Patents

Literature

70results about How to "Achieve the purpose of modification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

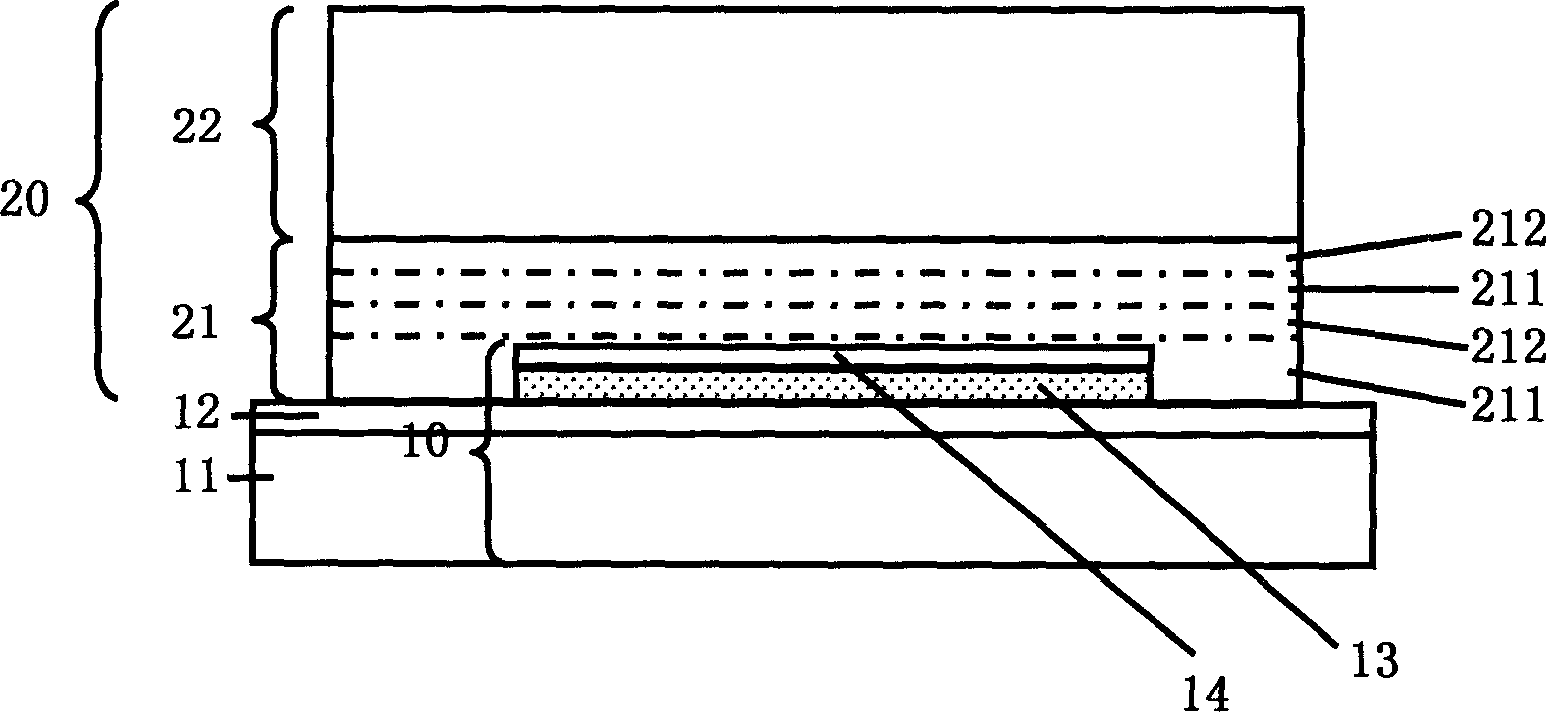

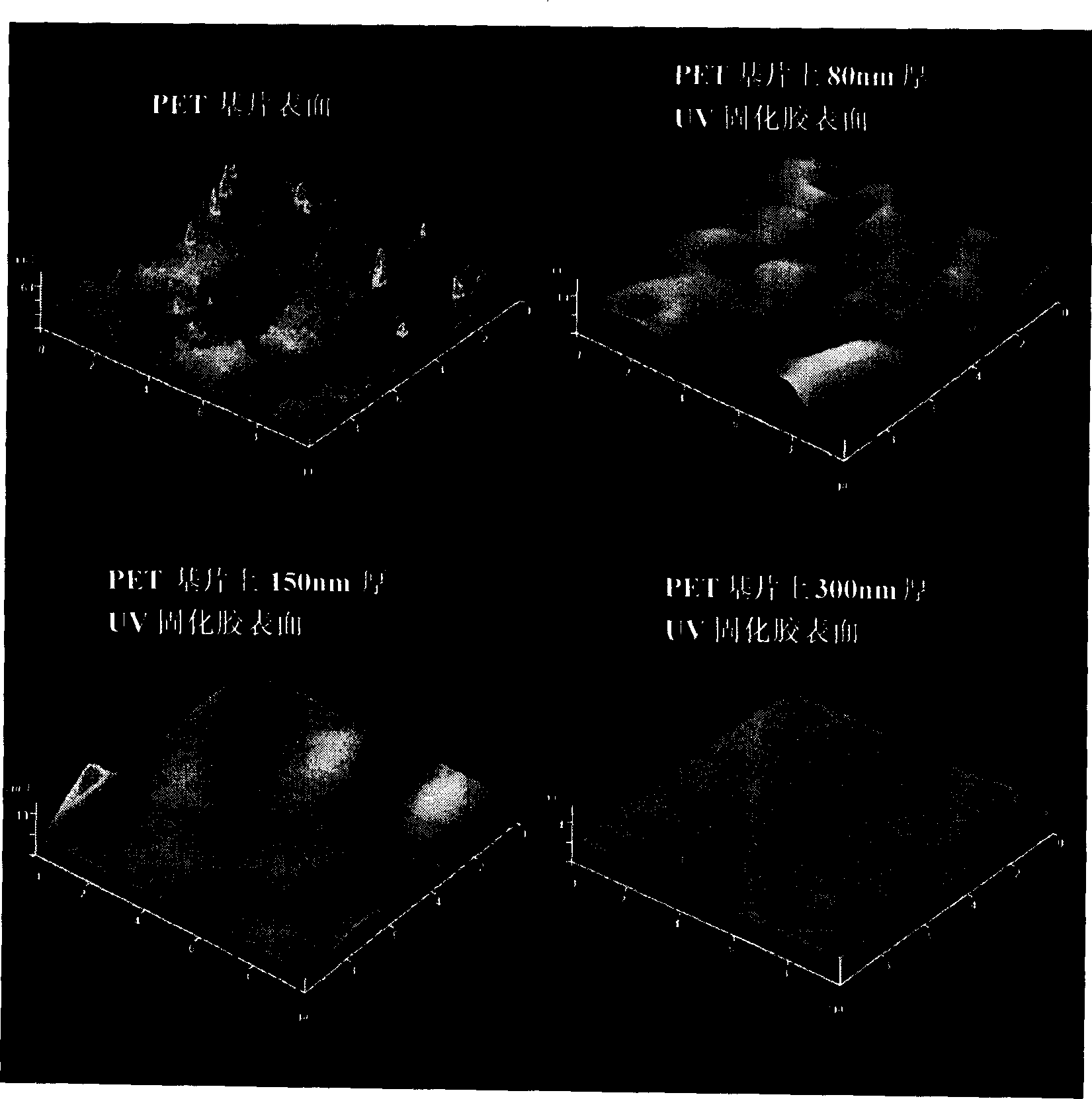

Package layer for organic electroluminescent device and its prepn method and application

InactiveCN1418042AImprove flexibilityImprove barrier propertiesElectroluminescent light sourcesSolid-state devicesPlastic filmOrganic electroluminescence

The package layer for organic electroluminescent device is in one or two sides of the device, and includes thin film layers of alternately superposed polymer material layer and ceramic material layeras well as one thick film layer of organic insulating material on the thin film layer. The thick film layer of organic insualting material can further raise the flexibility and water and oxygen blocking performance of the package, raise mechanical performance of the device, prolong the life of the device and simplify the packing process. The method of the present invention is used for modifying plastic sheet and in preparing flexible sheet with high water and oxygen blocking performance.

Owner:TSINGHUA UNIV

Plasma and enzyme combined anti-felting method for tidying wool knitted fabric

InactiveCN101177915AProcess for improving felting resistanceBurst downBiochemical fibre treatmentUltrasonic/sonic fibre treatmentEngineeringEnzyme

The invention relates to an antifelting finish method of wool knits combining plasma and bio-enzyme, comprising the steps that: wool washing, plasma treatment, protease treatment, water washing, Transglutaminase treatment, water washing, and drying. The invention can lead wool knits to reach machine washable standard (with a felting rate less than 2 percent) while the intensity is ensured (intensity damage is less than 10 percent), and has little damage during the finish process, with safety and environmental protection performance, and is an energy-conservation and clean wool post-treatment technique.

Owner:DONGHUA UNIV

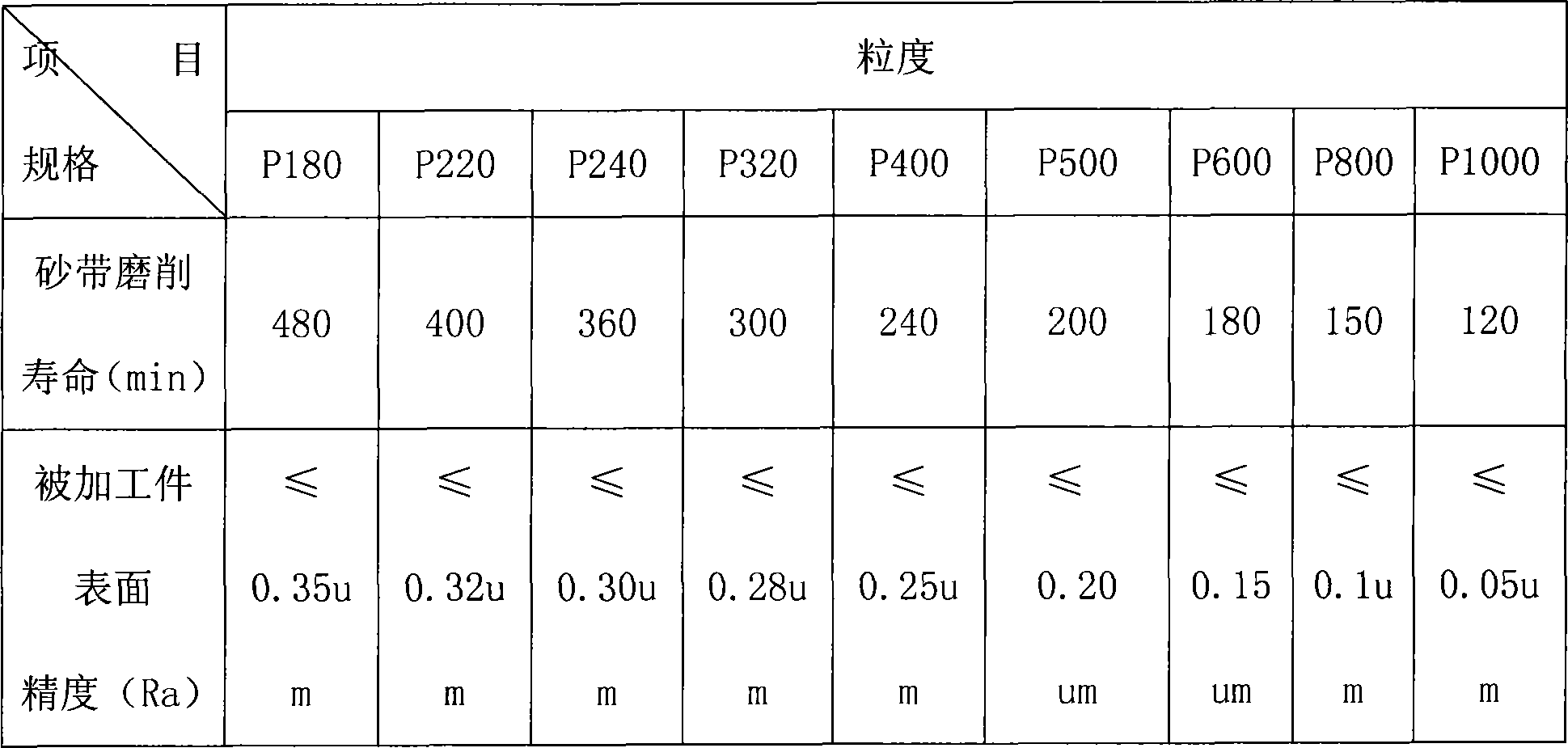

Zirconium corundum heavy load strong abrasive band

ActiveCN101134300AImprove toughnessImprove grinding effectAbrasion apparatusHeavy loadMaterials science

The present invention relates to abrasive belt, and is especially one kind of powerful zirconia corundum supported abrasive belt comprising cloth base, adhesive and grinding material zirconia corundum adhered onto the cloth base. It features the adhesive comprising thermosetting phonetic resin 28-36 wt%, diphenol propane type epoxy resin 4-8 wt%, melamine resin 1-4 wt%, boron 0.2-0.6 wt%, dispersant 0.1-0.3 wt%, coupling agent 0.1-0.3 wt%, diluent 3-6 wt%, fluoride salt 45-60 wt%, fluoride of inert gas 0.5-1 wt%. The abrasive belt has high heat resistance high adhesion strength at high temperature, capacity of softening metal surface and lowering surface hardness, no damage to metal surface and high grinding efficiency.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

