Patents

Literature

82results about How to "High film hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

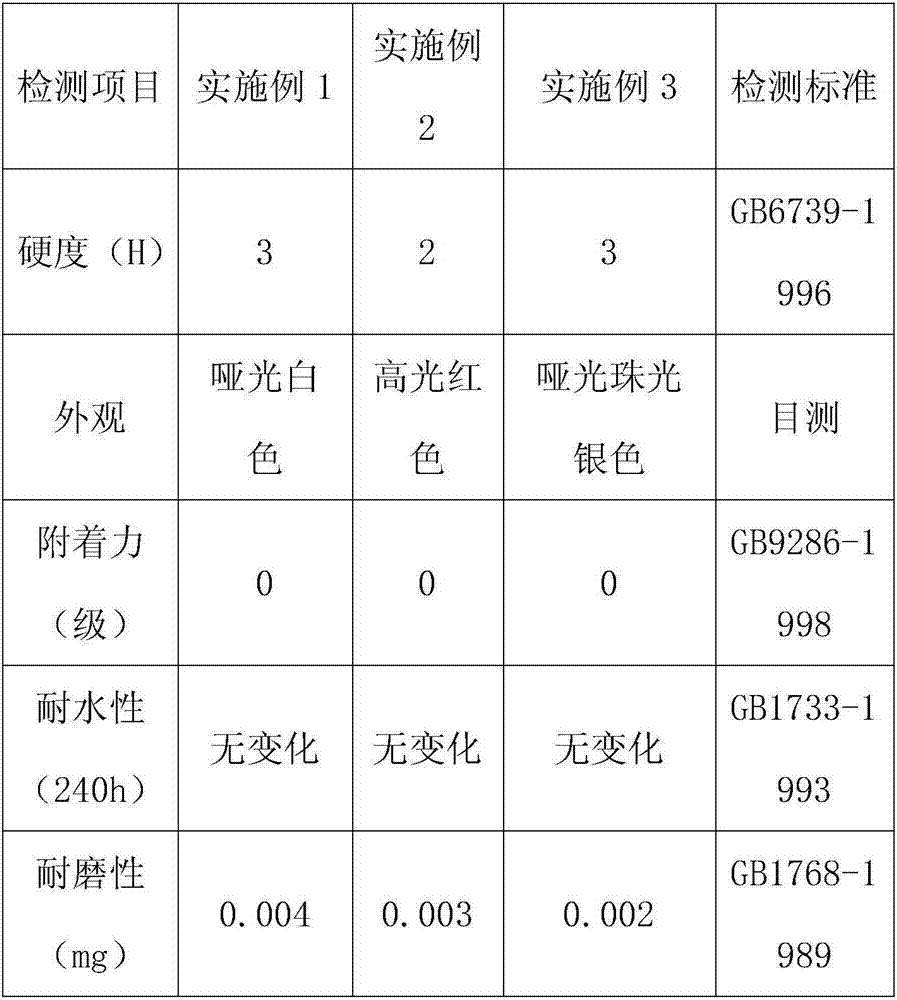

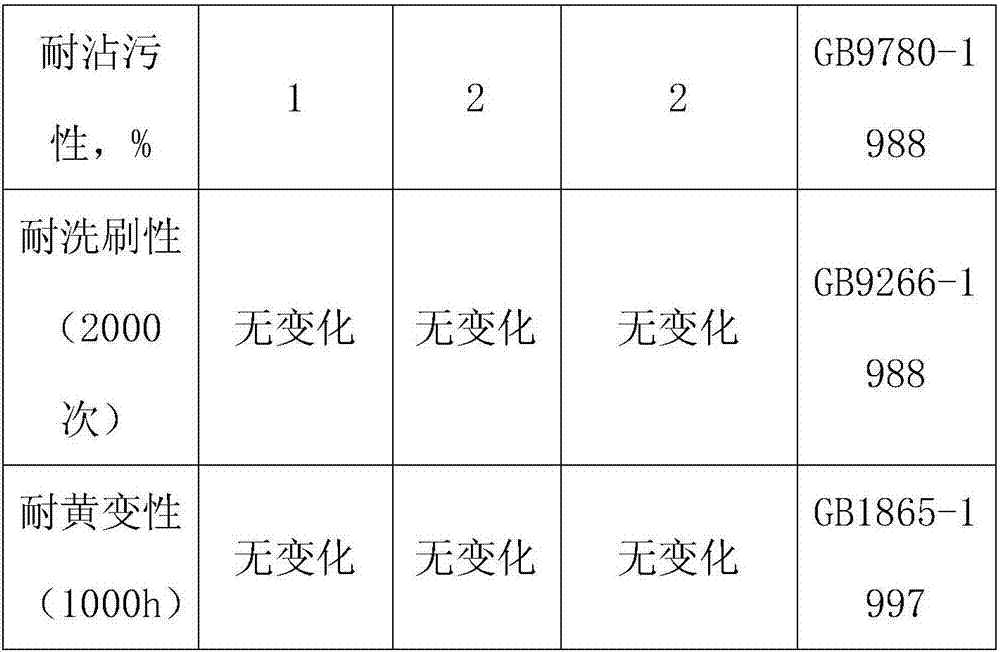

Aqueous organic-inorganic composite coating and preparation method thereof

The invention discloses an aqueous organic-inorganic composite coating, comprising the base materials of water-soluble film-forming material, pigment, filler, additive and water. The aqueous organic-inorganic composite coating is specifically composed of the following component, by weight: 15-25 parts of potassium silicate, 10-20 parts of styrene-acrylic emulsion, 0.2-0.5 part of stabilizer, 0.2-0.5 part of dispersing agent, 0.3-0.6 part of defoaming agent, 0.2-0.5 part of film-forming additive, 0.2-0.5 part of antifreeze, 0.1-0.3 part of thickening agent, 14-20 parts of titanium dioxide, 15-25 parts of heavy calcium, 5-10 parts of talcum powder and 20-25 parts of water. The invention has the following advantages: high film hardness, no cracking, excellent weather fastness, lasting replenished film, no addition of preservatives, excellent environmental protection performance, long recoating period of film and resource saving. In addition, the product has minimal construction resistance, and is easy for painting, promotion and application. The aqueous organic-inorganic composite coating has wide application range, and can be applied to coating of basement, underground parking, inner wall and outer wall.

Owner:广东嘉宝莉科技材料有限公司

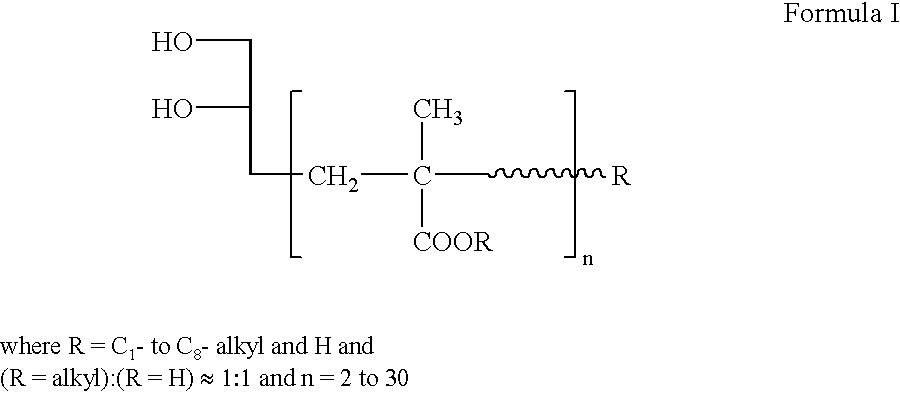

Polyurethane dispersion with high film hardness, process for preparing it, and its use

InactiveUS20020193507A1Wide scope for variationHigh film hardnessPolyurea/polyurethane coatingsPolyurethane dispersionPolymer science

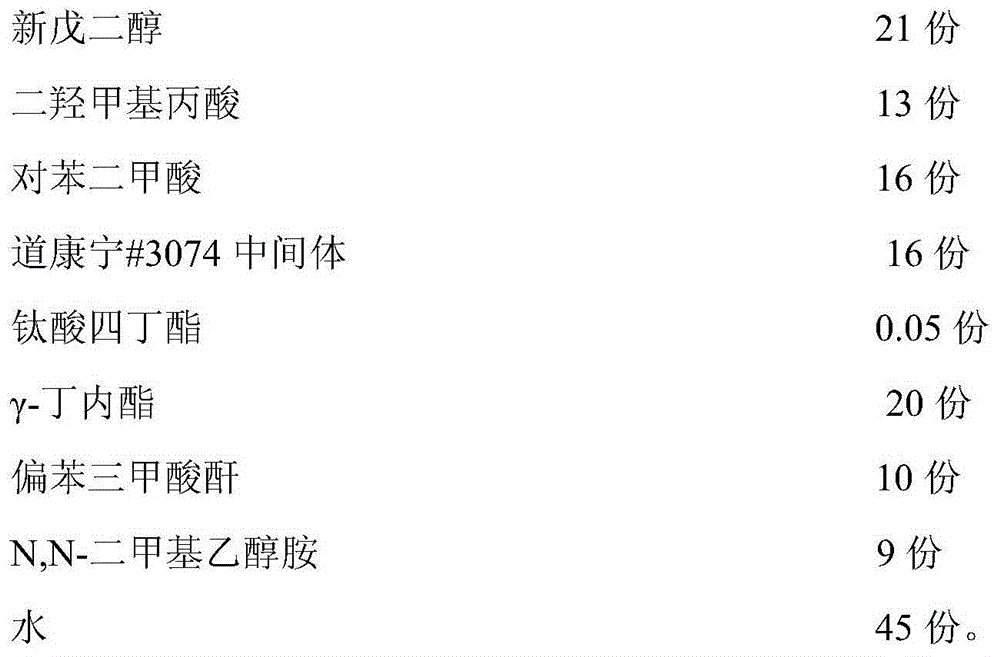

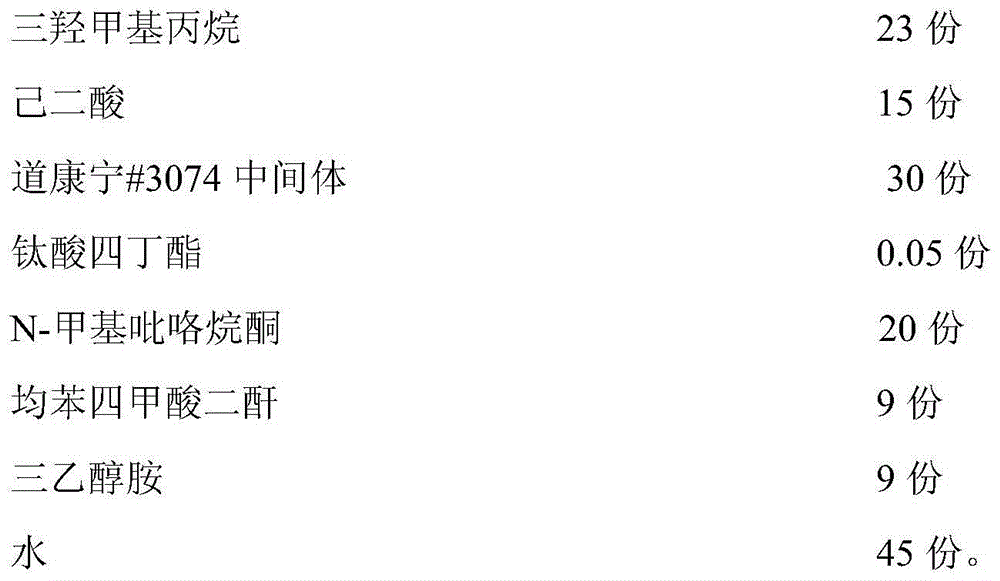

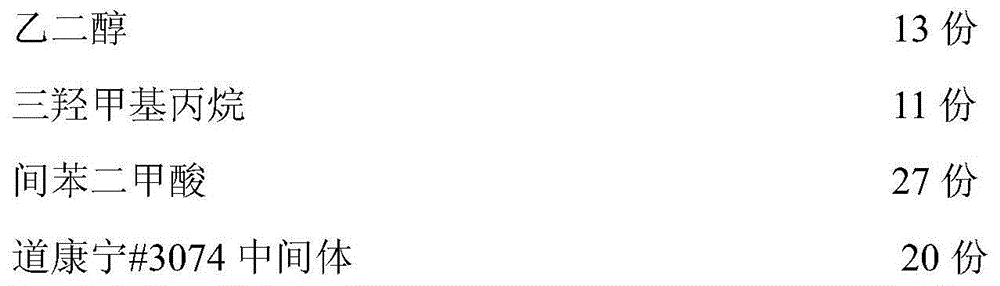

A description is given of a polyurethane (hybrid) dispersion with high film hardness, high flexibility and good emulsion stability which comprises the following reaction components: (A) from 3 to 25% by weight of a polyol component consisting of (i) from 2 to 20% by weight of a polymeric polyol having two or more polyisocyanate-reactive hydroxyl groups and a molar mass of from 500 to 4 000 daltons (ii) from 0.5 to 5% by weight of a low molecular mass polyol having two or more polyisocyanate-reactive hydroxyl groups and a molar mass of from 50 to 500 daltons (B) from 3 to 30% by weight of an anionically modifiable 1,2-polymethacrylatediol, (C) from 2 to 20% by weight of a polyisocyanate component, (D) from 0 to 6% by weight of a solvent component, (E) from 0.15 to 1.5% by weight of a neutralizing component composed of at least one organic or inorganic base, (F) from 0 to 1% by weight of a chain extender component composed of one or more polyamines having two or more polyisocyanate-reactive amino groups, and, optionally (G) from 5 to 40% by weight of a monomer component, (H) from 0.01 to 1.5% by weight of an initiator component, and water as the remainder.

Owner:TH GOLDSCHMIDT AG

Aqueous self-crosslinking copolymer dispersions, a process for preparing them and their use in binders for coating materials

InactiveUS6515042B2Solve the lack of lifeHigh film hardnessLiquid surface applicatorsPlastic/resin/waxes insulatorsDicarboxylic acidCompound c

Aqueous self-crosslinking copolymer dispersions ABC obtainable by free-radically initiated copolymerization in the first stage of a monomer mixture A comprising olefinically unsaturated monomers A1 having carbonyl groups, unsaturated carboxylic acids or monoesters of unsaturated dicarboxylic acids A2, monomers A3 selected from vinylaromatic compounds, n-butyl methacrylate and also alkyl esters of unsaturated carboxylic acids or dialkyl esters of unsaturated dicarboxylic acids, esters A4 selected from alkyl esters of unsaturated carboxylic acids of dialkyl esters of unsaturated dicarboxylic acids, and other free-radically polymerizable monomers A5, and subsequent addition of a second monomer mixture B and further polymerization in the second stage, the mixture B comprising olefinically unsaturated monomers B1 corresponding to A1, esters B2 corresponding to A4, and monomers B3 corresponding to A5, and subsequently adding compounds C having hydrazine or hydrazide groups.

