Liquid pressure forming method of composite material

A technology of liquid pressure and composite materials, which is applied in the field of liquid molding of resin-based composite materials, can solve problems such as molding difficulties, and achieve the effects of large fiber volume content, high dimensional accuracy, and easy paving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

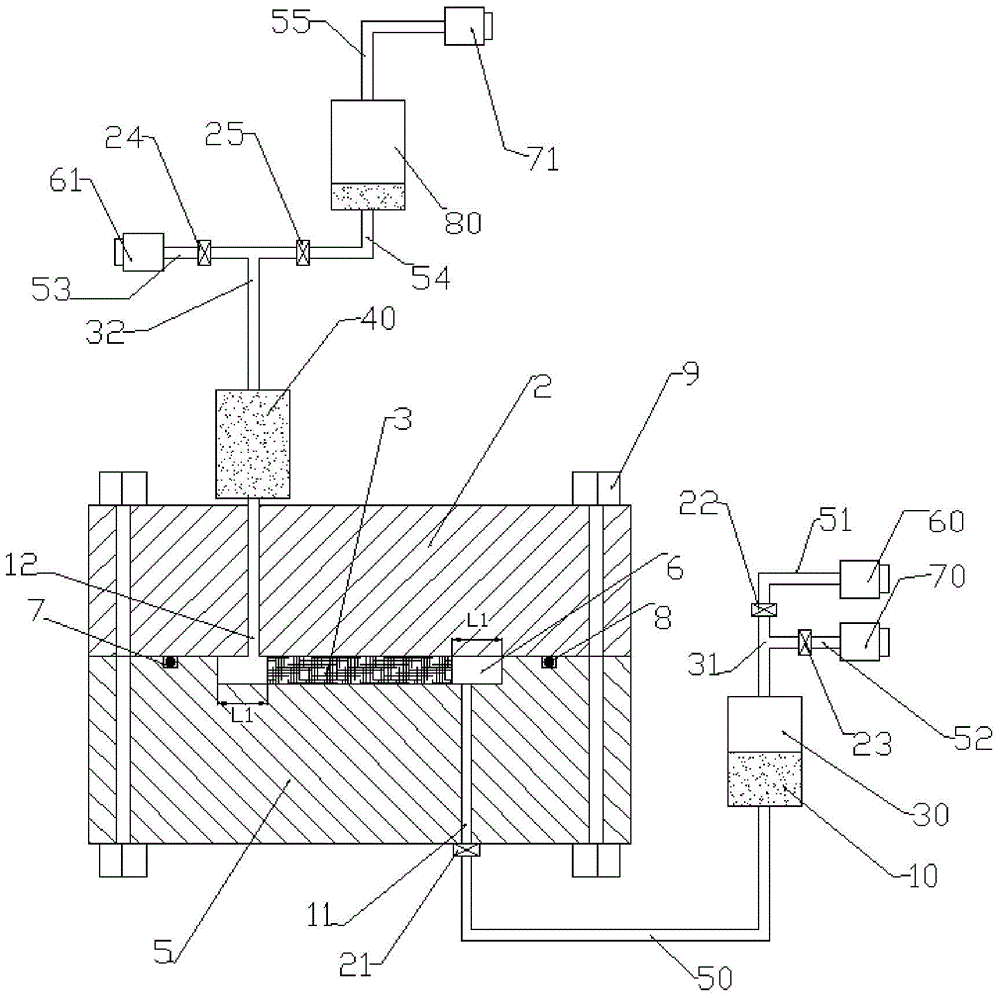

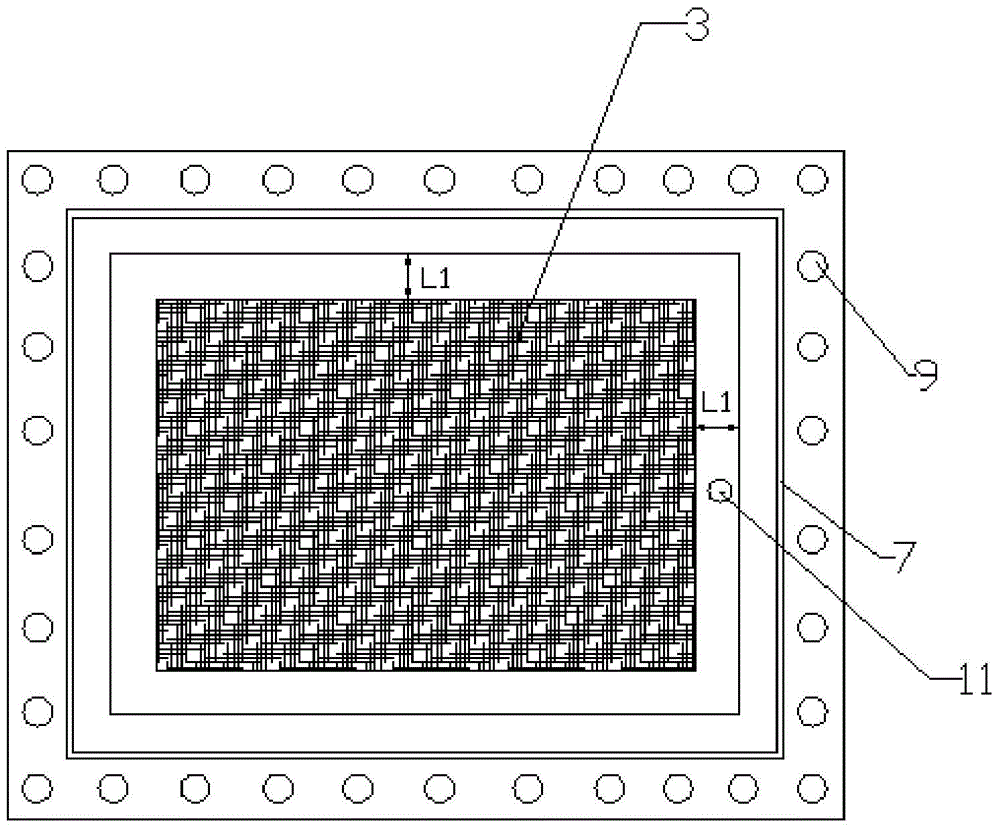

[0086] The prefabricated fabric 3 is a composite laminate structure, the material system is CF3031 / BA9914LPM, and the fiber volume content of the material is 58%±3%; CF3031 is a T300 grade carbon fiber fabric with a specification of 3K produced by Shandong Weihai Development Company, and BA9914LPM resin It is a special resin developed for the liquid molding process by AVIC Composite Materials Co., Ltd. The external dimensions of the parts are: 500mm×500mm×3.65mm (length×width×thickness), and the cavity size of the forming mold is: 600mm×600mm×3.65mm (Length × width × thickness), the design requires the tolerance range of part thickness to be ±6%, and the fiber volume content to be 58%±3%. System layout such as figure 1 .