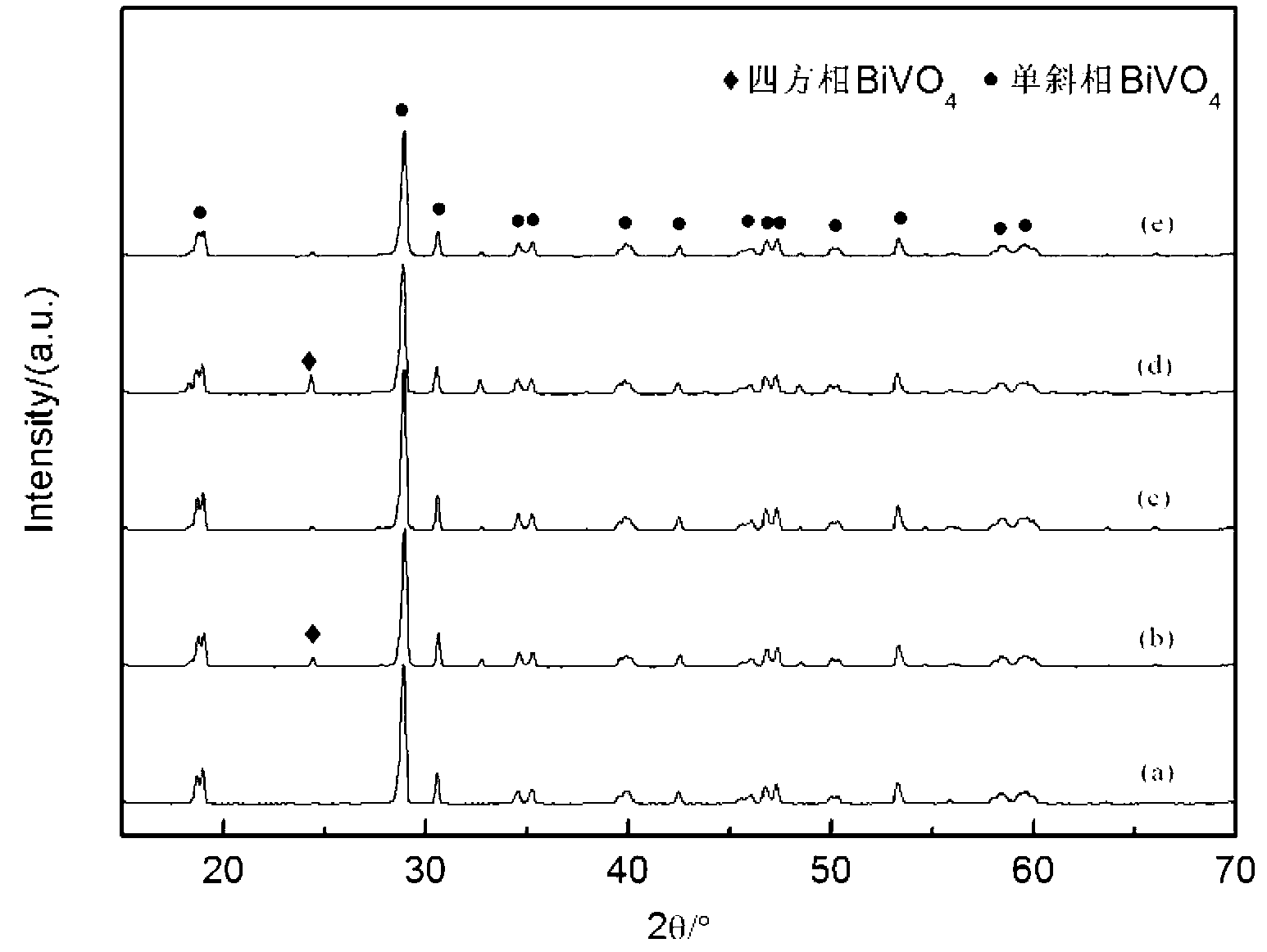

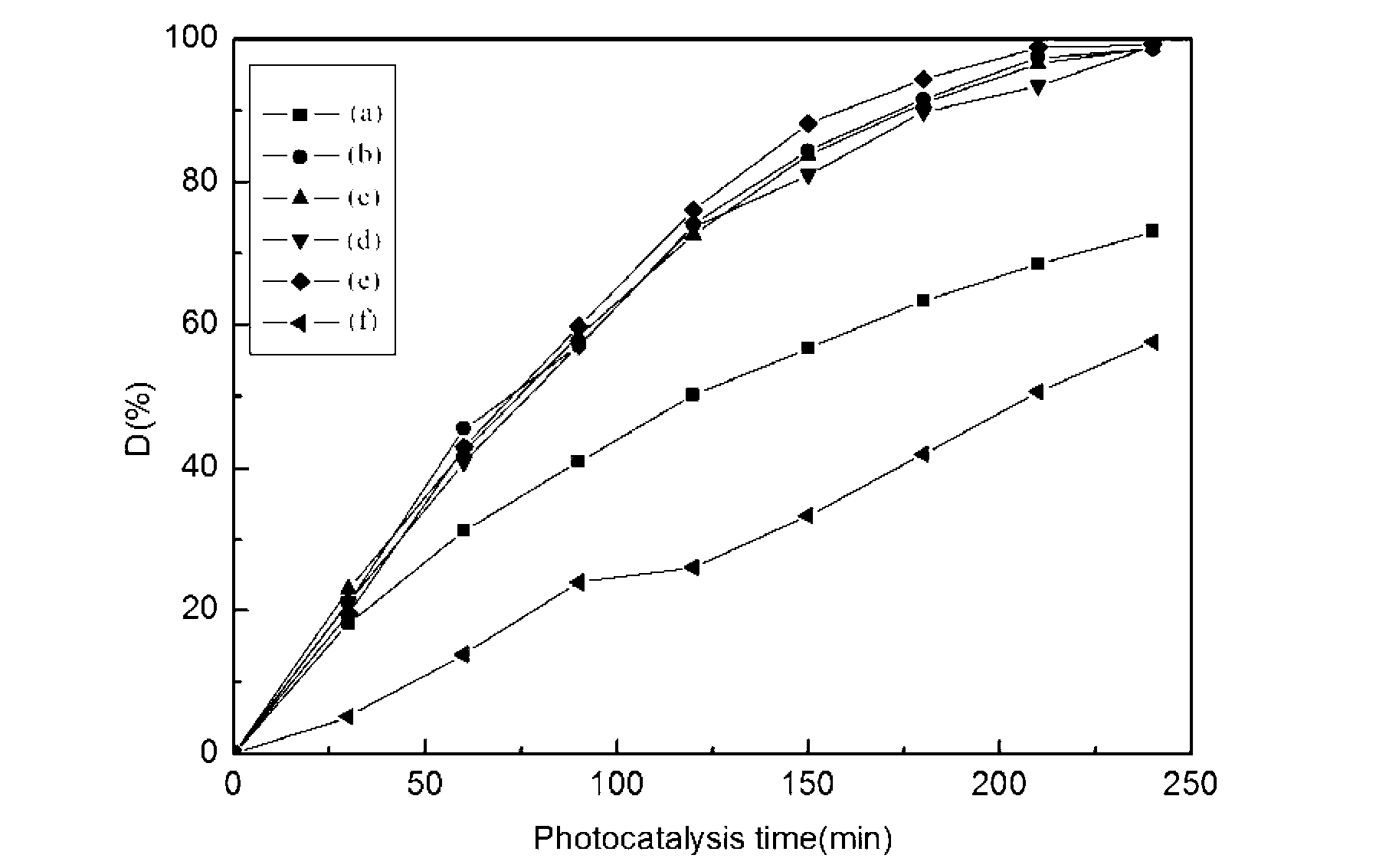

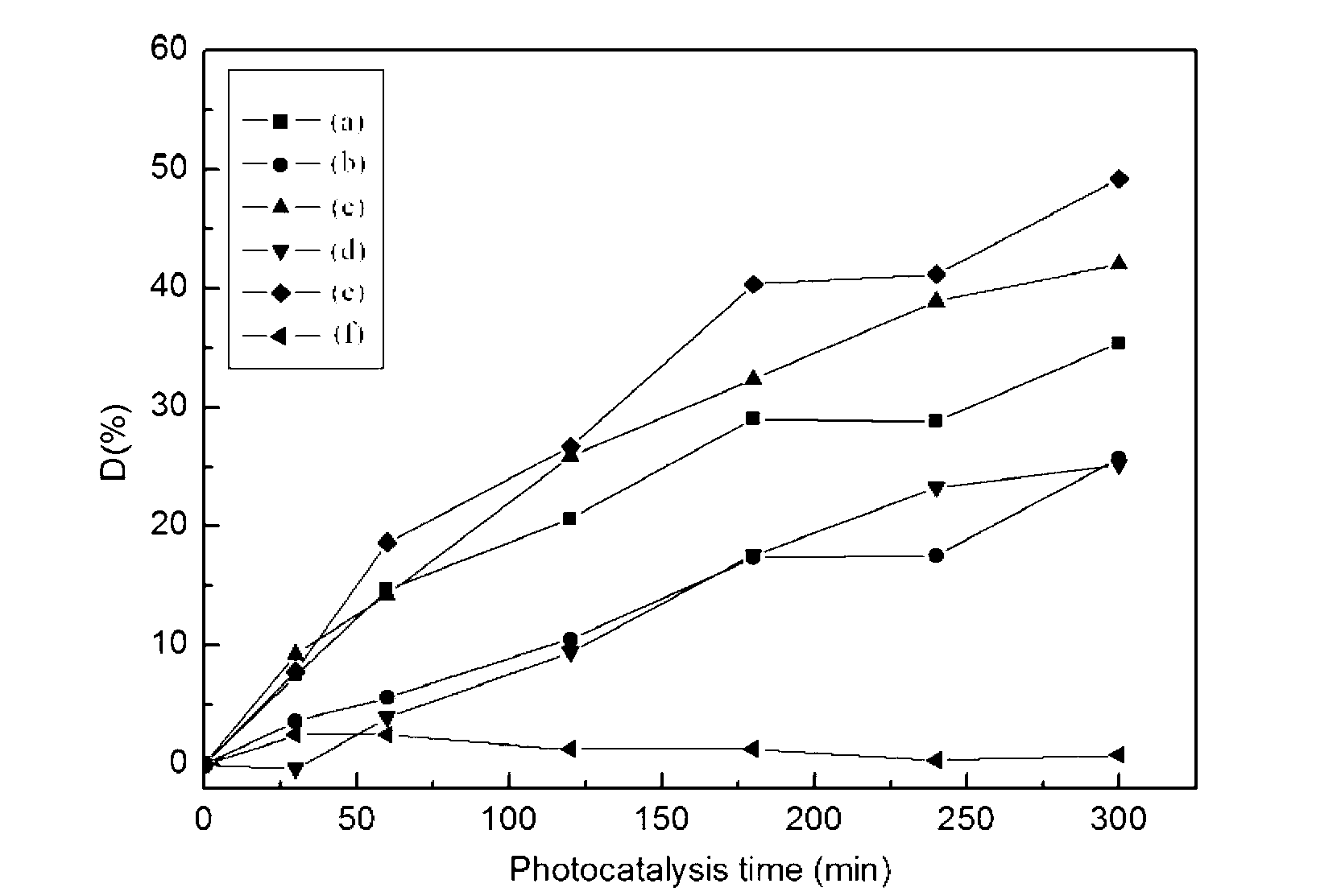

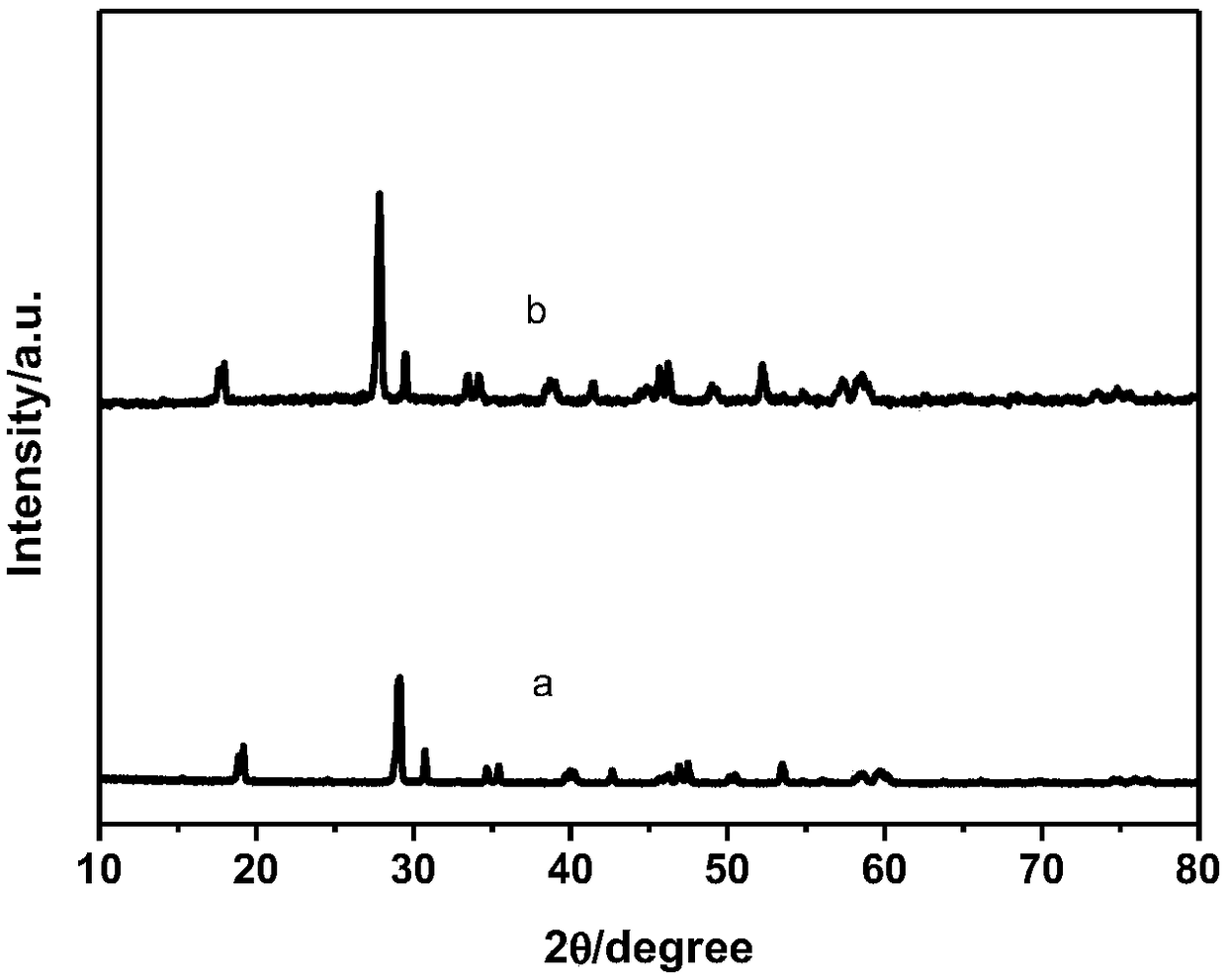

Method for synthesizing carbon-doped BiVO4 photocatalyst by using microwave hydrothermal method

ActiveCN103007921AImprove photocatalytic activityAchieve the purpose of modificationCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsMicrowaveReaction temperature

The invention relates to a method for synthesizing carbon-doped BiVO4 photocatalyst by using a microwave hydrothermal method. The method comprises the following steps: dissolving Bi(NO3)3.5H2O and NH4VO3 into deionized water respectively, and mixing according to the molar ratio of Bi:V=1:1 to obtain a mixed liquor; adding glucose into the mixed liquor according to the molar ratio of C6H12O6:Bi(NO3)3.5H2O=(0.01-0.15):1 and stirring uniformly to form a precursor; and placing the precursor into a reaction kettle, setting the reaction temperature to be 200 DEG C, insulating for 40 min, taking out generated sediment, washing and drying, so as to obtain the carbon-doped BiVO4 photocatalyst. According to the invention, the microwave hydrothermal method is adopted to synthesize the carbon-doped BiVO4 photocatalyst with one step, and calcination is not needed, so that the operation is simple, and the synthesized carbon-doped BiVO4 photocatalyst has favorable photocatalytic activity, as a result, the purpose of modifying BiVO4 is achieved.

Owner:SHAANXI UNIV OF SCI & TECH

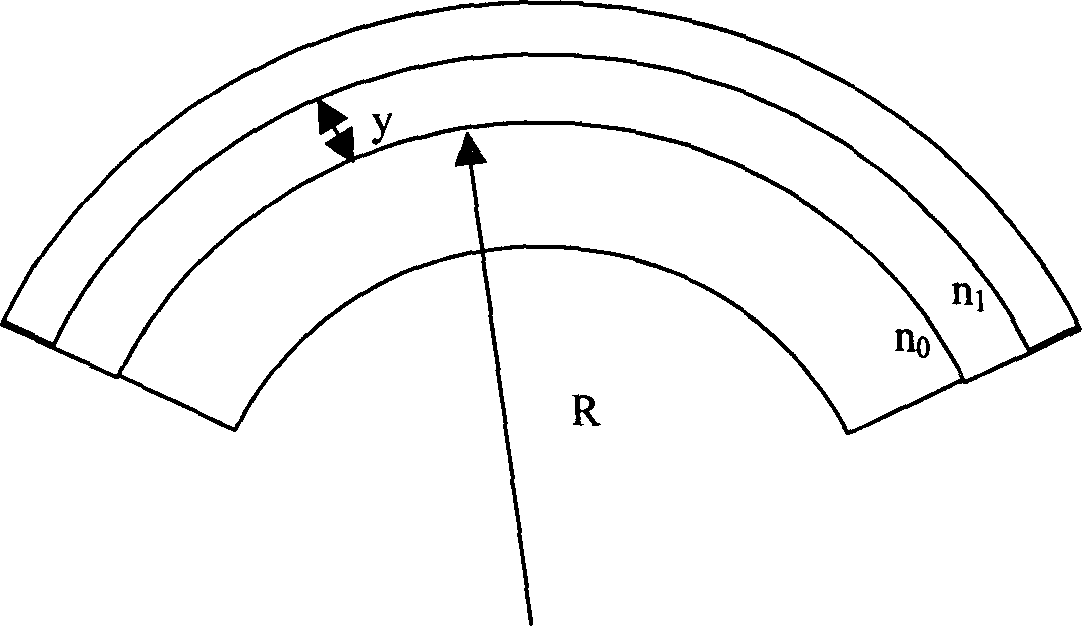

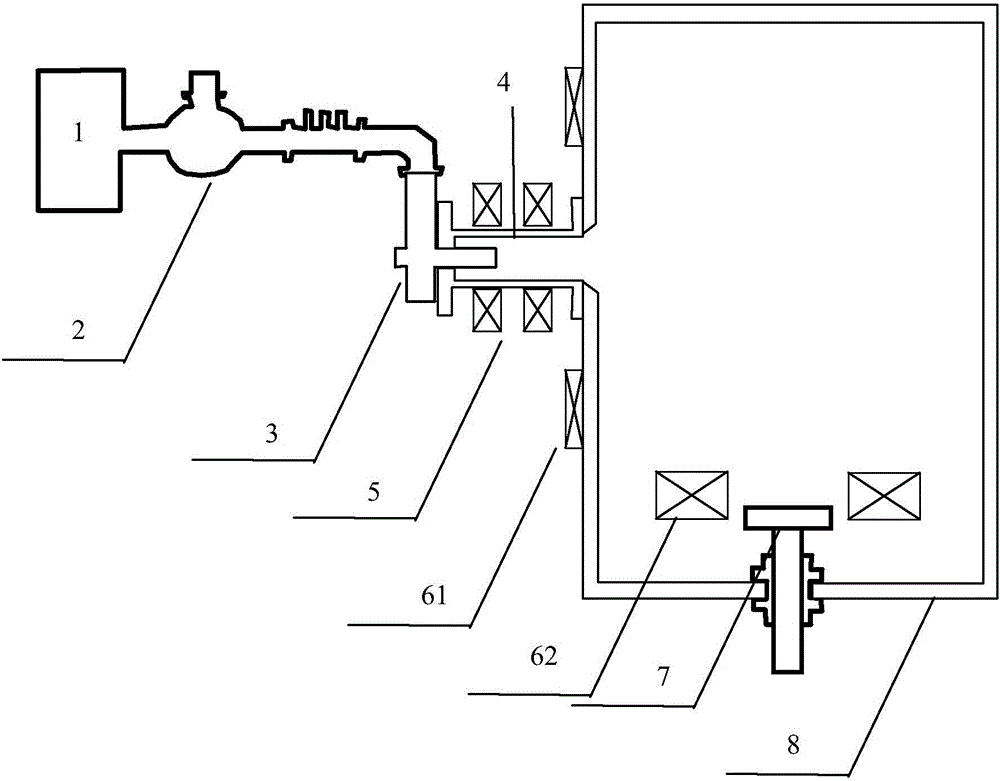

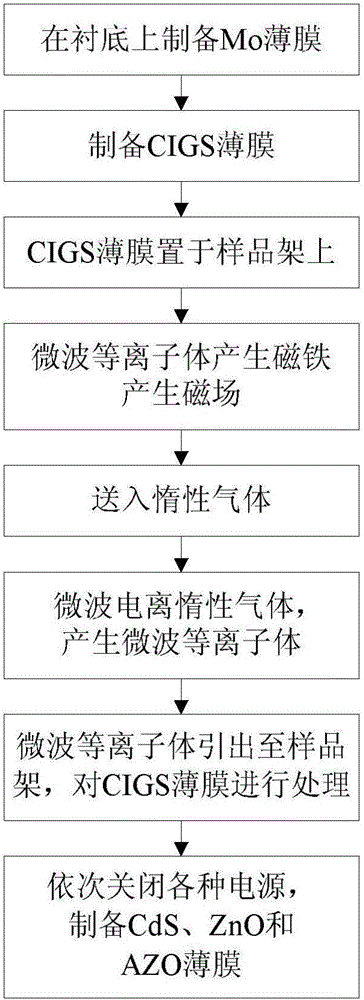

Microwave plasma-based treatment method and system for surface modification of copper indium gallium selenide (CIGS)

InactiveCN105088161AReduce unevennessImprove photoelectric conversion efficiencyVacuum evaporation coatingSputtering coatingIonizationCopper indium gallium selenide solar cells

The invention discloses a microwave plasma-based treatment method and system for surface modification of copper indium gallium selenide (CIGS).According to the invention, microwave plasma is generated through microwave ionization of inert gases and acts on the surface of a CIGS film. By micron dimension high-strength resputtering and annealing, Cu-Se phase on the surface can be removed and the film can be further annealed, so that non-uniformity of Ga can be relieved, and the purpose of material surface modification can be achieved. The CIGS film serves as a main absorption layer of a CIGS solar cell. The quality of the film directly determines the quality of the CIGS solar cell. The CIGS film subjected to ECR (Electron Cyclotron Resonance) modification lays a foundation for obtaining a CIGS cell with higher photoelectric conversion efficiency, and is feasible and practical as proved through experimental verification.

Owner:PEKING UNIV

Synthesis method of organic fluorine and silicon modified waterborne polyurethane

InactiveCN112079983AImprove performanceHigh mechanical strengthPolyurea/polyurethane coatingsPolymer scienceBackbone chain

The invention discloses a synthetic method of organic silicon and fluorine modified waterborne polyurethane. According to the invention, excellent surface properties of organic fluorine and organic silicon are utilized, and organic fluorine and organic silicon are introduced into a molecular main chain of waterborne polyurethane through gradual polymerization, so as to achieve the purpose of modification. The waterborne polyurethane product prepared by the synthesis method disclosed by the invention is greatly improved in price economy and various properties (mechanical strength, water resistance, solvent property, high-temperature resistance, wear resistance and the like).

