Patents

Literature

45results about How to "Control degree of aggregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing polyvinyl alcohol with low polymerization degree

InactiveCN102108107AEasy to separate and recycleImprove conversion ratePolymer sciencePolyvinyl acetate

The invention provides a method for preparing polyvinyl alcohol with low polymerization degree, which comprises: mixing a vinylacetate monomer and a methanol solvent in a mass ratio of (50-80):20, adding azodiisobutyronitrile serving as an initiator in an amount which is 0.05 to 0.5 percent based on the mass of the monomer, uniformly dripping aldehyde serving as a chain transfer agent in an amount which is 0.2 to 5 percent based on the mass of the monomer, and reacting for 2 to 5 hours at 50 to 71 DEG C to obtain polyvinyl acetate with low polymerization degree; dissolving the polyvinyl acetate in methanol to obtain polyvinyl acetate methanol solution at a concentration of 15 to 40 percent; and adding NaOH at 40 to 55 DEG C according to a NaOH to polymer molar ratio of 0.003 to 0.02, and performing alcoholysis for 10 to 90 minutes to obtain polyvinyl alcohol with low polymerization degree.

Owner:HUNAN XIANGWEI

Method for catalyzing butene oligomerization by using ionic liquid as catalyst

InactiveCN101190861AImprove conversion rateControl degree of aggregationHydrocarbons from unsaturated hydrocarbon additionButeneEconomic benefits

The invention discloses a method of producing medium and mid-high olefines, such as C8, C12, C16 and C20, etc. with ionic liquid as catalyst to catalyze butylene to carry out butylene oligomerization. The method adopts the butylene as raw material; cation of the ionic liquid catalyst comes from hydrohalide of amine with alkyl, and anion of the ionic liquid catalyst is produced by a metallic compound that has one or two metals. In the technique of the invention, volume ratio of catalyst to butylene is low; conversion efficiency of butylene is high; selectivity of oligomerized product is high; distribution of oligomerized product is improved, and the invention has good social and economic benefits.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

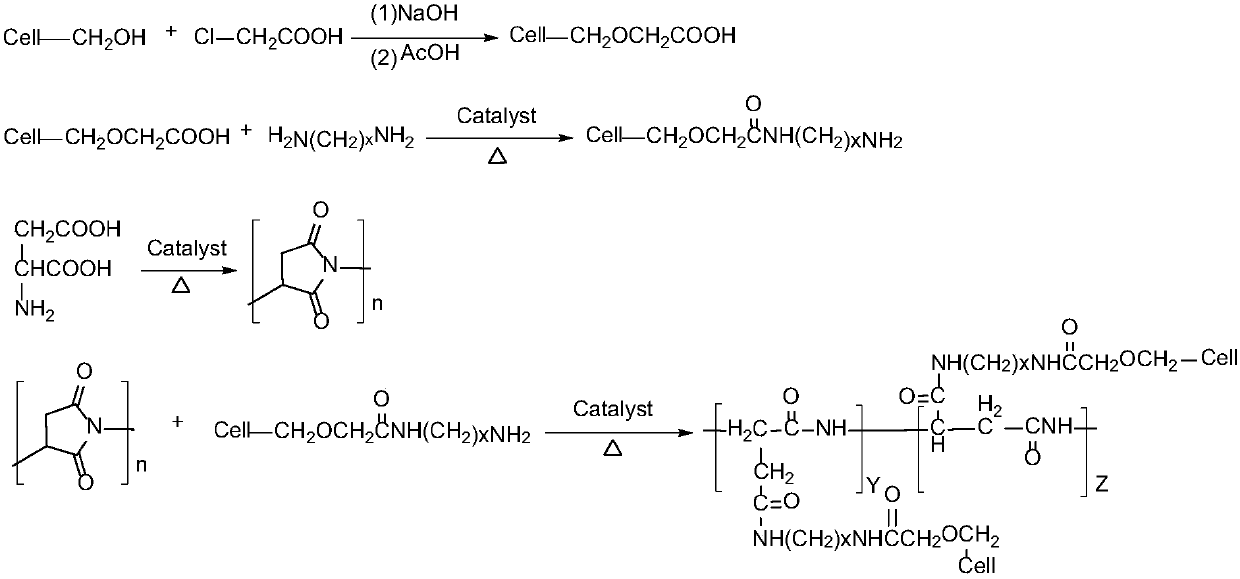

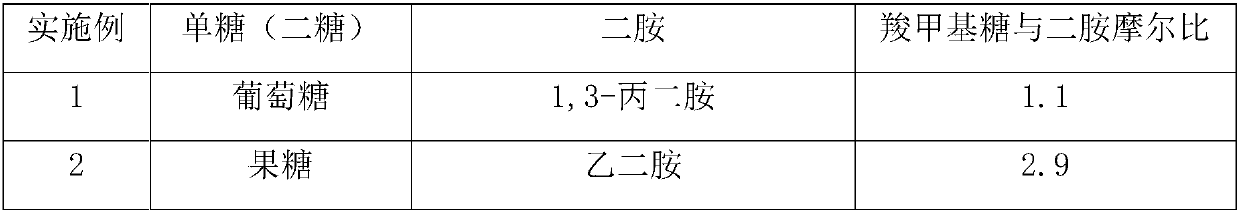

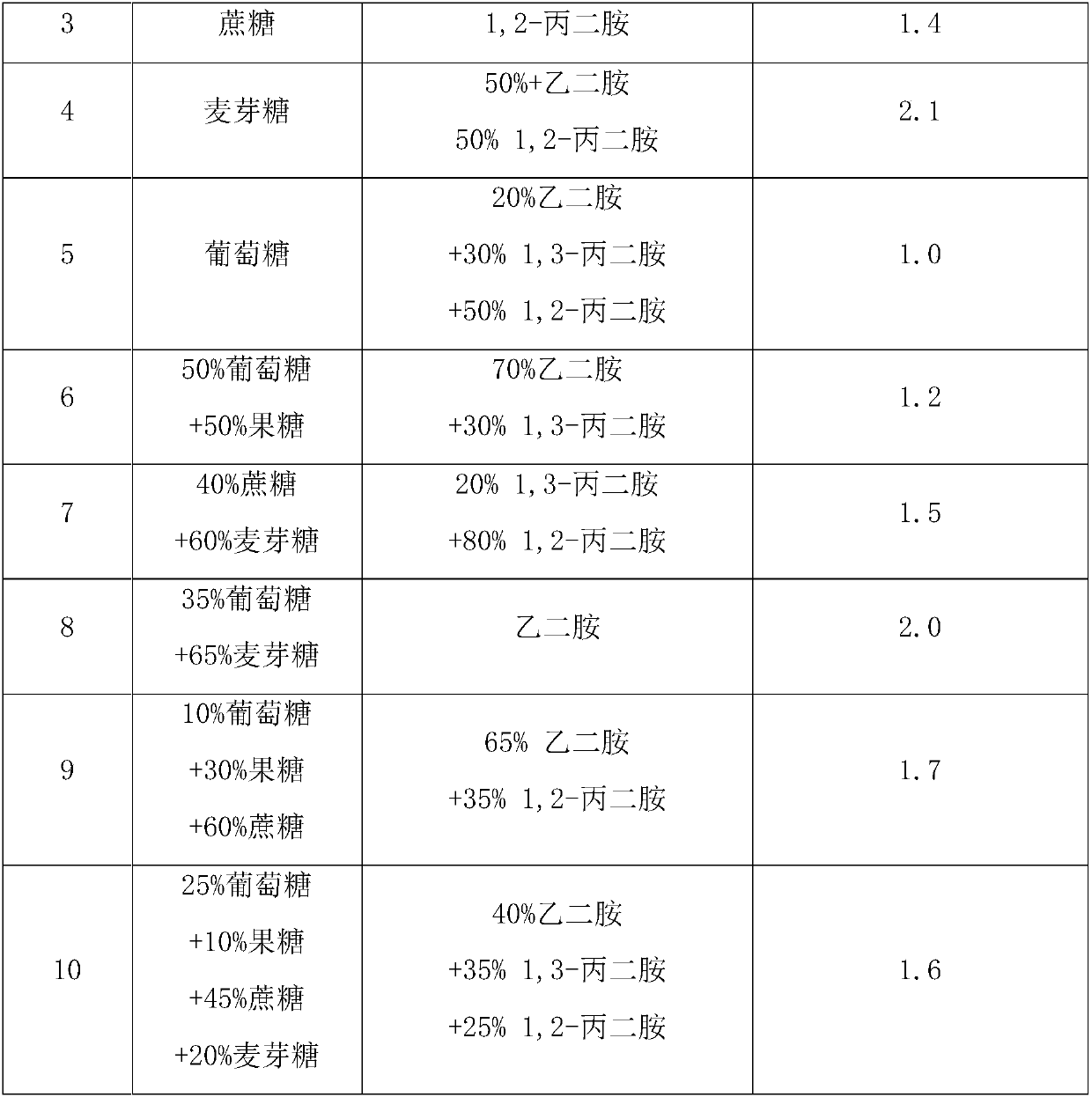

Polyaspartic acid derivative and synthetic method thereof

InactiveCN107602858APrevent the growth of the main chainIncreased side chain branching rateSide chainPhosphoric acid

The invention provides a polyaspartic acid derivative synthetic method. The method comprises the following steps: monosaccharide or disaccharide and monochloro acetic acid are reacted under catalysisof NaOH, and a reactant is subjected to further acidifying and purification to obtain carboxymethyl saccharide; carboxymethyl saccharide and diamine are subjected to dehydration condensation under catalysis of phosphoric acid to obtain glycosyl acetyl diamine; L-aspartic acid and phosphoric acid are respectively added in a kneading reactor for mixing, a mixture is stirred and heated, polymerization is carried out for preset time to obtain polysuccinimide; glycosyl acetyl diamine is added in a reaction vessel of polysuccinimide for a reaction, polysuccinimide is subjected to ring-opening and grafting reaction to obtain a polysuccinimide derivative; the polysuccinimide derivative is added in a hydrolysis kettle, an aqueous solution of alkali is add drop by drop, a hydrolysis reaction is carried out, and a liquid-phase product after hydrolysis is a glycosyl acetyl diamine-grafted modified polyaspartate aqueous solution. The synthetic method is simple and easy to operate, a grafting modification step and a polymerization step are coupled, so that the side-chain grafting rate is increased and the polymericular weight can be regulated and controlled.

Owner:苏州美瑞姿生物科技有限公司

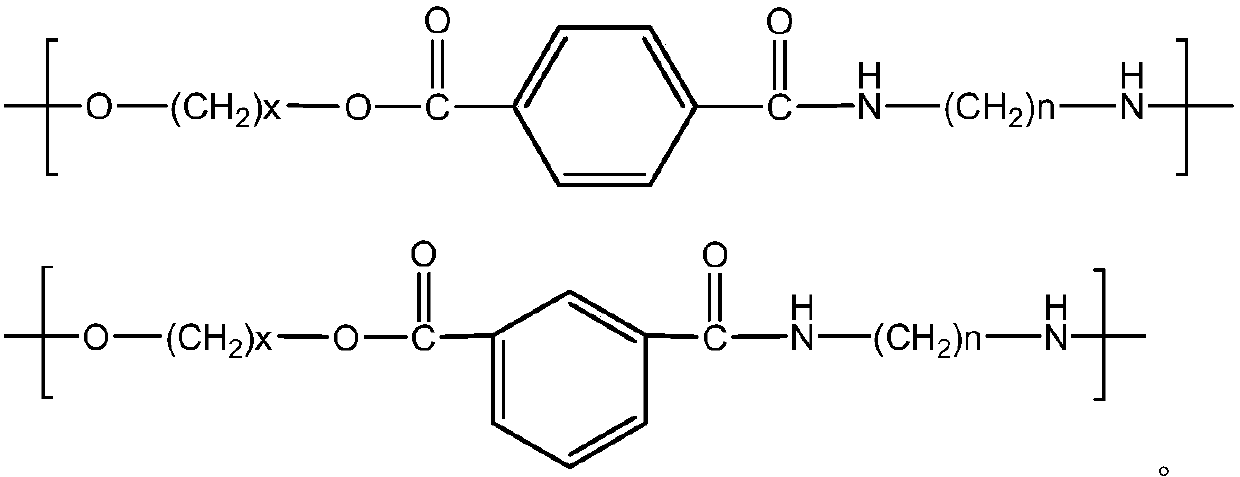

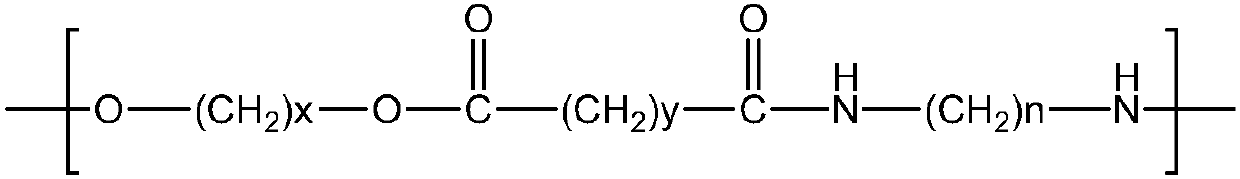

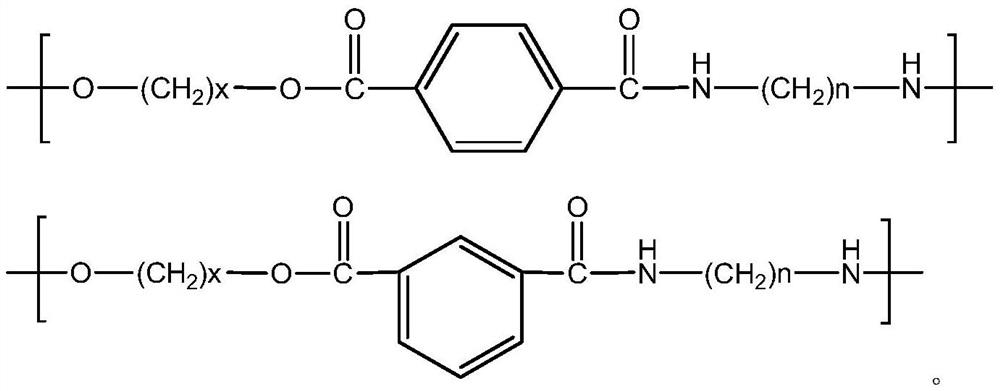

Polyester amide and preparation method thereof

The invention provides a preparation method of a polyester amide. According to the method, by optimizing the pre-polymerization and polycondensation reaction conditions, the yellowing of the polyesteramide in the polymerization process is effectively reduced, and the yellow index of the prepared polyester amide is low, so that the polyester amide is suitable for industrialized production and haswide application prospect.

