Patents

Literature

36results about How to "Short hot pressing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Adhesive-bonded panel made of bamboo and wood and its prodn. method

ActiveCN1903529AEnsure stable qualityIncrease profitAldehyde/ketone condensation polymer adhesivesWood veneer joiningAdhesiveEngineering

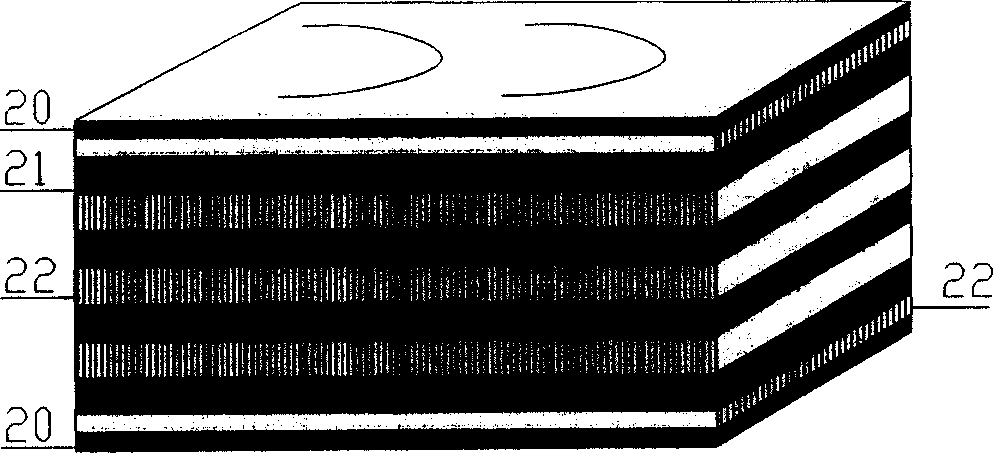

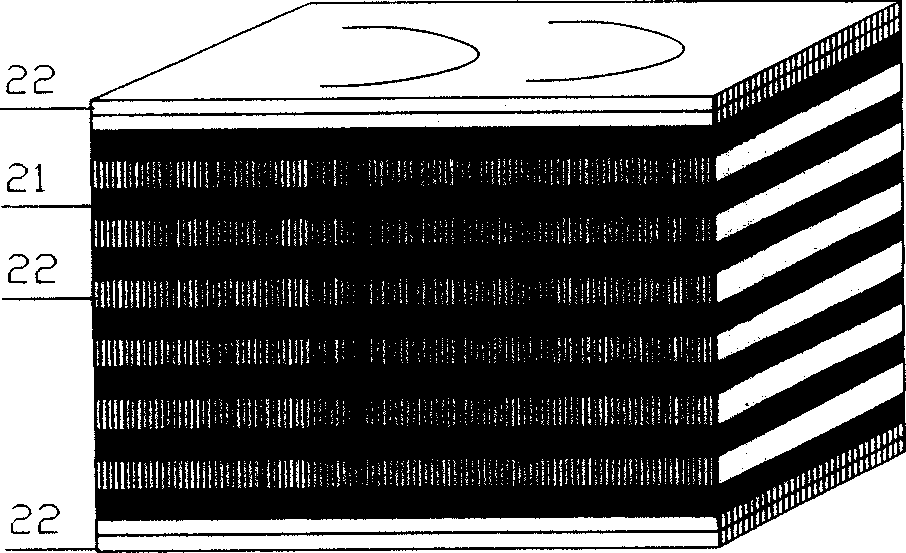

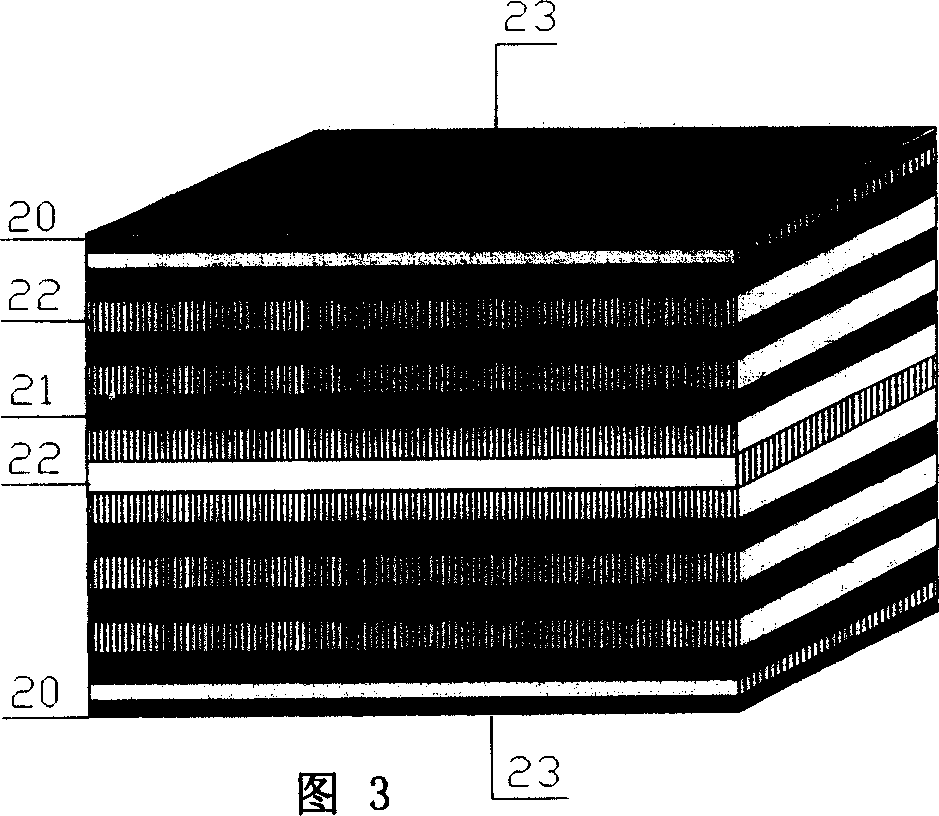

A plyboard is made up of multiple wood plys and multiple bamboo plys through alternative laminating and hot pressing.

Owner:中集新型环保材料股份有限公司

Anisotropic conductive rubber film comprising oxidation-reduction initiating system microcapsule and its preparation

InactiveCN1775884AImprove performanceShort hot pressing timeFilm/foil adhesivesElectrically-conducting adhesivesLacquerAnisotropic conductive adhesive

The invention discloses an anisotropy conductive lacquer containing oxidation reduction primosome system microcapsule. The feature is making the oxidation reduction primosome system to microcapsule and shielding its activity to achieve the effect of storing anisotropy conductive film in room temperature. The invention has advantages of high cementing reliability, good conductivity, and convenience using.

Owner:湖北省化学研究院

Substrate-free low temperature reactive hot melt adhesive tape and glue used by same, and preparation methods of hot melt adhesive tape and glue

ActiveCN108250993AQuick unblockSave equipment costPolyureas/polyurethane adhesivesMacromolecular adhesive additivesKetoneSolvent

The invention discloses a formula and a preparation method of substrate-free low temperature reactive hot melt adhesive tape. The adhesive tape consists of substrate-free dry glue and a double-sided release film or double-sided release paper; the glue is prepared from 100-150 parts of thermoplastic polyurethane, 50-150 parts of rosin glyceride, 1-40 parts of a blocked crosslinking agent, 1-10 parts of a wetting leveling agent, 1-10 parts of a defoaming agent, 1-10 parts of a rheological agent, 0.1-5 parts of an anti-aging agent and 100-400 parts of a mixed solvent of ketones and esters; the substrate-free low temperature reactive hot melt adhesive tape is prepared by coating a substrate with the glue, drying, winding, and cutting. By designing the deblocking temperature of the crosslinkingagent and the softening point of the resin, the adhesive tape can be stored and transported at room temperature, and can realize a bonding strength of 2-3 N / mm<2> at a lower heating temperature (90-110 DEG C) and a lower pressure (1-2 bar). Therefore, the substrate-free low temperature reactive hot melt adhesive tape can solve the problems that the existing low-temperature hot melt adhesive is low in bonding strength, and the low-temperature reactive hot-melt adhesive requires special storage and transportation conditions; the substrate-free low temperature reactive hot melt adhesive tape cangreatly reduce the raw material storage and transportation costs of the electronic device manufacturer, and meets the bonding requirements for small parts of the current electronic products.

