Composite waterborne alkyd resin with high storage stability

A technology of water-based alkyd resin and storage stability, applied in the field of coatings, can solve the problems of poor storage stability and poor performance, and achieve the effects of enhanced hardness of the paint film, increased dispersion, and diversified chain segments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

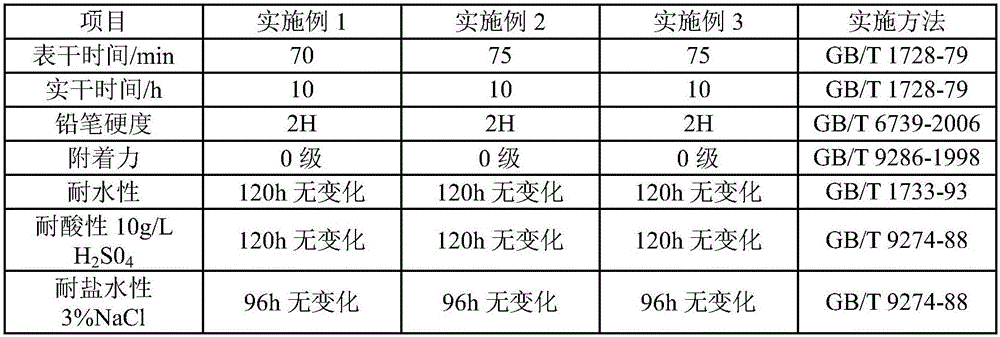

Examples

Embodiment 1

[0024] (1) Preparation of sulfonate prepolymer: add 48.27g (0.18mol) isophthalic acid-5-sulfonic acid in a four-neck flask with stirring rod, thermometer, condenser, water separator, and nitrogen conduit Sodium, 93.74g (0.90mol) neopentyl glycol, 0.076g dibutyltin oxide, 15.0g deionized water, nitrogen gas, keep at 118°C for 1h, then raise the temperature to 158°C, keep hold for 1h, then gradually raise the temperature to 198°C ℃, keep warm for esterification until the acid value is lower than 5, discharge the material while it is hot, and grind it to powder after cooling to obtain the sulfonate prepolymer, which is stored under dry conditions for later use.

[0025] (2) Preparation of acrylic acid prepolymer: 14.5g α-methacrylic acid, 60g methyl methacrylate, 40g styrene, 20g butyl acrylate, 200g xylene, 6g benzoyl peroxide, 4g n- After dodecyl mercaptan is fully mixed, it is equally divided into two parts according to the mass, one part is added to a four-necked bottle with ...

Embodiment 2

[0030] (1) Preparation of sulfonate prepolymer: add 48.27g (0.18mol) isophthalic acid-5-sulfonic acid in a four-neck flask with stirring rod, thermometer, condenser, water separator, and nitrogen conduit Sodium, 68.49g (0.90mol) 1,3-propanediol, 0.080g dibutyltin dilaurate, 17.8g deionized water, nitrogen gas, keep warm at 120°C for 2h, then raise the temperature to 160°C, keep warm for 2h, then gradually Raise the temperature to 200°C, keep warm for esterification until the acid value is lower than 5, discharge the material while it is hot, and grind it to powder after cooling to obtain the sulfonate prepolymer, which is stored under dry conditions for future use.

[0031] (2) Preparation of acrylic acid prepolymer: in a beaker, 12g α-methacrylic acid, 8g acrylic acid, 50g methyl acrylate, 50g ethyl acrylate, 20g acrylonitrile, 260g xylene, 7.5g azobisisobutylcyanide, After 5.5g of 2-mercaptoethanol is fully mixed, it is divided into two parts according to the mass, one part ...

Embodiment 3

[0036] (1) Preparation of sulfonate prepolymer: add 48.27g (0.18mol) isophthalic acid-5-sulfonic acid in a four-neck flask with stirring rod, thermometer, condenser, water separator, and nitrogen conduit Sodium, 106.2g (0.90mol) of 1,6-hexanediol, 0.084g of dibutyltin dichloride, 21.3g of deionized water, nitrogen, at 122 ℃ for 1.5h, then heated to 162 ℃, 1.5 h, then gradually raise the temperature to 205°C, keep warm for esterification until the acid value is lower than 5, discharge the material while it is hot, grind it to powder after cooling, and obtain the sulfonate prepolymer, which is stored under dry conditions for future use.

[0037] (2) Preparation of acrylic acid prepolymer: 6g maleic anhydride, 17g allyl glycidyl ether, 30g methacrylamide, 20g styrene, 40g octadecyl acrylate, 30g methyl Isobornyl acrylate, 312g toluene, 9.6g tert-butyl hydroperoxide and 7.2g mercaptosuccinic acid are fully mixed, divided into two equal parts according to the mass, and one part is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com