Patents

Literature

133results about How to "Low yellow index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

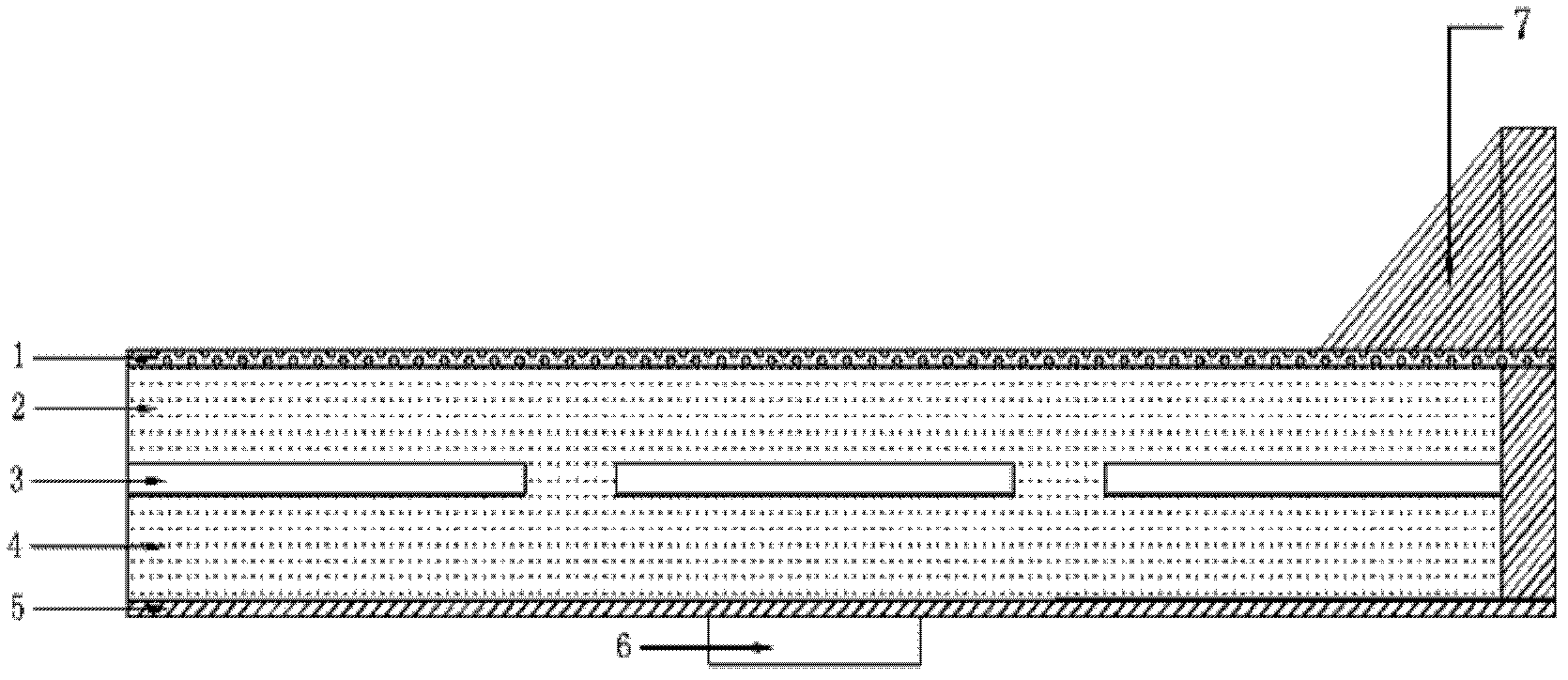

Solar cell packaging EVA adhesive film capable of resisting heat, humidity, ultraviolet light and aging

InactiveCN101626039AIncrease crosslink densityModerate reaction temperatureElectrical equipmentGlass/slag layered productsAntioxidantPhosphate

The invention relates to a solar cell packaging EVA adhesive film capable of resisting heat, humidity, ultraviolet light and aging, which comprises the following materials by weight portions: 100 portions of copolymer of ethylene vinyl acetate, 0.8-1.4 portions of crosslink curing agent, 0.05-0.15 portion of crosslink curing accelerator, 0.2-0.6 portion of tackifier, 0.1-0.5 portion of antioxidant, 0.05-0.25 portion of ultraviolet light stabilizer and 0.1-0.3 portion of ultraviolet light absorbent, wherein the crosslink curing agent is tert butyl peroxy 2-ethyl hexyl carbonate; the crosslink curing accelerator is triallyl isocyanurate; the tackifier is r-glycidyl ether oxy-propylltrimethoxysilane; the antioxidant is one or two selected from the group consisting of bis(2,4-dicumylphenyl)pentaerythritol diphosphite, distearyl pentaerythritol diphosphite, tris(nonyl phenyl)phosphate and tris(2,4-butylphenyl)phosphate; and ultraviolet light absorbent is gas phase silicon dioxide. The solar cell packaging EVA adhesive film can resist high temperature of 85 DEG C, humidity of 85 percent, ultraviolet light and thermal oxidative aging.

Owner:苏州爱康商务咨询服务有限公司

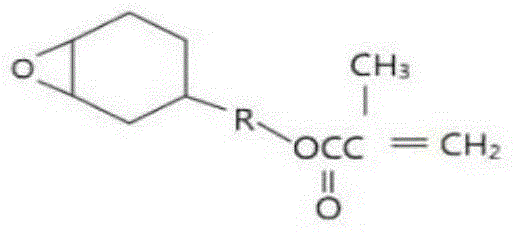

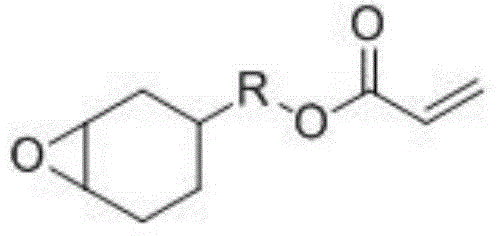

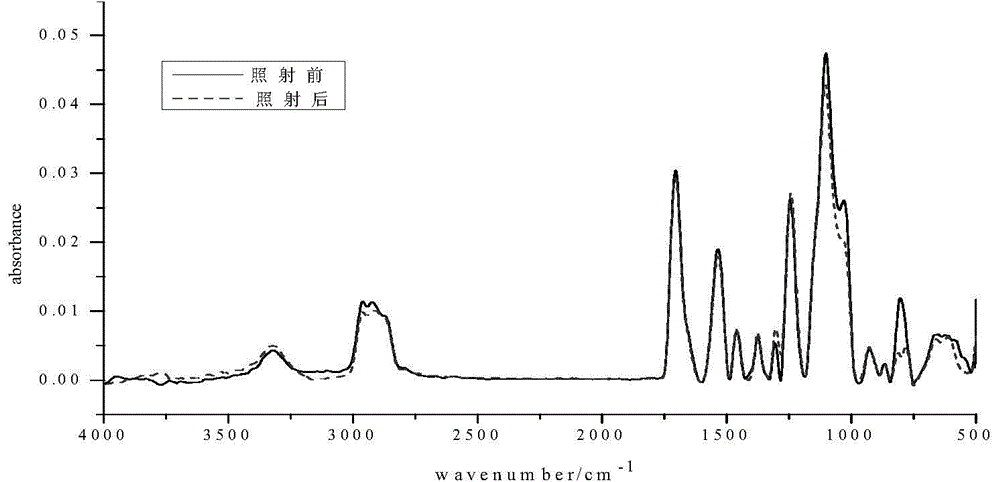

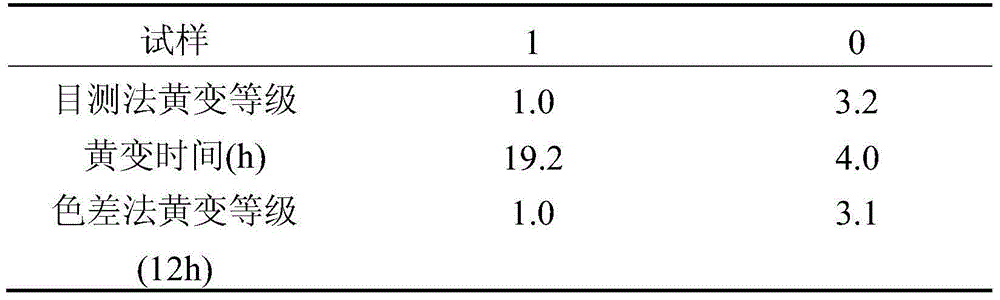

Ultraviolet-heat dual curing optical adhesive containing epoxidized polybutadiene resin

ActiveCN104449419ASynergistic priming effect is goodIncrease the polymerization rateOrganic non-macromolecular adhesivePolyolefinFast tempo

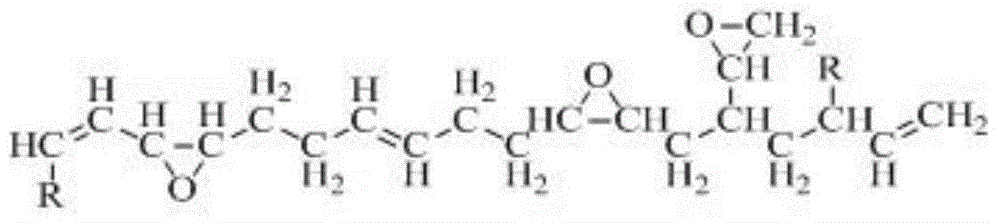

The invention belongs to the technical field of adhesives, and particularly relates to an ultraviolet-heat dual curing optical adhesive containing epoxidized polybutadiene resin. The ultraviolet-heat dual curing optical adhesive comprises the following components in percentage by weight: 14.5%-45% of epoxidized polybutadiene resin, 10%-40% of alicyclic epoxy modified resin, 5%-15% of polyolefin liquid rubber, 25.5%-35% of an acrylic ester reactive diluent, 2.4%-3.4% of a free radical photoinitiator, 0.1%-0.2% of a cationic photoinitiator and 2%-2.5% of a peroxide initiating curing agent. The optical adhesive disclosed by the invention is relatively completely solidified at a shaded part, a dark adhesive layer part or a thick adhesive layer part, has excellent optical properties such as high refractive index and high transmittance after being solidified, has the advantages of shock resistance, low yellowing coefficient, low haze, low shrinking percentage, easiness in repairing and good flexibility, meets the requirements of optical, physical and chemical properties of display devices, and is suitable for fast-tempo and high-efficiency production processes.

Owner:信泰永合(烟台)新材料有限公司

Anti-yellowing cationic water-based polyurethane leather finishing agent

InactiveCN104610870AImprove stabilityGood yellowing resistanceFibre treatmentPolyurea/polyurethane coatingsCross-linkWater based

The invention relates to an anti-yellowing cationic water-based polyurethane leather finishing agent, and belongs to the technical field of textile chemicals. The anti-yellowing cationic water-based polyurethane leather finishing agent is prepared by using polyalcohol, aliphatic diisocyanate, diethanol amine and a cross-linking agent as raw materials to synthesize cationic water-based polyurethane, and adding an antioxidant and an uvioresistant absorbent for modifying the cationic water-based polyurethane. The prepared cationic water-based polyurethane finishing agent has the advantages of high stability, yellowing resistance and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A carbodiimide composition with suppressed yellowing, a stabilizer against hydrolysis and a thermoplastic resin composition

ActiveCN1590439AImprove adhesionImprove heat resistanceOrganic chemistryChemical inhibitorsAntioxidantHeat resistance

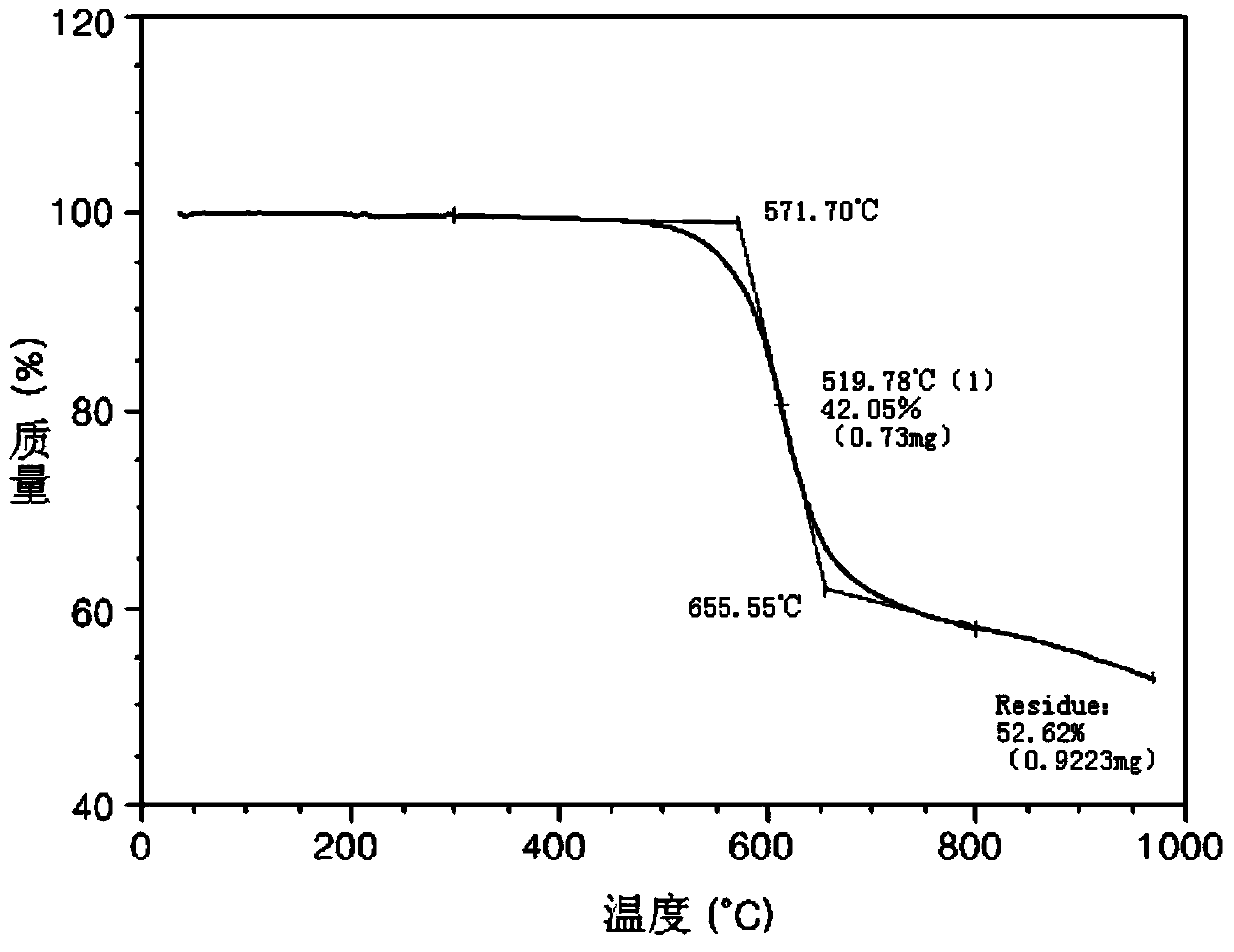

A carbodiimide composition having an improved heat resistance which had been a conventional requirement for a carbodiimide compound to be compounded in an ester-group-containing resin or a biodegradable plastic, exhibiting no coloring problems due to yellowing, and having more superior stabilizing effect against hydrolysis, a stabilizer against hydrolysis mainly comprising the carbodiimide composition and a thermoplastic resin composition containing the same. More specifically, a carbodiimide composition comprising a carbodiimide compound (A) and an antioxidant (B), having not lower than 250 DEG C of 5 % weight loss temperature as determined by a thermogravimetric (TG) method, wherein an antioxidant (B) is dispersed and present in the composition by admixing during synthesis of a carbodiimide compound (A), a stabilizer against hydrolysis mainly comprising the carbodiimide composition and a thermoplastic resin composition containing the same.