Owner:SUZHOU SHIHUA NEW MATERIAL TECH

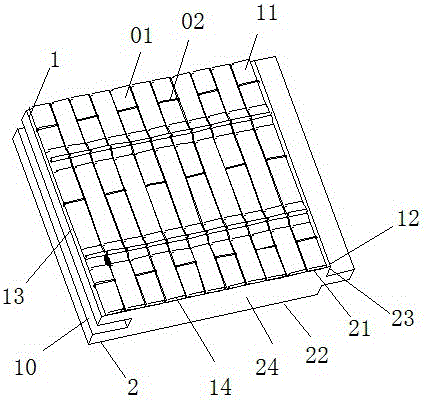

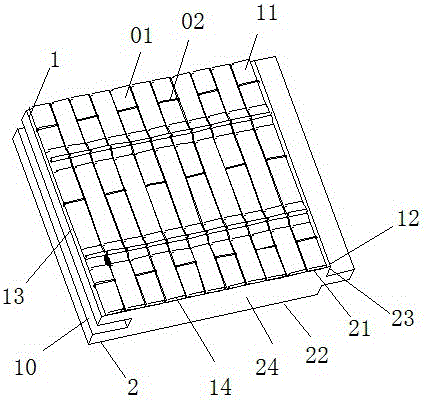

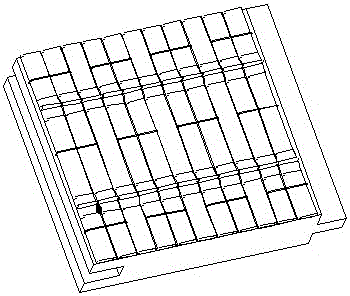

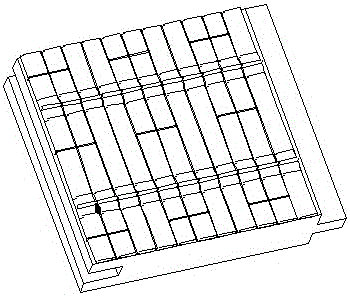

Composite strand woven bamboo floor

InactiveCN106193524AHigh strengthReduce lossCane mechanical workingWood veneer joiningFiberEngineering

The invention relates to a bamboo floor, in particular to a composite strand woven bamboo floor. The composite strand woven bamboo floor comprises a bamboo plate surface plate formed by arranging and performing hot pressing on a plurality of bamboo fiber strips and a bamboo plate base plate arranged below the bamboo plate surface plate. The bamboo plate surface plate is provided with a body, a surface plate end face, a pressed surface exposed to display a bamboo joint shape, a surface plate bottom surface arranged above the bamboo plate base plate and at least one surface plate side face formed by cutting. The base plate is provided with a base plate surface connected with the bottom surface of the bamboo plate surface plate, a base plate bottom surface opposite to the base plate surface, a base plate side face connected with the surface plate side face and a base plate end face connected with the surface plate end face. A method for preparing the composite strand woven bamboo floor comprises a step (1) of prefabrication of the bamboo plate surface plate; a step (2) of drying; a step (3) of preparation of the bamboo plate base plate; a step (4) of hot pressing; a step (5) of maintenance; and a step (6) of side cut. The composite strand woven bamboo floor is high in strength and processing efficiency and low in production cost.

