Waterborne acrylic modified polyurethane emulsion as well as preparation method and application thereof

A water-based acrylic and polyurethane emulsion technology, which is applied in the field of polymer emulsion, can solve the problems of slow drying speed of paint film, poor chemical corrosion resistance, poor fullness of paint film, etc., to reduce the cost of emulsion, good weather resistance, and improve difficult emulsification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

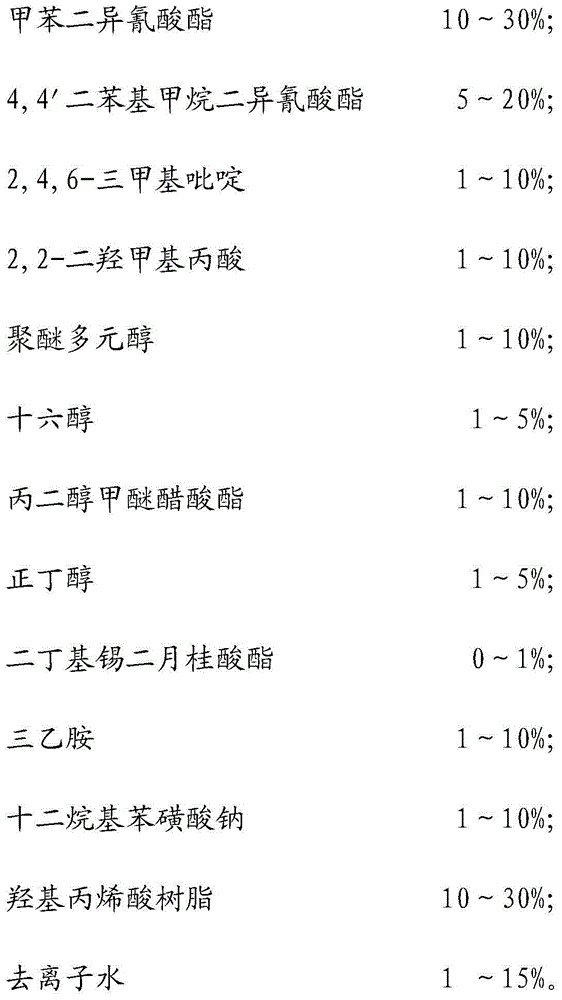

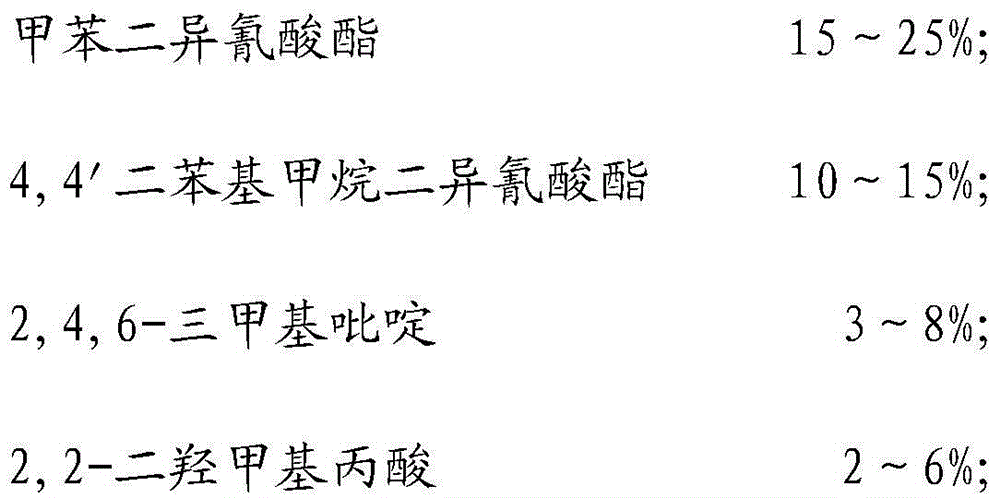

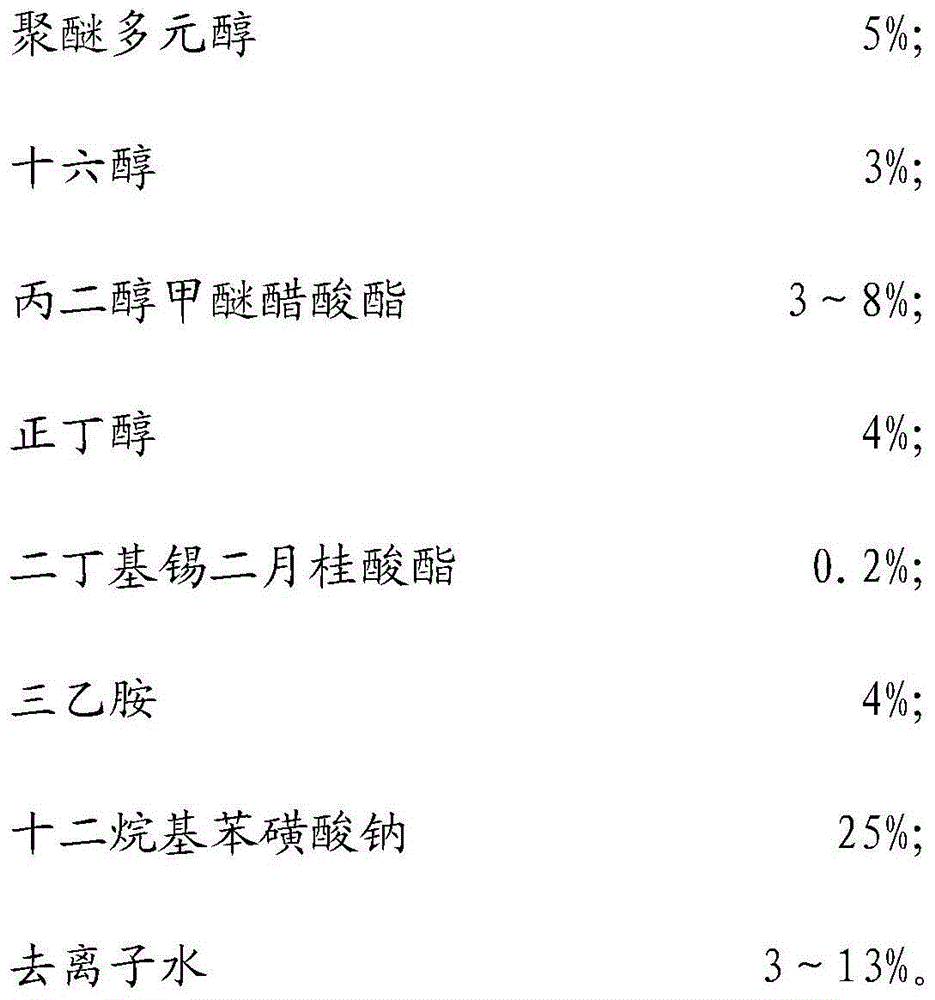

[0040] The present invention also provides a kind of preparation method of waterborne acrylic acid modified polyurethane emulsion as described above, comprises the following steps:

[0041] a. Weigh an appropriate amount of toluene diisocyanate, 4,4' diphenylmethane diisocyanate, 2,4,6-collidine, 2,2-dimethylolpropionic acid, polyether polyol according to the above mass percentage Alcohol, cetyl alcohol, propylene glycol methyl ether acetate, n-butanol, and hydroxyl acrylic resin are put into the reaction kettle;

[0042] b. Heating the reactor in step a, the heating temperature is controlled at 70-75°C, stirring the contents in the reactor during the heating process to fully react the contents in the reactor, and detecting the NCO value during the reaction, Cool down to 30-50°C until NCO reaches the theoretical value;

[0043] NCO content refers to the mass fraction of NCO groups in the water-based acrylic modified polyurethane emulsion. The theoretical value can be calculat...

Embodiment 1

[0050] Equipped with 100Kg of water-based acrylic modified polyurethane emulsion 1 of the present invention, which is prepared by the following components by weight.

