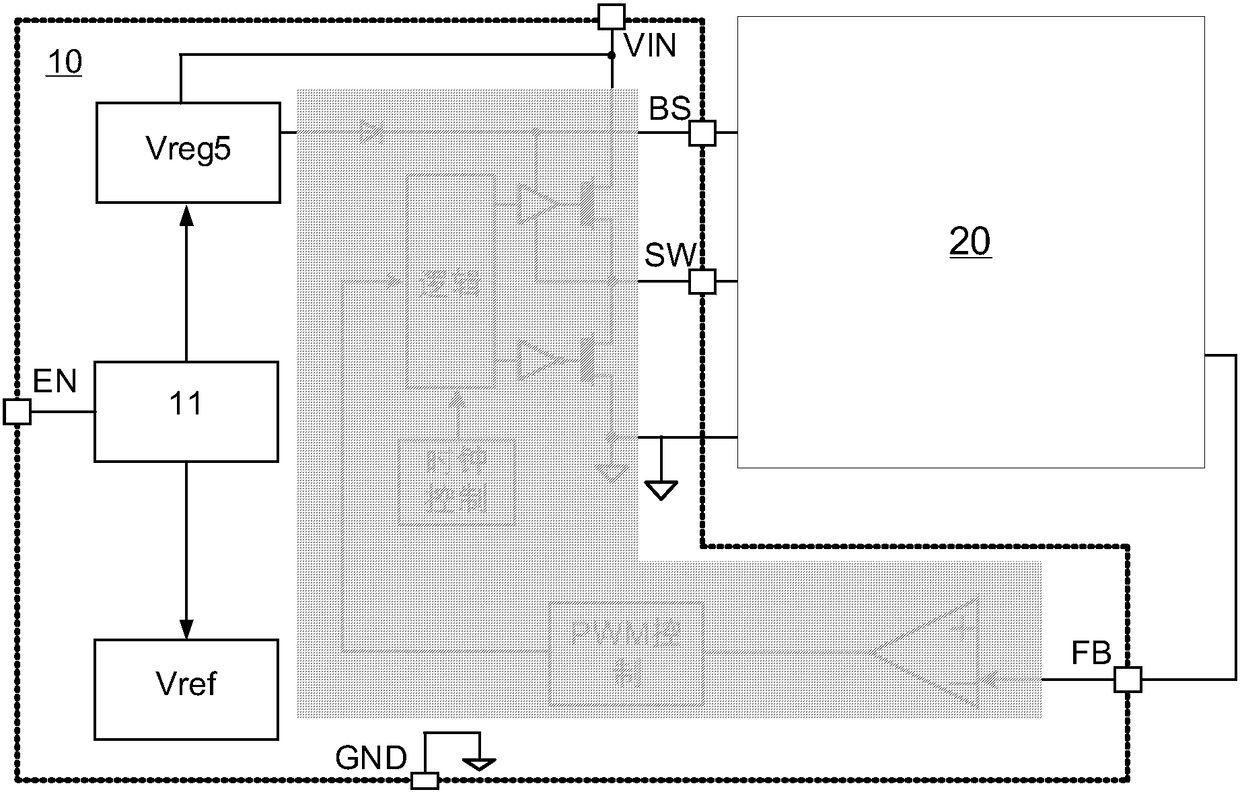

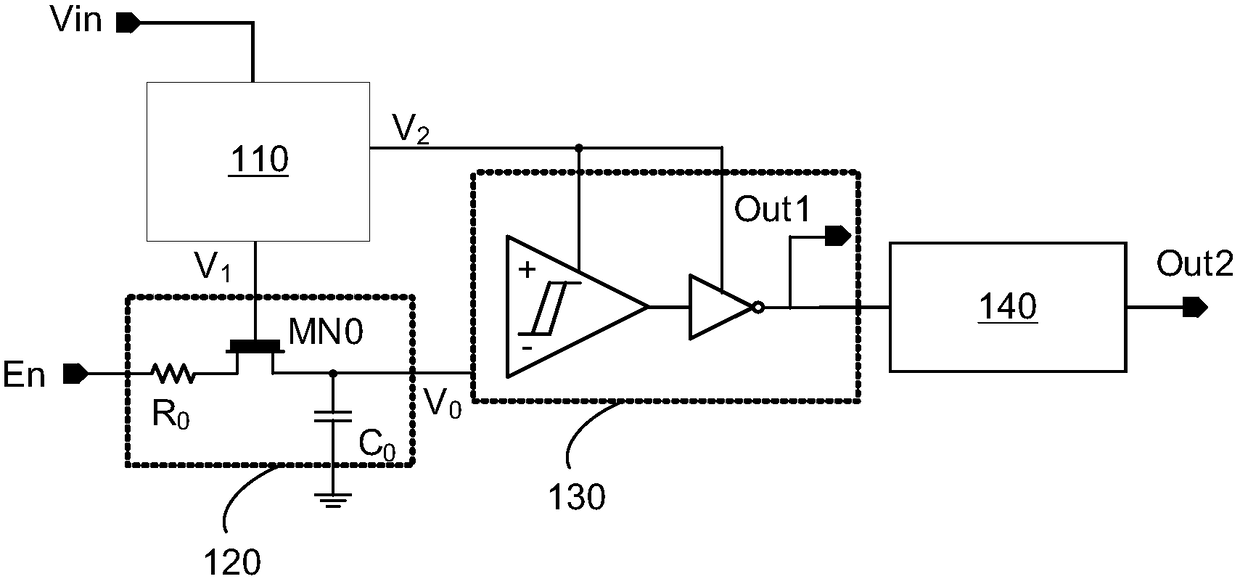

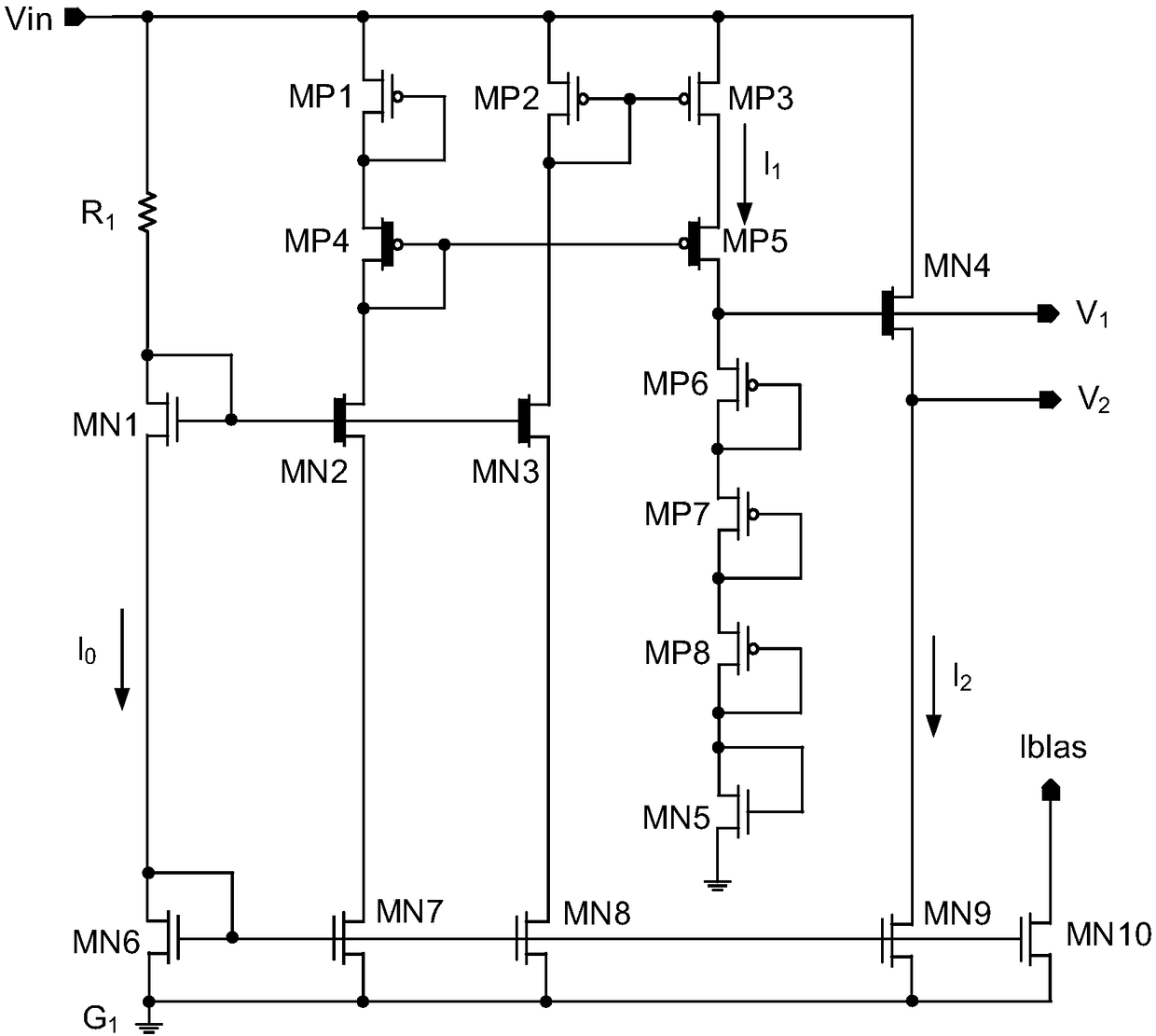

High-voltage enabling circuit for DC-DC converter

PendingCN108599544ASimple structureReduce processing costsMultiple input and output pulse circuitsVoltage measurements onlyLow voltageTerminal voltage

Disclosed is a high-voltage enabling circuit for a DC-DC converter. The high-voltage enabling circuit comprises an internal power generation unit, a voltage detection unit and a comparison judgment unit, wherein the internal power generation unit is provided with a first high-voltage power input end, a first low-voltage power output end and a second low-voltage power output end; the voltage detection unit is provided with a first detection input end, a second detection input end and a first detection output end; the first detection input end is connected to an enabling pin, and the second detection input end is connected to the first low-voltage power output end; the comparison judgment unit is provided with a first comparison input end, a second comparison input end and a first comparisonoutput end; the first comparison input end is connected to the first detection output end; the second comparison input end is connected to the second low-voltage power output end, and the first comparison output end is connected to an analog module. The high-voltage enabling circuit enables a corresponding chip to be directly connected to a high-voltage power supply without using a special process, thereby reducing the process cost.