Owner:ZHEJIANG YONGYU FURNITURE CO LTD

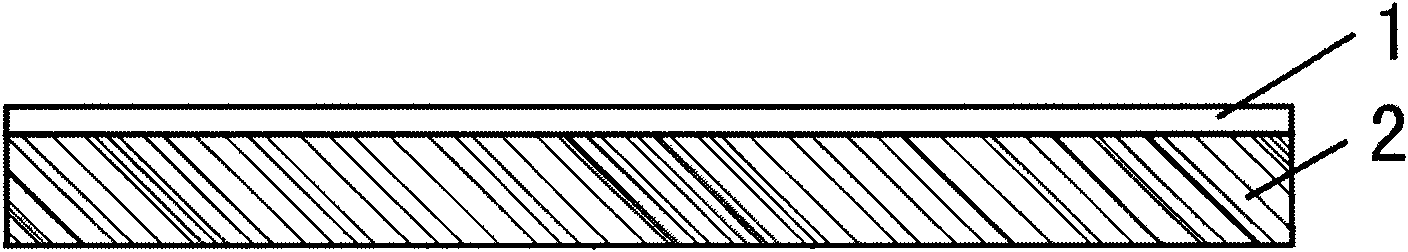

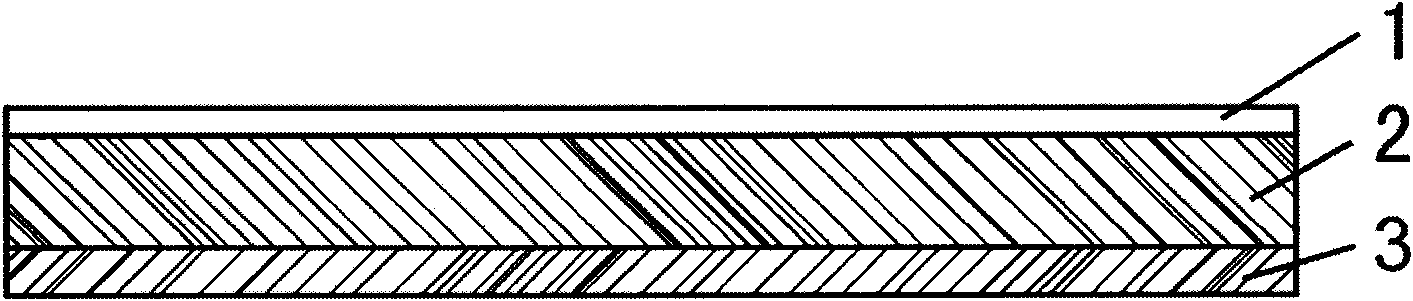

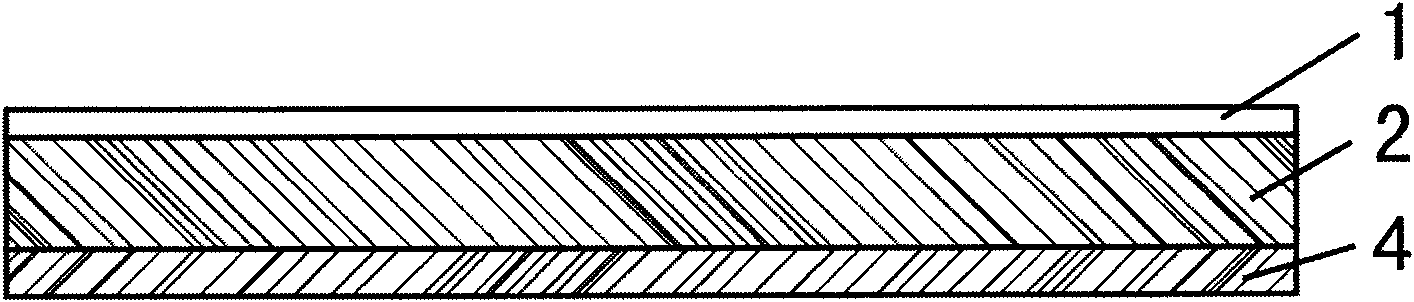

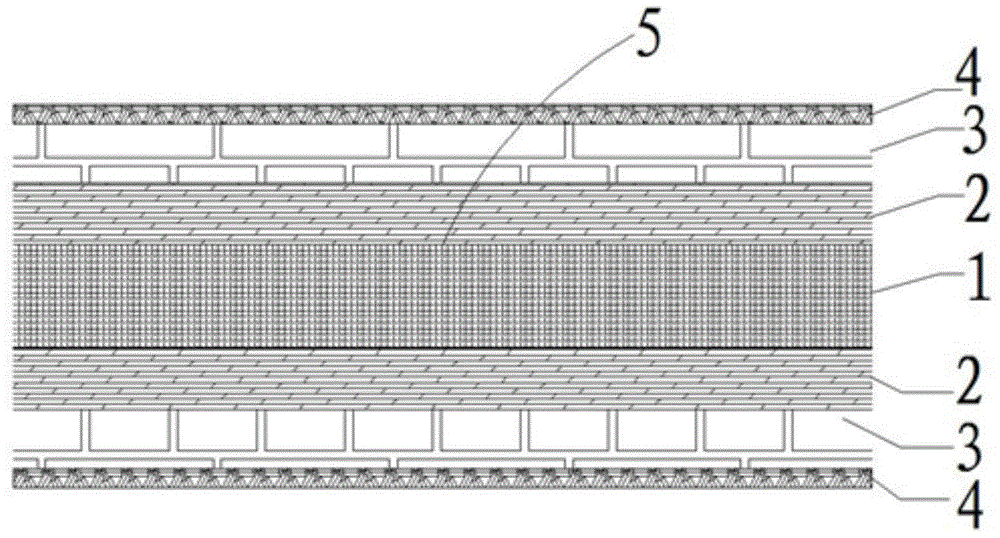

Bendable thermosetting resin impregnated paper high-pressure laminate

InactiveCN101954765AImprove waterproof performanceImprove flame retardant performanceSynthetic resin layered productsWood layered productsSurface layerEngineering

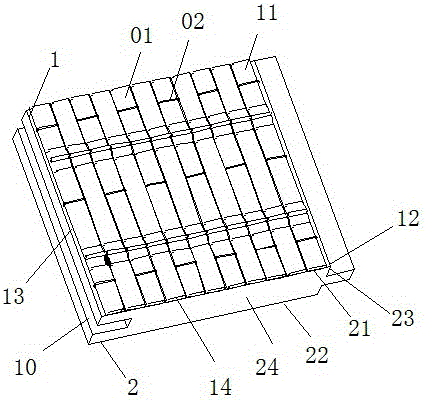

The invention discloses a bendable thermosetting resin impregnated paper high-pressure laminate which comprises a thermosetting resin impregnated paper surface layer (1) and a veneer equilibrium layer (2), and the thermosetting resin impregnated paper surface layer (1) and the veneer equilibrium layer (2) form the thin high-pressure laminate through interlayer compounding. The thermosetting resin impregnated paper surface layer (1) is an artificial board surface decoration material prepared by drying dedicated paper impregnated with initial polycondensate or prepolymer of synthetic resin. The high-pressure laminate has the advantages of good chamfer bending property, good waterproofing property, good flame resistance, good environmental protection property, convenience without surface treatment after coating, good decorative property, smoothness, cleanness, no need of painting, easy maintenance, simple production process, short thermocompression time, energy saving and high efficiency. The high-pressure laminate can be widely applied to coating lines of door pockets and door windows and can also be directly used as decorative surfaces of door plates and cupboards.

Owner:庄启程 +2

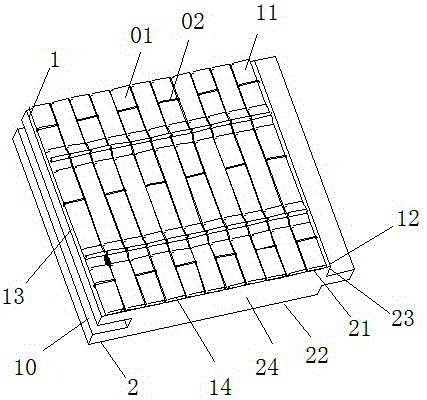

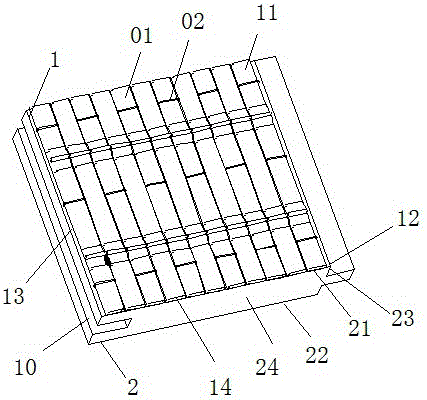

Heavy bamboo composite board

InactiveCN105965620AHigh strengthImprove processing efficiencyLamination ancillary operationsLayered product treatmentFiberWood veneer

The invention relates to a bamboo board, in particular to a heavy bamboo composite board. The heavy bamboo composite board comprises a bamboo board surface board formed by arranging multiple bamboo fiber strips and conducting hot pressing on the bamboo fiber strips and a bamboo board bottom board arranged under the bamboo board surface board; the bamboo board surface board is provided with a body, surface board end faces, a pressed surface which is exposed to show a bamboo joint shape, a surface board bottom face arranged on the bamboo board bottom board and at least one surface board side face formed by cutting; the bottom board is provided with a bottom board surface connected with the bottom face of the bamboo board surface board, a bottom board bottom face arranged to be opposite to the bottom board surface, bottom board side faces connected with the surface board side faces and bottom board end faces connected with the surface board end faces; the bamboo board bottom board is provided with more than one stress groove; a wood veneer or a bamboo filament or a bamboo bunch or a bamboo sheet or a flattened bamboo type wide-breadth bamboo board or a bamboo board bottom board formed by jointly curing first thermosetting resin and bamboo fiber strips is adopted as the bamboo board bottom board. The heavy bamboo composite board is high in strength and processing efficiency and low in production cost.

Owner:ZHEJIANG YONGYU FURNITURE CO LTD

Surface decorated wood-based panel with dermatoglyph paper impregnated thermosetting resin, and production method thereof

InactiveCN103991265AWear-resistantScratch resistantLaminationLamination apparatusProcess engineeringTransfer operation

The present invention provides a surface decorated wood-based panel with a dermatoglyph paper impregnated thermosetting resin, and a production method thereof. The method comprises: assembling a dermatoglyph stainless steel template and a buffer cushion into a single layer hot pressing machine, and placing the buffer cushion between the hot pressing plate of the hot pressing machine and the dermatoglyph stainless steel template to form a wood-based panel slab; carrying out transfer operation on the substrate by using a plurality of vacuum suction disks, and carrying out gas blowing dust removing and anti-plate overlaying adhesion treatment; and carrying out hot pressing through the hot pressing machine to form the surface decorated wood-based panel with the dermatoglyph paper impregnated thermosetting resin, wherein the hot pressing temperature is controlled to 180-190 DEG C, the hot pressing pressure is controlled to 25-28 kg / cm<2>, and the hot pressing time is controlled to 20-28 s. According to the present invention, characteristics of simple manufacturing process, easy mechanized mass production, low production cost, strong texture of the surface decorated wood-based panel, high simulation degree, beautiful and stylish property, no use of glue during production, environmental protection and cost saving are provided, and the multiple steps of the production process are improved so as to provide characteristics of energy saving and time saving.

Owner:惠州市好的板科技有限公司

Method for preparing lignin-based adhesive through enzymatic modification

ActiveCN111454690AImprove the degree of modificationHigh mechanical strengthNon-macromolecular adhesive additivesWood veneer joiningPolymer scienceActive agent

The invention relates to a method for preparing a lignin-based adhesive by enzymatic modification, which comprises the following steps: mixing alkali lignin with a compound enzyme, a mediator and a surfactant to obtain a reaction solution, and reacting for 3-3.5 hours under the conditions that the pH value is 3.5-3.8 and the temperature is 51-53 DEG C to obtain the lignin-based adhesive prepared by enzymatic modification, wherein the mediator is a mixture of ABTS, 1-hydroxybenzotriazole and vanillic aldehyde, the mass ratio of the alkali lignin to the compound enzyme is 10: (2-3) and the surfactant is Triton X-100. According to the method, the hot pressing time can be shortened, the mechanical strength is enhanced, the modification reaction efficiency is improved, and the enzyme consumption is reduced.