Owner:NISSHINBO IND INC

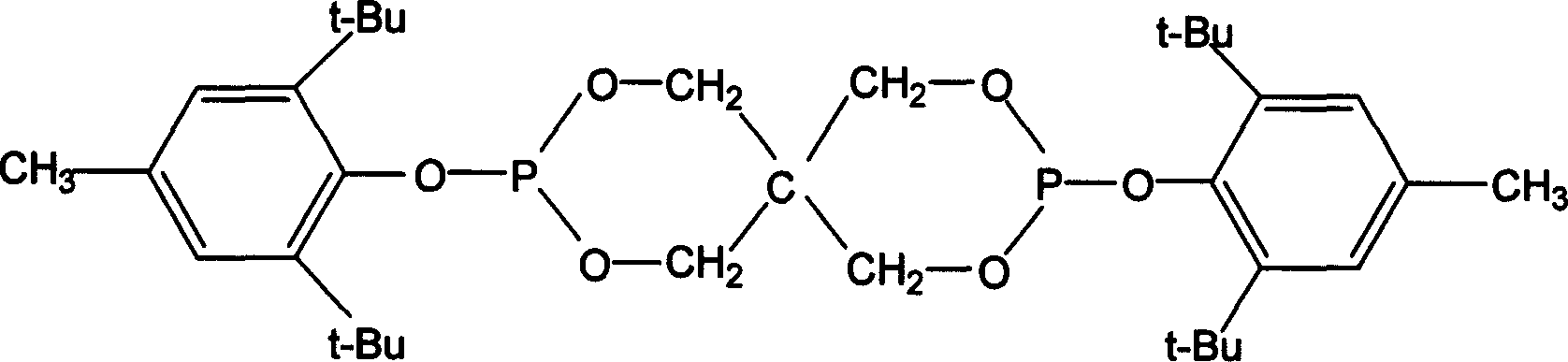

Composition with capability of providing thermal stability for polymer and application of composition

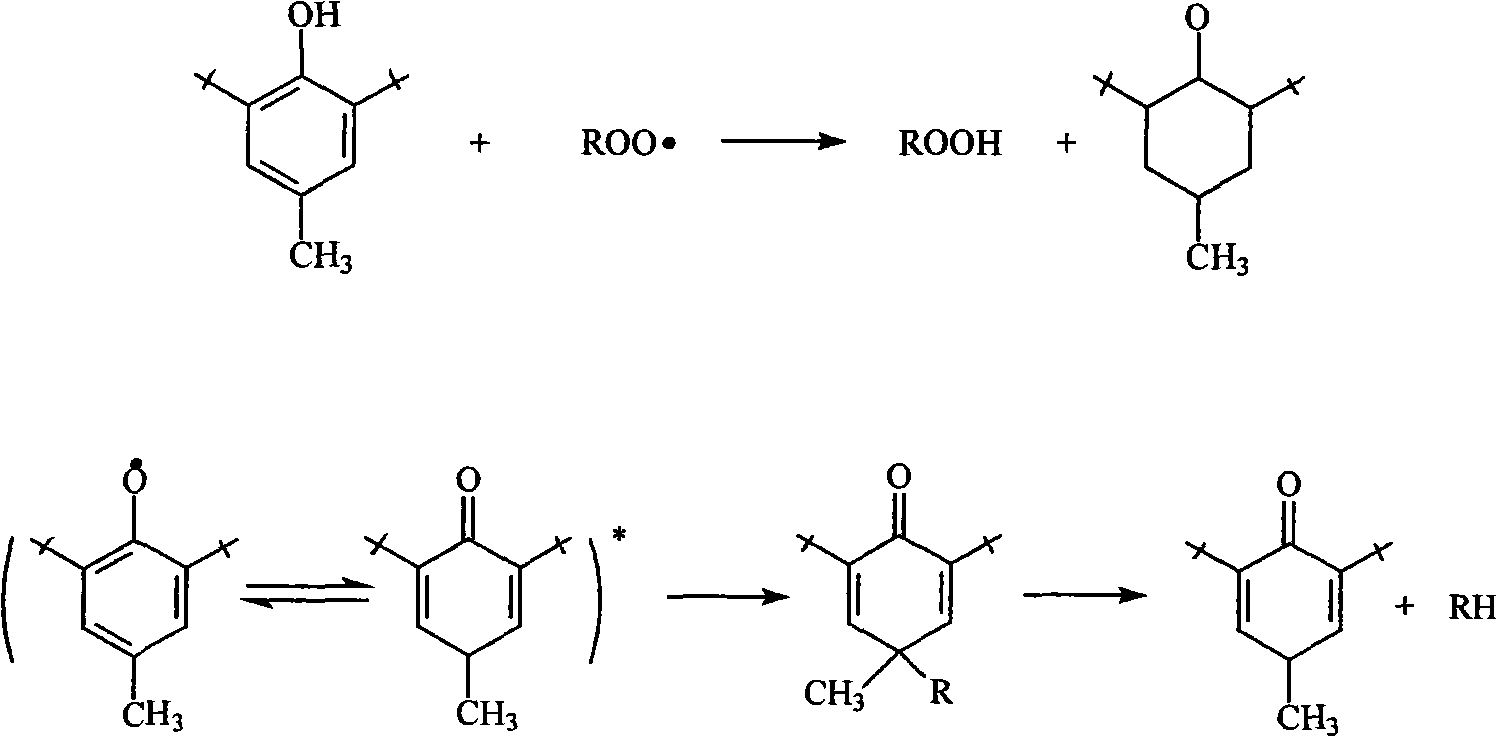

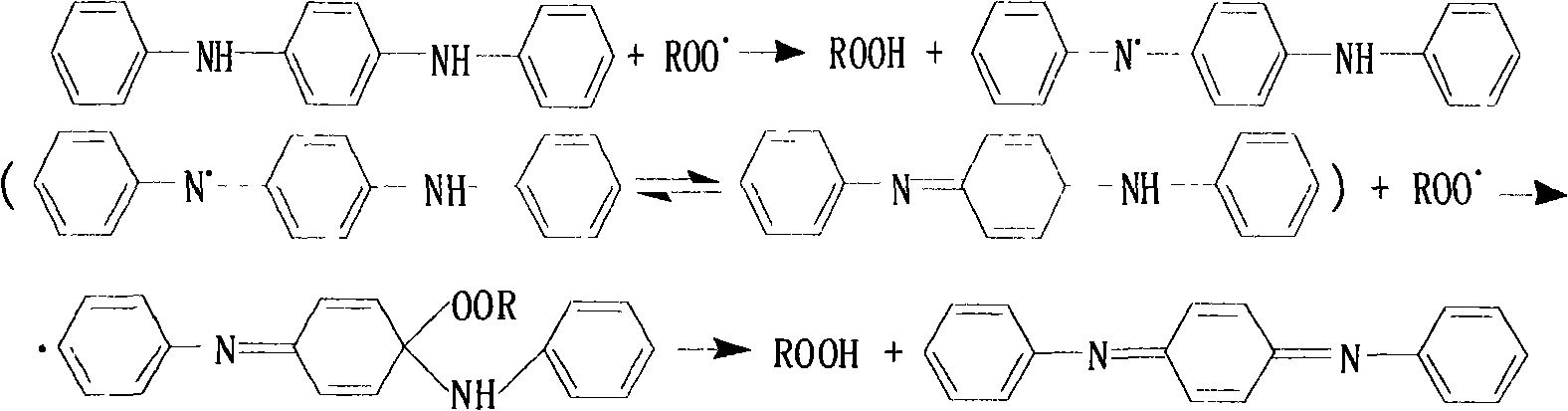

The invention relates to a composition with the capability of providing the thermal stability for polymer and application of the composition. The composition is prepared from the following raw materials: (1) hindered phenol, (2) phosphate or thioester, (3) an acid-removing agent and (4) sulfite, bisulfate or sulfide, wherein the mass ratio of hindered phenol, phosphate or thioester, the acid-removing agent and sulfite, bisulfate or sulfide is 1:(1-4):(0.5-2):(0.5-3). The invention also provides the application of the composition serving as an antioxidant in polymer resin. The composition is capable of lowering the melt index of polyolefin, eliminating a quinones compound serving as an intermediate and lowering the yellow index of polyolefin.