Owner:南京博科新材料产业研究院有限公司

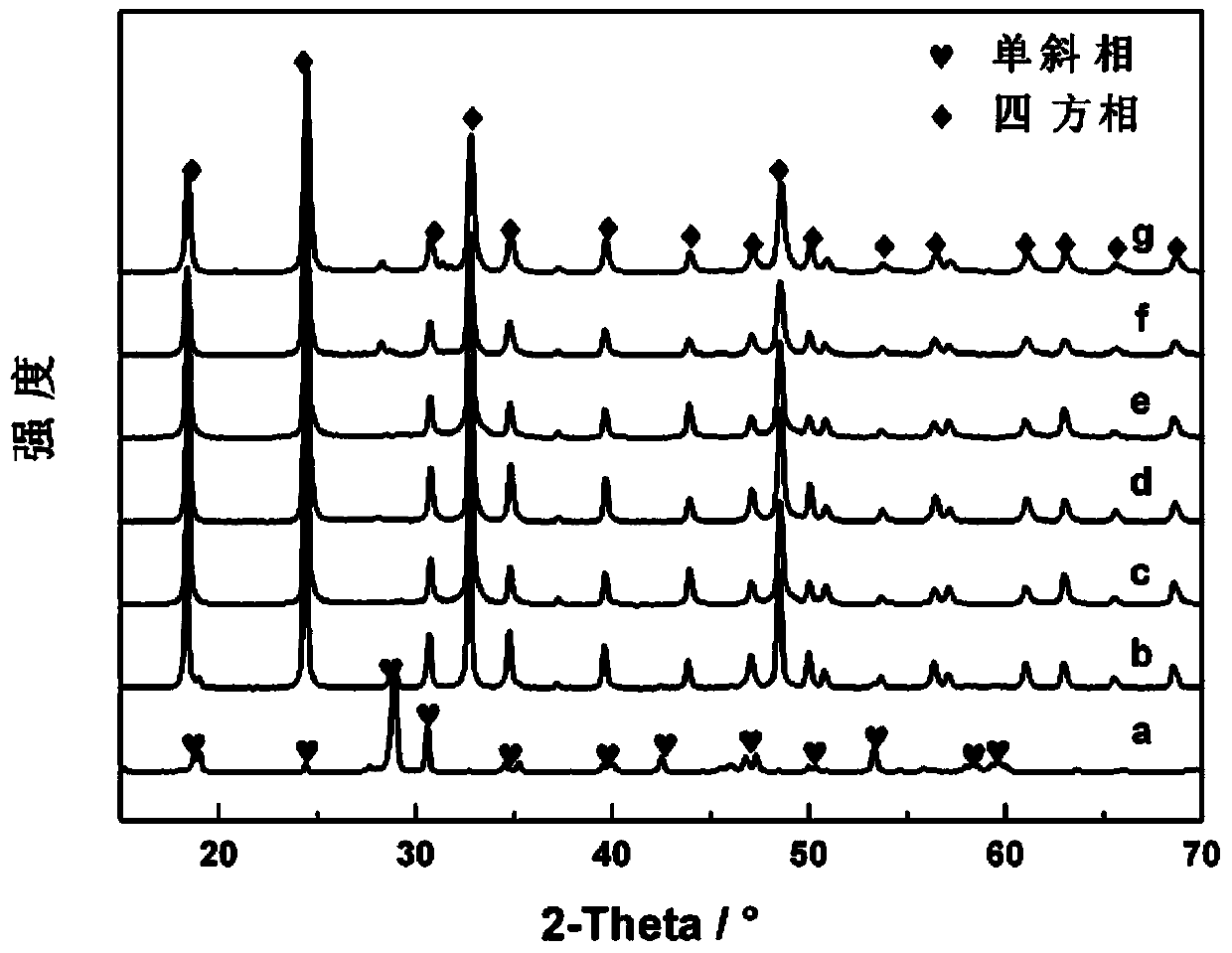

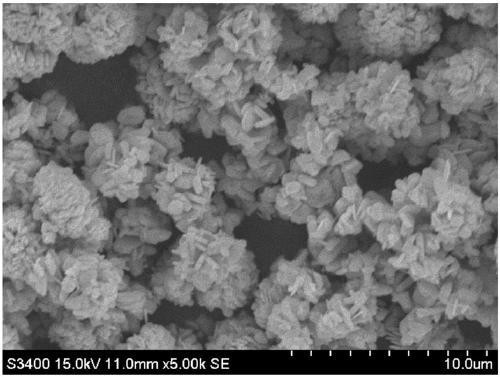

Multi-morphologic Ho/BiVO4 composite photocatalyst, and preparation method and application thereof

ActiveCN103464137AOvercome the disadvantage of uneven heatingImproving the efficiency of photocatalytic degradation of organic matterMetal/metal-oxides/metal-hydroxide catalystsAmmonium metavanadatePhotochemistry

The invention relates to a multi-morphologic Ho / BiVO4 composite photocatalyst, and a preparation method and an application thereof. The main component of the multi-morphologic Ho / BiVO4 composite photocatalyst is BiVO4, the BiVO4 has a tetragonal zircon phase structure, and the crystal lattice of the BiVO4 contains Ho<3+>. The preparation method comprises the following steps: respectively dissolving bismuth nitrate pentahydrate and ammonium metavanadate in water to obtain a bismuth salt solution and a vanadium salt solution, adding the vanadium salt solution to the bismuth salt solution according to a molar ratio of Bi to V of 1:1 to obtain a mixed solution, adjusting the pH value of the mixed solution to 8, adding holmium nitrate hexahydrate according to a molar ratio of Ho to Bi of (2.04-13.64):100, and maintaining the temperature at 180DEG C unchanged for 40min under a power of 300W by using a microwave hydrothermal method to prepare Ho / BiVO4. The preparation method has the advantages of uniform heating, fast heating speed, mild reaction condition, simple process flow, shortened reaction time and increased work efficiency, and the synthesized multi-morphologic Ho / BiVO4 composite photocatalyst has a high photocatalytic activity and can be used for degrading environmental pollutants.

Owner:盐城宇航包业有限公司

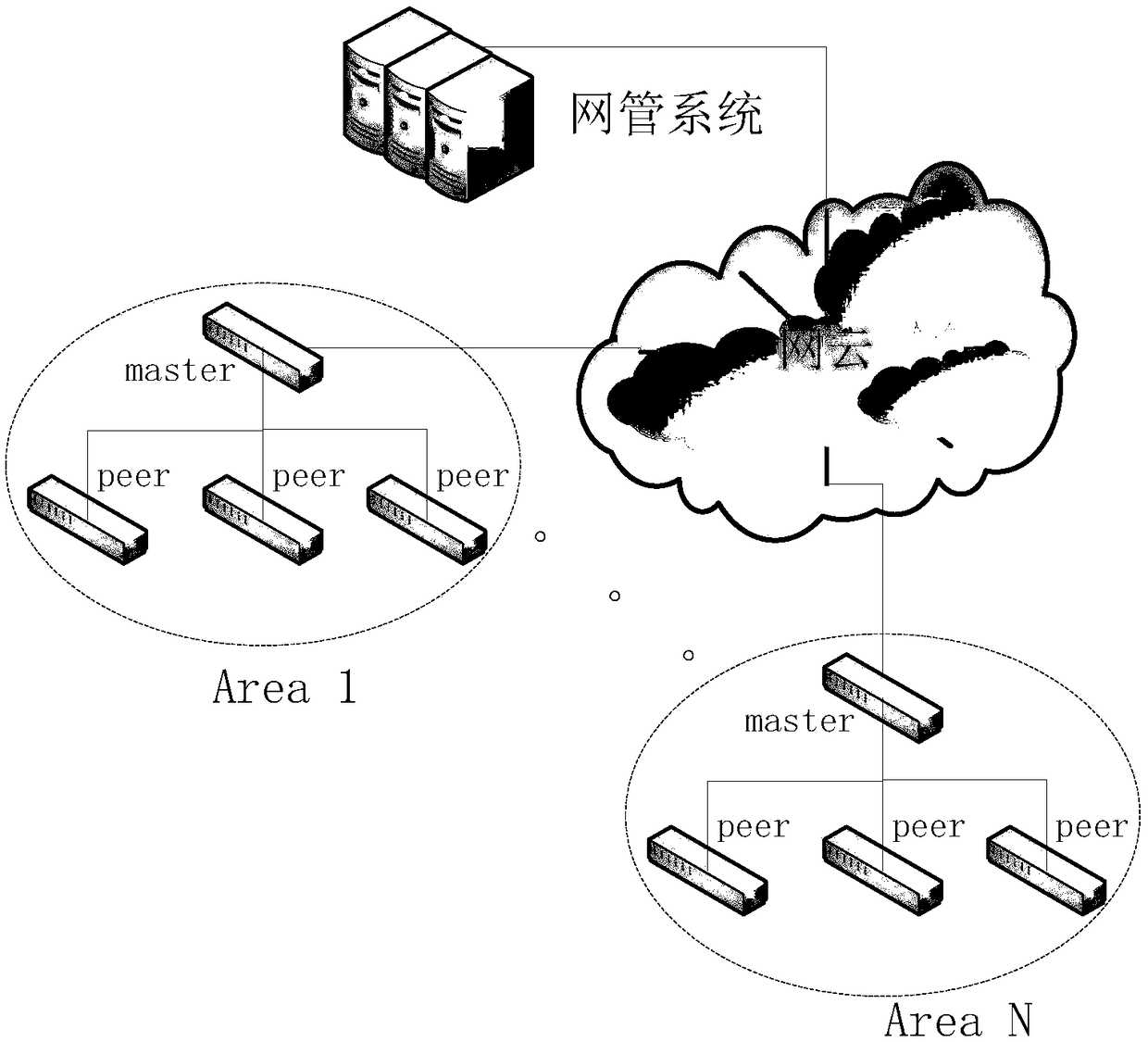

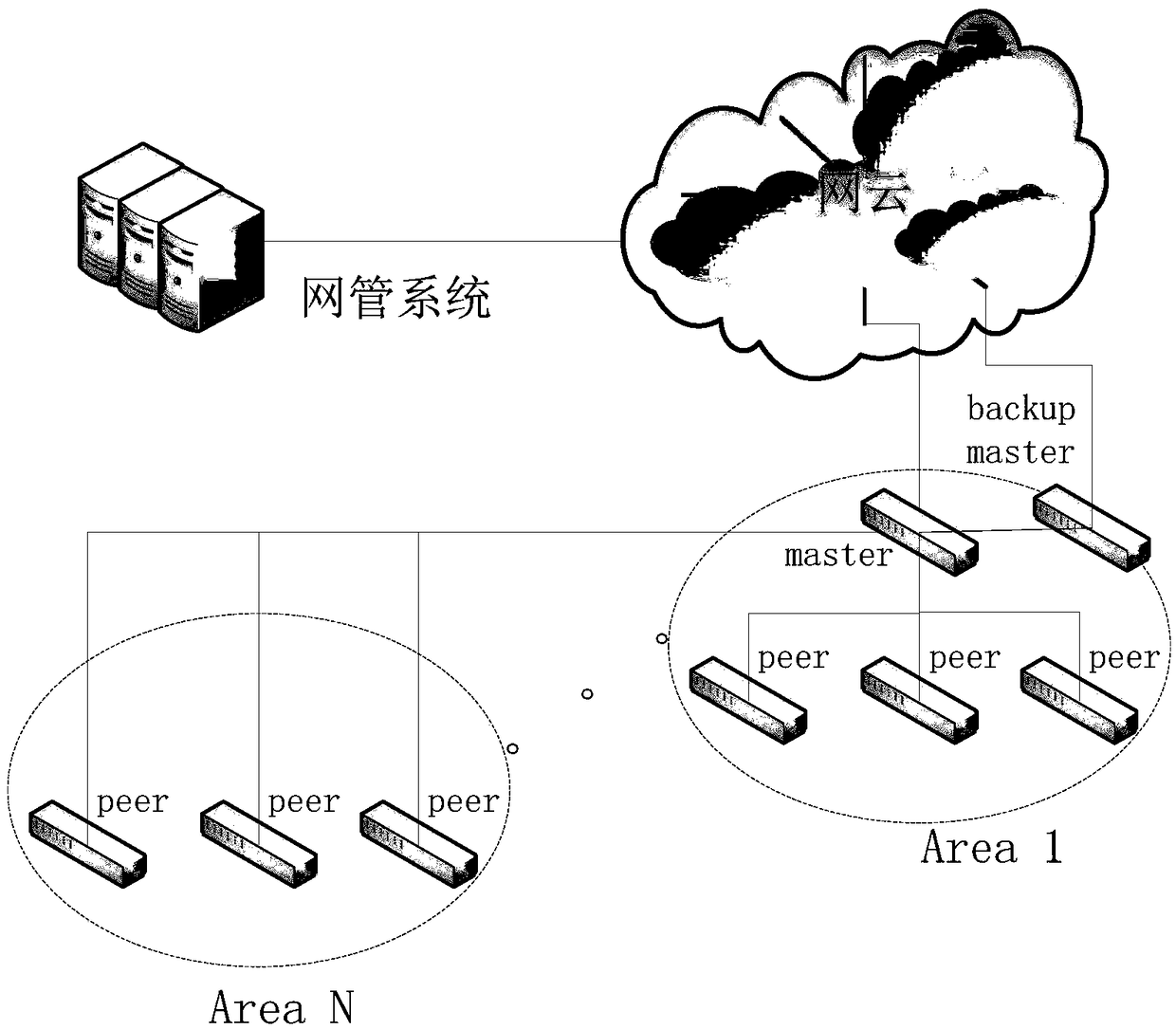

Grouping method for use under DMR transfer station IP interconnection

ActiveCN108650116ASimplify operational complexityReduce loadData switching networksRouting tableGroup method

The invention relates to a grouping method for use under DMR transfer station IP interconnection. One transfer station in a network is taken as a Master as well as a master node for managing and controlling the whole network; other transfer stations are taken as Peer nodes which are connected and registered on the Master; the Master performs service group division on all Peers in the network according to a network management rule; the Peers acquire network routing tables of service groups in which the Peers are located from the Master, and mutually perform registration in all the service groups according to the network routing tables; heartbeat packets are transmitted between successful registration transfer stations; and when a Peer in the network receives a call, the Peer transmits callinformation to a network management system through the Master for calling. Only one Master exists, so that the transfer stations in the whole network can be managed uniformly; the operation complexityof a network management office is lowered; and the network becomes more flat.

Owner:FUJIAN KIRISUN ELECTRONICS

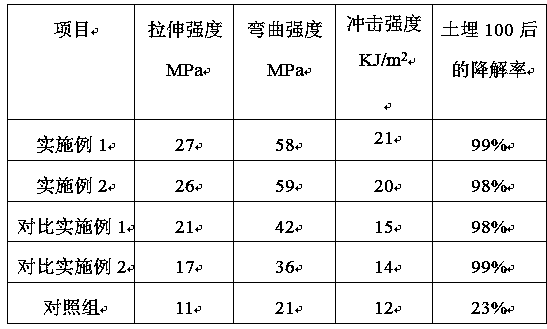

Method for preparing cotton swab stick material from montmorillonite-composite modified straw fiber powder-polylactic acid

The invention discloses a method for preparing a cotton swab stick material from montmorillonite-composite modified straw fiber powder-polylactic acid. The method comprises the following steps: dryingpowdery polylactic acid in a drying box; adding the dried polylactic acid, reactive montmorillonite, straw fiber powder subjected to alkali-coupling agent composite modification treatment and a toughening agent, maleic anhydride grafted polylactic acid, a silane coupling agent, zinc stearate, a plasticizer, a lubricant and a foaming agent into a high-speed mixing mill and mixing; adding into a mold and putting the mold on a heated plate vulcanizing machine; carrying out mold pressing and molding; and after the mold is cooled, taking out to prepare the cotton swab stick material. A cation exchange principle is utilized, and 3-chloro-2 hydroxypropyl trimethyl ammonium bromide is used for carrying out organic modification on sodium-based montmorillonite to prepare the reactive montmorillonite; the modified montmorillonite is high in organic adsorption amount and large in lamellar spacing; and the reactive montmorillonite has a stripping state and also has an intercalation state in a polylactic acid matrix, and has a good modification effect on the polylactic acid, so that the thermal stability and mechanical properties of the polylactic acid can be improved.

Owner:蚌埠尚岛宜家日用品科技工业有限公司

Preparation method for floating type powdery aluminum pigment

ActiveCN104479427AGood dispersionIncrease floating valuePigment treatment with non-polymer organic compoundsSilver pasteSolvent

The invention discloses a preparation method for a floating type powdery aluminum pigment. The preparation method includes the step of solvent displacement, wherein a solvent is used for cleaning floating type aluminum silver paste; the step of primary filter pressing, wherein filter pressing is conducted on the floating type aluminum silver paste obtained in the solvent displacement step to obtain a first filter cake; the step of liquid phase dispersion, wherein a solvent is adopted for dispersing the first filter cake to obtain an aluminum sheet suspension; the step of surface treatment, wherein aluminum sheets in the aluminum sheet suspension are coated with surface treating agents. The preparation method has the advantages that the preparation process is simple, consumed time is short, repeatability is high and the stability of the obtained floating type powdery aluminum pigment is high. The floating type powdery aluminum pigment obtained through the method has a remarkable mirror plane effect, is good in dispersing performance and also has good floating performance.

Owner:长沙族兴新材料股份有限公司

Ion exchanger of natural mineral for seawater desalination

InactiveCN101049994AAchieve the purpose of modificationAchieving zero emissionsSeawater treatmentWater/sewage treatment by ion-exchangeHazardous substancePotassium

This invention discloses a method for preparing natural mineral ion exchanger for desalting seawater. The natural mineral ion exchanger is composed of smectite, attapulgite, zeolite, maifanite and sepiolite. The method comprises: pulverizing the above minerals, soaking, squeezing, air-drying, grinding and packaging. Na+ and K+ in seawater can perform ion exchange with the natural mineral ion exchanger, thus the contents of NaCl, KCl, Na2SO4 and Na2CO3 in seawater can be effectively reduced. The useful natural mineral ion exchanger can be replaced and dissolved in seawater. Besides, heavy metals such as Hg, Pb and As, chlorides and residual pesticides can be adsorbed by the natural mineral ion exchanger. The natural mineral ion exchanger can be used for purification of seawater as well as brackish water in northwestern regions in China.