Owner:南宁雄晋生物科技有限公司

Combined double-sided adhesive tape structure and method

The invention relates to the technical field of mutual sticking of multiple metals and plastics, and in particular relates to a combined double-sided adhesive tape structure and a production method thereof. The combined double-sided adhesive tape structure comprises a pressure-sensing double-sided adhesive tape, a hot-pressed double-sided adhesive tape, a single-side adhesive tape and transfer release paper, wherein the upper layer is a single-side adhesive tape layer, the sticky surface of the single-side adhesive tape is downward, a self-release paper layer is connected below the single-side adhesive tape layer, an adhesive tape layer is connected below the self-release paper layer, a transfer releaser paper layer is connected below the adhesive tape layer, the adhesive tape layer comprises the pressure-sensing double-sided adhesive tape and the hot-set double-sided adhesive tape, and the release paper is arranged above each of the pressure-sensing double-sided adhesive tape and the hot-set double-sided adhesive tape. The combined double-sided adhesive tape structure is convenient to operate, a dispensing device is not required, the combined double-sided adhesive tape structure can be directly attached on a product to be stuck, the adhesive overflow quantity is very small, the combined double-sided adhesive tape structure has no peculiar smell and can not cause air pollution or bodily harm, and the hot-pressing time is short; reheating is irreversible and the separation of a cemented part can be avoided; and the combined double-sided adhesive tape structure can be directly sent to a flow line for continually performing the next process step operation after hot pressing.

Owner:郑振华 +1

Bamboo floorboard and making method thereof

InactiveCN105926898AHigh strengthImprove processing efficiencyLayered product treatmentSynthetic resin layered productsFiberEngineering

The invention relates to a floorboard, in particular to a bamboo floorboard which comprises a floorboard surface board and a core board arranged below the floorboard surface board. The floorboard surface board is jointly formed by first thermosetting resin and multiple bamboo fiber, the bamboo fiber strips are arranged in a parallel-like manner, the floorboard surface board comprises a body, a pressing surface exposed to display shape of bamboo joints, a connecting surface connected with the core board, at least one surface board side face formed by cutting and a surface board end face, and the core board comprises a core board surface connected with the floorboard surface board, a core board undersurface arranged opposite to the core board surface, a core board side face parallel to the surface board side board, and a core board end face parallel to the surface board end face. The bamboo floorboard is high in strength, high in machining efficiency and low in production cost.

Owner:ZHEJIANG YONGYU FURNITURE CO LTD

Short cycle hot press inorganic adhesive, preparation method and application thereof

ActiveCN108485535AImprove curing speedReduce brittlenessNon-macromolecular adhesive additivesMacromolecular adhesive additivesROSIN POWDERAdhesive

The invention discloses a short cycle hot press inorganic adhesive, which comprises the following components by weight: 40-60 parts of aluminum tripolyphosphate, 60-80 parts of sodium silicate, 10-15parts of phosphoric acid, 3-8 parts of a wetting agent, 6-8 parts of a toughening agent, 5-8 parts of rosin powder, 10-20 parts of bisphenol A cyanate ester resin, and 20-50 parts of water. The invention also provides a preparation method and application of the short cycle hot press inorganic adhesive. The inorganic adhesive contains the pre-locking agent bisphenol A cyanate ester resin and the initial adhesive rosin. When the inorganic adhesive is used for artificial boards, the hot press time is shorter, and the hot press time can be shortened by 50% or more. In addition, the artificial boards prepared with the inorganic adhesive have no emission of free formaldehyde or other toxic gases.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Manufacturing technology for ultra-matte artificial board

InactiveCN107487046AShort hot pressing timeRealize short-cycle pressing and pasting productionLaminationLamination apparatusManufacturing technologyBOAR

The invention discloses a manufacturing technology for an ultra-matte artificial board. A conventional matte panel with glossiness scope within 20-30GS is converted into the ultra-matte artificial board with surface modified by melamine and with glossiness scope within 3-5GS. The capacity of reflecting light of the ultra-matte artificial boar is weaker than the capacity of the conventional matte panel; through the measurement of a glossiness tester, the glossiness scope of the conventional matte panel is within 20-30GS and the glossiness scope of the ultra-matte artificial boar is within 3-5GS; under the effect of low-glossiness panel, the pattern and texture of the ultra-matte veneer are more realistic and compatible, so that the ultra-matte veneer can meet the requirement of the consumer for original natural household.

Owner:广东欣创新材料科技有限公司

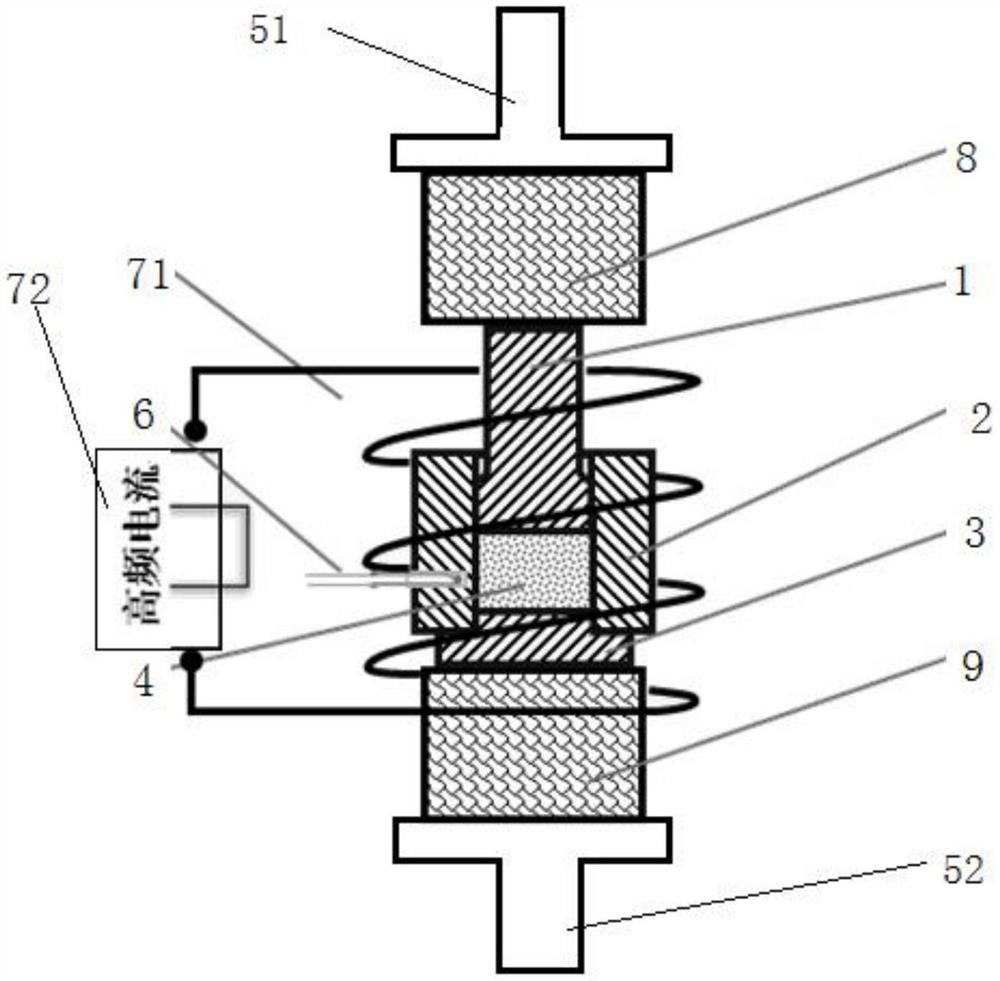

Forming method of SiCp/Al composite material

The invention discloses a forming method of a SiCp / Al composite material. The forming method comprises the following steps that 1) powder mixing is conducted, specifically, SiC particles and Al powderor Al alloy powder are evenly mixed according to the volume ratio of (10-90%): (90-10%) to obtain SiC / Al powder, the diameter of the SiC particles is 14-63 microns, and the particle size of the Al powder or the Al alloy powder is 50-150 microms; 2) cold pressing forming is conducted, specifically, the SiC / Al powder obtained through even mixing in the step 1) is put into a steel mold, and a SiC / Alblank is formed through pressurization under the stress of 50-200MPa; and 3) hot pressing sintering is conducted, specifically, under the atmospheric pressure condition, the SiC / Al blank formed through cold pressing in the step 2) is put into a hot pressing mold, hot pressing is conducted on the SiC / Al blank through a press machine and a rapid heater, and the SiCp / Al composite material is obtained after hot pressing is completed. The problems that an existing preparation method of the SiCp / Al composite material is low in production efficiency, high in process cost and high in labor cost are solved.