[0051] The preparation of water-based acrylic modified polyurethane emulsion 1 is as follows:

[0052]Put 24Kg of TDI, 11Kg of MDI, 3Kg of TMP, 6Kg of DMPA, 5Kg of polyether polyol, 3Kg of cetyl alcohol, 3Kg of PMA, 4Kg of n-butanol, and 24Kg of hydroxyacrylic resin into the reactor; then heat the reactor, The heating temperature is controlled at 70-75°C. During the heating process, the materials in the reactor are stirred to fully react the materials in the reactor to form a uniform solution. During the reaction, measure the NCO value while reacting until the NCO reaches the theoretical value. Cool down; then add T-120.2Kg, control the heating temperature at 65-70°C, stir the contents of the reactor during the heating process, so that the contents of the reactor can fully react to form a uniform solution until ...

Embodiment 2

[0054] Equipped with 100Kg of the water-based acrylic modified polyurethane emulsion 2 of the present invention, which is prepared by the following components by weight.

[0055] The preparation of water-based acrylic modified polyurethane emulsion 2 is as follows:

[0056] Put 22Kg of TDI, 12Kg of MDI, 5Kg of TMP, 4Kg of DMPA, 5Kg of polyether polyol, 3Kg of cetyl alcohol, 5Kg of PMA, 4Kg of n-butanol, and 22Kg of hydroxyacrylic resin into the reactor; then heat the reactor, The heating temperature is controlled at 70-75°C. During the heating process, the materials in the reactor are stirred to fully react the materials in the reactor to form a uniform solution. During the reaction, measure the NCO value while reacting until the NCO reaches the theoretical value. Cool down; then add T-120.2Kg, control the heating temperature at 65-70°C, stir the contents of the reactor during the heating process, so that the contents of the reactor can fully react to form a uniform solution u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com