Owner:XIAMEN YUANSHUN MICROELECTRONICS TECH +1

Preparation method of aluminum-doped cobalt hydroxide for high-voltage LCO coating material

ActiveCN110642299ALow solid contentReduce the probability of collisionPositive electrodesLi-accumulatorsSlurryAnti oxidant

The invention belongs to the technical field of preparation of lithium battery positive electrode materials, particularly relates to a cobalt hydroxide preparation method, and provides a preparation method of aluminum-doped cobalt hydroxide for a high-voltage LCO coating material, wherein the method comprises: carrying out wet co-precipitation reaction on a cobalt-aluminum mixed solution and a liquid alkali, adding an antioxidant during the process to protect the divalent cobalt from being oxidized into the trivalent cobalt, and improving the dispersity of the particles by controlling the reaction rate and the crystal nucleus growth rate; and carrying out filter pressing on the synthesized slurry, washing, carrying out low-temperature drying, and breaking by adopting a jet mill to finallyobtain an agglomeration-free aluminum-doped cobalt hydroxide finished product with D50 of less than 1 [mu]m. According to the invention, the aluminum-doped cobalt hydroxide prepared by the method is wide in aluminum doping range, wherein the aluminum doping range can reach 0.1-1%.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

Connecting structure of lithium battery plate lugs and poles and manufacturing method thereof

ActiveCN104466075AAvoid it happening againPlay the role of security protectionCell component detailsUltrasonic weldingButt joint

The invention discloses a connecting structure of lithium battery plate lugs and poles. The connecting structure comprises lugs of a multi-layer foil sheet structure formed by superposing a plurality of layers of foil sheets, wherein the plate lugs comprise a positive electrode plate lug and a negative electrode plate lug; the plate lugs are pressed and packaged by virtue of buffer foil sheet machinery; butt-joint side foil sheets of the buffer foil sheets packaging the plate plugs are superposed and pressed; the plate lugs and the buffer foil sheets are mechanically pressed for pre-connected by virtue of ultrasonic welding; poles are arranged at single-layer sides of the buffer foil sheets; the poles, the plate plugs and the buffer foil sheets are connected by welding; and the adopted welding mode is a filling type stirring friction spot-welding mode. The connecting structure of lithium battery plate lugs and poles manufactured by the manufacturing method disclosed by the invention has the advantages of good reliability and conductivity, capacity of improving the battery consistency, beautiful appearance, and relatively strong processing suitability.