Owner:陕西冶焰绿陶新材料有限公司

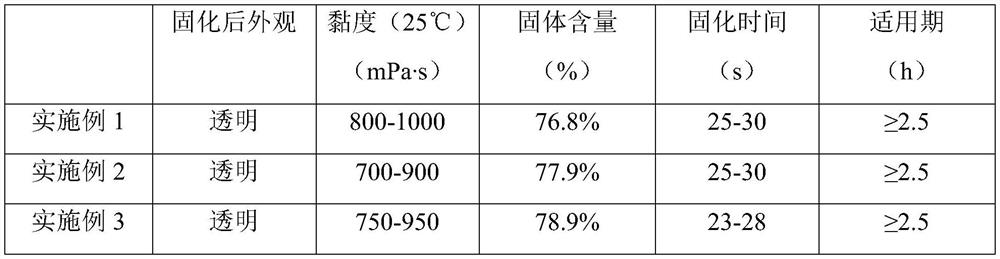

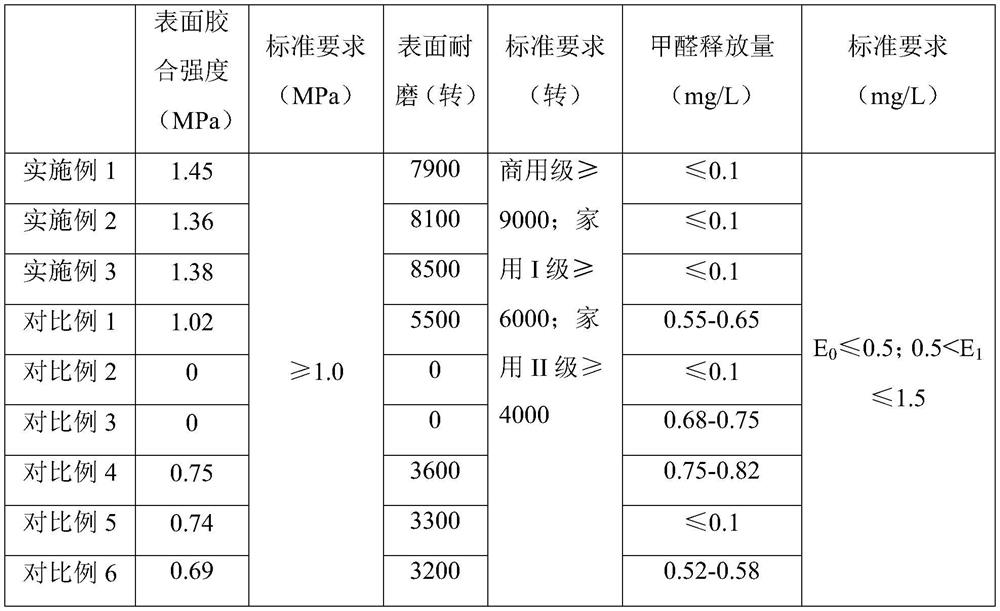

Novel water-resistant composite resin for impregnation of surface layer of laminated wood floor and preparation method of novel water-resistant composite resin

ActiveCN114134751AAppropriate molecular weightSuitable viscositySpecial paperWater-repelling agents additionPolymer sciencePtru catalyst

Owner:山东亿森美居新材料科技有限公司

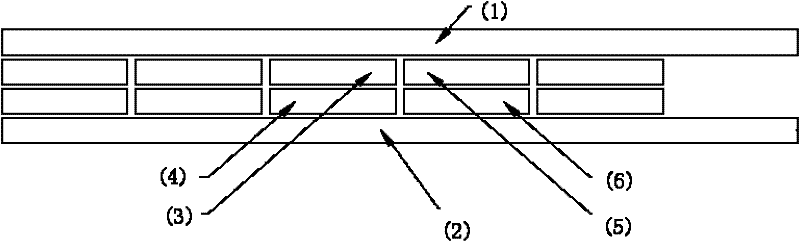

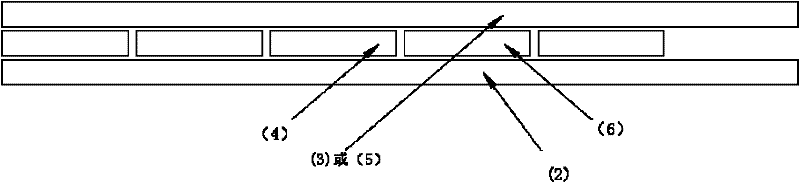

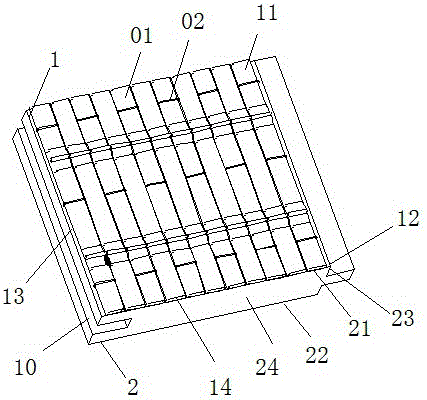

Novel composite plate and production method thereof

InactiveCN104416626AIncrease profitGuaranteed StrengthLaminationLamination apparatusWood shavingsEngineering

The invention discloses a novel composite plate. A shaving board is taken as a center layer; bamboo split plates dipped with phenolic resin glue are respectively laid on the upper and lower surfaces of the shaving board; wooden mono-plate layers are respectively laid on the upper and lower outer surfaces of the bamboo split plates; phenolic resin glue dipped paper is respectively adhered to the upper and lower outer surfaces of the wooden mono-plates. A production method of the novel composite plate comprises the following steps: step 1, preparing a shaving board by shaving a wooden sheet or a bamboo sheet; step 2, dipping the bamboo split plates in the phenolic resin glue and then removing the water; step 3, drying the bamboo split plates which are removed from water; step 4, respectively laying a bamboo split plate layer on the upper and lower outer surfaces of the shaving board prepared in the step 1; step 5, distributing glue on one surface of each wooden mono-plate, and respectively laying a wooden mono-plate on the upper and lower outer surfaces of a blank bamboo split plate; step 6, respectively adhering the upper and lower outer surfaces of the blank wooden mono-plate plates with phenolic resin glue dipped paper; step 7, pre-pressing the assembled blank plates; step 8, thermally pressing the pre-pressed blank plates; step 9, sawing and milling edges, and slitting to obtain a finished product.

Owner:上海骏雄木业有限公司

Bamboo fiber strip composite floor and preparation method thereof

The invention relates to a floor, in particular to a bamboo fiber strip composite floor. The bamboo fiber strip composite floor comprises first thermosetting resin and a floor surface board together formed by curing multiple bamboo fiber strips, wherein the floor surface board comprises a main body, a pressing surface which is exposed to display shapes of bamboo joints, a connecting surface connected with a core board, at least one surface board lateral surface formed by cutting, and a surface board end surface; bamboo fiber strip connecting pieces which transversely penetrate through multiple bamboo fiber strips and have strength in the non-parallel directions of the bamboo fiber strips are arranged in the floor surface board, and arranged in a staggered manner in the up-down directions of one or more than two adjacent bamboo fiber strips; transverse penetrating includes horizontal penetrating or inclined penetrating at an angle less than a right angle with the bamboo fiber strips; the floor surface board is a bamboo fiber strip knitted curtain hot pressing board formed by carrying out hot pressing on one layer or more than two layers of bamboo fiber strip knitted curtains; a floor bottom board is further arranged below the core board. The bamboo fiber strip composite floor disclosed by the invention has high strength, high processing efficiency and low production cost.

