LED (light-emitting diode) curing waterborne UV (ultraviolet) furniture home decoration paint and preparation method thereof

A water-based, home improvement technology, applied in biocide-containing paints, anti-fouling/underwater coatings, devices for coating liquids on surfaces, etc., can solve problems such as insufficient decoration, low production efficiency, and long drying time. Achieve the effect of excellent decorative effect and protective function, high production efficiency and good fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

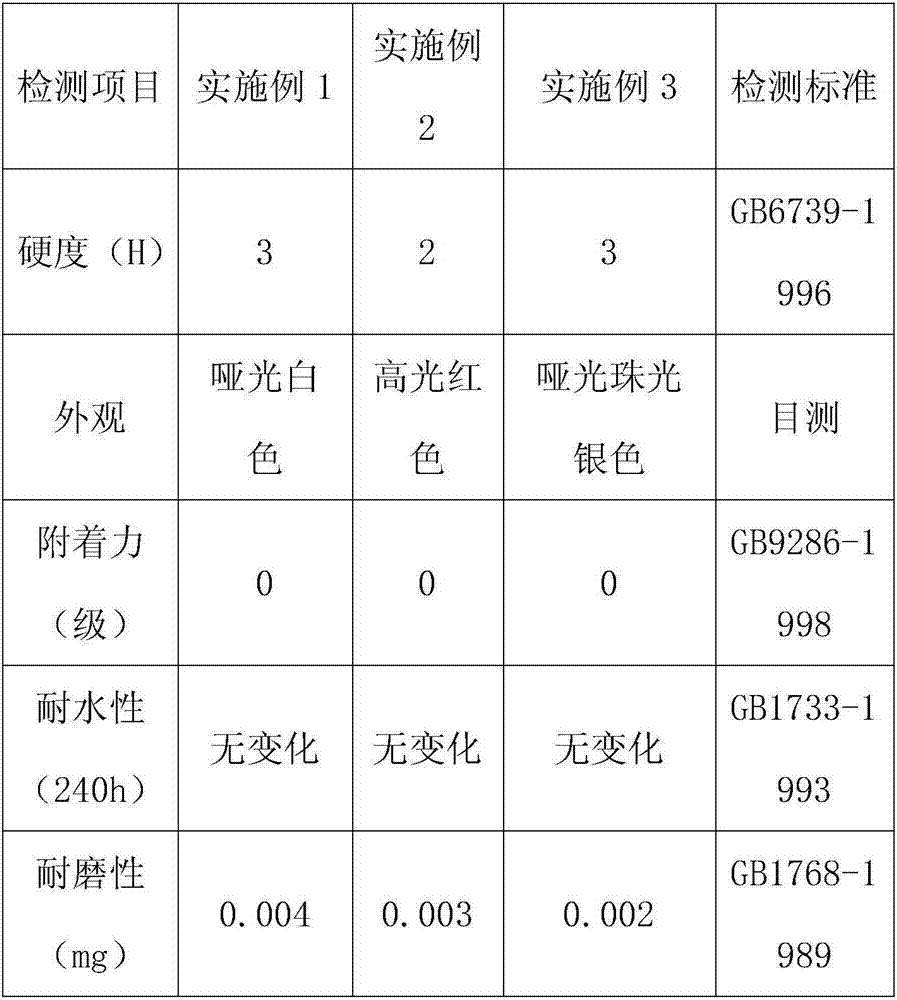

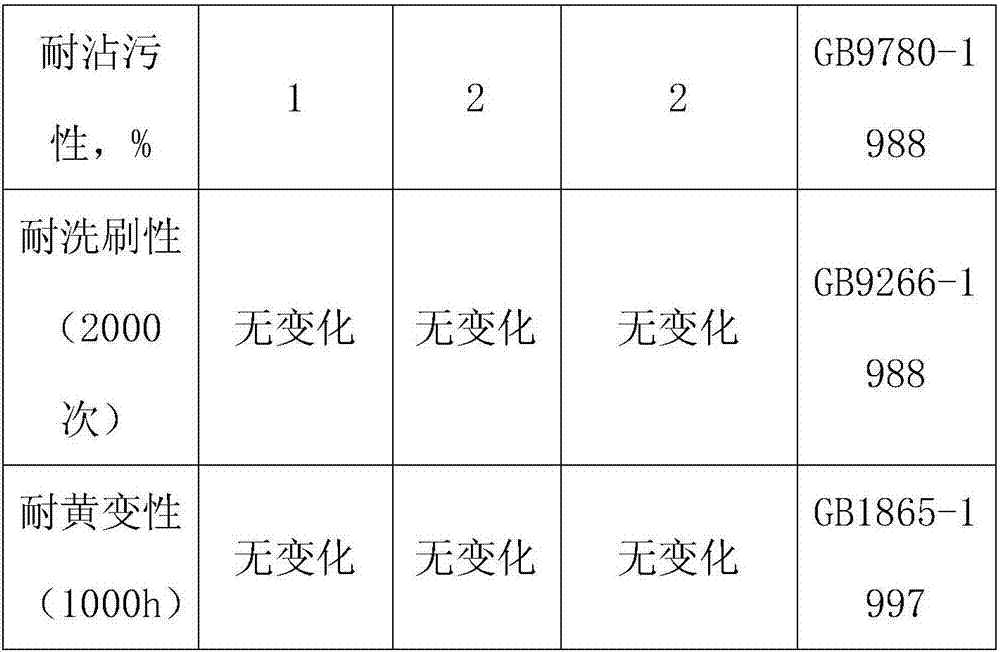

[0030] Embodiment 1. White LED curing water-based UV furniture home improvement paint

[0031] Select a plywood with a specification of 1.2m×2.44m×6mm. After cleaning, roll-coat a layer of LED-cured water-based UV adhesion primer on its surface. After drying, enter it with 2 LED lights with a power of 300W and a wavelength of 365nm. The irradiation speed is 15m / min curing machine, after curing, a coating I with a thickness of 20um is formed. Roll-coat a layer of LED-curable water-based UV white colorant on the surface of coating Ⅰ, and after drying, enter a curing machine equipped with 3 LED lamps with a power of 1KW and a wavelength of 395nm and an irradiation speed of 15m / min. Coating II. Then roll coat a layer of LED curable water-based UV protective topcoat on the surface of the coating II, level it under the infrared leveling line at a temperature of 80°C for 60 seconds, and then enter it with 5 LED lamps with a power of 2KW and a wavelength of 365nm, and the irradiatio...

Embodiment 2

[0035] Example 2. Red LED curing water-based UV furniture home improvement paint