Owner:ALLNEX AUSTRIA GMBH

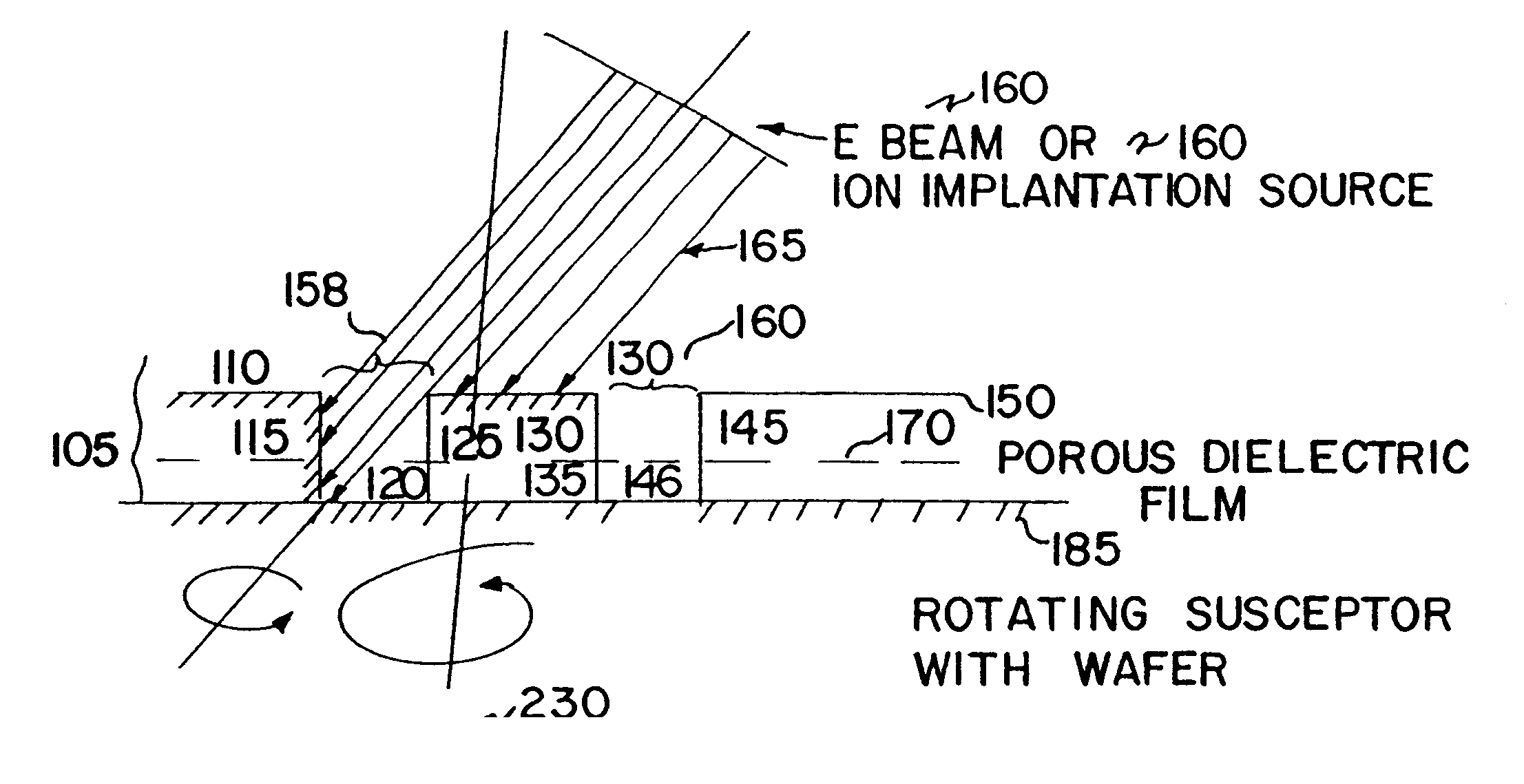

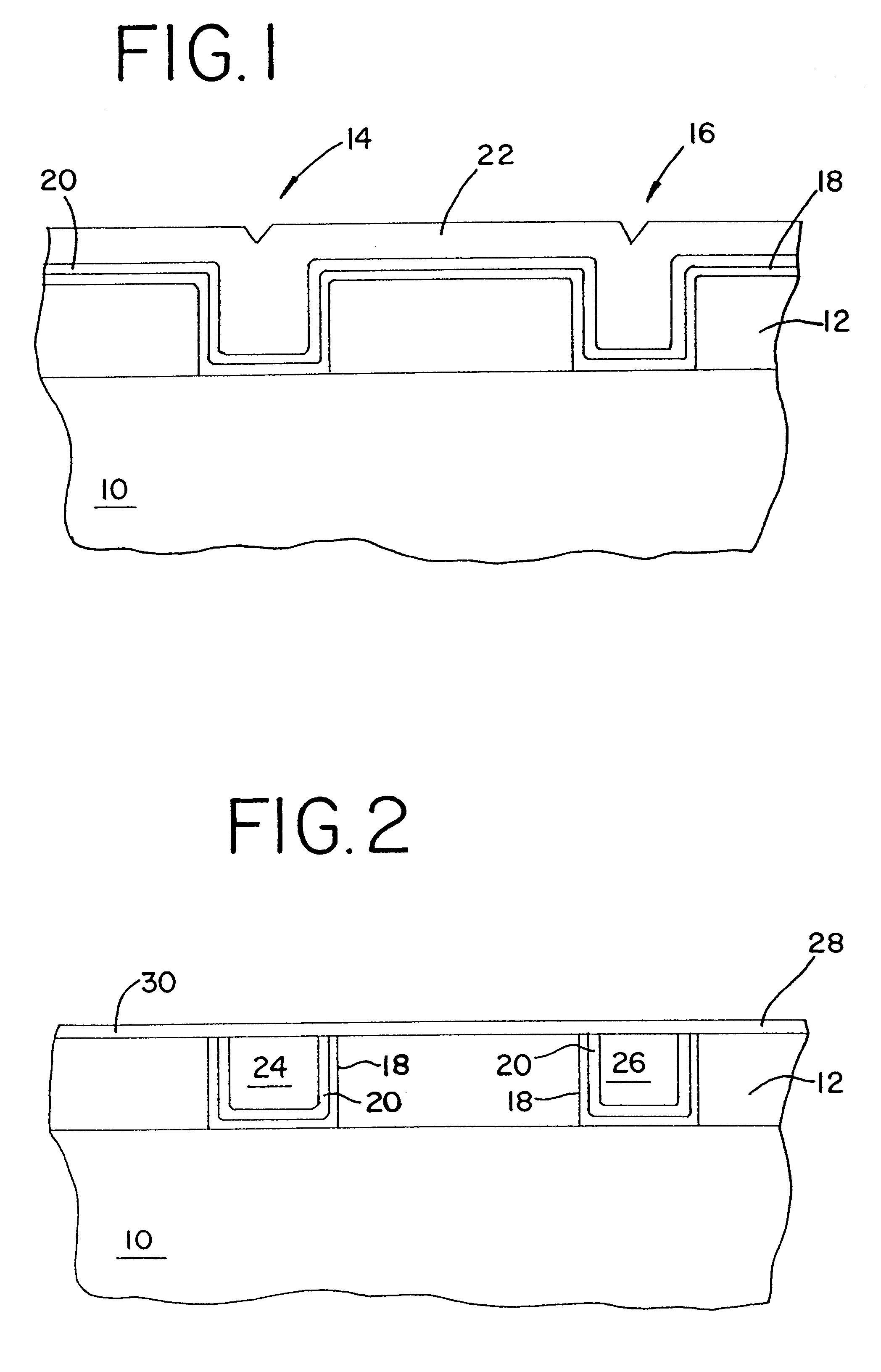

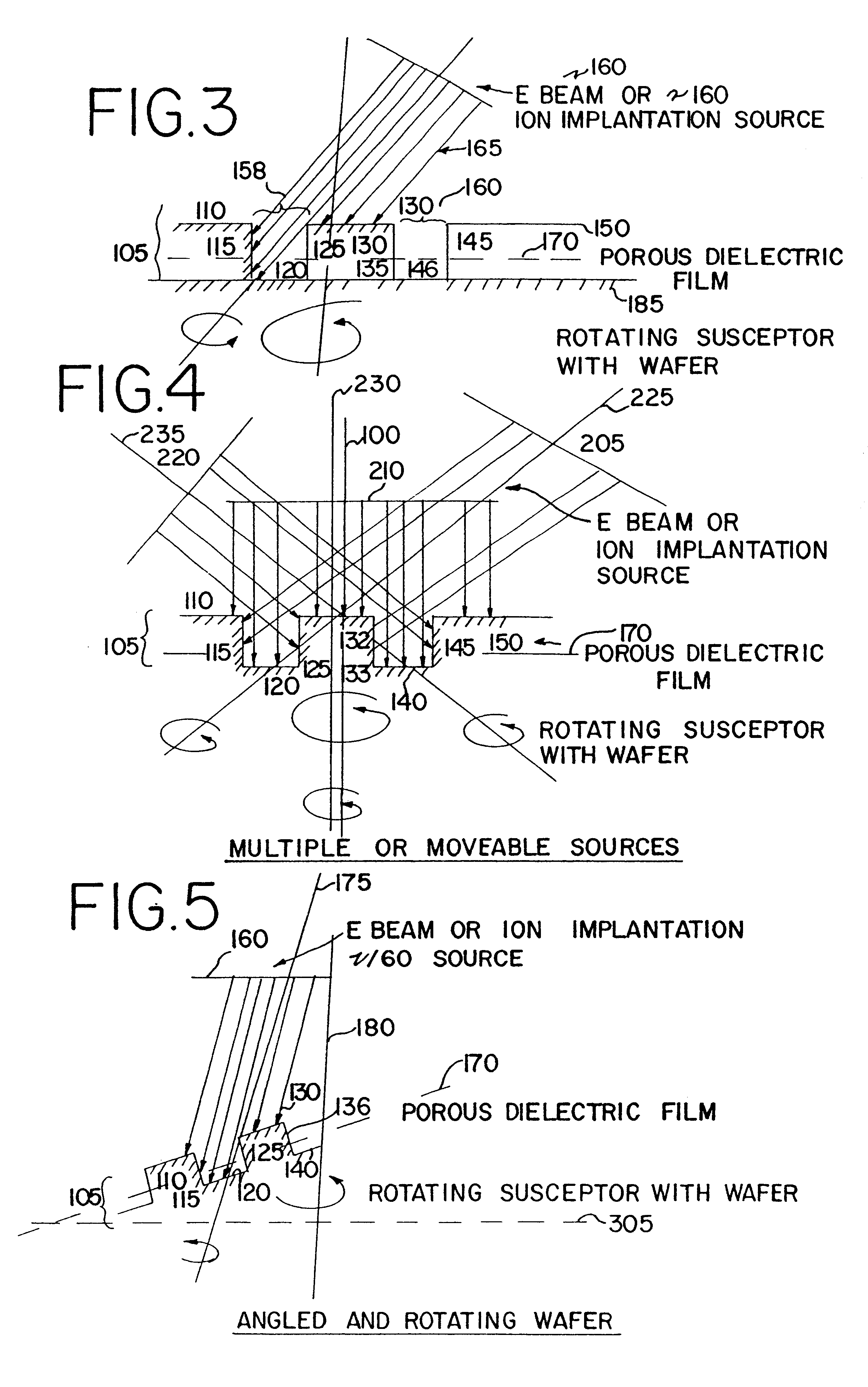

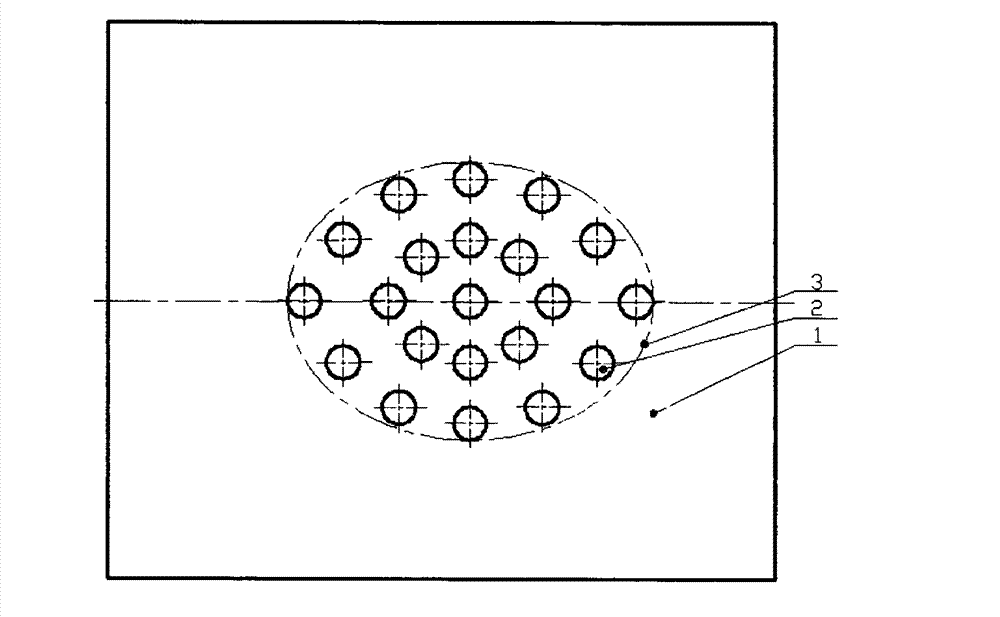

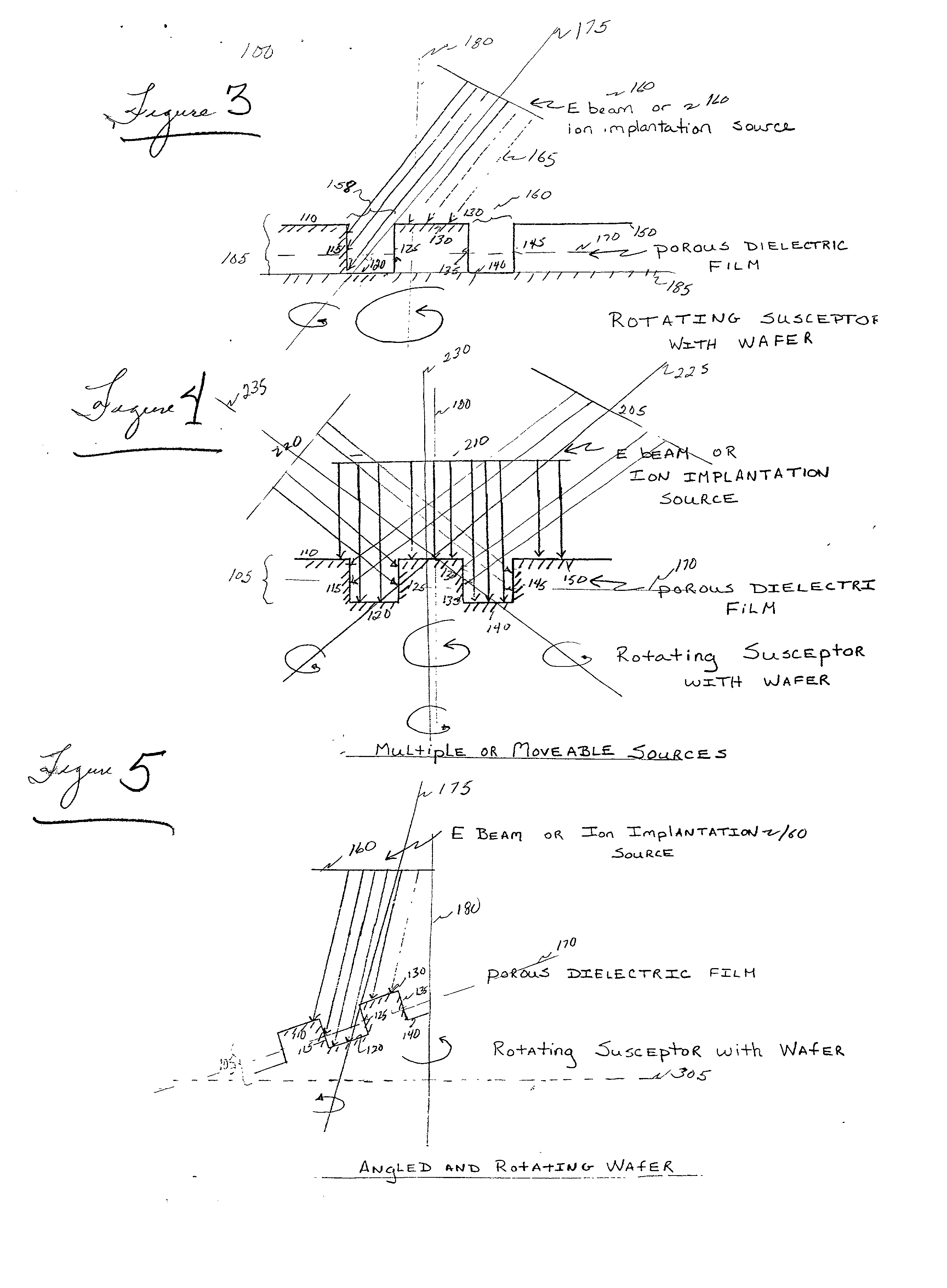

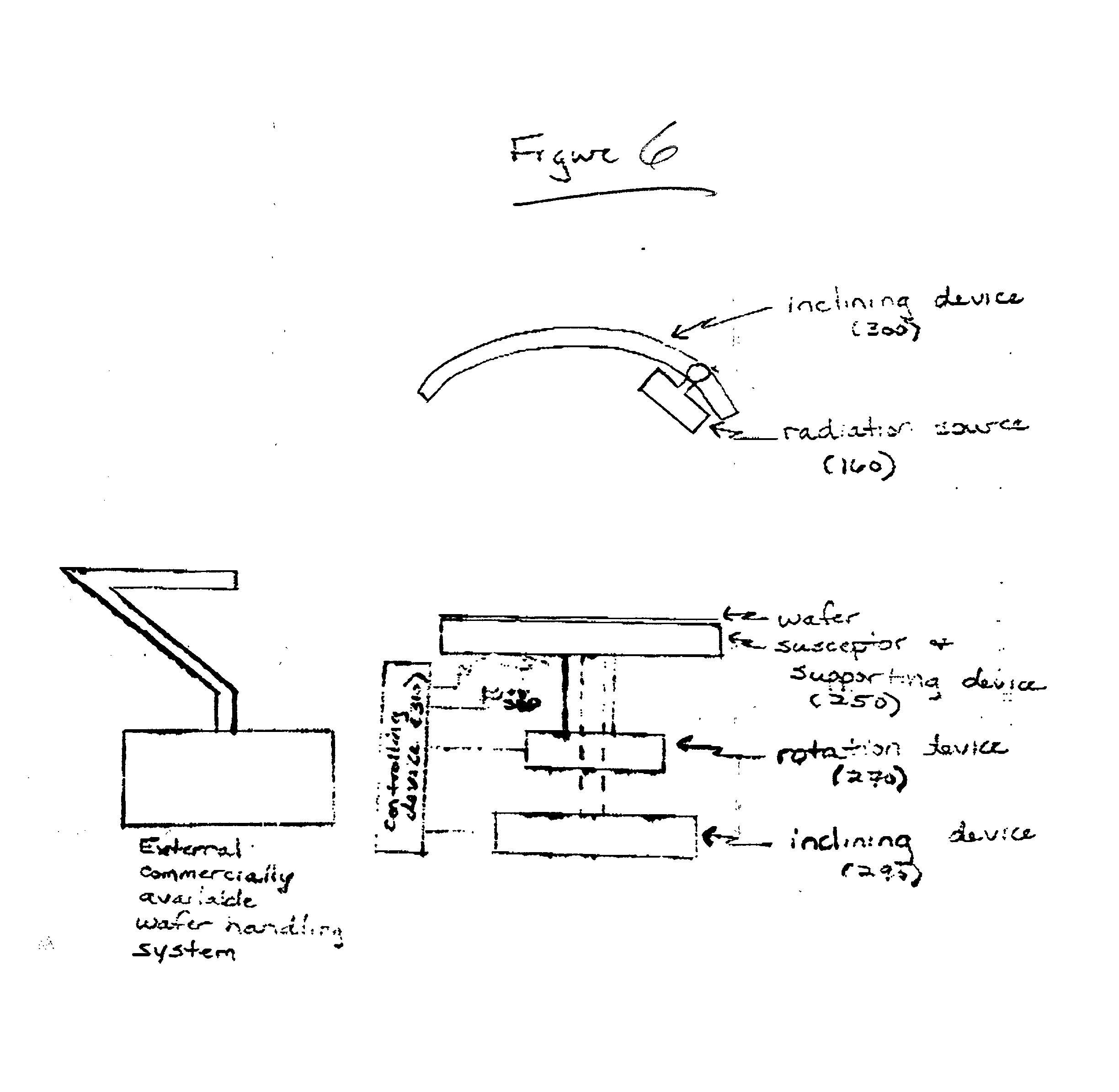

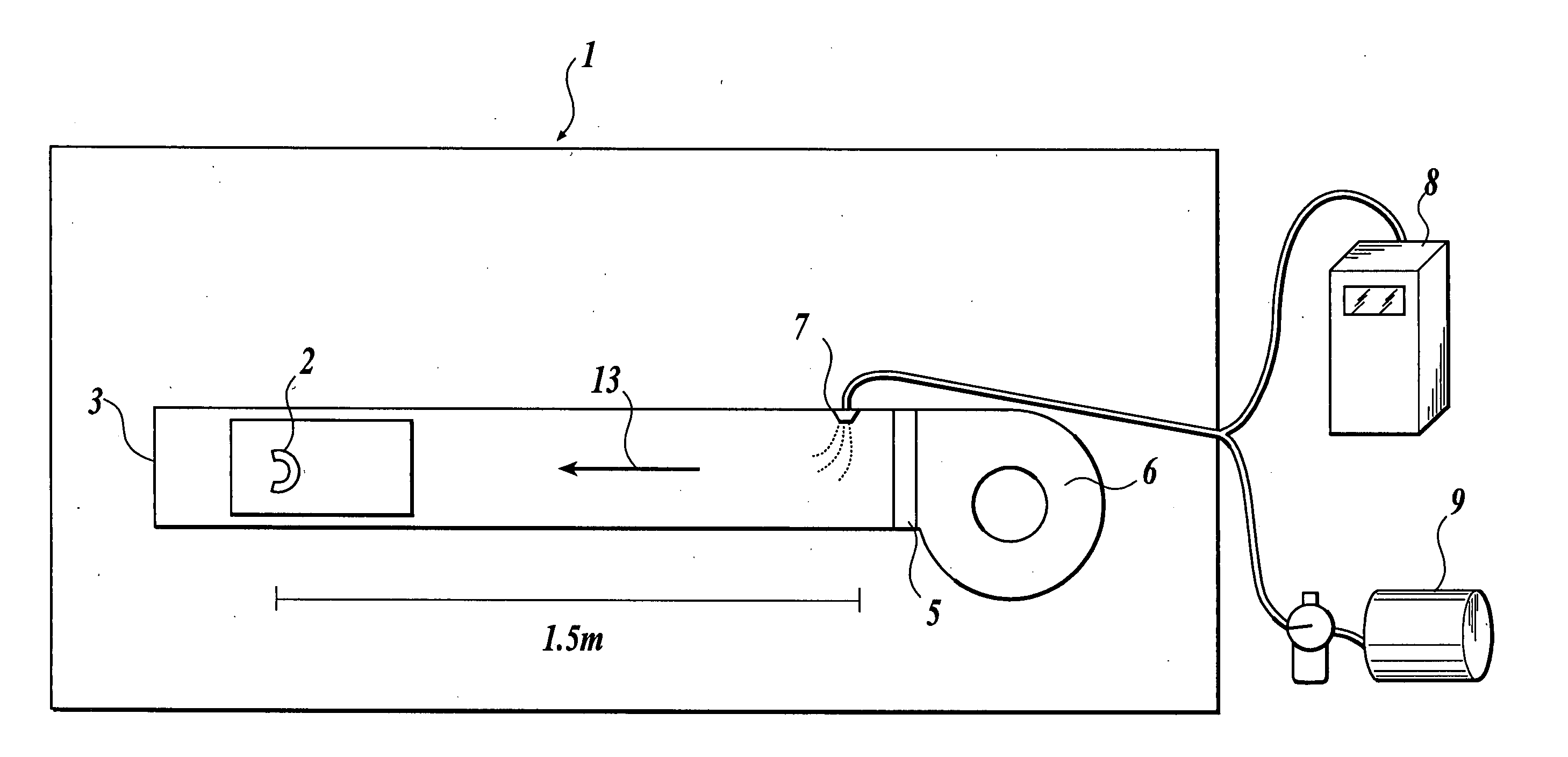

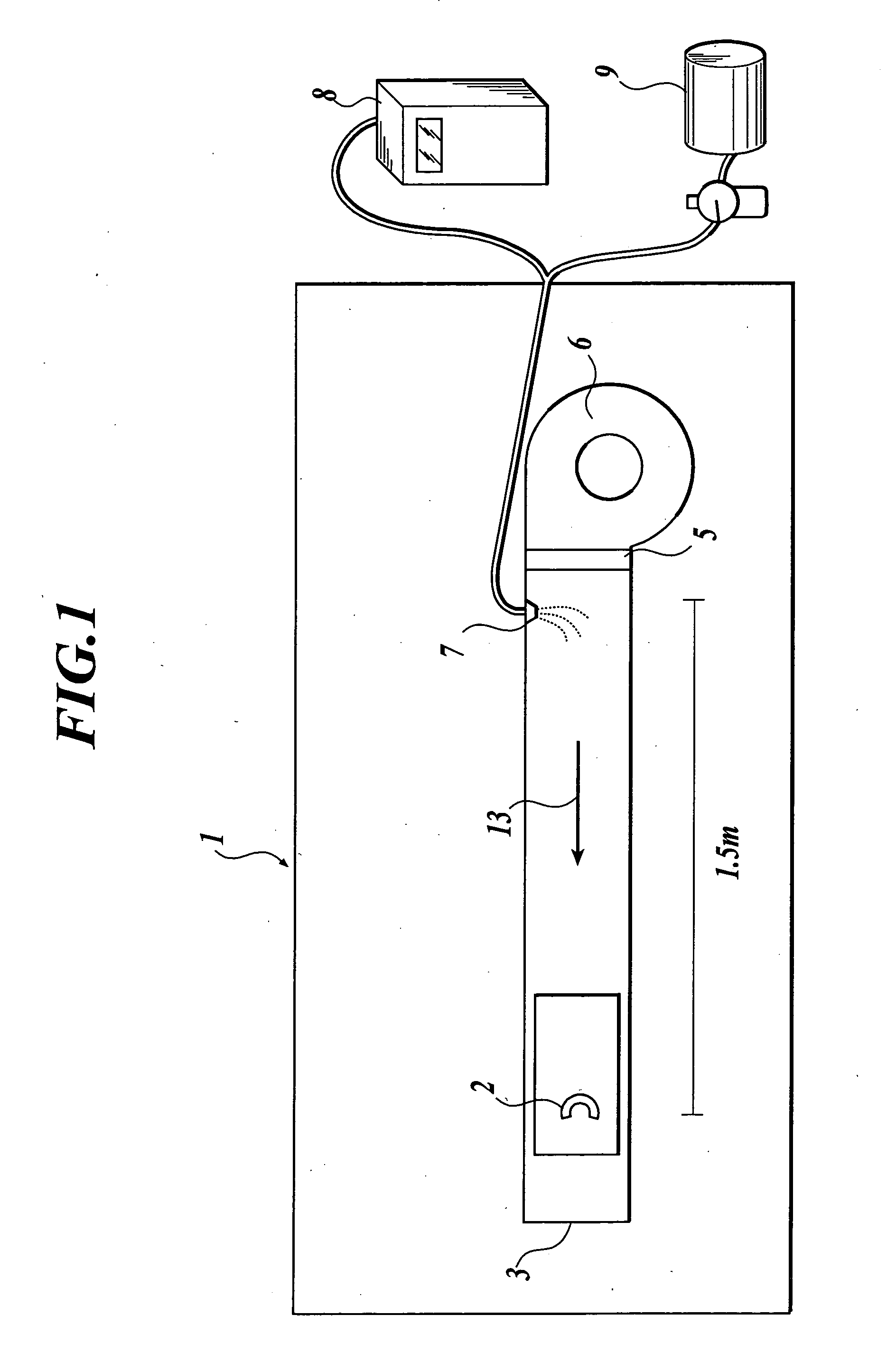

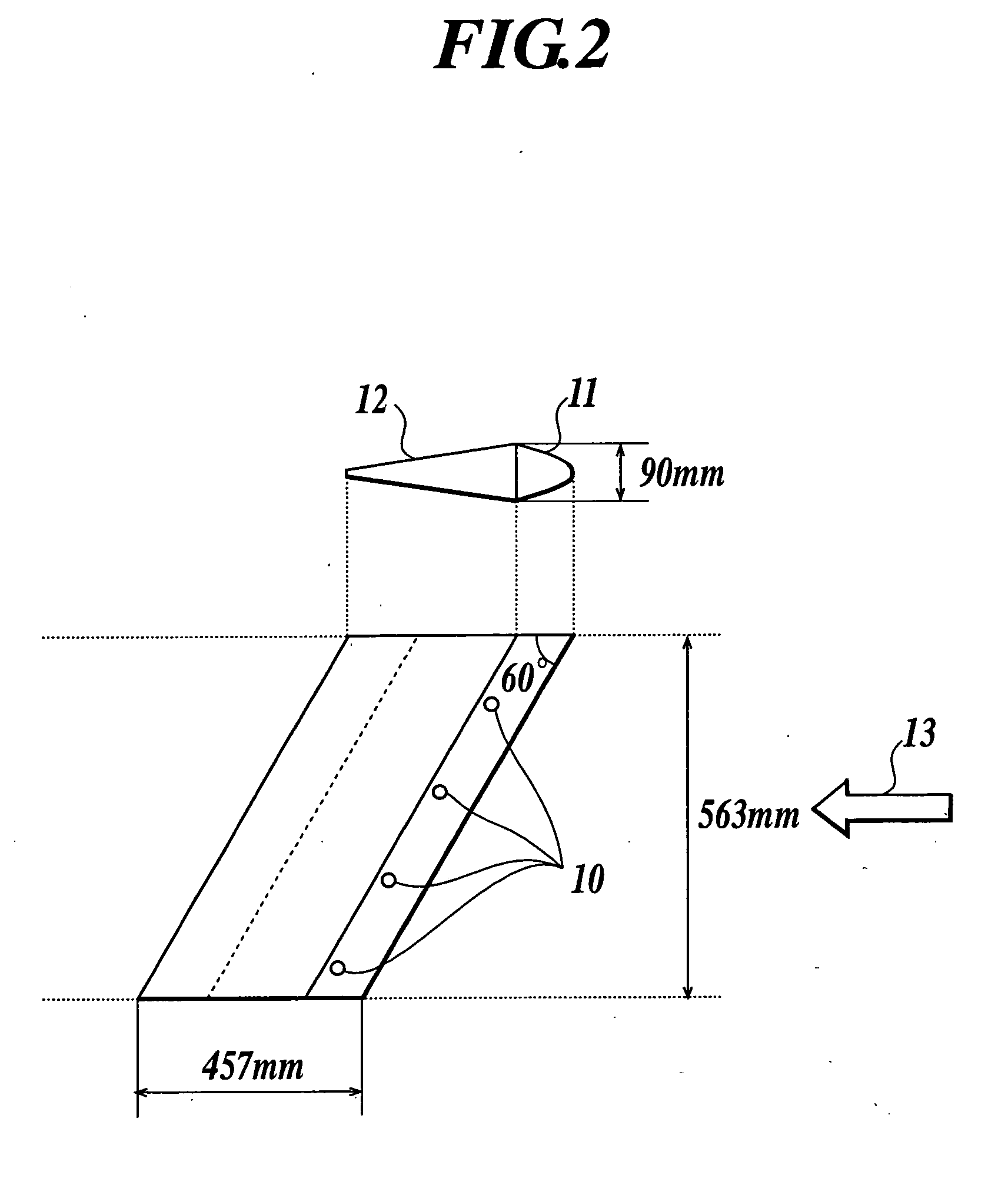

Method and system for modifying and densifying a porous film

InactiveUS6361837B2Reduce porosityHigh film hardnessElectric discharge heatingRadiation applicationsBeam sourceSemiconductor

The invention provides a system and a method for densifying a surface of a porous film. By reducing the porosity of a film, the method yields a densified film that is more impenetrable to subsequent liquid processes. The method comprises the steps of providing a film having an exposed surface. The film can be supported by a semiconductor substrate. When the film is moved to a processing position, a focused source of radiation is created by a beam source. The exposed surface of the film is then irradiated by the beam source at the processing position until a predetermined dielectric constant is achieved. The film or beam source may be rotated, inclined, and / or moved between a variety of positions to ensure that the exposed surface of the film is irradiated evenly.