Owner:陶韬

Semi-crisp corundum fine grinding abrasive band

ActiveCN101143431AImprove brittlenessOvercome the disadvantage of poor heat resistanceAbrasion apparatusAldehyde/ketone condensation polymer adhesivesAdhesivePliability

The invention relates to an abrasive belt, a semi-friable alumina finishing abrasive belt in detail. The abrasive belt consists of a fabric base, an adhesive and grinding material, wherein the grinding material is the semi-friable alumina and usually is adhered to the fabric base by the adhesive. The abrasive belt is characterized in that the adhesive consists of the following components of the specific weight percentage: 36percentage-40percentage A-stage thermosetting phenolic resin; 4 percentage-5.5 percentage diphenol-propane epoxy resin; 1.8 percentage-2.8 percentage melamine resin; 0.1 percentage-0.6 percentage boron; 0.1 percentage-0.3 percentage dispersant; 0.1 percentage-0.3 percentage resin acceptor; 2 percentage-6 percentage thinner;18 percentage-26 percentage calcium carbonate; 18 percentage-26 percentage fluoride salt; and 0.1 percentage-0.5 percentage inert gas fluoride. The adhesive of the invention equips with sufficient strength, excellent heat resistance and necessary flexibility in the grinding process. The finishing abrasive belt combined with the semi-friable alumina has the advantages of good sharpness and high hardness, thus improving the degree of finish and precision of the work-pieces requiring processing.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

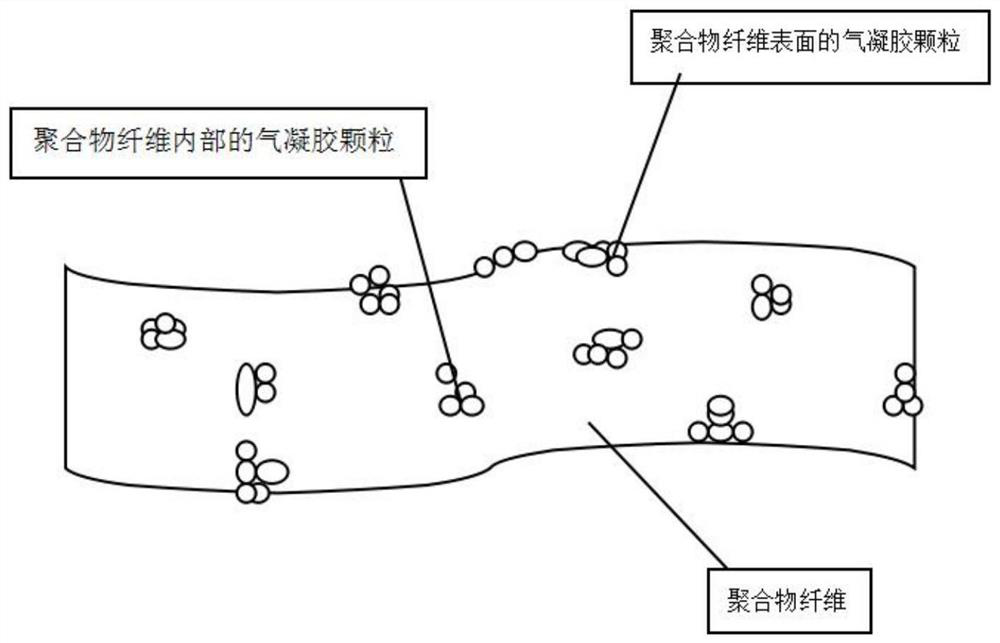

Modified polymer fibers as well as preparation method and application thereof

PendingCN112609259AOmit mixing granulation and remixing melt spinning processLow costMonocomponent copolyesters artificial filamentMonocomponent polypropylene artificial filamentMelt spinningPolymer

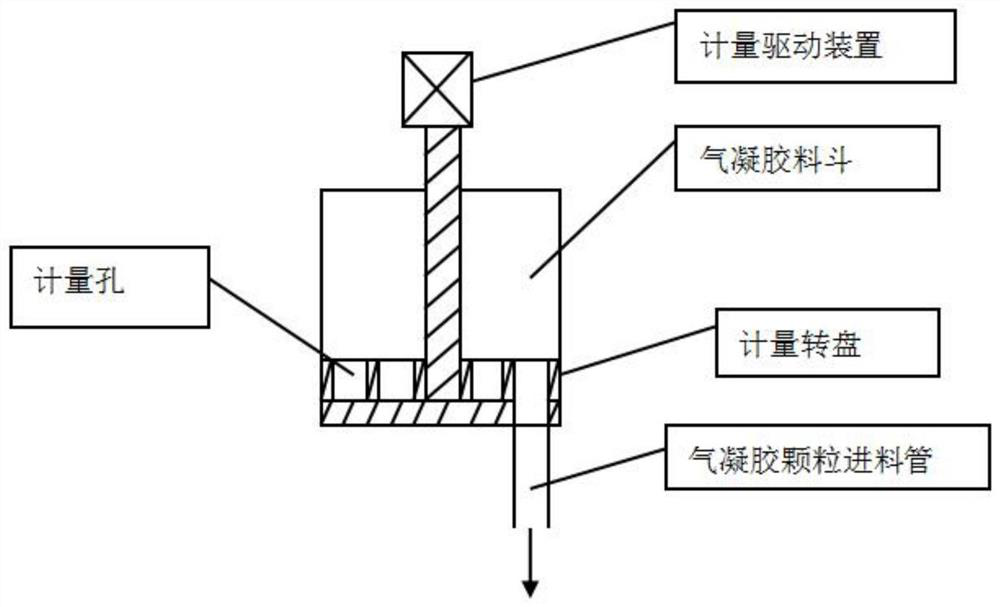

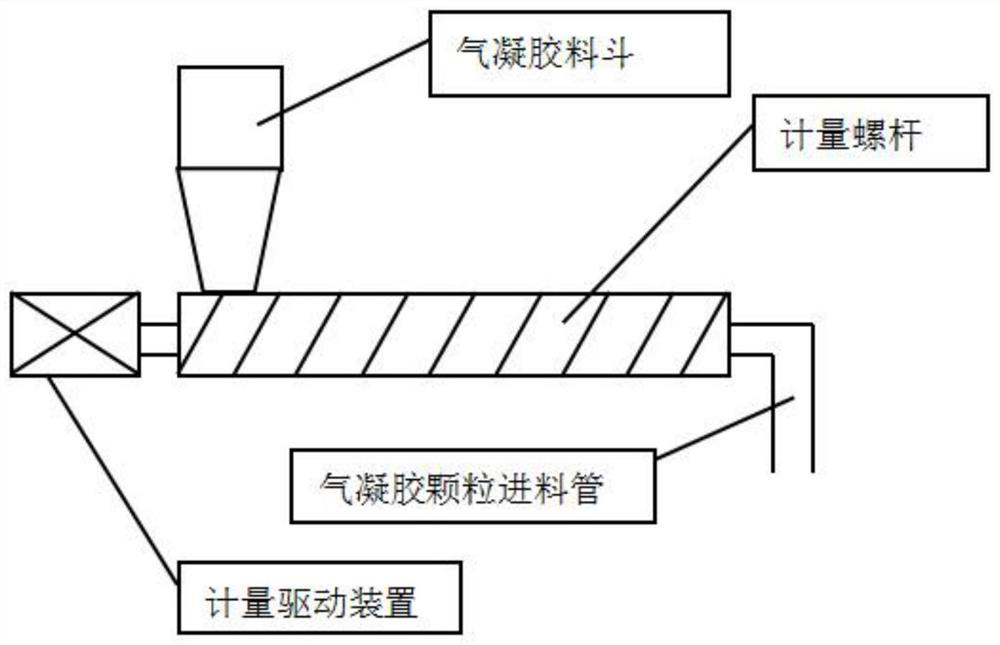

The invention provides modified polymer fibers as well as a preparation method and application thereof, and belongs to the technical field of fiber material modification. The modified polymer fibers provided by the invention comprise polymer fibers and aerogel particles, wherein the aerogel particles are uniformly distributed in the polymer fibers or on the surfaces of the polymer fibers. In the modified polymer fibers, the aerogel particles are distributed in the polymer fibers and on the surfaces of the polymer fibers, and the polymer fibers and products thereof can be endowed with different properties (such as heat insulation property and adsorbability) compared with original polymer fibers and products thereof by changing the varieties and content of the aerogel particles, so that the purpose of modifying polymer fibers and products processed from the polymer fibers is achieved. According to the invention, polymer particles and the aerogel particles are directly spun through corresponding metering, the procedures of mixing granulation and then mixing melt spinning are omitted, the cost is saved, the method is simple and easy to implement, the production efficiency is improved, and the method has wide application prospects.

Owner:苏州薄暖御寒科技有限公司

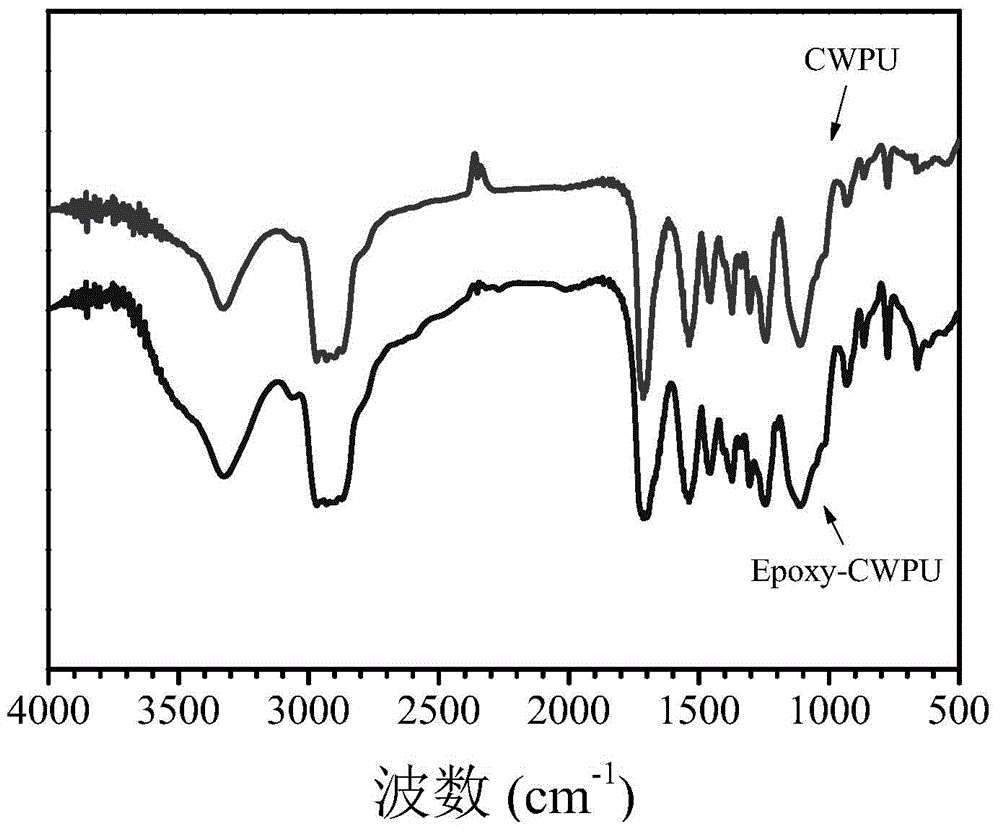

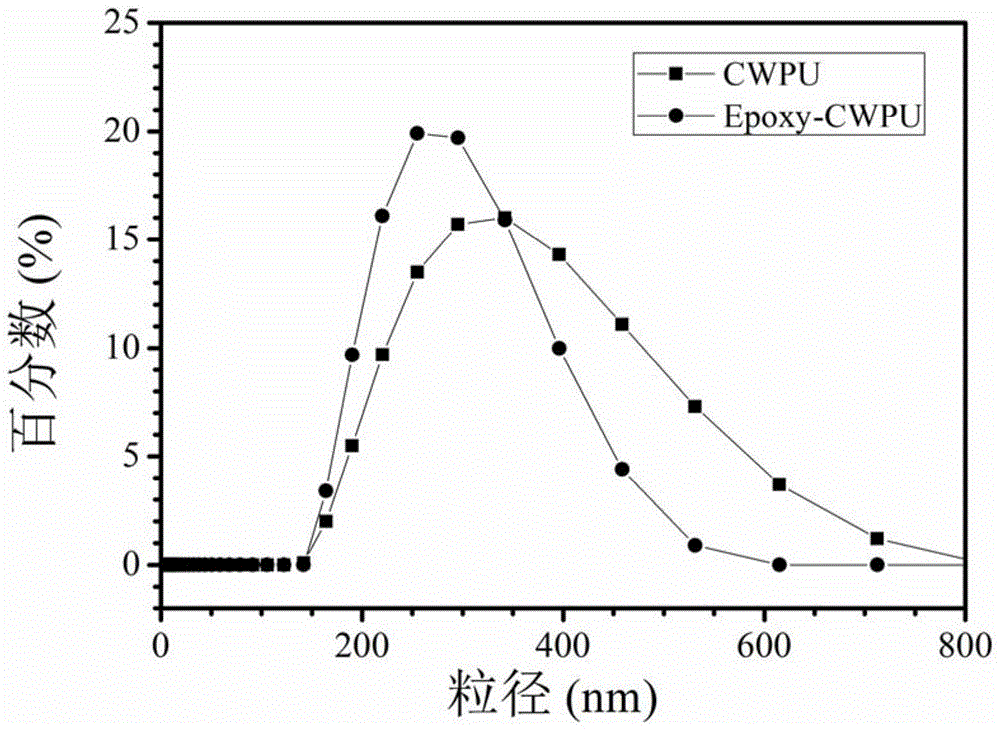

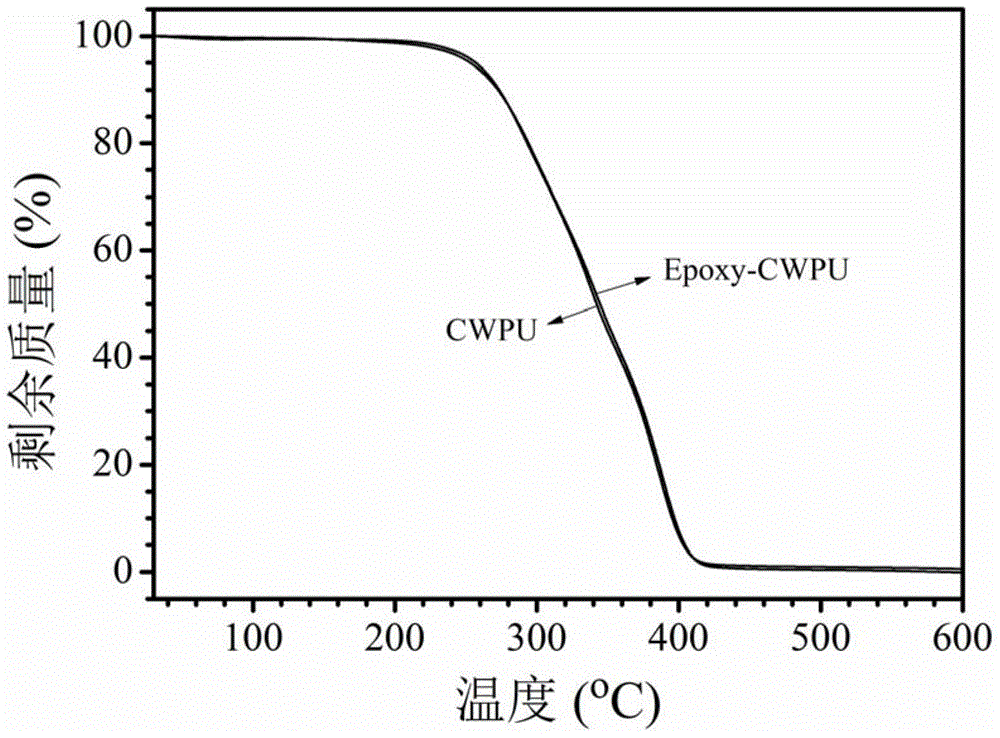

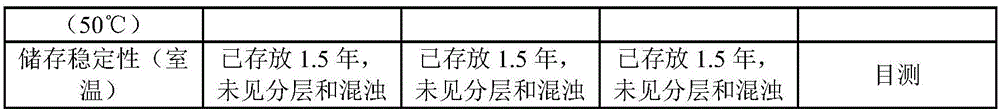

Preparation method of waterborne polyurethane based on glycidyl methacrylate

The invention discloses a preparation method of waterborne polyurethane based on glycidyl methacrylate. The preparation method comprises the following steps: firstly carrying out a reaction between diisocyanate and macromolecular dihydric alcohol, micromolecular dihydric alcohol and a hydrophilic chain extender; adding an end-capping reagent to obtain a double bond-terminated polyurethane prepolymer; and carrying out copolymerization by adding glycidyl methacrylate so as to obtain epoxy group-controllable block cationic waterborne polyurethane. According to the method, the epoxy group is bonded to polyurethane through a chemical bond to form a single component system which is convenient to use, can be used along with amines, polyatomic acid or polyisocyanate compounds for cure-crosslinking, modification and the like and has stronger machinable property. The synthesized block cationic waterborne polyurethane has smaller particle size, narrower particle size distribution and higher emulsion storage stability.

Owner:UNIV OF SCI & TECH OF CHINA

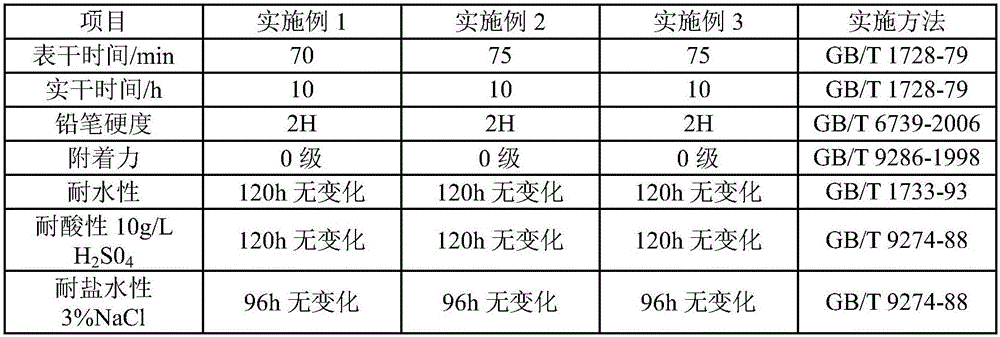

Composite waterborne alkyd resin with high storage stability

The invention belongs to the field of coatings, and particularly relates to composite waterborne alkyd resin with high storage stability. The composite waterborne alkyd resin is prepared according to the following method: adding vegetable oil and polyols into a reaction vessel under the protection of nitrogen, raising the temperature to 118 to 122 DEG C, adding an alcoholysis catalyst, raising the temperature to 240 to 245 DEG C, preserving heat to an alcoholysis endpoint, reducing the temperature to 165 to 180 DEG C, adding an acrylic prepolymer, raising the temperature to 220 to 225 DEG C, preserving heat for esterification until the acid value is equal to or lower than 5, reducing the temperature to 145 to 160 DEG C, adding polyacid, a sulfonate prepolymer, a water-carrying agent and an esterification catalyst, raising the temperature to 220 to 225 DEG C, preserving heat for esterification until the acid value is lower than 15, adding modified attapulgite, preserving heat to continue reaction for 2 to 3h, reducing the temperature to 150 to 160 DEG C, performing reduced pressure vacuumizing to remove the water-carrying agent, reducing the temperature to 110 to 115 DEG C, adding 15 to 20 parts of a co-solvent, reducing the temperature to 50 to 80 DEG C, adding 70 to 85 parts of de-ionized water, performing complete stirring and regulating the pH to a proper value to obtain the composite waterborne alkyd resin. The composite waterborne alkyd resin has the beneficial effect that the prepared composite waterborne alkyd resin has extraordinarily high storage stability.