Owner:INST OF CHEM CHINESE ACAD OF SCI

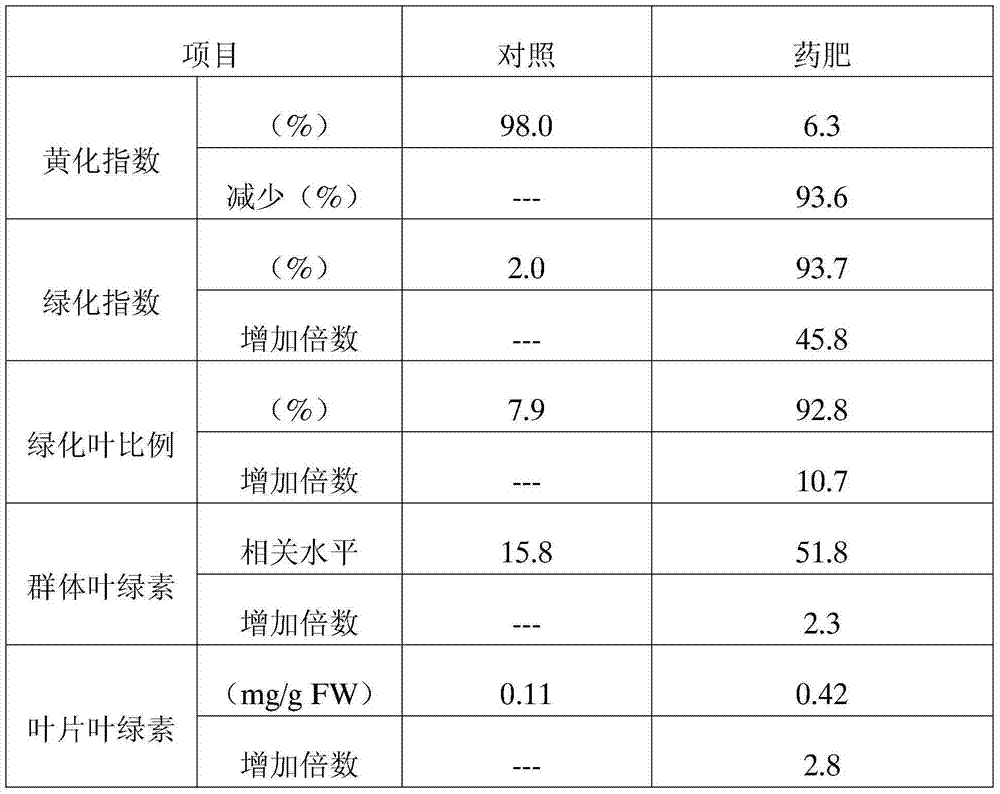

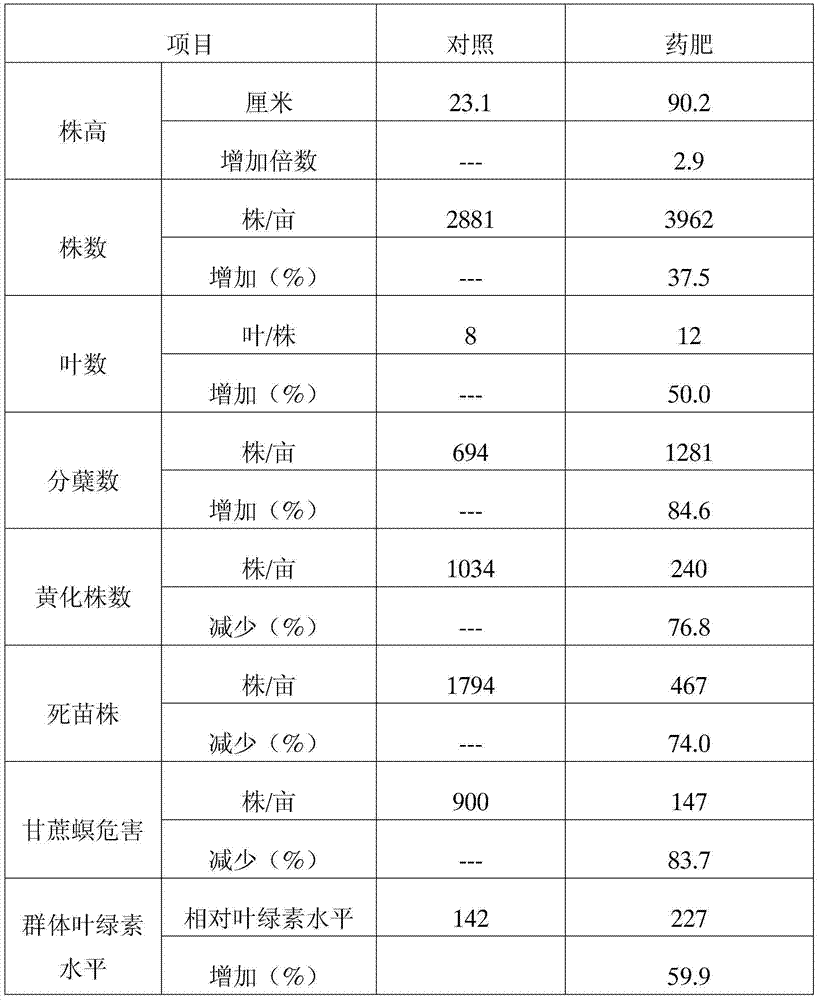

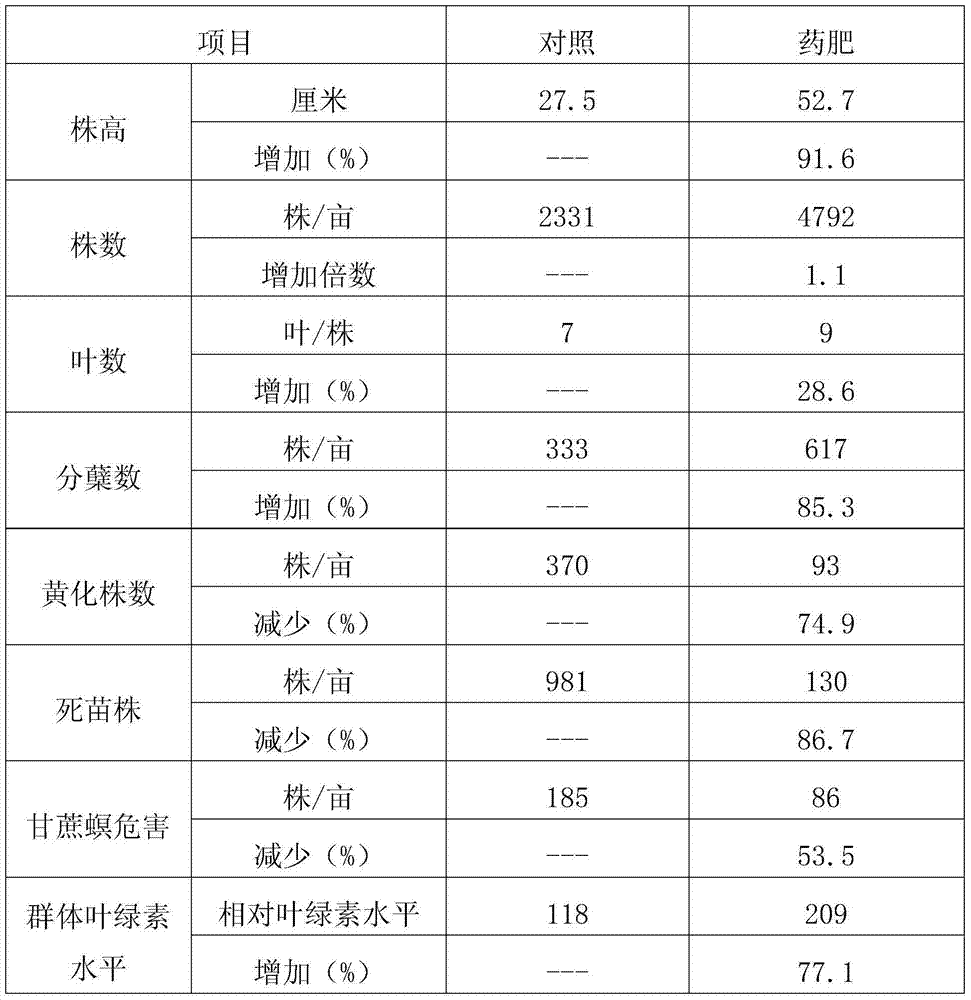

Pesticide fertilizer for preventing and treating sugarcane yellows and application method thereof

ActiveCN104261984AReduced number of etiolated plantsLow yellow indexFertilising methodsFertilizer mixturesManganeseIron absorption

The invention discloses a pesticide fertilizer for preventing and treating sugarcane yellows. The pesticide fertilizer comprises a pharmaceutical preparation and a fertilizer, wherein the fertilizer comprises the following components in parts by weight: 150-450 parts of iron fertilizer, 160-800 parts of nitrogen fertilizer, 30-100 parts of citric acid, 0.05-1 part of Tween, 0.01-0.1 part of methyl orange and 500-1500 parts of water. The pesticide fertilizer provided by the invention provides a high-efficiency iron source for sugarcanes, supplements active iron deficient in seedlings suffering from sugarcane yellows caused by excessive manganese in acid soil and eliminates an antagonistic effect of excessive manganese on sugarcane body cell iron absorption; and after the pesticide fertilizer is applied, the sugarcane seedlings suffering from yellows obviously turn green. The fertilizer for preventing and treating the sugarcane yellows is added into an insecticide, the sugarcane yellows are cured in the process of spraying insecticides to control sugarcane borers, the labor is saved, and the working efficiency is improved. A synergist for promoting fertilizer absorption and transport is added into the pesticide fertilizer, so that the performance of the pesticide fertilizer is improved, and mineral nutrition in urgent need of the greened sugarcane seedlings is provided.

Owner:GUANGXI UNIV

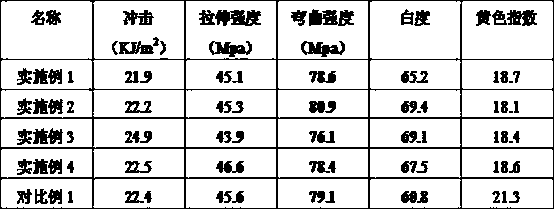

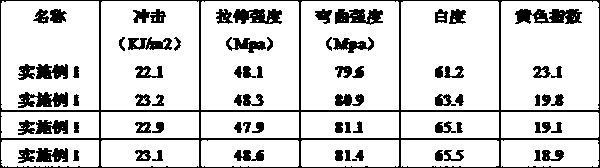

Preparation method of yellowing-resistant and high-brightness ABS resin

The invention relates to a preparation method of yellowing-resistant and high-brightness ABS resin and belongs to the field of synthetic resin. A functional monomer polymerized phosphate monomer is introduced in the synthetic process of ABS grafting powder and is chelated with metal ions in a matrix resin, so that the defects of the ABS resin are reduced, the thermo-oxidative aging resistance of the ABS resin is improved, the crosslinking aging level of butadiene double bonds in the resin is decreased, the annulation reaction among cyano groups is prevented, the yellow color index is decreased, and the whiteness is increased.

Owner:中化国际聚合物(连云港)有限公司

Aerogel catalyst and preparation method thereof

ActiveCN102441370ANot prone to agglomerationHigh activityPhysical/chemical process catalystsCopolyesterBiodegradable polymer

The invention provides an aerogel catalyst. The aerogel catalyst is aerogel particles containing TiO2 and SiO2. The particle diameter of each aerogel particle is 10-200 nanometers, and the density of the aerogel particles is 30-600 mg / cm<3>. The invention also provides a preparation method of the aerogel catalyst. Biodegradable copolyester prepared by using the aerogel catalyst provided by the invention has higher polymerization degree, the distribution of molecular weights is more centralized, and the defect of yellow color of the biodegradable copolyester is relieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

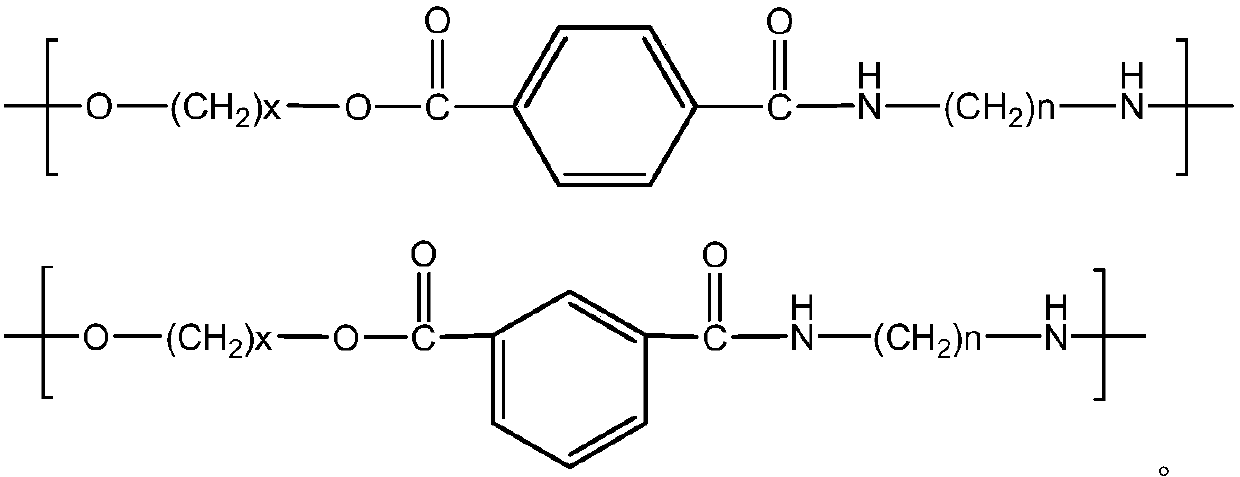

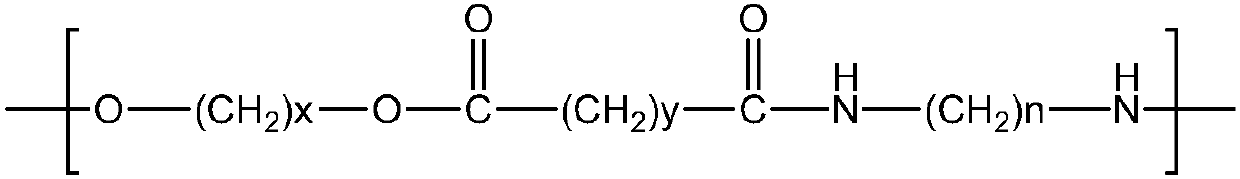

Polyester amide and preparation method thereof

The invention provides a preparation method of a polyester amide. According to the method, by optimizing the pre-polymerization and polycondensation reaction conditions, the yellowing of the polyesteramide in the polymerization process is effectively reduced, and the yellow index of the prepared polyester amide is low, so that the polyester amide is suitable for industrialized production and haswide application prospect.

Owner:CATHAY R&D CENT CO LTD +1

Method for chemically modifying waterborne wood coating by using nano-cellulose dispersed graphene

ActiveCN108977045AHigh reactivityLarge specific surface areaCellulose coatingsPolyurea/polyurethane coatingsDispersityNanoparticles dispersion

The invention relates to a method for modifying waterborne wood coating, in particular to a method for chemically modifying the waterborne wood coating by using nano-cellulose dispersed graphene, aiming at solving the problem that the existing waterborne wood coating modified by using nanometer materials is poor in nano particle dispersity, so that the waterborne paint film is poor in mechanical properties. The method comprises the following steps: 1, preparing a hemicellulose-containing nanocellulose aqueous solution enabling cellulose raw materials to be sequentially subjected to extractiontreatment and delignification treatment to obtain holocellulose; then, carrying out mechanical pretreatment or chemical and mechanical mixed pretreatment to obtain a hemicellulose-containing nanocellulose aqueous solution; 2, stably dispersing graphene by using nano-cellulose; 3, carrying out in-situ chemical modification on the waterborne wood coating by using the nano-cellulose dispersed graphene. The method can remarkably improve the mechanical properties, such as adhesion, wear resistance, hardness and impact resistance, of the waterborne wood coating, and even endows the paint film with certain functionality such as electrical conductivity, thermal conductivity, ultraviolet resistance and aging resistance. The method provided by the invention is used for the field of waterborne wood coatings.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