Owner:ADVANCED MICRO DEVICES INC

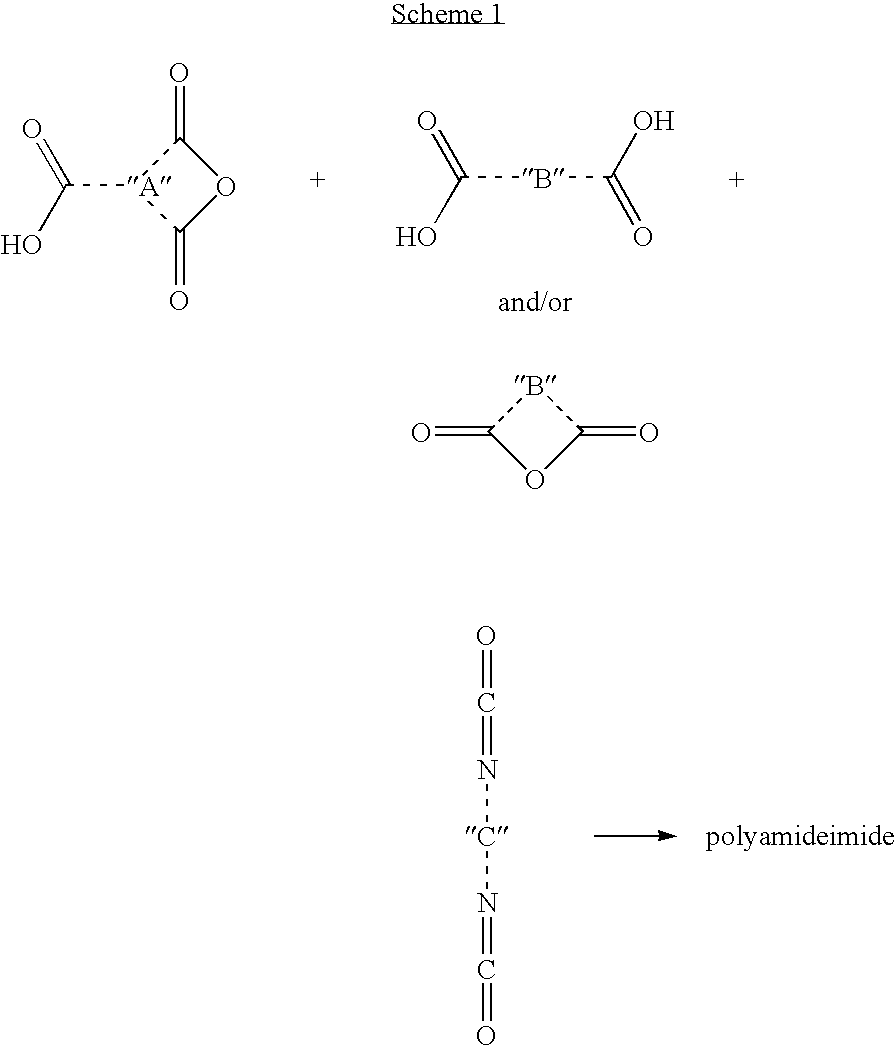

Polyamideimide compositions having multifunctional core structures

InactiveUS20050282010A1Improve toughnessIncrease stiffnessPlastic/resin/waxes insulatorsSynthetic resin layered productsPolyamide-imideMaterials science

Owner:GENERAL CABLE TECH CORP

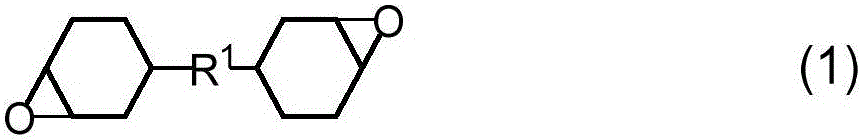

Liquid crystal aligning agent for forming liquid crystal alignment film, liquid crystal alignment film and liquid crystal display device using the same

ActiveCN105969405AGood orientationHigh hardnessLiquid crystal compositionsNon-linear opticsForeign matterCarbon number

The invention relates to a liquid crystal aligning agent, a liquid crystal alignment film, and a liquid crystal display element; the liquid crystal aligning agent comprises at least one of the following compound represented by the formula (1); the liquid crystal aligning agent can form the liquid crystal alignment film with high hardness and excellent liquid alignment performance, and the film is hard to scratch; the liquid crystal display element using the liquid crystal aligning film cannot have bad bright spot caused by foreign matters, and display feature is excellent; in the formula 1, R1 represents a single bond, carbon number 1-8 linear chain alkylene, carbon number 2-8 branch chain alkylene, or carbon number 3-8 divalent organic group with an alicyclic structure.

Owner:JNC CORP +1

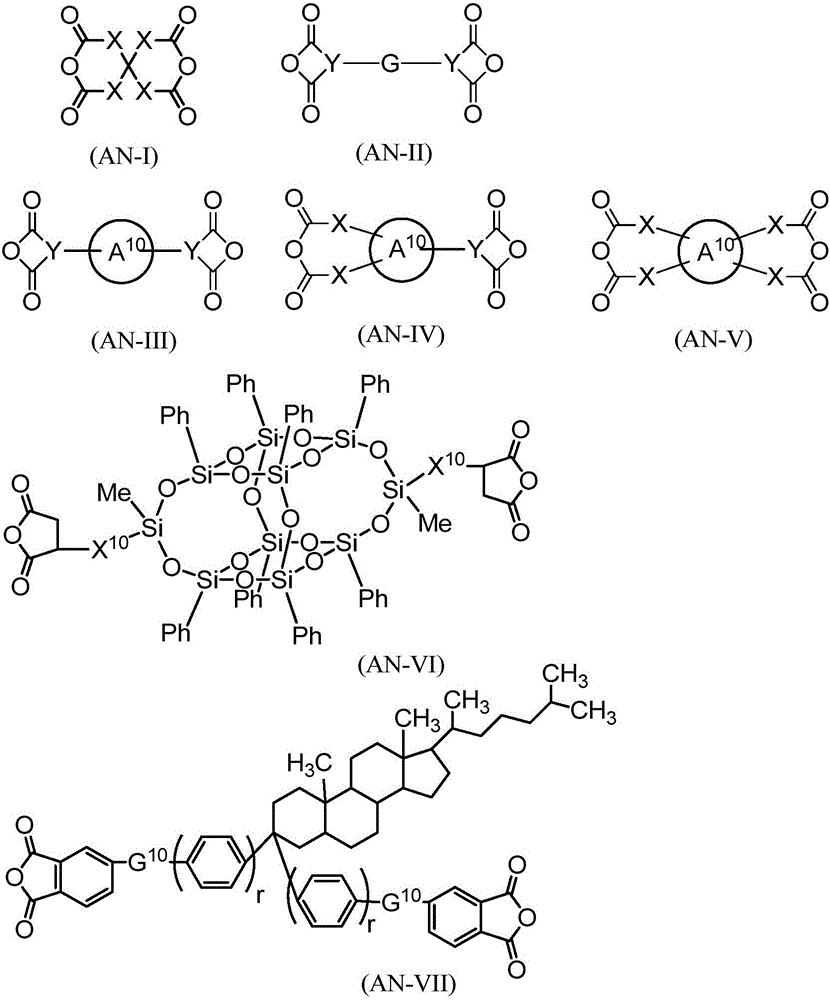

Process for Producing Silica-Based Fine Particle Dispersion Sols, Silica-Based Fine Particle Dispersion Sol, Coating Composition Containing the Dispersion Sol, Curable Coating Film, and Substrate Having the Curable Coating Film

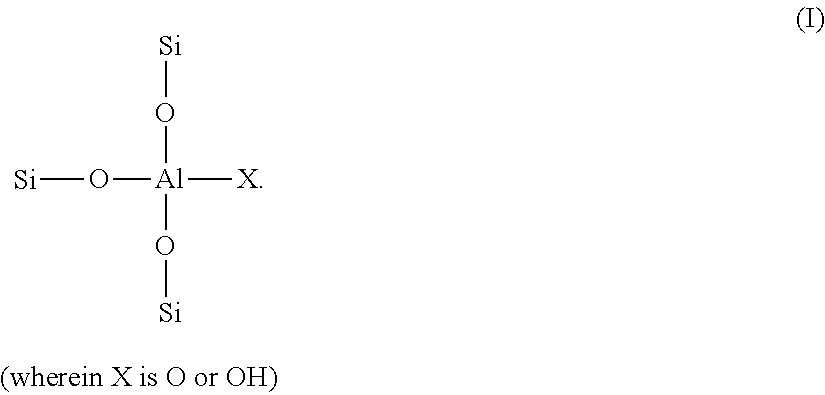

ActiveUS20120103231A1Good dispersionHigh transparencyPigmenting treatmentMaterial nanotechnologyAluminateIon exchange

Provided are silica-based fine particle dispersion sols, processes for producing the sols, coating compositions containing the dispersion sol, curable coating films obtained from the coating composition, and substrates having the coating film. A process includes (1) mixing an aqueous aluminate solution to an alkaline silica sol which contains water-dispersible silica fine particles in a given ratio; (2) heating the mixture liquid obtained in the step (1) to 60 to 200° C. and stirring the mixture liquid at the temperature for 0.5 to 20 hours; and (3) contacting the mixture liquid obtained in the step (2) with a cation exchange resin to remove by ion exchange alkali metal ions contained in the mixture liquid and thereby controlling the pH of the mixture liquid to be in the range of 3.0 to 6.0.

Owner:JGC CATALYSTS & CHEM LTD

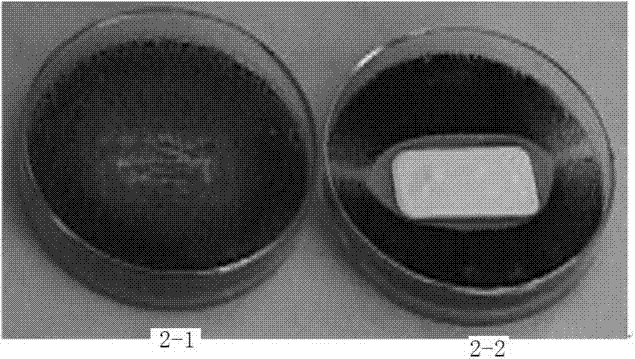

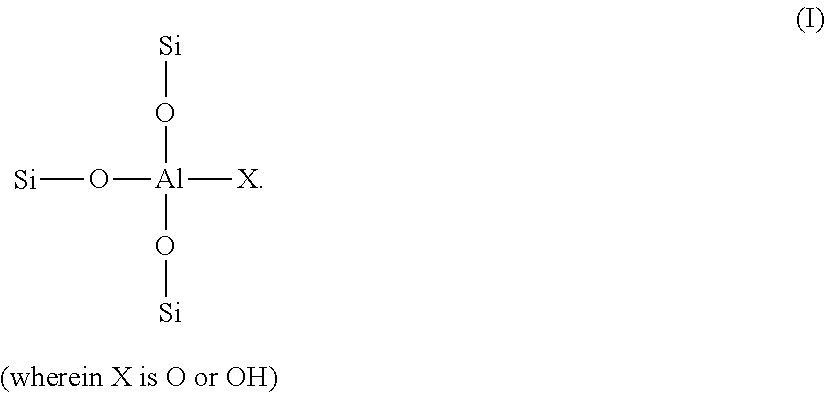

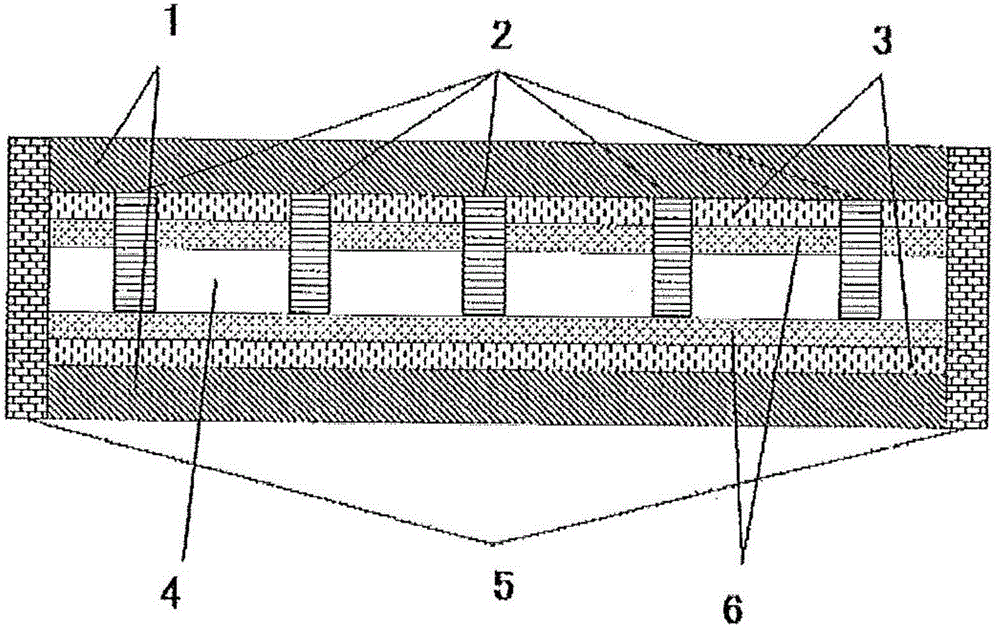

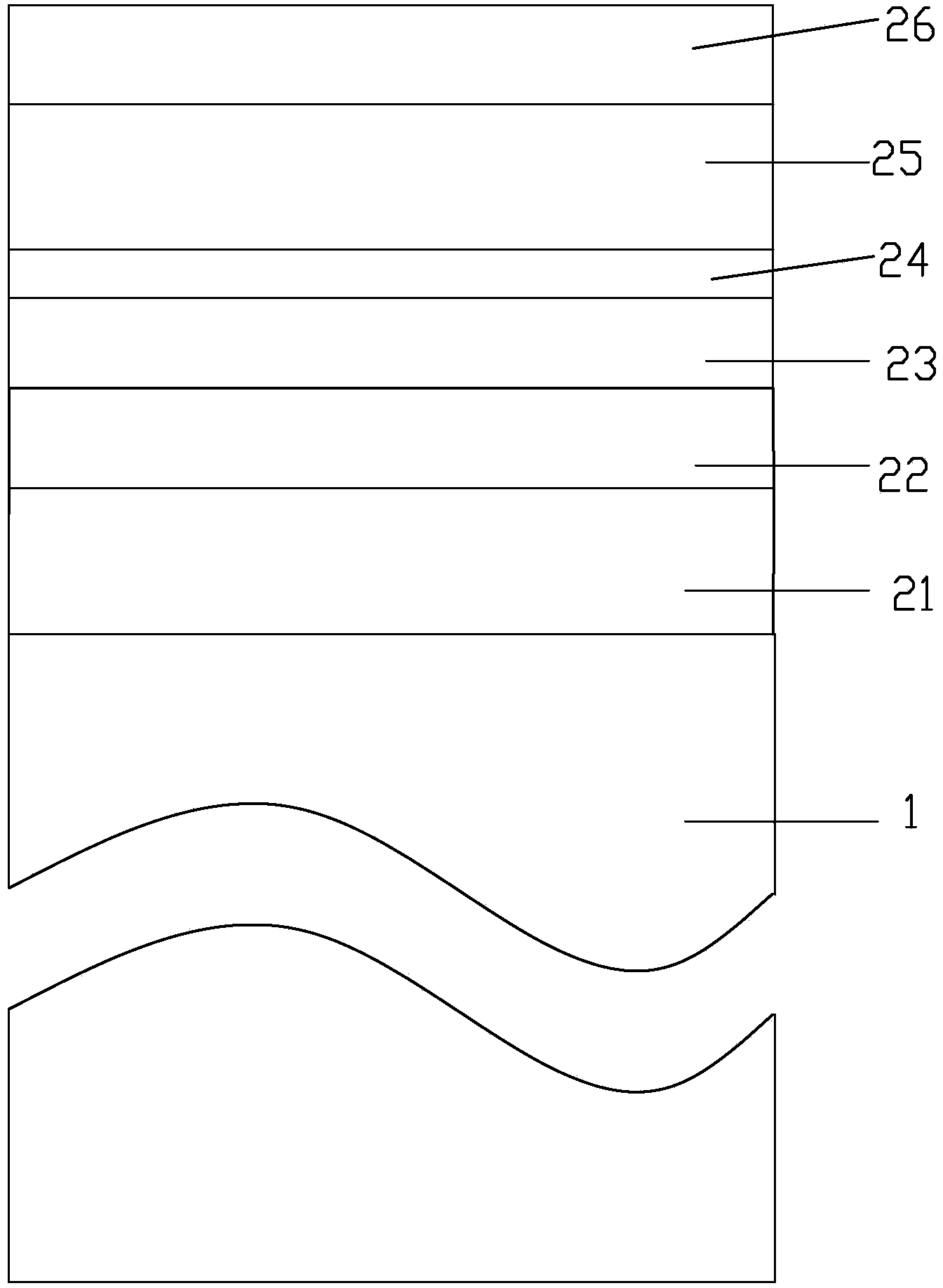

Preparation method of multi-metal doping hydrogen-free diamond carbon film

InactiveCN102965619AHigh film hardnessImprove the binding force of membrane baseVacuum evaporation coatingSputtering coatingSputteringHydrogen

The invention discloses a preparation technology of a multi-metal doping hydrogen-free diamond carbon film. The preparation technology is characterized in that by using an ion beam auxiliary deposition technology, a multi-metal mosaic target (formed by mosaicking a mosaic block 2 in a sputtering region 3 on a base target material 1) and a graphite target are used for double-target sputtering, and the multi-metal doping hydrogen-free diamond film is deposited and prepared on the surface of a workpiece. The preparation technology comprises the following specific steps: preparing the mosaic target, cleaning and activating ions on the surface of the workpiece, and depositing and preparing the multi-metal doping hydrogen-free diamond film. Compared with the prior art, the film prepared by the method has the advantages of higher hardness, film-based bonding force, elasticity modulus, abrasion resistance and hot stability property; and doping components can be adjusted so that the film can meet the requirement of transmission parts of precise instruments for accuracy and increases the reliability of the transmission parts. The film is suitable for surface treatment of silicon and various metal workpieces.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Method and system for modifying and densifying a porous film

InactiveUS20010038889A1Reduce porosityHigh film hardnessElectric discharge heatingRadiation applicationsBeam sourceSheet film

The invention provides a system and a method for densifying a surface of a porous film. By reducing the porosity of a film, the method yields a densified film that is more impenetrable to subsequent liquid processes. The method comprises the steps of providing a film having an exposed surface. The film can be supported by a semiconductor substrate. When the film is moved to a processing position, a focused source of radiation is created by a beam source. The exposed surface of the film is then irradiated by the beam source at the processing position until a predetermined dielectric constant is achieved. The film or beam source may be rotated, inclined, and / or moved between a variety of positions to ensure that the exposed surface of the film is irradiated evenly.