[0087] 1. Place the laid-up pre-formed body 3 in the middle of the cavity 6 of the lower half-mold 5, and the predetermined pre-formed body 3 is 50 mm away from the edge around the cavity 6 of the lower half-mold 5;

[0088] 2. Put the sealing strip 8 in t...

Embodiment 2

[0108] Carry out as described in Example 1, the difference between Example 2 and Example 1 is that the material system in Example 2 is T800 / BA9918LPM, and the fiber volume content of the material is 60%±3%. Among them, T800 is the 12K T800 carbon fiber produced by Toray Corporation of Japan, and BA9918LPM resin is a special resin developed by AVIC Composite Materials Co., Ltd. for the liquid molding process. The external dimensions of the parts are 1000mm×800mm×2.8mm (length×width) ×thickness), the mold cavity size of the mold is 1200mm×1000mm×2.8mm (length×width×thickness); the design requires the tolerance range of part thickness to be ±6%, and the fiber volume content to be 60%±3%. System layout such as figure 1 shown.

[0109] 1. Place the laid-up pre-formed body 3 in the middle of the cavity 6 of the lower half-mold 5, and the predetermined pre-formed body 3 is 100mm away from the edge around the cavity 6 of the lower half-mold 5;

[0110] 2. Put the sealing strip 8 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com