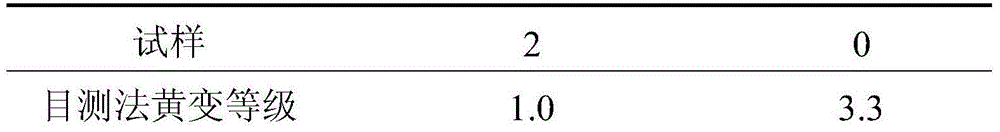

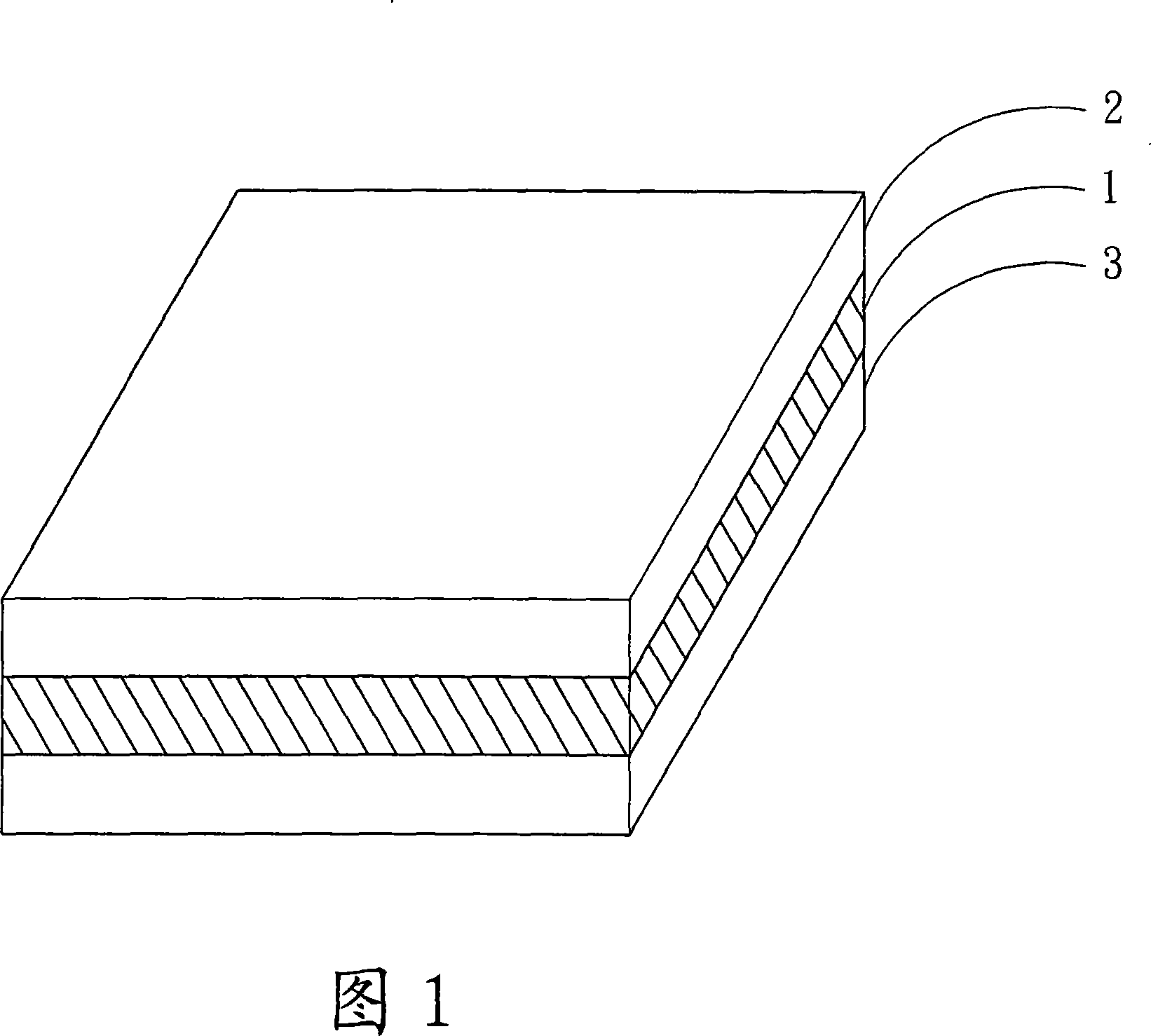

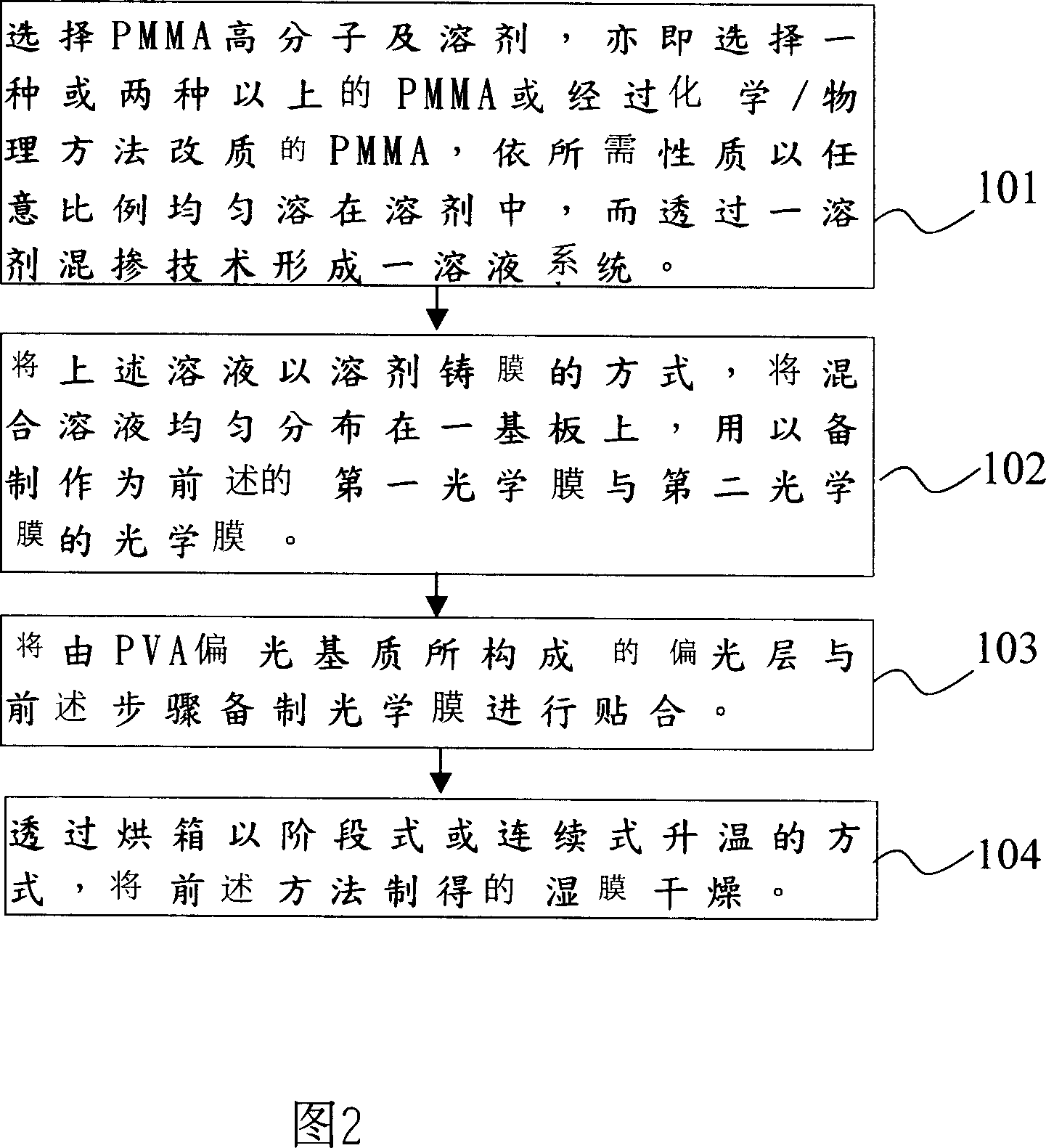

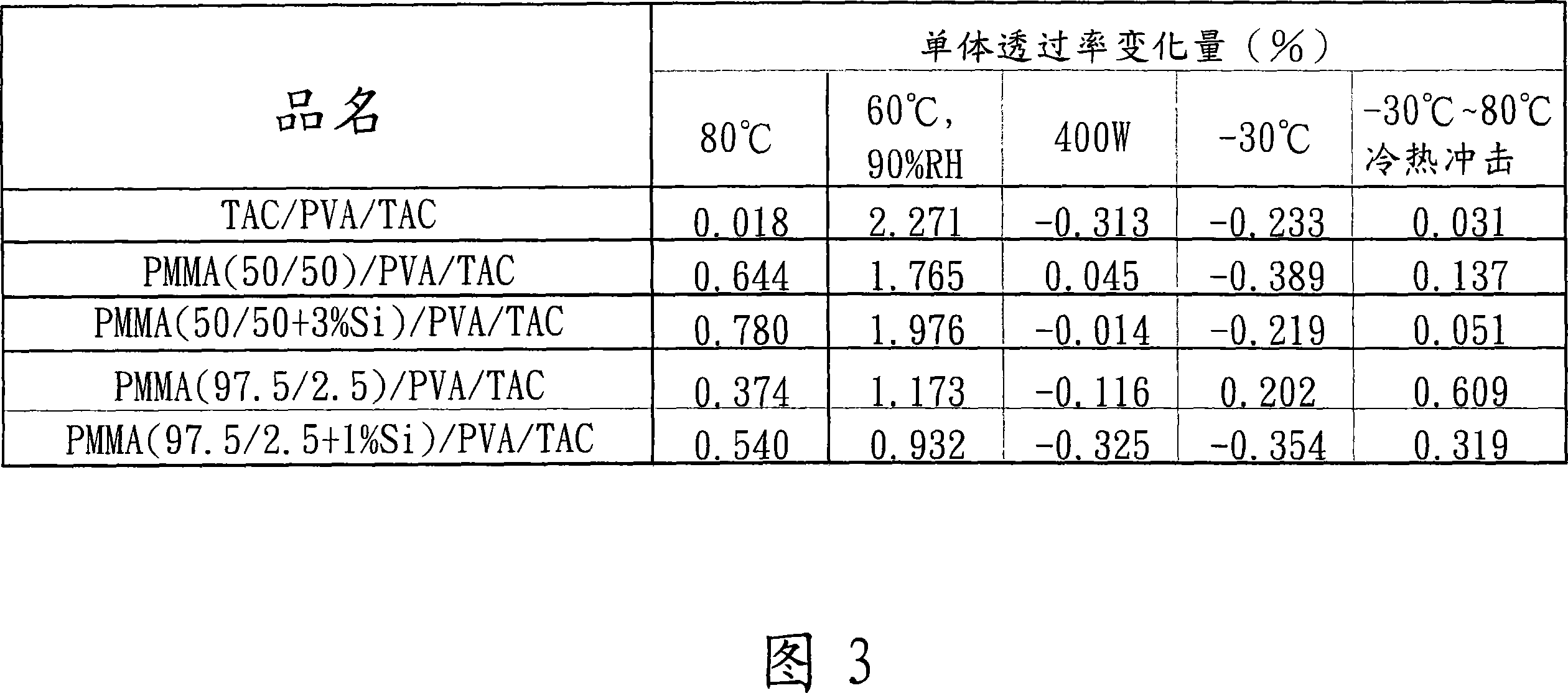

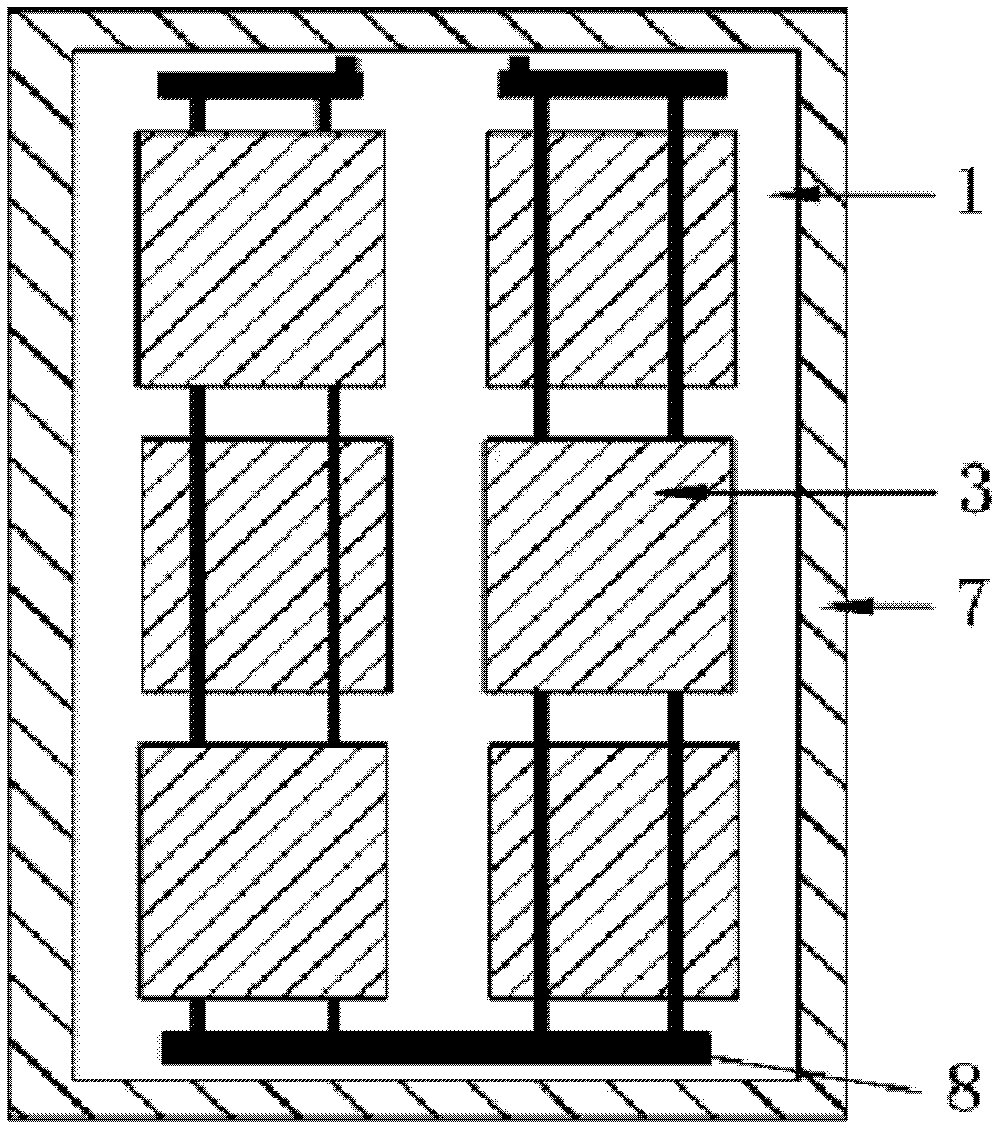

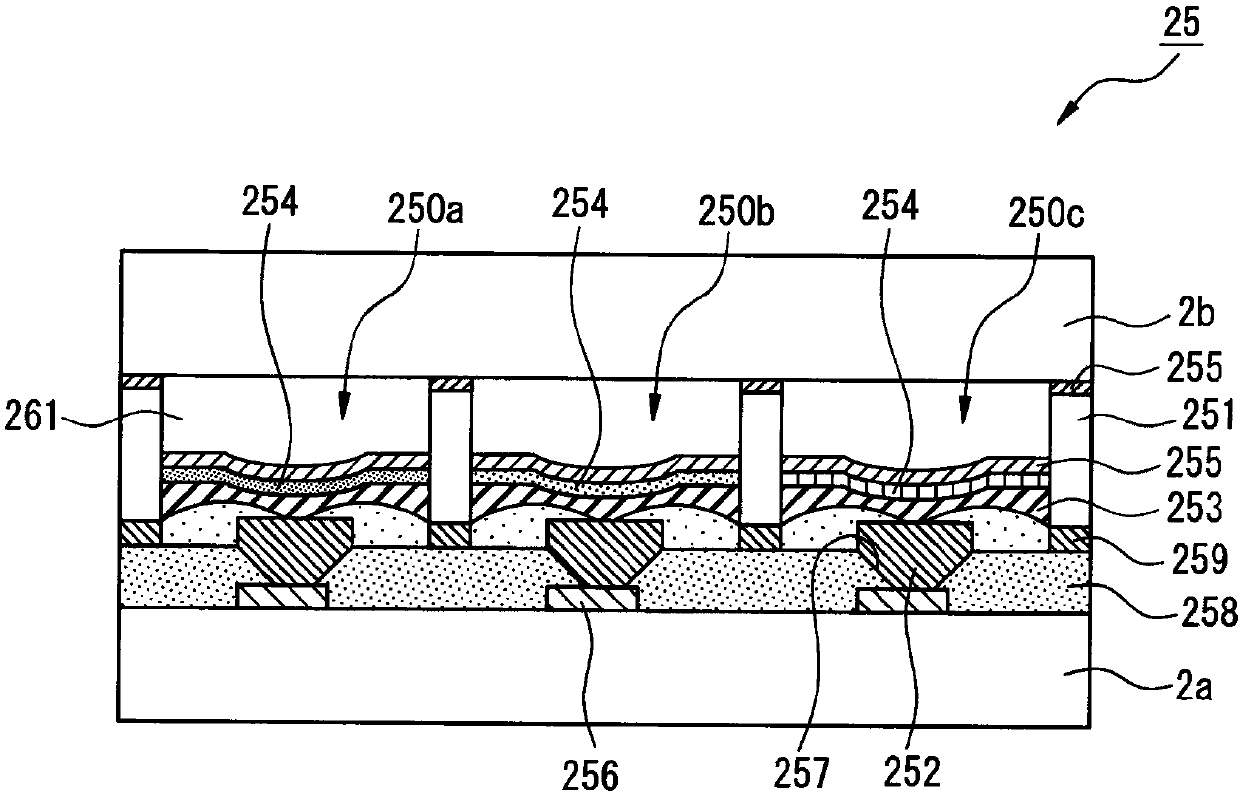

Polarized plate structure

InactiveCN101097269AGood heat resistanceModerate mechanical propertiesPolarising elementsBoard structureOptical film

The present invention relates to a polarized light board structure which is provided with a polarized light layer, a first optical film and a second optical film, the first optical film is formed above the polarized light layer and the second optical film is formed below the polarized light layer, wherein, at least one optical film selected from the first optical film and the second optical film is polymethyl methacrylate optical film. Into the bargain, the optical film is formed by pasting the mixed solution to the polarized light board and doing heat treatment when penetrating the mixed solution and distributing on the substrate to prepare for making have finished, or the optical film is formed by penetrating the mixed solution and distributing on the substrate and doing thermal treatment.