Owner:CATHAY R&D CENT CO LTD +1

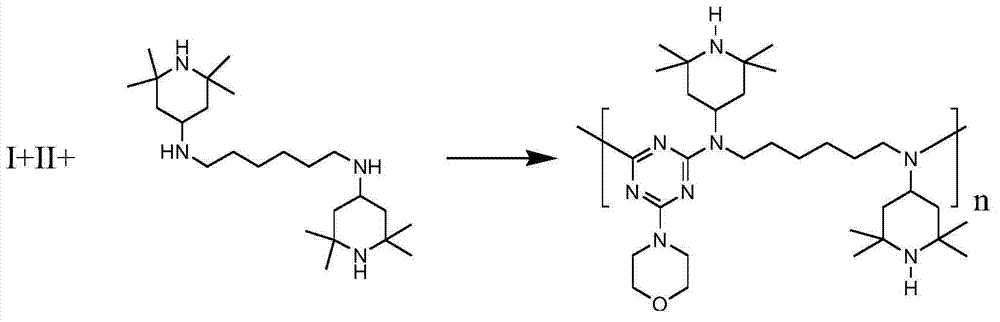

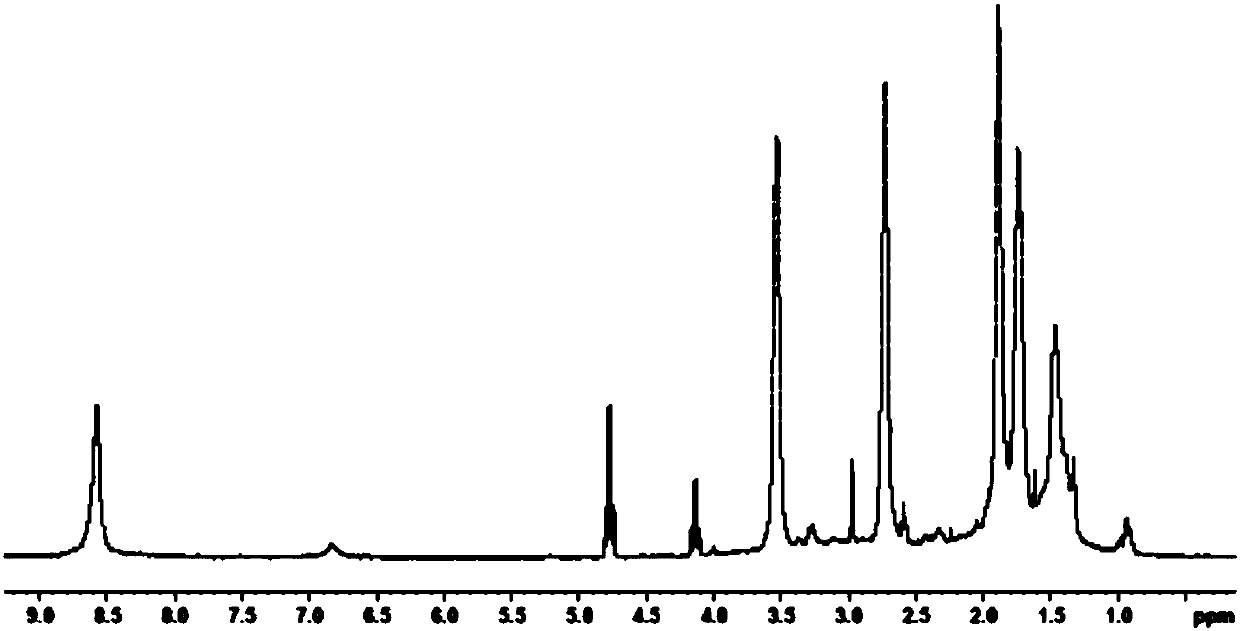

Hindered amine light stabilizer 3346 preparation method

ActiveCN104725361AControl degree of aggregationHigh light transmittanceOrganic chemistryEnvironmental resistance1,3,5-Triazine

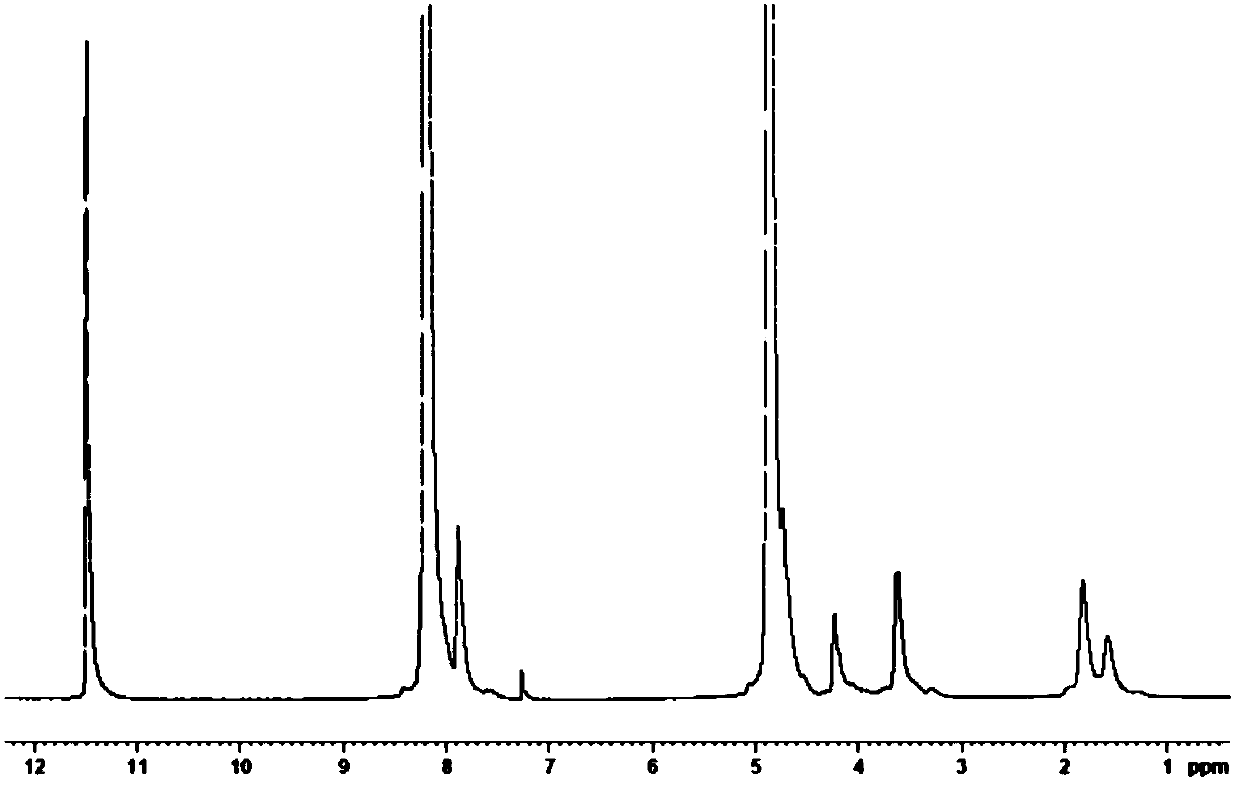

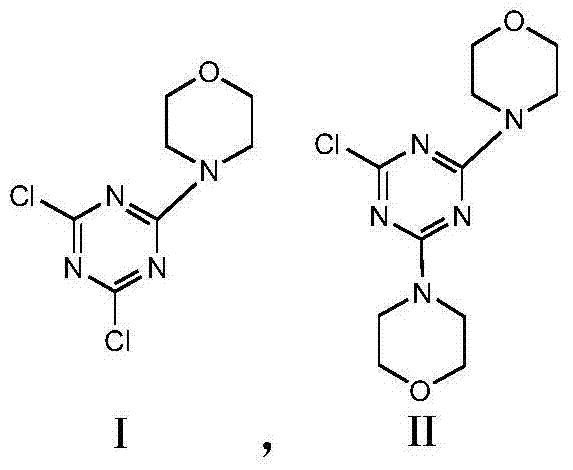

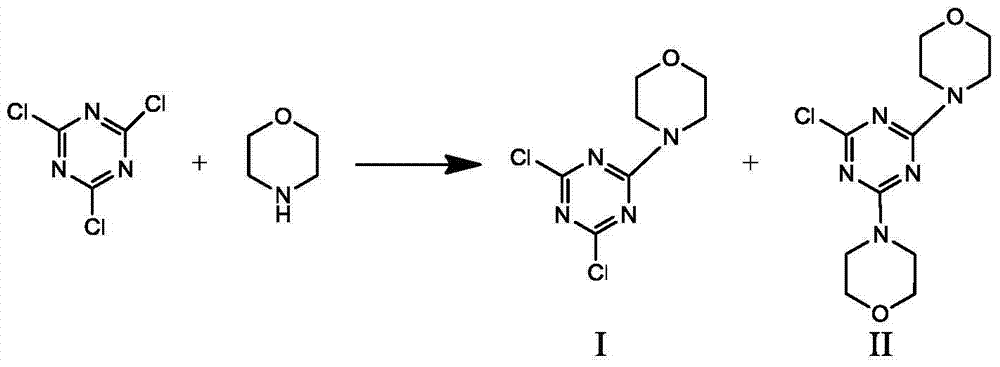

The invention discloses a hindered amine light stabilizer 3346 preparation method. The method includes the steps: 1) preparing a mixture of an intermediate I and an intermediate II according to a specific ratio by reaction of cyanuric chloride and morpholine, wherein the intermediate I refers to 2-morpholinyl-4,6-dichloro-1,3,5-triazine, and the intermediate II refers to 2,4-dimorpholine-6-chloro-1,3,5-triazine; 2) subjecting the intermediate mixture and hexanediamine piperidine to temperature-gradient heating under a pressure to obtain the light stabilizer 3346. The preparation method has the advantages that economy and environment friendliness are realized due to adoption of water as solvent at the first step, and the mixture of the intermediates I and II in the specific ratio is synthesized under proper conditions without separation; at the second step, reaction difficulty is raised due to different substitute degrees of three chlorines, and a product narrow in relative molecular mass distribution and excellent in transparency is obtained by means of temperature-gradient heating under a certain pressure.

Owner:江苏富比亚化学品有限公司

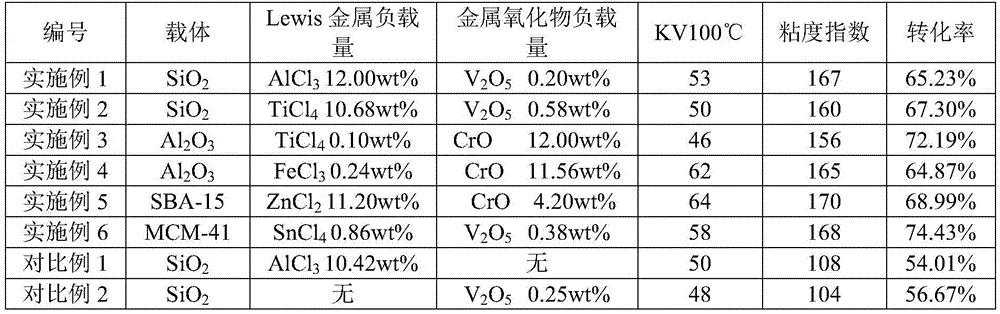

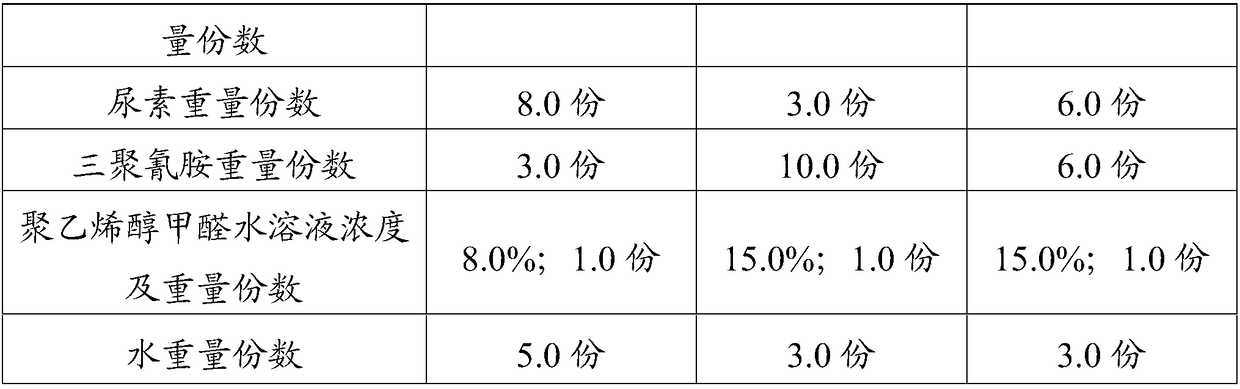

Catalyst for poly-alpha-olefin synthetic oil and preparation method for catalyst

ActiveCN106881119ALow viscosity indexEasy to prepareMolecular sieve catalystsLiquid hydrocarbon mixtures productionMuffle furnaceIon

The invention relates to a catalyst for poly-alpha-olefin synthetic oil. The catalyst comprises the following ingredients: a support and active ingredients, wherein the support is a porous inorganic support, and the active ingredients comprise a metal oxide and a Lewis acid type metal salt. The invention further provides a preparation method for the catalyst. The preparation method comprises the steps: dissolving a metal salt of the metal oxide, which serves as a raw material, in deionized water, dipping the support with the obtained metal salt solution, and then, carrying out drying, so as to obtain a metal salt loaded support; roasting the metal salt loaded support in a muffle furnace, so as to obtain a metal oxide loaded catalyst matrix; and then, adding the metal oxide loaded catalyst matrix into an organic solvent containing the Lewis acid type metal salt for loading, thereby obtaining a loaded dual-active-center catalyst.