Owner:HUBEI UNIV

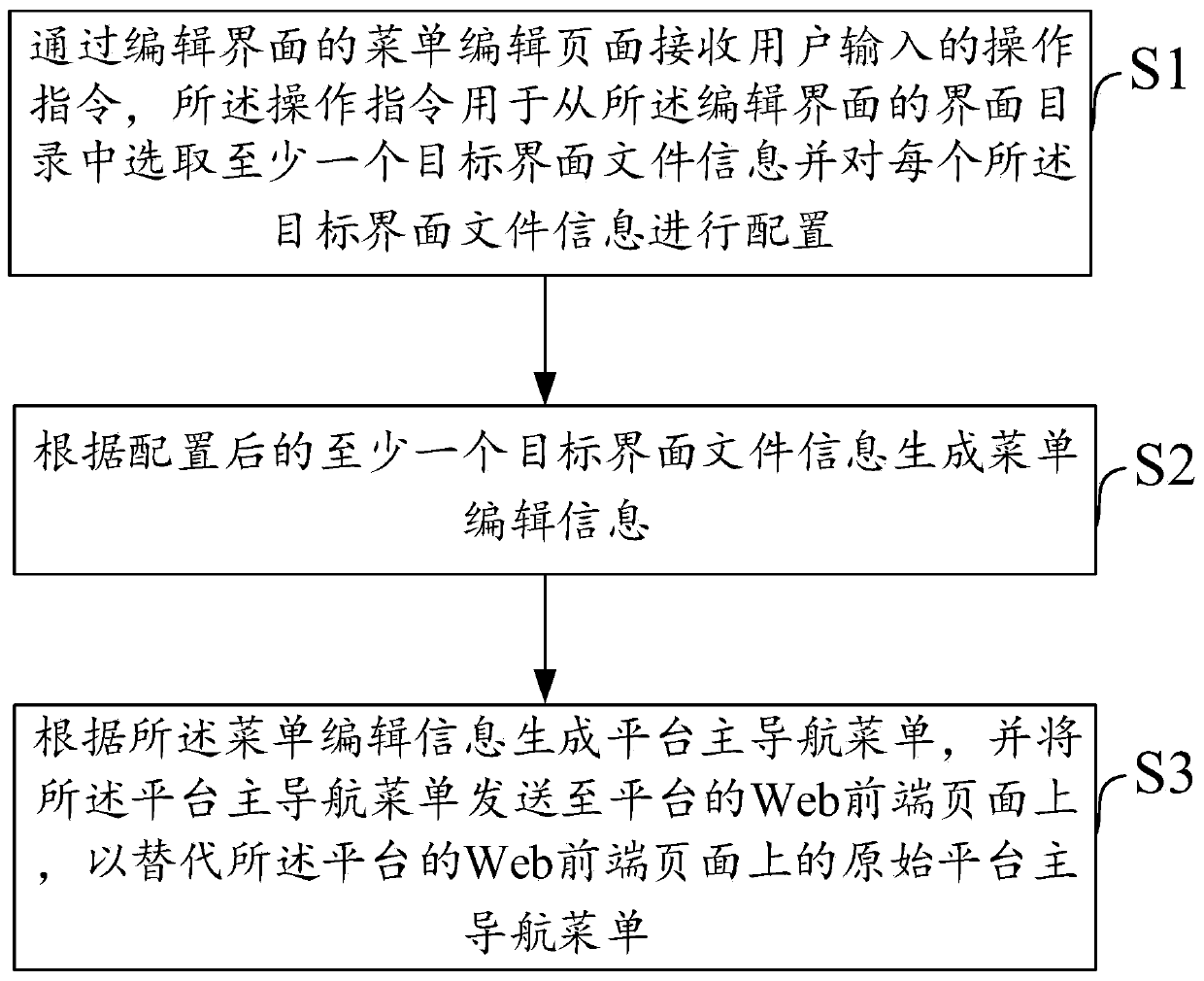

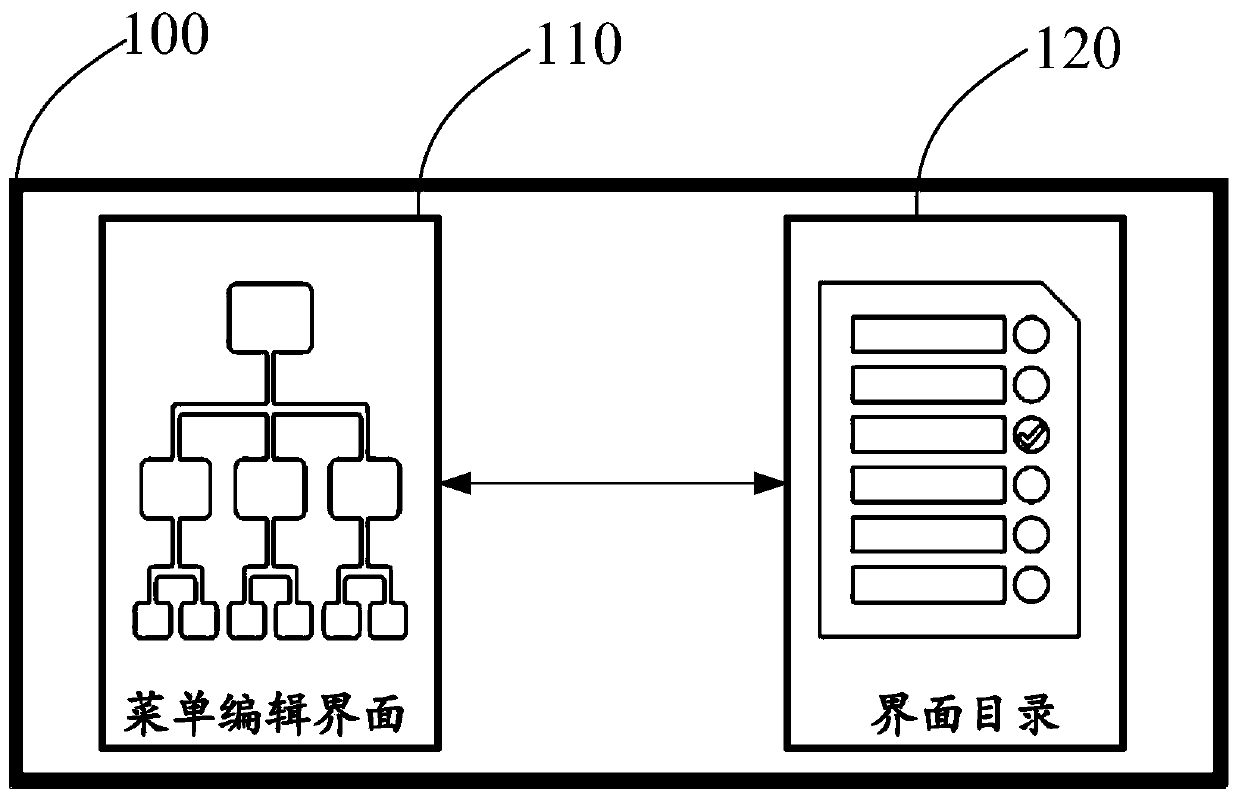

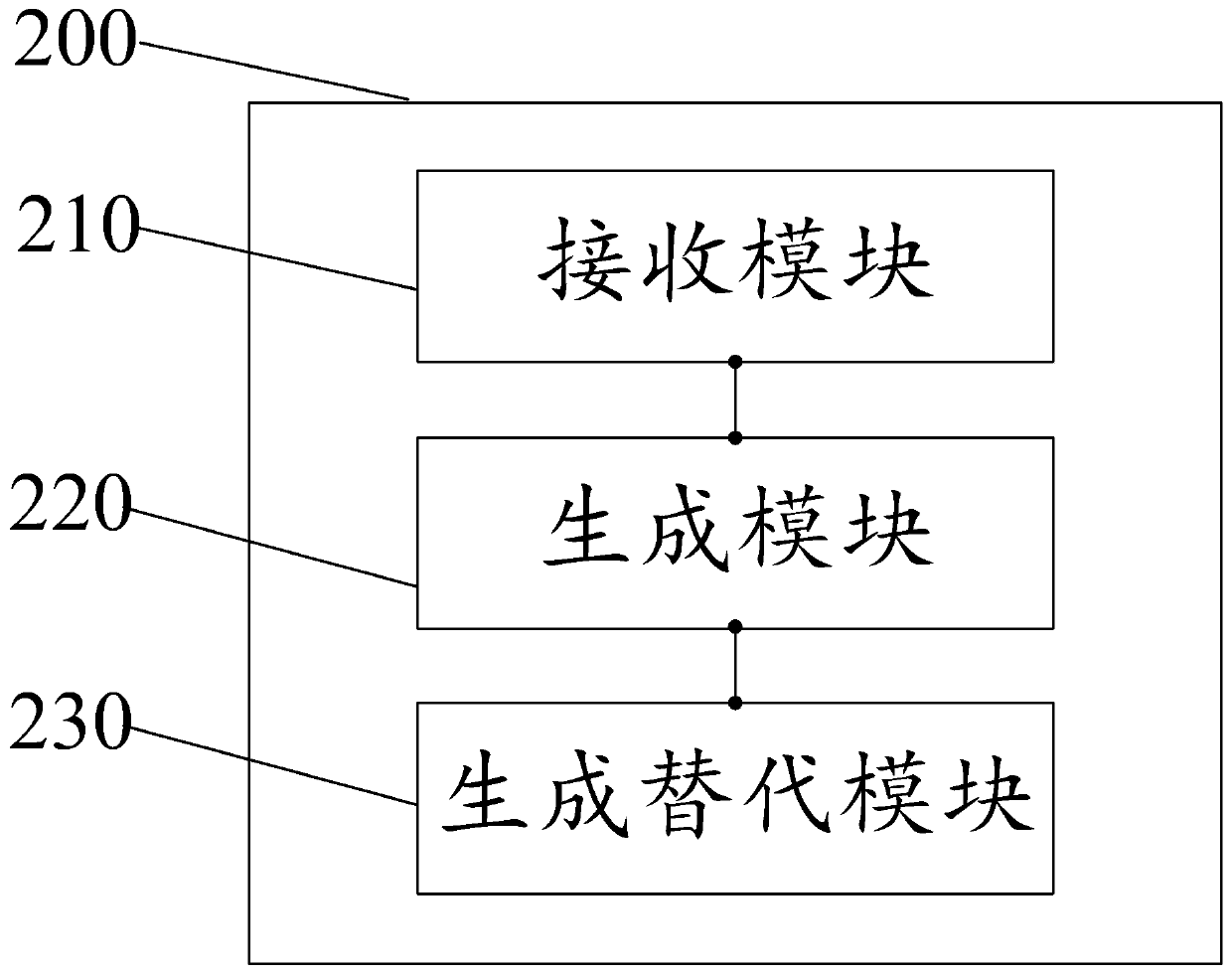

Method and system for visually modifying menus

PendingCN111538500AEasy to chooseReduced risk of errorWebsite content managementVisual/graphical programmingEngineeringHuman–computer interaction

The invention relates to a method and a system for visually modifying menus. A user can intuitively select target interface file information on an interface directory of an editing interface accordingto a modification requirement; a user can visually configure the target interface file information on a menu editing interface of an editing interface according to modification requirements to generate menu editing information; then, a platform main navigation menu is generated according to the menu editing information; the platform main navigation menu is used for replacing an original platformmain navigation menu on a Web front-end page of the platform, the purpose of modification is achieved, due to the fact that the modification process is visual, the modification efficiency is improved,the risk of errors of the platform main navigation menu is reduced, special developers are not needed for modification, and the technical threshold is low.

Owner:北京思特奇信息技术股份有限公司

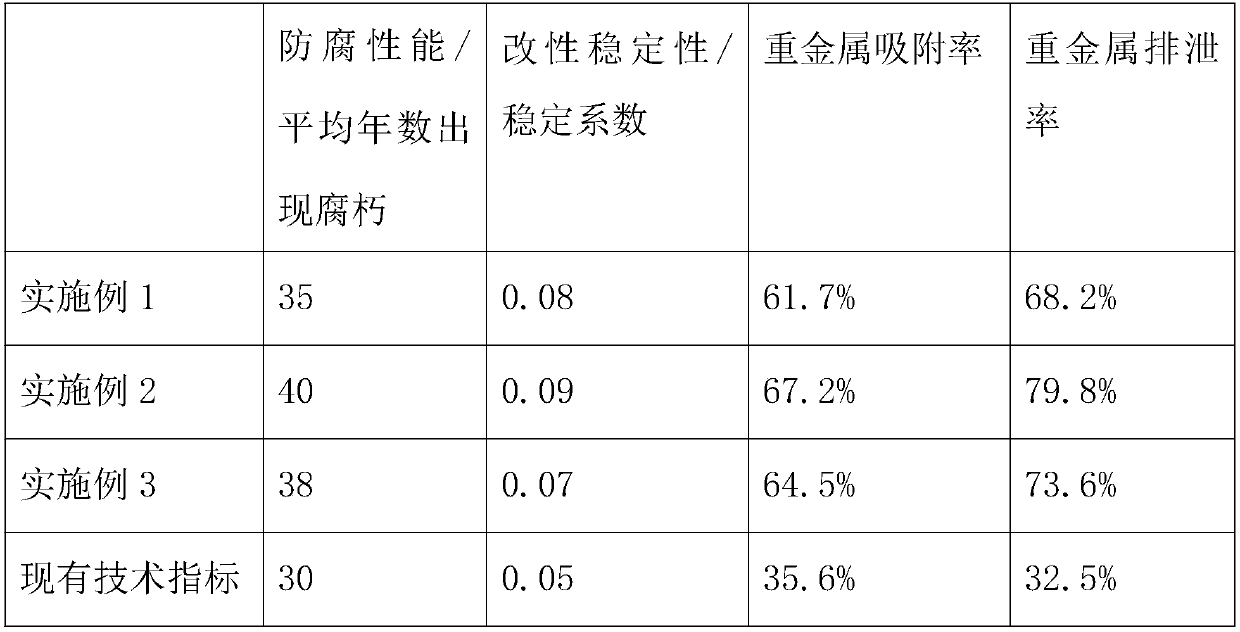

Eucalyptus plate modifying method

InactiveCN107839045AImprove anti-corrosion performanceAchieve the purpose of modificationRadiation/waves wood treatmentWood treatment detailsDissolutionSolvent

The invention discloses a eucalyptus plate modifying method which comprises the following steps: preparing a modifying agent; impregnating a eucalyptus plate; and carrying out drying, polymerization and modification. According to the eucalyptus plate modifying method, chitosan is easy to dissolve in a weak-acid solvent; particularly, a solution obtained after the dissolution contains amidogen (NH2+), and amidogen is bonded with a negative electron so as to inhibit bacteria, so that the anti-corrosion property of the eucalyptus plate can be effectively improved by bonding the modifying agent which contains the chitosan component with the eucalyptus plate; furthermore, chitosan has a significant characteristic of adsorbing capacity, that is, chitosan is capable of adsorbing and discharging heavy metal, so that the environment can be purified and the harm to the human body can be reduced; and accordingly, when the modifying agent which contains chitosan is bonded with the eucalyptus platethrough the eucalyptus plate modifying method, the properties of the eucalyptus plate can be greatly improved.

Owner:中垣林业科技(定南)有限公司

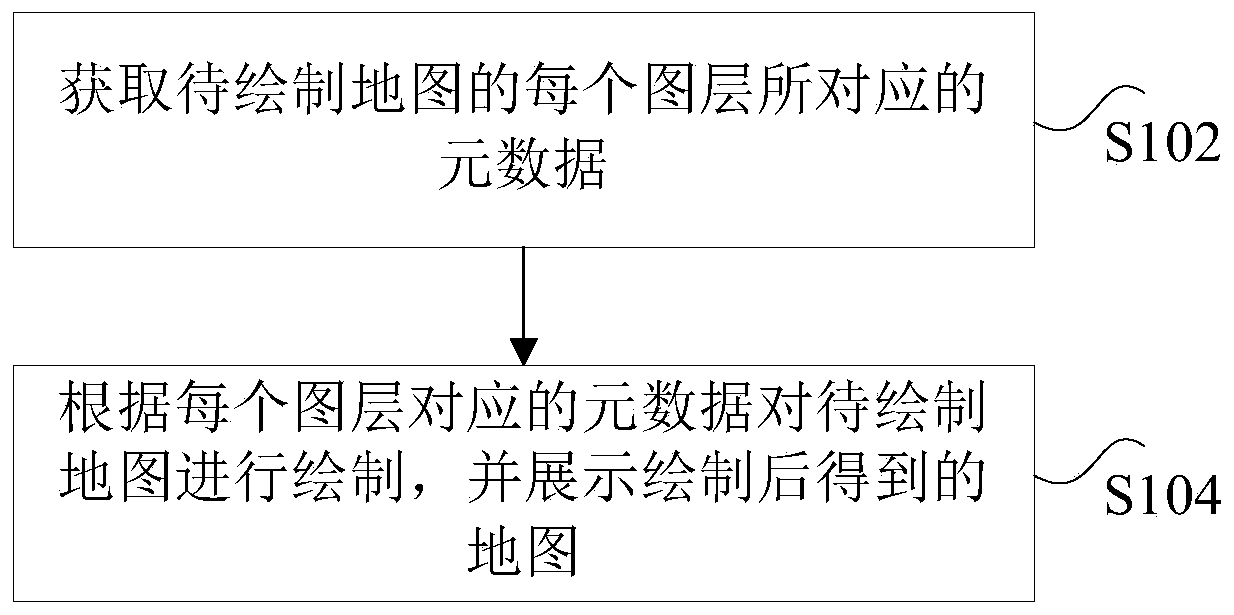

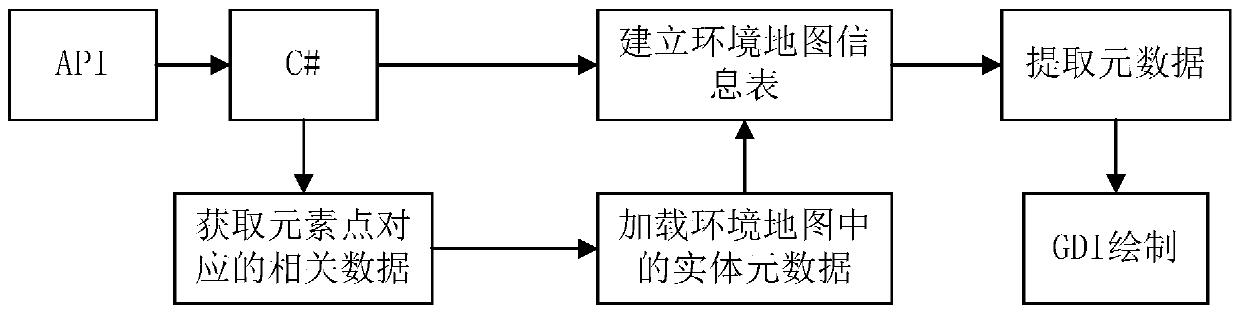

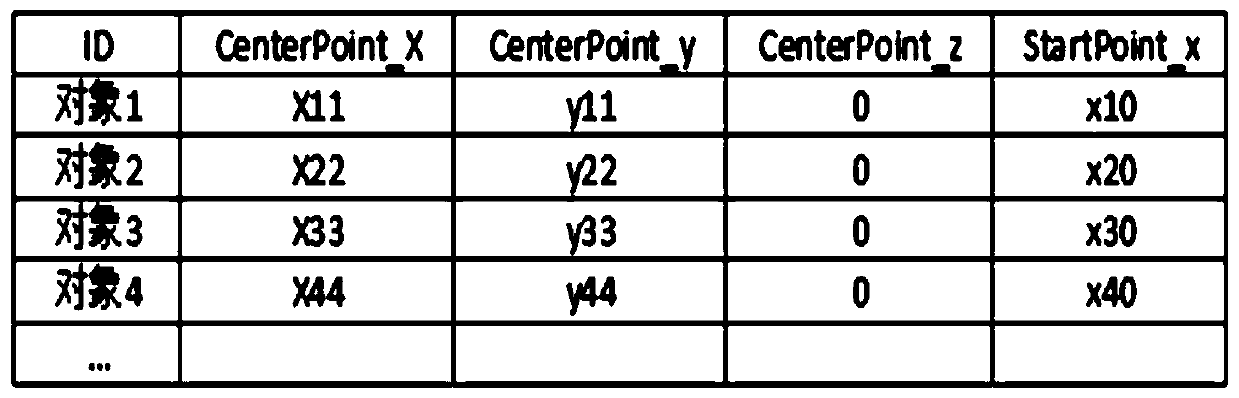

Map display method and device

ActiveCN109887054AReach drawAchieve the purpose of modificationDrawing from basic elementsComputer scienceMetadata

The invention discloses a map display method and device. The method comprises the steps that metadata corresponding to each layer of a map to be drawn is acquired, and each layer corresponds to different types of metadata; and the to-be-drawn map is drawn according to the metadata corresponding to each layer, and the drawn map is displayed. The technical problem that an existing screenshot map drawing mode is complex in drawing and modifying operation is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

