Novel water-resistant composite resin for impregnation of surface layer of laminated wood floor and preparation method of novel water-resistant composite resin

A technology of laminated wood flooring and composite resin, applied in the direction of adding non-polymer organic compounds, special paper, water repellent, etc., can solve the problems of low energy consumption, high formaldehyde emission and fast curing speed of laminated wood flooring, etc. Achieve fast curing speed, good surface performance, and improve the effect of bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Take 300 parts of diphenylmethane diisocyanate, add 8 parts of triethylenediamine, 2 parts of polyethylene glycol monomethyl ether, raise the temperature to 60°C, then gradually add 100 parts of polyvinyl alcohol within 1 hour, and stir for 0.5 hours Finally, take 700 parts of melamine formaldehyde resin, add it to the reaction mixture of polyvinyl alcohol and diphenylmethane diisocyanate, stir for 1 hour, then cool down to room temperature, and obtain a new type of water-resistant composite resin for impregnating the surface layer of the reinforced floor.

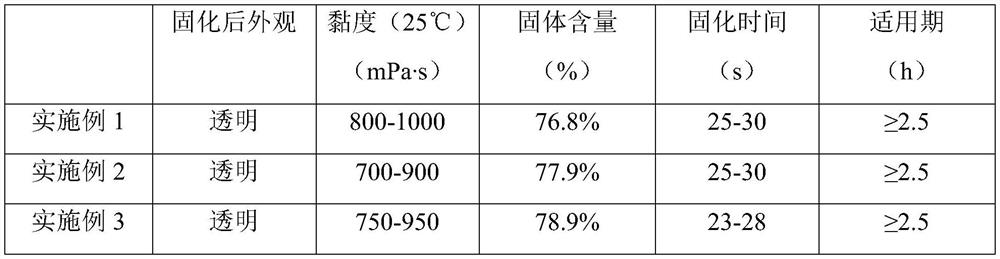

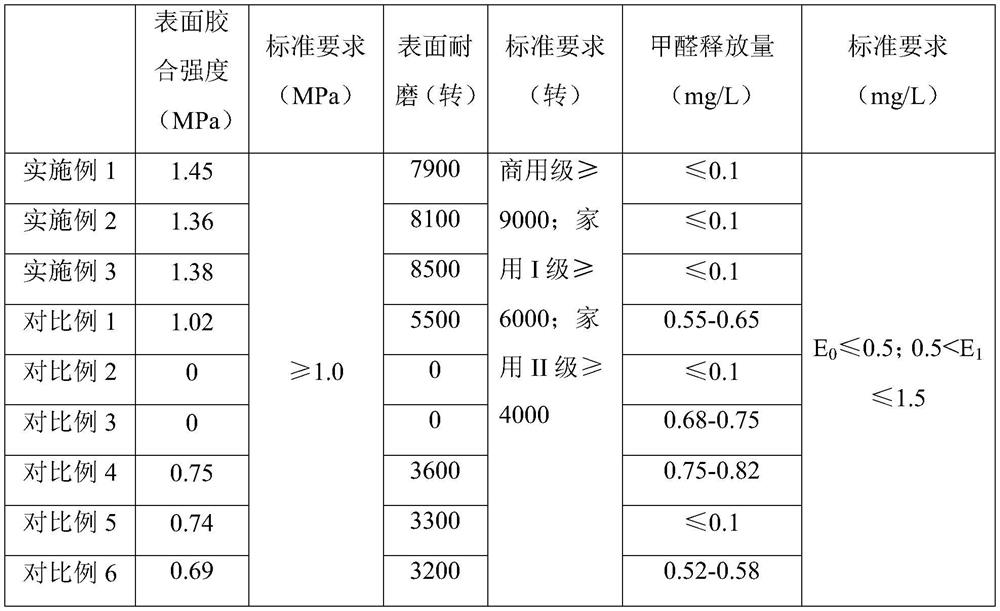

[0036] The performance index of the novel water-resistant composite resin for impregnating the laminated floor surface layer prepared in this example is shown in Table 1.

Embodiment 2

[0038] Take 400 parts of diphenylmethane diisocyanate, add 10 parts of triethanolamine, 4 parts of polyethylene glycol phthalate monoester, raise the temperature to 60°C, then gradually add 200 parts of polyvinyl alcohol within 1 hour, and stir for 0.5 hours Finally, take 900 parts of melamine formaldehyde resin, add it to the reaction mixture of polyvinyl alcohol and diphenylmethane diisocyanate, stir for 1 hour, then cool down to room temperature, and obtain a new type of water-resistant composite resin for impregnating the surface layer of reinforced flooring.

[0039] The performance index of the novel water-resistant composite resin for impregnating the laminated floor surface layer prepared in this example is shown in Table 1.

Embodiment 3

[0041] Take 350 parts of diphenylmethane diisocyanate, add 9 parts of triethylamine, 3 parts of polyoxyethylene ether, raise the temperature to 60°C, then gradually add 150 parts of polyvinyl alcohol within 1 hour, and take 800 parts of melamine after stirring for 0.5 hours The formaldehyde resin is added into the reaction mixture of polyvinyl alcohol and diphenylmethane diisocyanate, stirred for 1 hour and then cooled to room temperature to obtain a novel water-resistant composite resin for impregnating the surface layer of reinforced flooring.

[0042] The performance index of the novel water-resistant composite resin for impregnating the laminated floor surface layer prepared in this example is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com