Owner:PETROCHINA CO LTD

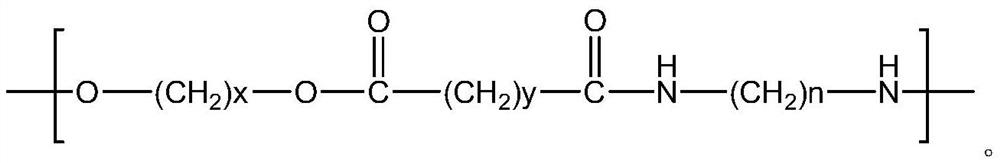

Polyester amide hot melt adhesive and preparation method thereof

ActiveCN109957108ASimple preparation processControl degree of aggregationAdhesivesPolyesterPolymer science

The invention provides a preparation method of a polyester amide hot melt adhesive. Through optimization of a technical process and regulation and control of reaction parameters such as polymerizationtemperature, pressure, proportioning of reaction raw materials, and the like, the prepared polyester amide hot melt adhesive is low in yellow index, relatively high in peel strength, low in peel strength loss rate after water washing, excellent in performance and wide in application range.

Owner:CATHAY R&D CENT CO LTD +1

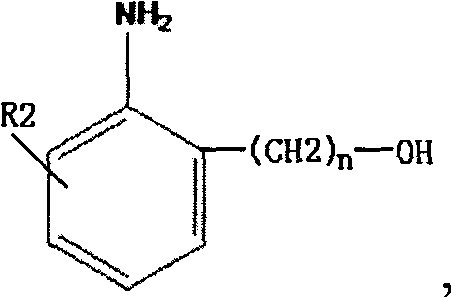

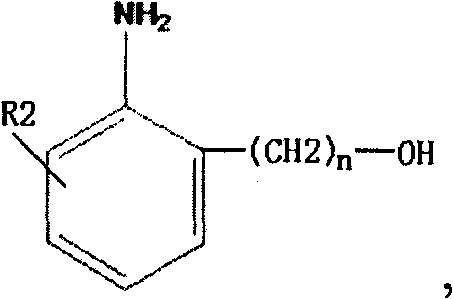

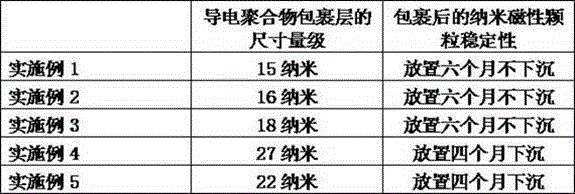

Preparation method of magnetic fluids with polyaniline derivatives wrapping nano magnetic particles

ActiveCN103617858AControl degree of aggregationThe degree of polymerization exceedsMagnetic liquidsPolyaniline derivativesAlkane

The invention relates to a preparation method of magnetic fluids with polyaniline derivatives wrapping nano magnetic particles. By step-by-step interpenetrating reactions, polyaniline derivatives can form chemical bonds firmly wrapping Fe3O4 nano particles. The method specifically includes: using anthranilic acid to modify the surfaces of the Fe3O4 nano particles, adding aniline monomer for polymerization to form the polyaniline derivatives, inoculating dodecylbenzene sulfonic acid to the surfaces of the Fe3O4 / polyaniline derivative composite particles, and allowing the Fe3O4 / polyaniline derivative composite particles to be stably scattered in basic carrier liquid due to the alkane parent non-polar features of the dodecylbenzene sulfonic acid so as to obtain the magnetic fluids with polyaniline derivatives wrapping nano Fe3O4 particles. The photoelectric performance of the magnetic fluids can change regularly under the action of a regularly changed magnetic field, so that the photoelectric performance indexes of the magnetic fluids can be adjusted by adjusting the strength of the magnetic field, a novel research branch is developed in researches of magnetic fluids, and signification research and application values are achieved.

Owner:NANCHANG HANGKONG UNIVERSITY

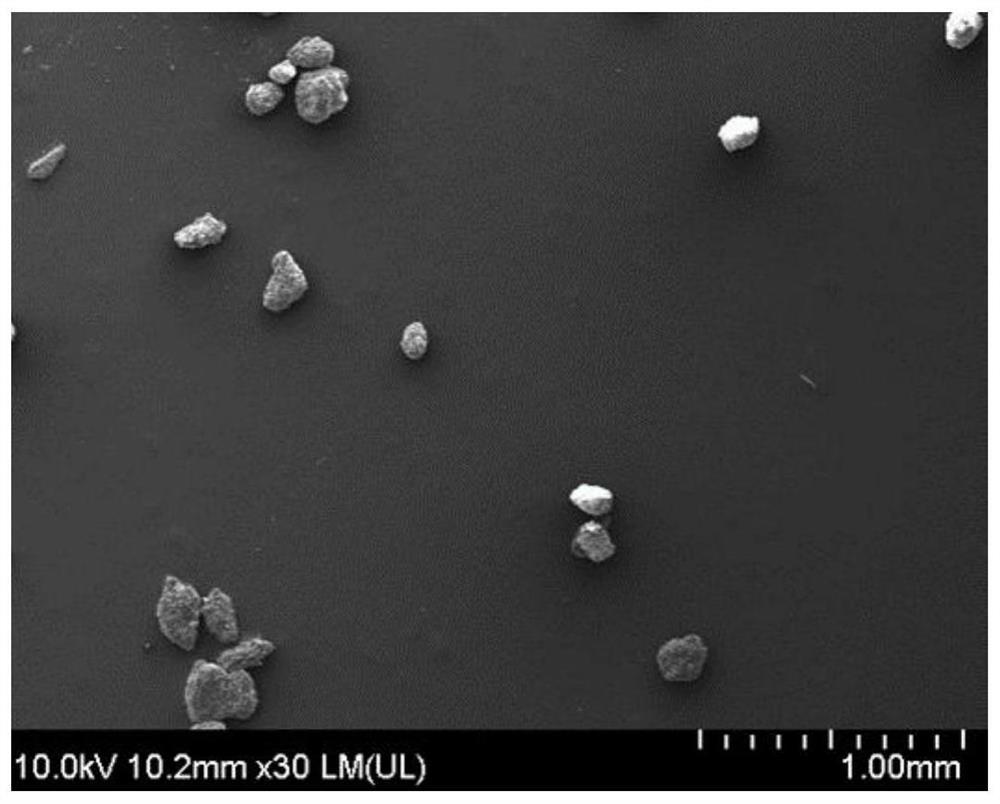

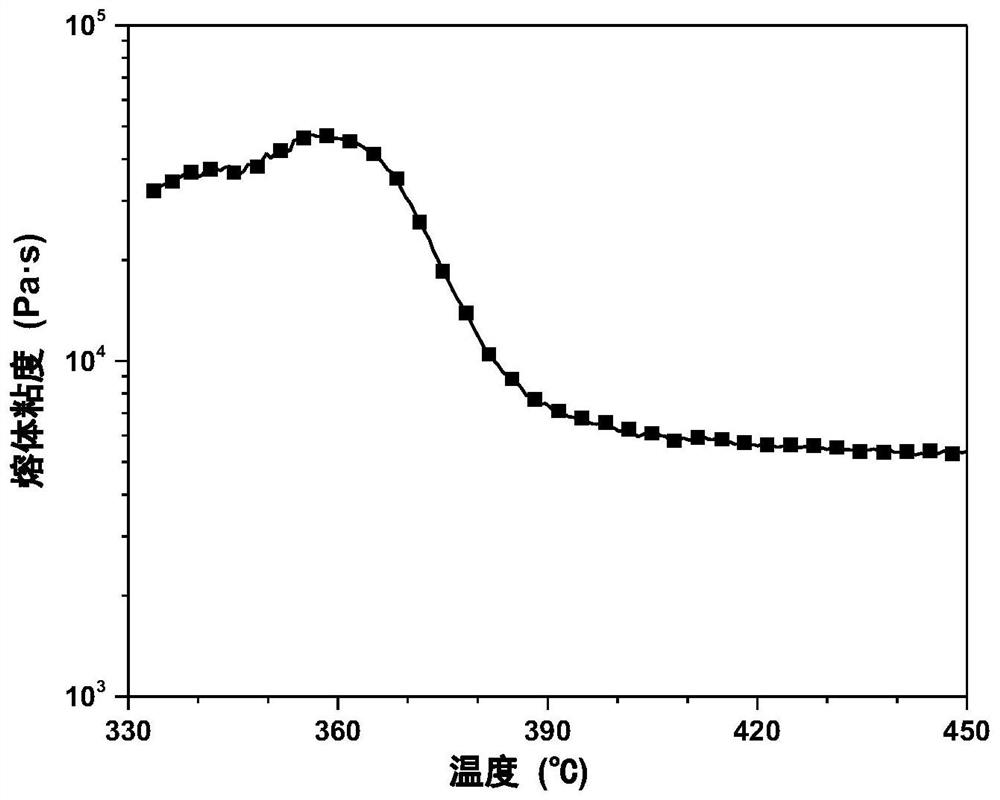

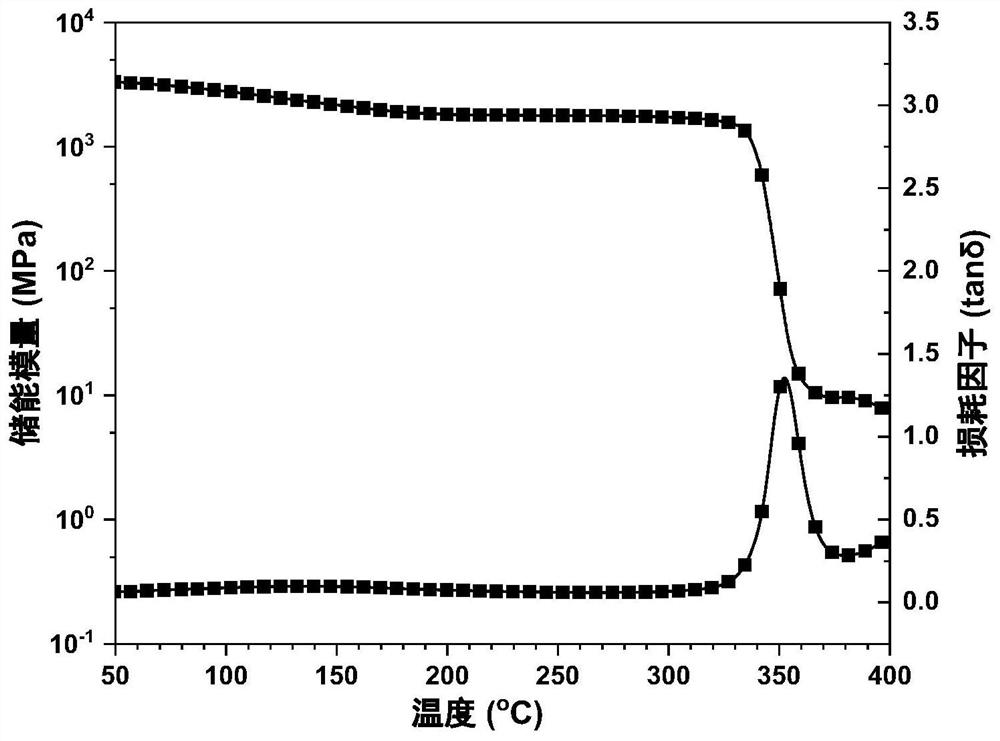

Thermoplastic polyimide with excellent comprehensive performance and preparation method and application thereof

The invention relates to thermoplastic polyimide with excellent comprehensive performance and a preparation method and application thereof, belongs to the technical field of polyimide, and solves the problem that good melting manufacturability and high heat resistance of existing thermoplastic polyimide are difficult to achieve at the same time. The thermoplastic polyimide is prepared from the following raw materials: fluorine-containing aromatic dianhydride, m-phenylenediamine, rigid aromatic diamine with a large-volume structure and a non-reactive end-capping reagent. The preparation method comprises the following steps: preparing a polyamide acid solution, preparing a polyimide solution, preparing a polyimide suspension, and carrying out post-treatment to obtain the polyimide powder. The thermoplastic polyimide resin disclosed by the invention can be used as a high-temperature-resistant engineering plastic, composite material matrix resin or a composite material interlayer toughening component, and is applied to the fields of aerospace, automobile manufacturing, power and electric appliances, microelectronics and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

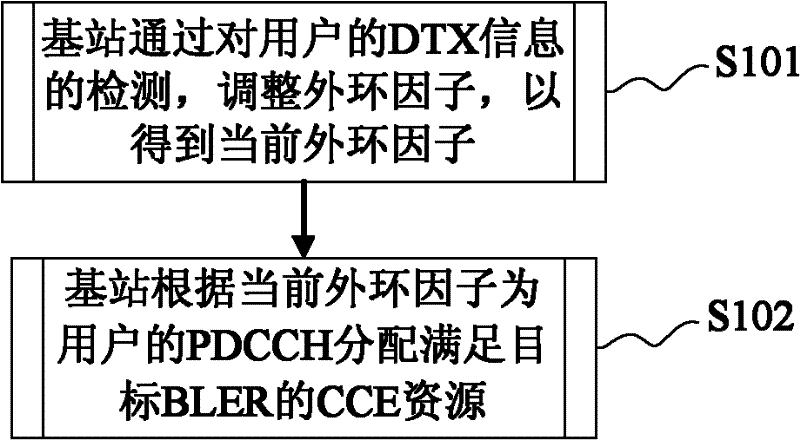

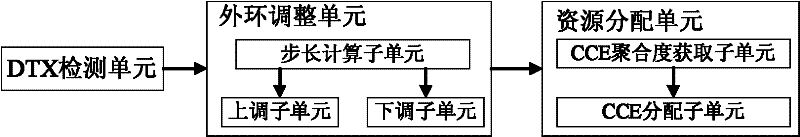

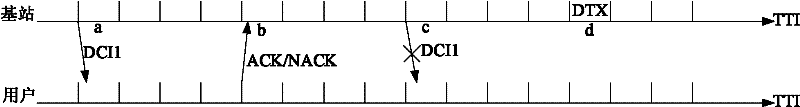

Physical downlink control channel (PDCCH) self-adaptive transmission method and device

ActiveCN102685893AControl degree of aggregationImprove reliabilityConnection managementControl channelSelf adaptive

The invention discloses a PDCCH self-adaptive transmission method and a device. The method includes that a base station adjusts outer ring factors by detecting users' discontinuous transmission (DTX) information to obtain current outer ring factors; and the base station distributes command control equipment (CCE) resources meeting target block error ratio (BLER) to users' PDCCH. According to the PDCCH self-adaptive transmission method and the device, polymerization degree of the CCE used by the PDCCH is controlled through the detection of users' DTX information by the base station, so that reliability of the PDCCH is improved.