[0036] Select solid wood with a specification of 1.0m×2.5m×10mm, after cleaning, pour a layer of LED curable water-based UV adhesion primer on its surface, and then enter it with 2 LED lamps with a power of 1KW and a wavelength of 385nm, and the irradiation speed is 15m / min curing machine, after curing, a coating I with a thickness of 80um is formed. A layer of LED curable water-based UV red colorant is sprayed on the surface of the coating Ⅰ, and then enters a curing machine equipped with 3 LED lamps with a power of 3KW and a wavelength of 420nm and an irradiation speed of 15m / min. After curing, a coating with a thickness of 50um is formed. Layer II. Then pour a layer of LED curable water-based UV protective topcoat on the surface of the coating II, level it under the infrared leveling line at a temperature of 80°C for 60 seconds, and then enter it with 5 LED lamps with a power of 5KW and a w...

Embodiment 3

[0040] Embodiment 3. Pearlescent silver LED curing water-based UV furniture paint

[0041] Select a three-plywood board with a specification of 1.2m×2.4m×12mm. After cleaning, spray a layer of LED curing water-based UV adhesion primer on its surface, and then enter it with 2 LED lights with a power of 0.5KW and a wavelength of 395nm. The irradiation speed is 15m / min curing machine, after curing, a coating I with a thickness of 28um is formed. Spray a layer of LED-cured water-based UV pearlescent silver colorant on the surface of coating Ⅰ, and then enter a curing machine equipped with 3 LED lamps with a power of 3KW and a wavelength of 420nm and an irradiation speed of 12m / min. After curing, a coating with a thickness of 32um is formed. Layer II. Then spray a layer of LED curable water-based UV protective topcoat on the surface of the coating II, level it under the infrared leveling line at a temperature of 80°C for 60 seconds, and then enter it with 5 LED lamps with a power ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com