Owner:ADVANCED MICRO DEVICES INC

LED (light-emitting diode) curing waterborne UV (ultraviolet) furniture home decoration paint and preparation method thereof

InactiveCN106905838AHigh film hardnessImprove fullnessAntifouling/underwater paintsPaints with biocidesUv protectionUltraviolet

The invention discloses an LED-curable water-based UV furniture home decoration paint, which comprises: a coating I which is attached to the surface of furniture and home decoration and cured by an LED-cured water-based UV adhesion primer; adhering to the surface of the coating I and colored by an LED-cured water-based UV Coating II cured by UV-curing agent; Coating III attached to the surface of Coating II and cured by LED curing water-based UV protective topcoat. The paint film has high hardness, good fullness, excellent adhesion, strong wear resistance and stain resistance, bright color, yellowing resistance, good decorative effect and protective function, and it is convenient and fast to cure during preparation. High production efficiency, low energy consumption, green and pollution-free.

Owner:ZHUHAI DONGCHENG UV MATERIALS

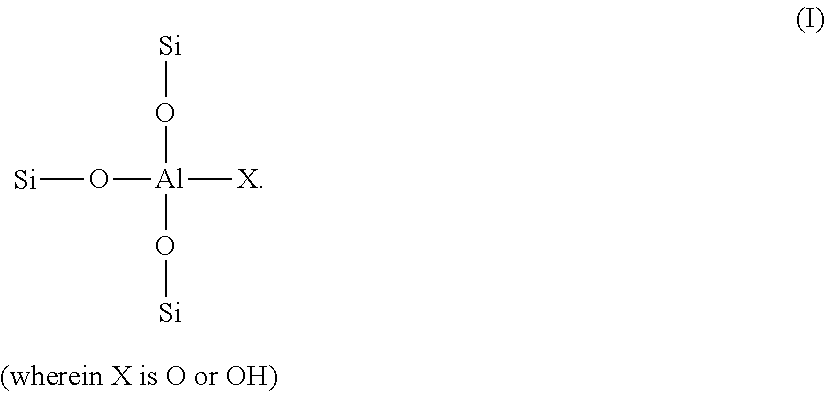

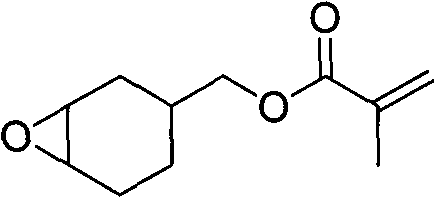

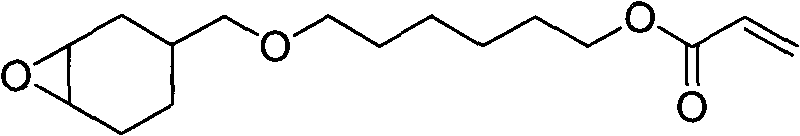

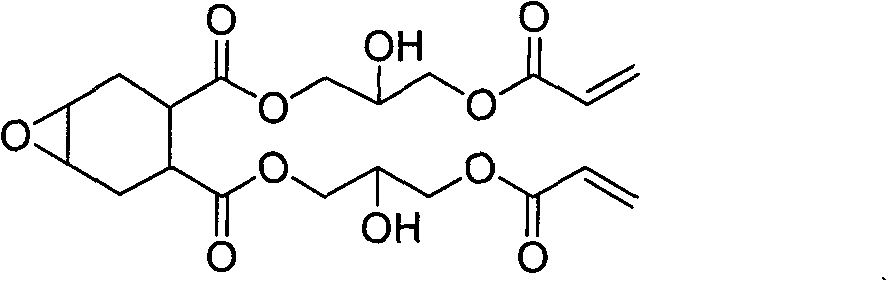

UV-curing water-based alicyclic epoxy acrylate emulsion

The invention relates to a UV-curing water-based alicyclic epoxy acrylate emulsion. The preparation method of the UV-curing water-based alicyclic epoxy acrylate emulsion comprises the following steps: preheating an emulsifier and a regulator to 50 DEG C, adding epoxy resin, a cross-linking monomer, a polymerization degree regulator and an acrylic acid monomer, and keeping the temperature for 0.5 hours while refluxing; heating part of the solution and an initiator to 80 DEG C; when emitting blue light, adding the rest of the solution and supplementing the initiator within 2.5 hours, keeping the temperature for 1 hour while refluxing, heating to 88 DEG C, and aging for 1 hour; regulating the temperature of the emulsion to 85 DEG C, adding glycidyl methacrylate, and heating to 90 DEG C to react for 2.5 hours; and after the reaction finishes, cooling to room temperature, and adding a free-radical initiator. The UV-curing water-based alicyclic epoxy acrylate emulsion has the advantages of high film hardness and high water resistance, overcomes the defects of poor weather resistance, poor damp heat resistance and the like in the existing bisphenol A epoxy resin, avoids the environmental pollution of the traditional solvent type paint, can be used for preparing outdoor paints, photocuring inks, technical paints and the like, and is a material having wide market prospects.

Owner:SHANGHAI ZHONGXIN YUXIANG CHEM

Novel aqueous light-cured alicyclic epoxy acrylic acid emulsion and preparation method thereof

InactiveCN102659976AGood chemical arc resistanceGood UV aging resistanceCoatingsCross-linkSolubility

The invention relates to a novel aqueous light-cured alicyclic epoxy acrylic acid emulsion and a preparation method thereof. The method comprises the following steps: adding an emulsifier and a regulator in a reactor, preheating to 50 DEG C, then adding epoxy resin, cross-linking monomers, polymerization degree regulator and acrylic acid monomers, preserving the heat of reflux for 0.5h; heating partial solution and an initiator to 80 DEG C, when glowing blue, adding dropwisely the rest solution in 2.5 h, and refilling the initiator, preserving the heat of reflux for 1h, cooling to room temperature after the reaction, and then adding a photoinitiator. The invention provides a light-cured alicyclic epoxy acrylic acid emulsion with stability and good water-solubility, overcomes the defects of bad weatherability and bad resistance to heat and humidity of existing bisphenol-A epoxy resin, and simultaneously prevents the environment from being polluted by traditional solvent-based coating. The emulsion can be used for preparing outdoor coatings, light-cured printing ink, craft paints and the like, has the advantages of excellent performance, simple technology, and low cost, and is an environment friendly material with a wide market prospect.

Owner:SHANGHAI ZHONGXIN YUXIANG CHEM

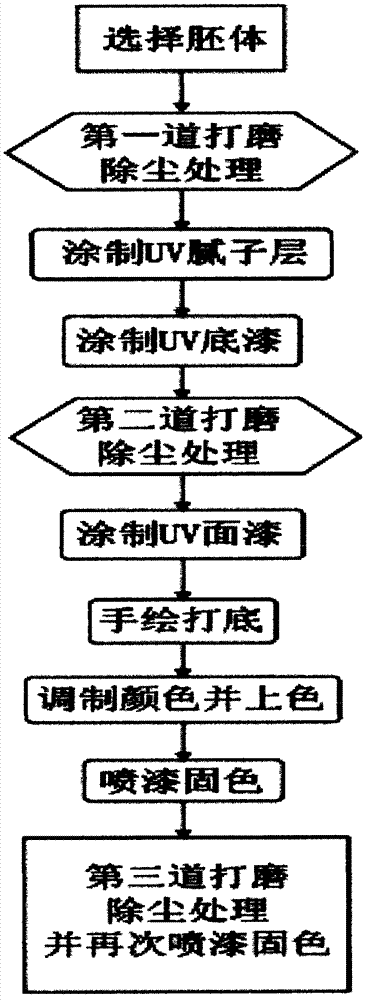

Method for manufacturing blue and white porcelain staircase

InactiveCN103085146AStrong paint adhesionHigh film hardnessPretreated surfacesWood working apparatusHandrailFiber layer

A method for manufacturing a blue and white porcelain staircase comprises the following steps: step a, selecting the blue and white porcelain process to manufacture a blank body, and performing first grinding and dust removal treatment on the blank body; manufacturing a tread plate, a vertical plate, a stand column, a handrail, a crossbeam and a samson post, wherein at least the vertical plate and the stand column are selected to manufacture the blank body through the blue and white porcelain process; and performing mechanical or manual sanding and dust removal on the blank body. The method for manufacturing the blue and white porcelain staircase has the advantages that a paint film gradually enters into wood fibers layer by layer and is performed with high-temperature ultraviolet light polymerization, the paint surface is strong in adhesive force, the paint film is high in hardness and has strong abrasion resistance and scraping resistance, a layer of porcelain glaze paint surface which is solid in texture and clear in color is formed on the paint surface, the paint film is full and smooth and enough in light sensation, presents blue and white porcelain like natural innervation and texture, and the blue and white porcelain staircase is strong in porcelain texture, obvious in three-dimensional color, rich in layering, capable of resisting ultraviolet radiation and not apt to fade.

Owner:上海捷步实业有限公司

Nanometer solvent-free epoxy antirust paint and preparation method thereof

ActiveCN103709901AGood wear resistanceEasy to maintainAnti-corrosive paintsEpoxy resin coatingsSolventCardanol

The invention discloses nanometer solvent-free epoxy antirust paint and a preparation method thereof. The nanometer solvent-free epoxy antirust paint comprises the following raw material components in parts by weight: component A: 20-40 parts of E-44 epoxy resin, 5-15 parts of active diluent, 10-20 parts of zinc phosphate, 5-20 parts of mica powder, 10-20 parts of nanometer alumina, 10-20 parts of ferric oxide powder and 5-10 parts of aluminum triphosphate; component B: alicyclic amine or anacardol serving as a curing agent. The weight ratio of the component A to the component B is (6-8): 1. The nanometer solvent-free epoxy antirust paint disclosed by the invention is good in antirust property, environment-friendly, free of VOC emission, not harsh in construction conditions and low in requirements on base material, and the paint can be thickly coated once; the nanometer solvent-free epoxy antirust paint can be widely applied to a variety of fields, for example, bridge, guardrail steel structure, building material, machinery, etc.

Owner:FOSHAN GAOMING FULITE CHEM CO LTD

Organic-silicon-modified aqueous polyester resin and preparation method of same

Owner:ZHEJIANG PFLUON TECH CO LTD

Aqueous self-crosslinking copolymer dispersions, a process for preparing them and their use in binders for coating materials

InactiveUS20020147262A1Solve the lack of lifeHigh film hardnessLiquid surface applicatorsPlastic/resin/waxes insulatorsDicarboxylic acidCompound c

Aqueous self-crosslinking copolymer dispersions ABC obtainable by free-radically initiated copolymerization in the first stage of a monomer mixture A comprising olefinically unsaturated monomers A1 having carbonyl groups, unsaturated carboxylic acids or monoesters of unsaturated dicarboxylic acids A2, monomers A3 selected from vinylaromatic compounds, n-butyl methacrylate and also alkyl esters of unsaturated carboxylic acids or dialkyl esters of unsaturated dicarboxylic acids, esters A4 selected from alkyl esters of unsaturated carboxylic acids of dialkyl esters of unsaturated dicarboxylic acids, and other free-radically polymerizable monomers A5, and subsequent addition of a second monomer mixture B and further polymerization in the second stage, the mixture B comprising olefinically unsaturated monomers B1 corresponding to A1, esters B2 corresponding to A4, and monomers B3 corresponding to A5, and subsequently adding compounds C having hydrazine or hydrazide groups.

Owner:ALLNEX AUSTRIA GMBH

Mixed coating material and manufacturing method of the same

InactiveUS20050234147A1High in anti-icing effectHigh in deicing effectOther chemical processesCoatingsTetrafluoroethyleneOrganic solvent

A mixed coating material includes: a mixed resin comprising an ultraviolet curable resin and a low molecular weight tetrafluoroethylene resin; and a hydrofluorocarbon-containing organic solvent, wherein the mixed resin and the hydrofluorocarbon-containing organic solvent are mixed to allow the coating material to have film hardness of 1H or more.