Owner:NANJING ZHONGXING SOFTWARE

Method for preparing protein chip by in-situ synthesis

InactiveCN101813701AEasy to manufactureQuick checkDecorative surface effectsMaterial analysis by electric/magnetic meansSynthesis methodsProtein molecules

In order to solve the problem, which troubles academic circles for a long time, about how to permanently bond protein molecules to the metal actively and fixe the protein molecules on the metallic surface of any detector or any independent addressing electrode in place at one step, the invention provides a method for preparing a protein chip. The method comprises the following steps of: by adopting an in-situ electrochemical combination synthesis method and independent addressing microelectrode array technique, making an aniline derivative monomer containing bioactive units and anilines in solution copolymerized on an electrode in a mode of active free radical polymerization, generating an electrode coverings which is bioactive and electrically conductive on the electrode in situ at one step, and under bionic conditions, making avidins connected with various proteins tightly bonded with the e electrode coverings to prepare the protein chip. The method has the advantages of laying a foundation for an unmarked analysis method, truly making mass production of protein chips possible, providing the possibility for the automatic production of the protein chips at the operation level forthe first time, along with high reproducibility.

Owner:WUXI ZHONGMEI YIXIN BIOTECH

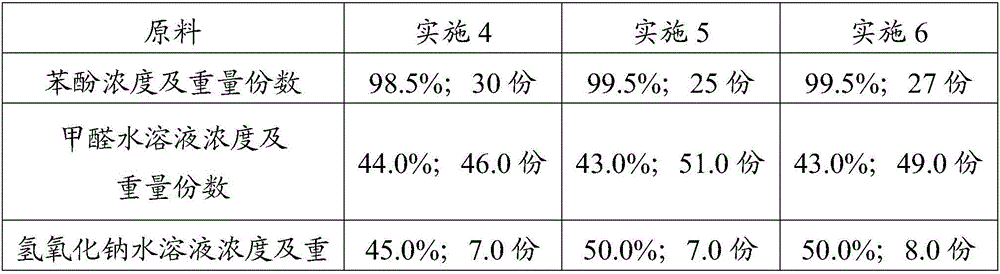

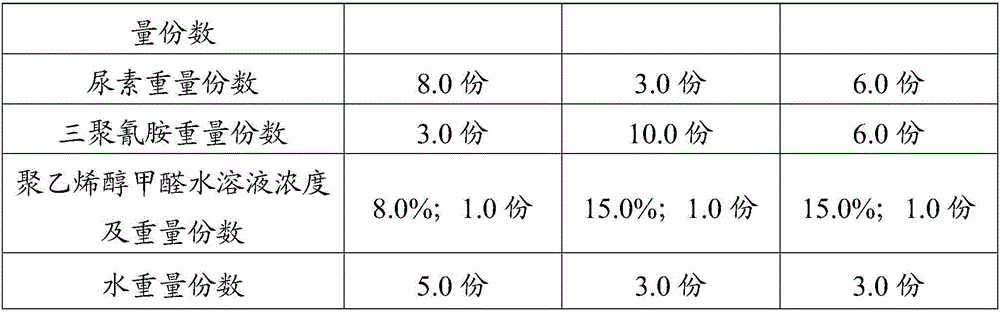

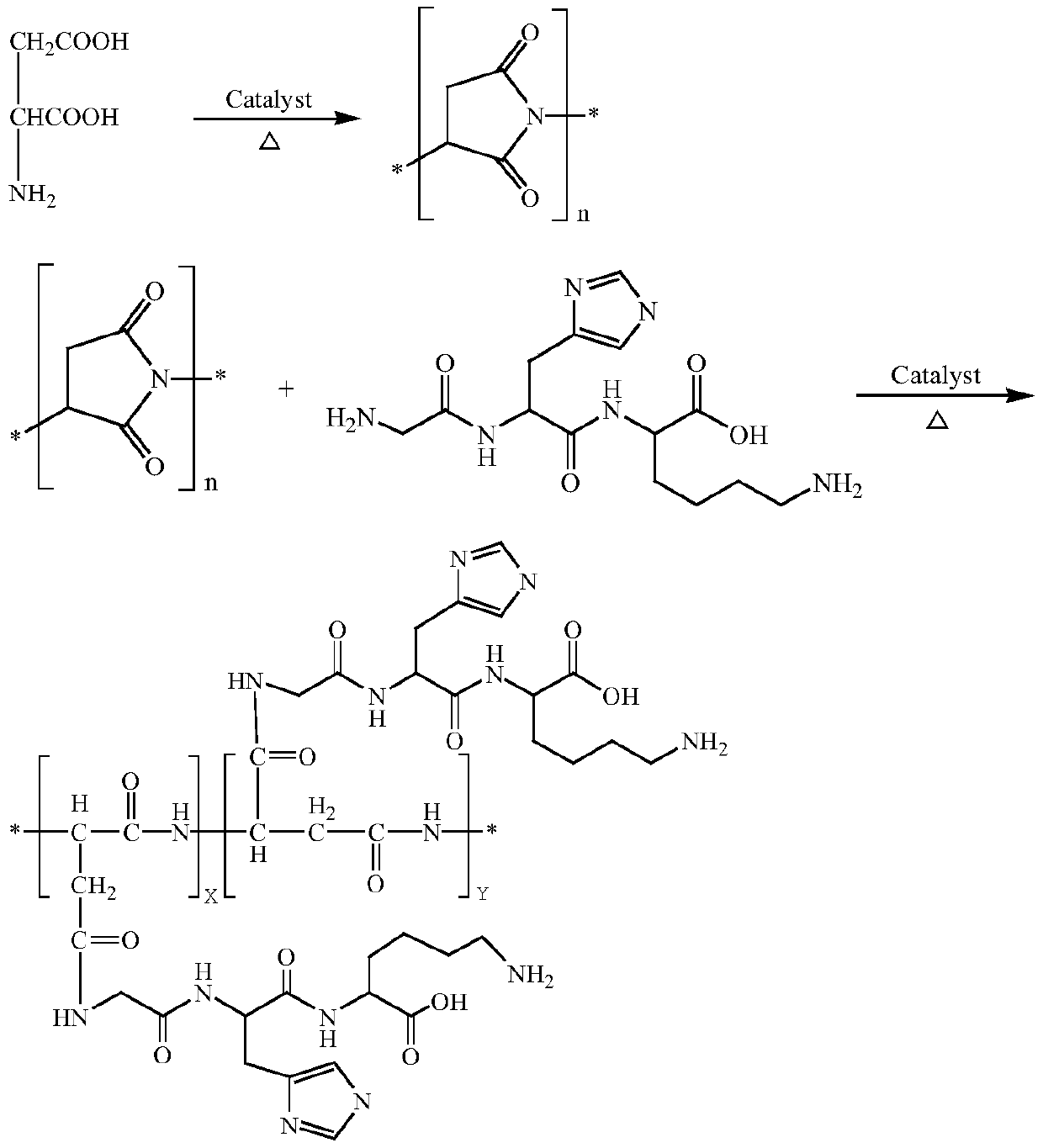

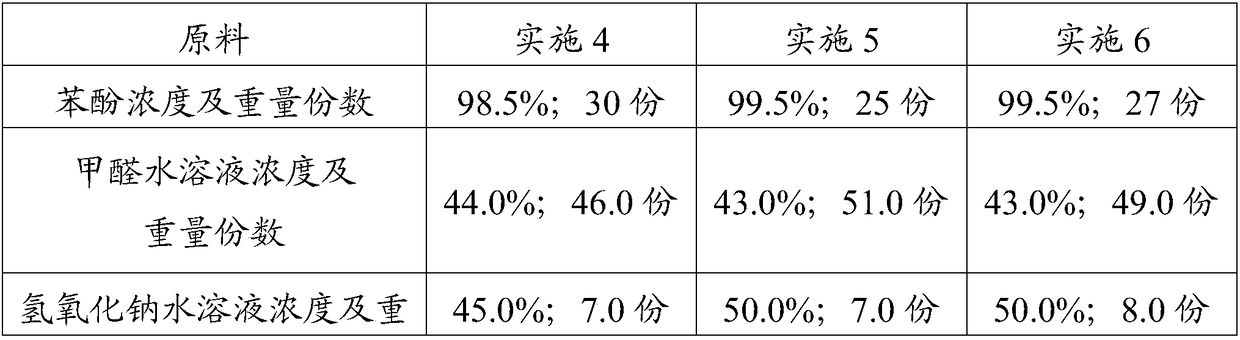

Modified phenolic resin used for outdoor recombination bamboo production and preparation method thereof

ActiveCN106589275AModerate viscosity valueEasy to diluteAldehyde/ketone condensation polymer adhesivesPVA - Polyvinyl alcoholSolid content

The invention discloses a modified phenolic resin used for outdoor recombination bamboo production and a preparation method thereof. The modified phenolic resin is prepared from the components of phenol, a formaldehyde aqueous solution, an alkaline aqueous solution, urea, melamine, a polyvinyl formal aqueous solution and water. In the preparation process of the modified phenolic resin, the phenol, the formaldehyde aqueous solution and the alkaline aqueous solution are added stepwise and fully react. The comprehensive performance of the modified phenolic resin is improved by changing preparation raw materials and improving the preparation method, the solid content of the modified phenolic resin is increased, the viscosity and the flexibility of the modified phenolic resin are improved, and the wettability of the modified phenolic resin is ensured.