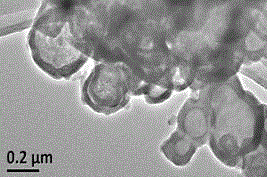

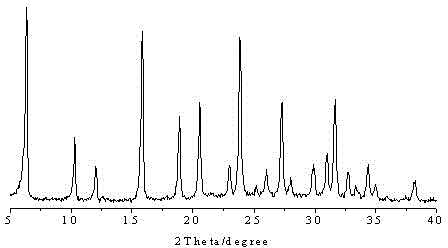

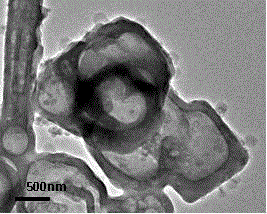

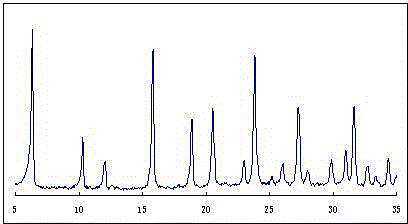

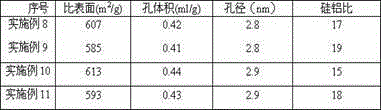

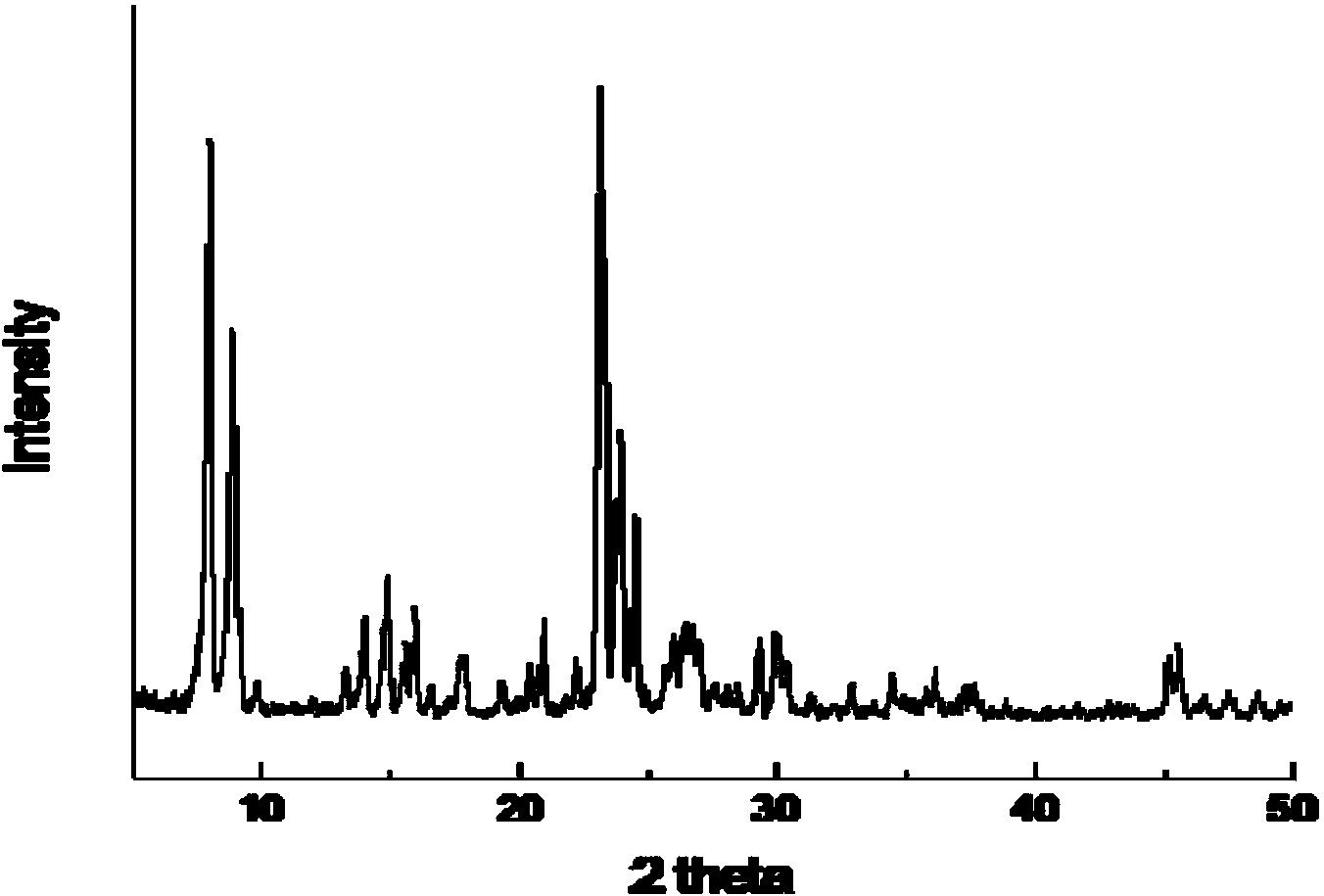

USY molecular sieve and preparation method thereof

ActiveCN105712375AAchieve the purpose of modificationHigh catalytic activityMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveSilicon oxide

The invention discloses a USY molecular sieve. The USY molecular sieve has a hollow structure. The USY molecular sieve has a silicon oxide-alumina mole ratio of 4.5-25, the grain size of 0.5-1.2 microns, a specific surface area of 420-800m<2> / g, a pore volume of 0.33-0.82ml / g and an average aperture size of 1.5-4.0nm. The USY molecular sieve has more exposed reaction active sites, greatly shortens a diffusion distance of reactants and improves molecular sieve catalysis performances.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hollow USY molecular sieve

ActiveCN105712374AAchieve the purpose of modificationHigh catalytic activityMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveEngineering

The invention discloses a preparation method of a hollow USY molecular sieve. The preparation method comprises 1, preparing a guiding agent, 2, preparing a mixed solution from an aluminum source, water and sodium hydroxide, adding a low silica-alumina ratio NaY molecular sieve and the guiding agent obtained through the step 1 into the mixed solution, carrying out uniform stirring, carrying out constant temperature crystallization on the gel at a temperature of 90-120 DEG C for 12-72h and carrying out cooling, washing, pumping filtration and drying to obtain a Y-Y composite molecular sieve, 3, carrying out ammonium exchange on the Y-Y composite molecular sieve prepared through the step 2, 4, treating the Y-Y composite molecular sieve subjected to ammonium exchange under hydro-thermal conditions and 5, washing the composite molecular sieve subjected to hydro-thermal treatment in the step 4 to obtain the hollow USY molecular sieve. The USY molecular sieve has more exposed reaction active sites, greatly shortens a reactant diffusion distance and improves molecular sieve catalysis performances.

Owner:CHINA PETROLEUM & CHEM CORP +1

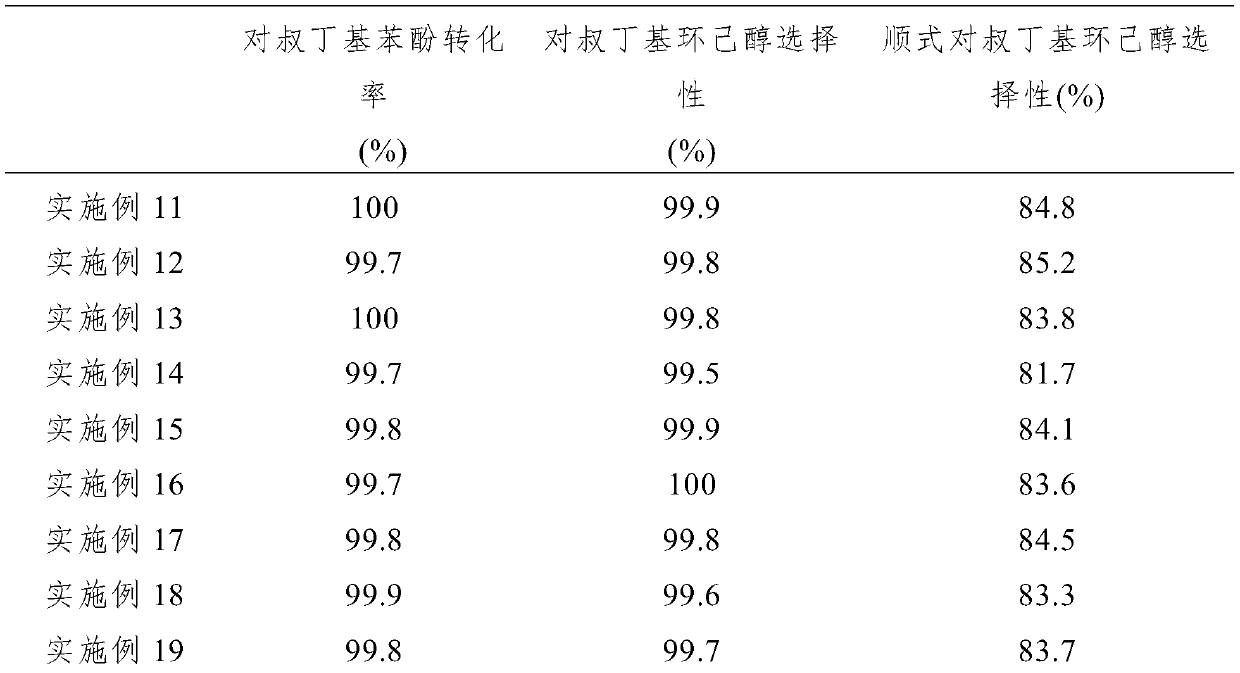

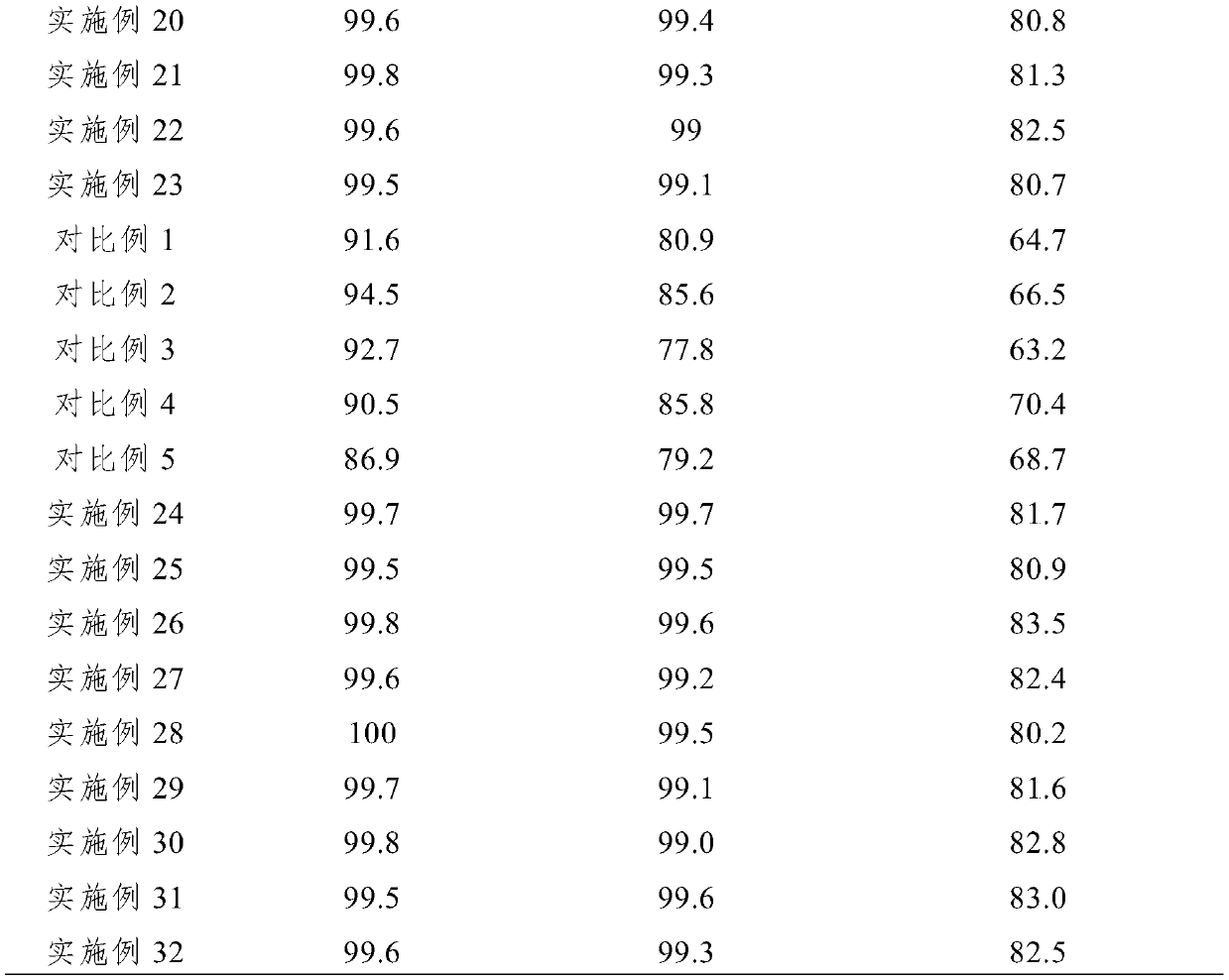

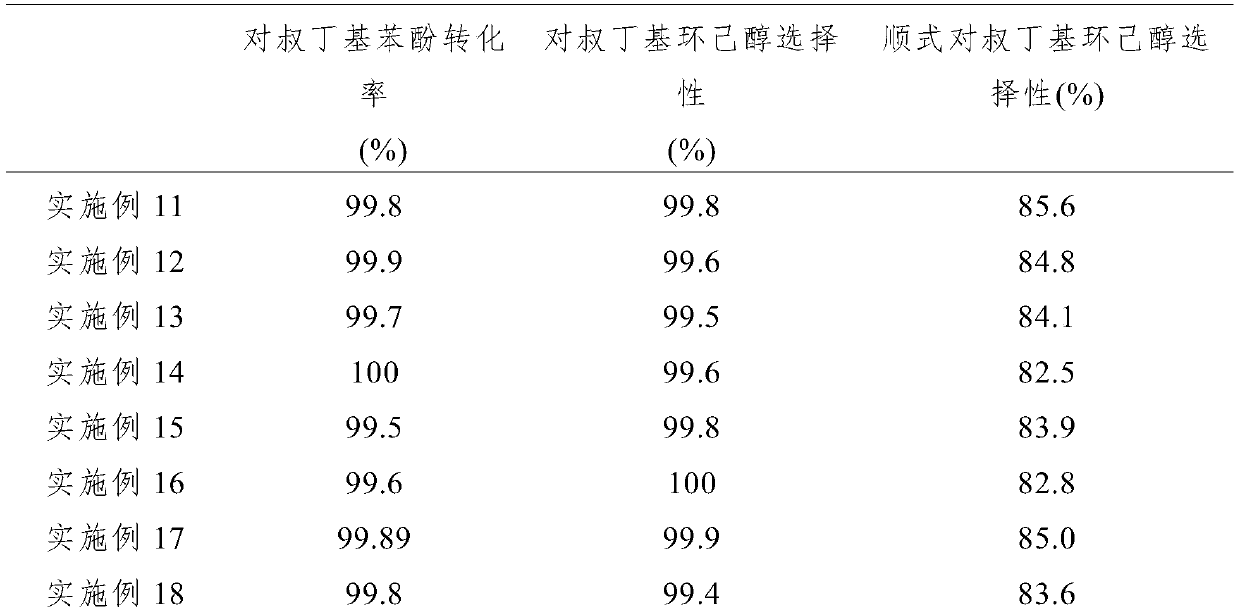

Catalyst for continuously preparing cis-p-tert-butylcyclohexanol, and preparation method and application

ActiveCN110743546AEnhanced Surface AcidityImprove stabilityMolecular sieve catalystsOrganic chemistry methodsPtru catalystP-tert-Butylphenol

The invention discloses a catalyst for continuously preparing cis-p-tert-butylcyclohexanol. The catalyst comprises a porous material carrier, Pd, Ru, a non-metal auxiliary agent component, and a metalauxiliary agent component, wherein a mass percentage of Pd is 0.05%-1%, a mass percentage of Ru is 0.2%-3%, a mass percentage of the non-metal auxiliary agent component is 0.01%-0.5%, a mass percentage of the metal auxiliary agent component is 0.05%-0.8%, the non-metal auxiliary agent component is one or more of P, F and B, and the metal auxiliary agent component is one or more of Mn, Zr, Wu, V,Nb and Ti. In addition, the invention also provides a preparation method and application of the catalyst. The catalyst can significantly improve the selectivity of continuously preparing cis-p-tert-butylcyclohexanol, a molar conversion rate of p-tert-butylphenol exceeds 99.5%, the selectivity of p-tert-butylcyclohexanol exceeds 99%, and the selectivity of cis-p-tert-butylcyclohexanol exceeds 80%.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

Modified aluminium phosphate molecular sieve and preparation method thereof

ActiveCN103816936ACrystallization intactSmall granularityMolecular sieve catalystsDiammonium phosphateAluminium phosphate

The invention provides a modified aluminium phosphate molecular sieve, which is prepared by a ZSM-5 molecular sieve, diammonium phosphate and zinc nitrate, wherein ratio of silica to alumina is 25-40. The preparation method comprises the following steps: adding 0.5-1.5 parts of ZSM-5 molecular sieve in 3-5 parts of purified water according to weight, adding 0.48-0.52 parts of diammonium phosphate and 0.006-0.010 parts of zinc nitrate solution in purified water, stirring for 30-40 minutes, then heating to the temperature of 120-150 DEG C, controlling the pressure at 0.18-0.40MPa, stirring for 120-150 minutes for completing an exchange reaction, then filtering and drying, and finally roasting for 2 hours under the temperature of 530-590 DEG C to obtain the modified ZSM-5 molecular sieve. The modified aluminium phosphate molecular sieve has strong B acid site, crystal phase conversion is not generated through high temperature and hydro-thermal treatment, and the modified aluminium phosphate molecular sieve has good heat and hydro-thermal stability, excellent adsorption performance and cracking performance. The invention also provides a preparation method of the modified aluminium phosphate molecular sieve.