Owner:SUBARU CORP

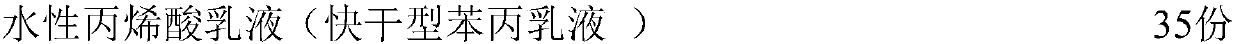

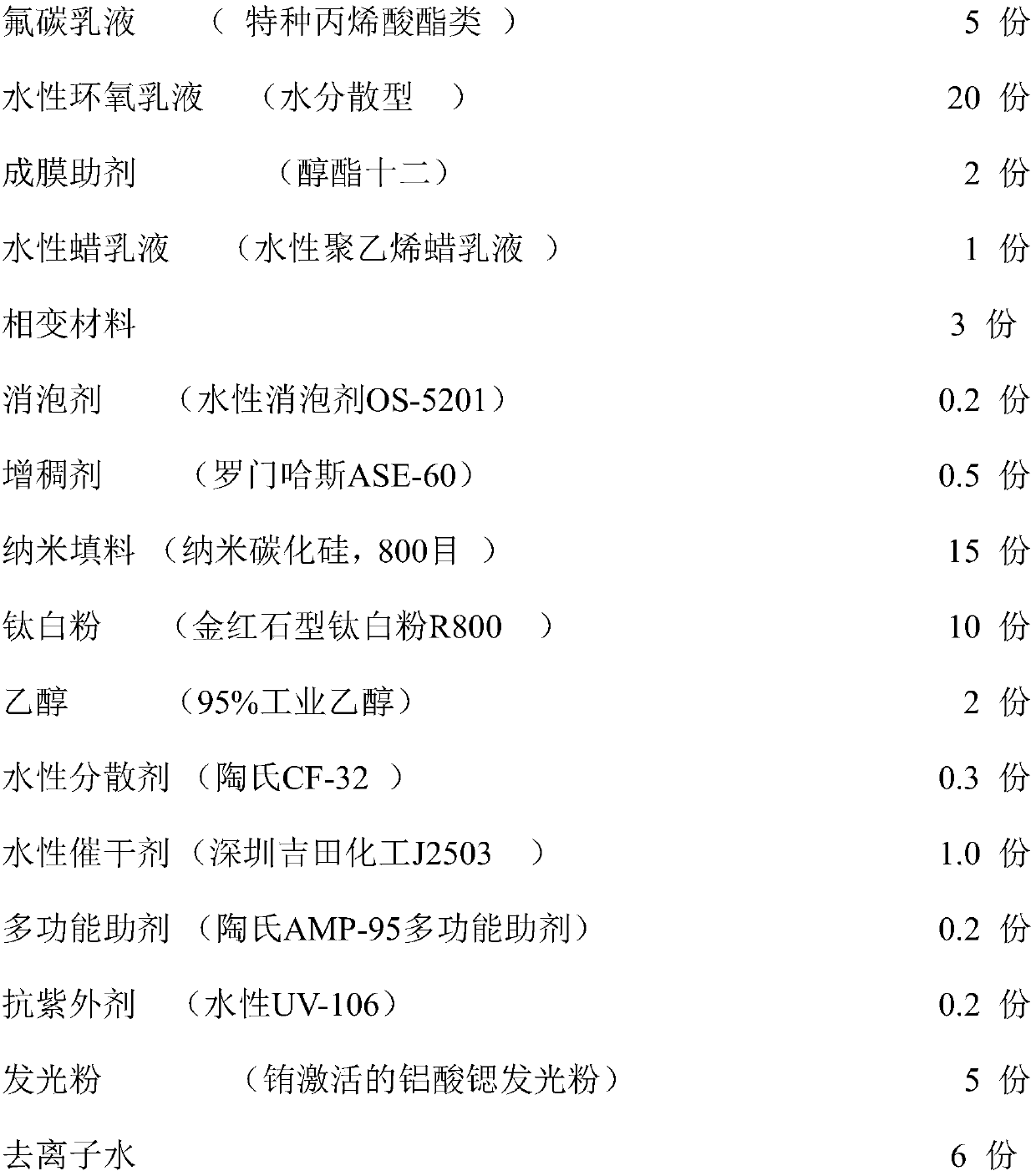

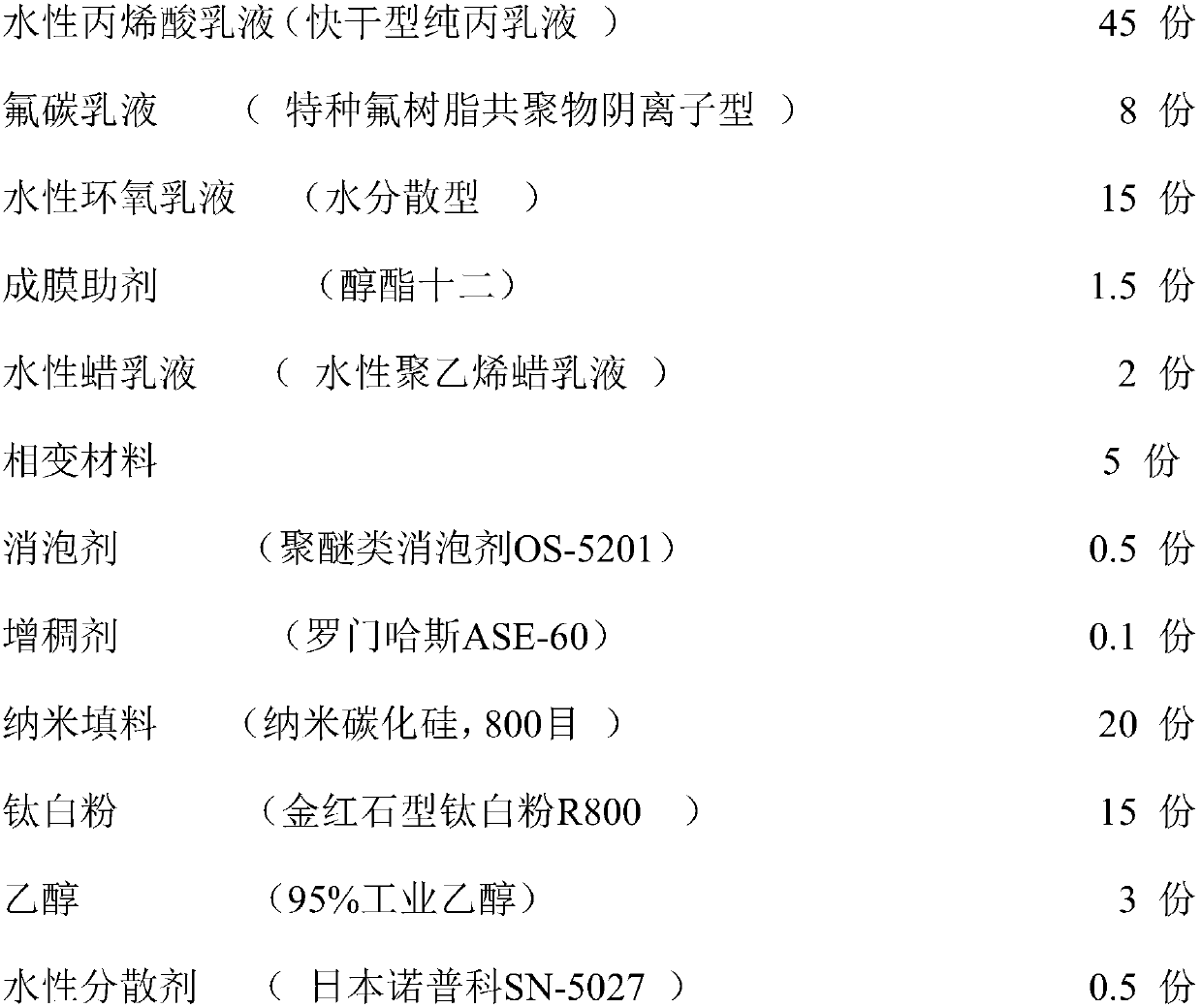

Water-based self-luminous marking coating and preparing method thereof

InactiveCN109651898AAlkali resistantGood weather resistanceAntifouling/underwater paintsLuminescent paintsEpoxyWater based

The invention relates to the technical field of chemical coatings, and particularly discloses a water-based self-luminous marking coating and a preparing method thereof. The water-based self-luminousmarking coating is prepared from 35-50 parts of water-based acrylic emulsion, 5-10 parts of fluorine-carbon emulsion, 10-20 parts of water-based epoxy emulsion, 1-3 parts of a film-forming auxiliary,1-3 parts of water-based wax emulsion, 3-7 parts of a phase-change material, 10-20 parts of a nanofiller, 10-20 parts of titanium dioxide, 1-3 parts of ethyl alcohol, 0.1-0.5 part of a water-based dispersing agent, 5-10 parts of luminescent powder and 4-6 parts of deionized water. By means of the water-based self-luminous marking coating, the quick dryness, weather resistance, abrasion resistance,fouling resistance, adhesion, crack resistance and other advantages of the water-based marking coating are improved, the marking identification degree at night is improved, and traffic driving safetyis ensured.

Owner:SUZHOU TOPOLINE TECH

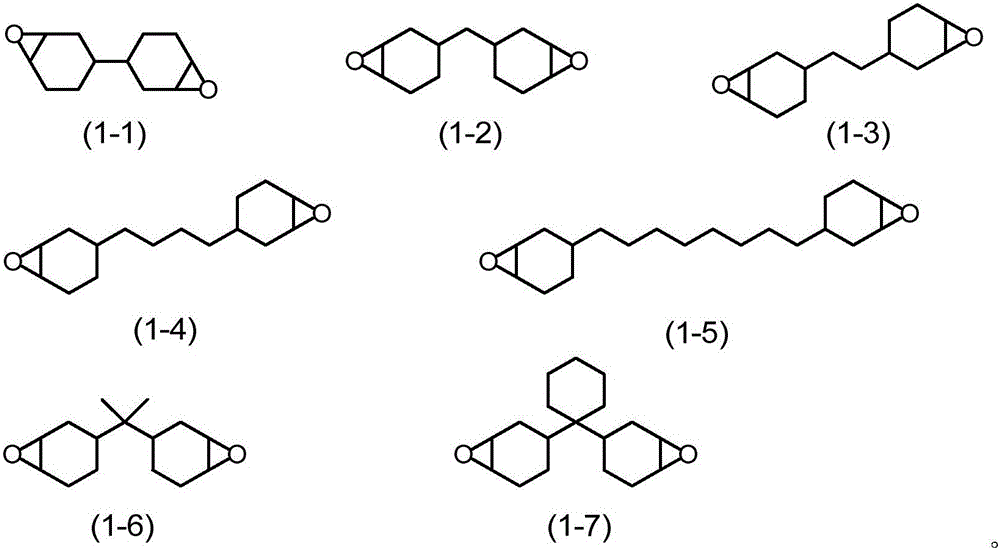

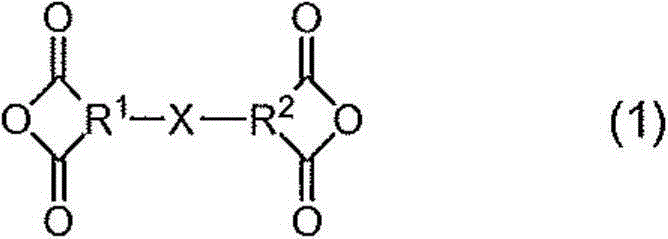

Tetracarboxylic dianhydride containing triazole, polymer, liquid crystal aligning agent, liquid crystal aligning membrane, and display element

ActiveCN105367560AHigh film hardnessGood liquid crystal orientationLiquid crystal compositionsOrganic chemistryCrystallographyEthyl group

The invention provides tetracarboxylic dianhydride containing triazole, a polymer, a liquid crystal aligning agent, a liquid crystal aligning membrane, and a display element. The tetracarboxylic dianhydride is represented by the formula (1); wherein in the formula (1), the X represents a divalent organic group containing at least one triazole ring, the R1 and R2 individually represent one of trivalent groups, which are represented in the description; and at least one hydrogen atom of these groups can be replaced by a methyl group, an ethyl group, or a phenyl group. The liquid crystal aligning agent can form a liquid crystal aligning membrane that is hard to peel off or eliminate.

Owner:长沙道安捷新材料有限公司

Article having a predetermined surface shape and method for preparation thereof

InactiveUS6849350B2High film hardnessImprove heat resistanceConductive materialOrganic conductorsHeat resistanceRefractive index

Owner:NIPPON SHEET GLASS CO LTD +1

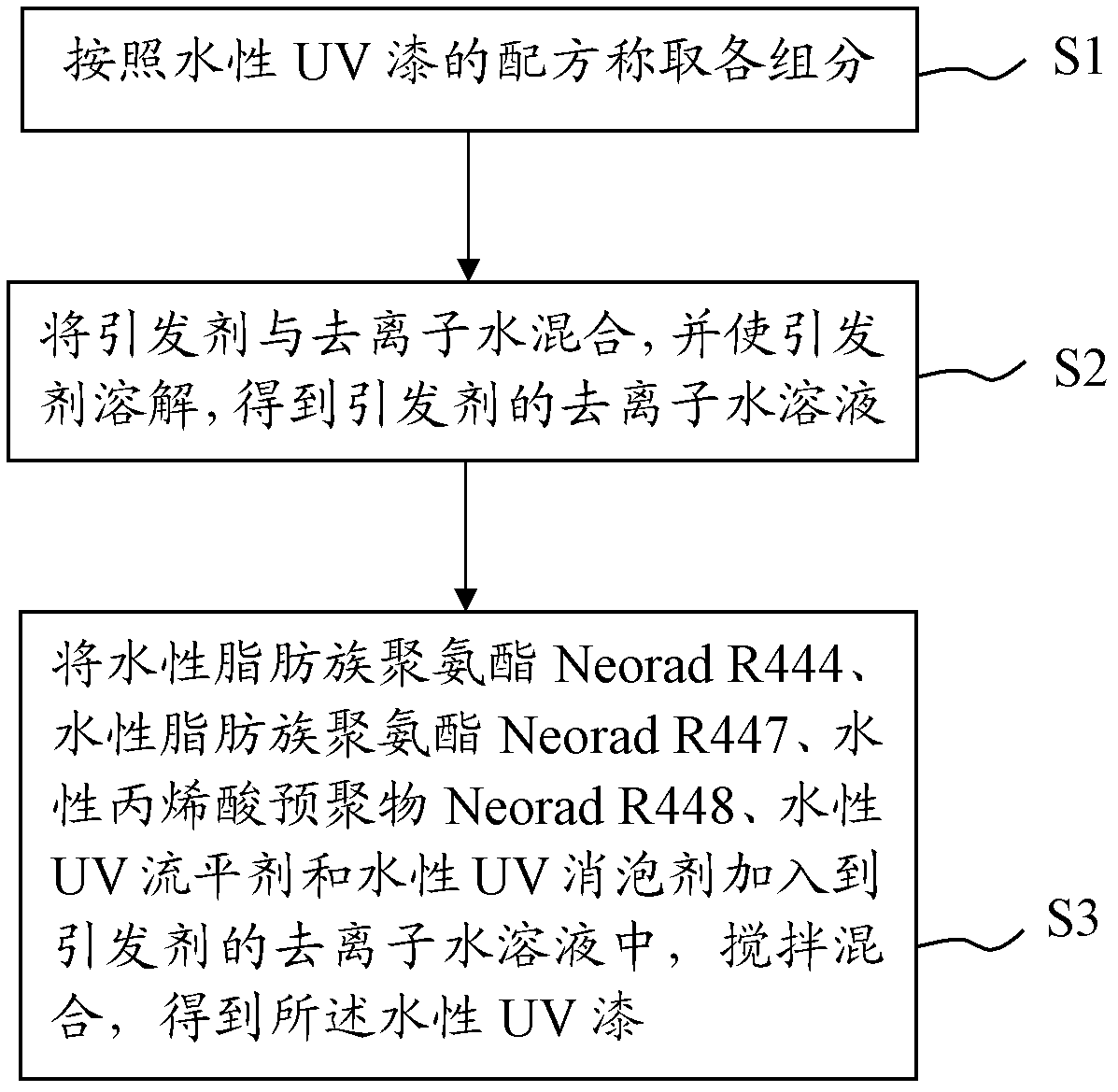

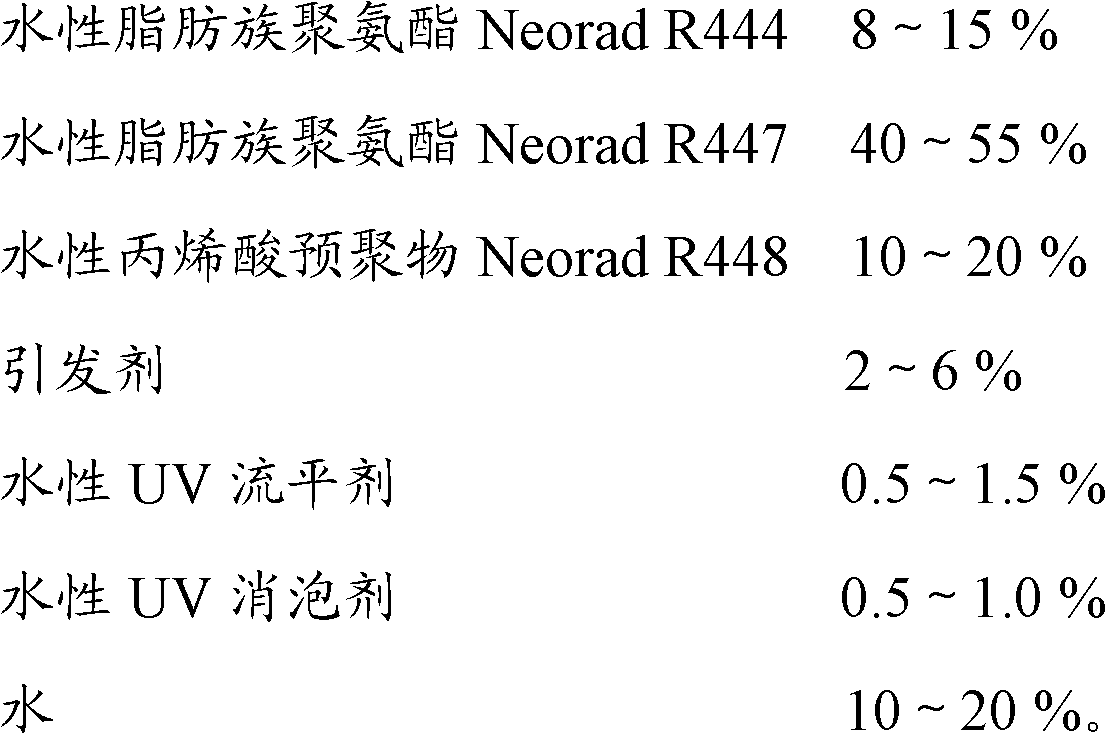

Aqueous UV paint and preparation method thereof

InactiveCN102977753AImprove the level ofGood chemical resistancePolyurea/polyurethane coatingsSolventWear resistance

The invention discloses aqueous UV paint and a preparation method thereof. The aqueous UV paint comprises: by weight, 8 to 15% of aqueous aliphatic polyurethane Neorad R444, 40 to 55% of aqueous aliphatic polyurethane Neorad R447, 10 to 20% of an aqueous acrylic acid prepolymer Neorad R448, 2 to 6% of at least one initiator, 0.5 to 1.5% of at least one aqueous UV flatting agent, and 0.5 to 1.0% of at least one aqueous UV defoamer. The aqueous UV paint is prepared from the components having appropriate content. The aqueous UV paint has good leveling properties, good chemical resistance, good wear resistance, strong adhesion, good paint film flexibility and a very low solvent discharge capacity. The preparation method of the aqueous UV paint has simple processes, can be controlled easily, has high production efficiency, and is suitable for industrial production. An aqueous UV paint system prepared from the aqueous UV paint is stable.