Owner:ZHEJIANG YONGYU FURNITURE CO LTD

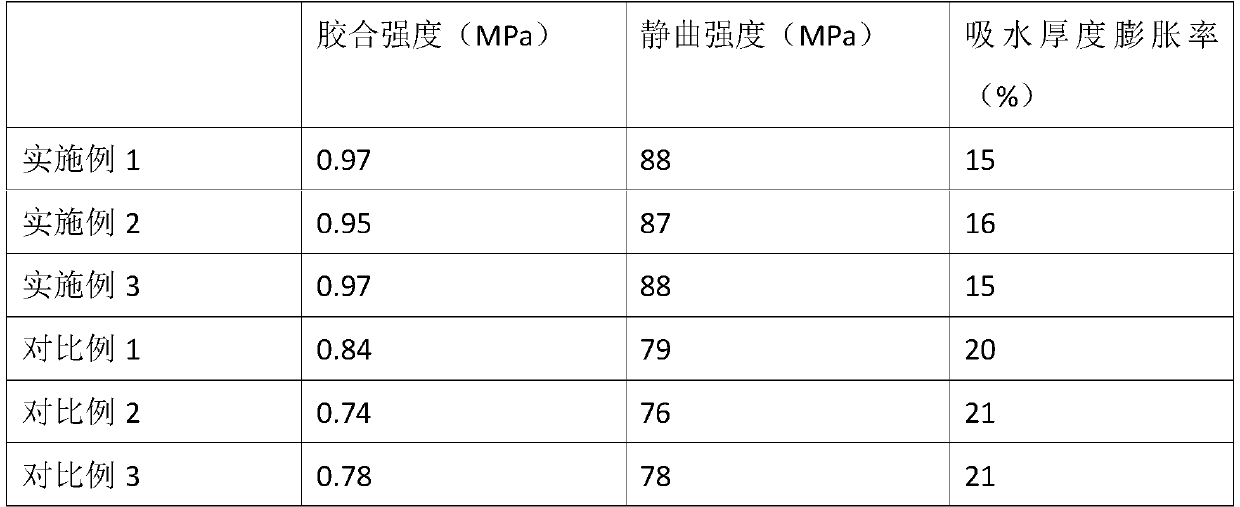

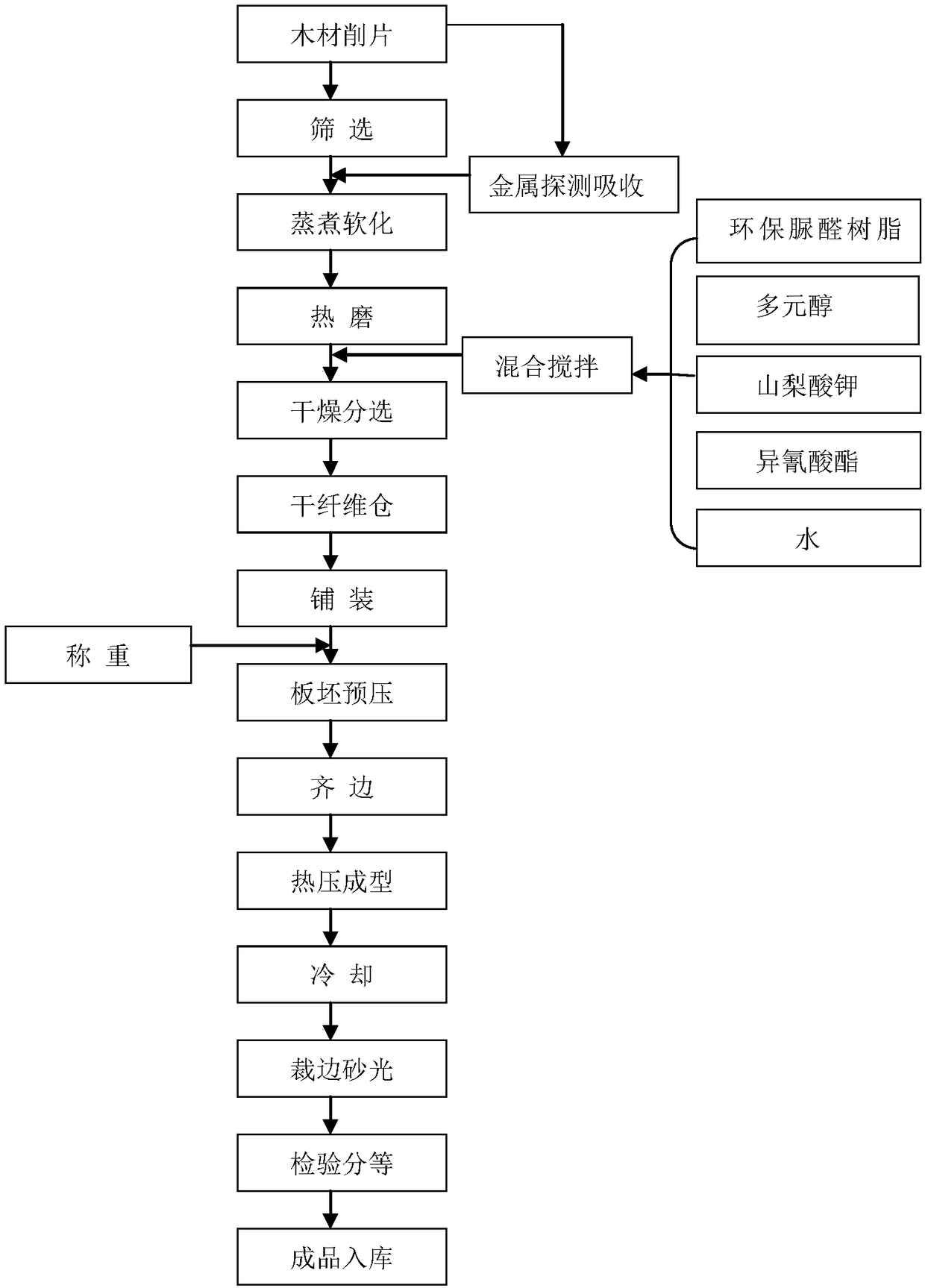

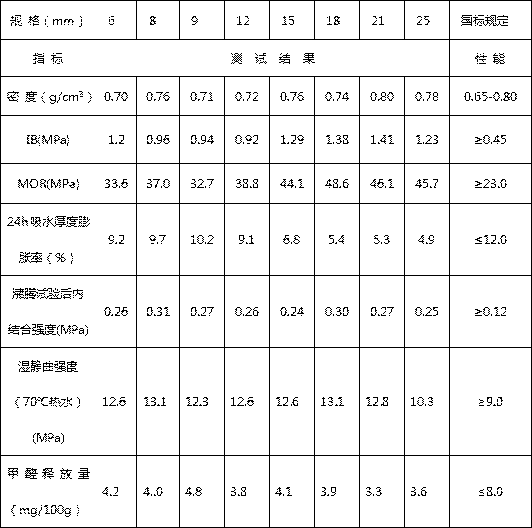

Preparation method of composite modified adhesive and manufacturing method of anti-damp fiberboard

InactiveCN109096967AShort hot pressing timeIncrease productivityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesWater resistantFiberboard

The invention provides a preparation method of a composite modified adhesive and a manufacturing method of an anti-damp fiberboard. The preparation method is characterized in that 70-80 parts of environment-friendly urea resin or melamine modified urea resin adhesive, 5-10 parts of potassium sorbate, 2-5 parts of polyatomic alcohol, 0.5-5 parts of isocyanate and 5-15 parts of water are evenly mixed according to the weight ratio, and the composite modified adhesive is obtained and applied to manufacturing of the anti-damp water-resistant fiberboard. According to the preparation method, the solidifying time of the adhesive during hot press of the fiberboard can be obviously shortened, the production efficiency is improved, the bonding strength and anti-damp performance of the fiberboard areimproved, the composite modified adhesive has the obvious advantages of high mechanical strength, good size stability and waterproof performance and the like, and the problem is solved that the fiberboard easily expands and deforms under the high-humidity environment and is poor in strength.

Owner:GUANGXI FENGLIN WOOD IND GRP CO LTD

Composite bamboo floor and preparing method thereof

InactiveCN105971224AHigh strengthImprove processing efficiencyTongue/grooves making apparatusCane mechanical workingFiberEngineering

Owner:ZHEJIANG YONGYU FURNITURE CO LTD

Compound bamboo board

InactiveCN106003277AHigh strengthImprove processing efficiencyLaminationLamination apparatusCivil engineeringHot pressing

The invention relates to a bamboo board, in particular to a compound bamboo board. The compound bamboo board comprises a bamboo board surface board formed by hot pressing of multiple bamboo fibre rods after arrangement and a bamboo board bottom board arranged below the bamboo board surface board; the bamboo board surface board has a body, a surface board end face, a pressing surface for exposing and showing bamboo joint shape, a surface board bottom surface arranged above the bamboo board bottom board and at least one surface board side surface formed by cutting; and the bottom board has a bottom board surface connected with the bottom surface of the bamboo board surface board, a bottom board bottom surface arranged opposite to the bottom board surface, a bottom board side surface connected with the surface board side surface, and a bottom board end face connected with the surface board end face. The compound bamboo board is high in strength, high in machining efficiency and low in production cost.

