Functional additive for liquid silicone rubber as well as preparation method and application thereof

A technology of liquid silicone rubber and functional additives, applied in the direction of coating, etc., can solve the problems of multiple applications, complex principles and processes, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

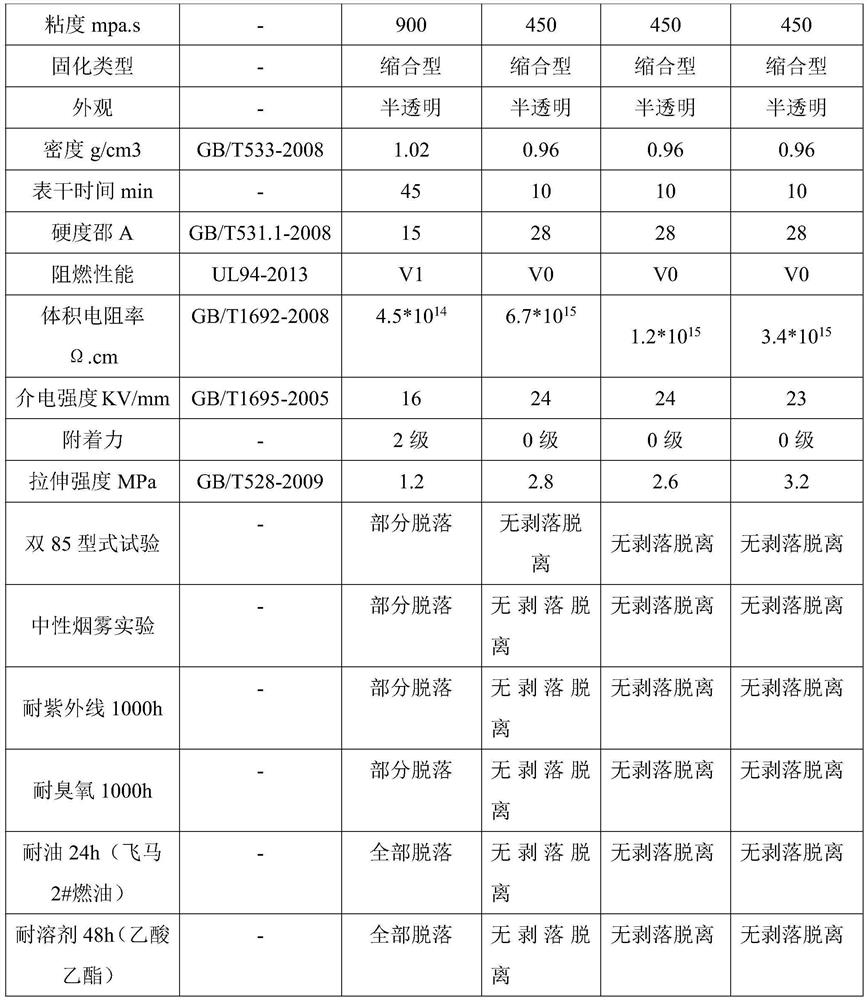

Embodiment 1

[0030]A functional additive for liquid silicone rubber, which is mainly prepared from acrylic monomers, vinyl siloxanes, and other vinyl monomer compounds through a suitable polymerization method. The specific preparation method is as follows:

[0031](1) 200g vinyl silicone oil (vinyl siloxane, viscosity 500mpa.s, vinyl mass content 0.43%), 0.2g n-dodecyl mercaptan (chain transfer agent), 20.8g perfluoroalkyl ethyl Acrylate (acrylate monomer), 116g of hydroxyethyl acrylate (acrylate monomer), and 100g of acetone (solvent) were placed in a four-necked flask, mixed well, heated to 80°C, and dripped while stirring Mixed solution, the mixed solution is made up of 10g AIBN (azobisisobutyronitrile, chain initiator), 80g acetone (solvent), 106g acrylonitrile (other vinyl monomer compounds) mixed evenly, and the dropping rate is controlled. The dripping is completed within 90 minutes, keep the temperature at 80°C, react for 6 hours to obtain a preliminary sample, and then select a methyl ethy...

Embodiment 2

[0036]A functional additive for liquid silicone rubber, which is mainly prepared from acrylic monomers, vinyl siloxanes, and other vinyl monomer compounds through a suitable polymerization method. The specific preparation method is as follows:

[0037](1) Combine 200g vinyl silicone oil (vinyl siloxane, viscosity 200mpa.s, vinyl mass content 0.70%) with 0.2g 3-mercaptopropionic acid isooctyl ester (chain transfer agent), 20.8g perfluoroalkyl Ethyl acrylate (acrylate monomer), 65g of hydroxyethyl methacrylate (acrylate monomer), and 100g of acetone (solvent) were placed in a four-necked flask, mixed well, heated to 80°C, and stirred At the same time, drip into the mixed solution, the mixed solution is made of 8g AIBN (azobisisobutyronitrile, chain initiator), 80g acetone (solvent), 53g acrylonitrile (other vinyl monomer compounds) mixed evenly, and the dropping speed is controlled. Rate, dropwise addition is completed within 90min, keep the temperature at 80℃, react for 8h, get the prel...

Embodiment 3

[0042]A functional additive for liquid silicone rubber, which is mainly prepared from acrylic monomers, vinyl siloxanes, and other vinyl monomer compounds through a suitable polymerization method. The specific preparation method is as follows:

[0043](1) 200g vinyl silicone oil (vinyl siloxane, viscosity 200mpa.s, vinyl mass content 0.70%) and 0.2g tetrakis (3-mercaptopropionic acid) quaternary tetraol ester (chain transfer agent), 130g Put hydroxyethyl methacrylate (acrylate monomer), 72g acrylic acid (acrylate monomer), and 100g acetone (solvent) in a four-necked flask, mix well, raise the temperature to 80°C, and drop in while stirring Mixed solution, the mixed solution consists of 8g AIBN (azobisisobutyronitrile, chain initiator), 80g acetone (solvent), 106g acrylonitrile (other vinyl monomer compounds) mixed evenly, and the dropping rate is controlled. The dripping is completed within 90min, keep the temperature at 80℃, react for 8h to obtain a preliminary sample, and then select...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com