Owner:SHENZHEN BAOGUANG IND

Anti-doodling coating with scabridulous structure of photocatalysis cooperating with fluoro-siloxane resin modification

InactiveCN105131829AHigh film hardnessWith photocatalytic self-cleaning effectAntifouling/underwater paintsPaints with biocidesPhotocatalytic reactionOrganic dye

The invention discloses anti-doodling coating with scabridulous structure of photocatalysis cooperating with fluoro-siloxane resin modification, and belongs to wall surface anti-bonding coating. The coating is formed by mixing the following components in percentage by weight: 5 to 20 percent of silicon resin, 1 to 10 percent of cross-linking agent, 1 to 10 percent of fluororesin, 1 to 10 percent of curing agent, 0.1 to 1.3 percent of catalyst, 60 to 88 percent of organic solvent, 1 to 5 percent of inorganic powder addition agent and 2 to 10 percent of photocatalytic material; the modified organosilicon coating shows a protection effect on oil dirt, water and specific bonding objects, and the hardness is far more than that of a traditional organic coating; the coating has a photocatalysis self-cleaning effect, and can decompose multiple types of organic matters and organic dyestuff under a light-catalyzed reaction within a short time, so as to further decrease the bonding capability of sticky matters, enable the oil dirt to be more easily cleaned, and play a certain role in purifying air; moreover, the coating can work at extremely high temperature and also has excellent environmental suitability under saline, acid and humidity environment.

Owner:NANJING MISURFACE NEW MATERIAL TECH

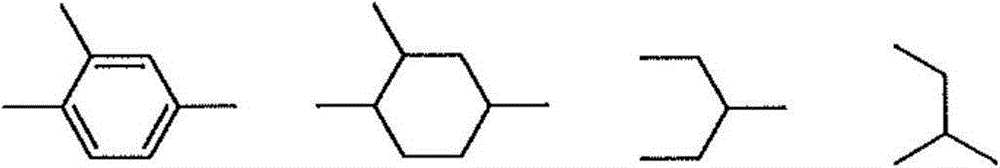

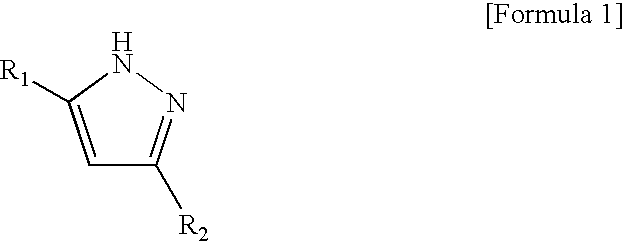

Novel block polyisocyanate and urethane composition containing the same

ActiveUS20100256324A1Excellent low-temperature curabilityExcellent appearancePolyurea/polyurethane coatingsPolymer chemistryIsocyanate compound

Disclosed is a block polyisocyanate obtained by blocking at least a part of isocyanate groups of a polyisocyanate, which is derived from an aliphatic diisocyanate and a polyol and satisfies all of the conditions (1)-(5) shown below, with a pyrazole compound. (1) Average number of isocyanate groups: 3.0-20 (2) Diisocyanate monomer trimer concentration: 10-50% by mass (3) Isocyanate group concentration: 5-22% by mass (4) Polyol content concentration: 5-40% by mass (5) Diisocyanate monomer concentration: 3% by mass or less.

Owner:ASAHI KASEI CHEM CORP

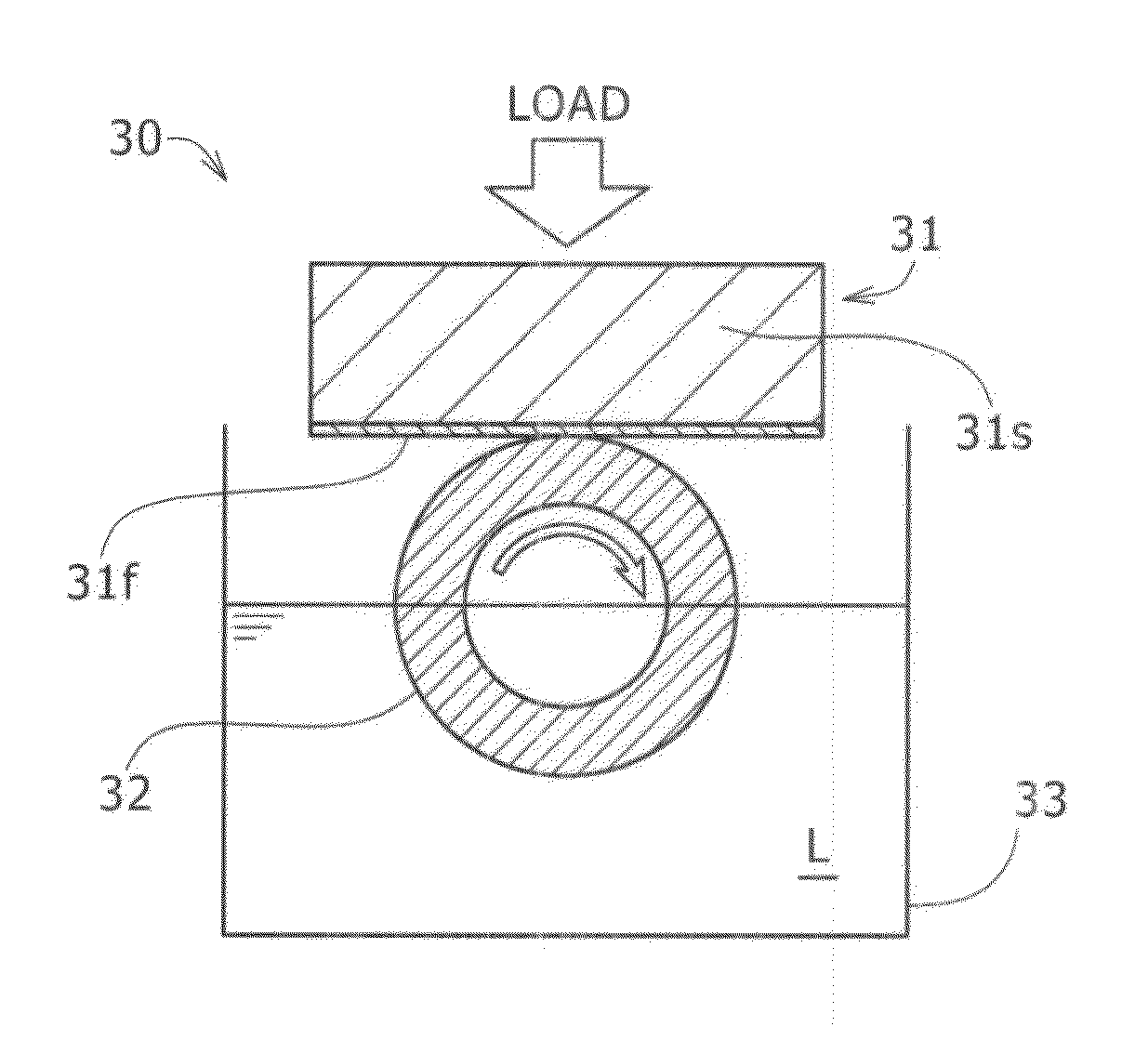

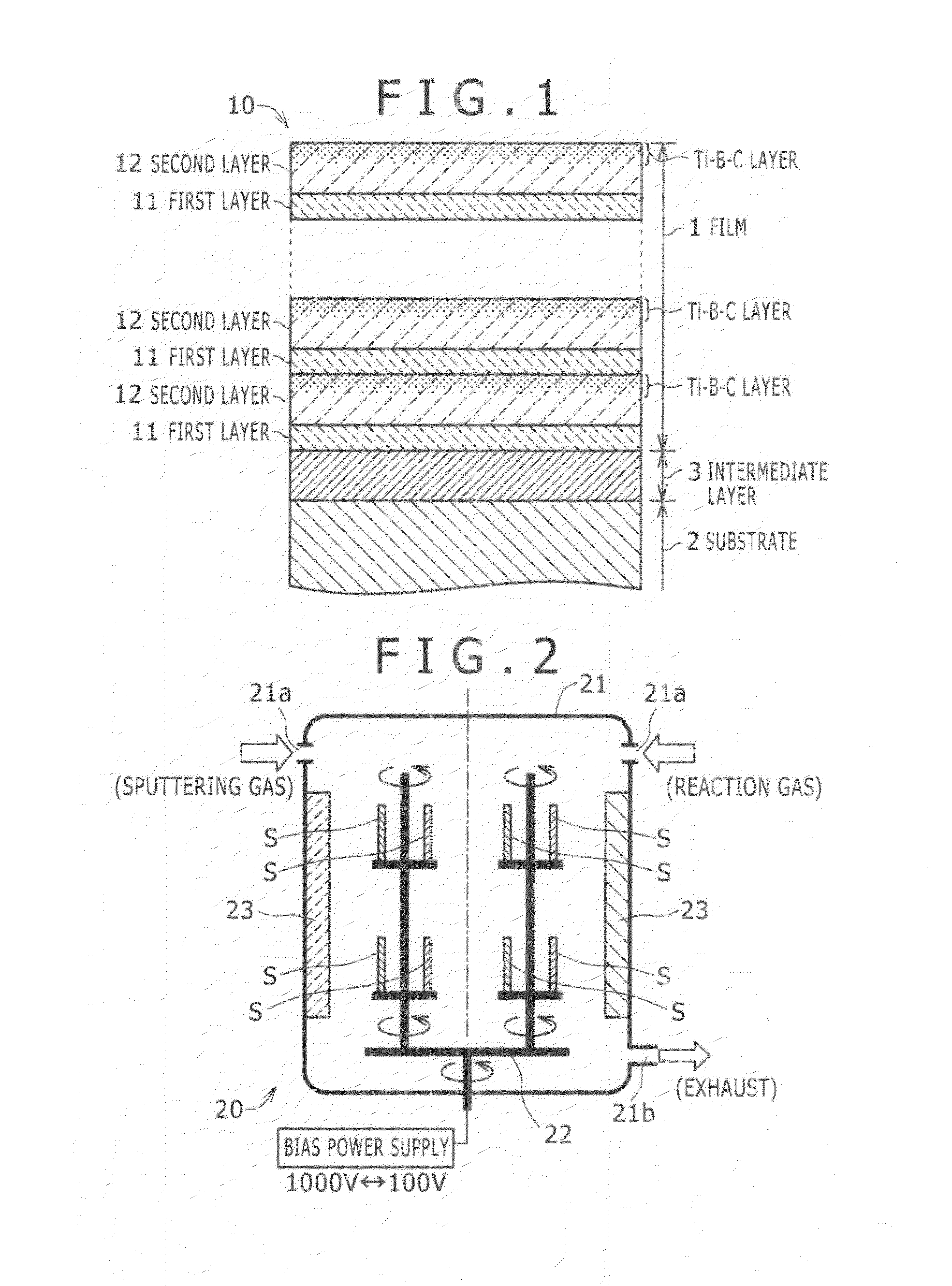

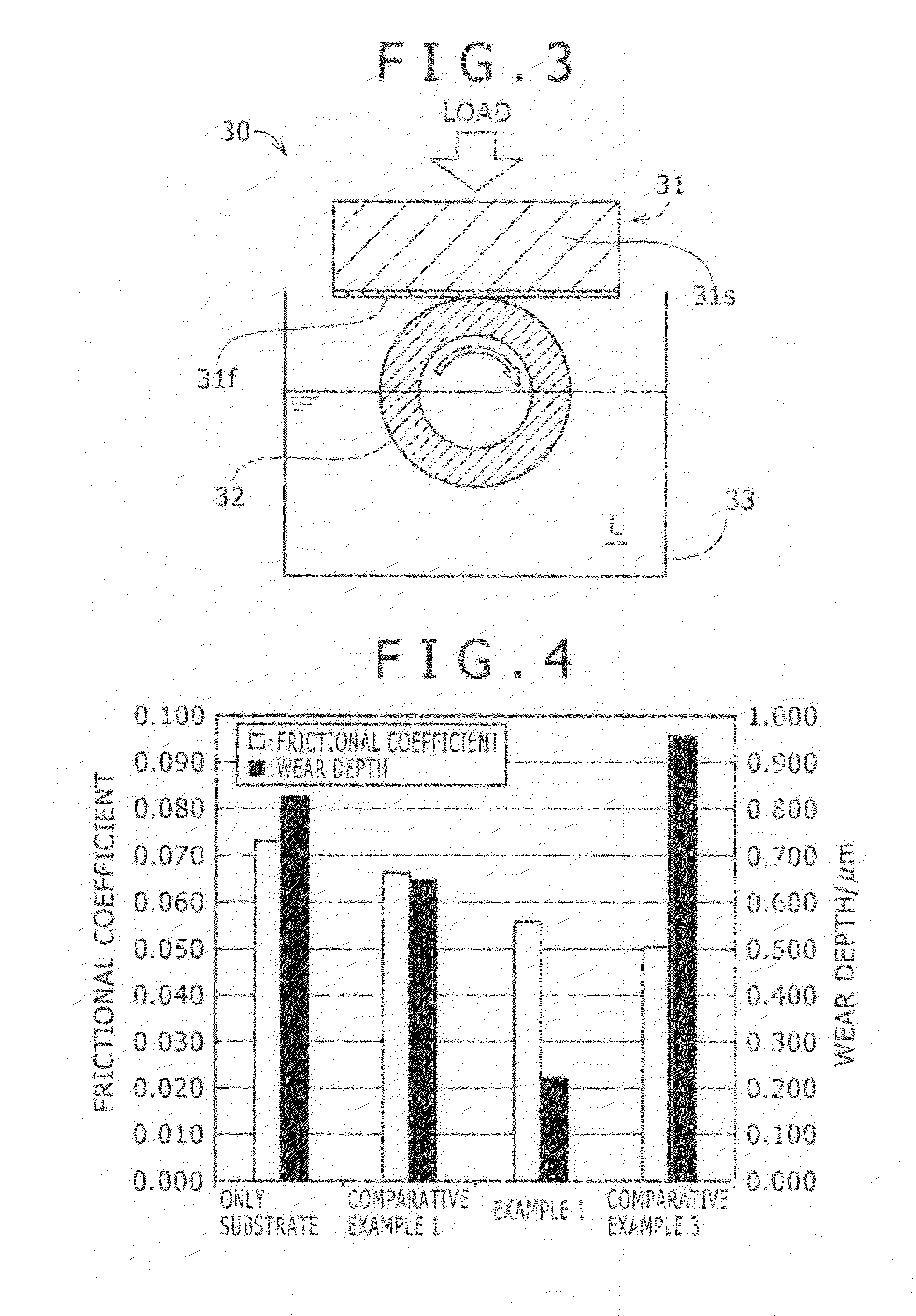

Sliding member

InactiveUS20140038868A1Reduce frictionImprove wear resistanceOrganic chemistryVacuum evaporation coatingTitaniumHardness

A sliding member includes: a substrate which has a sliding surface sliding under the presence of lubricating oil; and a film which is fixed to at least a part of the sliding surface. The film contains carbon (C), titanium (Ti), and boron (B), is obtained by repeatedly and alternately layering a first layer containing amorphous carbon as a principal component and a second layer containing C and Ti as principal components, and has hardness of 18 GPa or more.