Owner:OPTIMAX TECHNOLOGY CORPORATION

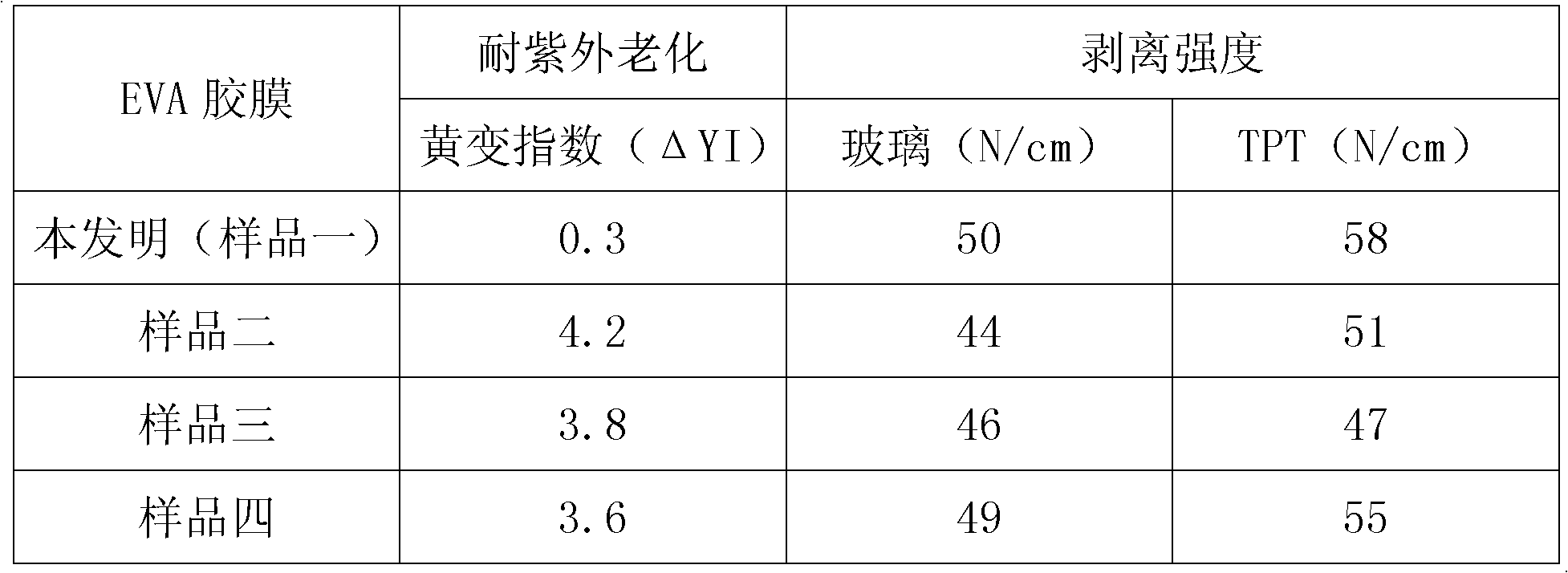

Novel ultraviolet-resistant EVA (Ethylene-Vinyl Acetate) glue film

InactiveCN102504713AExcellent UV aging resistanceLow yellowing indexNon-macromolecular adhesive additivesFilm/foil adhesivesTert butyl phenolSuperoxide

The invention discloses a novel EVA (Ethylene-Vinyl Acetate) glue film for a solar battery; the EVA glue film has excellent characteristics of ultraviolet adsorption and anti-ultraviolet aging; when the EVA glue film is applied to a solar component, a solar backplane is protected from being damaged by ultraviolet lights, and the service life of the backplane material of the component with the EVA glue film is greatly prolonged. The EVA in the EVA glue film mainly comprises the following components: 90-100 parts of ethylene-vinyl acetate, 0.05-5 parts of superoxide crosslinking agent, 5-10 parts of lipid antioxidant, 5-10 parts of hindered amine light stablizer and 0.005-5 parts of thickening agent. The EVA glue film has strong intense light energy to absorb ultraviolet by adding a novel ultraviolet light absorbing agent 2-(2'-hydroxy-3', 5'- di-tert-butyl phenol) and greatly prolongs the service life of packaging material.

Owner:CHANGSHU CANADIAN SOLAR ELECTRIC POWER TECHCO +1

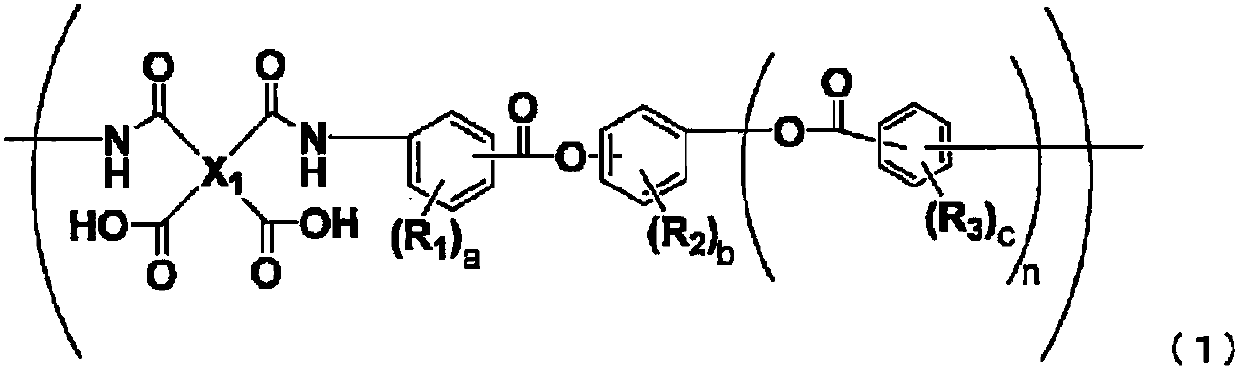

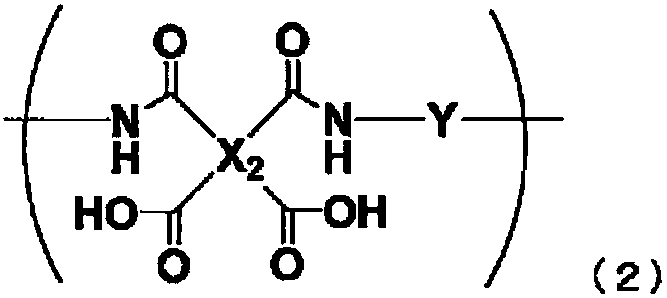

Polyimide precursor, resin composition, and method for producing resin film

ActiveCN108026273AReduce residual stressReduce warpageSynthetic resin layered productsCircuit susbtrate materialsOrganic groupStructural unit

Provided is a polyimide precursor comprising a structural unit L represented by formula (1) (in the formula, X1 represents a tetravalent group having 4-32 carbon atoms, each of R1, R2, and R3 independently represents a monovalent organic group having 1-20 carbon atoms, n represents 0 or 1, and each of a, b, and c is an integer of 0-4) and a structural unit M represented by formula (2) (in the formula, X2 represents a tetravalent group having 4-32 carbon atoms) such that 1 / 99 <= (number of moles of structural unit L / number of moles of structural unit M) <= 99 / 1 is satisfied.

Owner:ASAHI KASEI KK

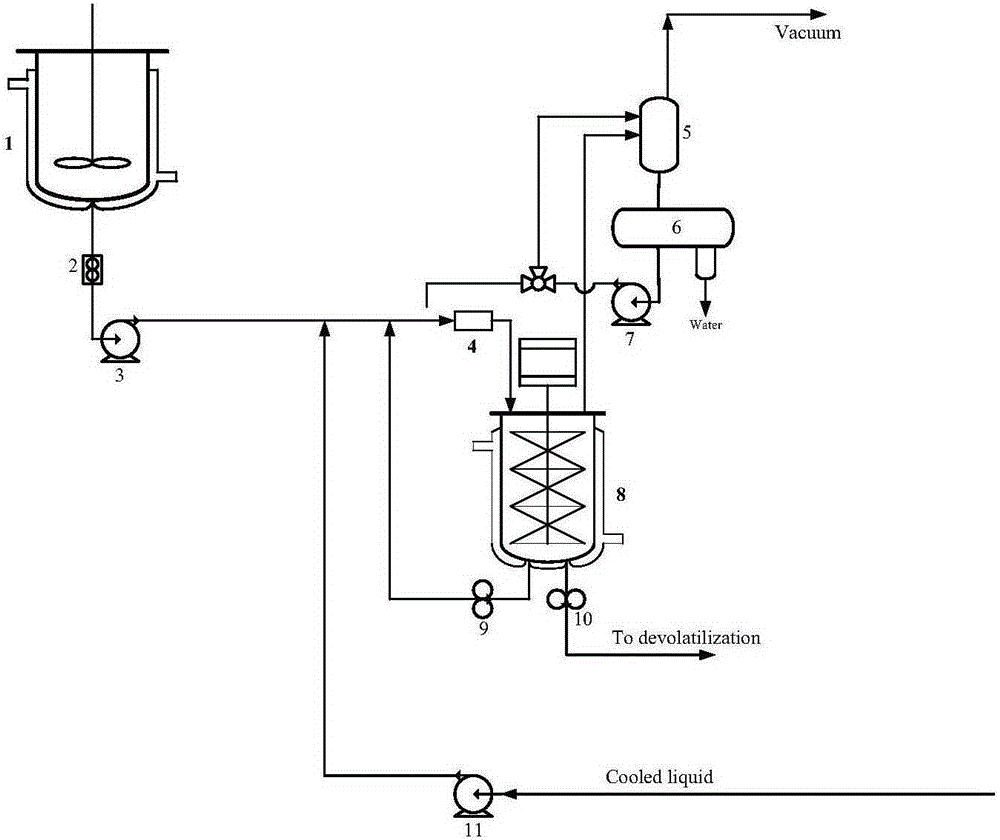

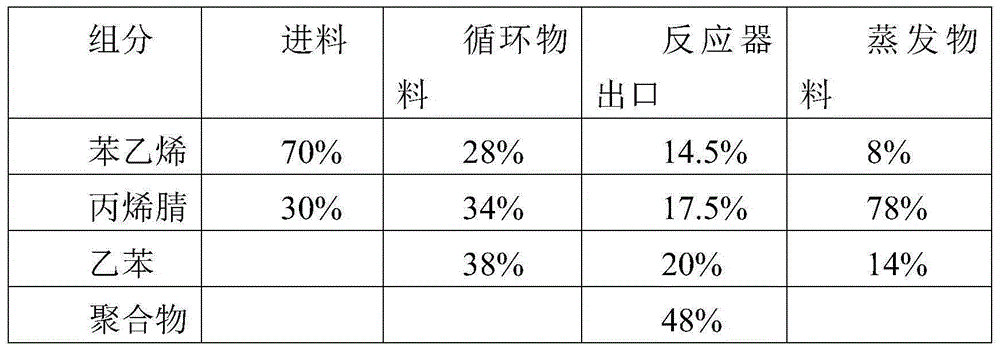

High-nitrile SAN resin and production method thereof

InactiveCN106188374ANarrow molecular weight distributionReduce yellow indexAcrylonitrileMelt flow index

The invention relates to a production method of high-nitrile SAN resin. The method comprises the specific steps of (a) mixing acrylonitrile with part of styrene cinnamene to obtain a mixture A, then mixing the mixture A with a circulating material and a condensation circulating material outside a reactor in a static mixer through a metering pump so as to obtain a mixture B, and then continuously leading the mixture B to the reactor; and enabling the rest of the styrene to be pumped into a steam condenser at the top of a reaction kettle through the metering pump, to be in contact with steaming air flows of the reactor, and to be mixed with condensation steam to become a condensation circulating material, and enabling the condensation circulating material to enter the reactor through a static mixer ; (c) polymerizing a reaction mixture at 140-160 DEG C in the reactor for 1.5-2.5 hours so as to obtain an SAN copolymer; and (d) performing two-stage devolatilization in a devolatilization machine, and performing pelleting in a pelletizer, so as to obtain the high-nitrile SAN resin with narrow distribution. According to the high-nitrile SAN resin produced by the method disclosed by the invention, the percentage by mass of acrylonitrile is greater than or equal to 32%, the melt indexes of products are smaller than 6g / 10min(230 DEG C, 2.16Kg), and the yellow index of the products is smaller than 12.

Owner:PETROCHINA CO LTD

Aerogel catalyst and preparation method thereof

ActiveCN102443154ANot prone to agglomerationHigh activityBulk chemical productionPolymer scienceCopolyester

The invention provides an aerogel catalyst which is aerogel particle containing TIO2 and ZrO2, the particle diameter of the aerogel particle is 10-200mn, and the density is 30-600mg / cm<3>. The invention also provides a preparation method of the aerogel particle. Biodegradable copolyester prepared from the aerogel catalyst provided by the invention has high degree of polymerization and more intensive molecular weight distribution, and the detect that the color of the biodegradable copolyester is yellow color is alleviated.

Owner:CHINA PETROLEUM & CHEM CORP +1

Formula and preparation method of special compound additive for polypropylene film material

InactiveCN104558826AProlonged oxidation induction periodHigh tensile strengthPolymer scienceColor index

The invention relates to a formula of a special compound additive for a polypropylene film material. The formula comprises an antioxidant 626, an antioxidant 1010, a deacidification agent DHT-4A and a nucleating agent HyperformHPN-20E. The preparation method comprises the following steps: mixing and stirring the components, throwing the uniformly mixed and stirred components into a squeezing granulator for granulation, and sieving the obtained granules by using 1-5 layers of sieves, wherein granules with apertures equal to or larger than 4mm are finished products, and the granules with apertures smaller than 4mm are recycled. The formula provided by the invention is low in production cost, can be used for increasing the oxidation induction time of the polypropylene film material to be equal to or more than 35 minutes, reducing the yellow color index, improving the fracture strain and increasing the tensile strength of the film, the transparency and stiffness of the special compound additive for the polypropylene film material are high, no dust pollution is generated, various addition procedures in a polypropylene device in the traditional working manner are replaced by one addition procedure, and the good performance of a single agent can be protected.