Owner:ZHEJIANG YONGYU FURNITURE CO LTD

Bamboo-woven floor

InactiveCN106013698AHigh strengthImprove processing efficiencyCane mechanical workingWood veneer joiningFiberEngineering

The invention relates to a floor, in particular to a bamboo-woven floor. The bamboo-woven floor comprises a floor surface board which is formed by first thermoset resin and a plurality of bamboo fiber strips in a curing mode. The floor surface board is provided with a body, a pressed surface exposed to show the bamboo joint shape, and at least one surface board side face formed in a cutting mode. Bamboo fiber strip connecting pieces which transversely penetrate through the bamboo fiber strips and have strength in the non-parallel direction of the bamboo fiber strips are arranged in the floor surface board, and are arranged in a staggered mode above and below one or more adjacent bamboo fiber strips. The preparation method includes the first step of floor surface board prefabrication, the second step of drying, the third step of core board preparation, the fourth step of hot-pressing, the fifth step of curing, and the sixth step of lateral cutting. The bamboo-woven floor is high in strength, high in processing efficiency and low in production cost.

Owner:ZHEJIANG YONGYU FURNITURE CO LTD

Writing board and production method thereof

InactiveCN103909769ASimple control processReduce the temperatureWriting boardsFiberMedium density fiberboard

The invention discloses a writing board and a production method thereof. The method includes assembling a high-luminance stainless steel template and a cushion into a single-layer hot press, and putting the cushion between a hot press plate of the single-layer hot press and the high-luminance stainless steel template; blowing and dedusting each middle-density fiber plate; covering melamine steeped bond paper on the middle-density fiber plates to form a plate blank; feeding the plate blank into the hot press, closing the single-layer hot press to start pressing, and controlling the hot press temperature at 190-200 DEG C, the hot press pressure at 25-28kg / cm<2> and the hot press time for 16-25 seconds to acquire the writing board. By the method, operation procedure is simplified, cost is reduced, and production efficiency and product quality are improved; temperature of hot press technology is low, hot press time is short, easiness in control and operation is realized, and plates does not deform and warp; product surfaces are smooth and compact, so that written words can be erased easily without any solvent.

Owner:惠州市好的板科技有限公司

A short-cycle hot-press inorganic adhesive and its preparation method and application

ActiveCN108485535BShort hot pressing timeShorten the hot pressing timeNon-macromolecular adhesive additivesMacromolecular adhesive additivesROSIN POWDERPolymer science

The invention discloses a short cycle hot press inorganic adhesive, which comprises the following components by weight: 40-60 parts of aluminum tripolyphosphate, 60-80 parts of sodium silicate, 10-15parts of phosphoric acid, 3-8 parts of a wetting agent, 6-8 parts of a toughening agent, 5-8 parts of rosin powder, 10-20 parts of bisphenol A cyanate ester resin, and 20-50 parts of water. The invention also provides a preparation method and application of the short cycle hot press inorganic adhesive. The inorganic adhesive contains the pre-locking agent bisphenol A cyanate ester resin and the initial adhesive rosin. When the inorganic adhesive is used for artificial boards, the hot press time is shorter, and the hot press time can be shortened by 50% or more. In addition, the artificial boards prepared with the inorganic adhesive have no emission of free formaldehyde or other toxic gases.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Plant fiber insect-repelling density board

PendingCN113696299AWith termite protectionReduce dosageNon-macromolecular adhesive additivesWood treatment detailsAdhesivePlant fibre

The invention provides a manufacturing method of a plant fiber insect-repelling density board. The preparation method comprises the following steps of (1) preparing materials; (2) manufacturing fiber; (3) soaking the fiber obtained in the step (2) in a flame retardant, and drying the fiber at 95 DEG C after soaking until the water content of the fiber is 40%-50%, wherein a preparation method of the flame retardant comprises the steps that 1.0 part of ammonium polyphosphate is taken and dissolved in 20 parts of water, 0.5 part of dry layered zirconium phosphate is added, the materials are stirred to be uniform, and then turbid emulsion is obtained, (4) coating the dry fiber surface with an adhesive; (5) forming a blank board in the mode of conducting pre-pressing and cutting while conducting laying; (6) feeding the formed blank board into a cold molding machine through a plate loader, and conveying the blank board into a curing chamber through a plate unloader to be cured after cold pressing, and (7) conducting demolding, airing or drying, edge cutting, sanding and thickness fixing in sequence on the cured blank board, and obtaining the plant fiber particle insect-repelling density board. The density board does not release free formaldehyde, is flame retardant, has mosquito-repellent and mothproof performance, and is friendly to the environment and human health.

Owner:江苏美标家居科技有限公司

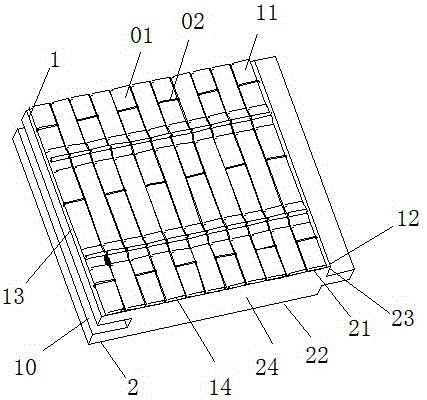

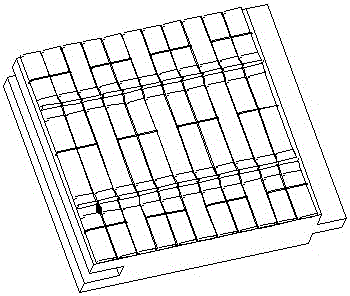

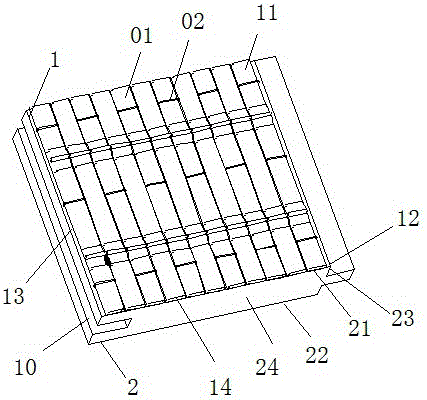

Multi-layer composite bamboo board

InactiveCN106003278AHigh strengthImprove processing efficiencyPlywood pressesLamination ancillary operationsEngineeringHot melt

The invention relates to a bamboo board, in particular to a multi-layer composite bamboo board. The multi-layer composite bamboo board comprises a bamboo board surface board and a bamboo board bottom board arranged below the bamboo board surface board, wherein the bamboo board surface board is formed in the manner that a plurality of bamboo fiber strips are arranged and then subjected to hot pressing. The bamboo board surface board is provided with a body, a surface board end face, a pressed surface naked so as to display the bamboo joint shape, a surface board bottom face arranged above the bamboo board bottom board and at least one surface board side face formed through cutting. The bottom board is provided with a bottom board surface connected with the bottom face of the bamboo board surface board, a bottom board bottom face opposite to the bottom board surface, bottom board side faces connected with the surface board side faces, and a bottom board end face connected with the surface board end face. The bamboo board surface board and / or the bamboo board bottom plate are / is internally provided with bamboo fiber strip woven curtains / a bamboo fiber strip woven curtain, wherein the bamboo fiber strip woven curtains / the bamboo fiber strip woven curtain are / is formed in the manner that the multiple bamboo fiber strips are subjected to thread sewing, thread weaving, adhesive tape bonding, hot melt adhesive tape bonding, bonding and splicing through a batten or non-woven fabric or paper slips, clamping through a clamping device or connecting and arranging through bamboo fiber strip connecting pieces. The multi-layer composite bamboo board is high in strength and processing efficiency and low in production cost.