Owner:KOBE STEEL LTD

950-DEG G grade heat-insulating high-temperature-resisting and wear-resisting coating and preparation method thereof

InactiveCN104650698AReduce transfer speedChange delivery routeAnti-corrosive paintsEpoxy resin coatingsCelluloseCarbide silicon

The invention discloses a 950-DEG G grade heat-insulating high-temperature-resisting and wear-resisting coating which comprises components I and II, wherein the component I is a double component composition which is mixed by components A and B in a proportion of 1:1.5, and the component A in the component I comprises the following components: nano-montmorillonite silicate, a coupling agent and blocking function filler in a mass ratio of 1: 1: 1.5; the component B comprises the following components in parts by mass: 20-35 parts of black silicon carbide, 25-30 parts of fine crystal aluminum oxide, 5-10 parts of a dispersant, 1-5 parts of zinc oxide, 10-15 parts of modified epoxy resin and 2-6 parts of a delustering agent; the component II comprises the following components in parts by mass: 2-6 parts of a delustering agent, 2-6 parts of a wetting agent, 20-50 parts of a curing agent, 5-10 parts of a thickening agent, 5-10 parts of hydroxyethyl cellulose, 1-5 parts of a pH adjustor, 50-60 parts of organosilicone modified epoxy resin, 20-30 parts of filler, 5-10 parts of antimonous oxide and 5-10 parts of a coalescing agent. The invention further designs a preparation method of the 950-DEG G grade heat-insulating high-temperature-resisting and wear-resisting coating.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Chloroethylene-isooctyl acrylate copolymer emulsion and preparation method thereof

ActiveCN102977249AGood waterproof and acid, alkali and salt corrosion resistanceHigh film hardnessInksCoatingsAmmonium sulfateIon

The invention relates to chloroethylene-isooctyl acrylate copolymer emulsion and a preparation method thereof, and mainly relates to an emulsion product for water-based industrial coating base materials, belonging to the technical field of industrial coatings. The copolymer emulsion is prepared by taking chloroethylene and isooctyl acrylate as monomers, allyl nonylphenol polyethylene ether ammonium sulfate, sodium dodecyl sulfate and OP-4 as emulsifying agents and water-soluble ammonium persulfate as an initiating agent to carry out emulsion polymerization. The copolymer emulsion has the advantages that compared with other water-based coatings, the copolymer emulsion, used as a water-based industrial coating, has better waterproofing property and acid, alkali and salt corrosion resistances, hard film, good wear and scratching resistances and low cost, has qualified mechanical stability, calcium ion stability and heat stability and is free from demulsification and delamination after being stored for a year.

Owner:WUXI HONGHUI NEW MATERIALS TECH

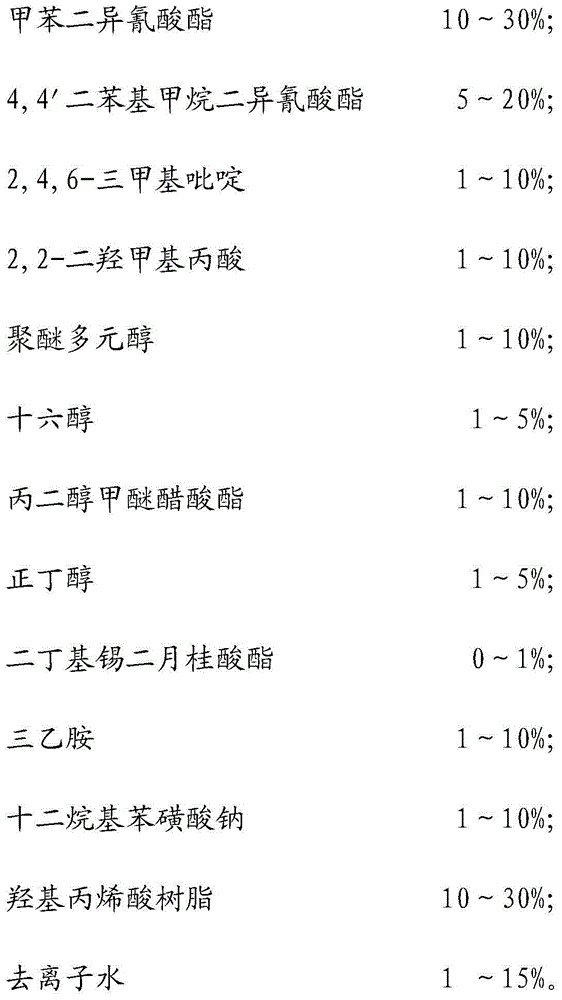

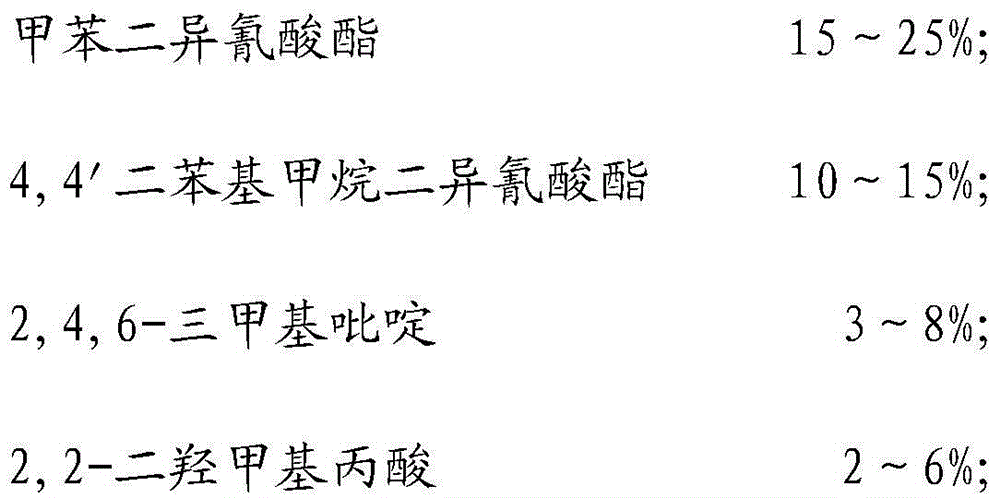

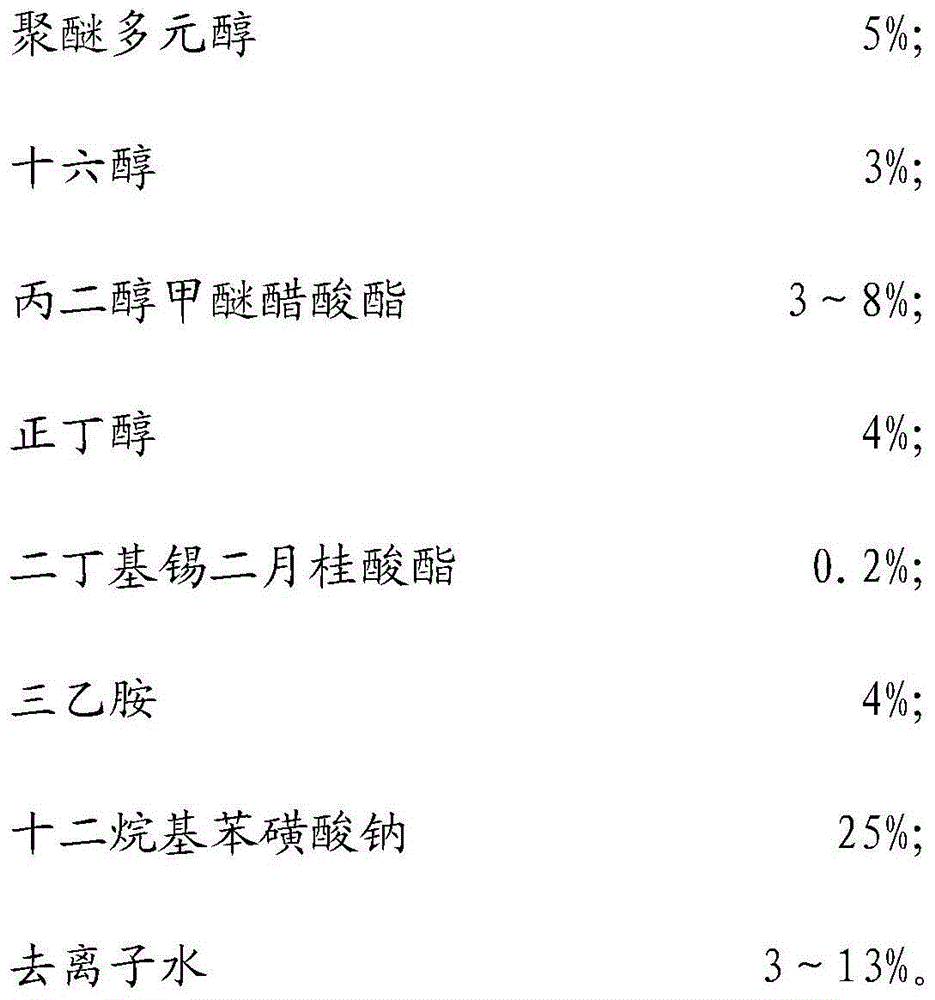

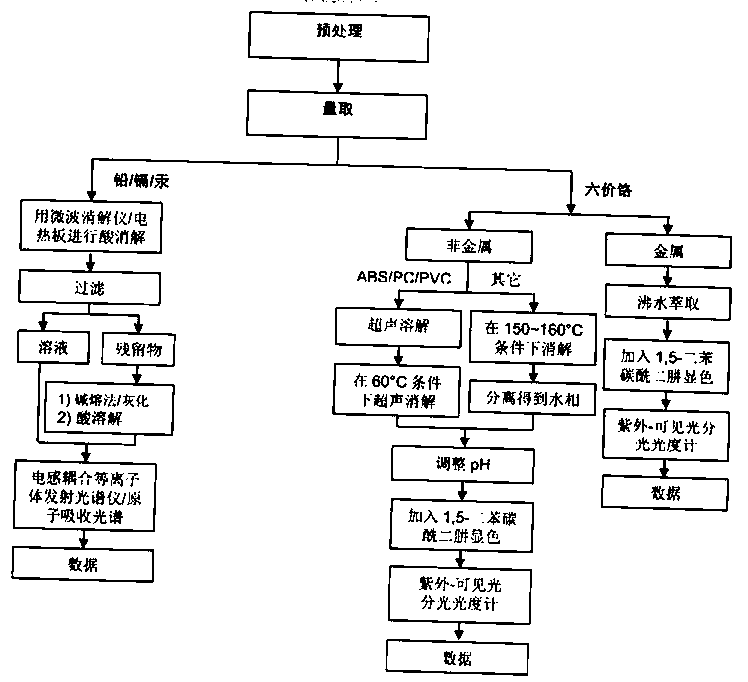

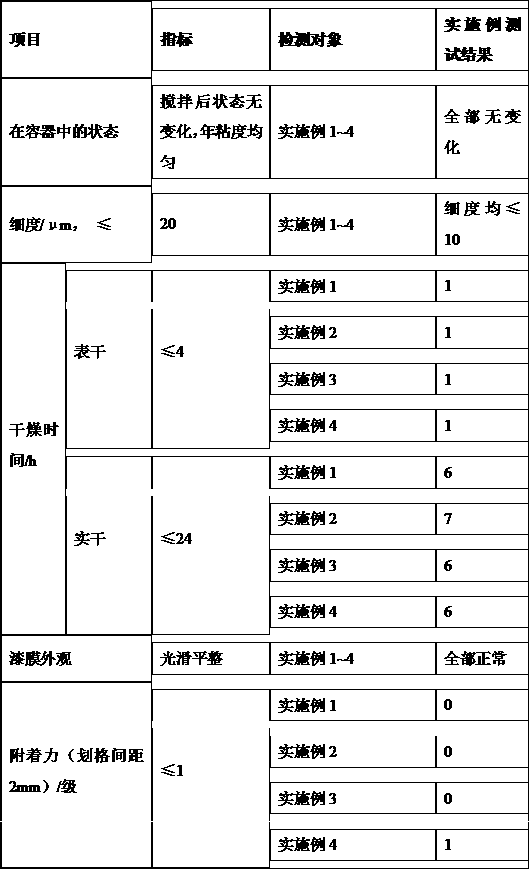

Waterborne acrylic modified polyurethane emulsion as well as preparation method and application thereof

InactiveCN104592484AGood weather resistanceLow pricePolyurea/polyurethane coatingsPolymer scienceToluene diisocyanate

The invention discloses a waterborne acrylic modified polyurethane emulsion as well as a preparation method and application thereof. The waterborne acrylic modified polyurethane emulsion comprises the following components in percentage by weight: 10-30% of toluene diisocyanate, 5-20% of 4,4'-diphenyl methane diisocyanate, 1-10% of 2,4,6-trimethylpyridine, 1-10% of 2,2-dihydroxymethyl propionic acid, 1-10% of polyether polyol, 1-5% of hexadecanol, 1-10% of propylene glycol methyl ether acetate, 1-5% of n-butanol, 0-1% of dibutyl tin dilaurate, 1-10% of triethylamine, 1-10% of sodium dodecylbenzenesulfonate, 10-30% of hydroxyl acrylic resin and 1-15% of deionized water. Toluene diisocyanate and 4,4'-diphenyl methane diisocyanate are used so that the cost of the emulsion is greatly decreased; and meanwhile, hexadecanol is creatively used for modifying so that the problem that the generally synthesized polyurethane emulsion is difficult to emulsify is solved.

Owner:GUANGDONG VALSPAR CHEM IND

Environment-friendly wax oil and preparation method thereof

InactiveCN109054638AImprove performanceGood weather resistanceWax coatingsRosin coatingsWaxNatural resin

The invention belongs to the technical field of coatings, and particularly relates to an environment-friendly wax oil, which is prepared from the following materials in parts by weight: isocyanate-modified alkyd resin, vegetable oil, biological wax, polyfluo-wax, natural resin, rare-earth catalyst, fatty alcohol polyoxyethylene methyl-terminated polyether and free radical absorbent. The environment-friendly wax oil disclosed by the invention not only is suitable for being brushed on indoor wooden ware, but also is applicable to indoor and outdoor wooden ware products, and has the advantages ofgood weatherability, quick drying, good stability and good yellowing resistance; and moreover, the environment-friendly wax oil cannot easily sag during brushing, and the formed film is tough.

Owner:东莞公民实业有限公司

Metallic film reflector and manufacturing method thereof

InactiveCN104345362AHigh film hardnessImprove mechanical propertiesMirrorsVacuum evaporation coatingHigh reflectivityHigh transmittance

The invention discloses a metallic film reflector which comprises a glass substrate, wherein a compounded surface of the glass substrate is sequentially and adjacently compounded with six film layers from the inside to the outside. The metallic film reflector is characterized in that the first film layer is a SiO2 layer as the innermost layer; the second layer is an Al2O3 layer; the third layer is an Ag layer; the fourth layer is an Al2O3 layer; the fifth layer is a SiO2 layer; the outermost layer is a TiO2 layer. The invention aims at overcoming the defects in the prior art, provides the metallic film reflector with the advantages of high transmittance, high reflectivity, low refractive index as well as good mechanical properties and strong adhesive force of film layers and also provides a manufacturing method for the metallic film reflector.

Owner:ZHONGSHAN CHUANGKE RES TECH SERVICE

Waterborne wood lacquer and preparation method thereof

The invention discloses waterborne wood lacquer. The waterborne wood lacquer is prepared from a first mixed component, a second mixed component and water, and the mass ratio of the first mixed component to the second mixed component to the water is 100 to (12 to 18) to (10 to 20), wherein the first mixed component is prepared from 10 percent to 30 percent of waterborne polyurethane resin, 50 percent to 70 percent of waterborne acrylic resin, 1 percent to 5 percent of matte powder, 0.5 percent to 2 percent of wax paste, 3 percent to 6 percent of a film-forming auxiliary agent, 0.1 percent to 0.2 percent of a pH (Potential of Hydrogen) regulator, 0.5 percent to 1 percent of a rheological agent, 1 percent to 2.5 percent of a multifunctional auxiliary agent and 2 percent to 10 percent of water; the second mixed component is prepared from 15 percent to 30 percent of PMA (Polymethyl Acrylate) and 70 percent to 85 percent of a waterborne curing agent. By adopting the waterborne wood lacquer disclosed by the invention, the adhesive force between a waterborne finish paint layer and an oily primer layer can be remarkably improved, and the rigidity and the water resistance of a paint film are improved; the invention further discloses a preparation method of the waterborne wood lacquer, which has a simple preparation process, is easy to implement and is suitable for large-batch production requirements.

Owner:广东顺德嘉乐士涂料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com