Owner:江苏汉光实业股份有限公司

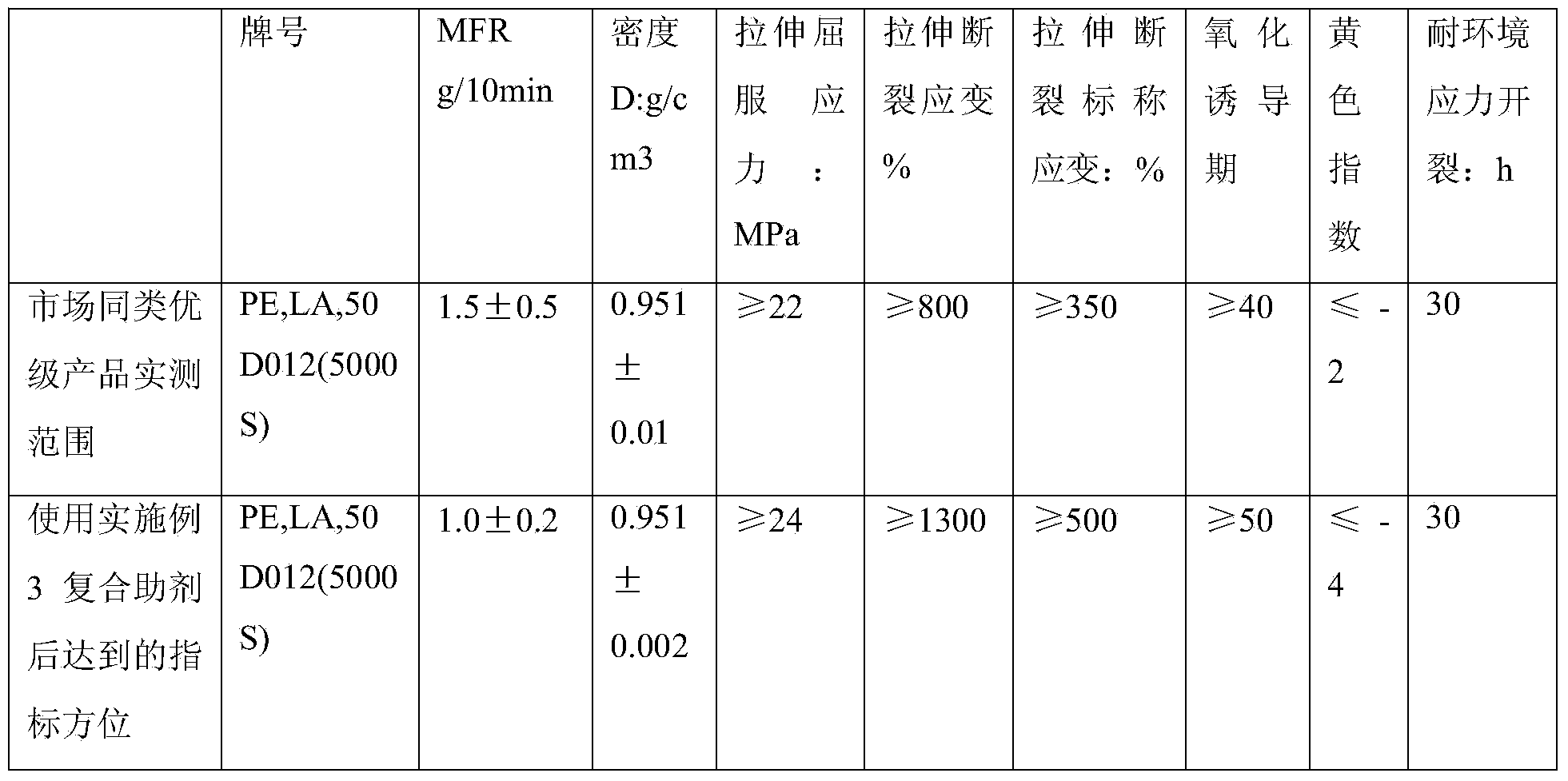

High-density polyethylene compound additive and preparation method thereof

The invention discloses a high-density polyethylene compound additive and a preparation method thereof, and belongs to the field of chemical engineering. The compound additive comprises an antioxidant, a nucleating agent, an acid acceptor and an antistatic agent, wherein the antioxidant comprises an antioxidant 330, an antioxidant 168 and an antioxidant 1076. The preparation method of the compound additive comprises the following steps: mixing the raw components, and uniformly stirring; granulating the uniformly mixed components so as to obtain granules; and sieving the obtained granules. The compound additive has the advantages that the 5000S-oxidation induction time can be prolonged to above 50 minutes through the synergistic effect among the additives, the yellow index is reduced, the fracture strain is improved, and the like.

Owner:江苏汉光实业股份有限公司

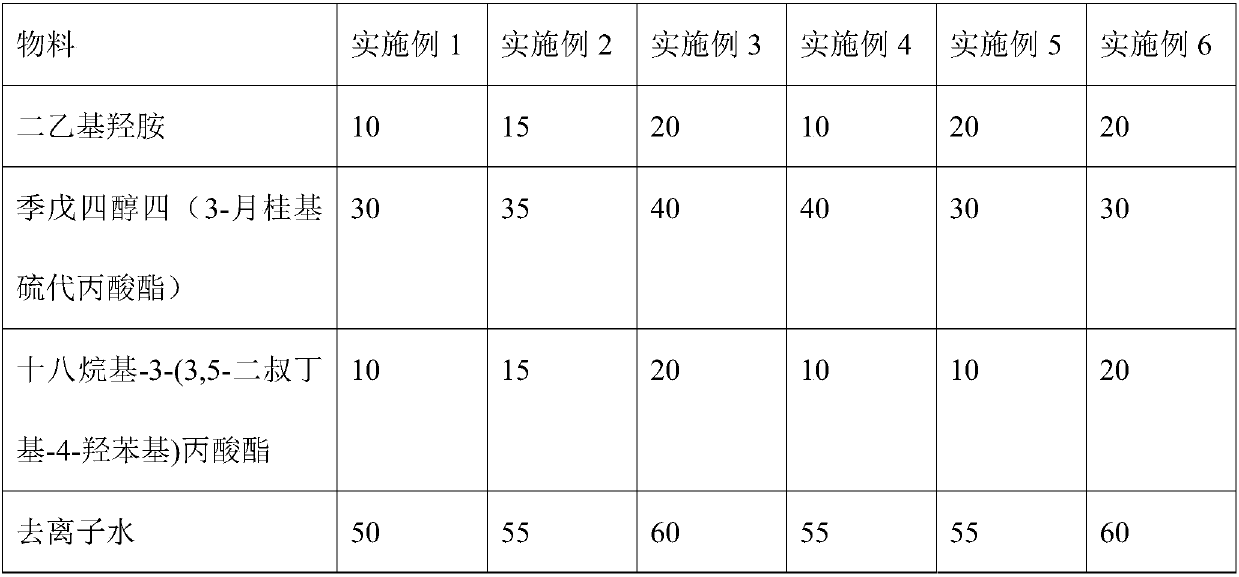

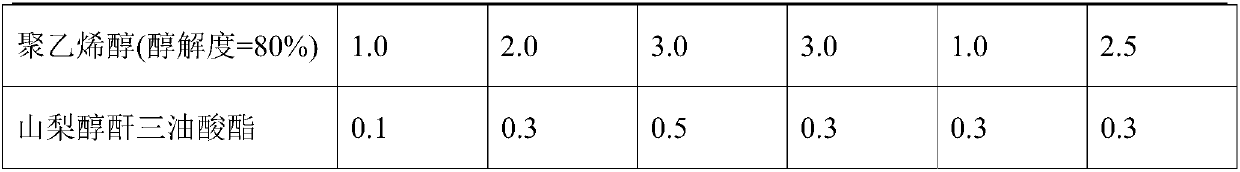

Vinyl chloride polymerization terminator as well as preparation method and application thereof

ActiveCN110760019AGood polymerization termination effectImprove aging whitenessPropionatePolymer science

The invention belongs to the field of resin synthesis, and particularly relates to a vinyl chloride polymerization terminator as well as a preparation method and application thereof. The terminator comprises the following raw materials in parts by weight: 10-20 parts of diethyl hydroxylamine, 30-40 parts of pentaerythritol tetra(3-dodecylthiopropionate), 10-20 parts of octadecyl-3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate, 50-60 parts of deionized water, 1-3 parts of a dispersing agent and 0.1-0.5 part of an emulsifying agent. All the components have a synergistic effect, so that a good vinyl chloride polymerization termination effect can be achieved, the aging whiteness of the resin can be effectively improved, and the vinyl chloride polymerization terminator has the advantages that the termination efficiency is high, PVC (vinyl chloride) resin has high whiteness and a PVC transparent product has low yellow indexes. The invention further provides a preparation method of the vinylchloride polymerization terminator. The preparation method ensures that the emulsion of the composite terminator is stable and uniform in each batch when being metered and added, and has favorable flowability in a process pipeline.

Owner:CHINA PETROLEUM & CHEM CORP

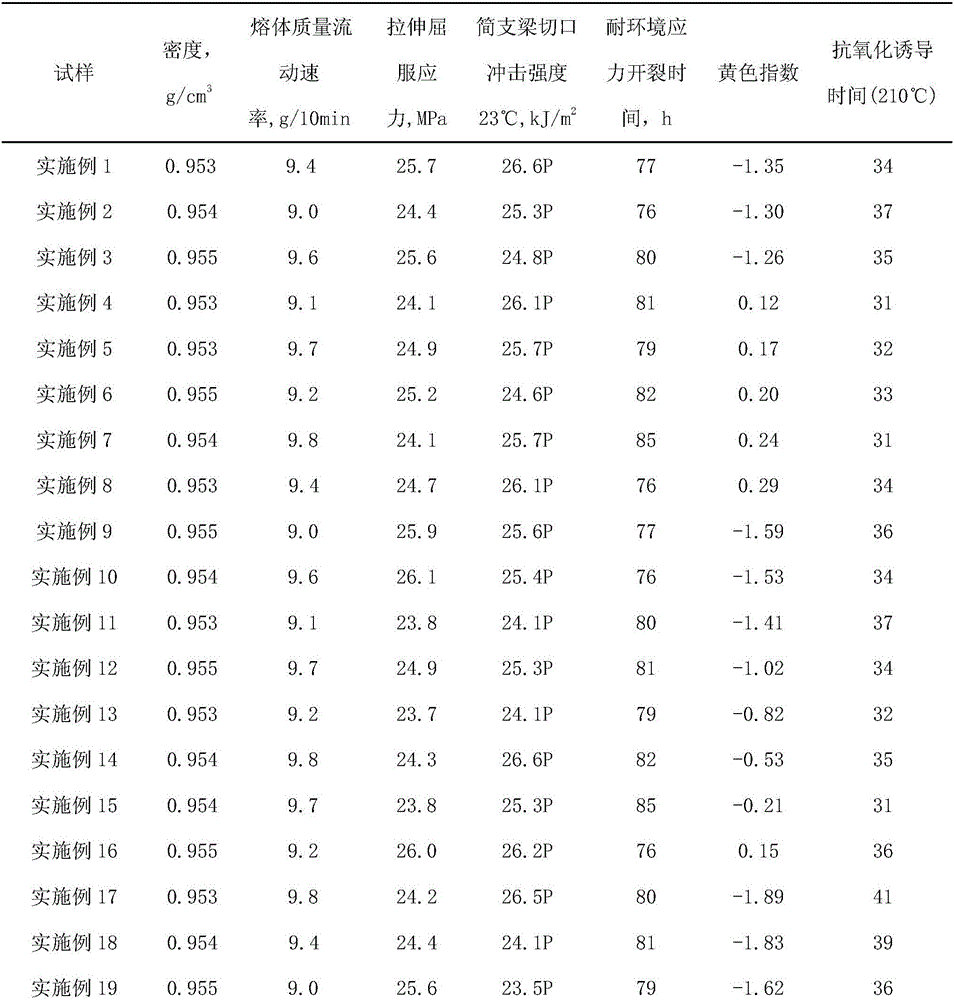

High density polyethylene resin for blow molding of middle-sized hollow container and preparation method thereof

The invention discloses a high density polyethylene resin for blow molding of a middle-sized hollow container and a preparation method thereof. The yellow color index of the resin ranges from -2 to 1, the antioxidant induction time t is more than or equal to 30min (210 DEG C) and time t for resisting environmental stress cracking is more than or equal to 75h (F50). The raw materials include 100 parts of ethylene hexane copolymerized high density polyethylene base resin, 0.05-0.10 part of a main antioxidant, 0.14-0.19 parts of a complex auxiliary antioxidant, 0.10 part of a light stabilizer and 0.05-0.15 parts of a halogen absorbent. The blow molding material for the middle-sized hollow container has excellent environmental stress cracking resistance, is characterized by excellent oxidation resistance, lower yellow color index, higher strength, and the like, meets the processing performances and various physical indexes required by the middle-sized hollow blow molding, is suitable for the blow molding of various anti-corrosion hollow containers, can be widely used for packaging in the industries of chemical engineering, petroleum, medicines, and the like, is easy to produce and is stable to supply.