Owner:ZHEJIANG YONGYU FURNITURE CO LTD

A kind of low-temperature reaction type hot-melt adhesive tape without base material and its glue and preparation method

ActiveCN108250993BQuick unblockMild sizing conditionsPolyureas/polyurethane adhesivesMacromolecular adhesive additivesPolymer scienceSilicone tape

The invention discloses a formula and a preparation method of substrate-free low temperature reactive hot melt adhesive tape. The adhesive tape consists of substrate-free dry glue and a double-sided release film or double-sided release paper; the glue is prepared from 100-150 parts of thermoplastic polyurethane, 50-150 parts of rosin glyceride, 1-40 parts of a blocked crosslinking agent, 1-10 parts of a wetting leveling agent, 1-10 parts of a defoaming agent, 1-10 parts of a rheological agent, 0.1-5 parts of an anti-aging agent and 100-400 parts of a mixed solvent of ketones and esters; the substrate-free low temperature reactive hot melt adhesive tape is prepared by coating a substrate with the glue, drying, winding, and cutting. By designing the deblocking temperature of the crosslinkingagent and the softening point of the resin, the adhesive tape can be stored and transported at room temperature, and can realize a bonding strength of 2-3 N / mm<2> at a lower heating temperature (90-110 DEG C) and a lower pressure (1-2 bar). Therefore, the substrate-free low temperature reactive hot melt adhesive tape can solve the problems that the existing low-temperature hot melt adhesive is low in bonding strength, and the low-temperature reactive hot-melt adhesive requires special storage and transportation conditions; the substrate-free low temperature reactive hot melt adhesive tape cangreatly reduce the raw material storage and transportation costs of the electronic device manufacturer, and meets the bonding requirements for small parts of the current electronic products.

Owner:SUZHOU SHIHUA NEW MATERIAL TECH

A writing board and its manufacturing method

InactiveCN103909769BSimple control processReduce the temperatureWriting boardsFiberVolumetric Mass Density

Owner:惠州市好的板科技有限公司

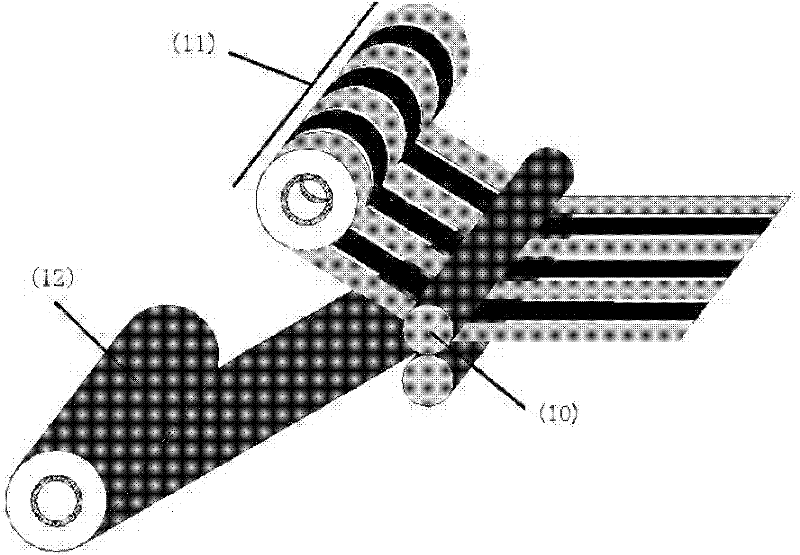

Production method for anti-deformation material-saving paint-free three-laminated composite plate

The invention relates to a production method of an anti-deformation material-saving paint-free three-laminated composite plate. A panel and a baseplate are melamine-impregnated laminated plates, and the middle plate is a lateral assembly finger-jointed fir plate. The production method includes slicing the middle plate in to stripes, extracting material of the middle plate, processing rough blanks of the middle plate, finger-jointing the middle plate, hot- pressing the middle plate, repairing the middle plate, compositely pressing the entire plate and post-processing the entire plate. Since special processing is adopted, wasted small or short fir material which is lower than 0.65 cm in thickness, 2cm in length and 1.5 cm in width can be utilized, waste of edge material can be controlled effectively, a four-side moulding procedure can be omitted during processing the rough blanks of the middle plate after the fir material is dried, mortising and finger jointing can be performed directly, energy consumption is lowered by 12%, utilizing rate of fir with diameter ranging from 8 to 10 cm is increased by more than 15% after being processed into three-laminated finger-jointed plates by calculating, and the rate of non-section plate material is increased by more than 30%.

Owner:江西益佳木业有限公司

Preparation method of low-density fiberboards

ActiveCN102152372BReduce weightReduce consumptionDomestic articlesFlat articlesFiberMelamine formaldehyde resin

The invention discloses a preparation method of low-density fiberboards, which comprises the steps of timber chipping, fiber preparation, fiber sizing, pavement, prepressing, hot pressing, and treatment of rough boards, wherein the ratio of fibers to adhesives is 10:1.2-2 in parts by weight in the step of fiber sizing, and the adhesives are prepared by mixing 90-99wt% of melamine-modified urea resin adhesive and 1-10wt% of melamine-formaldehyde resin adhesive, the mole ratio of formaldehyde to urea in the melamine-modified urea resin adhesive is 1.2:1, and the weight ratio of melamine to formaldehyde in the melamine-formaldehyde resin adhesive is 0.9:1. Low-density fiberboards with density of 450-650kg / m<3>, prepared with the method, can be used as furniture boards or loading boards. Because the low-density fiberboards have lower density than that of furniture type medium-density fiberboards, fewer timbers are consumed in production, and a great number of timber resources can be saved.

Owner:FUJIAN YONGAN FORESTRY GRP CO LTD +1

Primer disposal method for wood veneer panel

InactiveCN110665780AImprove permeabilityGood heat curing strengthPretreated surfacesProtein coatingsWood veneerPulp and paper industry

The invention discloses a primer disposal method for a wood veneer panel. An oil paint primer is replaced by soybean protein glue, and the wood veneer panel is coated by means of a gluing machine. According to the primer disposal method for the wood veneer panel, by means of a characteristic that formaldehyde-free soybean protein glue is good in heating and curing strength, the wood veneer panel is coated by means of the gluing machine, and the soybean protein glue is roll-coated by means of a heating machine of a press, so that the hot pressing time is short, the smearing is uniform, the permeating effect is good, the production period is shortened, the work efficiency is improved, and meanwhile, air is isolated and moisture is prevented from being sucked. Therefore, the panel is in a stable state for a long time, so that the perfection of furniture is guaranteed and the service life of the furniture is prolonged, too. The soybean protein glue which is formaldehyde-free and environmental-friendly is adopted, so that the production cost is lowered.

Owner:孙世权

A leather-grain impregnated film paper-decorated wood-based panel and its manufacturing method

InactiveCN103991265BWear-resistantScratch resistantLaminationLamination apparatusEngineeringTransfer operation

The present invention provides a surface decorated wood-based panel with a dermatoglyph paper impregnated thermosetting resin, and a production method thereof. The method comprises: assembling a dermatoglyph stainless steel template and a buffer cushion into a single layer hot pressing machine, and placing the buffer cushion between the hot pressing plate of the hot pressing machine and the dermatoglyph stainless steel template to form a wood-based panel slab; carrying out transfer operation on the substrate by using a plurality of vacuum suction disks, and carrying out gas blowing dust removing and anti-plate overlaying adhesion treatment; and carrying out hot pressing through the hot pressing machine to form the surface decorated wood-based panel with the dermatoglyph paper impregnated thermosetting resin, wherein the hot pressing temperature is controlled to 180-190 DEG C, the hot pressing pressure is controlled to 25-28 kg / cm<2>, and the hot pressing time is controlled to 20-28 s. According to the present invention, characteristics of simple manufacturing process, easy mechanized mass production, low production cost, strong texture of the surface decorated wood-based panel, high simulation degree, beautiful and stylish property, no use of glue during production, environmental protection and cost saving are provided, and the multiple steps of the production process are improved so as to provide characteristics of energy saving and time saving.

Owner:惠州市好的板科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com