Owner:广西玉林利而安化工有限公司

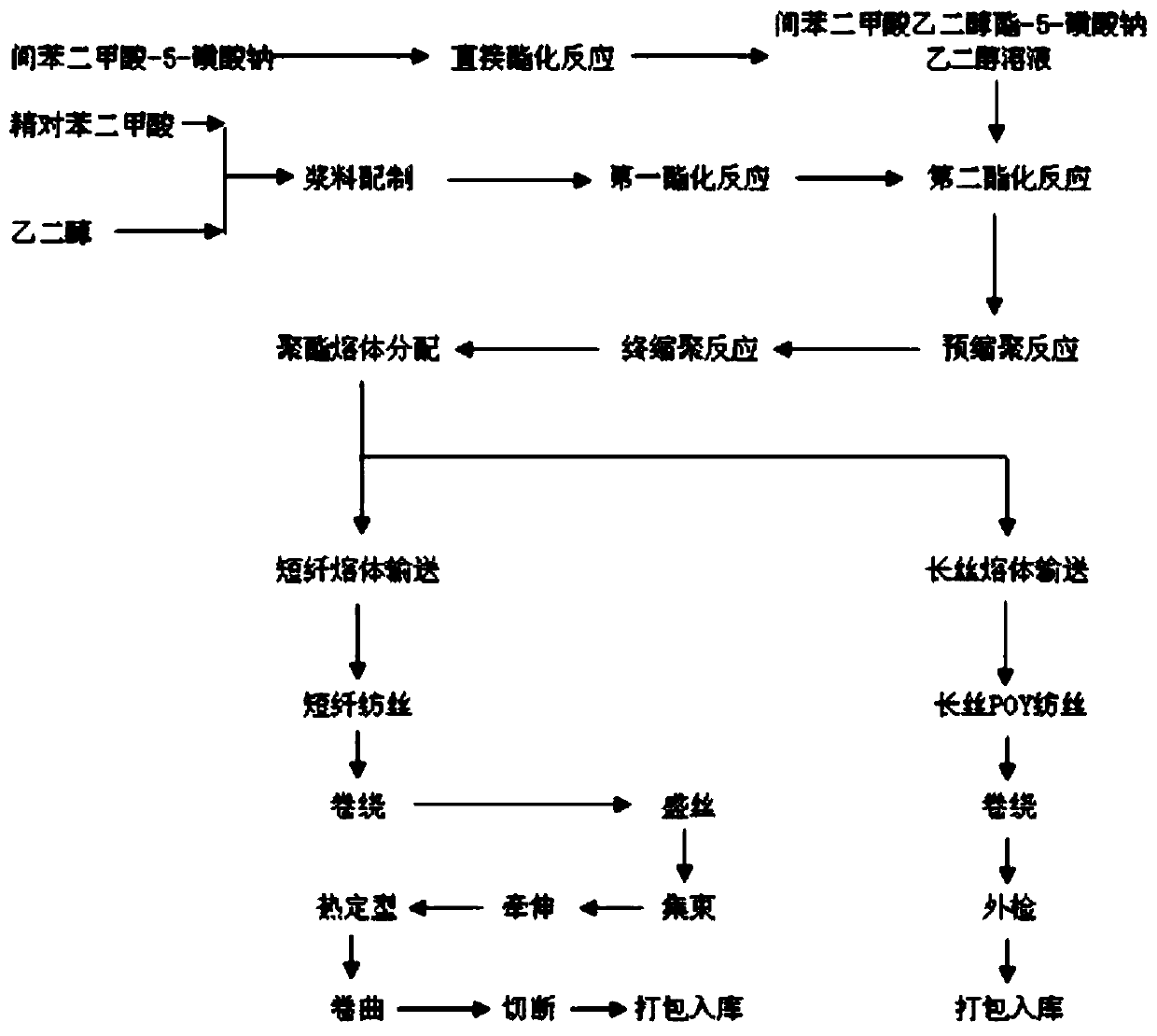

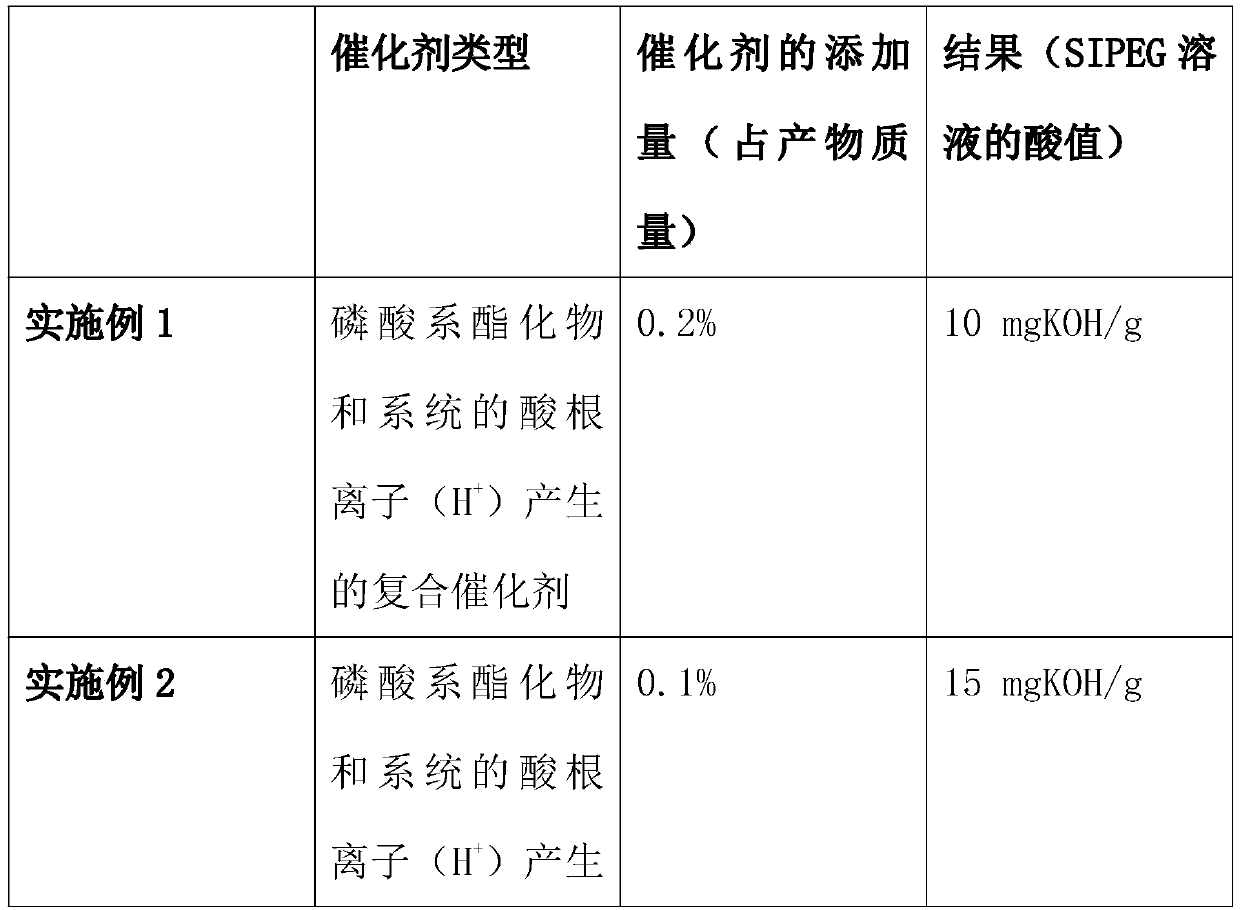

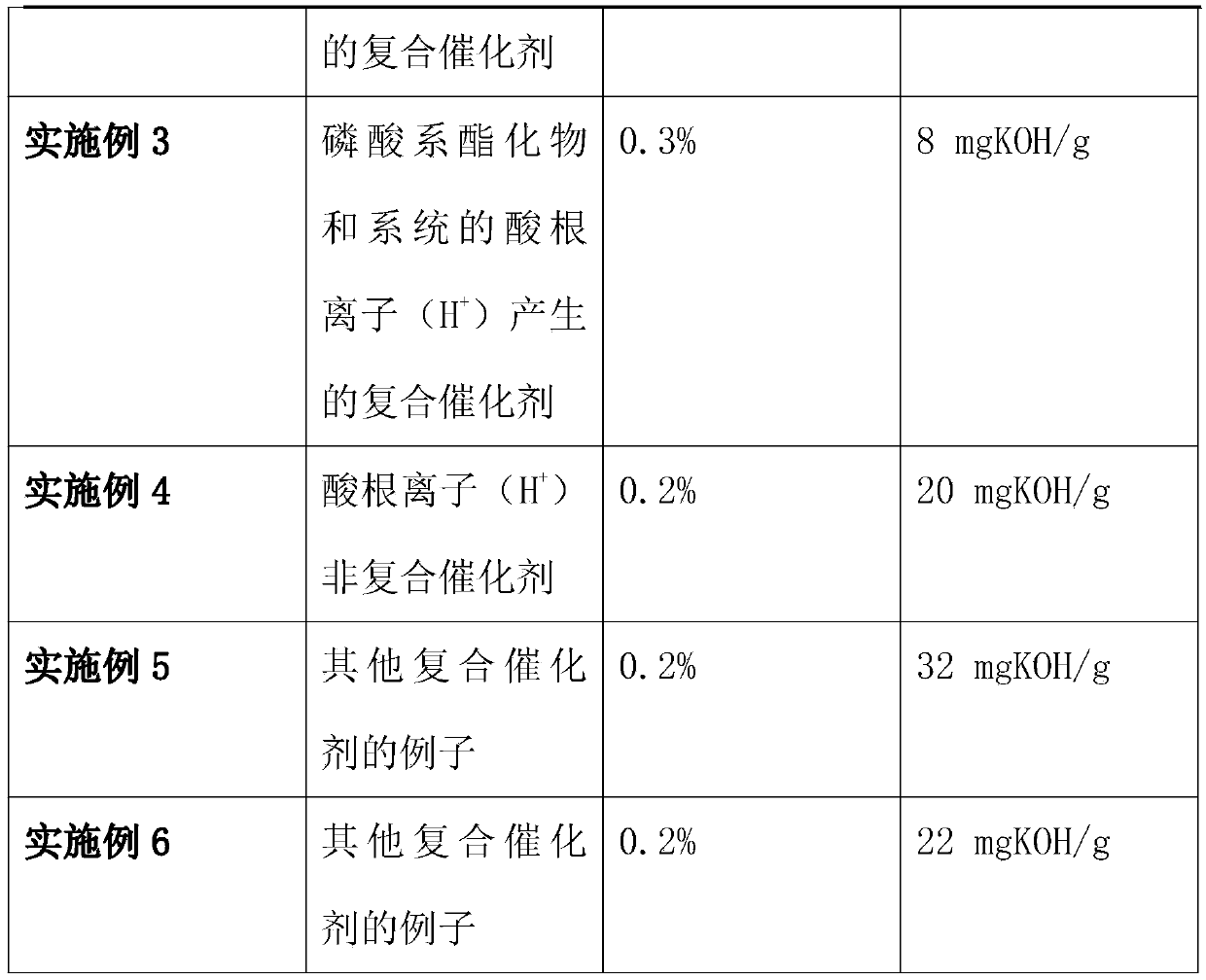

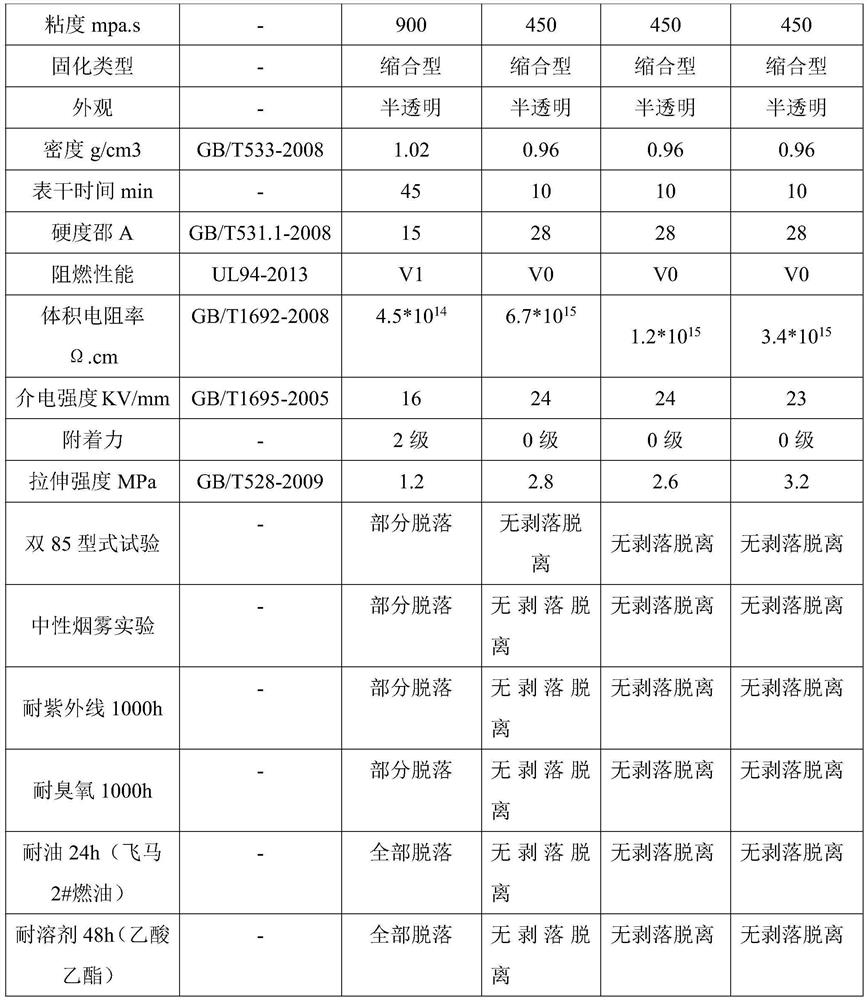

Production process for cationic polyester melt and application method for cationic polyester melt

ActiveCN110760058AHigh strengthControl degree of aggregationMonocomponent copolyesters artificial filamentMelt spinning methodsPolyesterChemical synthesis

The invention relates to the field of processing of fibers for direct spinning of cationic polyester filaments and chopped fibers and particularly relates to the technical field of chemical synthesisof a polyester third monomer, i.e., sodium ethylene glycol-5-sulfonate m-phthalate by a direct esterification method through processes of esterification synthesis, polycondensation synthesis and the like. A production process for a cationic polyester melt is disclosed by the invention and comprises the following steps: (1) obtaining an esterified substance, i.e., sodium ethylene glycol-5-sulfonatem-phthalate; (2) obtaining an esterified substance, i.e., ethylene glycol terephthalate; (3) obtaining a mixed esterified substance; (4) enabling the mixed esterified substance obtained in the step (3) to reach certain inherent viscosity, and completing a prepolycondensation reaction, so as to obtain a prepolycondensation reactant; and (5) enabling the prepolycondensation reactant to enter a final polycondensation reactor, reaching inherent viscosity of a polymer under the action of further improving a reaction temperature and a degree of vacuum, and completing a final polycondensation reaction, thereby obtaining the polyester melt required for production of the cationic polyester filaments and the chopped fibers through melt direct-spinning.

Owner:杭州观晨实业有限公司 +1

Preparation method of microcrystalline cellulose

ActiveCN106749686AImprove qualityBroaden sources of raw materialsPulping with inorganic basesSlurryHydrolysis

The invention discloses a preparation method of microcrystalline cellulose. The preparation method is characterized by comprising the following steps: (1) preprocessing a chemical pulp board: dispersing a chemical pulp board in water to prepare a paper pulp turbid liquid (0.1-15%), soaking the pulp board for 12 to 72 hours to swell the pulp board, and delivering the pulp board into a reactor to carry out reactions to obtain slurry; (2) carrying out an alkali treatment on the slurry: after the pretreatment, subjecting the obtained slurry to solid-liquid separation, washing the solid slurry by clean water until the solid slurry becomes neutral, and processing the solid slurry by alkali liquor; (3) carrying out an acid treatment on the slurry: after the alkali treatment, washing the slurry by clean water until the slurry becomes neutral, then adding diluted acid (0.5-5 mol / L), and carrying out hydrolysis at a temperature of 65 to 95 DEG C to obtain a mixture containing microcrystalline cellulose; and (4) obtaining microcrystalline cellulose: subjecting the mixture to solid-liquid separation, washing the solids by clean water until the solid becomes neutral, and drying the solids in vacuum to obtain the microcrystalline cellulose.

Owner:江苏宣泰药业有限公司

Hydroxy group and epoxide group co-terminated linear polysiloxane preparation technology

InactiveCN109897184AImprove smoothnessImprove hydrophilicityFibre treatmentEpoxyCatalyst degradation

The invention belongs to the field of fine chemistry, and relates to hydroxy group and epoxide group co-terminated linear polysiloxane preparation technology. The hydroxy group and epoxide group co-terminated linear polysiloxane preparation technology comprises followingsteps: DMC is introduced into a polymerization reaction vessel for heating to 80 to 85 DEG C; at nitrogen gas protection, a catalyst is added for ring-opening polymerization reaction; polymerization reaction is carried out until the viscosity reaches 200000 to 400000cs, and water is introduced into the reaction vessel for end capping degradation, wherein the mass amount of added water accounts for 0.03 to 0.5% of DMC; 1,3-bis(3-glycidoxypropyl)-1,1,3,3-tetramethyldisiloxane is introduced into the reaction vessel for epoxy end capping degradation; after end capping degradation, heating is carried out for catalyst degradation, vacuum removing of low boiling point volatile substances is carried out so as to obtain the hydroxy group and epoxide group co-terminated linear polysiloxane product.