Owner:CHINA PETROLEUM & CHEM CORP

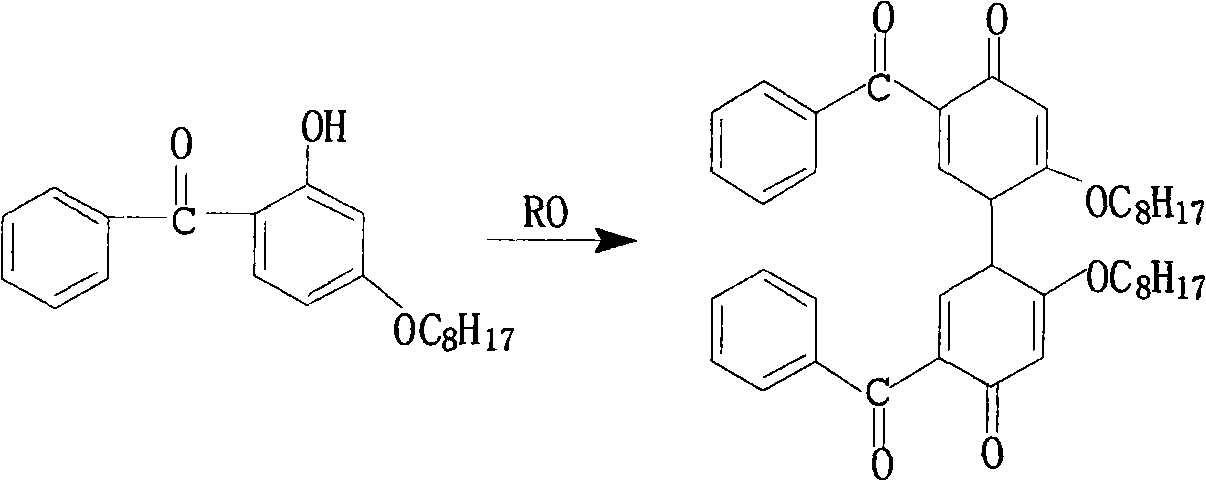

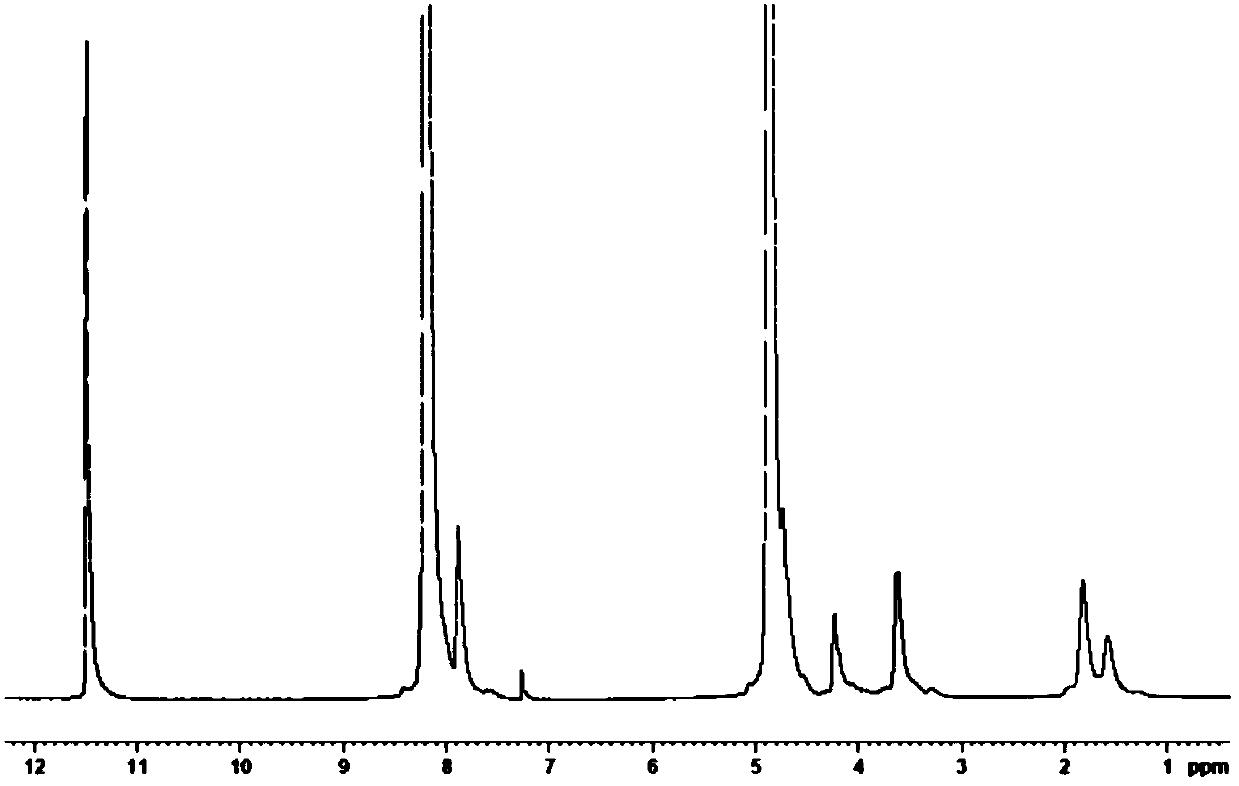

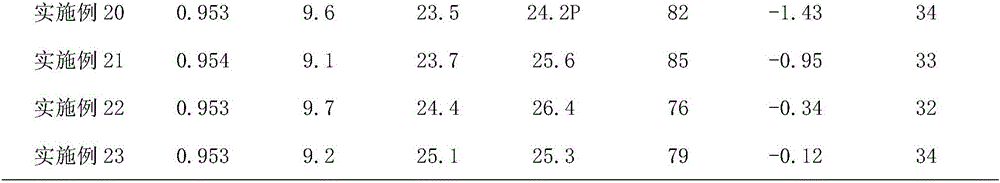

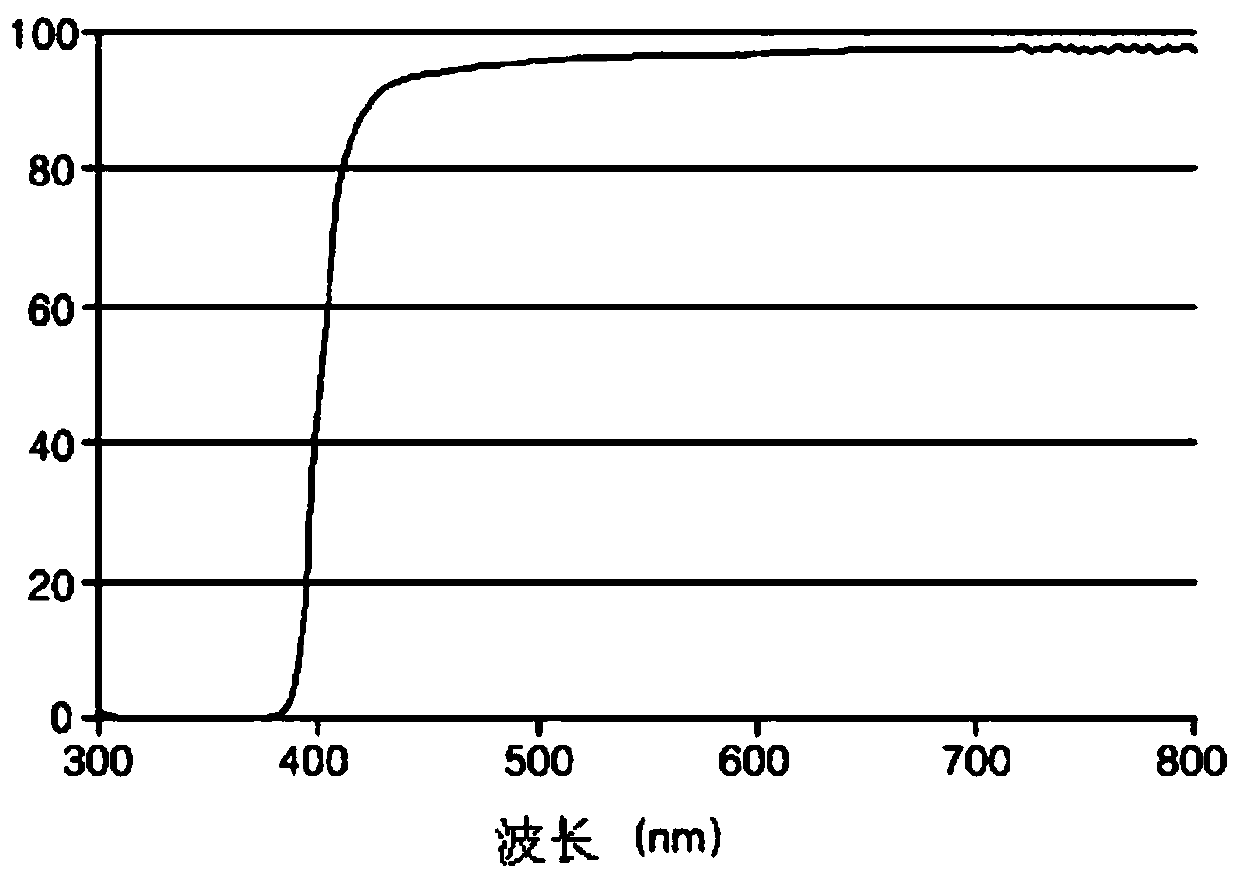

Preparation method of polyimide resin and polyimide resin thin film prepared by preparation method

ActiveCN104211963ASufficient commercial applicabilityImprove thermal stabilityImideThermal dilatation

The invention relates to a preparation method of a polyimide resin and a polyimide resin thin film prepared by the preparation method. The method can be used for polymerizing plural benzophenonetetracarboxylic dianhydrides which are different from diamine in types, and the thermal stability is excellent and the yellow color index is low. The preparation method of the polyimide resin comprises the following steps: a forming stage of dissolving diamine in a solvent to form a first solvent; a second forming stage of mixing the benzophenonetetracarboxylic dianhydride shown in a chemical formula (1), the benzophenonetetracarboxylic dianhydride shown in a chemical formula (2) and the benzophenonetetracarboxylic dianhydride shown in a chemical formula (3) in the first solution to generate a second solution containing polyamide acid; and a thermal treatment stage of the second solvent. The polyimide resin thin film can be further prepared by using the polyimide resin. The prepared polyimide thin film has excellent commercial applicability. The polyimide resin thin film not only has excellent thermal stability in thermal performance, but also the coefficient of thermal expansion can be further reduced to below existing coefficient. The polyimide resin thin film has excellent dimensional stability.

Owner:JILIN OPTICAL & ELECTRONICS MATERIALS

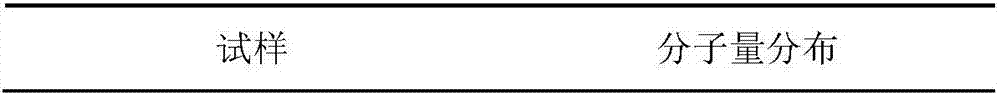

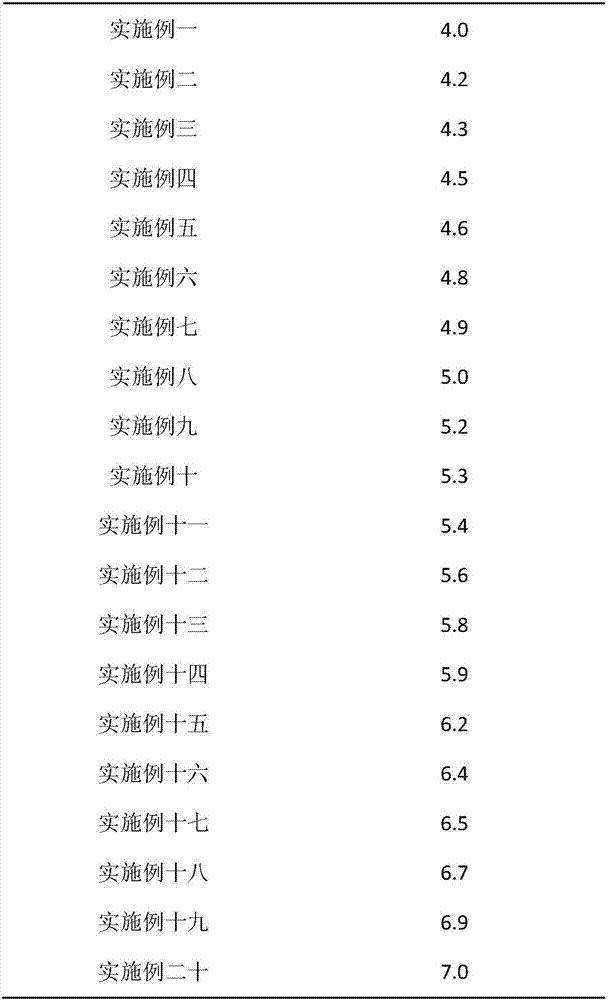

Resin special for plastic suction molding of transparent broad molecular weight-distributed random copolymer polypropylene and preparation method of resin

Owner:CHINA PETROLEUM & CHEM CORP

Polyester amide hot melt adhesive and preparation method thereof

ActiveCN109957108ASimple preparation processControl degree of aggregationAdhesivesPolyesterPolymer science

The invention provides a preparation method of a polyester amide hot melt adhesive. Through optimization of a technical process and regulation and control of reaction parameters such as polymerizationtemperature, pressure, proportioning of reaction raw materials, and the like, the prepared polyester amide hot melt adhesive is low in yellow index, relatively high in peel strength, low in peel strength loss rate after water washing, excellent in performance and wide in application range.

Owner:CATHAY R&D CENT CO LTD +1

Composition and application thereof for providing thermal stability to polymers

The invention relates to a composition with the capability of providing the thermal stability for polymer and application of the composition. The composition is prepared from the following raw materials: (1) hindered phenol, (2) phosphate or thioester, (3) an acid-removing agent and (4) sulfite, bisulfate or sulfide, wherein the mass ratio of hindered phenol, phosphate or thioester, the acid-removing agent and sulfite, bisulfate or sulfide is 1:(1-4):(0.5-2):(0.5-3). The invention also provides the application of the composition serving as an antioxidant in polymer resin. The composition is capable of lowering the melt index of polyolefin, eliminating a quinones compound serving as an intermediate and lowering the yellow index of polyolefin.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Preparation method of yellowing-resistant abs resin

PendingCN109608782AGood yellowing resistanceImprove thermal stabilityPolymer scienceFunctional monomer

The invention discloses a preparation method of yellowing-resistant ABS (acrylonitrile butadiene styrene) resin, and belongs to the technical field of synthetic resin and plastic. The invention specifically relates to a preparation method of ABS (acrylonitrile butadiene styrene) resin with high whiteness and low yellow index. According to the invention, the ABS resin with the whiteness value greater than 66, the yellow index lower than 19 and the excellent mechanical property can be prepared. According to the invention, the technical problem is solved, and the preparation method is provided inthe synthesis process of an ABS (acrylonitrile butadiene styrene) graft emulsion, and a functional monomer with an epoxy group is introduced into the shell layer of the ABS grafted powder, by utilizing an epoxy group and a cyano group, so that the cyclization reaction between the acrylonitrile groups in the ABS resin in the heating process is relieved, so that the apparent performance of the ABSresin can be improved, for example, the whiteness can be improved, and the yellow index and the like can be reduced. The ABS resin prepared by the method can be preferentially used in a household appliance shell, automobile apparent parts and the like, and has a wide market prospect.