Owner:鹤壁博文科峰催化技术有限公司

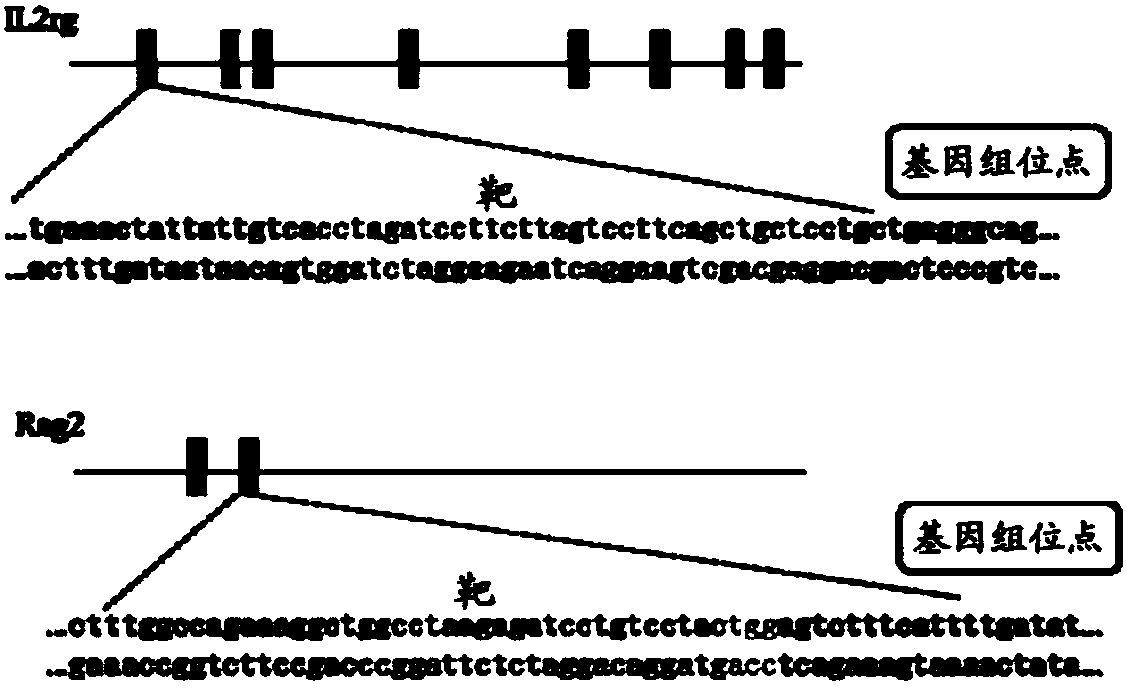

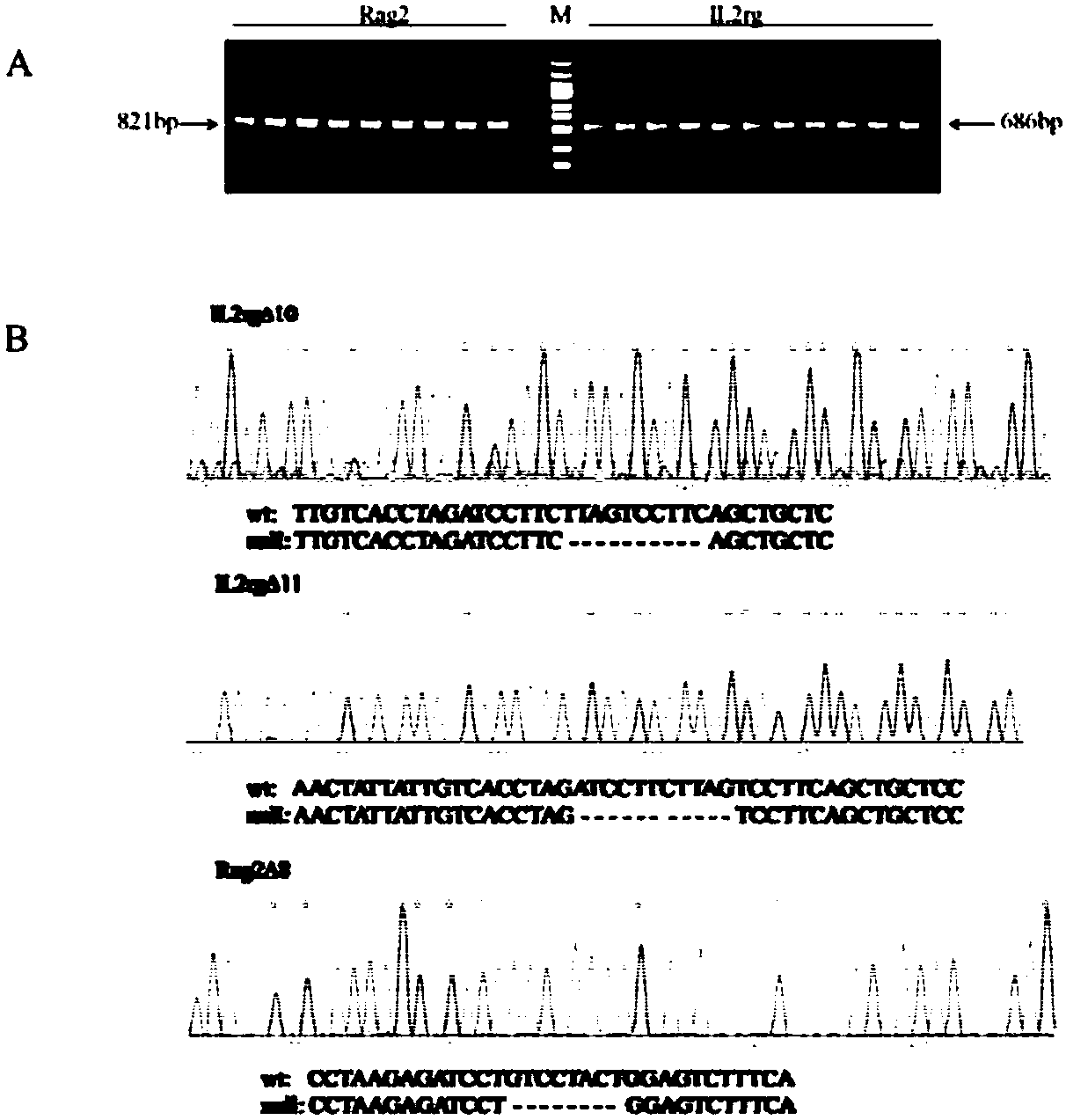

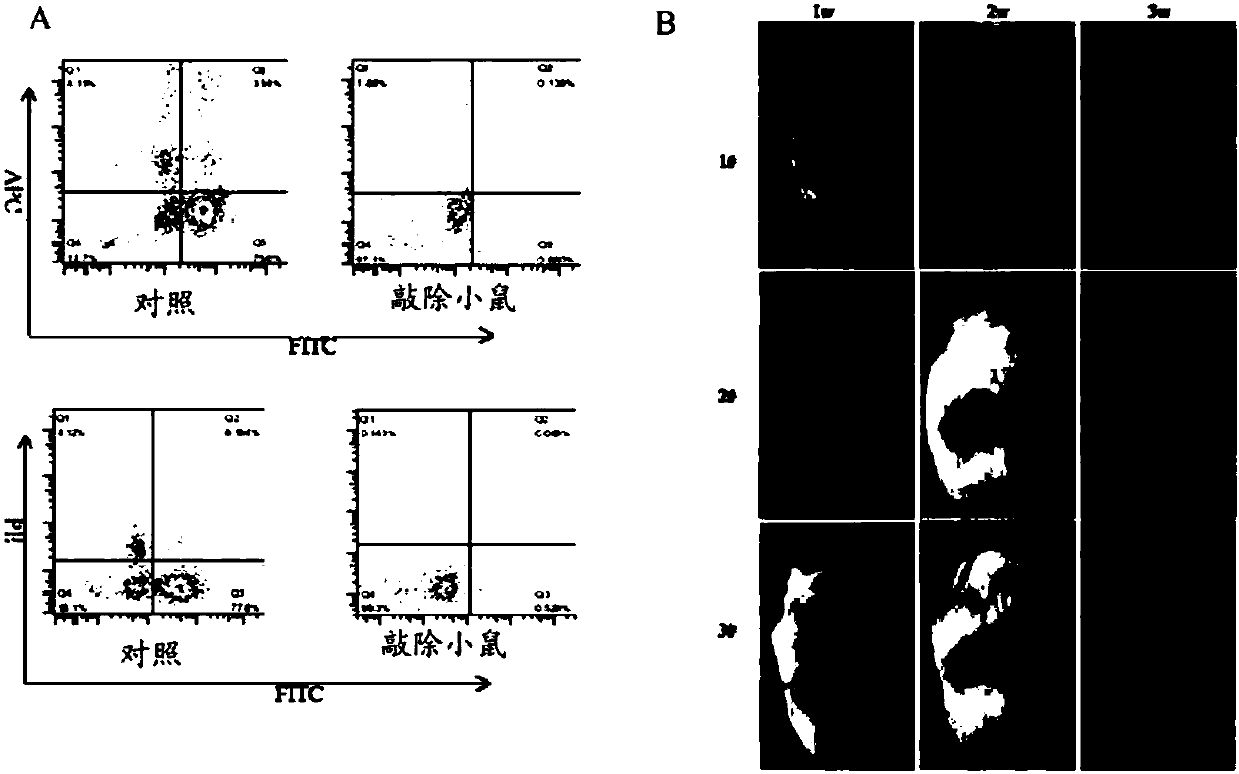

Construction and application of severe combined immunodeficiency animal model

InactiveCN107760720AReliable knockout efficiencyTumor cells growing wellHydrolasesMicroinjection basedIL2RG geneSevere Combined Immunodeficiency Syndrome

The invention relates to construction and related application of a severe combined immunodeficiency animal model. According to the construction method, Rag2 genes for encoding animal T and B cells andIl2rg genes involved in encoding cytokine receptors are removed in a targeted mode by means of a CRISPR / Cas9 technology, and the construction of the animal model with a higher immunodeficiency degreeis achieved.

Owner:北京艾德摩生物技术有限公司 +1

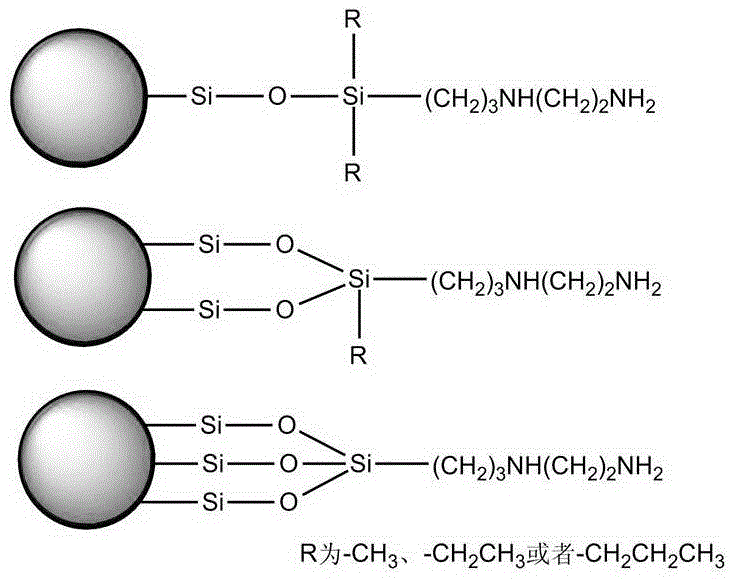

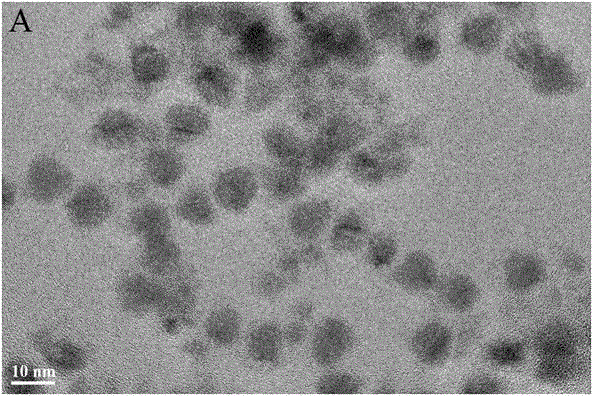

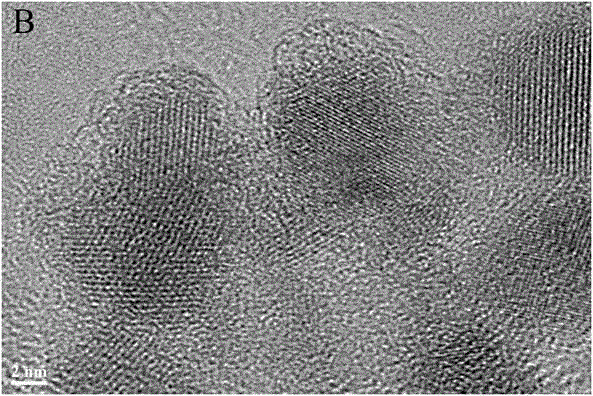

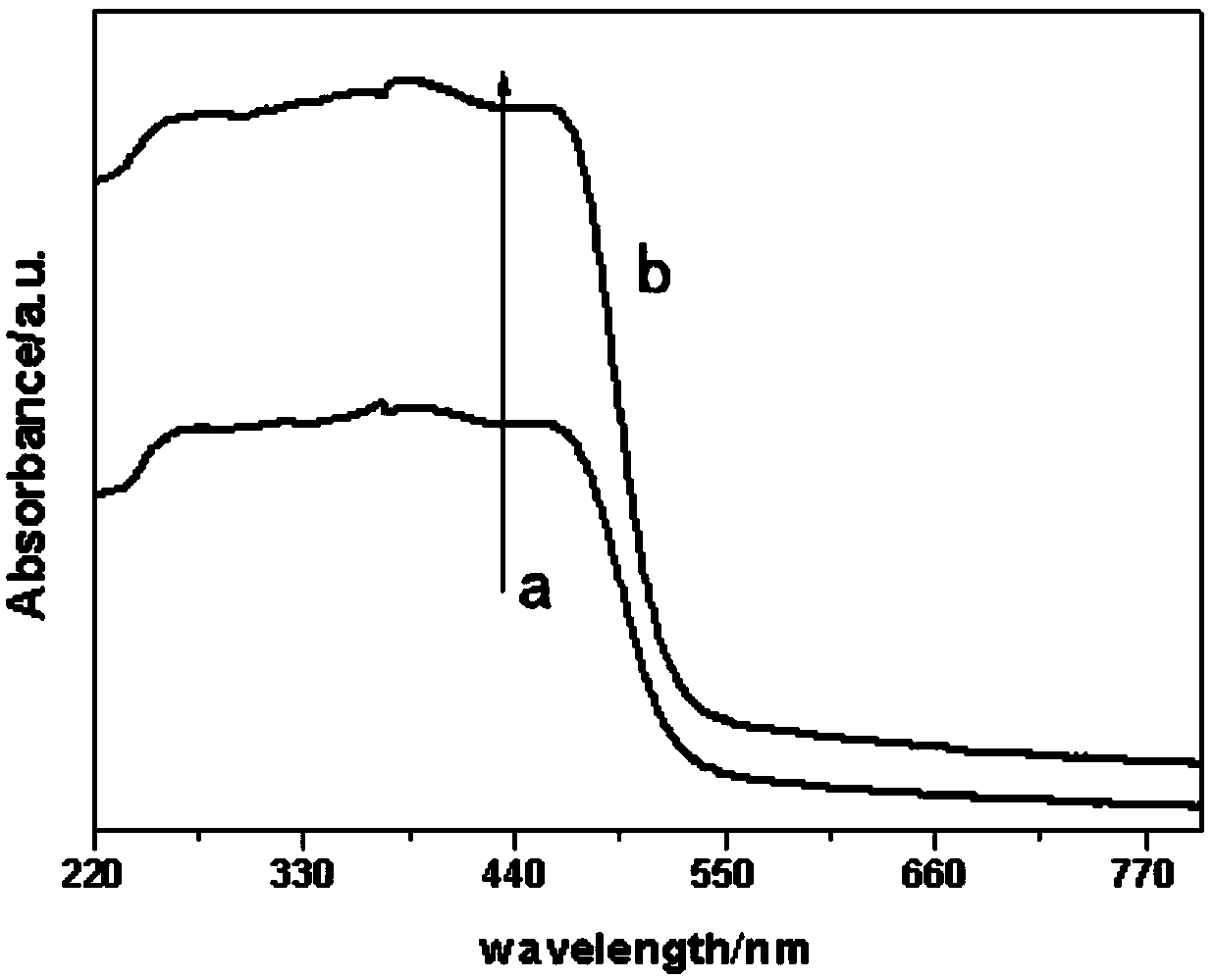

Amino-modified water-soluble fluorescent quantum dot and preparation method thereof

InactiveCN105623644AGood oil solubilityRealize multi-function detectionLuminescent compositionsFluorescenceBiocompatibility Testing

The invention relates to an amino-modified water-soluble fluorescent quantum dot and a preparation method thereof. The water-soluble fluorescent quantum dot is of a multi-layer core-shell structure, an oil-soluble fluorescent quantum dot (such as CdSe / ZnS) is adopted as a core, the surface of the oil-soluble fluorescent quantum dot is subjected to a silanization rection, so that the lipophilic and hydrophobic properties of the quantum dots are modified into hydrophily in one step; furthermore, an amino group (-NH2) is adopted, so that surface amino modification for the water-soluble quantum dot is finished; the prepared amino-modified water-soluble quantum dot has an average size of 10nm and is uniform in size, has a wide excitation spectrum continuously distributed in a range of 250-602nm, and has good emission spectrum monochromaticity with a maximum emission wavelength of 634nm and fluorescence-emission half peak width of 43nm. The amino-modified quantum dot is good in biocompatibility, can be coupled with various bioactive substances, and has great practical value and application prospect in the biology and medicine fields such as immunofluorescence diagnose, cell imaging and living imaging.