Owner:TANGSHAN SANYOU SILICON IND

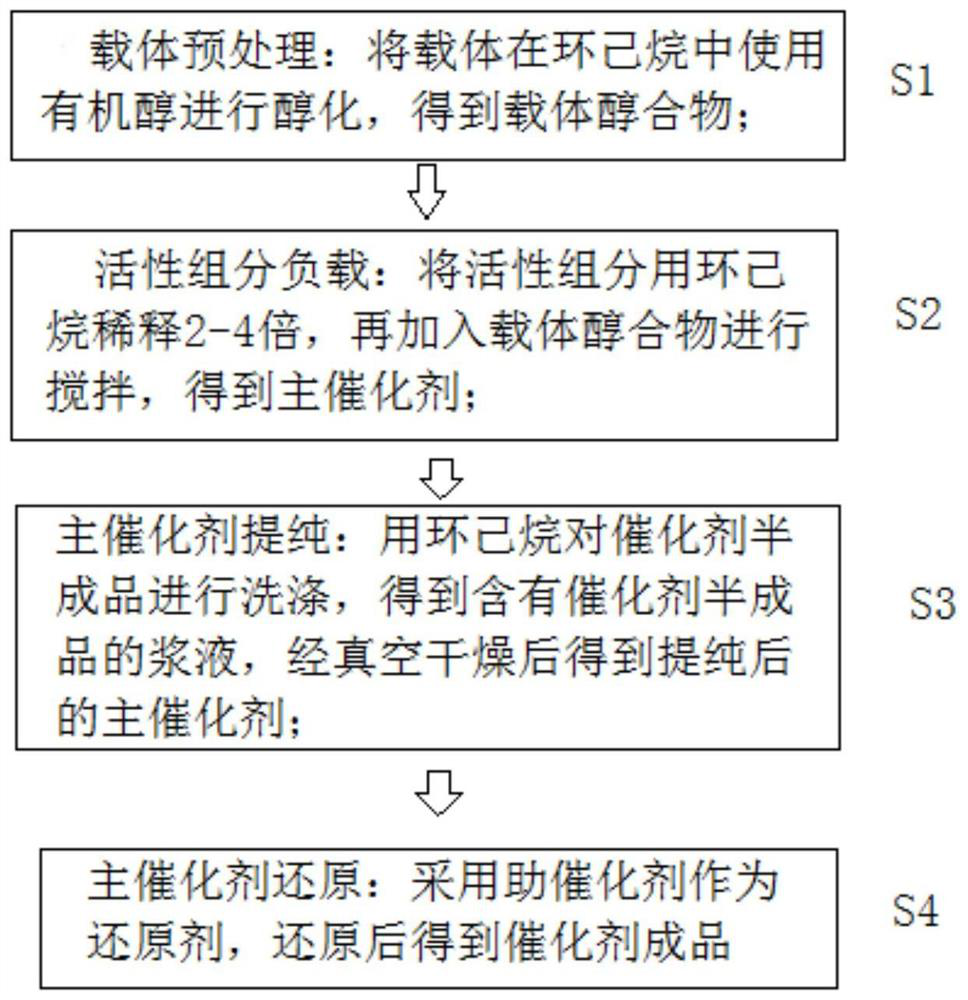

Alpha-olefin polymerization catalyst, preparation method thereof and alpha-olefin polymerization method

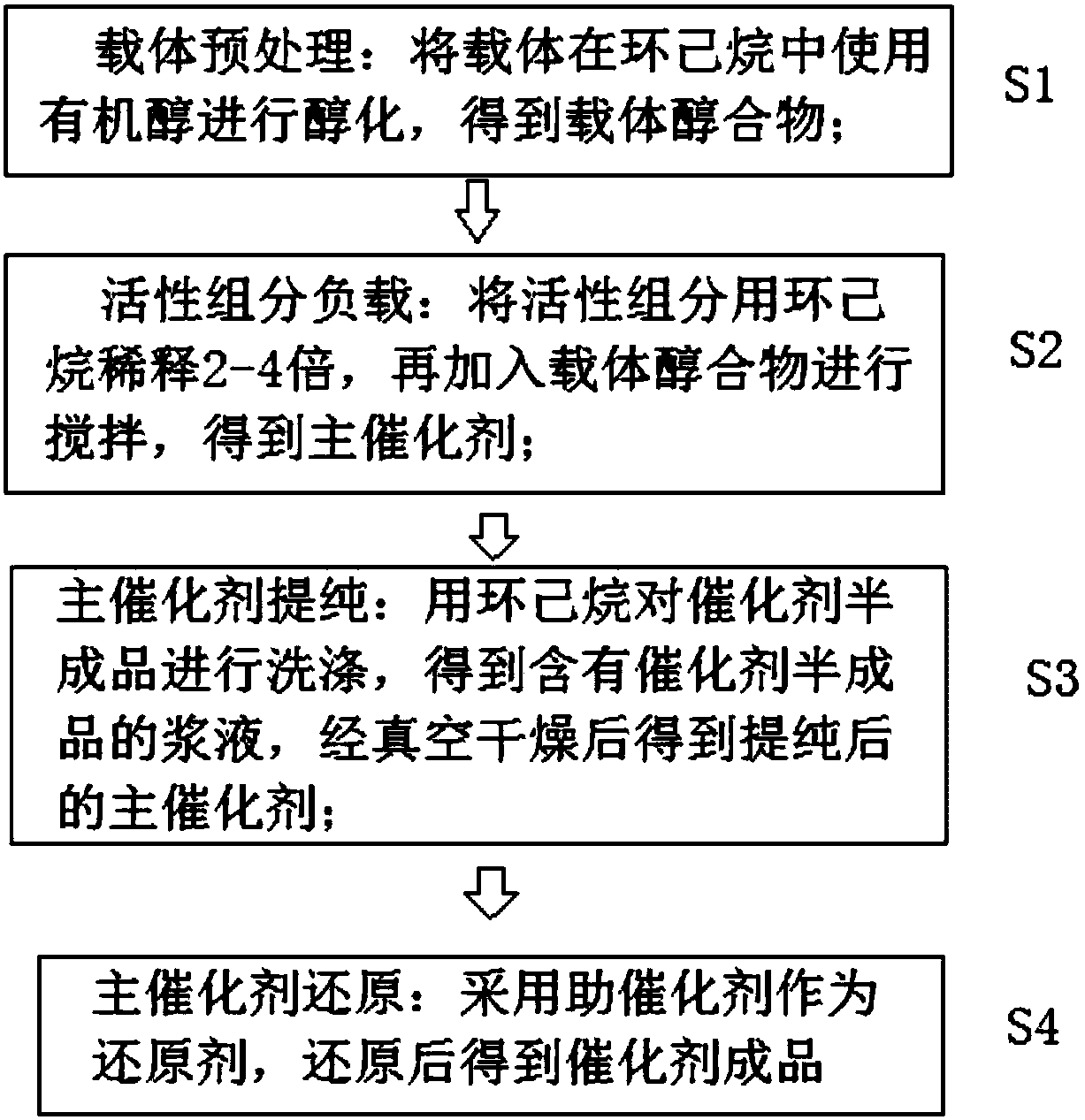

The invention discloses a preparation method of an alpha-olefin polymerization catalyst. The preparation method comprises the following steps: S1, carrier pretreatment: alcoholizing a carrier in cyclohexane with organic alcohol to obtain a carrier alcoholate; S2, active component support: diluting an active component titanium compound by 2-4 times with cyclohexane, and dropwise adding the dilutedtitanium compound to the carrier alcoholate while stirring to obtain a main catalyst; S3, purification of the main catalyst: washing a semi-finished catalyst product with cyclohexane to obtain slurrycontaining the semi-finished catalyst product, and performing vacuum drying to obtain a purified main catalyst; S4, reduction of the main catalyst: reducing the main catalyst with a catalyst promoteras a reducing agent to obtain the finished catalyst product. The invention also discloses the catalyst prepared with the method, an alpha-olefin polymerization method using the catalyst prepared withthe preparation method.

Owner:PETROCHINA CO LTD

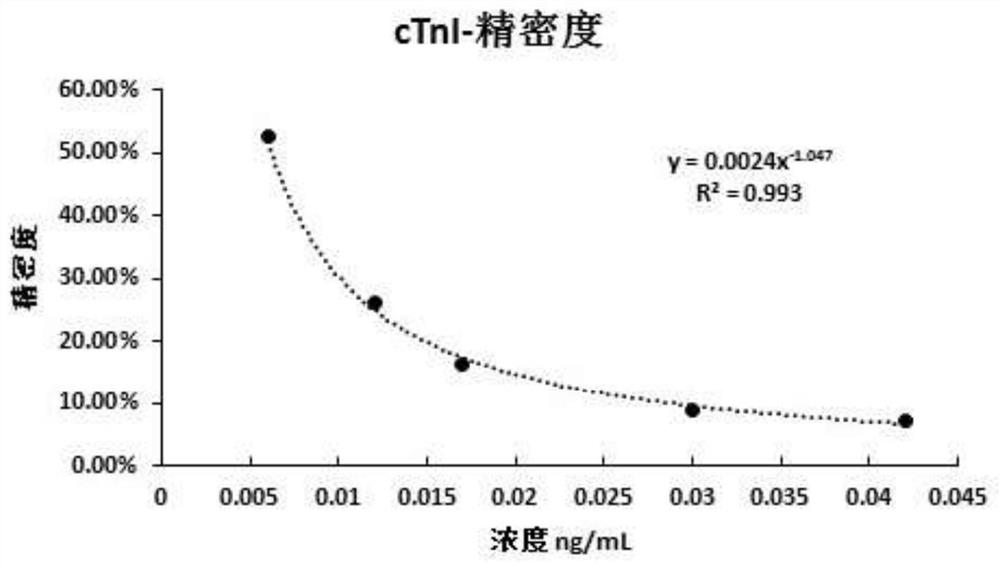

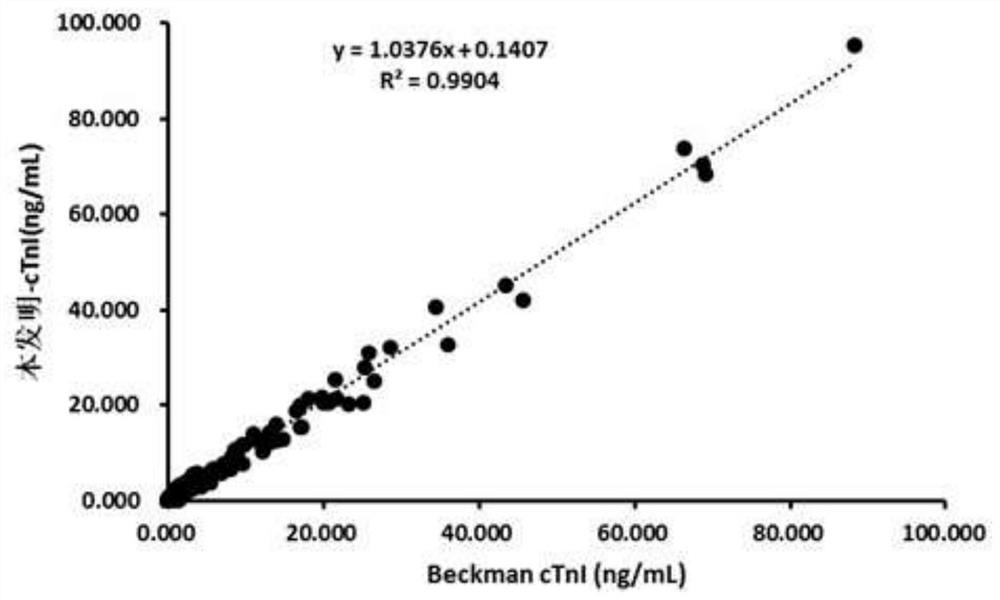

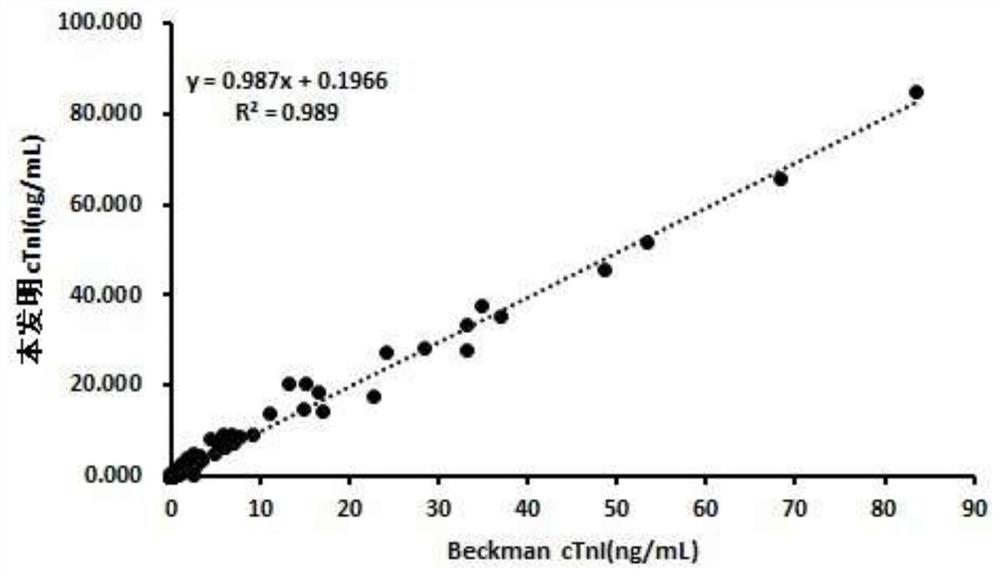

Composition for antigen detection and preparation method

InactiveCN112763704AControl degree of aggregationHigh detection sensitivityBiological testingMolecular biologyAntigen testing

The invention relates to the field of immunodetection, in particular to a composition for antigen detection and a preparation method, and discloses the composition for antigen detection, which realizes high-sensitivity and high-accuracy detection of antigens by utilizing a long-chain activator to amplify the length of an antigen-antibody connecting arm.