Owner:昆山斯格威电子科技有限公司

Lead-free high-frequency brazing method for deformed zinc alloy grafting structure

InactiveCN102886579AShort liquefaction processReduce the degree of oxidationWelding/cutting media/materialsWelding/soldering/cutting articlesZinc alloysFiller metal

The invention discloses a lead-free high-frequency brazing method for a deformed zinc alloy grafting structure. The lead-free high-frequency brazing method is characterized by comprising the following steps of: a, inspection process: inspecting a weldment and a brazing filler metal; b, treatment process before assembling: using abrasive paper to grind a brazing part, and using acetone to clean the brazing part; c, assembling process: inserting a zinc alloy bar in an inserting hole, keeping the zinc alloy bar in an upright state and inserting the zinc alloy bar to the bottom, annularly sleeving the the brazing filler metal at a part to be brazed, and coating a brazing flux at a brazing seam; d, high-frequency sensing brazing process: adjusting specification parameters according to the type of a brazing machine to weld; and e, treatment process after brazing: timely using clear water to clean residuals at the brazing seam. Compared with the existing technology, the lead-free high-frequency brazing method has the advantages that: the lead-free brazing filler metal is used so that the working condition is greatly improved, the lead-free high-frequency brazing of the deformed zinc alloy is achieved by the the steps of assembling before brazing, the adjustment of the high-frequency sensing brazing process parameters and the treatment after brazing, the obtained brazing seam is full and smooth, and the connection strength is improved.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

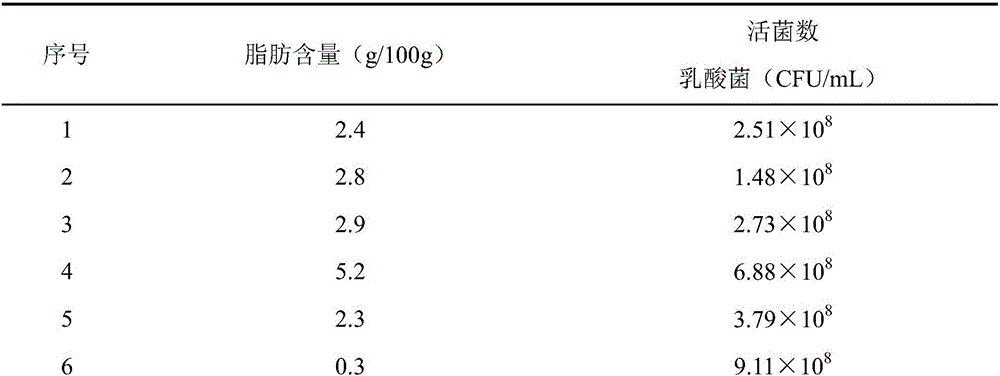

Bubble yoghurt with long shelf life and preparation method thereof

InactiveCN106359586AExtended shelf lifeExpand sales radiusMilk preparationMilk preservationEmulsionWhey protein

The invention discloses bubble yoghurt with a long shelf life and a preparation method thereof and relates to a formula of the bubble yoghurt with a long shelf life and the preparation method thereof. The invention aims at providing bubble yoghurt with high protein content, low fat content, long shelf life and high viable bacteria content and the preparation method thereof. The bubble yoghurt with a long shelf life is prepared from the components in parts by mass: milk, 0.5-2.0 parts of condensed whey protein, 6-10 parts of white granulated sugar and 0.3-1 part of compound thickening agent. The preparation method comprises the following steps: weighing of raw materials; hydration of protein and milk powder; melting; mixing to a constant volume; homogenization; sterilization; inoculation fermentation; emulsion breaking and cooling; encapsulation and post maturation; and refrigeration of finished products. The fat content of the bubble yoghurt with a long shelf life is reduced from 6.0-8.0% in the existing market products to 2.5-3.0%, beneficial viable bacteria in the yoghurt are reserved, simultaneously the shelf life is prolonged, obvious bubbles are formed after the product is shaken, and the product is uniform and stable before and after being shaken. The bubble yoghurt with a long shelf life and the preparation method thereof are used for the technical field of dairy processing.

Owner:HEBEI BROS ILONG FOOD TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com