Owner:SUZHOU ENRICHING BIOTECH CO LTD

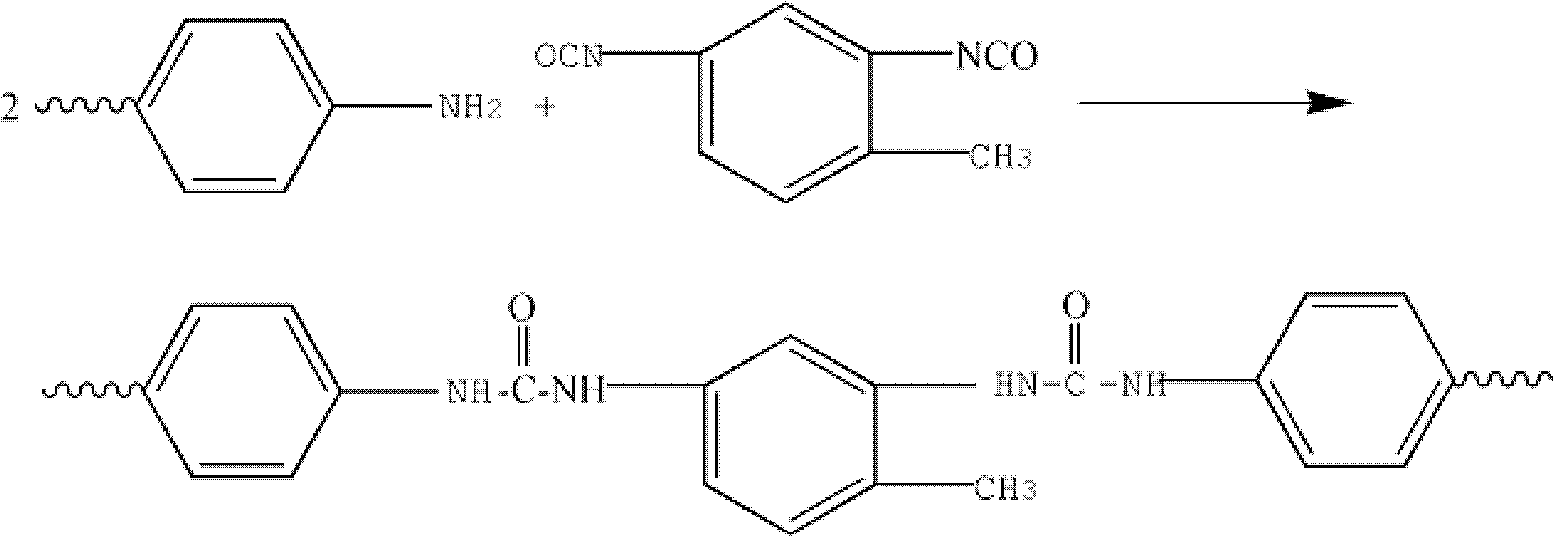

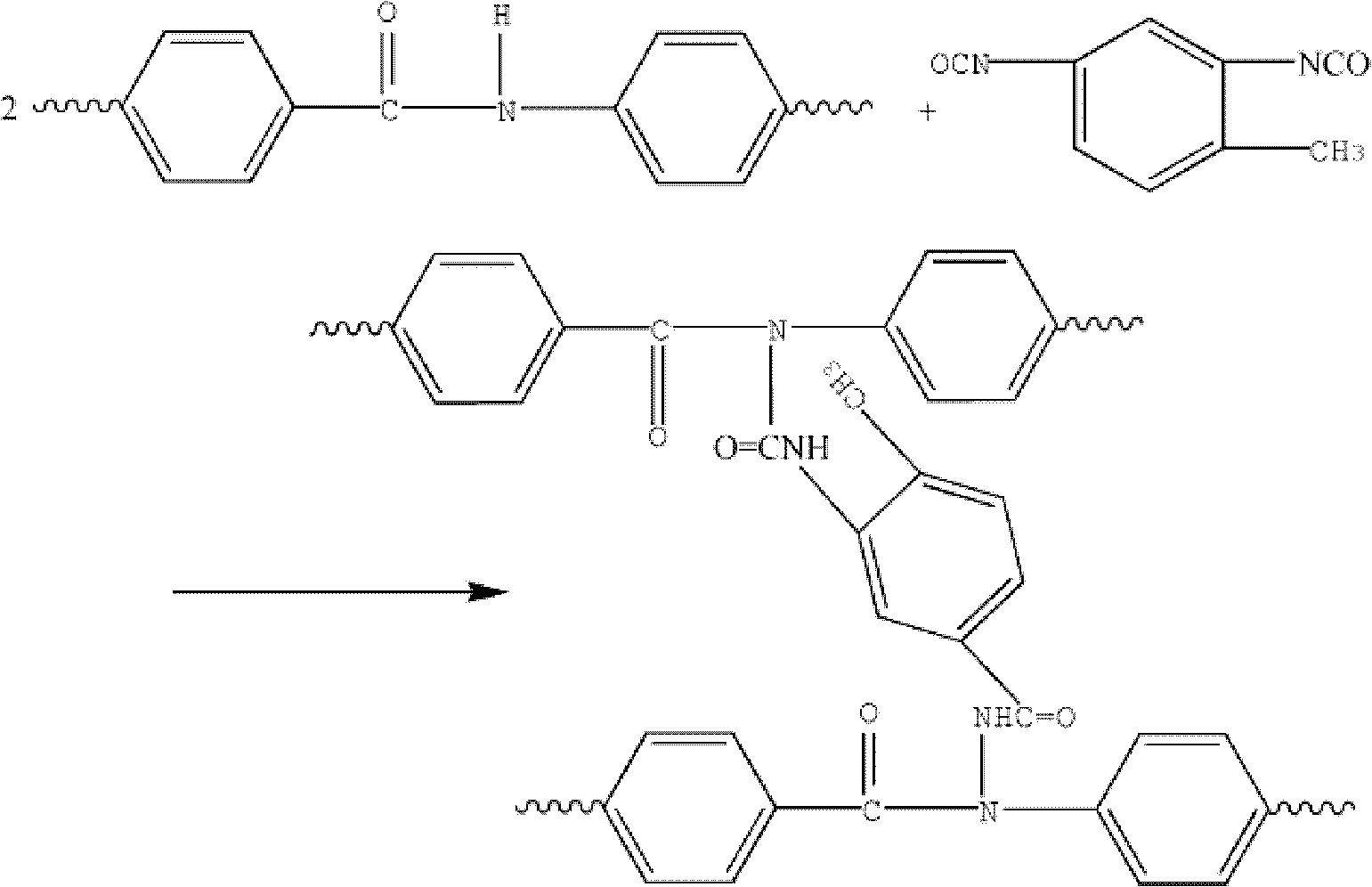

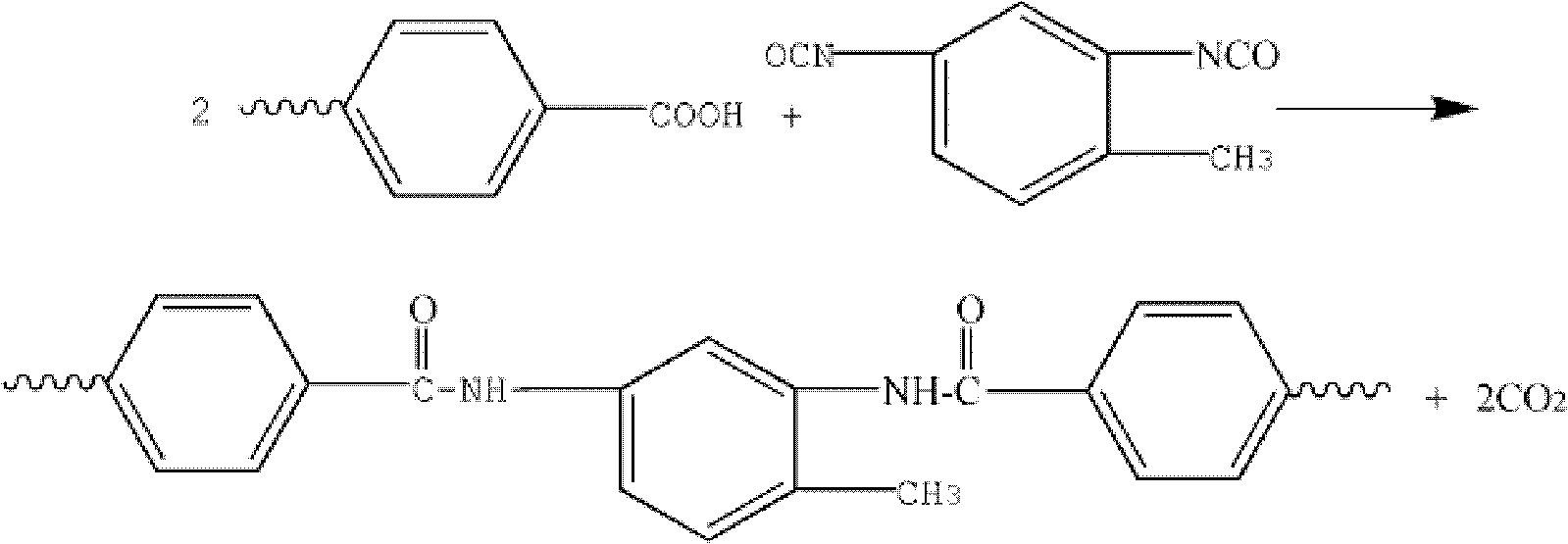

Method for modifying interior and surface of aramid fiber through isocyanate in supercritical CO2

The invention relates to a method for modifying the interior and the surface of an aramid fiber through isocyanate in supercritical CO2. The method comprises the following steps of: (1) cleaning the surface of the aramid fiber with anhydrous acetone and drying under vacuum; (2) placing the isocyanate and the aramid fiber obtained in the step (1) into a reactor, wherein the isocyanate and the aramid fiber are not contacted, closing the reactor, after air is exhausted, filling CO2 into the reactor at room temperature, keeping the system in a supercritical CO2 state, after swelling and reaction are finished, cooling and releasing pressure, and taking out the fiber; and (3) washing the modified aramid fiber with the anhydrous acetone, and drying the fiber under vacuum. The method is economic and environment-friendly, and reaction is controllable; a solvent and a product are simply separated; a chain extension bridging reaction can be effectively performed in a fiber amorphous area by the method; the tensile modulus and the tensile strength of the aramid fiber are improved; an organic functional group can be effectively grafted on the surface through the grafting reaction of the surface; and the aim of modifying the interior and the surface of the fiber at the same time is fulfilled.

Owner:DONGHUA UNIV

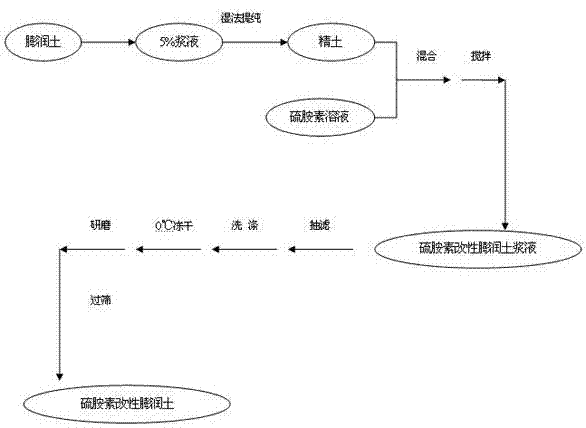

Preparation method for thiamine modified bentonite

The invention relates to preparation methods of bentonite, in particular to a preparation method for thiamine modified bentonite. The method includes: preparing original soil into soil suspension of 5%, stirring for 20min, standing for 5min, using the siphon method to take upper serous liquid, standing for 1 day, taking the upper serous liquid for centrifugation, drying bottom pasty soil, grinding, and going through a sieve of 0.074mm for standby; preparing modifier solution, namely, using hydrochloric acid of 0.1mol / L and analytically pure thiamine to prepare thiamine solution with a mass concentration of 3.5g / L; and finally preparing the thiamine modified bentonite, namely, taking 100mL of the thiamine solution with the mass concentration of 3.5g / L to be uniformly mixed with refined soil, stirring for 60min, leaching, washing, freeze-drying at 0 DEG C, grinding, and going through the 0.074mm sieve to obtain the thiamine modified bentonite. The prepared modified bentonite has no toxic effect on human, animals and plants, and the modified bentonite after use can be recycled as feed and fertilizer, so that secondary pollution is avoided.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Method for synthesizing nitrogen-doped bismuth vanadate photocatalyst and application thereof

ActiveCN109317177AAchieve the purpose of modificationImproving the performance of photocatalytic degradation of organic matterPhysical/chemical process catalystsWater/sewage treatment by irradiationBismuth vanadateAmmonium metavanadate

The invention discloses a preparation method and application for synthesizing a nitrogen-doped bismuth vanadate photocatalyst through a hydrothermal method. The method comprises the steps: dissolvingbismuth vanadate pentahydrate and polyvinylpyrrolidone into concentrated nitric acid to be prepared into a bismuth salt solution, dissolving ammonium metavanadate into an ammonium hydroxide solution to form a vanadium salt solution, adding urea into the vanadium salt solution according to the molar ratio of N to Bi is equal to (1 to 1.5) to 1 to form a mixed solution, then adding the bismuth saltsolution into the mixed solution and adjusting a pH to be 7 to obtain a precursor solution, then transferring the precursor solution into a high-pressure kettle to perform hydrothermal reaction and centrifuging, washing and drying a product to obtain the nitrogen-doped bismuth vanadate photocatalyst after reaction finishes.

Owner:JIANGSU UNIV OF TECH

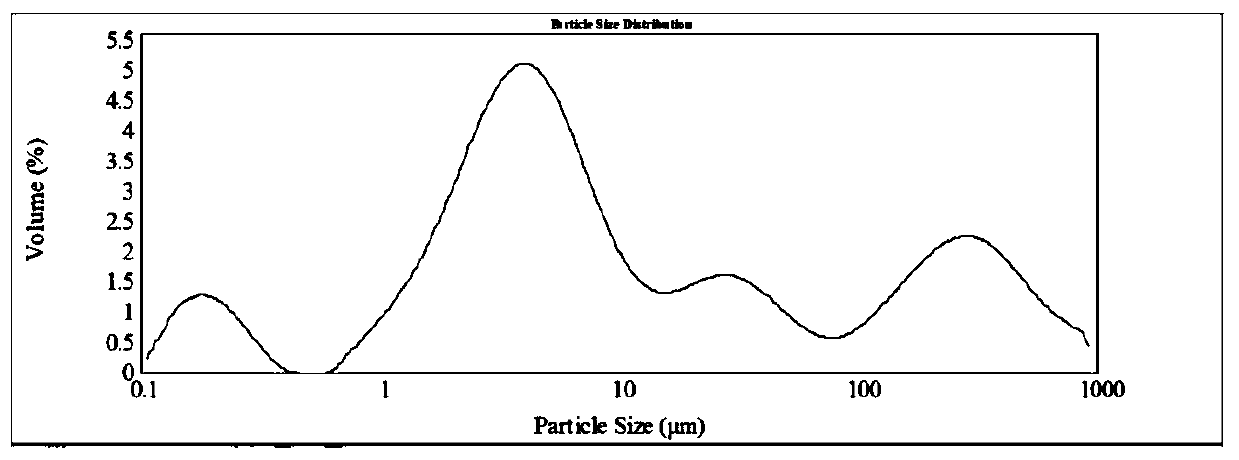

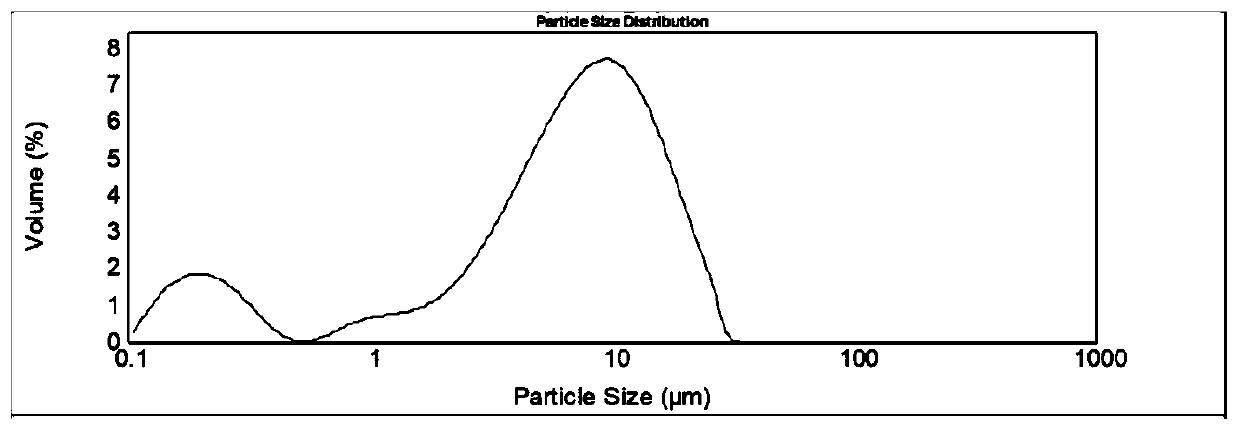

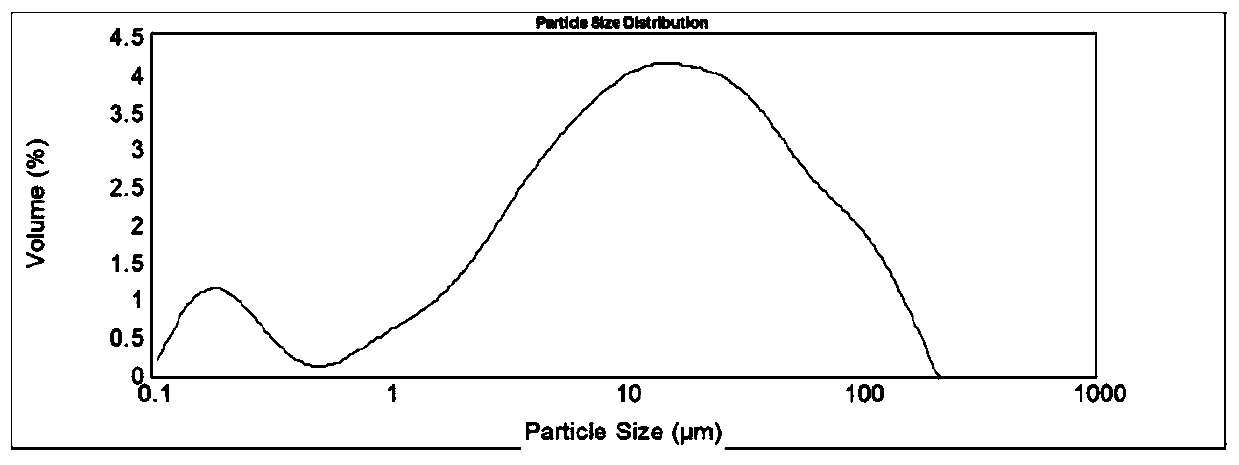

Graphene modification method of phthalocyanine blue pigment

ActiveCN111334085AHigh tinting strengthReduce molecular aggregationPorphines/azaporphinesPhthalocyanineGraphene

The invention provides a graphene modification method of a phthalocyanine blue pigment. The graphene modification method specifically comprises modifying the phthalocyanine blue pigment by using graphene through a non-covalent bond or a covalent bond-non-covalent bond acting force. According to the modification method, the coloring capacity of phthalocyanine blue is improved, the specific surfacearea of the pigment is increased, molecular aggregation among organic pigment compounds can be reduced, and the particle size distribution of obtained pigment particles is more centralized.

Owner:DEZHOU UNIV

High-strength PET polyester fiber and preparation method thereof

ActiveCN113293458ALow softening temperatureHigh activityConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsPolyesterPolymer science

The invention discloses high-strength PET polyester fiber and a preparation method thereof. The preparation method comprises the following steps of preparing PET300 based on solid PET; adding PET300 and polyethylene glycol into a dopamine solution to prepare PETPre; and after PET300, PETPre and cellulose acetate fiber are blended, enabling a mixture and poly-bis-Schiff base to be subjected to a mixed reaction, so that the high-strength PET polyester fiber is obtained. PET can be modified through dopamine, the poly-bis-Schiff base and the cellulose acetate fiber, the addition amount of auxiliaries is small, the abrasion resistance is improved through environment-friendly dopamine, burrs are effectively reduced, the melt spinning technology is not changed, the production cost is basically not increased, and the very important application value is achieved.

Owner:上海茂腾针织有限公司

Granular dry modifier for asphalt and preparation method thereof

InactiveCN111138874AAvoid stickingEfficient modificationBuilding insulationsRoad engineeringRoad surface

The invention discloses a granular instant dry SBS modifier for an asphalt pavement and a preparation method and application thereof, belonging to the field of road engineering materials. The main component of the granular instant dry SBS modifier is powdery SBS, and a separant, hydrotropic oil, a main cross-linking agent and an auxiliary cross-linking agent can be selectively added. The preparation method comprises the following steps: crushing SBS particles; then adding the separant, the hydrotropic oil, the main cross-linking agent and the auxiliary cross-linking agent into the obtained SBSpowder; and then carrying out cold granulation at a temperature of not higher than 80 DEG C in a flat die or circular die extruder with a cutting length of 10-30 mm so as to obtain the granular dry modifier. The granular dry modifier for asphalt prepared in the invention inherits the advantages of a dry-method process and a wet-method process, and can effectively improve the construction qualityof a pavement while enhance construction flexibility; and in addition, the problems of floating and dust flammability caused by only using micron-sized SBS powder are solved by adopting a prepared cold granulation mode.

Owner:BEIJING ZHONGLU PAVING TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com