Owner:ZYBIO INC

A kind of α-olefin polymerization catalyst and its preparation method, α-olefin polymerization method

Owner:PETROCHINA CO LTD

Method for producing cellooligosaccharides from lignocellulose

ActiveCN109082451BReduce manufacturing costRaw materials are widely sourced and cheapMicroorganism based processesFermentationBiotechnologyCellulose

The invention provides a cellulosome based novel enzyme preparation cello-oligosaccharide preparation method aiming at problems of low efficiency, low yield, high cost and the like in industrial cello-oligosaccharide production in the prior art. The preparation method includes steps of raw material pretreatment, preparation of enzyme preparations, enzymolysis, aftertreatment and the like. Comparedwith an existing technique for producing cello-oligosaccharide from lignocelluloses, the method has advantages that production cost caused by high price of enzymes is reduced; in addition, due to extensive raw material sources and low cost, industrial promotion is technically supported. Further, by adoption of the method, technical problems of (1) serious feedback inhibition caused by cellobioseto cellulosome activity and (2) purification of oligosaccharide subjected to enzymolysis in adoption of cellulosome and production bacterial strains for cello-oligosaccharide preparation are solved. More importantly, compared with the prior art, the method has the advantage of high cello-oligosaccharide yield and conversion rate.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

A preparation method of poly-3-methylthiophene-coated nano-nickel-zinc ferrite particle magnetic liquid

InactiveCN103632798BSmall particle sizeImprove stabilityMagnetic liquidsInorganic material magnetismIn situ polymerizationSynthesis methods

Owner:EAST CHINA UNIV OF TECH +1

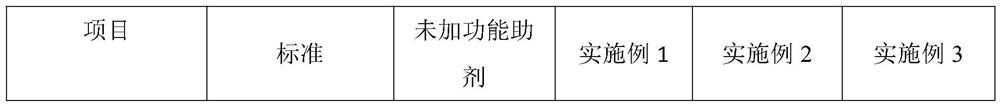

Functional additive for liquid silicone rubber as well as preparation method and application thereof

The invention discloses a functional additive for liquid silicone rubber. The functional additive is mainly prepared by polymerizing acrylate monomers, vinyl siloxane and other vinyl monomer compoundsaccording to the mass ratio of 80-300: 100-200: 20-120. The functional additive smoothly realizes the purpose of simultaneously modifying the liquid silicone rubber for several times, so that the performance of the organic silicon material is further improved. The preparation method comprises the following steps: mixing vinyl siloxane, an acrylate monomer, a chain transfer agent and a solvent, dropwise adding a chain initiator, other vinyl monomer compounds and a solvent, controlling the temperature to be 40 DEG C and 120 DEG C, making reacting for 2-8 hours to obtain a primary sample, performing extracting, performing distilling under reduced pressure, and removing the solvent, thereby obtaining the functional additive. The method is simple to operate, can smoothly implement industrial application, and can easily and effectively control the molecular structure, polymerization degree and the like of the functional additive.

Owner:CHEMCHINA ZHUZHOU RUBBER RES & DESIGN INST

A kind of cationic polyester melt production process and its application method

ActiveCN110760058BHigh strengthControl degree of aggregationMonocomponent copolyesters artificial filamentMelt spinning methodsPolyesterChemical synthesis

The invention relates to the field of fiber processing of cationic polyester filaments and short fibers directly spun by melt, in particular to the synthesis of polyester third monomer ethylene glycol isophthalate-5-sodium sulfonate and ester by direct esterification The technical field of chemical synthesis such as chemical synthesis and polycondensation synthesis. A cationic polyester melt production process of the present invention comprises the following steps: (1) obtaining the esterified product ethylene glycol isophthalate-5-sodium sulfonate; (2) obtaining the esterified product ethylene terephthalate ester; (3) to obtain the mixed esterified product; (4) the mixed esterified product obtained in step (3) reaches a certain intrinsic viscosity to complete the pre-condensation reaction to obtain the pre-condensation reaction product; (5) the pre-condensation reaction product enters the final polycondensation reaction Under the action of further increasing the reaction temperature and vacuum, the intrinsic viscosity of the polymer is reached to complete the final polycondensation reaction, and the polyester melt that meets the requirements for the production of cationic polyester filaments and staple fibers by melt direct spinning is obtained.

Owner:杭州观晨实业有限公司 +1

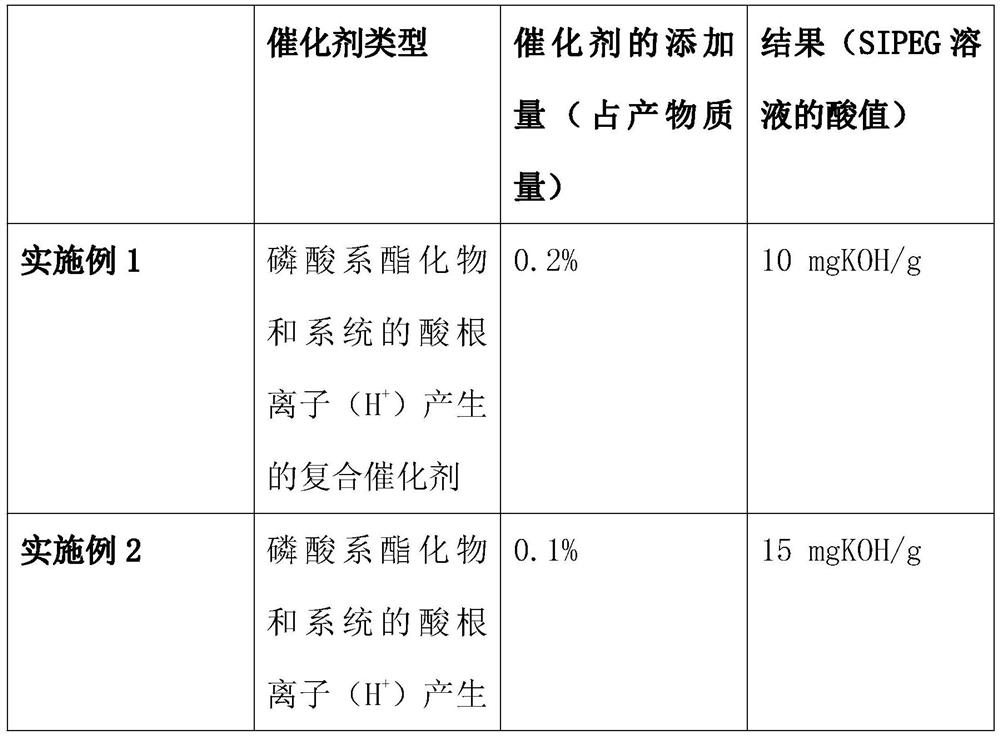

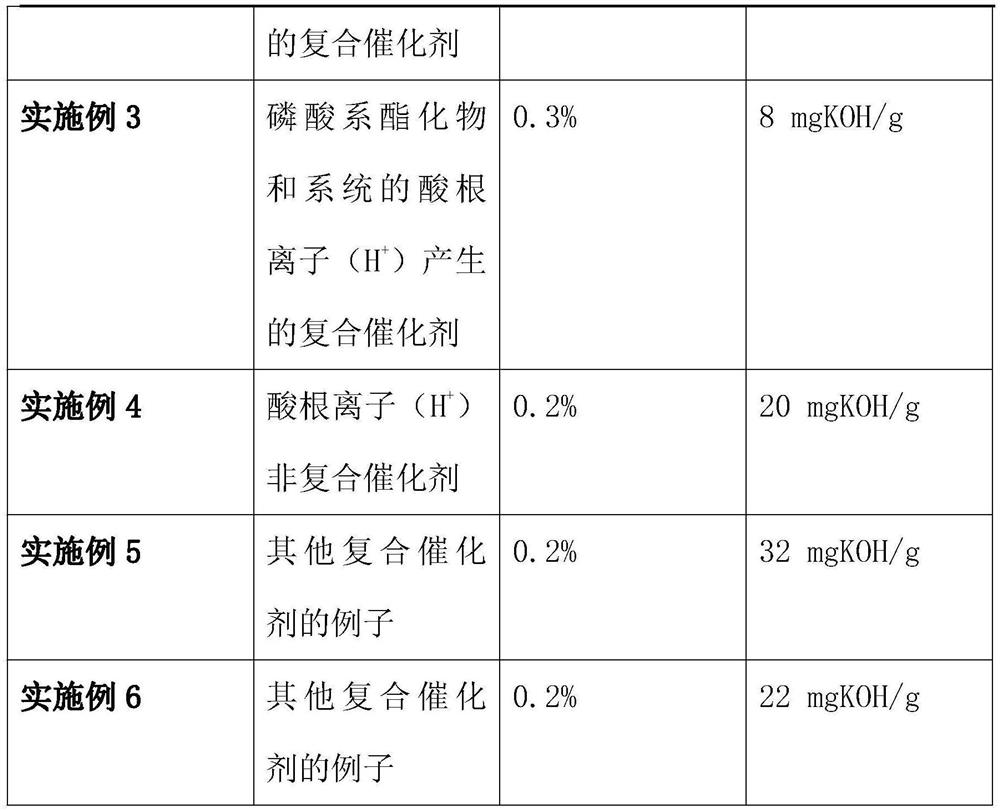

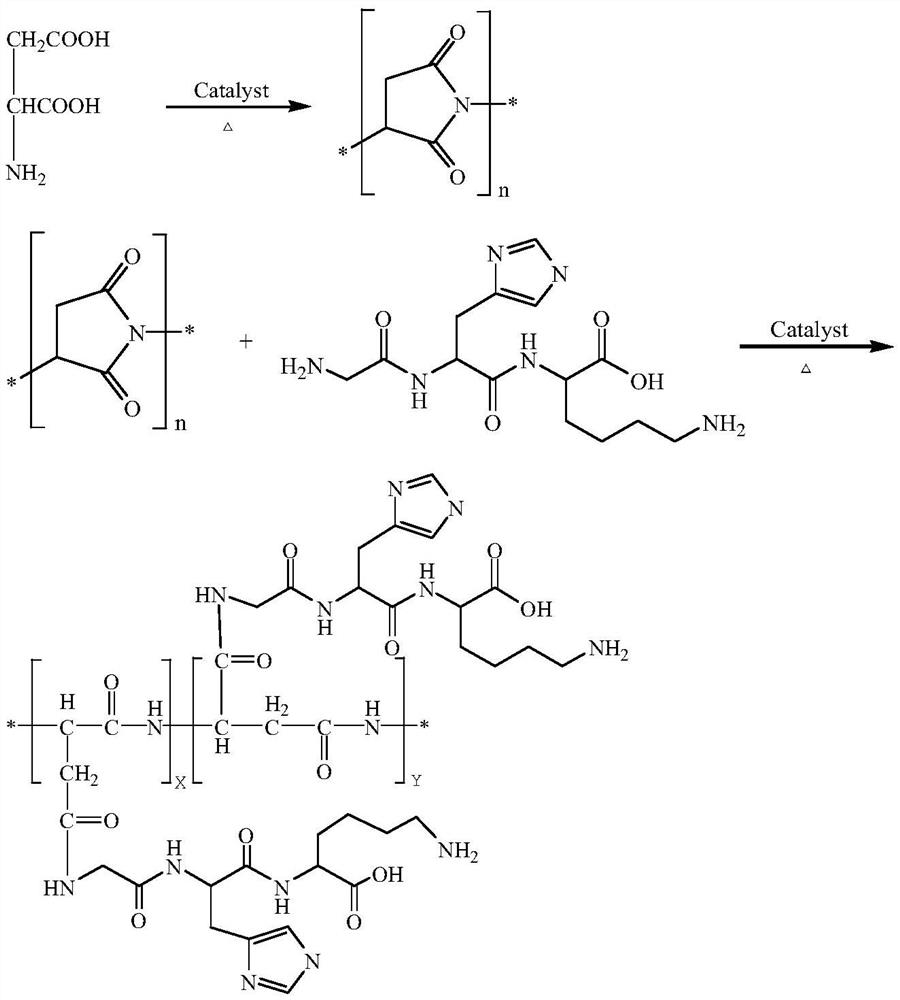

Synthetic method for glycyl-histidyl-lysine grafted polyaspartic acid derivative

The invention provides a synthetic method for a glycyl-histidyl-lysine (GHK) grafted polyaspartic acid derivative. The derivative is synthesized by using GHK tripeptide compound and L-aspartic acid asraw materials and phosphoric acid as a catalyst. The synthetic method provided by the invention is simple and easy to operate, and innovatively couples a graft modification step and a polymerizationstep in one reactor to achieve the purposes of simplifying the process steps and regulating and controlling a polymerization degree and a grafting rate; the polyaspartic acid derivative synthesized byusing the GHK as a modifier is used as a polypeptide polymerization multi-functional novel biomedical product, has the characteristics of having a high molecular weight, strong moisturizing propertyand good coordination ability, and being capable of promoting cell growth, anti-wrinkle and environmentally-friendly, and can be used as a moisturizer, anti-wrinkle additive and pharmaceutical carrieror sustained release agent of cosmetics and health-care products; and the method has a green environmentally-friendly production process, and is an economical preparation method for the value-added polyaspartic acid product.

Owner:湖南黛薇尔新材料有限公司

A kind of modified phenolic resin for producing outdoor recombined bamboo and its preparation method

ActiveCN106589275BModerate viscosity valueEasy to diluteAldehyde/ketone condensation polymer adhesivesPVA - Polyvinyl alcoholSolid content

The invention discloses a modified phenolic resin used for outdoor recombination bamboo production and a preparation method thereof. The modified phenolic resin is prepared from the components of phenol, a formaldehyde aqueous solution, an alkaline aqueous solution, urea, melamine, a polyvinyl formal aqueous solution and water. In the preparation process of the modified phenolic resin, the phenol, the formaldehyde aqueous solution and the alkaline aqueous solution are added stepwise and fully react. The comprehensive performance of the modified phenolic resin is improved by changing preparation raw materials and improving the preparation method, the solid content of the modified phenolic resin is increased, the viscosity and the flexibility of the modified phenolic resin are improved, and the wettability of the modified phenolic resin is ensured.