Owner:CHANGCHUN UNIV OF TECH

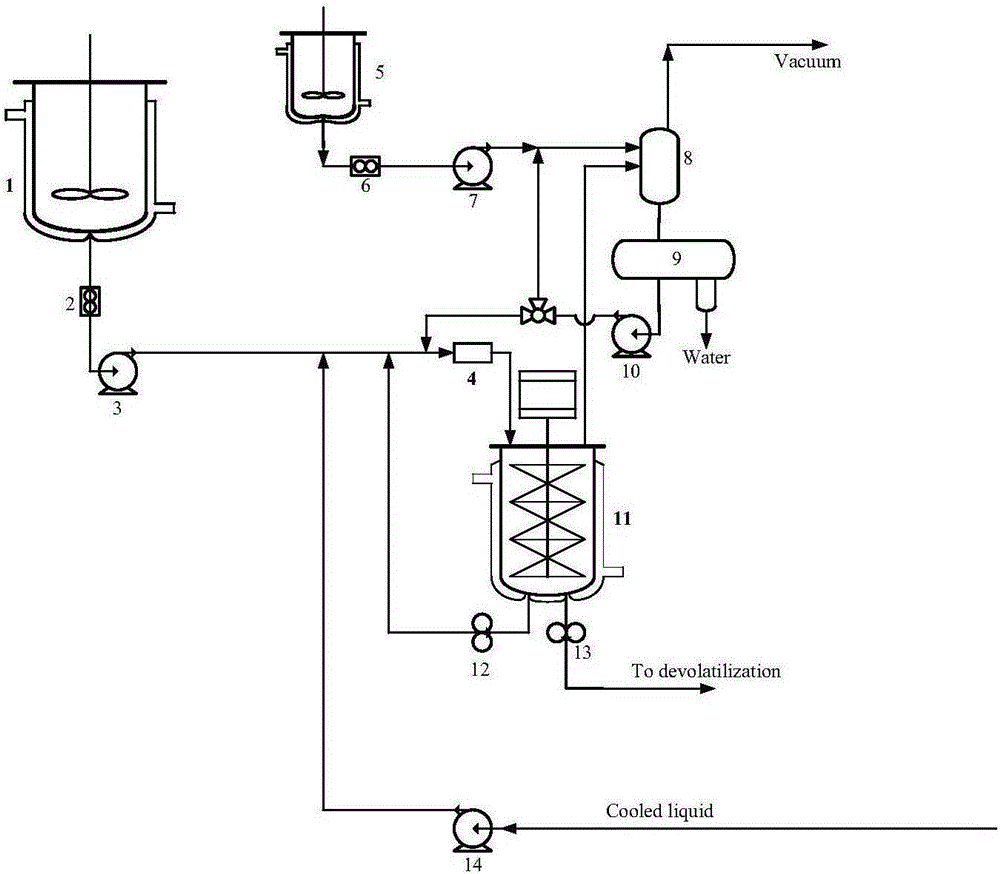

Preparation method of styrene-acrylonitrile copolymer

The invention provides a preparation method of a styrene-acrylonitrile copolymer, which comprises the following steps: mixing a styrene monomer and an acrylonitrile monomer, cooling, feeding an obtained mixture into a first reactor, reacting while keeping a full state, controlling the temperature, feeding an obtained product into a second reactor, continuously reacting while keeping the full state, and finally devolatilizing. The invention also provides the styrene-acrylonitrile copolymer prepared by the preparation method provided by the invention. According to the preparation method providedby the invention, heat insulation or nearly heat insulation can be achieved in the whole polymerization reaction process; the stability of the polymerization reaction temperature can be effectively controlled without external heat transfer so as to ensure the stability of the composition of the obtained copolymer, the prepared copolymer has excellent optical performance, and the preparation method has characteristics of simple process, easy control and no requirement of complex equipment, such that the method is suitable for large-scale industrial production.

Owner:WANHUA CHEM GRP CO LTD

EMMA optical film for full fitting of electronic screen and preparation method thereof

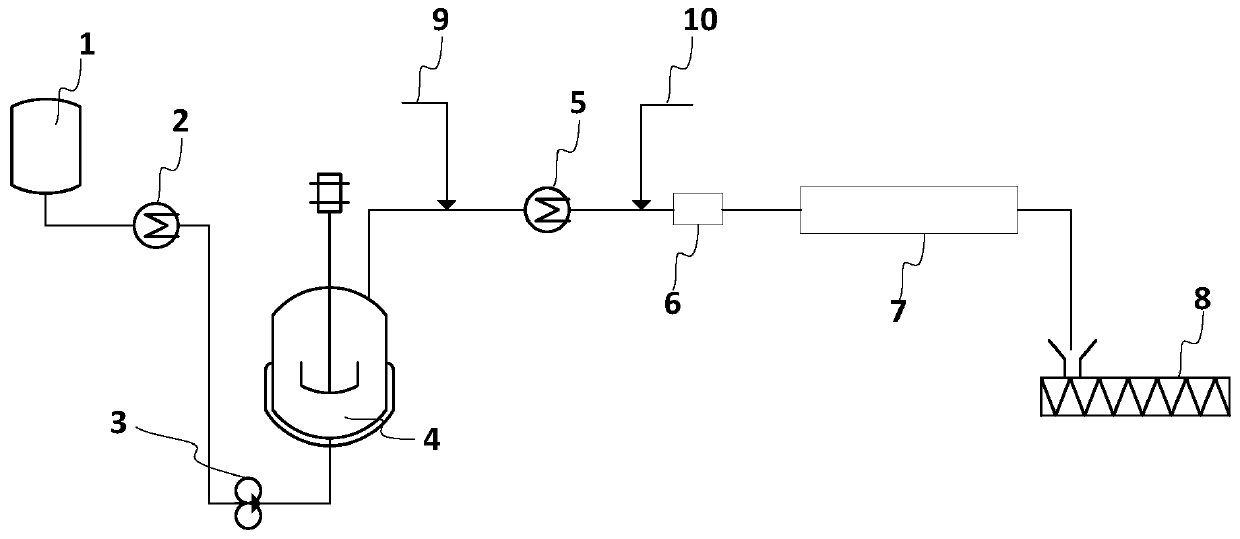

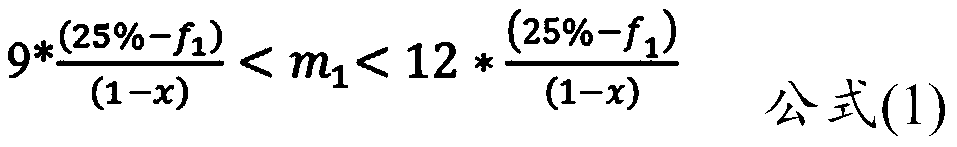

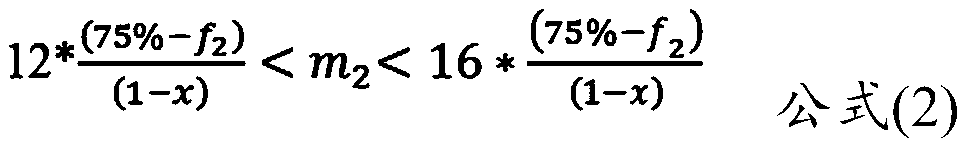

InactiveCN108165181AImprove processing phenomenonSolve process defects such as difficulty in laminationNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveControl layerWater vapor

The invention discloses an EMMA optical film for full fitting of an electronic screen and a preparation method thereof. The EMMA optical film for full fitting of the electronic screen is prepared by pre-mixing 100 parts by weight of an ethylene-methyl methacrylate copolymer (EMMA), 0.5-2.0 parts by weight of a photoinitiator, 0.3-1.5 parts by weight of a crosslinking agent, 0.3-1.2 parts by weightof a tackifier, 0.1-0.6 part by weight of an optical stabilizer, 0.1-1.1 parts by weight of a plasticizer and 0.2-1.0 part by weight of an antioxidant by a stirrer, putting the mixture into a single-screw tape-casting machine and tape-casting into the optical film according to set process parameters. The prepared EMMA optical film has the advantages of excellent bonding properties, high light transmittance, low water vapor transmittance and high weather resistance, also is in thermal plasticity before curing, easily fills segment gaps, adapts to the complex interface fitting, and can adapt torequirements of fitting of electronic screen protection layers, touch control layers and display layers with different sizes.

Owner:GUANGDONG POLYTECHNIC OF ENVIRONMENTAL PROTECTION ENG

Glass fiber-reinforced acrylonitrile butadiene styrene (ABS) material

InactiveCN102417689AGood compatibilityImprove flame retardant performanceAntioxidantPolyvinyl chloride

The invention relates to a glass fiber-reinforced acrylonitrile butadiene styrene (ABS) material. The glass fiber-reinforced ABS material is characterized by comprising the following components in part by weight: 100 parts of ABS material, 20 to 40 parts of polyvinyl chloride (PVC), 15 to 35 parts of filling agent, 1 to 10 parts of talcpowder, 1 to 4 parts of antioxidant, 5 to 20 parts of silane coupling agent, 1 to 20 parts of organic silicon rubber / metallic soap, 1 to 10 parts of zinc stearate, 1 to 10 parts of stearic acid, 1 to 10 parts of chitosan and 10 to 40 parts of glass fiber. The ABS material has high heat resistance, toughness and strength, does not crack in the using process, and can be applied to parts such as automobile parts, fan blades and the like.

Owner:WUJIANG MINGFENG POLYURETHANE PROD

Polyvinyl alcohol and method for producing same

ActiveUS20190119414A1Good water solubilityLow indexOrganic-compounds/hydrides/coordination-complexes catalystsVinyl esterWater soluble

A polyvinyl alcohol is produced in a method comprising: a polymerization step comprising polymerizing vinyl ester monomers by controlled radical polymerization in the presence of a radical initiator and an organic cobalt complex to obtain a polymer solution containing a polyvinyl ester; an extraction step comprising extracting a cobalt complex from the polymer solution by contacting an aqueous solution containing a water-soluble ligand with the polymer solution; and a saponification step comprising saponifying the polyvinyl ester after the extraction step to obtain a polyvinyl alcohol. A method for producing a polyvinyl alcohol is thus provided that has a narrow molecular weight distribution and a high number-average molecular weight with good hue and further good solubility in water.

Owner:KURARAY CO LTD +1

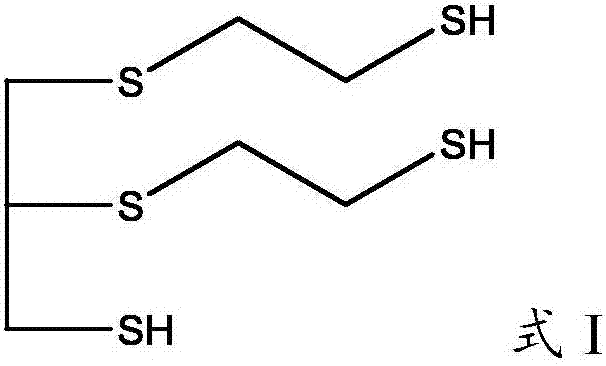

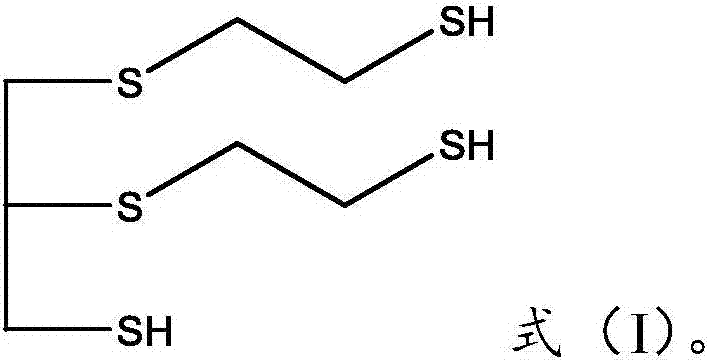

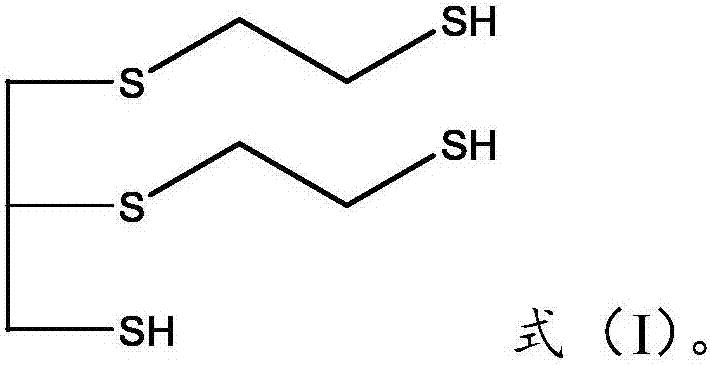

Post-treatment method of multi-sulfhydryl compound crude product

ActiveCN107235876AReduce chromaLow yellow indexOrganic chemistryOrganic compound preparationActivated carbonSulfite salt

The invention provides a post-treatment method of a multi-sulfhydryl compound crude product. The method comprises the following steps: A) the multi-sulfhydryl compound crude product with the structure shown in formula (I) is washed with water and then mixed with a reducing agent for vacuum dehydration, wherein the reducing agent is selected from one or more of sodium sulfite, sodium bisulfite, sodium hydrosulfite and sodium thiosulfate; B) the product obtained in step A) is mixed with an adsorbent and filtered, and a purified polythiol compound is obtained; the adsorbent is selected from one or more attapulgite, bentonite, diatomaceous earth and activated carbon.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Preparation method of UV (ultraviolet) moisture dual-curable modified organic silicone polymer

The invention discloses a preparation method of a UV (ultraviolet) moisture dual-curable modified organic silicone polymer. The preparation method includes the steps: performing condensation reactionon silanol-terminated polydimethylsiloxane and R1 substituted amino propyl trimethoxy silane under catalysis of bismuth octoate in vacuum at room temperature; adding a certain stoichiometric amount ofmethacrylic acid 2-isocyanato ethyl ester; performing stirring under the condition of nitrogen filling. The preparation method overcomes the shortcoming of high curing energy of current existing products and solves the problem that a traditional UV glue shaded area cannot be cured due to absence of illumination. Cured volume shrinkage is smaller than 0.5%, the problem of cracking of pulled thin plastic films due to over-high shrinkage is avoided, the polymer has performance indexes including yellowing index smaller than 0.5, bonding strength higher than 2MPa and refractive index of 1.49-1.51,a glue film is soft, elastic and low in hardness of Shore A15-20, shrinkage glue fault is not easily caused, and reliability is high.

Owner:深圳市库泰克电子材料技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com