Owner:广西玉林利而安化工有限公司

Adhesive for high-density wear-resistant environment-friendly tires and preparation method thereof

The invention discloses an adhesive for high-density wear-resistant environment-friendly tires and a preparation method thereof. The adhesive comprises: 200-250 parts of hexamethylolmelamine, 40-50 parts of di-tert-butyl Benzothiazole, 8-10 parts of internal lubricant, 50-60 parts of film-forming compound, 15-20 parts of multibranched polymer, 4-6 parts of film-forming aid, 4-6 parts of defoamer, 3- 5 parts oily dispersing wetting agent, 2‑4 parts polymerizable emulsifier. In the preparation process of the adhesive, the present invention adds a film-forming compound and a multi-branched polymer, by adding a film-forming compound to form a film layer inside and outside on the basis of the original adhesive, the adhesive can be further improved. Excellent bond strength and aging resistance. In short, the adhesive prepared by the present invention through reasonable proportioning and multiple optimized process parameters has high bond strength, aging resistance and tear resistance, thereby improving the wear resistance and safety of tires, and the production process is green and environmentally friendly , which is of great practical significance to the development of energy conservation and emission reduction work in my country's rubber additives industry.

Owner:JIANGSU GUOLI CHEM TECH

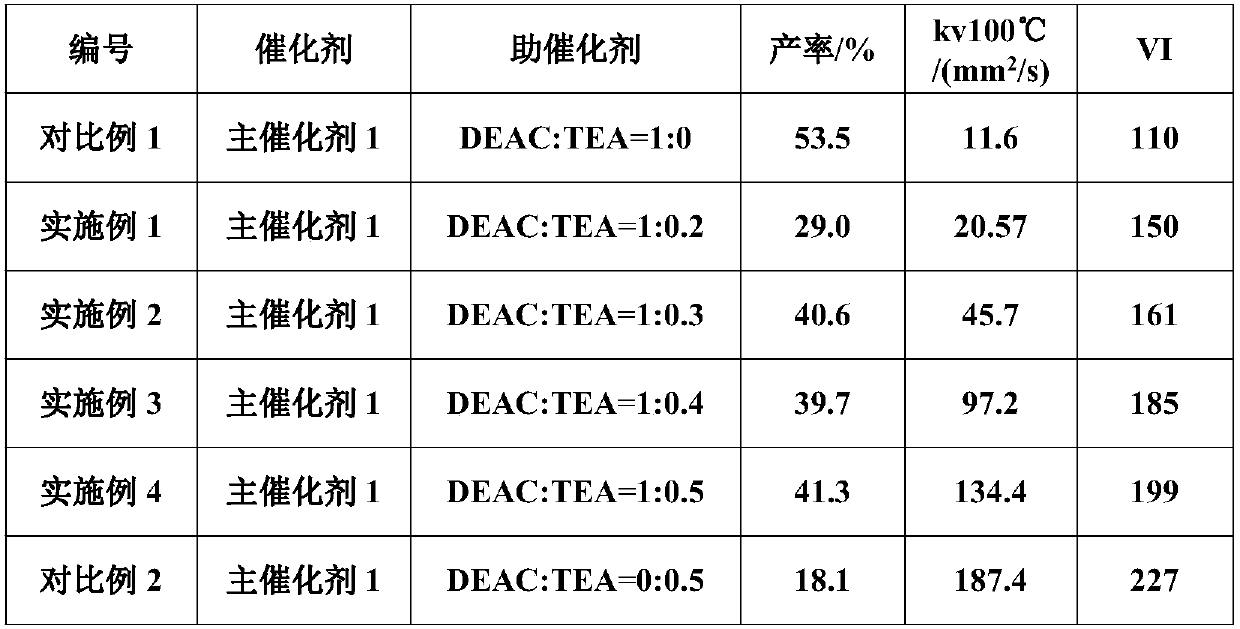

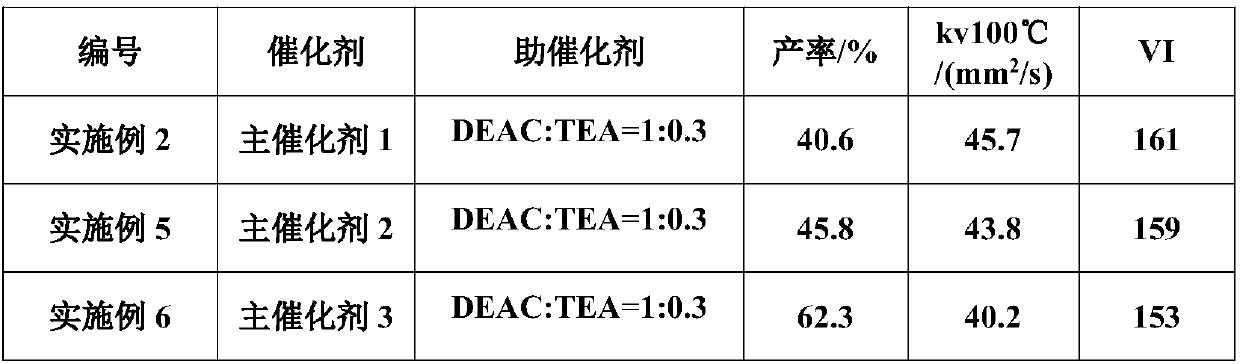

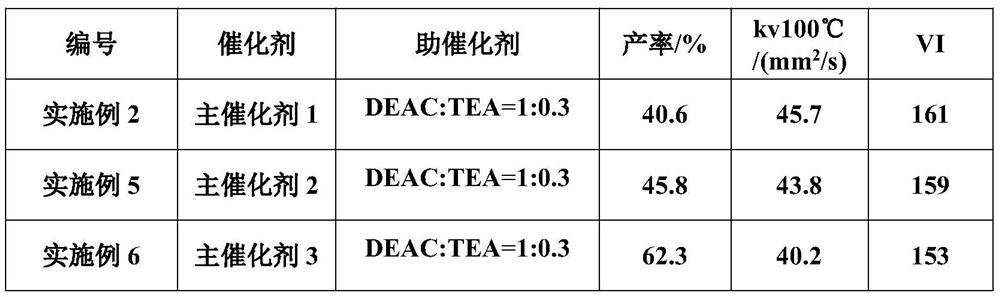

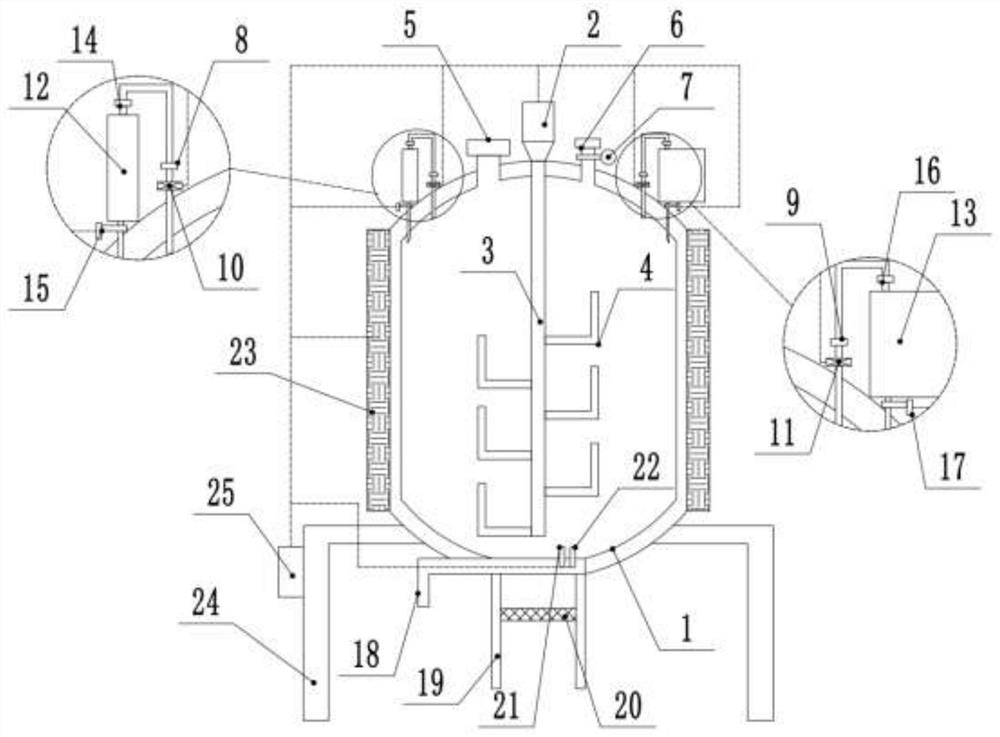

A kind of preparation method of the polyalpha-olefin synthetic oil of high viscosity index

ActiveCN106883899BIncrease profitLow costCatalystsHydrocarbon preparation catalystsDistillationEconomic benefits

The invention relates to a method for preparing poly-alpha-olefin synthetic oil with a high viscosity index. The method comprises the following steps: adding an oligomerization catalyst into raw materials, and carrying out a reaction for 30 to 120 minutes at the temperature of 20 DEG C to 50 DEG C; and separating the catalyst, a reaction product and an unreacted alpha-olefin monomer, and subjecting the reaction product to distillation and hydrogenation, thereby obtaining the poly-alpha-olefin synthetic oil which has the kinematic viscosity of greater than 40cSt and the viscosity index of greater than 150 at the temperature of 100 DEG C. According to the method, PAO with the high viscosity index is polymerized by taking cheap branched-chain alpha-olefin as a synthesis raw material instead of expensive 1-decene. By taking the branched-chain alpha-olefin as the synthesis raw material, byproducts can be utilized so as to increase utilization ratio, and the PAO with the high viscosity index is polymerized by using self-produced decene instead of the expensive 1-decene, so that the cost is reduced, and the economic benefit is increased.

Owner:PETROCHINA CO LTD

Method for fixing noble metal nano particles on single-crystal silicon surface polymer brush

InactiveCN102173865BHigh aggregation densityControl degree of aggregationCupric bromideCuprous chloride

The invention relates to a method for fixing noble metal nano particles on a single-crystal silicon surface polymer brush, which comprises the following steps: soaking a single-crystal silicon wafer in a hydrofluoric acid solution to obtain a silicon wafer A; dropwisely adding 4-vinylbenzyl chloride onto the surface, radiating, rinsing with acetone, drying, and adding into a monomer-containing solvent; adding copper bromide or copper chloride, cuprous bromide or cuprous chloride and ligand into the solvent to carry out surface-initiated atom transfer and free radical polymerization, thus obtaining a silicon wafer C; putting the silicon wafer C in a dichloromethane solution of trifluoroacetic acid, and stirring to obtain a carboxyl-containing polymer brush; and sufficiently soaking the polymer brush in a solution containing noble metal ions, then taking out, and finally reacting in a sodium borohydride solution, thus fixing the noble metal nano particles on the single-crystal silicon surface polymer brush. The invention achieves the following technical effects: the activity is controllable in the polymerization process, the graft polymerization density is high; the polymer chain isprevented from falling off the substrate; and the controllable fixation of the noble metal nano particles is effectively implemented.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Synthetic method of polyaspartic acid derivative grafted with glycyl histidyl lysine

A kind of synthetic method of the polyaspartic acid derivative of glycyl histidyl lysine grafting, it is based on glycyl histidyl lysine (GHK) tripeptide compound, L-aspartic acid As a raw material, phosphoric acid is synthesized as a catalyst. The synthesis method of the present invention is simple and easy to operate, innovatively coupling the grafting modification step and the polymerization step to complete in one reactor, achieving the purpose of simplifying the process steps and regulating the degree of polymerization and grafting rate. The polyaspartic acid derivative synthesized by histidyl lysine as a modifier is a multifunctional new biomedical product of polypeptide polymerization, which has high molecular weight, strong moisture retention, good coordination ability, and can promote cell growth. , anti-wrinkle and environmental bio-friendly advantages, can be used in cosmetics and health products as moisturizers, anti-wrinkle additives and pharmaceutical carriers or slow-release agents, the production process is green and environmentally friendly, and it is an economical polyaspartic acid product with high added value method of preparation.

Owner:湖南黛薇尔新材料有限公司

A kind of preparation method of microcrystalline cellulose

ActiveCN106749686BImprove qualityBroaden sources of raw materialsPulping with inorganic basesSlurryHydrolysis

The invention discloses a preparation method of microcrystalline cellulose. The preparation method is characterized by comprising the following steps: (1) preprocessing a chemical pulp board: dispersing a chemical pulp board in water to prepare a paper pulp turbid liquid (0.1-15%), soaking the pulp board for 12 to 72 hours to swell the pulp board, and delivering the pulp board into a reactor to carry out reactions to obtain slurry; (2) carrying out an alkali treatment on the slurry: after the pretreatment, subjecting the obtained slurry to solid-liquid separation, washing the solid slurry by clean water until the solid slurry becomes neutral, and processing the solid slurry by alkali liquor; (3) carrying out an acid treatment on the slurry: after the alkali treatment, washing the slurry by clean water until the slurry becomes neutral, then adding diluted acid (0.5-5 mol / L), and carrying out hydrolysis at a temperature of 65 to 95 DEG C to obtain a mixture containing microcrystalline cellulose; and (4) obtaining microcrystalline cellulose: subjecting the mixture to solid-liquid separation, washing the solids by clean water until the solid becomes neutral, and drying the solids in vacuum to obtain the microcrystalline cellulose.

Owner:江苏宣泰药业有限公司

A kind of polyester amide and preparation method thereof

The invention provides a preparation method of polyester amide. By optimizing the reaction conditions of prepolymerization and polycondensation, the yellowing of polyester amide in the polymerization process is effectively reduced, and the prepared polyester amide has a low yellow index and is suitable for industrial production. , has a wide range of application prospects.

Owner:CATHAY R&D CENT CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com